Automatic yarn separating machine

A technology of automatic yarn splitter and yarn splitter bar, which is applied in the directions of skeining, textile, textile and papermaking, etc. It can solve the problems of visual fatigue, high labor intensity, and low production efficiency, achieve accurate and clear yarn splitting, and reduce labor costs. The effect of strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

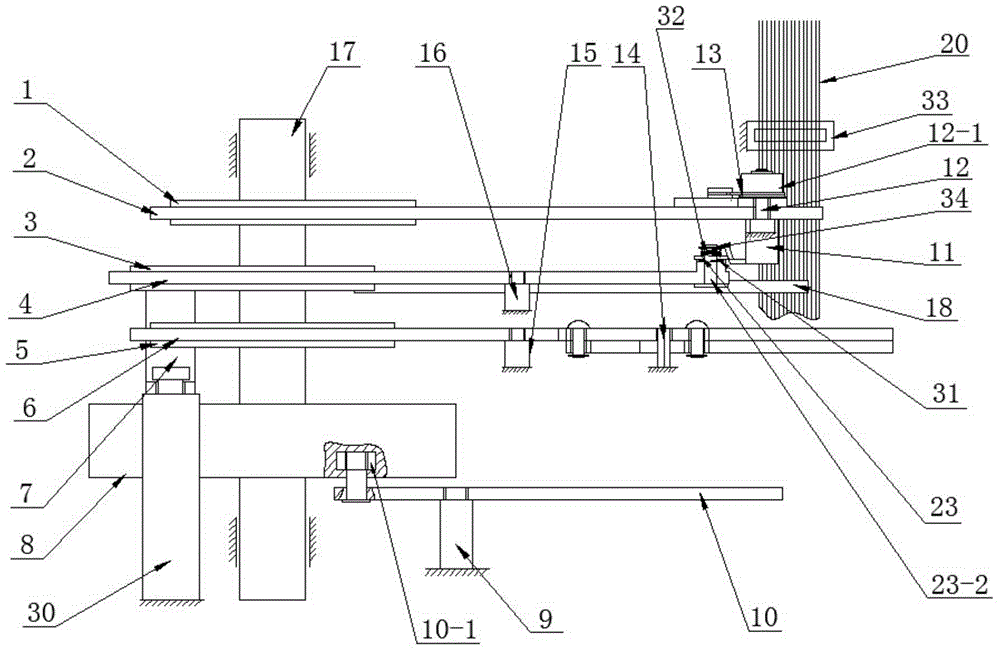

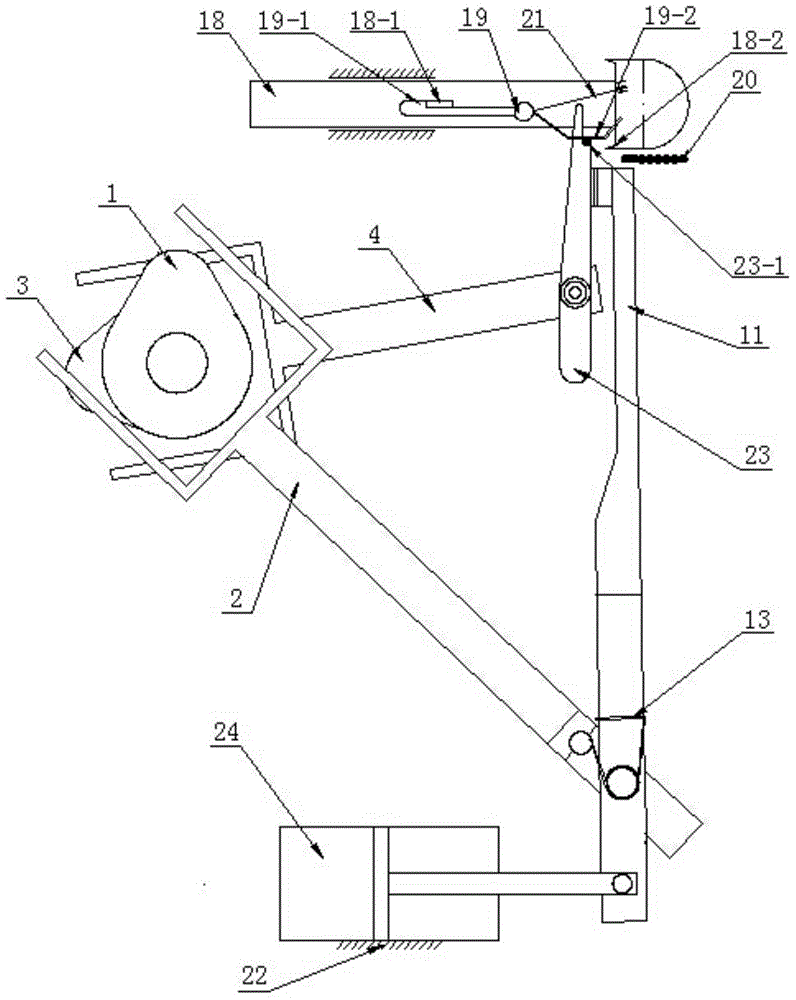

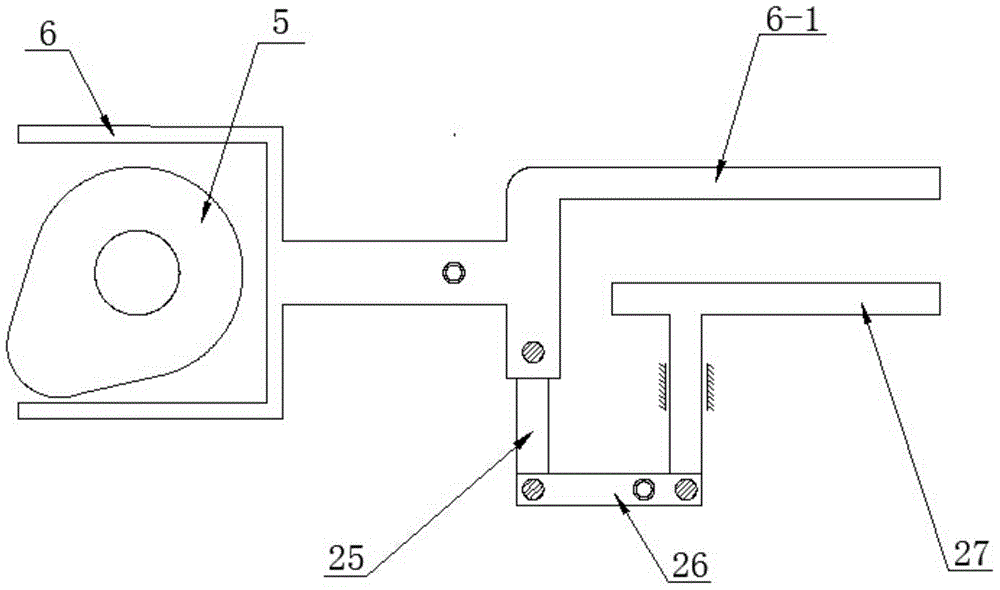

[0024] see Figure 1 to Figure 4 , The automatic yarn splitting machine of this embodiment includes a frame 22, a motor, a camshaft 17, an upper cam 1, a middle cam 3, a lower cam 5, an end cam 8, a limit mechanism, a yarn splitting mechanism, a yarn clamping mechanism, and a feeder Yarn mechanism.

[0025] The upper cam 1, the middle cam 3, the lower cam 5 and the end cam 8 are sequentially fixed on the cam shaft 17 from top to bottom, and the motor drives the cam shaft 17 to rotate. The limit mechanism, the yarn dividing mechanism, the yarn clamping mechanism and the yarn feeding mechanism are matched with the upper cam 1, the middle cam 3, the lower cam 5 and the end cam 8 respectively. The limit mechanism is used to limit the position of the yarn splitting mechanism. The yarn dividing mechanism pushes out a yarn at the foremost end on the weaving shaft yarn car. The yarn clamping mechanism stretches the yarn ejected from the yarn splitting mechanism. The yarn feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com