Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Membrane gas separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas mixtures can be effectively separated by synthetic membranes made from polymers such as polyamide or cellulose acetate, or from ceramic materials. While polymeric membranes are economical and technologically useful, they are bounded by their performance, known as the Robeson limit (permeability must be sacrificed for selectivity and vice versa). This limit affects polymeric membrane use for CO₂ separation from flue gas streams, since mass transport becomes limiting and CO₂ separation becomes very expensive due to low permeabilities. Membrane materials have expanded into the realm of silica, zeolites, metal-organic frameworks, and perovskites due to their strong thermal and chemical resistance as well as high tunability (ability to be modified and functionalized), leading to increased permeability and selectivity. Membranes can be used for separating gas mixtures where they act as a permeable barrier through which different compounds move across at different rates or not move at all. The membranes can be nanoporous, polymer, etc. and the gas molecules penetrate according to their size, diffusivity, or solubility.

Synthesis gas production

InactiveUS20030223931A1Hydrocarbon from carbon oxidesDispersed particle separationSyngasMembrane gas separation

A method for forming a synthesis gas with a tailored hydrogen / carbon dioxide ratio that is optimized for use in one or more predetermined downstream processes wherein membrane gas separation is employed to form a hydrogen rich stream and a separate synthesis gas product which product has said tailored ratio.

Owner:EQUSR CHEM LP

Three-stage membrane gas separation process

ActiveUS7604681B2Minimize methane lossPromote recoverySemi-permeable membranesMembranesThree stageNitrogen

A process for removing carbon dioxide or nitrogen from gas, especially natural gas. The process uses three membrane separation stages without compression between the second and third stages.

Owner:MEMBRANE TECH & RES +1

Process For Natural Gas Purification

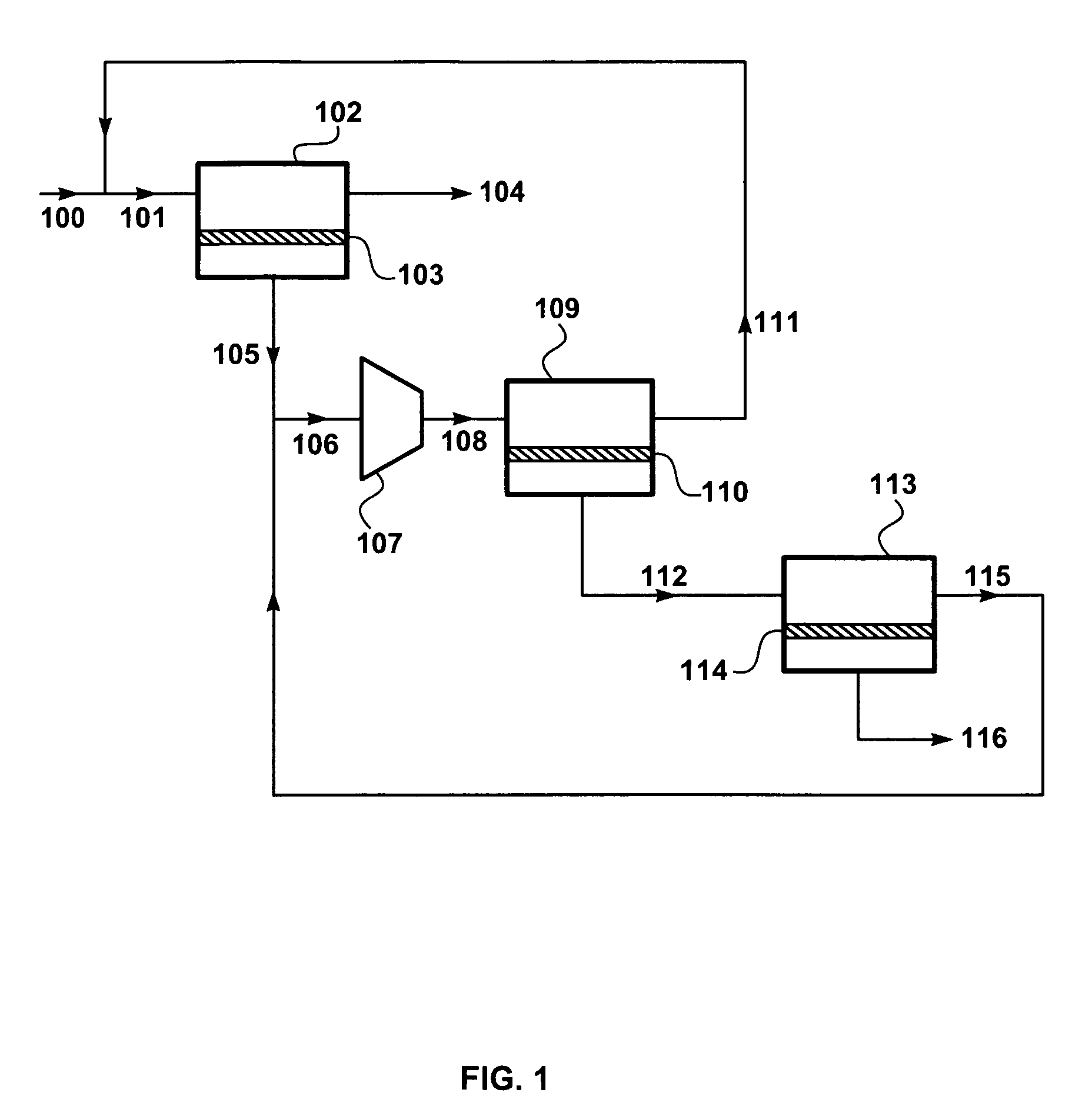

The present invention is directed toward a method for purifying a natural gas stream comprising: 1) removing the bulk of CO2 by at least one non-membrane gas separation means; and 2) removing oxygen and other impurities by at least one additional gas separation means, wherein the final natural gas product has low level of CO2 and oxygen.

Owner:GUILD ASSOCS

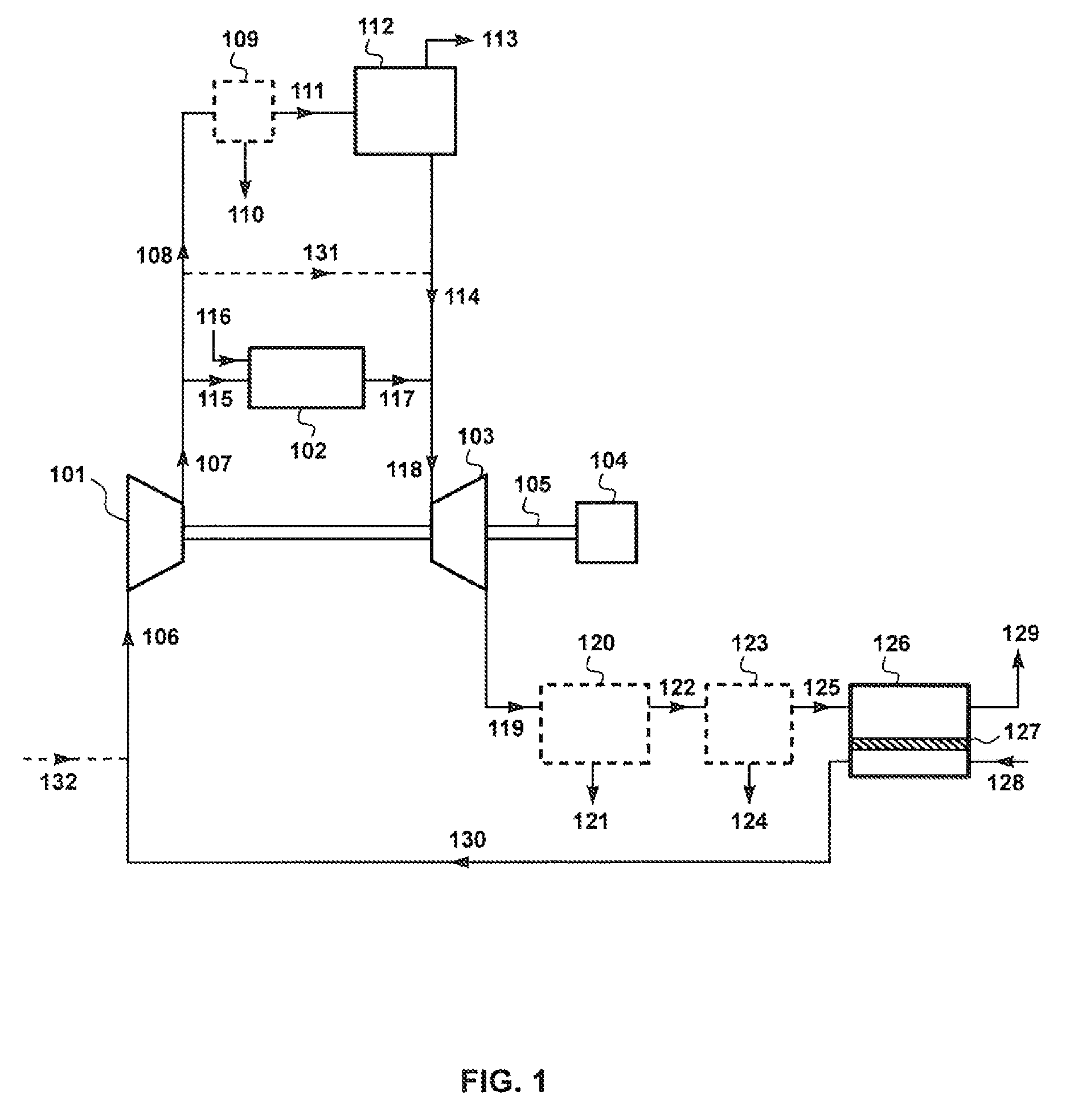

Sweep-Based Membrane Gas Separation Integrated With Gas-Fired Power Production And CO2 Recovery

ActiveUS20130200625A1Reduce environmental impactEasy to handleGas turbine plantsDirect carbon-dioxide mitigationPower stationMembrane gas separation

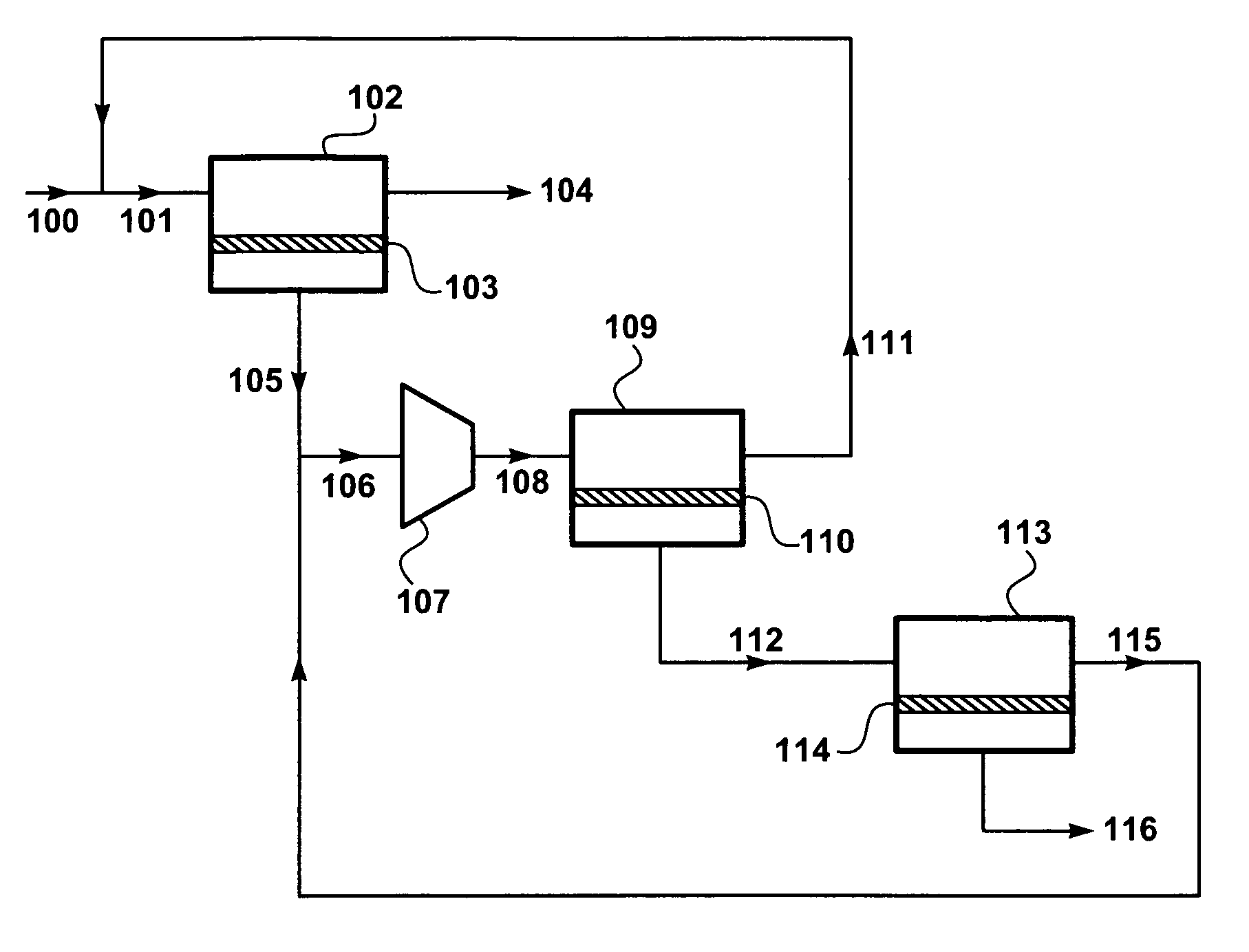

A process involving membrane-based gas separation and power generation, specifically for controlling carbon dioxide emissions from gas-fired power plants. The process includes a compression step, a combustion step, and an expansion / electricity generation step, as in traditional power plants. The process also includes a sweep-driven membrane separation step and a carbon dioxide removal or capture step. The carbon dioxide removal step is carried out on a portion of gas from the compression step.

Owner:MEMBRANE TECH & RES

Three-stage membrane gas separation process

ActiveUS20070272079A1Promote recoveryReduce downtimeMembranesSemi-permeable membranesThree stageNitrogen

A process for removing carbon dioxide or nitrogen from gas, especially natural gas. The process uses three membrane separation stages without compression between the second and third stages.

Owner:MEMBRANE TECH & RES +1

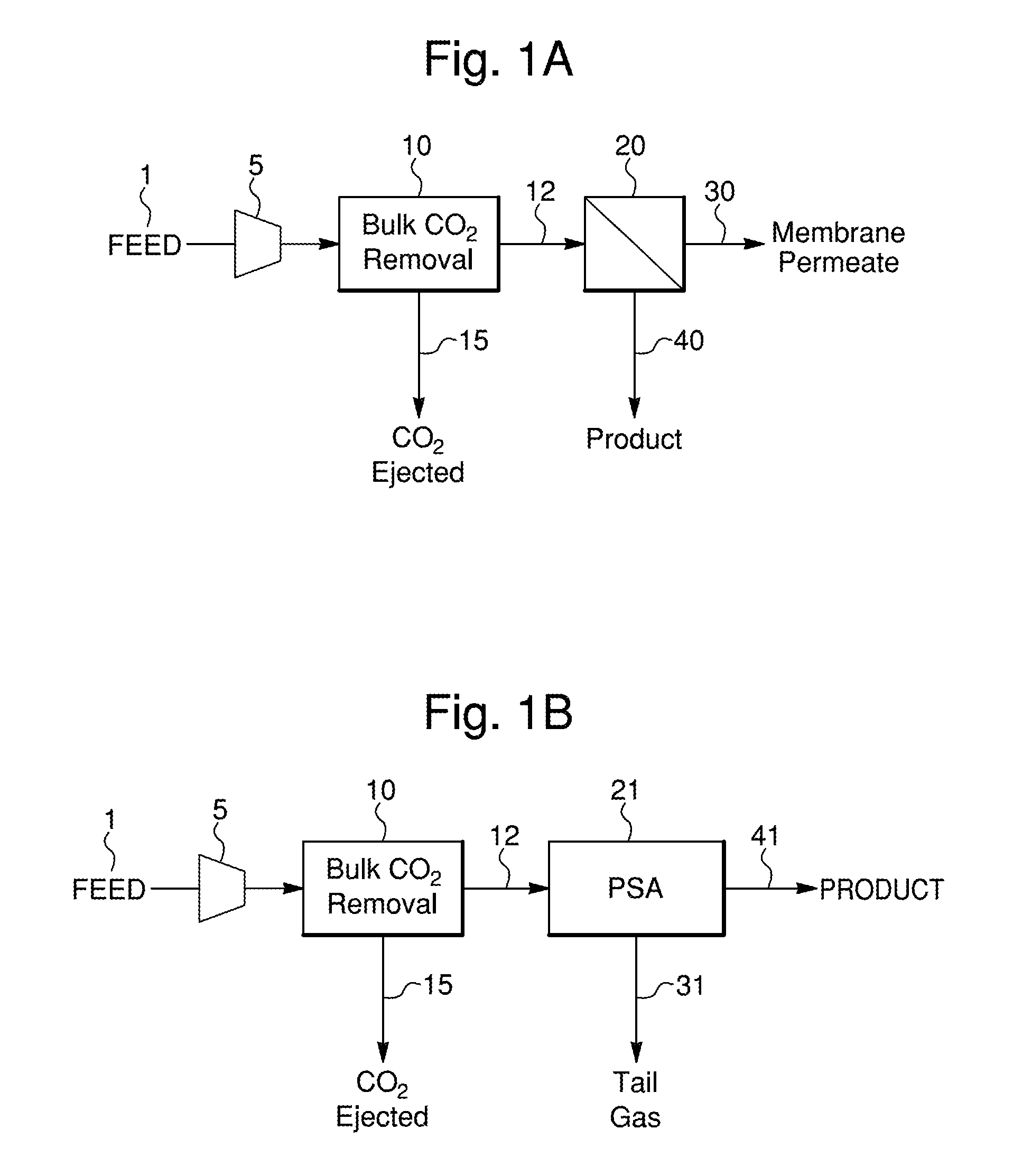

Process for regenerating facilitated-transport membranes

InactiveUS20060016750A1Limit disruptionExtended service lifeSemi-permeable membranesDispersed particle separationParaffin oilsMembrane gas separation

A process for regenerating a facilitated-transport membrane, such as a gas separation membrane, that contains an ionic complexing agent, and that has lost performance as a result of reduction of at least some of the ions to a less charged or uncharged form. The process involves exposing the membrane to an oxidizing agent, such as hydrogen peroxide. The invention also includes membranes that have been regenerated in this way, and their use, particularly for separating light olefins from light paraffins by membrane gas separation.

Owner:MEMBRANE TECH & RES

Sweep-based membrane gas separation integrated with gas-fired power production and CO2 recovery

InactiveUS9140186B2Easy to handleReduce energy lossGas turbine plantsDirect carbon-dioxide mitigationPower stationMembrane gas separation

Owner:MEMBRANE TECH & RES

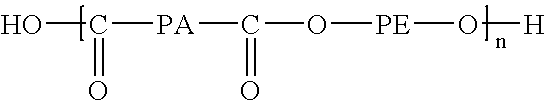

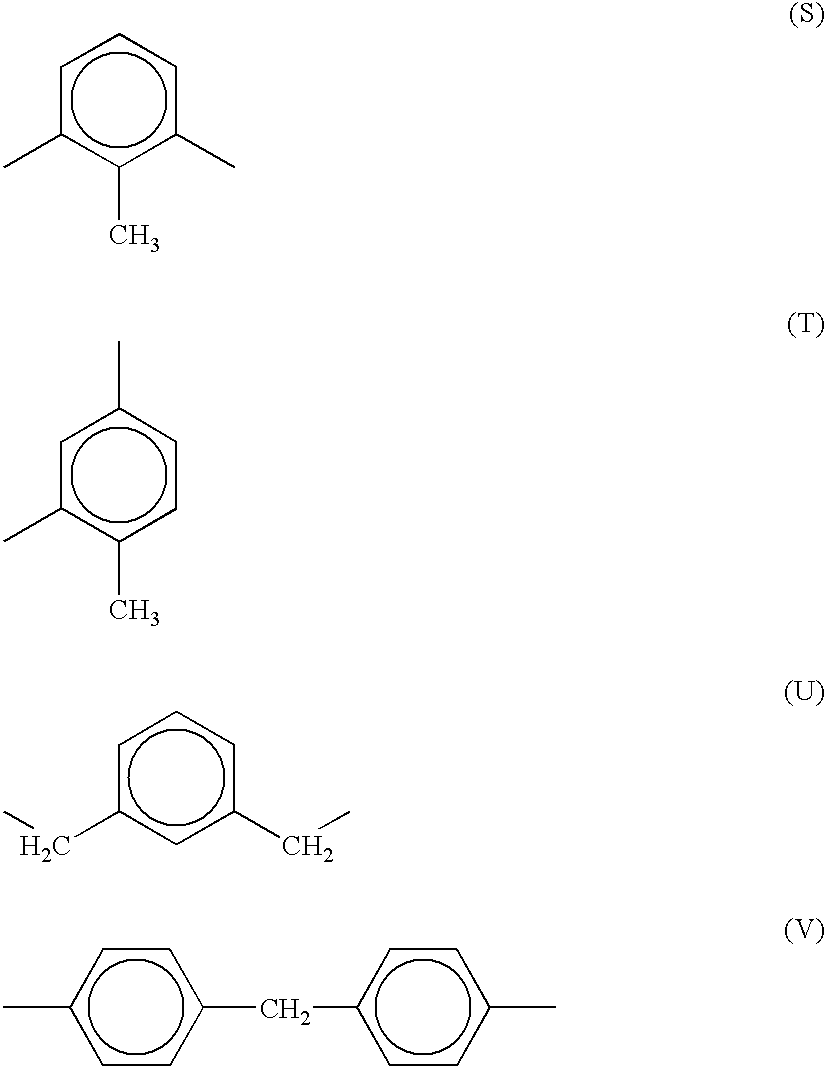

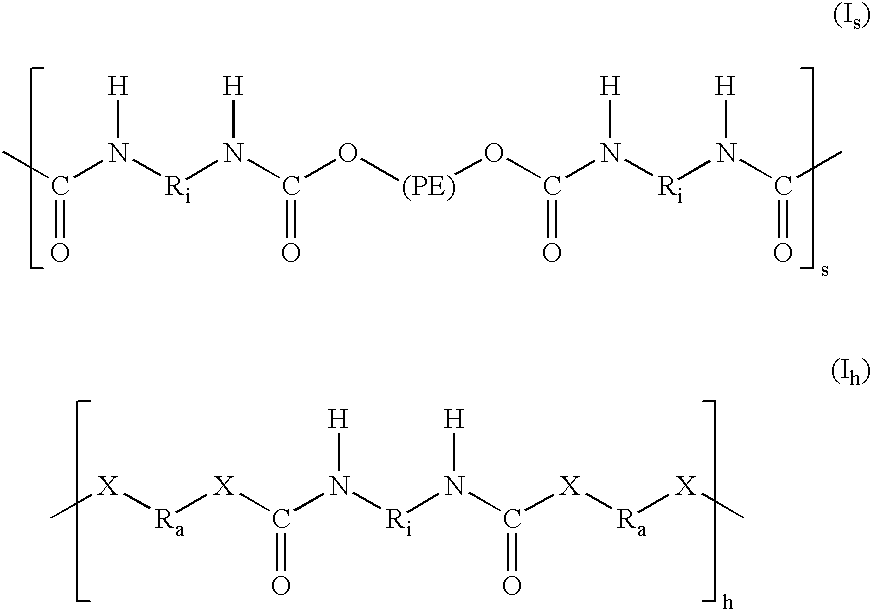

Block polyurethane-ether and polyurea-ether gas separation membranes

Gas separation membranes formed from polyether-urethane or polyether-urea block copolymers are useful for separating gases from gas mixtures. The membranes and processes are especially suited for separating polar gases from mixtures that contain polar and non-polar species. The novel membranes exhibit good permeability and permselectivity, as well as durability, making them well suited for industrial applications such as removal of acid gases from natural gas and removal of carbon dioxide from synthesis gas.

Owner:LAIR LIQUIDE ADIRECTOIRE & CONSELL DE SURVEILLANCE POUR LETUD ET LEXPL DES PROCEDES GEOR CLAUDE +1

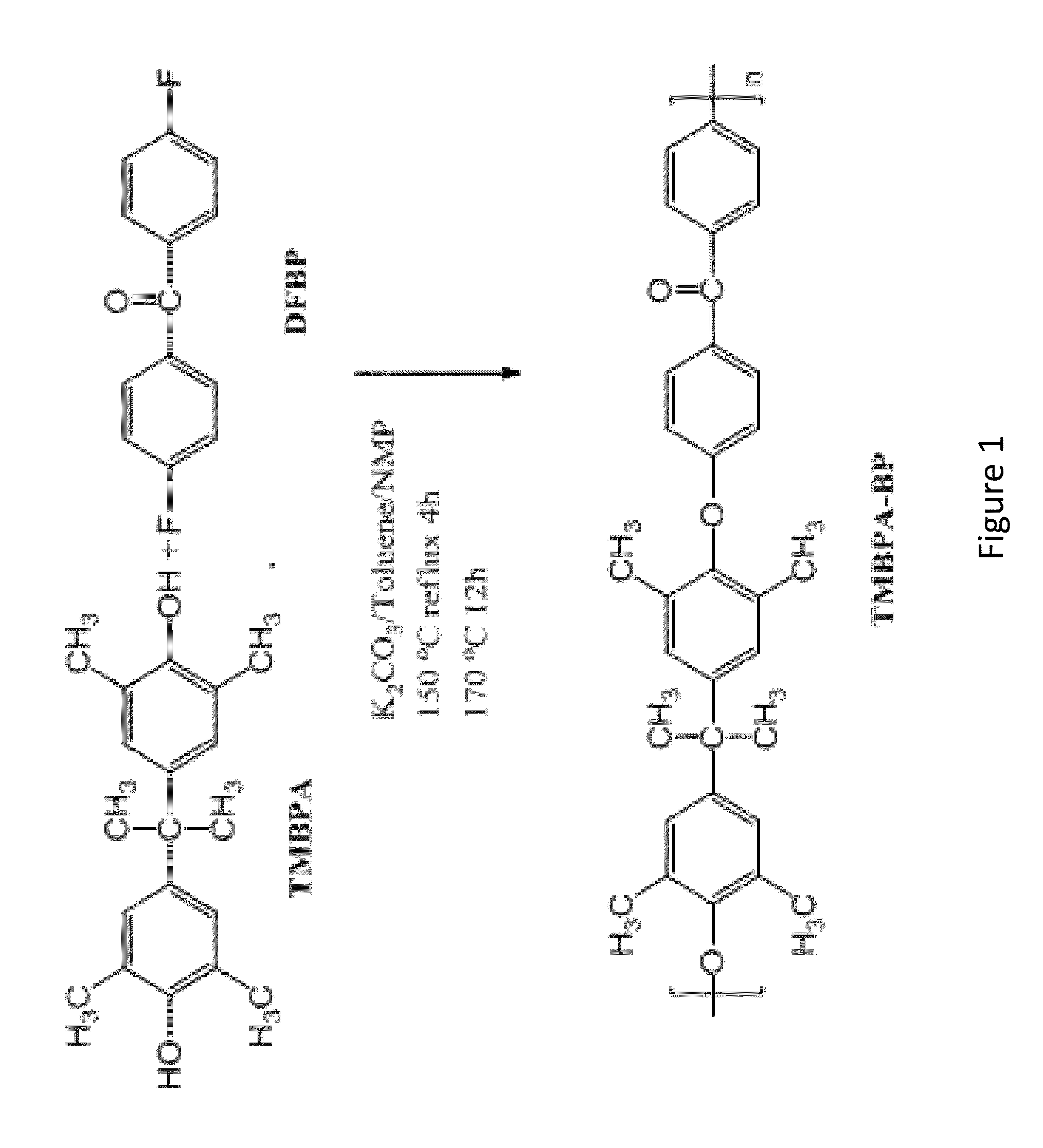

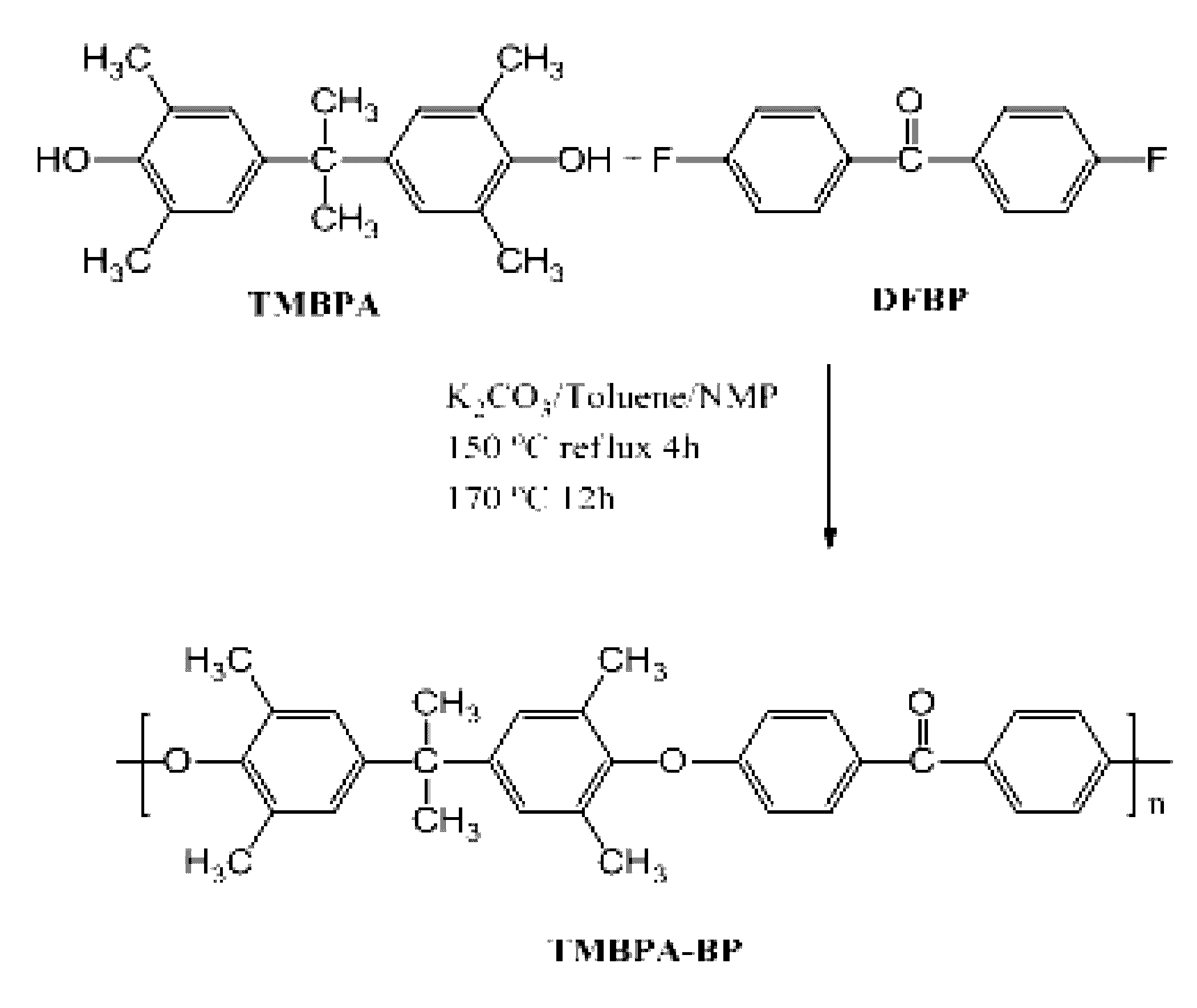

Crosslinked Polymer Compositions, Gas Separation Membranes of Such Crosslinked Polymer Compositions, Methods Of Making Such Membranes, and Methods of Separating Gases Using Such Membranes

Gas separation membrane compositions including at least one crosslinked polymer, gas separation membranes made of such compositions, methods for making such gas separation membranes, and methods of using such membranes to separate gases are described. In one embodiment, the crosslinked polymer includes polyarylene ethers (PAE).

Owner:VIRGINIA TECH INTPROP INC +1

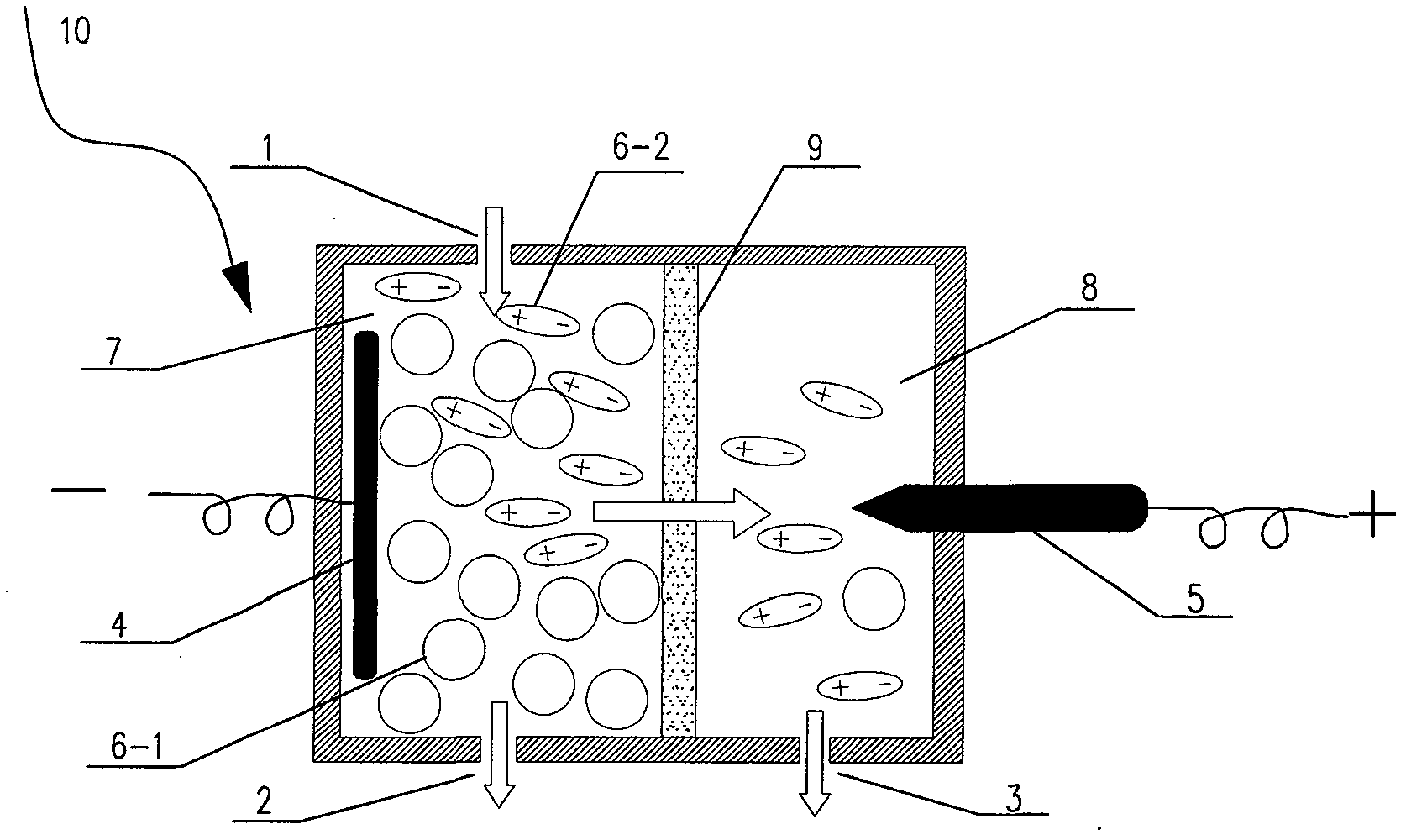

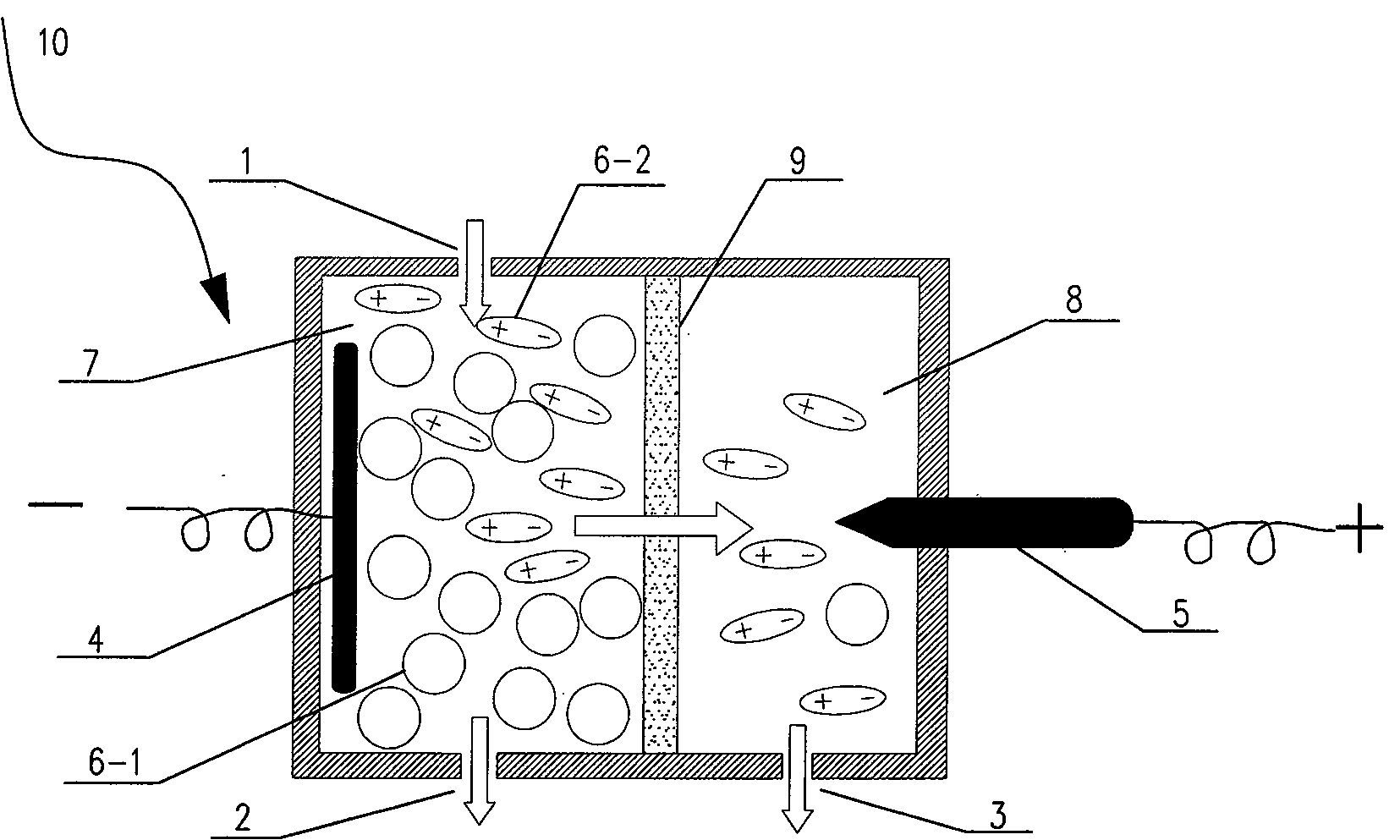

A device and method for membrane gas separation

ActiveCN102274677AFast separationIncrease mass transfer rateDispersed particle separationDual actionElectrical polarity

The invention relates to an asymmetric electrostatic field coupling membrane gas separation device which comprises a raw material chamber, a permeating chamber, a membrane and an electrode, wherein the electrode can be used for generating an asymmetric electrostatic field; the electrode comprises a flat electrode and a needle electrode; a 101-104V direct current voltage is applied to the electrode; the raw gas containing polar gas molecules enters into the raw material chamber; under the dual action of chemical potential gradient and electric potential gradient of the asymmetric electrostatic field, the raw gas spreads and permeates through the membrane at a speed higher than the speed under the existence of pure chemical potential gradient, thereby forming the penetrating gas and flowing from the permeating chamber; and the remaining gas flows from the raw material chamber, thereby separating the raw gas. The invention also relates to an asymmetric electrostatic field coupling membrane gas separation method.

Owner:TIANJIN POLYTECHNIC UNIV

Water treatment system and method

PendingCN107473474ADecline in healthShorten survival timeWater treatment parameter controlWater/sewage treatment by irradiationWater qualityTreatments water

The invention discloses a water treatment system and method. The system comprises a water quality monitoring device, a water quality evaluating device and a water body purifying device, wherein the water quality monitoring device is installed in a water body to be detected and used for obtaining various physical, biological and chemical indexes of the water body to be detected; the water quality evaluating device is used for comparing the various physical, biological and chemical indexes obtained by the water quality monitoring device with the water quality standard to determine whether the water body needs to be treated or not; the water body purifying device is arranged on the water quality monitoring device to be communicated and used for receiving the water body which is determined by the water quality evaluating device and needs to be treated and purifying the water body through at least one treatment device. According to the film and gas separation technology, by applying the film diffusion principle, poisonous and harmful ammonia nitrogen and carbon dioxide in aquatic products in the water body are removed in a physical mode, chemical and biological removal are avoided, the system is applicable to the fast-pace business traffic, and no other chemical matter in the water body is added.

Owner:宁波琅华泰阁海洋科技有限公司

Membrane gas separation plant and method for operating same

A method is proposed for operating a plant for purifying a high-pressure gas mixture from easily permeating components, which plant comprises membrane gas separating units having a high-pressure chamber and a low-pressure chamber with a selectively permeable membrane therebetween, in which method the low-pressure chamber of at least one membrane gas separating unit is continuously flushed with purified gas mixture (semi-finished product or product), wherein the pressure difference between the aforementioned chambers of the membrane gas separating unit and, likewise, the flow rate of the purified gas mixture used for flushing are maintained so that the amount of each easily permeating component in the product does not exceed the desired values. The proposed method makes it possible to purify a raw material (high-pressure gas mixture) from one or more easily permeating components simultaneously (in particular helium, hydrogen sulphide, mercaptans, carbon dioxide, water and / or heavy hydrocarbons), increase purification efficiency (i.e. the ratio between the total area of the selectively permeable membrane in the plant, the productivity of said membrane and the specific energy consumption of the gas separation process), and provide the possibility of using (treating or preparing) raw material with a higher content of easily permeating components.

Owner:"盖瑞斯"股份有限公司

Two-Step Membrane Gas Separation Process

InactiveUS20150129413A1Increase membrane areaLow selectivityMembranesGas treatmentTwo stepTarget concentration

A gas separation process for treating a gas stream containing vapors of condensable components. The process includes two membrane separation steps, the second step using membranes of lower selectivity than the first step. Advantageously, the first membrane separation step may be carried out outside the pressure-ratio-limited region and the second membrane separation step may be carried out within the pressure-ratio-limited region. The second residue stream is a desired product of the process, and the process is particularly useful for applications where the target concentration of component A in this product is low, such as below 1-2 vol %.

Owner:MEMBRANE TECH & RES

Crosslinked polymer compositions, gas separation membranes of such crosslinked polymer compositions, methods of making such membranes, and methods of separating gases using such membranes

Owner:VIRGINIA TECH INTPROP INC +1

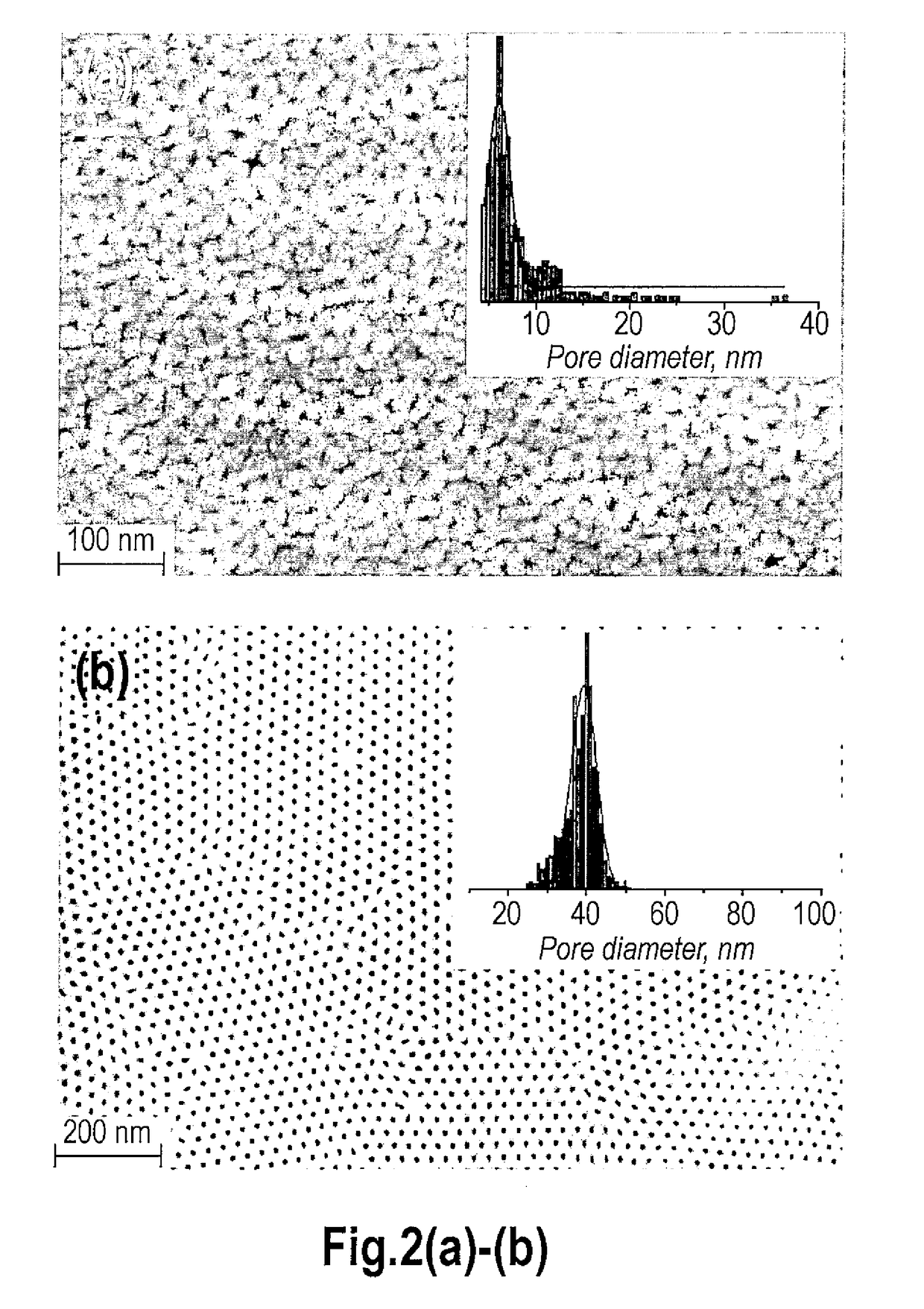

Method of extracting components of gas mixtures by pertraction on nanoporous membranes

The invention relates to the field of membrane gas separation. A method of removing components of gas mixtures which is based on passing the components of a gas mixture through a nanoporous membrane and subsequently selectively absorbing them with a liquid absorbent that is in contact with the nanoporous membrane, wherein to prevent the gas from getting into the liquid phase of the absorbent and the liquid phase of the absorbent from getting into the gas phase, a nanoporous membrane with homogeneous porosity (size distribution less than 50%) and a pore diameter in the range of 5-500 nm is used, and the pressure differential between the gas phase and the liquid absorbent is kept below the membrane bubble point pressure. An acid gas removal performance of more than 0.3 nm3 / (m2 hour) in terms of CO2 is achieved at a hollow-fiber membrane packing density of up to 3200 m2 / m3, which corresponds to a specific volumetric performance of acid gas removal of up to 1000 nm3 (m3 hour). The technical result is that of providing effective extraction of undesirable components from natural and process gas mixtures.

Owner:ROSNEFT OIL CO ROSNEFT

A self-polymerized microporous polyimide gas separation membrane and its preparation method and application

ActiveCN112275147BImprove thermal stabilityImprove mechanical propertiesMembranesSemi-permeable membranesPolymer scienceBackbone chain

The invention relates to a self-polymerized microporous polyimide gas separation membrane and its preparation method and application, belonging to the technical field of membrane gas separation, in order to prepare and synthesize a polymer gas separation membrane with high selectivity and high permeability , to meet the requirements of practical industrial applications. In the present invention, the main chain of self-polymerized microporous polyimide contains a ladder structure, which increases the distance between polymer chains, facilitates the separation and diffusion of gases, and reduces the hydrogen bonds between polymer molecules. function, improve the solubility of the polymer, the present invention utilizes two kinds of diamines with ladder structure and dianhydrides with different structures to prepare through homopolymerization or copolymerization reaction. In the present invention, two kinds of ladder-shaped diamine monomers containing oxa-naphthalene structure were synthesized for the first time, and the trapezoidal self-polymerizing microporous polyimide polymer containing oxa-naphthene structure was synthesized through polycondensation reaction, which has good thermal stability and Mechanical properties, high selectivity to oxygen / nitrogen, can meet the practical application of gas separation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Membrane gas separation under magnetic field

ActiveUS20200338496A1High separation selectivityOvercomes drawbackSemi-permeable membranesMembranesParticle physicsMembrane gas separation

Apparatus, methods and uses for separating gas mixtures of at least two different gases under magnetic field and employing a membrane are described.

Owner:KHALIFA UNIV OF SCI & TECH

Membrane gas separation device and method

ActiveCN102274677BFast separationIncrease mass transfer rateDispersed particle separationDual actionElectrical polarity

The invention relates to an asymmetric electrostatic field coupling membrane gas separation device which comprises a raw material chamber, a permeating chamber, a membrane and an electrode, wherein the electrode can be used for generating an asymmetric electrostatic field; the electrode comprises a flat electrode and a needle electrode; a 101-104V direct current voltage is applied to the electrode; the raw gas containing polar gas molecules enters into the raw material chamber; under the dual action of chemical potential gradient and electric potential gradient of the asymmetric electrostatic field, the raw gas spreads and permeates through the membrane at a speed higher than the speed under the existence of pure chemical potential gradient, thereby forming the penetrating gas and flowing from the permeating chamber; and the remaining gas flows from the raw material chamber, thereby separating the raw gas. The invention also relates to an asymmetric electrostatic field coupling membrane gas separation method.

Owner:TIANJIN POLYTECHNIC UNIV

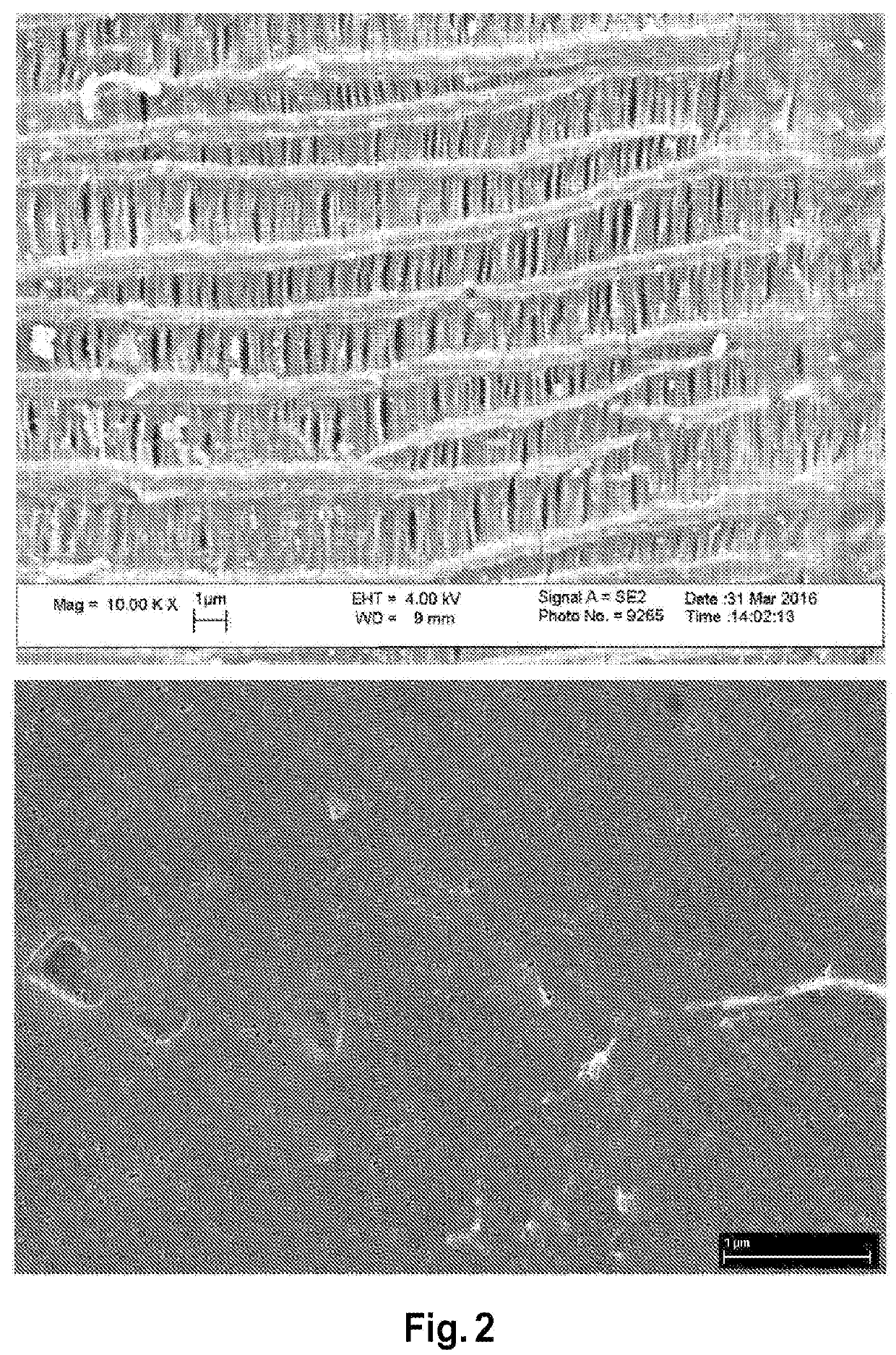

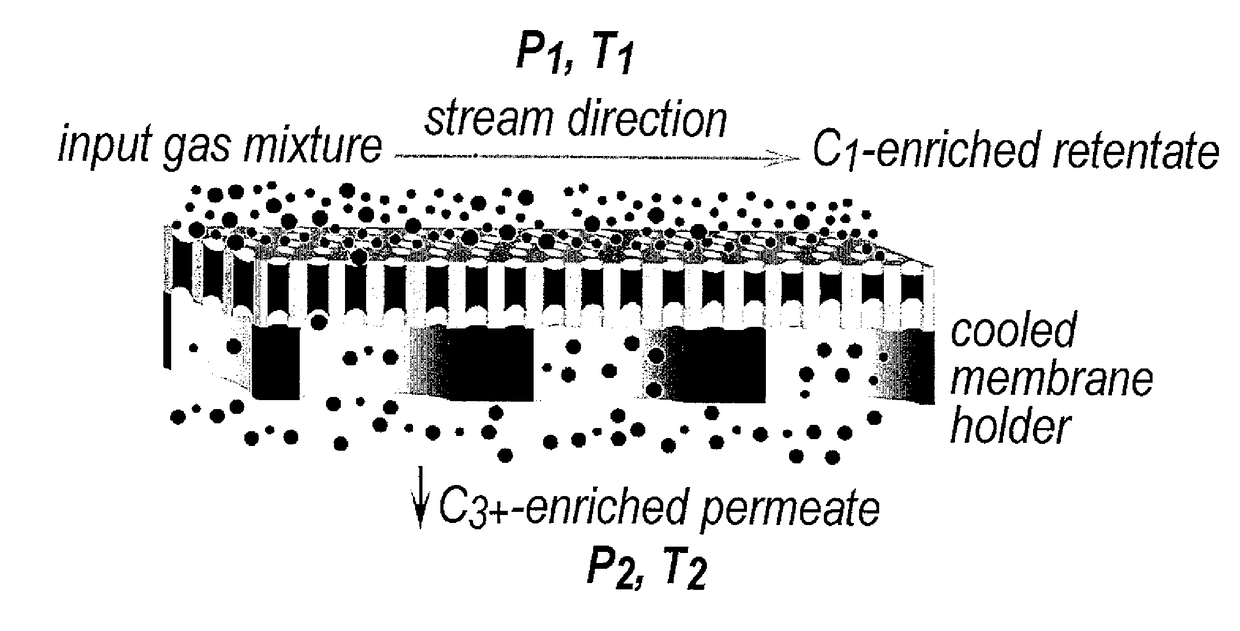

Method of fractionating mixtures of low molecular weight hydrocarbons

ActiveUS10047306B2Reduce solubilityReduce energy costsMembranesSemi-permeable membranesAssociated petroleum gasHydrocarbon mixtures

Owner:ROSNEFT OIL CO

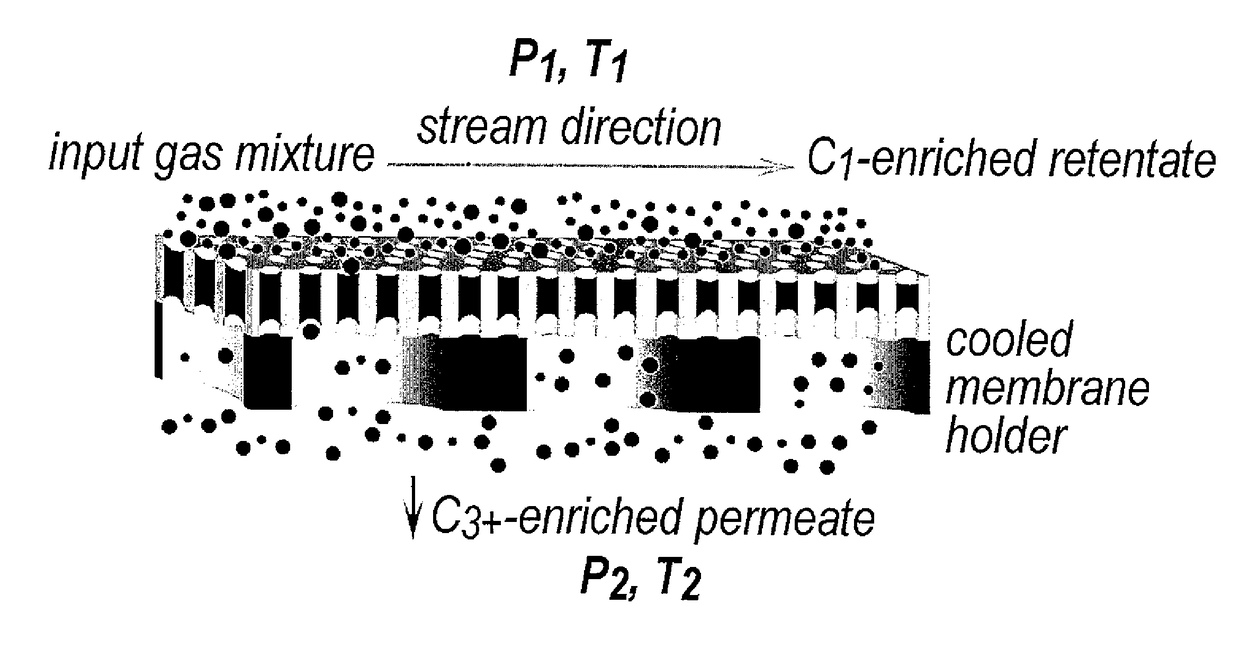

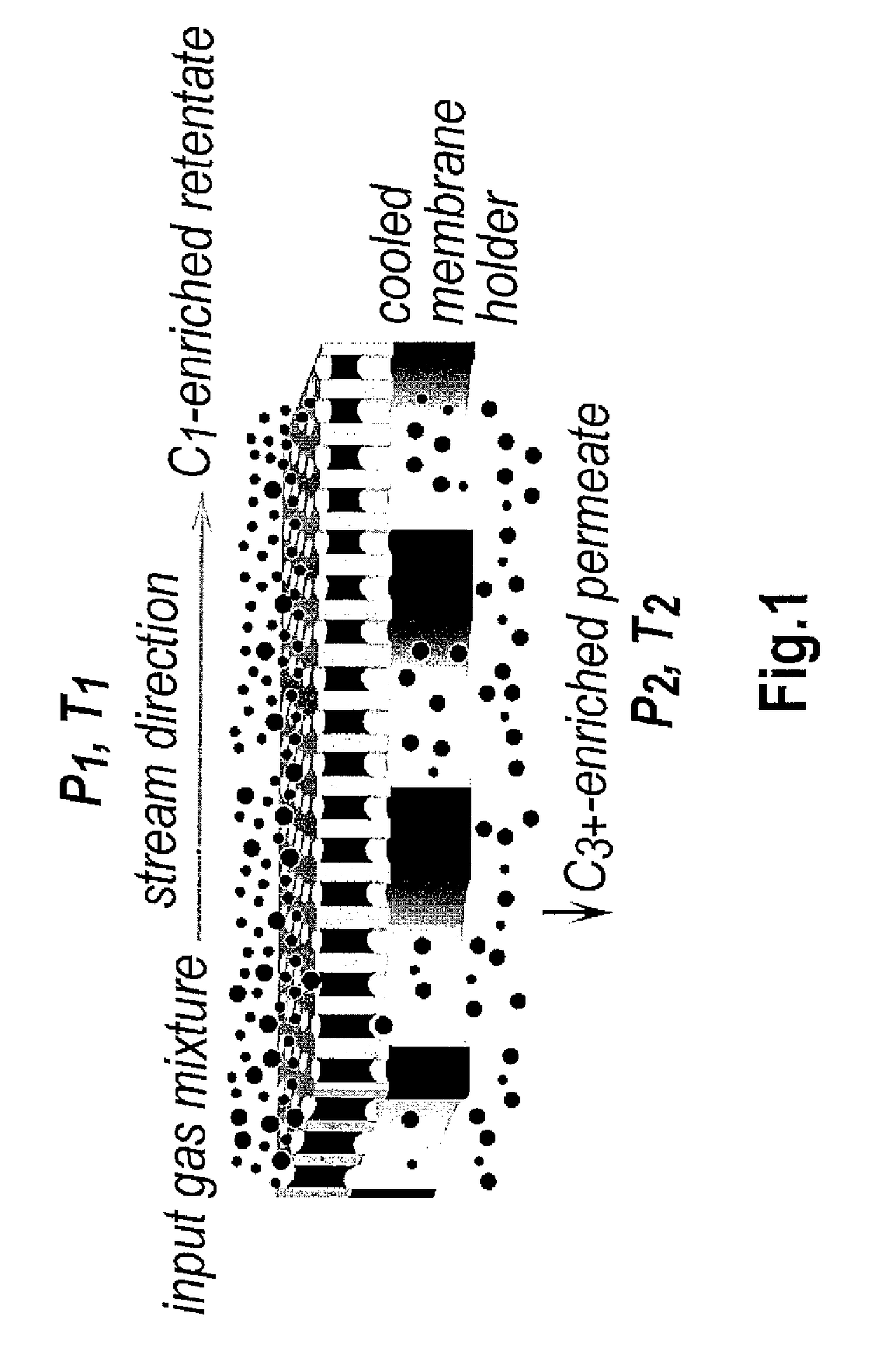

Four stage membrane gas separation with cooling and use of sweep gas

Separation of a gas mixture comprising first and second gases may be improved using four stages of gas separation membrane modules that includes the additional techniques of cooling the feed gas stream that is fed to the first (feed) stage and using a portion of the fourth (second permeate) stage retentate as a sweep gas on the permeate stage.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Membrane gas separation under magnetic field

Apparatus, methods and uses for separating gas mixtures of at least two different gases under magnetic field and employing a membrane are described.

Owner:KHALIFA UNIV OF SCI & TECH

Three stage membrane gas separation with cooling and use of sweep gas

Separation of a gas mixture comprising first and second gases may be improved using three stages of gas separation membrane modules that includes the additional techniques of cooling the feed gas stream that is fed to the feed stage and using a portion of the permeate stage retentate as a sweep gas on the permeate stage.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Double separation method and double separation system for oxygen gas and nitrogen gas

The object of the present invention is to provide a device that can not only separate and obtain high-purity oxygen from air etc. by using a PSA gas separation device, but also continuously and efficiently separate and obtain high-purity nitrogen from the desorption gas continuously supplied by the PSA gas separation device. methods and systems. The invention comprises a PSA gas separation process implemented by a PSA gas separation device (1) and a membrane gas separation process implemented by a membrane gas separator (2). In the PSA gas separation process, oxygen-enriched gas and mainly nitrogen-containing but also Oxygen-containing desorbed gas. In the membrane gas separation process, the permeate side of the gas separation membrane (2A), which preferentially permeates oxygen, is depressurized to a pressure lower than atmospheric pressure, and the desorbed gas is separated into permeate gas by the gas separation membrane (2A). Gas permeated by the gas separation membrane (2A) and non-permeated gas (nitrogen-enriched gas) not permeated by the gas separation membrane (2A).

Owner:SUMITOMO SEIKA CHEM CO LTD

Two-stage membrane gas separation with cooling and use of sweep gas

Separation of a gas mixture comprising first and second gases may be improved using two cascaded stages of gas separation membrane modules that includes the additional techniques of cooling the feed gas stream that is fed to the feed stage and using a portion of the feed stage retentate as a sweep gas on the feed stage.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method of Fractionating Mixtures of Low Molecular Weight Hydrocarbons

ActiveUS20180100109A1Reduce energy costsReduce solubilitySemi-permeable membranesMembranesSeparation factorAssociated petroleum gas

The invention relates to the field of membrane gas separation and can be used for the energy-efficient fractionation of hydrocarbon mixtures, including separation and drying of natural and associated petroleum gases. Proposed is a method of fractionating mixtures of low molecular weight hydrocarbons which is based on the capillary condensation of the components of a mixture in the pores of microporous membranes with uniform porosity and a pore diameter in a range of 5 to 250 nm, wherein, for capillary condensation, the temperature of the membrane and the pressure on the permeate side are kept below the temperature and the pressure of the feed mixture such that the equilibrium pressure of the saturated vapors of the separated components on the permeate side is lower than the partial pressure of the components in the feed stream. This method makes it possible to significantly increase membrane permeability with respect to condensable components (over 500 m3 / (m2·atm·h) for n-butane), and also component separation factors (the n-C4H10 / CH4 separation factor is greater than 60 for a mixture having an associated petroleum gas composition), while also making it possible to dispense with deep cooling of the gas stream fed to a membrane module, and to carry out gas separation under insignificant cooling of the membrane on the permeate side (down to −50° C.) For more effective gas separation, permeate is collected in a liquid state. A technical effect of the invention resides in providing a method that makes it possible to efficiently remove high-boiling hydrocarbons (C3-C6) from natural gas and associated petroleum gases, as well as to obtain gas mixtures with a constant composition.

Owner:ROSNEFT OIL CO

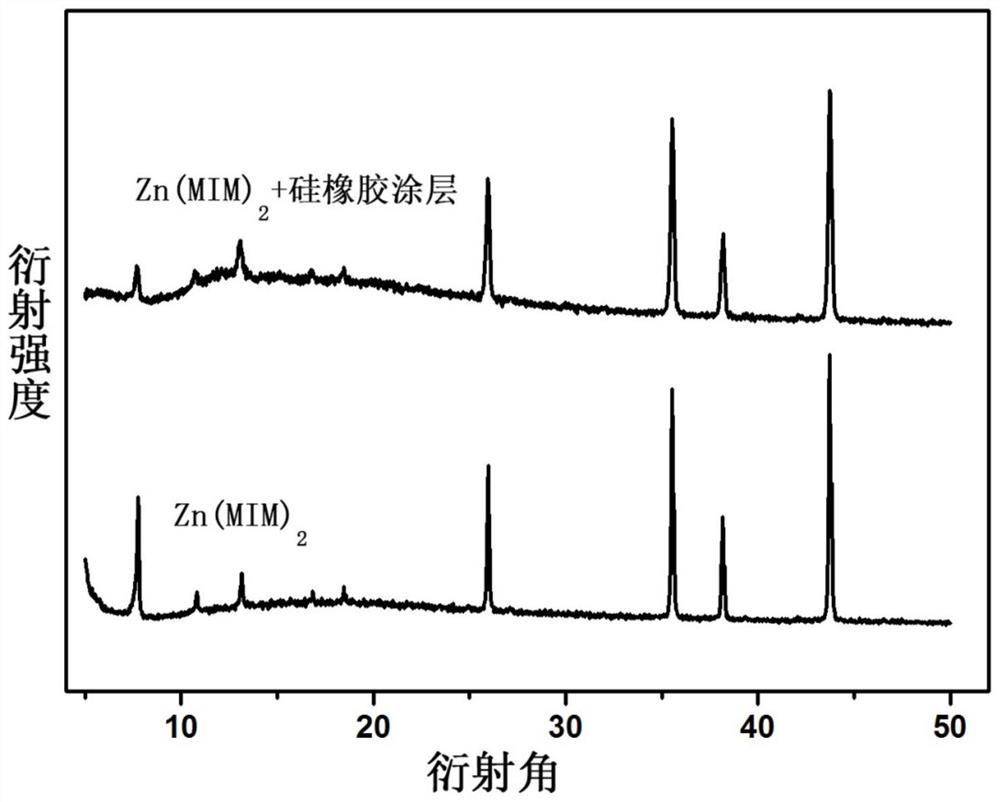

A method for improving the gas separation performance of supported MOF membranes by using polymer coatings

ActiveCN108939958BEasy to separateGood repeatabilitySemi-permeable membranesDispersed particle separationChemical physicsPhysical chemistry

The invention provides a method for improving the gas separation performance of a supported MOF membrane by using a polymer coating. A layer of polymer coating is coated on the surface of the MOF membrane, which can repair the defects of the MOF membrane; The material coating can effectively prevent the flexibility of the MOF framework and limit the expansion of its pore size, thereby effectively improving the gas separation performance. In addition, the externally applied polymer coating can significantly improve the hydrothermal stability of the MOF membrane, and the coating also effectively protects the brittleness of the MOF membrane itself. The method for repairing the MOF membrane by using the polymer coating mentioned in the present invention has wide application value in the field of gas separation.

Owner:NANJING TECH UNIV

Electronegative gas electromigration membrane separation method

ActiveCN108815998AHigh energy consumptionImprove efficiencyGas treatmentDispersed particle separationIon clustersGas passing

The invention provides an electronegative gas electromigration membrane separation method. To-be-separated electronegative and non-electronegative mixed gas is filled into a gas separation device; electrons are generated by utilizing an electron generator in the gas separation device; after electronegative gas in the mixed gas is collided with the electrons, stable negative ions or negative ion clusters are generated; the negative ions or the negative ion clusters enter an electric field consisting of a cathode and an anode in the gas separation device together with a gas flow; a gas separation membrane is arranged in the electric field closed to the inside of the anode; the negative ions or the negative ion clusters permeate and pass through the gas separation membrane under the pushing action of electric field force and a concentration difference between two sides of the gas separation membrane; and the gas passing through the gas separation membrane is further collected, so as to implement separation of the electronegative and non-electronegative mixed gas. By adopting the method provided by the invention, system resistance of membrane gas separation can be greatly reduced; themethod is particularly applicable to the separation of electronegative gas such as O2, H2S, SO2 and the like, and non-electronegative gas such as N2, H2 and the like; and low-energy-consumption high-efficiency separation of the gas can be implemented.

Owner:WUHAN UNIV

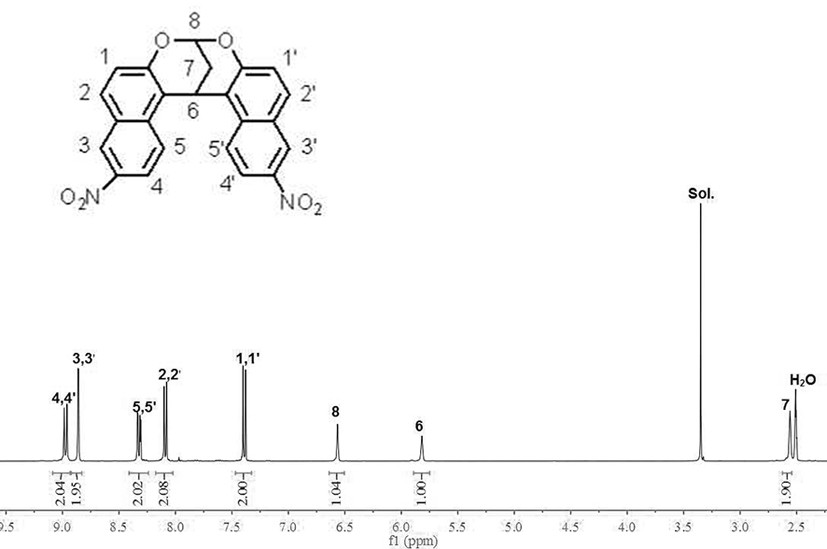

A kind of phosphoric acid-treated tröger`s Base polymer gas separation membrane and its preparation method and application

ActiveCN112275146BWide variety of sourcesLow priceSemi-permeable membranesGas treatmentO-Phosphoric AcidPhysical chemistry

The invention relates to a preparation method and application of a phosphoric acid-treated Tröger`s Base polymer gas separation membrane, which belongs to the technical field of membrane gas separation and solves the separation selectivity of existing separation membranes for light gases such as hydrogen and carbon dioxide Low, low separation efficiency technical problems. The solution is: First, use the rigid skeleton structure of Tröger`s base to obtain a large free volume and increase the efficiency of gas transmission. After phosphoric acid treatment, use the interaction between N on the main chain and phosphoric acid to maintain phosphoric acid in the polymerization Stability in the material, improve the selectivity of hydrogen to carbon dioxide. The selectivity can be adjusted by changing the acid treatment conditions of the polymer. Experiments have shown that the performance of the treated membrane exceeds the current 2008 Robeson upper limit at room temperature and high temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method of extracting components of gas mixtures by pertraction on nanoporous membranes

The invention relates to the field of membrane gas separation. A method of removing components of gas mixtures which is based on passing the components of a gas mixture through a nanoporous membrane and subsequently selectively absorbing them with a liquid absorbent that is in contact with the nanoporous membrane, wherein to prevent the gas from getting into the liquid phase of the absorbent and the liquid phase of the absorbent from getting into the gas phase, a nanoporous membrane with homogeneous porosity (size distribution less than 50%) and a pore diameter in the range of 5-500 nm is used, and the pressure differential between the gas phase and the liquid absorbent is kept below the membrane bubble point pressure. An acid gas removal performance of more than 0.3 nm3 / (m2 hour) in terms of CO2 is achieved at a hollow-fiber membrane packing density of up to 3200 m2 / m3, which corresponds to a specific volumetric performance of acid gas removal of up to 1000 nm3 (m3 hour). The technical result is that of providing effective extraction of undesirable components from natural and process gas mixtures.

Owner:ROSNEFT OIL CO ROSNEFT

A method for electronegative gas electromigration membrane separation

ActiveCN108815998BHigh energy consumptionImprove efficiencyGas treatmentDispersed particle separationIon clustersChemical physics

The invention provides an electronegative gas electromigration membrane separation method. To-be-separated electronegative and non-electronegative mixed gas is filled into a gas separation device; electrons are generated by utilizing an electron generator in the gas separation device; after electronegative gas in the mixed gas is collided with the electrons, stable negative ions or negative ion clusters are generated; the negative ions or the negative ion clusters enter an electric field consisting of a cathode and an anode in the gas separation device together with a gas flow; a gas separation membrane is arranged in the electric field closed to the inside of the anode; the negative ions or the negative ion clusters permeate and pass through the gas separation membrane under the pushing action of electric field force and a concentration difference between two sides of the gas separation membrane; and the gas passing through the gas separation membrane is further collected, so as to implement separation of the electronegative and non-electronegative mixed gas. By adopting the method provided by the invention, system resistance of membrane gas separation can be greatly reduced; themethod is particularly applicable to the separation of electronegative gas such as O2, H2S, SO2 and the like, and non-electronegative gas such as N2, H2 and the like; and low-energy-consumption high-efficiency separation of the gas can be implemented.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com