Foam for mitigation of flow assurance issues in oil and gas systems

A foam, hydrocarbon fluid technology, applied in the use of liquid cleaning methods, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as unaware of foam applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

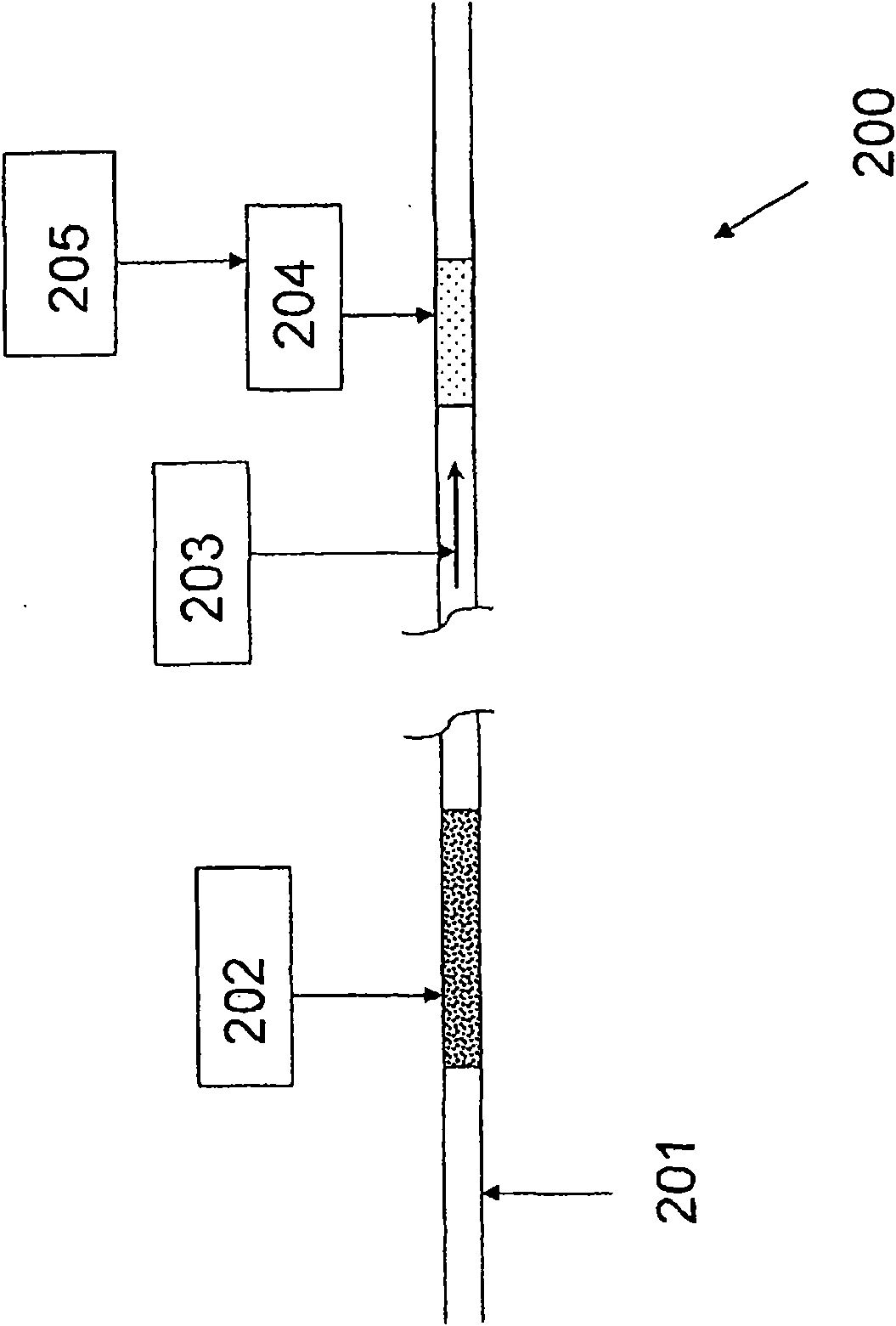

[0032] refer to figure 2 , an illustrative general system 200, in some embodiments the invention generally relates to a system for delivering foam through a delivery pipeline, the system comprising: a delivery pipeline (201) for delivering a hydrocarbon fluid; Means (202) for foams and foams in combinations thereof; means (203) for transporting said foam a distance through a delivery pipe; and means (204) for breaking up the foam within the delivery pipe after delivering said foam. For the above method embodiments, such hydrocarbon fluids transported with the system are typically predominantly gaseous.

[0033] Corresponding to related method embodiments, in some such system embodiments, generating foam (ie, foaming provided by device 202) can be performed in situ or in a side stream. In the latter case, this side stream is generally in fluid communication with the transfer conduit. In addition, there is generally a means for introducing the foam into the delivery conduit 2...

Embodiment 1

[0050] This example serves to illustrate methods and corresponding systems for generating foam in situ (ie, in-line), according to some embodiments of the invention.

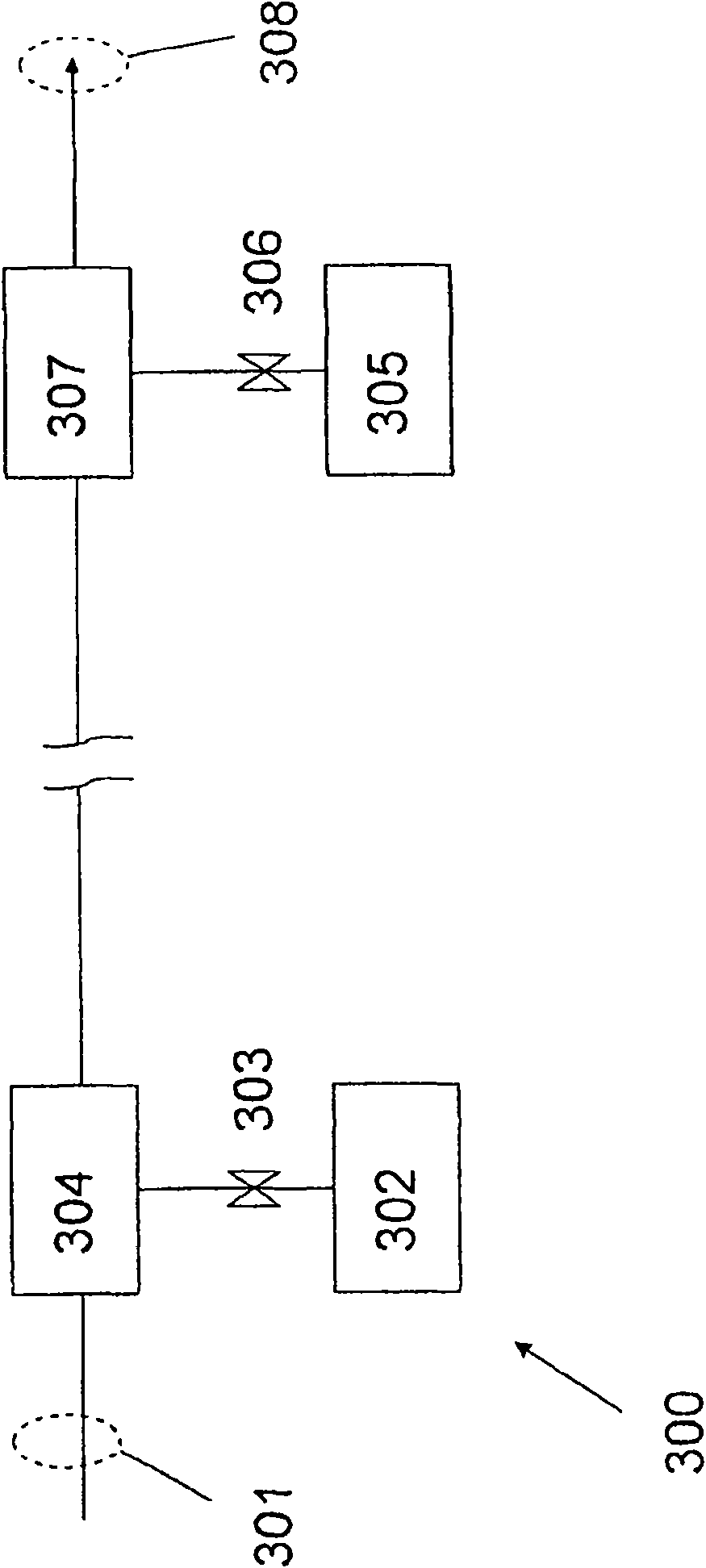

[0051] refer to image 3 , which depicts an exemplary system 300 in which a predominantly gaseous hydrocarbon fluid flows through a delivery pipeline 301 where it is foamed by means 302 upon reaching 304 . In this embodiment, the foam comprises a hydrocarbon fluid and the foam generating device is separable from the fluid by valve 303 to allow continuous or intermittent foaming of the hydrocarbon fluid. In this embodiment, foaming is performed in-line in zone 304 using a mixing device and foaming additive provided by device 302 . The foam then moves to zone 307 and is defoamed there by defoaming device 305 , which is separable from zone 307 by valve 306 . In this embodiment, the foamed hydrocarbon fluid is destabilized by the addition of a defoamer, diluent, heat and / or mechanical force by the defoaming device...

Embodiment 2

[0053] According to some embodiments of the invention, this example serves to illustrate a method and corresponding system for generating foam in an auxiliary side stream for subsequent injection into the main transfer line (ie, the main stream).

[0054] refer to Figure 4 , which depicts an alternative exemplary system 400 in which gas-based hydrocarbon fluid flows through transfer line 401 where it is directed to auxiliary side stream 403 upon reaching valve 402 and foamed by foaming device 404 . In this embodiment, a blowing agent is added to the hydrocarbon fluid via foaming device 404 to produce a hydrocarbon-based foam. The foam then re-enters delivery pipe 401 through valve 405 and is transported a distance through this pipe until reaching valve 406 . Upon reaching valve 406 , the hydrocarbon-based foam is directed into side stream 407 and defoamed by defoamer 408 . In this embodiment, the defoamer is introduced via defoaming device 408 . After defoaming, the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com