Air inlet channel for double-combustion-chamber scramjet engine and air inlet control method

A technology of scramjet and dual combustion chambers, which is applied in the direction of ramjet engines, machines/engines, gas turbine devices, etc., can solve problems such as difficulty in adapting to the working Mach number range, flow channel and structure design, and parallel arrangement of turbine channels. Achieve the effects of reducing the adjustment of additional mass, broadening the range of working Mach number, and facilitating the combustion organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

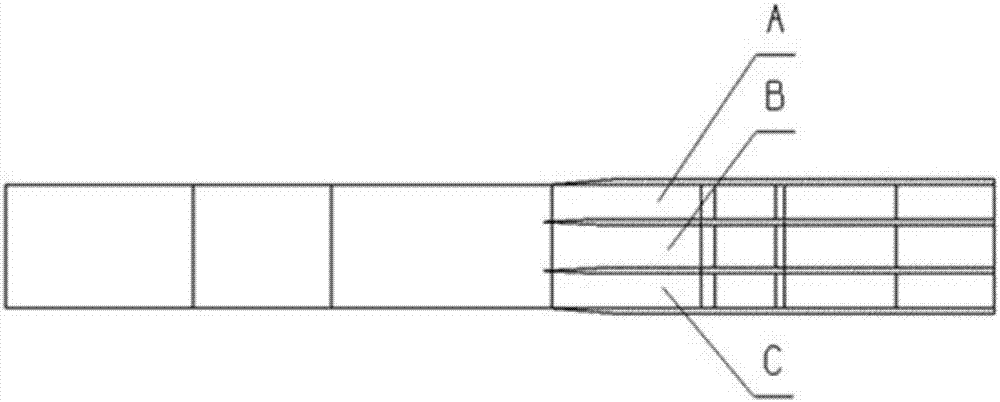

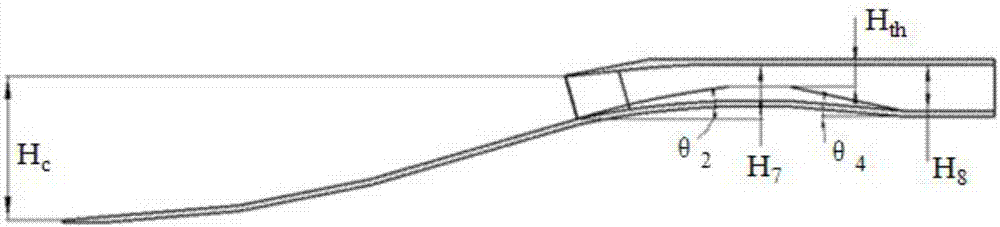

[0044] This embodiment provides a dual-combustion chamber transcendental ramjet intake port, figure 1 Schematic diagram of the layout of the inlet channel of the dual-combustion chamber transcendental ramjet provided by the embodiment of the present invention; figure 2 It is a schematic diagram of the air inlet channel adjustment scheme in the embodiment of the present invention; image 3 A schematic diagram illustrating the flow channel adjustment parameters is shown. The inlet port adopts a binary inlet port configuration, and is divided into sub-combustion channel B and super-combustion channel A and C by a support plate along the flow direction. The B channel is an intermediate channel, connecting the subsonic combustion The A and C flow channels are distributed on both sides of the B flow channel to connect with the supersonic combustion chamber.

[0045] Further, according to the modular arrangement of the engine, the above-mentioned flow channel layout can also be in...

Embodiment 2

[0066] The present embodiment provides the above-mentioned air intake control method of the scramjet intake port of a dual combustion chamber scramjet, including:

[0067]When the flight Mach number reaches the first Mach number, the inner constriction section adjustment surface and the expansion section adjustment surface of the sub-combustion runner and the super-combustion runner are respectively close to the inner contraction section surface and the expansion section surface, and the sub-combustion runner The sonic combustion chamber and the supersonic combustion chamber start to ignite to maintain the total thrust to meet the needs of the aircraft, and the subsonic combustion chamber and the supersonic combustion chamber are both sub-combustion modes;

[0068] When the flight Mach number reaches the second Mach number, the inner constriction section adjustment surface and the expansion section adjustment surface of the sub-combustion flow channel and the super-combustion f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com