Turbo chiller

a chiller and rotating shaft technology, applied in the field of rotating shaft chillers, can solve the problems of unavoidable maintenance such as changing the lubricating oil and the oil filter, and achieve the effects of reducing the loss of rolling bearing bearings, reducing power loss, and increasing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

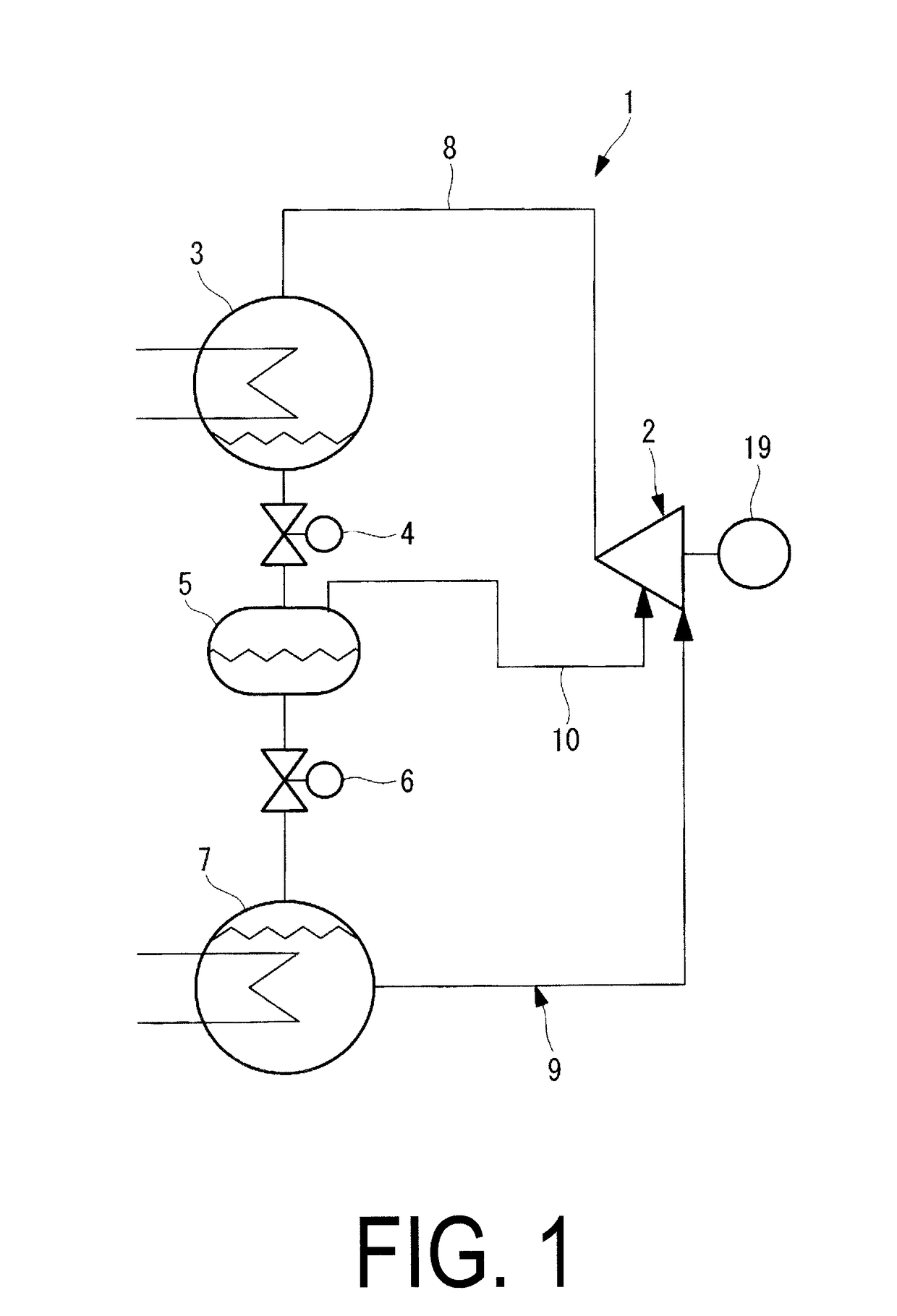

[0026]A first embodiment of the present invention will be described below, using FIGS. 1 and 2.

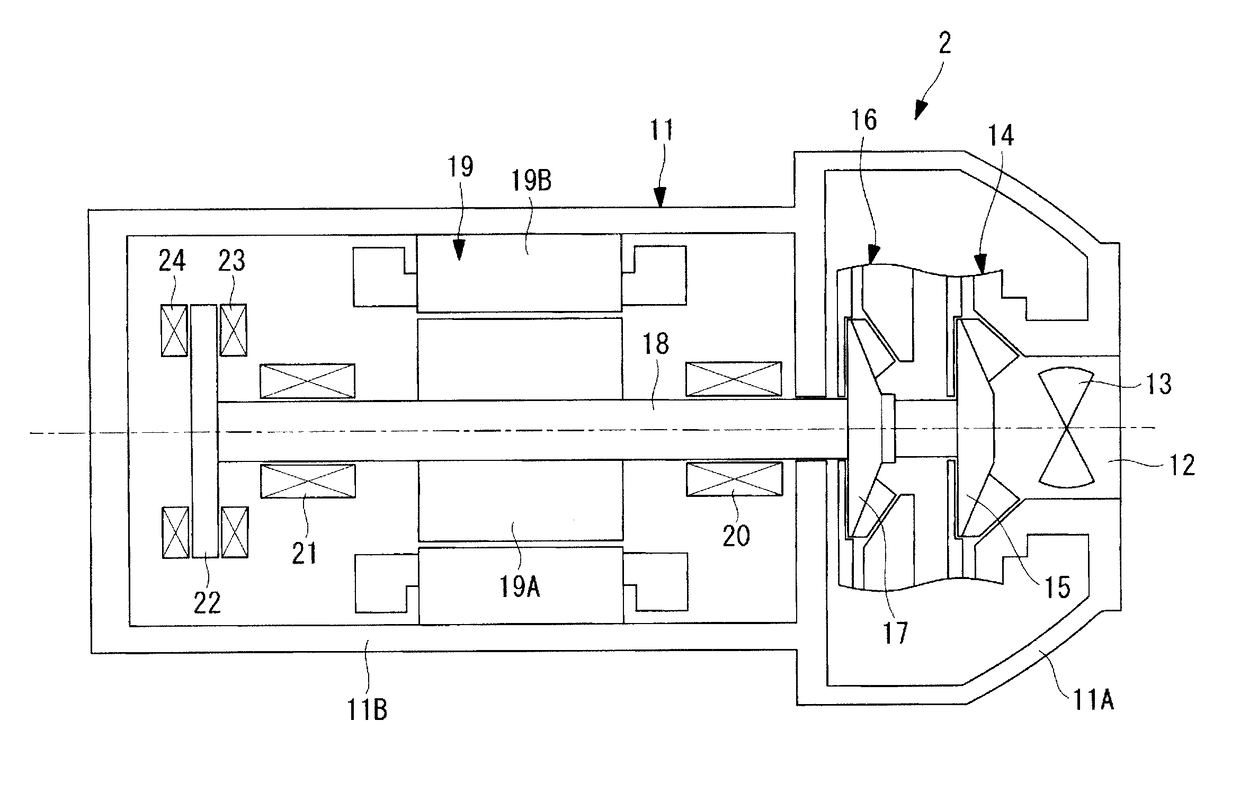

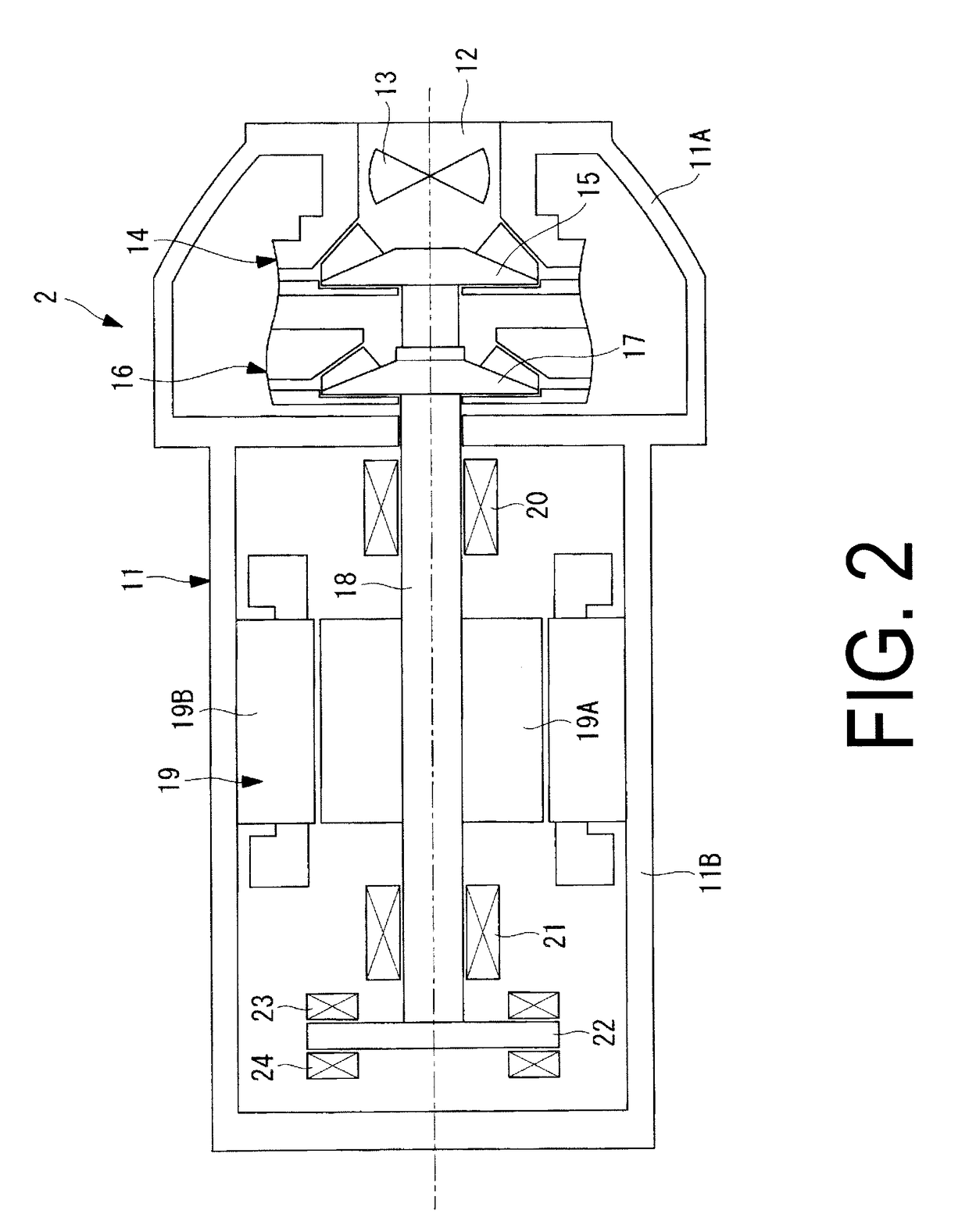

[0027]FIG. 1 illustrates a configuration diagram of a turbo chiller according to the first embodiment. FIG. 2 illustrates a schematic configuration diagram of a turbo compressor applied to the turbo chiller.

[0028]The turbo chiller 1, as illustrated in FIG. 1, is provided with a closed refrigeration cycle 9 in which a turbo compressor 2, a condenser 3, a first decompression device 4, a gas-liquid separator 5 that functions as an economizer, a second decompression device 6, and an evaporator 7 are connected in sequence via a refrigerant pipe (piping) 8.

[0029]The refrigeration cycle 9 of the present embodiment is further provided with a known economizer circuit 10 configured to inject the gas refrigerant separated at the gas-liquid separator 5 into the intermediate pressure refrigerant compressed at a lower stage compression portion 14 of the turbo compressor 2 via an intermediate port. The e...

second embodiment

[0045]Next, a second embodiment of the present invention will be described using FIGS. 3 and 4.

[0046]The present embodiment is different from the first embodiment in that the rotating shaft 18 is supported in a manner allowing free rotation by oil-free ceramic bearings 25, 26. Other points are similar to the first embodiment, so their descriptions are omitted here.

[0047]In the present embodiment, the rotating shaft 18 is supported in a manner allowing for free rotation by the oil-free ceramic slide bearings or rolling bearings 25, 26 (hereinafter, in the present invention, referred to as ceramic bearings) as illustrated in FIG. 3, instead of the radial magnetic bearings 20, 21 and the thrust magnetic bearings 23, 24.

[0048]The ceramic bearings 25, 26 are made from silicon nitride, have high durability, and a long lifetime despite being oil-free. In the present embodiment, the ceramic bearings 25, 26 can be cooled and lubricated by liquid refrigerant extracted from the refrigeration c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com