Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Flow assurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow assurance is a relatively new term in oil and gas industry. It refers to ensuring successful and economical flow of hydrocarbon stream from reservoir to the point of sale. The term was coined by Petrobras in the early 1990s in Portuguese as Garantia do Escoamento (pt::Garantia do Escoamento), meaning literally “Guarantee of Flow”, or Flow Assurance.

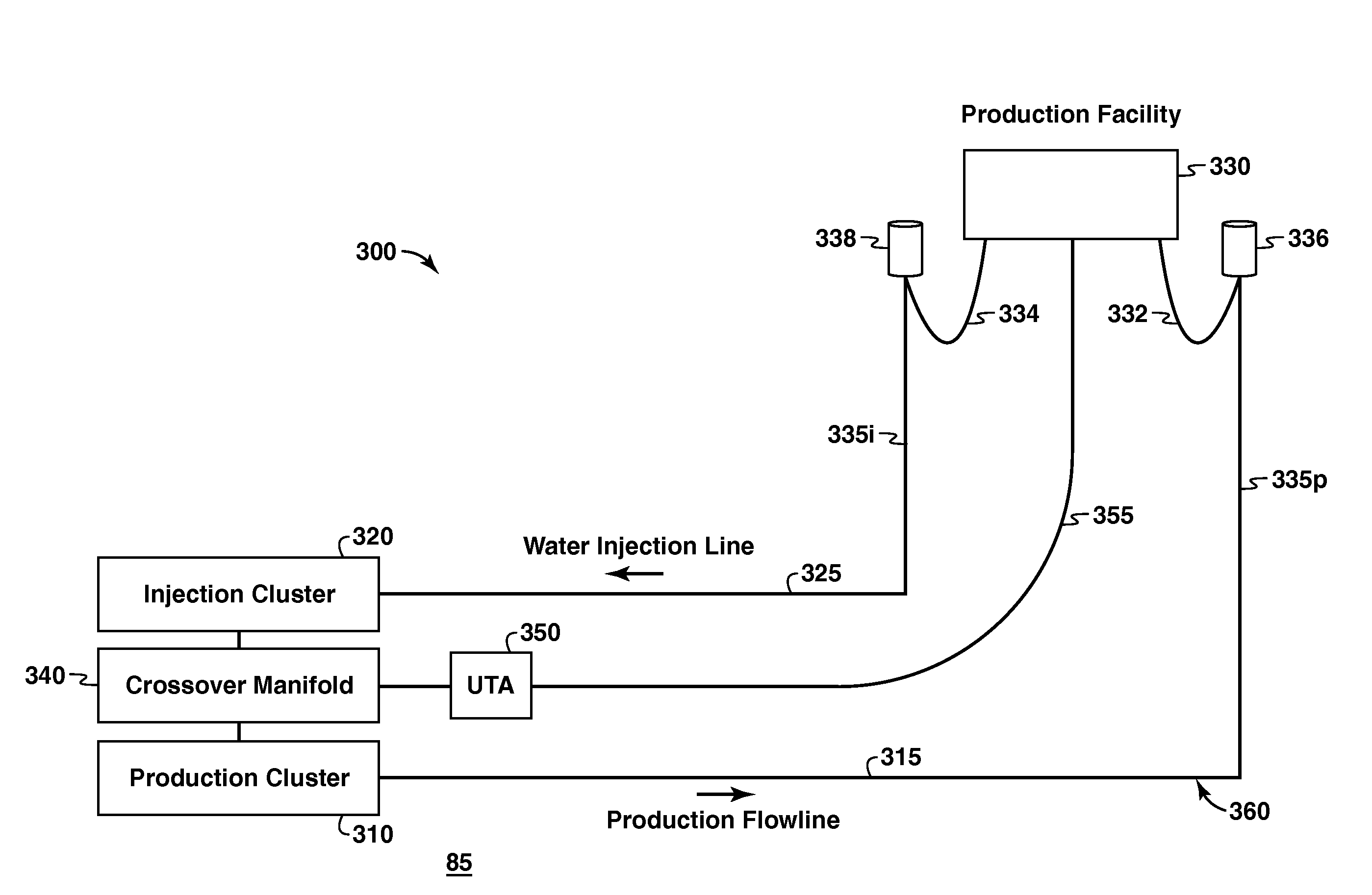

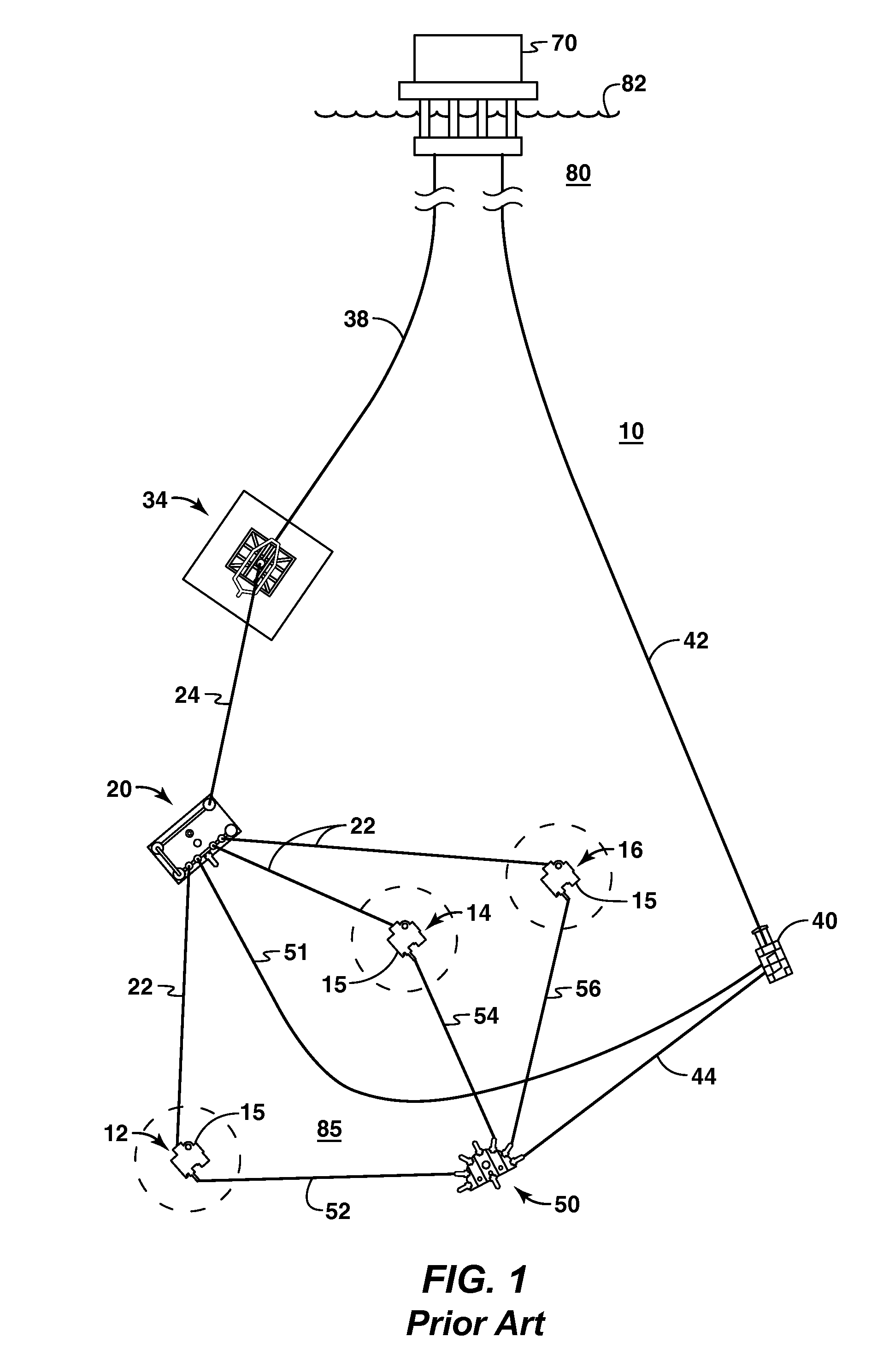

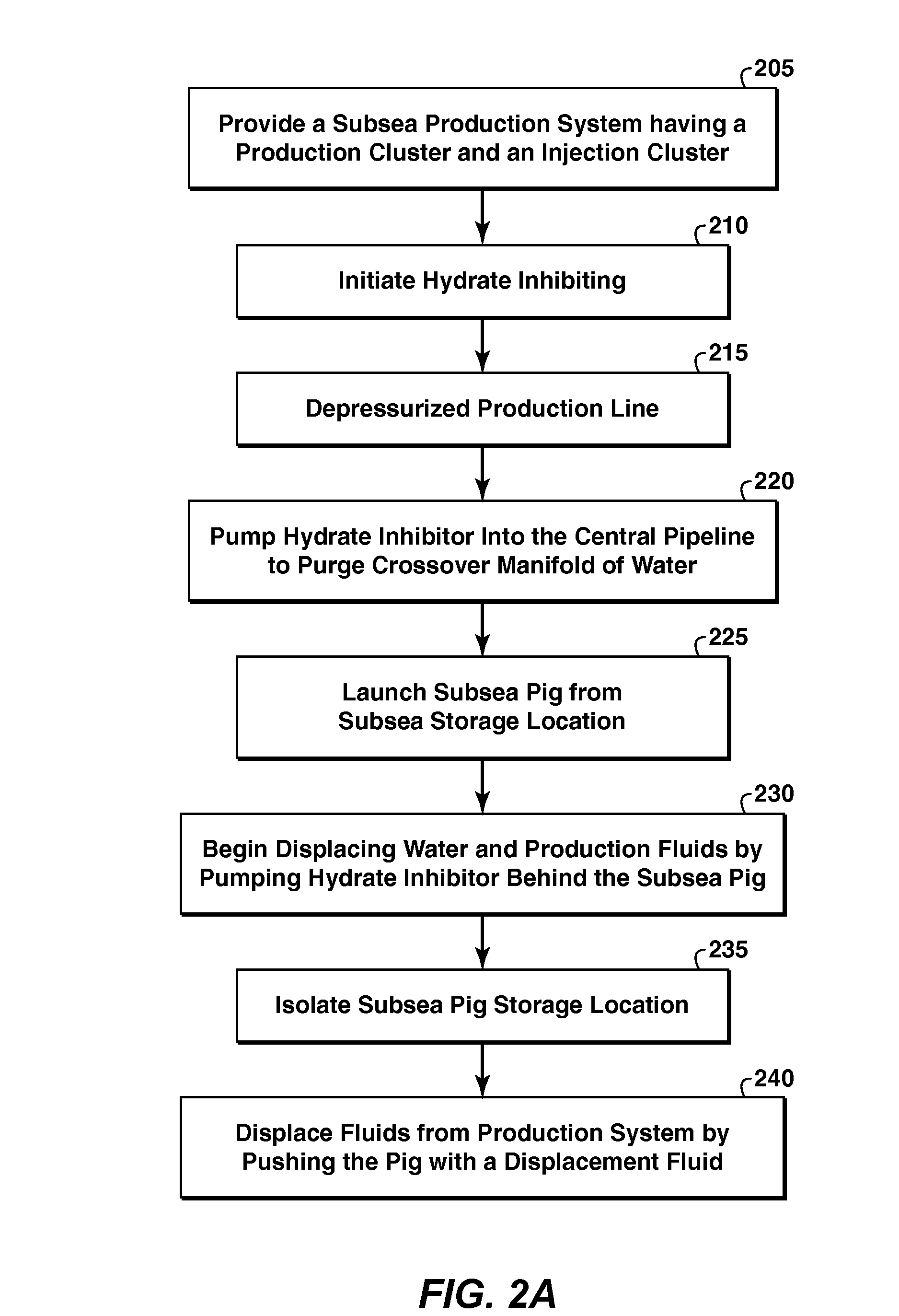

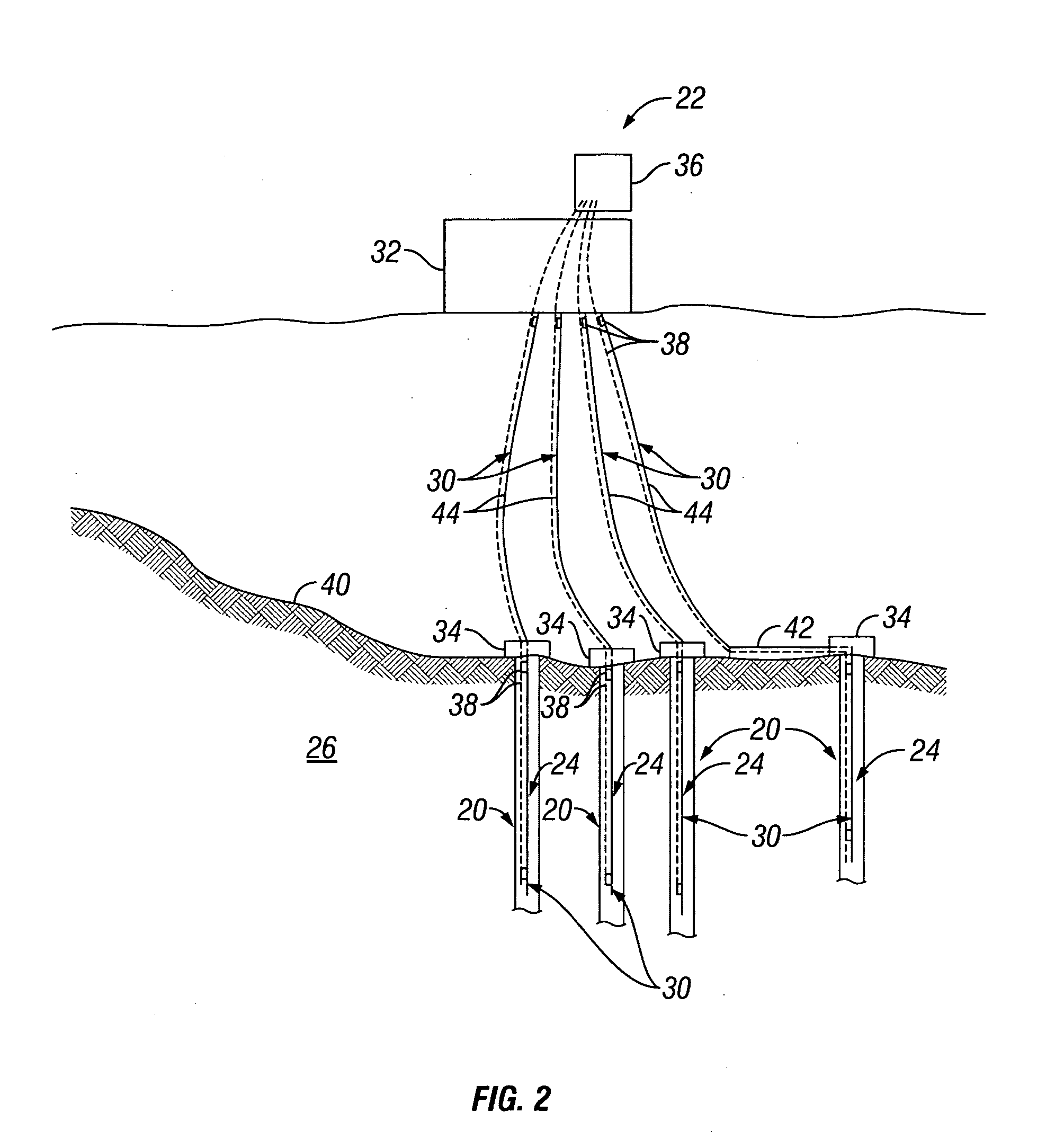

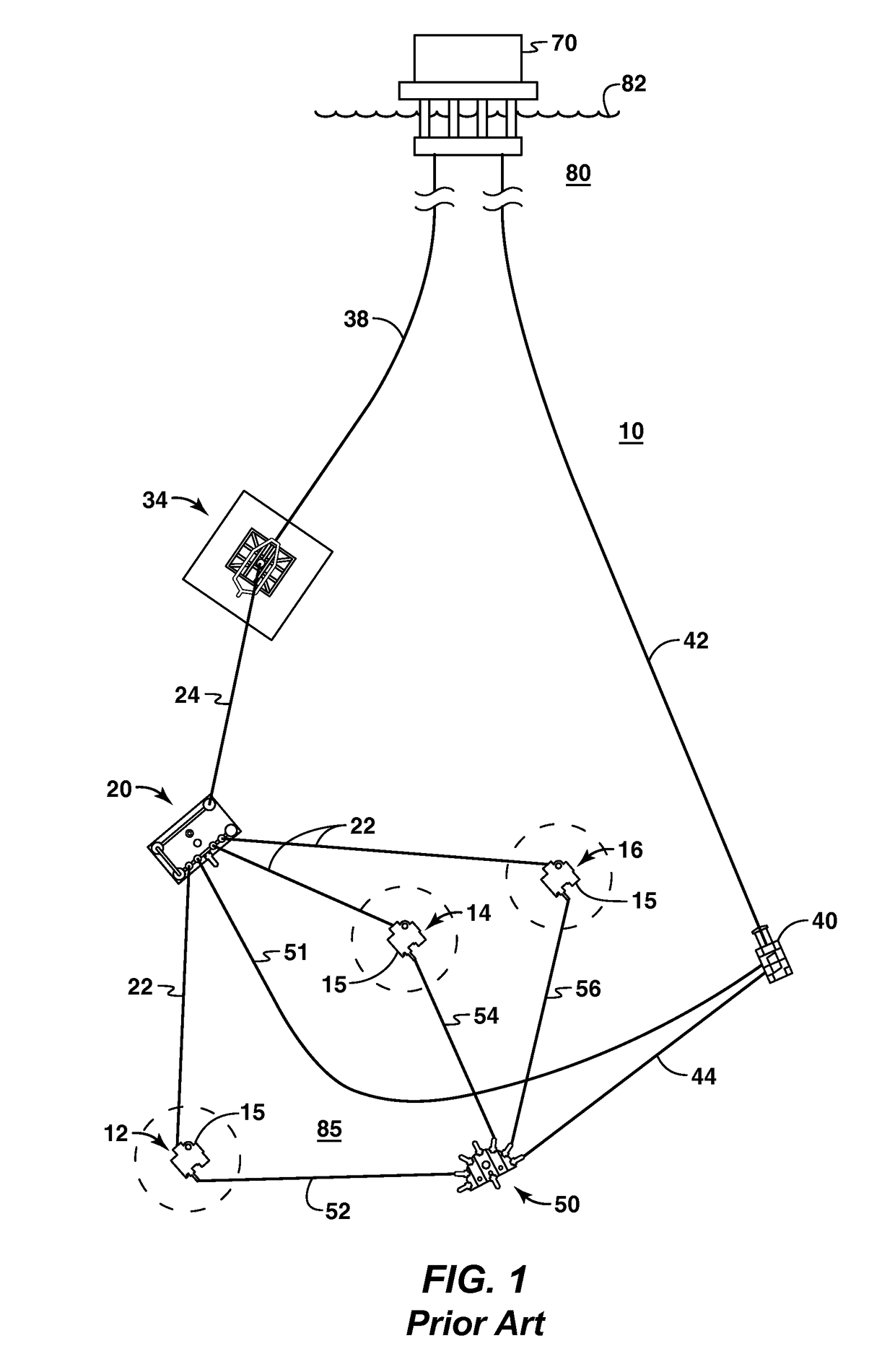

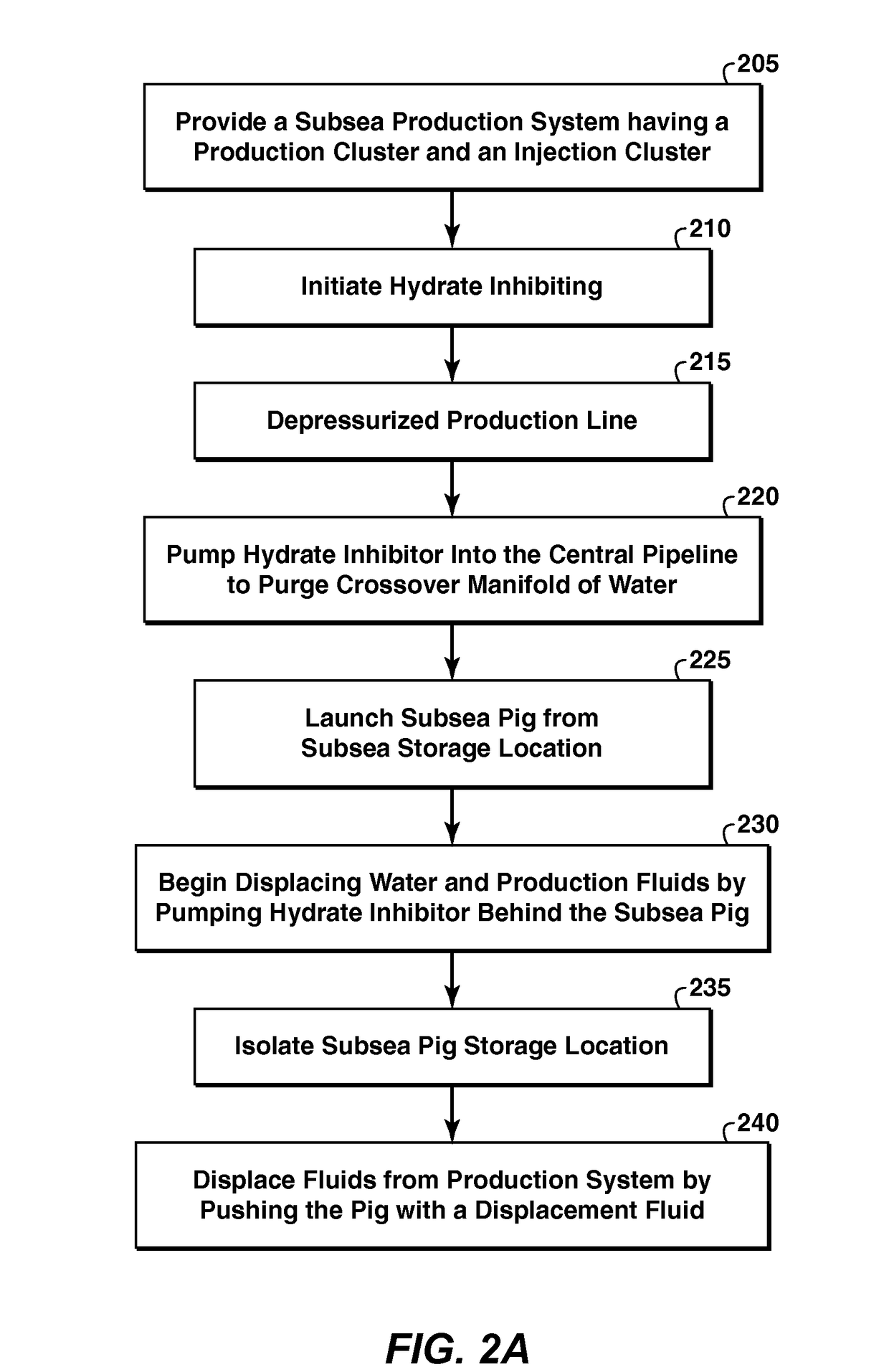

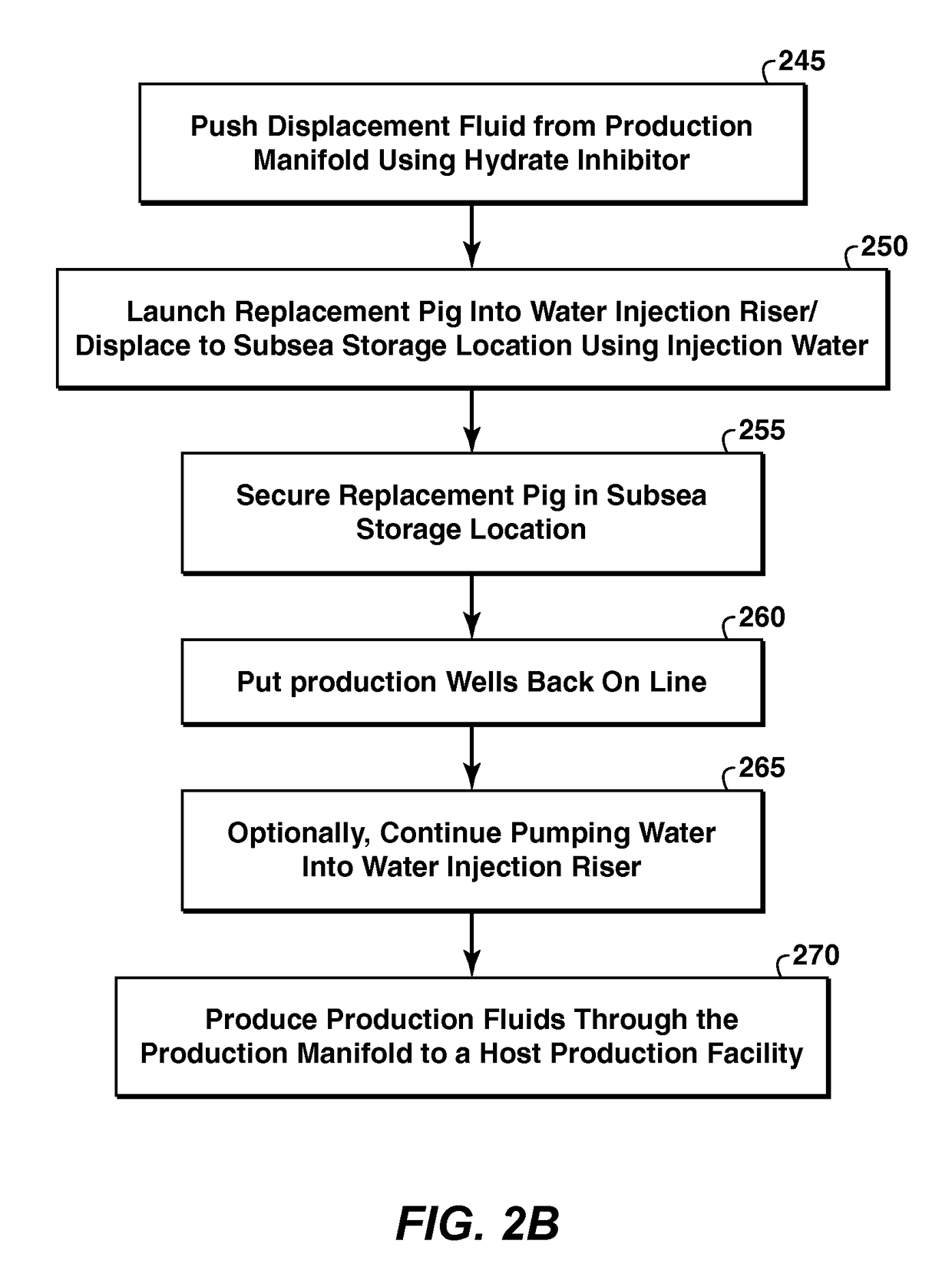

Method and Apparatus For Flow Assurance Management In Subsea Single Production Flowline

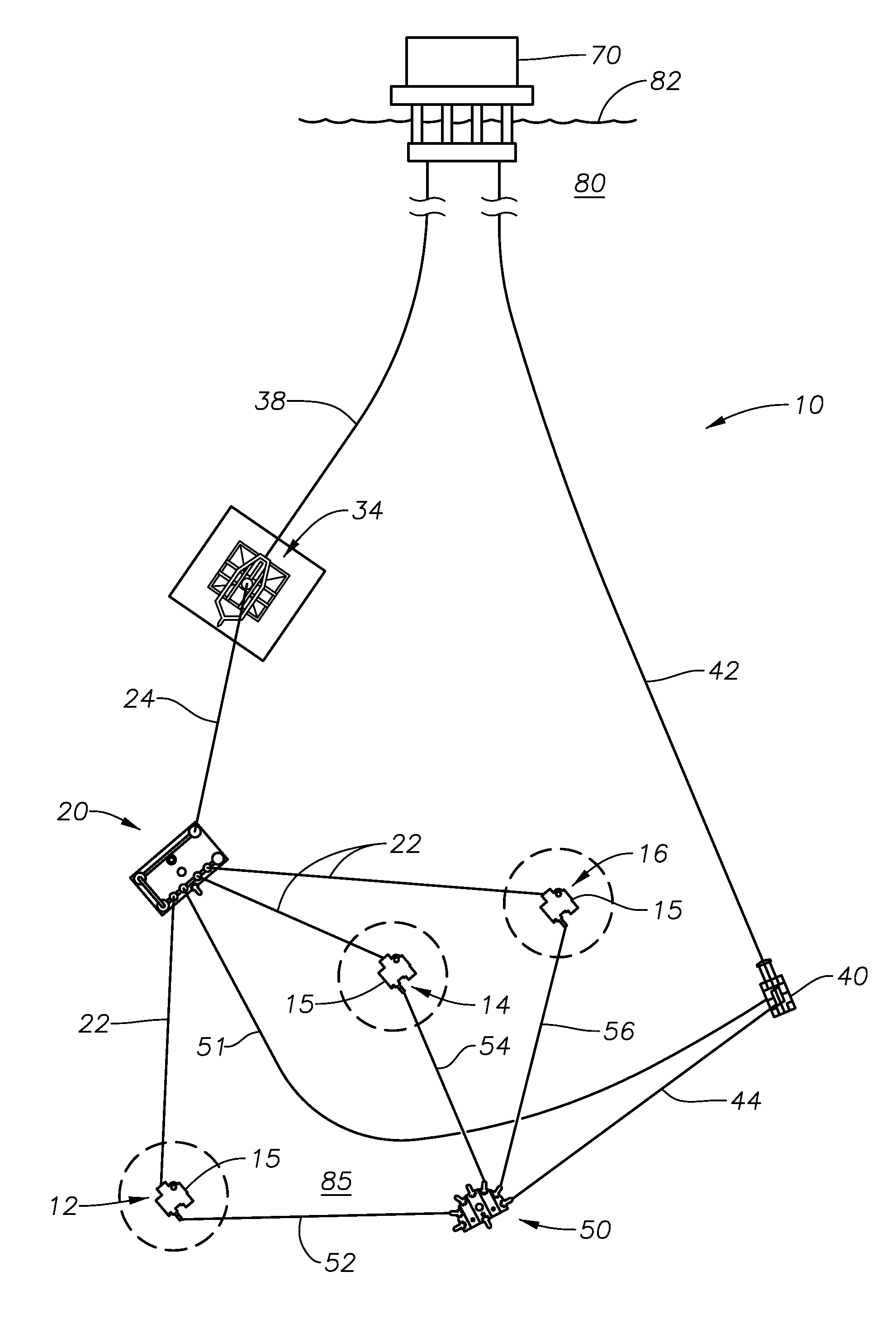

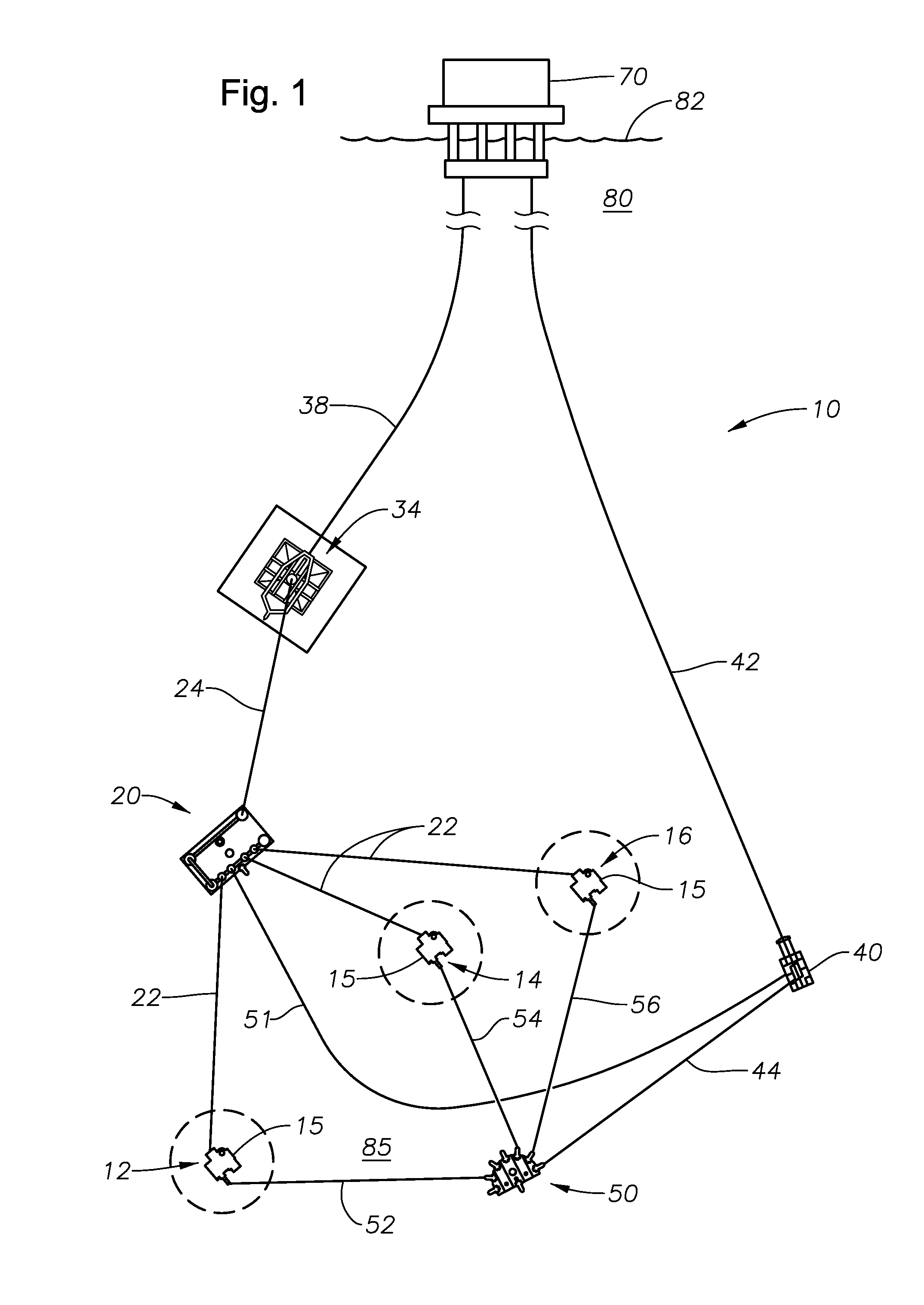

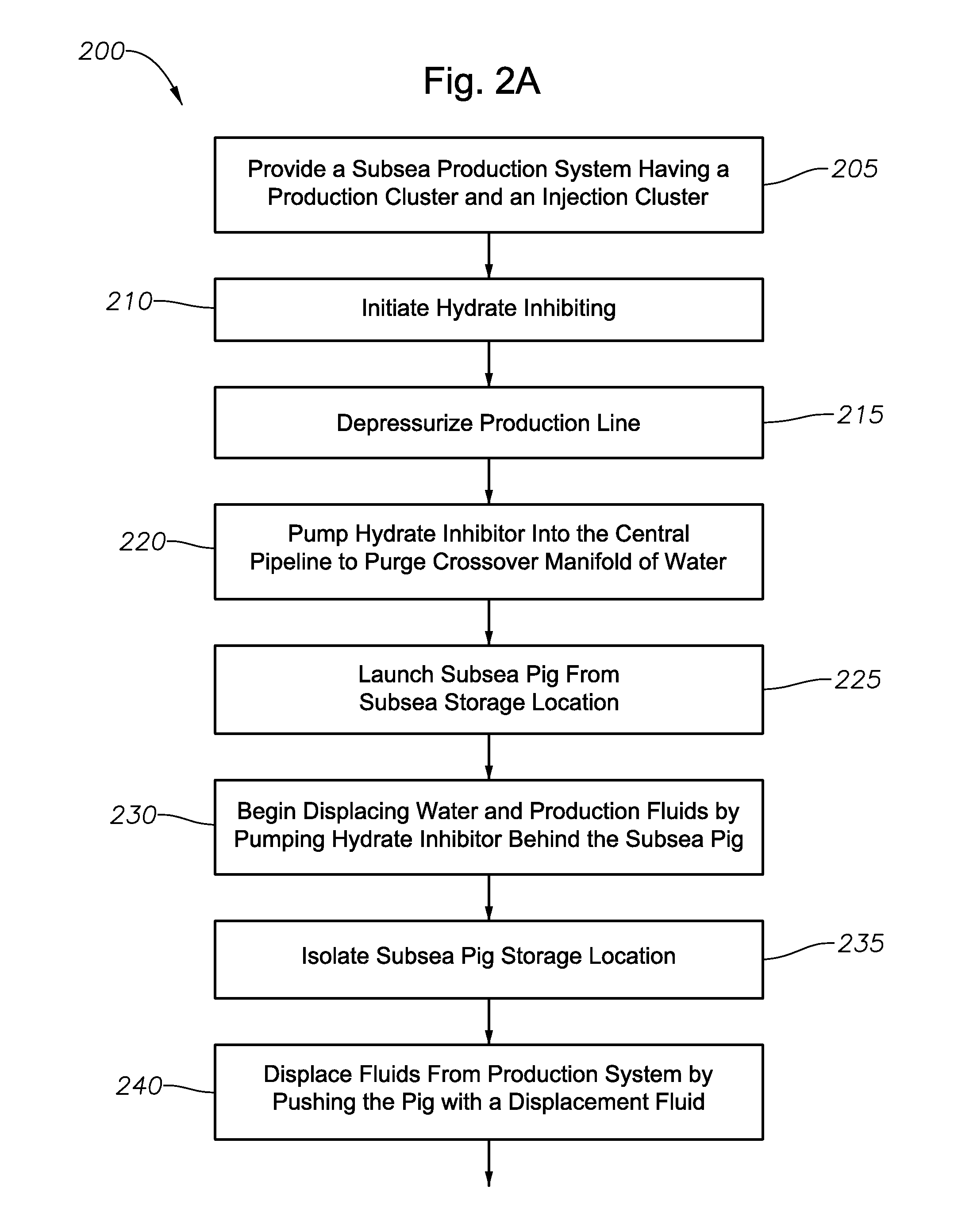

Managing hydrates in a subsea includes a host production facility, a production cluster comprising one or more producers, a water injection cluster comprising one or more water injectors, a water injection line, and a single production line for directing production fluid from the one or more producers to the host production facility. The methods comprise placing a pig in the subsea production system, shutting in production from the producers, and injecting a displacement fluid into the subsea production system in order to displace the hydrate inhibitor and any remaining production fluids in the production flowline and to further move the pig through the production flowline. The method may also include further injecting displacement fluid into the subsea production system in order to displace the hydrate inhibitor and pig through the single production line and to the host production facility.

Owner:EXXONMOBIL UPSTREAM RES CO

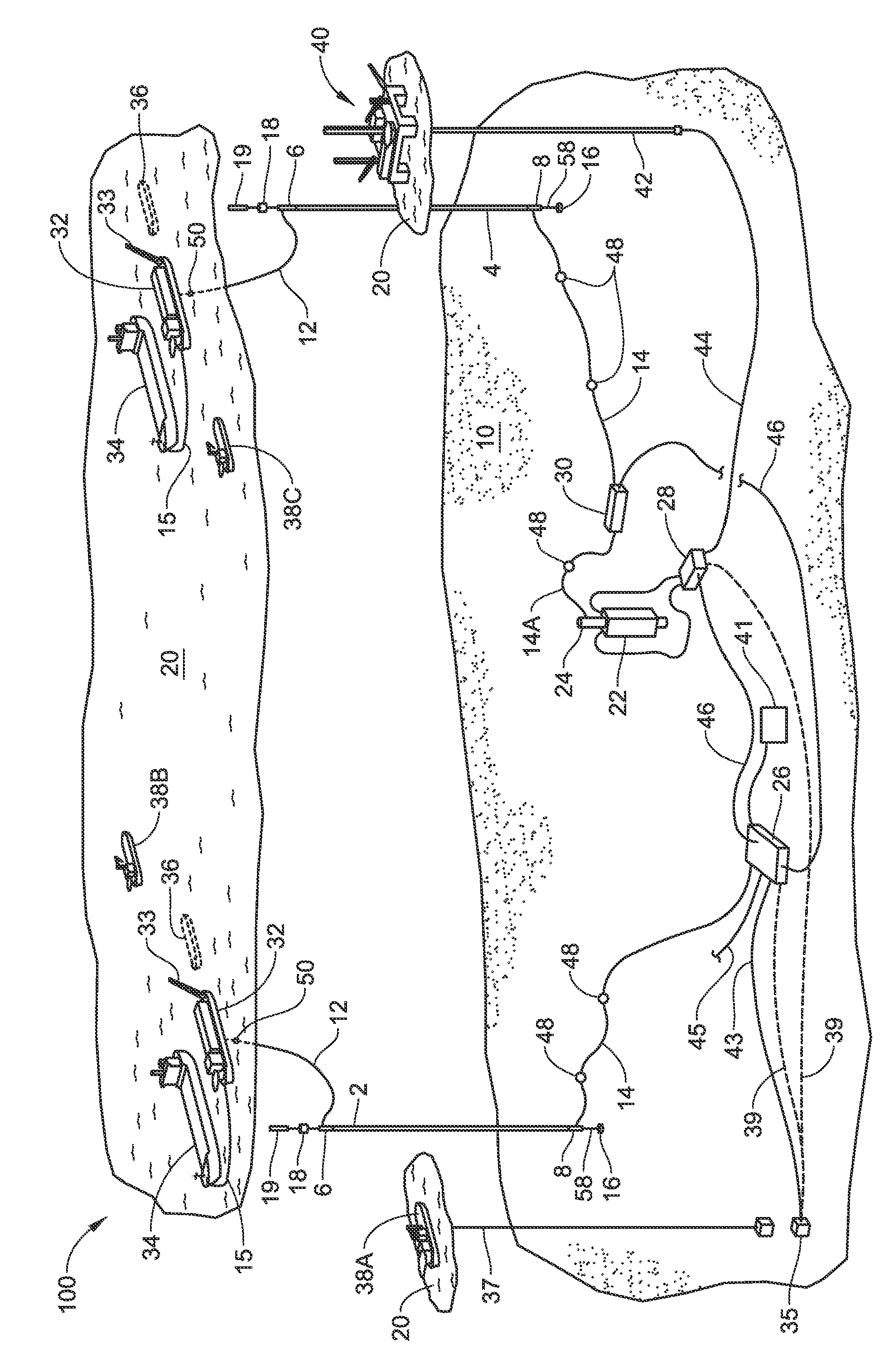

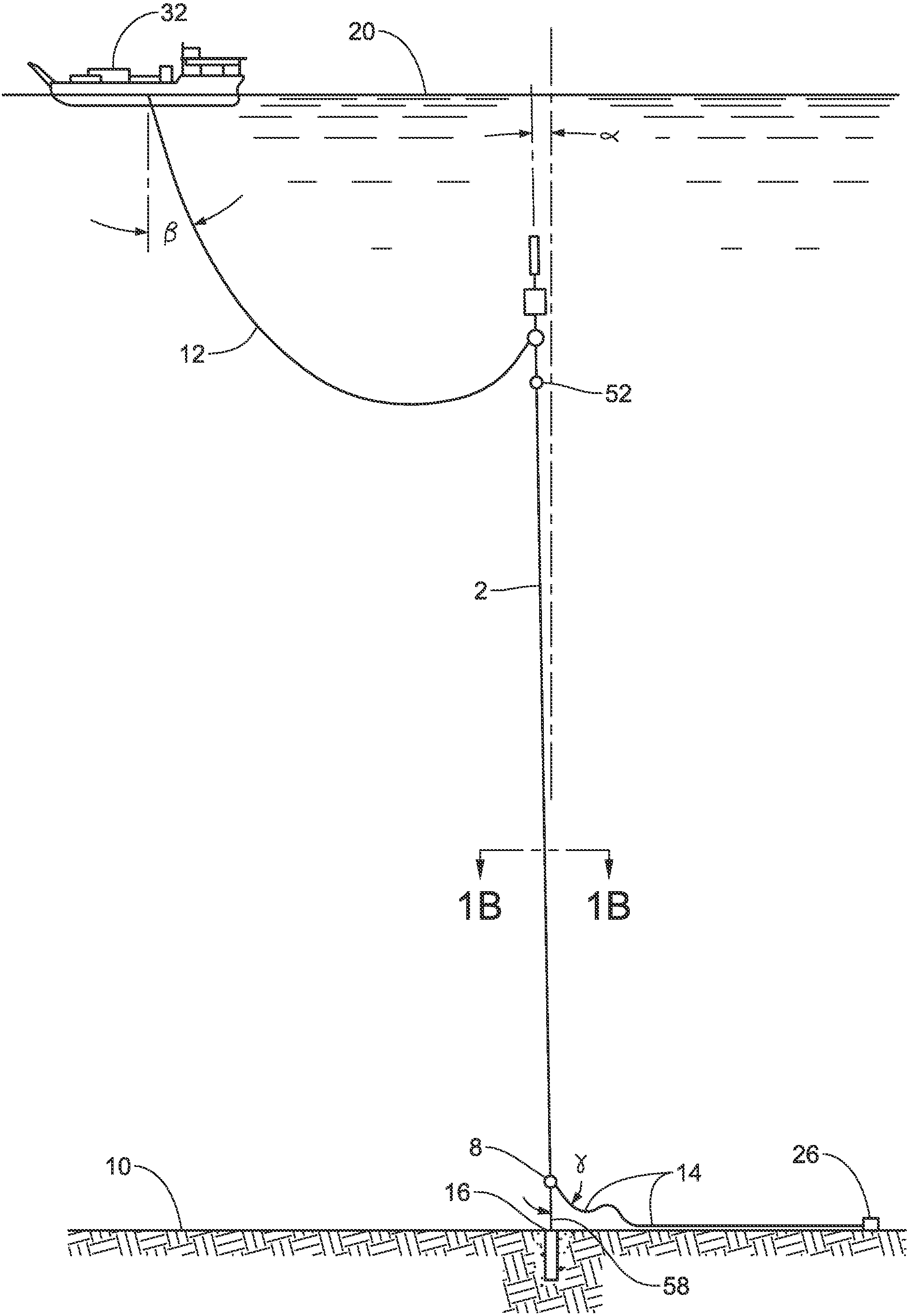

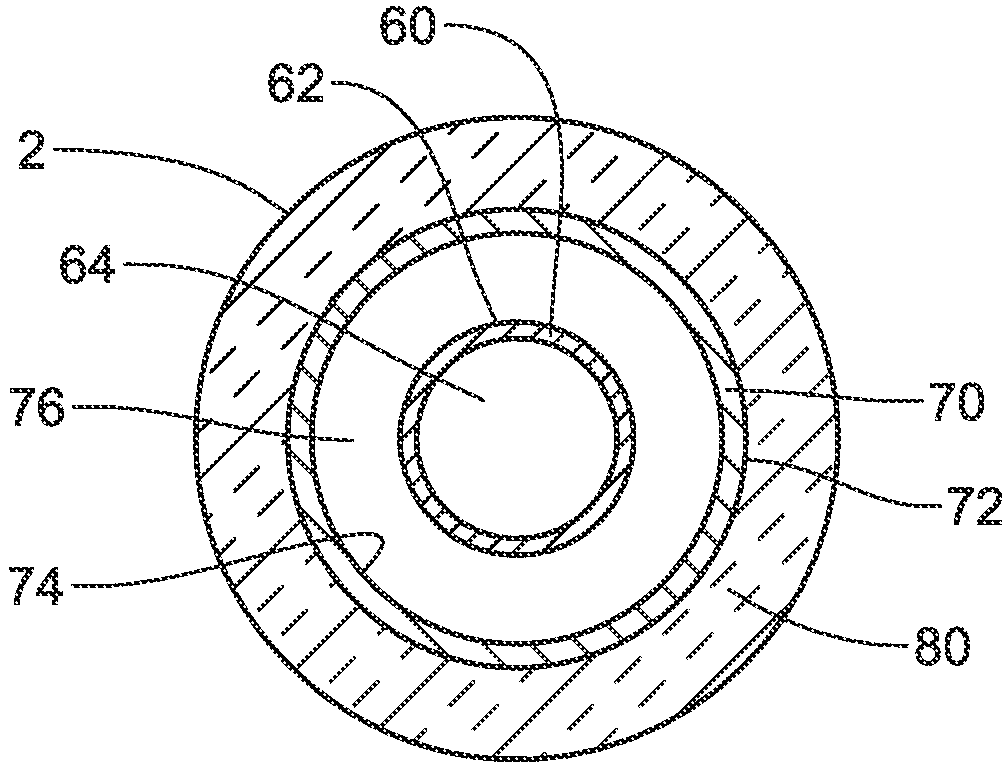

Marine subsea free-standing riser systems and methods

A free-standing riser system connects a subsea source to a surface structure. The system includes a concentric free-standing riser comprising inner and outer risers defining an annulus there between. A lower end of the riser is fiuidly coupled to the subsea source through a lower riser assembly (LRA) and one or more subsea flexible conduits. An upper end of the riser is connected to a buoyancy assembly and the surface structure through an upper riser assembly (URA) and one or more upper flexible conduits, the riser also mechanically connected to a buoyancy assembly that applies upward tension to the riser. The riser may be insulated for flow assurance, either by a flow assurance fluid in the annulus, insulation of the outside of the outer riser, or both. The system may include a hydrate inhibition system and / or a subsea dispersant system. The surface structure may be dynamically positioned.

Owner:BP CORP NORTH AMERICA INC +1

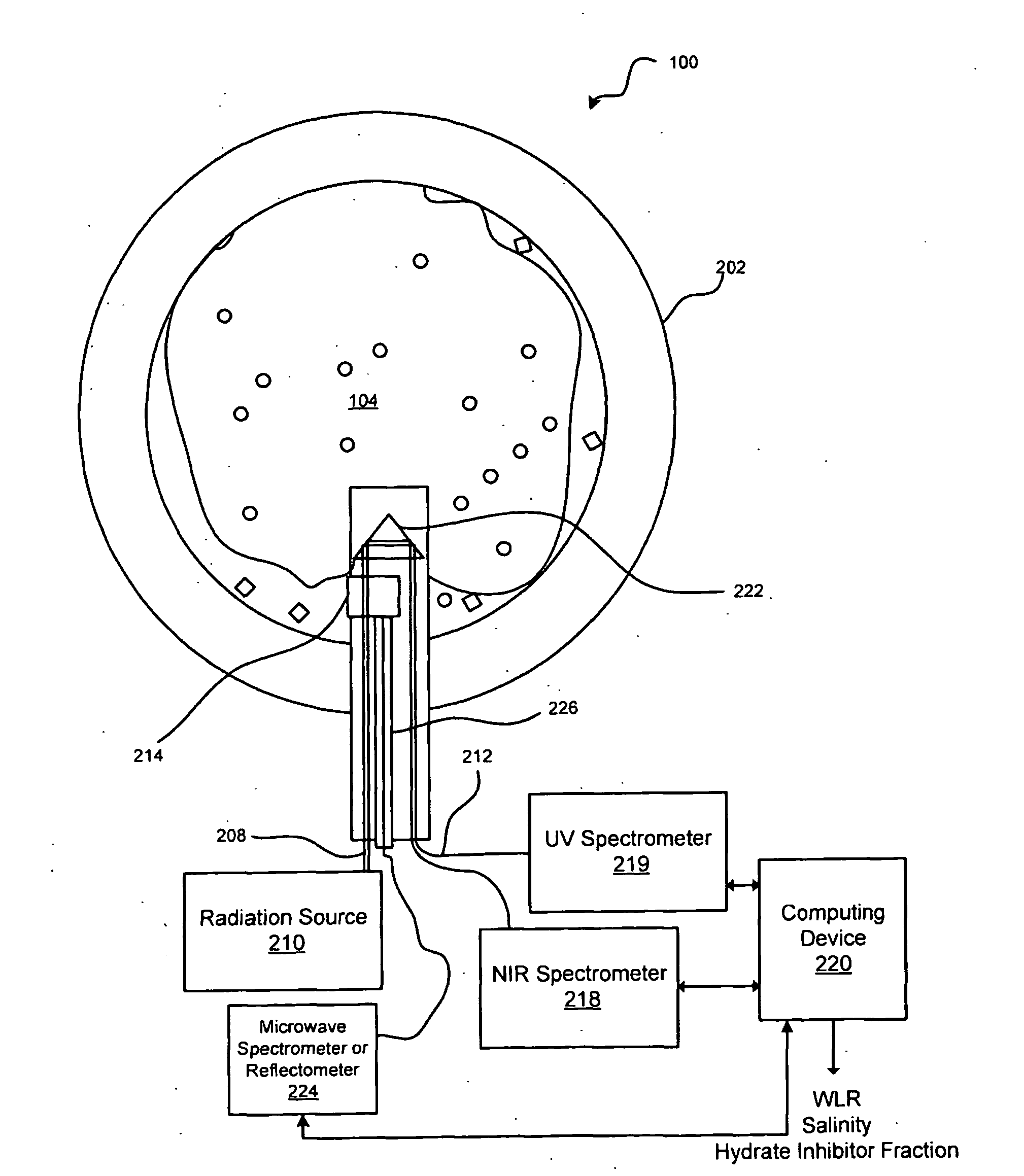

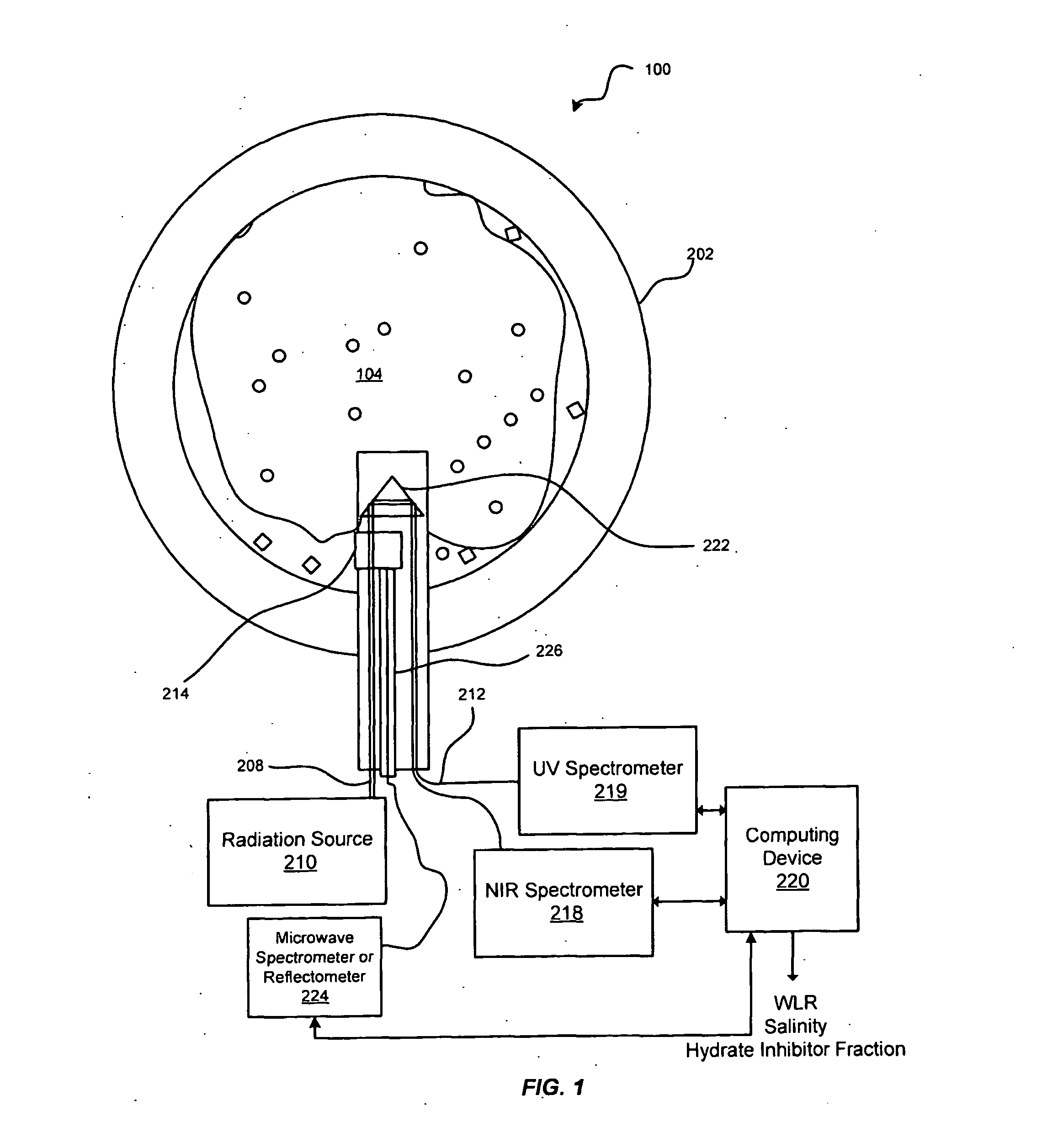

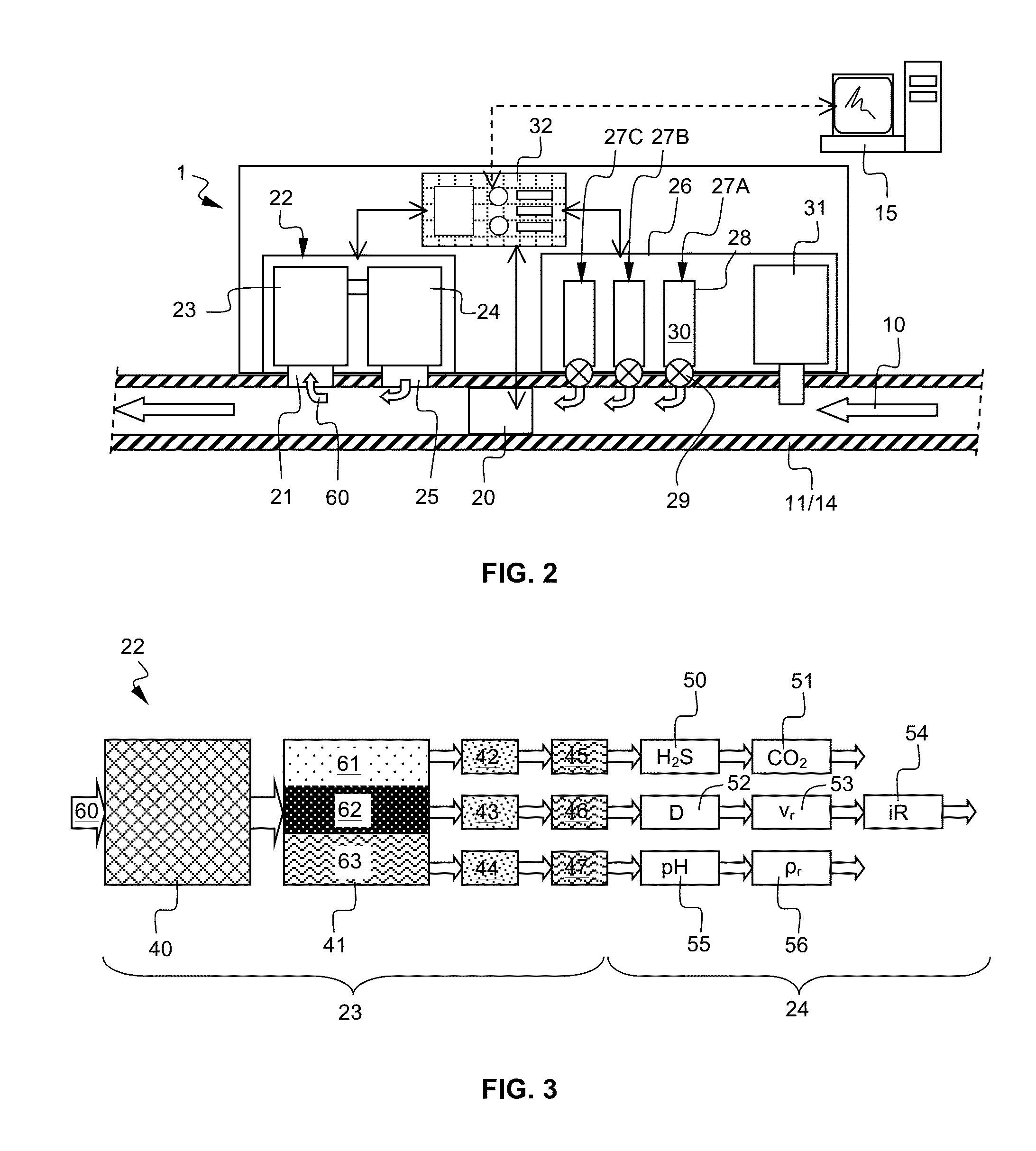

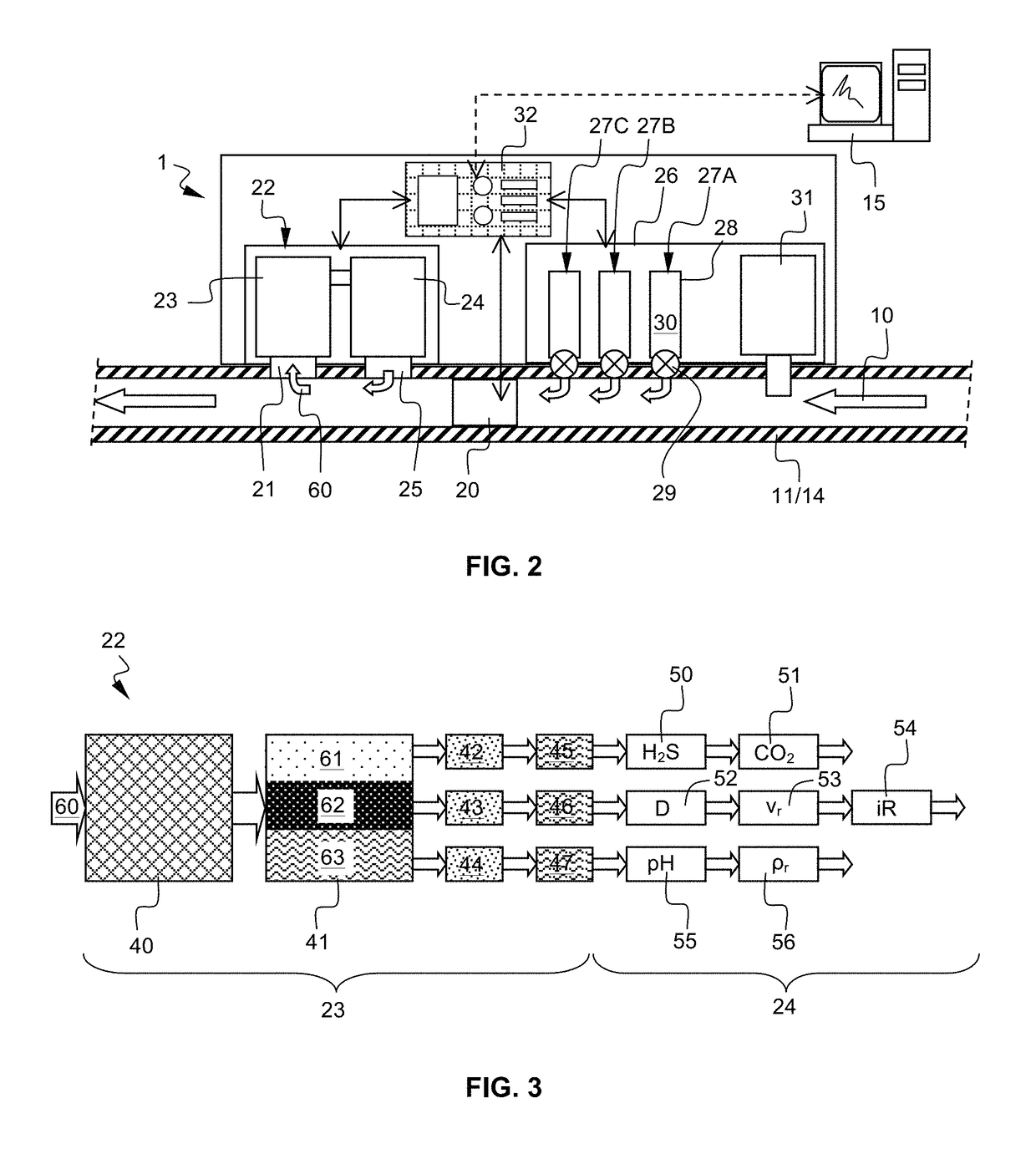

Immersion probe for multi-phase flow assurance

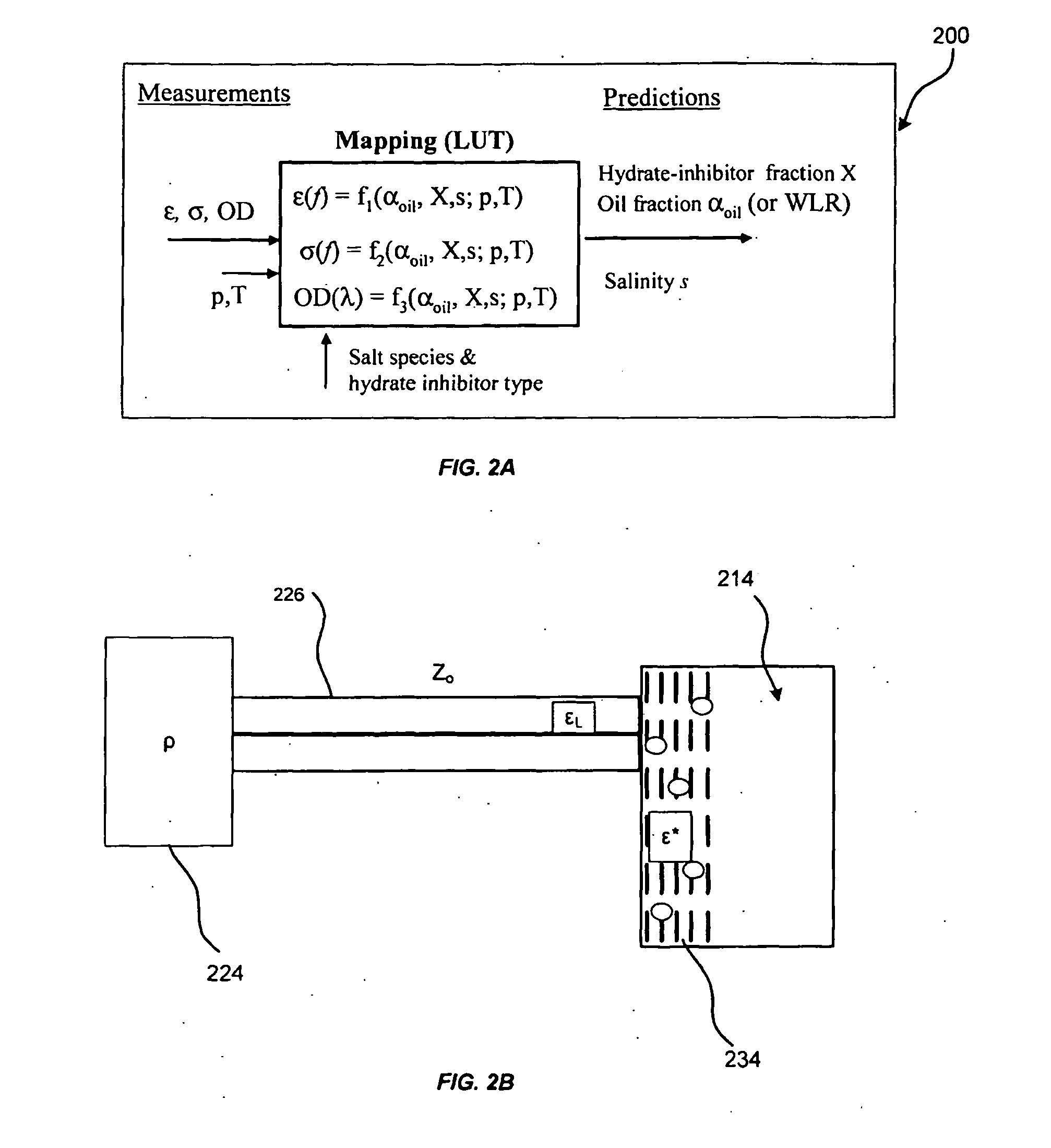

ActiveUS20130009048A1Preventing hydrate formationReduce excessElectric/magnetic detection for well-loggingRadiation pyrometryWater flowWater fraction

An immersion probe is described that includes sensing elements that allow for hydrate inhibitor dosage to be more efficiently provided into gas and / or oil wells. The immersion probe allows for detection of first appearance of water in a multiphase flow in a well, measuring the amount of inhibitor in water within the well, determining an accurate water-cut, and measuring other property such as water salinity. Accordingly, with the known water-cut, salinity and the water flow rate inferred from the inhibitor injection flow rate and inhibitor-in-water fraction, a correct dosage of the inhibitor can be injected to the well in order to prevent hydrate formation, while reducing overdosing. Water flow rate may also be inferred from an independently measured liquid flow rate and the immersion-probe measured water cut.

Owner:SCHLUMBERGER TECH CORP

Method and System For Flow Assurance Management In Subsea Single Production Flowline

InactiveUS20120031621A1Fluid removalUnderwater drillingElectrical resistance and conductanceProduction line

Method of managing hydrates in a subsea production system that includes a host production facility, one or more producers, one or more water injectors, a water injection line, and a single production line for directing production fluids from the producers to the host production facility. The method comprises placing a pig in the subsea production system, shutting in production from the producers, and injecting a displacement fluid into the subsea production system in order to displace production fluids in the production line. The method also includes applying electrically resistive heat along a selected portion of the single production line to maintain production fluids within the production line at a temperature above a hydrate formation temperature after production has been shut in.

Owner:EXXONMOBIL UPSTREAM RES CO

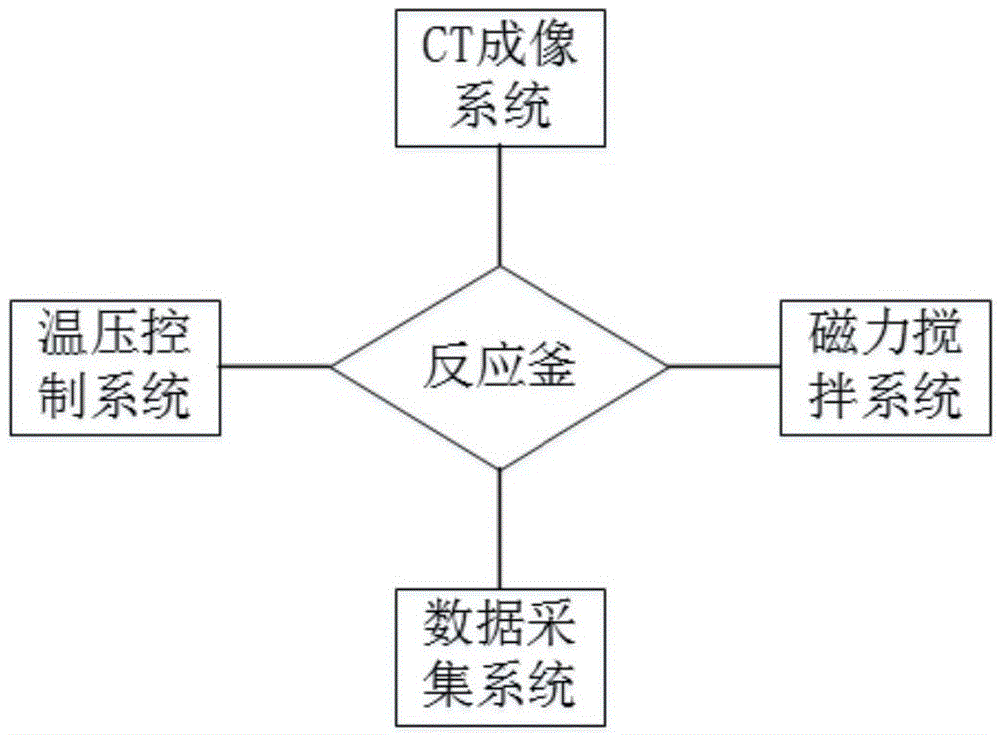

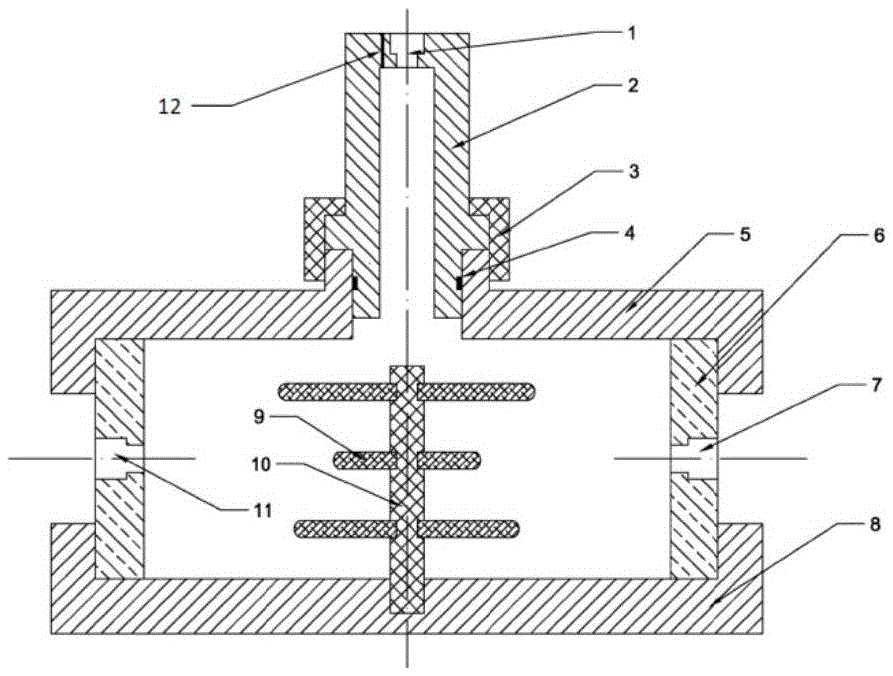

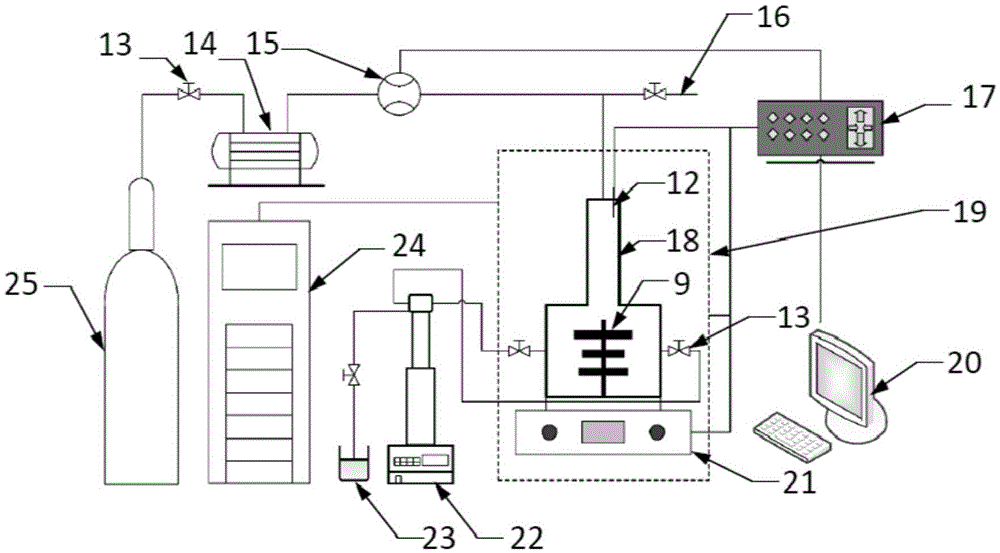

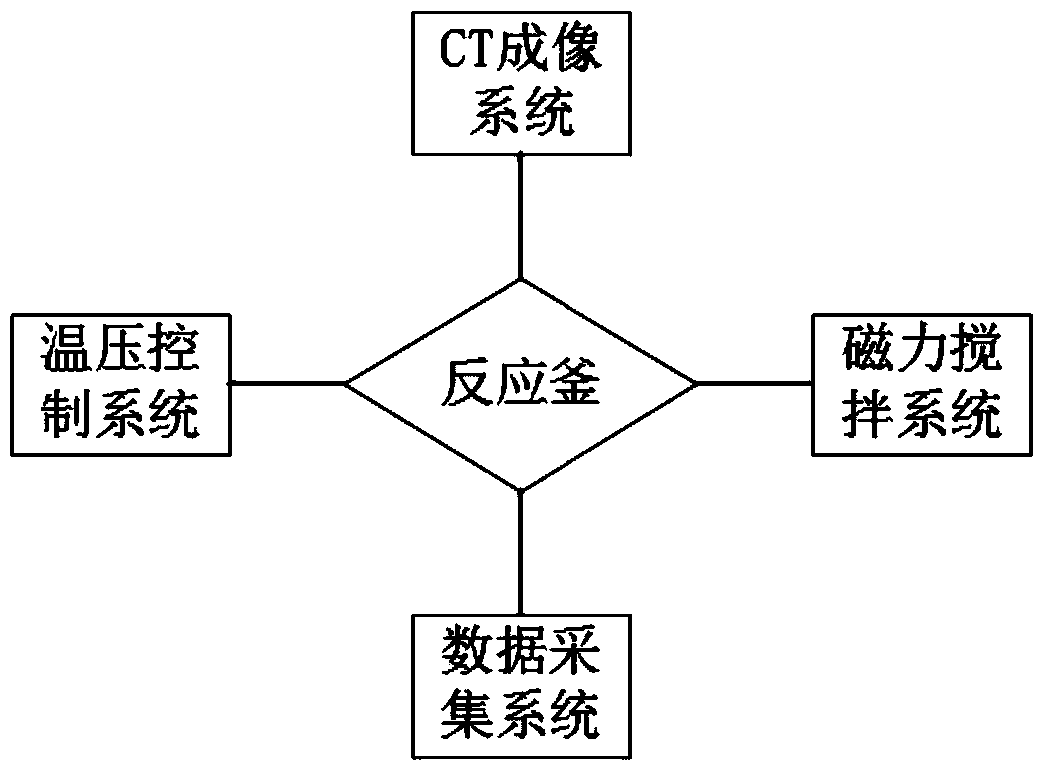

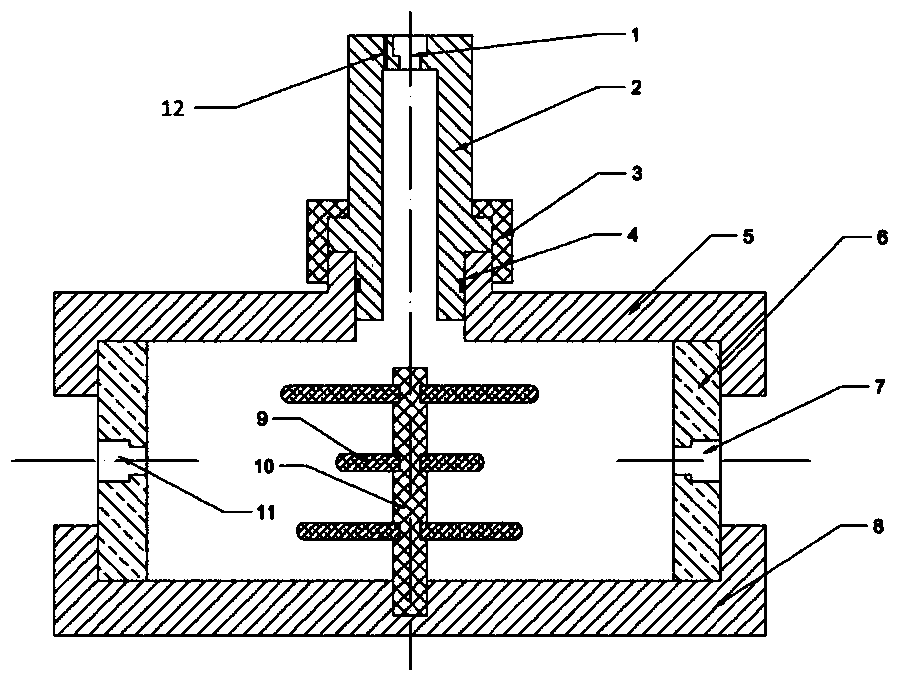

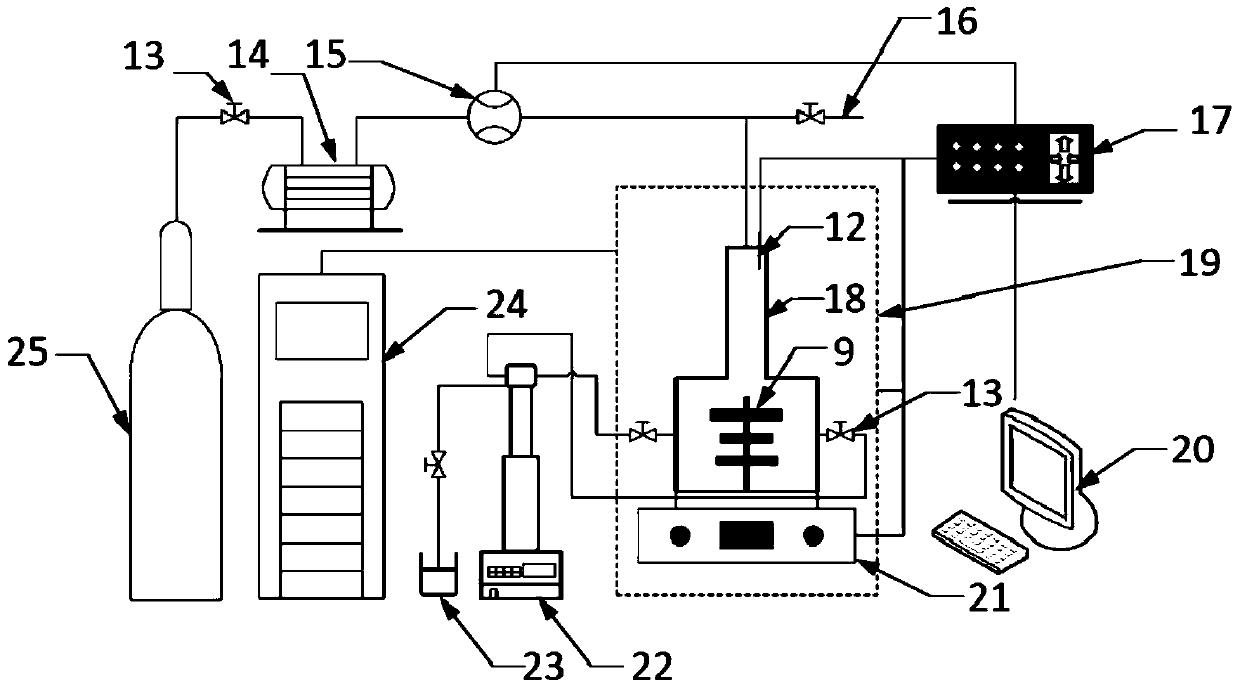

Device used for X-ray CT equipment to observe natural gas hydrate growth characteristics in blind pipe

ActiveCN105606634AImprove sealingJudgment generationEnergy based chemical/physical/physico-chemical processesMaterial analysis by transmitting radiationGas pipelineFlow assurance

The invention provides a device used for X-ray CT equipment to observe growth characteristics of natural gas hydrate in a blind pipe and belongs to the field of flow assurance in the delivery process of oil and gas. In-situ generation of the natural gas hydrate in the blind pipe of an oil-gas pipeline can be simulated, and growth conditions of the natural gas hydrate can be observed through the X-ray CT equipment. After liquid is injected into a reaction kettle and after leakage detection, gas is injected into the reaction kettle through a constant-pressure pump, and consumption of the gas is recorded to evaluate the growth conditions of the hydrate. During detection, a magnetic stirring system is used for stirring liquid in the reaction kettle, simulating flow of a liquid phase in the pipeline and promoting mutual cooperation of gas-liquid phases to generate hydrate. Every other certain period, X-ray CT photographing is conducted in the reaction kettle, the growth condition of hydrate in the blind pipe is observed, and growth characteristics of the hydrate in the blind pipe are studied. Measuring results are used for on-site guidance of a seabed oil-gas delivery system, and a powerful theoretical support can be provided for deep studying of hydrate risk control technology.

Owner:DALIAN UNIV OF TECH

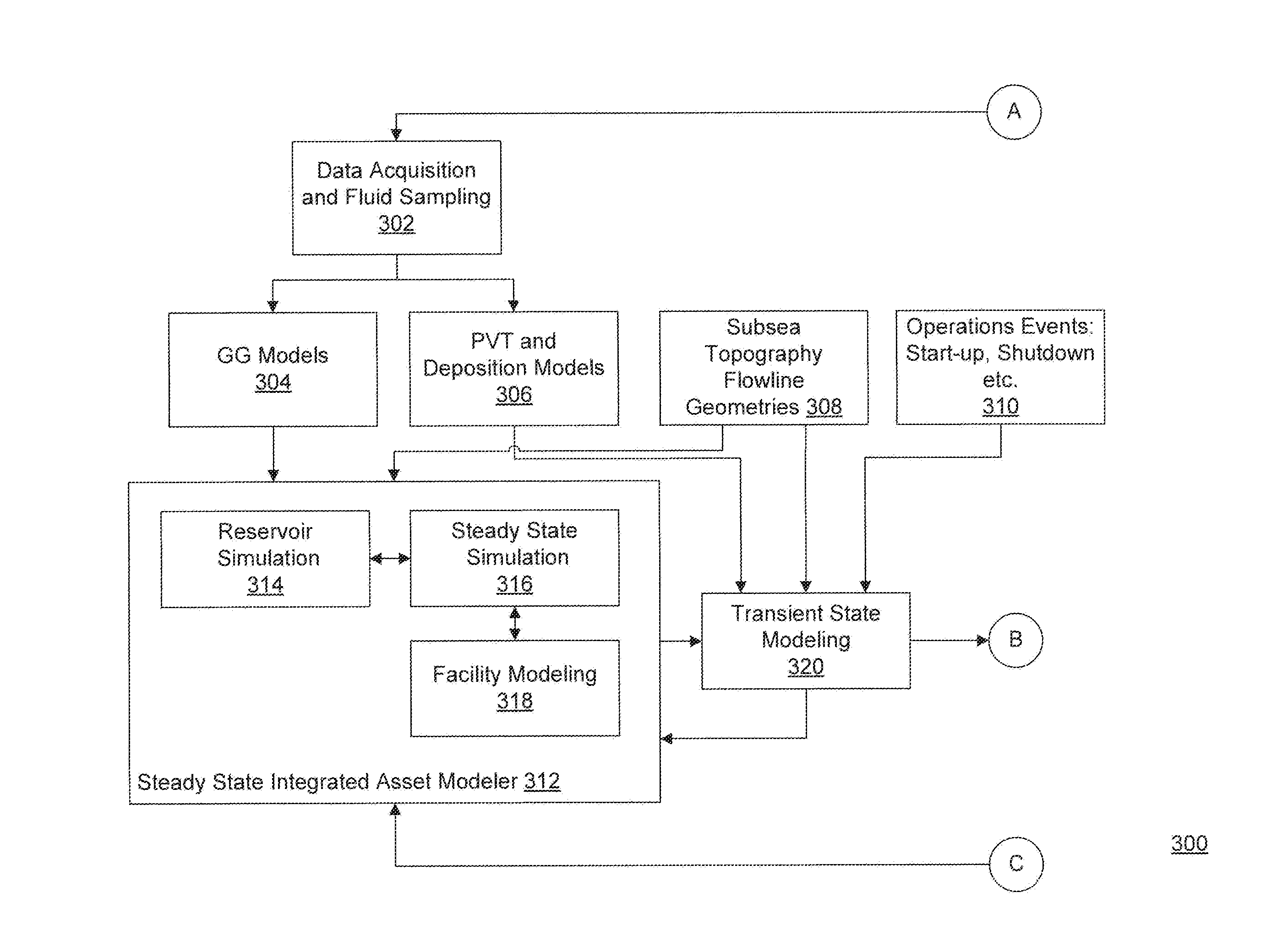

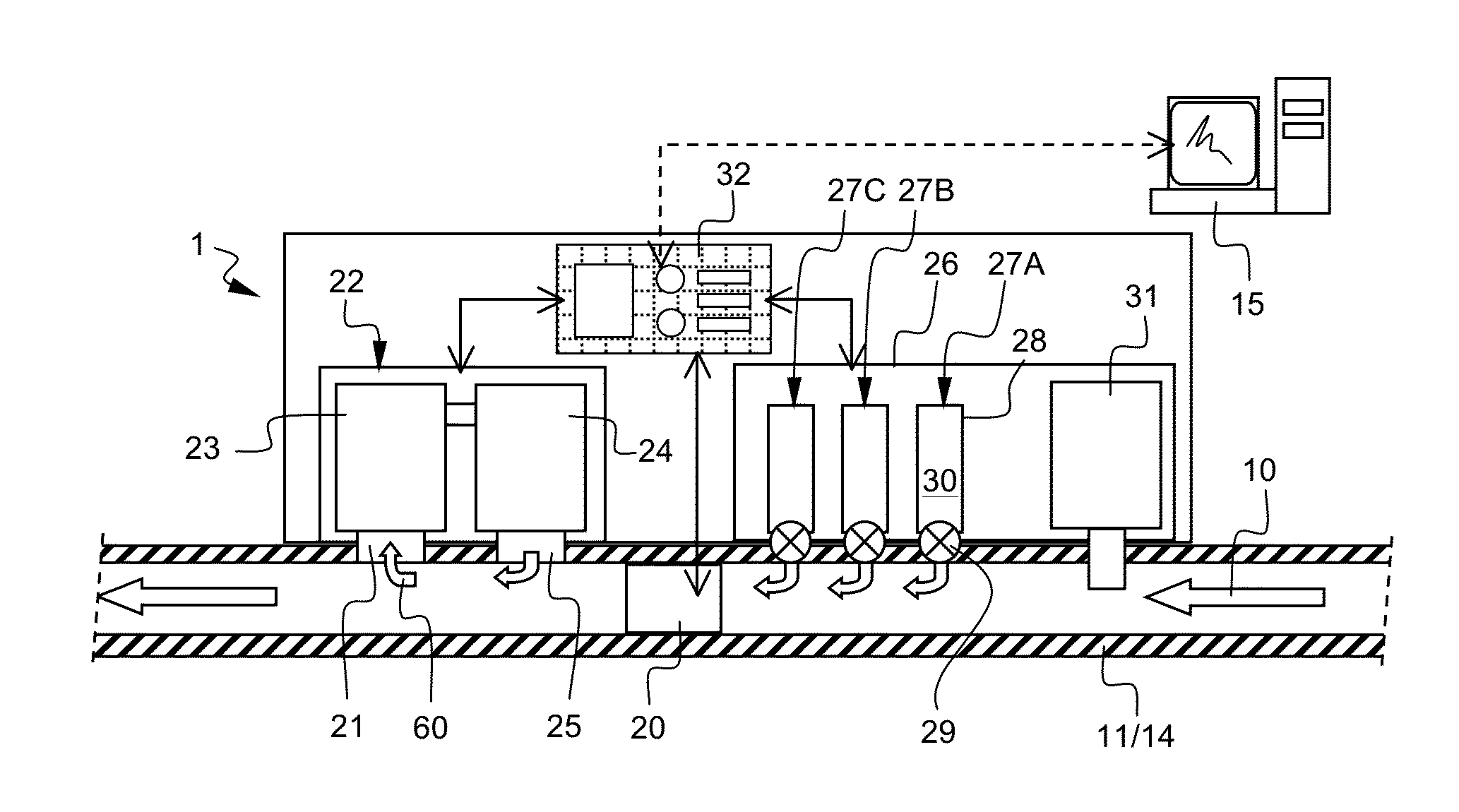

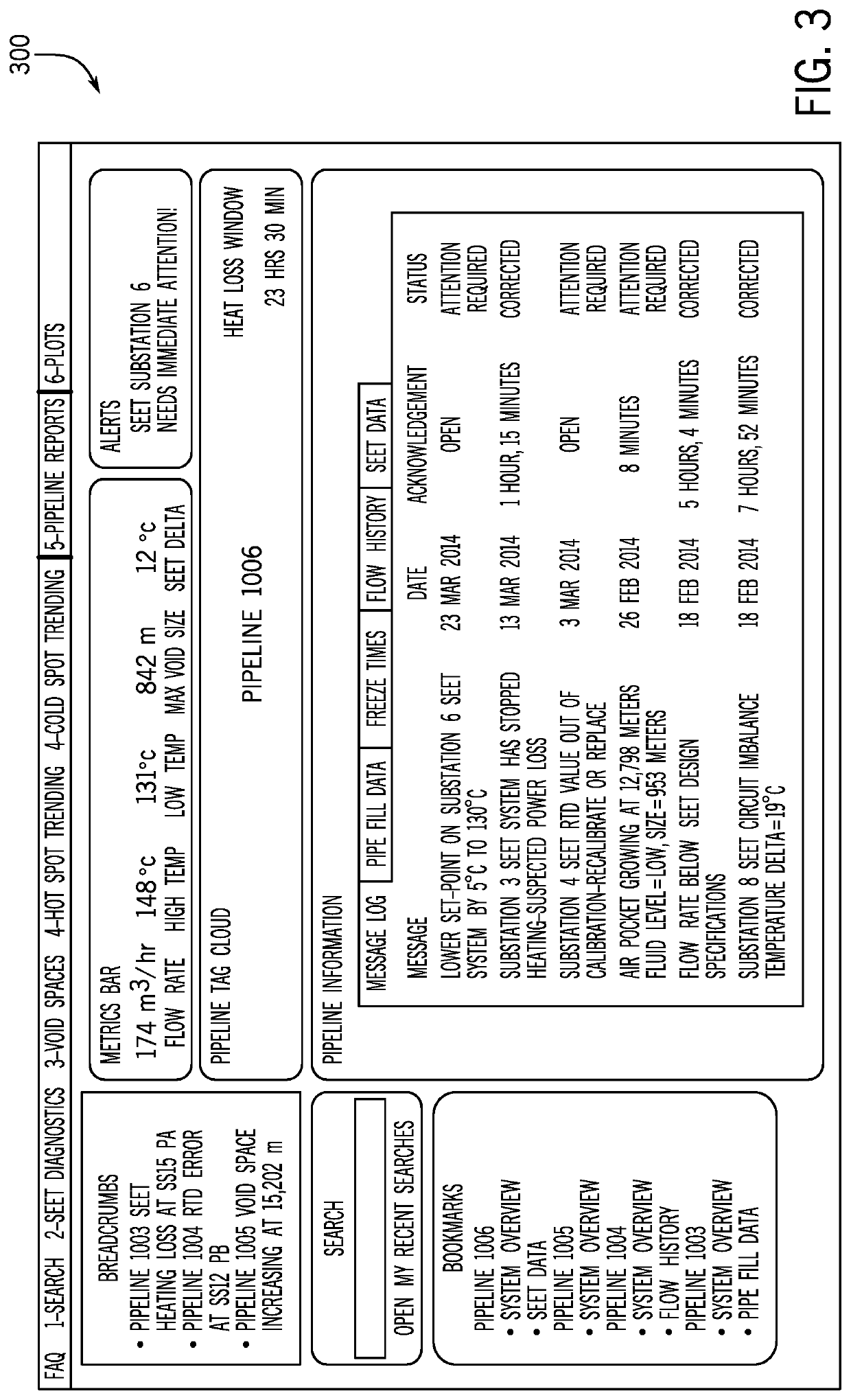

Integrated flow assurance system

InactiveUS20110224835A1Fast trainingImprove accuracyCleaning apparatusFluid removalSingle point of entryData input

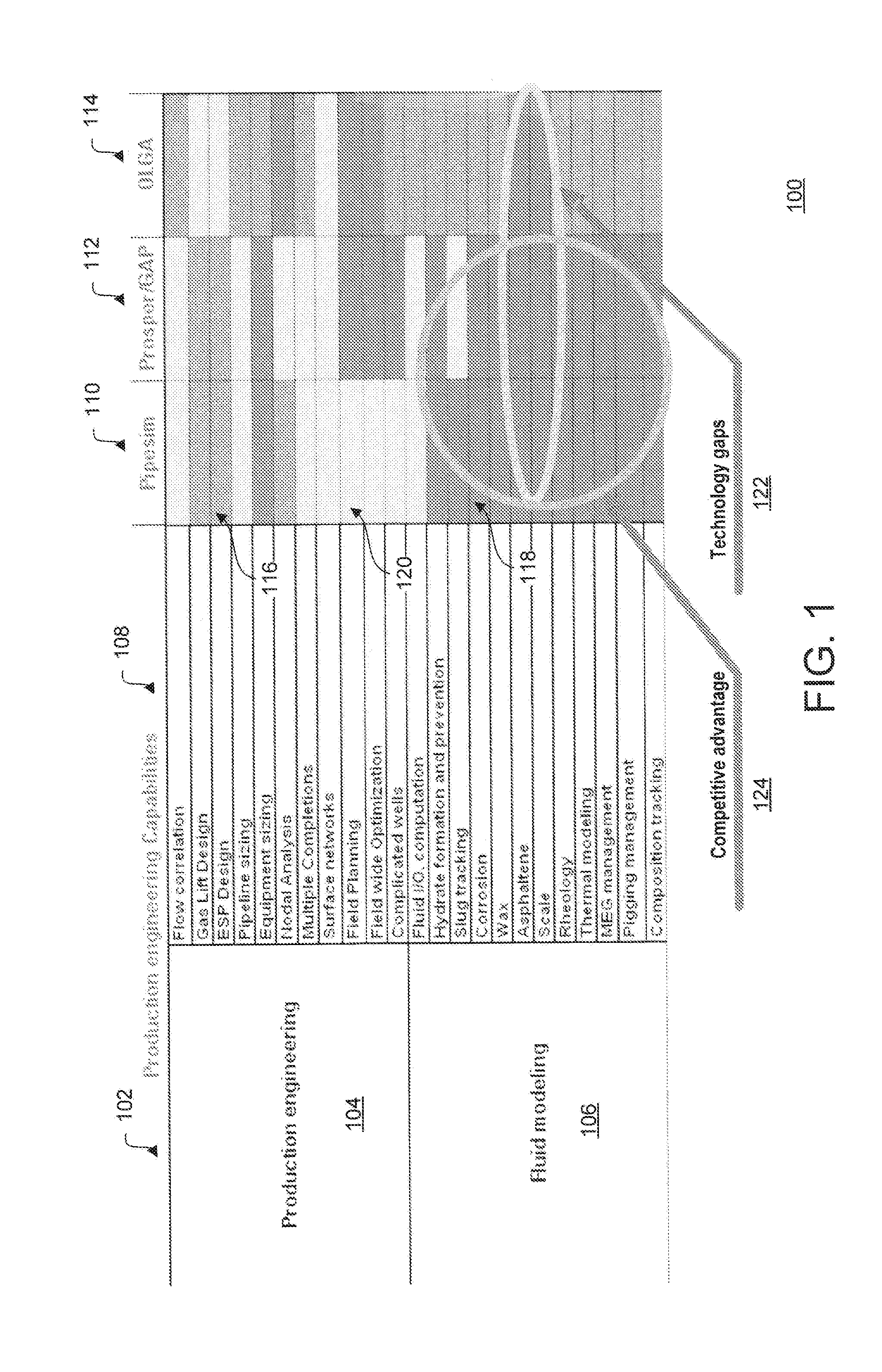

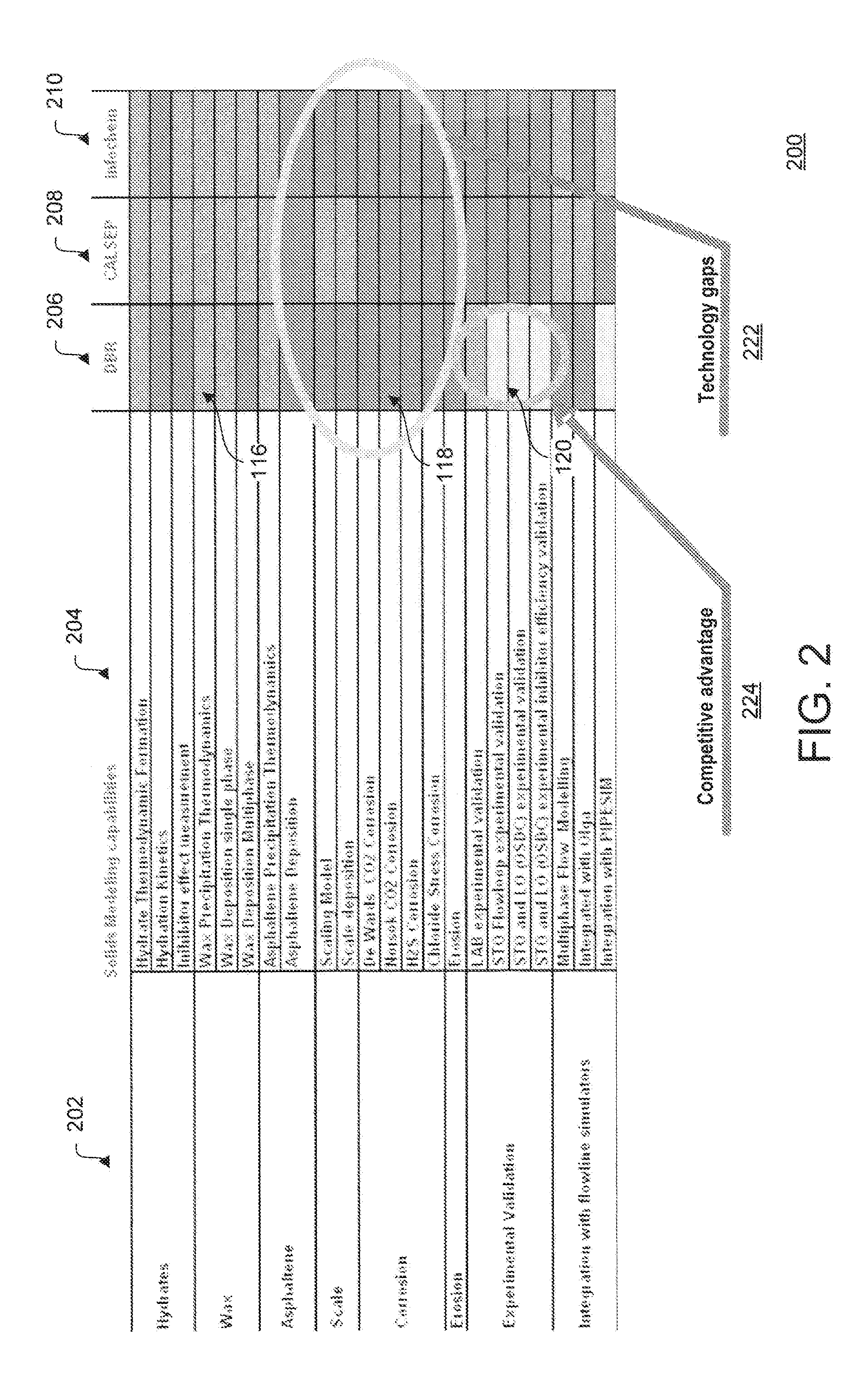

A flow assurance system comprising a plurality of flow assurance devices, each for performing a different flow assurance function. A platform device interfaces with the plurality of flow assurance devices to integrate the different flow assurance functions and enable a single point of entry of data for the flow assurances devices of the system.

Owner:SCHLUMBERGER TECH CORP

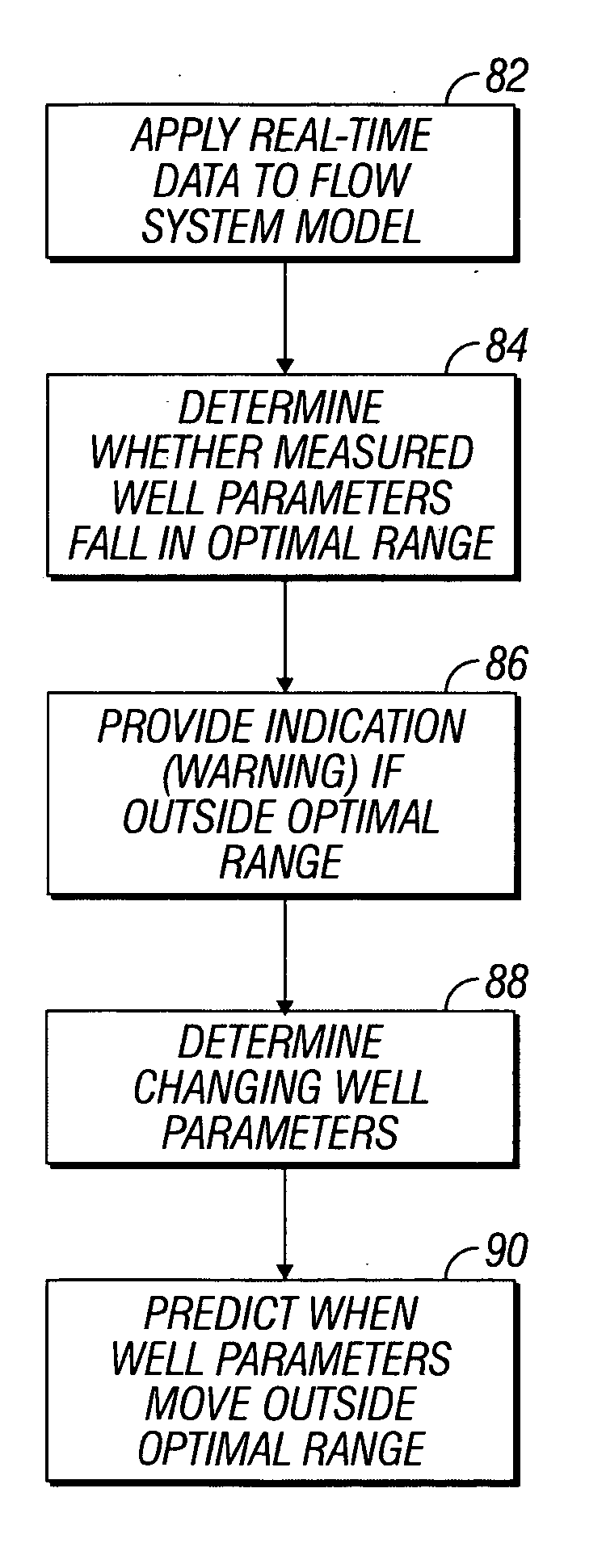

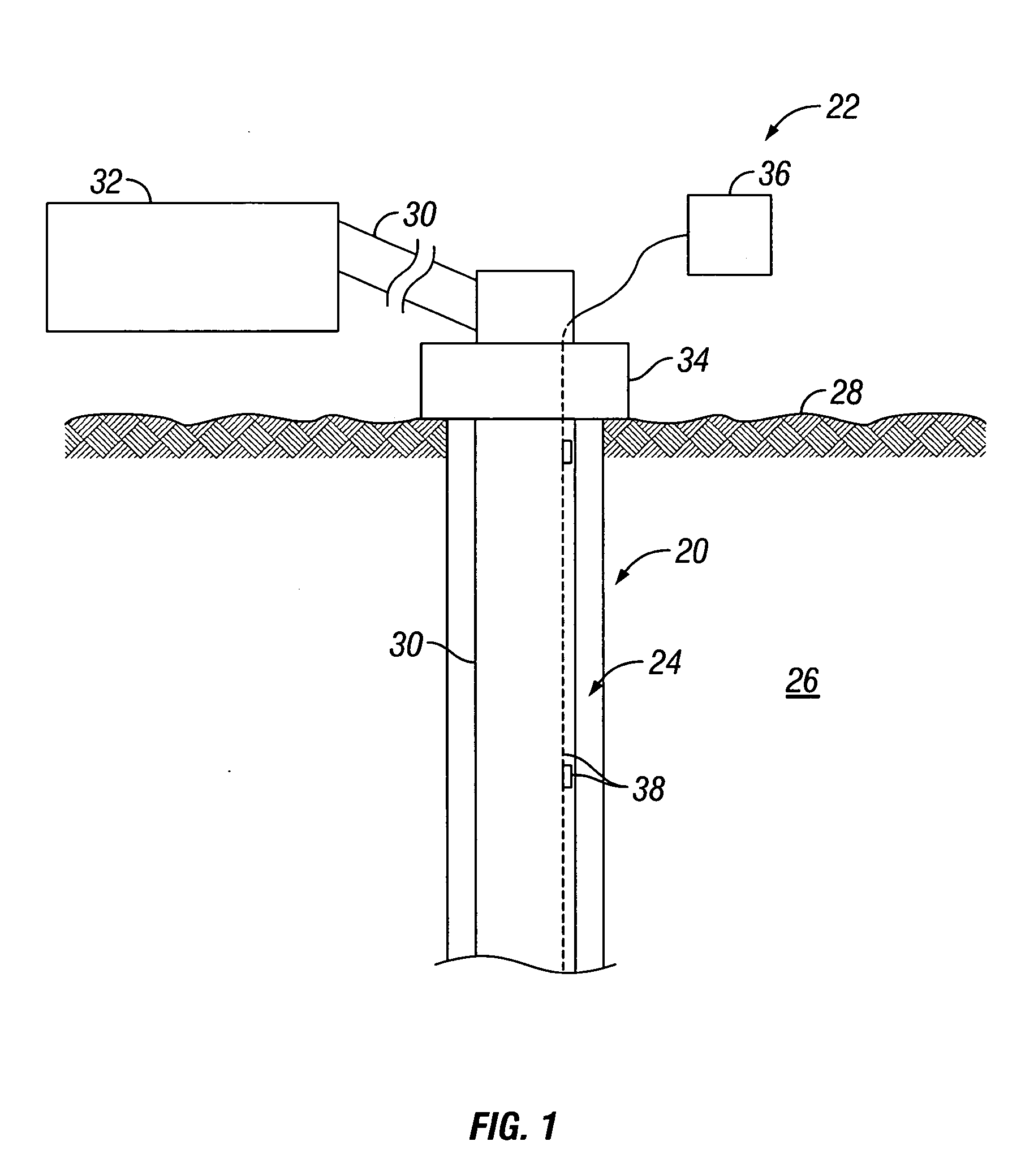

System and method of flow assurance in a well

A system and method is provided for assuring adequate flow in one or more wells. The system and method utilize a sensor system and a modeling technique that provides simple outputs readily usable by a non-specialist wellbore operator.

Owner:SCHLUMBERGER TECH CORP

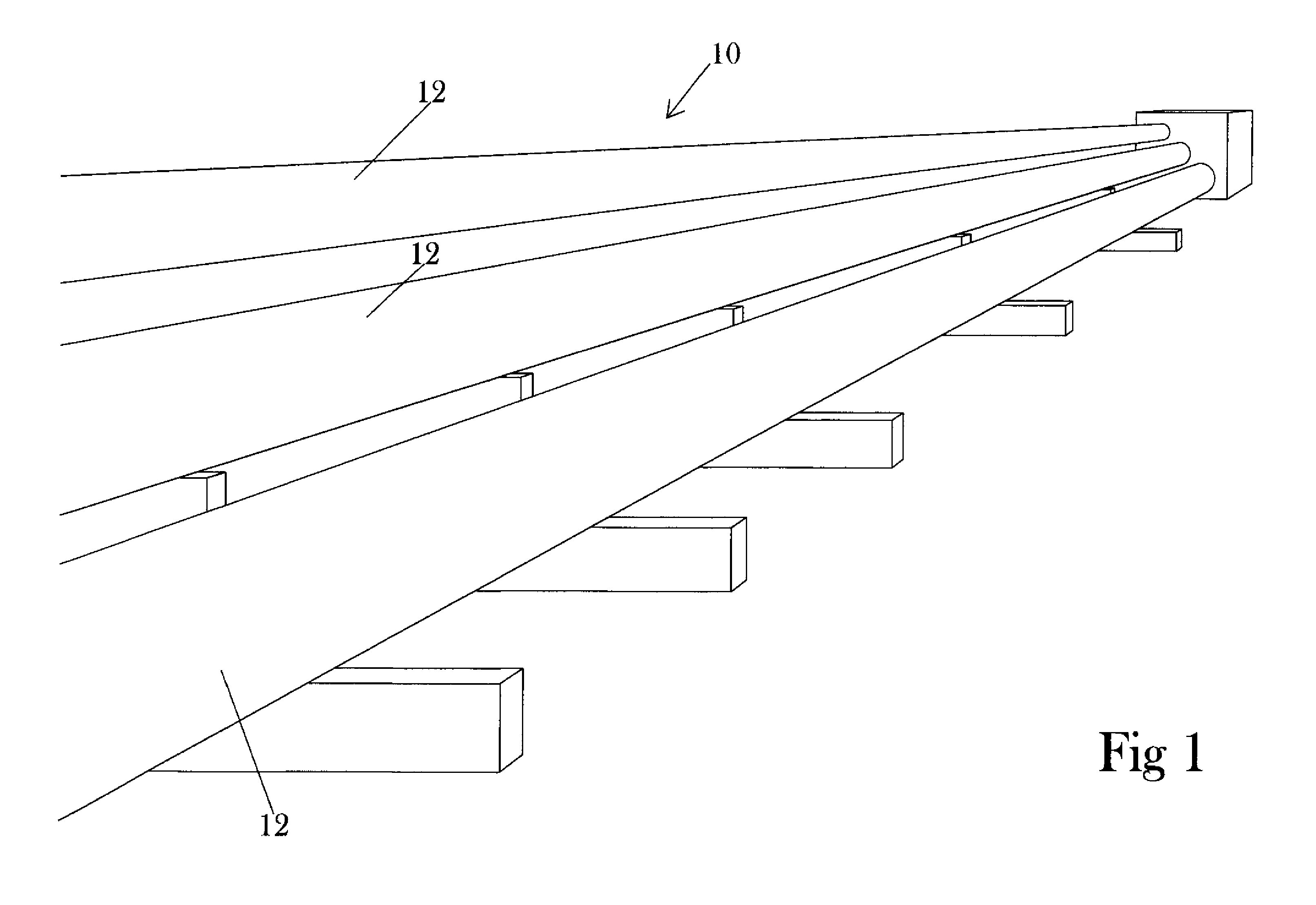

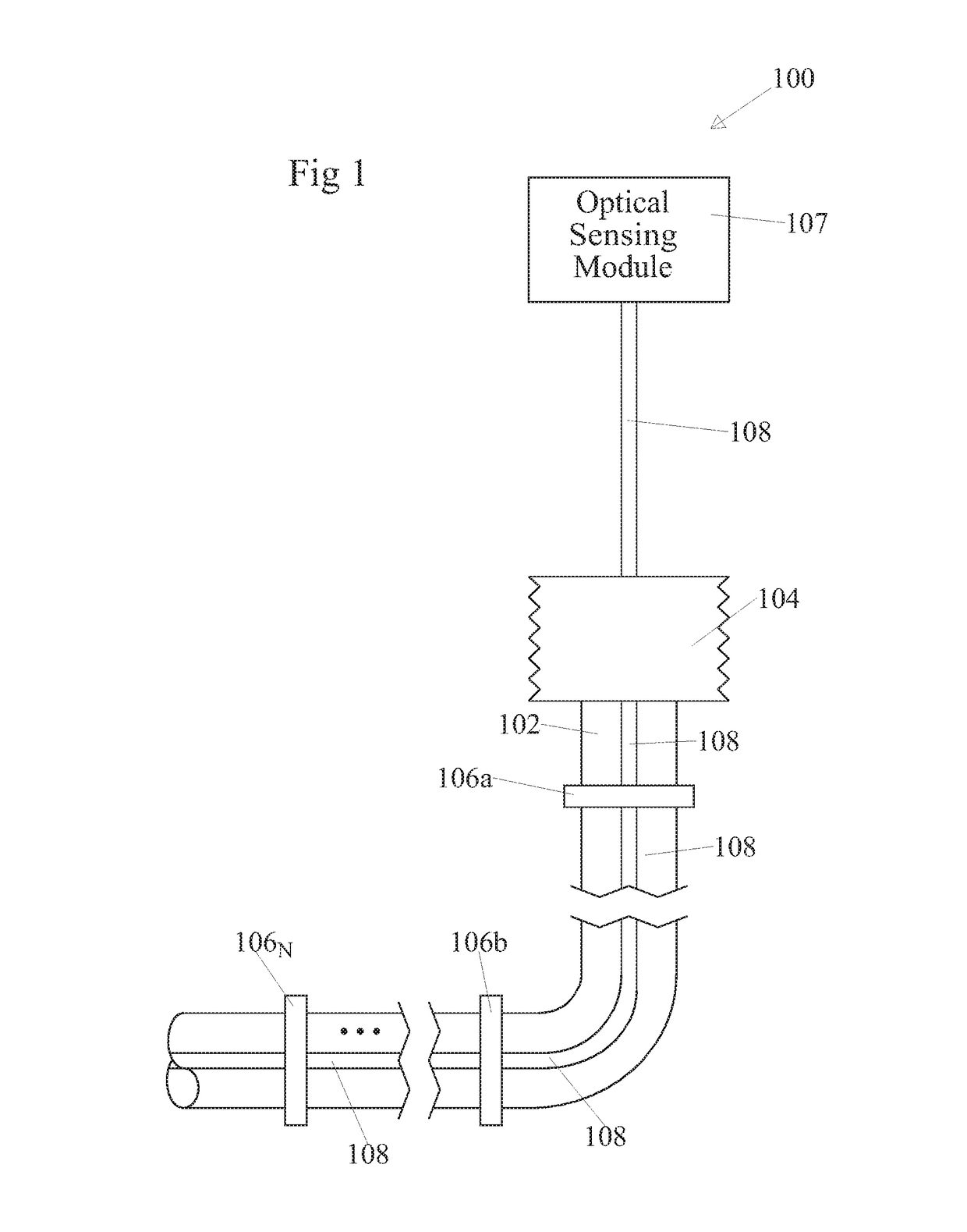

Apparatus to Monitor Flow Assurance Properties in Conduits

InactiveUS20110219866A1Delay light decayLong processSurveyVolume/mass flow measurementFiberOcean bottom

A combination of sensors are strategically placed along a pipeline to measure critical properties such as temperature and pressure of the flow product. The sensors are a combination of fiber optic sensing devices that are specifically designed to measure a range of properties within particular bandwidth, with a method to reduce light attenuation over the long pipeline distances. The pipeline is typically subsea and can range widely in diameter. In many cases the pipeline has a coating that acts as a barrier to the corrosive sea water and additional thermal barriers.

Owner:ASTRO TECH GRP LLC

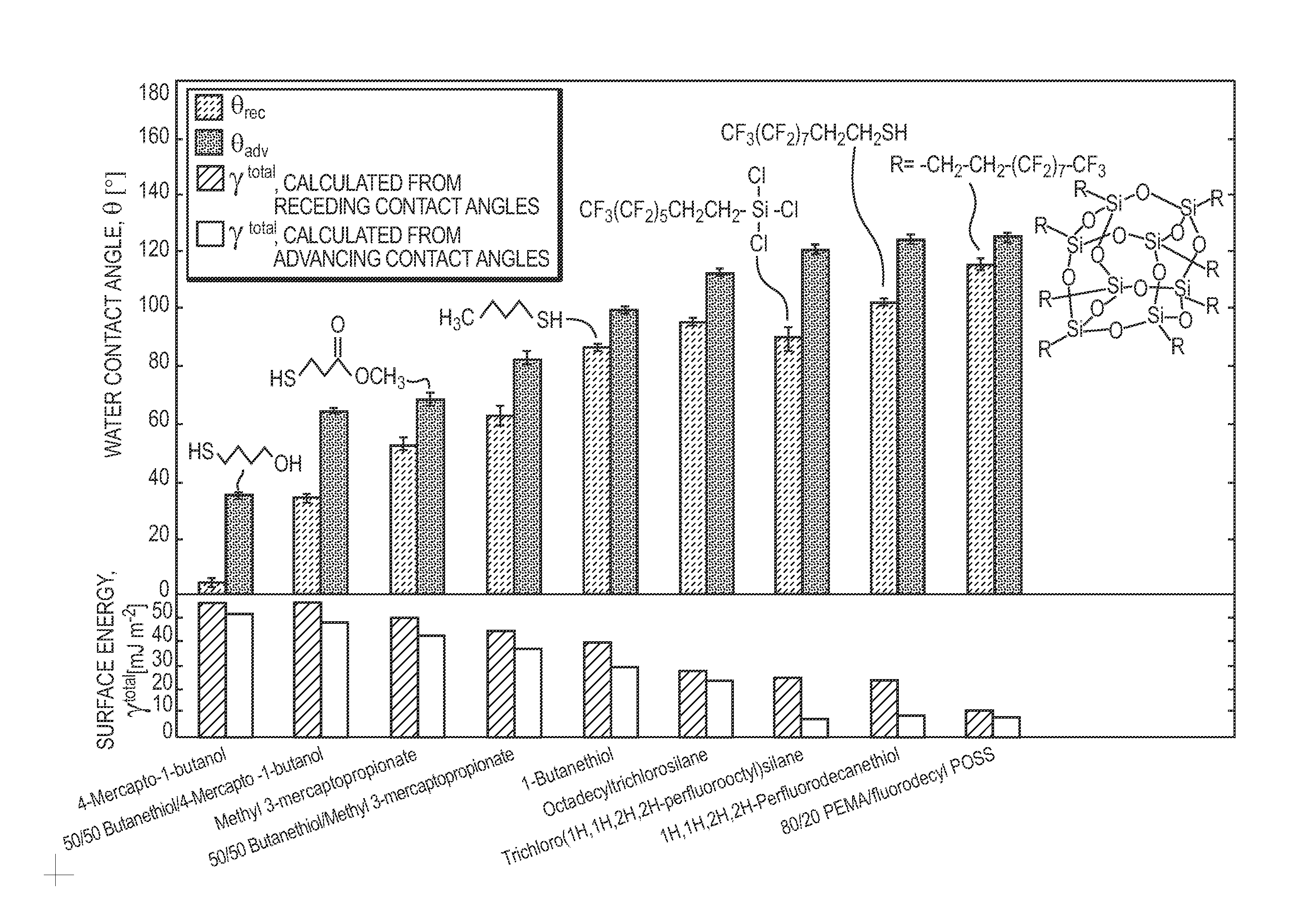

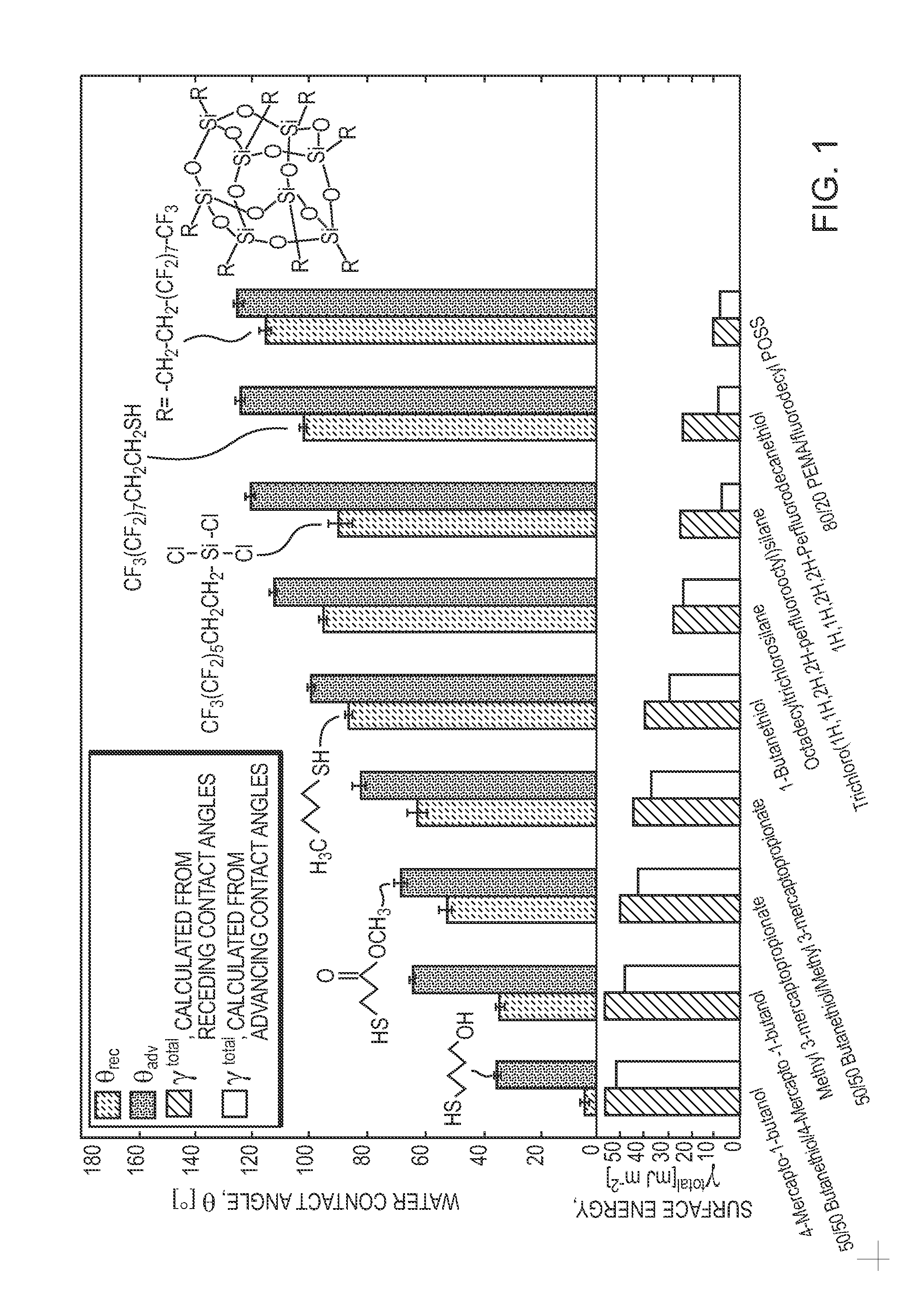

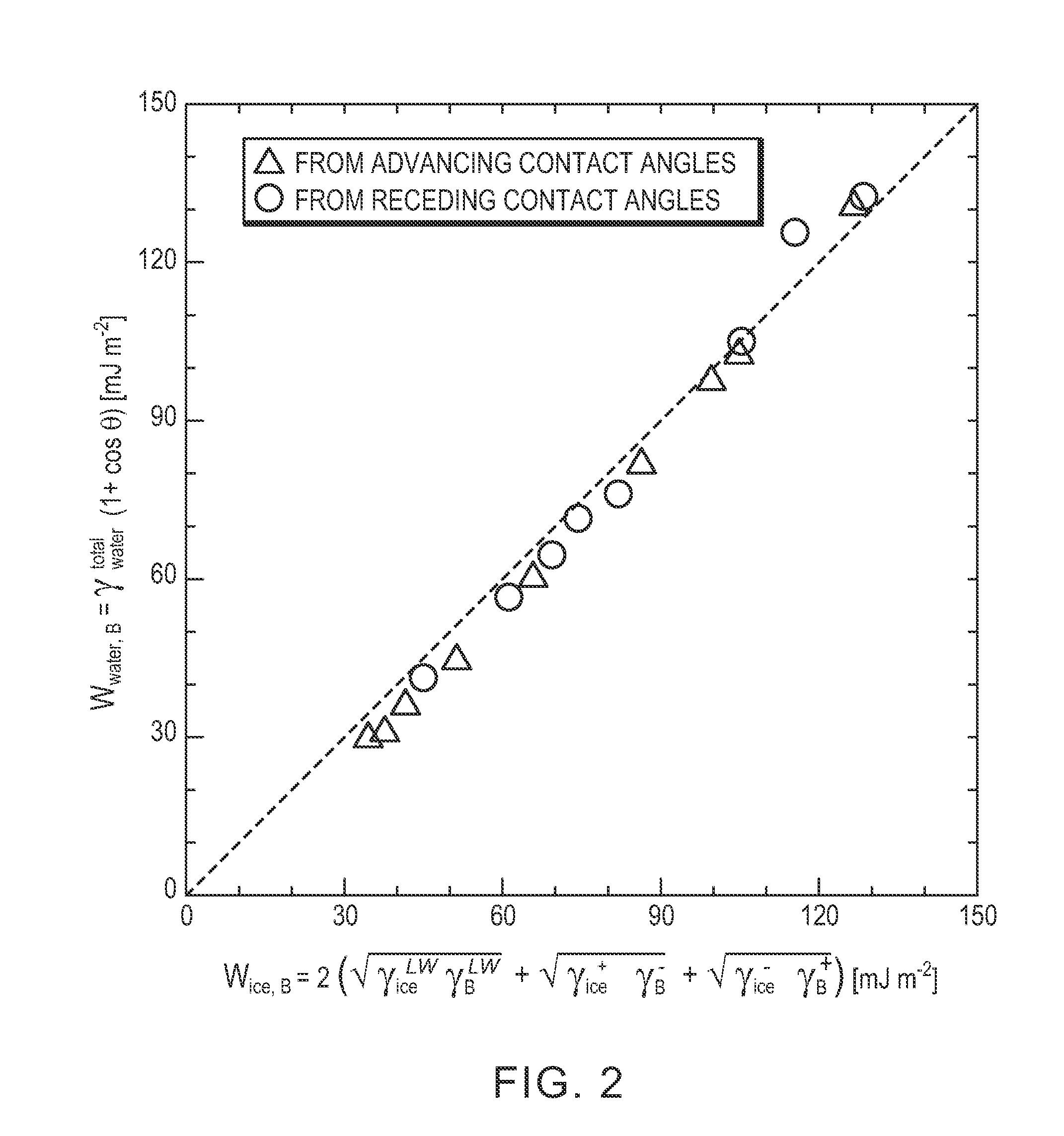

Articles and methods for reducing hydrate adhesion

This invention relates generally to articles, devices, and methods for gas hydrate mitigation in deep-sea drilling applications. In certain embodiments, hydrate-phobic surfaces are provided that ensure passive enhancement of flow assurance and prevention of catastrophic failures in deep-sea oil and gas operations.

Owner:MASSACHUSETTS INST OF TECH

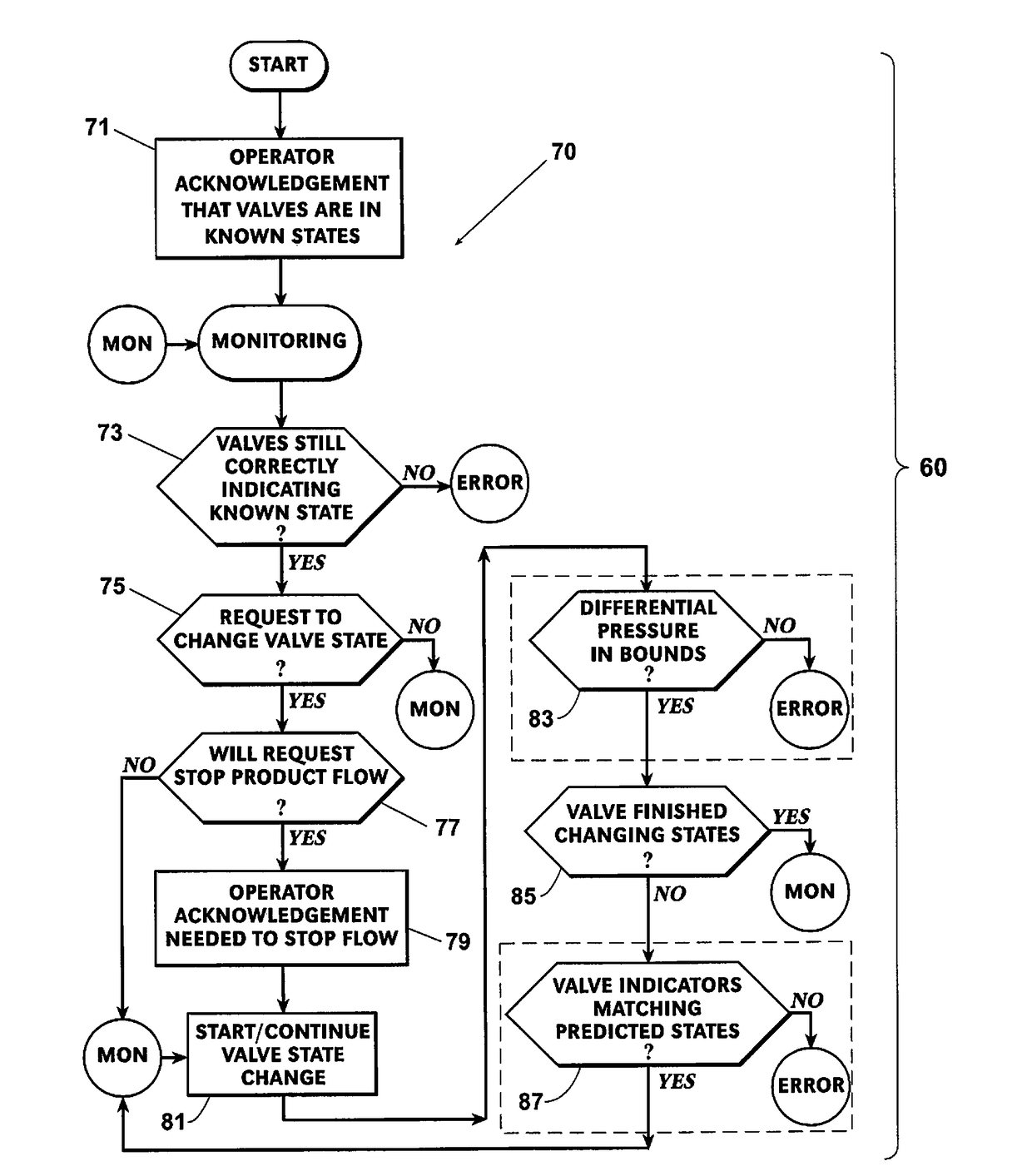

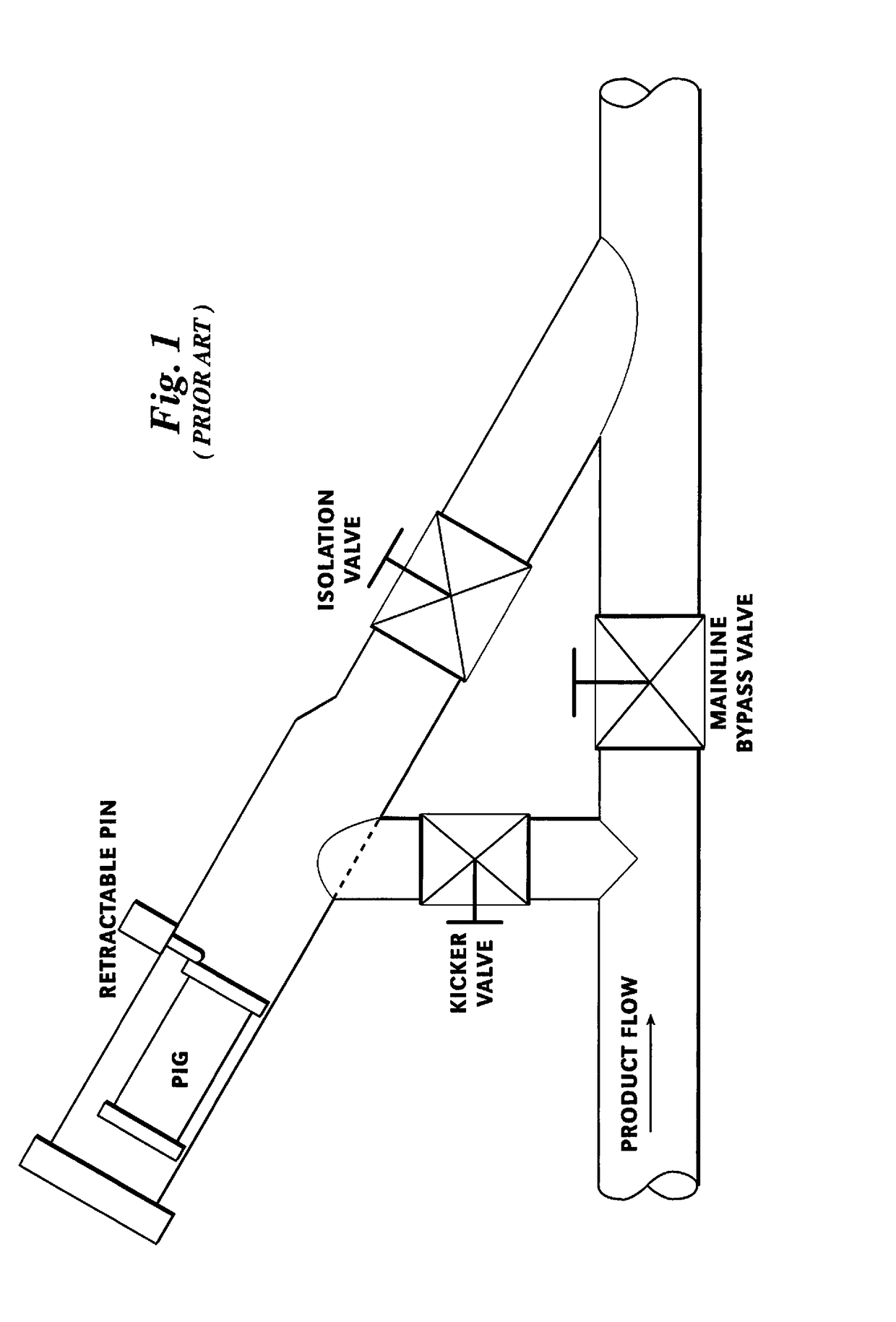

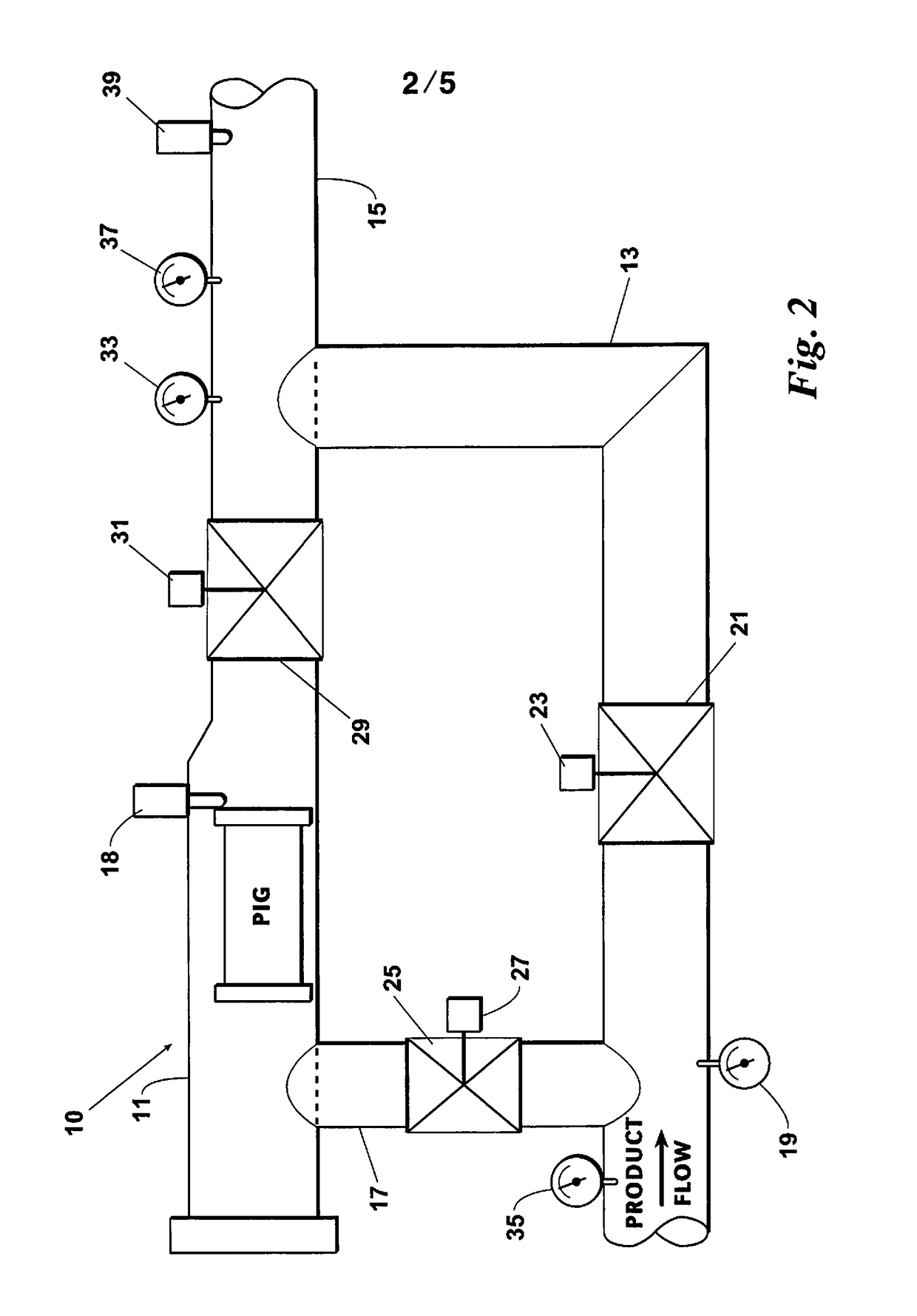

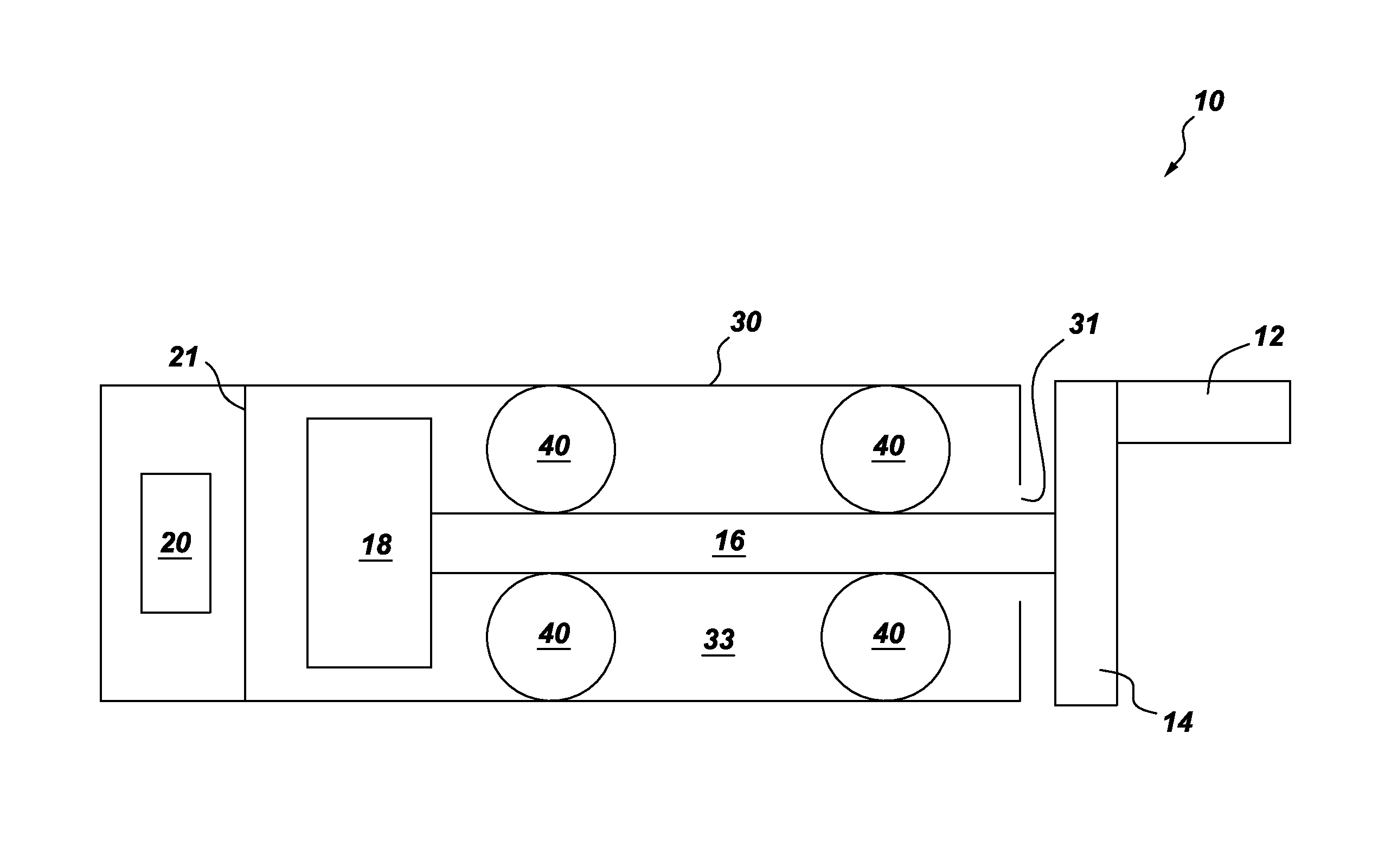

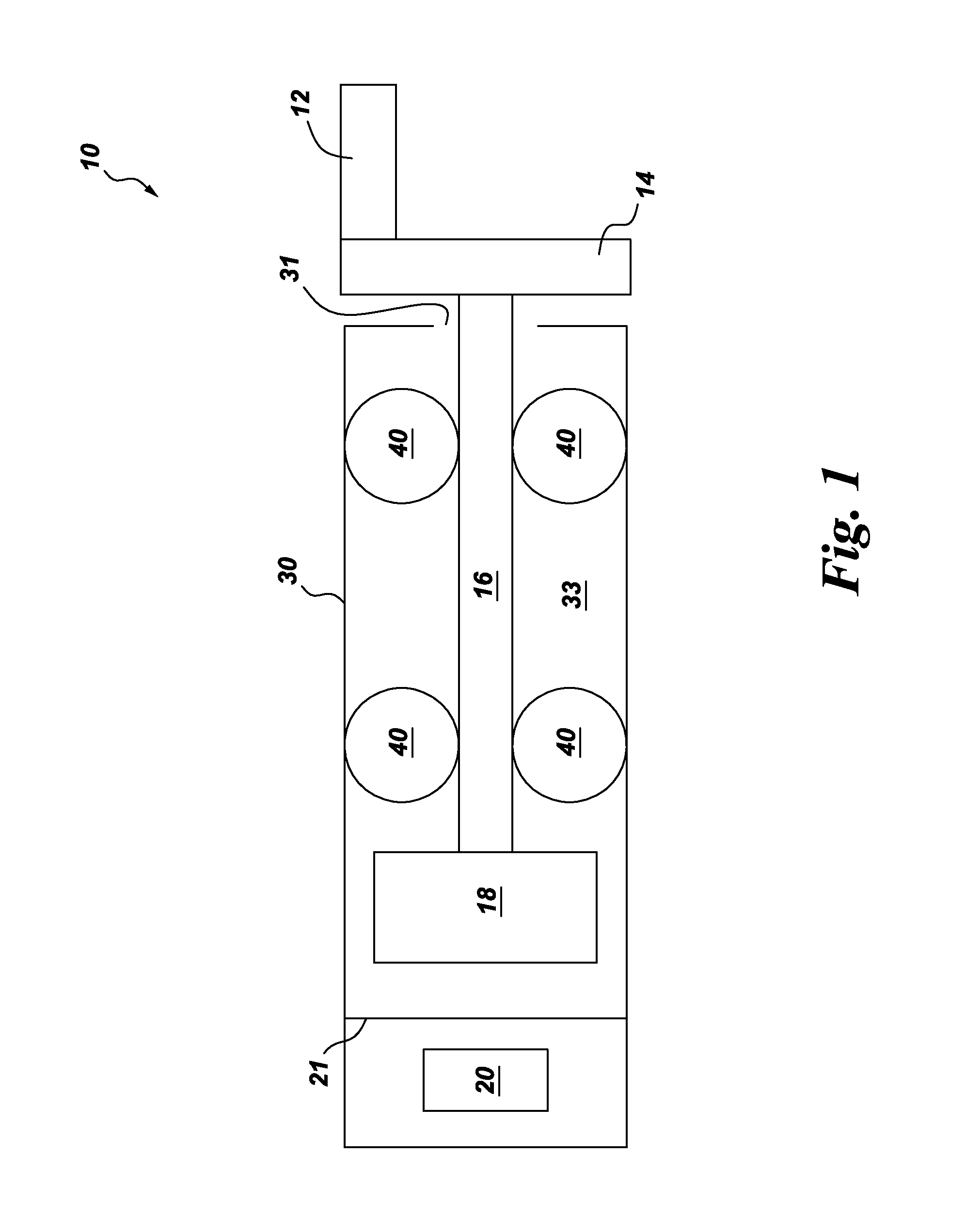

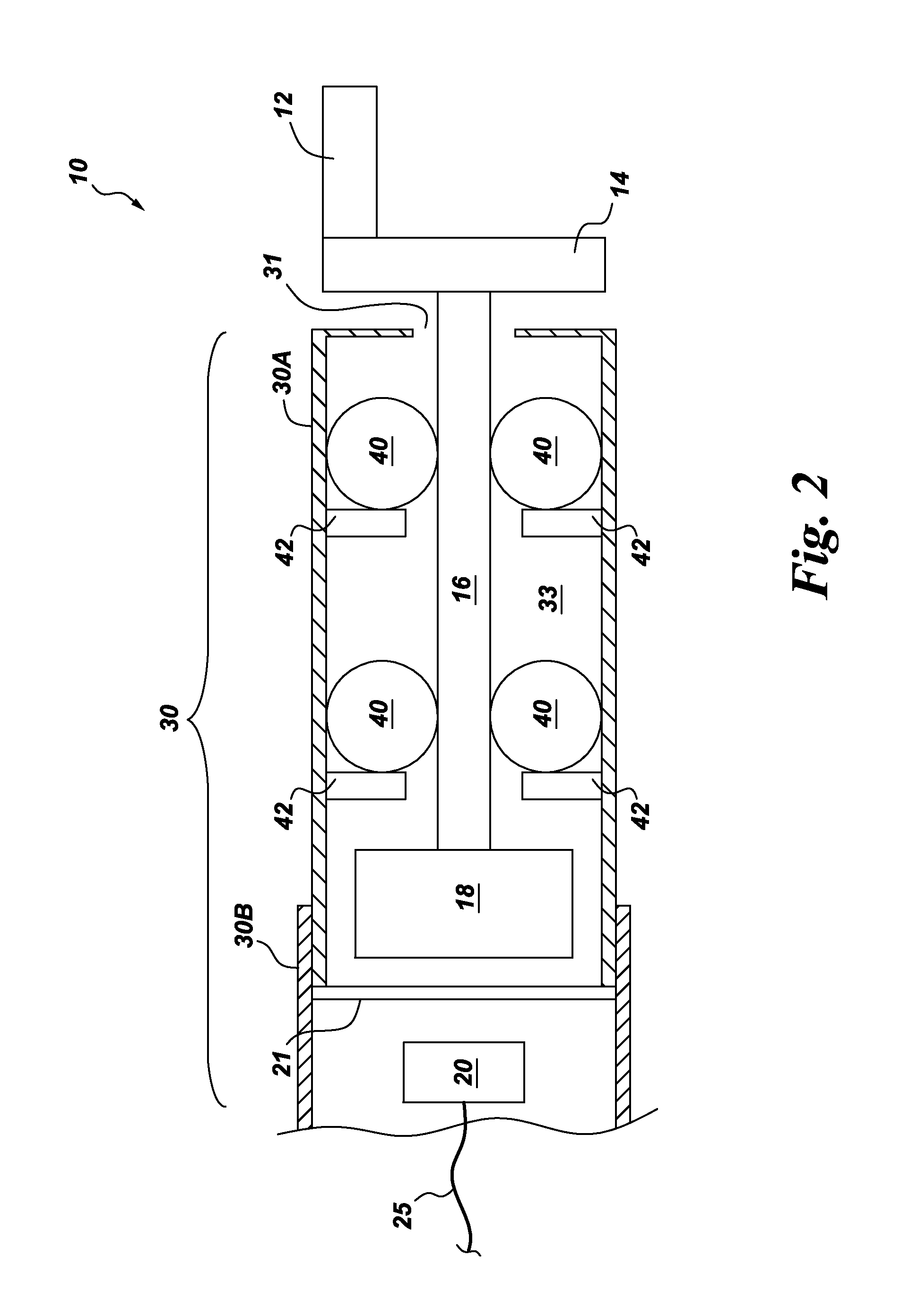

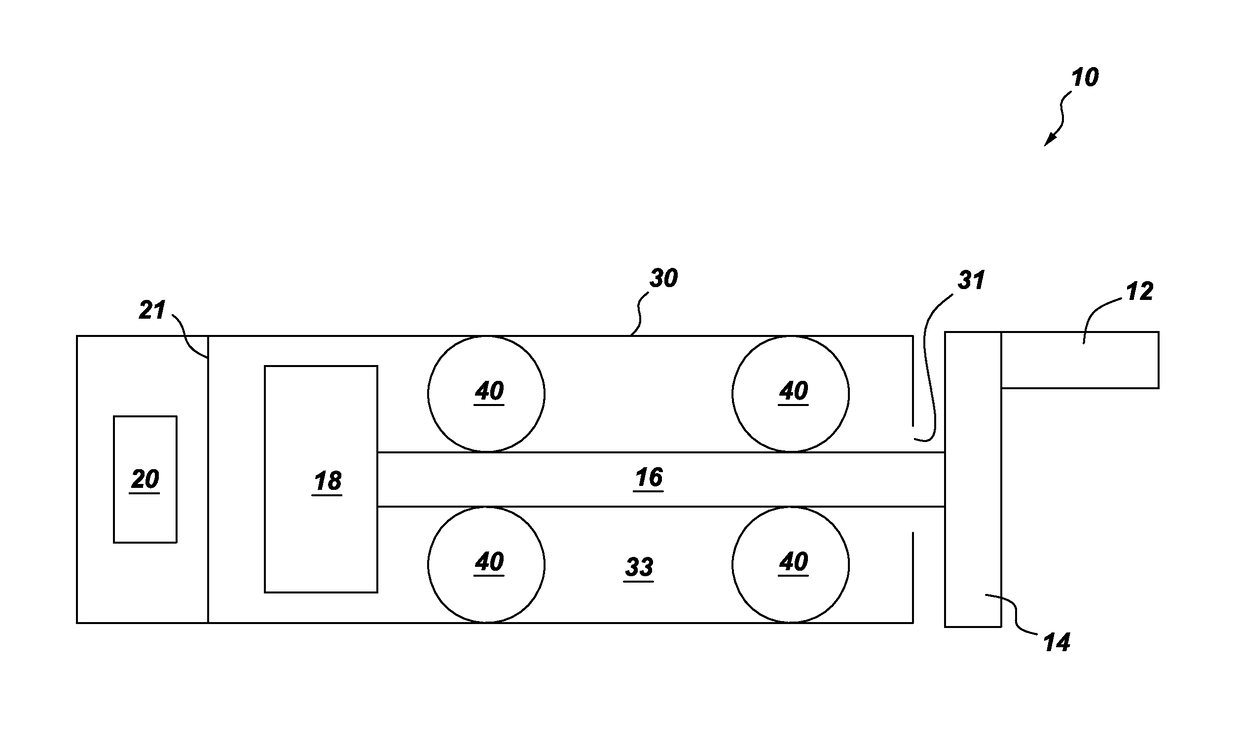

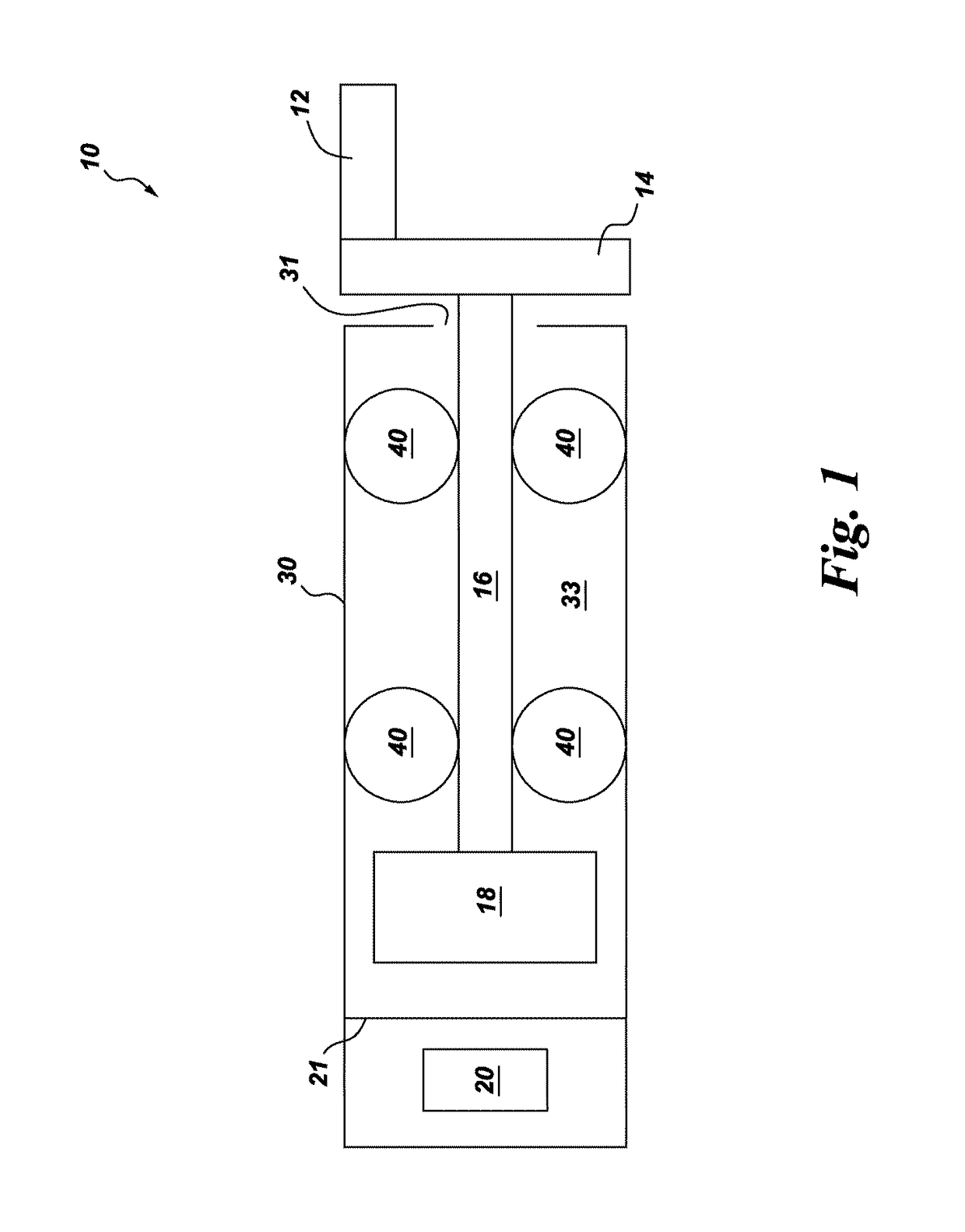

System and method of preventing flow blocking when using an automated pig launcher

ActiveUS9651190B1Avoid flowHollow article cleaningFluid pressure measurementIsolation valveEngineering

A flow assurance system and method includes procedures to query current valve states and determine the likely effect of new valve states on product flow when using an automated pig launcher. The system and method allows for modulating the mainline bypass valve, kicker valve, and isolation valve between fully opened and fully closed states; prevents flow blocking of the pipeline during this modulation; enables new and different, as well as a broader range of, pig launching options for an automatic pig launcher; and integrates with existing automatic pig launchers.

Owner:TDW DELAWARE INC

Natural gas hydrate dissociation gas release rate calculation method and apparatus

ActiveCN105426666ASafe and stable operationSpecial data processing applicationsInformaticsSlurryDissociation reaction

The invention provides a natural gas hydrate dissociation gas release rate calculation method and apparatus. The method comprises: according to a hydrate dissociation related theory basis, establishing a hydrate slurry dissociation kinetic model and fitting values of related parameters in the hydrate dissociation model; according to natural gas components, performing phase-state flash evaporation and performing calculation to obtain natural gas related parameters; obtaining an amount of substances of natural gas hydrate during initial natural gas hydrate dissociation and real-time temperature and pressure data after a dissociation reaction is performed; and according to the hydrate slurry dissociation kinetic model, the values of the related parameters in the hydrate dissociation model, the natural gas related physical parameters, the amount of the substances of the natural gas hydrate during the initial natural gas hydrate dissociation and the real-time temperature and pressure data after the dissociation reaction is performed, obtaining a natural gas hydrate dissociation gas release rate. The calculation method and apparatus are mainly applied to the aspects of natural gas hydrate mineral development, flow assurance of removal of natural gas hydrate freezing and plugging, natural gas hydrate storage and transport technology, hydrate separation and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

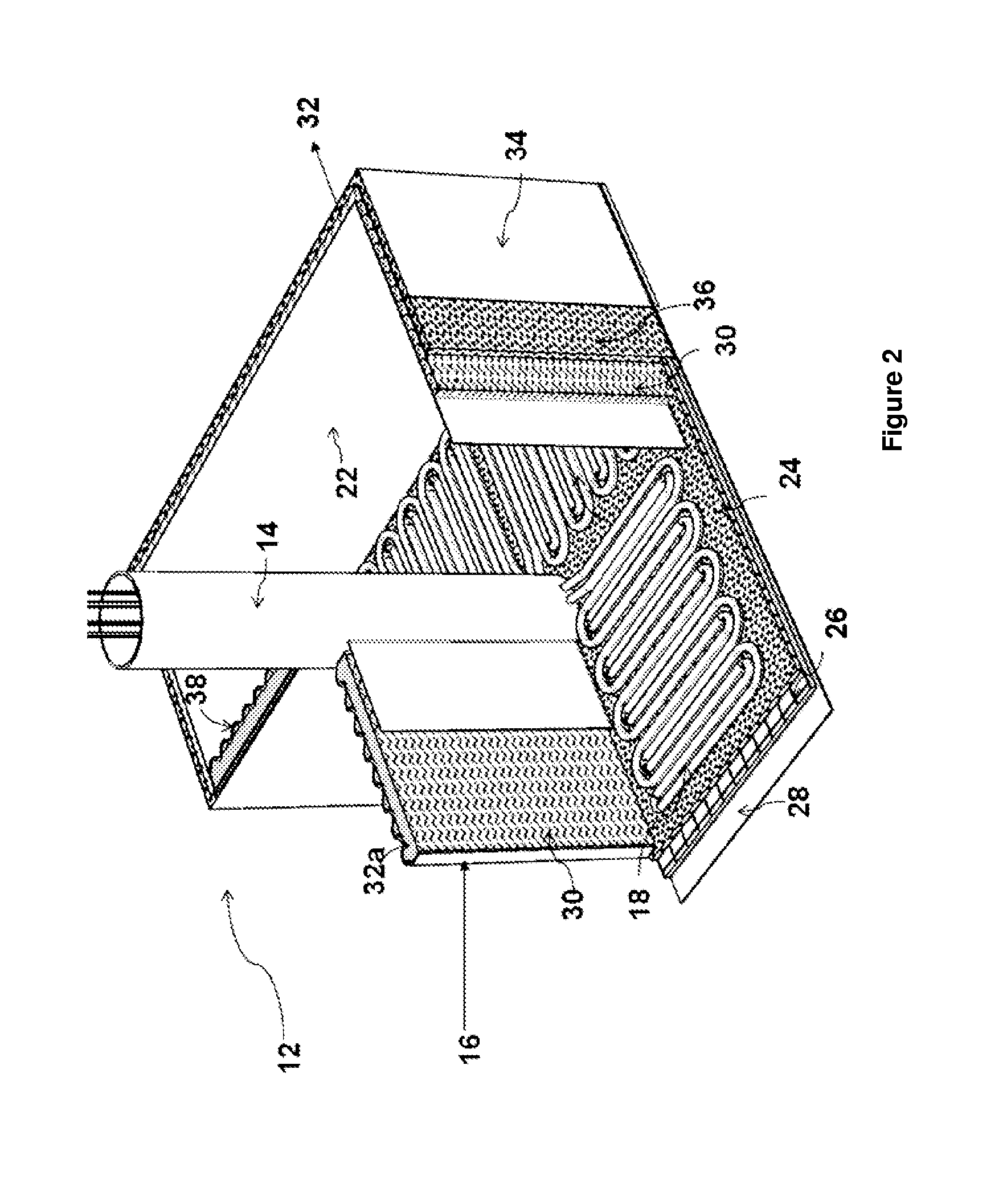

Enclosed offshore tank for storing crude oil

InactiveUS20120248099A1Avoid depositionPrevent heat lossAuxillariesVessel ventillation/heating/coolingMicrowaveWaveguide

An enclosed offshore tank for storing crude oil in a flowable form where the problems associated with flow assurance are prevented. The enclosed offshore tank includes a floor, an insulated cover and perimeter wall secured to a floor forming the offshore tank. The enclosed offshore tank can include a means of floor heating, wherein the floor is provided with piping which receives heated fluid to heat the crude oil. The perimeter wall can have an inner wall and an outer wall forming an annulus, wherein a heated fluid from a heating source fills the annulus to heat the crude oil. A microwave heating system can include at least one microwave generator, at least one waveguide and at least one radiating element to indirectly heat crude oil in the offshore tank.

Owner:KINGTIME INT

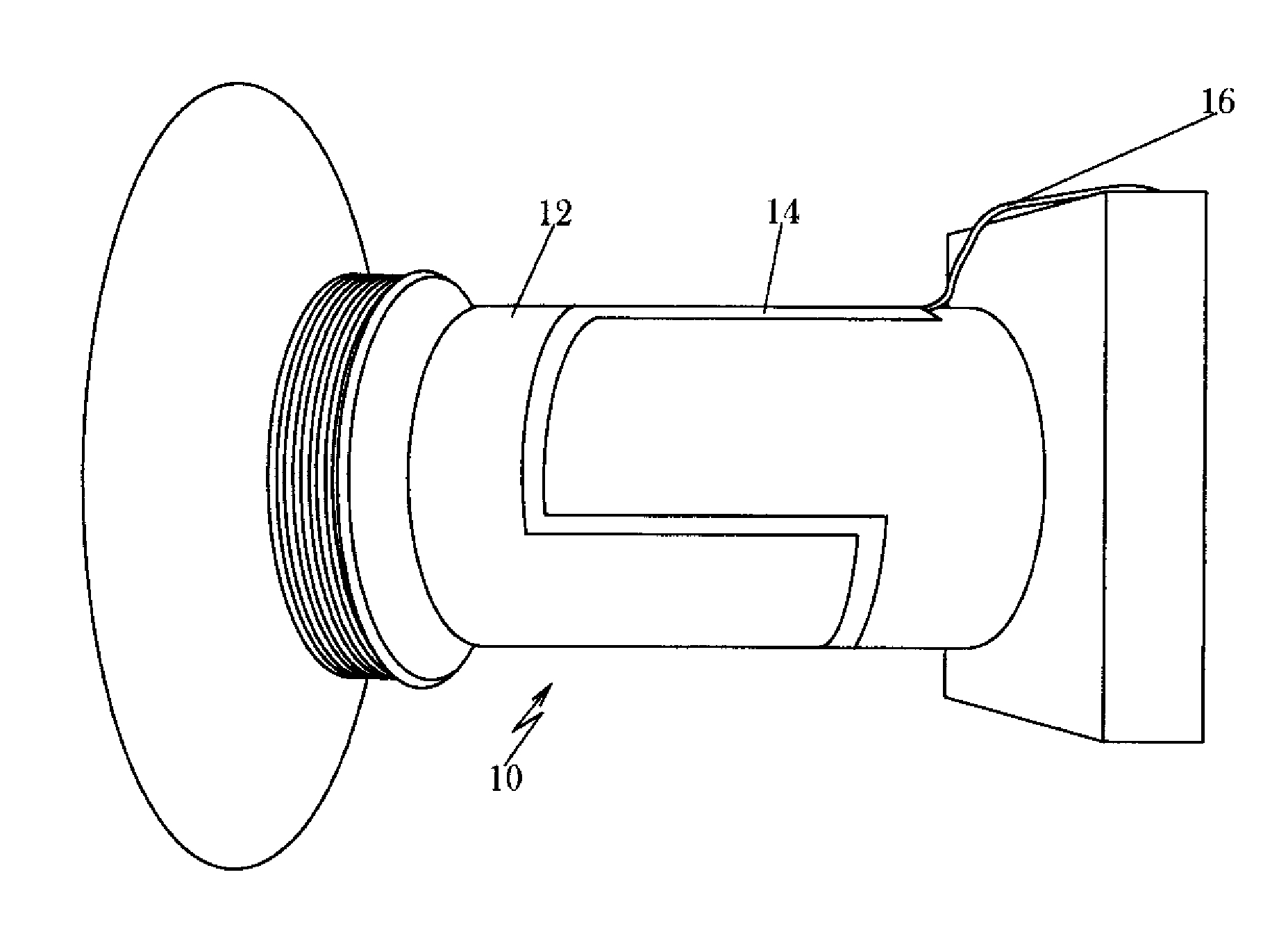

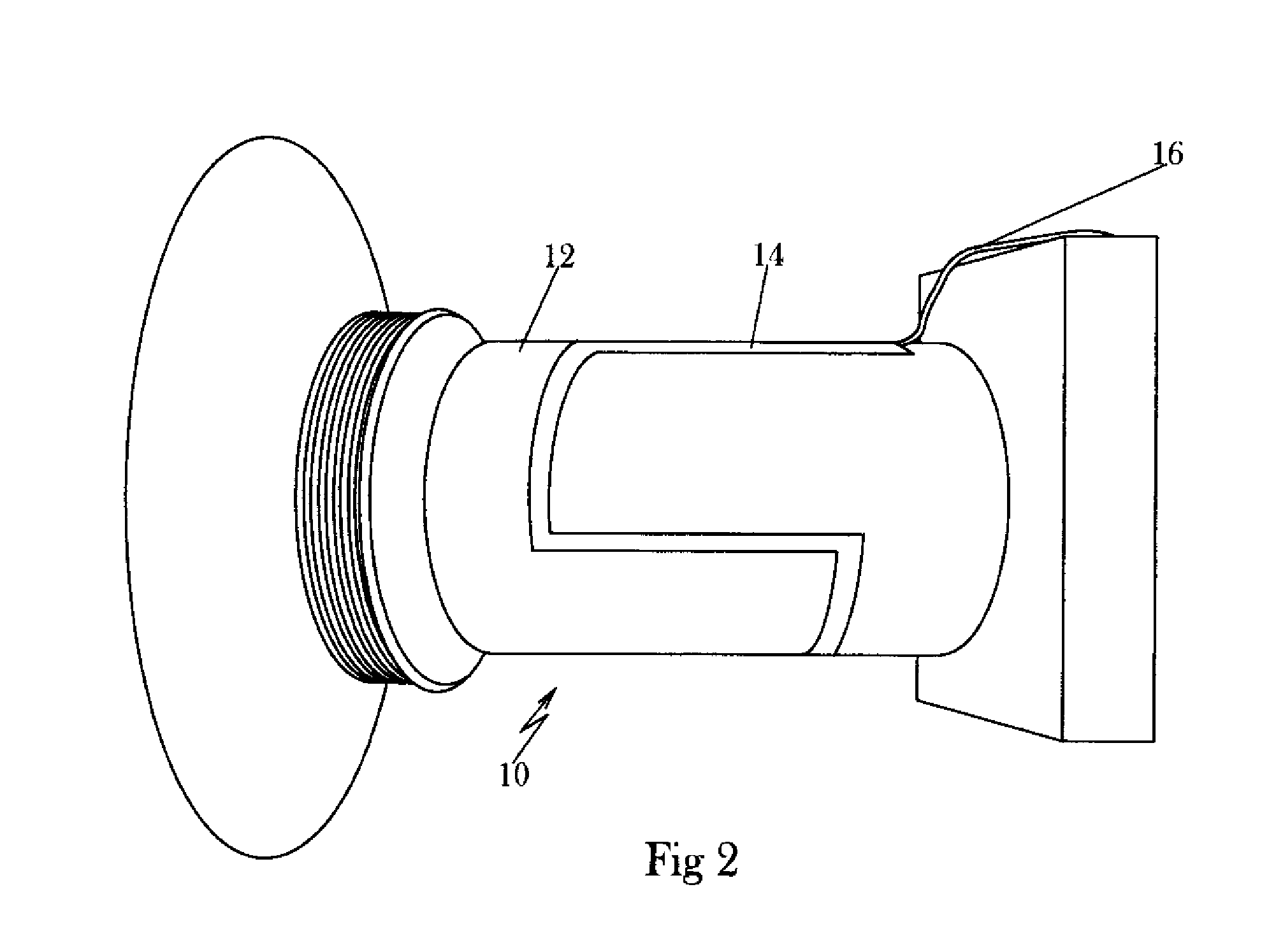

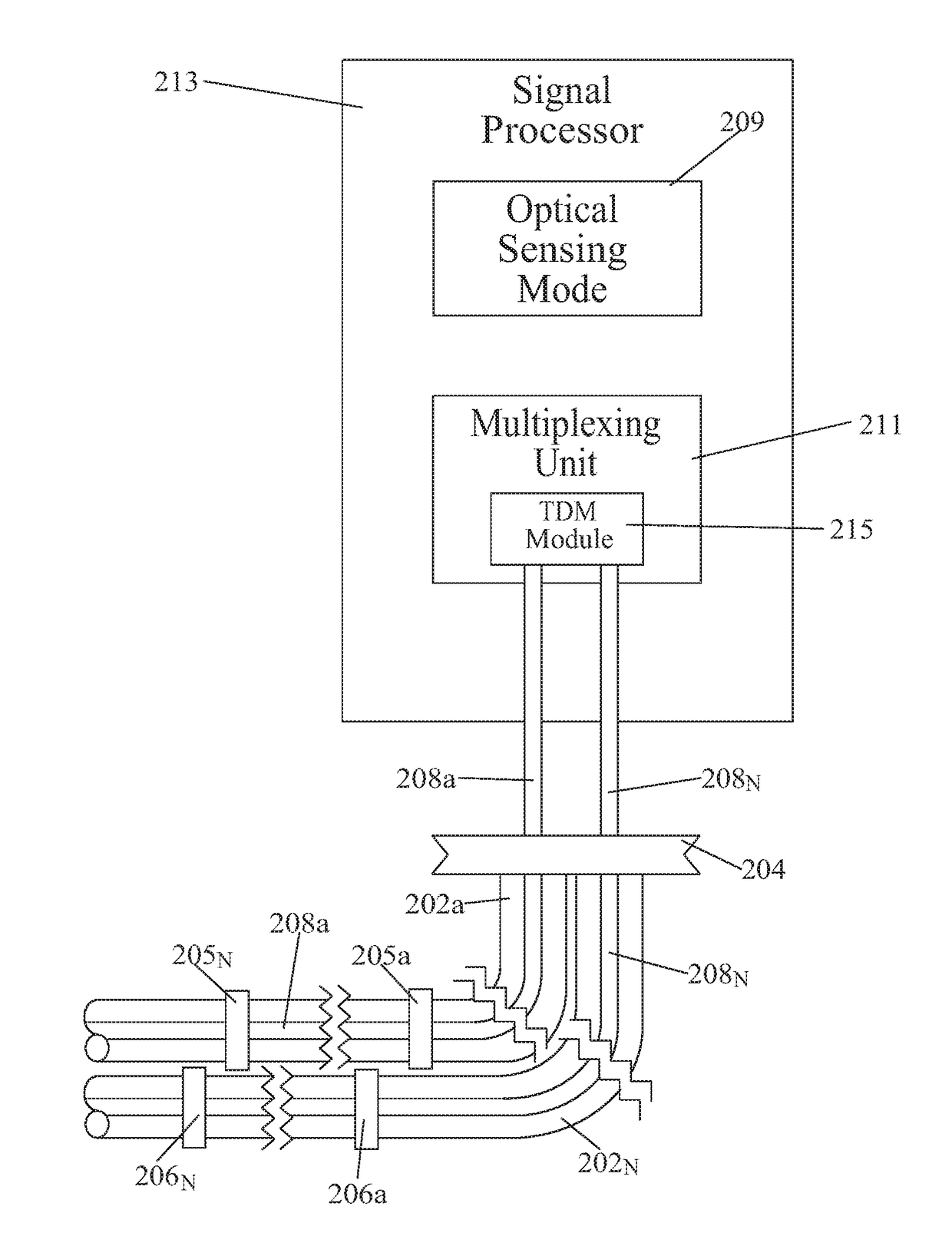

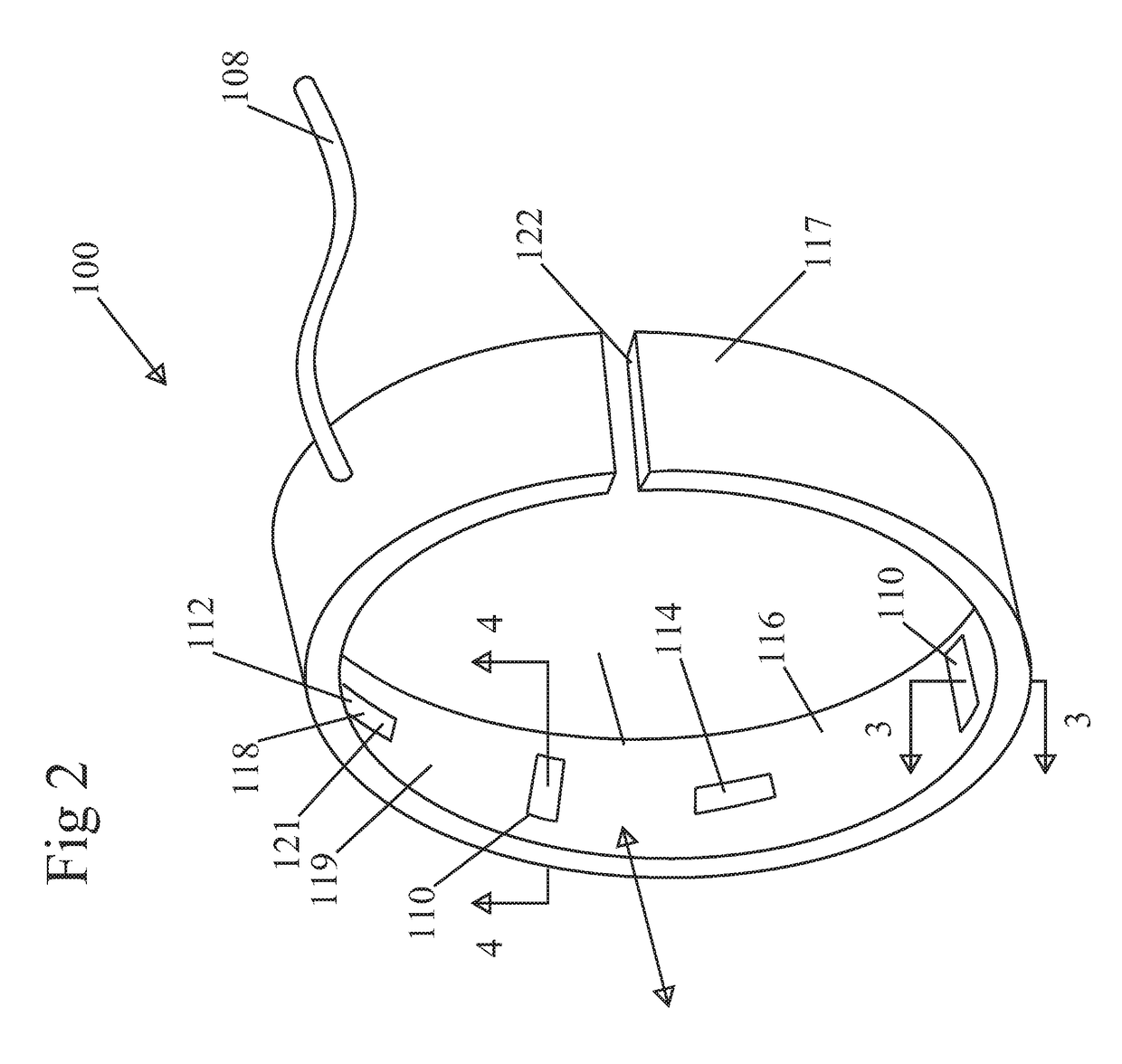

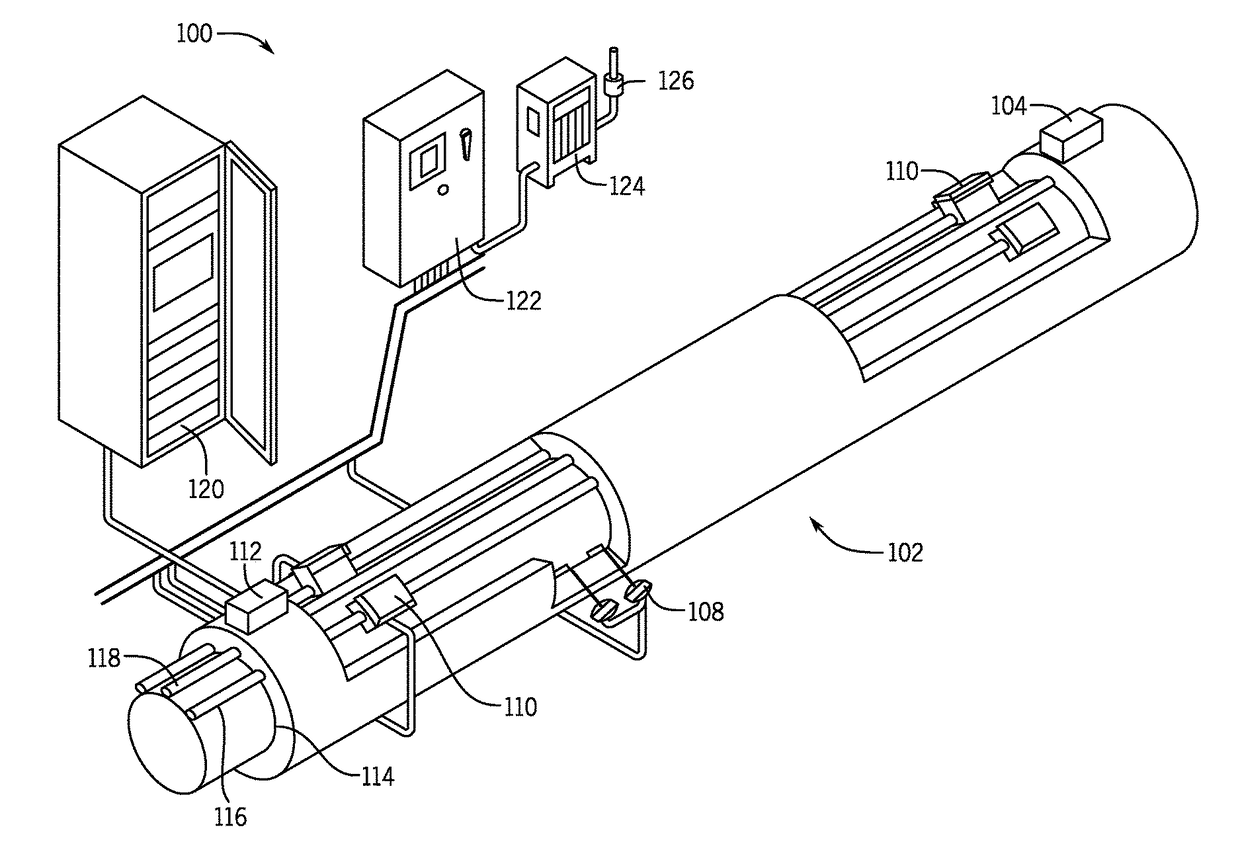

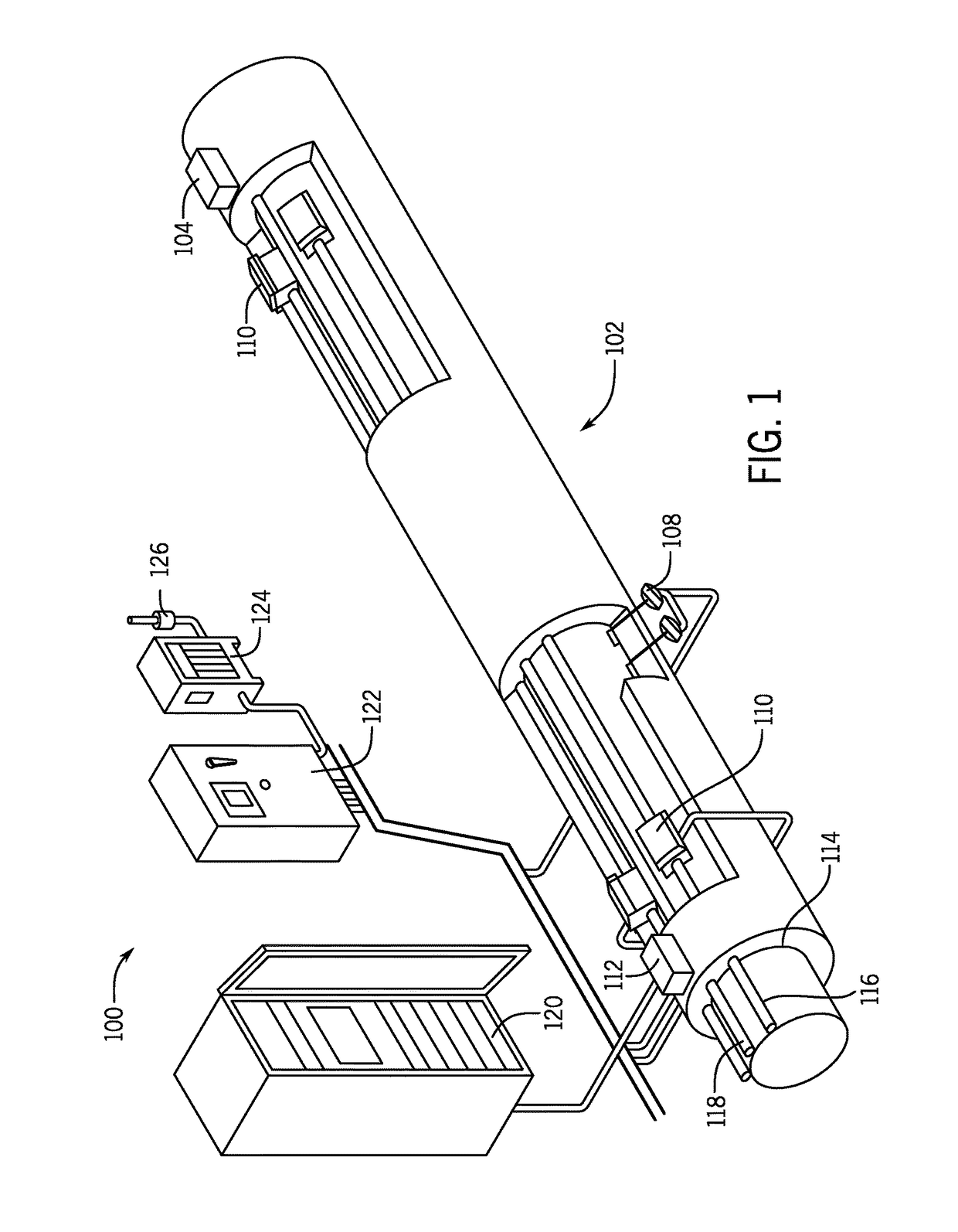

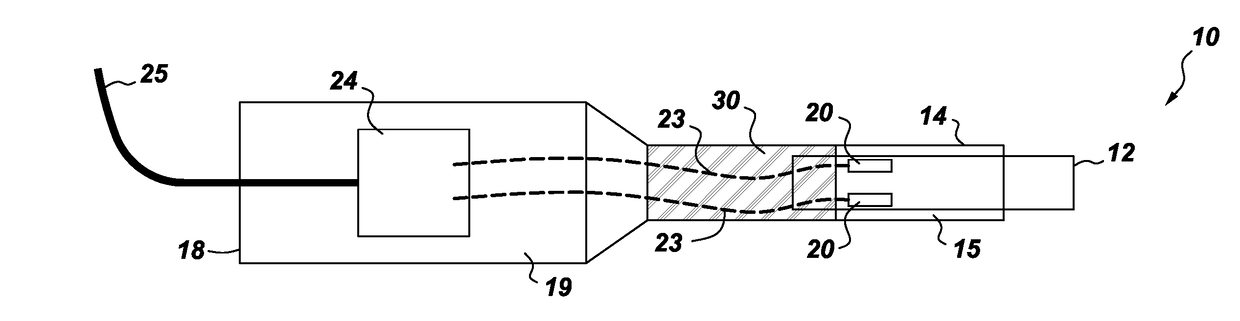

Apparatus, system and sensor housing assembly utilizing fiber optic sensors for enabling monitoring operating conditions within a structural member

ActiveUS9915579B1Simple yet effective and reliableArtificial islandsSurveyEngineeringOperant conditioning

Embodiments of the present invention provide a unique new approach to generating operating condition information used for assessing flow assurance and structural integrity. More specifically, apparatuses, systems and sensor housing assemblies configured in accordance with embodiments of the present invention utilize fiber optic sensors for enabling monitoring of operating condition information within one or more elongated tubular members. To this end, such fiber optic sensors are strategically placed at a plurality of locations along a length of each elongated tubular member thereby allowing critical operating conditions such as strain, temperature and pressure of the elongated tubular member and / or a fluid therein to be monitored.

Owner:ASTRO TECH GRP LLC

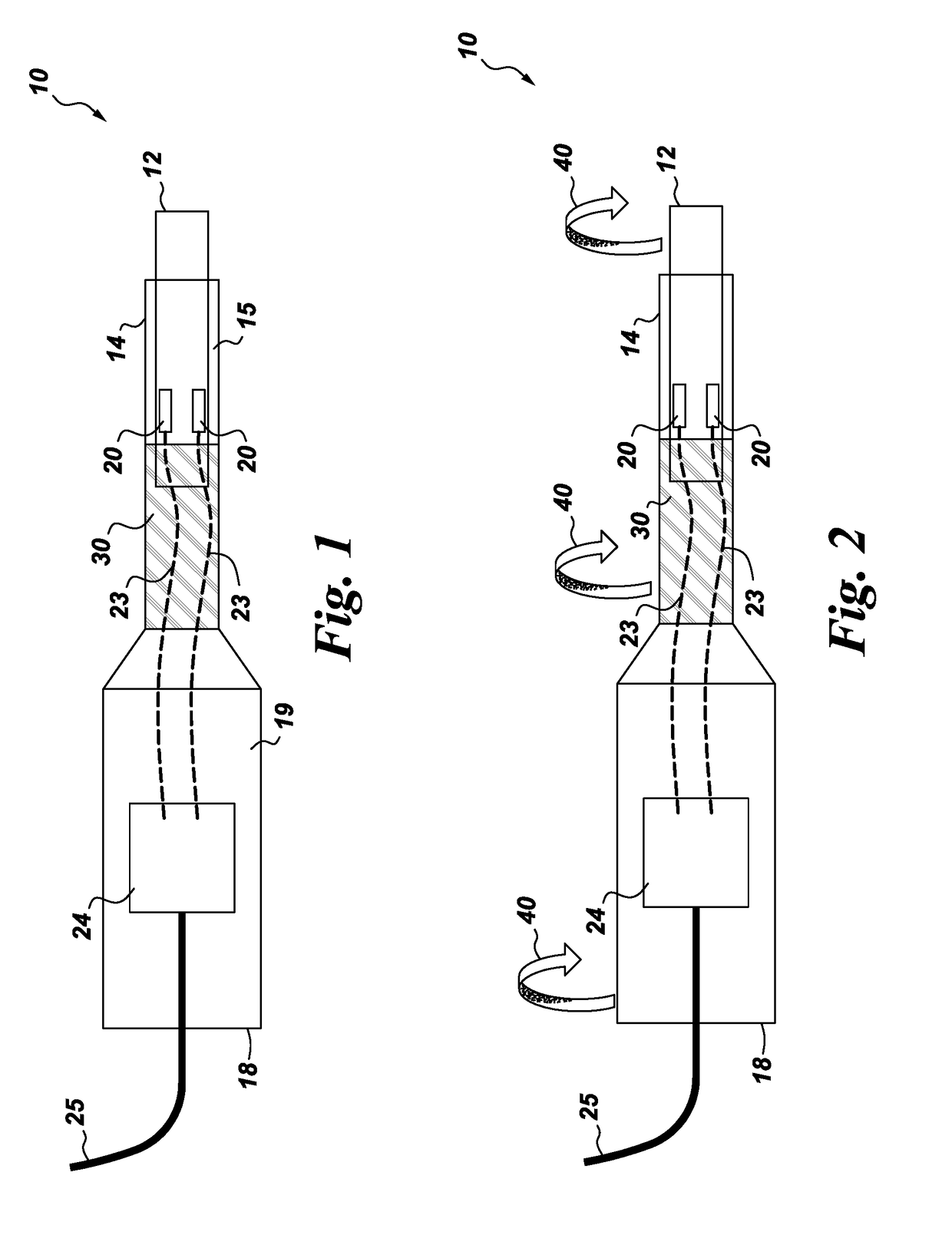

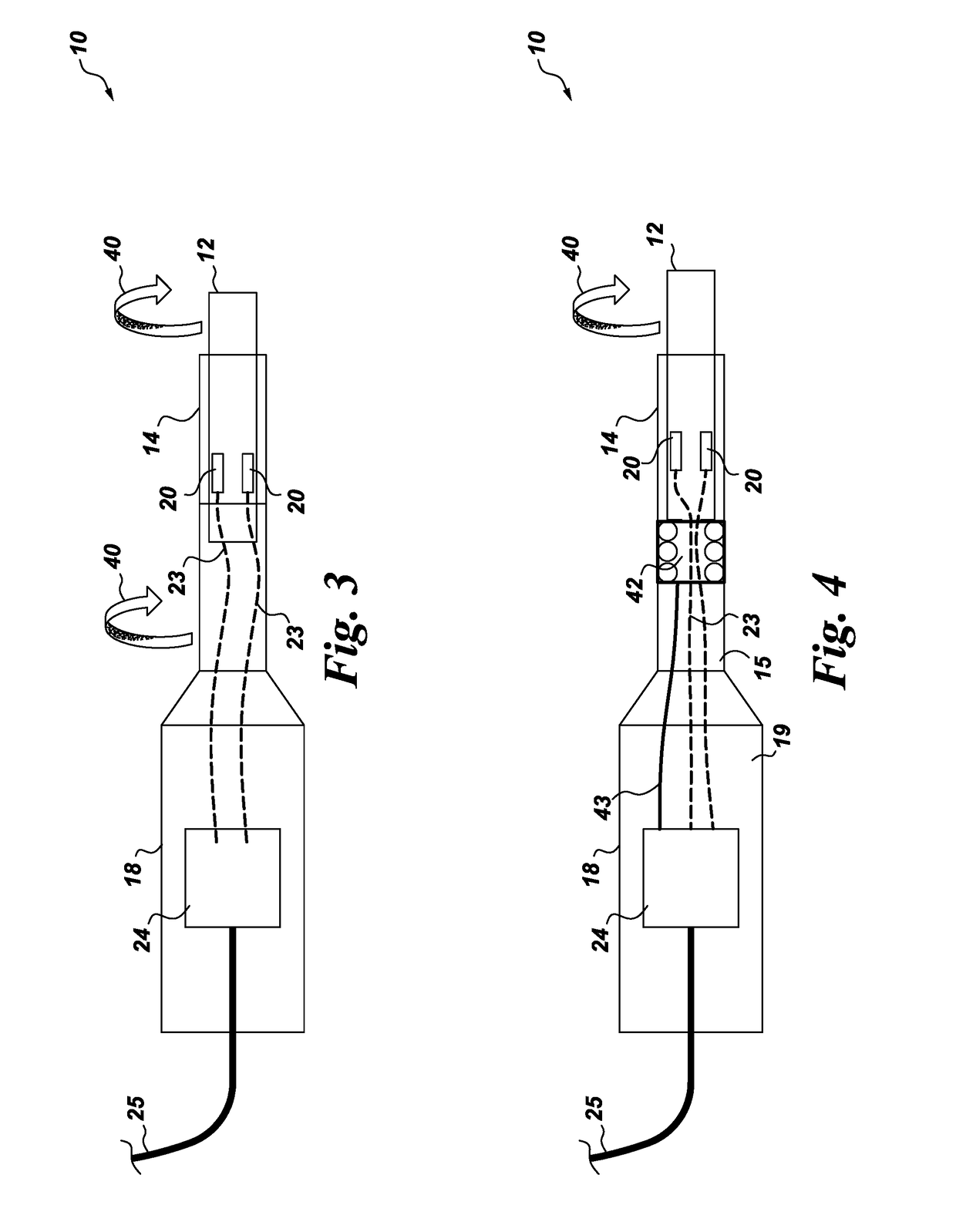

Flow angle probe

InactiveUS20160356805A1Indication/recording movementConverting sensor output electrically/magneticallyCatheterEngineering

A flow angle probe is provided comprising: (a) a probe vane configured to contact a moving fluid within a fluid conduit; (b) an optional probe mounting mechanically coupled to the probe vane; (c) a rotary shaft coupled either to the optional probe mounting or the probe vane; (d) a rotary encoder coupled to the rotary shaft; (e) a sensor hermetically isolated from the probe vane and configured to sense a change in position of the rotary encoder; and (f) a probe housing encompassing at least a portion of the rotary shaft, the rotary encoder and the sensor. The novel flow angle probes disclosed herein may be used in a wide variety of turbomachines and fluid processing systems, and applications, including turbomachine design and operational control, as well as in flow assurance.

Owner:VETCO GRAY SCANDINAVIA

Method and apparatus for flow assurance management in subsea single production flowline

Managing hydrates in a subsea includes a host production facility, a production cluster comprising one or more producers, a water injection cluster comprising one or more water injectors, a water injection line, and a single production line for directing production fluid from the one or more producers to the host production facility. The methods comprise placing a pig in the subsea production system, shutting in production from the producers, and injecting a displacement fluid into the subsea production system in order to displace the hydrate inhibitor and any remaining production fluids in the production flowline and to further move the pig through the production flowline. The method may also include further injecting displacement fluid into the subsea production system in order to displace the hydrate inhibitor and pig through the single production line and to the host production facility.

Owner:EXXONMOBIL UPSTREAM RES CO

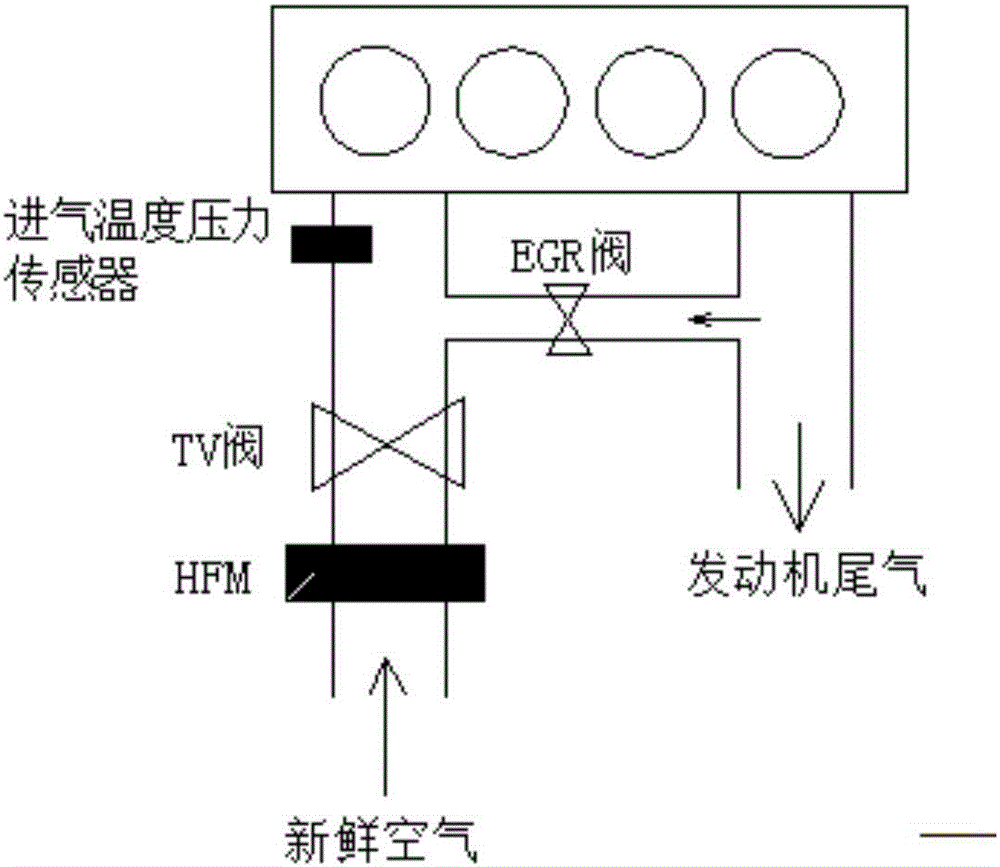

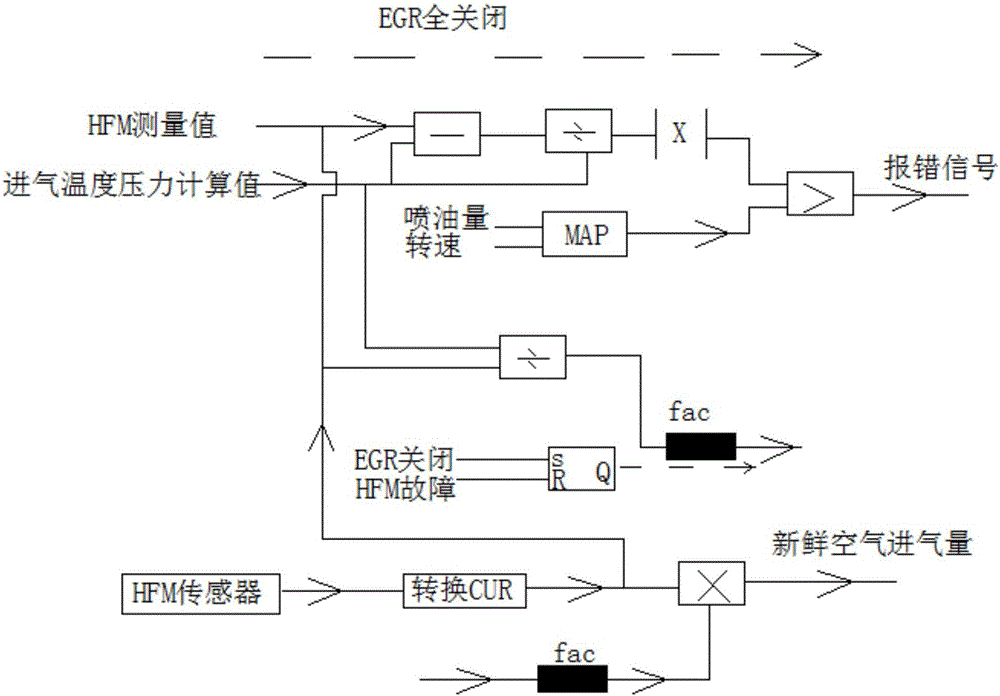

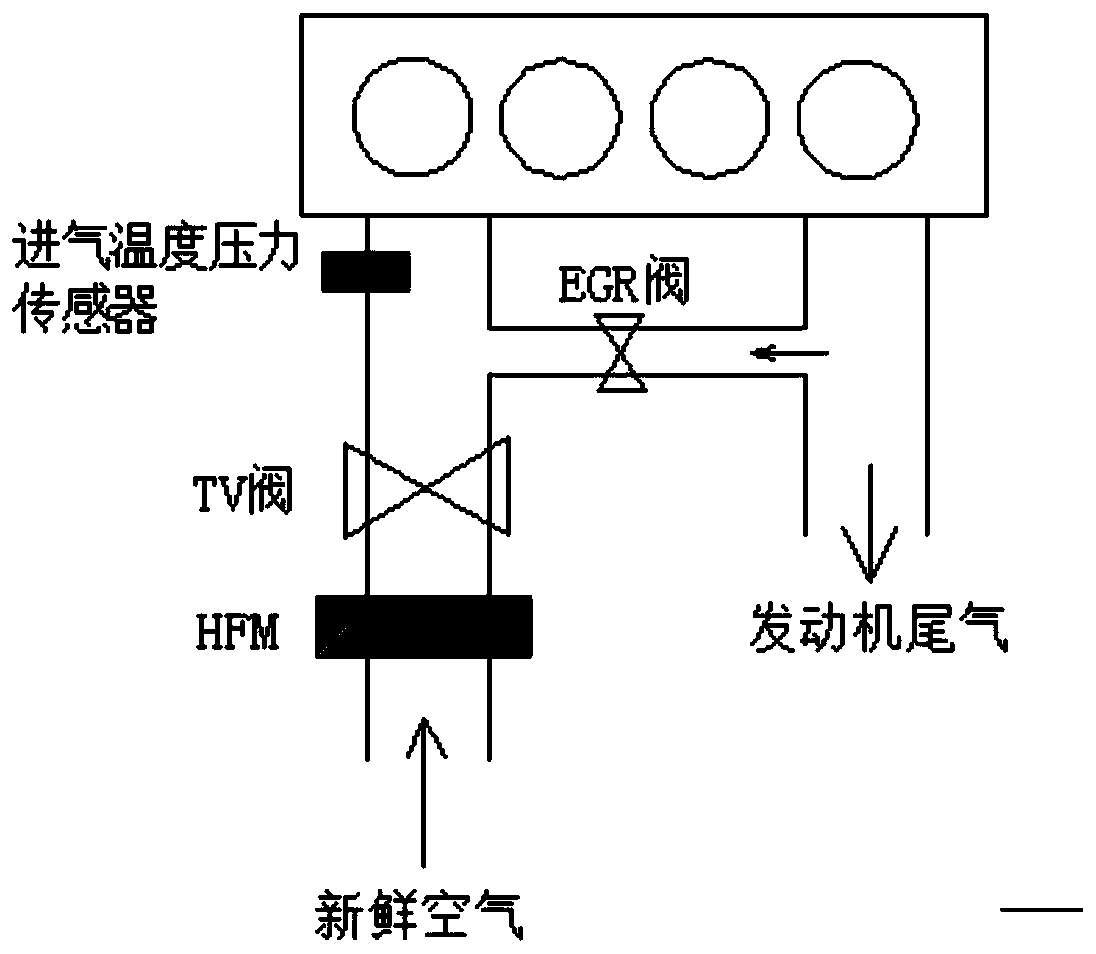

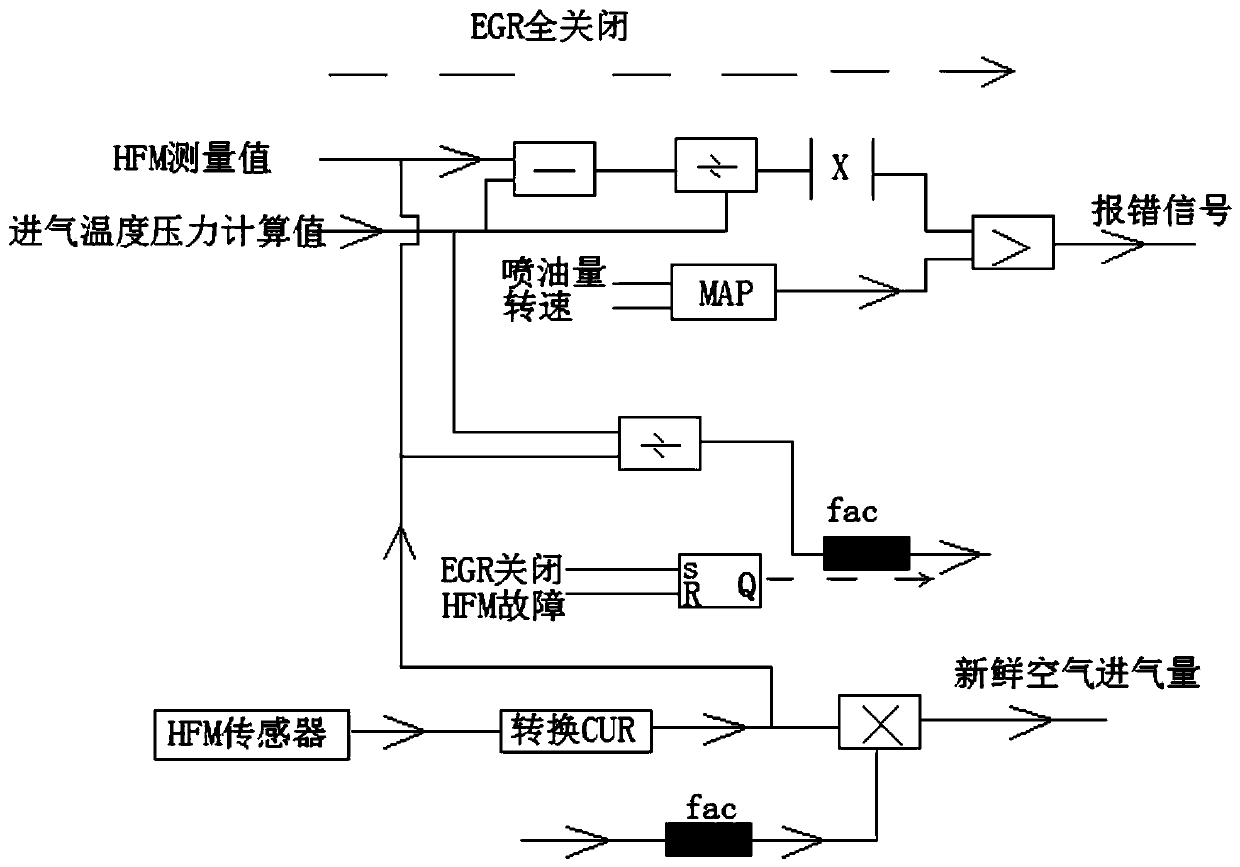

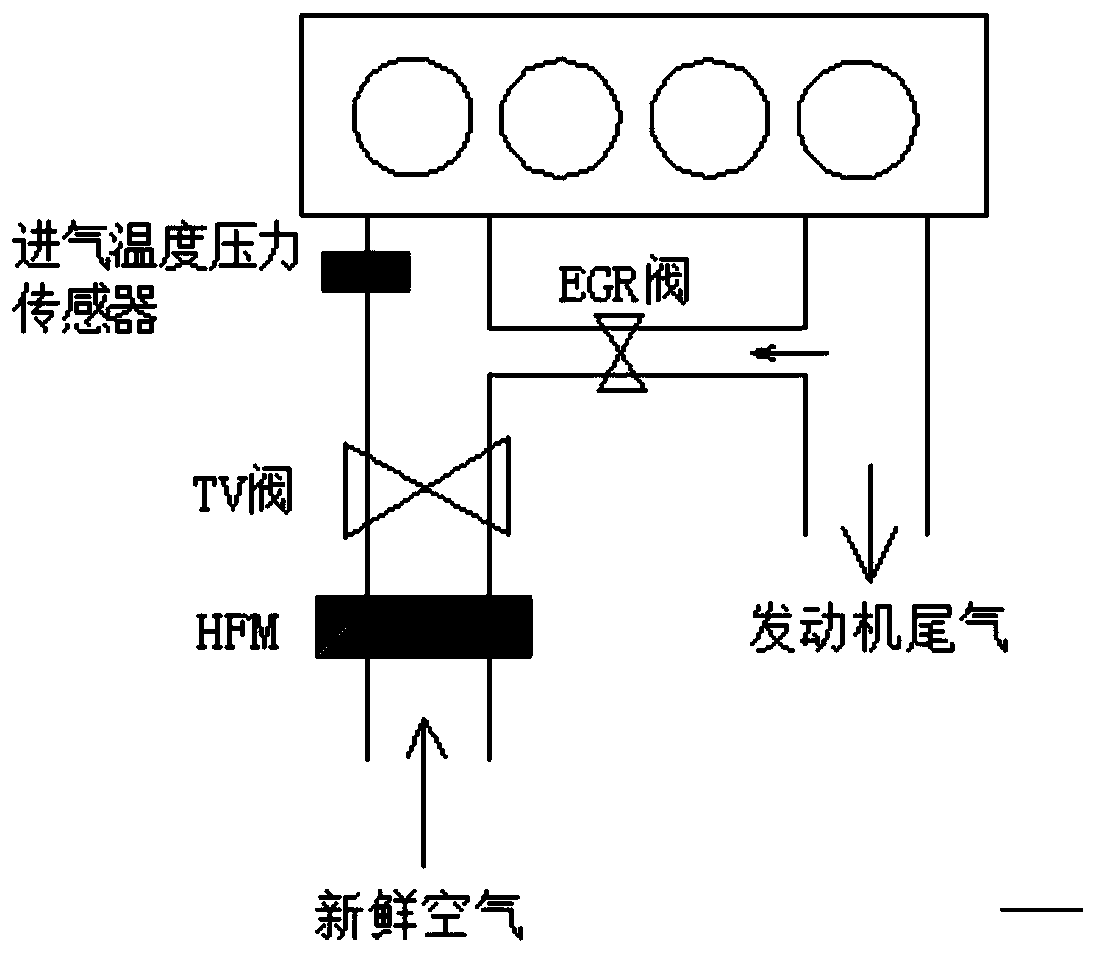

System and method for diagnosing engine air inflow measuring accuracy of HFM

The invention discloses a system and method for diagnosing the engine air inflow measuring accuracy of an HFM. The problem that currently, matched equipment or a corresponding method for diagnosing the air measuring accuracy of the HFM on a large commercial engine is not available is solved. The system and method can diagnose whether the air inflow measured by the HFM is accurate or not, and thus correct air flow assurance is provided for subsequent intra-cylinder fuel injection and for subsequent diesel engine post-treatment urea injection. According to the technical scheme, the system comprises an air flow meter and an air inlet pressure temperature sensor which are used for measuring the air mass flows entering the engine correspondingly and then sending the air mass flow to a controller, the air mass flows which are detected when an EGR valve is totally closed and entering the engine serve as a first measured value and a second measured value to be stored in the controller, and the controller receives the first measured value and the second measured value and obtains the deviation between the first measured value and the second measured value so as to judge whether the air mass flows, measured by the air flow meter HFM, entering the engine drift or not.

Owner:SHANDONG UNIV

A predictive flow assurance assessment method and system

ActiveUS20160186533A1Overcome limitationsElectric/magnetic detection for well-loggingCleaning apparatusEngineeringControl parameters

A system and method for predictive flow assurance assessment by measuring at least one actual parameter related to a multiphase fluid mixture flowing in a main flow line, taking a sample from the multiphase fluid mixture flowing in the main flow line, modifying at least one control parameter of the sample until a transition appears, wherein said transition would cause a flow issue when occurring in the main flow line, detecting the transition of the sample and determining a corresponding transition value associated with the at least one control parameter, calculating a difference between the at least one actual parameter and the at least one transition value, said difference being representative of a margin relatively to a similar transition appearance in the main flow line causing a flow issue in the main flow line, and implementing a flow issue preventing step when the difference exceeds a given threshold.

Owner:OPENFIELD

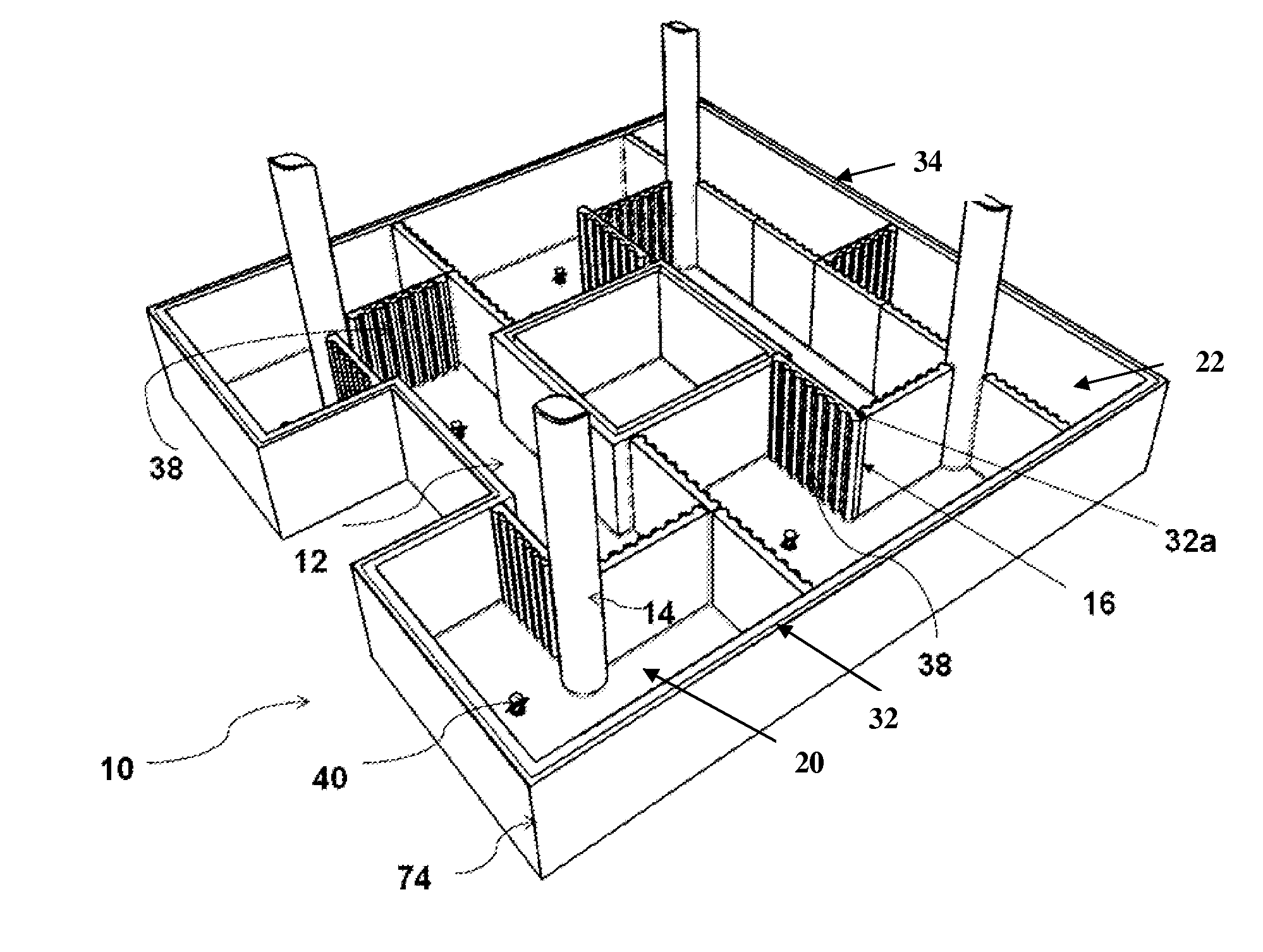

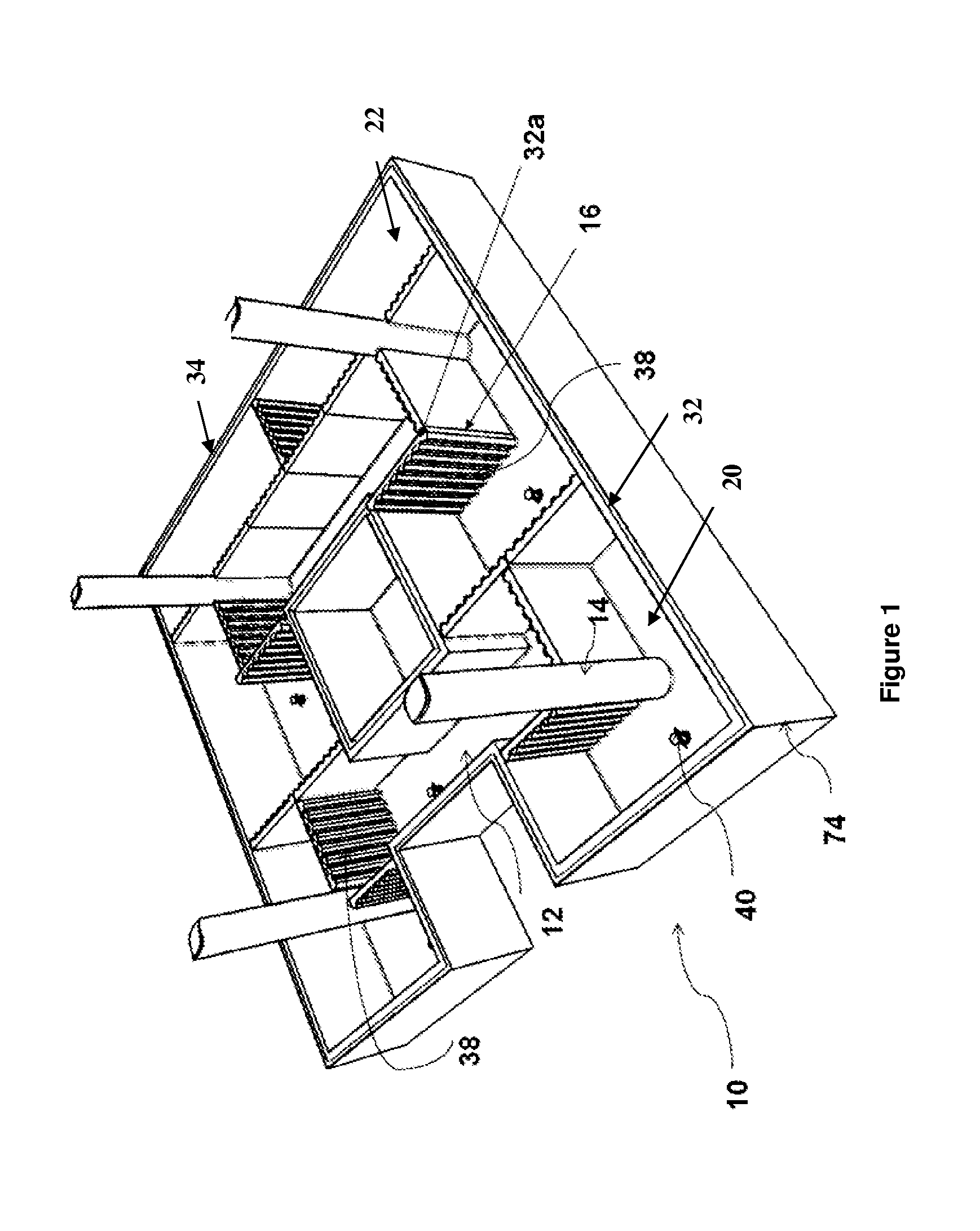

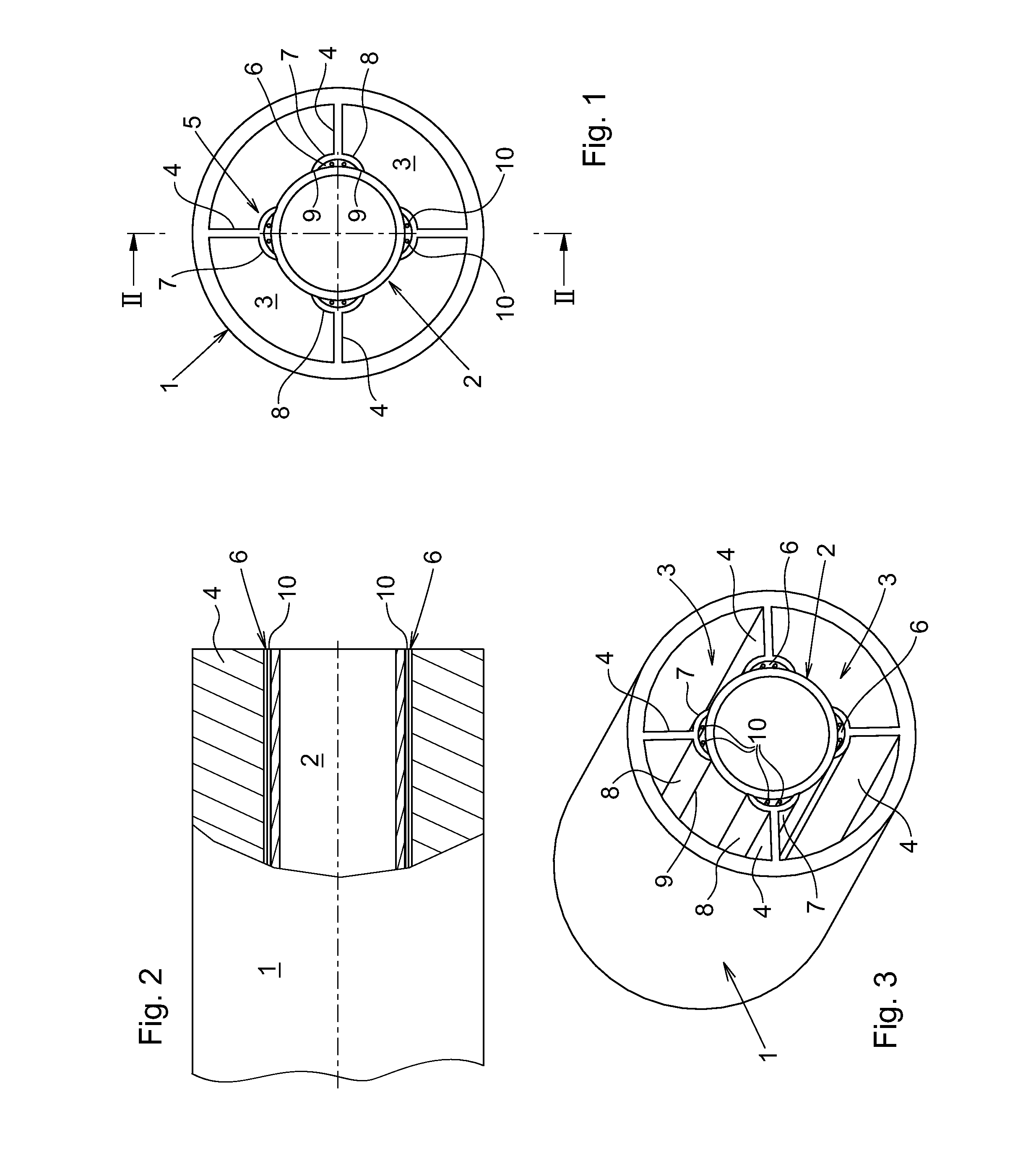

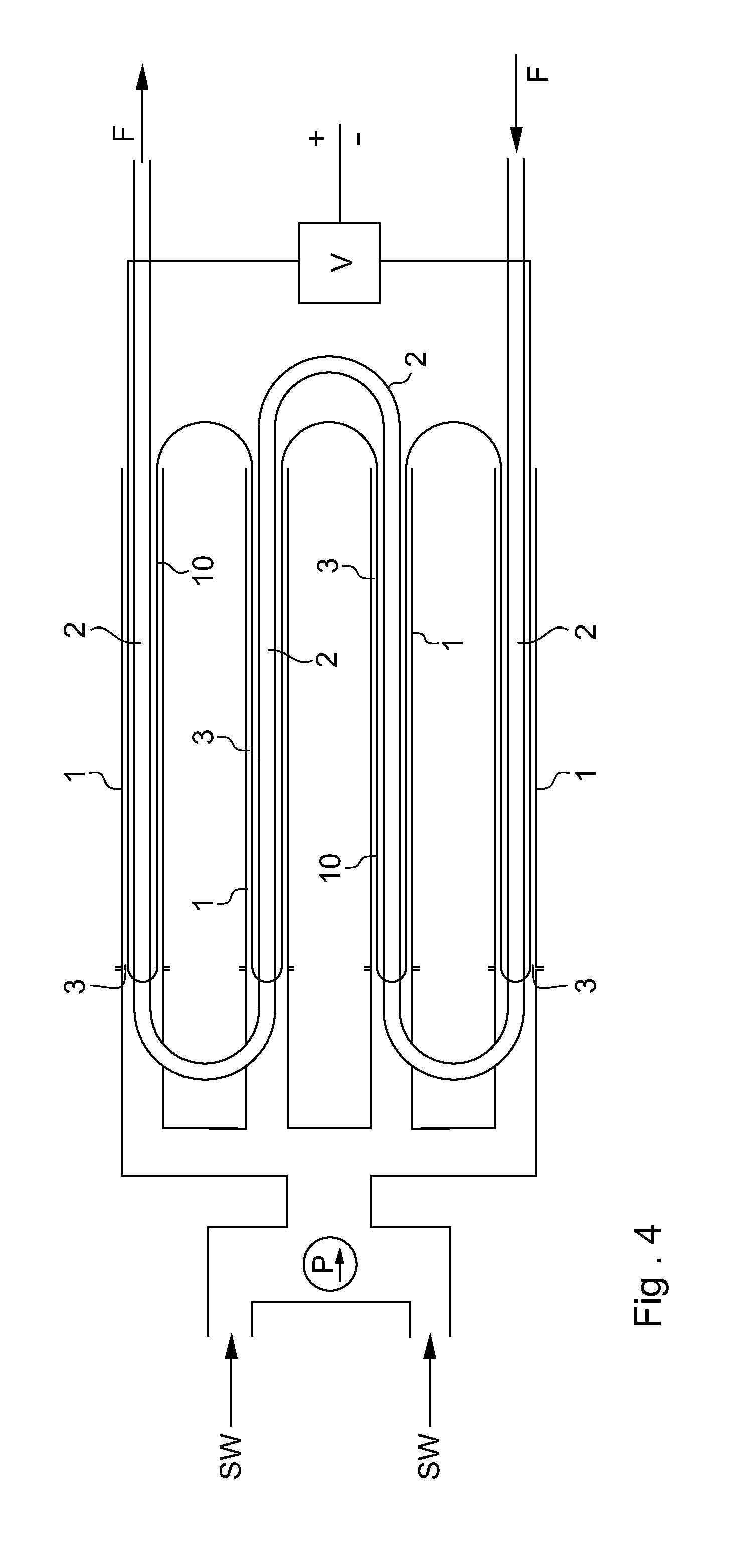

Pipe assembly and flow assurance system

InactiveUS20140270739A1Improve sealingReduce riskPipe supportsValve members for heating/coolingEngineeringTunnel wall

A pipe assembly comprising an outer pipe in surrounding relation about an inner pipe, wherein the inner pipe is suspended in free inner ends of legs extended in an annular space that is formed between the outer and inner pipes, the legs reaching radially towards the inner pipe from an inner periphery of the outer pipe. At least one of the legs carries in its inner end a support foot that is formed with a recess facing towards the inner pipe. The recess forms a tunnel that is defined through an outer periphery of the inner pipe and opposite tunnel walls that reach from the leg to the inner pipe.

Owner:VETCO GRAY SCANDINAVIA

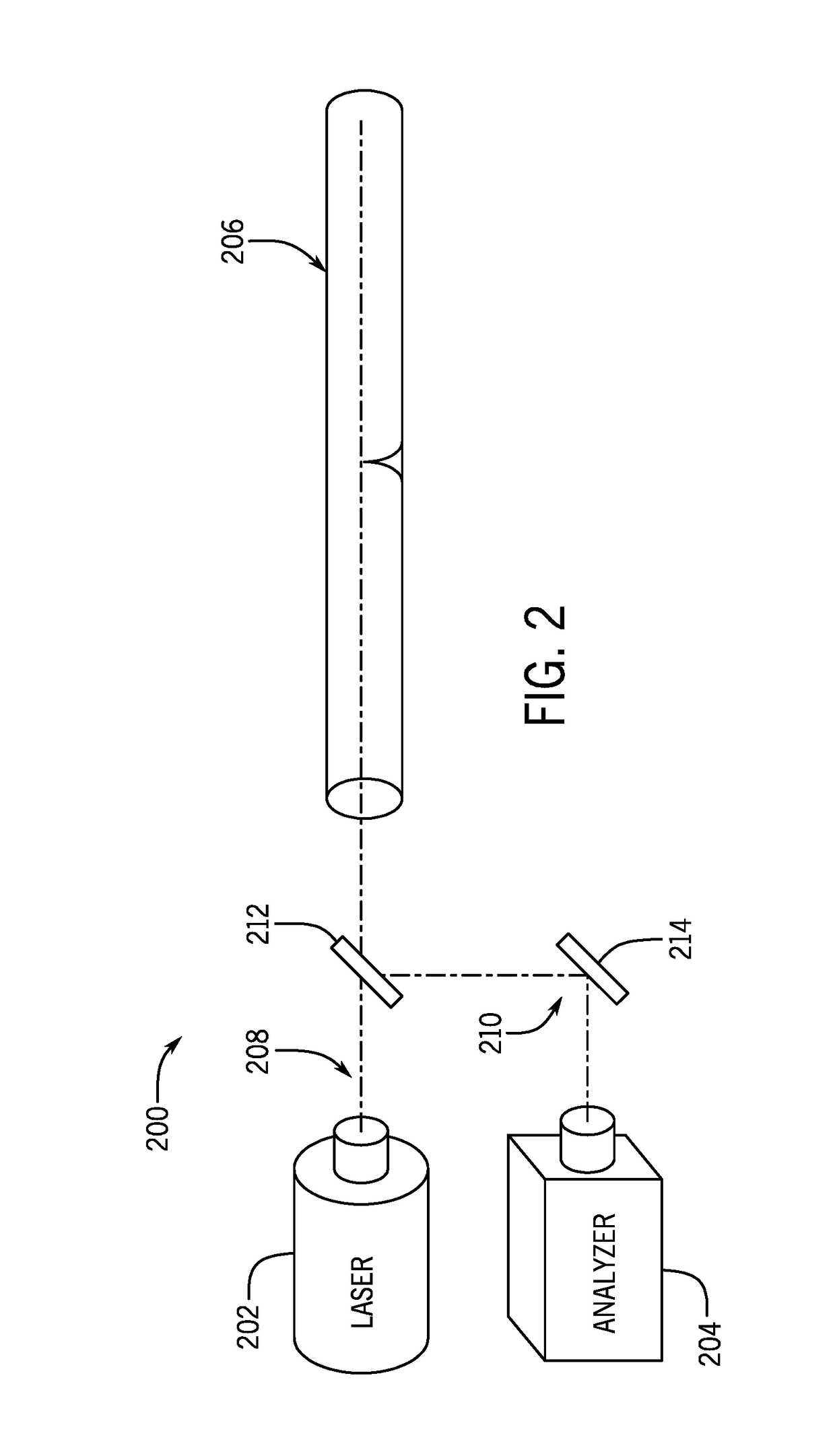

Automated Re-Melt Control Systems

A system may automatically control a pipeline heating system to maintain a desired temperature and / or to provide flow assurance of process fluid along a pipeline. The system may identify the occurrence and location of the solidification of a given process fluid or the melting of the given process fluid by monitoring temperatures along the pipeline and identifying from the monitored temperatures the occurrence and location of a latent heat signature associated with the solidification or melting of the given process fluid. The system may determine a distribution of solidified process fluid along the pipeline. The system may determine the percentage of a given section of pipeline that is filled with solid and / or liquid process fluid on a meter-by-meter basis. The system may perform automated re-melt operations to resolve plugs of solidified process fluid that may occur in the pipeline.

Owner:NVENT SERVICES GMBH

Automated re-melt control systems

A system may automatically control a pipeline heating system to maintain a desired temperature and / or to provide flow assurance of process fluid along a pipeline. The system may identify the occurrence and location of the solidification of a given process fluid or the melting of the given process fluid by monitoring temperatures along the pipeline and identifying from the monitored temperatures the occurrence and location of a latent heat signature associated with the solidification or melting of the given process fluid. The system may determine a distribution of solidified process fluid along the pipeline. The system may determine the percentage of a given section of pipeline that is filled with solid and / or liquid process fluid on a meter-by-meter basis. The system may perform automated re-melt operations to resolve plugs of solidified process fluid that may occur in the pipeline.

Owner:NVENT SERVICES GMBH

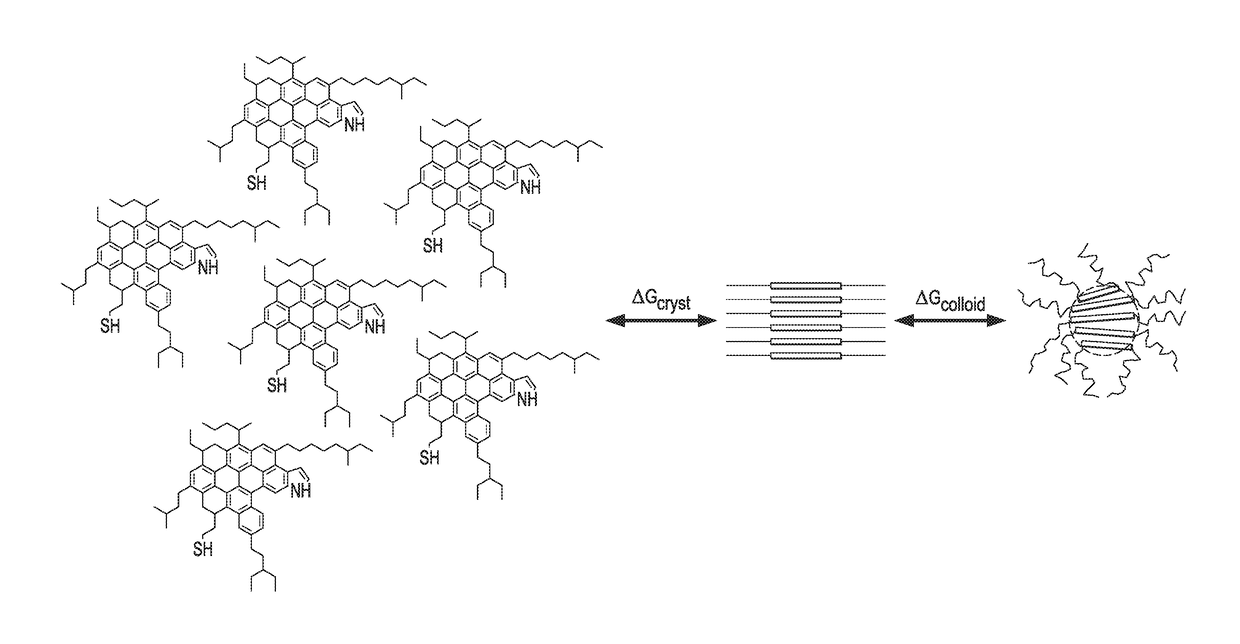

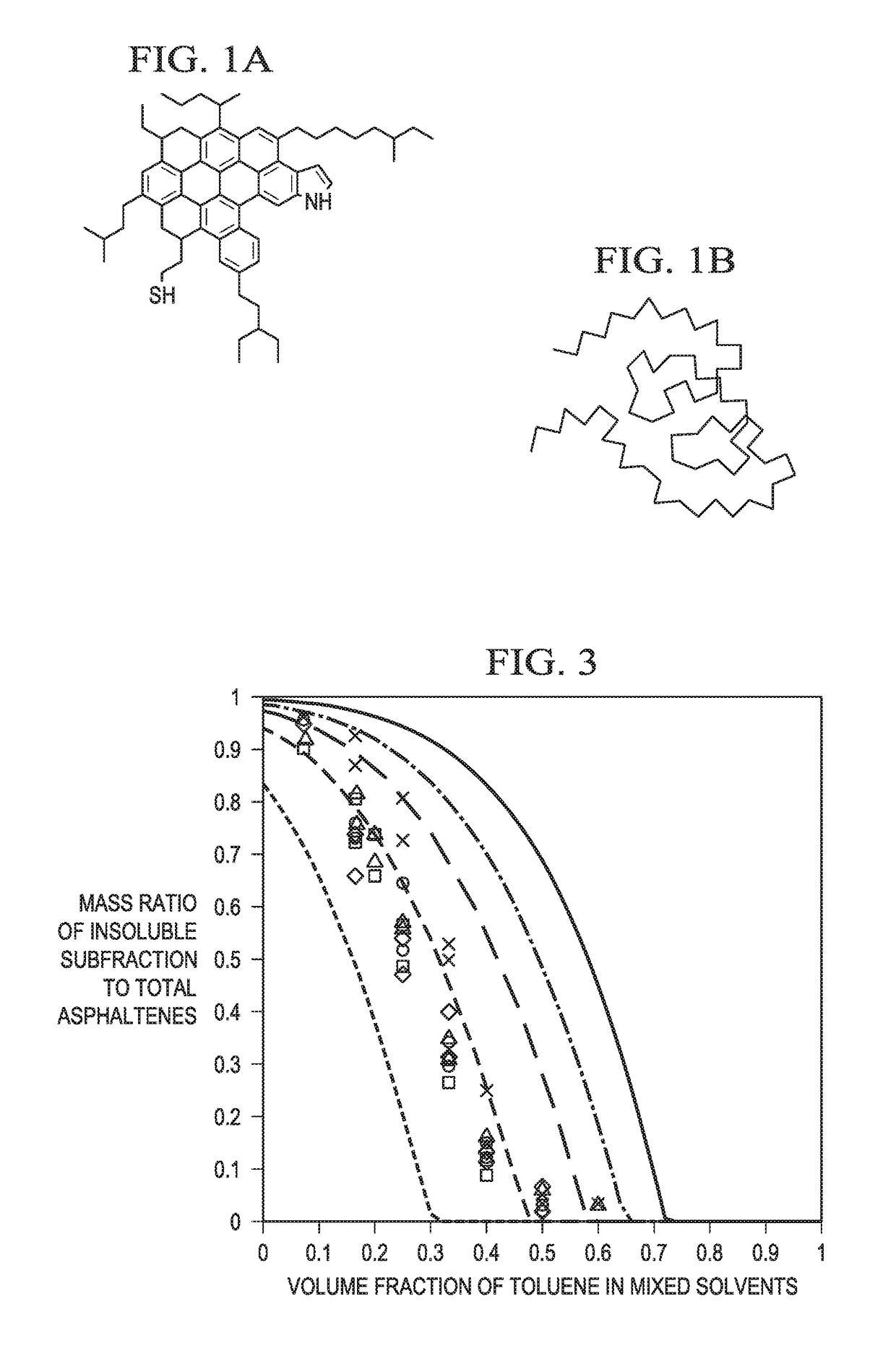

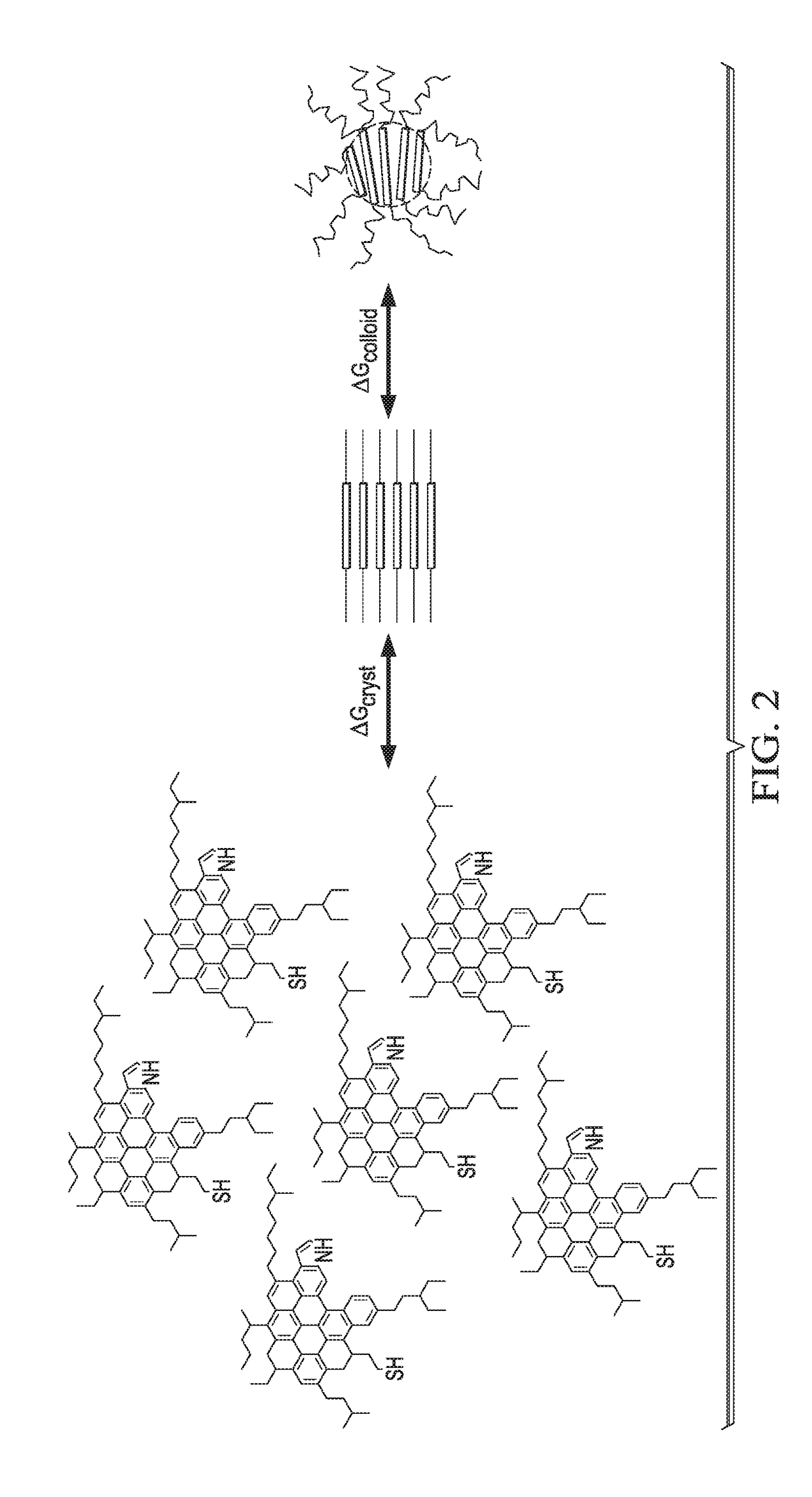

Apparatus and Computerized Method for Predicting Asphaltene Precipitation Based on Aggregation Thermodynamics

ActiveUS20180314806A1Prevent scalingFlow assuranceChemical property predictionCleaning apparatusSolubilityGibbs free energy

The present invention includes a method for thermodynamic modeling of asphaltene precipitation comprising: calculating the Gibbs free energy for the transition between asphaltene molecules in solution into an imaginary crystalline asphaltene nanoaggregates or asphaltene nanocrystals; calculating the Gibbs free energy for the transition between asphaltene nanoaggregates or nanocrystals redissolving into colloidal asphaltene nanoaggregates using the computer: and predicting asphaltene solubility in a solvent, wherein the predicted asphaltene solubility is used to add a solvent to a liquid, semi-solid, or solid comprising aspahaltenes to prevent, e.g., fouling of a wellbore, pipeline, downstream unit operations, to provide flow assurance for crude oil pipeline network, or for petroleum crude blending.

Owner:TEXAS TECH UNIV SYST

Predictive flow assurance assessment method and system

A system and method for predictive flow assurance assessment by measuring at least one actual parameter related to a multiphase fluid mixture flowing in a main flow line, taking a sample from the multiphase fluid mixture flowing in the main flow line, modifying at least one control parameter of the sample until a transition appears, wherein said transition would cause a flow issue when occurring in the main flow line, detecting the transition of the sample and determining a corresponding transition value associated with the at least one control parameter, calculating a difference between the at least one actual parameter and the at least one transition value, said difference being representative of a margin relatively to a similar transition appearance in the main flow line causing a flow issue in the main flow line, and implementing a flow issue preventing step when the difference exceeds a given threshold.

Owner:OPENFIELD

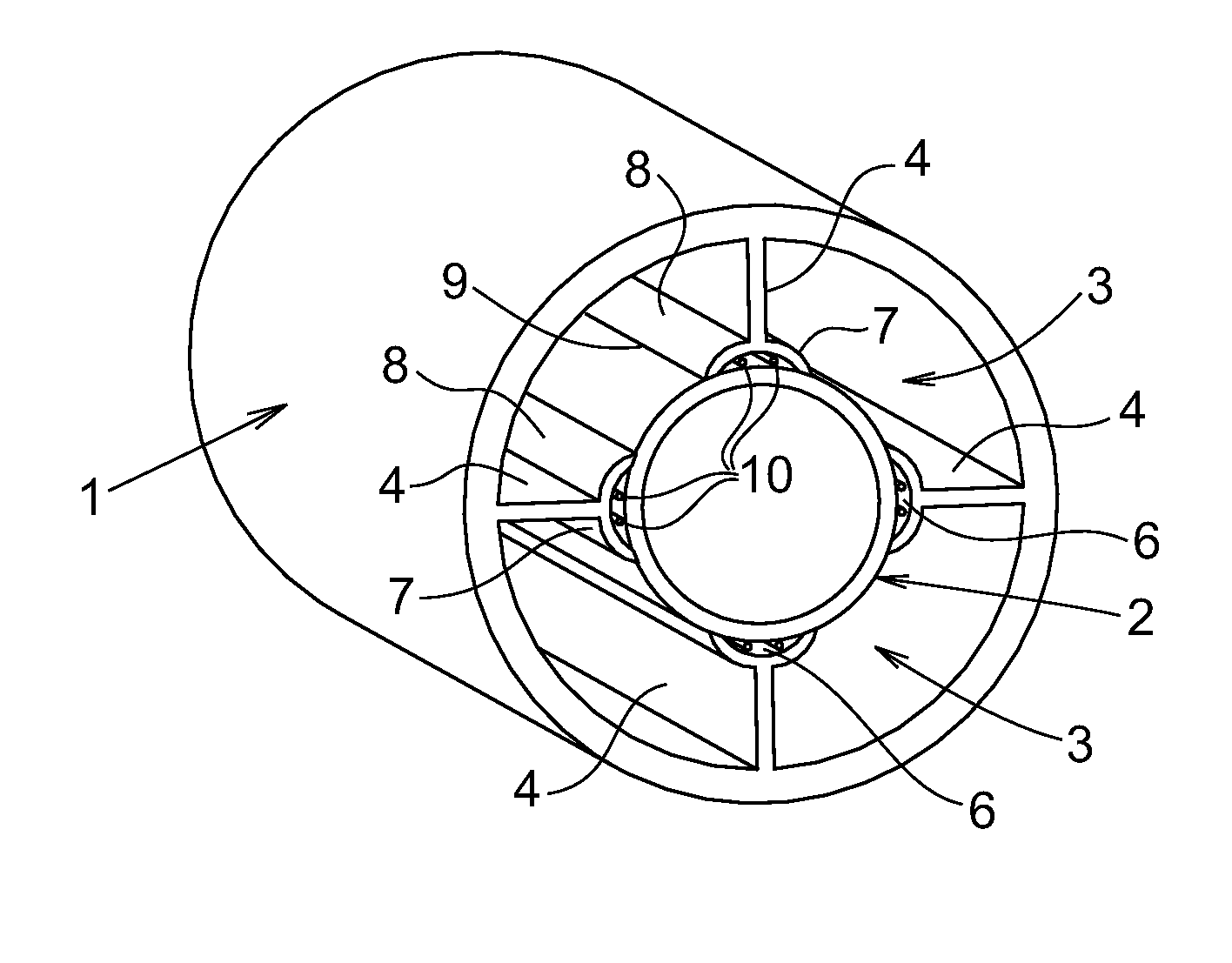

Flow angle probe with a passively rotating vane

InactiveUS9689886B2Indication/recording movementConverting sensor output electrically/magneticallyEngineeringCatheter

A flow angle probe is provided comprising: (a) a probe vane configured to contact a moving fluid within a fluid conduit; (b) an optional probe mounting mechanically coupled to the probe vane; (c) a rotary shaft coupled either to the optional probe mounting or the probe vane; (d) a rotary encoder coupled to the rotary shaft; (e) a sensor hermetically isolated from the probe vane and configured to sense a change in position of the rotary encoder; and (f) a probe housing encompassing at least a portion of the rotary shaft, the rotary encoder and the sensor. The novel flow angle probes disclosed herein may be used in a wide variety of turbomachines and fluid processing systems, and applications, including turbomachine design and operational control, as well as in flow assurance.

Owner:VETCO GRAY SCANDINAVIA

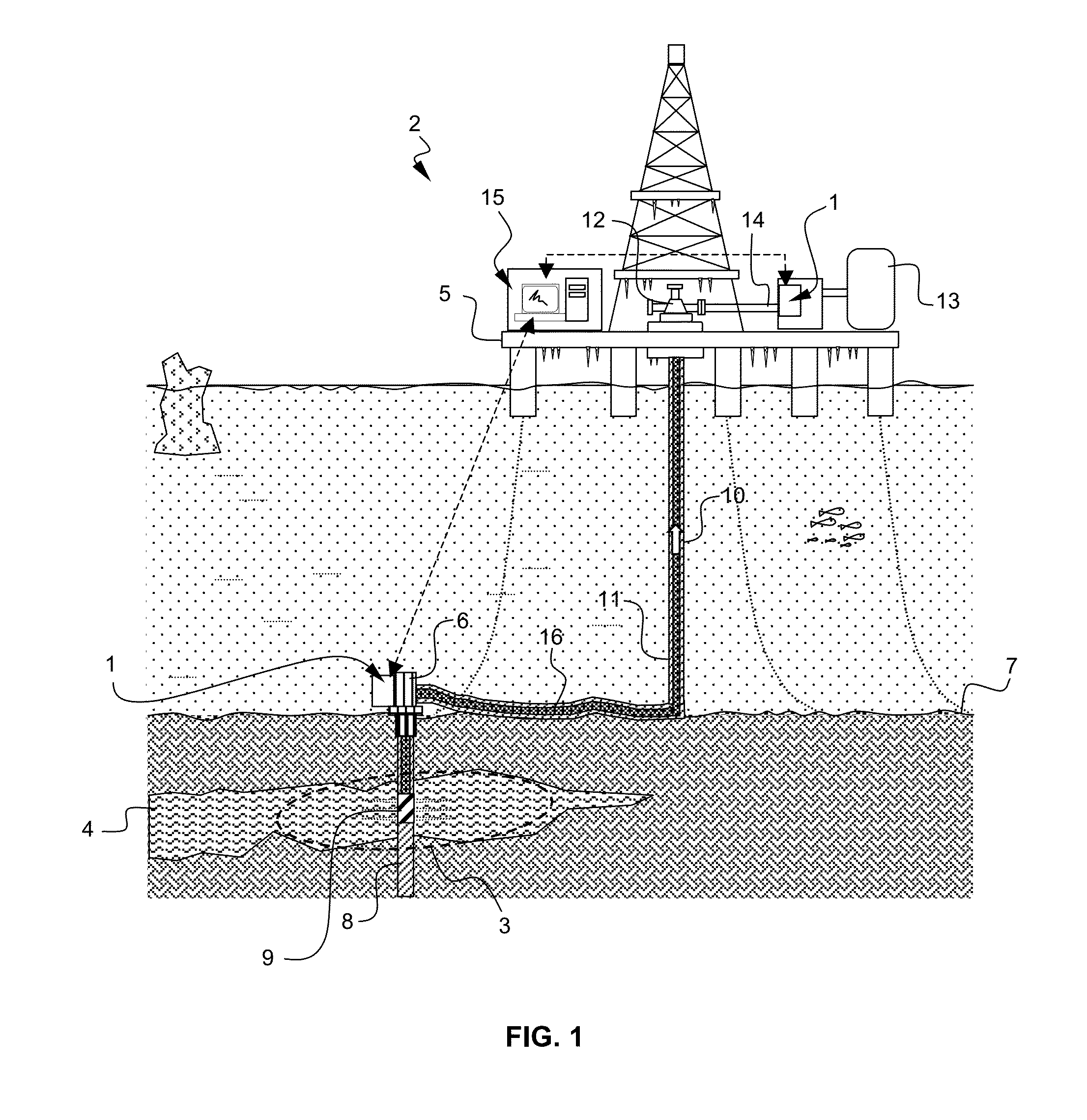

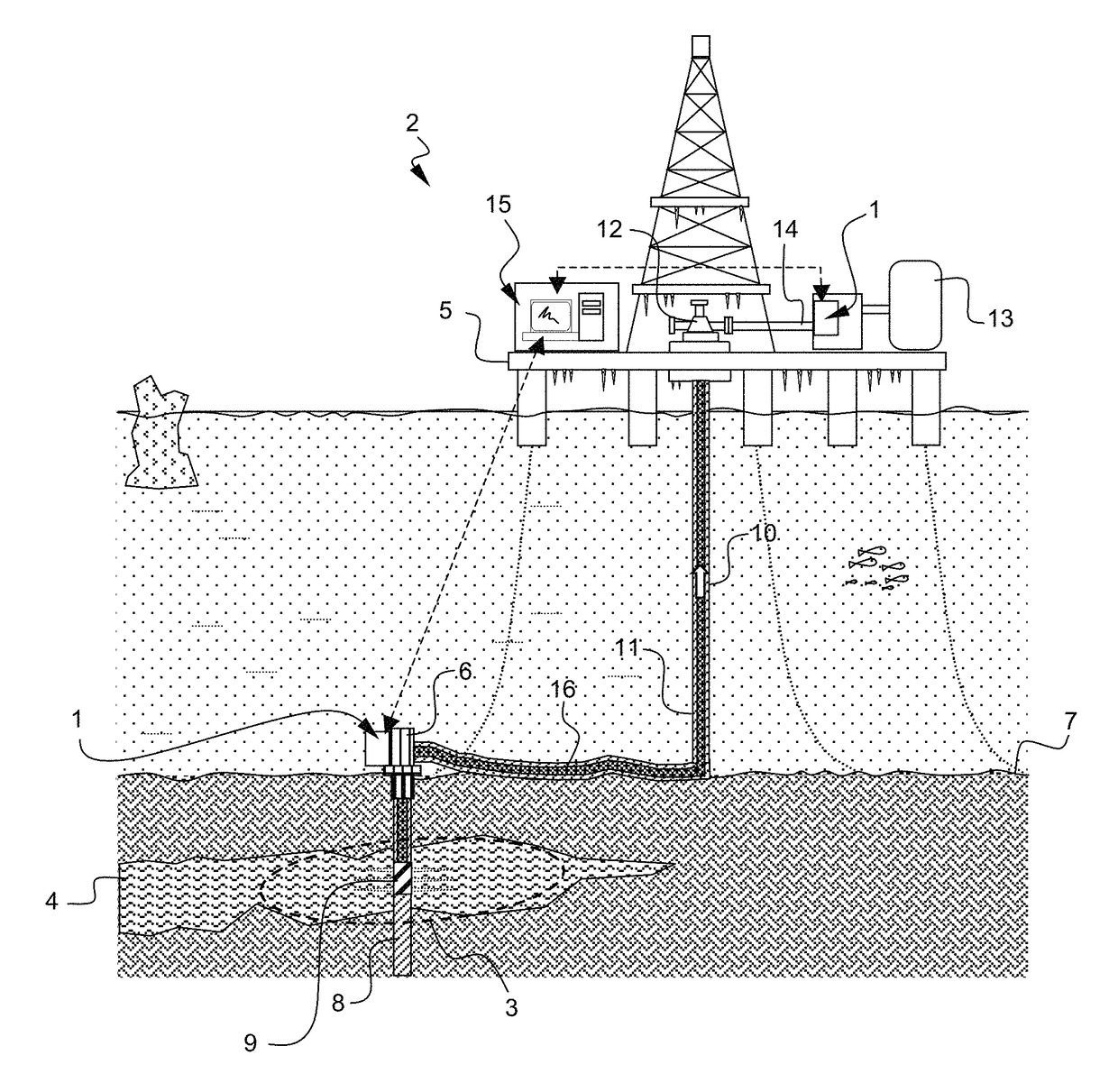

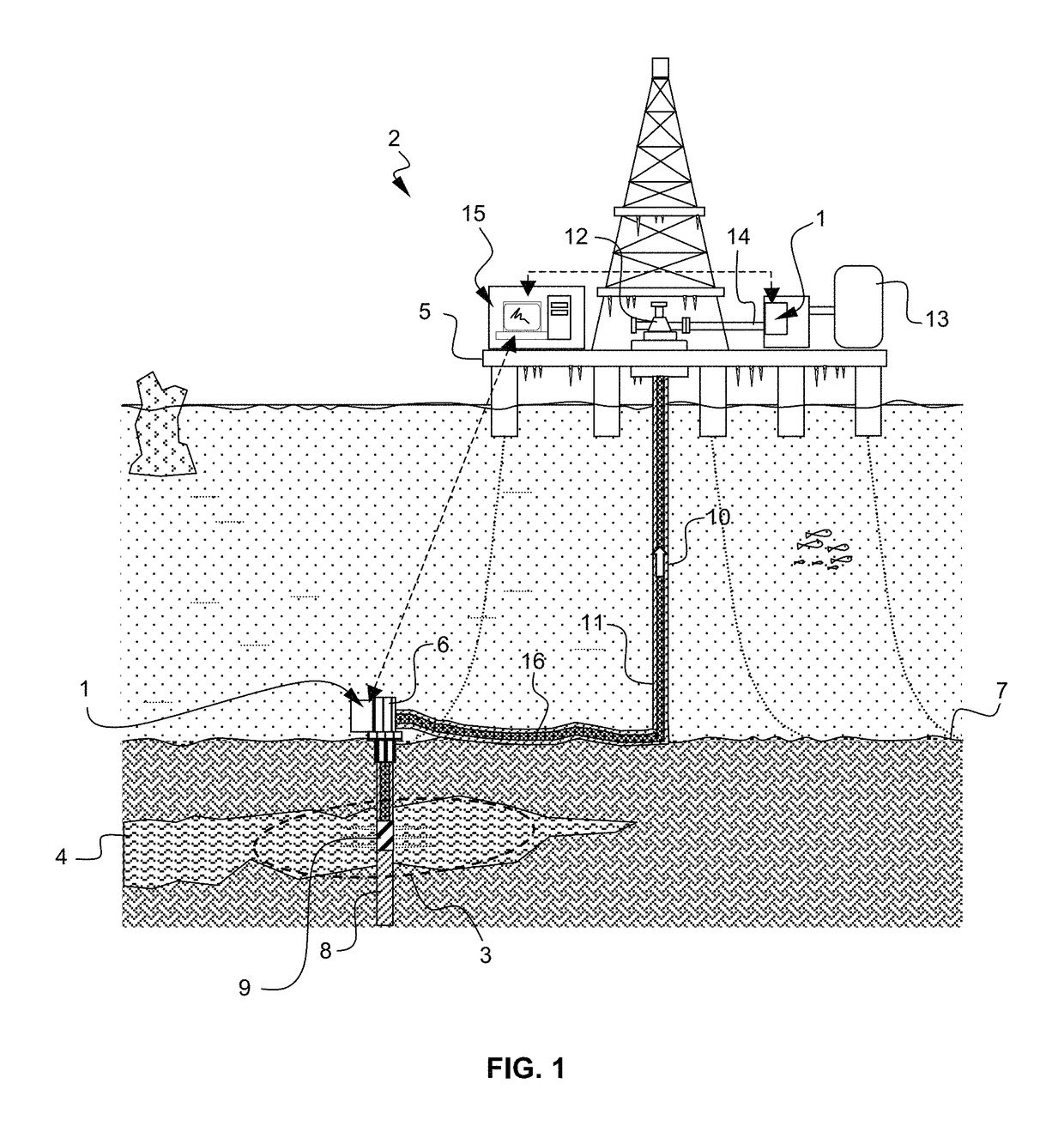

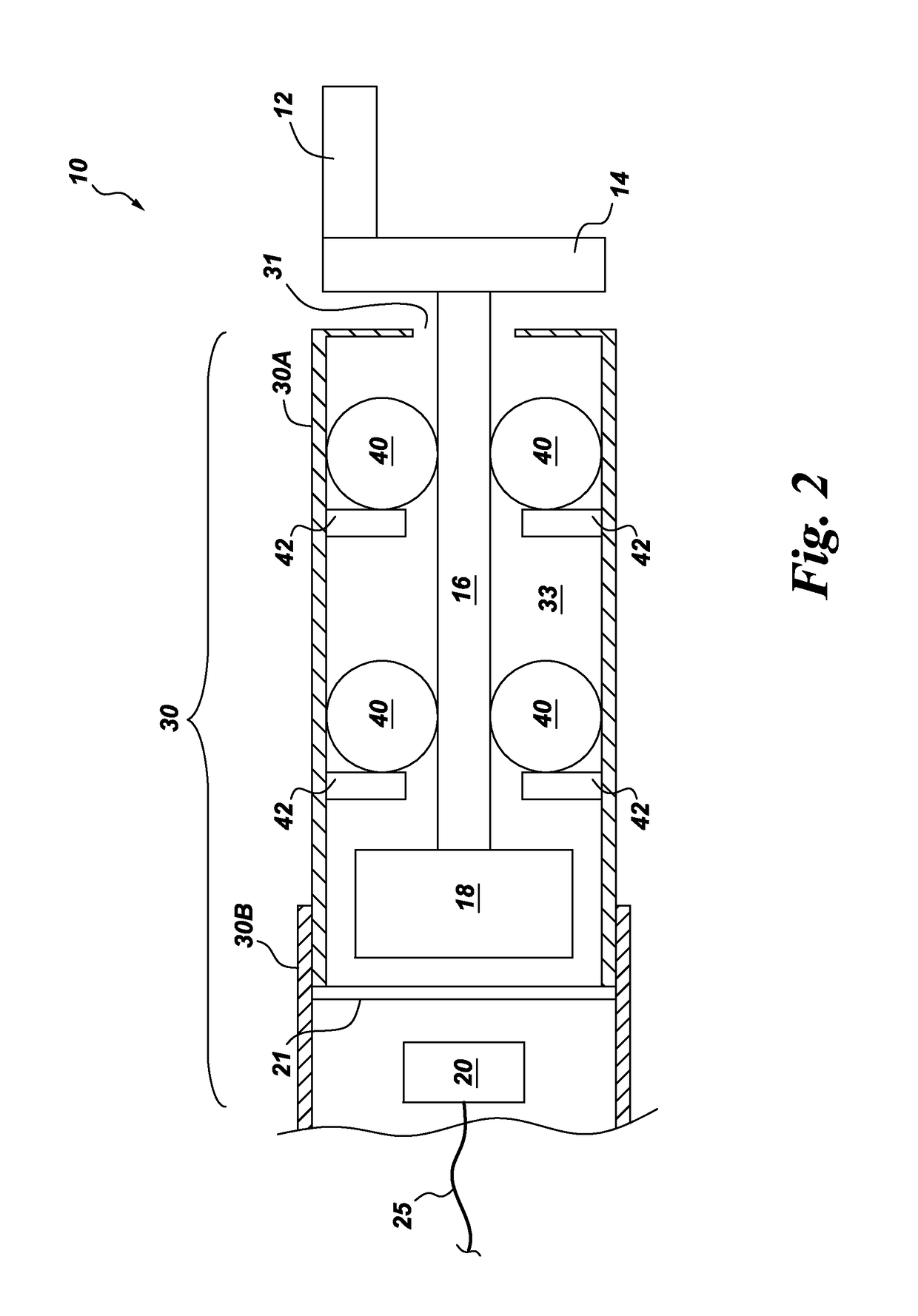

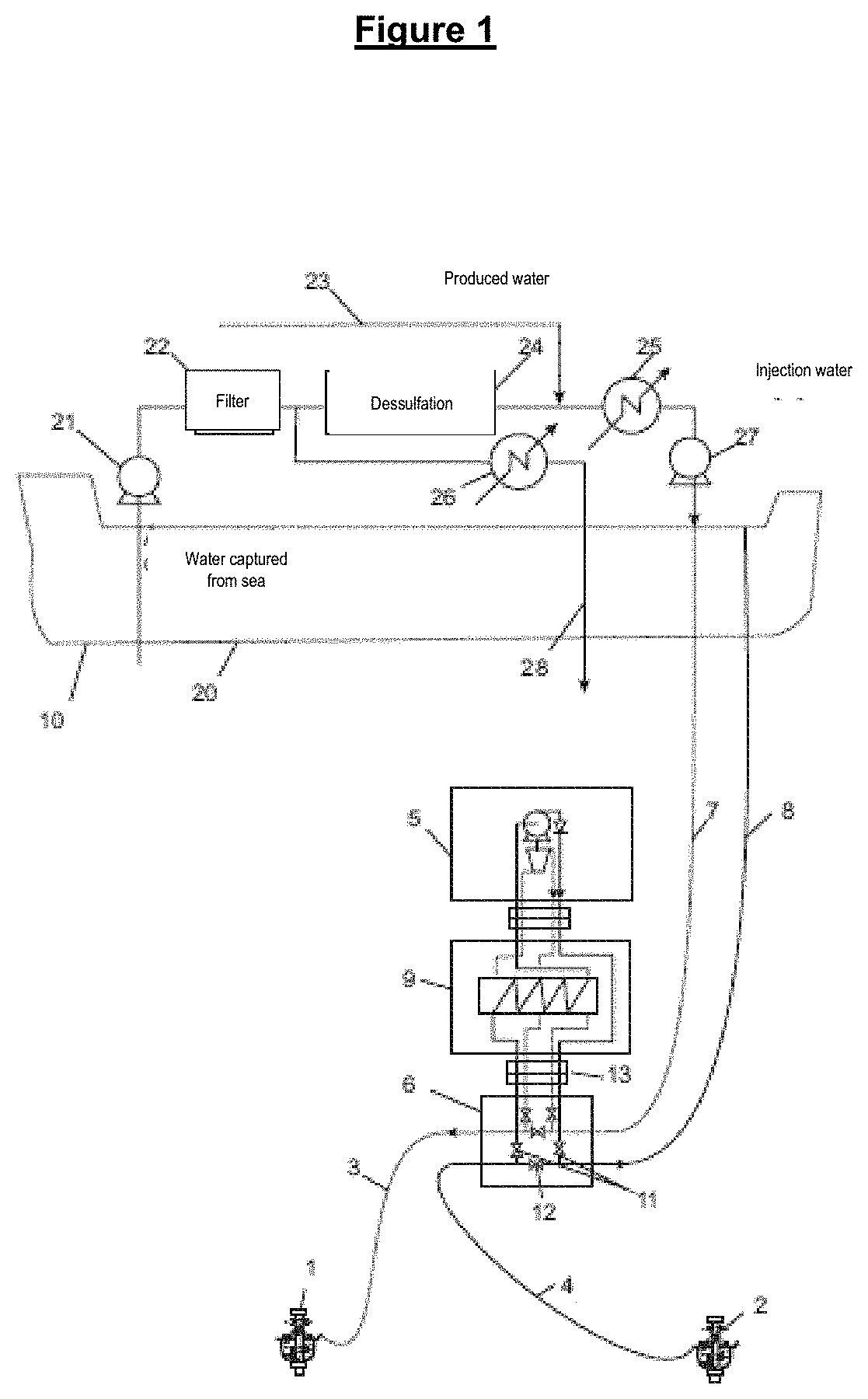

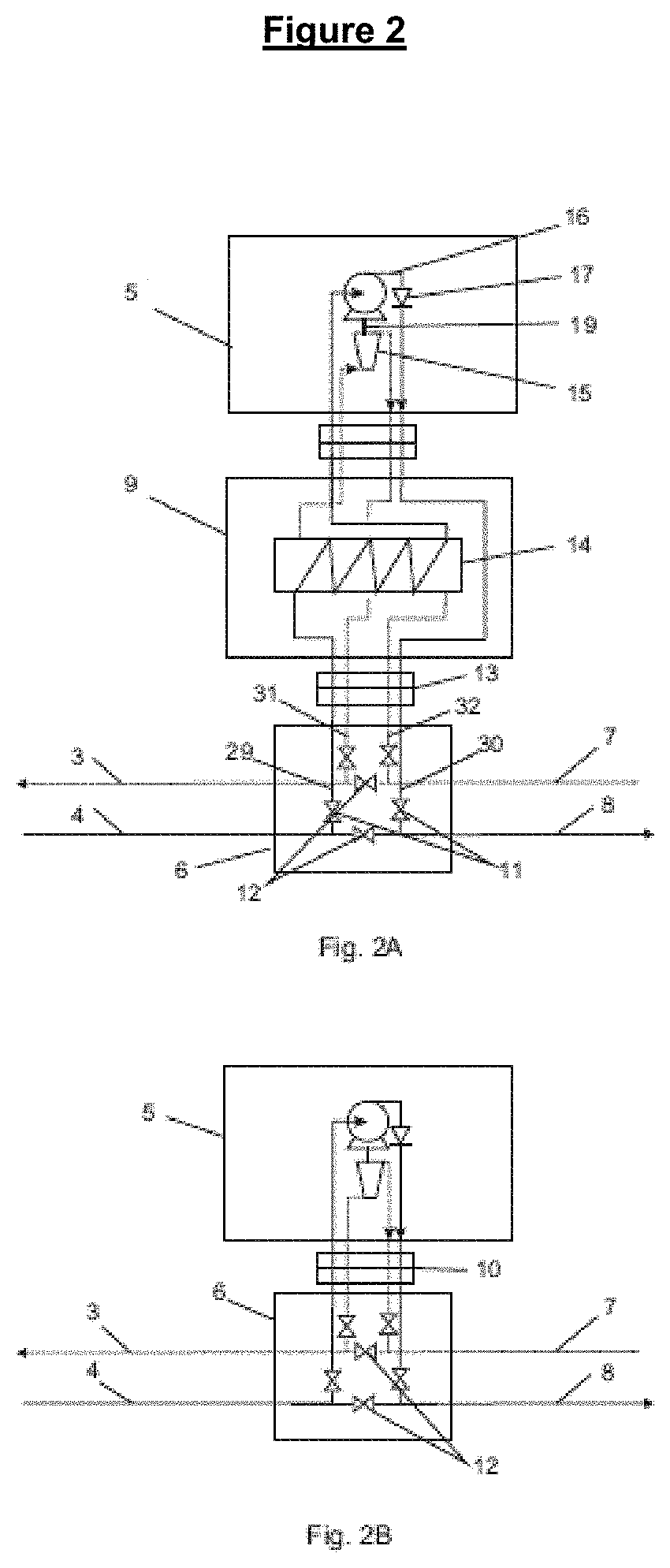

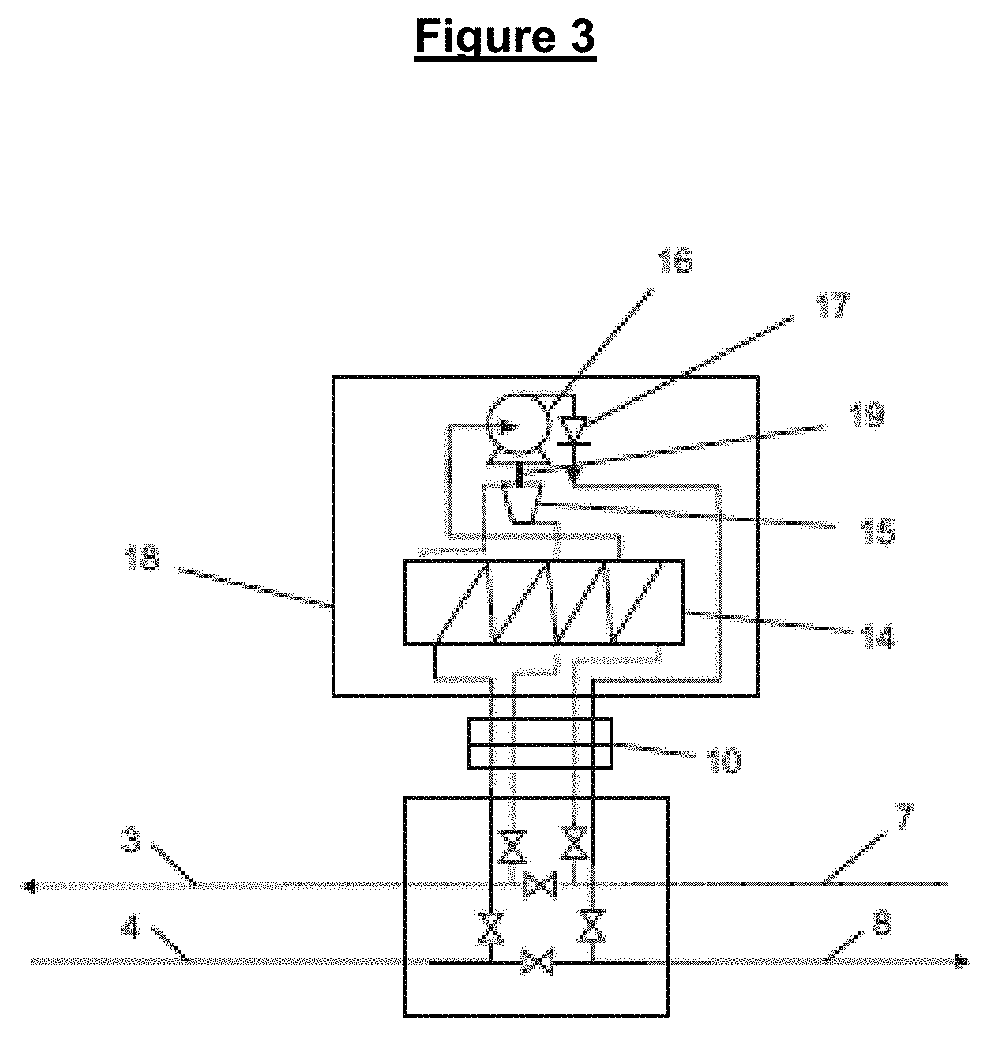

Integrated system for subsea heating and pumping of oil and water injection for reservoir pressurization, and method of heating, of subsea pumping hydraulically actuated and water injection

PendingUS20220290541A1Reduces optimizes lengthMinimized environmental impactInsulationFluid removalThermodynamicsInjection well

The present invention is related to artificial lifting systems and production flow assurance from subsea oil wells. In this sense, the present invention provides an integrated subsea oil heating and pumping system hydraulically actuated by heated injection water, the system comprising at least one recoverable pumping module (3) connected to a subsea base (6) which, in turn, receives the produced fluids from at least one subsea producing well (1). The subsea base (6) is connected to a production unit (10) through a riser (8) through which the produced oil flows and to an injection line (7) that feeds the pumping module (3) with water which, after activating the turbine (15) and pump (16) set, is injected through at least one injection well. The present invention further provides a hydraulically actuated subsea pumping method associated with the system described above.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

A device used for X-ray CT equipment to observe the growth characteristics of natural gas hydrate in a blind pipe

ActiveCN105606634BImprove sealingJudgment generationEnergy based chemical/physical/physico-chemical processesSimultaneous control of multiple variablesOcean bottomRisk Control

The invention provides a device used for X-ray CT equipment to observe growth characteristics of natural gas hydrate in a blind pipe and belongs to the field of flow assurance in the delivery process of oil and gas. In-situ generation of the natural gas hydrate in the blind pipe of an oil-gas pipeline can be simulated, and growth conditions of the natural gas hydrate can be observed through the X-ray CT equipment. After liquid is injected into a reaction kettle and after leakage detection, gas is injected into the reaction kettle through a constant-pressure pump, and consumption of the gas is recorded to evaluate the growth conditions of the hydrate. During detection, a magnetic stirring system is used for stirring liquid in the reaction kettle, simulating flow of a liquid phase in the pipeline and promoting mutual cooperation of gas-liquid phases to generate hydrate. Every other certain period, X-ray CT photographing is conducted in the reaction kettle, the growth condition of hydrate in the blind pipe is observed, and growth characteristics of the hydrate in the blind pipe are studied. Measuring results are used for on-site guidance of a seabed oil-gas delivery system, and a powerful theoretical support can be provided for deep studying of hydrate risk control technology.

Owner:DALIAN UNIV OF TECH

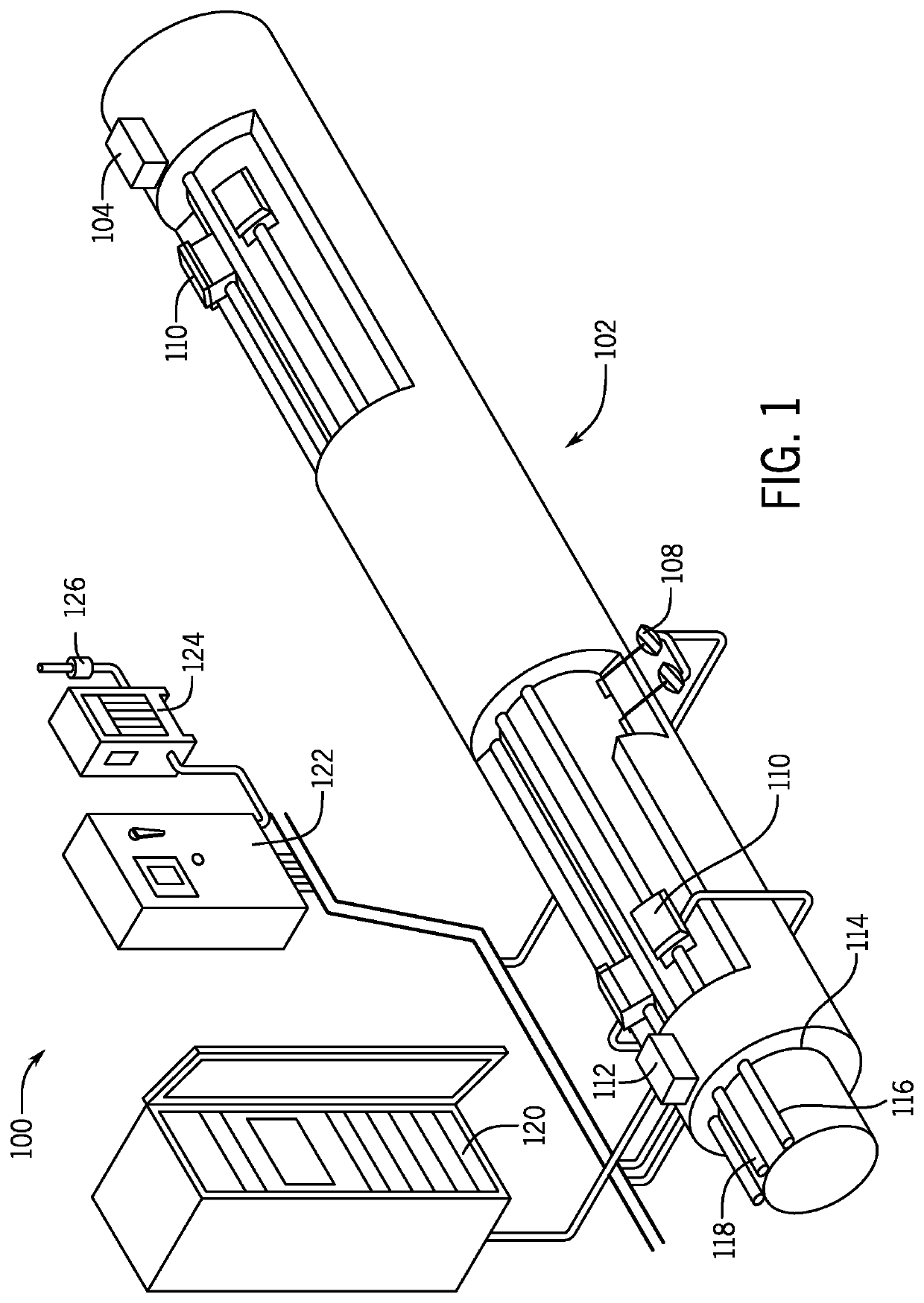

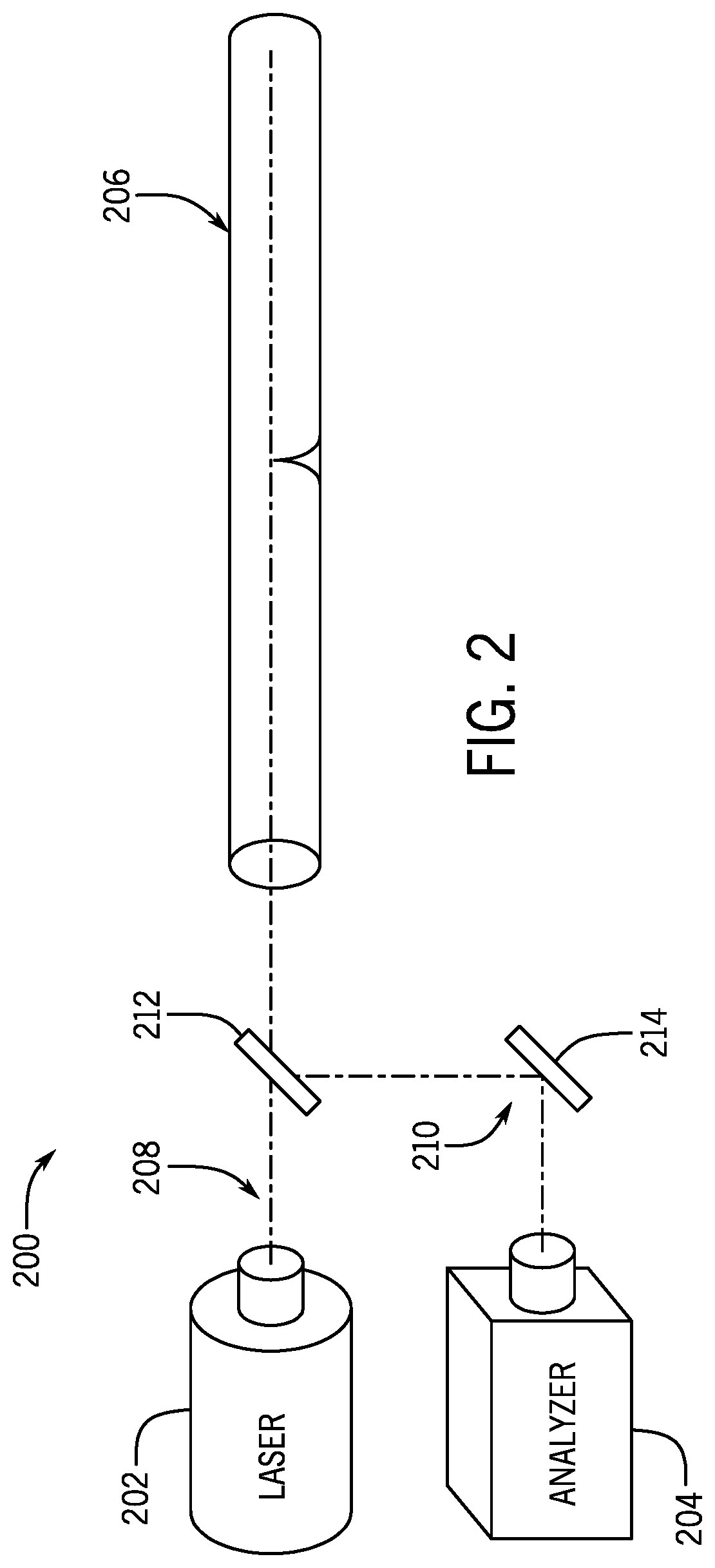

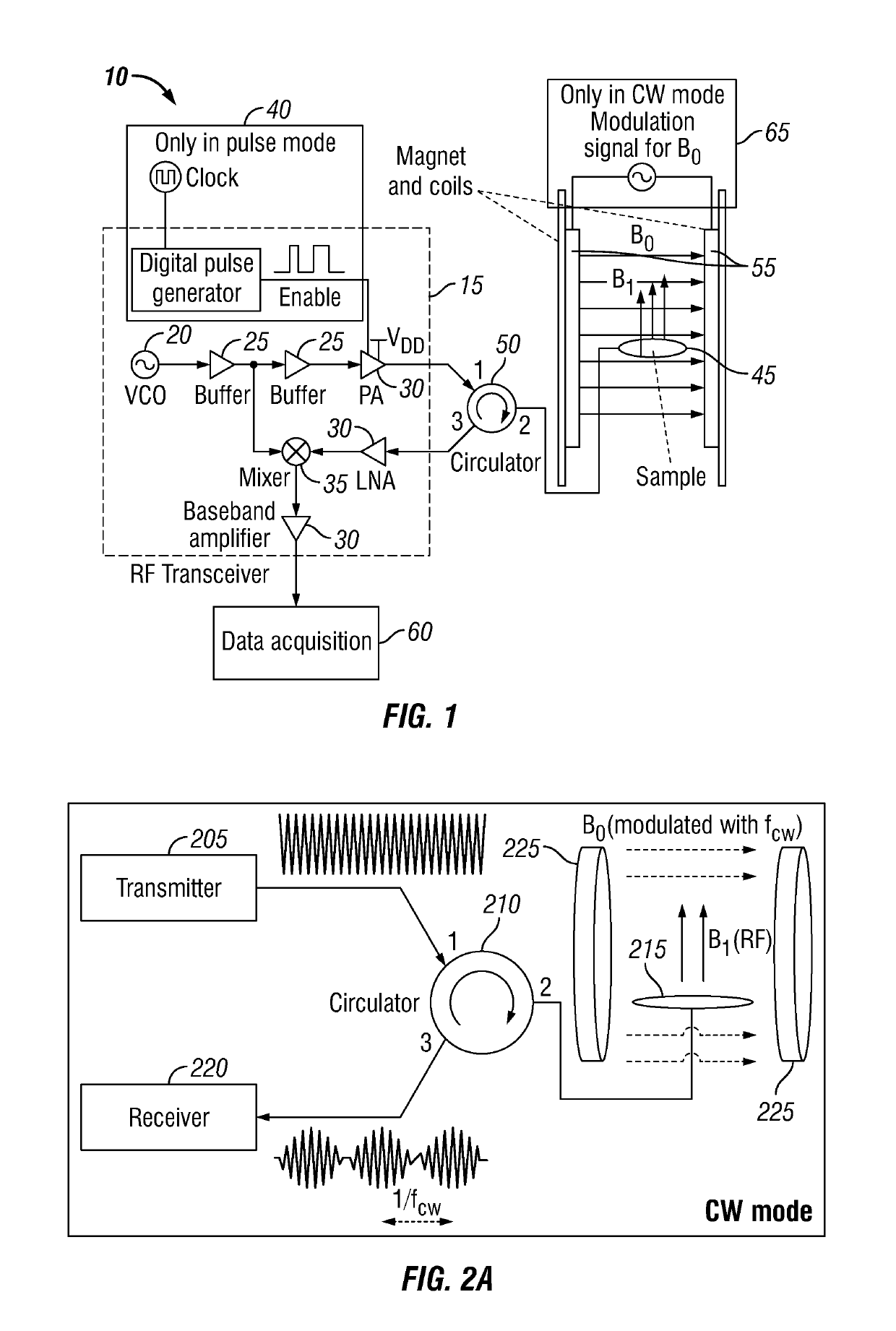

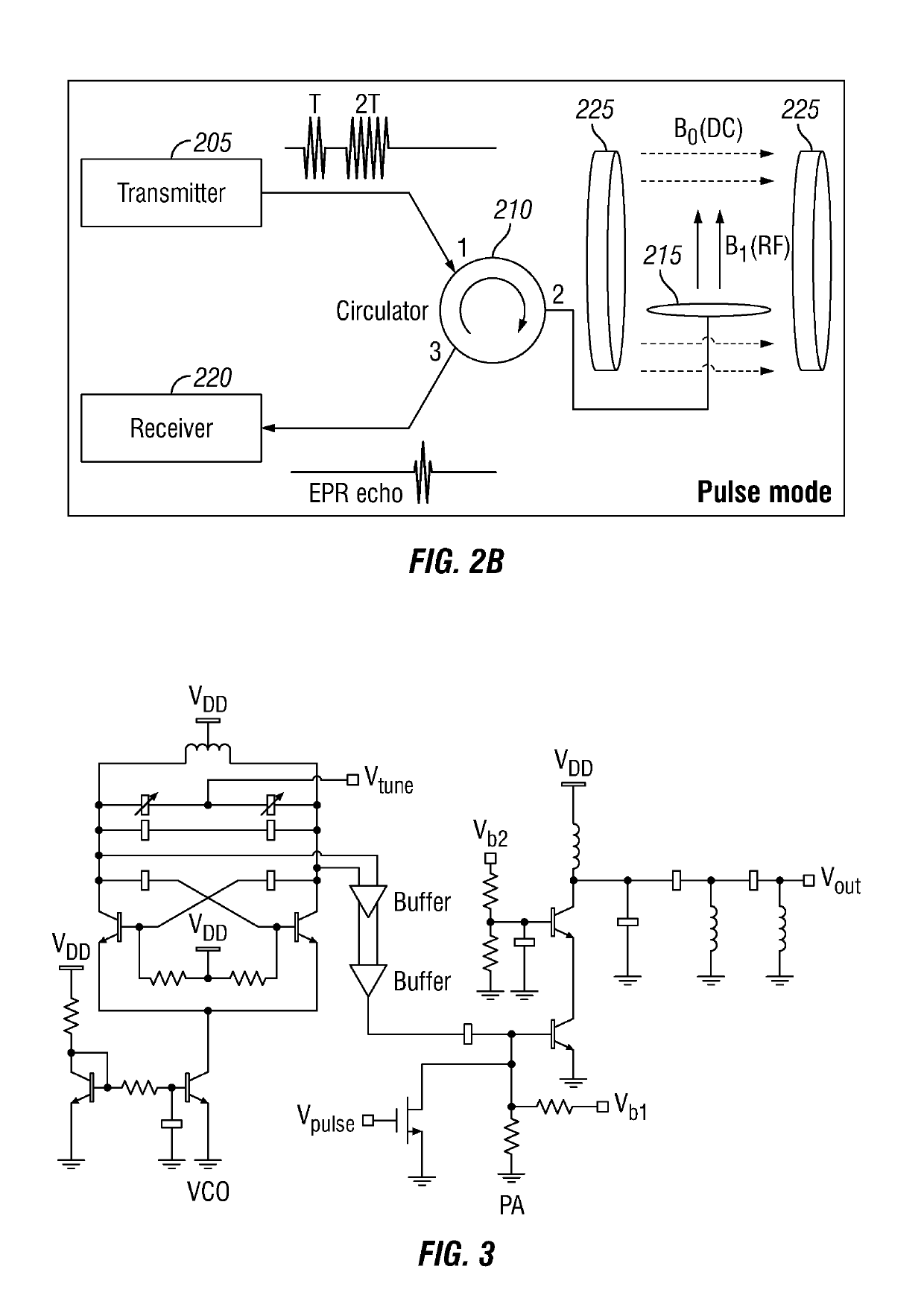

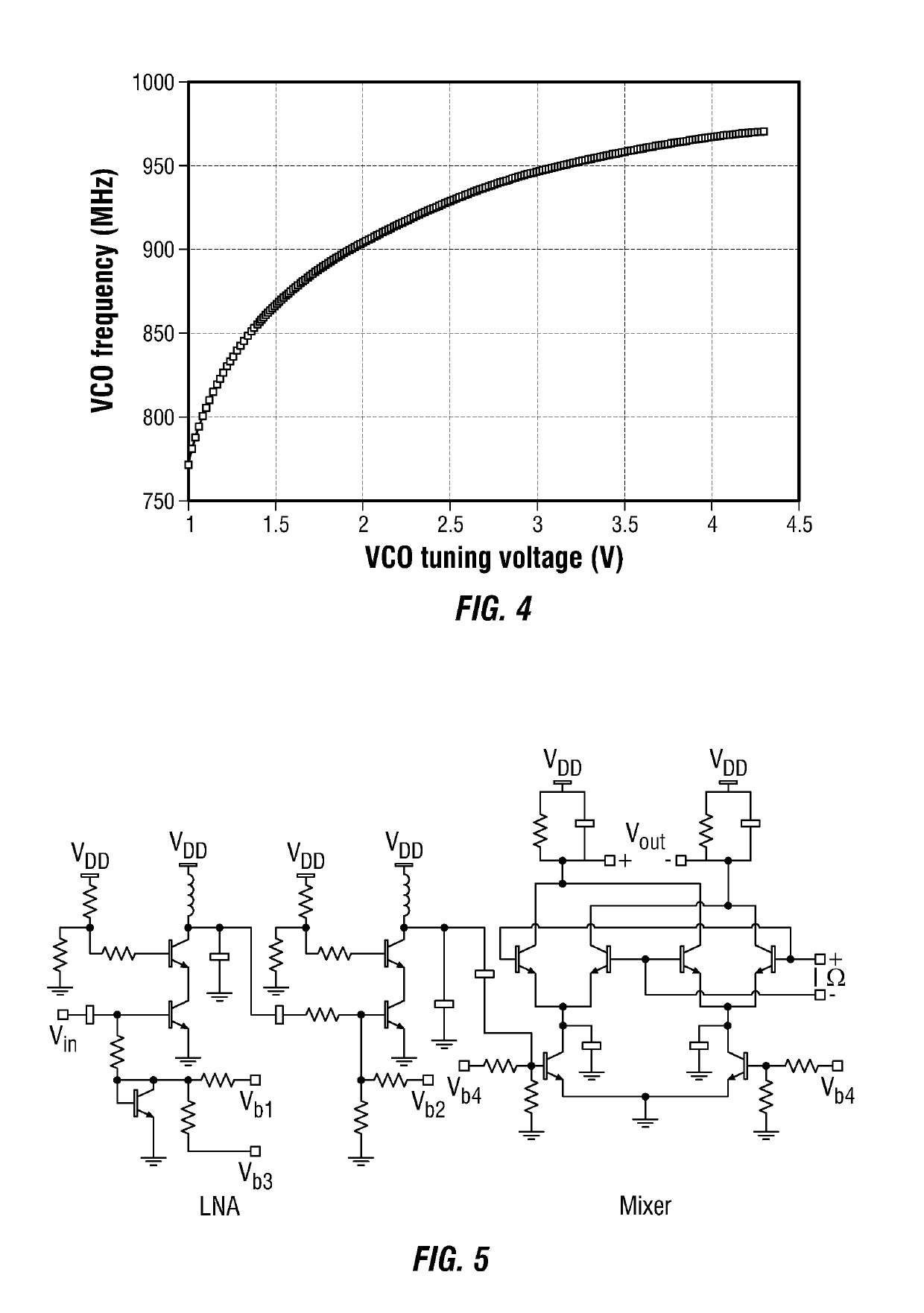

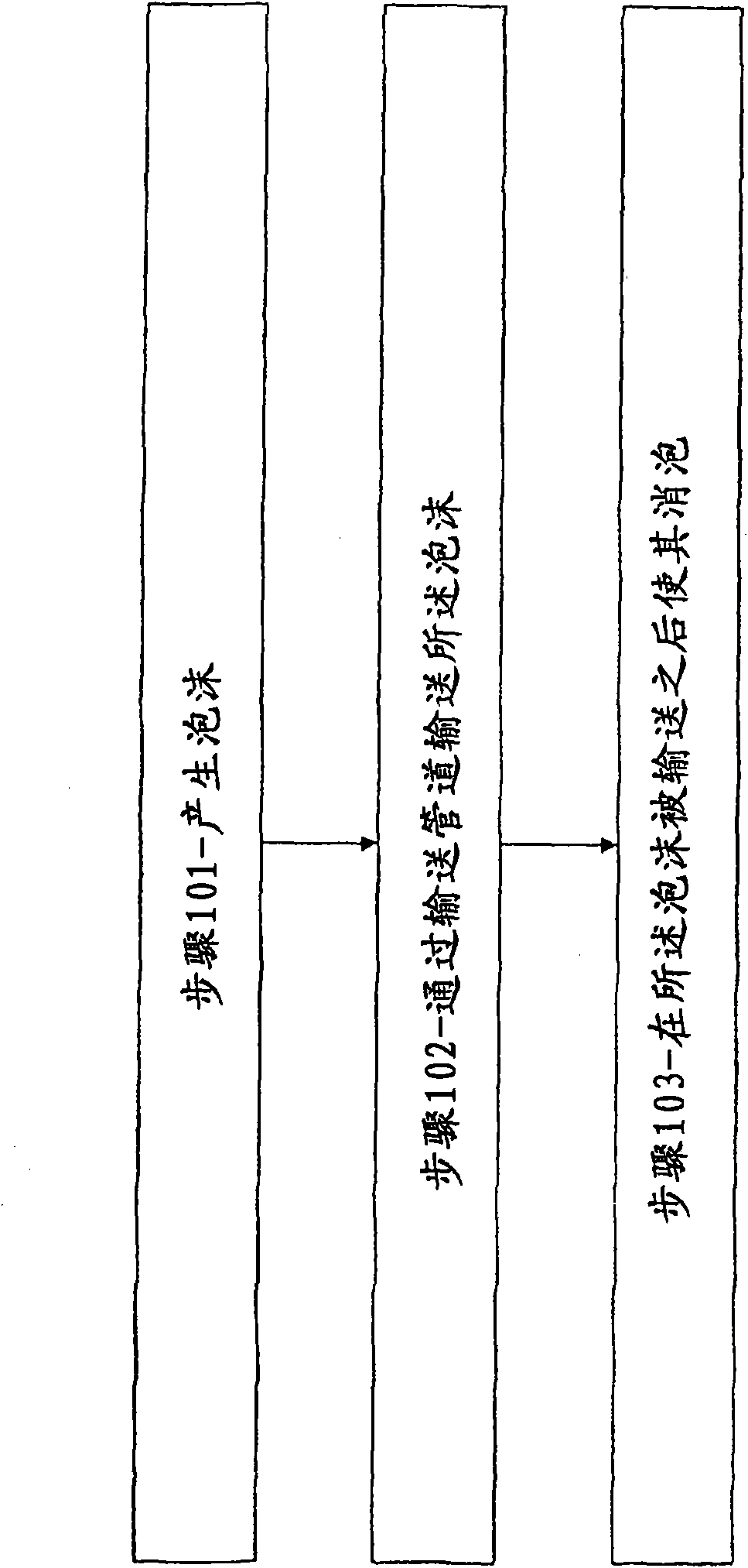

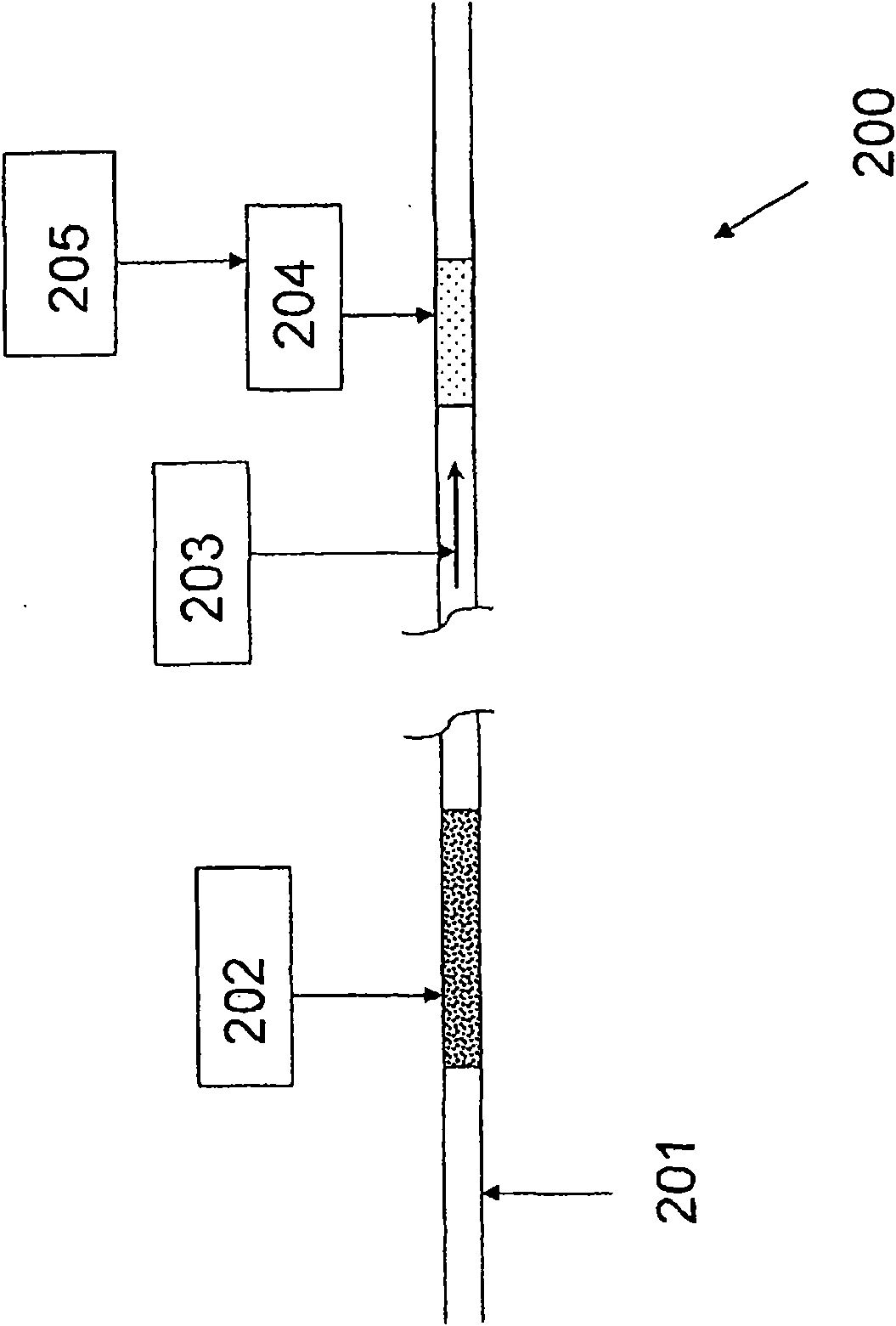

EPR systems for flow assurance and logging

An Electron Paramagnetic resonance (EPR) system and method allows the measurement paramagnetic characteristics of materials in real-time, such as heavy oil, hydrocarbons, asphaltenes, heptane, vanadium, resins, drilling fluid, mud, wax deposits or the like. The EPR systems and methods discussed herein are low cost, small and light weight, making them usable in flow-assurance or logging applications. The EPR sensor is capable of measuring paramagnetic properties of materials from a distance of several inches. In some embodiments, a window will be used to separate the EPR sensor from the materials in a pipeline or wellbore. Since the sensor does need to be in direct contact with the materials, it can operate at a lower temperature or pressure. In other embodiments, the EPR sensor may be placed in the materials.

Owner:RICE UNIV

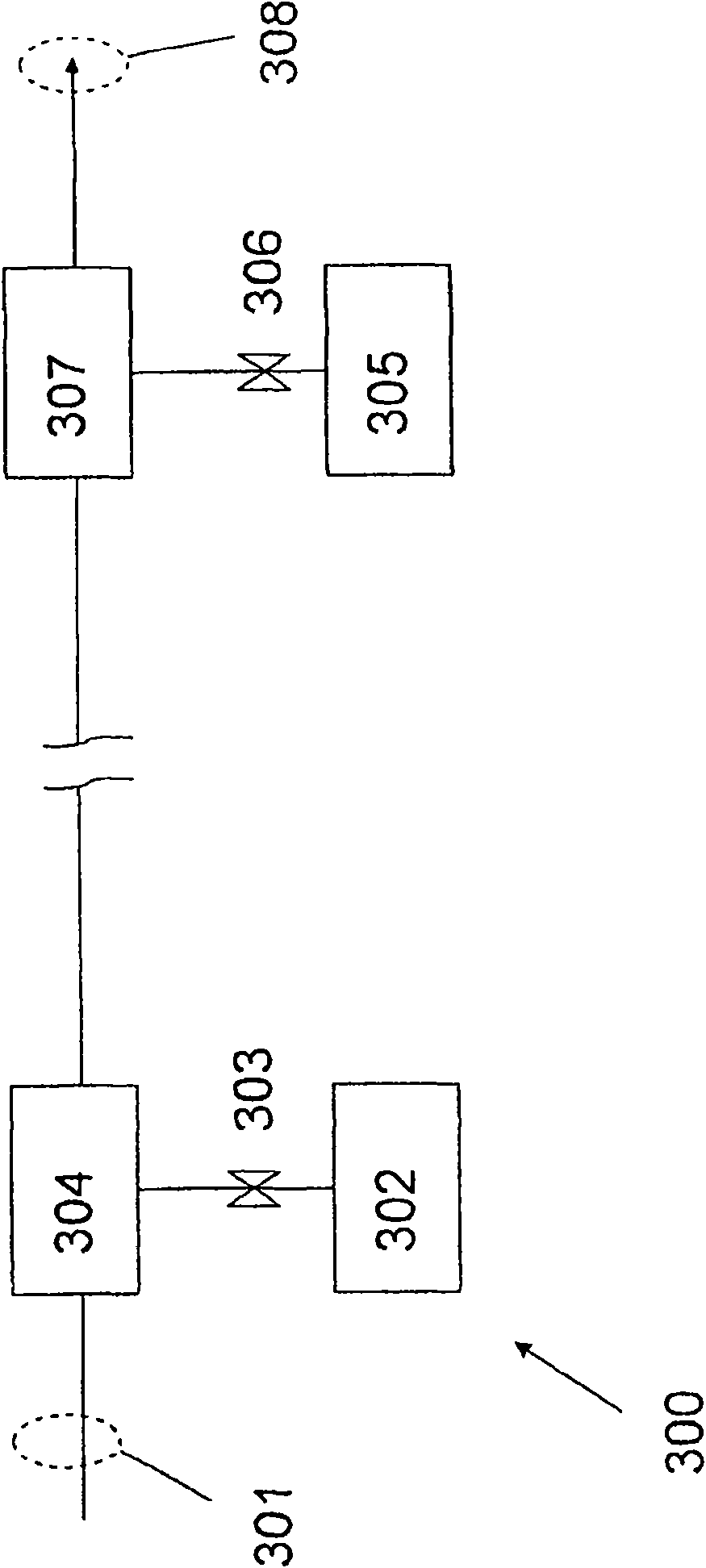

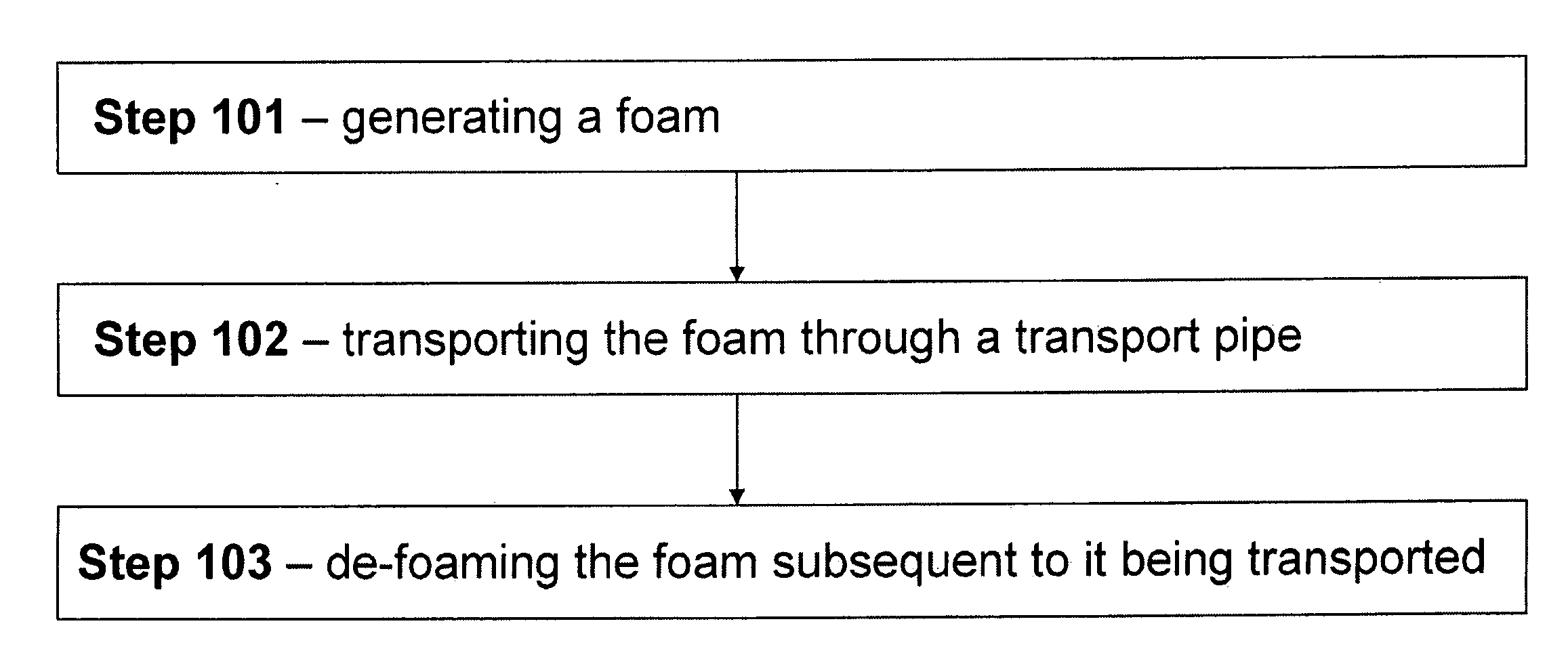

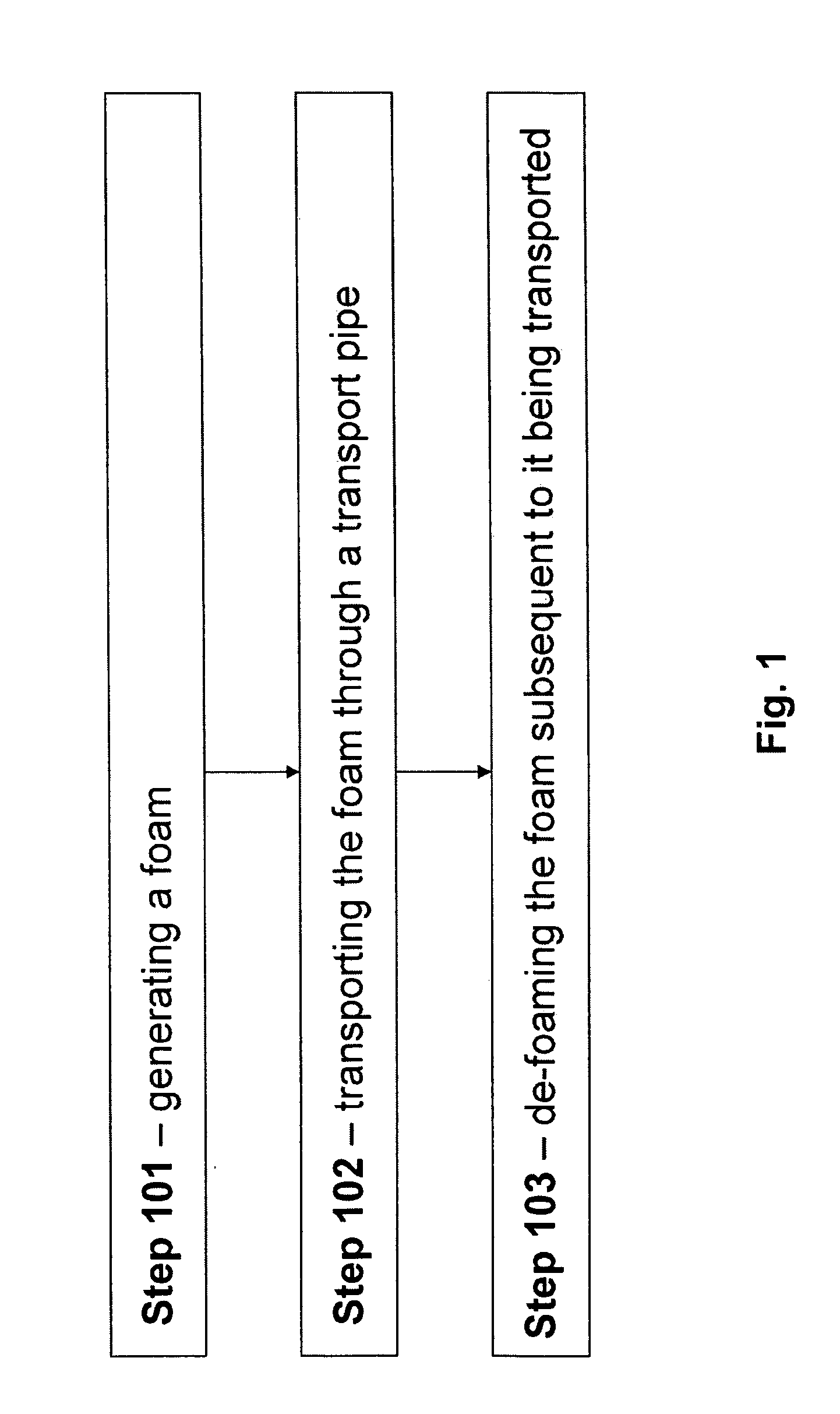

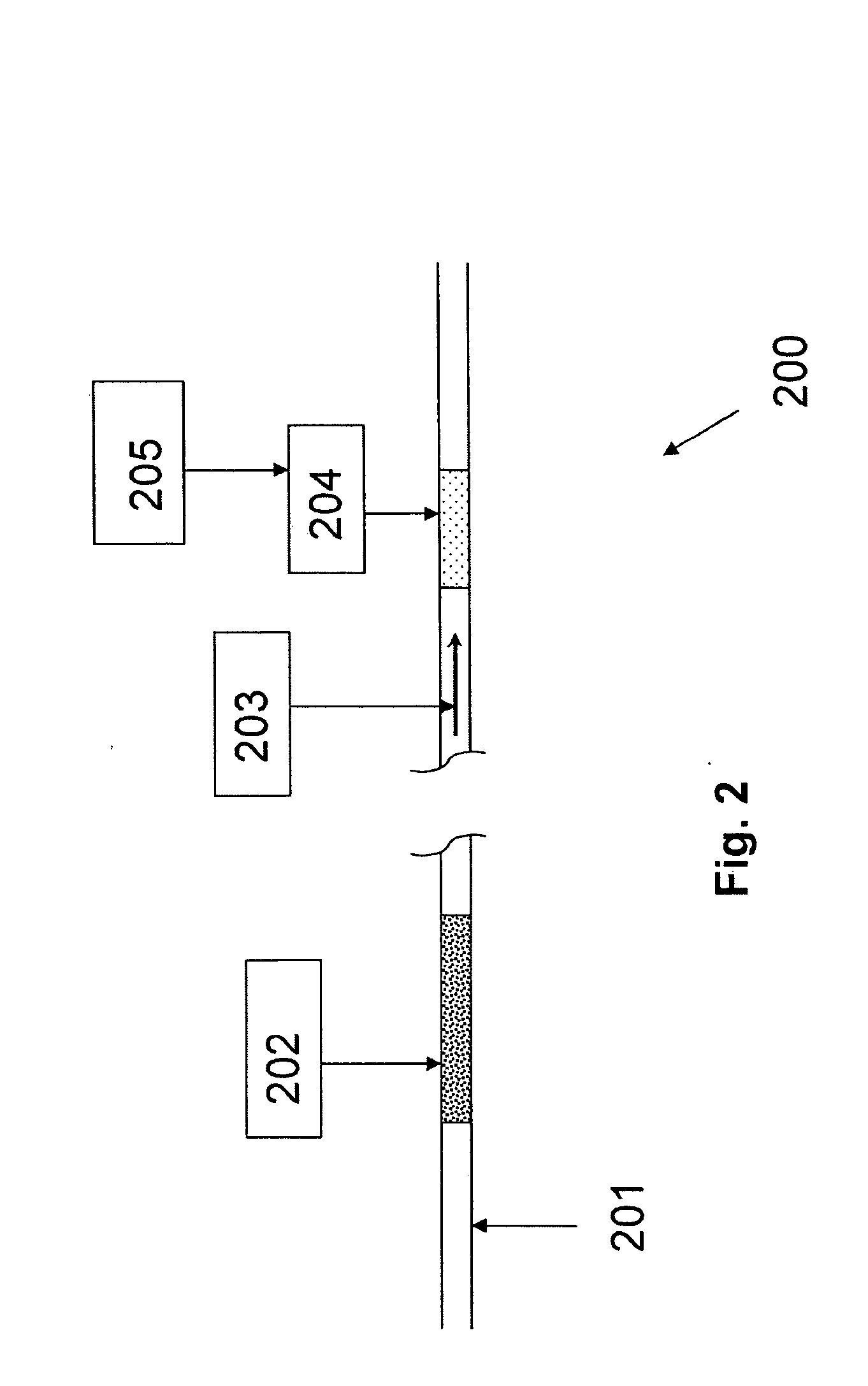

Foam for mitigation of flow assurance issues in oil and gas systems

InactiveCN101563406AEfficient removalDecrease stockPipeline systemsCleaning using liquidsProduct gasEngineering

The present invention is generally directed to methods and systems for mitigating flow assurance issues that arise in the pipe transport of hydrocarbon fluids, particularly wherein such hydrocarbon fluids are gas-dominated. Generally, such methods and systems rely on the formation and subsequent transport of a foam through an associated transport pipe.

Owner:CHEVROU USA INC

Foam for mitigation of flow assurance issues in oil & gas systems

InactiveUS20080099946A1Less liquid inventoryIncreasing apparent volume of liquidPipeline systemsCleaning using liquidsEngineeringProduct gas

The present invention is generally directed to methods and systems for mitigating flow assurance issues that arise in the pipe transport of hydrocarbon fluids, particularly wherein such hydrocarbon fluids are gas-dominated. Generally, such methods and systems rely on the formation and subsequent transport of a foam through an associated transport pipe.

Owner:CHEVROU USA INC

Flow angle probe

A flow angle probe is provided having (a) a probe flap for contacting a moving fluid within a fluid conduit; (b) a probe body mechanically coupled to the probe flap; (c) a force sensor disposed within the probe body and operationally coupled to the probe flap; and optionally (d) a probe shaft coupled to the probe body. A deflection of the probe flap caused by contact with the moving fluid produces a corresponding force sensor signal output which is minimized by rotation of the probe flap. The angle between this point of minimum deflection and a reference position is taken to be the flow angle of the moving fluid in the vicinity of the probe flap. The novel flow angle probes disclosed herein may be used in a wide variety of turbomachines and fluid processing systems, and applications, including turbomachine design and operational control, and in flow assurance.

Owner:VETCO GRAY SCANDINAVIA

A system and method for diagnosing the accuracy of HFM measurement of engine air intake

The invention discloses a system and method for diagnosing the engine air inflow measuring accuracy of an HFM. The problem that currently, matched equipment or a corresponding method for diagnosing the air measuring accuracy of the HFM on a large commercial engine is not available is solved. The system and method can diagnose whether the air inflow measured by the HFM is accurate or not, and thus correct air flow assurance is provided for subsequent intra-cylinder fuel injection and for subsequent diesel engine post-treatment urea injection. According to the technical scheme, the system comprises an air flow meter and an air inlet pressure temperature sensor which are used for measuring the air mass flows entering the engine correspondingly and then sending the air mass flow to a controller, the air mass flows which are detected when an EGR valve is totally closed and entering the engine serve as a first measured value and a second measured value to be stored in the controller, and the controller receives the first measured value and the second measured value and obtains the deviation between the first measured value and the second measured value so as to judge whether the air mass flows, measured by the air flow meter HFM, entering the engine drift or not.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com