Compound optical fiber fabric layer and compound optical fiber sheet and compound optical fiber adhesive tape containing the same

A composite optical fiber, fabric layer technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., to achieve the effects of non-interference of structural properties, excellent mechanical properties and durability of products, and efficient and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

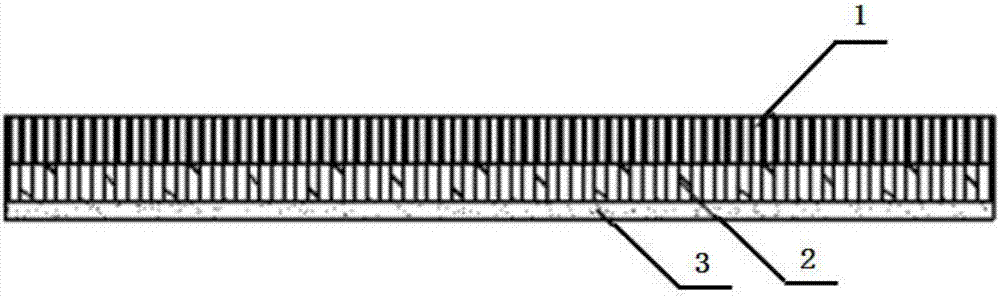

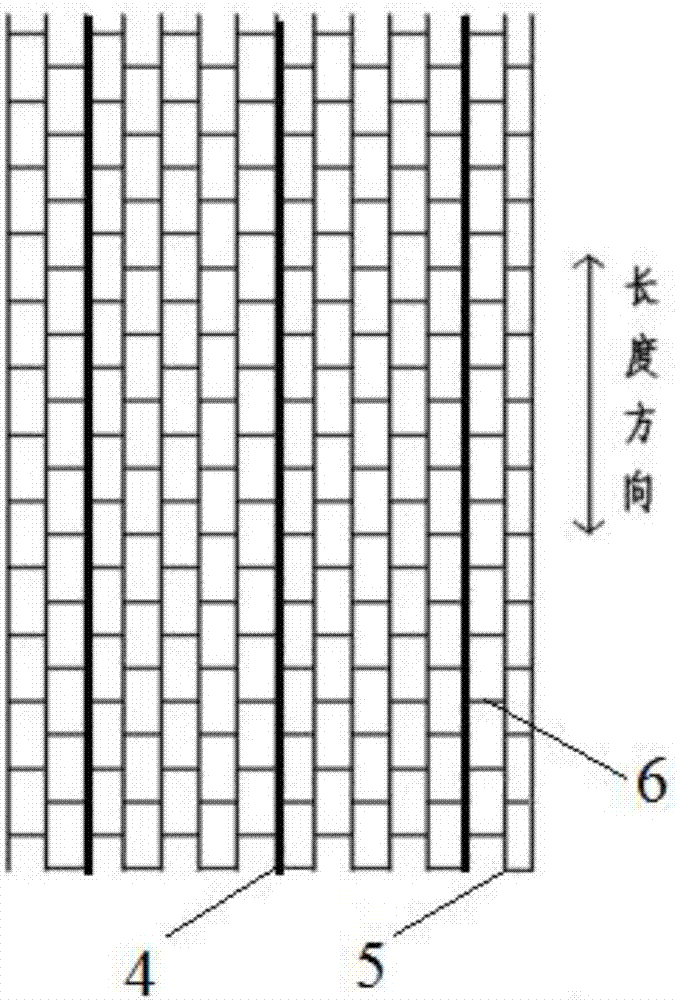

[0037] Please refer to the relevant drawings, the present invention provides a composite optical fiber fabric layer 1, which is formed by mixing and weaving optical fibers 4 and fibers.

[0038] In order to further optimize the above-mentioned technical scheme, the optical fiber 4 selects the appropriate optical fiber according to comprehensive factors such as the size of the monitored object, the resolution of the sensor acquisition signal, the sampling point, and the length and distance, and determines the distribution density of the optical fiber in the composite optical fiber fabric layer 1. , so it can meet different monitoring requirements, with stronger design, better adaptability, and reduced cost.

[0039] In order to further optimize the above technical solution, the distribution density of the optical fibers in the composite optical fiber fabric layer is 1-100 / m width.

[0040] In order to further optimize the above technical scheme, the weaving density of the compo...

Embodiment 2

[0046] A method for preparing a composite optical fiber fabric layer, specifically comprising the following steps:

[0047] 1) Select the appropriate optical fiber and fiber according to the needs of engineering applications, and determine the weaving density of the optical fiber and fiber; if there is a requirement for bearing capacity and durability in the weft direction of the composite optical fiber fabric layer, the fibers used in the warp and weft directions All choose high-performance fibers. If there is no requirement for bearing capacity and durability in the weft direction of the composite optical fiber fabric layer, choose high-performance fibers or ordinary fibers in the warp direction, and choose ordinary fibers in the weft direction;

[0048] 2) The optical fiber and the fiber are laid in parallel in the warp direction, and the optical fiber is evenly dispersed and sandwiched in the fiber;

[0049] 3) Weaving and fixing the fibers laid in step 2) and fibers for o...

Embodiment 3

[0056] A composite optical fiber sheet comprising a composite optical fiber fabric layer 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Weaving density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com