Ultralow temperature high-pressure insulation connector

A high-voltage insulation, ultra-low temperature technology, applied in the direction of pipes/pipe joints/fittings, flange connections, through components, etc., can solve the problems of poor insulation performance, short service life, easy leakage, etc., to improve bending strength and compact structure. Beautiful appearance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

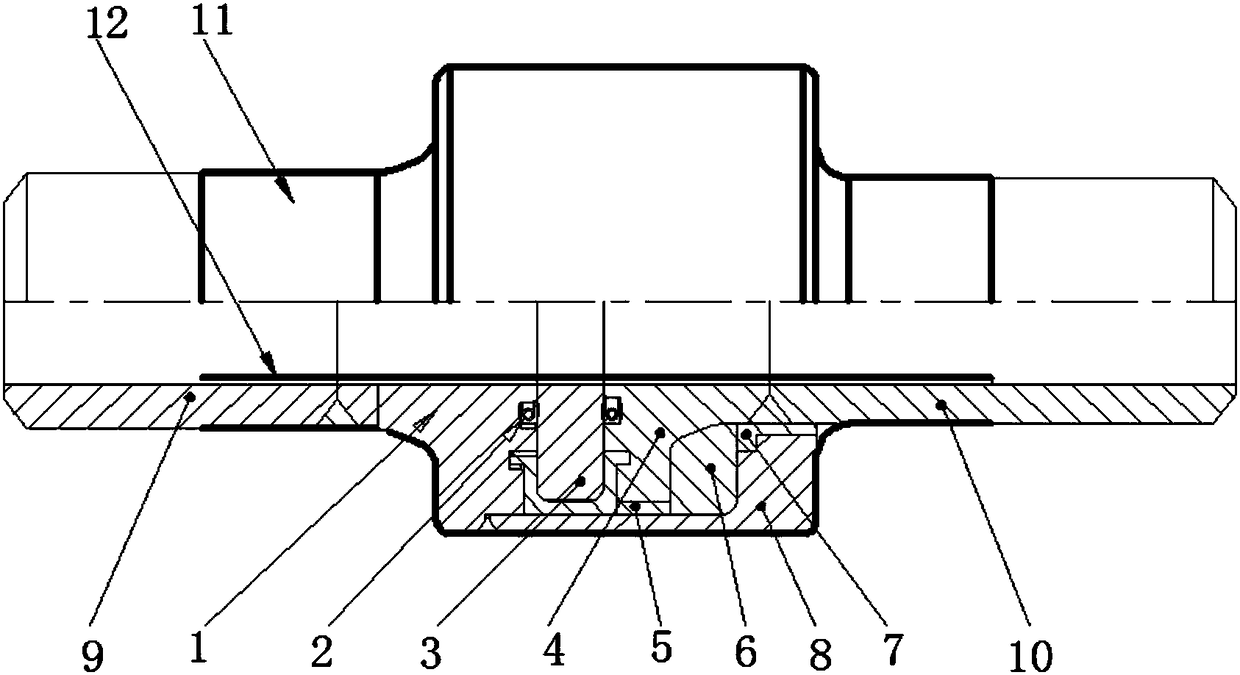

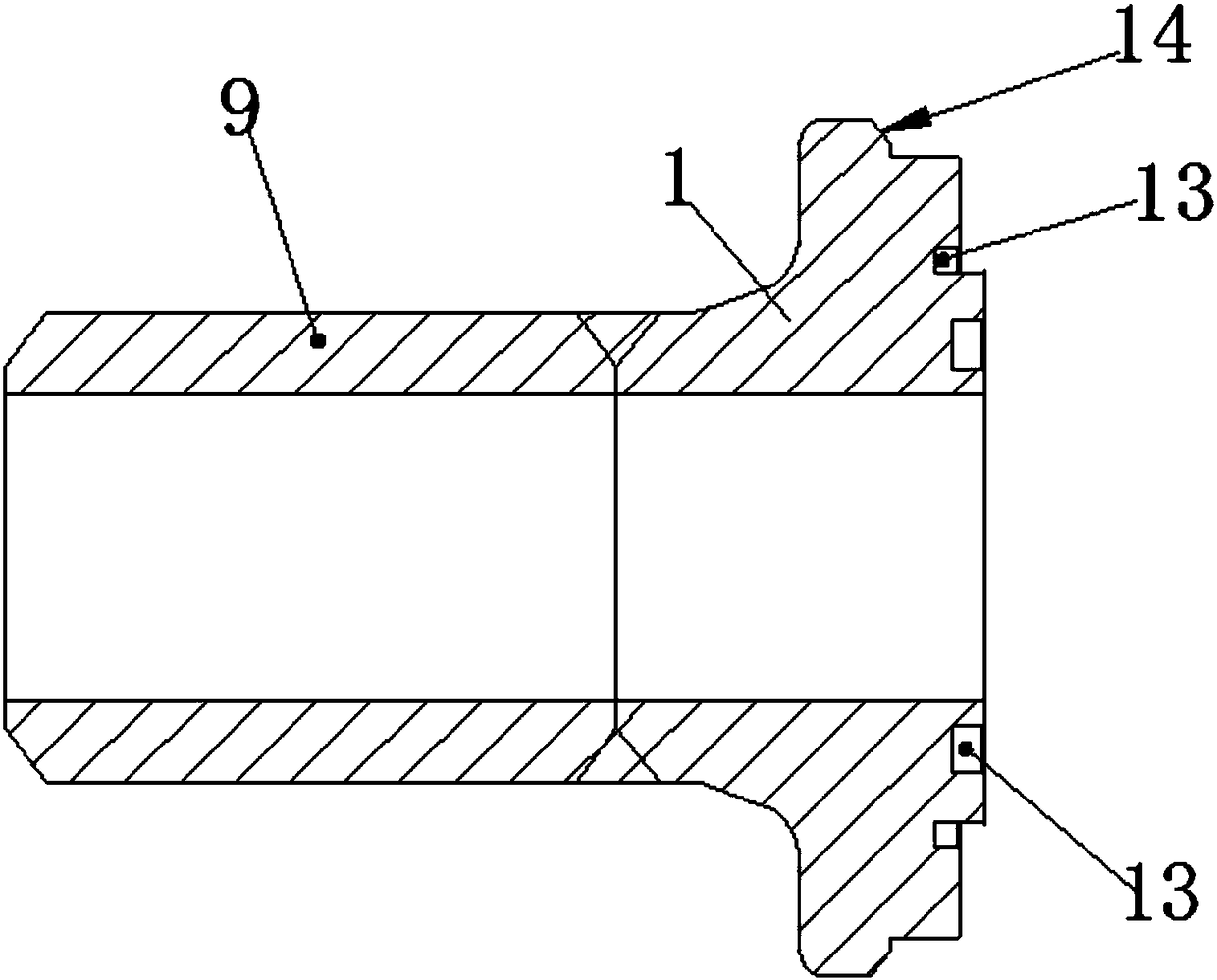

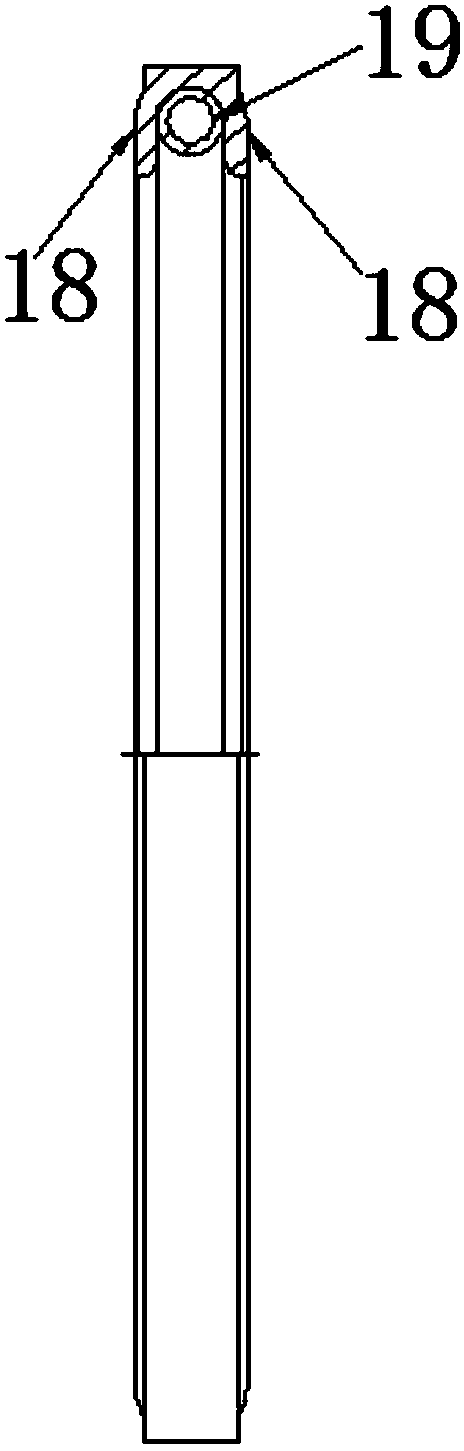

[0028] Such as figure 1 and combine Figure 2 to Figure 9 As shown, an ultra-low temperature and high voltage insulating joint includes a first short pipe 9, a left flange 1, a combined insulating ring 3, a right flange 4, a second short pipe 10 and an outer insulating rubber sleeve 11, and the combined insulating ring 3 Clamped between the left flange 1 and the right flange 4, the first short pipe 9 is connected to the left end of the left flange 1, and the second short pipe 10 is connected to the right end of the right flange 4, so The inner wall of the outer insulating sleeve 11 is coated with an insulating layer 12 to form an insulator that is sealed inside and outside, and the outer insulating rubber sleeve 11 is respectively set on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com