Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

386 results about "Gear stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gear stick (rarely spelled gearstick), gear lever (both, UK English), gearshift or shifter (US English) is a metal lever attached to the shift assembly in a manual transmission-equipped automobile and is used to change gears. In an automatic transmission-equipped vehicle, a similar device is known as a gear selector. A gear stick will normally be used to change gear whilst depressing the clutch pedal with the left foot to disengage the engine from the drivetrain and wheels. Automatic transmission vehicles, semi-automatic transmissions, and those with continuously variable transmission gearboxes do not require a clutch pedal.

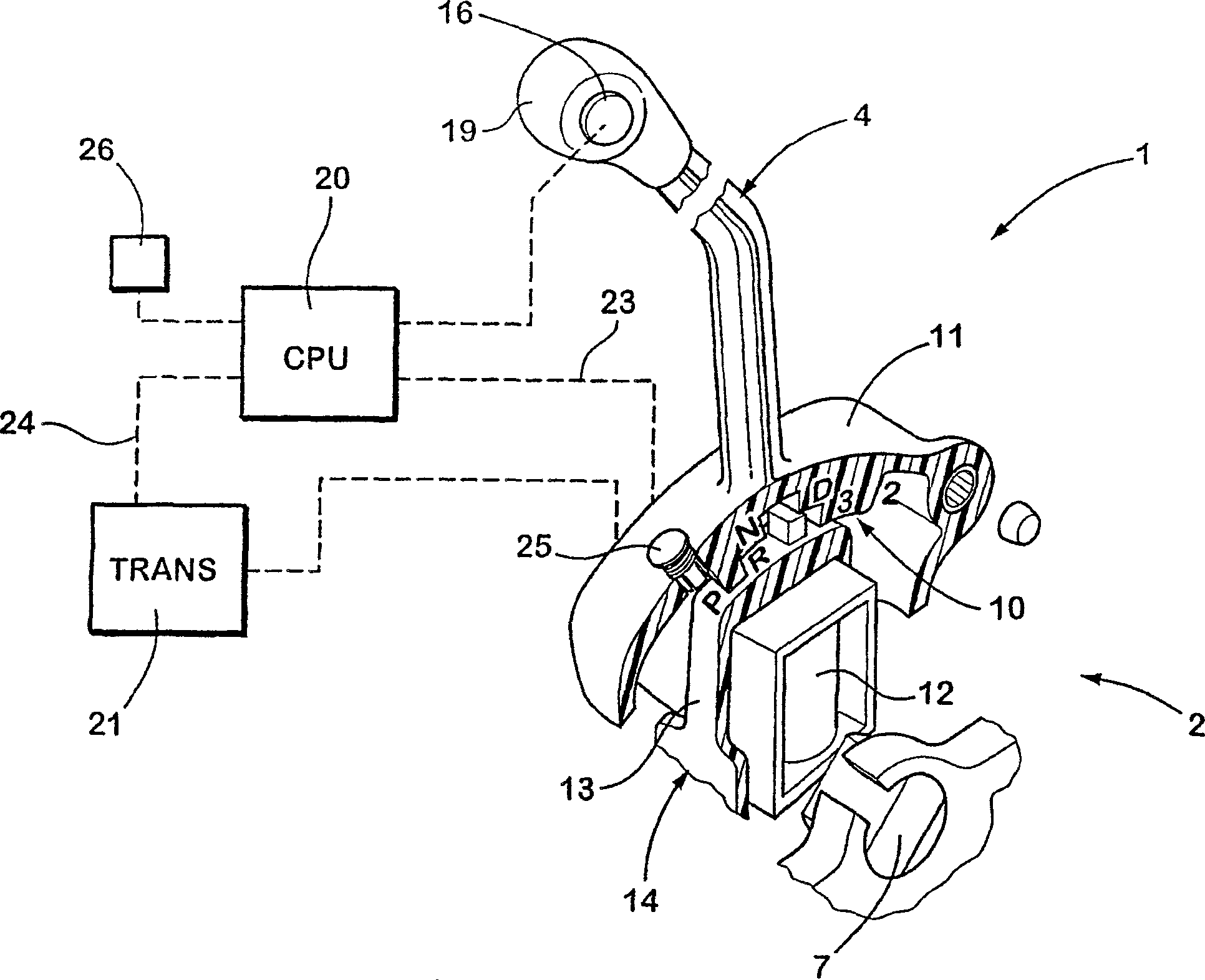

Haptic shifting devices

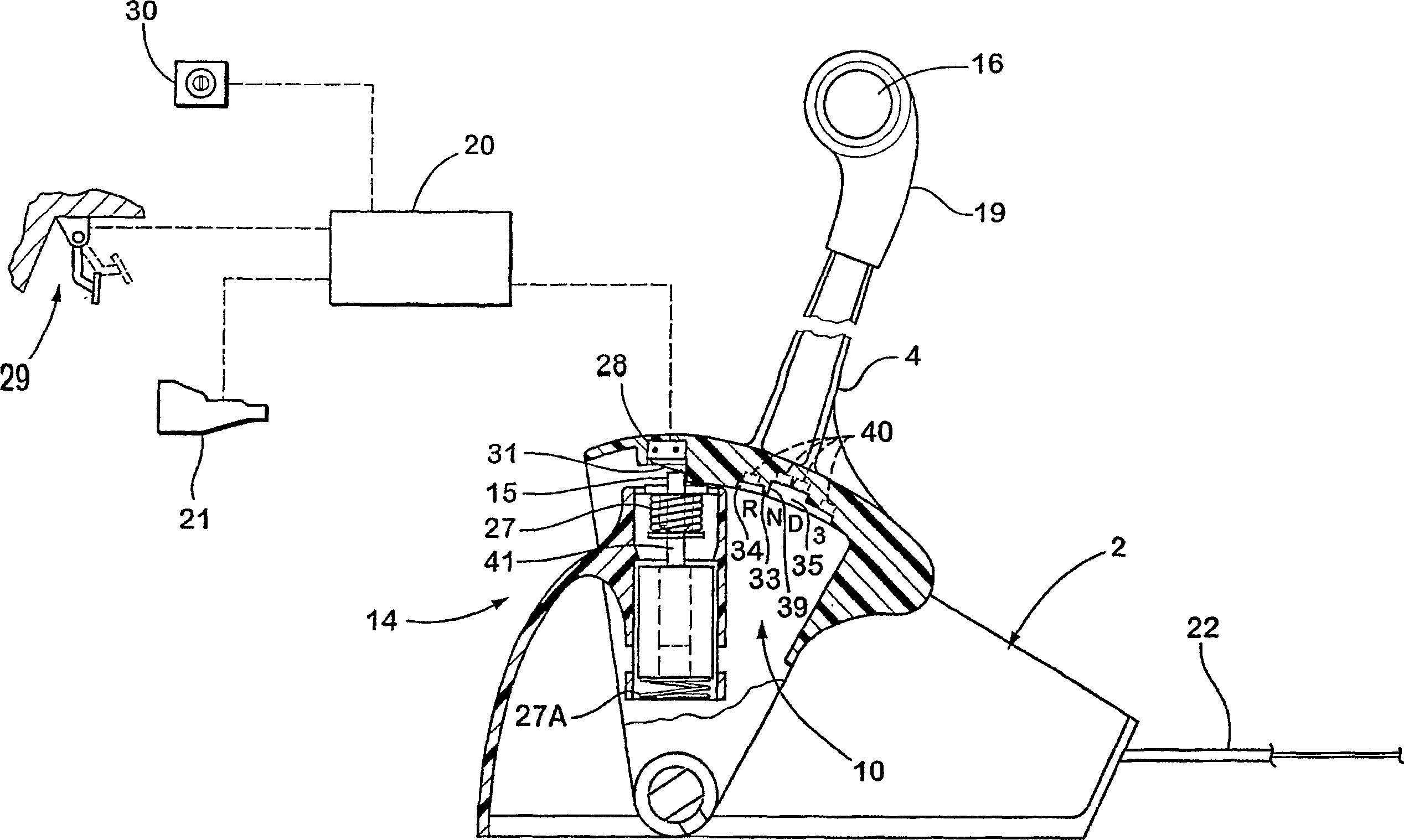

InactiveUS6904823B2Control operationsControl selectionManual control with multiple controlled membersGearing controlIn vehicleEngineering

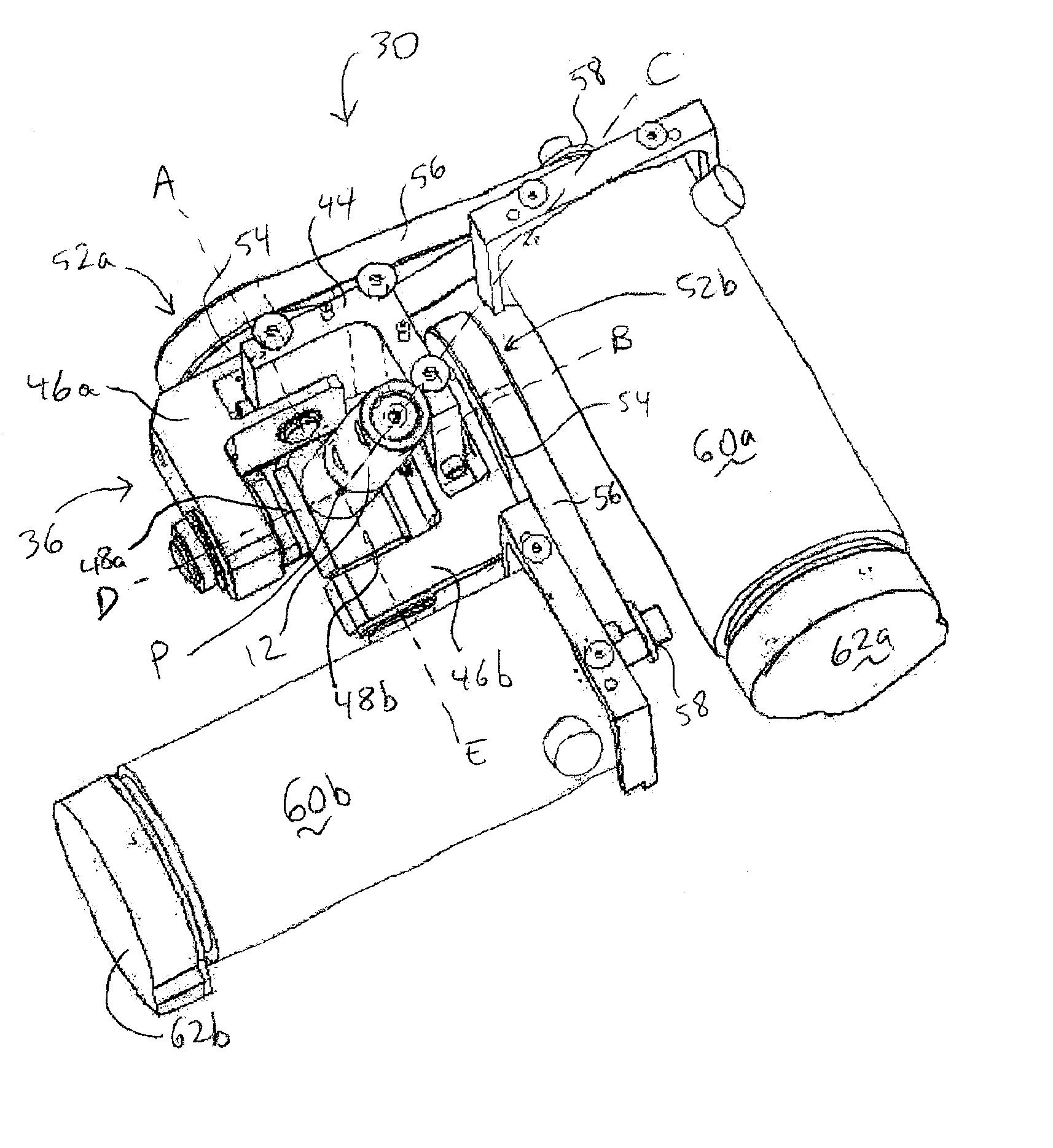

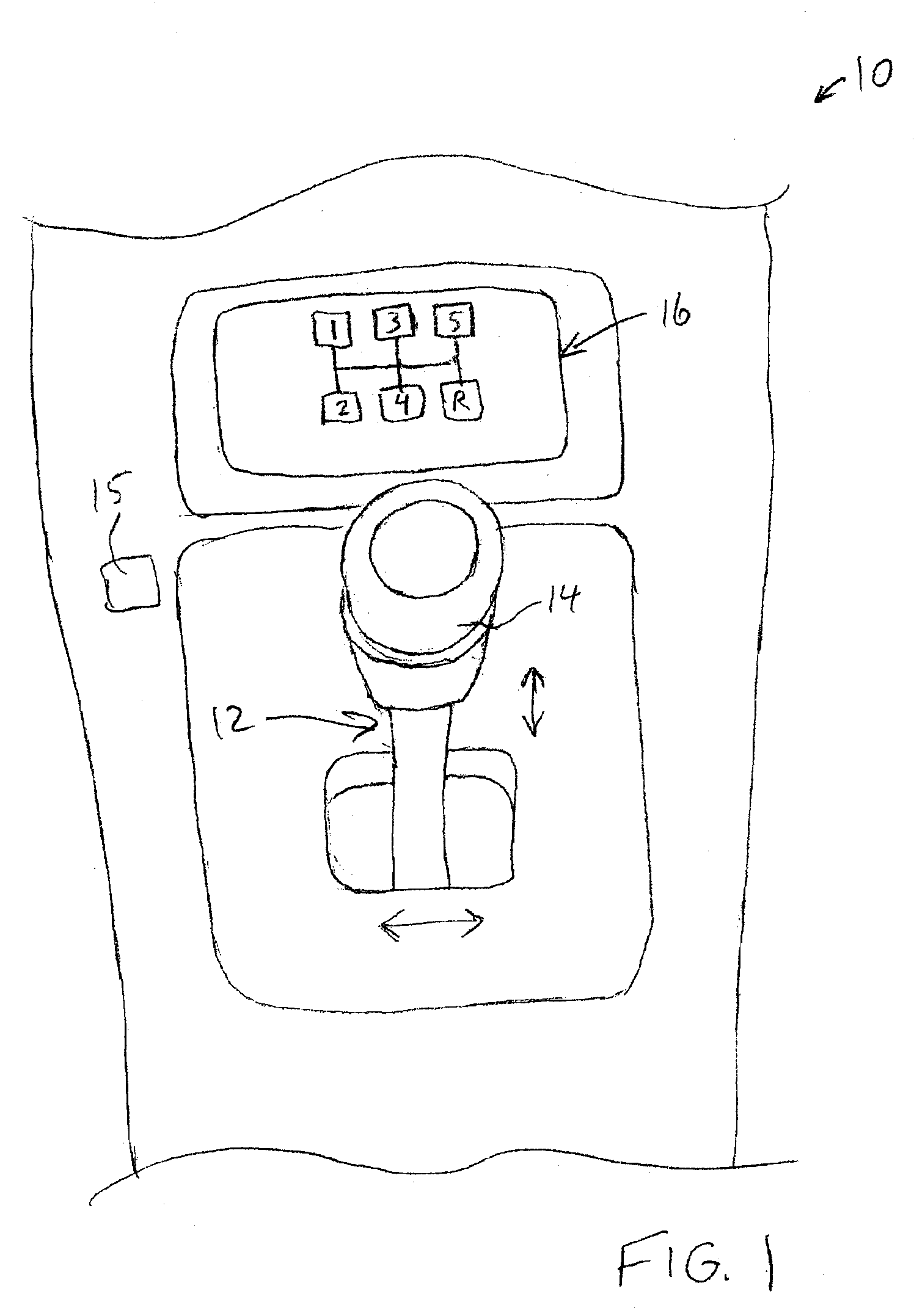

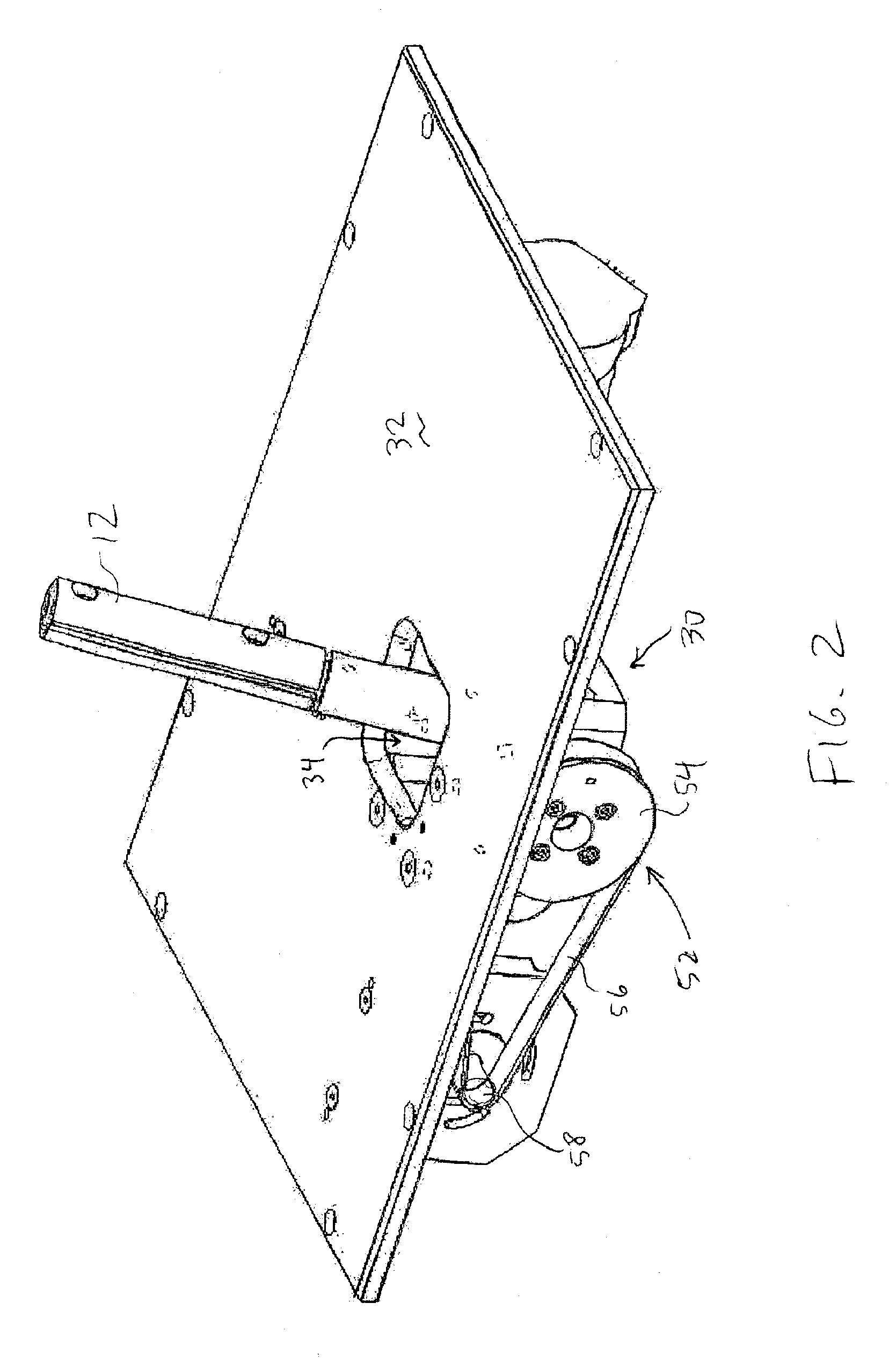

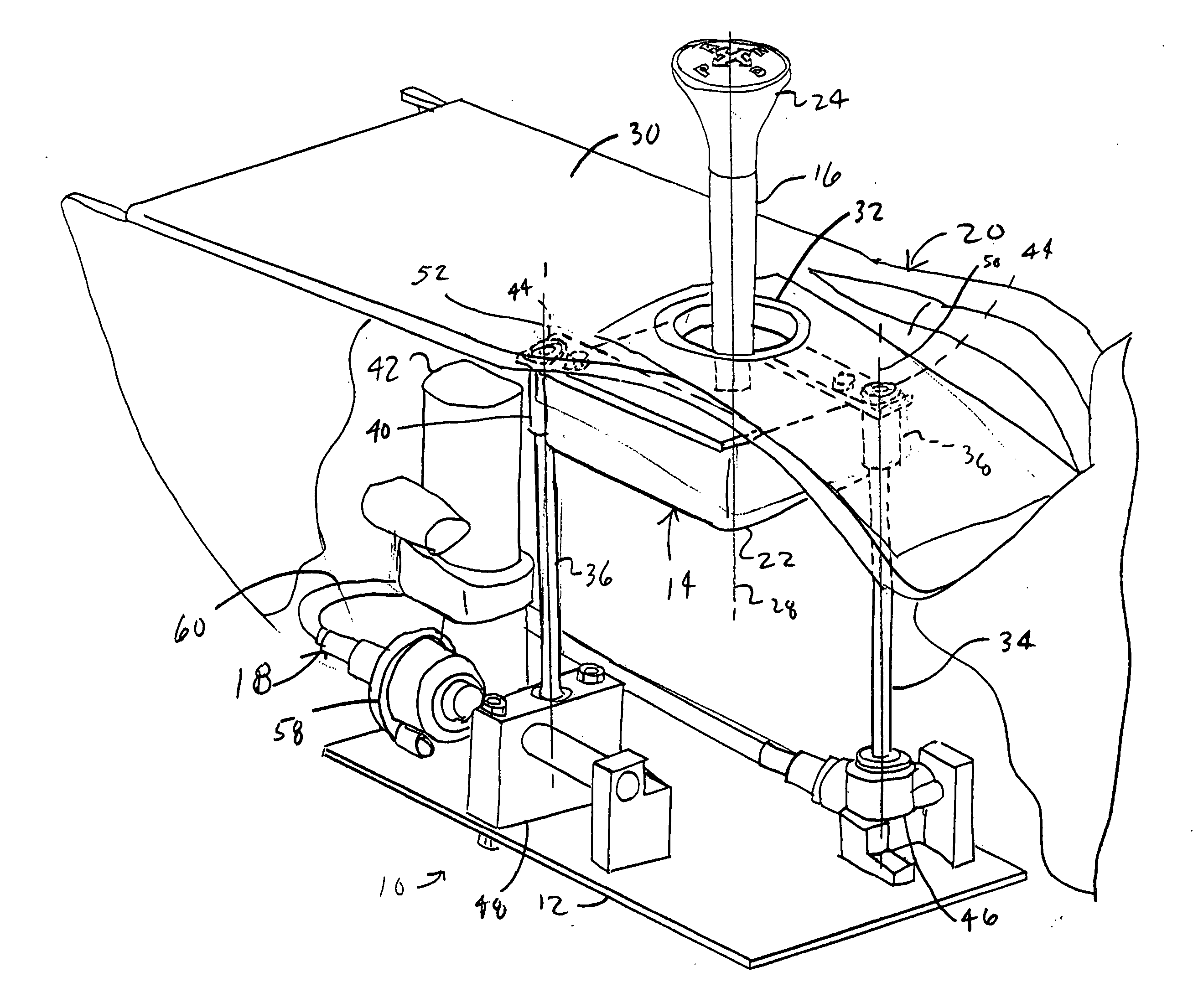

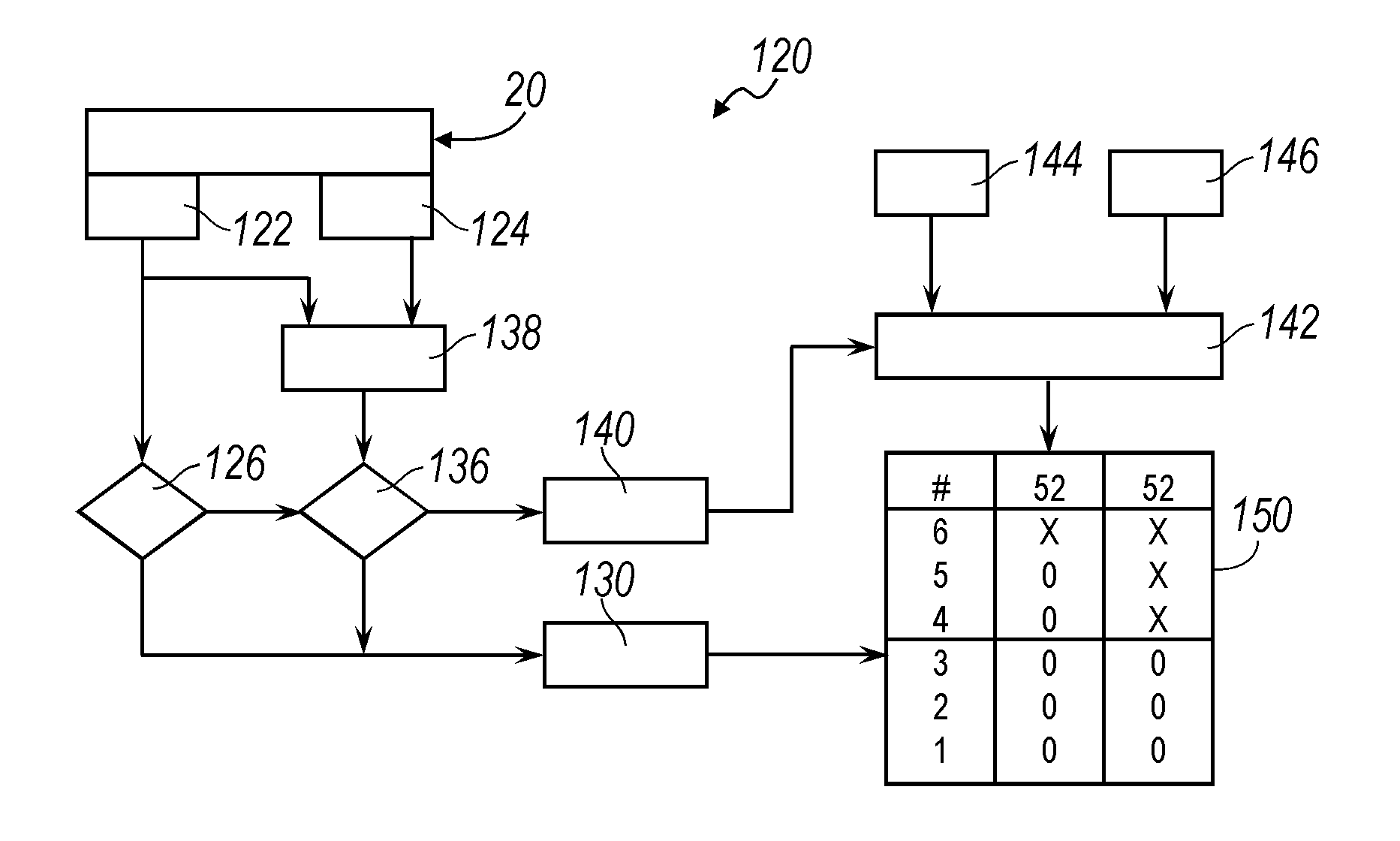

A haptic shift device for use in shift-by-wire systems in vehicles. The haptic shift device includes a shift lever manipulatable by a user. At least one sensor detects a position of the shift lever, and a transmission gear of the vehicle is caused to be changed based on the position of the shift lever. At least one electrically-controlled actuator outputs a force on the shift lever. In some embodiments, the shift lever is moveable within a pattern and is blocked from areas outside the boundaries of the pattern. The actuator(s) can be active or passive, and / or a variable mechanical gate can be used to implement the pattern. Provided shifting modes can include automatic, manual, and / or sequential modes. Other shifting modes can also be provided.

Owner:IMMERSION CORPORATION

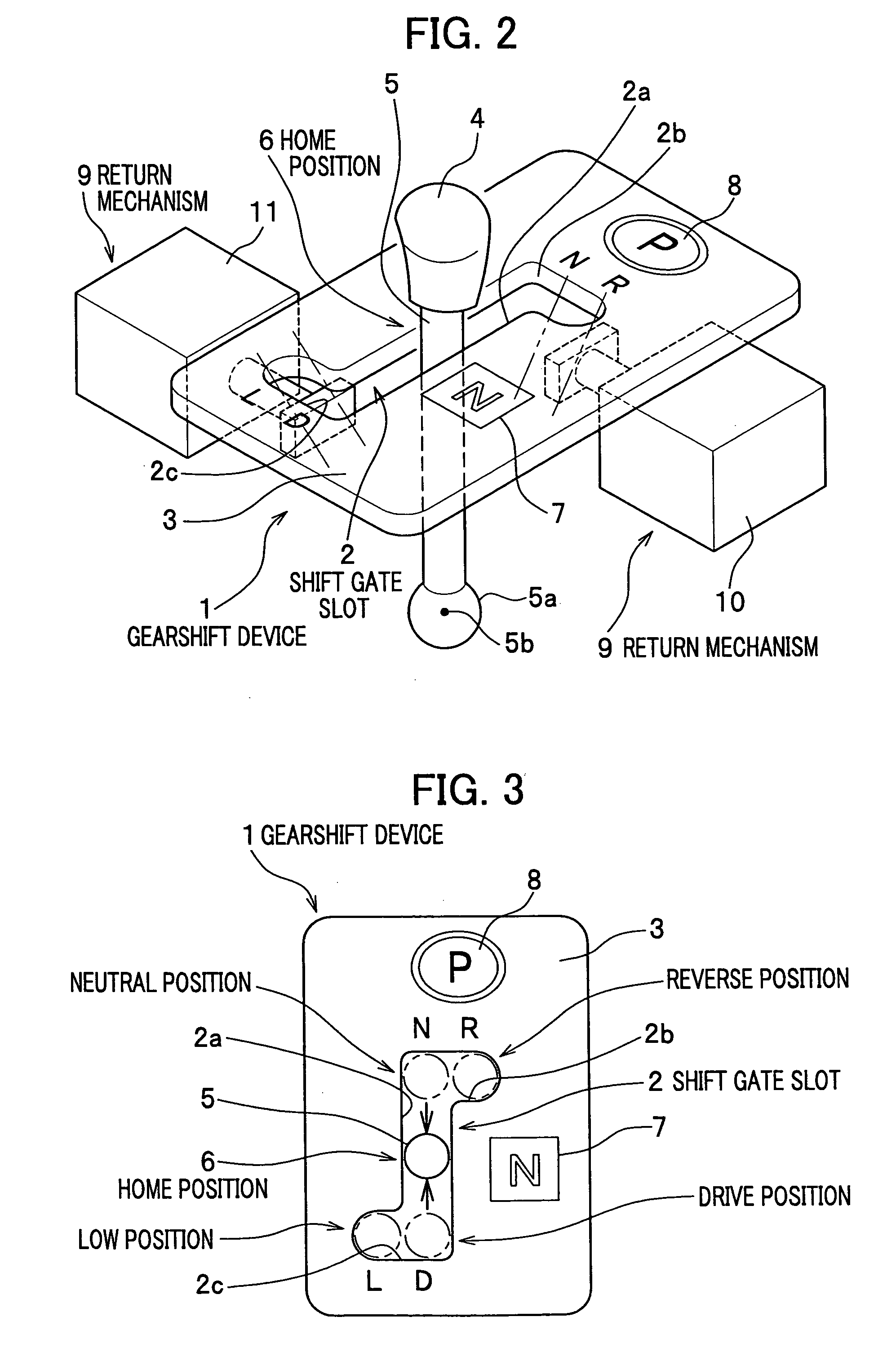

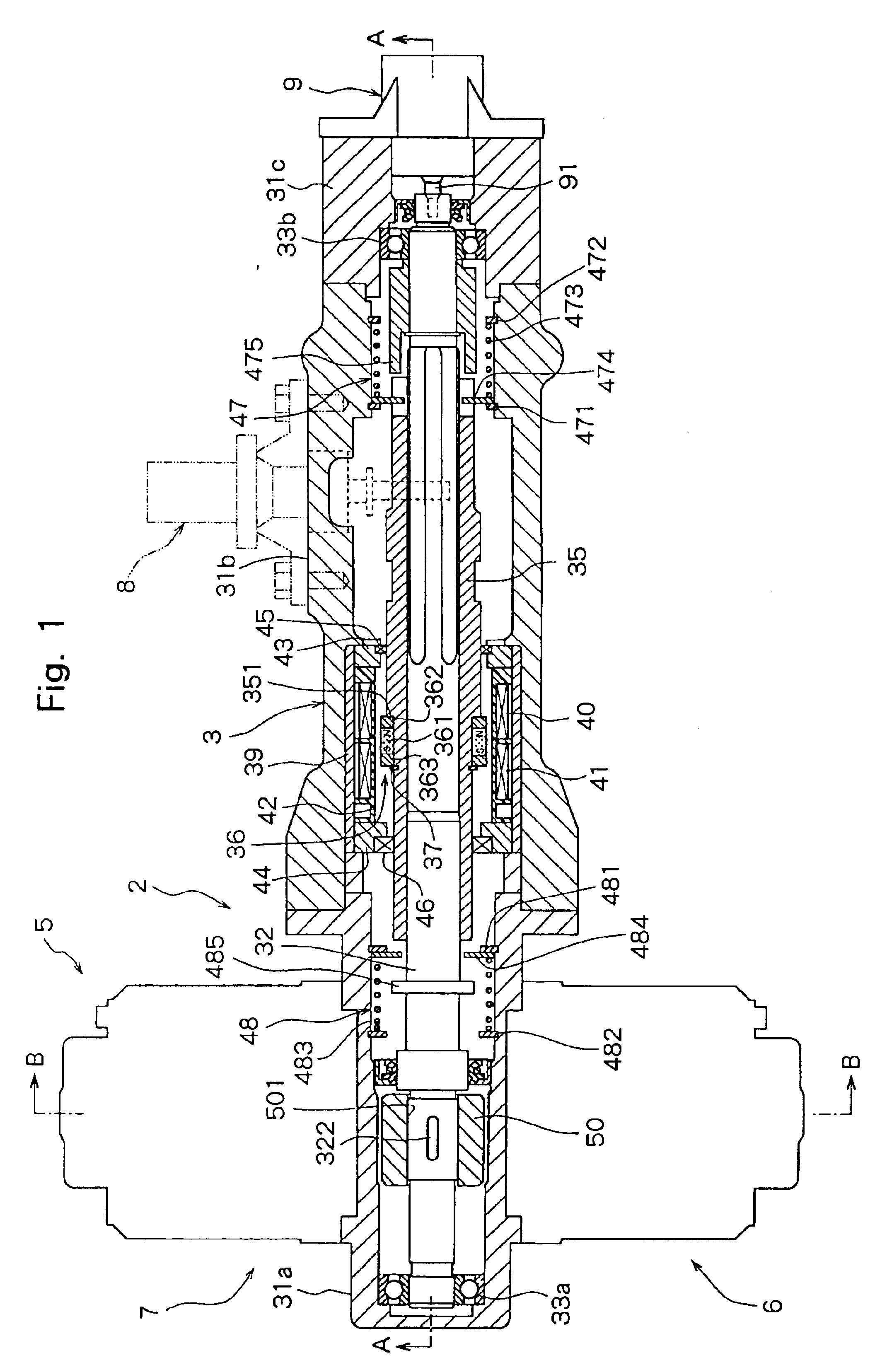

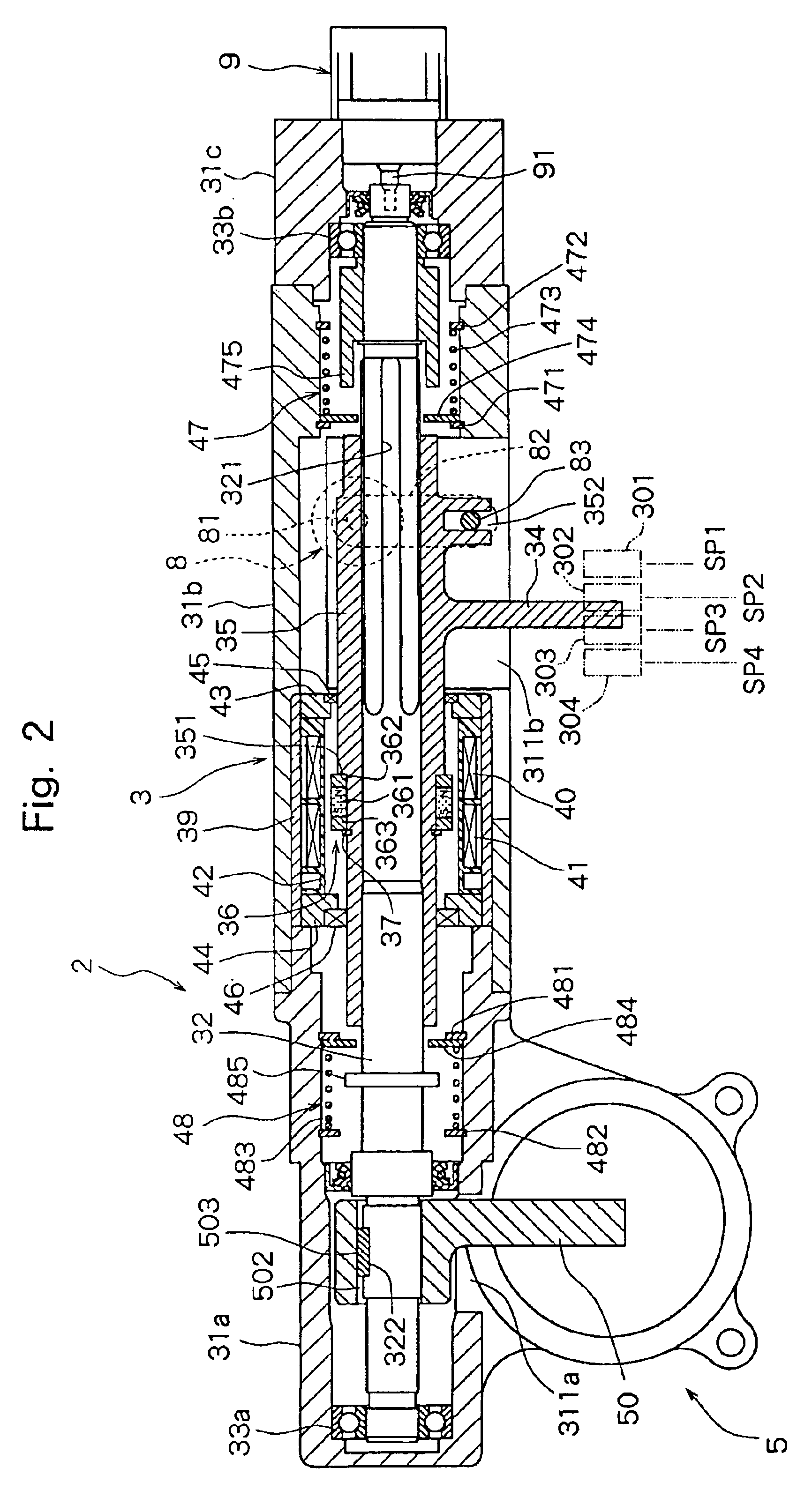

Gearshift device and method of controlling same

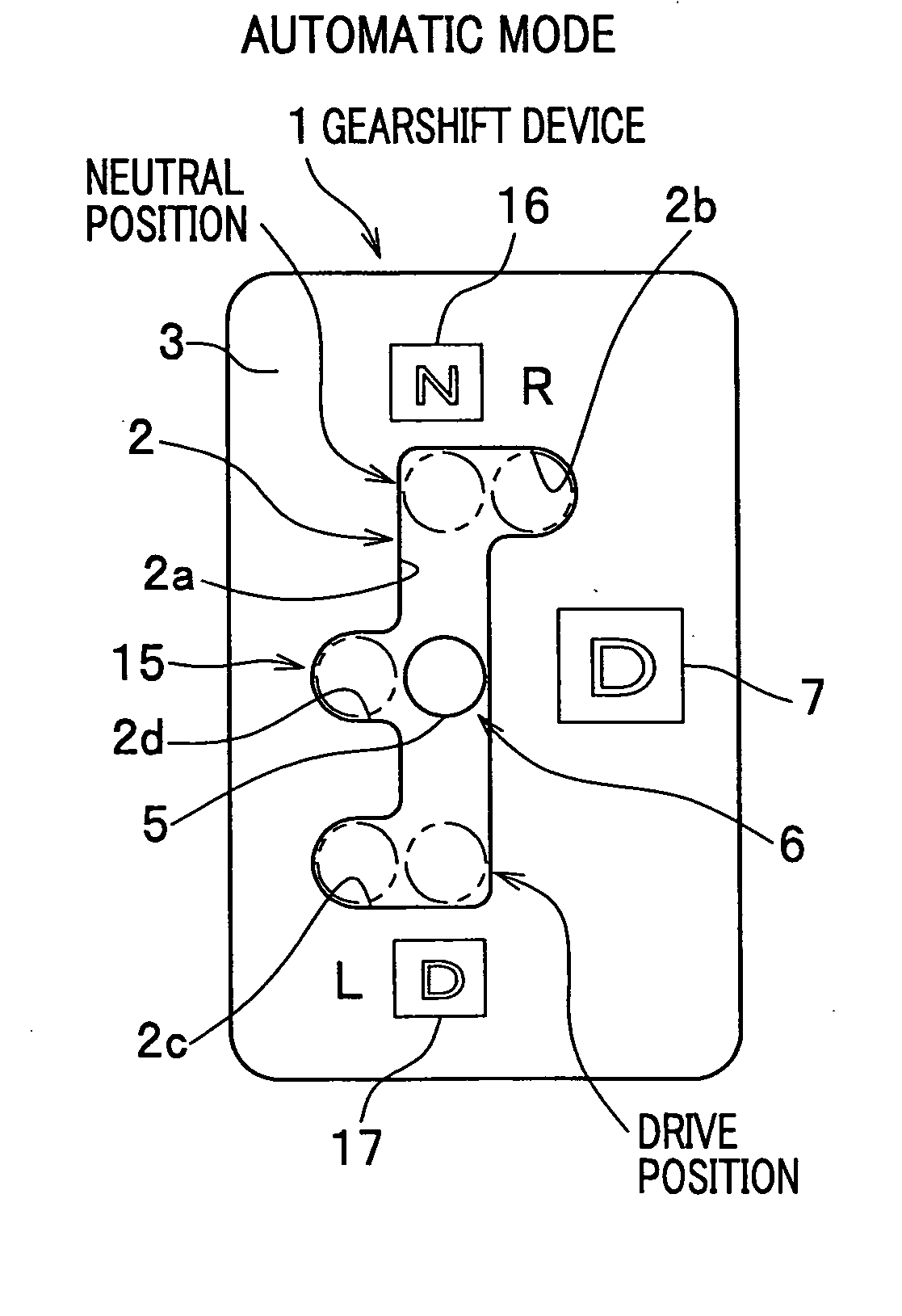

InactiveUS20060053930A1Easy to identifyEasy to operateManual control with multiple controlled membersGearing controlAutomatic transmissionControl engineering

In an automatic transmission, a shift lever is operable to move to one of a plurality of shift positions corresponding to ranges established as selectable options. The plurality of shift positions are each configured as one of a momentary position allowing the shift lever to automatically return to a home position and a retention position allowing the shift lever to be held therein. A return mechanism for causing the shift lever held in the retention position to return to the home position is provided. The return mechanism is enabled on one of conditions that the parking switch be turned on and that an ignition switch be turned off. In a manual transmission, a return mechanism for causing the shift lever held in a gear stage to return to a home position is provided, and the return mechanism is enabled on condition that an ignition switch be turned off.

Owner:HONDA MOTOR CO LTD

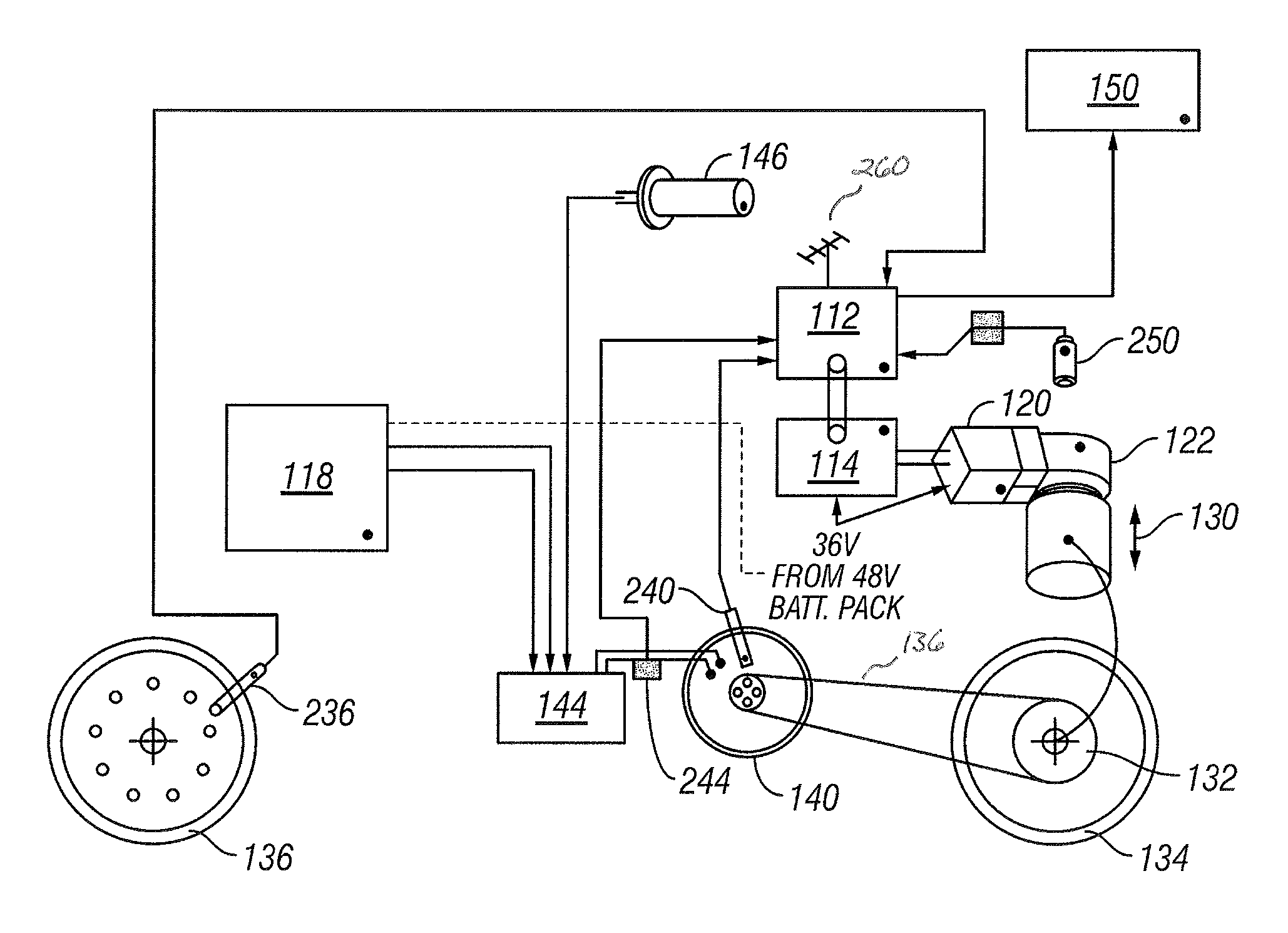

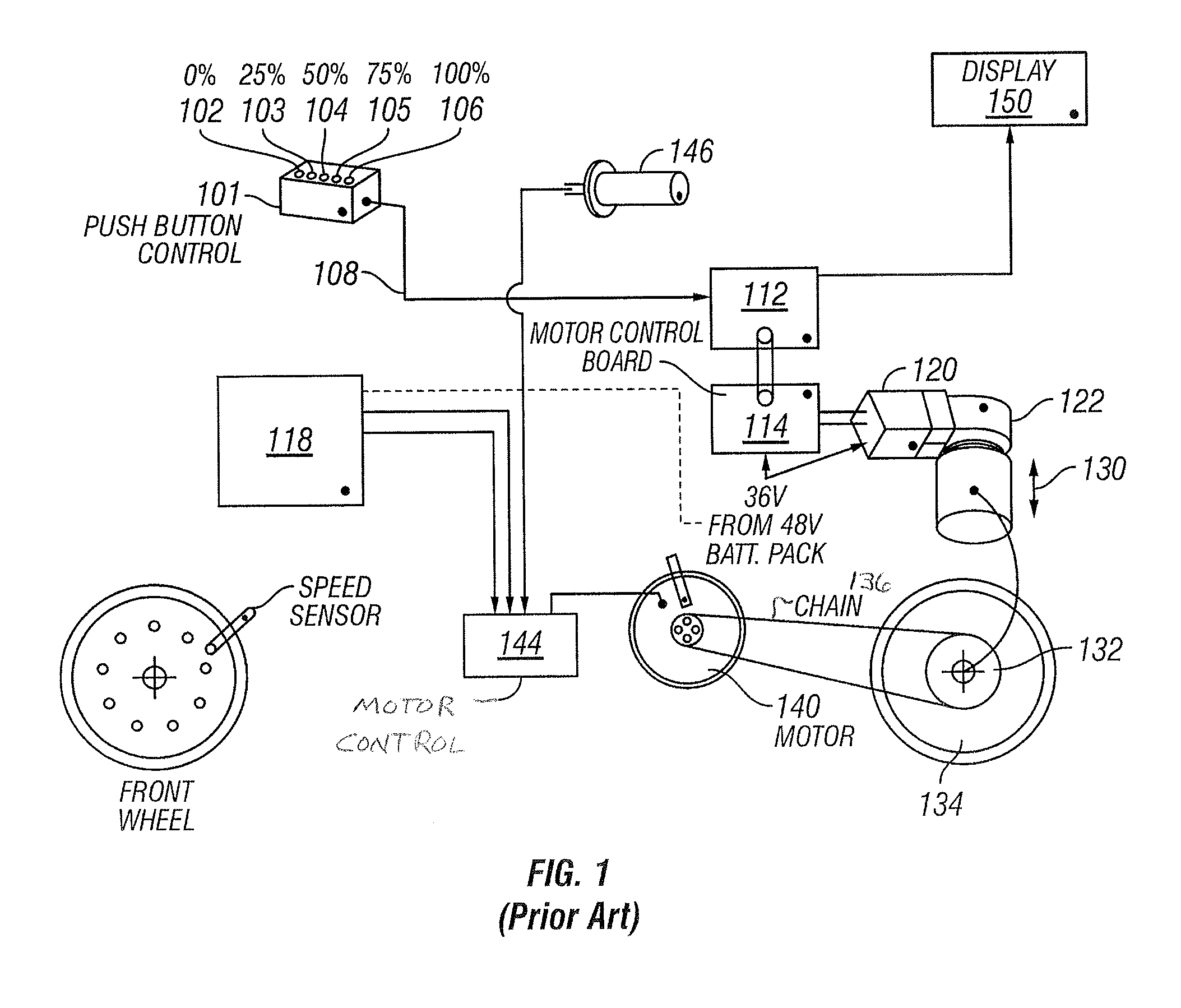

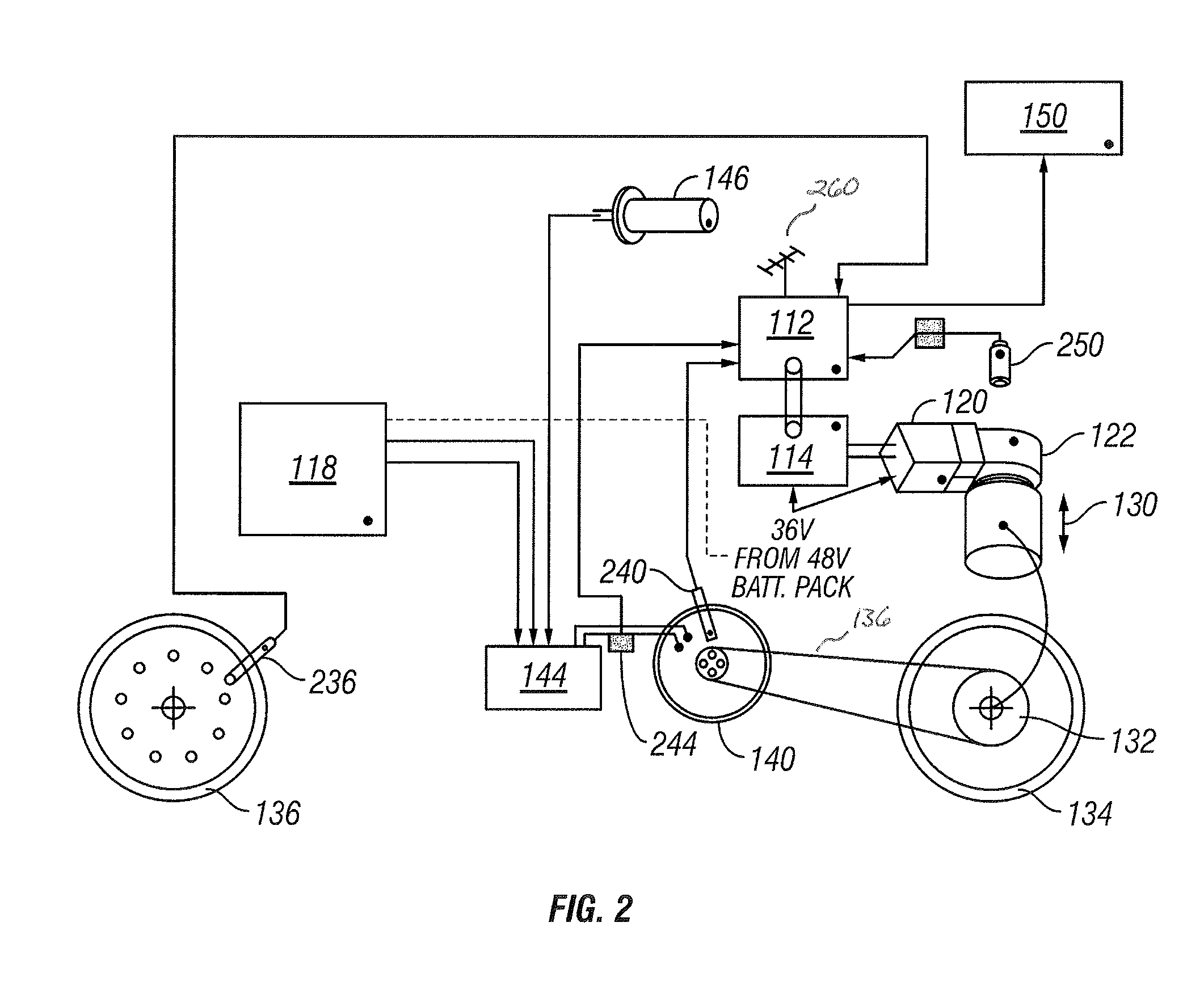

Scooter shifter

The present invention provides a system and method for automatically adjusting a continuously variable transmission (CVT) in a motorized vehicle. A microprocessor processor in the vehicle receives data about the operating status of the vehicle from a plurality. Examples of vehicle data include vehicle speed, motor speed, throttle position, current draw from a battery, and battery level. A servo motor is in mechanical communication with the CVT and provides an axial force to adjust the CVT. The microprocessor uses lookup tables of optimal set points for vehicle data to instruct the servo motor to adjust the transmission ratio of the CVT according to the vehicle data provided by the sensors.

Owner:FALLBROOK INTPROP COMPANY

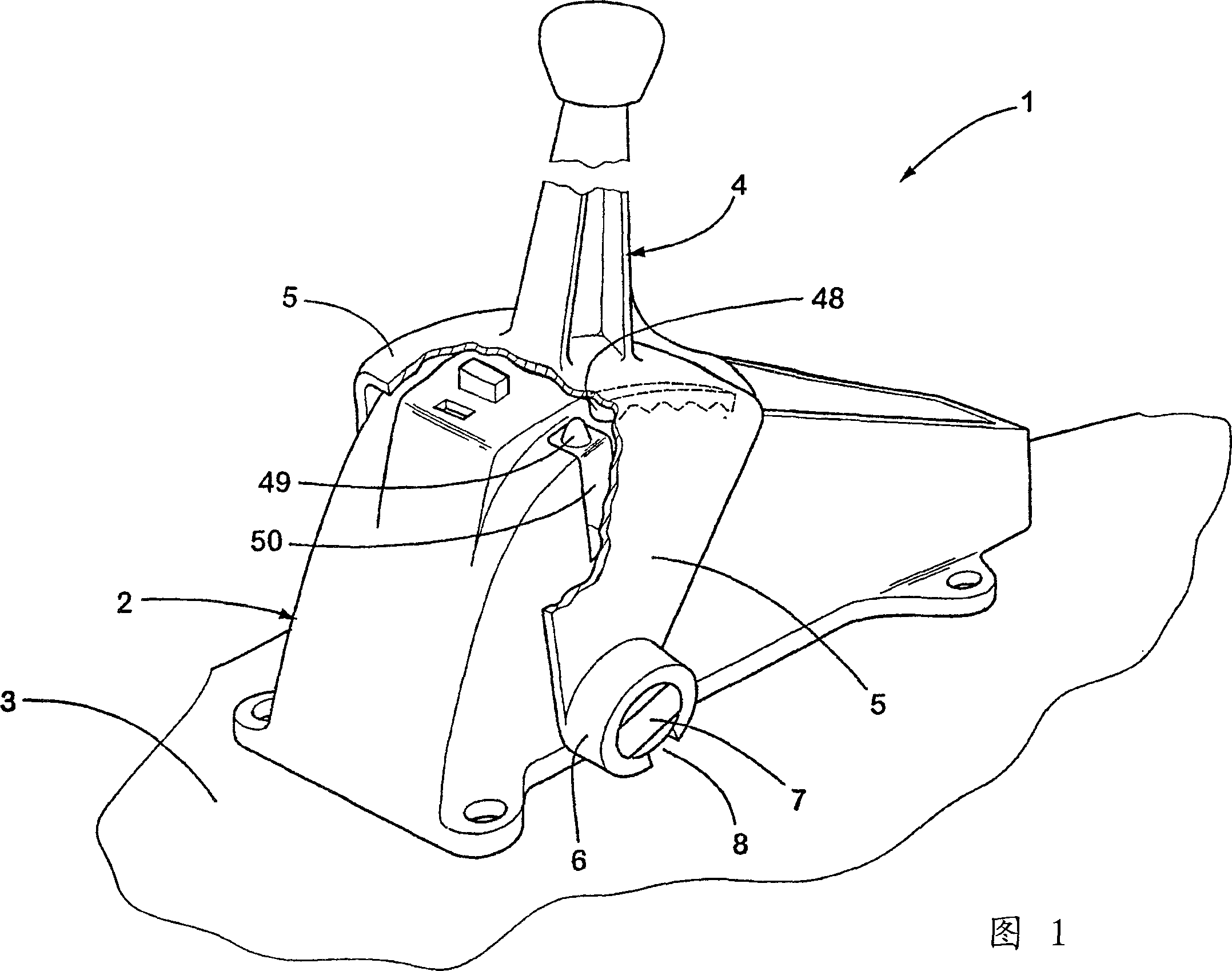

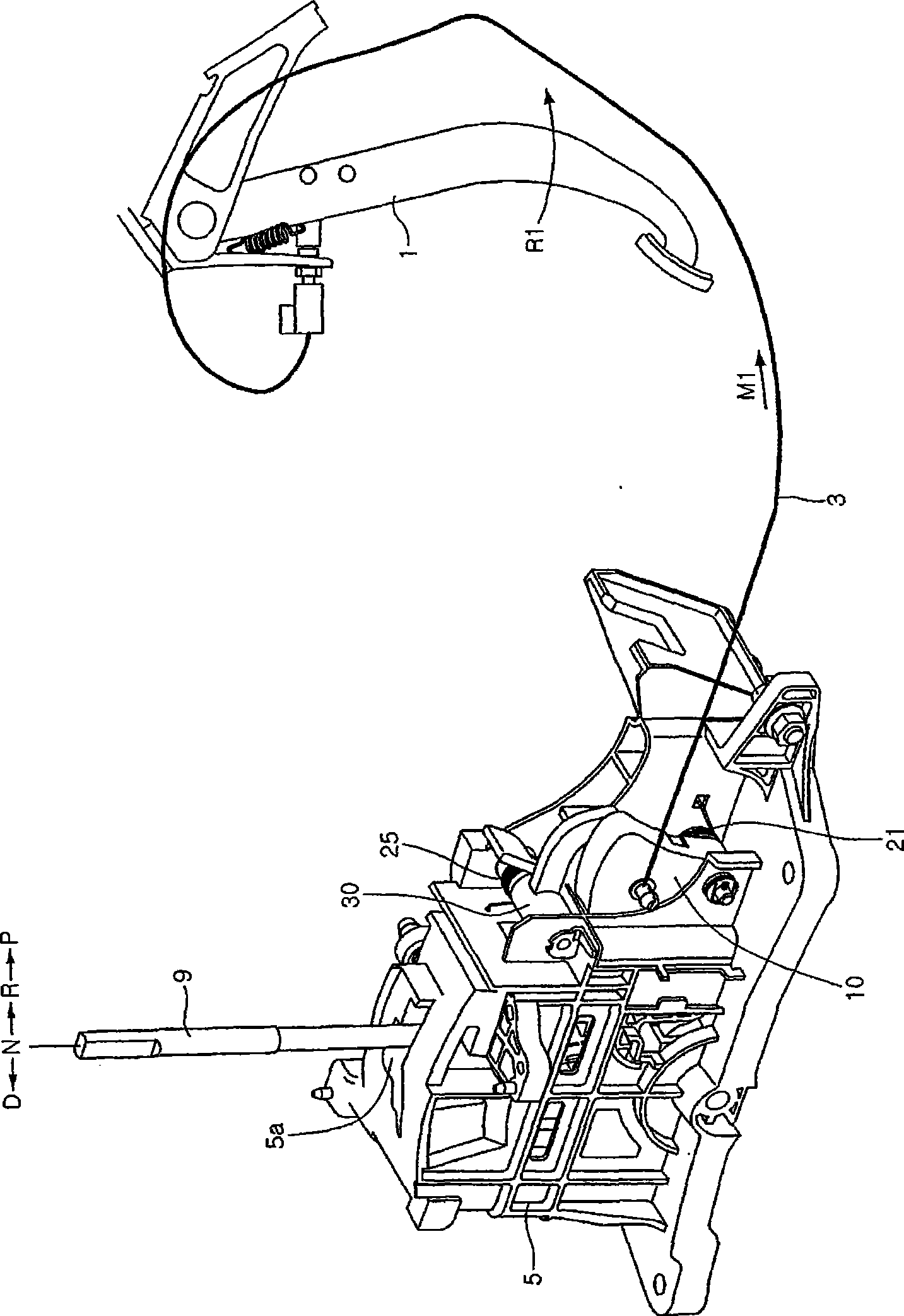

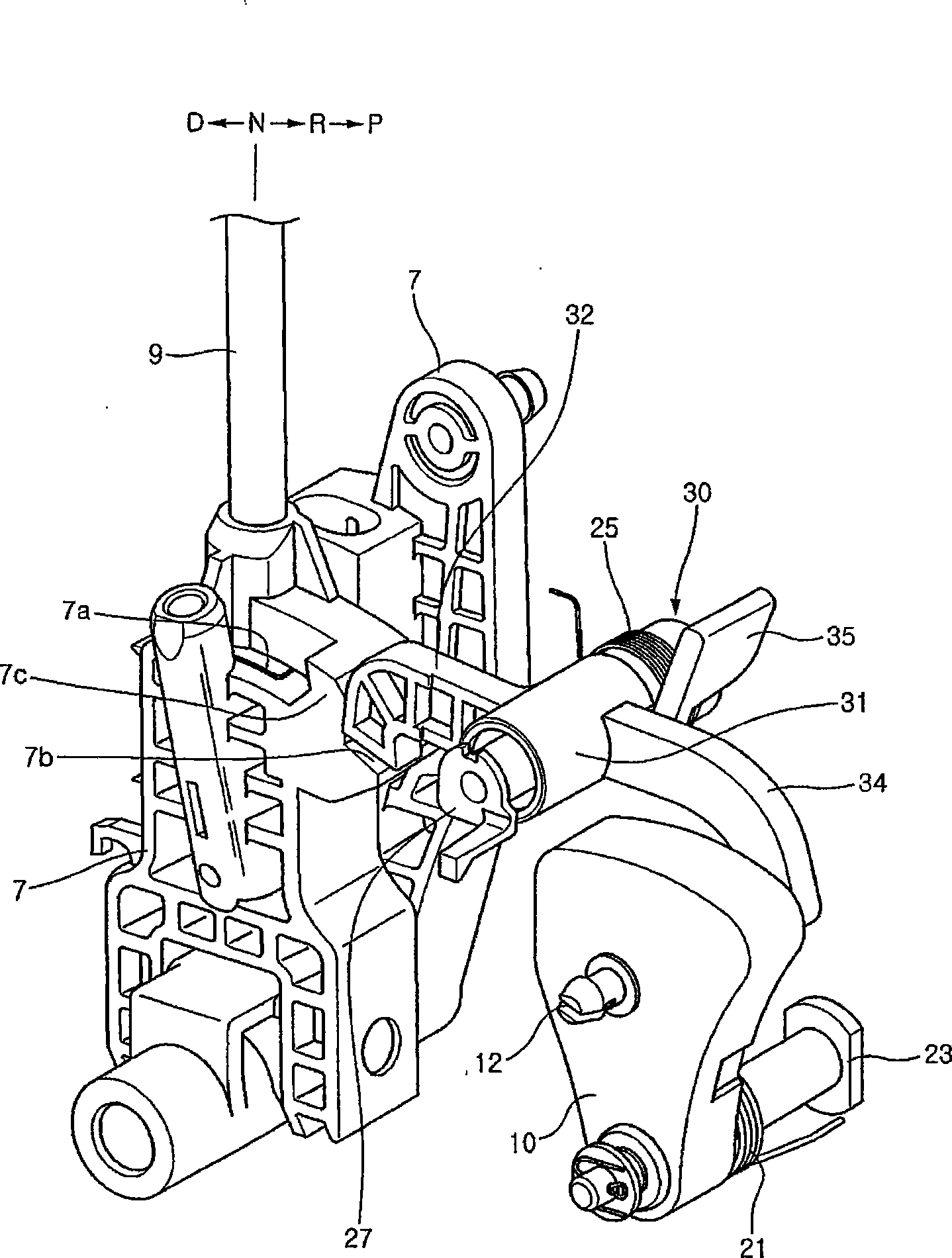

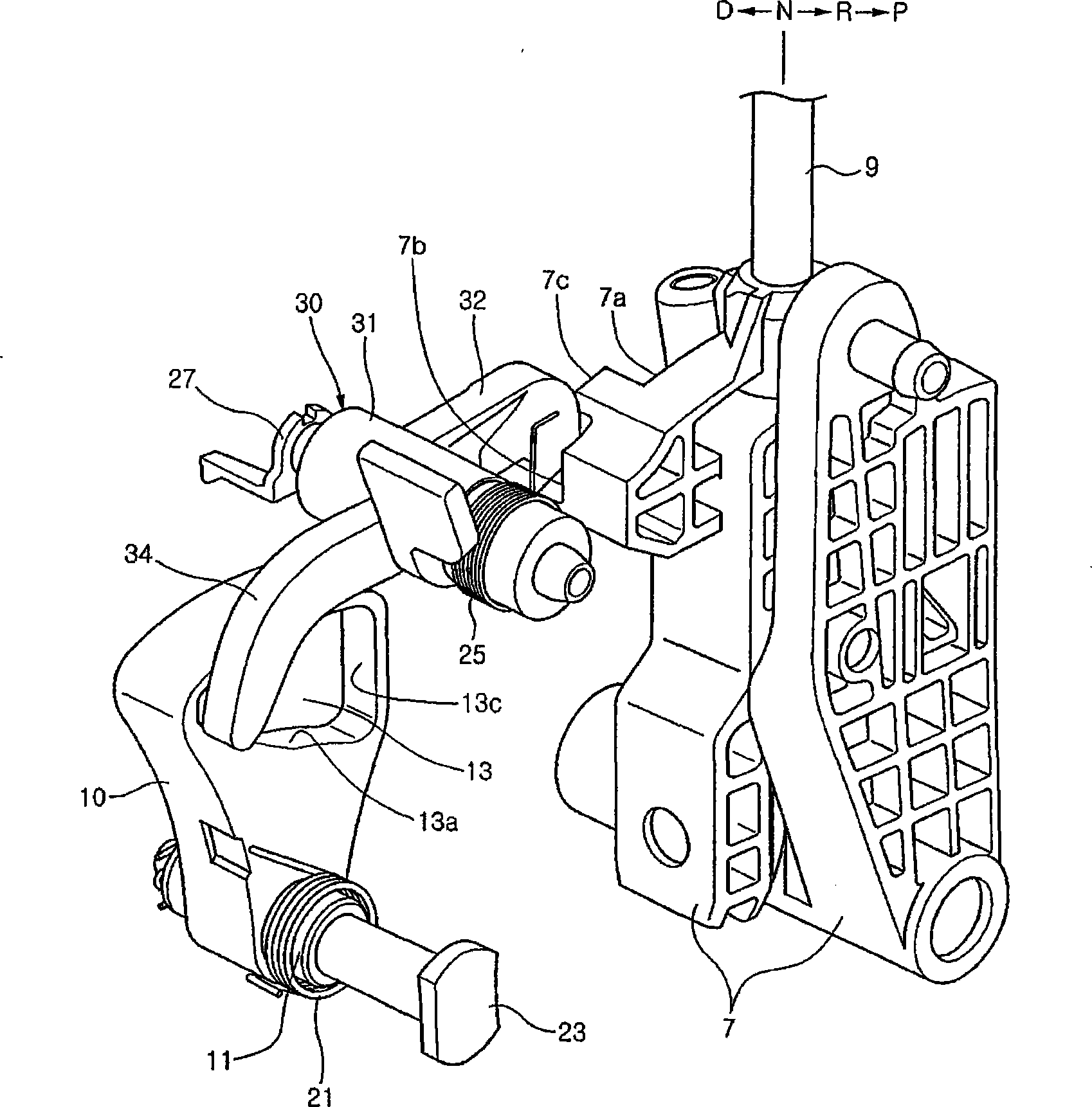

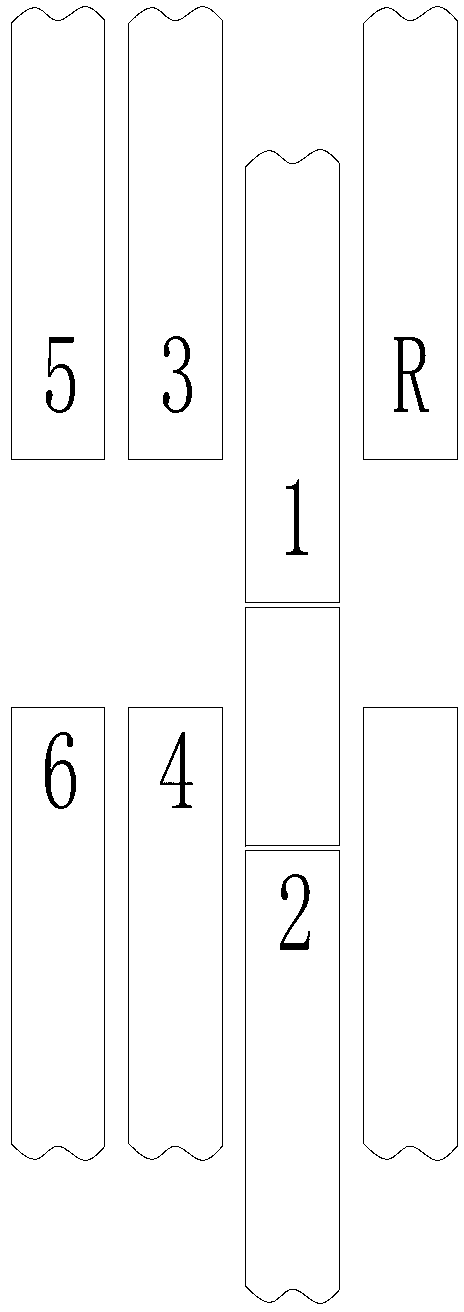

Shift lever unit

InactiveUS6718842B1Compact size of shiftEasy accessGearing controlLimiting/preventing/returning movement of partsElectricityElectrical control

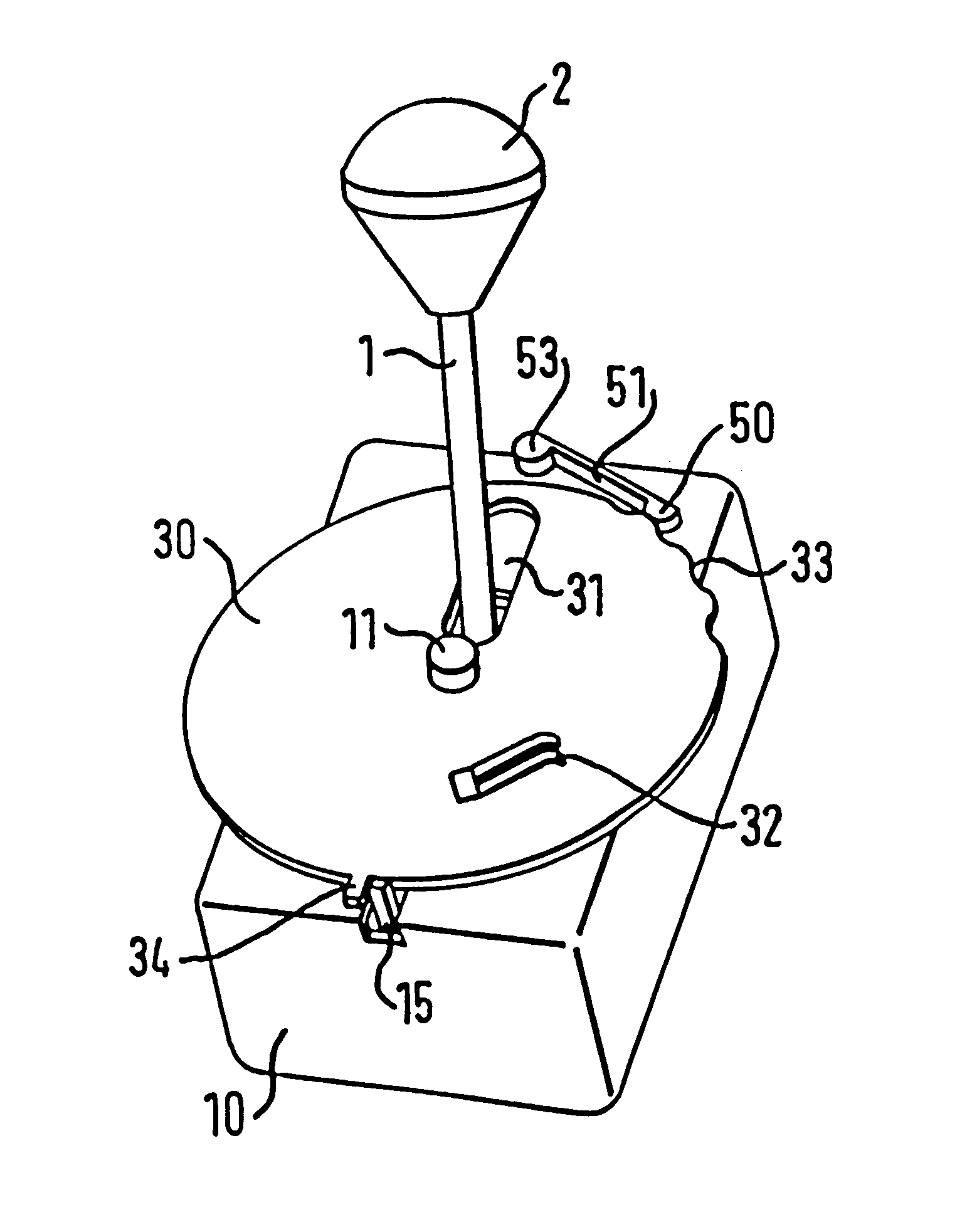

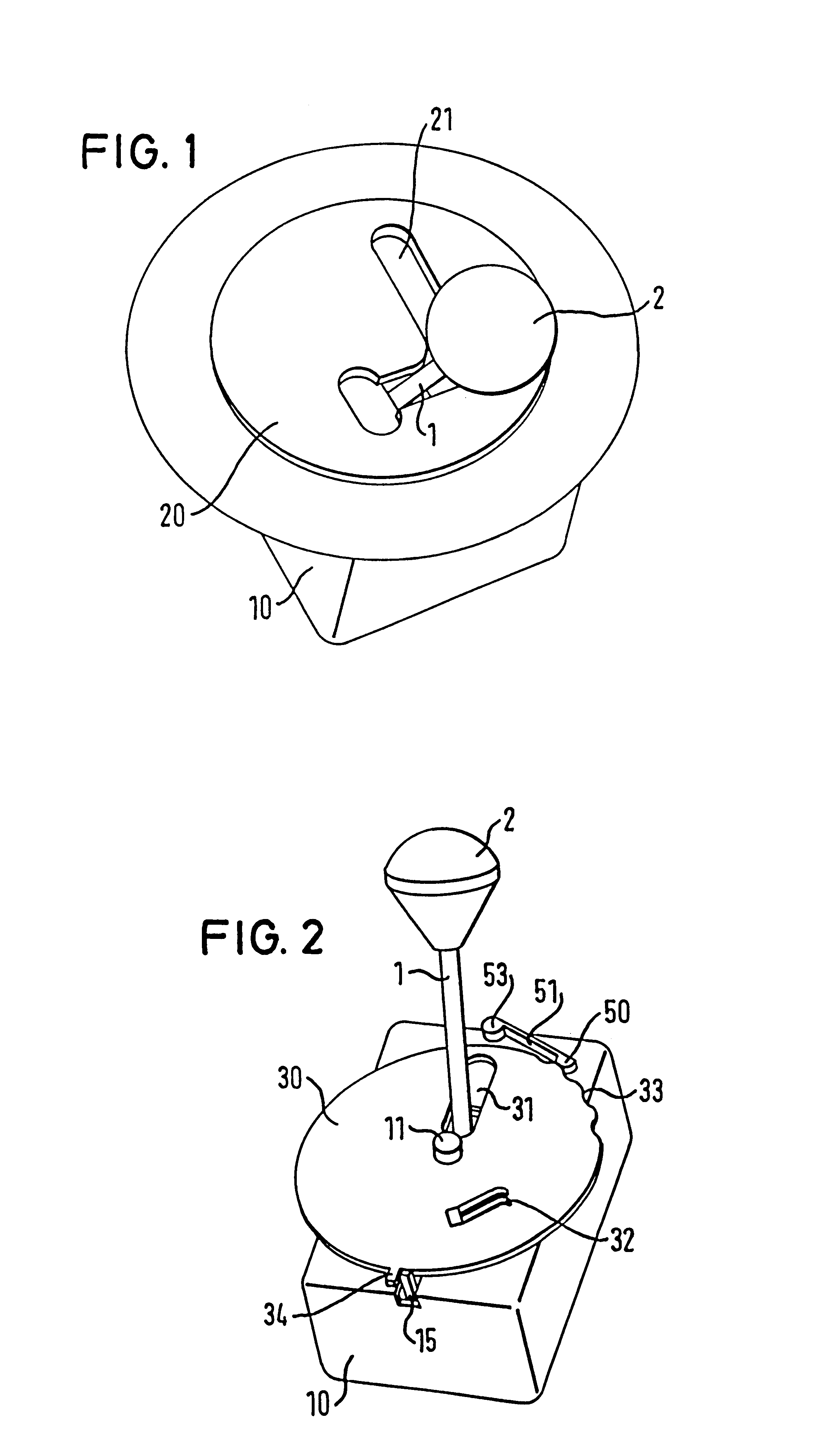

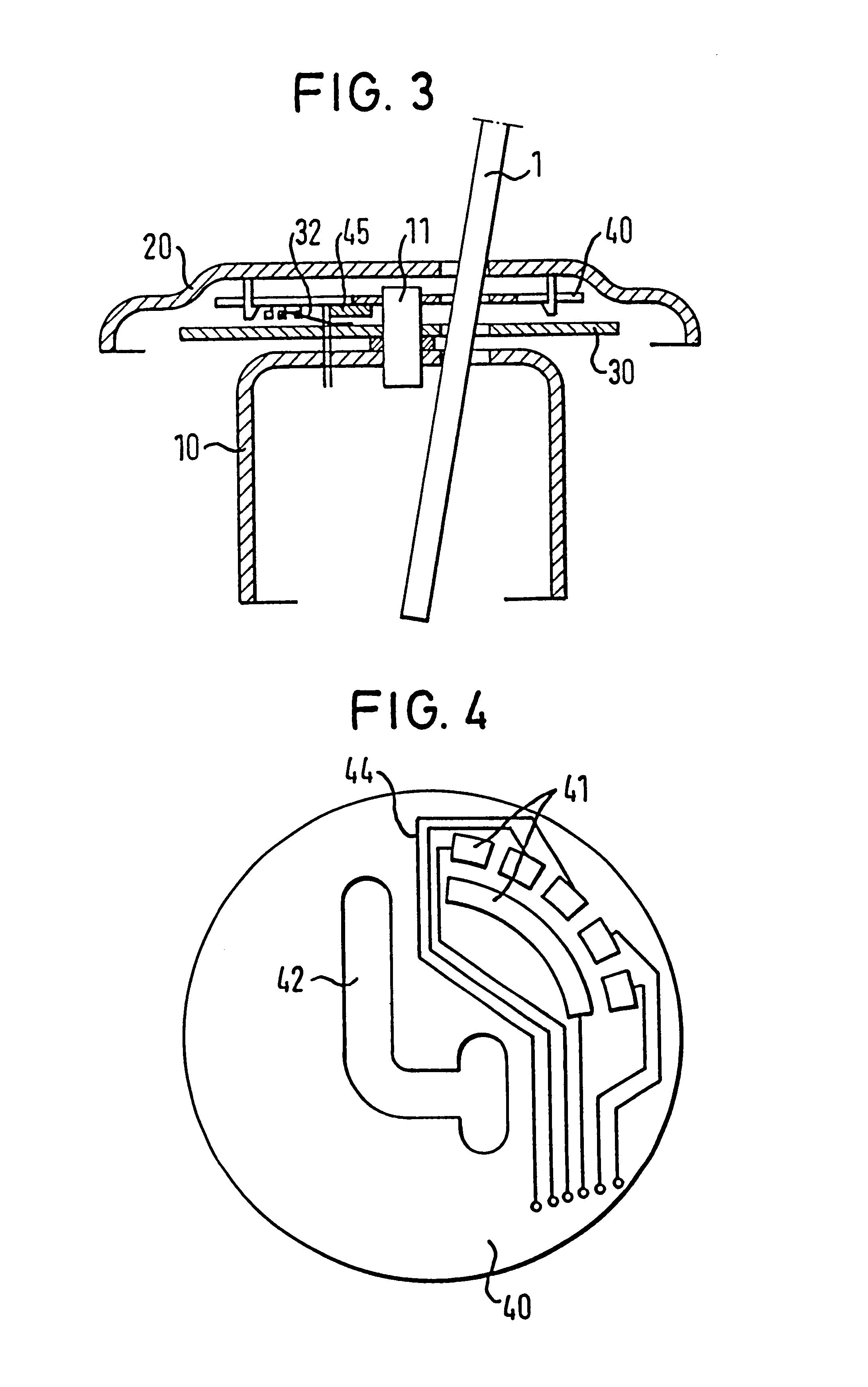

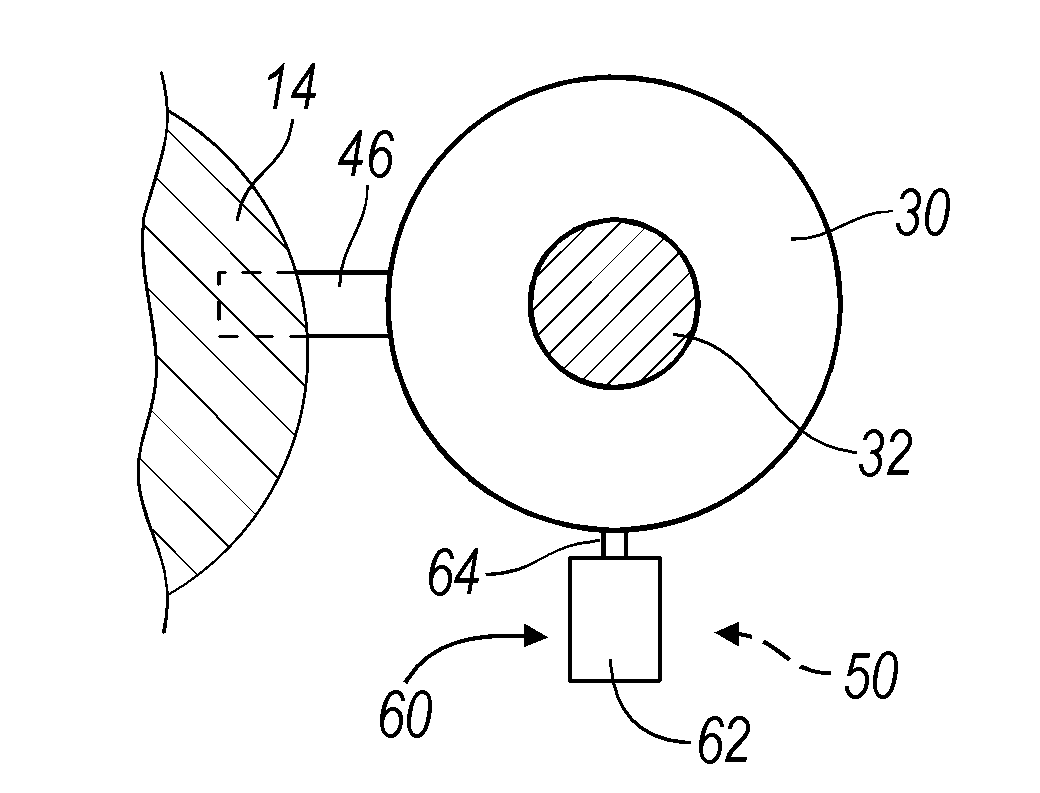

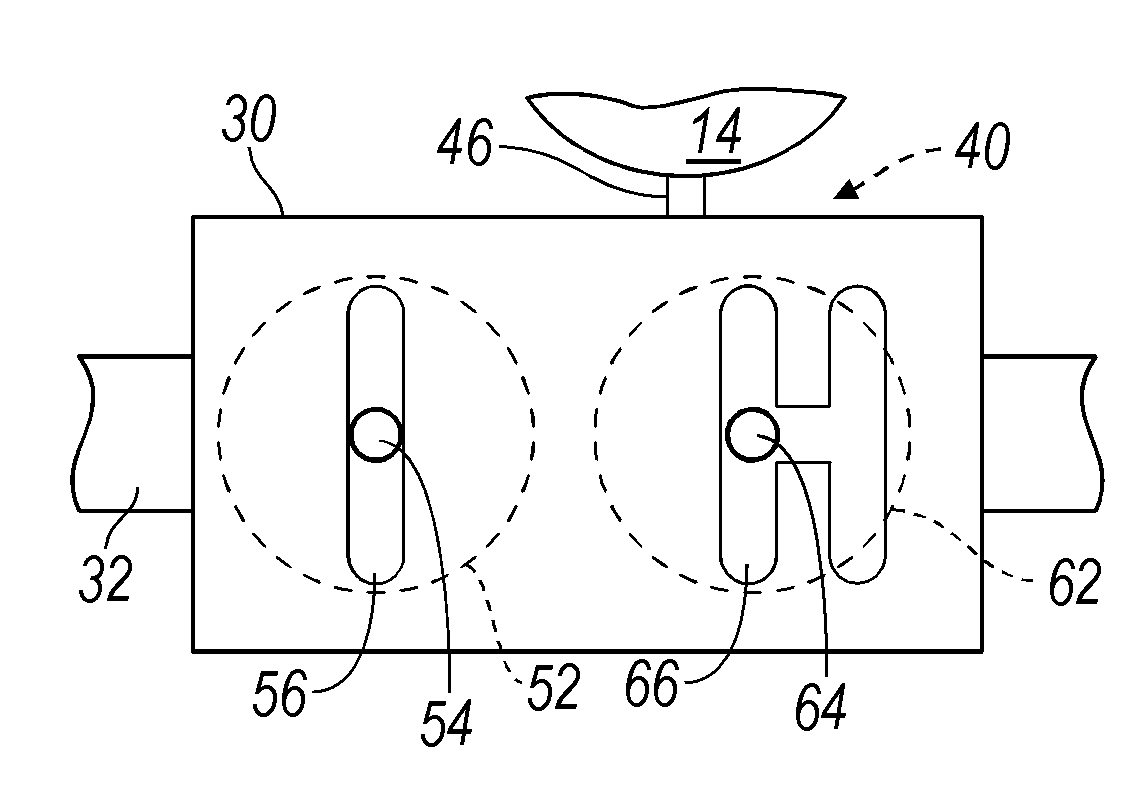

Shift lever unit for transforming the tilting movements of a shift lever (1) in electrical control signals, in particular for controlling a gearbox, with a shift lever, a rotating element (30, 3') which is rotated by the tilting movements of the shift lever (1) and a sensor (32, 41) detecting the angular position of the rotating element (30, 3') and transforming it into electrical signals.

Owner:TRIAD FICO +2

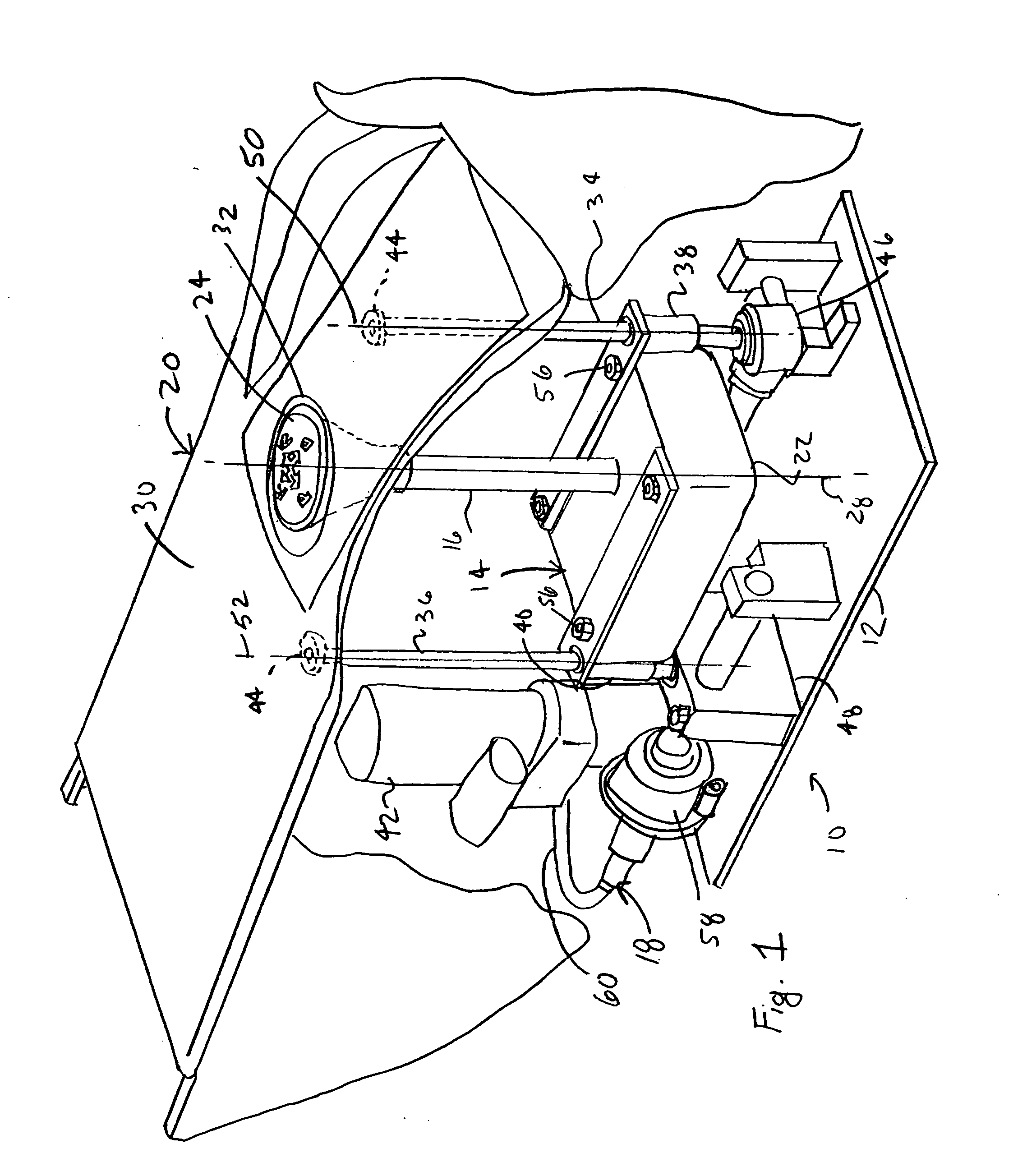

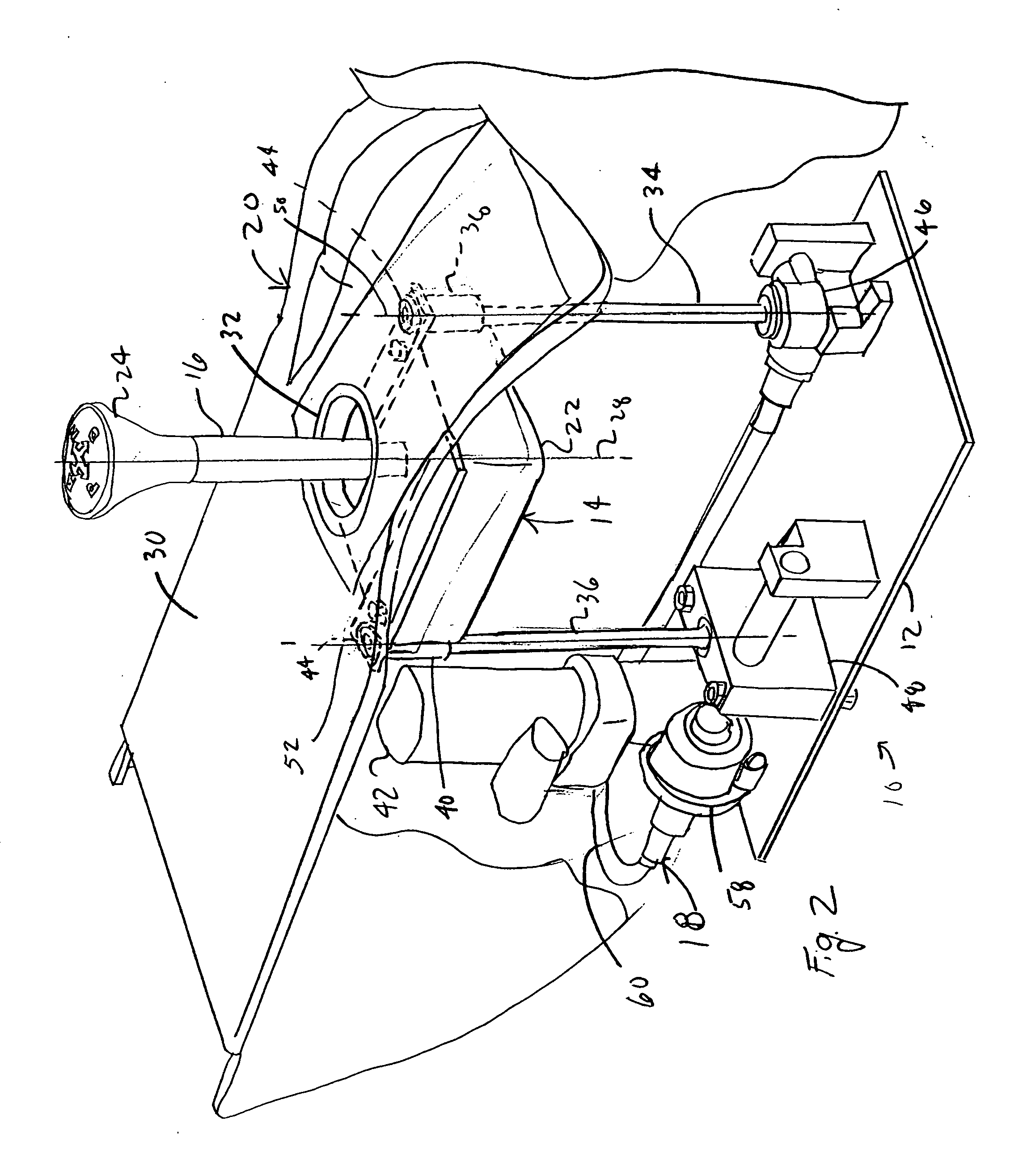

Self presenting electronic shifter

InactiveUS20070204718A1Quality improvementEasy assembly and adjustmentControlling membersManual control with multiple controlled membersControl theoryMechanical engineering

A shifter assembly includes an electronic shifter mechanism having a shift lever movable between a plurality of gear positions and an electrically powered drive system operatively connected to the shifter mechanism to selectively move the shifter mechanism between a first location wherein the shifter lever is located substantially within a housing and a second location wherein the shifter lever is located substantially outside the housing. The drive system moves the shifter mechanism along a vertical, linear path substantially parallel to a longitudinal axis of the shift lever such that the shift lever moves through an opening in the housing.

Owner:DURA GLOBAL TECH

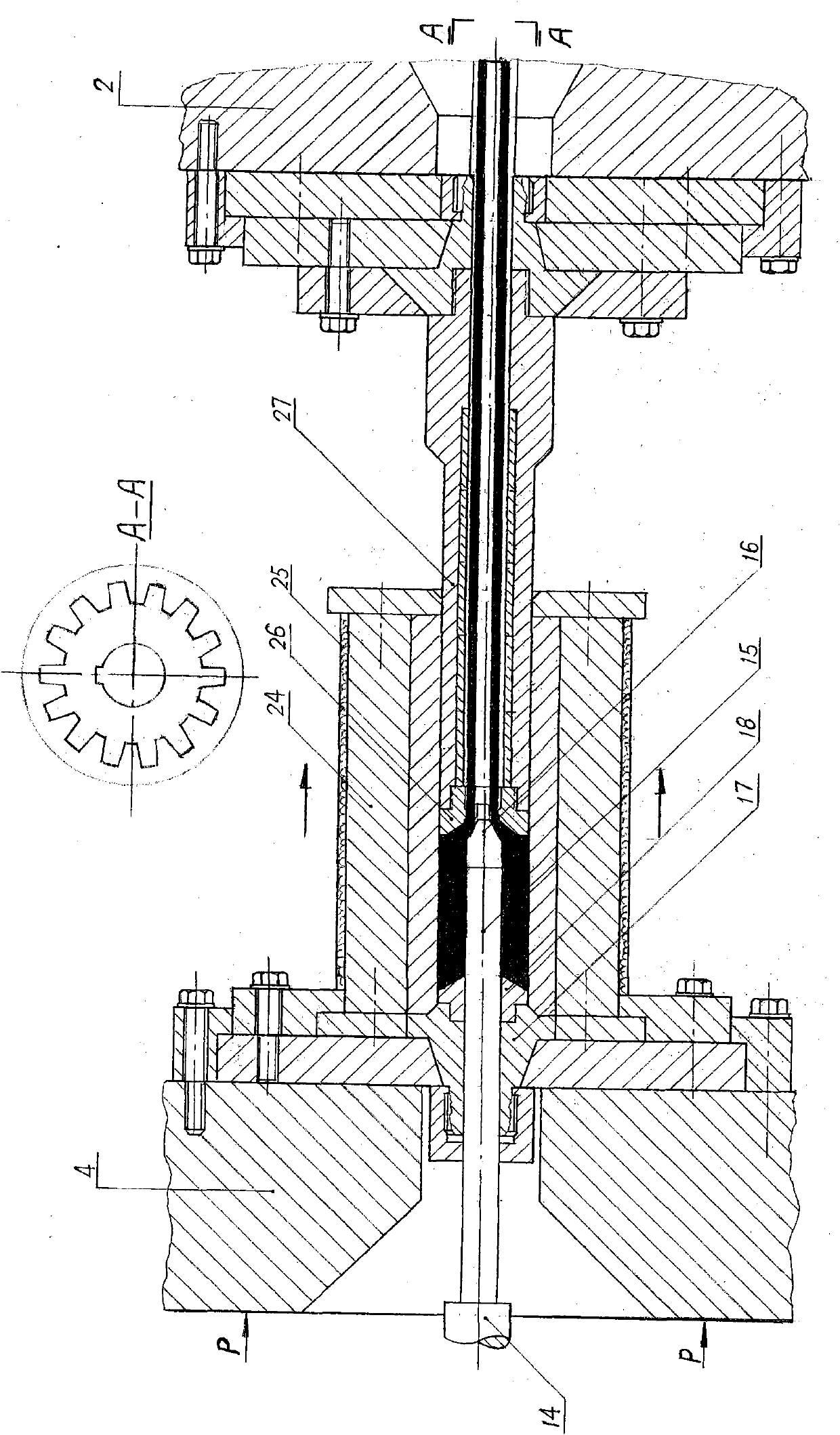

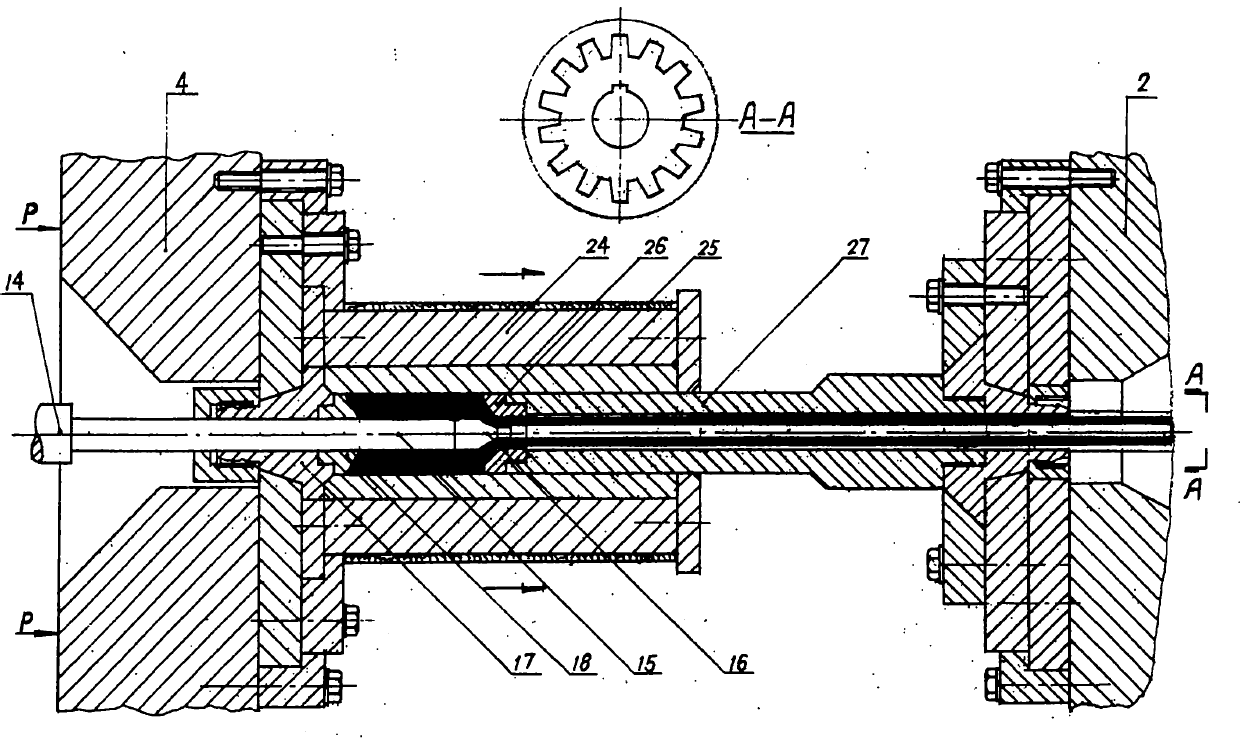

Chipless forming method for gear stick and section gear through hot extrusion

InactiveCN101905250AExtend your lifeImprove plasticityExtrusion diesFurnace typesEngineeringThick wall

The invention discloses a chipless forming method for a gear stick and a section gear through hot extrusion by utilizing an alloy steel horizontal type backward extruder, solving the problems that the existing gear cutting process has more working procedures, low efficiency, large metal loss, more operators for machine tool processing and high production cost and the like by utilizing the chip processes of lathing, milling, drilling, inserting and grinding. The method comprises the following steps: an inner cooling combined type double-conical surface gear squeezing die, a recipient and a floating pecker combined mandril are adopted by taking the producing principle of alloy steel thick wall special seamless steel tubes as an example; scale-free heating is rapidly carried out on the blank; lubricating warm-extrusion molding is carried out; center punching, shaft hole slotting and tooth surface extrusion are finished at a time; and the finished product of the gear stick is directly produced, then is subject to waste heat annealing, slicing by wire-electrode cutting and heating process to be manufactured into a finished product. Compared with a chip gear-cutting molding method, the invention has simplified working procedure, few labor, high efficiency, less metal loss, high gear strengthen and reduces the production cost, and then tooth surface precision reaches the standard. The method of the invention is a significant technological innovation of straight tooth and oblique tooth cylindrical gear process technologies.

Owner:周家镳

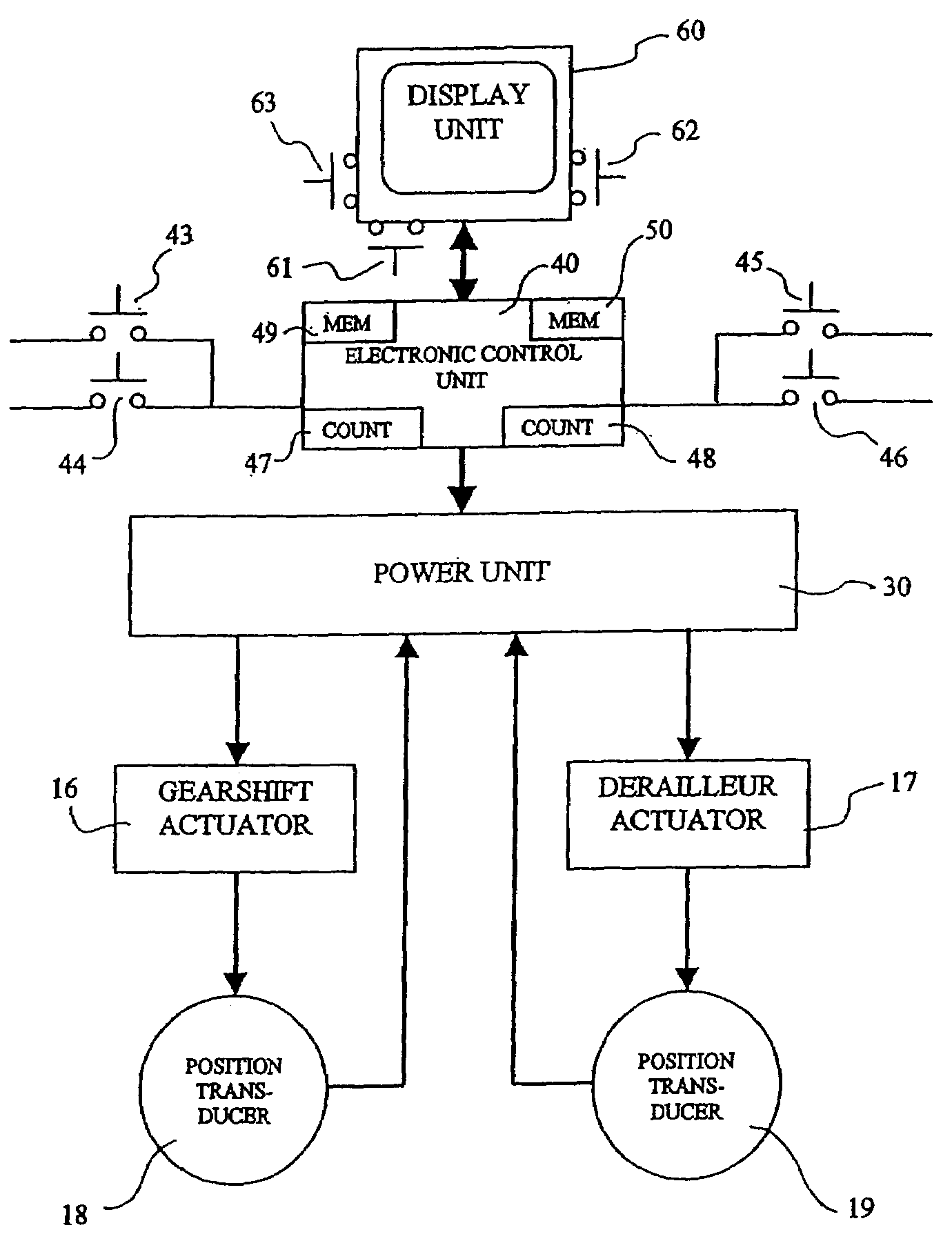

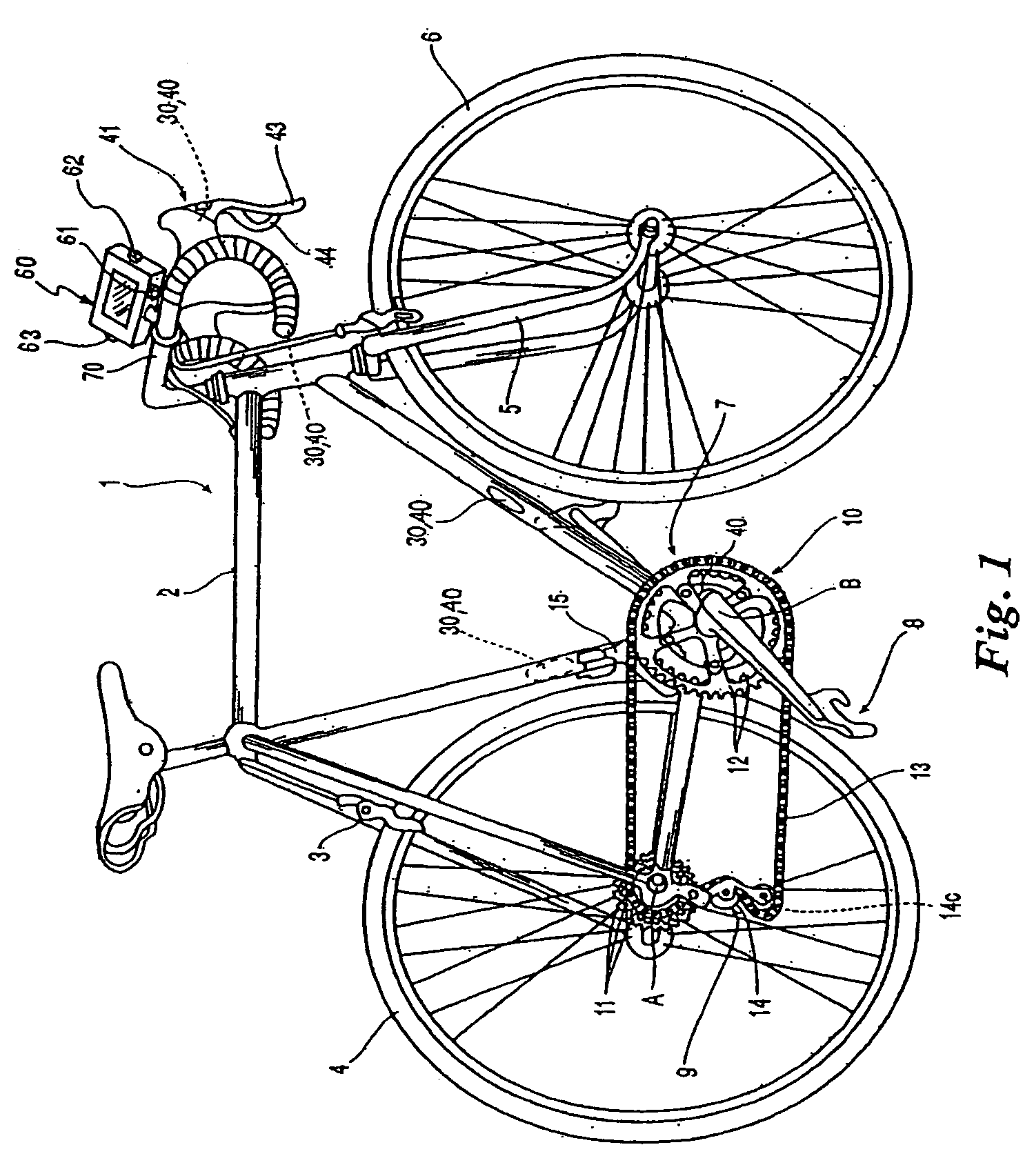

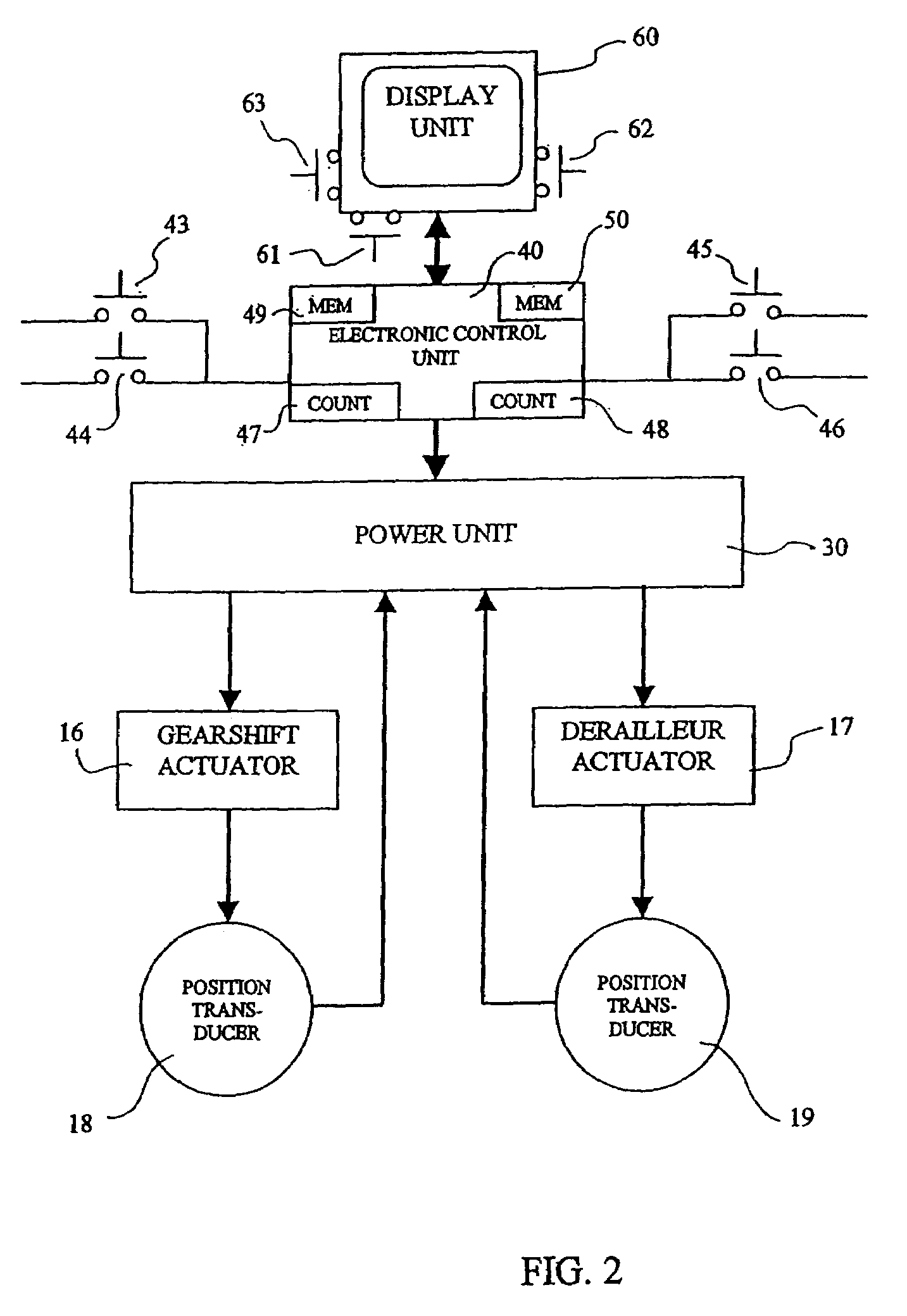

Electronically servo-assisted bicycle gearshift and related method

A method for electronically servo-assisting a bicycle gearshift to allow compensation for misalignments between the chain of a bicycle gearshift and one or more sprockets of the gearshift, the method including the steps of: driving an actuator of a bicycle gearshift to displace a chain of the gearshift in a chosen direction with respect to a gearshift group comprising at least two sprockets; receiving information on the desired alignment between the chain and a predetermined sprocket of the gearshift group; and setting an adjustment variable, of a logic value associated with the gear ratio relative to the predetermined sprocket, to a value corresponding to the displacement carried out in the step of driving the actuator.

Owner:CAMPAGNOLO SRL

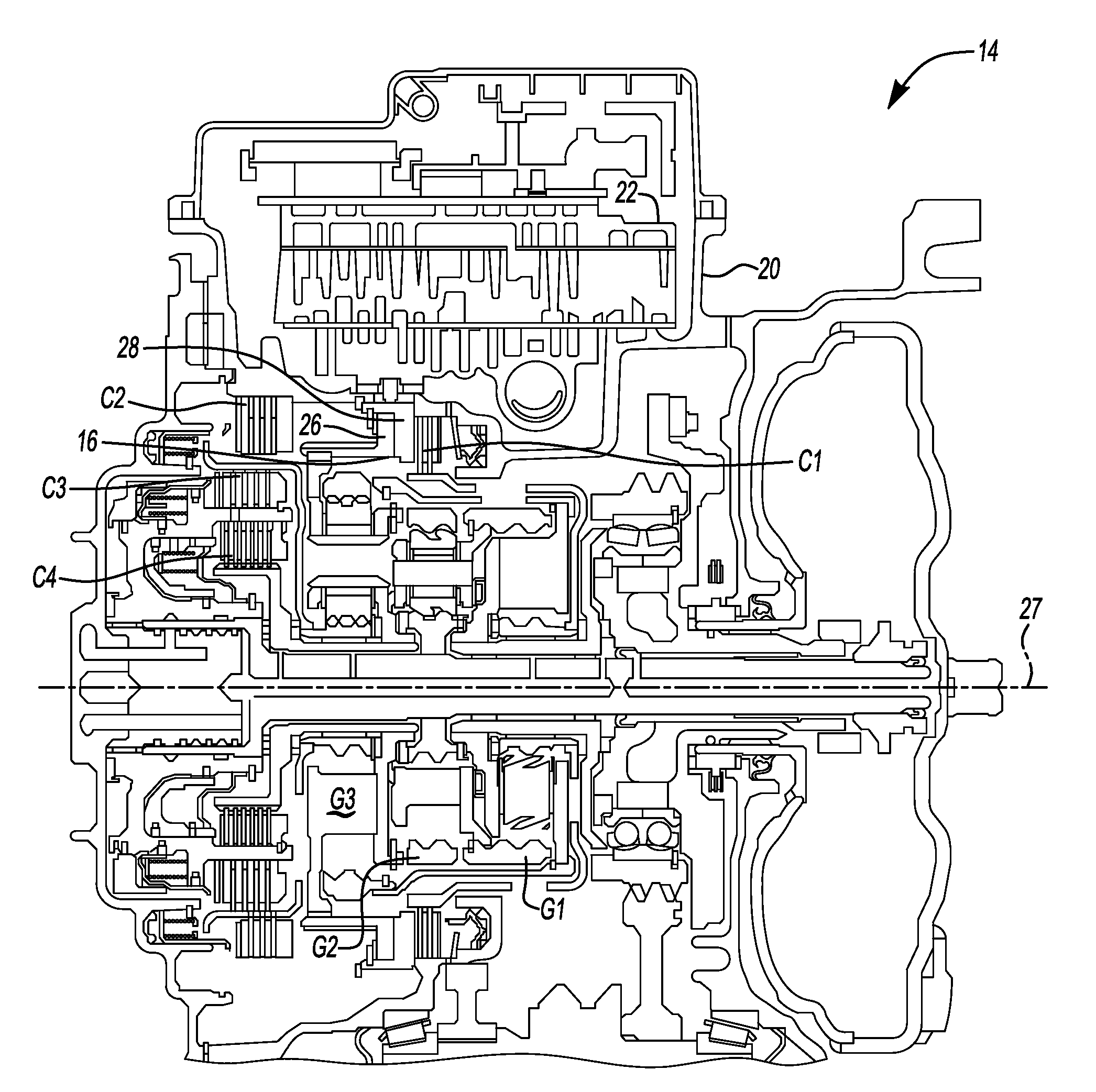

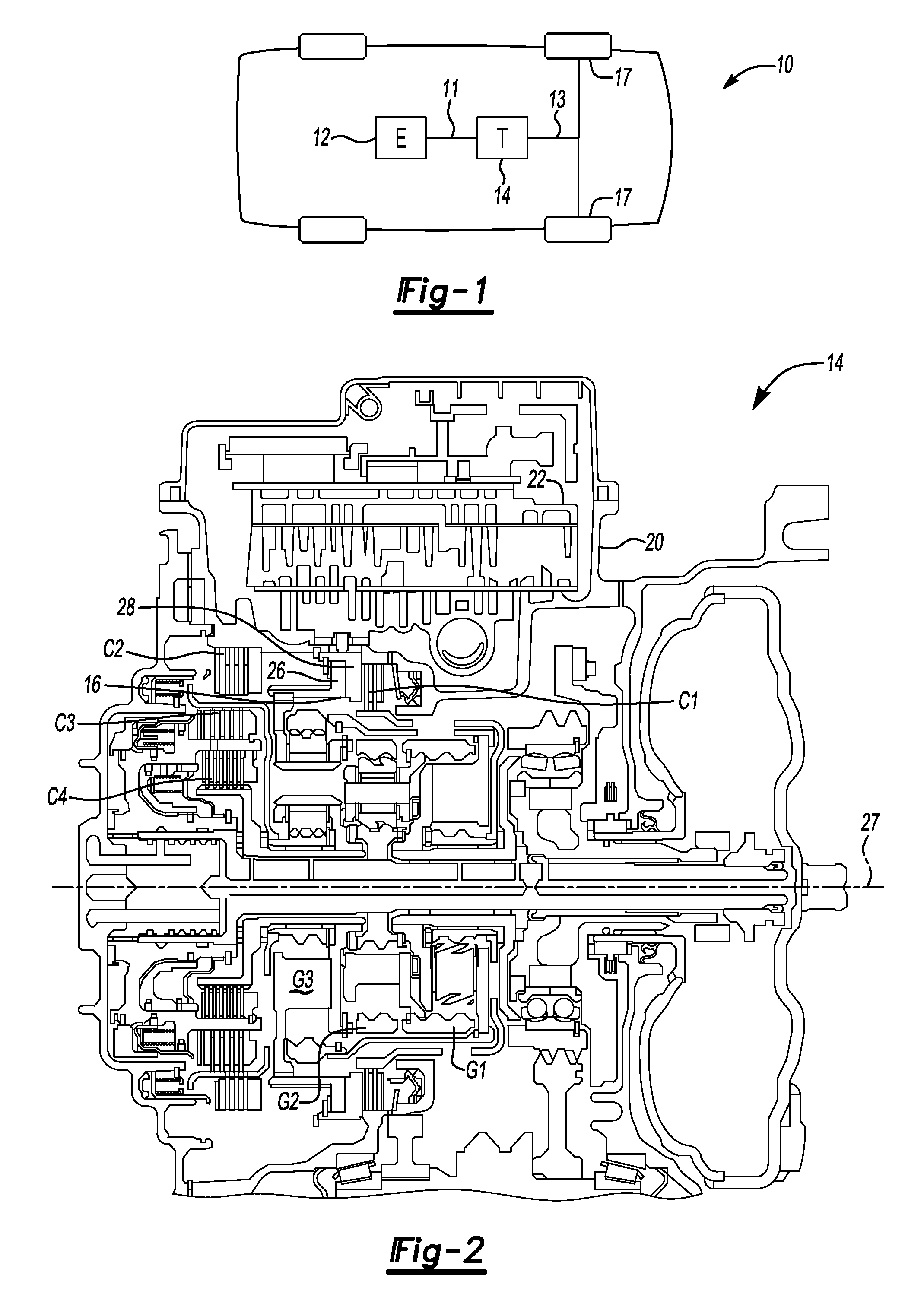

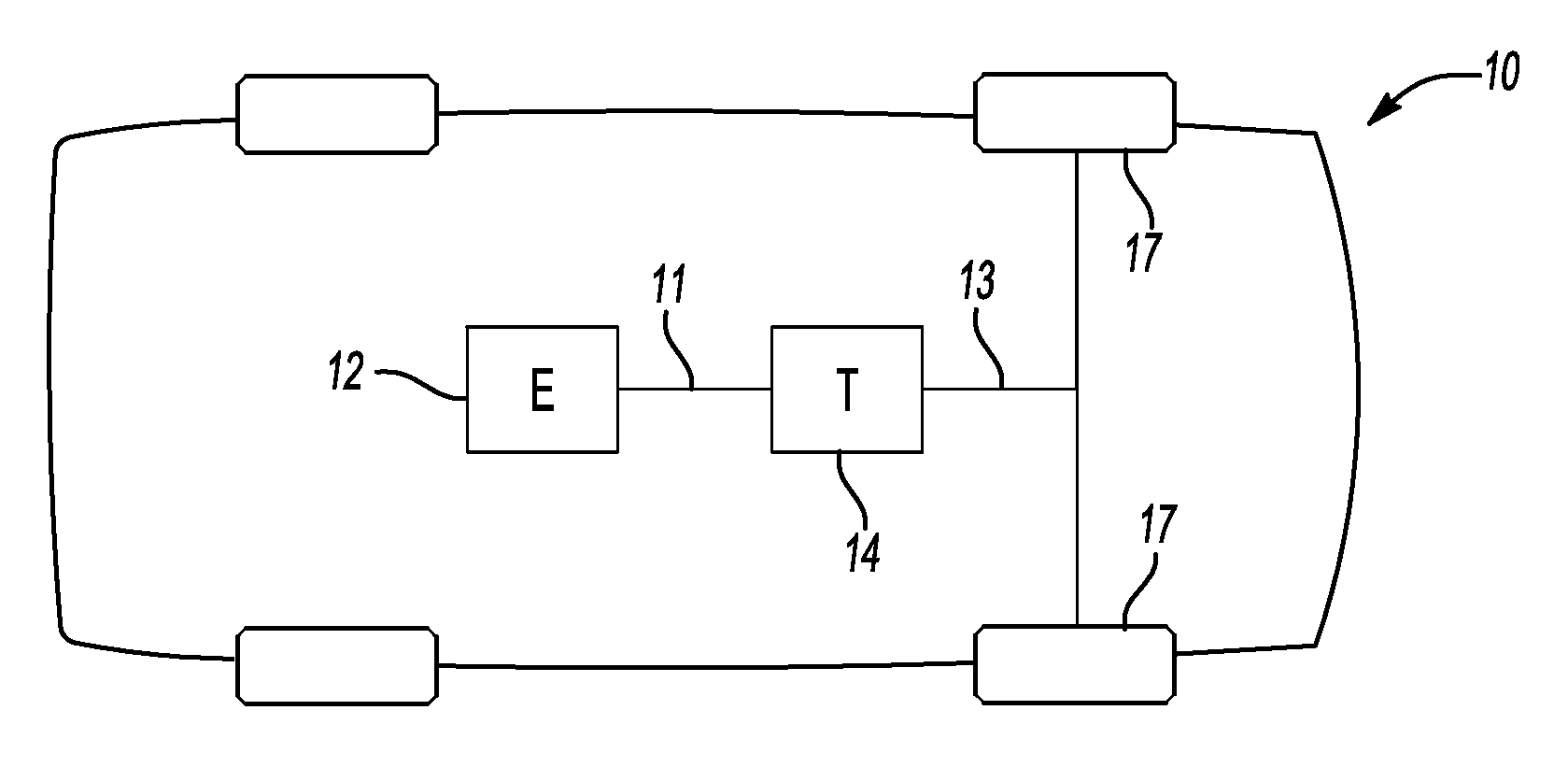

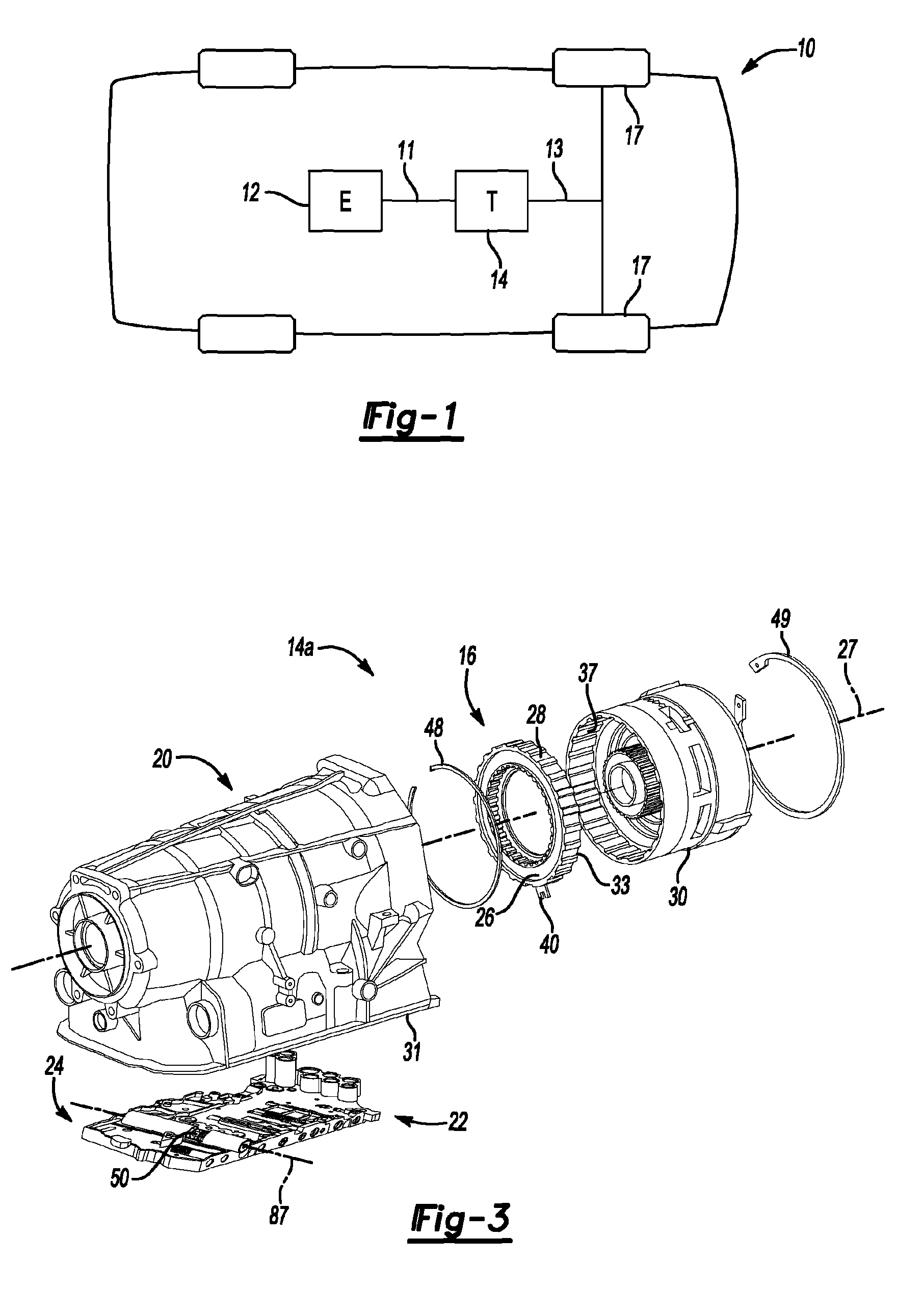

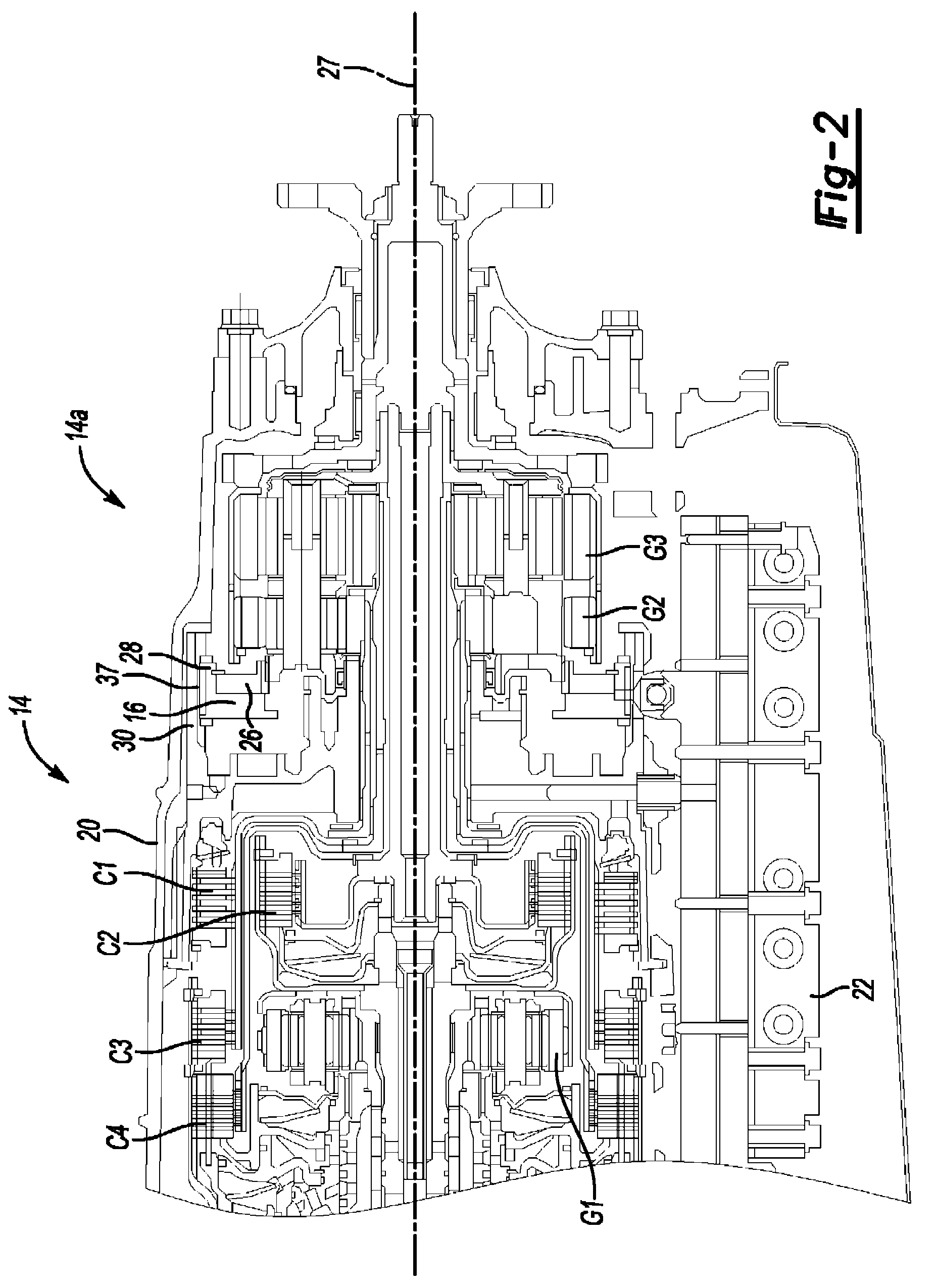

Front Wheel Drive Automatic Transmission with a Selectable One-Way Clutch

ActiveUS20100022342A1Reducing spin lossTransmission lossDigital data processing detailsToothed gearingsAutomatic transmissionOperation mode

Owner:GM GLOBAL TECH OPERATIONS LLC

Vehicle shifter

InactiveCN1819935AManual control with multiple controlled membersManual control with single controlling memberElectromagnetic coilGear stick

A shifter includes a powered pawl mechanism that selectively engages a shift gate. The powered pawl mechanism may include an electrically operated solenoid or the like, and may be mounted to the base of the shifter or to the shift lever. The pawl engages a shift gate that is mounted on the other of the shift lever and the base. A mechanical override may be utilized to disengage the pawl. The shifter includes an electrically operated push button or the like on the shift knob, and may utilize sensors that determine the shift lever position for controlling a transmission.

Owner:GHSP +1

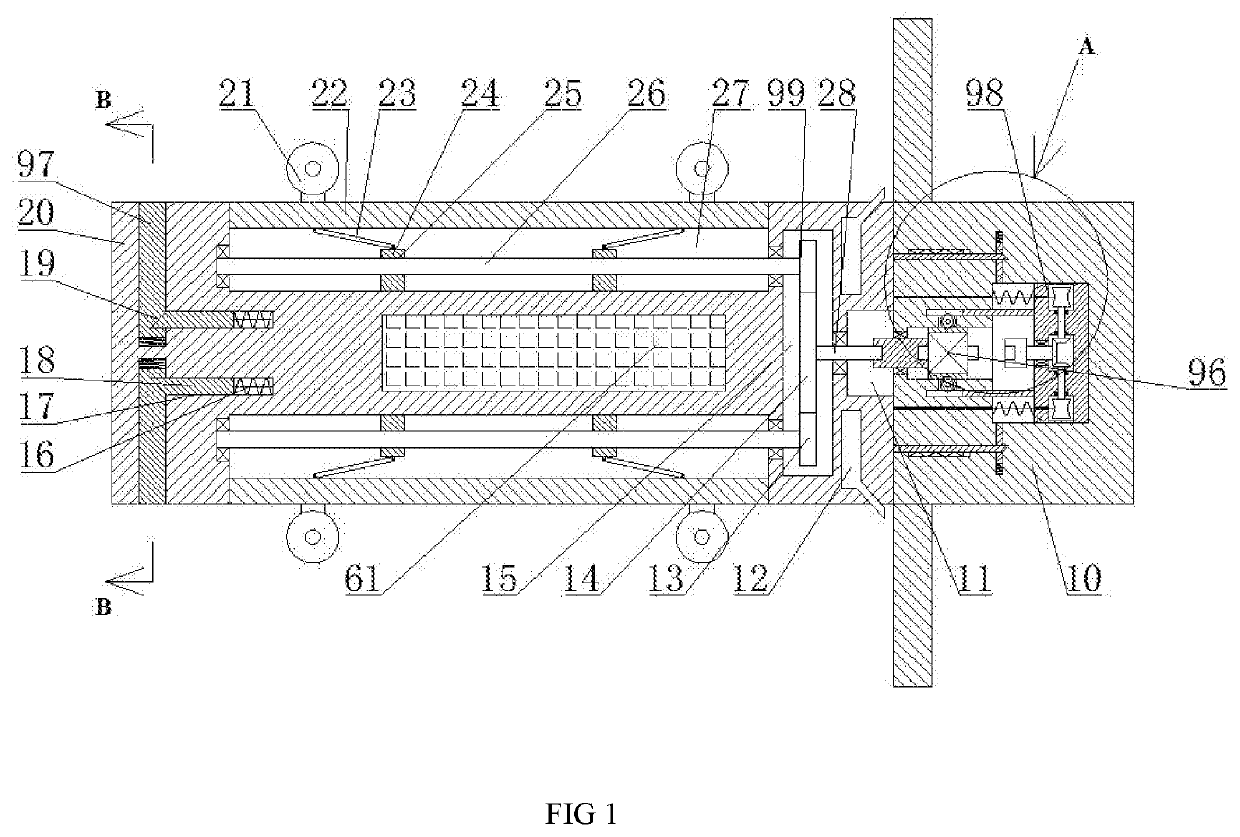

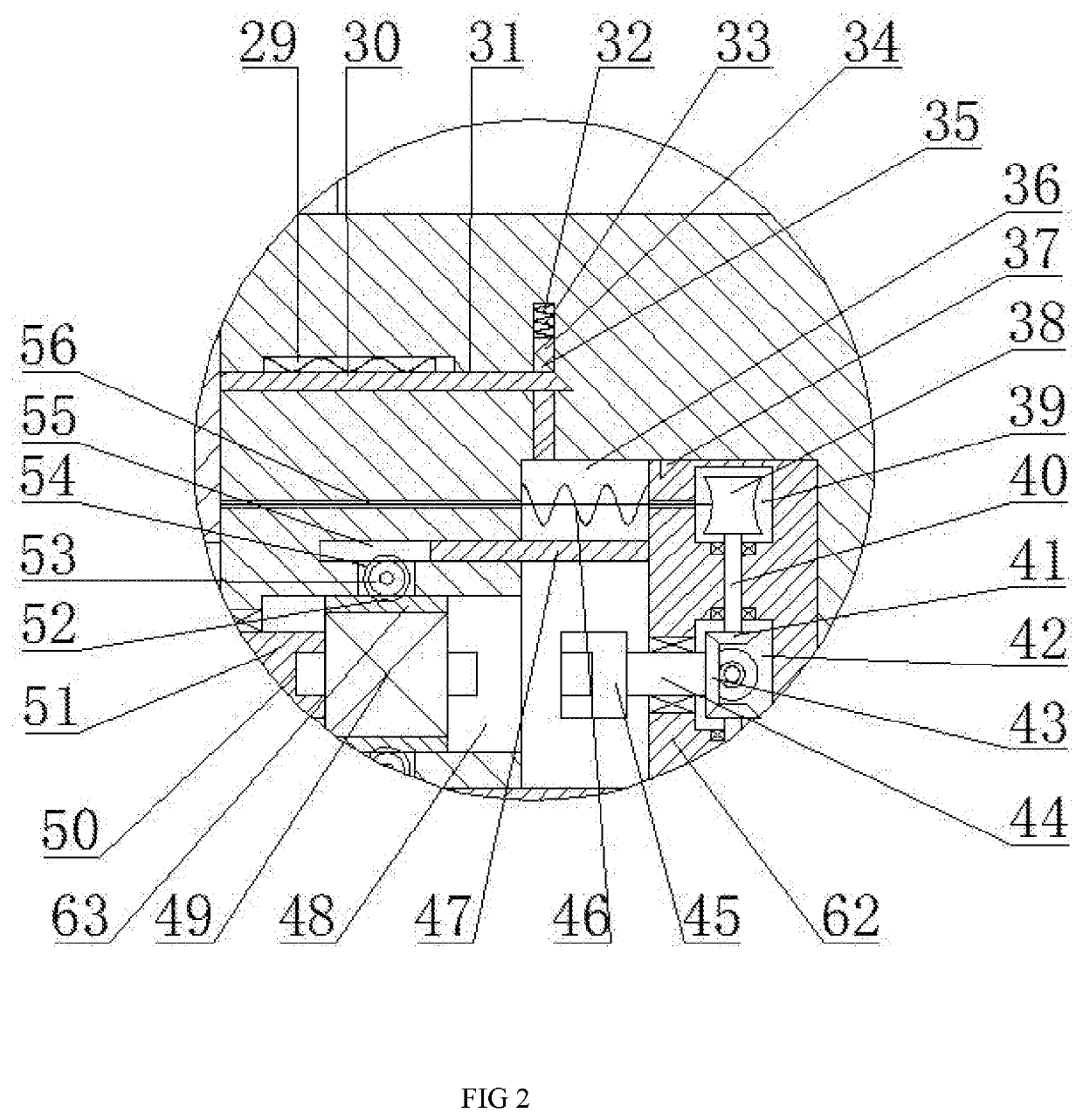

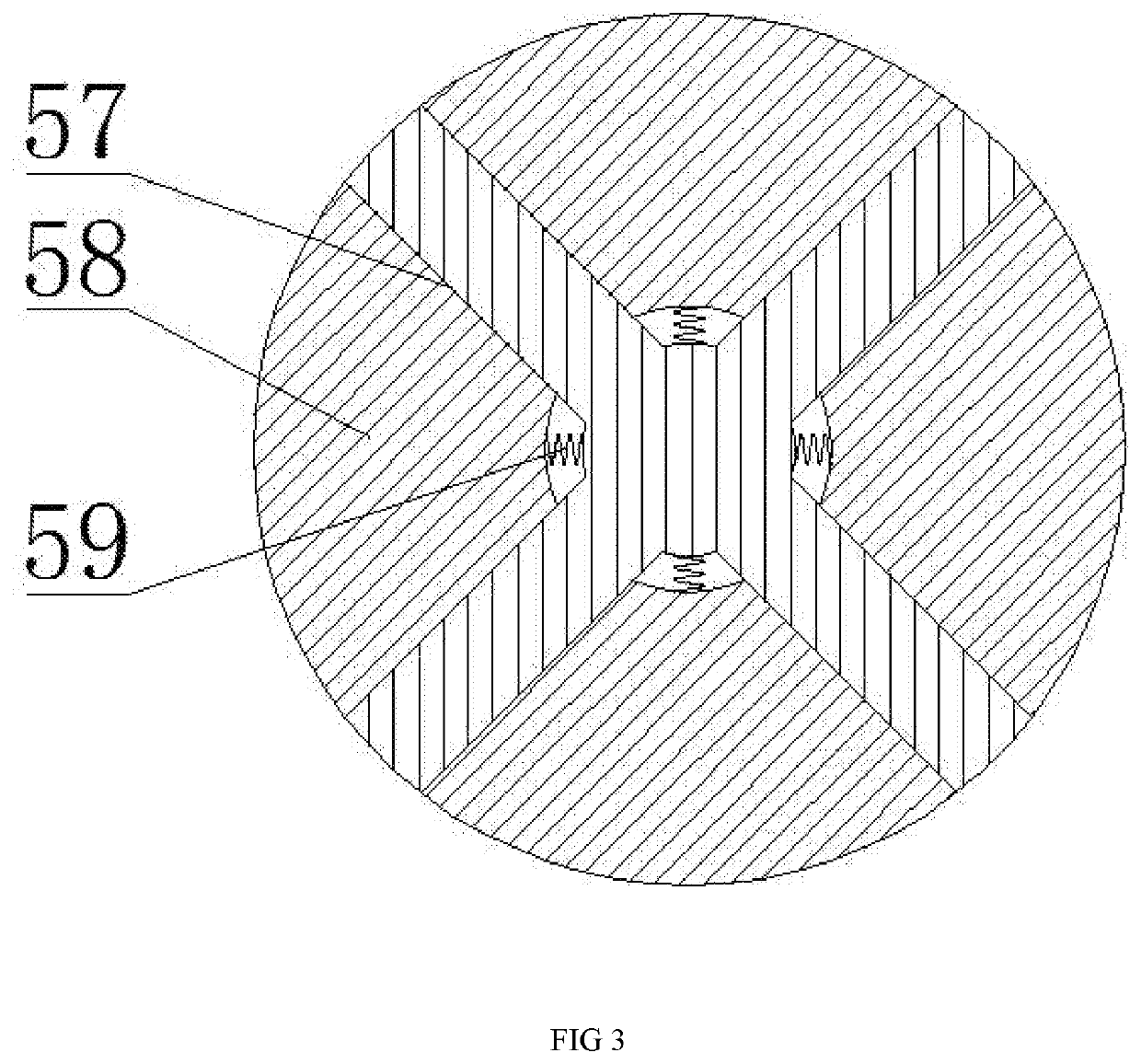

Air jet type pipeline decontamination machine

InactiveUS20200208393A1Improve practicalityOvercome defectsSewer cleaningHollow article cleaningJet propulsionJet flow

The invention relates to the field of jet propulsion application, in particular to a jet propulsion pipeline decontamination machine, which includes a fuselage and a fixing frame provided on the left side of the fuselage. In the gear lever fixedly connected to the fuselage, four guide grooves opening outward are symmetrically distributed in the center of the end wall of the fixed frame, and left and right symmetrical moving blocks are slidably arranged in the guide groove. The moving block is provided with left and right threaded holes with reverse threads passing through the left and right, and the threaded holes are internally connected with threaded rods. The jet propelled pipeline decontamination machine provided by the present invention can realize the sludge in the pipeline. For cleaning, the equipment uses jet propelling equipment to drive the scraper to the depth of the pipeline. When it moves to the maximum limit, it drives the scraper to abut against the pipe wall, and then pulls the scraper to the outside of the pipe through the wire drawing device, thereby contaminating the inner wall of the pipe Mud scraping, the device of the invention is completely scraped, and the scraping force is large, which is more efficient.

Owner:FANG DELAN

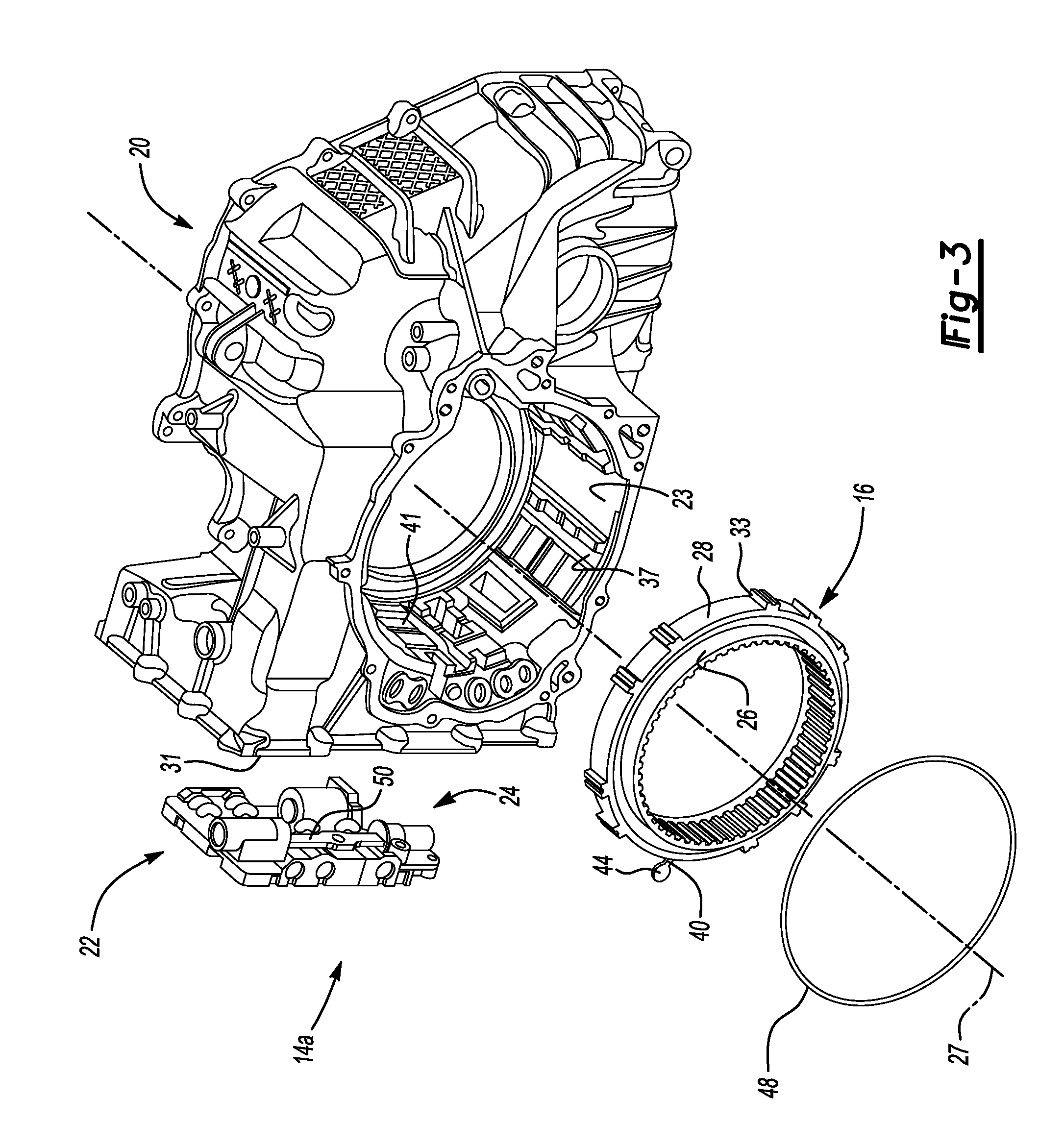

Rear wheel drive automatic transmission with a selectable one-way clutch

ActiveUS7824292B2Reducing spin lossTransmission lossFluid actuated clutchesGearing controlLow speedAutomatic transmission

A vehicle includes a rear-wheel drive (RWD) automatic transmission having a stationary member, a two-mode selectable one-way clutch (SOWC), pressurized fluid, and a valve body assembly (VBA). The VBA has a piston, a return spring, and an actuator linkage in contact with the piston and a shift lever of the SOWC. Fluid moves the piston and linkage in one direction to lock the SOWC and enable a reverse mode having no spin losses, and the spring moves the piston and linkage in another direction to unlock the SOWC in a forward mode. A method reduces spin losses by admitting fluid into the VBA to move the piston in one direction to thereby rotate the shift lever of the SOWC to one angular position to lock a driving member of the transmission to the stationary member during reverse, engine braking first gear, and manual low speeds.

Owner:GM GLOBAL TECH OPERATIONS LLC

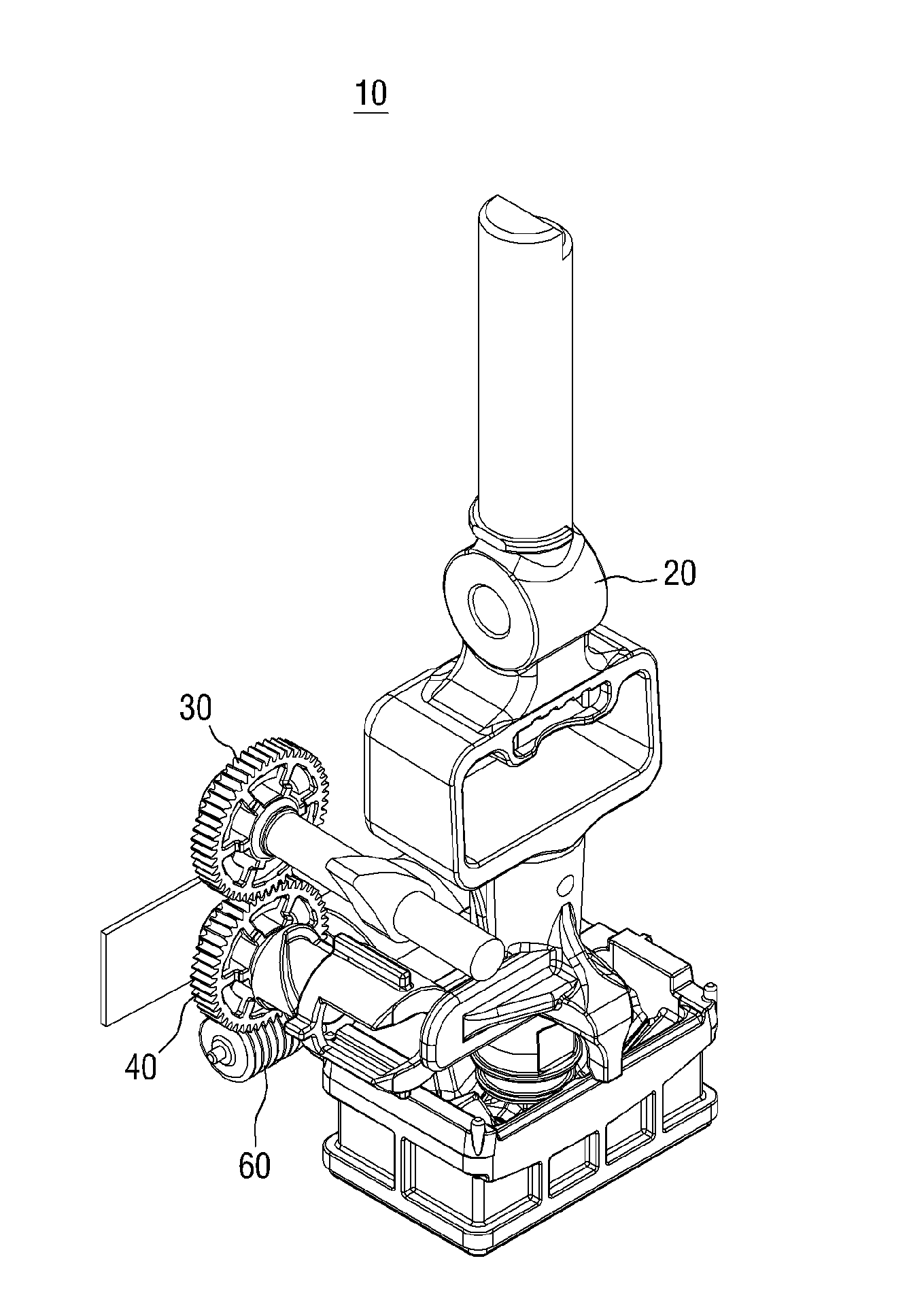

Apparatus for returning transmission to primary mode

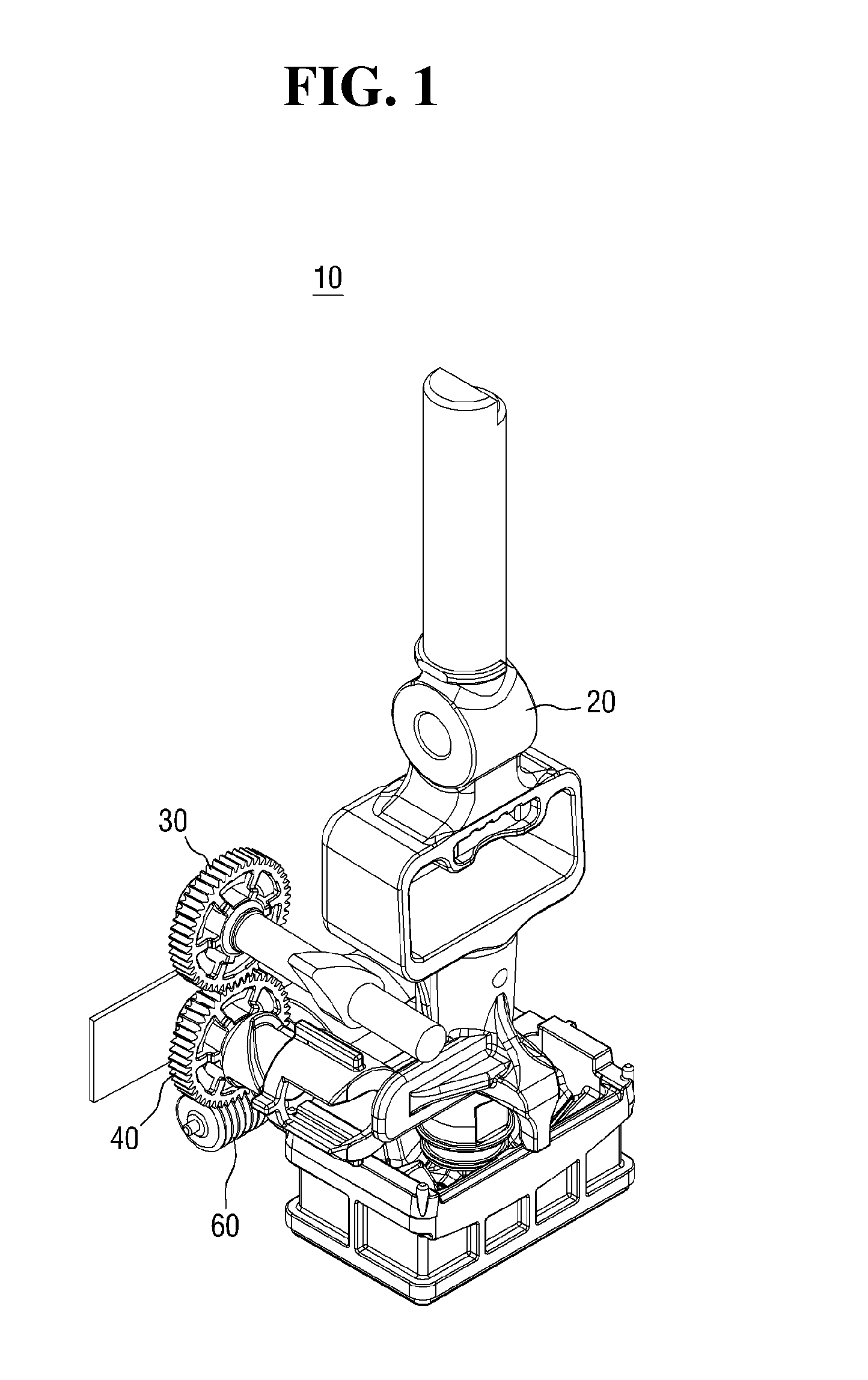

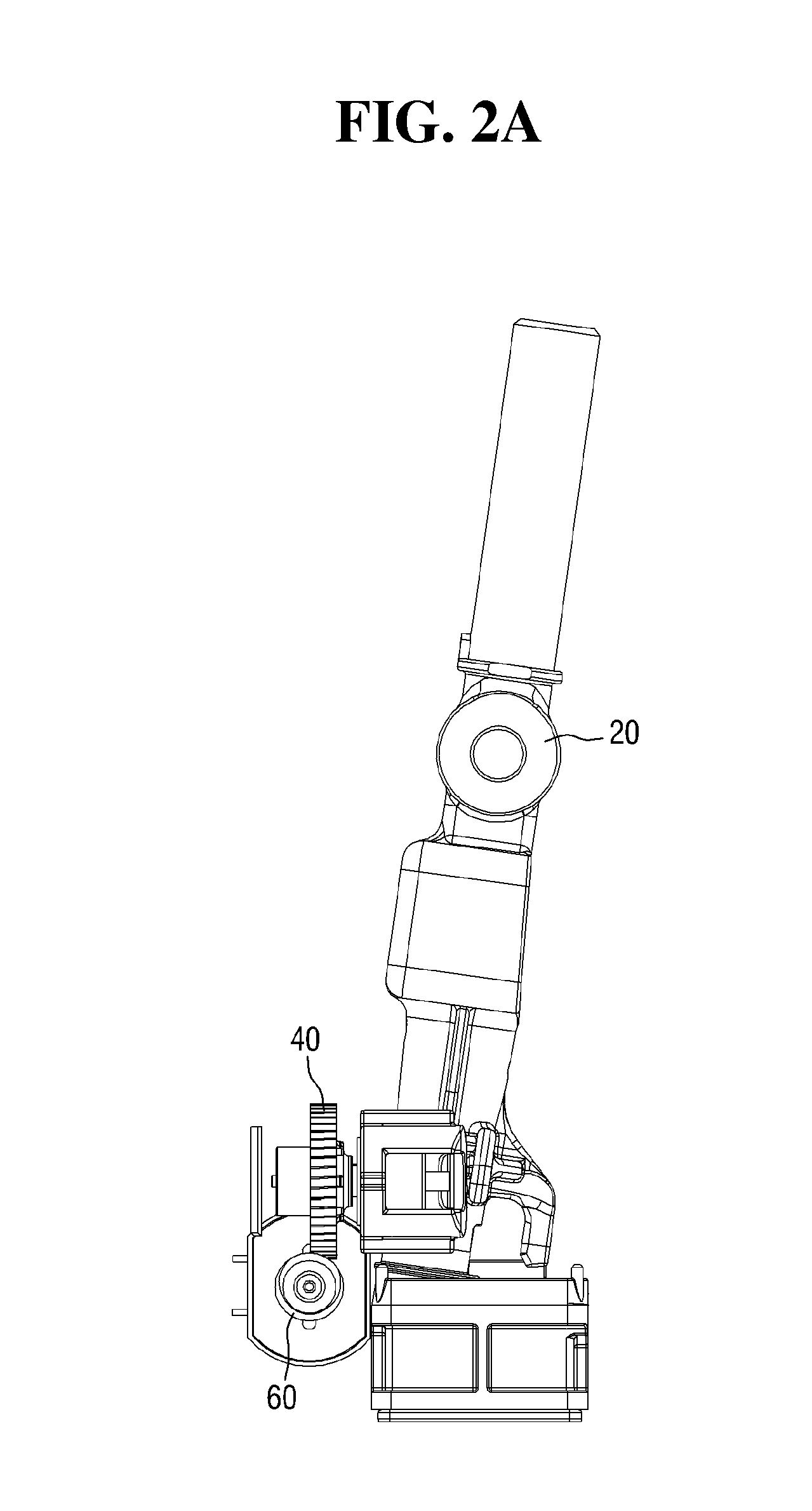

ActiveUS20140352476A1Increased Design FreedomImprove space utilizationGearing controlLimiting/preventing/returning movement of partsEngineeringGear stick

Owner:SL CORP

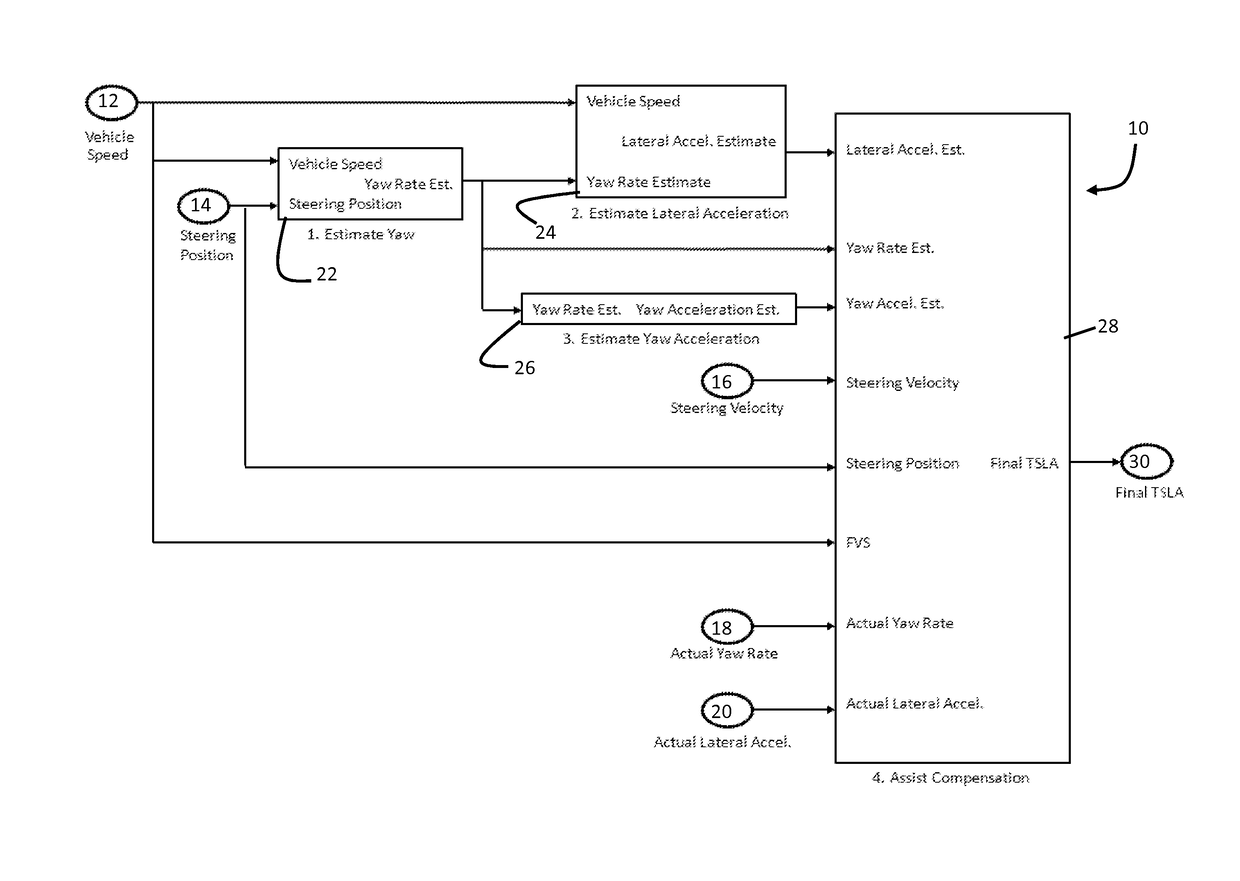

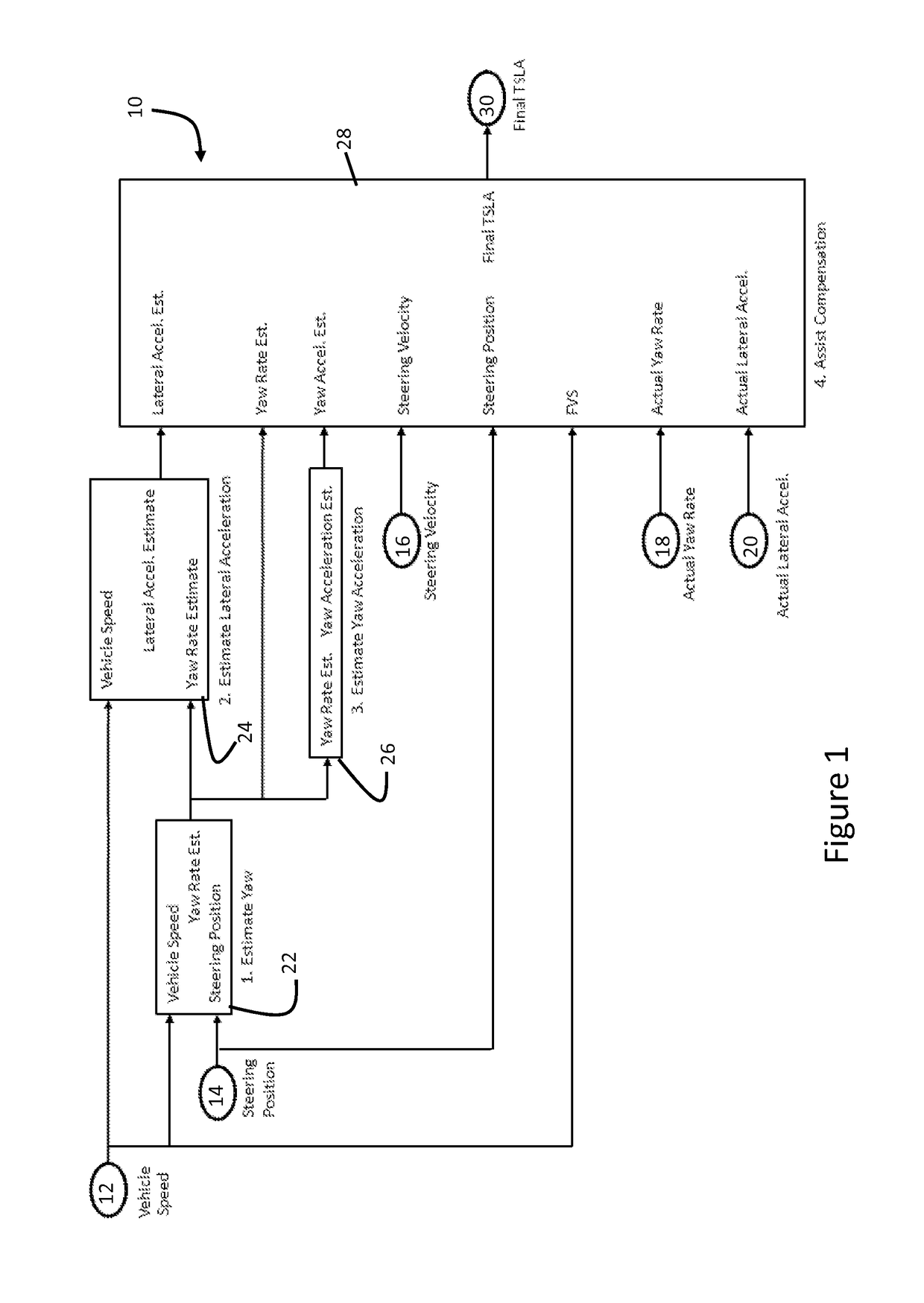

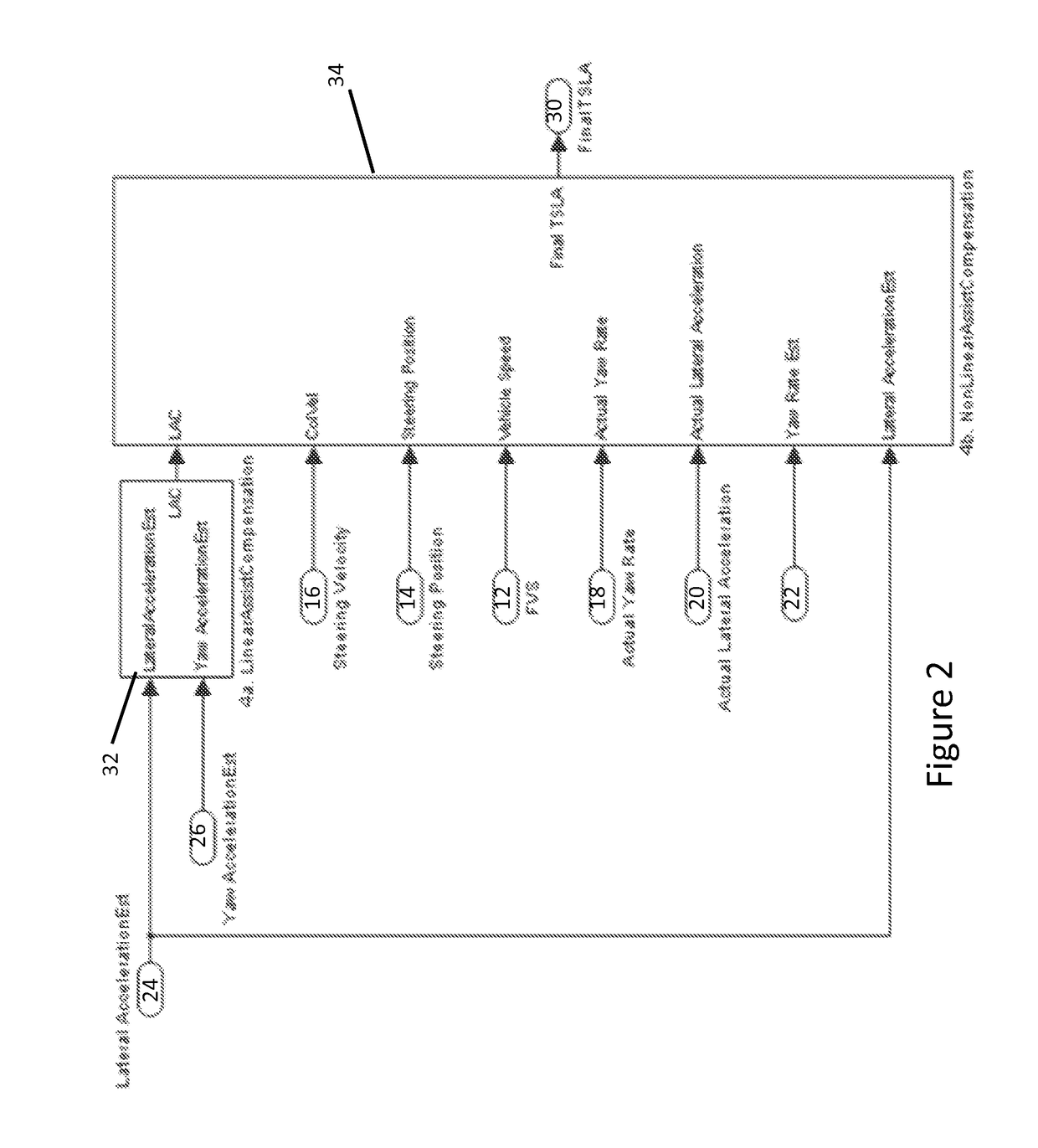

Assist Compensation For Actively Controlled Power Steering Systems

ActiveUS20170203785A1Steering linkagesAutomatic steering controlElectric power steeringSteering wheel

An electric power steering system includes a control for providing a calculated torque assist demand in the event of failure of a steering wheel torque sensor. The control is responsive to one or more of a vehicle speed, a steering column position, a steering column velocity, a gear lever position, a vehicle yaw rate and a vehicle lateral acceleration for generating the calculated torque assist demand. The control is operable to modify the torque assist demand by providing one or more of (a) friction and inertial compensation, (b) vehicle oversteer compensation, (c) reverse motion compensation, (d) damping compensation and (e) self steer prevention.

Owner:TRW AUTOMOTIVE US LLC

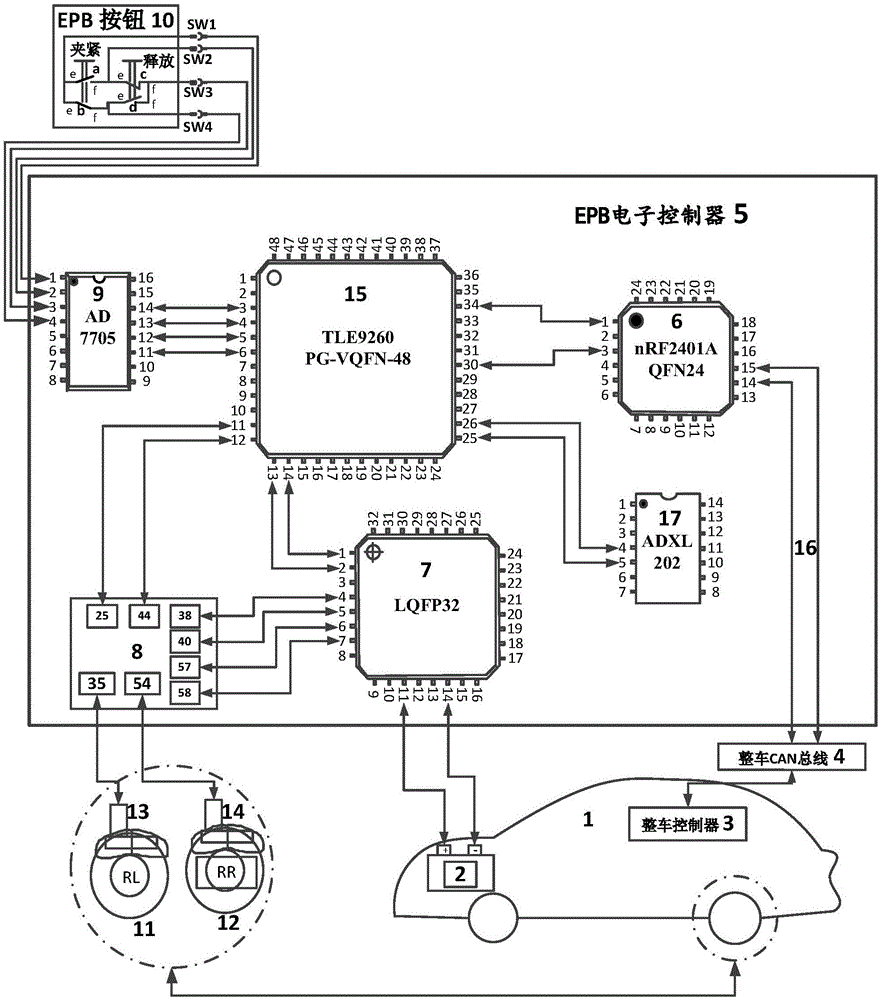

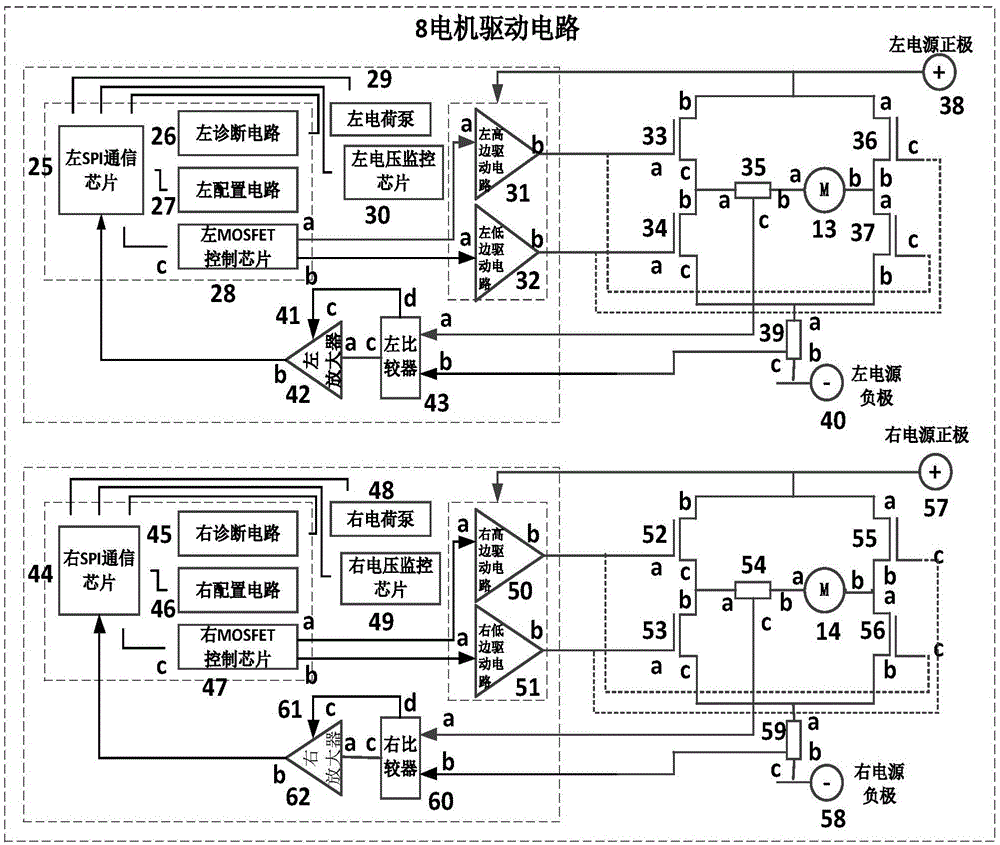

Braking system of electronic hand brake and control method thereof

ActiveCN105059282ASolve stuckAvoid stickingBraking action transmissionBrake-by-wireMotor driveElectronic controller

The invention discloses a braking system of an electronic hand brake and a control method thereof and aims at overcoming the problems that a speed changing rod is locked when a gear-P parking system of a speed changing box perform parking on a slope, the speed changing box is damaged in the running process due to misoperation after the a gear P is engaged and a pure electric vehicle is not parked and accordingly slides on the slope when being charged. The braking system of the electronic hand brake comprises an EPB button (10), an EPB electronic controller (5), a rear left brake (11) and a rear right brake (12). The EPB button (10) is in wired connection with a lead 1, a lead 2, a lead 3 and a lead 4 of a button identification chip (9) in the EPB electronic controller (5) through a signal wire SW1, a signal wire SW2, a signal wire SW3 and a signal wire SW4 sequentially, and a motor driving circuit (8) in the EPB electronic controller (5) is connected with a rear left motor (13) and a rear right motor (14) through cables sequentially. The invention further provides the control method of the braking system of the electronic hand brake.

Owner:苏州萨克汽车科技有限公司

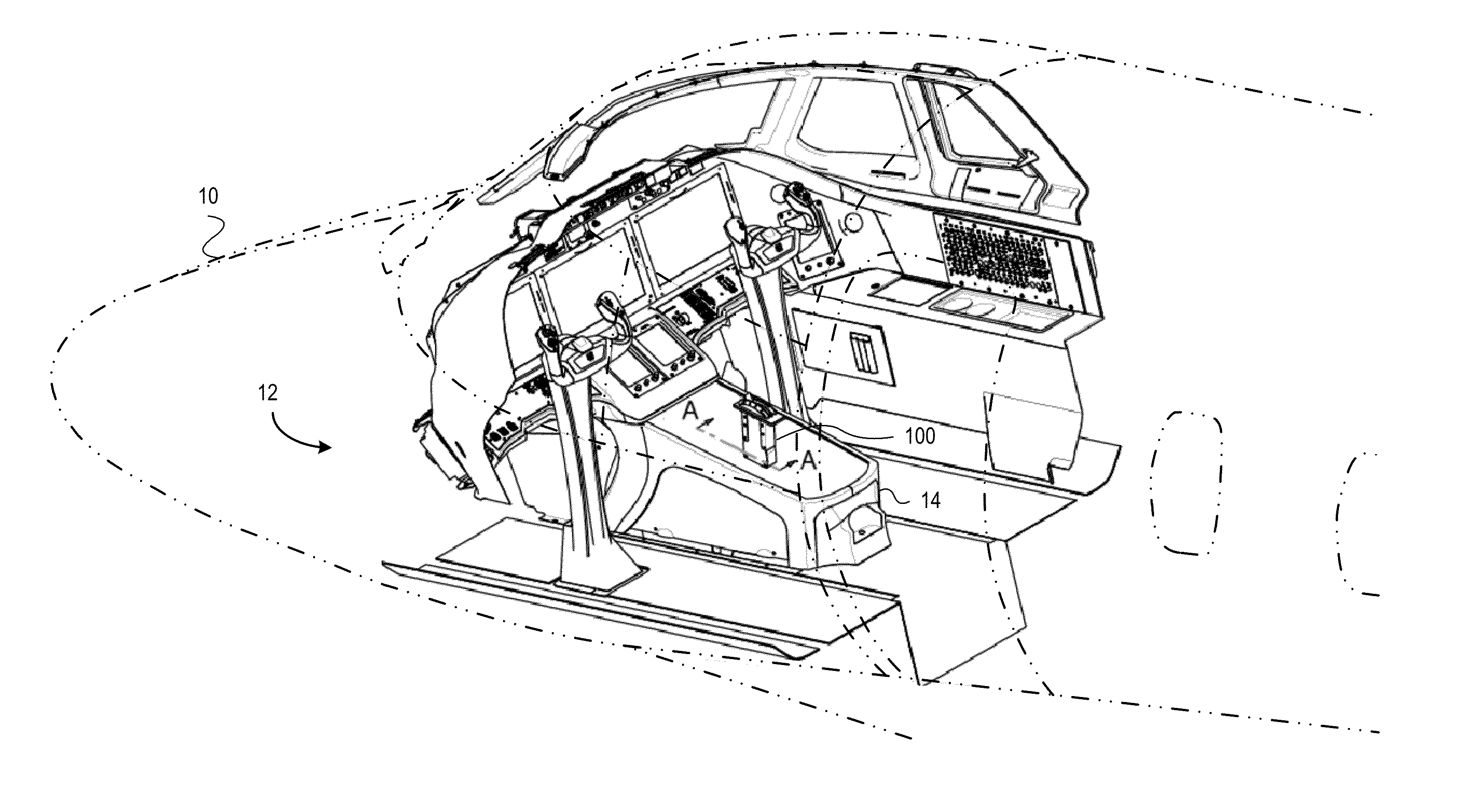

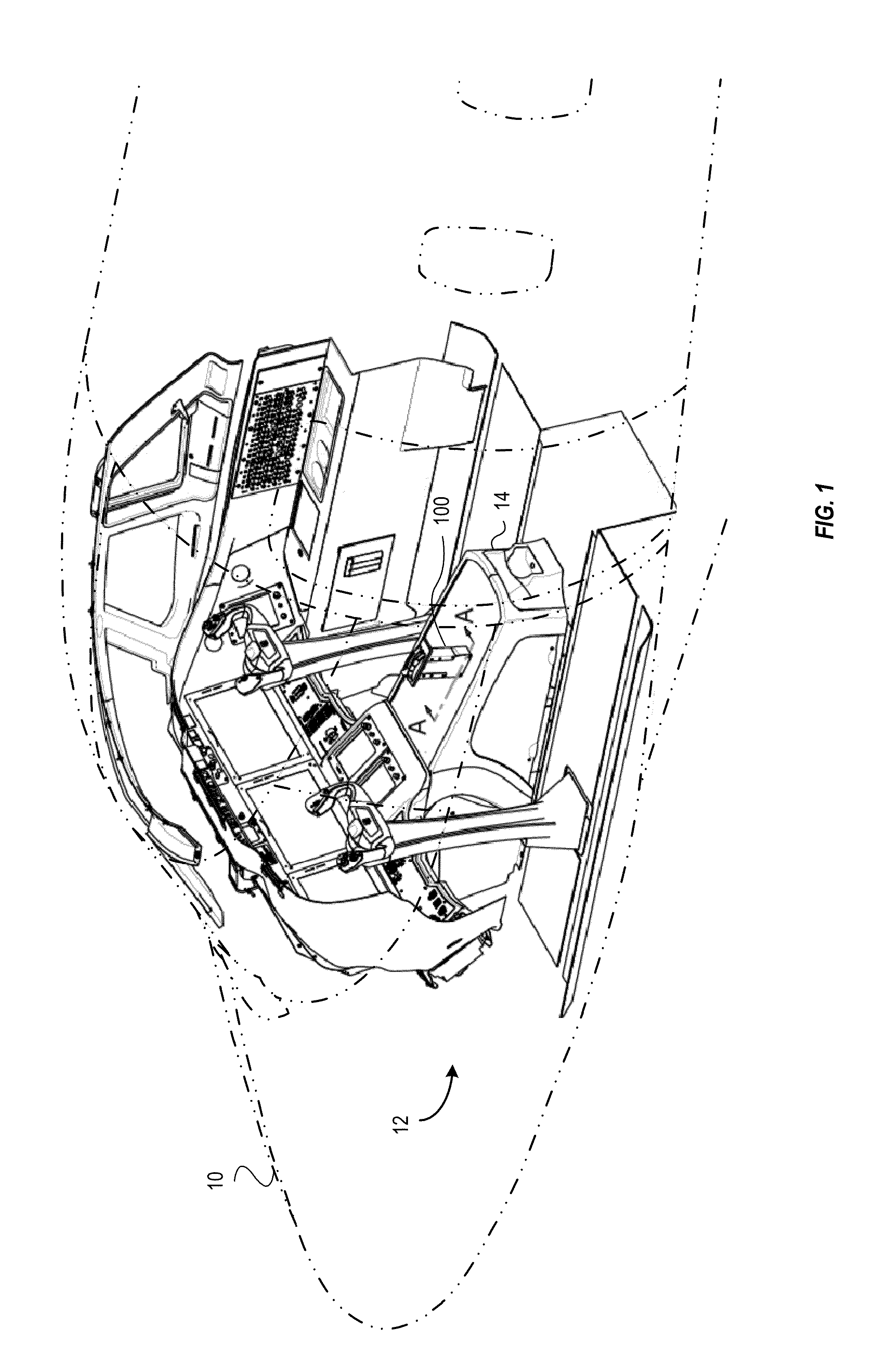

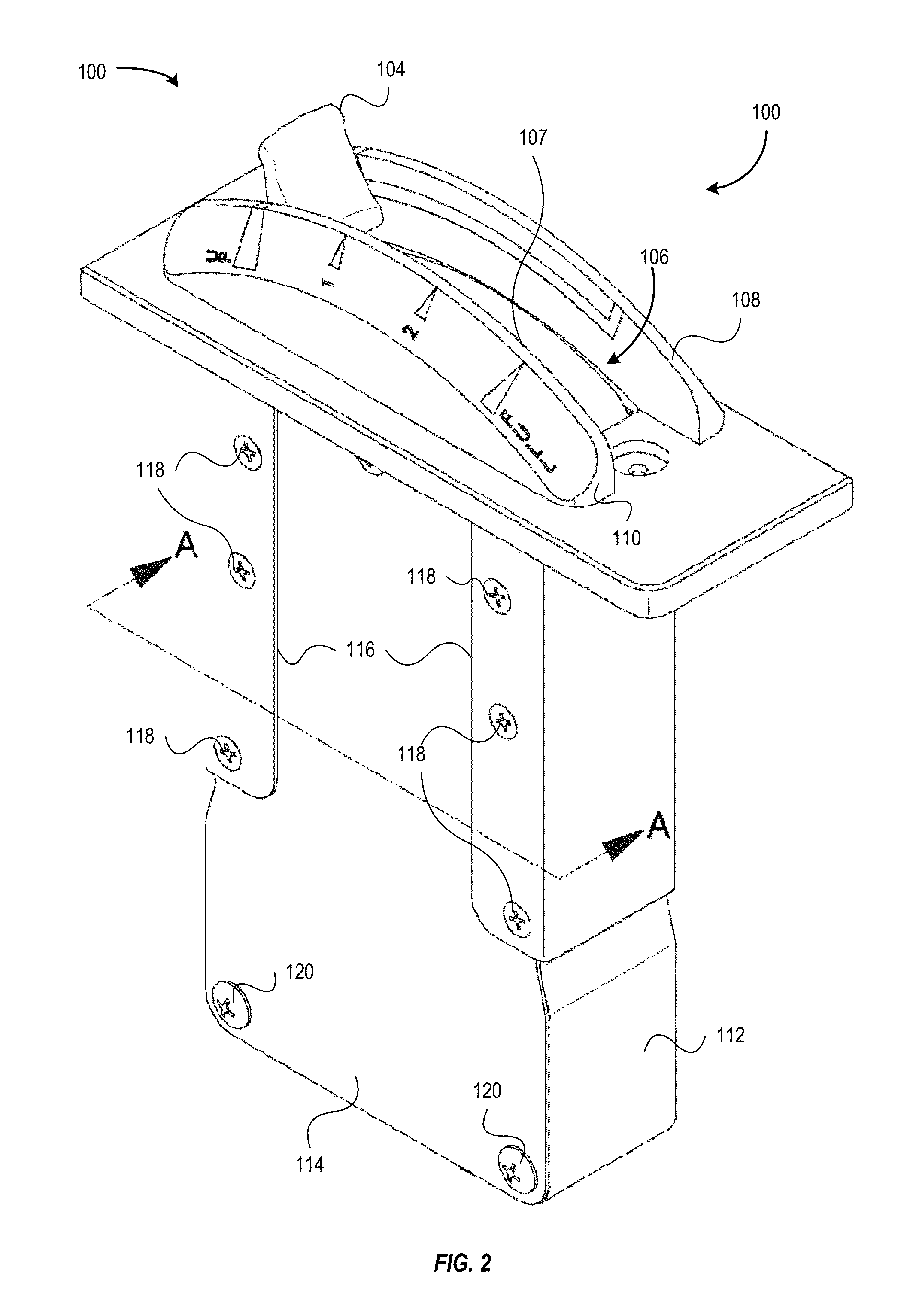

Self-centering aircraft flap position command apparatus

Owner:TEXTRON INNOVATIONS

Parking assistance apparatus

In the parking assist apparatus disclosed here, when the side parking mode switch is set at the initial stop position A, the controller calculates the backward movement start position B for parking based on the yaw angle and the steering angle of the vehicle, and upon determining the vehicle Guidance information is issued to stop the vehicle when the calculated backward movement start position B has been reached. After having sensed that the shift lever is shifted to the reverse position, the controller displays on the display an image captured by the camera about the area behind the vehicle, and the vehicle moves backward while maintaining the steering angle at the shift lever shift Next, the estimated vehicle space is also shown in an overlay on this display. The driver operates the steering wheel to establish an appropriate positional relationship between the estimated vehicle space and the target parking space on the display, thereby obtaining an appropriate steering angle in the backward moving vehicle.

Owner:TOYOTA IND CORP

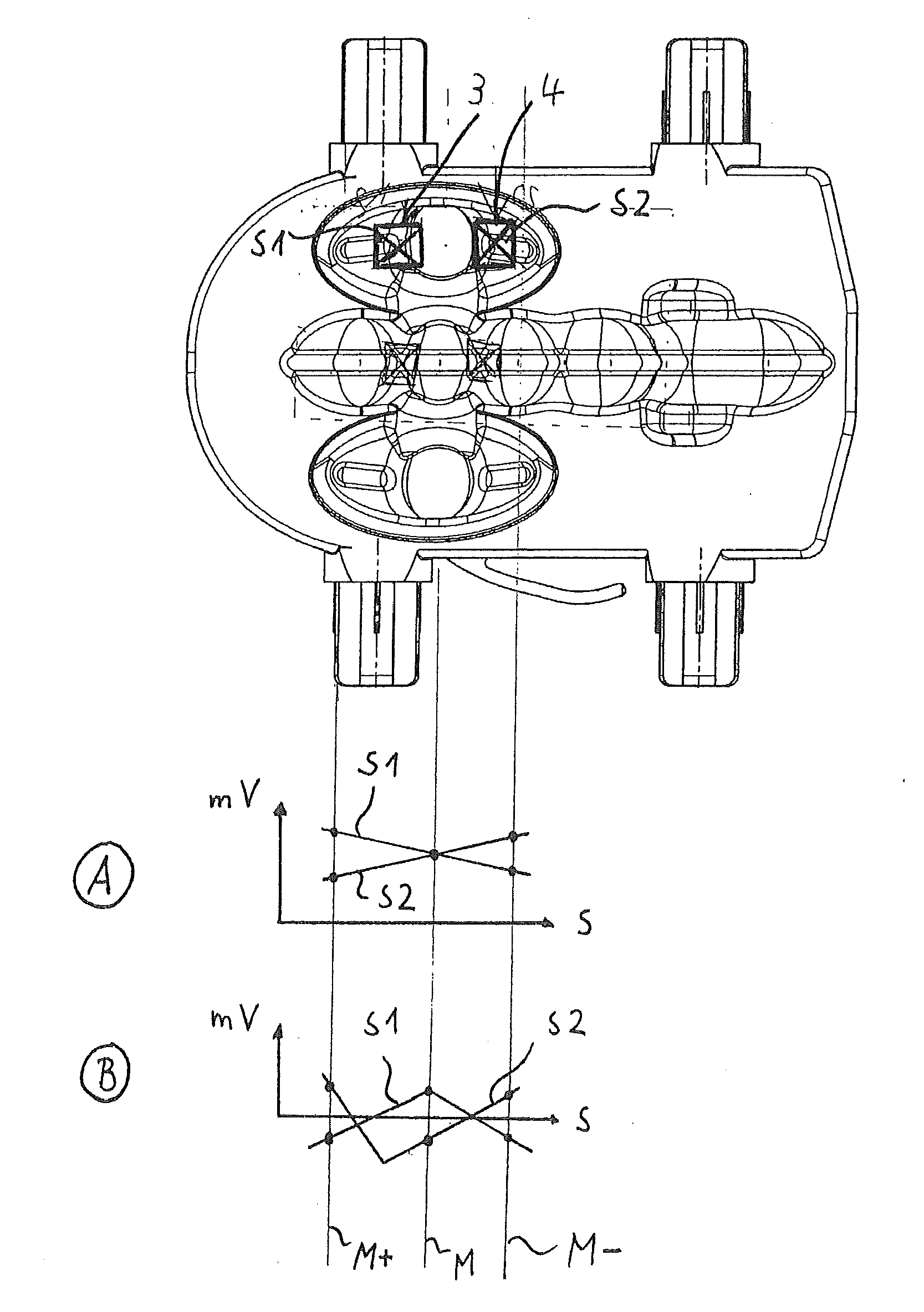

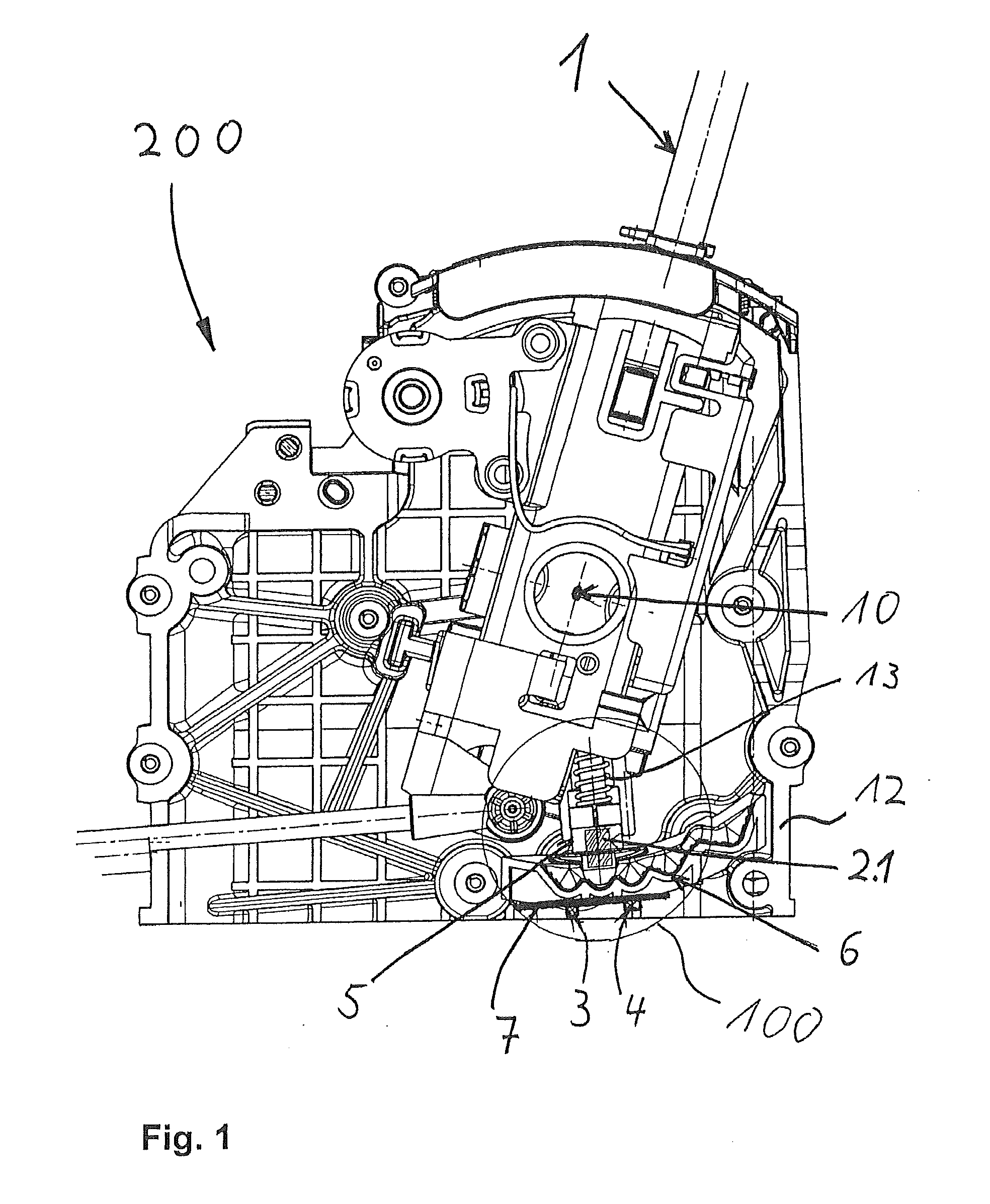

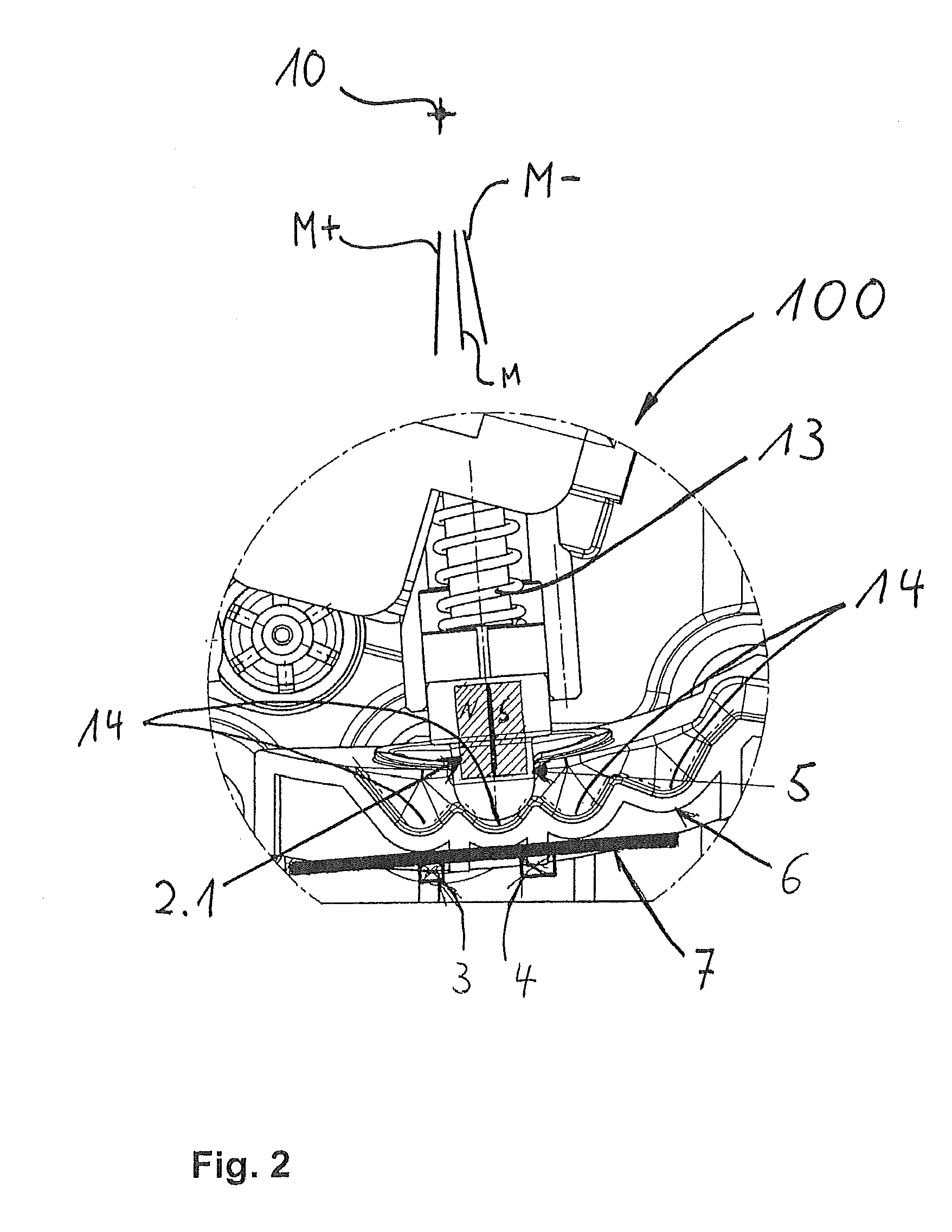

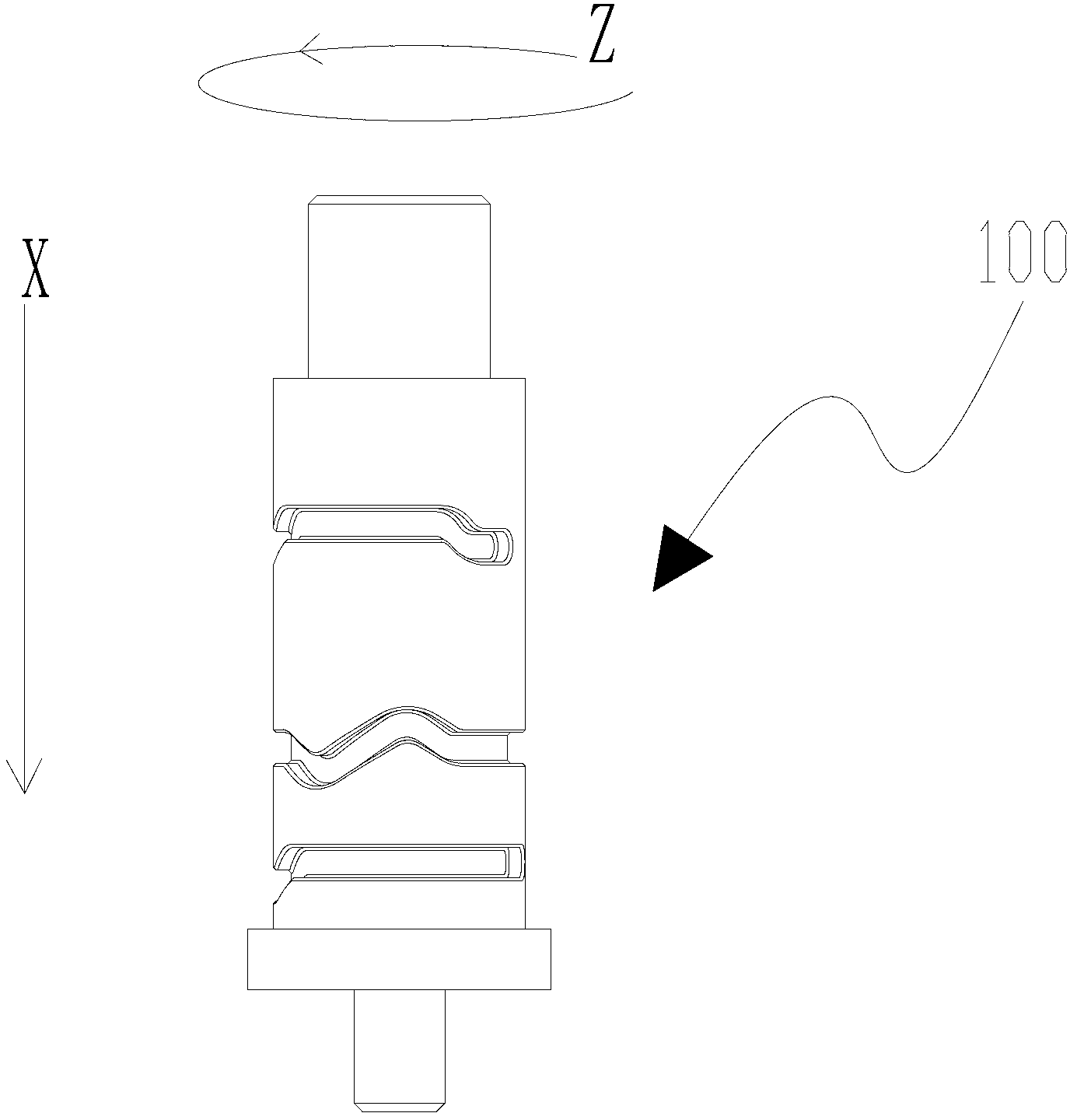

Device for detecting the position of a shift and/or selector lever for a transmission and shift device for the transmission of a motor vehicle

InactiveUS20120187940A1Improve reliabilityReduce riskMagnetic measurementsGearing controlTransducerAnalog signal

A device (100) for detecting the position of a gearshift lever and / or selector lever (1) for a transmission has a signal-generating element (2.1; 2.2) that can be moved together with the gearshift lever and / or selector lever (1). The detection device (100) also has, as the measuring transducer, at least one sensor element (3, 4) that detects the signal from the signal-generating element (2.1; 2.2). A locking means (5) for the gearshift lever and / or selector lever (1) is associated with the signal-generating element (2.1; 2.2). The sensor element (3, 4) delivers, as the measured value, an analog signal (S1, S2) that is dependent on the plus-minus sign. A shifting device (200) for a transmission, especially for use in a motor vehicle, may include the device (100) for detecting the position of a gearshift lever and / or selector lever (1).

Owner:ECS ENGINEERED CONTROL SYST

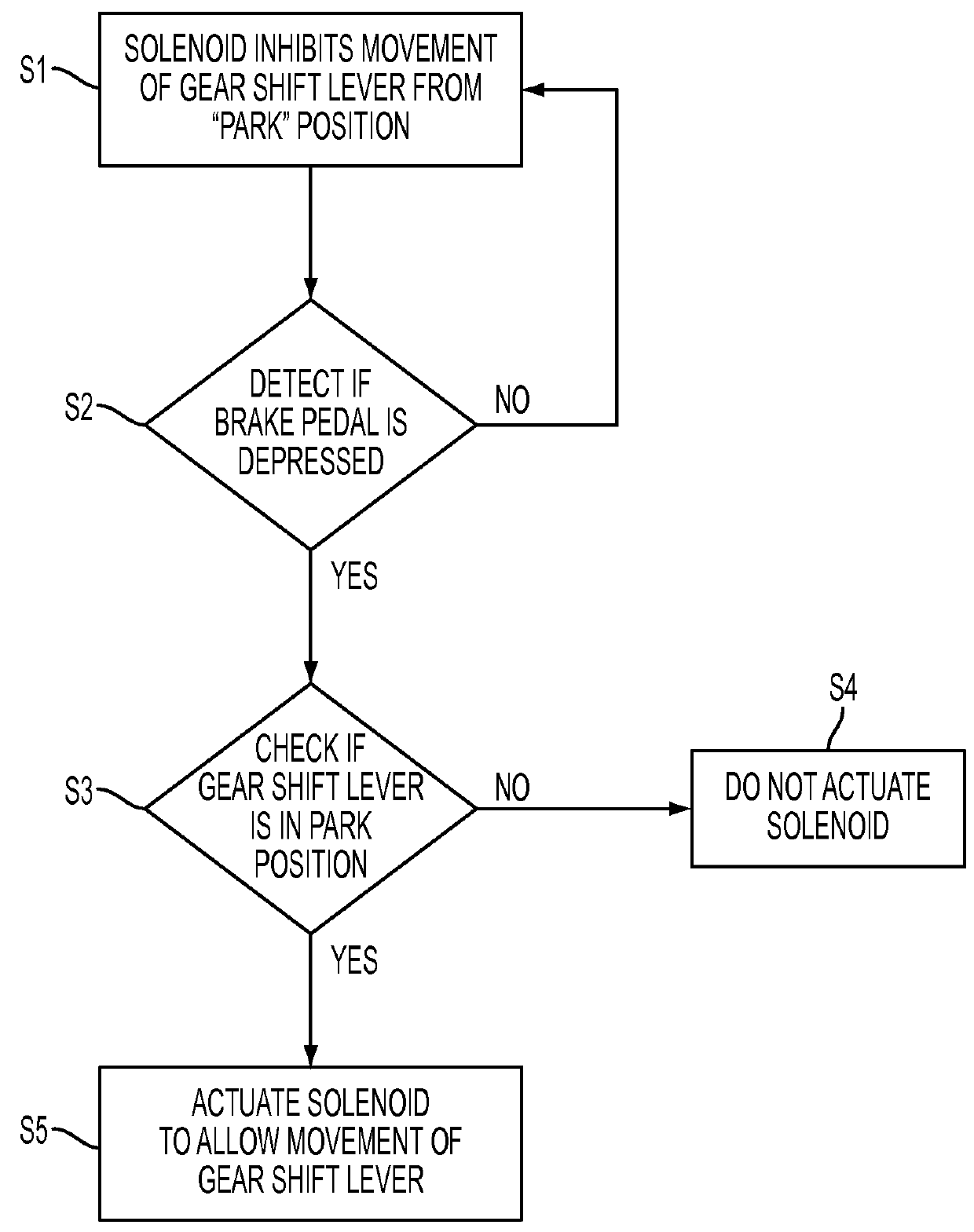

Gear shift lever lock system and method

Owner:STEERING SOLUTIONS IP HLDG

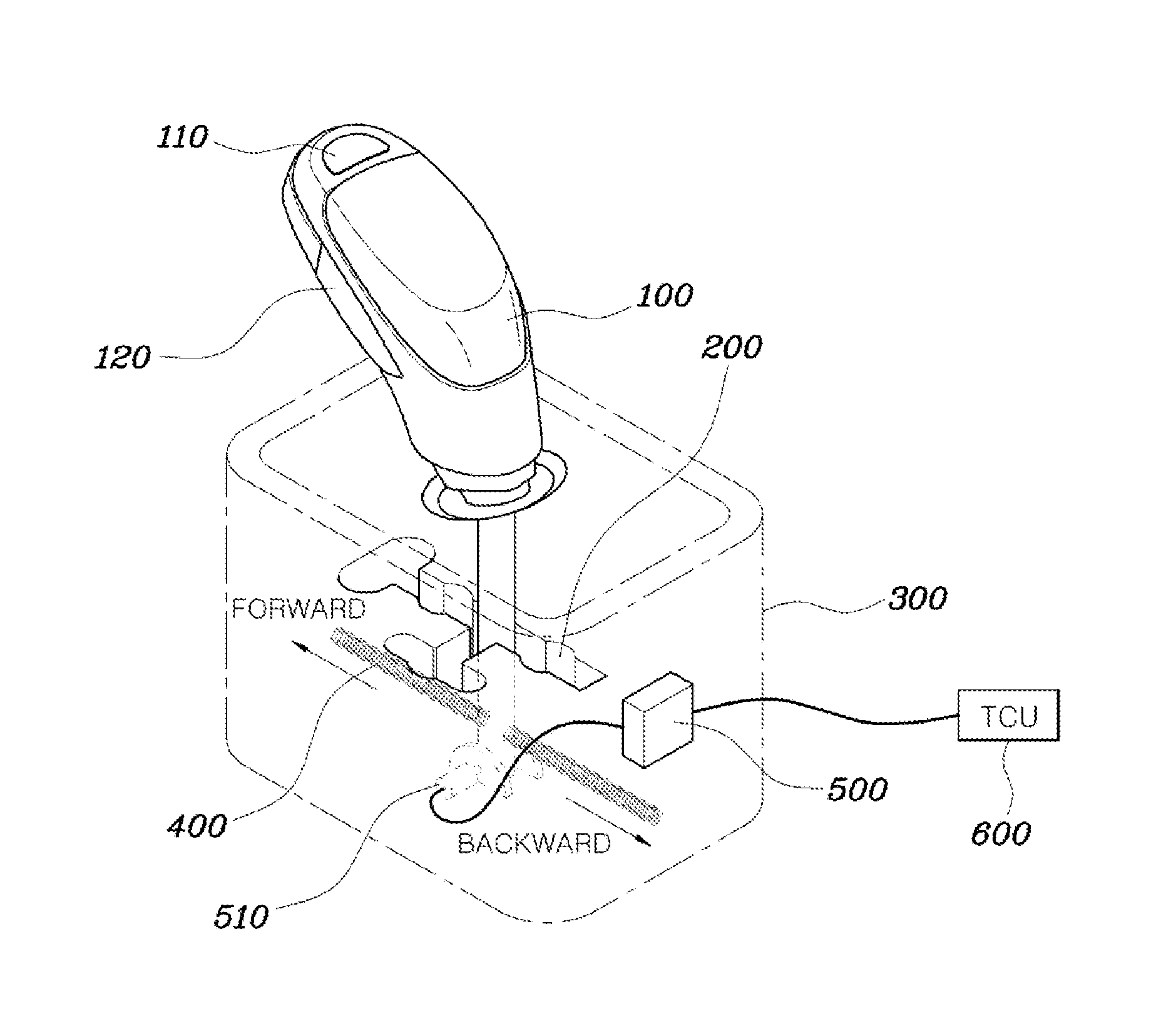

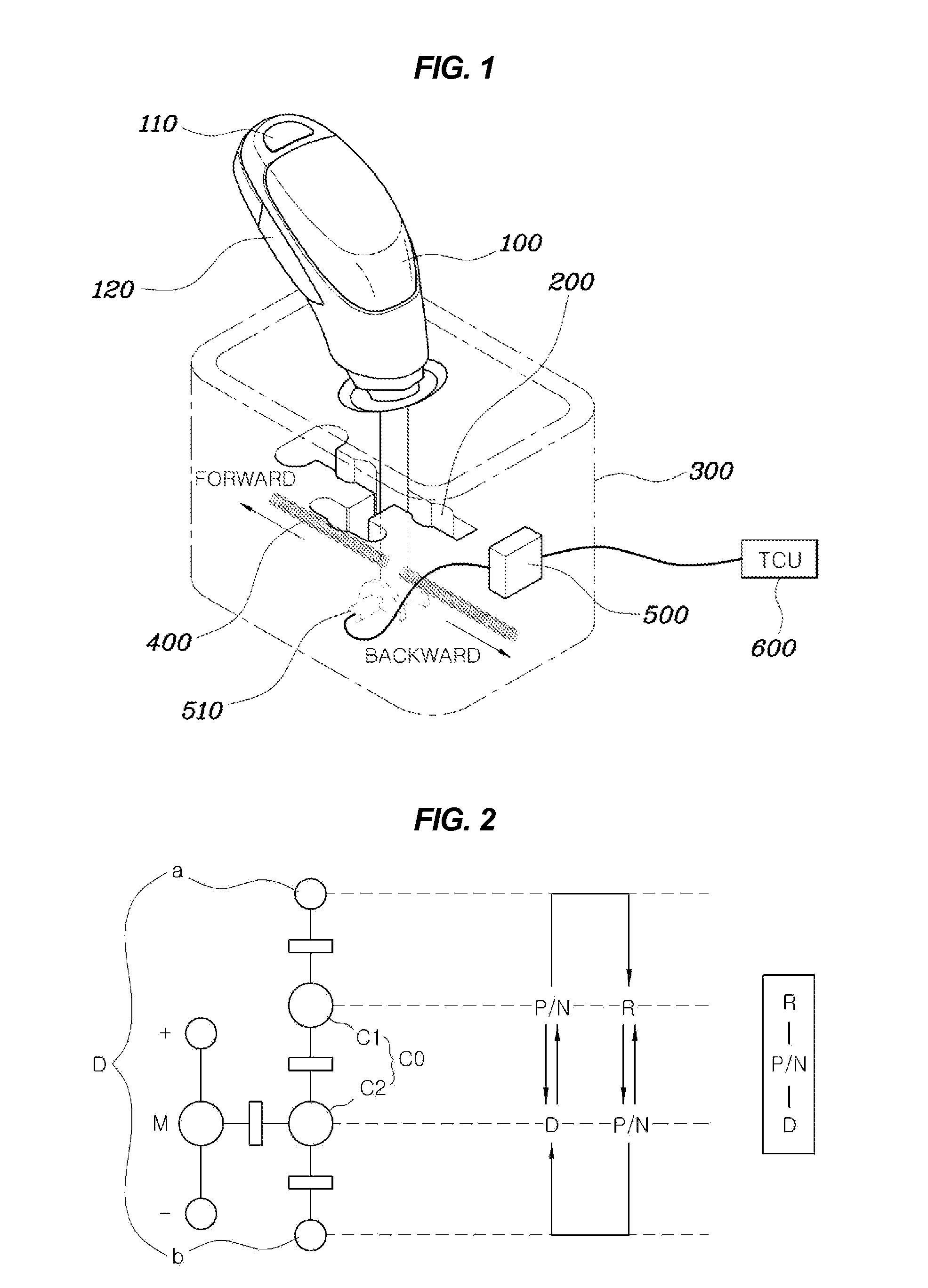

Shifting apparatus for vehicle

ActiveUS20150135878A1Controlling membersGearing controlGear stickElectrical and Electronics engineering

A shifting apparatus for a vehicle may include a lever position guide that is provided inside a gear lever box at which a gear lever is located, and has a reference position and multiple gear positions connected to the reference position, an elastic part engaged to the gear lever and the gear lever box and configured to return the gear lever to the reference position when the gear lever deviates from the reference position and thus is located at any one of the multiple gear positions, and a controller that shifts a gear range according to a preset shifting order when the gear lever moves between the reference position and the multiple gear positions, and shifts the gear range to a preset gear range when the gear lever is located at any one of the multiple gear positions for a longer time than a setting time.

Owner:HYUNDAI MOTOR CO LTD

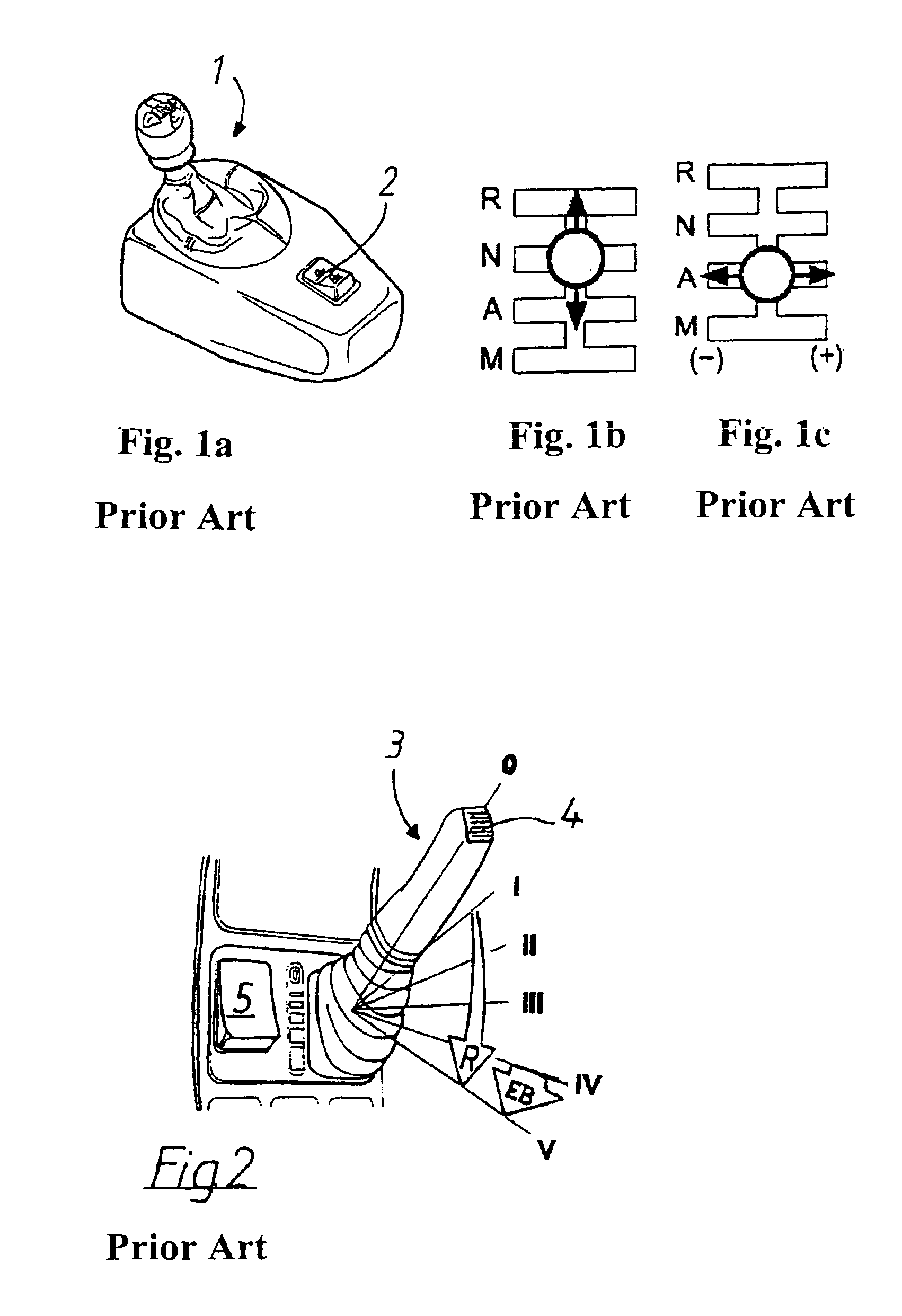

Control arrangement for a vehicle

InactiveUS6945349B2Better ergonomicsImprove securityManual control with multiple controlled membersControlling membersSemi automaticEngineering

A control device in a vehicle, which control device is connected to, and is for operating, a semi-automatic gearbox, can be set in various gearchange function positions and can, in at least one gearchange function position for traveling forwards, be operated for gear changing. The control device is also connected to, and is for operating, a supplementary brake. This control device replaces both the gear lever and the supplementary brake lever, resulting in increased driving safety and better ergonomics for the driver.

Owner:SCANIA CV AB

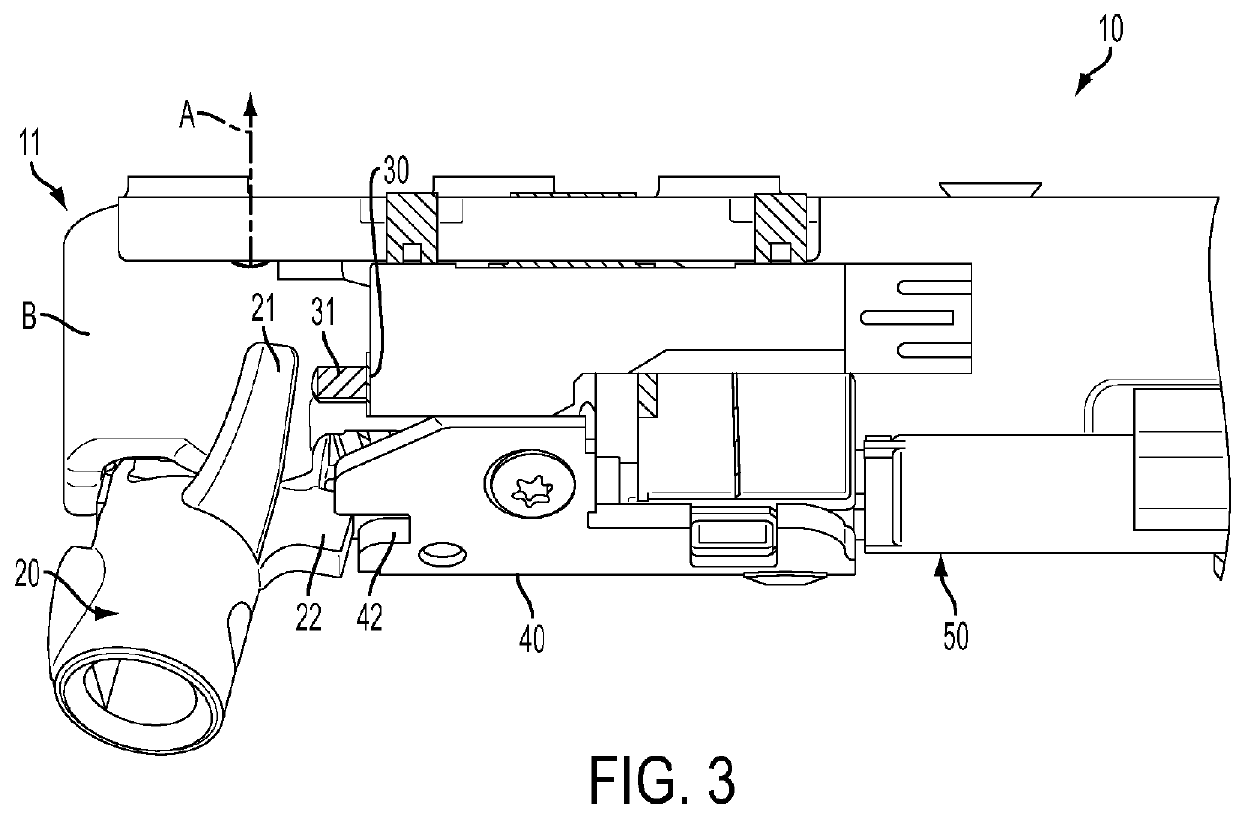

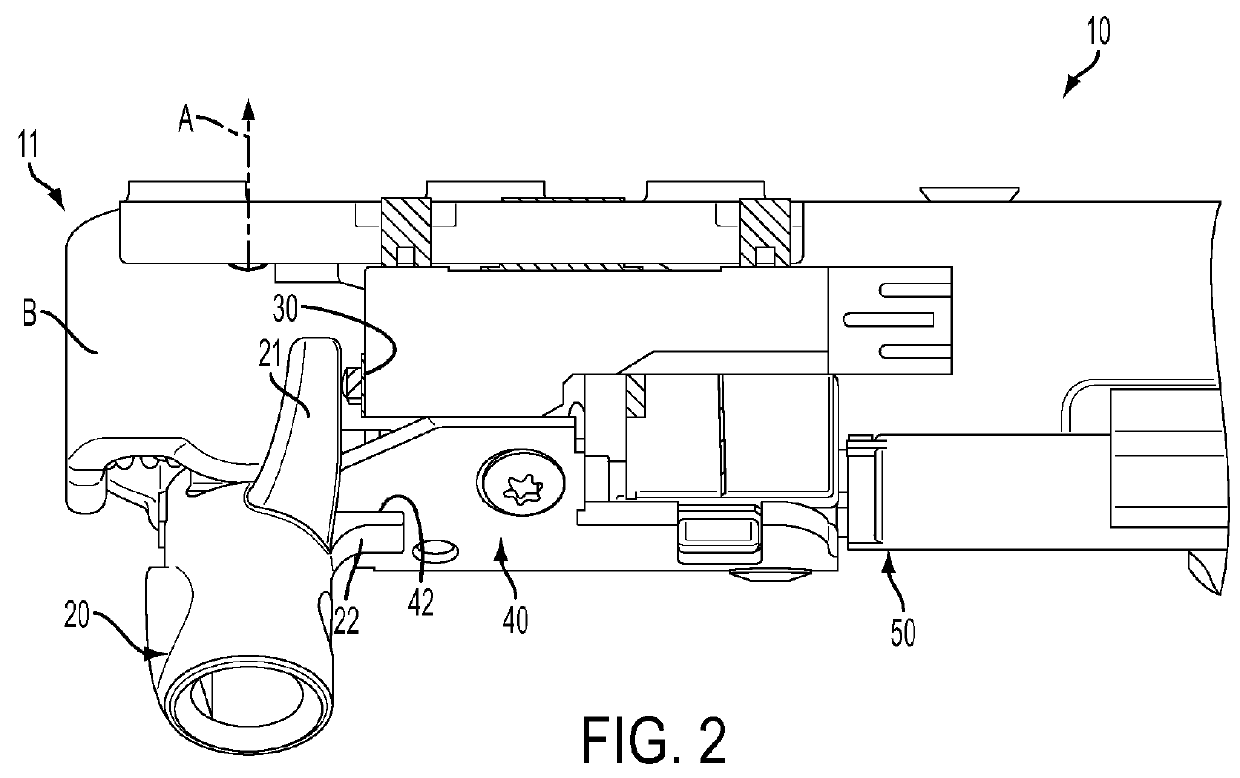

Apparatus for locking shift lever of automatic transmission in vehicle

Provided is an apparatus for locking a shift lever of an automatic transmission in a vehicle which includes: a shift lock cam including a position converting member and being connected with a brake pedal wherein the shift lock cam is pivotally coupled to a shift lever housing and elastically supported by a first elastic member, and a shift lock release lever that is pivotally coupled to the shiftlever housing and elastically supported by a second elastic member, wherein one end of the shift lock release lever is selectively coupled to a shift lever body and the other end of the shift lock release lever is eccentrically coupled to the position converting member of the shift lock cam.

Owner:HYUNDAI MOTOR CO LTD +1

Gear shifting mechanism of manual transmission

ActiveCN103062395ASimplify the shifting processShorten shift timeControlled membersGearing controlEngineeringShift time

The invention belongs to the field of manual transmissions and particularly relates to a gear shifting mechanism of a manual transmission. The gear shifting mechanism of the manual transmission comprises a gear shifting drum, a transmission shell, a guide groove structure and a gear shifting fork structure, the gear shifting drum rotates to enable gear shifting forks in the gear shifting fork structure to alternately ascend and descend along guide grooves, the gear shifting fork structure disengages a gear or engages a gear once by means of each ascending and descending action, one-gear movement of a shifting lever includes one gear disengagement action and one gear engagement action, and the gear shifting process is changed into clutch disengagement-shifting lever gear shifting-clutch engagement, so that the gear shifting process is simplified, and gear shifting time is shortened.

Owner:浙江万里扬新能源驱动有限公司

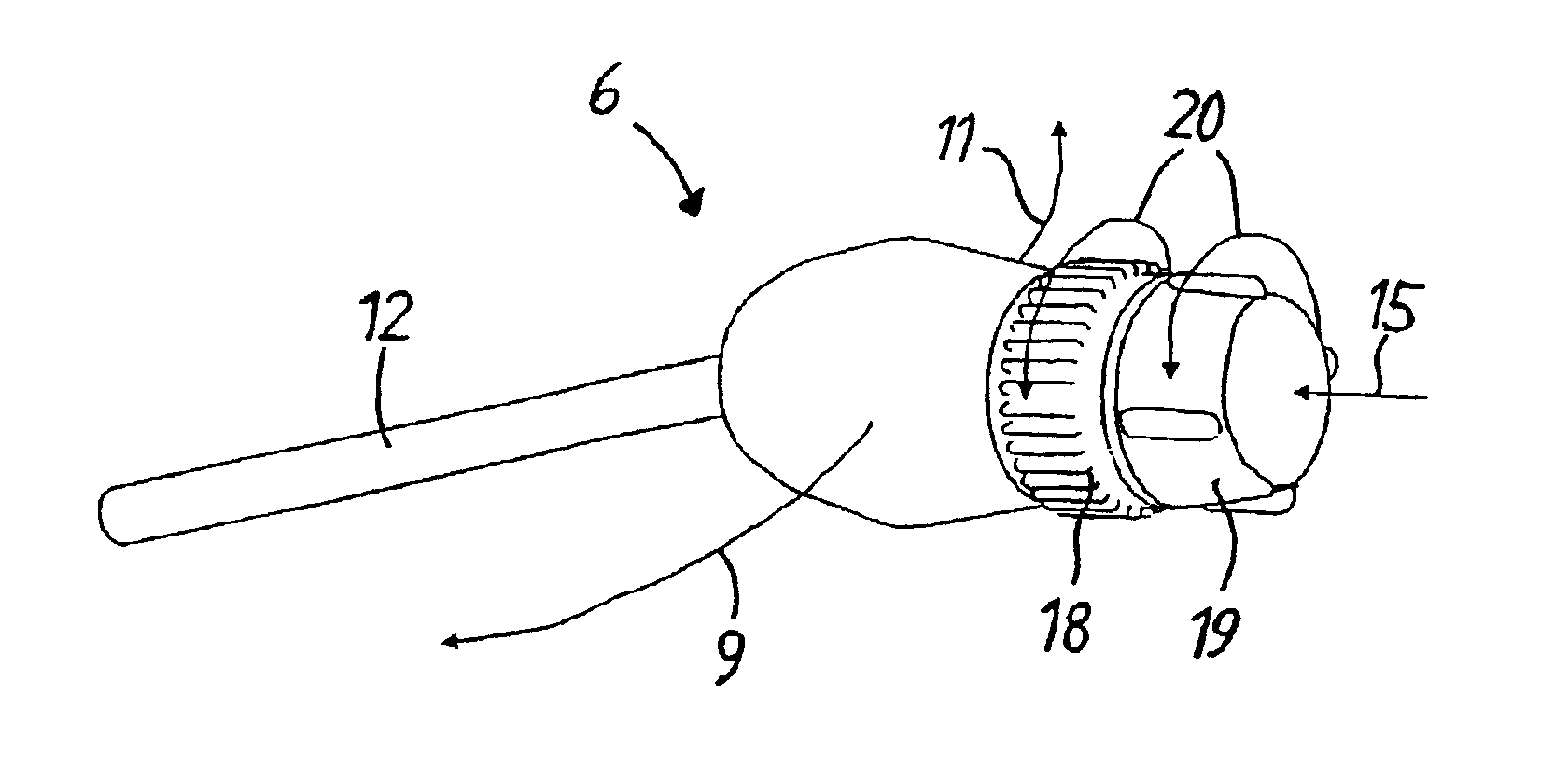

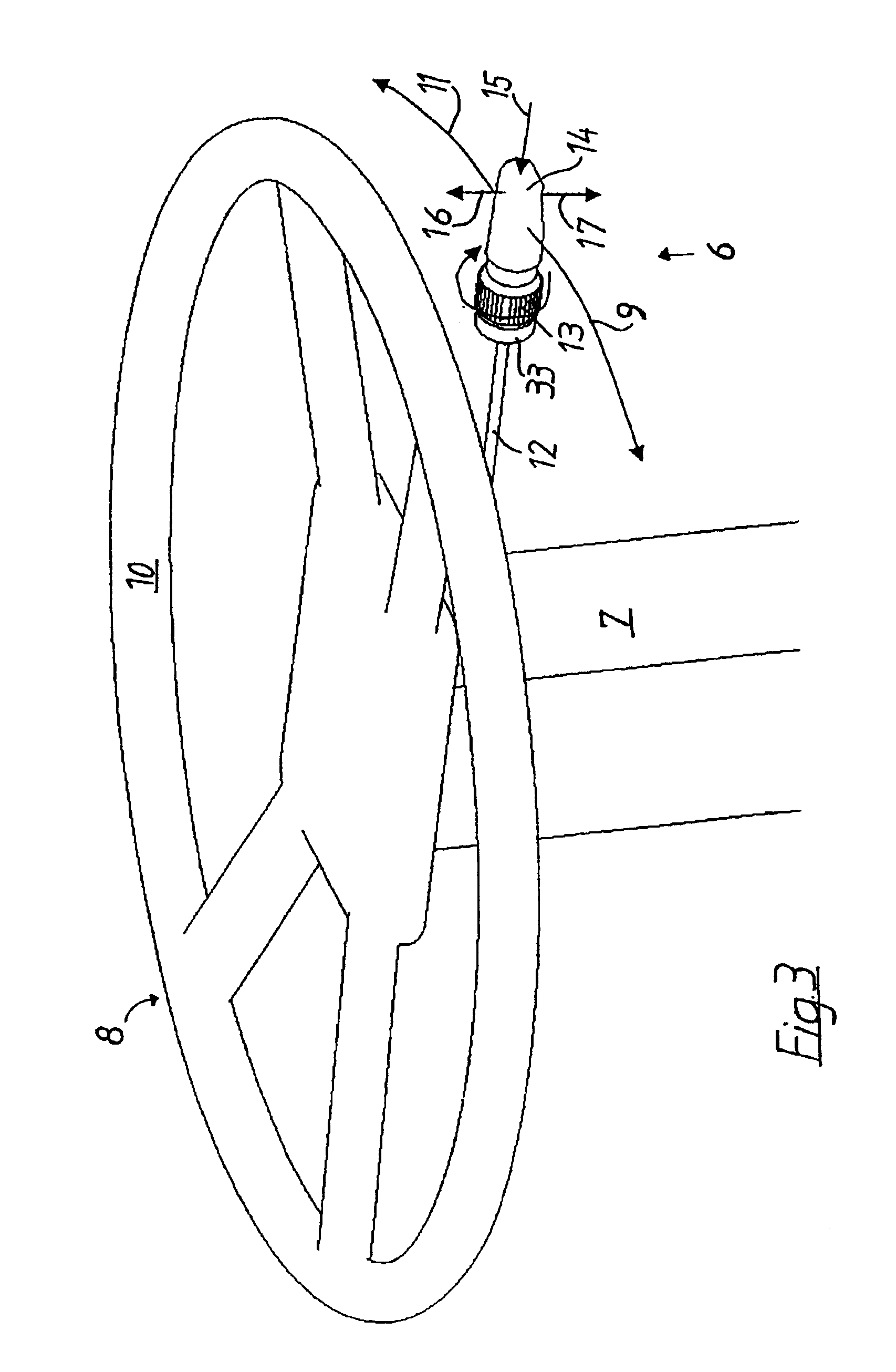

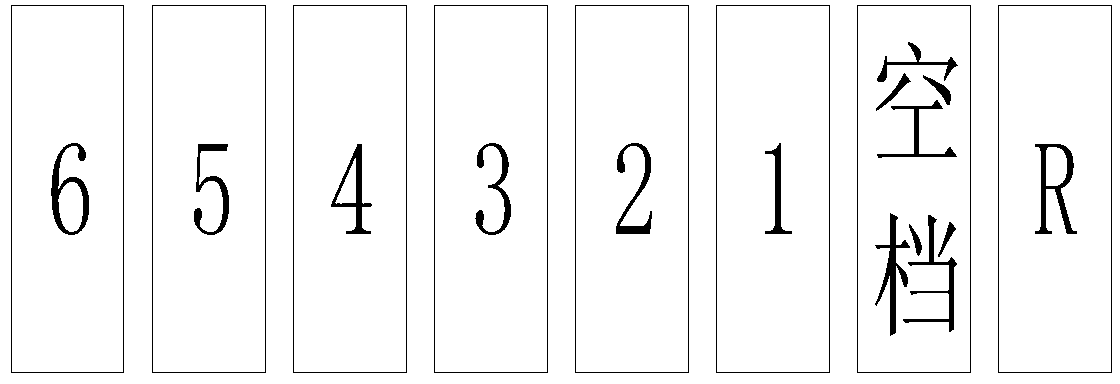

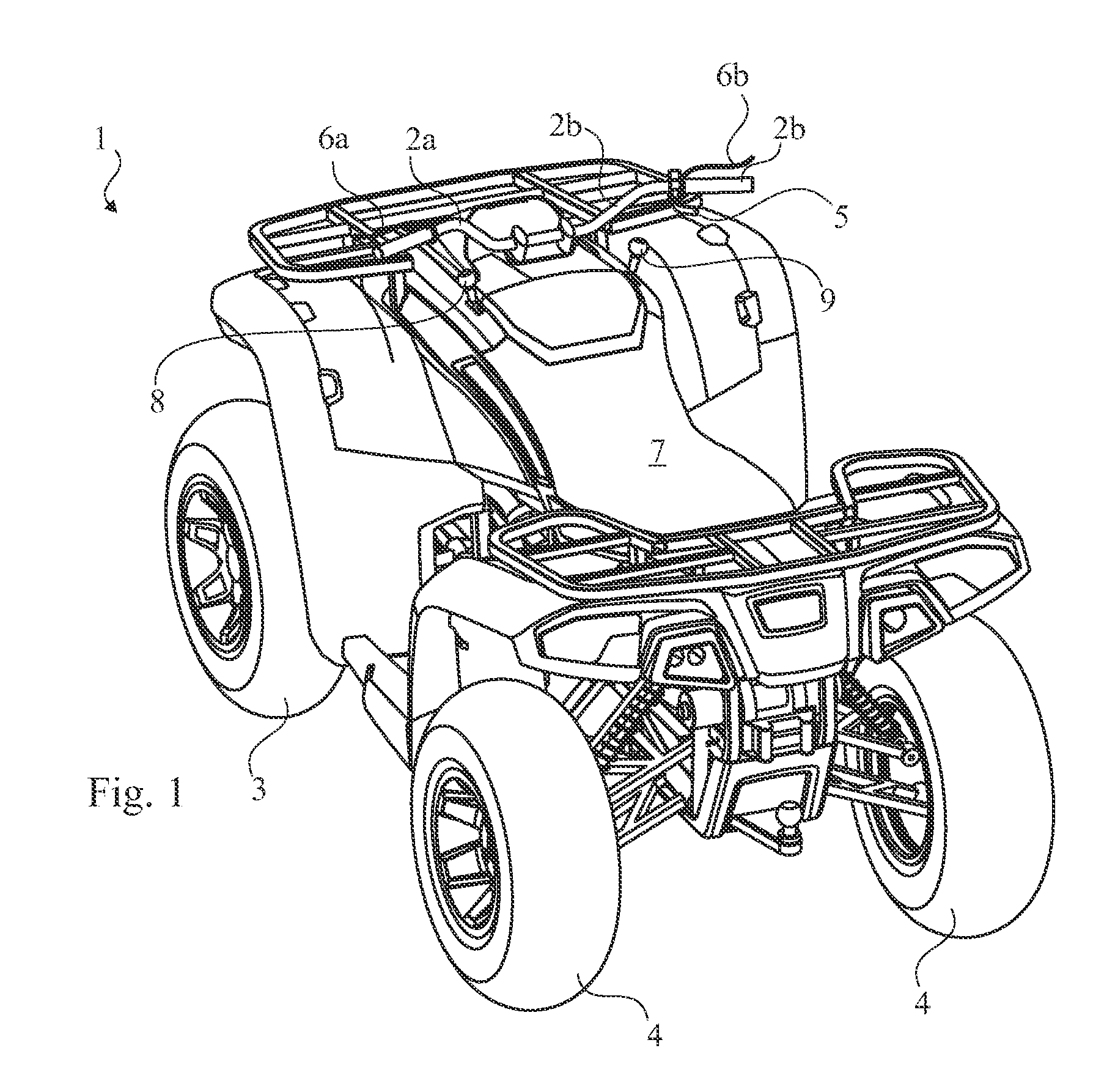

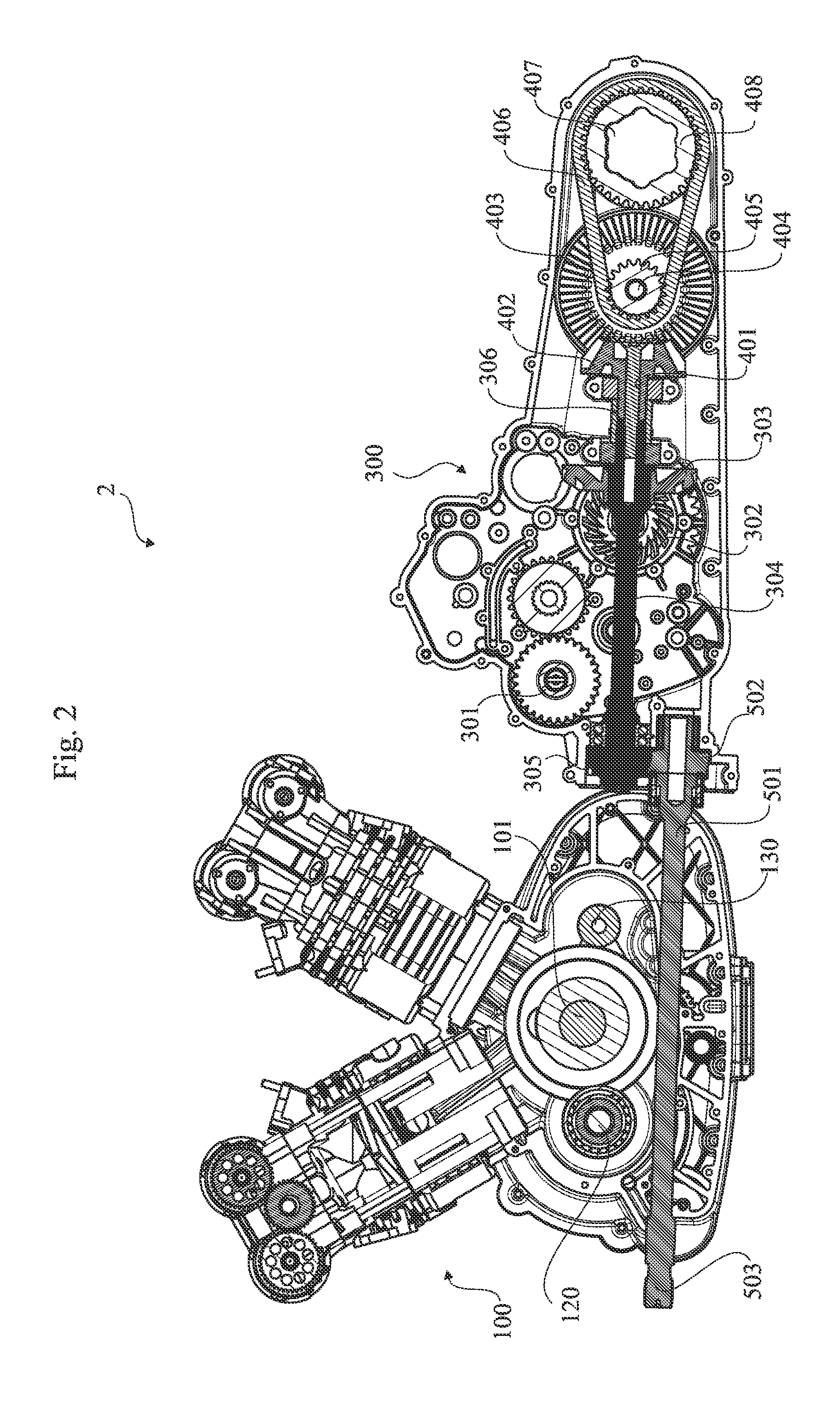

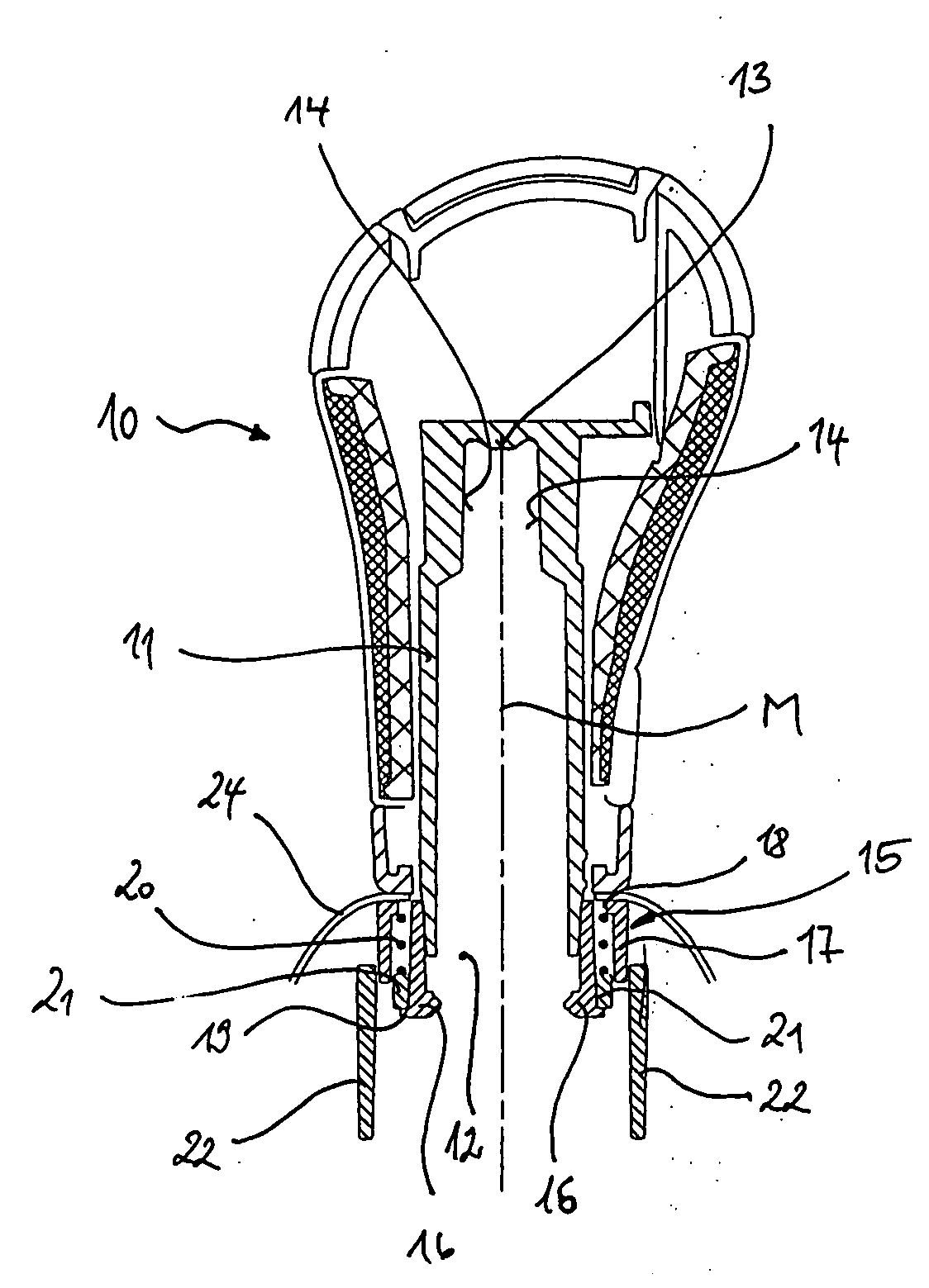

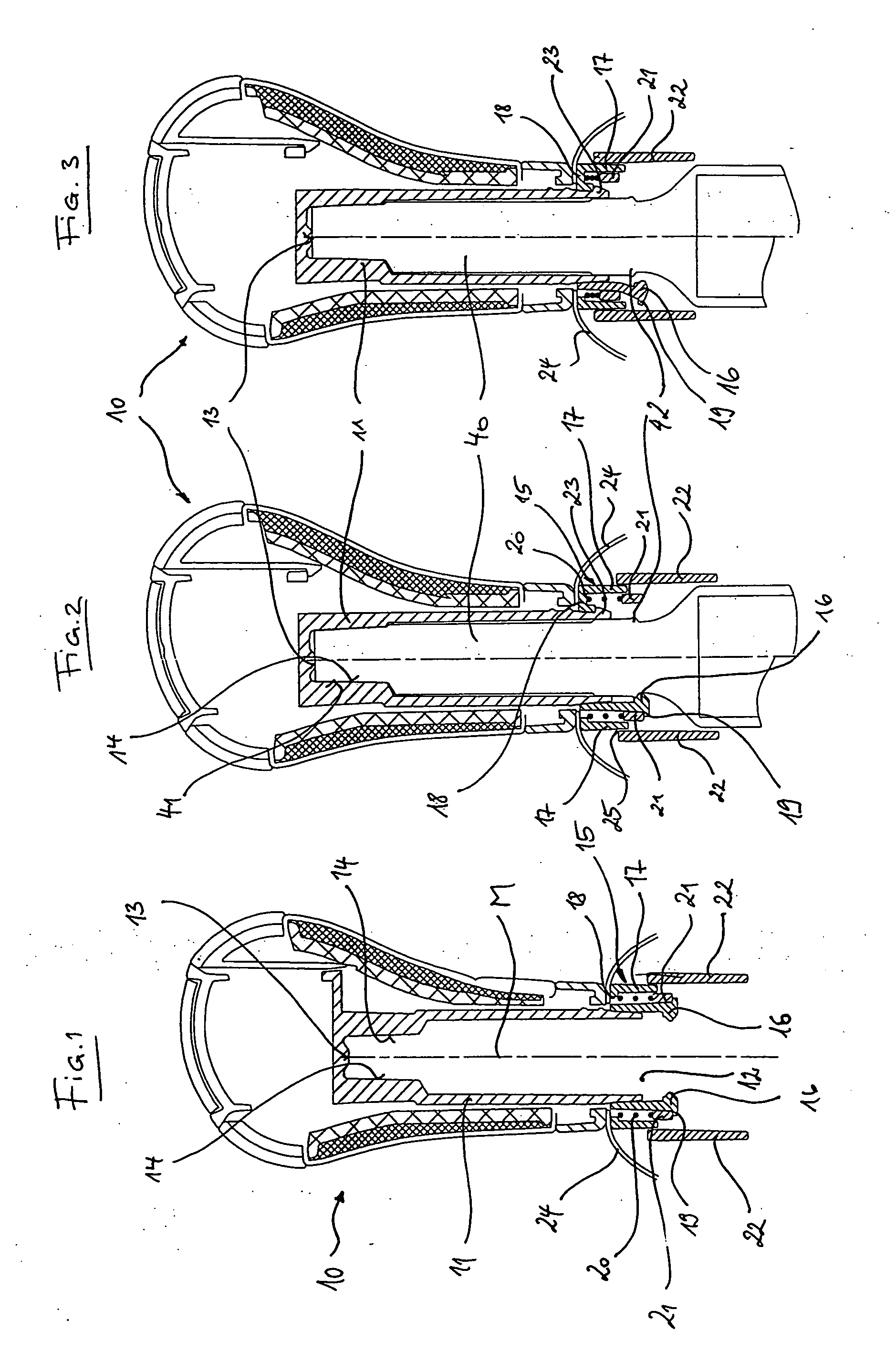

Gear shift arrangement for a vehicle

Gear shift arrangement for a shiftable manual gearbox (300) provided in a vehicle, e.g. an off road vehicle, scooter or snowmobile, comprising a shift operating mechanism (9, 8) to be operated by a driver, said gearbox having a first set of gears with positions for high speed, and at least one further gear from the group of gears low speed, neutral and parking, and a second set of gears with positions for at least forward and reverse. The positions of the first set of gears are shiftable under influence of a first shift lever (9), that the positions of the second set of gears are shiftable under influence of a second shift lever (8) separate from the first one, and each shift lever is movable in essentially only one plane.

Owner:HUSQVARNA AB

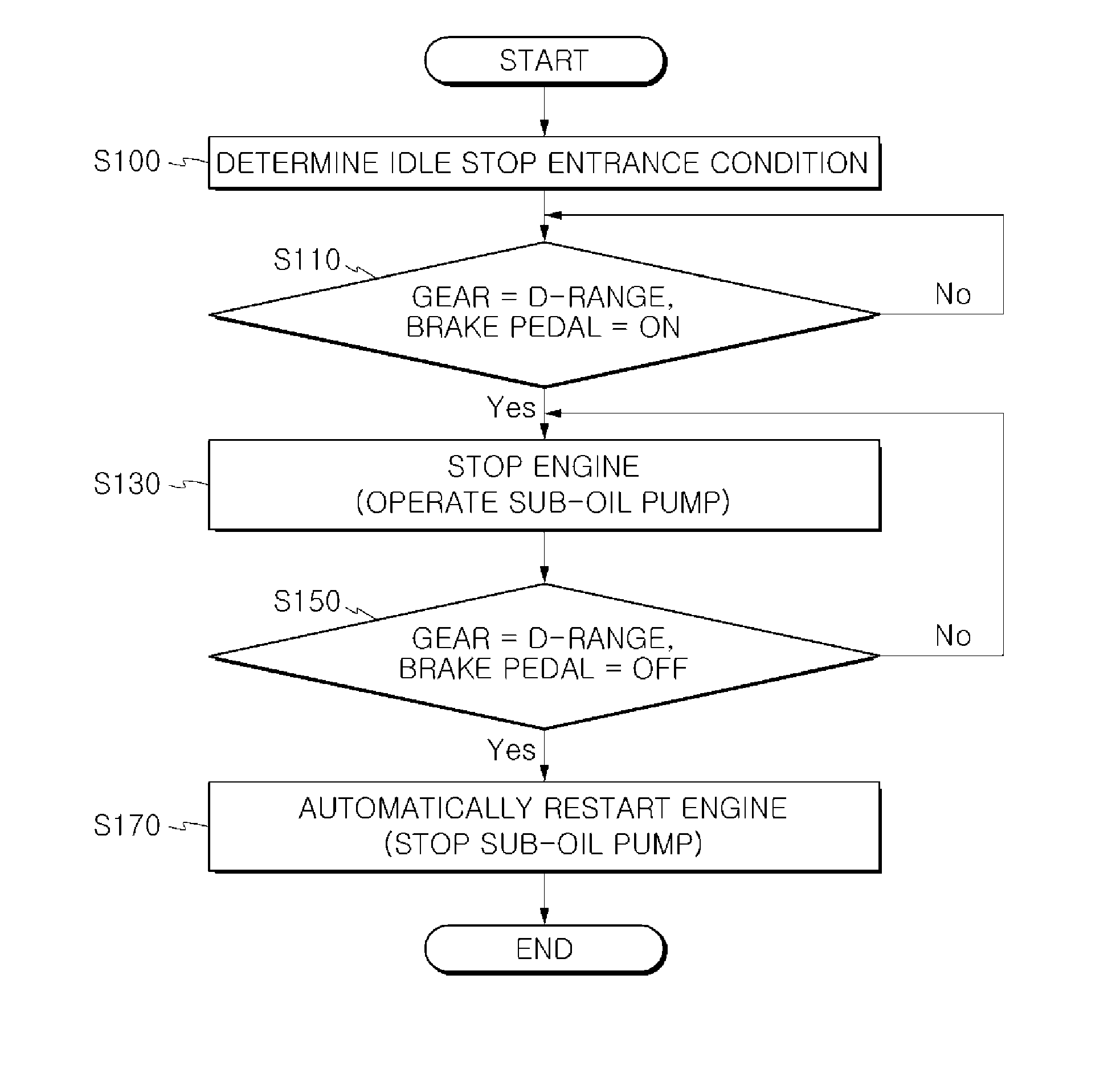

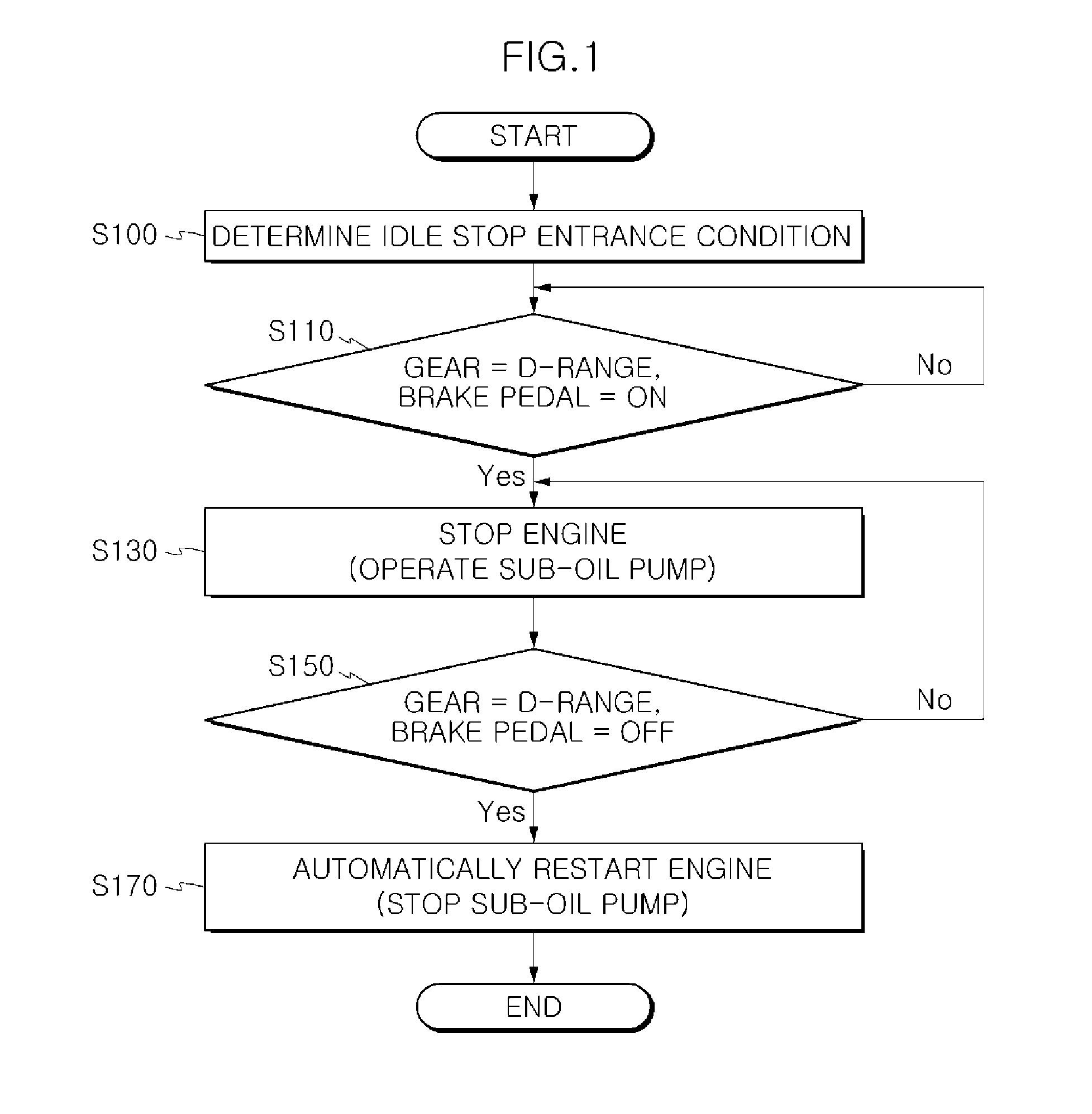

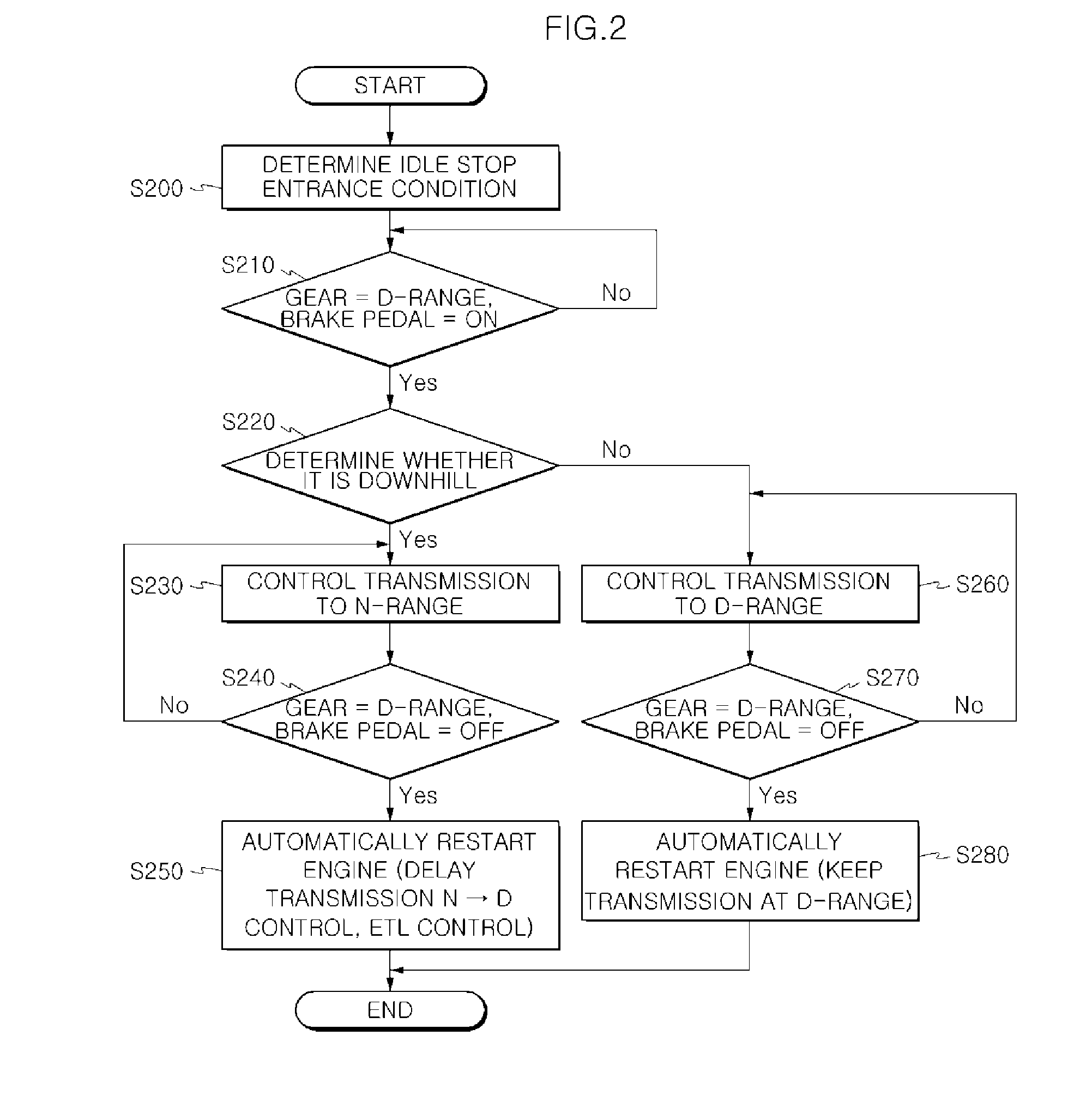

Method and device for controlling isg logic

ActiveUS20120142491A1Accurately consideringStable start of an ISG vehicleInternal combustion piston enginesEngine controllersGear stickAutomotive engineering

A device for controlling ISG logic is mounted in a vehicle equipped with an ISG system. The device includes a brake pedal switch, a shift lever switch that shows the current state of a gear of the vehicle, an inclination sensor that is mounted in the vehicle and measures the inclination of a road where the vehicle is positioned, a controller that internally controls the vehicle to an N (Neutral) state, regardless of the gear range shown by the shift lever switch, for the vehicle on a downhill, in accordance with the measured inclination, and an engine unit that performed idle stop when the brake pedal becomes ON, with the gear of the vehicle at a D (Drive) sate, and restarts the stopped engine when the brake pedal becomes OFF, with the gear of the vehicle at the D state.

Owner:HYUNDAI MOTOR CO LTD

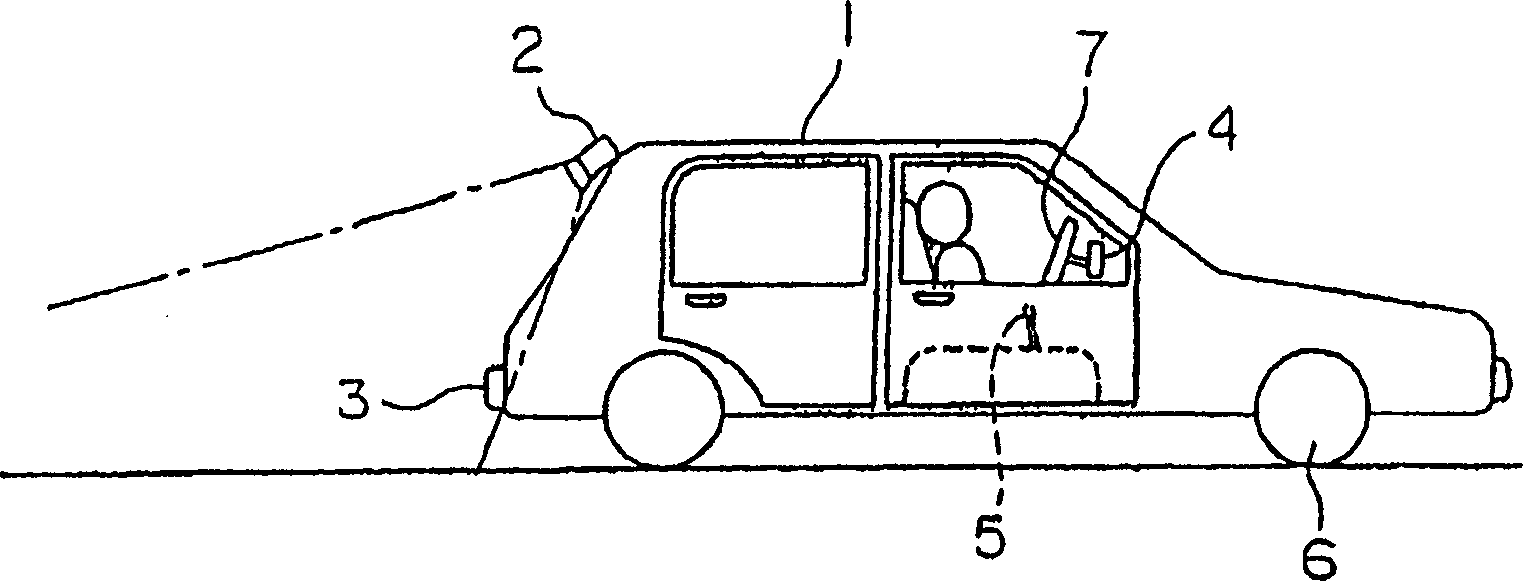

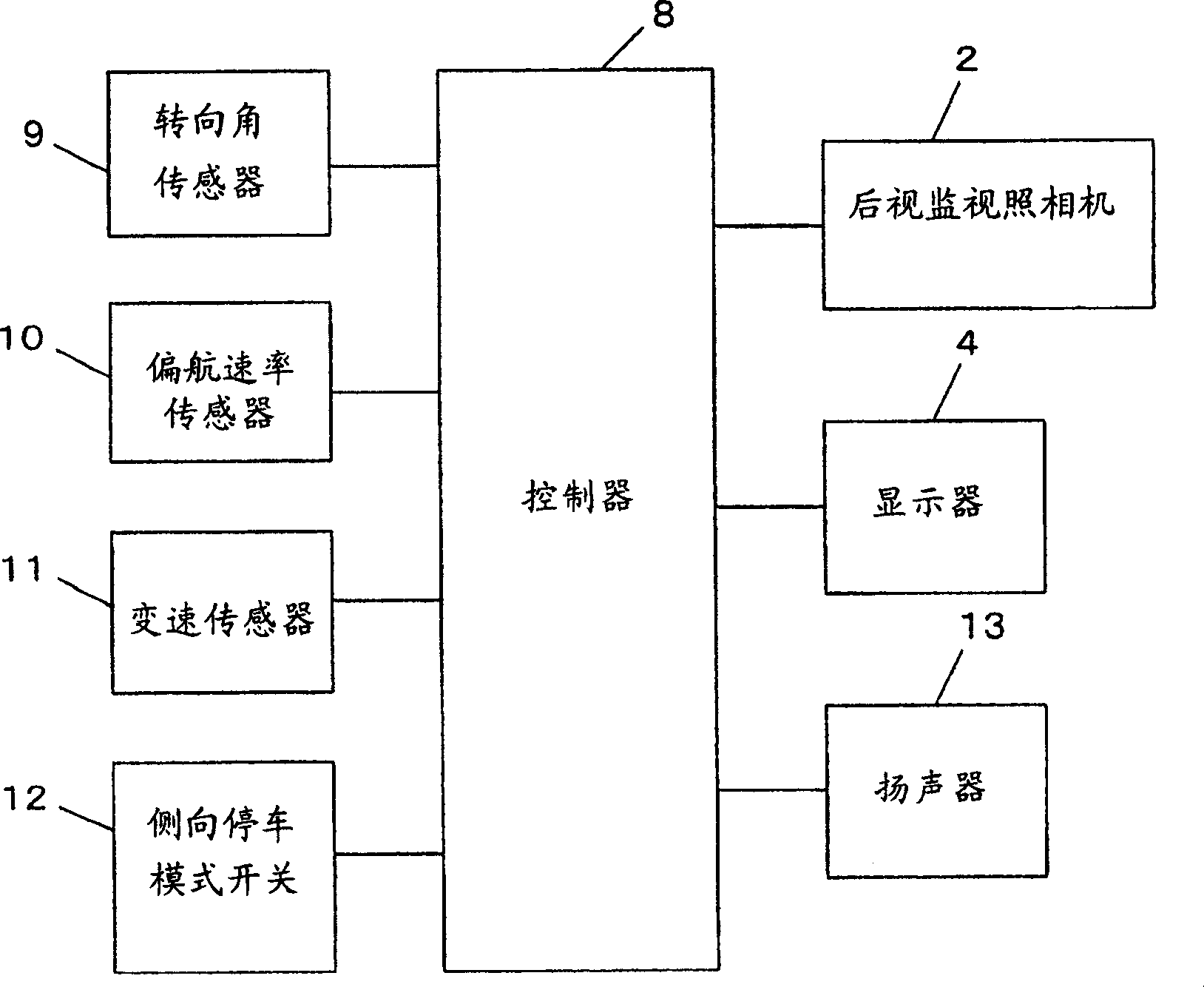

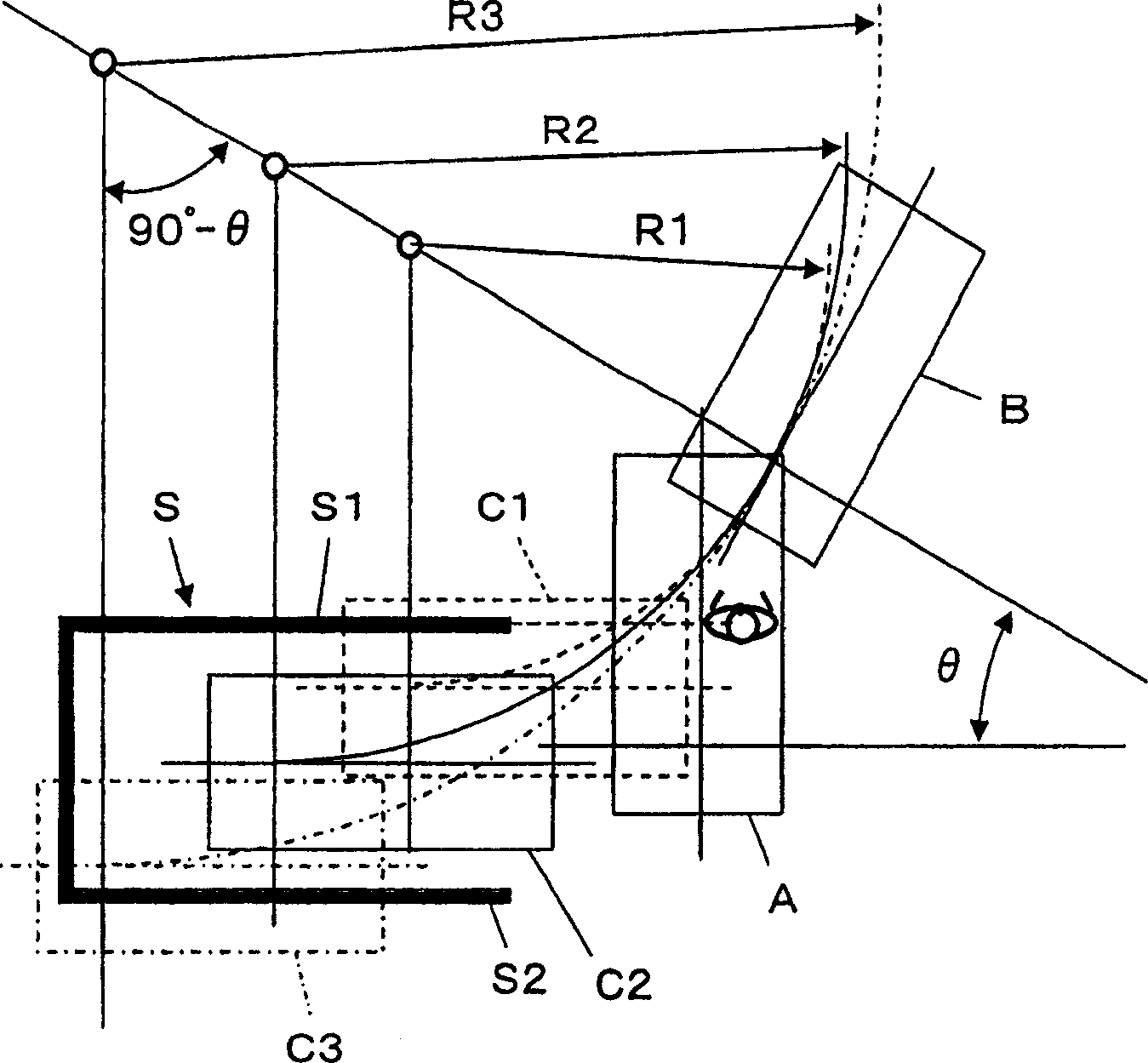

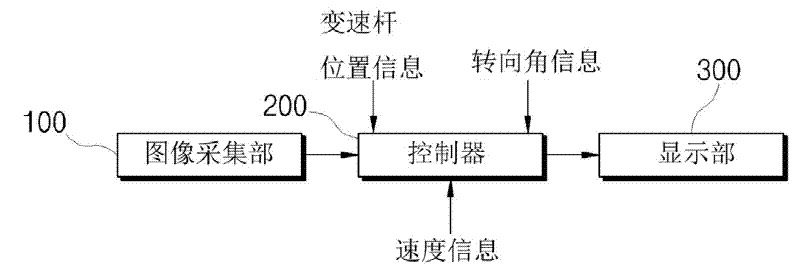

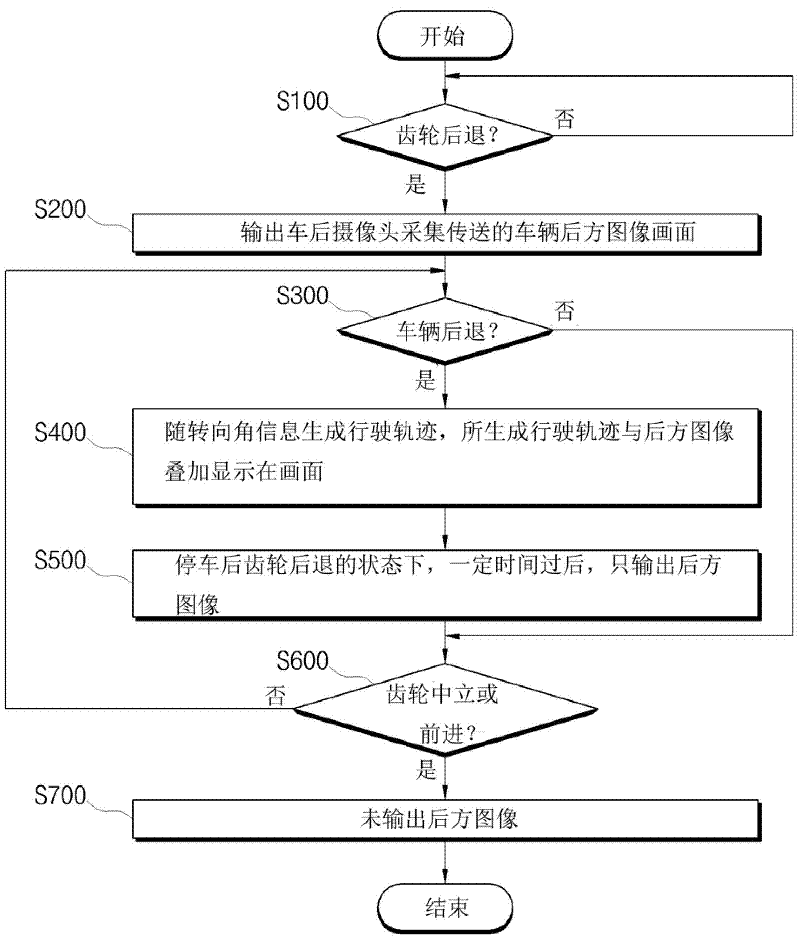

Reversing track auxiliary device based on vehicle information and method thereof

ActiveCN102673476AVehicle sub-unit featuresClosed circuit television systemsSteering angleControl engineering

The present invention discloses a reversing track auxiliary device based on vehicle information and a method thereof. The reversing track auxiliary device comprises: an image acquiring part used for acquiring an image in back of a vehicle; and a control part, wherein, the control part outputs the image in back of the vehicle acquired from the image acquiring part to a picture based on gear level position information after detecting that the gear level is in a reverse gear shift, if the vehicle reverses, the control part superposes a running track based on steering angle information with the image in back of the vehicle acquired by the image acquiring part and outputs the superposed image to the picture. According to the device and the method of the present invention, when the gear level of the vehicle is in the reverse gear shift and the vehicle does not yet reverse, only the picture about the image in back of the vehicle is output, and when the vehicle really reverses, the running track and the image in back of the vehicle are superposed and output to the picture. According to the present invention, when the vehicle does not yet reverse, a wide and neat image is output, only when the vehicle really reverses, the running track is displayed, thereby effectively assisting the vehicle to reverse and park safely.

Owner:HYUNDAI MOBIS CO LTD

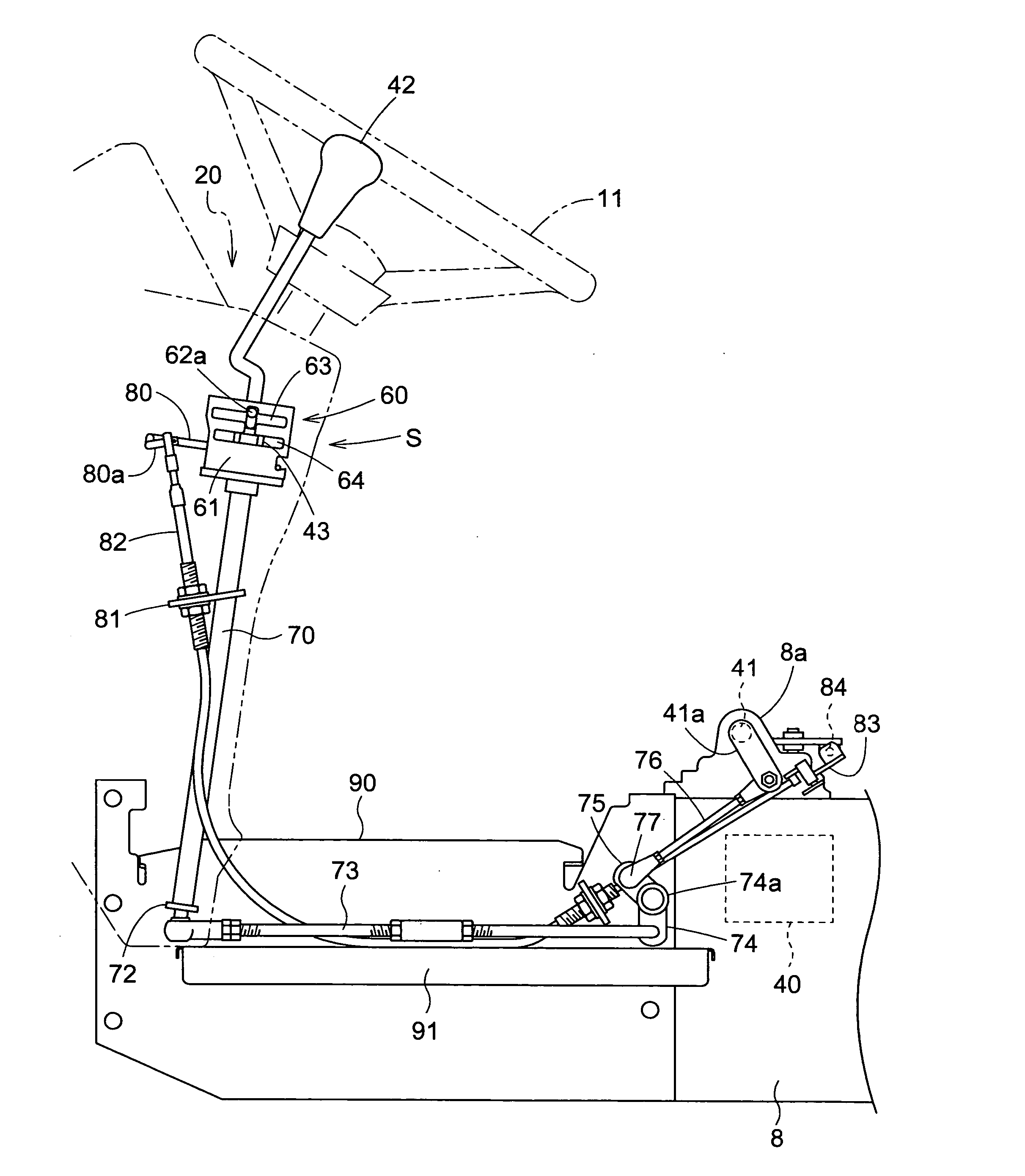

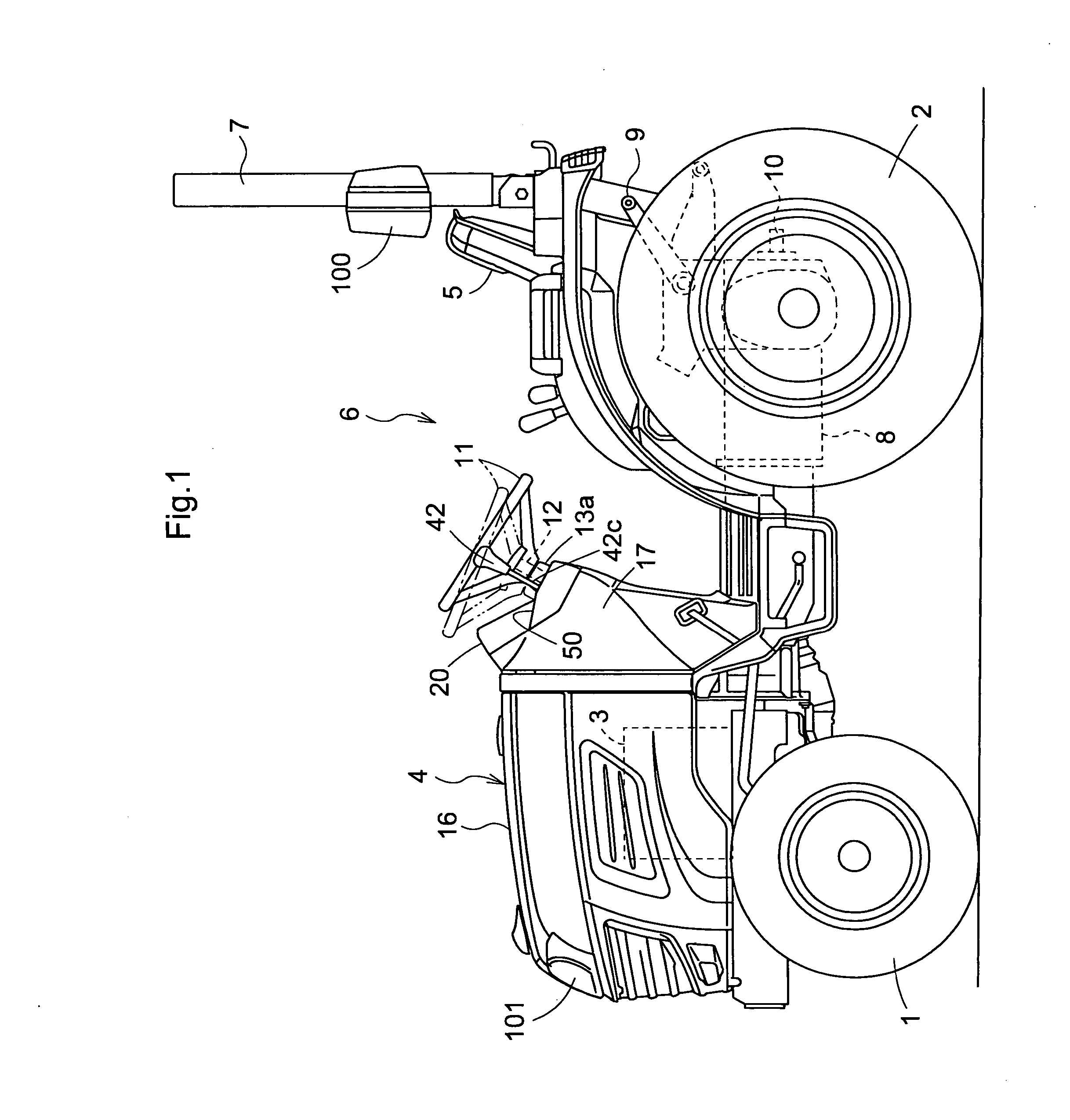

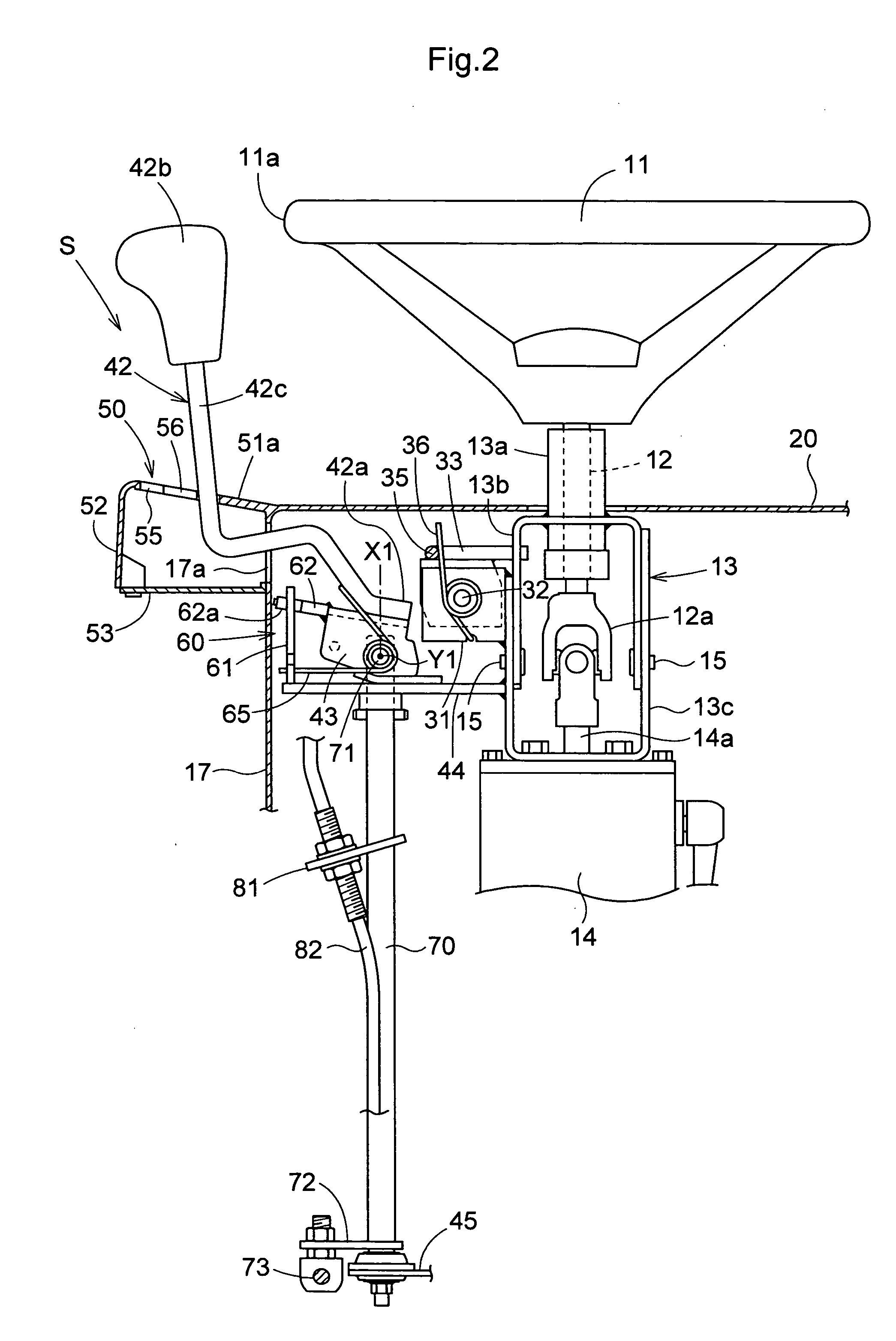

Speed shift arrangement for work vehicle

ActiveUS20070056793A1Easy to switchEasy to operateGearing controlLimiting/preventing/returning movement of partsSteering wheelEngineering

A work vehicle comprises a plurality of wheels; a propelling speed change device supported by the plurality of wheels and having at least one forward travel position and a reverse travel position with substantially the same speed reduction ratio as the forward travel position; a steering wheel for steering at least one of the plurality of wheels; a steering wheel support shaft for supporting the steering wheel; a speed change lever located in a position laterally of the steering wheel support shaft and operatively connected to the propelling speed change device to operate the propelling speed change device; a speed change lever guide for guiding the speed change lever, the guide including: a plurality of fore and aft channels extending substantially in the fore and aft direction of the work vehicle; a communication channel extending between the plurality of fore and aft channels; wherein one of the plurality of the fore and aft channels has a first lever position corresponding to the forward travel position and a second lever position corresponding to the reverse travel position.

Owner:KUBOTA LTD

Manual transmission clutch protection apparatus

A manual transmission clutch protection apparatus includes a shift gate cylinder acted upon by the operator controlled shift lever having a first shift pattern that represents all possible shift positions and two or more additional but limited shift patterns corresponding to certain gears which limit the gears selectable and enagageable by the vehicle operator. Two or more actuators which may be solenoids or other electric, hydraulic or pneumatic actuators translate blocking pins or plungers into the additional or limited shift patterns to lockout or block motion of the shift lever and shift gate cylinder into certain gears. Engine speed and temperature sensors, a vehicle speed sensor and a current gear sensor provide data which is utilized to compute which gears, under current sensed operating conditions, should be locked out, that is, unavailable for selection by the vehicle operator.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gear change device

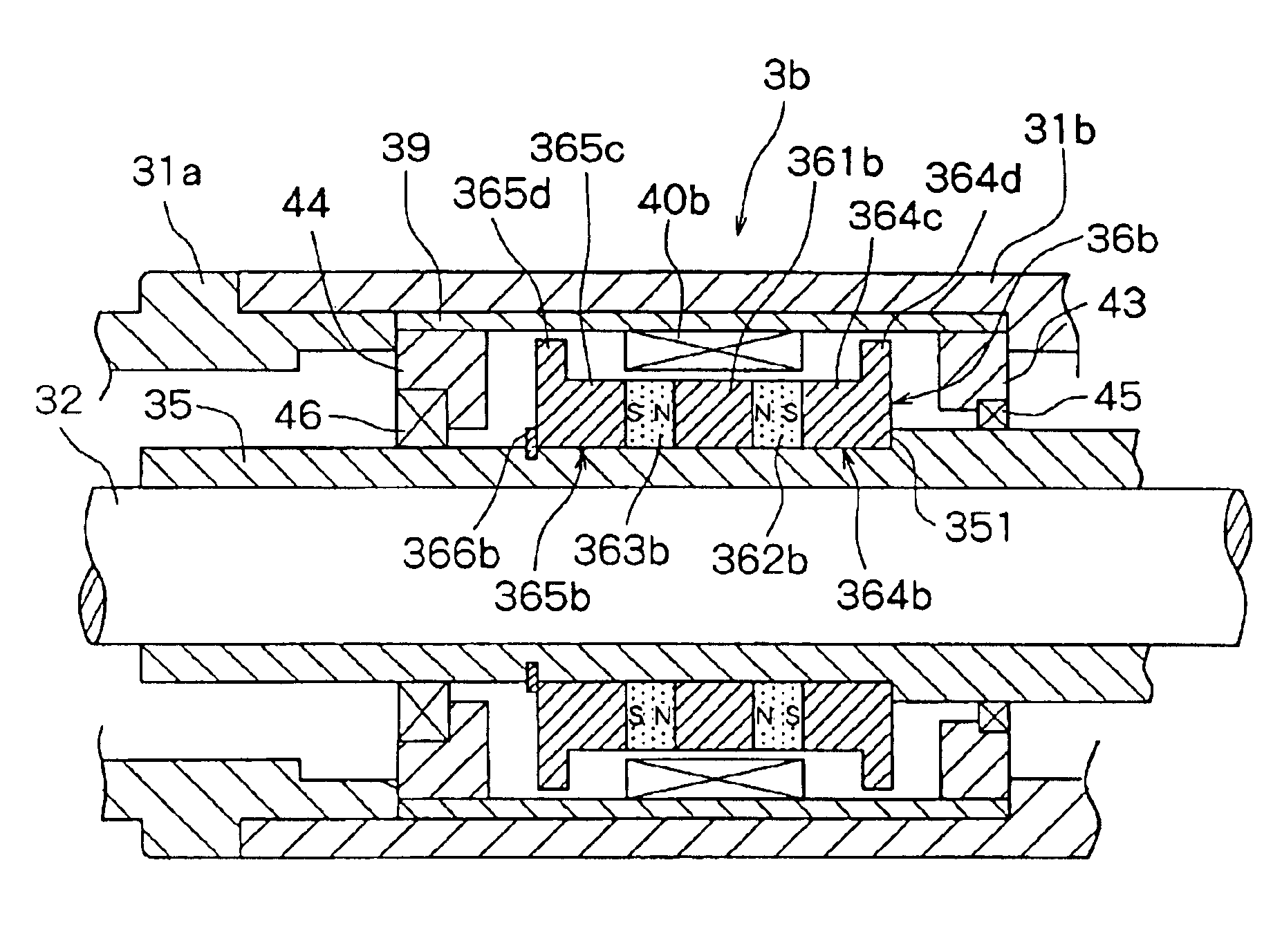

InactiveUS6877391B2Increased durabilityIncrease computing speedGearing controlDynamo-electric machinesEngineeringActuator

A gear change device includes a select actuator for operating a shift lever in a direction of selection and a shift actuator for operating the shift lever in a direction of shift. The select actuator includes a casing, a shift lever support member that is disposed in the casing so as to slide in an axial direction. The shift lever support member supports the shift lever, a magnetic moving member disposed on the outer periphery of the shift lever support member, a cylindrical fixed yoke surrounding the magnetic moving member, and a coil disposed on the inside of the fixed yoke.

Owner:ISUZU MOTORS LTD

Gear knob

A gear knob capable of assembly onto or removal from a gear stick of a vehicle as a sub assembly and / or without the use of tools. The gear knob has a latch that engage with an axial interlocking section of the gear stick. A manipulation device formed integrally with a retaining sleeve of the gear knob can move the latch away from the interlocking section of the gear stick.

Owner:LISA DRAXLMAIER GMBH

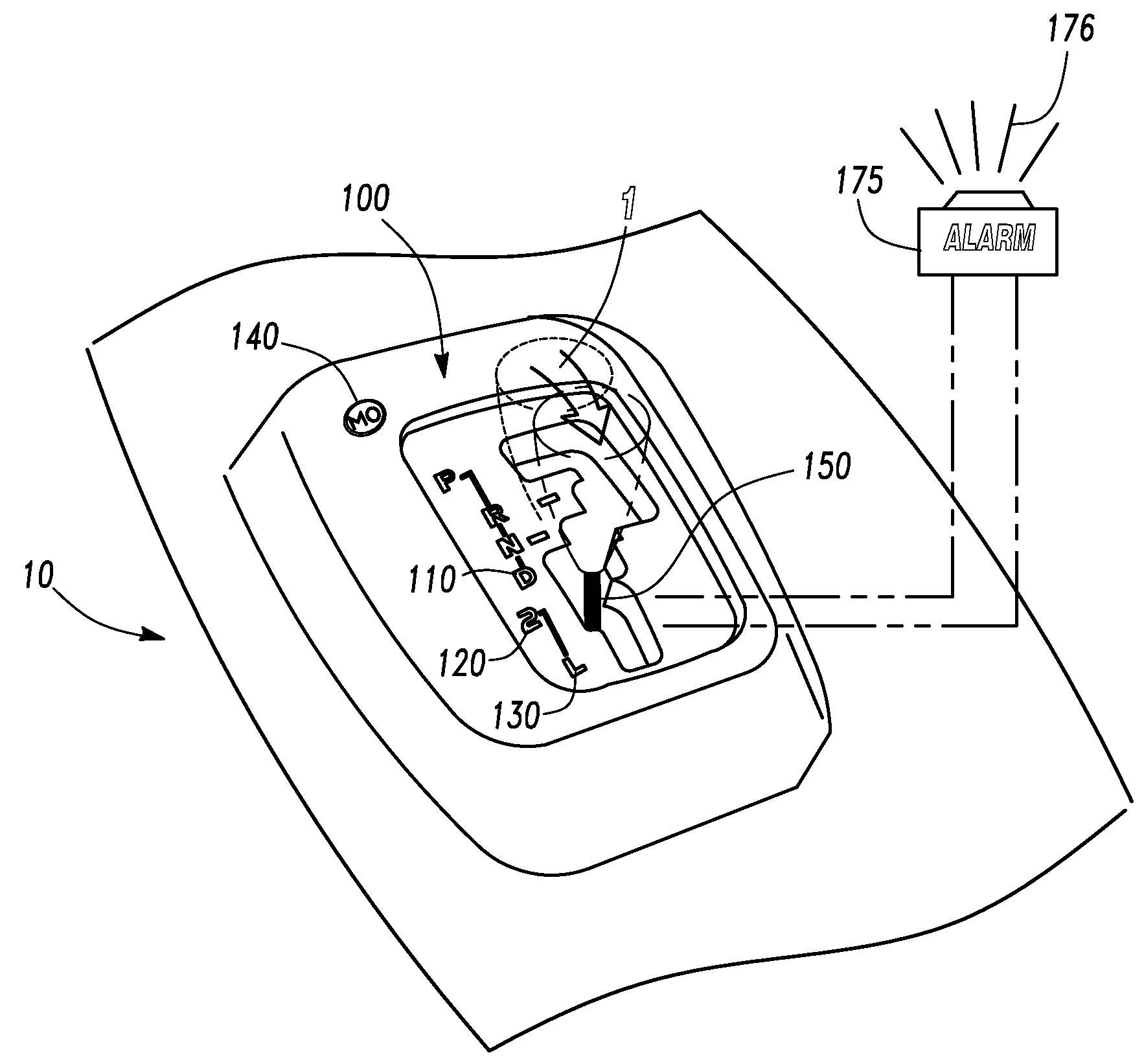

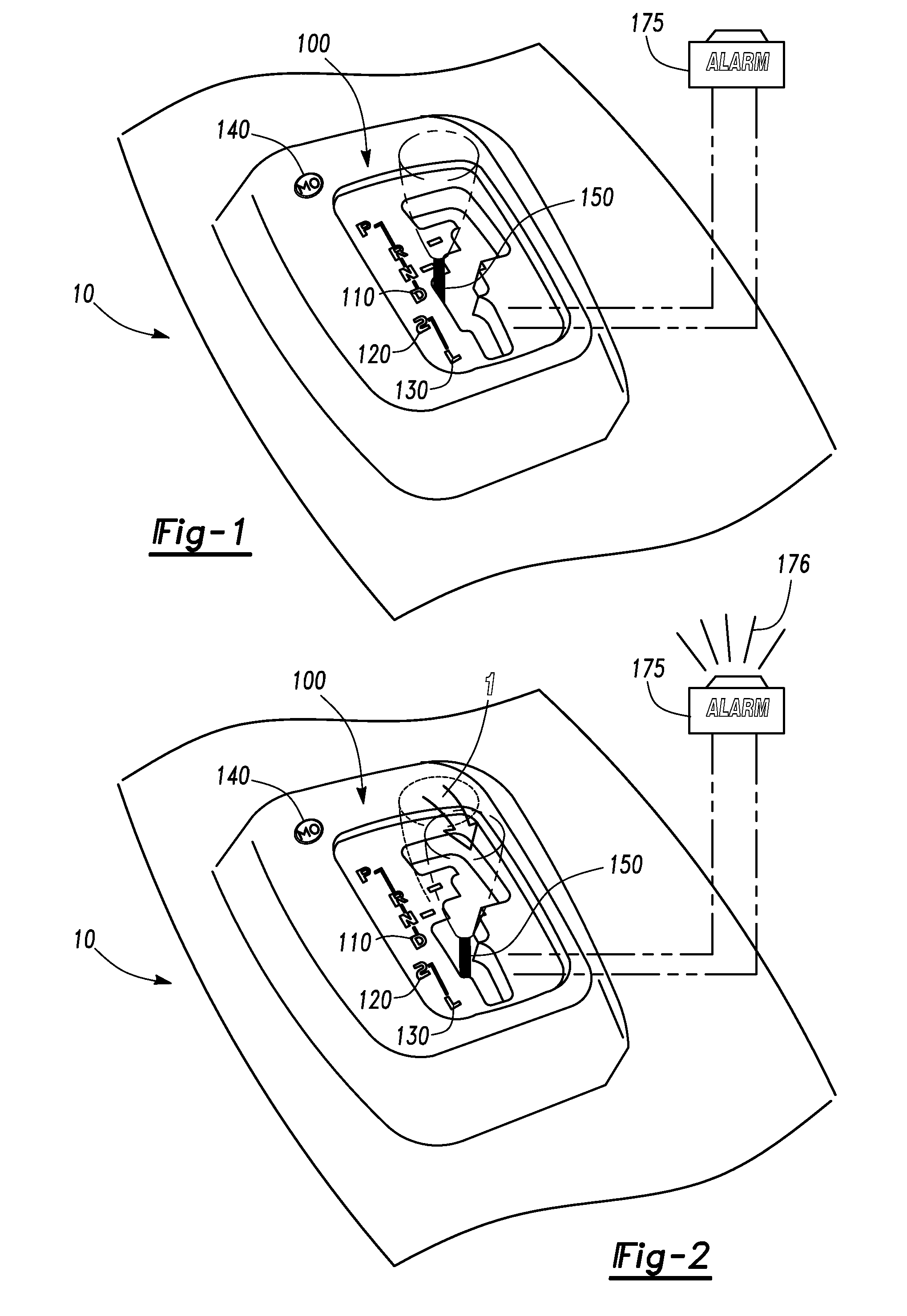

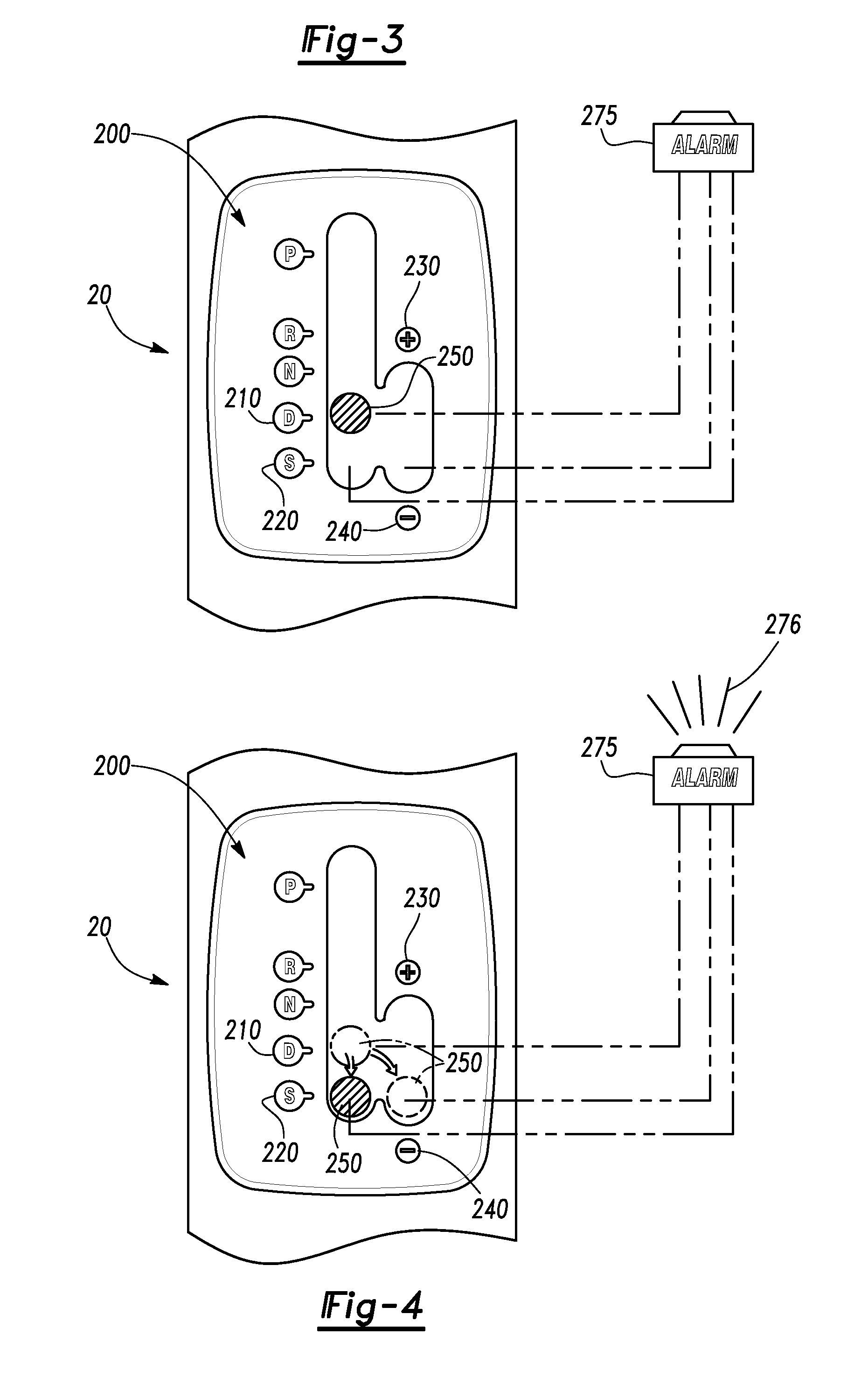

Shift lever position alarm

A gear range selector for a motor vehicle having an automatic transmission with more than one forward moving gear range is provided. The gear range selector provides a driver and / or an occupant of the motor vehicle with an alert signal that a shift lever has been moved from a Drive gear range position to another forward movement gear range position.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com