Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281 results about "Scramjet engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hypersonic flight vehicle adaptive fault-tolerant control method of considering attack angle constraint

The present invention discloses a hypersonic flight vehicle adaptive fault-tolerant control method of considering attack angle constraint which is used to solve the technical problem that a conventional hypersonic flight vehicle control method is poor in practicality. The method of the technical scheme is characterized by limiting a flight vehicle attack angle within a given range to guarantee the normal work of a scramjet engine; aiming at the fault case of an actuator, giving out a robust adaptive adjusting and controlling strategy, and utilizing a redundancy control mechanism to effectively compensate the influence brought by the failure to guarantee the safety of a system. Aiming at the model uncertainty, the method of the present invention combines the amplitude limiting design and a Barrier type lyapunov function to give out a controller, thereby being able to guarantee that the attack angle can be restrained within the given range, and guaranteeing the normal work of the scramjet engine. By using a neural network to learn and process the model uncertainty to substitute for the linear parameterization processing, the model analysis is simplified, and the actual application is convenient. Aiming at the fault case of the actuator, the redundancy control mechanism is utilized to compensate the influence brought by the faults effectively and adaptively, thereby being good in practicality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

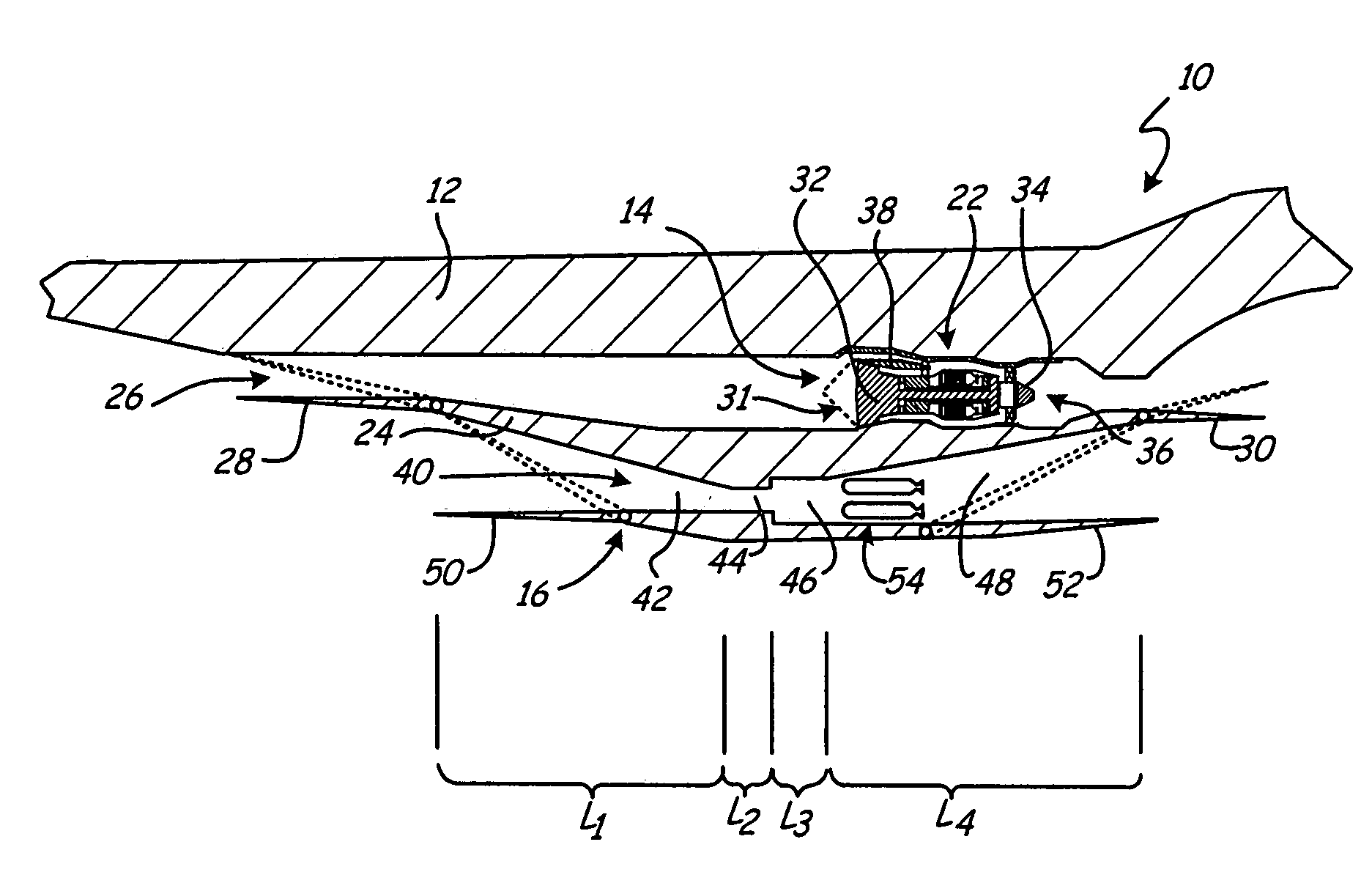

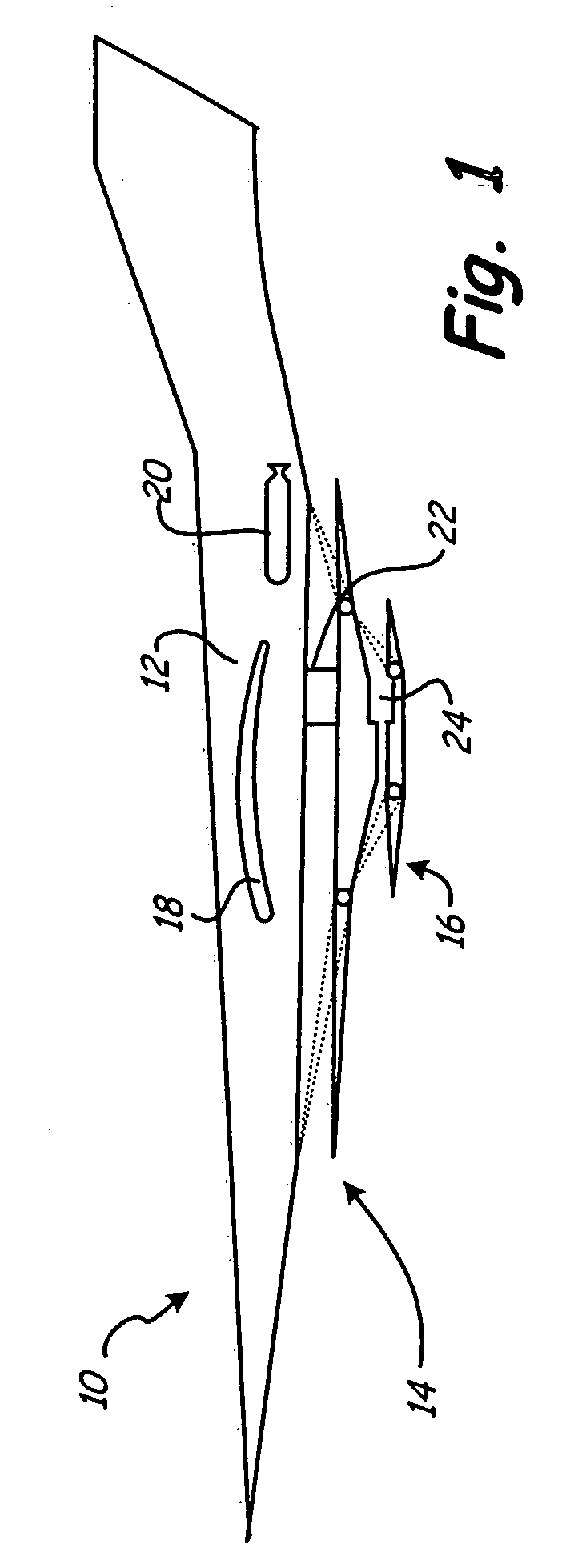

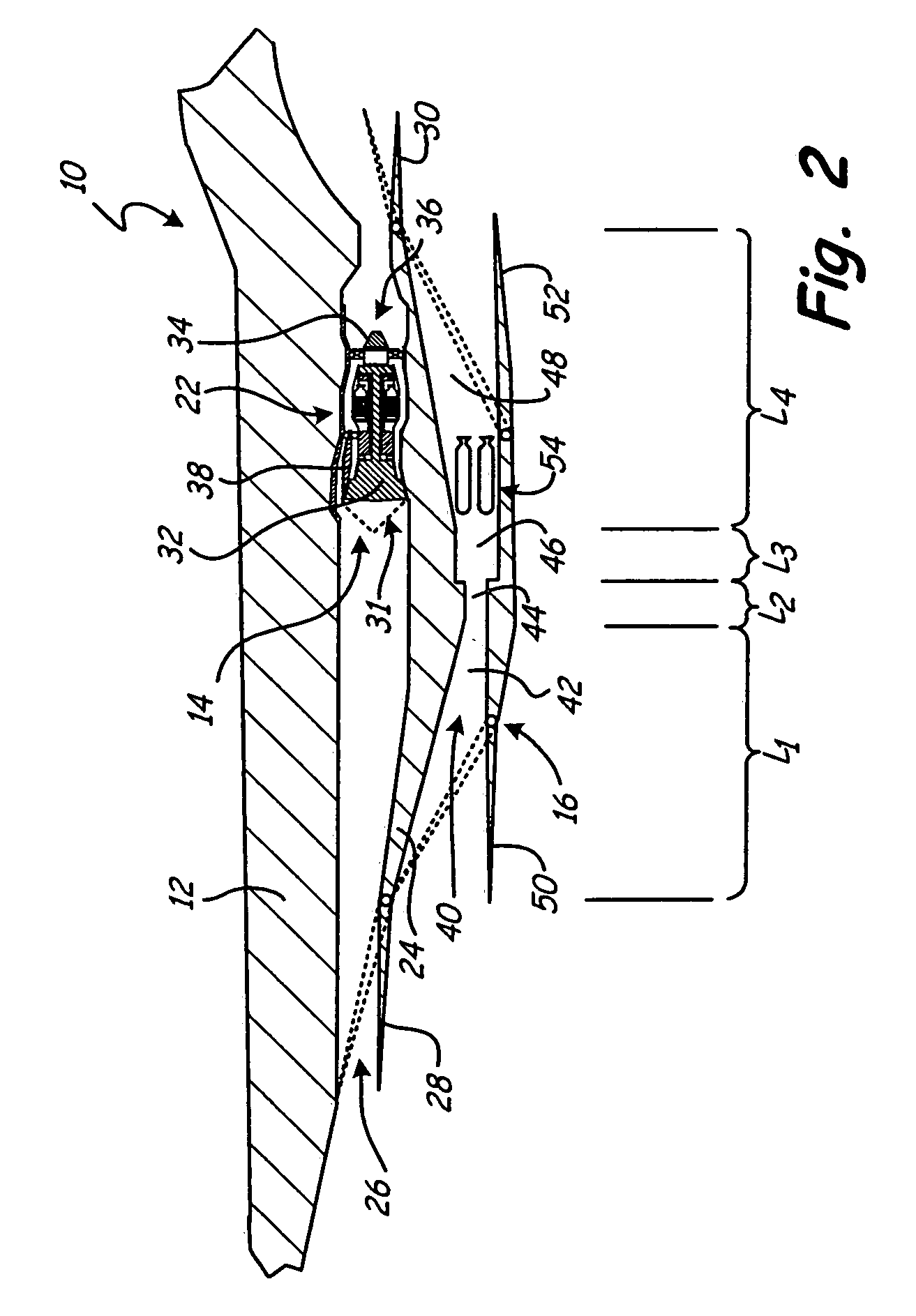

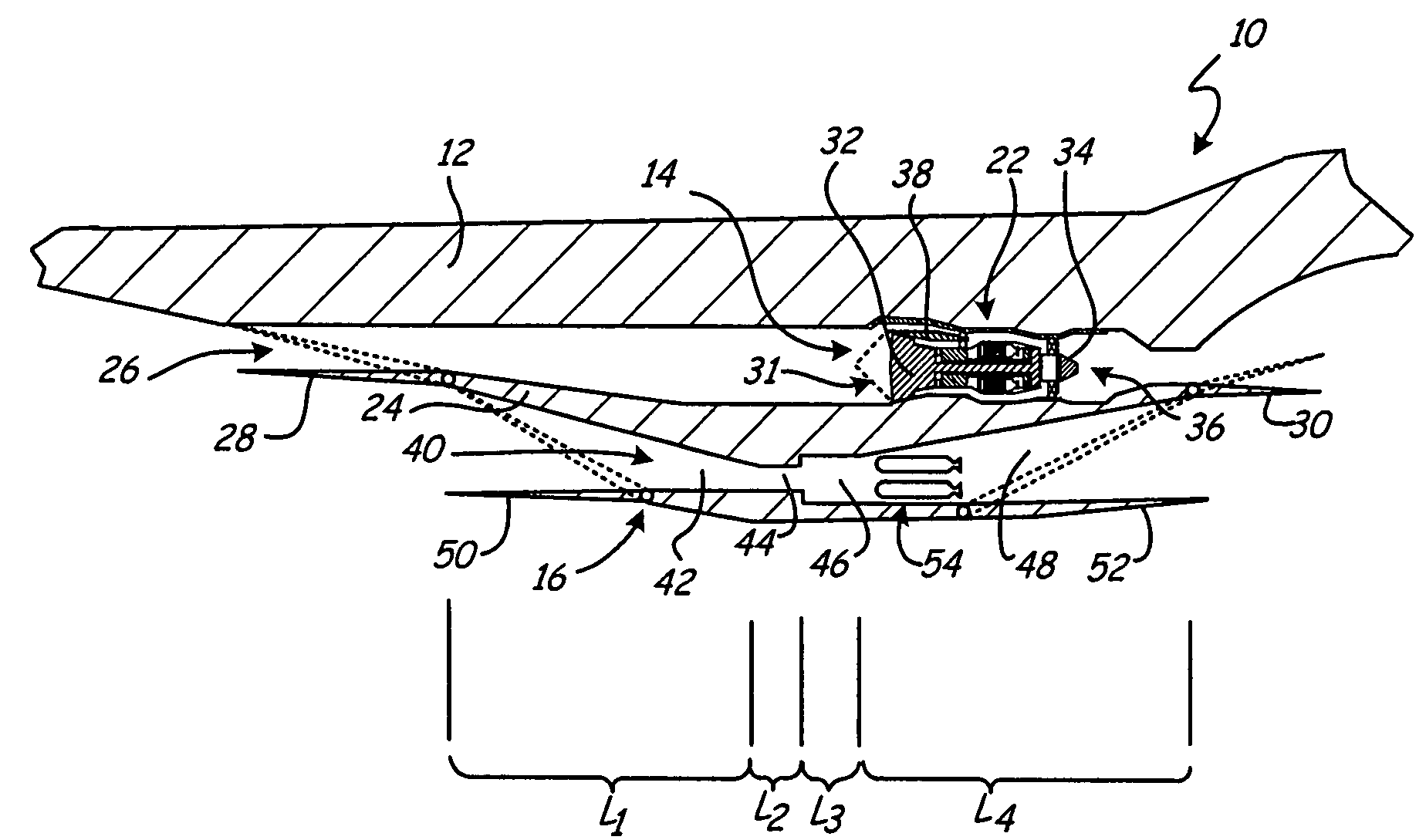

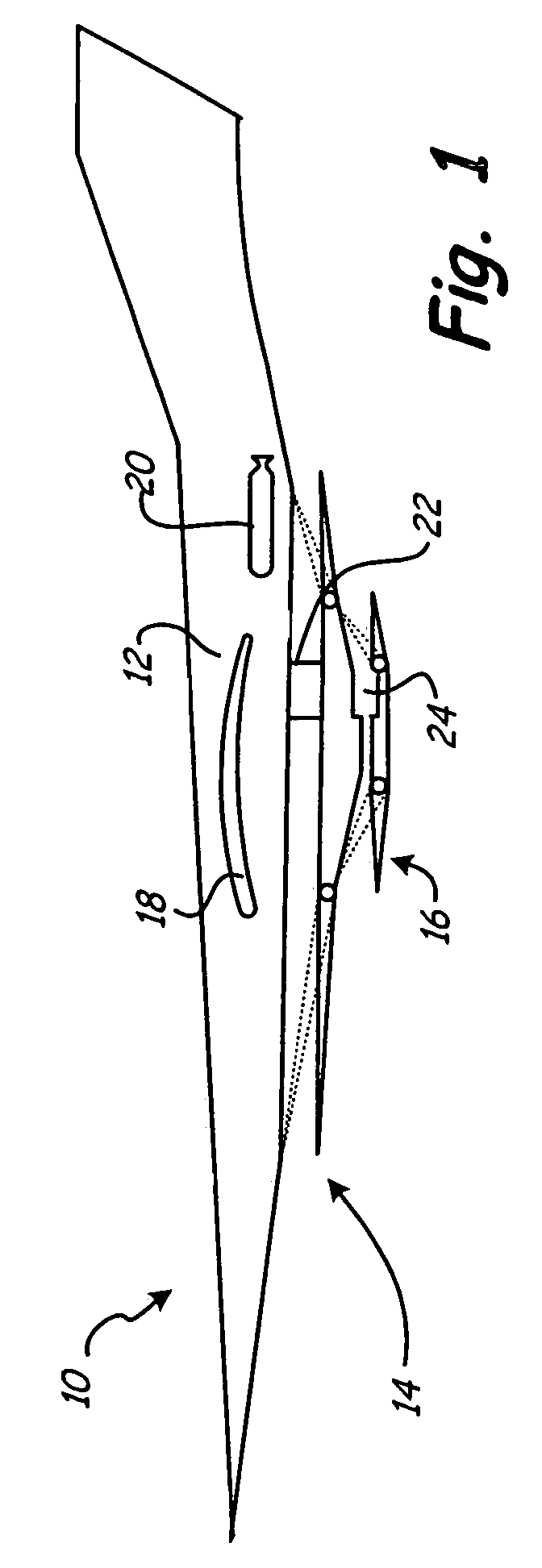

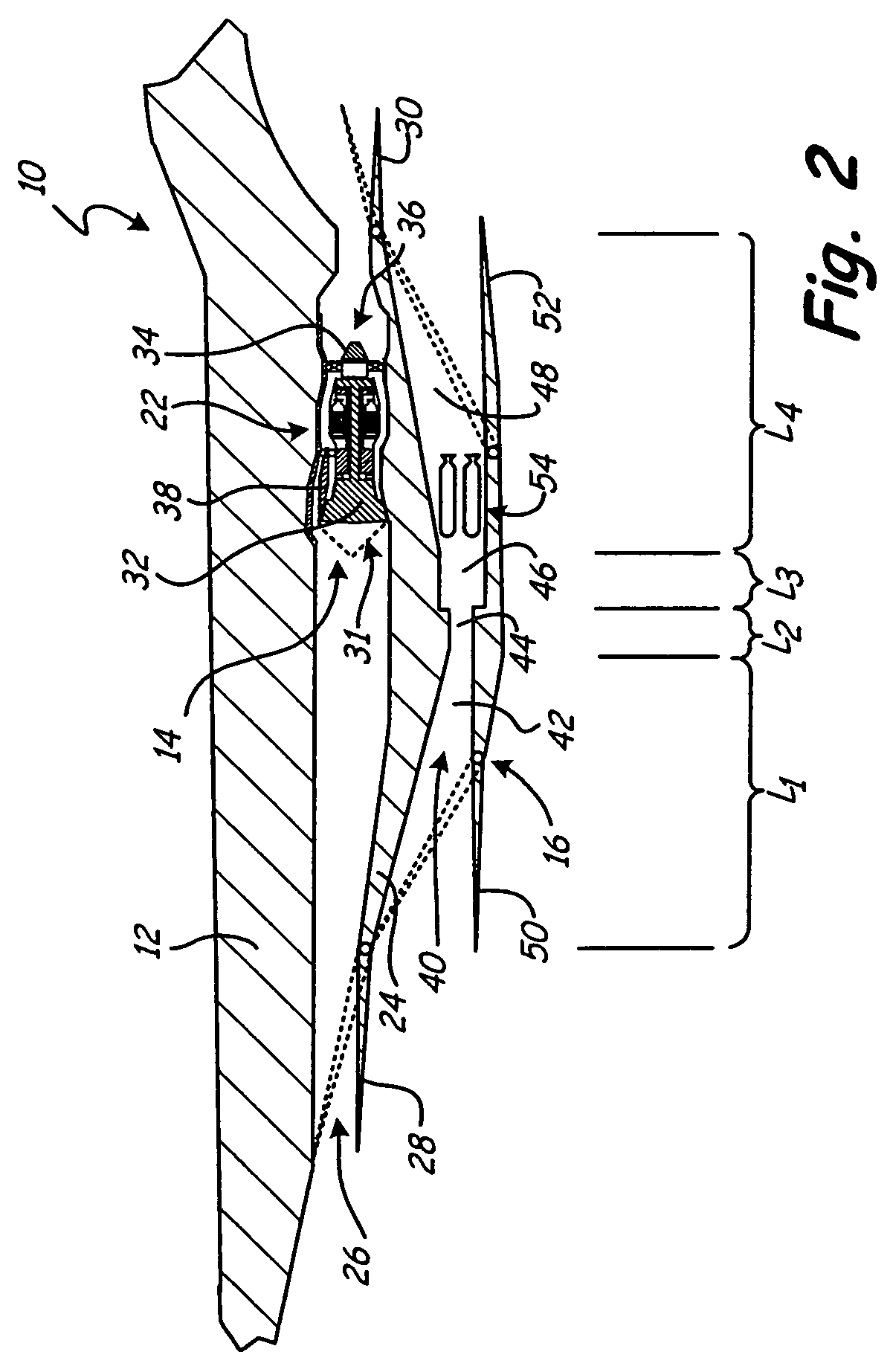

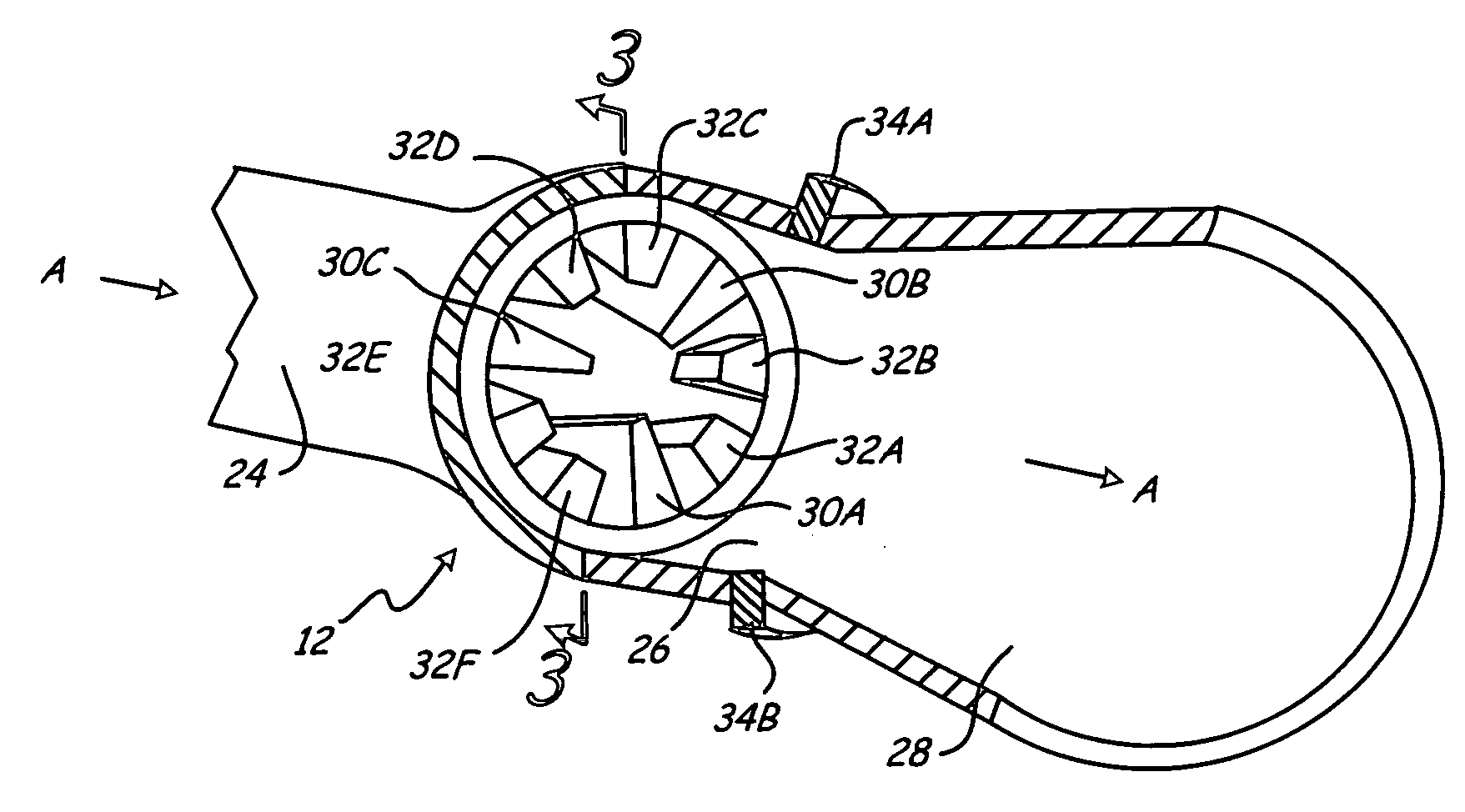

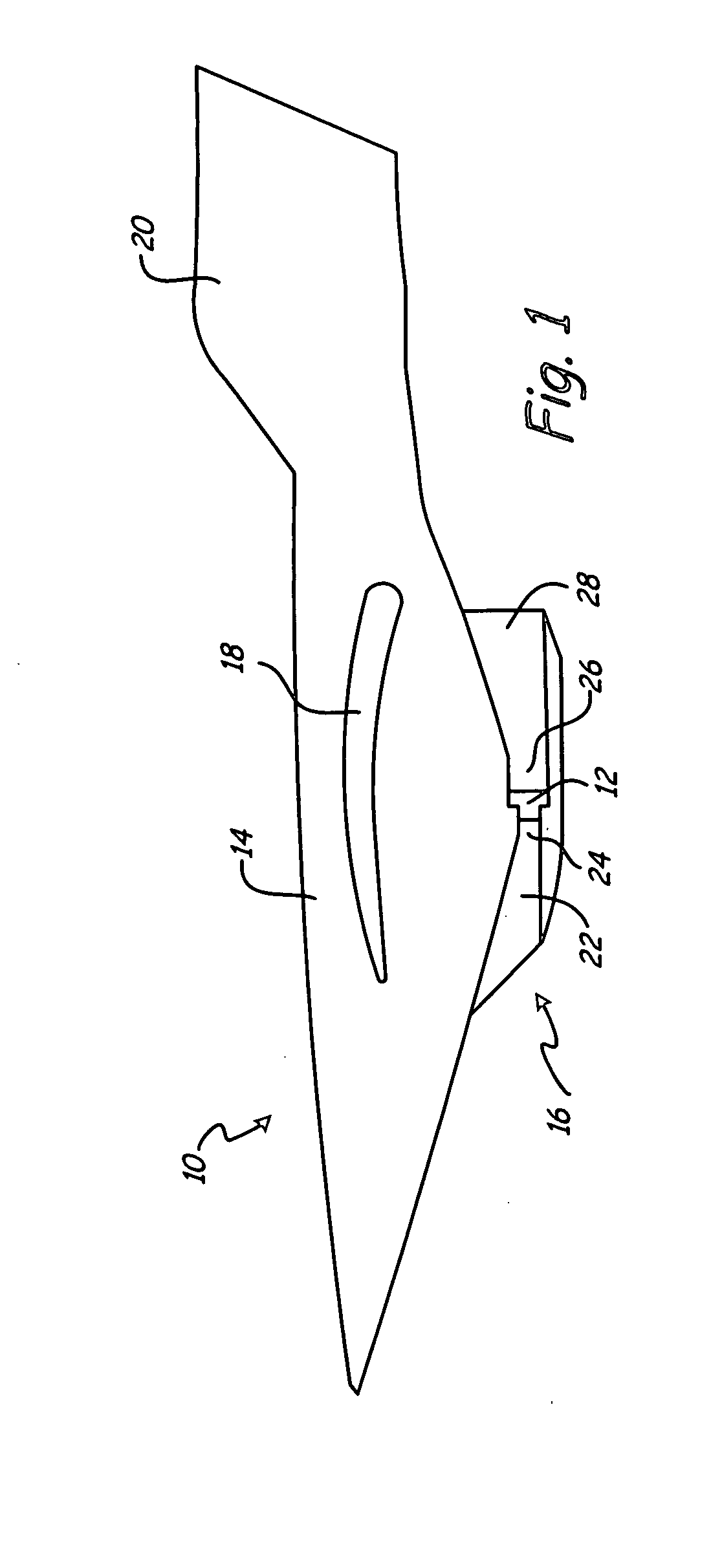

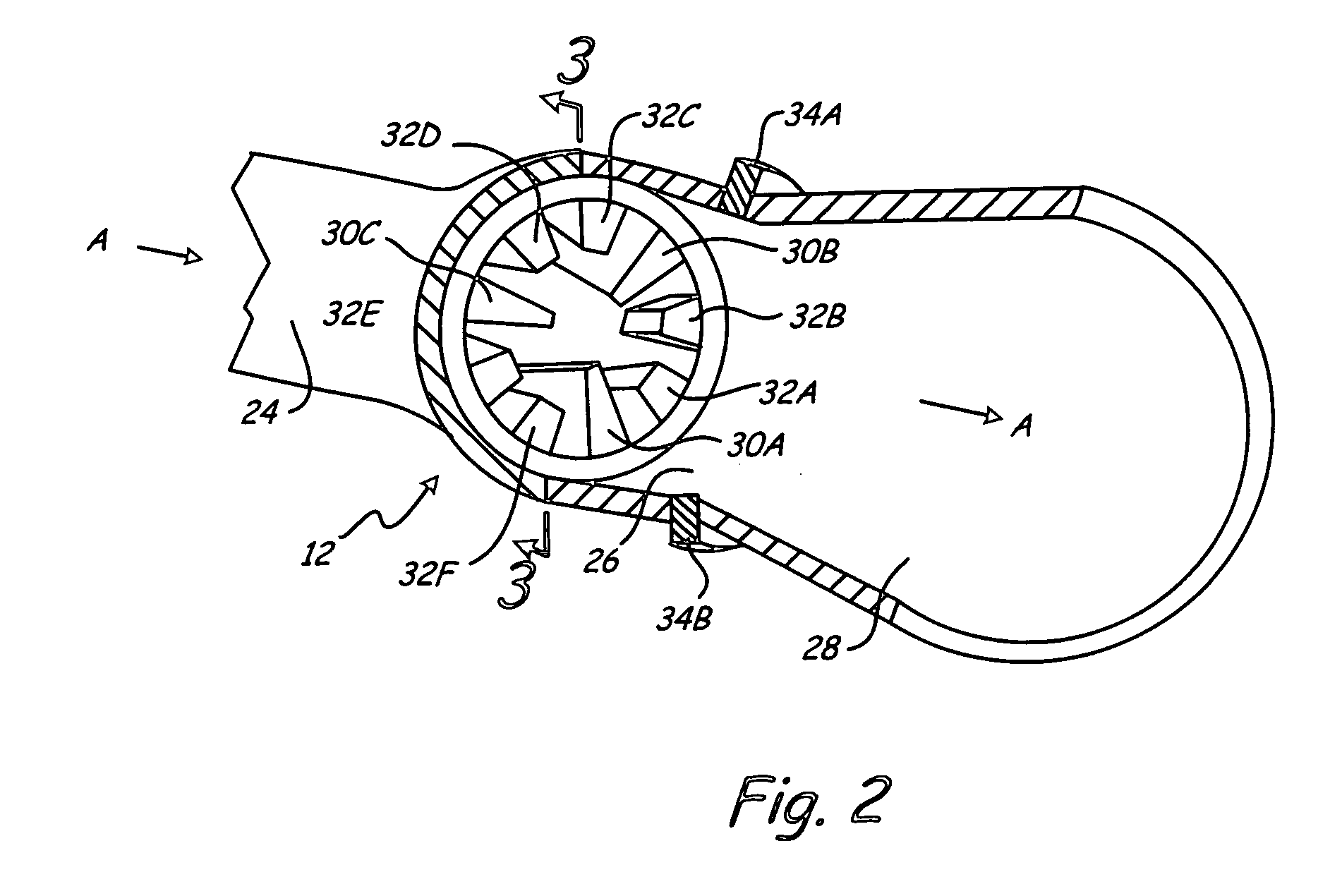

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS20080283677A1Reduce complexityShorten the lengthAircraft navigation controlPower plant exhaust arrangementsRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

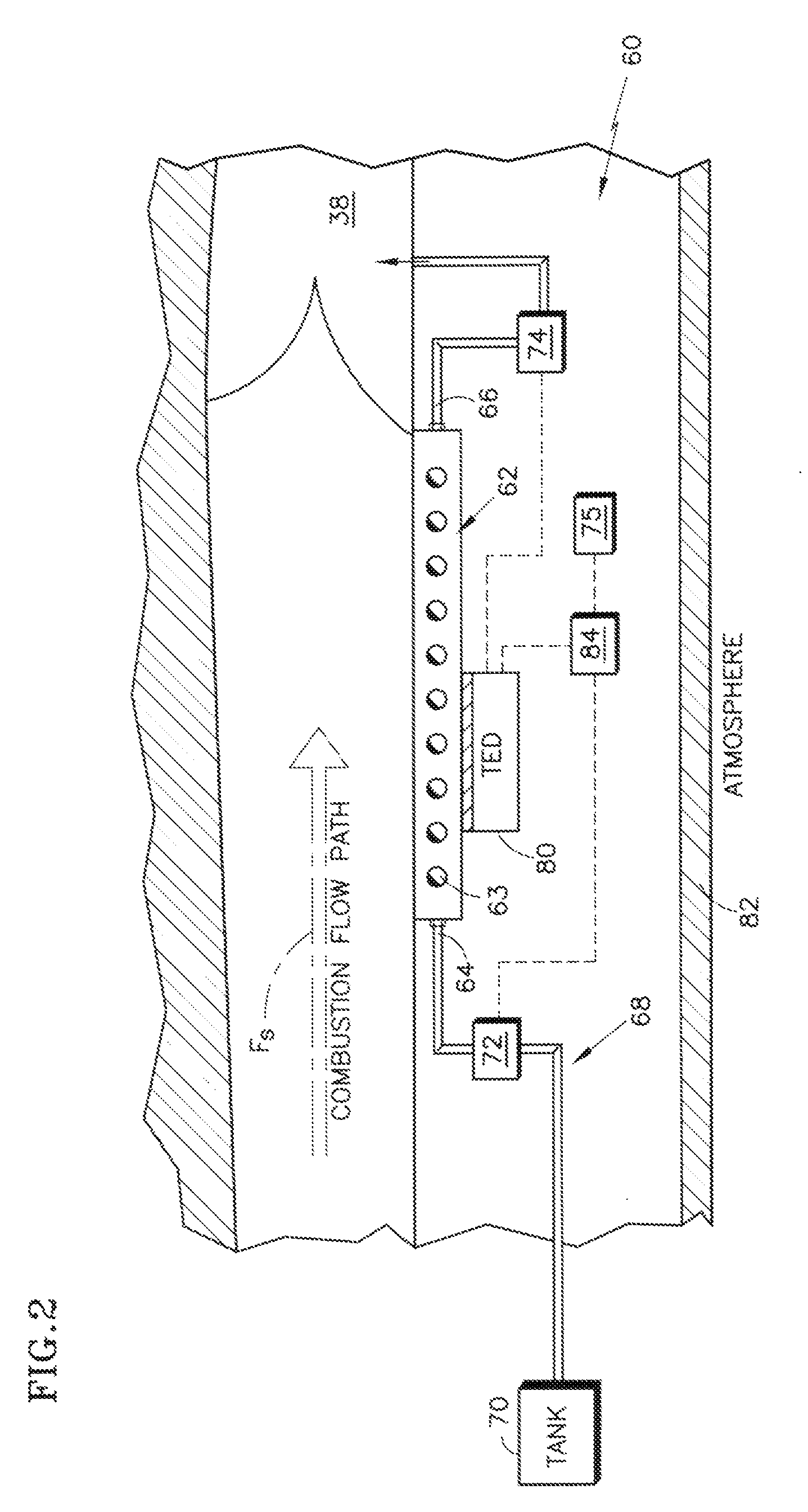

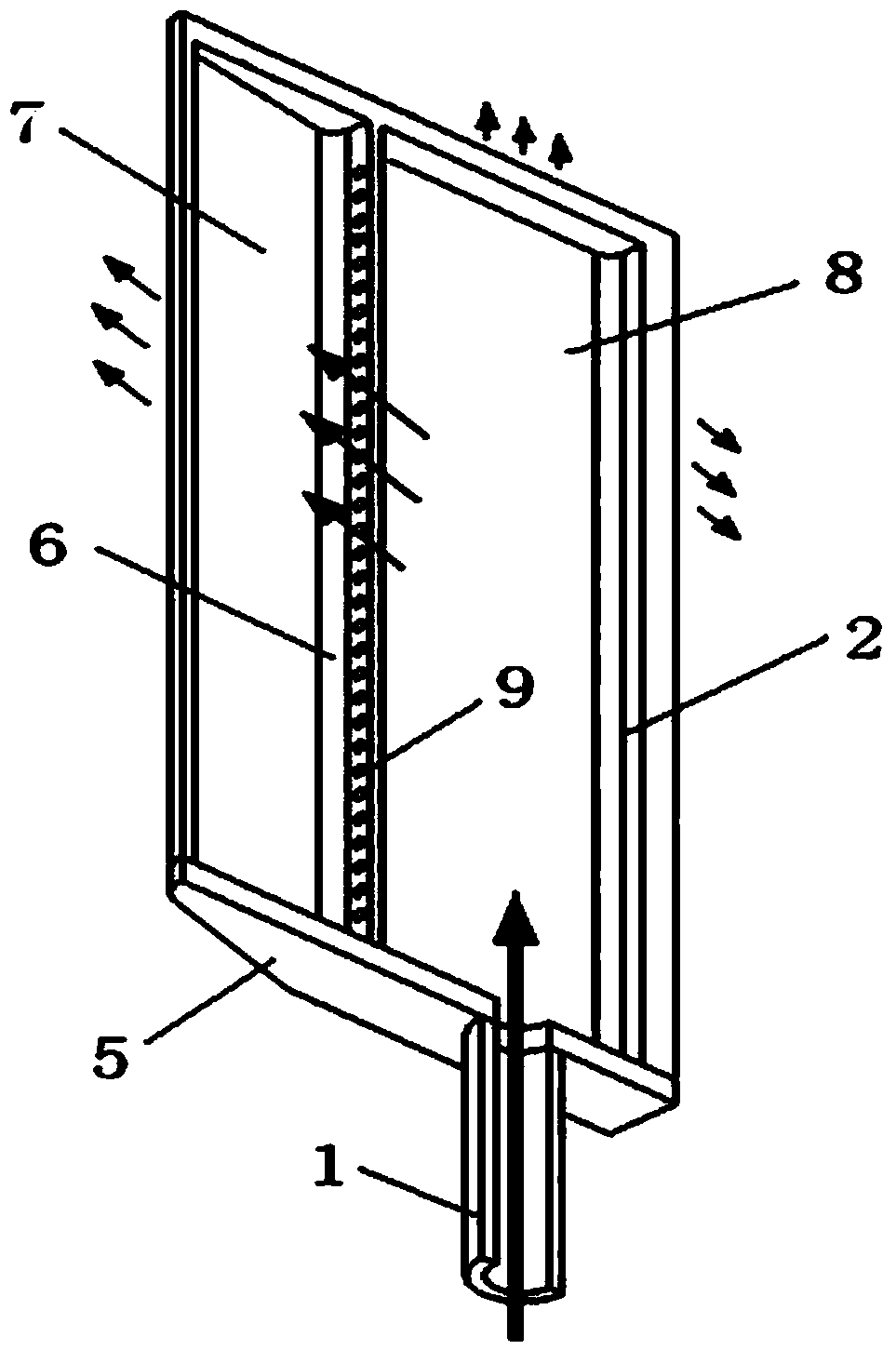

Flowpath heat exchanger for thermal management and power generation within a hypersonic vehicle

InactiveUS20090151321A1Maximize thermal gradientStress minimizationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal energyPlate heat exchanger

An electrical power generation system incorporates thermoelectric devices (TE Devices) for electrical power generation adjacent a flow path heat exchanger (HEX) adjacent to a vehicle flowpath structure such as a scramjet flow path to take advantage of the waste heat, high thermal gradients, and available, unused volume. A thermally conductive material communicates thermal energy from a vehicle external skin structure to the TE Device while a thermally conductive compliant material allows the TE Device to “float” with minimal mechanical stress.

Owner:AEROJET ROCKETDYNE OF DE

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS7762077B2Reduce complexityShorten the lengthPower plant exhaust arrangementsEfficient propulsion technologiesRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

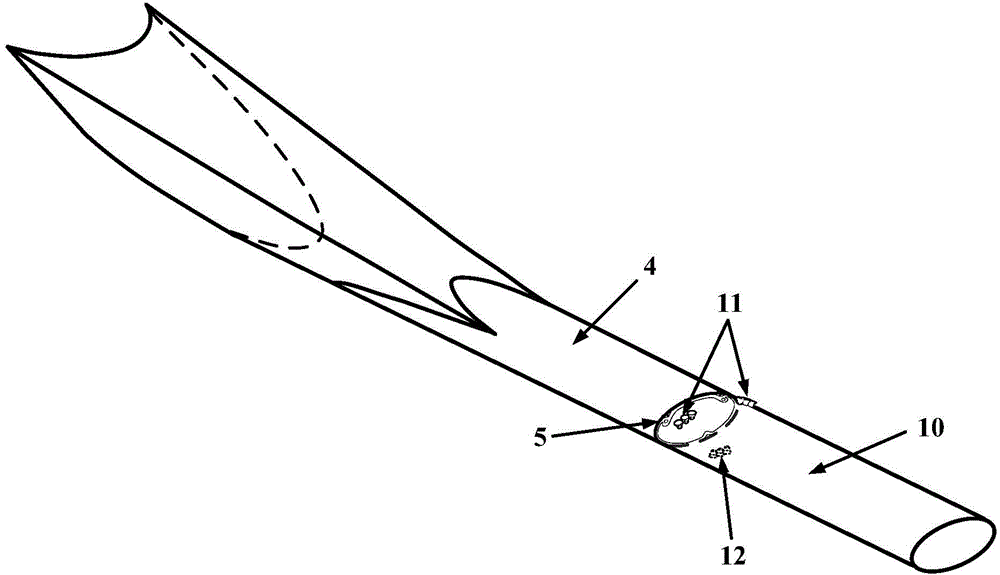

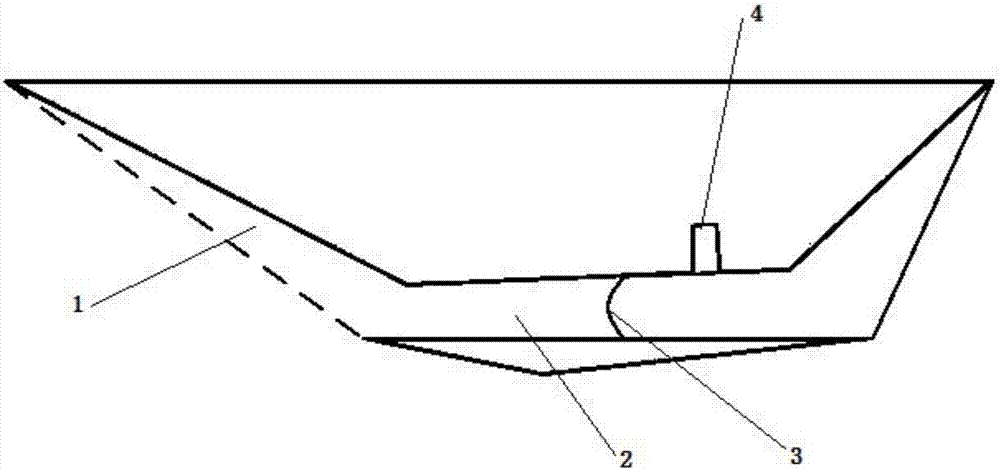

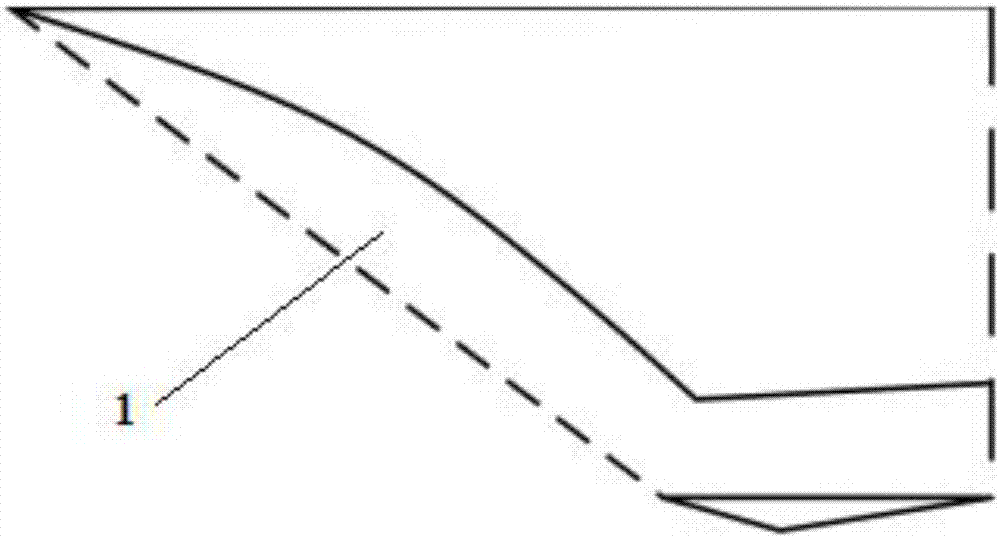

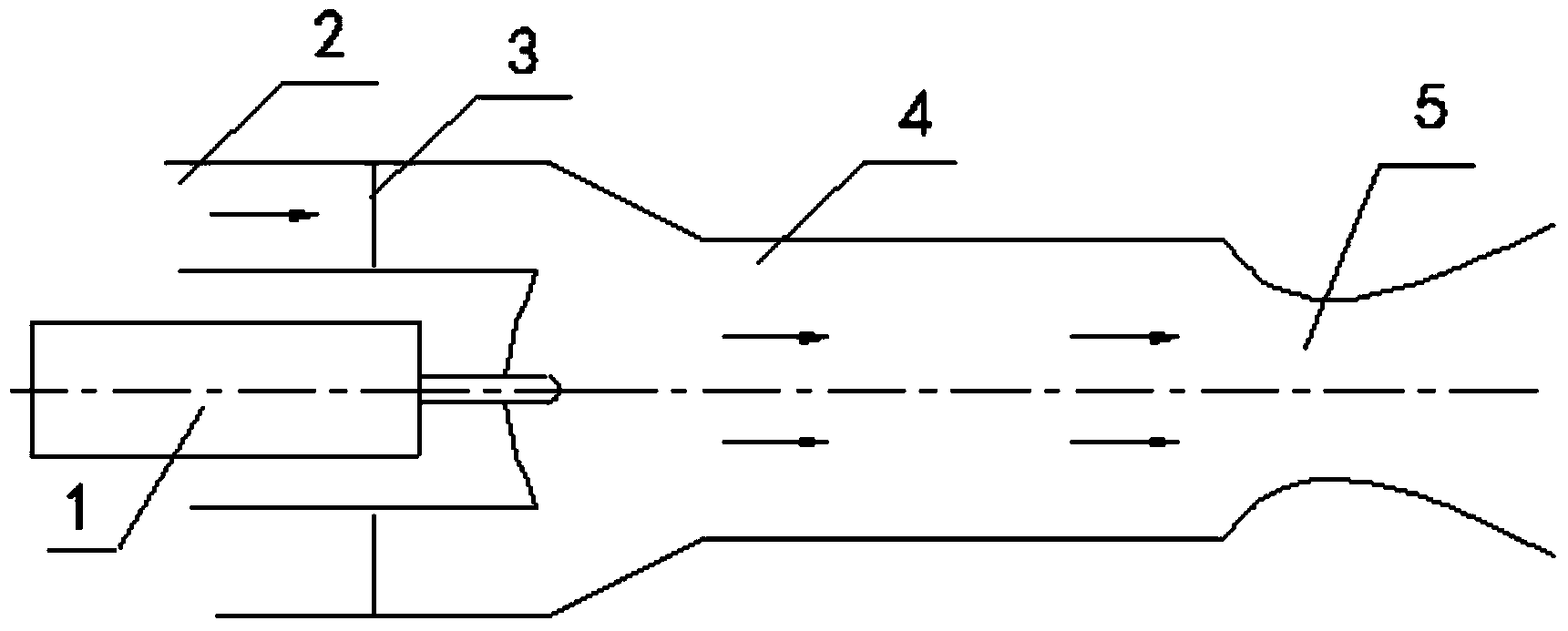

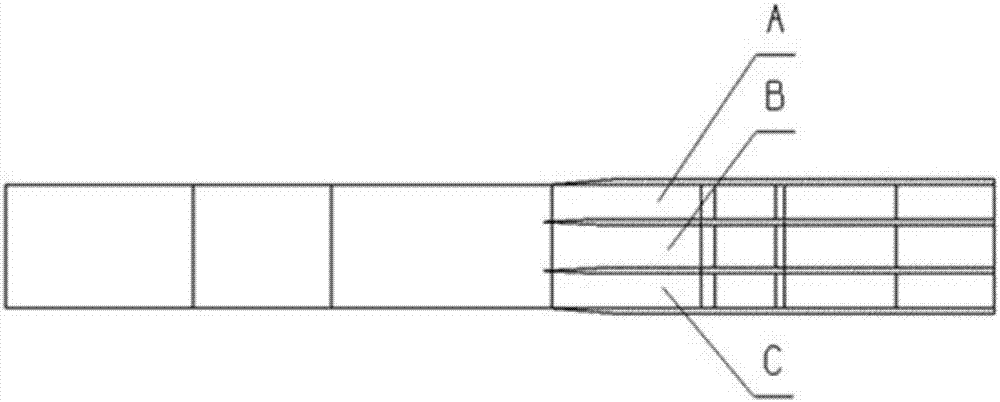

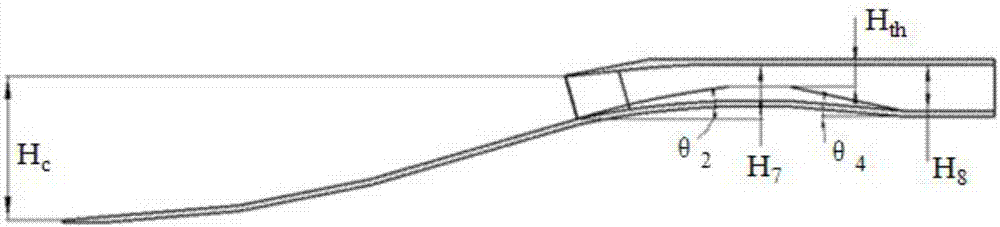

Body propelling integrated outer appearance modeling process for supersonic aircraft

A method for modeling a fuselage of a hypersonic aircraft by promoting outline integration comprises the following eight steps: 1, designing a geometric molding surface of a two-dimensional flow channel of a propulsion system; 2, designing a view-from-above contour curve of the fuselage of the aircraft; 3, designing a side-view contour curve of the fuselage of the aircraft; 4, designing section forms of longitudinal main station positions of the fuselage of the aircraft and variation modes of control parameters; 5, generating a three-dimensional fuselage of the aircraft; 6, generating a three-dimensional supersonic combustion ramjet hood; 7, designing an outline drawing of wing surfaces, and generating three-dimensional wing surfaces; and 8, generating a promotion integrated outline of the three-dimensional fuselage by assembling the fuselage, the ramjet hood and all the wing surfaces. The method has the advantage of simple and rapid modeling process, achieves the effect of promoting integration of the fuselage of the hypersonic aircraft, and is capable of improving paces and efficiencies in designing, developing and manufacturing the hypersonic aircraft.

Owner:BEIHANG UNIV

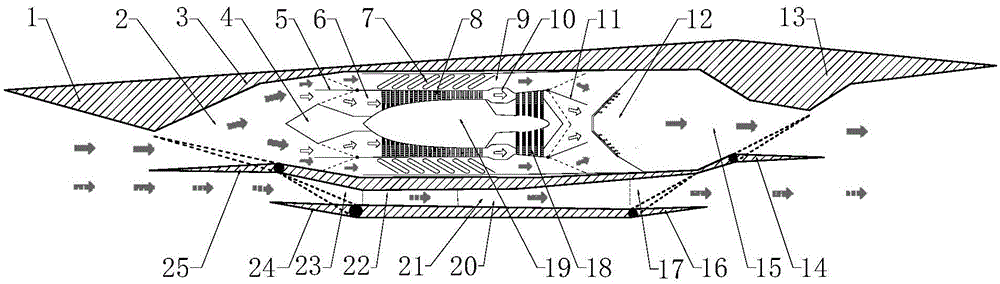

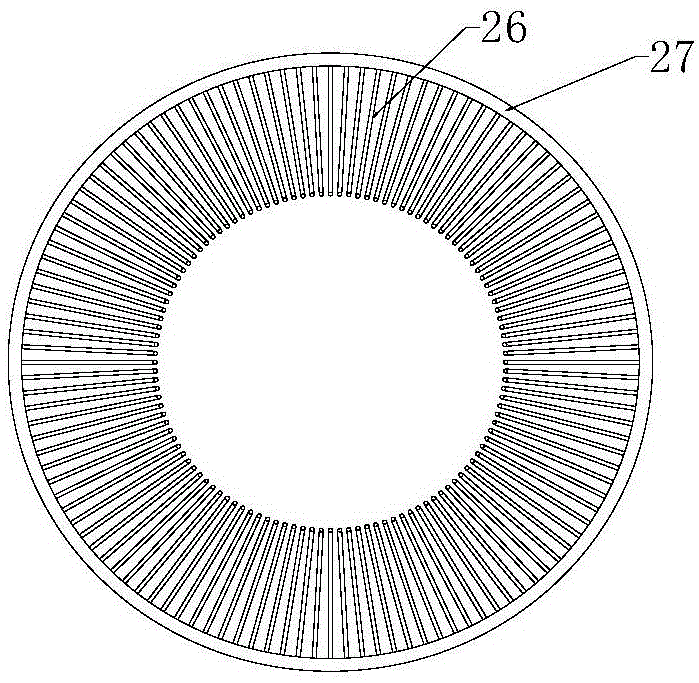

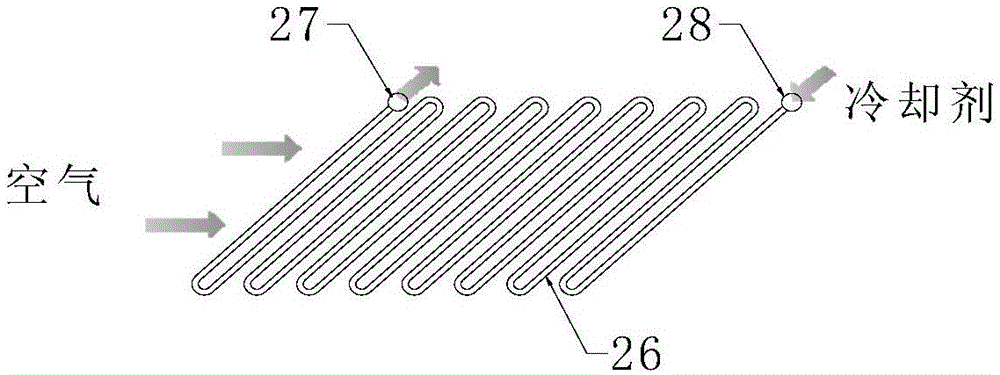

Pre-cooling air-breathing type variable cycle engine

InactiveCN105156227ALower airflow temperatureReduce the temperatureTurbine/propulsion engine coolingGas turbine plantsRamjetCombustion chamber

The invention discloses a pre-cooling air-breathing type variable cycle engine and relates to the reusable pre-cooling air-breathing type variable cycle engine applied to aeronautics and astronautics devices. The engine mainly consists of a pre-cooler, a turbine engine, a super combustion chamber and a super combustion ramjet engine, wherein the pre-cooler and the super combustion chamber form a subsonic combustion ramjet engine; a turbine subsonic combustion ramjet engine is connected with the super combustion ramjet engine in parallel; working states of the turbine subsonic combustion ramjet engine and the super combustion ramjet engine are selected by adjusting a switching adjusting device, so that the working modal of the whole engine is controlled. The pre-cooler can reduce an inlet gas flow temperature of a super combustion chamber, can increase the efficiency of the super combustion chamber, can expand the working range of a subsonic combustion punching modal, and can make up insufficient thrust force when turbine subsonic combustion ramjet engine is transferred to the super consumption ramjet engine, so that the pre-cooling air-breathing type variable cycle engine has the advantage that the transfer class of a combined engine is stably transferred.

Owner:TSINGHUA UNIV

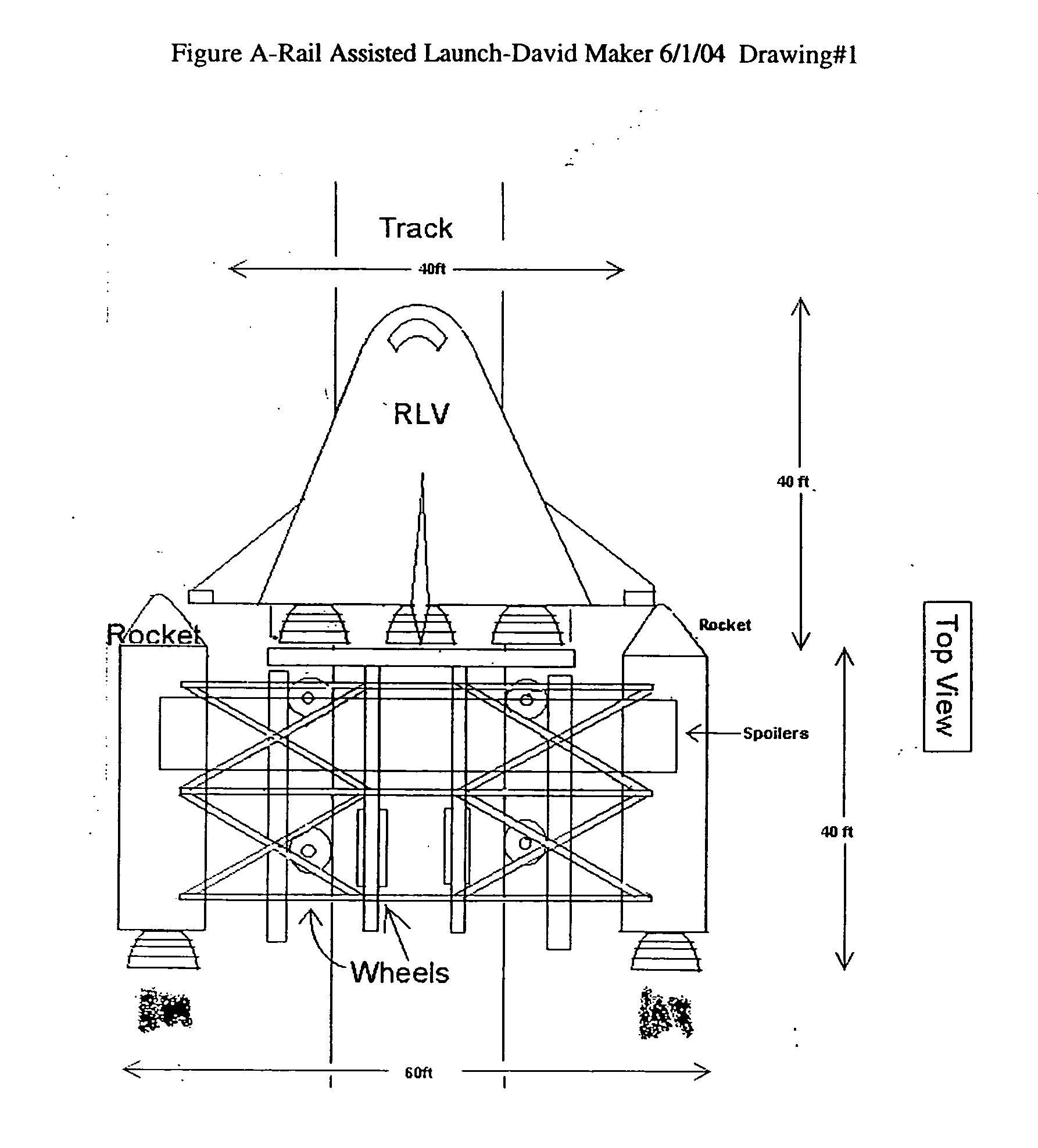

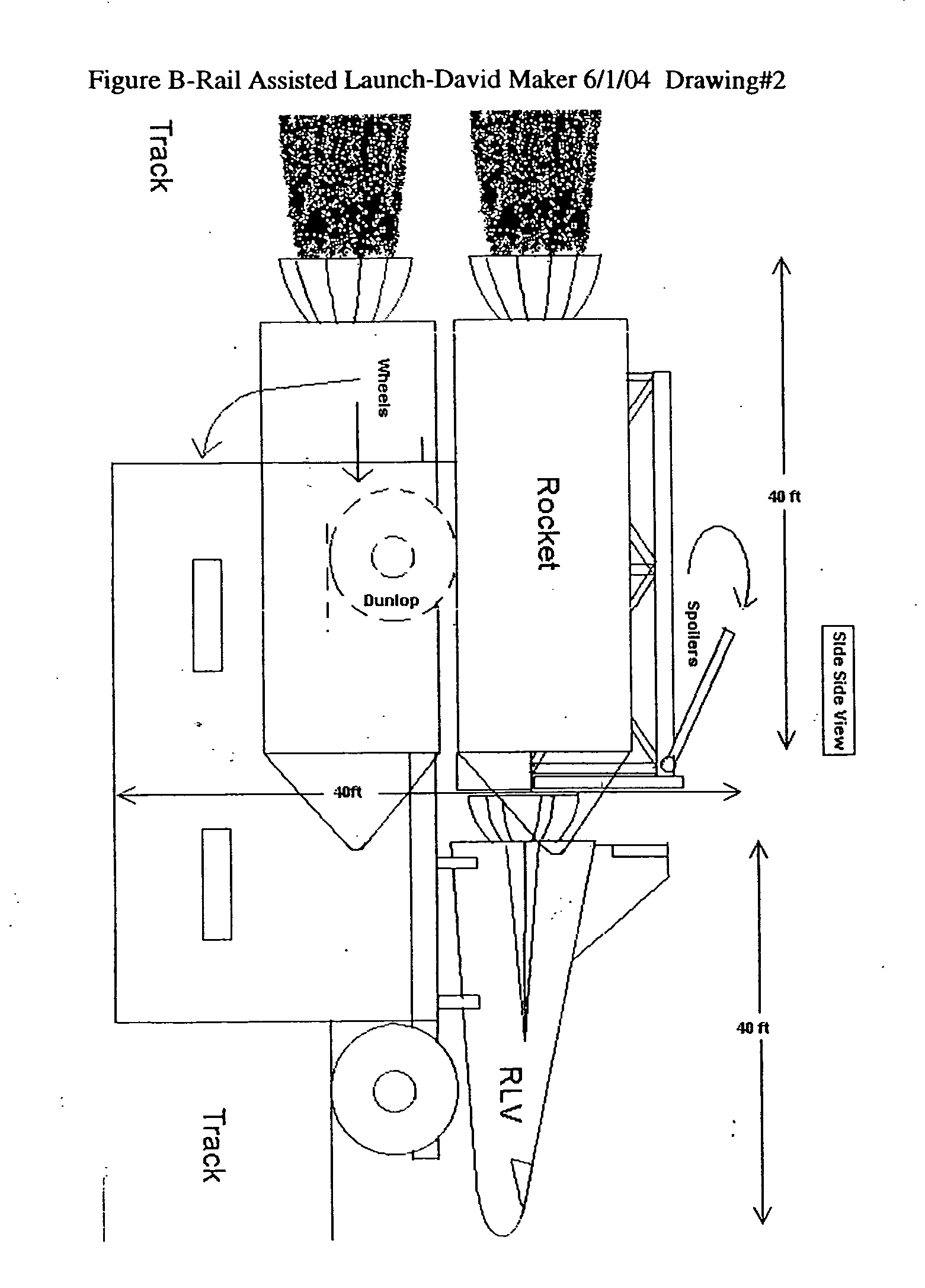

Reusable thrust-powered sled mounted on an inclined track for launching spacecraft and airborne vehicles at supersonic speeds

InactiveUS20060032986A1Small sizeReduce weightCosmonautic ground equipmentsLaunch systemsRamjetRocket launch

This invention will allow a reusable thrust-powered sled mounted on an inclined track to launch spacecraft or airborne vehicles from earth at supersonic speeds using existing technology properly integrated into an inclined track system. If launched up a tunnel track, a rear blast shield can trap the rocket exhaust to provide a pneumatic boost upon launch. The sled can also launch ramjet or scramjet powered vehicles from earth by achieving the Mach 2+ speed necessary to ignite their engines. This system is much safer than the traditional method of launching rockets since weather is less a factor and the launch can be aborted if problems develop. Moreover, it is far less costly since the engines on the sled can be reused hours after a launch and the track can accommodate a variety of sleds to launch objects of many different sizes.

Owner:MAKER DAVID +1

Core burning for scramjet engines

InactiveUS20080092519A1Reducing combustor heat loadReduces combustor heat loadCosmonautic vehiclesCosmonautic propulsion system apparatusRamjetCombustion chamber

A pilot for a scramjet provides a flame front whose arrival at the wall of the scramjet combustor is delayed thereby reducing combustor heat load. By combining in-stream injection of fuel with an interior pilot and a lean (fuel-poor) outer annulus, the bulk of combustion is confined to the scramjet combustor center. This concept, referred to as “core-burning,” further reduces combustor heat load. One such pilot is for a two dimensional scramjet effective to propel a vehicle. This pilot includes a plurality of spaced apart struts separated by ducts and a strut pilot contained within each strut. A second such pilot is for an axisymmetric scramjet engine has, in sequence and in fluid communication, an air intake, an open bore scramjet isolator and a scramjet combustor. This centerbody pilot pod includes a pilot isolator disposed between the air intake and a pilot diffuser, the pilot diffuser disposed between the pilot isolator and a pilot with the pilot disposed between the pilot diffuser and a pilot combustor. The pilot pod is in axis symmetry around a central axis of the scramjet isolator and supported by a plurality of struts extending from an inner wall of the open bore to an outer surface of the centerbody pilot pod.

Owner:AEROJET ROCKETDYNE INC

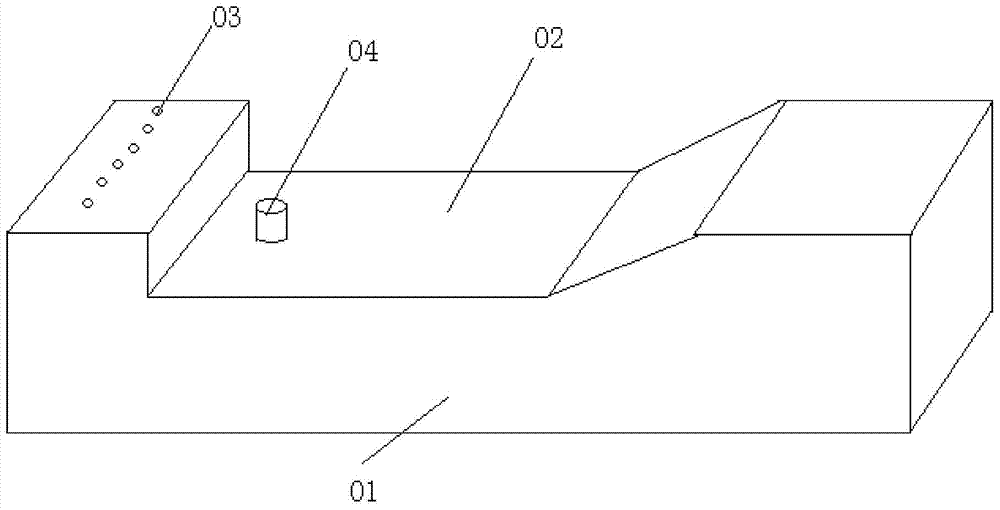

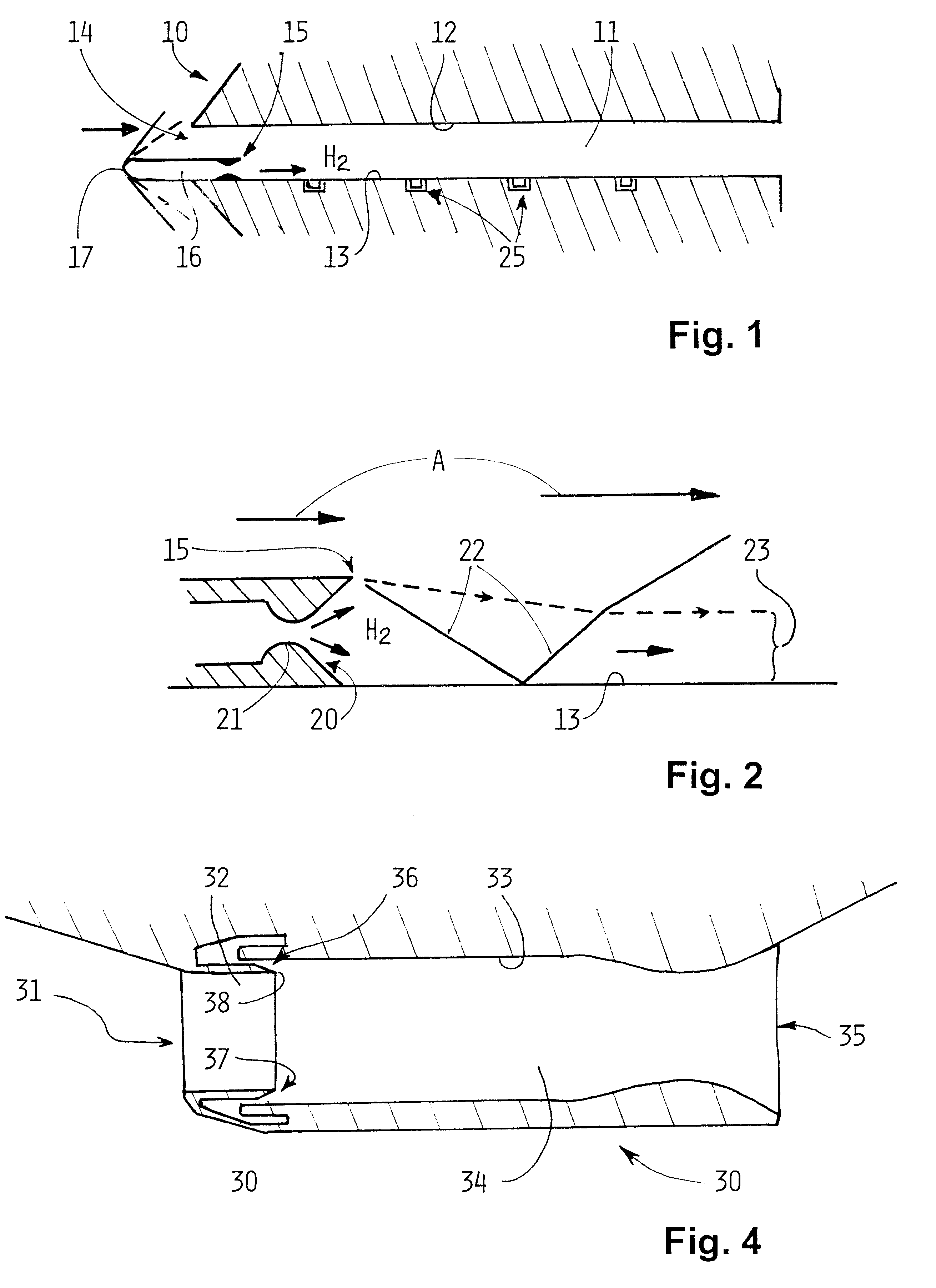

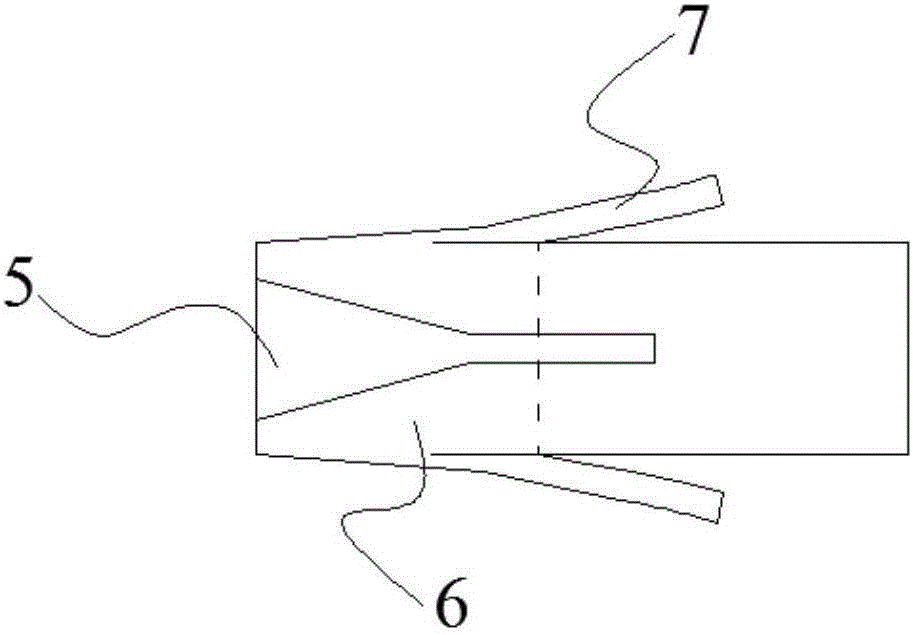

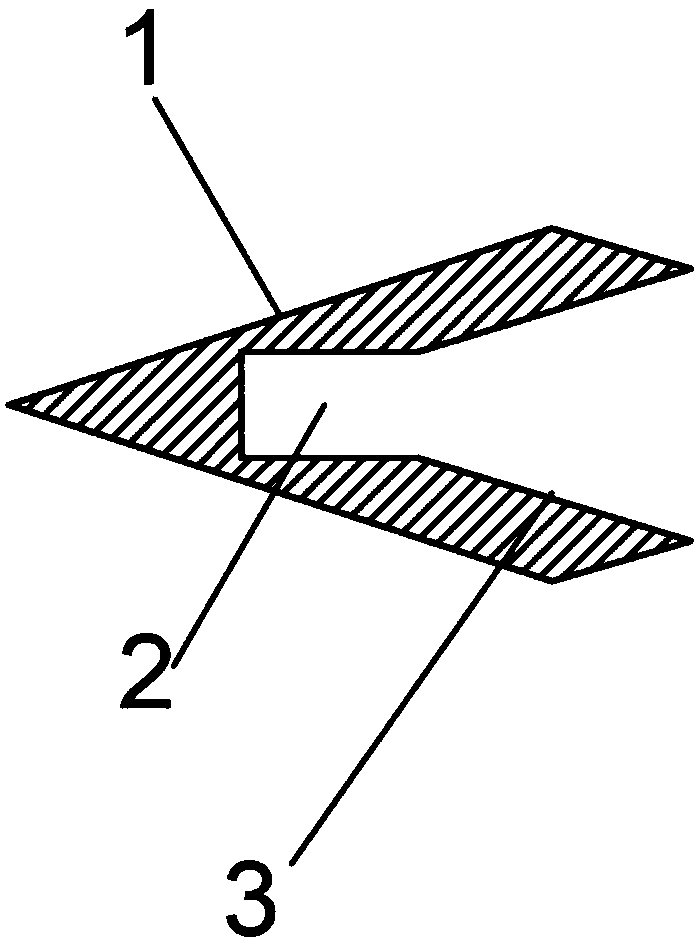

Supersonic combustion chamber cavity ignition device and scramjet engine

ActiveCN104764045APlay a lifting roleReduce enrichmentContinuous combustion chamberMixing ratioScramjet engine

The invention discloses a supersonic combustion chamber cavity ignition device and a scramjet engine. The supersonic combustion chamber cavity ignition device comprises an installation base. Fuel spray holes are formed in the upstream portion of the installation base. A cavity is formed in the downstream portion of the installation base. The fuel spray holes and the cavity are formed in the same plane of the installation base. An ignition plug is arranged on the bottom surface of the cavity. A stop piece is arranged in the downstream direction of the ignition plug. The stop piece comprises a left stop piece body and a right stop piece body which have the same triangular shape. One edge of the left stop piece body is connected with the edge, with the same length, of the right stop piece body, and the other group of adjacent edges of the left stop piece body and the right stop piece body are fixed to the bottom face of the cavity. The included angle a between the left stop piece body and the right stop piece body in the direction towards the ignition plug is smaller than 180 degrees. According to the supersonic combustion chamber cavity ignition device, fuel is lifted through the stop piece, the probability that the fuel is accumulated at the position of the ignition plug is effectively reduced, it is guaranteed that the fuel and air have an appropriate mixing ratio, and the success rate of ignition is improved.

Owner:NAT UNIV OF DEFENSE TECH

Liquid-nitrogen cooling system of scramjet engine

InactiveCN104989550ASolve the cooling problemImprove securityRam jet enginesLiquid nitrogen coolingAttitude control

The invention discloses a liquid-nitrogen cooling system of a novel scramjet engine. The liquid-nitrogen cooling system is combined with the scramjet engine through a heat structure, and the system mainly comprises a liquid nitrogen supply device, a high-pressure air source generation device, an engine casing pipe type heat exchange panel, a high-pressure gas collection chamber and a movable spraying pipe. The liquid-nitrogen system mainly executes three masks including (1) solving the problems in heat dissipation of the scramjet engine; (2) serving as a secondary power device so as to assist a hypersonic vehicle in acceleration and attitude control; and (3) providing low-temperature high-pressure nitrogen for subsystems of cabin environment control, fire prevention and the like. The liquid nitrogen serves as a low-temperature refrigerant so as to have the higher heat sink capacity, the wall face of the engine can be fully cooled, and in the cooling process of the liquid nitrogen, chemical cleavage does not exist; compared with a traditional system, refrigeration cooling is easily achieved; and the reliability and safety of the system are higher. The ultrahigh heat flow of the wall face of the scramjet engine will make the liquid nitrogen to achieve phase changes and expansion sufficiently, and the efficient auxiliary power is provided for an aircraft.

Owner:BEIHANG UNIV

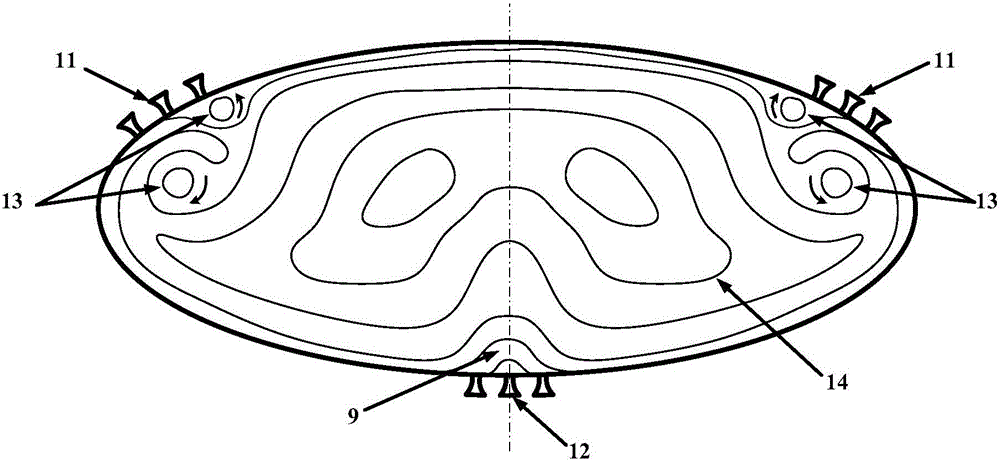

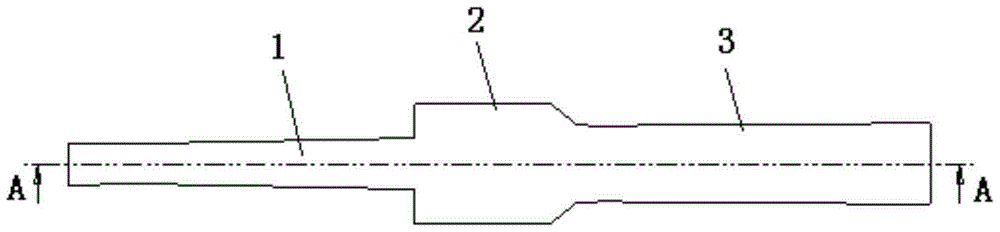

Design method of fuel injection system for scramjet engine

ActiveCN103605876ASuppress non-uniformitySmooth connectionSustainable transportationSpecial data processing applicationsCombustion chamberInlet channel

The invention discloses a design method of a fuel injection system for a scramjet engine and relates to a near space vehicle. Nozzles can be distributed in the following three ways: according to flowing characteristics, the nozzles are distributed on a near vortex wall surface circumferentially, or distributed along the flowing direction, or distributed in a 'triangle' shape on the near vortex wall surface. In the component design of the existing scramjet engine, the defect that the outlet uniformity needs to be controlled as much as possible in the design of a gas inlet channel, while a non-uniform vortex structure needs to be artificially introduced in the design of a combustion chamber, is solved. By virtue of a low-energy / low-velocity zone and a corner vortex structure of the outlet of a three-dimensional internal-retraction gas inlet channel, the nozzles of a combustion chamber are reasonably arranged, the relation of flowing characteristics between the gas inlet channel and a supersonic combustion chamber is strengthened, and the fuel injection and mixing effects can be enhanced, so that the combustion efficiency is raised indirectly, and the overall performance of the scramjet engine is improved.

Owner:XIAMEN UNIV

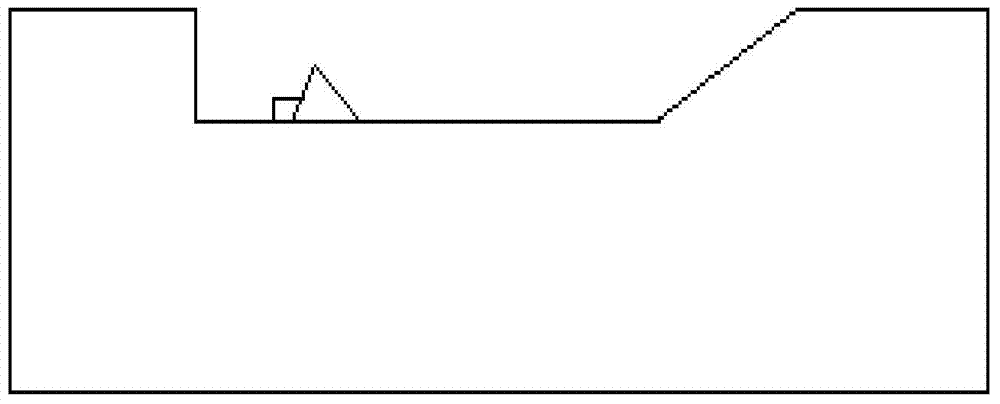

Scramjet engine based on detonation combustion

ActiveCN107084071ASimplify the multi-stage compression structure of the intake portSimplified multi-stage compression structureRam jet enginesCombustion chamberInlet channel

A scramjet engine based on detonation combustion comprises an air inlet channel and a combustion chamber. The air inlet channel of the engine is designed in a one-time linear compression mode. The upstream wall surface of the air inlet channel is provided with fuel injection holes. A detonation device is arranged behind the combustion chamber of the engine and comprises a hot jet oxidation agent pipeline and a hot jet device carrying with jet fuel. An inlet of the hot jet oxidation agent pipeline is formed in the upper stream of the air inlet channel and located above all the fuel injection holes. An outlet of the hot jet oxidation agent pipeline is connected with the hot jet device and conducts mixed ignition with the fuel carried in the hot jet device, and hot jet is generated. Compared with a traditional scramjet engine, the novel scramjet engine based on detonation combustion is simplified in structure and high in thermodynamic cycle efficiency and energy release rate, and by testing, the thrust performance of the engine based on detonation combustion can be 30% or above higher than that of an existing engine based on isobaric combustion.

Owner:NAT UNIV OF DEFENSE TECH

Solid-liquid scramjet engine

The invention discloses a solid-liquid scramjet engine, and belongs to the technical field of engines. The engine comprises an air inlet channel, a combustion chamber, a tail spray pipe, a fuel gas generator, an oil tank system, a control system and the like. The oil tank system comprises a high-pressure gas cylinder, a pressure reducing valve, a safety valve, fuel oil, an oil filter, a leather bag and the like, and the control system provides fuel oil flow meeting requirements for the scramjet engine according to set requirements. The fuel gas generator is mainly composed of a heat insulation combustion chamber, a wrapped grain, a long tail pipe spray pipe component and an igniter. The fuel gas generator is fixedly arranged in the oil tank system, and a long tail pipe of the fuel gas generator penetrates through the head portion of the combustion chamber and stretches into the combustion chamber. The solid-liquid scramjet engine can keep the advantages that the specific impulse of the liquid fuel scramjet engine is high, and the solid fuel scramjet engine is not prone to being shut down under a large attack angle, and meanwhile the defects that the liquid scramjet engine is prone to being shut down under the large attack angle, the thrust of the solid fuel scramjet engine is hard to adjust, and the specific impulse is low are overcome.

Owner:BEIJING POWER MACHINERY INST

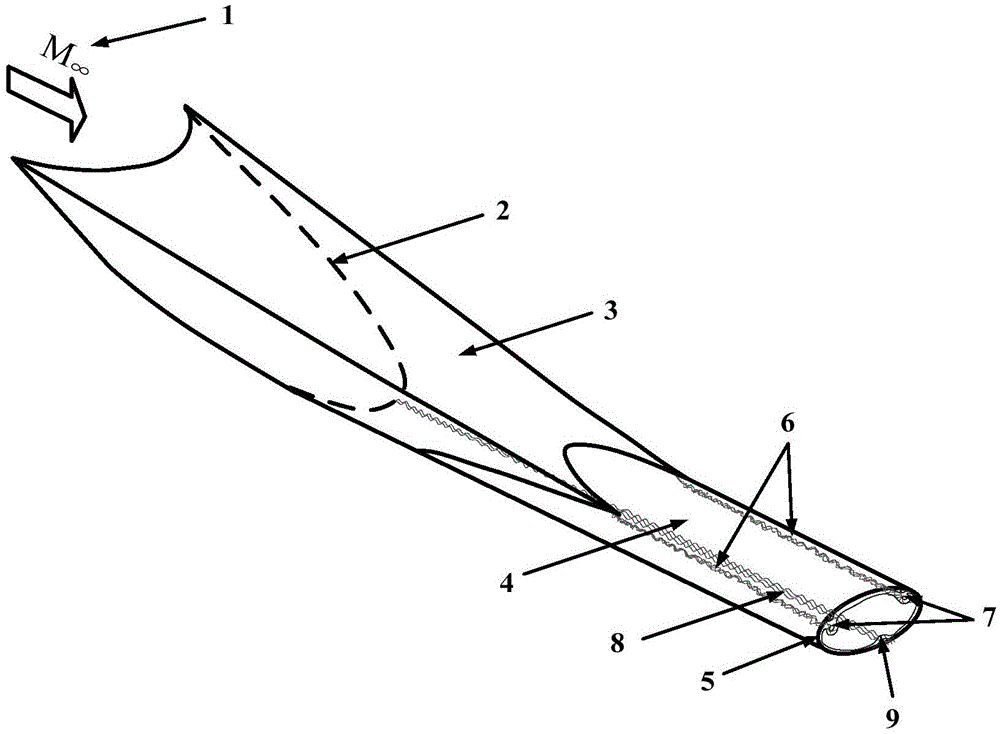

Reducing skin friction drag

InactiveUS6532728B1Reduce skin friction dragReduce frictionCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberEngineering

The skin friction drag acting on a surface of an article travelling at high speed such as a vehicle at supersonic or particularly hypersonic speed can be reduced by introducing a fuel into the boundary layer under conditions of the fuel introduction to ensure combustion in the boundary layer. The fuel is injected through orifice(s) or a slot provided at the surface so that the fuel enters the passing fluid with a major component of the direction of injection being parallel to the local flow direction. The fuel is injected at supersonic speed, e.g. at a speed of about Mach 1.5 or higher. The invention is applicable to scramjet engines with the fuel being injected around the entire internal circumference of the wall of the scramjet engine, upstream of the commencement of the combustion chamber.

Owner:QUEENSLAND UNIV OF

Multi-height ramp injector scramjet combustor

InactiveUS20080060361A1Optimize fuel distributionEfficient propulsion technologiesContinuous jet plantsCombustion chamberScramjet engine

A multi-height ramp injection system, for use in a supersonic propulsion system, comprises a plurality of multi-height ramp injectors for variably introducing a fuel into an airflow in a combustor. In one embodiment of the invention, the multi-height ramp injectors comprise a plurality of tall injectors for fueling an inner portion of the airflow, and a plurality of short injectors for fueling an outer portion of the airflow.

Owner:ROCKETDYNE

Method for expanding stability limit of supersonic combustion flames

ActiveCN103499106AAvoid destructionHigh speedContinuous combustion chamberCombustion chamberEngineering

The invention discloses a method for expanding stability limit of supersonic combustion flames. The method comprises the steps of determining a stationing area with the most stabilized flames, a base point with the flames stationed and a recirculation zone structure aiming at a flame stabilizing structure in a scramjet engine, jetting oxygen to the stationing area with the most stabilized flames of the flame stabilizing structure, and meanwhile preventing the original base point with the flames stationed and the original recirculation zone structure from being damaged. The method for expanding the stability limit of the supersonic combustion flames is easy to implement, convenient to operate and control, small in oxygen consumption and capable of being applied to the stabilizing of the flames in the combustion chamber of the scramjet engine.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Heat protection method for injection support plate of scramjet engine by utilizing sweat and impingement cooling

ActiveCN103615741AReduce the temperatureAvoid ablative damageContinuous combustion chamberPorous mediumEngineering

The invention relates to a heat protection method for an injection support plate of a scramjet engine by utilizing sweat and impingement cooling. The method includes the following steps that (1) a high-temperature-resistant material is used for making the injection support plate of a microporous structure, a supporting rib is arranged in the injection support plate and partitions the same into a front cavity and a rear cavity, impingement pores communicated with the front and rear cavities are formed in the supporting rib, and a fuel pipe of the scramjet engine is communicated with the rear cavity of the injection support plate; (2) by the process that fuel seeps out of pores of the injection support plate of the microporous structure, convection heat transfer is carried out forcedly to remove heat on the surface of the injection support plate, and the fuel seeps out of the surface of the injection support plate to form a film layer so as to block heat transfer of the mainstream to the injection support plate; (3) the fuel is injected from the rear cavity to the inner surface of the front cavity via the impingement pores in the supporting rib so as to perform convection heat transfer with the inner surface of the front cavity, and strength of the injection support plate is enhanced by the aid of the supporting rib in the injection support plate. Heat protection effect on the injection support plate is realized by combining the concept of impingement cooling and utilizing the fuel as a cooling agent according to porous medium characteristics, and the method can be widely applied to heat protection of injection support plates of scramjet engines in various Mach working ranges.

Owner:TSINGHUA UNIV

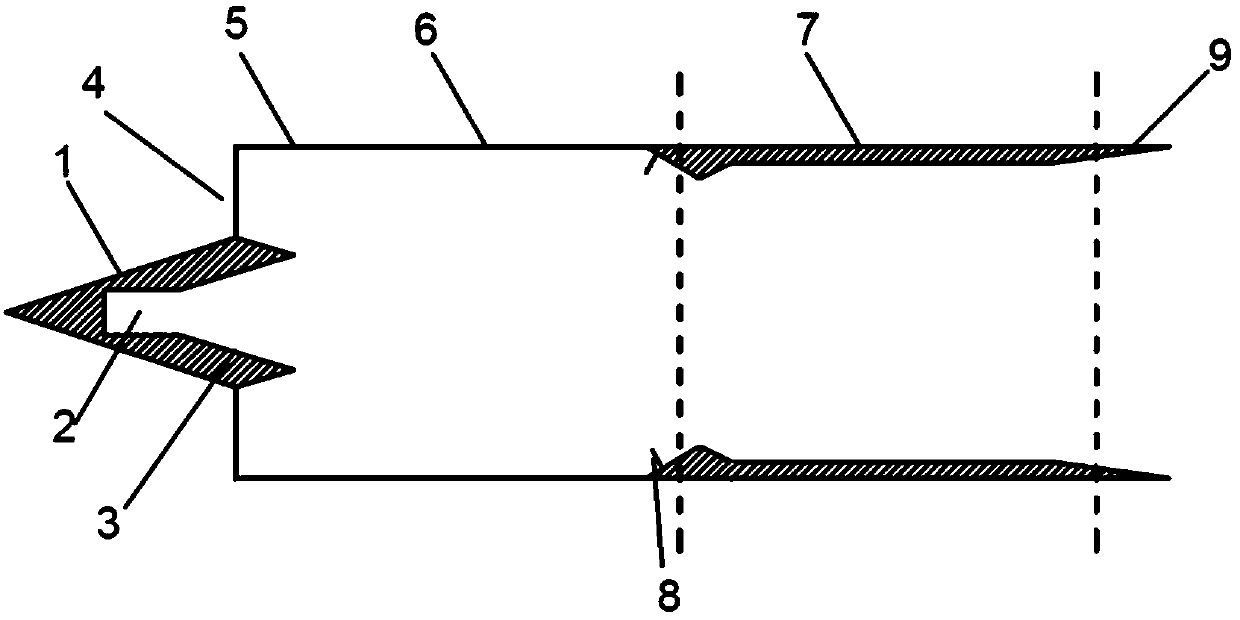

Double-combustion-chamber scramjet engine and control method thereof

ActiveCN107013327AReduce the difficulty of combinationReduce the difficulty of structural designGas turbine plantsRam jet enginesRamjetCombustion chamber

The invention aims at overcoming the defects in the prior art and provides a double-combustion-chamber scramjet engine and a control method thereof. Combustion chambers of the engine are in non-axismmetric layout, the combination difficulty of a ramjet and a turbine engine is lowered, and an air inlet way of the double-combustion-chamber scramjet engine is improved. Two-dimensional air inlet way configuration is adopted in the air inlet way, the air inlet way is divided into at least one subsonic combustion runner and at least two supersonic runners through supporting plates, wherein the supersonic combustion runners are evenly distributed on the two sides of the subsonic combustion runners. Due to the fact that inner shrinkage section adjusting molded surfaces and expansion section adjusting molded surfaces are additionally arranged in design of all the runners, the area of a throat of the air inlet way is controlled, the requirement for air in different compression degrees of the combustion chambers is met, the Mach number range of work of the engine is enlarged, and the performance of the engine is improved.

Owner:BEIJING POWER MACHINERY INST +1

Air inlet channel for double-combustion-chamber scramjet engine and air inlet control method

ActiveCN107013334ASolve air intake problemsSolve a wide range of work problemsGas turbine plantsRam jet enginesRamjetCombustion chamber

The invention aims to overcome defects in the prior art, provides an air inlet channel for a double-combustion-chamber scramjet engine and an air inlet control method, and solves the technical problem about air inlet of wide-range non-axisymmetric double-combustion-chamber scramjet engines. The air inlet channel adopts the two-dimensional air inlet channel configuration and is divided by supporting plates in the flow direction to form at least one subsonic combustion flow channel and at least two supersonic combustion flow channels; the at least two supersonic combustion flow channels are evenly distributed on two sides of the at least one subsonic combustion flow channel; inner contraction section adjusting profiles and expansion section adjusting profiles are added in various flow channel designs, so that the area of a throat of the air inlet channel is controlled, the requirements of various combustion chambers for air with different compression degrees are met, the working Mach number range of the engine is broadened, the performance of the engine is improved, and the problem of difficulty in relaying with a turbine engine is solved.

Owner:BEIJING POWER MACHINERY INST +1

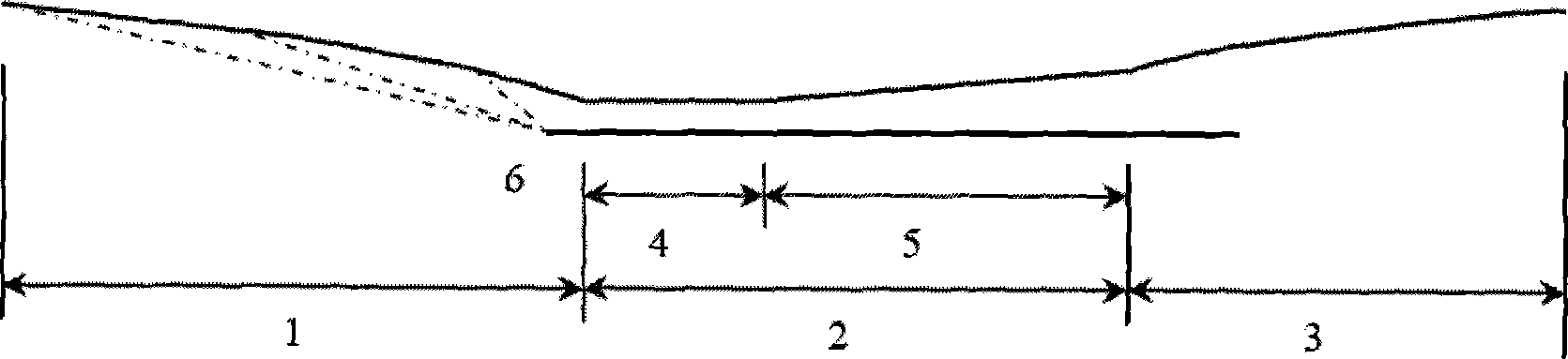

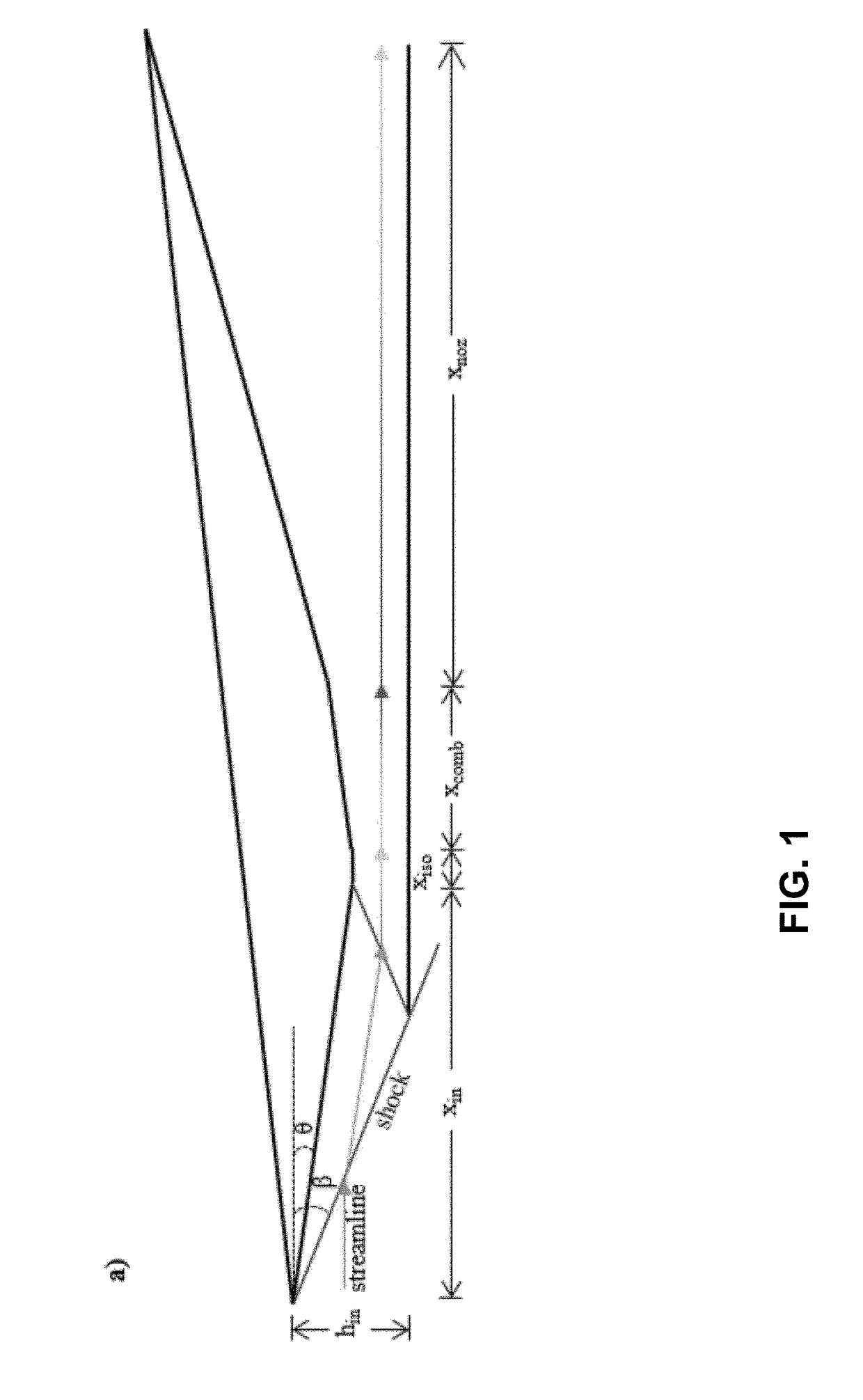

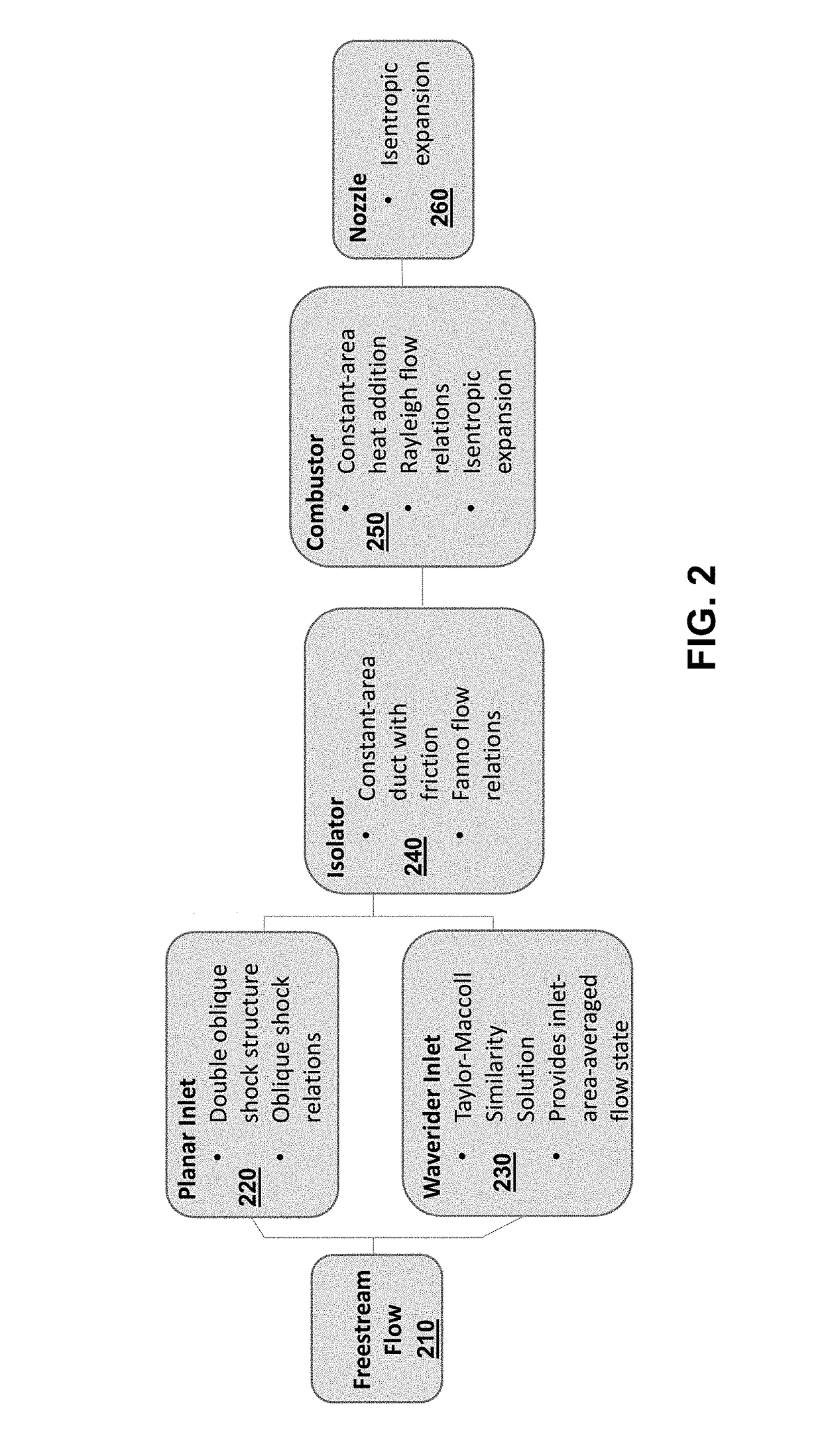

Numerical Modeling and Performance Analysis of a Scramjet Engine with a Controllable Waverider Inlet Design

A method for automatically determining performance characteristics of a scramjet engine uses a 1-dimensional approximation that includes obtaining a first set of environmental conditions defining freestream conditions; generating inlet outflow conditions by evaluating a change in flow from the freestream conditions across the inlet; generating isolator outflow conditions by modeling change in flow from the inlet outflow conditions across the isolator; generating combustor outflow conditions by modeling change in flow from the isolator outflow conditions across the combustor; and generating nozzle outflow conditions by modeling change in flow from combustor outflow conditions across the nozzle.

Owner:UNITED STATES OF AMERICA

Thermal protection method for scramjet engine fuel injection supporting plate by utilization of transpiration cooling

ActiveCN103672966AReduce the temperatureAvoid ablative damageContinuous combustion chamberRamjetEngineering

The invention relates to a thermal protection method for a scramjet engine fuel injection supporting plate by the utilization of transpiration cooling. The method includes the following steps that (1), high temperature resistant material is used for manufacturing the injection supporting plate of a multi-tiny-hole structure, and a fuel pipe of a scramjet engine is communicated with the injection supporting plate; (2), by the utilization of the process that fuel leaks through holes of the injection supporting plate of the multi-tiny-hole structure, and heat convection is performed forcibly, so that the heat on the surface of the injection supporting plate is taken away; (3), it is utilized that the fuel leaks through the surface of the injection supporting plate to form a thin layer, so that main flows are prevented from performing heat transfer on the injection supporting plate. The multi-tiny-hole structure is manufactured on the injection supporting plate material, the concept of transpiration cooling is used, the fuel serves as a cooling agent, so that strong heat convection happens between the fuel and the injection supporting plate in the process that the fuel flows through the injection supporting plate, meanwhile, the fuel forms the thin layer on the surface of the injection supporting plate, heat transfer between the high temperature main flows and the surface of the injection supporting plate is obstructed, thermal protection on the injection supporting plate and particularly the front edge part of the injection supporting plate is achieved, and the injection supporting plate is prevented from being ablated and damaged. The thermal protection method can be widely applied to thermal protection performed on various ramjet injection supporting plate structures.

Owner:TSINGHUA UNIV

Scramjet engine combustion chamber performance pre-evaluation method

ActiveCN103870683AAvoid problems prone to singular valuesHigh precisionSpecial data processing applicationsCombustion chamberParameter distribution

The invention provides a scramjet engine combustion chamber performance pre-evaluation method. By taking a thermal throat as a starting point, parameter distribution from the starting point to a combustion chamber inlet and from the starting point to a combustion chamber outlet is calculated, and the problem that a singular value is apt to occur in the thermal throat during solution due to a reason that the traditional one-dimension calculation is performed from the combustion chamber inlet is avoided. The scramjet engine combustion chamber performance pre-evaluation method fully considers the different working modes of the combustion chamber and provides a reference basis for the design of the combustion chamber within a wide flight Ma range.

Owner:BEIJING POWER MACHINERY INST

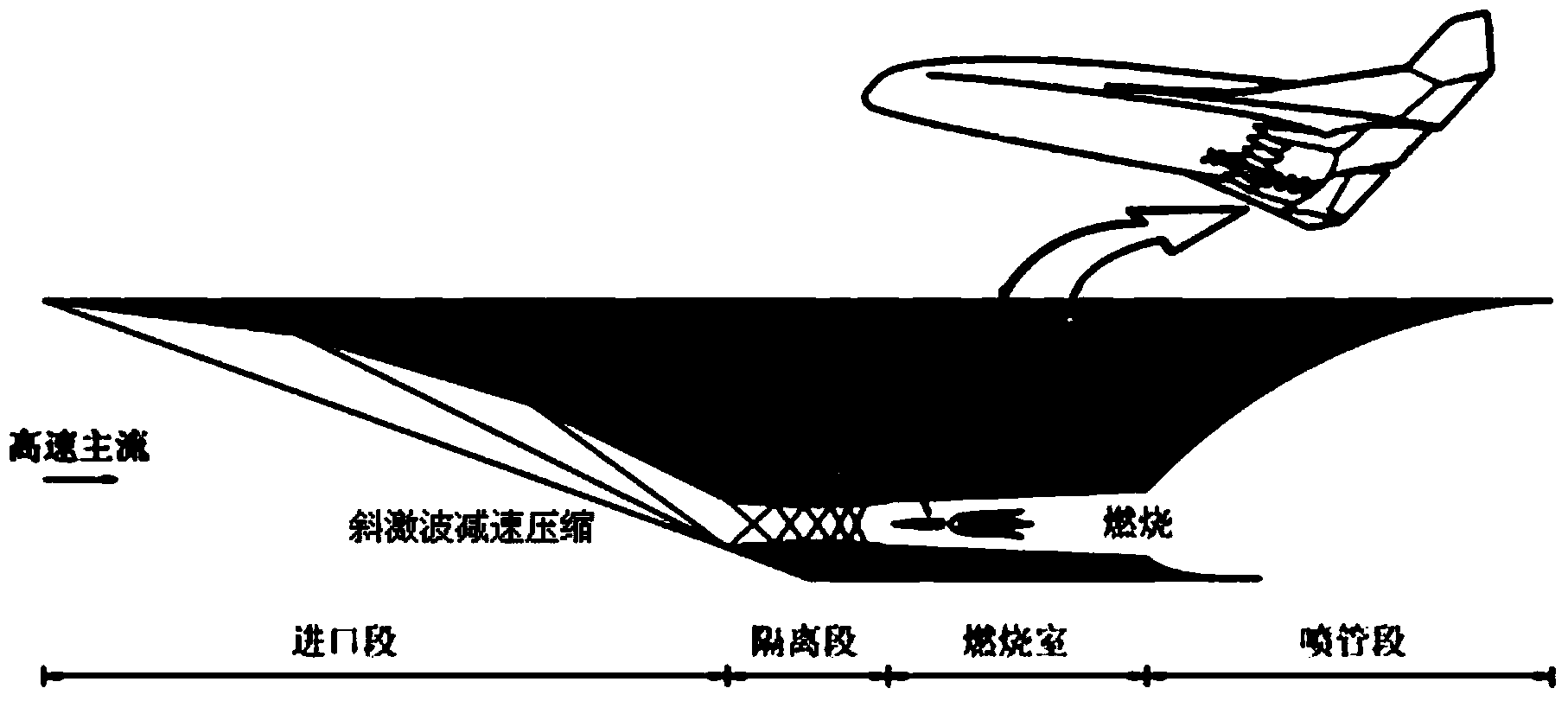

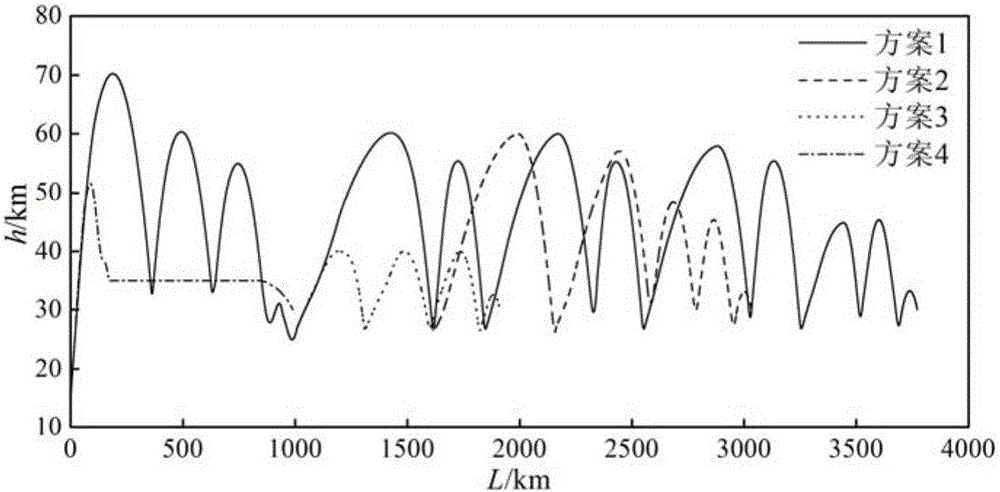

Method for optimizing boost-skip trajectory of air-breathing hypersonic missile

InactiveCN105930550AFlight altitude is not fixedIncrease rangeSpecial data processing applicationsFlight heightLongitudinal plane

The invention relates to a method for optimizing a boost-skip trajectory of an air-breathing hypersonic missile, and is technically characterized by comprising the steps of designing an air-breathing hypersonic missile trajectory scheme in which a scramjet engine ignites in an intermittent and periodic manner; establishing an air-breathing hypersonic missile longitudinal plane whole trajectory equations of motion including direct force control; and solving the trajectory optimizing problem by using a self-adaptive pseudo-spectral method The optimized boost-skip trajectory significantly improves the range of the missile, with the range being 3.81 times of a boost-cruise trajectory of a conventional air-breathing hypersonic missile; and the designed flight height of the boost-skip trajectory is not fixed and is relatively high at most of the time, a higher penetration capability is gained, and the trajectory mode has very promising prospects.

Owner:方洋旺

Scramjet engine directly connected test device capable of replacing free jet test and design method

InactiveCN106546433AReduce testing costsHigh degree of simulationGas-turbine engine testingJet-propulsion engine testingTest flowEngineering

The invention discloses a scramjet engine directly connected test device capable of replacing a free jet test, which comprises a round-to-square section, a subsonic velocity S bending section, a Laval nozzle section, a boundary layer developing section, an air inlet inner channel simulation section and a boundary layer overflow exhausting channel. The scramjet engine directly connected test device is characterized in that a wind tunnel nozzle is enabled to deflect by a certain angle upwards, the angle is equal to a top plate compression angle in front of the lip of the air inlet inner channel simulation section, a flow parameter of an outlet cross section of the nozzle is enabled to be equal to a cross section parameter of the lip inlet of an actual air inlet, and an internal compression channel at the downstream of the lip of the actual air inlet is simulated directly. The boundary layer developing section is connected between the nozzle and the inner channel simulation section, and the lip of the nozzle and the boundary layers at two side walls are pumped through the overflow exhausting channel at an internal compression section at the same time, thereby being convenient to start the test device, and enabling the boundary layers at the upper and lower walls to display asymmetry similar to a real state. The scheme disclosed by the invention is high in simulation degree, a flow field structure in an air inlet throat and a downstream isolation section is authentically simulated, and a directly-connected test flow field is enabled to be closer to the flow field of an actual engine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Combustion chamber of supersonic combustion ramjet engine

ActiveCN105180212AImprove flame stabilityImprove ignition performanceContinuous combustion chamberRamjetCombustion chamber

The invention discloses a combustion chamber of a supersonic combustion ramjet engine. The combustion chamber comprises a jet segment, a rear-edge sudden-enlargement cavity and an expansion segment, which are orderly communicated, wherein a fuel spray hole is formed in the jet segment. The combustion chamber further comprises a guide plate arranged at the front edge of the rear-edge sudden-enlargement cavity, and the guide plate is used for decreasing the amount of upstream wall fuel jet brought into the cavity by a shear layer. According to the combustion chamber, through the rear-edge sudden-enlargement cavity with the guide plate, the transverse jet of upstream wall fuel is not directly brought into the cavity by the shear layer; the mass flow rate of the flue entering the cavity is changed by adjusting the transverse space of the guide plate, therefore the equivalent ratio distribution of flue in the cavity and outside the cavity is optimized, the ignition performance in the cavity is improved, and the flame holding capacity of the cavity is improved.

Owner:NAT UNIV OF DEFENSE TECH

Rocket-type rotating detonation/ramjet combined engine

ActiveCN109184953ASimple structureImprove specific impulseRam jet enginesComposite engine plantsRamjetScramjet engine

The invention discloses a rocket-type rotating detonation / ramjet combined engine, and relates to a combined engine. The combined engine is provided with an air inlet passage, an expansion section, a rotating detonation rocket, a mixing section, a ramjet combustor and a tail pipe nozzle; the ramjet combustor and a rotating detonation rocket combustor are connected in series; the air inlet passage,the expansion section, the mixing section, the ramjet combustor and the tail pipe nozzle are connected in sequence; the air inlet passage and the expansion section, the expansion section and the mixing section, the mixing section and the ramjet combustor and the ramjet combustor and the tail pipe nozzle are connected by respective connecting pieces; and the rotating detonation rocket and a flame stabilizer are arranged in the mixing section. A working mode of the combined engine includes four stages: the first stage is that Mach is 0 to 2, and the rotating detonation rocket works alone; the second stage is that Mach is 2 to 3, and a joint-working mode of the rotating detonation rocket and a ramjet engine is employed; the third stage is that Mach is 3 to 4.5, and a working mode of a subsonic combustion ramjet engine is employed; and the fourth stage is that Mach is 4.5 to 7, and a working mode of a supersonic combustion ramjet engine is employed.

Owner:XIAMEN UNIV

Combined type scramjet engine cooling circulation system

ActiveCN112431675ASmall Prandtl numberAvoid blocking cooling passagesContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberFuel tank

The invention discloses a combined type scramjet engine cooling circulation system, and belongs to the technical field of air suction type scramjet engine thermal protection. The system comprises a fuel tank, a fuel pump, a heat exchanger, a first cooling channel, a second cooling channel, a fuel injector and an electromagnetic pump; an annular cavity is formed between the inner wall face and theouter wall face of an engine outer shell and divided into the first cooling channel and the second cooling channel; the fuel tank, the fuel pump, the heat exchanger, the first cooling channel and thefuel injector are sequentially connected through pipelines to form an open cooling circulation system, and kerosene serves as a working medium; and the electromagnetic pump, the second cooling channeland the heat exchanger are sequentially connected through pipelines to form a closed cooling circulation system, and the working medium is liquid metal. According to the combined type scramjet enginecooling circulation system, waste heat of the wall face of an engine combustion chamber is utilized, the advantages of an active regeneration cooling system are reserved, the problems of heat transfer deterioration, cracking coking and the like of a traditional cooling working medium are solved, and an efficient energy management circulating system is constructed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Engine combined of pulse detonation ejection and supersonic combustion ramjet

ActiveCN107762661AReduce complexityGuaranteed to workRam jet enginesComposite engine plantsRamjetCombustion chamber

The invention provides an engine combined of pulse detonation ejection and supersonic combustion ramjet, and the engine is mainly composed of the components of a pulse detonation burner, an ejector and the like. The ejector comprises an ejector inlet valve, a mixing isolation segment, a secondary burning chamber and ejector spray pipes. The engine combined of the pulse detonation ejection and thesupersonic combustion ramjet comprises two working modes of a pulse detonation ejection mode and a supersonic combustion ramjet mode. When the flight mach (Ma) number is equal to 0-5, the engine worksin the pulse detonation ejection mode, under the ejecting action of a combustion ejection flow jetted from the detonation burner, more air is ejected into an air inlet passage, the total air pressurerises, the combustion ejection flow is mixed with the ejected air, fuel is jetted to the mixed air flow, secondary detonation is performed, and at this time, the thrust of the engine is mainly provided by the pulse detonation burner and a secondary pulse detonation system; and when the Ma is larger that 5, the engine is switched from the pulse detonation ejection mode to the supersonic combustionramjet mode, and an aircraft continues to accelerate under the push of the supersonic combustion ramjet engine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multipurpose gas generator ramjet/scramjet cold start system

A system for starting a ramjet / scramjet engine includes a gas generator for lighting a combustor of a ramjet / scramjet engine, for generating electrical power for vehicle subsystems, for pumping fuel, and for preheating the fuel. In accordance with the present invention, there is provided a method for cold starting a ramjet / scramjet engine. The method comprises the steps of using a gas generator to light the combustor, to generate a gas product, using the gas product to generate electrical power for vehicle subsystems and to pump fuel, and using the gas product to preheat liquid fuel.

Owner:UNITED TECH CORP

Device for combined blending reinforcement of solid rocket scramjet engine

ActiveCN109139297AExtended stayImprove secondary combustion efficiencyRocket engine plantsCombustion chamberRocket

The invention discloses a solid rocket scramjet engine. The solid rocket scramjet engine comprises an isolated section and a combustion chamber, wherein the isolated section and the combustion chamberare front-and-rear connected. A plurality of spoiler devices are arranged side by side at intervals in the vertical direction on the left and right side walls in the combustion chamber. The interiorof the combustion chamber is divided into a plurality of gas flow passages in the direction parallel to the gas flow direction, and the upper and lower wall surfaces, corresponding to the position ofthe spoiler devices, in the combustion chamber are protruded outward to form an outwardly-protruding recessed cavity. The blending degree of air and gas in the solid rocket scramjet engine is enhanced, so that the air and the gas are fully contacted, the residence time of the primary gas in the combustion chamber is increased, the combustion efficiency of the primary gas is improved, and the overall performance of the solid rocket scramjet engine is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com