Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Motion barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The limit to motion; in defining barriers, the palpatory end-feel characteristics are useful.

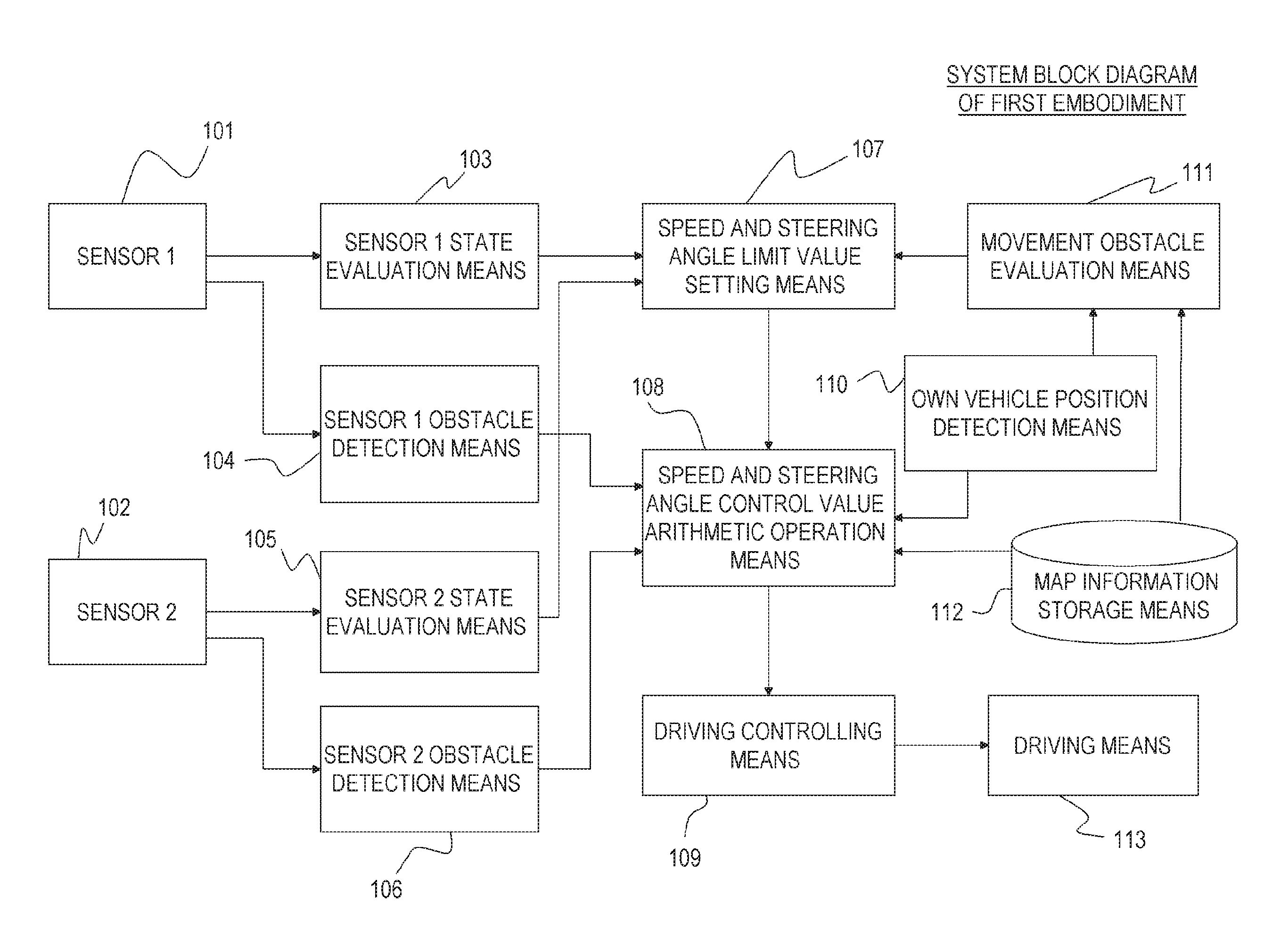

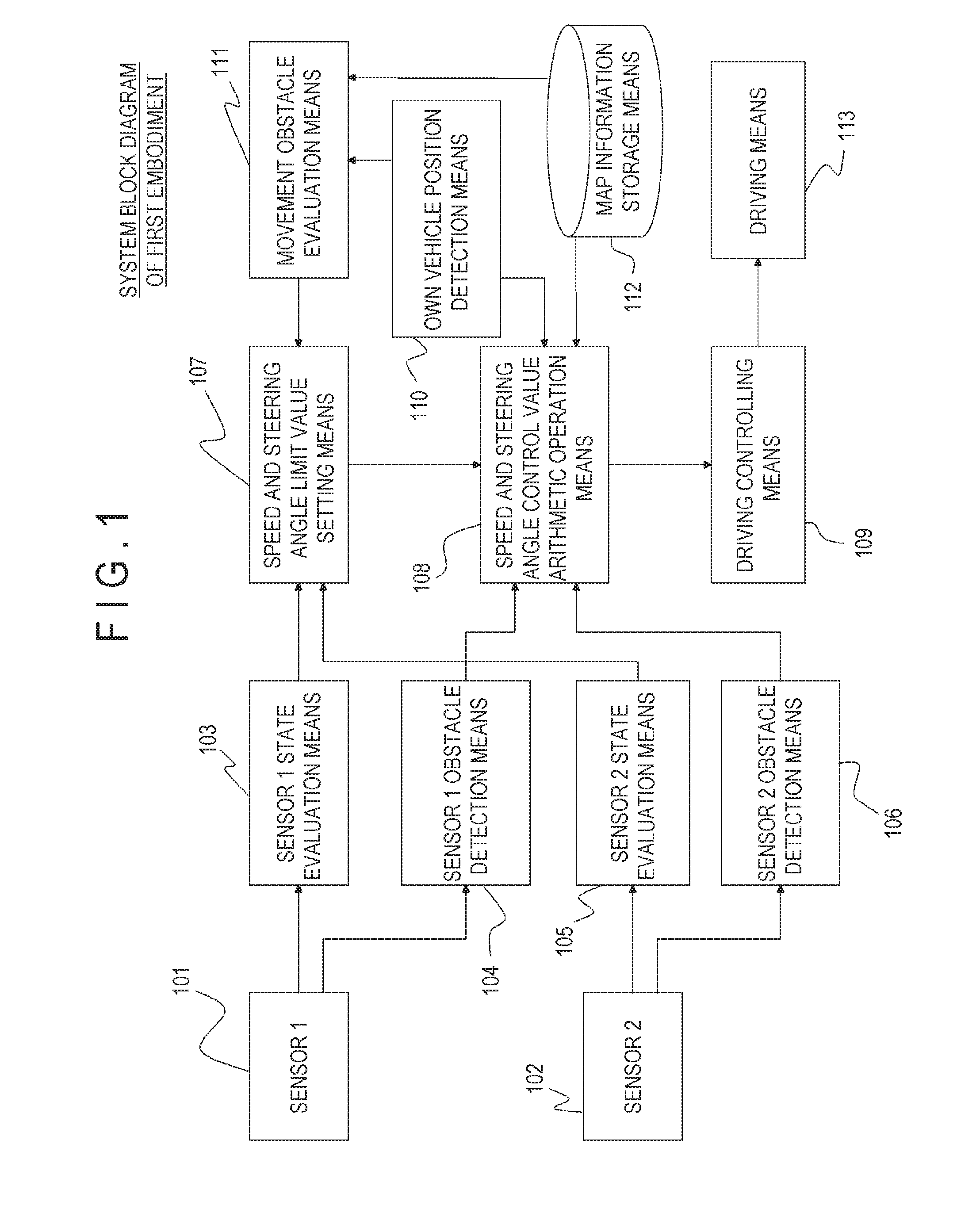

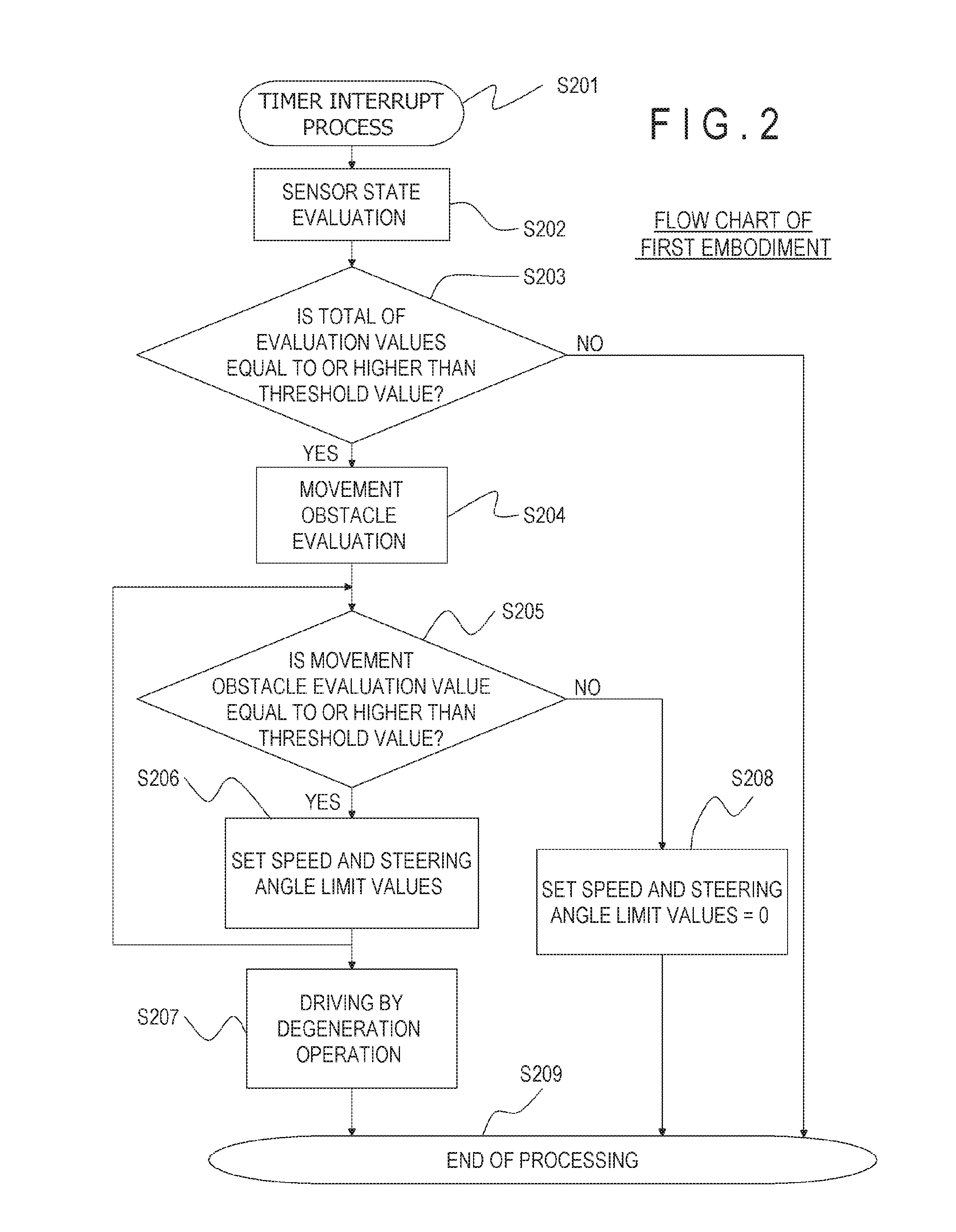

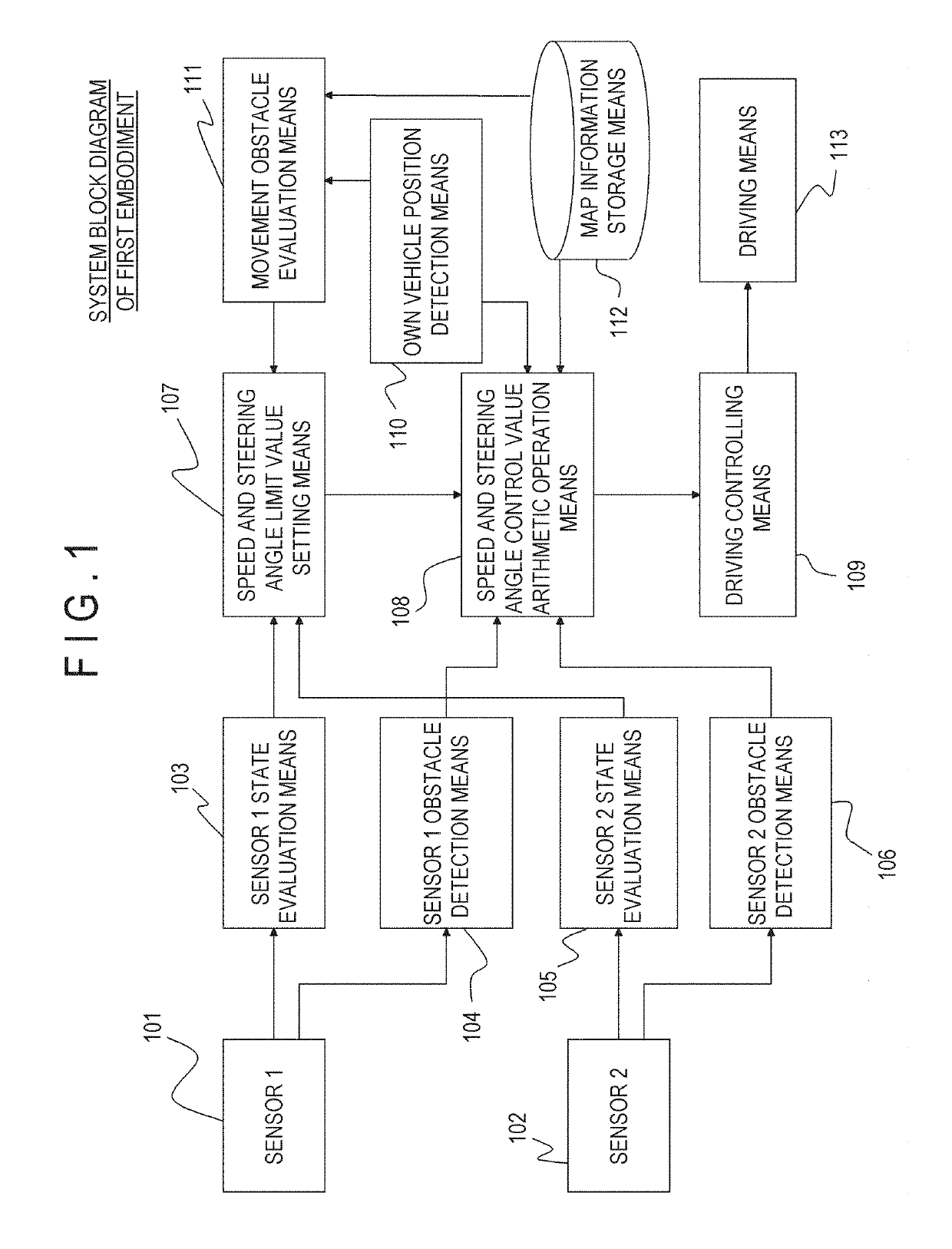

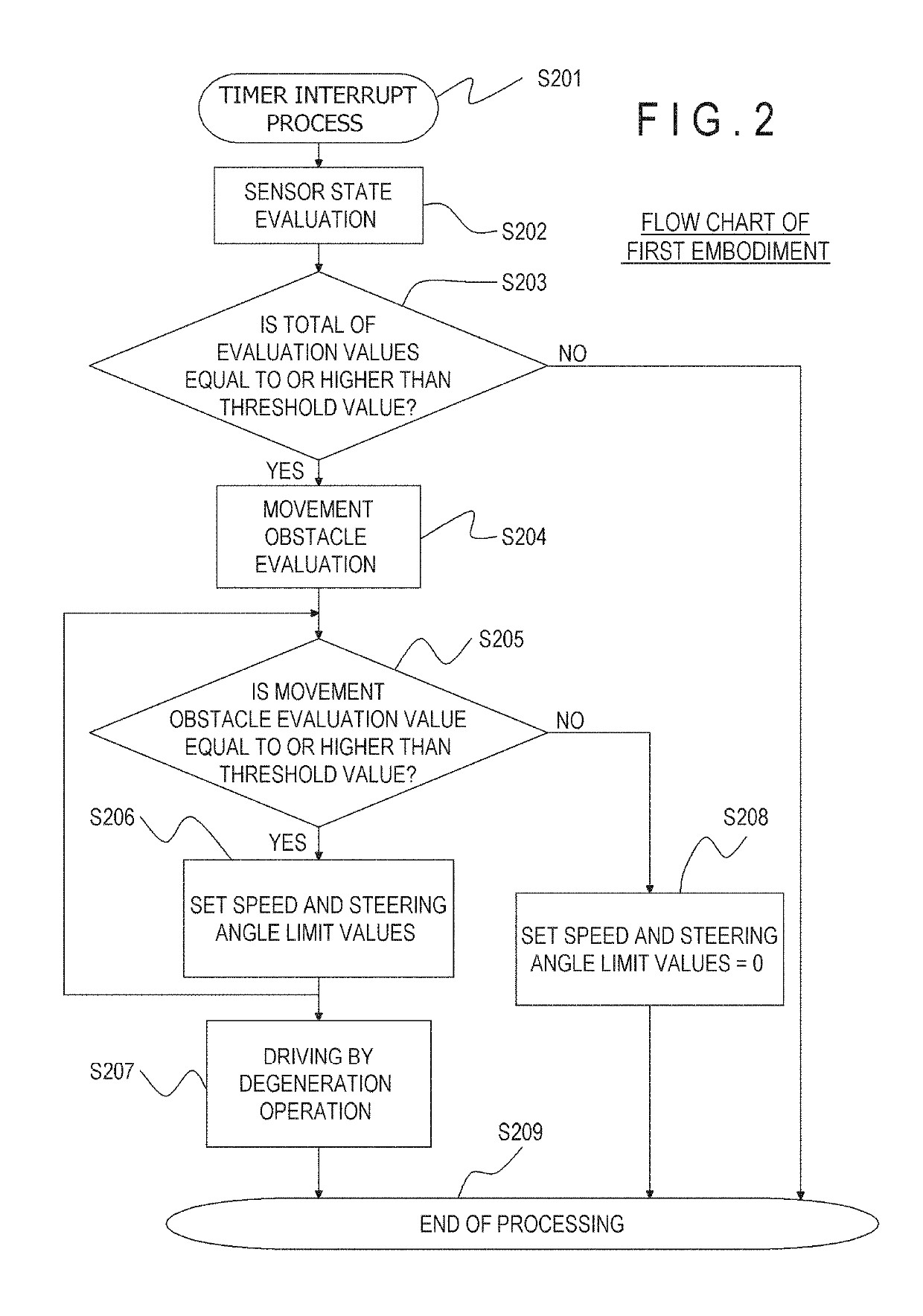

Autonomous Driving Vehicle and Autonomous Driving System

ActiveUS20160282874A1Improve securityAvoid stopAutonomous decision making processElectromagnetic wave reradiationSteering angleMotion barrier

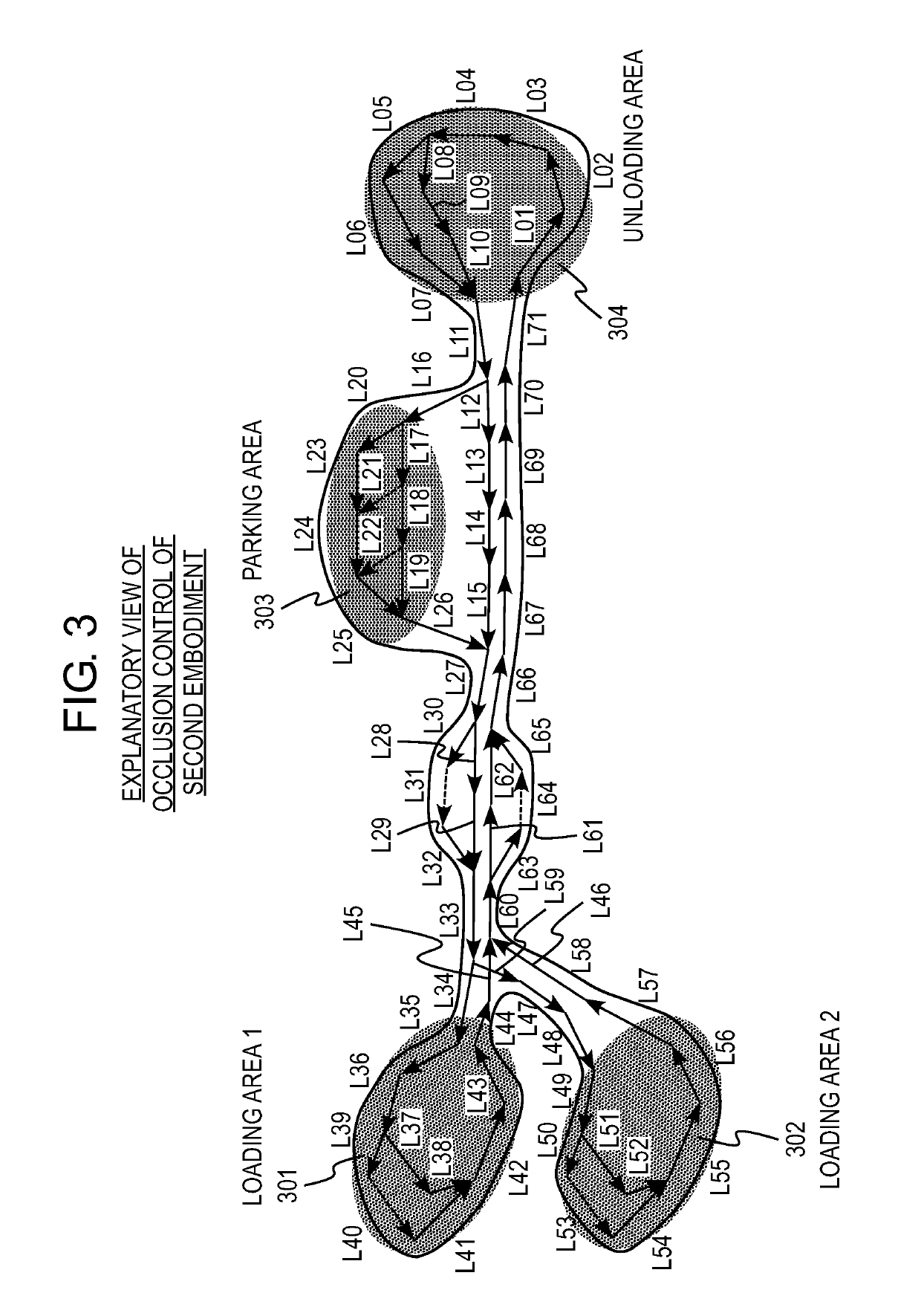

In an autonomous driving system in which a plurality of autonomous driving vehicles drive under the control by occlusion control, such a situation is prevented that a vehicle is disabled to drive by a failure of an external world sensor for recognizing an obstacle and stops in an occlusion region thereby to obstruct advancement of overall succeeding vehicles to remarkably degrade the efficiency of the overall transportation work. In the autonomous driving system of the present invention, an autonomous driving vehicle which detects an obstacle or a driving road by a sensor and performs autonomous driving includes sensor state evaluation means configured to evaluate a state of performance degradation of the sensor, speed and steering angle control value setting means configured to provide limit values to the driving speed and the steering angle based on a state of performance degradation of the sensor, and movement obstacle evaluation means configured to evaluate an influence on movement of other vehicles when the vehicle stops at a position at present. When the sensor suffers from performance degradation, the vehicle stops after it drives within the set limit values to the speed and the steering angle to a point at which the vehicle does not obstruct movement of other vehicles.

Owner:HITACHI LTD

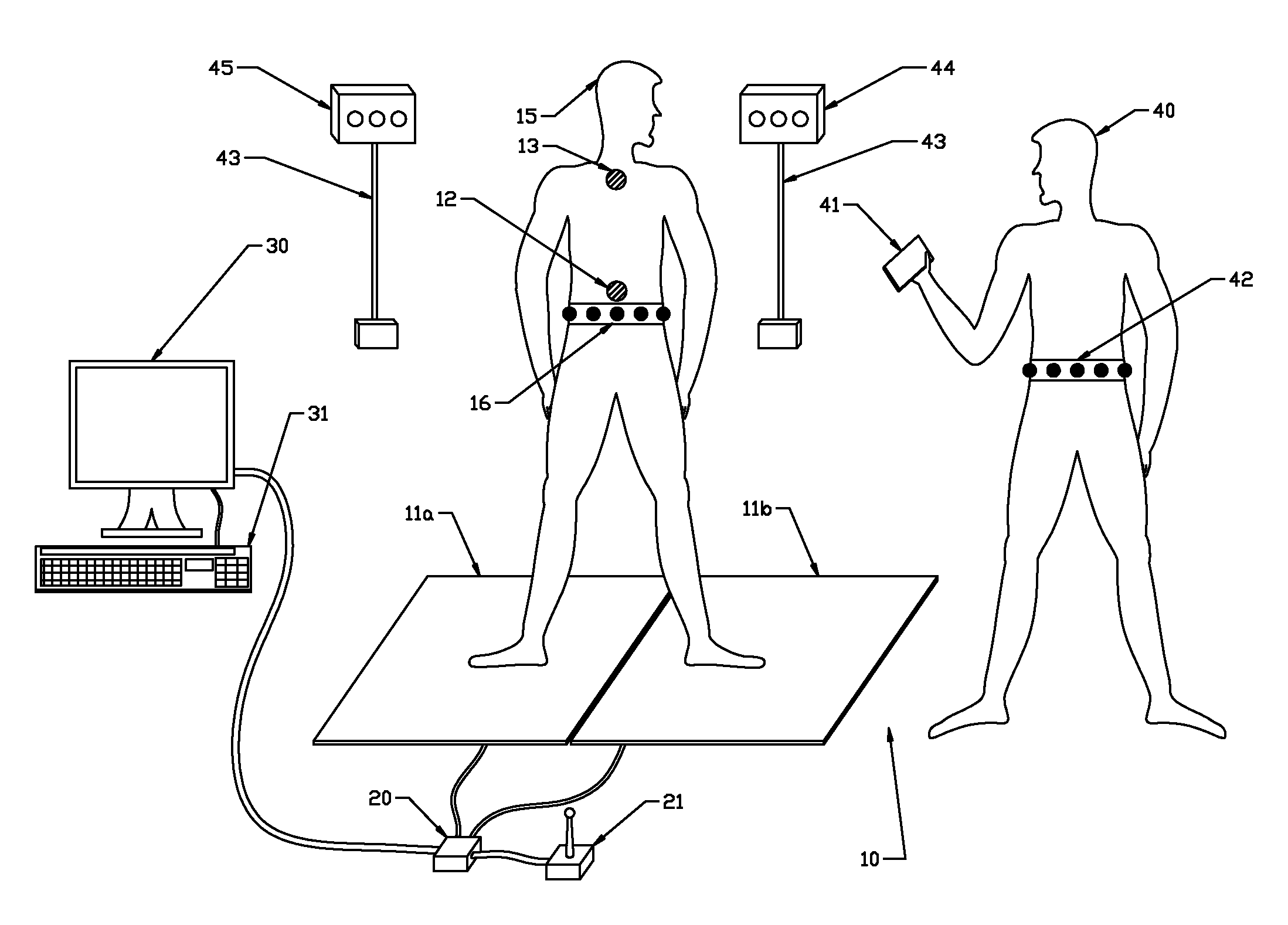

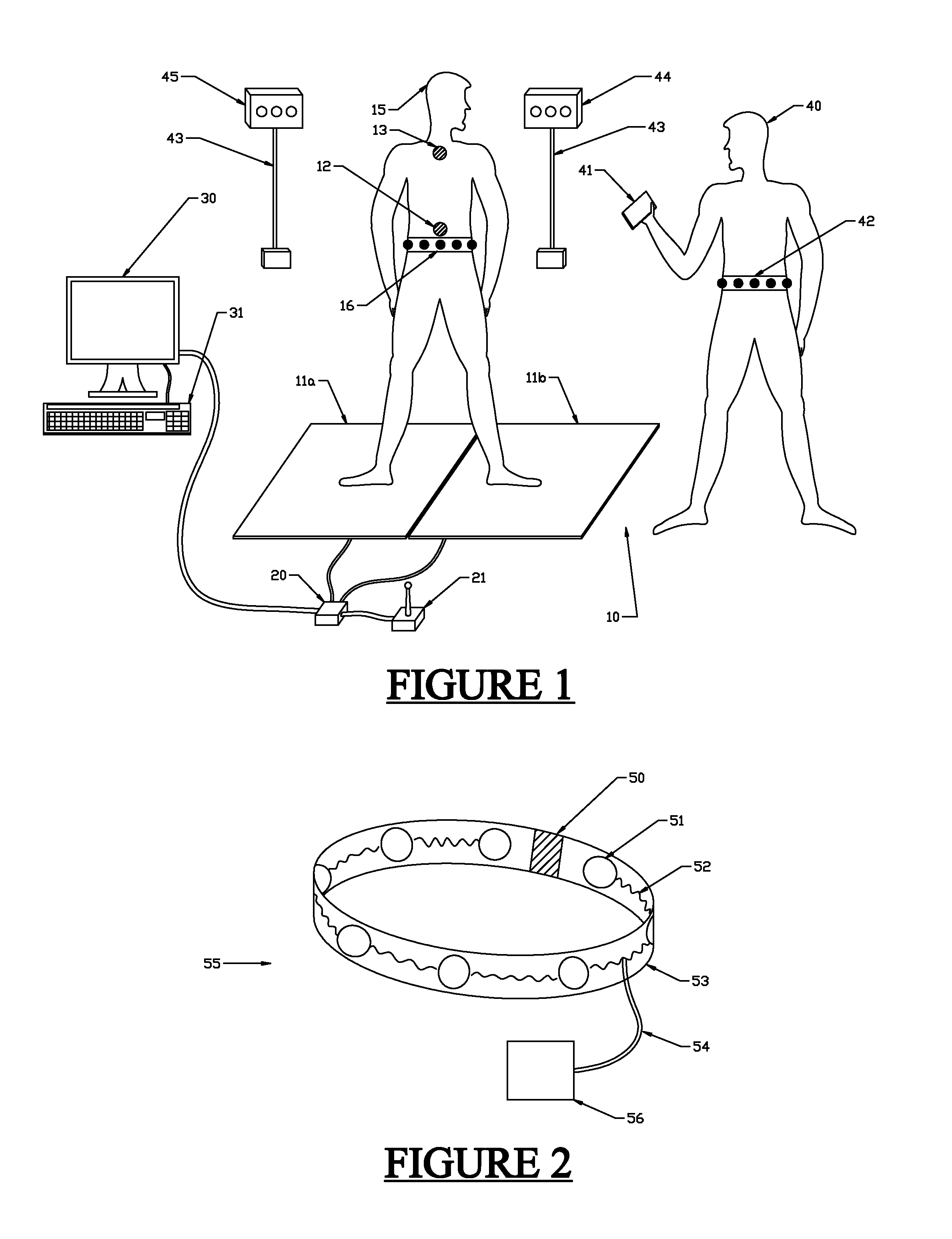

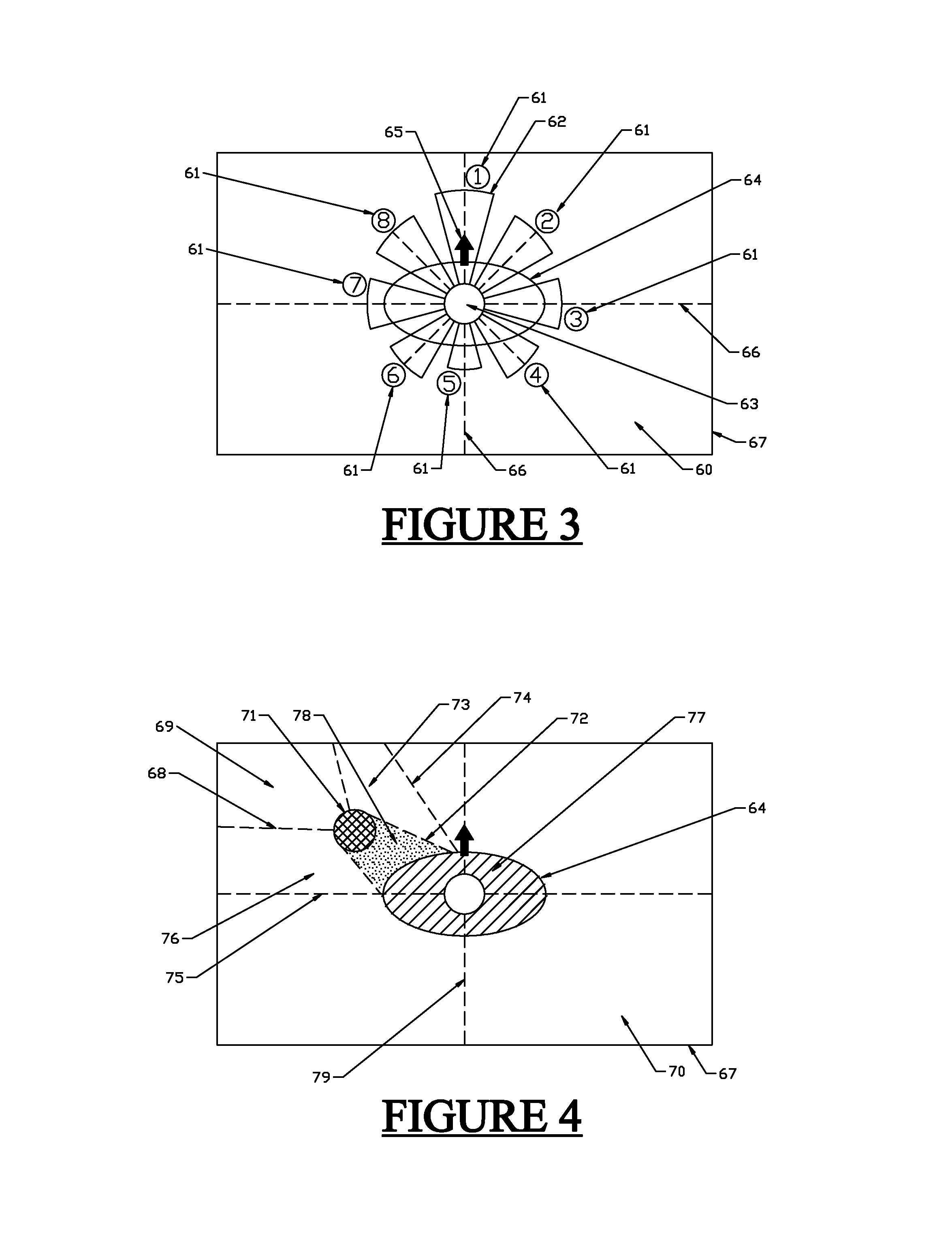

Enhanced system and method for assessment of disequilibrium, balance and motion disorders

A system and method for providing therapy and assessment utilizing vibrotactile feedback is disclosed. Such treatment is useful for the assessment and treatment of disequilibrium, movement and balance disorders. The system and method measures a subject's performance of predetermined tasks with respect to expected parameters using sensors such as force plates, inertial sensors, and three dimensional cameras. Predetermined motions are motions such as stand, sit-to-stand, reach, bend, functional gait, functional gait plus headshake, and other functional tasks. Vibrotactile stimulation may be applied during the subject's performance as disruptive input. Variance and rate of change of variance between measured and expected parameters is used as a tool for assessment of said subject, and is also used for providing real-time vibrotactile training to said subject. The invention is useful in the treatment of Traumatic Brain Injury (TBI), neurologic disorders causing disequilibrium and balance disorders, and the like.

Owner:ENG ACOUSTICS

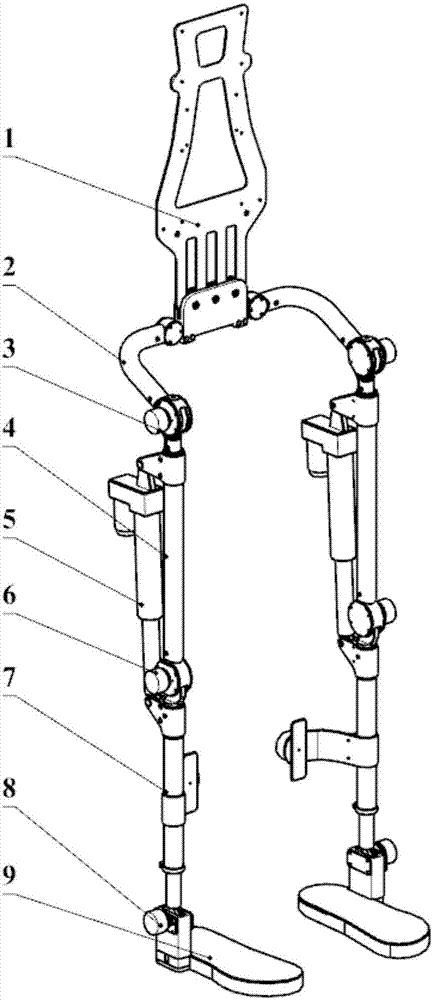

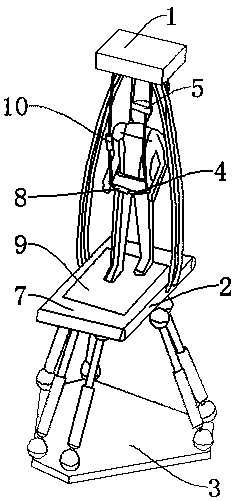

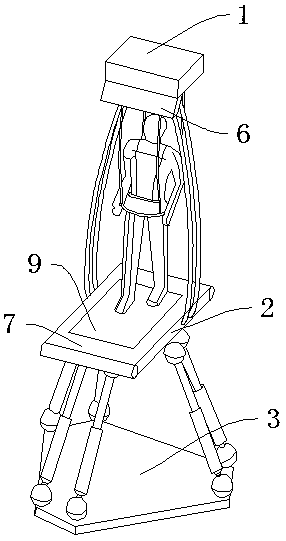

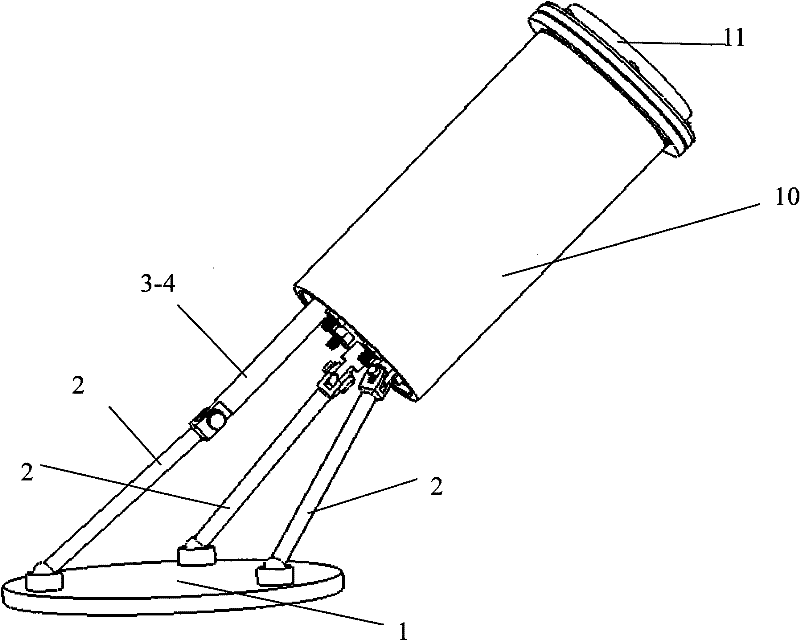

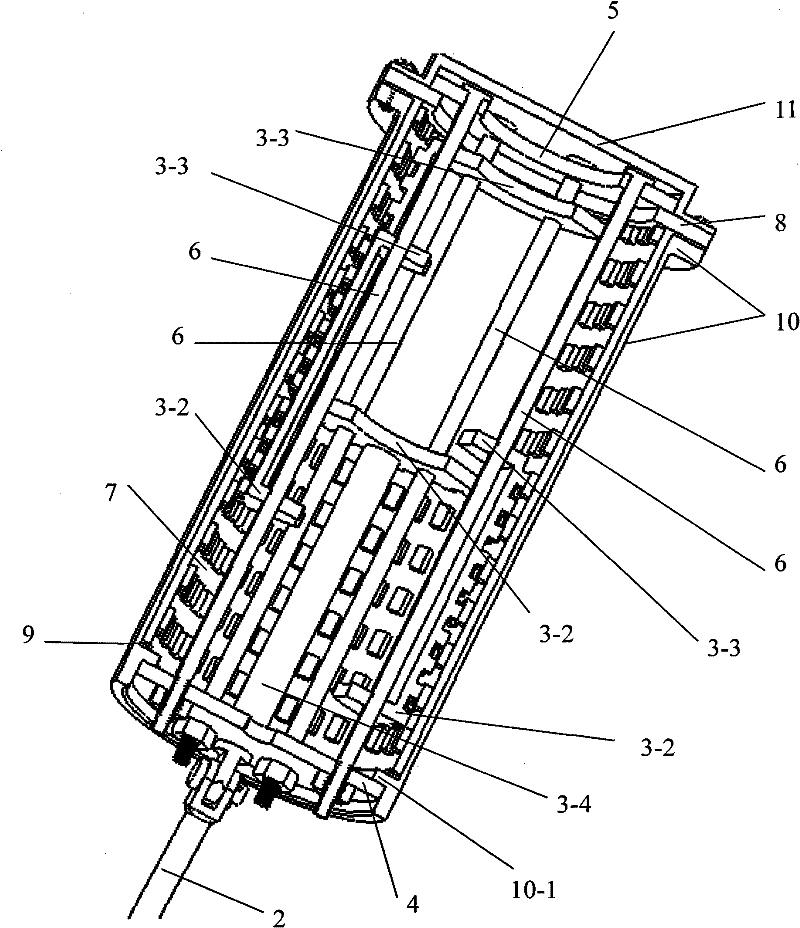

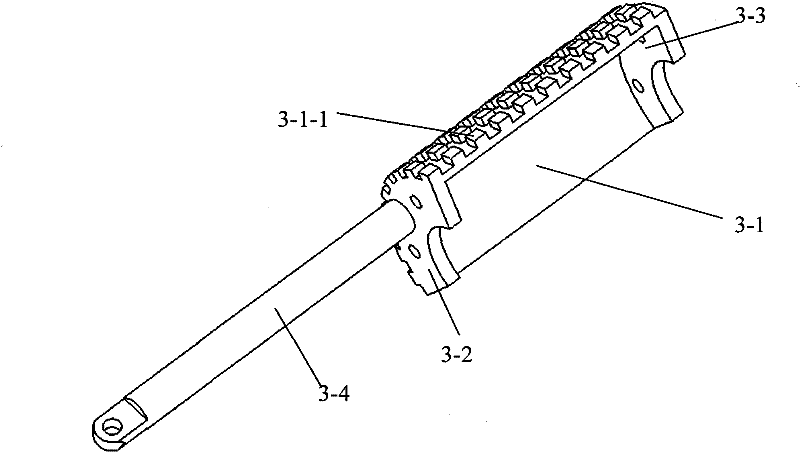

Tubular and modular wearable exoskeleton assisting device and control method thereof

PendingCN107320292ASimple structureCompact structureProgramme-controlled manipulatorChiropractic devicesKnee JointEngineering

The invention discloses a tubular and modular wearable exoskeleton assisting device and a control method thereof. The tubular and modular wearable exoskeleton assisting device comprises a back plate, a length-adjustable tubular thigh mechanism, a length-adjustable tubular shank mechanism, a width-adjustable tubular waist mechanism, ankle joints, a foot mechanism, hip joints and knee joints, wherein the hip joints and the knee joints are modularly adjustable in parts; the tubular and modular wearable exoskeleton assisting device has 14 degrees of freedom, 7 on each side and accordingly can simulate various motions of human lower limbs. The control method comprises collecting man-machine interaction information of a wearer and the device through sensors of the tubular shank mechanism and the foot mechanism, and taking joint encoder information as feedback to control an executor to drive the tubular and modular wearable exoskeleton assisting device to move. The tubular and modular wearable exoskeleton assisting device is simple in structure, modularized in replacement of parts and easy to control, and meanwhile, can be applied to enhancing loading capacity and assisting walking for a wearer and performing walking assistance and rehabilitation training on patients suffering from lower limb motor disturbance or myasthenia.

Owner:NANJING UNIV OF SCI & TECH

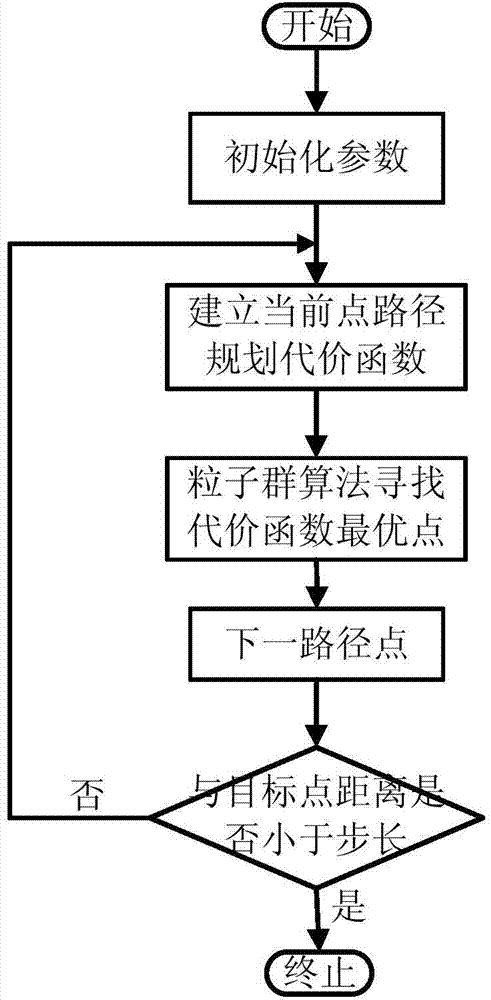

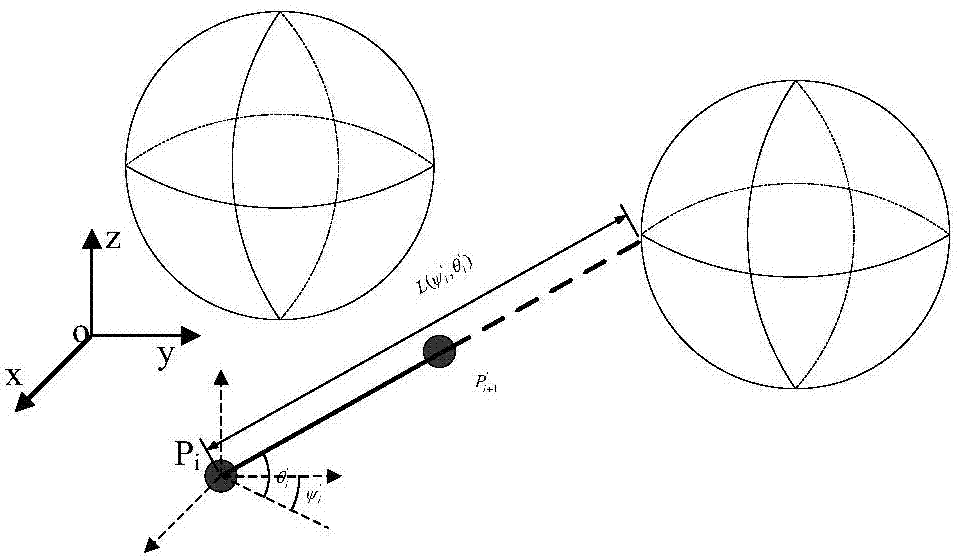

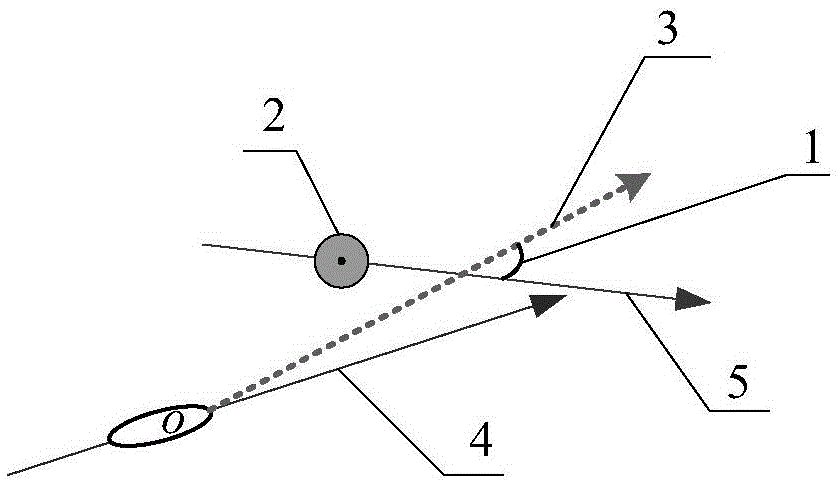

UUV three-dimension sea route planning method in moving obstacle environment

ActiveCN103777639AAvoid obstaclesRoute Planning OptimizationPosition/course control in three dimensionsPlanning approachObstacle avoidance

The invention relates to a UUV three-dimension sea route planning method in a moving obstacle environment. The method is characterized by comprising the following steps: step 1, establishing a UUV three-dimension obstacle avoidance cost function by calculating the time when a UUV encounters a fixed obstacle and a moving obstacle; step 2, establishing a UUV three-dimension target-approaching cost function by calculating the angle relation between the heading direction of the UUV and the target direction; and step 3, establishing a UUV three-dimension sea route planning cost function by combining the UUV three-dimension obstacle avoidance cost function and the UUV three-dimension target-approaching cost function.

Owner:哈尔滨船海智能装备科技有限公司

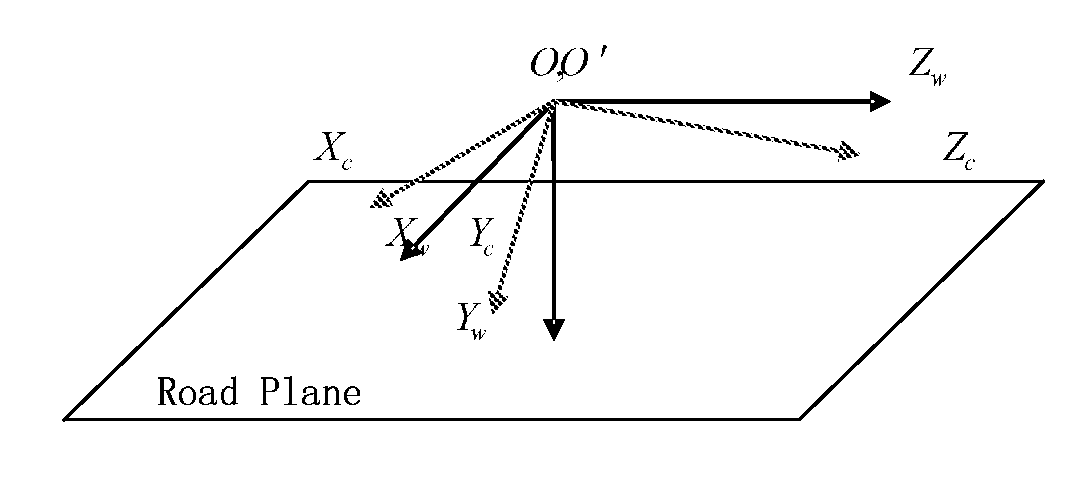

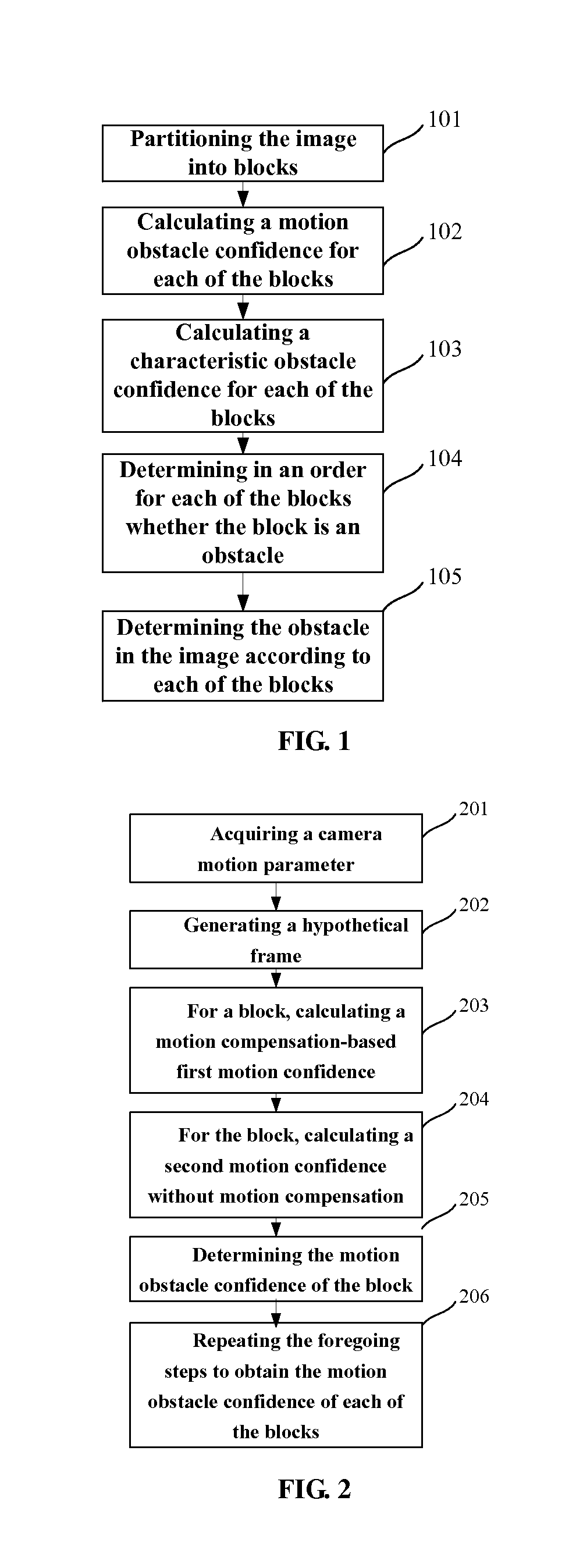

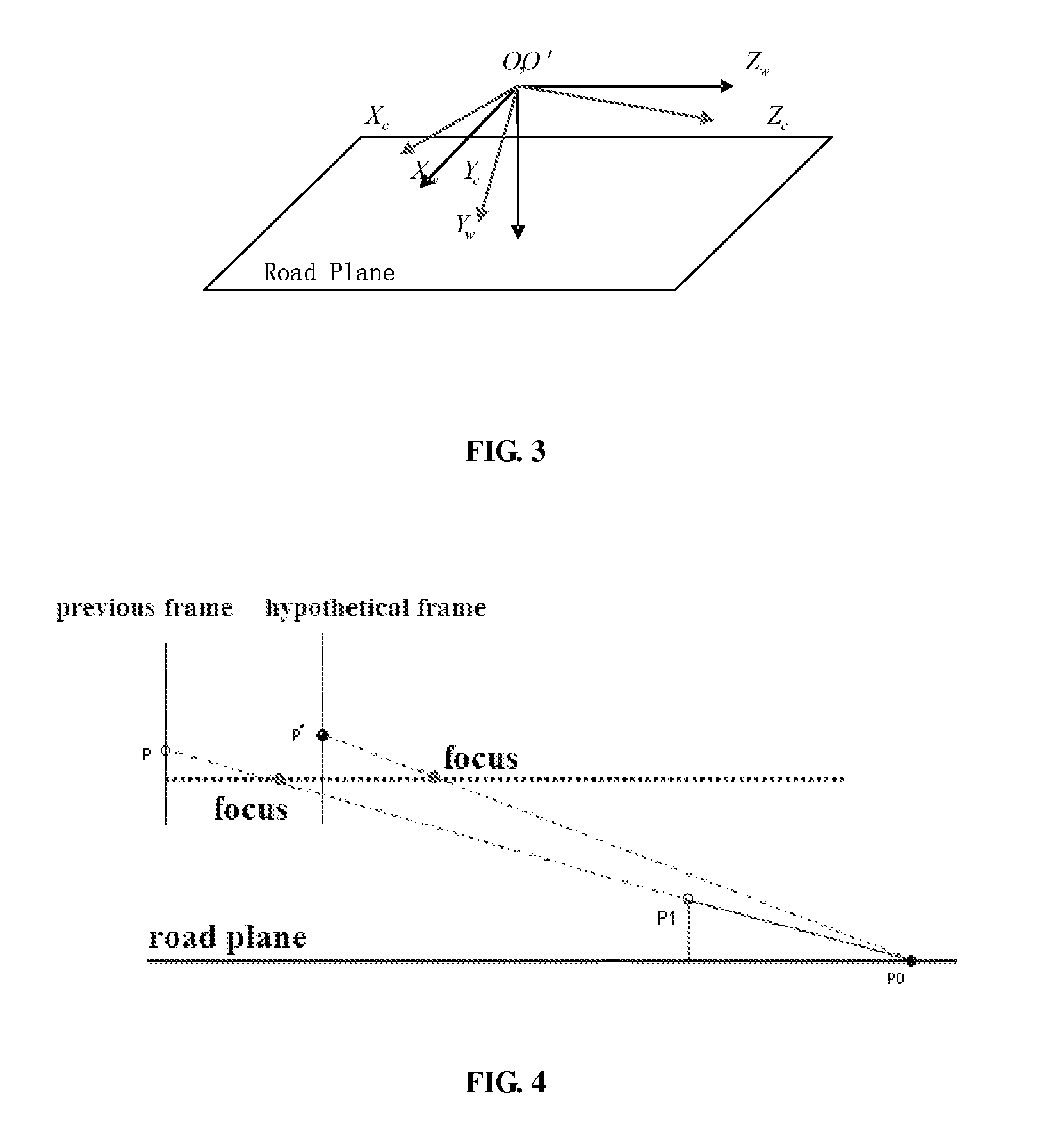

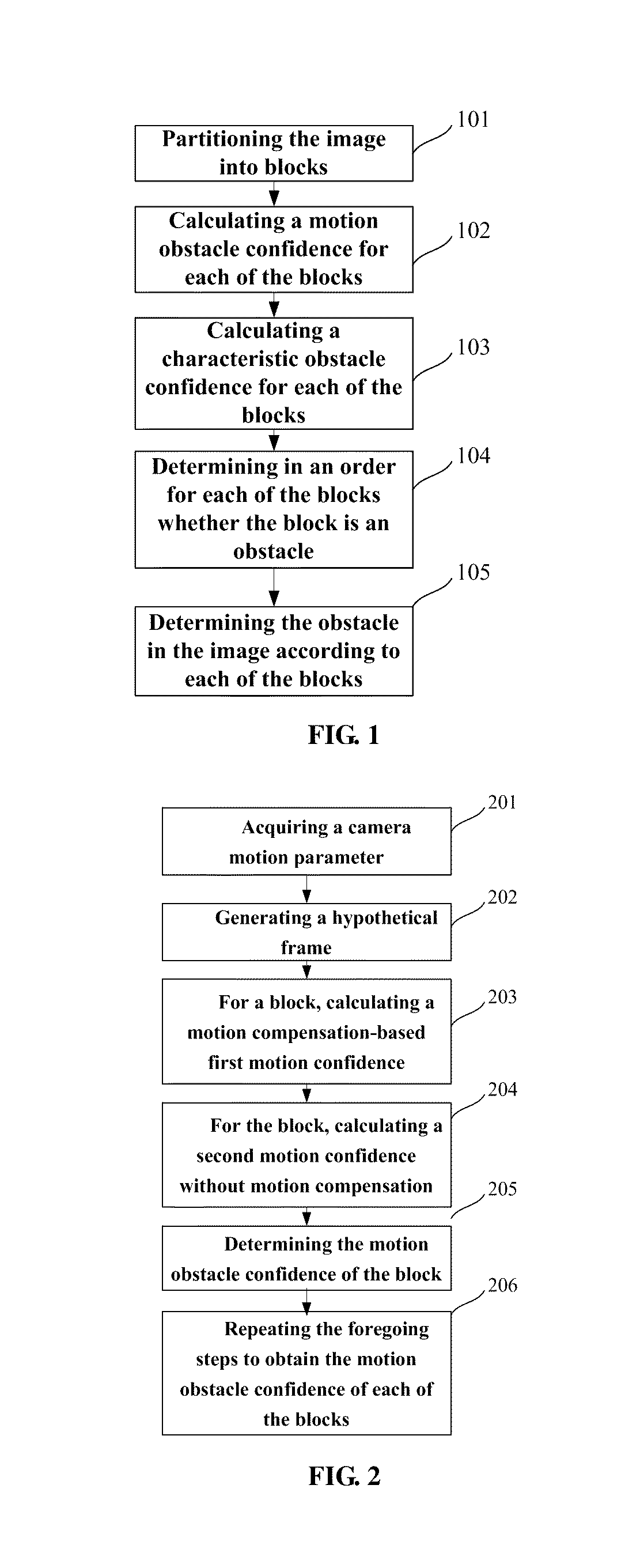

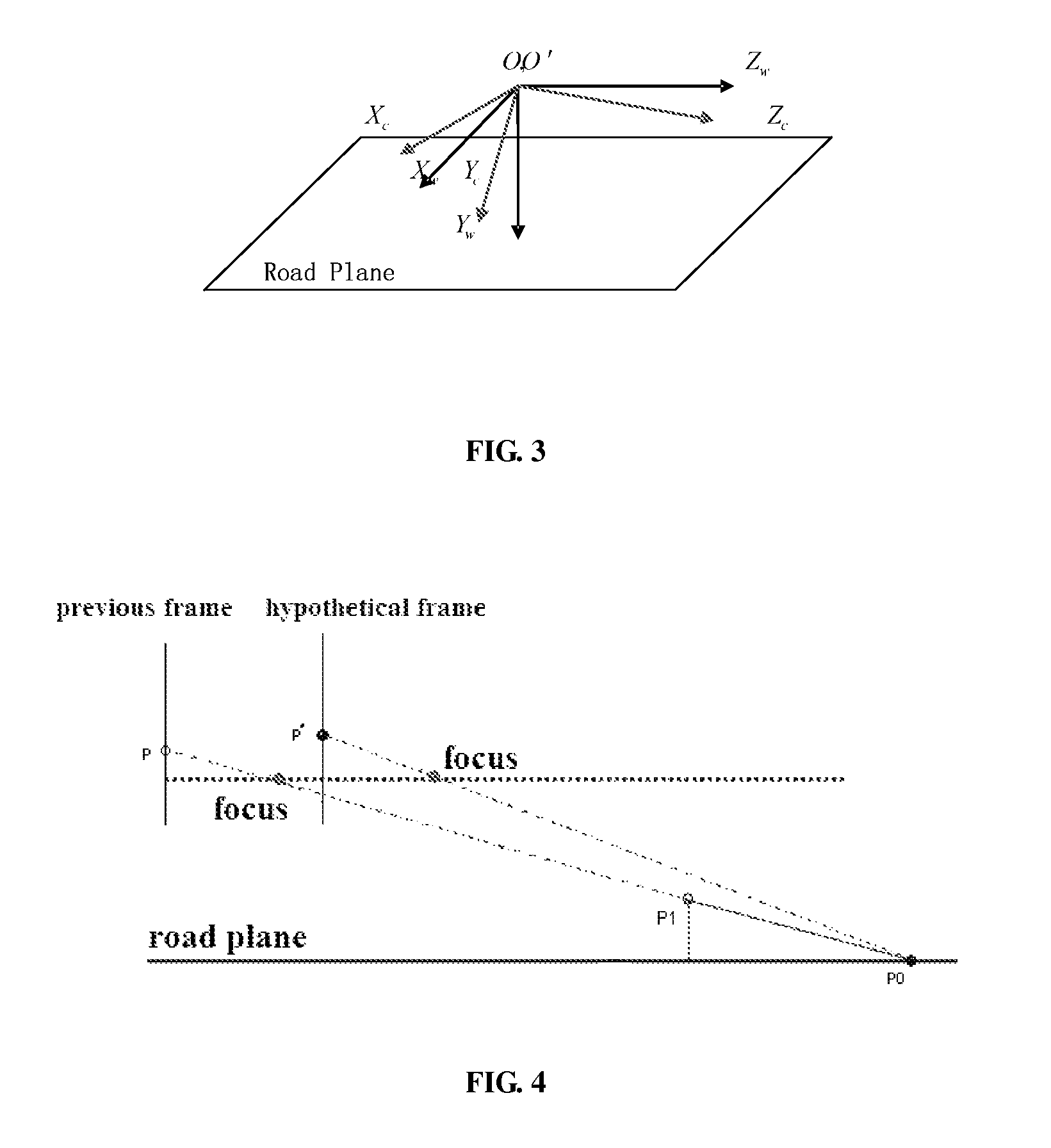

Method and apparatus for identifying obstacle in image

ActiveUS20110262009A1Detection errorImprove accuracyTelevision system detailsColor television detailsPattern recognitionComputer graphics (images)

A method for identifying barriers in images is disclosed. In the method, images of a current frame and N frame which is nearest to the current frame are obtained, the obtained images of the frames are divided in the same way, and the image of each frame obtains a plurality of divided block regions; the motion barrier confidence of each block region corresponding to the current frame and the N frame which is nearest to the current frame is calculated; whether each block region in the image of the current frame is decided successively according to the motion barrier confidence of each block region corresponding to the current frame and the N frame which is nearest to the current frame; the barriers in the images are determined according to each block region.

Owner:NEUSOFT REACH AUTOMOTIVE TECH SHANGHAI CO LTD

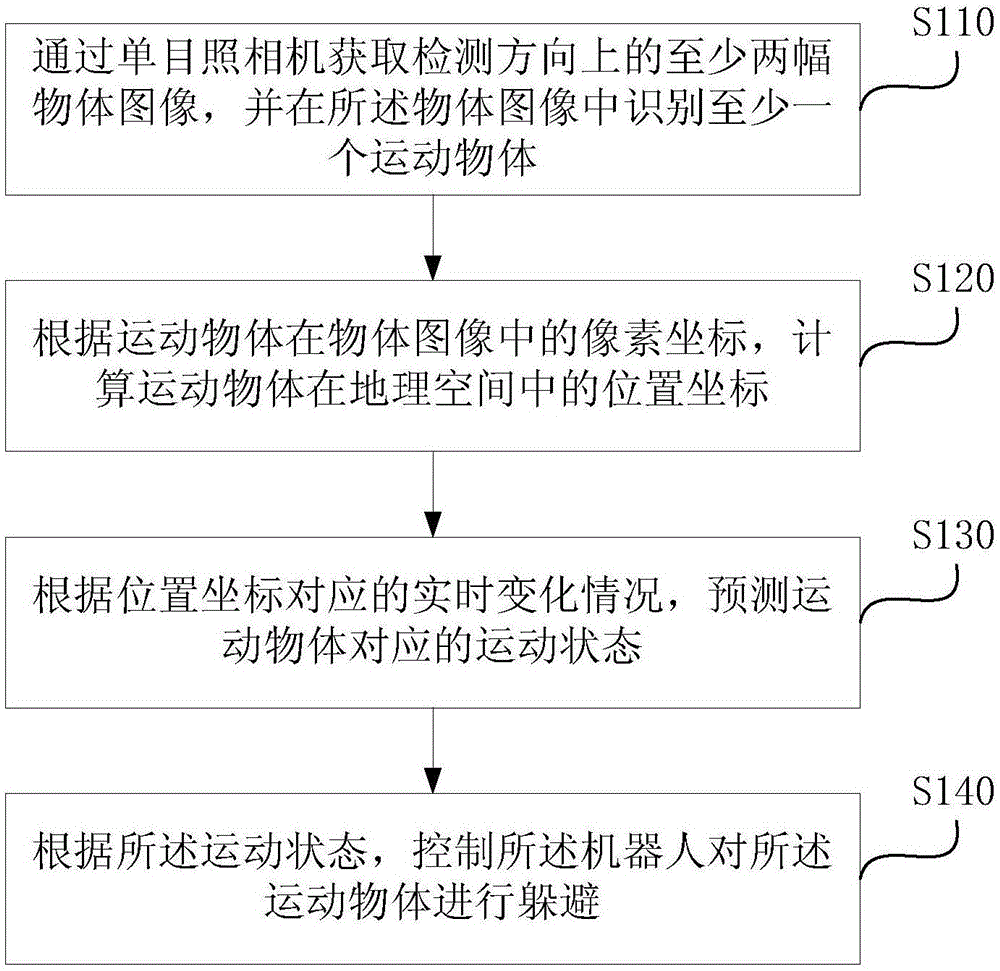

Robot avoidance controlling method and device

ActiveCN106598046AControl avoidanceDodge does not affectAutonomous decision making processPosition/course control in two dimensionsEffective solutionComputer graphics (images)

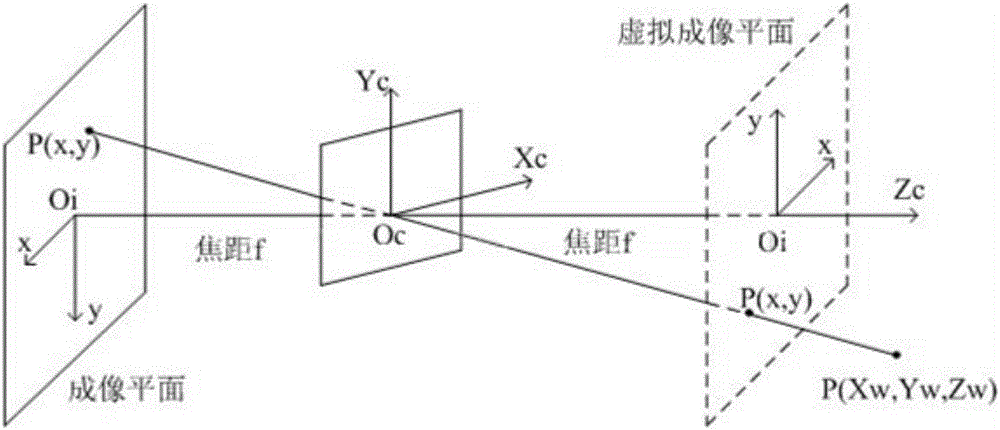

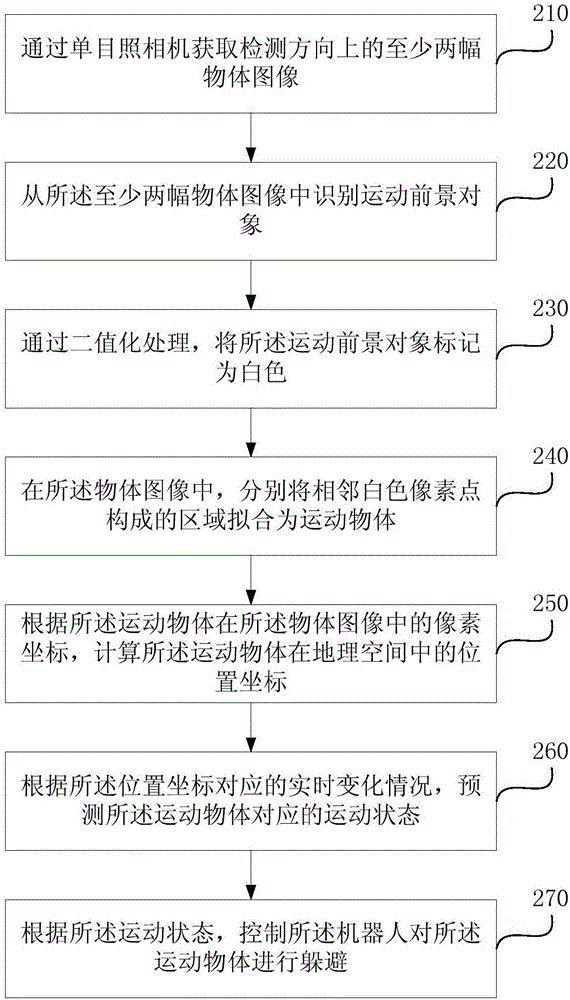

Embodiments of the present invention disclose a robot avoidance controlling method and a device. The method comprises the steps of acquiring at least two object images in the detection direction by means of a monocular camera, and identifying at least moving object in the object images; according to the pixel coordinates of the moving object in the object images, calculating the position coordinates of the moving object in the geographic space; according to the real-time changing condition corresponding to the position coordinates of the moving object, predicting the corresponding motion state of the moving object; according to the motion state, controlling a robot to avoid the moving object. According to the technical scheme in the embodiments of the present invention, in the prior art, no effective solution for controlling the robot to avoid a moving obstacle is provided. Therefore, the above method provides an effective solution to solve the above problem. The robot avoidance technique is optimized, and the universality of the robot avoidance technical scheme is improved. Meanwhile, the advantages of low cost and good avoidance effect are realized.

Owner:北京如布科技有限公司

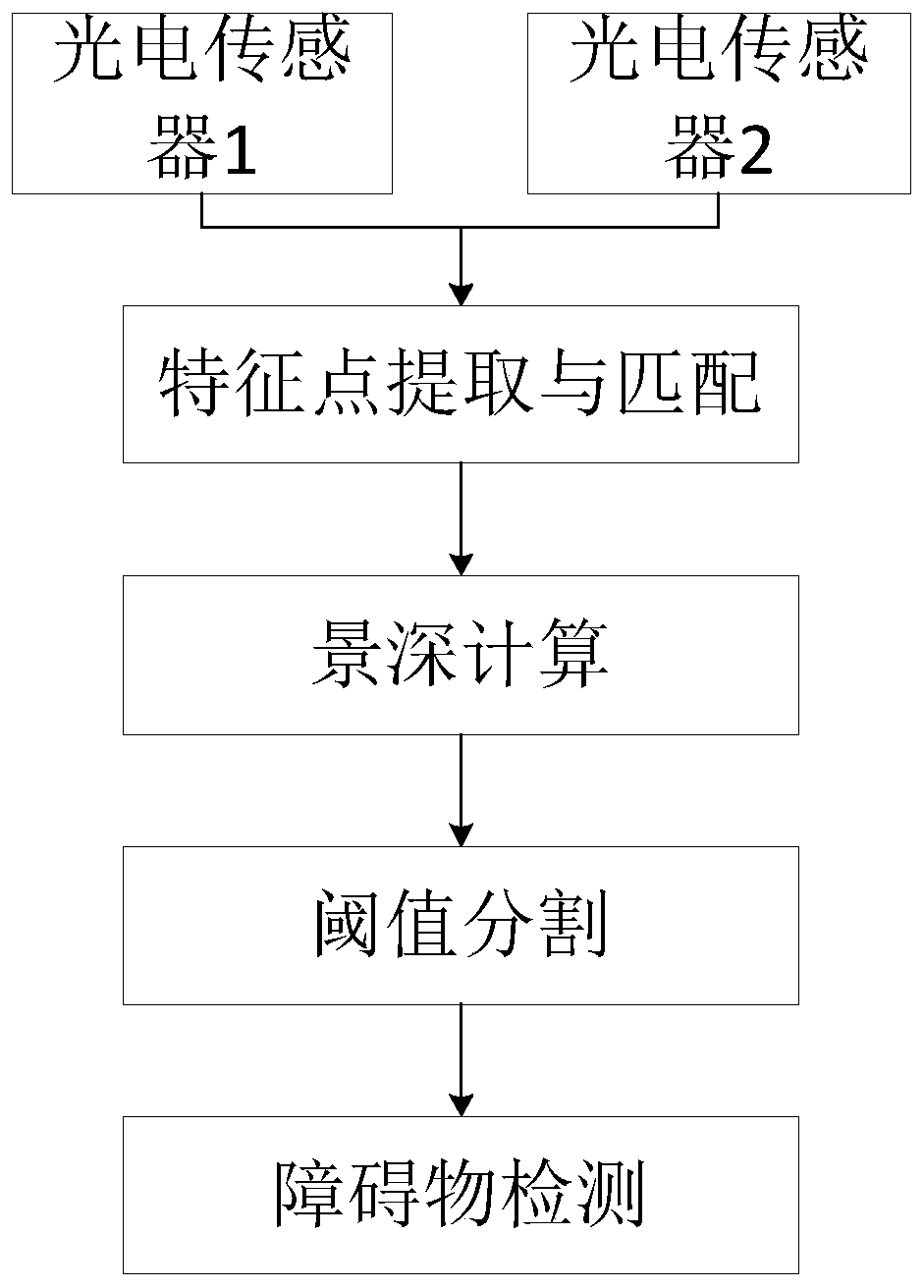

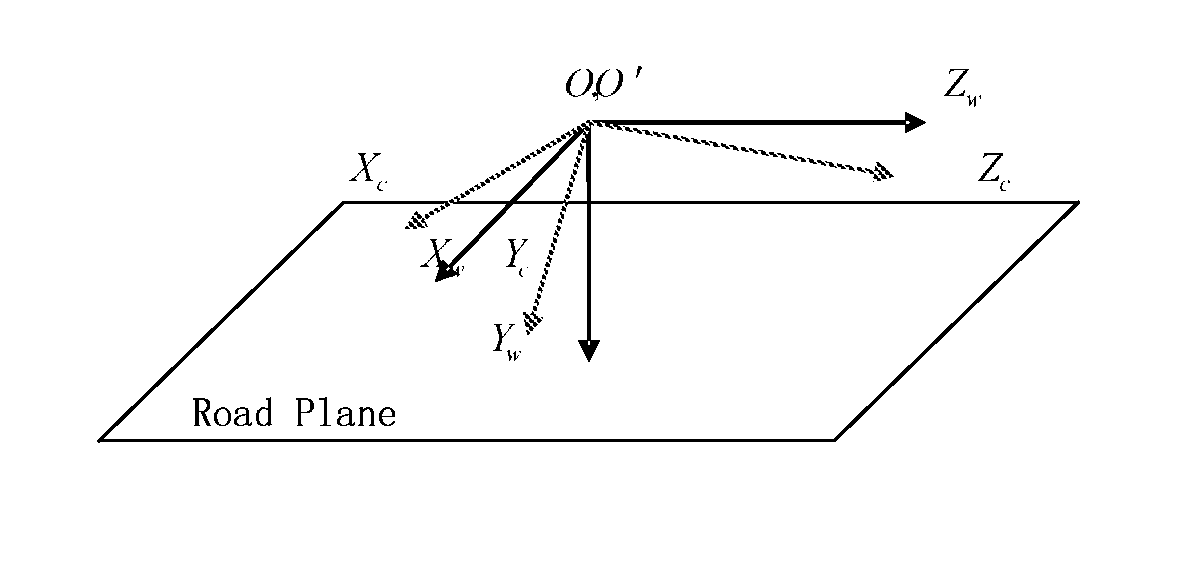

Motion obstacle detection and positioning method based on depth images

InactiveCN108805906APracticalMention location accuracyImage enhancementImage analysisVision basedImaging Feature

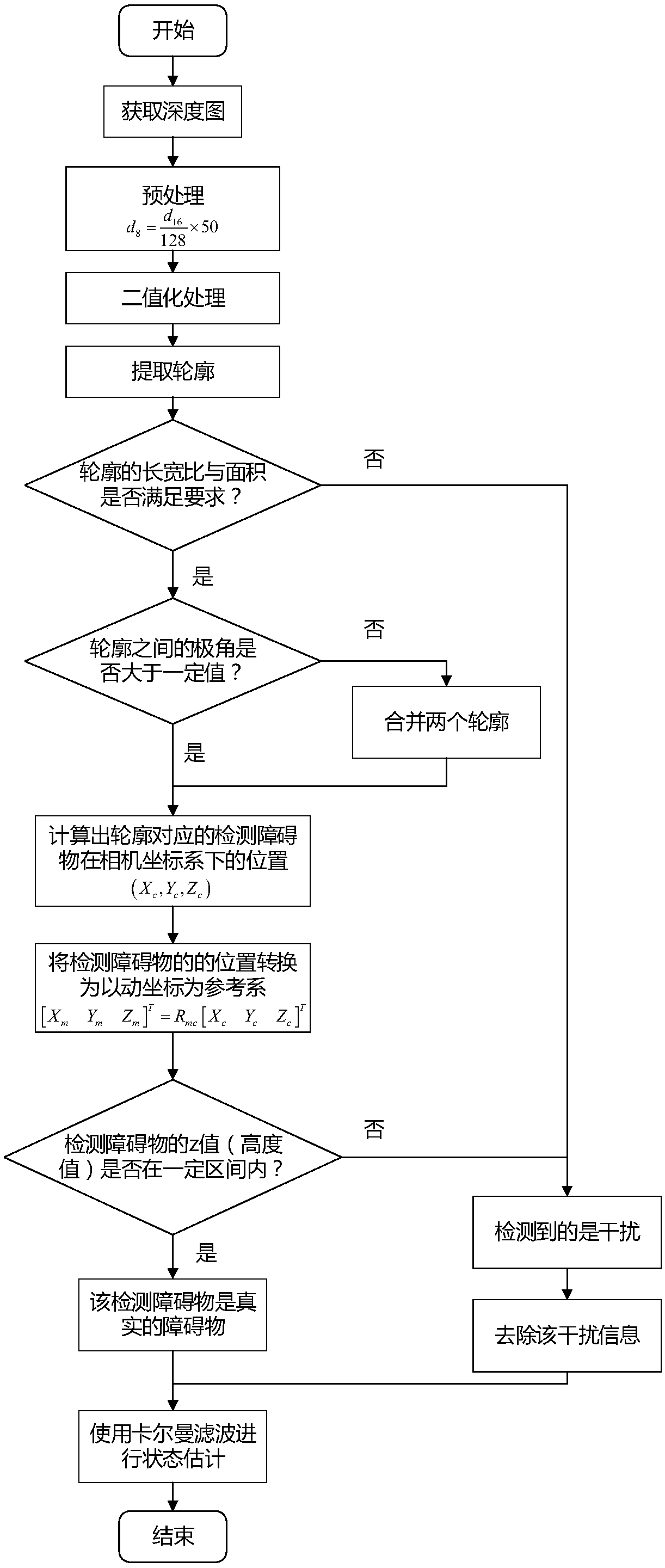

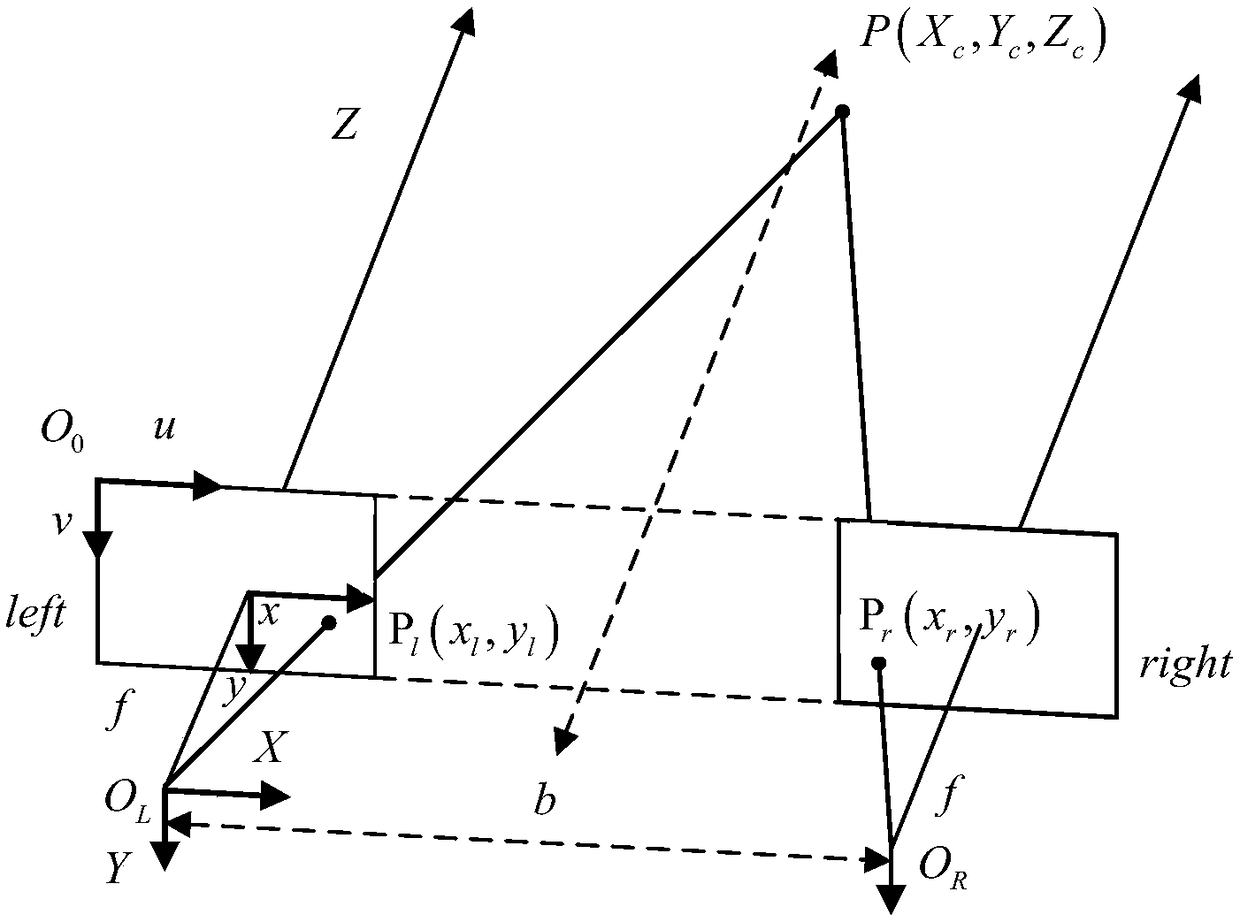

The invention discloses a motion obstacle detection and positioning method based on depth images and relates to a motion obstacle detection and positioning method based on binocular vision depth images. The method aims to solve the problems of an existing vision-based obstacle detection and positioning method that the calculation amount is large, instantaneity is poor, and it is difficult to distinguish obstacles and surroundings with similar image features. According to the method, the depth images are collected through binocular cameras configured in parallel, and denoising, binarization andother processing are performed on the depth images to obtain contours of candidate obstacles in the images; then the locations of the candidate obstacles are transferred into a local geographic coordinate system, and specific location interference is removed in combination with a spatial location relation; and a Kalman filtering mode is used to estimate the motion states of the obstacles so as toimprove the positioning accuracy of the obstacles. The method is suitable for motion obstacle detection and positioning based on the binocular vision depth images.

Owner:HARBIN INST OF TECH

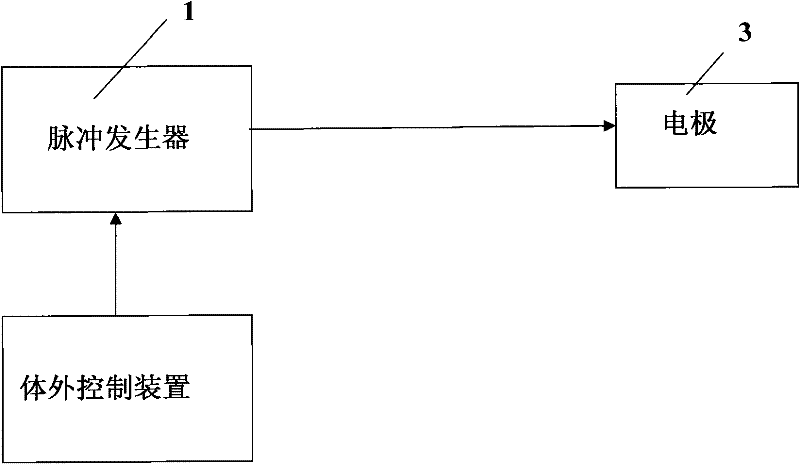

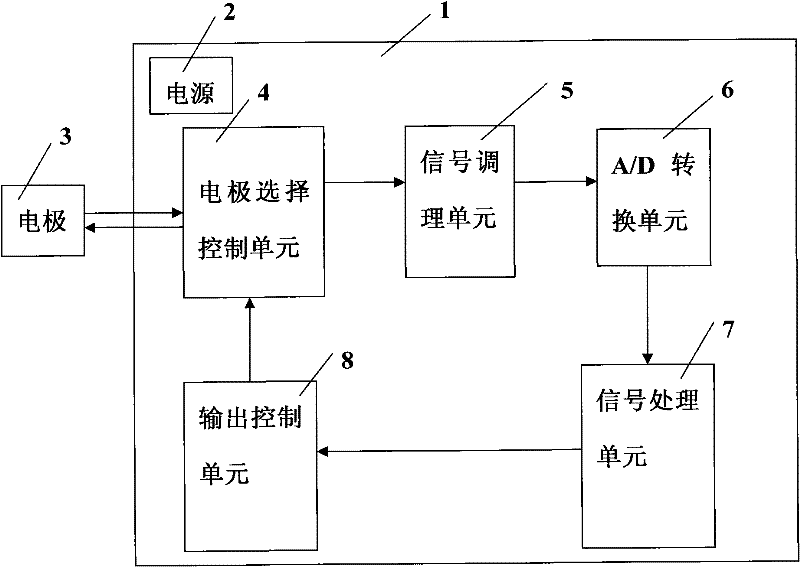

Feedback type nervous electrical stimulation system and feedback control method thereof

InactiveCN102343123AReduce power consumptionExtended service lifeArtificial respirationDiseasePattern perception

The invention discloses a feedback type nervous electrical stimulation system and a feedback control method thereof. An implanted electrode is employed as a signal acquisition unit. An acquired nervous electrical input signal goes through an electrode switching control unit, a signal conditioning unit, an A / D converter, a signal processing unit, an output control unit in order, and enters into an electrode selection control unit to form a feedback loop. When the signal processing unit determines that a user is in a deep sleep state, the output control unit automatically weakens or stops an output pulse signal of a pulse generator. Otherwise, the output control unit maintains or automatically recovers a conventional output pulse signal of the pulse generator. Compared with the prior art, without increasing extra perception parts and without artificial intervention, automatic output adjusting on demand is realized, wasted power consumption of stimulation which could be fully stopped because of symptom alleviation or elimination of a patient like a dyskinetic disease at deep night sleep is reduced, thus a service life of the nervous electrical stimulation system is substantially prolonged.

Owner:SCENERAY

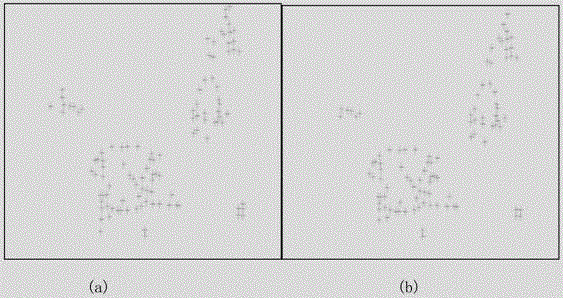

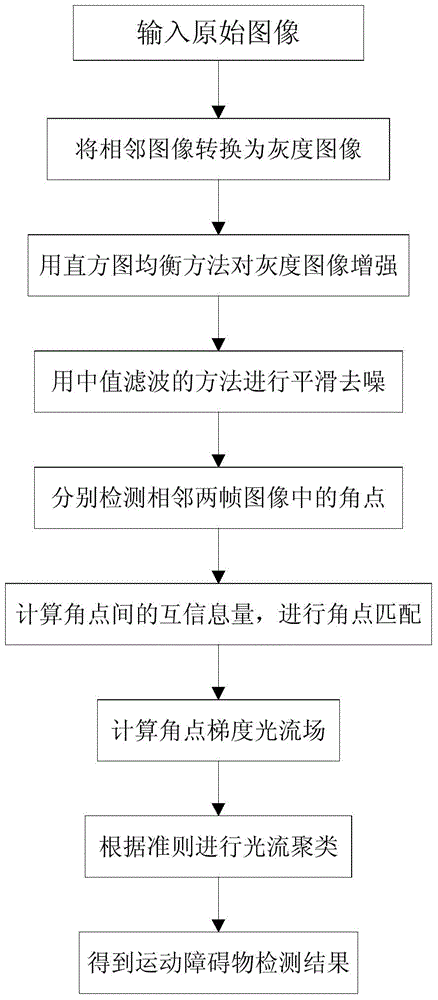

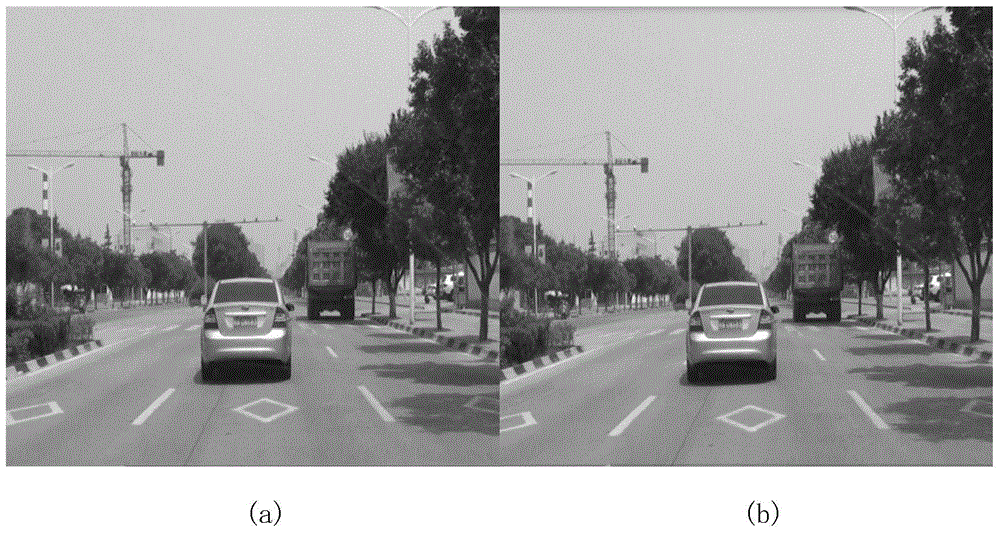

Vehicle front target detection method based on characteristic-point mutual information content and optical flow method

ActiveCN104881645AShorten the timeAccurate targetCharacter and pattern recognitionColor imageGray level

The invention discloses a vehicle front target detection method based on a characteristic-point mutual information content and an optical flow method. The method comprises the following steps: firstly, reading color images of two adjacent frames in a video and converting the color images into gray level images; secondly, carrying out pretreatment on the gray level images, using a histogram equalization method to carry out enhancement so as to increase a resolution ratio of a target lane line; thirdly, using a method based on a median filtering to carry out smoothing process; finally, after the pretreatment is performed, using the method based on the characteristic-point mutual information content and the optical flow field to detect vehicle front motion barrier. The last step comprises: 1) extracting a characteristic point; 2) marking; 3) determining the number of angle points; 4) selecting an area; 5) calculating the mutual information content; 6) determining a angle point chain; 7) calculating an angle point optical flow; 8) determining a distance and an angle criterion and deleting the angle points possessing a same vector; 9) carrying out thresholding and acquiring a final motion barrier detection result.

Owner:NANJING GENERAL ELECTRONICS

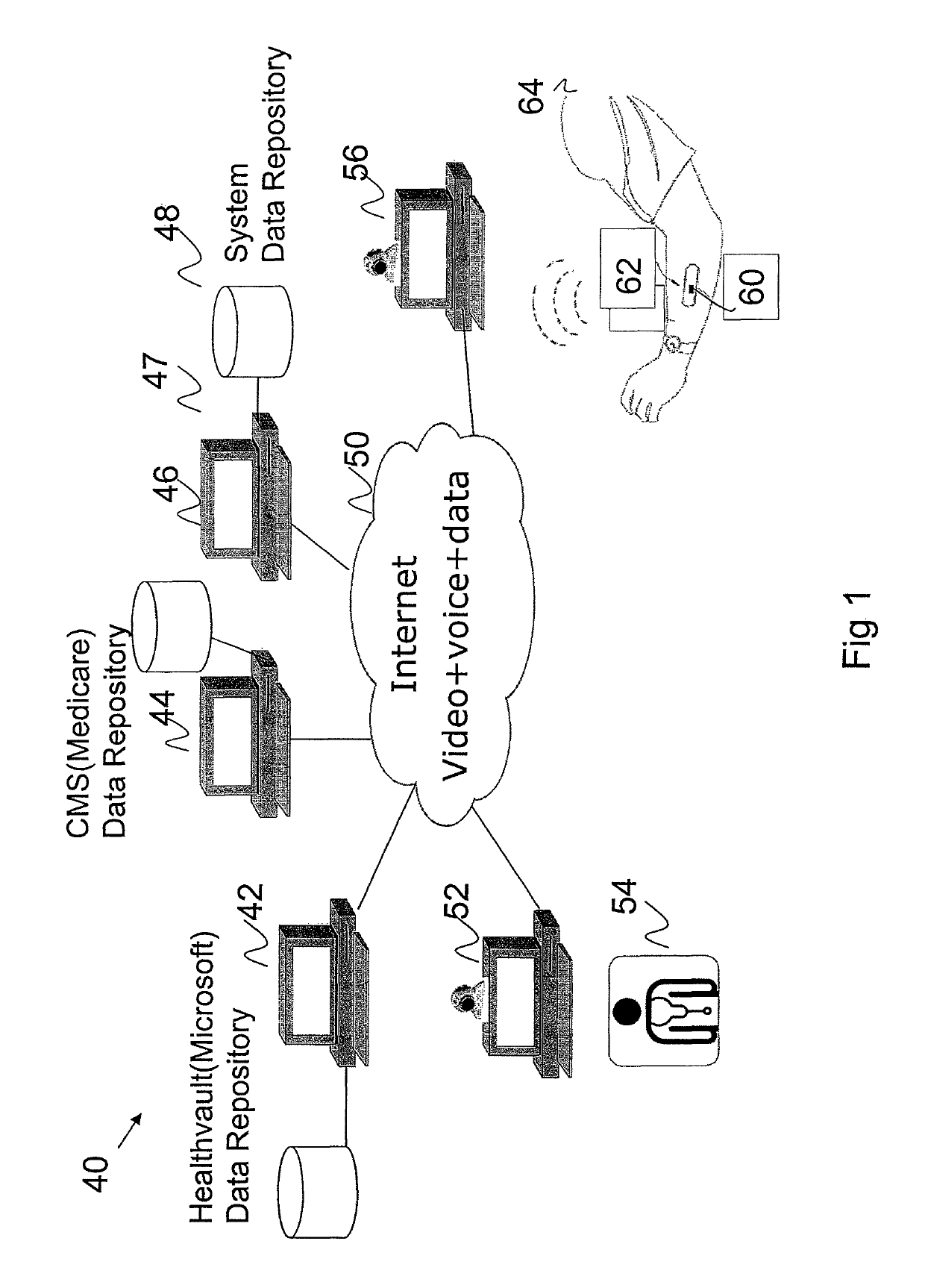

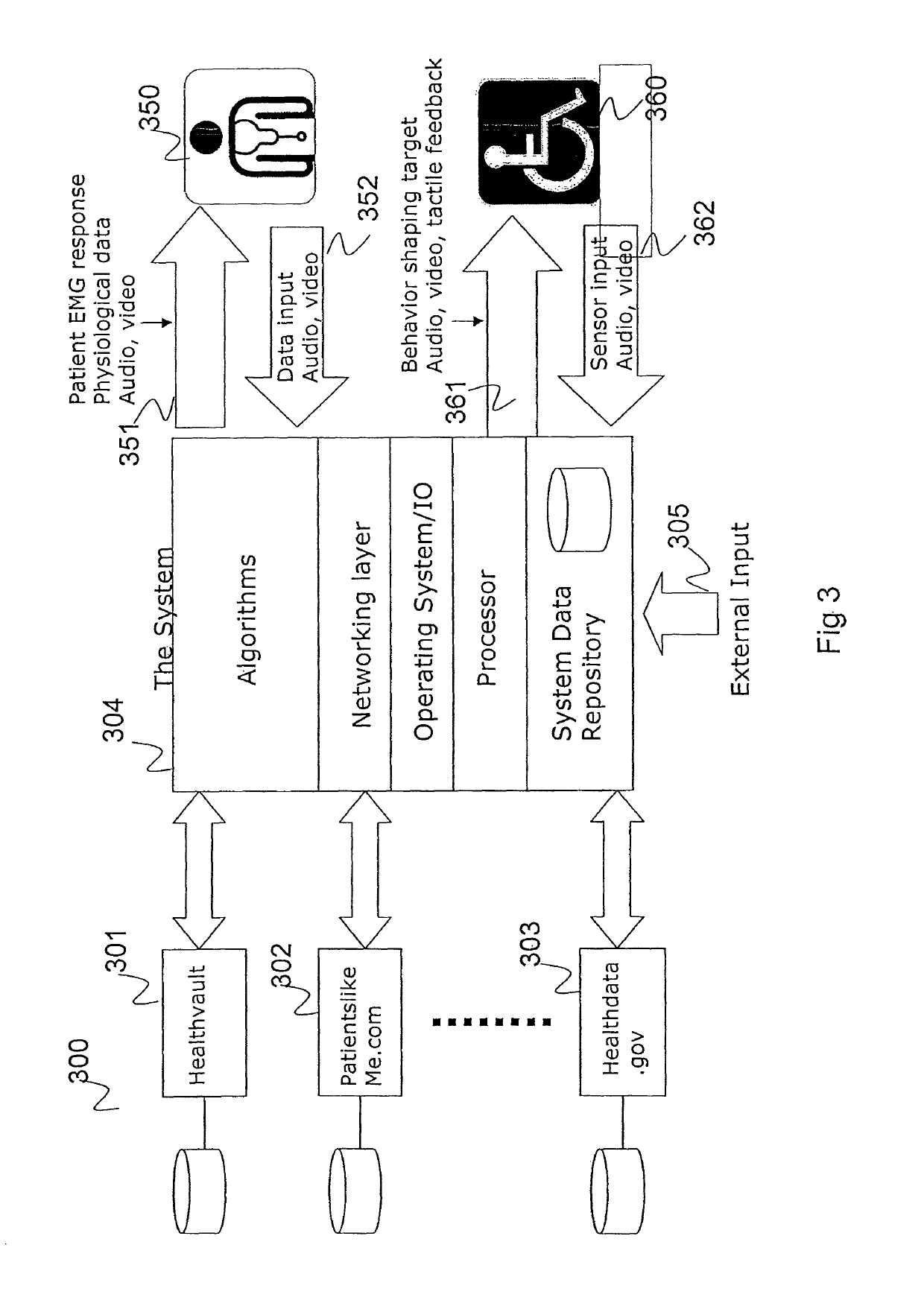

Method for determining rehab protocol and behavior shaping target for rehabilitation of neuromuscular disorders

ActiveUS10271768B1Improves access and delivery and efficacyQuality improvementElectrotherapyElectromyographyDiseaseNeuromuscular disease

A system for treating a patient with neurological disorders of movement includes a patient computing device for use in rehabilitative training and a sensor worn about a body part being rehabilitated. A healthcare computing device is used by a healthcare professional to assist remote patient rehabilitation by accepting input signals and determining for the patient a rehab protocol depending on selected parameters, and determining for the patient a behavior shaping target depending on selected parameters and the rehab protocol and behavior shaping target is communicated to the patient while the patient is undergoing rehabilitation. A plurality of remote health data sites and other public repositories of health data of patients undergoing rehabilitation following neurological events can be included. The remote computing device can include a data repository of publicly available patient data and patient data gathered by system of present invention.

Owner:JOGOHEALTH INC

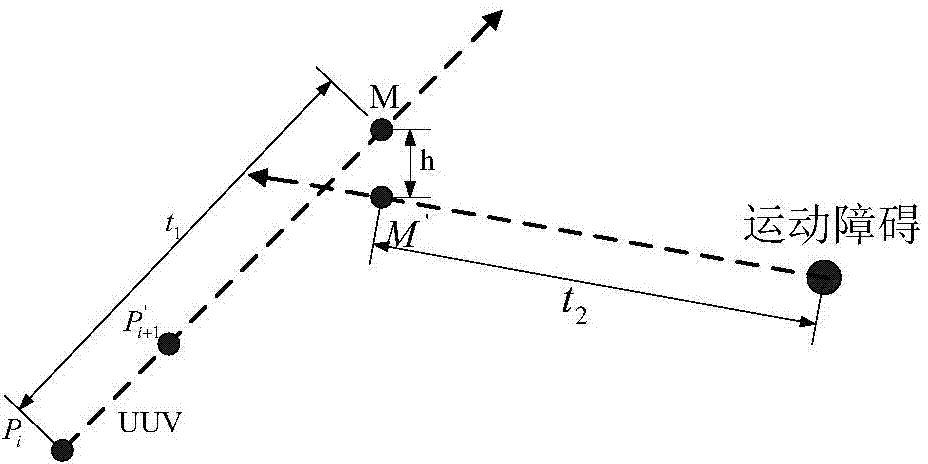

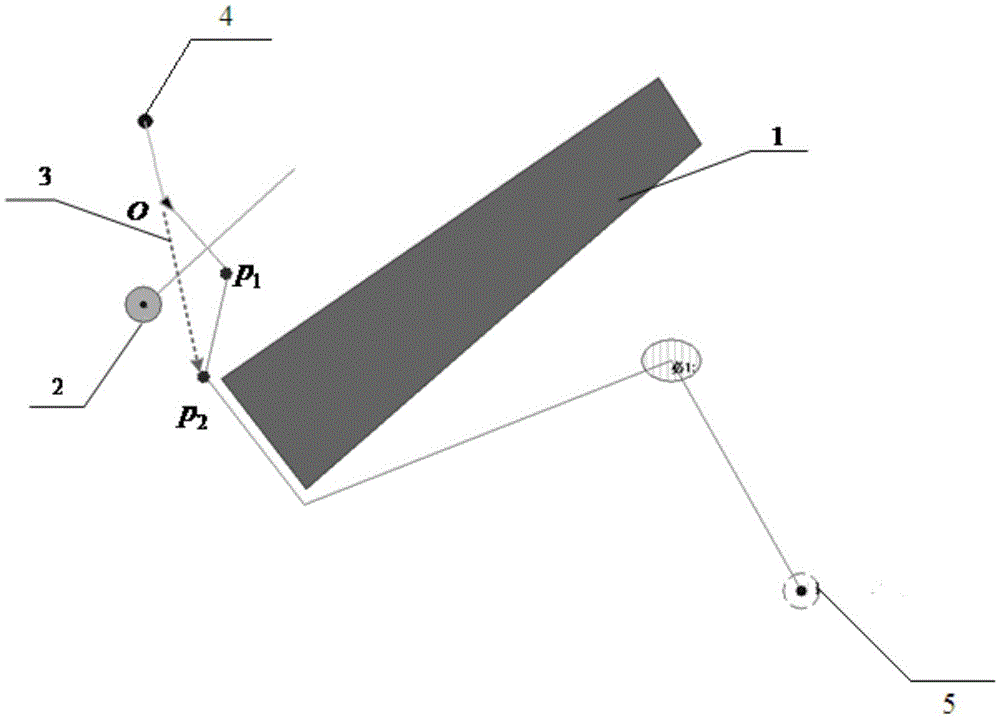

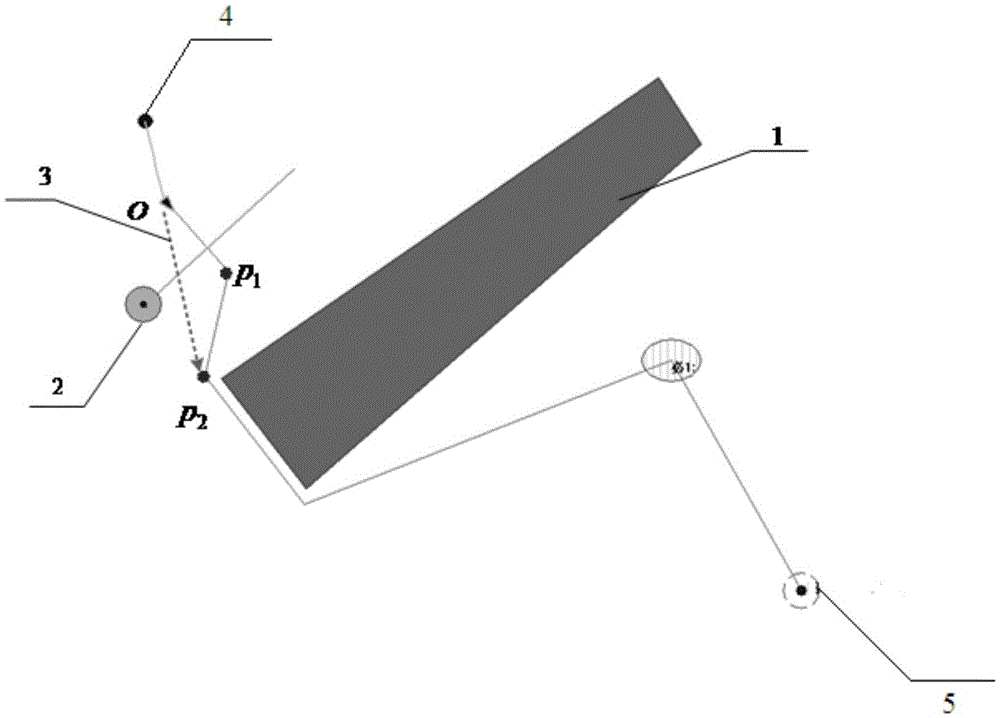

Evading method based on opposite-direction sailing of virtual puffed motion obstacle and UUV

The invention discloses an evading method based on opposite-direction sailing of a virtual puffed motion obstacle and a UUV. The invention is aimed to solve the problem that the opposite direction sailing motion obstacle evading method which is currently adopted is hard to accurately predict the motion sate of the motion obstacle. The invention determines that the UUV and the motion obstacle sail in the opposite directions according to the fact that the included angle between the motion obstacle course and the guidance course is headAngle; when the UUV and the motion obstacle are detected to be sailed in the opposite directions, the motion obstacle generates a rectangle virtual obstacle after circular puffing, and the measurement distance of the waterway planning algorithm is calculated and triggered; when the straight line distance M between UUV and the motion obstacle center point satisfies M<nextL, the waterway planning algorithm is triggered to calculate the measurement distance nextL of the next time triggered plan until the waterway planning algorithm is not triggered anymore. The invention is applicable to the UUV motion obstacle evading field.

Owner:HARBIN ENG UNIV

Evading method based on same direction sailing of virtual puffed motion obstacle and UUV

The invention discloses an evading method based on same direction sailing of a virtual puffed motion obstacle and a UUV. The invention is aimed to solve the problem that the opposite direction sailing motion obstacle evading method which is currently adopted is hard to accurately predict the motion sate of the motion obstacle. The evading method determines that the UVV and the motion obstacle sail in the same direction according to the included angle of the motion obstacle course and a guidance course; the same direction sailing has two position relations: the UUV pursues and attacks the motion obstacle and the motion obstacle pursues and attacks the UUV; when the UUV pursuits and attacks the motion obstacle, puffing and a rectangle virtual obstacle are adopted to adjust the heading of the UUV in order to evade the motion obstacle; when the obstacle pursuits and attacks the UUV, UUV constantly adjusts the motion speed according to the change of the relative position of the UUV and the motion obstacle, and the puffing and the rectangle virtual obstacle are adopted to adjust the heading of the UUV to evade the obstacle. The invention is applicable to the motion obstacle evading of the UUV.

Owner:HARBIN ENG UNIV

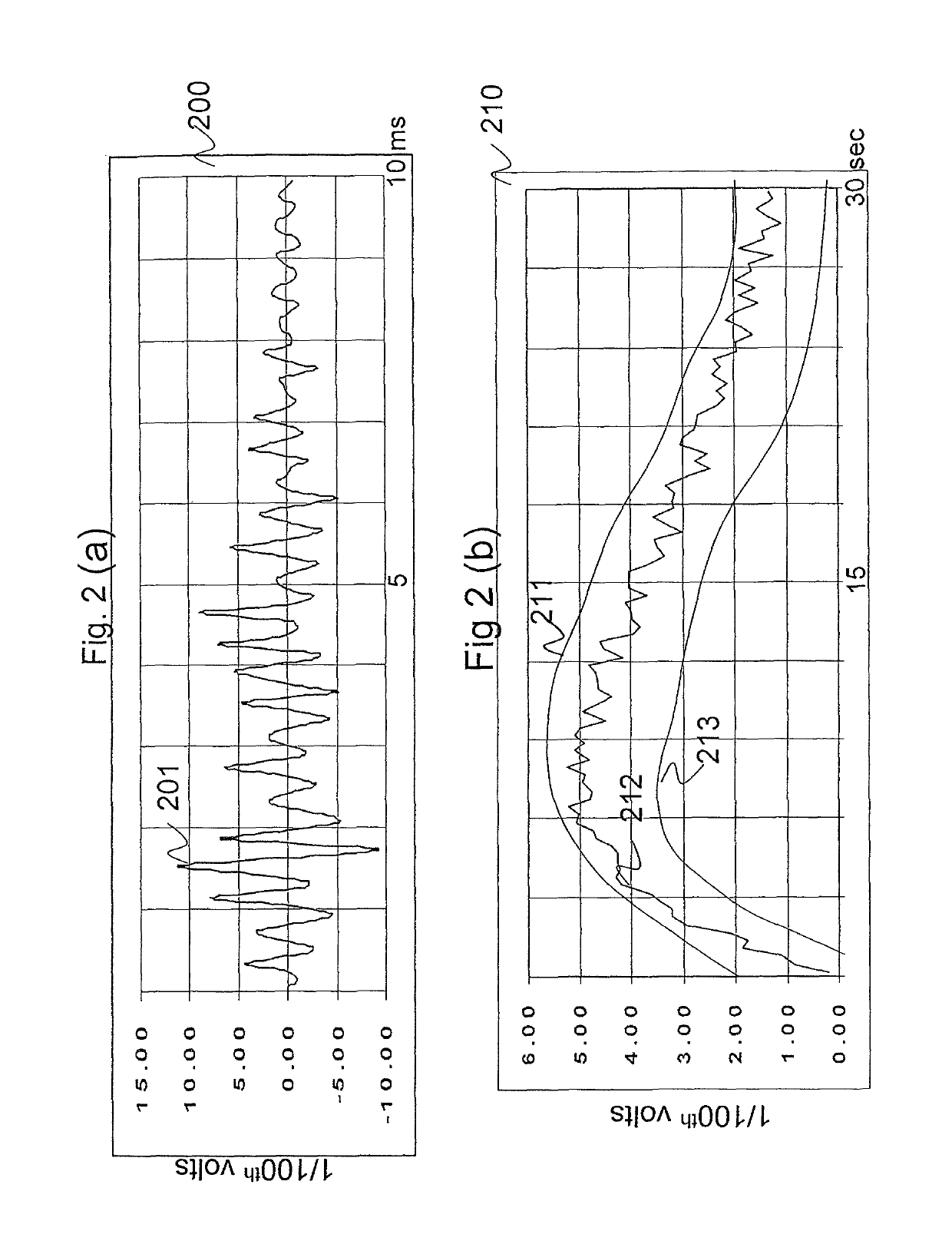

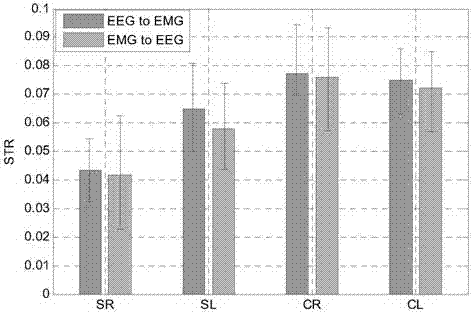

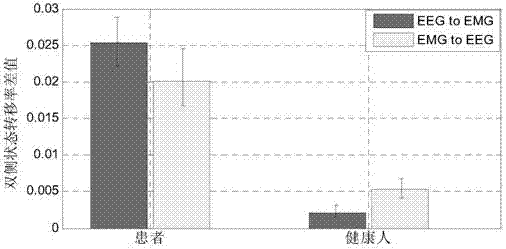

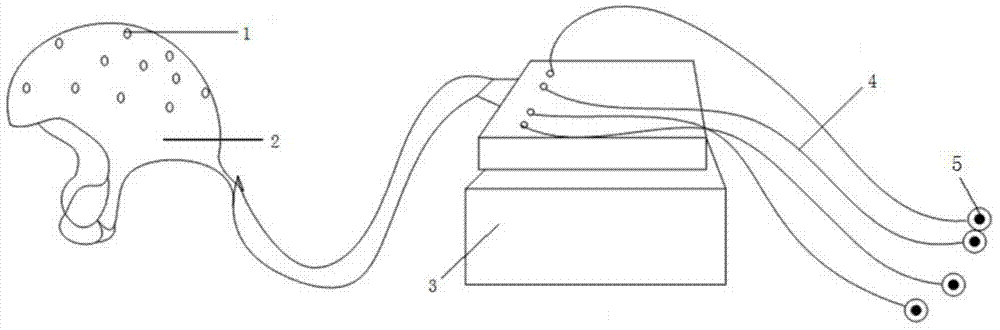

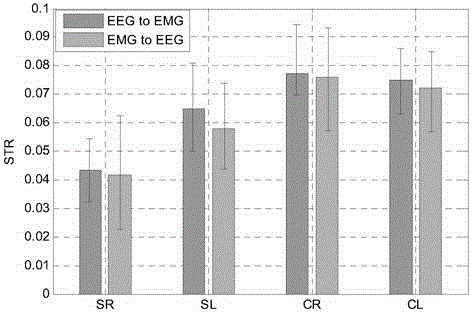

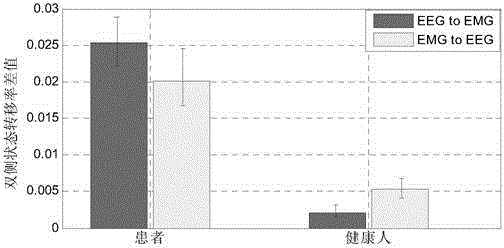

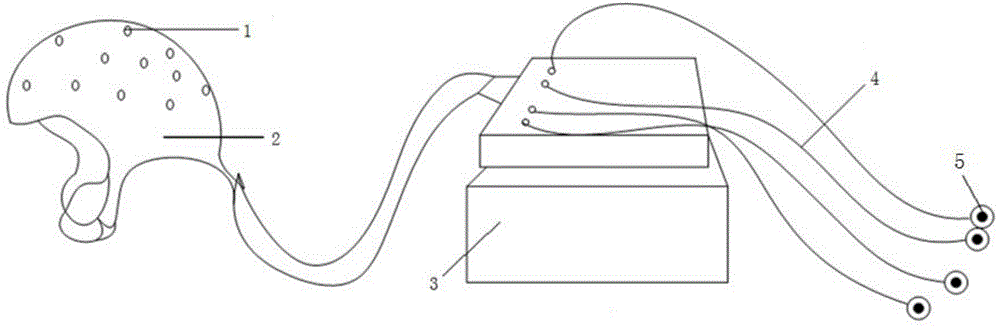

Electroencephalogram and electromyogram synchronous acquisition and information transfer characteristic analysis method

InactiveCN103584855AAids in the exploration of functional linkagesDiagnostic recording/measuringSensorsRehabilitation engineeringKnowledge Field

The invention relates to the fields of rehabilitation engineering, neural engineering and dyskinesia mechanism research, in particular to an electroencephalogram and electromyogram synchronous acquisition and information transfer characteristic analysis method. The method includes an electroencephalogram and electromyogram synchronous acquisition step and a signal processing step, the electroencephalogram and electromyogram synchronous acquisition step includes electroencephalogram acquisition and electromyogram acquisition, and the signal processing step includes signal preprocessing and an electroencephalogram and electromyogram transfer characteristic analysis method. The method has applicability and adoptability and has significant application value in the rehabilitation medicine field.

Owner:YANSHAN UNIV

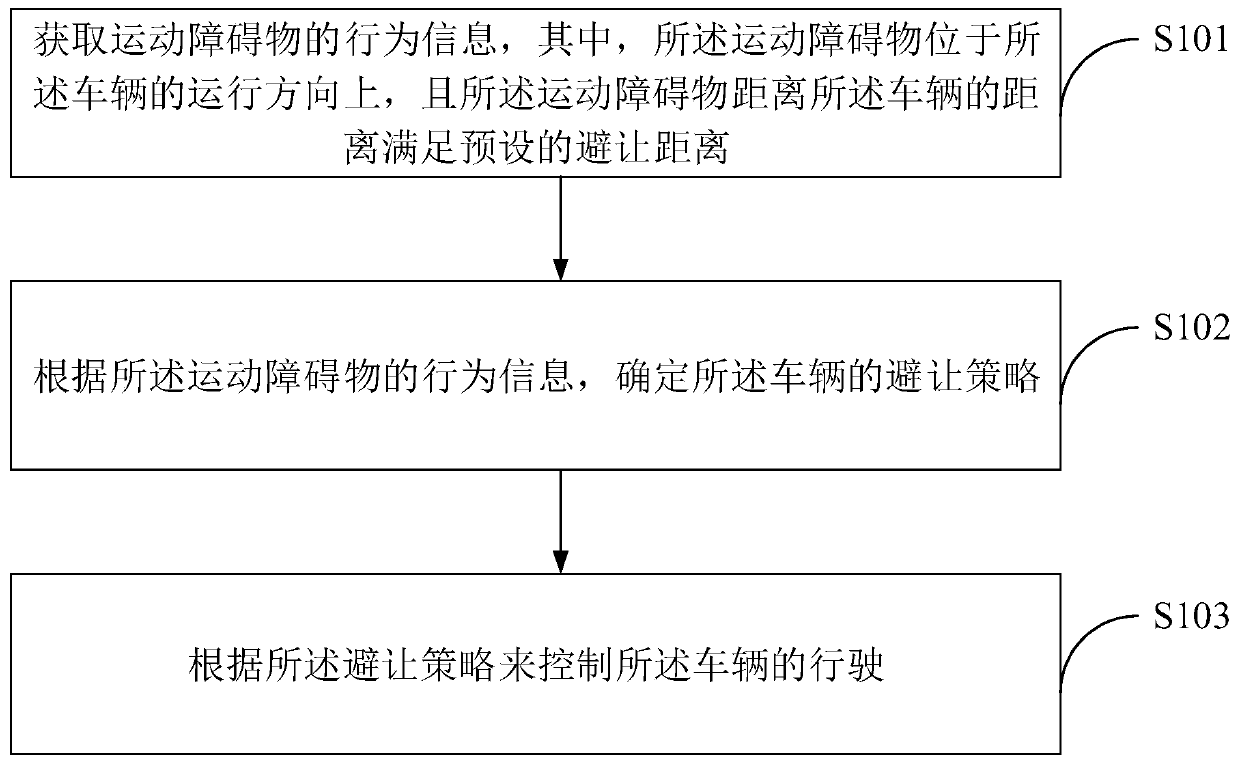

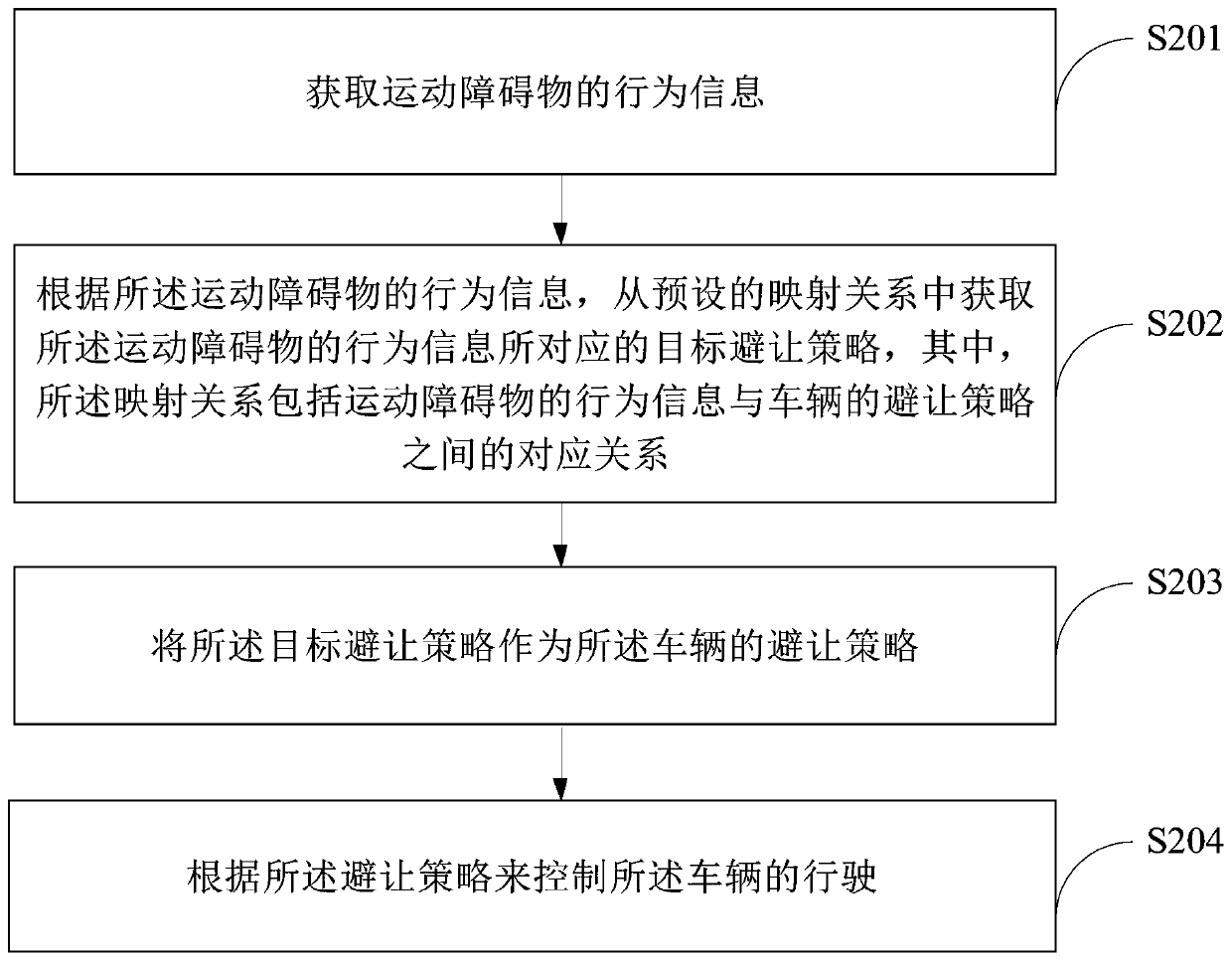

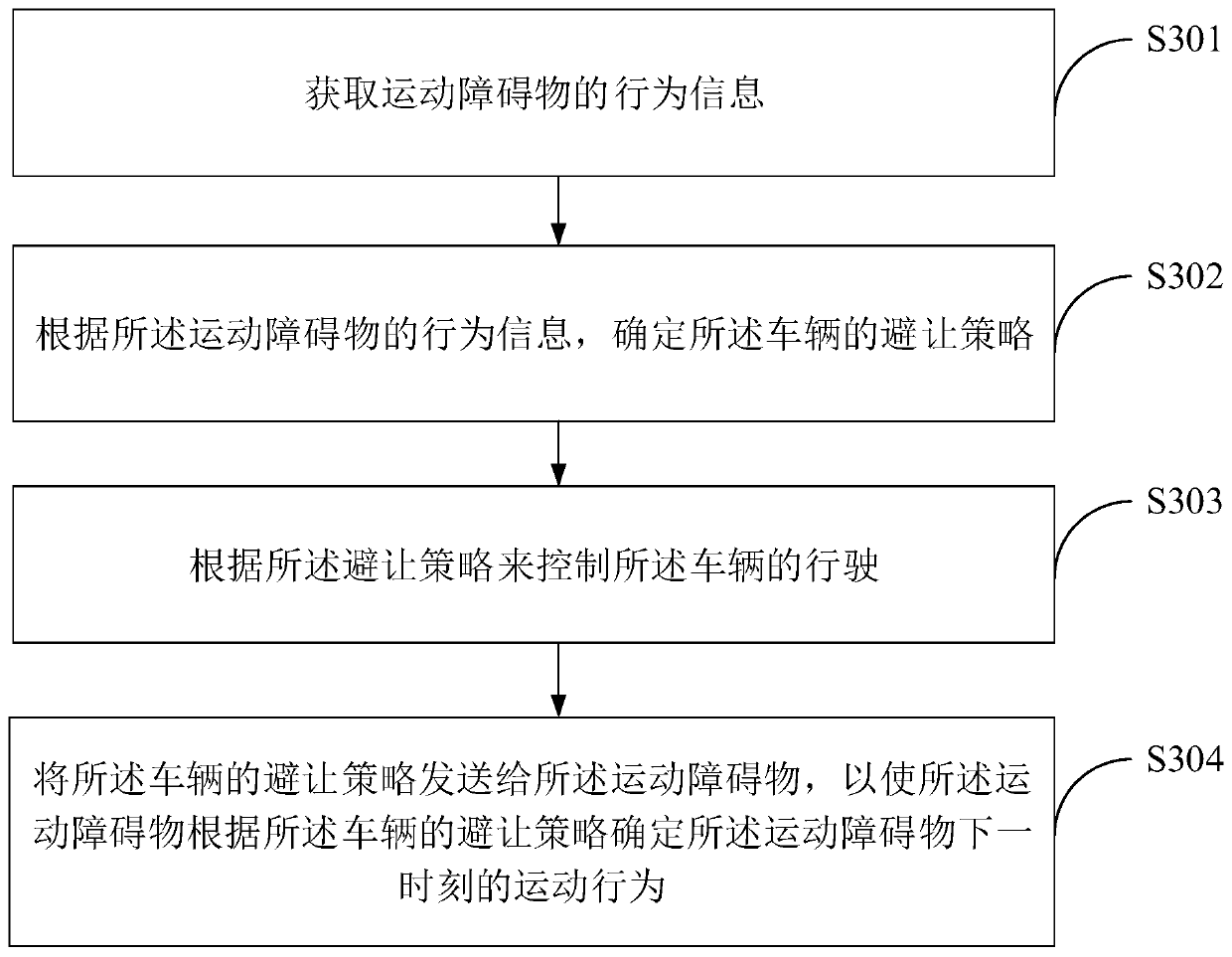

Vehicle collision avoidance control method and device, electronic equipment and storage medium

ActiveCN110320910AAvoid blockingImprove accuracyRoad vehicles traffic controlExternal condition output parametersVehicle drivingElectric equipment

The embodiment of the invention discloses a vehicle collision avoidance control method and device, electronic equipment and a storage medium. The method comprises the steps of acquiring behavior information of a moving obstacle, wherein the moving obstacle is located in a vehicle operating direction, and the distance from the moving obstacle to the vehicle satisfies a preset collision avoidance distance; determining a collision avoidance strategy of the vehicle according to the behavior information of the moving obstacle; and controlling vehicle driving according to the collision avoidance strategy. According to the method of the embodiment, the behavior information of the moving obstacle is considered in a process of controlling the vehicle collision avoidance; when the moving obstacle avoids, the vehicle driving can be controlled, thereby avoiding unnecessary avoidance of the vehicle so that the intelligent driving is in line with the actual situation, thus the accuracy of vehicle collision avoidance and the practicality of intelligent driving are improved.

Owner:APOLLO INTELLIGENT DRIVING (BEIJING) TECHNOLOGY CO LTD

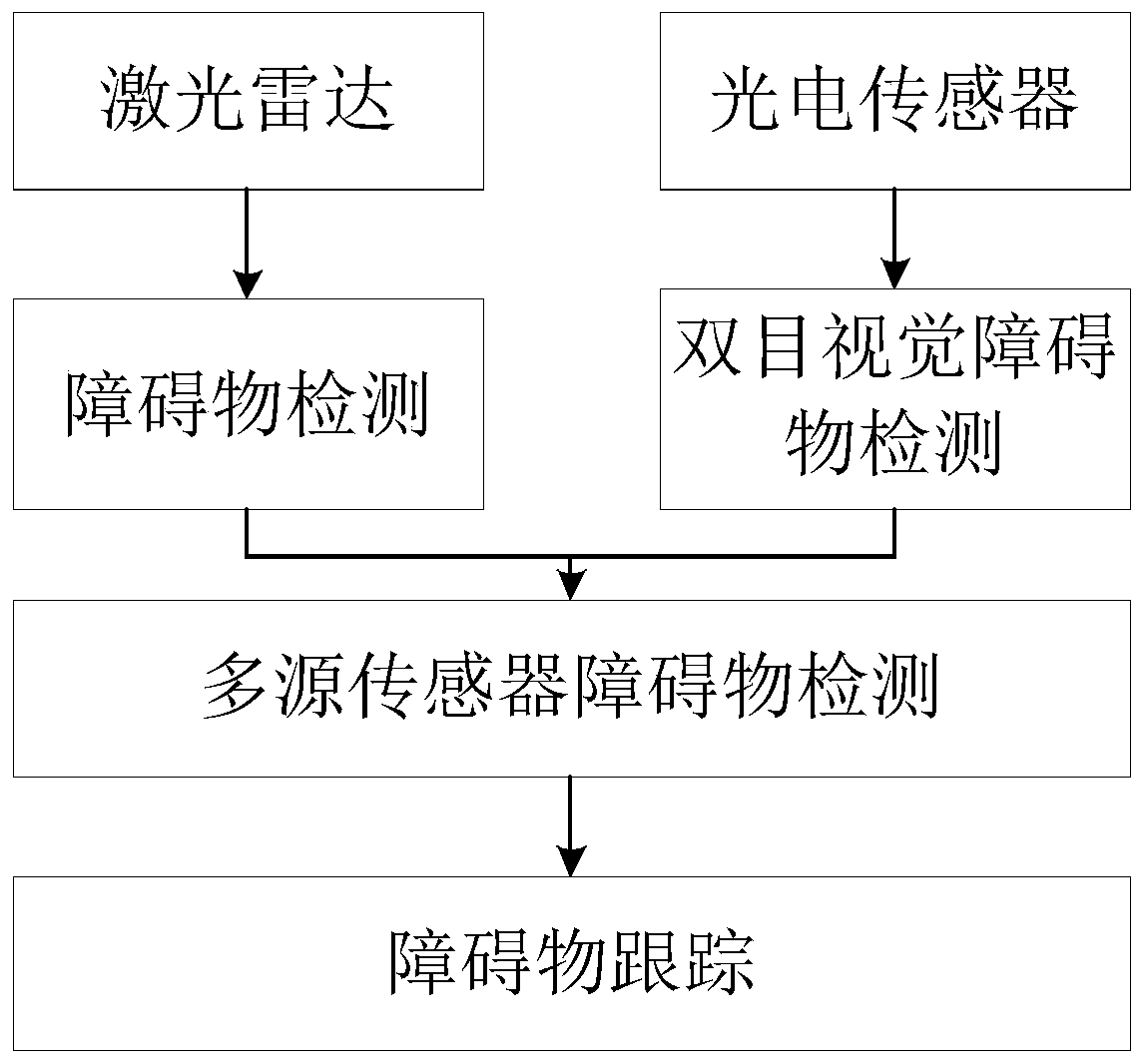

Man-machine moving obstacle monitoring method, readable storage medium and unmanned aerial vehicle

ActiveCN110568861AReal-time planning of 3D obstacle avoidance pathsEfficient identificationWave based measurement systemsTarget-seeking controlState modelMan machine

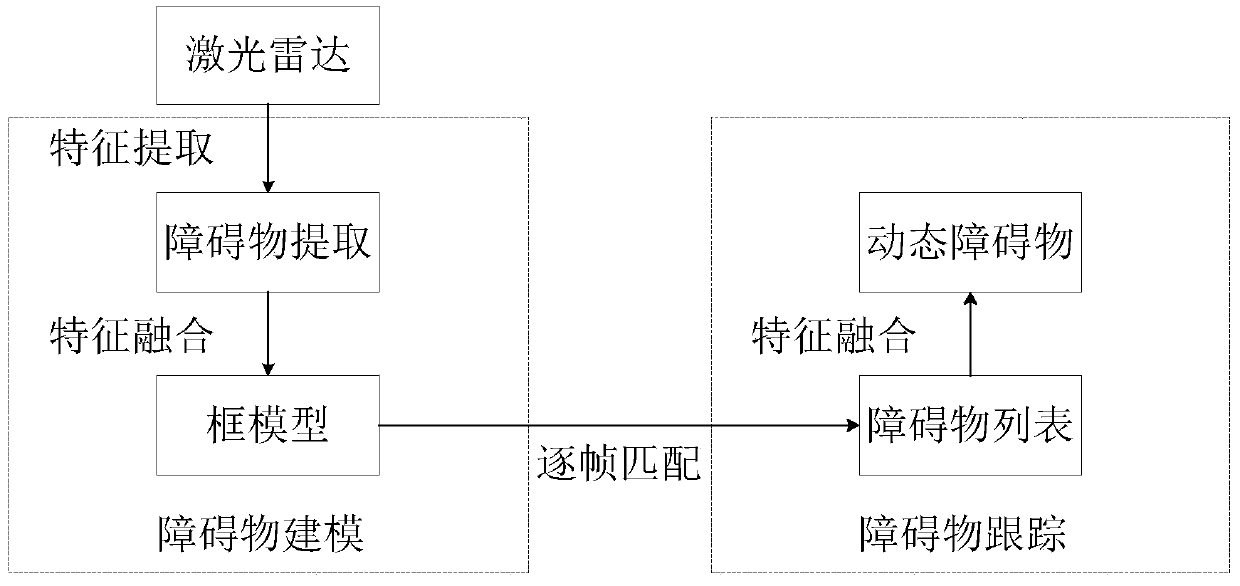

The invention discloses a man-machine moving obstacle monitoring method, a readable storage medium and an unmanned aerial vehicle. The method comprises a step of obtaining obstacle features of an obstacle through different sensors and building frame models based on the obstacle features to recognize the obstacle, a step of fusing the obstacle recognition results of different sensors to construct an obstacle motion state model and tracking the obstacle based on the obstacle motion state model. According to the embodiment of the invention, the frame models are established based on the obstacle features to identify the obstacle, the obstacle recognition results of different sensors are fused to construct the obstacle motion state model, and the obstacle is tracked based on the obstacle motionstate model, so that the unmanned aerial vehicle can effectively recognize, track and monitor the moving obstacle in a flight process, and a three-dimensional obstacle avoidance path of the unmannedaerial vehicle is planned in real time.

Owner:CHINA ACADEMY OF ELECTRONICS & INFORMATION TECH OF CETC

Autonomous driving vehicle and autonomous driving system

ActiveUS10466709B2Improve securityAvoid stopAutonomous decision making processElectromagnetic wave reradiationEngineeringLimit value

An autonomous driving vehicle includes map information storage means, sensor state evaluation means, movement obstacle evaluation means, and speed limit value setting means. When the result of the evaluation of the sensor state evaluation means is within a first range, and a result of the evaluation of the movement obstacle evaluation means is without a second range, then a speed limit value is set based on the result of the evaluation of the sensor state evaluation means and then driving is continued within a range of the limit value.

Owner:HITACHI LTD

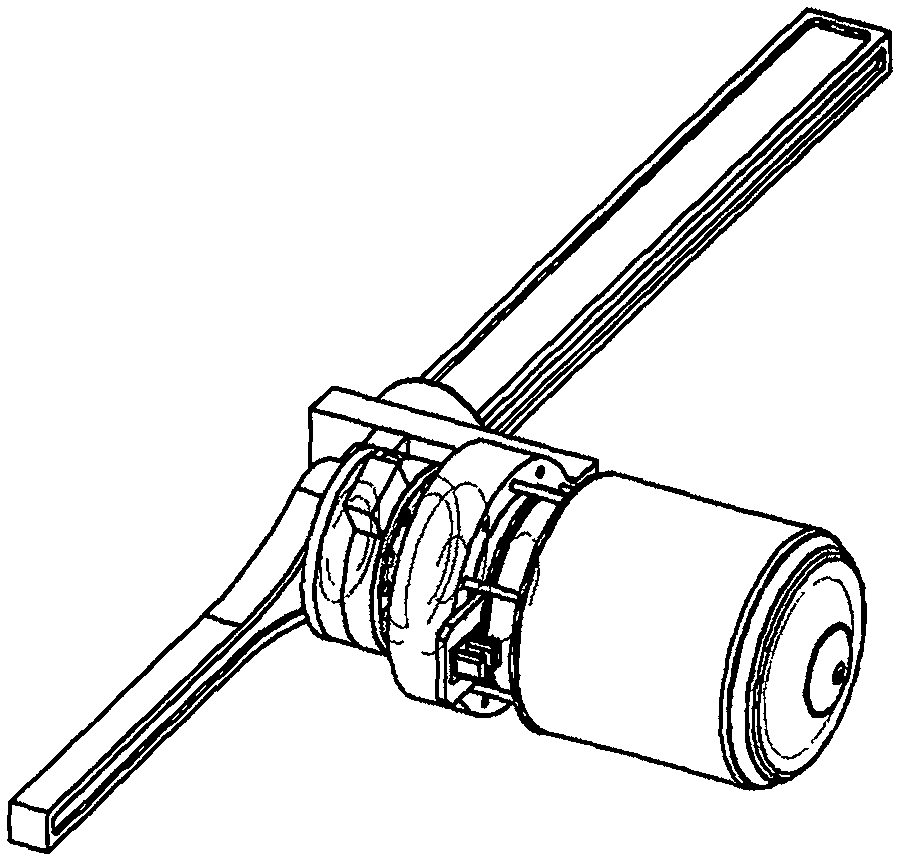

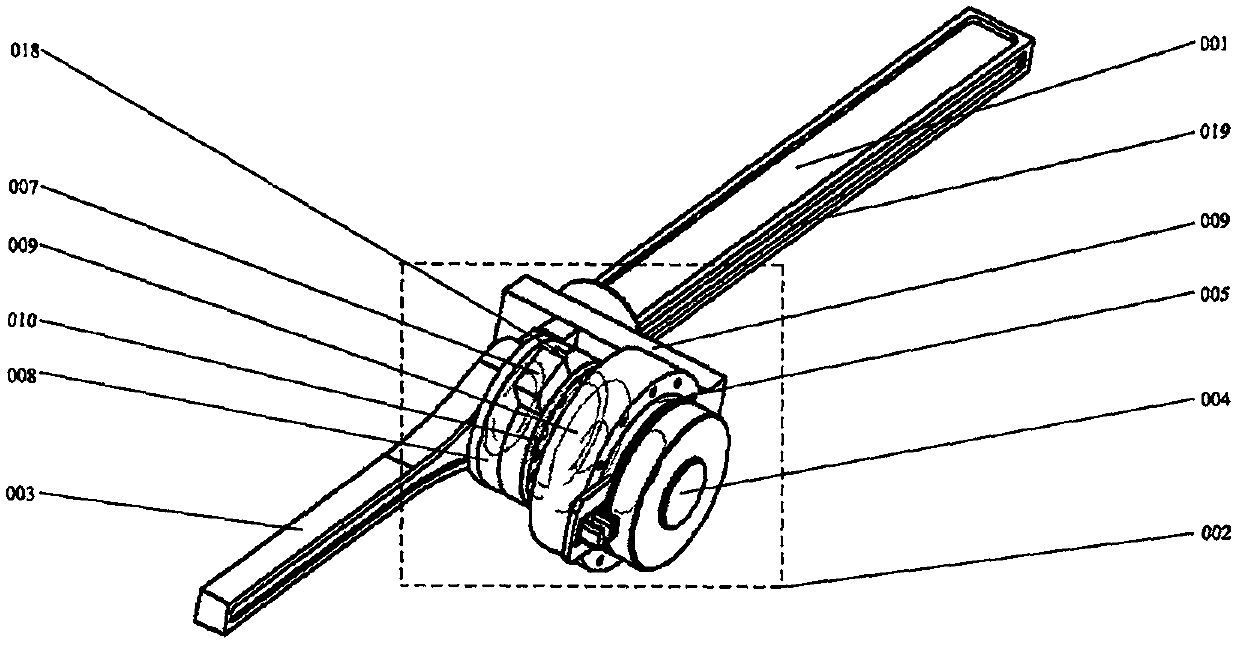

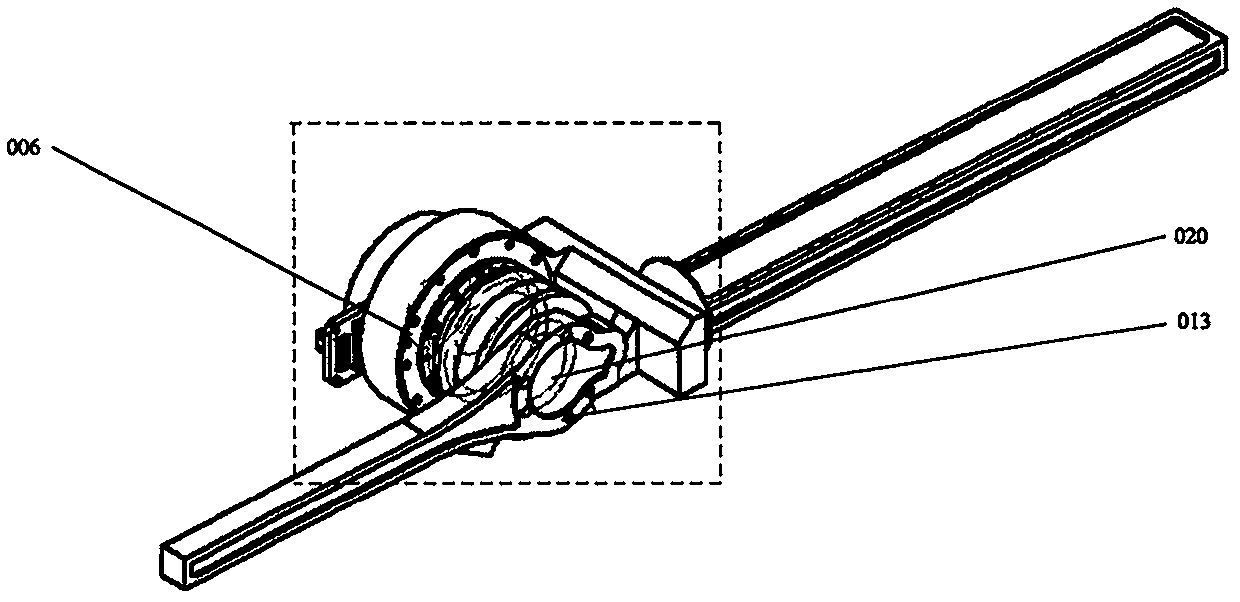

Electro-plastic friction stir spot welding device and method thereof

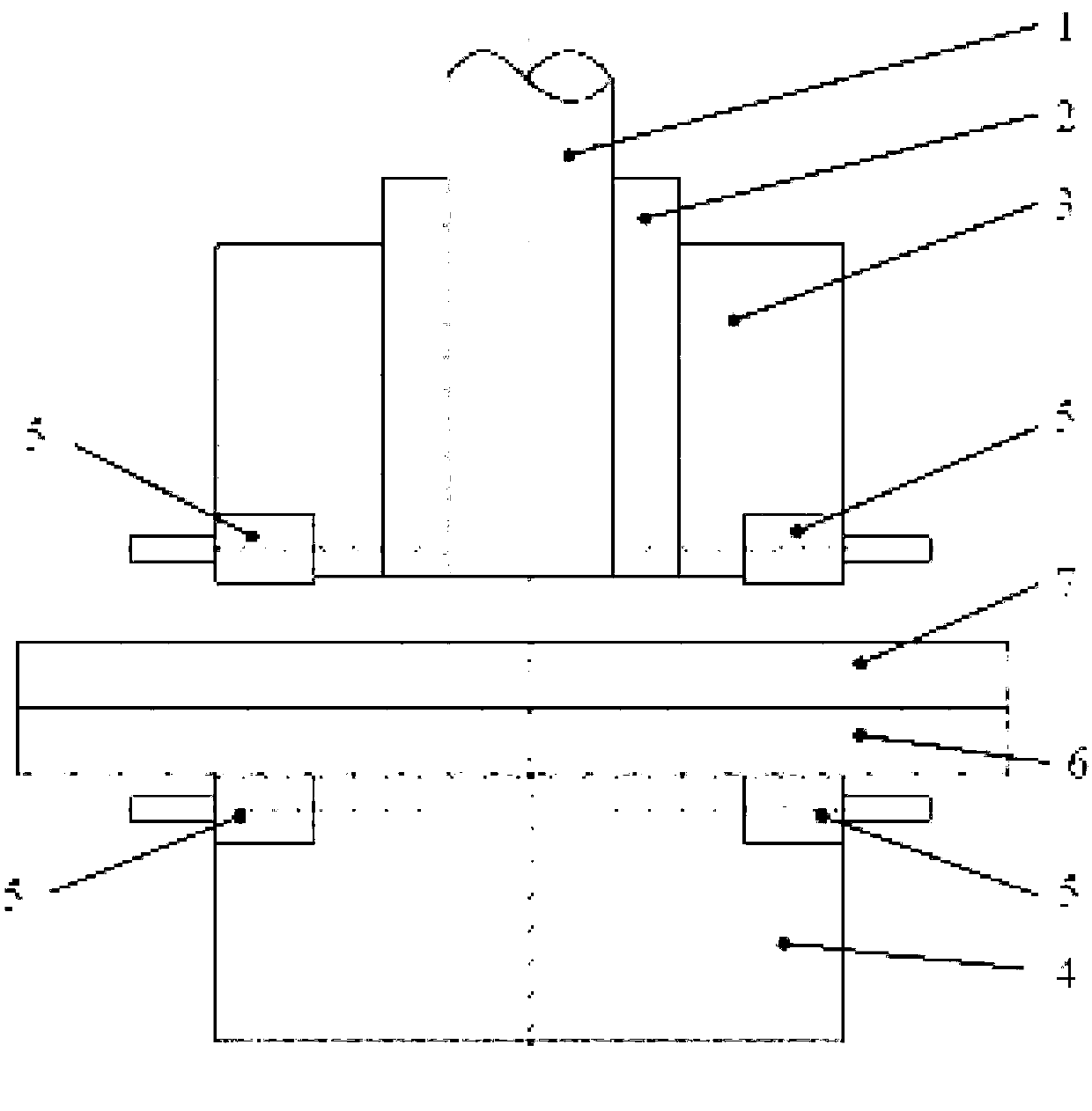

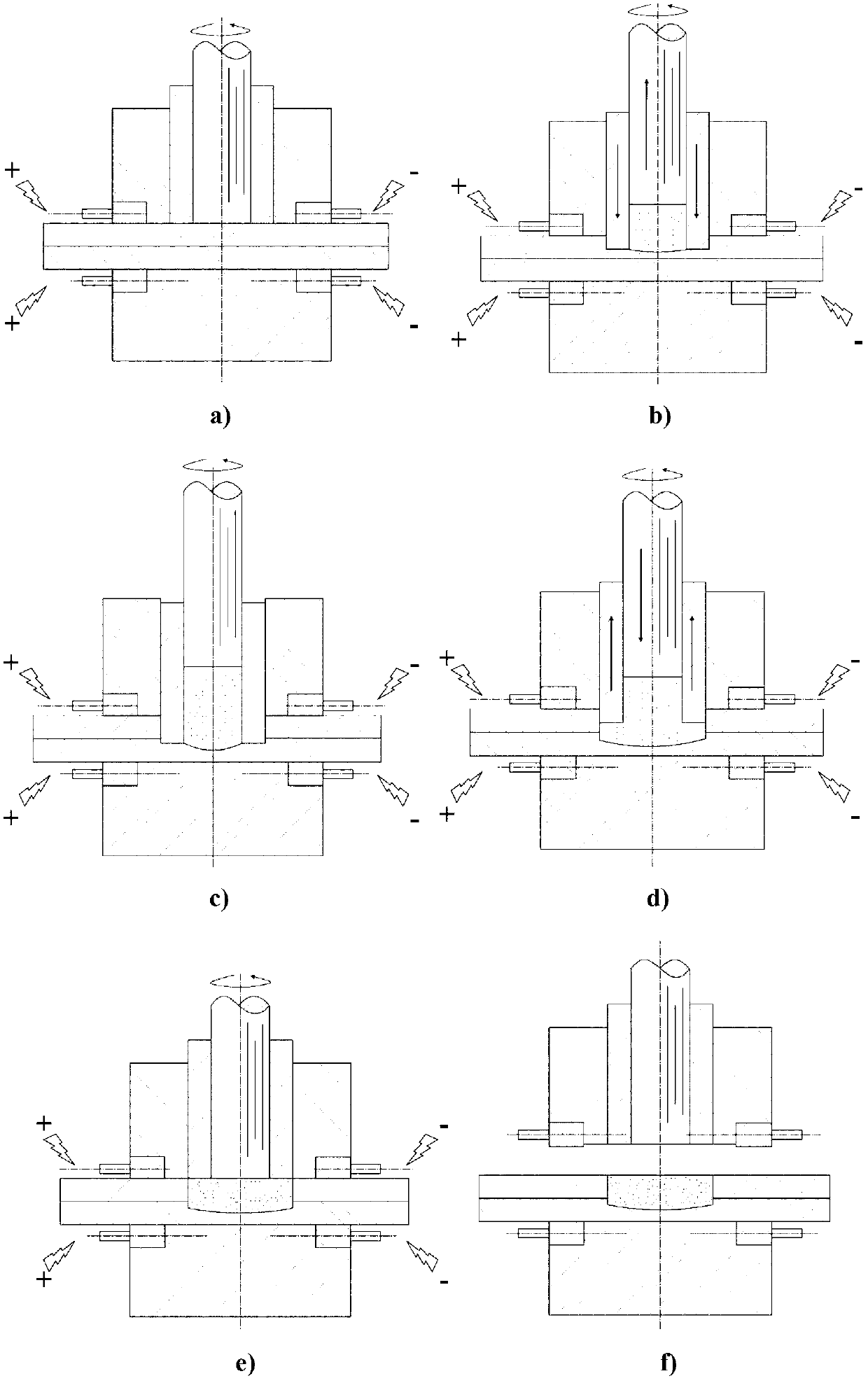

InactiveCN102974945AEasy plastic deformationImprove plastic fluidityNon-electric welding apparatusVertical planeMetallic materials

The invention provides an electro-plastic friction stir spot welding device, which comprises a stir sleeve, a stir needle in the stir sleeve, a clamping sleeve clamped outside the stir sleeve, and a welding cushion block, wherein two radial opening grooves are formed in the bottom of the clamping sleeve and the top of the welding cushion block respectively; electric brushes are mounted in the grooves; and the grooves are matched with the conductive blocks in the electric brushes in shape. The invention further provides an electro-plastic friction stir spot welding method, which comprises the steps of carrying out plastic softening on a metal material, communicating the two electric brushes with a direct current independently and respectively while compacting a welding workpiece by the clamping sleeve, enabling the polarities of the two electric brushes on the same horizontal plane to be opposite and the polarities of the two electric brushes on the same vertical plane to be the same, connecting a welding circuit, and finishing the welding operation by adopting a spot welding process. According to the invention, a high-density current is applied to the metal deformation direction by utilizing the electro-plastic effect of the metal material, so that the metal dislocation is promoted, the motion defect is overcome, the plastic flow capability of the metal material is improved, and the welding quality is improved.

Owner:SHANGHAI DIANJI UNIV

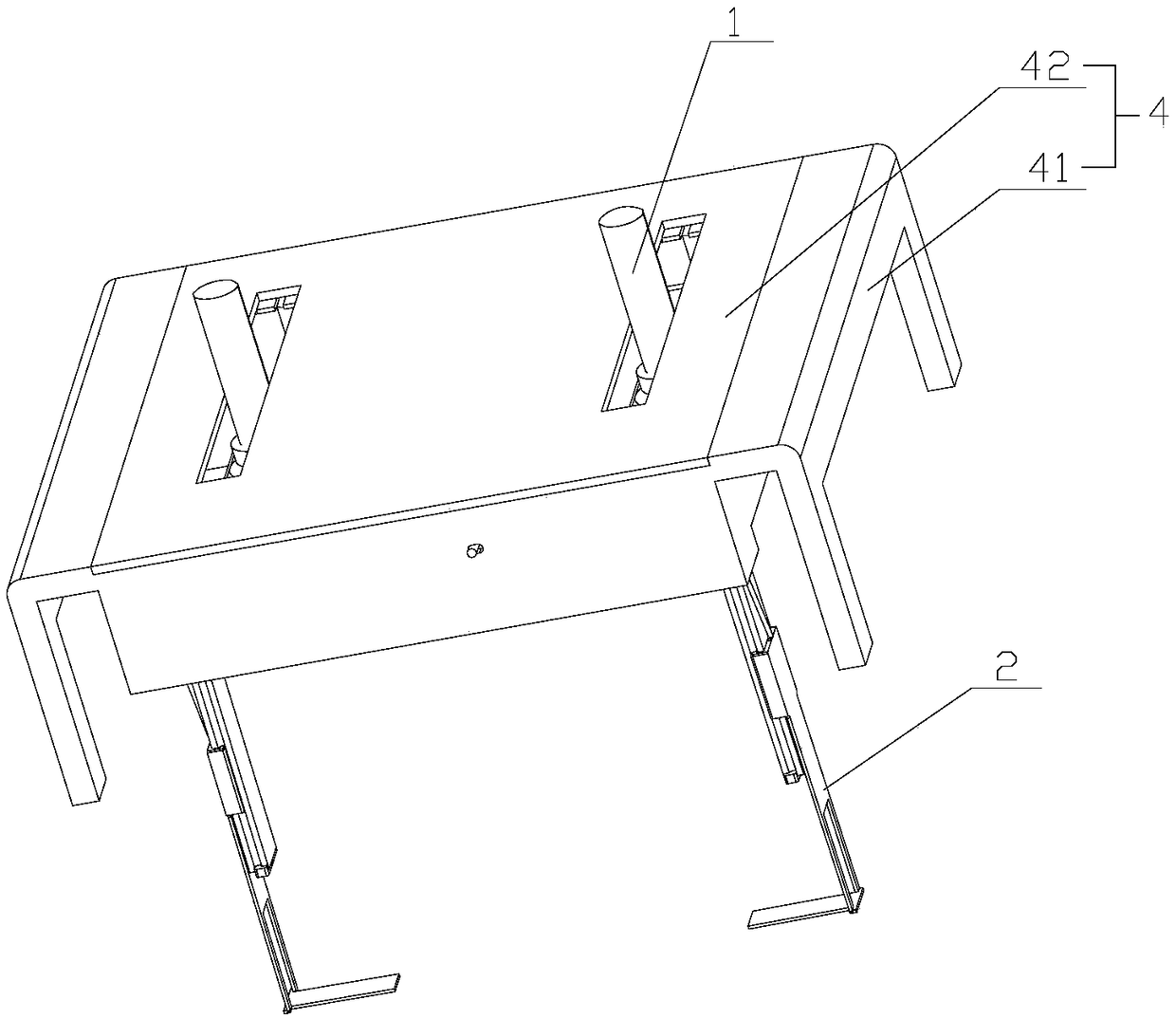

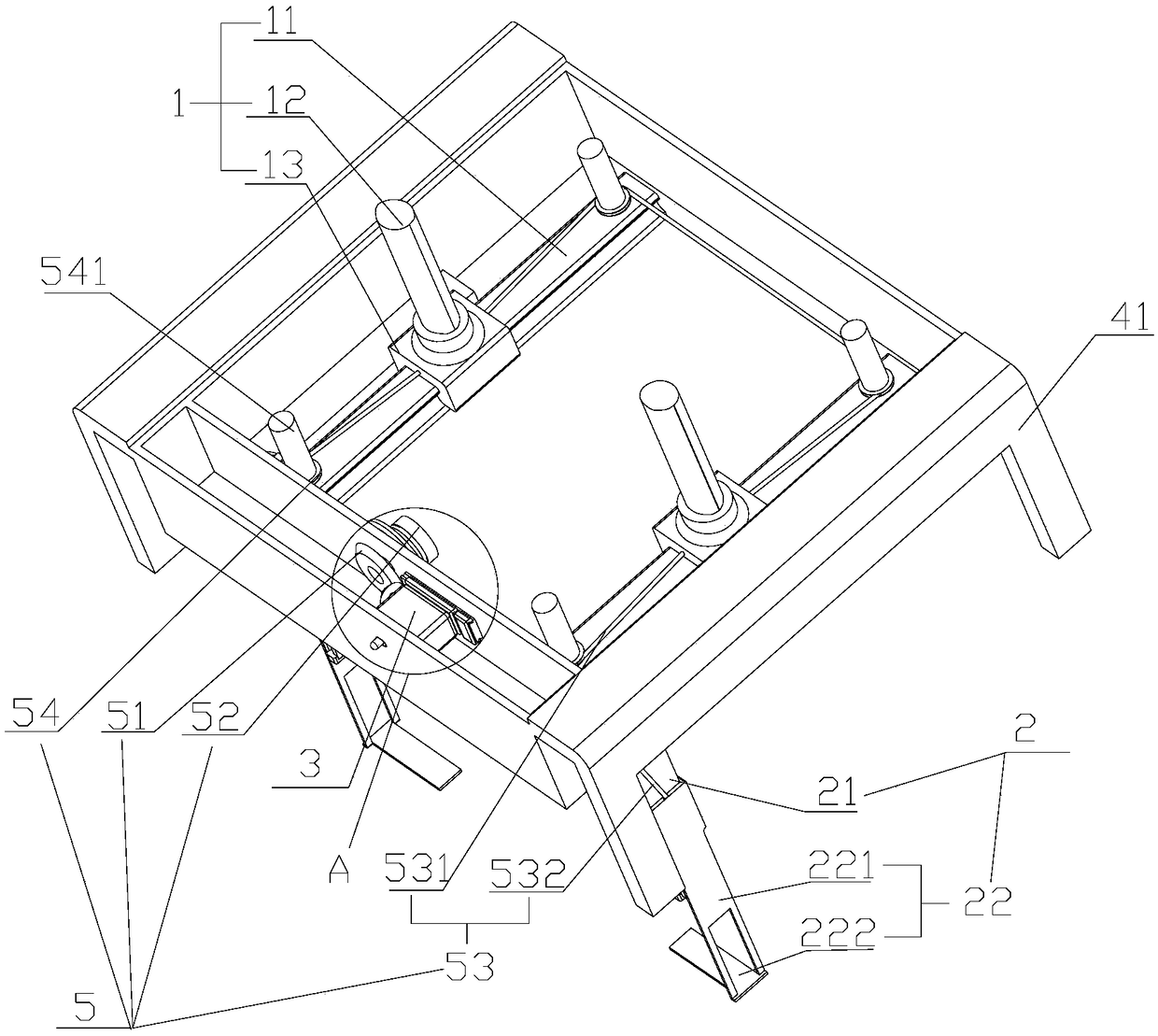

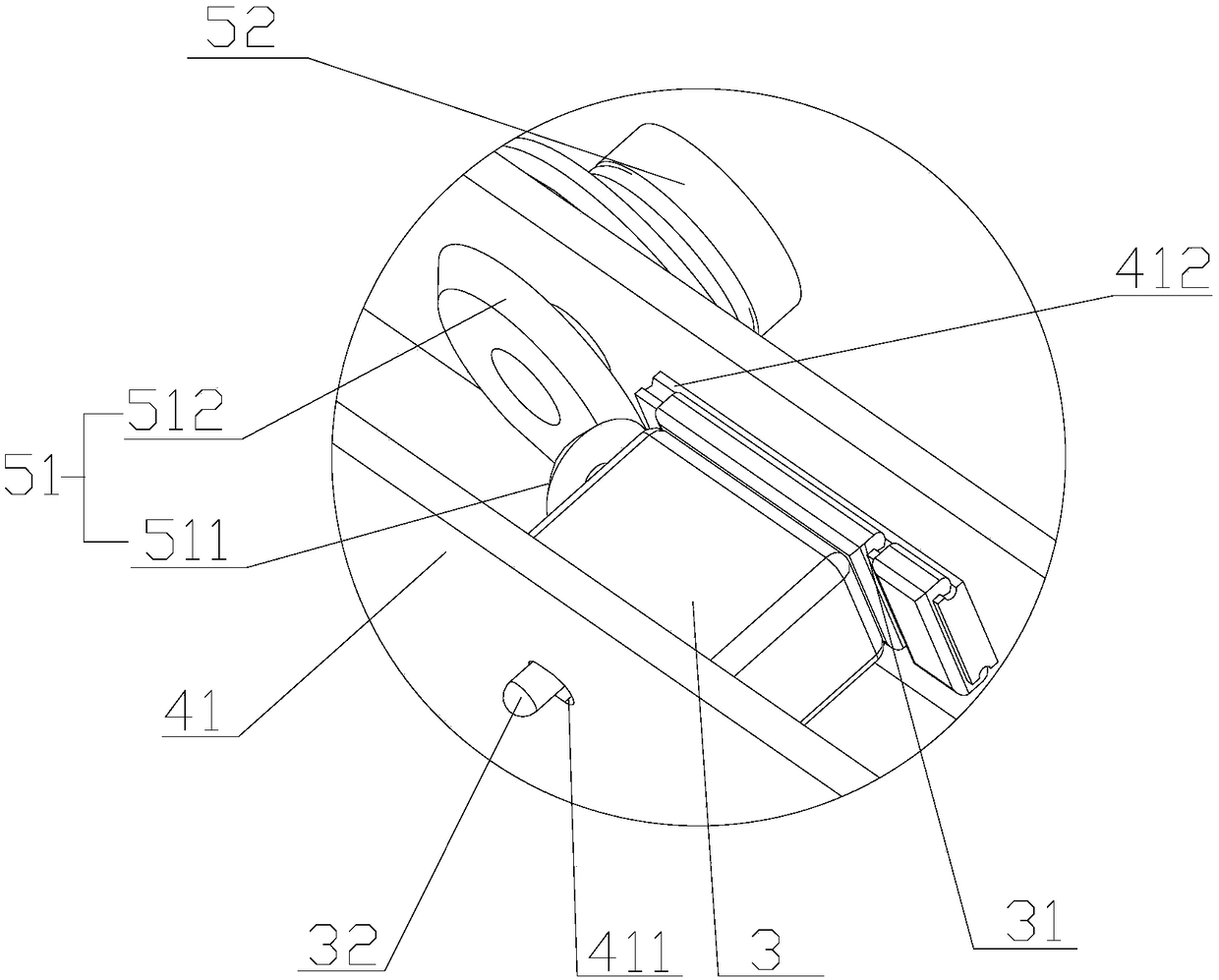

Active-passive integrated exercise device

PendingCN109009878AReduce re-injuryReduce usageGymnastic exercisingChiropractic devicesPassive exercisesActive exercise

The invention relates to the field of medical instruments and in particular to an active-passive integrated exercise device comprising an upper limb rehabilitation component, a lower limb rehabilitation component and a driving device, wherein the upper limb rehabilitation component, the lower limb rehabilitation component and the driving device are all disposed on a bracket; and the driving devicesimultaneously drives the upper limb rehabilitation component and the lower limb rehabilitation component to operate through a transmission component. The exercise device of the invention can realizethe integration of the active exercise and the passive exercise by using the driving device to drive a user to perform simple exercises. Compared with the active exercise by the patient, the passiveexercise is safer, does not cause sport injury, and reduces the possibility of further injury of the user. The active-passive integrated exercise device is very suitable for the elderly and patientsdisabled in mobility, assists the effective physical exercise of patients with congenital dyskinesia, solves the problems that a rehabilitation device in the prior art requires the active exercise ofthe patient, is likely to cause damage to the patient, and is not as safe as the passive exercise or as wide as the passive exercise in applicability.

Owner:JIANGSU UNIV OF TECH

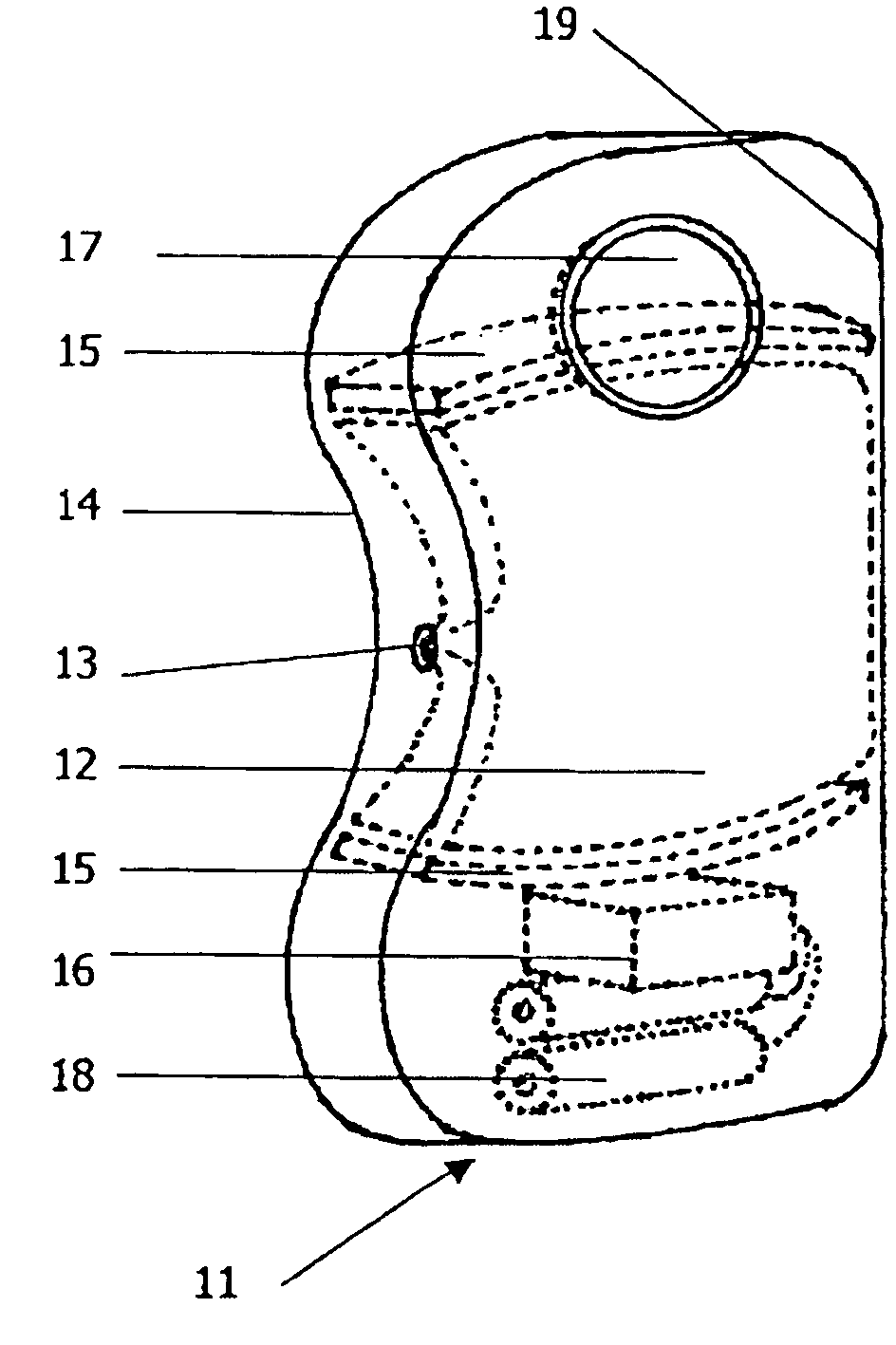

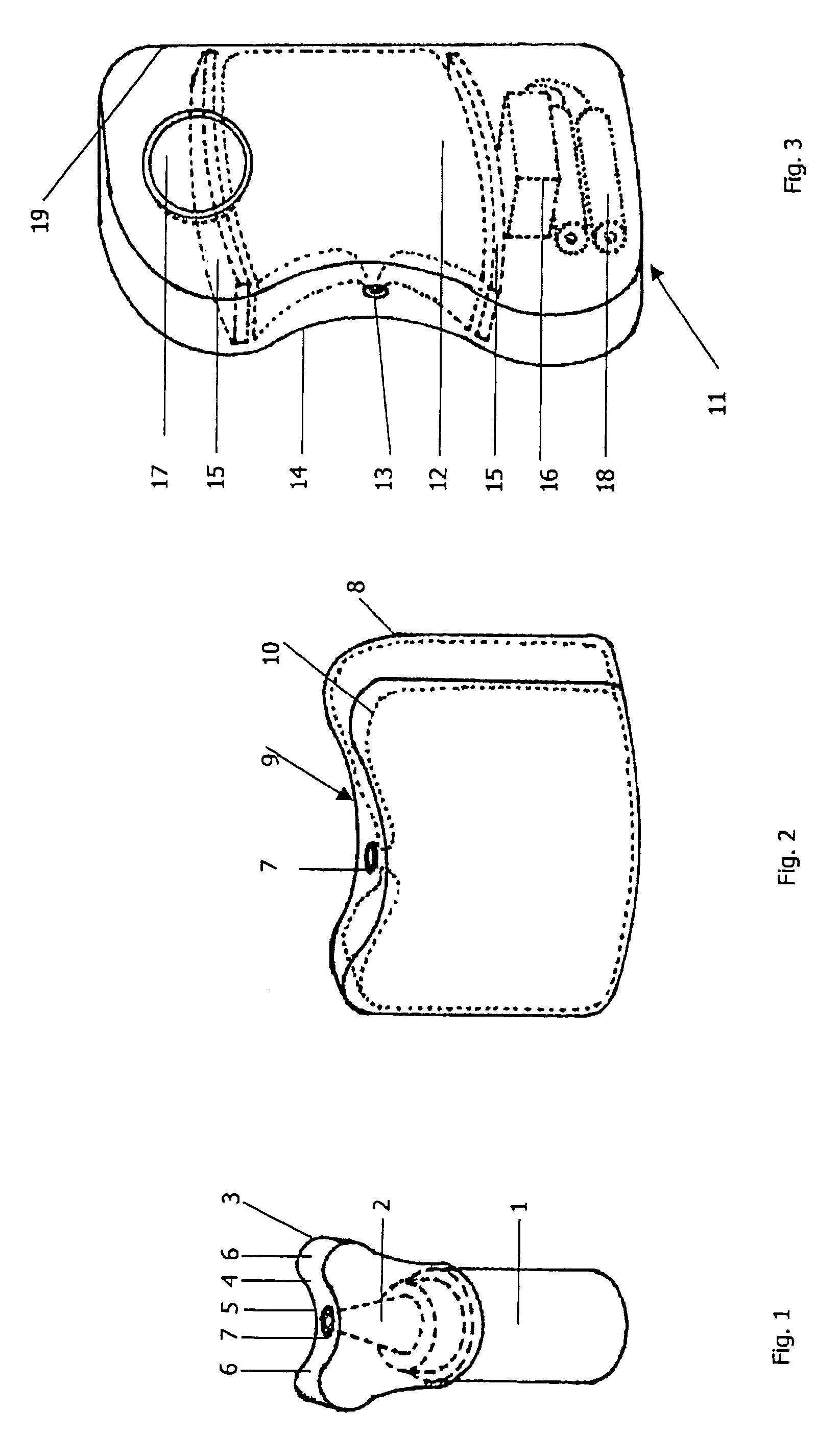

Container for medical ophthalmic preparations and protective cap for such a container

InactiveUS7296710B2Easy to prepareReduce processing stepsPharmaceutical containersLarge containersOphthalmic preparationsBiomedical engineering

The container for medical ophthalmic preparations has an exit opening which is formed in an arcuate indentation of the container wall that passes at both sides into a respective arcuate bulge. The container is placed with said wave-like container wall on the area of the eyebrow and cheekbones, the indentation making sure that there is no contact with the surface of the eye. A protective cap for a conventional container for medical ophthalmic preparations has a corresponding wave-like contour. Said contour ensures a safety distance from the eye, which excludes any injuries. The container and the protective cap can be handled easily in the case of a self-administration of the eye drops—even by persons with motoric disorders.

Owner:PETABCHNER THOMAS

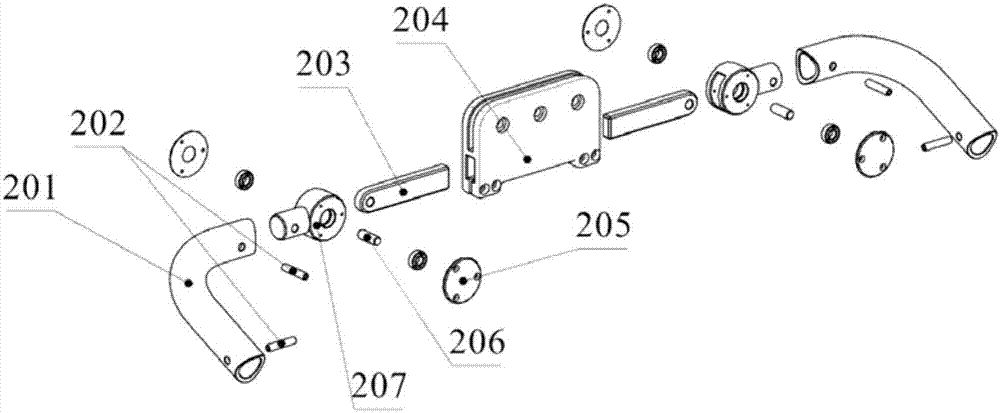

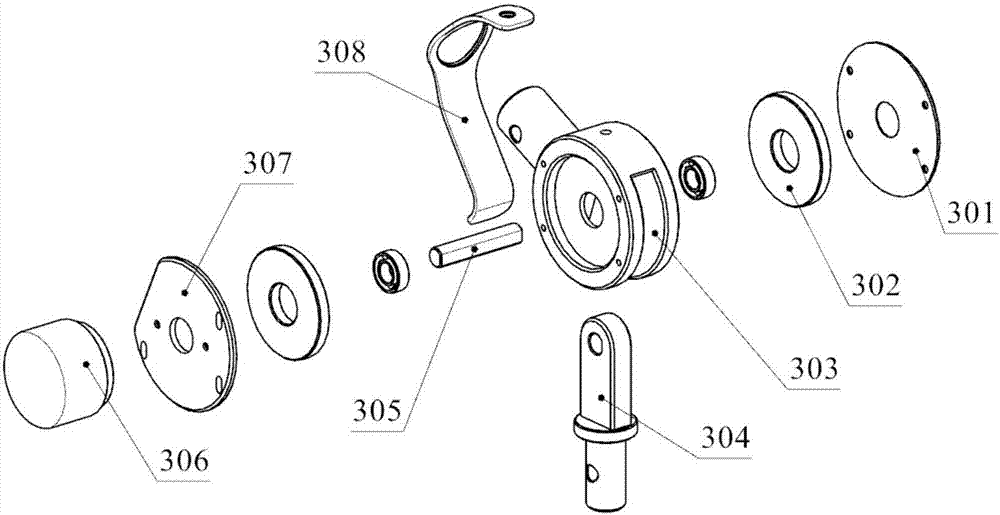

Modular knee joint of lower limb rehabilitation training robot

InactiveCN109953869ACompact structureHighly integratedGymnastic exercisingChiropractic devicesHuman bodyThree level

The invention relates to a modular knee joint of a lower limb rehabilitation training robot, and belongs to the field of service robots. The anthropomorphic design of a two-connecting rod series mechanism and a rotating mechanism is adopted; two connecting rods are adjustable connecting rods. The compatibility between different human body sizes and a system device is fully considered; patients canadjust a clamping buckle position arbitrarily according to the comfort level. The modular knee joint is internally equipped with double limit links, namely mechanical limit and electrical limit, andthe safety during system operation is ensured. The whole machine control module adopts three-level layered placement, has the advantages of high integration level, strong functional expansibility, wide range of versatility and easy replacement and maintenance. At the same time, electrical lines can be isolated and protected, and a hollow routing mode is adopted for a routing mode. The modular kneejoint has the advantages of compact structure, high integration level, strong expansibility, convenient installation, convenient maintenance and stable and reliable use during use, and carries out function rehabilitation training of motion functions for patients with motion disorder.

Owner:ZHEJIANG UNIV

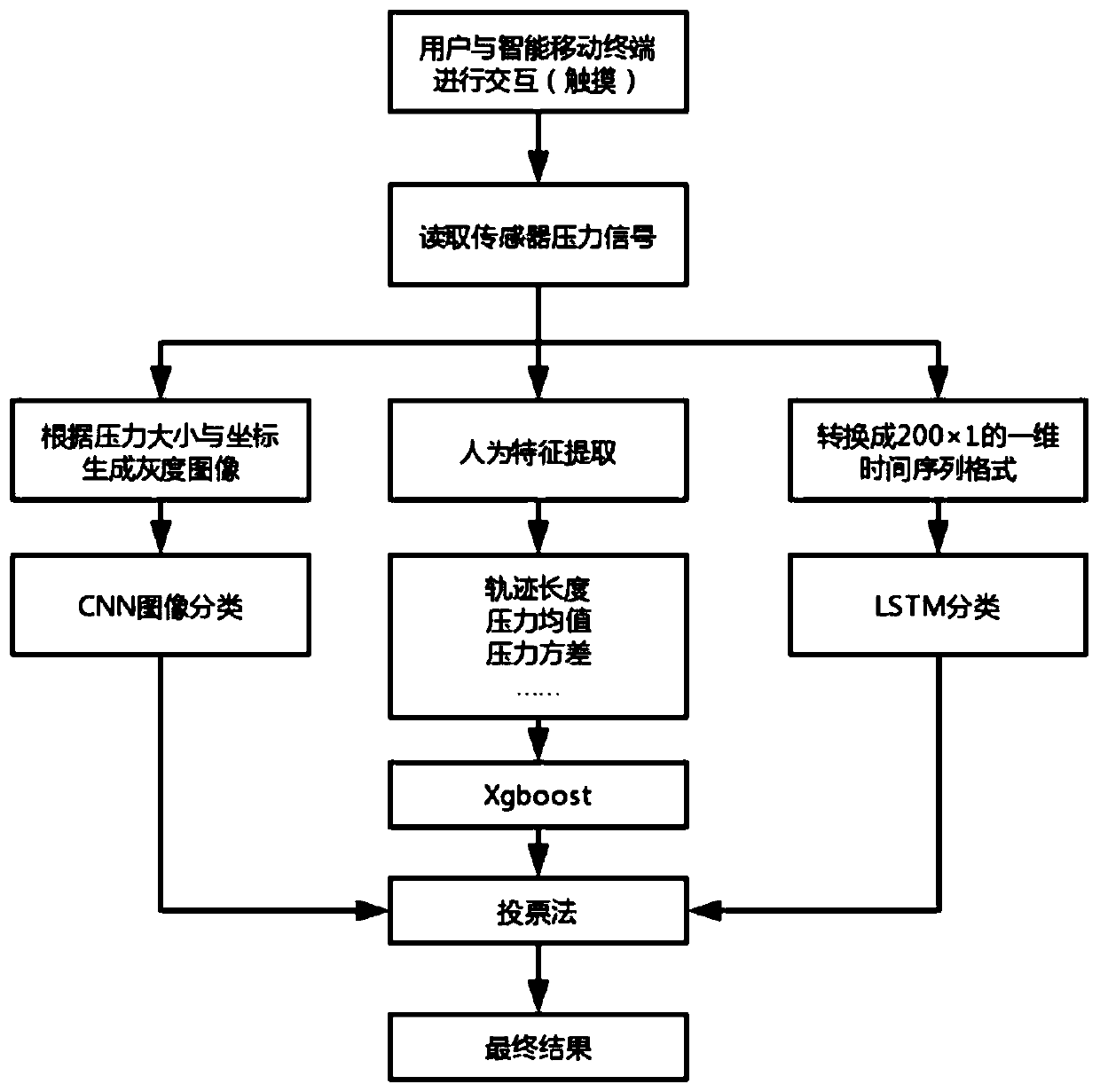

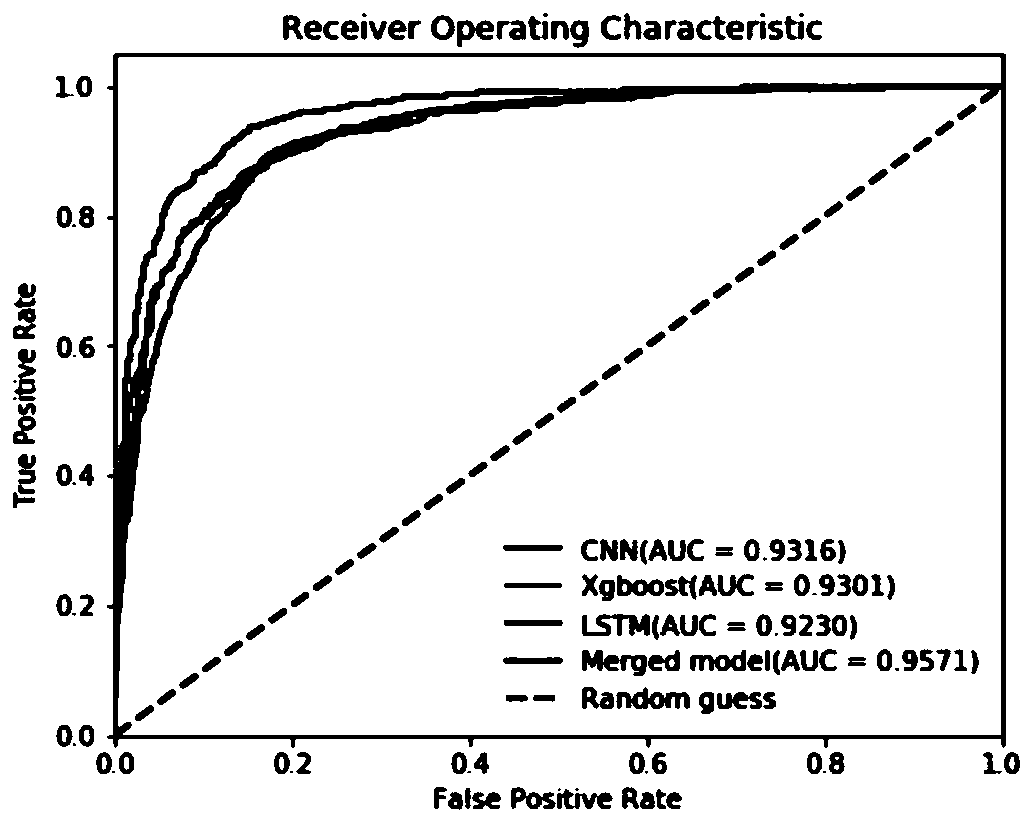

Finger flexibility detection method based on recognition of operation behaviors of smart mobile terminal

ActiveCN110123280AImprove convenienceImprove securityDiagnostic signal processingCharacter and pattern recognitionDiseasePattern recognition

Owner:ZHEJIANG UNIV

Electroencephalogram and electromyogram synchronous acquisition and information transfer characteristic analysis method

InactiveCN103584855BAids in the exploration of functional linkagesDiagnostic recording/measuringSensorsRehabilitation engineeringKnowledge Field

The invention relates to the fields of rehabilitation engineering, neural engineering and dyskinesia mechanism research, in particular to an electroencephalogram and electromyogram synchronous acquisition and information transfer characteristic analysis method. The method includes an electroencephalogram and electromyogram synchronous acquisition step and a signal processing step, the electroencephalogram and electromyogram synchronous acquisition step includes electroencephalogram acquisition and electromyogram acquisition, and the signal processing step includes signal preprocessing and an electroencephalogram and electromyogram transfer characteristic analysis method. The method has applicability and adoptability and has significant application value in the rehabilitation medicine field.

Owner:YANSHAN UNIV

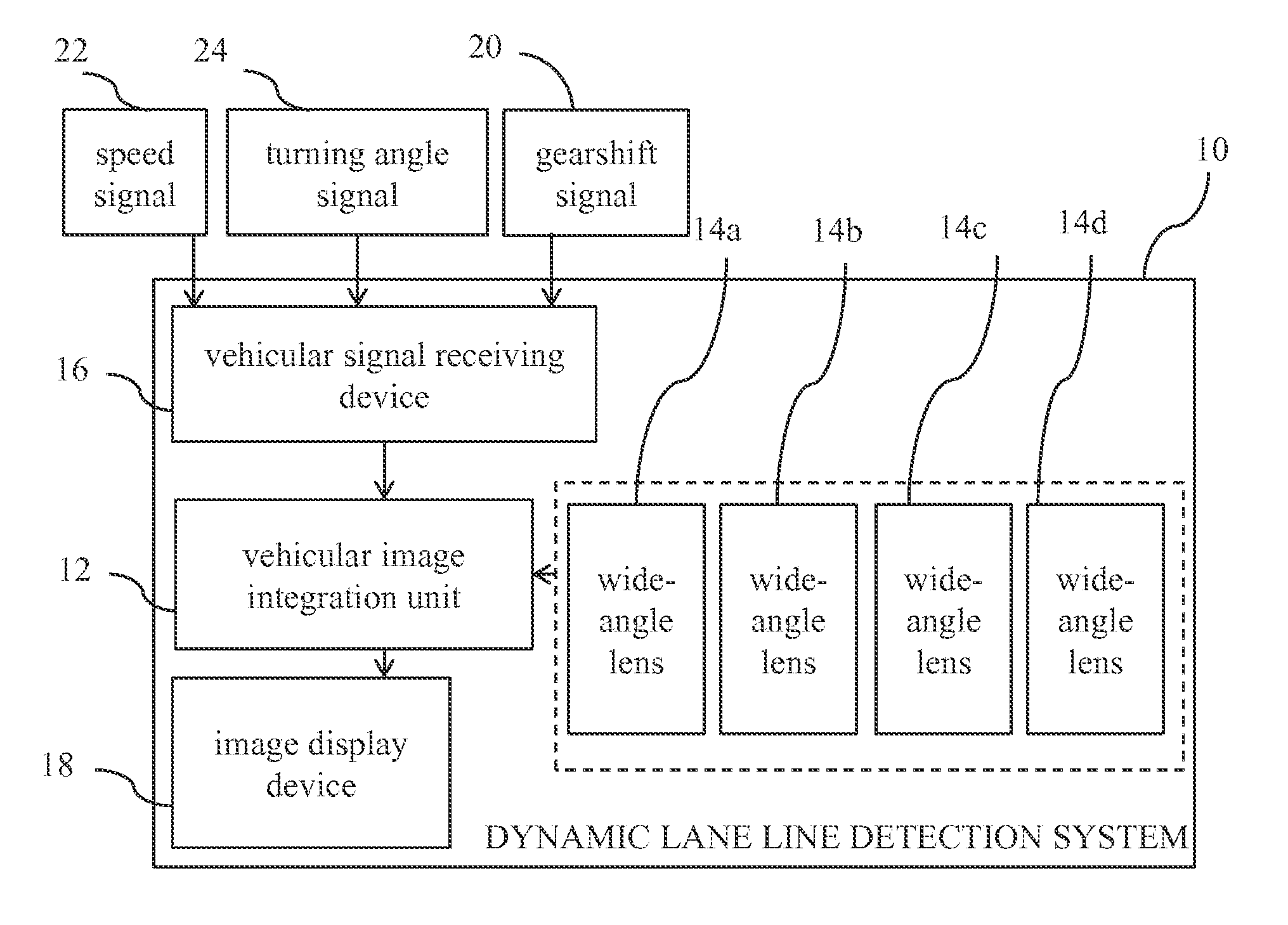

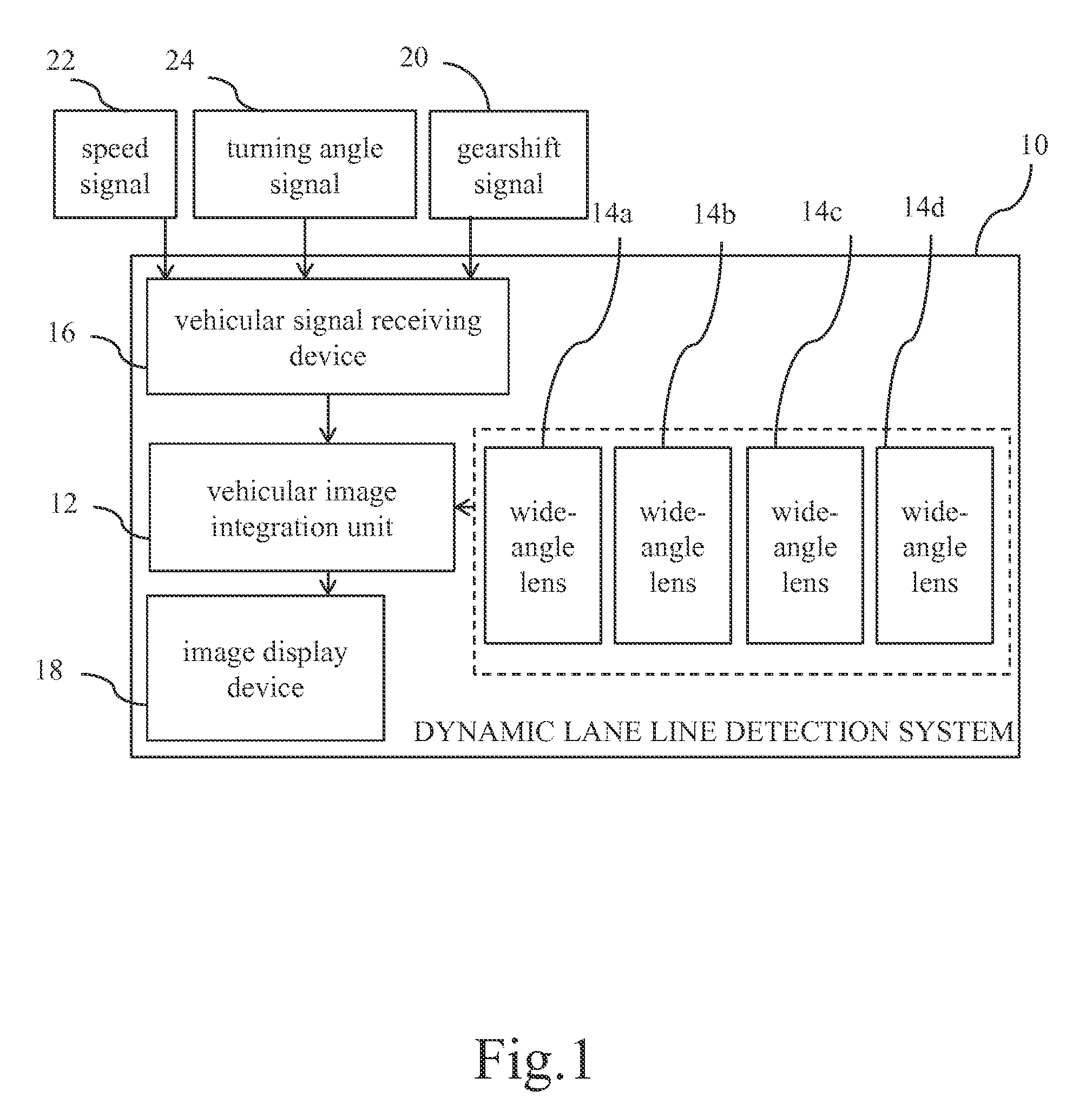

Dynamic lane line detection system and method

ActiveUS9508016B2Reduce financial burdenLower the volumeCharacter and pattern recognitionClosed circuit television systemsTurn angleComputer graphics (images)

Owner:AUTOMOTIVE RES & TESTING CENT

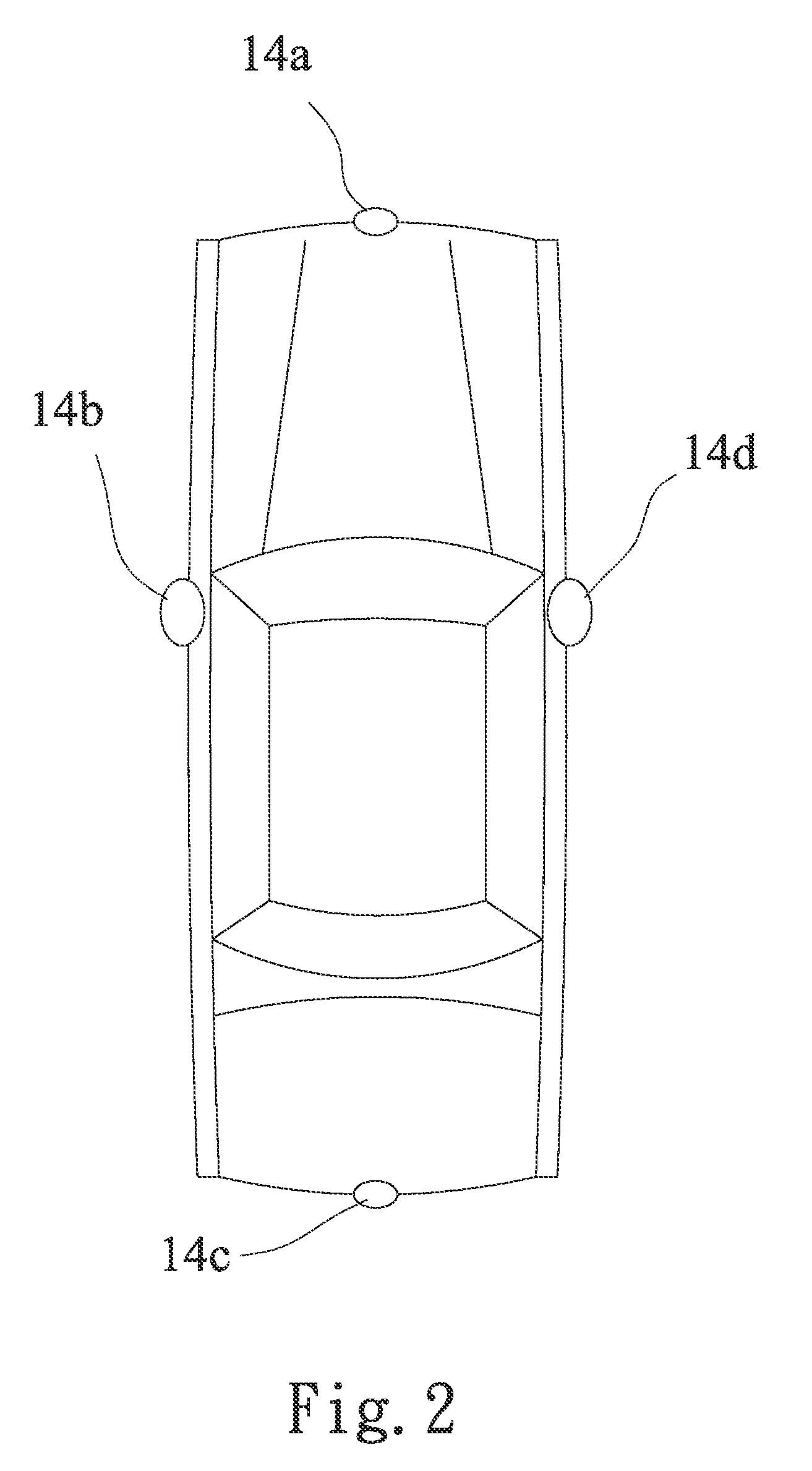

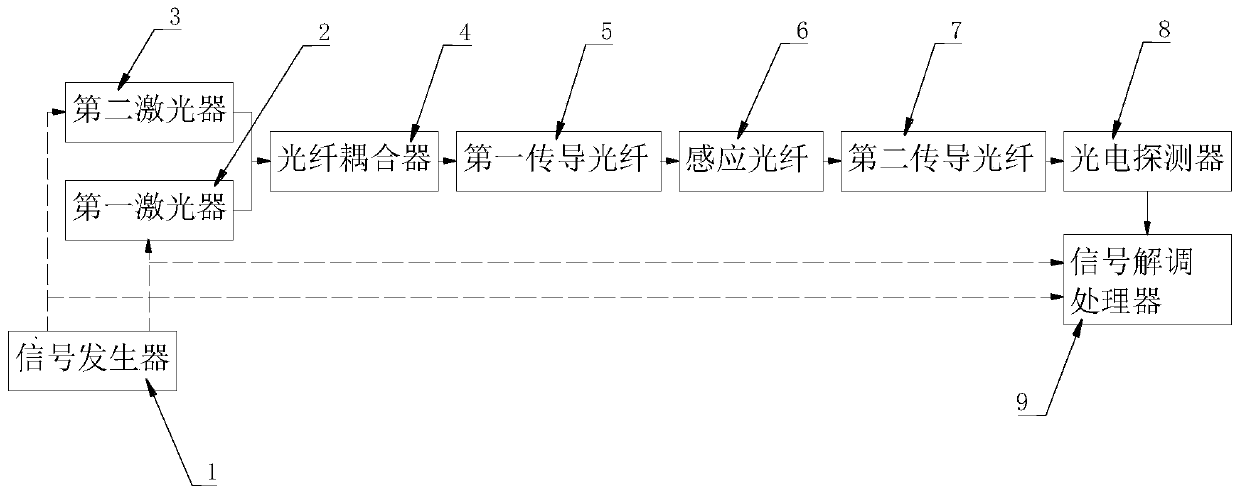

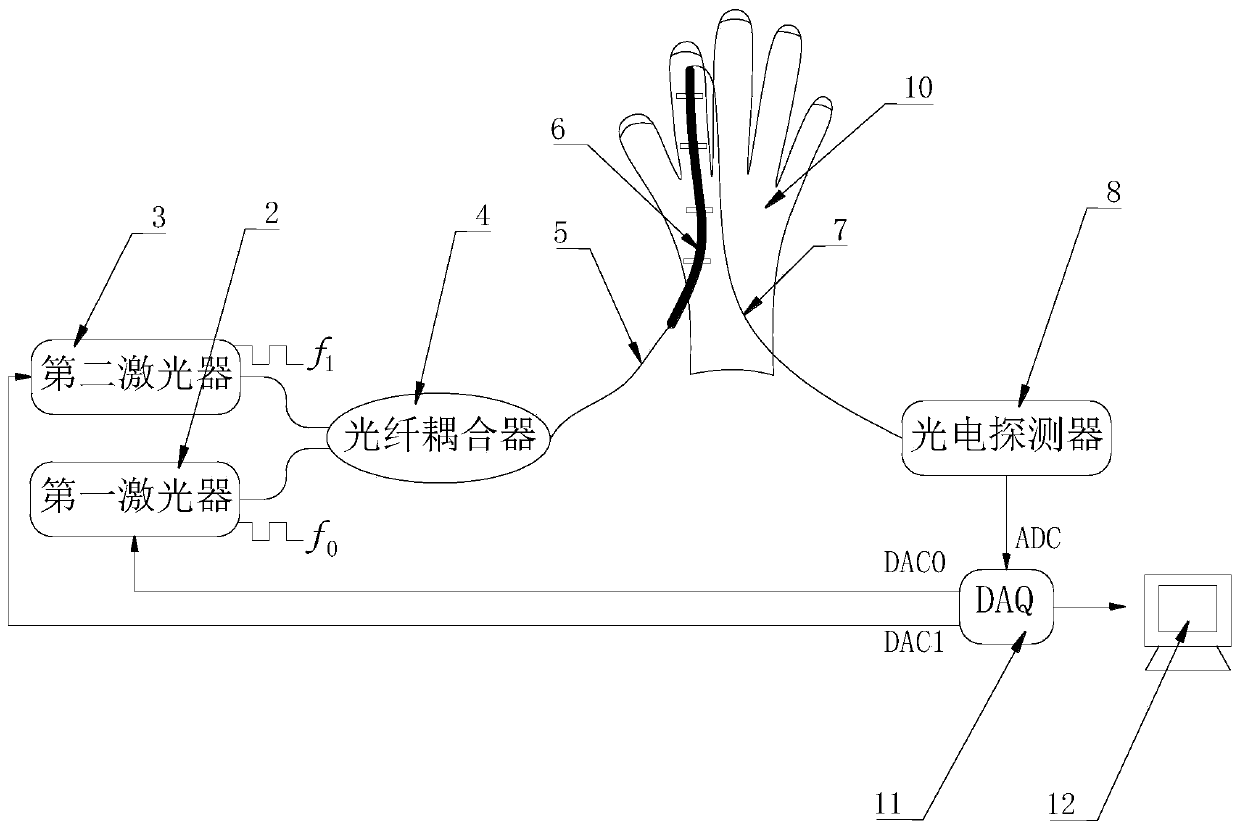

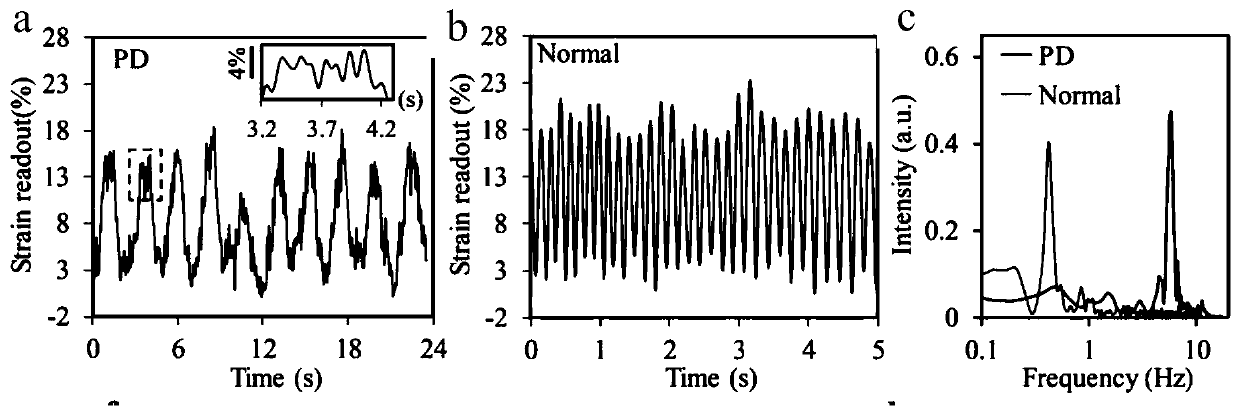

Monitoring system for human motion

PendingCN109820516ASimple structureLow costCladded optical fibreDiagnostic recording/measuringHuman bodyDisease

The invention discloses a monitoring system for human motion. The system comprises a signal generator, a laser, a first conduction optical fiber, a sensing optical fiber, a second conduction optical fiber, a photoelectric detector, a signal demodulation processor and a wearing device; the signal generator is connected with the laser through a circuit and used for generating a demodulation signal so as to drive the laser to output a laser pulse signal; the sensing optical fiber is a flexible sensing optical fiber, the wearing device can be worn on the movable joint of the human body, and the sensing optical fiber is fixed to the wearing device and can be bent and deform along with joint motion of the human body. According to the monitoring system for the human motion, the motion characteristics of all movable joints of the human body can be accurately reflected and monitored, and quantitative evaluation can be conducted. The motion characteristics have extremely important value on evaluation for dyskinesia diseases such as Parkinson's disease and fremitus.

Owner:GENERAL HOSPITAL OF PLA

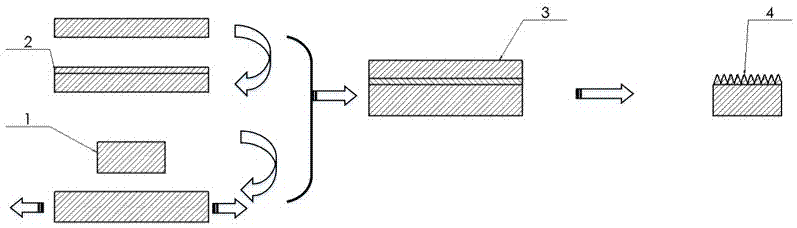

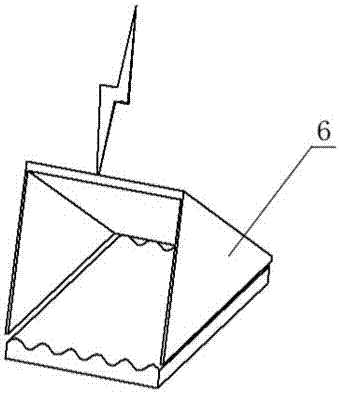

Wet gradient surface preparation method integrating waviness with chemical gradient

The invention discloses a wet gradient surface preparation method integrating waviness with chemical gradient. The wet gradient surface preparation method comprises the following steps: step (1) preparing a coating solution of polydimethyl siloxane; step (2) performing coating solution spin-coating; step (3) preparing a flexible wavy structure; step (4) preparing shielding plate; and step (5) preparing a surface integrating chemical gradient with the flexible wavy structure. According to the preparation method disclosed by the invention, the flexible material is adopted, and the flexible material is utilized to generate the wavy structure in the stress directions at the two sides, so that motion barriers at the two sides of liquid drop are improved; and plasma treatment is utilized to obtain a chemical gradient micro structure surface, so that liquid drop spreads in single direction; and the side surfaces of the wavy structure are of trigonometric function types.

Owner:ZHEJIANG UNIV OF TECH

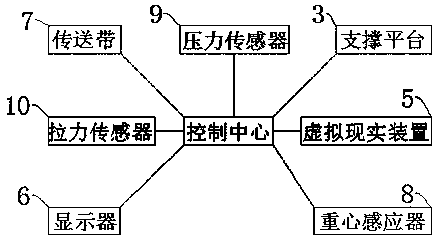

A kind of balance training equipment and using method thereof

The invention discloses a balance training device and a using method thereof. The balance training device comprises a training treadmill, a supporting platform and a control center. The training treadmill is provided with a conveying belt. The balance training device further comprises a pressure sensor. The supporting platform is a six-freedom-degree parallel robot platform, is connected with the training treadmill and used for supporting the training treadmill and achieving movement of the training treadmill in six degrees of freedom. The control center is used for controlling the training treadmill and the supporting platform. The balance training device has the advantages that the balance training device is simple in structure, convenient to operate and high in safety coefficient, the whole feedforward can be finished in the device, balance training is stressed, a true movement environment is simulated, the training becomes difficult from simple and proceeds in an orderly way and step by step, the training cost is reduced, training objects are ordinary balance function dysfunction people to apoplexy dyskinesia patients and the like, and the balance training device is of great significance for alleviating social economic burden and making a balance training system enter families and has wide market prospects.

Owner:SHENGJING HOSPITAL OF CHINA MEDICAL UNIV

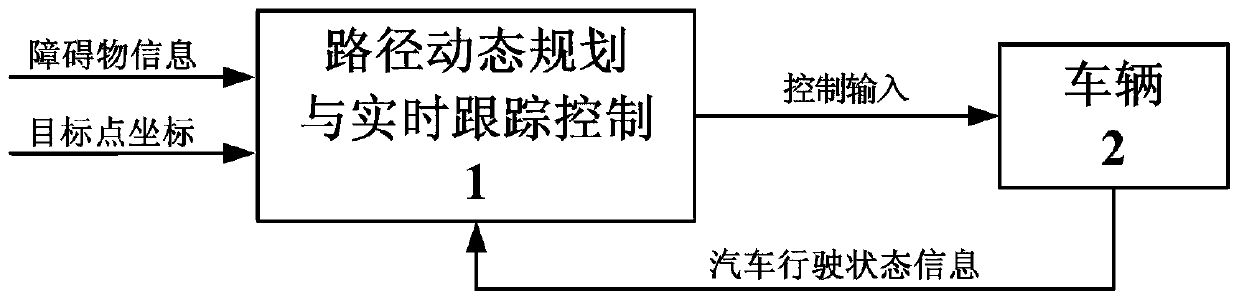

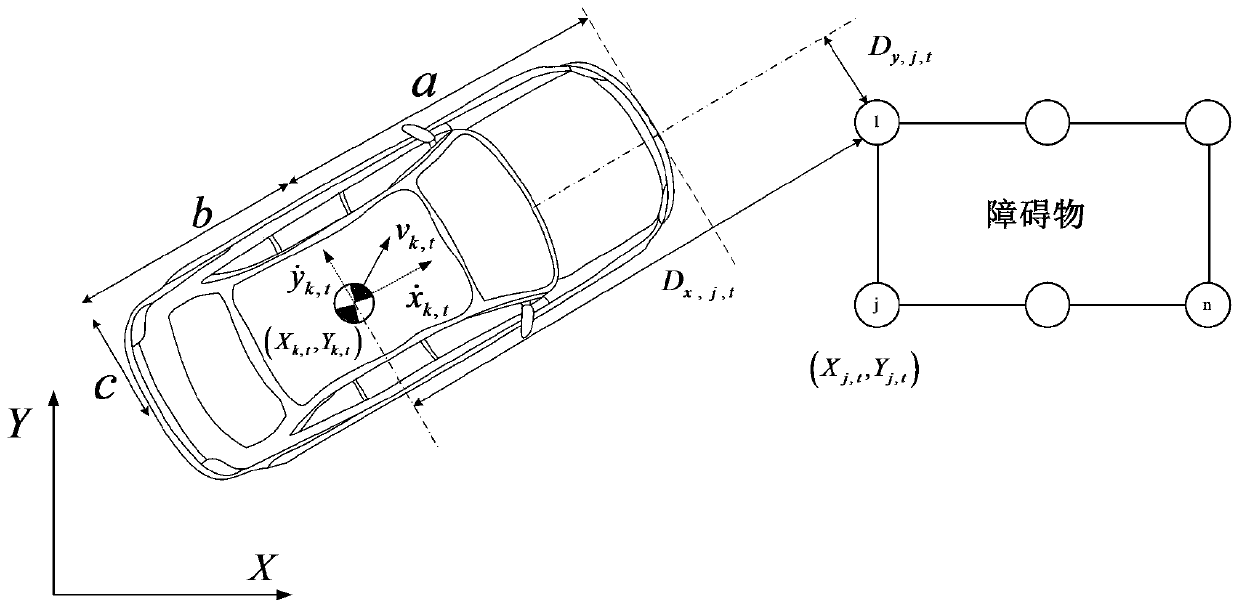

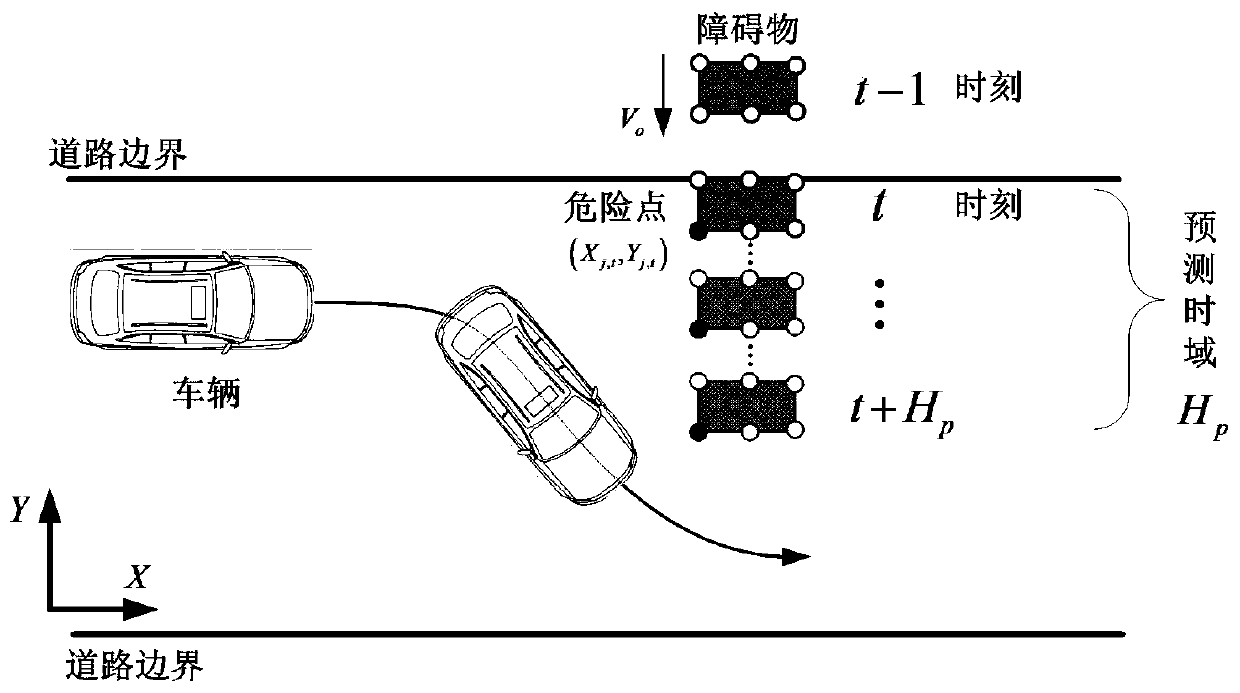

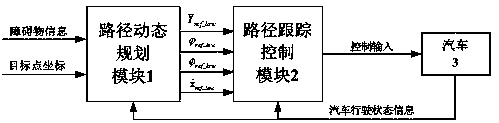

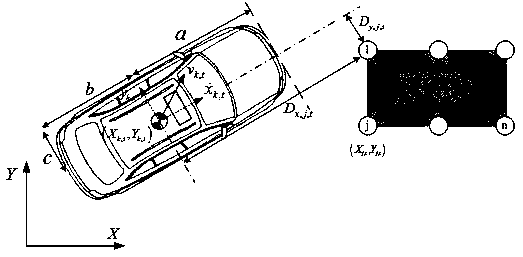

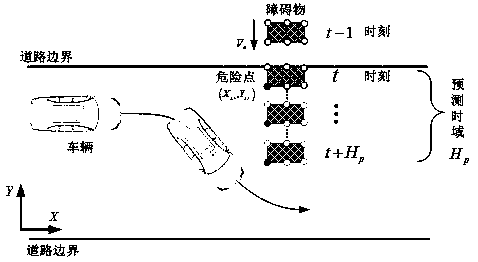

A vehicle emergency collision avoidance control method considering moving obstacles

InactiveCN107839683BSolve real-timeTroubleshoot movement barriersExternal condition input parametersDynamic planningCar driving

An automotive emergency collision avoidance control method considering moving obstacles relates to the technical field of advanced automobile driver assistance. The method utilizes a path dynamic planning and a real-time tracking control module for real-time optimization to obtain the slip ratio of automobile front-wheel angle and four wheels according to real-time acquisition obstacle information, target point coordinates and automobile driving status information, thereby controlling the car to achieve collision avoidance. The method constructs a multi-objective optimization problem based onmodel predictive control and then formulates a non-collision path in the form of dynamic constraint. Compared with the traditional hierarchical method, the real-time performance is high, the path satisfies the dynamic constraint, and the collision avoidance process is more reliable. The method transforms the motion of the obstacle into the dynamic constraint of collision avoidance control optimization solution through the change of the obstacle coordinates so as to solve the problem of the moving obstacle in collision avoidance control.

Owner:CHANGCHUN UNIV OF TECH

Four-degree-of-freedom integrated robot joint mechanism

InactiveCN101879721BSolve the problem that only one degree of freedom can be drivenHighly integratedJointsDot matrixSingle degree of freedom

The invention provides a four-degree-of-freedom integrated robot joint mechanism, relates to a robot joint, and aims to solve the problems of complex and huge whole mechanism of the robot because the conventional actually applied robot basically consists of single-degree-of-freedom joints. The robot joint comprises the technical key points that: the inner surface of a driving cylinder of the joint mechanism is provided with dot matrix windings; the outer surface of the main body of a driven element is provided with dot matrix permanent magnets; three first end plates and three second end plates are combined together respectively to form contours, and all the contours are circular rings which are coaxial with the inner surface of the driving cylinder; the main bodies of three cylindrical curve driven elements are combined together to form contours, and the contours are cylinders which are coaxial with the inner surface of the driving cylinder; each driven element axially slides along two corresponding guide rods; and one end of each of the three connecting rods is connected with the extending end of an extending end rod of each of the three driven elements, while the other end is connected with the inner side surface of an end platform through a spherical pair. The mechanism can be applied to the fields of robot joints and rehabilitation of patients with joint injuries or dyskinesia and the like.

Owner:HARBIN INST OF TECH

Method and apparatus for identifying obstacle in image

ActiveUS8406474B2Detection errorImprove accuracyTelevision system detailsColor television detailsPattern recognitionComputer graphics (images)

A method for identifying barriers in images is disclosed. In the method, images of a current frame and N frame which is nearest to the current frame are obtained, the obtained images of the frames are divided in the same way, and the image of each frame obtains a plurality of divided block regions; the motion barrier confidence of each block region corresponding to the current frame and the N frame which is nearest to the current frame is calculated; whether each block region in the image of the current frame is decided successively according to the motion barrier confidence of each block region corresponding to the current frame and the N frame which is nearest to the current frame; the barriers in the images are determined according to each block region.

Owner:NEUSOFT REACH AUTOMOTIVE TECH SHANGHAI CO LTD

A hierarchical control method for vehicle emergency collision avoidance considering moving obstacles

InactiveCN107867290BSolve real-timeTroubleshoot movement barriersExternal condition input parametersPosition/course control in two dimensionsTurn angleDynamic planning

The invention relates to an automobile emergency collision-avoidance layered control method taking moving obstacles into account. The automobile emergency collision-avoidance layered control method taking the moving obstacles into account is characterized by including the steps that through a path dynamic planning module, according to obstacle information, coordinates of target points and automobile driving state information which are collected in real time, a lateral displacement reference value, a yaw angle reference value, a yaw angular velocity reference value and a longitudinal velocity reference value of an expected trajectory are obtained by real-time optimization and are input into a path tracking control module, at the same time, through the path tracking control module, current automobile driving state information is collected, turning angles of front wheels and the slip rate of four wheels of an automobile are obtained by real-time optimization, and the automobile is controlled to avoid collision.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com