Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Fiber Choice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

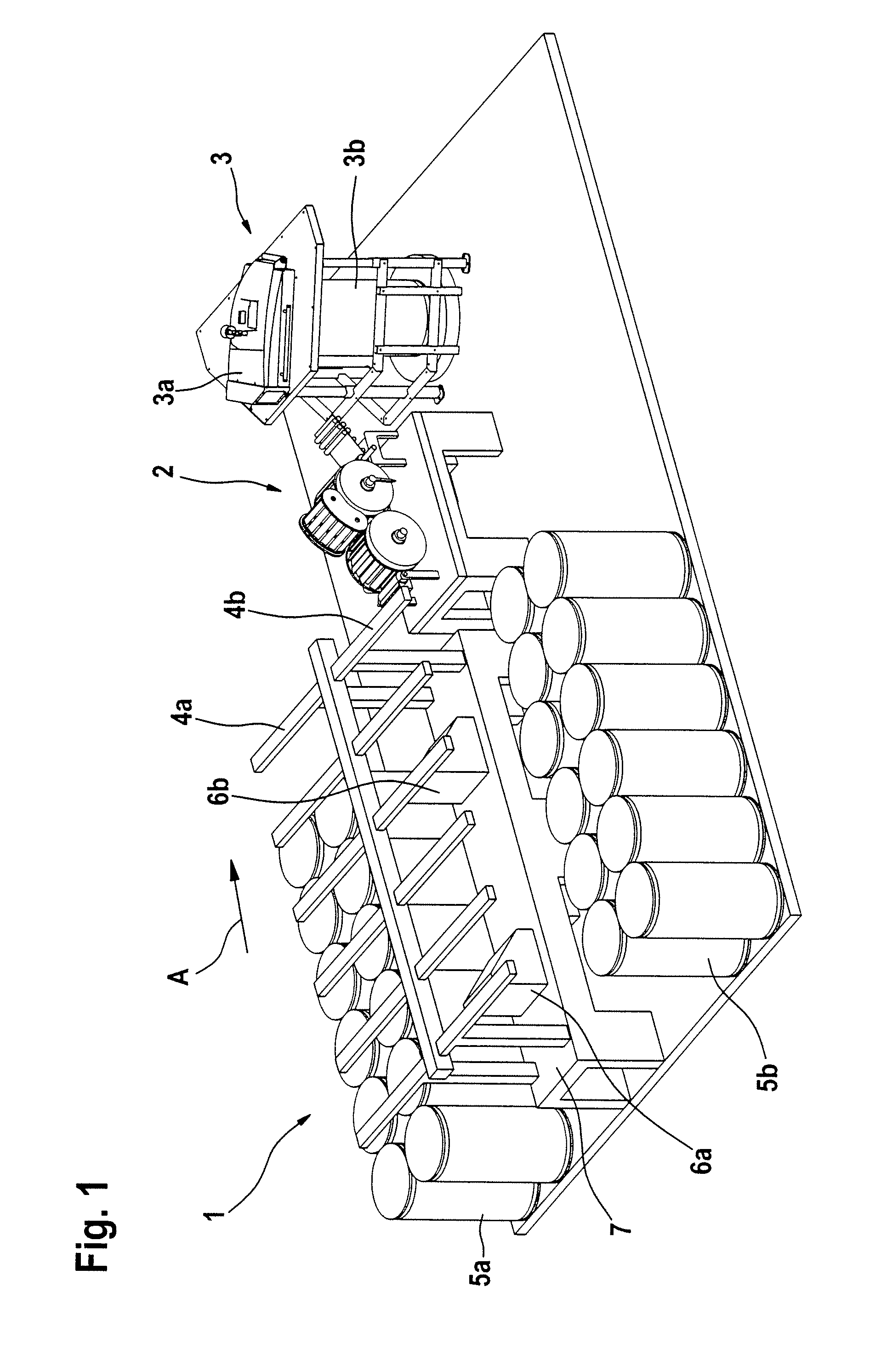

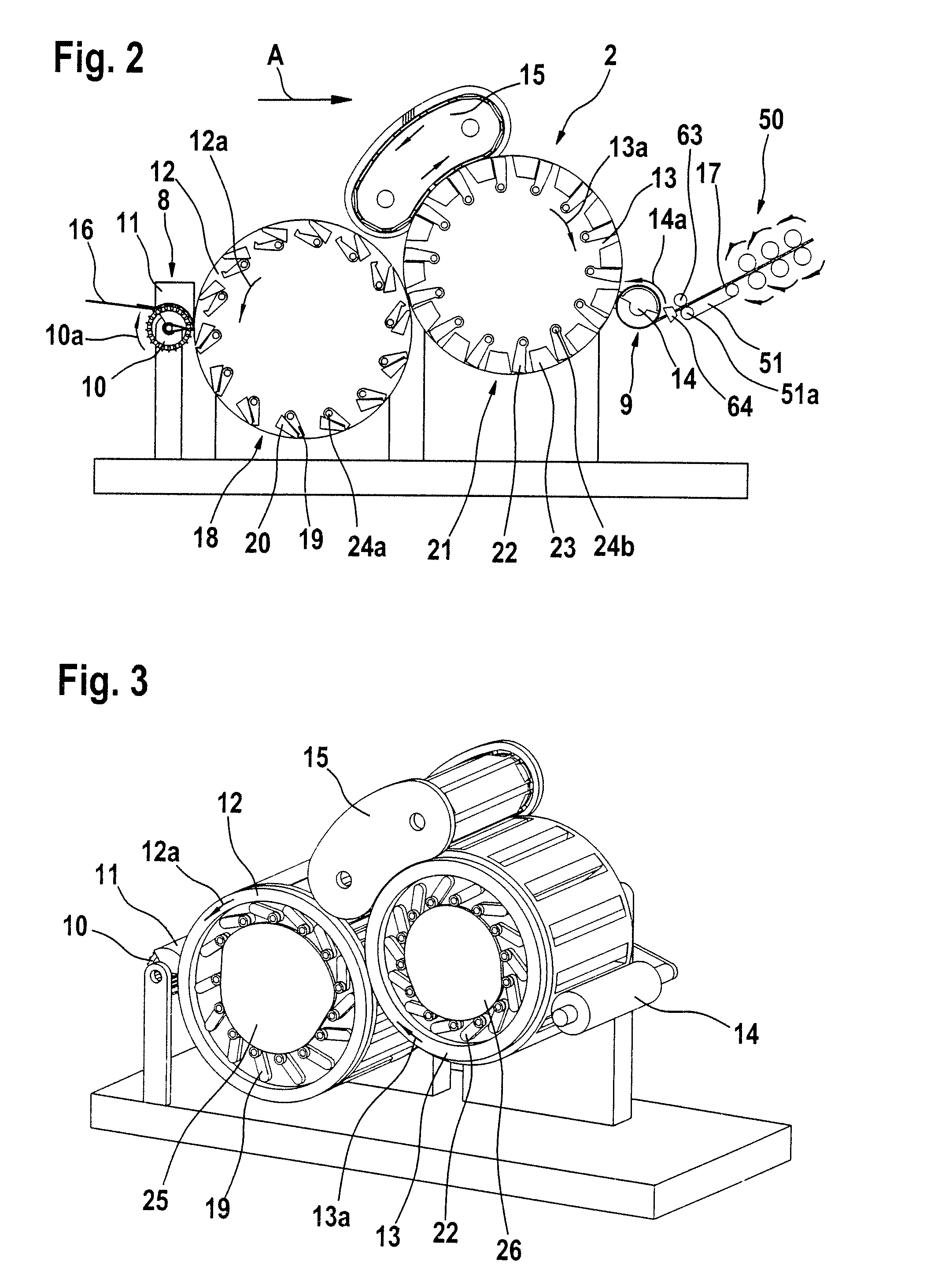

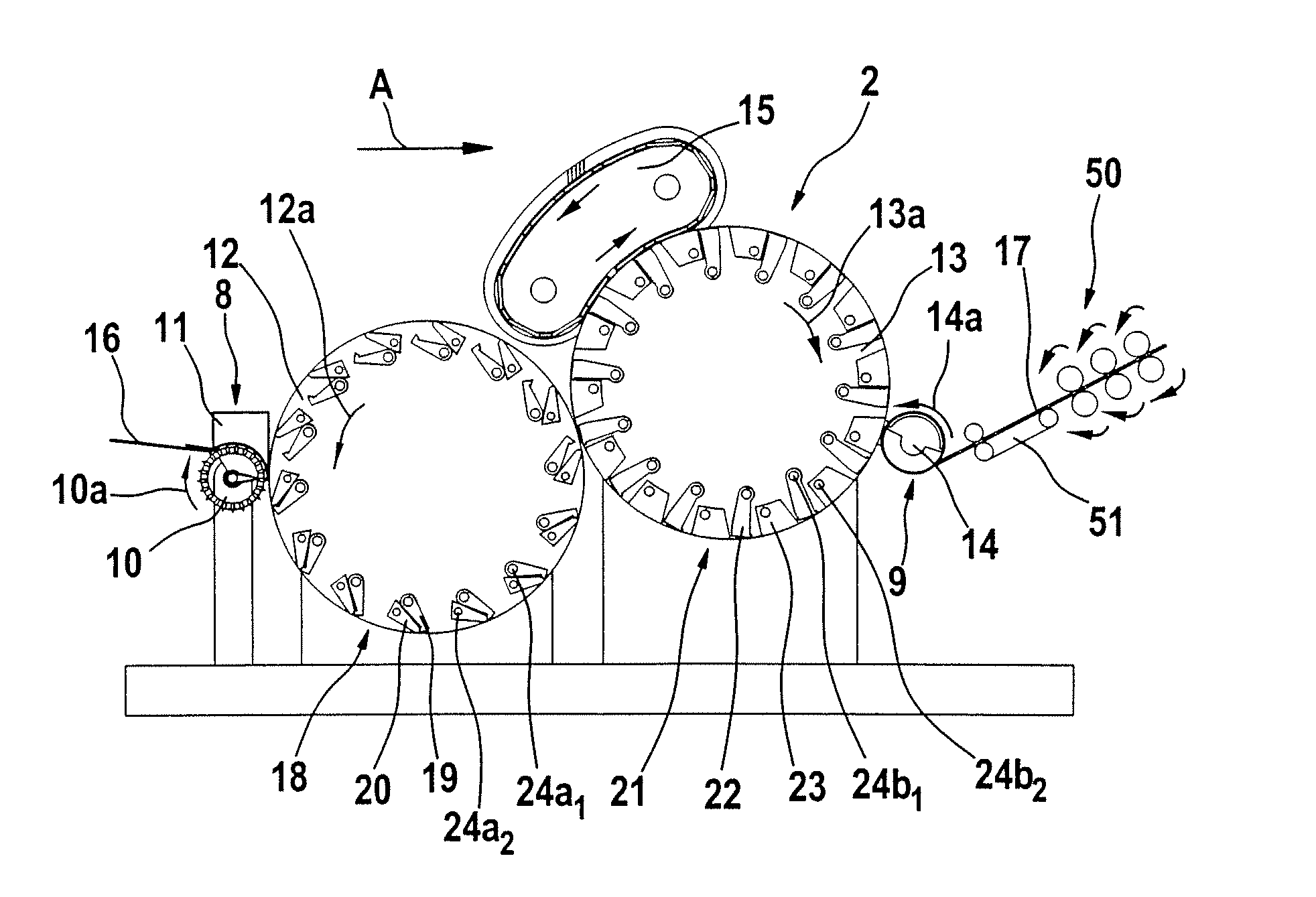

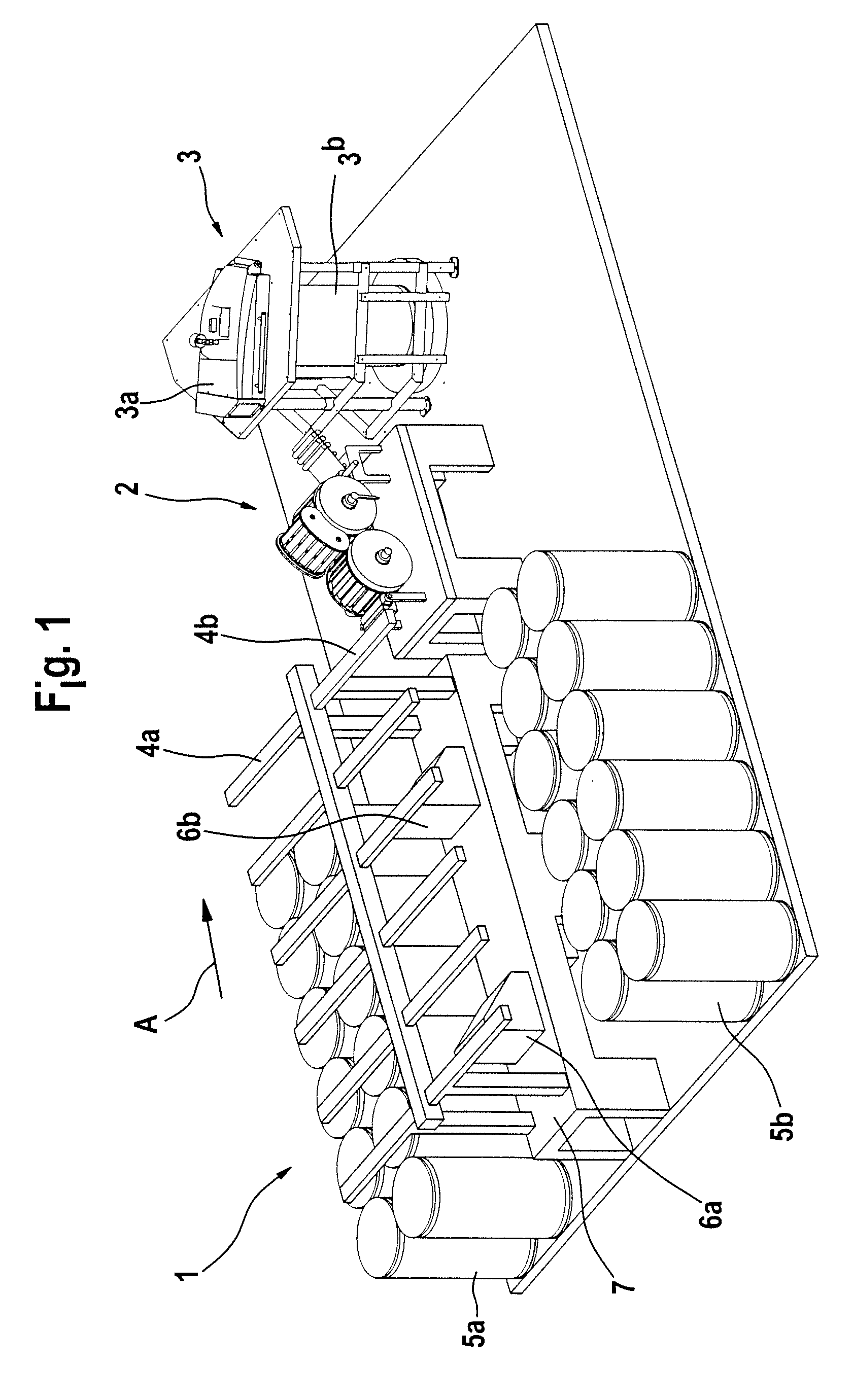

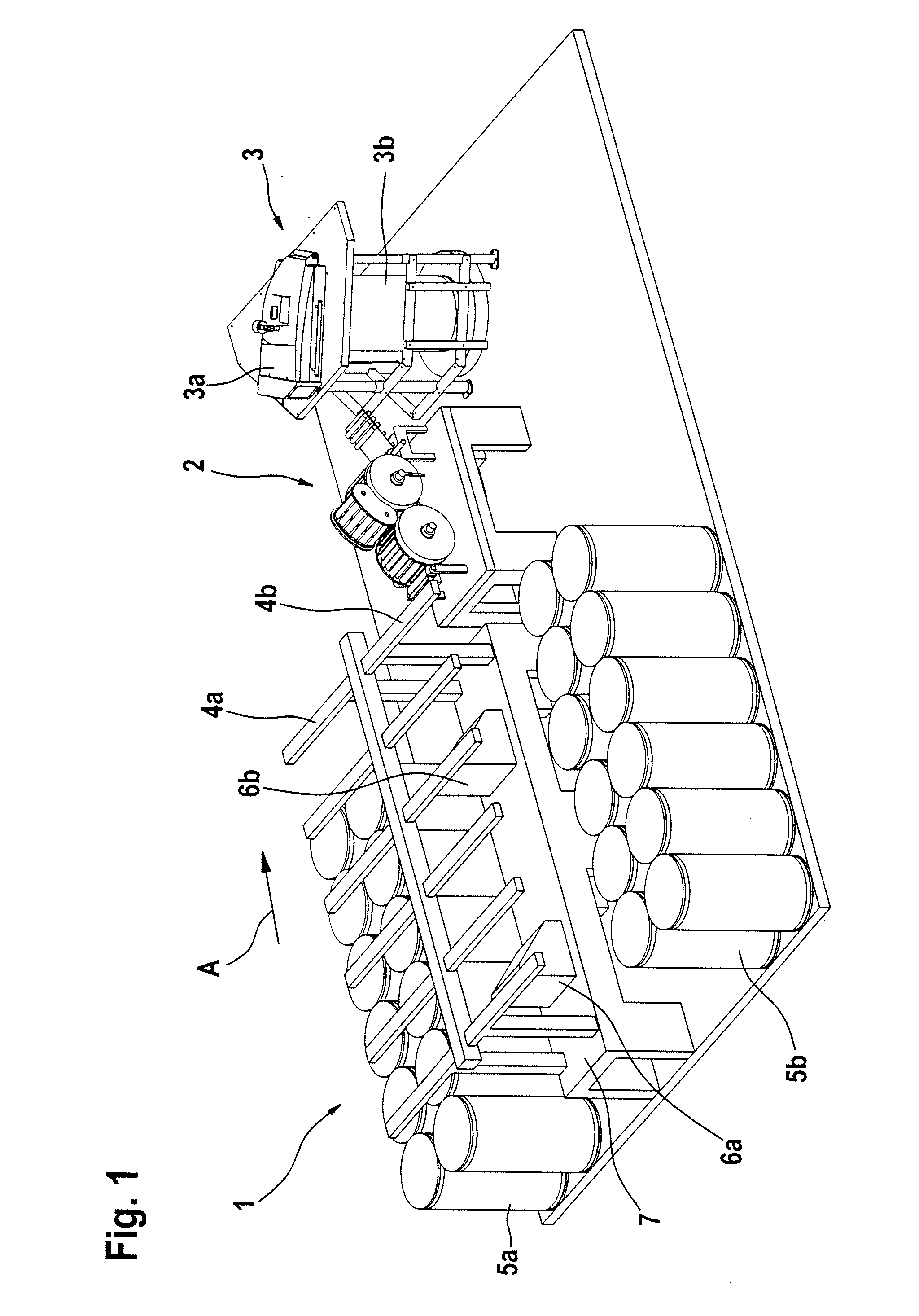

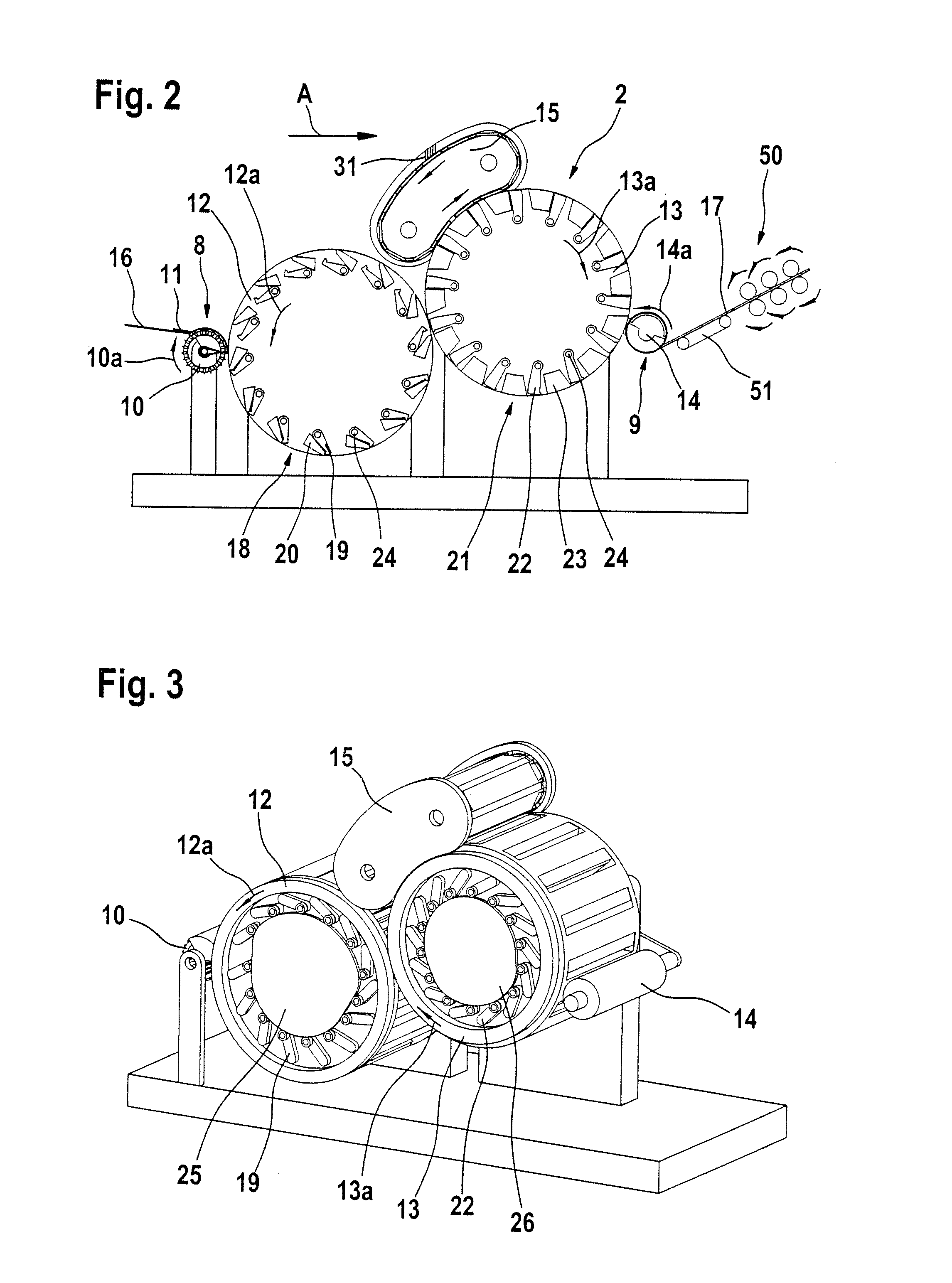

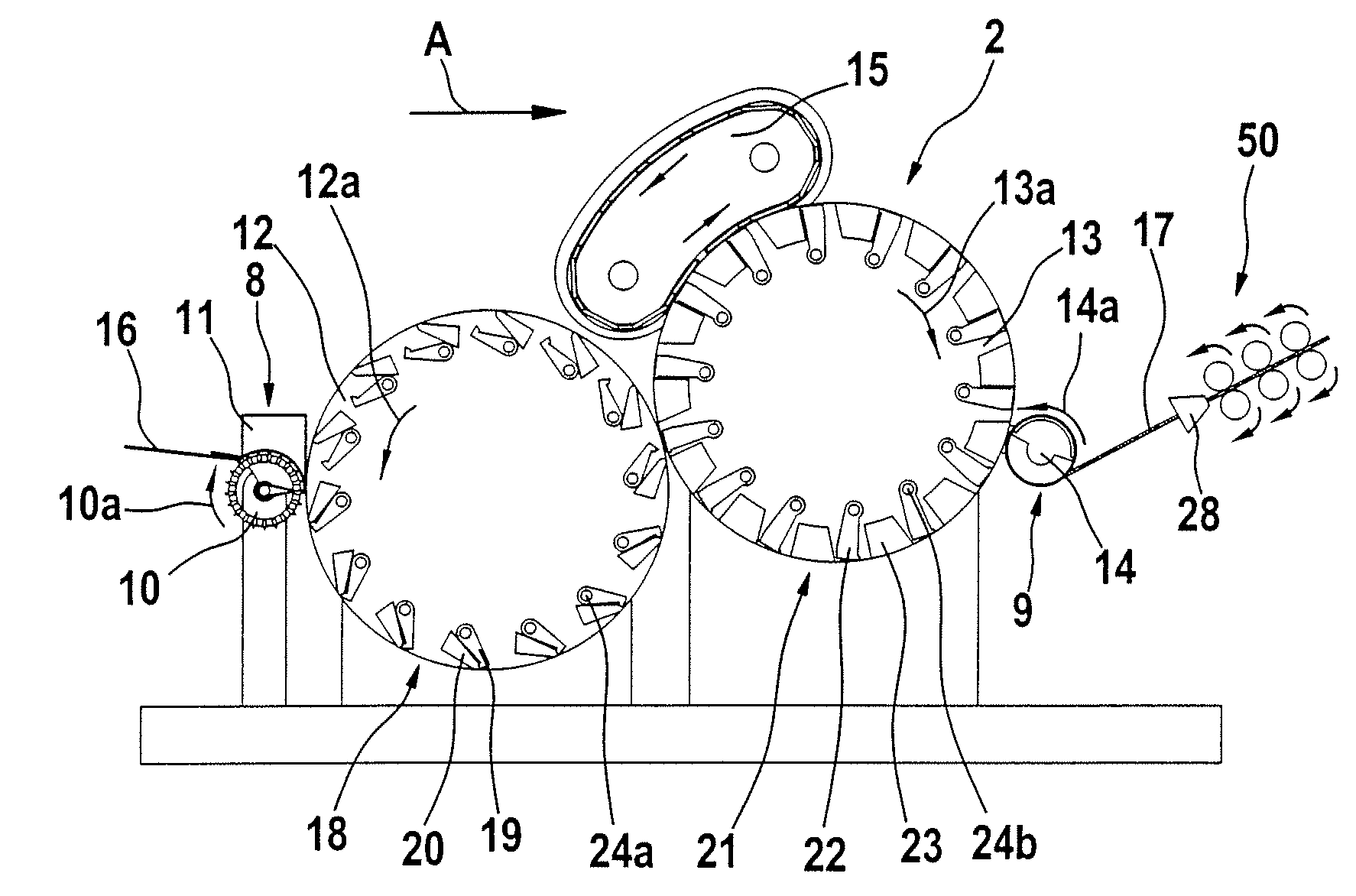

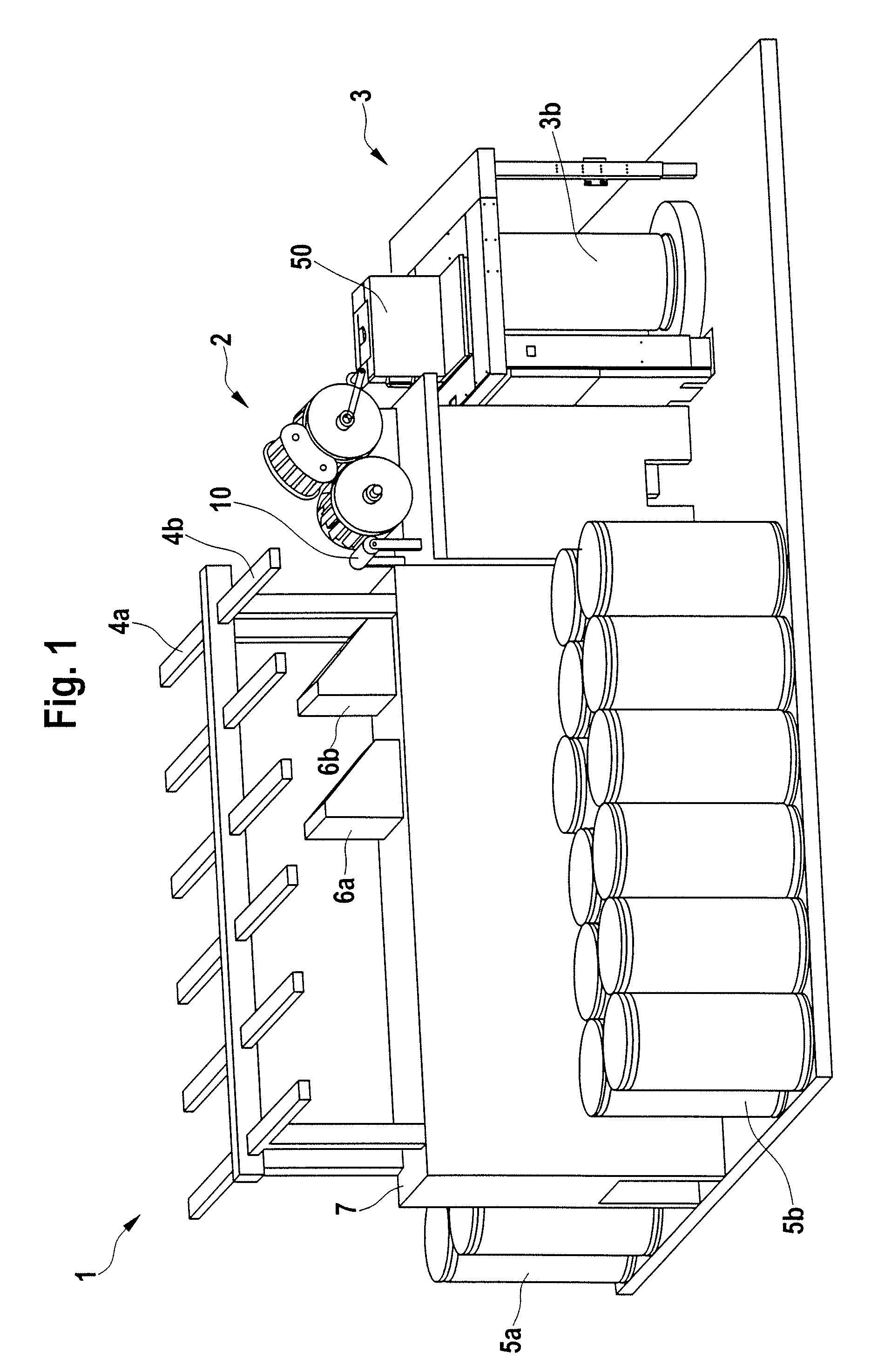

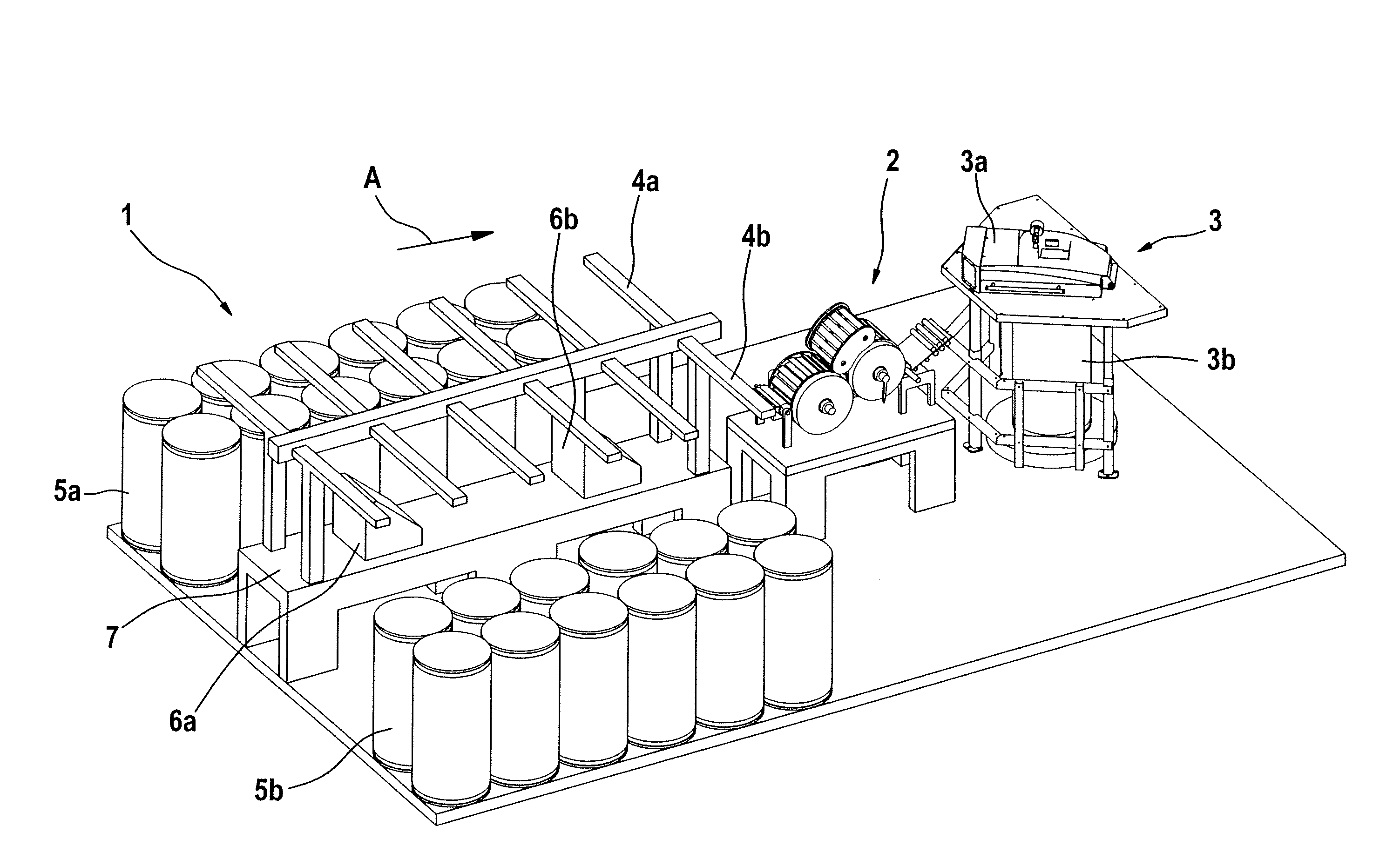

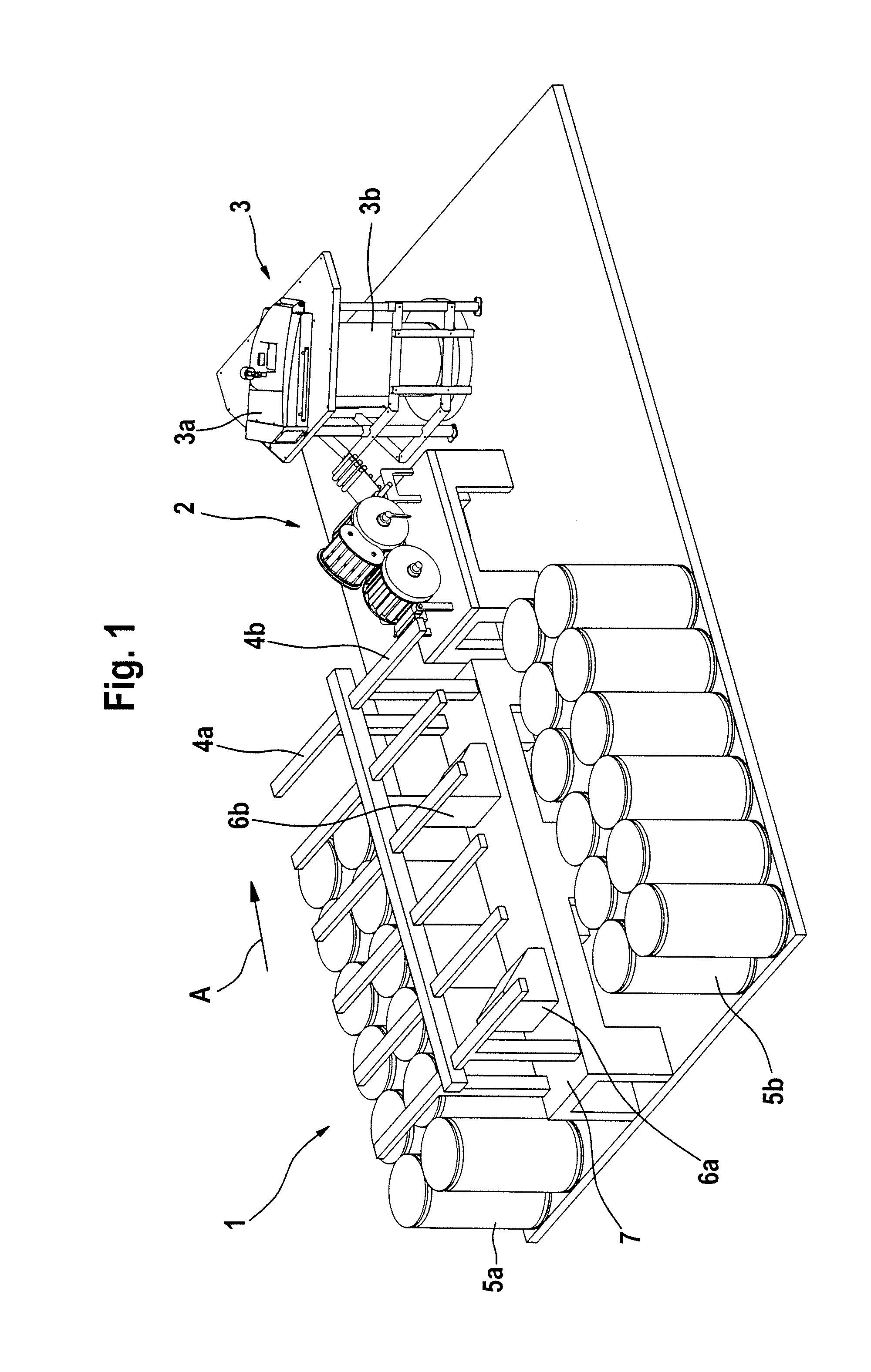

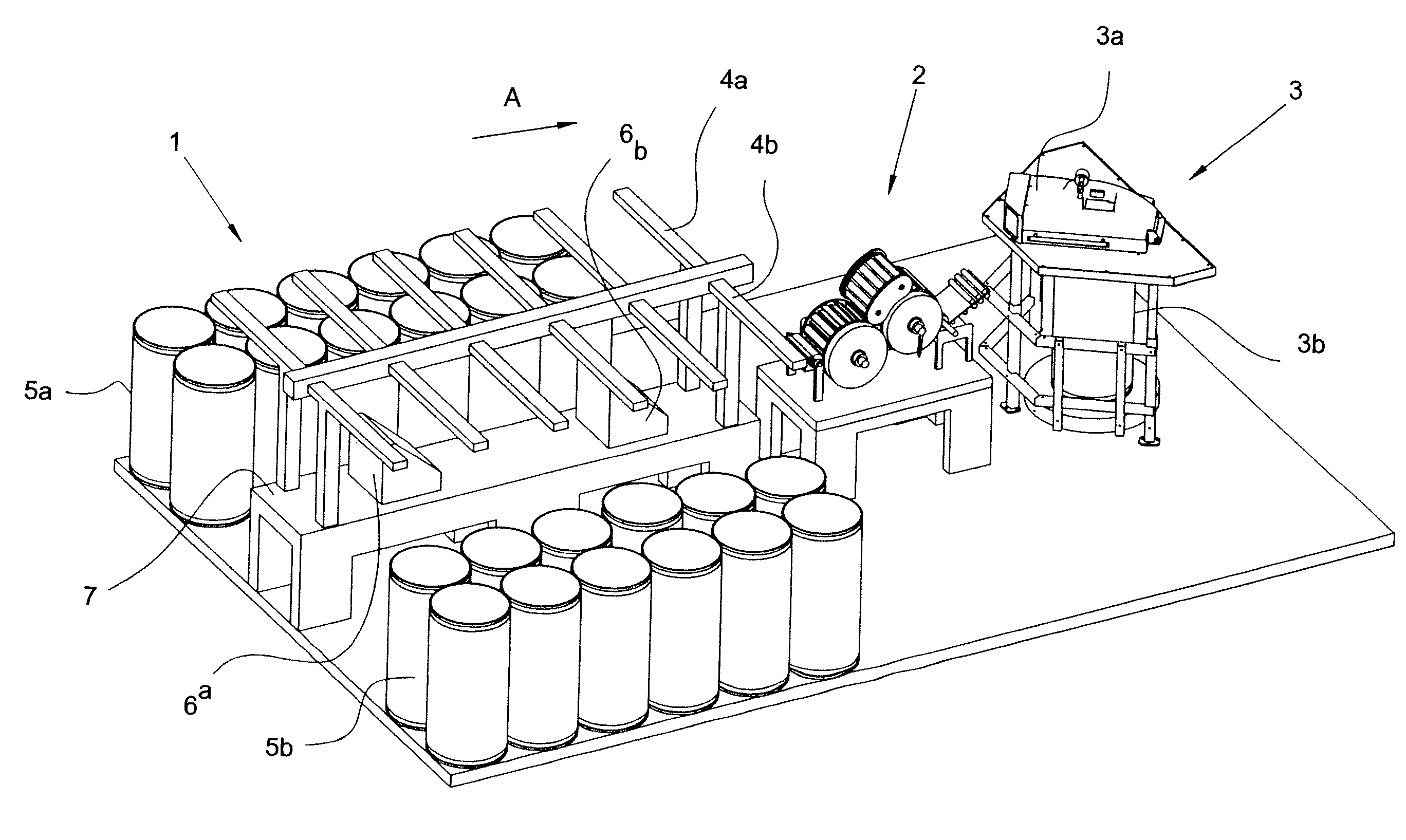

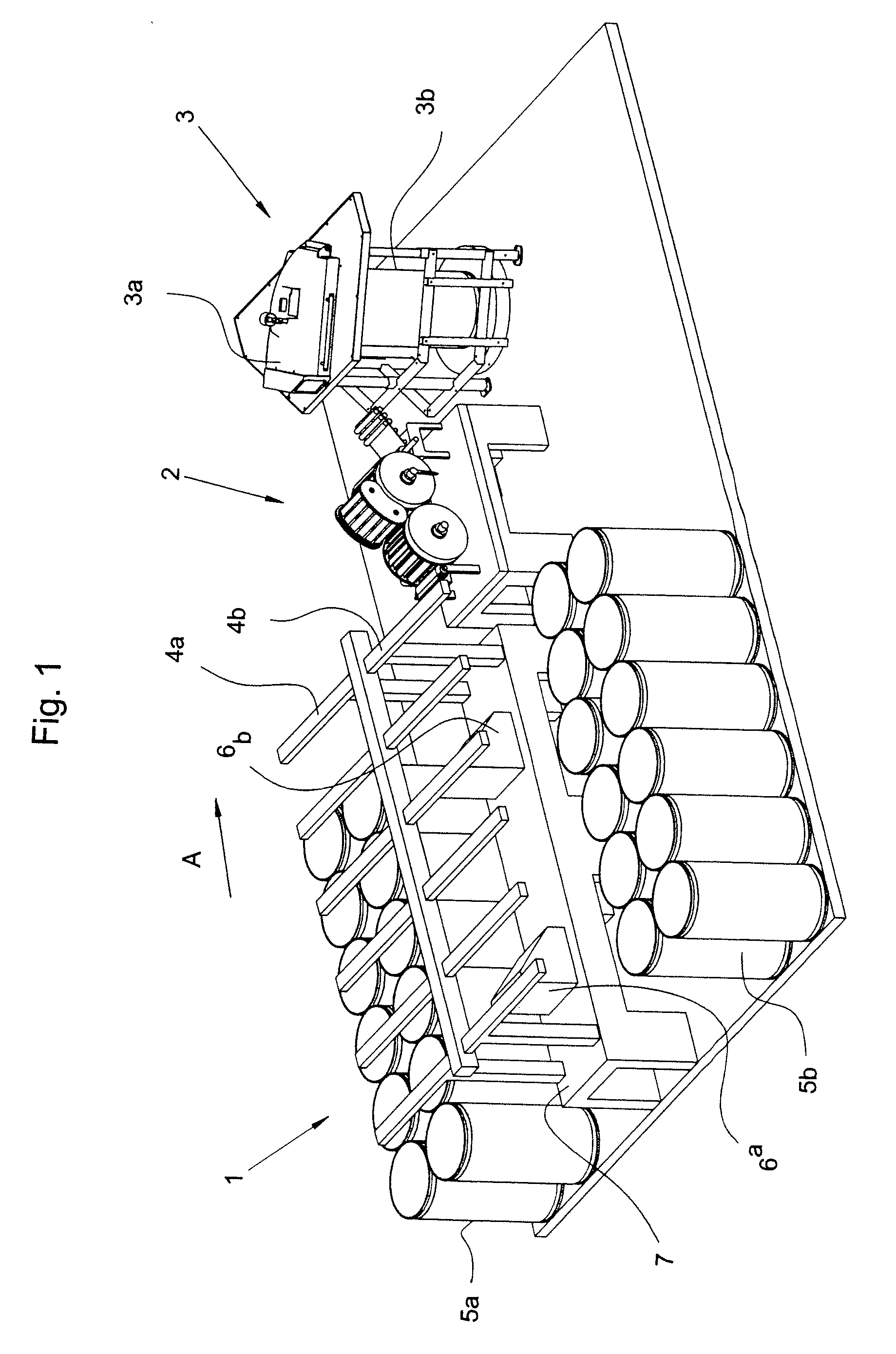

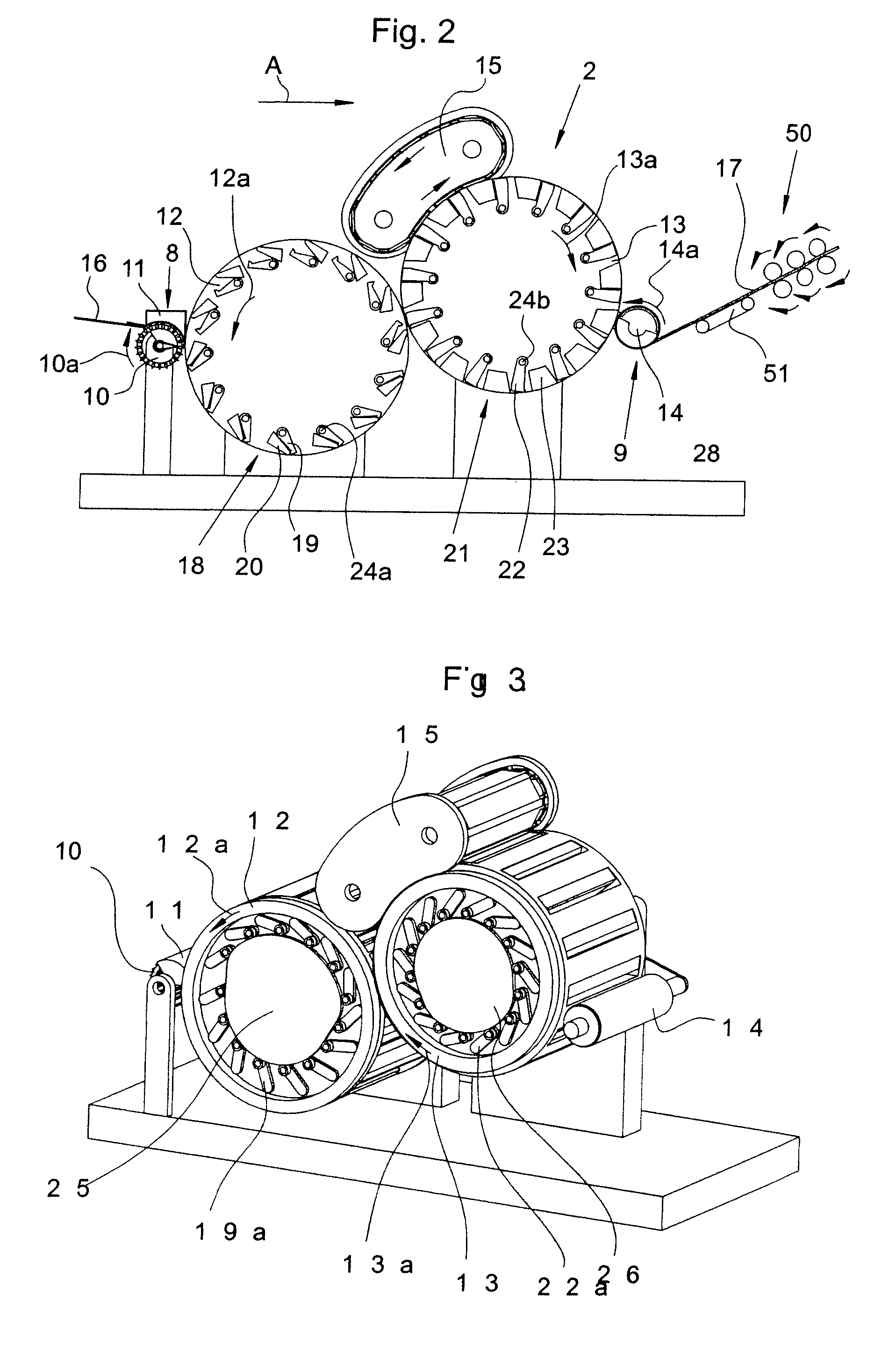

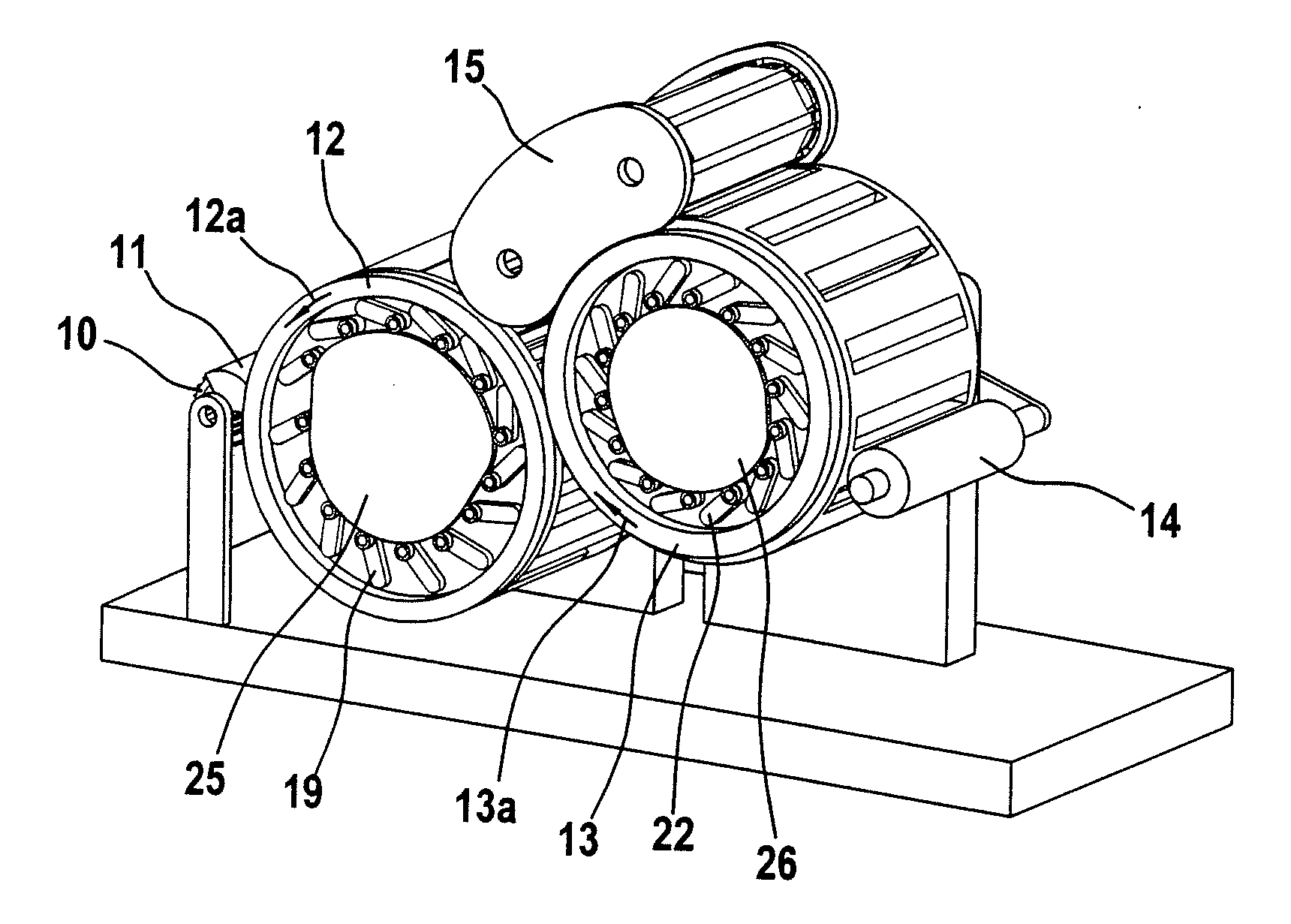

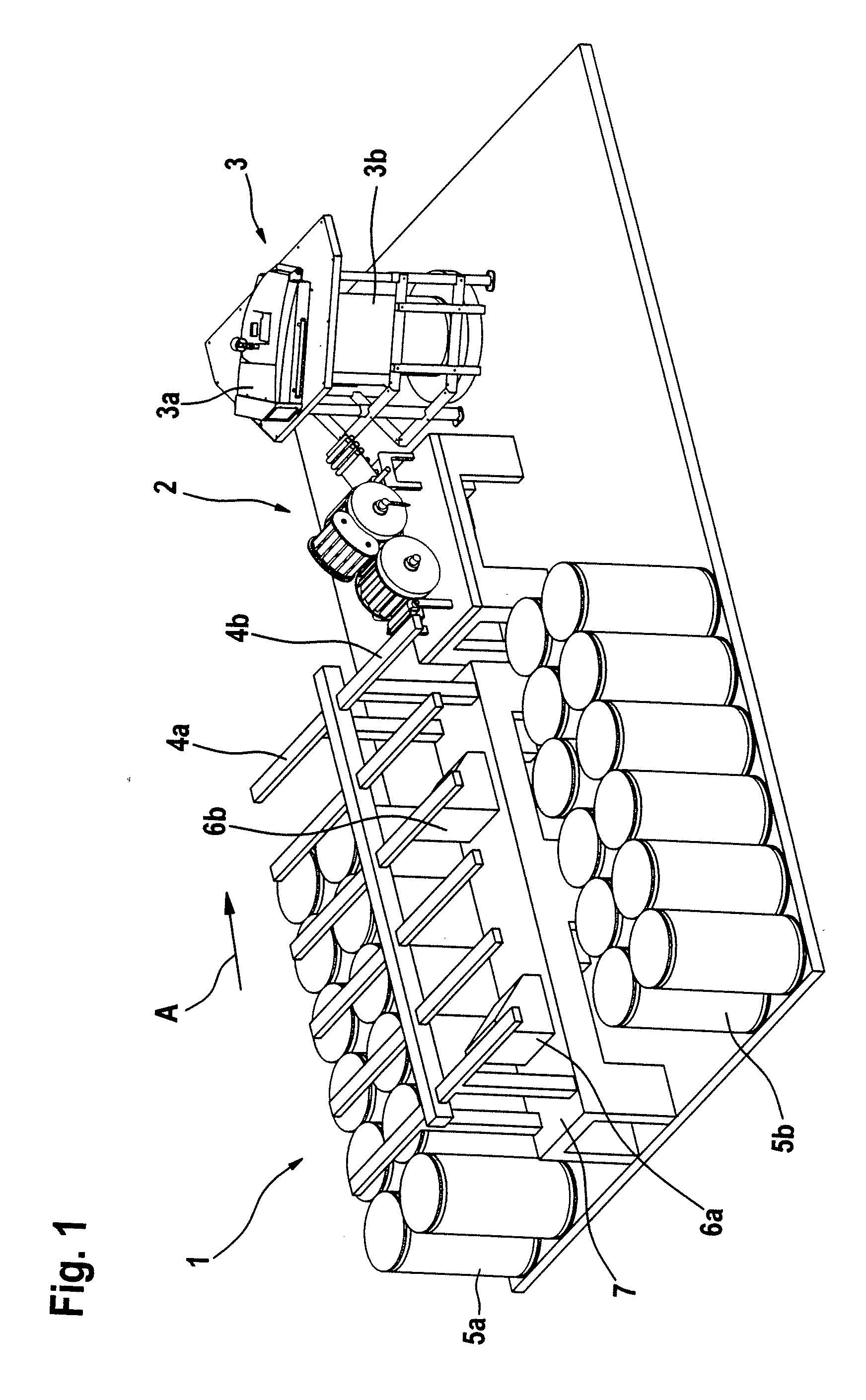

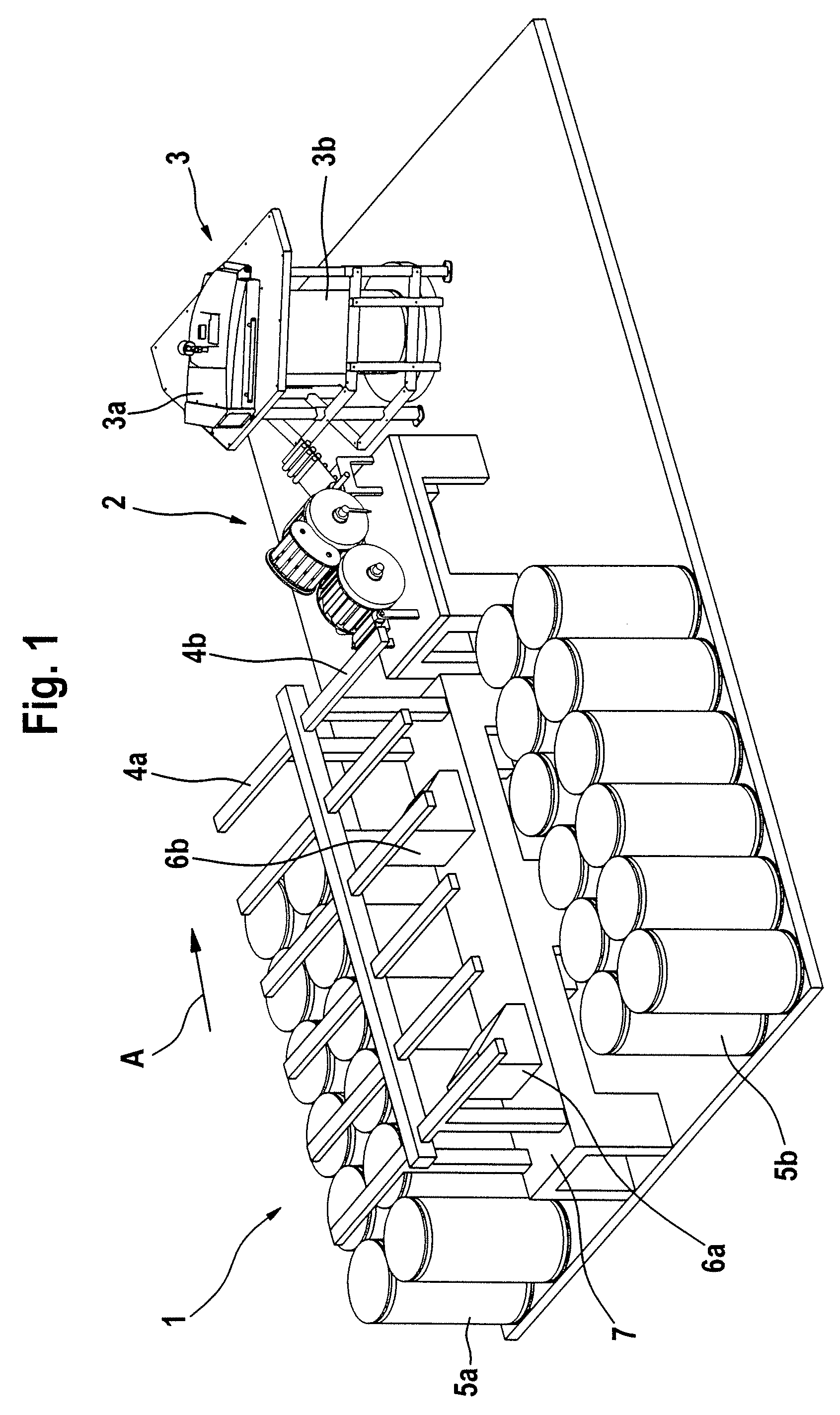

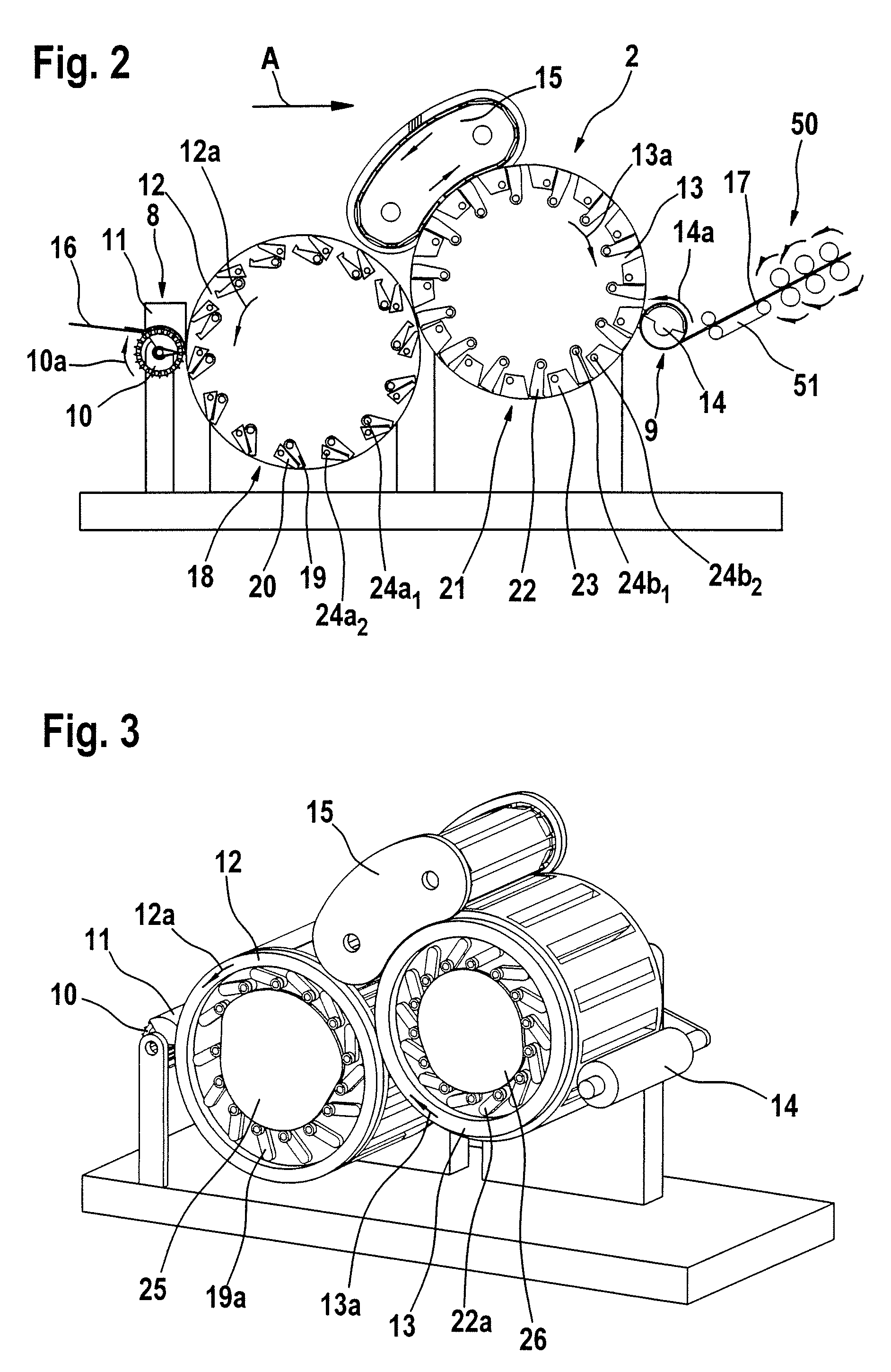

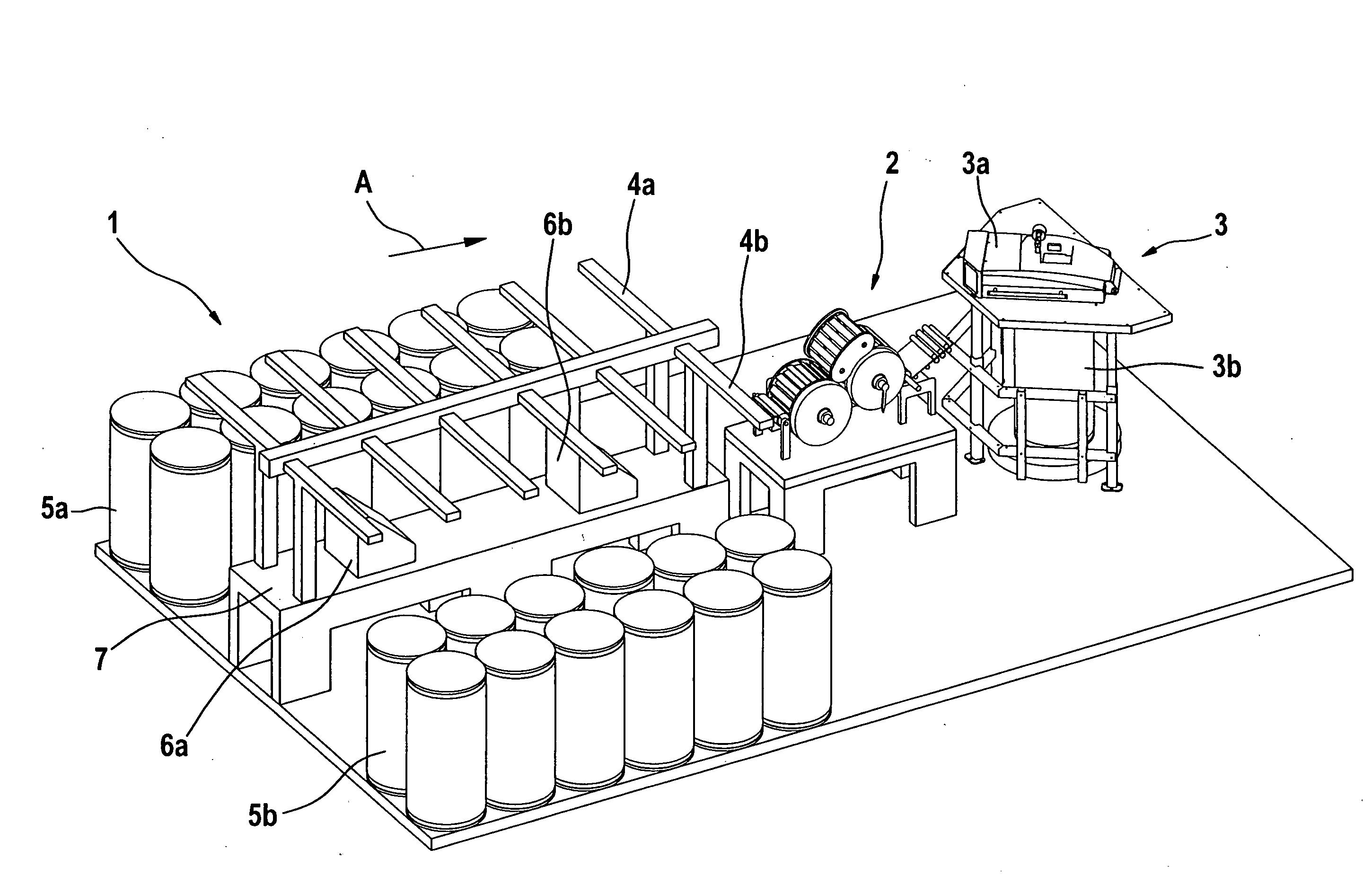

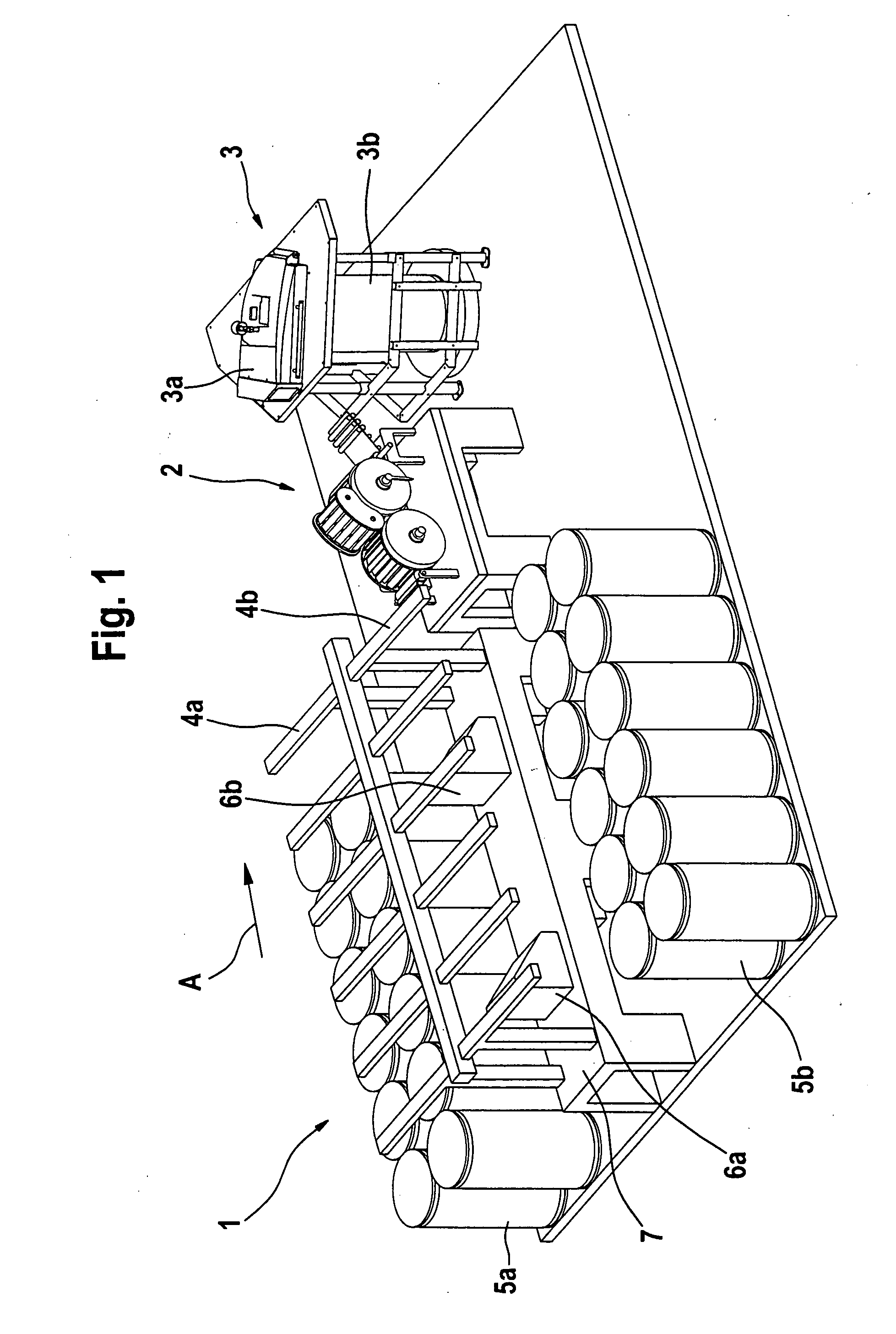

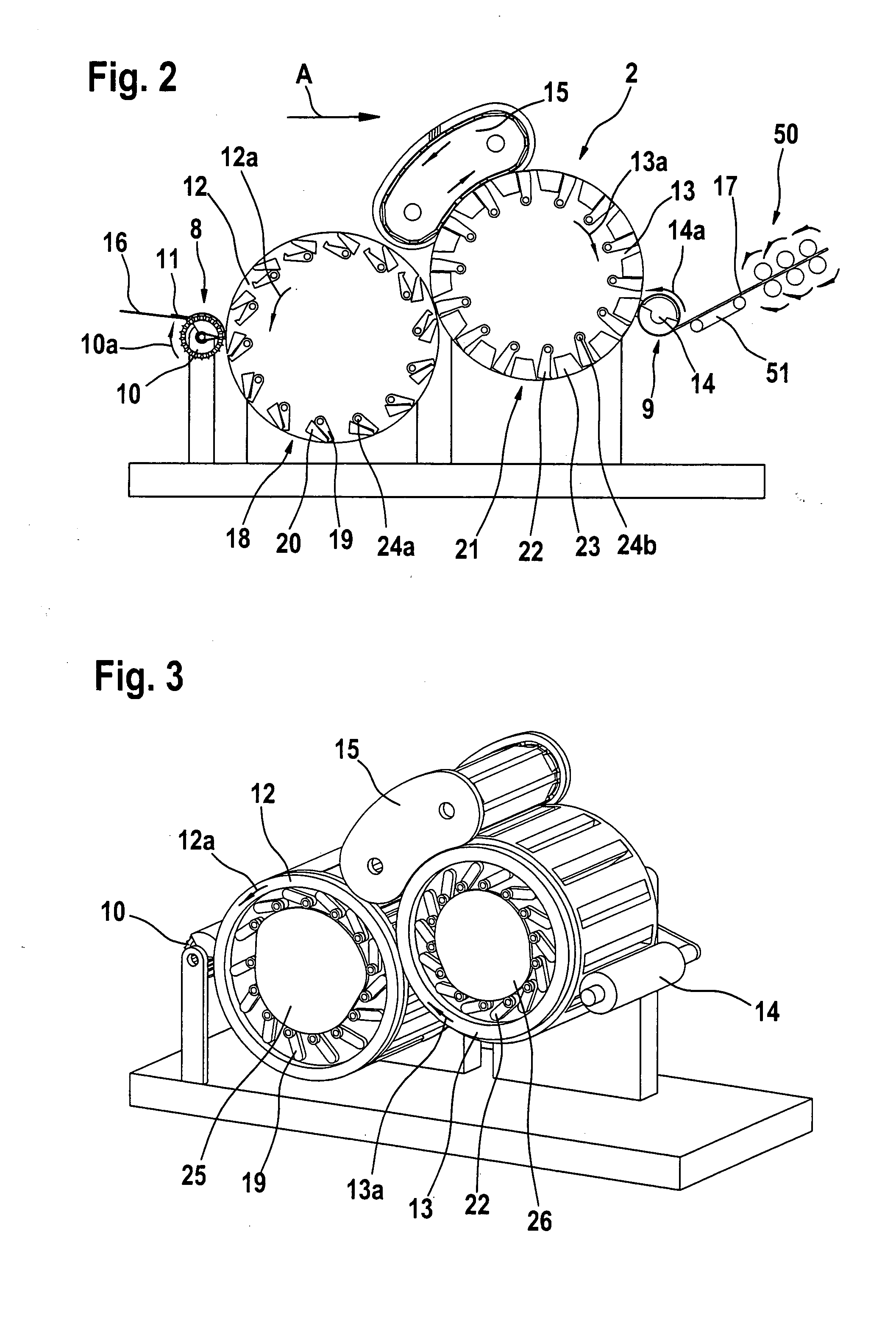

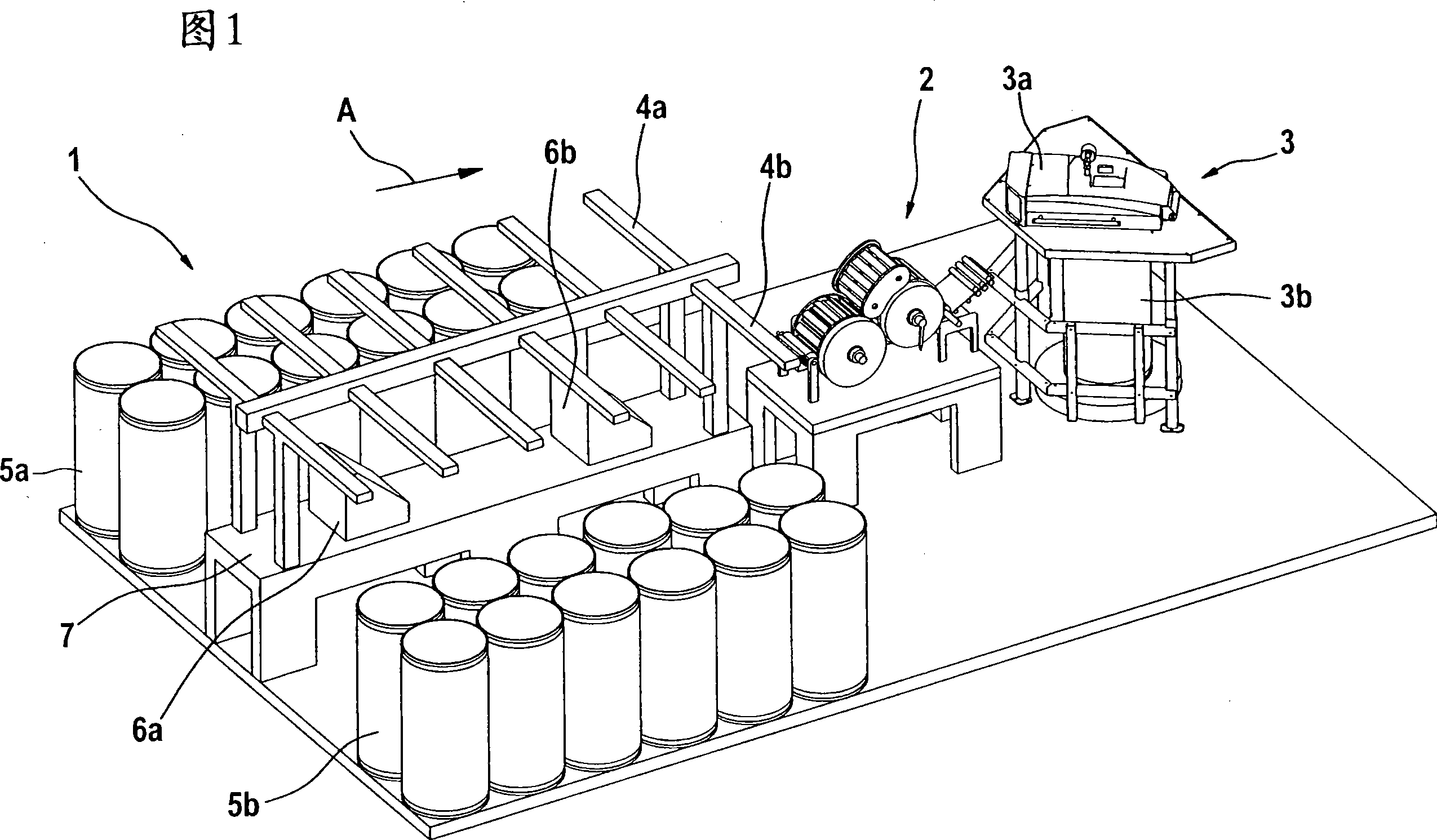

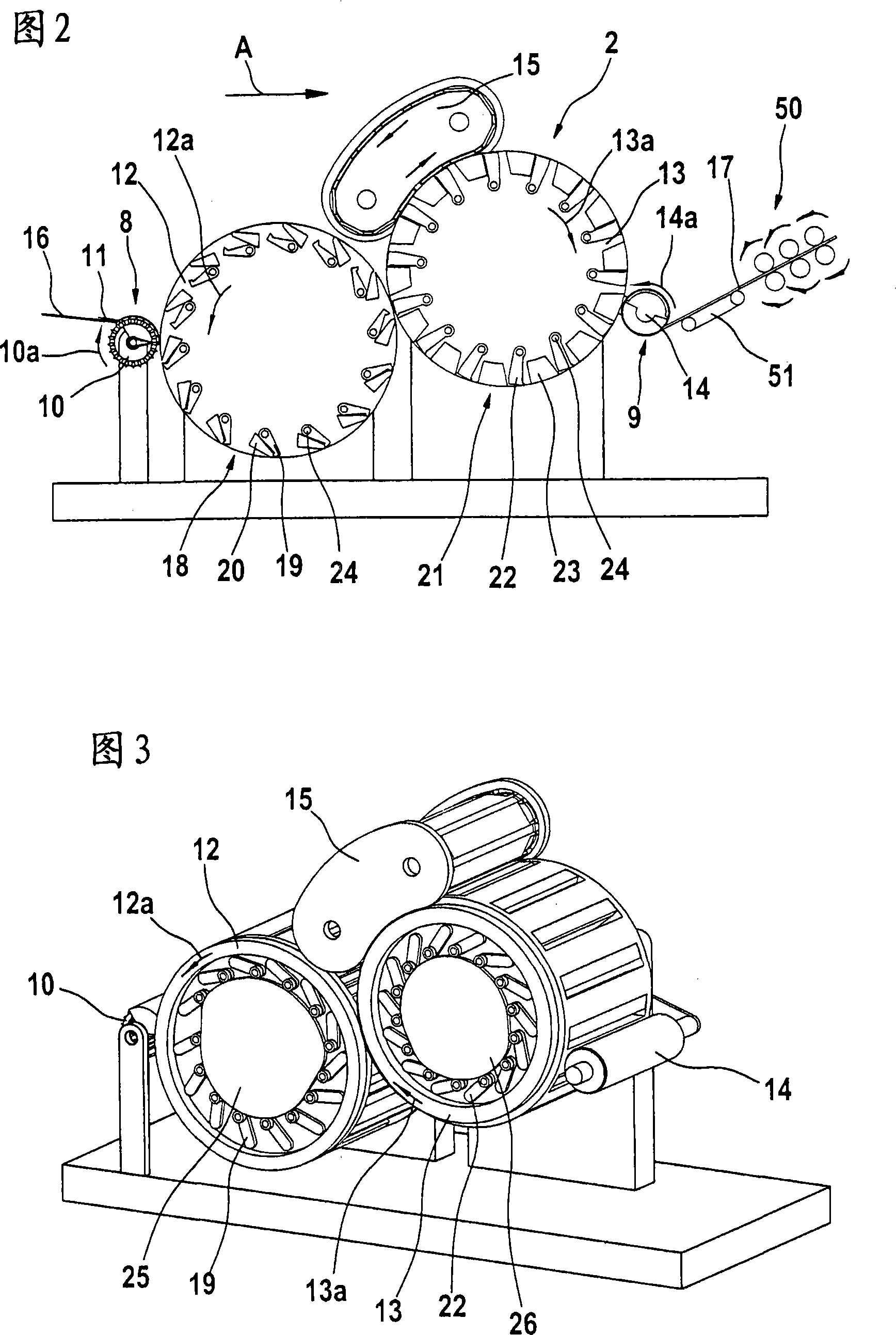

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000071A1Increase volumeImproved combed sliverCombing machinesTextile fiberFiber bundle

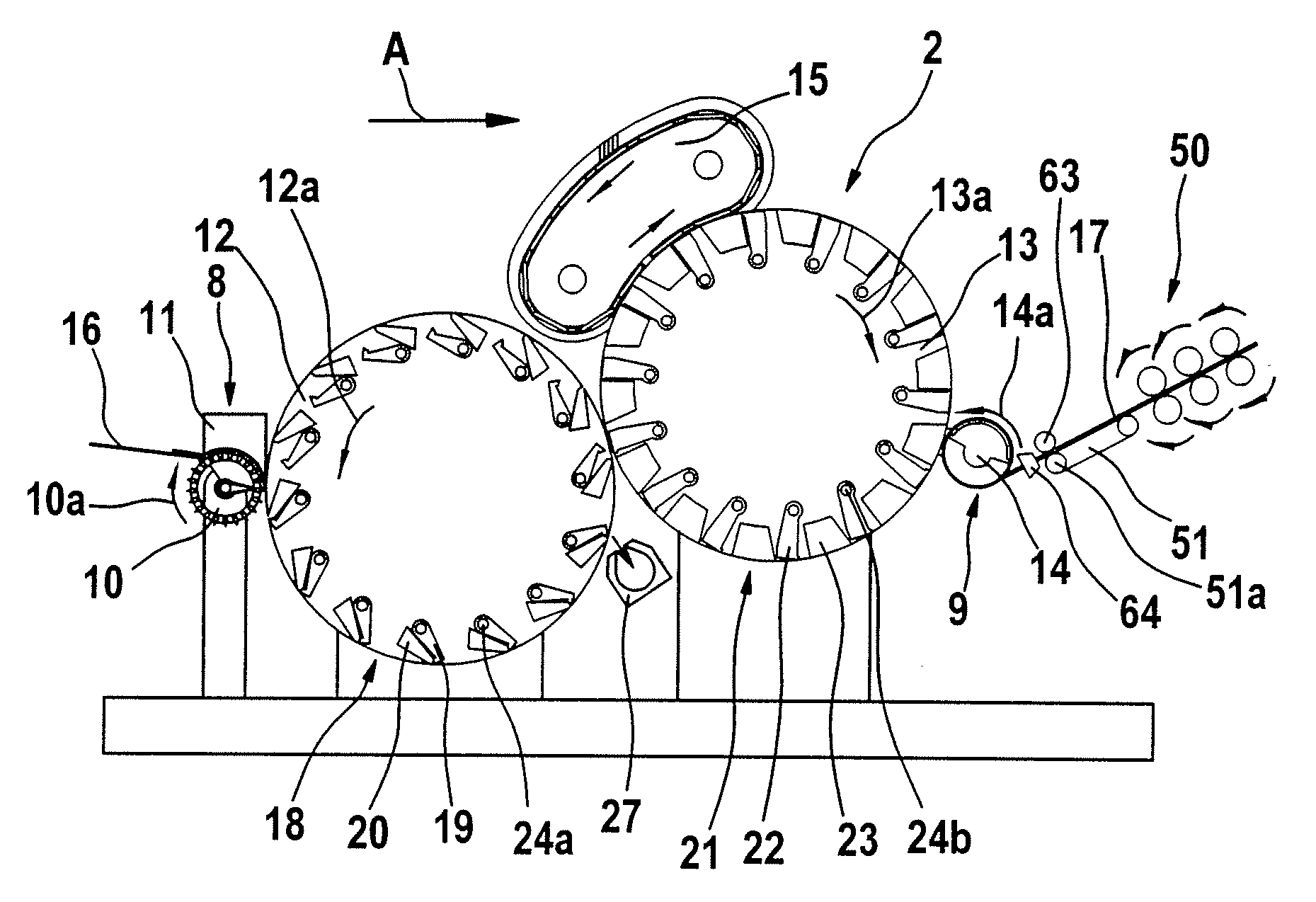

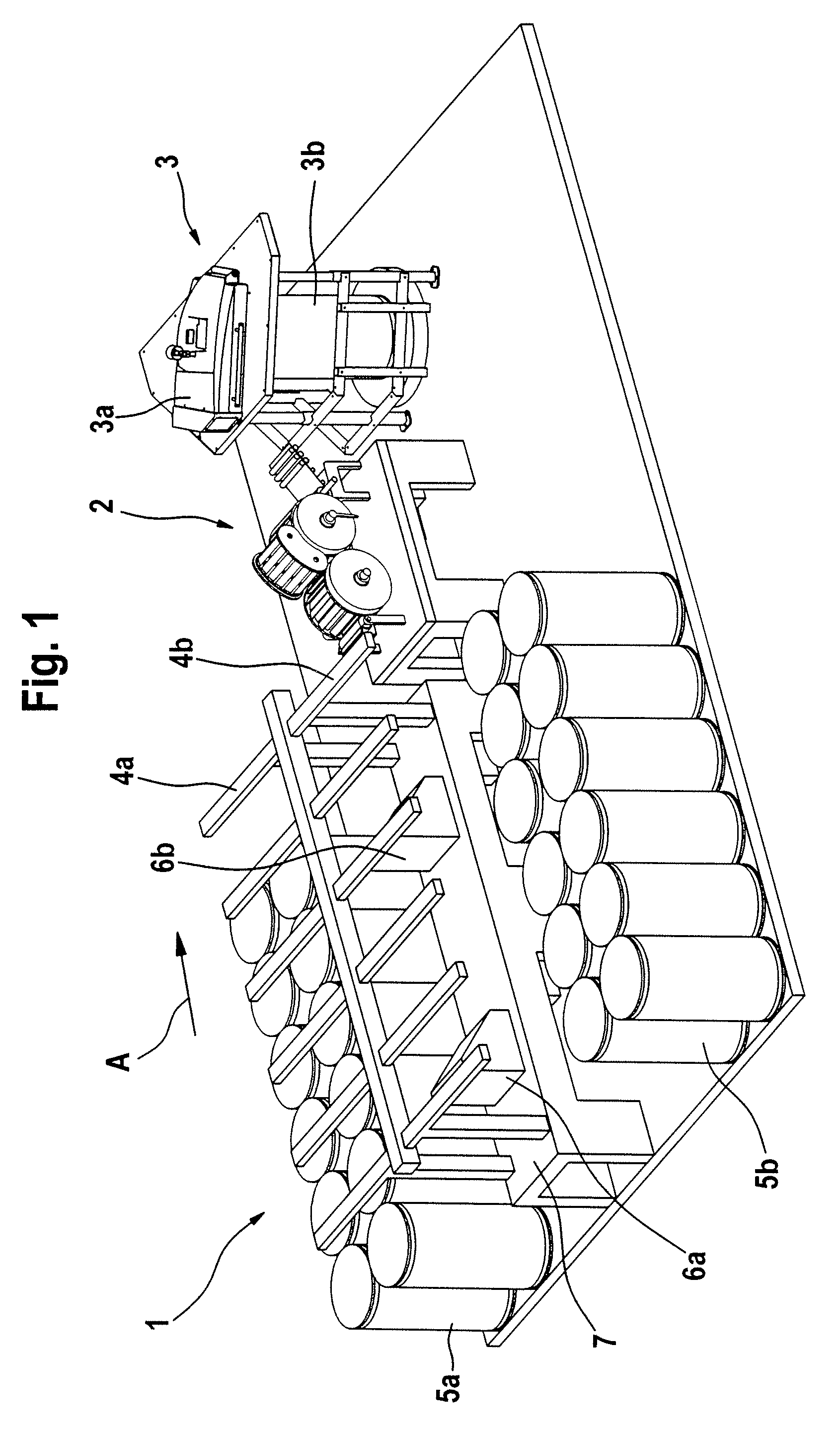

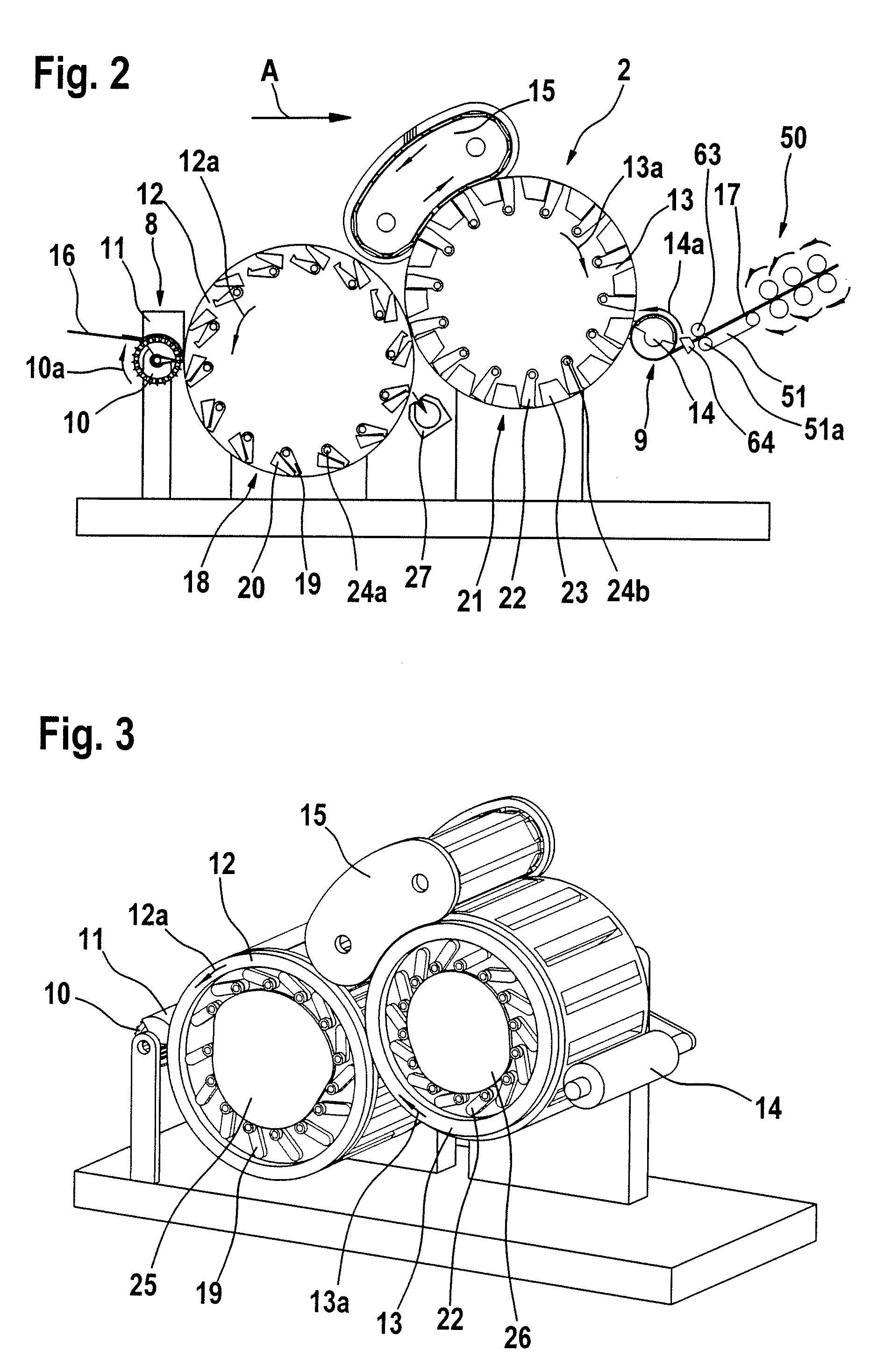

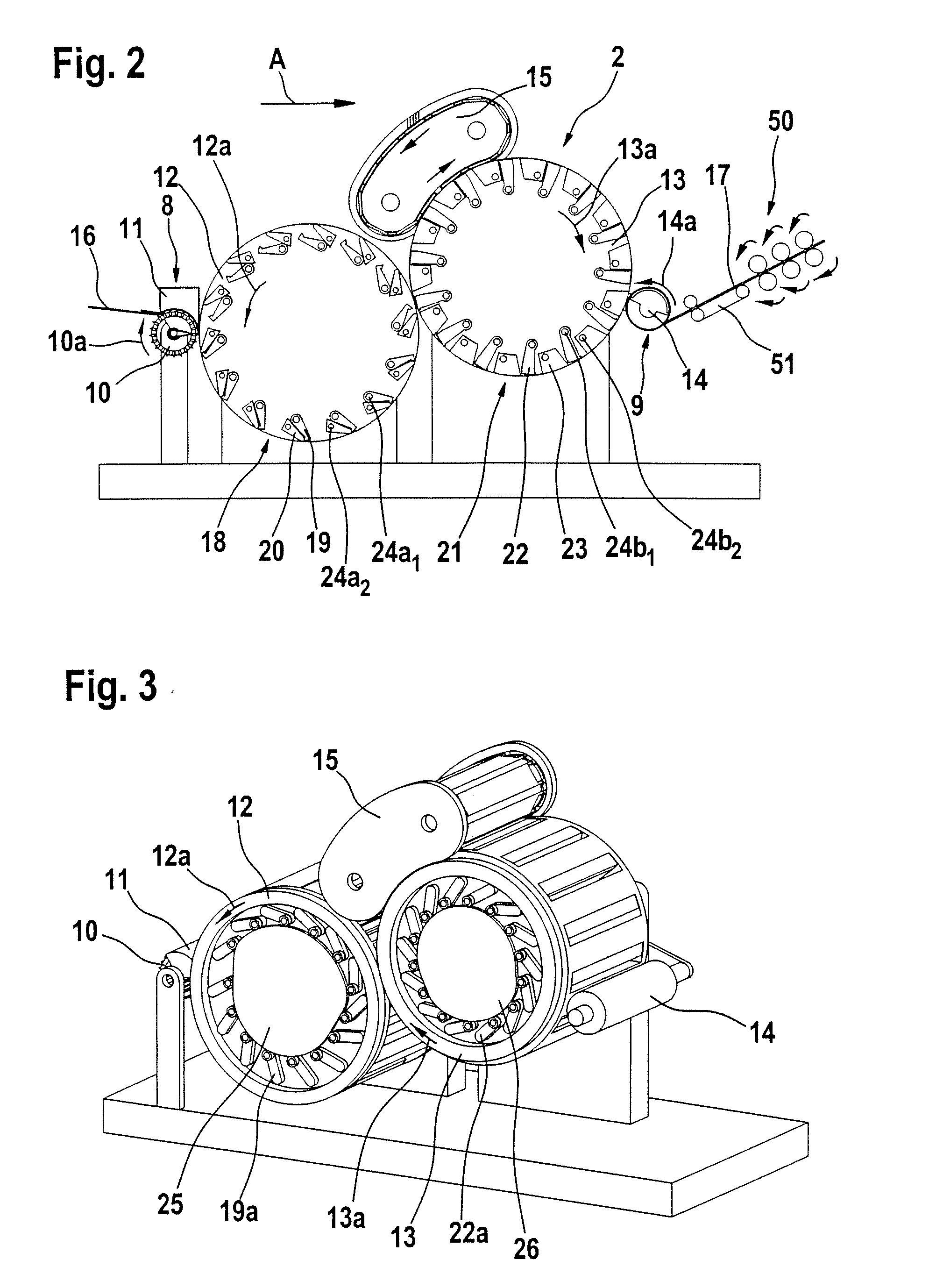

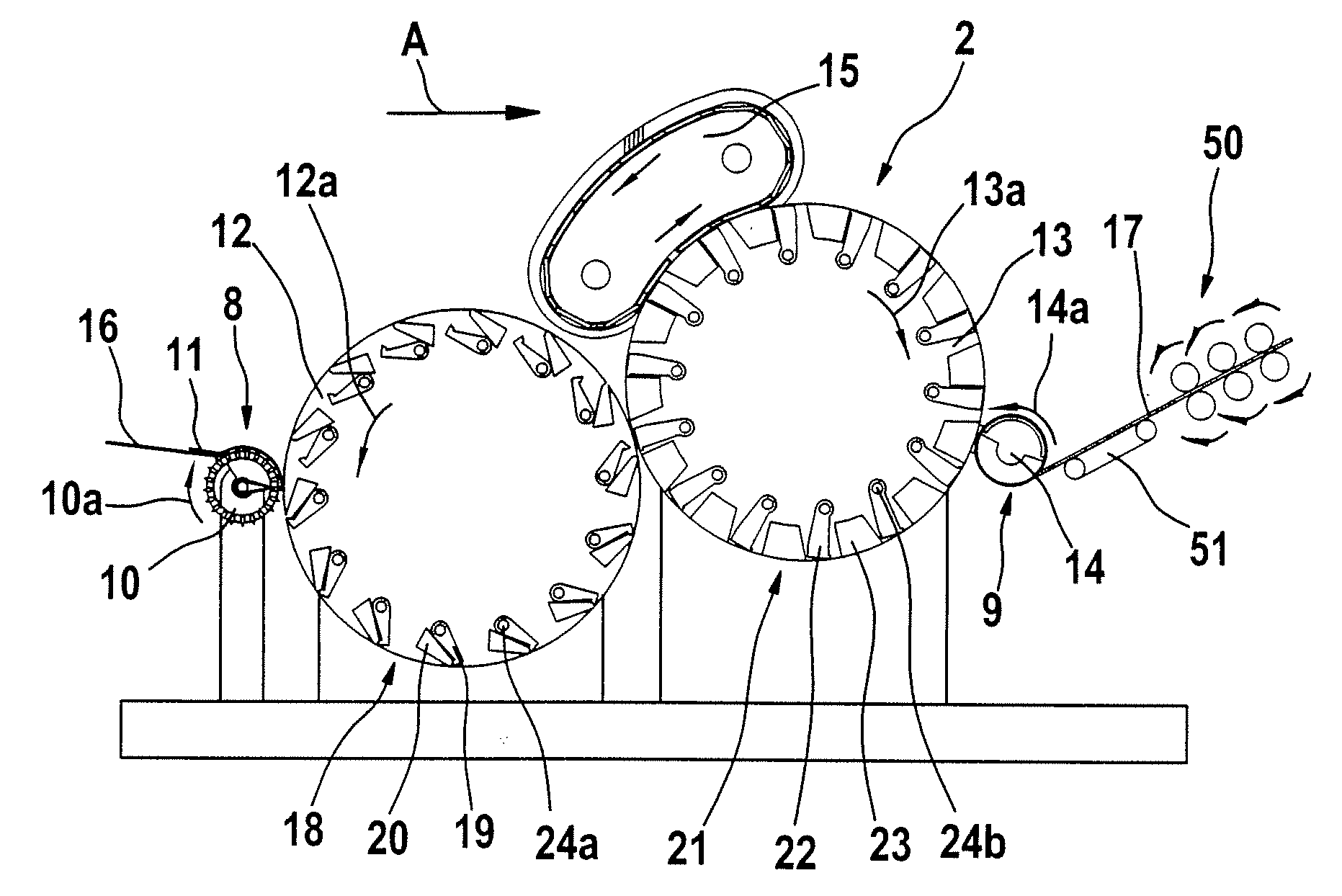

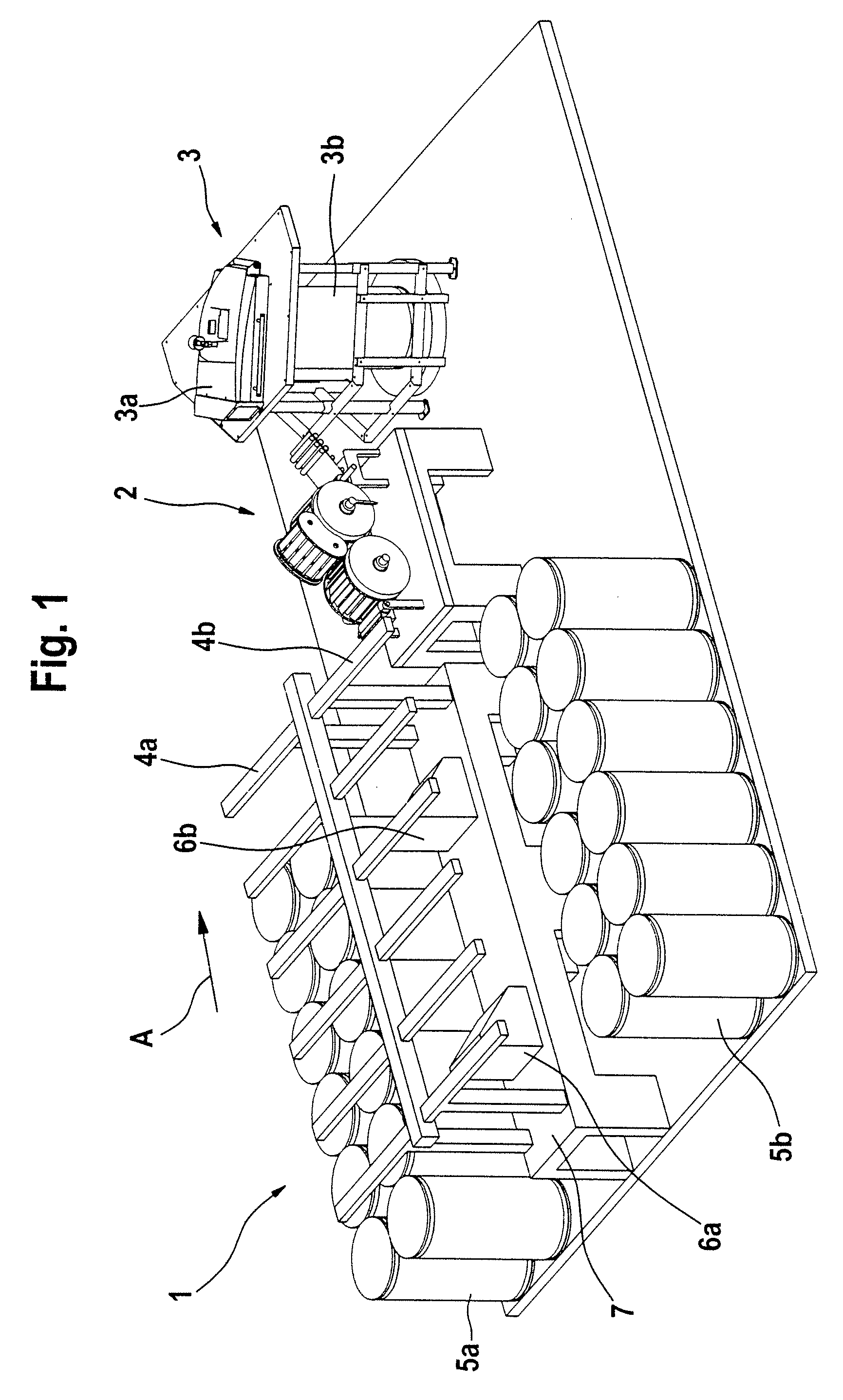

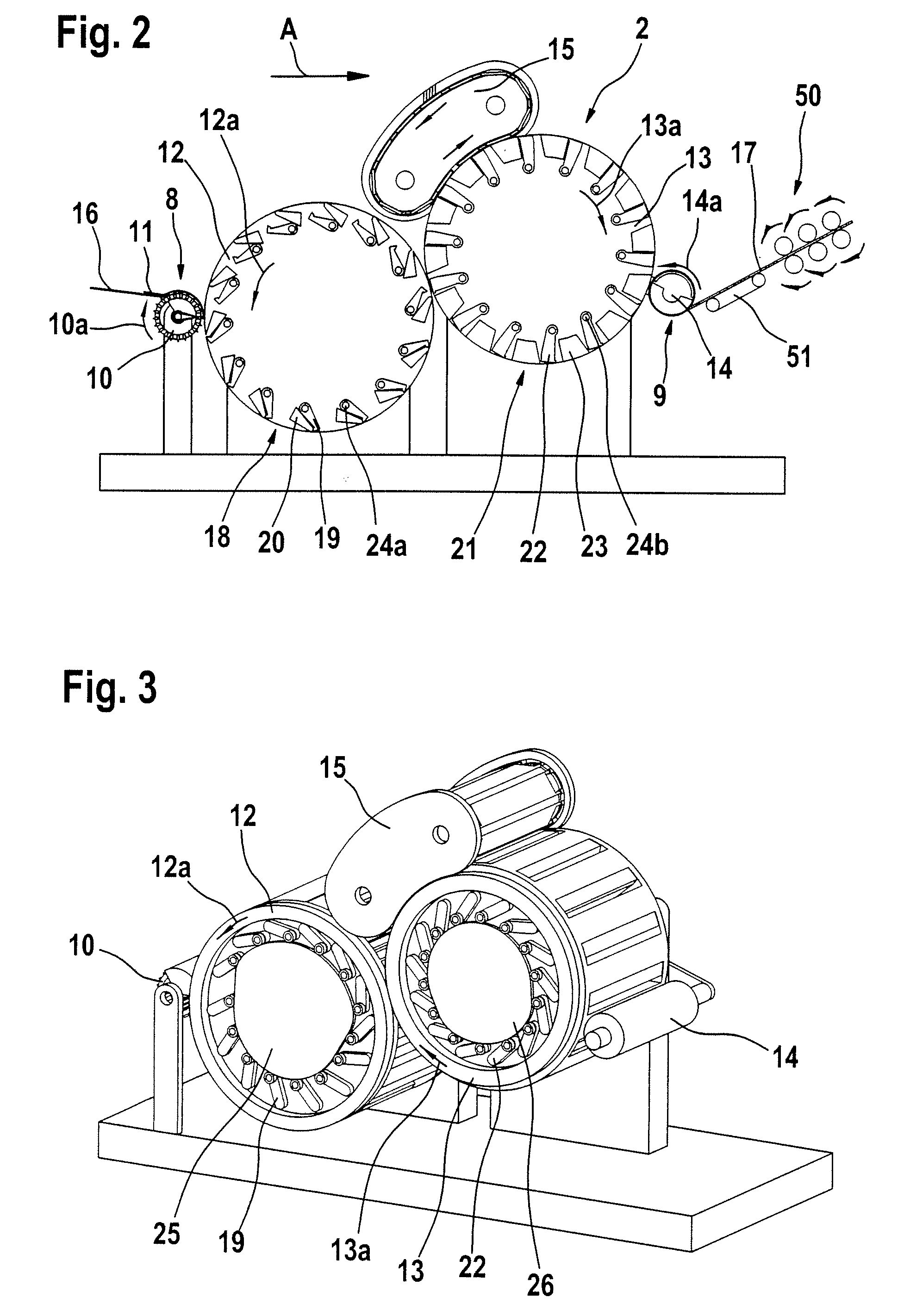

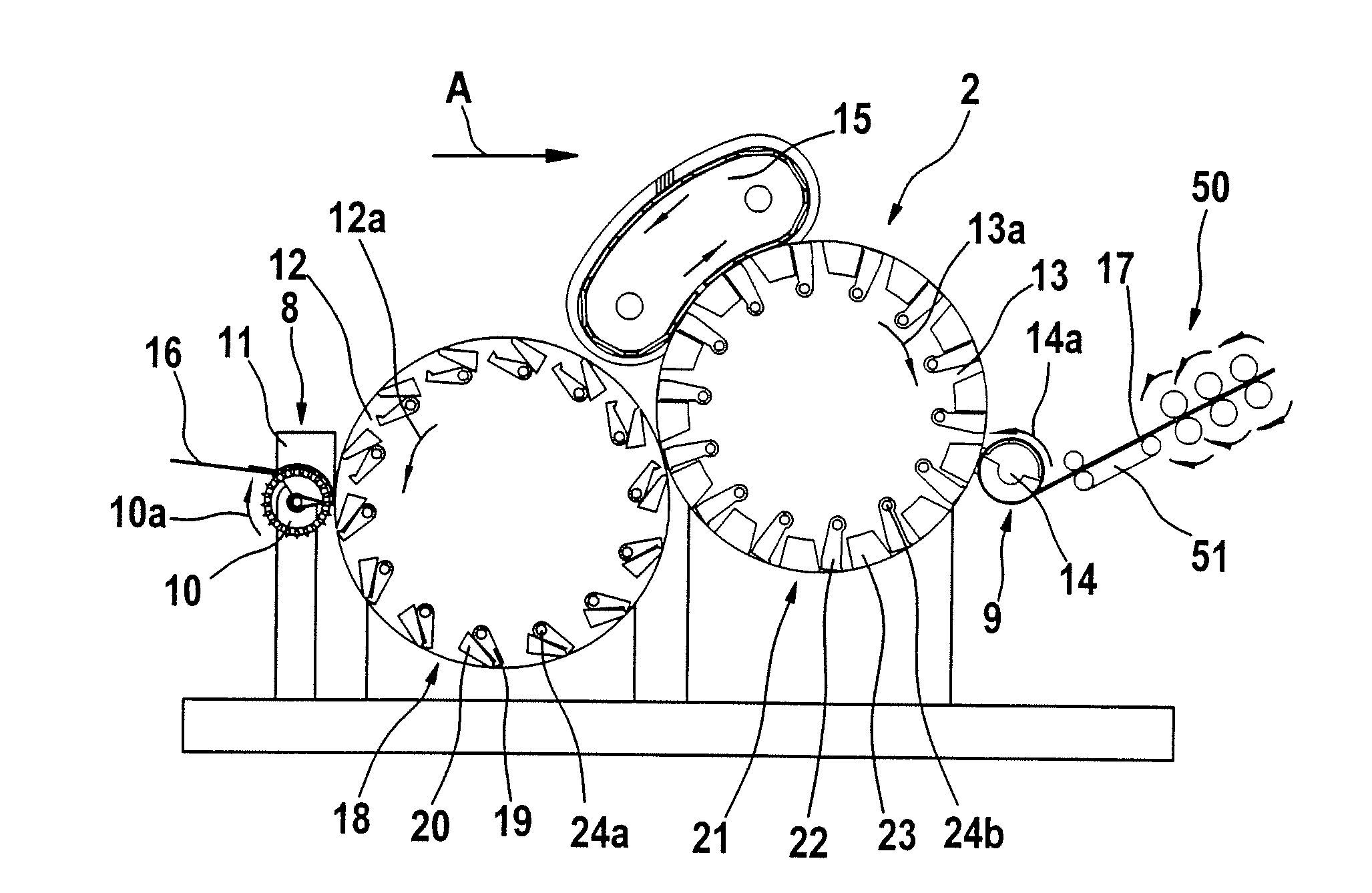

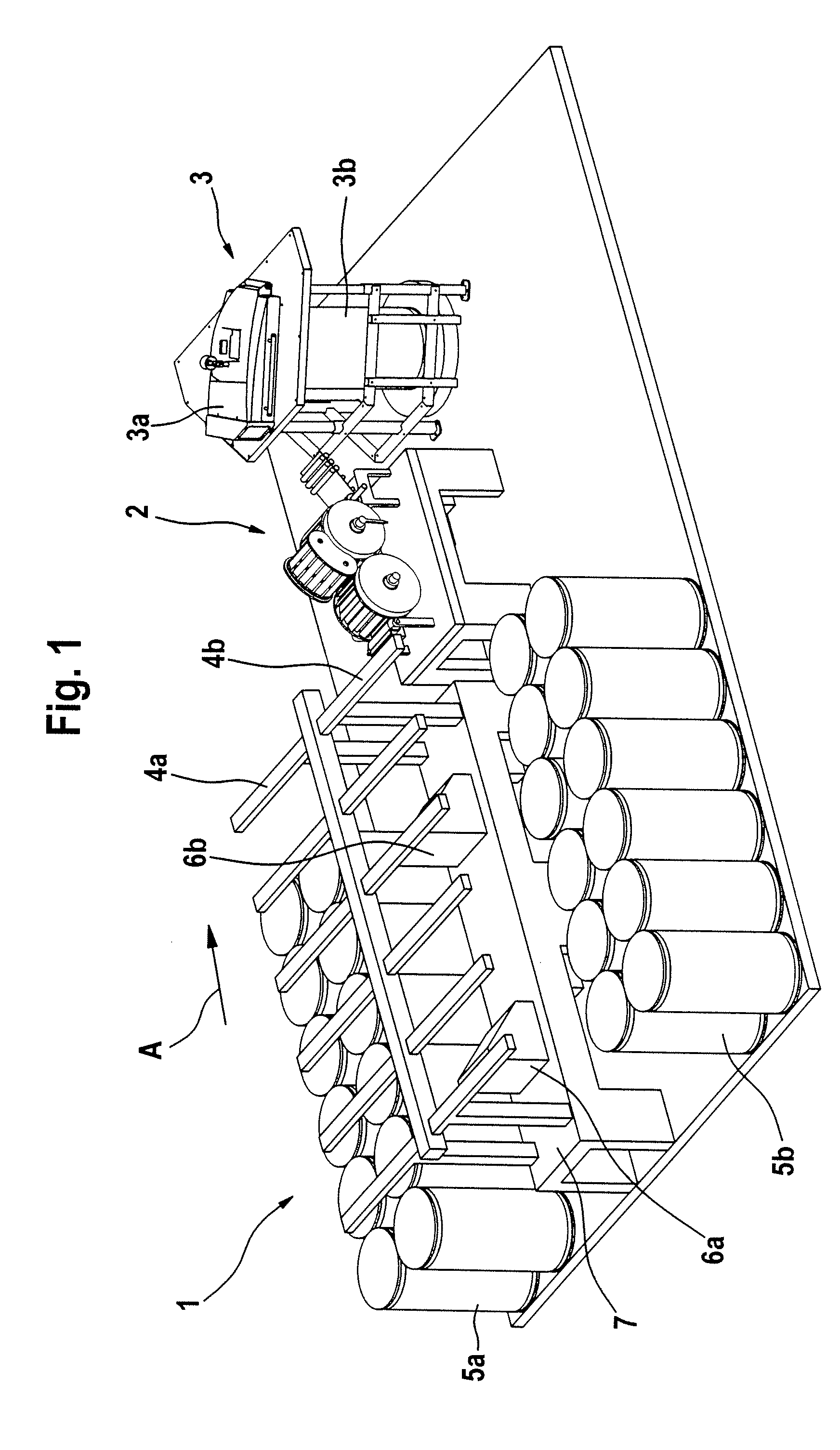

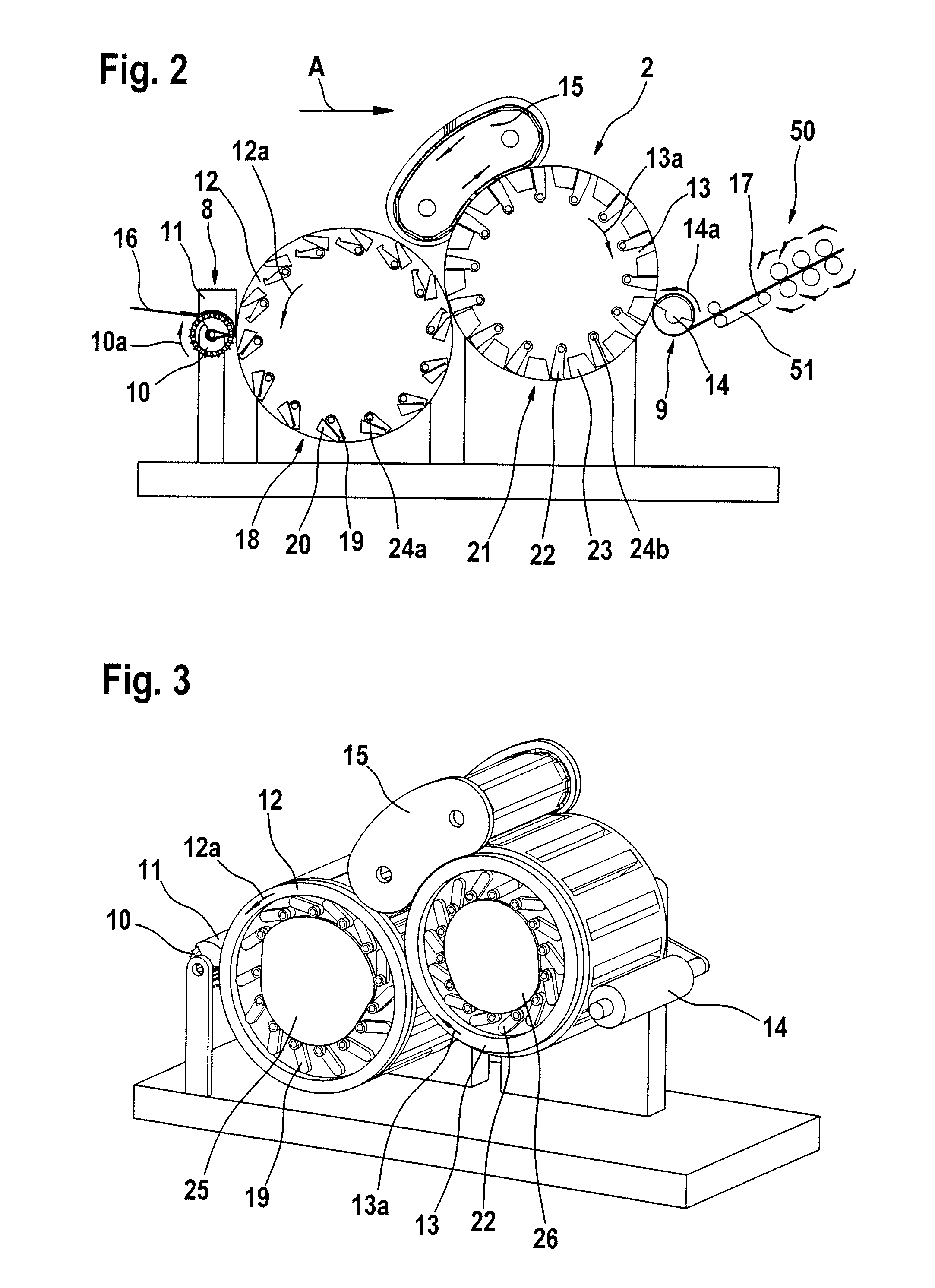

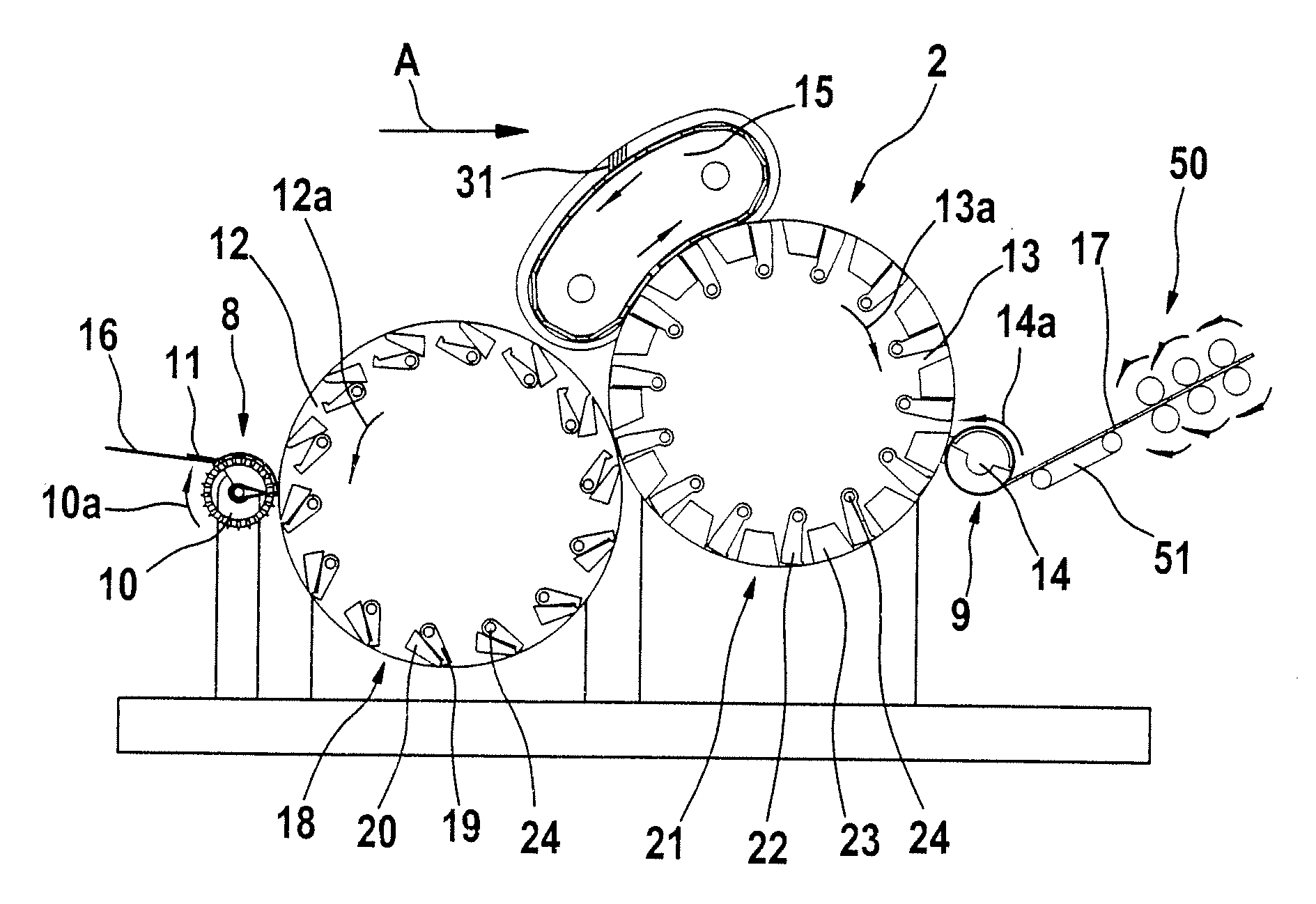

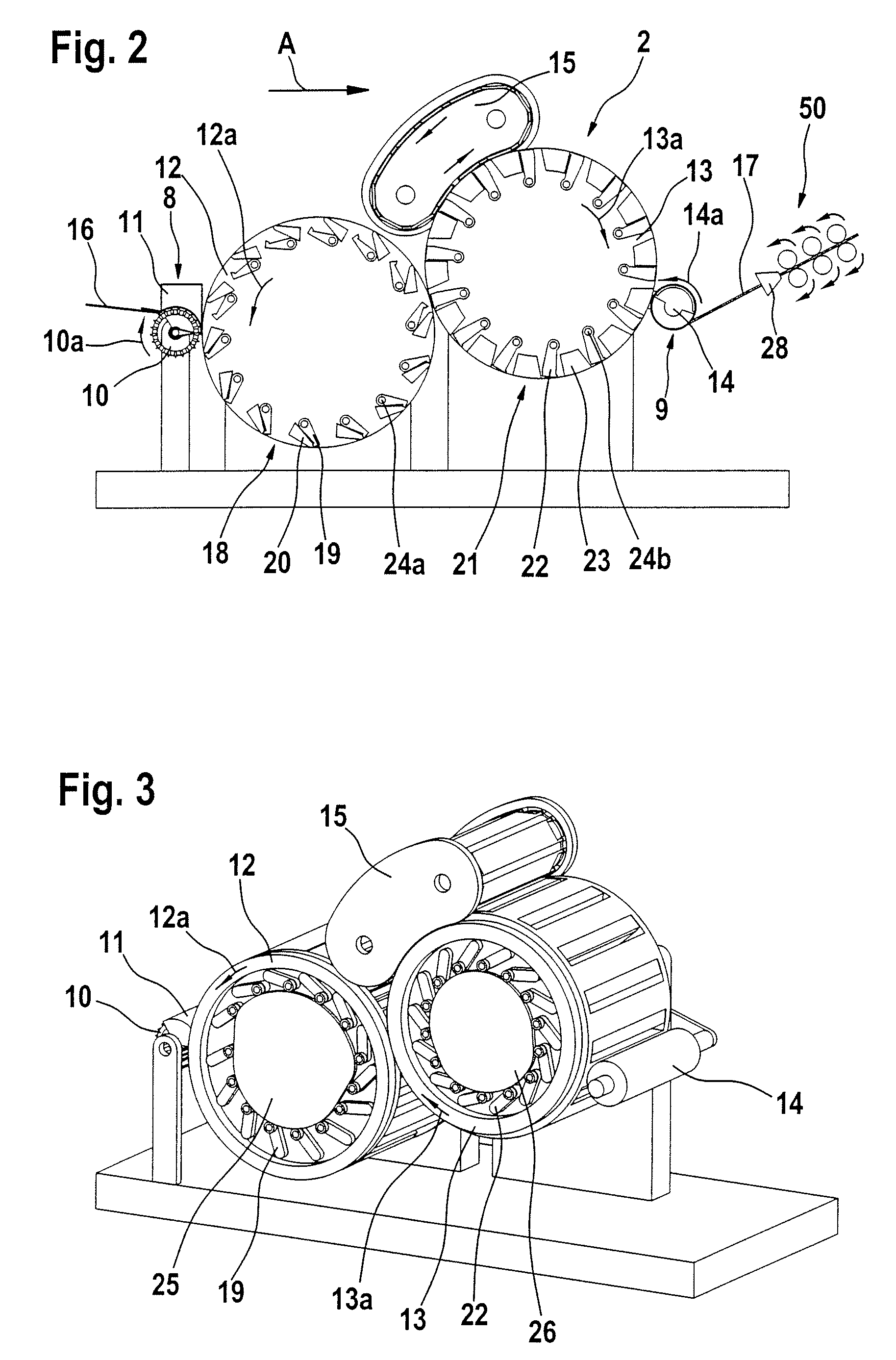

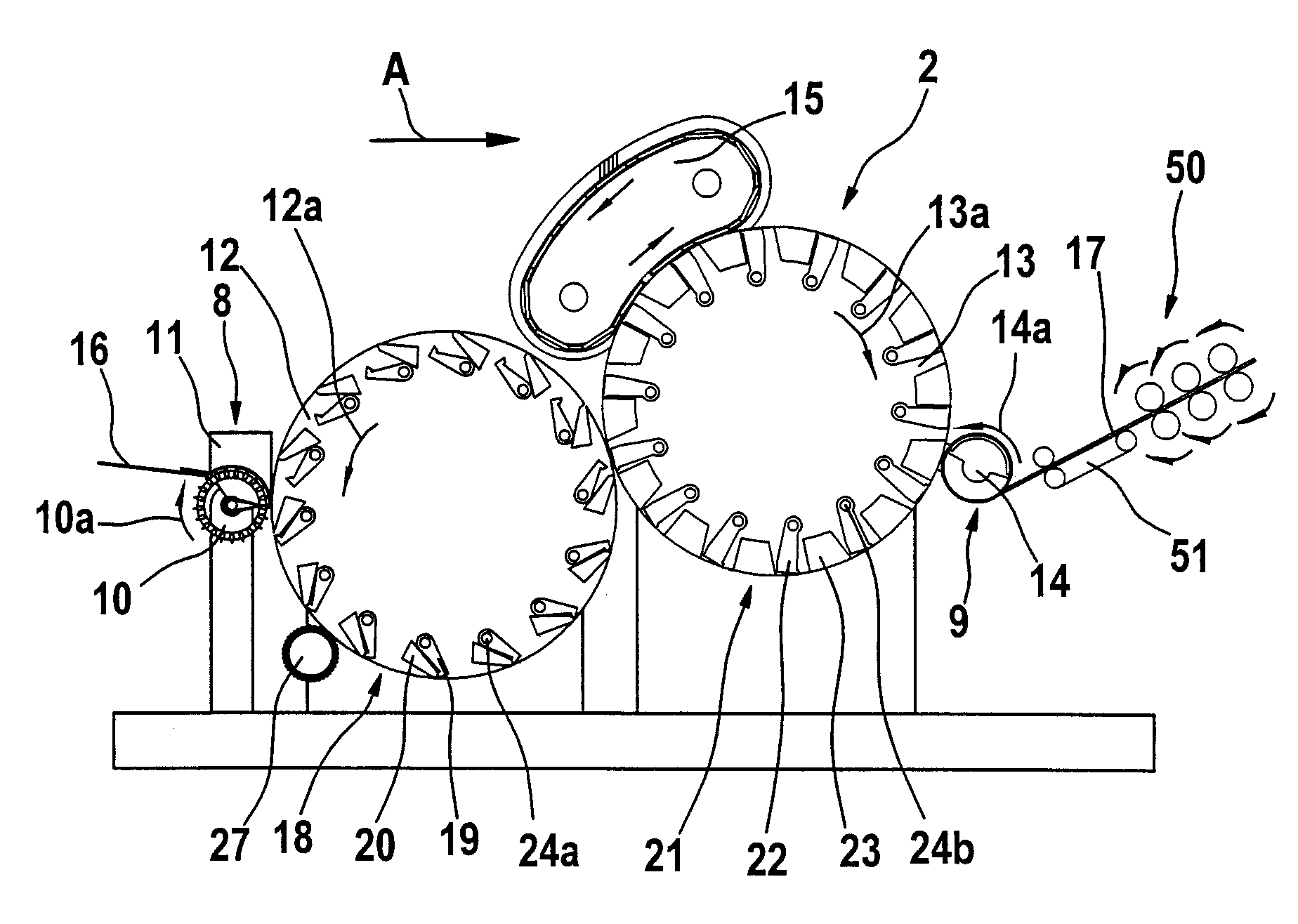

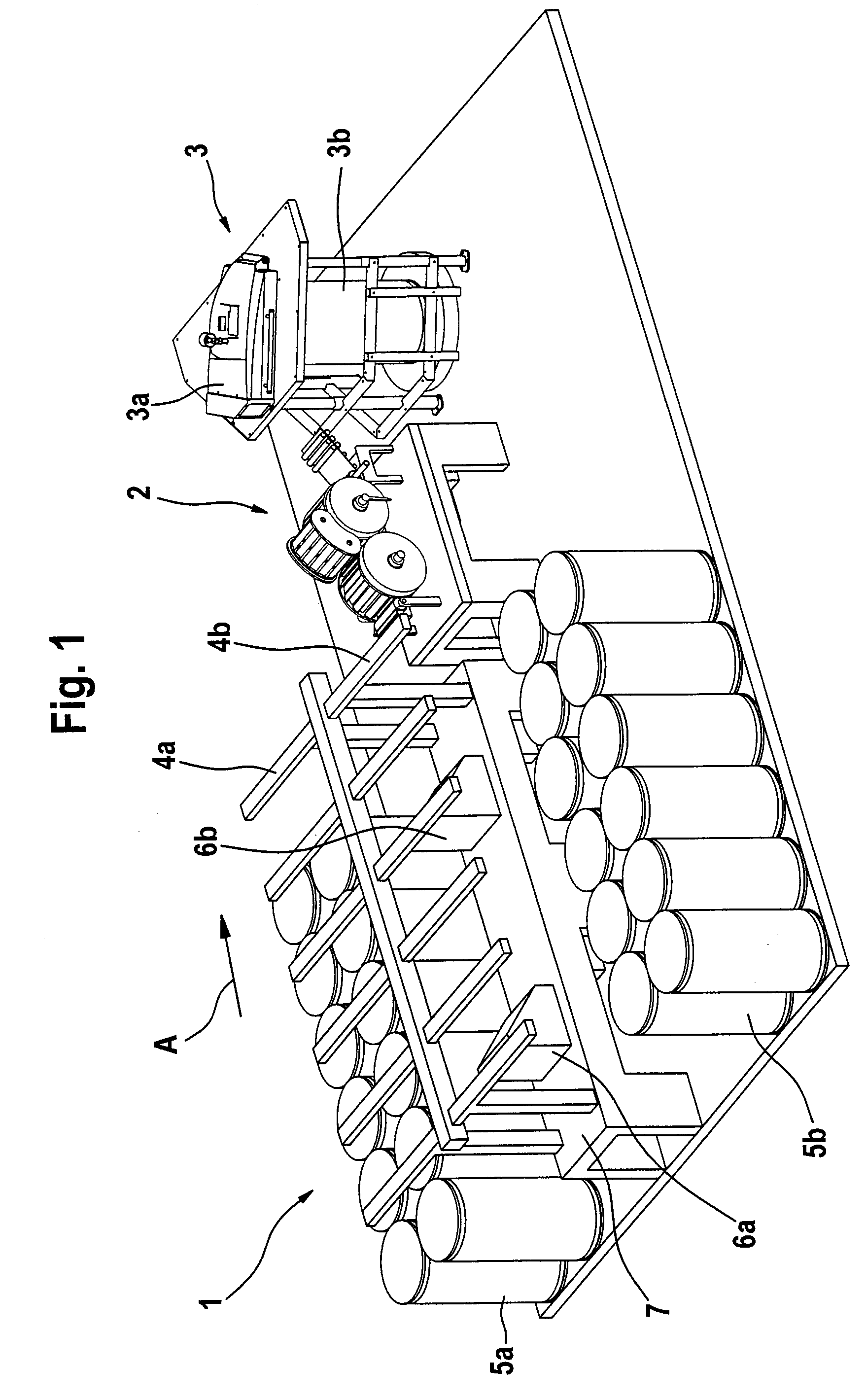

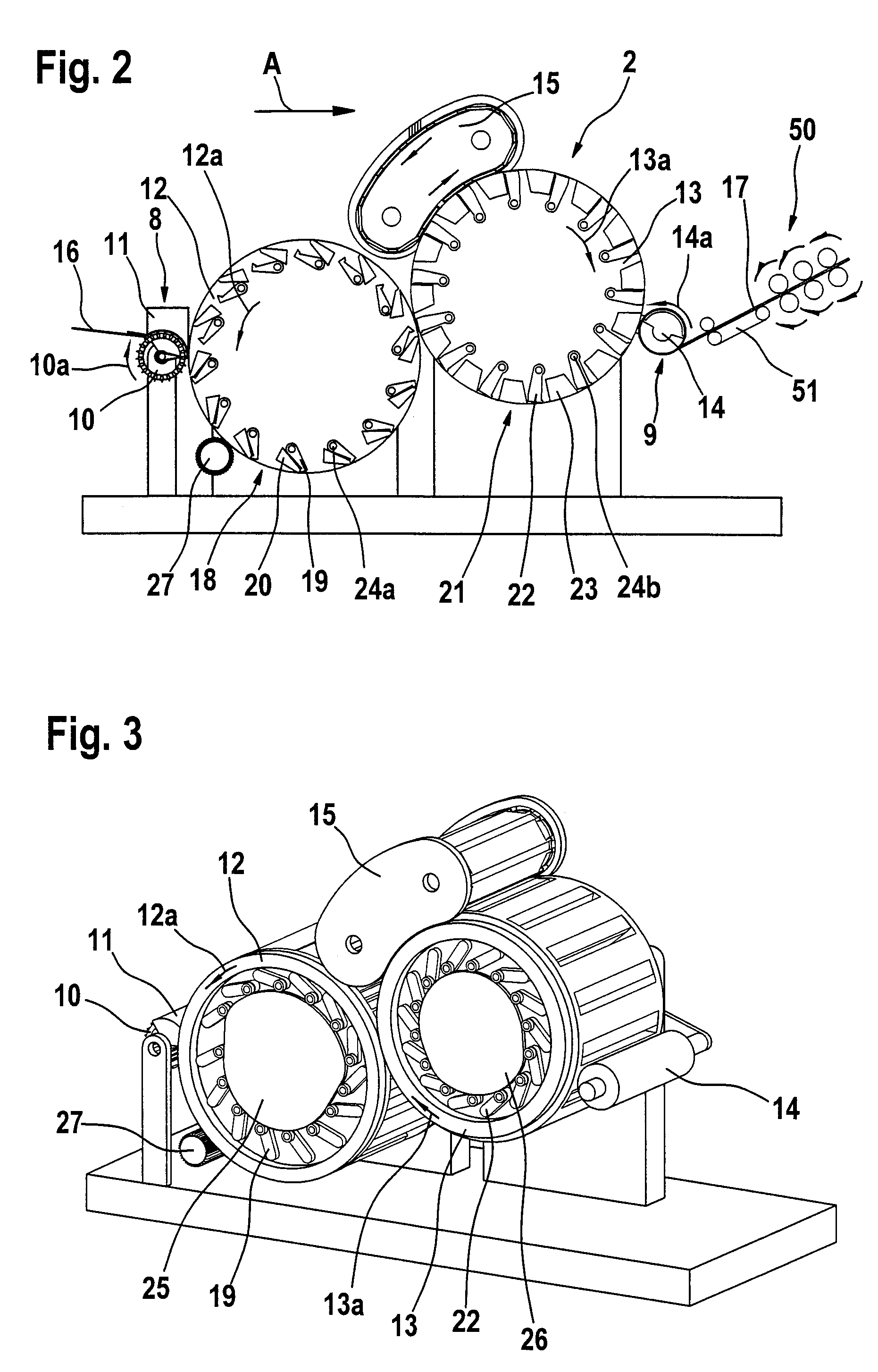

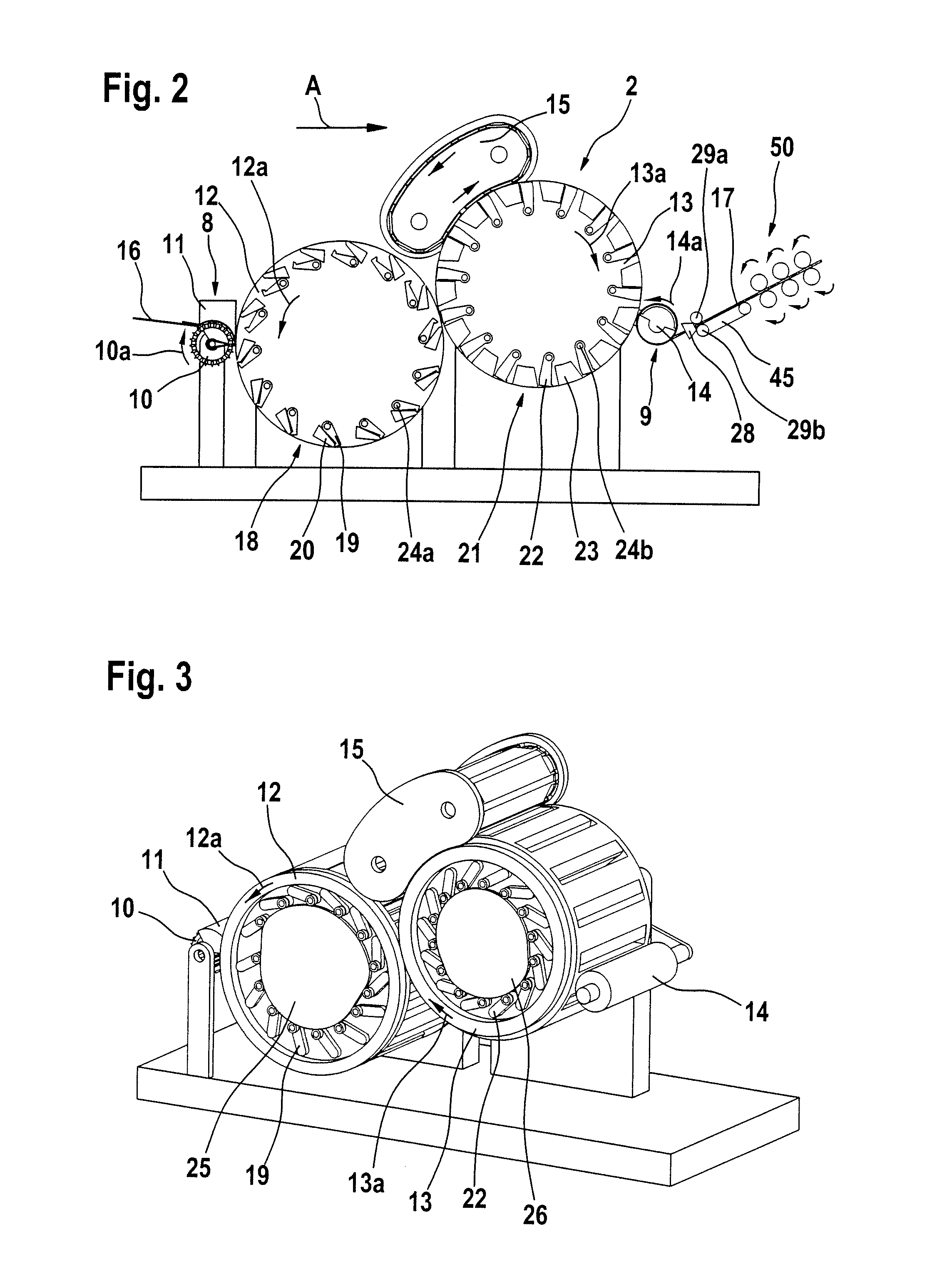

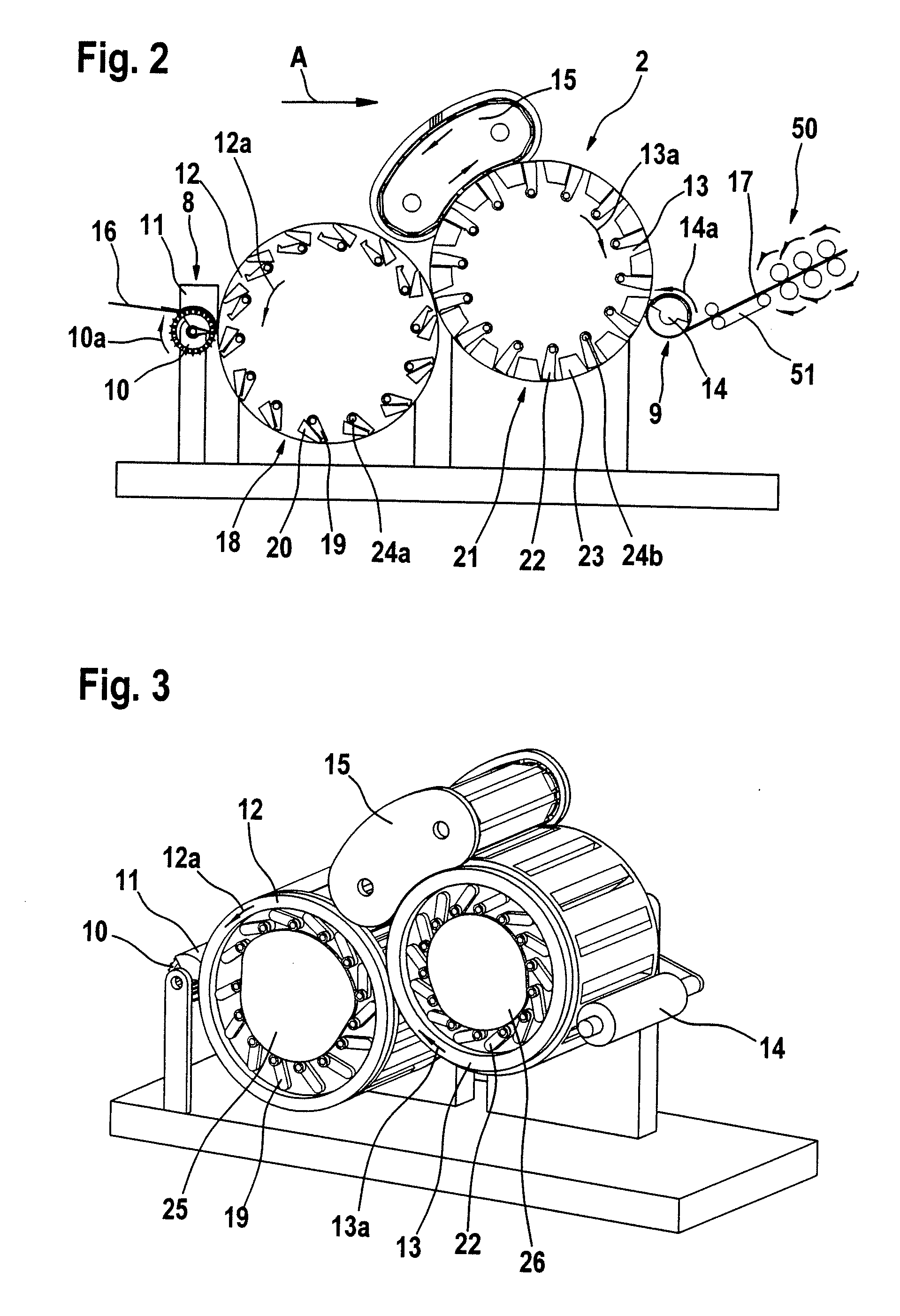

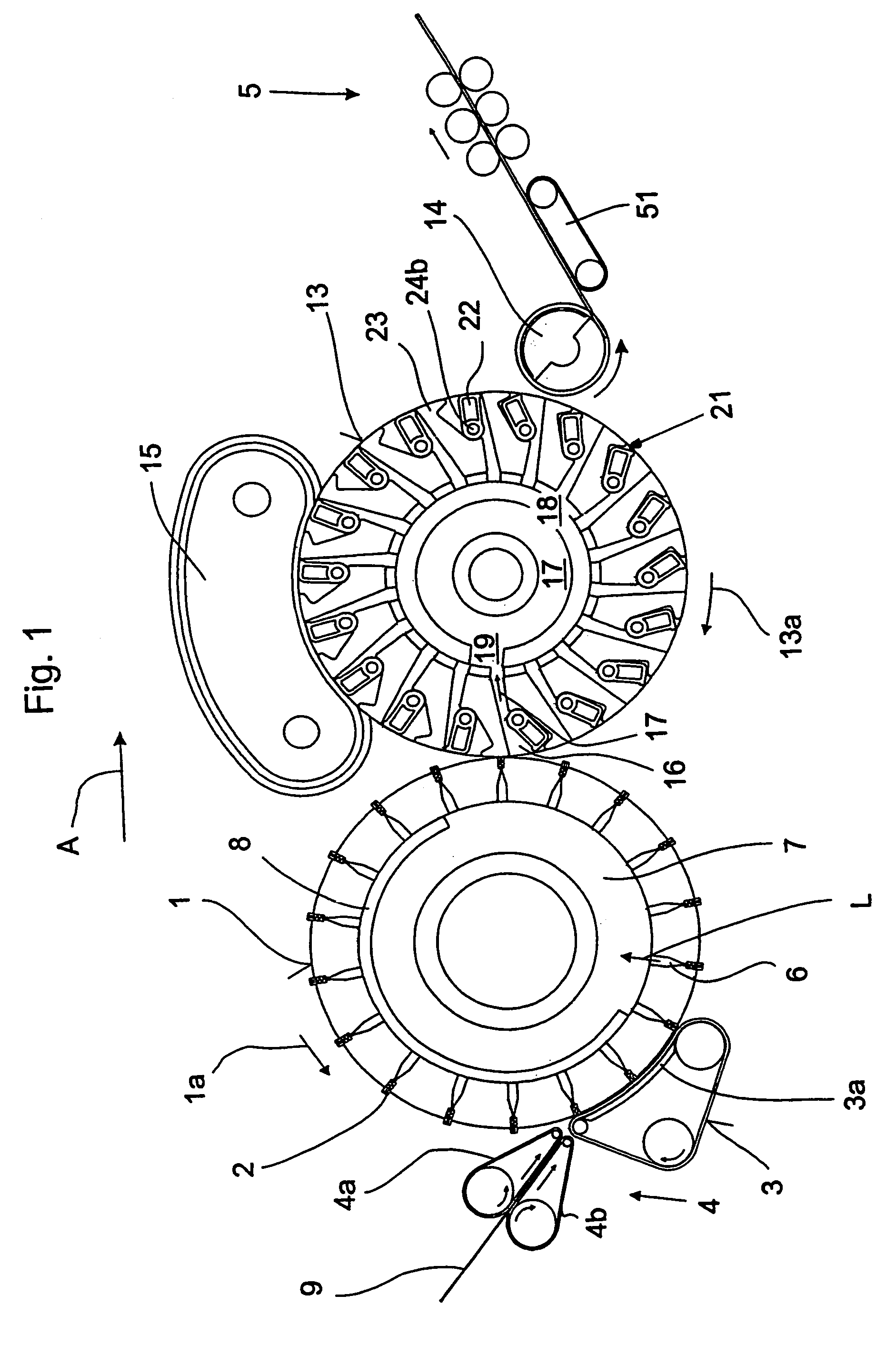

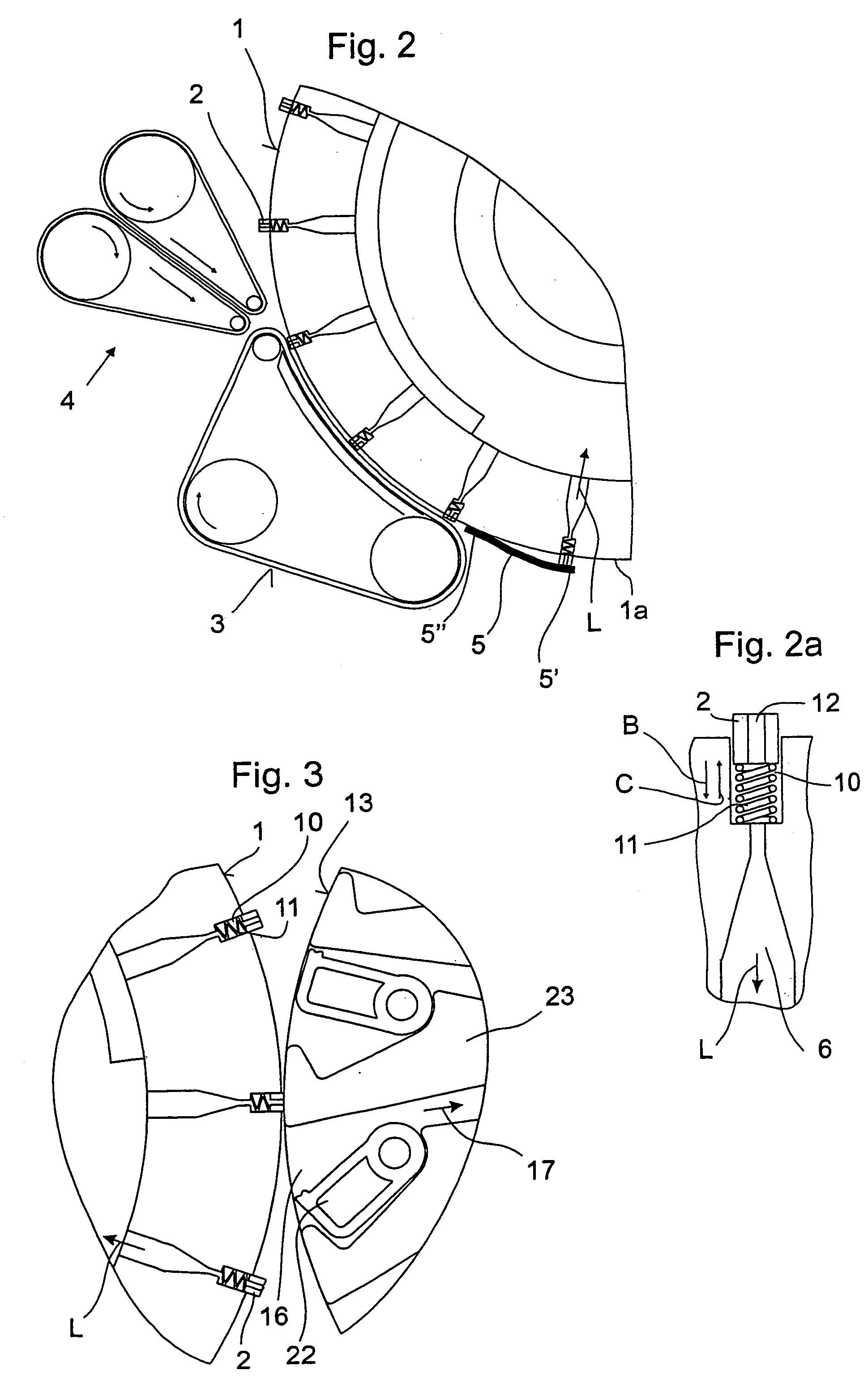

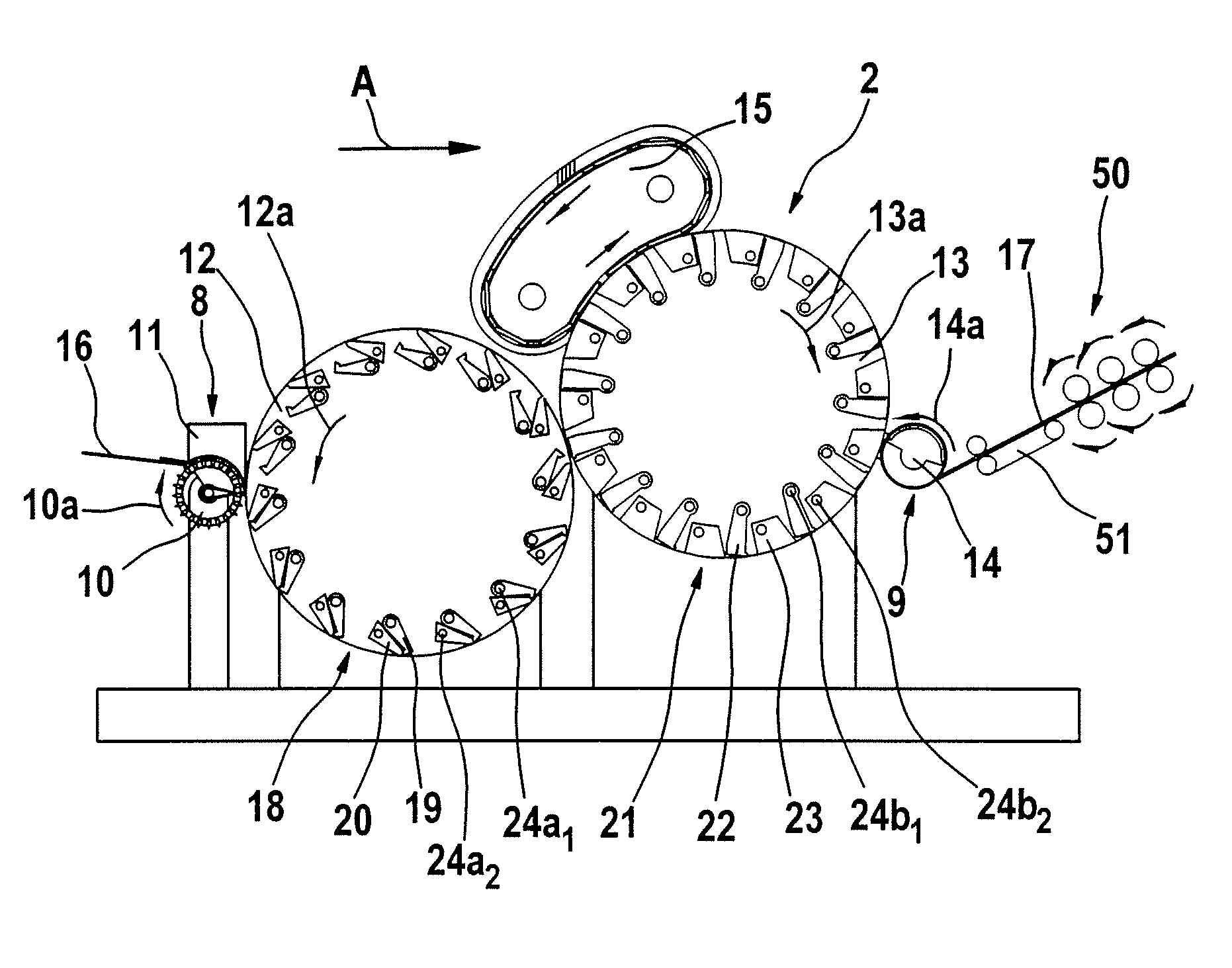

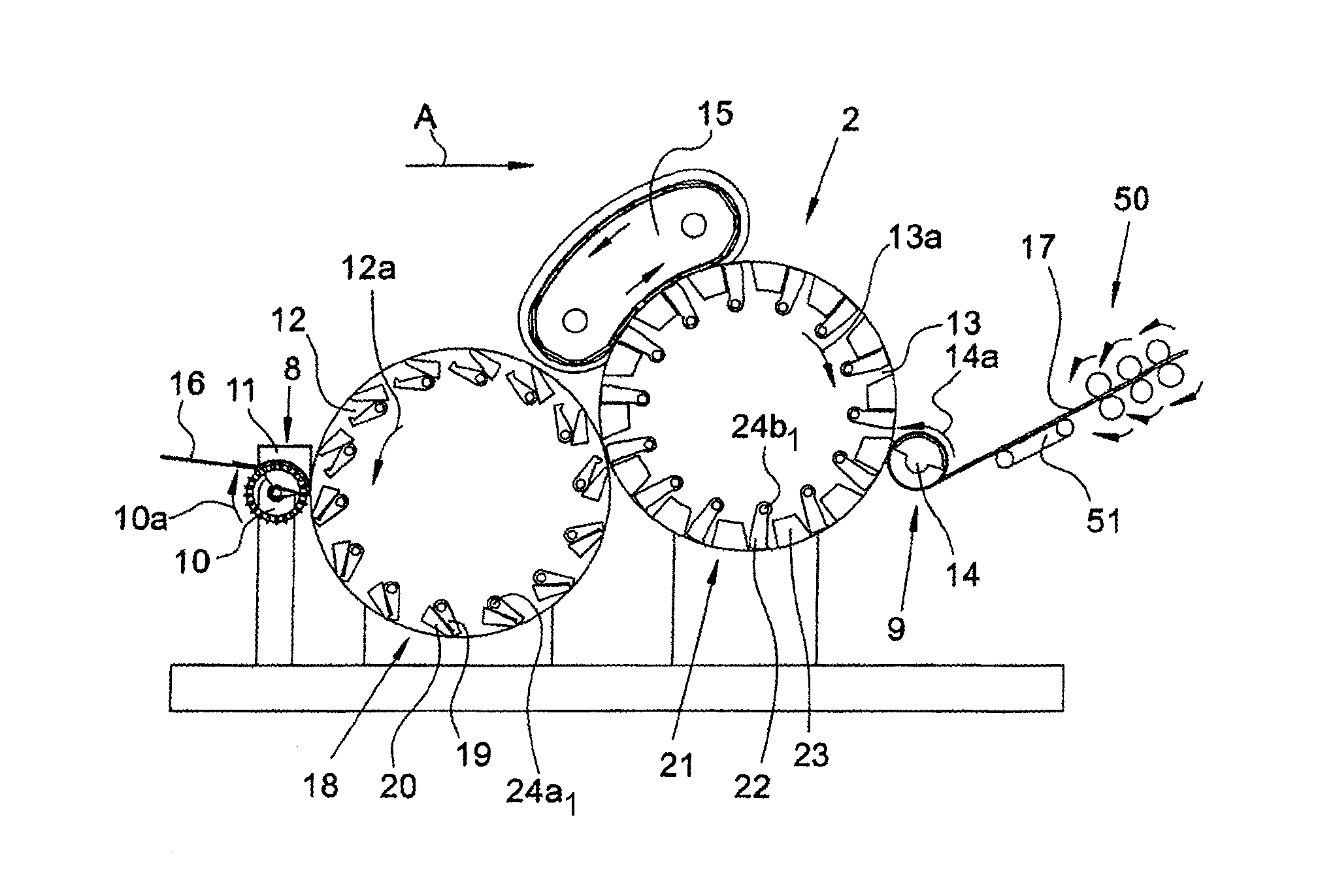

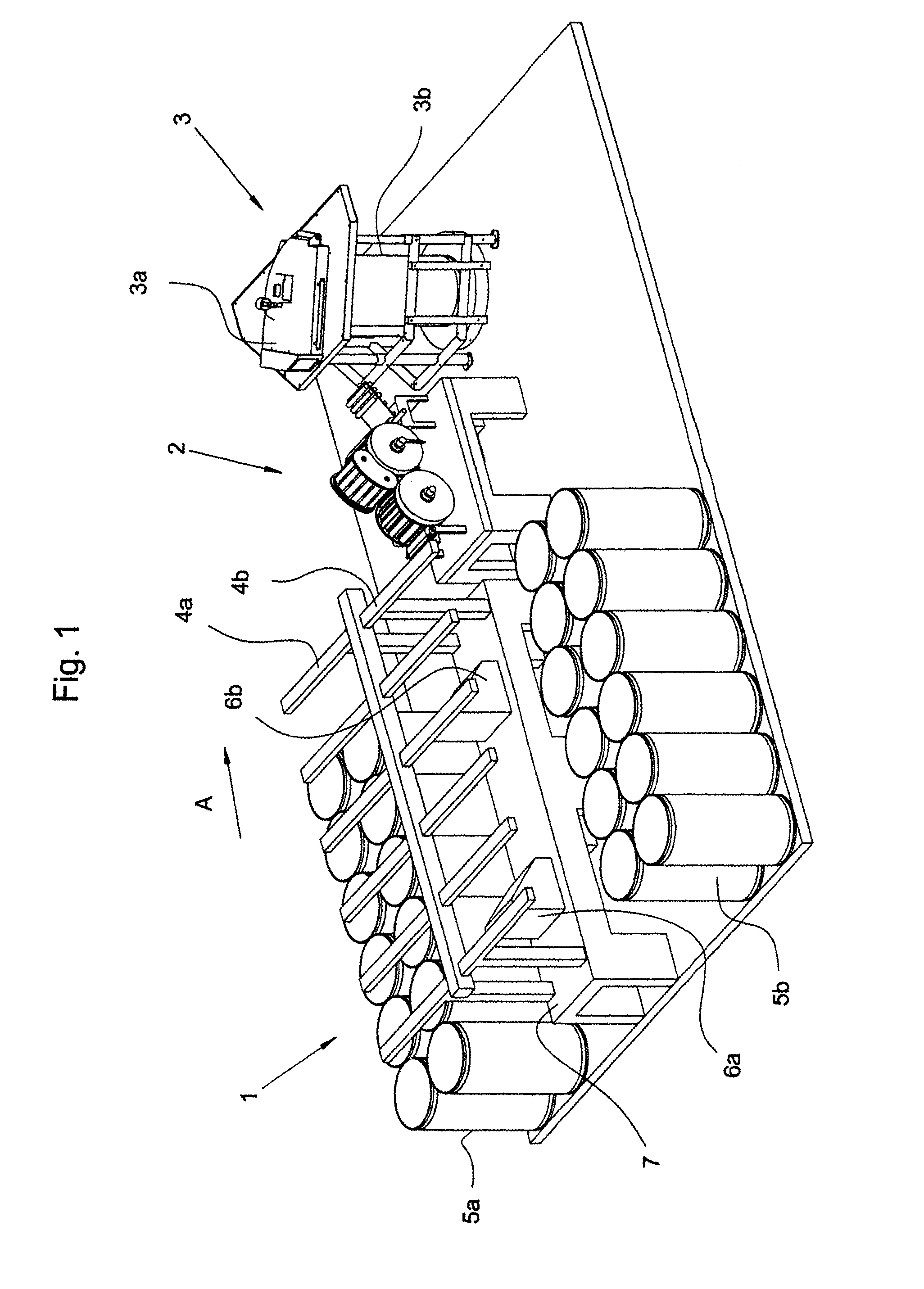

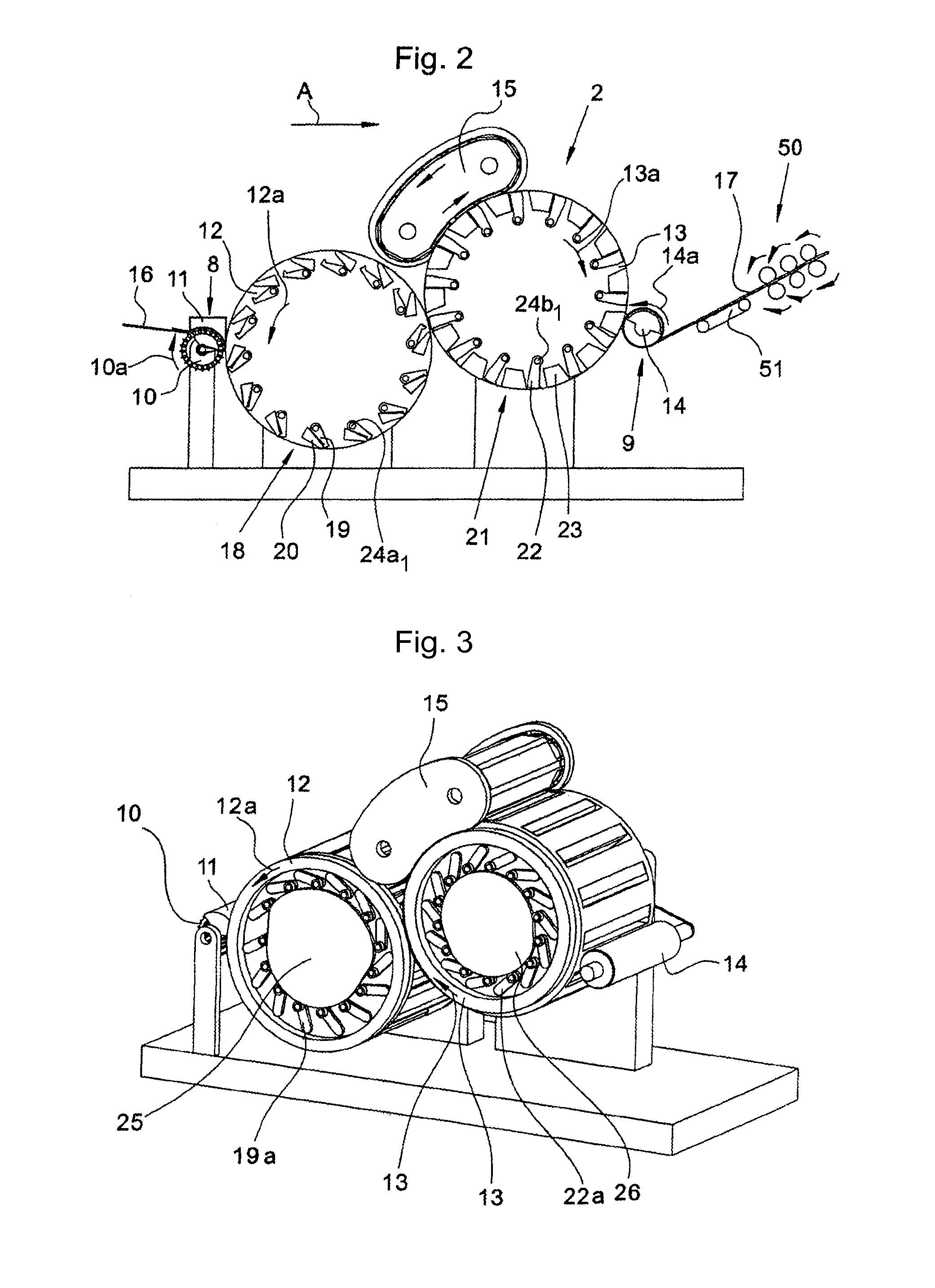

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action in order to loosen and remove non-clamped constituents from the fibre bundle, and a take-off device is present to remove the combed fibre material. To enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, which clamping devices are distributed around the periphery of the rollers, wherein in the region between the rollers, devices are present which provide an optimum feed of the fibre material and / or provide optimum positioning of the fibre material for transfer and take-up from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000067A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

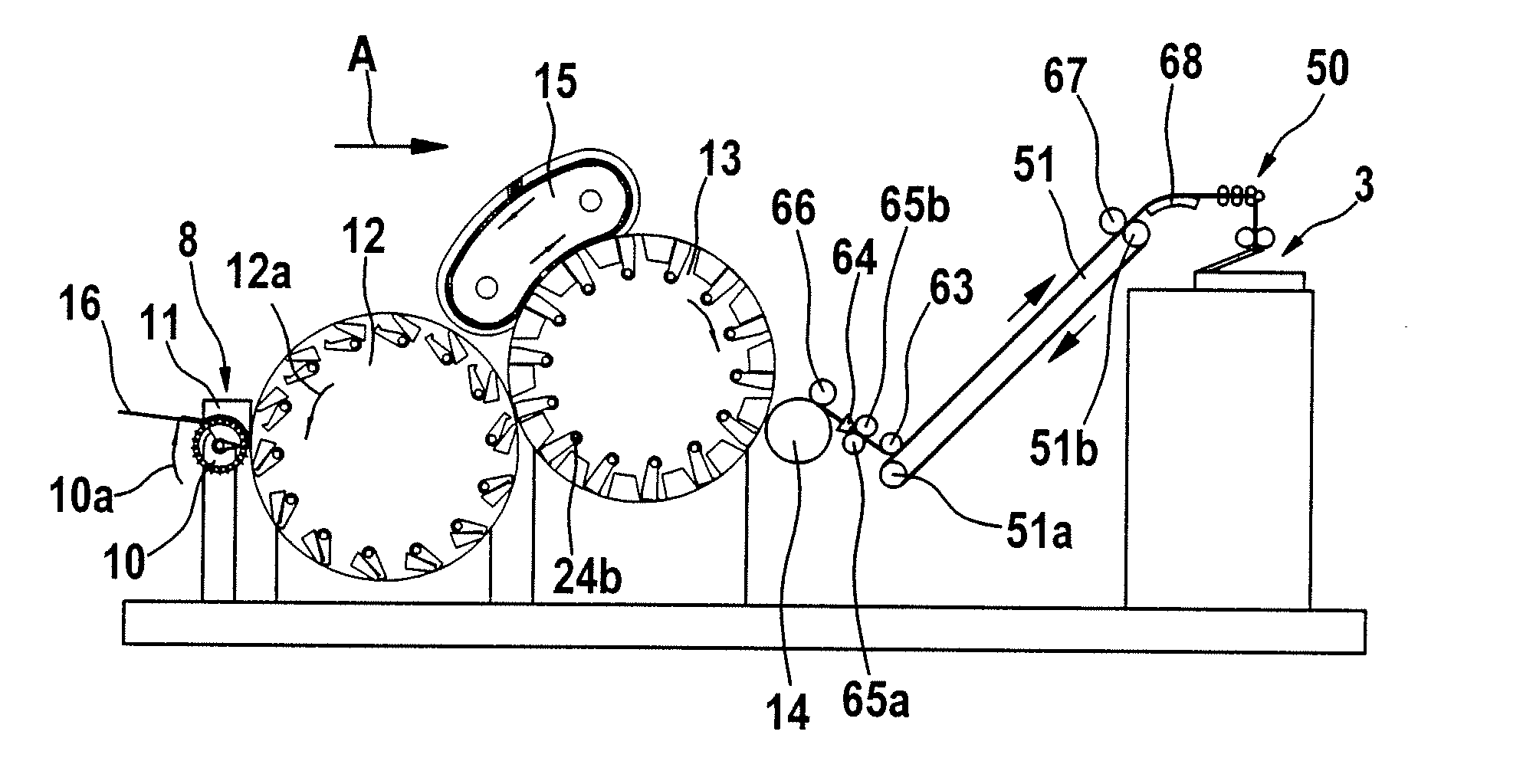

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of a supply device to a fibre-sorting device, especially a combing device, for removal of the combed fibre material at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices for the fibre bundle, and between the sliver-forming element and the drafting system at least one conveyor element for a formed combed sliver is present.

Owner:TRUETZSCHLER GMBH & CO KG

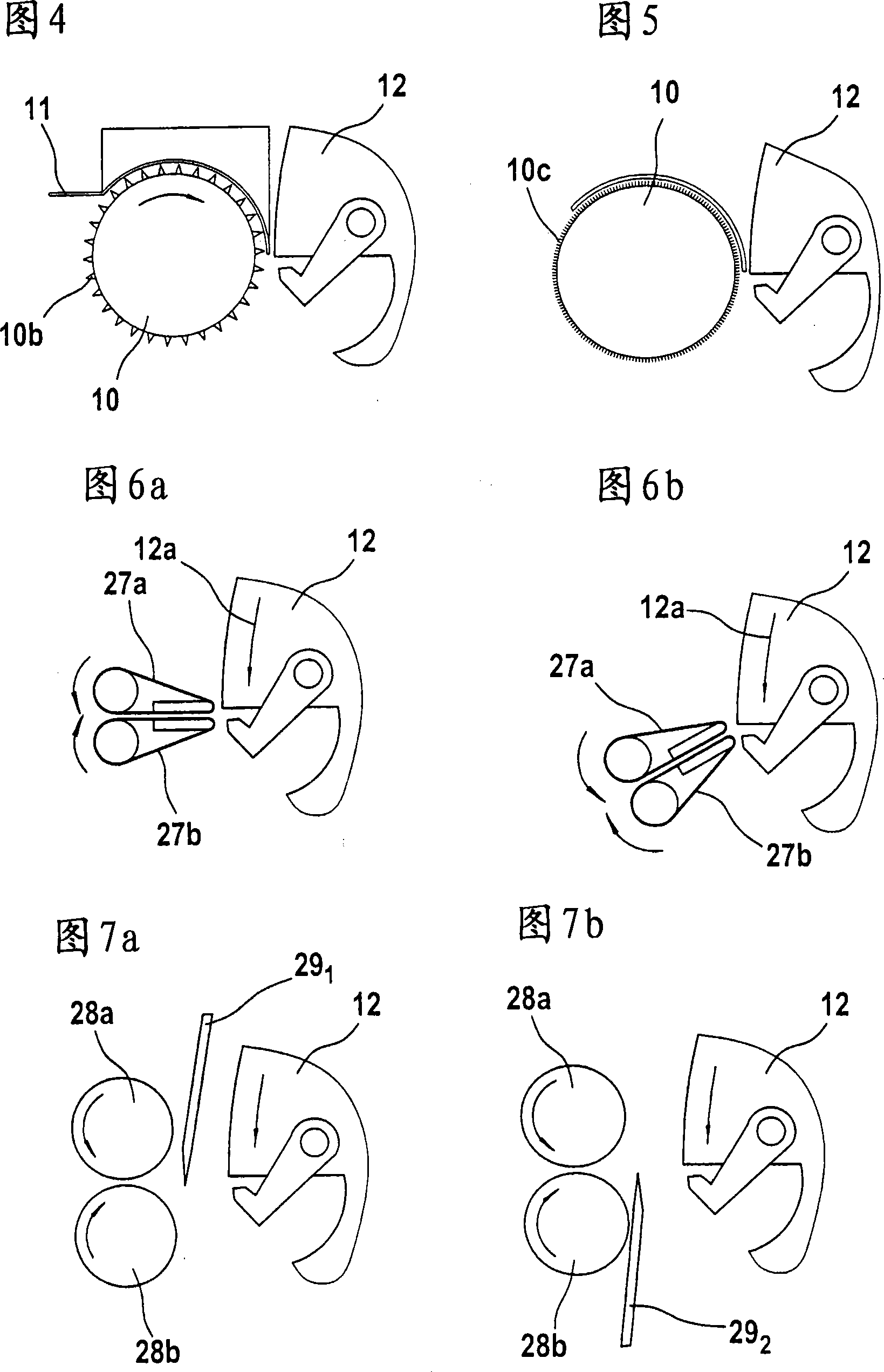

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000077A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part at least partially of a lightweight material. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000072A1Increase volumeImproved combed sliverCombing machinesProduction rateFiber bundle

In an apparatus for fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, the fibre bundle is supplied to a fibre-sorting device, clamping devices are provided, which clamp the fibre bundle at a distance from its free end, and mechanical device is present, which generates a combing action from the clamping site to the free end of the fibre bundle. To increase productivity in a simple manner and obtain an improved combed sliver downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, the combing device are associated with a said roller, and an arrangement for optimum feed and / or positioning of the fibre material to be combed is associated with the combing device.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000066A1Improved sliverIncrease volumeCombing machinesCarding machinesFiber bundleEngineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action to remove non-clamped constituents such as short fibres. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the supply device comprises a feed unit, which feed unit comprises a feed roller and at least one feed tray defining a nip between said feed roller and said feed tray, and the retaining force in the nip optimally retains the short fibres completely or substantially completely in the nip during separation of a fibre bundle by said clamping devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

In an apparatus for the fibre-sorting or fibre-selection a fibre bundle which is supplied by means of a supply device to a fibre-sorting device in which clamping devices are provided which clamp the fibre bundle at a distance from its free end, and in which a mechanical device is present which generates a combing action, for removal of the combed fibre material a revolving element is present. To enable the amount produced per hour (productivity) to be substantially increased in a simple manner and to permit a reliable removal and piecing at high production speed, downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre, which clamping devices are distributed around the periphery of at least one of the rollers and the device for generating a combing action is associated with a said roller, wherein after take-up of the free regions of the combed fibre bundles by the revolving element, the clamping of the ends of the combed fibre bundles is terminated.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000065A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device for removal of the combed fibre material at least one take-off means with a sliver-forming element is present, downstream of which is a drafting system to enable productivity to be substantially increased and an improved combed sliver to be obtained, downstream of the supply device there is arranged at least one rotatably mounted roller rotating rapidly without interruption, which is provided with clamping devices for the fibre bundle, which clamping devices are distributed spaced apart in the region of the periphery of the roller and the combed sliver formed is arranged to be supplied directly to the drafting system.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the Fibre-Sorting or Fibre-Selection of a Fibre Bundle Comprising Textile Fibres, Especially For Combing

InactiveUS20090000070A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateMechanical engineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of supply means to a fibre-sorting device, at least one mechanical device is present which generate a combing action to remove non-clamped constituents such as short fibres. To enable productivity to be substantially increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged at least first and second rotatably mounted rollers with clamping devices for the fibre bundles, and the apparatus further comprises at least two supply devices and / or at least one further high-speed roller and / or at least two take-off devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000064A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000068A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, fibre is supplied by a supply device to a fibre-sorting device, especially a combing device. Clamping devices clamp the fibre bundle at a distance from its free end, and a mechanical device combs the free end to loosen and remove non-clamped constituents, for example, short fibres, neps, dust and the like. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices, and measured value sensors for detecting values relating to the fibres or machine settings are connected to a control and regulation device, which is arranged to effect actions in dependence on the measured values.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000079A1Improved sliverIncrease volumeCombing machinesFibre separationProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device, in which a mechanical device is present which generates a combing action to loosen and remove non-clamped constituents, and a clamping element is present for transfer of the supplied fibre material. To enable productivity to be increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged two rotatably mounted rollers, which are provided with clamping devices for the fibre material having clamping elements that are distributed spaced apart in the region of the roller periphery and co-operate with counter-elements, the counter-elements in the case of the first roller being arranged opposite the roller periphery and in the case of the second roller on or in the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000069A1Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is suppled by a supply device to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and the clamping jaws of the each clamping device are arranged to be movable in relation to one another and separately drivable.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of fibre bundle comprising textile fibres, especially for combing

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, and a mechanical device is present which generates a combing action to remove non-clamped constituents such as short fibres, a clamping element is present. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the device for generating a combing action is associated with a said roller, wherein for the suction of the supplied fibre bundles, at least one suction device is associated with the clamping devices in the region of the transfer of the fibre bundle from the supply device to the first roller and / or in the region of the transfer of the fibre material from the first roller to the second roller.

Owner:TRUETZSCHLER GMBH & CO KG

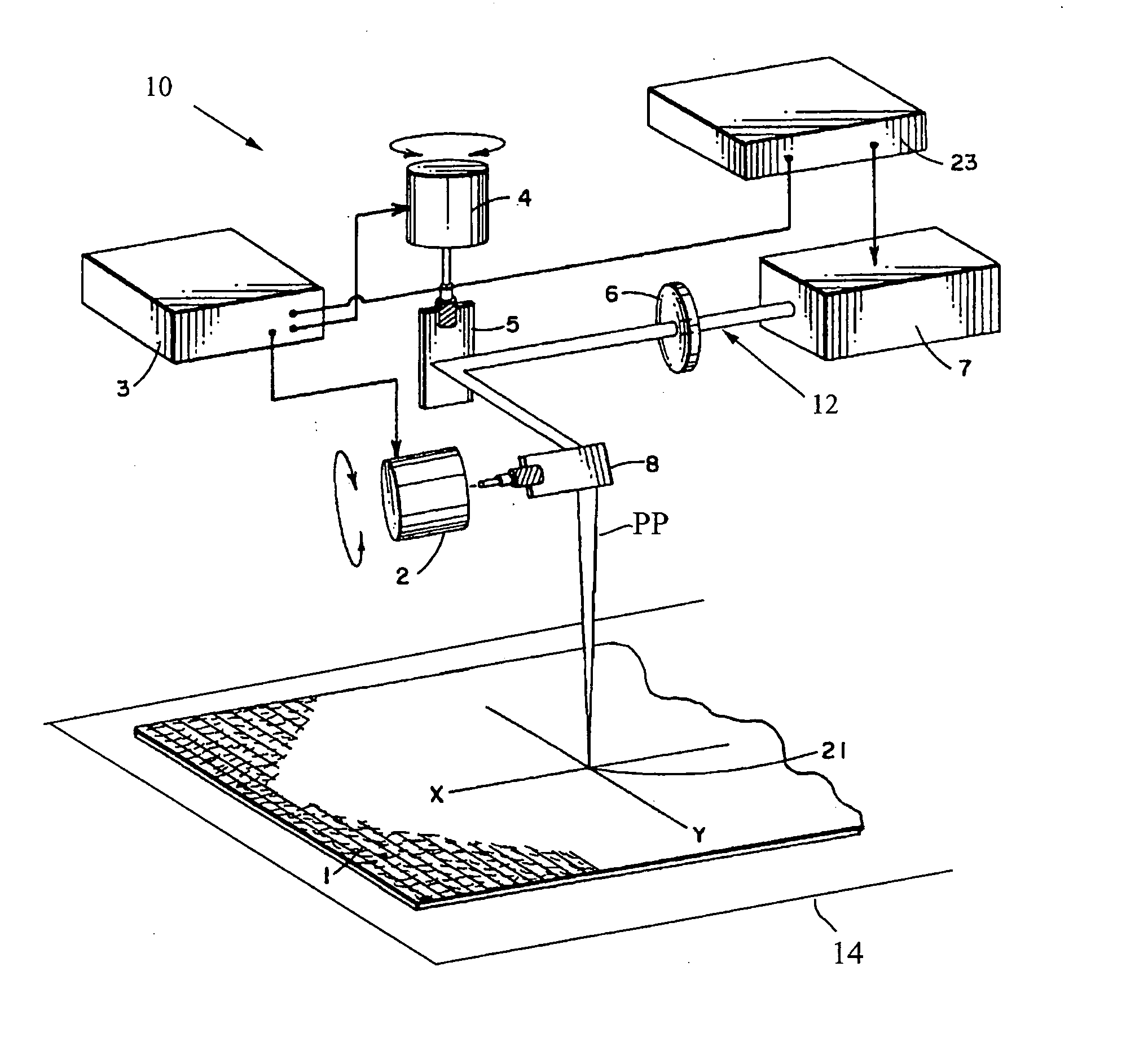

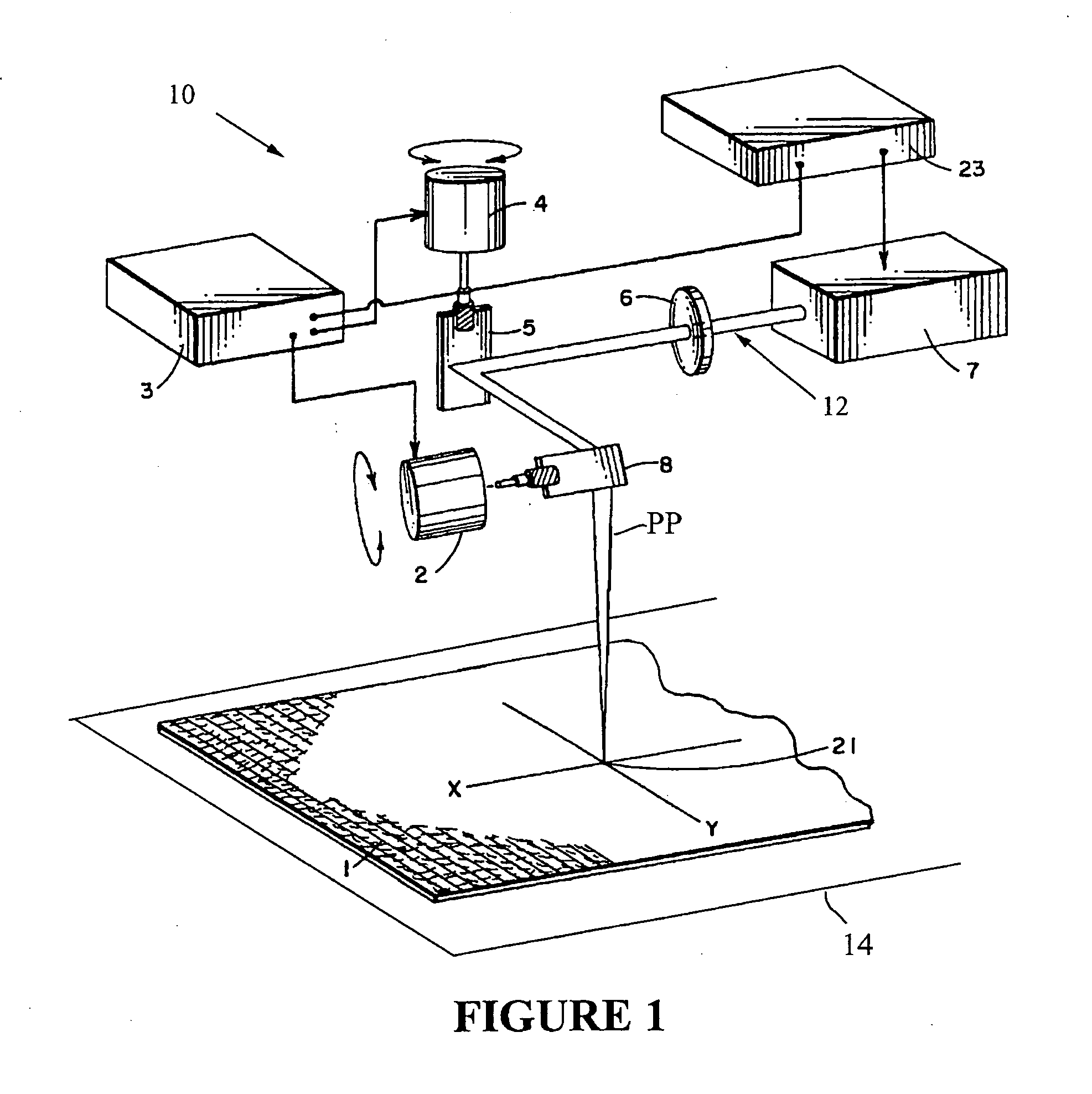

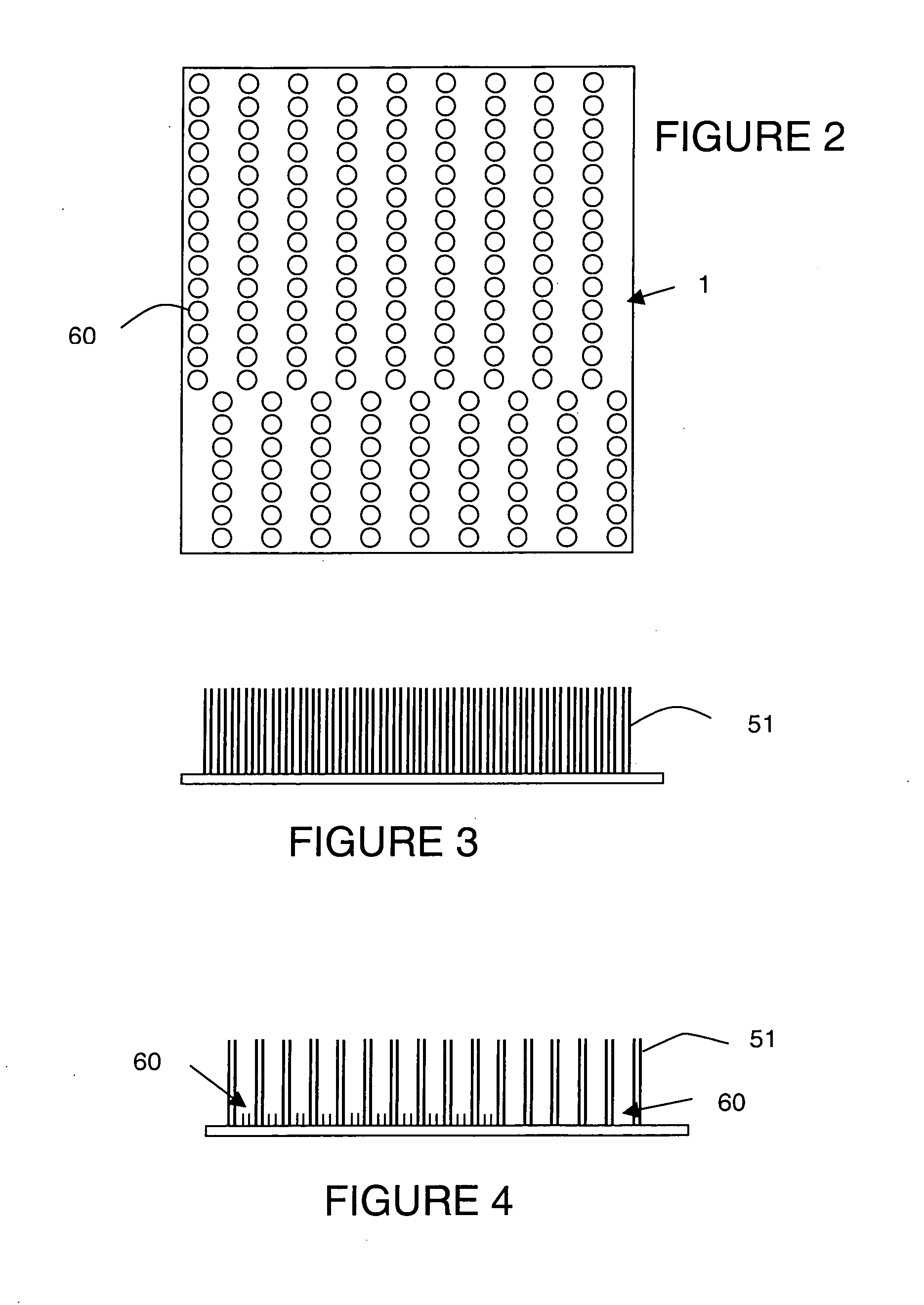

Selectively altering a fiber height in a pile fabric and apparatus

A region of a pile fabric is impacted with a laser at spaced illuminated areas in a dithered image, wherein the laser energy and duration of impact in the illuminated areas are selected to shorten the fibers within the illuminated area. The spacing of the illuminated areas within the region and the amount of shortening within the illuminated areas are selected to essentially maintain a hand or feel of the pile fabric. Fleece and corduroy can be sculpted to provide a three-dimensional image, while maintaining the hand of the fleece. In dyed pile fabrics, the illuminated areas can be selected to change the dye distribution within the pile material to provide an altered coloration.

Owner:ICON TEXTILE LASER SYST

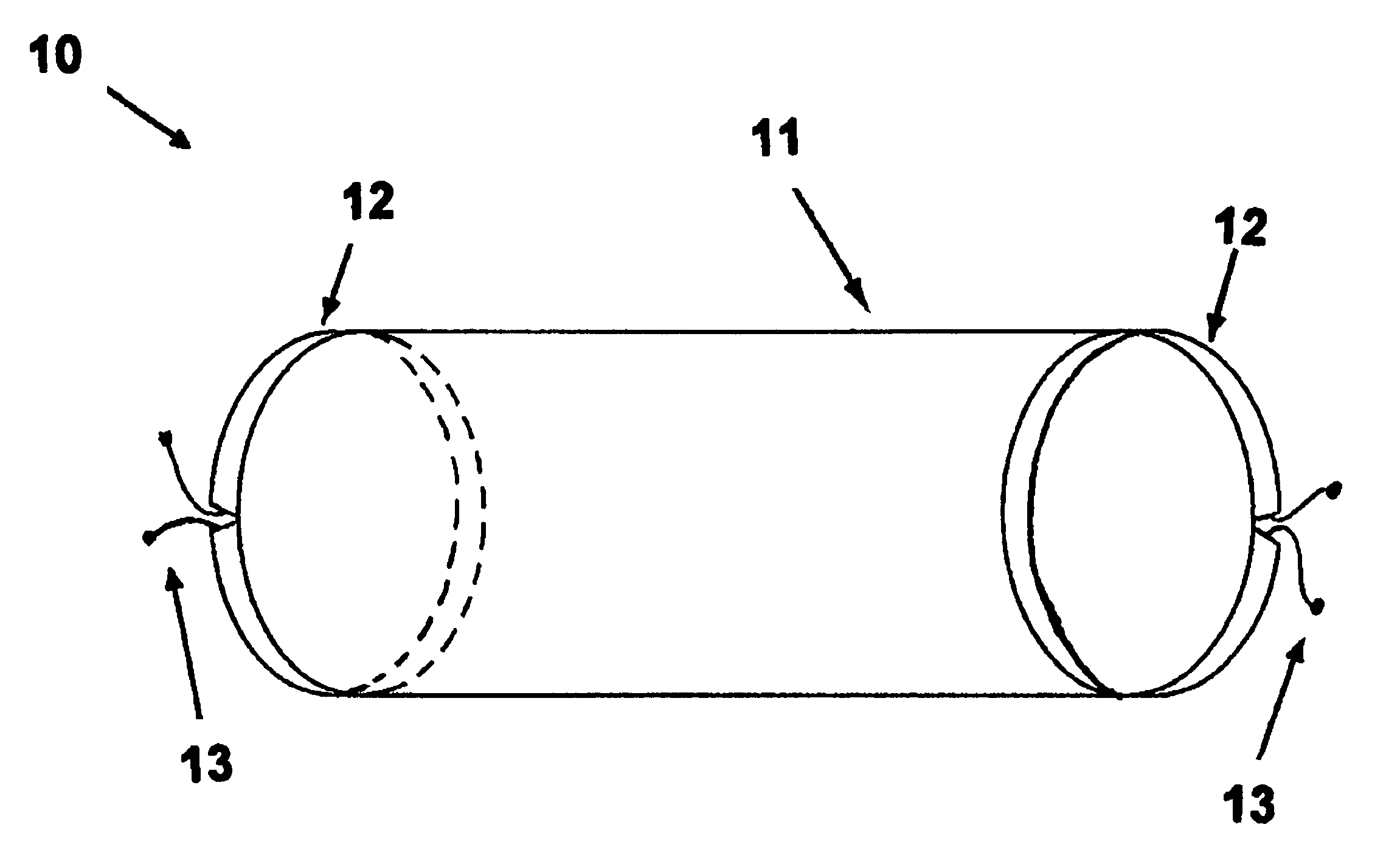

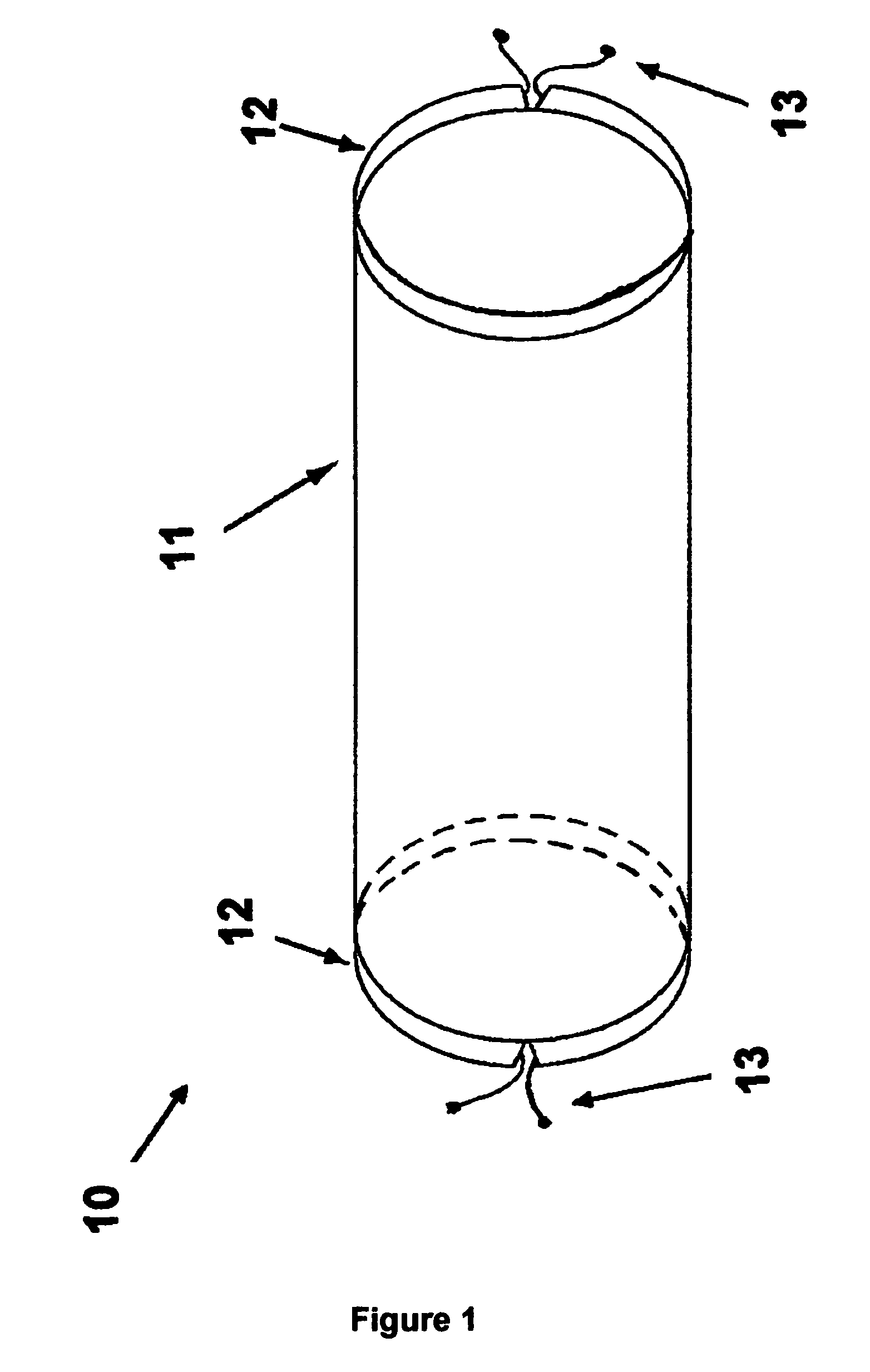

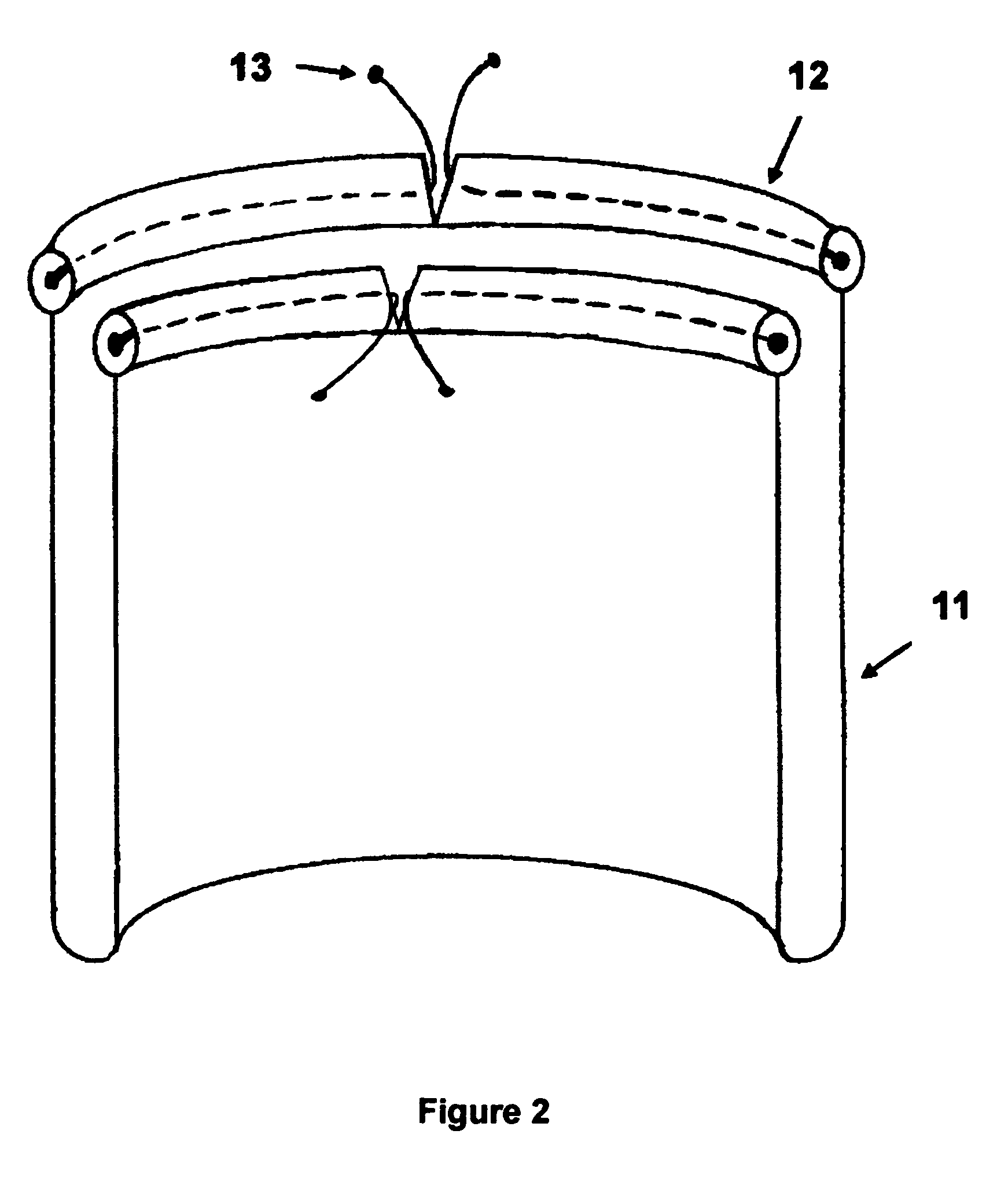

Apparatus and method for washing fibers

An apparatus for washing or otherwise wet-processing natural fibers in loose or “bulk” form comprises a generally cylindrical bag having cinch-type closures at both ends. The bag is doubled upon itself to form a generally annular cavity for holding the fibers. The inner cinch secures the first opening of the bag above the agitator of a conventional washing machine. After the fibers are placed into the bag, the outer cinch is secured, also above the agitator, thereby containing the fibers during selected washing or rinsing operations. The mesh size of the bag is selected to provide adequate fluid flow through the fibers while minimizing loss of the fibers or clogging of the plumbing. The two cinches are preferably tied together so that the bag and contents may be easily handled as a unit and hung as a unit for air drying.

Owner:STONE DAWIN W

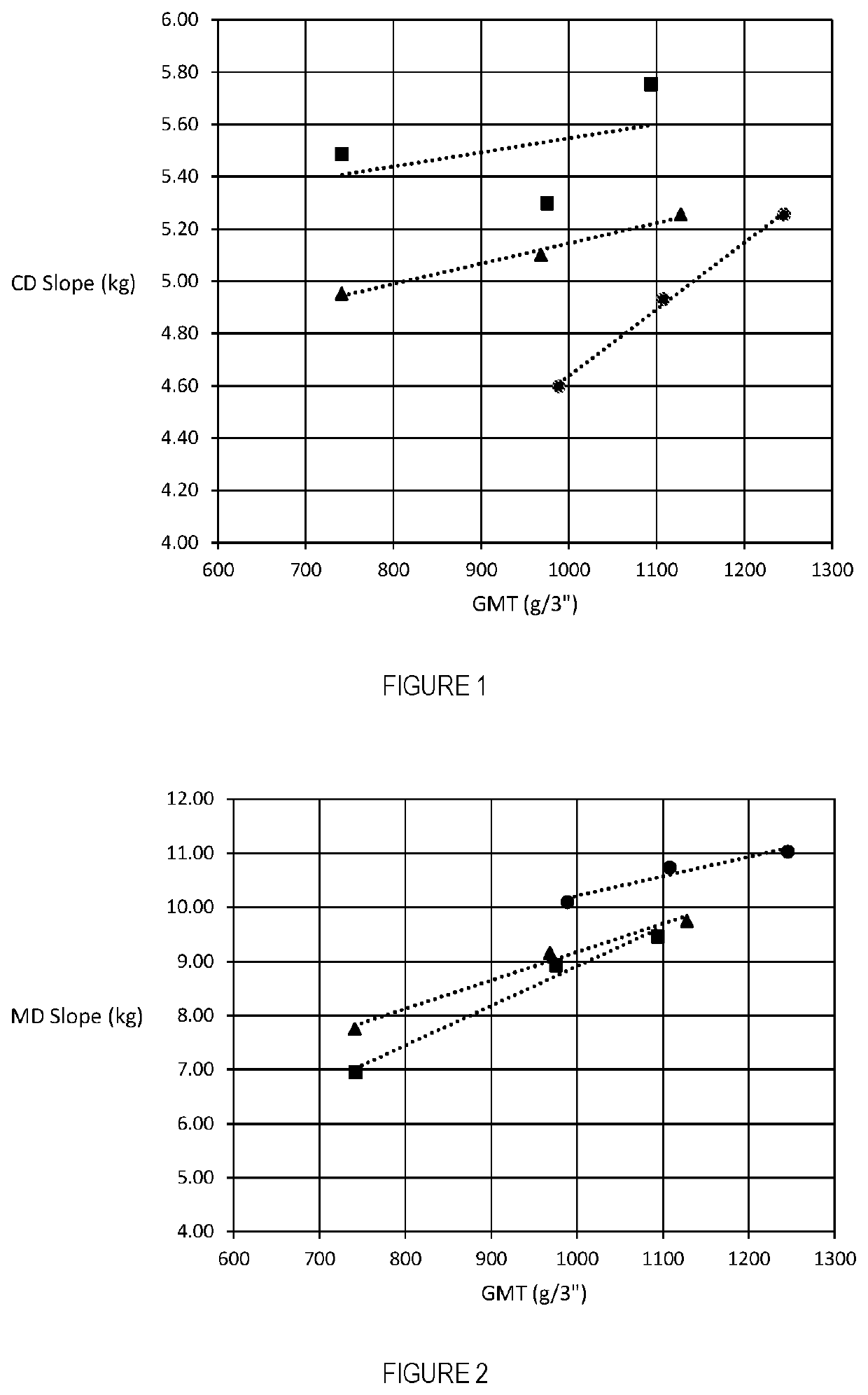

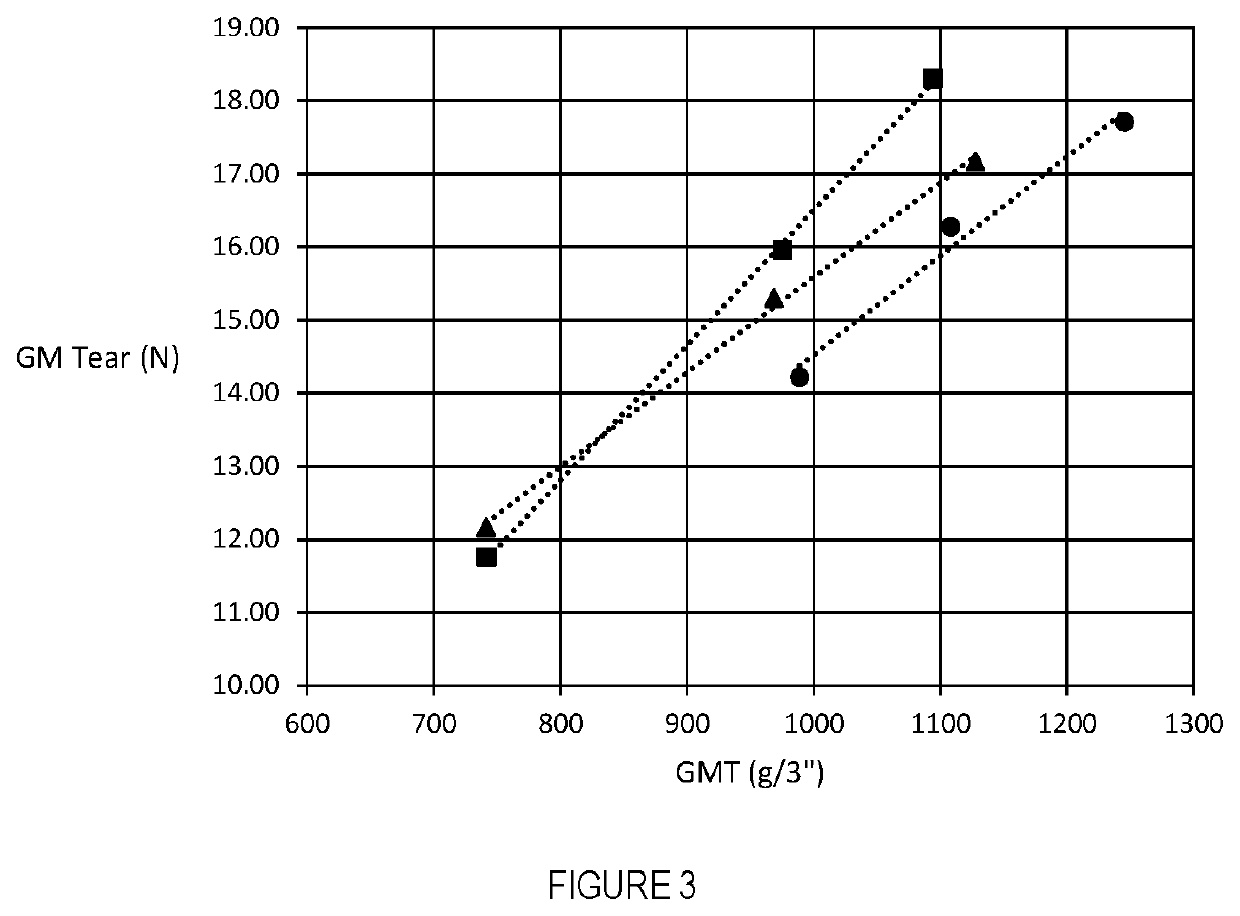

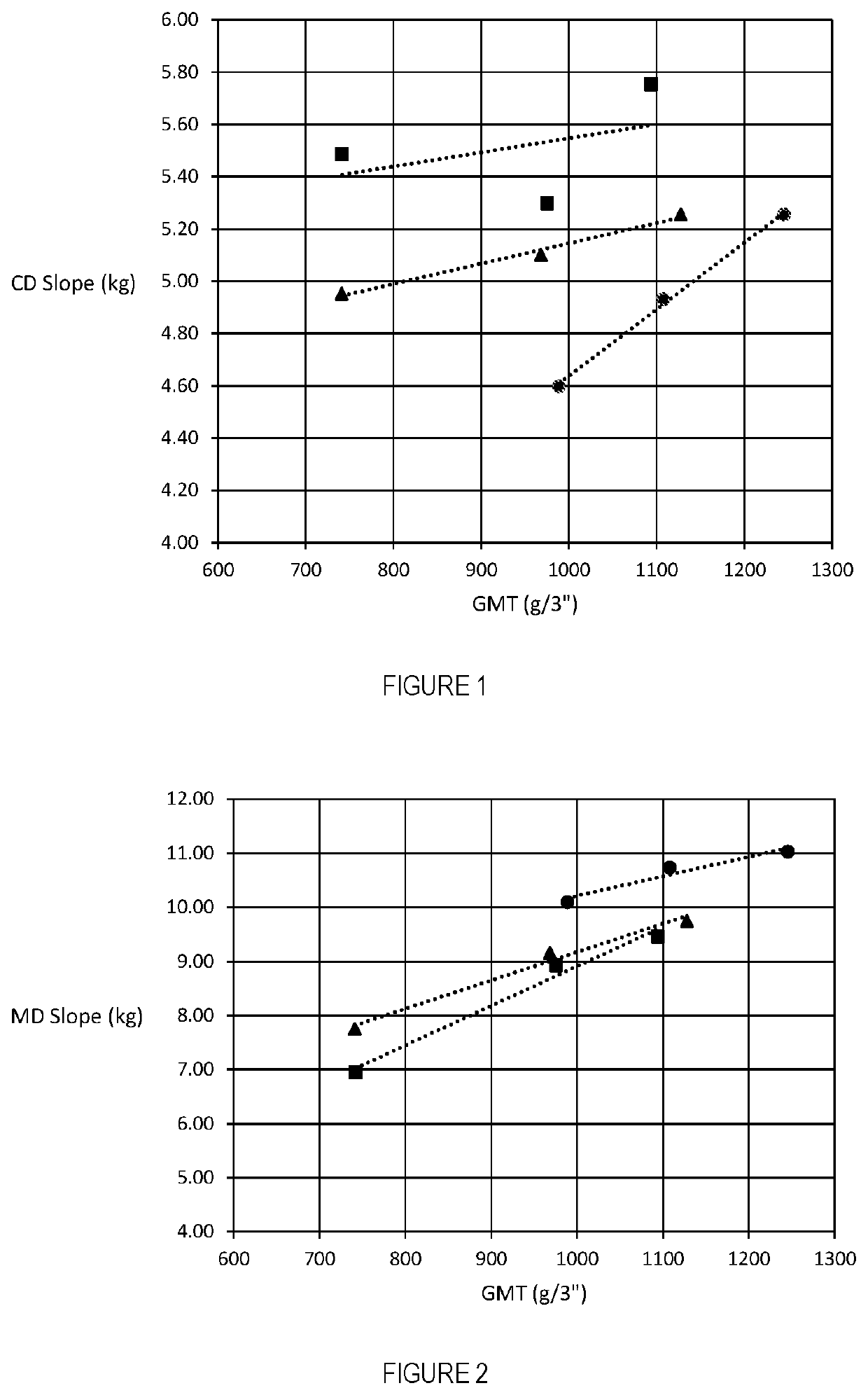

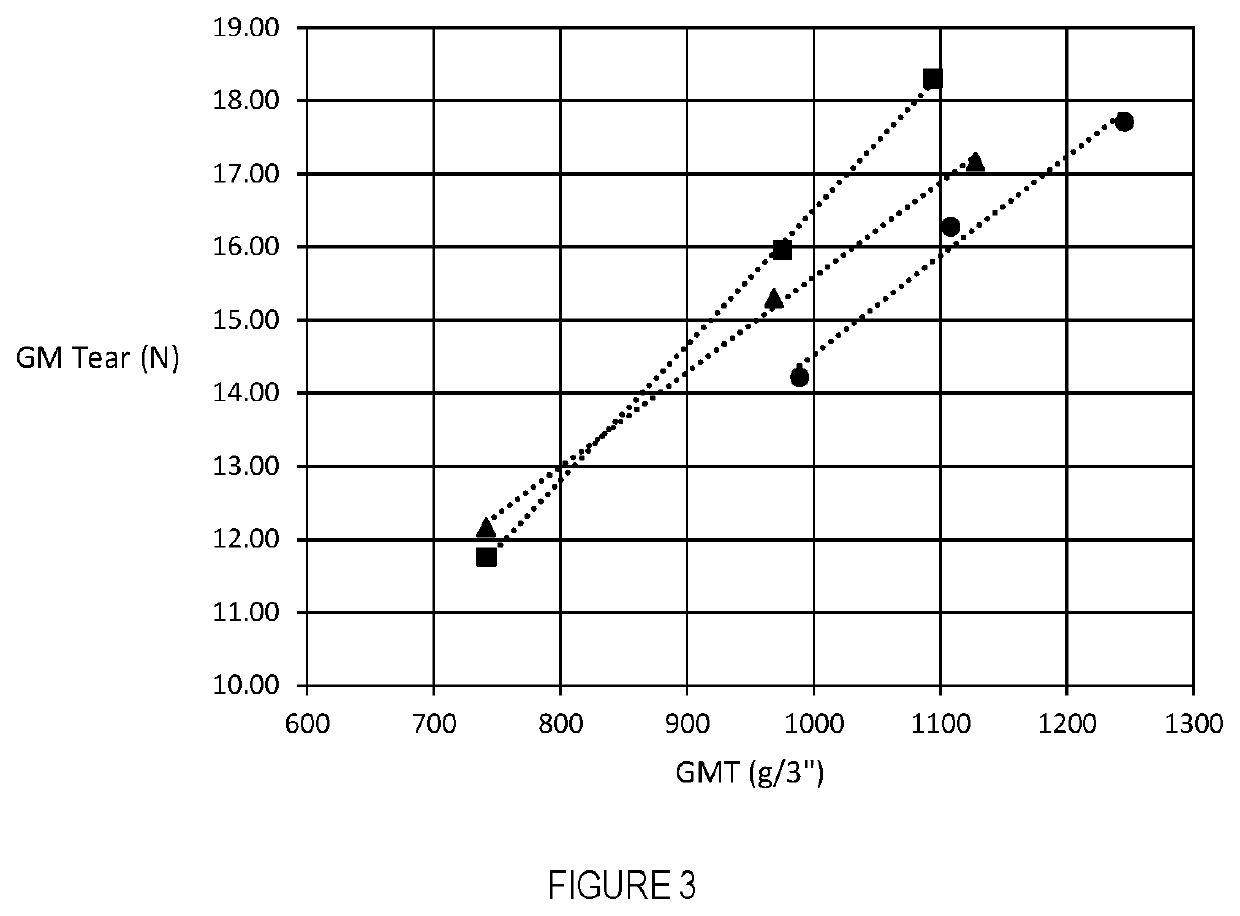

Layered tissue comprising non-wood fibers

The present invention provides multi-layered tissue webs, and tissue products comprising the same, the multi-layered webs comprising wood fibers and non-wood cellulosic fibers where the non-wood cellulosic fibers are selectively deposited in one or more outer layers of the multi-layered web. Surprisingly disposing non-wood cellulosic fibers in the outer layers, even in relatively modest amounts, alters the machine and / or cross-machine direction properties of the resulting web, such that MD:CD tensile ratio may be reduced.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Multi-functional knit fabric with enhanced insulating properties

InactiveUS20020102895A1Easy temperature adjustmentMaintained relatively longLayered productsWoven fabricsEngineeringPhase change

A fabric for use in outdoor apparel is disclosed comprising an insulating layer including a multitude of cross fibers disposed between exterior fabric layers, the combination of which creates a temperature regulating material suitable for maintaining a comfortable body temperature in environments where the ambient temperature is low. The fabric is created using a double needle bar knitting technique which allows several fiber choices to be incorporated into a single fabric sample and infuses the enclosed, insulating layer with a multitude of air spaces helpful in the insulating process. In addition to air spaces, the invention uses phase change technology in the insulating layer to regulate and stabilize the temperature of the air spaces that exist between the cross fibers, thus producing a thermal regulation effect greater than would be possible if either technology were used alone.

Owner:WILLARD WILLIAM F

Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

InactiveCN101165239AIncrease supplyEasy to separateCombing machinesCarding machinesTextile fiberMechanical engineering

An apparatus is used for carrying out fiber finishing or fiber selecting on fiber strip. Especially in an apparatus for combing, the fiber strip is supplied to a fiber finishing device by supply device; especially the combing device includes clamping device clamping the fiber strip on the certain distance far away from the free end thereof, a device for generating combing effect from clamping point to the free end of the fiber strip to loose and remove nor-clamping composition, such as short fiber, hair knot, dust and so on from the free end. At least one roller capable of rotating is installed on the upstream of the supply device in order to improve the amounts (productivity) generated each hour and obtain improving fiber strip. The clamping equipment used in the fiber strip is set on the roller, the periphery of which is distributed with interval around the stone roller. And the device (combing element) for generating combing effect is connected with the periphery of the roller.

Owner:TRUETZSCHLER GMBH & CO KG

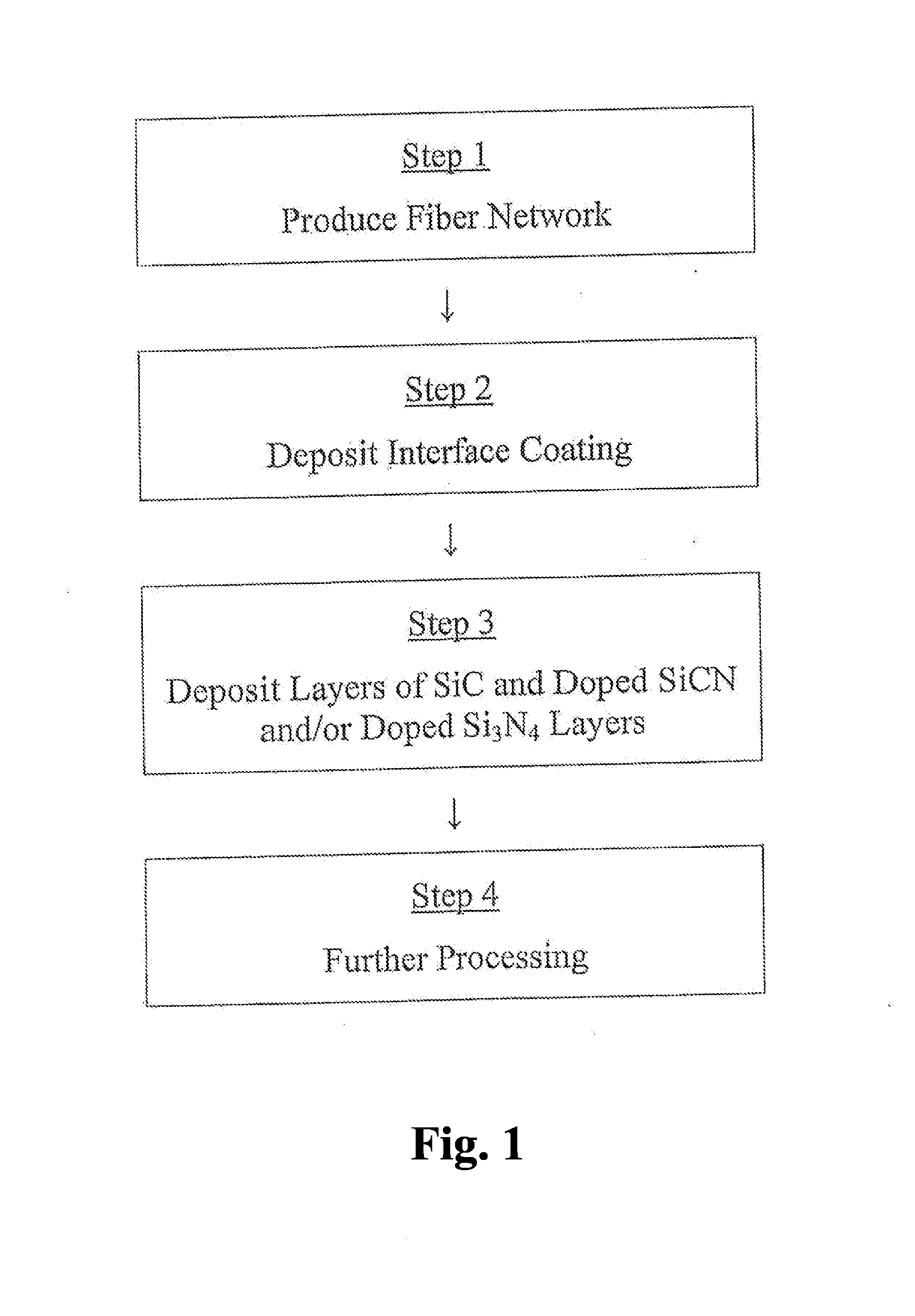

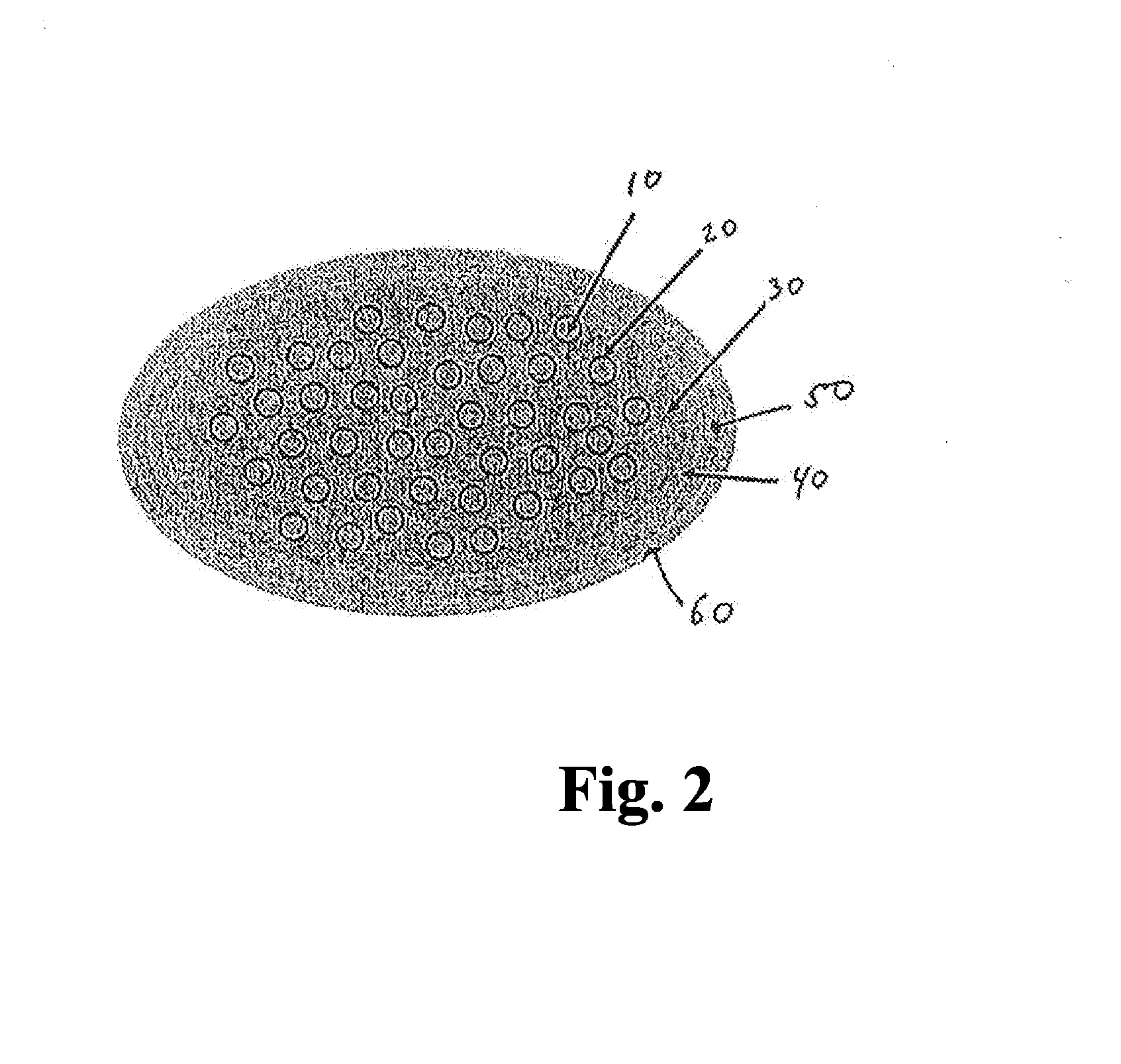

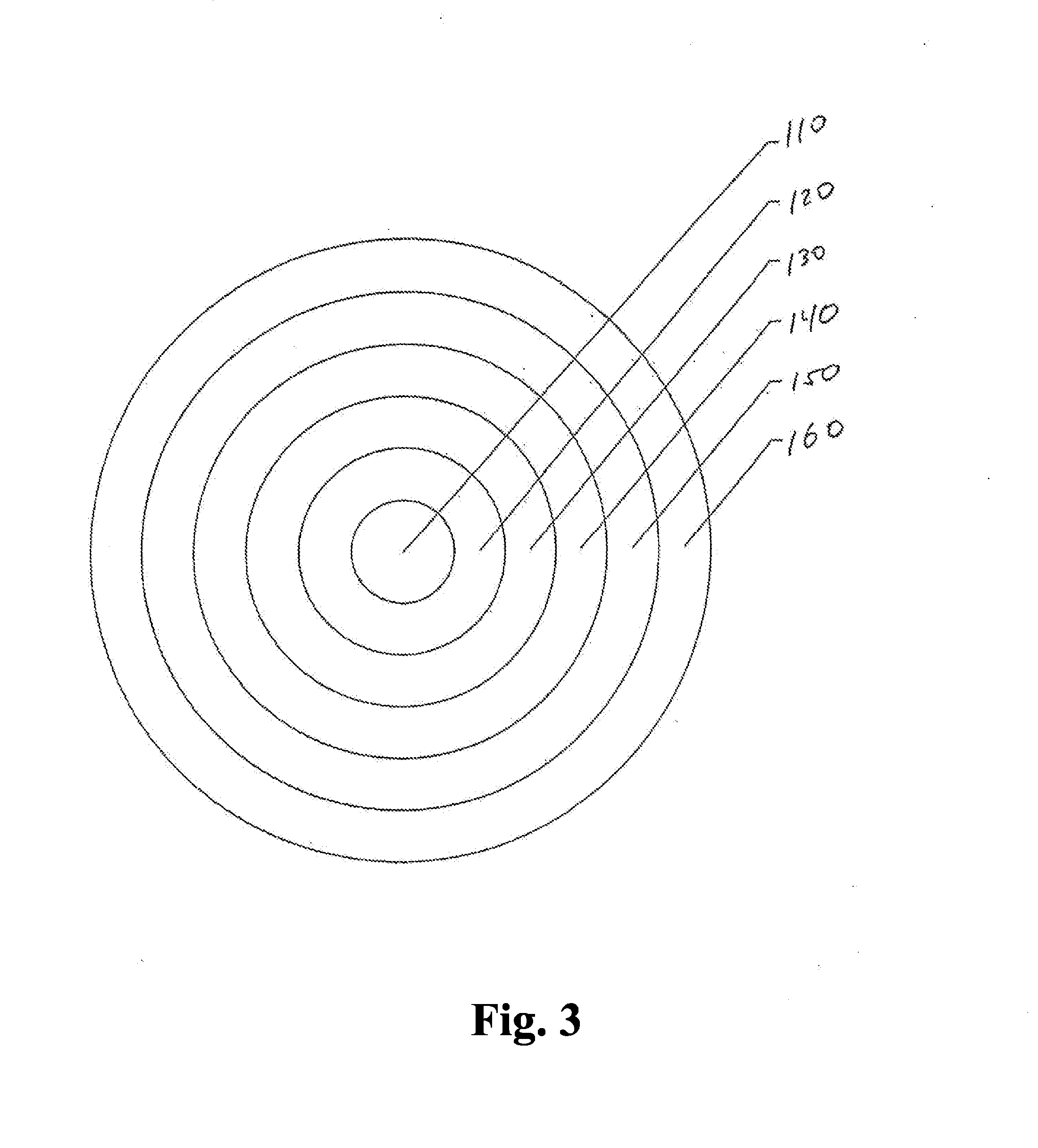

Ceramic matrix composites and methods for producing ceramic matrix composites

A ceramic matrix composite includes a plurality of fibers embedded in a matrix. The composition of the matrix is selected to achieve a desired relationship between the mechanical and thermal properties of the matrix and the fibers.

Owner:ROLLS ROYCE CORP

Layered tissue comprising non-wood fibers

ActiveUS20200232166A1Improve propertiesPaper/cardboardTissue/absorbent paperCellulosePolymer science

The present invention provides multi-layered tissue webs, and tissue products comprising the same, the multi-layered webs comprising wood fibers and non-wood cellulosic fibers where the non-wood cellulosic fibers are selectively deposited in one or more outer layers of the multi-layered web. Surprisingly disposing non-wood cellulosic fibers in the outer layers, even in relatively modest amounts, alters the machine and / or cross-machine direction properties of the resulting web, such that MD:CD tensile ratio may be reduced.

Owner:KIMBERLY-CLARK WORLDWIDE INC

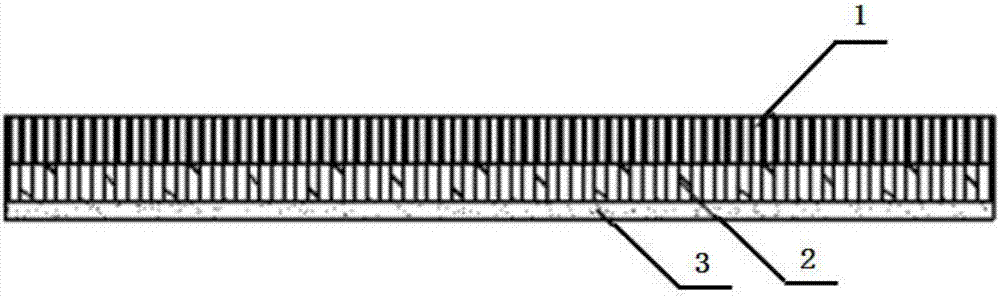

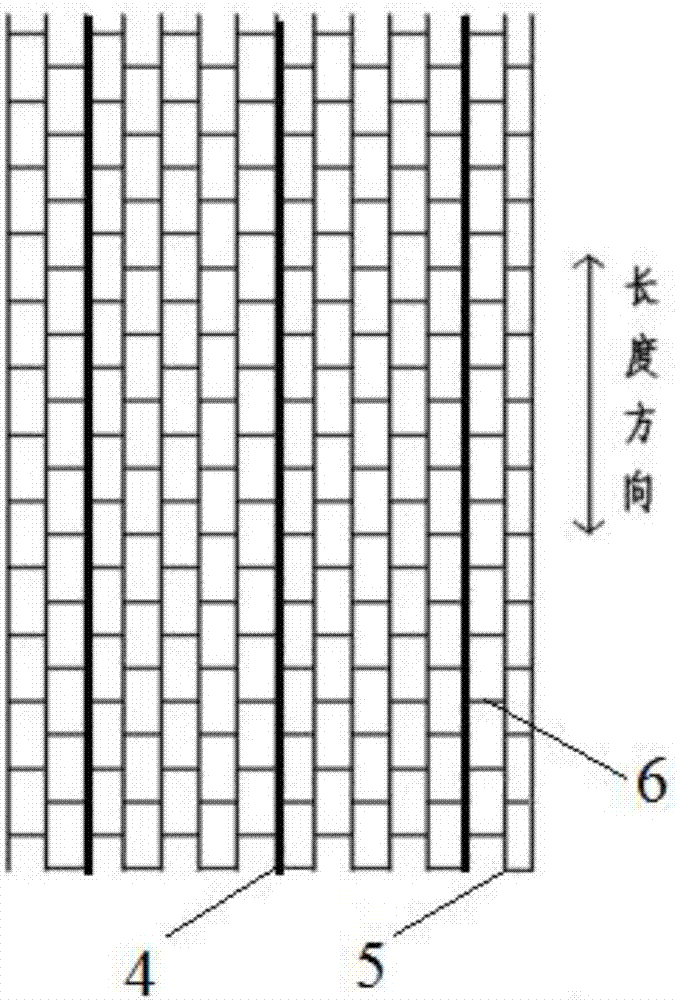

Compound optical fiber fabric layer and compound optical fiber sheet and compound optical fiber adhesive tape containing the same

PendingCN107984812AAvoid problems that significantly affect the accuracy of measurement dataSolve the technical problems of efficient compoundingLayered productsWoven fabricsAdhesive beltEngineering

The invention discloses a compound optical fiber fabric layer and a compound optical fiber sheet and a compound optical fiber adhesive tape containing the same. The compound optical fiber fabric layeris formed by mixing and weaving optical fibers and fibers. A preparation method of the compound optical fiber fabric layer comprises the steps of optical fiber and fiber selection, distribution density and weaving tightness design, longitudinal laying method, weft weaving, fixing method and the like. The compound optical fiber sheet contains the compound optical fiber fabric layer. The compound optical fiber adhesive tape comprises the compound optical fiber fabric layer and further comprises a gauze element layer and an adhesive layer. The preparation method of the compound optical fiber adhesive tape comprises the steps of width design, fiber selection, optical fiber selection, fiber laying method, adhesive tape preparation and the like. The preparation method has the advantage of easiness in operation. The compound optical fiber fabric layer disclosed by the invention has the advantages of simple and reasonable structure design, excellent product performance, long-time load use, stability in monitoring signals, high efficiency and convenience in product production and preparation, large-scale and industrial production, wide application to service monitoring of different areas of material, structures and the like and ability in providing powerful support and technical support for engineering construction, maintenance, monitoring and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

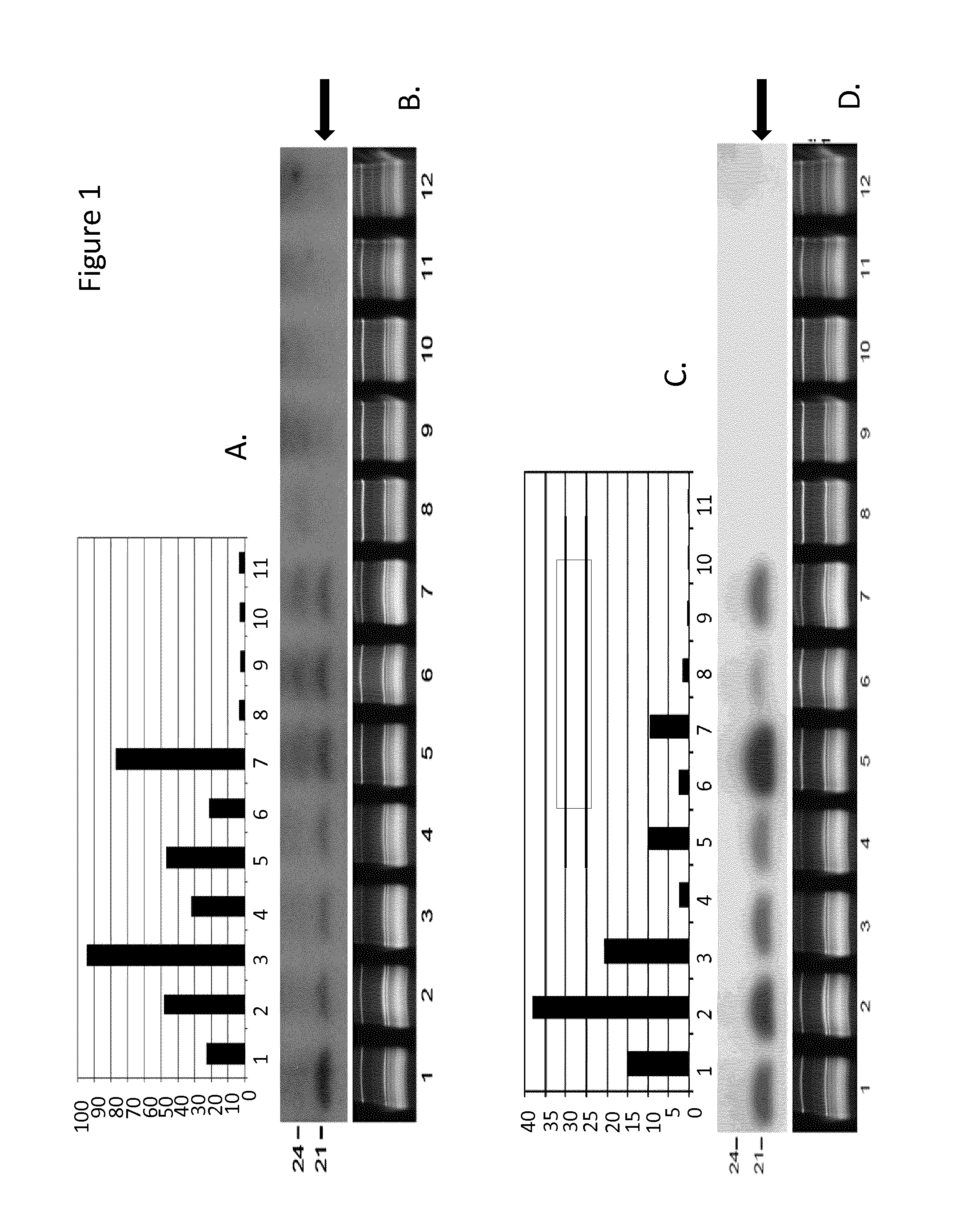

Enhanced selective expression of transgenes in fiber producing plants

Methods and means are provided to enhance the selective expression of transgenes under control of a fiber-selective promoter, in fiber cells, particularly cotton fiber cells by including target sites for naturally occurring microRNAs with a specific expression profile, particularly with a differential expression profile between cells leading to fibers and other cells of the fiber producing plant, into the transcribed region of genes of interest.

Owner:TEXAS TECH UNIVERSITY +1

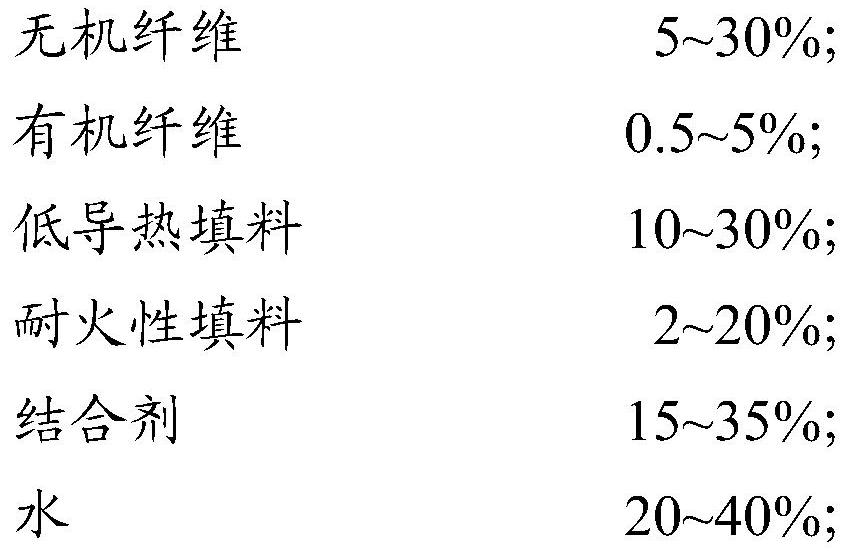

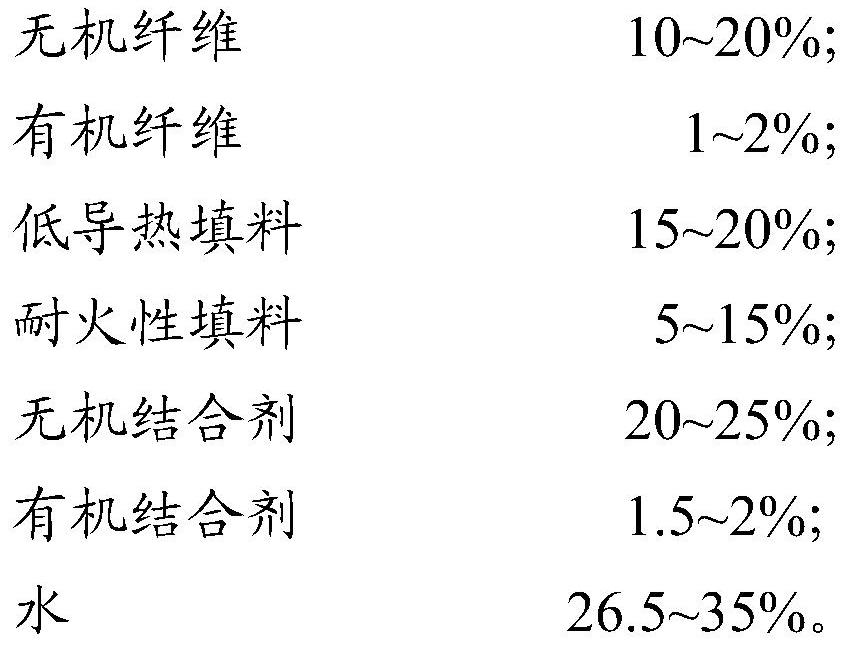

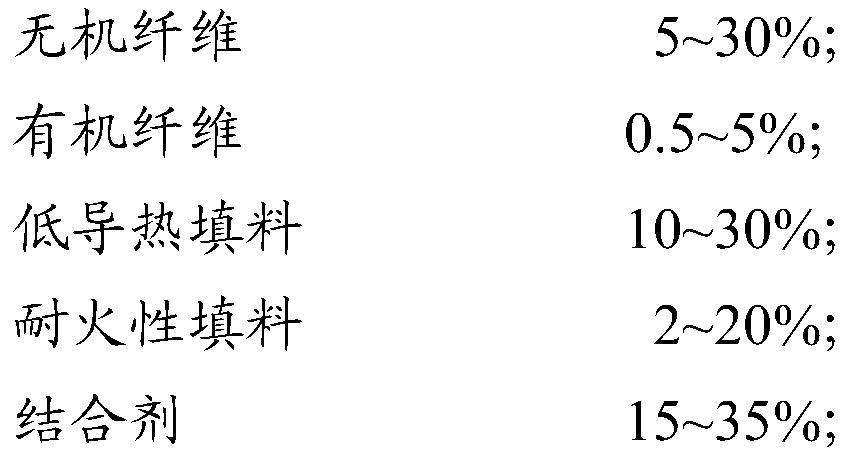

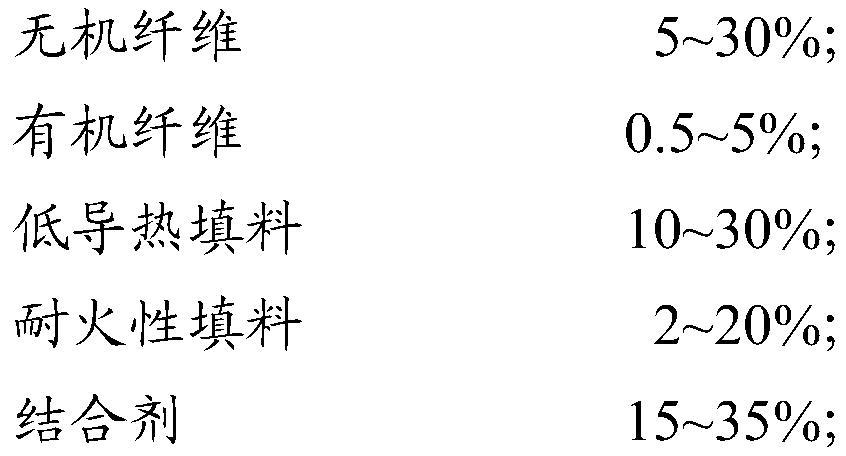

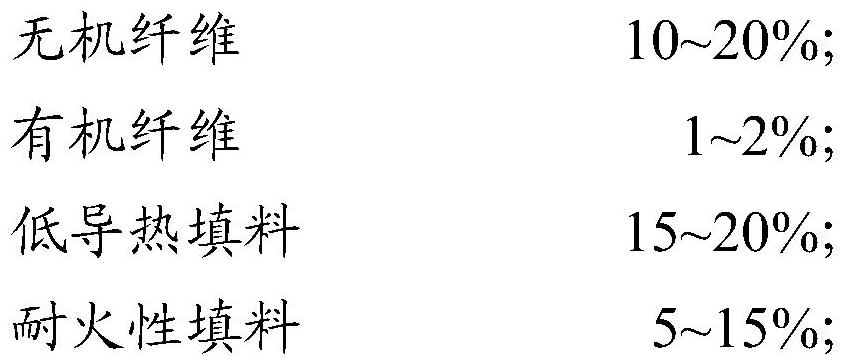

Thermal insulation coating, preparation method thereof and thermal insulation coating layer

The invention belongs to the field of thermal insulation materials, and particularly relates to a thermal insulation coating, a preparation method thereof and a thermal insulation coating layer. The thermal insulation coating provided by the invention comprises the following components: 5-30% of inorganic fiber; 0.5-5% of organic fiber; 10-30% of a low-thermal-conductivity filler; 2-20% of a fire-resistant filler; 15-35% of a binding agent; and 20-40% of water. The inorganic fibers are selected from rock wool fibers, aluminum silicate fibers and calcium magnesium silicate fibers; the organic fibers are paper pulp fibers; the low-thermal-conductivity filler is selected from perlite powder, expanded vermiculite powder, floating beads and hollow glass beads; and the fire-resistant filler is selected from kaolin and / or Zhangzhou mud. The components of the thermal insulation coating are optimally designed, and particularly the specific inorganic fibers, organic fibers and filler are selected, so that the use performance of the coating in a high-temperature environment is remarkably improved; and after the surface of a kiln lining is coated with the thermal insulation coating, a formed coating is low in heat conductivity coefficient, high in strength and free of cracking at high temperature.

Owner:山东鲁阳浩特高技术纤维有限公司

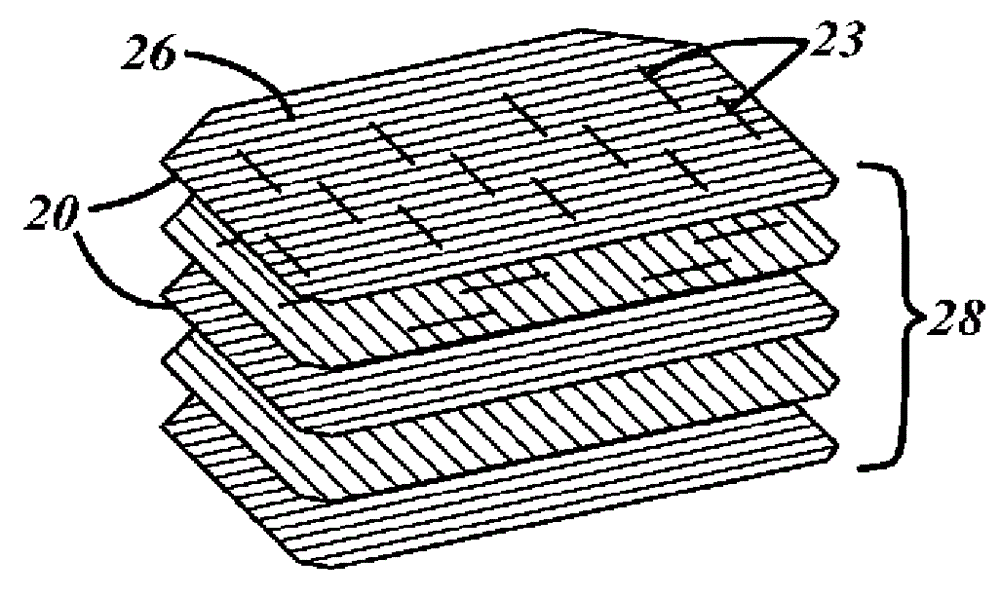

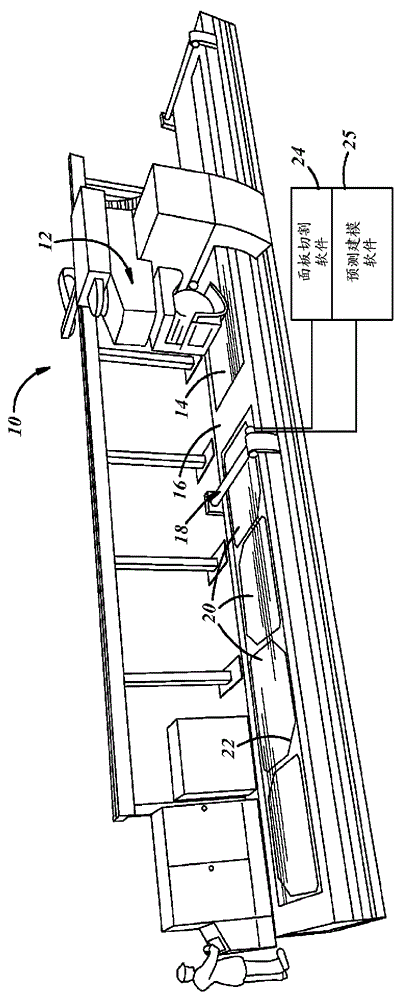

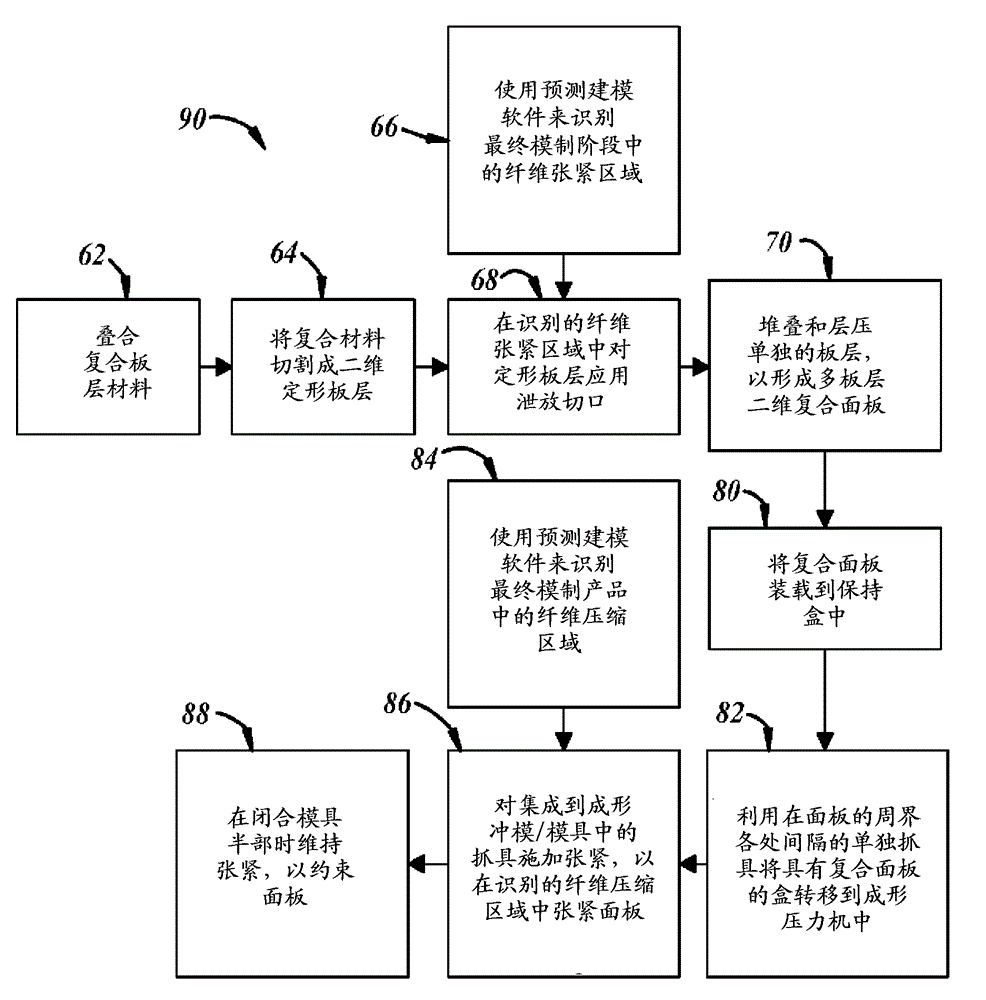

Process for molding a 3-dimensional part

A process uses predictive modeling software for selectively applying relief cuts and tension to the fibers in a 2-dimensional panel prior to shaping the panel into a 3-dimensional part. The predictive modeling software identifies areas of fiber tension in the final molded product, and relief cuts are made in those areas. The plies are loaded into grippers attached to a supporting frame and predictive modeling software is used to identify areas of fiber compression in the final molded product. Tension is applied to the identified areas of fiber compression. The panel is molded in a form and cure press, and the tension is maintained on the material while closing the mold halves. The molded part is able to conform to the final mold shape without tearing in areas of tension and without material buildup in areas of compression in the final molded part or post mold distortion.

Owner:FIVES MACHINING SYST

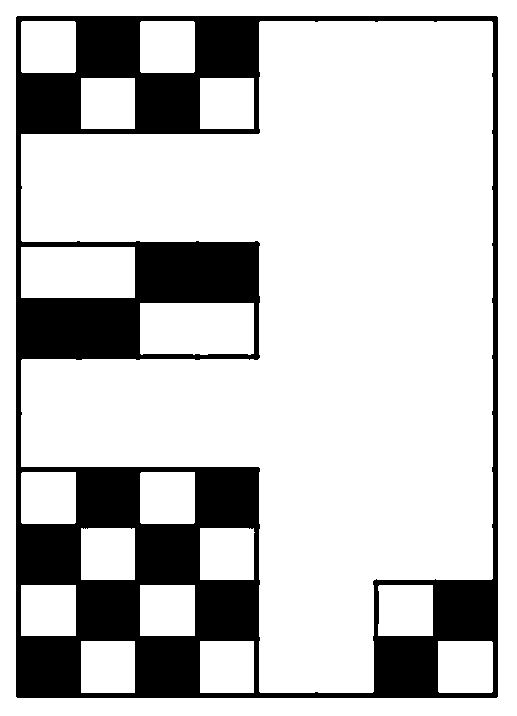

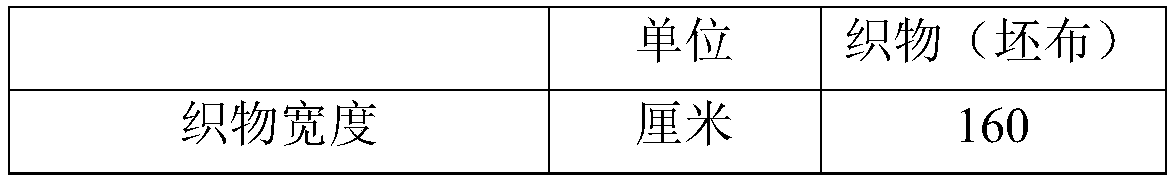

Preparation process of machine-washable compact siro spinning wool suit fabric

InactiveCN111074405AReduce frizzPromote sheddingSingeingDrafting machinesSpinningPulp and paper industry

The invention relates to a preparation process of a machine-washable compact siro spinning wool suit fabric, and belongs to the technical field of woven fabric preparation. Double-inlet anti-teryleneand Australian imported fine wool are used as raw materials, and spinning is carried out by adopting a siro compact spinning mode, so that the machine-washable compact siro spinning wool suit fabric is prepared. According to the method, starting from multiple aspects such as fiber selection, spinning mode, tissue structure, after treatment and the like, the Double-inlet anti-terylene is blended with the Australian imported fine wool, and the siro compact spinning mode is adopted; meanwhile, protease after-treatment processing design is adopted, and the singeing process is strictly controlled,the problem of pilling and felt shrinkage during the washing process of the wool fabric is solved while the style of the wool fabric is ensured, and the requirements of the market for the conveniencein maintaining the suit are met; and the fabric can reach the 3-4-grade anti-pilling level after a 36000-turn test result based on BS / EN 12954-1:2001 Textile-Anti-Pilling Performance Test.

Owner:WUXI TAIBO GARMENT

Novel vortex spinning colorful spun yarn and production process

PendingCN112941688AImprove antibacterial propertiesReduce breedingContinuous wound-up machinesDyeing processTextile fiberPolyester

The invention discloses a novel vortex spinning colorful spun yarn and a production process, and relates to the technical field of spinning. Now the following scheme is provided: the novel vortex spinning colorful spun yarn includes the following steps that S1, fiber selection: selecting common textile fibers such as polyester fibers, wherein the diameter of the selected polyester fibers is 0.6-0.8 mm; S2, diameter changing treatment: after the polyester fibers in the S1 are subjected to high-temperature stretching forming, performing equal-distance compression diameter changing treatment on the diameters of the polyester fibers which are formed just now; S3, dyeing: carrying out dyeing treatment on the treated polyester fibers; and S4, mixing with original white fibers. According to the production process, diameter changing treatment is carried out on the polyester fibers, so that the breathability of spun yarn of the polyester fibers can be improved, the comfort degree of people wearing the spun yarn is improved, meanwhile, hemp fibers and micro silver particles can improve the antibacterial performance of a textile and reduce breeding of bacteria in the spun yarn, and therefore, health of people is better protected.

Owner:滁州霞客无染彩色纺有限公司

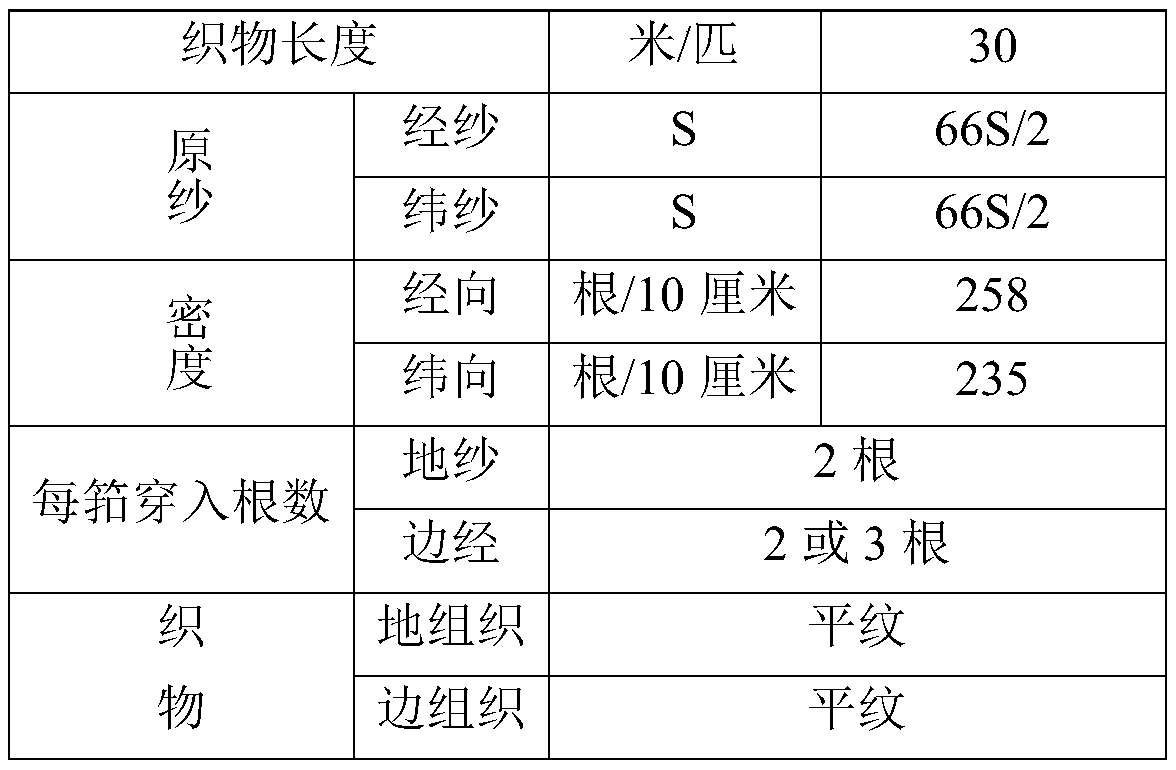

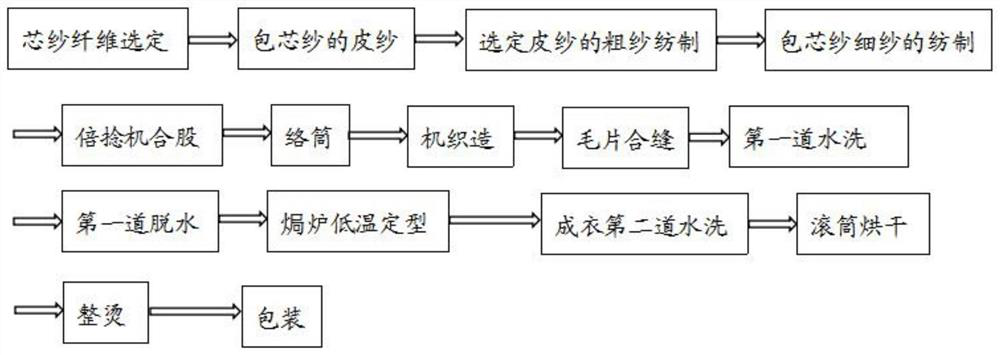

Process for producing high-elasticity flat knitting machine product

PendingCN111876890AShrinkage stableElastic stabilityWeft knittingLiquid/gas/vapor article treatmentYarnEngineering

The invention discloses a process for producing a high-elasticity flat knitting machine product. The process comprises the following steps of (1) yarn preparing, namely selecting core yarn fibers, selecting skin yarn of covering yarn, spinning rough yarn of the selected skin yarn, finishing spinning of spun yarn of the covering yarn, stranding by a two-for-one twister, and spooling to obtain a yarn raw material for flat knitting machine production; (2) feather piece weaving and sewing; and (3) ready-made clothes water washing after-finishing, namely carrying out first-pass in-vat water washingon the ready-made clothes, then taking out of the vat and dehydrating, adopting a special ready-made clothes elastic shaping process, taking the ready-made sweater into a vat after taking out of a furnace, adding a softening agent into normal-temperature water to carry out hand feeling finishing, and then taking out of the vat and dehydrating, drying and ironing to obtain the finished ready-madeclothes. According to the process for producing the high-elasticity flat knitting machine product, non-spandex covering yarn serves as a raw material and is combined with a ready-made clothes washingafter-finishing process and a process of weaving on a flat knitting machine, and the obtained non-spandex high-elasticity sweater is stable in shrinkage rate and excellent in elasticity and elastic recovery rate.

Owner:何炽斌 +1

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS7921518B2Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUTZSCHLER GMBH & CO KG

A kind of thermal insulation coating and its preparation method and thermal insulation coating

The invention belongs to the field of thermal insulation materials, and in particular relates to a thermal insulation coating, a preparation method thereof, and a thermal insulation coating. The thermal insulation coating provided by the invention comprises: inorganic fibers 5-30%; organic fibers 0.5-5%; low thermal conductivity fillers 10-30%; refractory fillers 2-20%; binders 15-35%; water 20-40% %; the inorganic fibers are selected from rock wool fibers, aluminum silicate fibers, and calcium magnesium silicate fibers; the organic fibers are pulp fibers; the low thermal conductivity fillers are selected from perlite powder, expanded vermiculite powder, floating beads, hollow glass microfibers beads; the refractory fillers are selected from kaolin and / or Zhangzhou mud. By optimizing the design of the composition of the thermal insulation coating, especially selecting specific inorganic fibers, organic fibers and fillers, the invention significantly improves the use performance of the coating in a high temperature environment; , The formed coating has low thermal conductivity, high strength and no cracking at high temperature.

Owner:山东鲁阳浩特高技术纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com