CAD system for composite type earth pressure shield cutter head

An earth pressure balance, shield cutter head technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low design reliability, long design cycle, lack of overall theoretical basis, etc. Effects of reliability and design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further explained in conjunction with specific drawings.

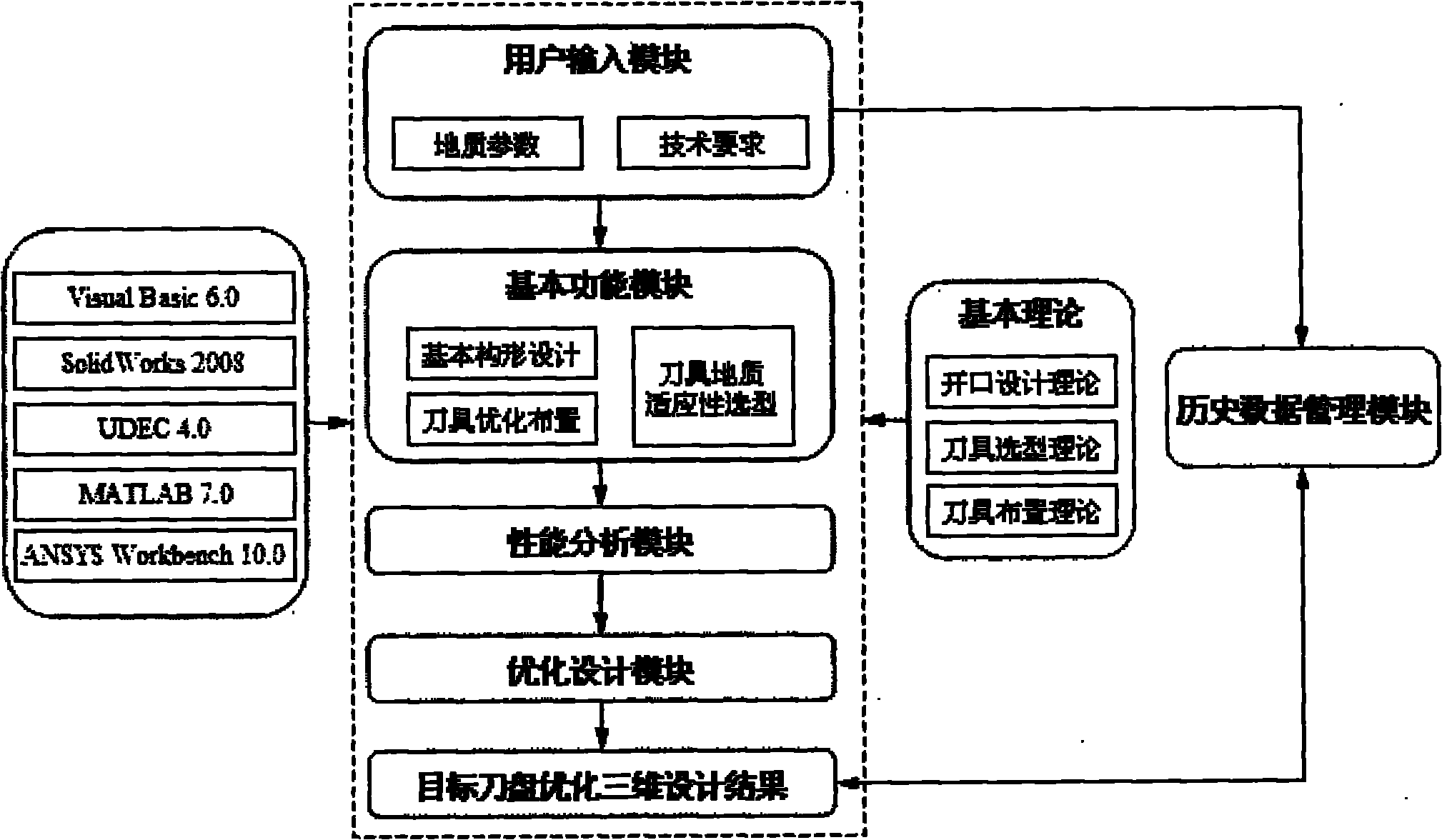

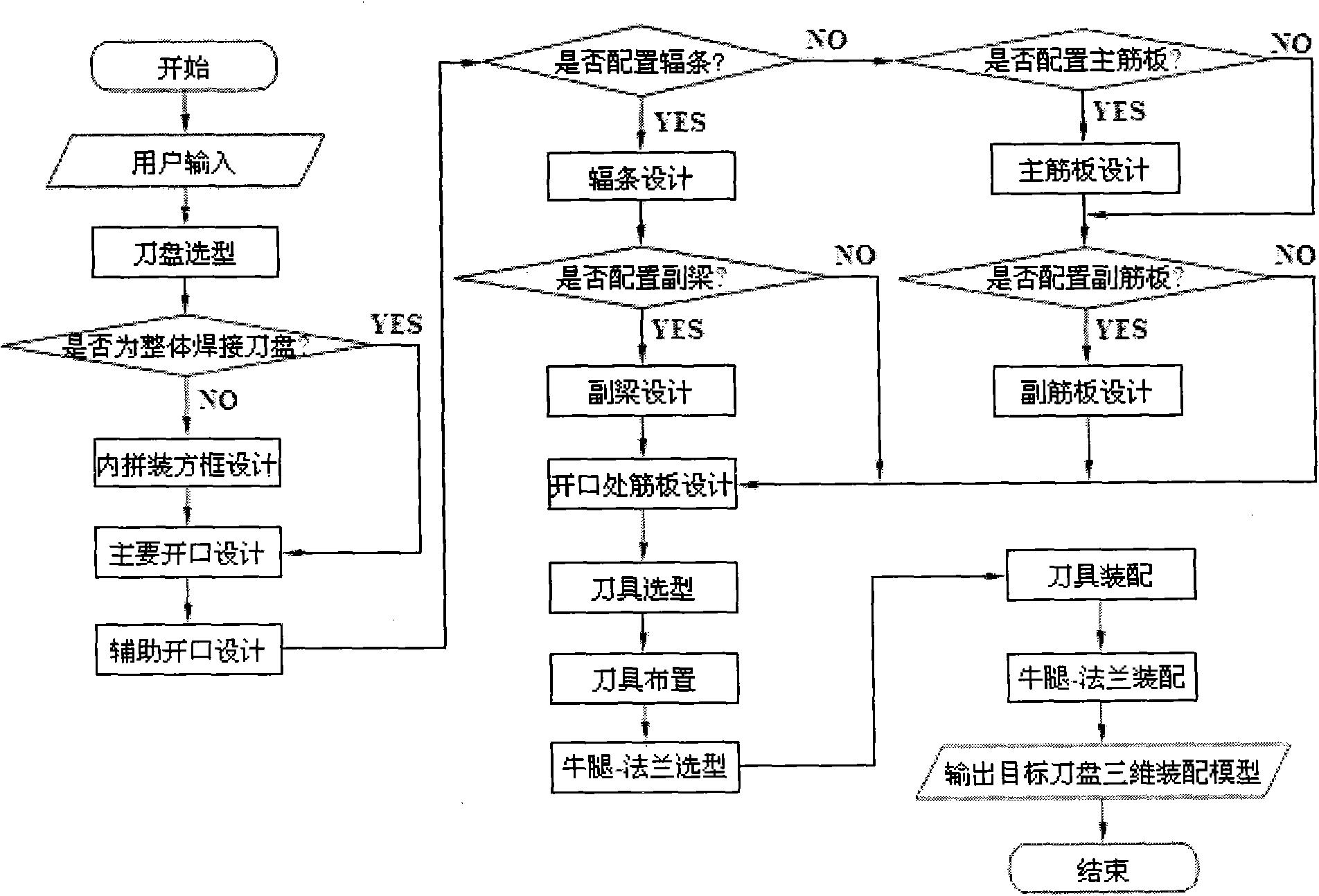

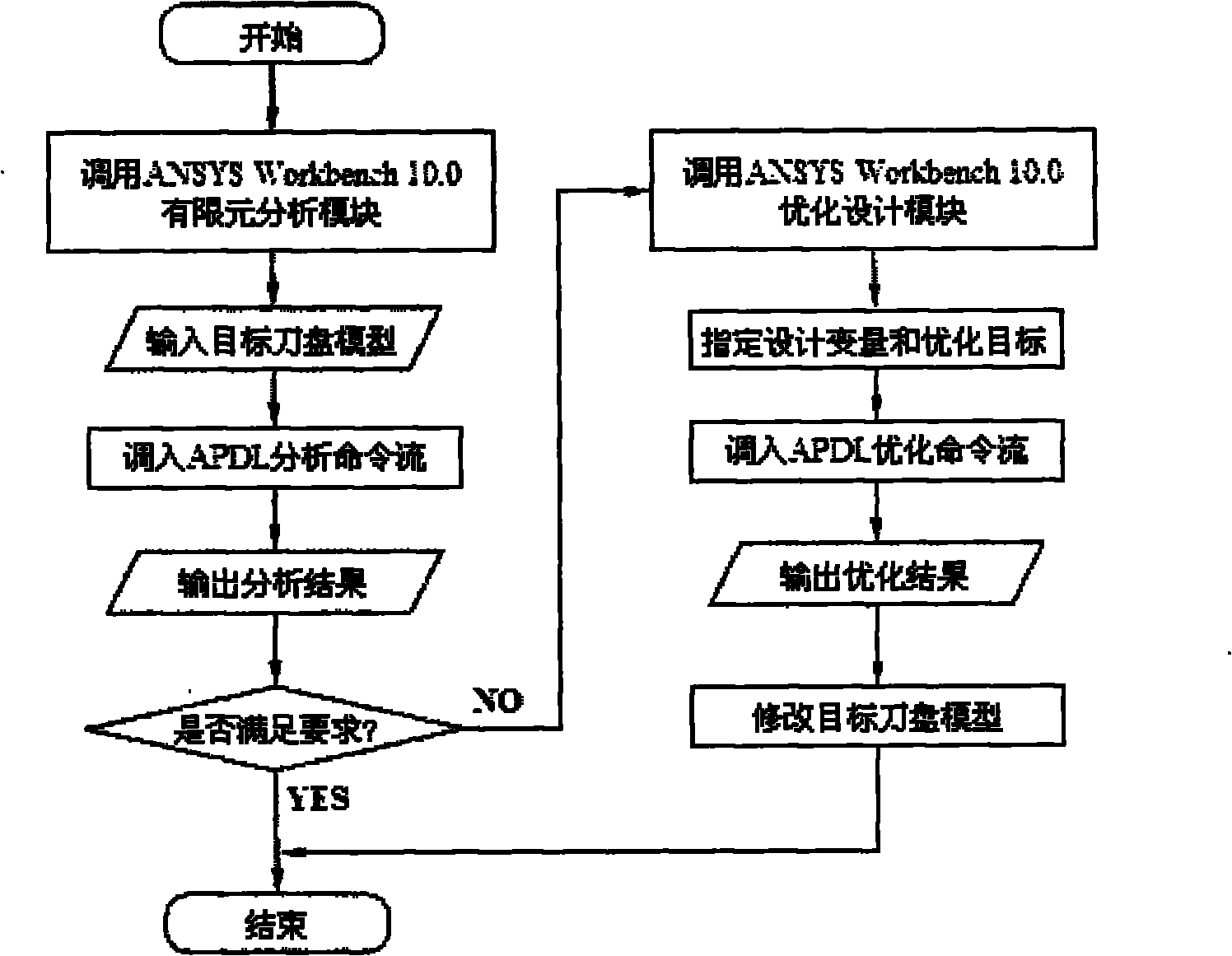

[0020] See figure 1 , This system includes user input module, basic function module, performance analysis module, optimization design module and historical data management module. Through the user input module, users can input geological parameters and technical requirements; the system is based on VisualBasic 6.0 to re-develop SolidWorks 2008 to realize parametric modeling; the system automatically combines relevant theories and technologies such as opening design, tool selection and tool layout, and Call UDEC 4.0 to calculate the optimal cutter spacing of hobs, call MATLAB7.0 to solve the mathematical model of hob layout optimization, obtain hob layout parameters, and realize the basic configuration design of the composite earth pressure balance shield cutter head and the geological adaptability of the cutters Model selection and optimal tool layout; the system uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com