Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about "Frictional elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone compositions, methods of manufacture, and articles formed therefrom

InactiveUS20090162651A1Better gripping surfaceImprove adhesionSolesWater sport boardsHydrogenSilica gel

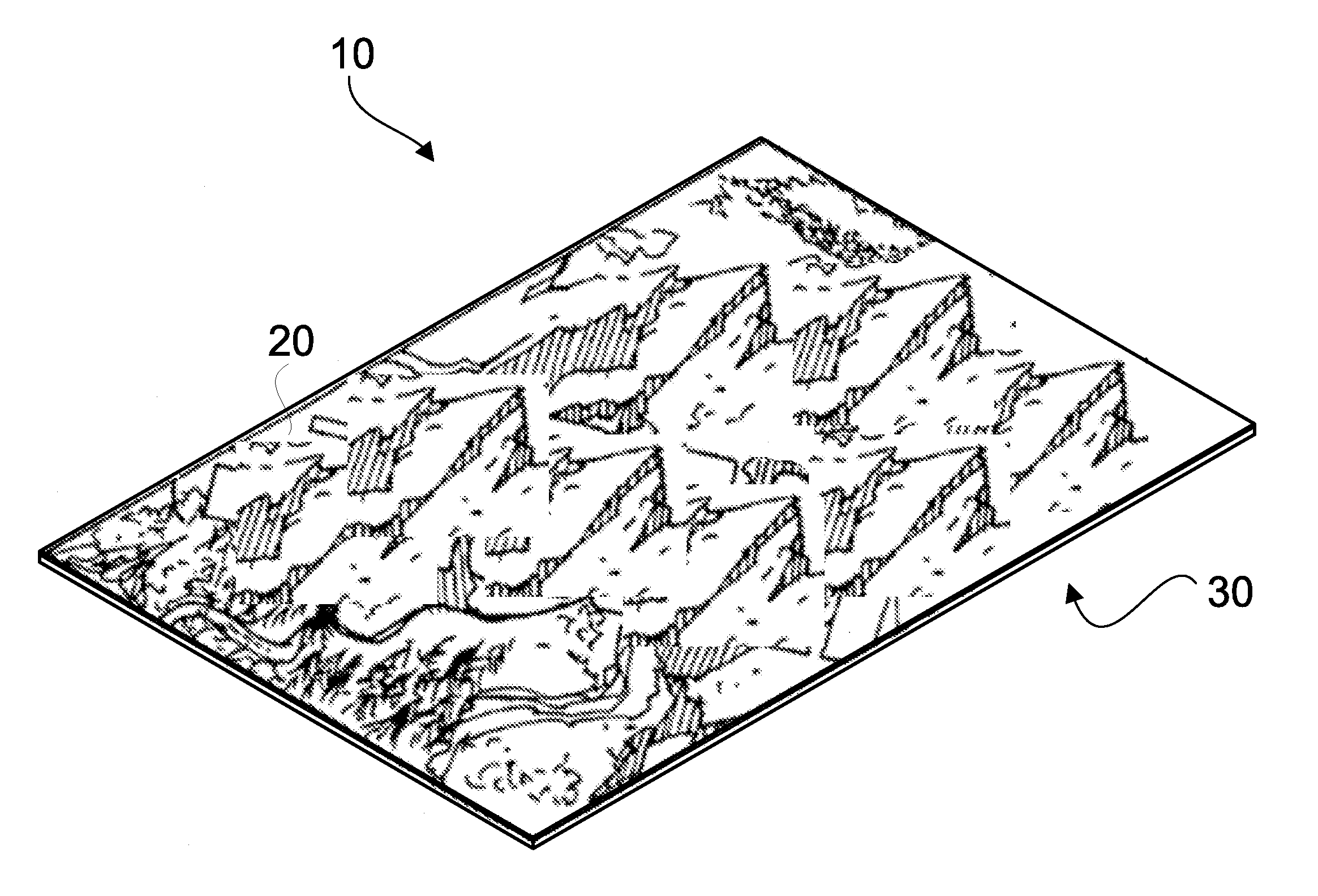

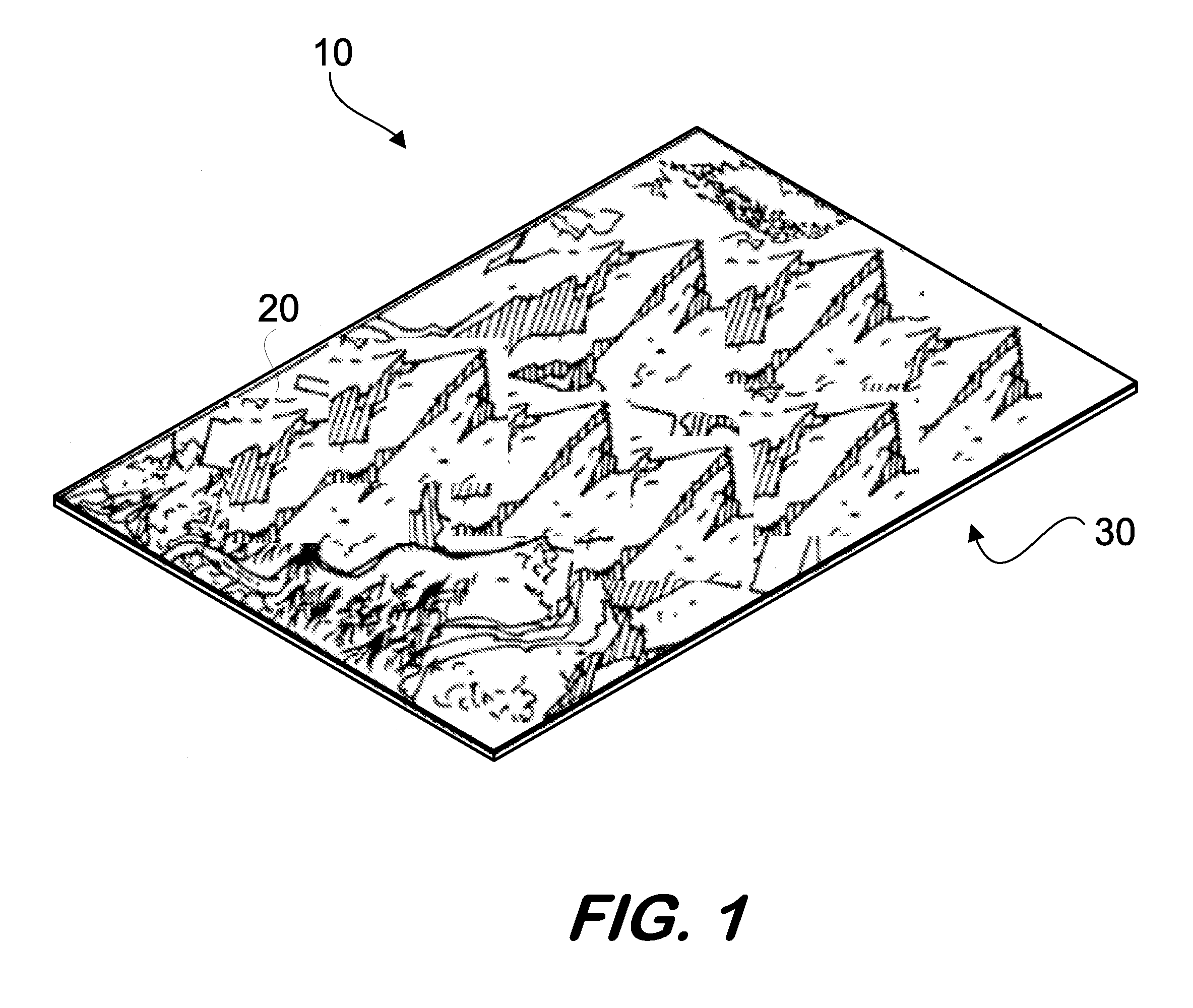

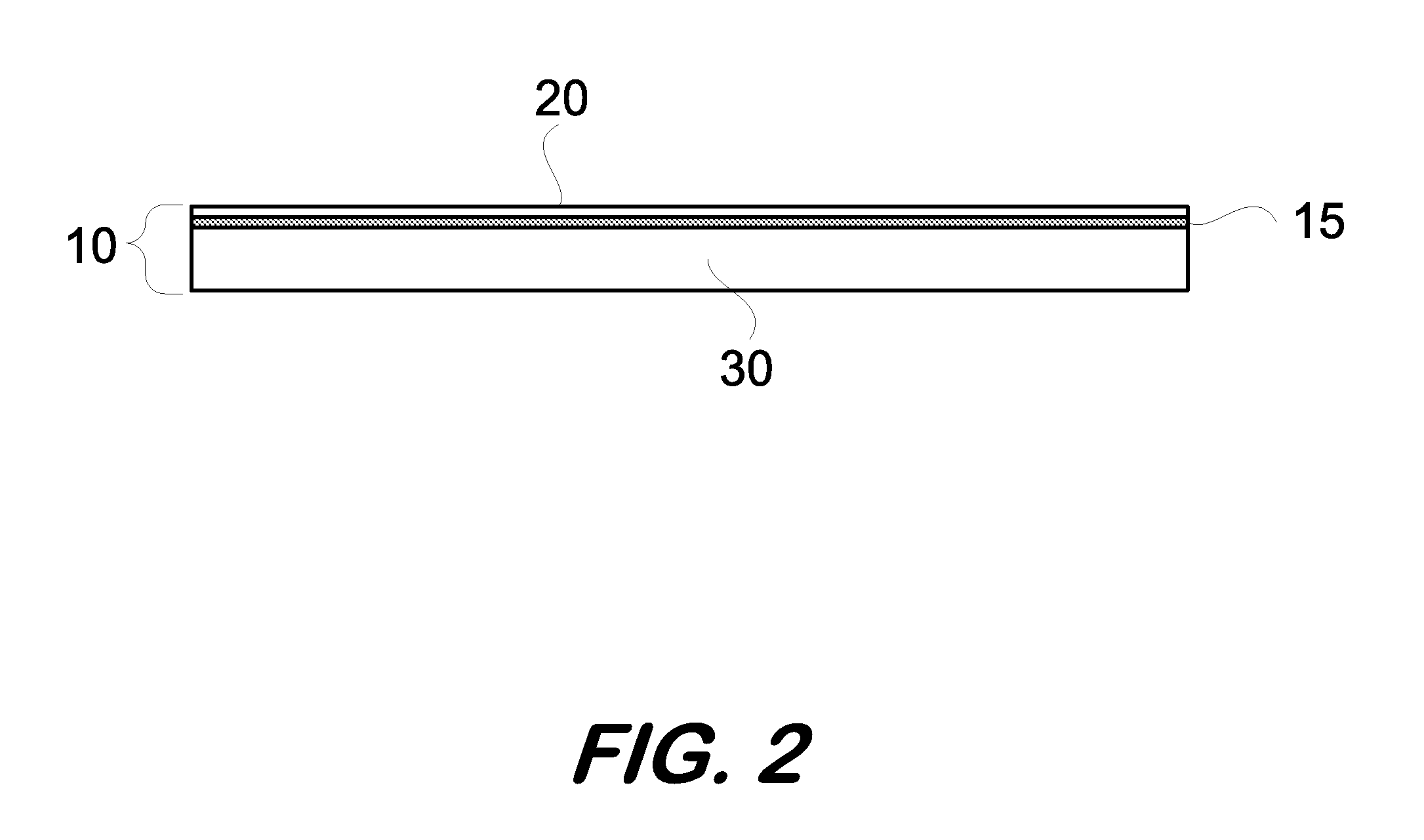

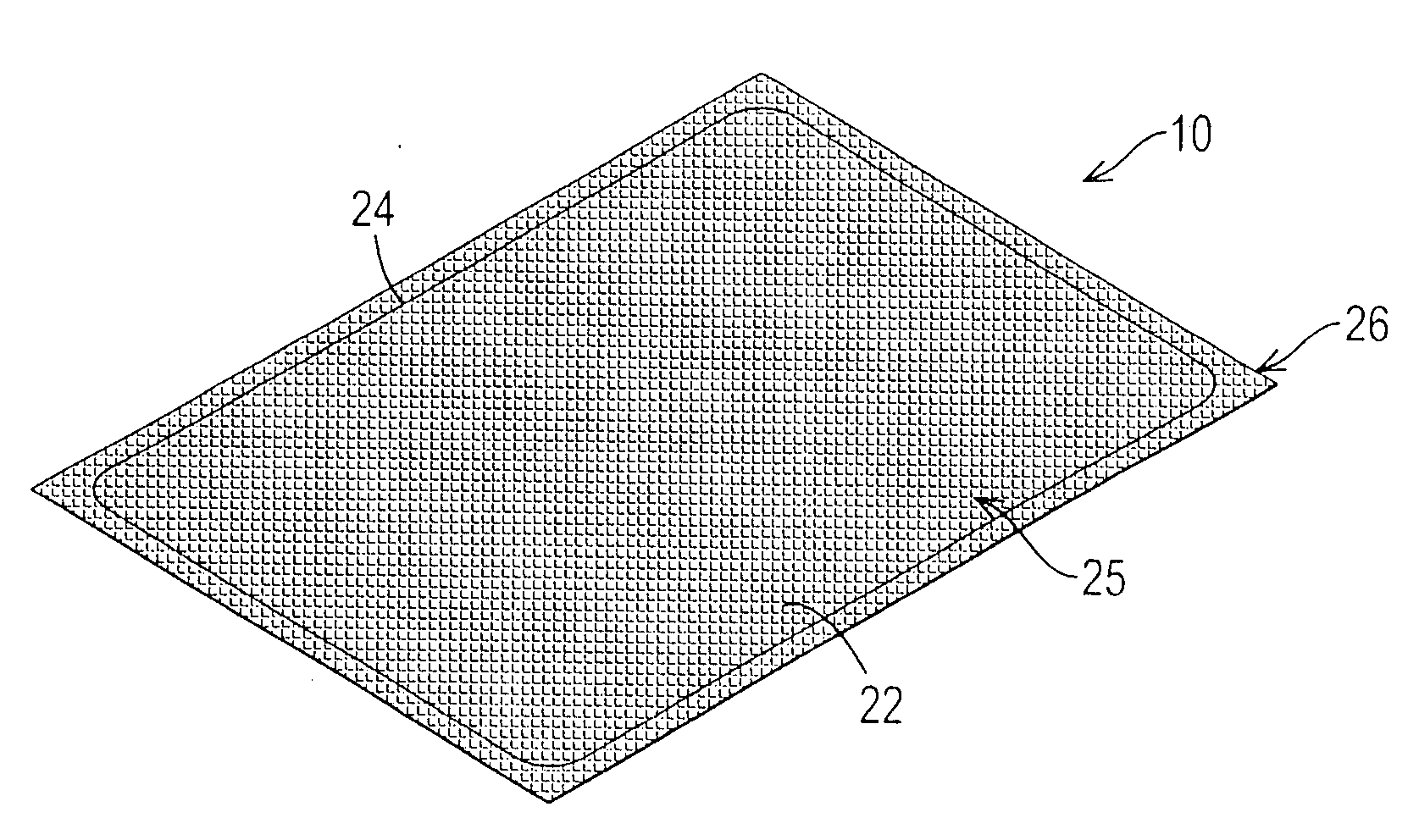

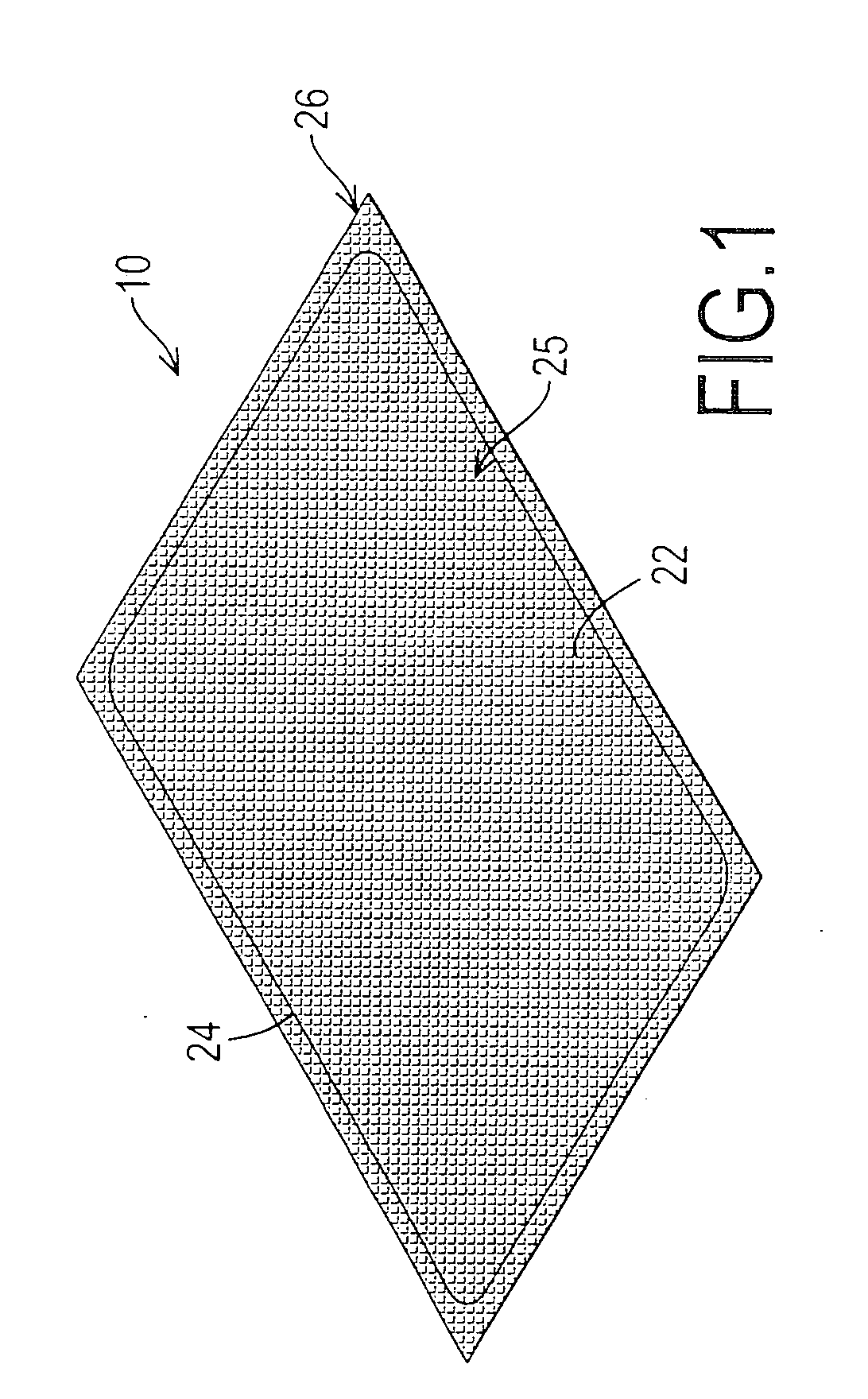

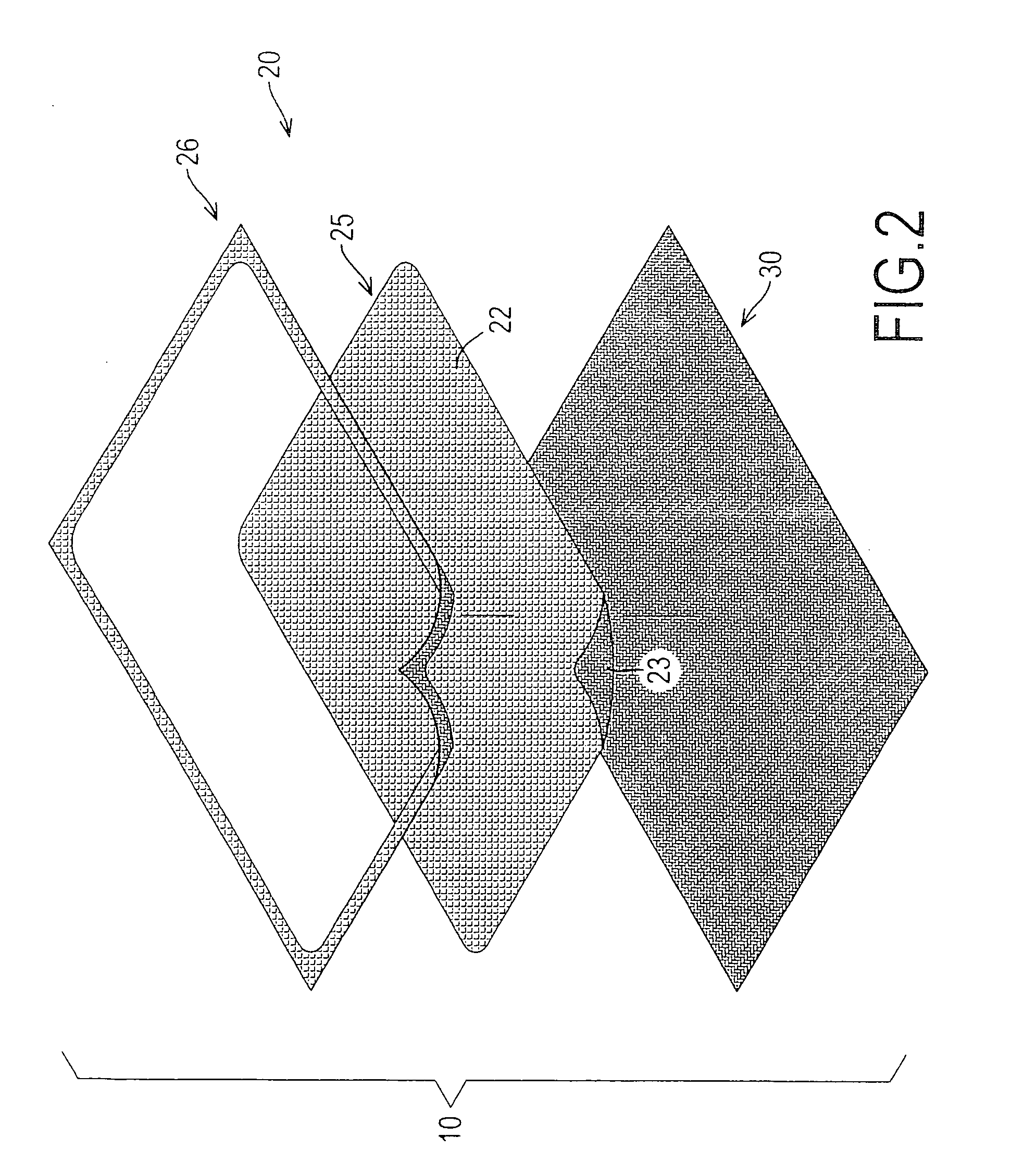

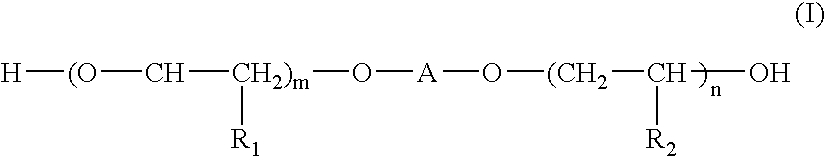

An article comprises a flexible support layer having an exterior surface and an interior surface; and a silicone grip disposed on, conformable, and in contact with the exterior surface of the flexible support layer, wherein the silicone grip comprises: a cured silicone layer with a Shore A Durometer of less than or equal to about 60 and having an exterior surface and an opposite, interior surface, wherein the silicone layer is formed from a curable silicone composition comprising a catalyst that promotes cure of the silicone composition, a higher molecular weight organopolysiloxane having at least two alkenyl groups per molecule, a lower molecular weight organopolysiloxane having at least two alkenyl groups per molecule, and an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule.

Owner:WORLD PROPERTIES

Silicone compositions, methods of manufacture, and articles formed therefrom

InactiveUS20090162596A1Better gripping surfaceImprove adhesionSolesWater sport boardsHydrogenSilica gel

A mat comprises a backing layer having a top surface and a bottom surface; a silicone grip disposed on, conformable, and in contact with the top surface of the backing layer to form a topside of the mat, wherein the silicone grip comprises: a cured silicone layer with a Shore A Durometer of less than or equal to about 60 and having an exterior surface and an opposite, interior surface; and wherein the silicone layer is formed from a curable silicone composition comprising a catalyst that promotes cure of the silicone composition, a higher molecular weight organopolysiloxane having at least two alkenyl groups per molecule, a lower molecular weight organopolysiloxane having at least two alkenyl groups per molecule, and an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule.

Owner:WORLD PROPERTIES

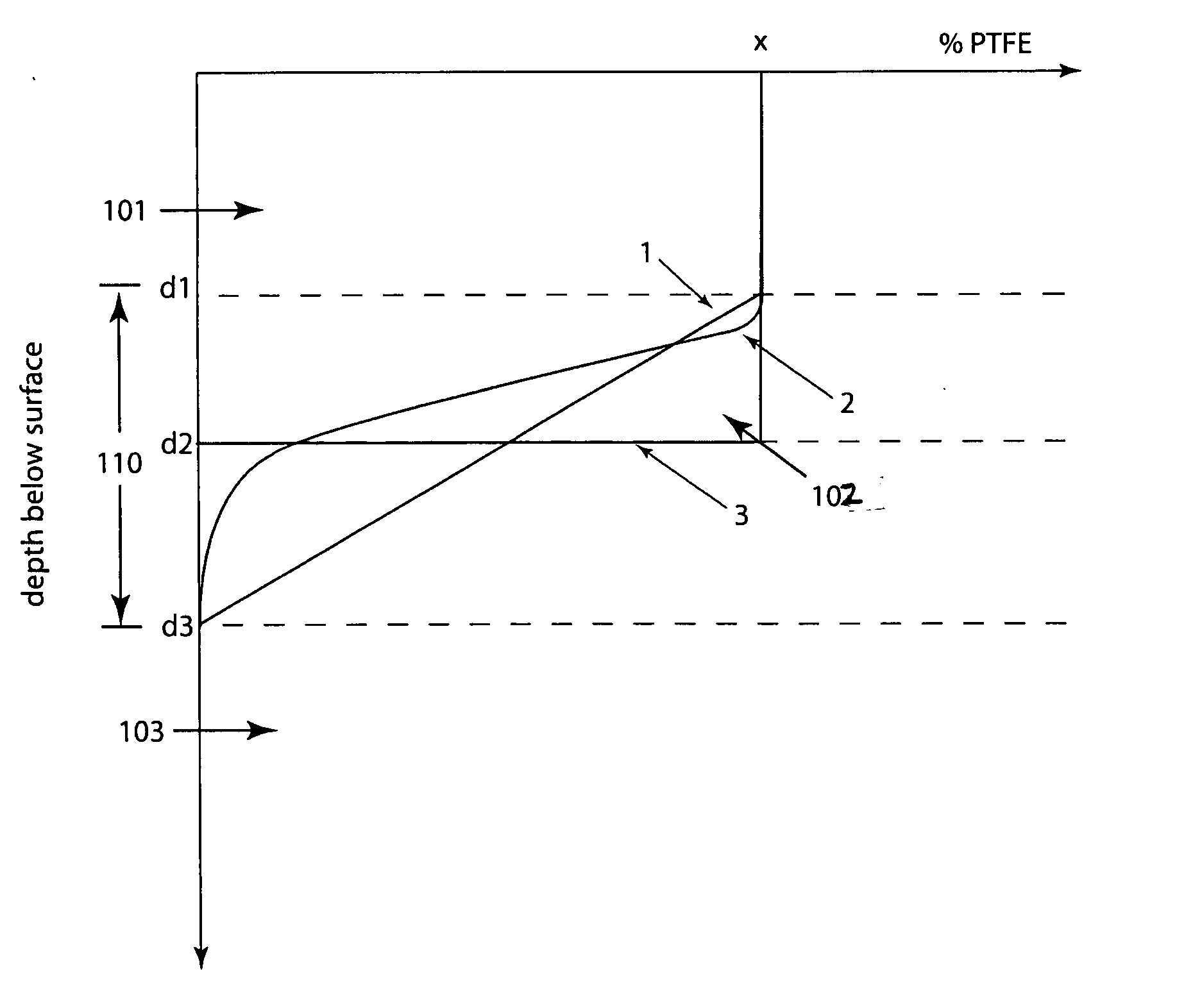

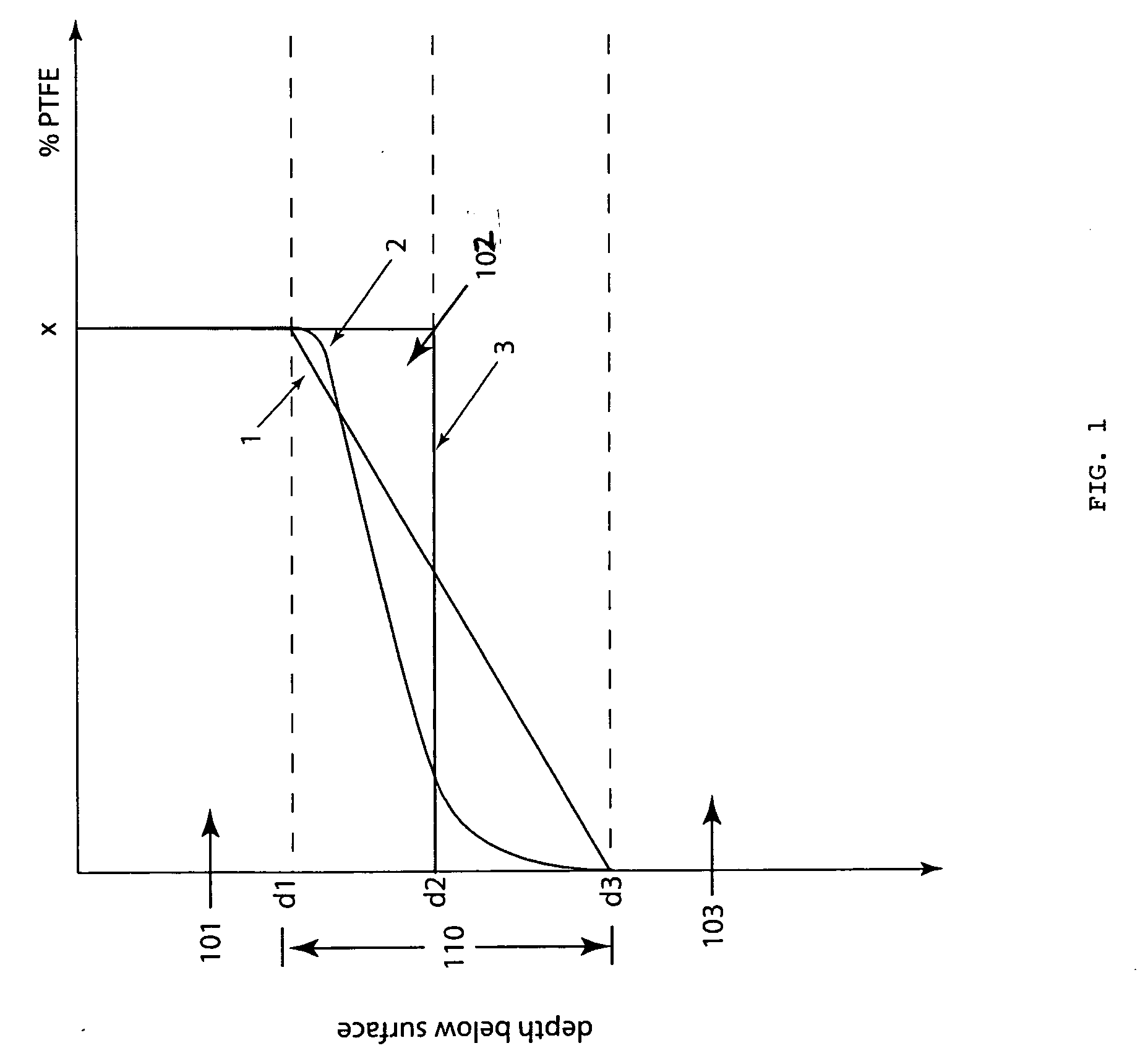

Multi-layer low friction and low wear polymer/polymer composites having compositionally graded interfaces

InactiveUS20060029795A1Reduce wearReduce frictionLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePolyether ether ketone

A high strength multi-layer polymeric article having a low wear surface includes a base polymer layer, and a polymer composite capping layer disposed on the base polymer layer. The capping layer includes a first polymer including a transfer film forming polymer, and a second polymer different from the first polymer for strengthening this polymer composite mixed with the first polymer. The first polymer provides at least 10 weight % of the composite capping layer. A transition layer composite including the first and second polymer is interposed between the capping layer and the base polymer layer, at least a portion of the transition layer providing a non-constant first or second polymer concentration. A wear rate of the article is <10−7 mm3 / Nm. The first polymer can be PTFE and the second polymer can be a polyaryletherketone (PEEK).

Owner:UNIV OF FLORIDA RES FOUNDATION INC

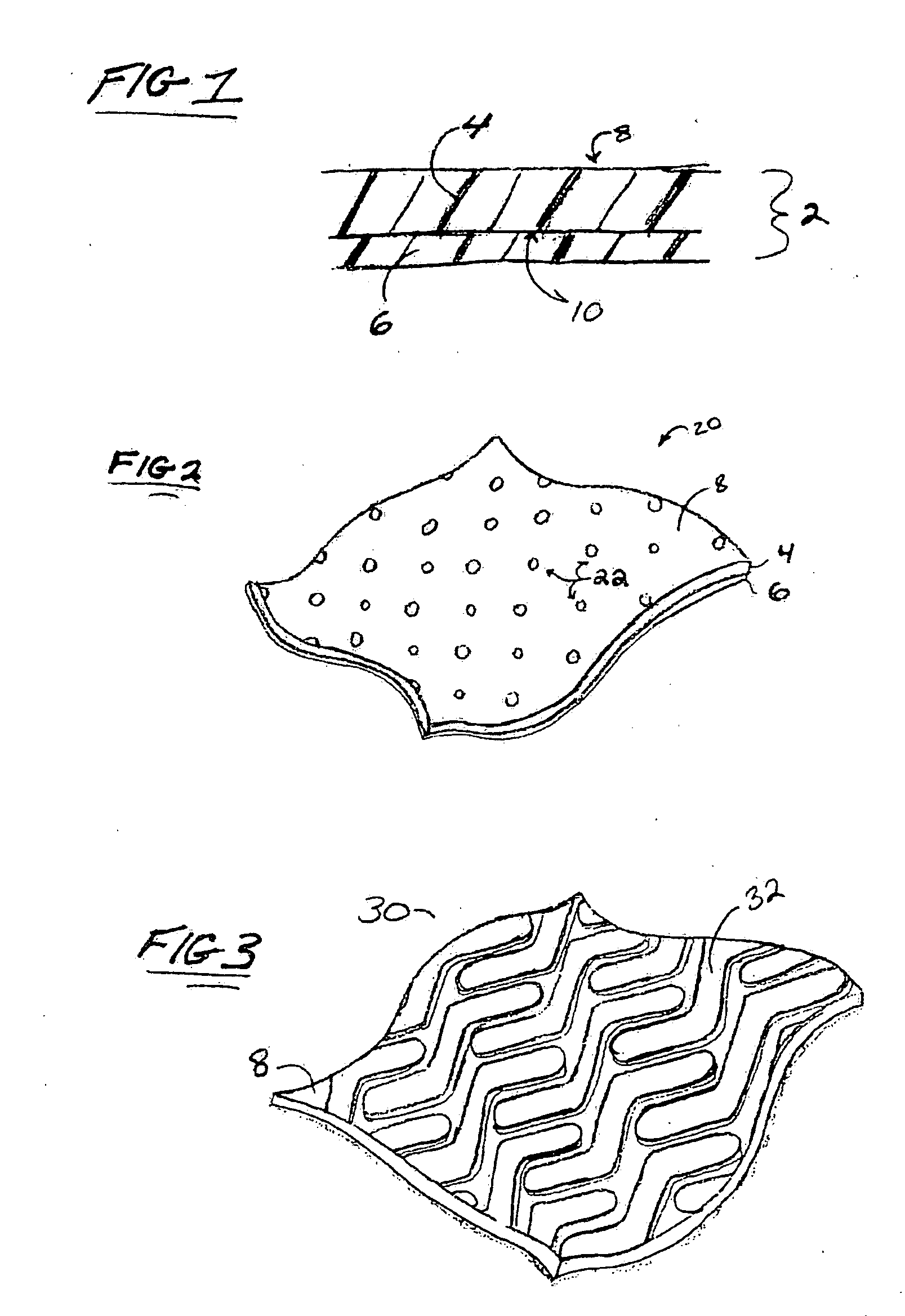

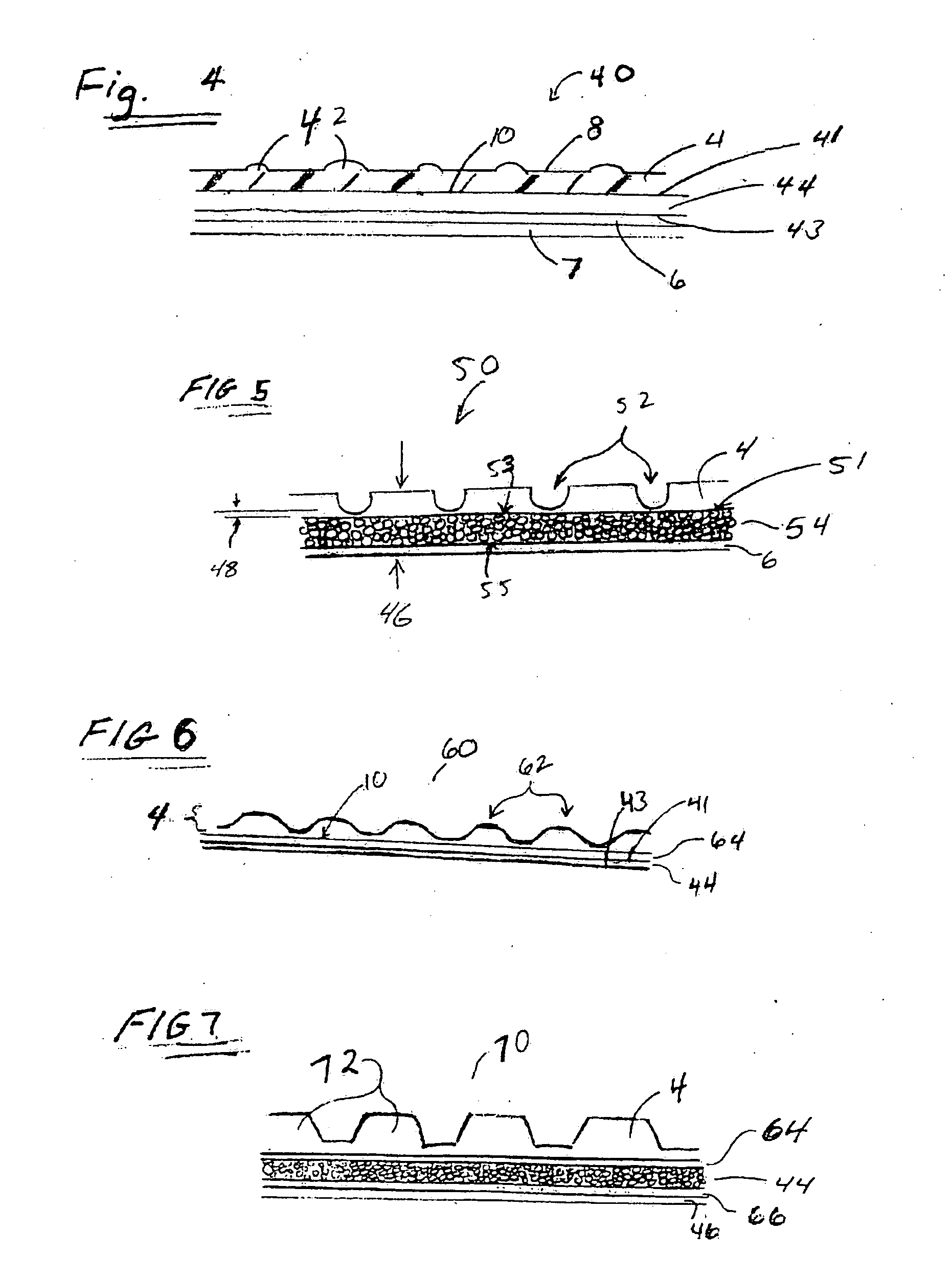

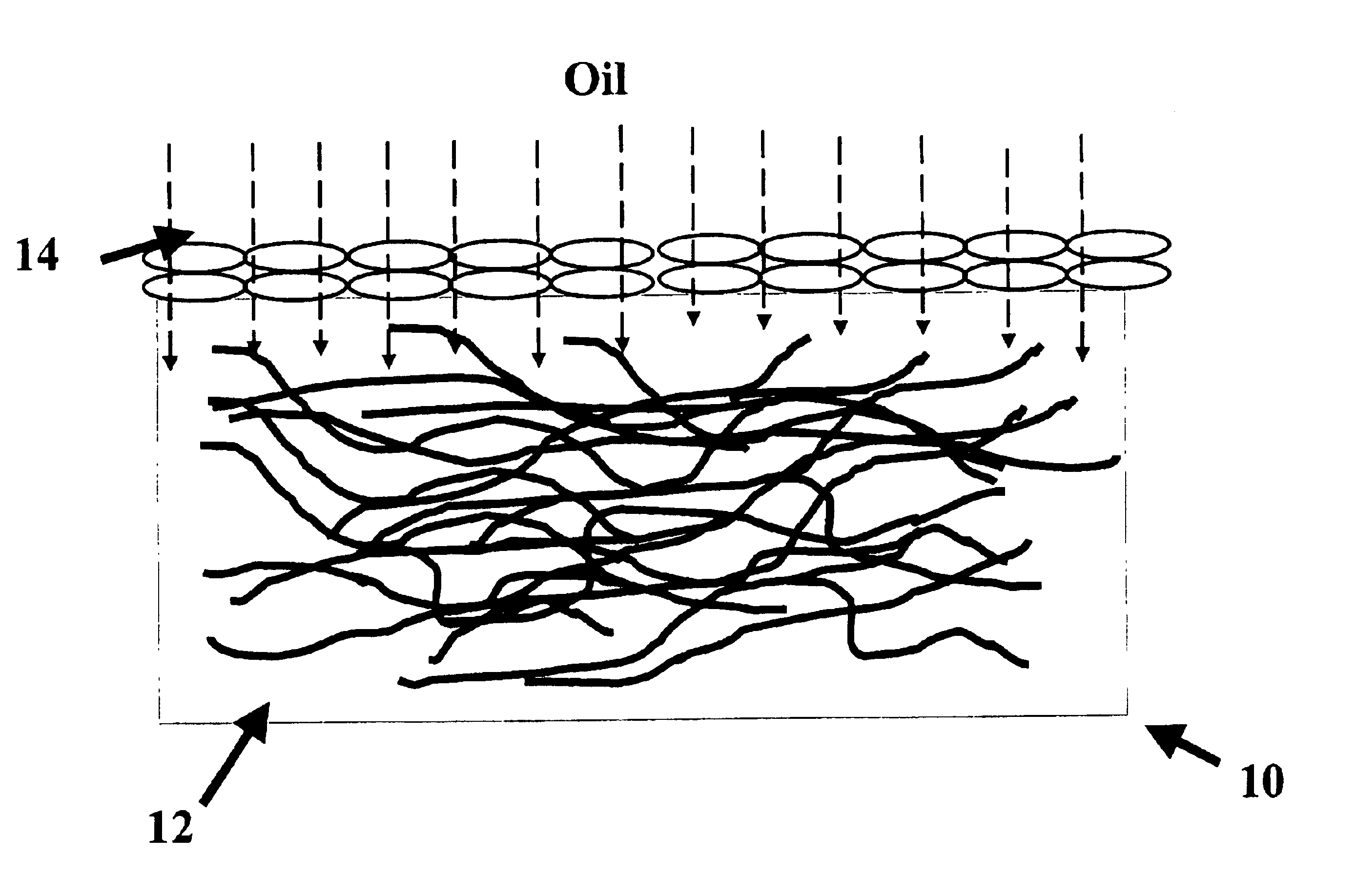

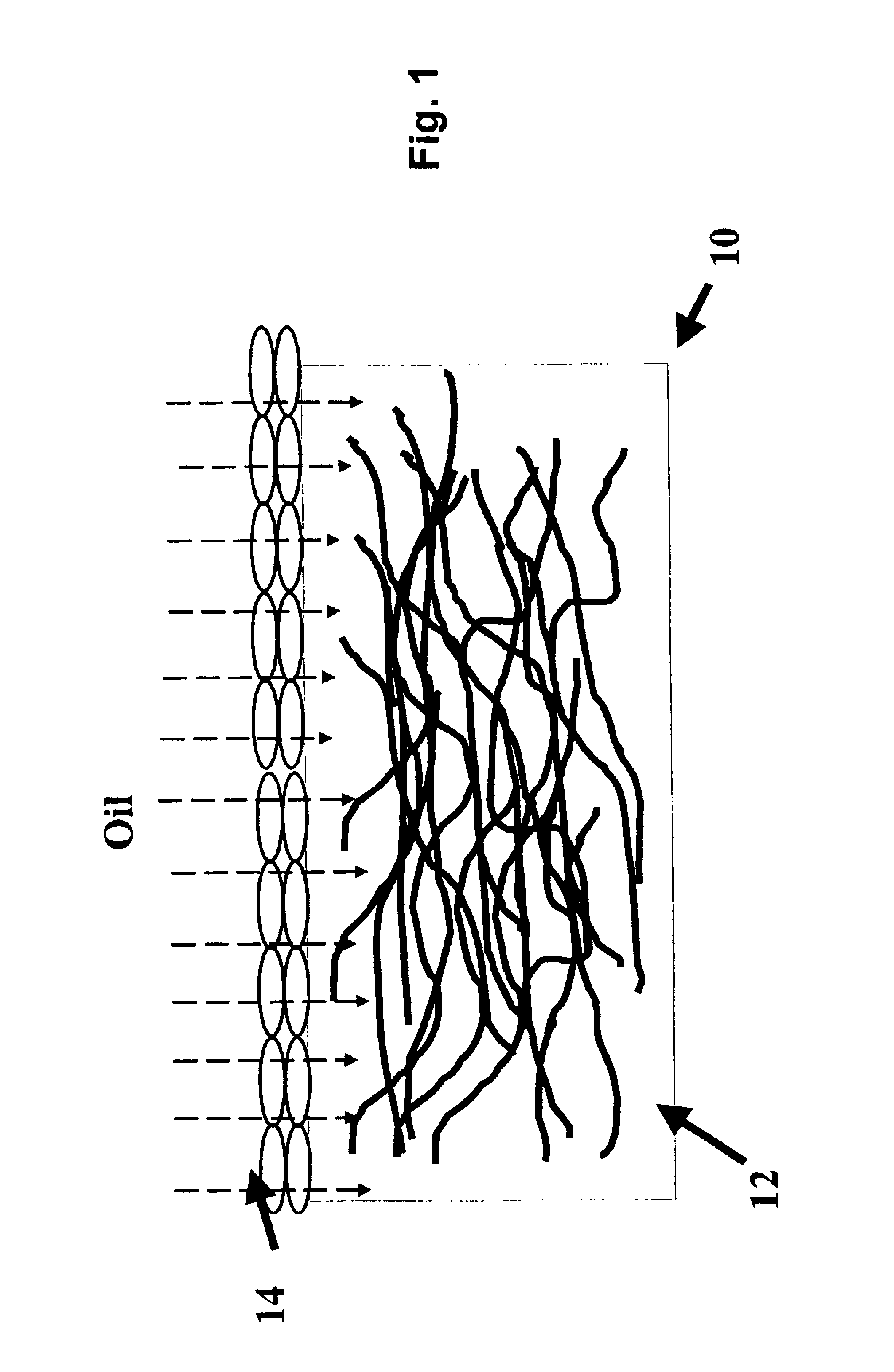

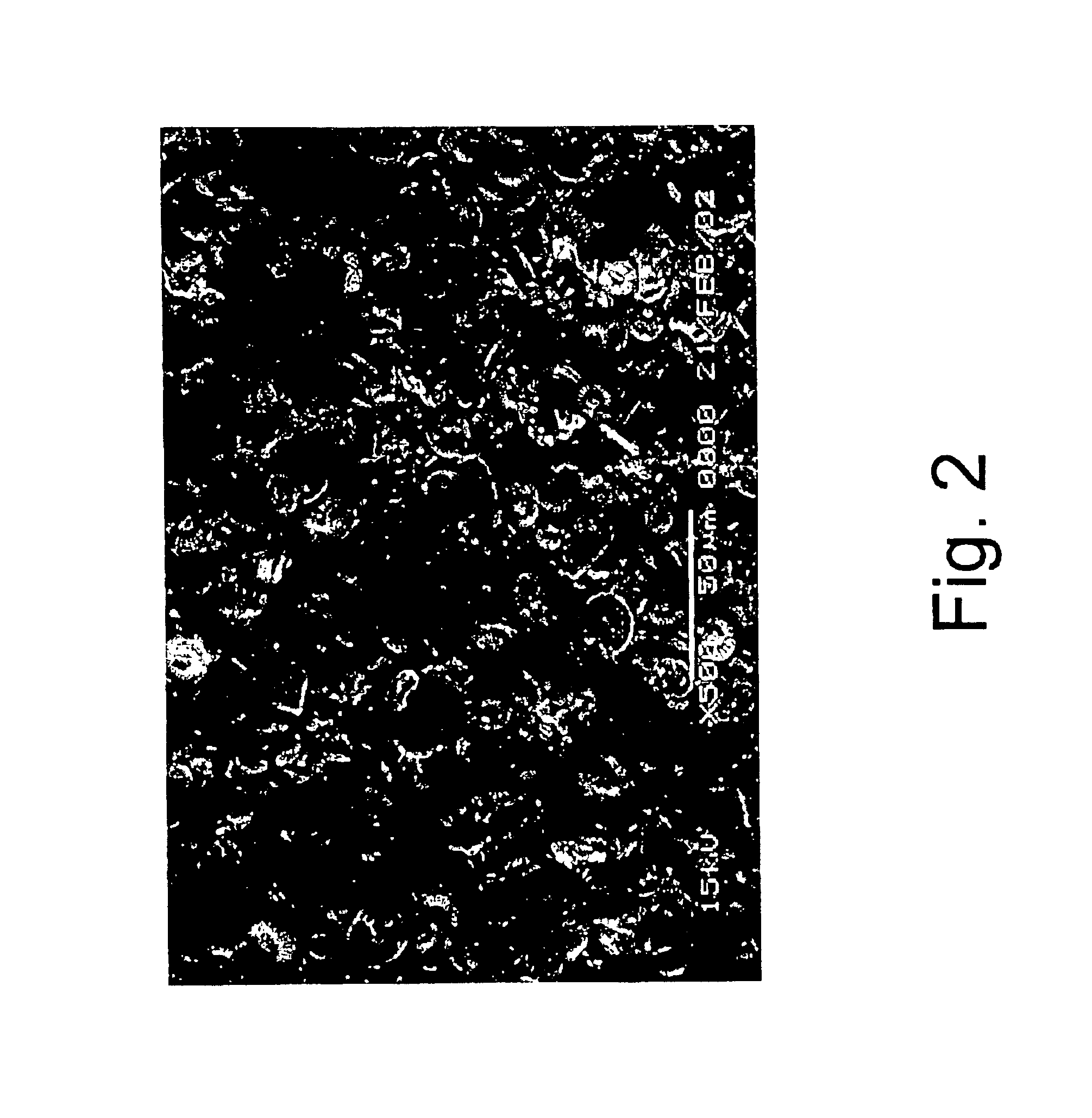

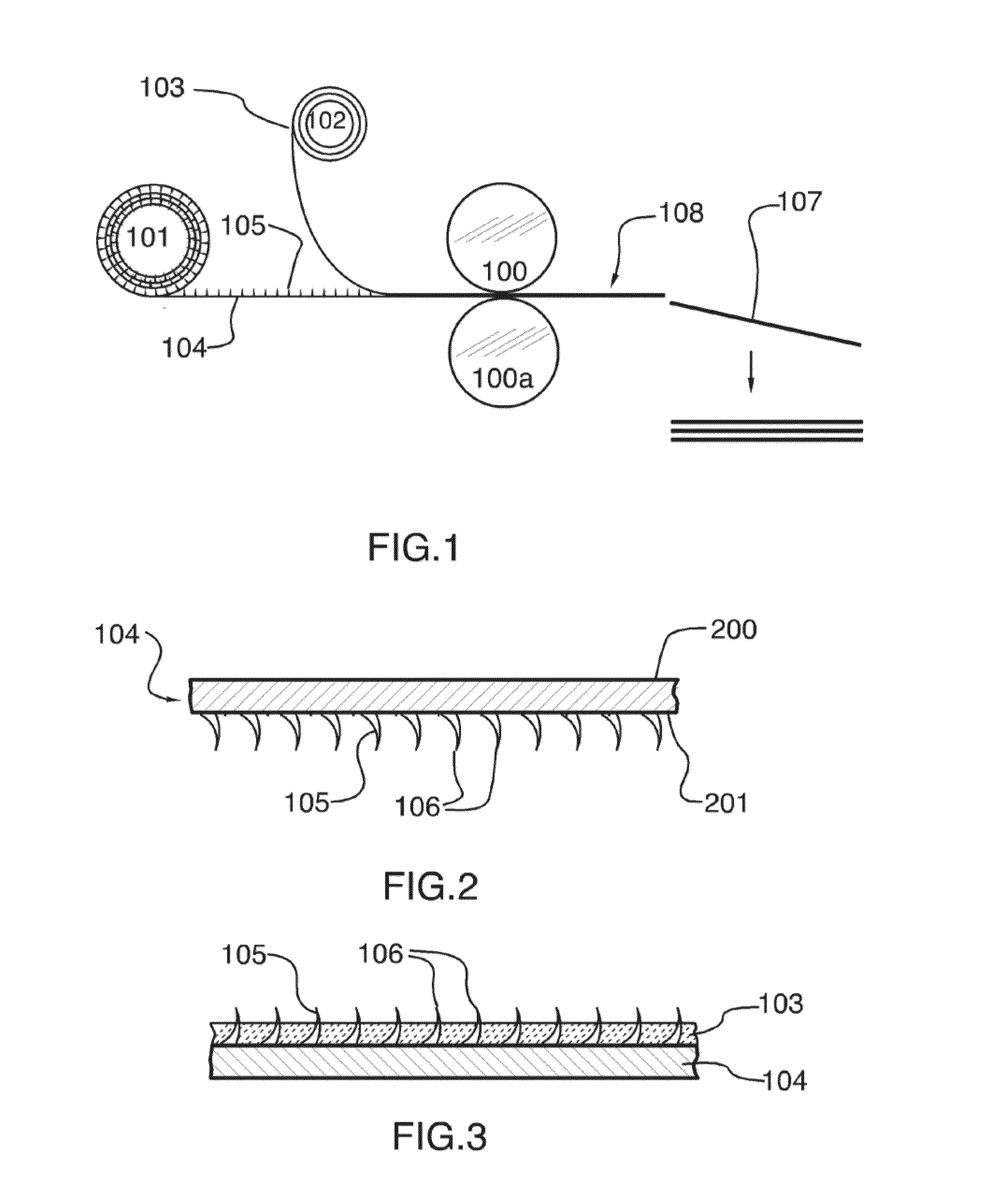

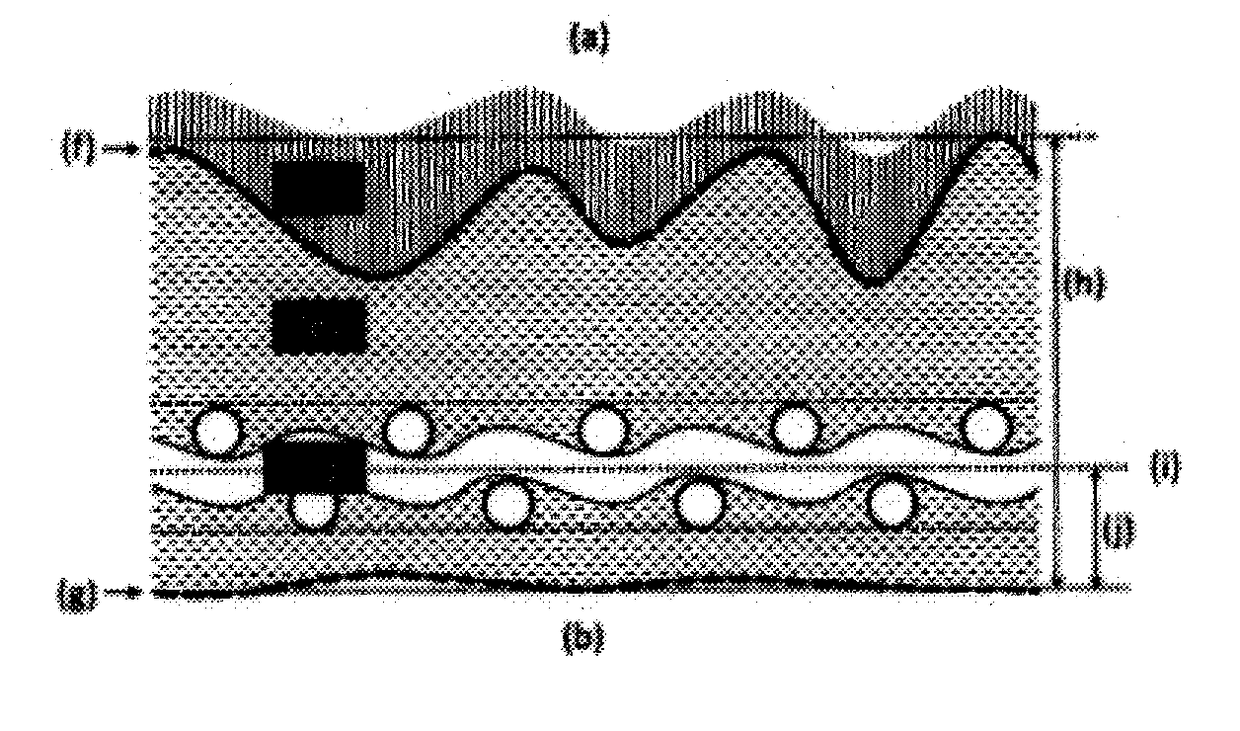

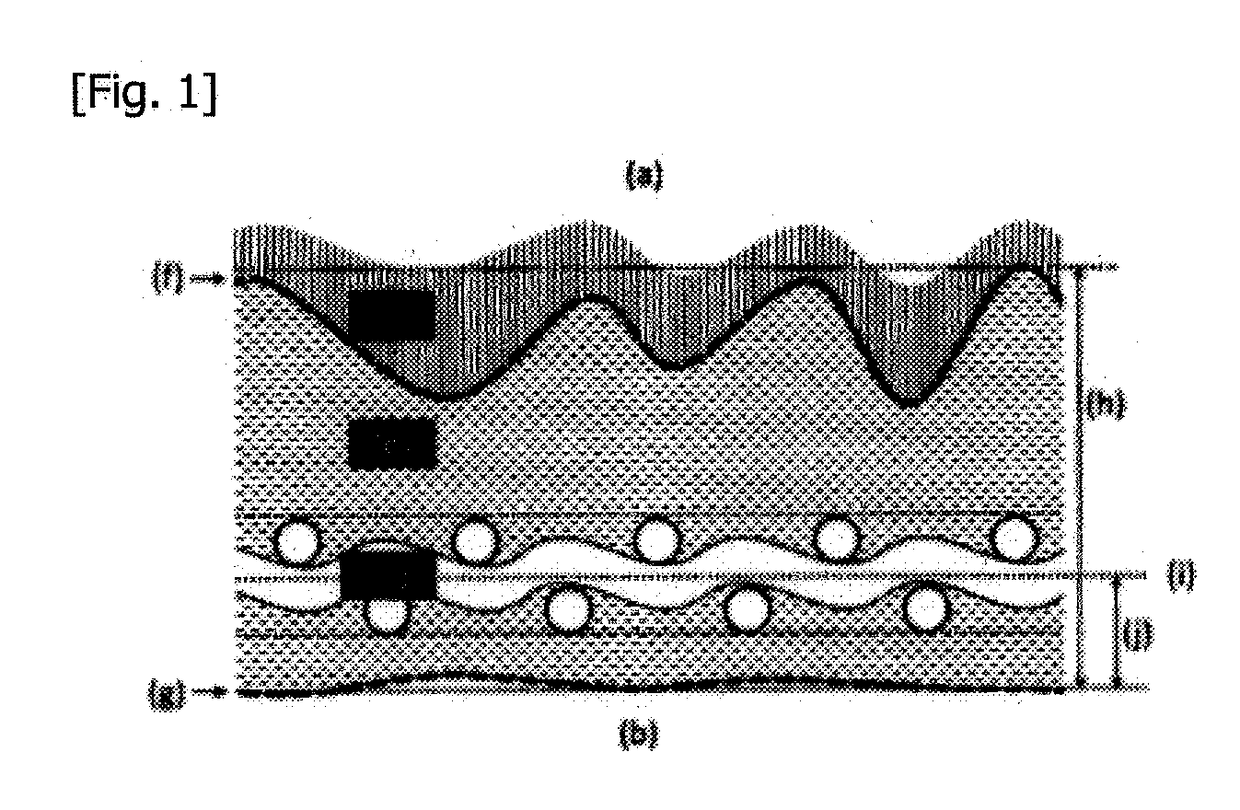

Friction material with friction modifying layer having symmetrical geometric shapes

InactiveUS6875711B2Natural cellulose pulp/paperOther chemical processesMaterials scienceSecondary layer

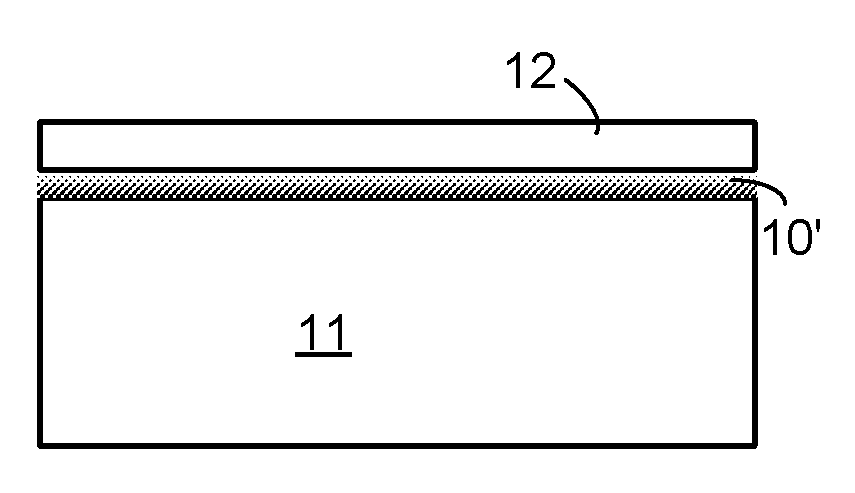

A friction material has a first layer of a base material and a second layer of at least one type of friction modifying particle having substantially symmetrical geometric shapes on a top surface of the base material. The second layer has an average thickness of about 30 to about 200 microns and the surface area coverage of about 80 to about 100% such that the top layer has a fluid permeability lower than the first layer.

Owner:BORGWARNER INC

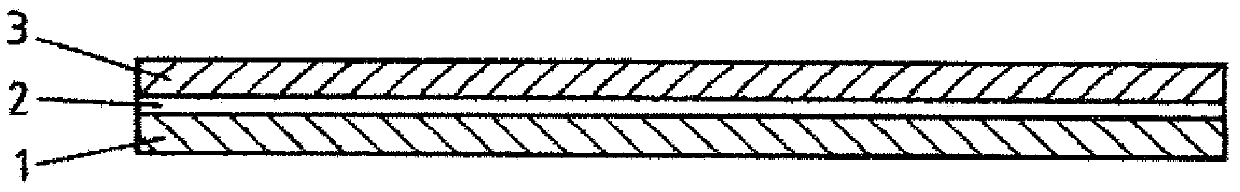

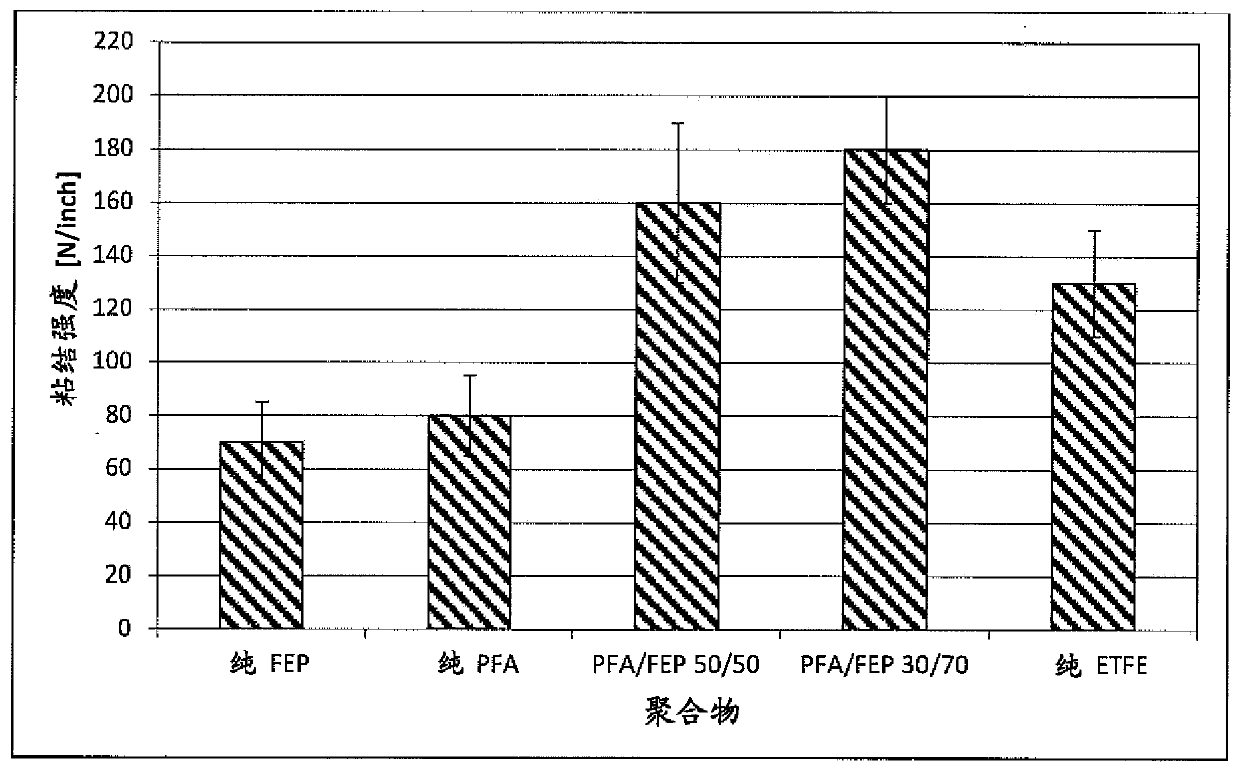

Maintenance-free slide bearing with FEP or PFA in the adhesive layer

Slide bearings and methods of producing slide bearings are disclosed. The slide bearing has a metal support, an adhesive layer and a sliding layer. The adhesive layer is applied directly to the metal support. The adhesive layer comprises a blend of at least two fluoropolymers P1 and P2, wherein P1 is selected from perfluoroalkoxyethylene (PFA) or tetrafluoroethylene-hexafluoropropylene (FEP). P2 is different from P1 and can be a fluoropolymer.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

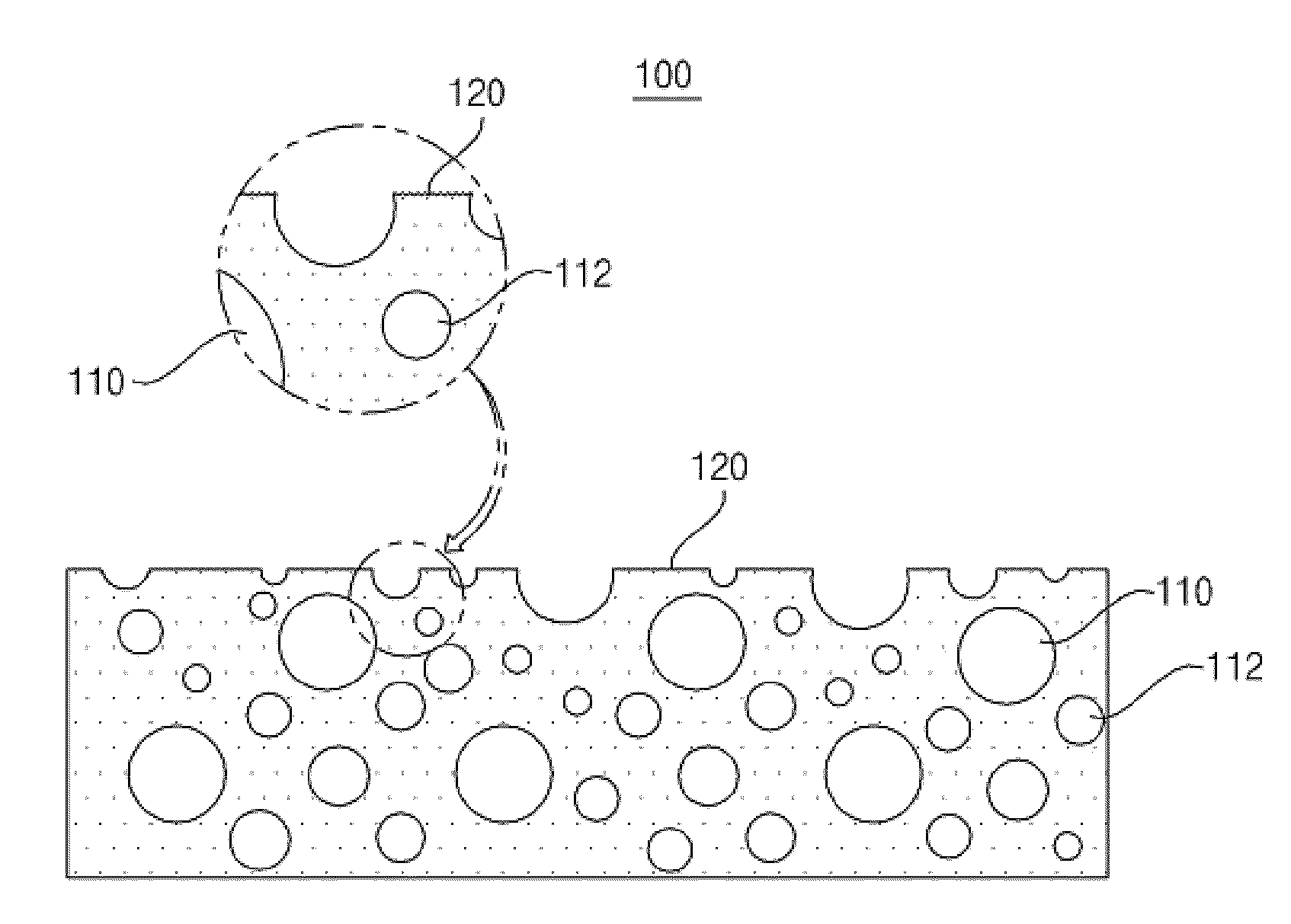

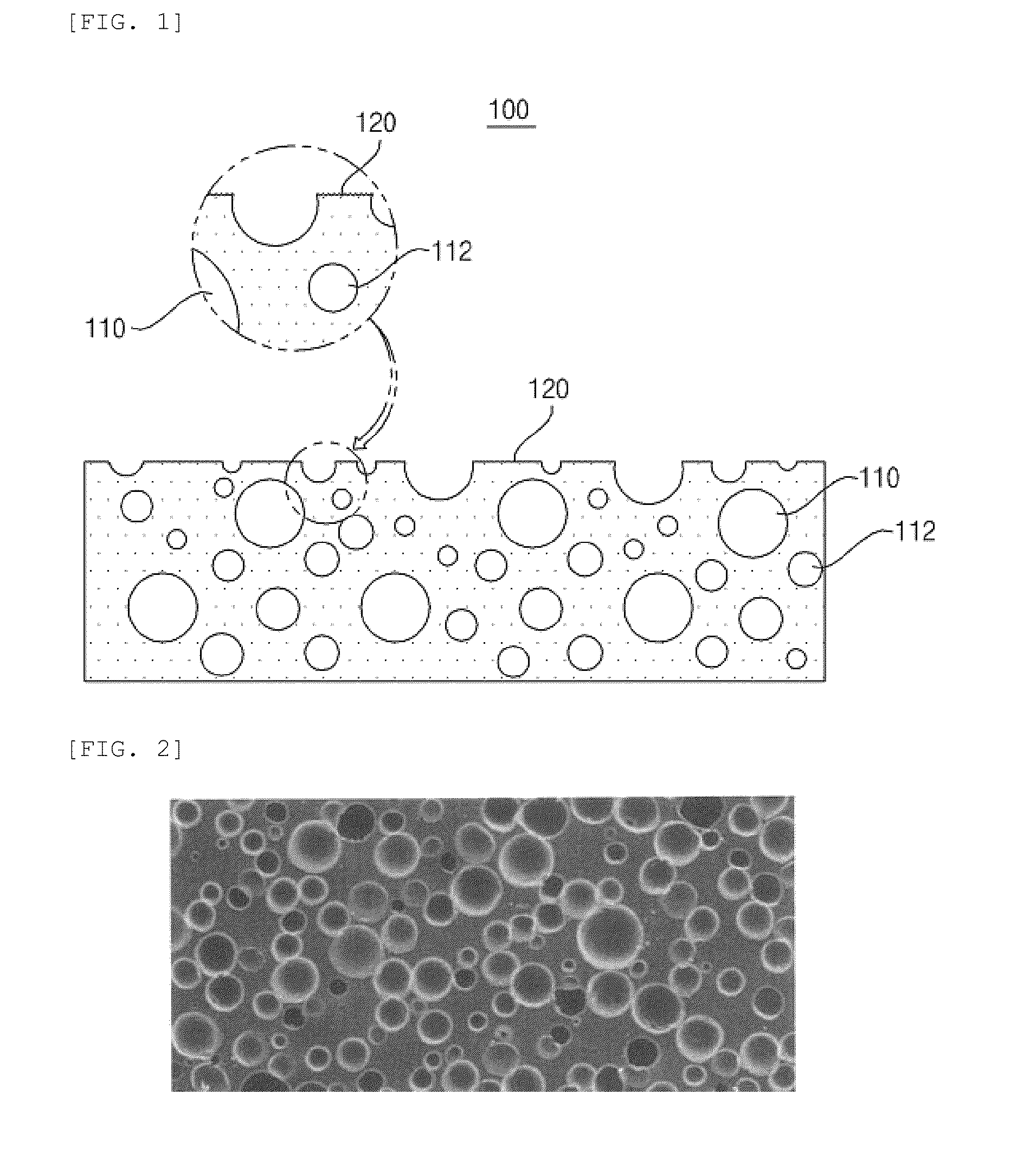

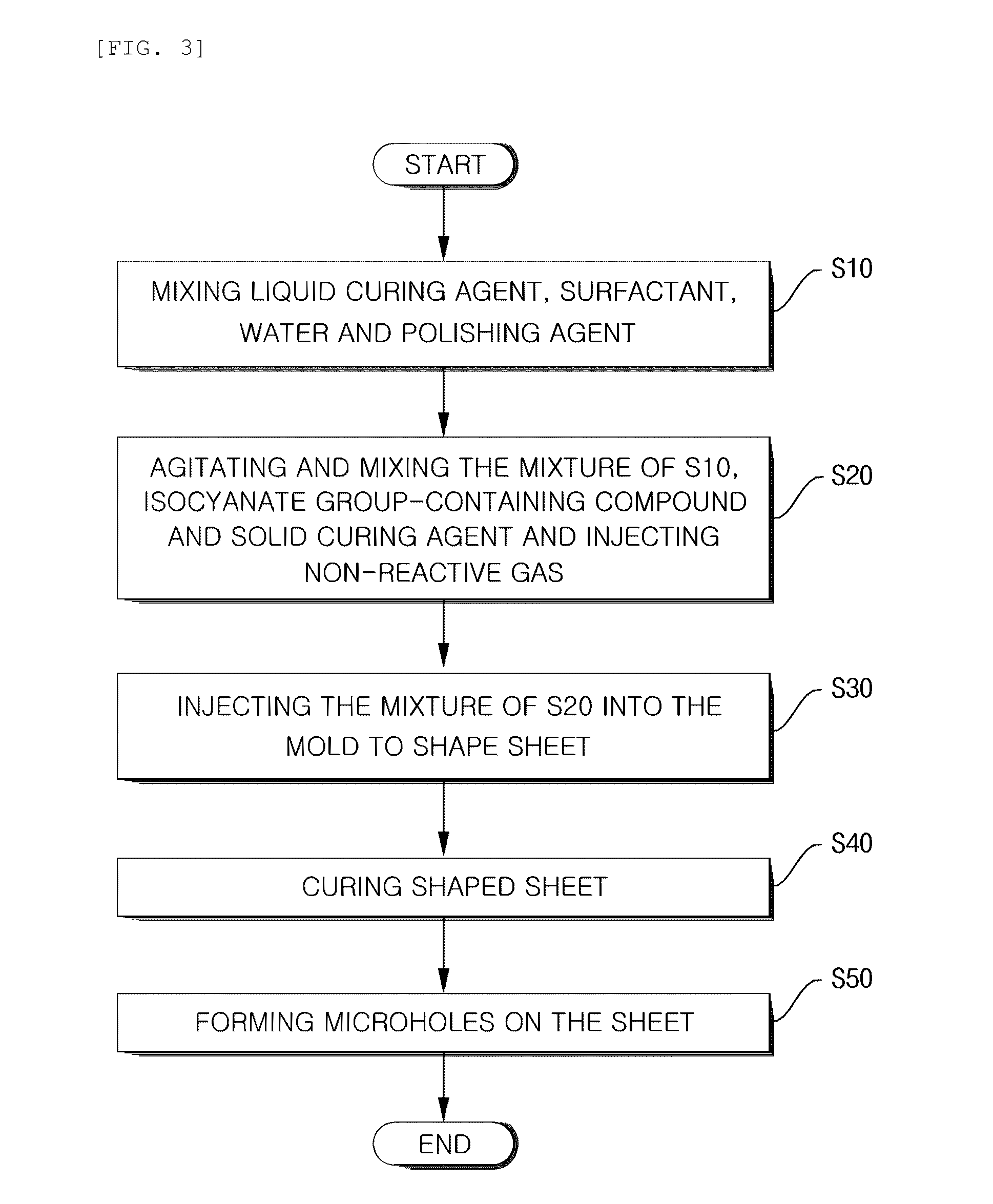

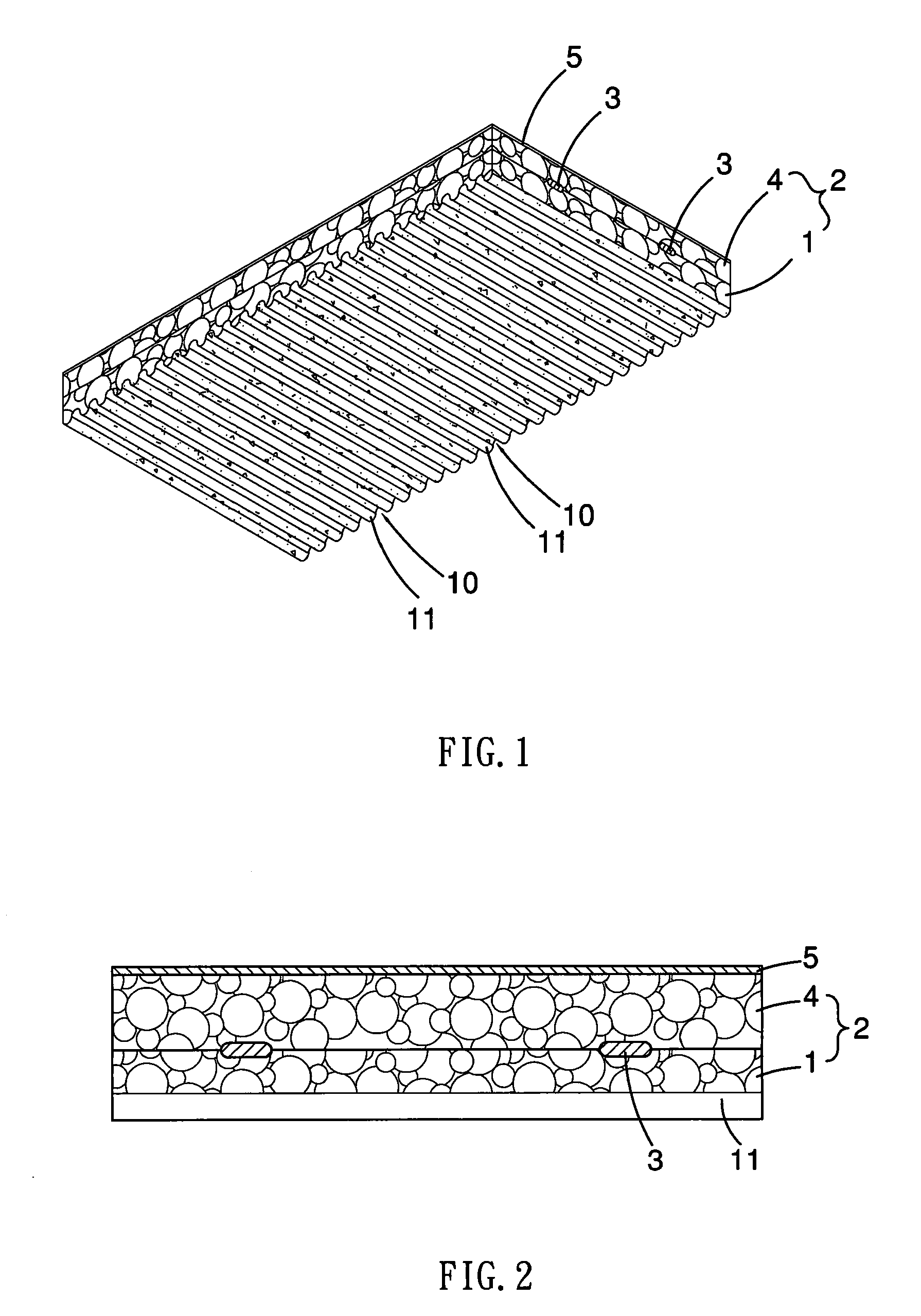

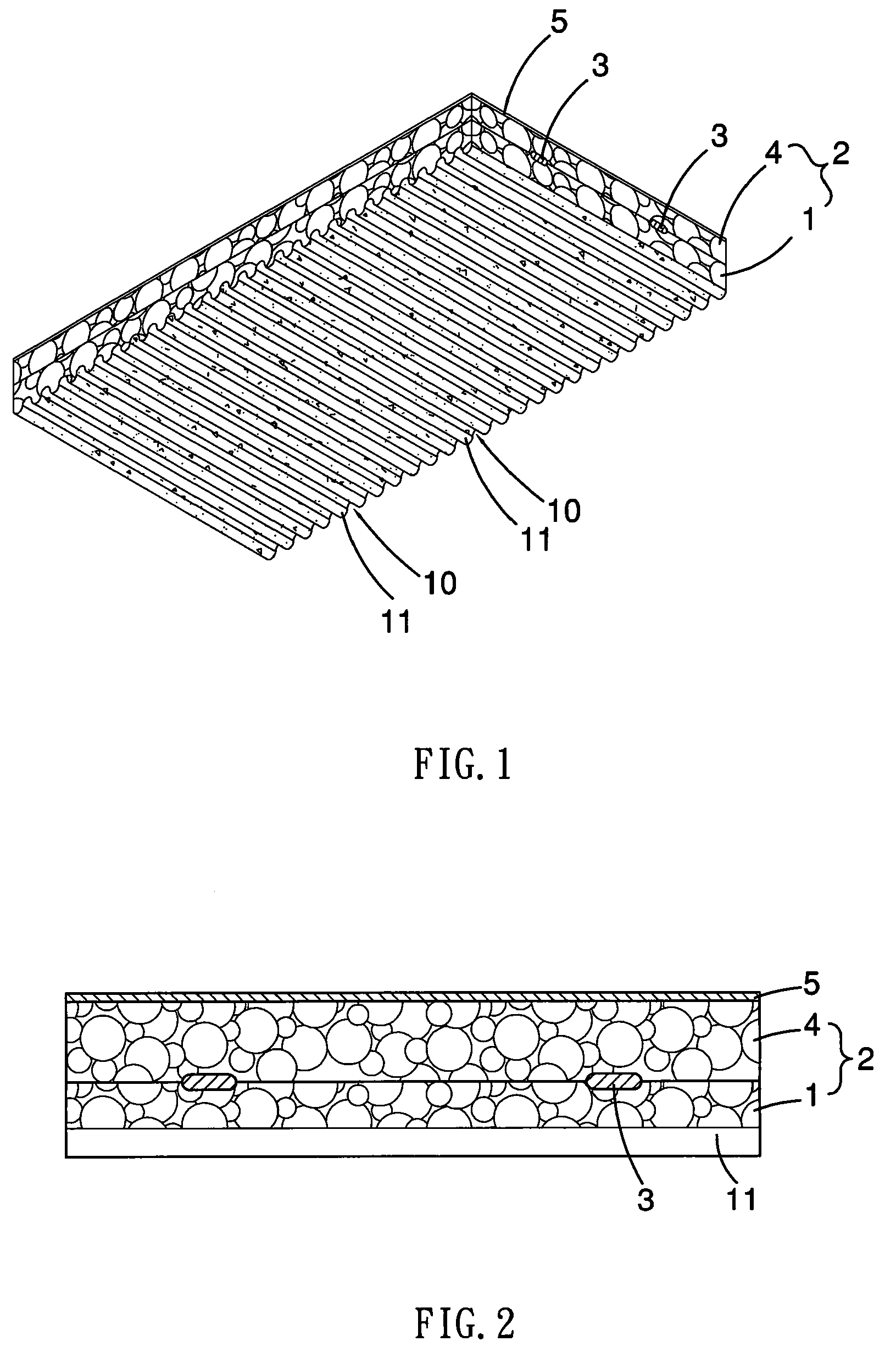

Polyurethane porous product and manufacturing method thereof and polishing pad having polyurethane porous product

InactiveUS20100247868A1Improve stabilityImprove uniformitySynthetic resin layered productsAbrasion apparatusIn planeHardness

The present invention relates to a method for manufacturing a polyurethane porous product, a polyurethane porous product according to the manufacturing method, and a polishing pad having the polyurethane porous product. According to the present invention, it is possible to manufacture a polishing pad that has excellent polishing efficiency and has a minimal difference in the polishing characteristic during a polishing process and improves uniformity in plane of material that will be polished because the polyurethane porous product of the present invention has small density difference, small hardness difference, and the stabilized quality of material.

Owner:CHA YOON JONG +1

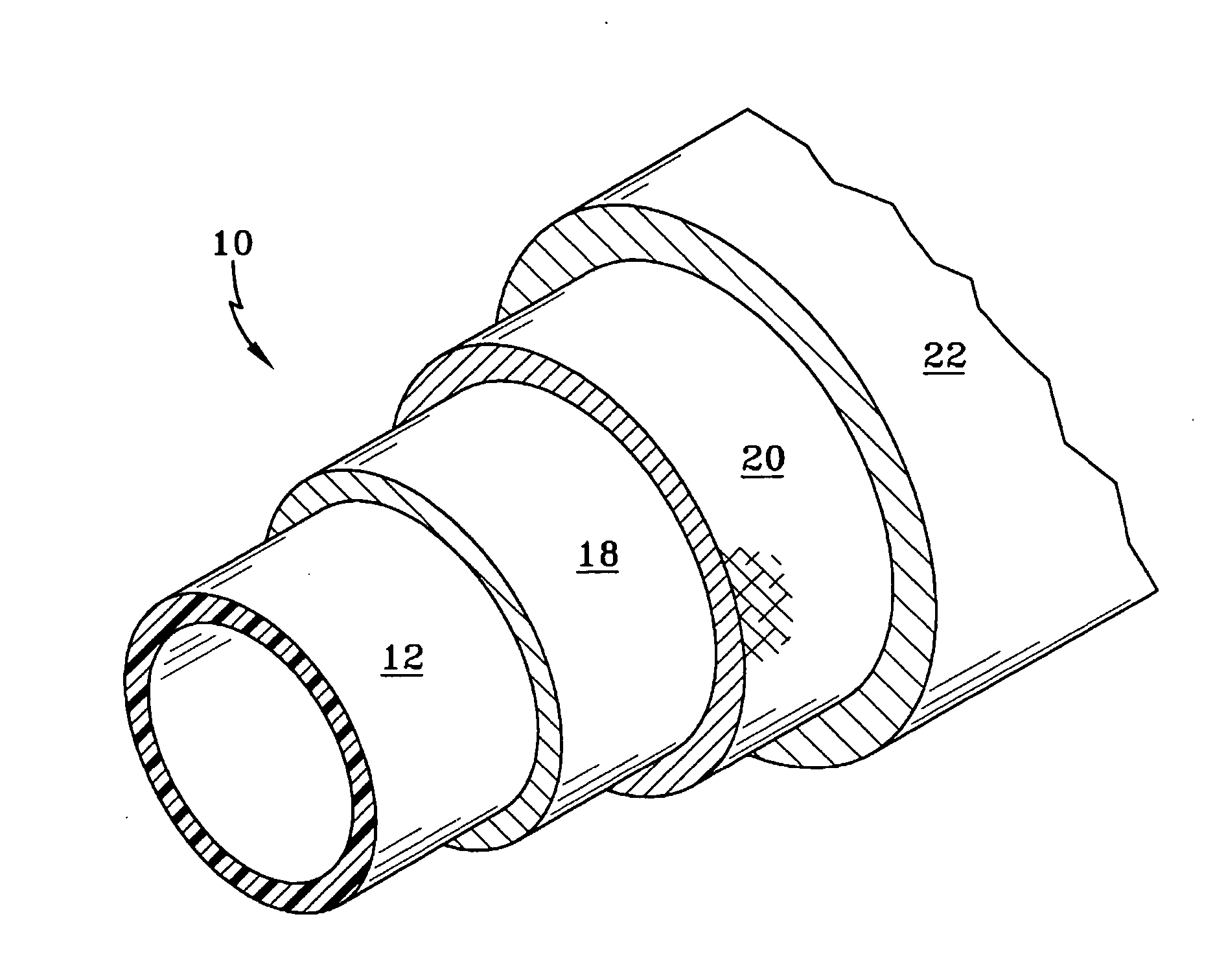

Low friction, abrasion-resistant bearing materials

InactiveUS20050185867A1Composite coefficient of frictionImprove wear resistanceShaftsSynthetic resin layered productsTetrafluoroethyleneWear resistant

A friction-reducing abrasion resistant bearing material is described. The material comprises a monolithic, porous polytetrafluoroethylene (ePTFE) having dispersed therein a wear-resistant thermosetting or thermoplastic resin material.

Owner:WL GORE & ASSOC INC

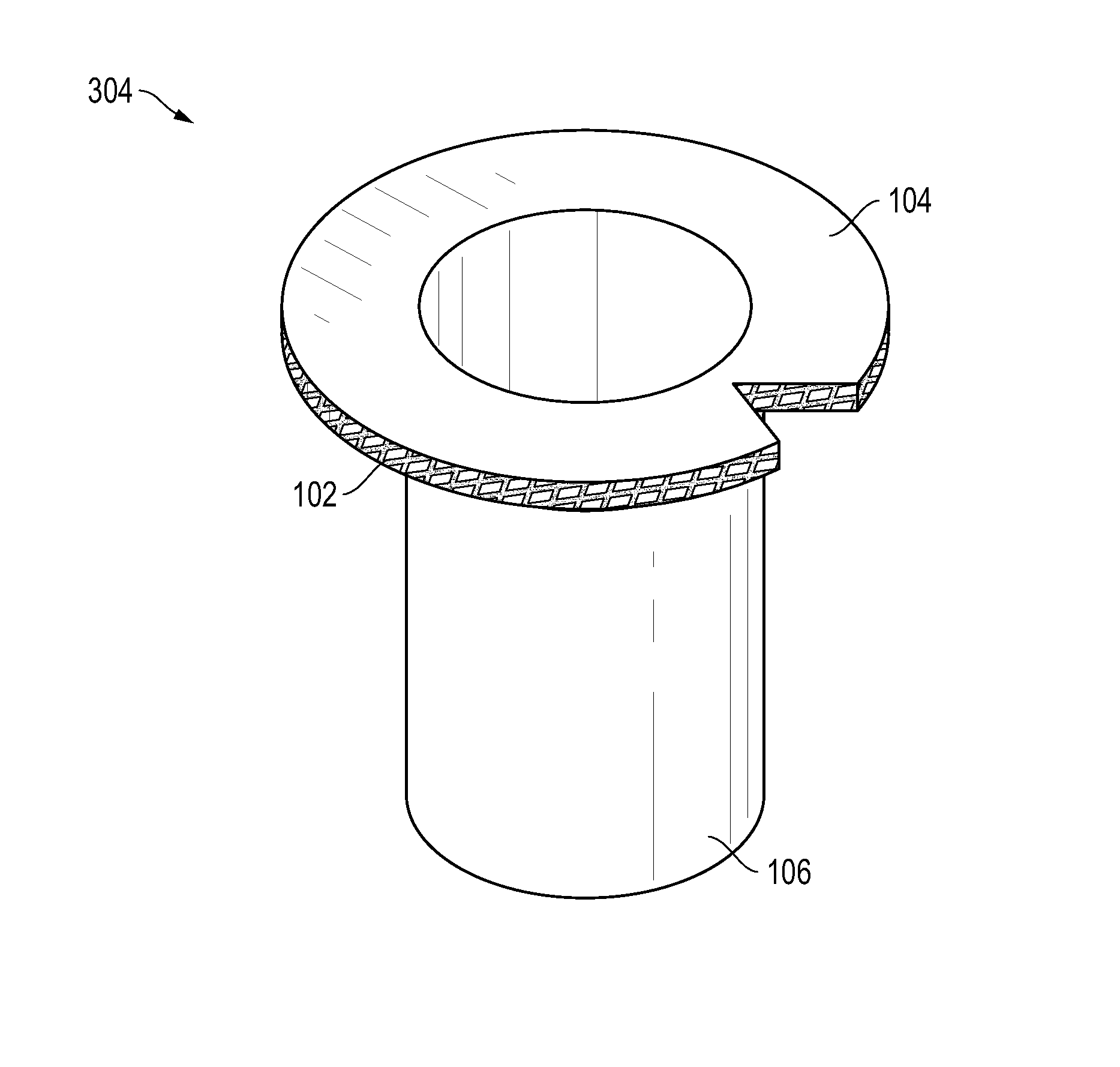

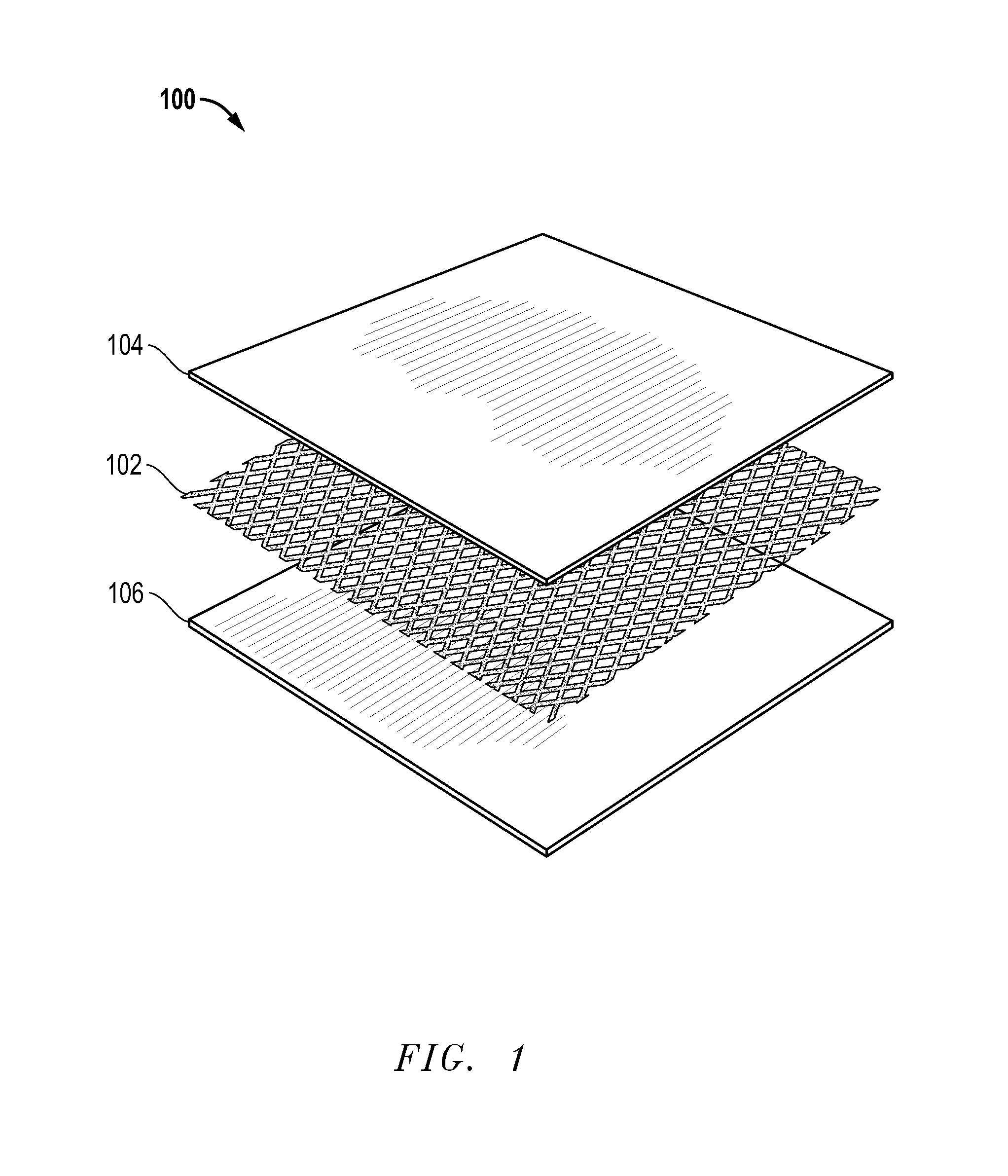

Corrosions reducing flexible plain bearing material and method of forming the same

A method of reducing corrosion of a corrosive metal containing work piece includes providing a corrosive metal containing work piece having a non-planar surface. The method can further include covering at least about 10% of the non-planar surface with a laminate. The laminate can include an aluminum alloy mesh having a first major surface and a second major surface. The laminate can further include a sliding layer overlying the first major surface. The sliding layer can be in direct contact with the aluminum alloy mesh. In another aspect, a corrosion protection article can include a bushing. The bushing can be in a non-planar shape. The bushing can further be shaped to enfold a work piece. The bushing can include an aluminum alloy mesh having a first major surface and include a sliding layer overlying the first major surface. The sliding layer can be in direct contact with the aluminum alloy mesh.

Owner:ANDELKOVSKI ZIVKO

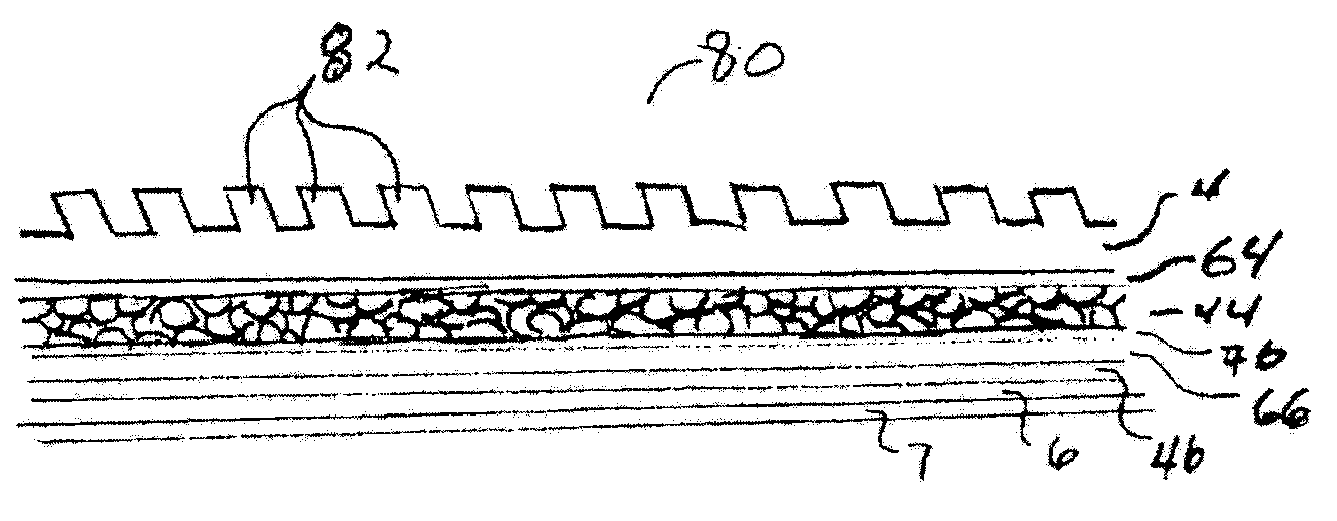

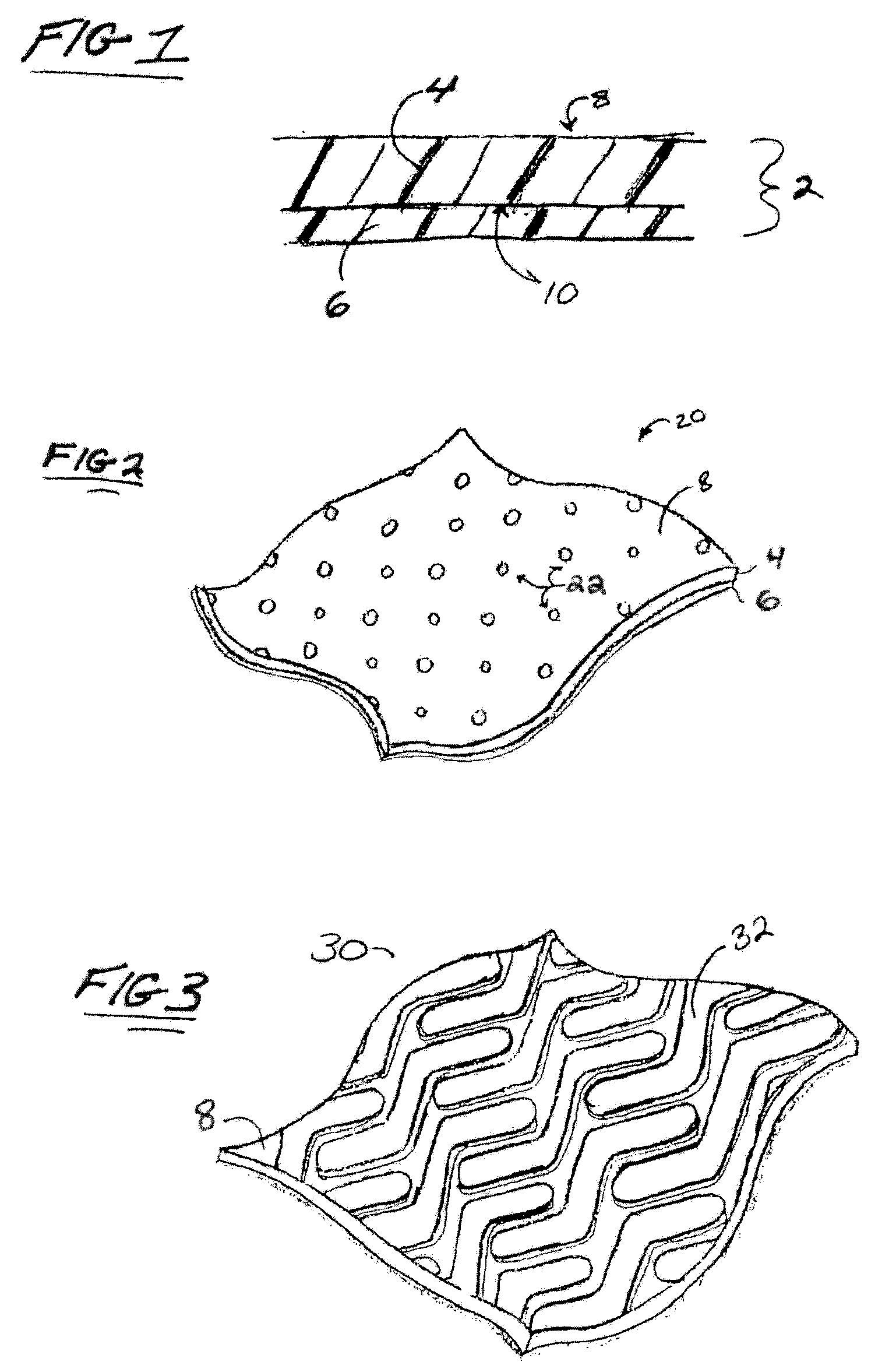

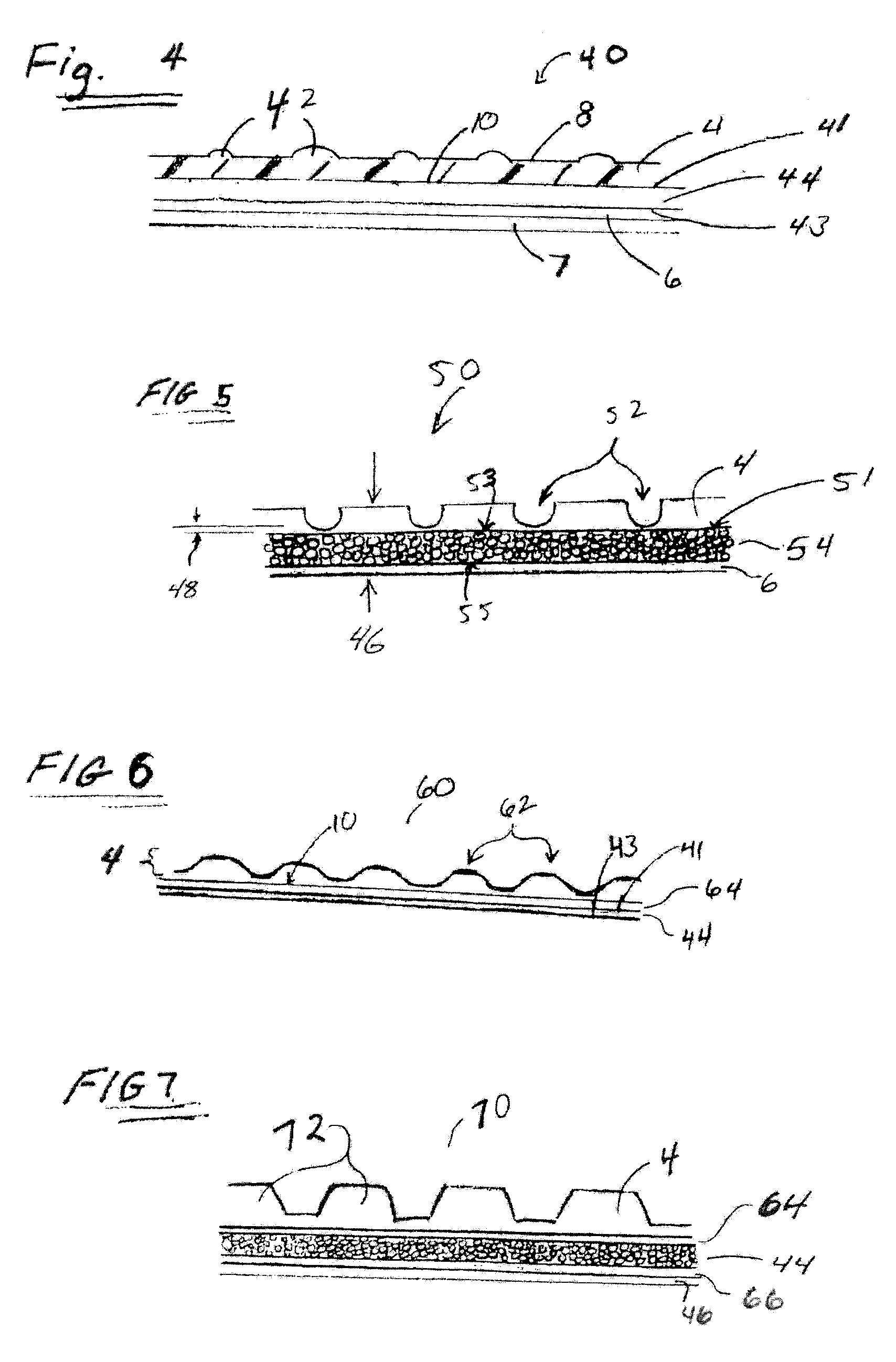

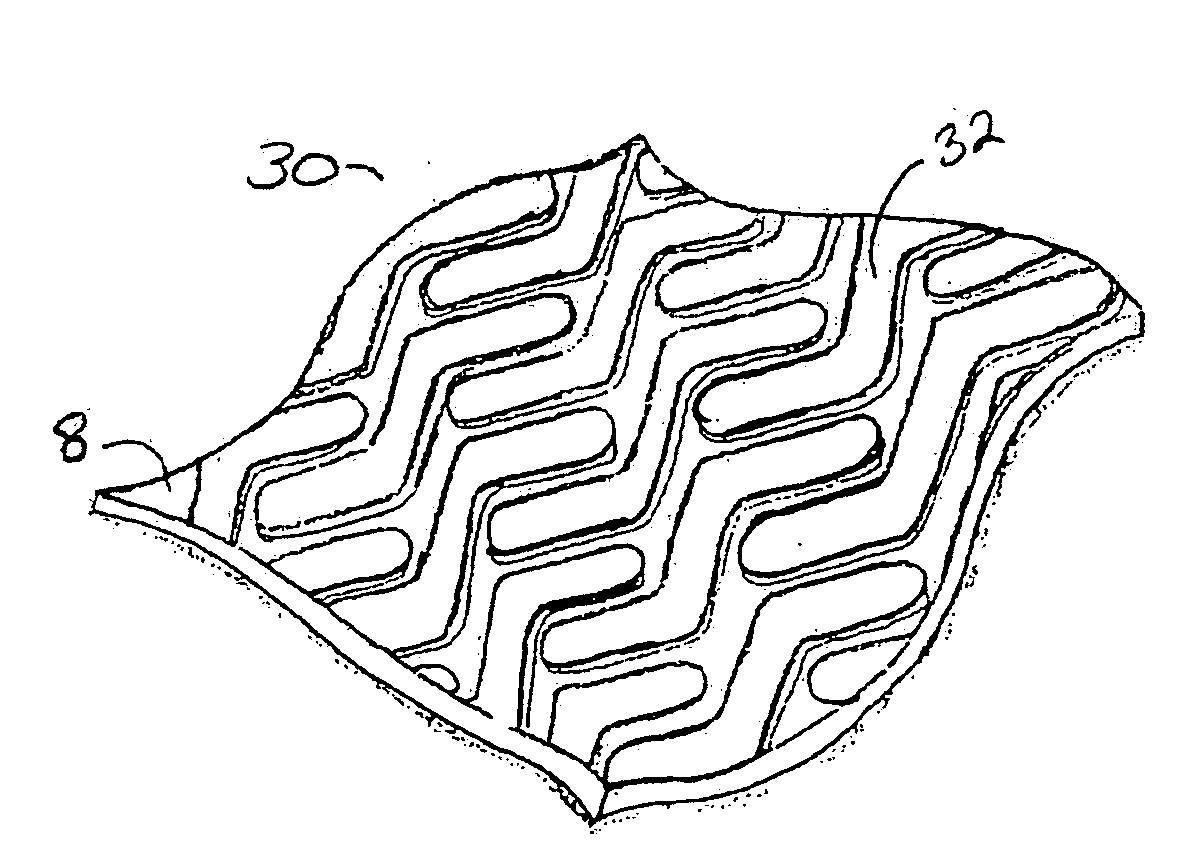

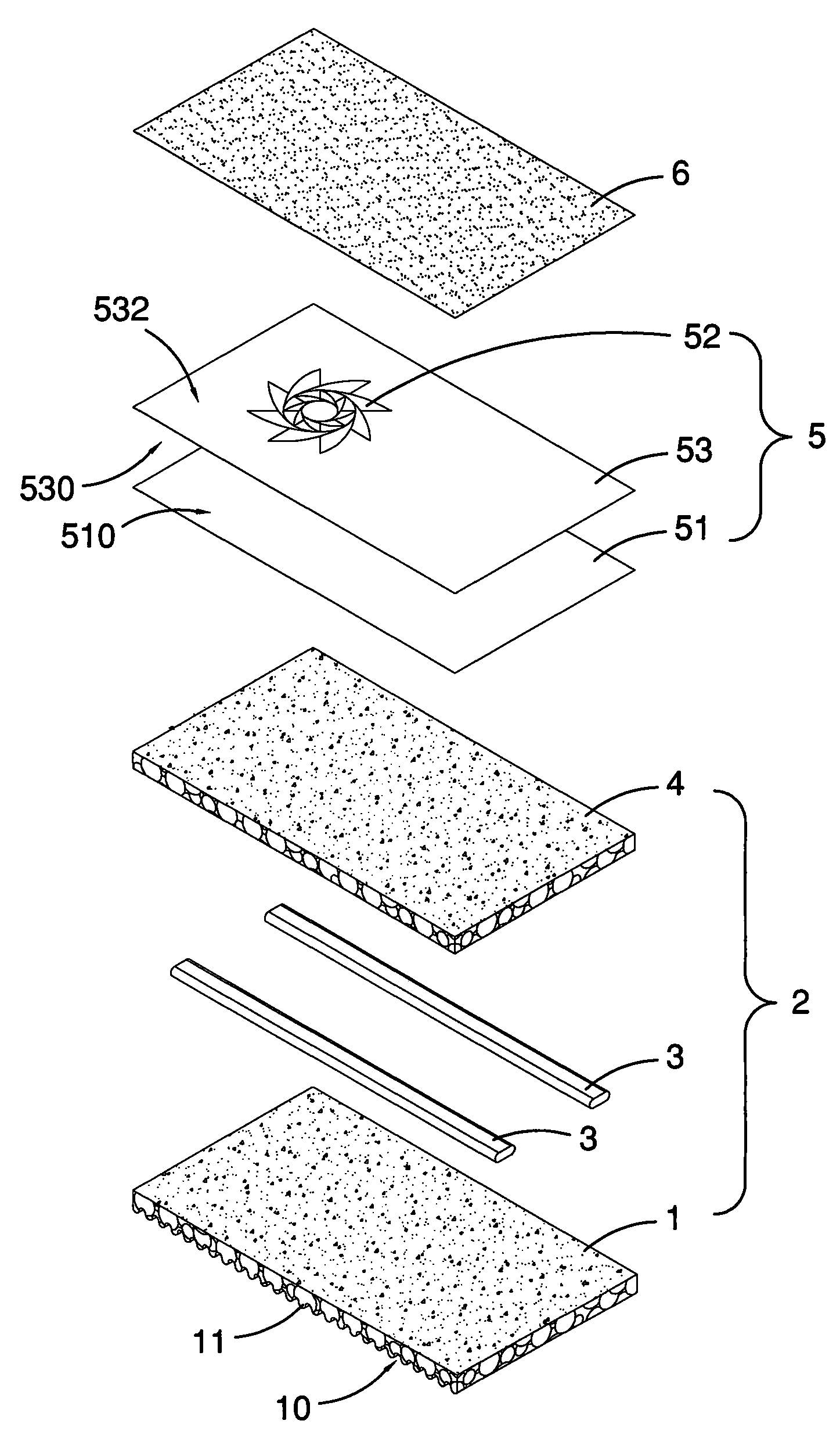

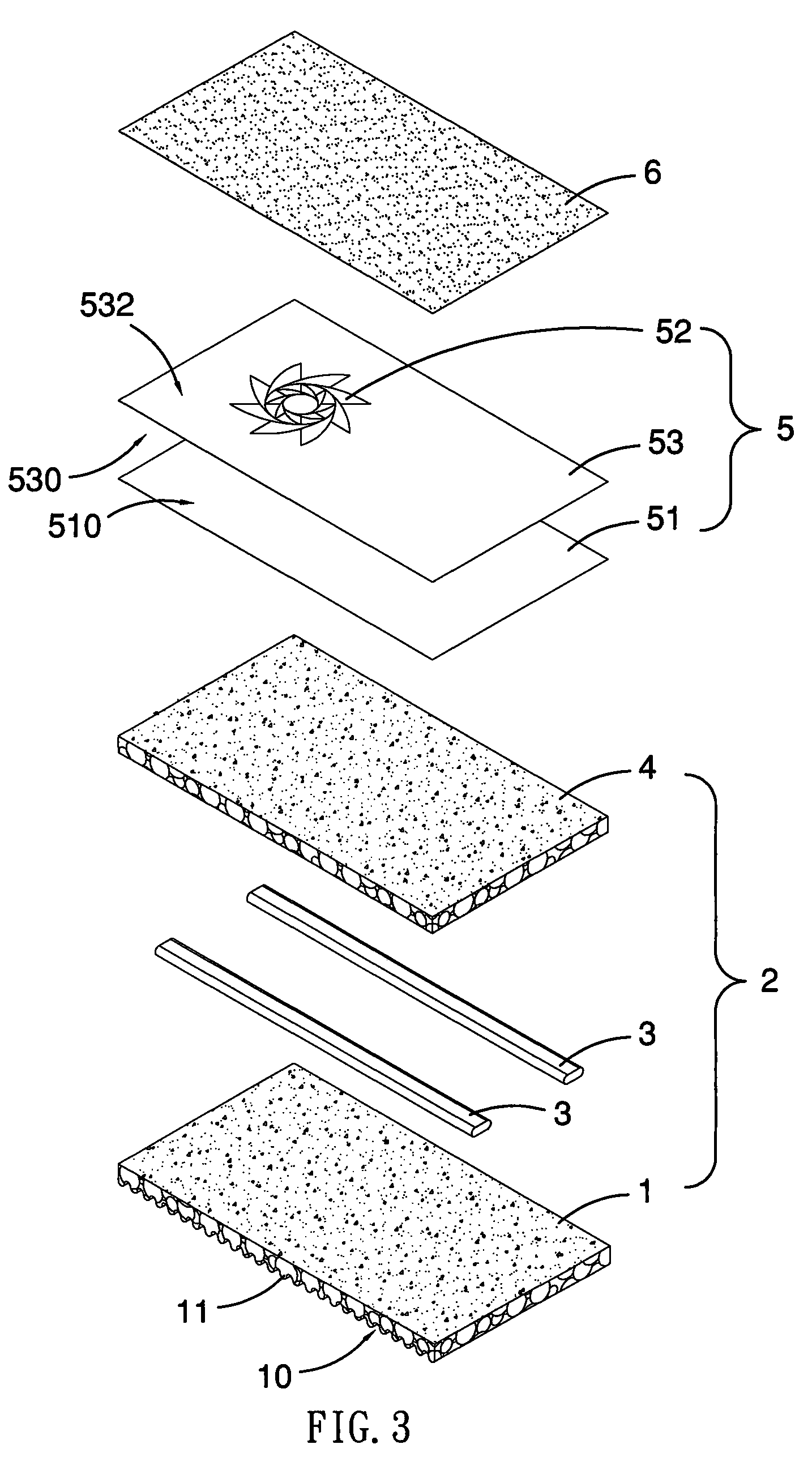

Skidproof sports mat

InactiveUS20090148666A1Controlled resilienceBeautiful appearanceWater sport boardsCoatingsEngineeringPlastic film

A sports mat includes a foam sheet, a patterned laminate and a skid proof layer. The foam sheet is made of polyethylene foam. The patterned laminate includes a first plastic film, a second plastic film and a pattern. The first plastic film is laminated on top of the foam sheet. The second plastic film is laminated on top of the first plastic film. The pattern is placed in between the first plastic film and the second plastic film and visible from outside of the sports mat. The skid proof layer is coated over the top surface of the second plastic film. Additionally, the skid proof layer together with the pattern laminate and the second foam layer defines a plurality of indentations and protrusions spread over a top surface of the skid proof layer so as to strengthen connection therebetween.

Owner:AGIT GLOBAL IP HLDG LLC

Skidproof sports mat

InactiveUS7850498B2Controlled resilienceBeautiful appearanceWater sport boardsCoatingsEngineeringPlastic film

A sports mat includes a foam sheet, a patterned laminate and a skid proof layer. The foam sheet is made of polyethylene foam. The patterned laminate includes a first plastic film, a second plastic film and a pattern. The first plastic film is laminated on top of the foam sheet. The second plastic film is laminated on top of the first plastic film. The pattern is placed in between the first plastic film and the second plastic film and visible from outside of the sports mat. The skid proof layer is coated over the top surface of the second plastic film. Additionally, the skid proof layer together with the pattern laminate and the second foam layer defines a plurality of indentations and protrusions spread over a top surface of the skid proof layer so as to strengthen connection therebetween.

Owner:AGIT GLOBAL IP HLDG LLC

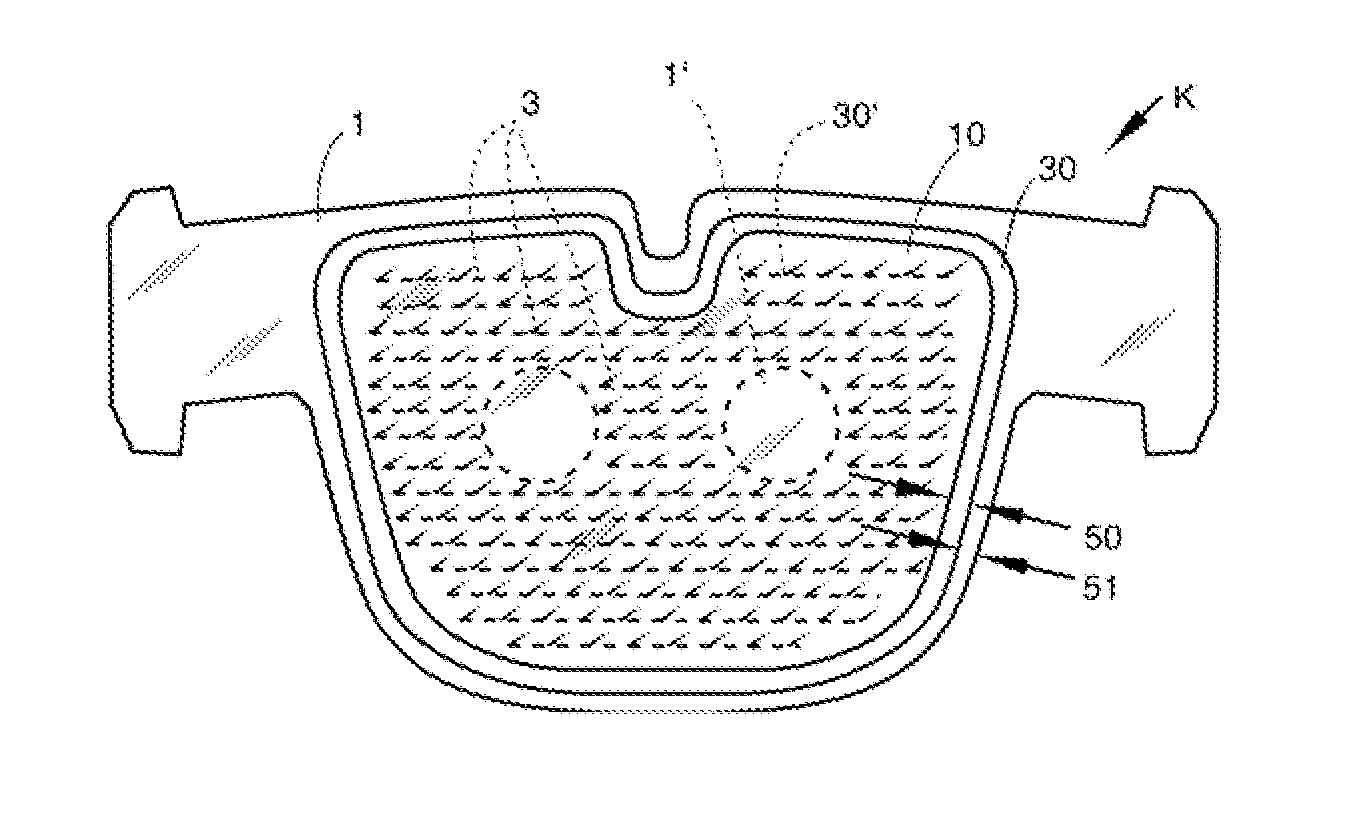

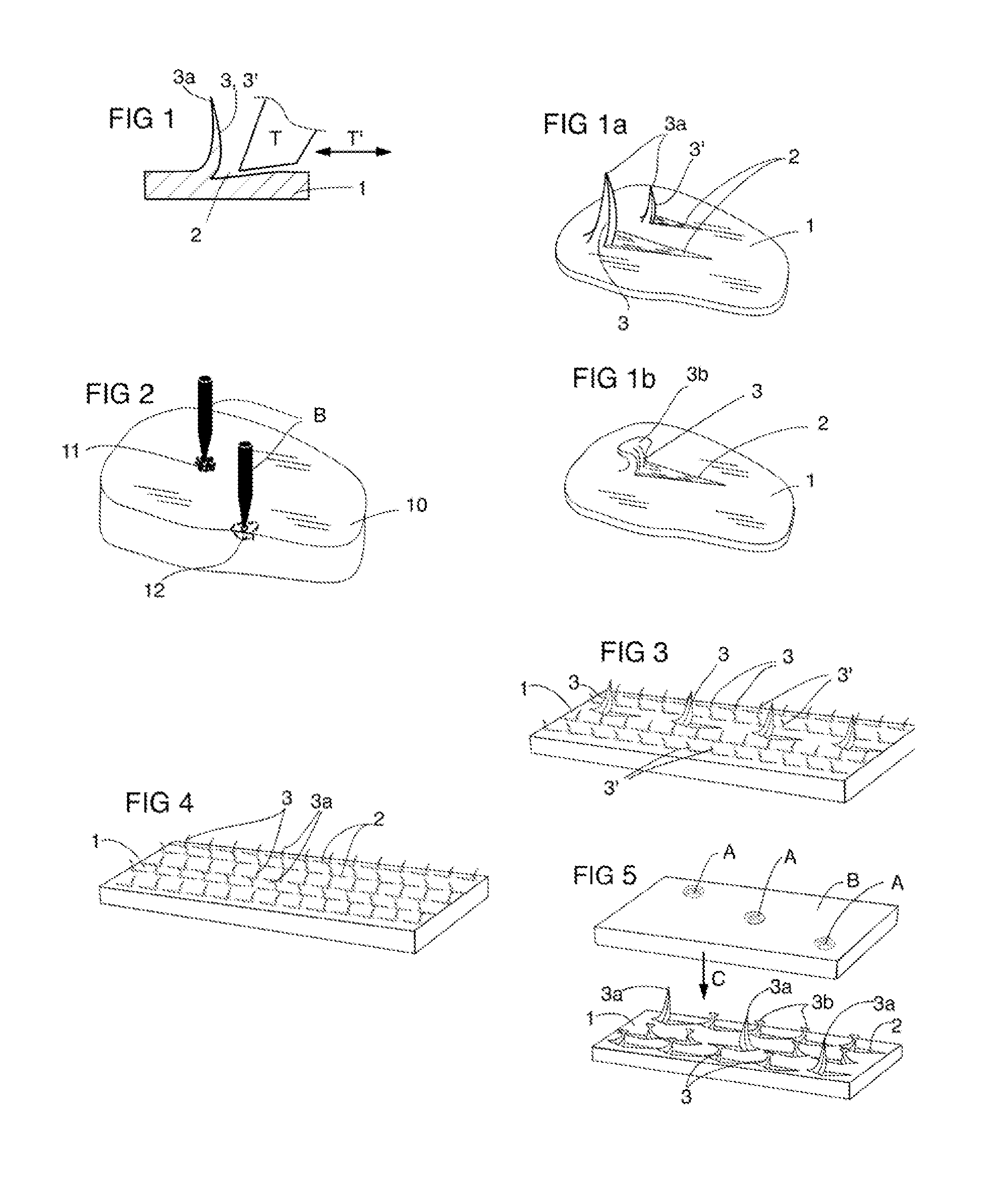

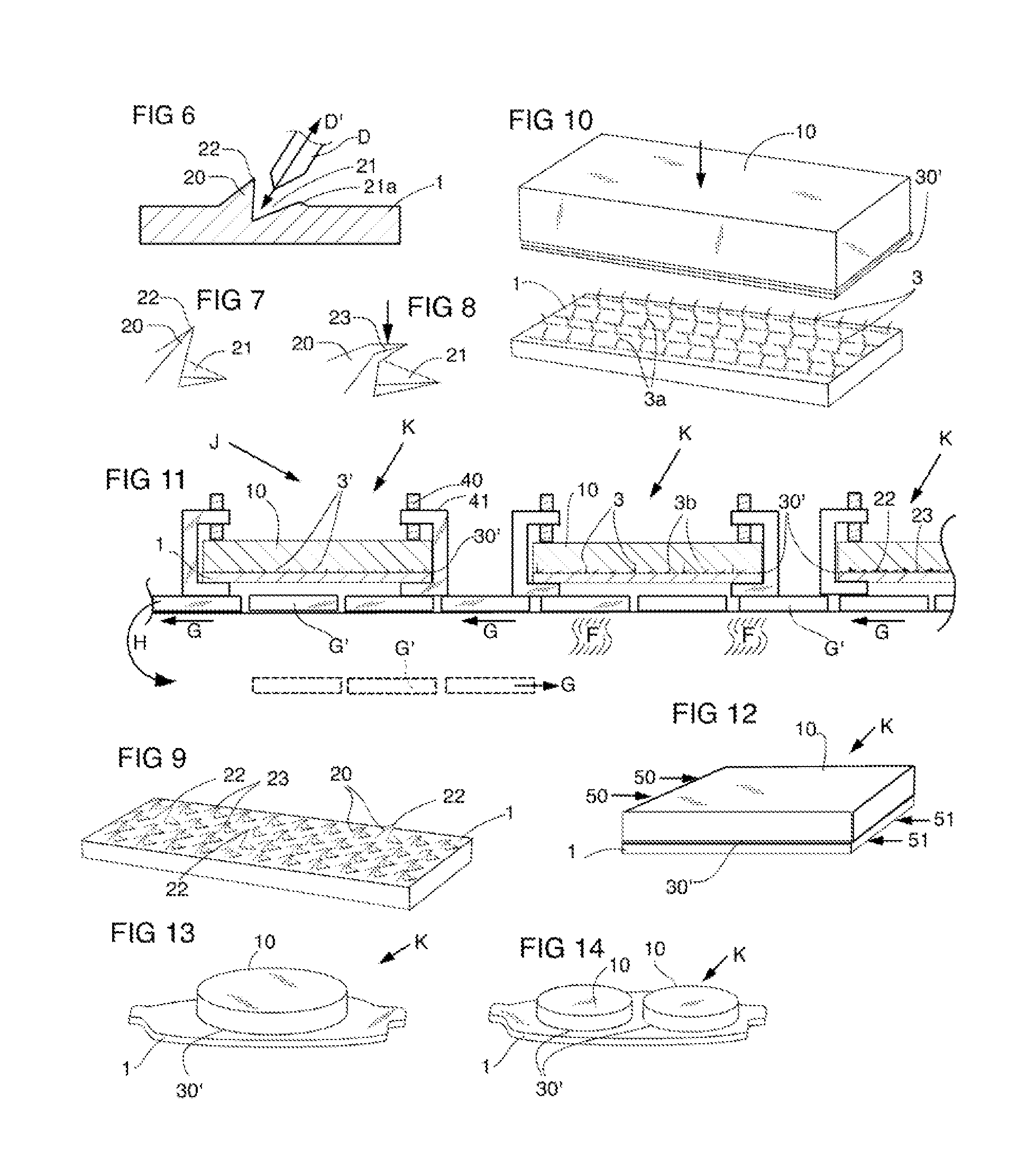

Friction fusion fastening system

A laminate comprises a first ductile material textured with barbs and a second friable material. First material is preferably electro-plated steel. Second material may be a brake friction composition. Barbs may be pointed or headed or in combination. Second material may be in the form of castings, sheets or pads. Second material may be impaled by at least some of the barbs. Lamination of first and second materials preferably includes an adhesive therebetween. The adhesive may include uncured rubber to be vulcanized in place.

Owner:NUCAP IND

Printed Mat

InactiveUS20090155536A1Prevent slippingAvoid stickingDecorative surface effectsTransfer printing processPolyesterCushioning

A floor mat is provided having a top layer made with polyester felt capable of receiving printing by sublimation printing techniques, a bottom layer made with latex foam, and an adhesive layer between the top and bottom layers. The top layer includes a four color process printing applied thereon by sublimation of sublimation inks. The floor mat may further include a middle layer made with foam to provide extra cushioning for the floor mat.

Owner:BOCHANG MFG

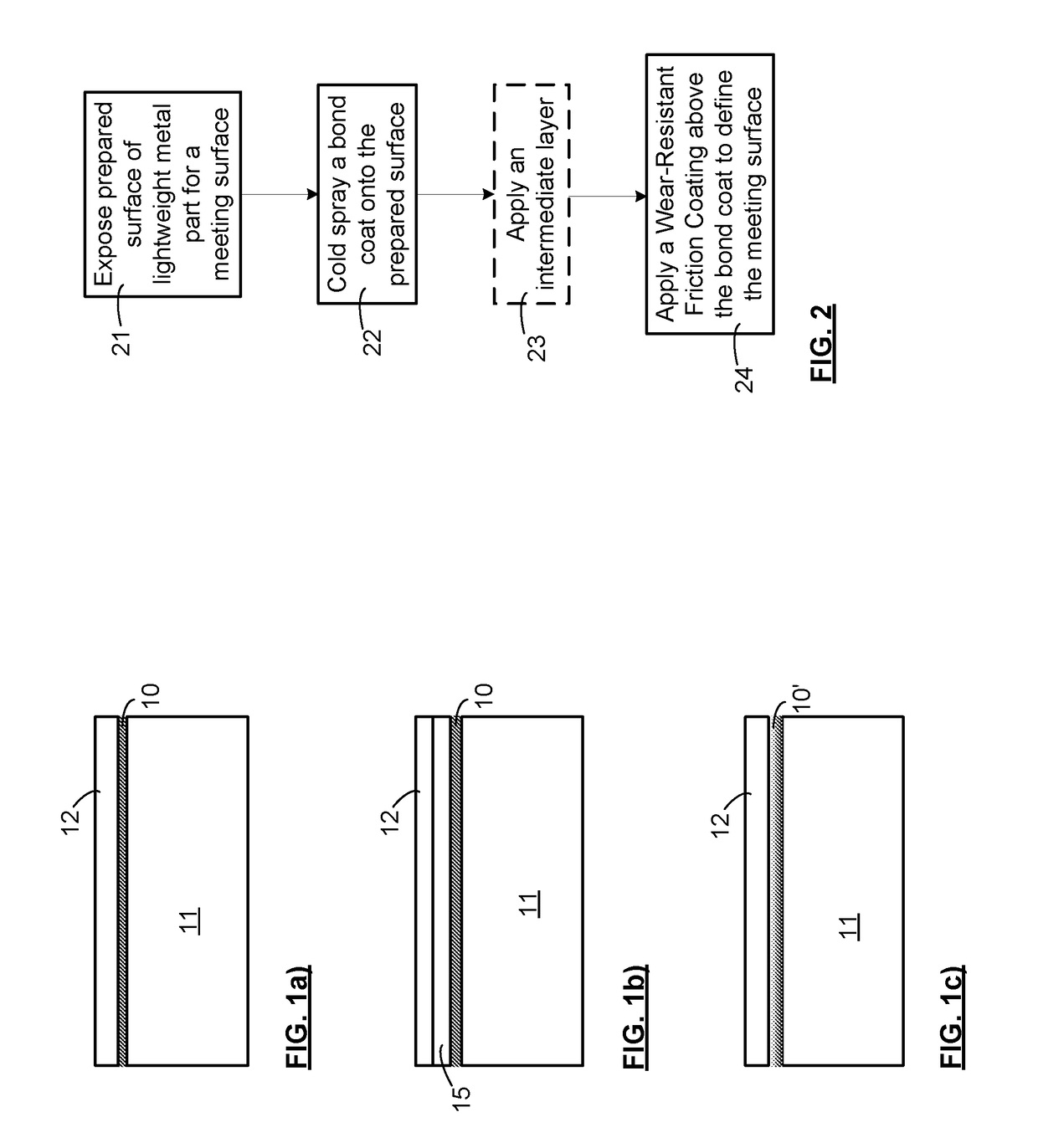

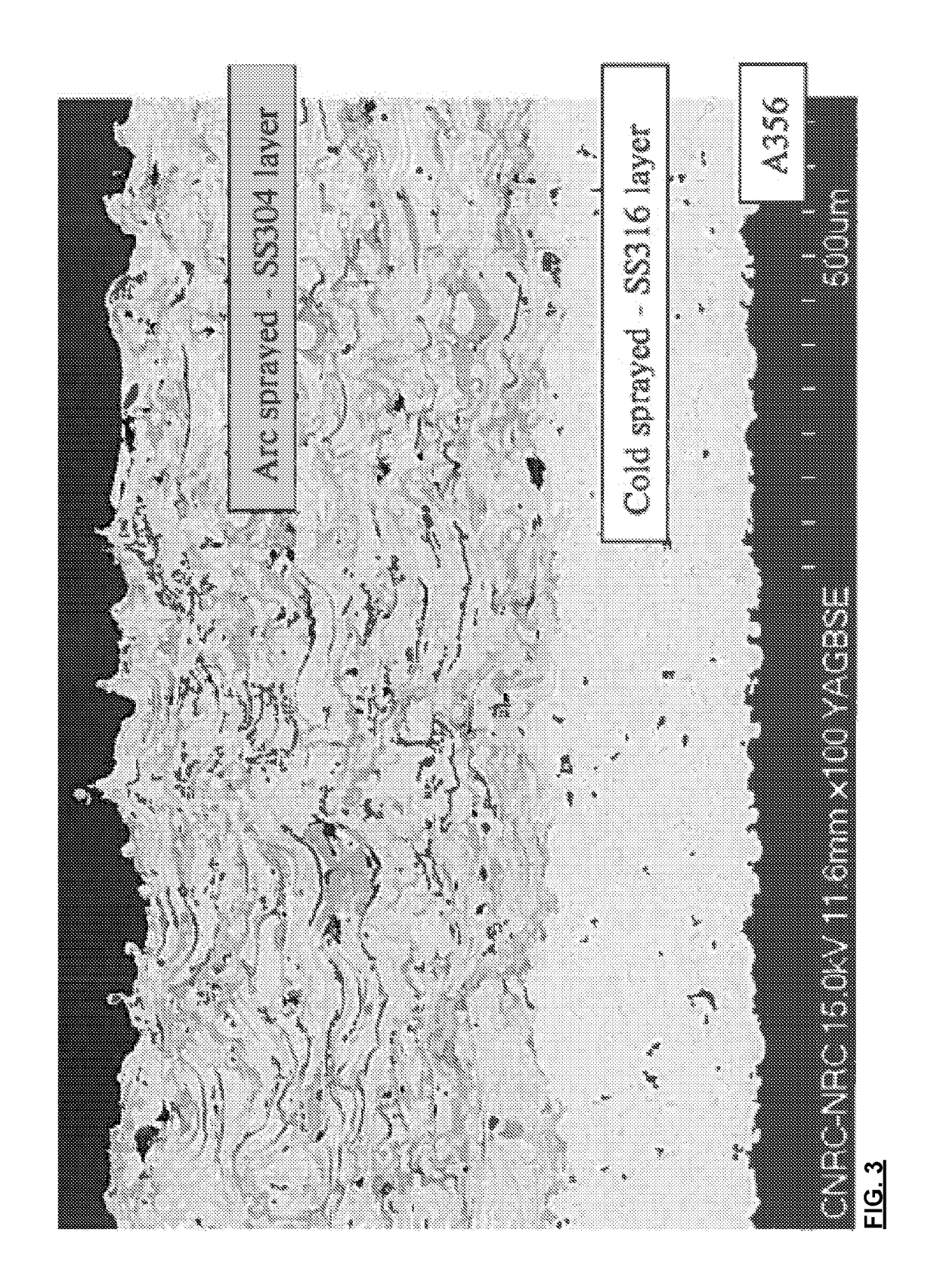

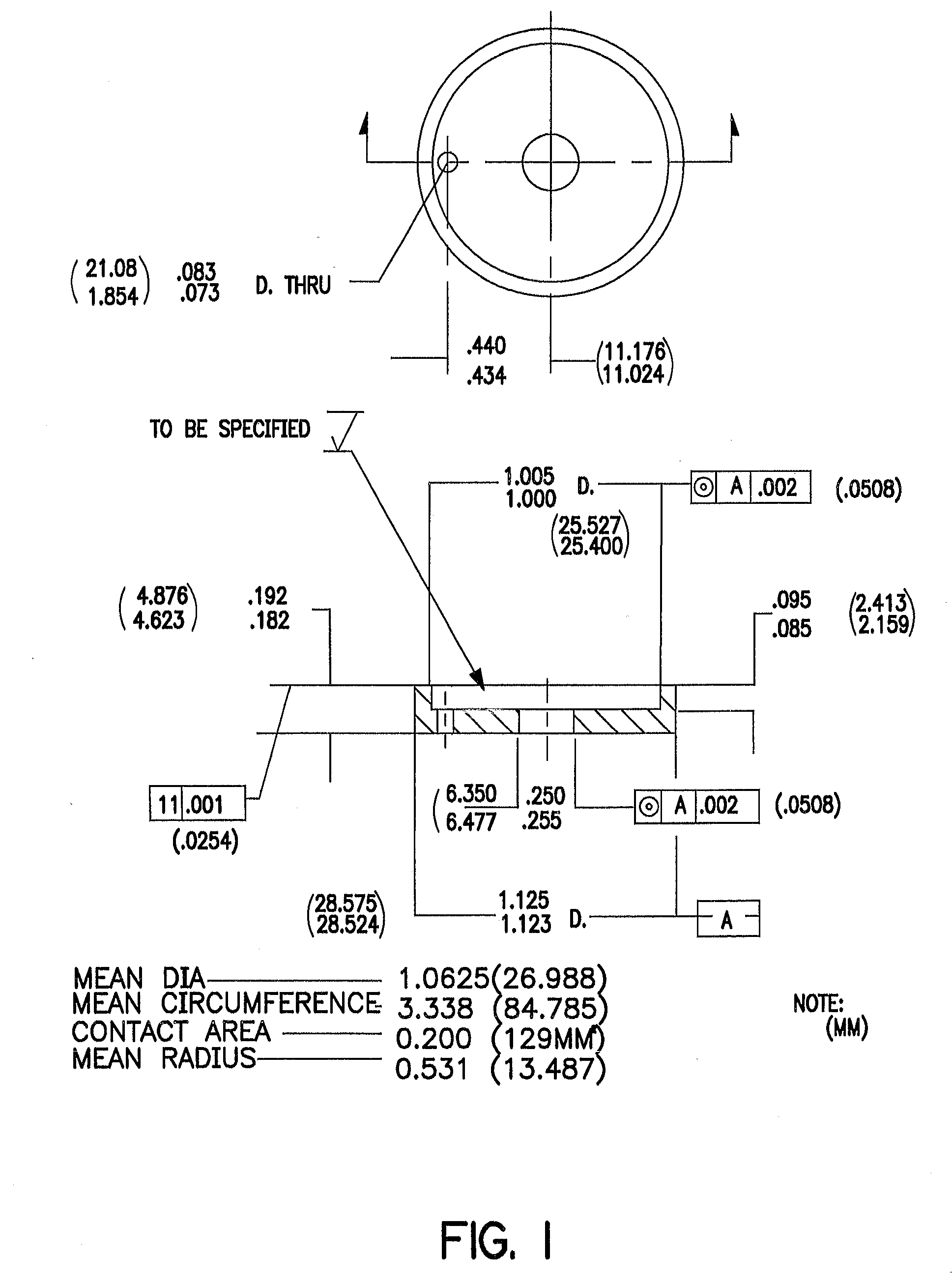

Bi-layer iron coating of lightweight metallic substrate

InactiveUS20170204920A1Improve adhesionImprove wear resistanceMolten spray coatingBraking discsThermal sprayingWear resistant

A wear resistant friction coating (WRFC) can be applied on a lightweight metallic substrate, by applying a cold gas dynamic spray bond coat containing more iron than any other single element directly onto a surface of the substrate, and thermal spraying the WRFC coating over the bond coat to a thickness of at least 500 μm. Corrosion resistance, adhesion, thermal cycling resistance, and wear resistance have been demonstrated.

Owner:NAT RES COUNCIL OF CANADA

Low Friction, Abrasion-Resistant Bearing Materials

InactiveUS20070123652A1Improve wear resistanceReduce coefficient of frictionSynthetic resin layered productsShaftsTetrafluoroethyleneWear resistant

A friction-reducing abrasion resistant bearing material is described. The material comprises a monolithic, porous polytetrafluoroethylene (ePTFE) having dispersed therein a wear-resistant thermosetting or thermoplastic resin material.

Owner:WL GORE & ASSOC INC

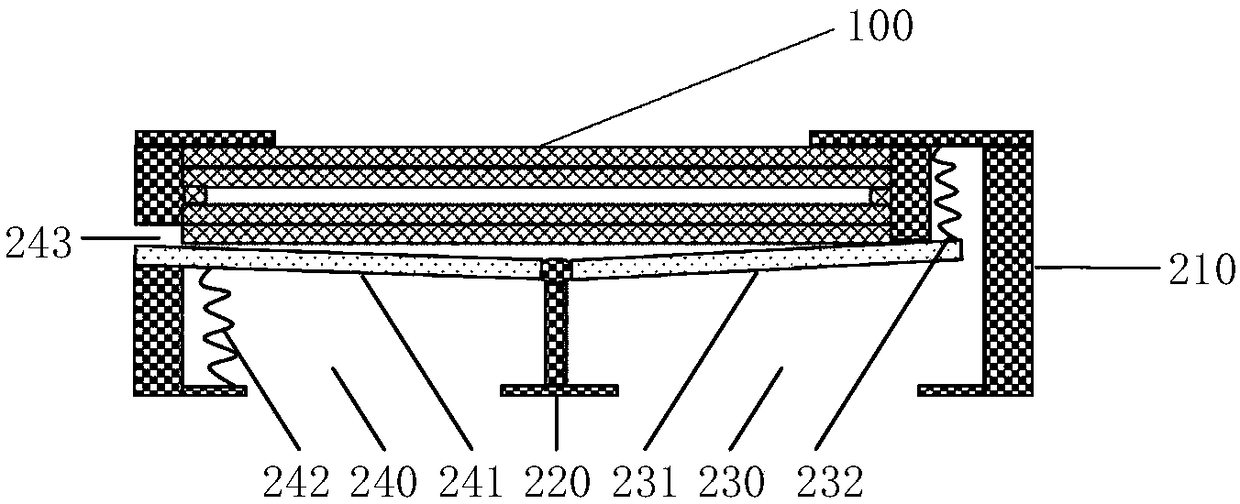

Nano power generation unit, dual-channel respiratory system and mask

The invention relates to the technical field of power generation, in particular to a power generation unit, a dual-channel respiratory system and a mask, wherein the nano power generation unit comprises a first friction assembly and a second friction assembly arranged opposite to each other; the first friction assembly comprises a first conductive layer and a first friction layer; the second friction assembly includes a second conductive layer and a second friction layer; a separation station and a compression station are arranged between the first friction assembly and the second friction assembly; the first friction layer and the second friction layer are in frictional contact with each other to generate contact charges and output through the first conductive layer and the second conductive layer when the first friction member and the second friction member are in the compression station, and the first friction layer and the second friction layer are separated from each other when the first friction member and the second friction member are in the separation station; and the first friction assembly and the second friction assembly have a porous air permeable structure. The nano power generation unit is capable of filtering micron-to sub-micron-scale fine particles in the inhaled air.

Owner:中科纳清(江苏)科技有限公司

Low friction, abrasion-resistant bearing materials

InactiveUS7147378B2Improve wear resistanceImprove thermal stabilityShaftsSynthetic resin layered productsTetrafluoroethyleneWear resistant

A friction-reducing abrasion resistant bearing material is described. The material comprises a monolithic, porous polytetrafluoroethylene (ePTFE) having dispersed therein a wear-resistant thermosetting or thermoplastic resin material.

Owner:WL GORE & ASSOC INC

Refrigerant hose

InactiveUS20050011571A1Reduce penetrationSynthetic resin layered productsVehicle heating/cooling devicesPolyamideEngineering

Owner:VEYANCE TECH

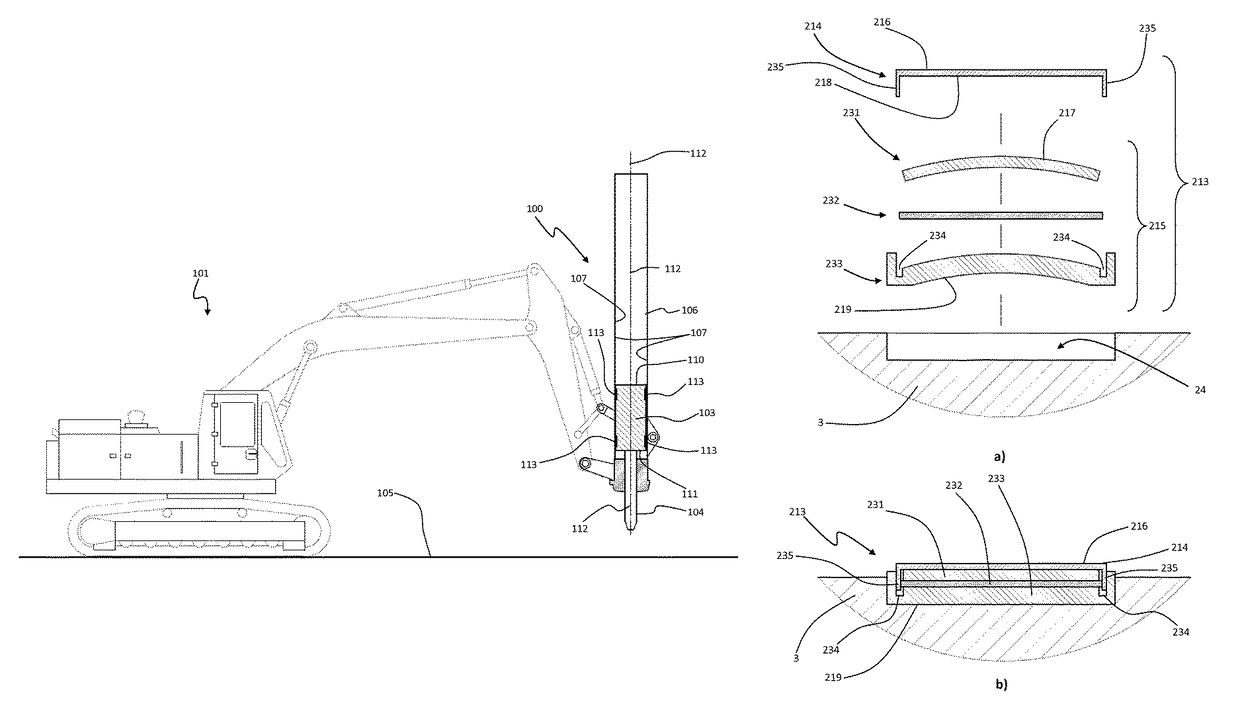

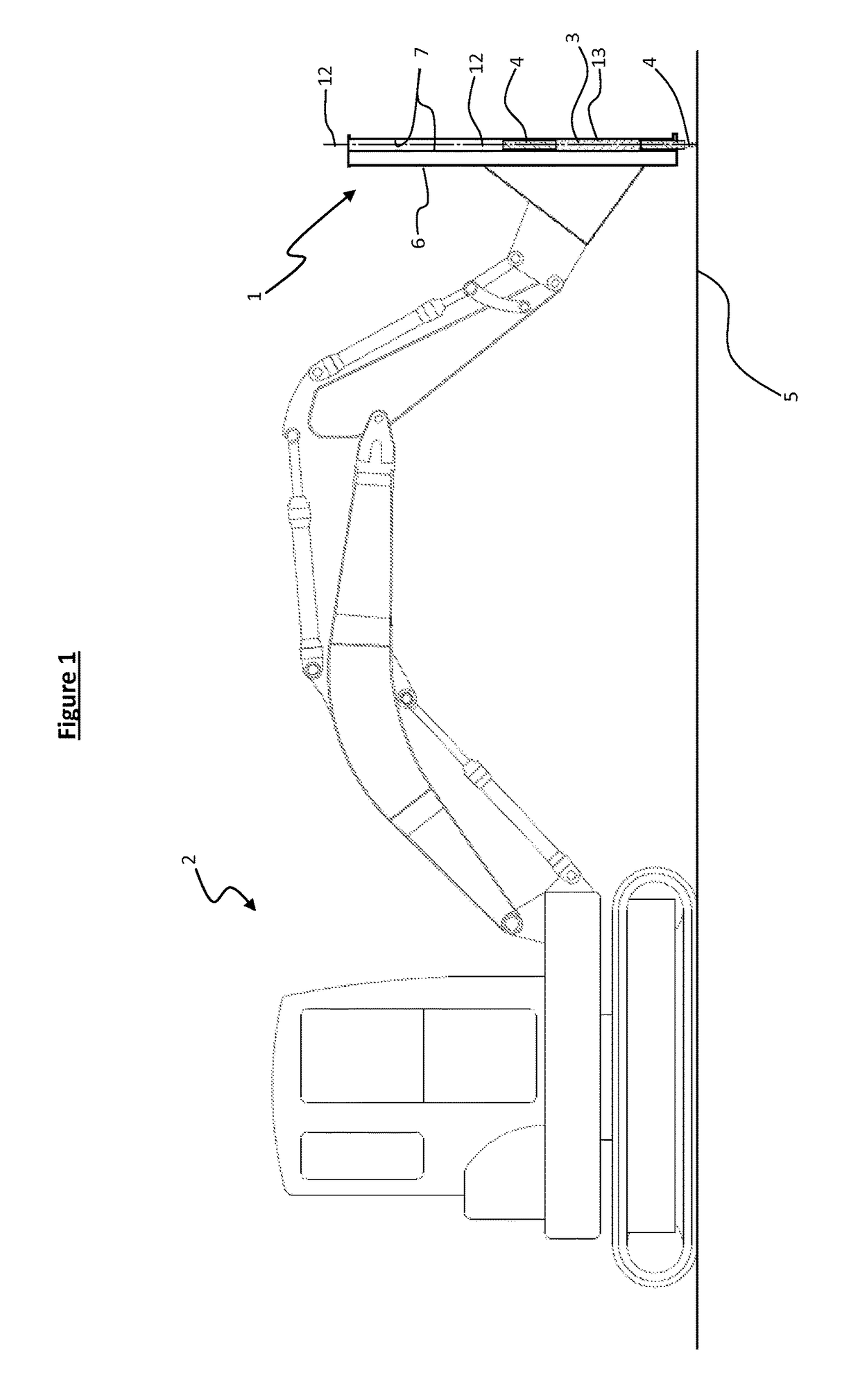

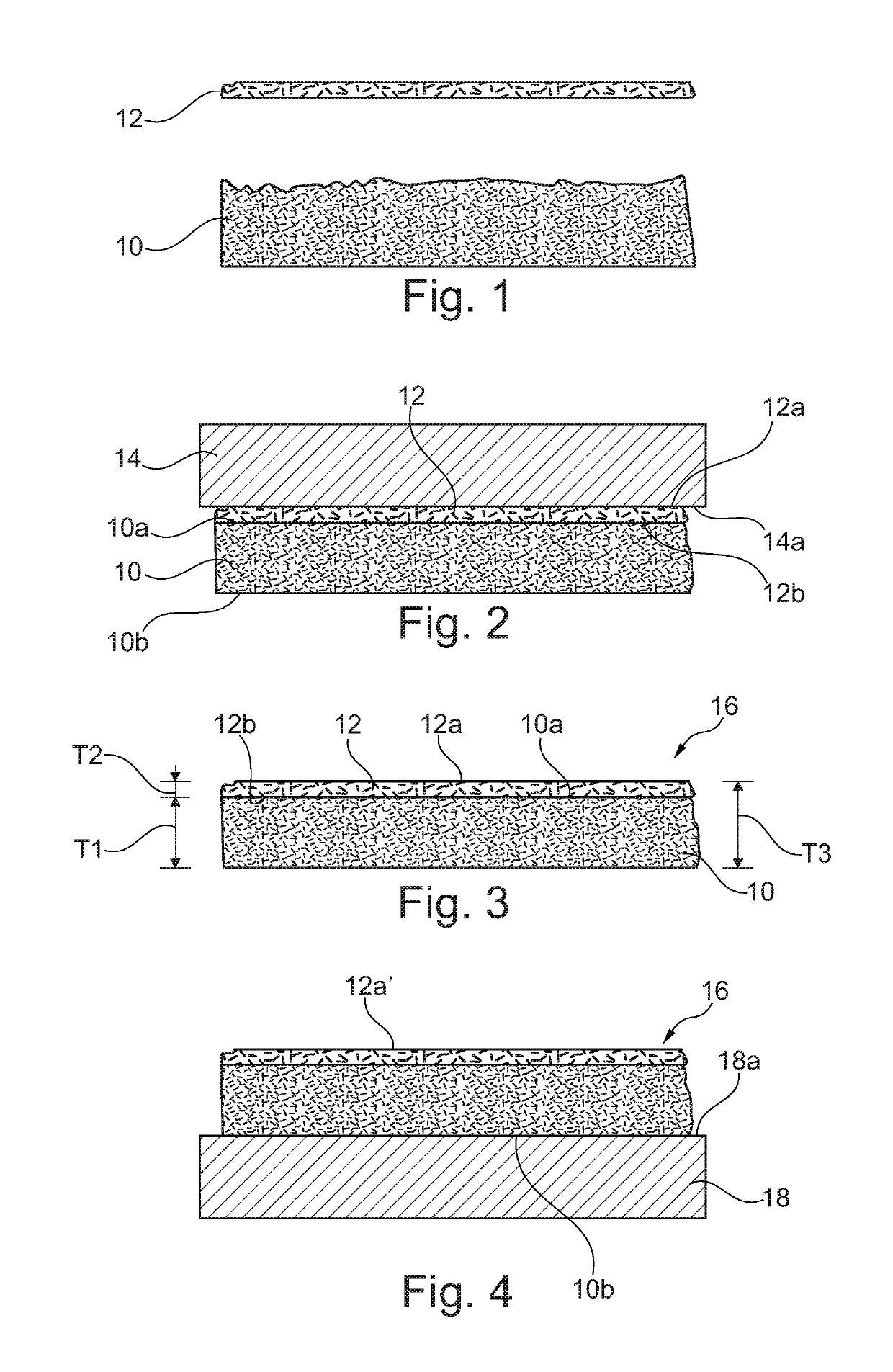

Cushioning slides

ActiveUS9821447B2Reduce verbosityAccurate placementLinear bearingsReciprocating drilling machinesCushioningReciprocating motion

An apparatus (1) with a reciprocating component (3) fitted with composite cushioning slides (13) on an exterior surface (8, 9). The reciprocating component (3) is movable along a reciprocation path and the composite cushioning slide (13) includes an exterior first layer (14) and an interior second layer (15). The first layer (14) is formed with an exterior surface (16) configured and orientated to come into sliding contact with a containment surface (7) of the apparatus (1) during the reciprocating movement of the reciprocating component (3), the first layer (14) is formed from a material of predetermined friction and / or abrasion resistance properties. The interior second layer (15) is located between the first layer (14) and reciprocating component (3) and is formed from a shock-absorbing material having predetermined shock absorbing properties.

Owner:TERMINATOR IP

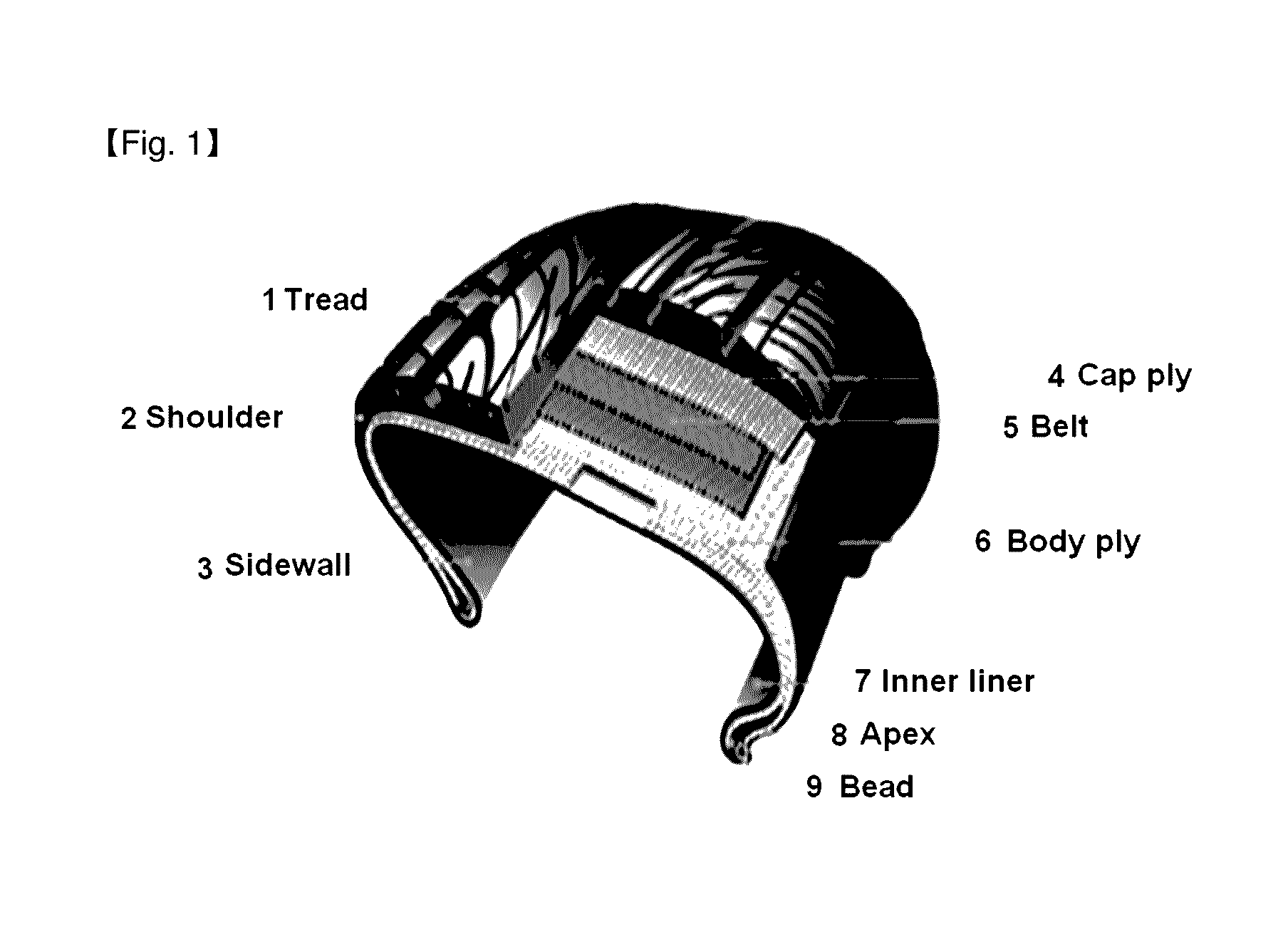

Method for manufacturing polymer film and co-extruded film

ActiveUS20160318227A1Reduce weightImprove fuel efficiencyWithout separate inflatable insertsSynthetic resin layered productsPolyamidePolymer thin films

The present invention relates to: a method for manufacturing a polymer film, the method including a base film forming step for co-extruding a first resin containing a polyamide-based resin and a second resin containing a copolymer including polyamide-based segments and polyether-based segments; a co-extruded film including a base film including a first resin layer containing a polyamide-based resin, and a second resin layer containing a copolymer having polyamide-based segments and polyether-based segments; to a co-extruded film including a base film including a first resin layer and a second resin layer, which have different melting points; and to a method for manufacturing a polymer film, the method including a base film forming step including a step of co-extruding a first resin and a second resin, which have different melting points.

Owner:KOLON IND INC

Mouse Pad

A mouse pad has a base and a release sheet. The base has a substrate, an adsorbent layer, a non-slip layer and at least one perforation line. The substrate has a top face and a bottom face. The adsorbent layer is formed on the top face of the substrate. The non-slip layer is formed on the bottom face of the substrate. The at least one perforation line is formed through the base to define a central segment and a peripheral segment. The release sheet is detachably mounted with the non-slip layer of the base to aid printing. Therefore, a surface provided by the mouse pad is uniform and the peripheral segment can be removed to allow the entire central segment to be covered by printing.

Owner:KUO CHUN FU

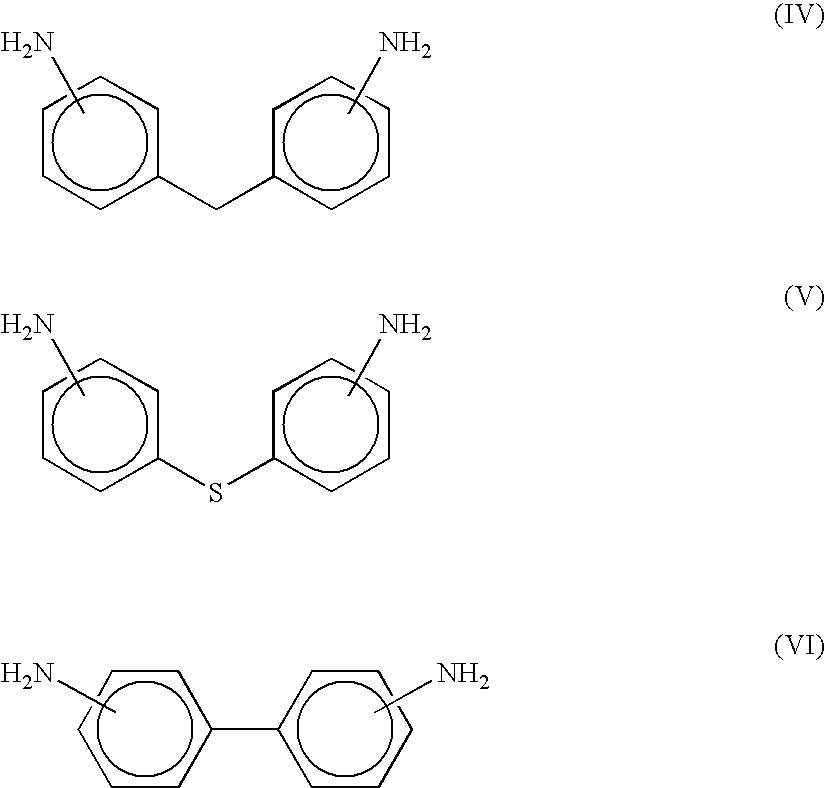

Polyurethane Urea Polishing Pad with Window

InactiveUS20070021045A1Synthetic resin layered productsAbrasion apparatusFoaming agentCompound (substance)

The present invention relates to an article for altering a surface of a work piece, or a polishing pad having a window. In particular, the polishing pad includes a polyurethane urea material wherein the polyurethane urea material contains cells which are at least partially filled with gas. The polyurethane urea material can be prepared by combining polyisocyanate and / or polyurethane prepolymer, hydroxyl-containing material, amine-containing material and blowing agent. The polishing pad according to the present invention is useful for polishing articles, and is especially useful for chemical mechanical polishing or planarization of microelectronic and optical electronic devices such as but not limited to semiconductor wafers. The window of the polishing pad is at least partially transparent and thus, can be particularly useful with polishing or planarizing tools that are equipped with through-the-platen wafer metrology.

Owner:PPG IND OHIO INC

Double layer wet friction material

A method of making a wet friction material is provided. The method includes obtaining a base layer sheet; obtaining an outer layer sheet; and laminating the outer layer sheet and the base layer sheet together to form the wet friction material. The base layer sheet includes a proportion of first fiber material and a proportion of first filler material and the outer layer sheet includes a proportion of second fiber material and a proportion of second filler material. The proportion of second fiber material is less than the proportion of first fiber material and the proportion of second filler material is greater than the proportion of first filler material.

Owner:SCHAEFFLER TECH AG & CO KG

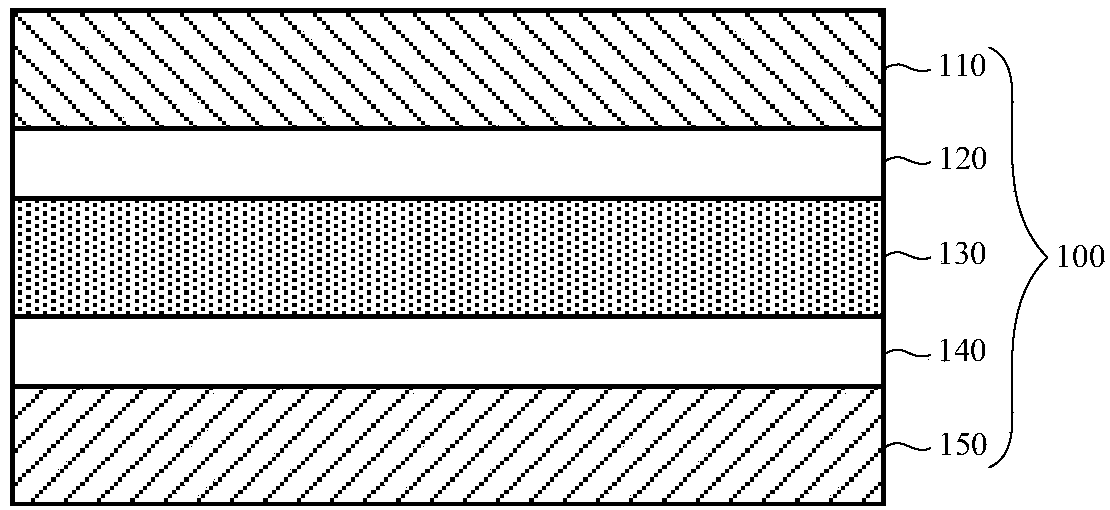

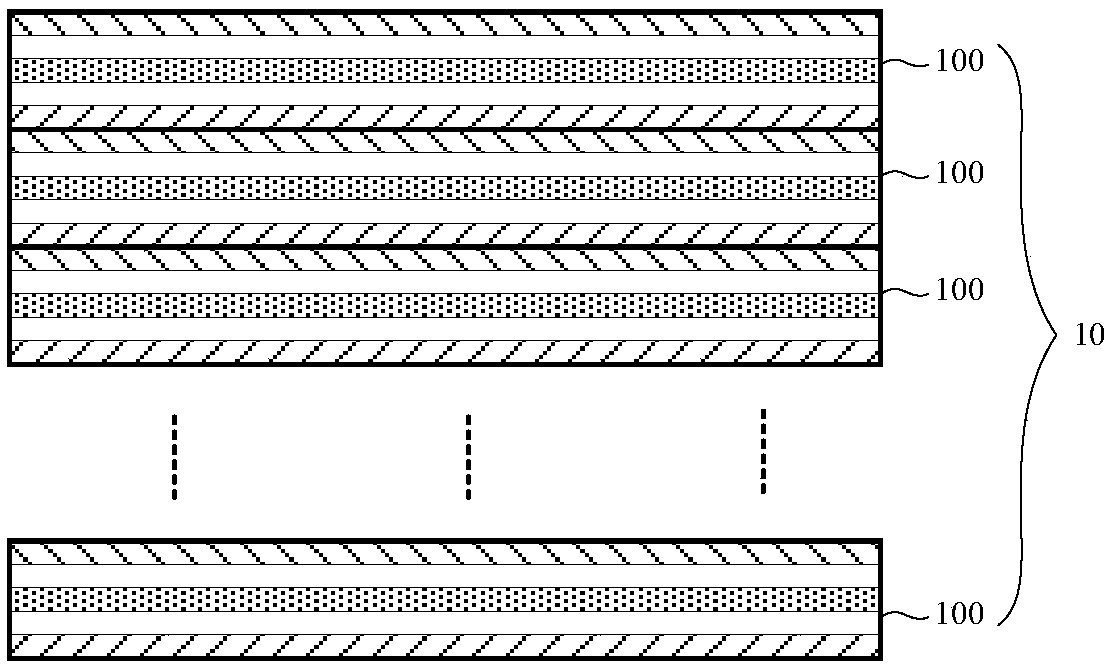

Power generation unit, composite nano generator, system, sensor and paper

ActiveCN109130426ABatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesNanogeneratorEngineering

The invention relates to the technical field of power generation, in particular to a power generation unit, a composite nano generator, a system, a sensor and paper. The power generation unit comprises a first friction layer, first conductive layer, piezoelectric module, second conductive layer and second friction layer which are sequentially stacked and arranged. The piezoelectric module is usedfor converting the pressure applied to the power generation unit into an electric signal, and the first friction layer and the second friction layer are used for converting the friction into an electric signal. The power generation unit is capable of converting mechanical energy into electric signals through the piezoelectric module and / or the friction layer, so that the power generation unit canbe used as a sensor in the Internet of Things, and can supply electric energy to the sensor, thereby being beneficial to the rapid development of the Internet of Things.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Metal and graphite laminate

The present invention is a laminate sheet having two laminae. The first lamina is a relatively hard material having first and second surfaces. The first surface has a plurality of raised and generally pointed piercing structures, each structure having a tip. The second lamina is graphite foil material, which is mated to the relatively hard material, such that at least some of the piercing structures pierce the graphite foil material. In one embodiment, the first lamina has no perforations and is uniformly smooth. In another embodiment, the second surface also has a plurality of piercing structures and a third lamina comprising graphite foil is mated to the second surface.

Owner:R A INVESTMENT MANAGEMENT S A R L

Refrigerant hose

InactiveUS7044168B2Synthetic resin layered productsVehicle heating/cooling devicesPolyamideEngineering

Owner:VEYANCE TECH

Artificial leather and a production method therefor

InactiveUS20170183815A1High density nappingLittle color inconsistencyDomestic upholsteryLayered productsElastomerMaterials science

The present invention provides an artificial leather including an entangled fiber mass of ultrafine fibers having a monofilament fineness of 0.01 dtex or more and 0.50 dtex or less and a polymeric elastomer; wherein at least one surface is napped; the cross-sectional profile curve of the napped surface has an arithmetic mean height Pa of 26 μm or more and 100 μm or less; the arithmetic mean height Pa of the cross-sectional profile curve of the opposite surface is 20% or more and 80% or less of the cross-sectional roughness Pa of the napped side; the existence frequency of asperity peaks found in the cross-sectional profile curve of the napped surface is 1.8 or more and 20 or less per 1.0 mm; and a woven or knitted fabric lamination is present near the opposite surface at a depth position of 10% or more and 50% or less.

Owner:TORAY IND INC

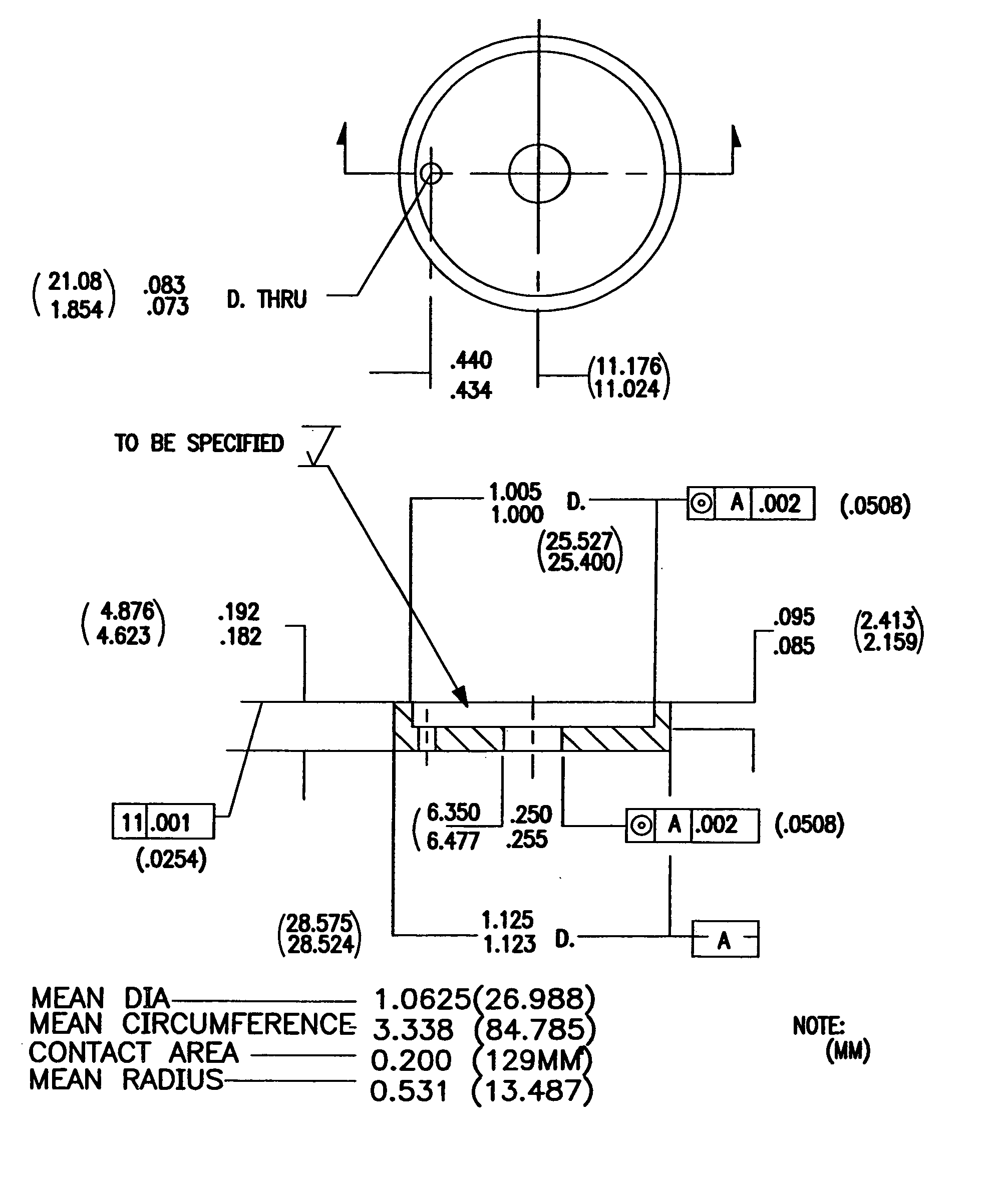

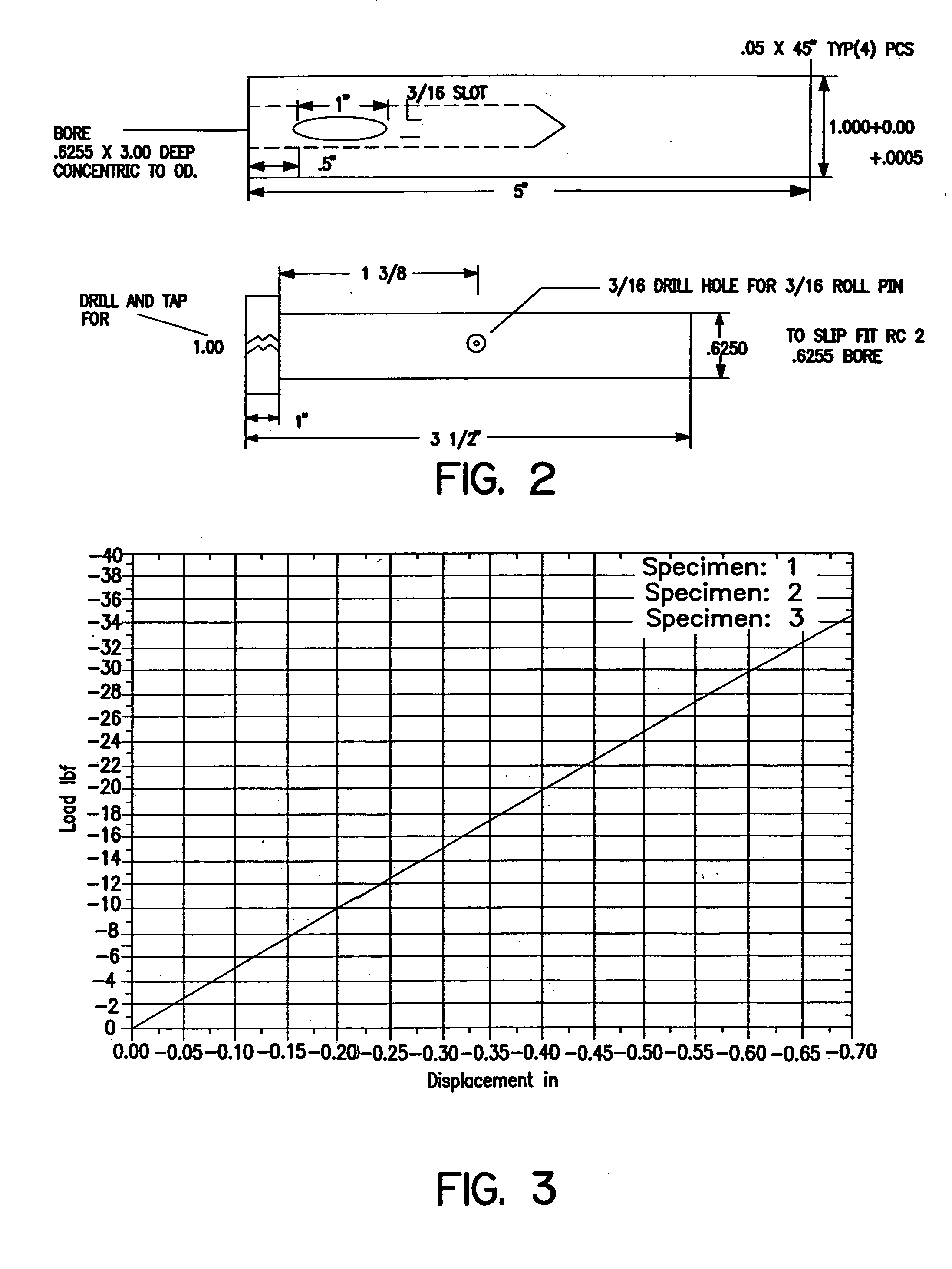

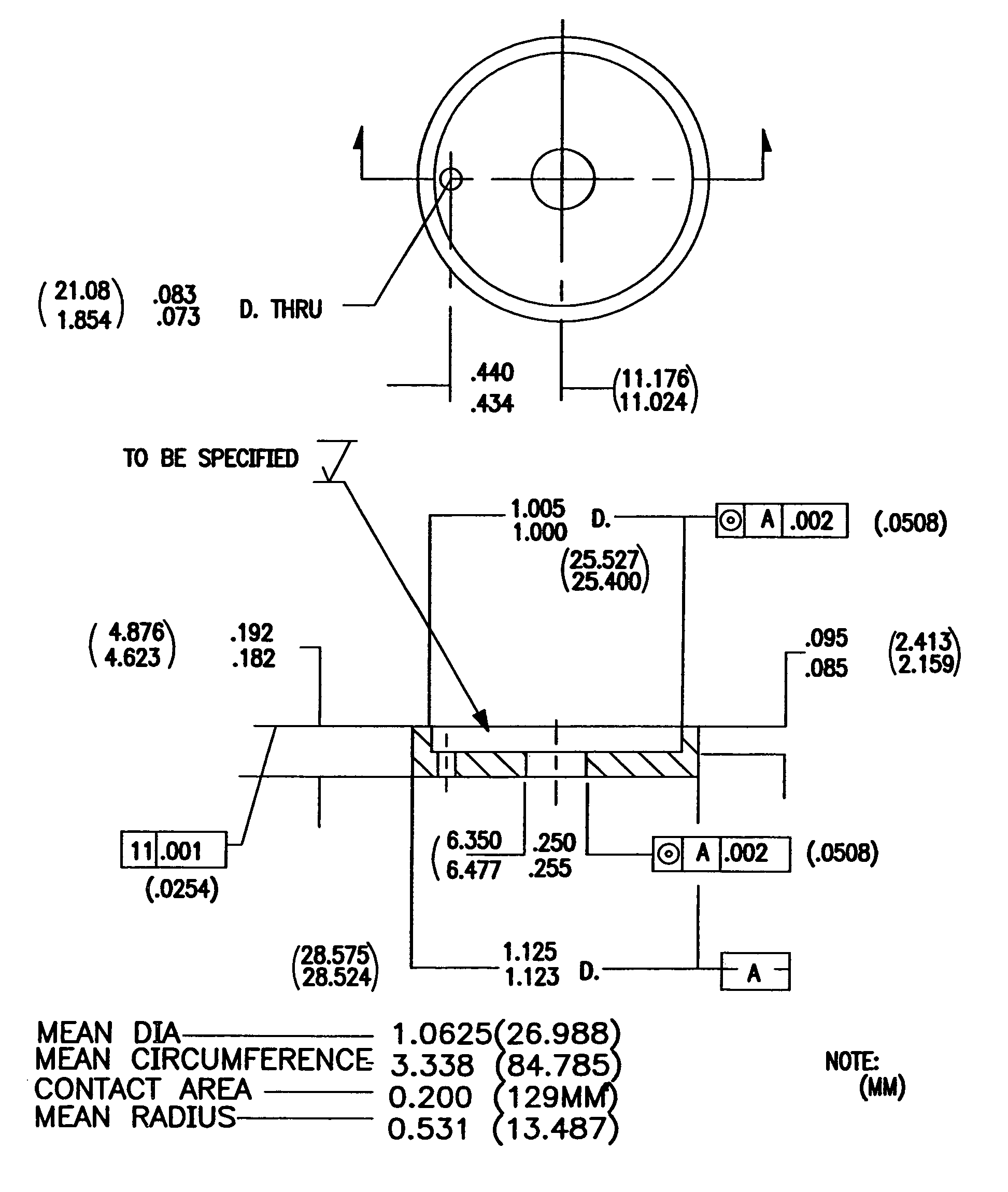

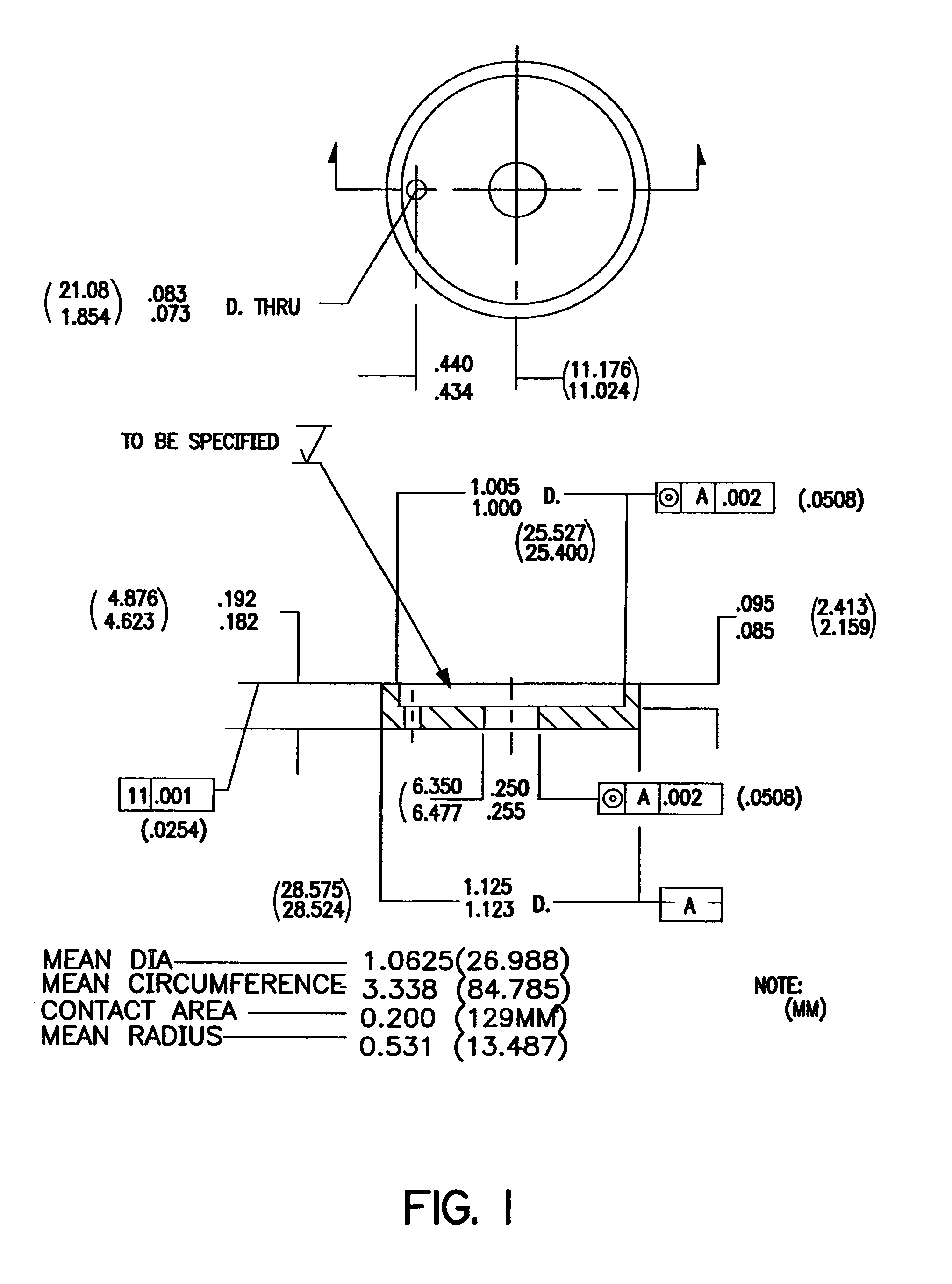

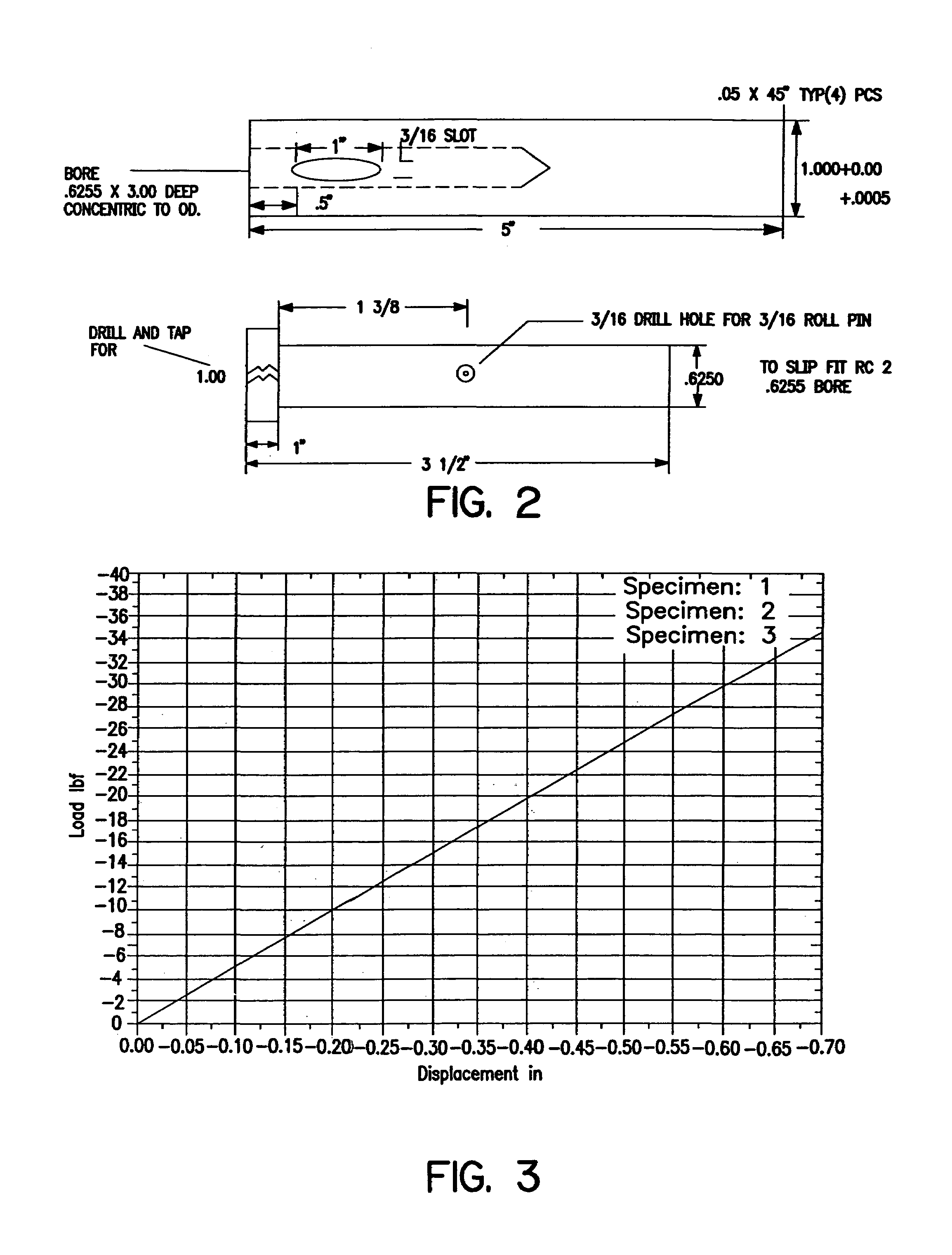

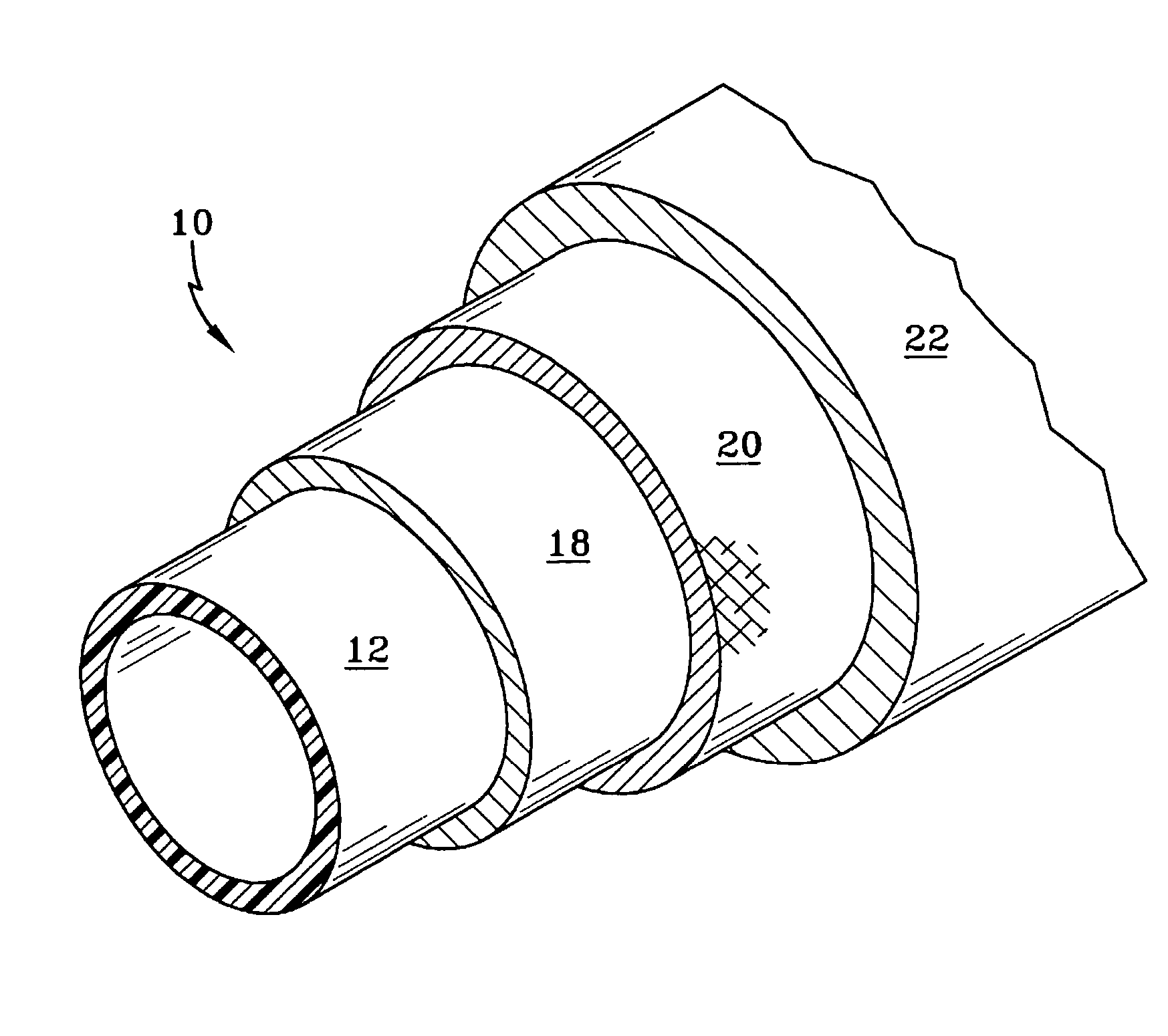

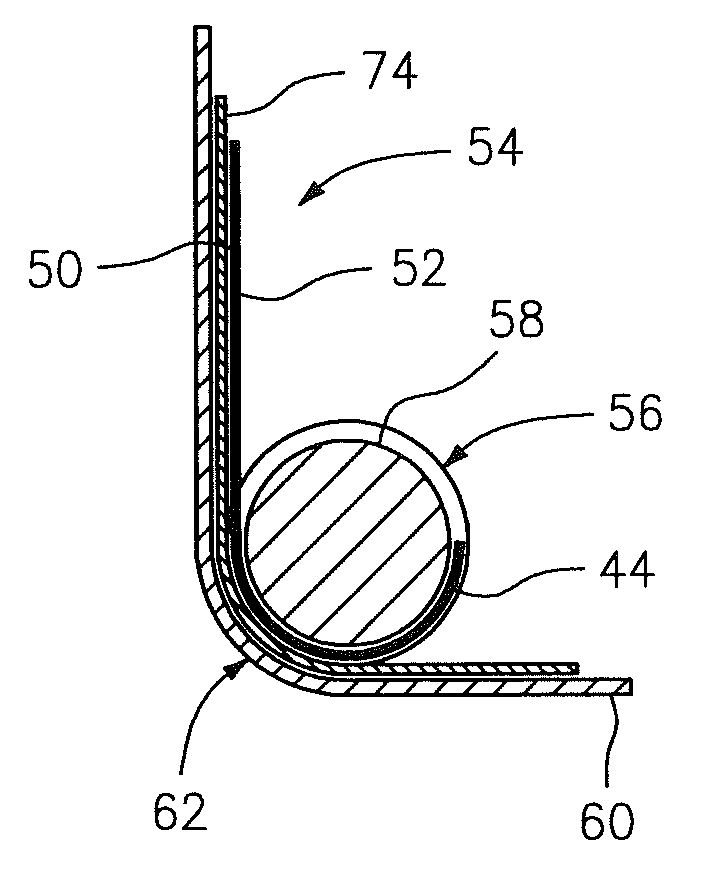

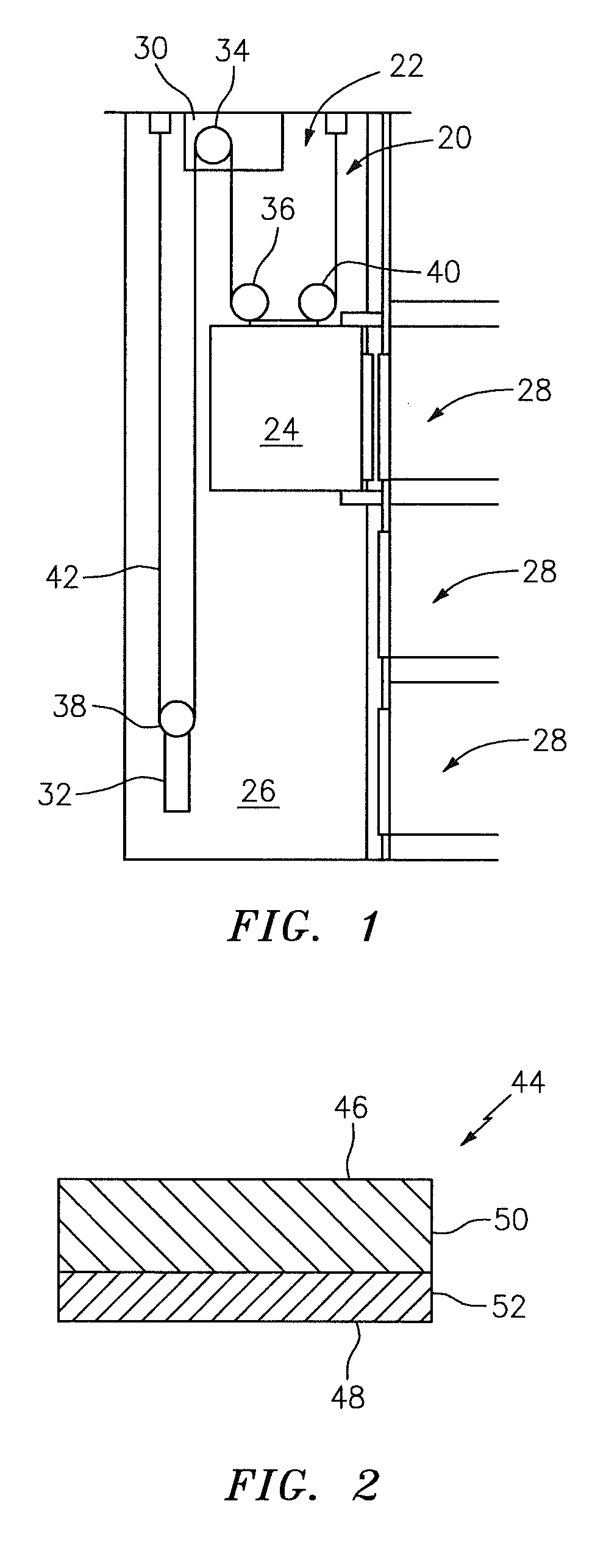

Methods and apparatuses for applying a substrate onto an elevator sheave

An elevator maintenance kit is provided for surfacing an elevator sheave that engages with an elevator tension member. The kit includes a substrate with an adhesive backing, and a substrate applicator that is operable to apply the substrate to the sheave as the sheave is rotated. The adhesive backing is operable to attach the substrate to the sheave during the sheave rotation.

Owner:OTIS ELEVATOR CO

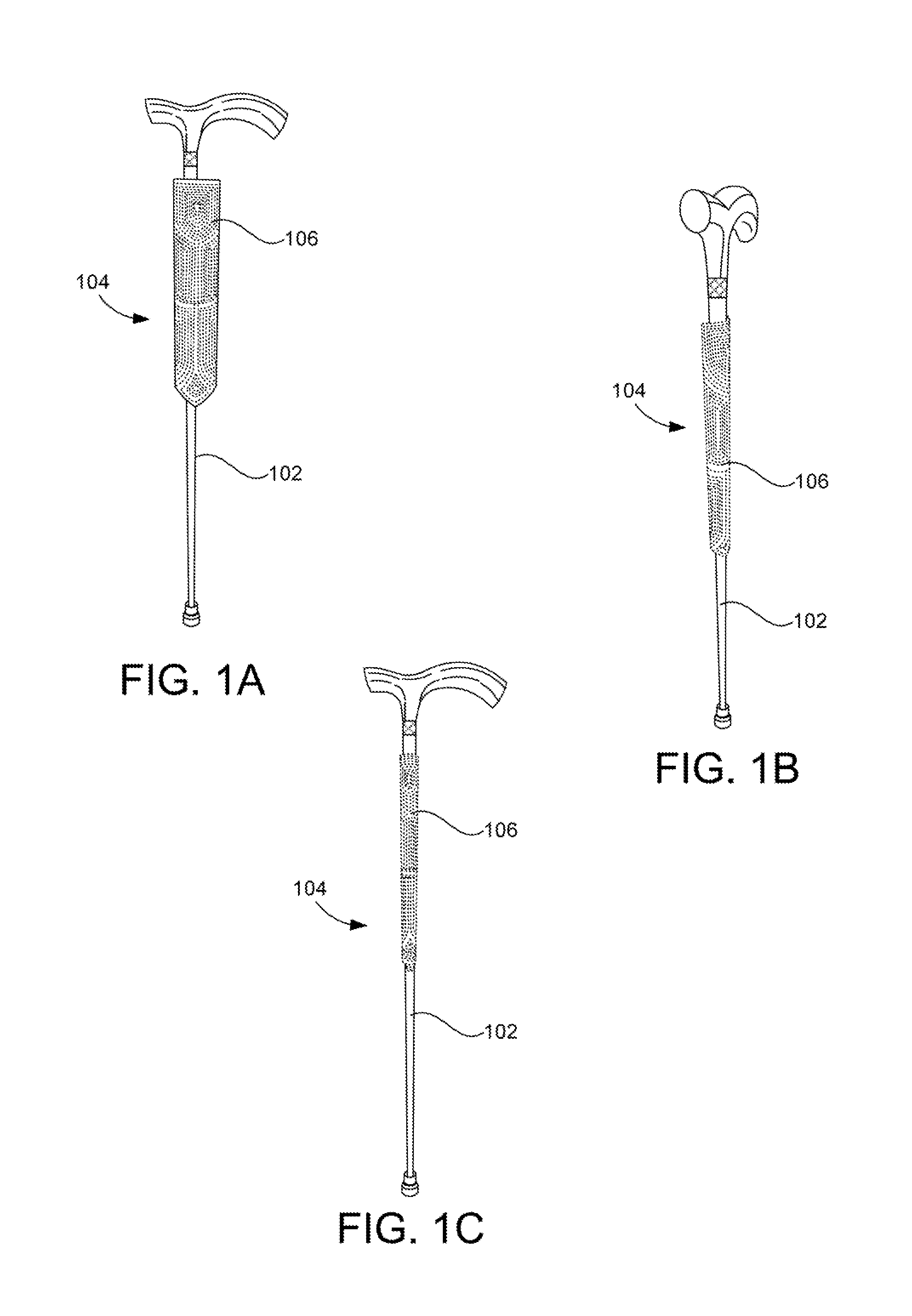

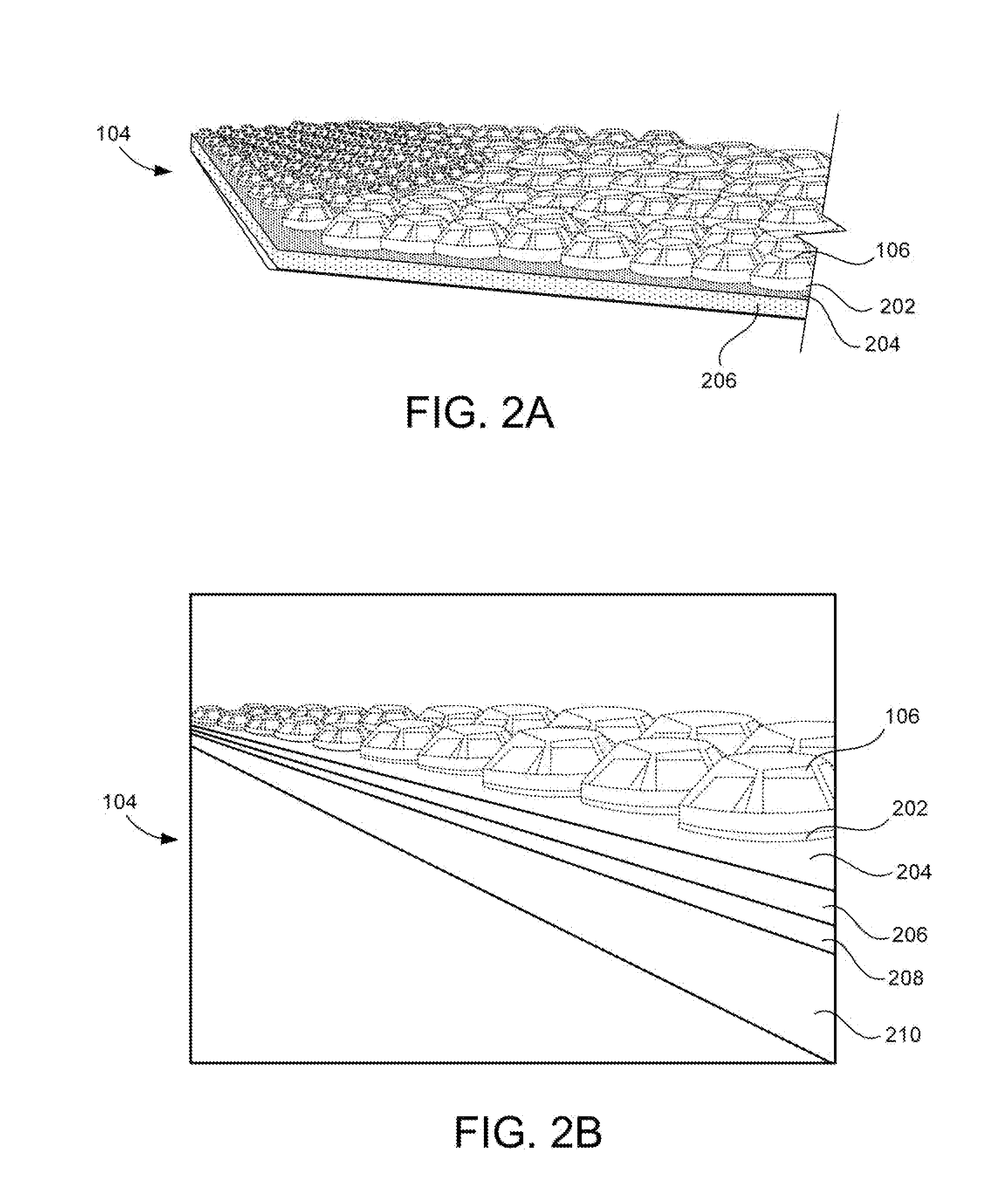

Decorative covering device

A covering device wraps around a mobility aid, such as a walking cane, to display a decorative design. The device includes at least one panel that can be triggered to form a tensioned grip on a mobility aid and display a decoration, message, or image on a portion of the mobility aid. A spring layer having a slight curve and woven metal coils creates a tension therebetween. The tension is released upon contact with the mobility aid to enable the panel to wrap around the mobility aid and form a snug grip. The panel also utilizes a mounting layer having a frictional polyurethane composition creating friction with the mobility aid and creating a non-slip surface. While joined with the mobility aid, the covering device displays a decoration, message, label, or symbol in the form of a decorative portion, like rhinestones, enabling personal expression.

Owner:SHAPIRO CHARLES +1

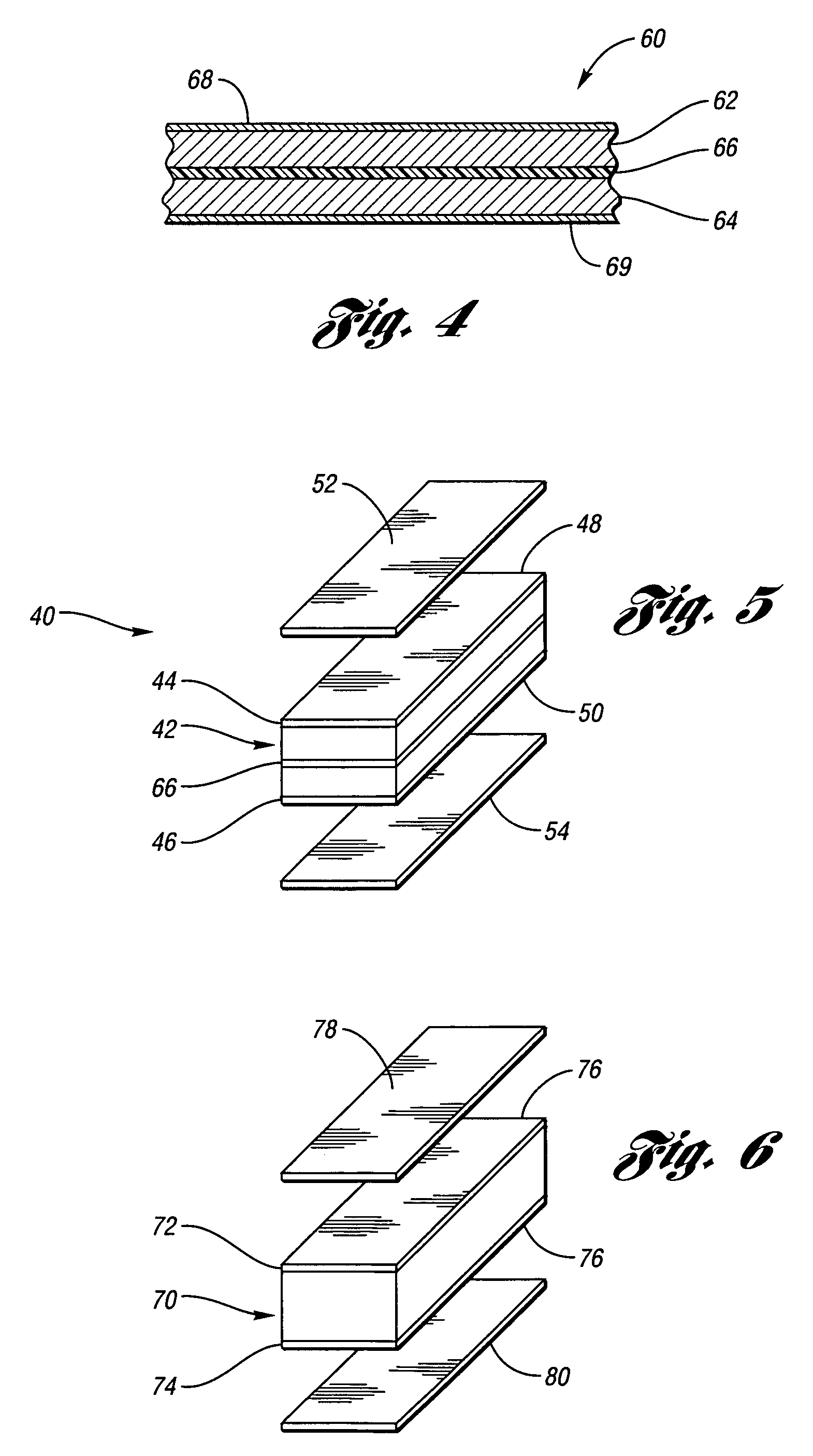

Damped clutch plate system and method

InactiveUS7401690B2Minimize vibration and noiseRotating vibration suppressionSpringsEngineeringSheet structure

The invention seeks to minimize the vibration and noise in a clutch plate system, by damping either or both the clutch plate and pressure plate with the use of various engineered viscoelastic materials. A clutch plate assembly is provided, comprising a plate body having a first surface and a second surface. In a first embodiment of the invention, the plate body is formed from a laminated sheet structure including two layers of steel having a viscoelastic core between the two layers and coextensive with the two layers. The viscoelastic core may be tunable to damp at different temperatures. In a second embodiment of the invention, an engineered viscoelastic material is used as a layer of bonding material for the first and second surface of the plate body. A method for damping a clutch plate assembly is provided.

Owner:MATERIALS SCI CORP

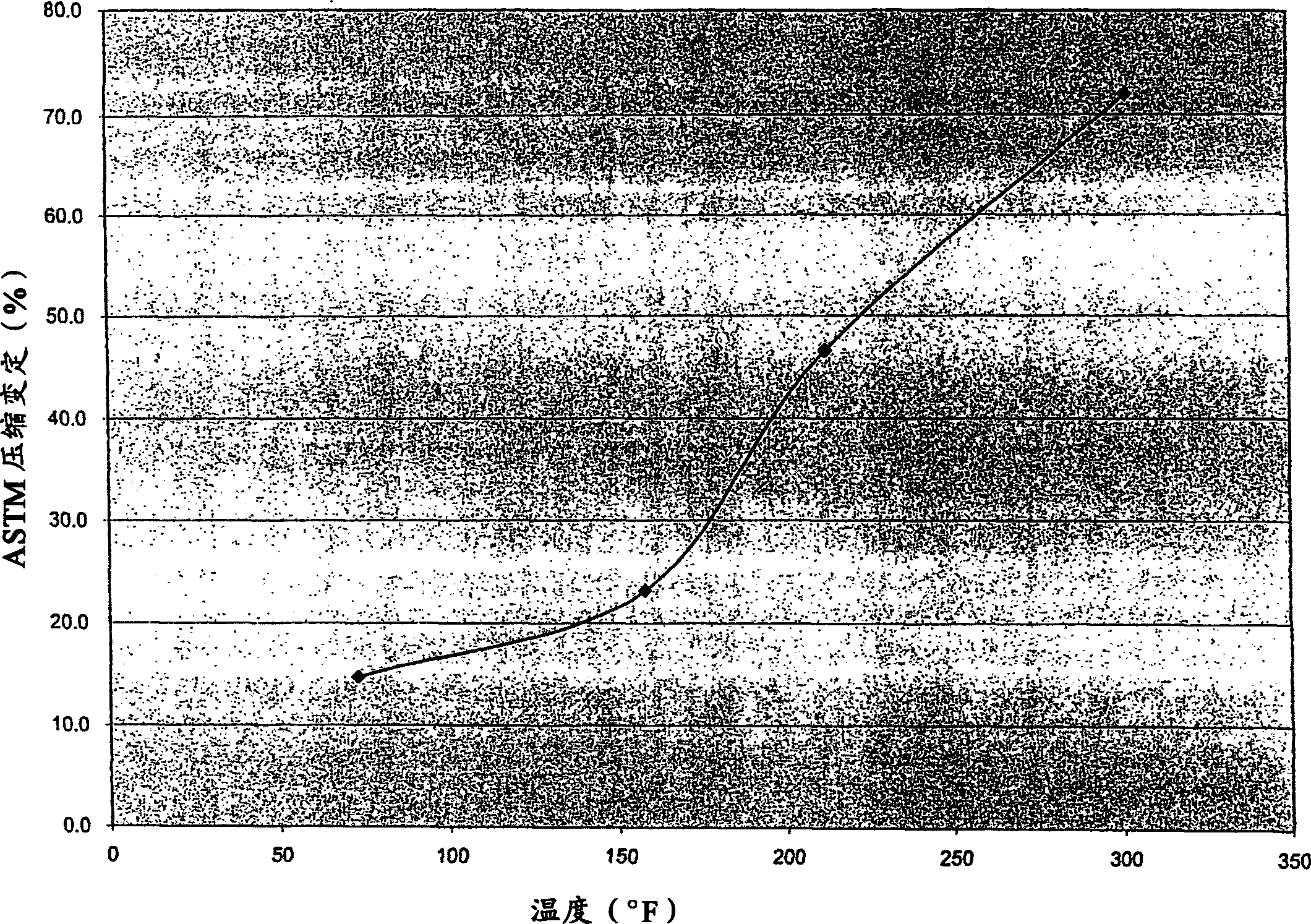

Vulcanized rubber composition and articles manufactured therefrom

ActiveCN1871123ABalanceSolve the lack of hardnessOperating means/releasing devices for valvesLaminationPolymer sciencePlasticizer

The rubber composition described herein have been found to have an exceptionally long life as a spring-biased actuator diaphragm material that maintains its position compressed, e.g., bolted, between opposed flanges, while maintaining excellent compressibility, low temperature flexibility, hydrocarbon resistance, abrasion resistance and mechanical strength. The compositions include a copolymer rubber component; a plasticizer for the copolymer rubber; a vulcanizing agent for the copolymer rubber; a silica filler; and a coupling agent, such as a silane coupling agent, capable of coupling the silica filler to the copolymer rubber. Ranges may be expressed herein as from 'about' or 'approximately' on particular value and / or to 'about' or 'approximately' another particular value. When such a range is expressed, another embodiment includes from the one particular value and / or to the other particular value.

Owner:FISHER CONTROLS INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com