Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Heated shoe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

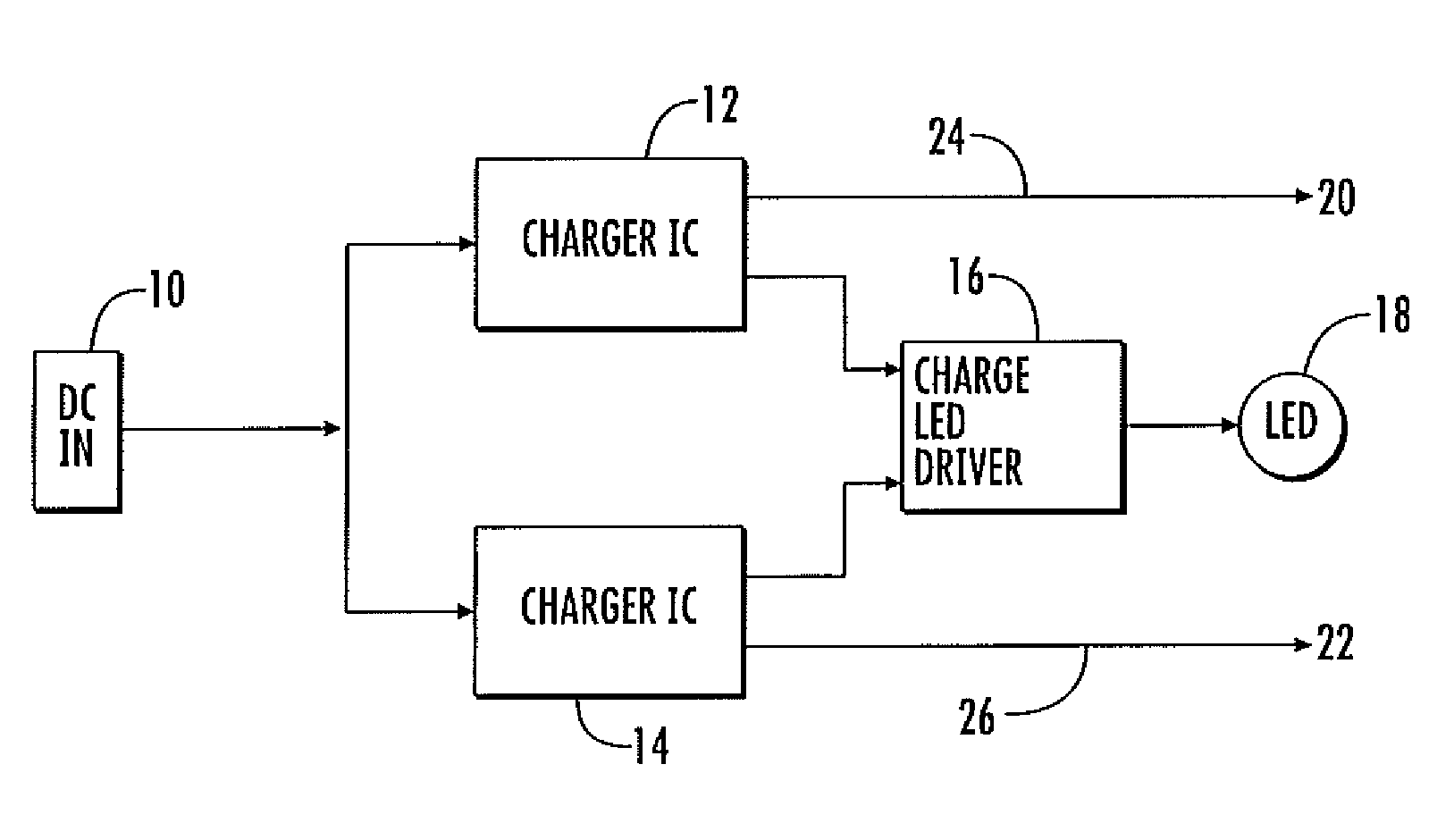

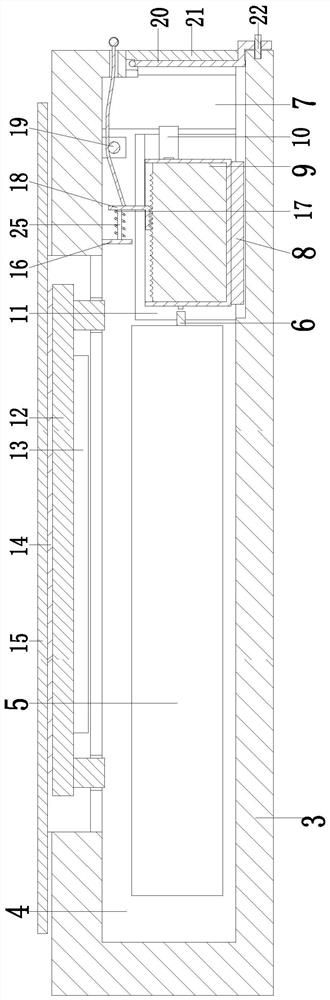

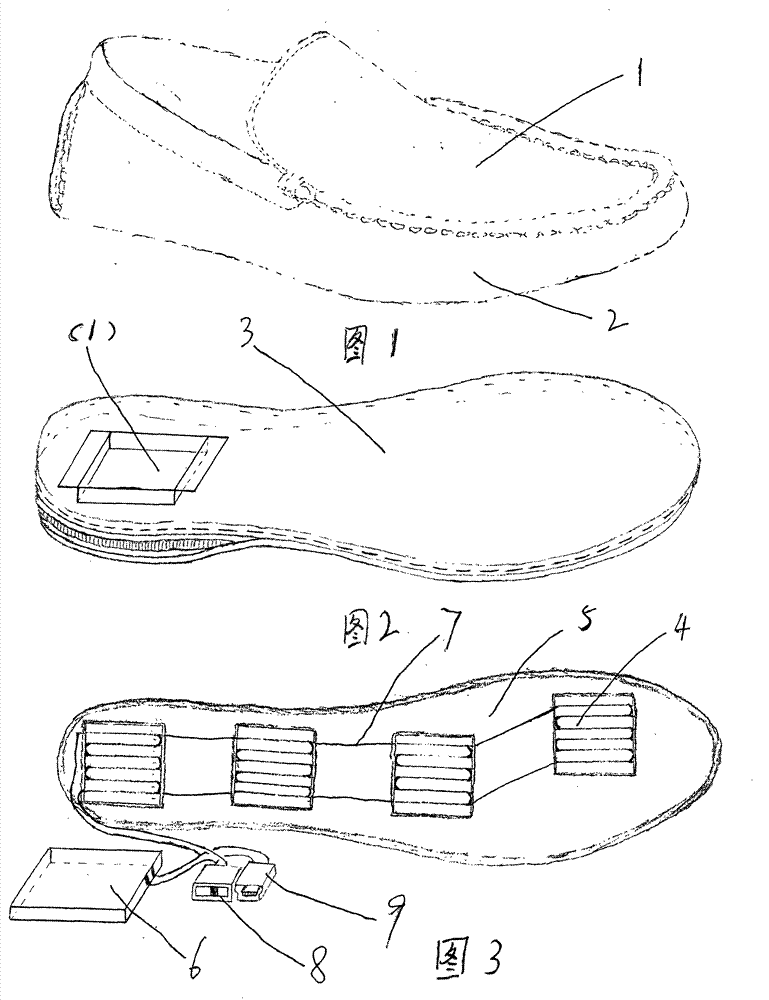

Heated insoles

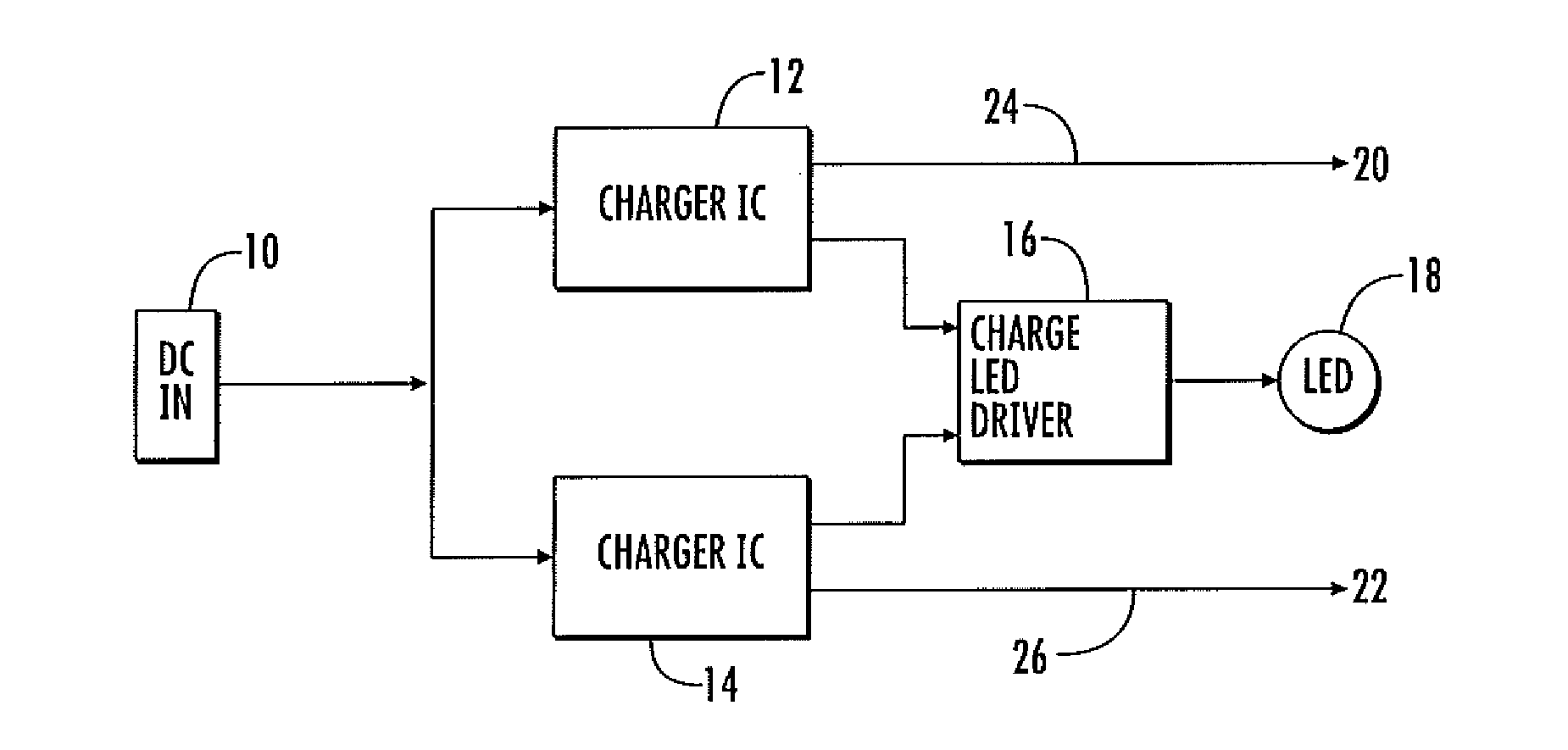

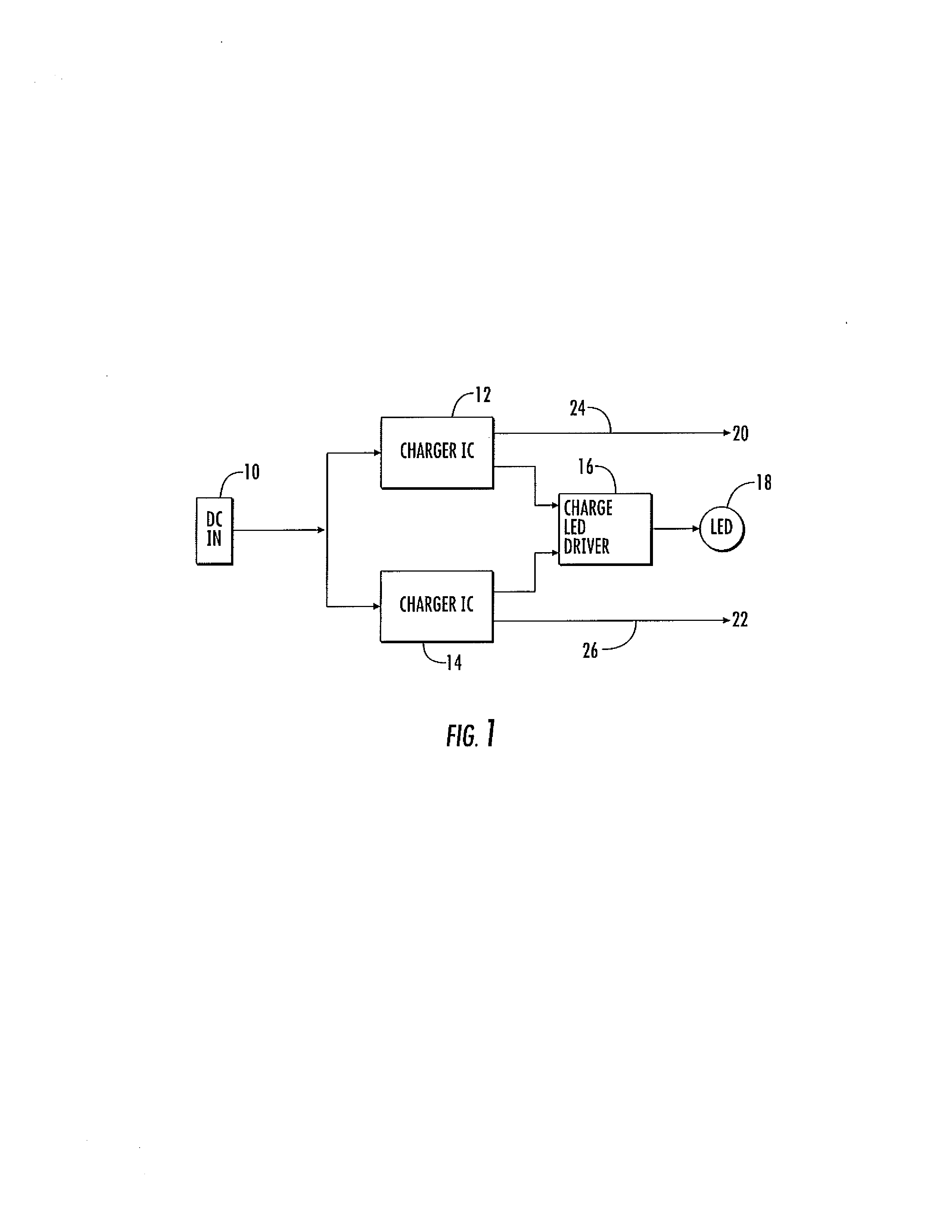

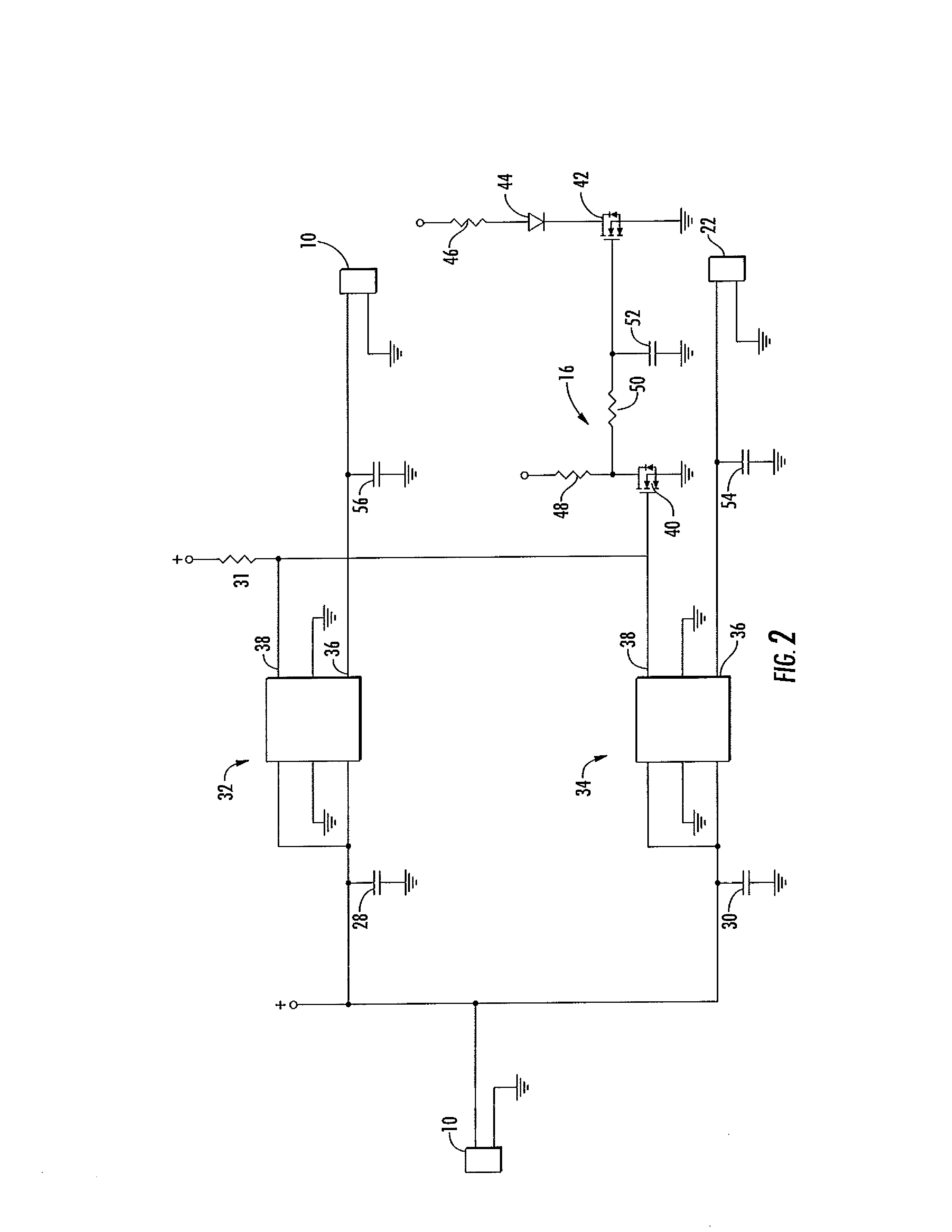

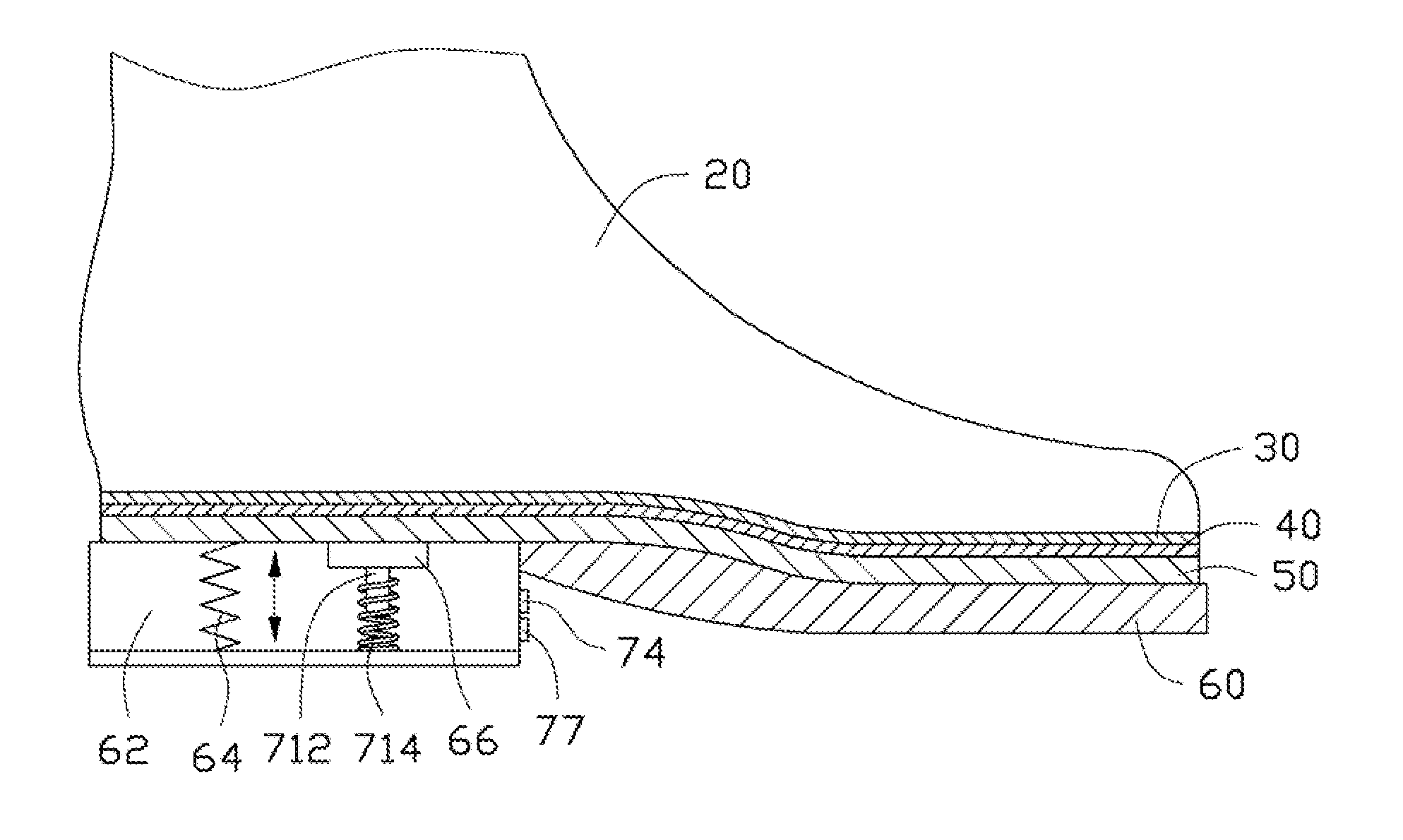

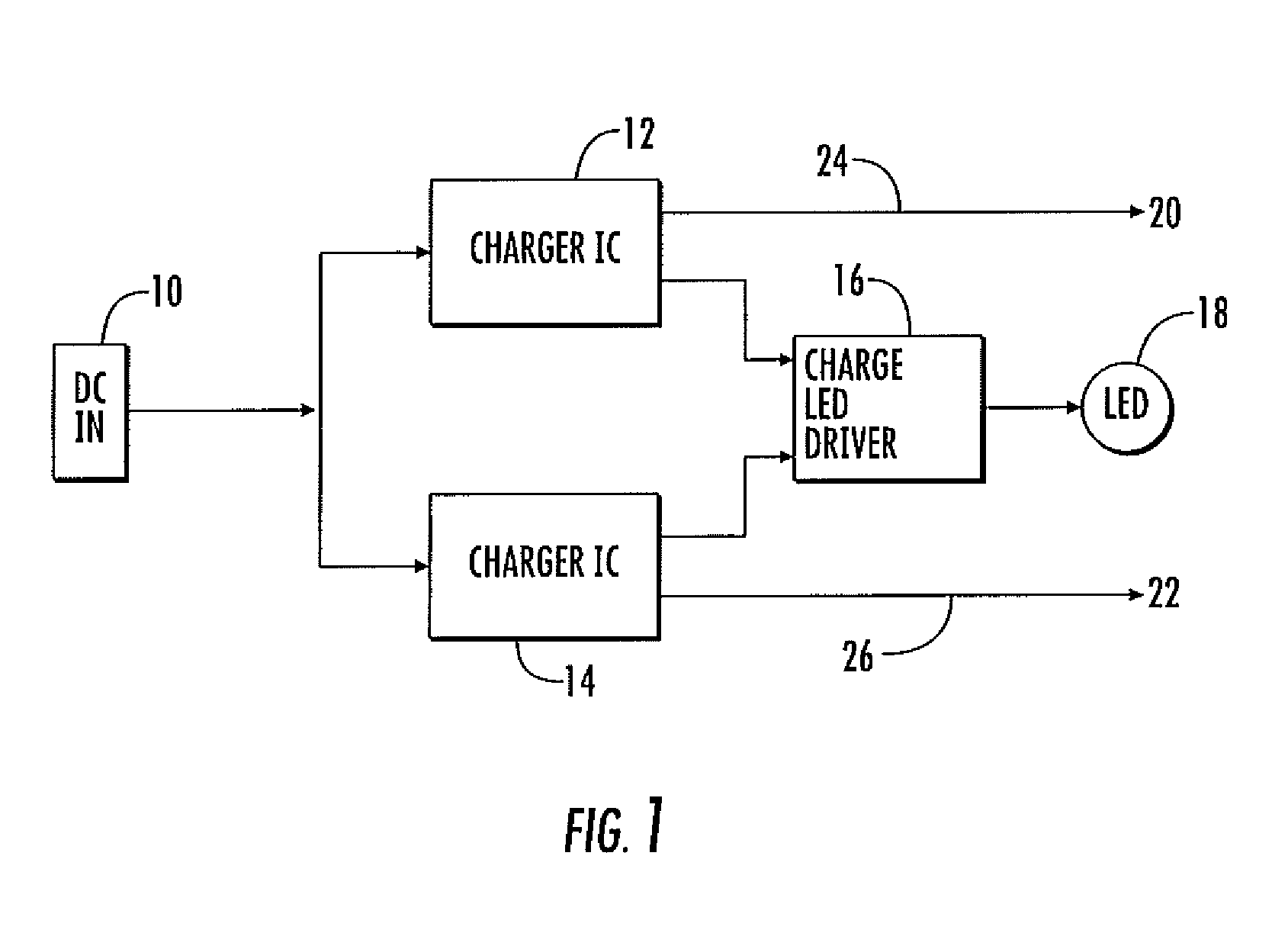

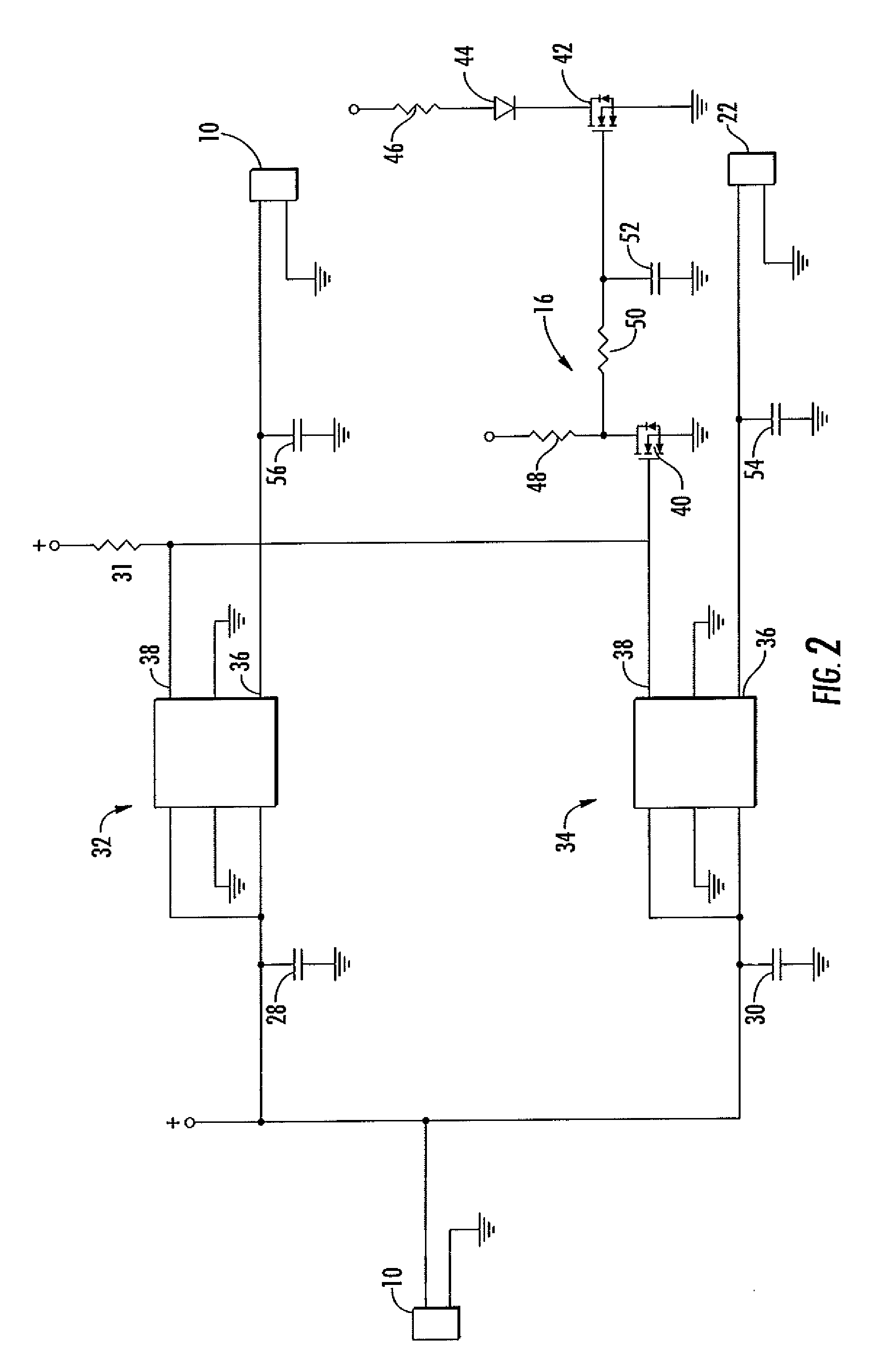

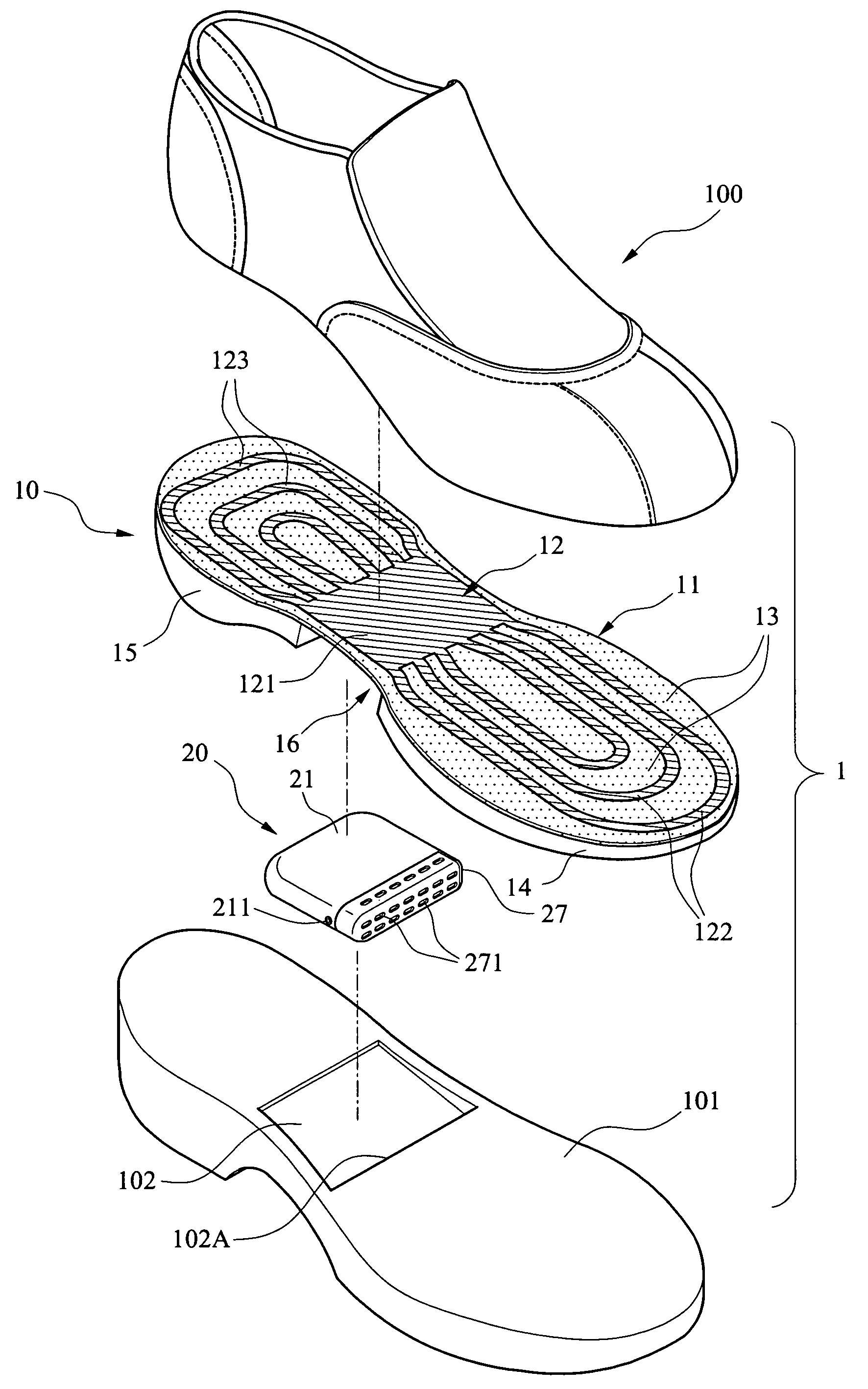

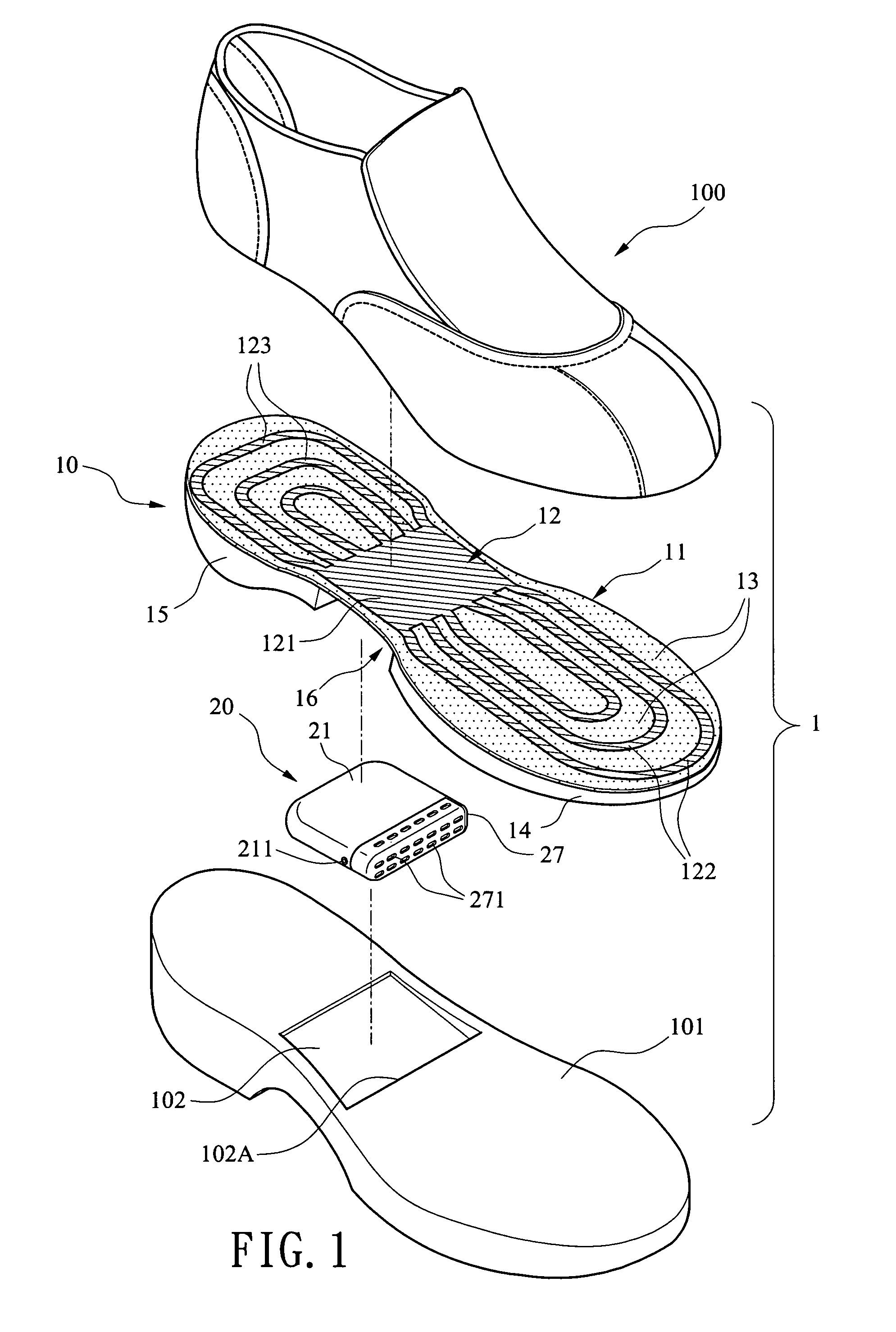

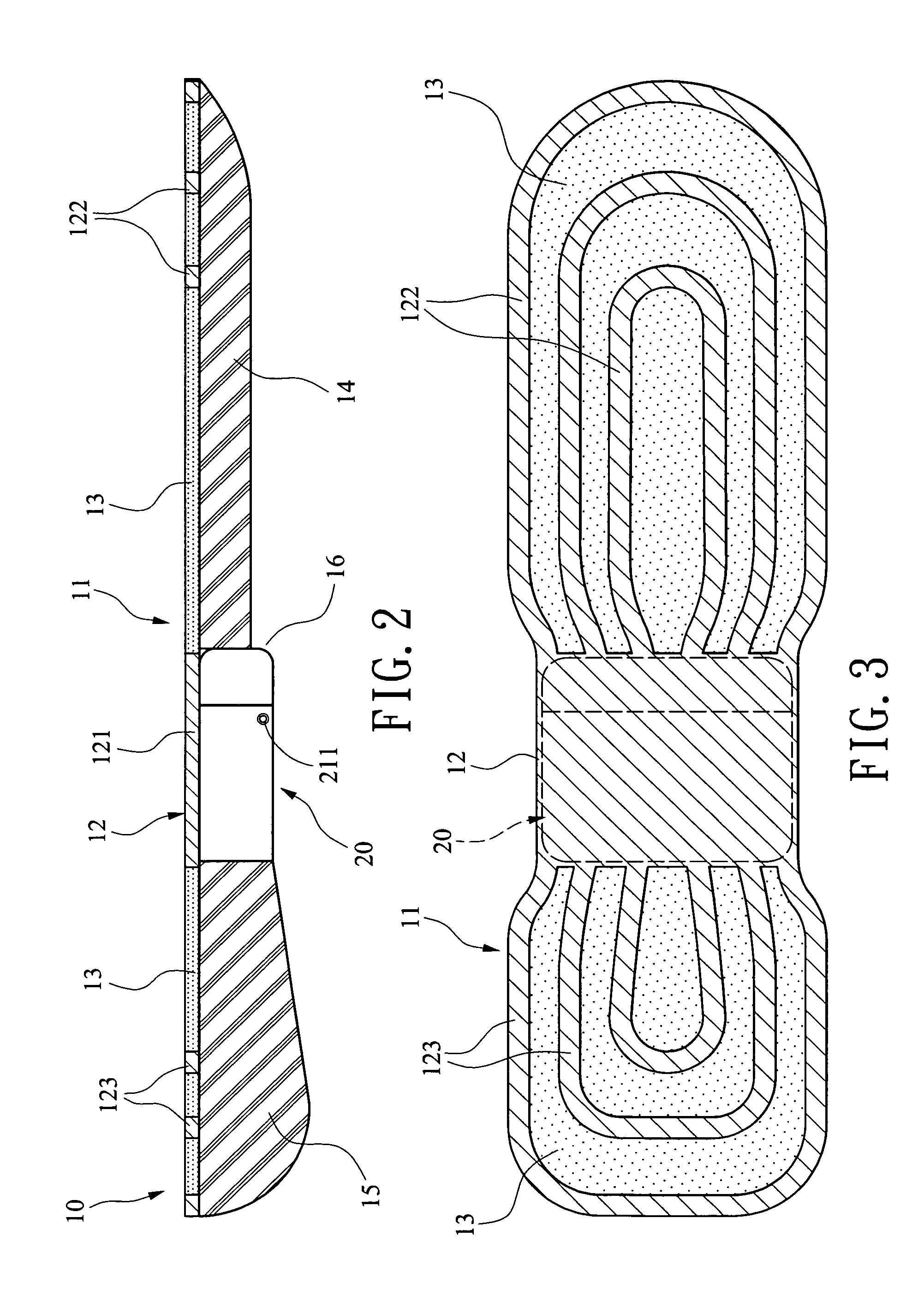

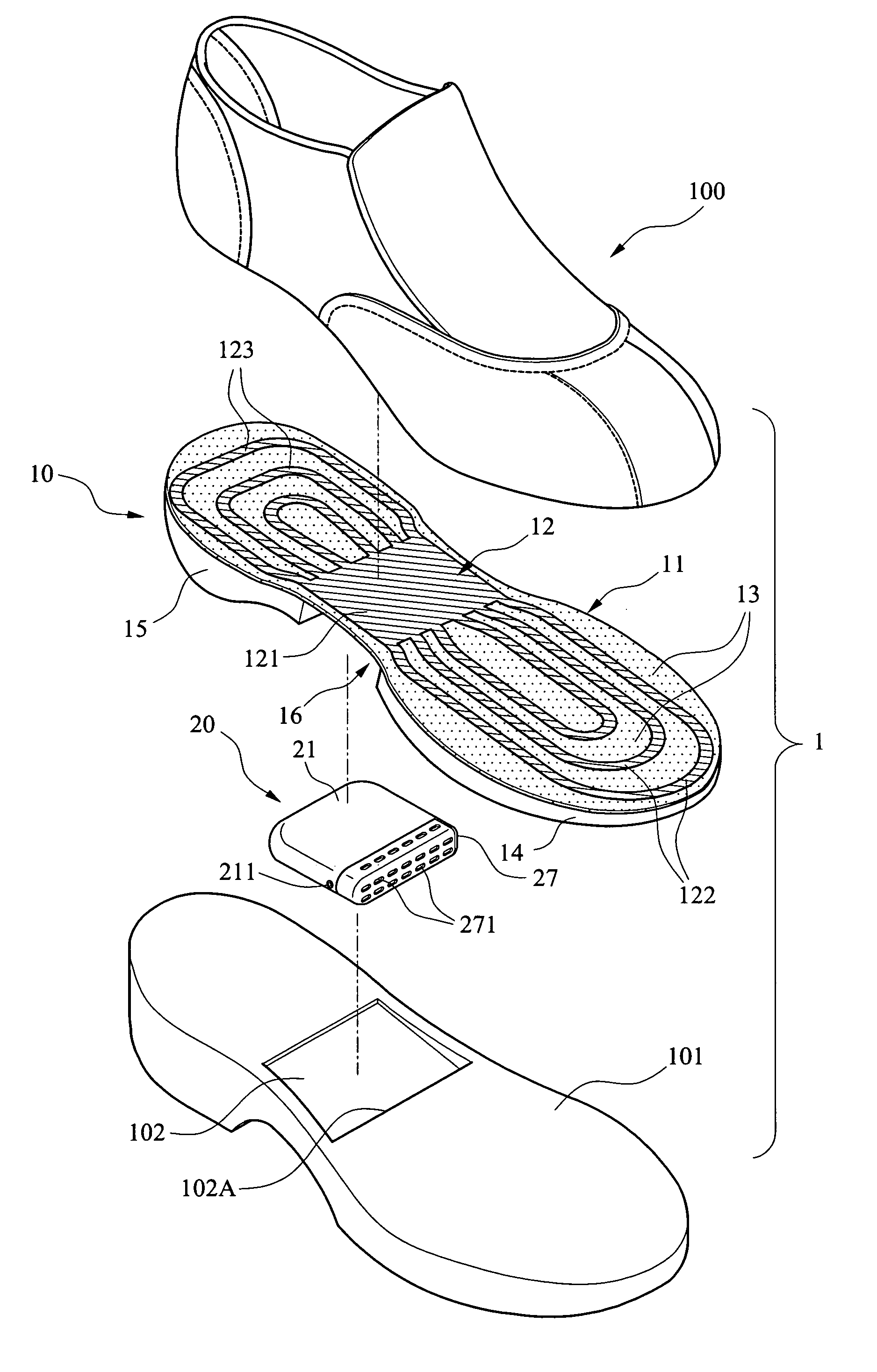

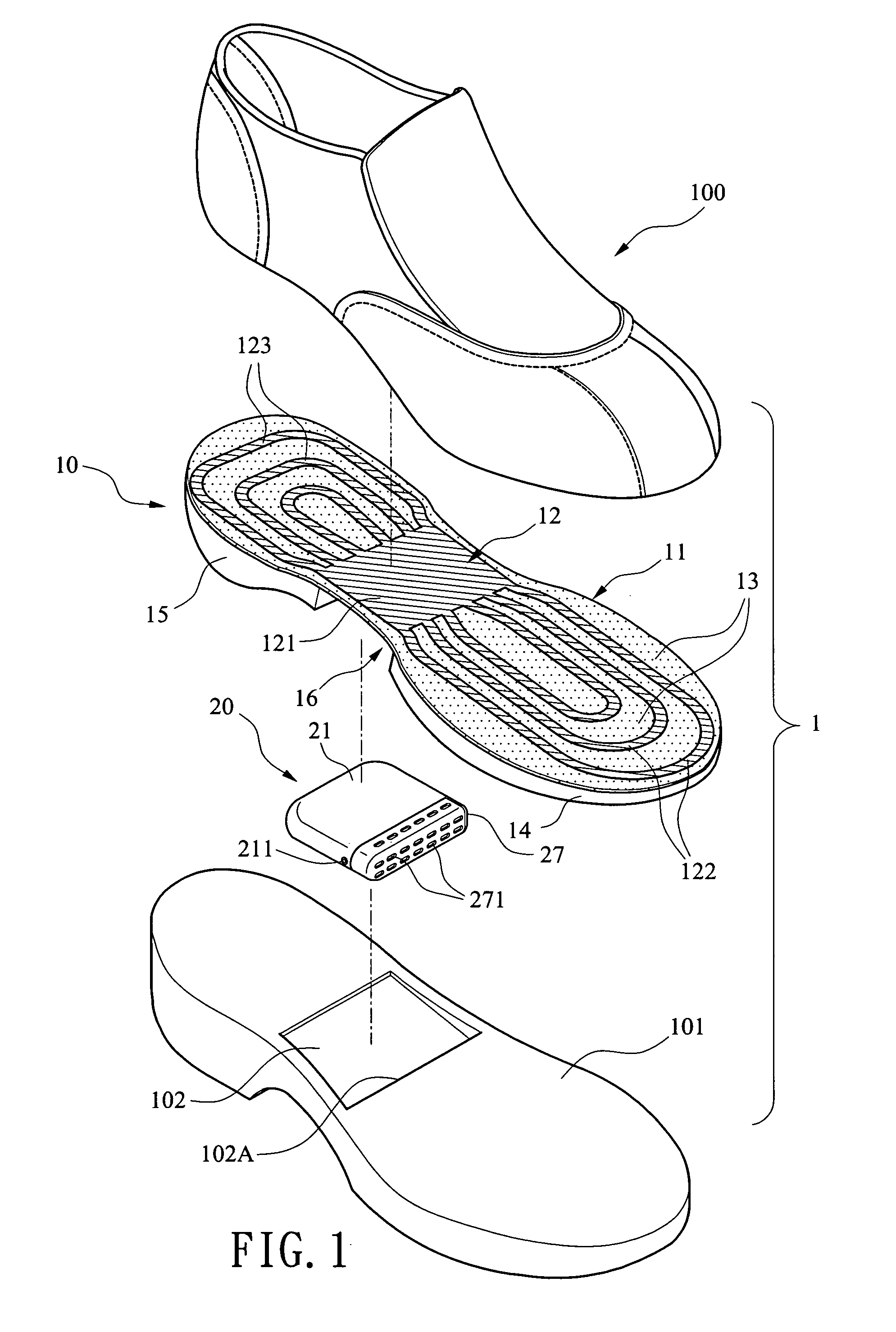

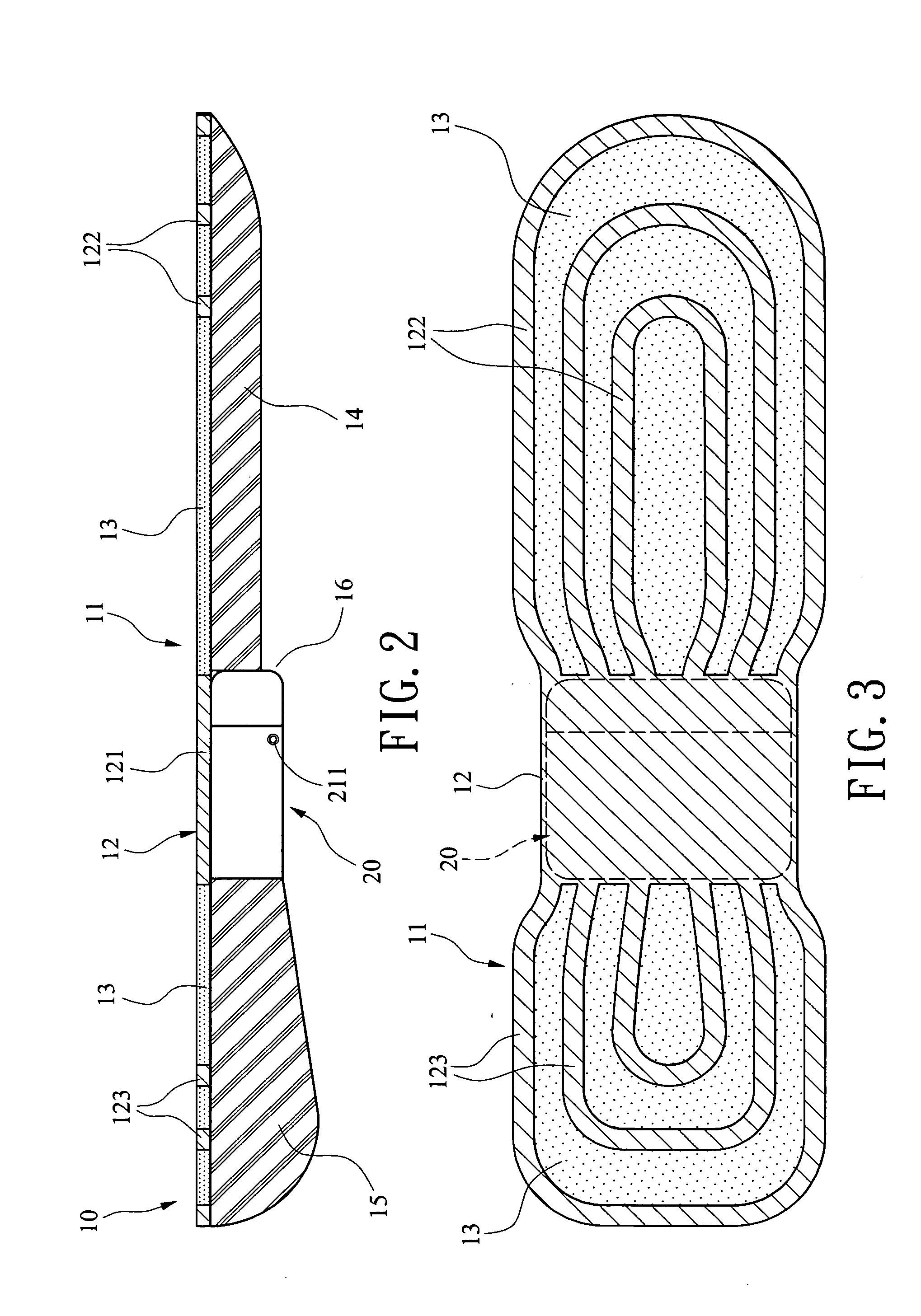

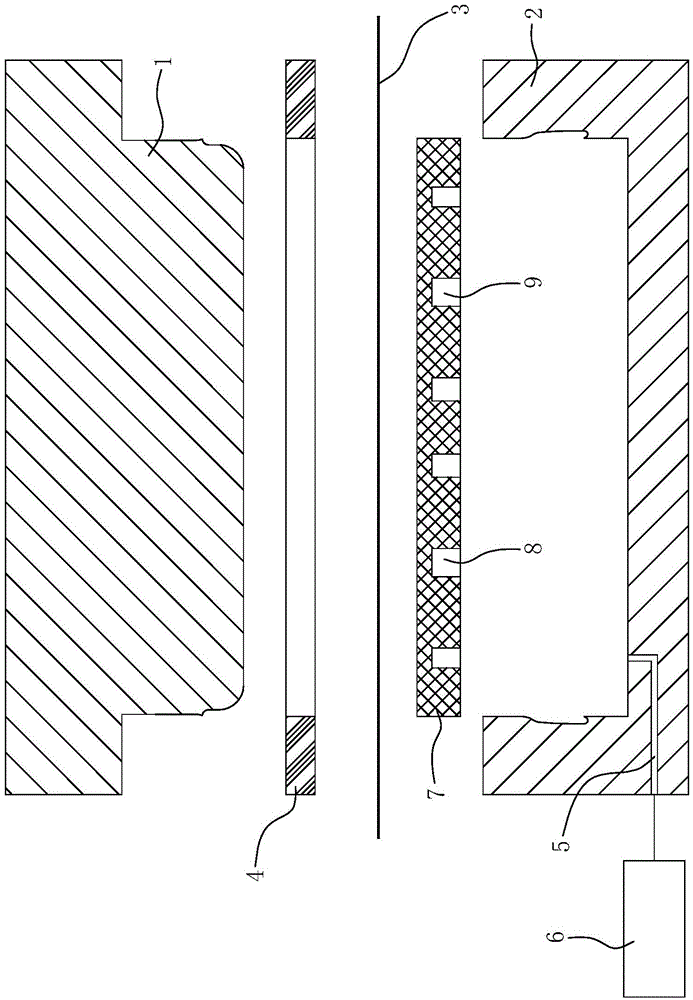

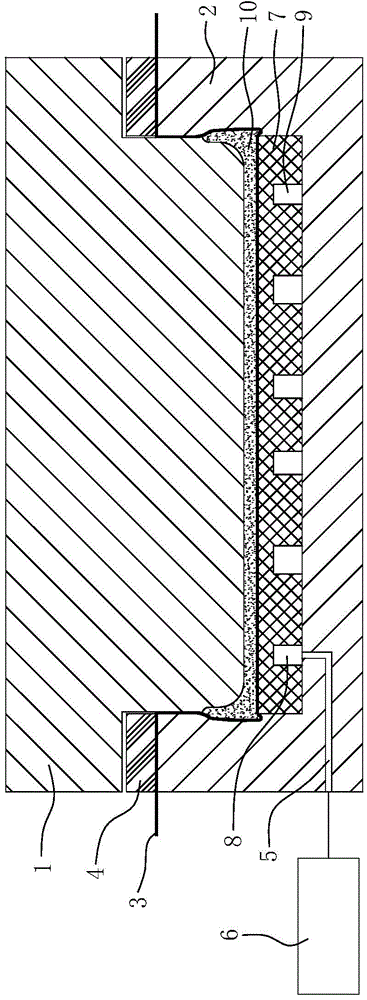

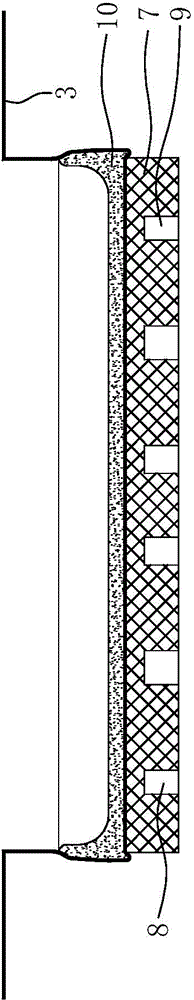

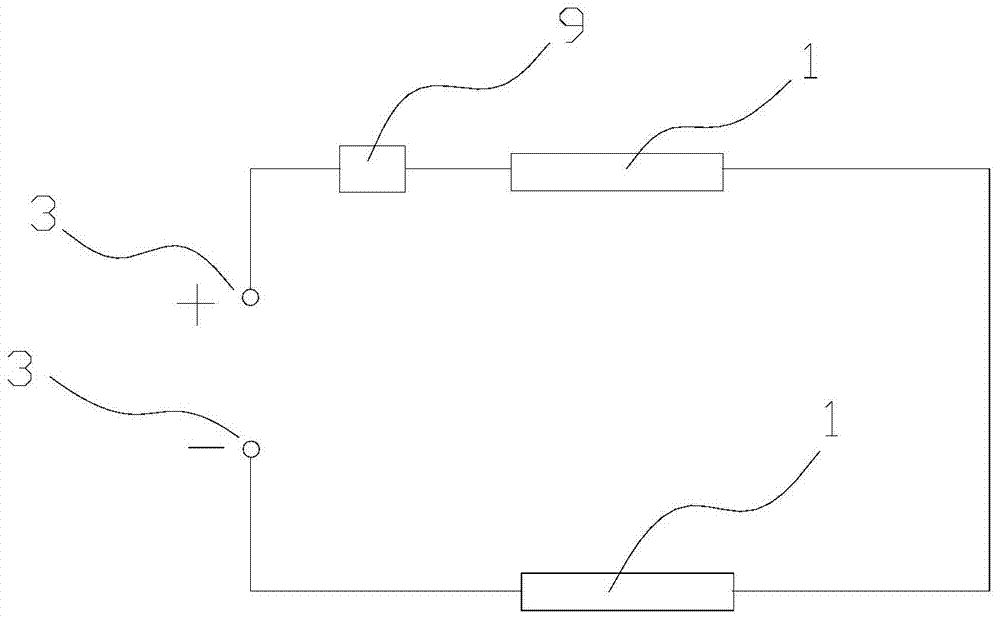

ActiveUS20130181662A1Provide heating efficiencyEfficient and economicalBatteries circuit arrangementsSolesHeat conductingEngineering

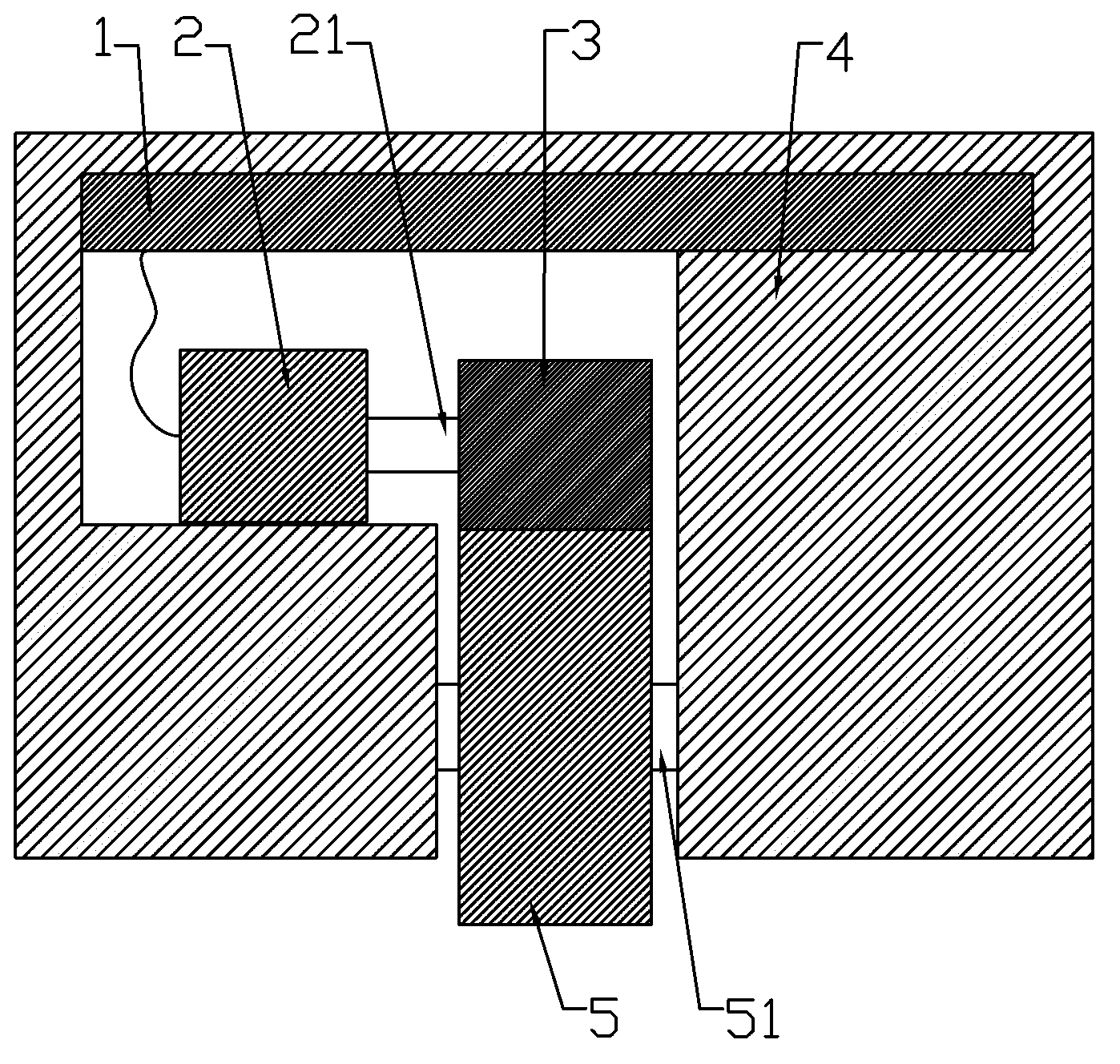

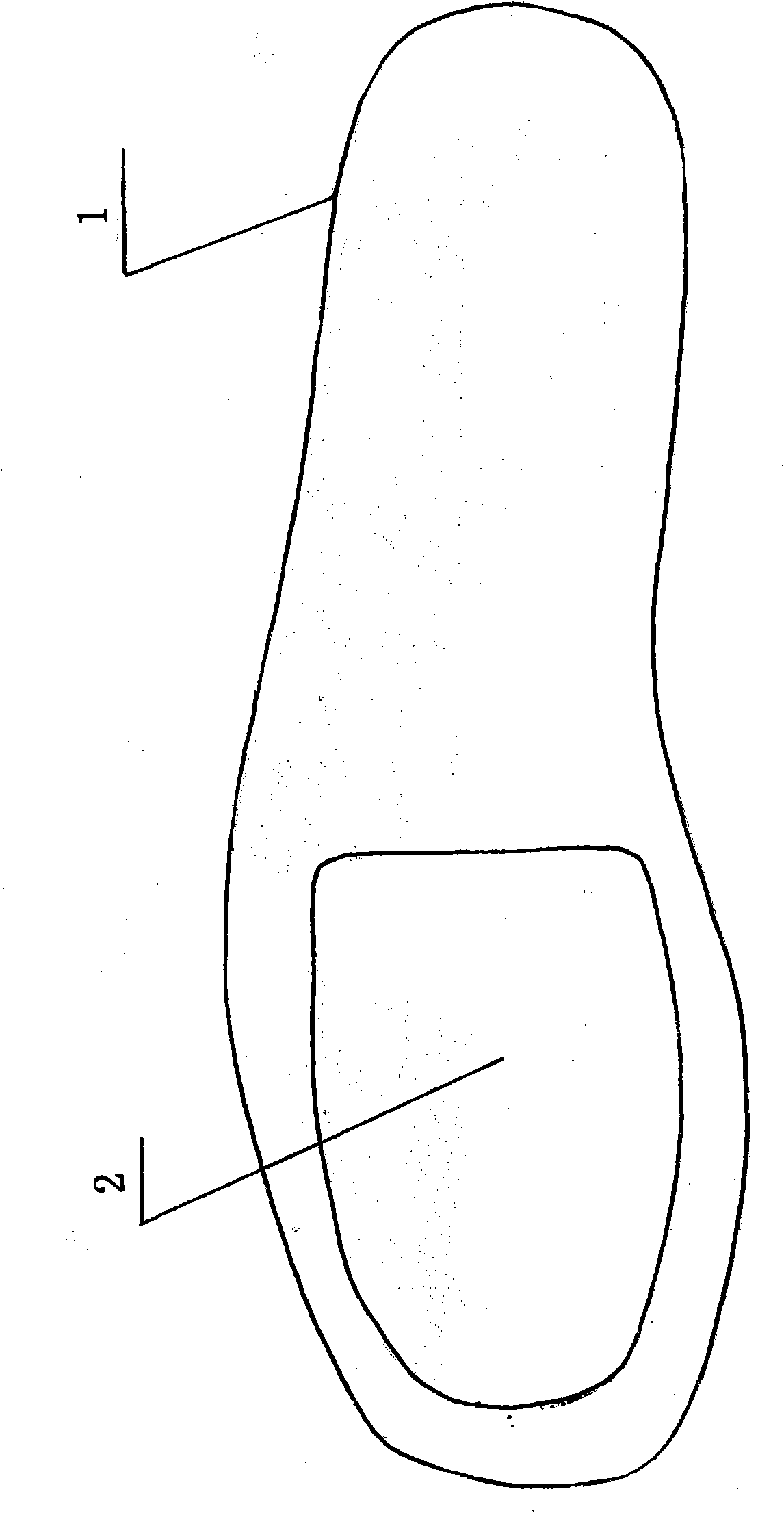

An efficient system to heat the insole of a heated insole of a shoe in which the Intelligent Circuit (IC) for a flat lithium battery is located outside the shoe and the placement of the heater for the insole is between more efficient heat insulation and heat conducting members.

Owner:SCHAWBEL TECH

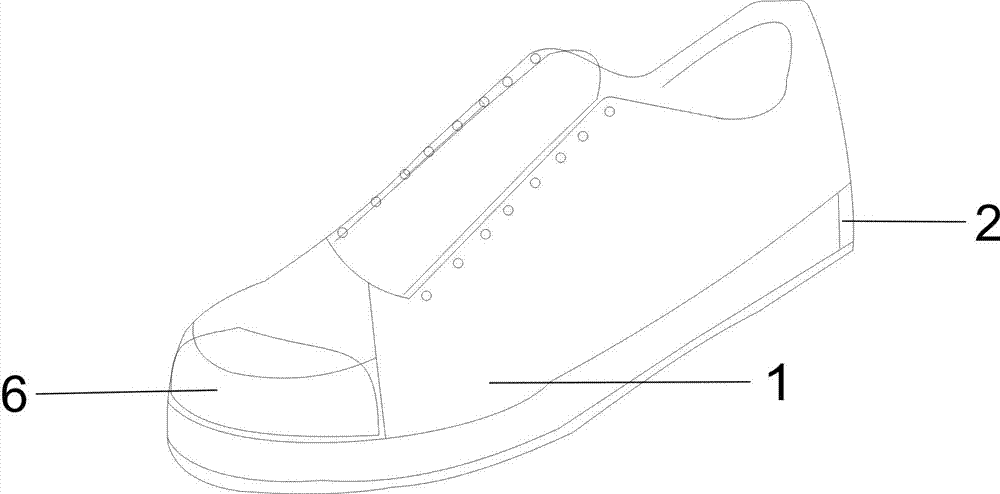

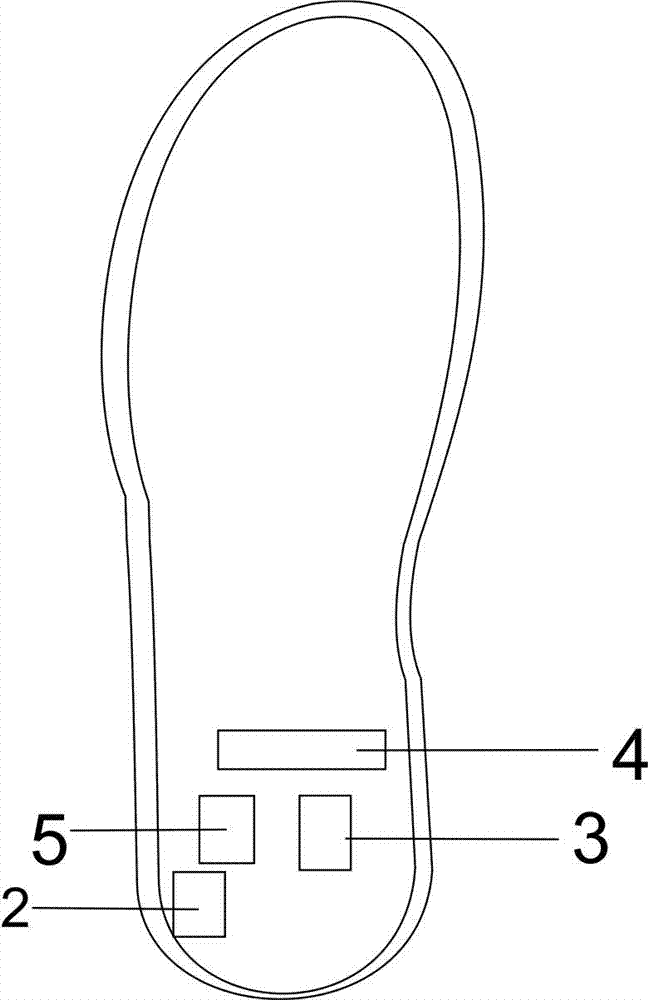

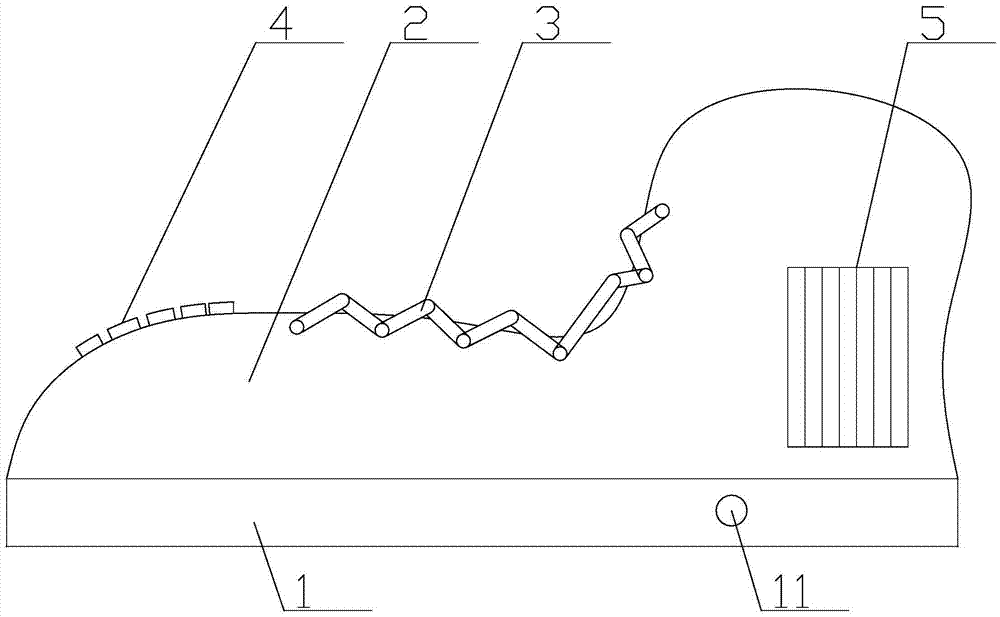

Heated shoe

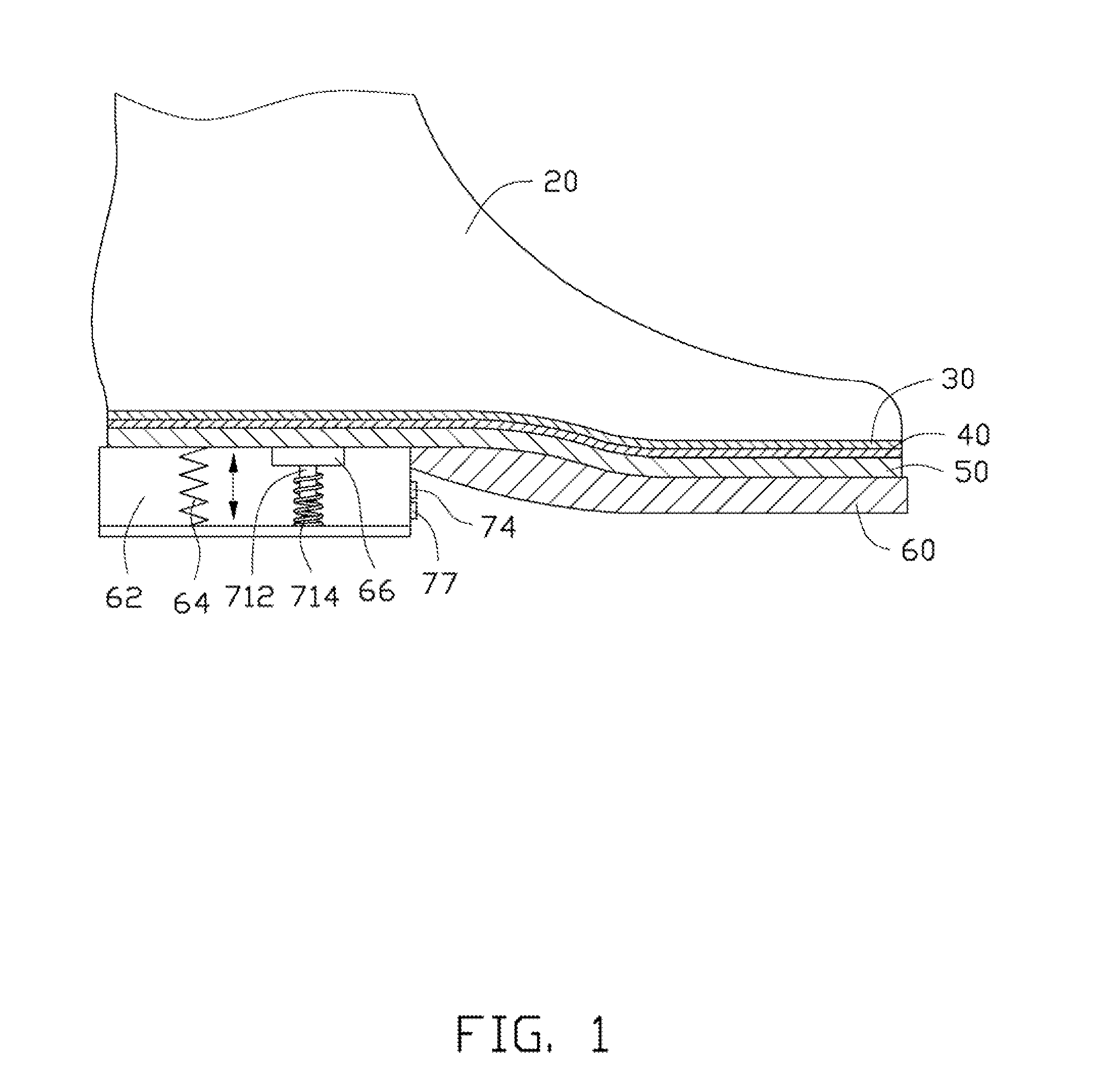

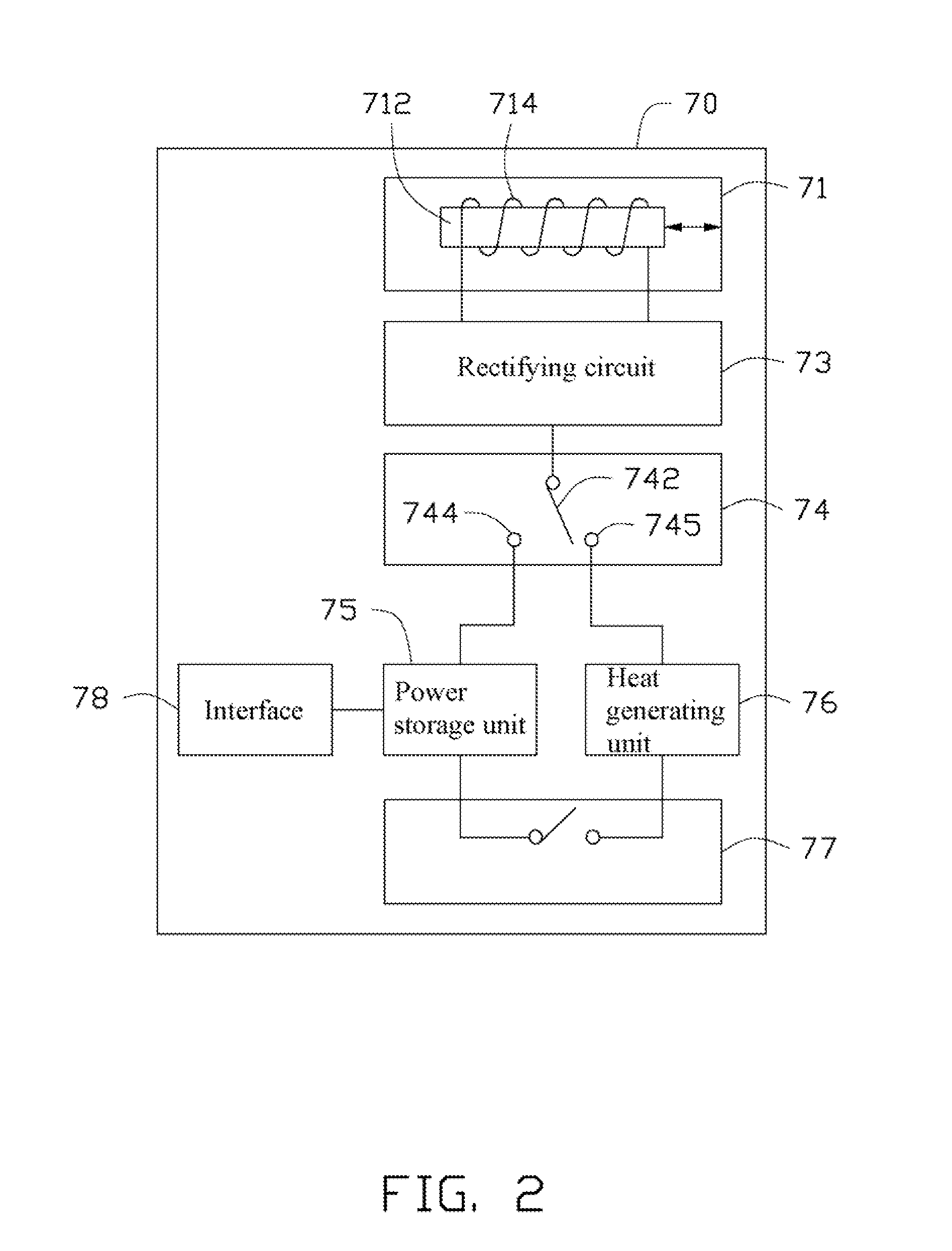

A heated shoe includes a main body, a sole, a heat conducting layer and a heat generating module. The heat generating module includes a power generating unit, a rectifying circuit and a heat generating unit, which are electrically connected in series. The power generating unit and the rectifying circuit are located in the sole, and the heat generating unit is located at the heat conducting layer. The power generating unit provides and outputs induced current, the rectifying circuit receives, rectifies and processes the induced current from the power generating unit. The heat generating unit converts electric energy from the rectifying circuit into heat, and the heat conducting layer outputs the heat.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

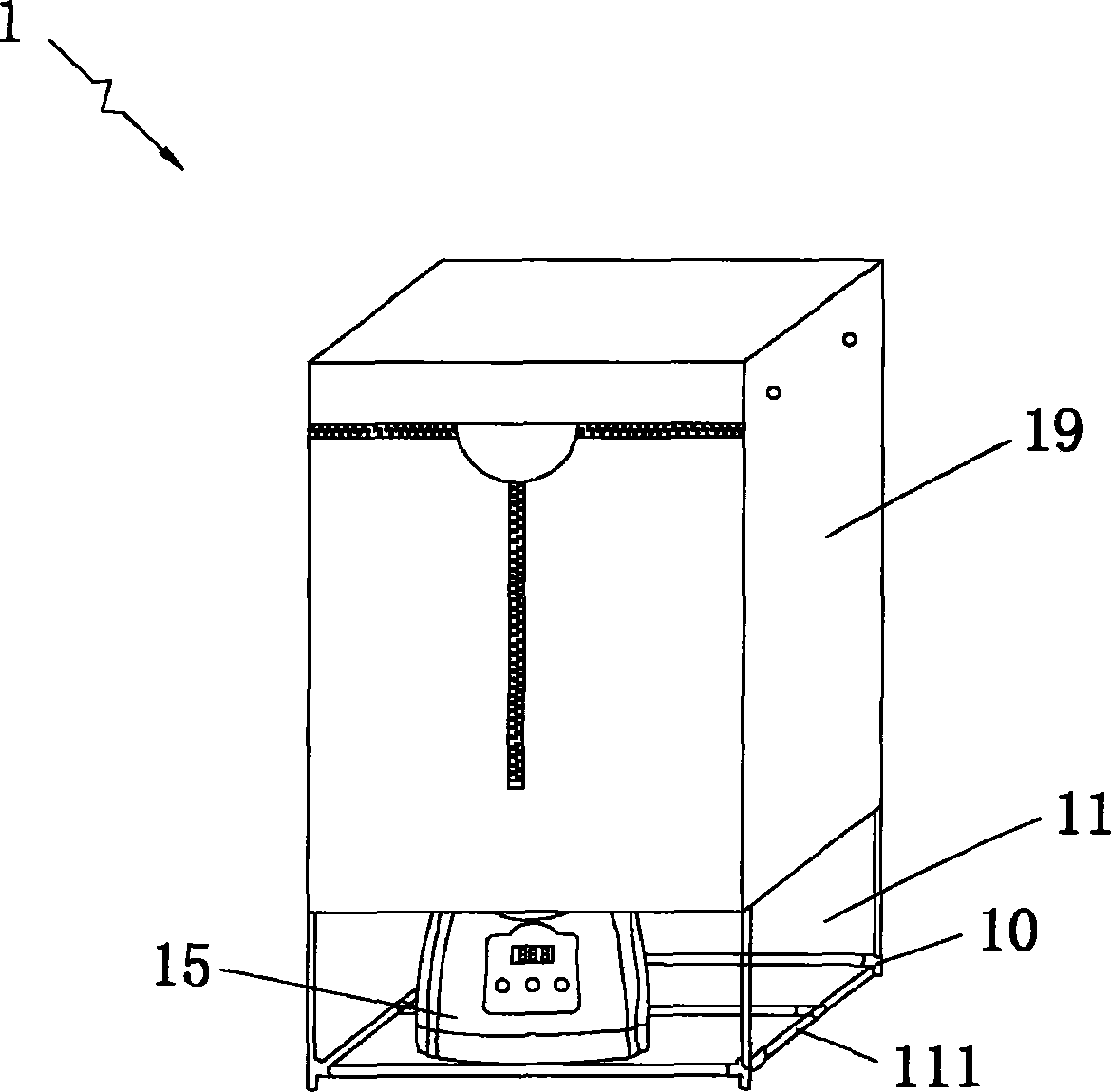

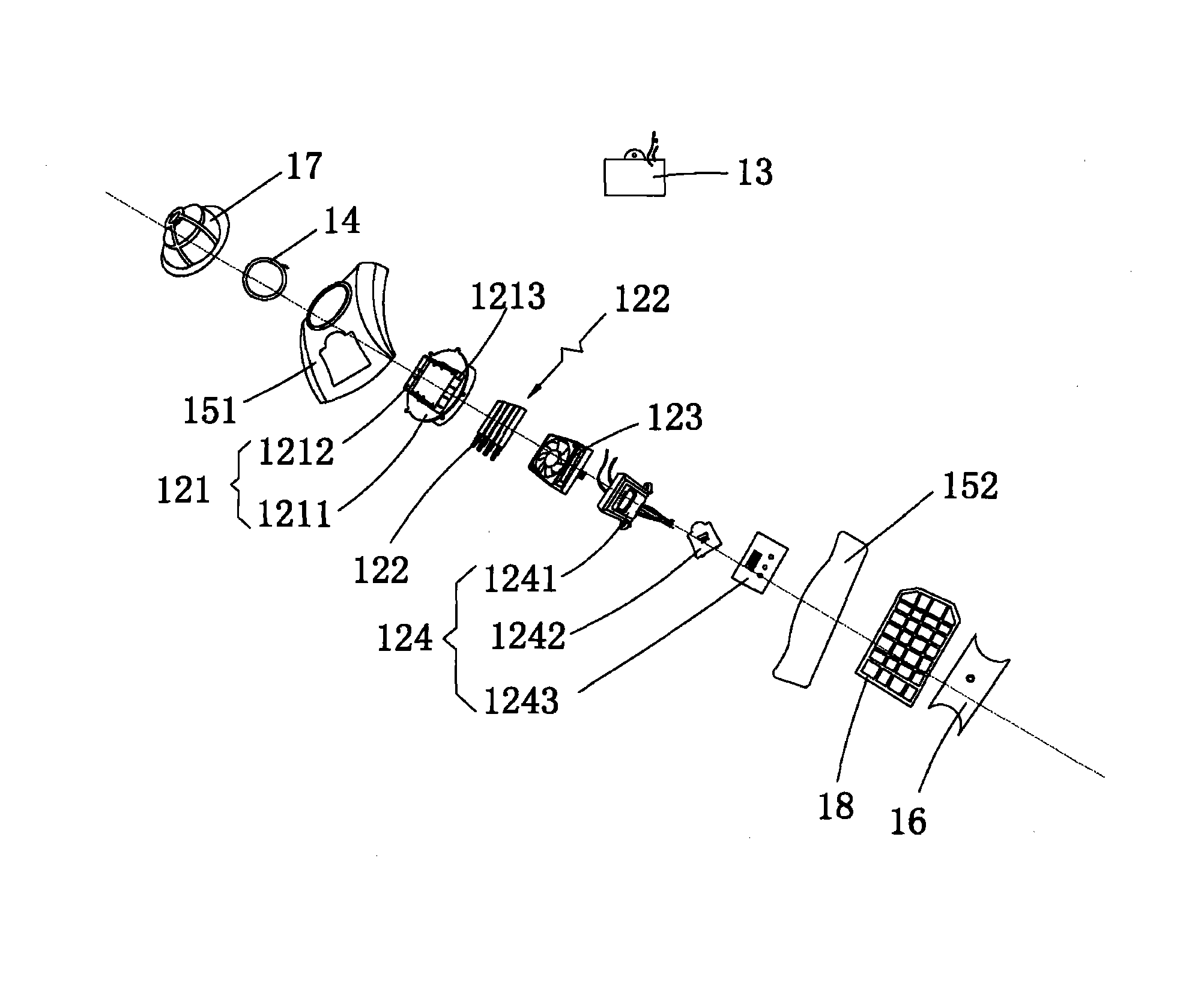

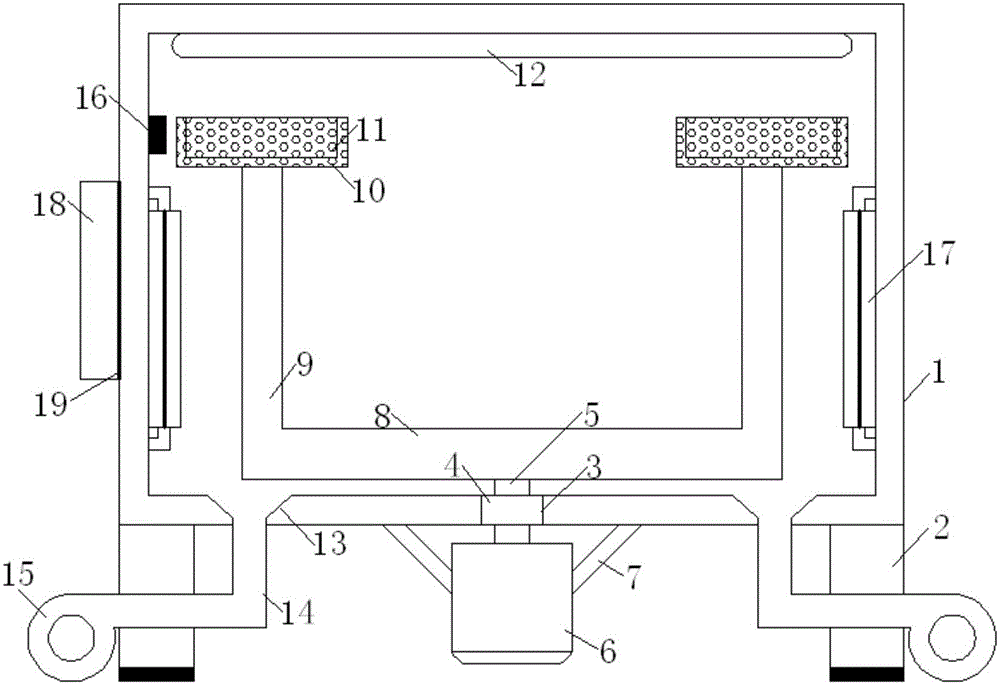

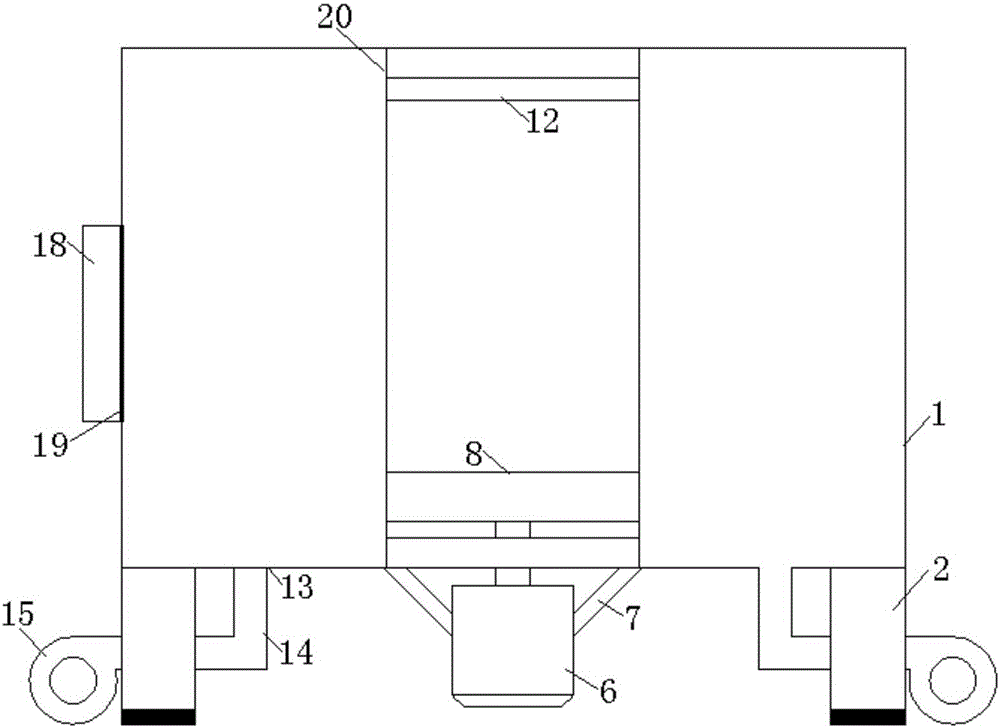

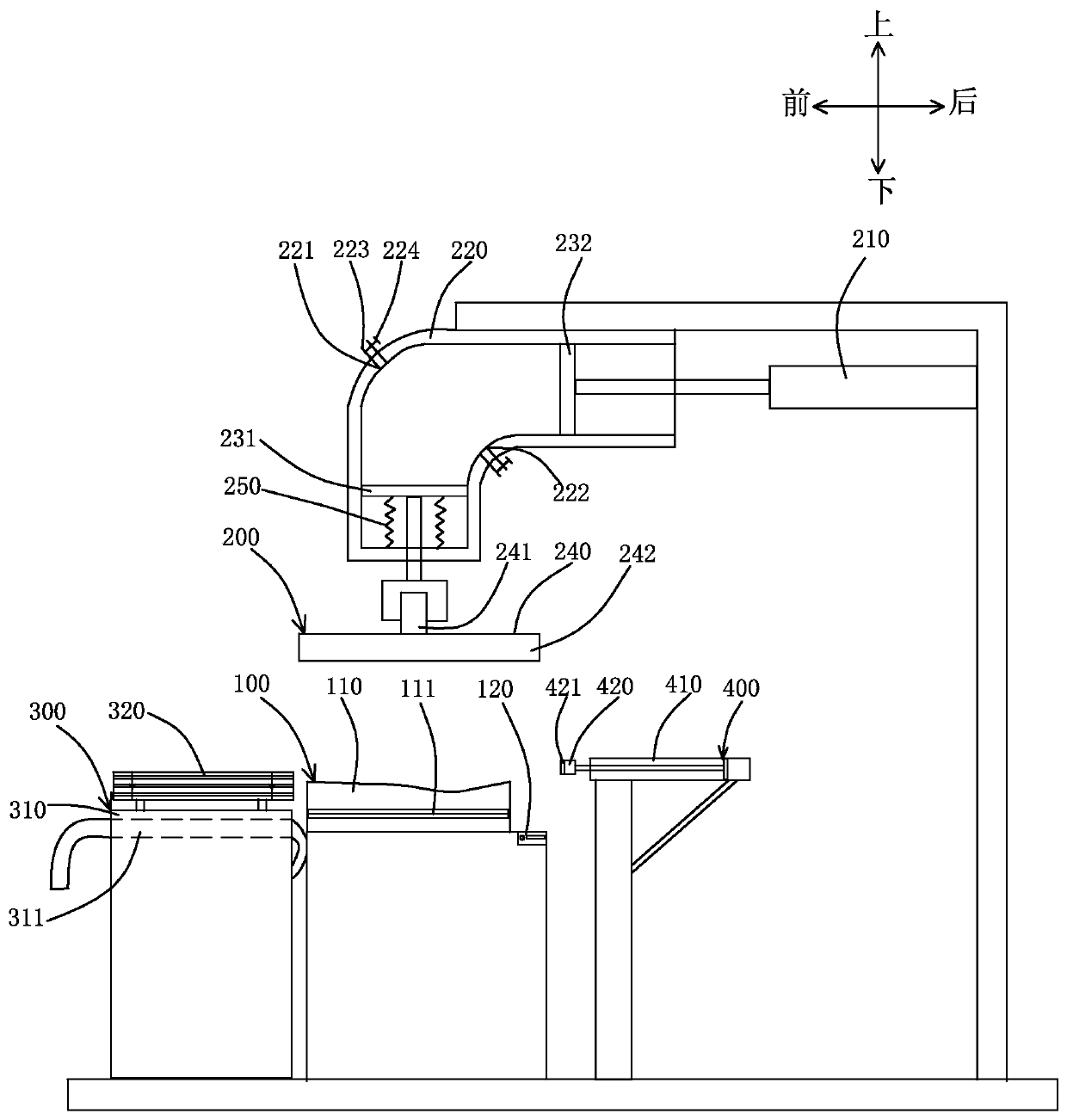

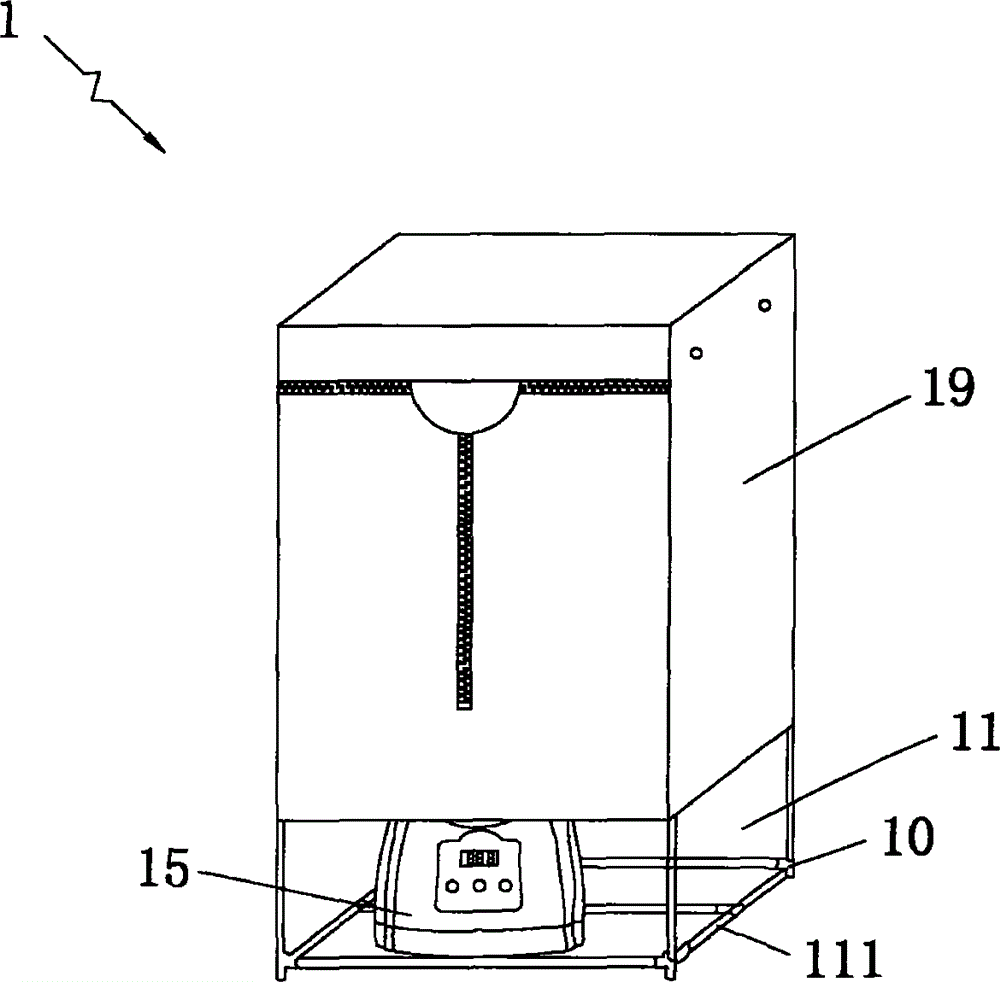

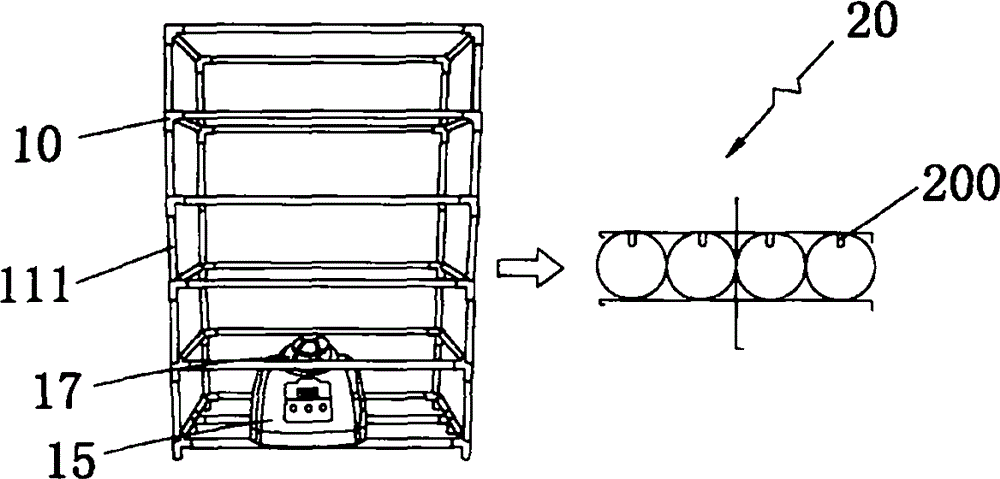

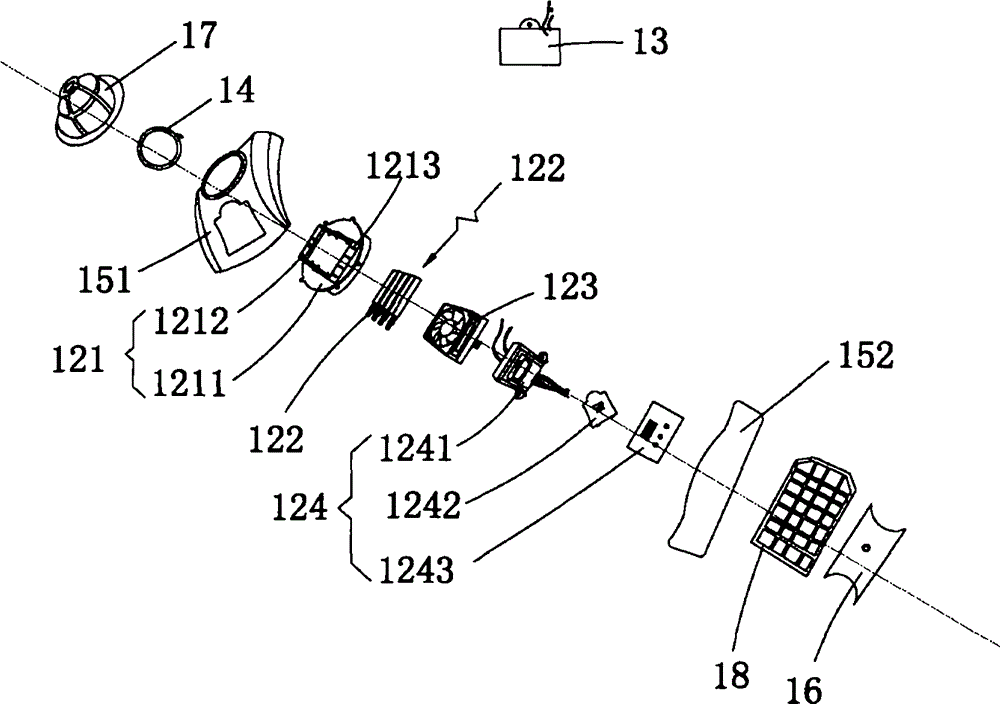

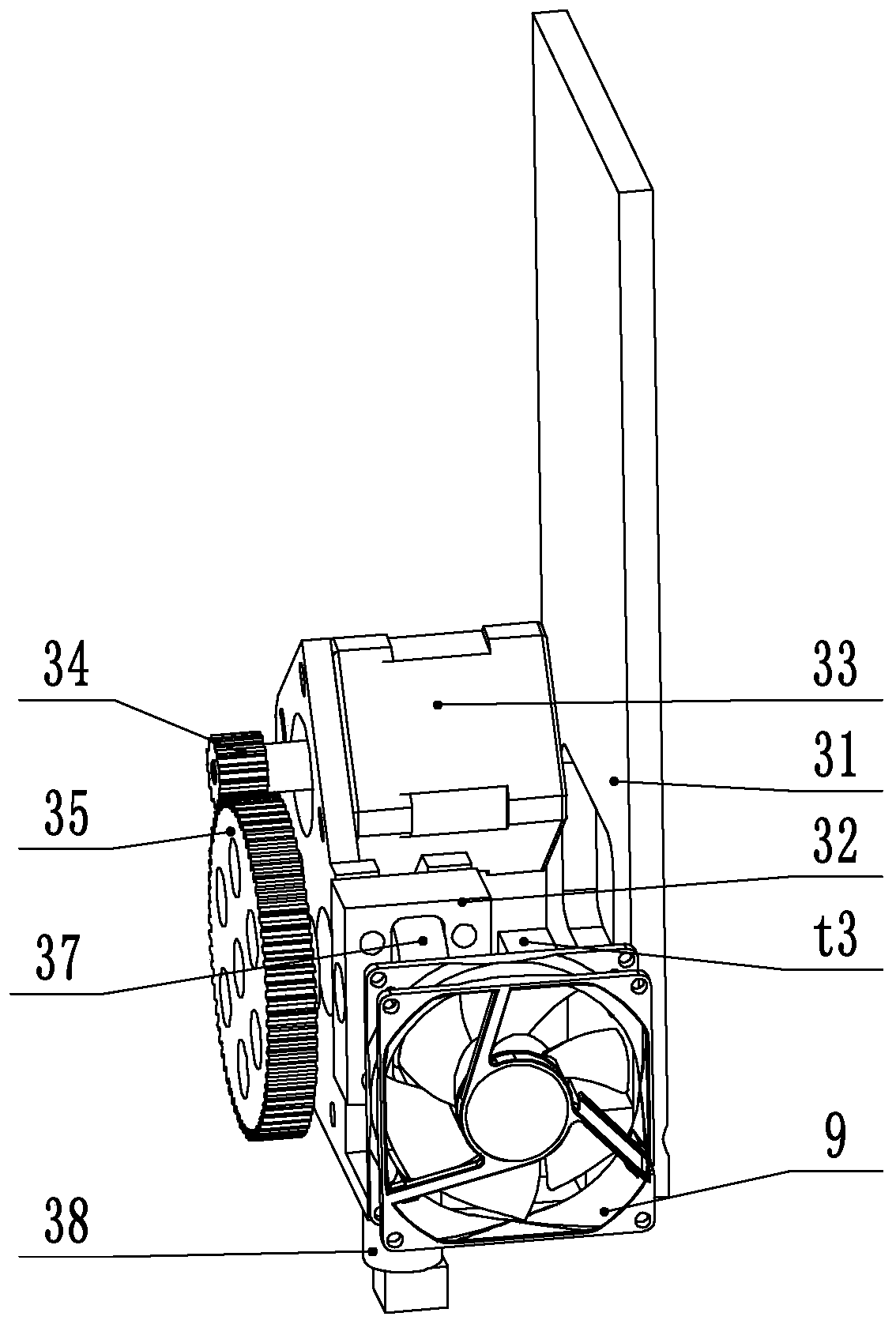

Multifunctional intelligent shoe cabinet

The invention provides a multifunctional intelligent shoe cabinet which comprises a shoe cabinet body, a drying device, an anion generator capable of releasing anions and a sterilization tube capable of emitting ultraviolet rays; anions can refresh the air; the sterilization tube can disinfect and sterilize the shoe cabinet and eliminate bad odours in shoes; the drying device is mounted in a casing in the shoe cabinet body and comprises a bracket, a PTC (Positive Temperature Coefficient) heater, a fan and a power supply device for supplying power for the fan; the PTC heater is clamped inside the bracket; and the fan capable of dispersing heat produced by the PTC heater is connected to the lower end of the bracket. Through heating of the PTC heater, air is heated and then conveyed to heated shoe bodies from the bottom up by the fan, so that moisture caused by foot sweat in the shoes can be eliminated, beriberi can be inhibited, and the insides of the shoes are kept warm, dry and clean, further, feet can be protected when the shoes are worn, and the purpose of ensuring human health can be achieved; and meanwhile, through the heating manner, no naked fire is generated during heating, visual fatigue can not be caused, and potential safety hazards can be avoided.

Owner:中山市美翔电器科技有限公司

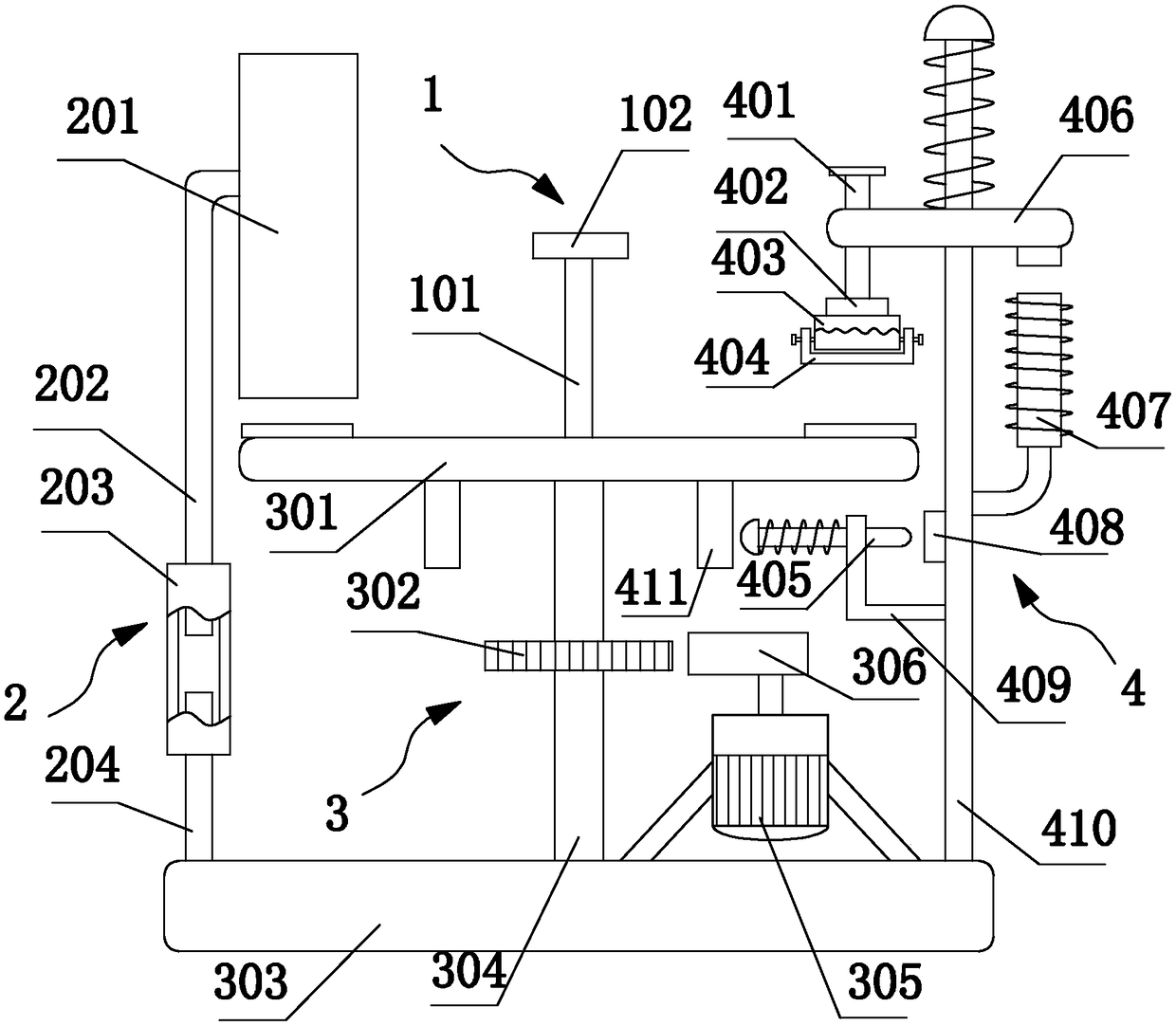

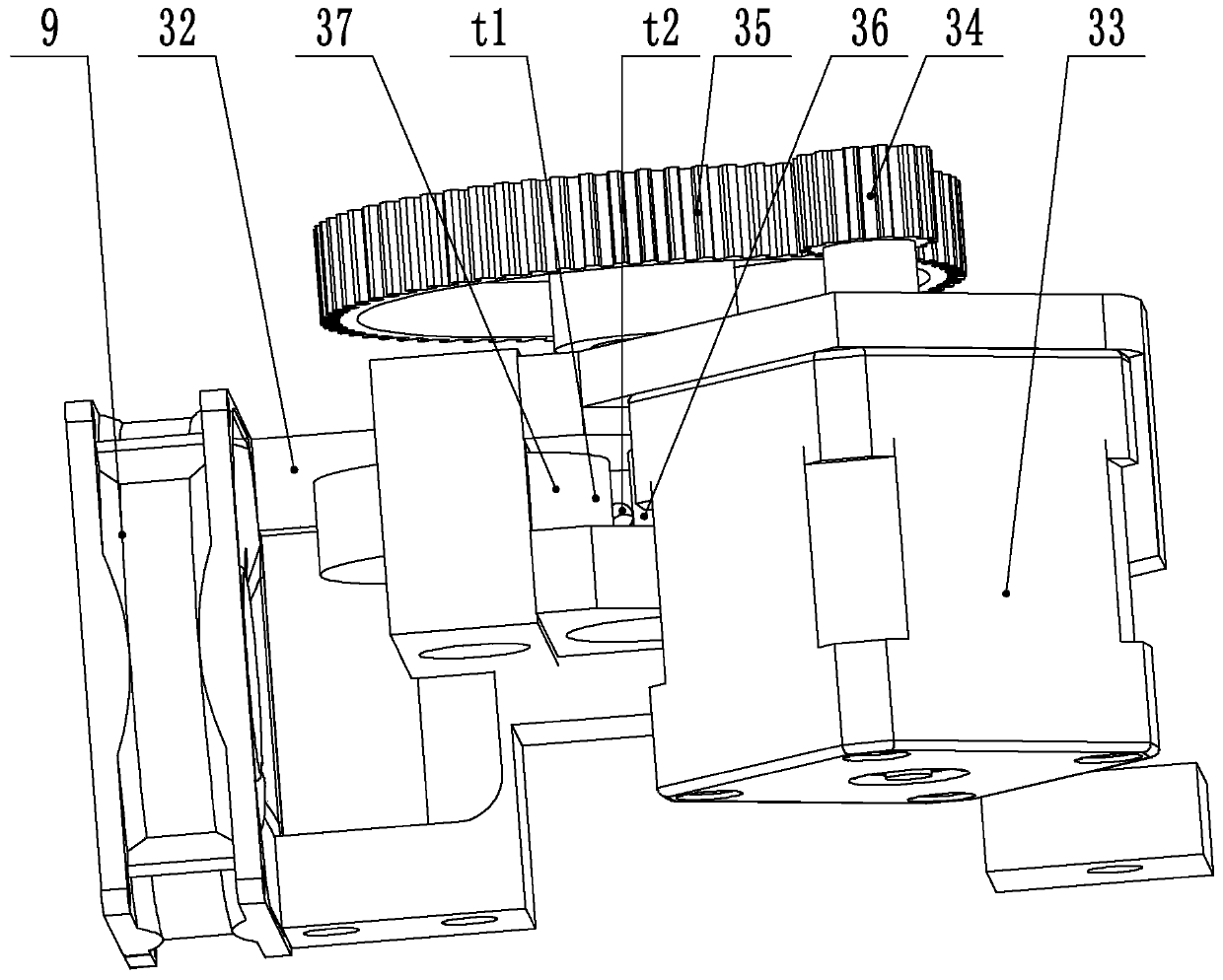

Shoe-shaped one-step extrusion, ironing and shaping process and special equipment thereof

InactiveCN102028340AHarmonious light refraction effectGuaranteed ironing effectLastingShoe sizeWork in process

The invention discloses a shoe-shaped one-step extrusion, ironing and shaping process and special equipment thereof. The shoe-shaped one-step extrusion, ironing and shaping process comprises the following steps of: a, manufacturing a boot tree die, sleeving a semi-finished product shoe to be shaped on the boot tree, and placing the boot tree into the one-step extrusion and ironing boot tree die; b, heating the boot tree die and heating, extruding and ironing an opposite upper face and a lined material of the boot tree, wherein the temperature is controlled to be between 80 and 122 DEG C and the heat is preserved for 3 to 12 seconds; and c, opening the boot tree die and taking out the shoe. According to the technical scheme, the shoe-shaped one-step extrusion, ironing and shaping process and the special equipment thereof have the advantages that: due to the precision consistency of the boot trees with the same shoe size and the uniform consistency of the upper materials, the upper faceis extruded and ironed through the surface of the high-temperature smooth boot tree die, so that the upper and the vamp are attached to the boot tree, materials are redistributed, the internal organization structure of the upper material is improved, the boot tree has the visual effects of a smooth line, a dense and flat upper face and a harmonious upper face photorefractive effect, and the ironing effect of the upper face can be guaranteed.

Owner:JIHUA 3515 LEATHER & SHOES

Rubber shoe sole embossing equipment

The invention discloses rubber shoe sole embossing equipment which comprises a machine table. The machine table comprises a base, the top of the base is rotationally connected with the lower end of amain shaft, a rotating disc is connected with the upper end of the main shaft, and the main shaft is in sleeved connection with an all gear. A feeding mechanism can achieve automatic feeding, shoe soles can constantly fall down to a rotating disc, meanwhile, the distance between a storage barrel and the rotating disc can be adjusted through the cooperation of an upper vertical rod, a thread sleeveand a lower vertical rod according to the thicknesses of the shoe soles, and smooth falling of the shoe soles is ensured; an embossing mechanism achieves rapid embossing through high temperature andpressure, a grain board is convenient to disassemble so as to be replaced with grain boards with different grains, the requirement for different grains is met, and applicability is improved. A push mechanism automatically pushes out heated shoe soles from a work site, manual unloading is not needed, therefore the condition that scalding is caused by manual unloading is avoided, time and labor aresaved, and the efficiency is high.

Owner:江西舒乐佳家庭用品有限公司

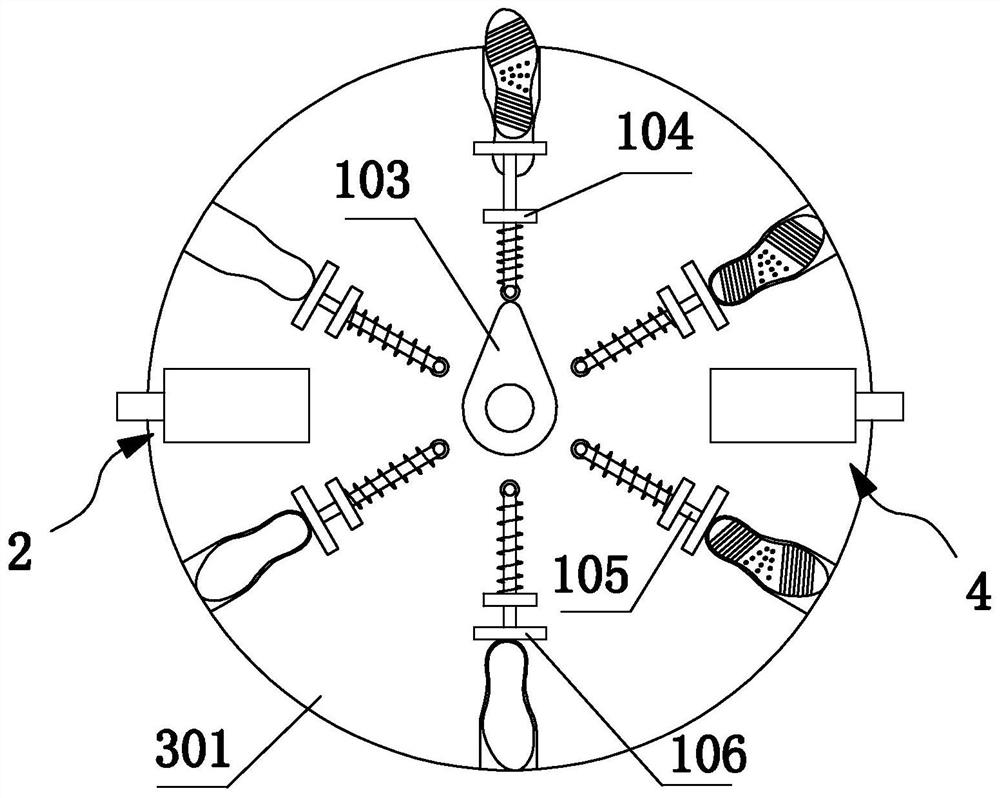

Rotation type softening machine for shoe making

The invention discloses a rotation type softening machine for shoe making. The rotation type softening machine for shoe making comprises a box body. A baffle is arranged at the upper end of each tray in the circumferential direction and is of a hollowed structure. A heating pipe is arranged at the upper end of an inner cavity of the box body. Gas outlets are formed in the bottom of the box body and connected with exhaust fans through gas guide pipes. A temperature sensor is arranged on the side wall of the inner cavity of the box body. Infrared ray lamp pipes are evenly arranged on the side wall of the inner cavity of the box body. A controller is arranged at the left end of the box body. A heat insulation plate is arranged between the controller and the box body. A shoe getting opening is formed in the front side of the box body. A motor, the heating pipe, the exhaust fans and the temperature sensor are electrically connected with the controller. According to the rotation type softening machine for shoe making, shoes on the trays continuously rotate and can not stay at one place to be heated, in this way, the shoes are heated evenly, the heated shoes can be taken down when passing through the shoe getting opening, a new shoe is put, continuous operation can be conducted and the rotation type softening machine for shoe making is beneficial to industrialization production.

Owner:WENZHOU JUNA SHOES IND CO LTD

Heated insoles

ActiveUS9548618B2Provide heating efficiencyEfficient and economicalBatteries circuit arrangementsSolesHeat conductingEngineering

An efficient system to heat the insole of a heated insole of a shoe in which the Intelligent Circuit (IC) for a flat lithium battery is located outside the shoe and the placement of the heater for the insole is between more efficient heat insulation and heat conducting members.

Owner:SCHAWBEL TECH

Warming shoe pad

InactiveUS7775204B2Not hindering walkingSufficient supplyExothermal chemical reaction heat productionSolesFiberThin metal

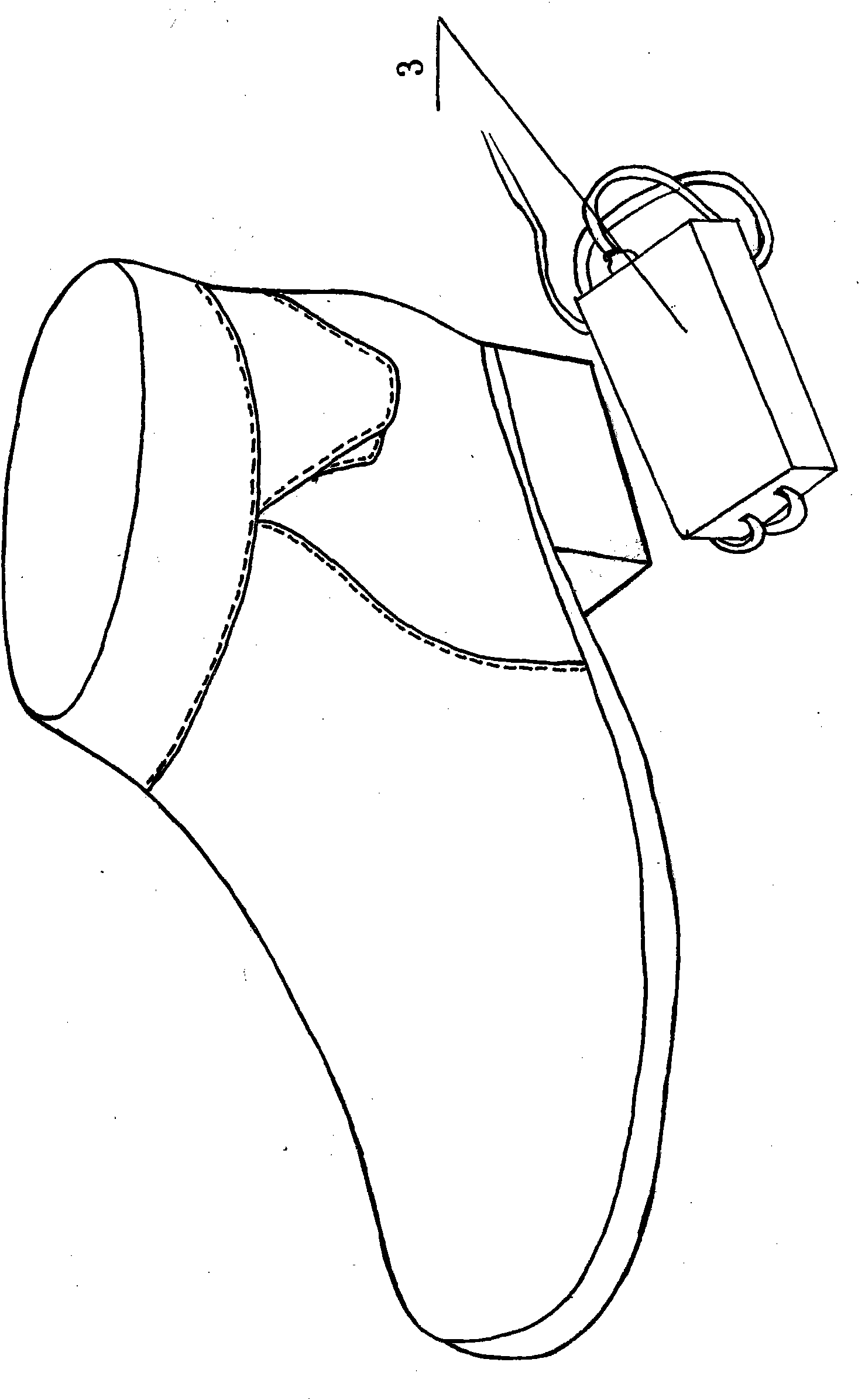

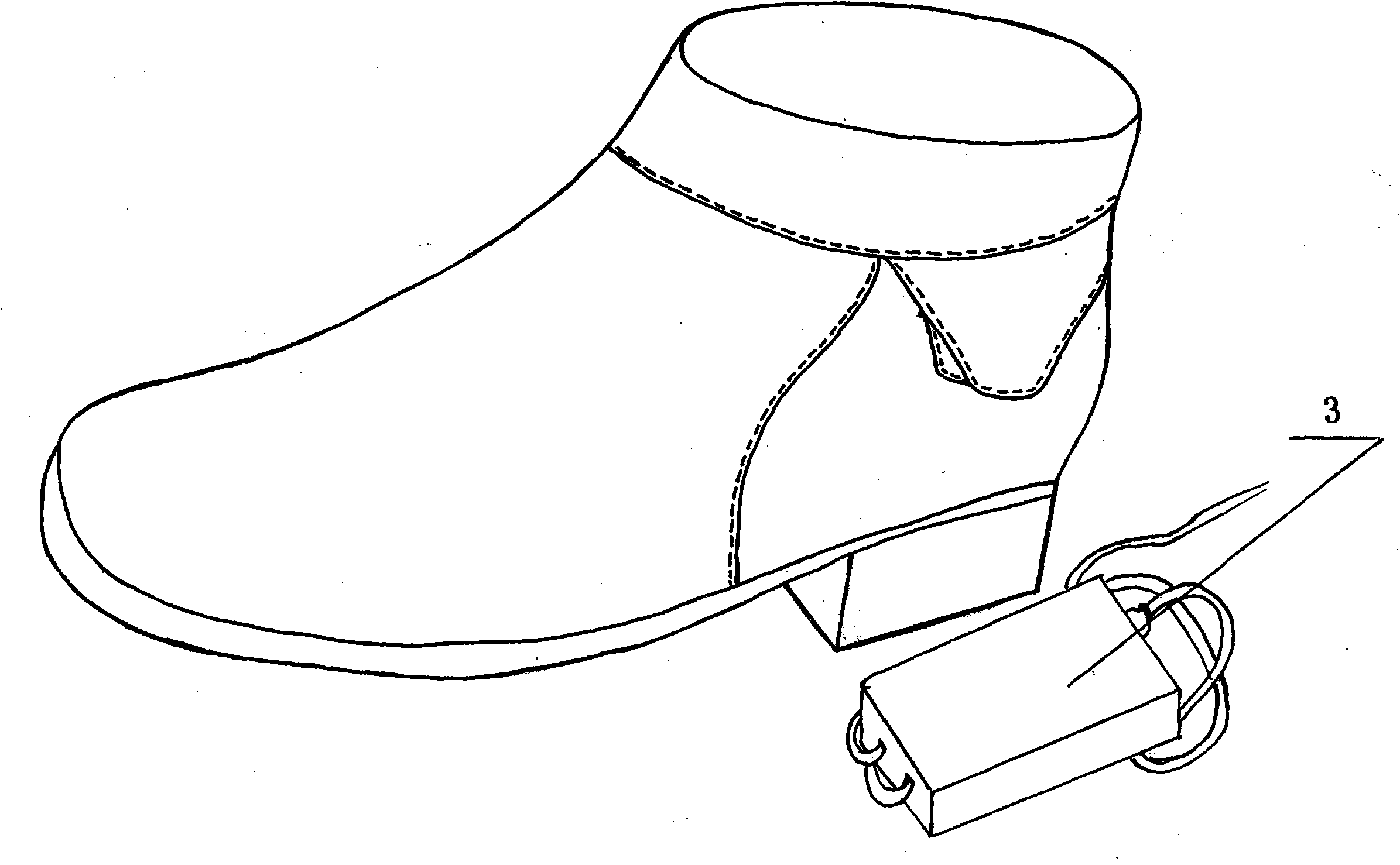

A device for warming a shoe is disclosed. An insole has a top cavity. A releasable shoe pad includes a top padding member and a recess between forward and rearward bottom portions. The device includes a thin metal member formed on the pad and including an intermediate conductive member, a forward conductive section extended from the conductive member, and a rearward conductive section extended from the conductive member, and a heater unit fastened in a space defined by the recess. The heater unit includes a fuel chamber, a combustion chamber filled with zirconia fibers, and a channel interconnected the fuel and the combustion chambers, the channel including fibers and a wick having one end immersed in the fuel chamber and the other end connected to the fibers.

Owner:INT METROPLE CORP

Warming shoe pad

InactiveUS20080163861A1Not hindering walkingImprove heat transfer efficiencyExothermal chemical reaction heat productionSolesCombustion chamberHeated shoe

A device for warming a shoe is disclosed. An insole has a top cavity. A releasable shoe pad includes a top padding member and a recess between forward and rearward bottom portions. The device includes a thin metal member formed on the pad and including an intermediate conductive member, a forward conductive section extended from the conductive member, and a rearward conductive section extended from the conductive member, and a heater unit fastened in a space defined by the recess. The heater unit includes a fuel chamber, a combustion chamber filled with zirconia fibers, and a channel interconnected the fuel and the combustion chambers, the channel including fibers and a wick having one end immersed in the fuel chamber and the other end connected to the fibers.

Owner:INT METROPLE CORP

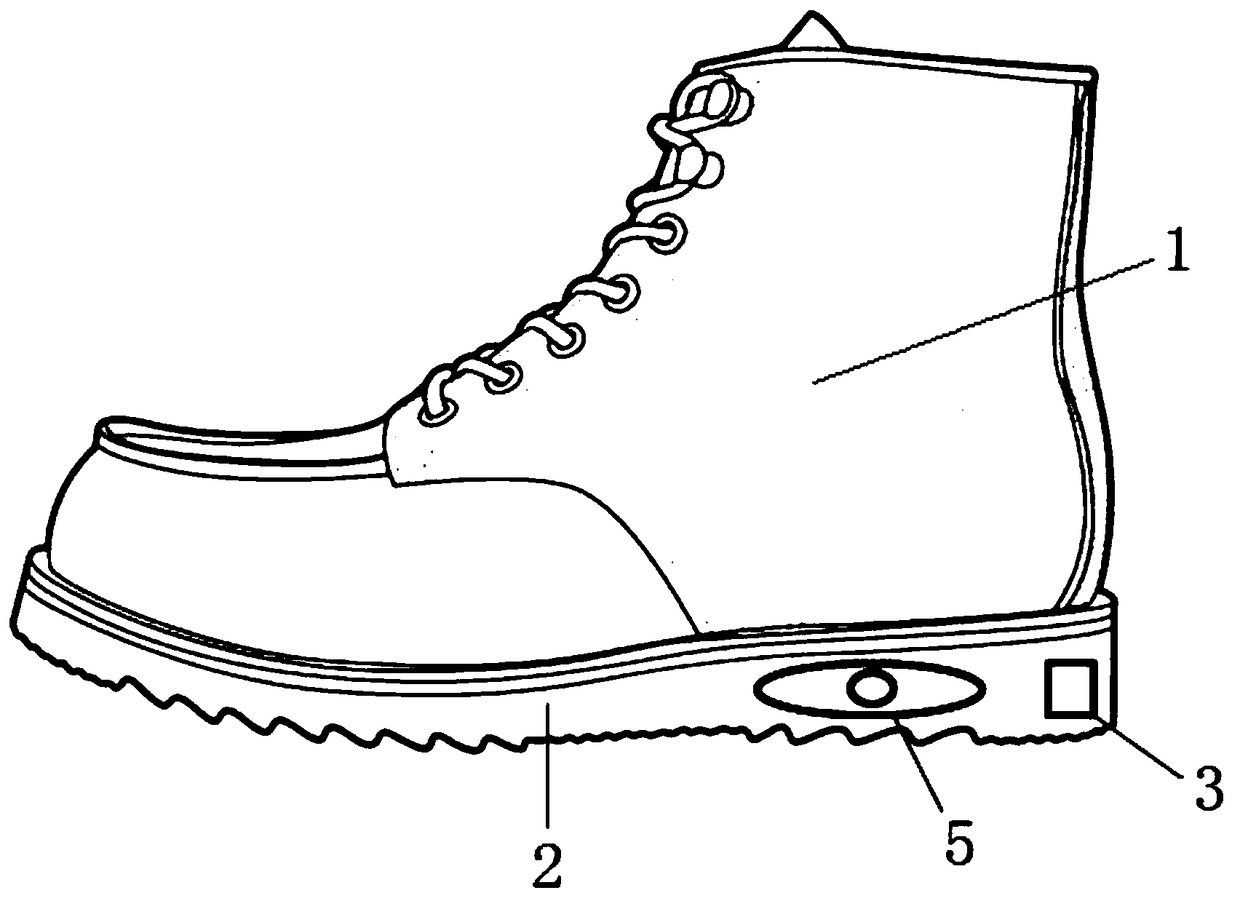

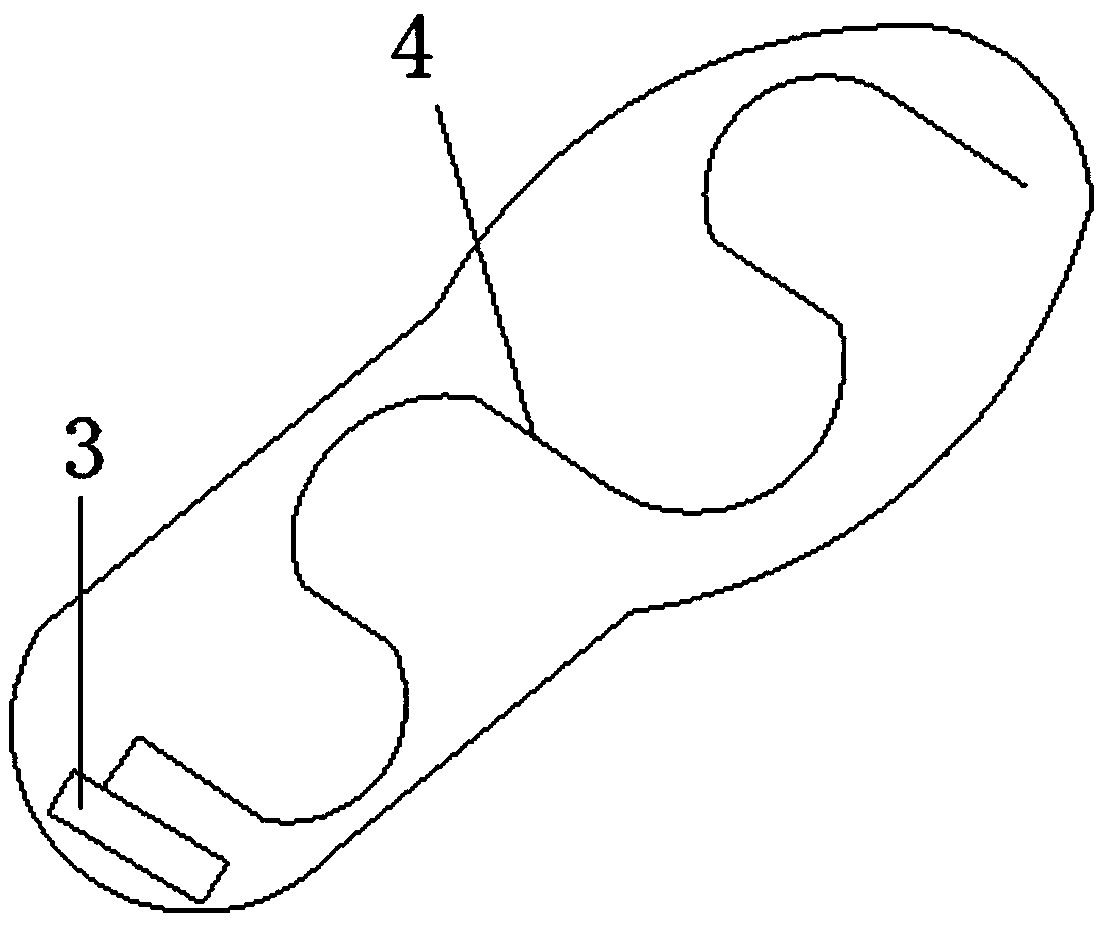

Temperature-sensitive heating shoe

InactiveCN102845919ASolve the function of automatic heatingPromote blood circulationFootwearComputer moduleAir temperature

A temperature-sensitive heating shoe comprises a shoe body, a temperature sensor, a pressure sensor, a lithium battery, a control module and a heating film, and is characterized in that the control module, the lithium battery and the pressure sensor are arranged in a heel; the temperature sensor is arranged at a position, which is close to the top, of a side surface of the heel; the temperature sensor and the pressure sensor are connected with a signal input end of the control module; the heating film is connected with a power output end of the control module; the heating film is mounted at a toe cap; and an anode and a cathode of the lithium battery, two terminals of a socket and a power input end of the control module are connected with one another in parallel. When the air temperature is lower than 10 DEG C and the pressure sensor senses the weight of a human body, the heating film is conducted by the control module; and when a foot of the human body is far away from the shoe body, the control module cannot receive information of the pressure sensor, and even if the temperature detected by the temperature sensor is lower than 10 DEG C, the power of the heating film can be switched off by the control module. The temperature-sensitive heating shoe has the advantages that the shoe body has an automatic heating function, and blood circulation of feet of people is promoted.

Owner:庄景阳

Heating drying shoe

The invention discloses a heating drying shoe. The shoe comprises a shoe upper and a shoe sole, a heating structure and a power supply for supplying power to the heating mechanism are arranged in theshoe sole, and a heat insulation structure is arranged on the upper surface of the shoe sole. By arranging the heating structure and the power supply in the shoe sole, when heating is needed in winter, a power switch is switched on, the power supply supplies power to the heating structure, and the heating structure generates heat through warming for heating. By arranging the heat insulation structure, the situation is avoided that since the shoe sole is in direct contact with the heated shoe sole, scalding is caused.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Heating shoe

InactiveCN103892514ASolve the problem of not being able to heatReduce the chance of failureSolesEngineeringElectronic component

The invention discloses a heating shoe comprising a shoe body. A cavity is formed inside a sole of the shoe body, a heating element, a motor, a gear and a roller are arranged in the cavity of the sole, the heating element is arranged at the inner top of the cavity of the sole and connected with the motor through a wire, the circle center of the gear is fixed on a rotating shaft of the motor, the roller is fixed inside the sole through the rotating shaft of the roller, the upper end of the roller is meshed with the gear, and the lower end of the roller extends out from the bottom surface of the sole. The heating shoe is simple in structure and convenient to use, and the sole can be heated by rotation of the roller; meanwhile, a circuit is simplified as far as possible and number of electronic components is reduced, so that probability of circuit faults is lowered effectively, service life is prolonged greatly, and the heating shoe is suitable for the weak.

Owner:高月锋

Making method of charging heating shoes

The invention relates to a making method of a pair of charging heating shoes, characterized in that infrared electric heating films are arranged on the middle shoe soles and the front half parts of the soles. Each infrared electric heating film is an electric-heating infrared radiator, which is made of metal and sealed by an upper layer and a lower layer of plastic films with high insulation strength and resistances to aging and high temperature, so that the radiator is not in contact with air. After being connected with a power supply, the shoes can radiate infrared rays with physiotherapy action on human bodies; meanwhile, an external special charger is adopted for connecting an external power supply; after the shoes are fully charged once, the inside temperature of the shoes is controlled to range from 25 DEG C to 28 DEG C and can be kept for about 8 h so that a person can be in a warm state for a long time and the person need is met, and thus, the making method of the charging heating shoes is realized.

Owner:QINGDAO HENGDA CO LTD +1

Portable household shoe dryer

InactiveCN108236448AIncrease temperatureImprove ventilationFootwear cleanersRadiationEngineeringAir blower

The invention discloses a portable household shoe dryer. The portable household shoe dryer comprises a shell assembly and a drying assembly, wherein the shell assembly comprises an operation box and astorage pipe arranged above the operation box; the drying assembly comprises a hot-air blower, a venting pipe, an ultraviolet lamp, a lampshade, an electric heating wire and a telescopic pipe, the hot-air blower is arranged on the inner side wall of the operation box and is fixed with the operation box through bolts, and the venting pipe is arranged at the top end of the hot-air blower. When theportable household shoe dryer is utilized for drying the inside of a shoe of a user, the inner side wall of the shoe can be rapidly heated, the temperature in the shoe is rapidly increased, air is blown into the shoe by virtue of the hot-air blower during the heating, hot air is introduced into the shoe, and the moisture in the shoe is exhausted, so that the venting effect in the shoe is improved;and bacteria in the shoe is killed by virtue of the radiation of the ultraviolet lamp during the drying in the shoe, so that the drying quality is improved.

Owner:嘉兴市雅棠科技有限公司

Shoe sole forming device

The invention discloses a shoe sole forming device which comprises a heating device, a pressing device, a cooling device and a pushing device; the heating device is used for heating a shoe sole; the pressing device is located above the heating device and used for pressing the shoe sole when the heating device heats the shoe sole; the cooling device is located on one side of the heating device andused for cooling the shoe sole; the pushing device is located on the other side of the heating device and used for pushing the shoe sole to the cooling device. Full-automatic process production from heating shaping to cooling shaping is achieved, the automation degree is high, the labor cost is saved, and the shoe sole shaping effect is good.

Owner:鹤山市新易高鞋业有限公司

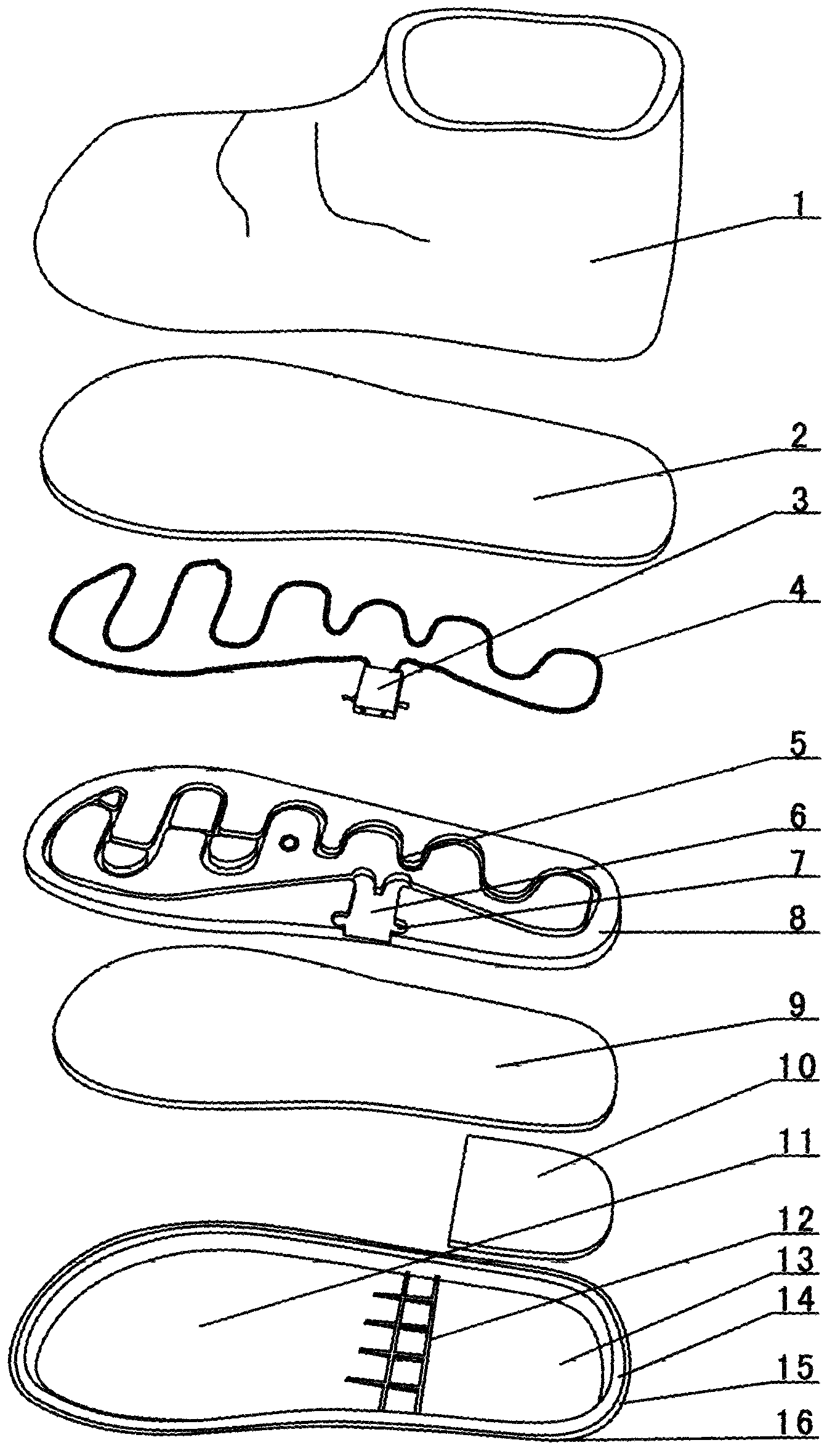

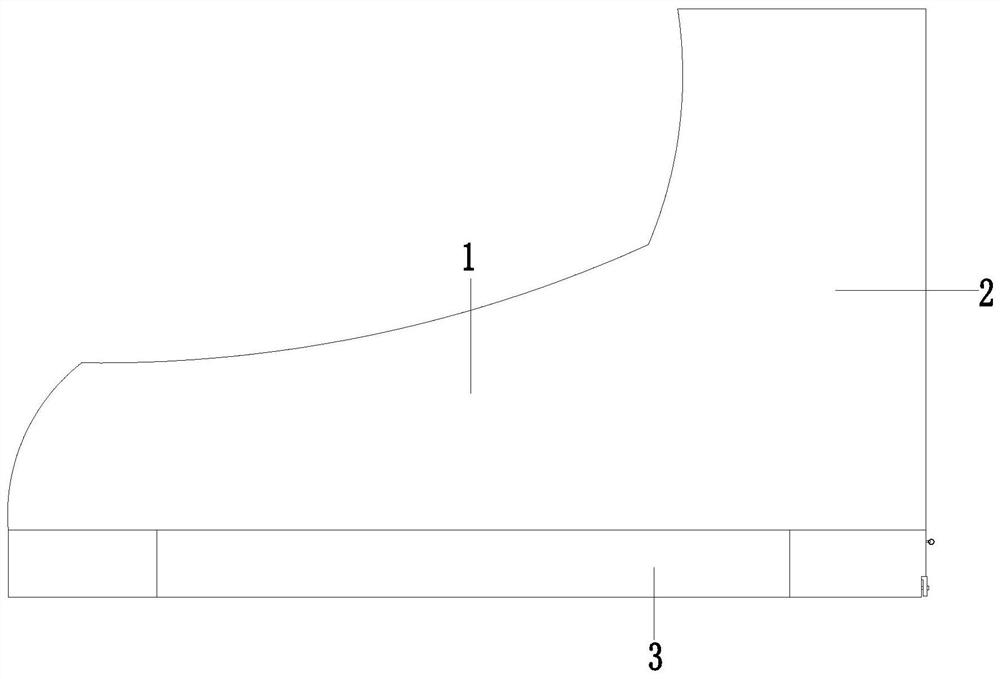

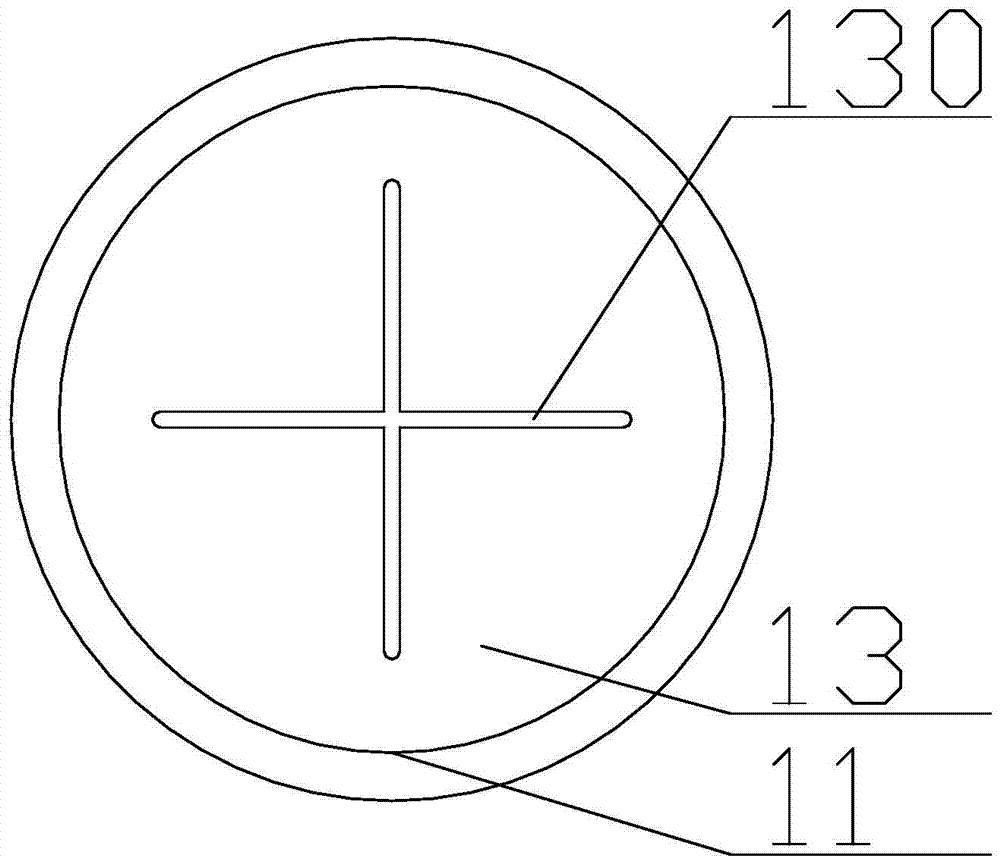

Electric heating shoe

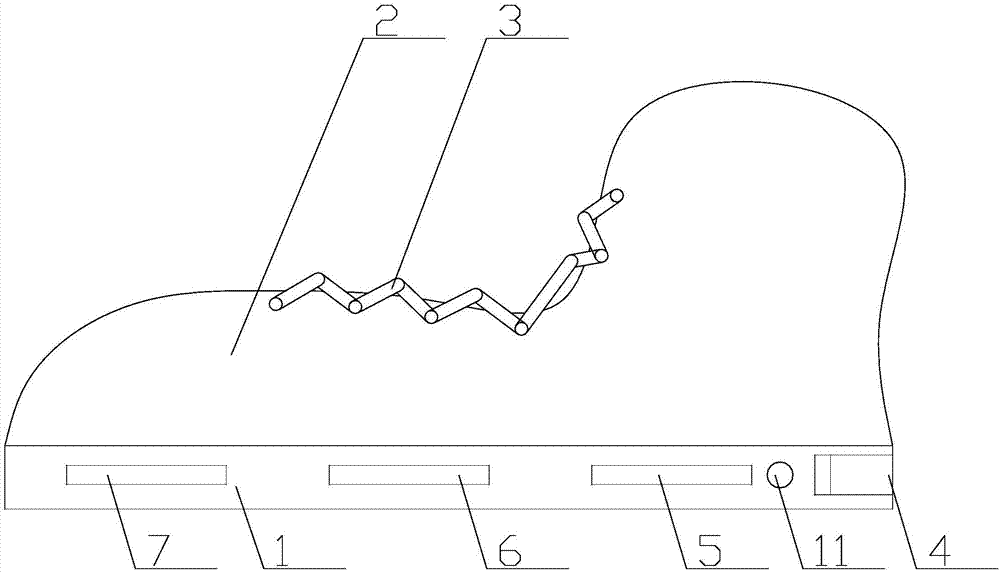

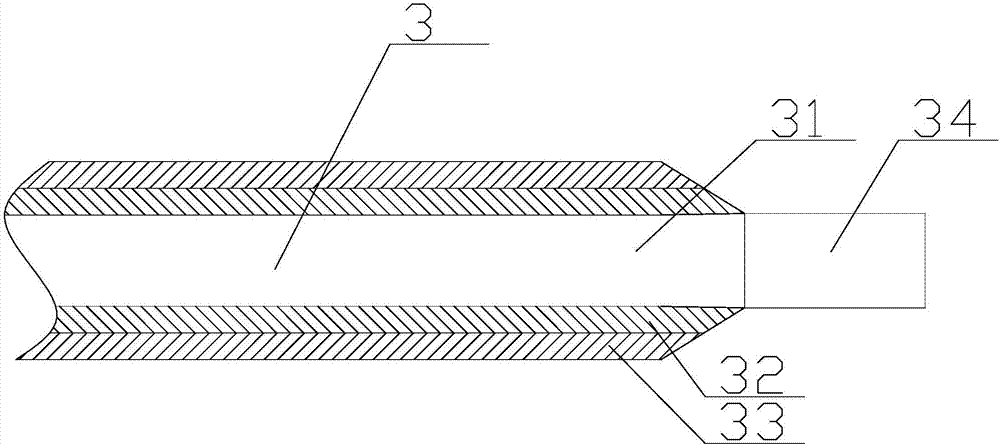

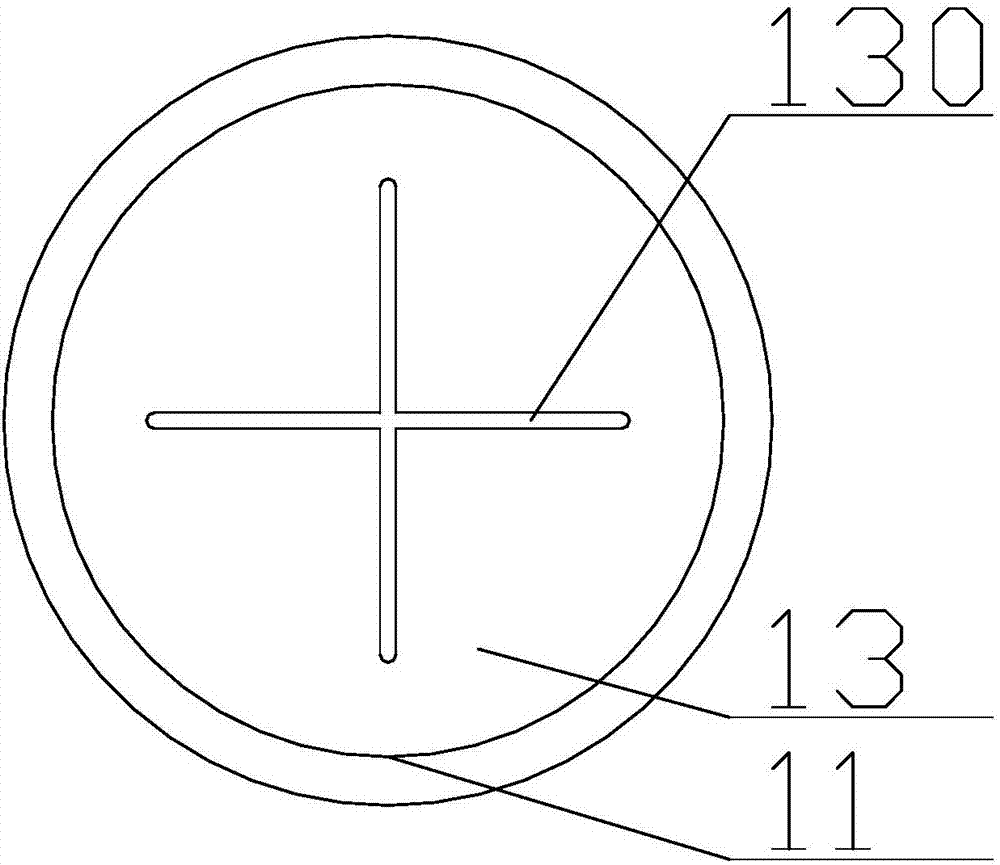

The invention relates to shoes, in particular to an electric heating shoe. A heel pad (10) is arranged in a heel recess (13) at the rear portion of a sole, a pad (9) is arranged on a front recess (11) and the heel pad, the outer edge of an insulation heating pad (8) is in butt joint with a pad placing recess face (14) on the sole, a connector placing groove (6) is arranged on one side on the insulation heating pad, grooves (5) are distributed on an upper face of the insulation heating pad evenly, and two ends of the grooves are communicated with the connector placing groove. Electric heating wires (4) are arranged in the grooves (5), two ends of the electric heating wires are connected with a power interface (3) of the connector placing groove respectively, and an insulation shoe pad (2) and a shoe upper (1) are sequentially stacked on the pad placing recess face to form an enclosed structure of the insulation heating pad. By placing the electric heating wires on the insulation heating pad and by means of the isolation of the insulation pad, users can heat shoe bodies at any time after wearing the electric heating shoes, and warm of feet in winter is guaranteed.

Owner:CIXI CITY FUHAI TOWN SONG BAI PLASTIC PROD FACTORY

Manufacturing technology and equipment of shoe outsole

InactiveCN104972667AColorful appearanceSolve the problem of difficult vulcanization and compoundingManufacturing technologyVulcanization

The invention discloses a manufacturing technology of a shoe outsole. The technology comprises the steps that a, a base of the outsole is produced; b, an upper mold and a lower mold of the shoe outsole are prepared; c, a thin film is prepared, and the base or the thin film is coated with a binding agent; d, a base is placed at the bottom of the lower mold; e, the thin film is laid on the lower mold; f, a plastic uptake technology is adopted to enable the thin film on the lower mold to be adsorbed in a cavity of the lower mold; g, heated shoe outsole materials are shot on the thin film in the lower mold; and h, the upper mold and the lower mold are assembled, after cooling, boundary materials are cut off, and a finished shoe outsole product is prepared. Through the technical scheme, compared with the prior art, the manufacturing technology has the beneficial effects that due to the fact that the thin film can be conveniently manufactured into various colors and various patterns can be sprayed on the thin film quite conveniently, the appearance of the shoe outsole is rich and colorful, appearance defects due to foaming are overcome, and the problem that in the vulcanization molding process, rubber and polyurethane are difficultly vulcanized and composited.

Owner:佛山市南方鞋材有限公司

Multifunctional intelligent shoe cabinet

The invention provides a multifunctional intelligent shoe cabinet which comprises a shoe cabinet body, a drying device, an anion generator capable of releasing anions and a sterilization tube capable of emitting ultraviolet rays; anions can refresh the air; the sterilization tube can disinfect and sterilize the shoe cabinet and eliminate bad odours in shoes; the drying device is mounted in a casing in the shoe cabinet body and comprises a bracket, a PTC (Positive Temperature Coefficient) heater, a fan and a power supply device for supplying power for the fan; the PTC heater is clamped inside the bracket; and the fan capable of dispersing heat produced by the PTC heater is connected to the lower end of the bracket. Through heating of the PTC heater, air is heated and then conveyed to heated shoe bodies from the bottom up by the fan, so that moisture caused by foot sweat in the shoes can be eliminated, beriberi can be inhibited, and the insides of the shoes are kept warm, dry and clean, further, feet can be protected when the shoes are worn, and the purpose of ensuring human health can be achieved; and meanwhile, through the heating manner, no naked fire is generated during heating, visual fatigue can not be caused, and potential safety hazards can be avoided.

Owner:中山市美翔电器科技有限公司

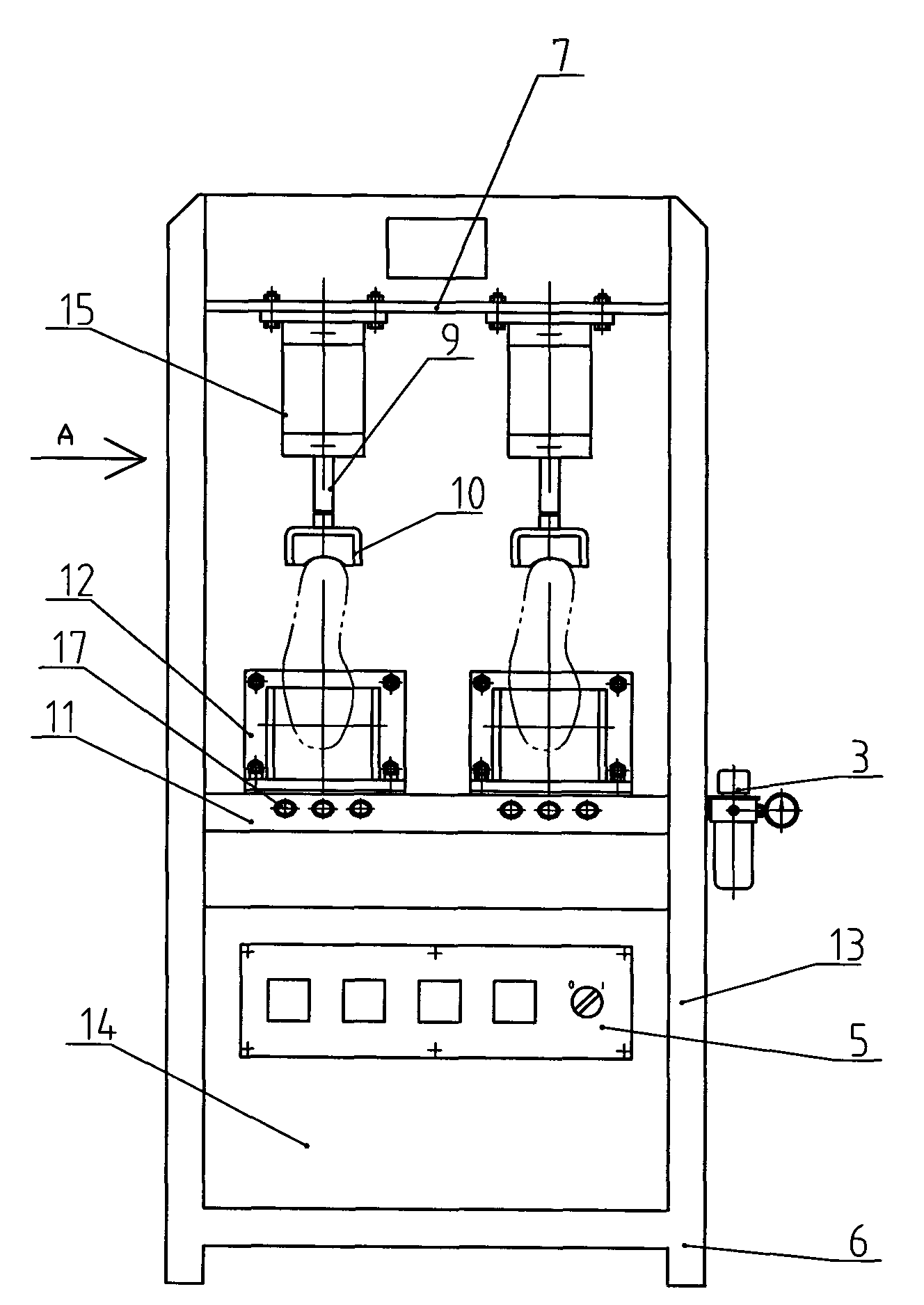

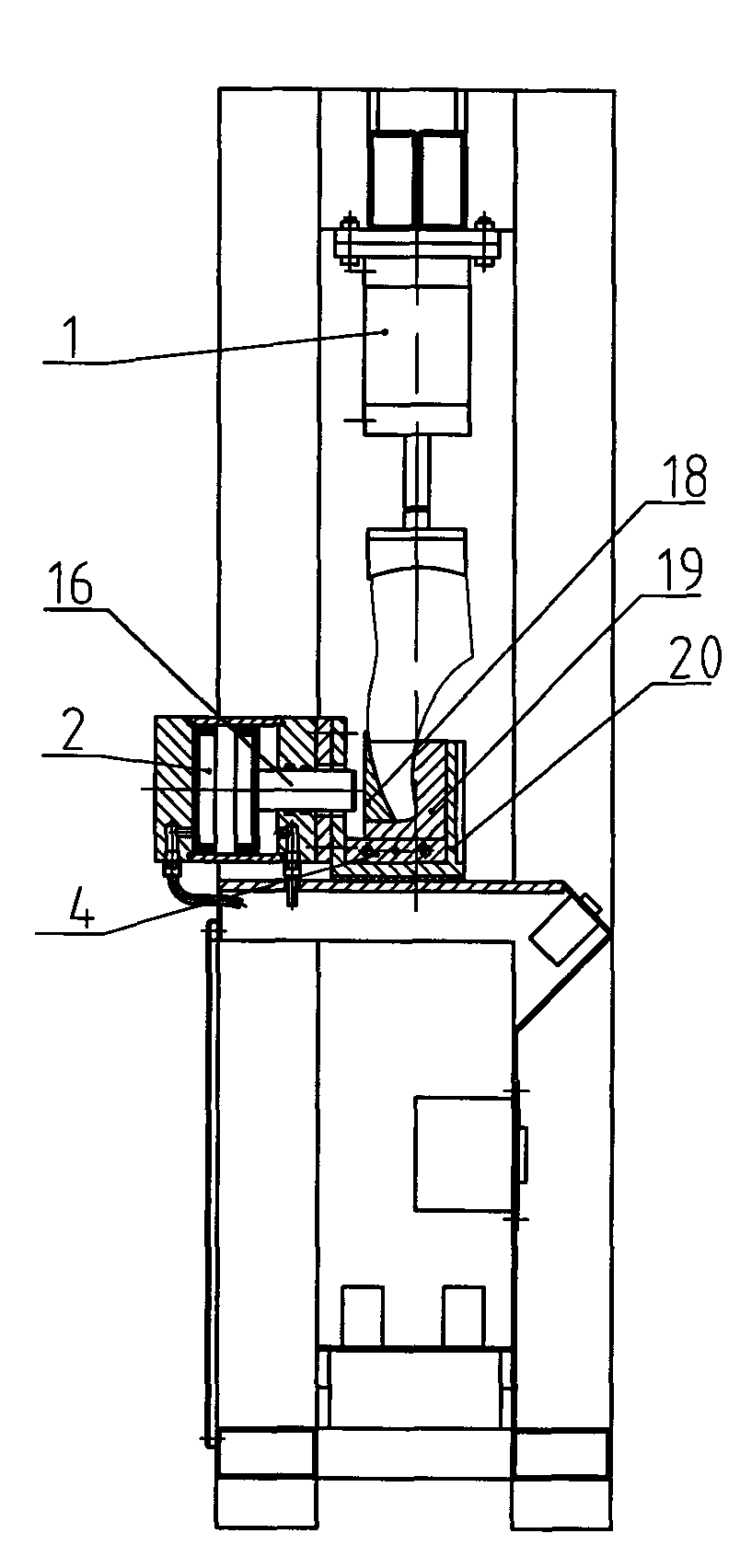

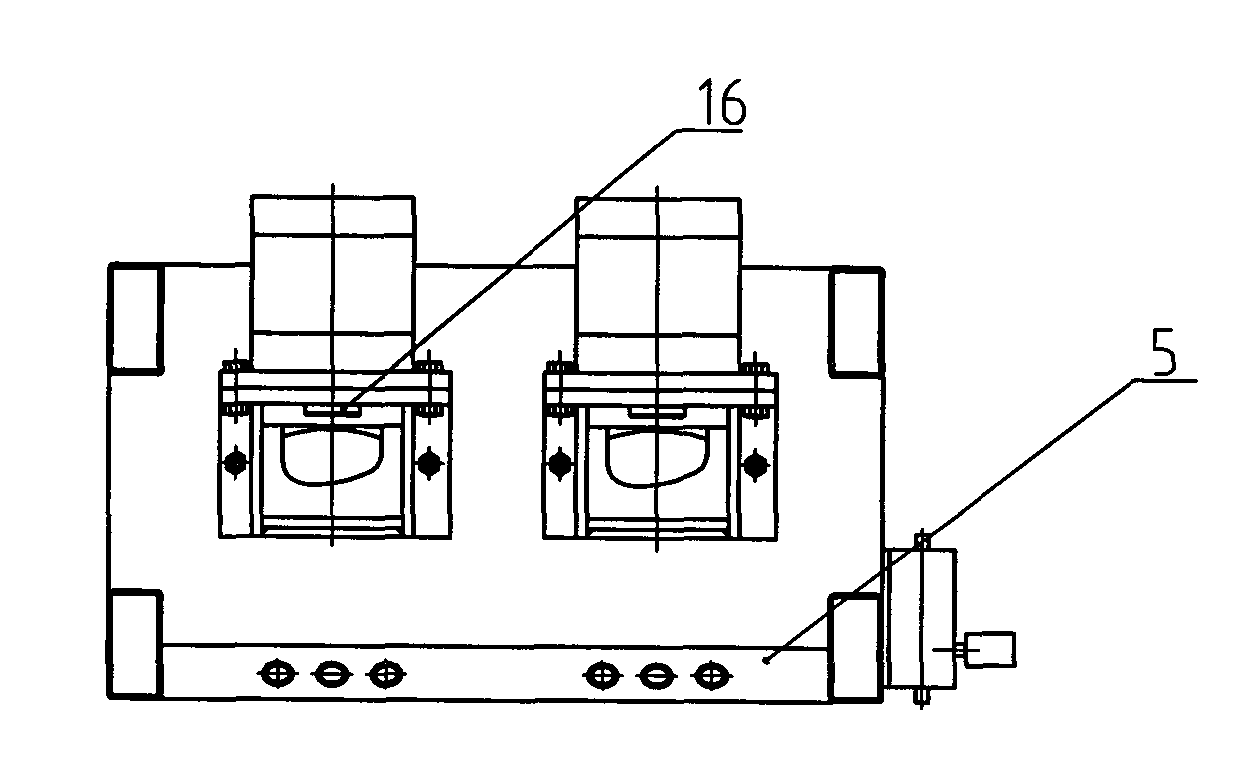

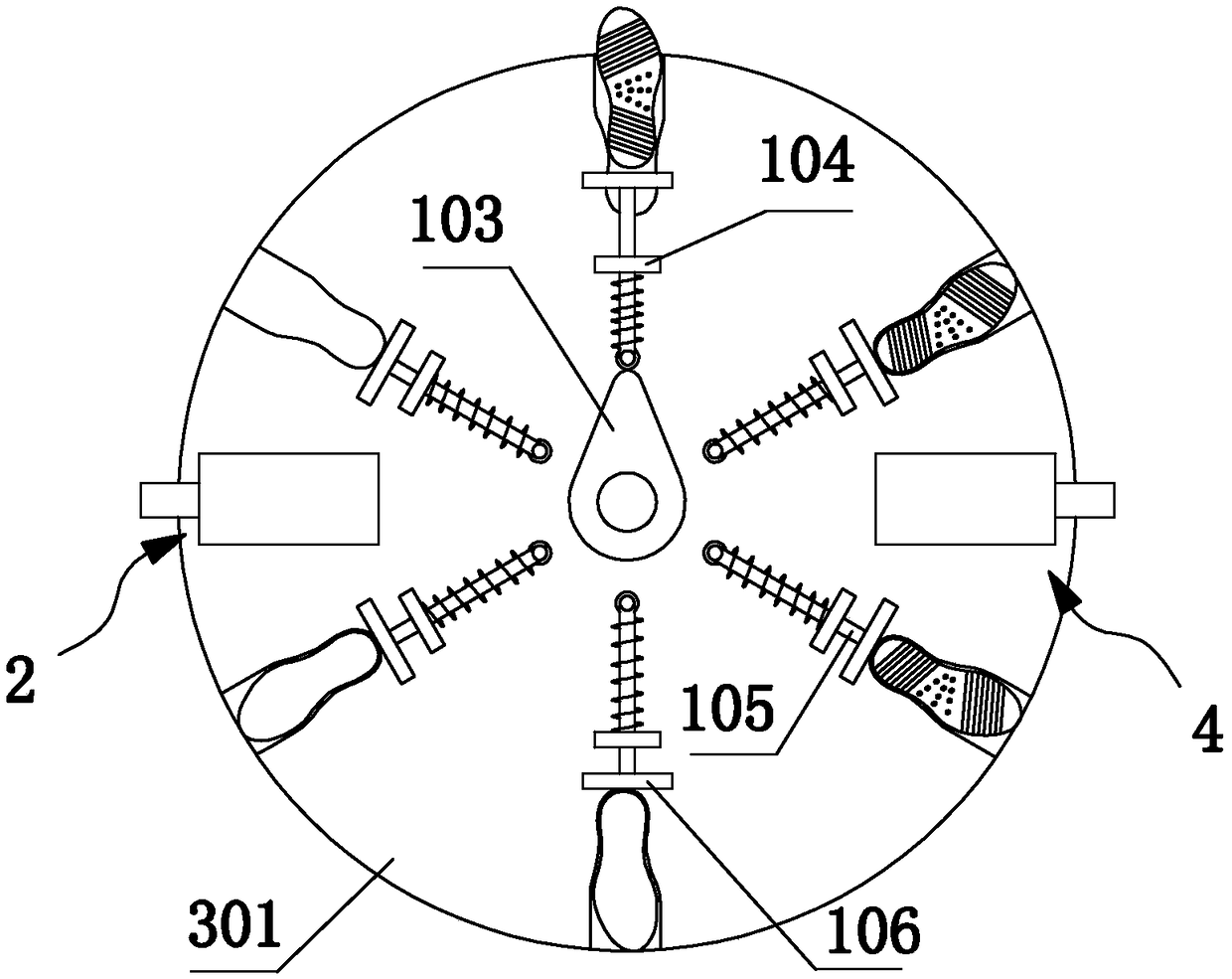

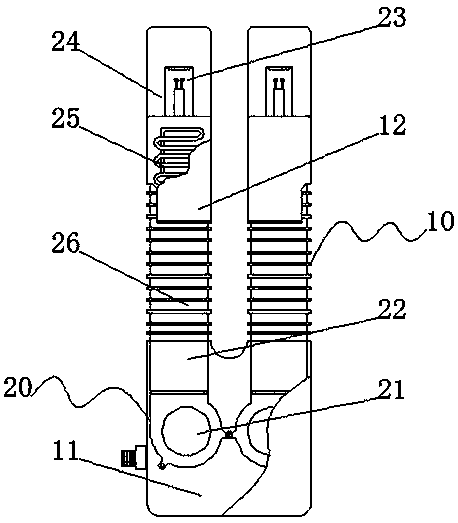

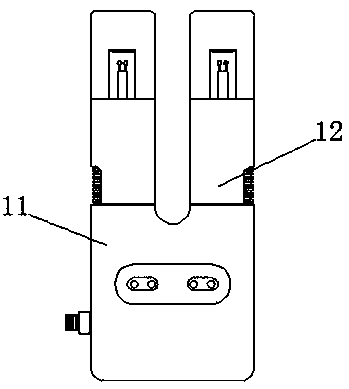

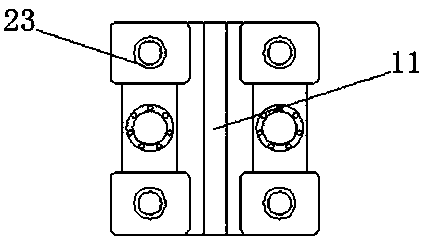

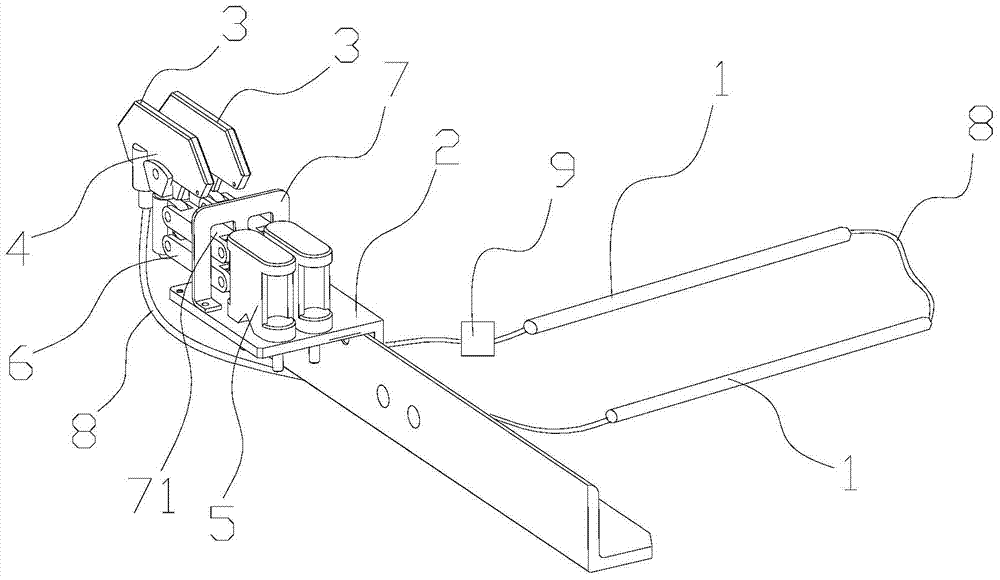

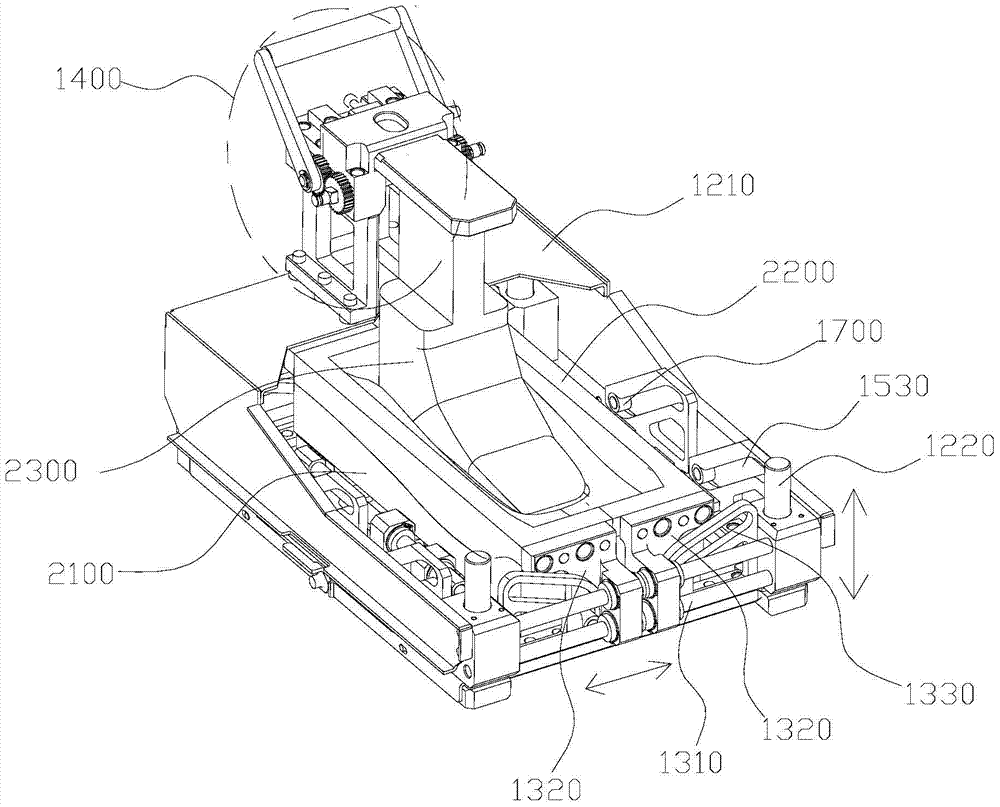

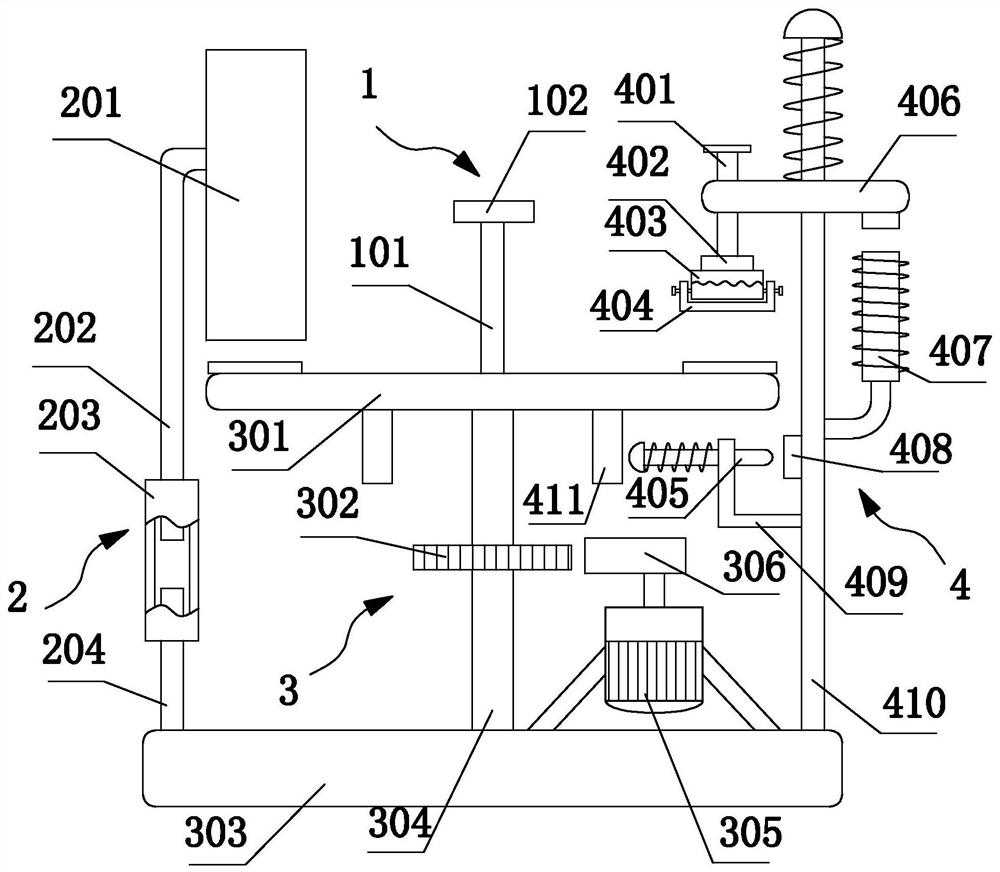

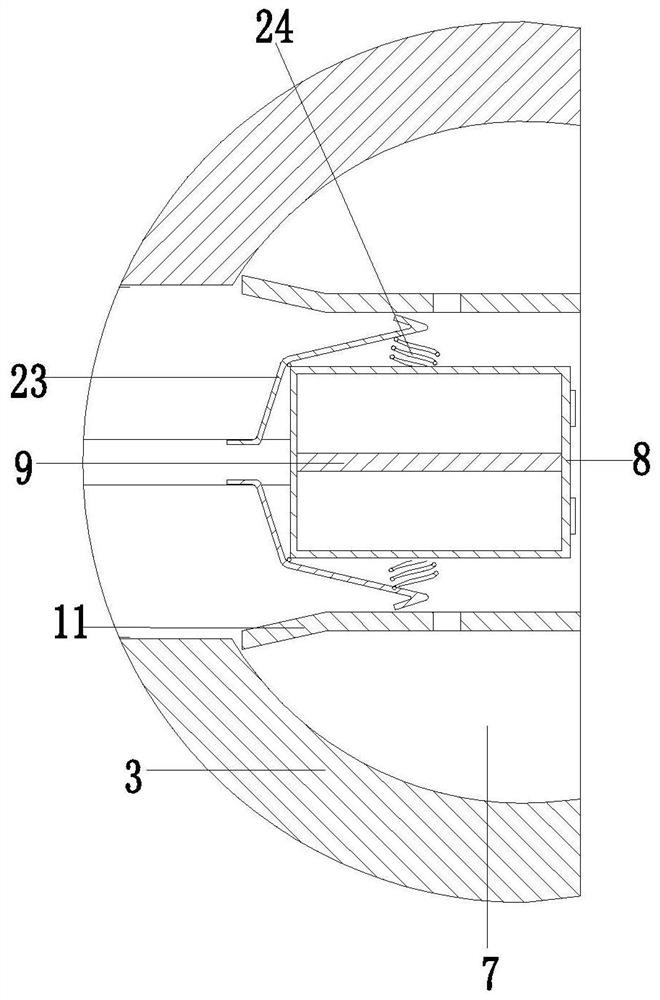

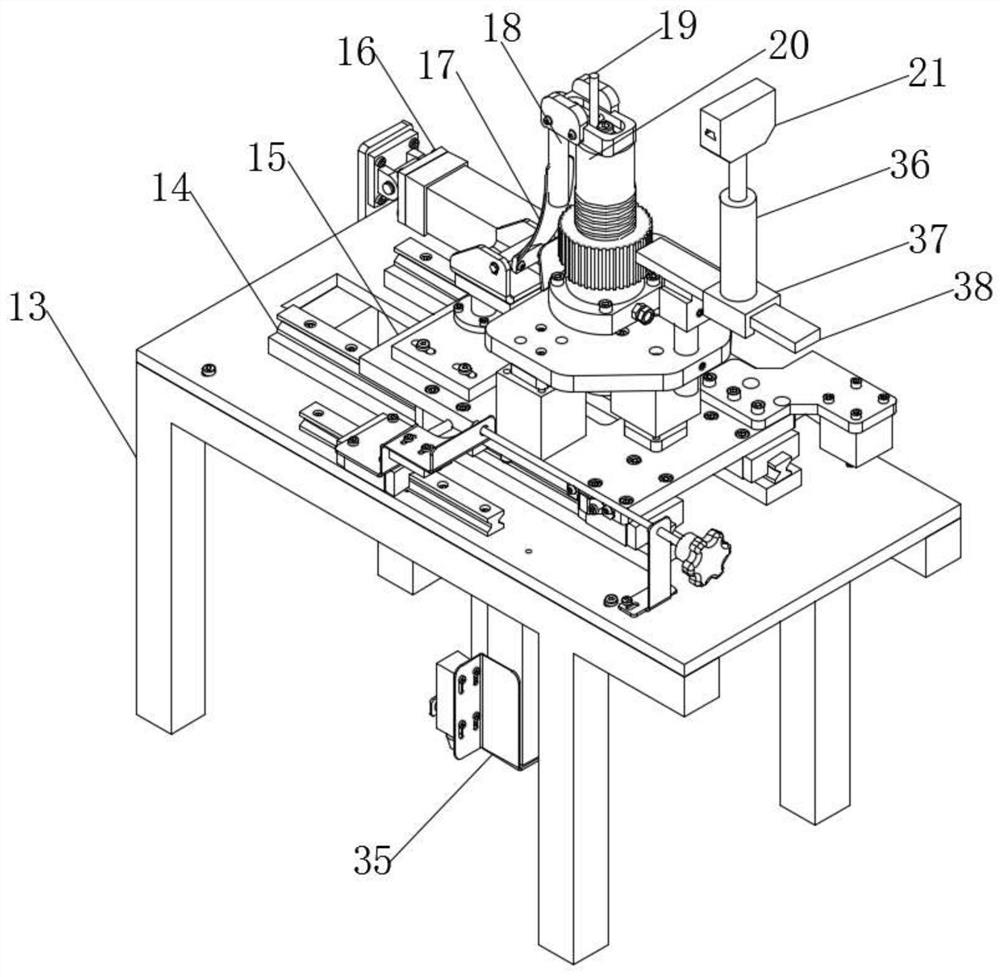

A self-contained heated shoe formwork unit for circular conveyor lines

ActiveCN104772845BAchieve individual heatingIncrease profitDomestic articlesElectricityProduction line

The invention discloses an independently heated shoe mold frame unit for a circular transportation line, which comprises a shoe mold frame body and a shoe mold installed in the shoe frame body, and also includes an independent heating mechanism, which includes at least An electric heater fixedly embedded in the bottom of the shoe mold and an independent power supply unit fixedly installed on the main body of the shoe mold frame; the independent power supply unit includes a mounting plate, a pressing mechanism fixed on the mounting plate and at least two A conductive sheet, the mounting plate is fixed on the main body of the shoe mold frame, the pressing mechanism presses the conductive sheet on the power supply track of the heating station of the circular transportation line, and the conductive sheet is electrically connected to the electric heater. The invention changes the oven heating structure of the traditional shoe-making production line, and proposes an independent heating shoe formwork unit, which has high heating efficiency, good uniformity, ideal polyurethane foaming effect, high utilization rate of heat energy, environmental protection and energy saving , to meet the heating requirements of the ring shoe production line.

Owner:NANHAI KOTO MACHINERY

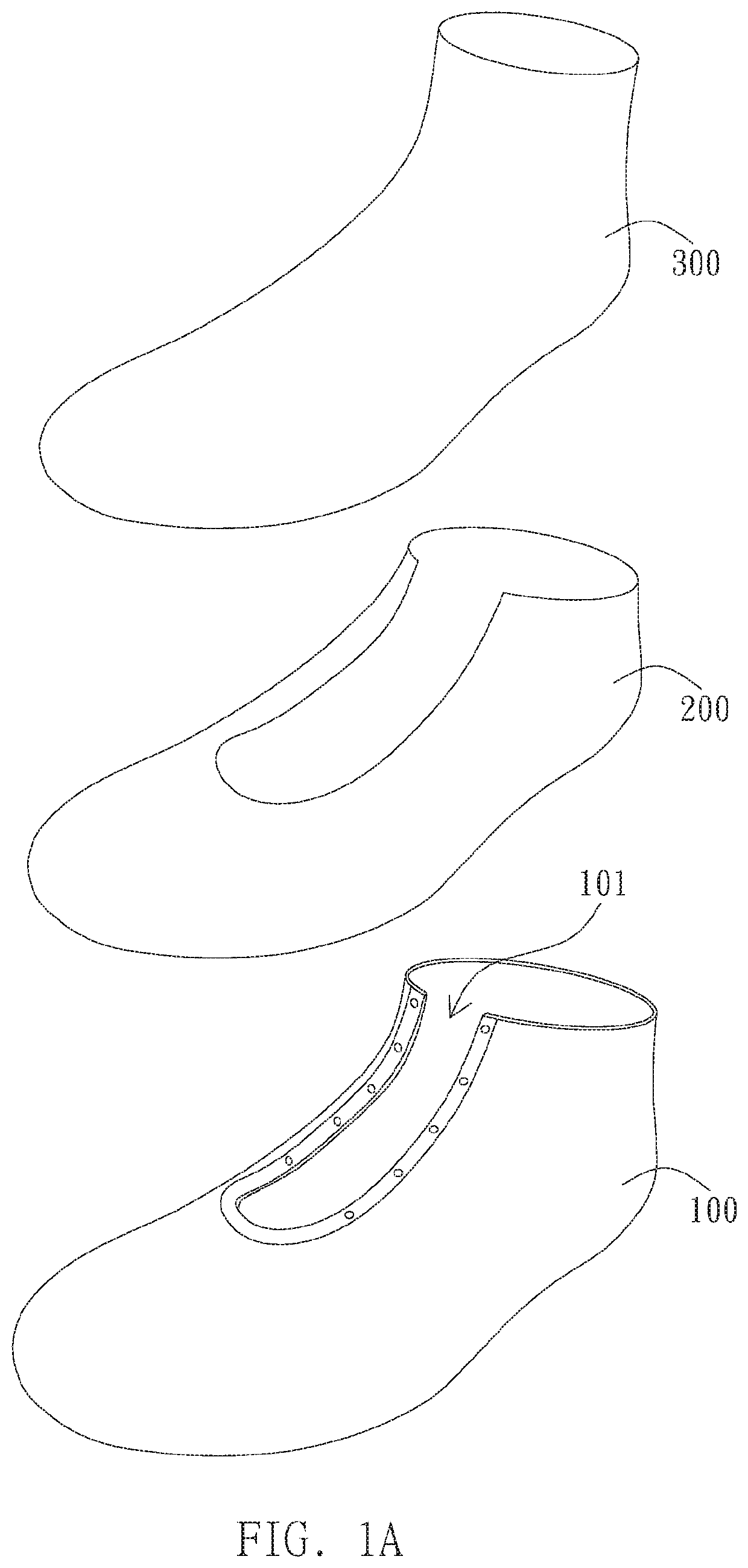

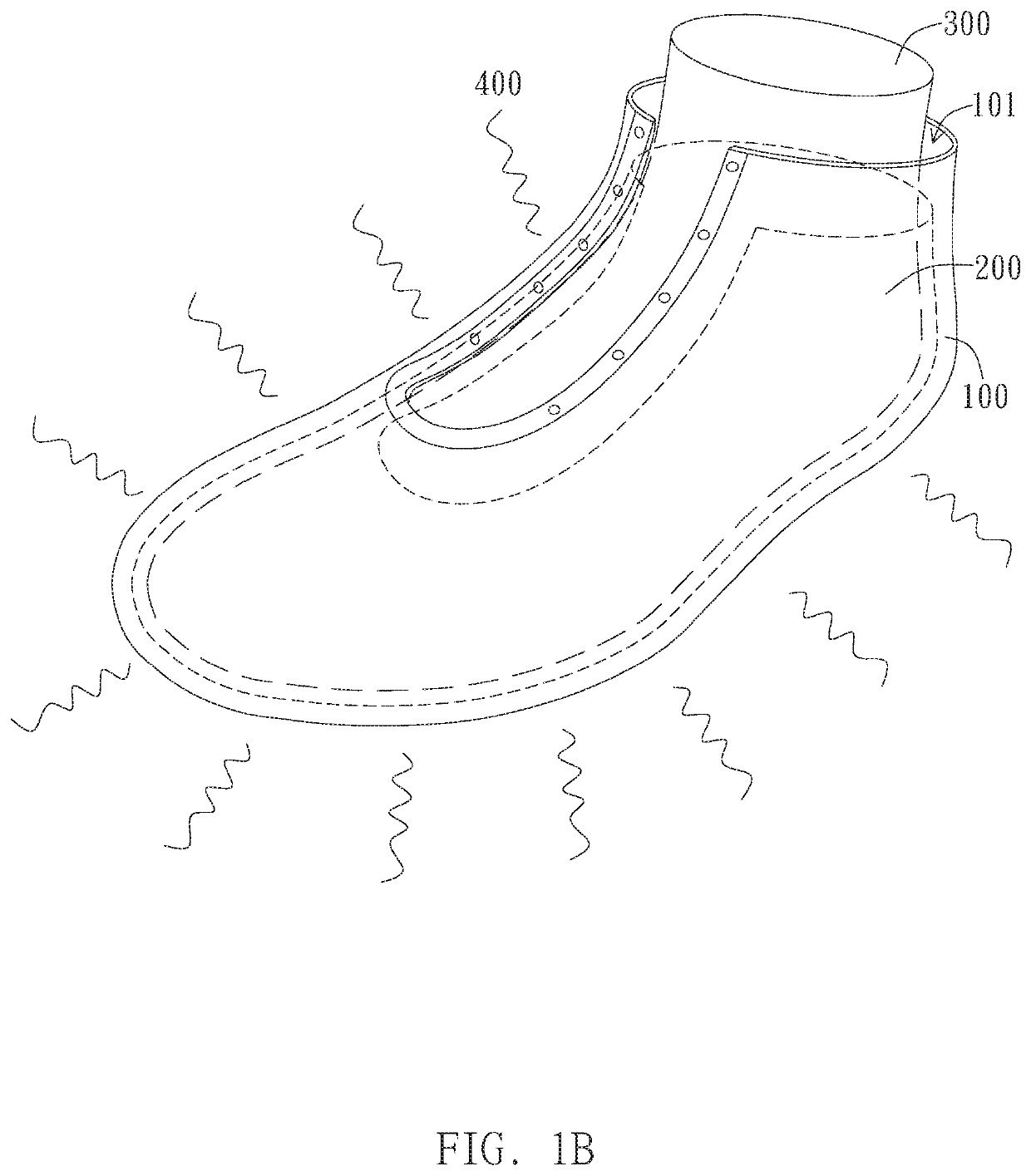

Method of forming and shaping waterproof and moisture permeable shoe upper and shoe upper thereof

ActiveUS11284672B2Conducive to simplificationSimple manufacturing processSolesInsolesMicrowave ovenHeated shoe

A method of forming and shaping a waterproof and moisture permeable shoe upper includes disposing a shoe upper and a waterproof and moisture permeable film on a shoe last, wherein at least one of the shoe upper and the waterproof and moisture permeable film includes microwave treatable material, and heating the shoe last with the shoe upper and the waterproof and moisture permeable film thereon by microwave, so that the shoe upper and the waterproof and moisture permeable film are combined by the microwave treatable material and shaped to form the waterproof and moisture permeable shoe upper after cooling.

Owner:SHENG LONG MATERIAL TECH LTD WS

Rubber sole embossing equipment

The invention discloses rubber shoe sole embossing equipment which comprises a machine table. The machine table comprises a base, the top of the base is rotationally connected with the lower end of amain shaft, a rotating disc is connected with the upper end of the main shaft, and the main shaft is in sleeved connection with an all gear. A feeding mechanism can achieve automatic feeding, shoe soles can constantly fall down to a rotating disc, meanwhile, the distance between a storage barrel and the rotating disc can be adjusted through the cooperation of an upper vertical rod, a thread sleeveand a lower vertical rod according to the thicknesses of the shoe soles, and smooth falling of the shoe soles is ensured; an embossing mechanism achieves rapid embossing through high temperature andpressure, a grain board is convenient to disassemble so as to be replaced with grain boards with different grains, the requirement for different grains is met, and applicability is improved. A push mechanism automatically pushes out heated shoe soles from a work site, manual unloading is not needed, therefore the condition that scalding is caused by manual unloading is avoided, time and labor aresaved, and the efficiency is high.

Owner:江西舒乐佳家庭用品有限公司

A comfortable heating shoe

The invention relates to a comfortable heating shoe, comprising a shoe body, the shoe body is composed of a vamp and a heel, a cavity is arranged inside the heel, a heating pad is arranged in the cavity, and the rear end of the heating pad is Conductive rods are provided, a control chamber is provided at the rear end of the heel, and a control chute is provided in the control chamber, and a battery rack is installed in the control chute through sliding fit, and an isolation plate is provided in the middle of the battery rack, and the front end of the battery rack against the conductive rod. The present invention can solve the problem that the existing shoes cannot provide effective antifreeze measures for the feet of the human body in cold weather, and the heating speed of the existing shoes with built-in heating function is slow, the waterproof effect of the shoes is poor, and the inside of the shoes is easily heated due to water ingress Equipment damage, troublesome replacement of internal heating equipment, and poor comfort when walking on complex roads.

Owner:BEIJING CHANGHENG LEATHER PROD MFG CO LTD

Micro-electrical heating shoe

The invention provides a micro-electrical heating shoe and aims at solving the technical problem of heating of common shoes. The micro-electrical heating shoe is mainly composed of a shoe vamp, a shoe upper, a shoe bottom, a shoe bottom battery groove, a heating piece, a shoe pad, a battery, a power line, a switch and a charging socket. The micro-electrical heating shoe is characterized in that the front edge position of the shoe vamp is sewn onto the front upper edge position of the shoe upper, and the lower edge position of the shoe upper is bonded to the protruding position of the upper edge of the shoe bottom to form the shoe. The heating piece is bonded on the surface of the shoe pad. A first power line section, a second power line section and a third power line section are used for being connected with the heating piece on the surface of the shoe pad, a fourth power line section is connected with the heating piece and the switch, a fifth power line section is connected with the switch and the battery, and a sixth power line section is connected with the external charging socket and the battery to form the heating shoe pad. The heating shoe pad is placed in the shoe, battery installation is performed to enable the battery to be firmly placed into the shoe bottom battery groove, and the heating shoe pad is used for bonding the shoe bottom and the surface of the battery to form the heating shoe.

Owner:刘小勇

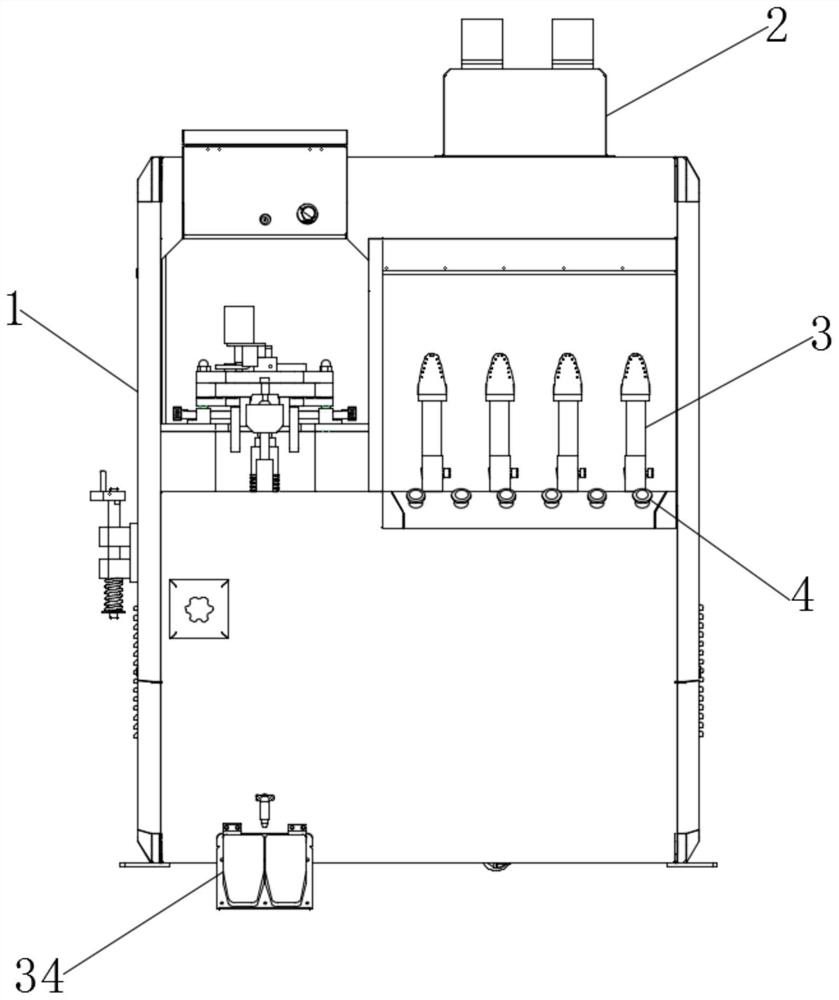

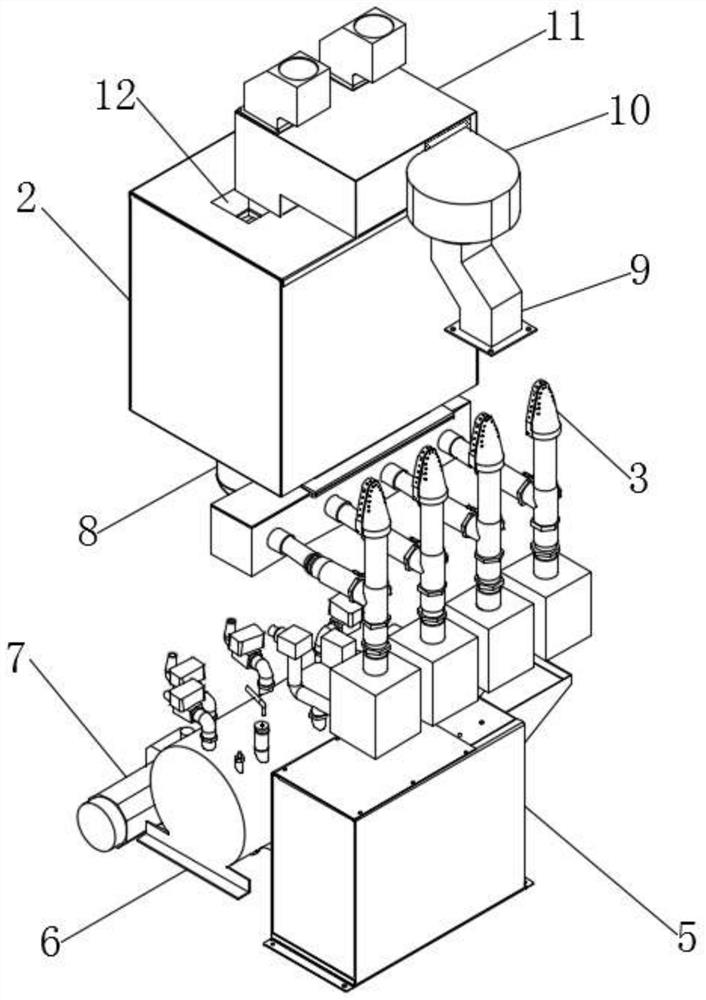

Heel lasting all-in-one machine

The invention belongs to the technical field of shoe production equipment, and particularly relates to a heel lasting all-in-one machine which comprises a cabinet and is characterized in that a steaming and wetting integrated heating unit used for heating shoes and a shoe last feeding unit used for pressing the shoes are installed in the cabinet; the steaming and wetting integrated heating unit comprises a plurality of shoe hanging bolts used for placing shoes, a steam heating mechanism and a hot air heating mechanism, a plurality of through holes are formed in the top ends of the shoe hanging bolts, and the steam heating mechanism and the hot air heating mechanism communicate with the shoe hanging bolts through pipelines correspondingly; and electromagnetic valves are arranged between the steam heating mechanism and the shoe hanging bolt and between the hot air heating mechanism and the shoe hanging bolt, and control buttons used for controlling the electromagnetic valves to be opened and closed are arranged at the front end of the shoe hanging bolt. The defects in the prior art are overcome, the four processes of hot air, steaming wetting, last entering and heel part shaping are integrated, a single person can independently control and operate along the ring, the occupied area is reduced, and the labor cost is saved.

Owner:莆田市驰胜机械科技有限公司

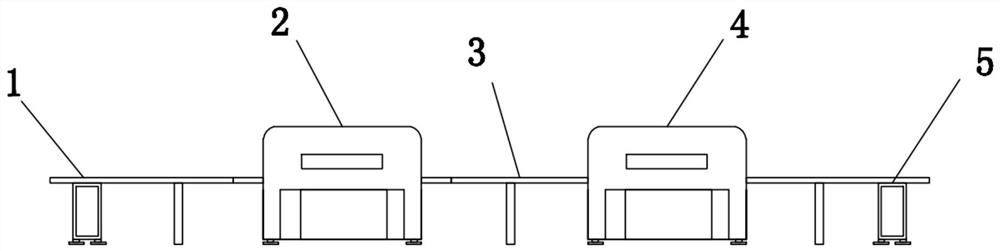

Equipment and method for strengthening durable antifouling property of shoes by using nano silicon-fluorine polymer

PendingCN111904105AAchieve anti-bacterial and anti-mildewAchieve waterproofShoemaking devicesRadiationProcess engineeringPolymer

The invention discloses equipment and a method for strengthening durable antifouling property of shoes by applying nano silicon-fluorine polymer, which comprises a finished product shoe spraying antifouling material platform, a heating and atomizing device, a pre-inspection platform, a cooling device and a finished product packaging platform, wherein the heating and atomizing device is arranged atthe output end of the finished shoe spraying antifouling, antibacterial, mildew-proof, odor-proof and waterproof material platform, finished shoes enter the heating and atomizing device after being sprayed with an antifouling, antibacterial, mildew-proof, odor-proof and waterproof polymer, and the pre-inspection platform is arranged at the output end of the heating and atomizing device. The cooling device is arranged at the output end of the pre-inspection platform and used for cooling the heated shoes and then enabling the shoes to enter the finished product packaging platform. According tothe equipment, the nano silicon-fluorine polymer is applied to the finished shoes, the antifouling, antibacterial, mildew-proof, anti-cracking, odor-proof and waterproof effects of the shoes are improved through a series of processing means, and the processing technology is improved.

Owner:上海盟峰国际贸易有限公司

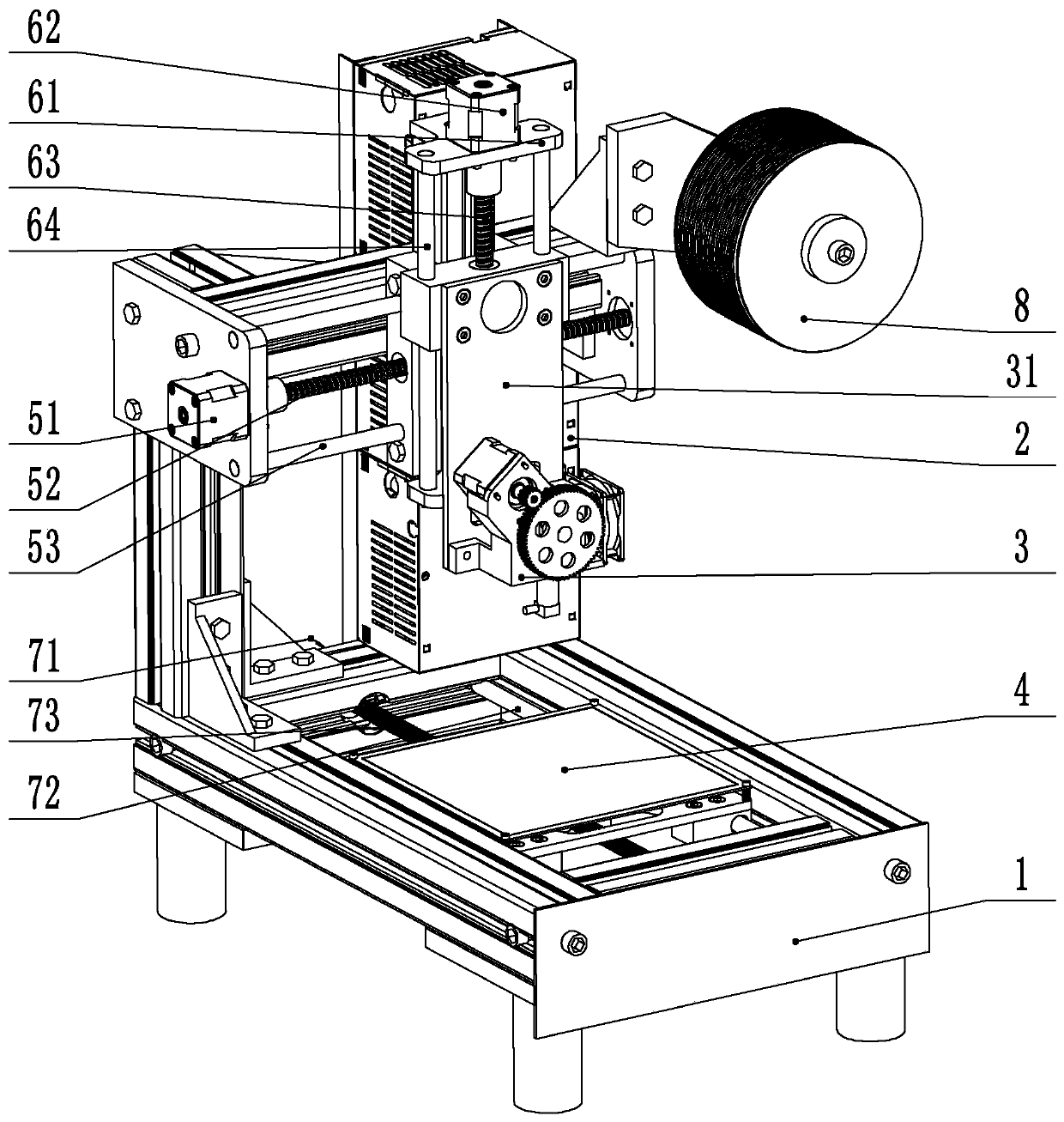

A 3D printing last forming method

ActiveCN108284589BReduce development costsHigh degree of design intention matchingAdditive manufacturing apparatusAdditive manufacturing processes3d printMicrowave oven

The invention discloses a 3D printing shoe-last forming method. The 3D printing shoe-last forming method comprises the steps that 1, a required shoe-tree model is downloaded, and a data format is modified; 2, shoe-tree data is output to a 3D printer, and a required shoe tree is printed; 3, an insole with the corresponding size and a heat insulating film with the corresponding size are selected, the shoe tree is sleeved with the heat insulating film, and the insole is nailed to the bottom of the shoe tree; 4, the shoe tree is sleeved with a shoe upper, the nails are used to fix the shoe upper to the shoe tree and the insole; 5, the shoe upper is repaired to be smooth through a hammer, then the insole and a lasting allowance of the shoe upper are bonded through glue, and then the nails are pulled out; and 6, a combining body of the shoe tree, the insole and the shoe upper is placed into a microwave oven for heating and sizing. According to the 3D printing shoe-last forming method, heating and sizing through the microwave oven can make the situation that a shoe last printed through a 3D printer can be manufactured into a shoe to be possible, and the heating and sizing time is greatlyreduced; and through the selective heating characteristic of the microwave oven, only the shoe upper is heated, and the shoe tree is not heated, so that swelling or melting of the shoe tree does not occur, and thus the sized upper part is more accurate.

Owner:新龙威(温州)鞋业科技有限公司

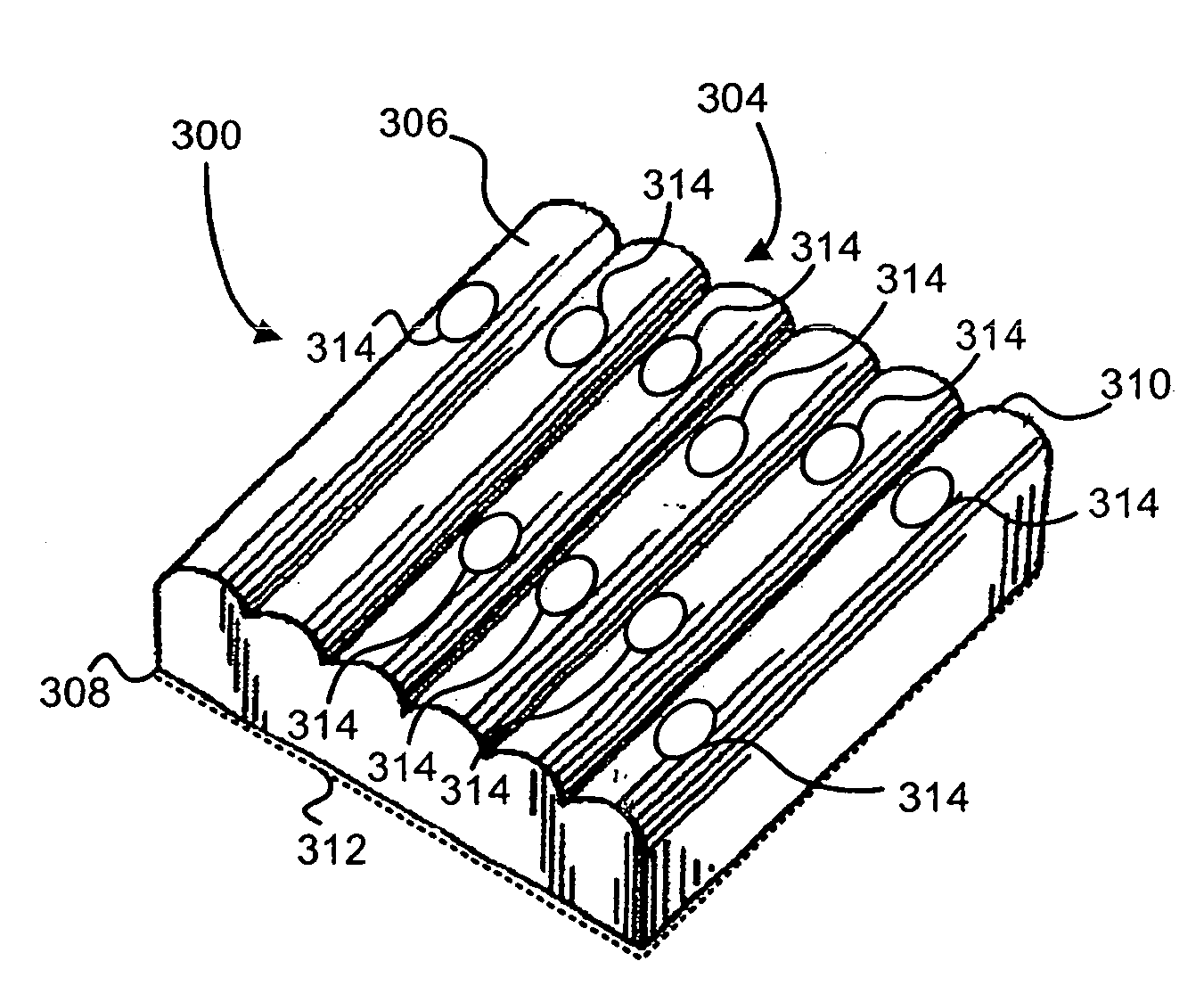

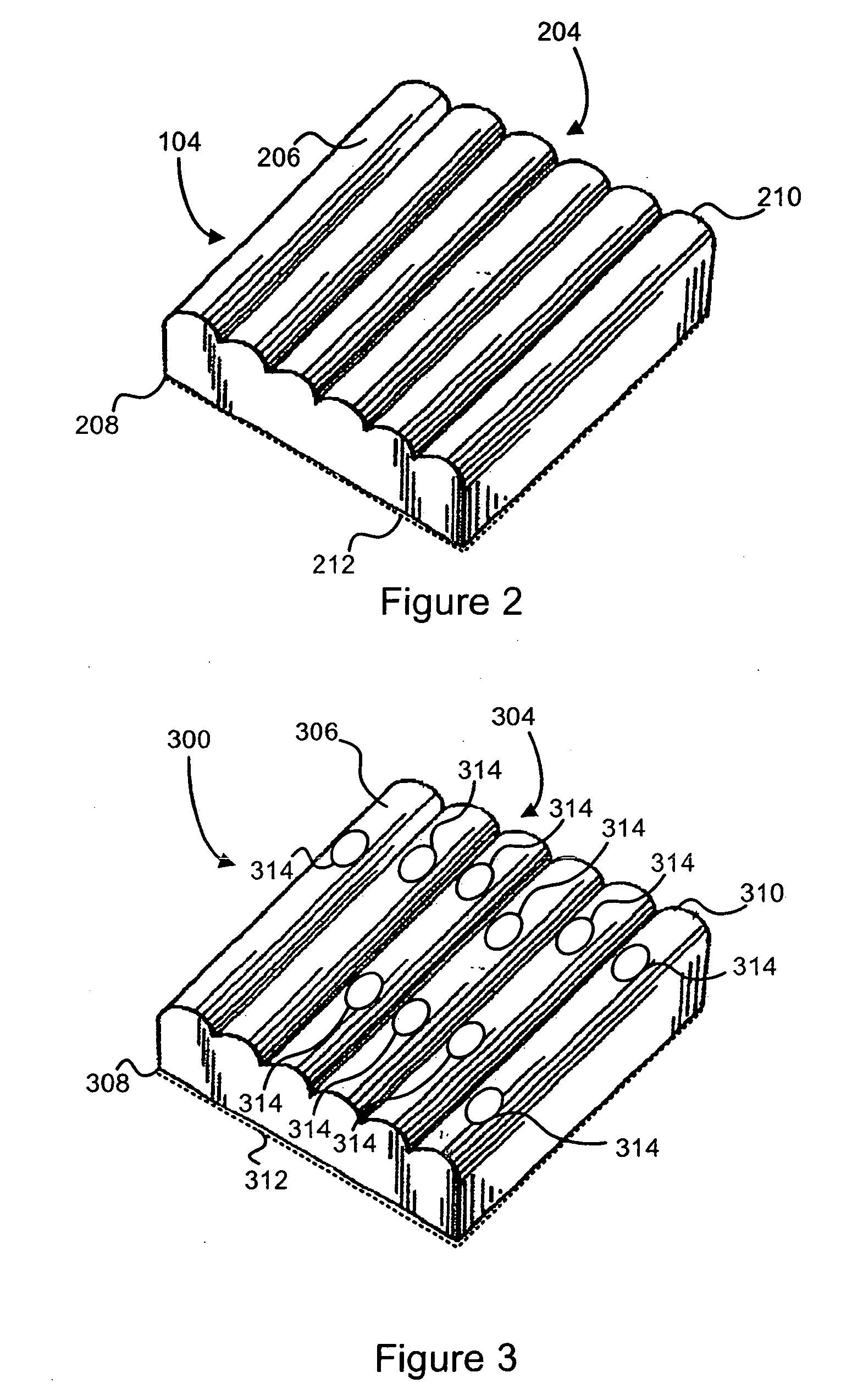

Microlens windows and interphased images for packaging and printing and methods for manufacture

InactiveUS20090071601A1Improve marketabilityMaintaining their functionalityAdhesive processesBox making operationsEngineeringMicrolens

Owner:NIMS JERRY +1

Solar foot warming shoe

The invention provides a solar foot warming shoe, and relates to the field of articles of daily use, in particular to the improvement for heating shoes. The novel foot warming shoe is exquisite in structure, good in stability and warming effect, and capable of conducting protection and warming from the source after being worn. A vamp is fixedly connected to a sole, and a lace is arranged on the vamp in a surrounding mode. The foot warming shoe is characterized by further comprising a first solar battery pack and a second solar battery pack, the vamp is provided with a toe cap part and a heel part, the first solar battery pack is detachably connected to the top face of the toe cap part, and the second solar battery pack is detachably connected to the side surface of the heel part; a positive hole and a negative hole which are communicated with both the first solar battery pack and the second solar battery pack are further formed in the sole. The solar foot warming shoe has the advantages of being good in warming effect and stability, and effectively solving the problem in the prior art that the sole of the foot is hot while the instep is cold.

Owner:吕忠光

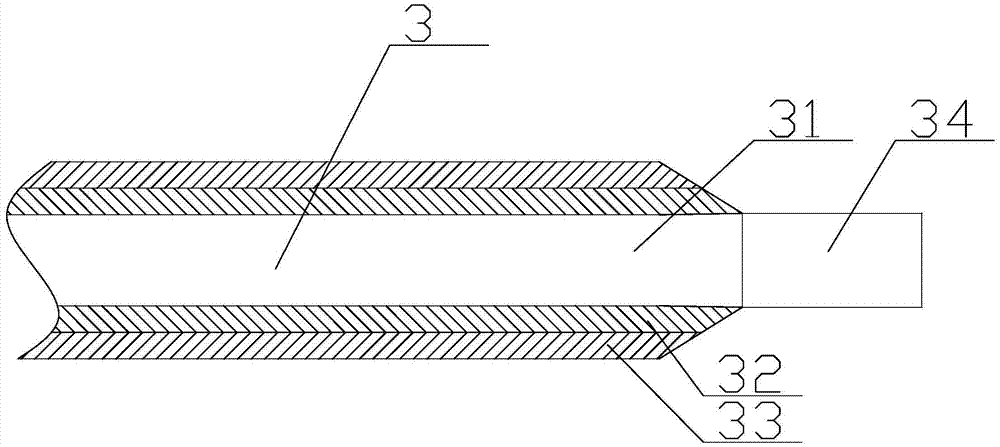

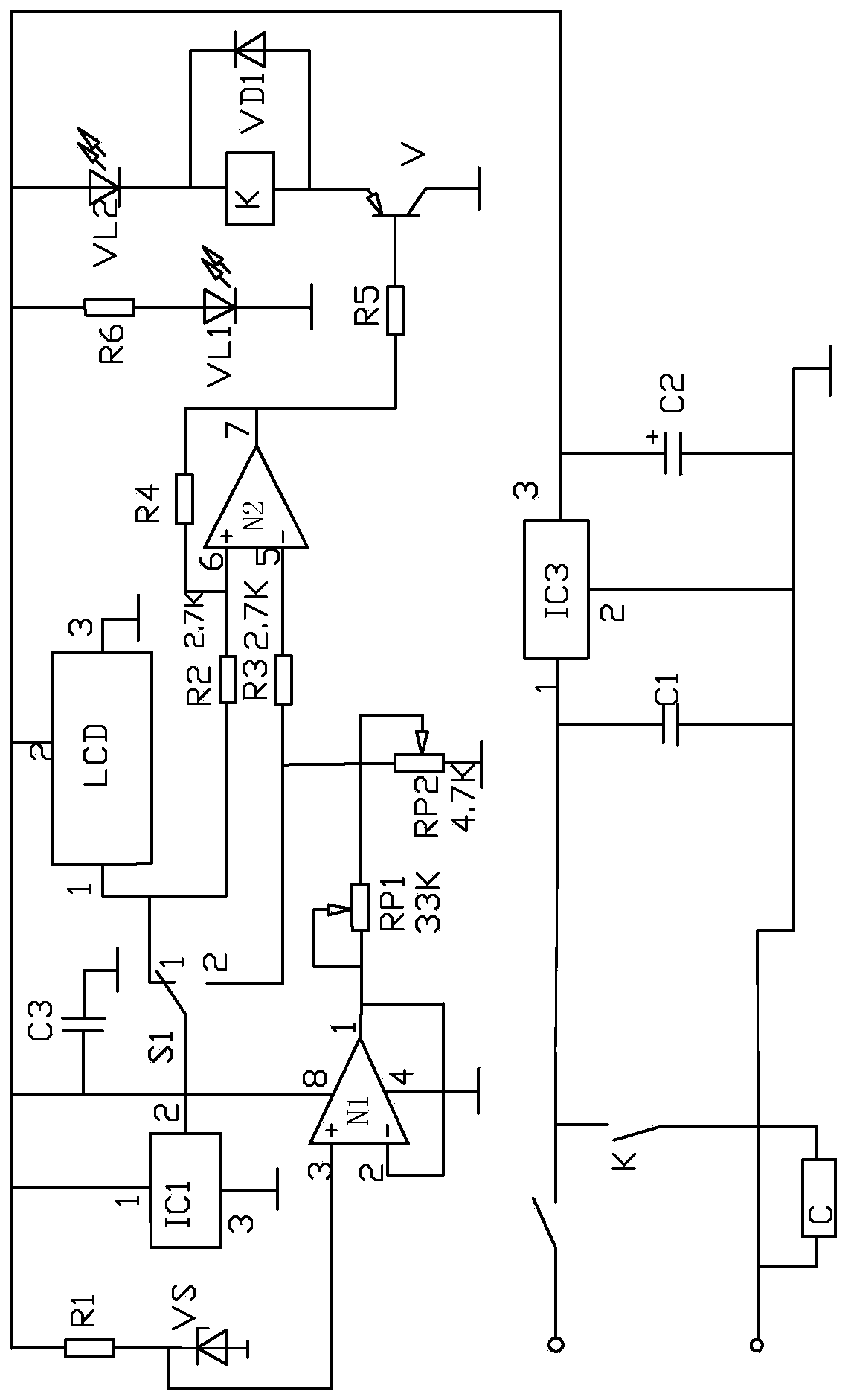

Carbon fiber heating shoes

PendingCN110831264AIntelligent temperature controlAchieve disconnectionOhmic-resistance heating circuitsFootwearFiberTemperature control

The invention discloses a fiber heating shoe that comprises a shoe body and an insole; the insole is built in the shoe body, and carbon fiber heating wires are arranged in the insole; a heating control circuit is arranged in the shoe body; the heating control circuit comprises a power supply circuit, a temperature detection circuit, a reference voltage circuit and a control circuit. The temperature detection circuit comprises a chip IC1, a switch S1 and a display LCD. A pin 2 of the chip IC1 is electrically connected with one end of the switch S1; the other end of the switch S1 is provided with a connecting point 1 and a connecting point 2, the connecting point 1 is electrically connected with a pin 1 of the display LCD, a pin 1 of the chip IC1 is electrically connected with a pin 2 of thedisplay LCD, and the display LCD is used for displaying temperature. The fiber heating shoe disclosed by the invention has an intelligent temperature control function, and can realize circuit disconnection when the temperature is higher than a set temperature and realize connection when the temperature is lower than the set temperature.

Owner:ZHEJIANG QIYI SPECIAL CLOTHING CO LTD

Novel foot warming shoe

InactiveCN107183831AGood warmth retentionImprove stabilityShoe lace fasteningsElectrical resistance and conductanceInsulation layer

The invention provides a novel foot warming shoe, and relates to the field of living goods, in particular to improvement of a heating shoe. The novel foot warming shoe which is delicate in structure, good in stability and good in warming effect is provided, and protection and warming can be conducted from the source after the novel foot warming shoe is worn. A shoe lace is arranged on a vamp in a wound mode. The foot warming shoe is characterized by further comprising a plug, a transformer, a rectifier and a storage battery; a sole is of a hollow structure, the transformer, the rectifier and the storage battery are all fixedly connected into the sole and in communication in sequence, and the plug is connected into the sole in a sliding mode and communicated with the transformer; an anode interface and a cathode interface which are communicated with the storage battery are formed in the sole; the shoe lace is composed of resistance wires, a heat insulation layer and a waterproof layer from inside to outside in sequence, and an anode adaptor and a cathode adaptor are arranged at both ends of the shoe lace. The novel foot warming shoe has the advantages of being good in warming effect and good in stability, and the problem that the foot sole is warm and the instep is cold in the prior art is effectively solved.

Owner:吕忠光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com