Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Finite element stress analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finite Element Analysis is a highly specialized skills subset of the stress analysis skills umbrella. Finite Element Analysis (FEA) and Modeling simply means breaking up a large structure into tiny pieces. In other words, discretizing the large structure into finite elements.

Method for determining the risk of rupture of a blood vessel

ActiveUS7805177B2Improve visualizationHeart stimulatorsDiagnostic recording/measuringRadiologyThree vessels

Owner:ASTUTE IMAGING LLC

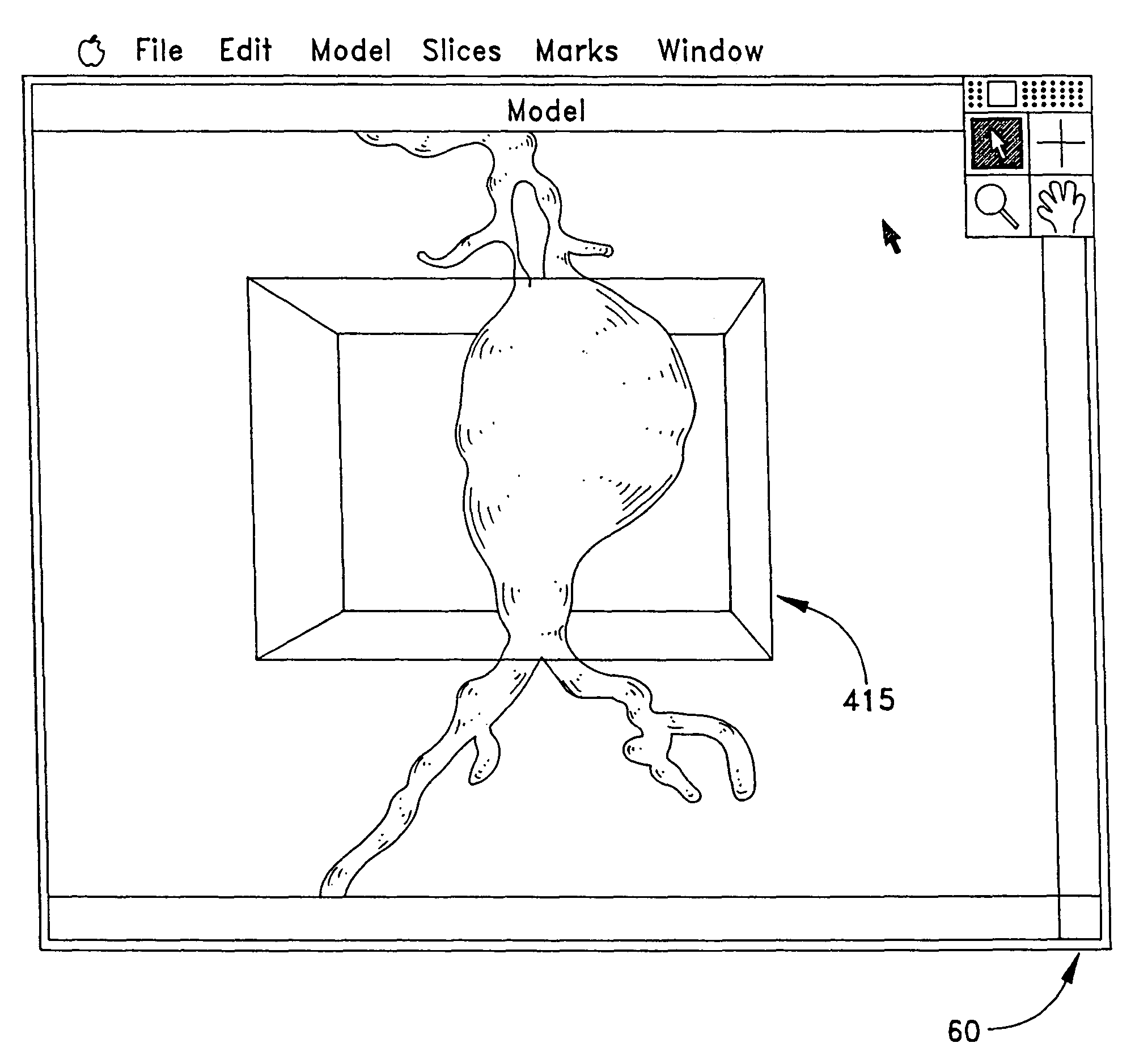

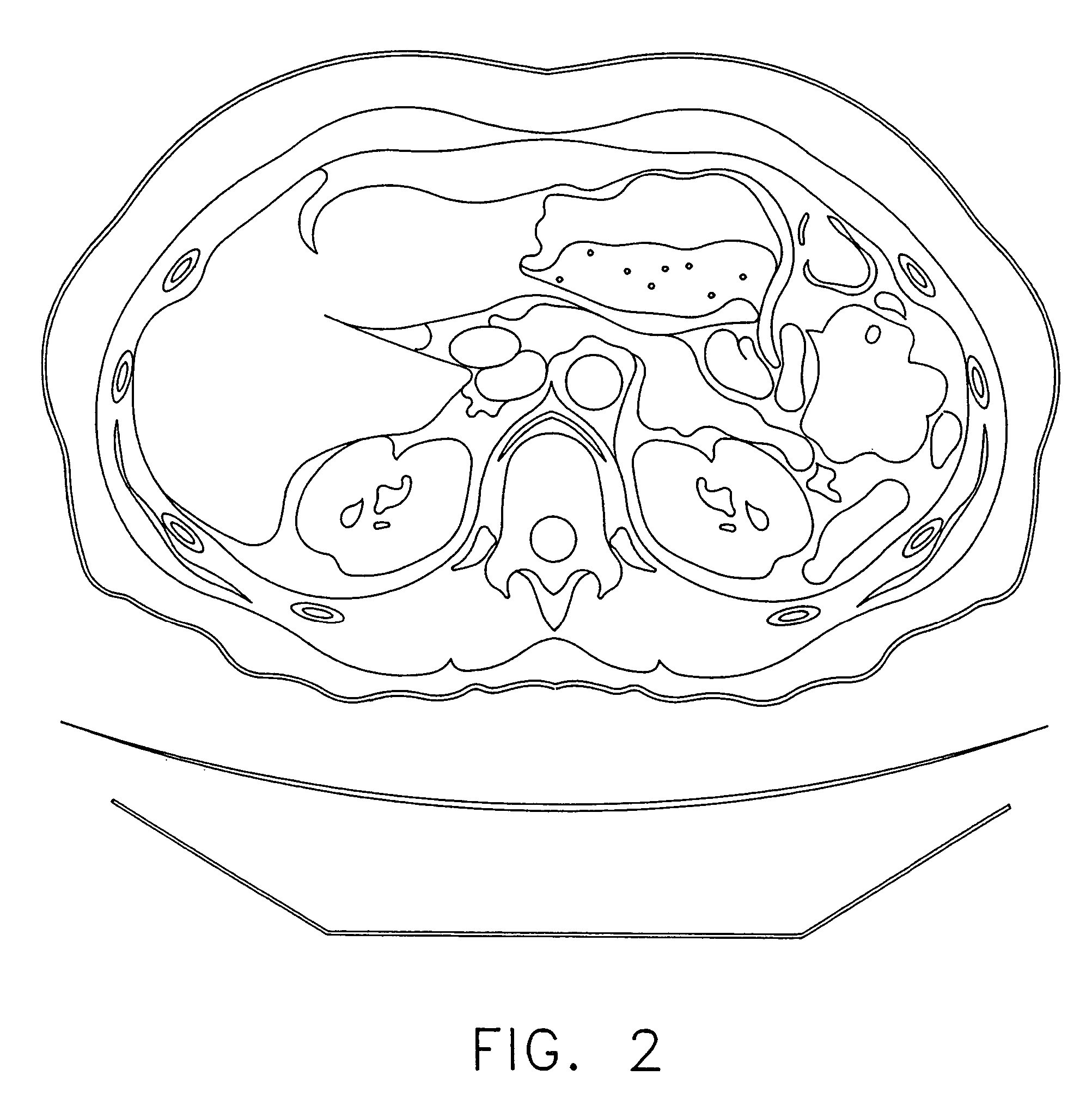

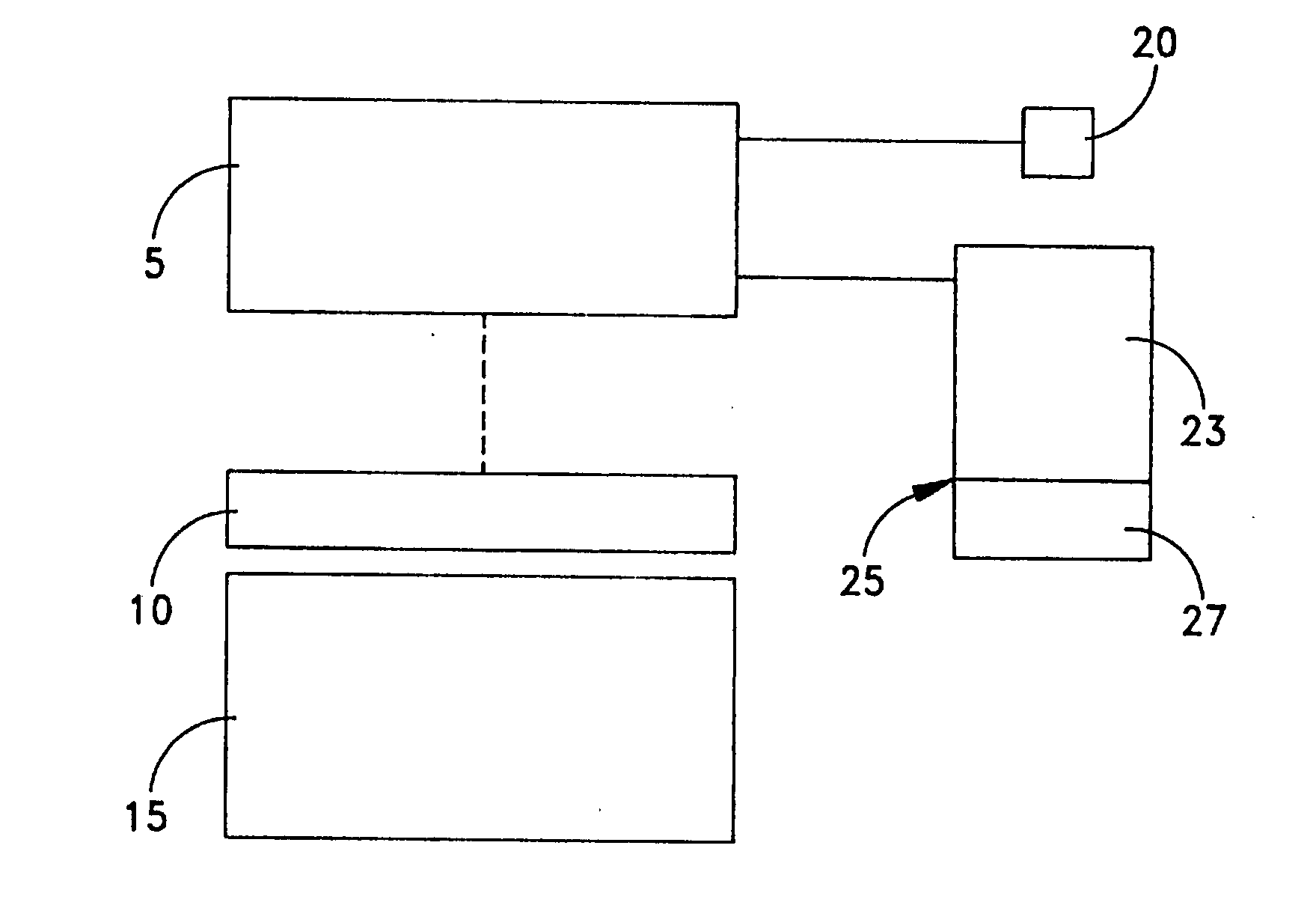

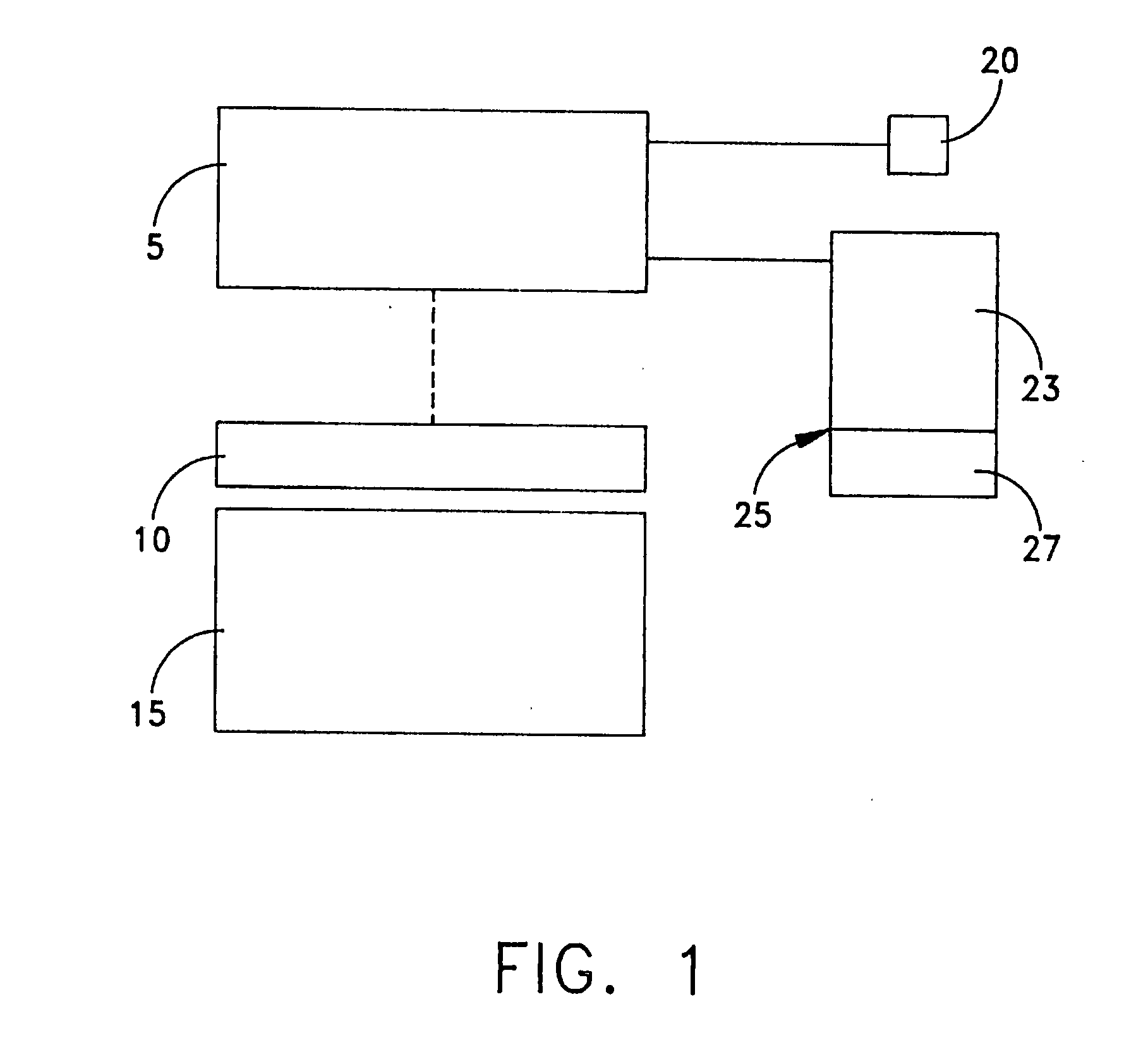

Anatomical visualization and measurement system

ActiveUS20080137929A1Improve visualizationUltrasonic/sonic/infrasonic diagnosticsImage enhancementRadiologyBlood Vessel Rupture

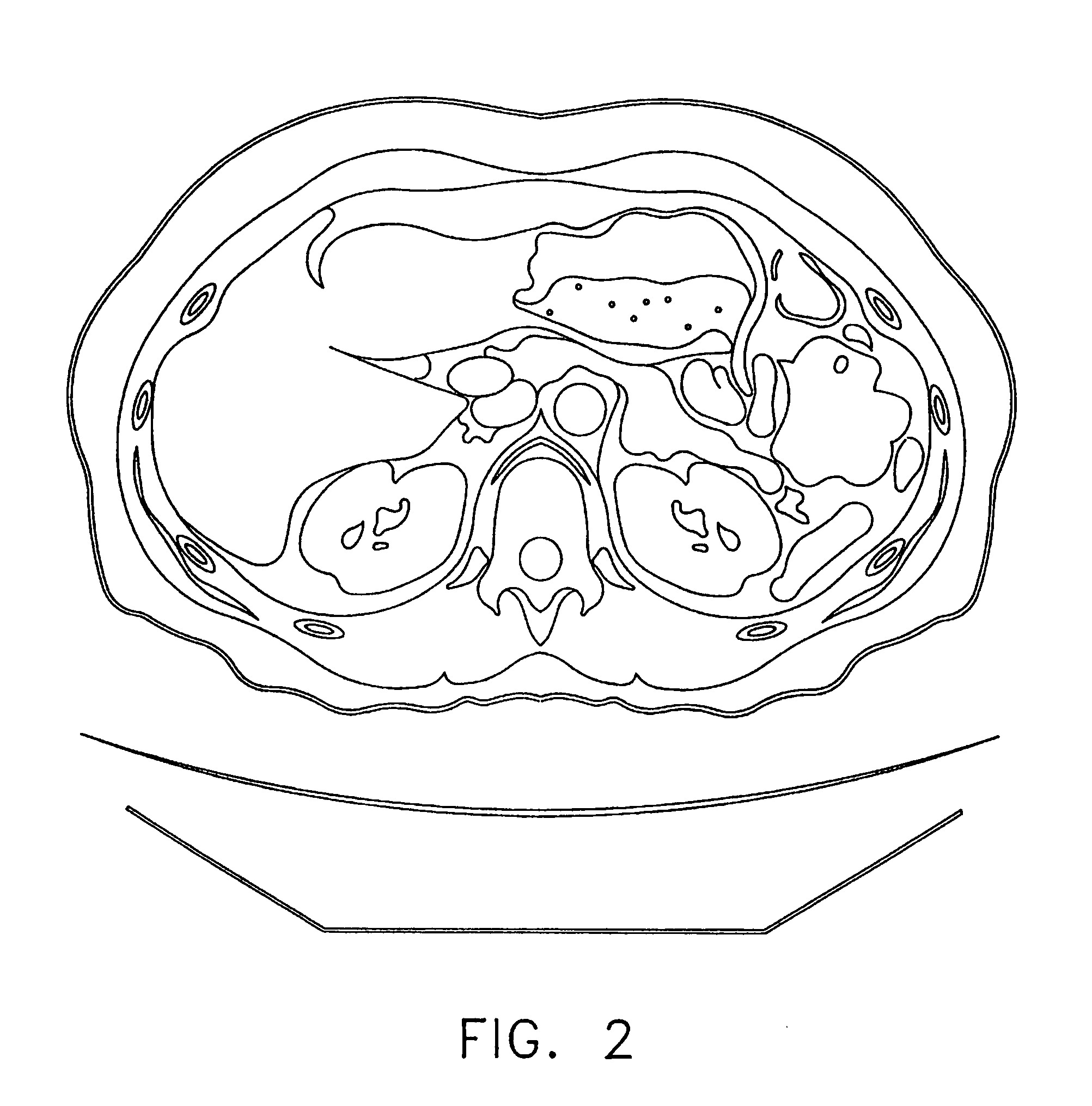

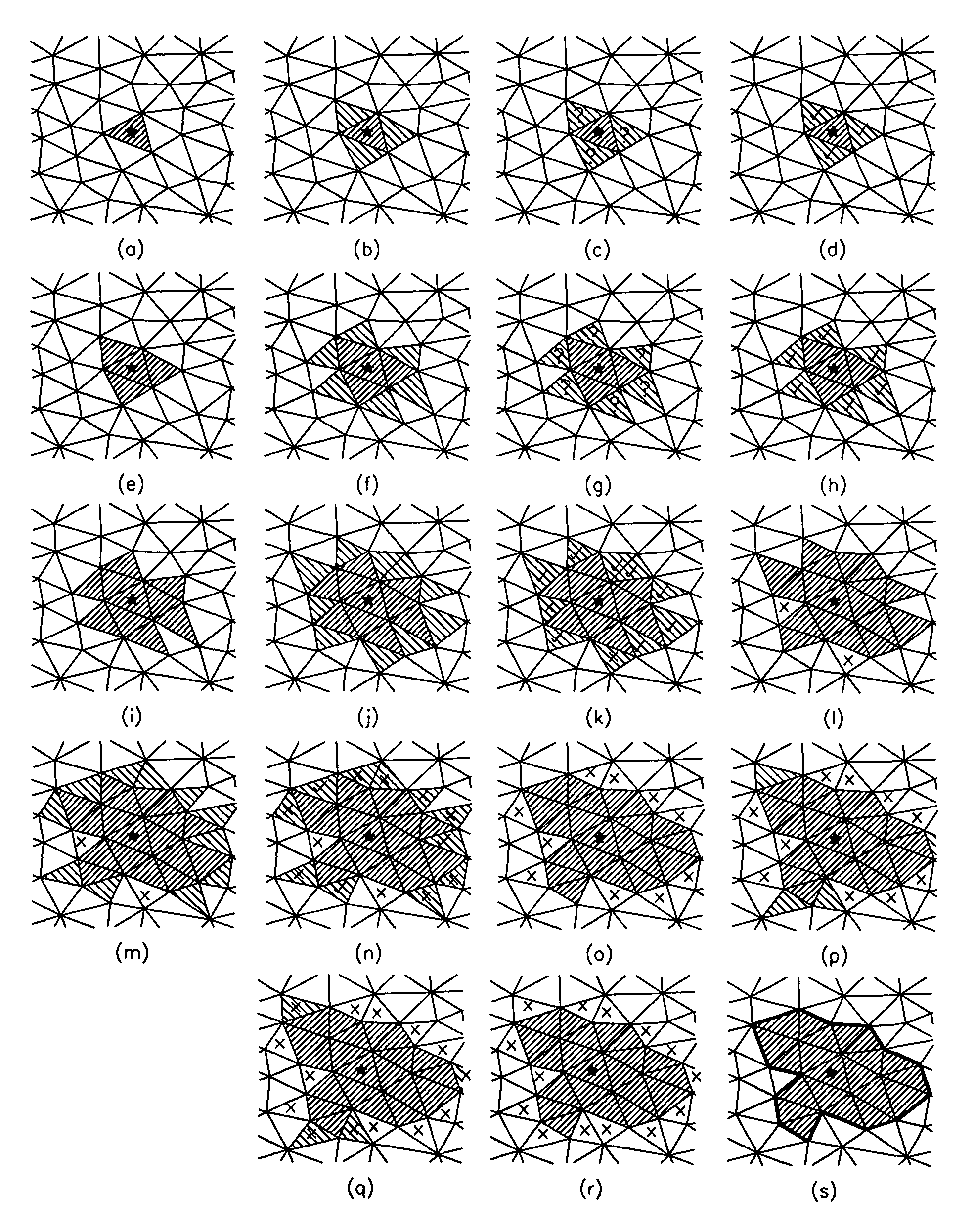

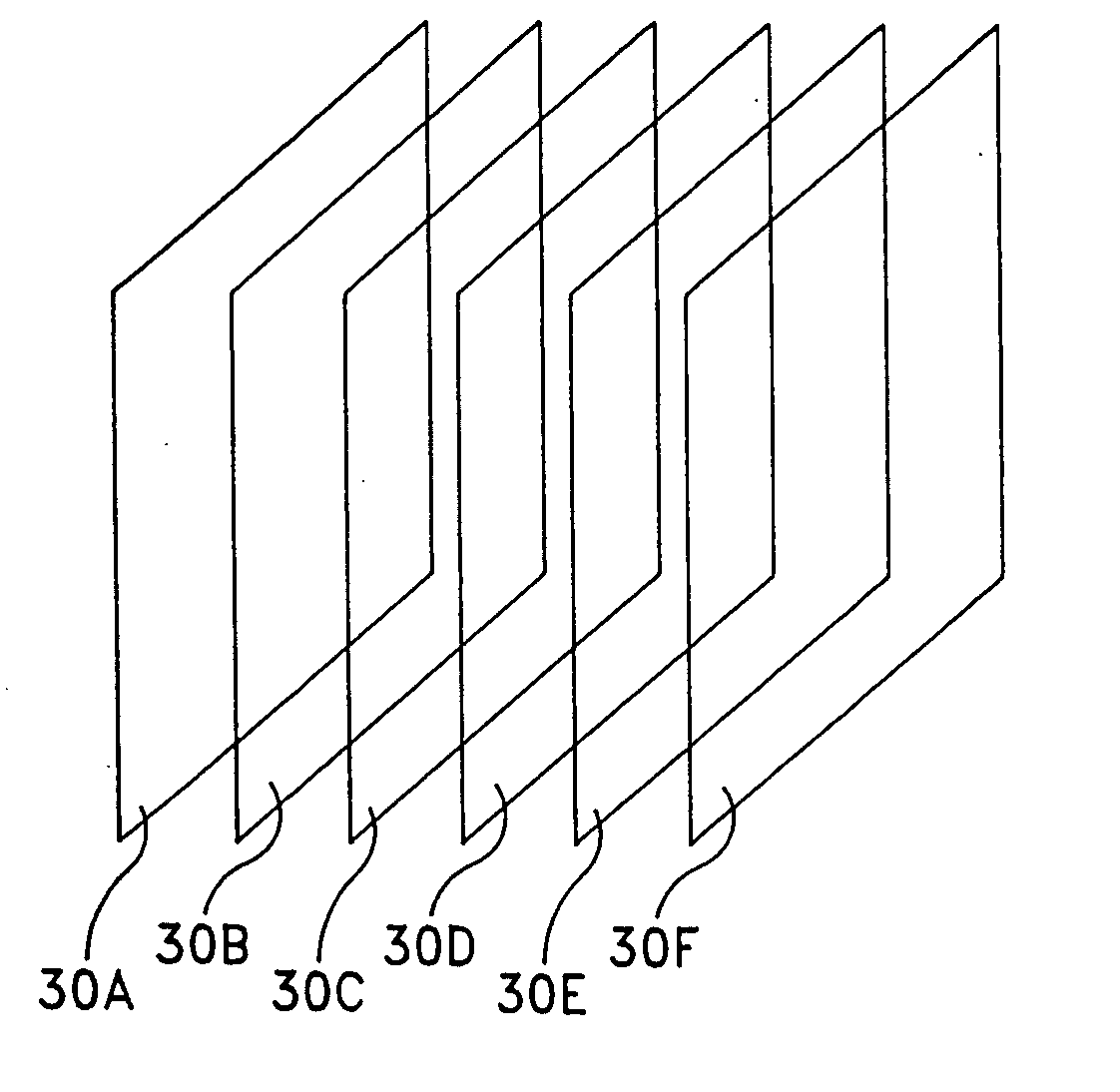

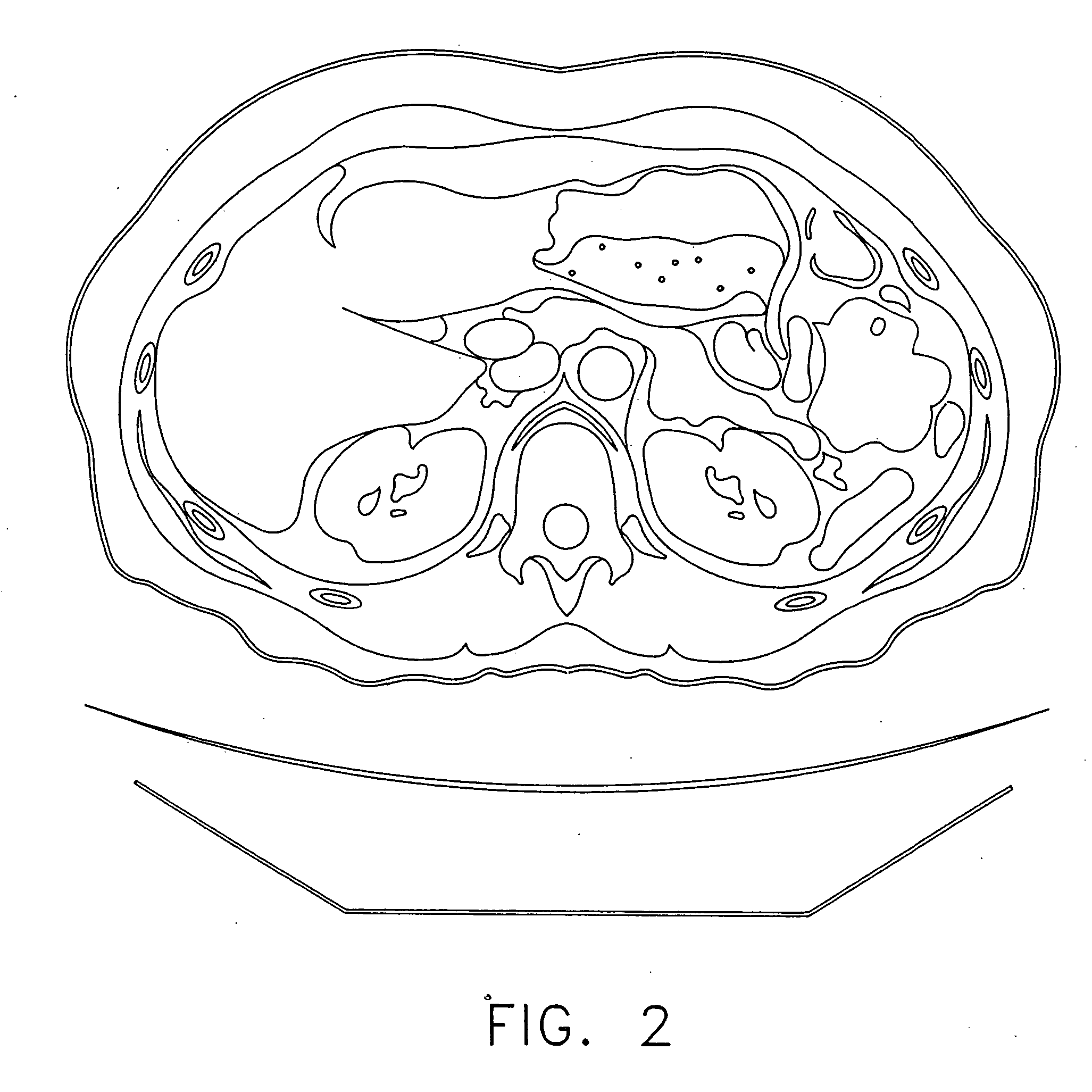

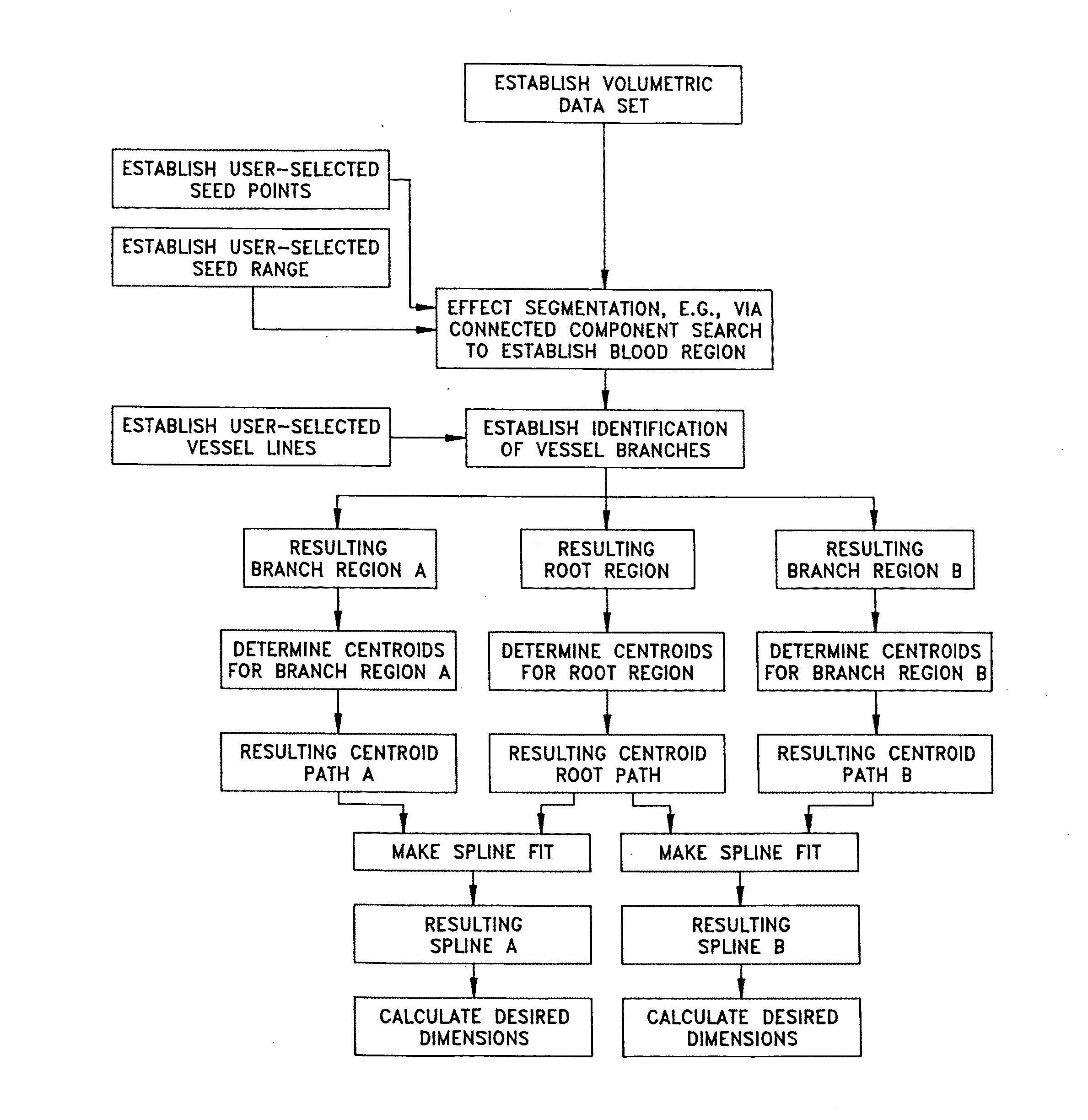

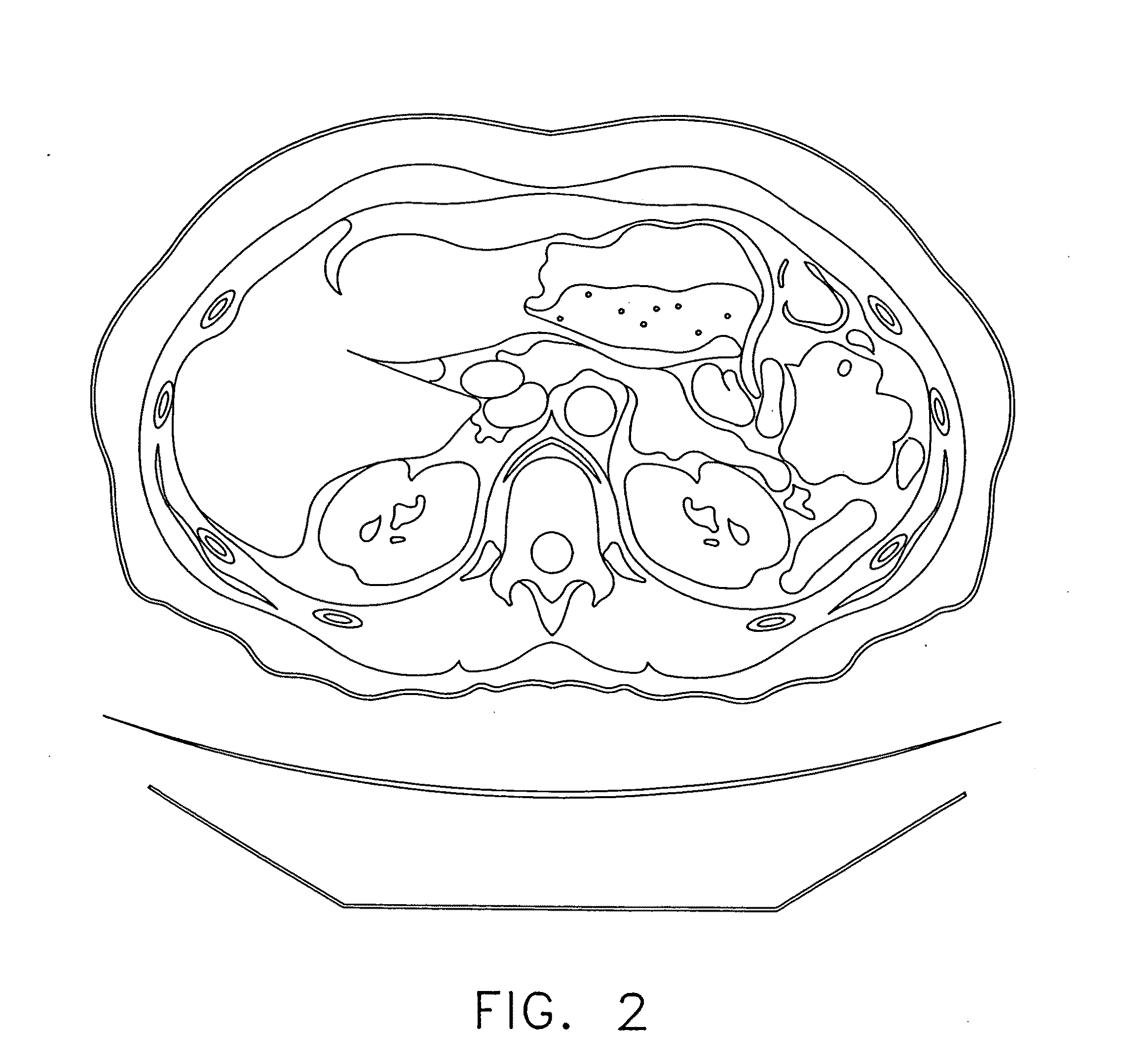

A method for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the method comprising: generating a mesh model of the blood vessel using the set of 2-D slice images; conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; and determining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model.

Owner:ASTUTE IMAGING LLC

Method and apparatus for determining the risk of rupture of a blood vessel using the contiguous element defined area

ActiveUS7899516B2Improve visualizationUltrasonic/sonic/infrasonic diagnosticsImage enhancementRadiologyBlood vessel

A method for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the method comprising: generating a mesh model of the blood vessel using the set of 2-D slice images; conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; and determining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model.

Owner:ASTUTE IMAGING LLC

Anatomical visualization and measurement system

ActiveUS20060100502A1Easily and accurately presentingAccurate measurementDiagnostic recording/measuringTomographyBiomedical engineeringBlood vessel

In another preferred form of the present invention, there is provided a method for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the method comprising: generating a mesh model of the blood vessel using the set of 2-D slice images; conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; and determining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model. In another preferred form of the present invention, there is provided an apparatus for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the apparatus comprising: apparatus for generating a mesh model of the blood vessel using the set of 2-D slice images; apparatus for conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; and apparatus for determining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model.

Owner:ASTUTE IMAGING LLC

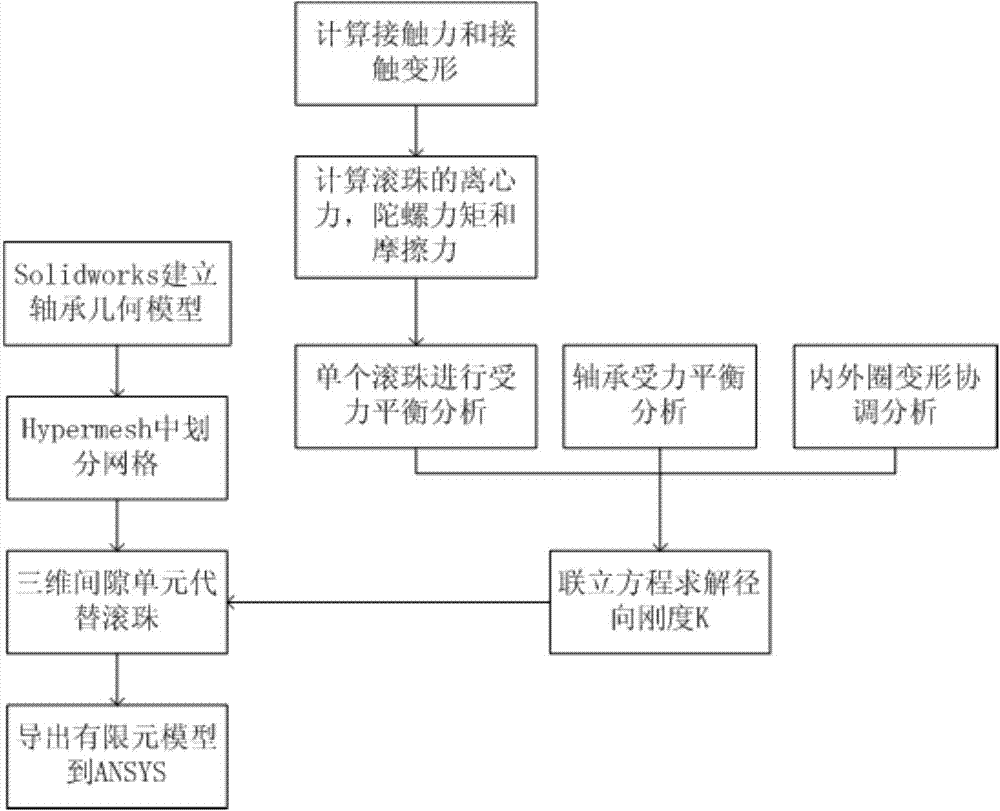

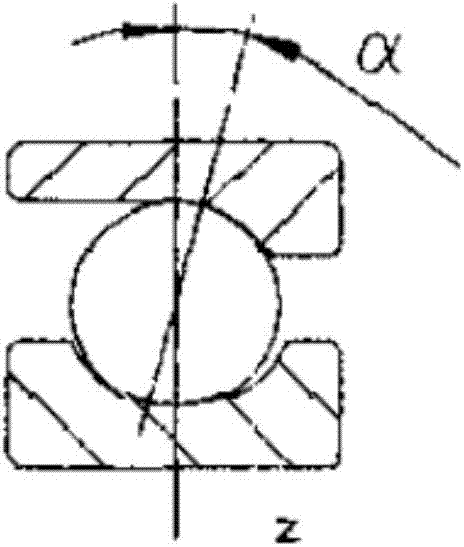

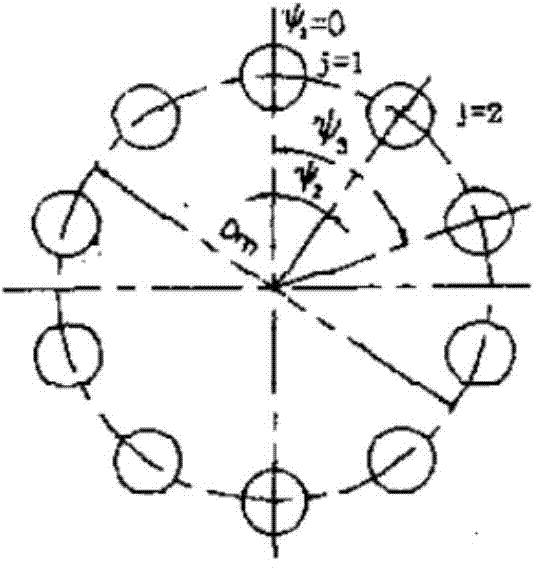

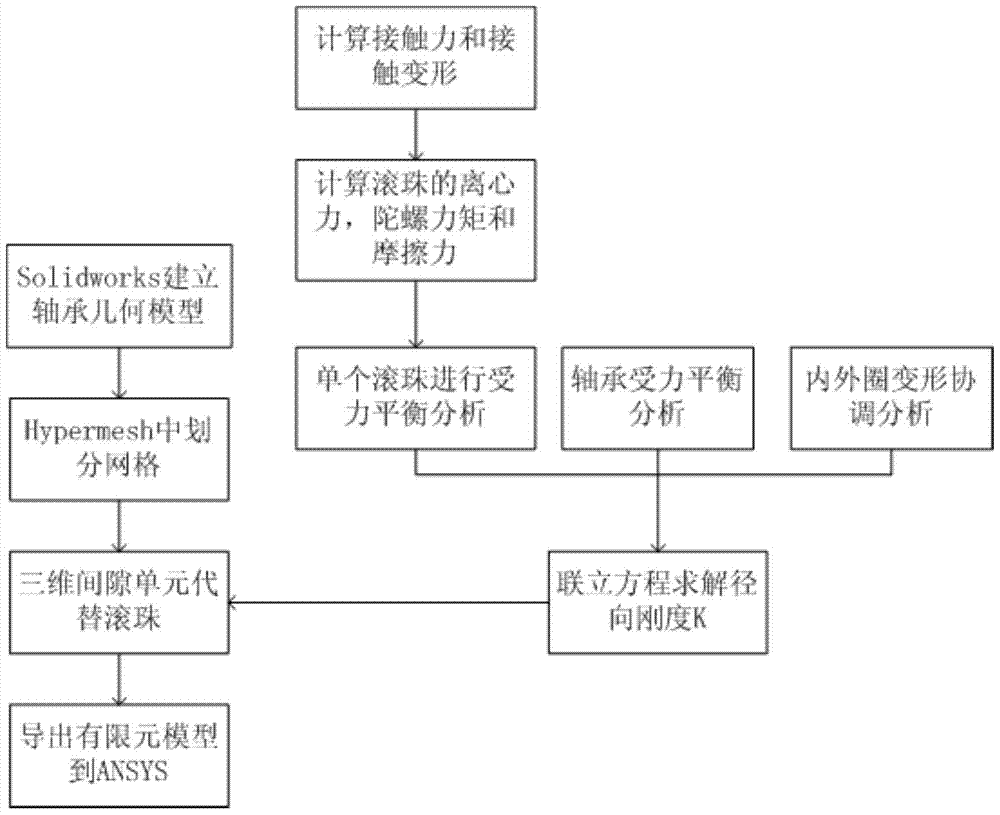

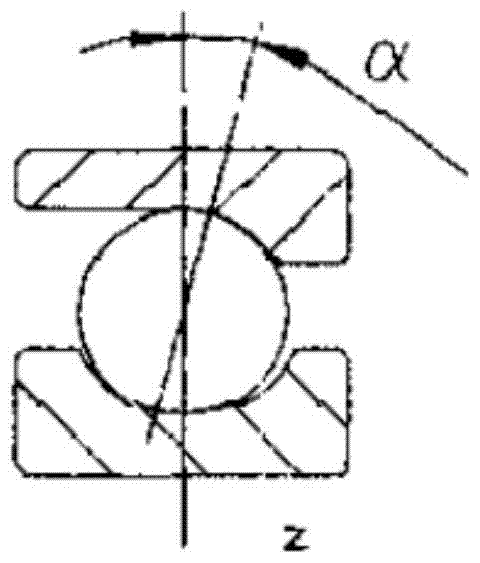

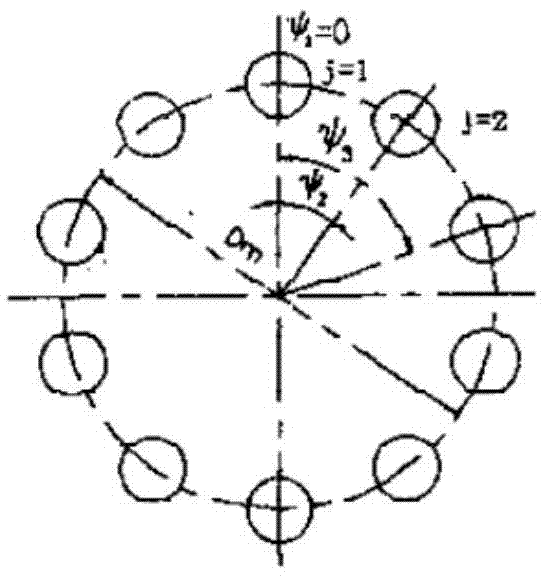

Bearing simplifying method in finite element simulation analysis

InactiveCN104239654AThe result is close to the realSimple calculationSpecial data processing applicationsElement modelElement analysis

The invention discloses a bearing simplifying method in finite element simulation analysis. According to the method, a three-dimensional gap unit is used for simplifying finite element analysis of an angular contact bearing, and a three-dimensional model of the bearing is drawn in three-dimensional mapping software solidworks. The bearing model is imported into finite element pre-processing software Hypermesh. An outer ring and an inner ring of the bearing are divided into hexahedral meshes. The outer ring and the inner ring of the bearing are connected through the three-dimensional gap unit. The spring stiffness K in the gap unit is worked out through a bearing radial stiffness calculation program. The finite element model is exported from the Hypermesh, then the finite element model is imported into engineering simulation software ANSYS, and mechanical calculation is conducted. According to the method, the calculation amount of finite element analysis can be simplified, the efficiency can be increased, and the calculation accuracy cannot be damaged.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

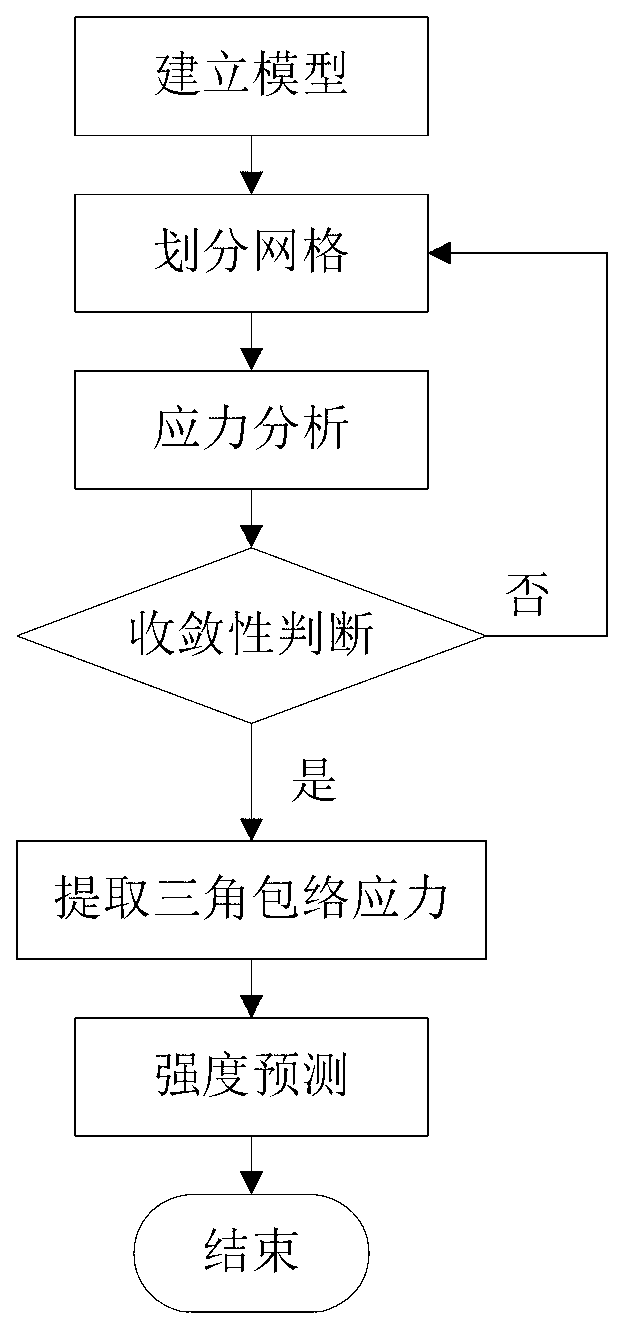

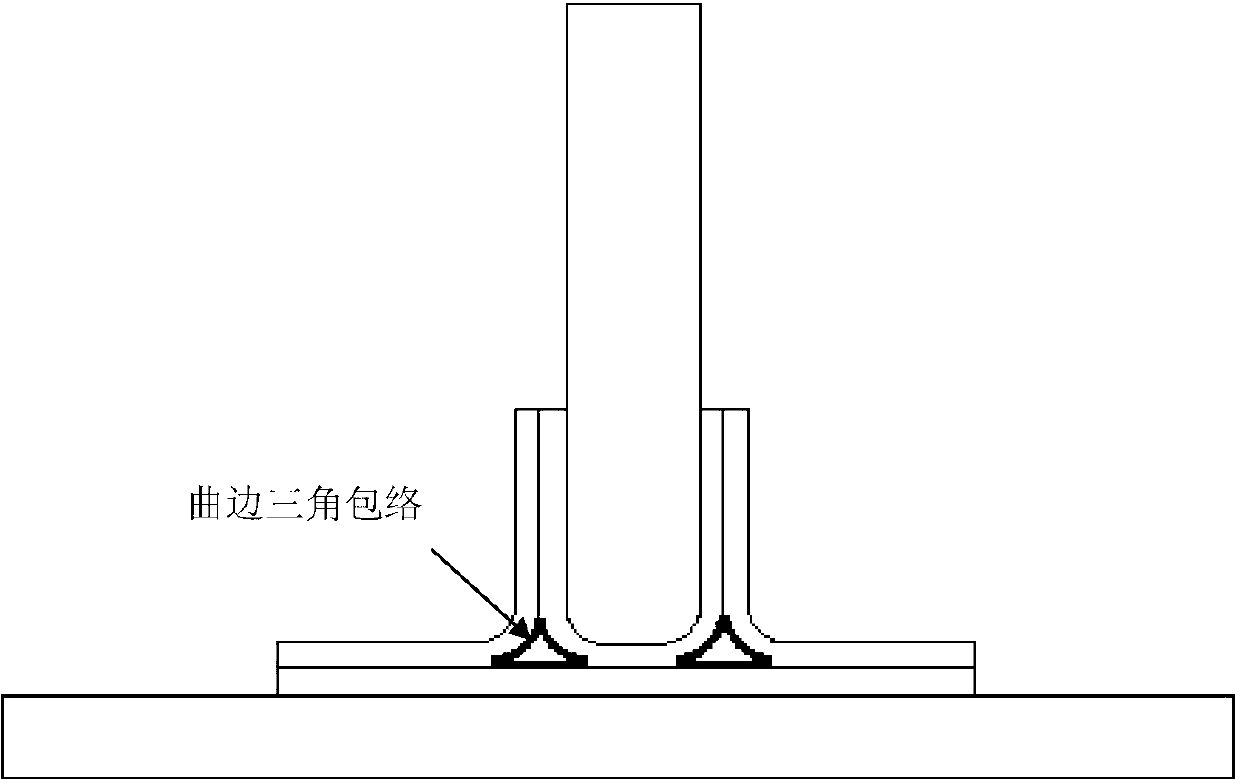

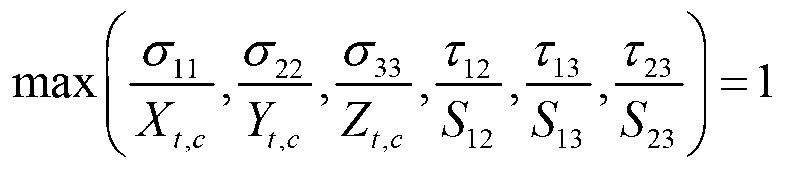

Method for predicating composite material Pi-shaped non-planar glue joint strength based on triangular envelopes

InactiveCN103345545AImprove consistencyGuaranteed prediction accuracySpecial data processing applicationsElement modelPredictive methods

The invention relates to a method for predicating composite material Pi-shaped non-planar glue joint strength based on triangular envelopes. The method includes the following steps that (1), according to parameters of a composite material Pi-shaped non-planar glue joint structure, a geometrical model is established; (2), according to actual working conditions of the composite material structure, loads and boundary conditions of the Pi joint geometrical model are determined; (3), grid partition is performed on the joint geometrical model, and a Pi joint three-dimensional finite element model is obtained; (4), on the basis of the Pi joint three-dimensional finite element model, a finite element stress analysis is performed; (5), according to the linear finite element stress analysis result, a curved edge triangular envelope route of a Pi negative moment steel padding region is set on the basis of the Pi joint three-dimensional finite element model, all stress component values on the curved edge triangular envelope route are extracted, and the average value of the stress component values is calculated and substituted to the failure criterion for predicating the strength. The method for predicating the composite material Pi-shaped non-planar glue joint strength based on the triangular envelopes is suitable for engineering application and can obviously shorten a development cycle and reduce experimentation cost.

Owner:BEIHANG UNIV

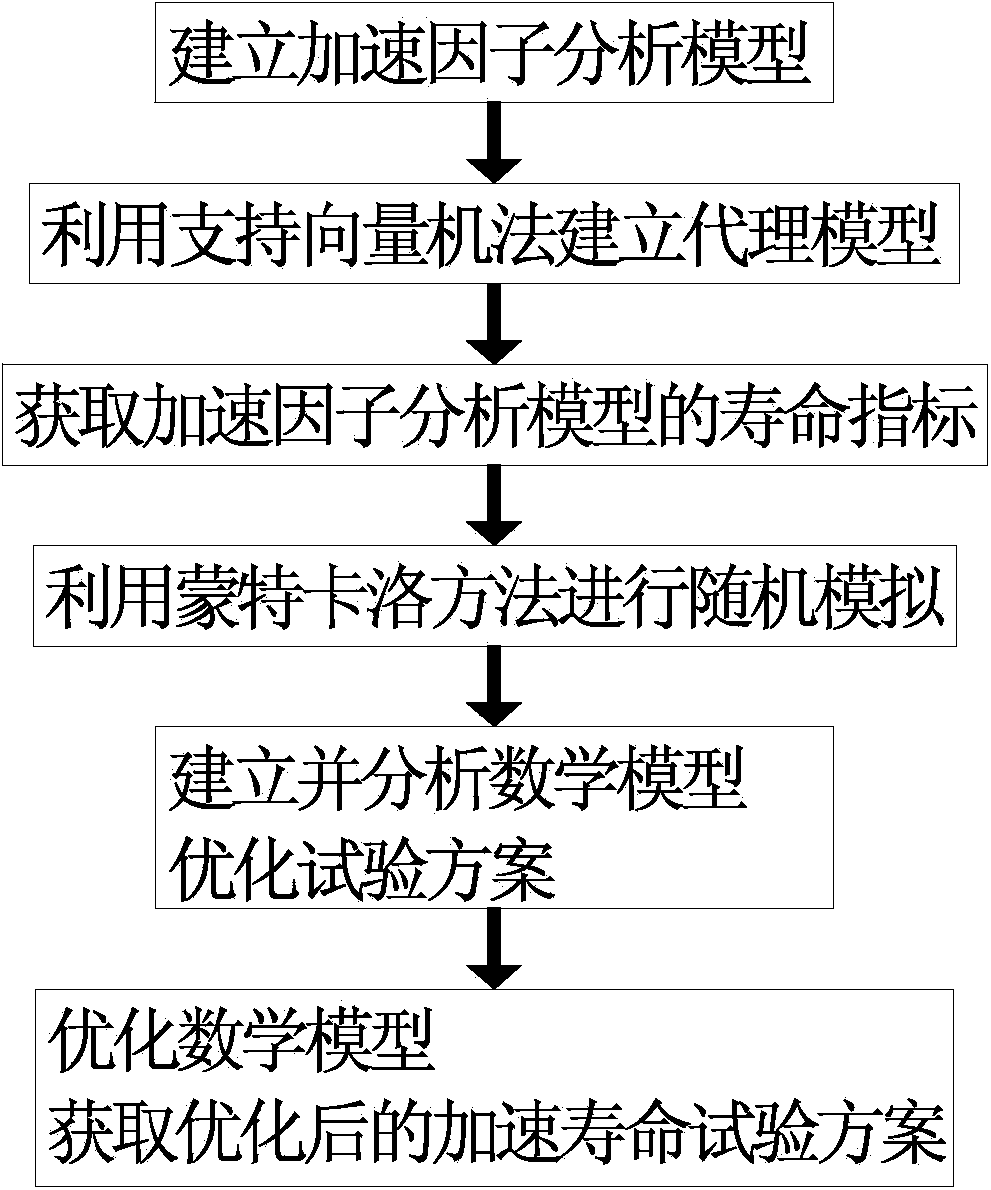

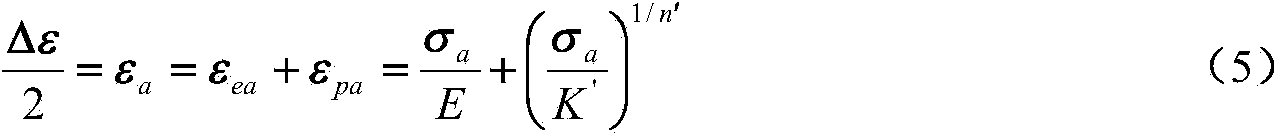

Test run method for accelerated life test of gas turbine engine

ActiveCN103970965AShorten life test cycleReduce test costsSpecial data processing applicationsAcceleration factorSupport vector machine

The invention discloses a test run method for an accelerated life test of a gas turbine engine. The test run method comprises the steps that an accelerated factor analysis model of the gas turbine engine under simulated running conditions is established; according to the accelerated factor analysis model, a support vector machine method is used for establishing a surrogate model of three-dimensional finite element stress analysis; the surrogate model is used for obtaining dangerous point stress of the accelerated factor analysis model, and then life indexes of the accelerated factor analysis model are obtained; a Monte Carlo method is used for conducting stochastic simulation on random variables of the life indexes; an optimal design mathematical model of an accelerated life test scheme of stress under the simulated running conditions of the gas turbine engine is established and analyzed, and the test scheme is optimized according to the optimal design mathematical model; a mixing optimization method is adopted to optimize the mathematical model, and the optimized accelerated life test scheme is obtained according to the optimized mathematical model. By means of the test run method, the test period is shortened, and life test expenditure is reduced.

Owner:CHINA AVIATION POWER MACHINE INST

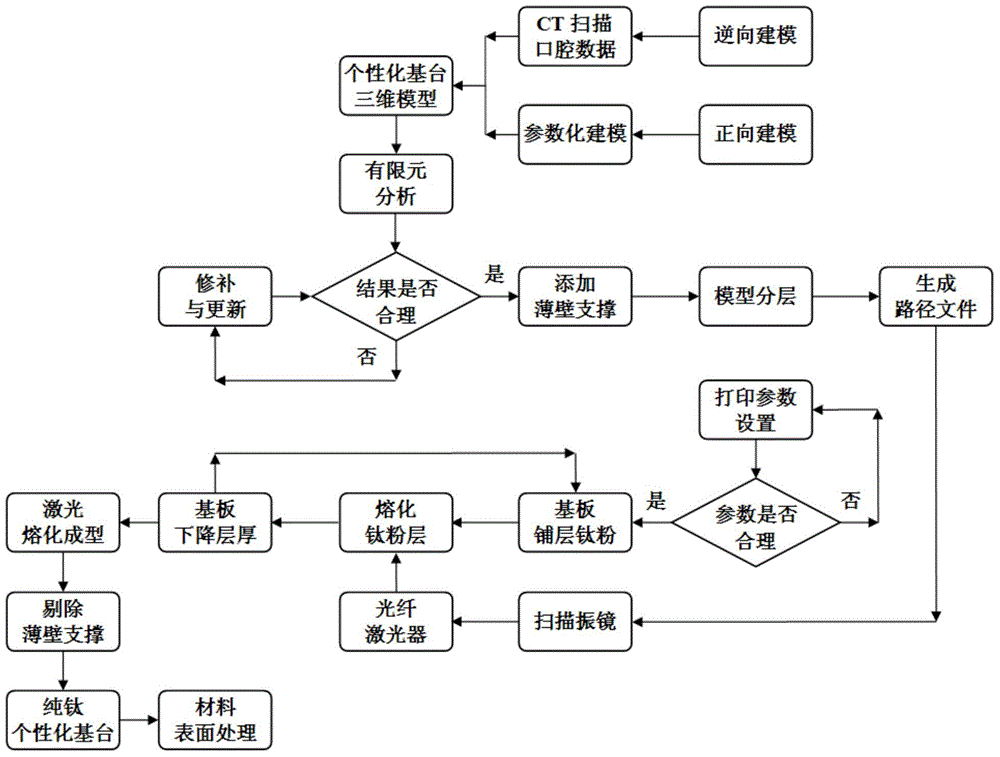

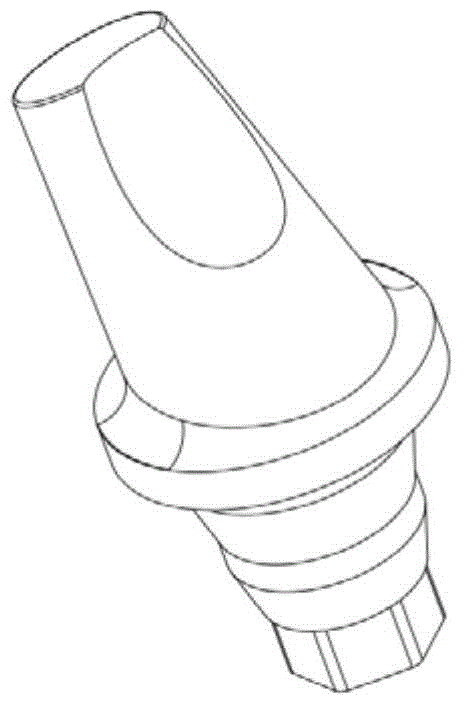

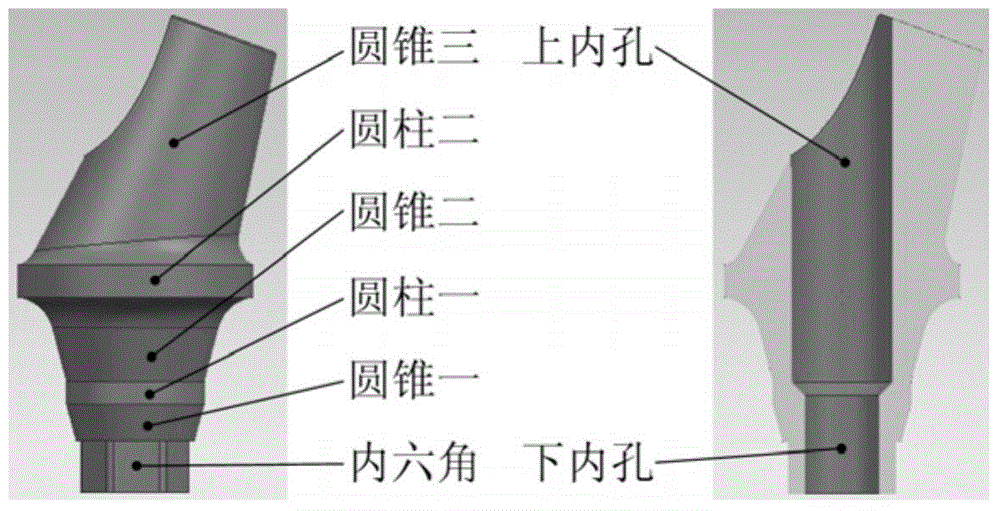

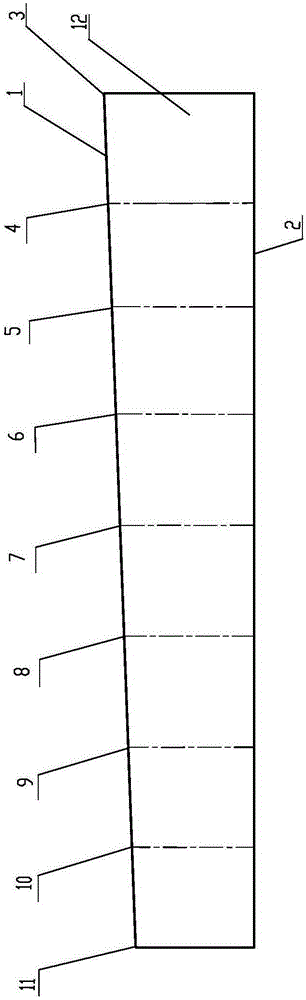

Individual abutment and manufacturing method thereof

ActiveCN105055037AFit closelyImplement a parametric design processDental implantsImpression capsSelective laser meltingComputed tomography

The invention relates to an individual abutment and a manufacturing method thereof. The manufacturing method comprises the following steps: carrying out reverse modeling through CT scanning and carrying out parametrization design on a model through Unigraphics NX, implementing precise repairing on the abutment model, carrying out simulation analysis on the abutment model by virtue of a finite element analysis method, and implementing model optimization design according to a finite element stress analysis result so as to meet the attributes of an abutment material; carrying out three-dimensional hierarchical slicing treatment on the abutment model meeting the attributes of the abutment material, and promoting the generation of a corresponding path file; and according to the path file, reasonably controlling the parameters of selective laser melting equipment and molding so as to obtain the individual abutment. The manufacturing method disclosed by the invention can be used for effectively guaranteeing the accuracy of stress direction and size of the abutment as well as the precision of molding, and the manufactured individual abutment can fit to jaw characteristics of a patient more precisely compared with the prior art, so that comfort in use is improved and the service life of the abutment is prolonged.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

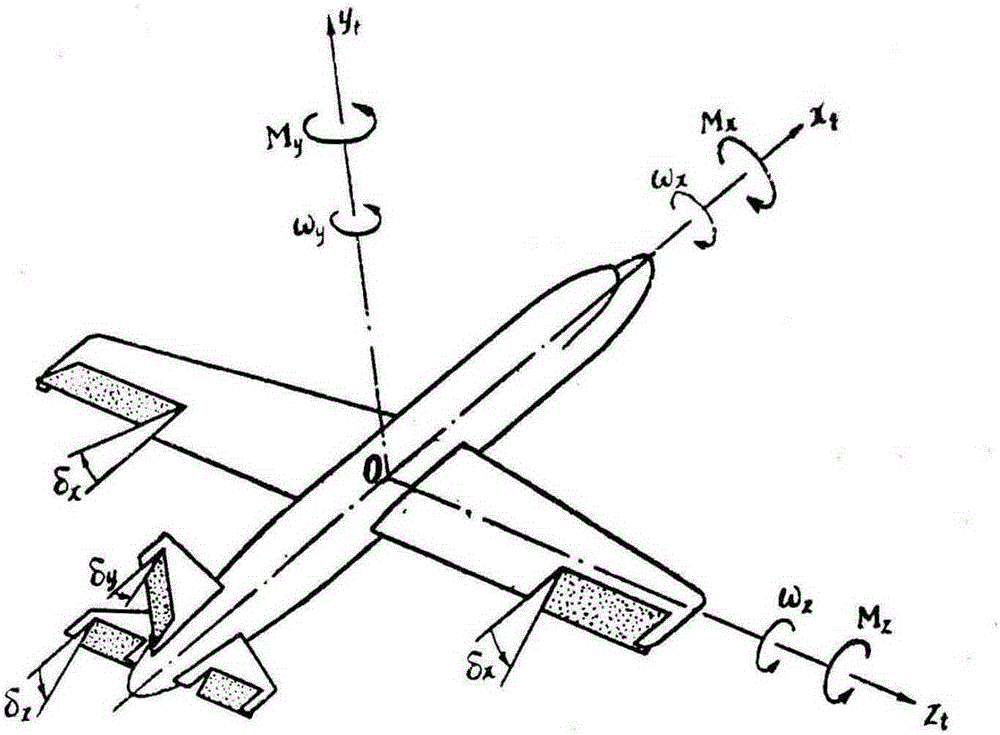

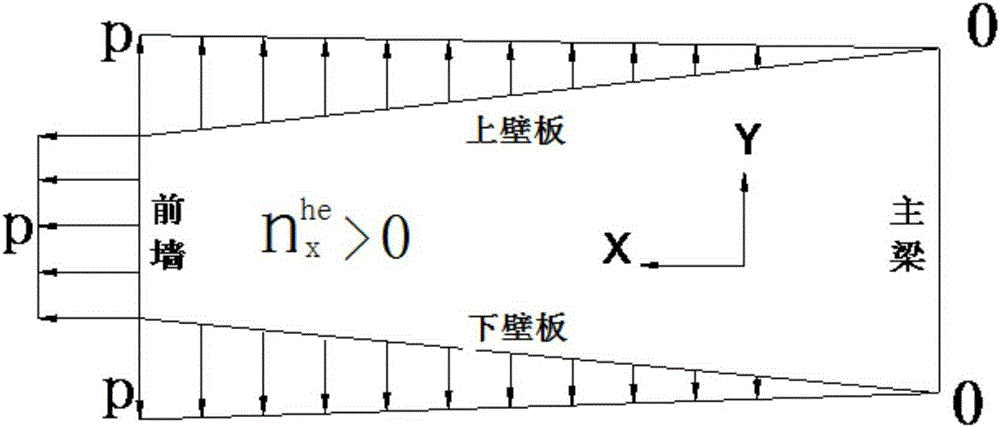

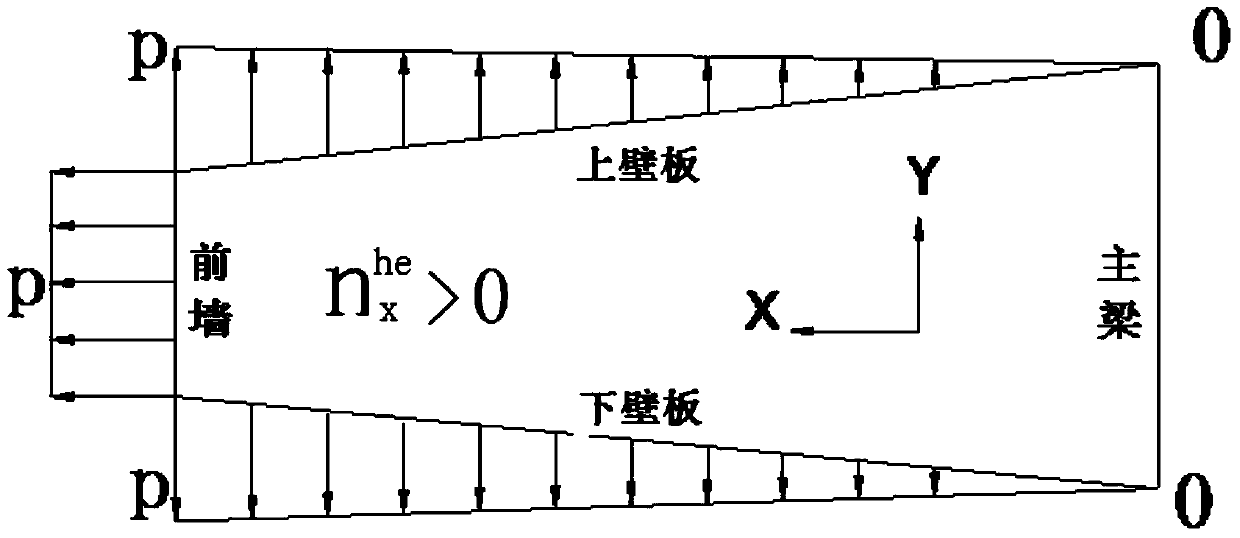

Method for calculating load of wing integral fuel tank

ActiveCN105205267AAccurately reflectSpecial data processing applicationsElement modelAerodynamic load

The invention discloses a method for calculating a load of a wing integral fuel tank. The method comprises the steps of first calculating loads which fuel is subjected to in the X-direction, Y-direction and Z-direction by utilizing the principle that the loads can be overlaid linearly in the structure on-line elastic range; respectively calculating pressure distribution of each end face of the inner wall of the fuel tank under unidirectional overloads; finally overlaying pressure generated by each unidirectional overload, and obtaining pressure distribution of the wing fuel tank; establishing a wing fuel tank local detail finite element model in a full-aircraft overall finite element model, adding the pressure load of each end face of the fuel tank to the finite element model, applying corresponding working condition aerodynamic loads, and performing finite element stress analysis to obtain finite element stress result under each working condition. Under the conditions that the aircraft wing integral fuel tank is not pressurized and an inertial load of the fuel to the fuel tank exists, the method for calculating the load of the fuel tank is used for intensity assessment, and the load which the fuel tank is subjected to can be reflected genuinely.

Owner:JIANGXI HONGDU AVIATION IND GRP

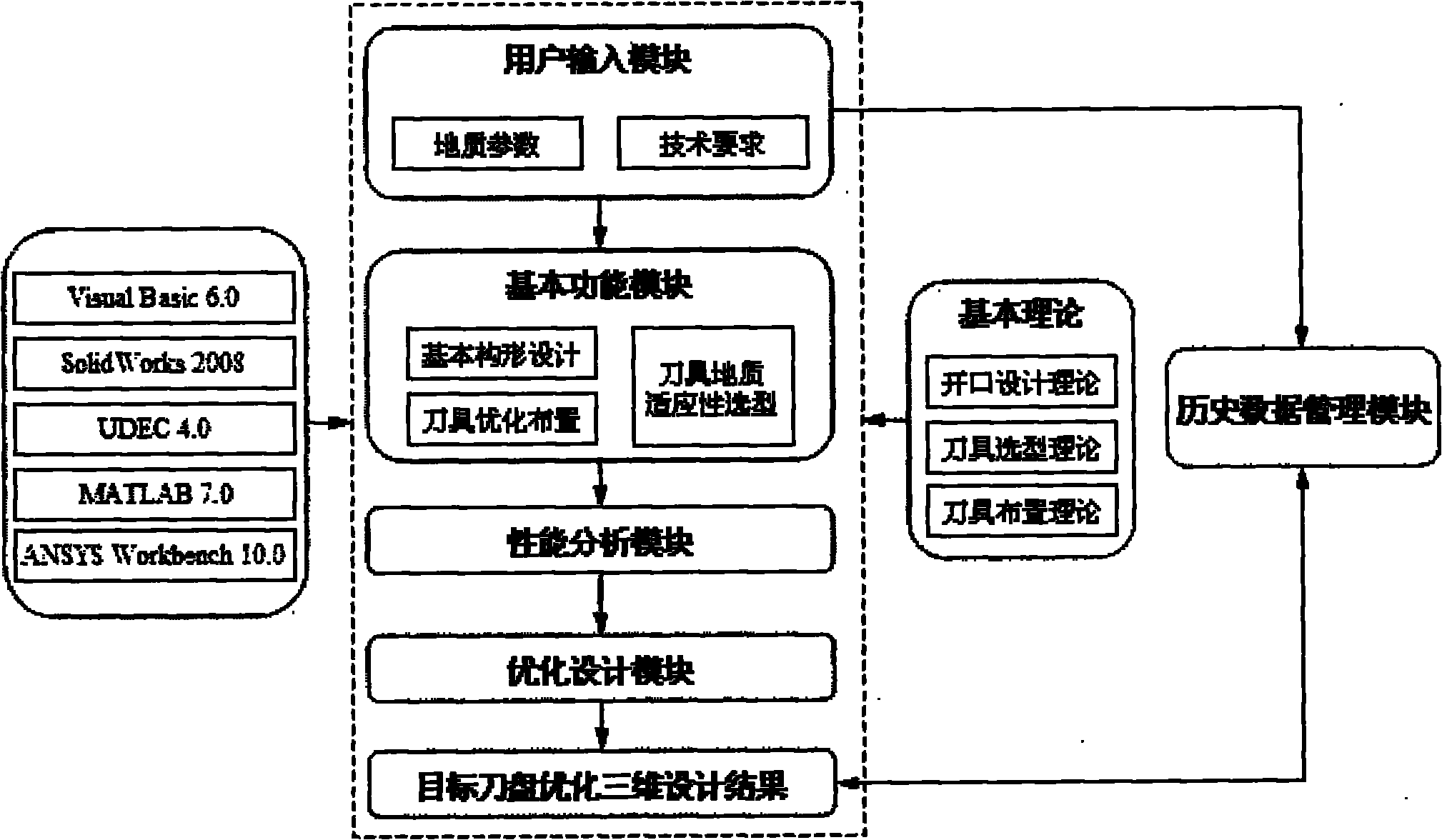

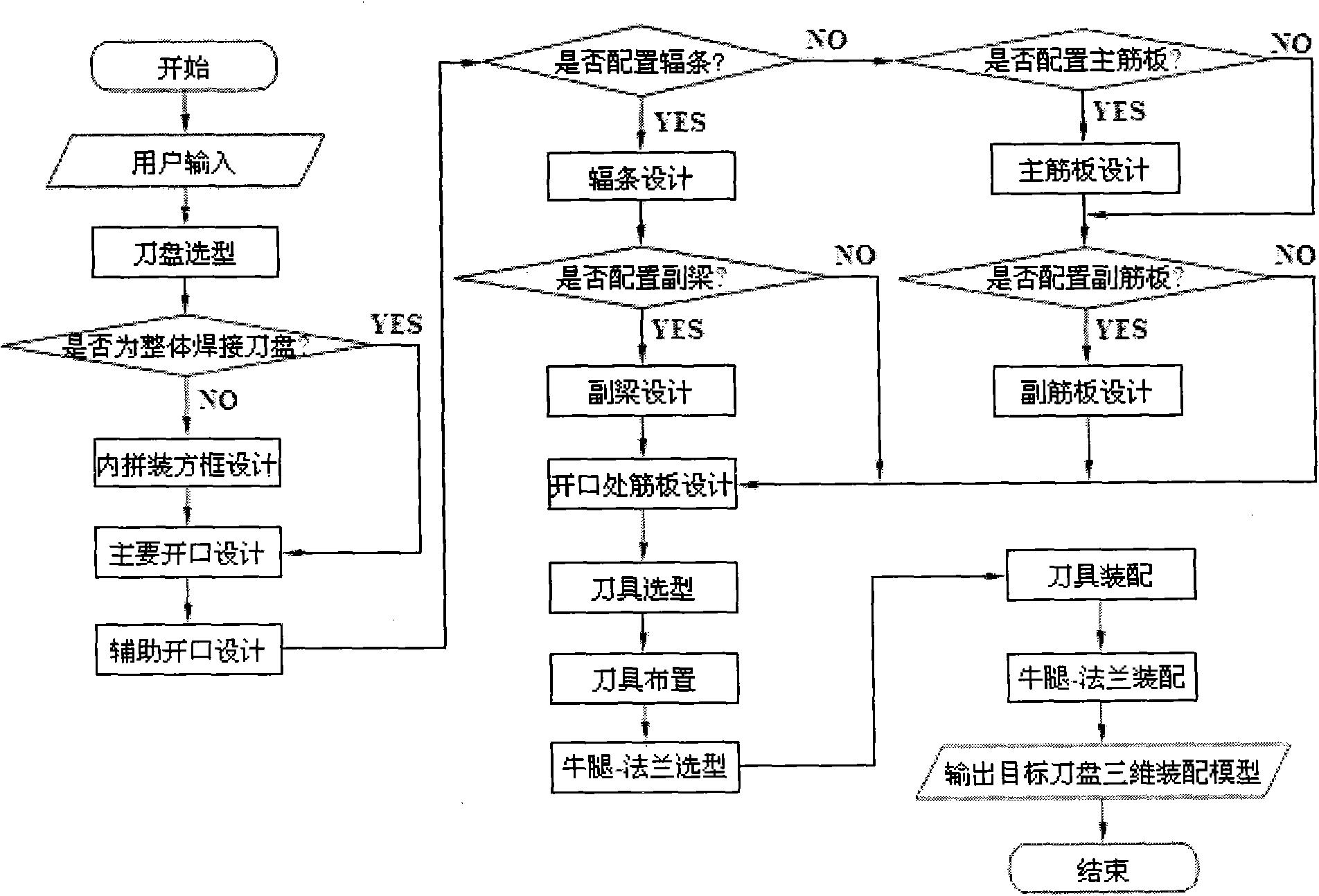

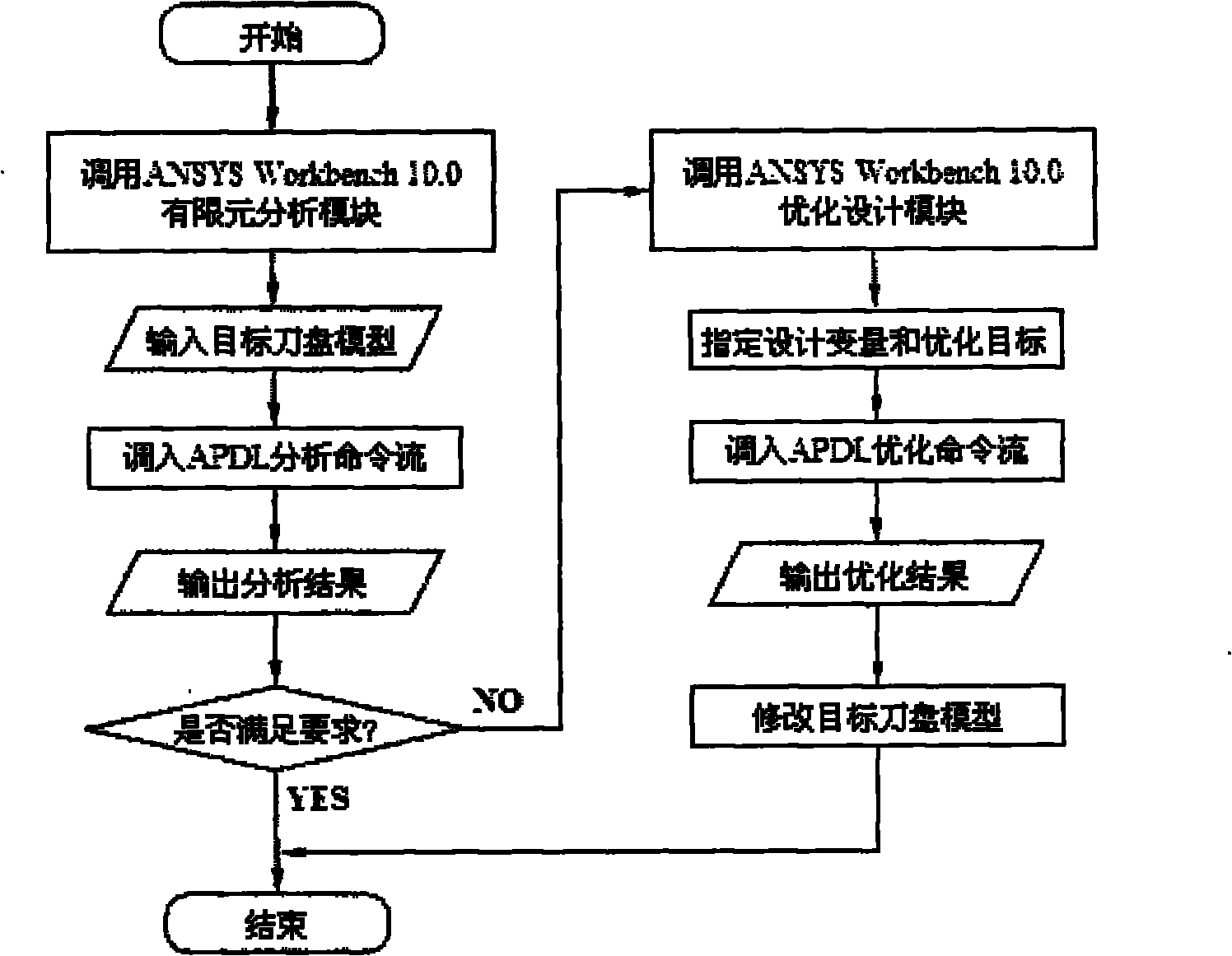

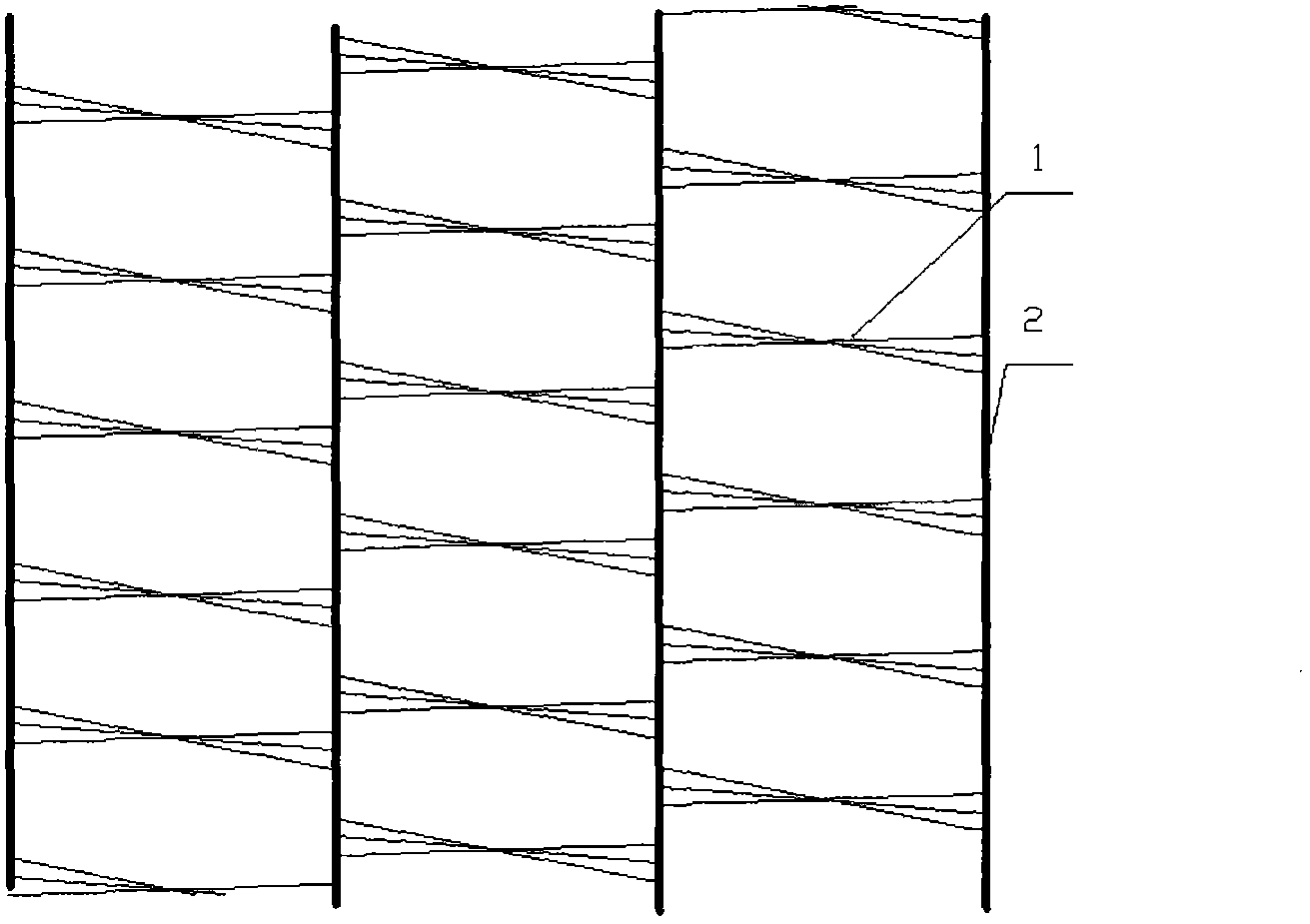

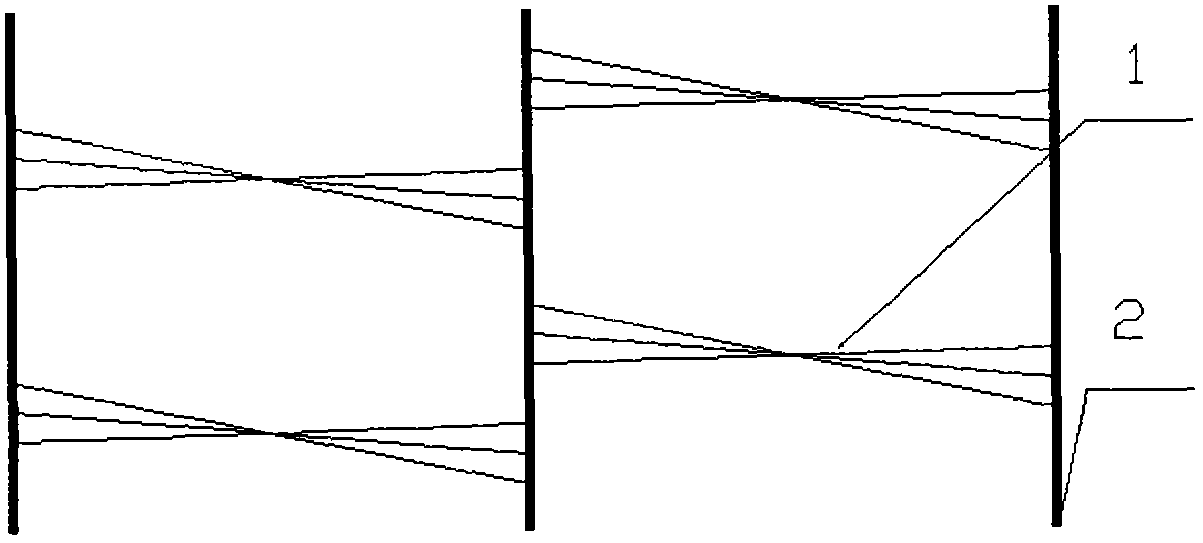

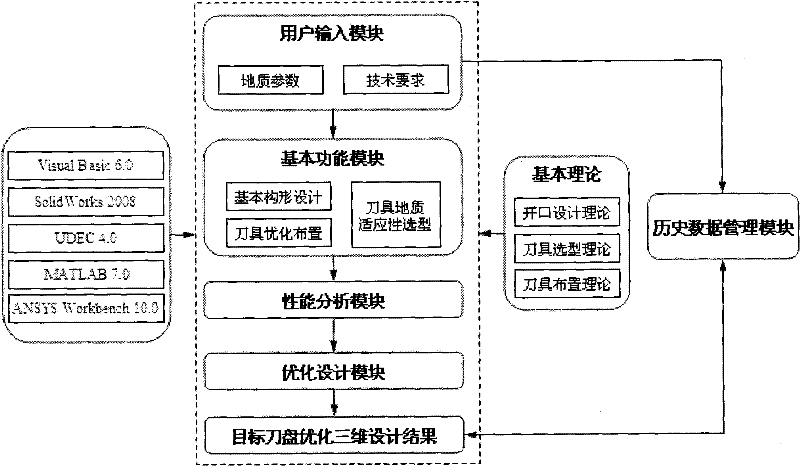

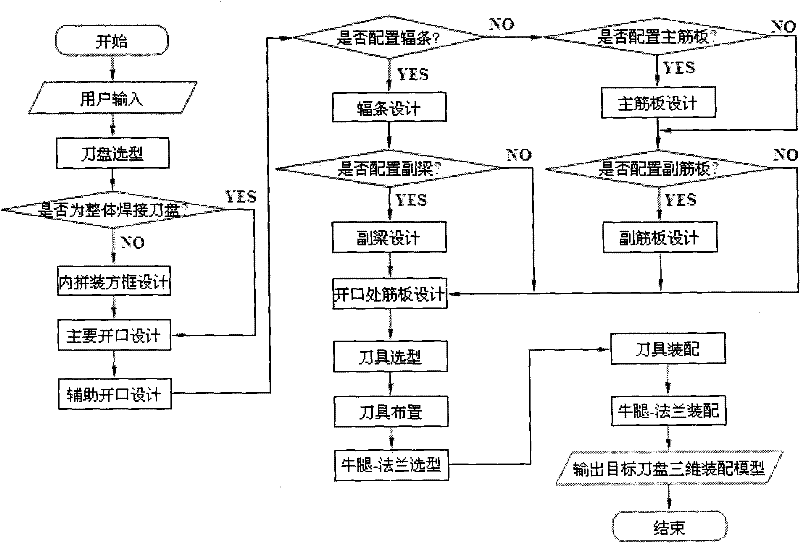

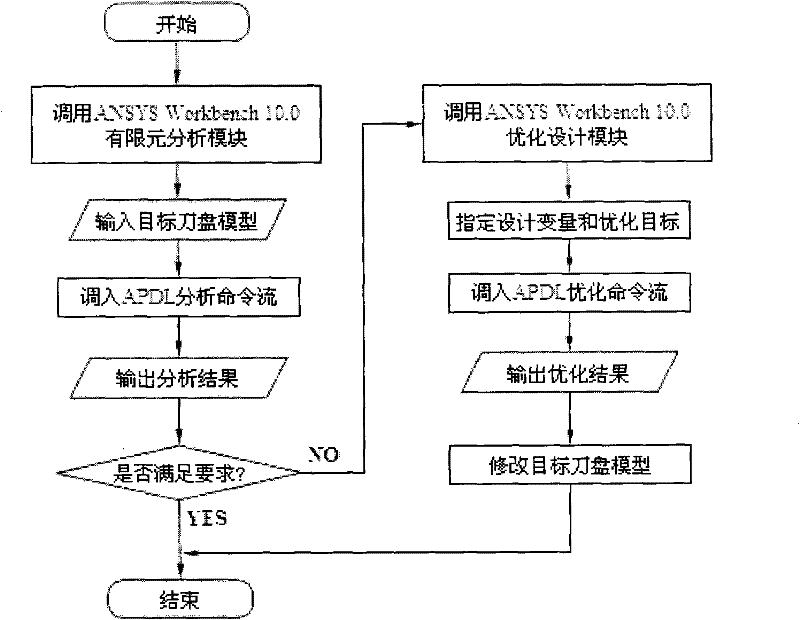

CAD system for composite type earth pressure shield cutter head

InactiveCN101980227AImprove mechanical propertiesSimple structureSpecial data processing applicationsVisual BasicConfiguration design

The invention discloses a computer aided design (CAD) system for a composite type earth pressure shield cutter head, which belongs to the field of computer software. In the system, Solidworks 2008 is developed secondarily based on Visual Basic 6.0 to realize parametric modeling, and UDEC 4.0, MATLAB 7.0 and ANSYS Workbench 10.0 are called to perform automatic analysis and optimization. The system comprises a user input module, a basic function module, a performance analysis module, an optimization design module and a historical data management module. A user inputs geological parameters and technical requirements, and the system automatically combines theories of opening design, cutting tool type selection and cutting tool layout to perform basic configuration design, cutting tool geology adaptability type selection, cutting tool optimization layout, cutter head finite element stress analysis and cutter head structural parameter optimization design on the composite type earth pressure shield cutter head so as to obtain an optimal three-dimensional design result of a target cutter head, and the system automatically stores the data input by the user and a corresponding design result. By the CAD system, a corresponding relation between the geological parameters and key design parameters of the cutter head can be quickly established, and design reliability and design efficiency can be improved.

Owner:CENT SOUTH UNIV

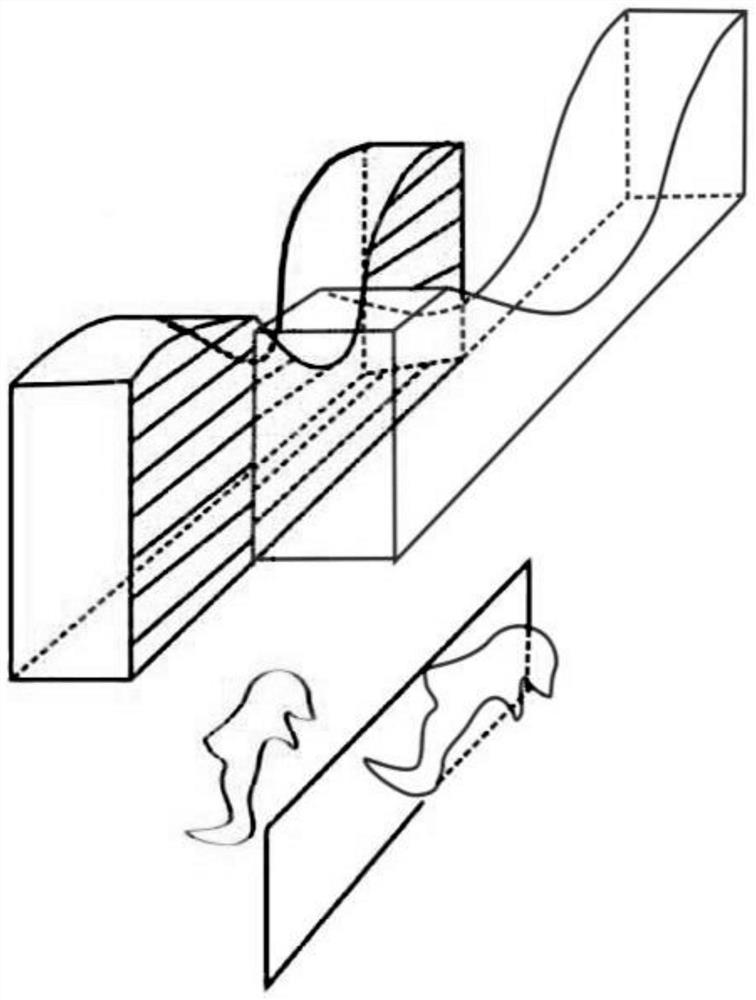

Method for modeling composite material preform with bionic structure

ActiveCN102693345AHigh tensile strengthHigh compressive strengthSpecial data processing applicationsSpatial structureFlexural strength

The invention discloses a method for modeling a composite material preform with a bionic structure. The method comprises the following steps of: 1) counting and analyzing space structure characteristic values of loofah sponge to obtain a mean value of the characteristic values; 2) performing modeling on the basis of the mean value of the characteristic values to obtain a primary loofah sponge structure model, wherein the primary loofah sponge structure model comprises a plurality of structural units which are connected; and 3) performing finite element stress analysis on the primary loofah sponge structure model, and structurally regulating the structural units according to a stress deformation nephogram of the primary loofah sponge structure model to obtain a loofah sponge structure model which is used as a structure model of the composite material preform. By using the technical scheme, the composite material preform with the bionic structure can be simulated and constructed; and by the bionic loofah sponge structure, the composite material preform has strong tensile strength, compressive strength and bending strength.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

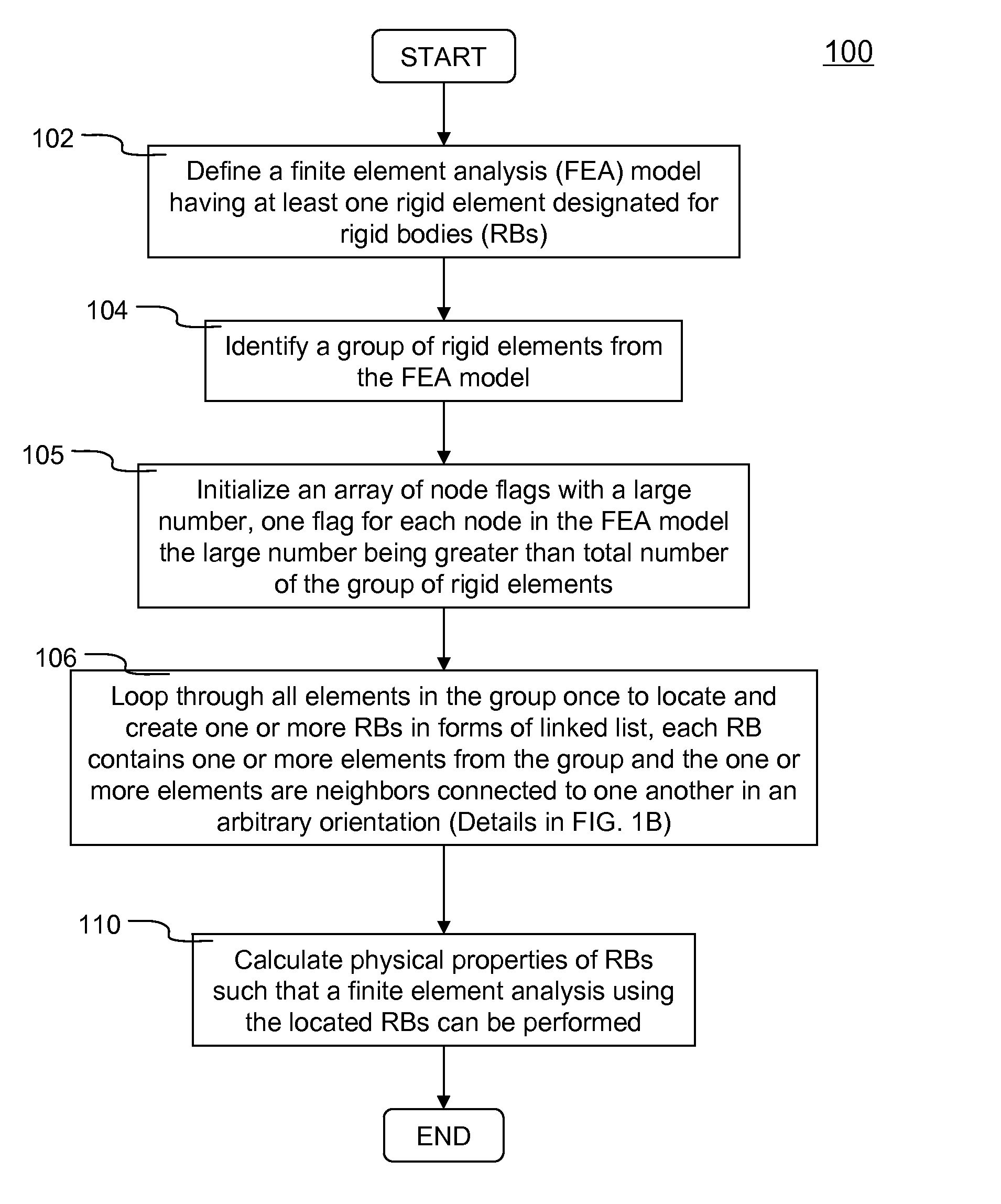

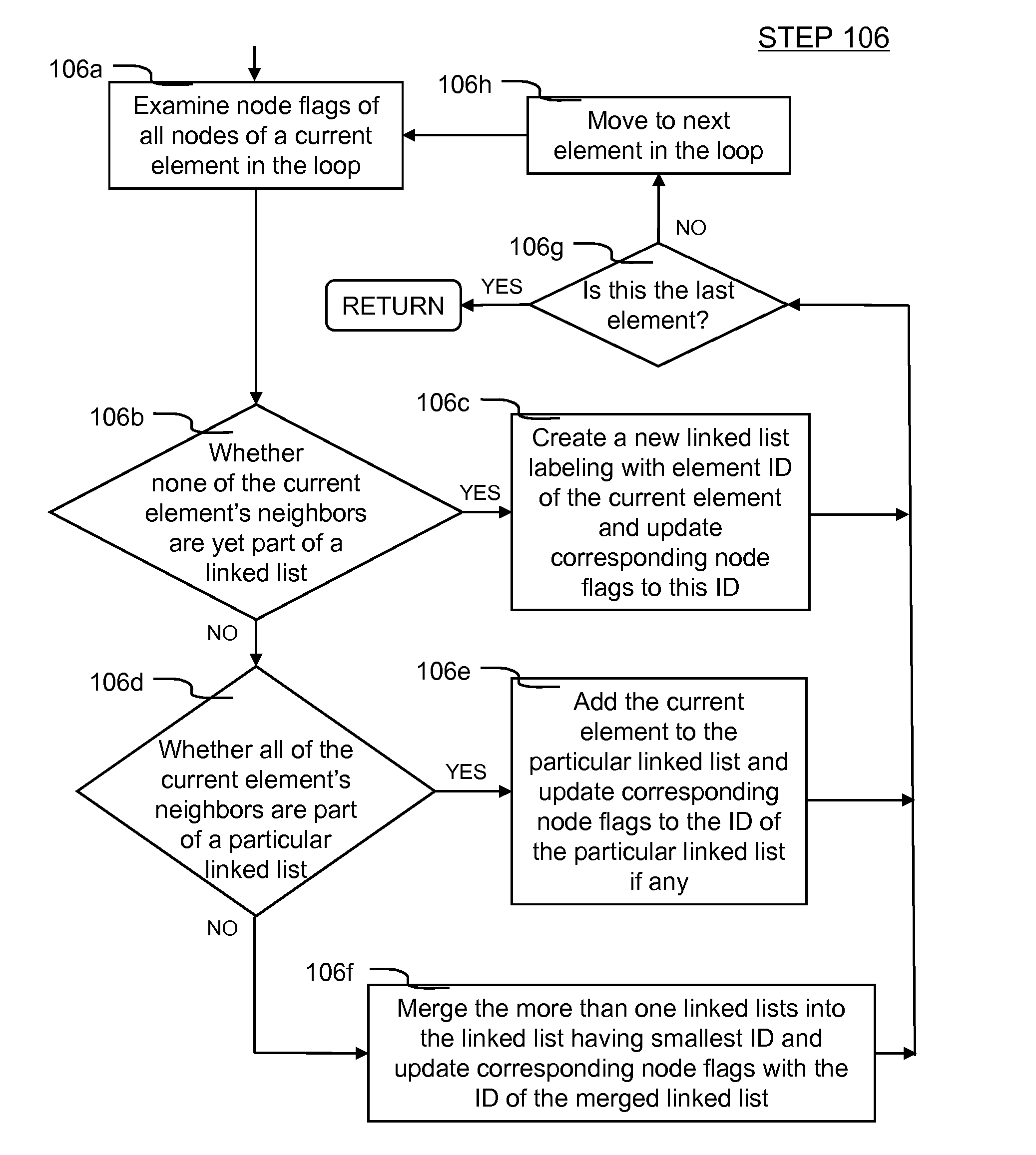

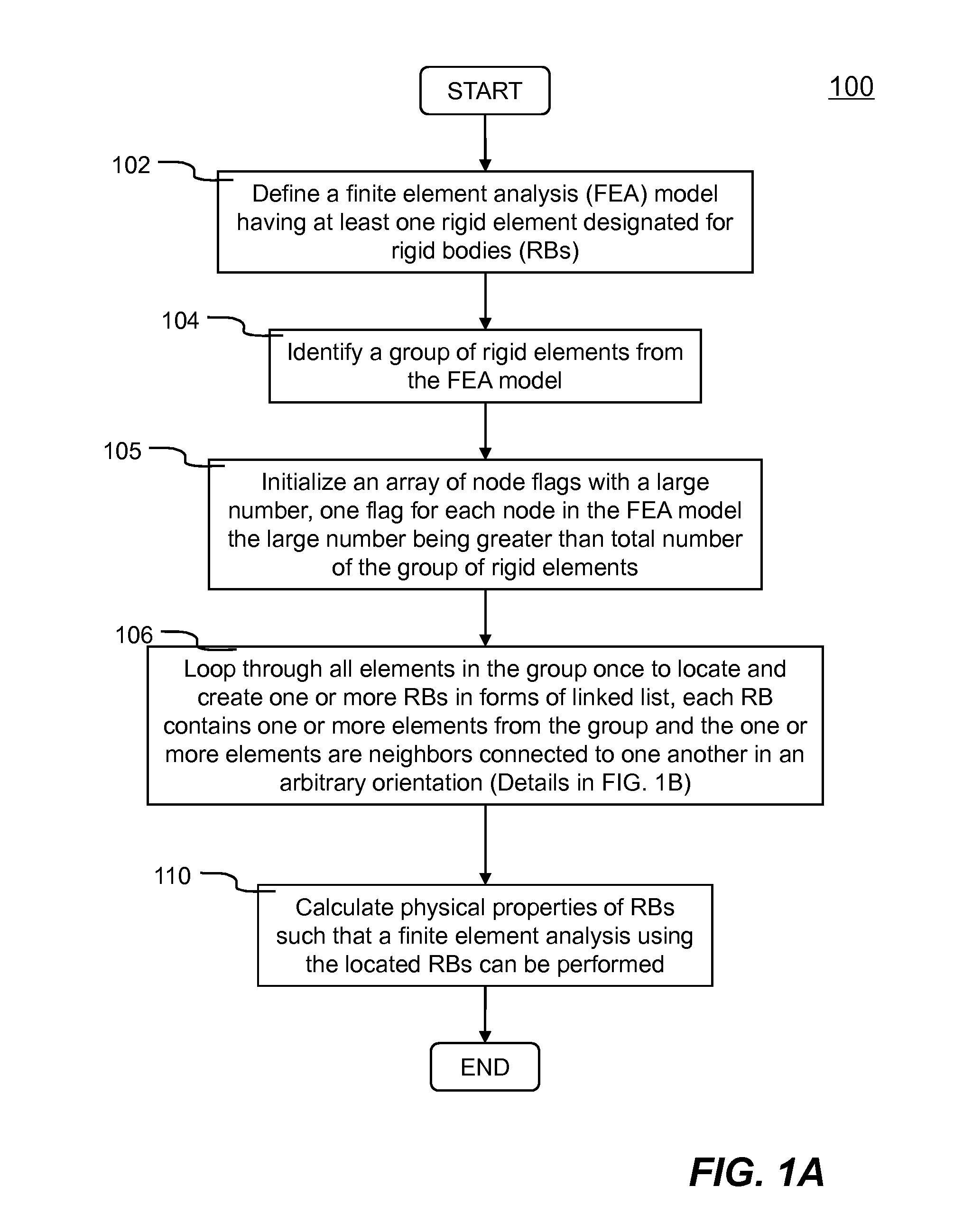

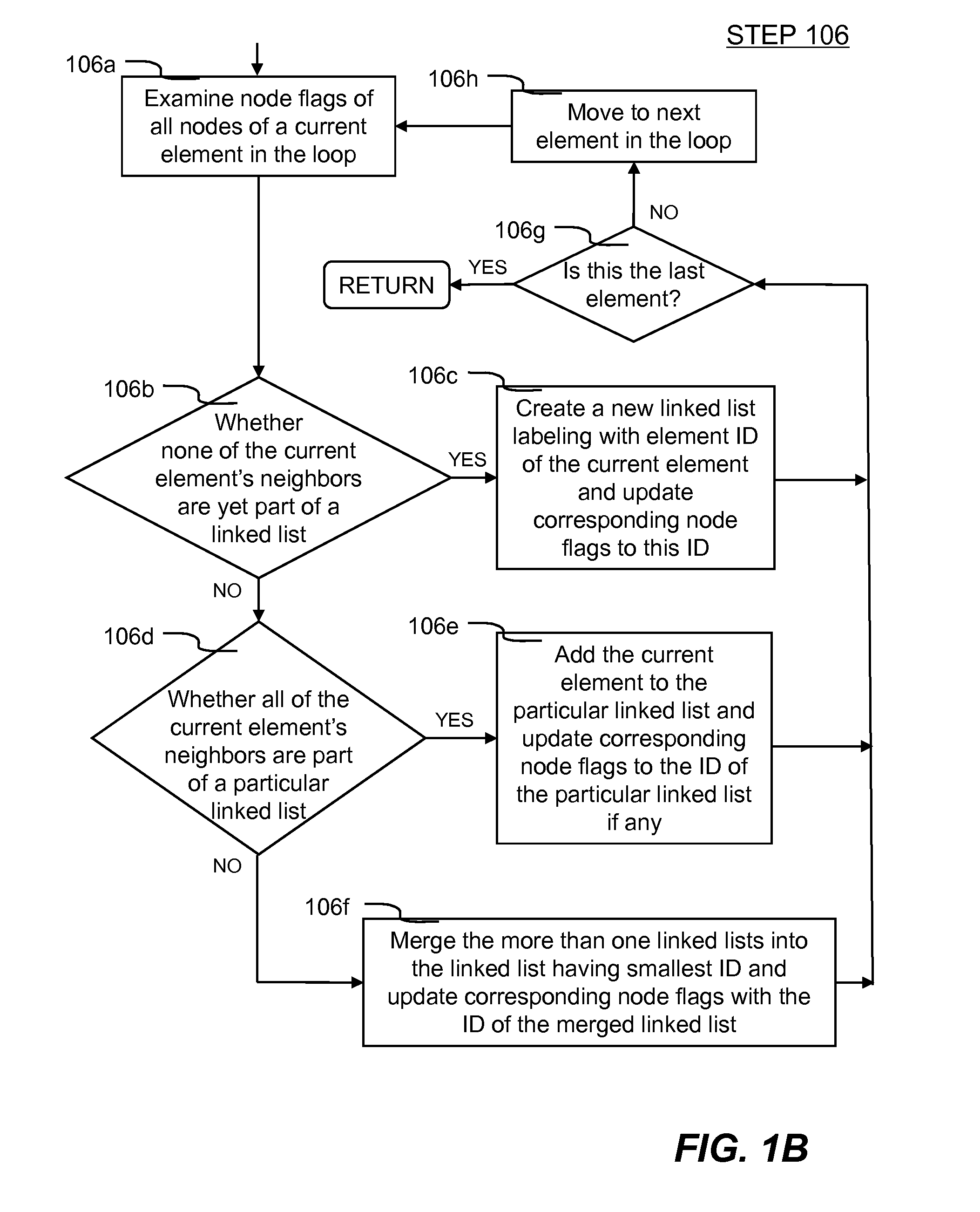

Creation of simulated disjoint rigid bodies in a finite element analysis

ActiveUS20110093240A1Computation using non-denominational number representationDesign optimisation/simulationElement modelElement analysis

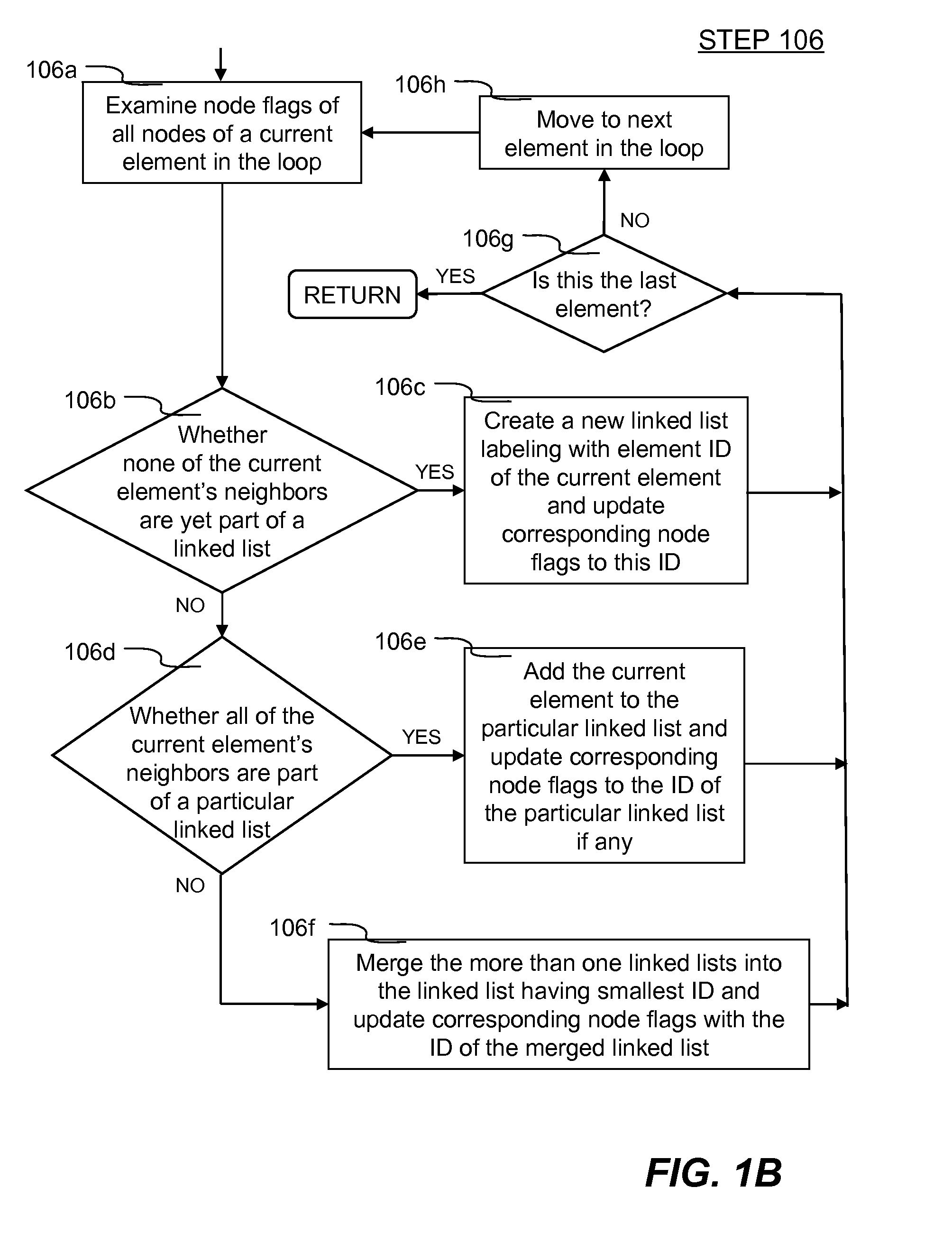

Improved methods and systems for defining and creating simulated rigid bodies in finite element analysis are disclosed. One or more rigid finite elements in a finite element model are designated for forming one or more simulated rigid bodies (RBs). Each simulated RB comprises an arbitrary number of rigid finite elements connecting to one another in an arbitrary shape. Each simulated RB is created by locating all of the elements embedded in the model through shared node or nodes. A procedure of using element definition as a guide to set up an array of node flags, each node flag for one node such that all RBs defined in the model can be located efficiently. Once all RBs have been located, each unique RB is defined as a unique list of connected rigid finite elements.

Owner:ANSYS

Anatomical visualization and measurement system

InactiveUS20110251474A1Easily and accurately presentingDiagnostic recording/measuringSensorsThree vesselsComputer science

In another preferred form of the present invention, there is provided a method for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the method comprising:generating a mesh model of the blood vessel using the set of 2-D slice images;conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; anddetermining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model.In another preferred form of the present invention, there is provided an apparatus for determining the risk of rupture of a blood vessel using an appropriate set of 2-D slice images obtained by scanning the blood vessel, the apparatus comprising:apparatus for generating a mesh model of the blood vessel using the set of 2-D slice images;apparatus for conducting finite element stress analysis on the mesh model to calculate the level of stress on different locations on the mesh model; andapparatus for determining the risk of rupture of the blood vessel based on the calculated levels of stress on different locations on the mesh model.

Owner:CHEN DAVID T +4

Spine near-end boundary angle operation optimization method based on finite elements and machine learning

ActiveCN111627560AReduce complicationsMedical simulationImage enhancementPattern recognitionSpinal column

The invention discloses a spine near-end boundary angle operation optimization method based on finite elements and machine learning. The spine near-end boundary angle operation optimization method comprises the following steps: s1, collecting patient information; s2, carrying out image segmentation on the preoperative CT; s3, respectively measuring the PJA angle alpha of the patient from the preoperative total spinal X-ray and the postoperative total spinal X-ray of the patient; s4, calculating the pressure F borne by the patient before and after the intervertebral disc operation under the upright condition, wherein the head end of the vertebral body is fixed at the uppermost end of the intervertebral disc; s5, carrying out static analysis; s6, establishing a machine learning model g (.) according to the patient information and the stress distribution change data obtained in the step s3; s7, training the machine learning model g (.); and s8, obtaining an optimal solution of the postoperative PJA. According to the method, the advantages of finite element stress analysis and machine learning efficient simulation are combined, and an automatic, personalized and accurate operation scheme optimization method is provided for a patient.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

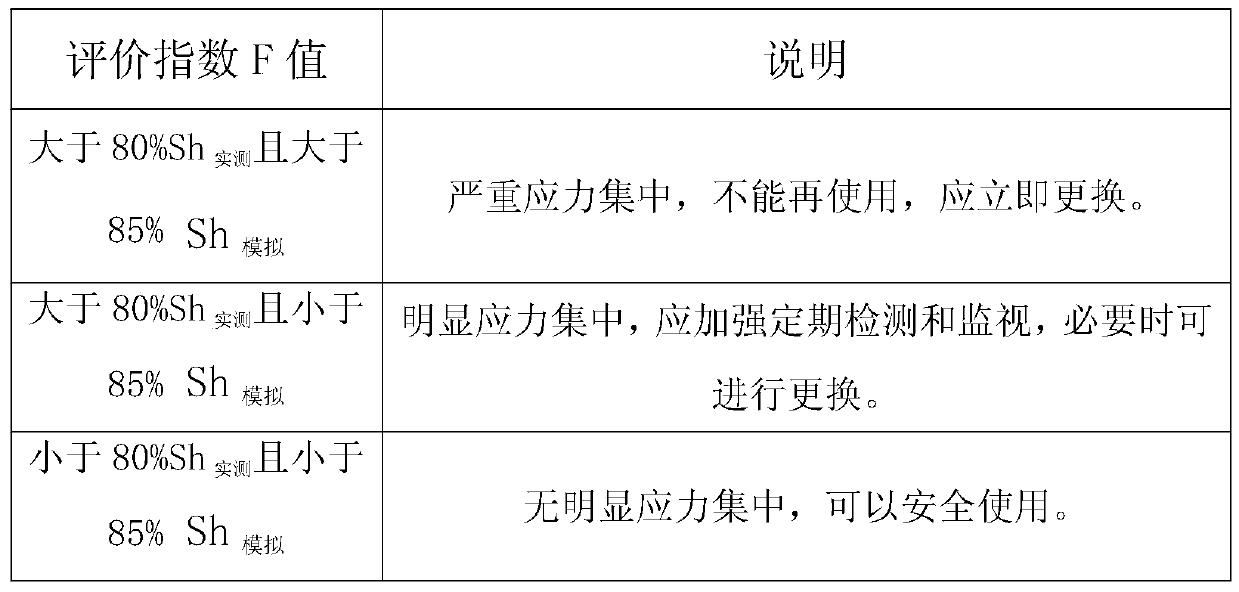

Safety state evaluation method for large-diameter thick-wall part of high-parameter unit

The invention relates to a safety state evaluation method for a large-diameter thick-wall part of a high-parameter unit, and the method comprises the steps: arranging a stress measurement point at thelarge-diameter thick-wall part of the unit, carrying out the field stress testing through an online stress monitoring device, and obtaining the actual measurement data; based on a finite element stress analysis method, carrying out numerical simulation calculation on the stress level of the position where the measuring points are arranged, and obtaining simulation data; carrying out linear fitting on the simulation data and the actual measurement data, and carrying out verification and correction on the simulation data and the actual measurement data to enable the deviation between the simulation data and the actual measurement data to be within a range of + / -5%; setting the stress early warning value of the on-site online stress monitoring device to be 80% of the allowable stress value of the corresponding material at the same temperature; setting a stress early warning value of a finite element stress analysis method to be 85% of an allowable stress value of the corresponding material at the same temperature; and obtaining a safety state evaluation result of the large-diameter thick-wall part based on the evaluation index F value. According to the invention, accurate evaluationof the safety state of the large-diameter thick-wall part is realized.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

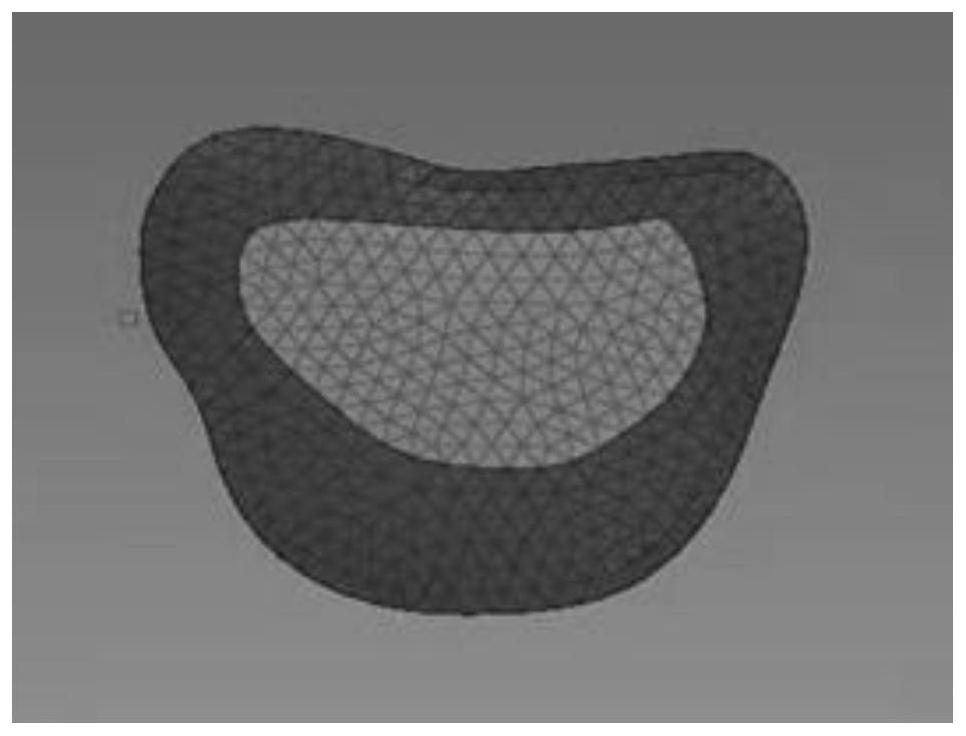

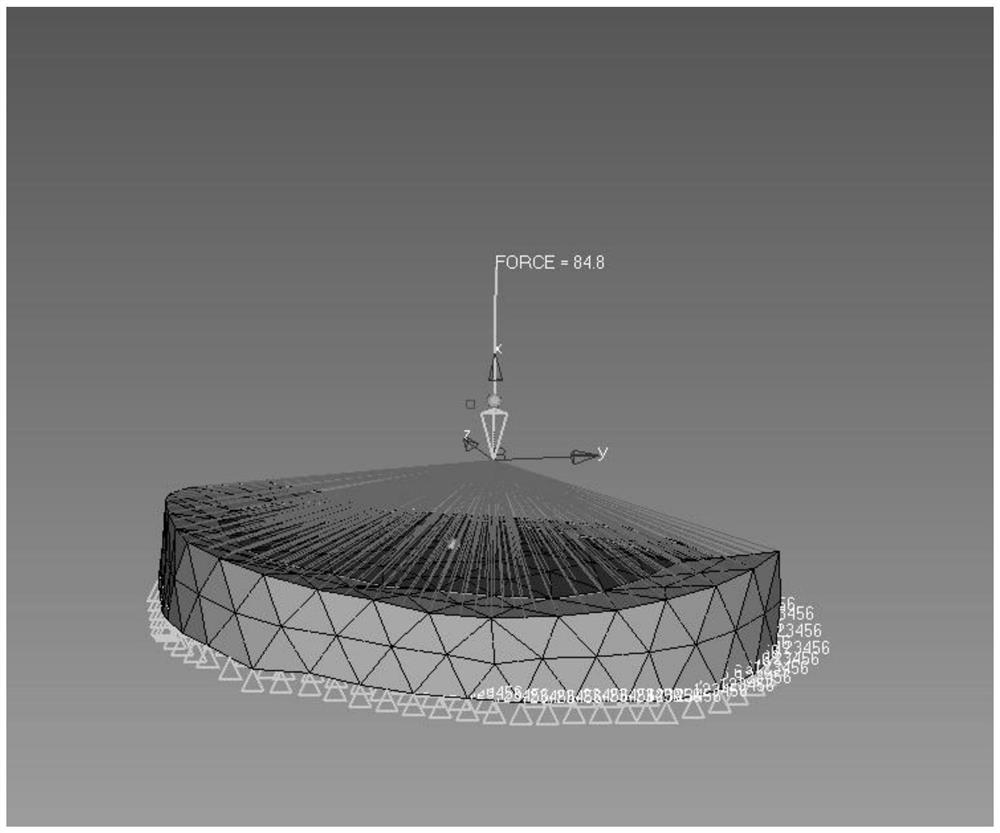

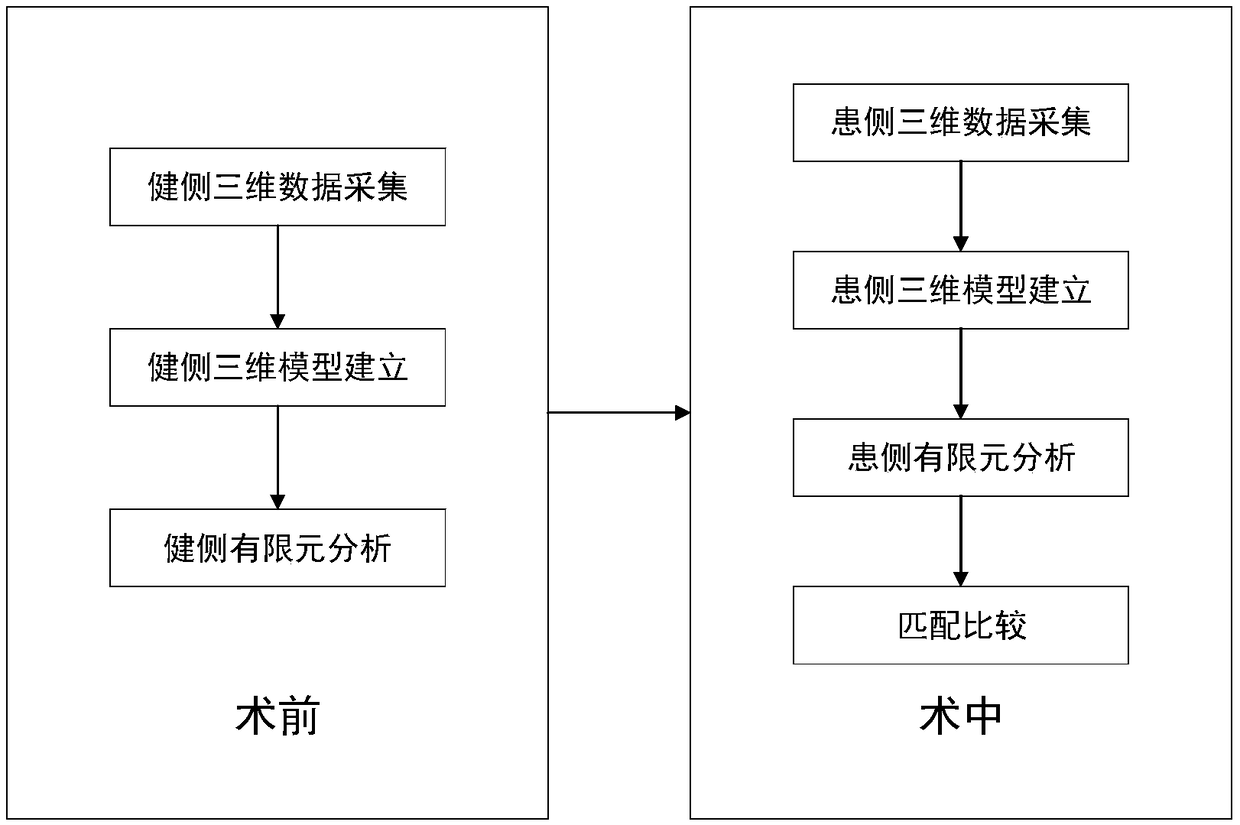

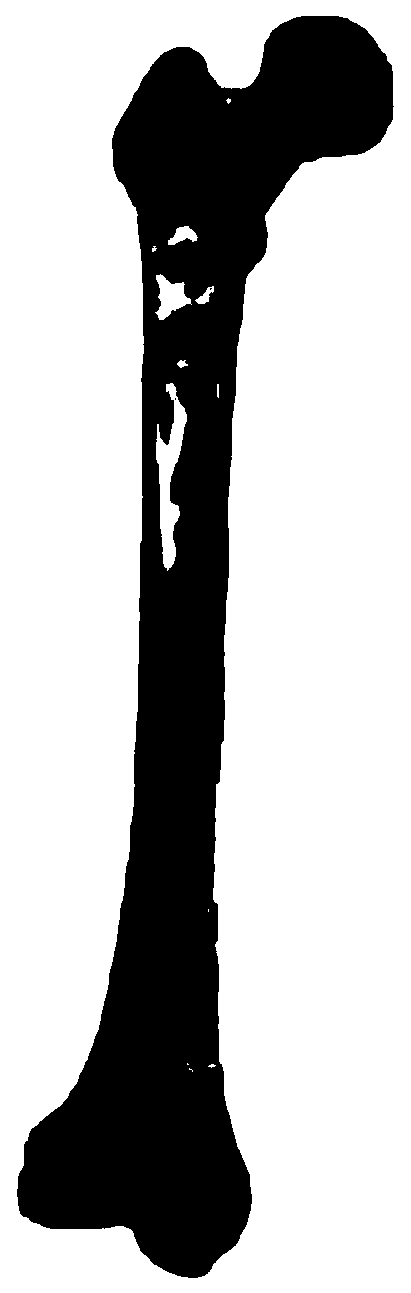

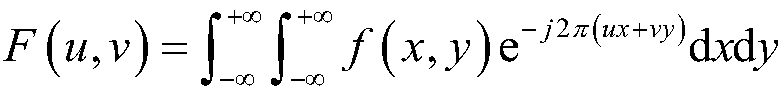

Novel method for determining force line balance in total knee arthroplasty by finite element analysis

InactiveCN108648278AEasy to operateImprove accuracyImage generation3D modellingLife qualityElement analysis

The invention discloses a novel method for determining force line balance in total knee arthroplasty by finite element analysis. The method comprises the following steps of carrying out data acquisition and modelling on a leg at an uninjured side before operation; carrying out finite element stress analysis on a leg model on the uninjured side of a patient, and carrying out data acquisition and modeling on a replaced knee joint in an operation process; making a mirror image of the model on the uninured side correspond to an affected side, carrying out data analysis through a Fourier transform-high-pass filtering image enhancement algorithm, and judging whether a force line of a lower limb of the affected side is in a balanced state; if the force line of the lower limb of the affected sideis in an unbalanced state, prompting a proper bone repair or prosthesis adjustment position to a doctor through the leg model on the uninjured side, and finally, enabling the knee joint to be in the balanced state; and keeping the position unchanged, and carrying out surgical suture. According to the method, the accuracy of knee joint balance in the operation is improved, the service life of the postoperative prosthesis is prolonged, the postoperative complications are reduced, and the method plays an important role in improving the postoperative life quality of the patient.

Owner:NANJING MEDICAL UNIV

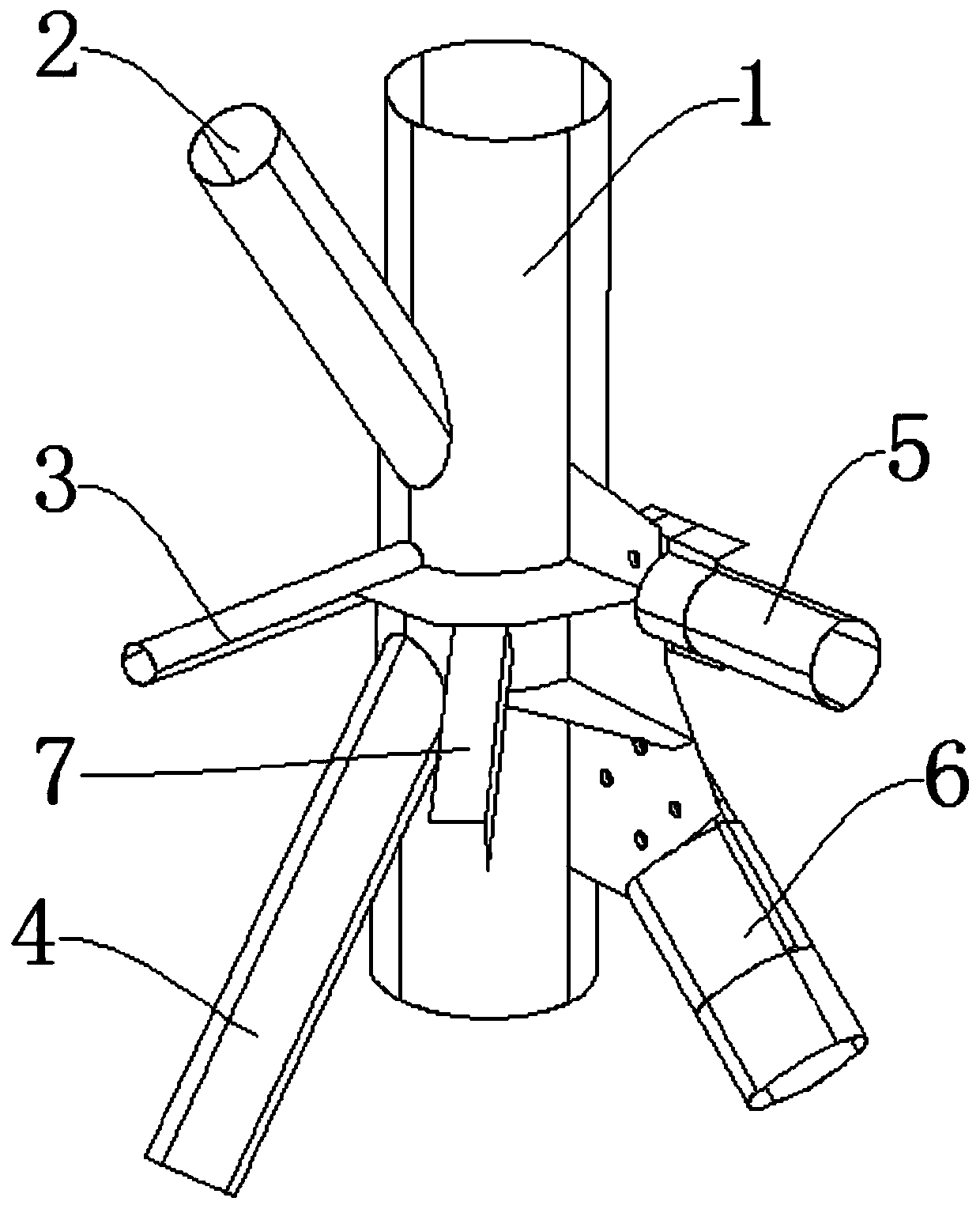

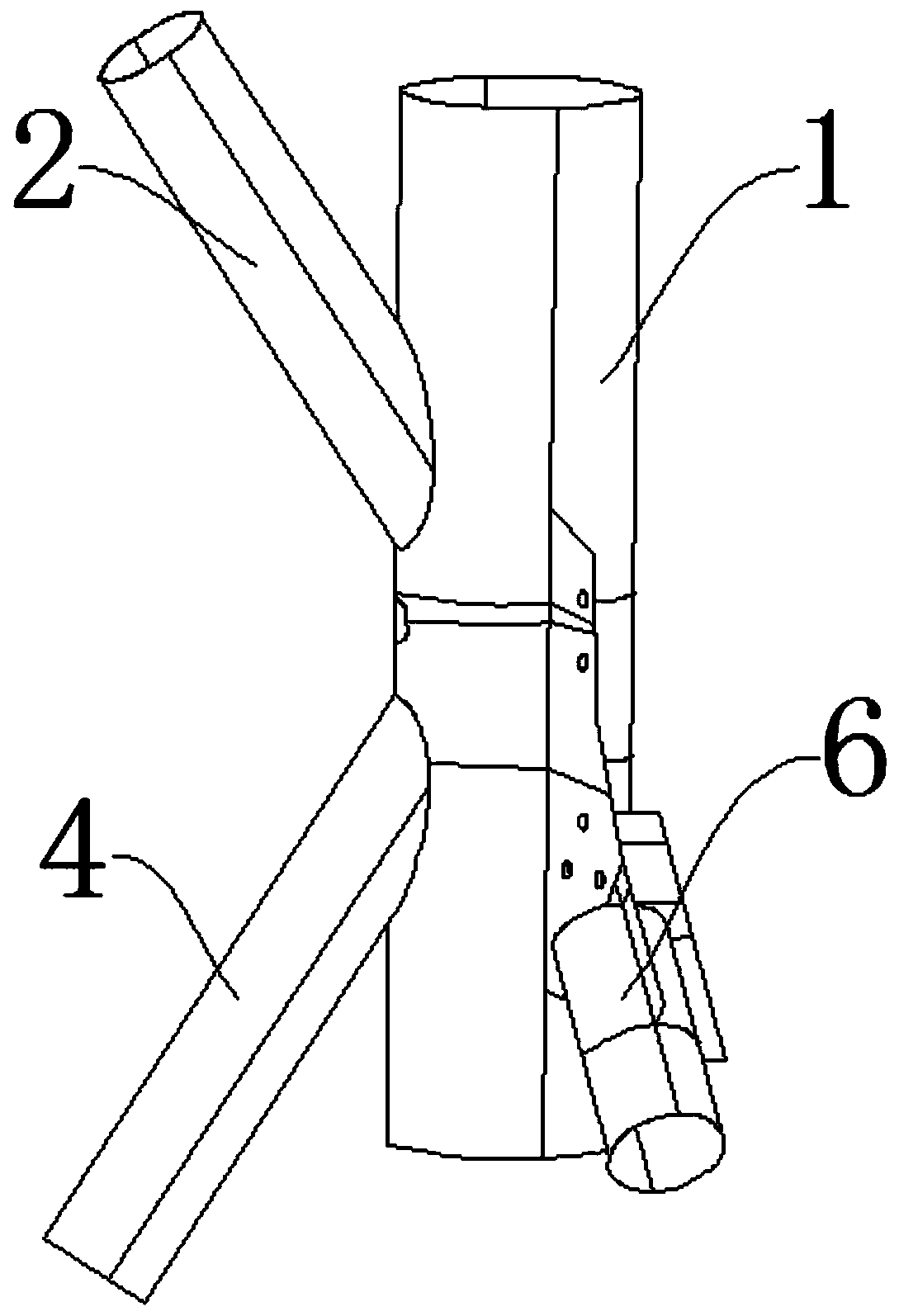

A spatial complex multi-branch pipe column joint bearing capacity calculation method

The invention discloses a method for calculating the joint bearing capacity of multiple spatial complex pipe columns. The method comprises the following steps: establishing a finite element model of the multiple spatial complex pipe columns; performing finite element analysis on the finite element models of the multiple spatial complex pipe columns to obtain a finite element analysis result; and performing regression fitting on the finite element analysis result to obtain a calculation formula of the ultimate bearing capacity of the spatial column node. According to the method, a calculation formula of the ultimate bearing capacity of the multiple spatial complex pipe column joints is fitted, and a reference can be provided for engineering design through calculation according to the formula.

Owner:重庆顺泰铁塔制造有限公司 +1

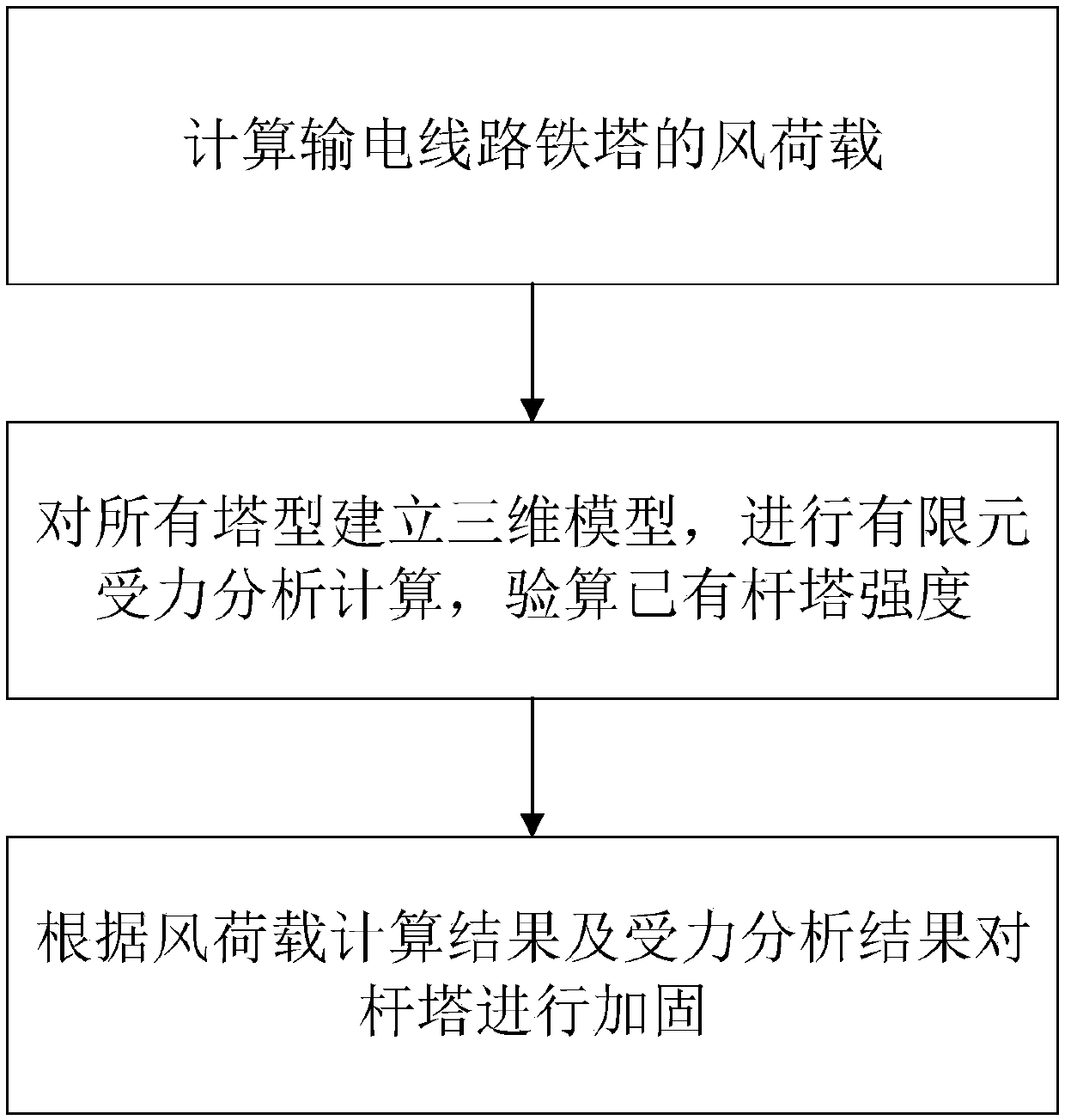

A windproof strength calculation and tower reinforcement method for a bottom-protecting power grid power transmission line

ActiveCN109885847AAvoid the "rip and rebuild" patternAvoid the “rip and rebuild” modelSpecial data processing applicationsPower gridEngineering

The invention discloses a novel windproof reinforcement design method for a bottoming power grid power transmission line, and the method comprises the following steps of S1, calculating the wind loadof a power transmission line iron tower, the wind load comprising a line wind load and a tower body wind load; S2, establishing a three-dimensional model for all tower types, carrying out finite element stress analysis and calculation, and checking the strength of the existing tower; and S3, reinforcing the tower according to the wind load calculation result and the stress analysis result.

Owner:GUANGDONG POWER GRID CO LTD +1

Creation of simulated disjoint rigid bodies in a finite element analysis

ActiveUS8200458B2Computation using non-denominational number representationDesign optimisation/simulationArray data structureElement model

Improved methods and systems for defining and creating simulated rigid bodies in finite element analysis are disclosed. One or more rigid finite elements in a finite element model are designated for forming one or more simulated rigid bodies (RBs). Each simulated RB comprises an arbitrary number of rigid finite elements connecting to one another in an arbitrary shape. Each simulated RB is created by locating all of the elements embedded in the model through shared node or nodes. A procedure of using element definition as a guide to set up an array of node flags, each node flag for one node such that all RBs defined in the model can be located efficiently. Once all RBs have been located, each unique RB is defined as a unique list of connected rigid finite elements.

Owner:ANSYS

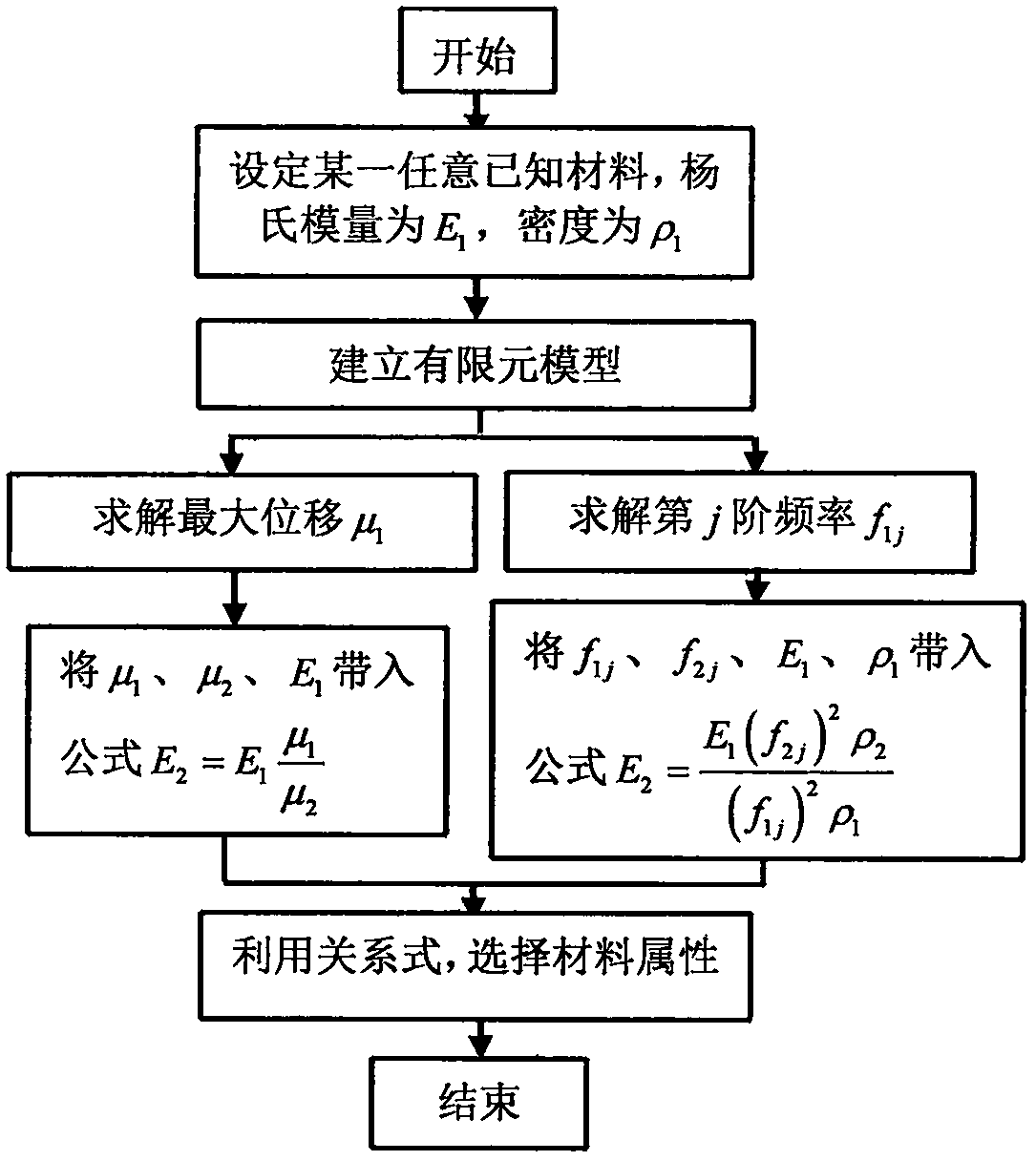

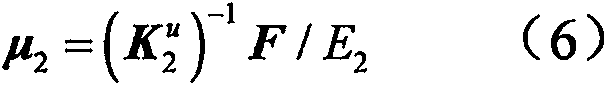

Structural material rapid selection method based on finite element analysis

InactiveCN107341307ASmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsElement analysisFinite element analyse

The invention relates to a structural material rapid selection method based on finite element analysis, and belongs to the field of mechanical structure finite element analysis. Two relational expressions of Young's modulus of a structural material satisfying corresponding design requirement conditions are deduced respectively through a theoretical relationship among a load, displacement and a stiffness matrix in a finite element theory, and a material meeting requirements can be selected rapidly by means of simple calculation and judgment through the two relational expressions, so that a rapid selection way is provided for the selection of the structural material. The method comprises the following specific implementation steps: firstly, solving a maximum displacement and corresponding j-order inherent frequency when the structural material is any certain known material through the finite element analysis; secondly, bringing a solving result and a corresponding design requirement into corresponding expressions, and calculating a material Young's modulus satisfying a requirement; and lastly, selecting an appropriate material according to the result. The method disclosed by the invention has the advantages of rapidness, small calculated amount, easiness in solving and the like.

Owner:GUIZHOU UNIVERSITY OF FINANCE AND ECONOMICS

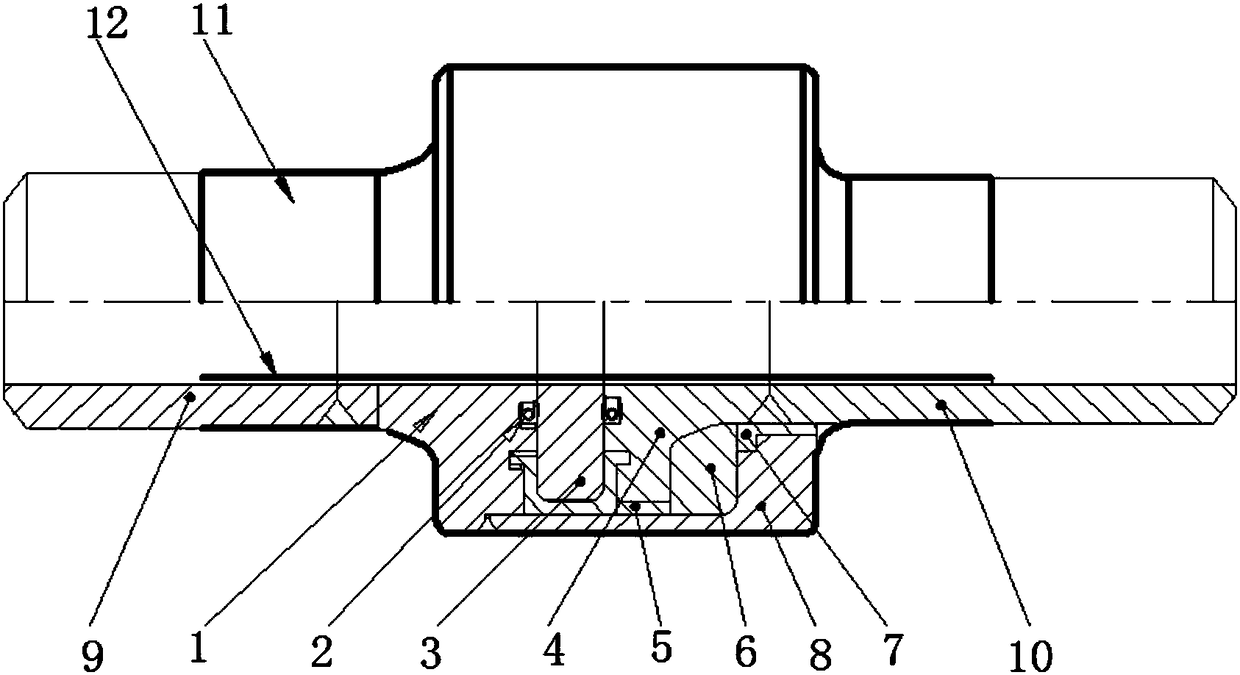

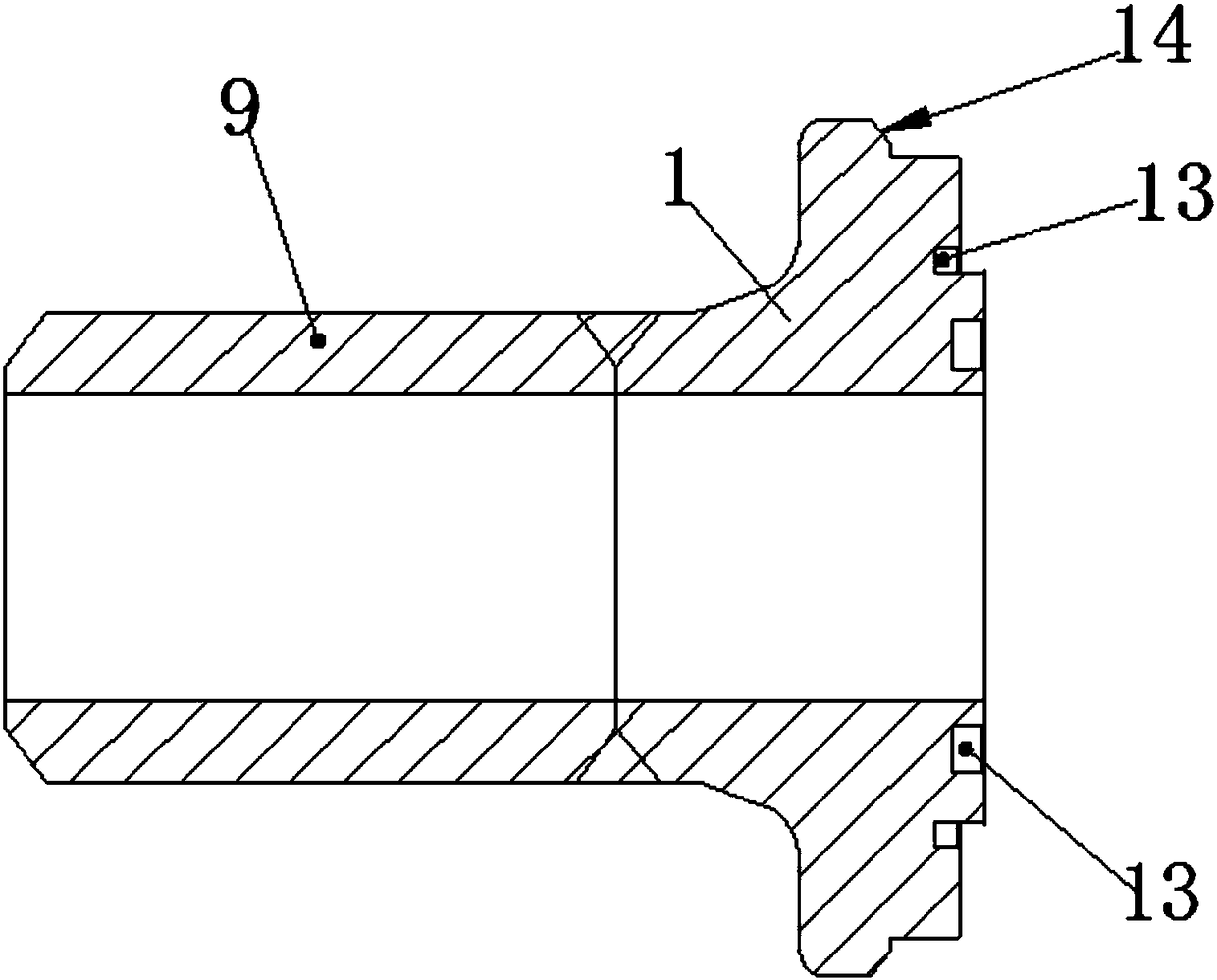

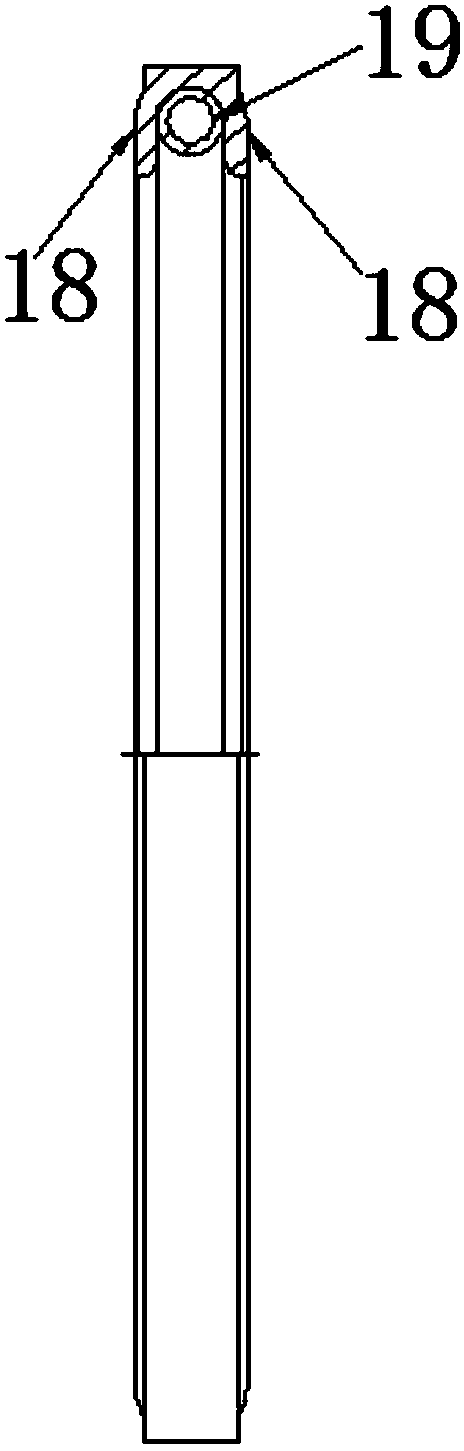

Ultralow temperature high-pressure insulation connector

PendingCN108167559AImprove sealingSimple production processFlanged jointsInsulation layerFlexural strength

The invention discloses an ultralow temperature high-pressure insulation connector which comprises a first short pipe, a left flange, a combined insulation ring, a right flange, a second short pipe and an outer insulation rubber sleeve. The combined insulation ring is clamped between the left flange and the right flange, the first short pipe is connected to the left end of the left flange, the second short pipe is connected to the right end of the right flange, the inner wall of the outer insulation rubber sleeve is coated with an insulation layer to form an internal and external sealed insulation body, the outer insulation rubber sleeve is arranged on the outer surfaces of the first short pipe, the left flange, the combined insulation ring, the right flange and the second short pipe in asleeving manner, and a pair of energy storage sealing rings are arranged on the peripheral part of the combined insulation ring in a surrounding manner. The ultralow temperature high-pressure insulation connector has the beneficial effects that through finite element stress analysis and optimal design, a sealing structure is analyzed and tested, the sealing performance is more reliable, the production process is simple, meanwhile, the anti-bending strength is improved, the structure is compact and attractive, standardization and serialization production can be achieved, the very high practicability is achieved.

Owner:HUBEI TAIHE PETROCHEM EQUIP

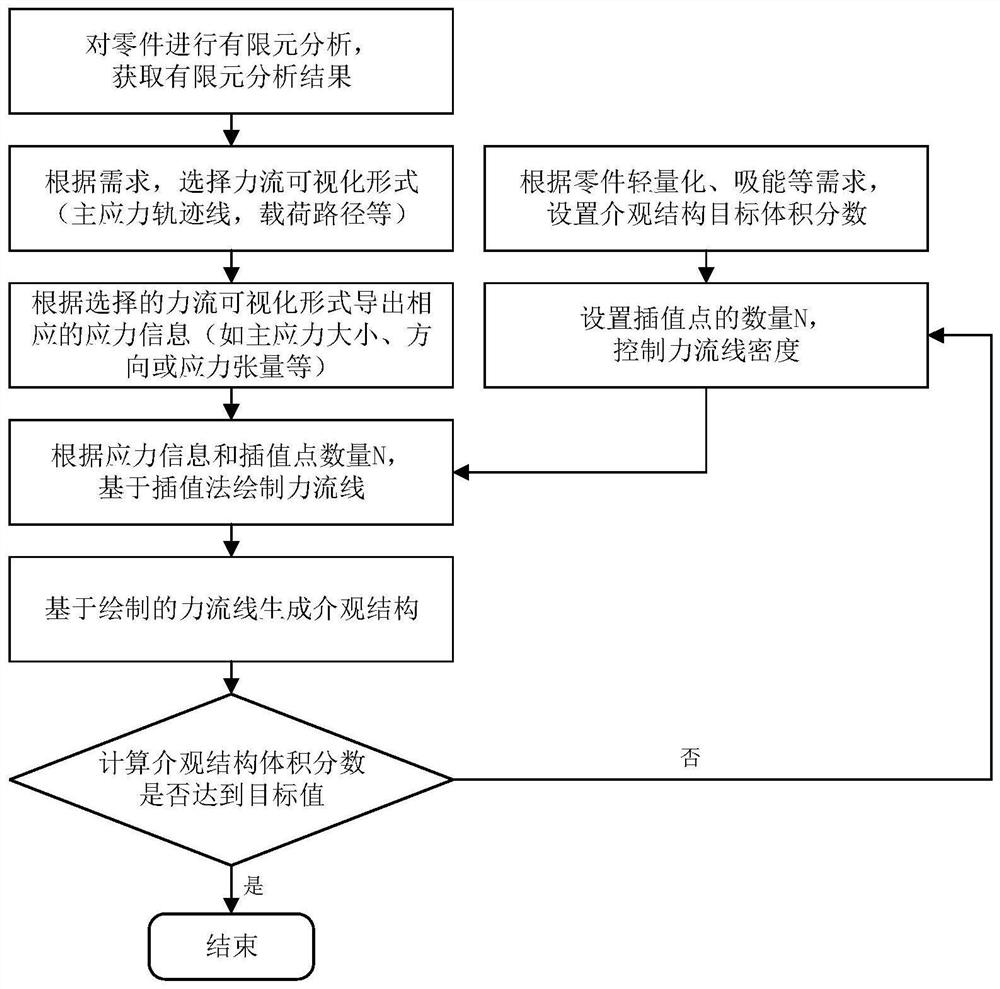

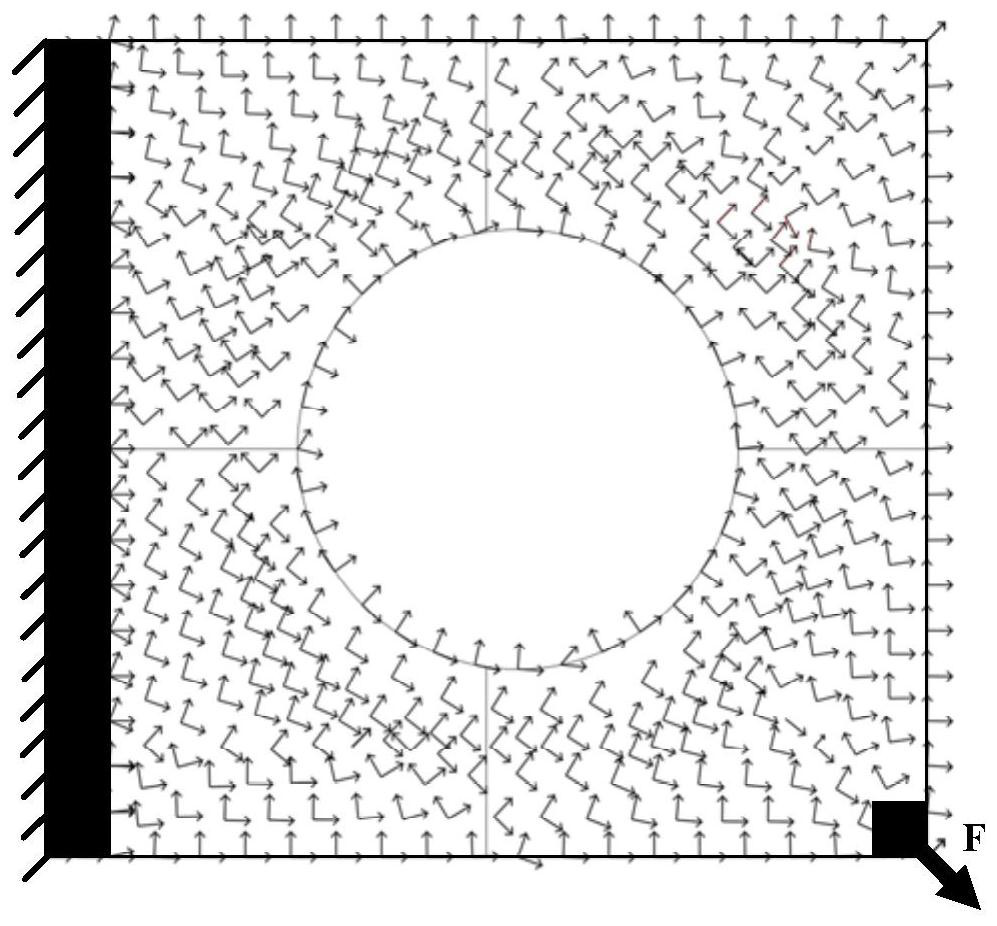

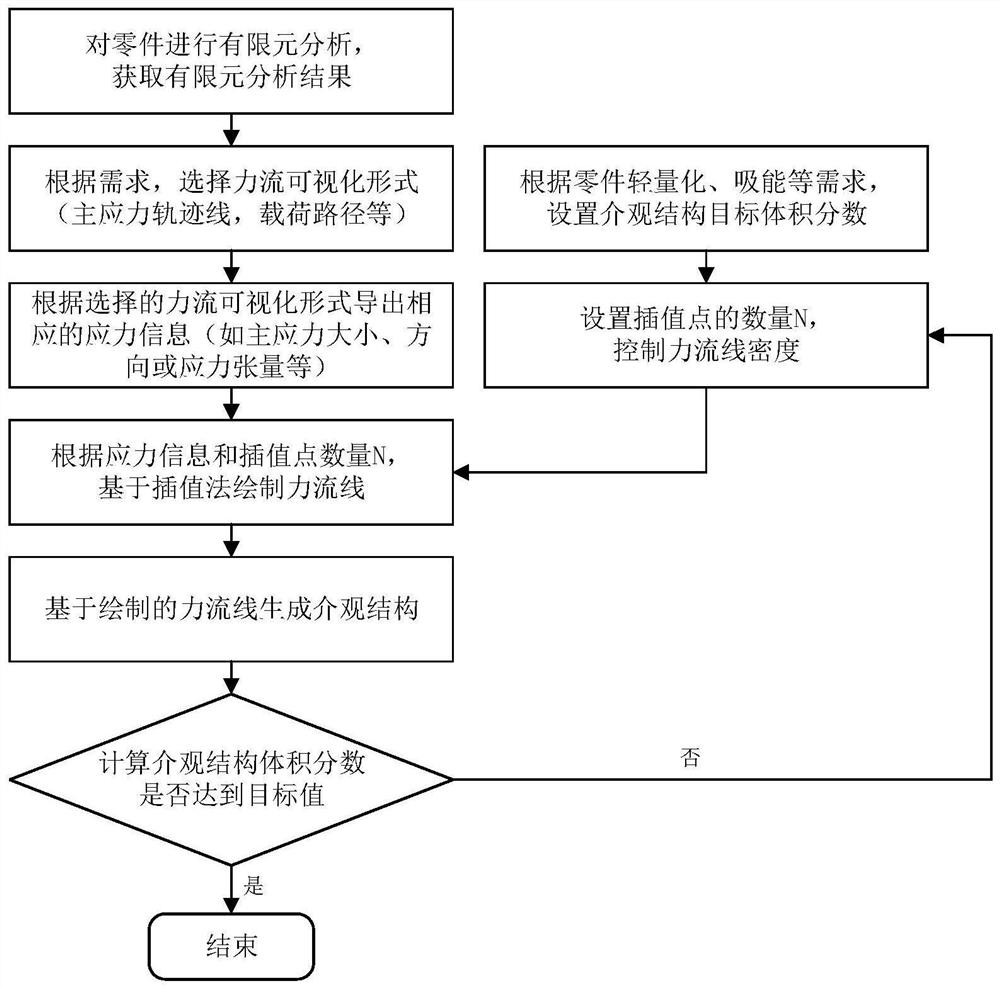

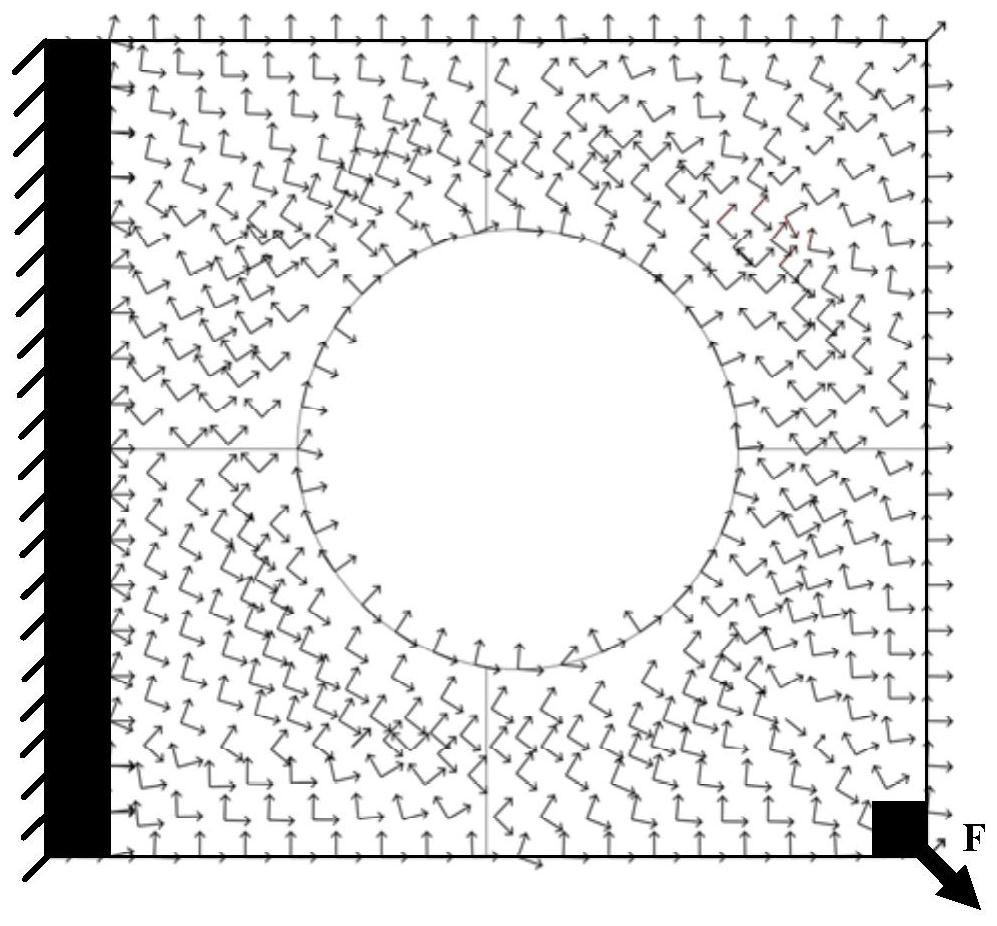

Force flow guided mesoscopic structure design method

ActiveCN112182806AHigh specific strengthHigher specific stiffnessGeometric CADDesign optimisation/simulationElement analysisClassical mechanics

The invention relates to a force flow guided mesoscopic structure design method, which comprises the following steps of: 1) establishing a finite element analysis model according to a load and a boundary condition of a part under an actual working condition, and obtaining a finite element stress analysis result; 2) obtaining stress information required by force flow visualization according to a finite element stress analysis result; 3) generating a force streamline according to the stress information and the number N of the interpolation points; and 4) generating a mesoscopic structure under the guidance of a force streamline. Compared with the prior art, the force flow information of the part under the actual working condition is considered, different force flow lines can be generated according to different force flow definitions, then mesoscopic structures of different arrangement modes are generated, different internal mesoscopic structure designs of the part under the same geometryare achieved, and the specific strength and the specific rigidity of the part structure are improved.

Owner:TONGJI UNIV

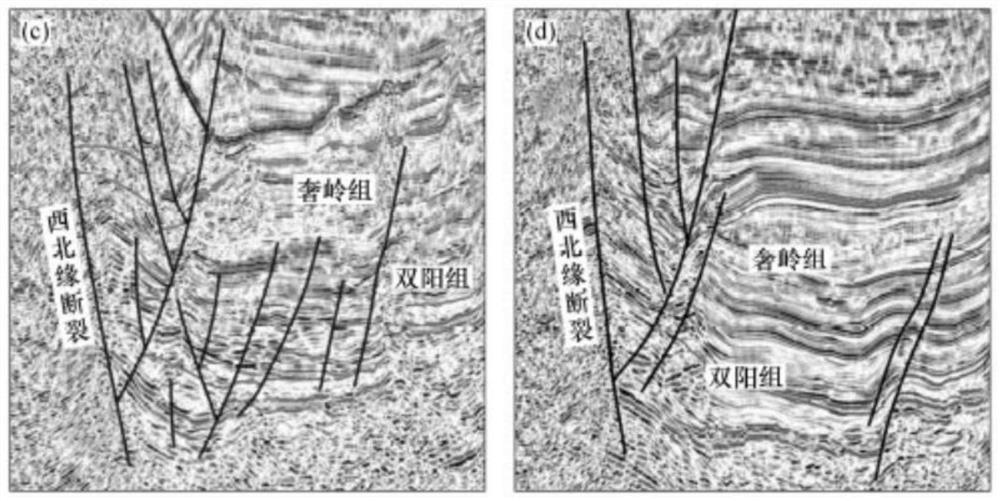

Exploration methods for oil and gas reservoirs controlled by strike-slip faults

Owner:西安幔源油气勘探开发研究有限公司

CAD system for composite type earth pressure shield cutter head

InactiveCN101980227BImprove mechanical propertiesSimple structureSpecial data processing applicationsVisual BasicConfiguration design

The invention discloses a computer aided design (CAD) system for a composite type earth pressure shield cutter head, which belongs to the field of computer software. In the system, Solidworks 2008 is developed secondarily based on Visual Basic 6.0 to realize parametric modeling, and UDEC 4.0, MATLAB 7.0 and ANSYS Workbench 10.0 are called to perform automatic analysis and optimization. The system comprises a user input module, a basic function module, a performance analysis module, an optimization design module and a historical data management module. A user inputs geological parameters and technical requirements, and the system automatically combines theories of opening design, cutting tool type selection and cutting tool layout to perform basic configuration design, cutting tool geology adaptability type selection, cutting tool optimization layout, cutter head finite element stress analysis and cutter head structural parameter optimization design on the composite type earth pressure shield cutter head so as to obtain an optimal three-dimensional design result of a target cutter head, and the system automatically stores the data input by the user and a corresponding design result. By the CAD system, a corresponding relation between the geological parameters and key design parameters of the cutter head can be quickly established, and design reliability and design efficiency can be improved.

Owner:CENT SOUTH UNIV

A Mesoscopic Structure Design Method Guided by Force Flow

ActiveCN112182806BHigh strengthIncrease stiffnessGeometric CADDesign optimisation/simulationElement analysisClassical mechanics

The invention relates to a mesoscopic structure design method guided by force flow, which comprises the following steps: 1) establishing a finite element analysis model according to the load and boundary conditions under the actual working condition of the part, and obtaining the finite element stress analysis result; The stress information required for force flow visualization is obtained from the meta-stress analysis results; 3) The force flow lines are generated according to the stress information and the number of interpolation points N; 4) The mesoscopic structure is generated guided by the force flow lines. Compared with the prior art, the present invention considers the force flow information under the actual working conditions of the parts, and can generate different force flow lines according to different force flow definitions, and then generate mesoscopic structures with different arrangements, realizing the same geometry of the parts Under the different internal mesoscopic structure design, the specific strength and specific stiffness of the part structure are improved.

Owner:TONGJI UNIV

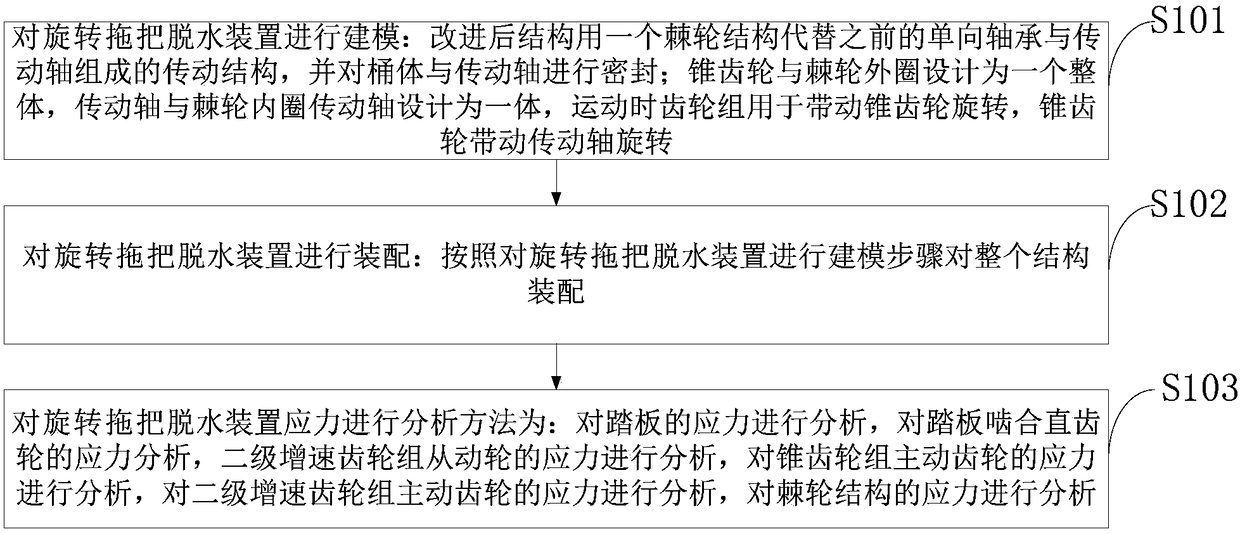

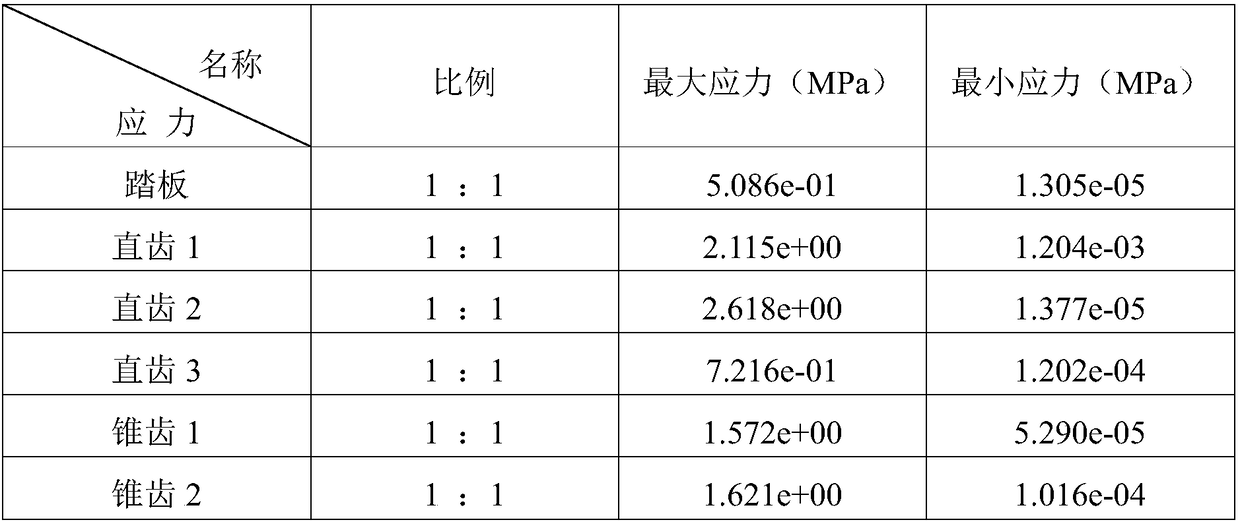

Design method of rotary mop dewatering device

The invention discloses a design method of a rotary mop dewatering device. The design method includes: modeling a rotary mop dewatering device, assembling the rotary mop dewatering device, and performing stress analysis on the rotary mop dewatering device. The design method has the advantages that in order to solve the problems that an existing rotary mop dewatering device is short in service life, relatively hard in part replacement and the like, modeling of the existing entity is completed through three-dimensional modeling software on the basis of the existing rotary mop dewatering device,simulation movement of rotary mop dewatering device is achieved, and finite element stress analysis is performed on all the parts of the whole structure on the basis of the simulation movement; by static analysis and fatigue analysis in the finite element stress analysis, the most dangerous parts, affecting the service life of the device, in the parts and a transmission process are found, and themost dangerous parts are optimized to improve and optimize the device.

Owner:LANZHOU JIAOTONG UNIV

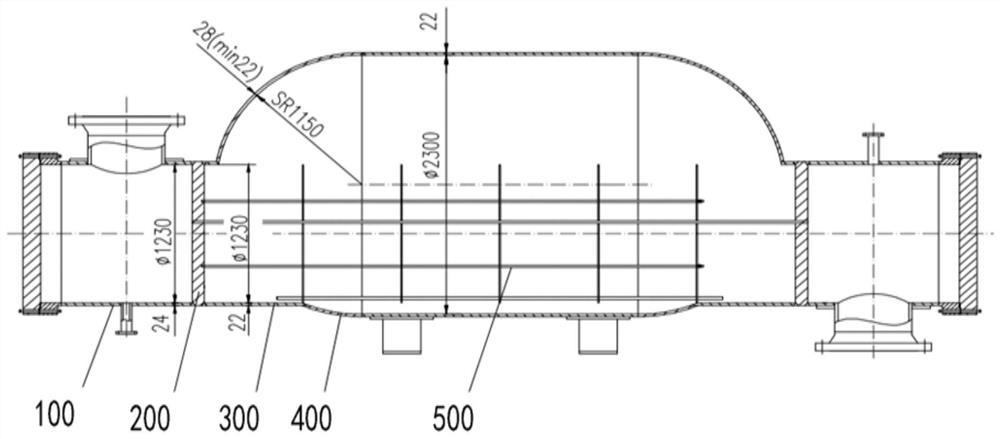

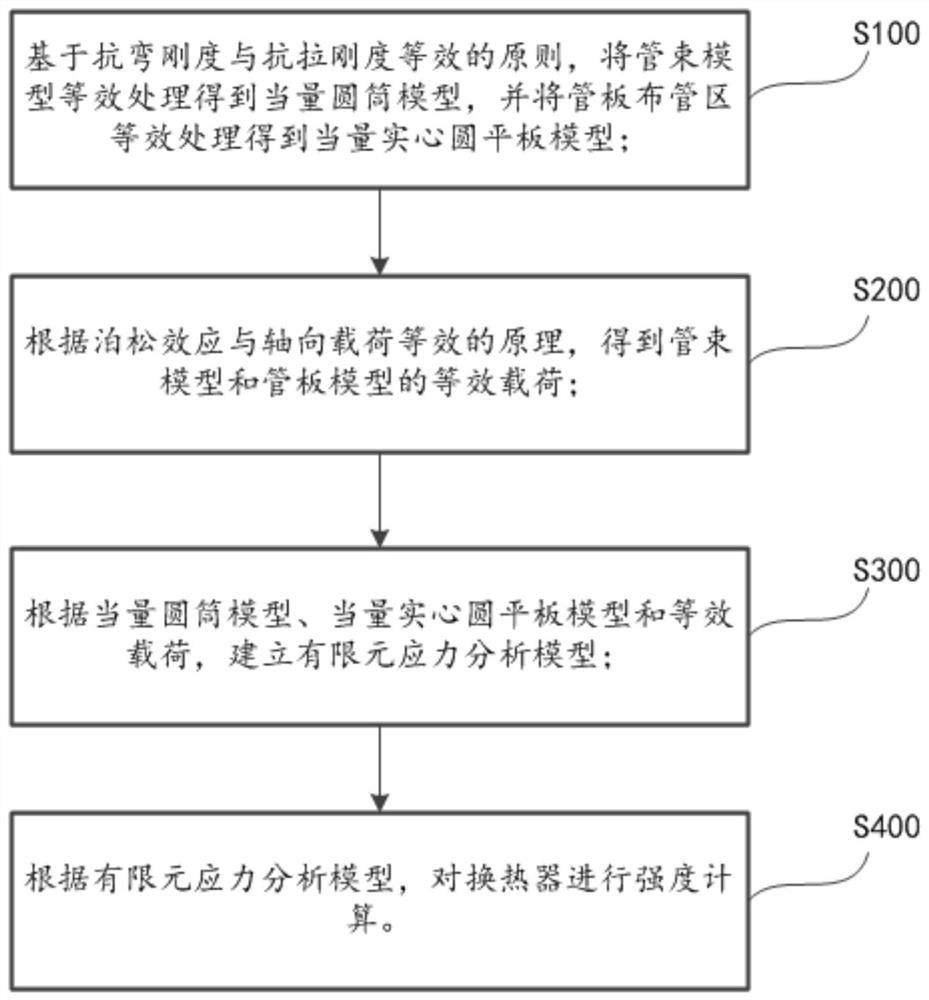

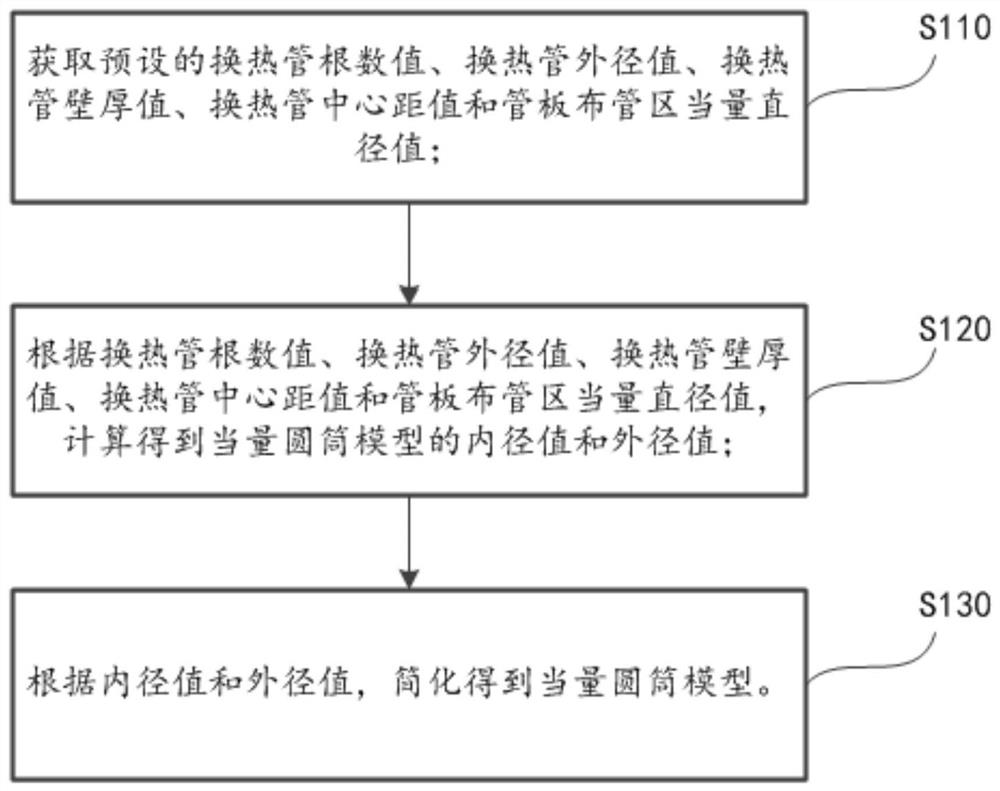

Strength calculation method of heat exchanger, electronic equipment and computer readable storage medium

PendingCN113901683APromote the development of structured designReduce difficultyDesign optimisation/simulationSpecial data processing applicationsMechanical engineeringMechanics

The invention discloses a strength calculation method of a heat exchanger, electronic equipment and a computer readable storage medium, a model of the heat exchanger comprises a tube bundle model and a tube plate model, the tube plate model is provided with a tube plate tube distribution area, and the tube bundle model is arranged in the tube plate tube distribution area in a penetrating mode; the method comprises the steps that based on the principle that bending rigidity and tensile rigidity are equivalent, equivalent treatment is conducted on a tube bundle model to obtain an equivalent cylinder model, and equivalent treatment is conducted on a tube plate tube distribution area to obtain an equivalent solid circular flat plate model; according to the principle that the Poisson effect is equivalent to the axial load, equivalent loads of the tube bundle model and the tube plate model are obtained; a finite element stress analysis model is established according to the equivalent cylinder model, the equivalent solid circular plate model and the equivalent load; and strength calculation is carried out on the heat exchanger according to the finite element stress analysis model. According to the scheme provided by the embodiment of the invention, the analysis difficulty can be reduced and the calculation time can be shortened under the condition of ensuring that the finite element stress analysis result is accurate.

Owner:JIANGMEN POLYTECHNIC

A Solution and Visual Display Method of Custom Stress Function

InactiveCN105069201BOvercoming the disadvantages of application limitationsStress AccurateSpecial data processing applicationsElement modelApplicability domain

A method for solving and visually displaying a self-defined stress function belongs to the technical field of finite element numerical simulation mechanical strength analysis. The present invention aims at the difficulties that may be encountered when general-purpose finite element software performs comprehensive analysis of specific theoretical requirements on the stress state of components under different working conditions, and is characterized in that: based on MSC.Marc / Mentat 2005 software, different working conditions For the finite element stress analysis results of the lower member, by extracting the stress component data of the unit integration points under various working conditions, set and calculate and solve the custom stress function data outside the general finite element software, and realize the custom stress function data by means of data replacement. Visualization of stress function data on MSC.Marc / Mentat 2005 finite element model. The advantages and positive effects of the present invention are that the realization method is simple and easy, the application range is wide, and the use limitation of professional software or secondary development can be avoided.

Owner:太原重工轨道交通设备有限公司 +2

A calculation method for integral fuel tank load of wing

The invention discloses a method for calculating a load of a wing integral fuel tank. The method comprises the steps of first calculating loads which fuel is subjected to in the X-direction, Y-direction and Z-direction by utilizing the principle that the loads can be overlaid linearly in the structure on-line elastic range; respectively calculating pressure distribution of each end face of the inner wall of the fuel tank under unidirectional overloads; finally overlaying pressure generated by each unidirectional overload, and obtaining pressure distribution of the wing fuel tank; establishing a wing fuel tank local detail finite element model in a full-aircraft overall finite element model, adding the pressure load of each end face of the fuel tank to the finite element model, applying corresponding working condition aerodynamic loads, and performing finite element stress analysis to obtain finite element stress result under each working condition. Under the conditions that the aircraft wing integral fuel tank is not pressurized and an inertial load of the fuel to the fuel tank exists, the method for calculating the load of the fuel tank is used for intensity assessment, and the load which the fuel tank is subjected to can be reflected genuinely.

Owner:JIANGXI HONGDU AVIATION IND GRP

A bearing simplification method in finite element simulation analysis

InactiveCN104239654BThe result is close to the realSimple calculationSpecial data processing applicationsElement modelElement analysis

The invention discloses a bearing simplifying method in finite element simulation analysis. According to the method, a three-dimensional gap unit is used for simplifying finite element analysis of an angular contact bearing, and a three-dimensional model of the bearing is drawn in three-dimensional mapping software solidworks. The bearing model is imported into finite element pre-processing software Hypermesh. An outer ring and an inner ring of the bearing are divided into hexahedral meshes. The outer ring and the inner ring of the bearing are connected through the three-dimensional gap unit. The spring stiffness K in the gap unit is worked out through a bearing radial stiffness calculation program. The finite element model is exported from the Hypermesh, then the finite element model is imported into engineering simulation software ANSYS, and mechanical calculation is conducted. According to the method, the calculation amount of finite element analysis can be simplified, the efficiency can be increased, and the calculation accuracy cannot be damaged.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com