Metal and graphite laminate

a graphite and metal technology, applied in the field of laminate materials, can solve the problems of reducing the thickness of the metal layer,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

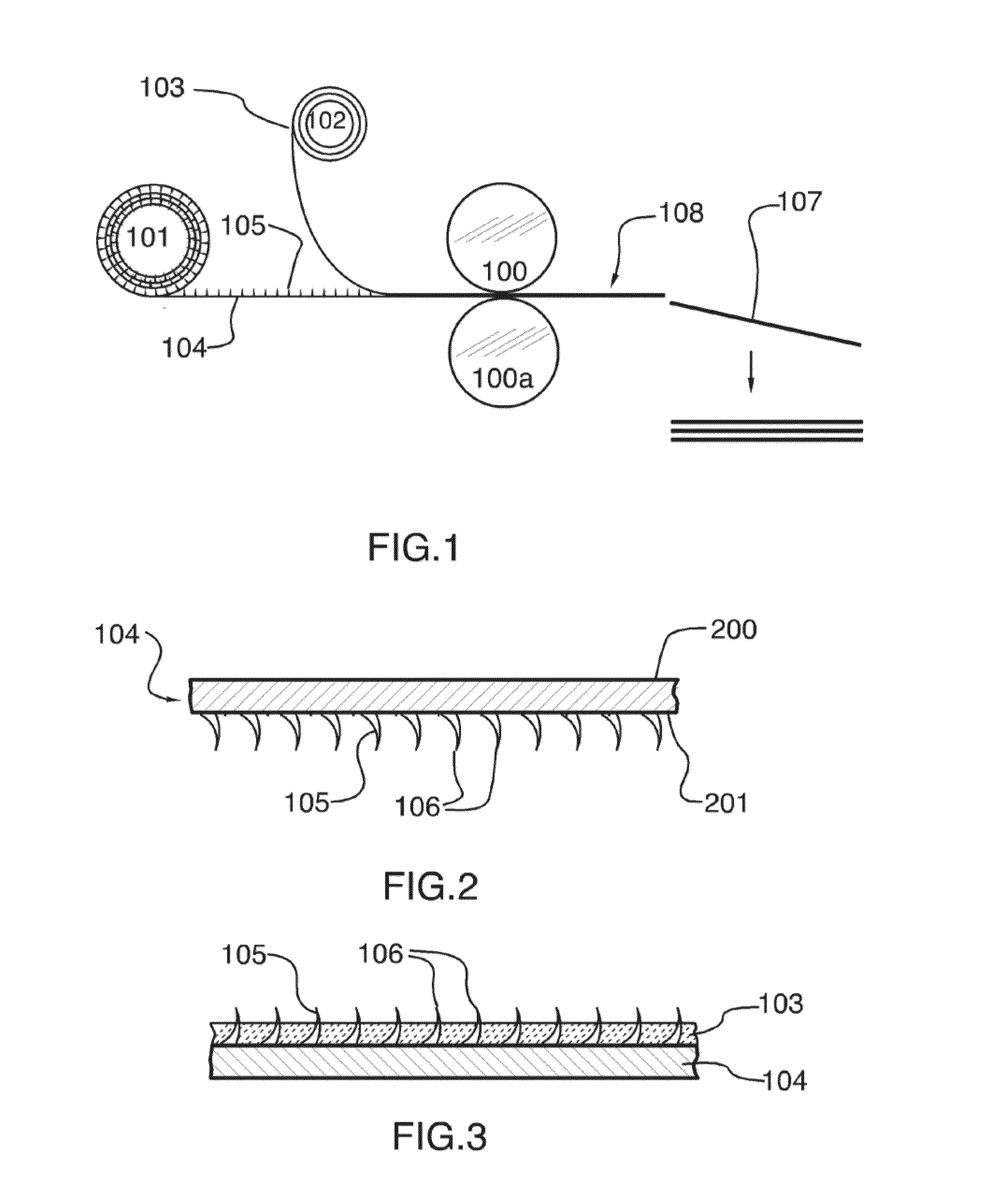

[0022]In the following description the word “clinch” (clinching, clinchable, clinched), is used to describe the act of bending over the exposed apex portion or “tip” of a pin- or nail-like structure that has pierced through two or more layers and extends therefrom. Clinching is common practice in the wood construction trade. Clinching is analogous to riveting in metal work, or to any other deformation of a fastener to prevent its easy withdrawal. The purpose of clinching is to impart greater cohesion between the two laminate layers that are so joined.

[0023]The terms “pointed structure” and “piercing structure” are used synonymously herein as a general term to describe any type of nail- or pin-like structure (or hooked or barbed structure) raised on the surface of a material (for embedding or piercing) that are capable of piercing and then penetrating the surface of a graphite foil. An appropriate choice of hardness of the material and shape and configuration of the piercing structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com