Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Ozone depletion potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ozone depletion potential (ODP) of a chemical compound is the relative amount of degradation to the ozone layer it can cause, with trichlorofluoromethane (R-11 or CFC-11) being fixed at an ODP of 1.0. Chlorodifluoromethane (R-22), for example, has an ODP of 0.05. CFC 11, or R-11 has the maximum potential amongst chlorocarbons because of the presence of three chlorine atoms in the molecule.

Stabilized hydrochlorofluoroolefins and hydrofluoroolefins

ActiveUS20100181524A1Low ozone depletionLower global warming potentialOther chemical processesNon-surface-active detergent compositionsScavengerOzone depletion potential

Disclosed is a combination of hydrofluoroolefins and / or hydrochlorofluoroolefins with stabilizers wherein the stabilizers minimize the degradation of the hydrofluoroolefins and hydrochlorofluoroolefins during storage, handling and use yet allow for atmospheric degradation. The combinations exhibit low or zero ozone depletion potential and lower global warming potential making them of interest as replacements for chlorofluorocarbons and hydrfluorocarbons. The combinations of the present invention comprise hydrofluoroolefins and / or hydrochlorofluoroolefins in combination with a stabilizer or stabilizers selected from free radical scavengers, acid scavengers, oxygen scavengers, polymerization inhibitors and combinations thereof.

Owner:ARKEMA INC

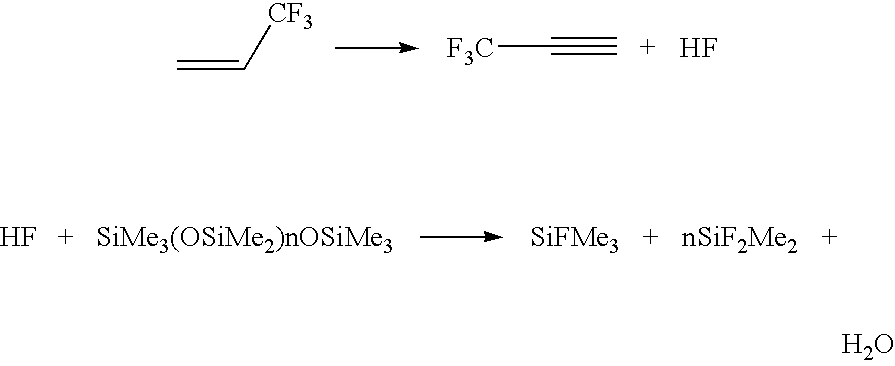

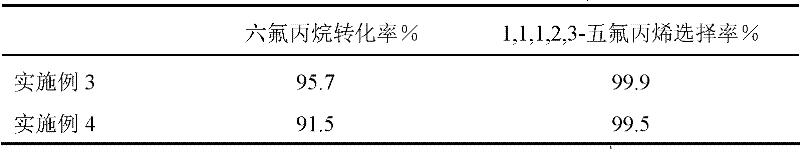

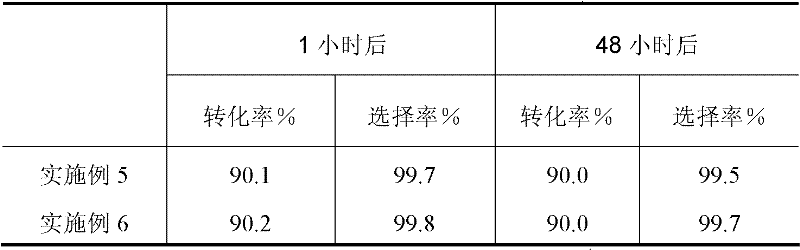

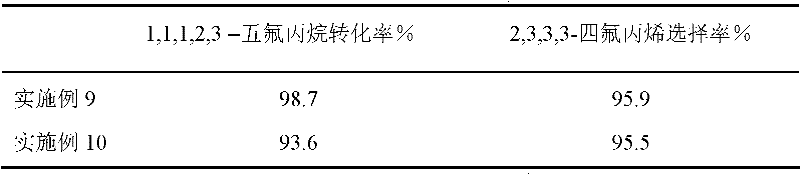

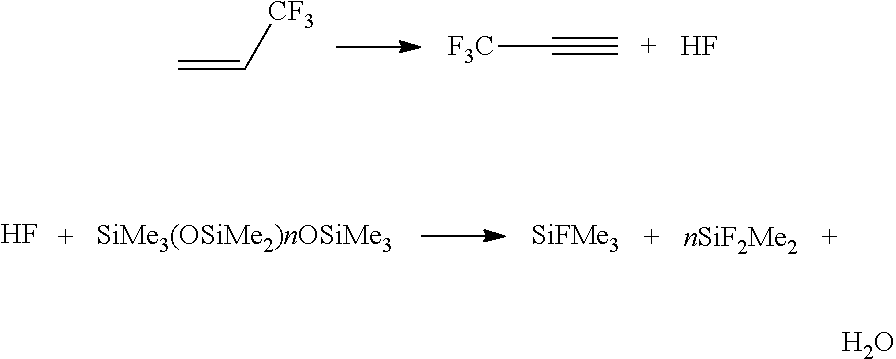

The synthetic method of 2,3,3,3-tetrafluoropropene

InactiveCN102267869AHigh yieldPreparation by hydrogen halide split-offHexafluoropropyleneOzone depletion potential

The present invention provides a method for synthesizing 2,3,3,3-tetrafluoropropene, which uses hexafluoropropene as a starting material, and undergoes multi-step hydrogenation reduction, HF removal and other steps to obtain high-purity target product 2,3 , 3,3-Tetrafluoropropene. The raw material hexafluoropropylene of the method is easy to obtain, and can be prepared by existing methods in the art, and can also be purchased commercially. The prepared 2,3,3,3-tetrafluoropropene is an excellent refrigerant substitute and has the advantages of zero ozone depletion potential (ODP) and low greenhouse effect potential (GWP value of 4).

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Environment-friendly refrigerant

InactiveCN101864276AMeet the protection requirementsPromote circulationHeat-exchange elementsOzone depletion potentialClimate change

The invention discloses an environment-friendly refrigerant used for refrigerators, air-conditioners and heat pumps. The refrigerant is composed of trans-1,3,3,3-tetrafluoropropene (HFO-1234ze(E)), 1,1-difluoroethane (HFC-152a) and difluoromethane (HFC-32). The preparation method is characterized by physically mixing the components under normal temperature according to corresponding proportion. The ozone depletion potential (ODP) is zero and the global warming potential (GWP) is low, therefore, the refrigerant conforms to the requirement of environmental protection, and the refrigerant has physical property equivalent to that of HFC-134a and can be used in the existing HFC-134a system and serve as the substitute refrigerant of HFC-134a.

Owner:JIMEI UNIV

Refrigerant composition with low GWP (Global Warming Potential) value

InactiveCN101864277AMeet the protection requirementsLow ODPHeat-exchange elementsOzone depletion potentialClimate change

The invention discloses a refrigerant composition with a low GWP value. The composition consists of 2,3,3,3-tetrafluoropropene(HFO-1234yf), 1,1-difluoroethane (HFC-152a) and dimethyl ether (DME). The preparation method comprises the step of physically mixing the above components at normal temperature in corresponding proportion. The refrigerant composition has zero Ozone-Depletion Potential (ODP), and very low global warming potential (GWP), meets the requirement of environmental protection, has physical property equivalent to HFC-134a, and can be directly used in the traditional HFC-134a system without redesigning a compressor.

Owner:JIMEI UNIV

Fluoroiodocarbon blends as CFC and halon replacements

InactiveUS7083742B1Low costImprove attributesOrganic chemistryOther chemical processesAlcoholOzone depletion potential

A new set of effective, environmentally safe, nonflammable, low-toxicity refrigerants, solvents, foam blowing agents, propellants, and firefighting agents is disclosed. The agents are clean, electrically nonconductive, and have short atmospheric lifetimes, zero ozone-depletion potential, and low global warming potentials. The agents comprise at least one fluoroiodocarbon agent satisfying the general formula CaHbBrcCldFeIfNgOh, wherein a is between and including 1 and 8; b is between and including 0 and 2; c, d, g, and h are each between and including 0 and 1; e is between and including 1 and 18; and f is between and including 1 and 2, either neat or mixed with additives selected from the group consisting of: alcohols, esters, ethers, fluoroethers, hydrocarbons, hydrofluorocarbons, and perfluorocarbons.

Owner:JSN FAMILY PARTNERSHIP 3

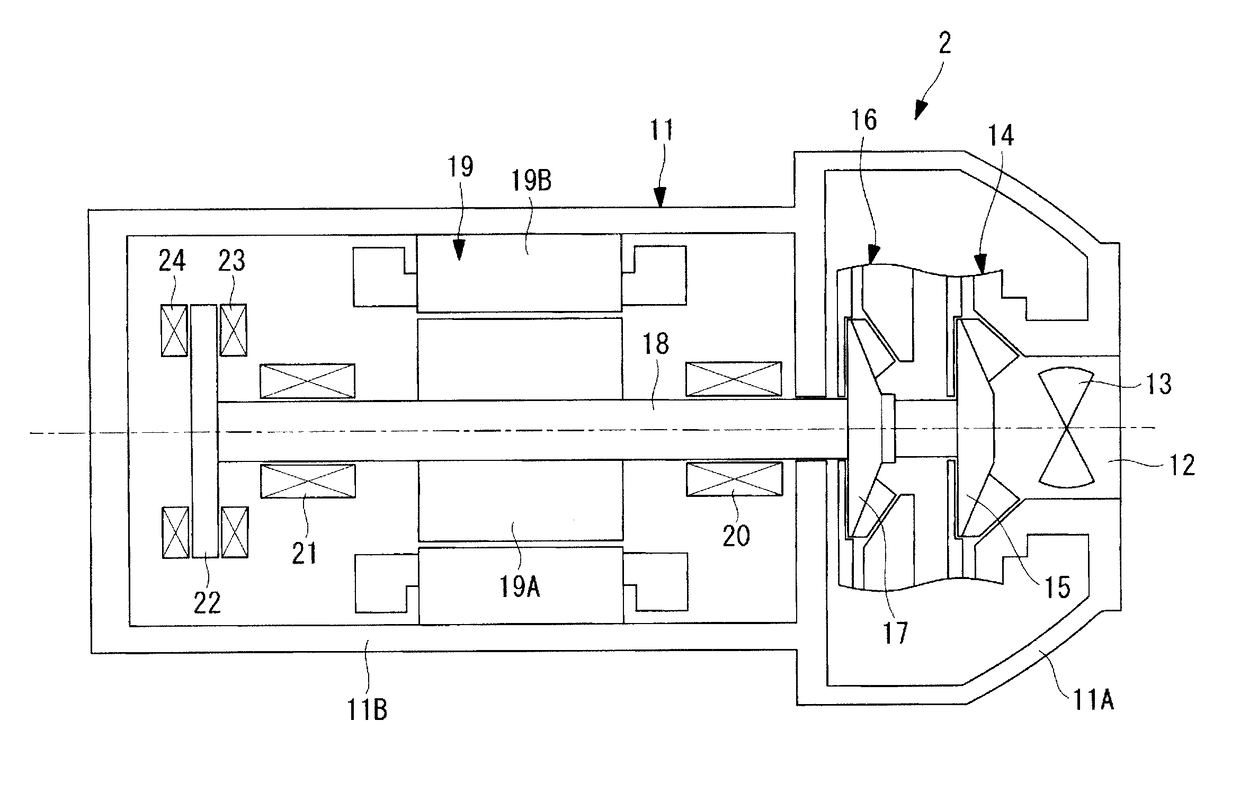

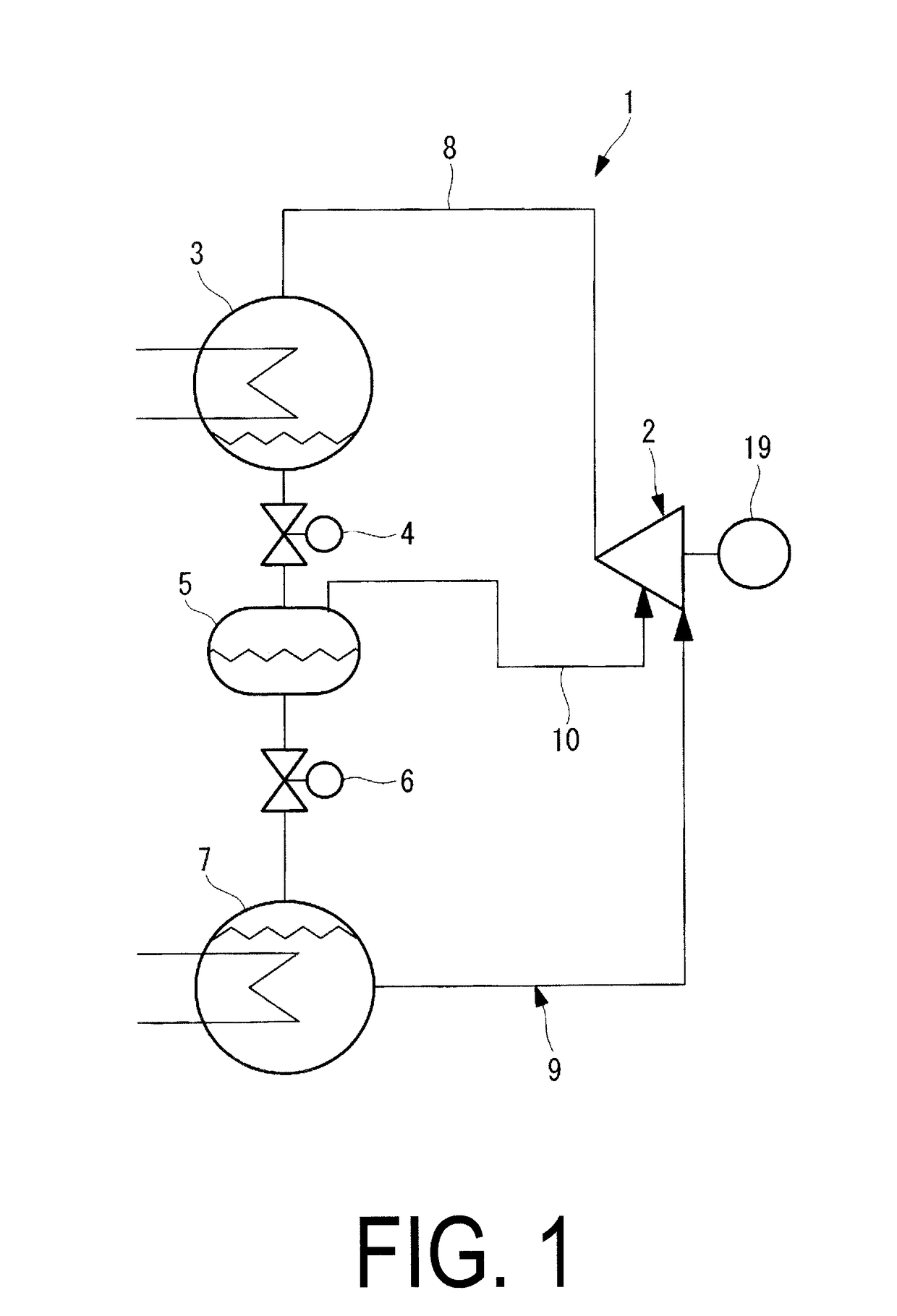

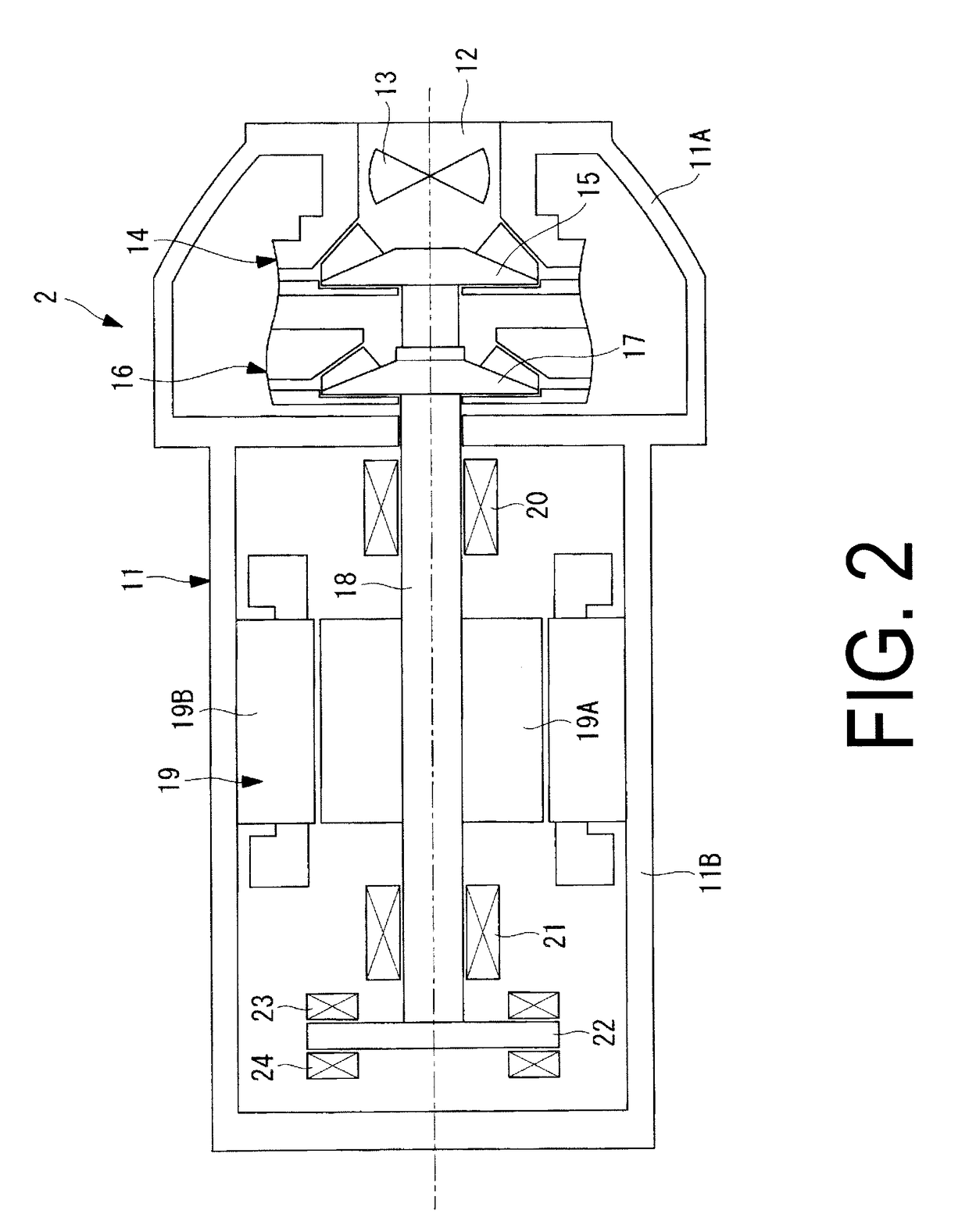

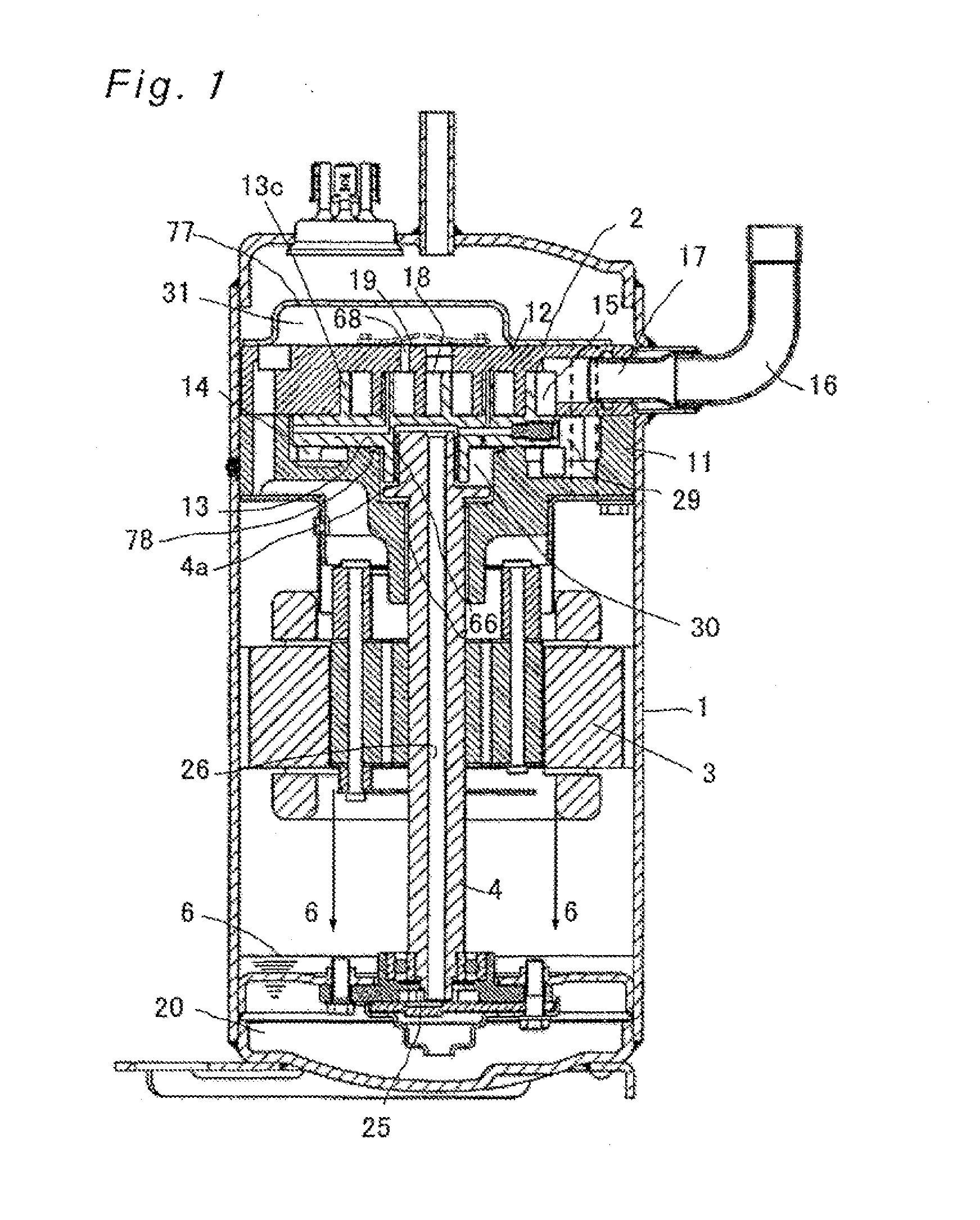

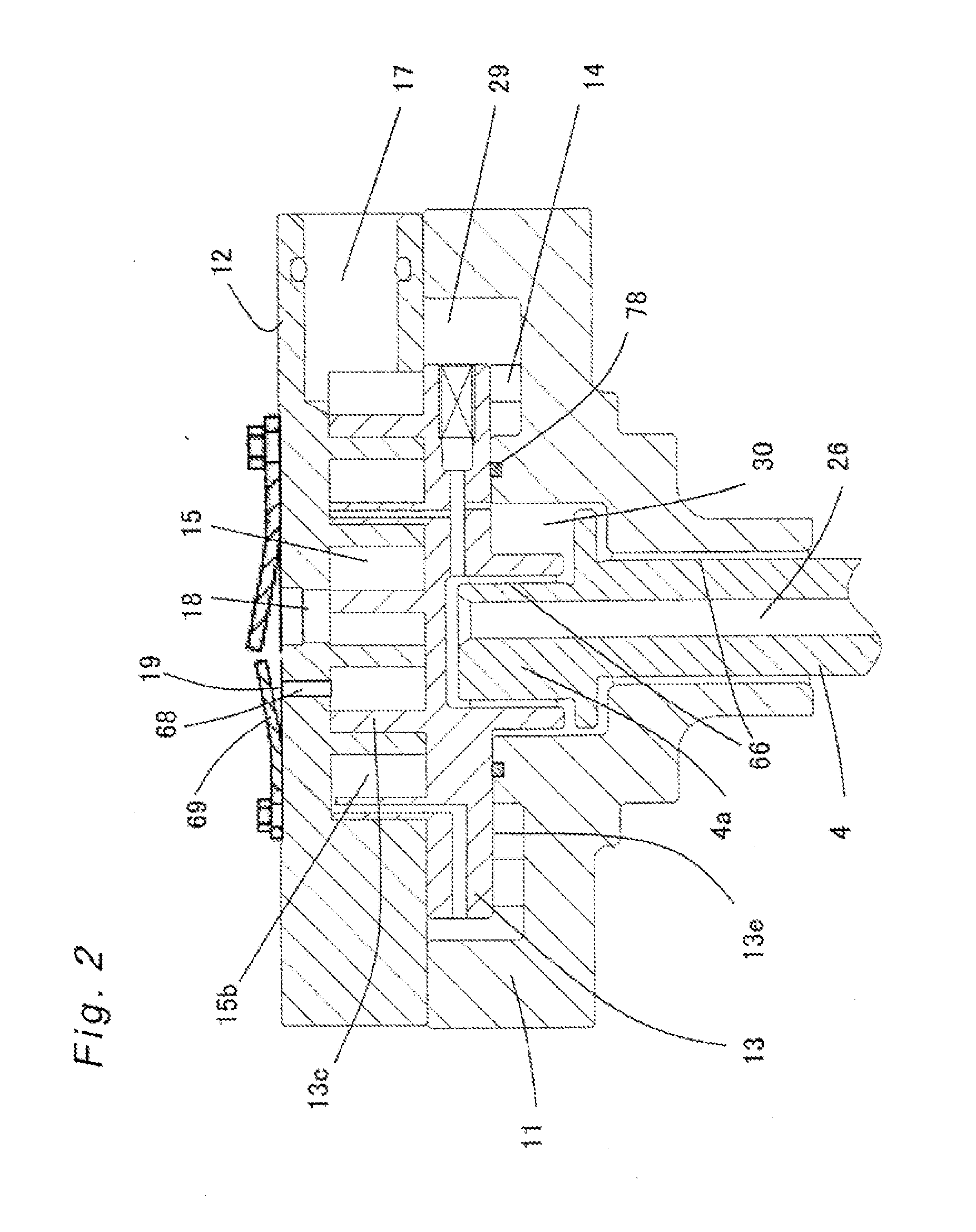

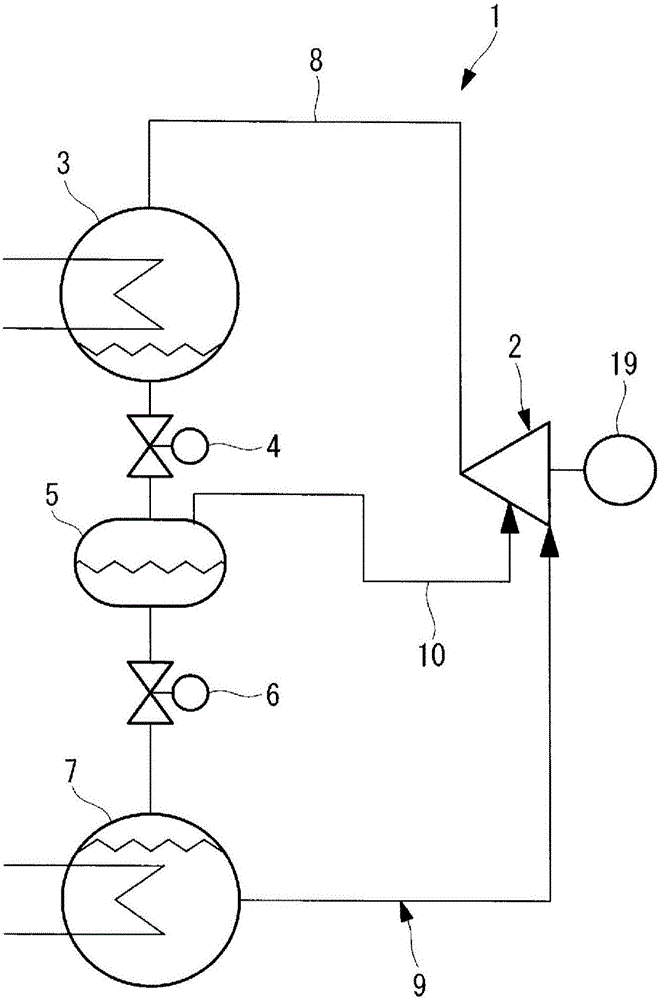

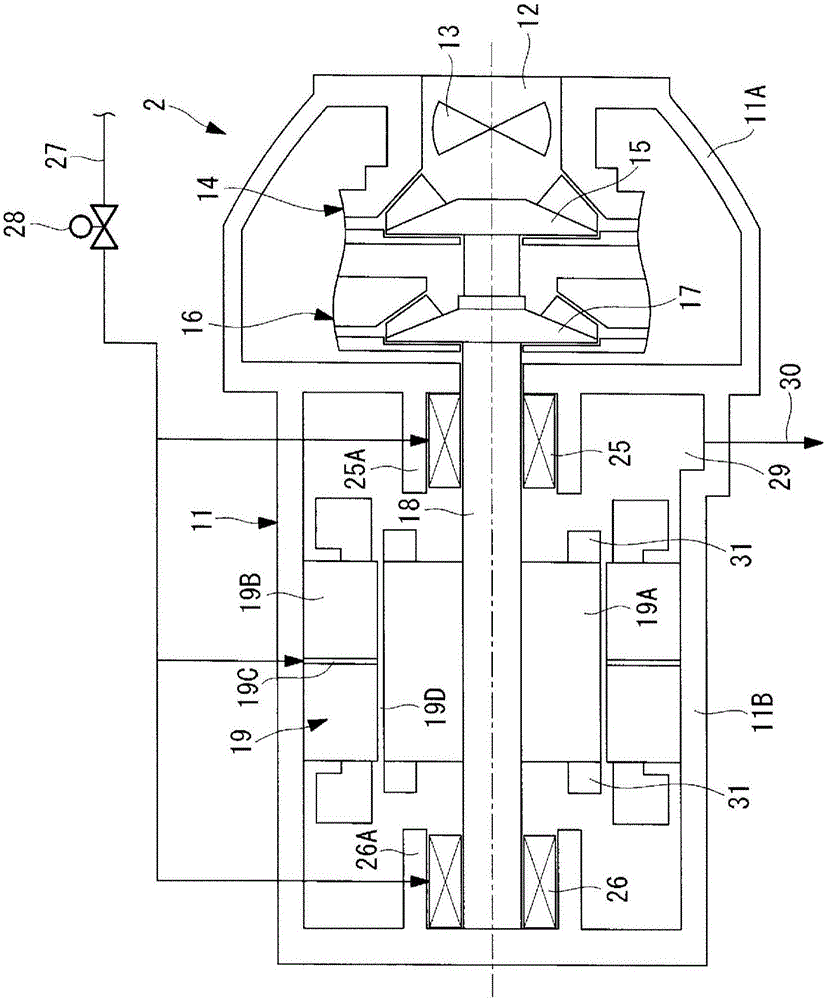

Turbo chiller

A turbo chiller that has an oil-free configuration, which reduces the frequency of maintenance and maintenance-induced release of refrigerant, and can achieve a reduced environmental impact by utilizing the characteristics of the low-pressure refrigerant R1233zd(E) that reaches negative pressure at a saturation temperature of 18° C. or lower. The turbo chiller comprises a refrigeration cycle that includes a turbo compressor, a condenser, a decompression device, and an evaporator connected in sequence via piping and is filled with a refrigerant; wherein the refrigerant is a low-pressure refrigerant R1233zd(E) refrigerant with low global warming potential and low ozone depletion potential; the turbo compressor has a direct drive configuration in which a rotating shaft of impellers is directly joined to a motor; and the rotating shaft is supported by magnetic bearings.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Stabilized hydrochlorofluoroolefins and hydrofluoroolefins

ActiveUS8388857B2Low ozone depletionLower global warming potentialOther chemical processesNon-surface-active detergent compositionsScavengerOzone depletion potential

Disclosed is a combination of hydrofluoroolefins and / or hydrochlorofluoroolefins with stabilizers wherein the stabilizers minimize the degradation of the hydrofluoroolefins and hydrochlorofluoroolefins during storage, handling and use yet allow for atmospheric degradation. The combinations exhibit low or zero ozone depletion potential and lower global warming potential making them of interest as replacements for chlorofluorocarbons and hydrfluorocarbons. The combinations of the present invention comprise hydrofluoroolefins and / or hydrochlorofluoroolefins in combination with a stabilizer or stabilizers selected from free radical scavengers, acid scavengers, oxygen scavengers, polymerization inhibitors and combinations thereof.

Owner:ARKEMA INC

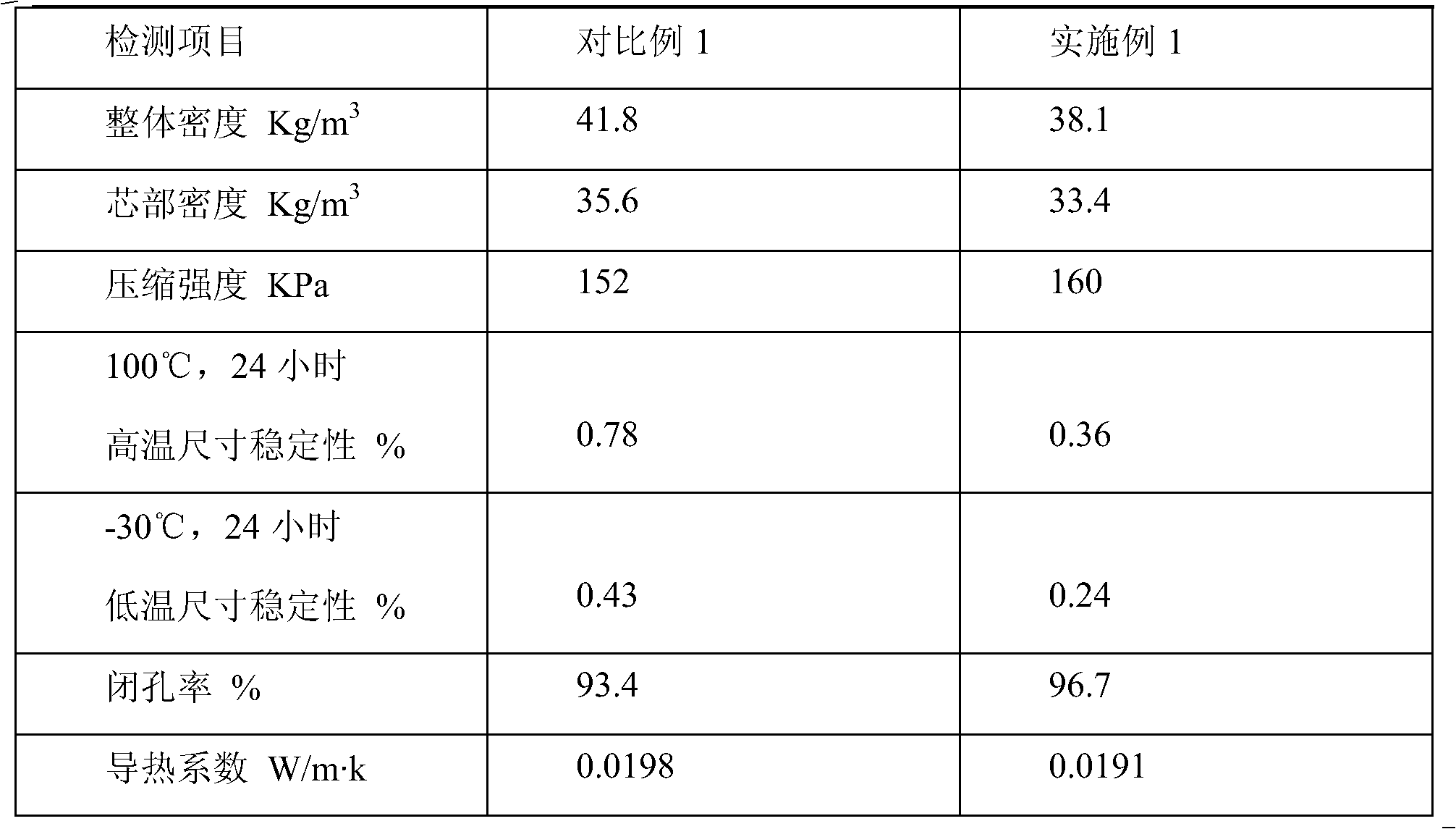

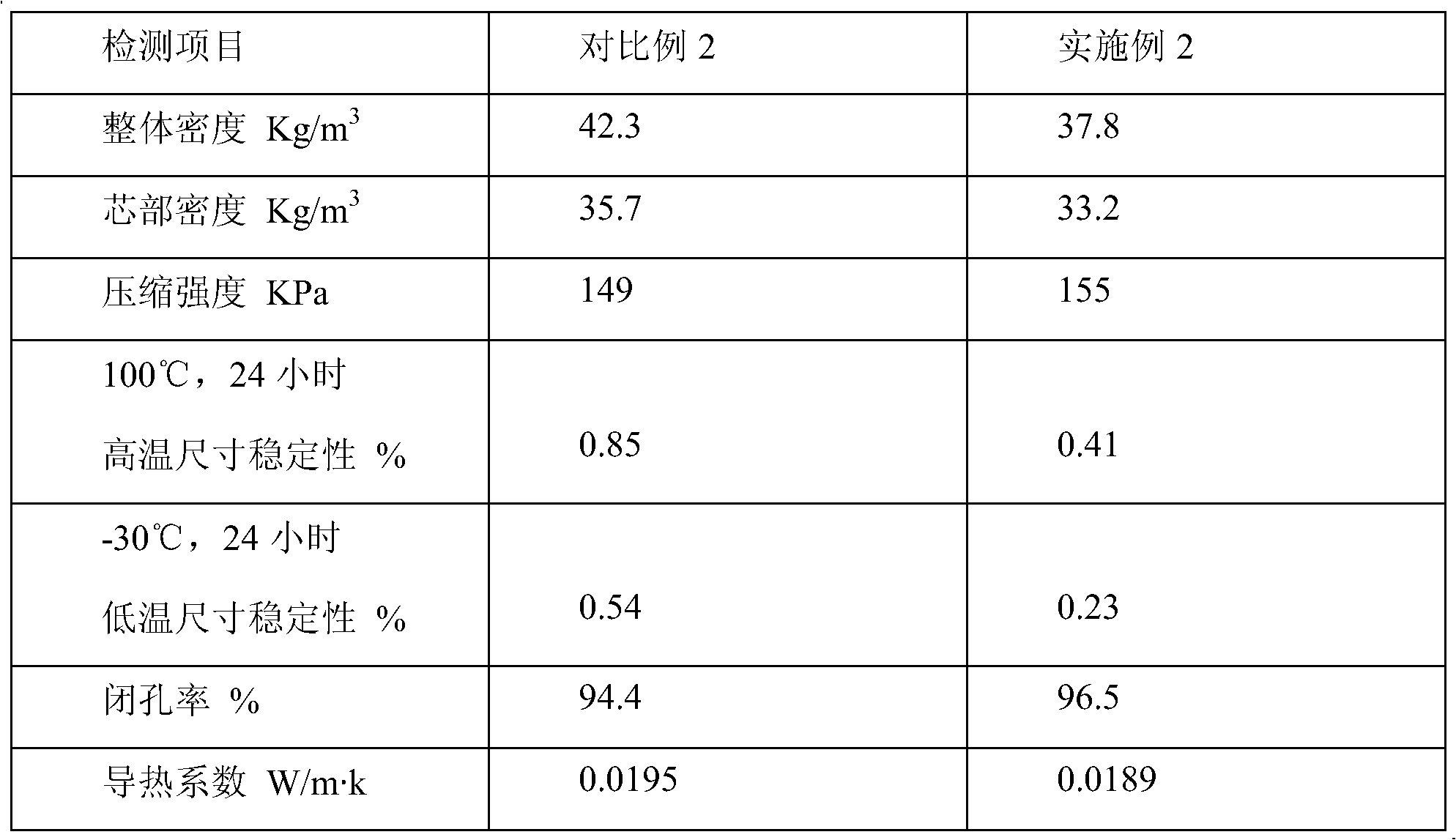

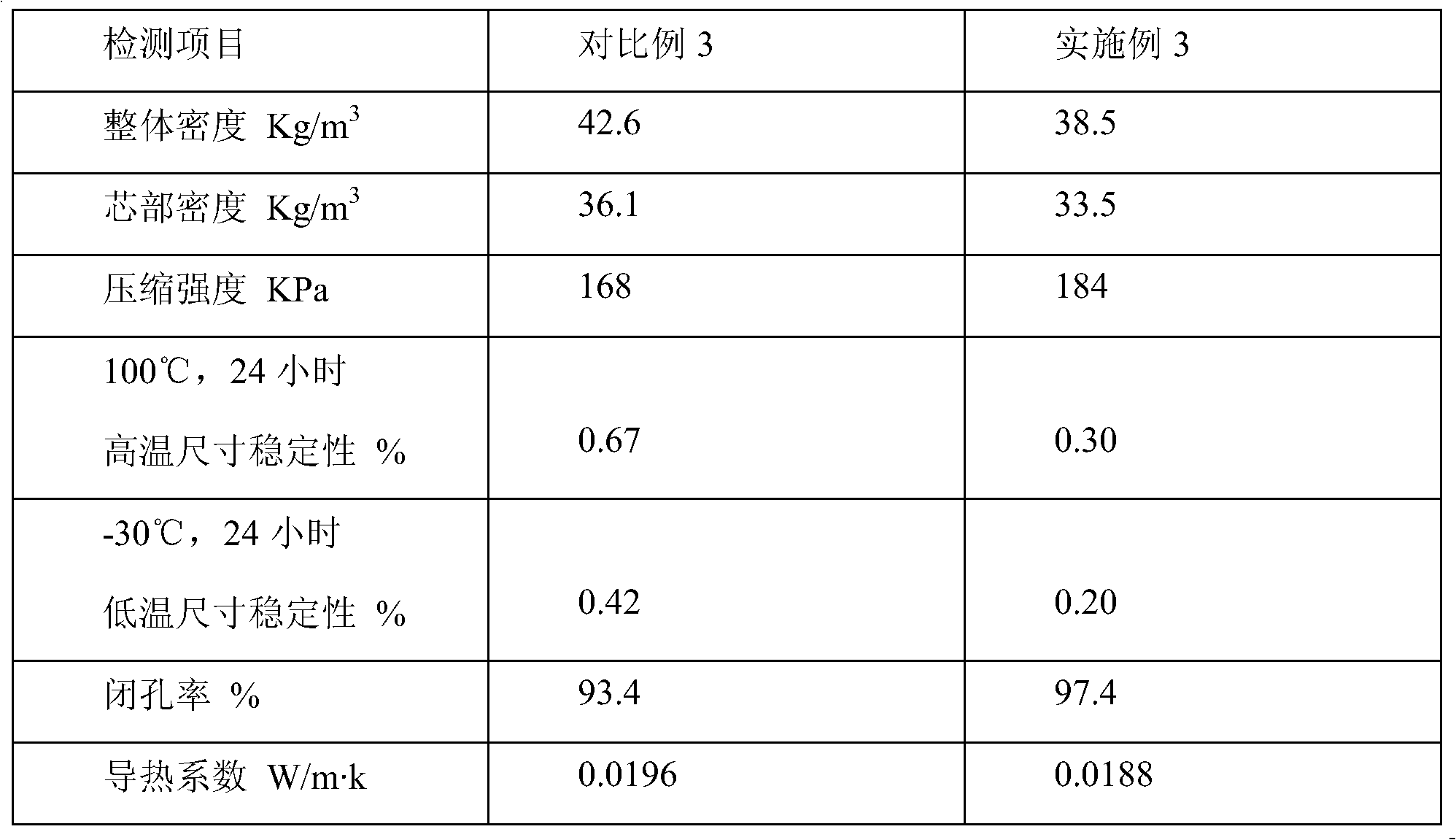

Conjugate polyether for hard polyurethane foam and using method thereof

InactiveCN102504163AHas a zero ODP valueProduction operation safetyFluid heatersEnvironmental resistanceChemical synthesis

The invention belongs to the field of chemical synthesis and relates to a conjugate polyether for hard polyurethane foam and a using method thereof. The hard polyurethane foam made of the conjugate polyether prepared by using a mixture of HFC-365mfc / HFC-227 as foaming agent has excellent dimension stability, compression strength and conductivity coefficient. The invention has the advantages that: the mixture of HFC-365mfc and HFC-227ea, which serves as the foaming agent, has a zero ozone depletion potential (ODP) value and therefore completely meets the environment-protection requirement on substitutive HCFC-141B in the electric water heater industry; and the mixture of HFC-365mfc and HFC-227ea is liquid at normal temperature and has no flashing point, so equipment reconstruction is not needed and the production is safe.

Owner:SHANGHAI DONGDA POLYURETHANE

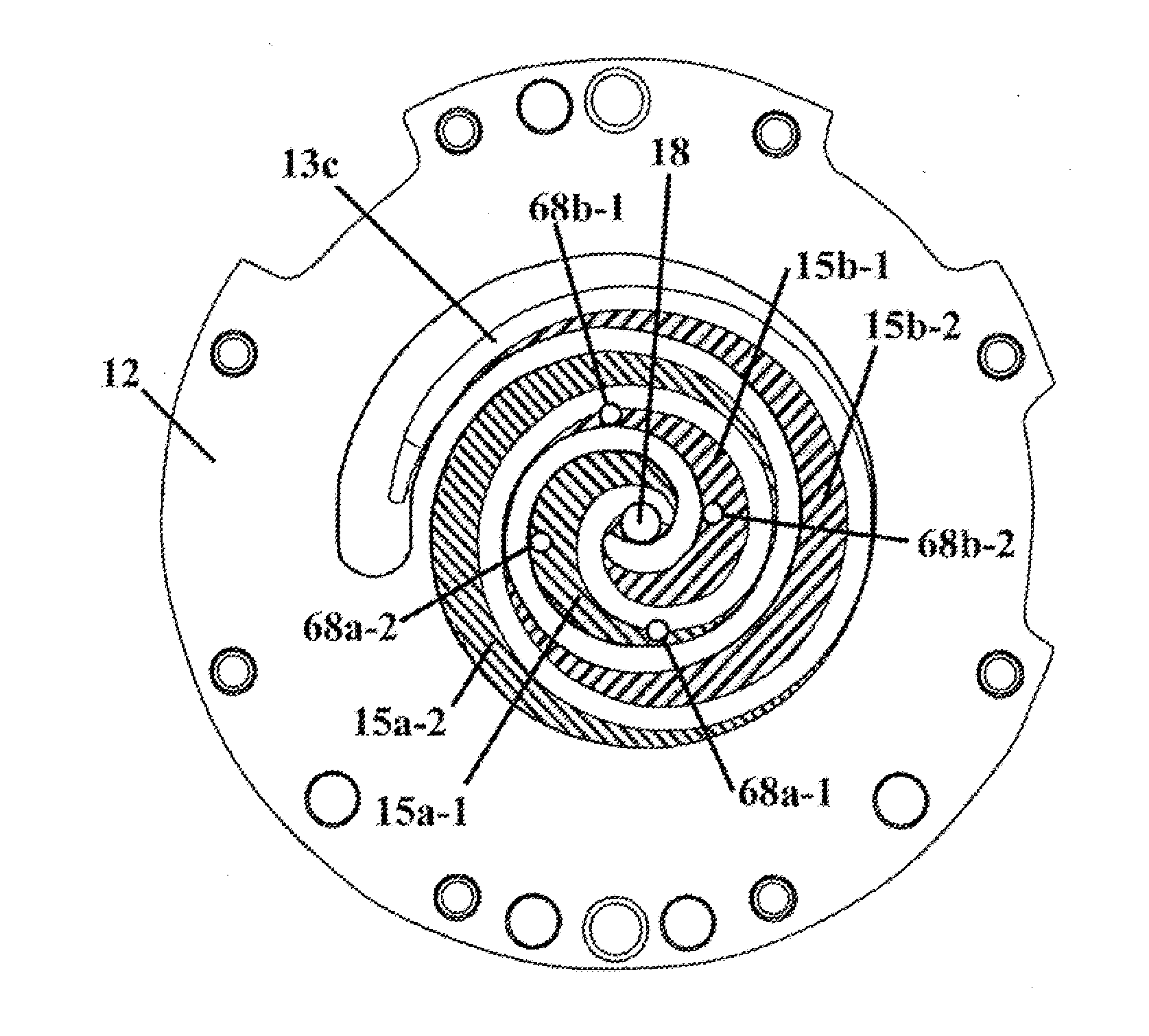

Scroll compressor

ActiveUS20130108496A1Promote decompositionImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDecompositionOzone depletion potential

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

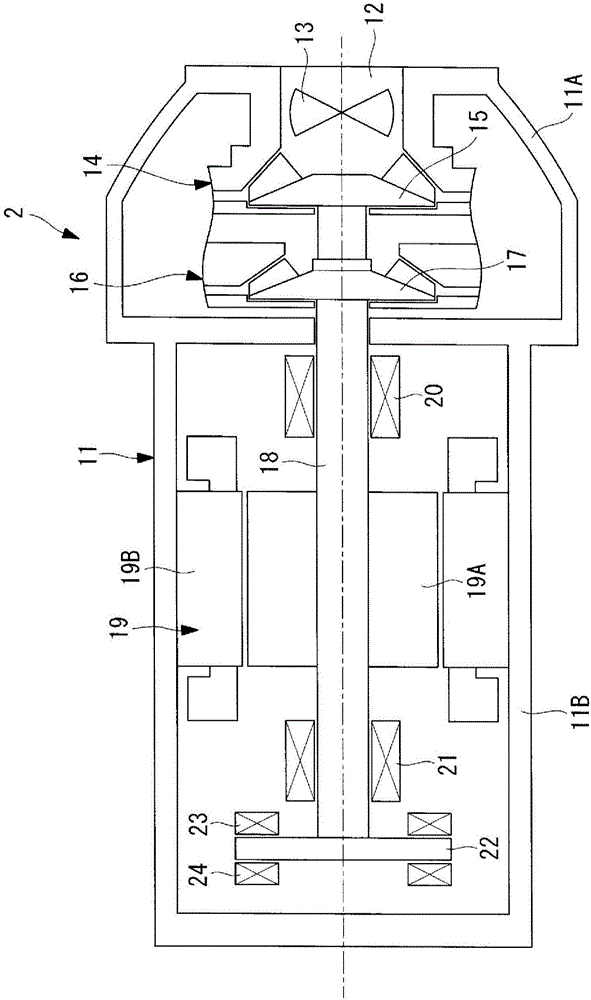

Turbo refrigerator

InactiveCN106662116AReduce power lossReduce maintenance frequencyCompressorPump componentsImpellerMagnetic bearing

The objective of the present invention is to provide a turbo refrigerator in which the frequency of maintenance and the incidence of oil leakage due to maintenance can be reduced by the use of an oil-less system, and in which the characteristics of the refrigerant R1233zd (E) can be used to reduce the impact on the environment, the refrigerant being a low-pressure refrigerant that reaches negative pressure at a saturation temperature of 18 DEG C or less. The turbo refrigerator in which the refrigeration cycle is configured by sequentially connecting, via a pipeline, a turbo compressor (2), a condenser, a pressure-reducing device, and an evaporator, and in which a refrigerant is charged into the cycle, wherein: the refrigerant is refrigerant R1233zd(E), which is a low-pressure refrigerant having both a low global warming potential and a low ozone depletion potential; the turbo compressor (2) is a directly coupled turbo compressor (2) in which a rotation shaft (18) of impellers (15, 17) is directly coupled with a motor (19); and magnetic bearings (20, 21, 23, 24) are used as the bearings for supporting the rotation shaft (18).

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Environment-friendly low-viscosity high-strength polyurethane grouting lifting material and preparation method thereof

The invention discloses an environment-friendly low-viscosity high-strength polyurethane grouting lifting material and a preparation method thereof. The environment-friendly low-viscosity high-strength polyurethane grouting lifting material consists of a component A and a component B, wherein the component A mainly comprises composite polyether polyol, a low-viscosity epoxy resin compound, an amine catalyst, a foam stabilizing agent, water and a flame retardant; the component B mainly comprises an organic tin catalyst, polyisocyanate and the like. The ozone depletion potential of the environment-friendly low-viscosity high-strength polyurethane grouting lifting material disclosed by the invention is 0, the environment-friendly low-viscosity high-strength polyurethane grouting lifting material is clean and environment-friendly, and meanwhile has the characteristics of relatively low slurry viscosity, good flowbility, good groutability and the like, the rise time of the material can be controlled within 10-30 seconds, the foaming time of the material can be adjusted within 60-120 seconds, the foam appearance core density of the material can be within 50-80 kg / m<3>, the foams are uniform and dense, and the compression strength of the material is 0.45-0.70 MPa. Meanwhile as foams, rock and soil are all relatively good in adhesion property, the material is applicable to lifting mediation of buildings, traffic roads and projects under different geological conditions.

Owner:HEFEI UNIV OF TECH

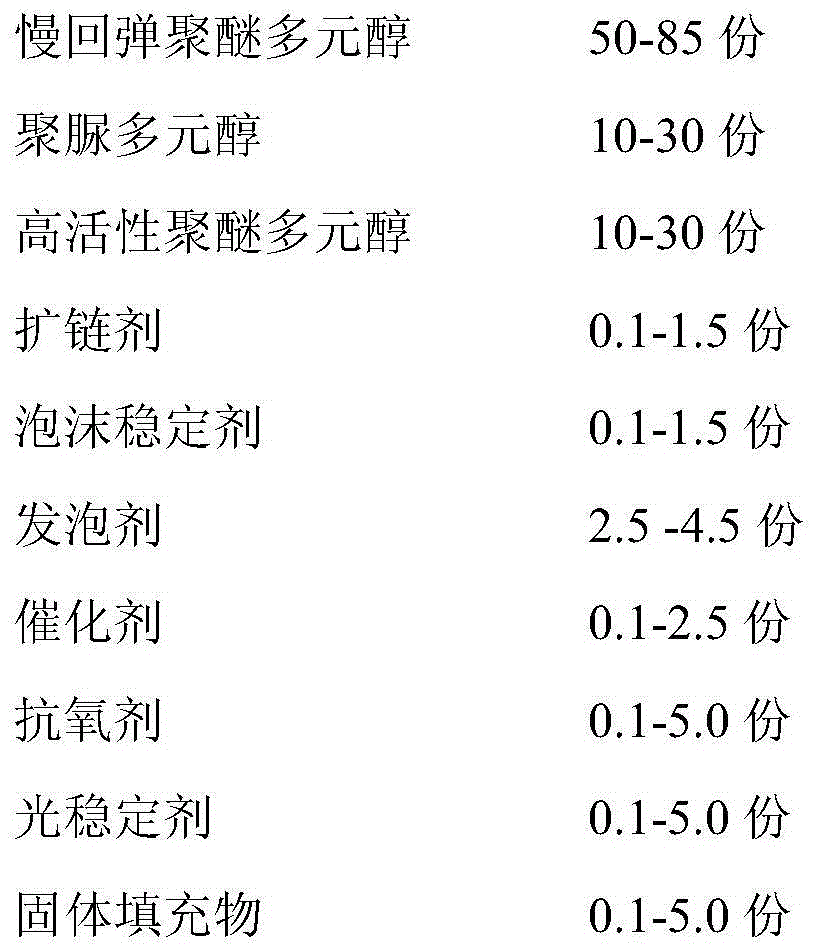

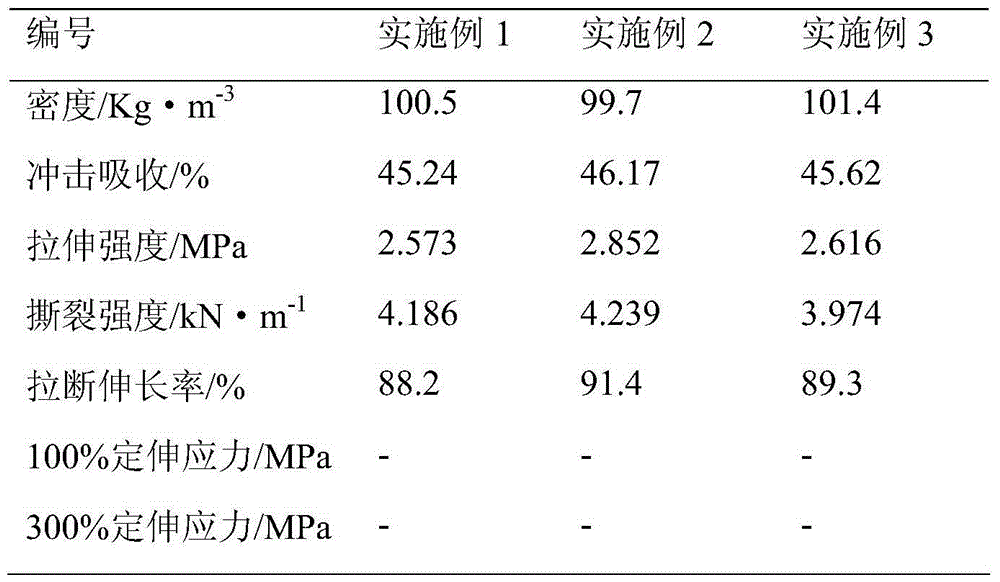

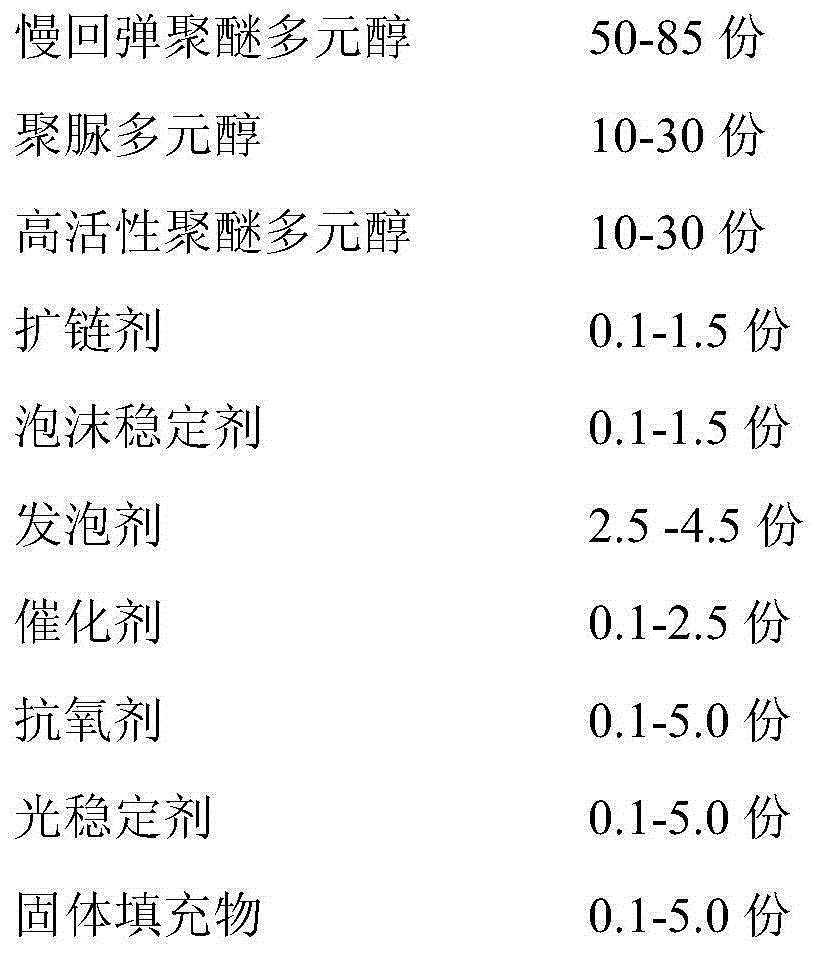

Composition for polyurethane boxing glove filler and preparation method of composition

The invention belongs to the technical field of polyurethane materials, and specifically relates to a composition for polyurethane boxing glove filler and a preparation method of the composition. The composition for the polyurethane boxing glove filler is prepared from a component A and a component B, wherein the component A is prepared from slow-rebound polyether polyol, polyurea polyol, high activity polyether polyol, a chain extender, a foam stabilizer, a foaming agent, a catalyst, an antioxidant, a light stabilizer and a solid filler; the component B is prepared from polyether polyol, isocyanate and a storage stabilizer. According to the composition for the polyurethane boxing glove filler, the all-water-blown formula design is performed, so that the ozone depletion potential ODP is zero, the prepared composition is nontoxic and protects the environment and is an environmentally-friendly material; the prepared polyurethane boxing glove products are outstanding in knock resisting and buffering performance and high in bearing rebound capacity, and therefore, the wrist and fingers can be prevented from being injured during boxing.

Owner:SHANDONG INOV POLYURETHANE

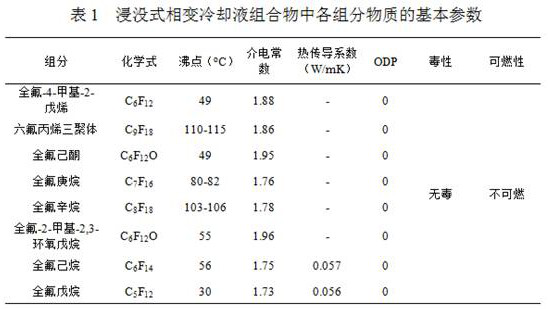

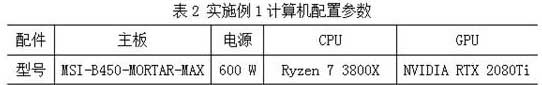

Immersed liquid phase change cooling medium and application thereof in cooling system of electronic equipment

InactiveCN111726971AImprove data transfer performanceHigh electrical insulationCooling/ventilation/heating modificationsEpoxyMeth-

The invention discloses an immersed liquid phase change cooling medium and application thereof in a cooling system of electronic equipment, wherein the cooling medium is a mixture formed by mixing one, two or three of perfluoro-4-methyl-2-pentene, a hexafluoropropylene tripolymer, perfluorohexanone, perfluoroheptane, perfluorooctane, perfluoro-2-methyl-2, 3-epoxy pentane, perfluorohexane and perfluoropentane. The immersed phase change cooling medium provided by the invention has the characteristics of high electrical insulation property, low viscosity, relatively low boiling point, high gasification latent heat, good compatibility and stability, incombustibility, combustion inhibition, low global warming potential (GWP), zero ozone depletion potential (ODP) and the like.

Owner:ZHEJIANG UNIV OF TECH

Stabilized hydrochlorofluoroolefins and hydrofluoroolefins

ActiveUS20140166922A1Low ozone depletionLower global warming potentialOrganic chemistryOther chemical processesOzone depletion potentialChlorofluorocarbon

Disclosed is a combination of hydrofluoroolefins and / or hydrochlorofluoroolefins with stabilizers wherein the stabilizers minimize the degradation of the hydrofluoroolefins and hydrochlorofluoroolefins during storage, handling and use yet allow for atmospheric degradation. The combinations exhibit low or zero ozone depletion potential and lower global warming potential making them of interest as replacements for chlorofluorocarbons and hydrofluorocarbons. The combinations of the present invention comprise hydrofluoroolefins and / or hydrochlorofluoroolefins in combination with a stabilizer or stabilizers selected from free radical scavengers, acid scavengers, oxygen scavengers, polymerization inhibitors and combinations thereof.

Owner:ARKEMA INC

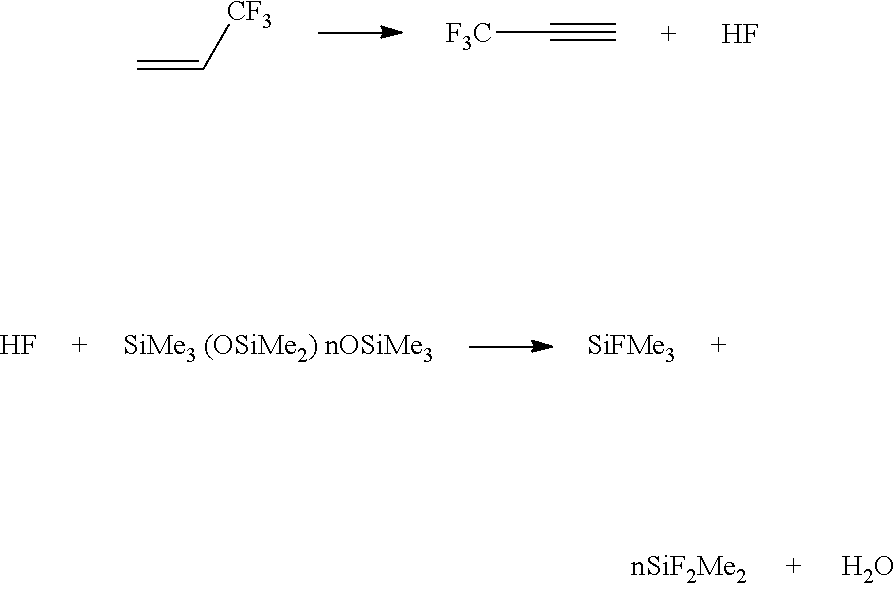

Mixing refrigerant in use for repalcing R12 and R500

InactiveCN1872940ALittle change in boiling pointHeat-exchange elementsOzone depletion potentialFreon

This invention relates to a refrigerant composition that can substitute Freon R12 and R500. The refrigerant composition mainly comprises CHCIF2, dimethyl ether, and additive selected from CF3I, CHF2CF3, CF3CHFCF3, and CO2. The refrigerant composition is suitable for all kinds of lubricating oils without the need for changing the previous freezing equipment. Besides, the refrigerant composition has low ozone depletion potential (ODP) and global warming potential (GWP), thus can substitute Freon series R12 and R500 for environmental protection.

Owner:珠海亚路精细化工有限公司

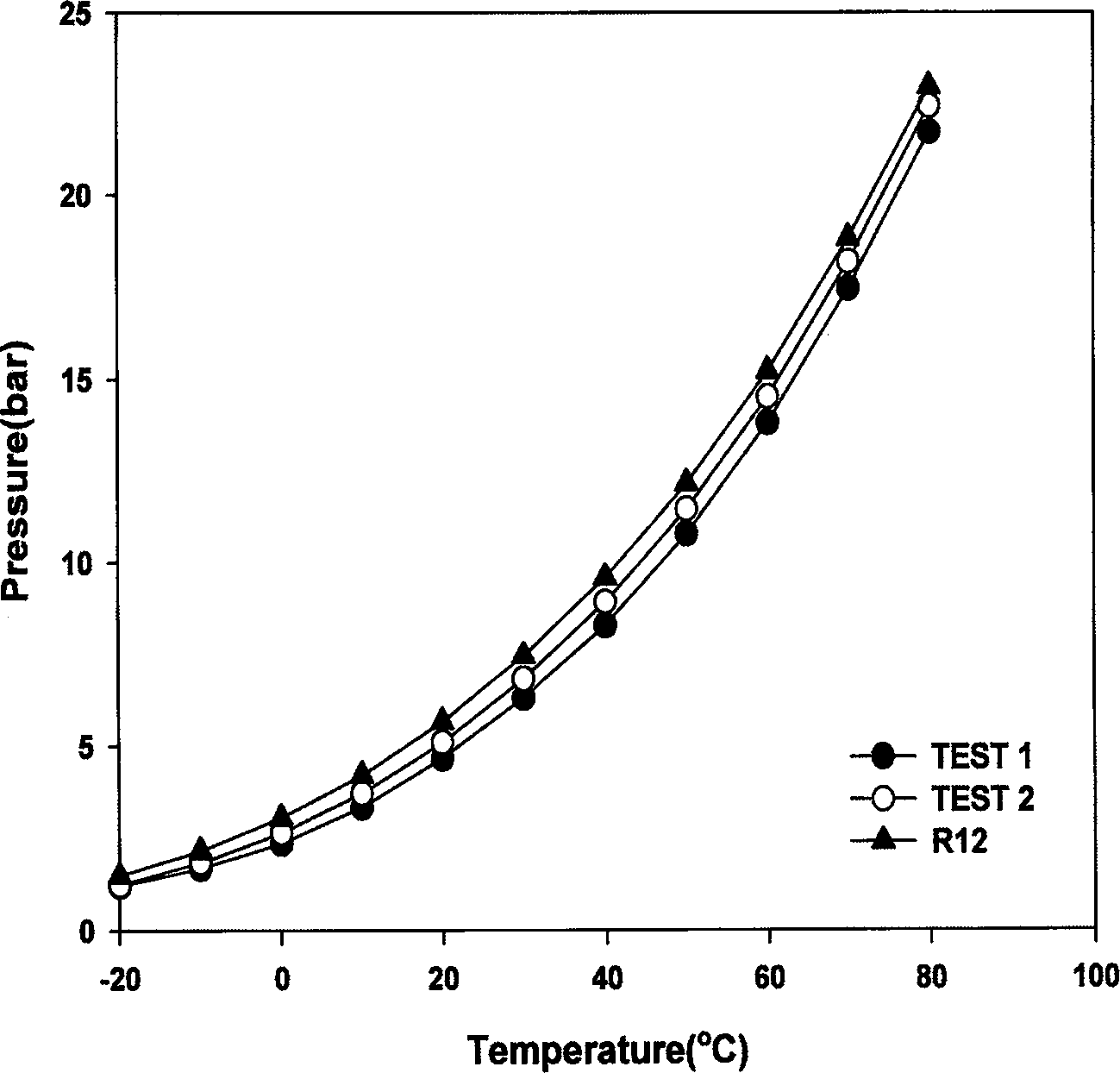

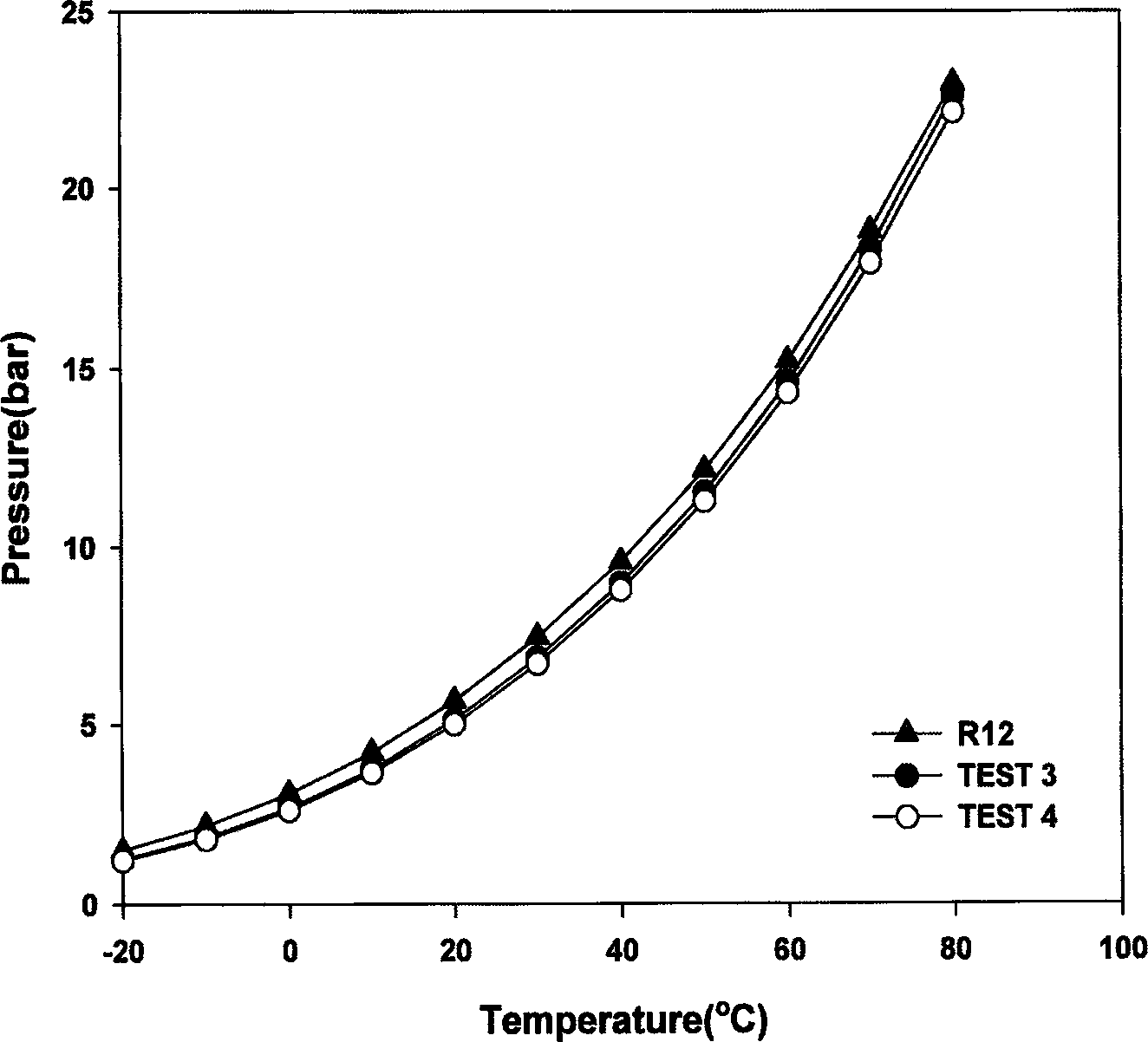

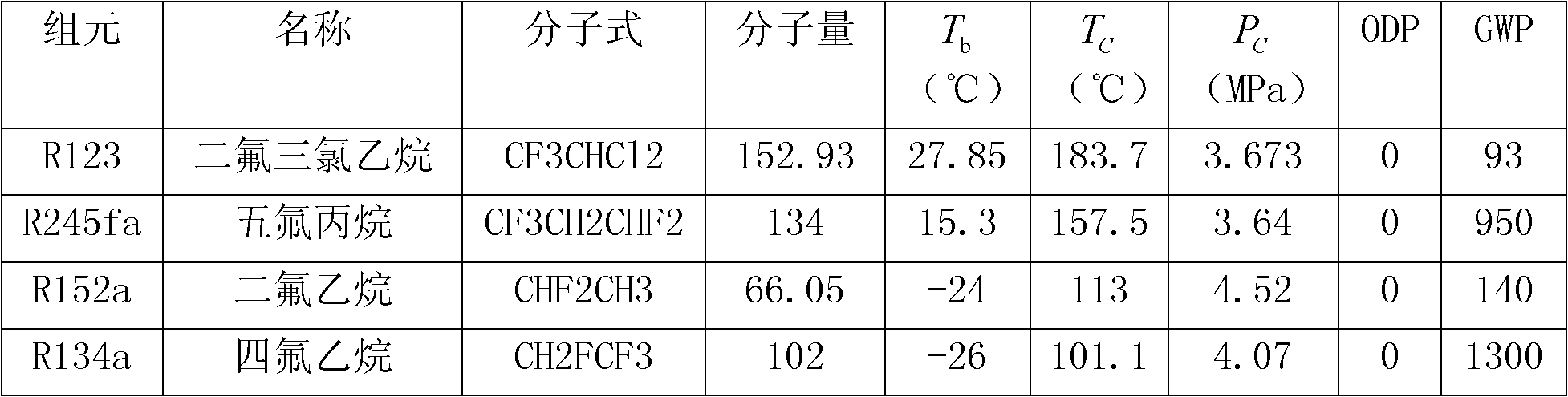

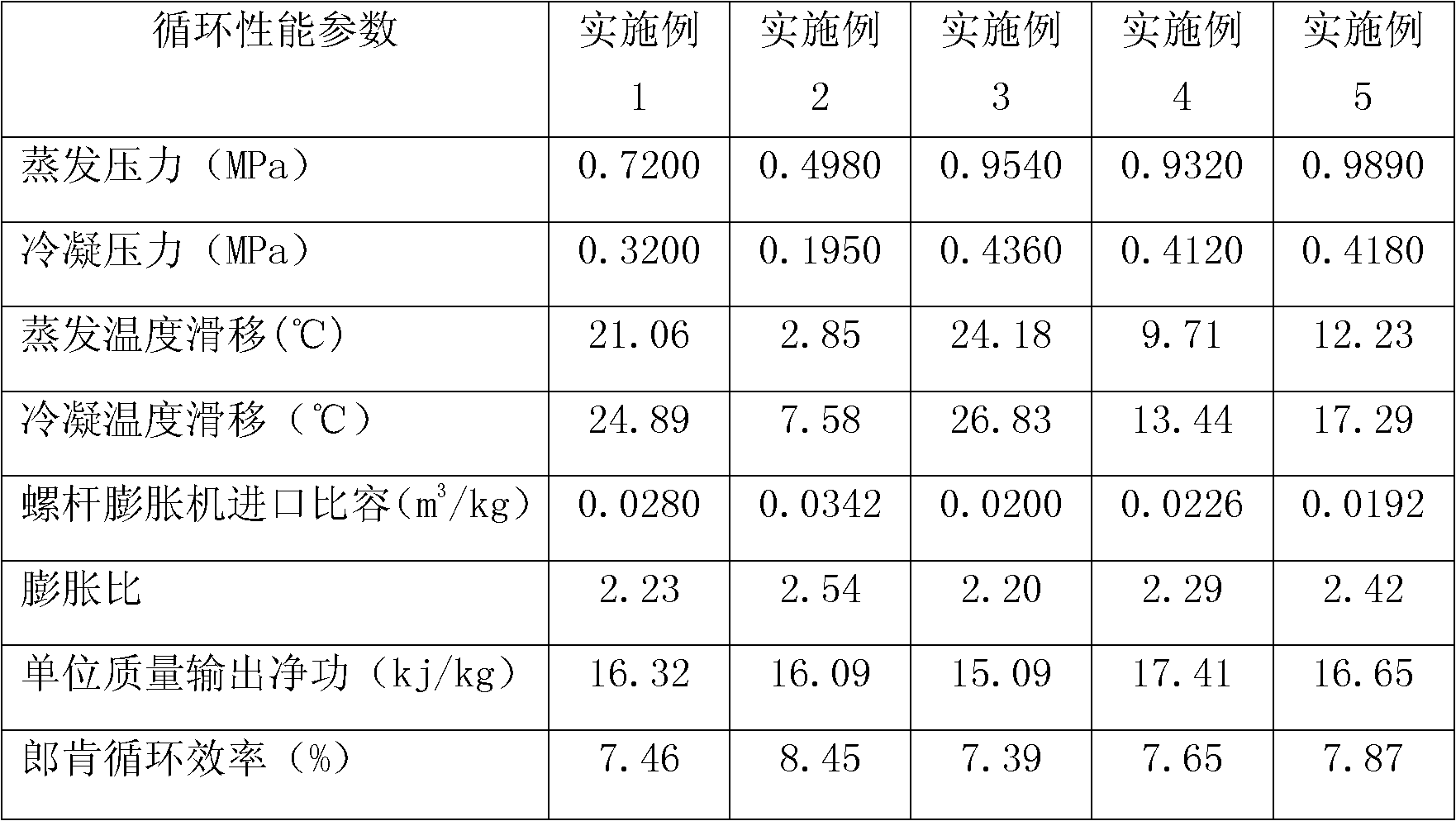

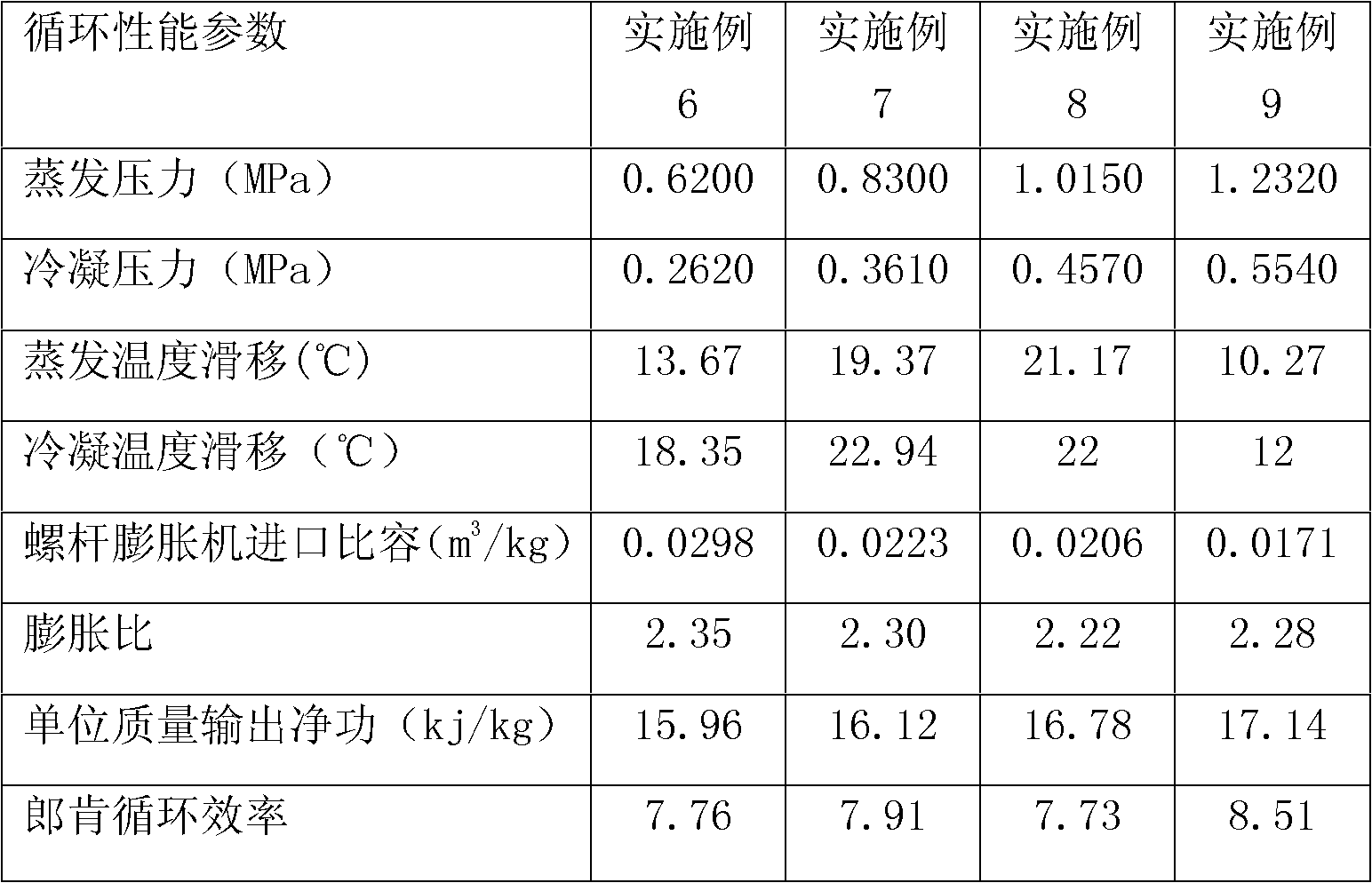

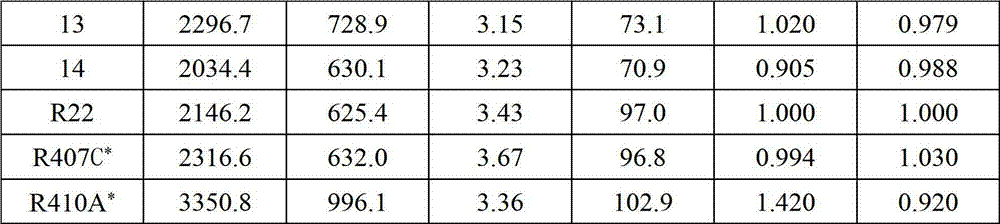

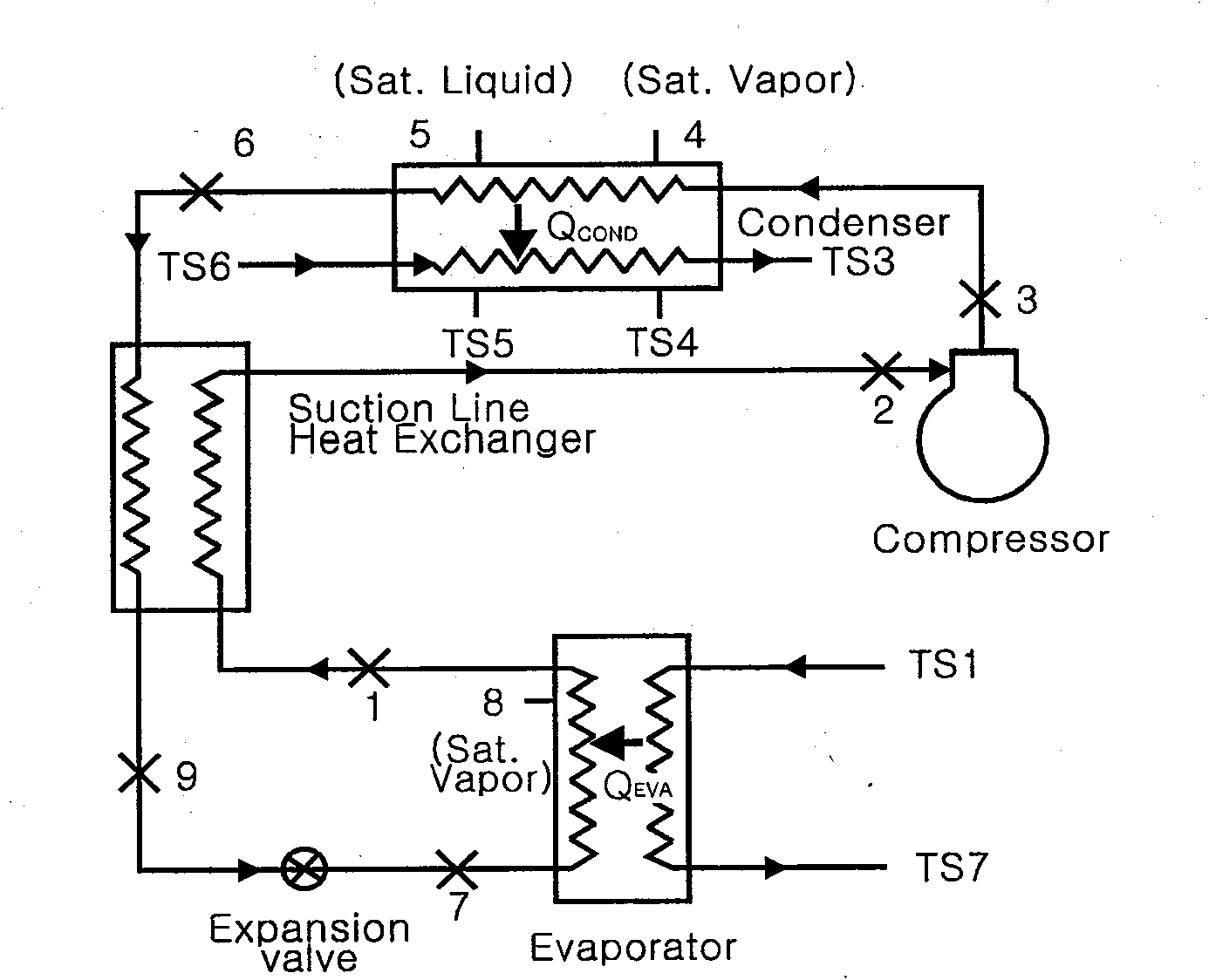

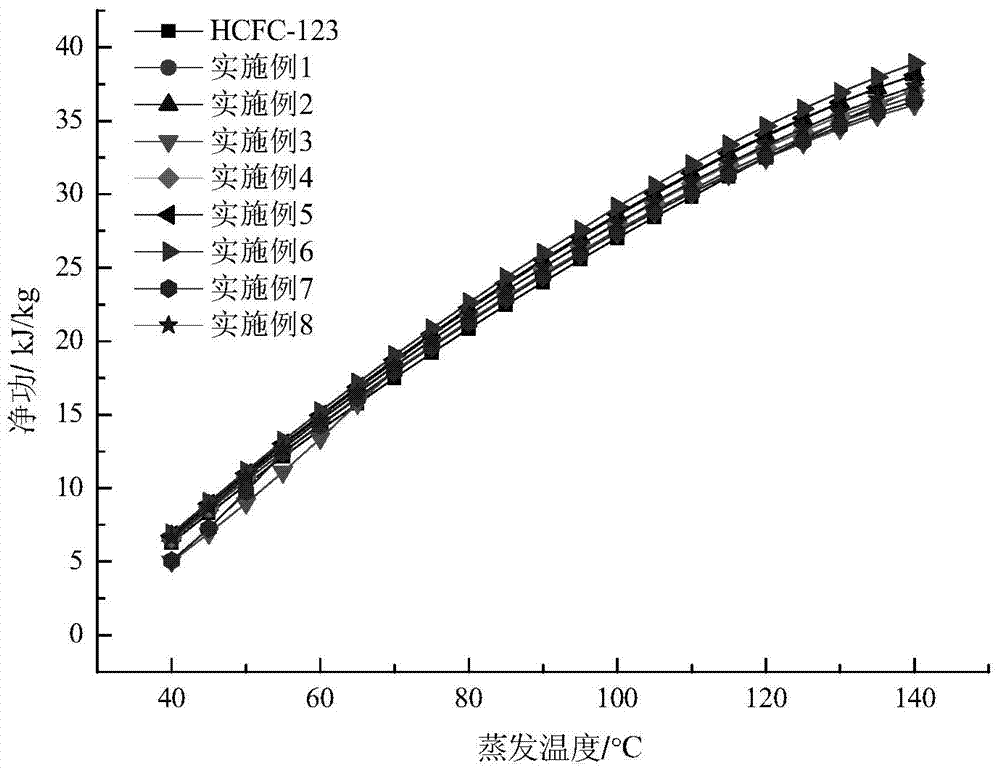

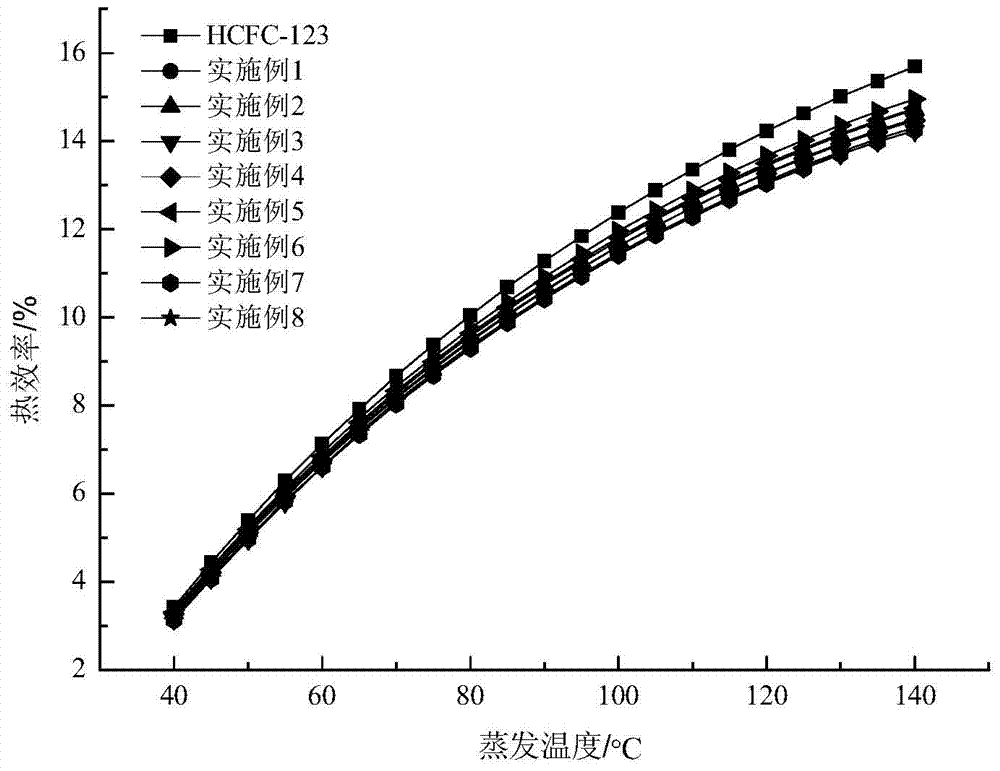

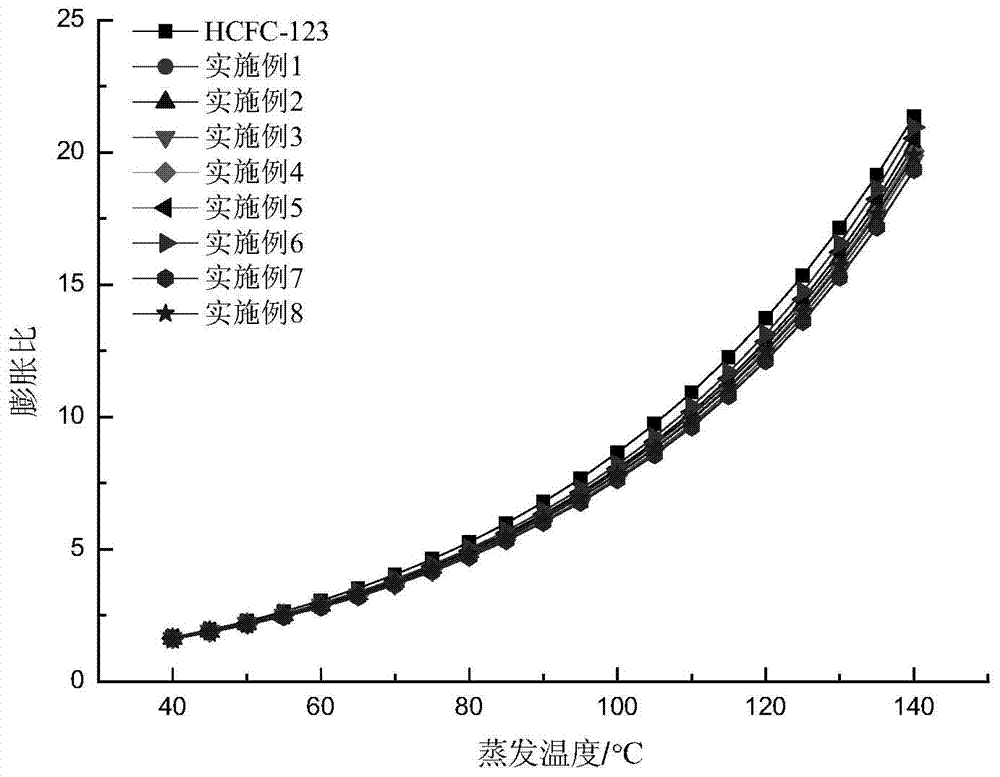

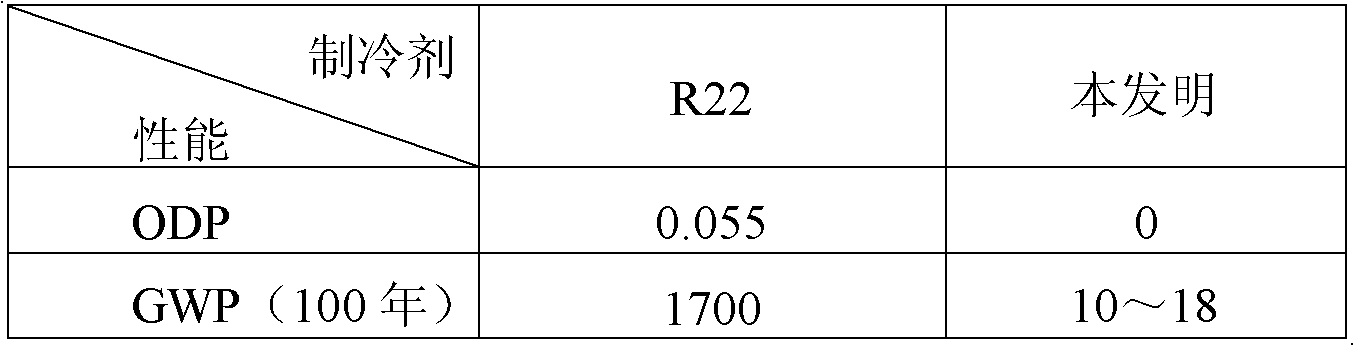

Mixed working medium for organic working medium rankine cycle system of screw expander

InactiveCN102127397APromote circulationIncreased net work output per unit mass cycleHeat-exchange elementsMass ratioOzone depletion potential

The invention discloses a mixed working medium for an organic working medium rankine cycle system of a screw expander. The mixed working medium consists of two or three of four organic working media, namely HCFC(hydrochlorofluorocarbon)-123 (2,2-dichloro-1,1,1-trifluoroethane), HFC(hydro-fluoro-carbon)-245fa (1,1,1,3,3-pentafluoropropane), HFC-152a (1,1-difluoroethane) and HFC-134a (1,1,1,2-tetrafluoroethane). The sum of mass percentage of components of each mixed working medium is 100 percent. The preparation method for the mixed working medium comprises the following step of: physically mixing the components in the set mass ratio at normal temperature. The mixed working medium meets environmental protection requirement, namely has the ozone depletion potential (ODP) of zero, low global warming potential (GWP), suitable thermal parameters, good cycle performance and high cycle heat utilization rate.

Owner:TIANJIN UNIV

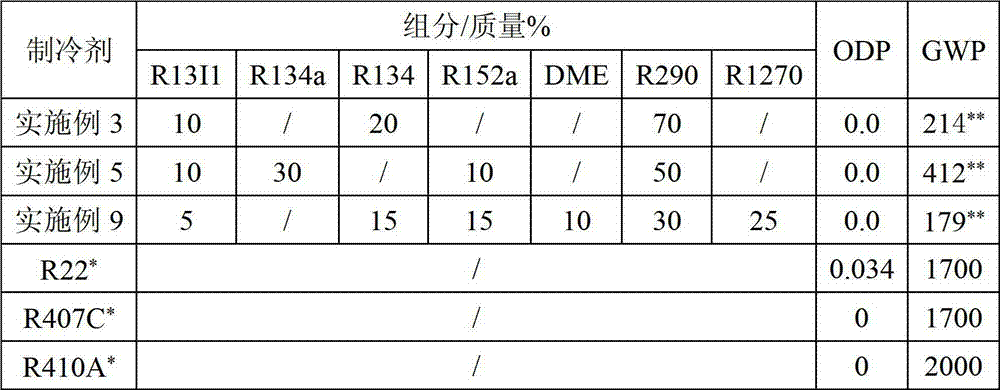

Mixed refrigerant containing trifluoroiodomethane

ActiveCN102925108AReduce flammabilityWon't breakHeat-exchange elementsCombustionOzone depletion potential

The invention relates to a mixed refrigerant containing trifluoroiodomethane, which is formed by physically mixing a component 1, a component 2 and a component 3, wherein the component 1 is trifluoroiodomethane having the function of inhibiting combustion and explosion; the component 2 is 1,1-difluoroethane; and the component 3 is propane. In the mixed refrigerant, the content of the component 1 is 1-10 wt%, the content of the component 2 is 20-40 wt%, and the content of the component 3 is 50-75 wt%. The ODP (ozone depletion potential) value of the mixed refrigerant is zero, the GWP (global warming potential) value is much smaller than that of a conventional HFC (hydrofluorocarbon) working medium, and the mixed refrigerant has favorable lubricating oil intersolubility; and thus, the mixed refrigerant can directly substitute an R22 working medium without great changes in the refrigeration system. Since the mixed refrigerant has the combustion inhibiting component, the refrigerant has greatly lower flammability and is even non-flammable, so that the safety of the refrigeration system is greatly enhanced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Novel environmental-protection refrigerant component for substituting 1, 1, 1, 2- tetrafluoroethane (hydrochlorofluorocarbon (HFC)-134a)

InactiveCN101984013AReduced global warming potentialLow global warming potentialHeat-exchange elementsOzone depletion potentialSilicone oil

The invention relates to a novel environmental-protection refrigerant for substituting 1, 1, 1, 2- tetrafluoroethane (hydrochlorofluorocarbon (HFC)-134a), which is characterized in that 50 to 56kg of propane (R-290) and 40 to 49kg of isobutene (R-600a) of hydrocarbon series are taken as a basis; 2 to 5kg of n-butane (R-600) and 1 to 3kg of propylene (R-1270) are added; and a near-azeotropic mixture refrigerant with the ozone depletion potential (ODP) of 0 and the global warming potential (GWP) of 3 is formed after 0.5 to 1kg of an additive-hexamethylene silicone oil are added for near-azeotropic.

Owner:濮阳市中炜精细化工有限公司 +1

High-density rigid polyurethane foam material prefabricated heat insulating pipeline and prefabricating method

InactiveCN106366276ADamage to zeroDestroy zeroThermal insulationPipe protection by thermal insulationHigh densityPolyol

A high-density rigid polyurethane foam material prefabricated heat insulating pipeline and a prefabricating method. The heat insulating pipeline is composed of an inner layer working steel pipe, a middle high-density polyurethane heat insulating layer, and an outer layer protective pipeline. The high-density polyurethane heat insulating layer is formed by uniformly mixing combined polyether, a foam stabilizer, a catalyst, a foamer and polyisocyanate and pouring the mixture. During prefabrication, the weighed polyether polyol, foam stabilizer, catalyst and foamer are added into a mixing kettle and are stirred for 30-60 min until uniformly mixed. The temperature of a blank material and the polyisocyanate is regulated to 20-25 DEG C. The blank material and the polyisocyanate are uniformly mixed according to the mass ratio of 1:1-1.3 by means of a high-pressure foaming machine, and the mixture is poured into a pipeline prefabricating cavity die so that the polyurethane stock liquid is foamed in the sealed space under a free pressure to form the high-density polyurethane heat insulating layer. In the method, water serves as the foamer, so that the method is zero in ozone depletion potential. The polyurethane heat insulating layer has high density and high compressive strength, and satisfies the function of supporting the working steel pipe.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

Environment-friendly cut tobacco expanding agent composition

InactiveCN101766328AHigh decomposition temperatureGood chemical stabilityTobacco treatmentAlkaneAlcohol

The invention relates to an environment-friendly cut tobacco expanding agent composition, which comprises the following components in percentage by weight: 50-99 percent of hydrofluoroalkane and 1-50 percent of alcohol or ether or alkane, wherein the hydrofluoroalkane is one or any combination of several kinds of pentafluoropropane, pentafluorobutane, decafluoropentane or methoxyl heptafluoropropane, preferably 80-99 percent of hydrofluoroalkane and 1-20 percent of alcohol or ether or alkane; and more preferably, 90-99 percent of hydrofluoroalkane and 1-10 percent of alcohol or ether or alkane. The environment-friendly cut tobacco expanding agent composition has favorable chemical stability; and the ozone depletion potential (ODP) index of the environment-friendly cut tobacco expanding agent composition is zero which is far lower than CFC-11, so the environment-friendly cut tobacco expanding agent composition is beneficial to the environmental protection.

Owner:北京航天科创技术开发有限公司 +1

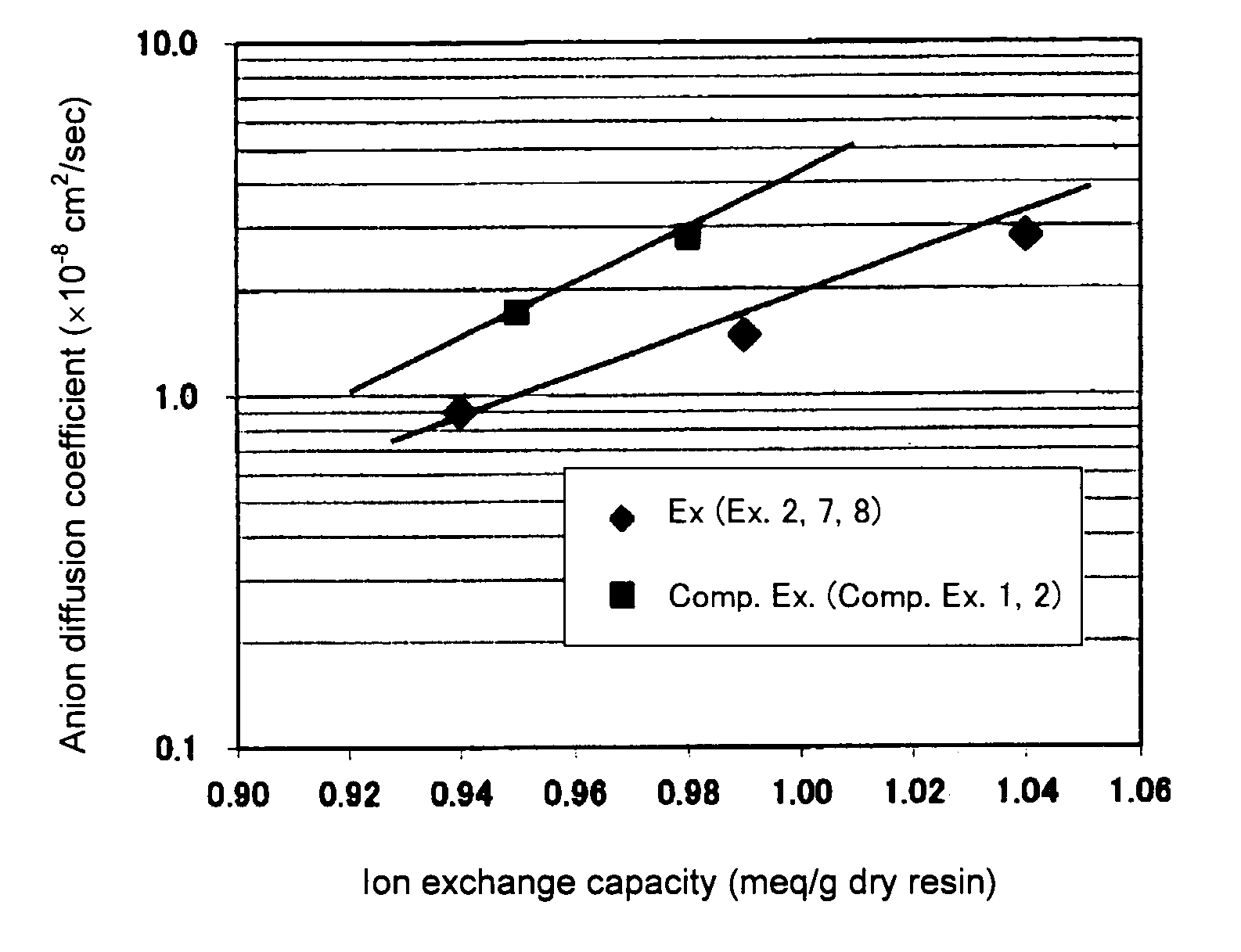

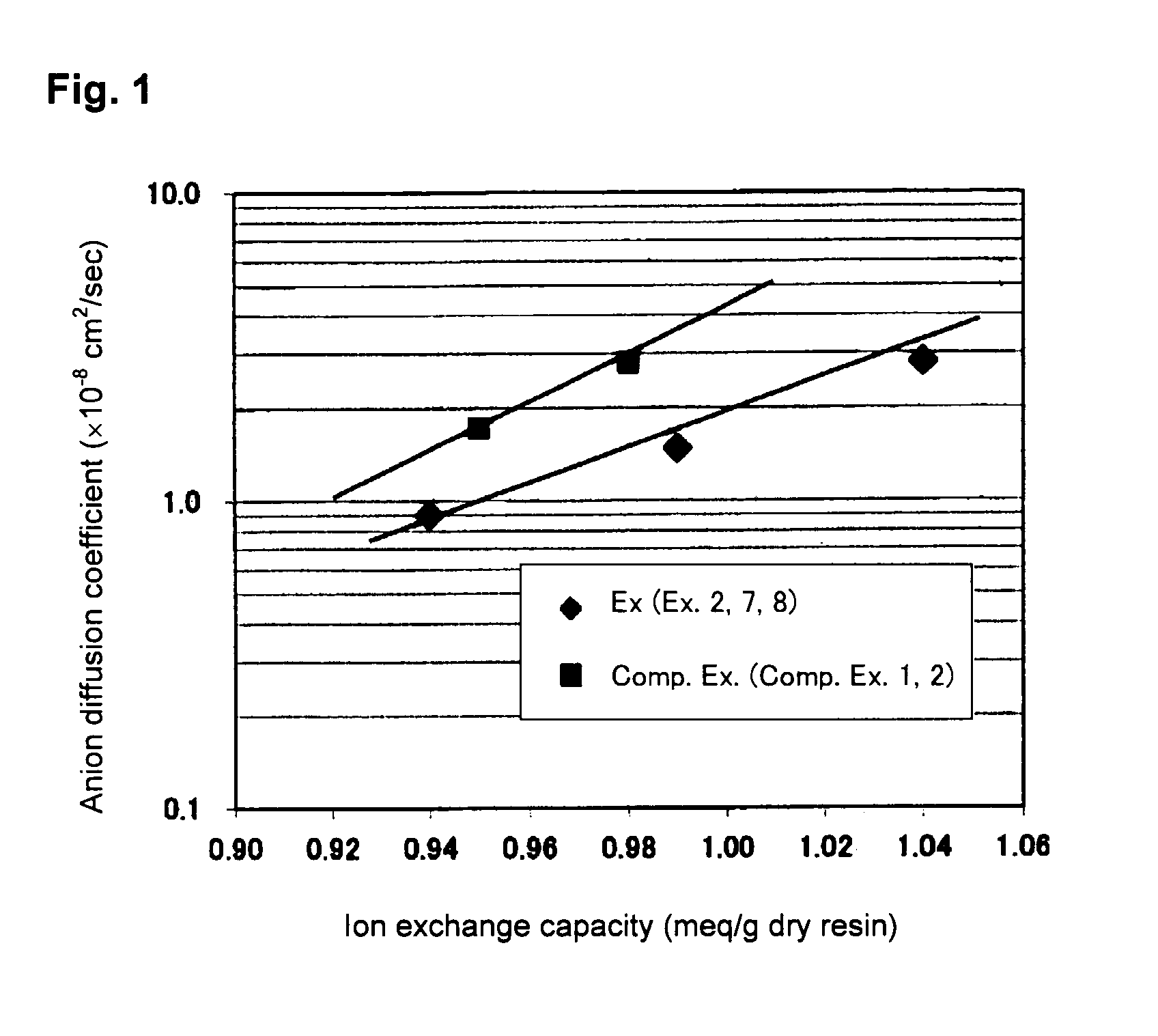

Process for producing fluoropolymer, and fluorinated ion exchange membrane

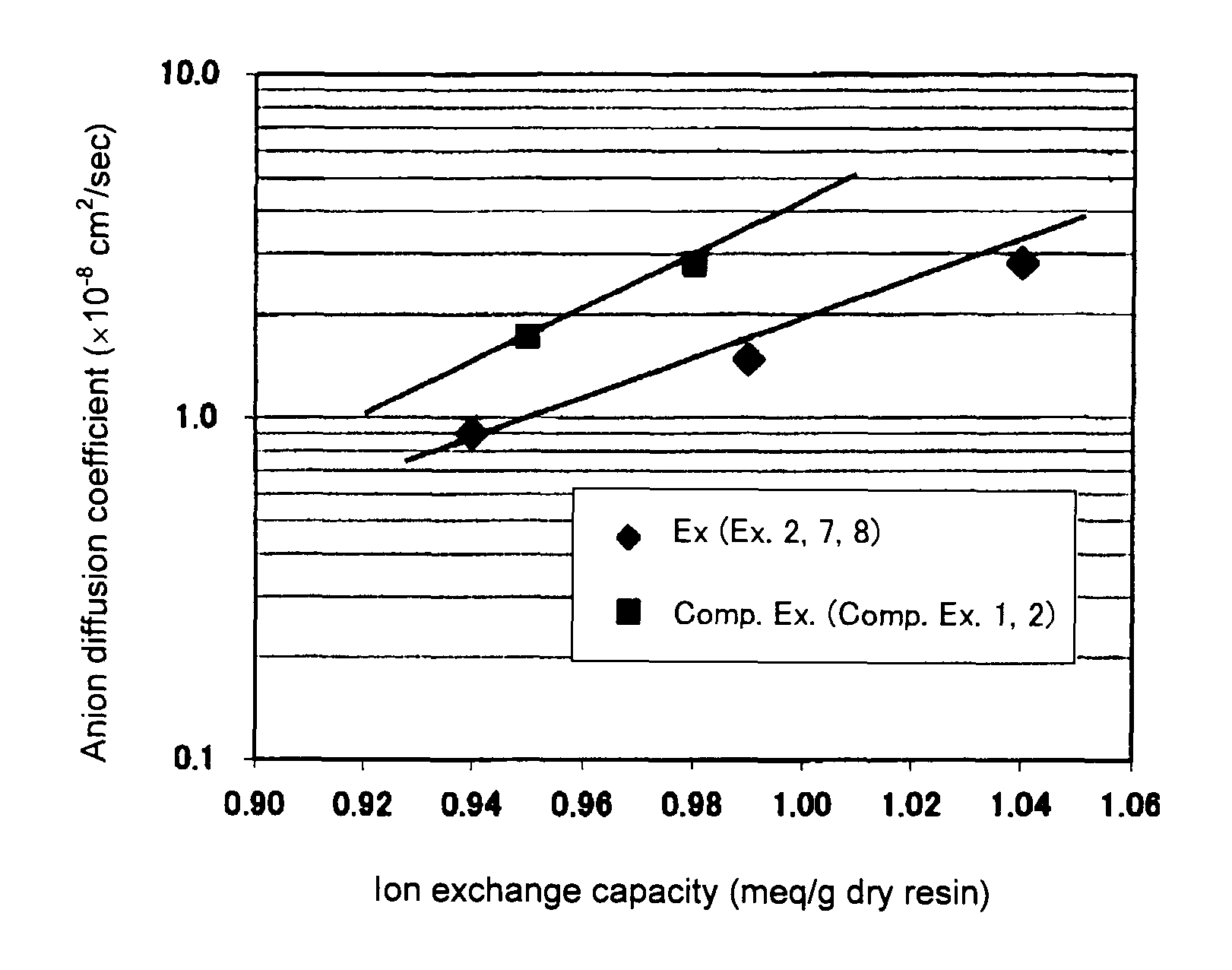

ActiveUS8377998B2Efficient and stable productionSmall ozone depletionCation exchanger materialsIon-exchanger regenerationPolymer scienceFluoropolymer

A polymerization medium having small ozone depletion potential and small global warming potential and having a small chain transfer constant is used, to efficiently produce a fluoropolymer having a high molecular weight and having excellent heat resistance, solvent resistance, chemical resistance, etc. A process for producing a fluoropolymer, which comprises polymerizing a fluoromonomer having a carboxylic acid type functional group and a fluoroolefin using a hydrofluorocarbon as a medium, wherein the hydrofluorocarbon as the medium has 4 to 10 carbon atoms and has a ratio (molar basis) of the number of hydrogen atoms / the number of fluorine atoms (H / F ratio) of from 0.05 to 20.

Owner:ASAHI GLASS CO LTD

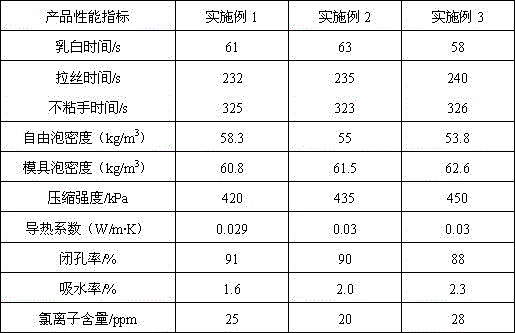

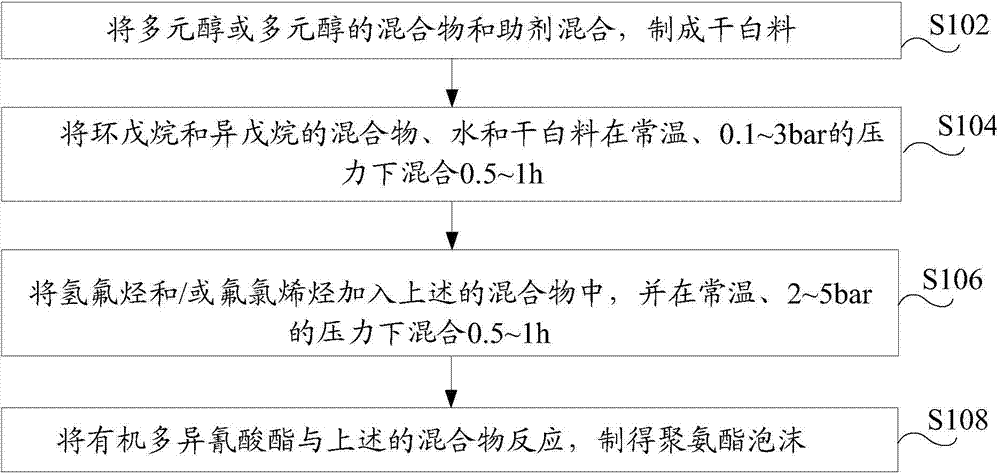

Foaming agent composition, polyurethane foam and manufacturing method thereof

The invention provides a foaming agent composition, a polyurethane foam and a manufacturing method thereof. The foaming agent composition comprises a cyclopentane-isopentane mixture, hydrofluorocarbon and / or fluorochloroalkene and water. The polyurethane foam prepared from the foaming agent composition has greatly lower molding density; and in the process of manufacturing equivalent polyurethane foam, the mass of the required foaming agent composition and other materials for manufacturing the polyurethane foam is reduced, thereby lowering the manufacturing cost of the polyurethane foam. Besides, the ODP (ozone depletion potential) of the foaming agent composition is zero, so the foaming agent composition is harmless to the ozone and is more environment-friendly. In addition, the polyurethane foam prepared from the foaming agent composition has the advantages of lower heat conductivity coefficient, favorable thermal-insulation property, favorable flowability, uniform density distribution, smooth surface, higher foam compression strength and higher dimensional stability, so that the performance of the polyurethane foam can be enhanced.

Owner:HEFEI HUALING CO LTD

Spraying polyurethane material of environment-friendly foaming agent and preparation method thereof.

InactiveCN107417886AWon't breakMeet future development needsPolyurea/polyurethane coatingsOzone layerFoaming agent

The invention belongs to the technical field of polyurethane and particularly relates to a spraying polyurethane material of an environment-friendly foaming agent and a preparation method thereof. The spraying polyurethane material has the characteristics that CFA-8125 is used as a foaming agent, the foaming agent is an environment-friendly foaming agent with ODP (Ozone Depletion potential) value of 0 and GWP (Global Warming Potential) value of 1, can not destroy the ozone layer, also can not cause serious greenhouse effect, conforms to the requirements of future development of products, and is an ideal substitute of HCFC-141b; and the foaming agent has no flashing points, and when the foaming agent participates in production of component A, the equipment does not need to be transformed. The spraying polyurethane material and the preparation method have the beneficial effects that flame-retardant elements and flame-retardant structures are introduced into molecular chains to form structural flame retardance, reach corresponding flame-retardance level and maintain persistence of flame retardance. Simultaneously, by induction of a catalyst, excessive isocyanate generates a PIR (Polyisocyanurate) structure, and the PIR structure and high-functionality polyether generate high cross-linking degree, so that good size stability at high and low temperature is realized.

Owner:烟台市顺达聚氨酯有限责任公司

Organic Rankine cycle mixed working medium

InactiveCN103937458ANon-flammableLow ODPHeat-exchange elementsOrganic Rankine cycle1,3,3,3-Tetrafluoropropene

The invention discloses an organic Rankine cycle mixed working medium. The organic Rankine cycle mixed working medium comprises the following components by mass percentage: 70-98% of trans-1-chloro-3, 3, 3-trifluoropropene and 2-30% of second component, wherein the second component is one or two of 2, 3, 3, 3-tetrafluoropropene and trans-1, 3, 3, 3-tetrafluoropropene. The mixed working medium disclosed by the invention is incombustible, the ODP (ozone depletion potential) is close to zero, and the GWP (global warming potential) is very low, so that the mixed working medium is in line with environment-friendly requirements; and thermal parameters are appropriate and the cycle performance is excellent. Under the corresponding working conditions, the cycle efficiency is 8.7-10.9%, and the net power output per unit mass is 13.6-26.0kJ / kg.

Owner:XI AN JIAOTONG UNIV +1

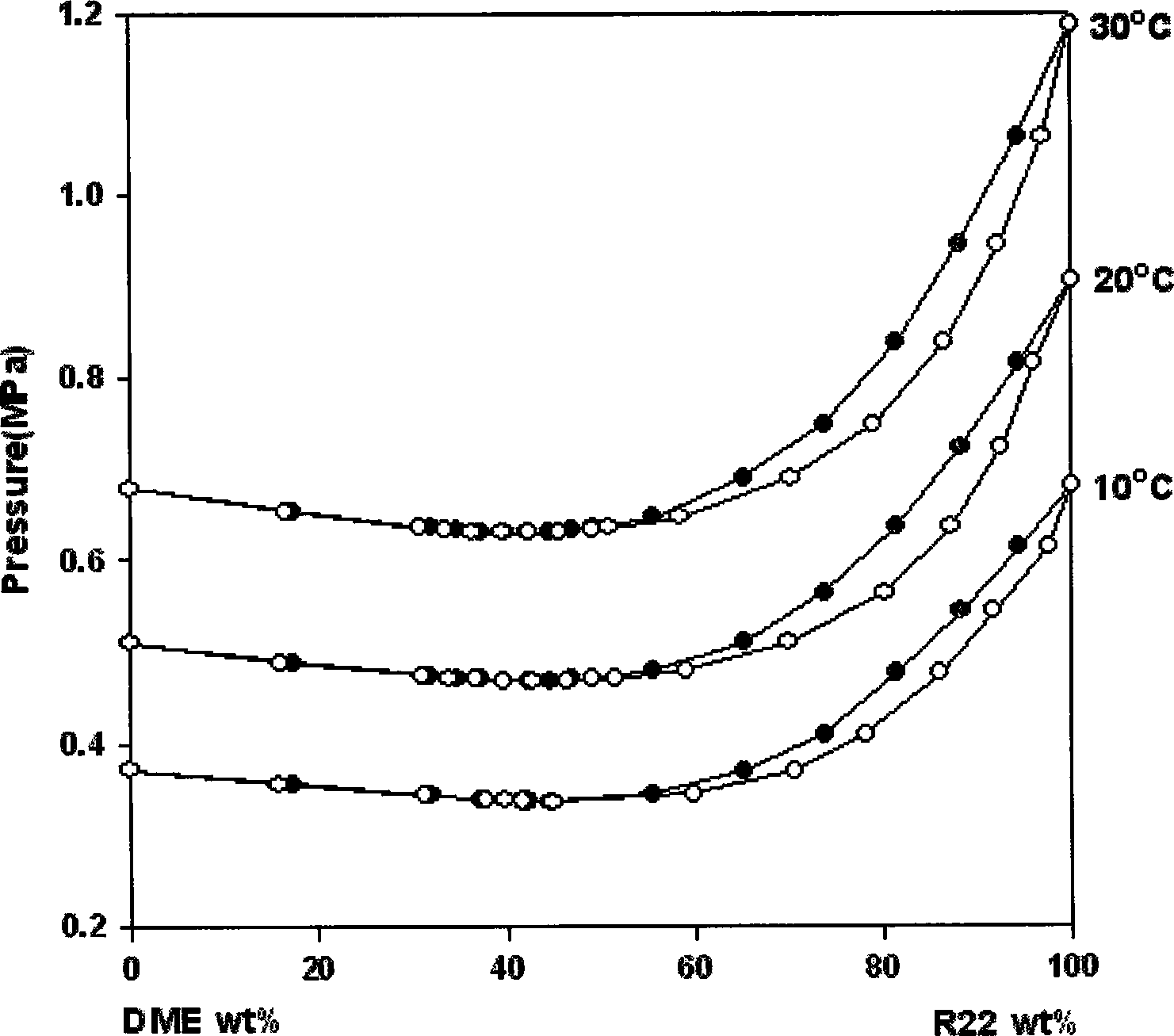

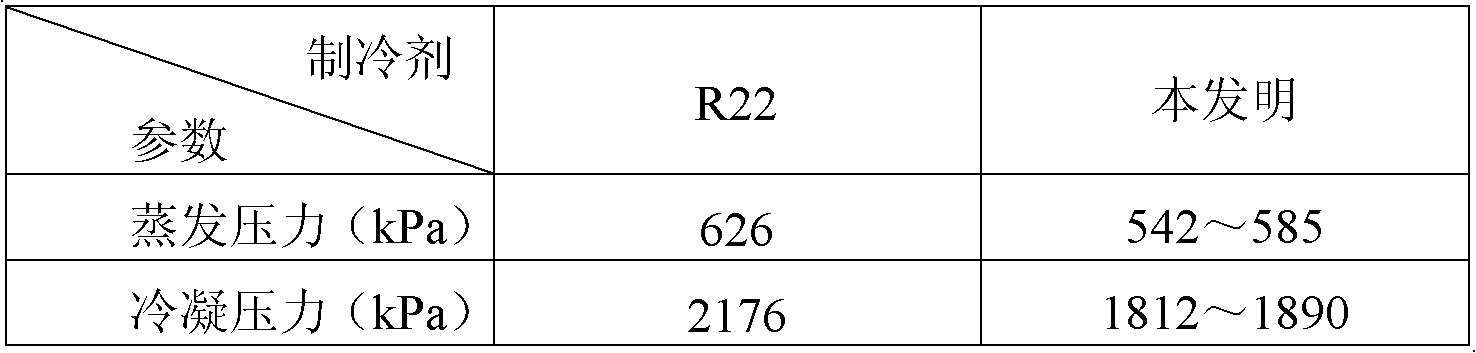

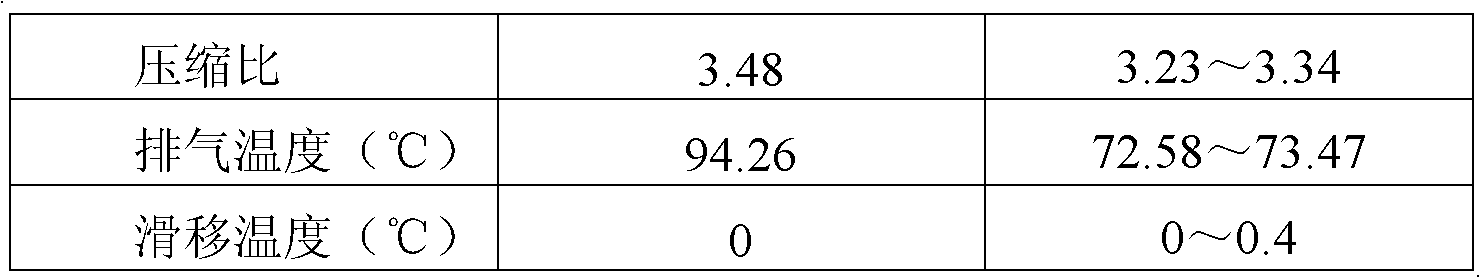

Composition with low global warming potential (GWP) value

InactiveCN102241962AReduce chargeMeet load demandChemical industryHeat-exchange elementsOzone depletion potentialEngineering

The invention provides a low global warming potential (GWP) refrigerant composition, which is directly filled to replace R22 in systems such as a household air conditioning / heat pump and the like. The refrigerant consists of propane and 2,3,3,3-tetrafluoropropene, and a preparation method comprises a step of physically mixing various components in a liquid phase in corresponding proportions. The ozone depletion potential (ODP) value of the refrigerant composition is zero, the GWP value is very low, and the refrigerant composition completely meets the environment-friendly requirement of replacing R22 abroad and at home at present, and represents the development direction of an environmental performance index of next refrigerant substitutes; the pressure of the refrigerant composition is close to that of the R22 and slightly lower than that of the R22, the compression ratio is smaller than that of the R22, and the discharge temperature is greatly superior to that of the R22, which are favorable for long-term operation of a compressor; the COP is slightly higher than that of the R22, and a certain energy-saving effect is achieved; he refrigerating capacity in unit mass is superior to that of the R22, and the refrigerant filling amount of a system can be reduced correspondingly; the refrigerating capacity in unit volume is equal to that of the R22, and the load requirement of a refrigeration air conditioning after the refrigerant composition replaces the R22 can be met; the equipment and parts of the conventional R22 refrigeration air conditioning are not needed to be changed; and the refrigerant composition is soluble with mineral oil, so the refrigerant composition can be directly filled.

Owner:SHANDONG DONGYUE CHEM

Process for producing fluoropolymers

There is provided the process for effectively preparing the fluorine-containing polymer without using CFC and HCFC which have a high polymerization rate and a high ozone depletion potential and a coating film having excellent mechanical properties, solvent resistance and chemical resistance can be formed using the obtained fluorine-containing polymer. In preparing the fluorine-containing polymer by polymerizing a monomer containing a fluoroolefin in a polymerization medium, the fluorine-containing solvent having an ozone depletion potential of 0 and a solubility of hydroxybutyl vinyl ether of not less than 0.5% is used as the polymerization medium.

Owner:DAIKIN IND LTD

Multi-element mixed refrigerant

ActiveCN109971433AWill not harmCause damageHeat-exchange elementsOzone depletion potentialBoiling point

The invention provides a multi-element mixed refrigerant which comprises 3,3,3-trifluoropropene and propane. The molar percentage concentration of 3,3,3-trifluoropropene is 5-85%, and the molar percentage concentration of propane is 15-95%. The multi-element mixed refrigerant is suitable for a stand-alone compressing and refrigerating system, has the ozone depletion potential (ODP) of zero, and cannot harm the atmospheric ozone layer and has quite small global warming potential (GWP) after being used for a long time. In addition, since the multi-element mixed refrigerant comprises 3,3,3-trifluoropropene and propane, for a two-element mixture, azeotropic refrigerating working substances can keep the stable evaporating working state under the boiling point, and convenience is provided for the injection of the refrigerant and the maintenance of the refrigerating system. In addition, the multi-element mixed refrigerant has a small pressure ratio, and the efficiency of a compressor can be effectively improved by reducing the pressure ratio.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Polymer foam with low bromine content

Prepare extruded polymer foam comprising at least 50 weight-percent alkenyl aromatic polymer, a brominated flame retardant providing 0.8 to 1.4 weight percent bromide, 0.05 to 0.5 weight-percent hydrobromic acid scavenger, at least 1.5 weight-percent graphite and less than 0.1 weight-percent C—C and O—O labile organic compounds using a blowing agent composition comprising at least 0.3 weight-parts per 100 weight parts polymer and that consists of blowing agents having an ozone depletion potential of zero and a global warming potential that is less than 1000.

Owner:DOW GLOBAL TECH LLC

Process for producing fluoropolymer, and fluorinated ion exchange membrane

ActiveUS20110015283A1Efficient and stable productionIncrease polymerization rateCation exchanger materialsIon-exchanger regenerationPolymer scienceCarboxylic acid

A polymerization medium having small ozone depletion potential and small global warming potential and having a small chain transfer constant is used, to efficiently produce a fluoropolymer having a high molecular weight and having excellent heat resistance, solvent resistance, chemical resistance, etc.A process for producing a fluoropolymer, which comprises polymerizing a fluoromonomer having a carboxylic acid type functional group and a fluoroolefin using a hydrofluorocarbon as a medium, wherein the hydrofluorocarbon as the medium has 4 to 10 carbon atoms and has a ratio (molar basis) of the number of hydrogen atoms / the number of fluorine atoms (H / F ratio) of from 0.05 to 20.

Owner:ASAHI GLASS CO LTD

Non-flash point industrial cleaning agent

ActiveCN101302461AEasy to cleanImprove solubilityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsOzone depletion potentialCleansing Agents

The invention discloses no-flash-point industrial detergent. The compositions by weight percentage of the no-flash-point industrial detergent are: 15 to 45 percent of 3-methoxyl butyl alcohols, 15 to 52 percent of N-methyl pyrrolidone, 16 to 28 percent of 2-methyl pentanediol and 12 to 28 percent of active solvent. The no-flash-point industrial detergent has the advantages of safety and environmental protection, no corrosion, strong decontaminating and dissolving capacity, good stability, ozone depletion potential ODP and GWP being zero, etc.

Owner:广东新球清洗科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com