Air inlet compensation control method for high-power diesel engine in plateau environment

A high-power diesel engine, compensation control technology, applied in the direction of fuel air intake, mechanical equipment, combustion engine, etc., can solve the problems of diesel engine oil and gas matching imbalance, increased fuel consumption rate and smoke level, and inability to accurately control, etc. The effect of optimizing oil and gas matching, preventing insufficient boost pressure, and fast dynamic control compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

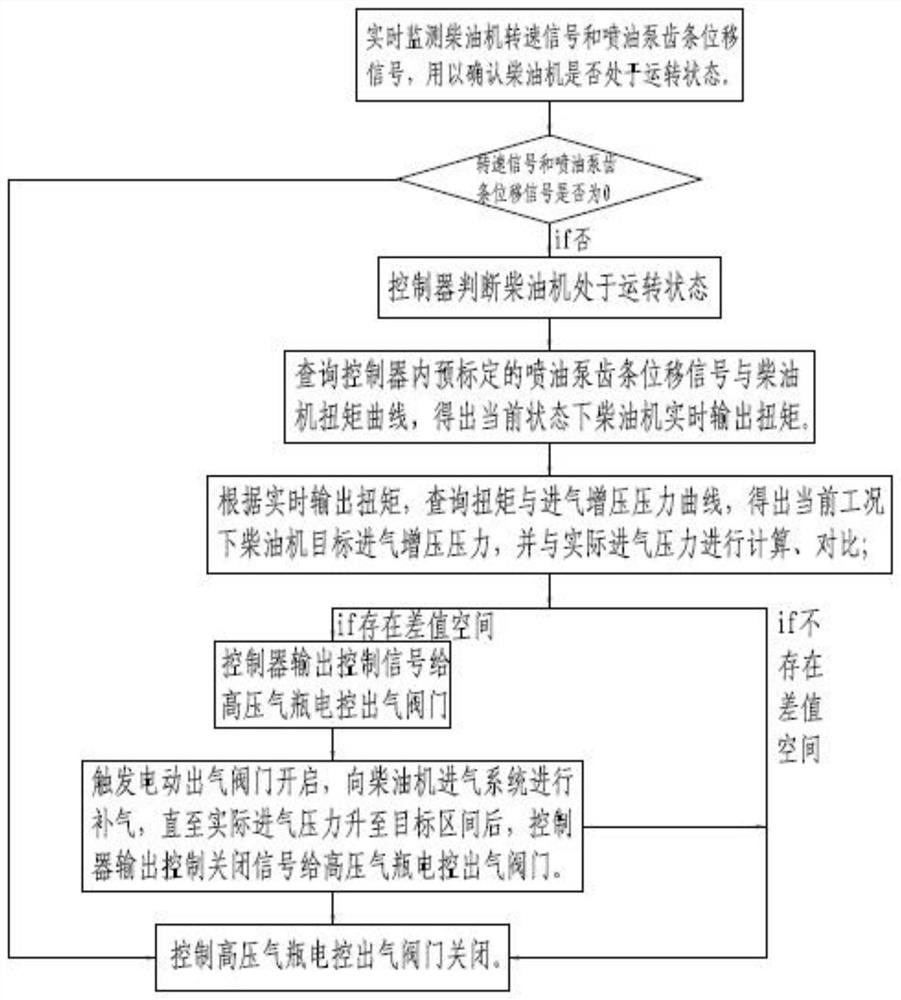

[0020] A high-power diesel engine intake compensation control method in a plateau environment according to the present invention, its specific steps are as follows:

[0021] Pre-calibration: Pre-calibrate and store the fuel injection pump rack displacement signal and diesel engine torque curve, torque and intake boost pressure curve in the controller on the diesel engine standard test bench;

[0022] Step1: The side control system monitors the diesel engine speed signal and the fuel injection pump rack displacement signal in real time to confirm whether the diesel engine is running;

[0023] Step2: If it is detected that the above-mentioned diesel engine speed signal and fuel injection pump rack displacement signal are not 0, the controller judges that the diesel engine is in a running state, and queries the pre-calibrated fuel injection pump rack displacement signal and diesel engine torque curve in the controller to obtain the current Real-time output torque of diesel engine...

Embodiment 2

[0028] The difference from Embodiment 1 is that the opening of the electronically controlled outlet valve can be pre-calibrated in the controller, and the controller outputs the control displacement after calculating the difference between the actual intake pressure and the target intake boost pressure. When the actual intake pressure rises to the target range, the controller outputs a control closing signal to the high-pressure gas cylinder electronically controlled gas outlet valve, and controls the high-pressure gas cylinder’s electronically controlled gas outlet valve to close. , the control is more precise and rapid.

[0029] Circuit control methods not described in detail herein are in the prior art.

[0030] The invention not only solves the problem of diesel engine intake air supply in the plateau environment, but also monitors real-time intake pressure parameters based on the real-time working torque of the diesel engine to determine whether it is within the target in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com