Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114 results about "Model based control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Model Based Control is exactly what is sounds like. Designing a control system based on a model of the system. So if you have a transfer function of the system and design a controller (PID, lead/lag, just K, etc) that is model based control.

Methods and Systems for Model-Based Control of Gas Turbines

ActiveUS20080243352A1Reduce errorsAnalogue computers for vehiclesGas turbine plantsClosing loopsEngineering

Embodiments of systems and methods for tuning a turbine are provided. In one embodiment, a method may include receiving at least one of a measured operating parameter or a modeled operating parameter of a turbine during operation; and tuning the turbine during operation. The turbine may be tuned during operation by applying the measured operating parameter or modeled operating parameter or parameters to at least one operational boundary model, applying the measured operating parameter or modeled operating parameter or parameters to at least one scheduling algorithm, comparing the output of the operational boundary model or models to the at output of the scheduling algorithm or algorithms to determine at least one error term, and closing loop on the one error term or terms by adjusting at least one turbine control effector during operation of the turbine.

Owner:GENERAL ELECTRIC CO

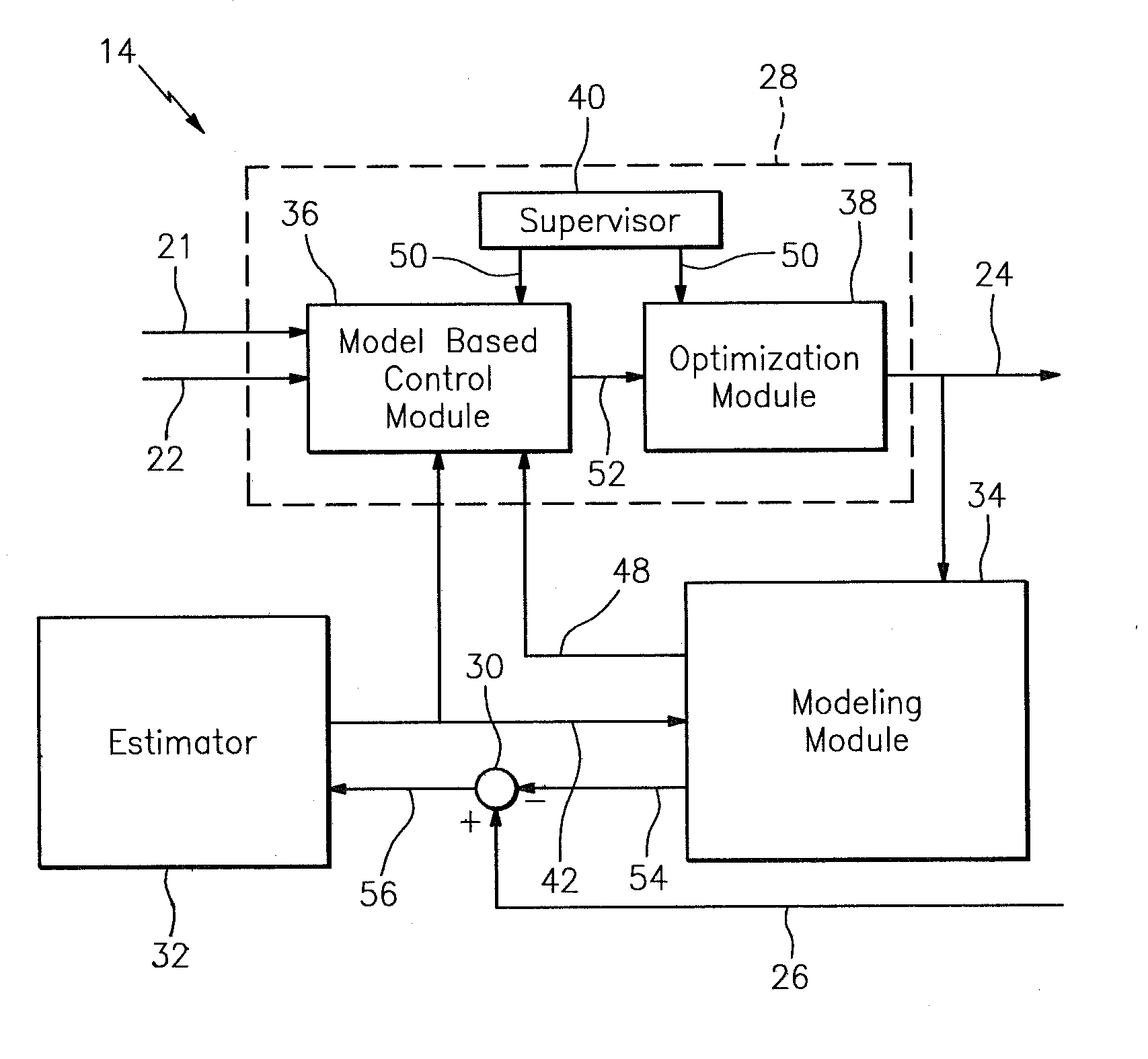

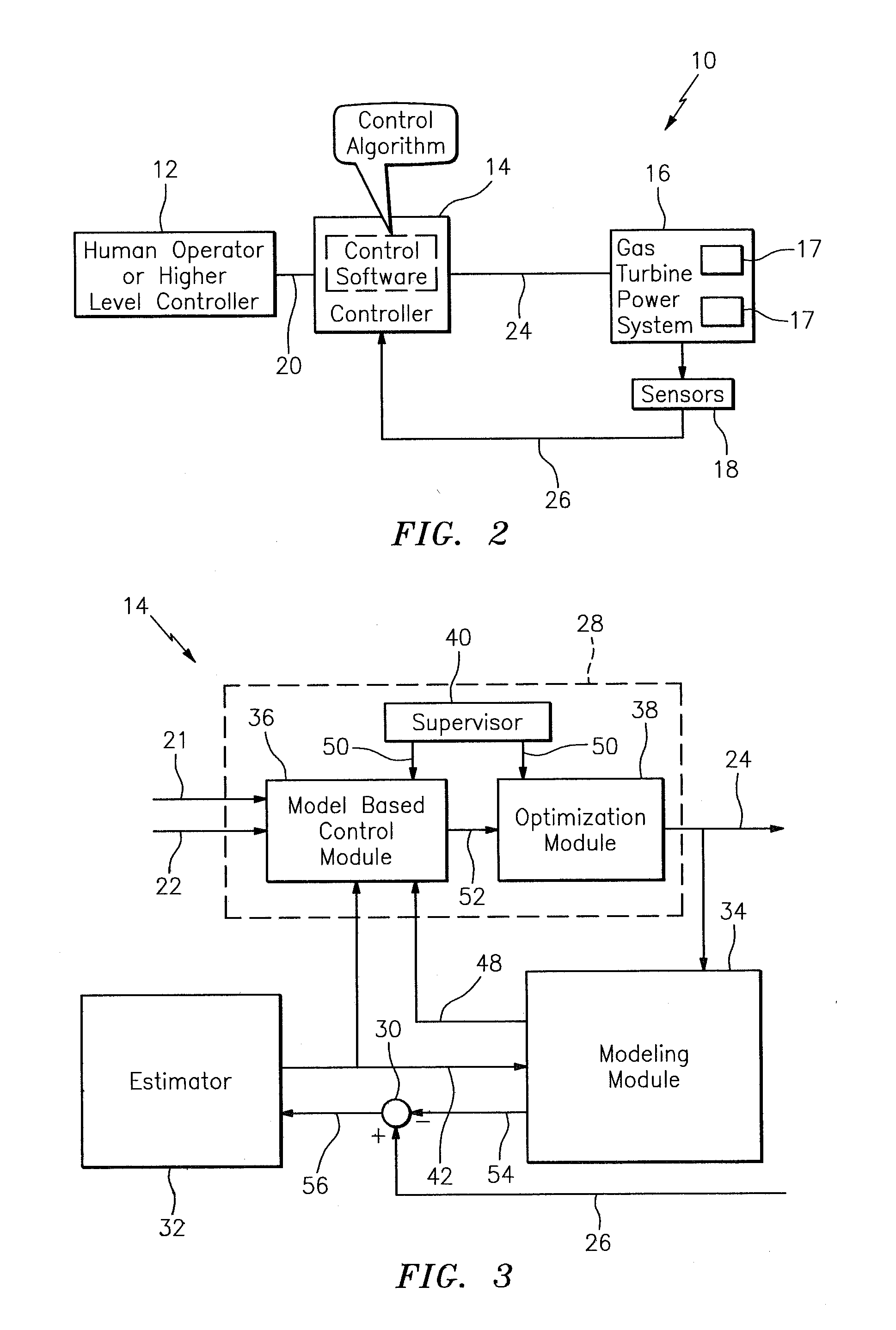

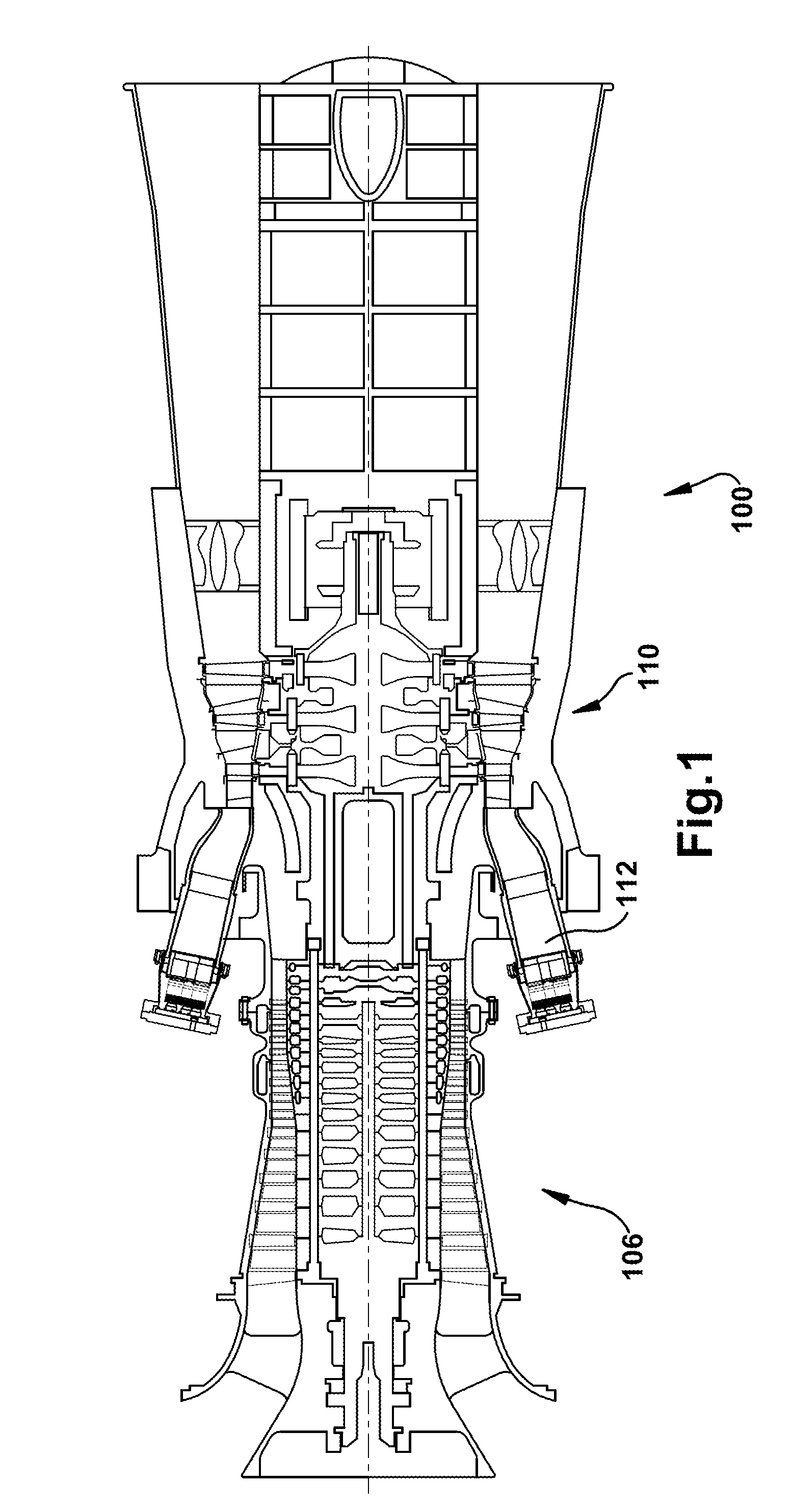

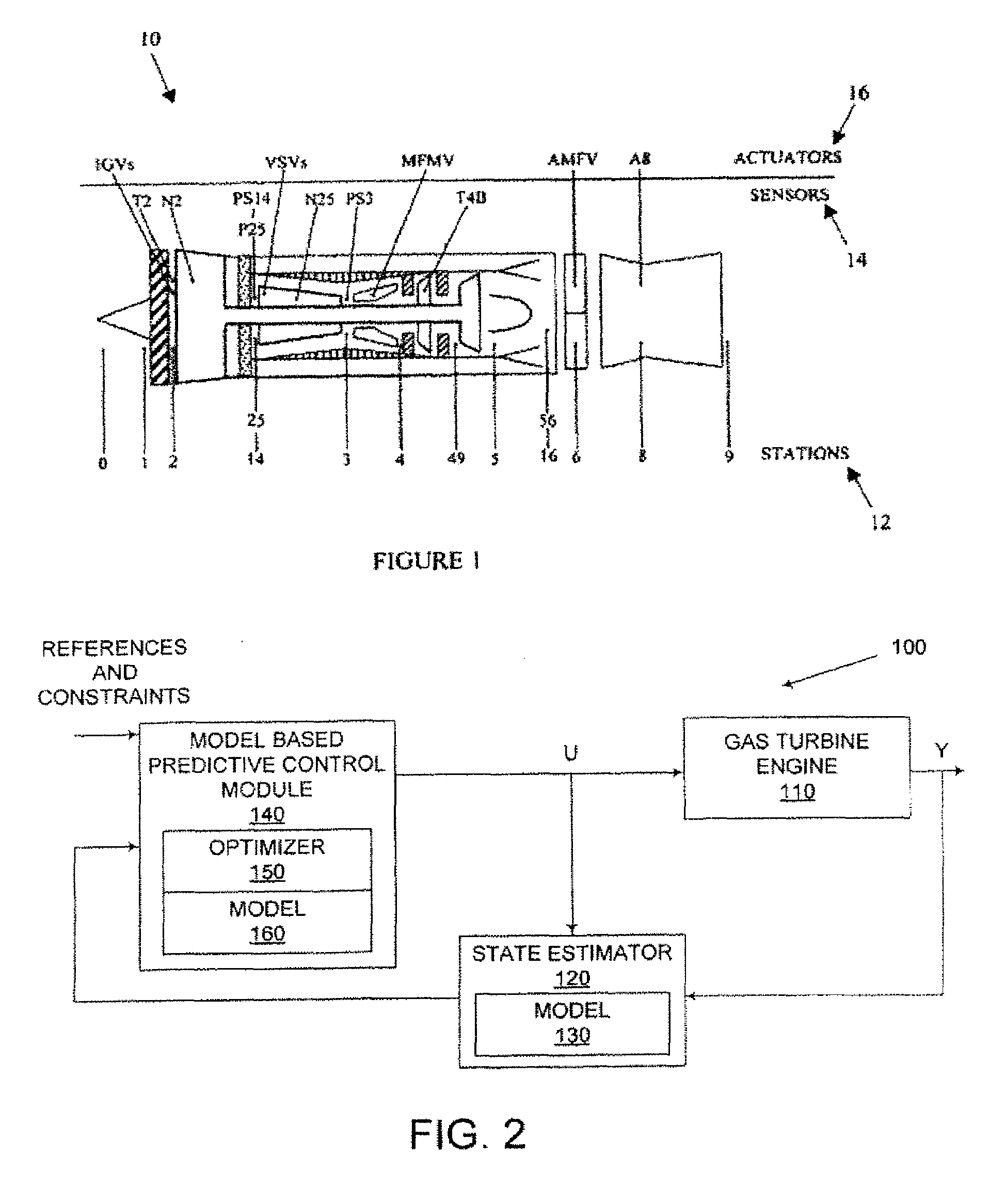

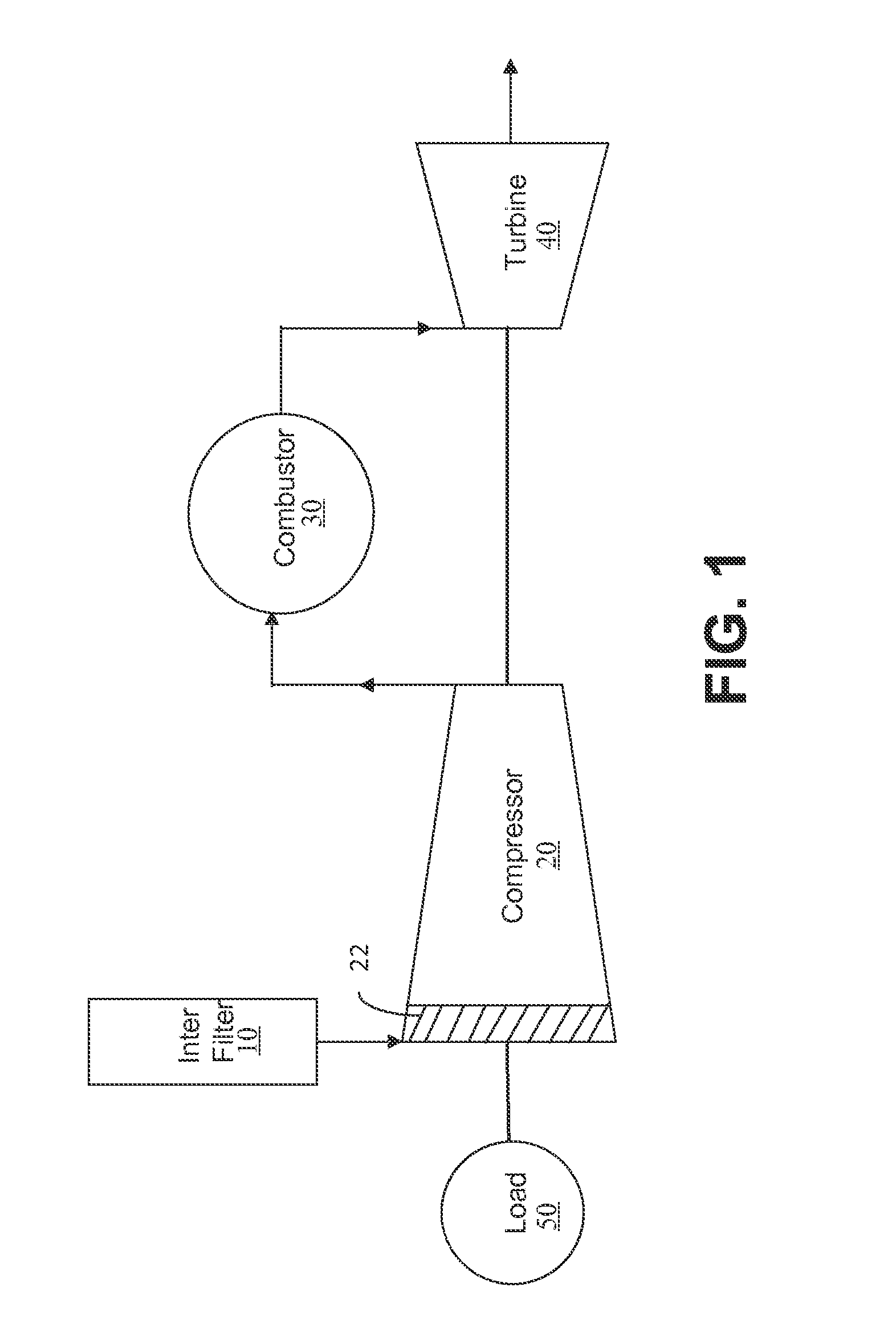

Model-based control systems and methods for gas turbine engines

A method and system of controlling a gas turbine engine is disclosed. The engine has sensors to detect one or more parameters and actuators adapted to respond to commands. The method includes receiving data from the sensors of the engine for one or more measured or sensed parameters, estimating a state of the engine by estimating one or more unmeasured or unsensed parameters using the data from the sensors and a predictive model of the engine, generating commands for the actuators based on the state using an optimization algorithm; and transmitting the commands to the engine. The system includes a state estimator adapted to estimate a state of the engine by estimating one or more unmeasured or unsensed parameters using data from the sensors of the engine for one or more measured or sensed parameters. The estimator includes a model of the engine. The system also includes a control module adapted to generate commands for the actuators based on the state. The control module includes an optimization algorithm for determining the commands.

Owner:GENERAL ELECTRIC CO

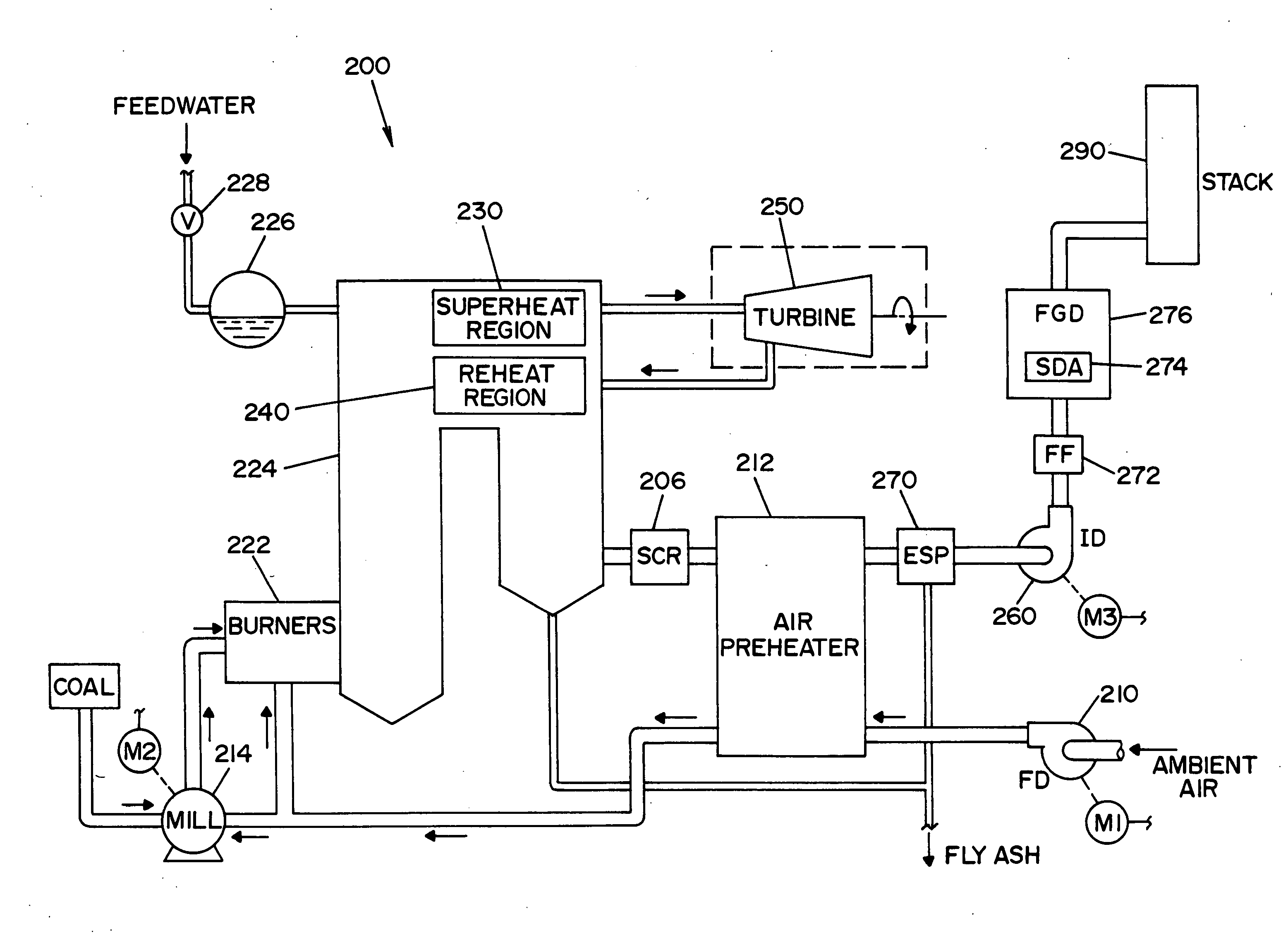

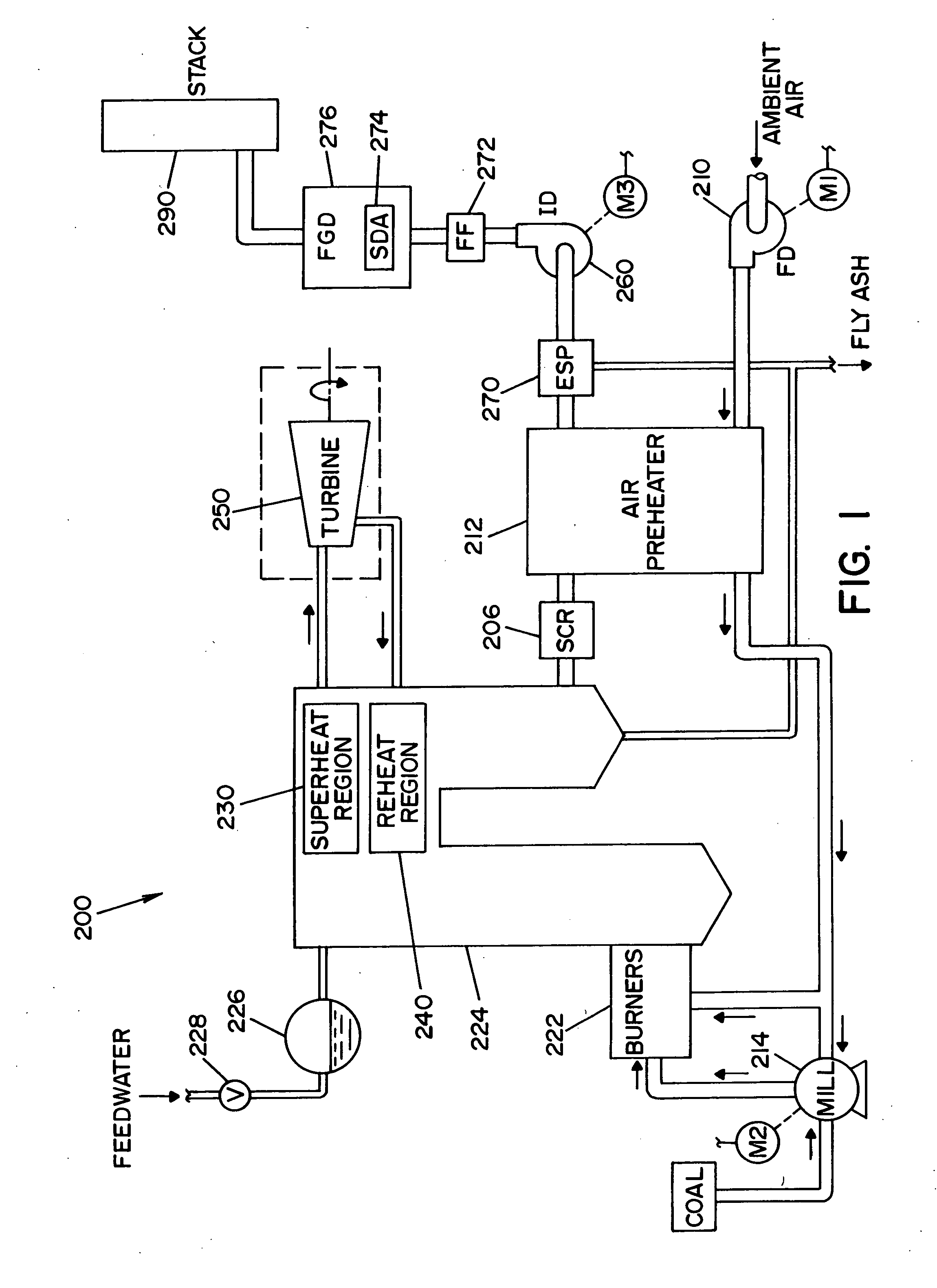

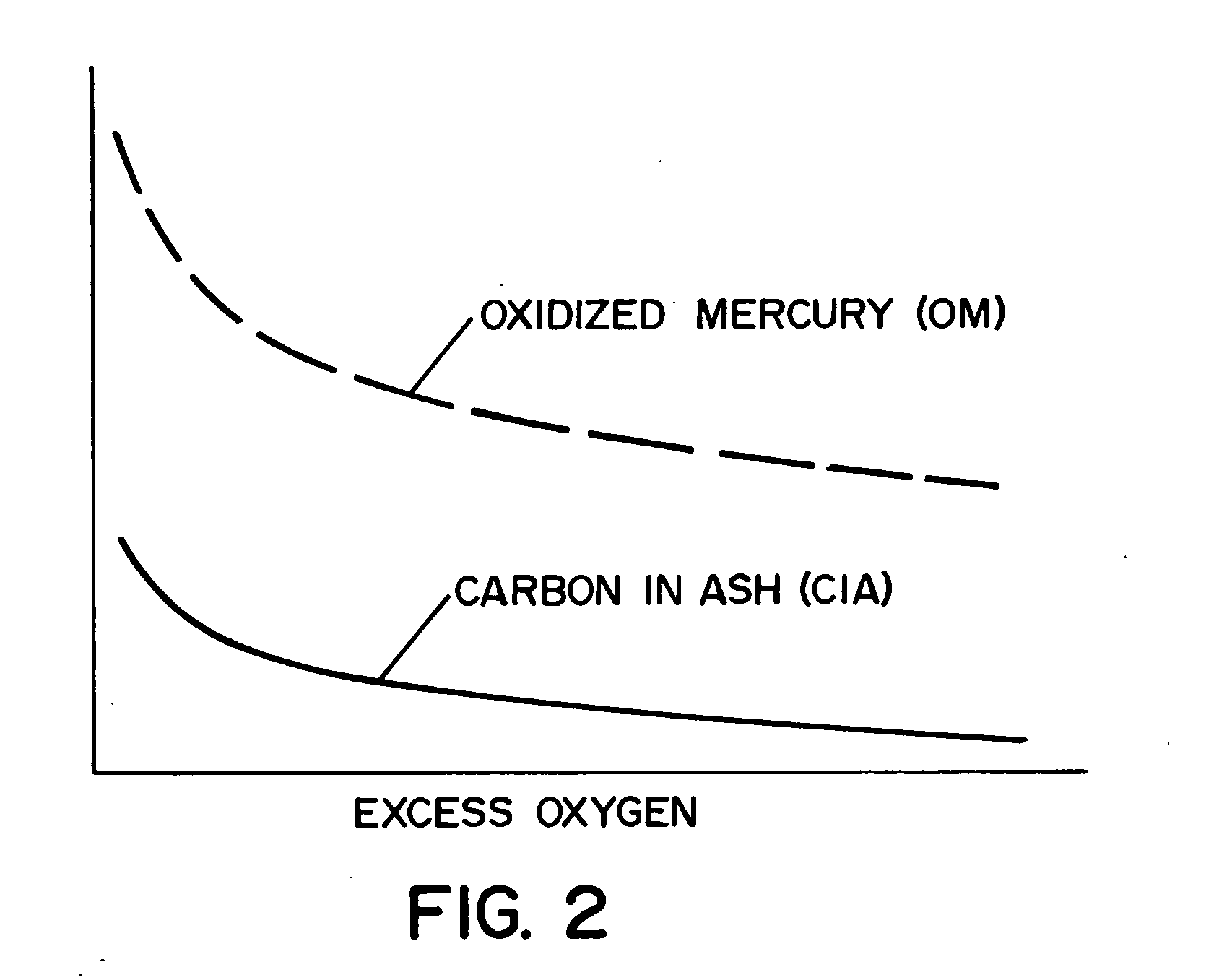

Model based control and estimation of mercury emissions

ActiveUS20070156288A1Cost-effectiveSampled-variable control systemsAdaptive controlEngineeringModel based control

A method and apparatus for estimating and / or controlling mercury emissions in a steam generating unit. A model of the steam generating unit is used to predict mercury emissions. In one embodiment of the invention, the model is a neural network (NN) model. An optimizer may be used in connection with the model to determine optimal setpoint values for manipulated variables associated with operation of the steam generating unit.

Owner:GENERAL ELECTRIC CO

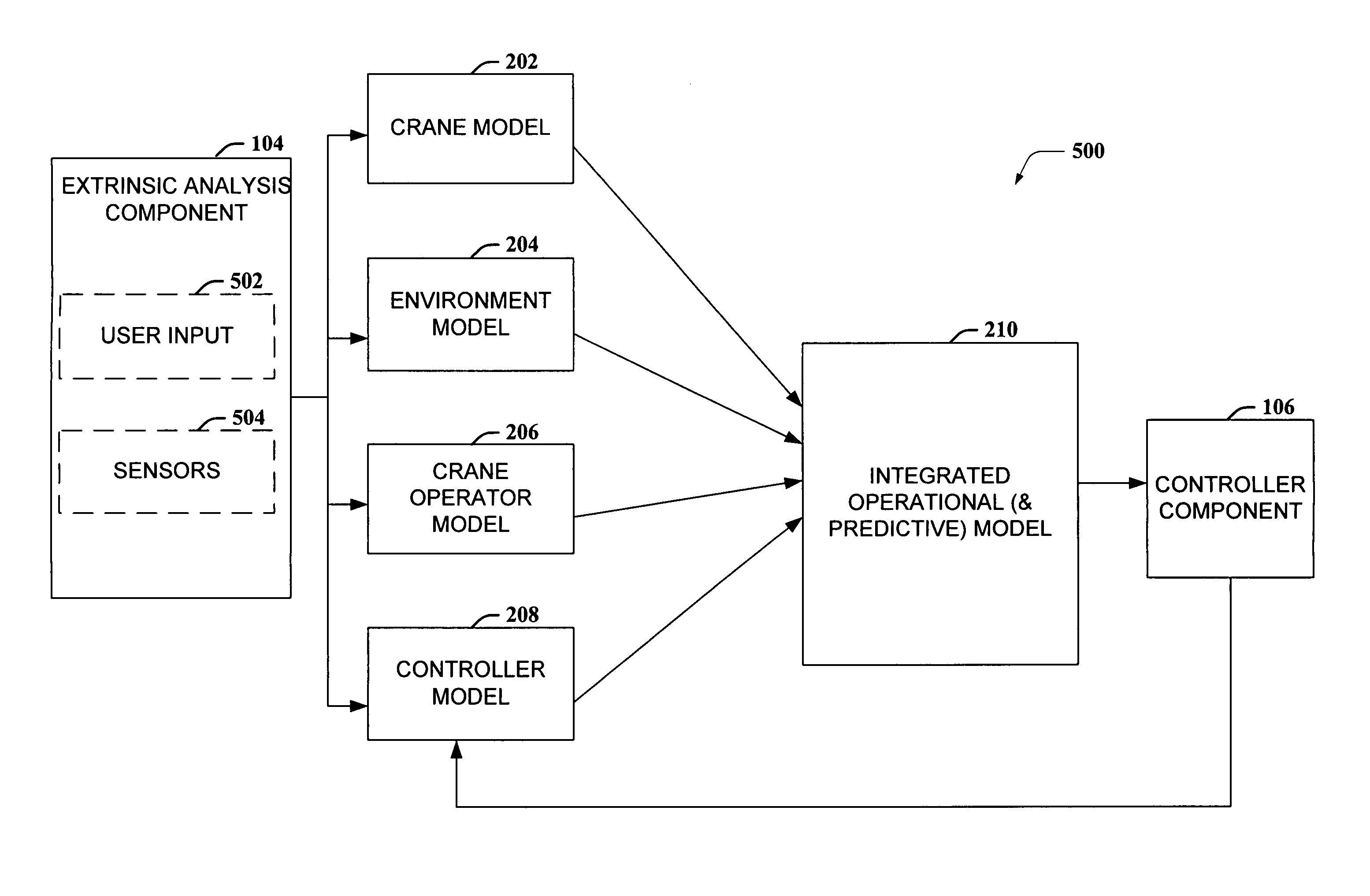

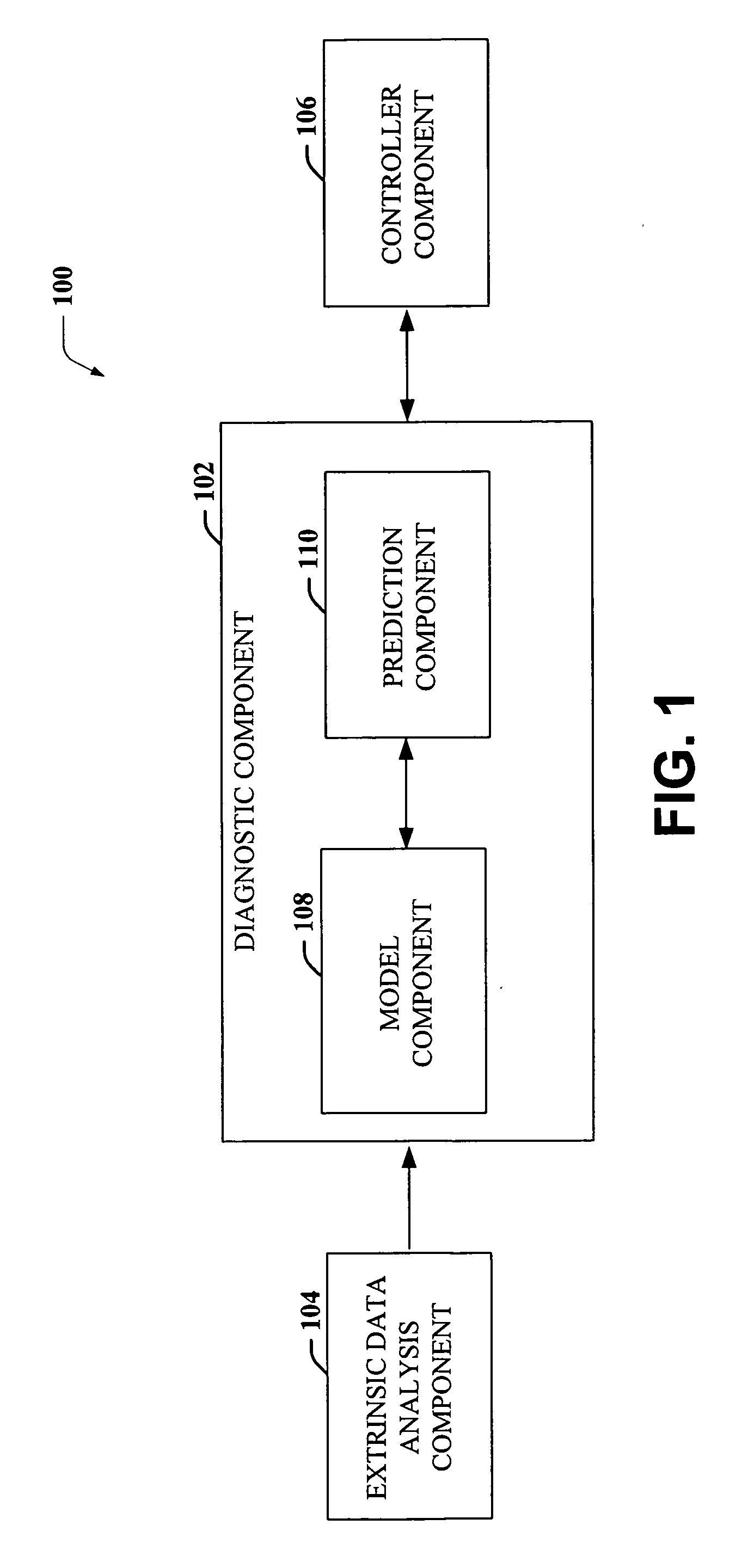

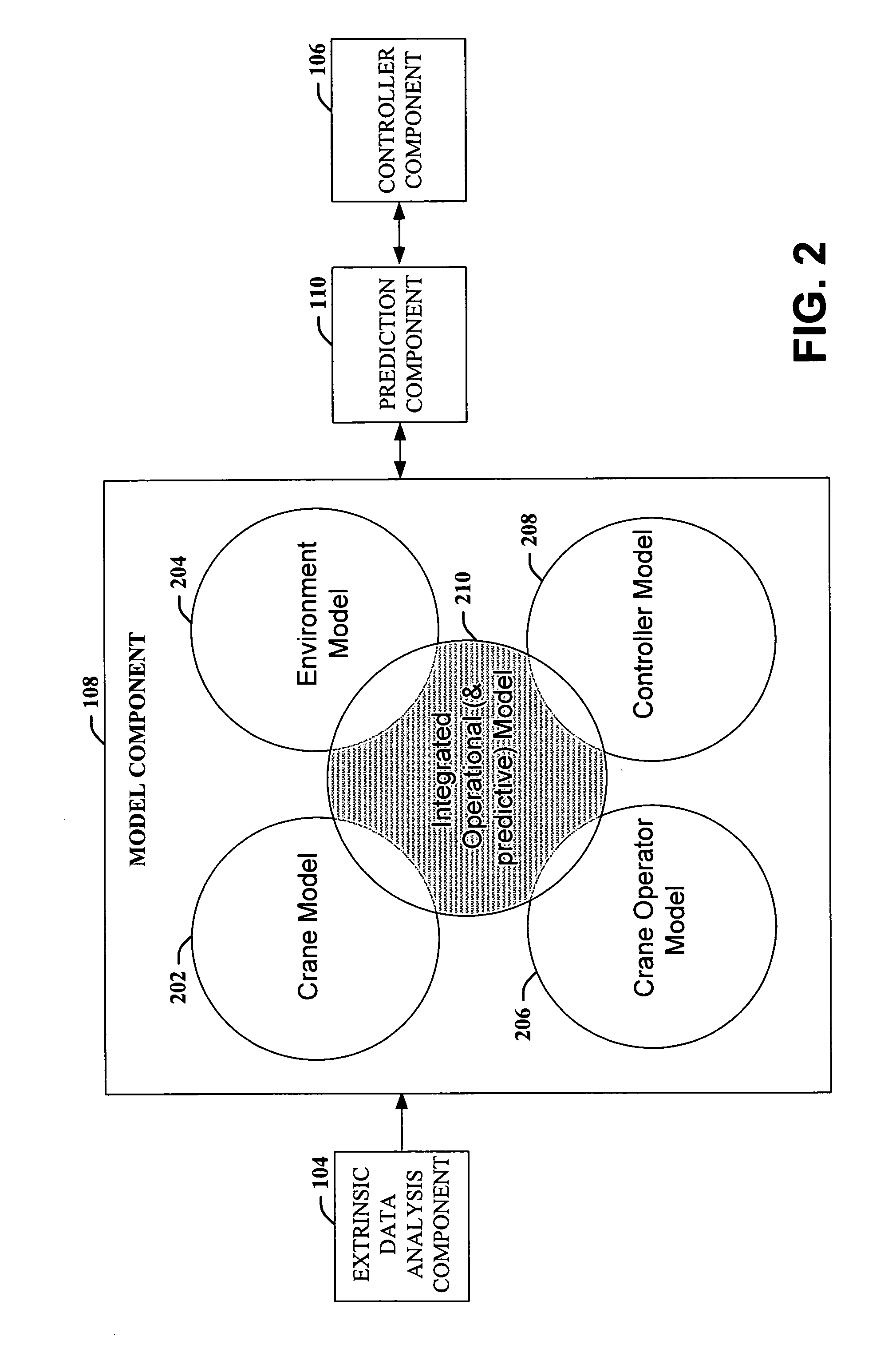

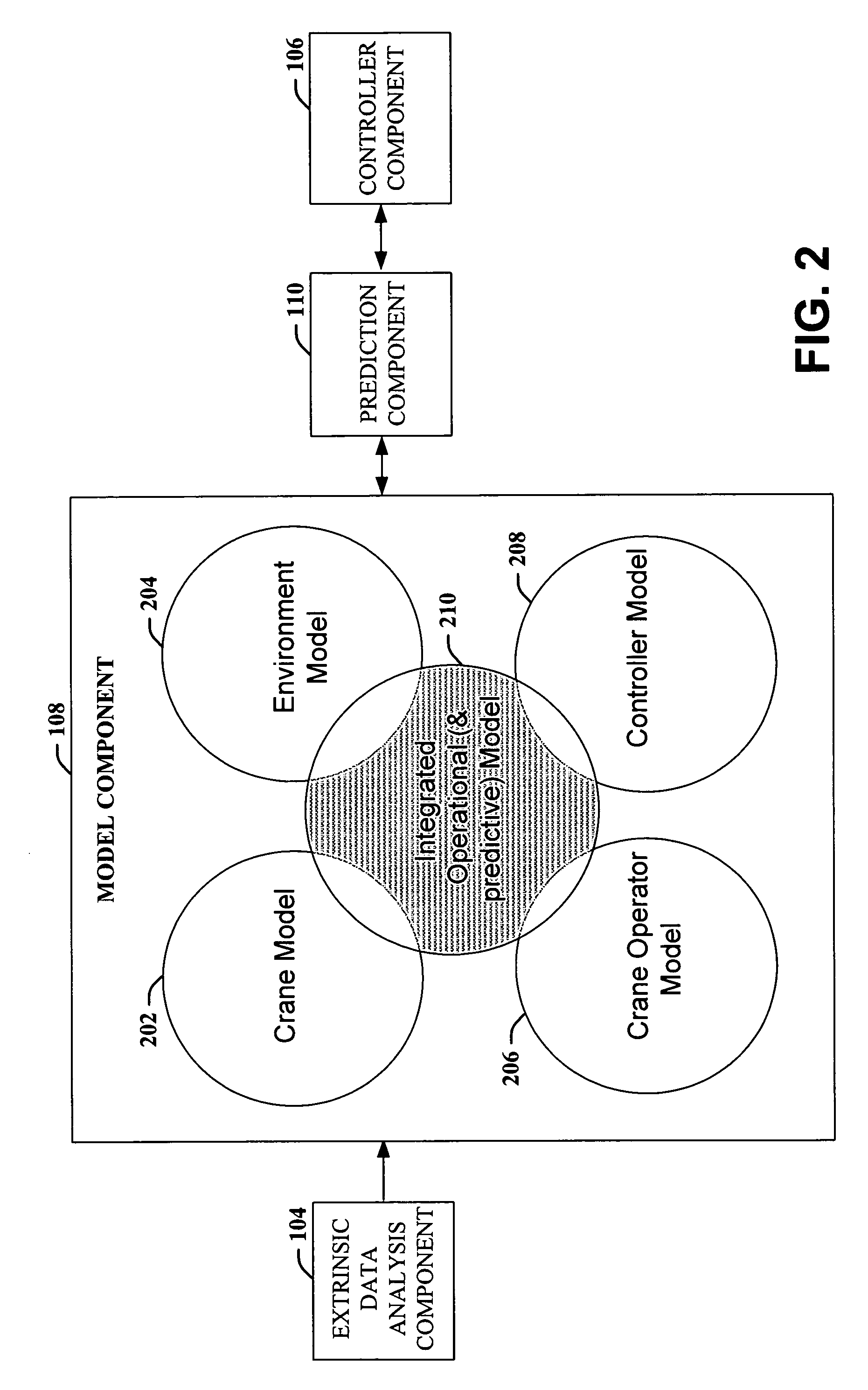

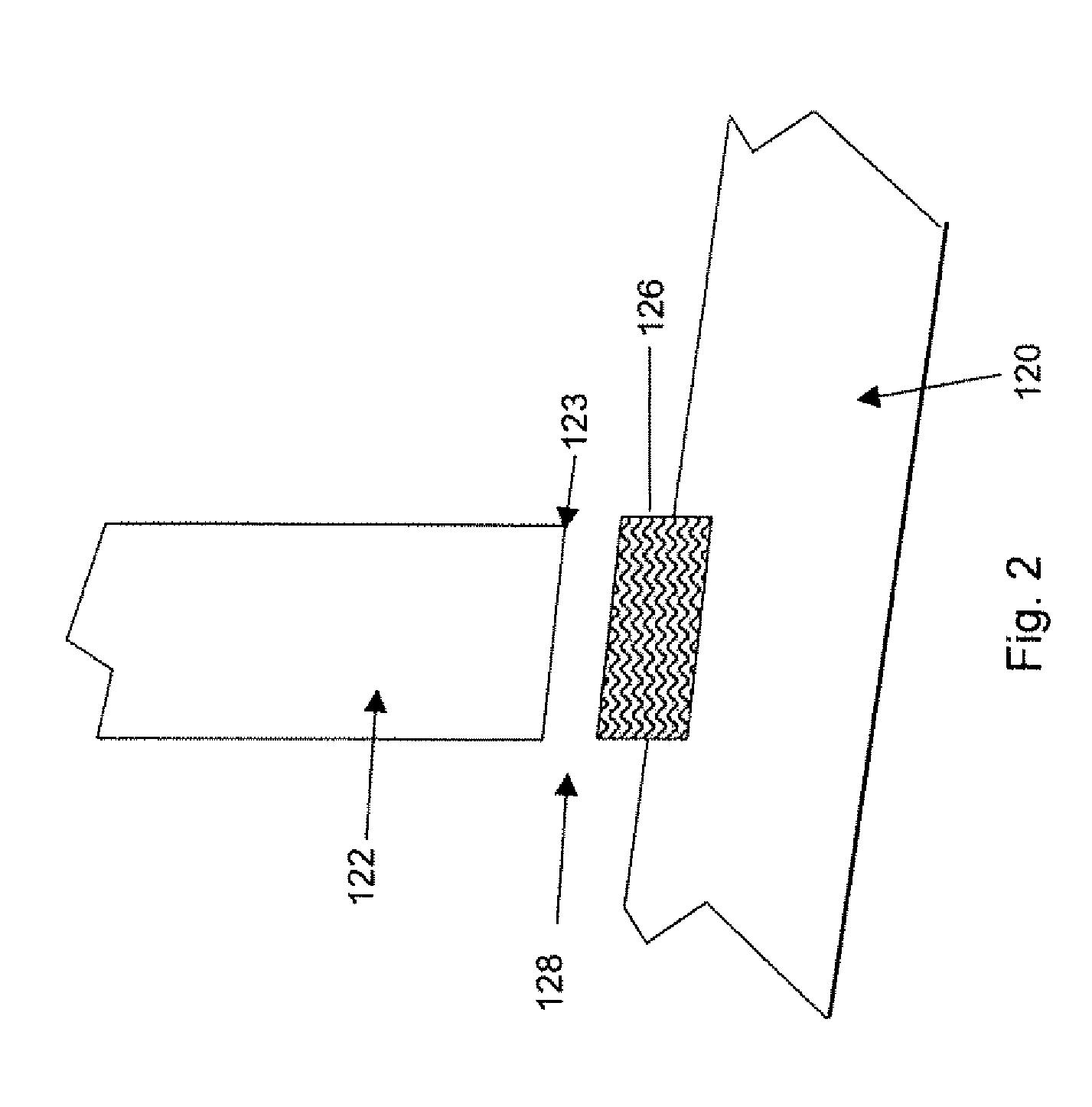

Model-based control for crane control and underway replenishment

ActiveUS20070050115A1Easy to controlMitigates container swayAnalogue computers for trafficTrolley cranesTransport timeExternal data

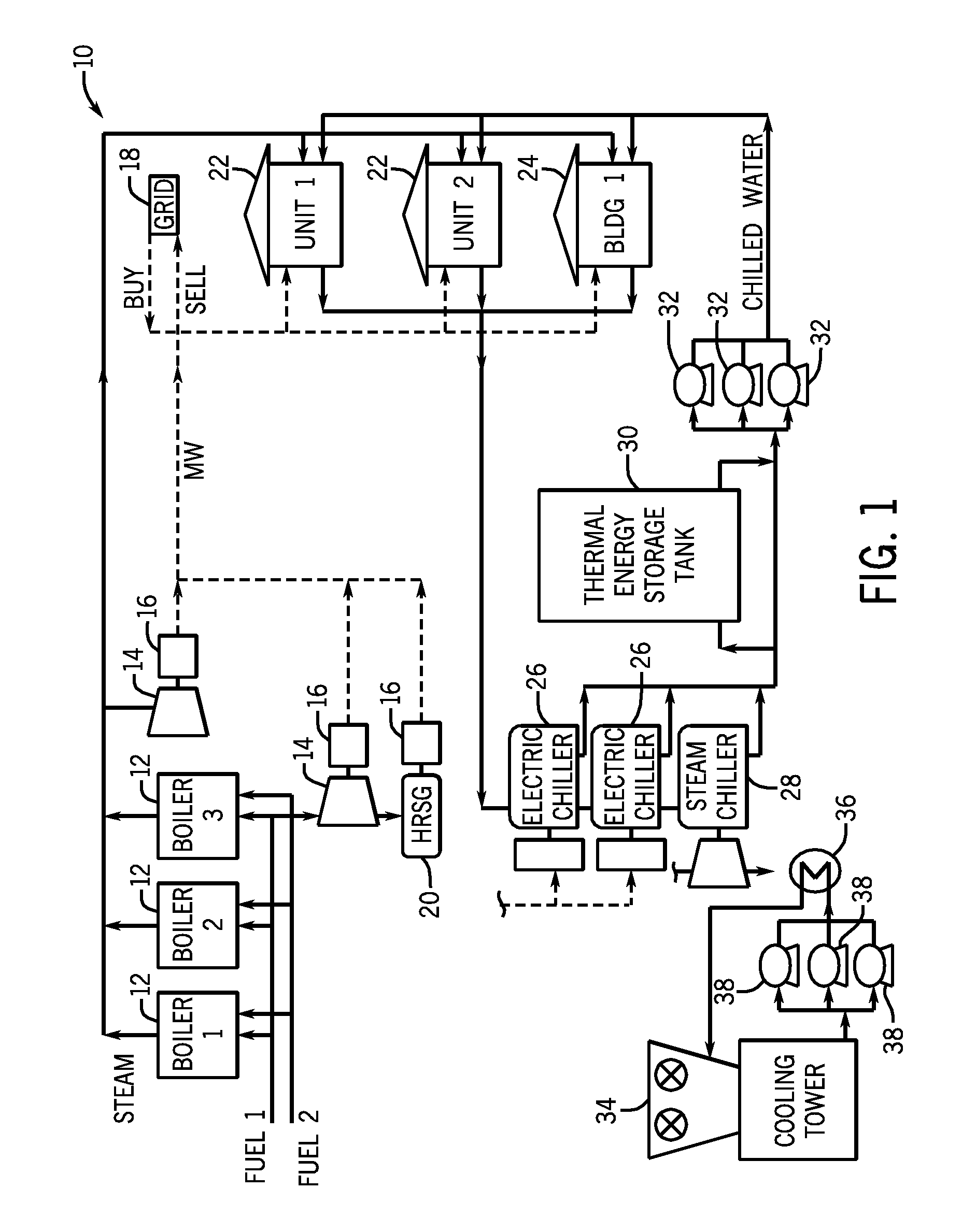

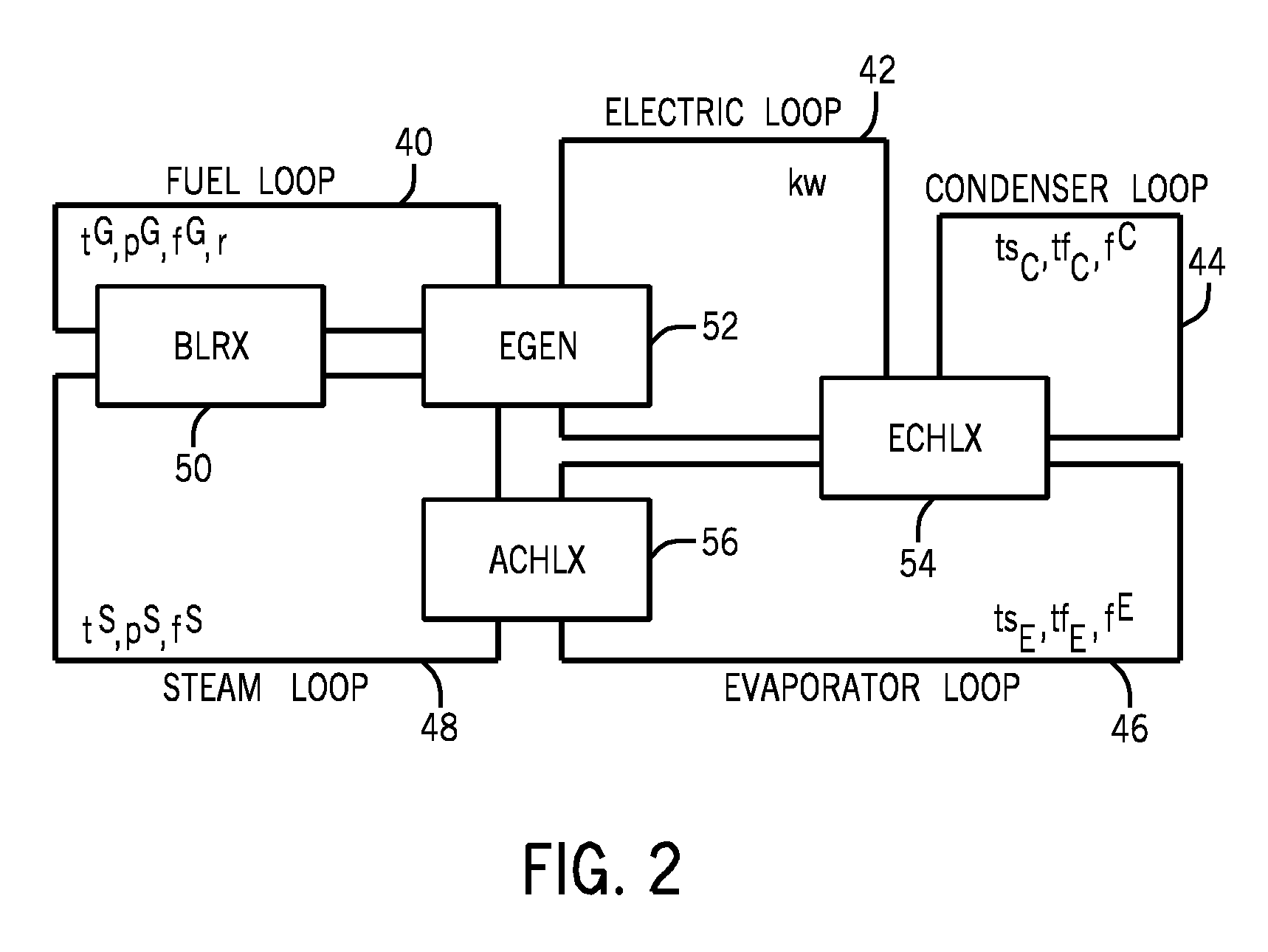

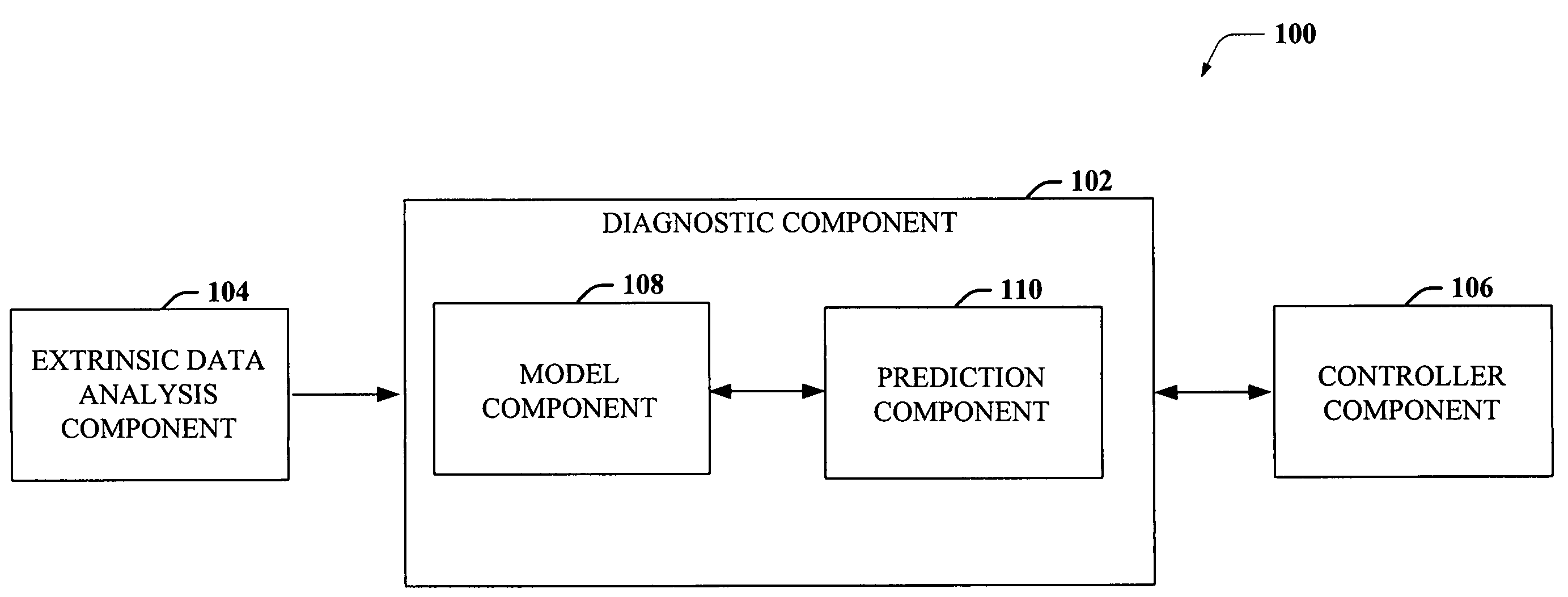

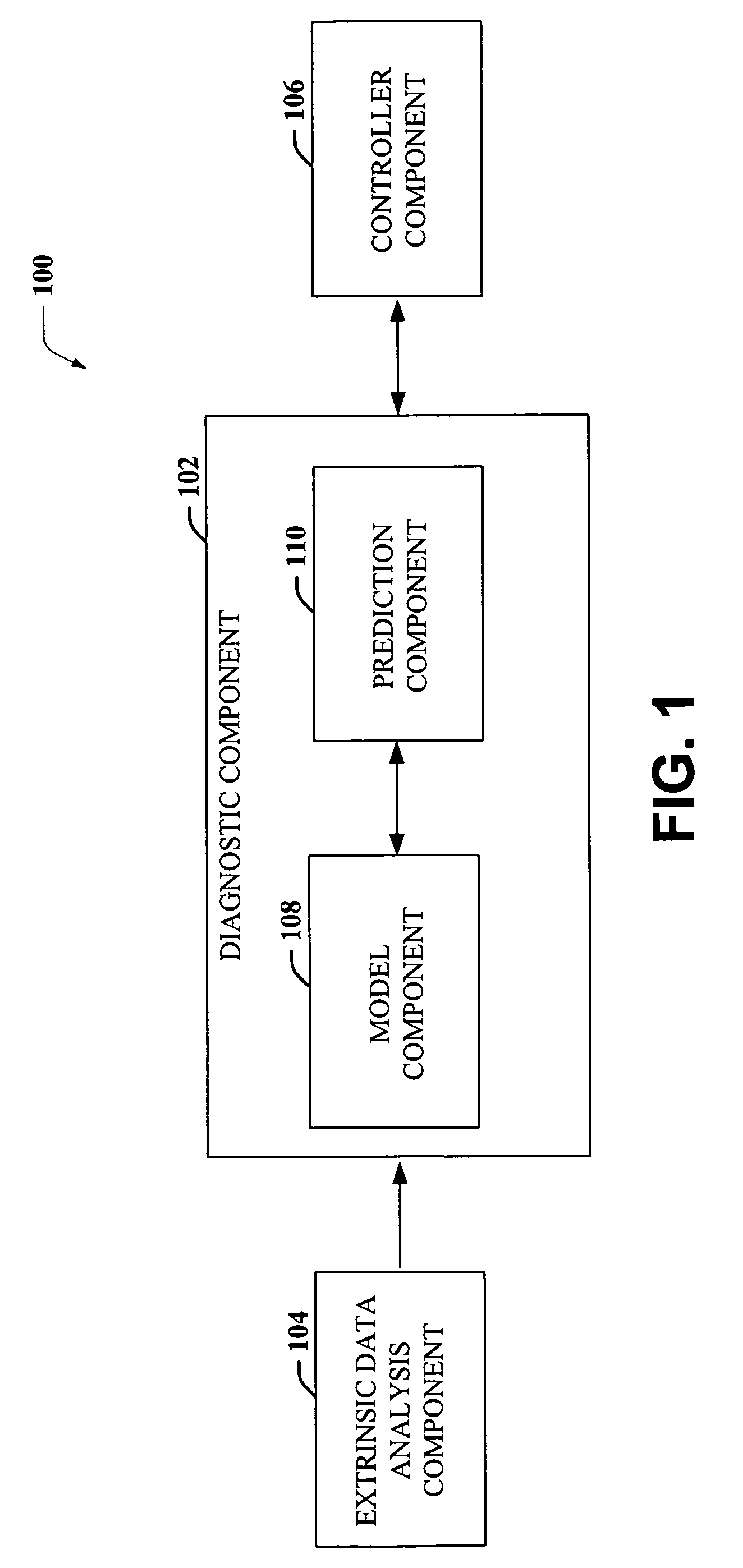

Crane control and anti-sway are facilitated utilizing a diagnostic component that includes a model component and a control component. The diagnostic component interfaces with an extrinsic data analysis component and a controller component. The diagnostic component receives operating condition information from the extrinsic data analysis component and performs predictive modeling, based on a current status and stored information. Further, the diagnostic component predicts the affect of the operating conditions on a crane and implements and / or recommends actions to mitigate the affect of the existing and / or predicted operating conditions. The diagnostic component further mitigates crane sway and / or induces crane sway to reduce container transit time. Intelligent agents are employed to provide trajectory planning and execution and / or to detect potential component failure.

Owner:ROCKWELL AUTOMATION TECH

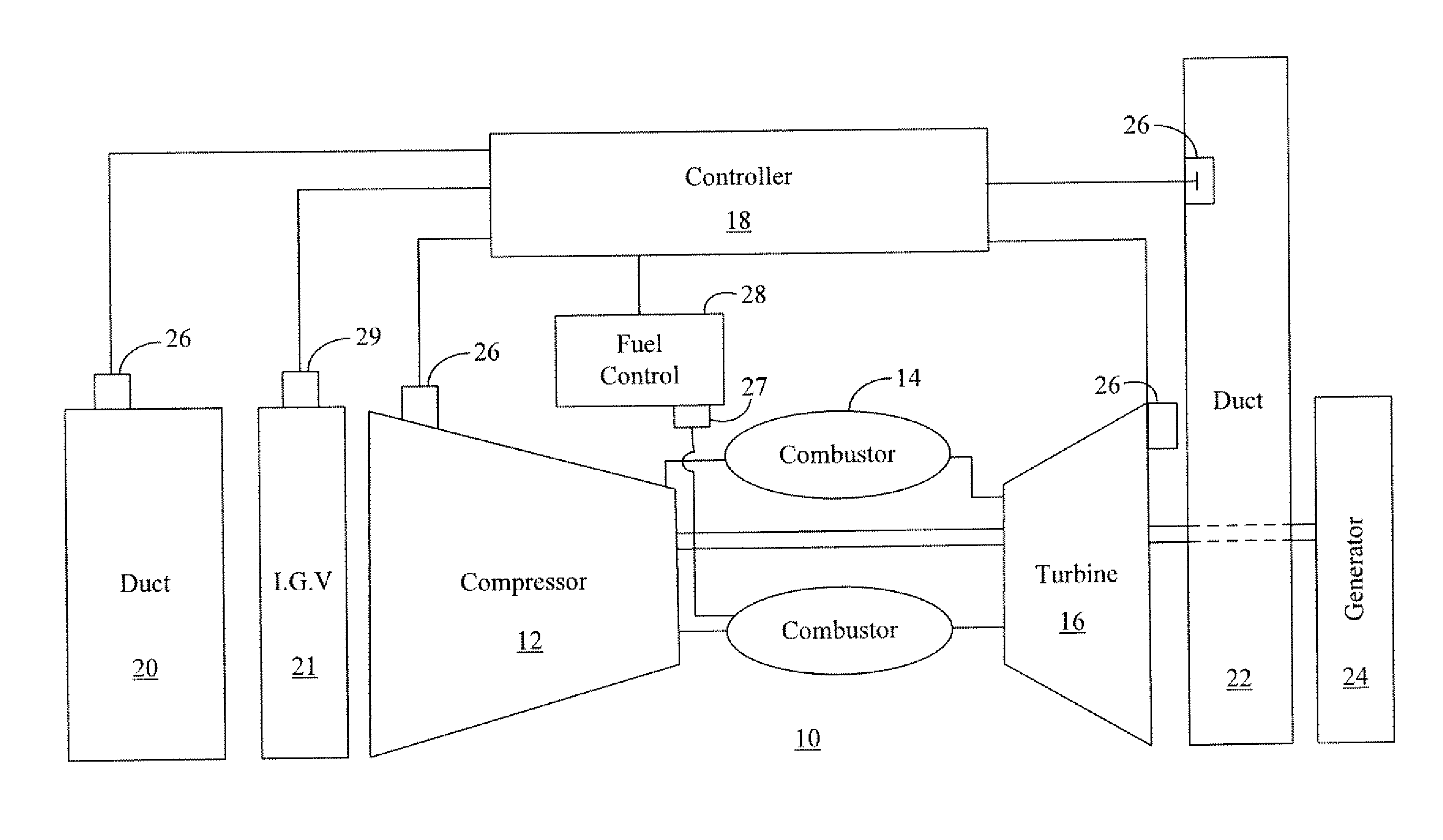

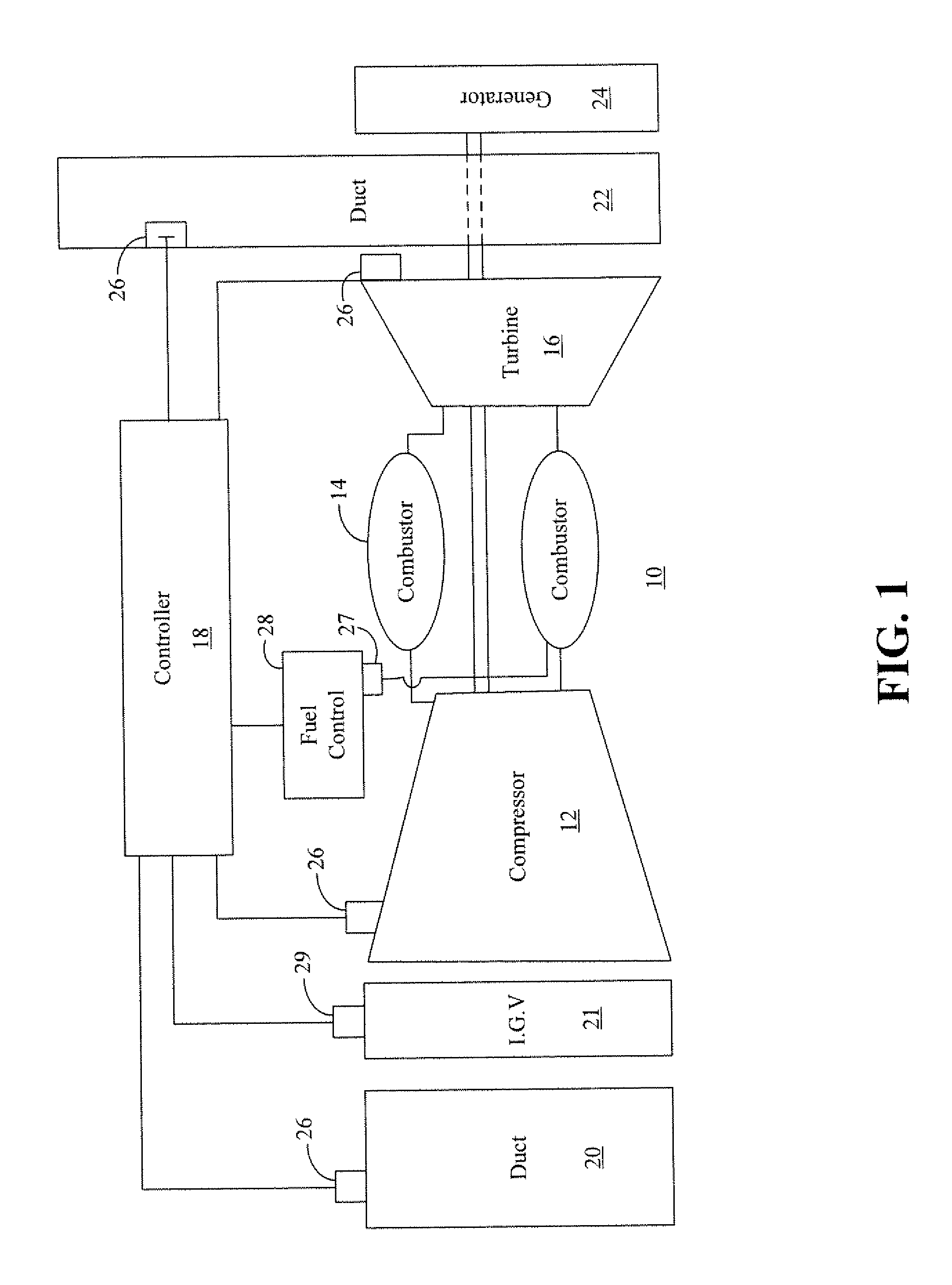

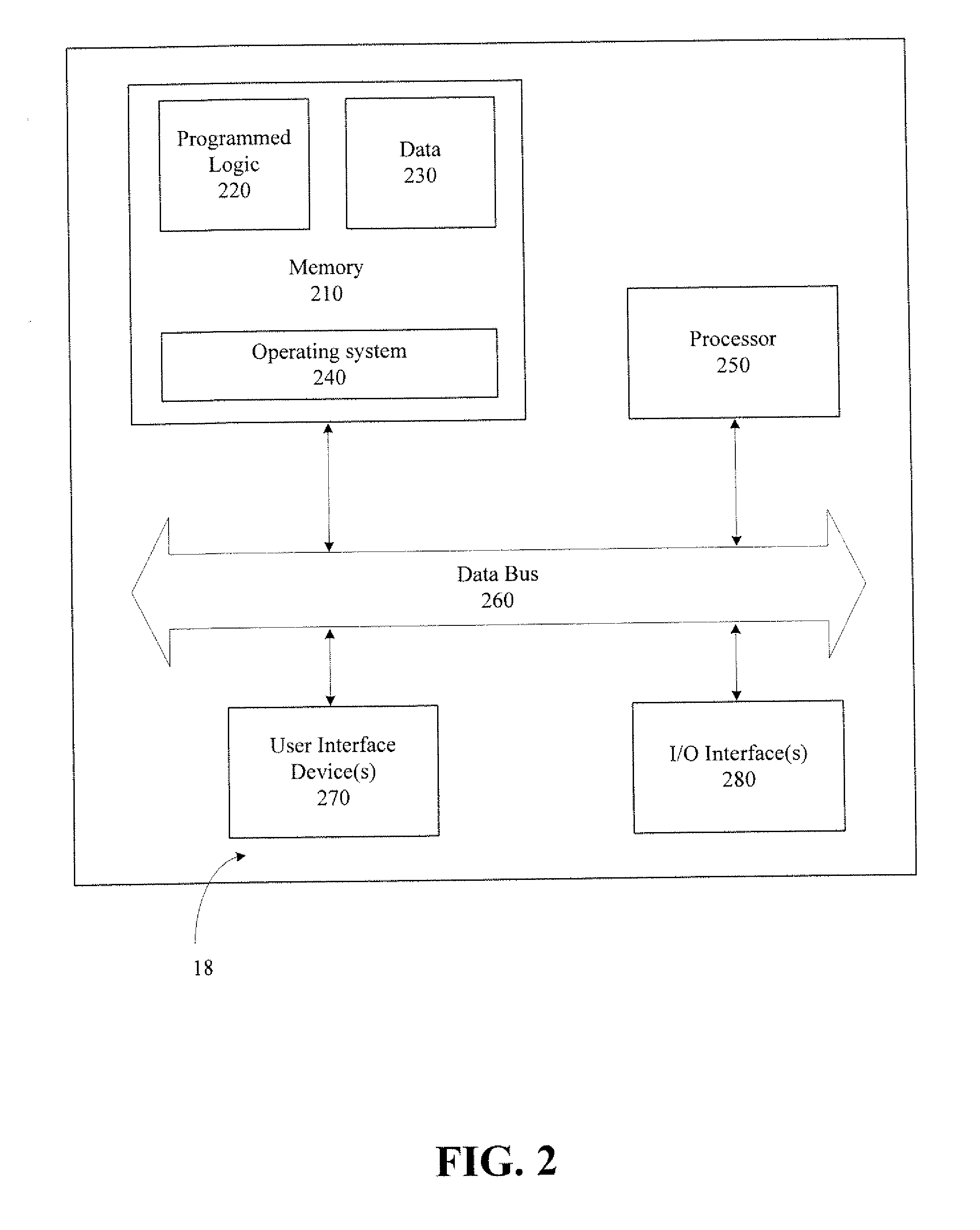

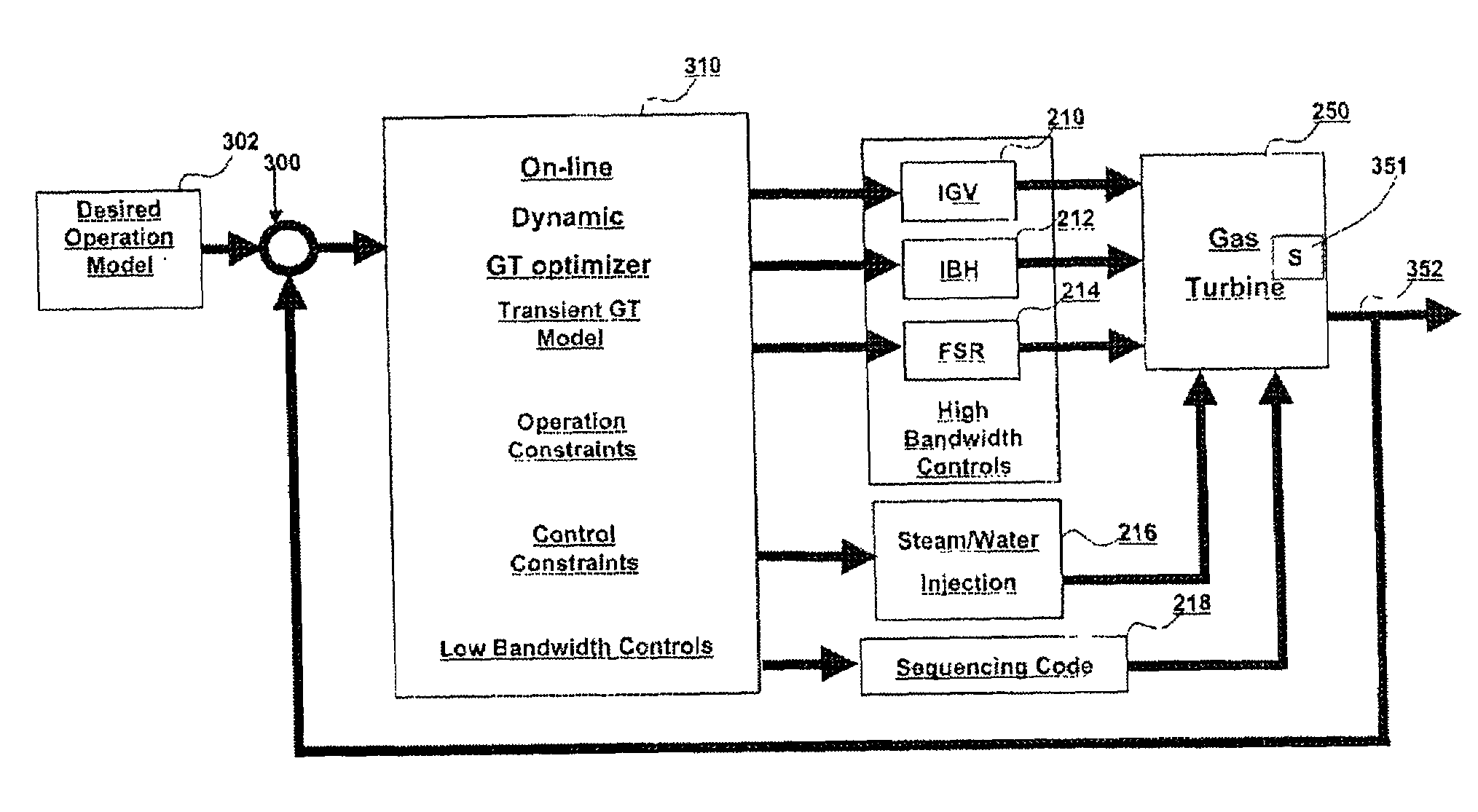

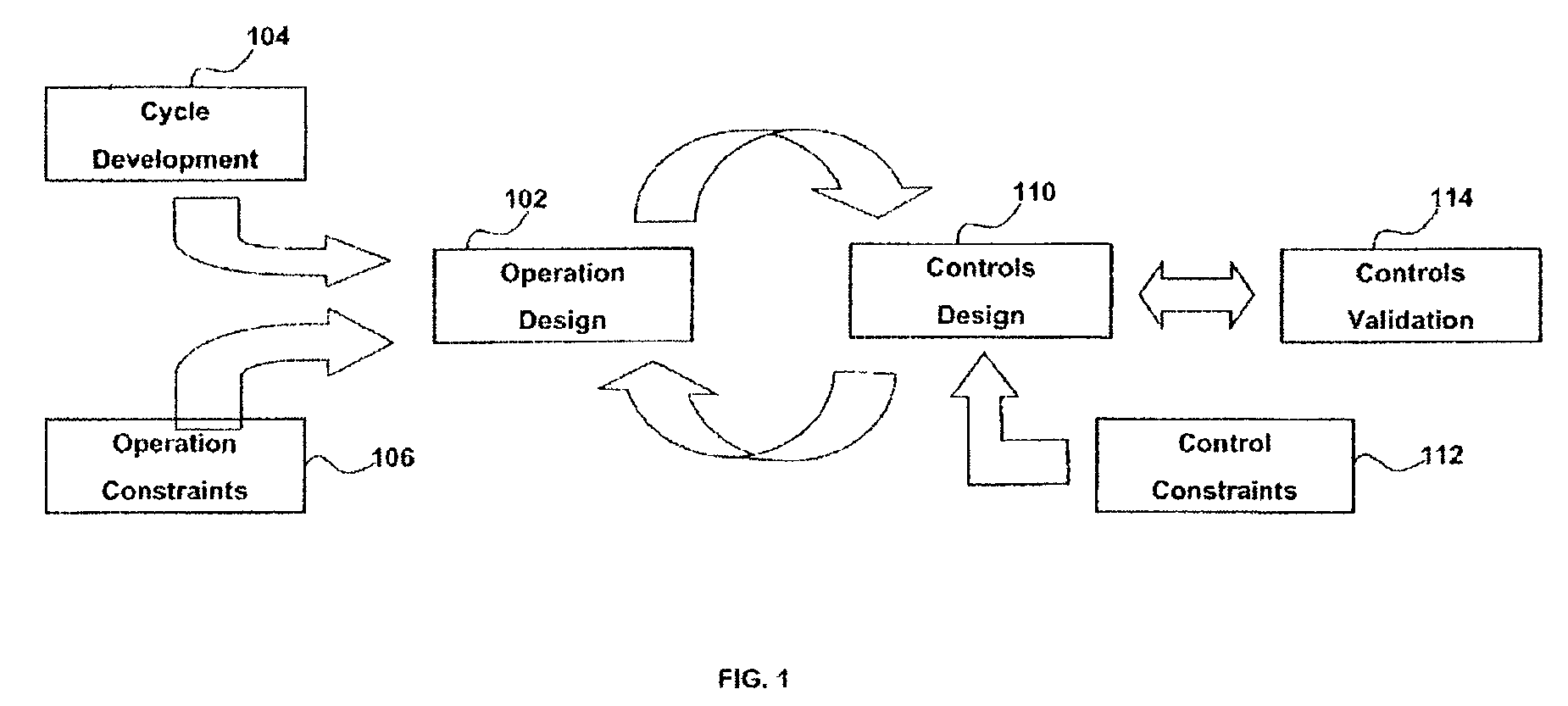

Method and system for model based control of heavy duty gas turbine

ActiveUS7219040B2Reduce riskAnalogue computers for vehiclesLevel controlDynamical optimizationProcess engineering

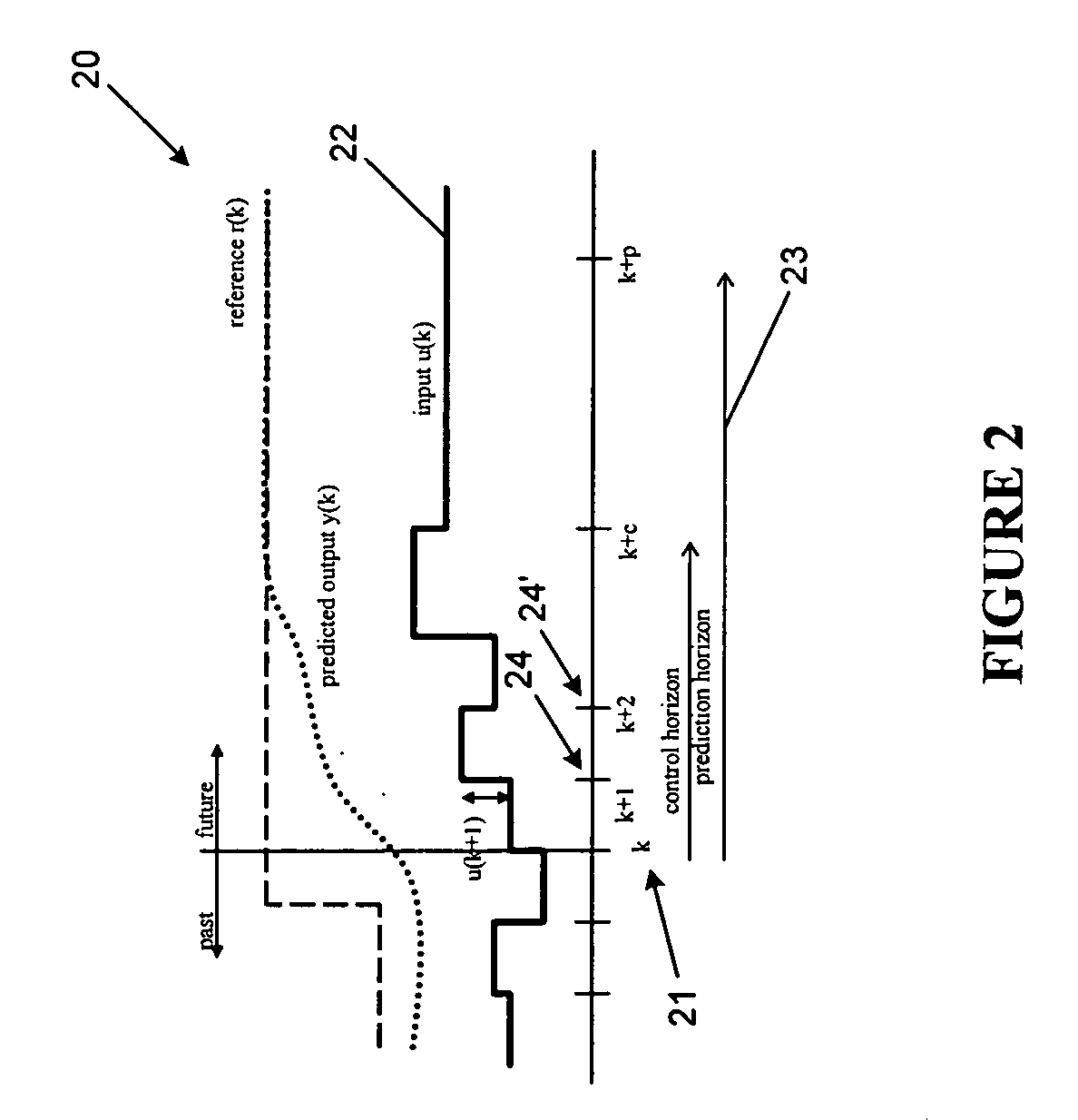

A method and system of designing the operations and controls of a gas turbine, includes generating an operations model for the gas turbine including at least one objective function and defining operations and control constraints for the operations model of the gas turbine. An online dynamic optimizer / controller dynamically optimizes and controls operation of the gas turbine using model based control based on the operations model and the operations and control constraints. The model based control may include model predictive control.

Owner:GENERAL ELECTRIC CO

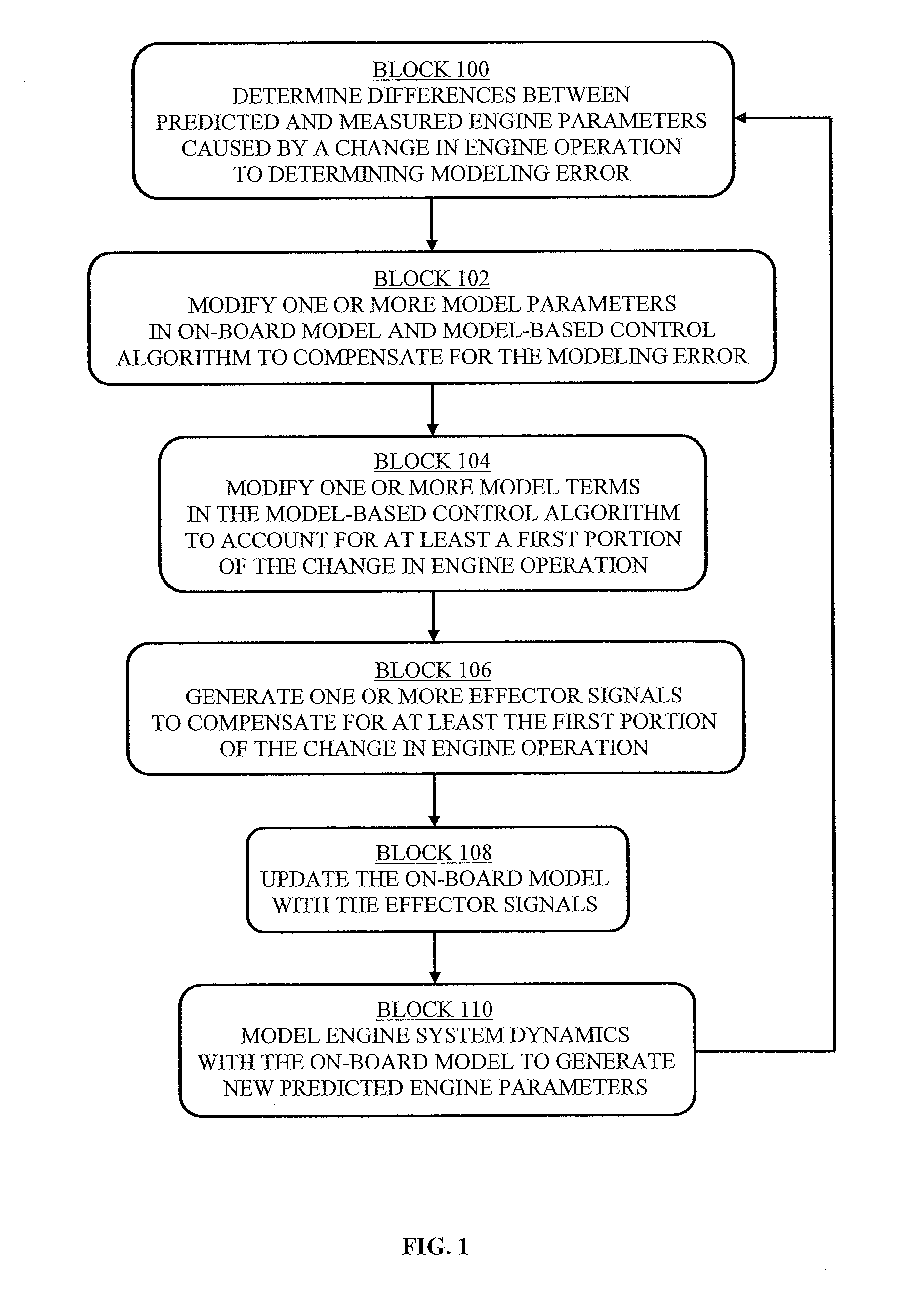

Adaptive control for a gas turbine engine

A method for controlling a gas turbine engine includes: generating model parameter data as a function of prediction error data, which model parameter data includes at least one model parameter that accounts for off-nominal operation of the engine; at least partially compensating an on-board model for the prediction error data using the model parameter data; generating model term data using the on-board model, wherein the on-board model includes at least one model term that accounts for the off-nominal operation of the engine; respectively updating one or more model parameters and one or more model terms of a model-based control algorithm with the model parameter data and model term data; and generating one or more effector signals using the model-based control algorithm.

Owner:RTX CORP

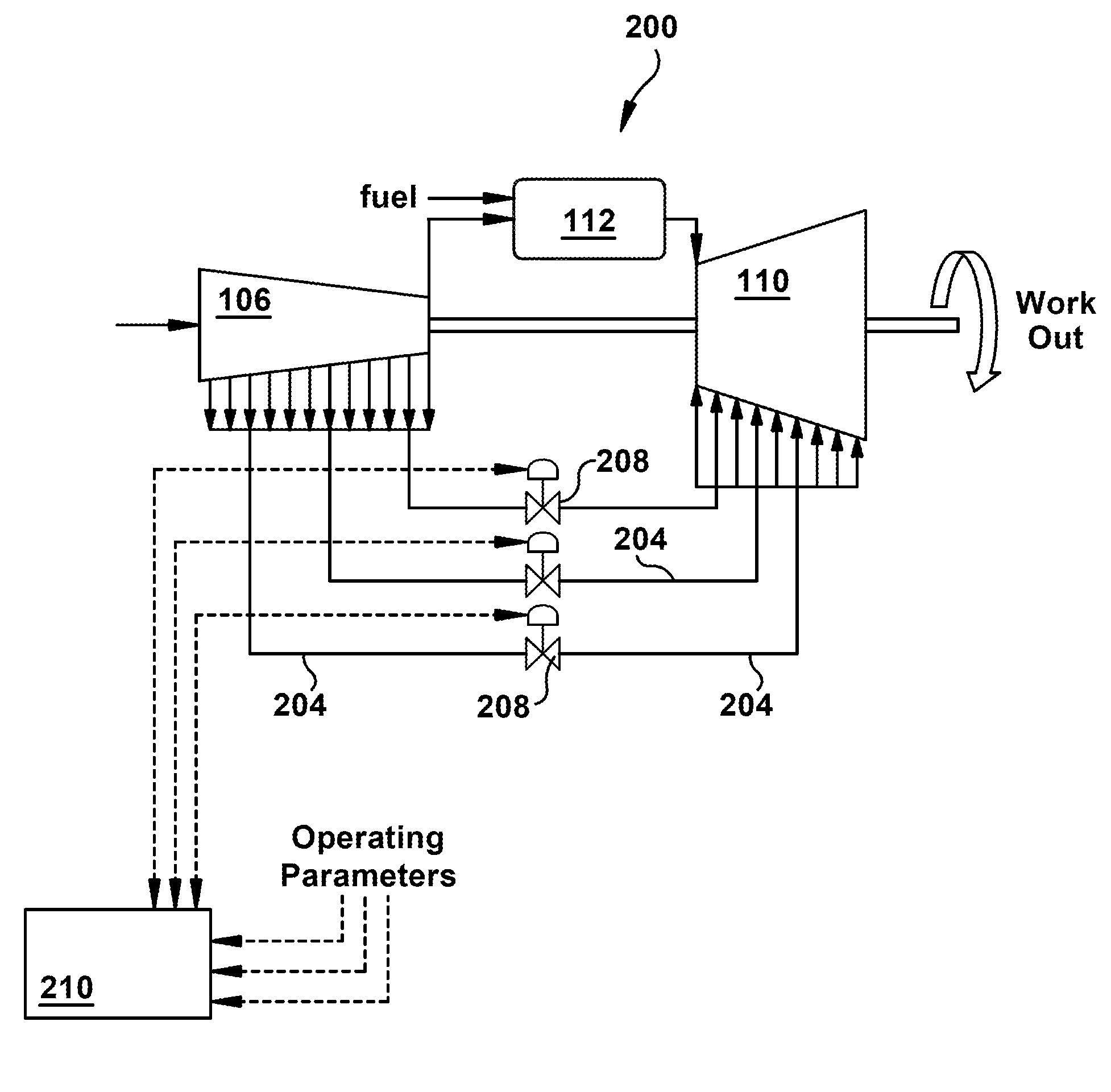

Methods relating to gas turbine control and operation

ActiveUS20100286889A1Increased and maximum levelAnalogue computers for vehiclesGas turbine plantsMaximum levelStream flow

A method of controlling variable extraction flow in a combustion turbine engine, wherein extraction flow comprises a supply of compressed air extracted from the compressor and supplied to the turbine through extraction conduits, and wherein the extraction conduits includes a variable extraction orifice, the method comprising the steps of: measuring a plurality of turbine engine operating parameters; monitoring, by a control unit, the measured operating parameters of the combustion turbine engine; setting the variable extraction orifices to a setting that allows an approximate maximum level of extraction flow; calculating, by the control unit, at least one calculated operating parameter based upon model-based control and the measured operating parameters, including at least a current turbine inlet temperature and a maximum turbine inlet temperature; and manipulating the setting for the supply of fuel to the combustor such that an increased and / or maximum level of engine output is determined by comparing the values for the current turbine inlet temperature and the maximum turbine inlet temperature.

Owner:GENERAL ELECTRIC CO

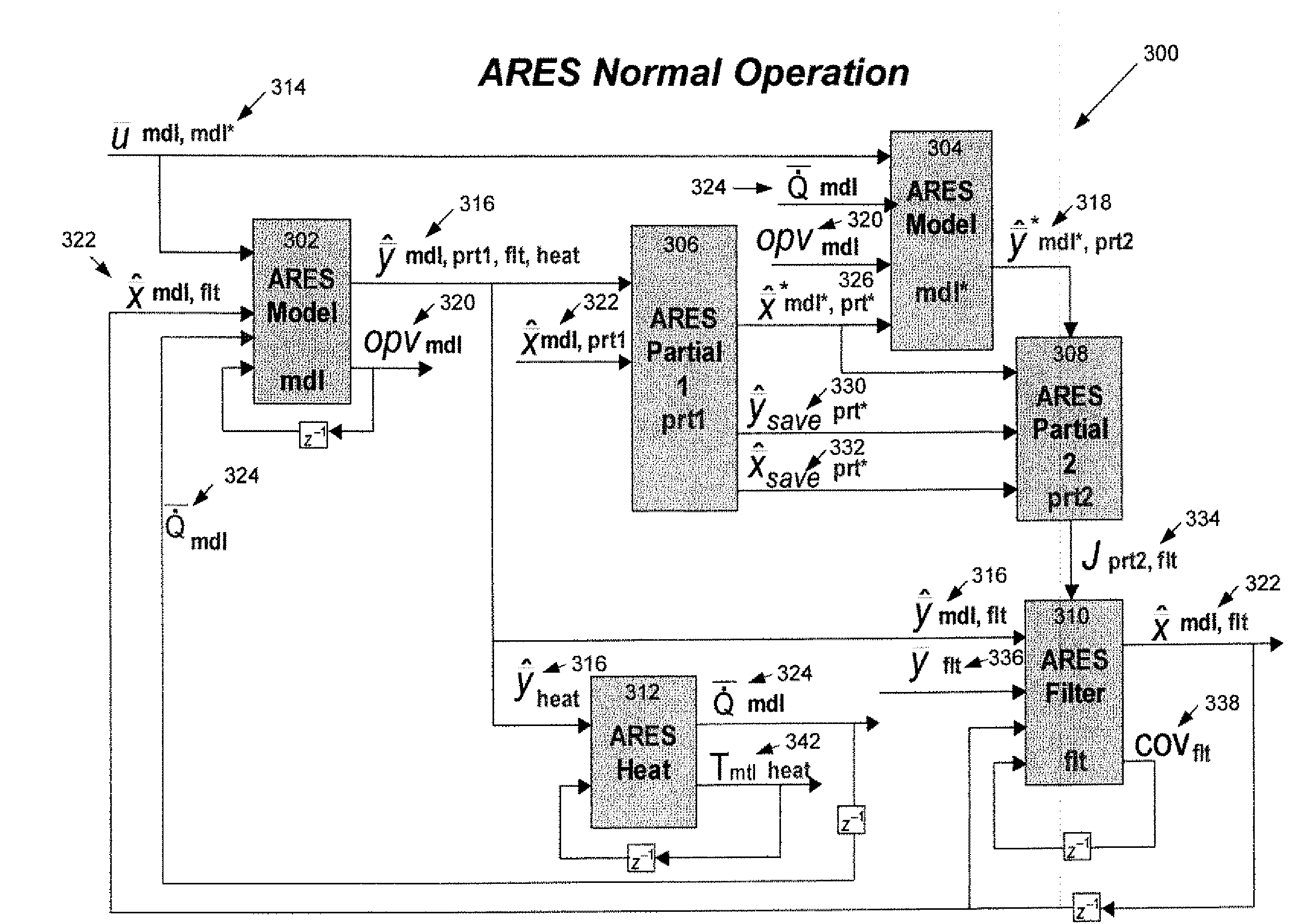

Systems and Methods for Initializing Dynamic Model States Using a Kalman Filter

Embodiments of the invention can provide systems and methods for initializing dynamic model states using a Kalman or similar type filter. In one embodiment, an adaptable model-based control system for controlling a gas turbine engine is provided. The system can include at least one sensor adapted to obtain dynamic-type information about a current state of the engine. Furthermore, the system can include an engine model adapted to receive information from the sensor, and further adapted to reflect the current state of the engine. In addition, the system can include a model filter adapted to initialize the model with at least a portion of the dynamic-type information, wherein at least one value based at least in part on the dynamic-type information is input to the engine model. Moreover, the model can be further adapted to determine an output from the engine model based at least in part on the at least one value. Further, the system can include a controller adapted to determine an engine control action based at least in part on the output from the engine model, and further adapted to output a control command to implement the engine control action.

Owner:GENERAL ELECTRIC CO

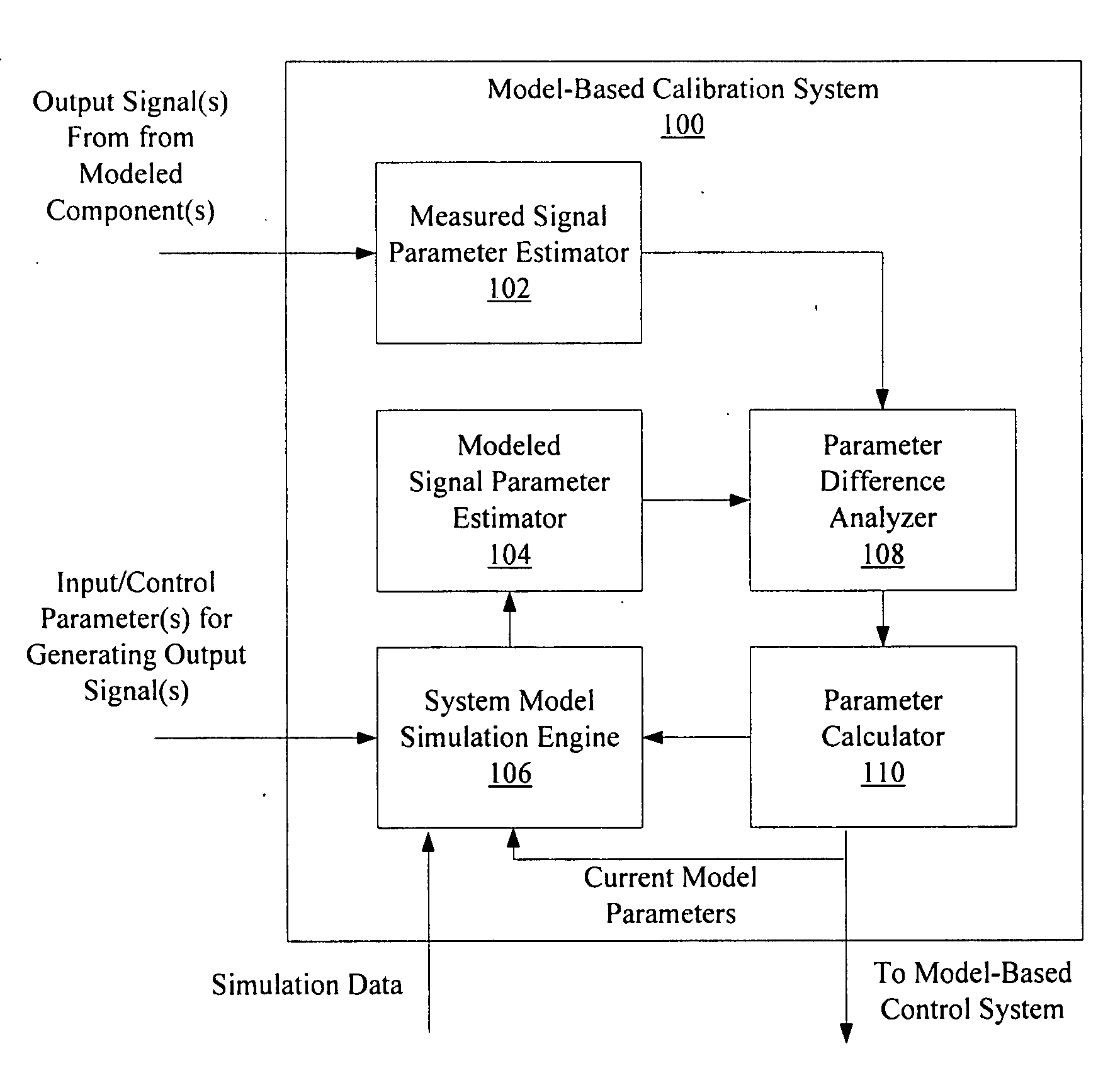

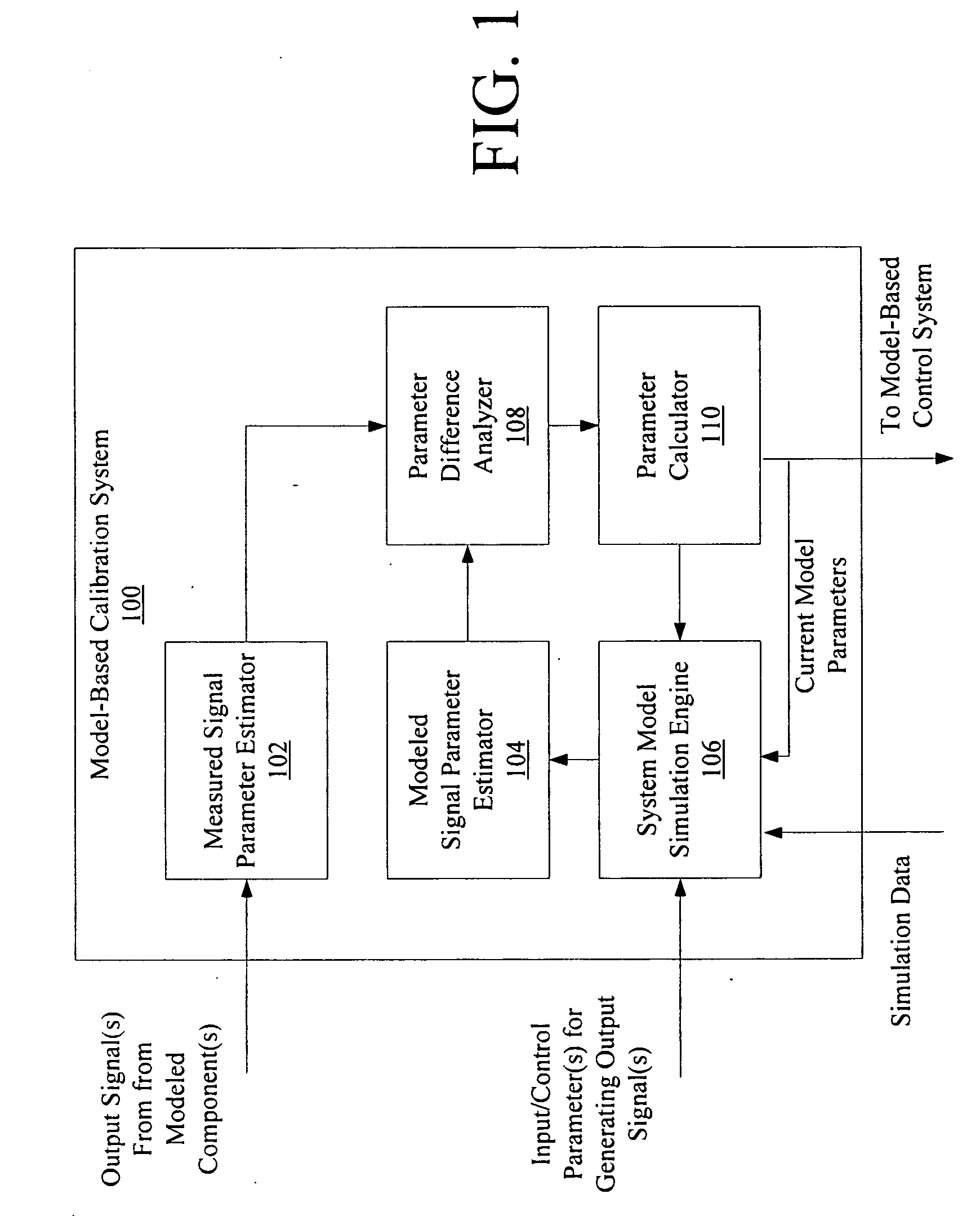

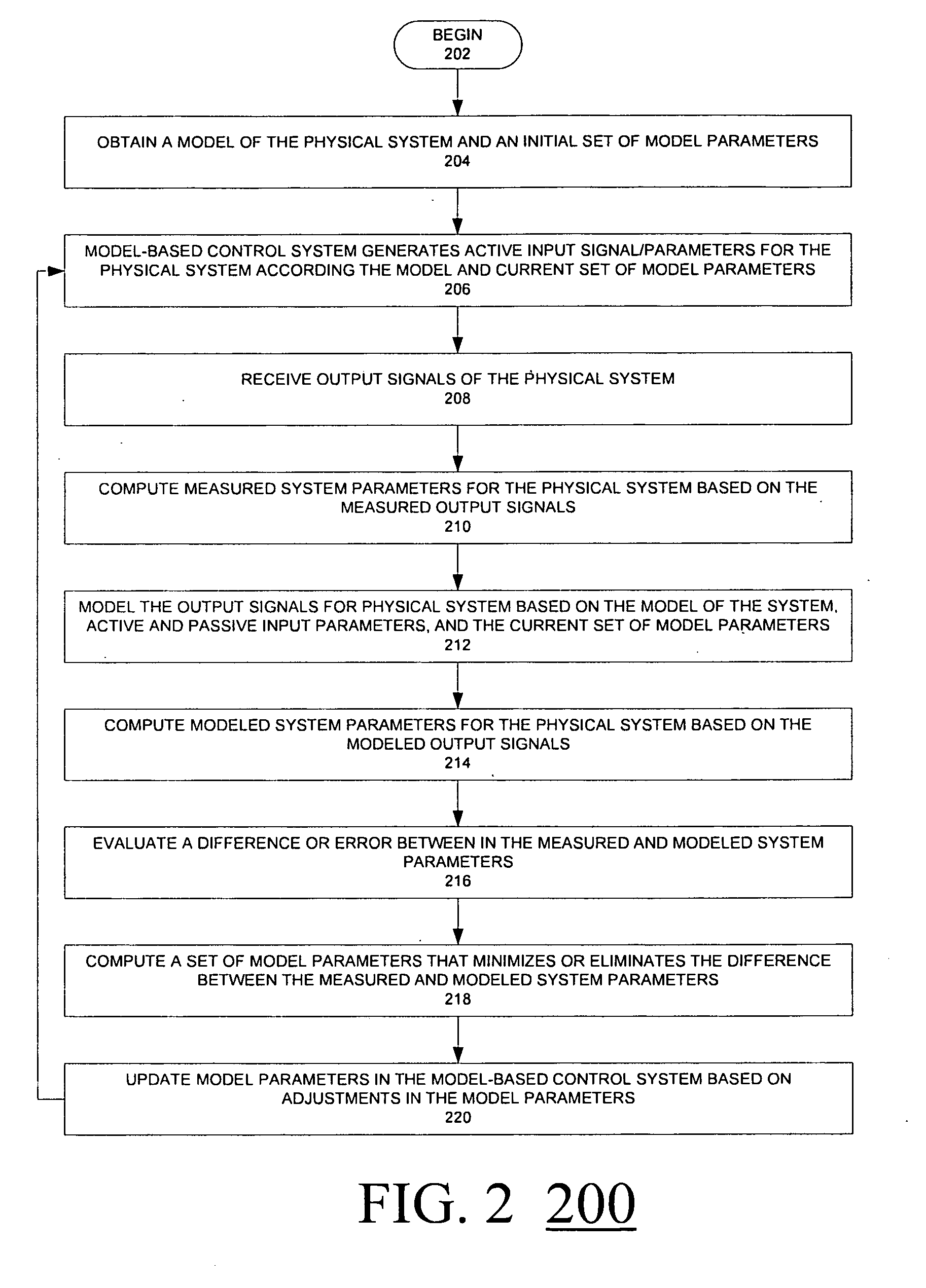

Model-based system calibration for control systems

InactiveUS20100125347A1Analogue computers for control systemsComputation using non-denominational number representationControl systemEngineering

A system and method for model-based control of a the physical system, based on a computer simulation model approximating operating characteristics of at least a portion of the plurality of components and having one or more model parameters for adjusting a modeled operating characteristic of at least one of the plurality of components is provided. In the system and method at least one active input parameter for the physical system is generated based on current values for the model parameters and the computer simulation model and at least one measured system parameter value and at least one modeled system parameter value are obtained for measuring the performance of physical system responding to the active input parameter. The system and method also evaluate a difference between the measured system parameter value and the modeled system parameter value and update the current values for the model parameters to minimize the difference.

Owner:HARRIS CORP

Robust process model identification in model based control techniques

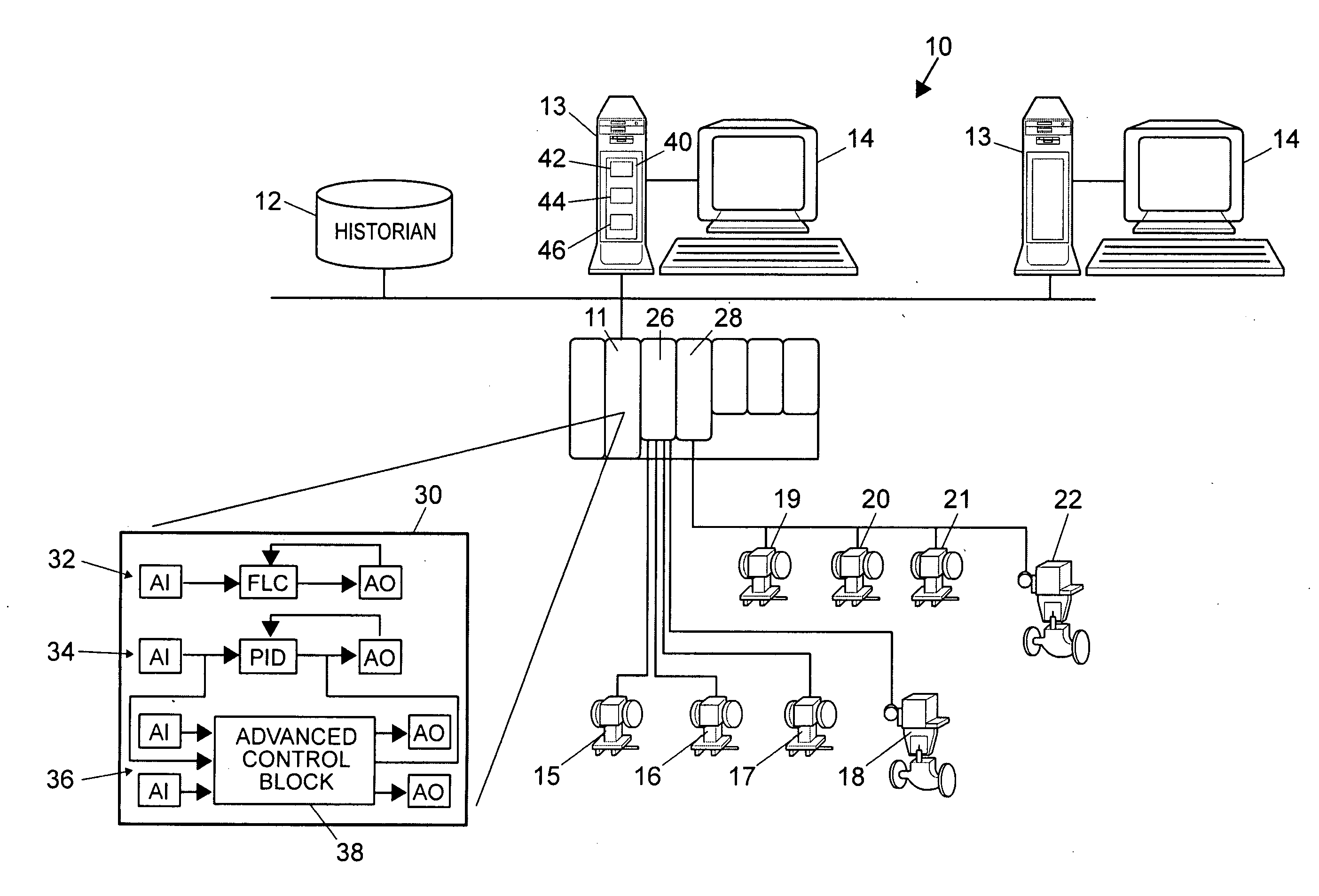

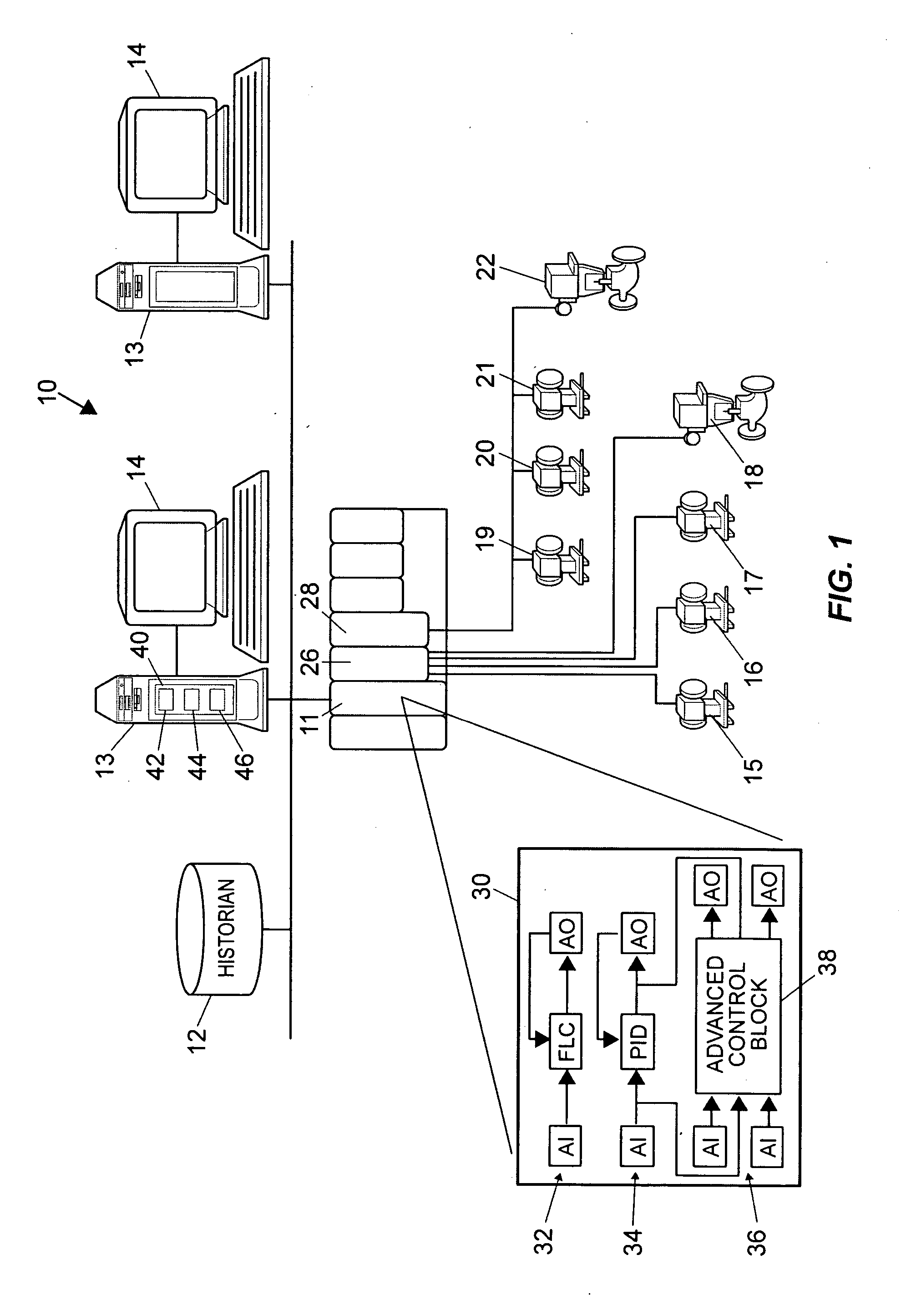

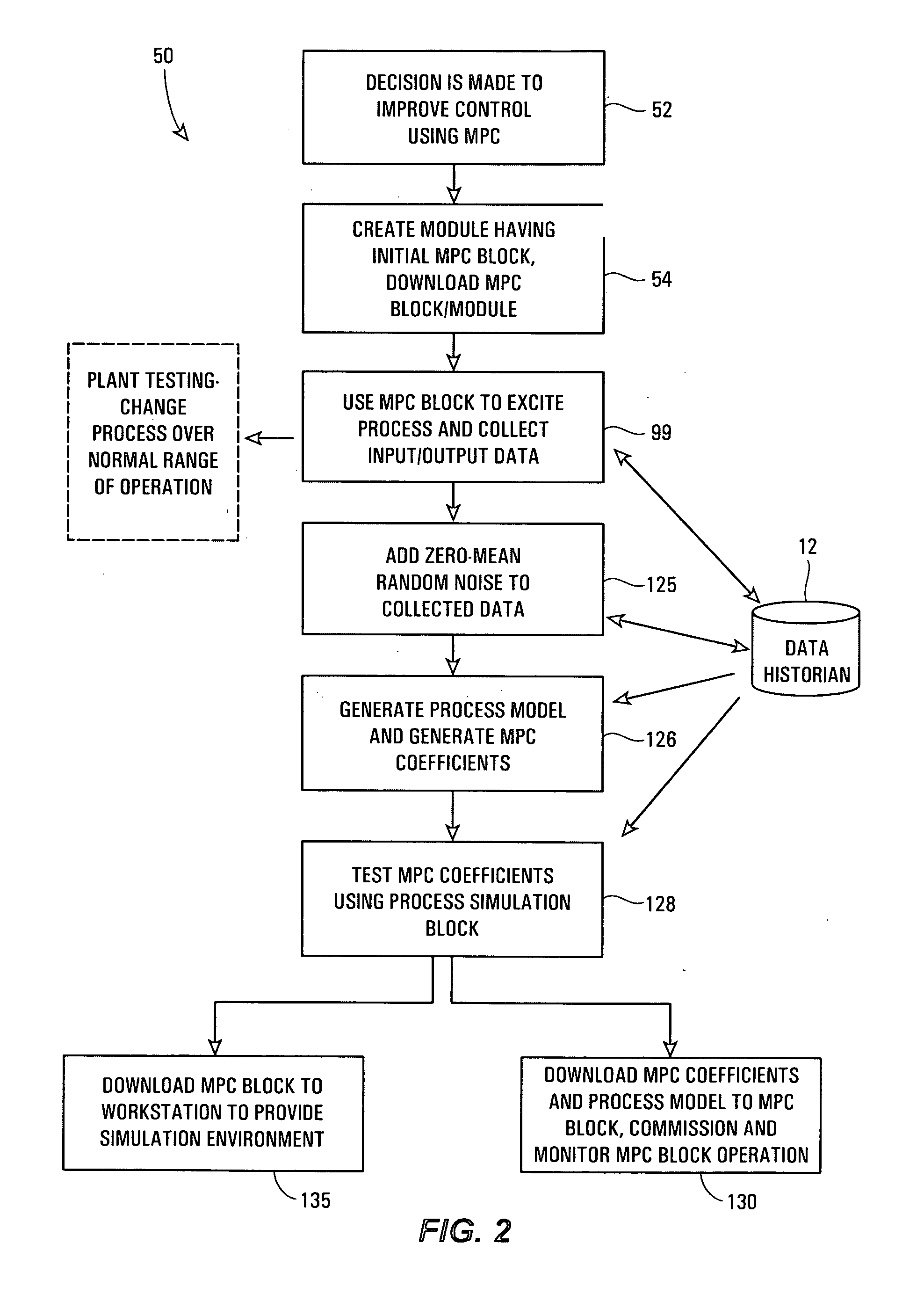

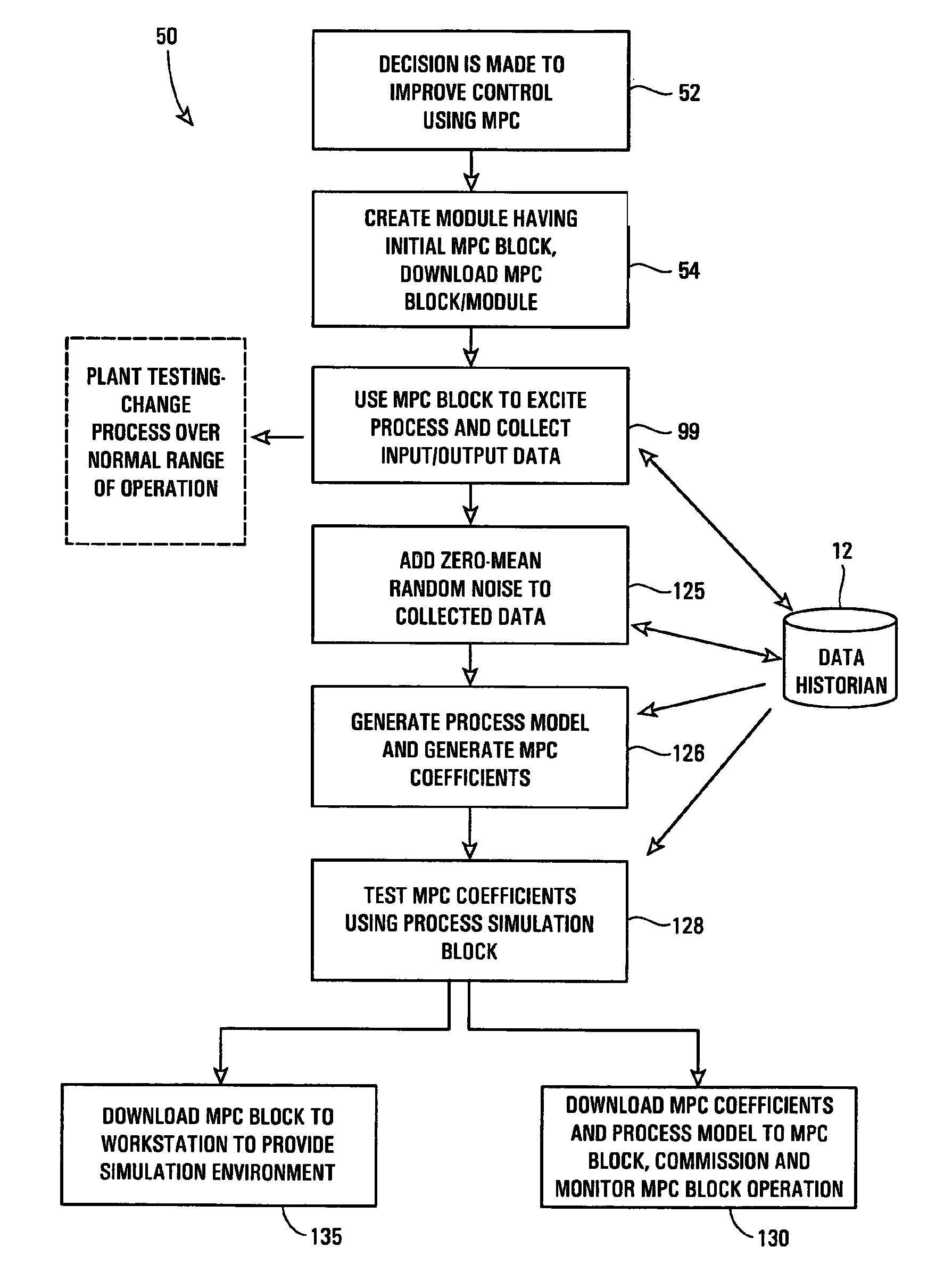

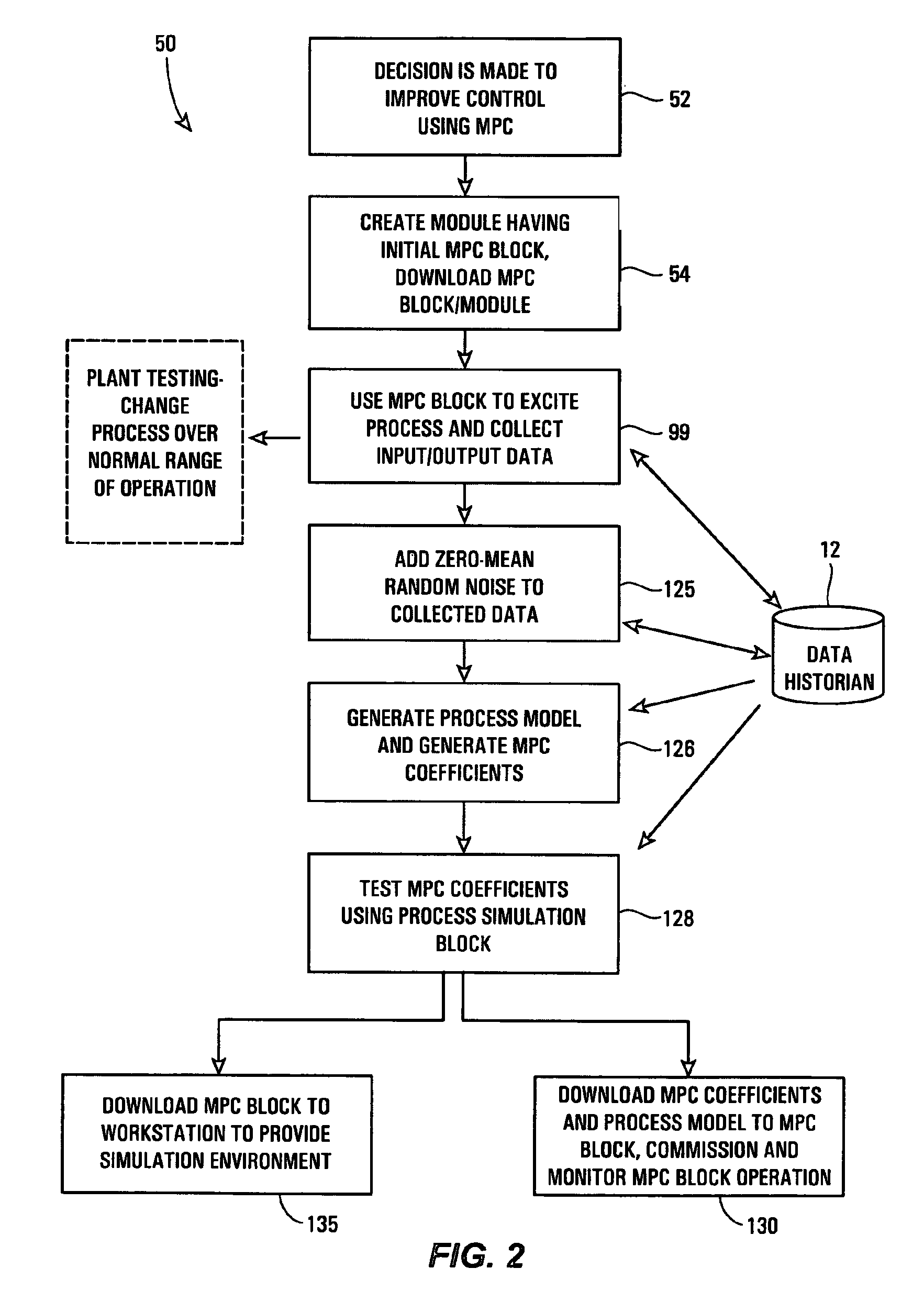

ActiveUS20070244575A1Robust methodAmplifier modifications to reduce noise influenceSimulator controlGeneration processTest input

A robust method of creating process models for use in controller generation, such as in MPC controller generation, adds noise to the process data collected and used in the model generation process. In particular, a robust method of creating a parametric process model first collects process outputs based on known test input signals or sequences, adds random noise to the collected process data and then uses a standard or known technique to determine a process model from the collected process data. Unlike existing techniques for noise removal that focus on clean up of non-random noise prior to generating a process model, the addition of random, zero-mean noise to the process data enables, in many cases, the generation of an acceptable parametric process model in situations where no process model parameter convergence was otherwise obtained. Additionally, process models created using this technique generally have wider confidence intervals, therefore providing a model that works adequately in many process situations without needing to manually or graphically change the model.

Owner:FISHER-ROSEMOUNT SYST INC

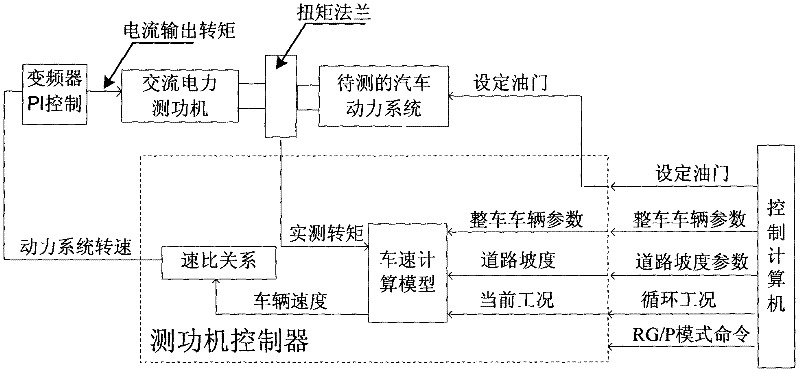

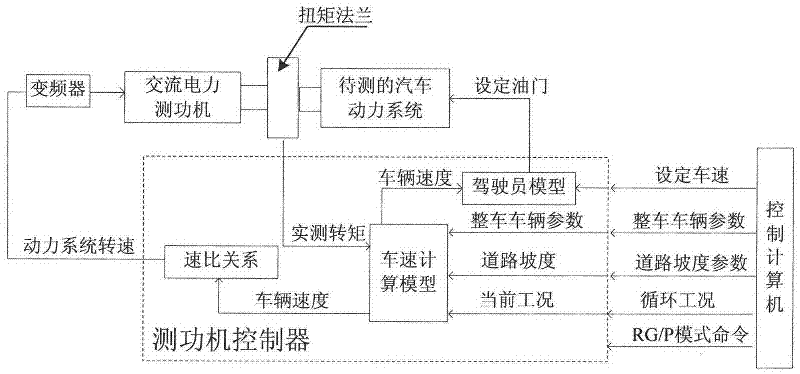

Dynamic load simulating device and method for automobile power system test

InactiveCN102305715AAvoid Differential ValuesImprove dynamic stabilityMachine gearing/transmission testingEngine testingRolling resistanceDynamometer

The invention relates to a dynamic load simulating device and a dynamic load simulating method for an automobile power system test, and belongs to the technical field of vehicle power system tests. The dynamic load simulating device comprises a control computer, a dynamometer controller, a frequency converter, an alternating current (AC) power dynamometer and a torque flange with a controller. A virtual automobile model-based control algorithm is adopted, a virtual automobile model is driven by an actual measurement torque, and the simulation of the rolling resistance, wind resistance and the inertia resistance of a vehicle is realized under the conditions of not calculating angular acceleration of the dynamometer. The dynamic load simulating device and the dynamic load simulating method have high stability and high simulation precision, are favorable for shortening the development cycle of an automobile power system and providing convenient test environment for the development of the power system. A process that the vehicle acceleration is acquired by differentiating the rotation speed of the automobile power system is avoided in the calculation process, and a phenomenon that accurate differential values are difficult to acquire due to relatively large noise caused by the process of differentiating the rotation speed is prevented.

Owner:TSINGHUA UNIV

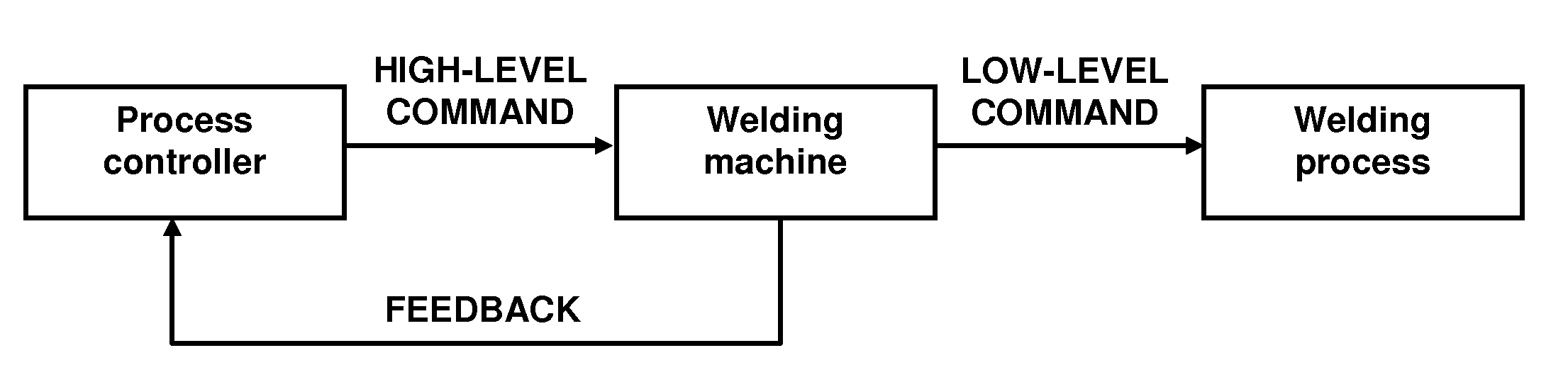

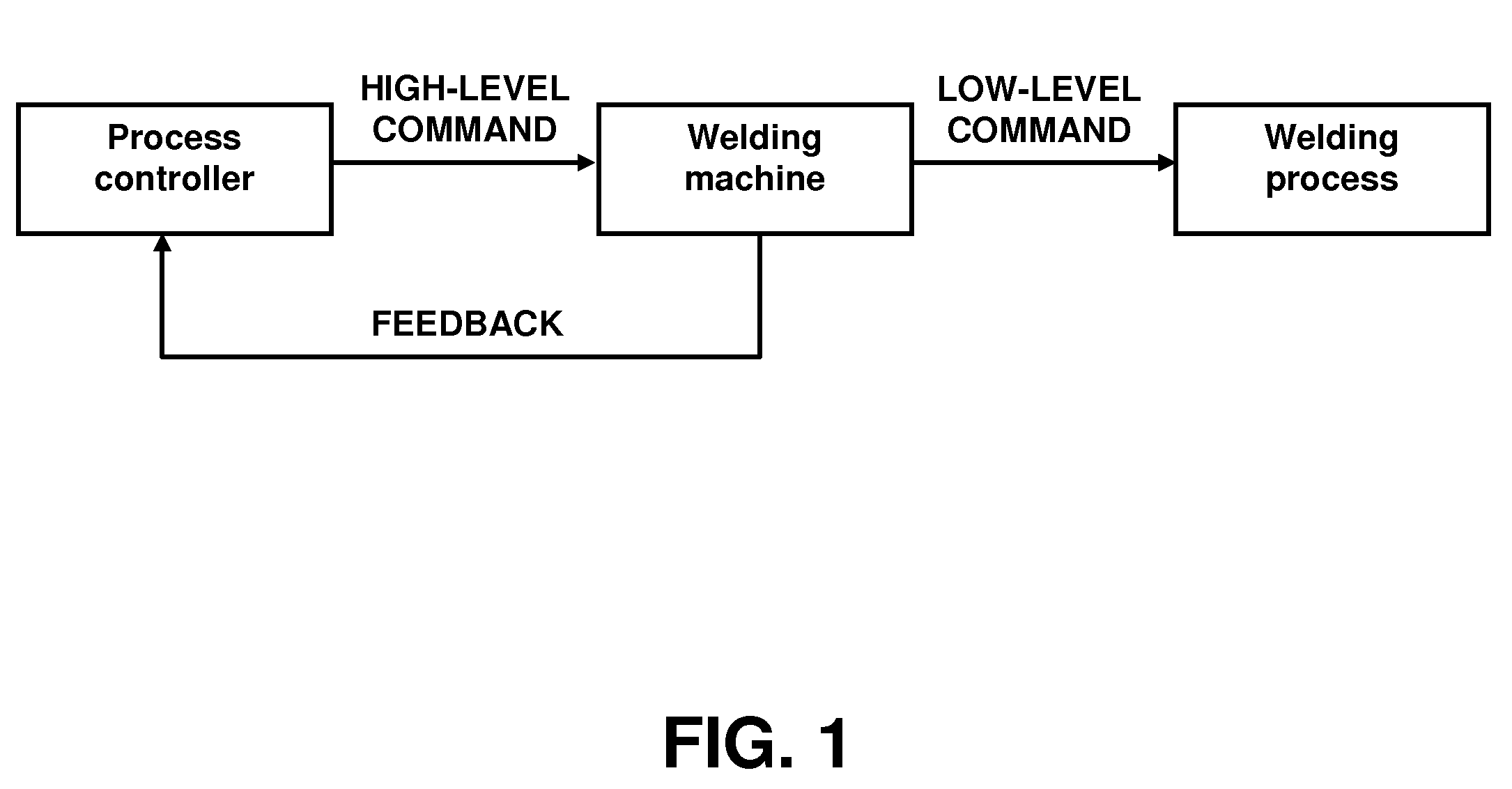

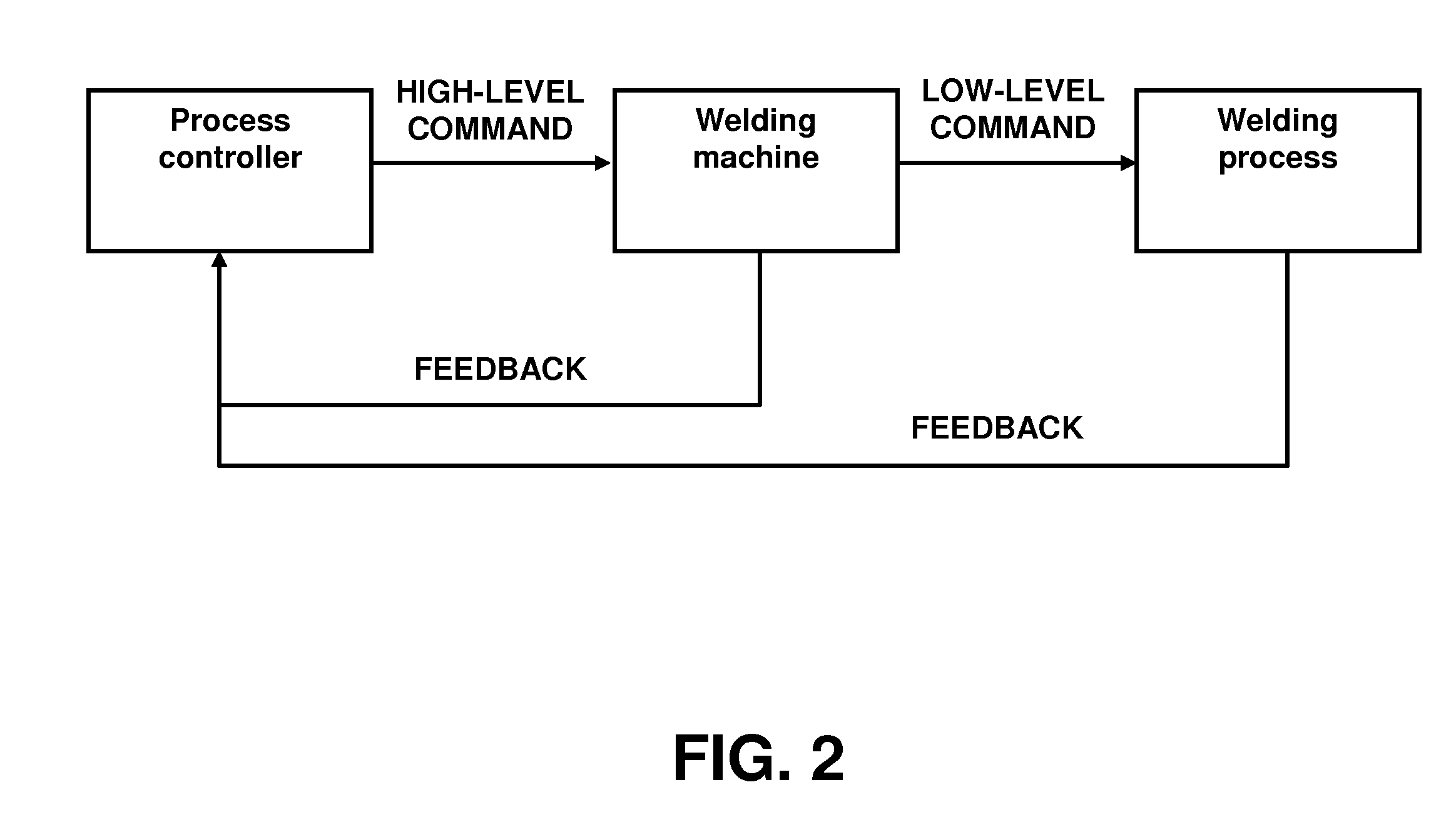

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

Robust process model identification in model based control techniques

ActiveUS7840287B2Robust methodAmplifier modifications to reduce noise influenceSimulator controlGeneration processTest input

A robust method of creating process models for use in controller generation, such as in MPC controller generation, adds noise to the process data collected and used in the model generation process. In particular, a robust method of creating a parametric process model first collects process outputs based on known test input signals or sequences, adds random noise to the collected process data and then uses a standard or known technique to determine a process model from the collected process data. Unlike existing techniques for noise removal that focus on clean up of non-random noise prior to generating a process model, the addition of random, zero-mean noise to the process data enables, in many cases, the generation of an acceptable parametric process model in situations where no process model parameter convergence was otherwise obtained. Additionally, process models created using this technique generally have wider confidence intervals, therefore providing a model that works adequately in many process situations without needing to manually or graphically change the model.

Owner:FISHER-ROSEMOUNT SYST INC

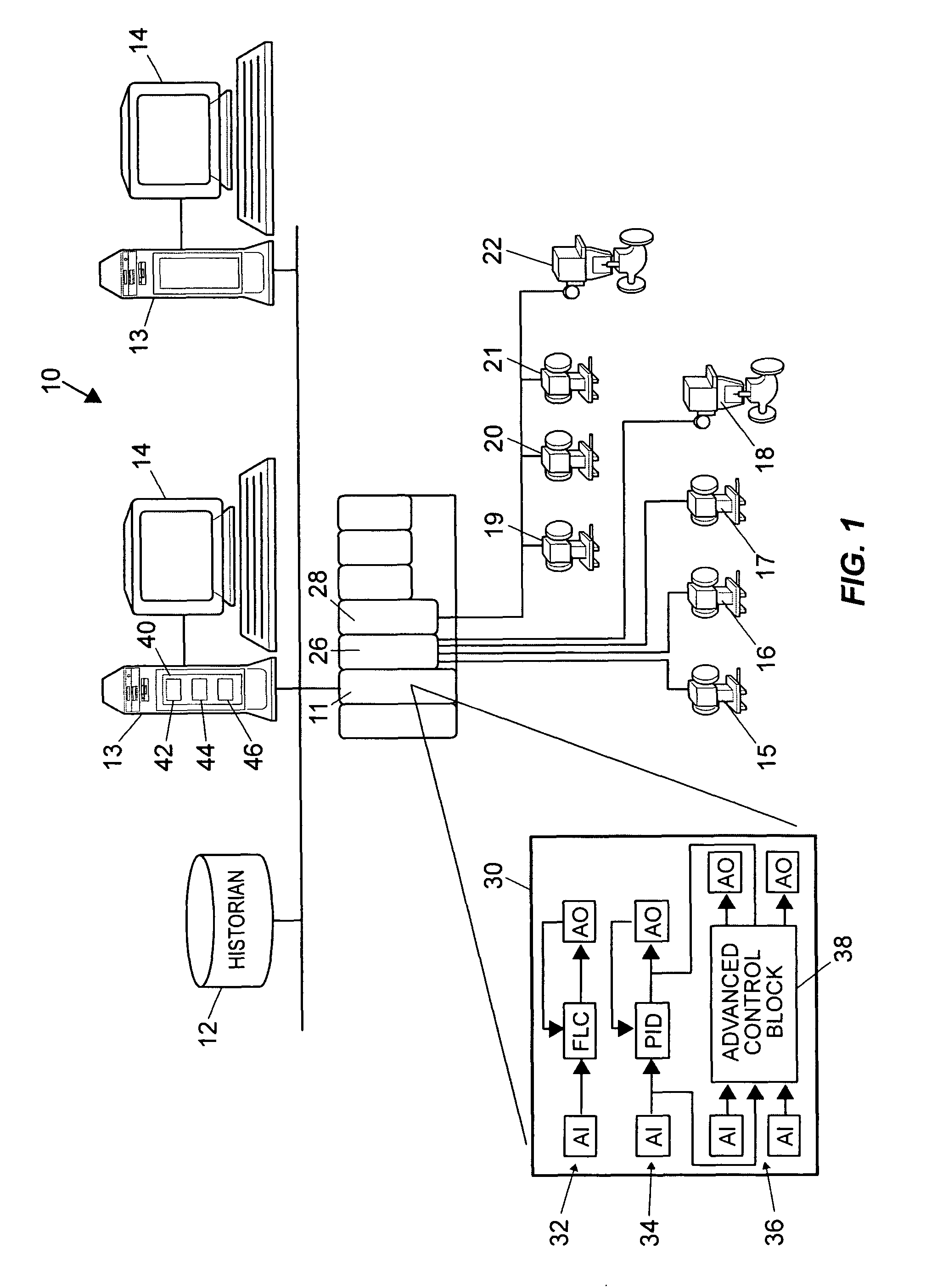

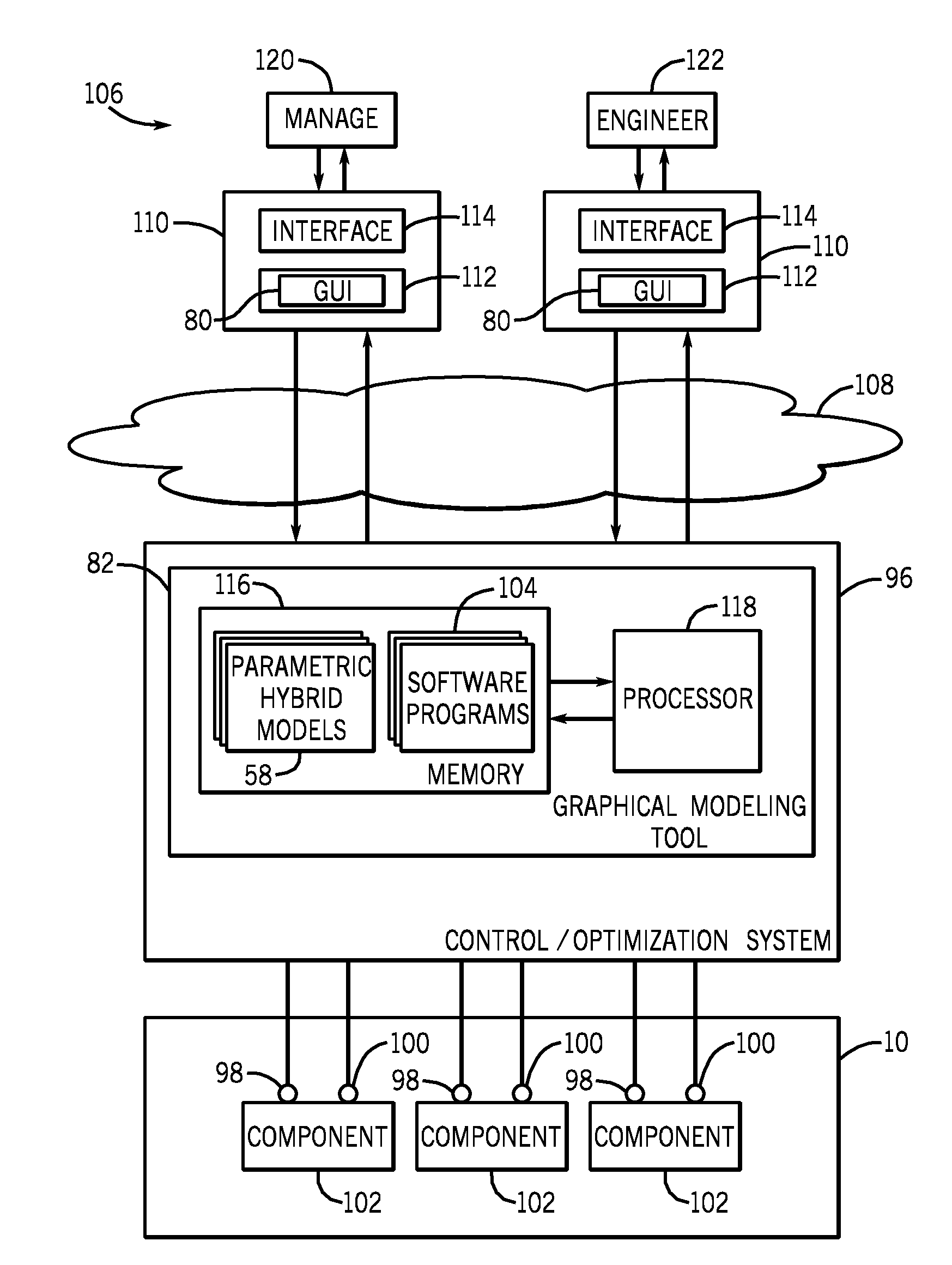

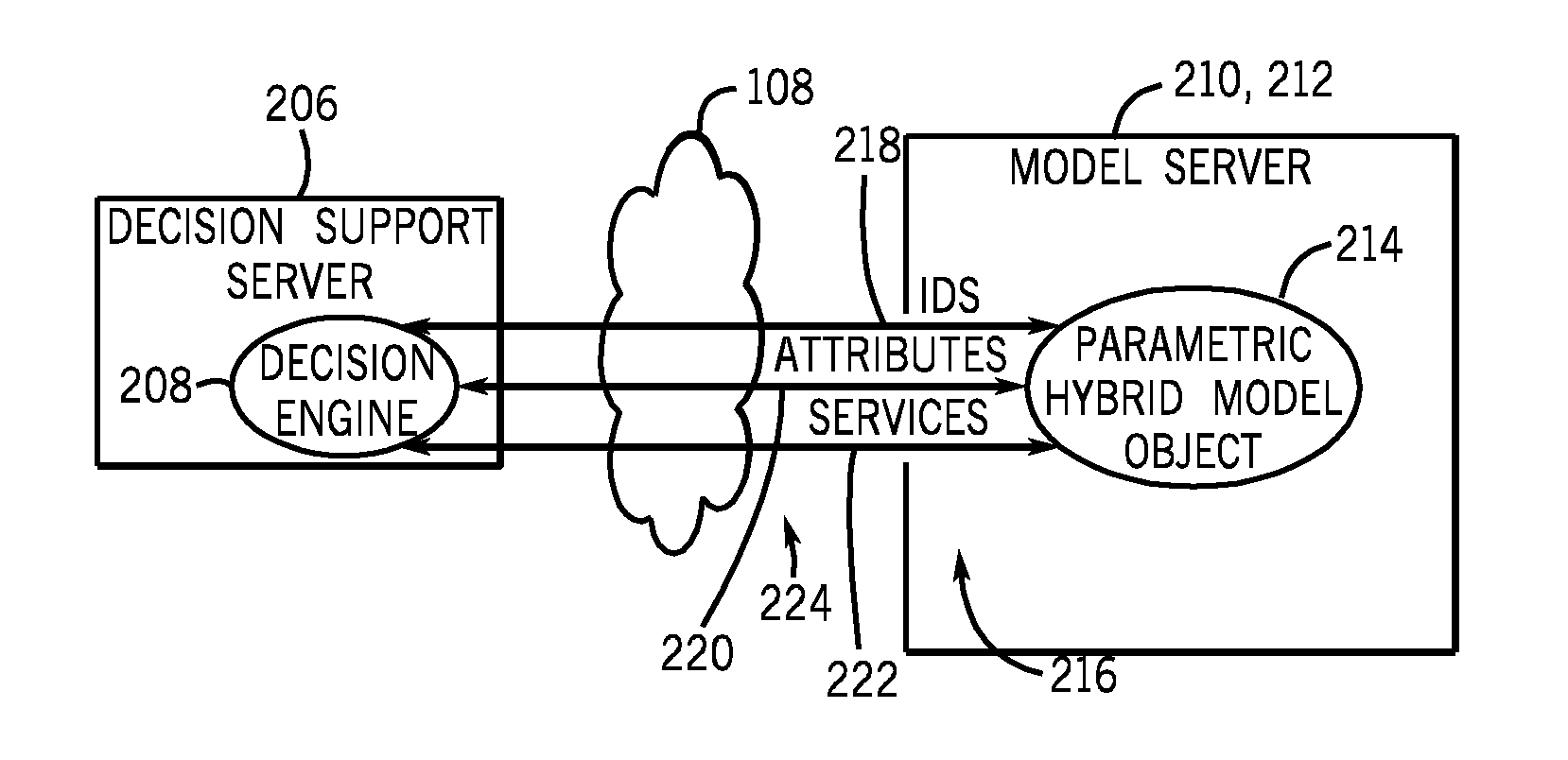

Secure models for model-based control and optimization

In certain embodiments, a control / optimization system includes an instantiated model object stored in memory on a model server. The model object includes a model of a plant or process being controlled. The model object comprises an interface that precludes the transmission of proprietary information via the interface. The control / optimization system also includes a decision engine software module stored in memory on a decision support server. The decision engine software module is configured to request information from the model object through a communication network via a communication protocol that precludes the transmission of proprietary information, and to receive the requested information from the model object through the communication network via the communication protocol.

Owner:ROCKWELL AUTOMATION TECH

Model-based control for crane control and underway replenishment

ActiveUS7599762B2Easy to controlMitigates container swayAnalogue computers for trafficTrolley cranesTransport timeExternal data

Crane control and anti-sway are facilitated utilizing a diagnostic component that includes a model component and a control component. The diagnostic component interfaces with an extrinsic data analysis component and a controller component. The diagnostic component receives operating condition information from the extrinsic data analysis component and performs predictive modeling, based on a current status and stored information. Further, the diagnostic component predicts the affect of the operating conditions on a crane and implements and / or recommends actions to mitigate the affect of the existing and / or predicted operating conditions. The diagnostic component further mitigates crane sway and / or induces crane sway to reduce container transit time. Intelligent agents are employed to provide trajectory planning and execution and / or to detect potential component failure.

Owner:ROCKWELL AUTOMATION TECH

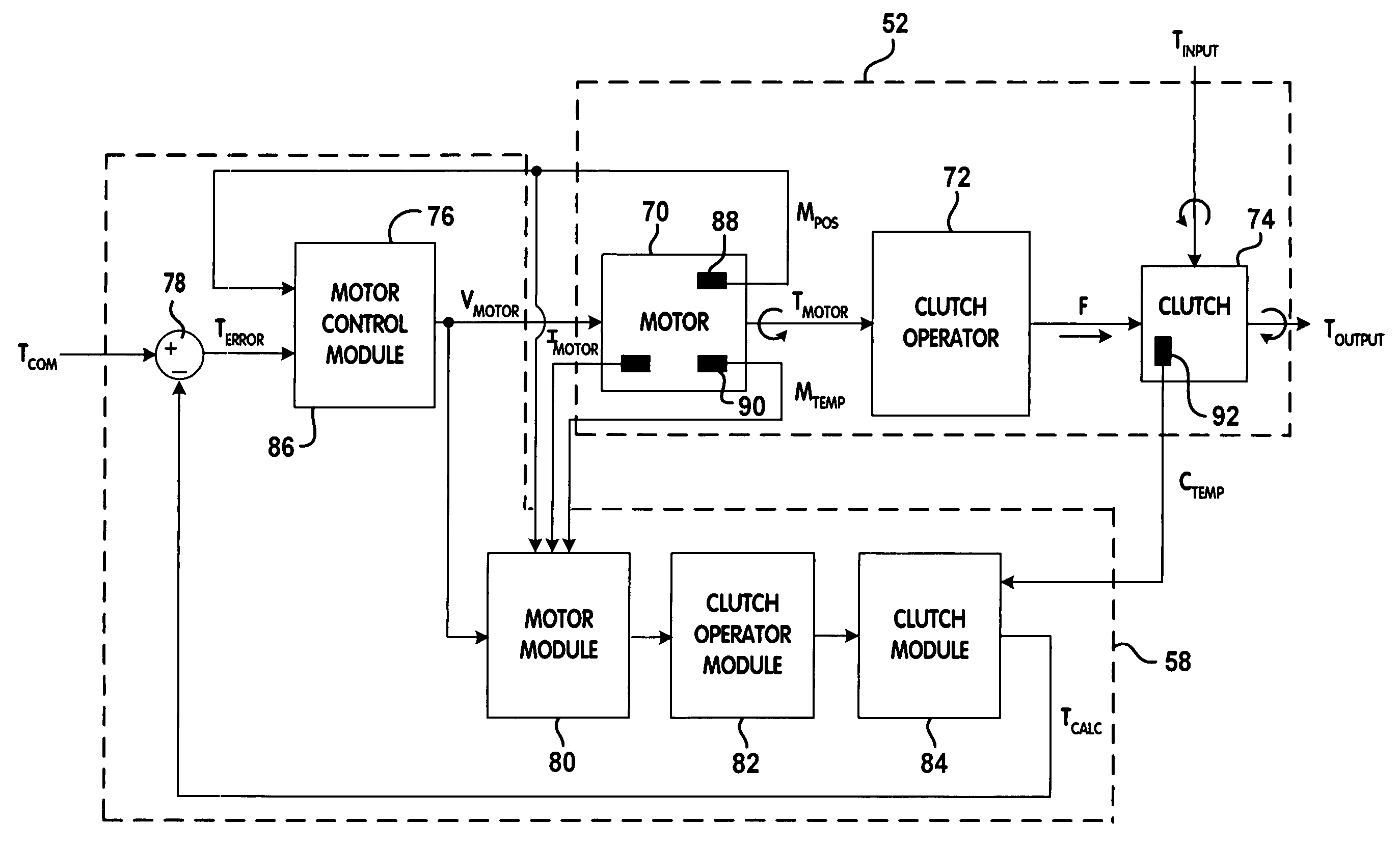

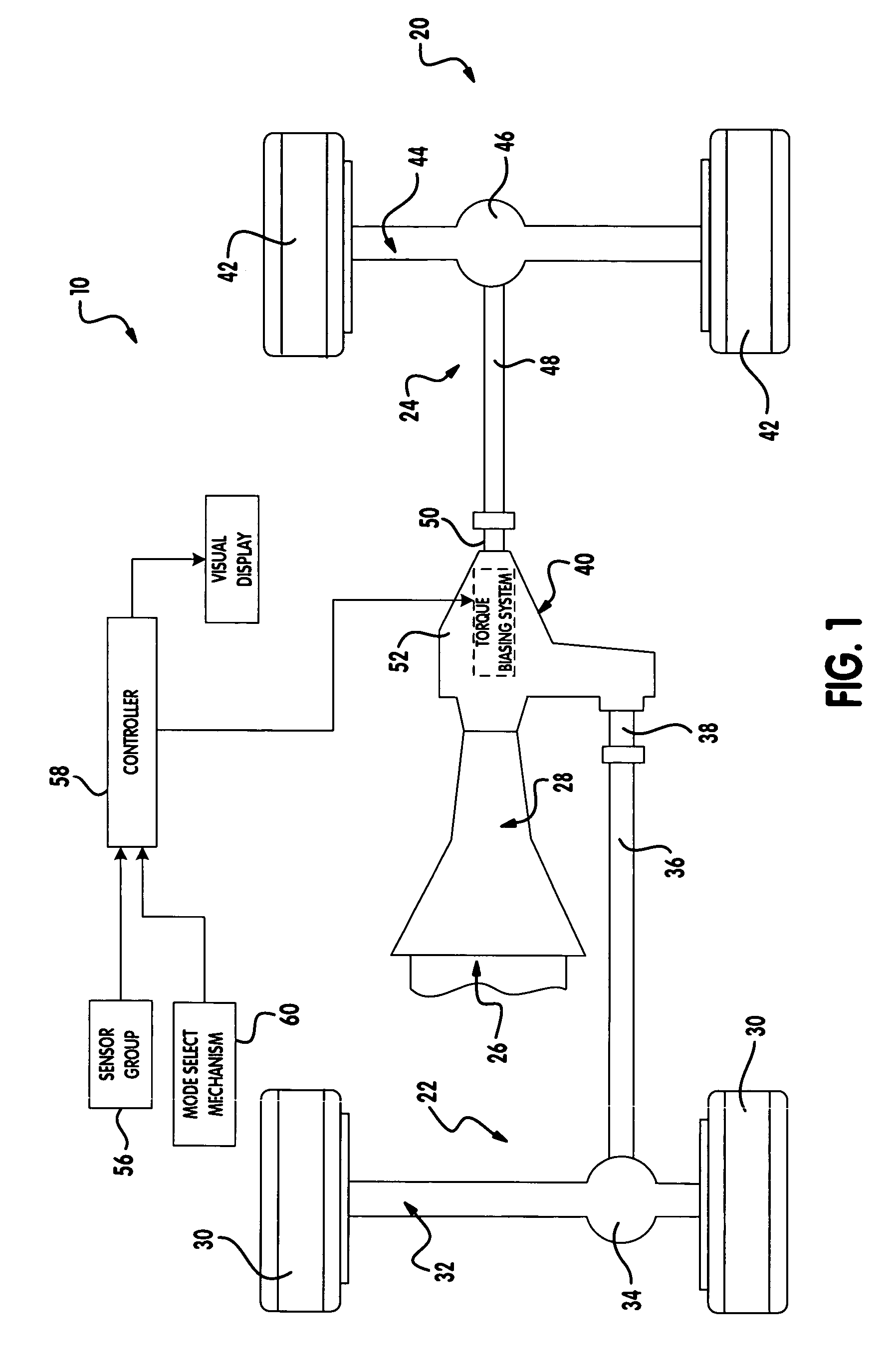

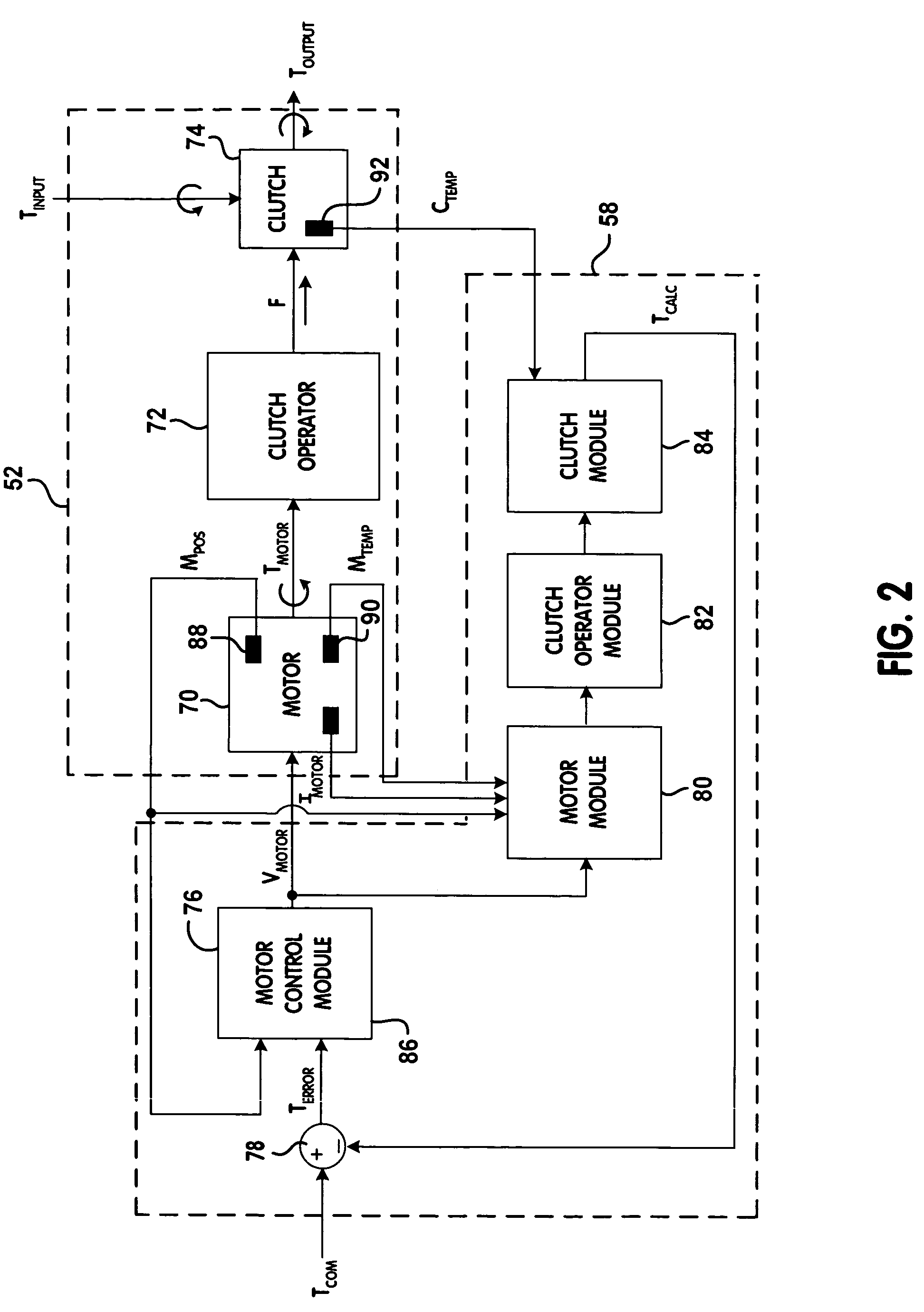

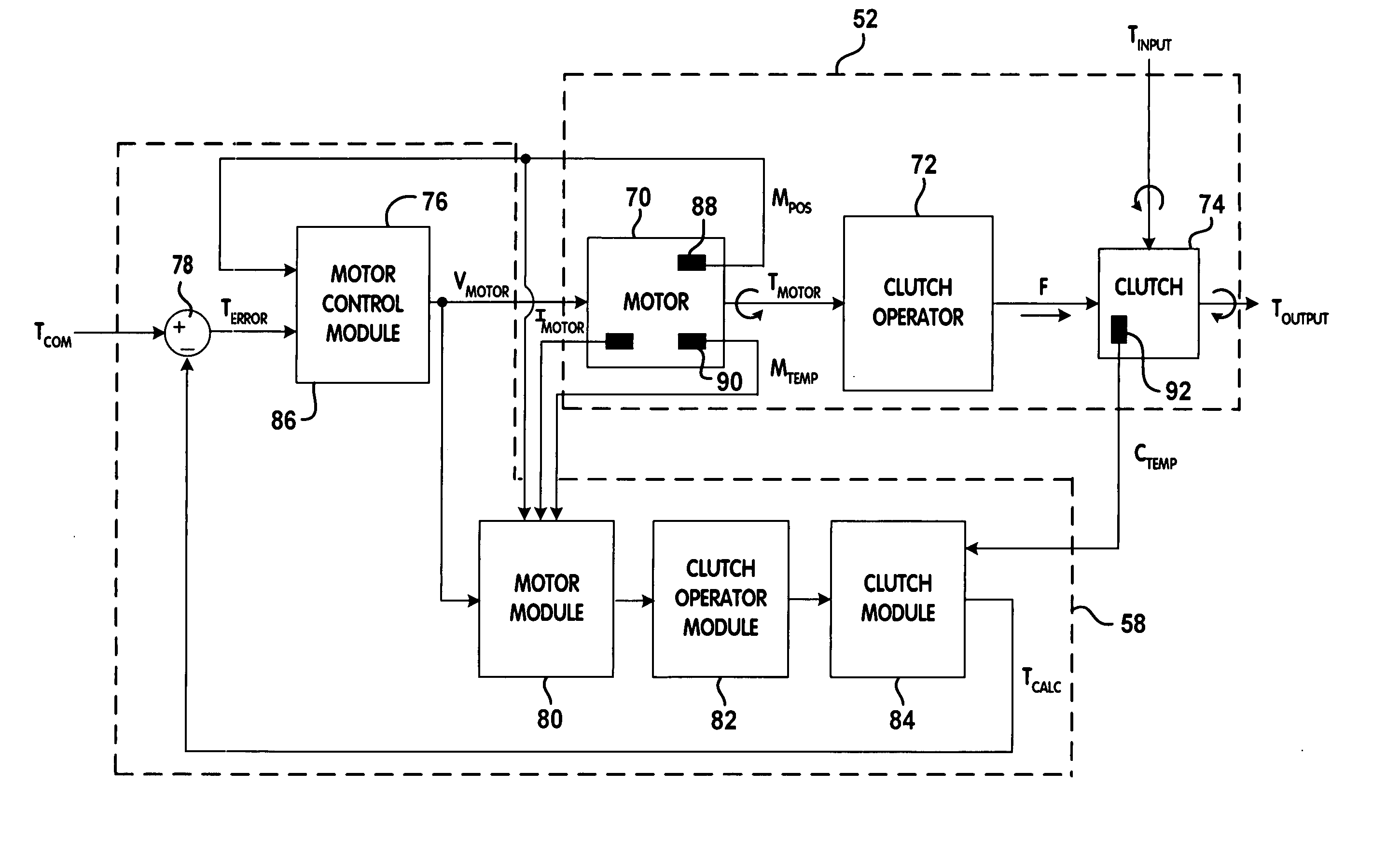

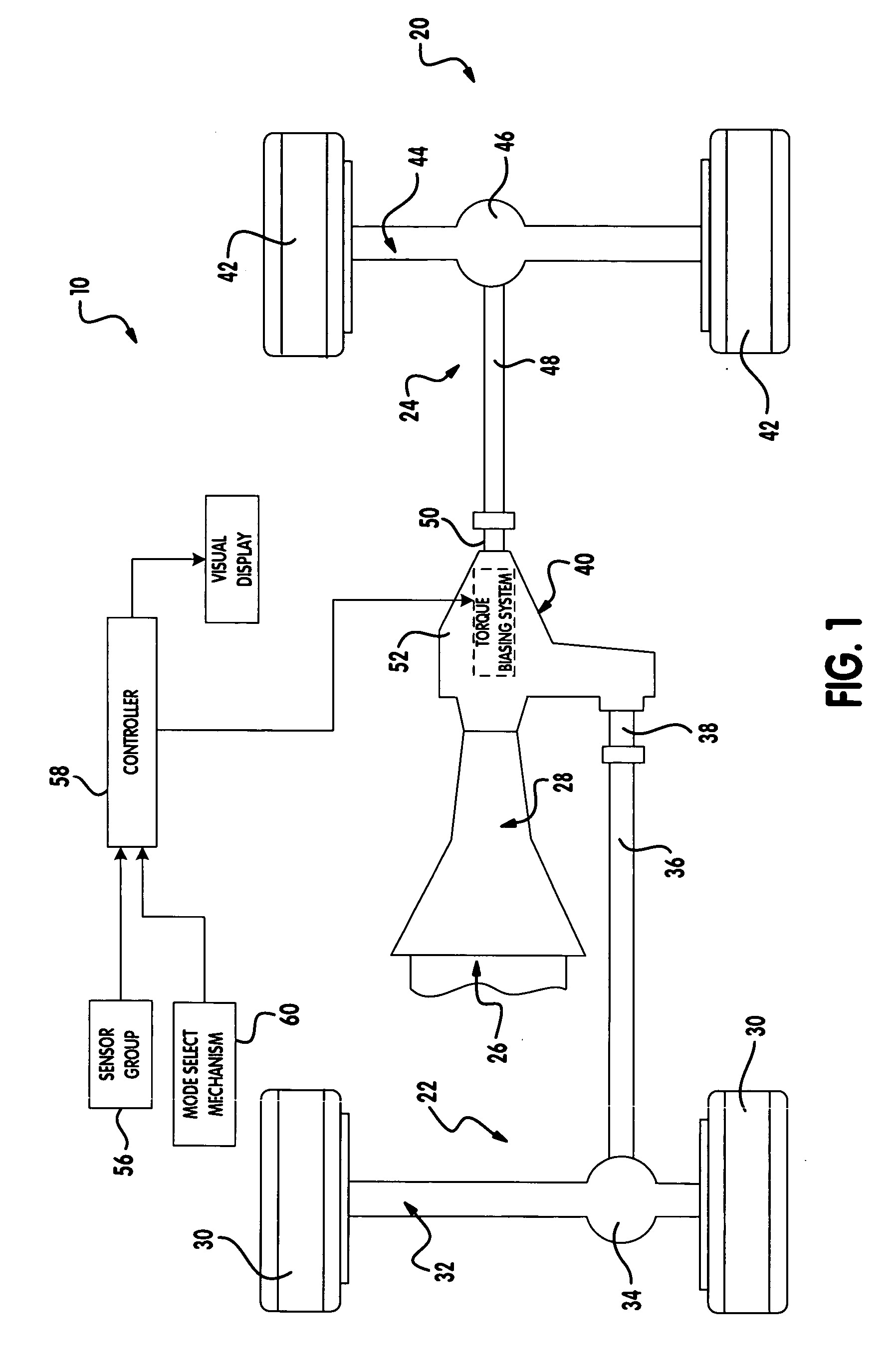

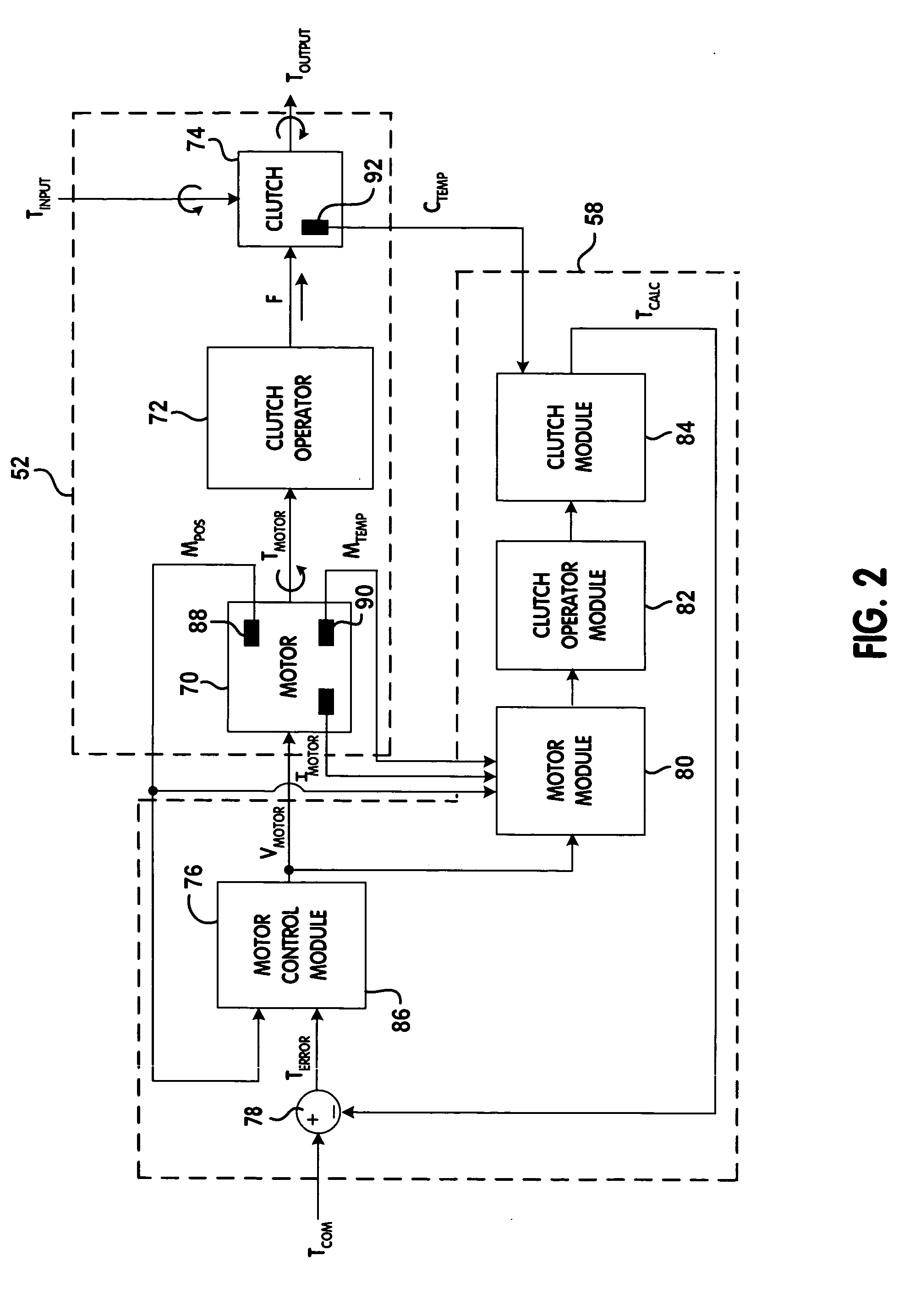

Model-based control for torque biasing system

A method of controlling a torque biasing system includes determining a torque command, calculating a torque error based on the torque command and a model-based torque. A control signal is generated based on the torque error and the torque biasing system is operated based on the control signal.

Owner:NEW VENTURE GEAR INC

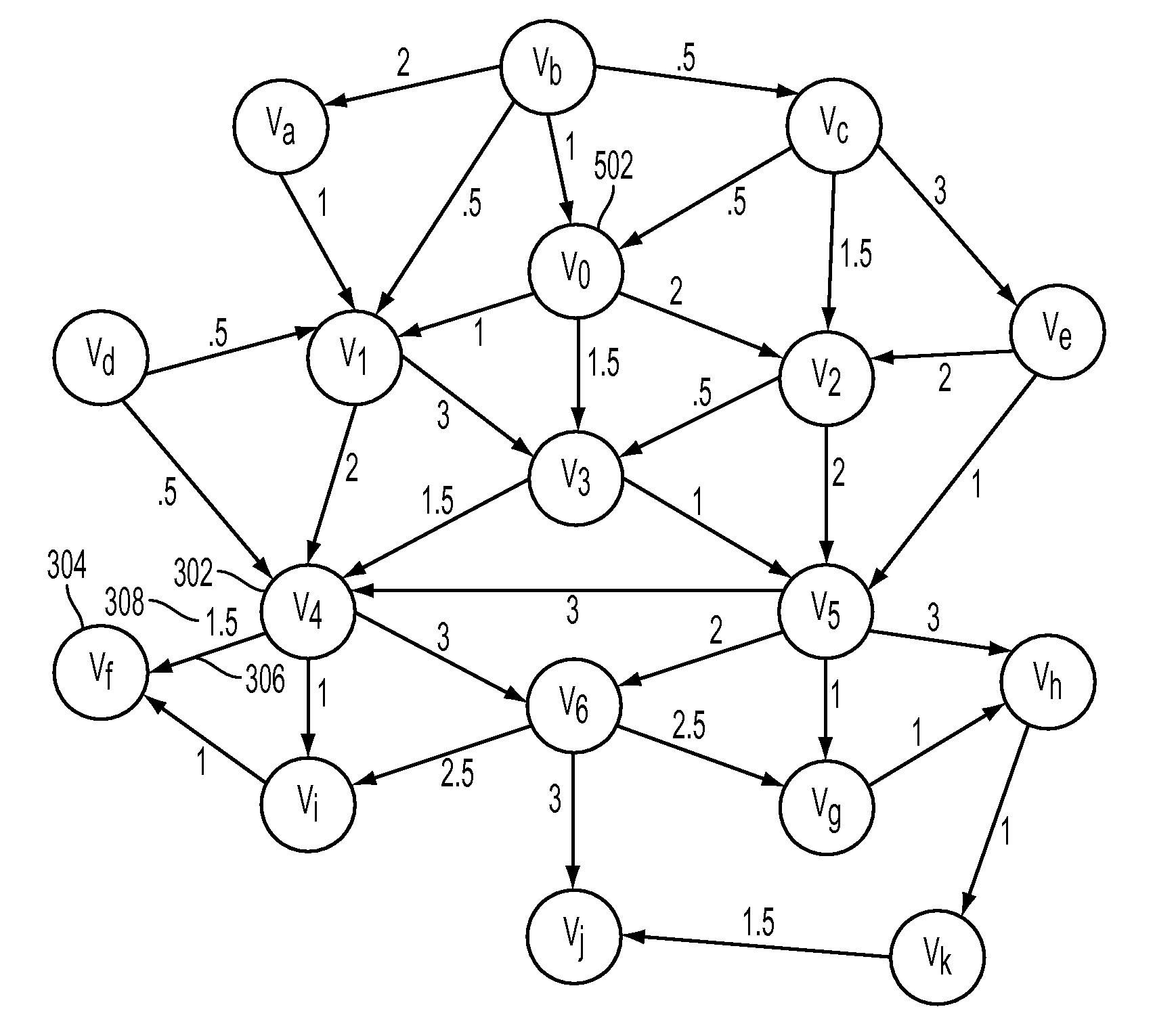

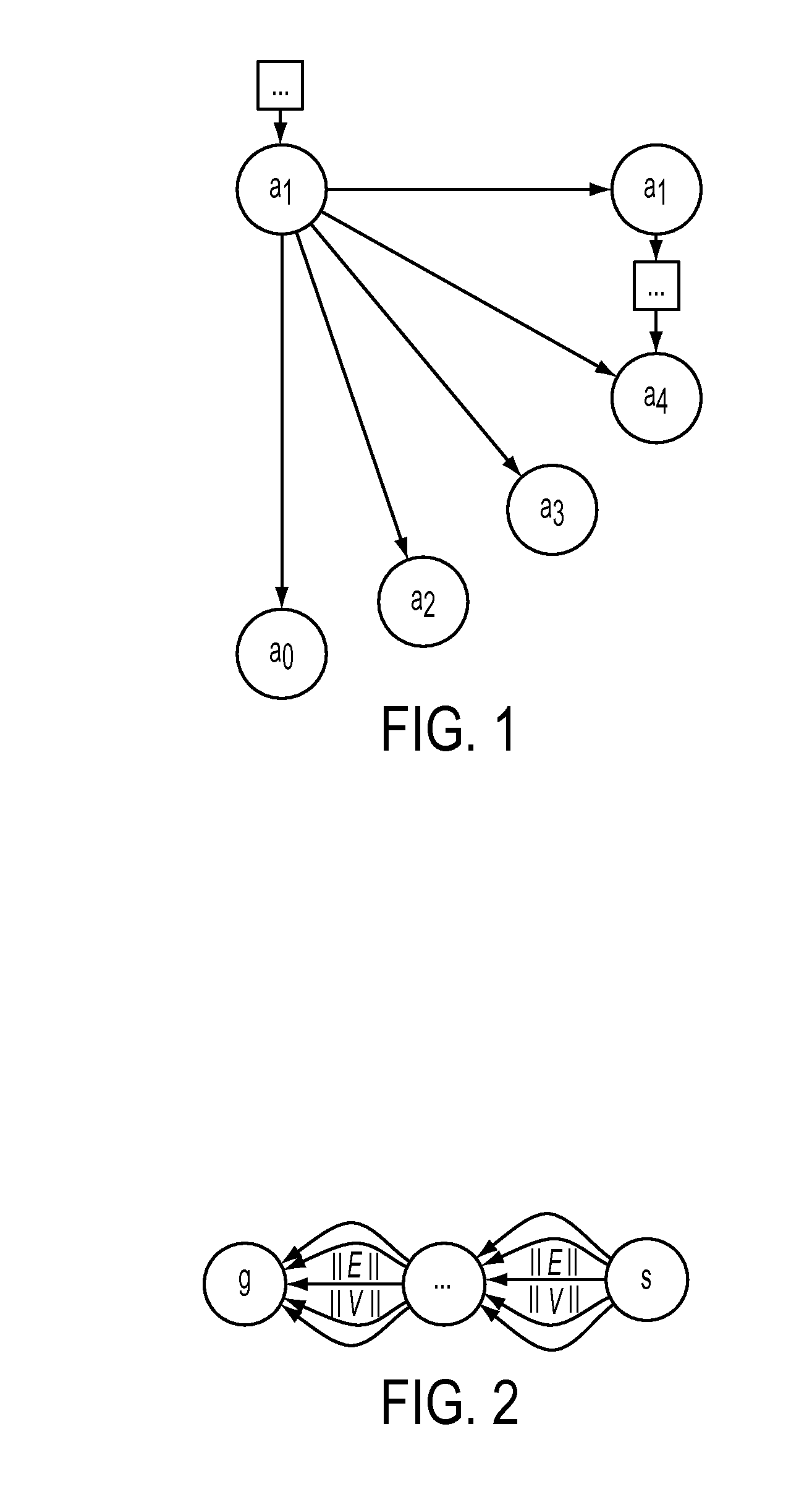

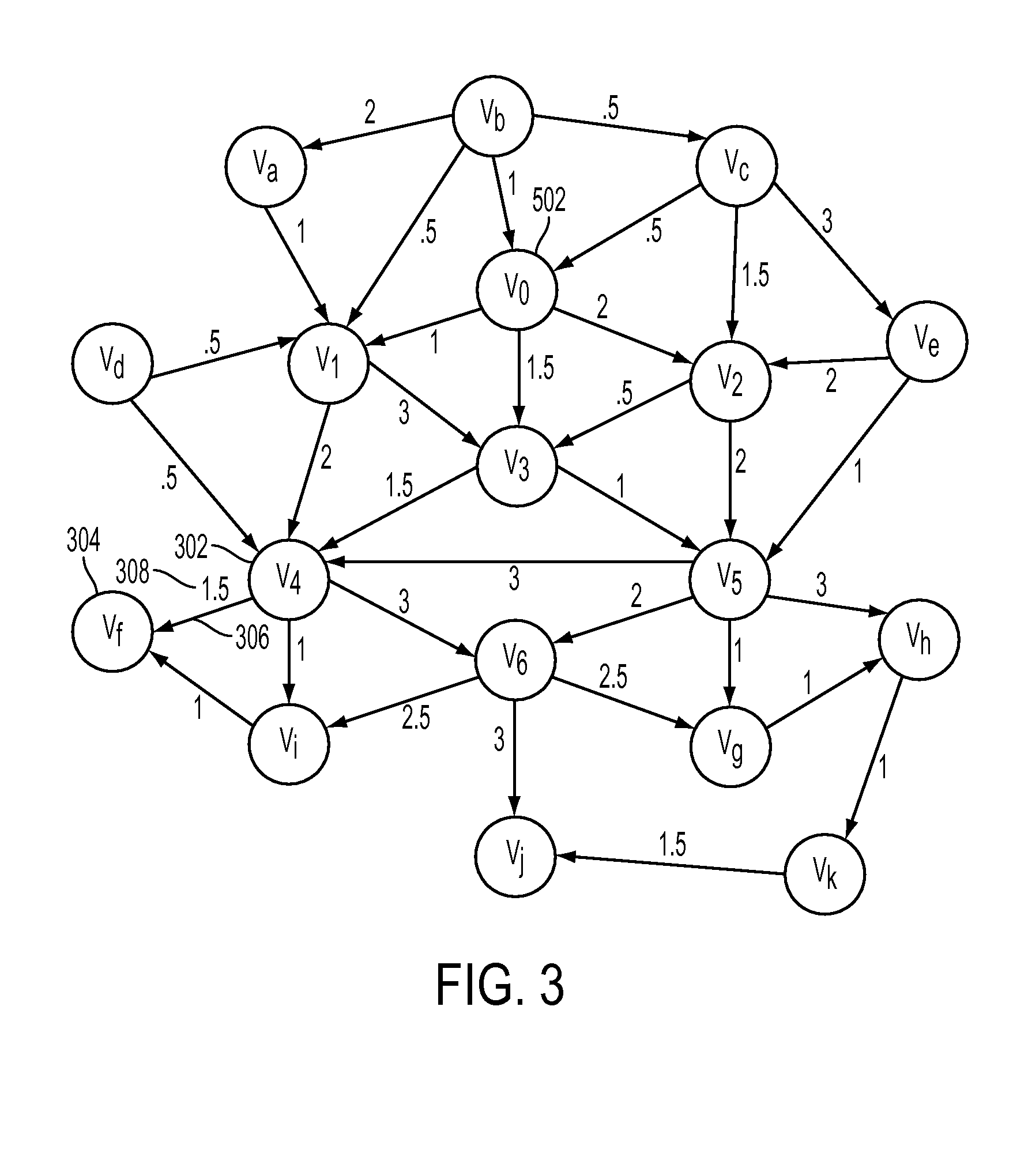

Depth-First Search For Target Value Problems

A method for determining a target path for a model-based control system. The model-based control system includes a directed acyclic graph, where the directed acyclic graph includes a plurality of vertices interconnected by a plurality of edges. The method includes the steps of performing a depth-first search of the directed acyclic graph for the target path. The depth-first search is operative to return an explicit solution or an implicit solution, wherein the implicit solution is determined using a heuristic. The method further includes determining if the depth-first search returned an explicit solution or an implicit solution, and if the depth-first search returned an implicit solution, constructing the target path from the implicit solution. The method may further include constructing a pattern database.

Owner:XEROX CORP

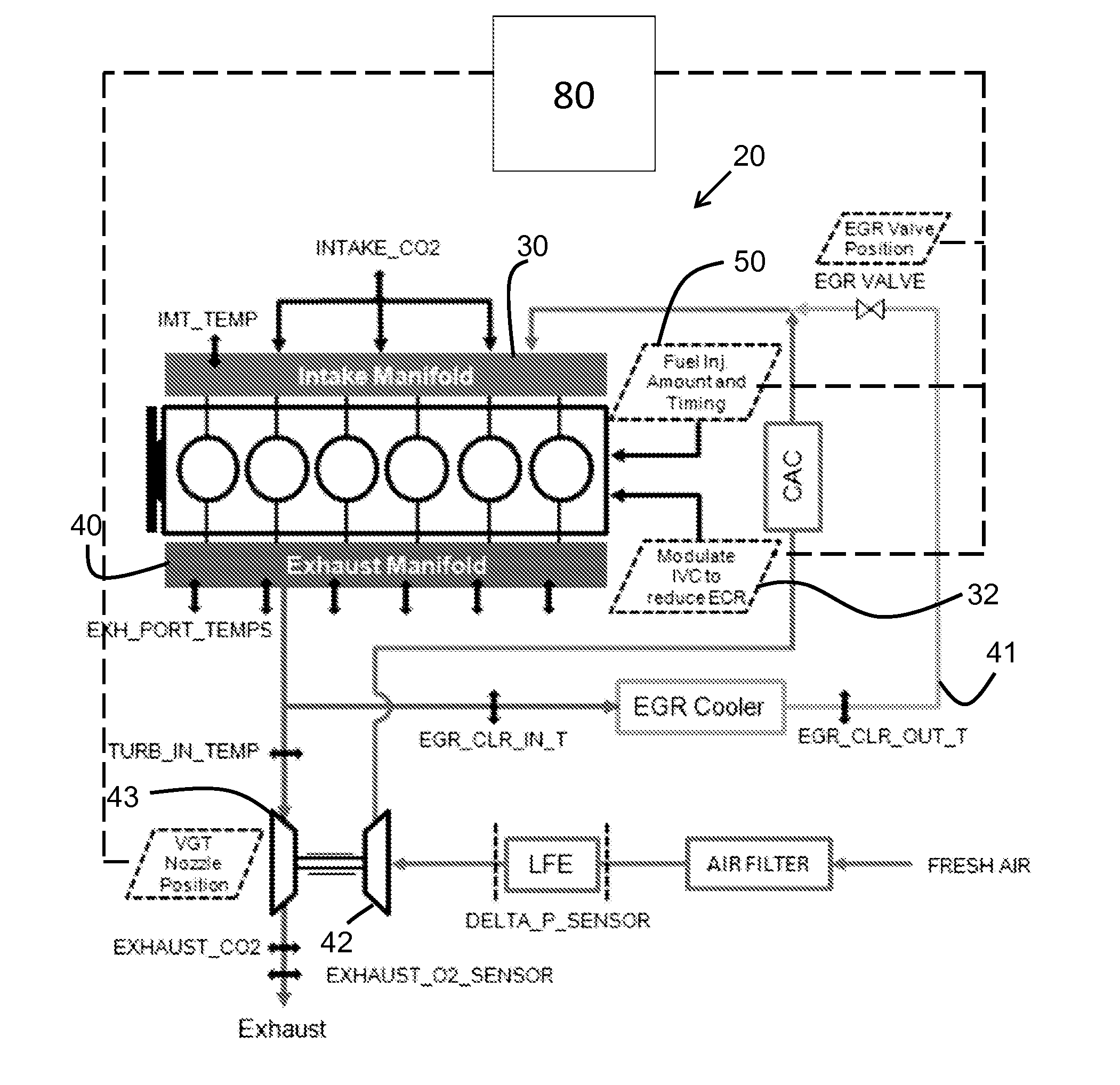

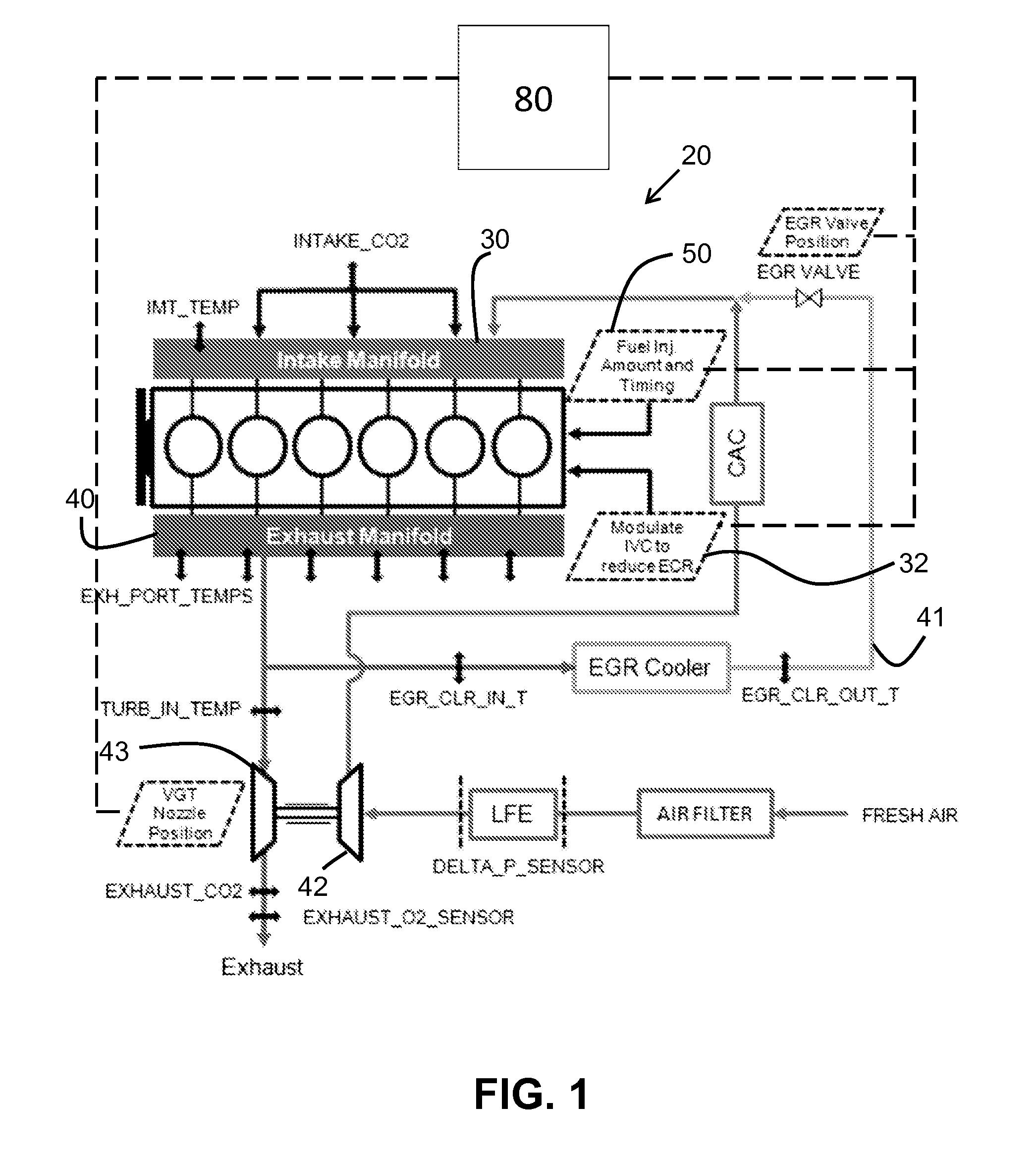

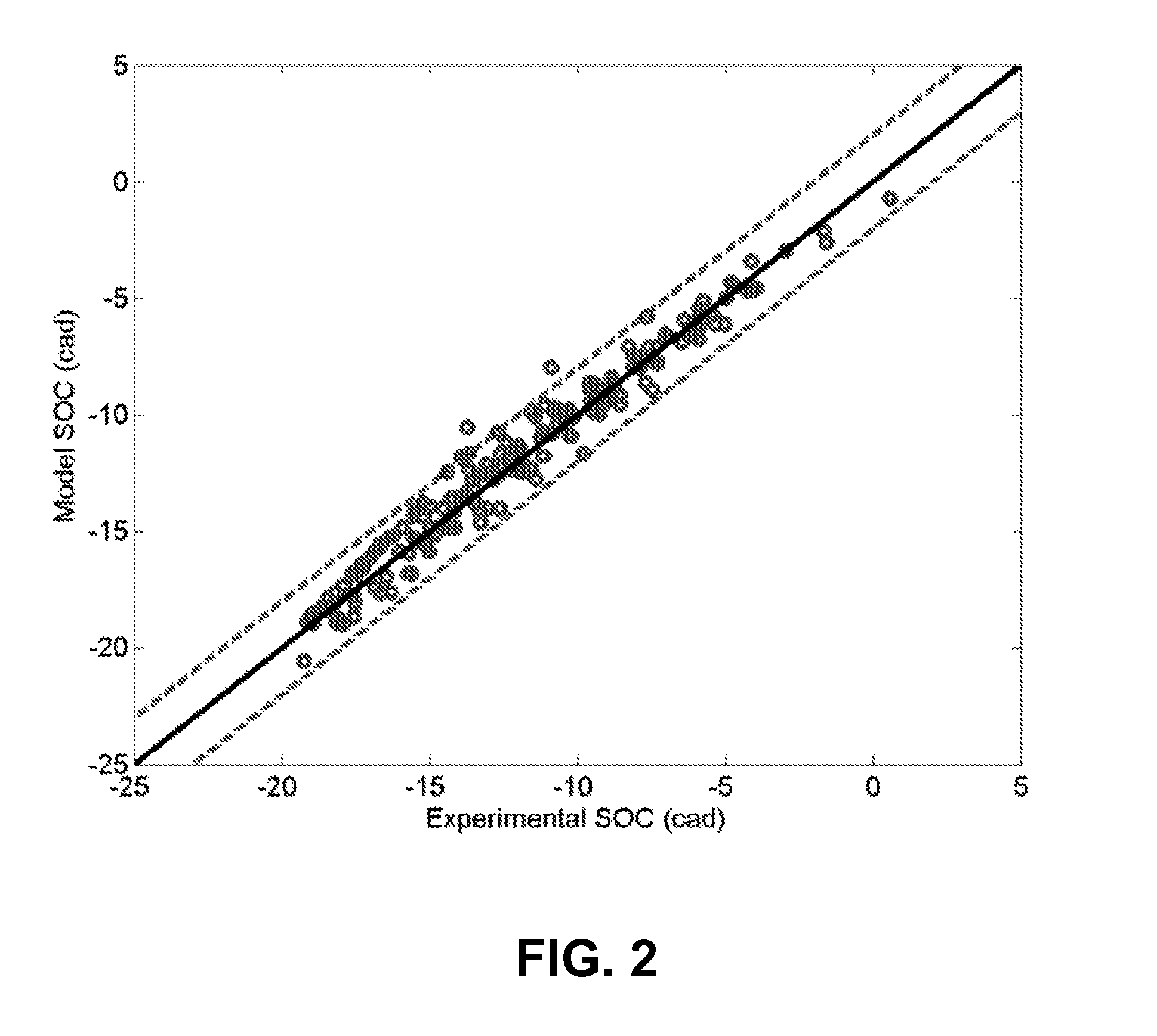

Nonlinear model-based controller for premixed charge compression ignition combustion timing in diesel engines

ActiveUS20150330326A1Electrical controlInternal combustion piston enginesNonlinear modelModel based controller

Advanced combustion modes, such as PCCI, operate near the system stability limits. In PCCI, the combustion event begins without a direct combustion trigger in contrast to traditional spark-ignited gasoline engines and direct-injected diesel engines. The lack of a direct combustion trigger encourages the usage of model-based controls to provide robust control of the combustion phasing. The nonlinear relationships between the control inputs and the combustion system response often limit the effectiveness of traditional, non-model-based controllers. Accurate knowledge of the system states and inputs is helpful for implementation of an effective nonlinear controller. A nonlinear controller is developed and implemented to control the engine combustion timing during diesel PCCI operation by targeting desired values of the in-cylinder oxygen concentration, pressure, and temperature during early fuel injection.

Owner:PURDUE RES FOUND INC

Model-based control for torque biasing system

A method of controlling a torque biasing system includes determining a torque command, calculating a torque error based on the torque command and a model-based torque. A control signal is generated based on the torque error and the torque biasing system is operated based on the control signal.

Owner:NEW VENTURE GEAR INC

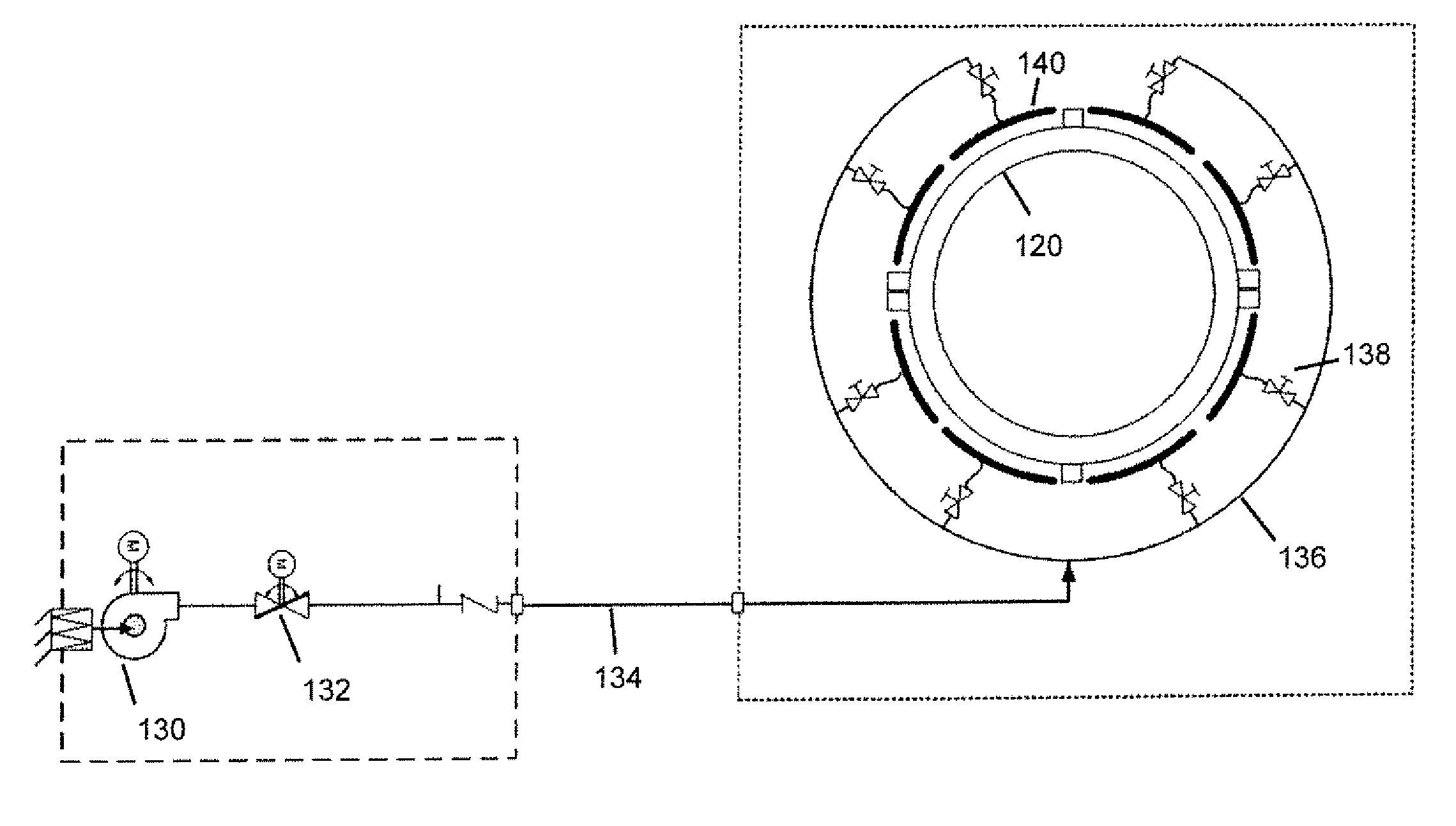

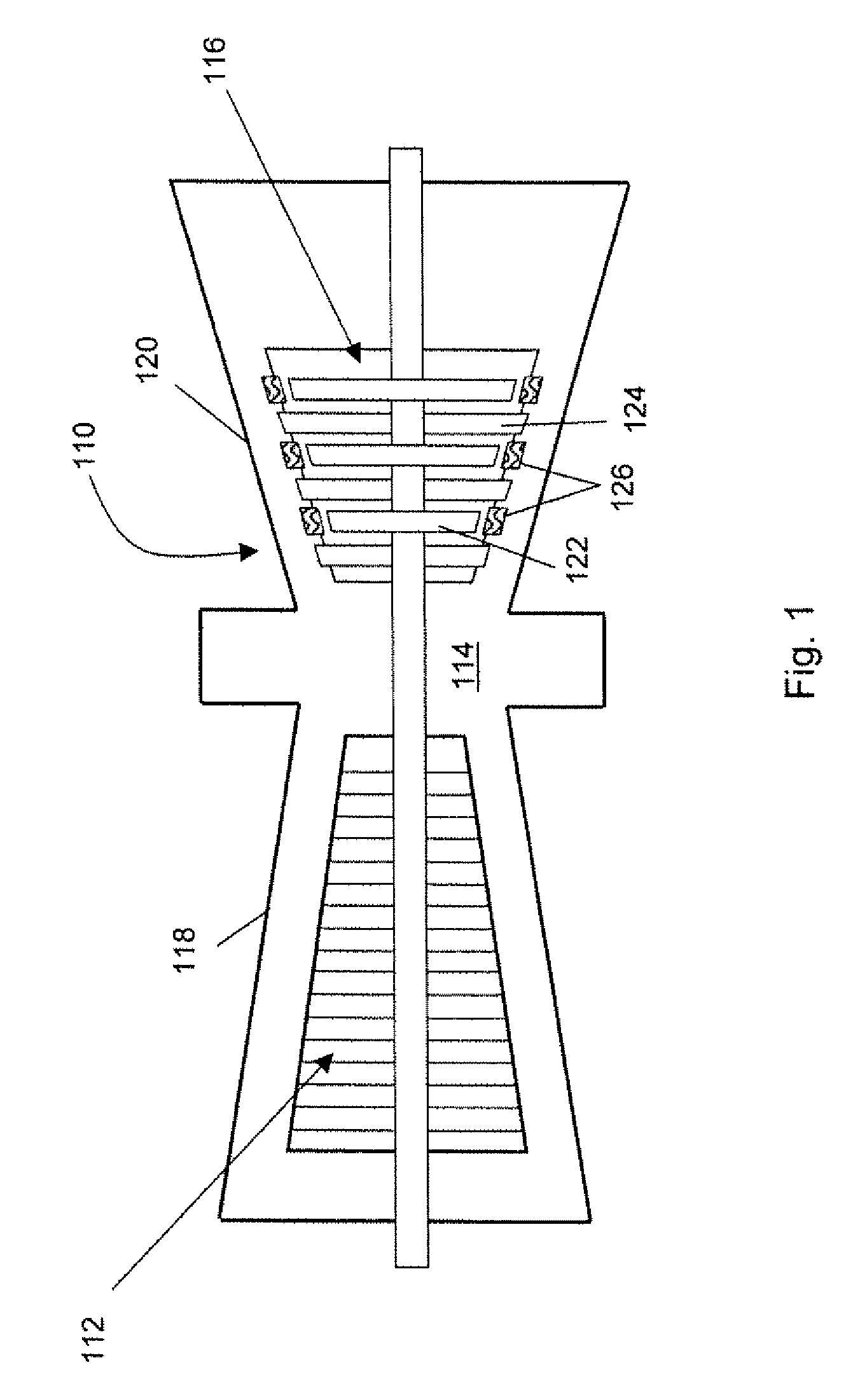

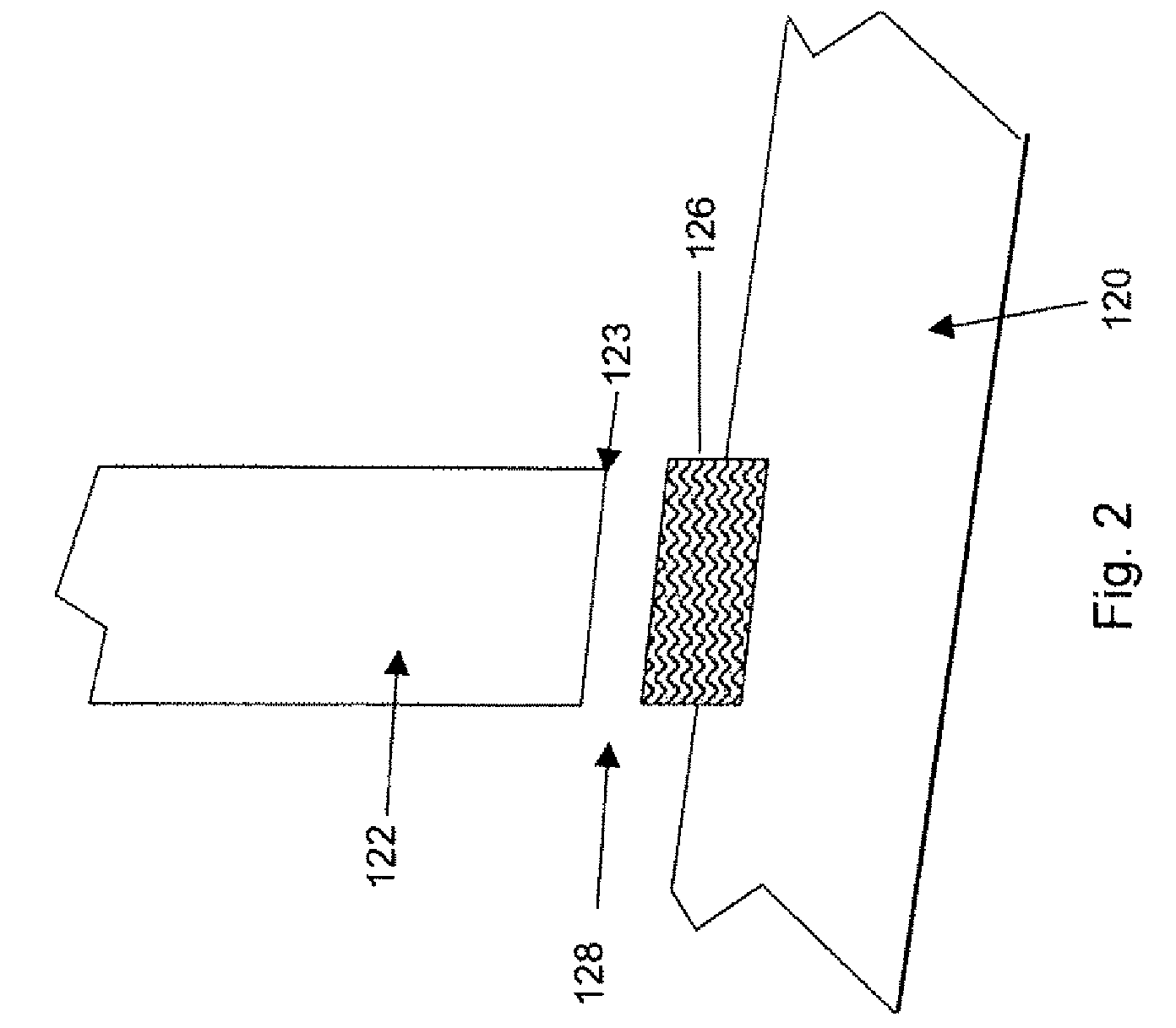

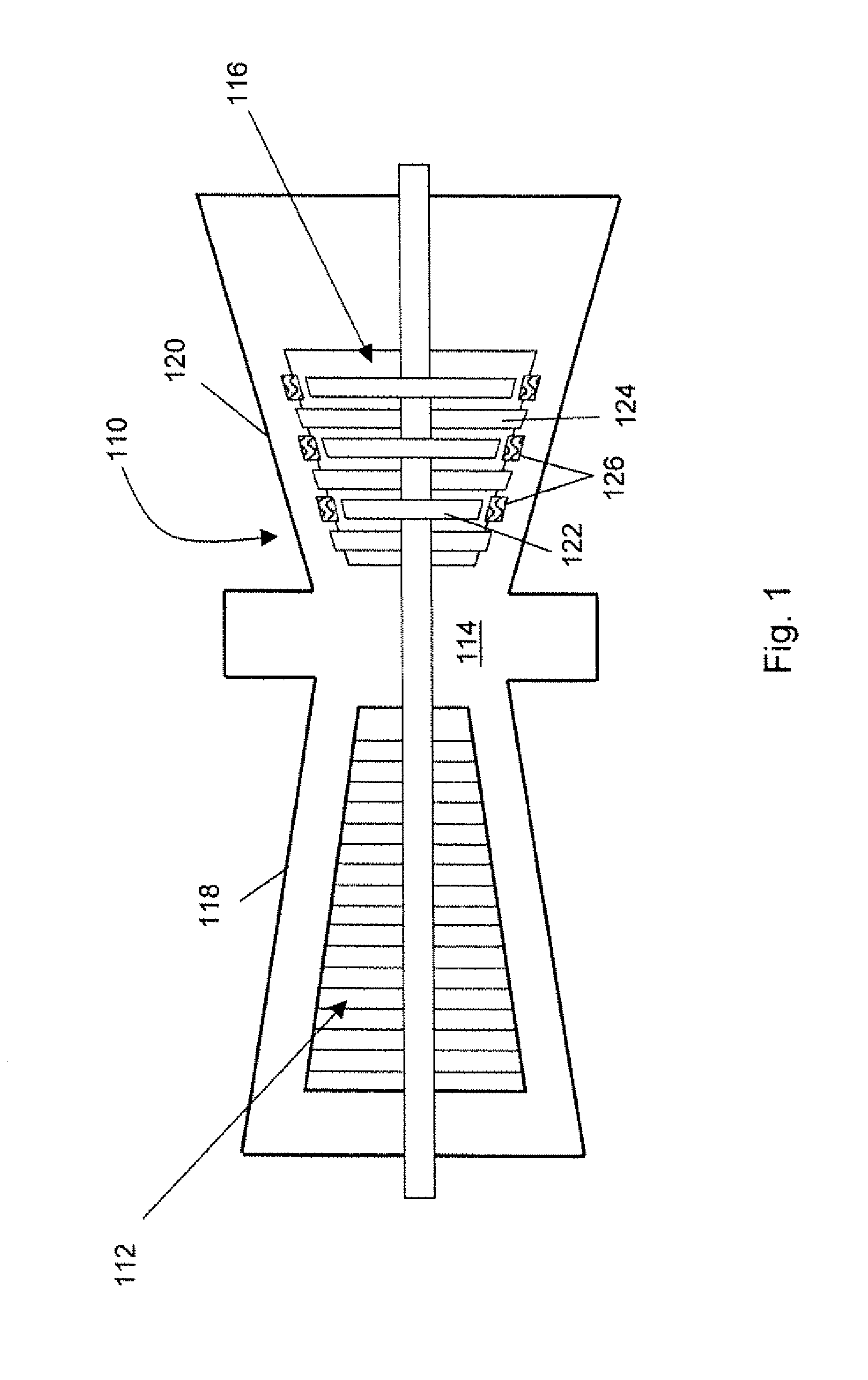

Predictive model based control system for heavy duty gas turbines

A system for controlling the clearance between a turbine blade and the turbine casing that includes an impingement cooling manifold attached to a turbine casing, a temperature sensing device for determining the temperature of the turbine casing, a blower, a control system logic for determining the setting temperature of the casing, and a controller for controlling the blower, wherein the blower forces air onto the impingement cooling manifold to cool the casing towards the setting temperature and control the clearance.

Owner:GENERAL ELECTRIC CO

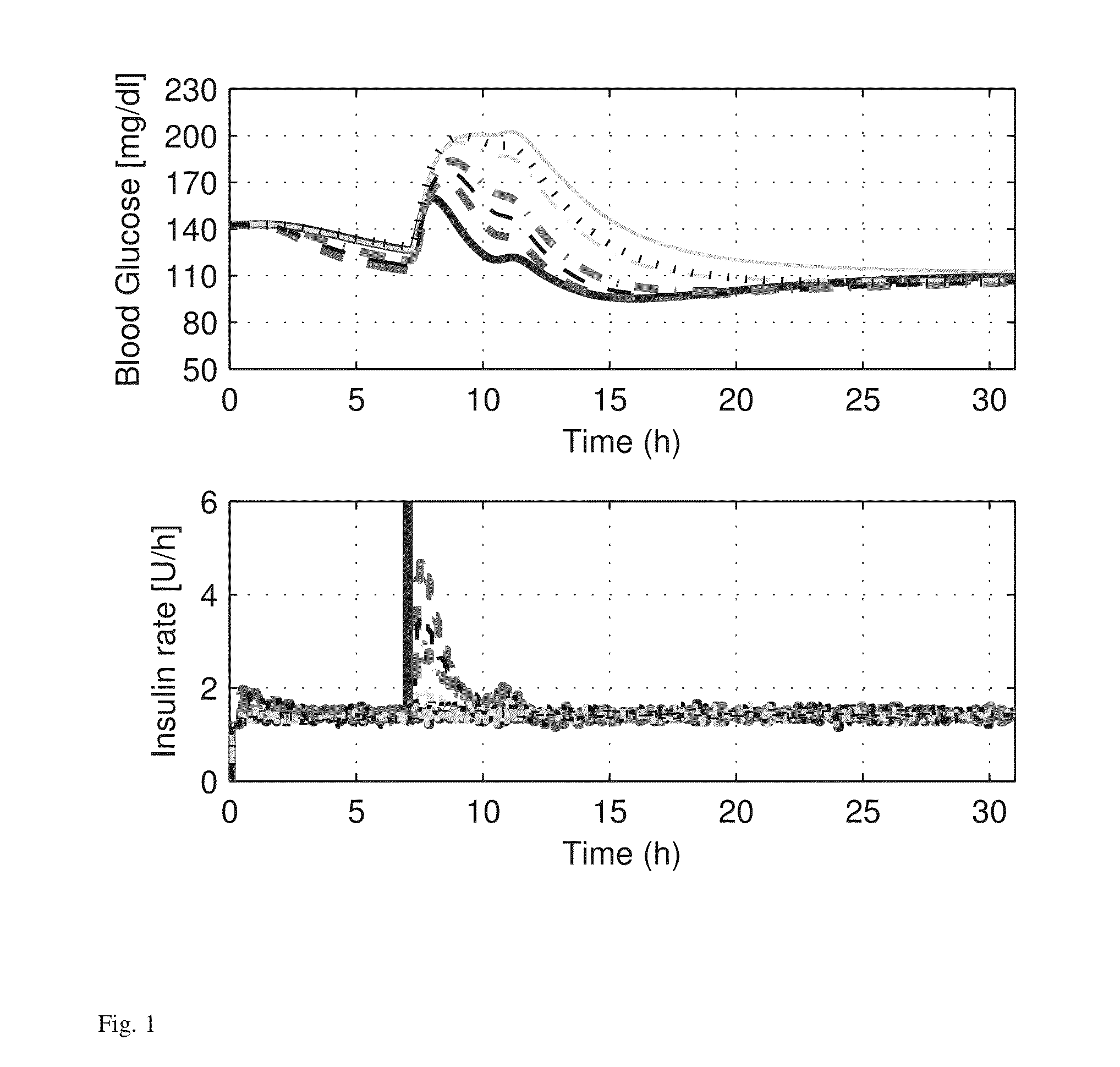

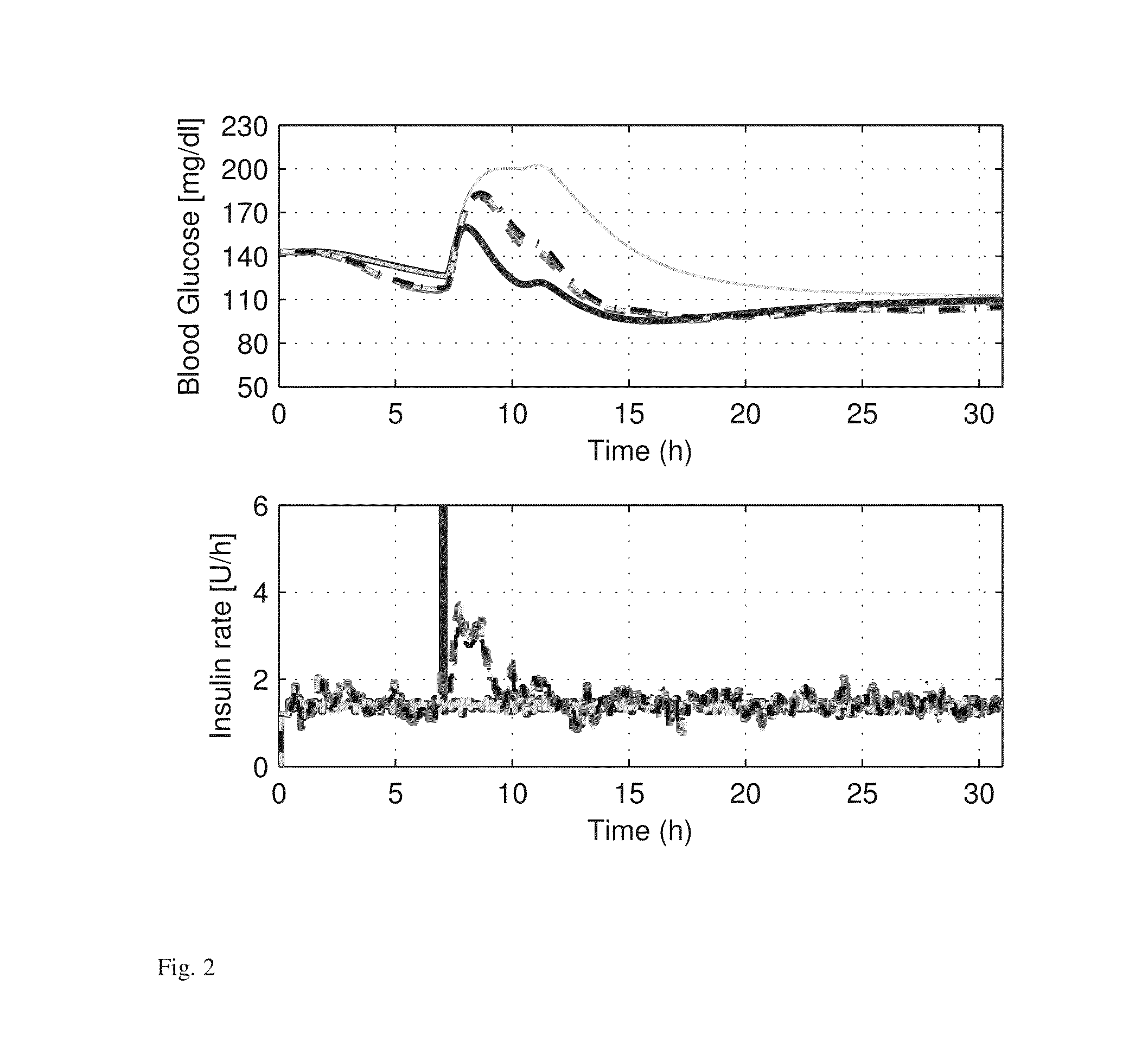

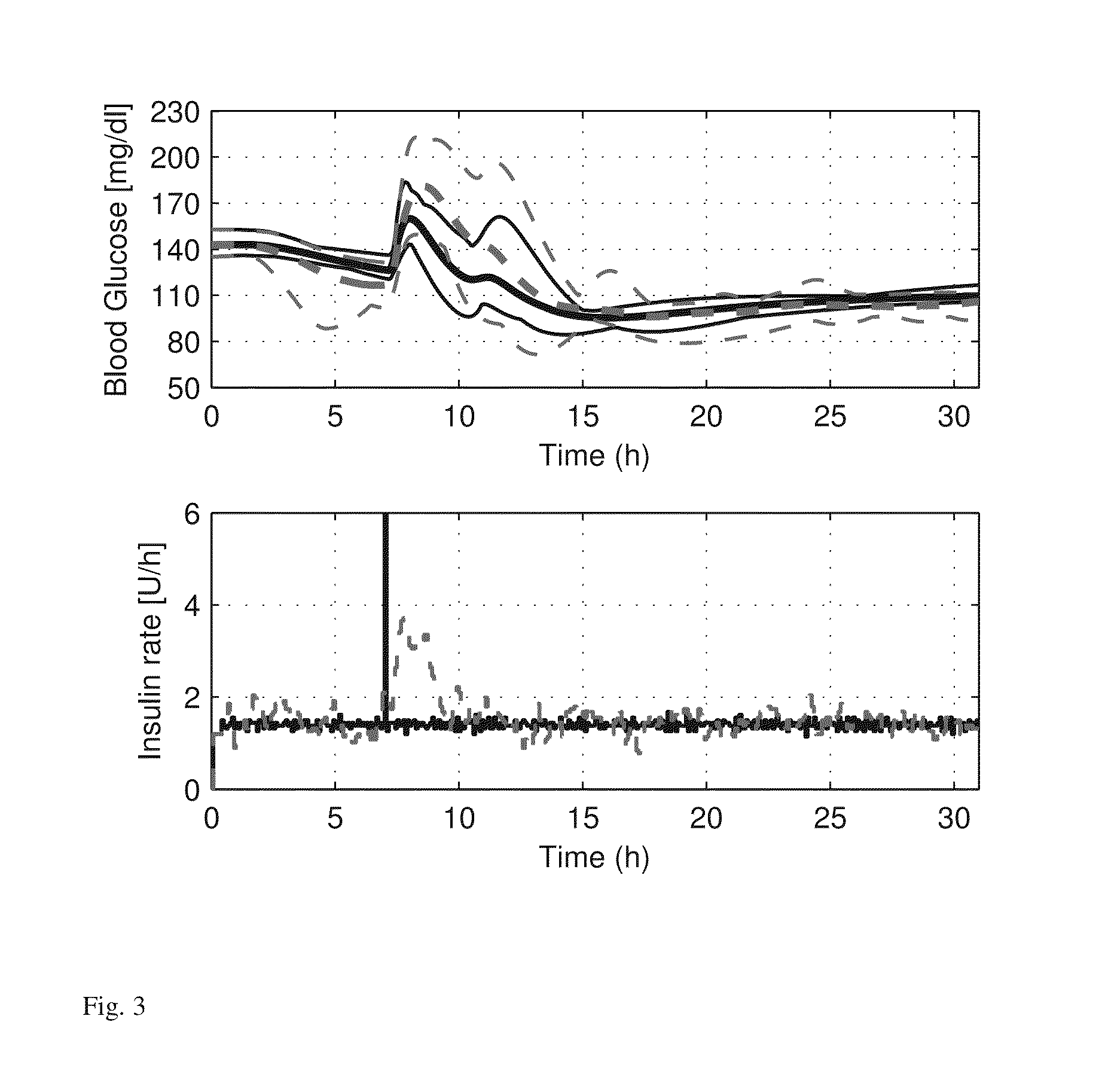

Model-Based Personalization Scheme of an Artificial Pancreas for Type I Diabetes Applications

ActiveUS20150306314A1Improve performanceImproved profileMedical devicesFlow monitorsPersonalizationMedicine

A model-based control scheme consisting of either a proportional-integral-derivative (IMC-PID) controller or a model predictive controller (MPC), with an insulin feedback (IFB) scheme personalized based on a priori subject characteristics and comprising a lower order control-relevant model to obtain PID or MPC controller for artificial pancreas (AP) applications.

Owner:RGT UNIV OF CALIFORNIA

Predictive Model Based Control System for Heavy Duty Gas Turbines

A system for controlling the clearance between a turbine blade and the turbine casing that includes an impingement cooling manifold attached to a turbine casing, a temperature sensing device for determining the temperature of the turbine casing, a blower, a control system logic for determining the setting temperature of the casing, and a controller for controlling the blower, wherein the blower forces air onto the impingement cooling manifold to cool the casing towards the setting temperature and control the clearance.

Owner:GENERAL ELECTRIC CO

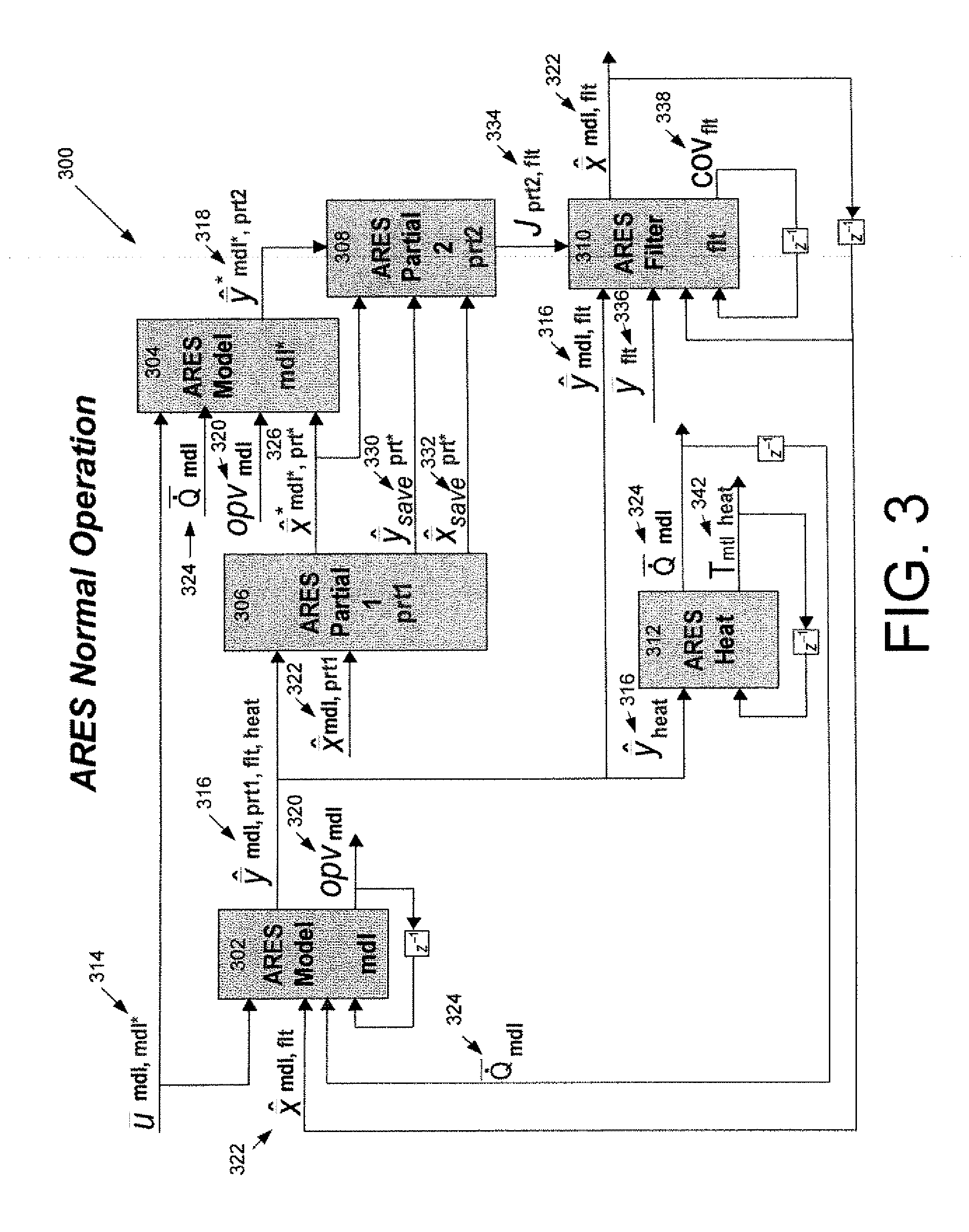

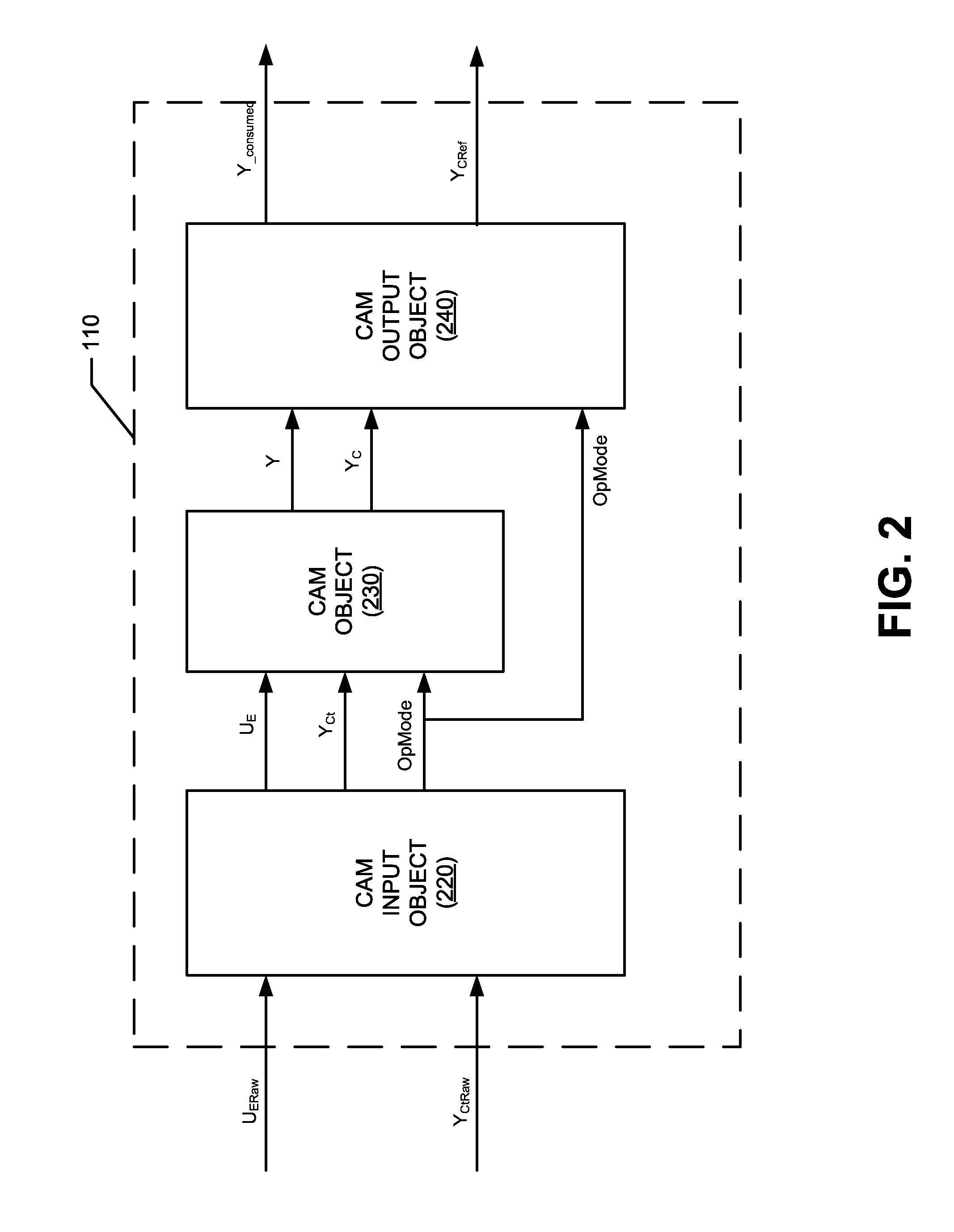

Compact aero-thermo model based control system

Owner:RTX CORP

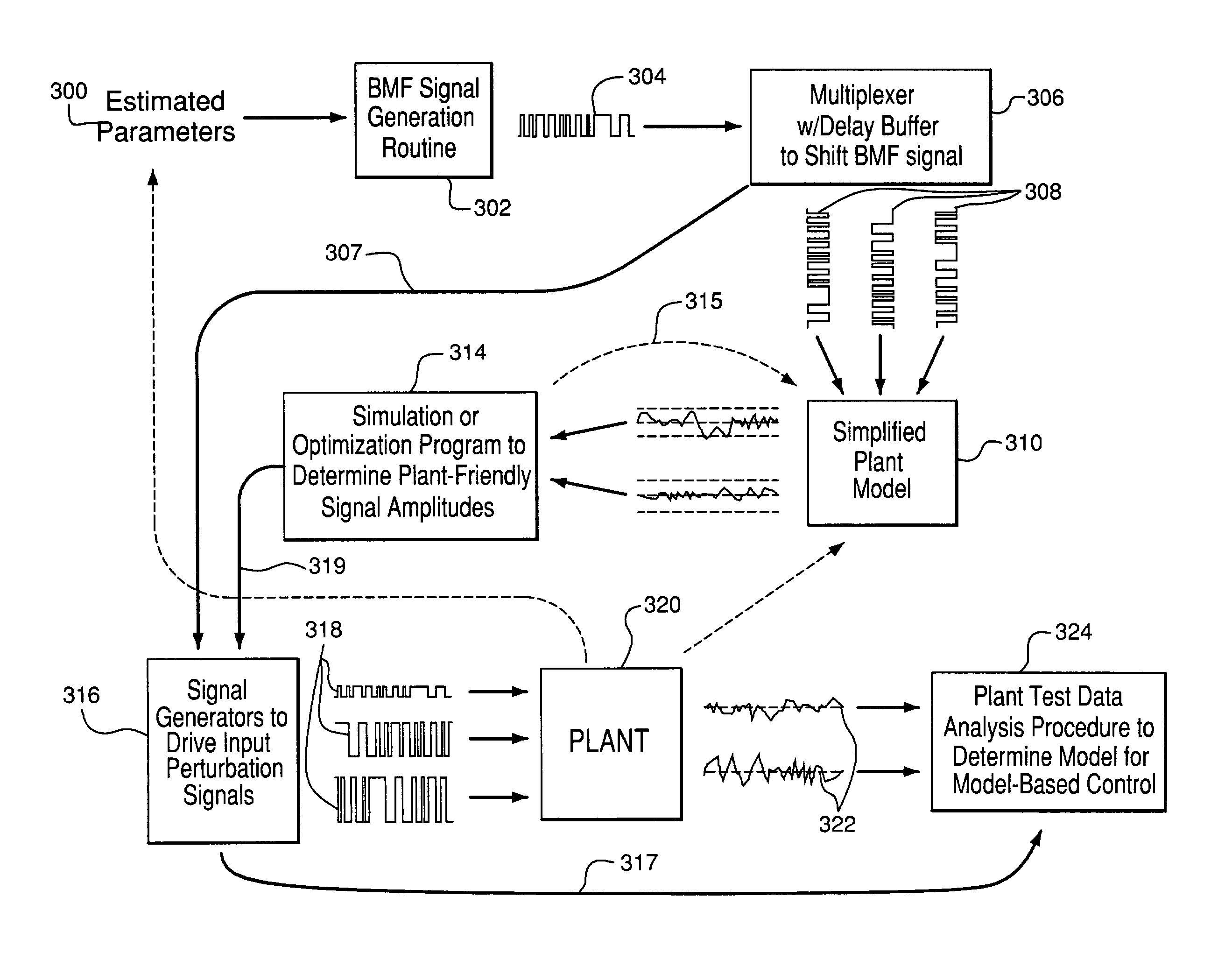

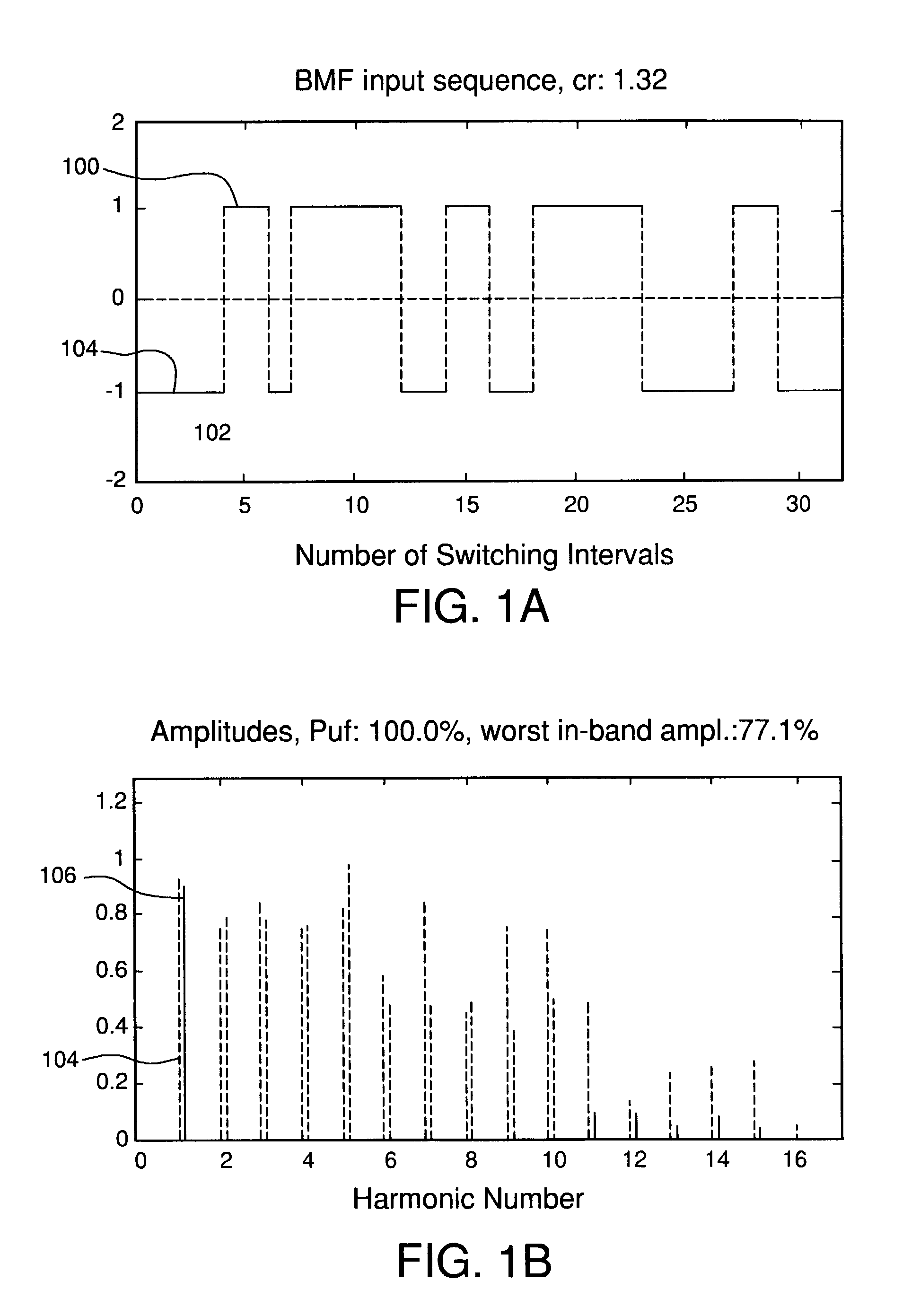

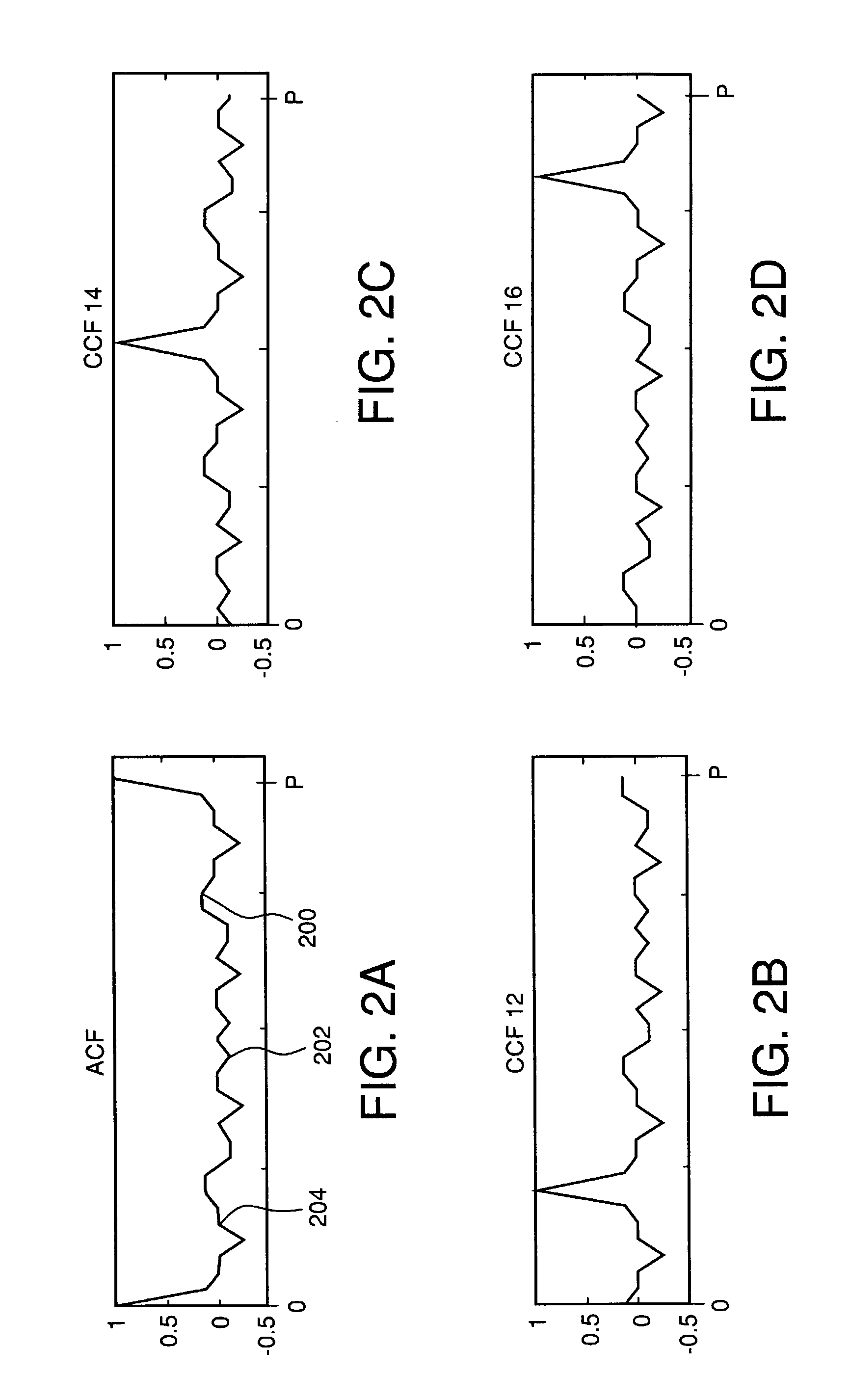

Fast plant test for model-based control

InactiveUS7194317B2Simple modelData processing applicationsElectronic circuit testingFrequency spectrumModel based controller

A method and apparatus for designing perturbation signals to excite a number of input variables of a system, in order to test that system for the purpose of obtaining models for the synthesis of a model-based controller. The method begins with providing input parameters of the system. A plurality of binary multi-frequency (BMF) signals are generated based on these input parameters and the frequency spectra of these BMF signals are calculated. One BMF signal is selected out of the set of BMF signals so that the frequency spectrum of the selected BMF signal most closely matches a desired frequency spectrum specified by the input parameters. The selected BMF signal is used as a first perturbation signal for testing the system. The selected BMF signal is also shifted by predetermined amounts of samples to create delayed copies of the original BMF signal to be used as additional perturbation signals.

Owner:AIR PROD & CHEM INC

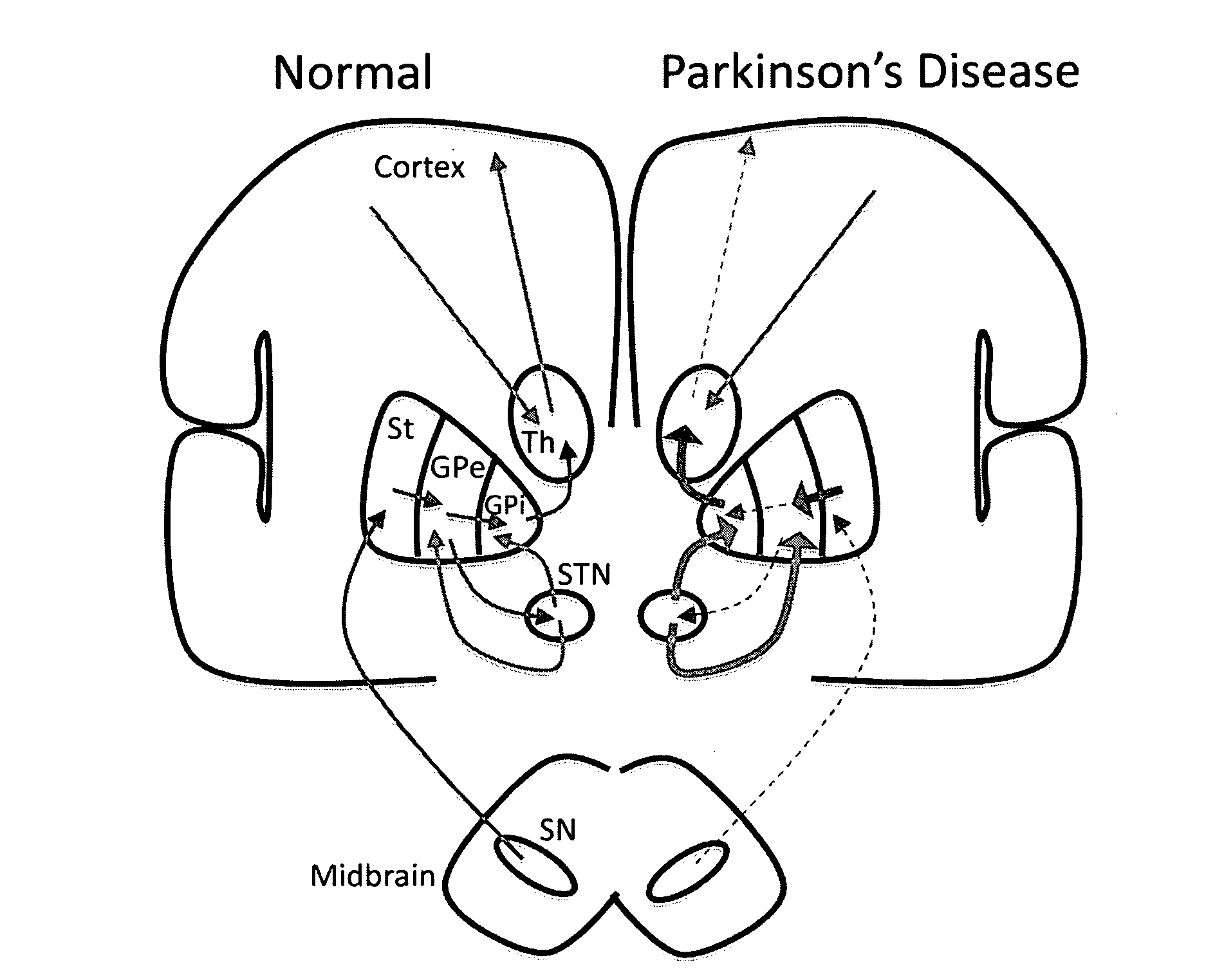

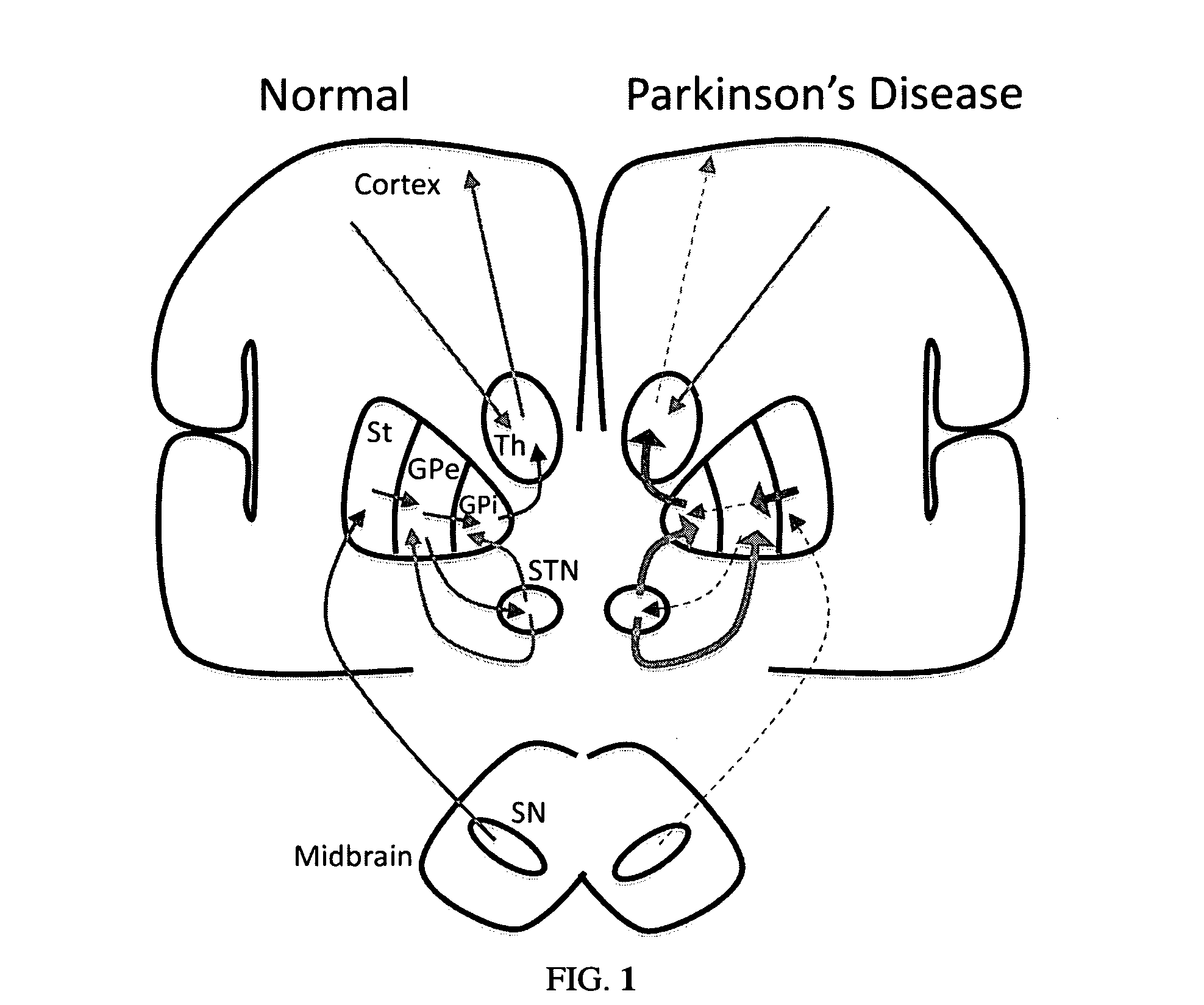

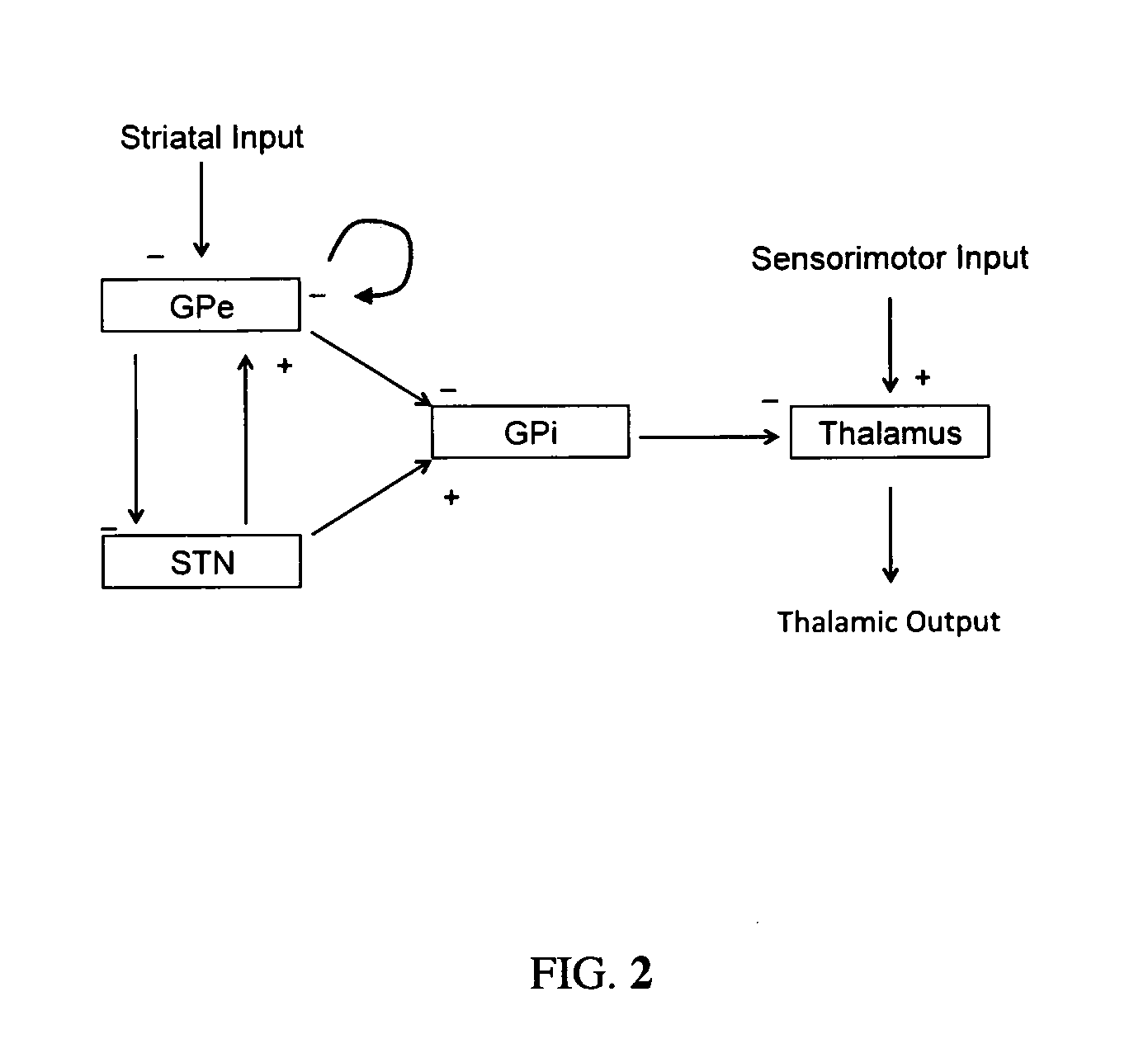

Model Based Control of Parkinson's Disease

ActiveUS20130102919A1Out errorOut noiseElectroencephalographyMedical simulationModel reconstructionComputational model

The present invention relates to a novel means to use a fundamental model of the parts of the brain that are dysfunctional in Parkinson's disease, and related dynamical diseases of the brain, as part of a feedback control system to modulate the signs and symptoms of disease. Fundamental computational models that embody our knowledge of the anatomy, neurons, and dynamics of the parts of the brain we wish to control, and use those models to reconstruct what is inaccessible to our measurements. Through emulation the controller synchronizes to the parts of the brain we wish to observe and track. By passing simultaneous control pulses to both the model controller, as well as the brain, we control both the model and the brain. The detailed framework to embed fundamental models of the brain within a control scheme to control symptoms of Parkinsons and related dynamical diseases of the brain are disclosed.

Owner:SCHIFF STEVEN J DR

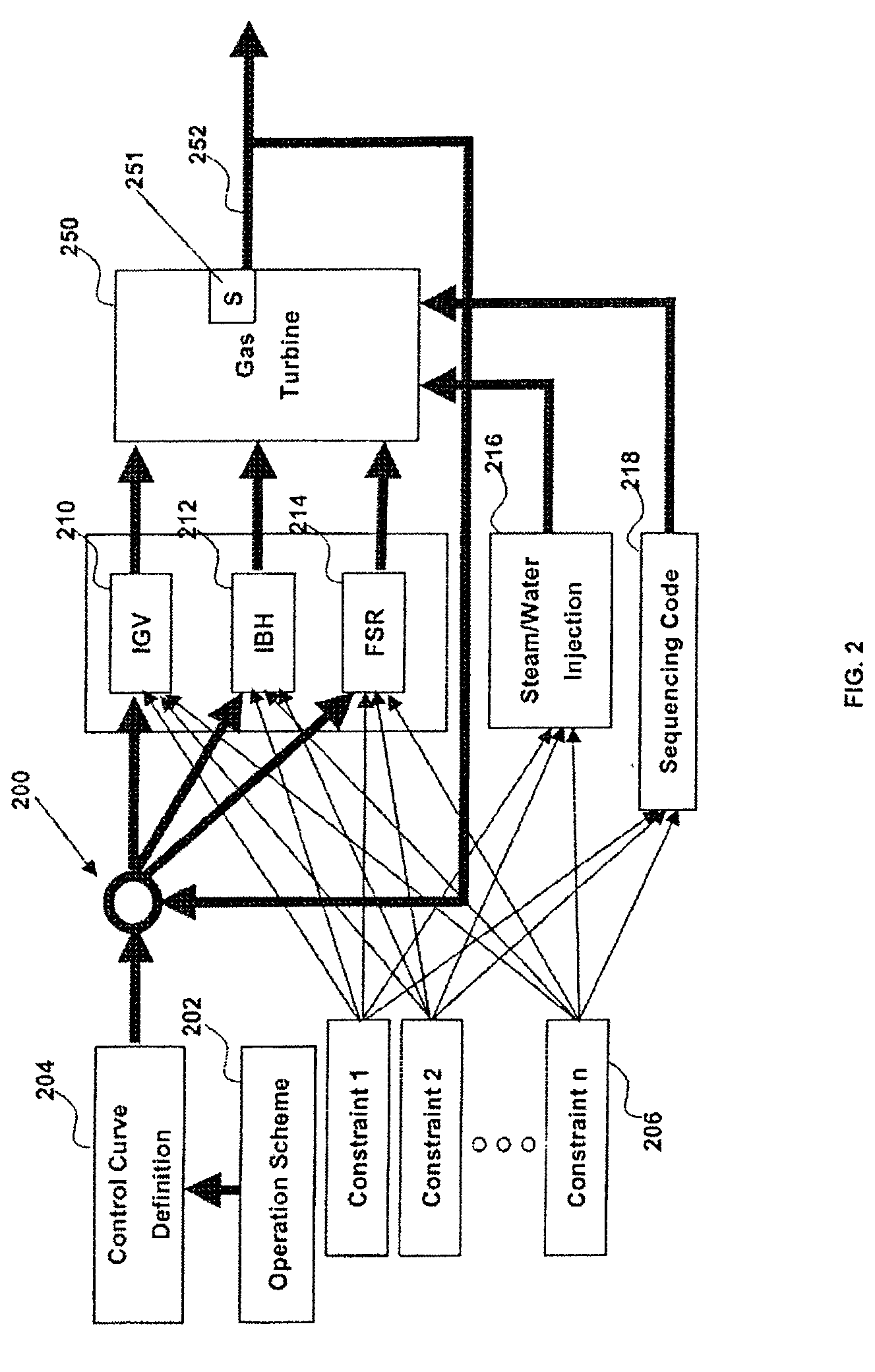

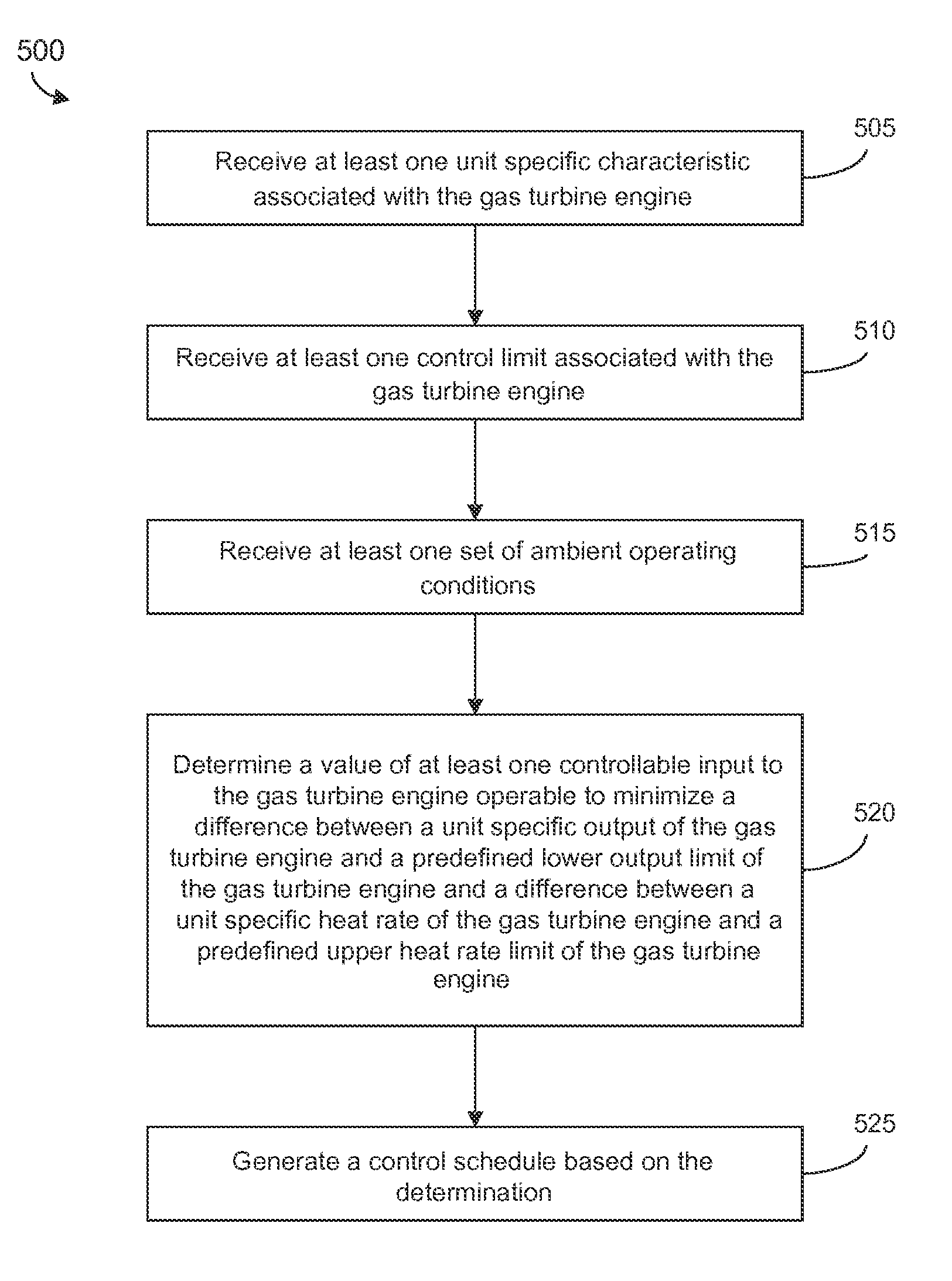

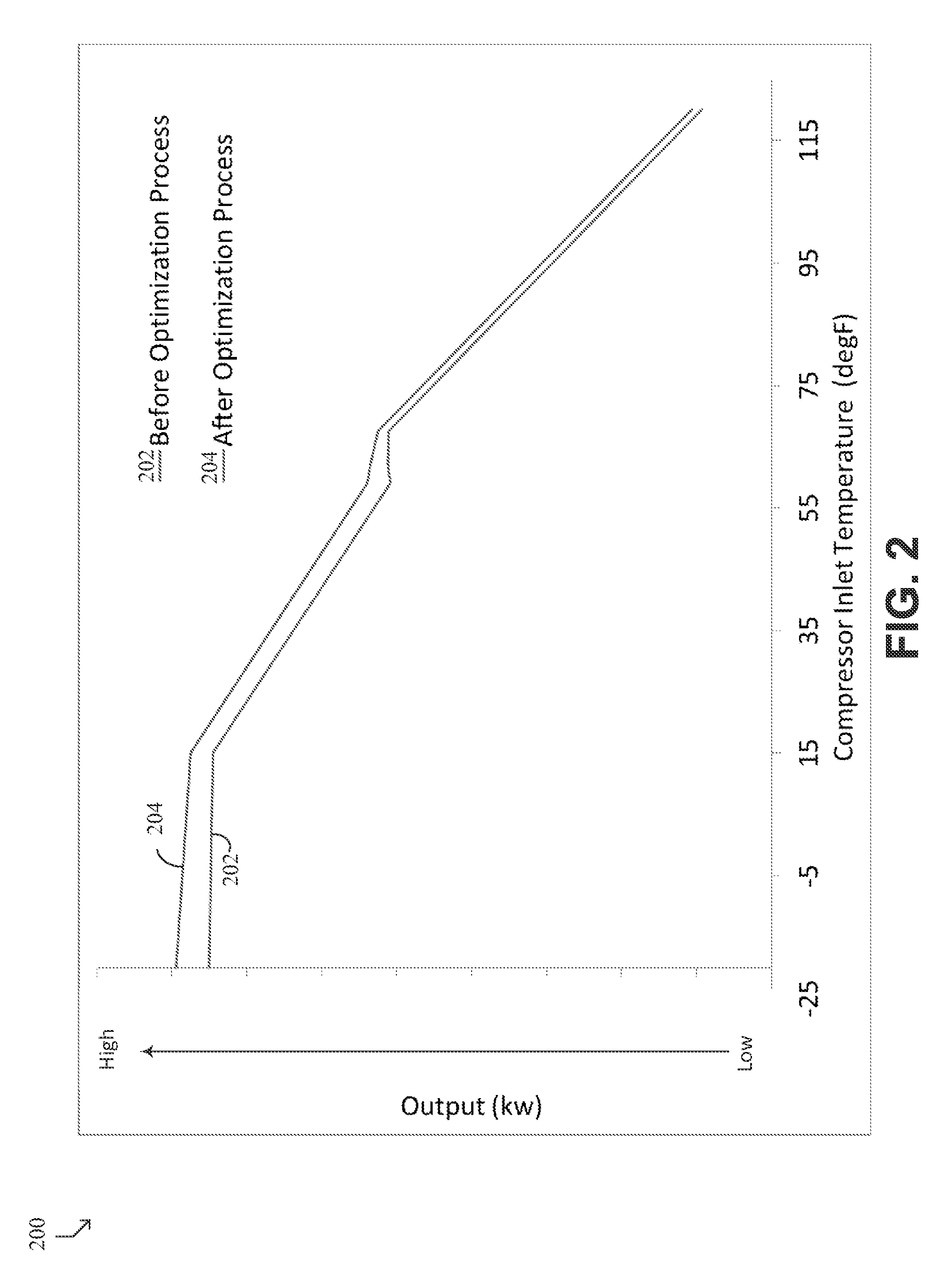

Model based control tuning process for gas turbines

ActiveUS9103279B2Analogue computers for vehiclesGas turbine plantsProcess engineeringModel based control

Systems and methods for model based control optimization for gas turbine systems. In one embodiment, a nonlinear optimization process with multiple nonlinear constraints create a set of control schedules that can work across an ambient range based on specific unit characteristics derived from a single test ambient. As part of model based control for a gas turbine system, all of the control schedules are defined based on a nominal unit. Multiple control loops are active across the ambient range with each control loop being active at a different ambient condition. This optimization process provides a set of control schedules to provide optimized performance for a specific gas turbine system or unit over a wide operation range.

Owner:GE INFRASTRUCTURE TECH INT LLC

Secure models for model-based control and optimization

In certain embodiments, a control / optimization system includes an instantiated model object stored in memory on a model server. The model object includes a model of a plant or process being controlled. The model object comprises an interface that precludes the transmission of proprietary information via the interface. The control / optimization system also includes a decision engine software module stored in memory on a decision support server. The decision engine software module is configured to request information from the model object through a communication network via a communication protocol that precludes the transmission of proprietary information, and to receive the requested information from the model object through the communication network via the communication protocol.

Owner:ROCKWELL AUTOMATION TECH

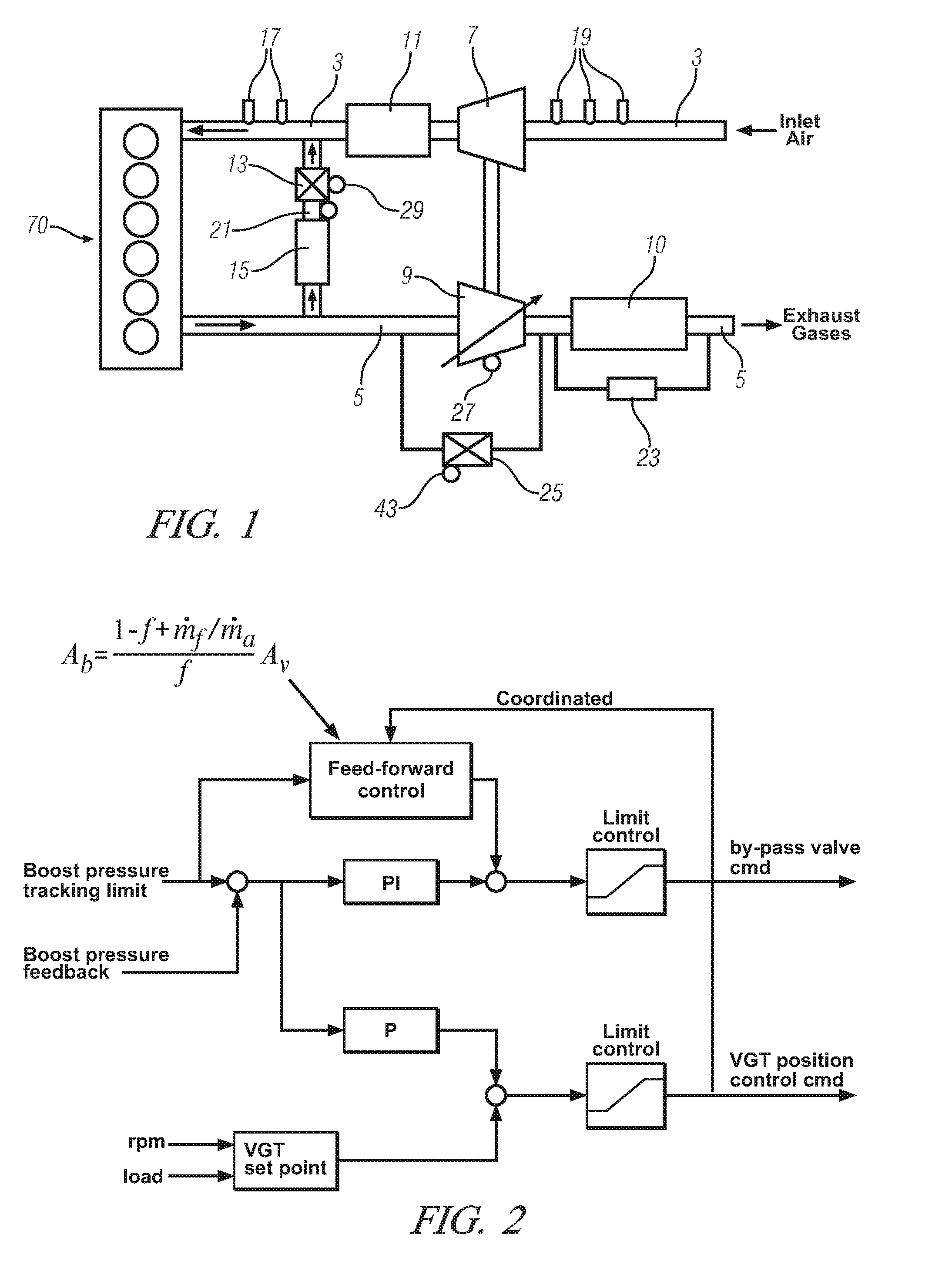

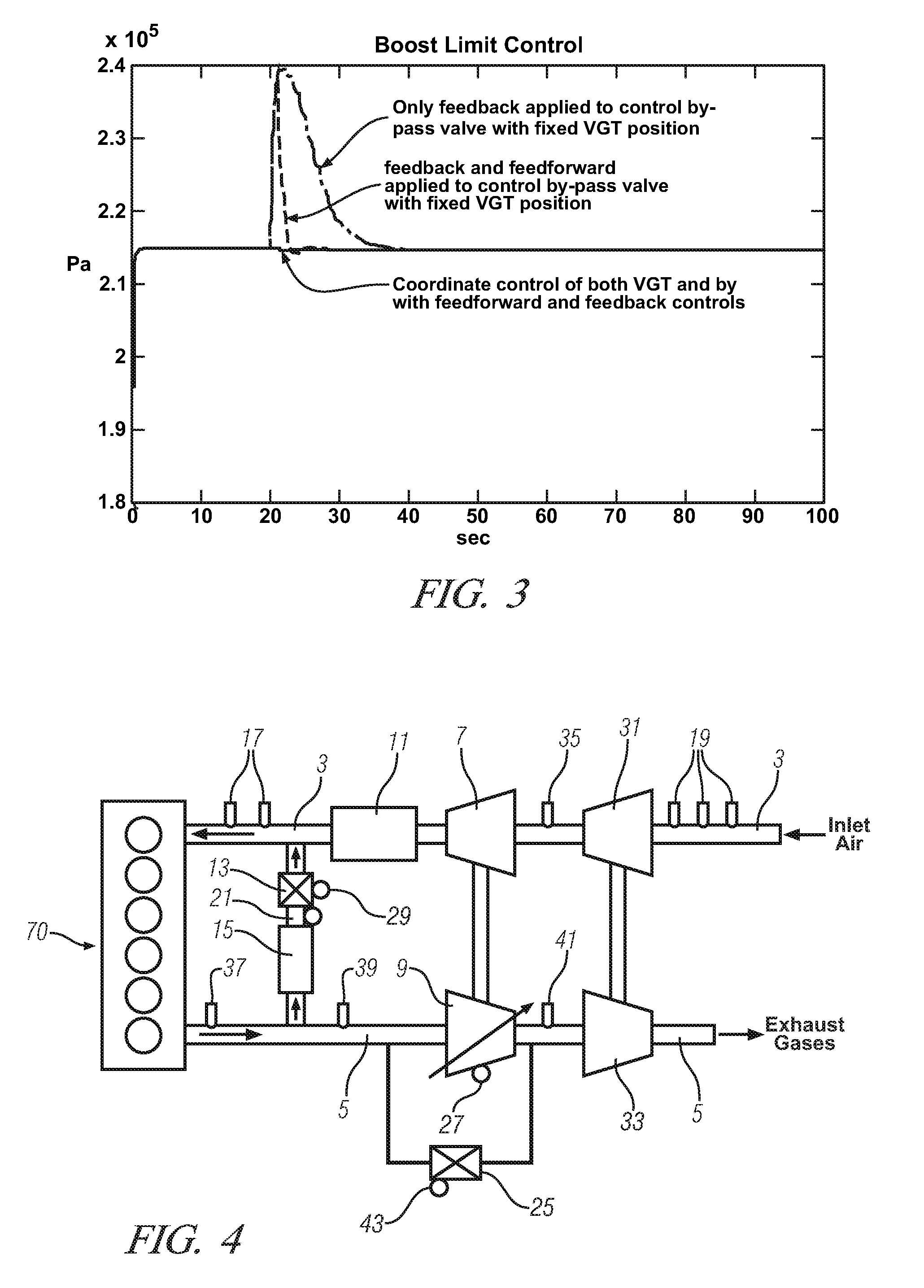

Model-based control of airpath pressure limits by modulating a turbo charger by-pass valve and a variable-geometry turbine

ActiveUS8209979B2Analogue computers for vehiclesElectrical controlVariable geometry turbineInternal combustion engine

Simultaneous or independent control of a by-pass valve and a variable-geometry forced induction component on a combustion engine is based on operational parameters measured by various sensors provided as inputs to a control module. Sudden loss of power due to low turbine efficiencies is prevented during transitions between operating conditions of engine speed and load. Excessive peak cylinder pressures are also prevented by controlling engine boost pressure to a permitted limit at high engine speed and load.

Owner:GM GLOBAL TECH OPERATIONS LLC

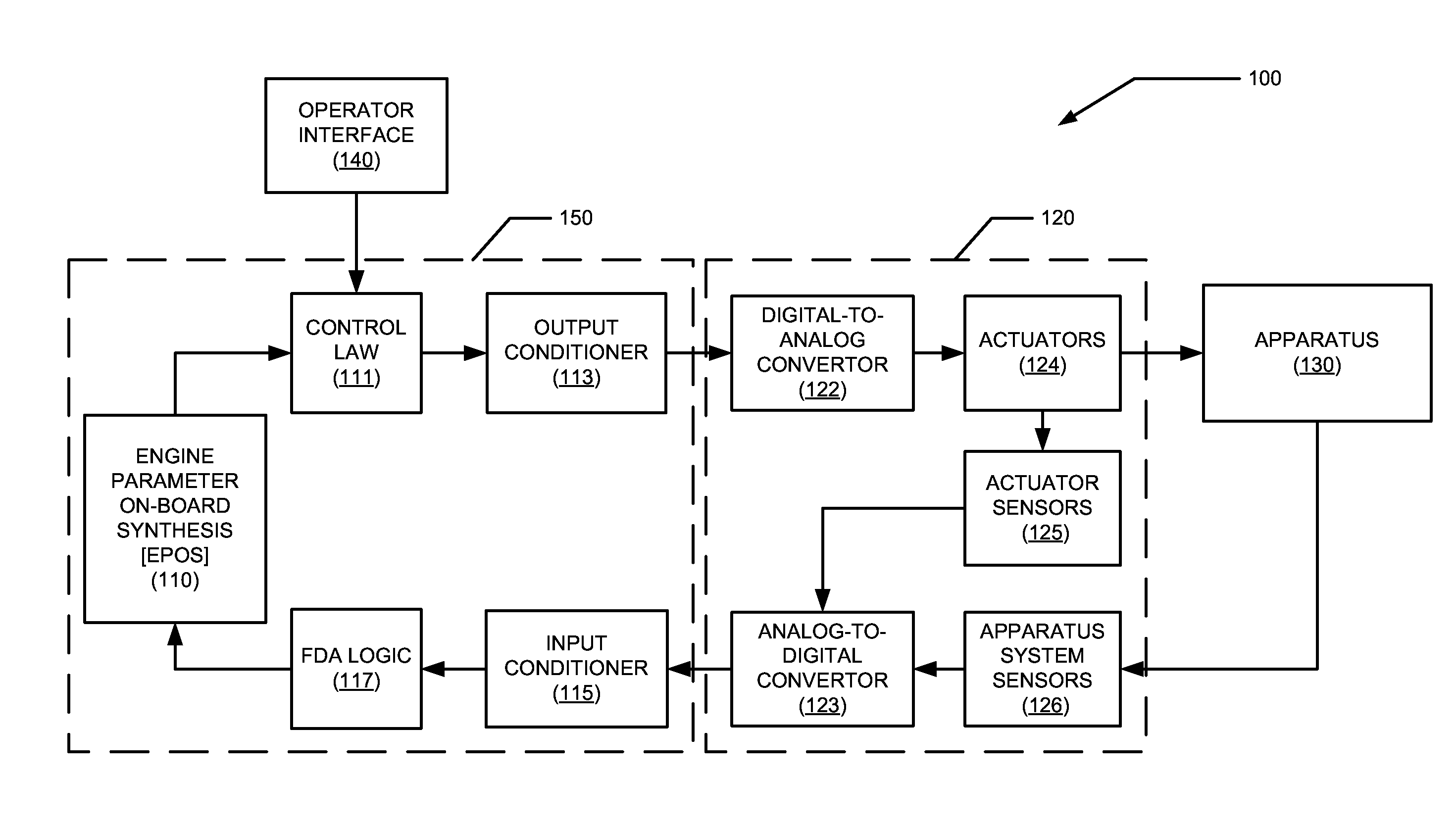

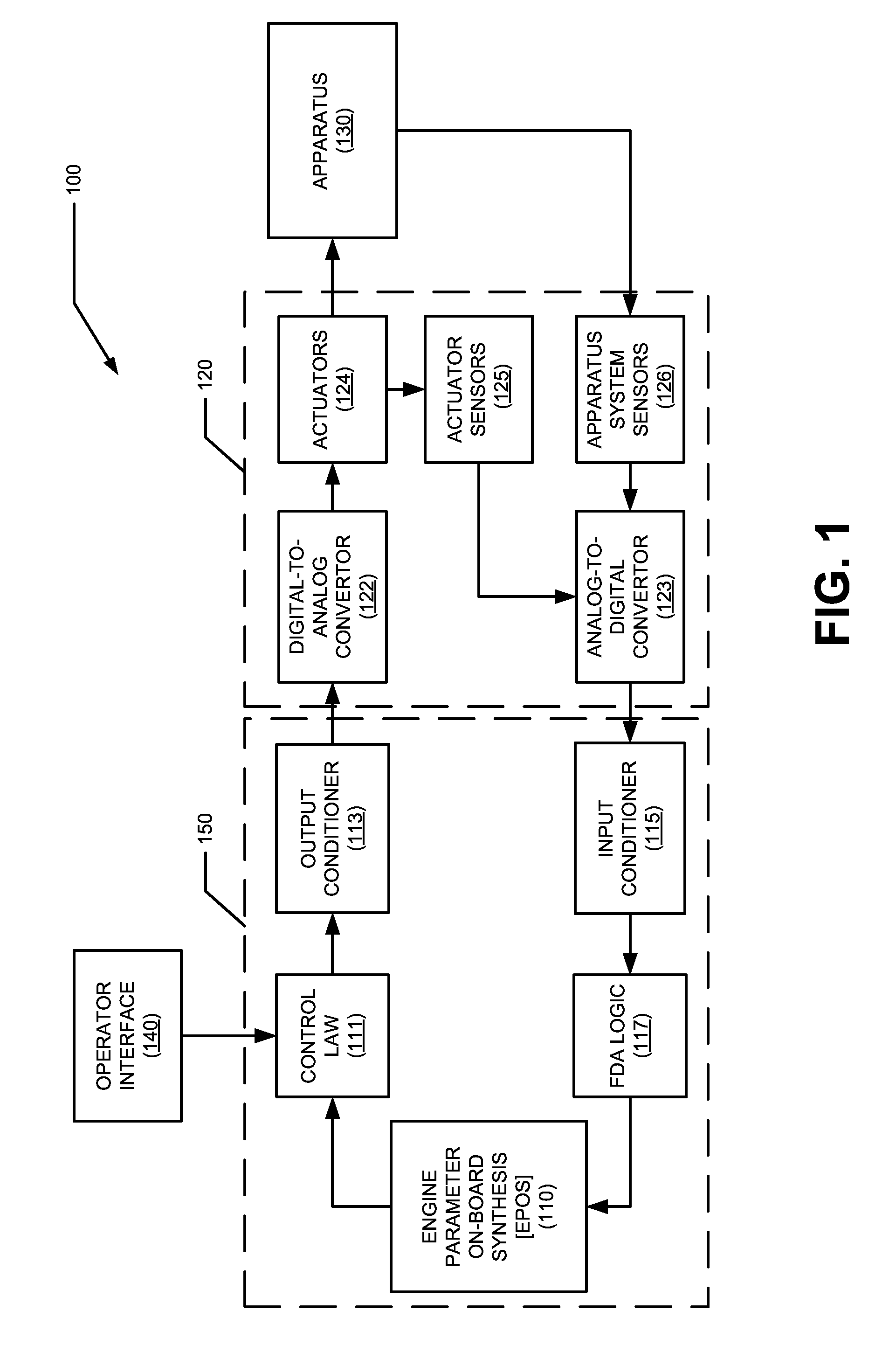

Fault-accommodating, constrained model-based control using on-board methods for detection of and adaption to actuation subsystem faults

ActiveUS20180300191A1Improve engine performanceMinimize thrustFluid-pressure actuator testingElectrical controlHorizonData information

Owner:RAYTHEON TECH CORP

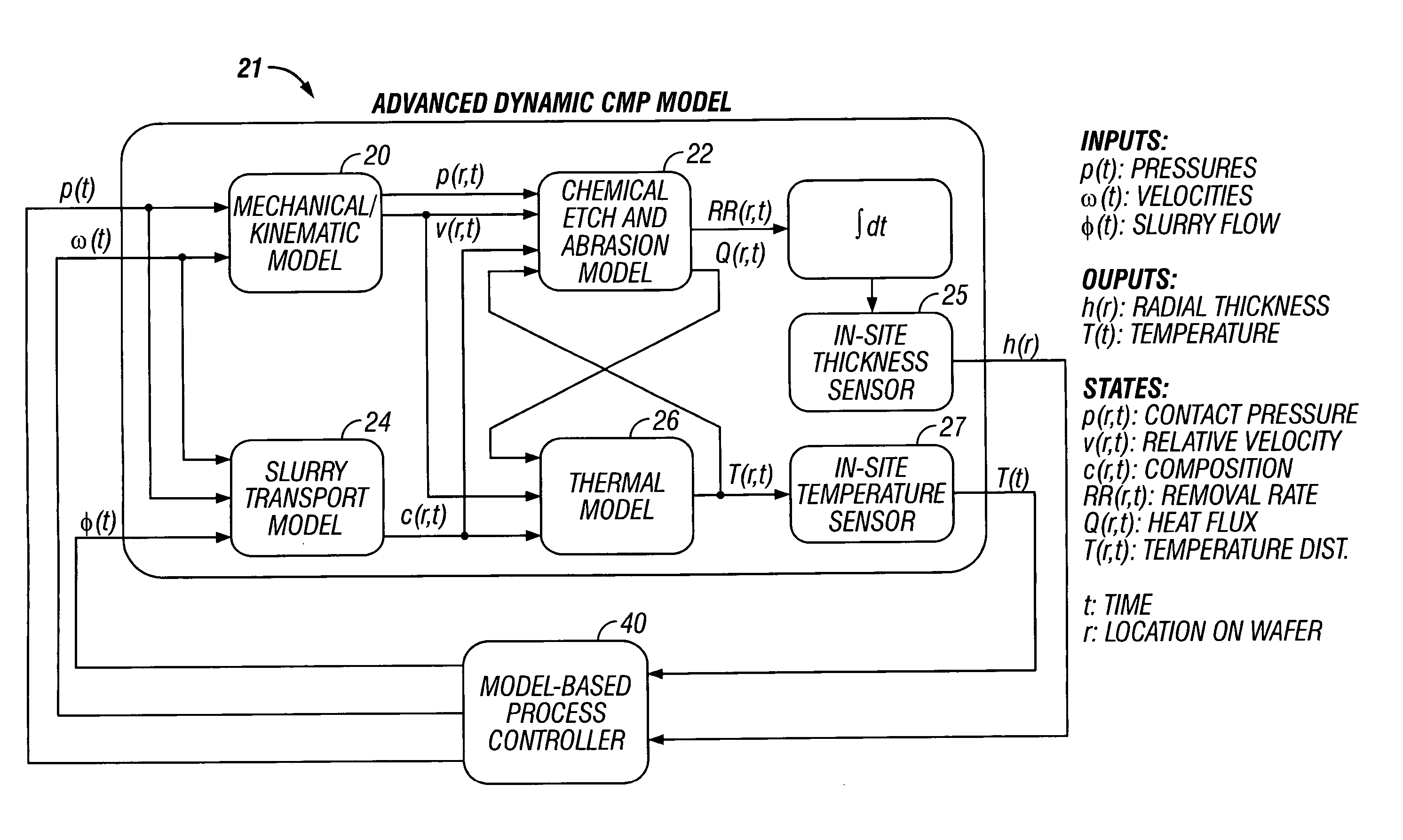

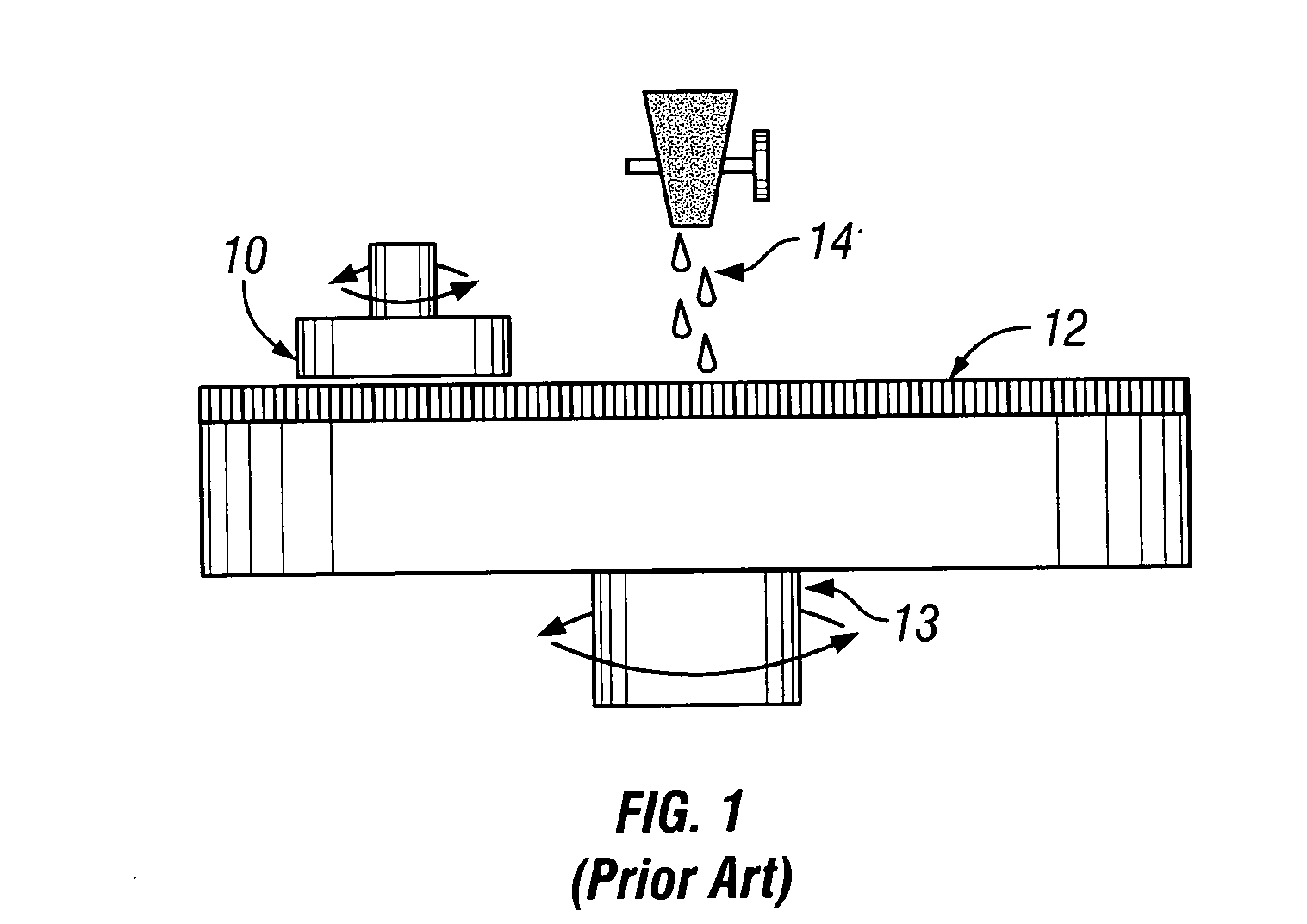

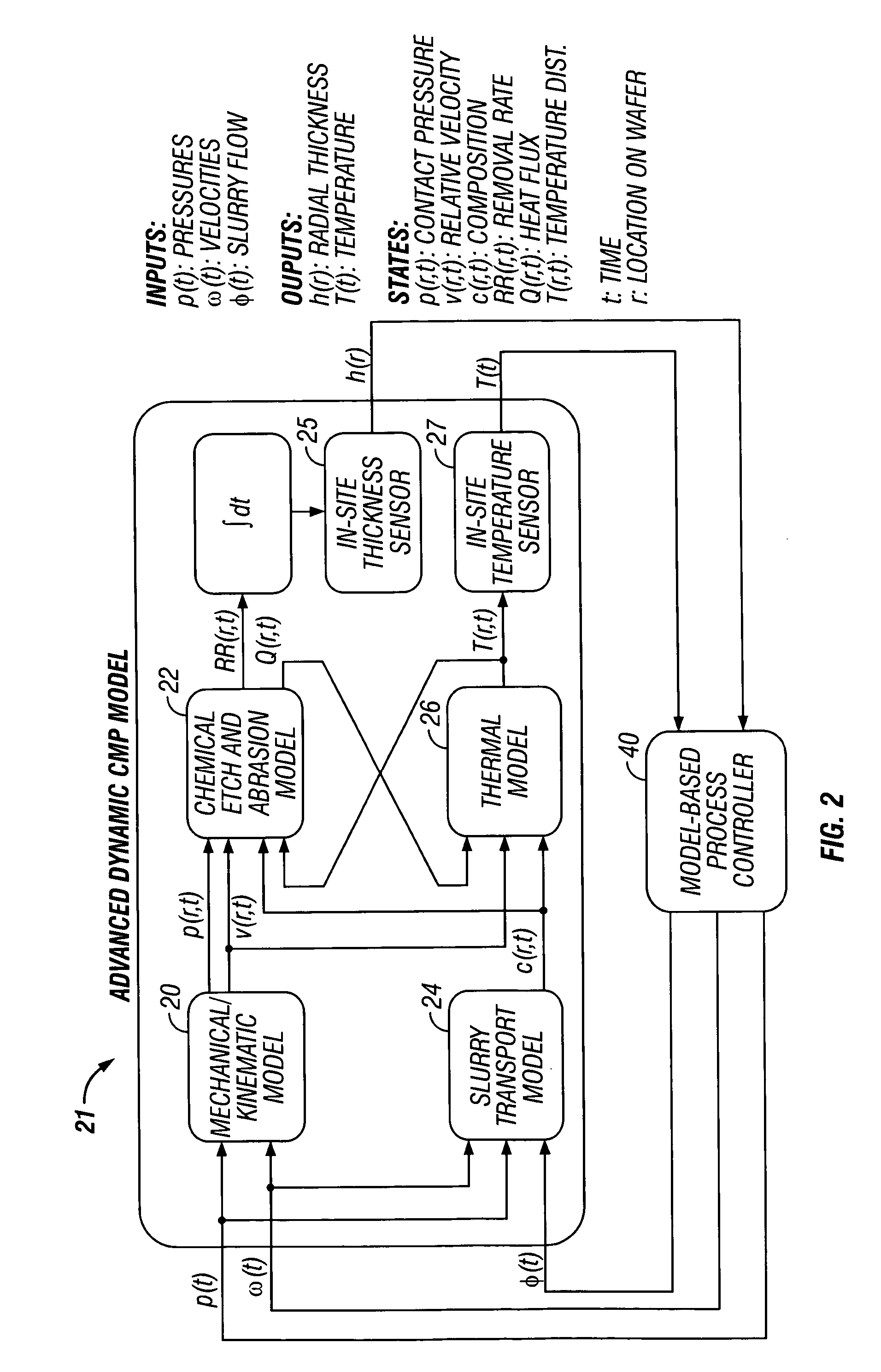

Chemical-mechanical planarization controller

ActiveUS20050143852A1Programme controlRevolution surface grinding machinesMathematical modelControl system

The invention provides a model-based control approach to chemical-mechanical planarization (CMP) control. The preferred embodiment comprises mathematical models of the CMP process. These models play a critical role in obtaining superior control performance. Model-based Control Design involves the construction of a dynamic mathematical model of the system to be controlled, e.g. a removal rate model of a CMP system. The model can then be evaluated via computer simulations, and validated using data from the system. The invention provides a method and apparatus that processes in-situ data from a suite of real-time sensors and produces real-time commands to multiple actuators, such as applied pressures, slurry-flow rate, and wafer / pad velocity. A key aspect of the invention is an integrated model-based pressure-temperature-velocity-slurry flow control system that includes many innovations in real-time mode identification, real-time gain estimation, and real-time control.

Owner:SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com