Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "First specimen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

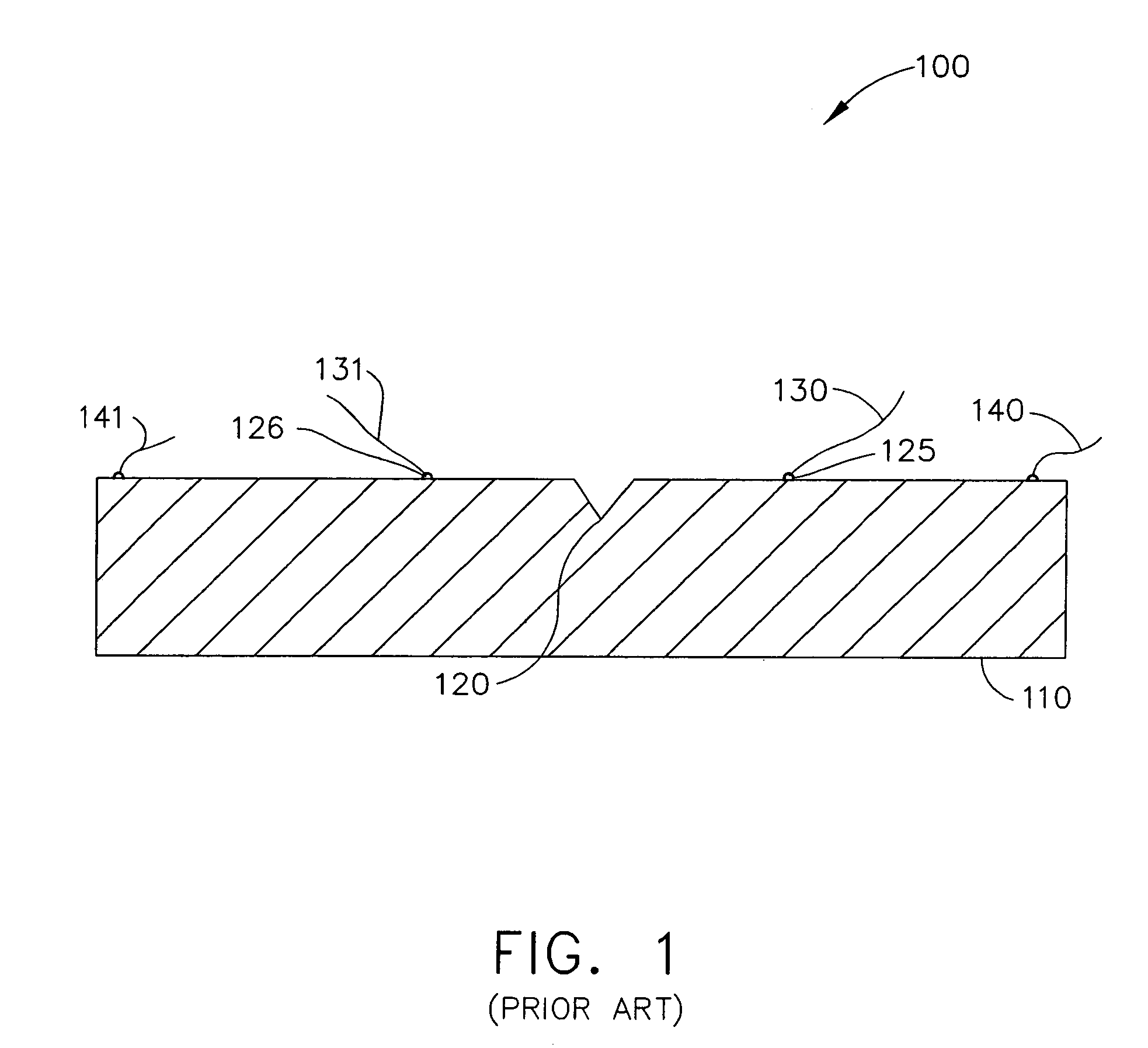

Methods for forming a calibration standard and calibration standards for inspection systems

InactiveUS7027146B1Size accuracy is loweredRemove uncertaintyPhotometry using reference valueOptically investigating flaws/contaminationFull width at half maximumFirst principle

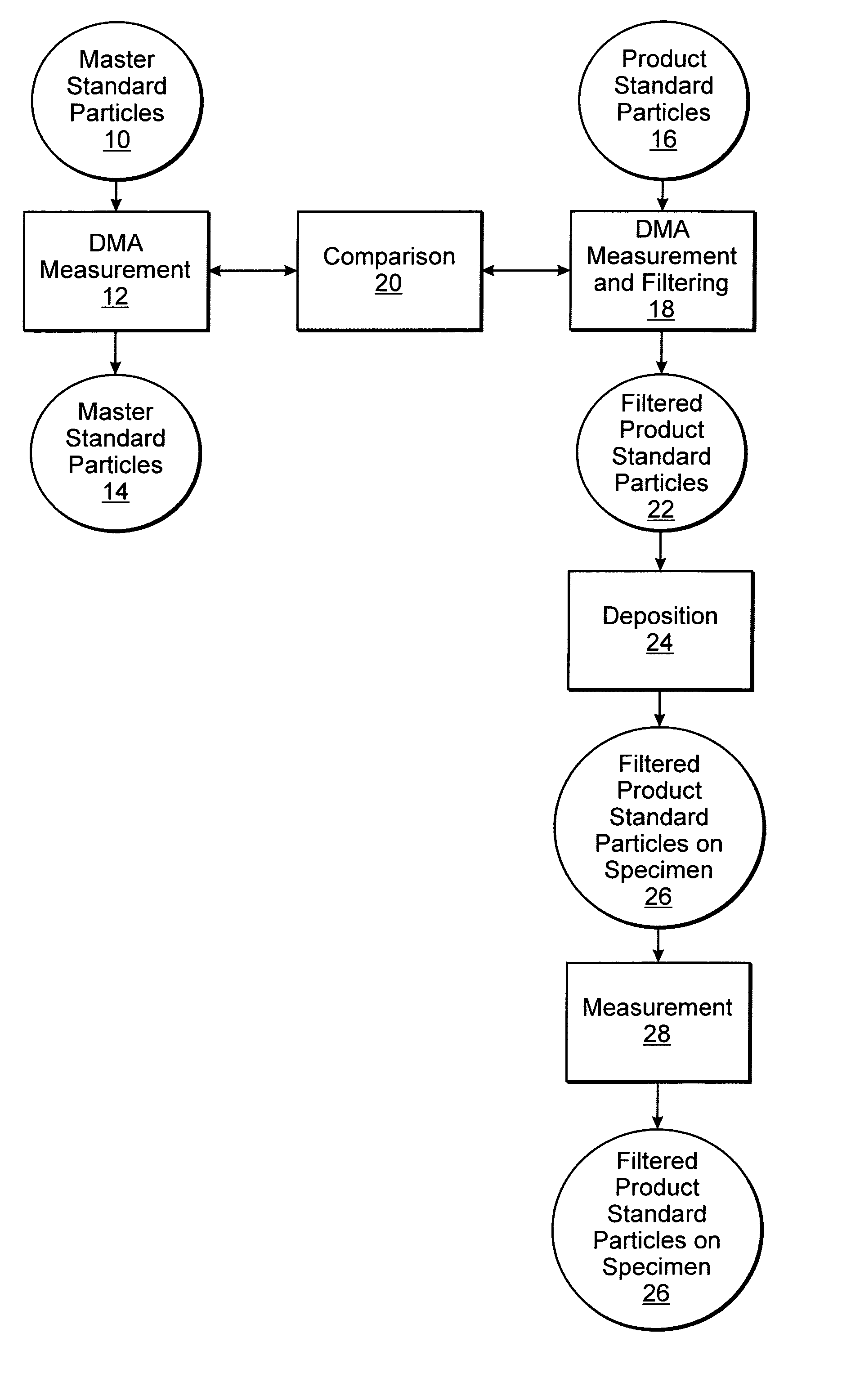

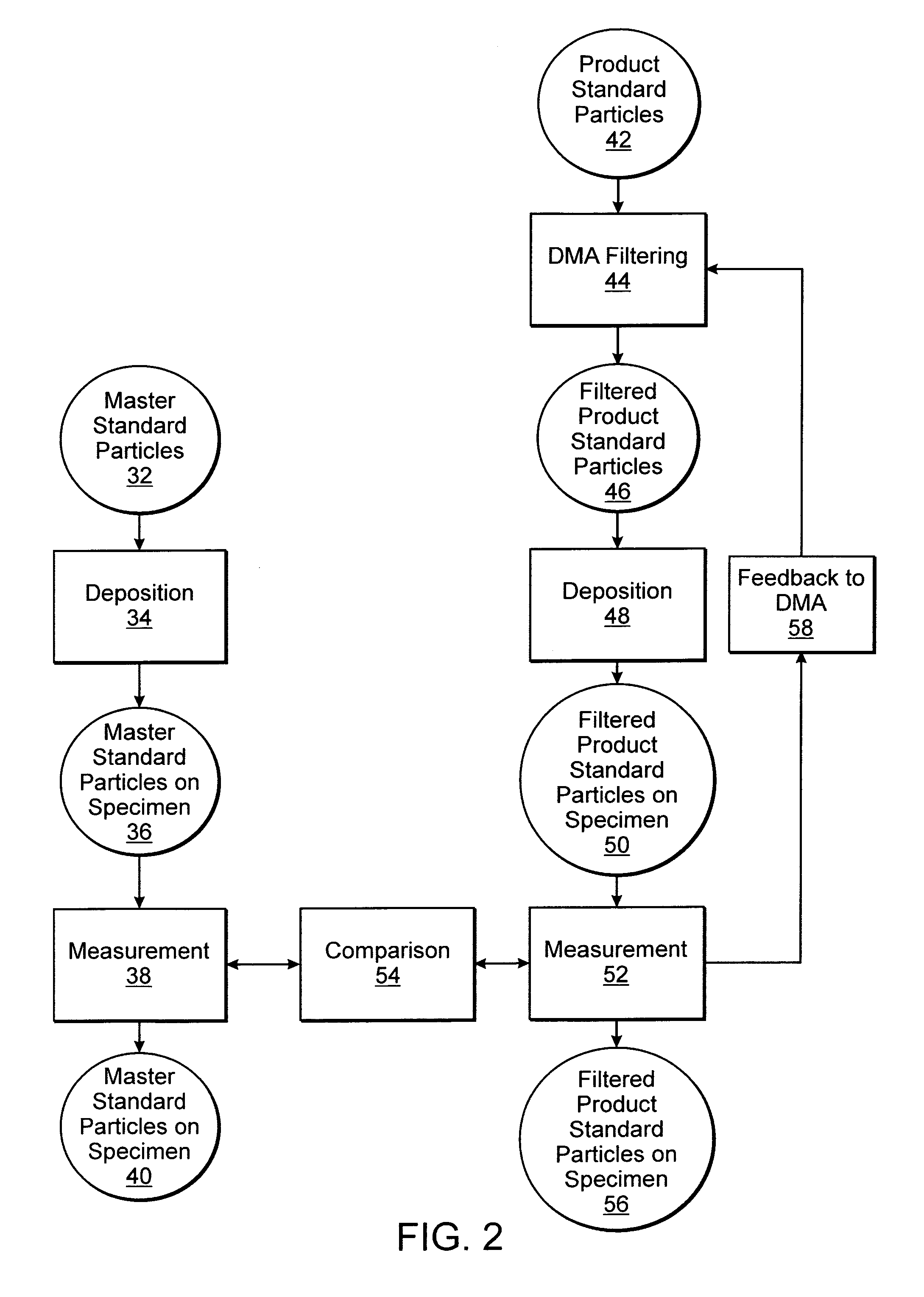

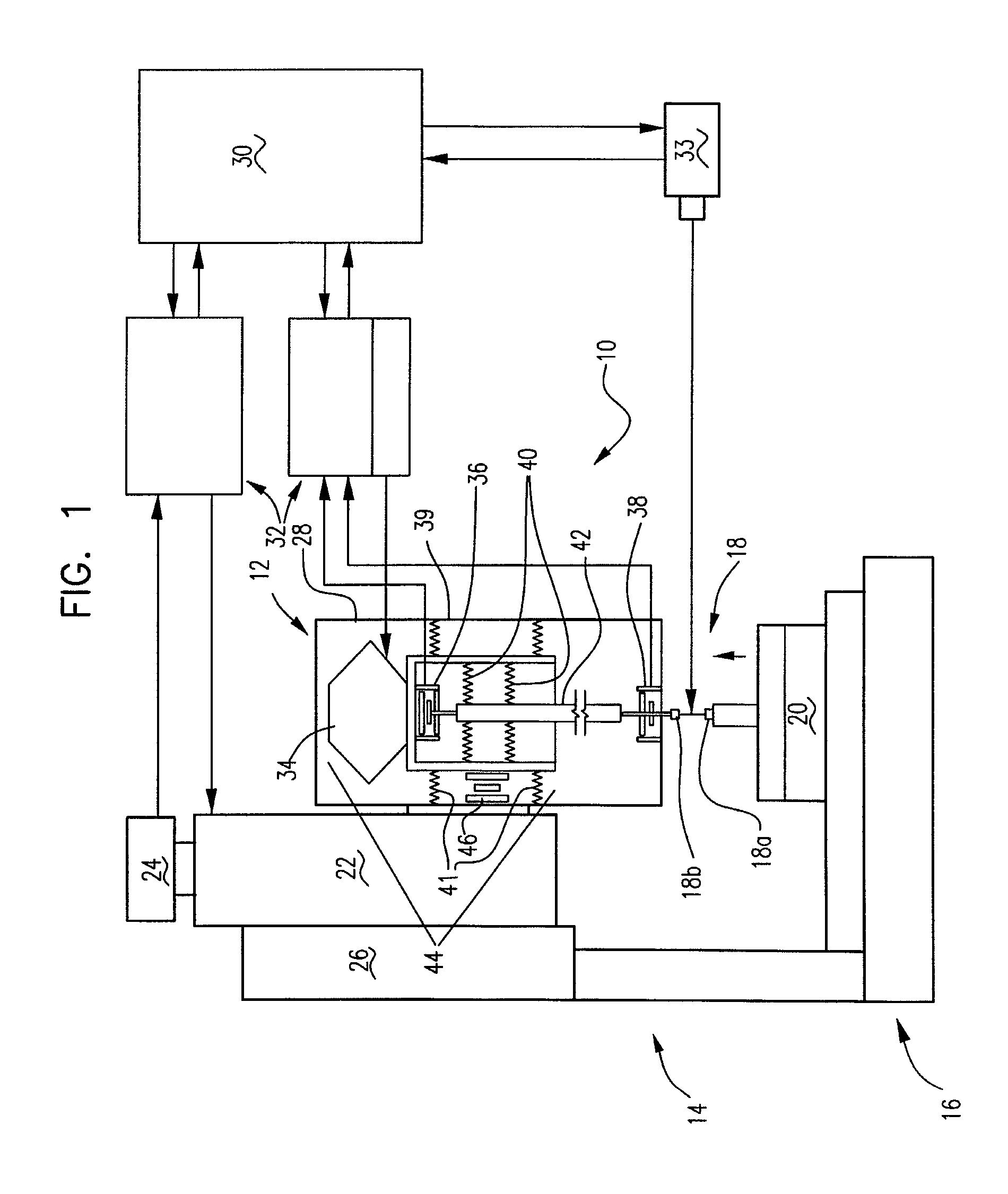

Methods for forming calibration standards for an inspection system and calibration standards are provided. One method includes scanning a first and a second specimen with an optical system. Master standard particles having a lateral dimension traceable to a national or international authority or first principles measurements are deposited on the first specimen. Product standard particles are deposited on the second specimen. In addition, the method includes determining a lateral dimension of the product standard particles by comparing data generated by scanning the two specimens. One calibration standard includes particles having a lateral dimension of less than about 100 nm deposited on a specimen. A distribution of the lateral dimension has a full width at half maximum of less than about 3%. The uncertainty of the lateral dimension is less than about 2%. Therefore, the standard meets the requirements for the 130 nm technology generation of semiconductor devices.

Owner:KLA TENCOR TECH CORP

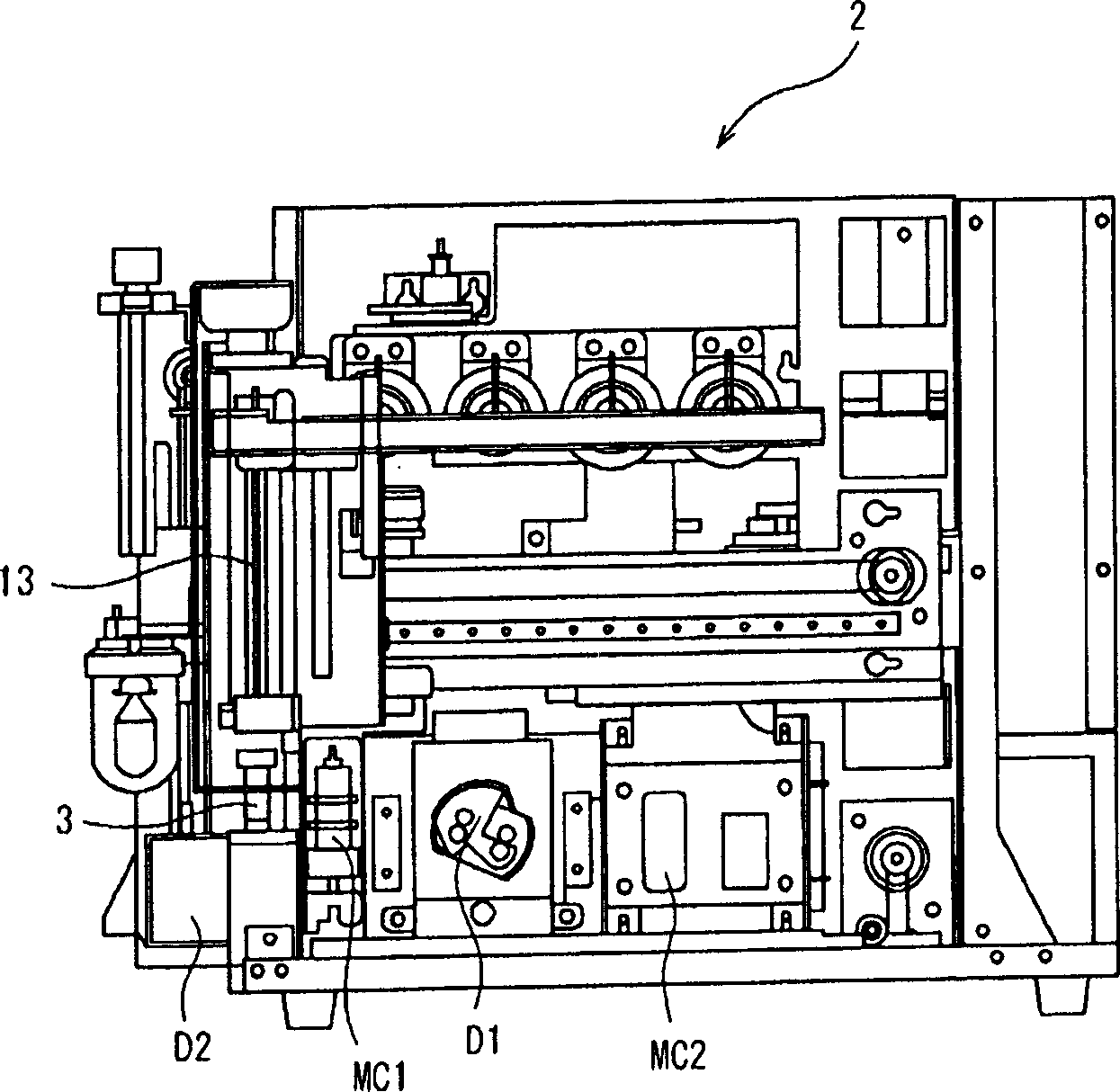

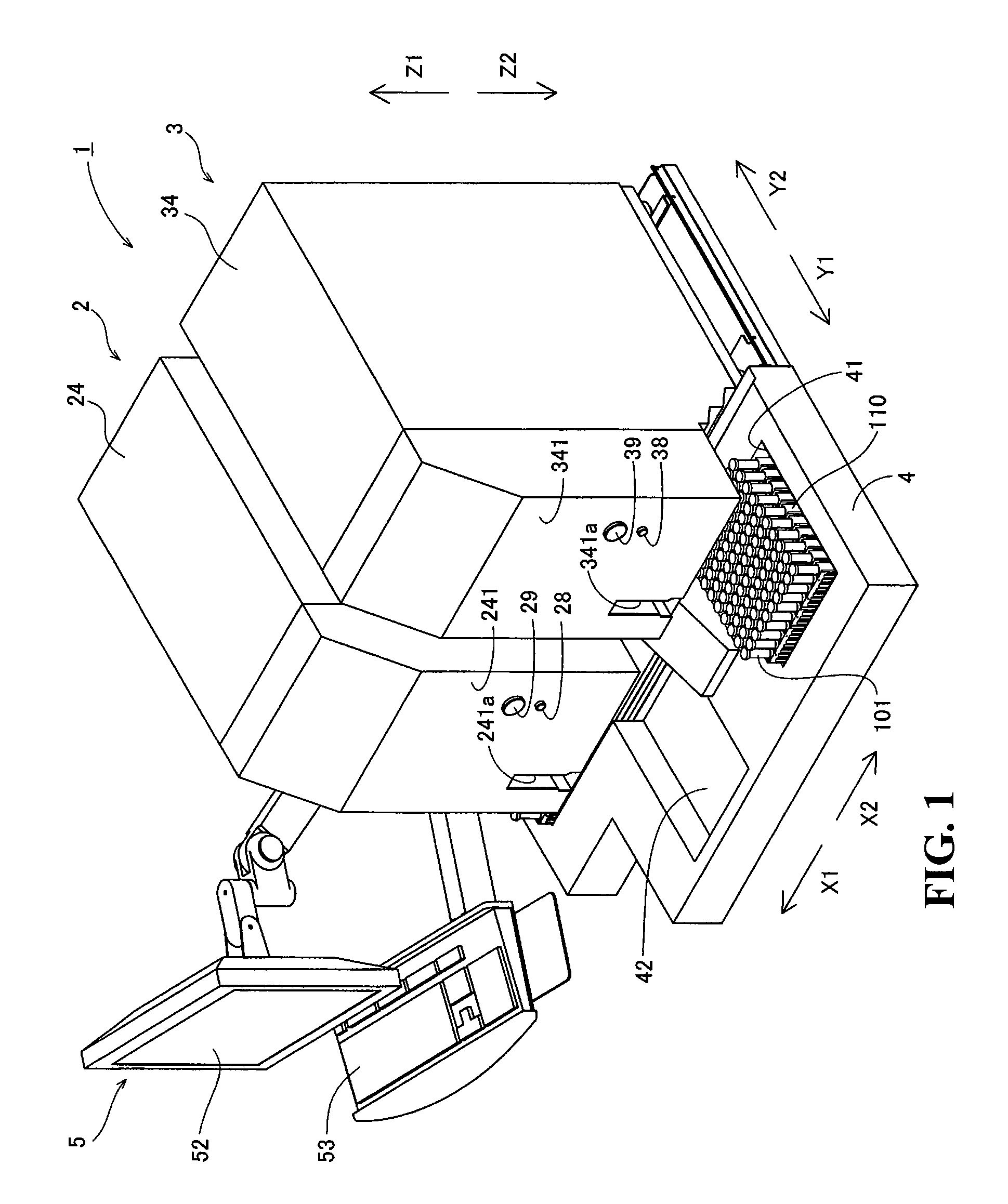

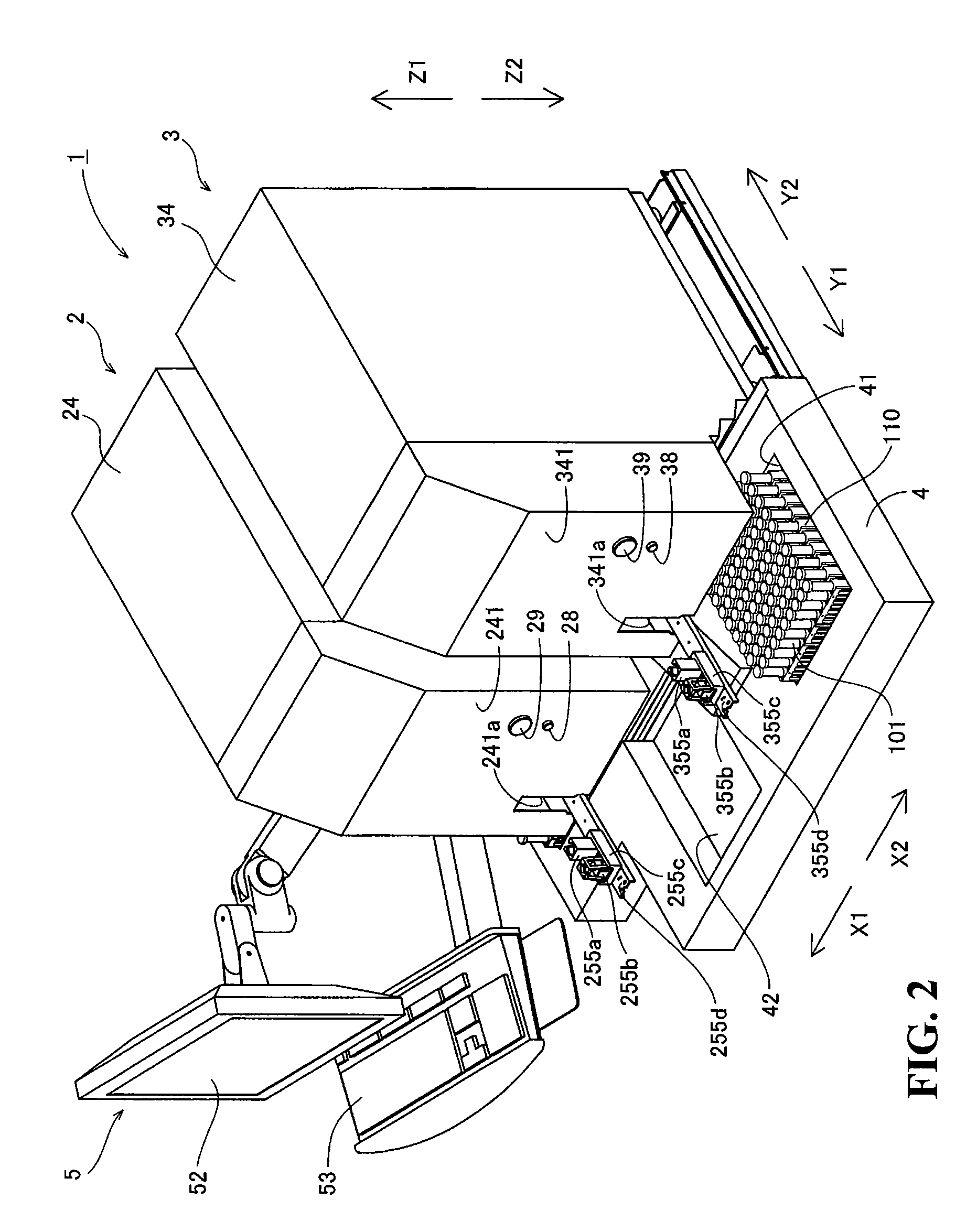

Multi-scale & three-axis sensing tensile testing apparatus

ActiveUS7681459B1Easy to measureForce measurementMaterial strength using tensile/compressive forcesFirst specimenEngineering

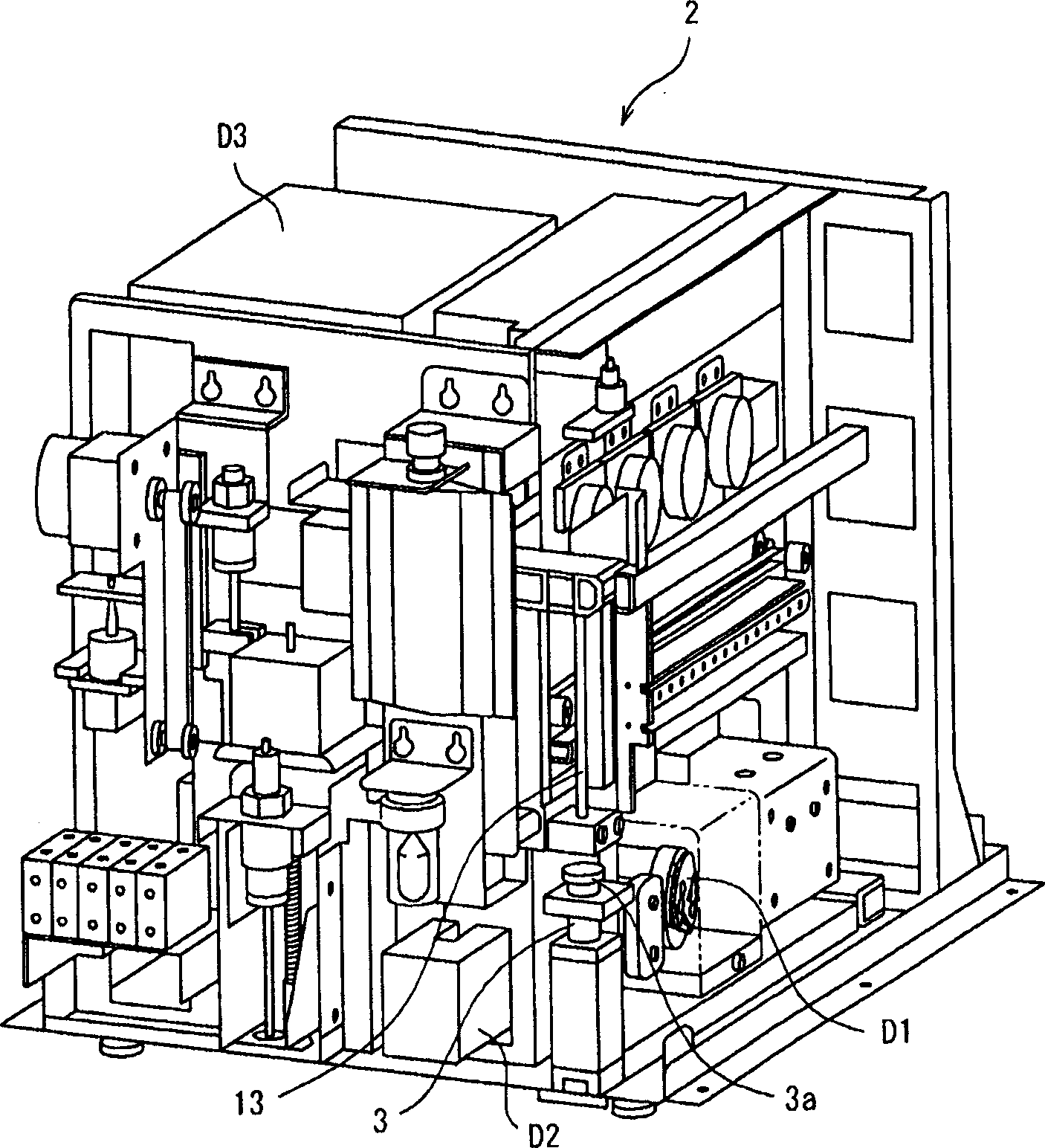

A tensile testing apparatus is provided, and generally includes an X-Y automated stage, and a first specimen holder for holding and transferring force to a specimen to a first portion of a specimen. The first specimen holder is operatively supported by the X-Y automated stage. A Z-automated stage, a multi-function nanotensile transducer head assembly, and a second specimen holder for holding and transferring force to a second portion of the specimen is further provided. The second specimen holder is operatively linked to the Z-automated stage via the nanotensile transducer head assembly. Variable displacement modalities, and non-Z alignment assessment and adjustment are enabled by the multi-function nanotensile transducer head assembly, as well as the X, Y, and Z automated stages.

Owner:BRUKER NANO INC

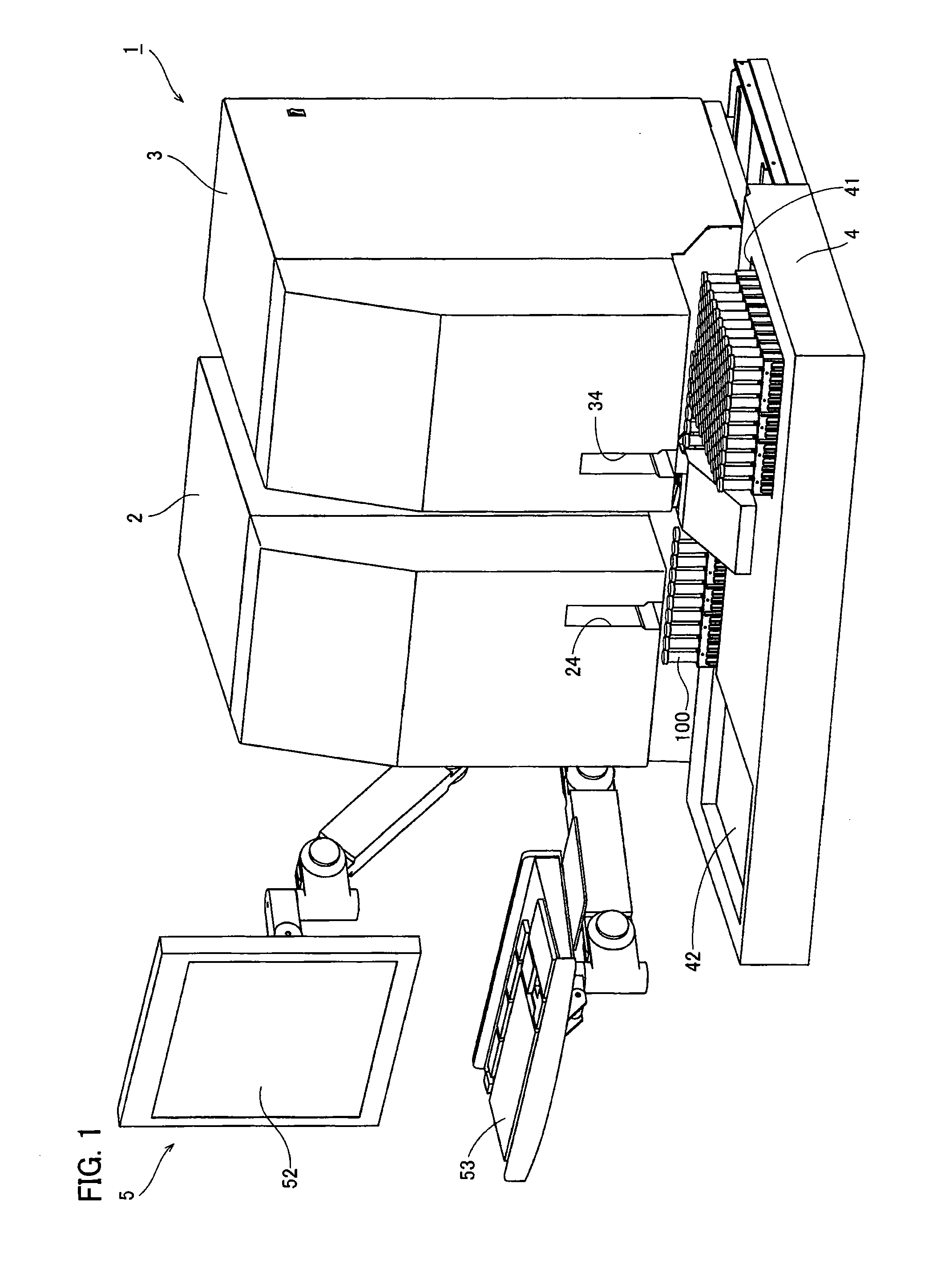

Sample analyzer and sample analyzing method

InactiveCN1834659AMaterial analysis by optical meansIndividual particle analysisAnalysis methodFirst specimen

The invention relates to a specimen analyzer, which can analyze the mixed specimen with specimen and agent. It comprises: a container, a specimen supplier, the first specimen supplier, the second specimen supplier, the first detecting part, the first mixture specimen supplier, the second detecting part, and the second mixture specimen supplier. Wherein, the container is used to contain the mixture specimen and the specimen; the specimen supplier supplies the specimen to said container; the first specimen supplier supplies the first specimen to the container; the second specimen supplier supplies the second specimen to the container; the first detecting part detects the first mixture specimen of specimen and the first specimen; the first mixture specimen supplier supplies the first mixture specimen from the container to the first detecting pat; the second detecting part detects the second mixture specimen of first specimen and second specimen; the second mixture specimen supplier supplies the second mixture specimen from the container to the second detecting part; the first mixture specimen supplier keeps some first mixture specimen in the container and supplies some to the first detecting part; and the second specimen supplier supplies some second specimen to the container that contains left first mixture specimen to prepare the second mixture specimen.

Owner:SYSMEX CORP

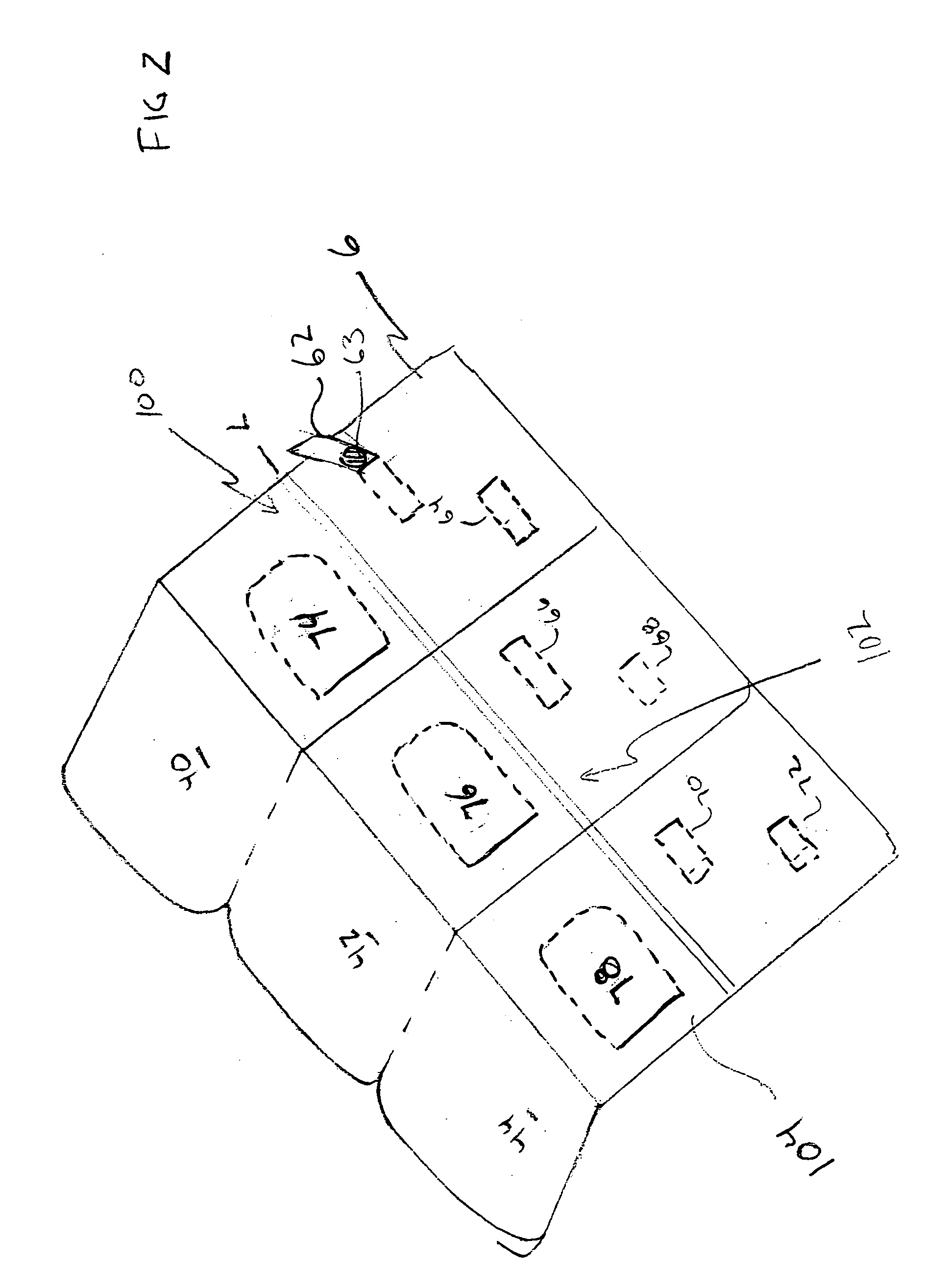

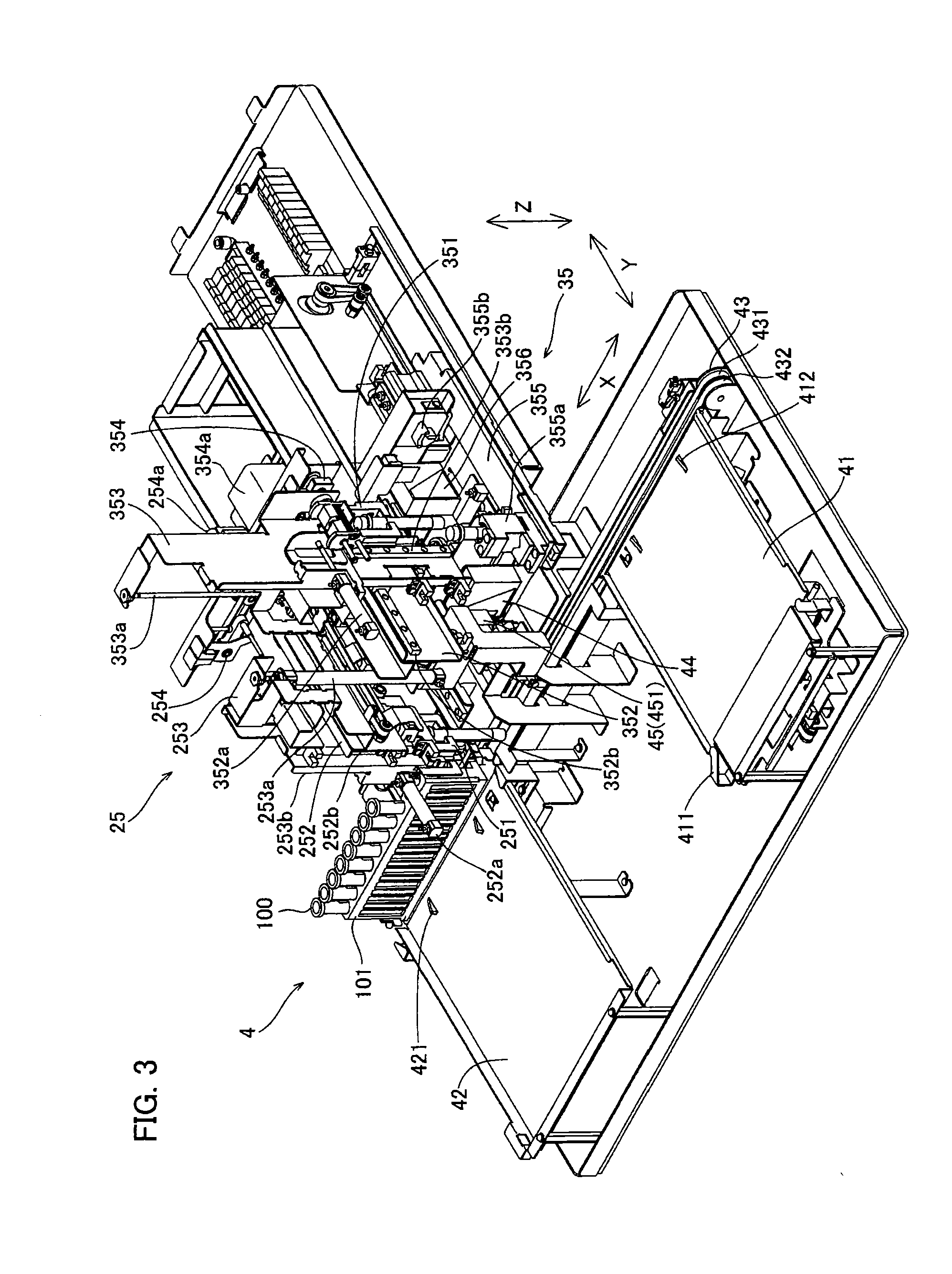

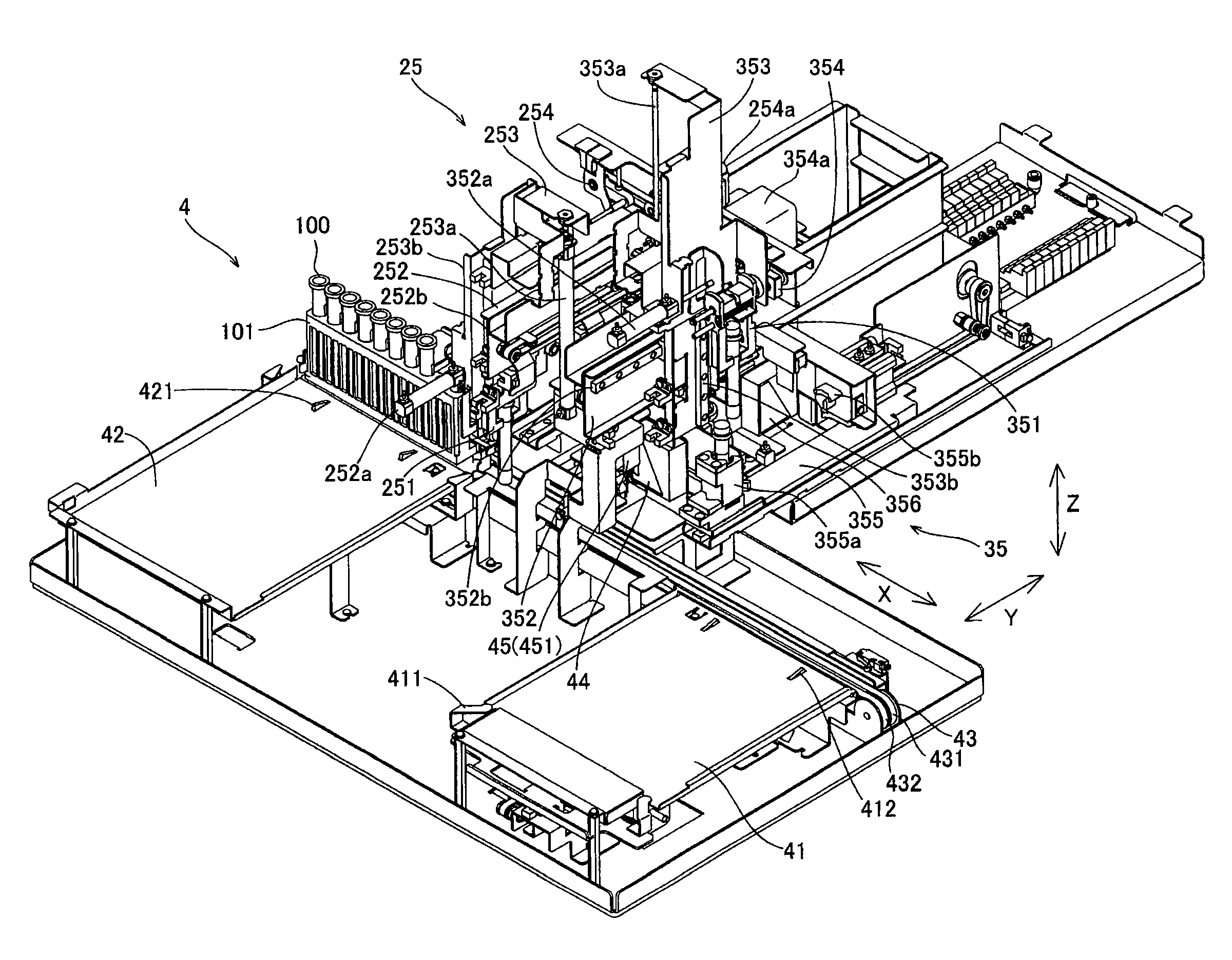

Analyzer

ActiveUS20090325274A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFirst specimenEngineering

An analyzer comprising: a first specimen holder configured to hold a plurality of first specimen containers; a conveying assembly for conveying the first specimen containers held in the first specimen holder; a second specimen holder arranged at a position higher than an upper end of the first specimen containers held in the first specimen holder; a holder moving assembly for moving the second specimen holder so as to pass the upper side of at least one of the first specimen containers held in the first specimen holder; a container transferring assembly for transferring at least one of the first specimen containers from the first specimen holder to the second specimen holder; and a controller for controlling the holder moving assembly and the container transferring assembly, is disclosed.

Owner:SYSMEX CORP

Multiple-input Analytical System

ActiveUS20110159578A1Bioreactor/fermenter combinationsBiological substance pretreatmentsHuman papillomavirusComputer science

The present disclosure provides an automated sample processing system that can receive samples in different first and second formats and process both sample formats. The disclosure also provides a human papillomavirus testing apparatus. The apparatus has a first input to receive first test specimens in the form of pre-processed cervical samples, and a second input to receive unprocessed cervical samples. A first subsystem prepares second test specimens from the unprocessed cervical samples, and a second subsystem selectively processes and tests first specimens, second test specimens, or first and second test specimens to determine the presence of one or more human papillomavirus indicators.

Owner:BECTON DICKINSON & CO

Specimen analysis apparatus and specimen analysis method

ActiveUS20070231208A1Material analysis by optical meansBurettes/pipettesAnalysis methodFirst specimen

A specimen analysis method, comprising: bringing a first specimen vessel to a sucking position for sucking specimens; obtaining a first measurement result of a first specimen contained in the first specimen vessel; bringing a second specimen vessel to the sucking position before the first measurement result is obtained; obtaining a second measurement result of a second specimen contained in the second specimen vessel; bringing a third specimen vessel to the sucking position after the first measurement result is obtained; obtaining a third measurement result of a third specimen contained in the third specimen vessel; and obtaining a fourth measurement result of the second specimen when the first measurement result is higher than a threshold, the second specimen being sucked at the sucking position again for obtaining the fourth measurement result before bringing the third specimen vessel to the sucking position, is disclosed. A specimen analysis is also disclosed.

Owner:SYSMEX CORP

Apparatus for analyzing particles in urine and method thereof

ActiveCN101173888AMaterial analysis by optical meansBiological particle analysisFluorescenceRed Cell

An apparatus, intended for use in analyzing particles in urine is disclosed, that comprising: a sample distribution section for distributing urine samples to a first aliquot and a second aliquot; a first specimen preparing section for preparing a first specimen for measuring urinary particles, containing at least erythrocytes, by mixing a first stain reagent and the first aliquot; a second specimen preparing section for preparing a second specimen for measuring bacteria by mixing a second stain reagent and the second aliquot; and an optical detecting section comprising a light source for irradiating a light to a specimen being supplied, a scattered light receiving element for detecting scattered light emitted from the specimen, and a fluorescence receiving element for detecting fluorescence emitted from the specimen. A method intended for use in analyzing particles in urine is also disclosed.

Owner:SYSMEX CORP

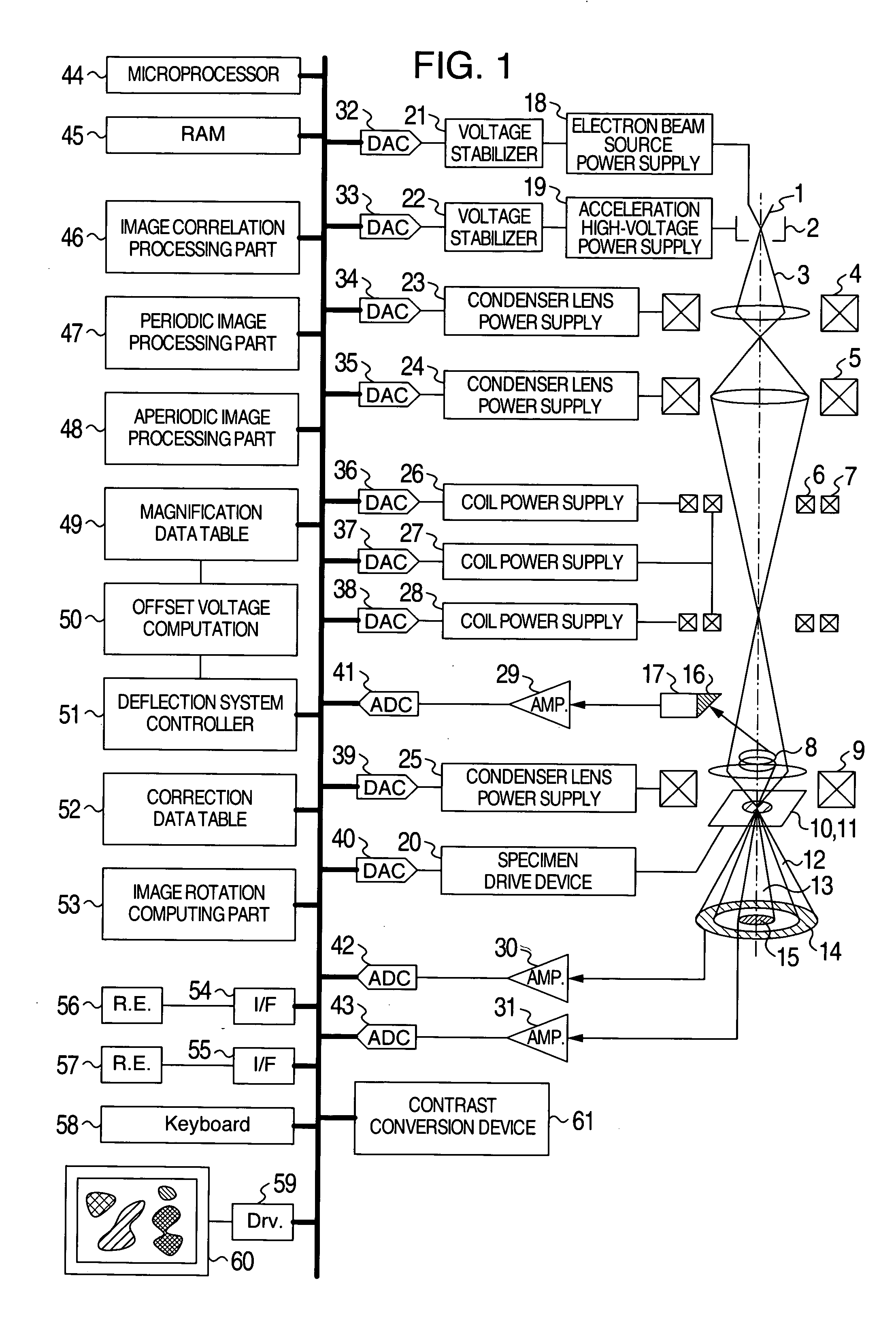

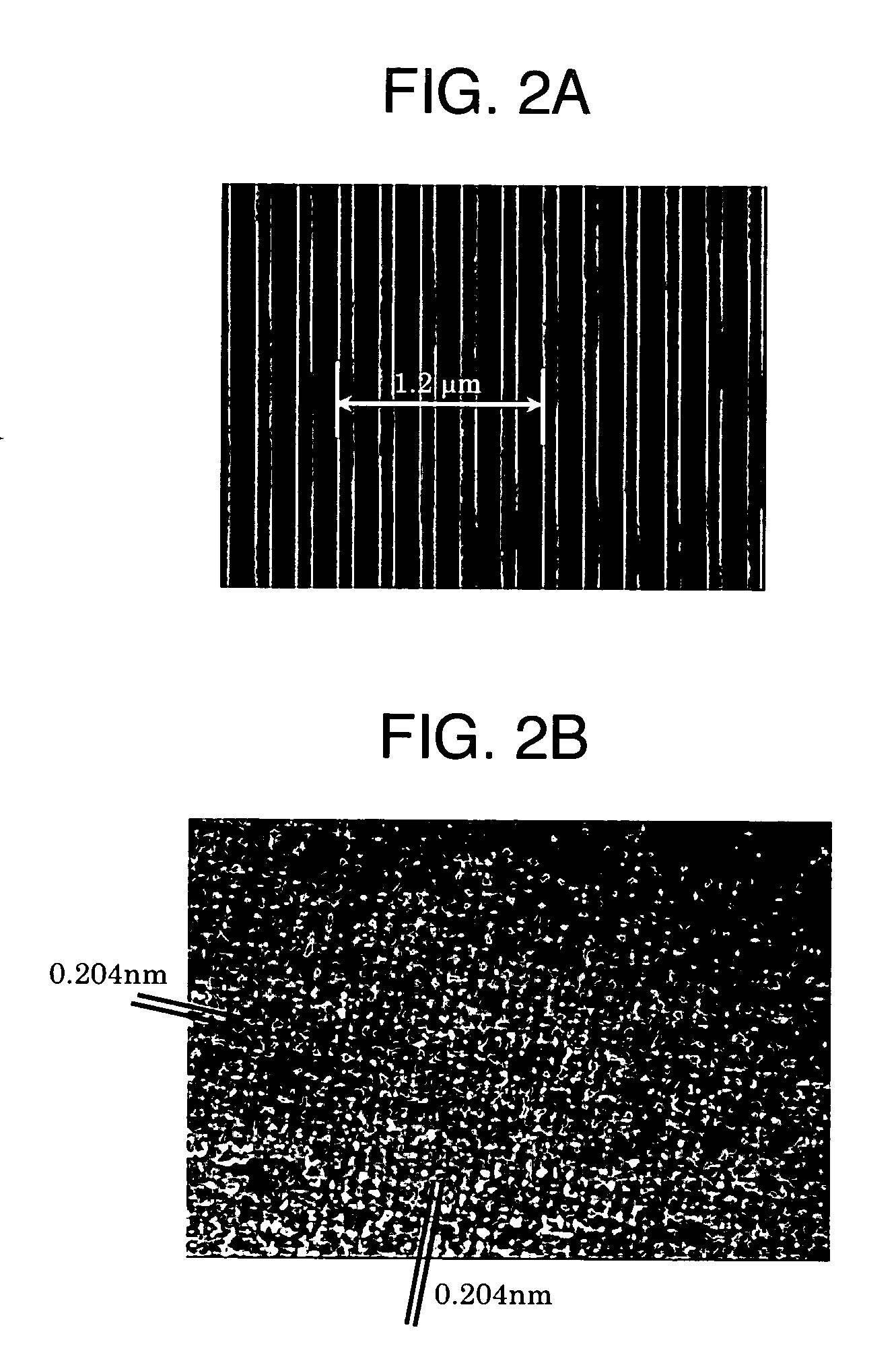

Charged particle beam equipment and charged particle microscopy

ActiveUS20060151697A1Reduce the impactGuaranteed accuracyMaterial analysis using wave/particle radiationElectric discharge tubesParticle beamLight beam

On the basis of a displacement of the field of view before and after a deflection of a charged particle beam, extracted from a first specimen image, including a displacement of the field of view recorded by causing a charged particle beam to deflect by a predetermined amount by a beam deflector in an image in which a specimen image is captured at a first magnification calibrated by using a specimen enlarged image of a specimen as a magnification standard, and also a displacement of the field of view before and after a deflection of the charged particle beam, extracted from a second specimen image, including a displacement of the field of view recorded by causing a charged particle beam to deflect by the predetermined amount by the beam deflector in an image in which a specimen image is captured at a second magnification, the second magnification is calibrated.

Owner:HITACHI HIGH-TECH CORP

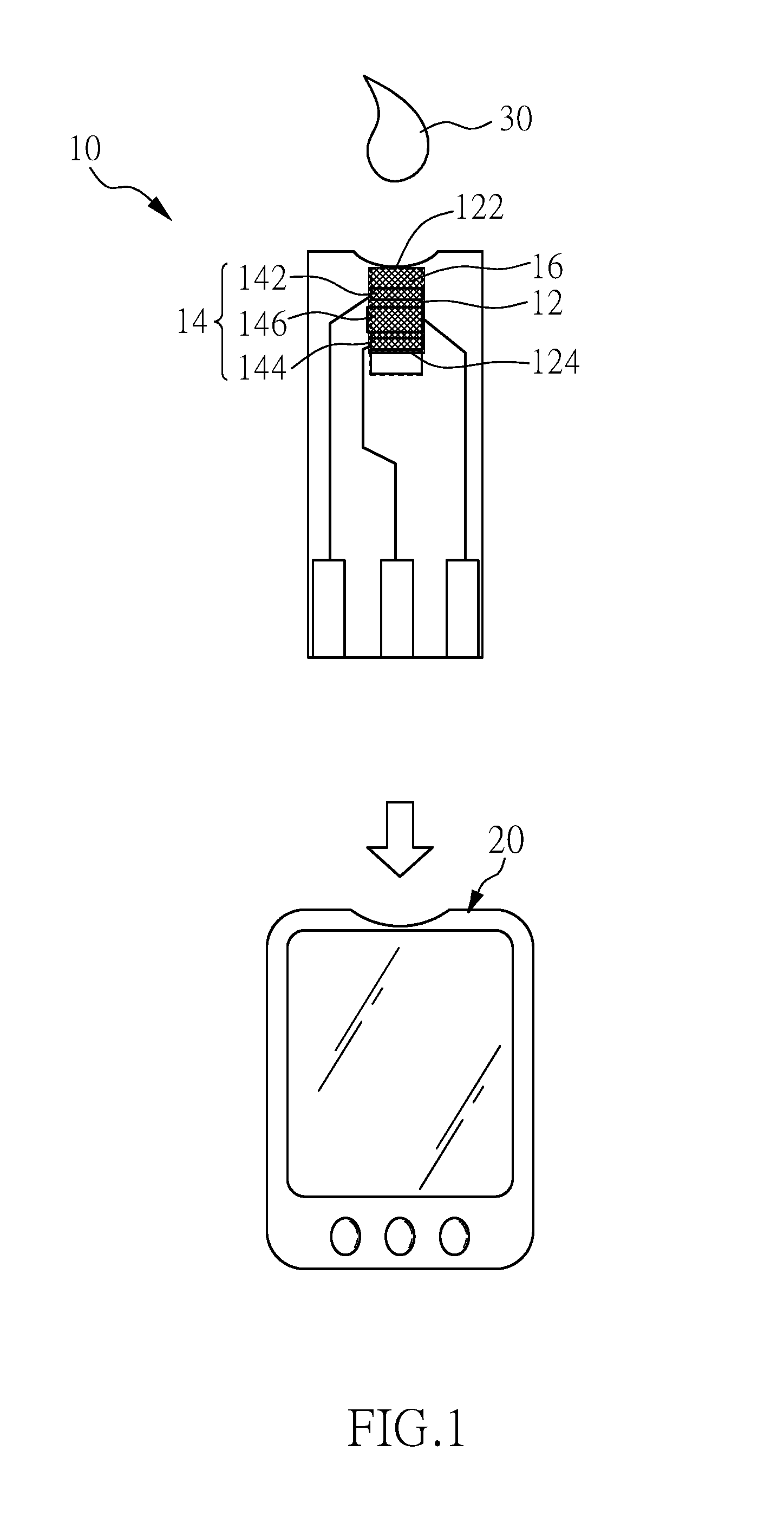

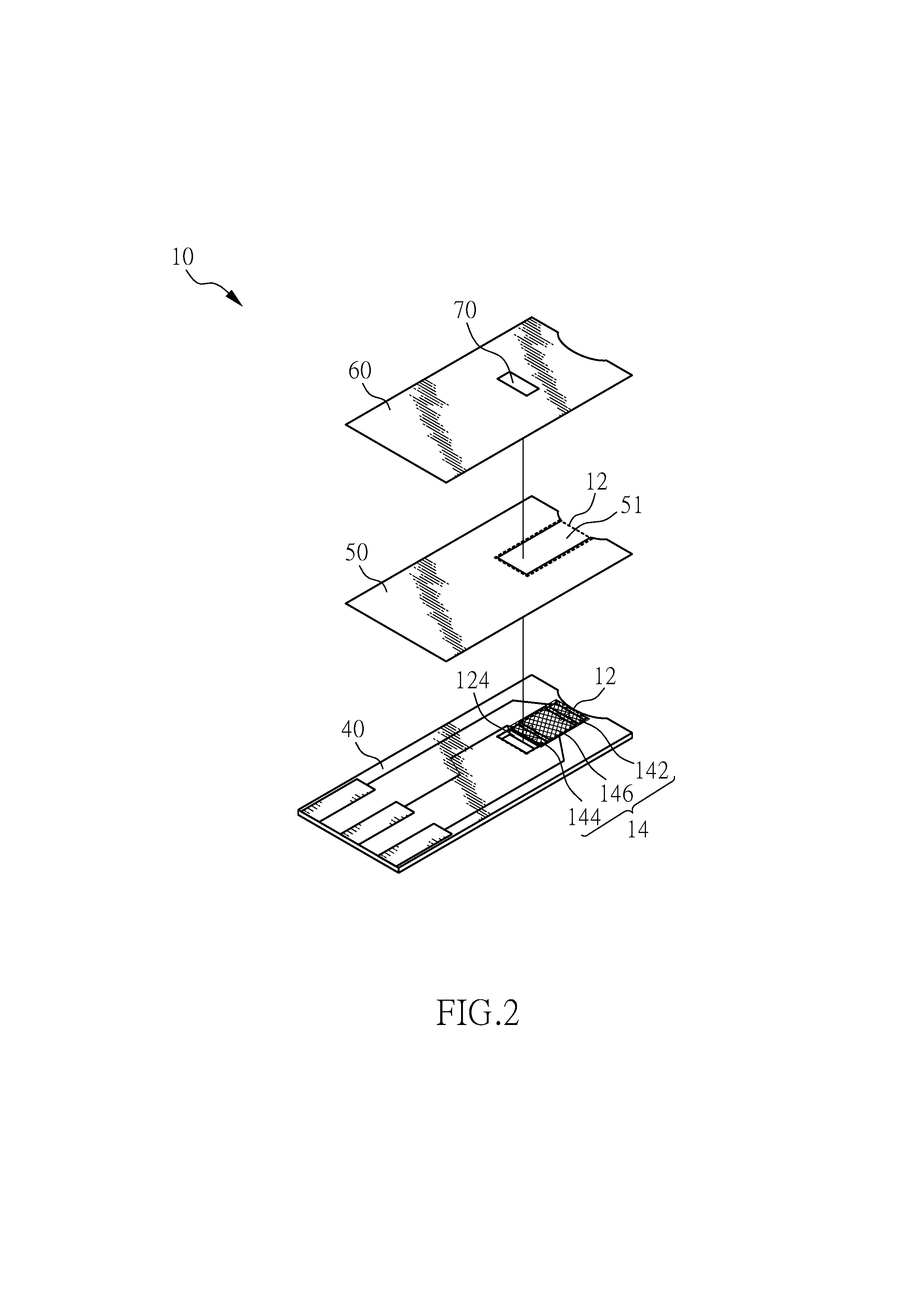

Test Strip and Detecting Device

InactiveUS20130341186A1Accurate detectionAccurate concentrationImmobilised enzymesBioreactor/fermenter combinationsAnalyteOxidation-Reduction Agent

A test strip and a detecting device are disclosed. The test strip can be used with an electrochemical instrument to accurately detect the viscosity and concentration of an analyte of a specimen. The test strip includes a first specimen path, a first electrode set, a redox reagent, a second specimen path, a second electrode set, and a reaction reagent. The redox reagent includes at least a redox pair. When the specimen enters the first specimen path, the redox pair dissolves and generates an electrochemical redox reaction for obtaining a flow time of the specimen. When the specimen enters the second specimen path, the reaction reagent is used to obtain the analyte concentration of the specimen, and the concentration of the analyte can be corrected by the flow time.

Owner:HMD BIOMEDICAL

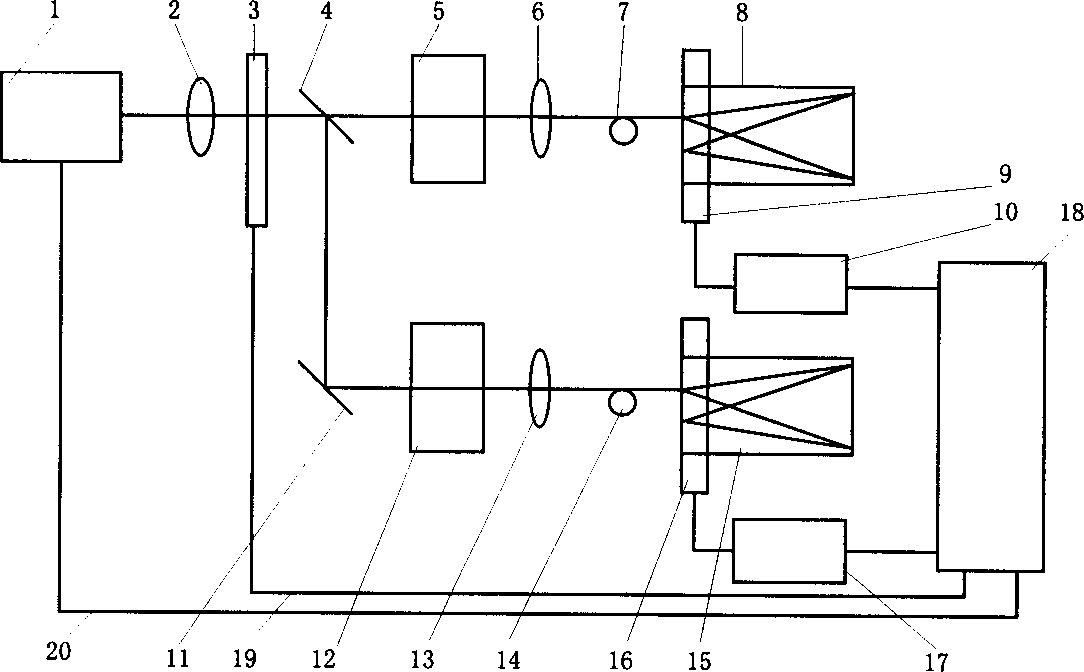

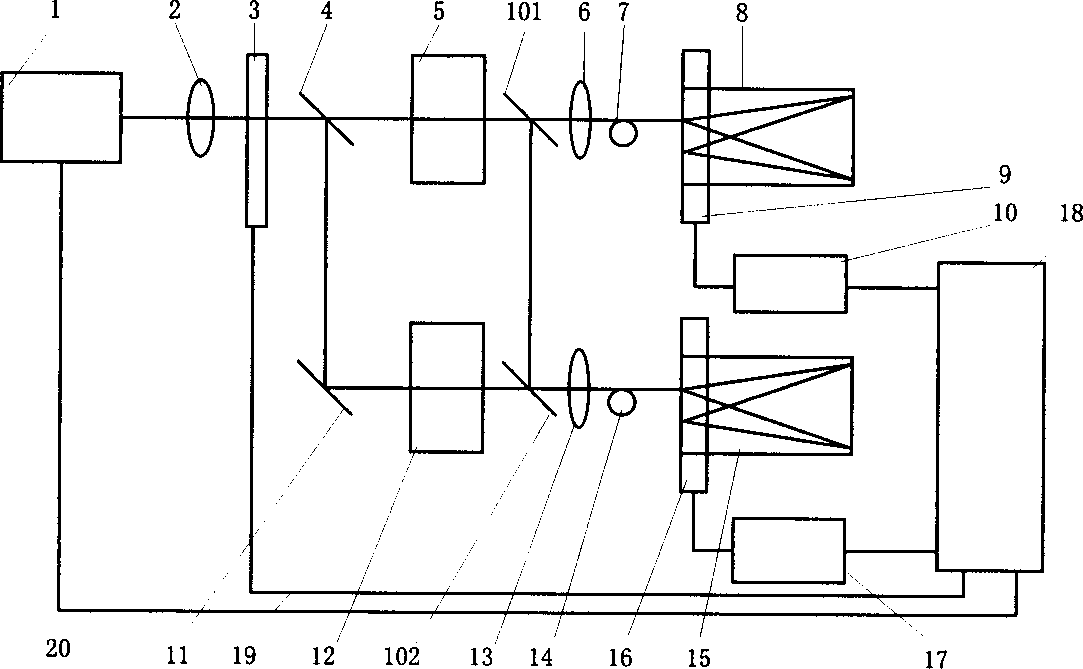

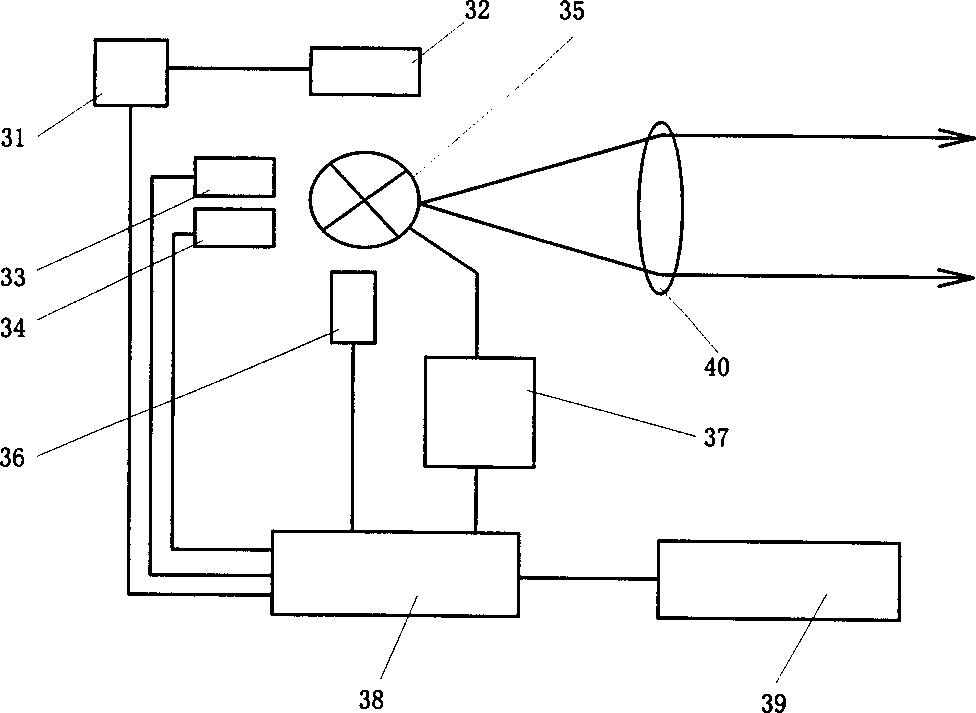

Miniature biochemical analyzer using dual-spectrum detection

InactiveCN1338623AHigh sensitivityLarge measurement dynamic rangeRadiation pyrometryMaterial analysis by optical meansTime errorData treatment

A miniature biochemical analyzer using dual-spectrum detection is composed of the first optical channel consisting of adaptive regulatable light source, optical attenuator, the first specimen chamber, the first integrated spectrometer and the first A / D converter, the second optical channel consisting to the second specimen chamber, the second integrated spectrometer and the second A / D converter, and the computer data processing system. Its advantages include wide dynamic range and more functions of adaptive dynamic regulation, self scaling, and real-time error correction.

Owner:周向前 +1

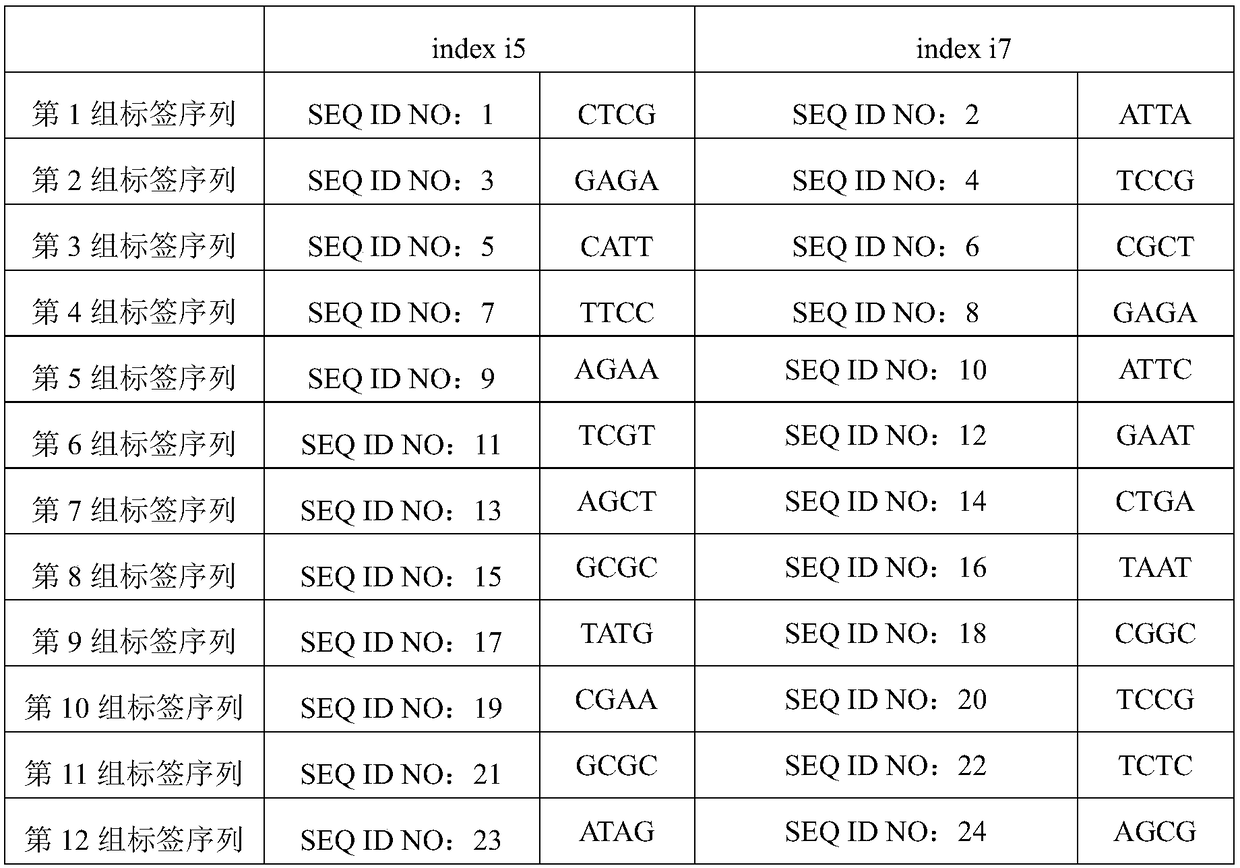

Low frequency mutation detection method, kit and device

InactiveCN108949941AEfficient constructionEfficient detectionMicrobiological testing/measurementLibrary creationMutation detectionFirst specimen

The invention provides a sequencing adapter, which has a Y-like structure and includes: a first chain, which comprises a first specimen label sequence and a first molecular label sequence that are connected to each other; a second chain, which includes a second specimen label sequence and a second molecular label sequence that are connected to each other; therefore, by means of the sequencing adapter, a high-throughput sequencing library of a genome DNA sample is effectively constructed, especially effectively constructing a high-throughput sequencing library suitable for detecting low frequency mutation. By sequencing the library and performing data analysis on the basis of a sequencing result, sequence information is obtained. The method can detect the genome DNA sample, high-effectively, accurately and rapidly and can be applied extensively.

Owner:杭州莲和医学检验所有限公司

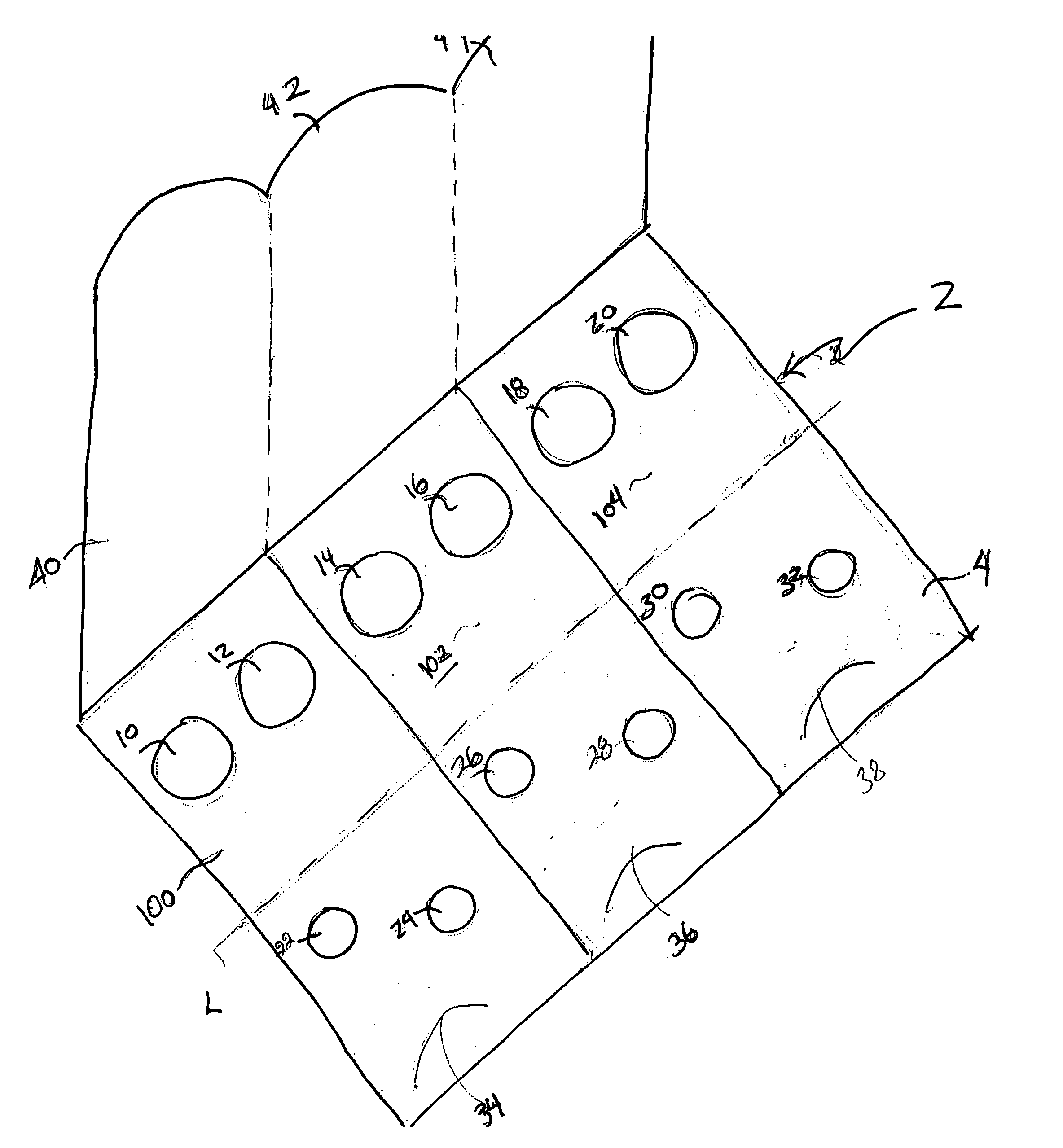

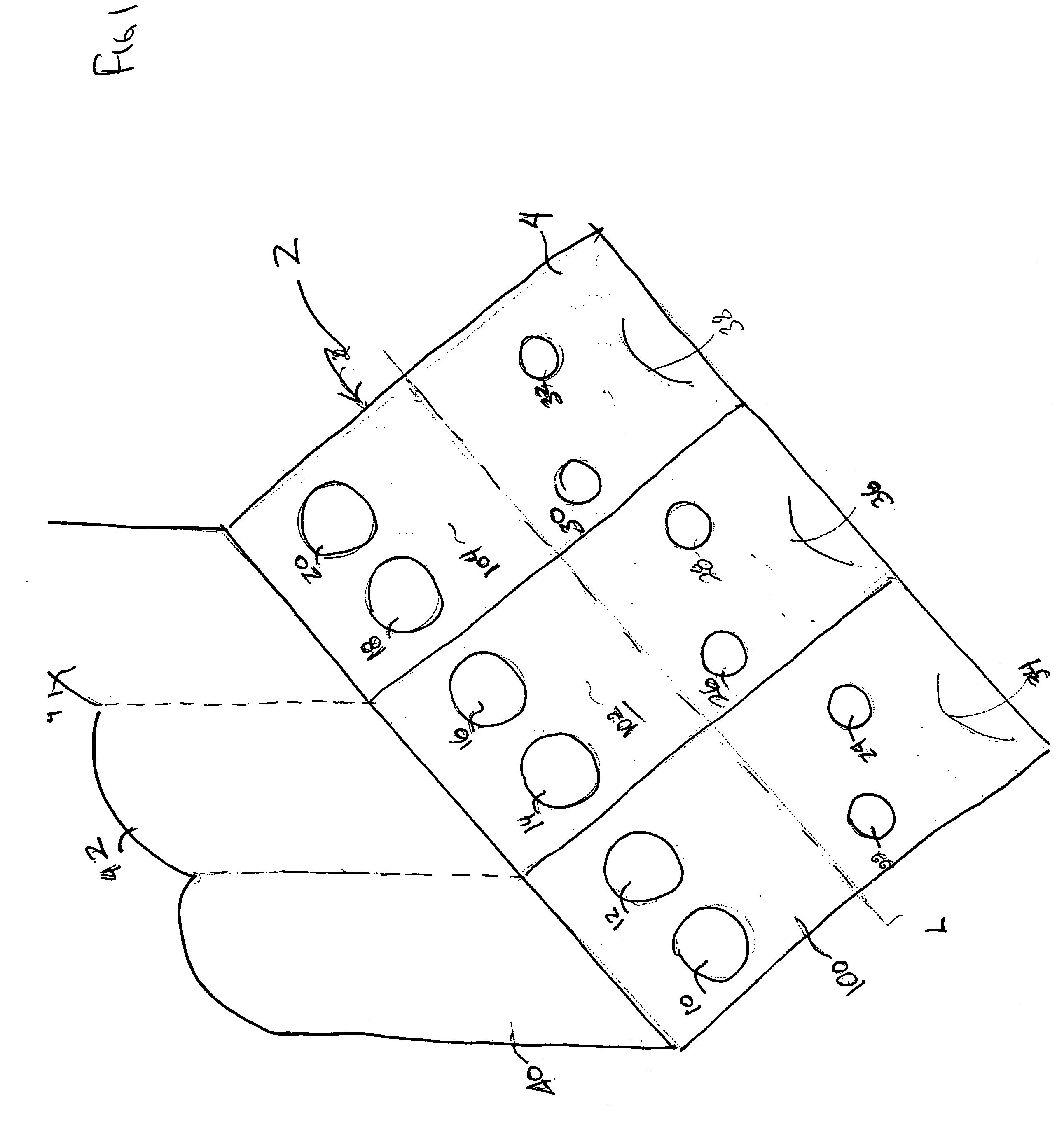

Overlaying replica, heaping replica and methods of manufacturing same

A replica of fossil or the like can be handily manufactured using color prints obtained by photographing the fossil without preparing a mother mold. An overlaying replica is manufactured by preparing a plurality of prints, each having the same size, and obtained by photographing a collected specimen from given angles, cutting specimen parts to form a plurality of specimen prints, bonding said specimen prints by a solid paste one by one substantially in the same direction while they are overlaid on one another and kept at a given interval therebetween. A heaping replica is manufactured by preparing two prints, each having the same size and obtained by photographing a collected specimen from given angles, cutting specimen parts to form two specimen prints, molding a specimen dimensionally on the first specimen print by plastics using a spatula, and overlaying and bonding the second specimen print onto the molded three-dimensional specimen.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Fecal occult blood testing device and method

InactiveUS20060018789A1Easy to identifyAnalysis using chemical indicatorsVaccination/ovulation diagnosticsTest fixtureTest procedures

A specimen testing device having a first panel including a first aperture for receiving a first specimen and a second aperture for receiving a second specimen; a second panel; a sheet disposed between the first and second panels for receiving at least the first specimen through the first aperture, wherein the sheet includes a test area having a reagent for possible reaction to the first specimen as part of a primary test procedure; and a removable tab at least partially aligned with the second aperture for receiving the second specimen, the removable tab accessible from an exterior of the device and available for use in a secondary test procedure. A method of testing for the presence of blood in fecal matter including primary and secondary testing of the fecal matter. A test kit including a specimen testing device and reagents for performing a primary test a secondary test on specimens.

Owner:IMMUNOSTICS

Analysis apparatus and analysis method

ActiveUS20100330609A1Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAnalysis method

This analysis apparatus includes a transporter transporting the specimens to the first measurement unit and the second measurement unit, and a control portion so controlling the transporter as to transport a first specimen container, stored in the rack, storing a first specimen to the first measurement unit and as to transport a second specimen container, stored in the rack along with the first specimen container, storing a second specimen to the second measurement unit.

Owner:SYSMEX CORP

Analysis apparatus and analysis method

ActiveUS8865072B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAnalysis method

This analysis apparatus includes a transporter transporting the specimens to the first measurement unit and the second measurement unit, and a control portion so controlling the transporter as to transport a first specimen container, stored in the rack, storing a first specimen to the first measurement unit and as to transport a second specimen container, stored in the rack along with the first specimen container, storing a second specimen to the second measurement unit.

Owner:SYSMEX CORP

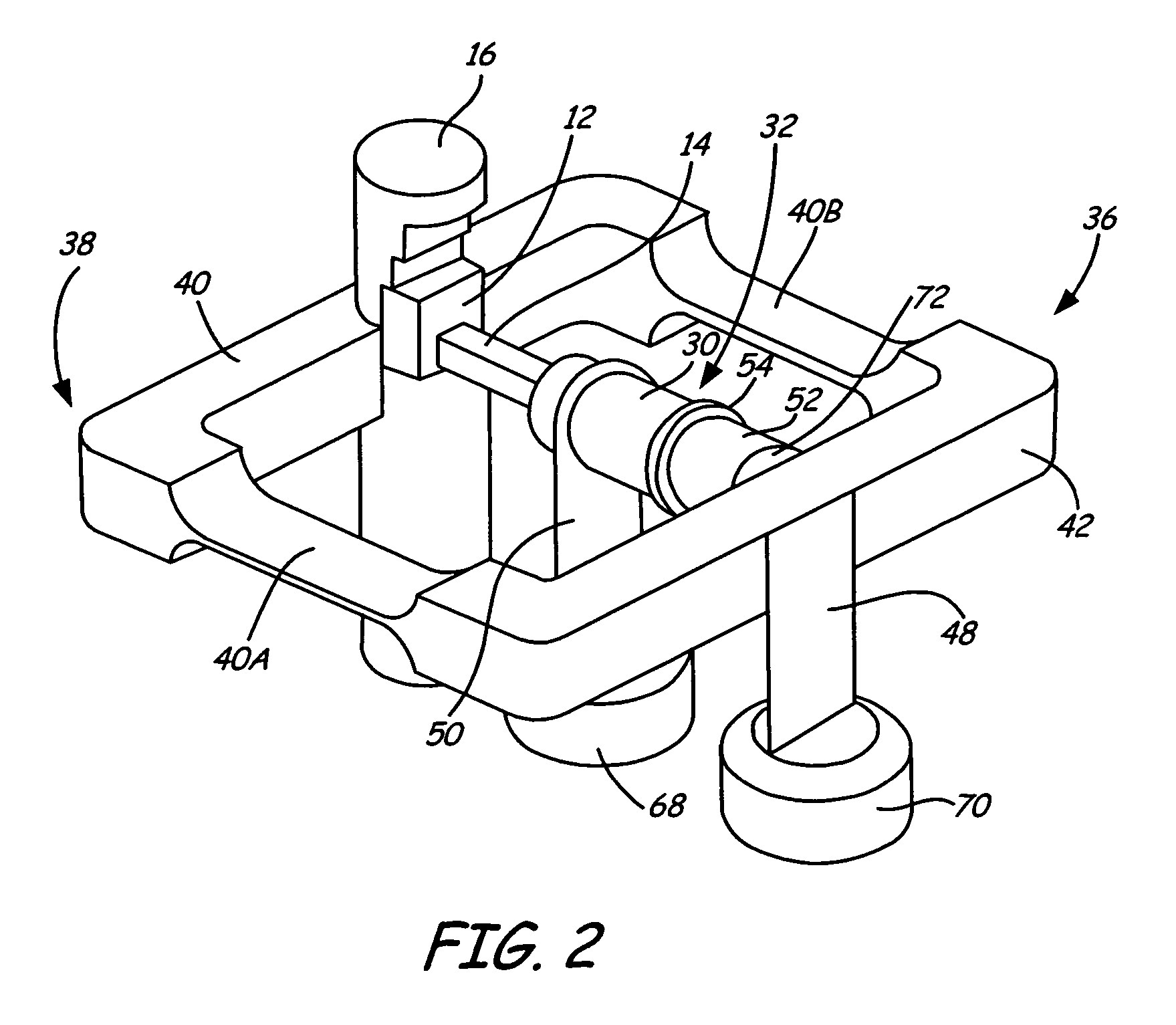

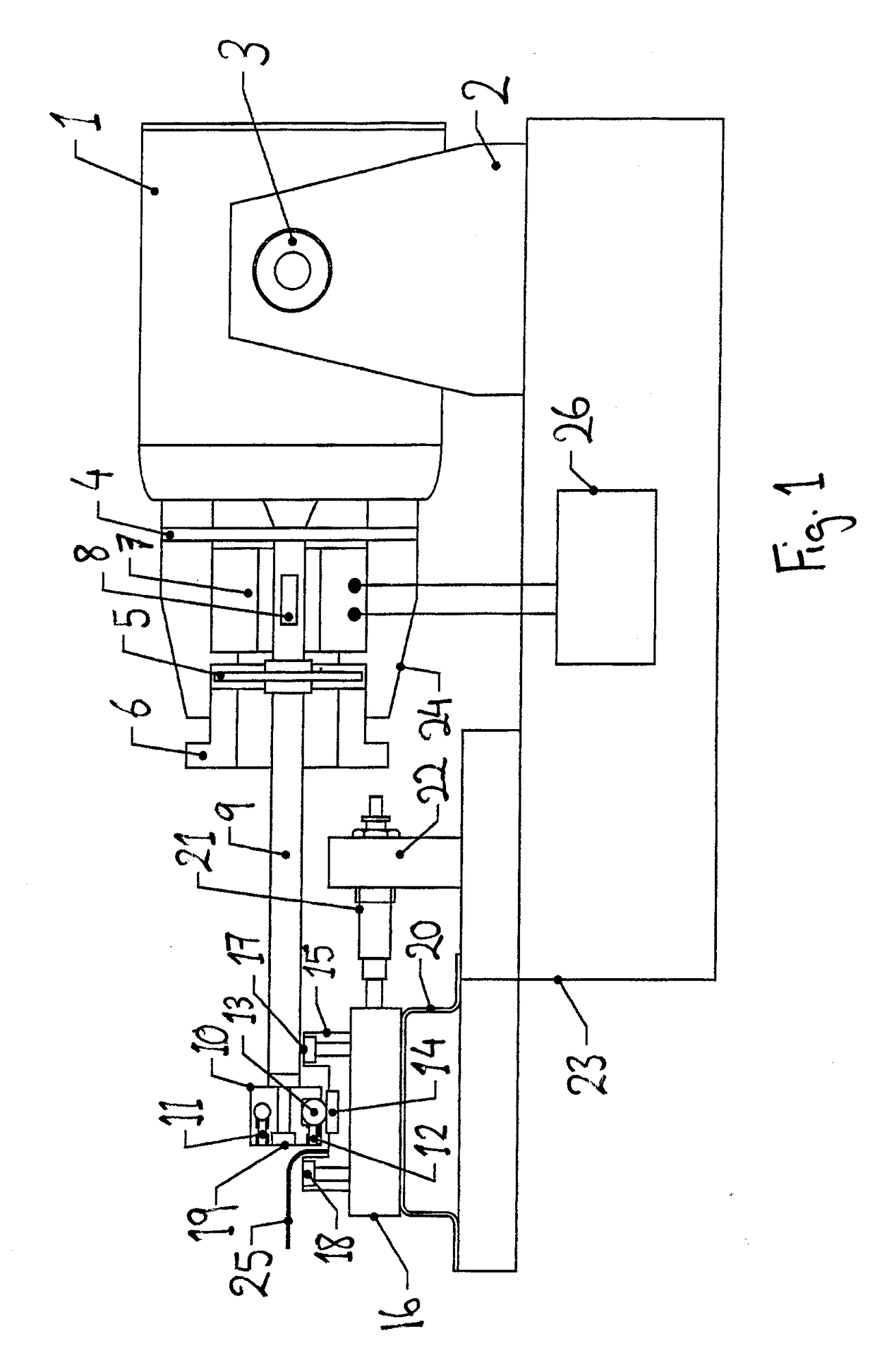

Wear tester

InactiveUS20070017300A1Well formedMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceEngineeringFirst specimen

A test assembly structure having a first specimen support, a displacement mechanism joined to the first specimen support and a second specimen support. A loading assembly is joined to the second specimen support and configured so as to engage a specimen held by the second specimen support with a specimen held by the first specimen support. A self-reacting structure is joined to the loading assembly having a flexure substantially rigid in the direction of loading of the loading assembly and substantially compliant in the direction of displacement of the displacement mechanism. A second flexure can be configured to support the second specimen support and / or loading assembly on a base. The second flexure is substantially compliant in the direction of loading of the loading assembly and substantially rigid in the direction of displacement of the displacement mechanism.

Owner:MTS SYSTEMS CORPORATION

Test strip, detecting device and detecting method

ActiveUS20140224672A1Accurate detectionEasy to captureImmobilised enzymesBioreactor/fermenter combinationsAnalyteFlow time

A test strip, a detecting device, and a detecting method are disclosed. The test strip includes a first specimen path, a first electrode set, a second specimen path, a second electrode set, and a reaction reagent. When the specimen contacts the first electrode set and the second electrode set, a first pulse signal and a second pulse signal are generated for obtaining a flow time of the specimen. When the specimen contacts the reaction reagent, the analyte concentration of the specimen can be obtained, and the concentration of the analyte can be corrected by the flow time.

Owner:HMD BIOMEDICAL

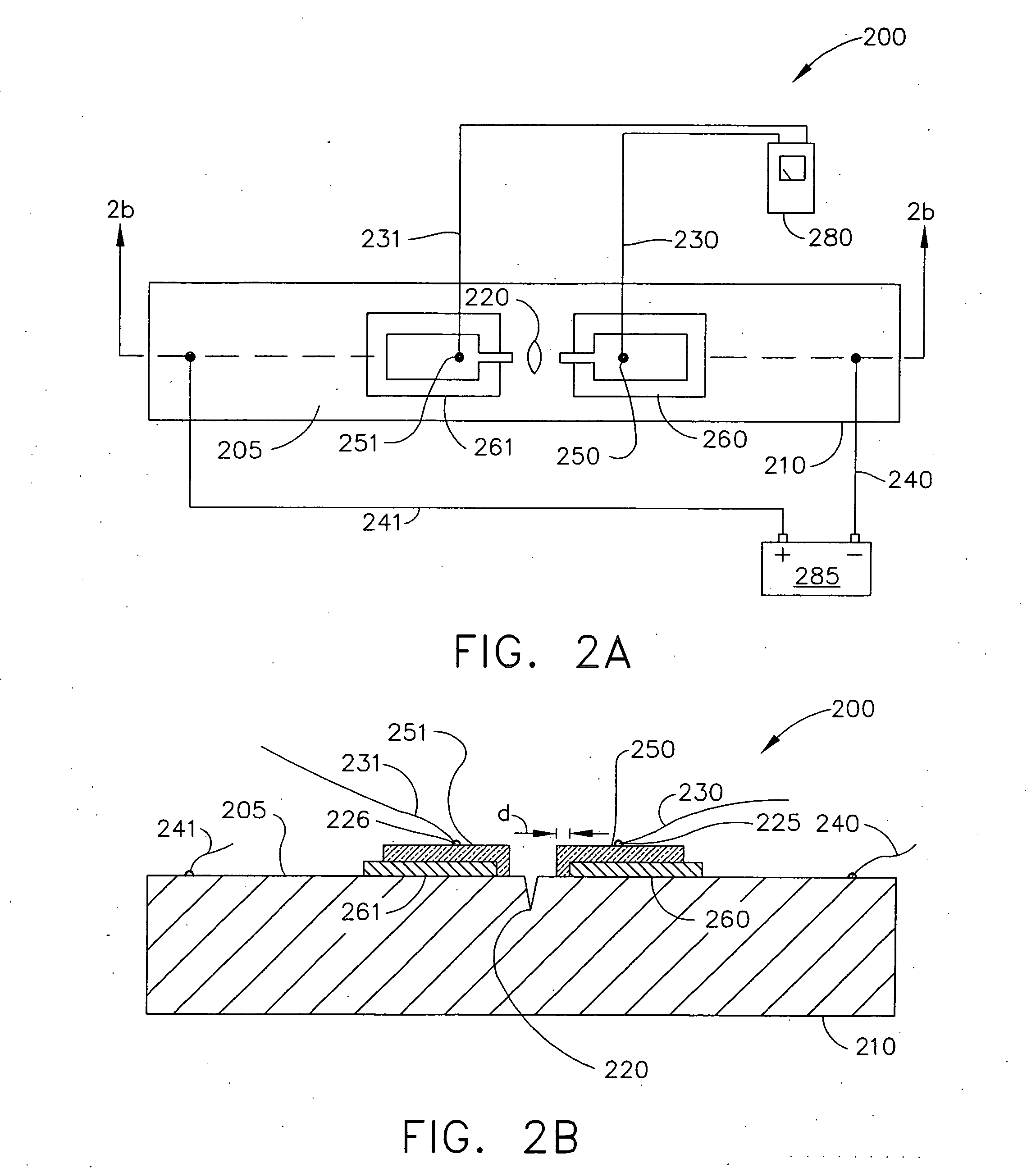

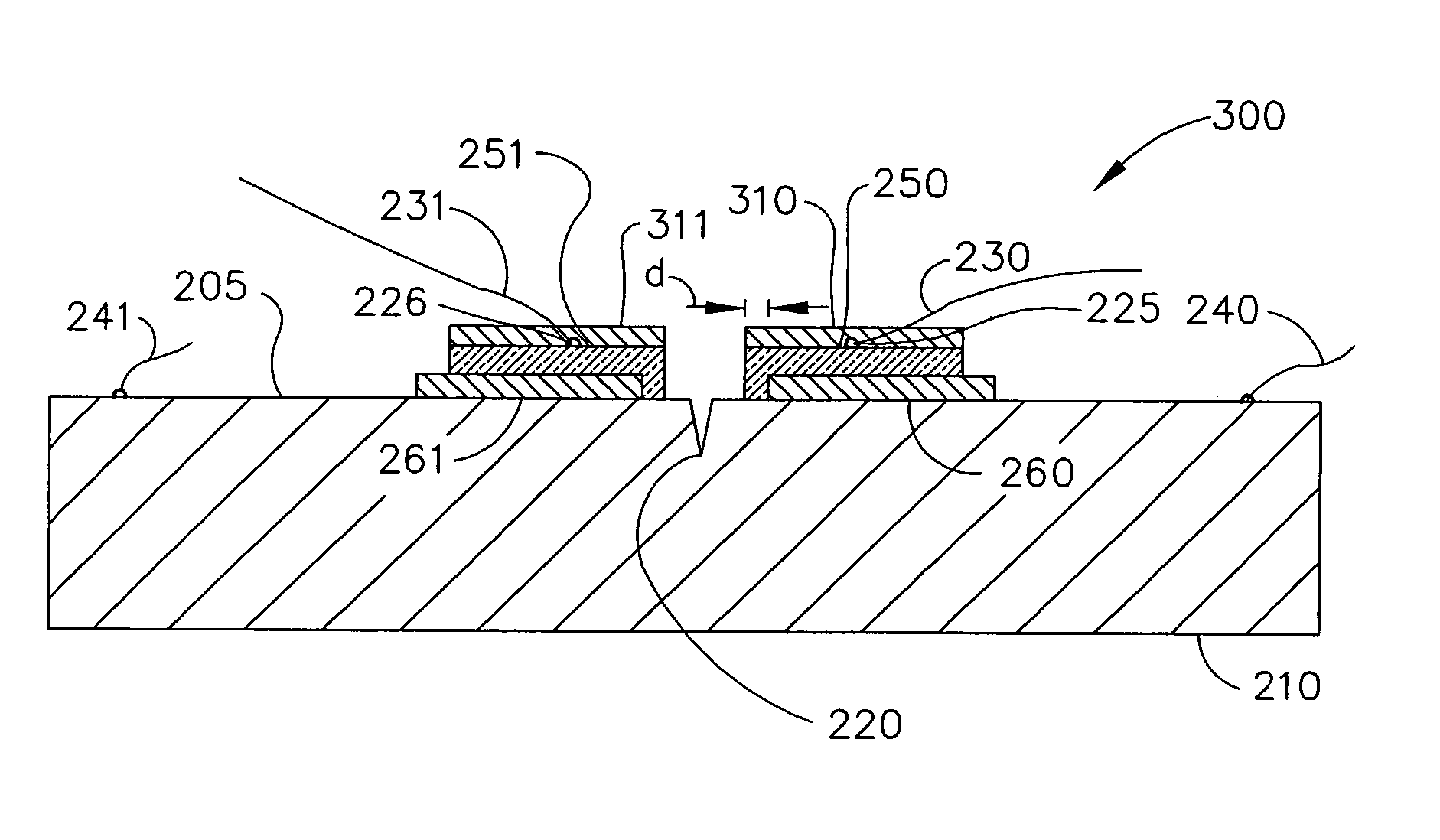

Instrumentation and method for monitoring change in electric potential to detect crack growth

InactiveUS20060137466A1Sensitive measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesResistance/reactance/impedenceElectricityConductive materials

Instrumentation for monitoring crack growth using a change in electric potential across a starter crack as the crack propagates is disclosed. The instrumentation includes a specimen of a material to be analyzed for crack growth propagation having a surface with a starter crack formed therein, a plurality of current leads to pass electric current through the specimen, a layer of insulating material disposed on each of opposite sides of the crack, a layer of conductive material disposed on each layer of insulating material, where a portion of each layer of conductive material is in electrical contact with the first specimen surface, and a pair of sensing leads, one sensing lead attached to each layer of conductive material. A method for using the instrumentation to monitor crack growth by measuring is also disclosed.

Owner:GENERAL ELECTRIC CO

Analyzer

ActiveUS8097211B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFirst specimen

Owner:SYSMEX CORP

Instrumentation and method for monitoring change in electric potential to detect crack growth

InactiveUS7185545B2Sensitive measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesResistance/reactance/impedenceElectricityConductive materials

Instrumentation for monitoring crack growth using a change in electric potential across a starter crack as the crack propagates is disclosed. The instrumentation includes a specimen of a material to be analyzed for crack growth propagation having a surface with a starter crack formed therein, a plurality of current leads to pass electric current through the specimen, a layer of insulating material disposed on each of opposite sides of the crack, a layer of conductive material disposed on each layer of insulating material, where a portion of each layer of conductive material is in electrical contact with the first specimen surface, and a pair of sensing leads, one sensing lead attached to each layer of conductive material. A method for using the instrumentation to monitor crack growth by measuring is also disclosed.

Owner:GENERAL ELECTRIC CO

Charged particle beam equipment and charged particle microscopy

ActiveUS7435957B2Guaranteed accuracyReduce variationMaterial analysis using wave/particle radiationElectric discharge tubesLight beamMagnification

On the basis of a displacement of the field of view before and after a deflection of a charged particle beam, extracted from a first specimen image, including a displacement of the field of view recorded by causing a charged particle beam to deflect by a predetermined amount by a beam deflector in an image in which a specimen image is captured at a first magnification calibrated by using a specimen enlarged image of a specimen as a magnification standard, and also a displacement of the field of view before and after a deflection of the charged particle beam, extracted from a second specimen image, including a displacement of the field of view recorded by causing a charged particle beam to deflect by the predetermined amount by the beam deflector in an image in which a specimen image is captured at a second magnification, the second magnification is calibrated.

Owner:HITACHI HIGH-TECH CORP

Friction testing apparatus and method

The invention relates to a test method and apparatus for measuring the frictional properties of a fluid and comprises; a first specimen holder which is adapted to hold a first specimen in the fluid being tested in contact with a second specimen surface of a second specimen in a second specimen holder, with means for applying a measurable load between the two specimens, and with oscillatory driving means for oscillating at least one of the specimen holders along a first direction, and a motion inducing means, for inducing a motion between the first and second specimen holders in a second direction to induce a compound movement between the specimens which has been found results in more accurate readings. The first specimen holder is connected to a shaft which is induced to move in the first direction being the direction of the length of the shaft and the motion inducing means for inducing a motion in a second direction may be an off-centre counter weight located on the shaft.

Owner:PCS INSTR

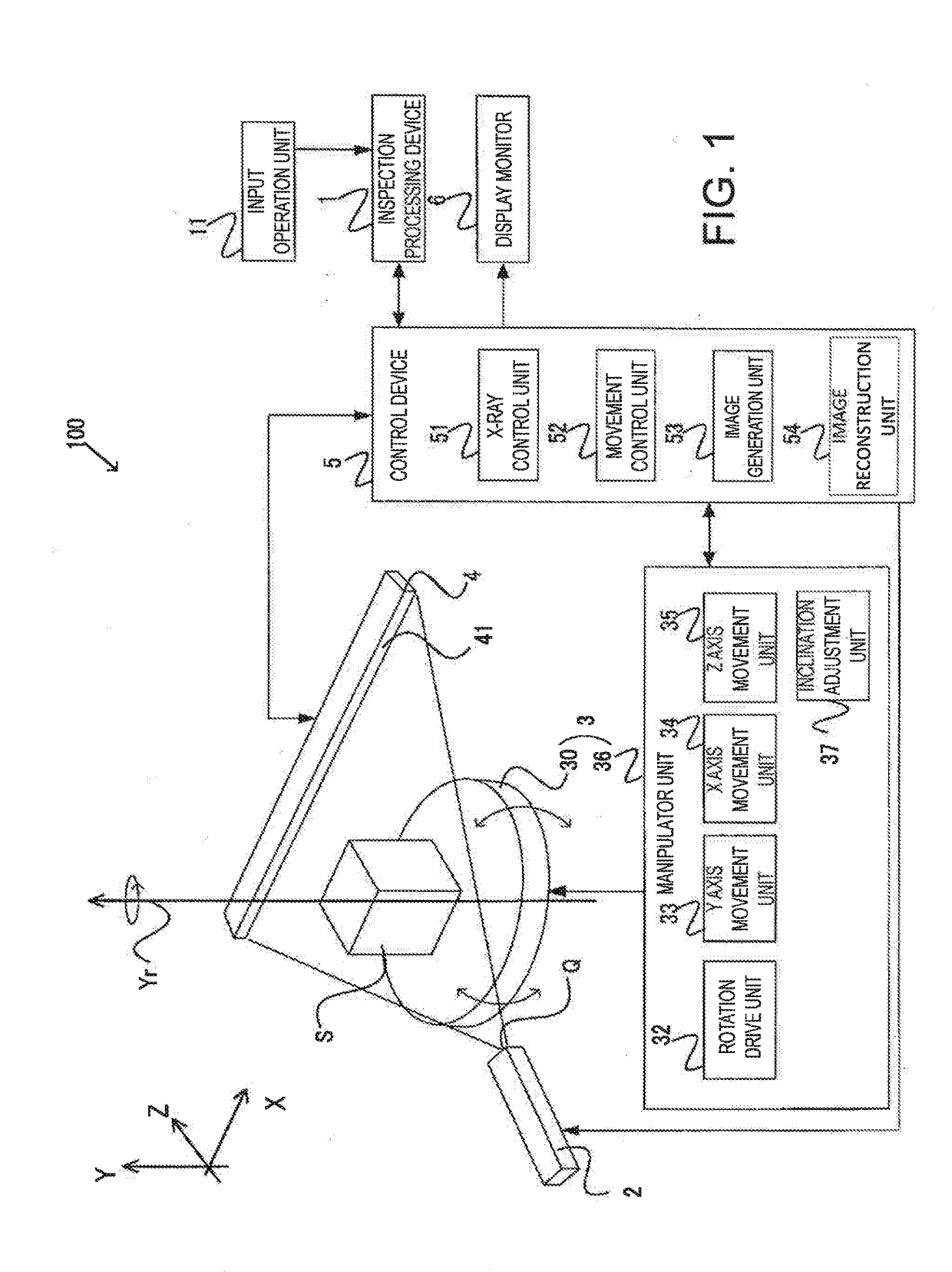

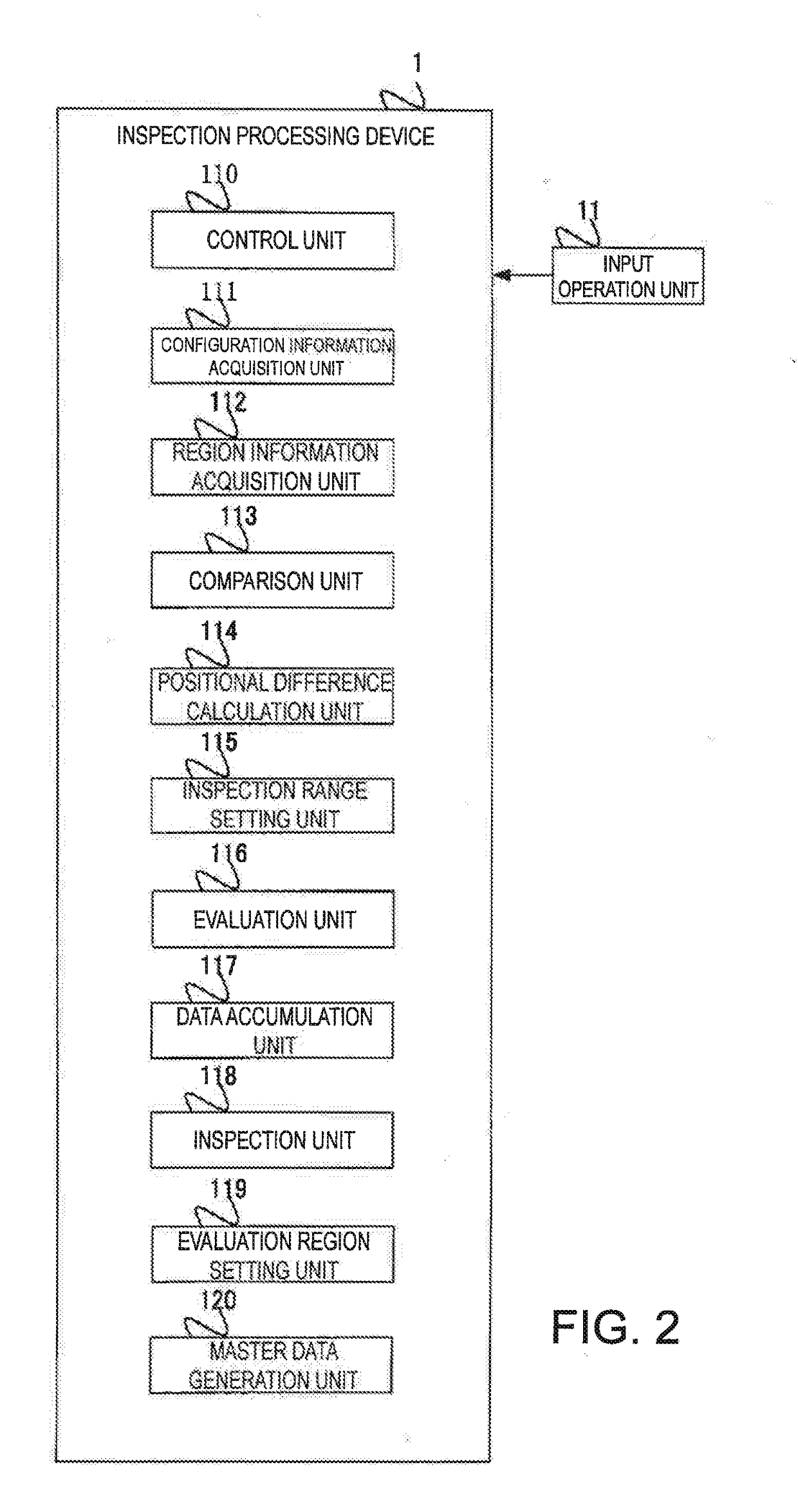

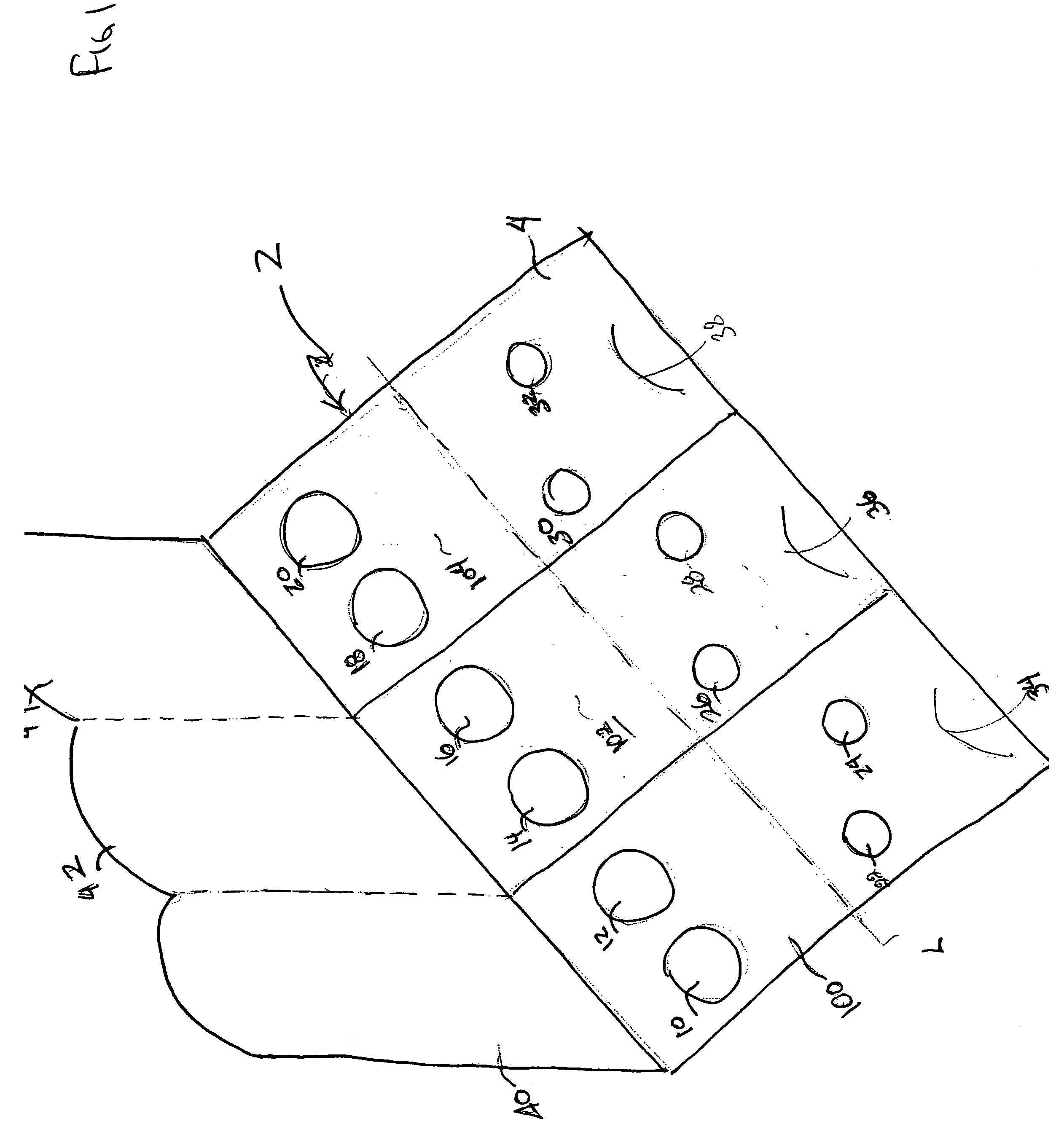

Measurement processing device, x-ray inspection device, measurement processing method, measurement processing program, and structure manufacturing method

A measurement processing device used for an X-ray inspection device includes: a region information acquisition unit that acquires first region information based on X-rays passing through a first region that is a part of a first specimen; a storage unit that stores second region information related to a second region of a second specimen, the second region being larger than the first region; and a determination unit that determines whether or not a region corresponding to the first region is included in the second region, based on the first region information and the second region information.

Owner:NIKON CORP

Fecal occult blood testing device and method

InactiveUS7427505B2Easy to identifyAnalysis using chemical indicatorsVaccination/ovulation diagnosticsTest proceduresFecal occult blood

A specimen testing device having a first panel including a first aperture for receiving a first specimen and a second aperture for receiving a second specimen; a second panel; a sheet disposed between the first and second panels for receiving at least the first specimen through the first aperture, wherein the sheet includes a test area having a reagent for possible reaction to the first specimen as part of a primary test procedure; and a removable tab at least partially aligned with the second aperture for receiving the second specimen, the removable tab accessible from an exterior of the device and available for use in a secondary test procedure. A method of testing for the presence of blood in fecal matter including primary and secondary testing of the fecal matter. A test kit including a specimen testing device and reagents for performing a primary test a secondary test on specimens.

Owner:IMMUNOSTICS

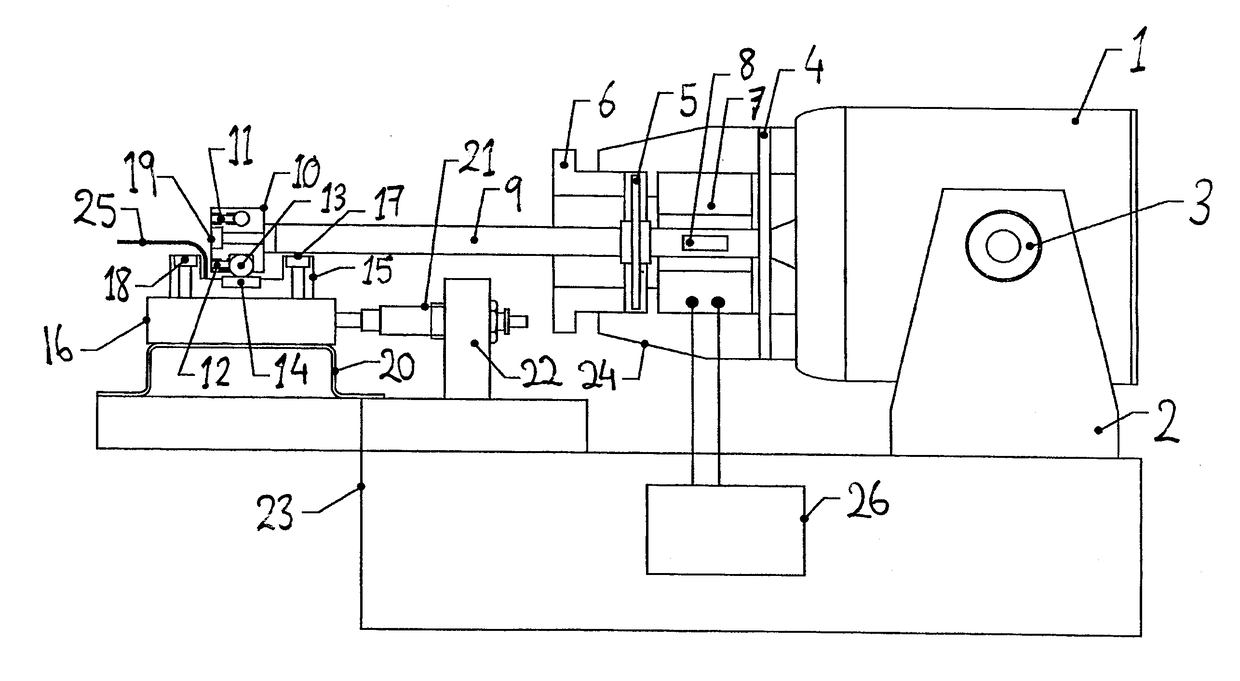

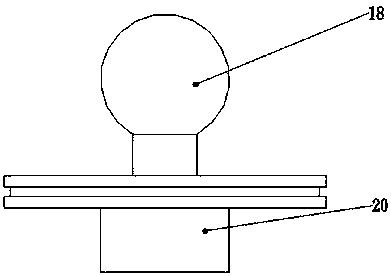

Hip joint prosthesis friction wear testing machine

PendingCN107764677AAchieve twisting motionThe test results are accurate and objectiveInvestigating abrasion/wear resistanceWear testingMotor drive

Hip joint prosthesis friction and wear testing machine, including a base and a test box installed on the base. The test box is divided into an upper cavity and a lower cavity by a box partition, and a servo electric cylinder is installed in the lower cavity. The output shaft of the cylinder passes through the through hole of the box partition and is fixedly connected to the bottom end of the pressure sensor arranged in the upper chamber, the top end of the pressure sensor is fixedly connected to the lower test piece mounting seat, and the top end of the lower test piece mounting seat is screwed to the joint The head specimen; the rear side of the test box is fixedly installed with a servo motor, the servo motor drives the crank rocker mechanism to drive the torque sensor to twist, the bottom of the torque sensor is connected with the top of the upper specimen mounting seat, and the bottom of the upper specimen mounting base The acetabular test piece is fixedly installed at the end; a sealing cover is provided between the upper test piece mounting seat and the lower test piece mounting seat; semiconductor cooling chips, heating resistors and thermocouple sensors are installed on the side of the upper cavity. The invention realizes the tribological test of the hip joint prosthesis at the set ambient temperature, and makes the test result more accurate.

Owner:XUZHOU NORMAL UNIVERSITY

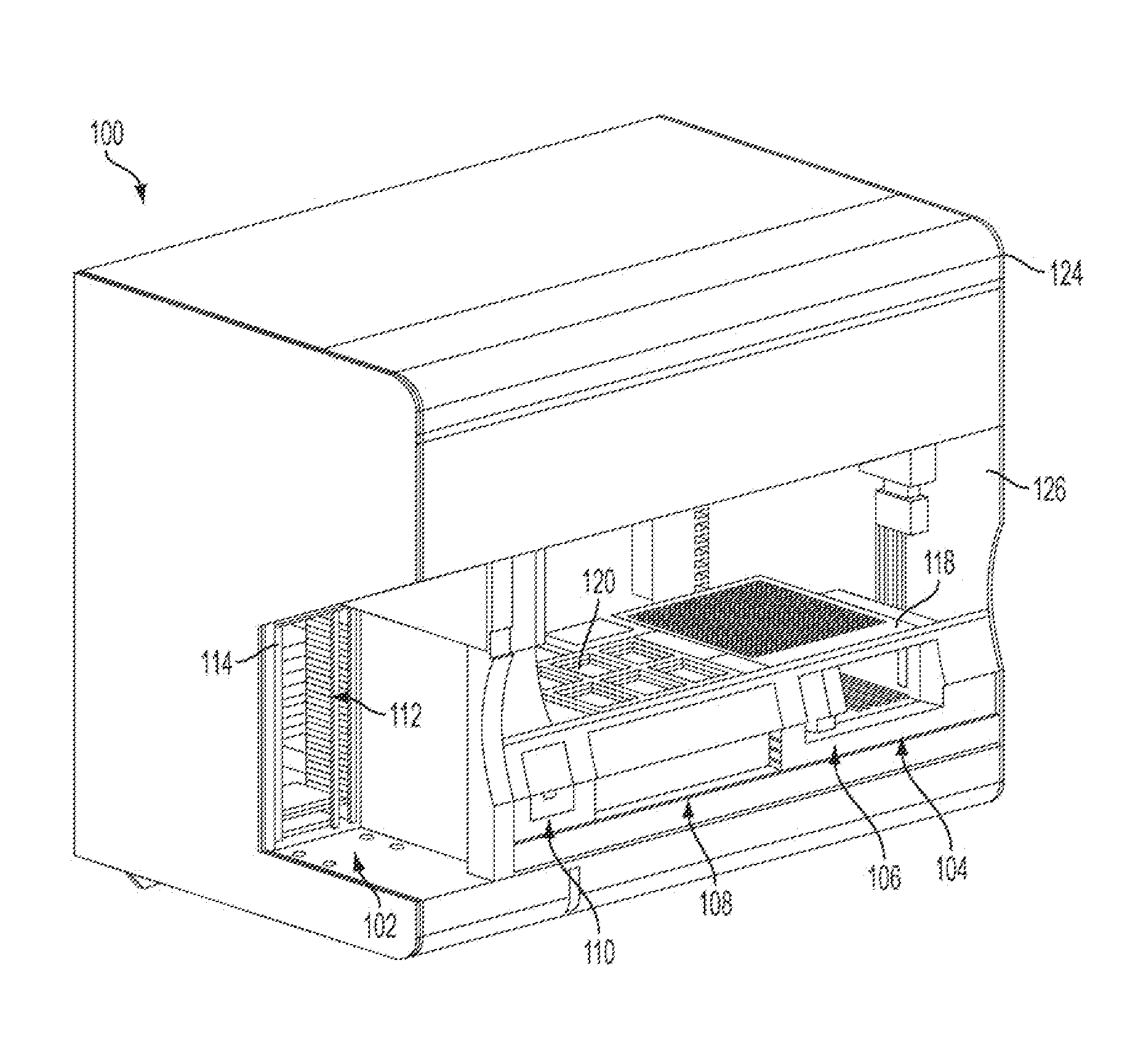

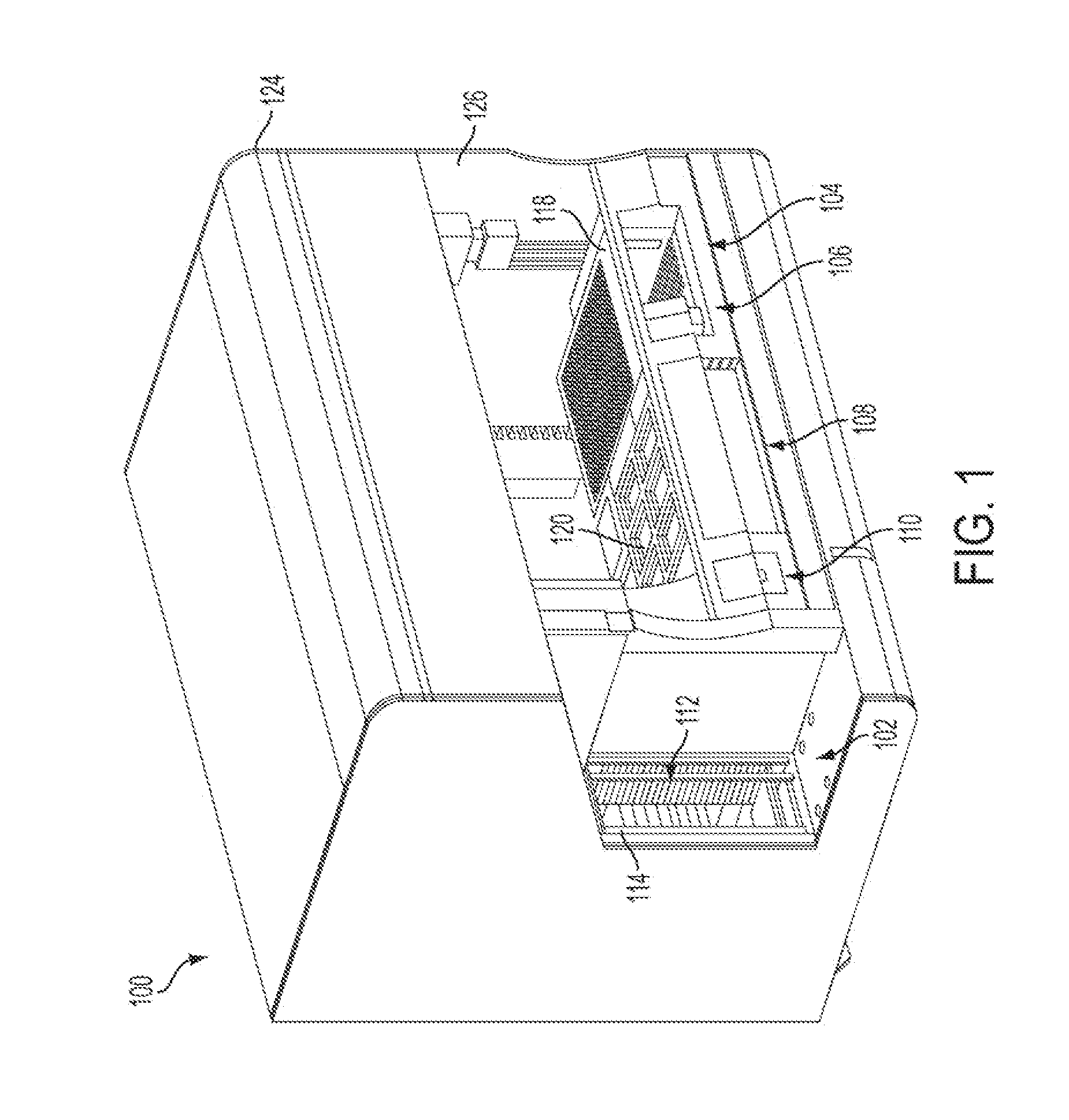

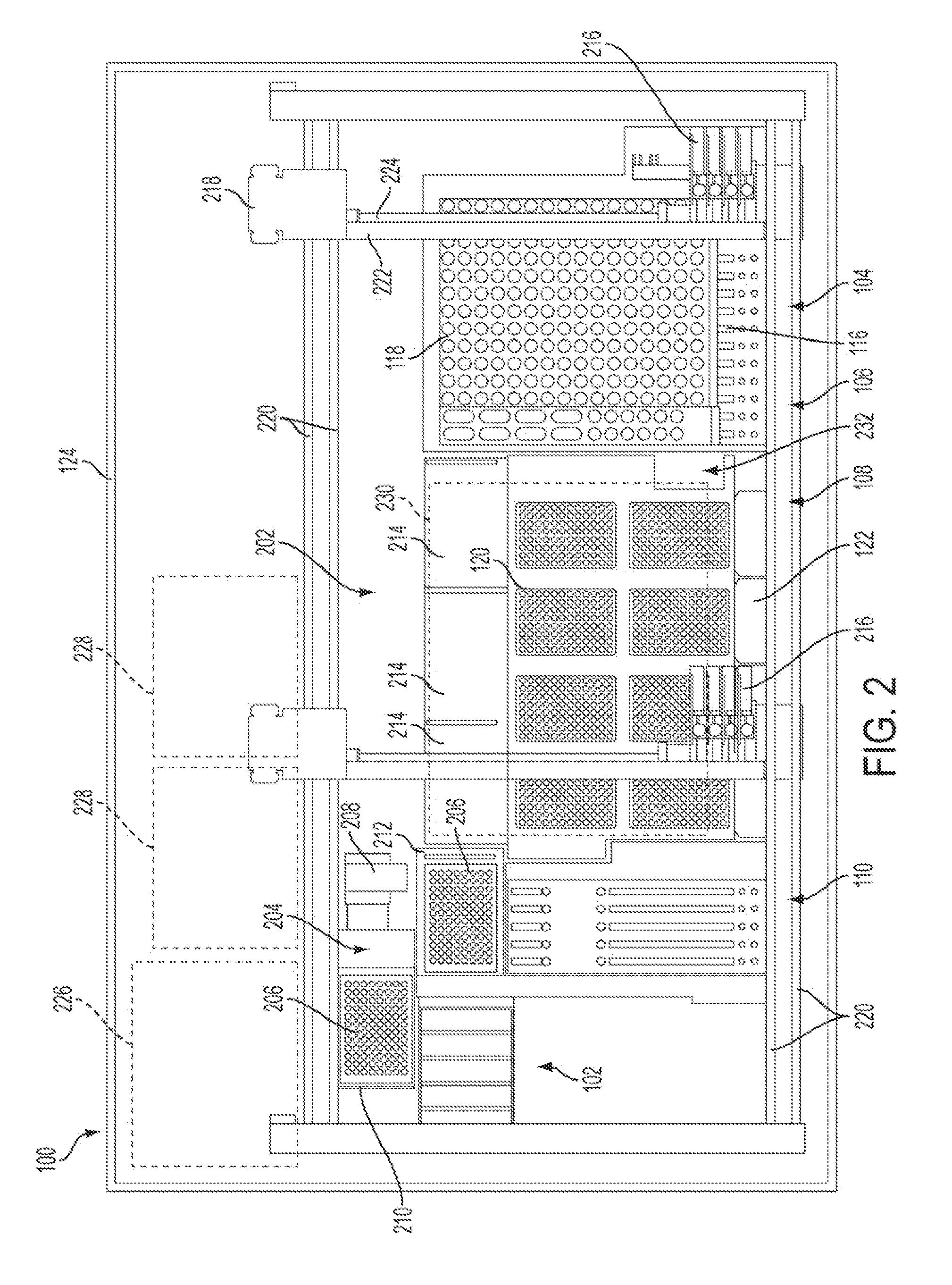

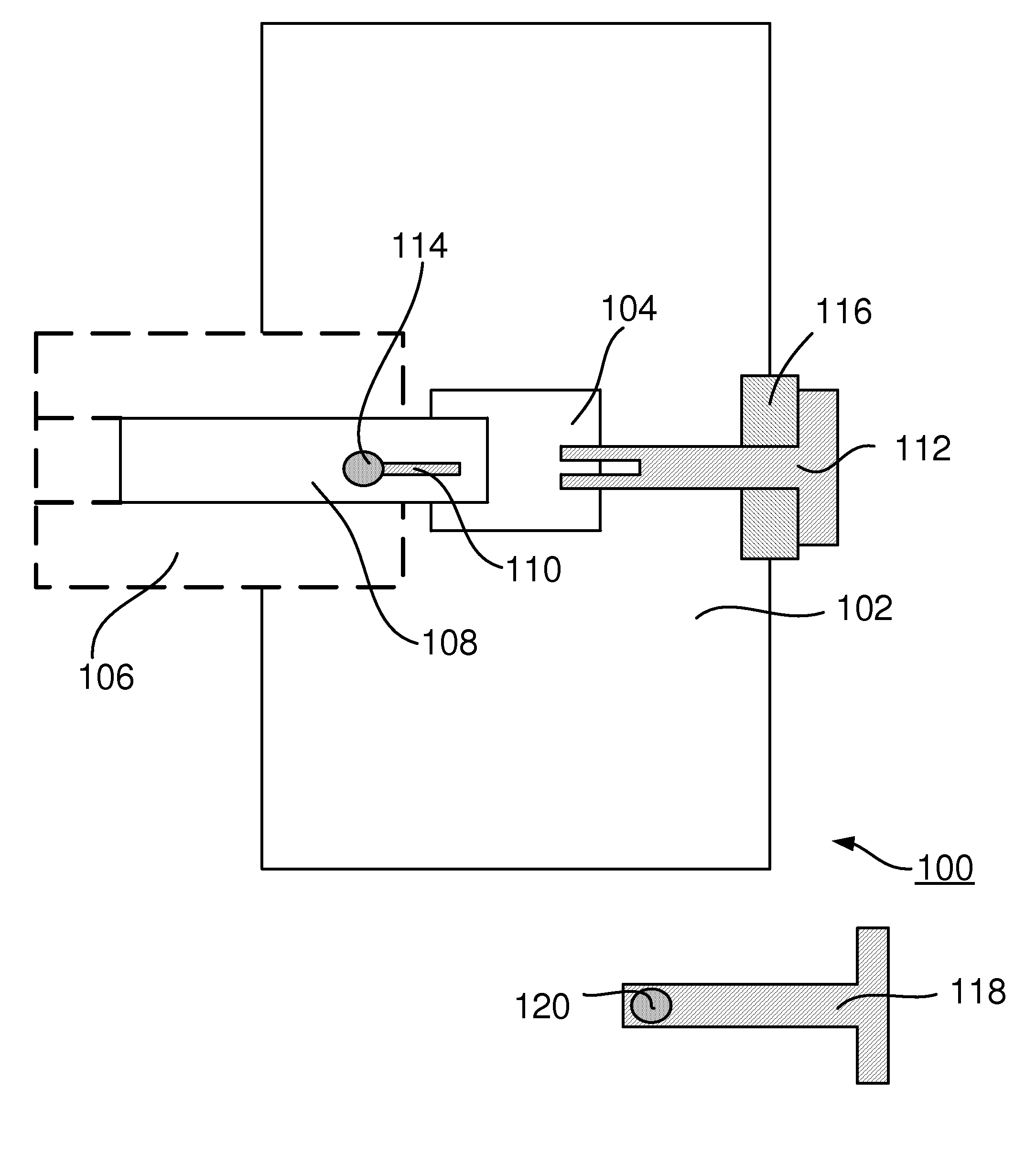

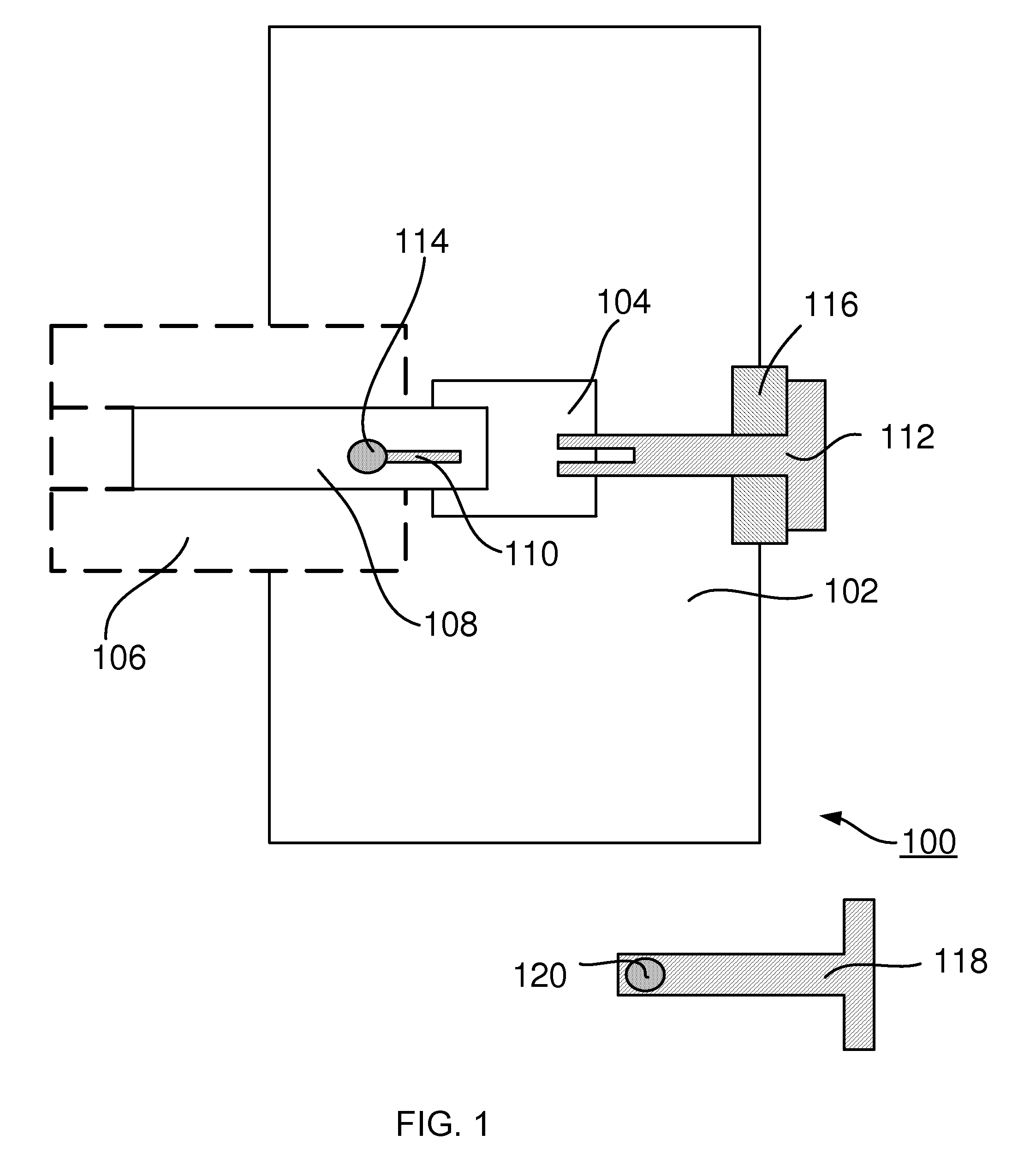

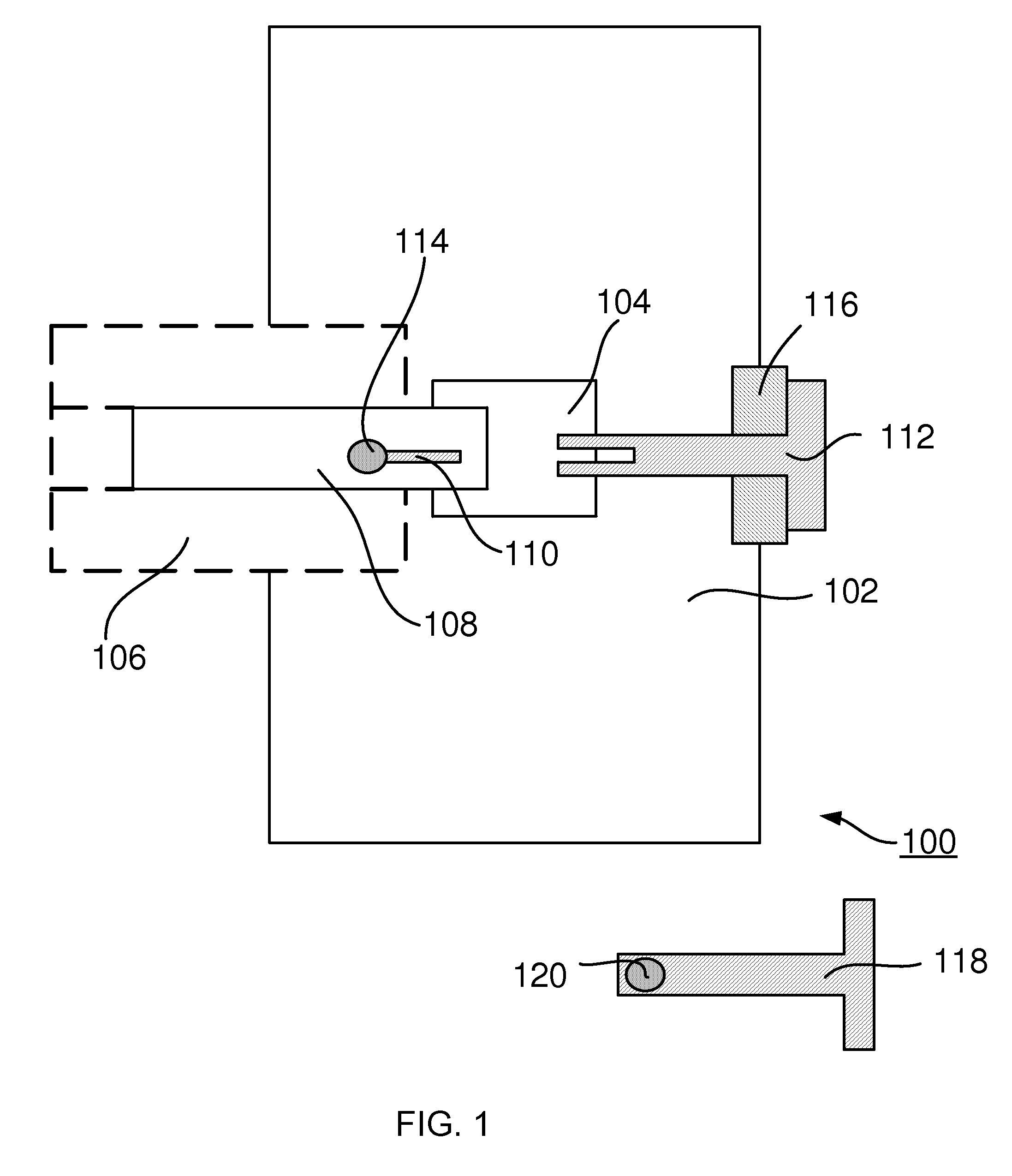

Charged-particle optical system with dual loading options

ActiveUS20100108907A1Conveniently configuredMaintains its operational flexibilityNanotechElectric discharge tubesElectron microscopeVacuum chamber

A charged-particle optical system (100) such as an electron microscope has a vacuum chamber (102) with a space (104) for accommodating a specific one (114) of multiple specimens in operational use. The charged-particle optical system has a loader (106) with a part (108) that is moveable into and out of the space. The part is configured for attaching a specimen carrier (110), brought from outside the system, to a first holder (112) or to detach the carrier from the first holder and to remove the carrier from inside the system. The carrier accommodates a first specimen. The system has an interface (116) in a wall of the chamber for removably accommodating the first holder (112) or a second holder (118) with a second specimen (120) mounted thereon.

Owner:FEI CO

Electrochemical test strip and corresponding analyzer

ActiveCN103487353AViscosity detectionAccurate concentrationBlood flow measurement devicesVolume/mass flow measurementAnalyteOxidation-Reduction Agent

A test strip and a detecting device are disclosed. The test strip can be used with an electrochemical instrument to accurately detect the viscosity and concentration of an analyte of a specimen. The test strip includes a first specimen path, a first electrode set, a redox reagent, a second specimen path, a second electrode set, and a reaction reagent. The redox reagent includes at least a redox pair. When the specimen enters the first specimen path, the redox pair dissolves and generates an electrochemical redox reaction for obtaining a flow time of the specimen. When the specimen enters the second specimen path, the reaction reagent is used to obtain the analyte concentration of the specimen, and the concentration of the analyte can be corrected by the flow time.

Owner:HMD BIOMEDICAL

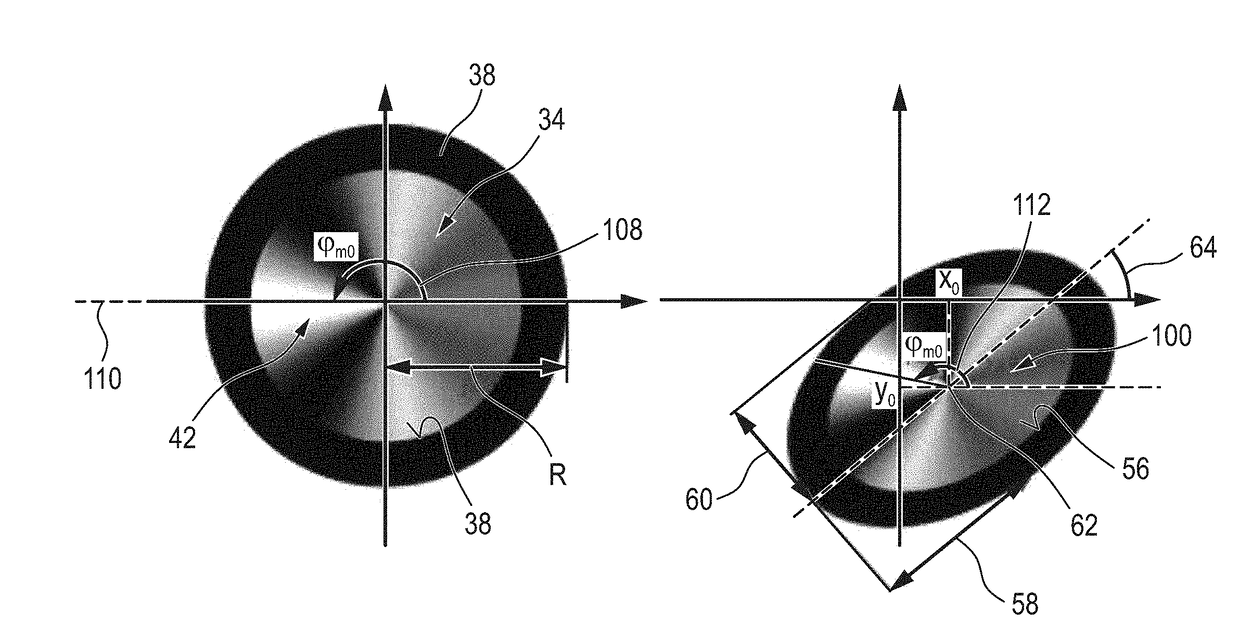

Method and system for determining a 3D position of an object in space

ActiveUS20180137646A1Improve accuracyCost-effective mannerImage enhancementImage analysisData setData value

A specimen of an artificial marker is arranged on an object, the position of which is to be determined. The artificial marker defines a nominal marker pattern with nominal characteristics. The specimen embodies the nominal marker pattern with individual characteristics. One or more images of the specimen are captured while the specimen is arranged on the object. An image representation of the specimen is analyzed using a data set. The data set comprises measured data values representing the individual characteristics as individually measured on the first specimen. Position values representing a 3D position of the specimen relative to a coordinate system are determined. A 3D position of the object is determined based on the position values of the specimen.

Owner:CARL ZEISS IND MESSTECHN GMBH

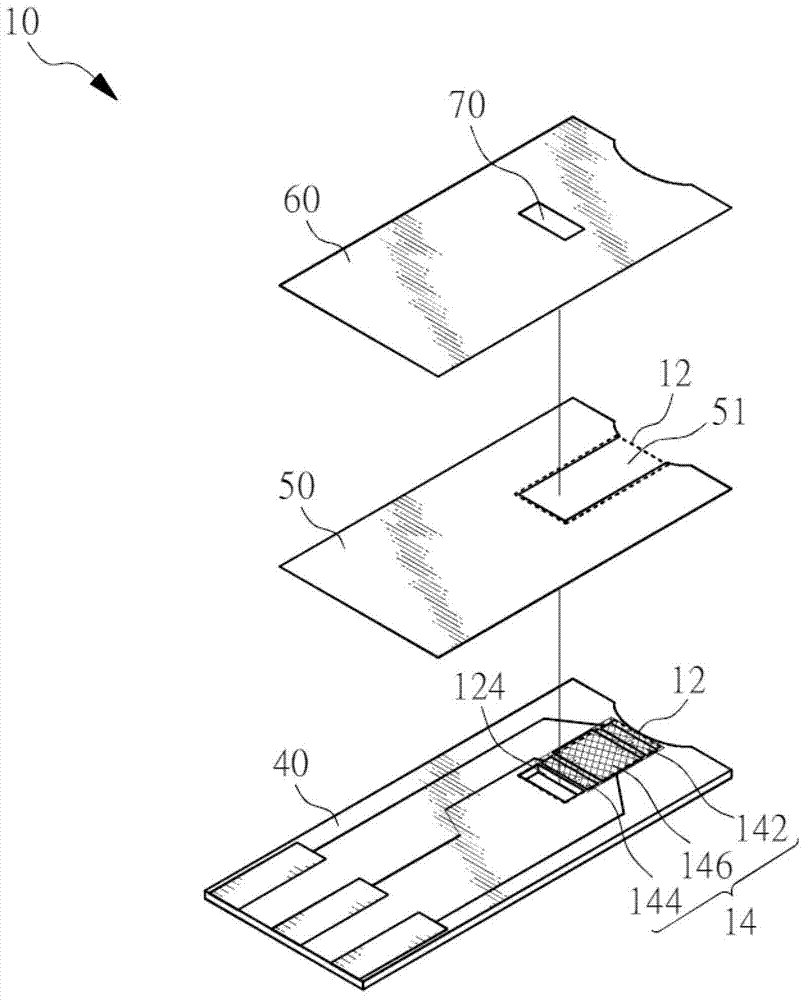

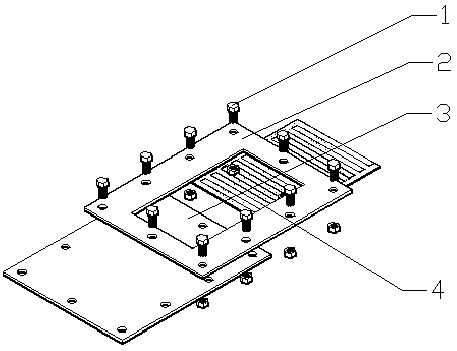

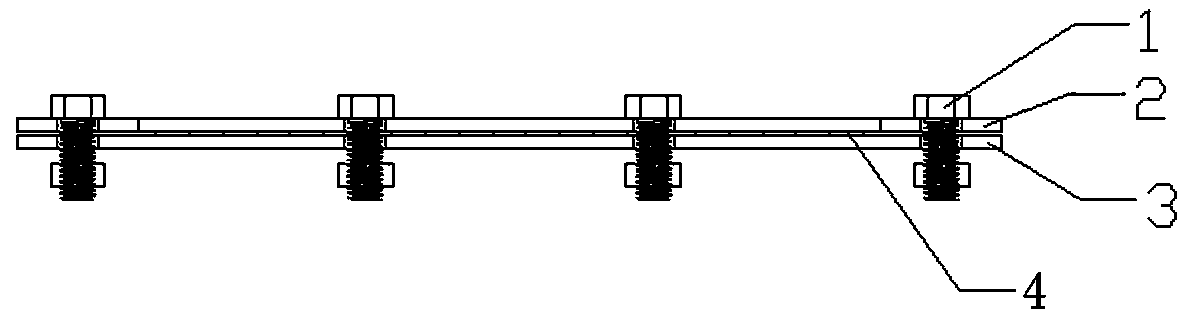

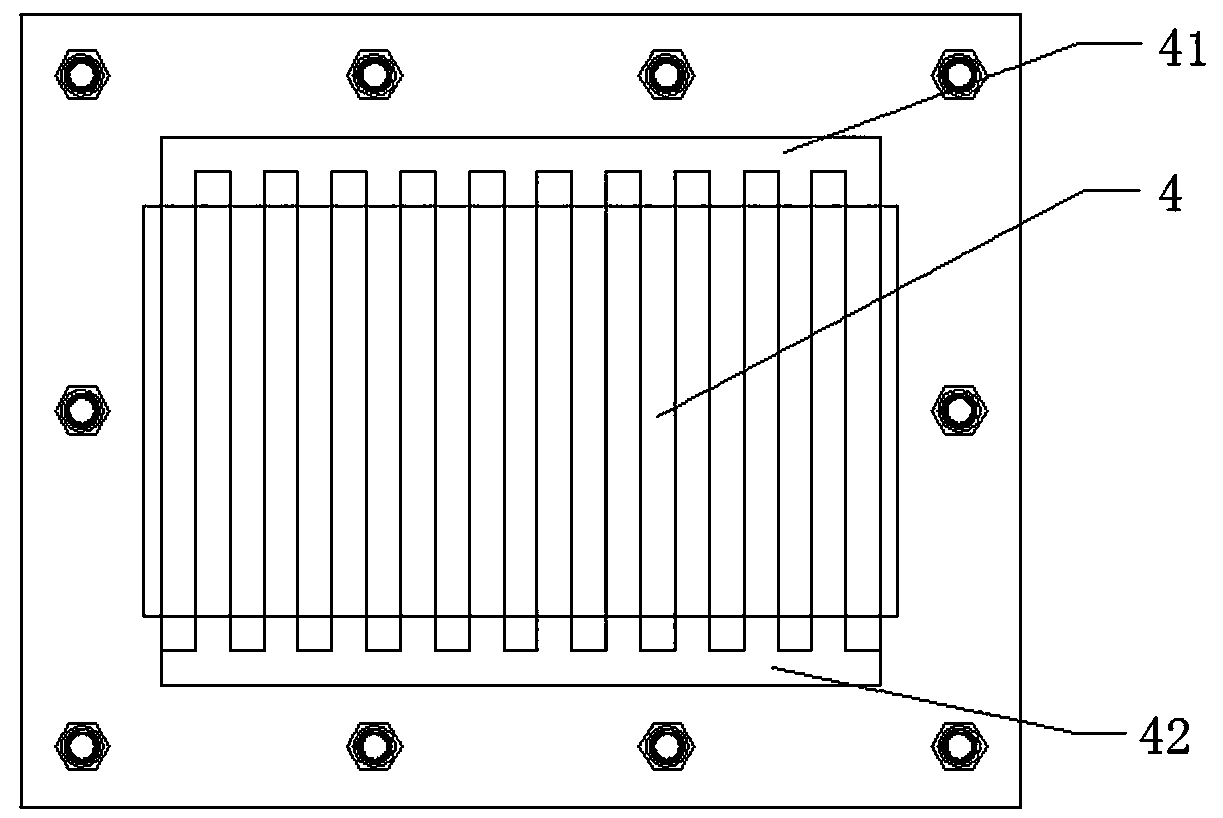

Device and method for preparing curvature method residual stress test specimen

PendingCN107817150ARealize acquisitionAchieve impactPreparing sample for investigationWork holdersTest sampleEngineering

The present invention relates to the field of mechanical processing and manufacturing, and more particularly relates to a device and a method for preparing a curvature method residual stress test specimen. The device includes an upper clamp plate, a lower clamp plate, and a coating specimen plate. The coating specimen plate comprises a first specimen plate and a second specimen plate. The first specimen plate and the second specimen plate are interspersed with each other, an opening is formed in the middle of the upper clamp plate, and the upper clamp plate and the lower clamp plate press thecoating specimen plate. Through a single process, a plurality of test specimens can be obtained simultaneously. The fixture is simple in operation, strong in practicability, low in cost and high in efficiency, and can be used to prepare a variety of different coating residual stress specimens.

Owner:LINGNAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com