Preparation process of machine-washable compact siro spinning wool suit fabric

A preparation process, a technology of siro spinning, applied in textile, singeing, spinning machine and other directions, can solve problems such as difficult to take care of, achieve the improvement of anti-felt shrinkage effect, promote hydrolysis and shedding, and uniform yarn evenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

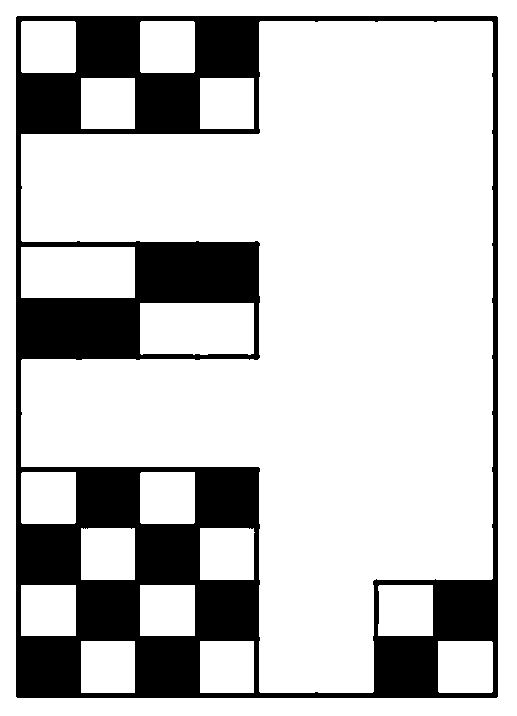

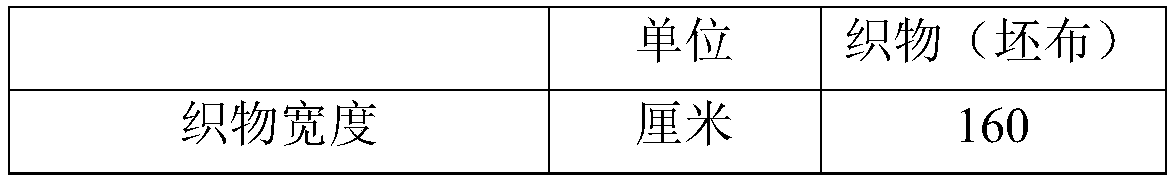

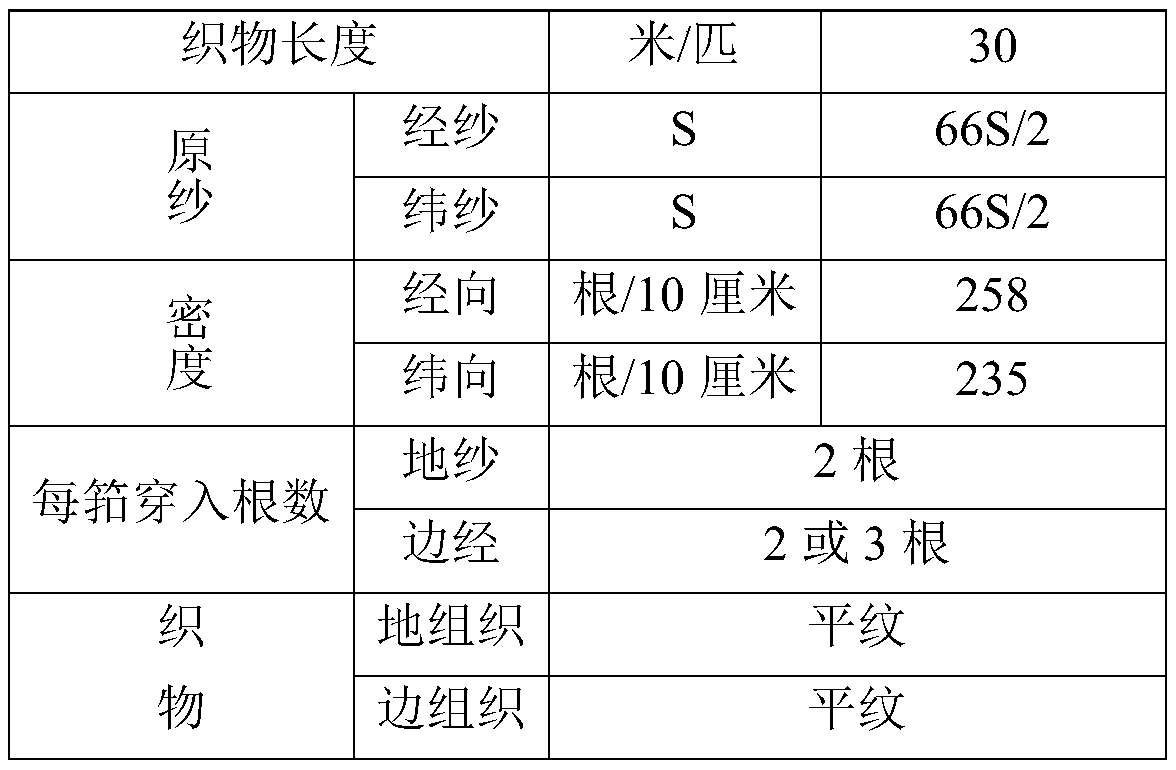

Image

Examples

Embodiment 1

[0031] Embodiment 1 uses dual imported anti-polyester and fine wool imported from Australia as raw materials, and uses the Siro compact spinning method for spinning. The specific process is as follows:

[0032] (1) Preparation of warp and weft yarns:

[0033] a. Raw wool scouring: B052 type five-slot rake-type wool scouring machine is used. The raw wool first passes through the dipping tank (the first tank), and the wool fiber is wetted with clean water and washed to remove impurities; then it passes through the washing tank (second, Three tanks), wash away most of the lanolin and non-grease impurities with detergent, the process is soap solution mass concentration 0.18%-0.2%, soda ash mass concentration 0.18%-0.2%, pH value 9-10, temperature 45- 50°C; Finally, wash away the remaining impurities and detergents in the wool through the rinsing tank (the fourth and fifth tanks) with clean water;

[0034] b. Fiber blending: by weight, 55-65 parts of 15 μm double-resistant polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com