Device used for X-ray CT equipment to observe natural gas hydrate growth characteristics in blind pipe

A growth characteristic, hydrate technology, applied in the direction of material analysis using radiation, chemical/physical/physical chemical process, chemical/physical process using energy, etc., can solve the problem of staying, insufficient to explore the hydrate formation characteristics in the dead pipe and other problems to achieve the effect of enhancing the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and example.

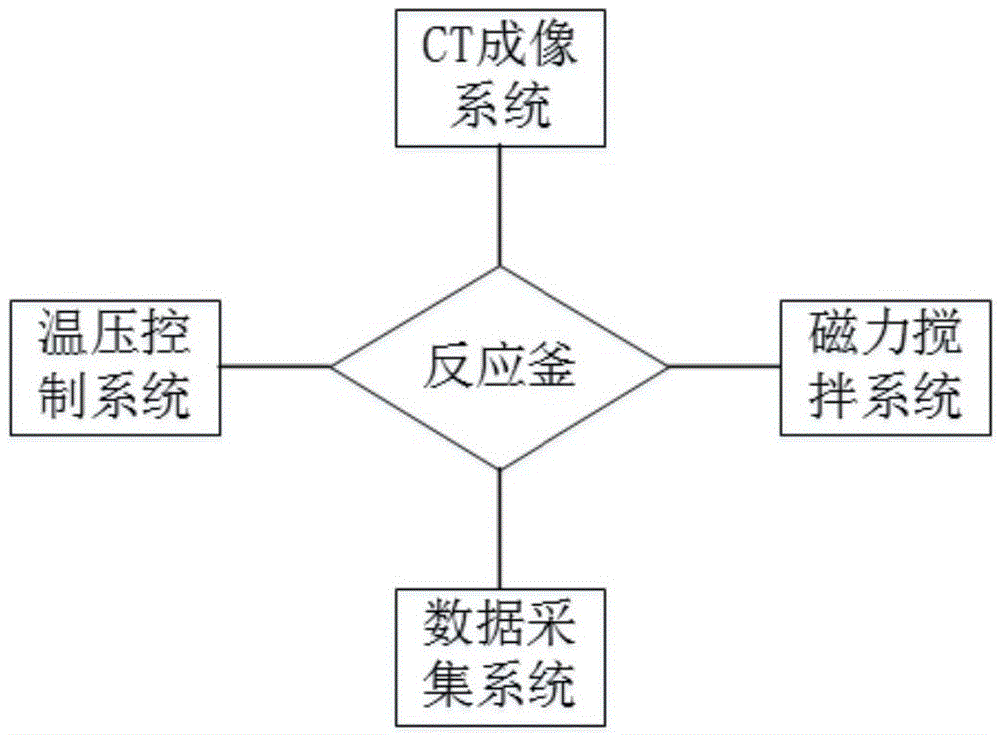

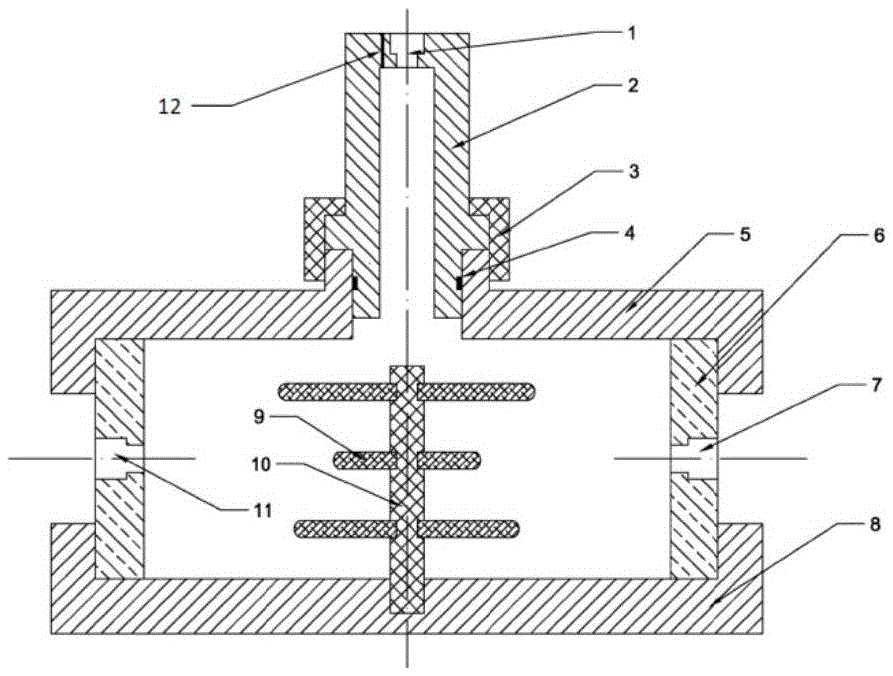

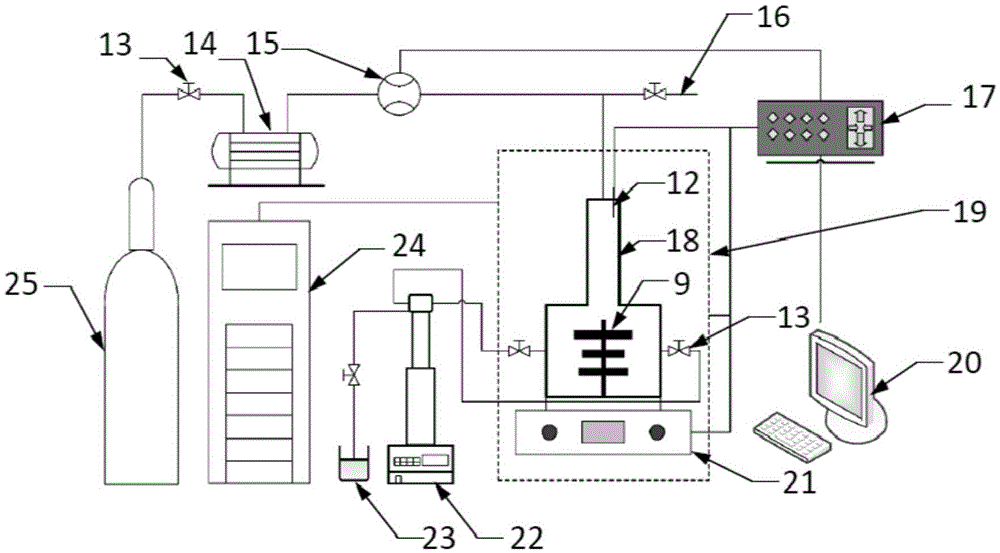

[0035] figure 1 Shown is the block diagram of the working principle of the device used for X-ray CT equipment to observe the growth characteristics of natural gas hydrate in the blind pipe. The working process is as follows: after adding liquid phase water or oil-water mixture into the reactor, install the reactor and connect the pipeline system, Check the airtightness of the device, the gas is input into the reactor through a constant pressure pump, and the flow meter records the amount of gas input. Turn on the air bath to control the temperature of the reactor, and turn on the magnetic stirrer to make the gas and liquid phases in the reactor mix with each other to form hydrates. The temperature, pressure, flow and other parameters during the reaction process are collected and analyzed in real time by the data acquisition system. During the process, X-ray CT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com