Flat plate fatigue bending machine

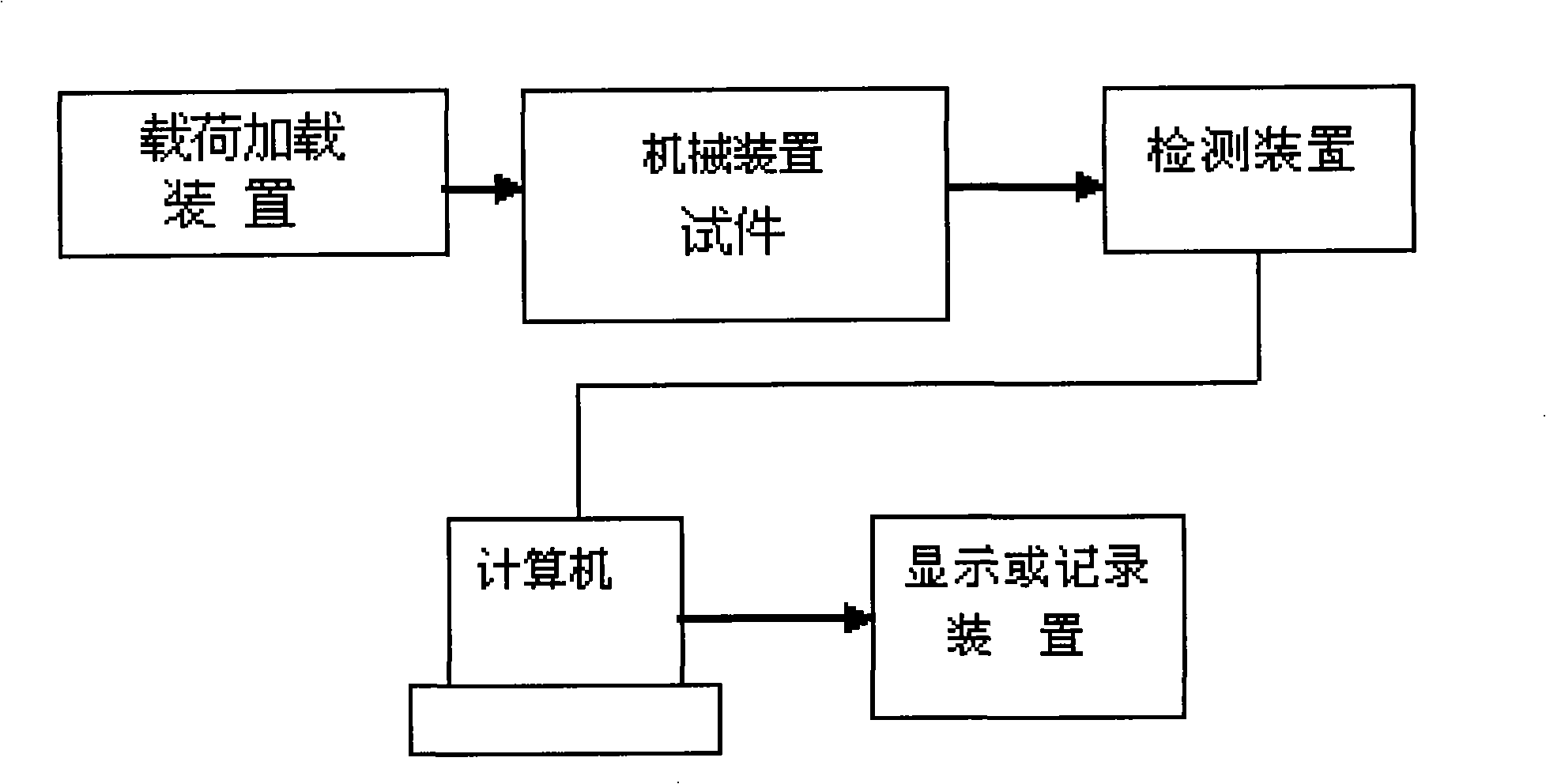

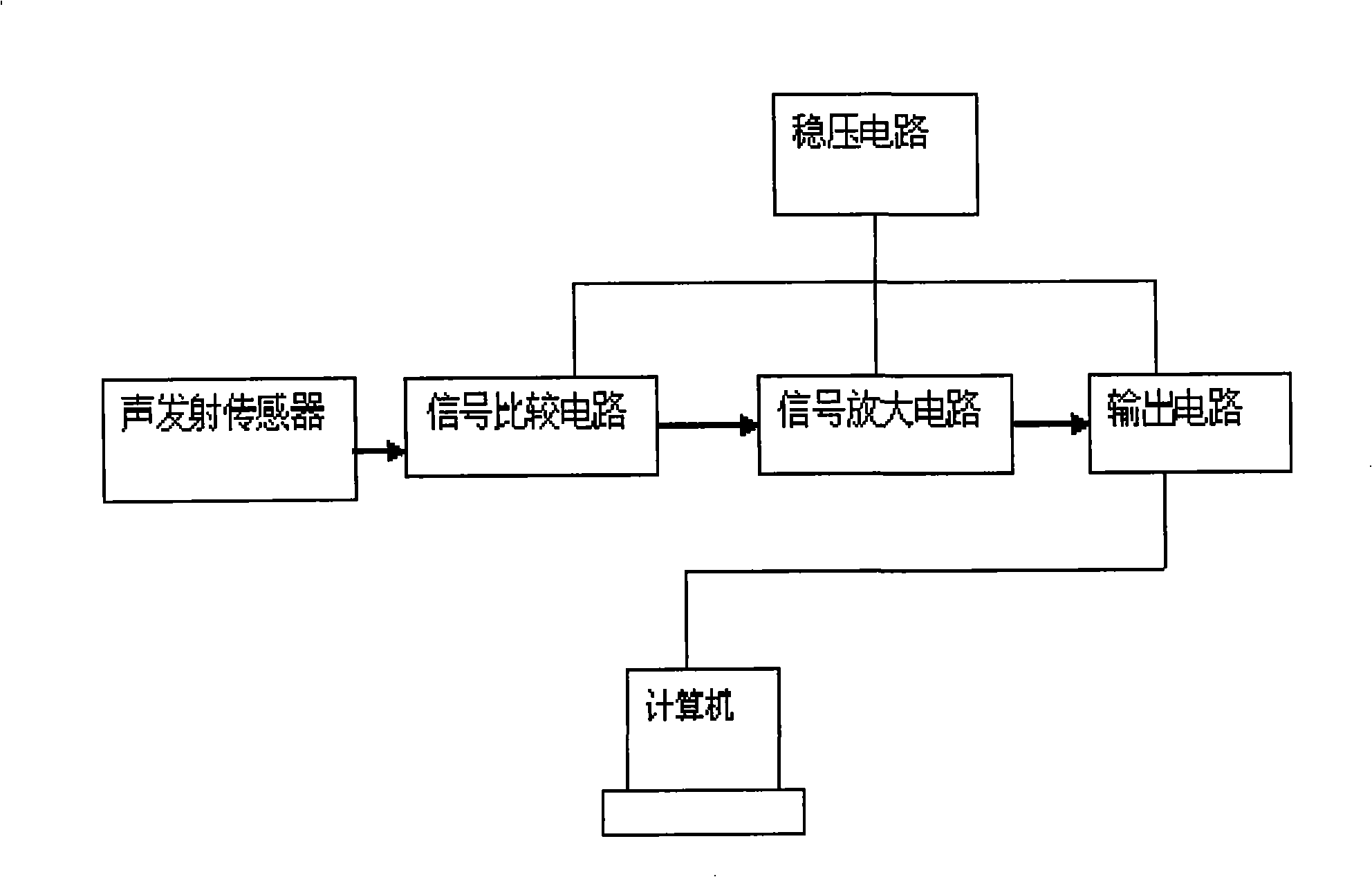

A bending fatigue, testing machine technology, used in the testing of mechanical parts, the testing of machine/structural parts, the use of repetitive force/pulse force to test the strength of materials, etc., can solve the problem of high cost, complex control system and large size of the detector and other problems, to achieve the effect of low power consumption, simple control system and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Complete the three-point bending fatigue test. as attached figure 2 As shown, the mechanical device of the present invention includes a frame 1, a locknut 2, a connecting rod hinge block 3, a connecting rod 4, an eccentric wheel 5, a driving rod 6, a chute (rail) 7, a clamp support seat 8, and a bearing 9 , Fixture 10, test piece 11, test piece splint 12, bearing 13, rotating shaft 14, gear 15, nut 16. The frame 1 is placed on the test field, the driving rod 6 is fixed on the chute (guide rail) 7, and the lower end is fastened with the locknut 2, and the shaft 14 is equipped with a bearing 13, a gear 15 and a nut 16, which are installed on the frame 1 The side of the test piece 11 is installed between the fixtures 10 with the test piece splint 12. The fixture support seat 8 and the bearing 9 are arranged on the fixture 10. The driving rod 6 and the rotating shaft 14 are hinged with the eccentric wheel 5 through the connecting rod 4.

Embodiment 2

[0022] Embodiment 2: Complete the cantilever bending fatigue test. as attached image 3 As shown, the present invention comprises, frame 1, lock nut 2, connecting rod hinged block 3, connecting rod 4, eccentric wheel 5, driving rod 6, chute (guide rail) 7, test piece splint 17, test piece 18, Fixture 19, bearing seat 11, bearing 12, rotating shaft 13, gear 14, nut 15, frame 1 is placed on the test field, driving rod 6 is fixed on chute (guide rail) 7, the lower end is fastened with lock nut 2, and the rotating shaft Bearing 13, gear 15 and nut 16 are installed on 14, and they are installed on the side of frame 1, and test piece 18 is installed between fixture 19 with test piece splint 17, and driving rod 6 and rotating shaft 14 pass connecting rod 4 and eccentric wheel 5 hinged.

[0023] When performing the bending fatigue test: install the flat specimen on the fixture, the rotating shaft 13 drives the eccentric wheel 5 to rotate, and the connecting rod 4 connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com