Multicolor warp sample hank reeling machine

A yarn reeling machine and colored warp technology, applied in the field of multi-color warp yarn sample reeling machines, can solve the problems of low winding efficiency, error-prone, multi-color warp yarns cannot be wound at the same time, etc., and achieve precise winding and accurate calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

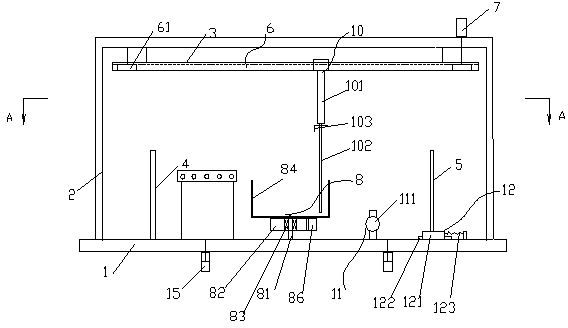

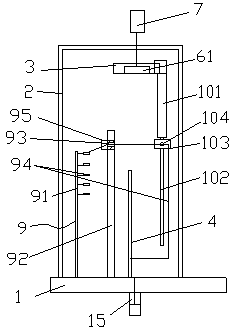

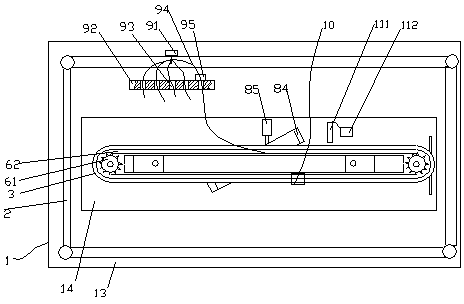

[0024] The multi-color warp sample shaking machine of the present invention includes a base 1, an upward track and a driving device 7, a yarn supply winding device, a U-shaped vertical rod splitting device 8, a tension guide frame device 9, a yarn selection rod device 10 and a detection device. Counting device 11.

[0025] The up track and the driving device 7 include two vertical supports 2 symmetrically distributed on the left and right sides of the base 1, a track 3 between the two vertical supports 2, and a traveling device 6 placed in the track 3 and moving along the direction of the track 3 , drive the traveling device 6 to move and be fixedly arranged on the drive device 7 on any one of the two vertically arranged supports 2, and the bottoms of the two vertically arranged supports 2 are all fixedly arranged on the base 1;

[0026] The yarn supply winding device, the yarn supply winding device includes two vertical pillars symmetrically arranged on the left and right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com