Sizing yarn technology utilizing short fiber sizing machine to produce DTY filament varieties

A fluff pulp and filament technology, used in liquid/gas/vapor fiber/sliver/roving processing, manufacturing tools, textiles and papermaking, etc. quality and other issues, to reduce the waste of equipment and raw materials, increase production costs, and ensure absolute efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

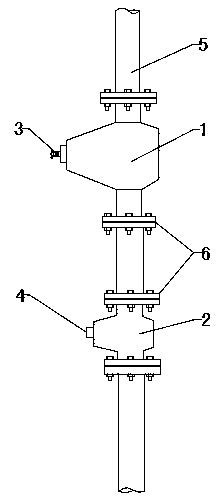

Image

Examples

Embodiment 1

[0034] 1. Thoroughly clean the rollers, rubber rollers, guide rollers, and drying cylinders of the yarn guide channel of the staple fiber sizing machine, especially the size tank, without any pulp skins, pulp particles, and any sundries, hairs, Cotton sheet, to prevent the filament yarn from sticking to debris during the sizing process, and to prevent the occurrence of adhesion after sizing and tearing due to high resistance during sizing, resulting in broken threads or fluffing of the filament; firstly adjust the staple fiber sizing machine when starting up The vehicle speed is 24m / min, and the filaments first enter the size tank after being unwound from the creel for sizing. The size tank is filled with PS-25L filament slurry diluted with water to a solid content of 4.5%. The amount of silk 3Kg / 10,000 meters is evenly mixed with antistatic agent.

[0035] 2. The sized filaments are drawn to the wax tank of the staple fiber sizing machine for oiling. The wax tank is filled wi...

Embodiment 2

[0041] 1. Thoroughly clean the rollers, rubber rollers, guide rollers, and drying cylinders of the yarn guide channel of the staple fiber sizing machine, especially the size tank, without any pulp skins, pulp particles, and any sundries, hairs, Cotton sheet, to prevent the filament yarn from sticking to debris during the sizing process, and to prevent the occurrence of adhesion after sizing and tearing due to high resistance during sizing, resulting in broken threads or fluffing of the filament; firstly adjust the staple fiber sizing machine when starting up The vehicle speed is 23m / min, and the filaments first enter the size tank after being unwound by the creel for sizing. The size tank is filled with PS-25L filament slurry diluted with water to a solid content of 4.5%. The amount of silk 2.5Kg / 10,000 meters is evenly mixed with antistatic agent.

[0042] 2. The sized filaments are drawn to the wax tank of the staple fiber sizing machine for oiling. The wax tank is filled wi...

Embodiment 3

[0048] 1. Thoroughly clean the rollers, rubber rollers, guide rollers, and drying cylinders of the yarn guide channel of the staple fiber sizing machine, especially the size tank, without any pulp skins, pulp particles, and any sundries, hairs, Cotton sheet, to prevent the filament yarn from sticking to debris during the sizing process, and to prevent the occurrence of adhesion after sizing and tearing due to high resistance during sizing, resulting in broken threads or fluffing of the filament; firstly adjust the staple fiber sizing machine when starting up The vehicle speed is 22m / min, and the filaments first enter the size tank after being unwound by the creel for sizing. The size tank is filled with PS-25L filament slurry diluted with water to a solid content of 5.5%. The amount of silk 2.8Kg / 10,000 meters is evenly mixed with antistatic agent.

[0049] 2. The sized filaments are drawn to the wax tank of the staple fiber sizing machine for oiling. The wax tank is filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com