Scramjet engine directly connected test device capable of replacing free jet test and design method

A technology of scramming and test equipment, which is applied in gas turbine engine testing, jet engine testing, etc., can solve the problems of unfavorable data collection, high experiment cost, large size, etc., and achieve the effect of high simulation degree and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] The present invention will be further described below in conjunction with an embodiment.

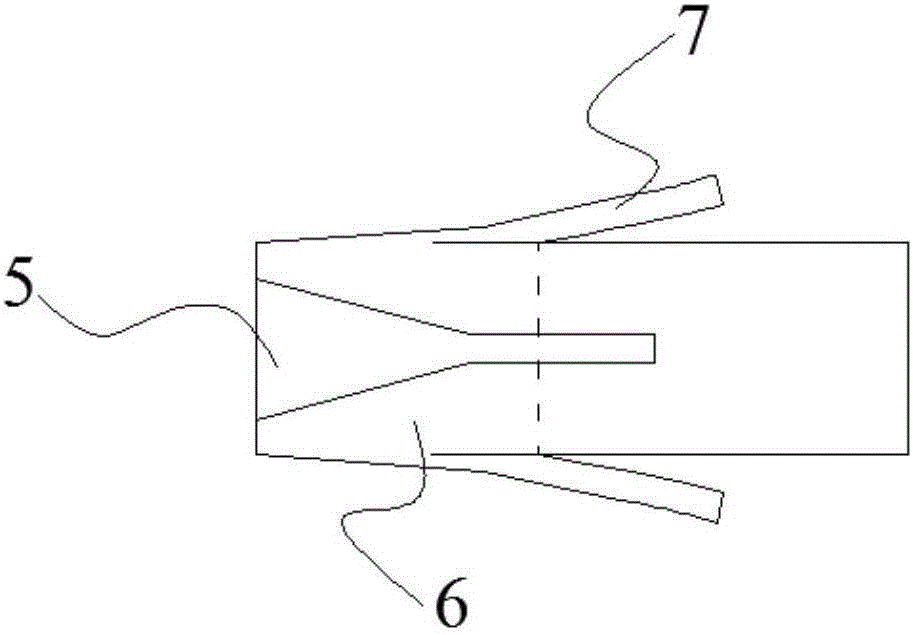

[0057] Figure 4 A schematic diagram of a typical binary hypersonic inlet model is given. The design point of the inlet is Ma6, +4° angle of attack state, and the working range is: Ma4~Ma7. The total shrinkage ratio of the inlet at 0° angle of attack 5.44, when the angle of attack is +4°, the total shrinkage ratio reaches 7.14, which can meet the compression requirements of the air inlet for the airflow. At the same time, in order to avoid the first-stage compression angle being too large under the state of attack angle, the first-stage wedge angle of the external pressure section is set at 4°, followed by two stages of 6° compression angle. Point-time three oblique shock wave pneumatic sealing. The inlet flow field is selected as the target flow field of the test, and the test conditions correspond to the state of Ma4 / Ma6 and 0° angle of attack.

[0058] In the first step, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com