A kind of thermal insulation coating and its preparation method and thermal insulation coating

A technology of thermal insulation coating and thermal insulation coating, which is applied in the field of thermal insulation coating, thermal insulation coating and its preparation, can solve the problems of destroying the overall structure of furnace lining, crystallization, pulverization, slag removal, and shortening the service life of high temperature resistant furnace, etc. The effect of low thermal conductivity, prolonging service life and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

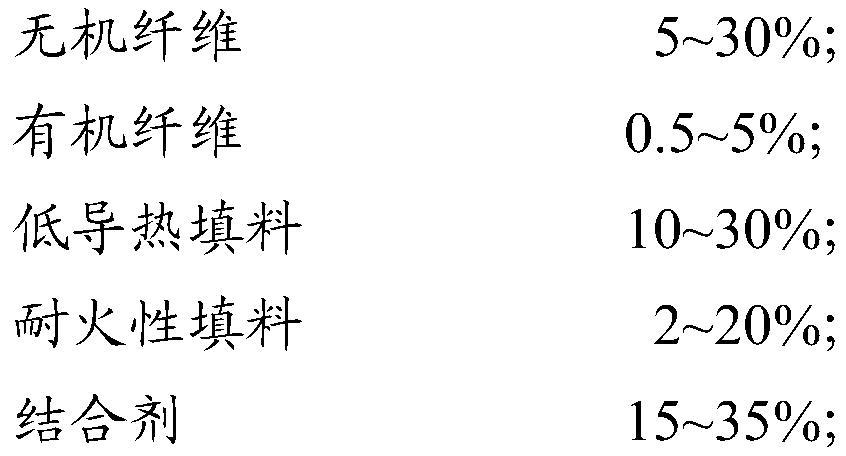

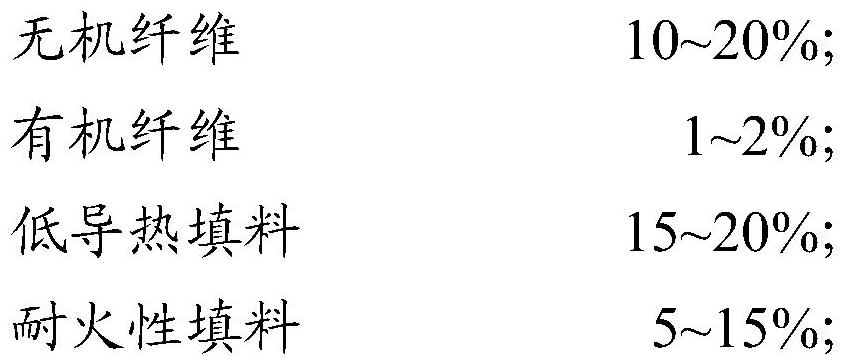

[0039] The present invention also provides a preparation method of the thermal insulation coating described in the above technical solution, comprising the following steps:

[0040] Inorganic fibers, organic fibers, low thermal conductivity fillers, refractory fillers, binders and water are mixed to obtain thermal insulation coatings.

[0041] In the preparation method provided by the present invention, the thermal insulation coating provided by the present invention can be obtained by directly mixing inorganic fibers, organic fibers, low thermal conductivity fillers, refractory fillers, binders and water uniformly in proportion.

[0042] The thermal insulation coating and the preparation method thereof provided by the present invention significantly improve the use performance of the coating in a high temperature environment by optimizing the design of the components of the thermal insulation coating, especially selecting specific inorganic fibers, organic fibers and fillers; ...

Embodiment 1

[0073] Quality composition of thermal insulation coating: 15% aluminum silicate fiber, 1% pulp fiber, 20% hollow glass beads, 7% kaolin, 20% silica sol, 2% cellulose, 35% tap water; mix the above raw materials in proportion Evenly, the thermal insulation coating is obtained.

[0074] The thermal insulation coating prepared in this example is detected, and the results are as follows: wet bulk density 1100kg / m 3 ;The bulk density after drying at room temperature is 500kg / m 3 ; Compressive strength 1.25MPa; heating wire shrinkage (1000℃×24h) 1.83%; thermal conductivity, hot surface 200℃ is 0.79W / m.k, hot surface 600℃ is 0.114W / m.k, hot surface 800℃ is 0.132W / m.k, the hot surface is 0.152W / m.k at 1000℃.

Embodiment 2

[0076] Quality composition of thermal insulation coating: calcium magnesium silicate fiber 10%, pulp fiber 1.5%, float 15%, Zhangzhou mud 15%, silica sol 25%, cellulose 1.5%, tap water 32%; mix the above raw materials in proportion Evenly, the thermal insulation coating is obtained.

[0077] The thermal insulation coating prepared in this example is detected, and the results are as follows: wet bulk density 1150kg / m 3 ;The bulk density after drying at room temperature is 550kg / m 3 ; Compressive strength 1.6MPa; heating wire shrinkage (1000℃×24h) 1.7%; thermal conductivity, hot surface 200℃ is 0.76W / m.k, hot surface 600℃ is 0.115W / m.k, hot surface 800℃ is 0.135W / m.k, the hot surface is 0.151W / m.k at 1000℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com