Marine subsea free-standing riser systems and methods

A standpipe and free technology, applied in the direction of drill pipe, casing, earthwork drilling and mining, etc., can solve problems such as unsolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

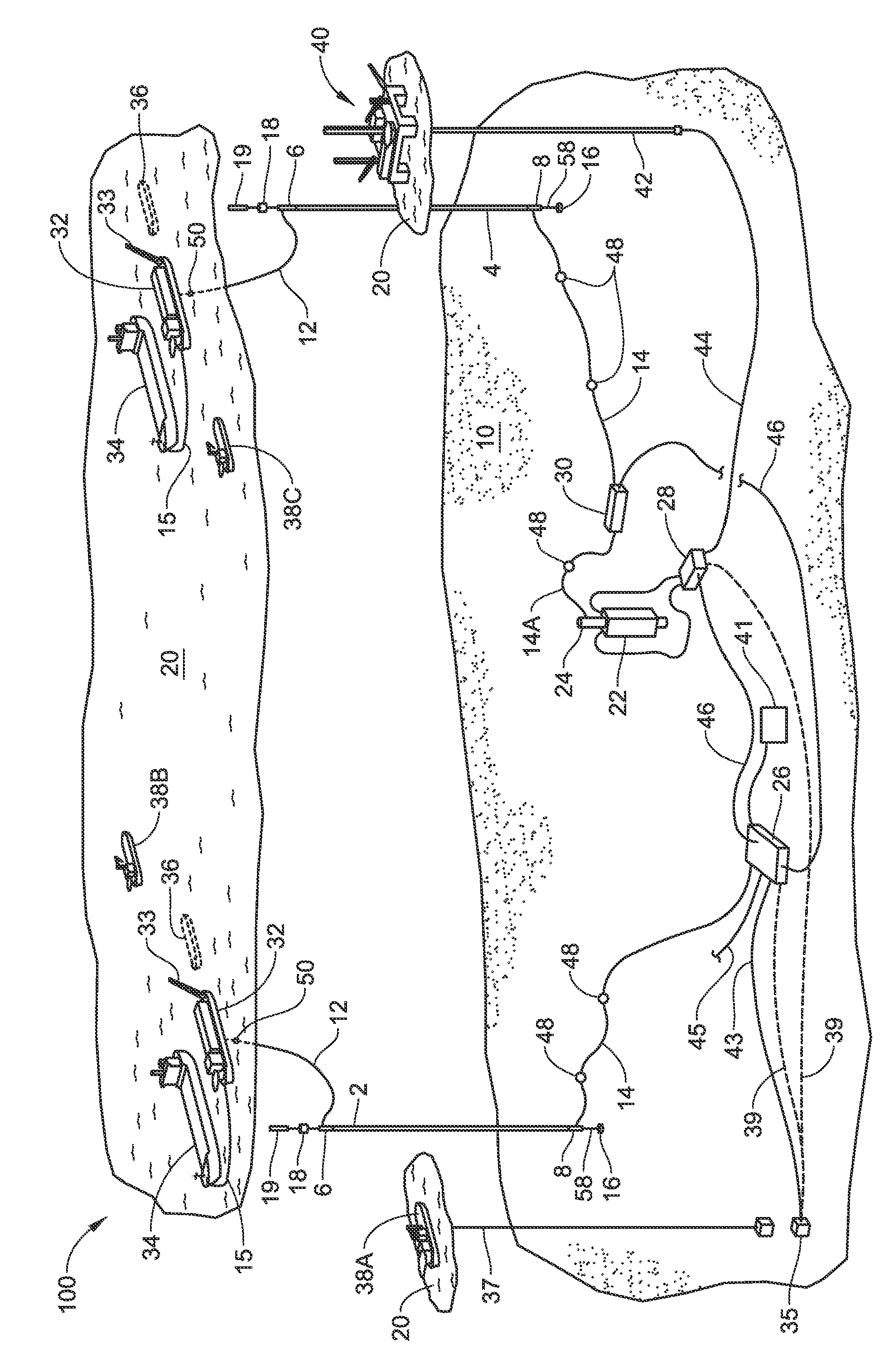

Embodiment 100

[0229] Free standing risers 2 and 4 in embodiment 100 may be a tube-in-tube design based in part on a "dry tree" riser design, wherein the annulus is filled with a flow assurance fluid (e.g., low pressure nitrogen) Air to improve liquidity assurance. While further details are set forth here, the main parts of system 100 may be:

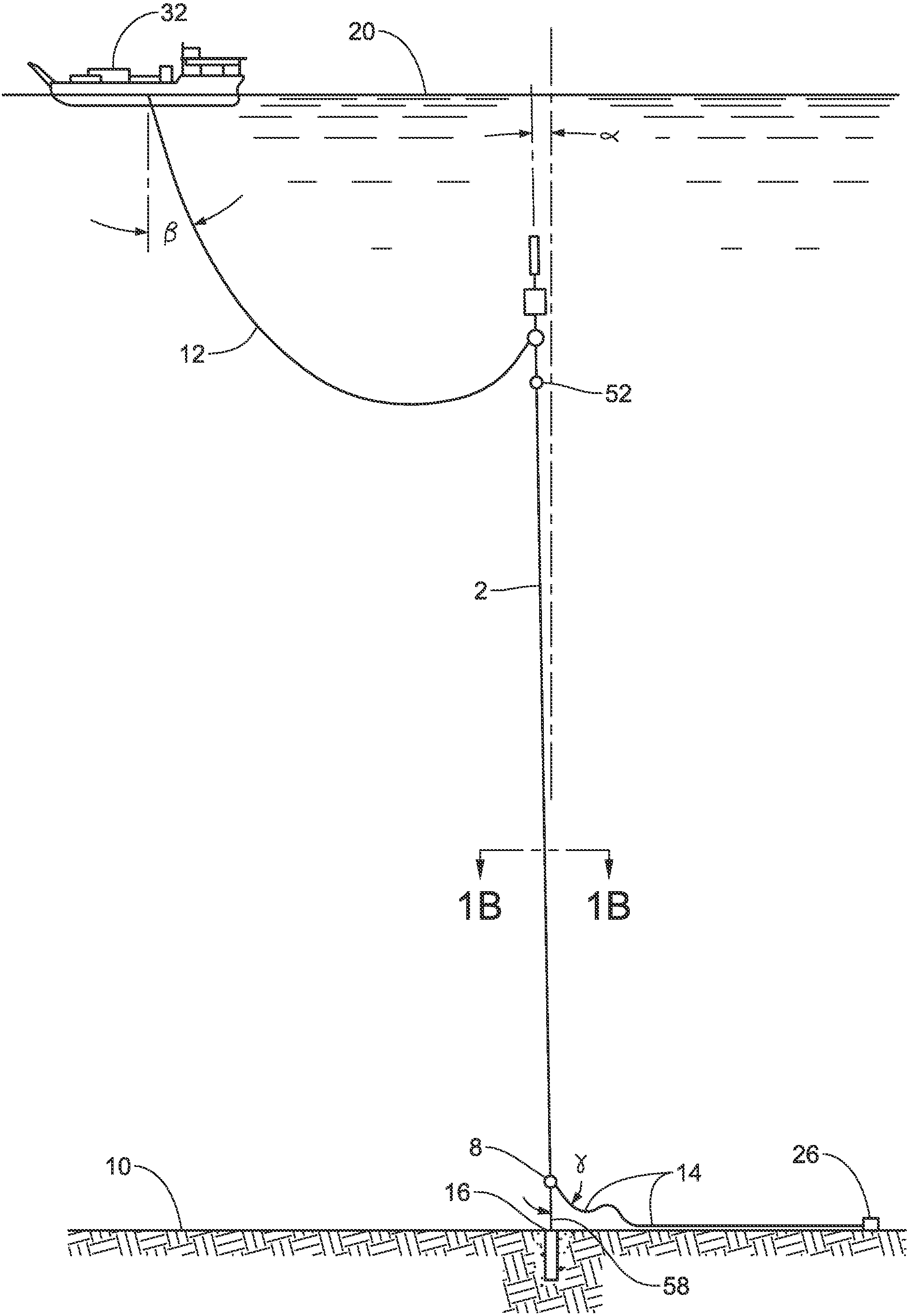

[0230] 6 inches (15 cm) of slow wave ID flexible jumper 14 with distributed buoyancy modules 48 connected from the base of each FSR to the subsea manifold on the seabed (in the case of the first FSR (2), distributed buoyancy The module 48 may be connected to the closed process manifold (CDM) marked 26, while in the case of the second FSR (4) the decentralized buoyancy module 48 may be connected to the BOP stack manifold 30, the BOP stack Sink 30 is fluidly connected to BOP stack cap 24 via flexible jumper 14A, and to CDM 26 via flexible piece 46);

[0231] a suction pile foundation 16 and a chain rope 58 connectable to the respective bases of FSR2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com