Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Diffusion flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

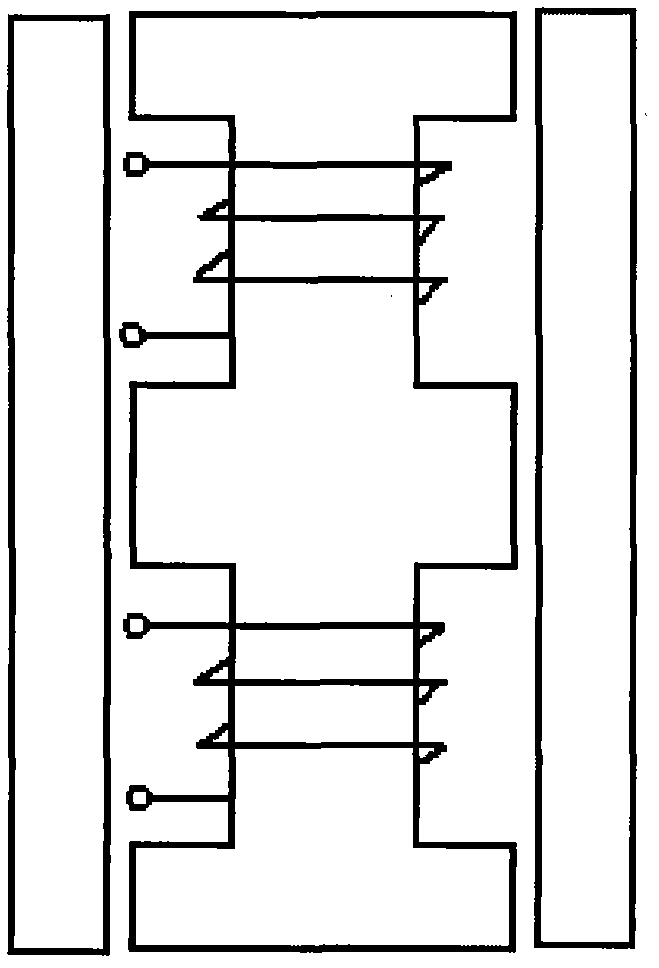

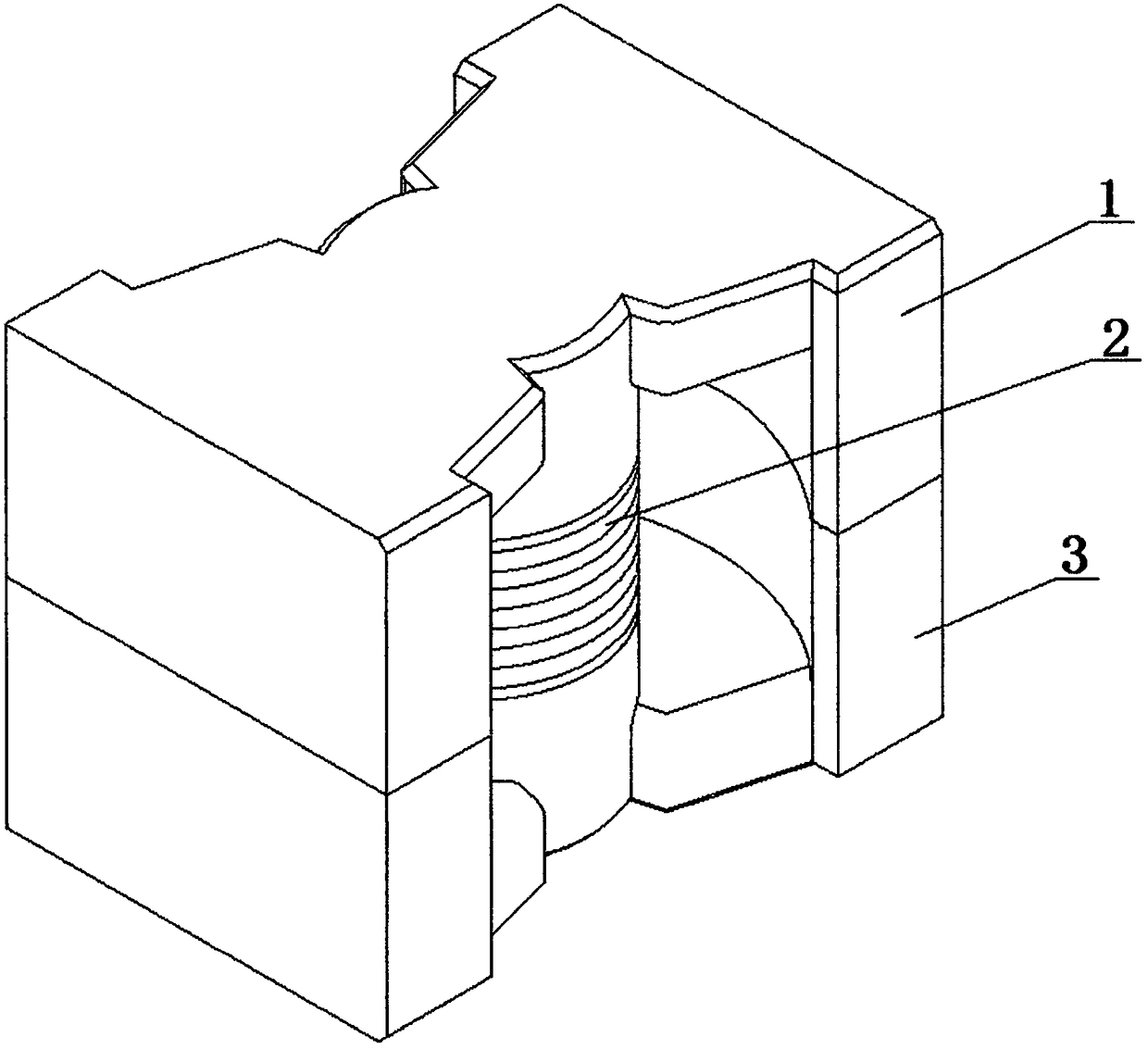

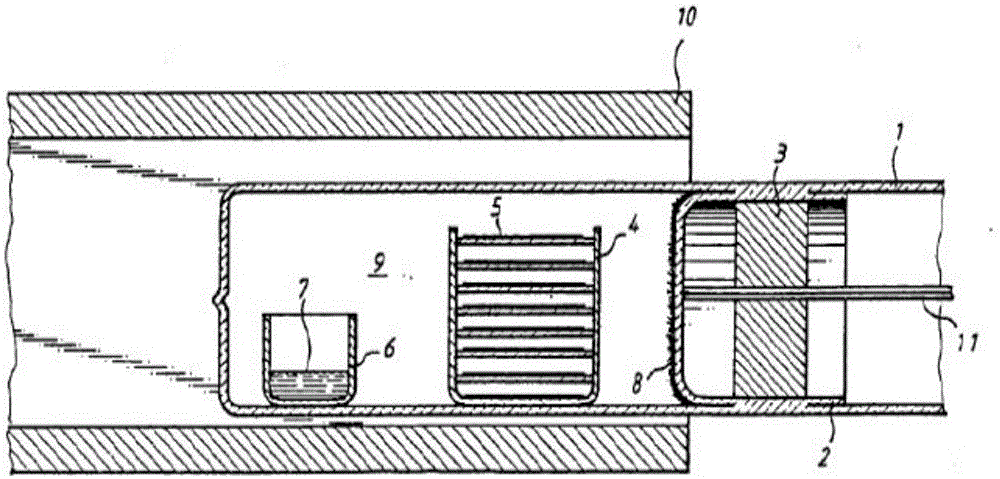

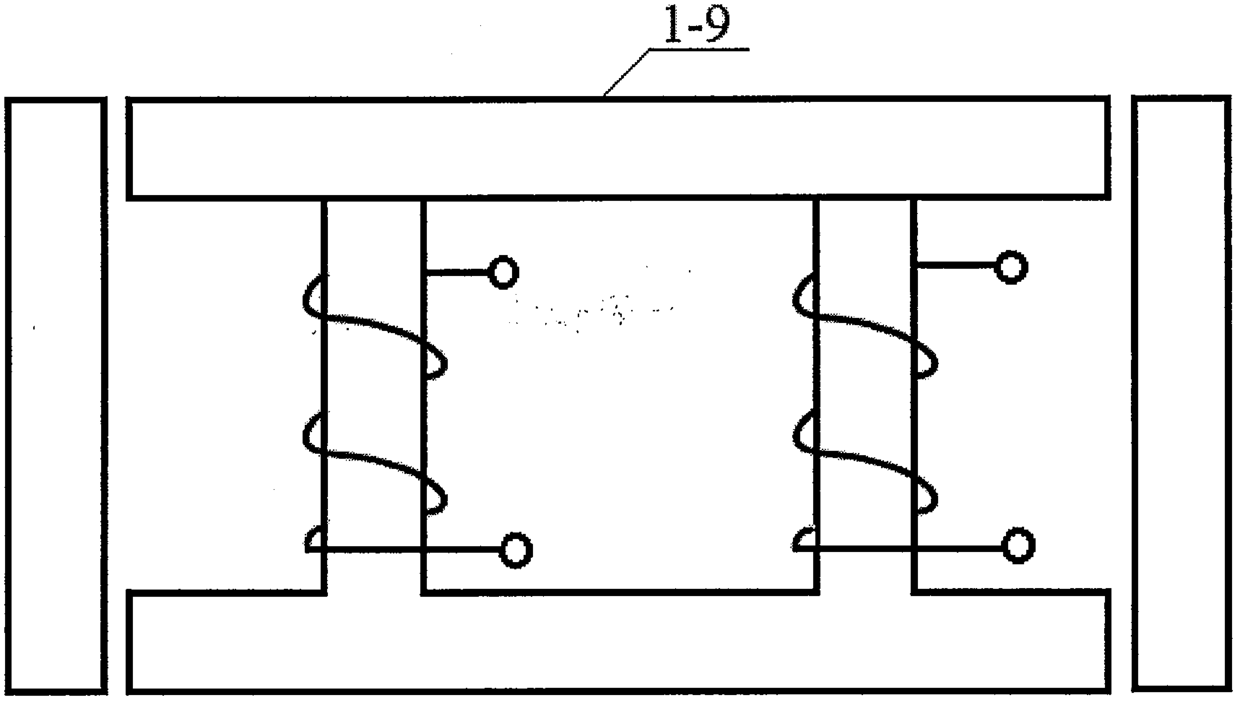

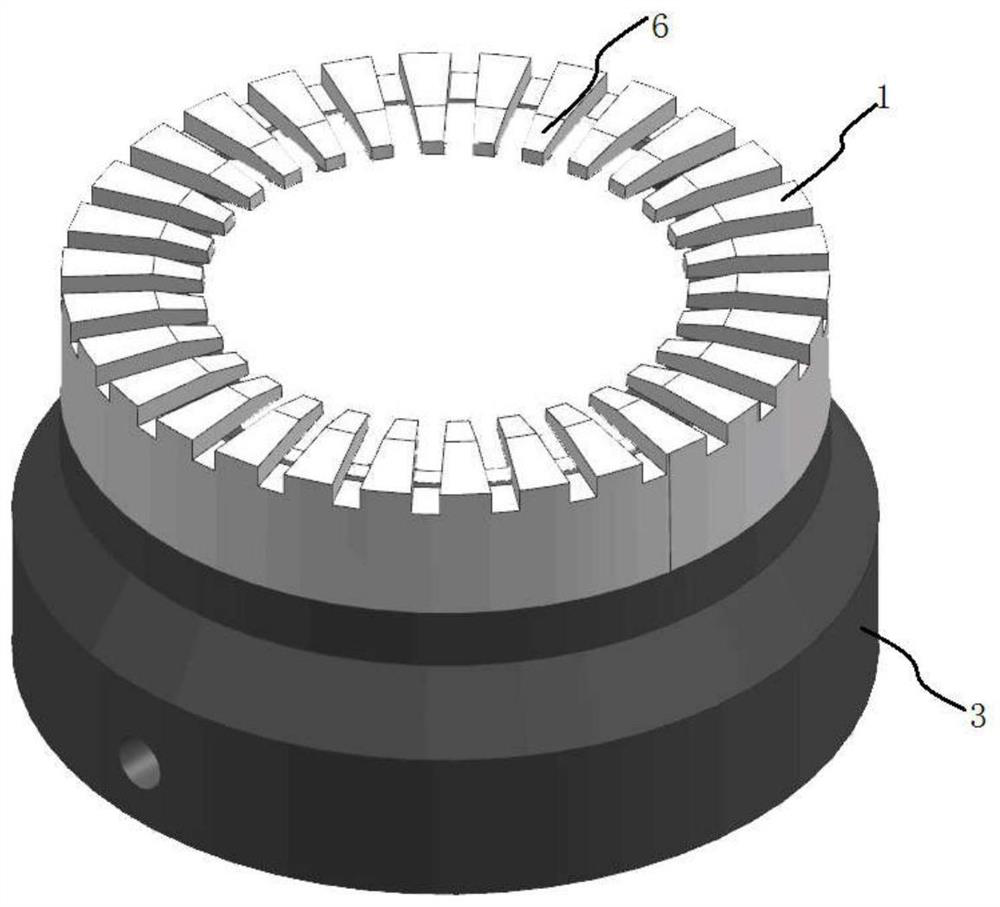

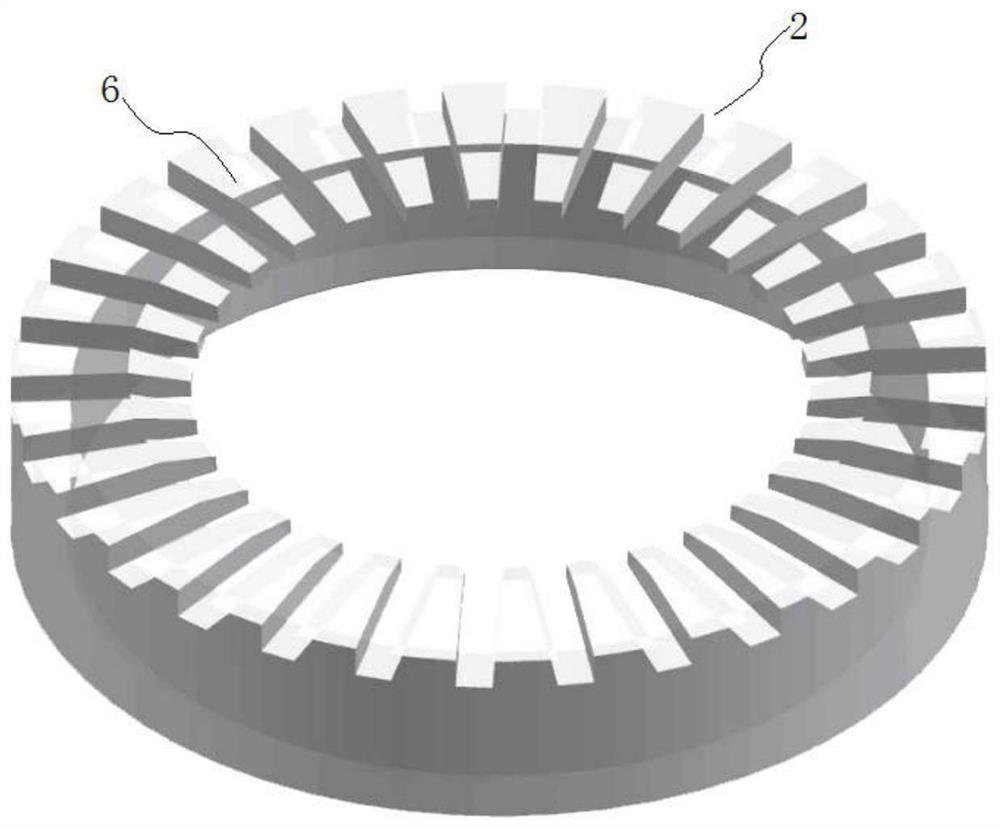

Planar transformer

ActiveCN105914011AEasy to produceIncreased reluctanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic reluctanceMiniaturization

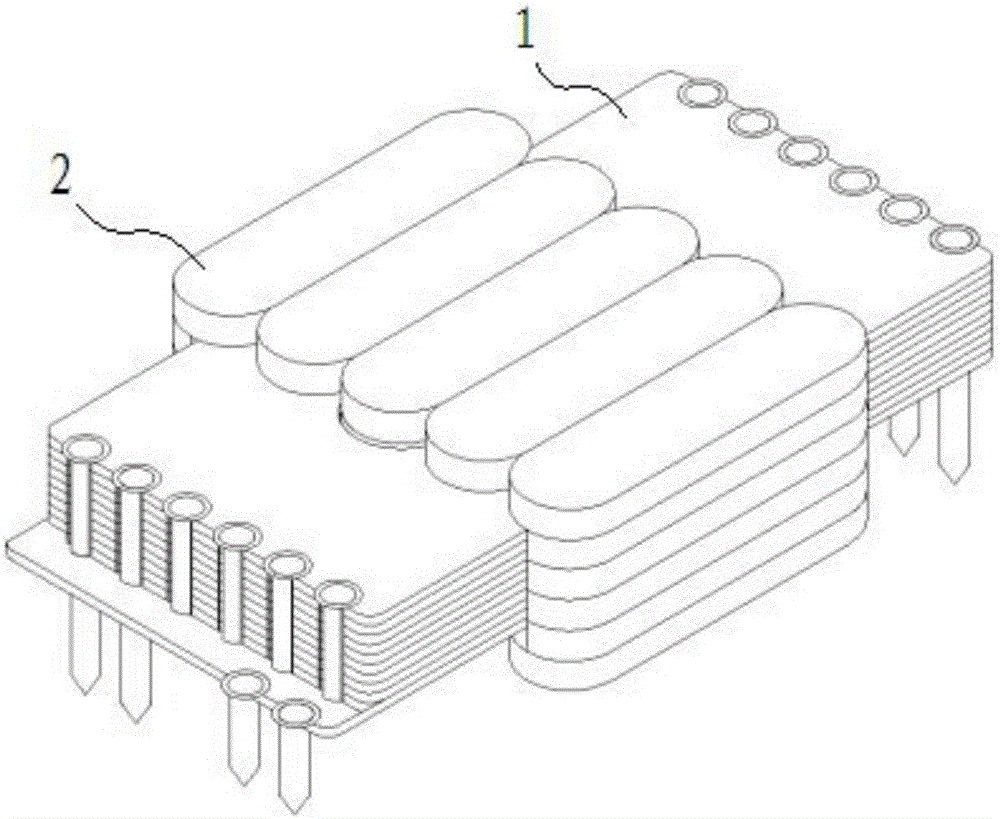

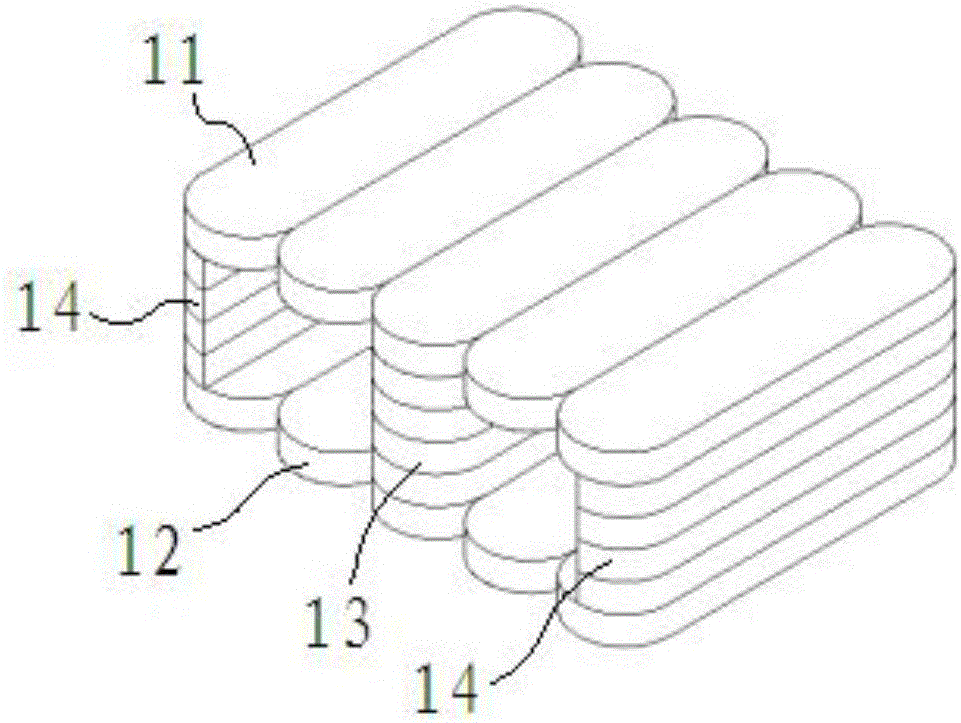

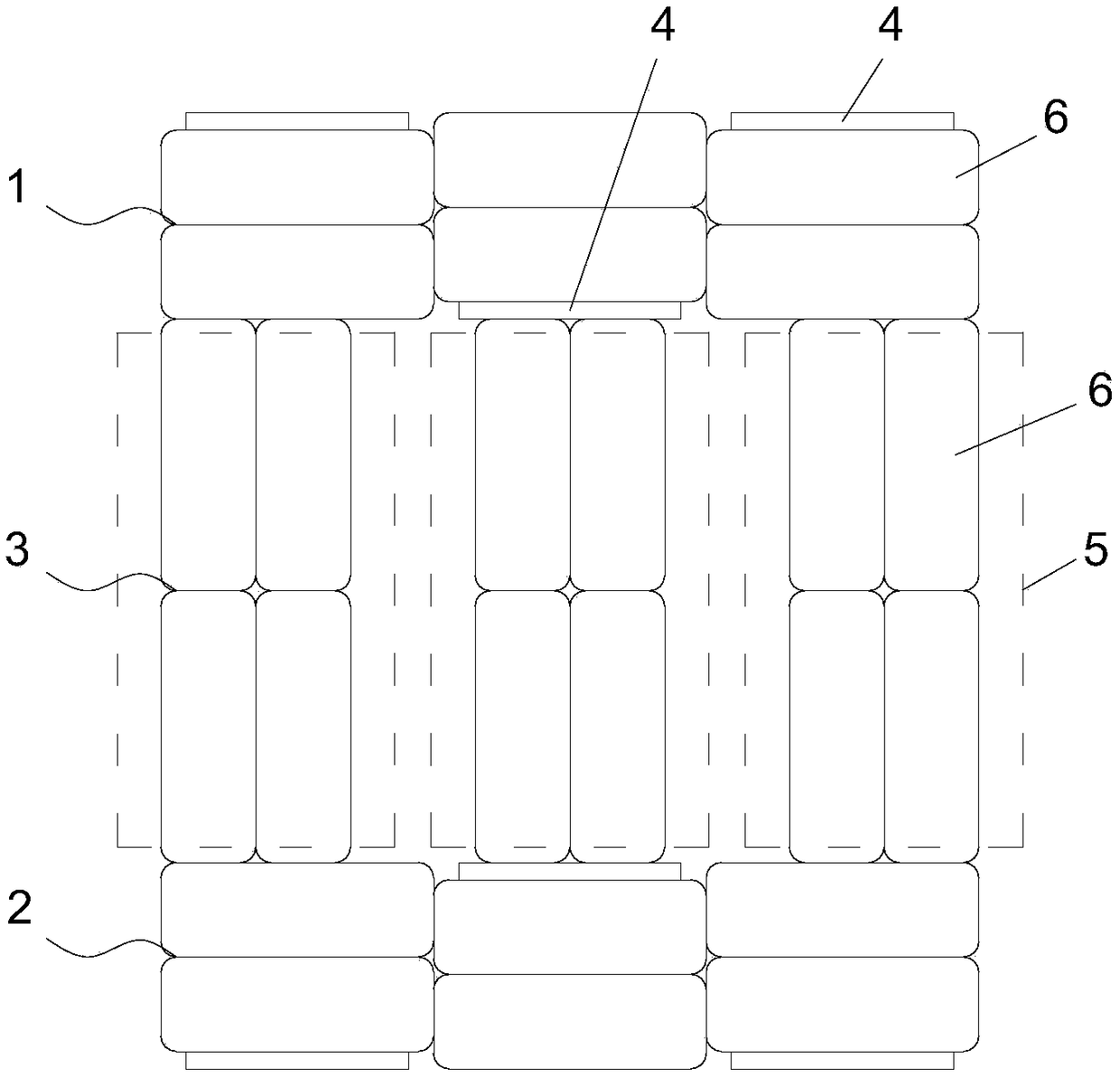

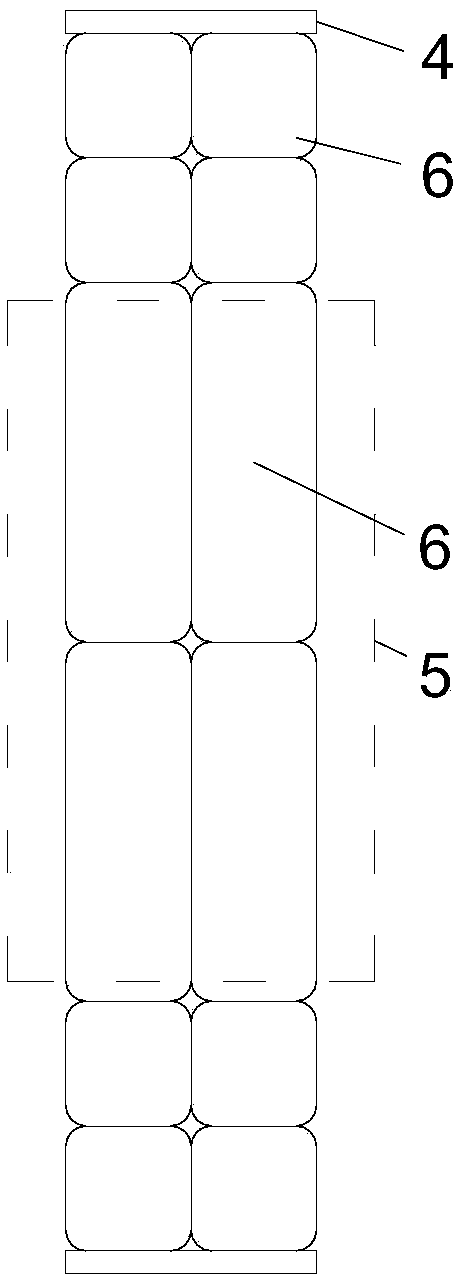

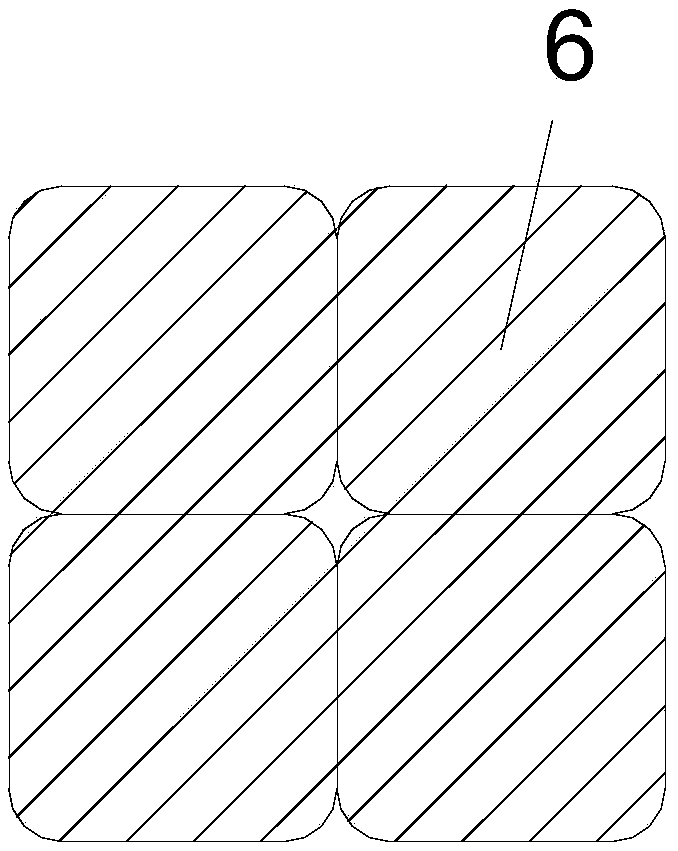

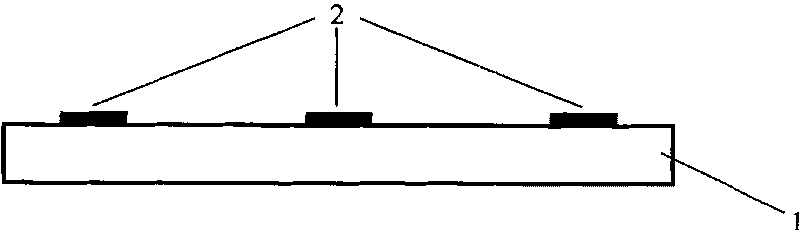

The invention discloses a planar transformer which comprises a magnetic core and a coil winding; the magnetic core comprises a top plate, a bottom plate, a middle column and two edge columns, the middle column and the two edge columns are located between the top plate and the bottom plate, the coil winding and the magnetic core are assembled together, the top plate and the bottom plate are composed of a whole magnetic block or formed by laying and splicing a plurality of unit magnetic block bodies, and the middle column and the edge columns are formed by stacking multiple unit magnetic block bodies; each unit magnetic block body is a flat strip-shaped block body, and a preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced. The whole magnetic core is formed by piling multiple unit magnetic block bodies, the transformer can still maintain high efficiency under high frequency, the unit magnetic block body is the flat strip-shaped block body, it is convenient to produce the magnetic core, it is beneficial to miniaturization and planarizartion, and a piled production mode is more beneficial to automated generation; the preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced, magnetic resistance between every two unit magnetic block bodies is increased, an edge magnetic line can be drawn close to the magnetic core, and thus diffusion flux is reduced.

Owner:SHENZHEN MAIJIRUI TECH CO LTD

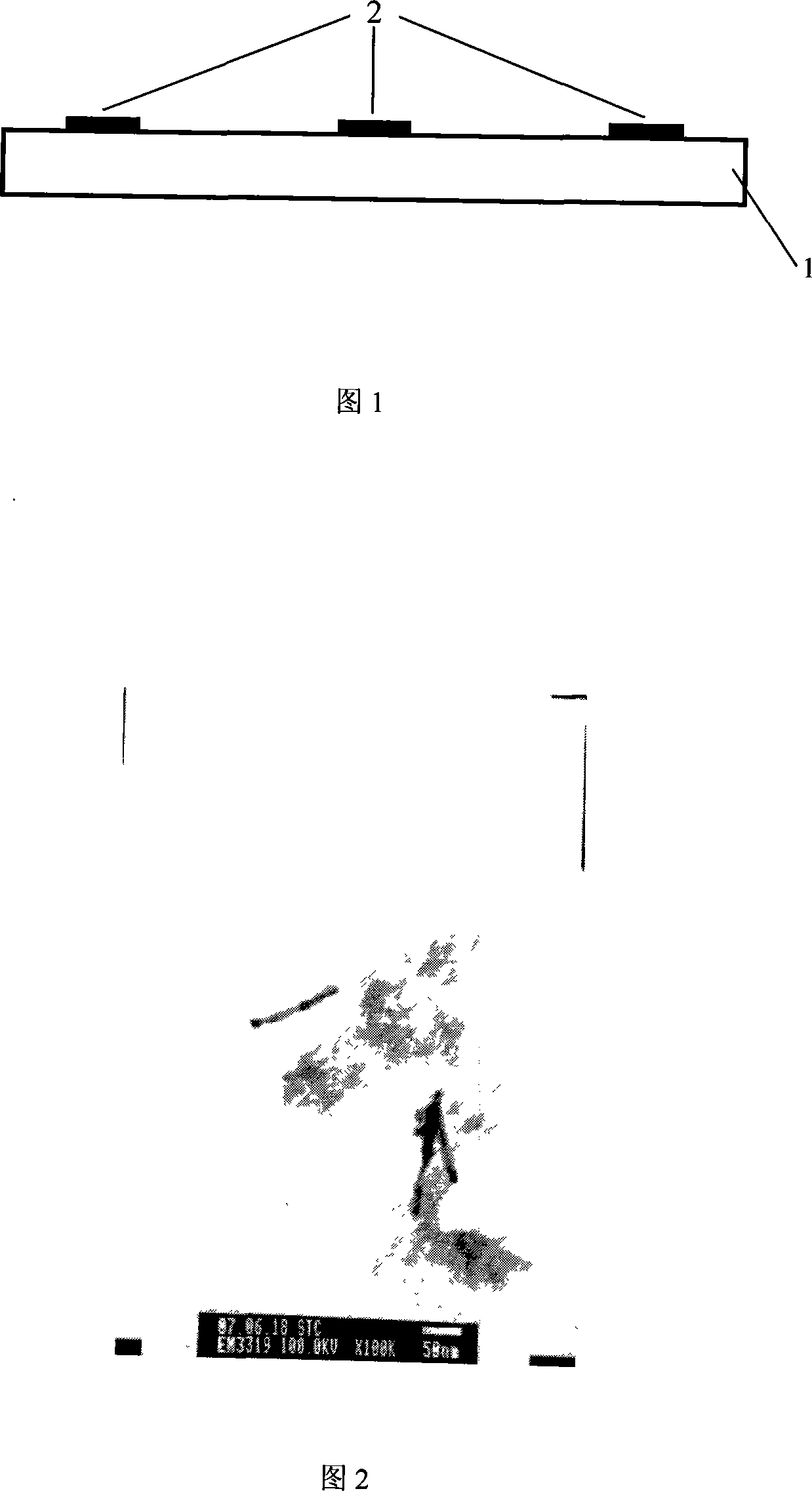

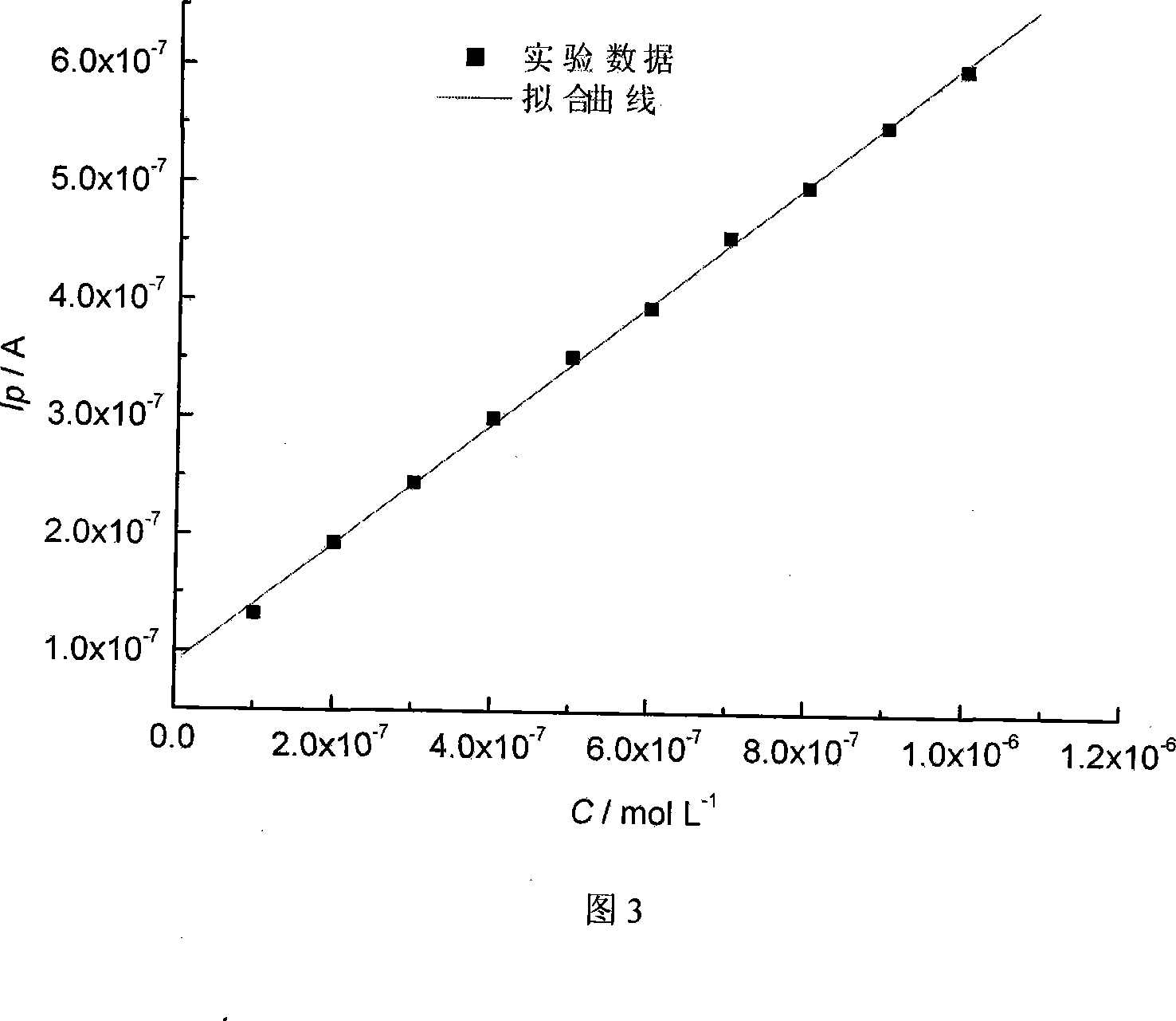

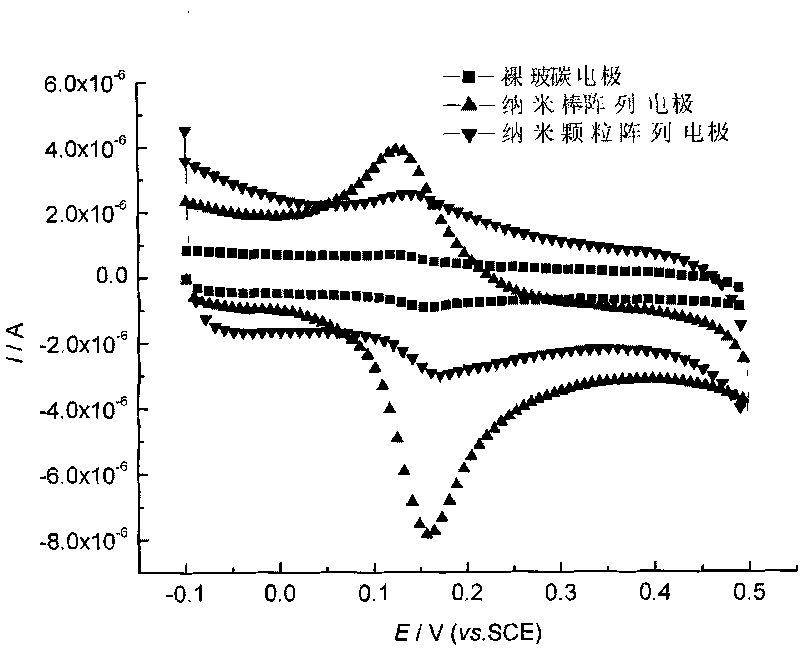

Method for preparing nano-stick array electrode capable of self-assembling after dispersing

InactiveCN101165213ATake advantage ofImprove electrocatalytic activityActive material electrodesMaterial electrochemical variablesSolventMetal

The present invention relates to nanometer rod array electrode, and is especially nanometer metal rod dispersing and self-assembling process of preparing nanometer rod array electrode with best utilization of surface area. The process includes the following steps: dissolving the template for growing nanometer metal rods, adding dispersant to the solvent and ultrasonically treating for well dispersing nanometer metal rods in the solvent, and regulating the concentration of nanometer metal rods to self-assemble nanometer metal rods onto the surface of electrode base in controllable intervals. The nanometer metal rod array electrode has best utilization of the great surface area of the nanometer metal rods, very high diffusion flux and faraday current, and very high electrically catalytic activity.

Owner:HARBIN INST OF TECH

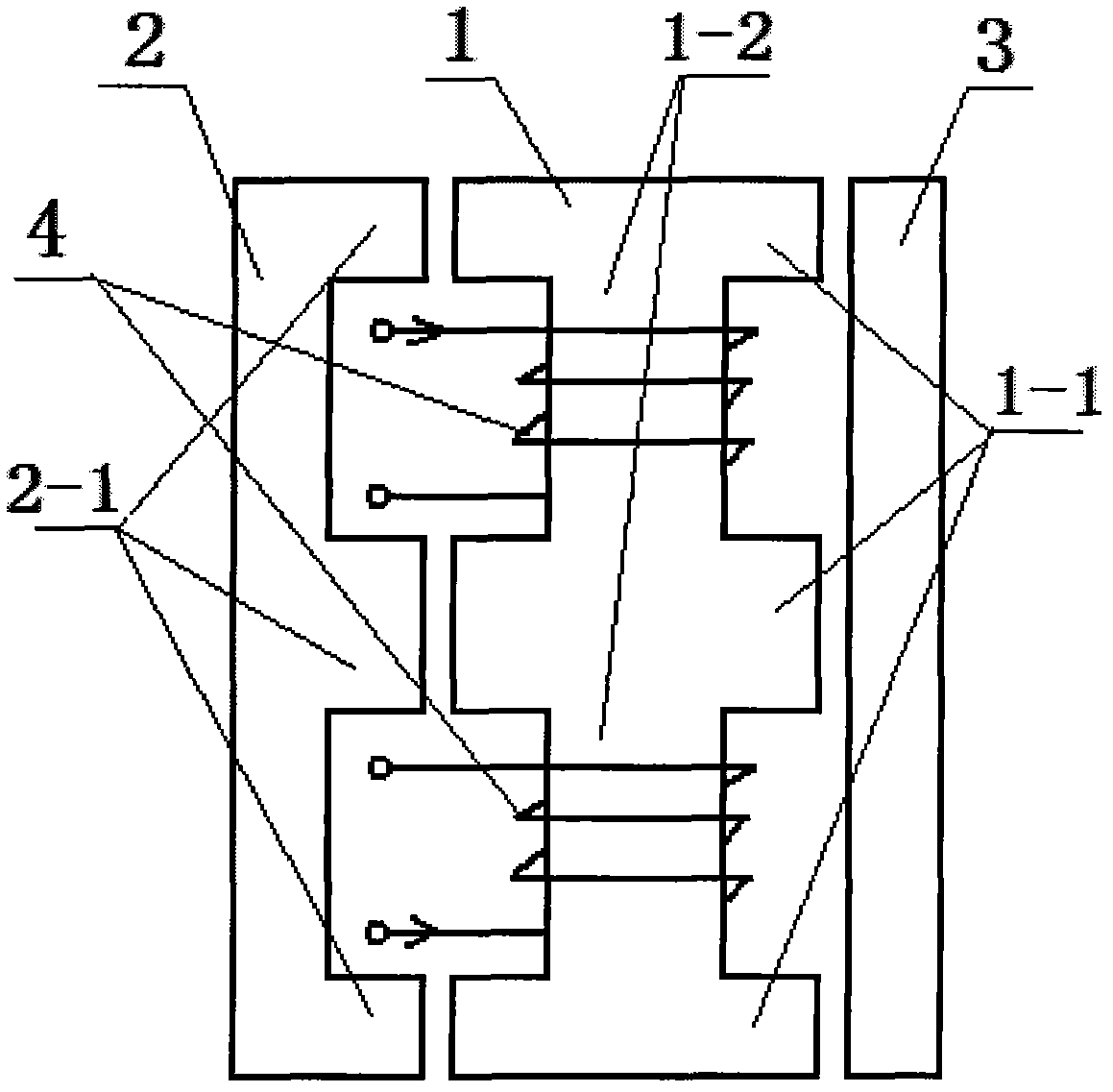

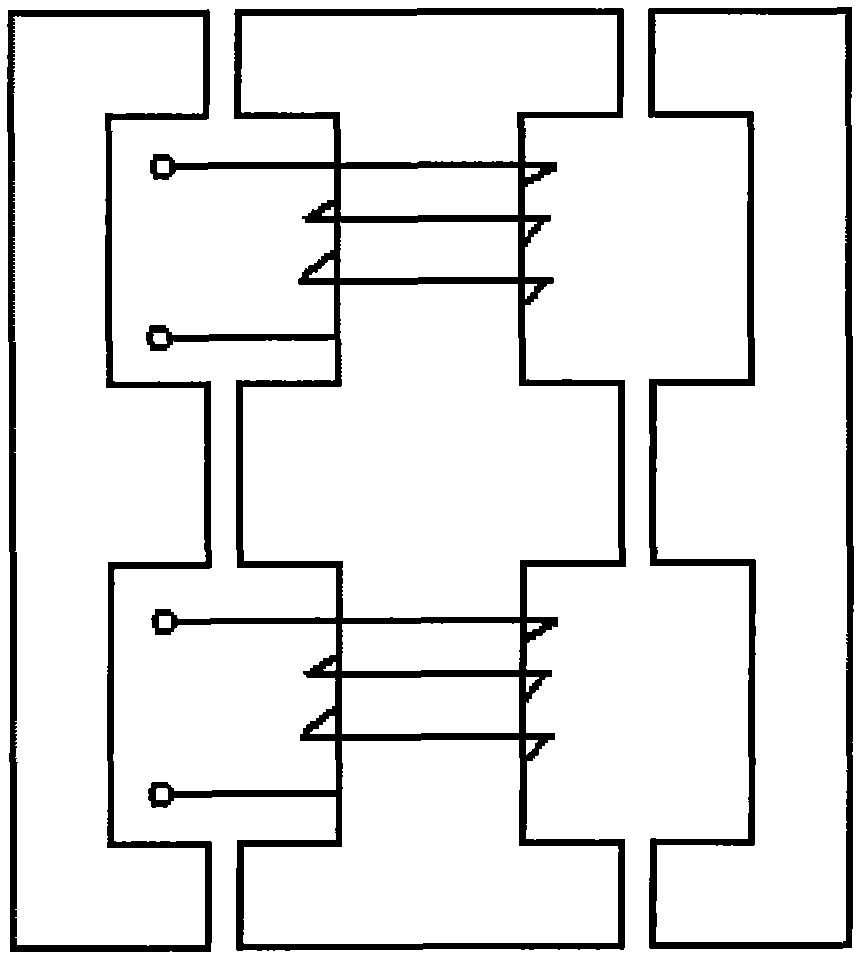

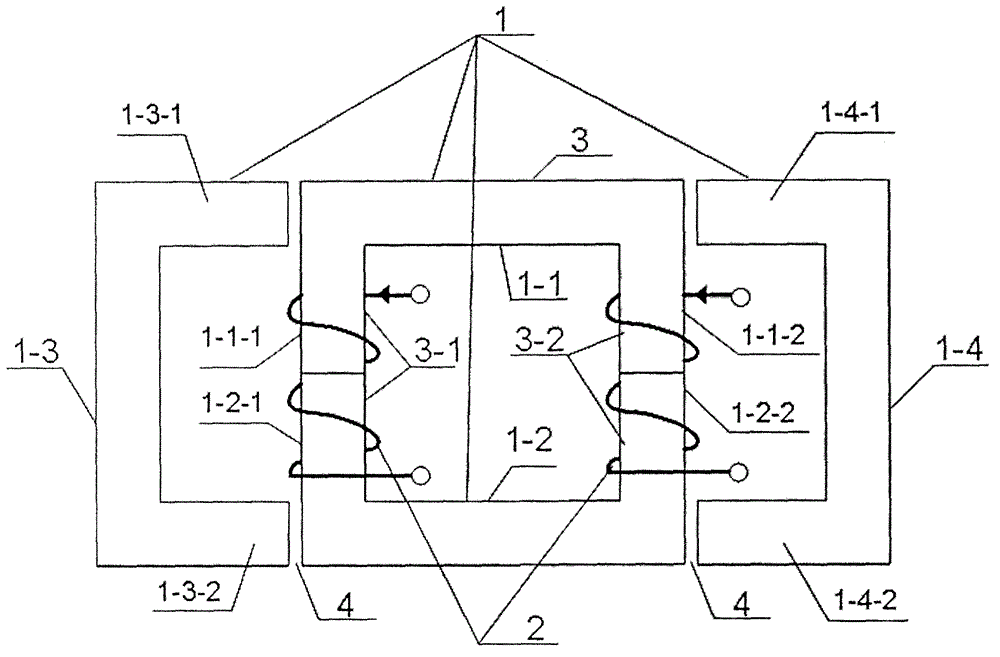

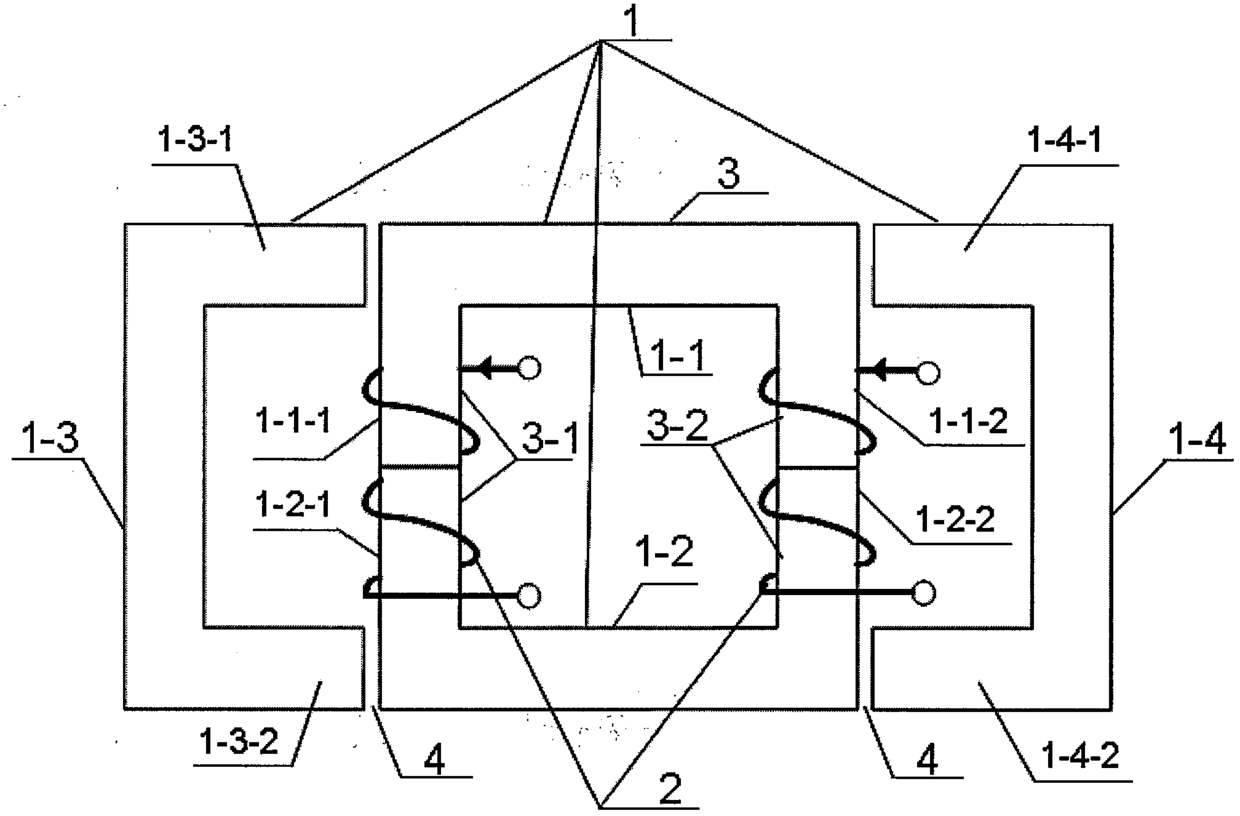

Interleaved magnetic integration type coupling inductor

InactiveCN103077803AAchieve integrationMiniaturizationTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresChinese charactersMagnetic integration

The invention relates to an interleaved magnetic integration type coupling inductor, consisting of an E-Chinese character 'Wang'-I-shaped core body and a coil, wherein the E-Chinese character 'Wang'-I-shaped core body consists of a Chinese character 'Wang'-shaped core, an E-shaped core and an I-shaped core; the E-shaped core and the I-shaped core are arranged at the both sides of the Chinese character 'Wang'-shaped core in the middle of the core body; two-phase coils are respectively wound on two middle posts of the Chinese character 'Wang'-shaped core; three magnetic path air gaps are arranged at contact positions of one sides of three transverse yokes of the Chinese character 'Wang'-shaped core and three transverse yokes of the E-shaped core; and other three magnetic path air gaps are arranged at contact positions of the other sides of the three transverse yokes of the Chinese character 'Wang'-shaped core and the I-shaped core. The interleaved magnetic integration type coupling inductor provided by the invention has the beneficial effects in that the coupling inductor is used for inductive coupling integration; the quantity of the air gaps is increased for one time; the length of the air gaps is reduced for a half; the diffusion flux of the air gaps can be obviously reduced; energy and materials can be saved; and the electromagnetic interference is reduced.

Owner:杨玉岗

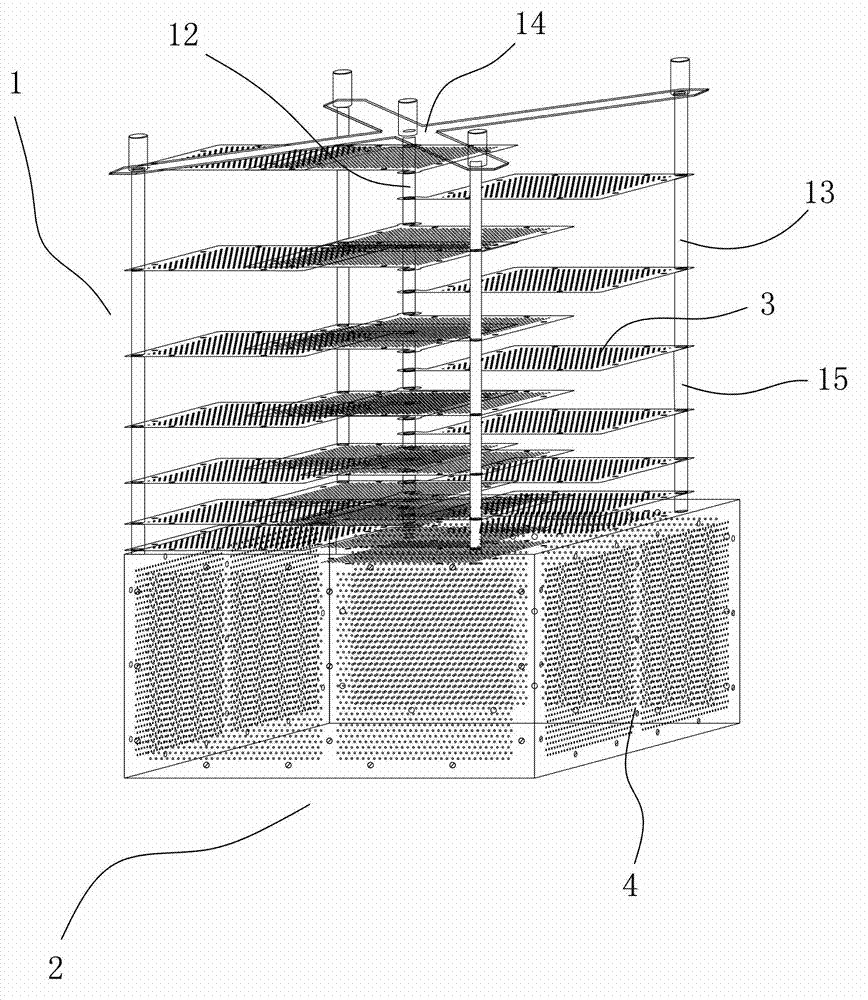

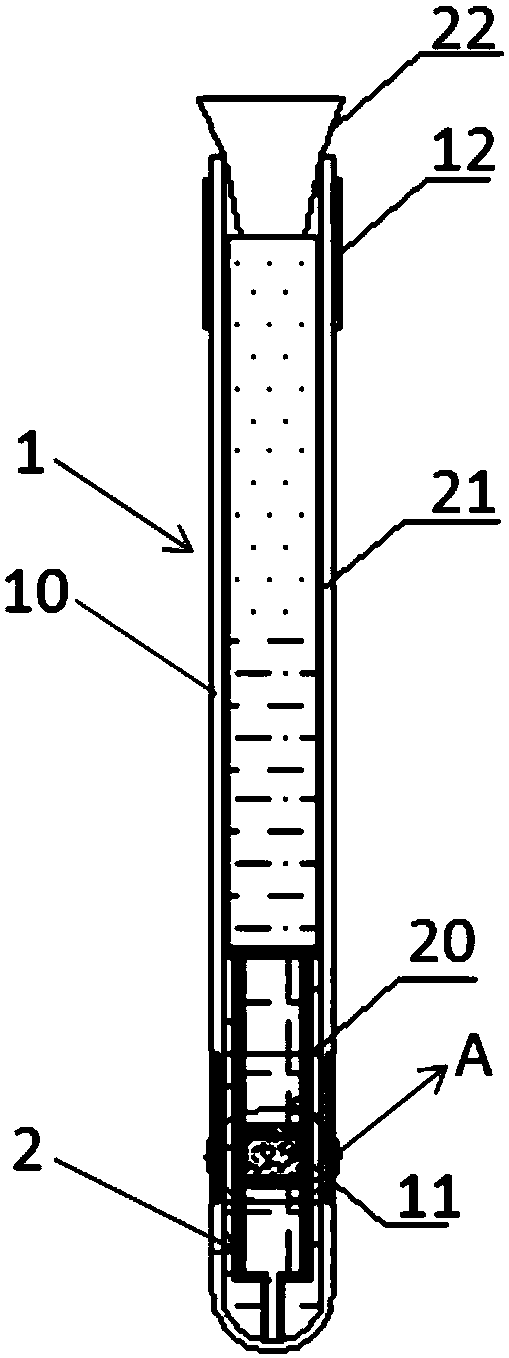

Gradually-rising spiral passive sampler for organic pollutants on water-sediment interface

The invention discloses a gradually-rising spiral passive sampler for organic pollutants on a water-sediment interface. The gradually-rising spiral passive sampler comprises a sediment pore water sampler and a water sampler arranged above the sediment pore water sampler, wherein a plurality of sediment sampling units are vertically arranged inside the sediment pore water sampler; a plurality of transversely-arranged water sampling units are sequentially arranged inside the water sampler in a vertical direction; the sediment pore water sampler and the water sampler are organically combined together, the sediment sampling units are arranged vertically and the transversely-arranged water sampling units are sequentially arranged in the vertical direction, so that the concentration of the organic pollutants in sediment pore water in different depths and the concentration of the organic pollutants in overlying water at different heights at the same position can be accurately obtained at the same time, namely the concentrations at different positions in the sediment pore water and the overlying water can be measured from multiple points at the same time; and through mathematical calculation, the real diffusion flux between the sediment pore water and the overlying water can be obtained. The gradually-rising spiral passive sampler is applied to the technical field of sampling of pollutants in water.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Method for distinguishing gaseous water dispersing mode in bituminous mortar

ActiveCN108007811AThe proportion is conducive to clearSpecific gravityWeighing by absorbing componentAbsorption capacityRoad surface

The invention provides a method for distinguishing gaseous water dispersing mode in bituminous mortar, and belongs to the field of traffic pavement materials. The method comprises the following steps:manufacturing a thin-sheet type bituminous mortar test part of which the diameter-height ratio is beyond 10: 1; performing gaseous water absorbing test under constant temperature T and different relative humidity phi conditions; calculating equilibrium absorption capacity of the test part in each humidity; then performing gaseous water dispersing test under a constant-temperature and constant-humidity condition, wherein the constant temperature is identified as T; testing the overall mass of the test part device in different time until the stable stage that mass varies at constant speed as time goes one is achieved; then calculating the data obtained from the absorbing test and the dispersing test; and calculating the proportion of the diffusion flux of different dispersing modes in the total diffusion flux. With the adoption of the method, the problem that the gaseous water dispersing mode in the bituminous mortar cannot be distinguished by the prior art can be solved; and the methodis applicable to bituminous mortar damage mechanism study.

Owner:HARBIN INST OF TECH

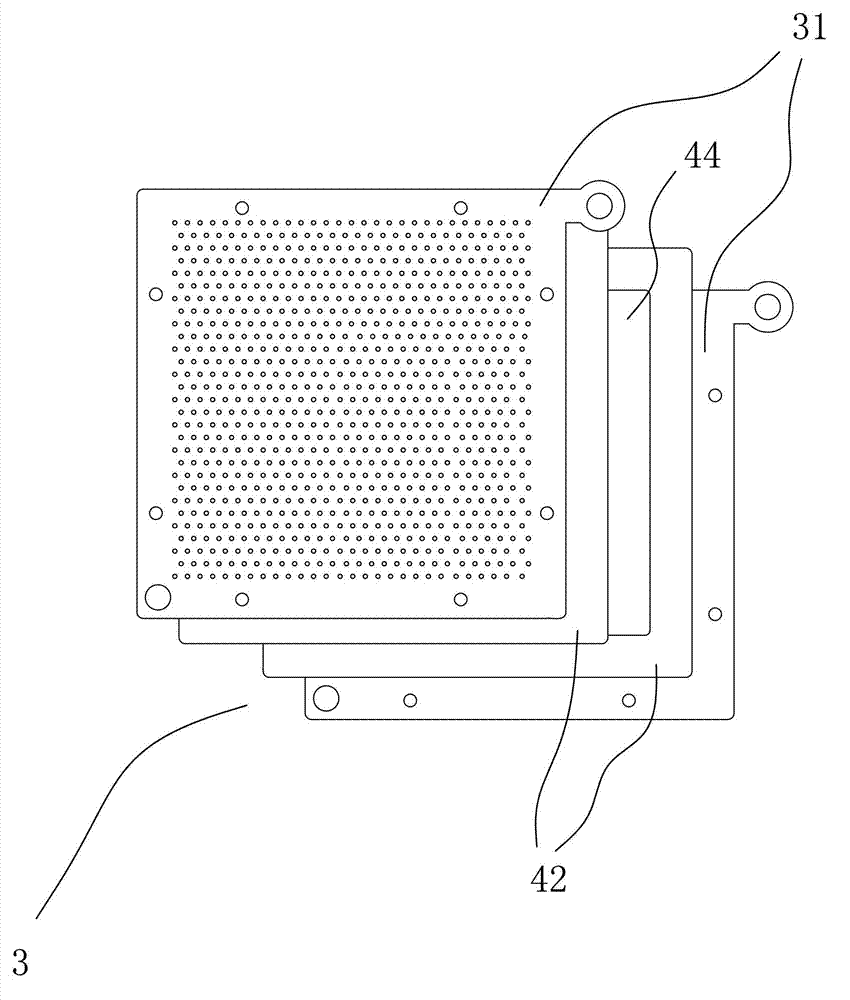

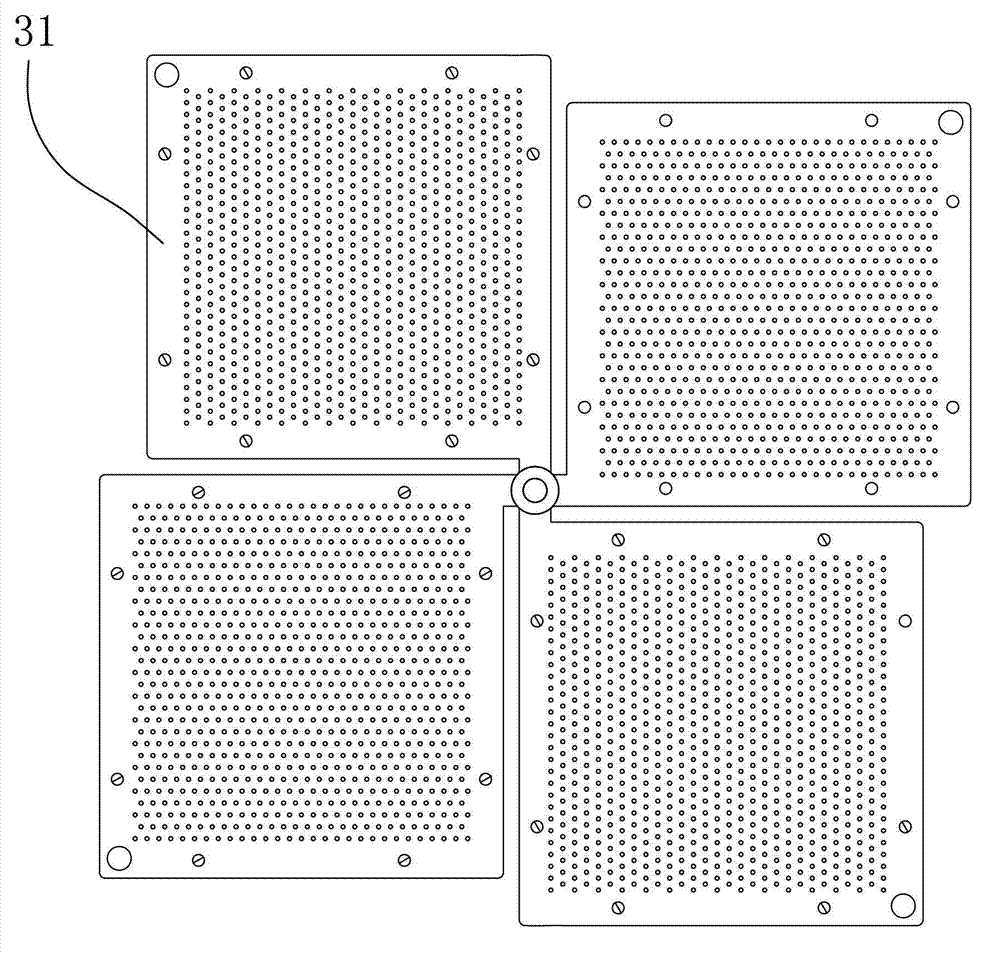

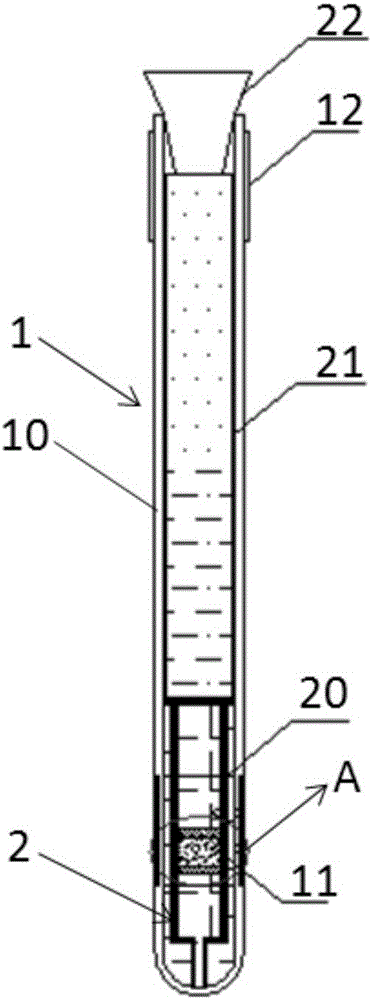

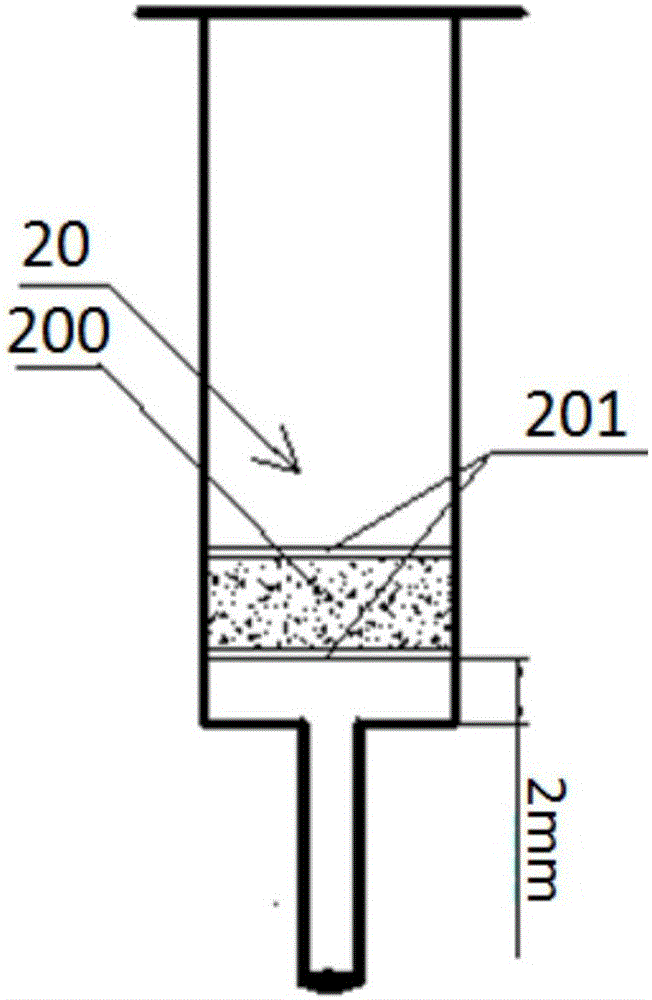

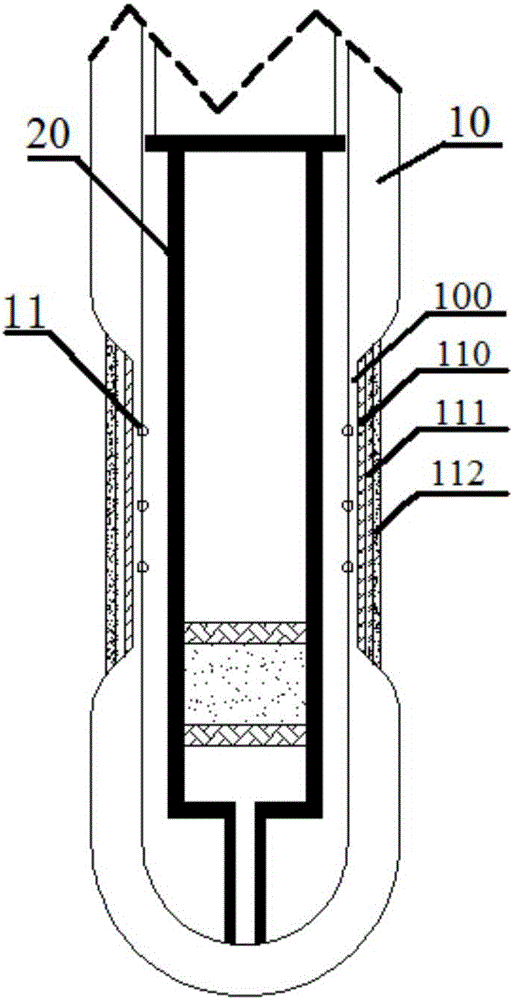

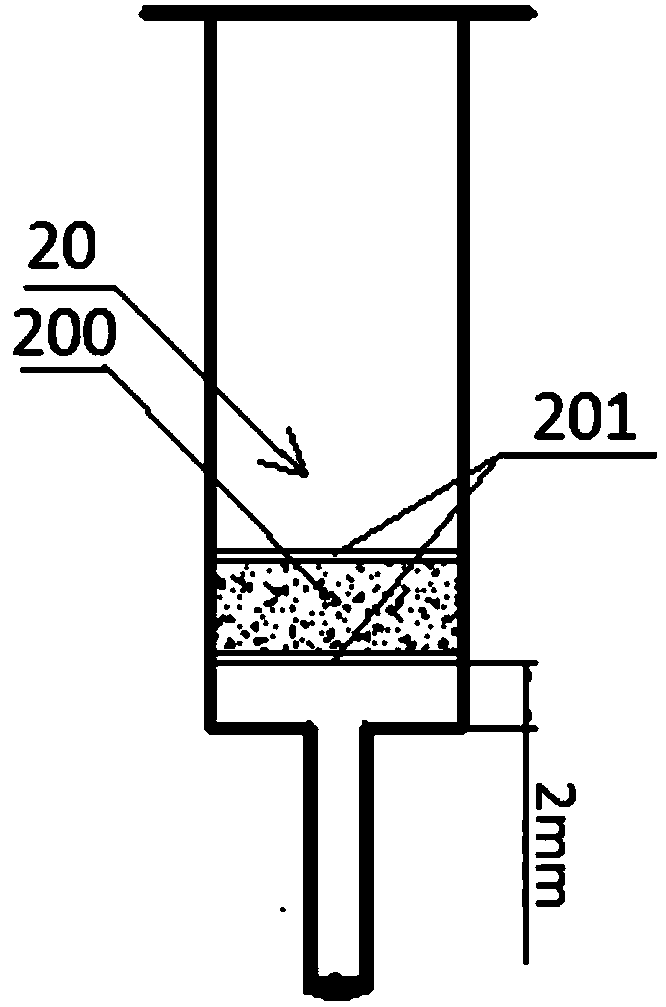

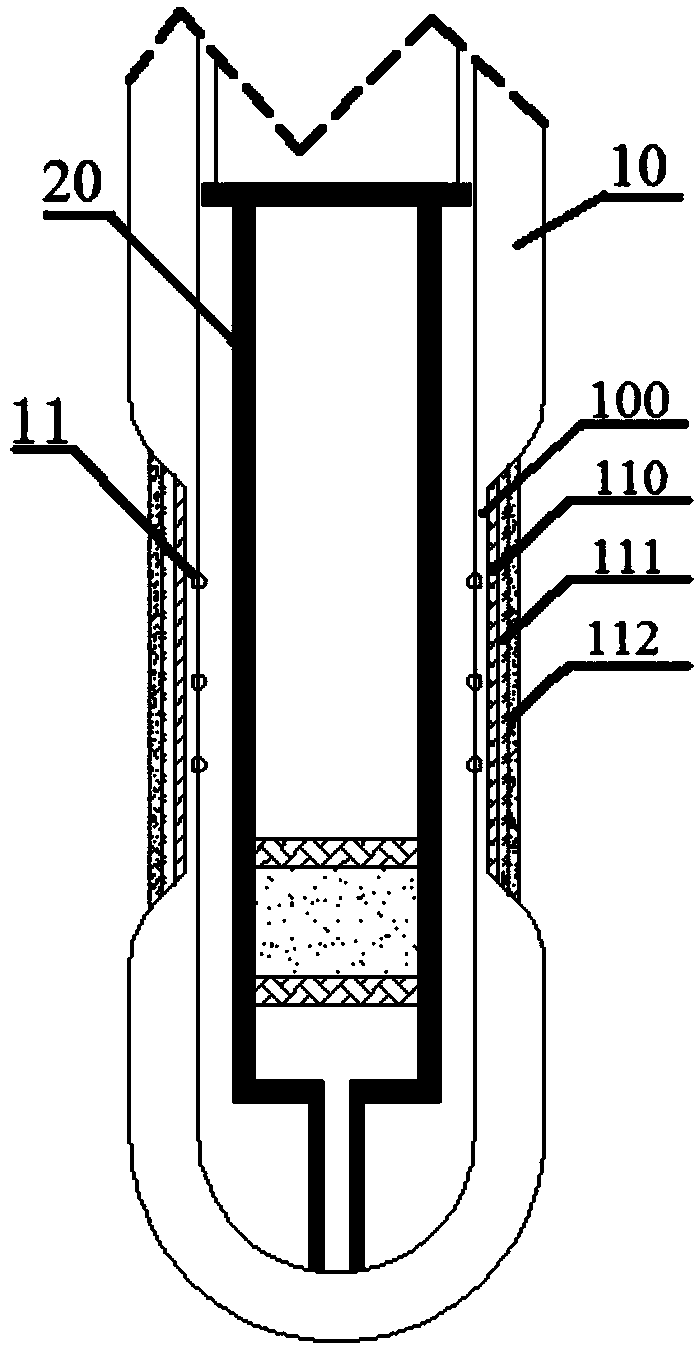

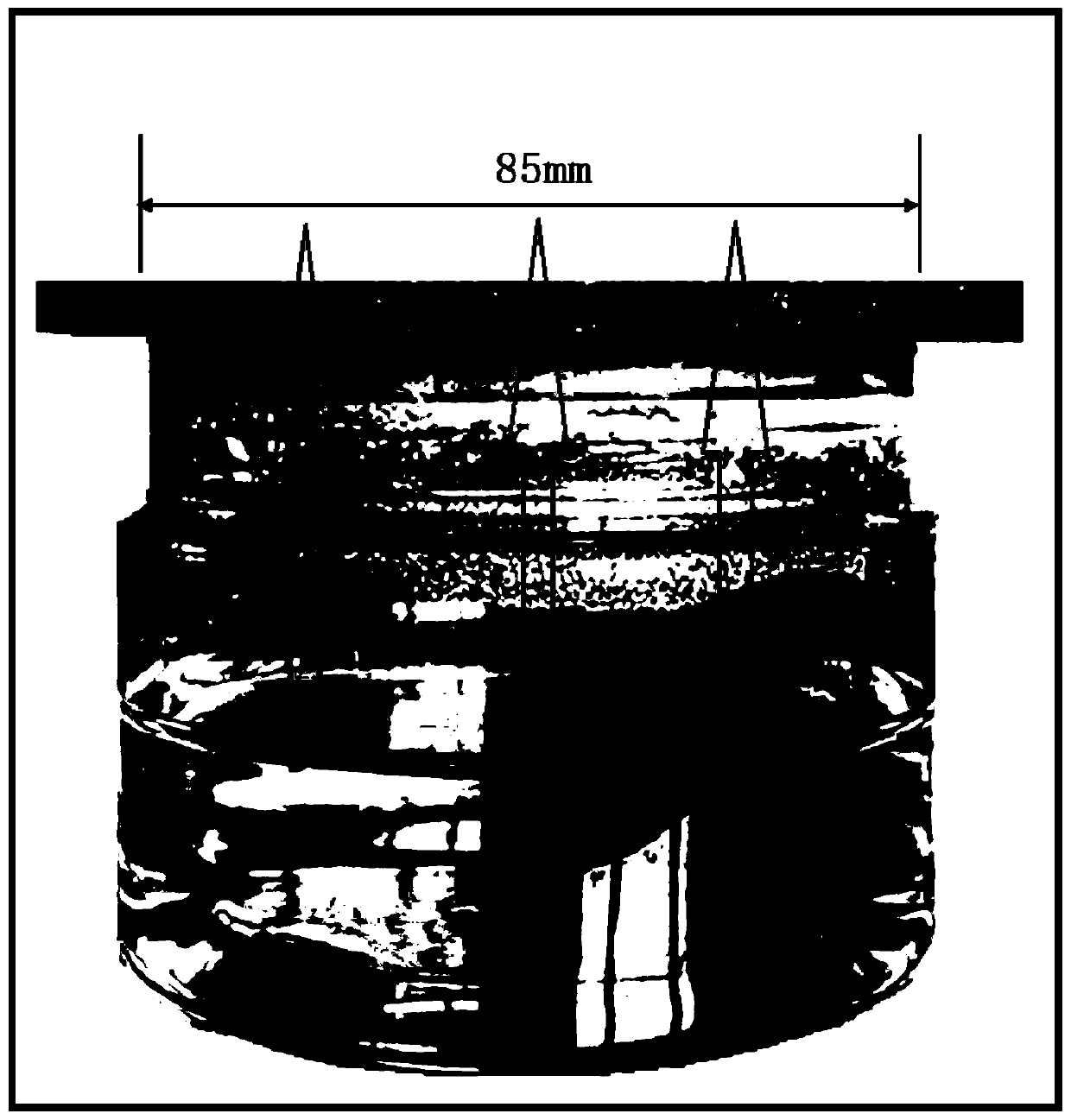

Root system simulation collecting system for monitoring diffusion flux of PAHs in soil

InactiveCN106018182AOvercome severe self-adsorptionLarge flow areaSurface/boundary effectGlass fiberSystems design

The invention discloses a root system simulation collecting system for monitoring diffusion flux of PAHs in soil. The root system simulation collecting system comprises a passive type soil solution collecting bin and a PAHs root system simulation collecting system arranged in the collecting bin. The passive type soil solution collecting bin comprises a collecting bin body glass column pipe, a Teflon jacket arranged on the bottom of the glass column pipe in a sleeving mode and a ground jacket arranged on the top of the glass column pipe in a sleeving mode, and a multihole water inlet with holes in the side portion is formed in the lower middle portion of the glass column pipe. The PAHs root system simulation collecting system comprises an SPE extraction column pipe arranged in the glass column pipe, the upper portion of the SPE pipe is packed with a glass hollow support pipe, and the upper portion of the support pipe is sealed through a rubber stopper. The multihole water inlet is formed in an annular inward-concave mode. A glass fiber filter membrane, a polytetrafluoroethylene millipore filtration interlayer and a stainless steel mesh support layer are sequentially arranged in the inward-concave position from interior to exterior. The root system simulation collecting system can be applicable to collecting and diffusion flux testing of PAHs in percolate under different natural environments, and the system is reasonable in design, simple in manufacturing process, low in cost, convenient to operate, efficient and durable.

Owner:HOHAI UNIV

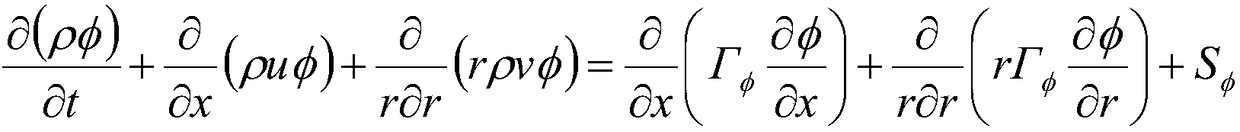

Fluent-based dust explosion simulation method

InactiveCN108446468AImprove adaptabilityEliminate Separation ErrorsDesign optimisation/simulationSpecial data processing applicationsDiffusionDust explosion

The present invention relates to a fluent-based dust explosion simulation method. Although numerical simulation has become an increasingly popular research tool, there is a lack of good models for describing the interaction between phases and between particles. The method provided by the present invention is characterized in that: for the gas-conservation equation of the general form of gas in thetwo-dimensional region, the finite volume method in the discretization method is used to calculate the fluid dynamics software FIUENT; in the integration process, constitutions of the convective fluxof the solved function itself on the interface and of the first derivative diffusion flux of the solved function are assumed to form different discrete formats; and only a discrete equation derived by using the finite volume method can guarantee conservation as long as the control volumes located on both sides of the interface in the interpolation method on the interface are the same. The methodprovided by the present invention is simple in calculation, and pseudo-diffusion cannot be generated when the particle has a more complex change experience and the motion value calculation of the particle can be better tracked.

Owner:HARBIN UNIV OF SCI & TECH

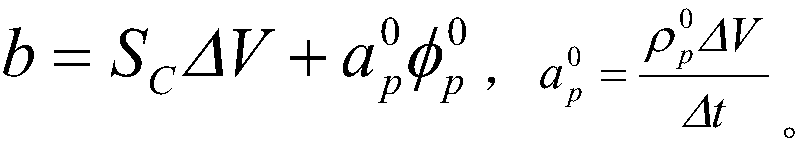

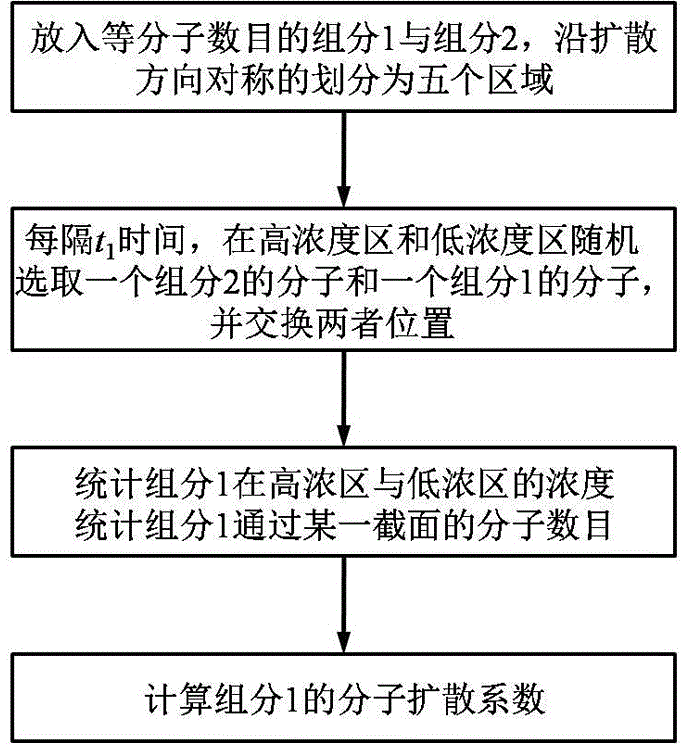

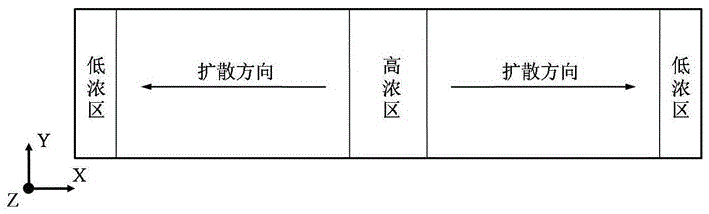

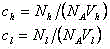

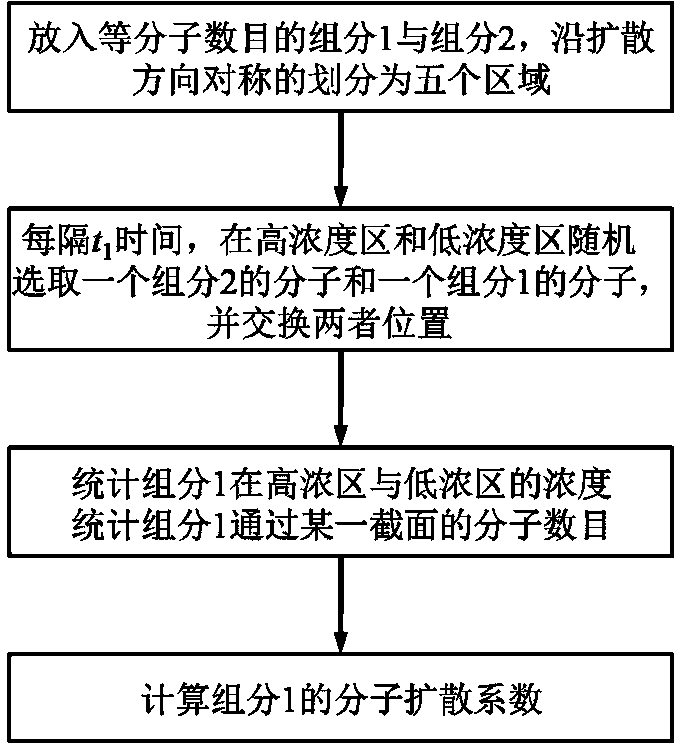

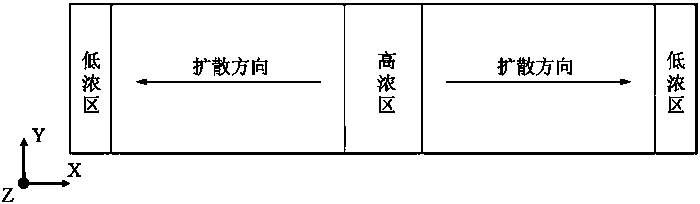

Method for calculating molecular diffusion coefficients through non-equilibrium molecular dynamics simulation

InactiveCN105653766AReduce difficultyImprove Simulation EfficiencySpecial data processing applicationsDiffusionChemical physics

The invention provides a method for calculating molecular diffusion coefficients through non-equilibrium molecular dynamics simulation. According to the method, the molecular dynamics simulation is purely adopted to directly calculate the concentration gradients and diffusion fluxes of components in mixtures along the diffusion direction, so that the molecular diffusion coefficients of the components can be accurately calculated. Compared with a double-control volume grand canonical molecular dynamics (DCV-GCMD) simulation method, the method provided by the invention is capable of effectively improving the simulation efficiency and remarkably reducing the simulation program compiling difficulty.

Owner:ZHONGBEI UNIV

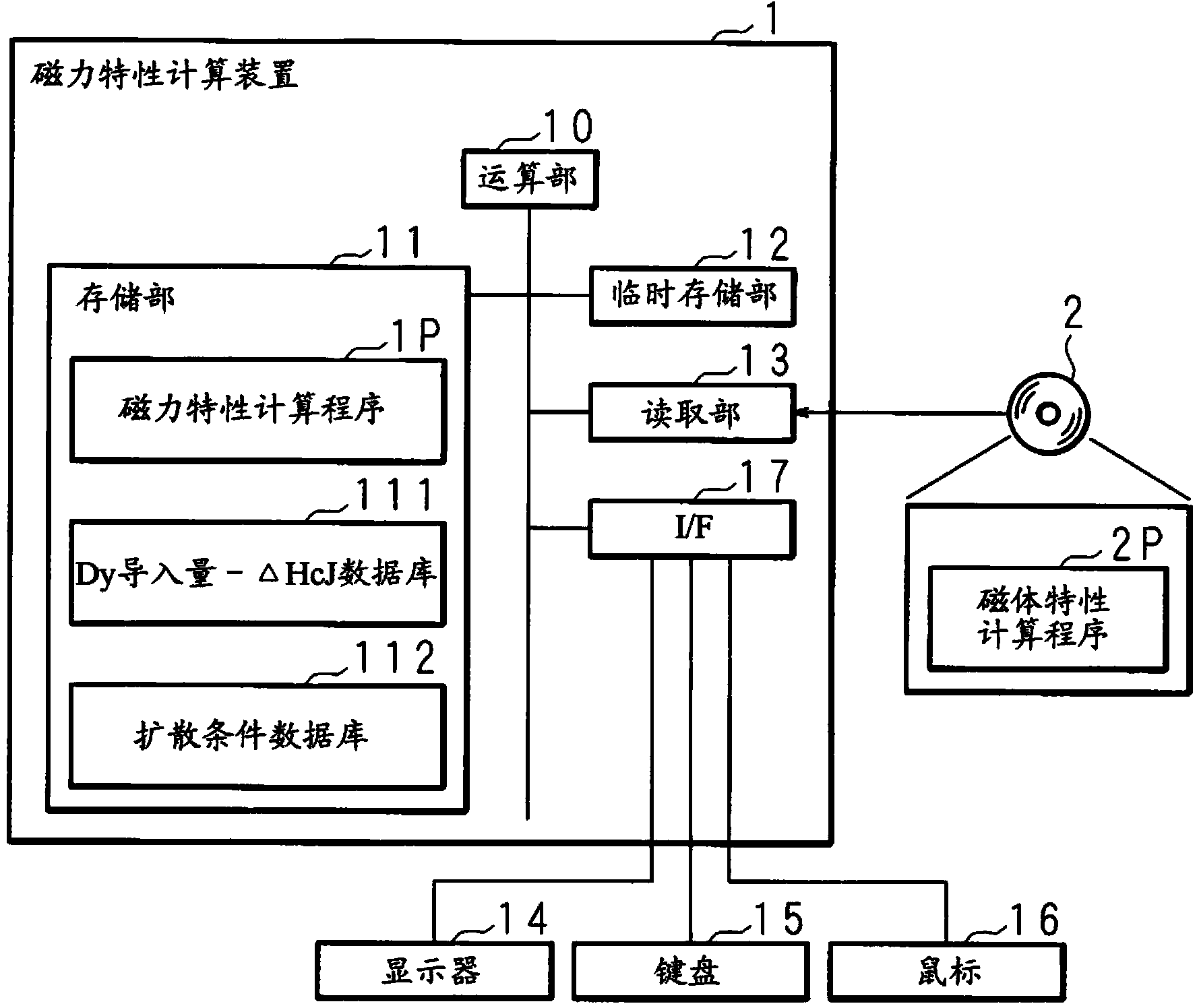

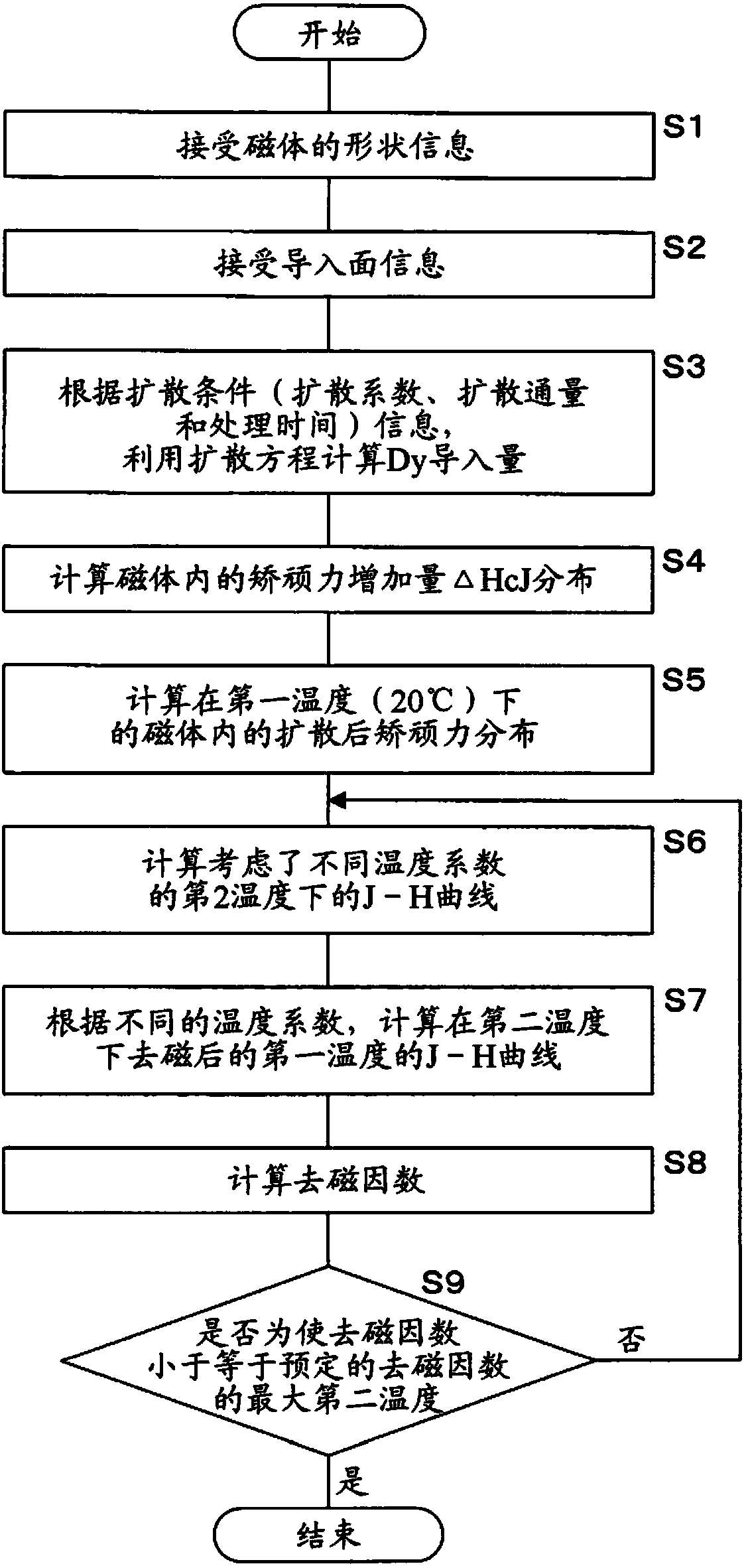

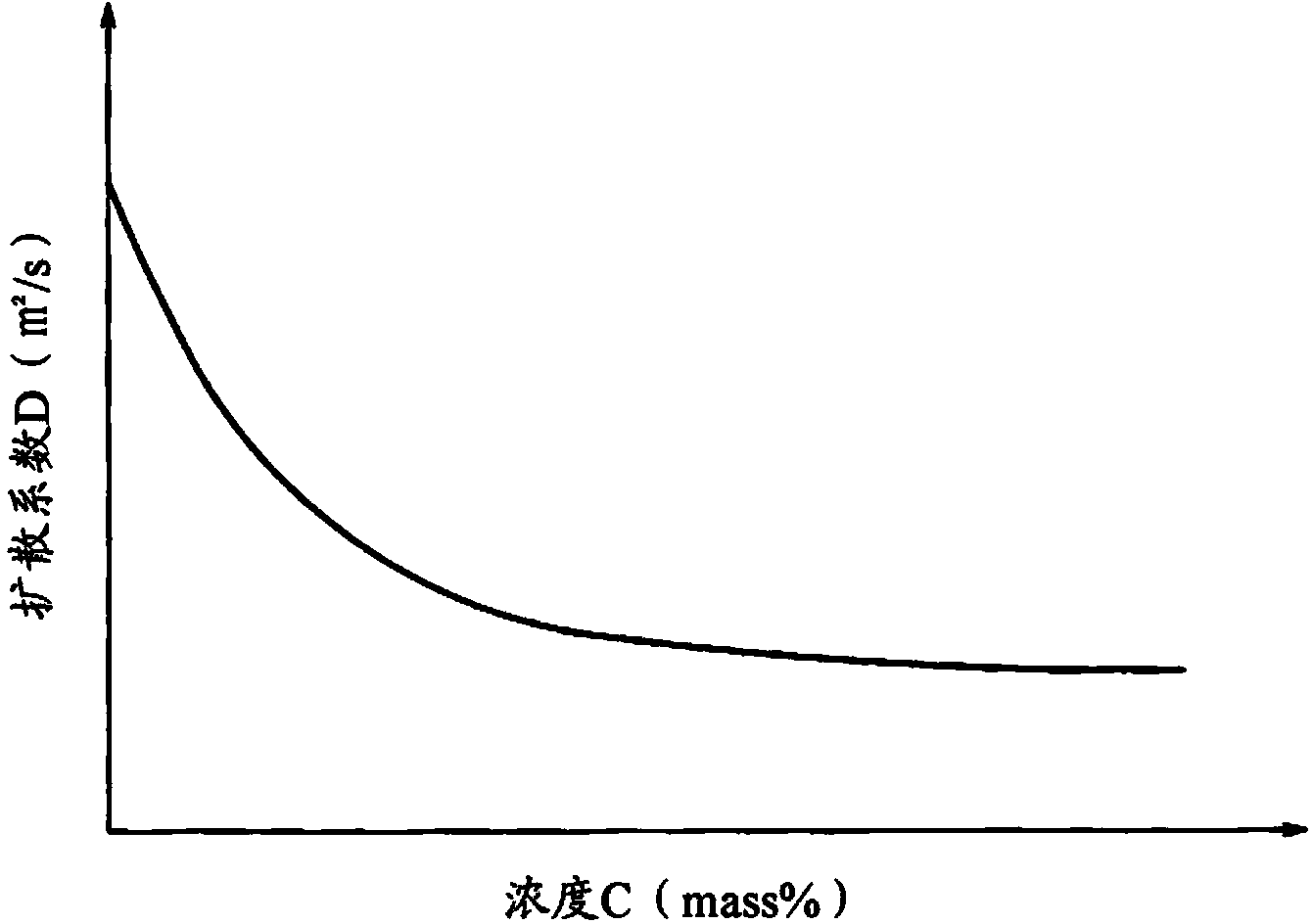

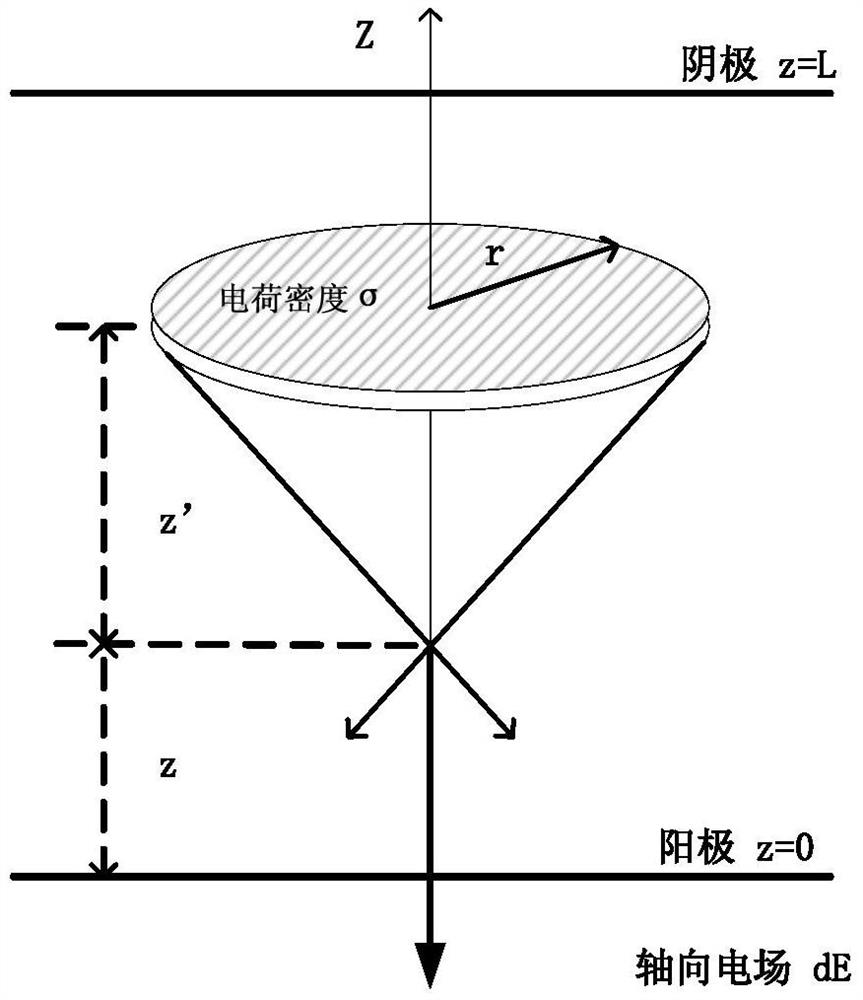

Magnetism characteristics calculation method, magnetism characteristics calculation device, and computer program

ActiveCN103620434AHigh-precision magnetic characteristicsHigh-precision calculation of demagnetization factorInductances/transformers/magnets manufactureSusceptibility measurementsDiffusionComputer science

Using a database indicating correspondence between d (depth) and -HcJ (amount of increase in coercivity) stored in advance and a database indicating information on Dy diffusion conditions (diffusion coefficient, diffusion flux and processing time for Dy diffusion), the distribution of the amount of Dy introduced into a magnet is calculated from information about the shape of the magnet and information about a Dy introduction surface, and the distribution of HcJ in the magnet is calculated from the distribution of the amount of introduced Dy. For magnets having a distribution in which coercivity is not homogeneous, the calculated HcJ distribution is used to calculate a J-H curve, and the demagnetizing factor at a predetermined temperature is calculated using a temperature coefficient.

Owner:HITACHI METALS LTD

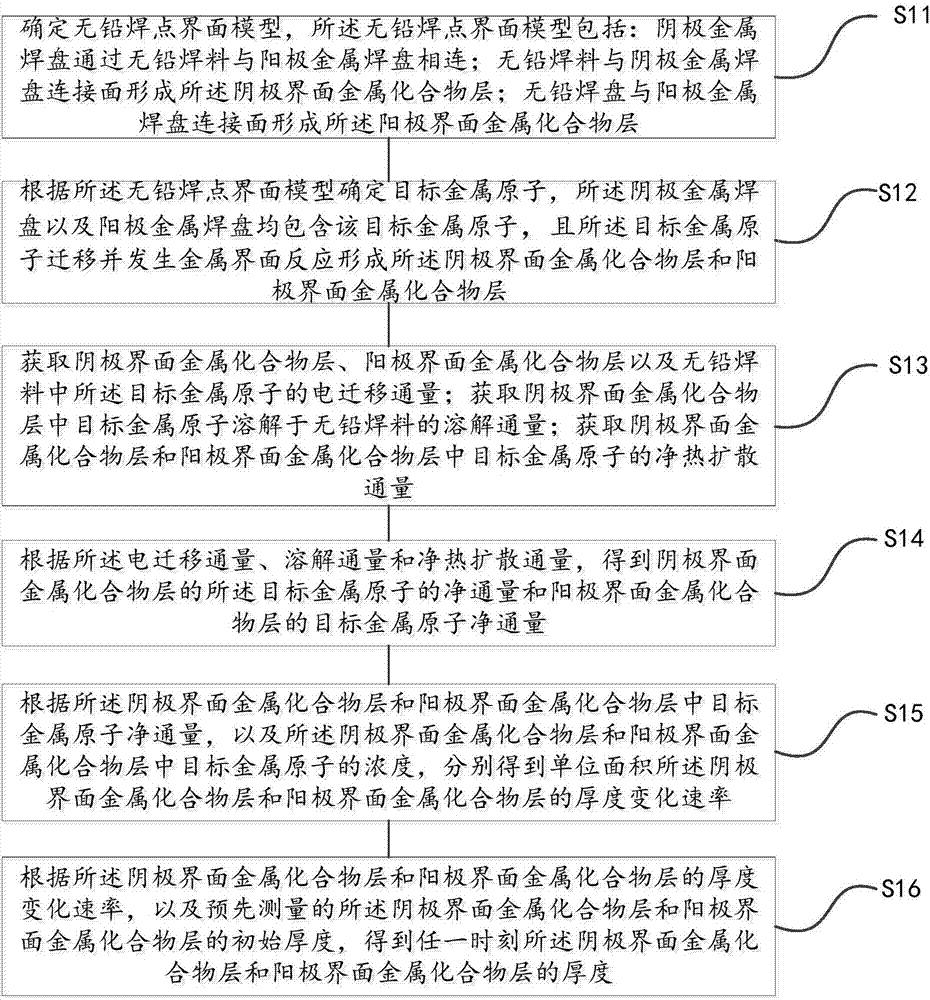

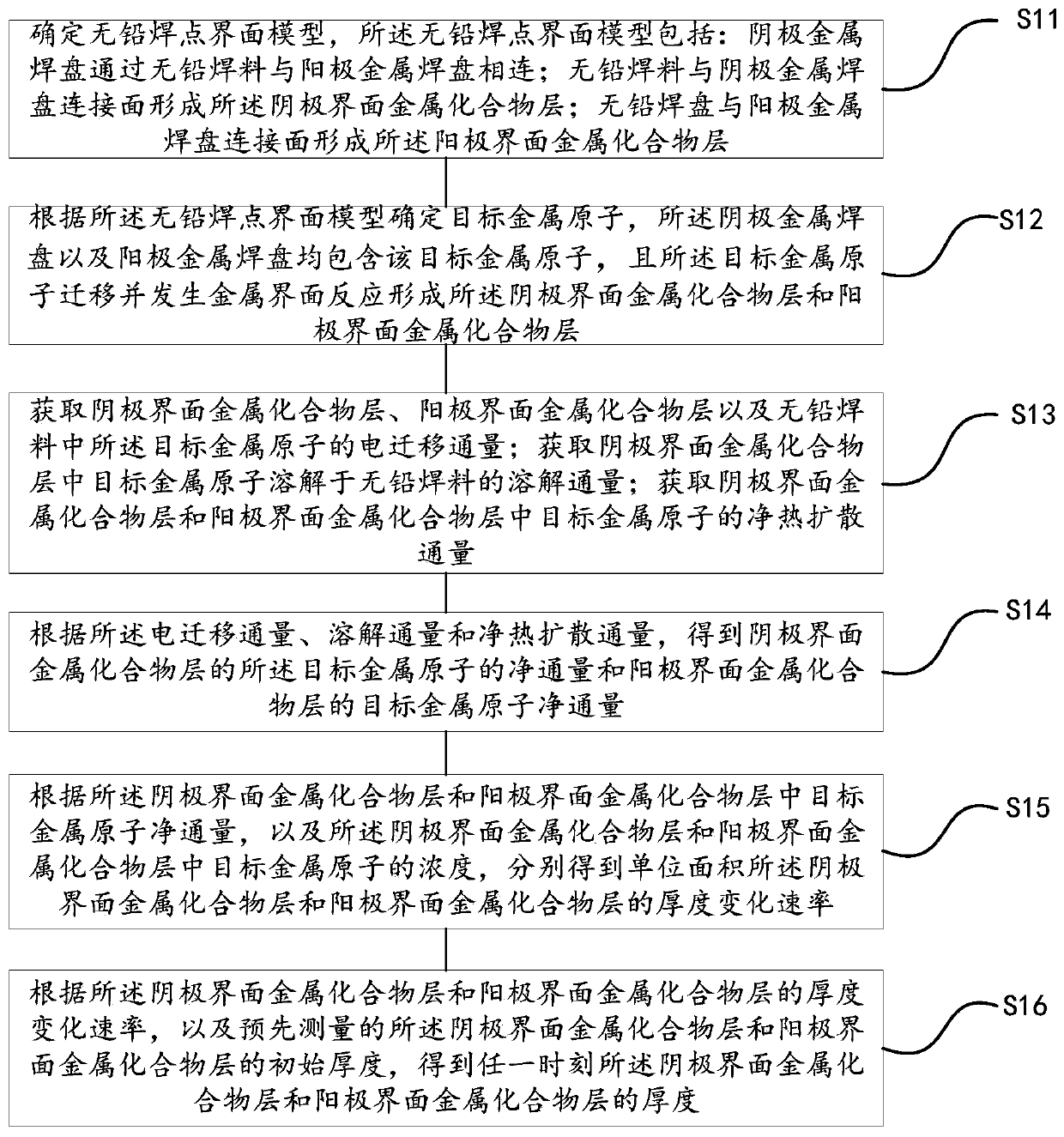

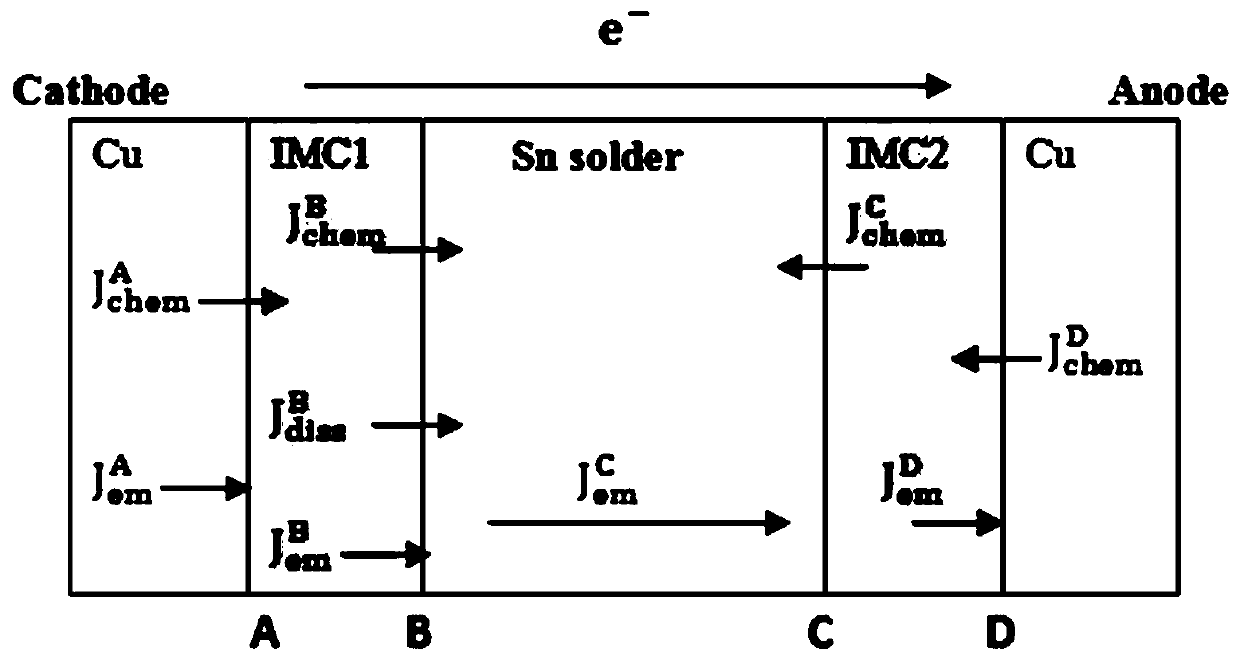

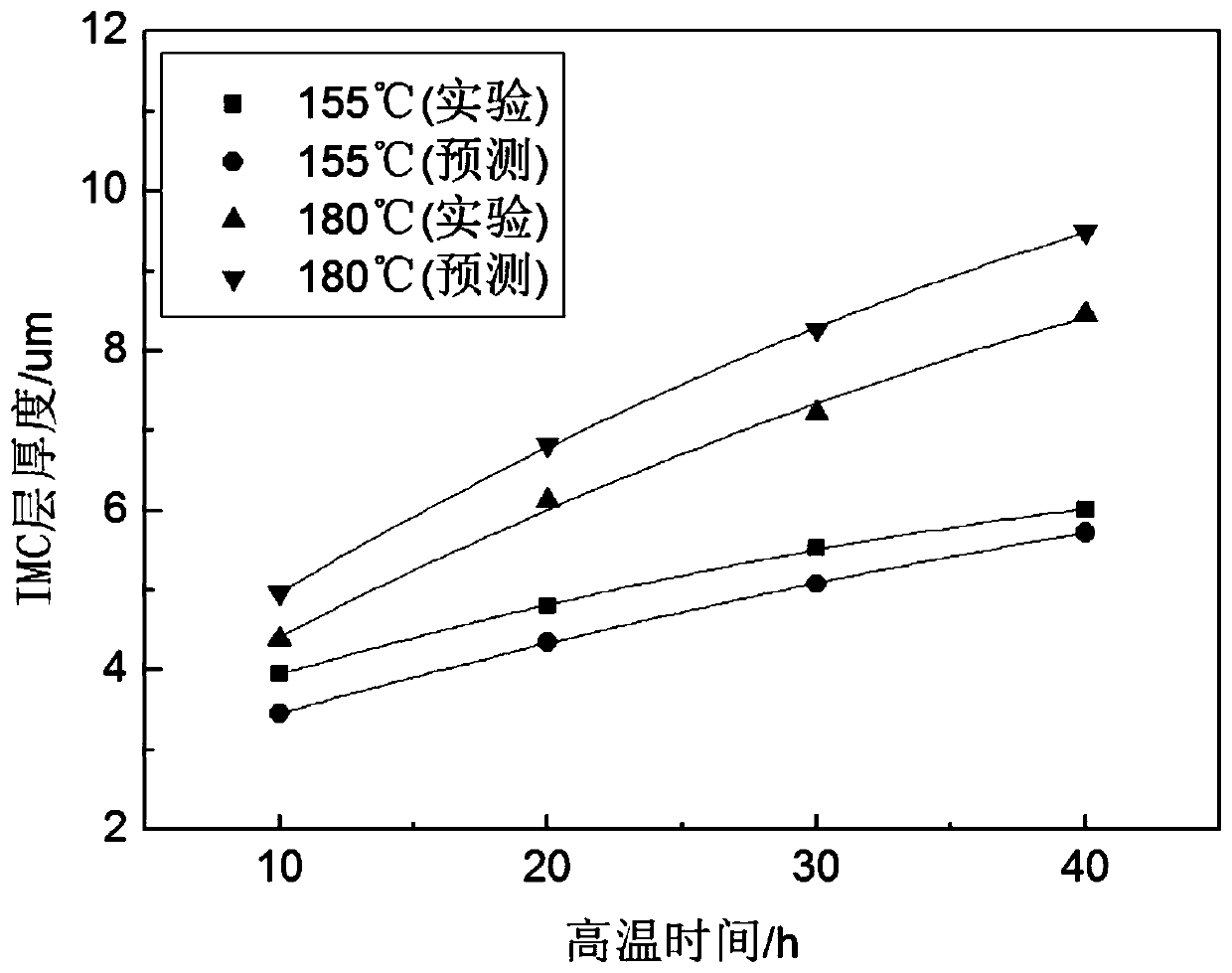

Leadless solder joint interface metallic compound growth thickness prediction method and system thereof

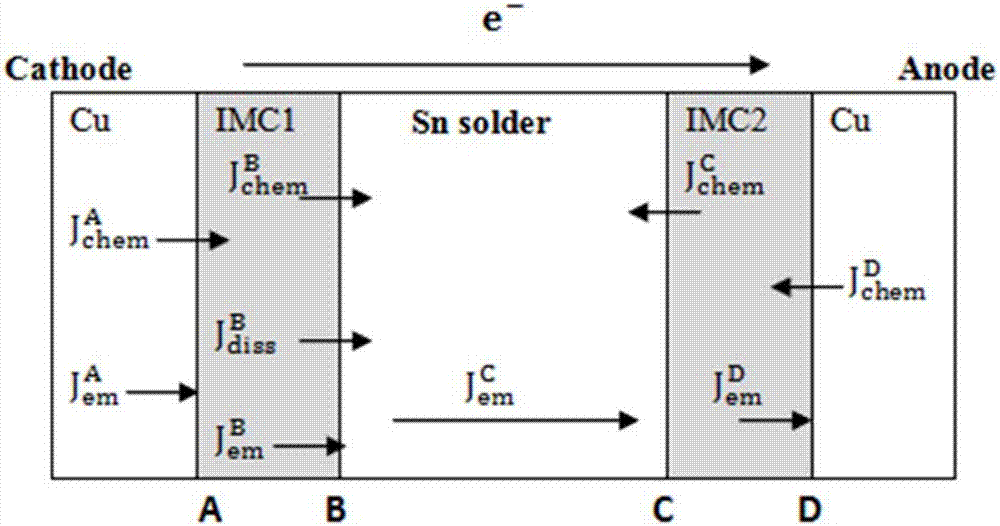

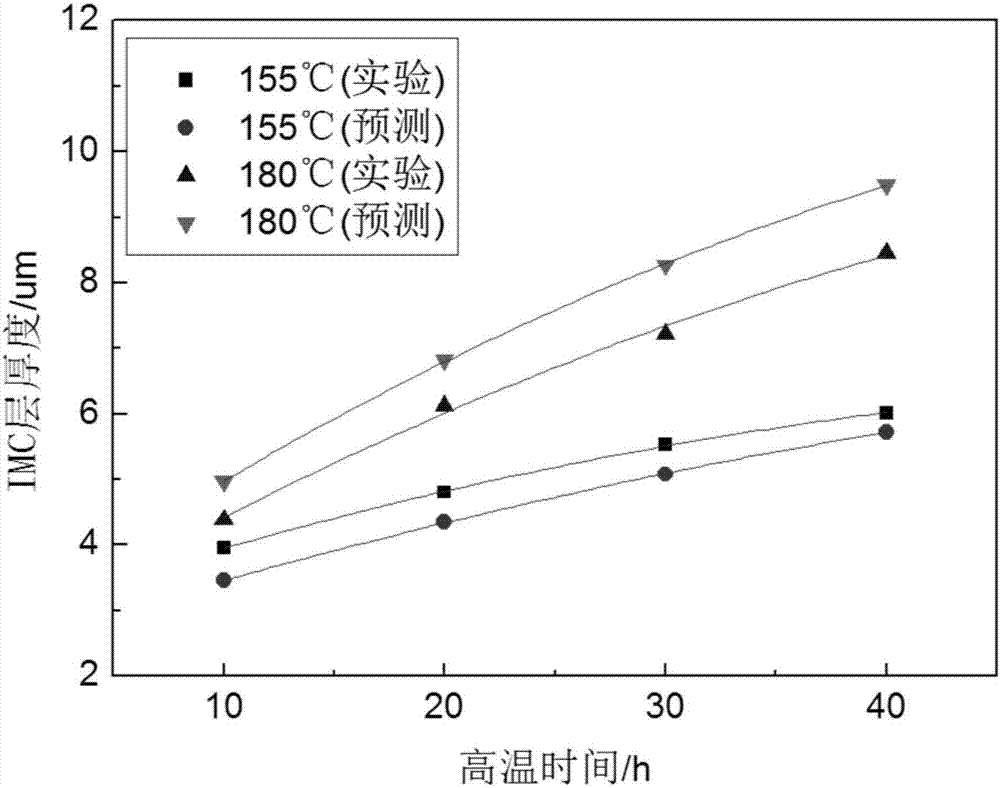

ActiveCN106918538ASolve the problem of inaccurate growth thickness prediction resultsSurface/boundary effectMaterial thermal analysisMetallurgyElectromigration

The invention relates to a leadless solder joint interface metallic compound growth thickness prediction method and a system thereof. The method comprises the following steps: determining a leadless solder joint interface model and a target metal atom, obtaining the electromigration flux, dissolving flux and net-heat diffusion flux, calculating the thickness change rate of a cathode interface metallic compound layer and an anode interface metallic compound layer, according to the thickness change rate and initial thickness, obtaining the thickness of the cathode interface metallic compound layer and the anode interface metallic compound layer at any time. The above method can accurately predict the growth thickness of the interface metallic compound layer.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

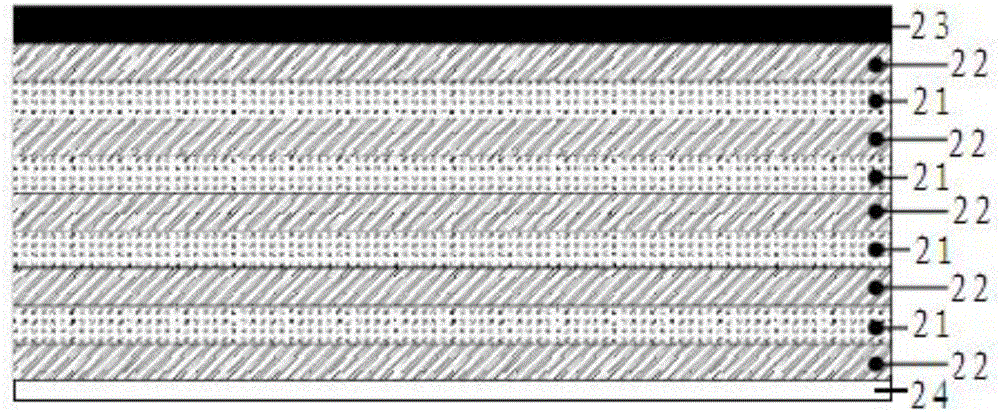

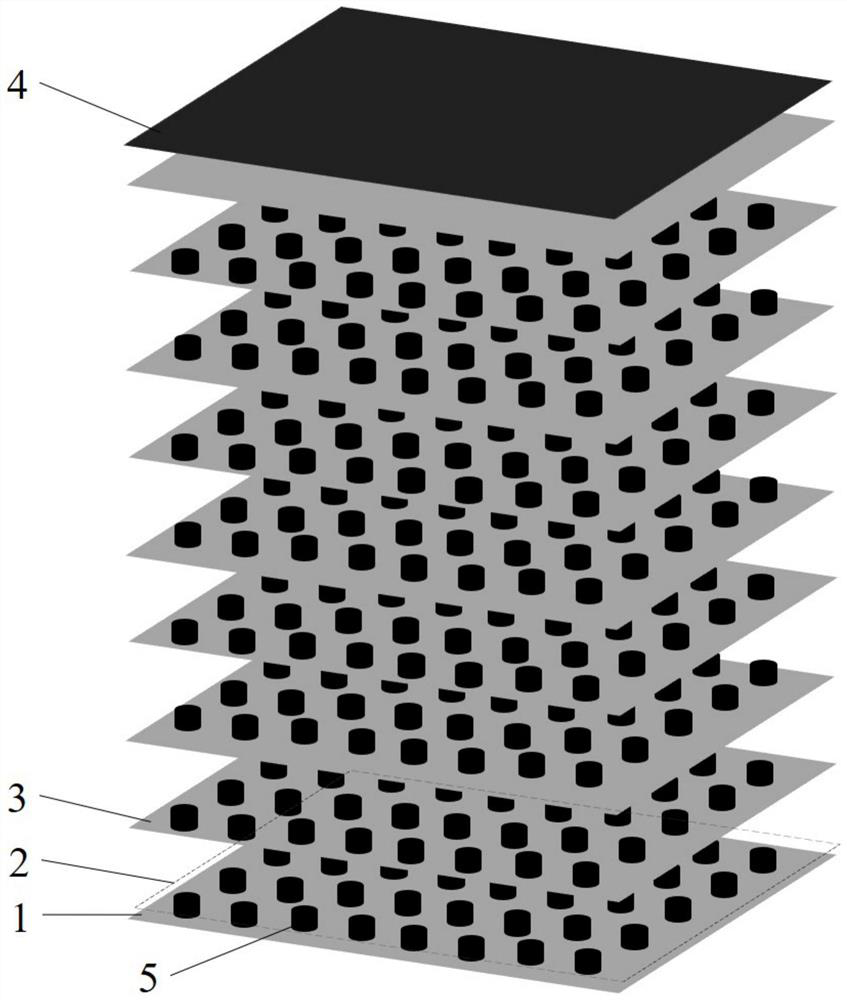

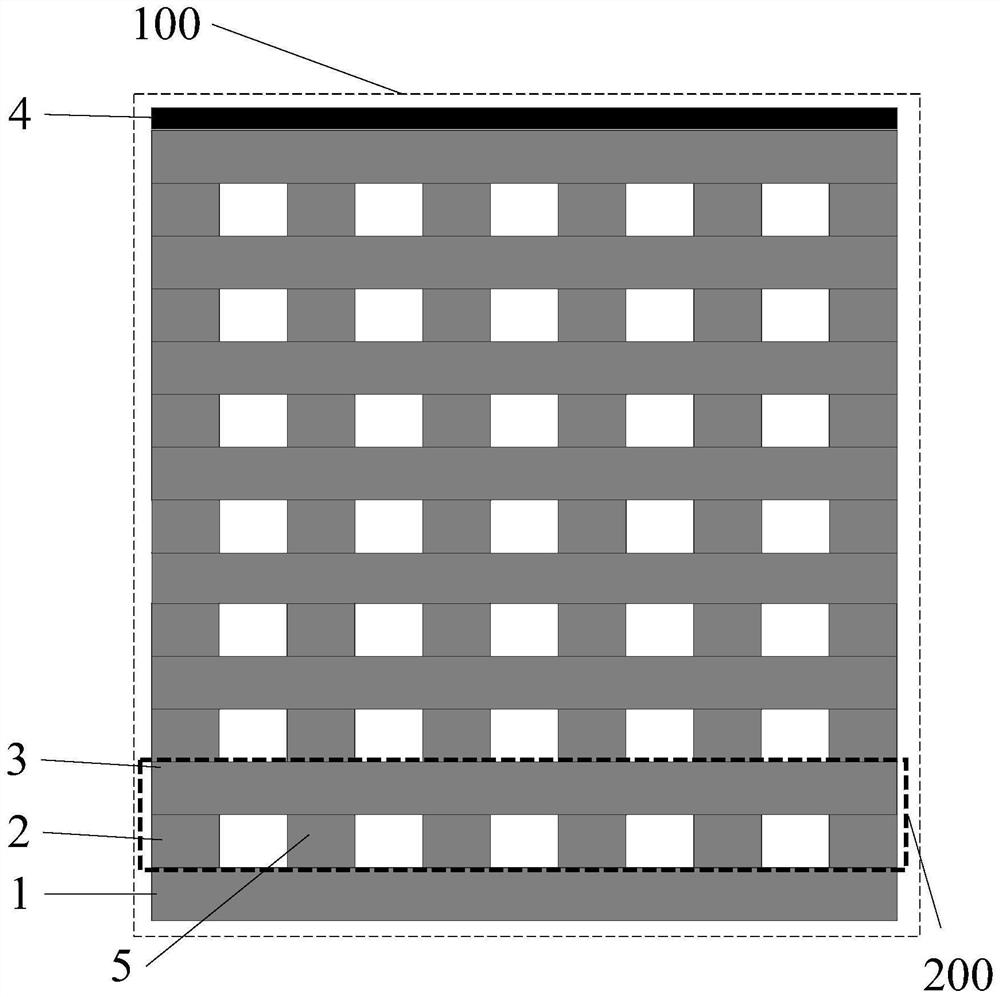

Current collector

ActiveCN114388813AIncreased diffusion fluxHigh diffusion fluxElectrode carriers/collectorsGaseous diffusionDiffusion resistance

The invention discloses a current collector, and relates to the technical field of electrochemical devices, the current collector comprises a first diffusion layer, a second diffusion layer, a third diffusion layer and a surface protection layer which are sequentially stacked from bottom to top, the first diffusion layer and the third diffusion layer are made of a porous material, and the surface protection layer is made of a porous material. The second diffusion layer comprises a plurality of conductive vitex strips which are arranged at intervals, so that gas channels are formed among the conductive vitex strips. The current collector is provided with the open type gas diffusion channel, so that the gas diffusion flux can be increased, the diffusion resistance of gas such as fuel or air in an electric pile can be reduced, and the distribution uniformity of the gas such as fuel or air on the surface of an electrode can be improved. According to the current collector provided by the invention, an open type gas diffusion channel is formed through the first diffusion layer, the second diffusion layer and the third diffusion layer, and the current collector has high gas diffusion flux.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

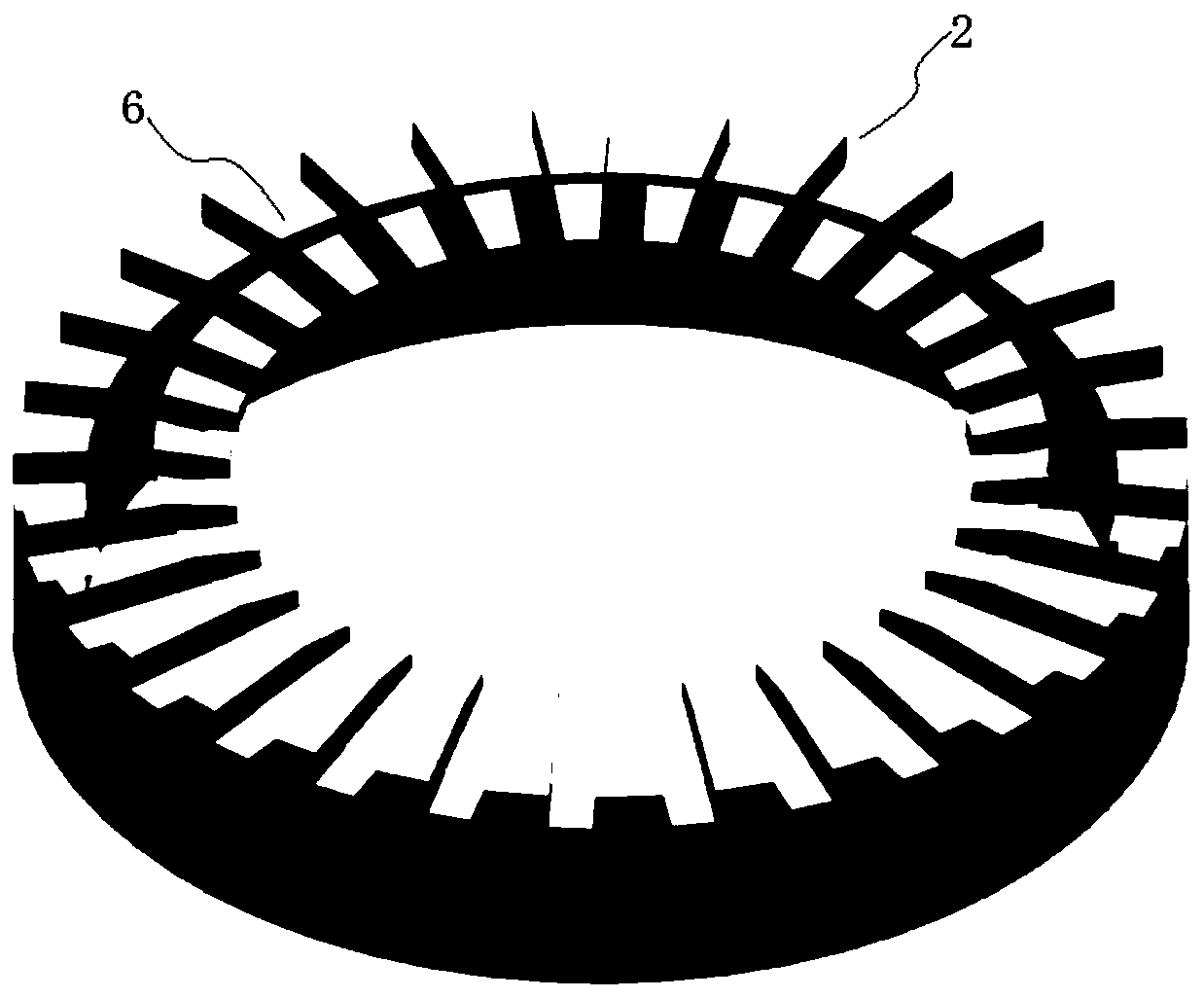

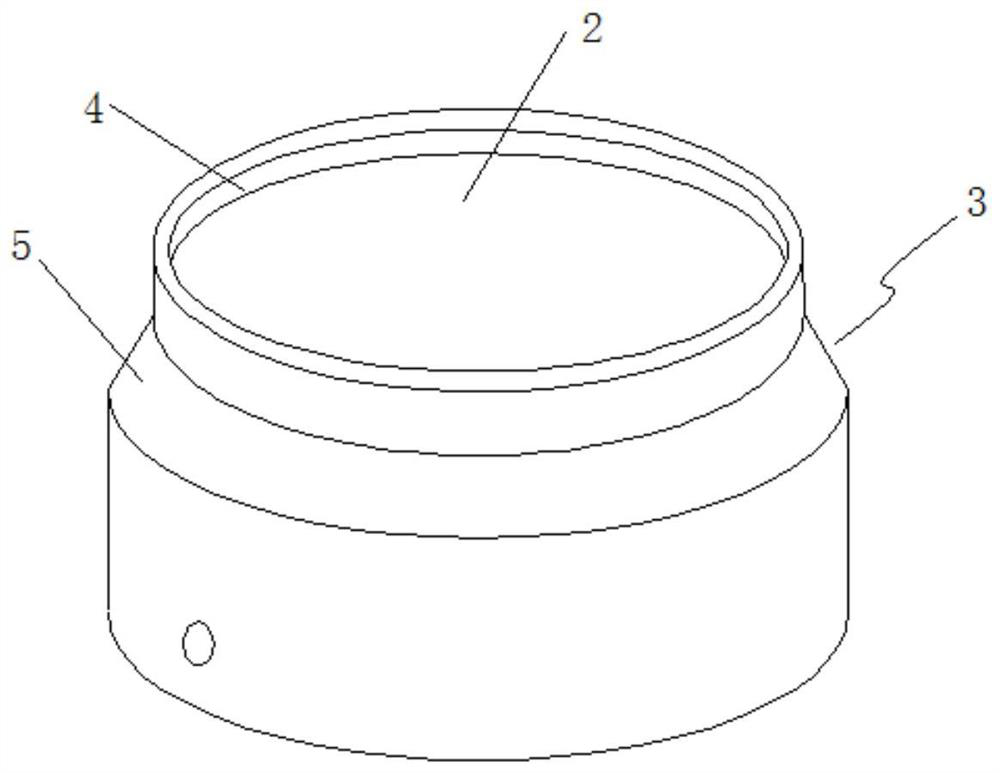

In-situ sampling device, detection device and detection method for maximum diffusion flux of sediment-water interface pollutants

ActiveCN109781588AEarly warning release riskOvercome the disadvantages of forming an anaerobic stateWithdrawing sample devicesSurface/boundary effectEngineeringUltimate tensile strength

The invention discloses an in-situ sampling device, a detection device and a detection method for maximum diffusion flux of sediment-water interface pollutants. The sampling device comprises an annular upper shell, a fixed film and a lower shell, a groove used for containing the fixed film is formed in the top of the lower shell, the fixed film is arranged in the groove of the lower shell, a plurality of fins are arranged at the upper end edge of the annular upper shell at intervals, the annular upper shell sleeves the upper end of the lower shell and fixes the fixed film, and the average densities of the sampling device is larger than water densities. According to the invention, the maximum diffusion flux of sediments can be measured, the operation is convenient, and the experimental strength is relatively low; The applicability is high, and the types of target objects capable of being measured are wide; the size is small, and the release flux of the whole lake can be estimated through large-scale arrangement in the lake.

Owner:中科智感(南京)环境科技有限公司

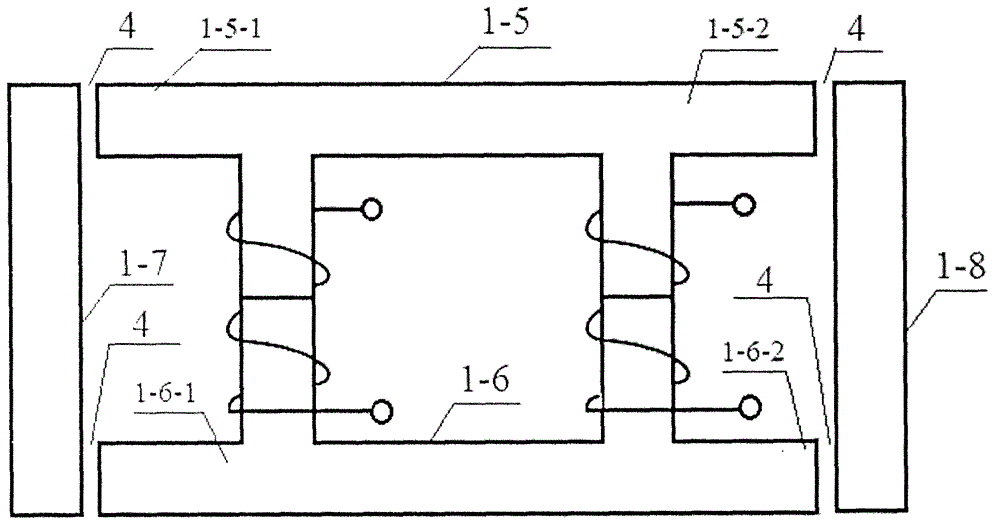

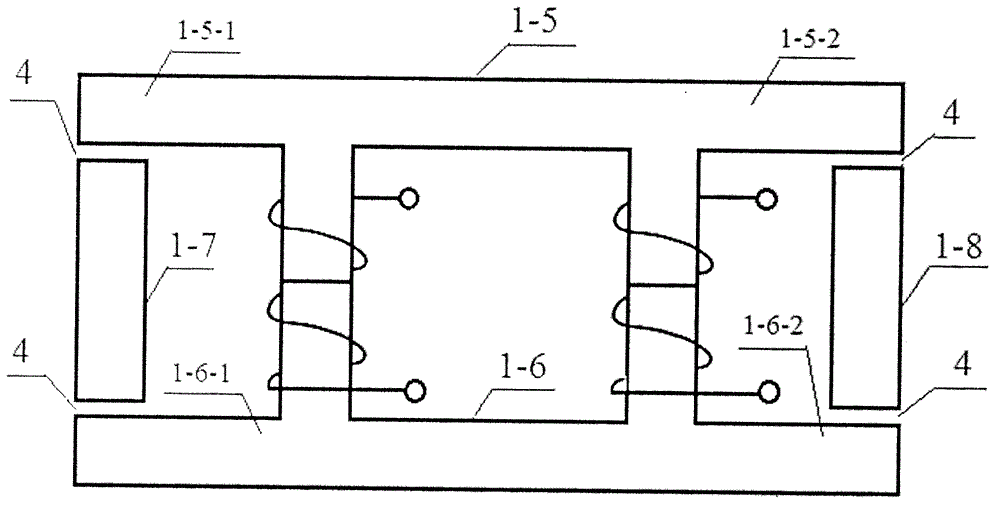

Integrated magnetic coupled inductor in the shape of Chinese character mu

ActiveCN105719784AAchieve integrationMiniaturizationTransformers/inductances magnetic coresInductance with magnetic coreChinese charactersMagnetic poles

The invention discloses an integrated magnetic coupled inductor in the shape of Chinese character mu, wherein the inductor is composed of an iron core body in the shape of Chinese character mu and two-phase coils; the iron core body in the shape of Chinese character mu is composed of four ''U'' shaped iron cores; the magnetic poles of two ''U'' shaped iron cores are arranged oppositely and form a square shaped iron core; the two-phase coils are wound on the two magnetic poles of the square shaped iron core; the other two ''U'' shaped iron cores are arranged at two sides of the magnetic poles of the square shaped iron core and are buckled on the two-phase coils; and the two magnetic poles of the other two ''U'' shaped iron cores keep certain distances with the magnetic poles of the square shaped iron core, thus forming air gaps. The inductor has the advantages that the inductor is used for inductance coupling integration; the quantity of the air gaps is doubled; the lengths of the air gaps are reduced to a half; the air gaps are symmetrical; the diffusion fluxes of the air gaps are clearly reduced; the mutual inductive magnetic circuit of the two coils is the shortest without the air gap; the mutual inductance and the self-inductance are high; the energy and the material are saved; and the electromagnetic interferences are reduced.

Owner:杨玉岗

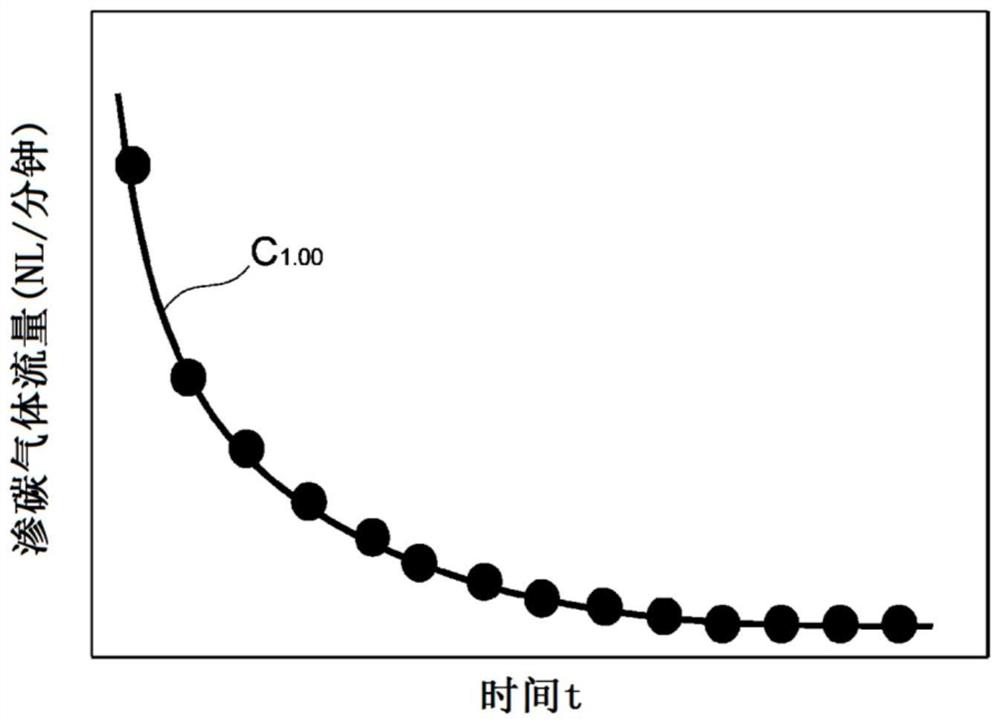

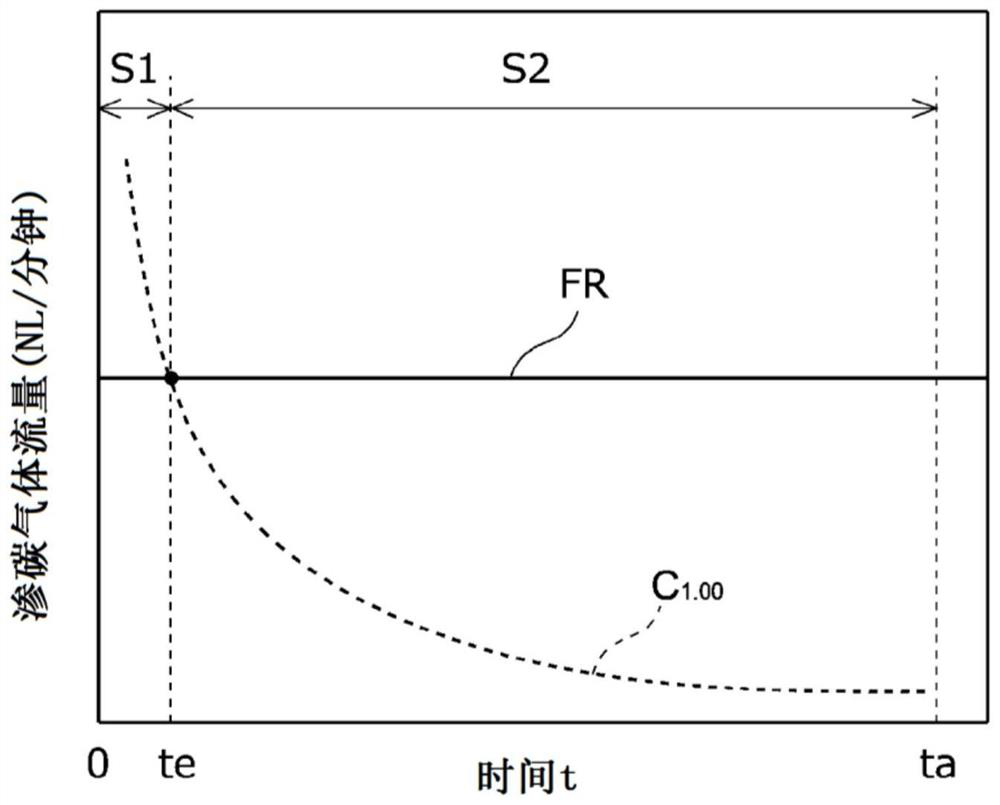

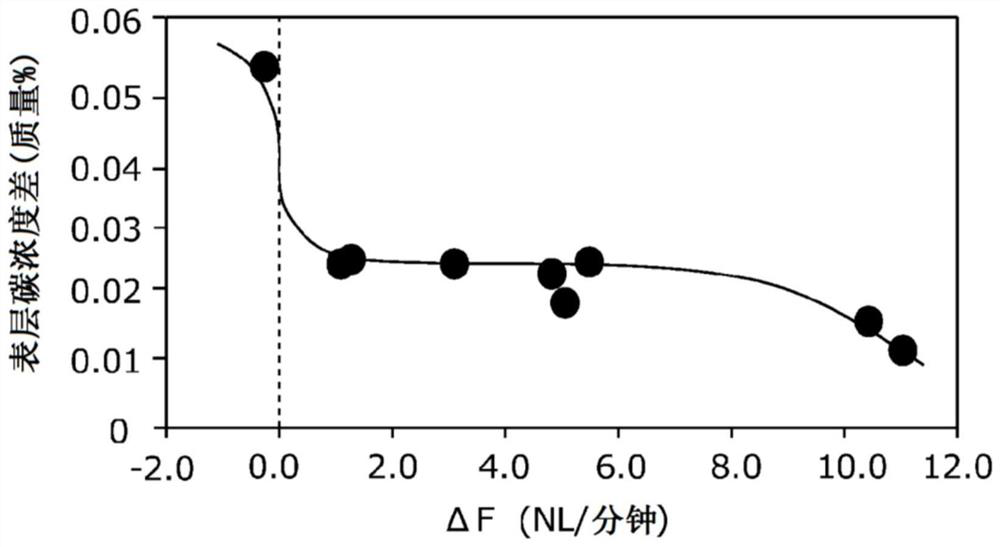

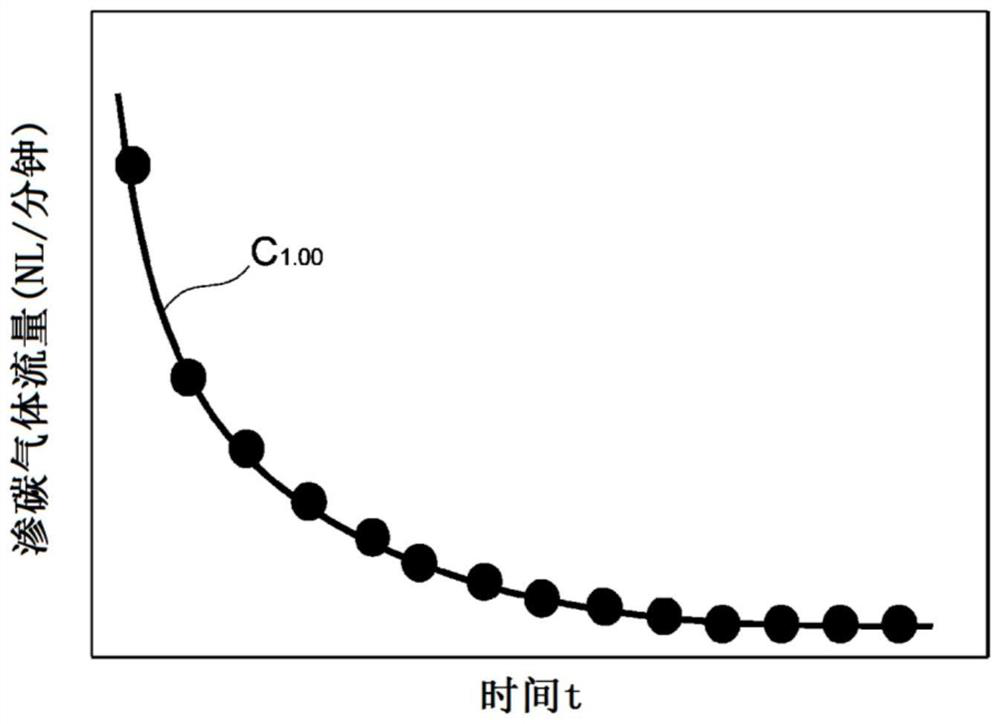

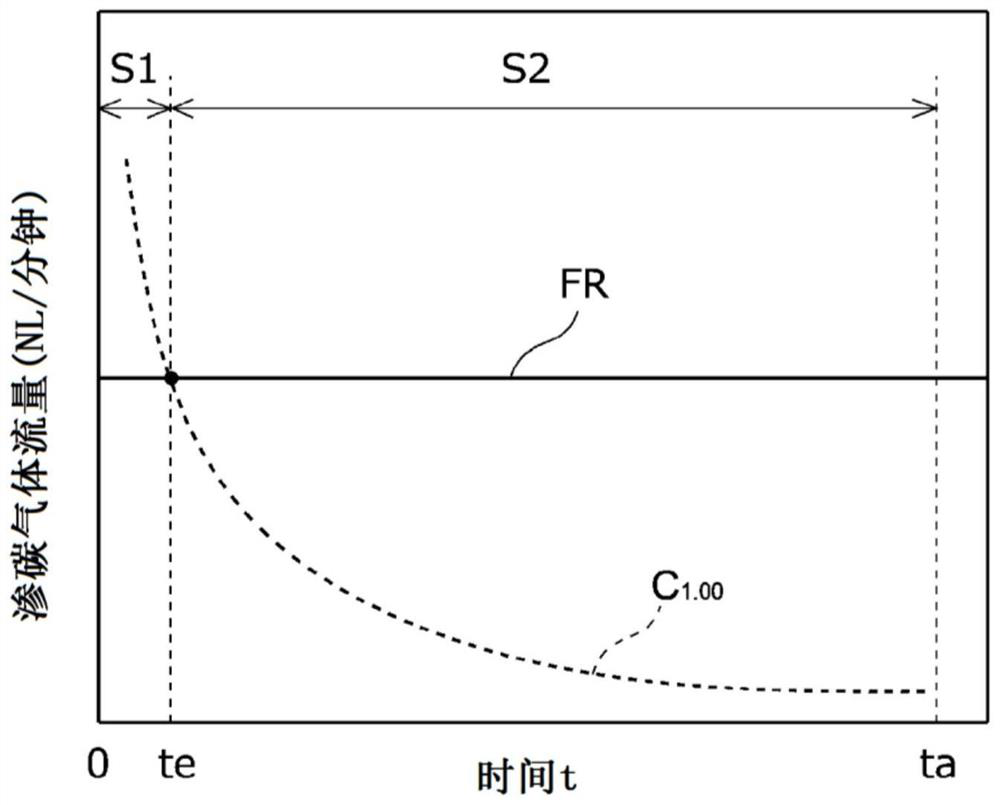

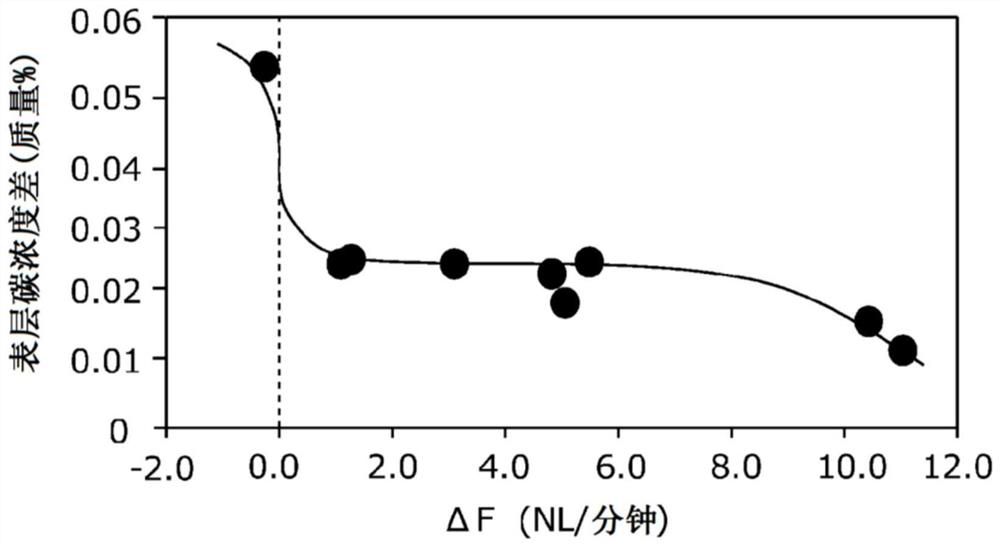

Vacuum carburization processing method, and method for manufacturing carburized component

ActiveCN111868292ASuppression of uneven carburization distributionSolid state diffusion coatingMetallurgyCarburizing

In the vacuum carburization processing method according to the present embodiment, when a flow of a carburizing gas, which has been calculated on the basis of a diffusion flux of carbon in a surface layer of a steel material, which is obtained in a diffusion simulation using a diffusion equation, is defined as a theoretical carburizing gas flow (FT), and when the time required for an actual carburizing gas flow to become equal to the theoretical carburizing gas flow after commencement of a carburizing step is defined as an intersection time te, the time from the commencement of the carburizingstep until the completion thereof is defined as a carburization time ta, and one-fifth of the carburization time is defined as a reference time ta / 5, an early carburizing step (S1) from the commencement of the carburizing step to the intersection time te is performed wherein an actual carburizing gas flow (FR) is set to be equal to or greater than a theoretical carburizing gas flow (FT(te)) at the point where the reference time ta / 5 has elapsed from the commencement of the carburizing step, and to be equal to or less than a theoretical carburizing gas flow (FT(20s)) at the point where twentyseconds have elapsed from the commencement of the carburizing step, and a late carburizing step (S2) from the intersection time te until the carburization time ta is performed wherein the actual carburizing gas flow (FR) is set to be within a range of 1.00 to 1.20 times of the theoretical carburizing gas flow (FT).

Owner:NIPPON STEEL CORP

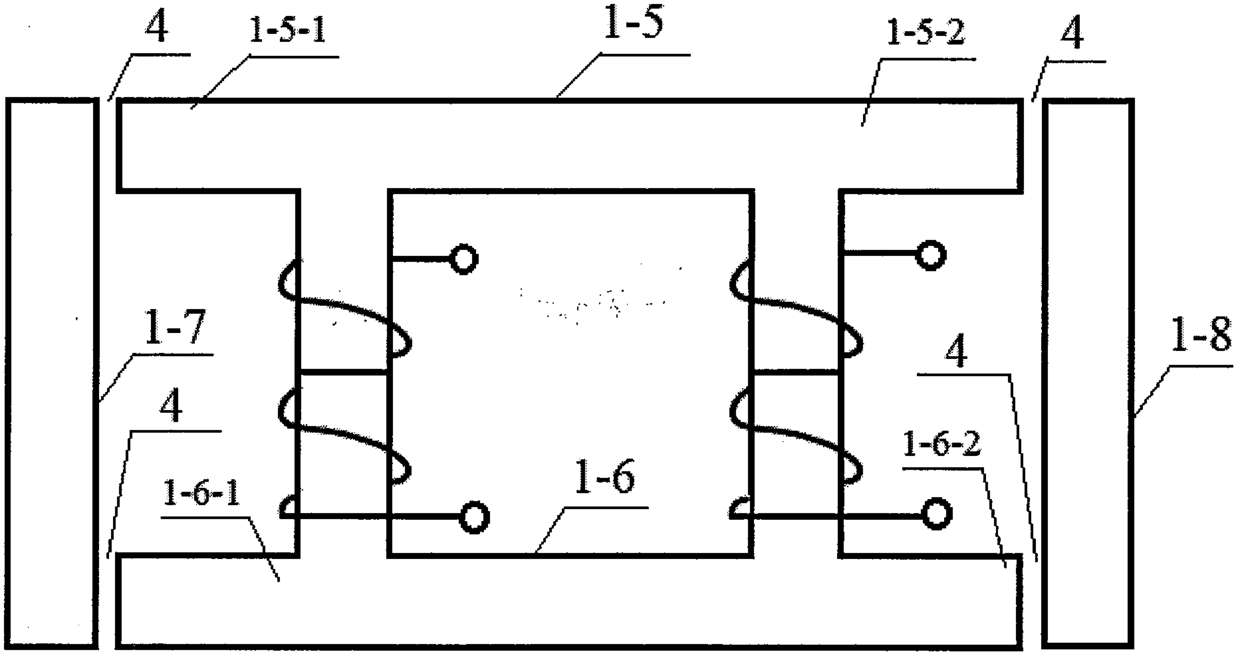

Multi-segment air gap type magnetic component

PendingCN108399994APerformance is not affectedThe effect of magnetic permeability is reducedTransformers/inductances magnetic coresCores/yokesButt jointEngineering

The invention relates to a magnetic component, and specifically relates to a multi-segment air gap type magnetic component. The multi-segment air gap type magnetic component comprises a first magneticcore and a second magnetic core, wherein the first magnetic core and the second magnetic core are symmetrically arranged, the left ends and the right ends of the first magnetic core and the second magnetic core are in butt joint with each other respectively, and central posts of the first magnetic core and the second magnetic core are opposite; a plurality of central post magnetic gaskets laminated vertically are assembled between the central post of the first magnetic core and the central post of the second magnetic core; and air gaps are formed between the central post of the first magneticcore and the central post magnetic gasket on the topmost layer, between the central post of the second magnetic core and the central post magnetic gasket on the bottommost layer and among the centralpost magnetic gaskets. Compared with a traditional magnetic component, the loss of leakage flux can be reduced and dispersed effectively, and the diffusion flux is reduced, so that the operating temperature of the magnetic component is reduced, and the operating efficiency of the magnetic component is promoted.

Owner:SHANDONG KAITONG ELECTRON

A Method for Calculating Molecular Diffusion Coefficient by Non-equilibrium Molecular Dynamics Simulation

InactiveCN105653766BReduce difficultyImprove Simulation EfficiencySpecial data processing applicationsDiffusionChemical physics

Owner:ZHONGBEI UNIV

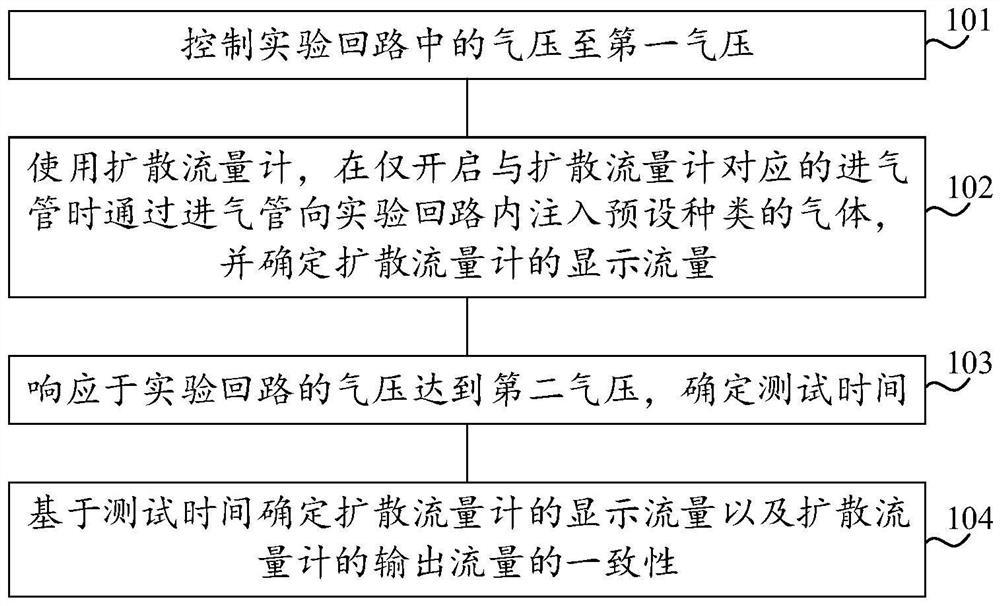

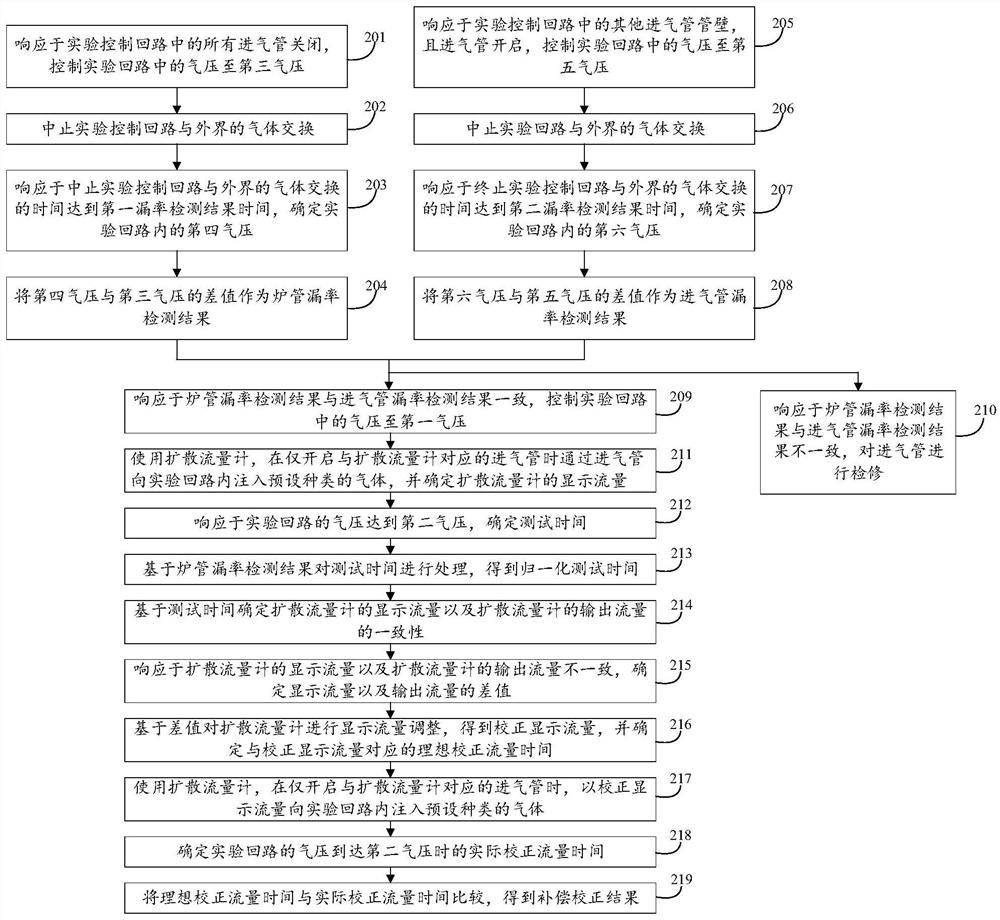

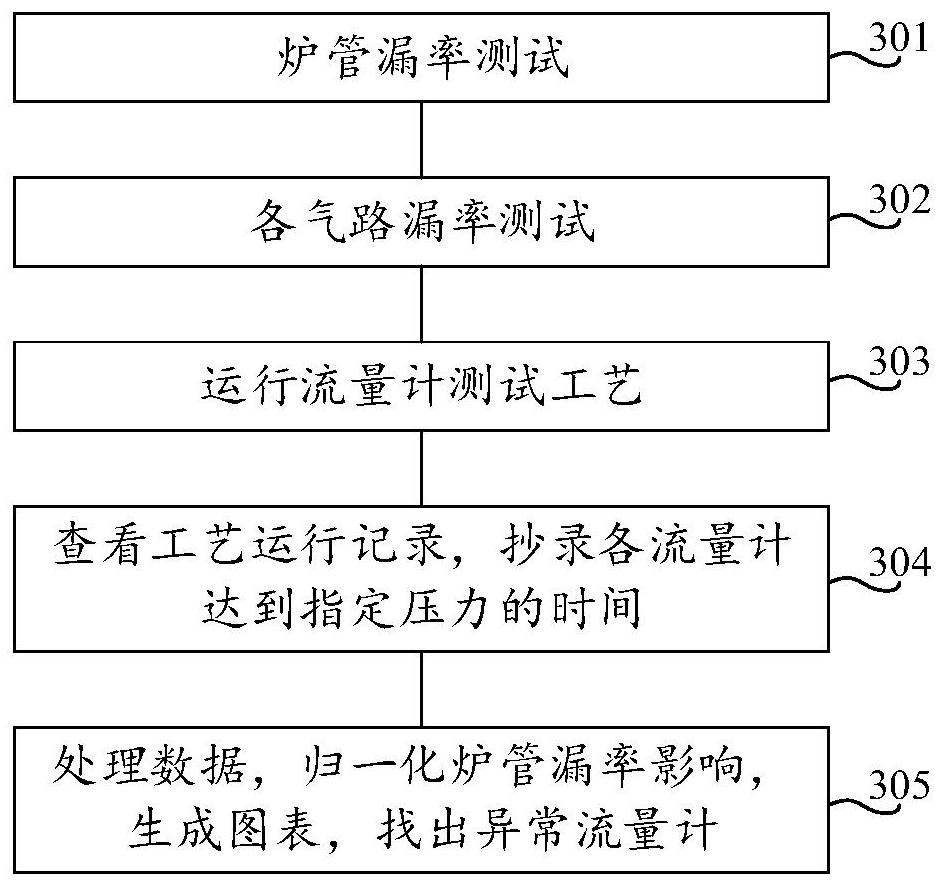

Consistency testing method for diffusion flow meter

PendingCN114754843AQuick and accurate determinationTesting/calibration for volume flowEngineeringTested time

The invention relates to a diffusion flow meter consistency testing method, and relates to the field of solar cell manufacturing. The method comprises the following steps: controlling air pressure in an experimental loop to a first air pressure; the diffusion flow meter is used, the display flow of the diffusion flow meter is determined, and the preset type corresponds to the type of the diffusion flow meter; determining test time; determining the consistency of the display flow of the diffusion flow meter and the output flow of the diffusion flow meter based on the test time, wherein the output flow of the diffusion flow meter indicates the diffusion flow meter to control the flow of the preset type of gas injected into the gas inlet pipe. The air inlet pipe controlled by the flow meter serves as a unique outlet of a closed air path and is a unique reason for air pressure change in an experimental loop, the actual flow of the diffusion flow meter can be directly determined according to the test time, and then whether the display flow of the diffusion flow meter is consistent with the output flow of the diffusion flow meter or not is obtained. Whether the diffusion flow meter has problems can be judged without dismounting the flow meter in environments such as a solar cell plant.

Owner:WUXI SUNTECH POWER CO LTD

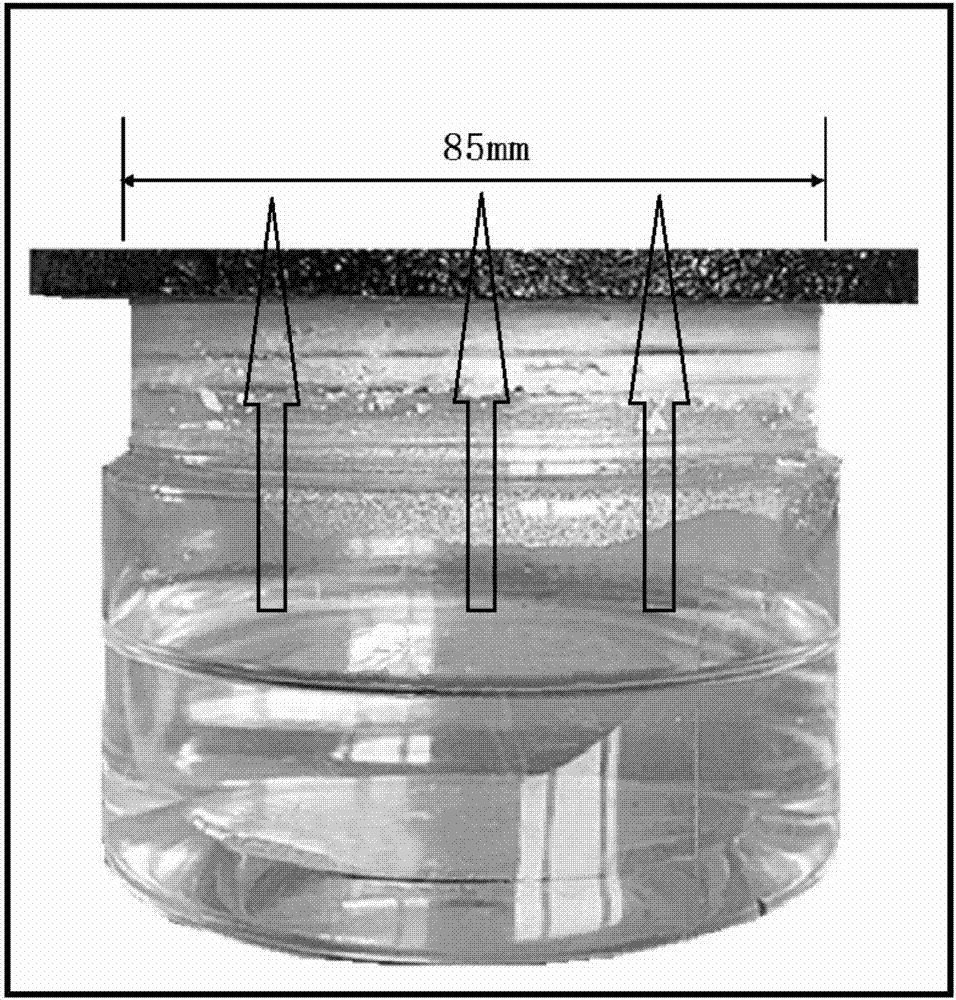

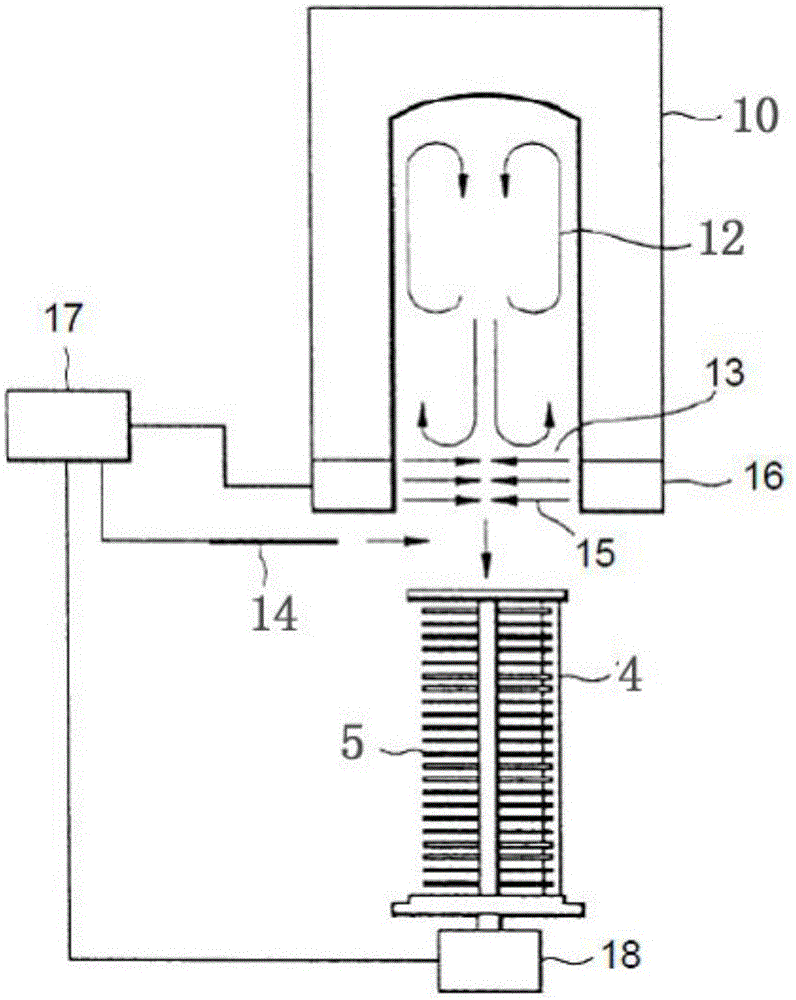

Diffusion chamber used in semiconductor manufacturing process and diffusion method thereof

ActiveCN103603051BImprove uniformityImprove yieldDiffusion/dopingSemiconductor/solid-state device manufacturingDiffusion methodsDiffusion

The invention relates to a diffusion chamber and a diffusion method used in process of producing semiconductor. A diffusion source is changed into a plane, parallel to a semiconductor sample, from points through a diffusion control device, namely, distances from the diffusion source to all areas of the sample are equal, the concentration degree and diffusion depth can be controlled, and the diffusion flux can be controlled in the semiconductor production process; the diffusion concentration and depth uniformity can be greatly improved, the concentration of source materials are evenly distributed in the semiconductor sample, and further the overall uniformity and yield of the sample can be greatly enhanced. The diffusion control device and a diffusion route thereof are close to the diffusion source (the source materials), once the source materials are volatilized, the diffusion control device can firstly play a blocking role, so that the lower surface of the diffusion control device is fast filled with the source material uniformly, then the source materials are redistributed by the diffusion route so as to uniformly arrive at all areas of the sample.

Owner:浙江光特科技有限公司

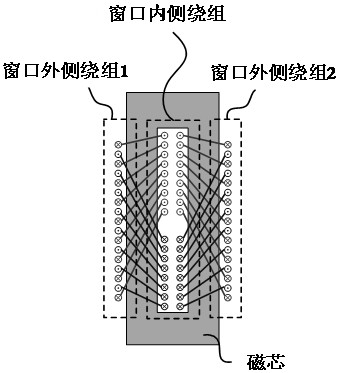

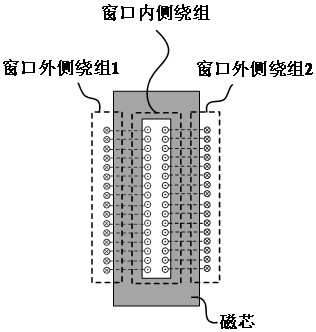

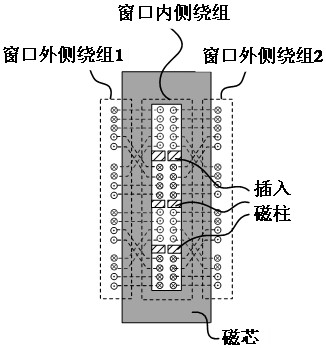

Integrated Magnetics Devices and Transformers

ActiveCN112563000BReduce volumeReduce Flux LeakageTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerCoupling

The application provides an integrated magnetic element device and a converter, which relate to the technical field of magnetic elements, including: primary and secondary windings and a magnetic core; the primary and secondary windings are arranged around the magnetic core, and the primary and secondary windings are used for transformers and The inductance provides the winding; the coupling degree of the primary and secondary windings outside the window of the core is higher than the preset coupling degree; the coupling degree of the primary and secondary windings inside the window of the core is lower than the preset coupling degree, which relieves the magnetic core Outer diffusion MFL is a big technical problem through.

Owner:HANGZHOU EV TECH CO LTD +1

Inductive balance magnetic core and three-phase reactor and three-phase reactor

PendingCN109326420AIncrease local temperatureSolve the service lifeTransformers/inductances magnetic coresUnwanted magnetic/electric effect reduction/preventionChinese charactersEddy current

The invention relates to the technical field of reactors, in particular to an inductance balance magnetic core of a three-phase reactor and a three-phase reactor. The inductive balance magnetic core of the three-phase reactor is mainly composed of a magnetic core shaped like a Chinese character 'ri', which is composed of an upper yoke part, a lower yoke part and three magnetic columns. Air gap gaskets are arranged between the middle magnetic column and the upper yoke part and lower yoke part. The magnetic core avoids a coil by arranging the air gaps at the upper and lower ends of the magneticcolumn, so that when the inductance of three groups of coils reaches the equilibrium state, no diffusion flux phenomenon occurs, and no eddy current loss is caused to the coil, thus the local temperature of the coil is not raised. The reactor is used to solve the problem of reduction of the service life of the reactor because the coil temperature at the air gaps of the reactor magnetic core is toohigh.

Owner:山西中磁尚善科技有限公司

Method for preparing modified nano-stick array electrode after dispensing

InactiveCN101165214BTake advantage ofImprove electrocatalytic activityActive material electrodesMaterial electrochemical variablesNanowireSolvent

The present invention relates to nanometer rod array electrode, and is especially nanometer metal rod dispersing and modifying process of preparing nanometer rod array electrode with best utilizationof surface area. The process includes the following steps: dissolving the template for growing nanometer metal rods, adding dispersant to the solvent and ultrasonically treating for well dispersing nanometer metal rods in the solvent, and regulating the concentration of nanometer metal rods to apply nanometer metal rods onto the surface of electrode base in controllable intervals. The nanometer metal rod array electrode has best utilization of the great surface area of the nanometer metal rods, very high diffusion flux and faraday current, and very high electrically catalytic activity.

Owner:HARBIN INST OF TECH

A Mesh-shaped Magnetic Integrated Coupled Inductor

ActiveCN105719784BAchieve integrationMiniaturizationTransformers/inductances magnetic coresInductance with magnetic coreChinese charactersMagnetic poles

Owner:杨玉岗

Root simulation acquisition system for monitoring the diffusion flux of PAHS in soil

InactiveCN106018182BOvercome severe self-adsorptionLarge flow areaSurface/boundary effectGlass fiberSystems design

The invention discloses a root system simulation collecting system for monitoring diffusion flux of PAHs in soil. The root system simulation collecting system comprises a passive type soil solution collecting bin and a PAHs root system simulation collecting system arranged in the collecting bin. The passive type soil solution collecting bin comprises a collecting bin body glass column pipe, a Teflon jacket arranged on the bottom of the glass column pipe in a sleeving mode and a ground jacket arranged on the top of the glass column pipe in a sleeving mode, and a multihole water inlet with holes in the side portion is formed in the lower middle portion of the glass column pipe. The PAHs root system simulation collecting system comprises an SPE extraction column pipe arranged in the glass column pipe, the upper portion of the SPE pipe is packed with a glass hollow support pipe, and the upper portion of the support pipe is sealed through a rubber stopper. The multihole water inlet is formed in an annular inward-concave mode. A glass fiber filter membrane, a polytetrafluoroethylene millipore filtration interlayer and a stainless steel mesh support layer are sequentially arranged in the inward-concave position from interior to exterior. The root system simulation collecting system can be applicable to collecting and diffusion flux testing of PAHs in percolate under different natural environments, and the system is reasonable in design, simple in manufacturing process, low in cost, convenient to operate, efficient and durable.

Owner:HOHAI UNIV

A Diffusion Method of Gaseous Water in Asphalt Mortar

ActiveCN108007811BThe proportion is conducive to clearSpecific gravityWeighing by absorbing componentEngineeringRoad surface

The invention provides a method for distinguishing gaseous water dispersing mode in bituminous mortar, and belongs to the field of traffic pavement materials. The method comprises the following steps:manufacturing a thin-sheet type bituminous mortar test part of which the diameter-height ratio is beyond 10: 1; performing gaseous water absorbing test under constant temperature T and different relative humidity phi conditions; calculating equilibrium absorption capacity of the test part in each humidity; then performing gaseous water dispersing test under a constant-temperature and constant-humidity condition, wherein the constant temperature is identified as T; testing the overall mass of the test part device in different time until the stable stage that mass varies at constant speed as time goes one is achieved; then calculating the data obtained from the absorbing test and the dispersing test; and calculating the proportion of the diffusion flux of different dispersing modes in the total diffusion flux. With the adoption of the method, the problem that the gaseous water dispersing mode in the bituminous mortar cannot be distinguished by the prior art can be solved; and the methodis applicable to bituminous mortar damage mechanism study.

Owner:HARBIN INST OF TECH

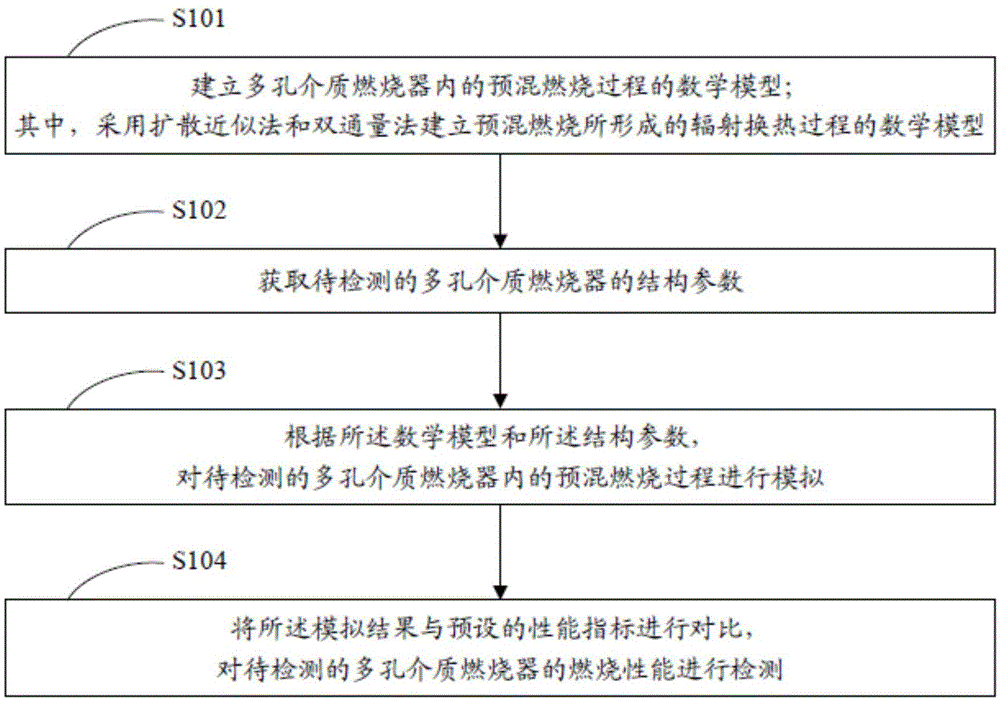

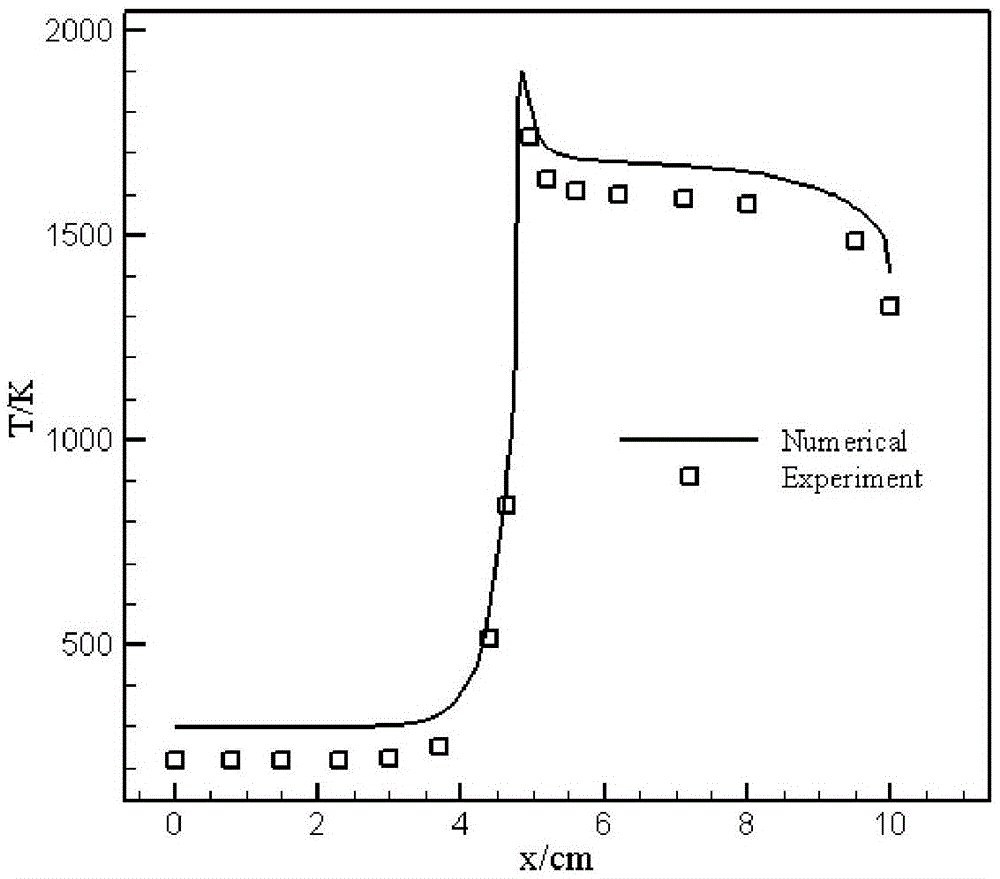

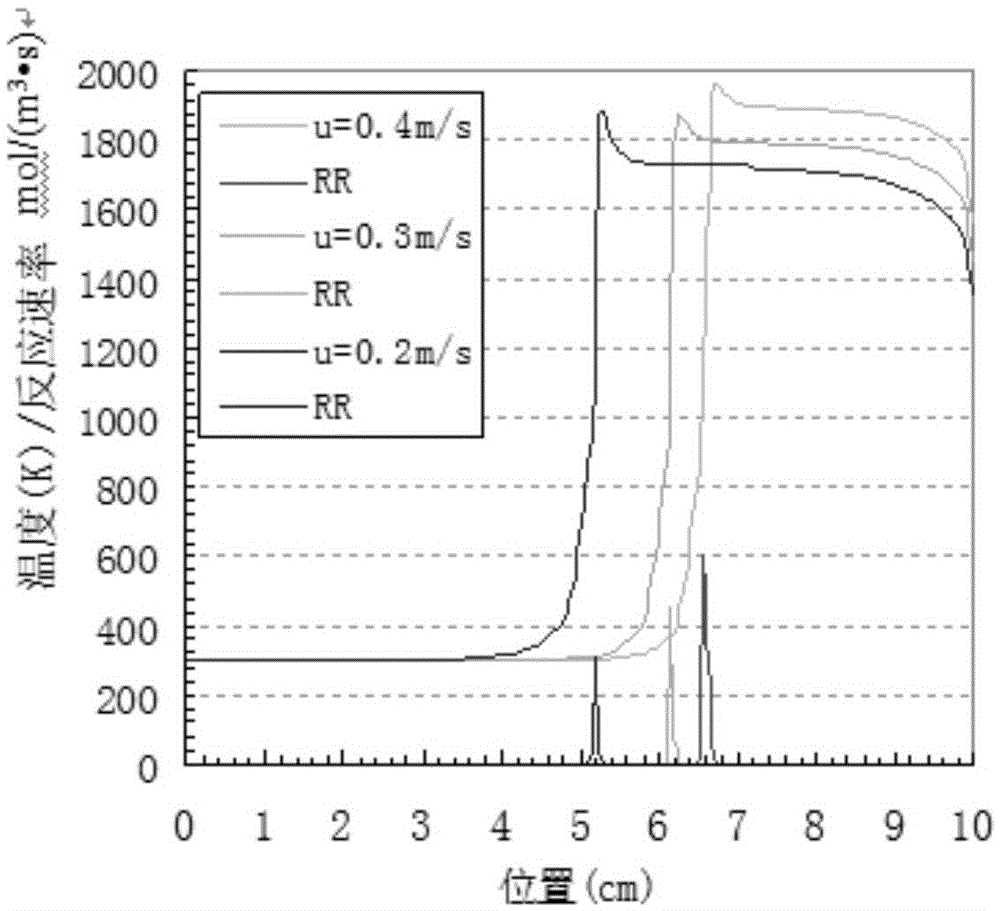

Performance testing method and device of porous media burner

ActiveCN103528837BDetect flammabilitySimulation results are accurateStructural/machines measurementDiffusionCombustor

The invention discloses a performance detection method of a porous media burner, which includes: establishing a mathematical model of the premixed combustion process in the porous media burner; wherein, the diffusion approximation method and the double flux method are used to establish the premixed combustion process The mathematical model of the radiation heat transfer process; obtaining the structural parameters of the porous media burner to be detected; simulating the premixed combustion process in the porous media burner to be detected; comparing the simulation results with the preset performance indicators, The combustion performance of the porous media burner to be tested is tested. In addition, a performance detection device of a porous media burner is also disclosed. The invention obtains various combustion performance indexes of the porous medium burner in the premixed combustion process, and then compares them with preset performance indexes to achieve the purpose of detection and verification. Combining the diffusion approximation method and the double-flux method to simulate the radiation heat transfer process makes the detection results more accurate and reliable.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

A sediment-water interface pollutant maximum diffusion flux sampling device and method

ActiveCN109781588BEarly warning release riskOvercome the disadvantages of forming an anaerobic stateWithdrawing sample devicesSurface/boundary effectThermodynamicsEngineering

The invention discloses an in-situ sampling device, a detection device and a detection method for the maximum diffusion flux of sediment-water interface pollutants. The sampling device includes an annular upper shell, a fixed film and a lower shell. The lower shell The top is provided with a groove for accommodating a fixed film, the fixed film is arranged in the groove of the lower shell, and the upper edge of the annular upper shell is provided with a plurality of fins at intervals, and the annular upper shell It is sleeved on the upper end of the lower casing and the fixed film is fixed, and the average density of the sampling device is greater than that of water. The invention can measure the maximum diffusion flux of the sediment, has the advantages of convenient operation, relatively small experimental intensity; strong applicability, wide range of target objects that can be measured; small volume, and can be deployed in a large range of lakes to estimate the release of the entire lake Flux and other advantages.

Owner:中科智感(南京)环境科技有限公司

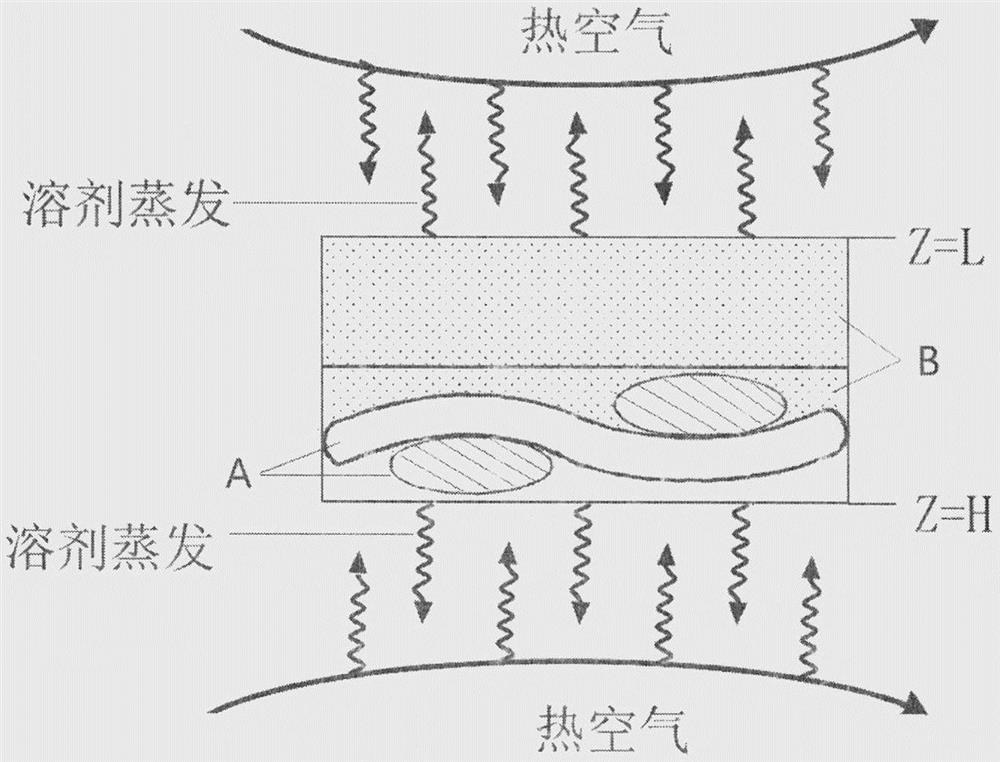

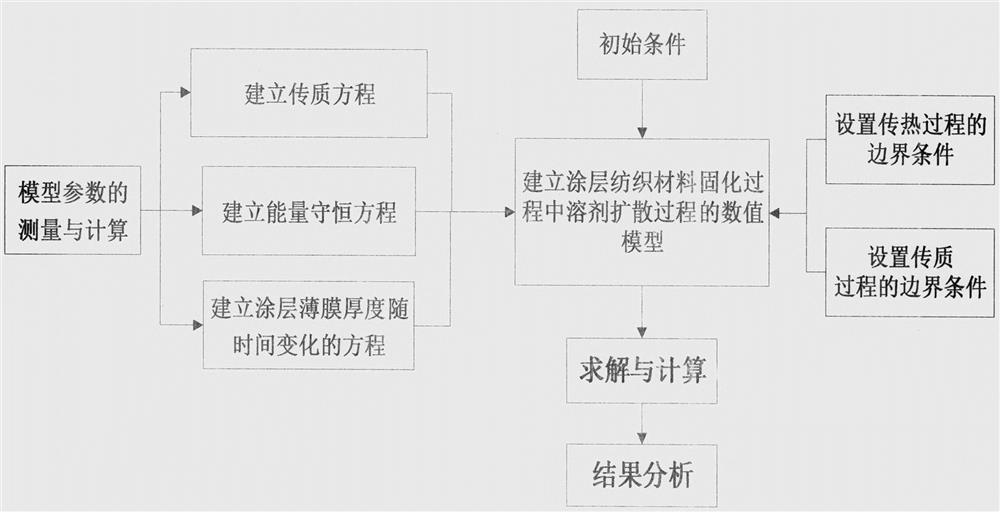

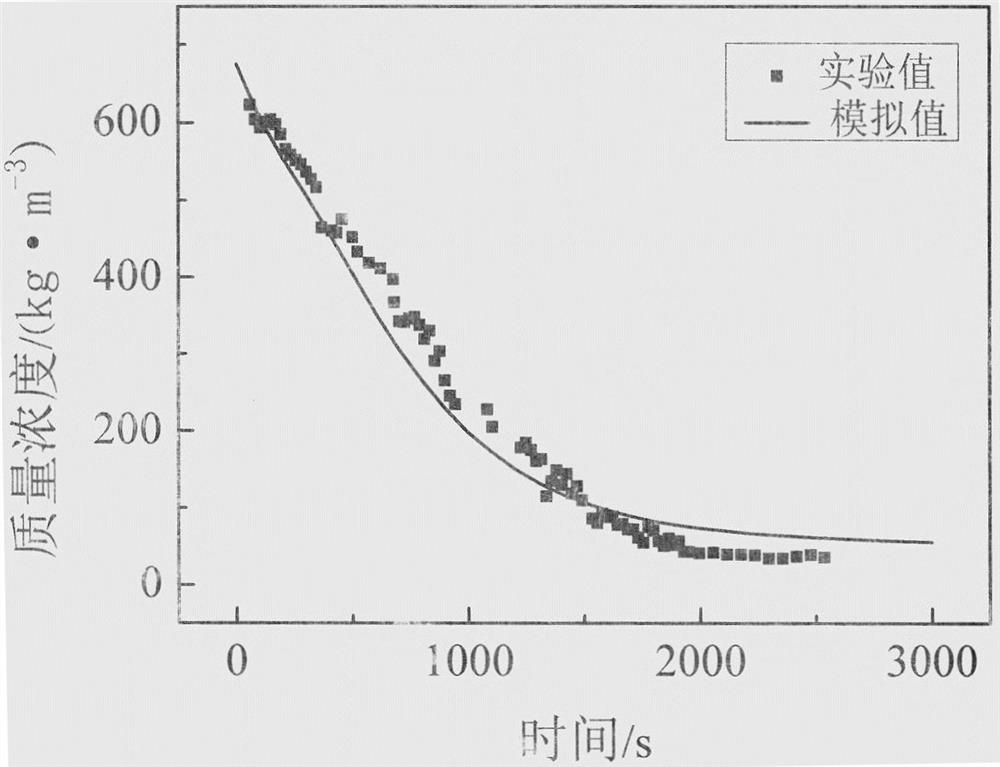

Numerical simulation method for solvent diffusion process in curing process of coated textile material

ActiveCN112131757AAccurate Concentration DistributionDesign optimisation/simulationSpecial data processing applicationsPorous mediumInterfacing

The invention discloses a numerical simulation method for a solvent diffusion process in a curing process of a coated textile material. The method comprises the following steps: coupling and solving amass transfer equation, an energy conservation equation and an equation that the thickness of a coating film changes along with time, and quantitatively calculating the change condition of the concentration of a solvent in the coating film along with the time. According to the method, a textile material is a porous medium, in a coated fabric energy conservation equation, a coating liquid conformsto fluid heat transfer characteristics, and a fabric is described by using a porous medium heat transfer equation: when boundary conditions for solving a mass transfer equation are set, diffusion flux equations of a solvent on a coating liquid and air interface and a fabric and air interface are respectively considered, therefore, a more accurate solvent concentration distribution condition can be obtained. The method can help to determine the time required for curing the coated fabric, the thickness of the cured coating and the concentration of the residual solvent. Theoretical guidance andscientific basis are provided for optimization of coating textile material curing conditions, elimination of coating defects and development and design of novel drying equipment.

Owner:TIANJIN POLYTECHNIC UNIV

Vacuum carburizing treatment method and manufacturing method of carburized parts

ActiveCN111868292BSuppression of uneven carburization distributionSolid state diffusion coatingMetallurgyCarburizing

In the vacuum carburizing treatment method according to this embodiment, the flow rate of carburizing gas calculated from the diffusion flux of carbon in the surface layer of the steel material obtained from the diffusion simulation using the diffusion equation is defined as the theoretical carburizing gas flow rate (FT) , the moment when the actual carburizing gas flow rate is equal to the theoretical carburizing gas flow rate after the carburizing process starts is defined as the intersection time te, and the time from the beginning to the end of the carburizing process is defined as the carburizing time ta, and the carburizing process is defined as The time of 1 / 5 of the time is defined as the reference time ta / 5. At this time, in the early carburizing process (S1) from the start of the carburizing process to the intersection time te, the actual carburizing gas flow rate (FR) It is: the theoretical carburizing gas flow rate (FT(te)) above the reference time ta / 5 from the start of the carburizing process, and the theoretical carburizing gas flow rate (FT(20s) at 20 seconds from the start of the carburizing process )) or less; in the late carburizing process (S2) from the intersection time te to the carburizing time ta, the actual carburizing gas flow rate (FR) is 1.00 to 1.20 times the theoretical carburizing gas flow rate (FT) within range.

Owner:NIPPON STEEL CORP

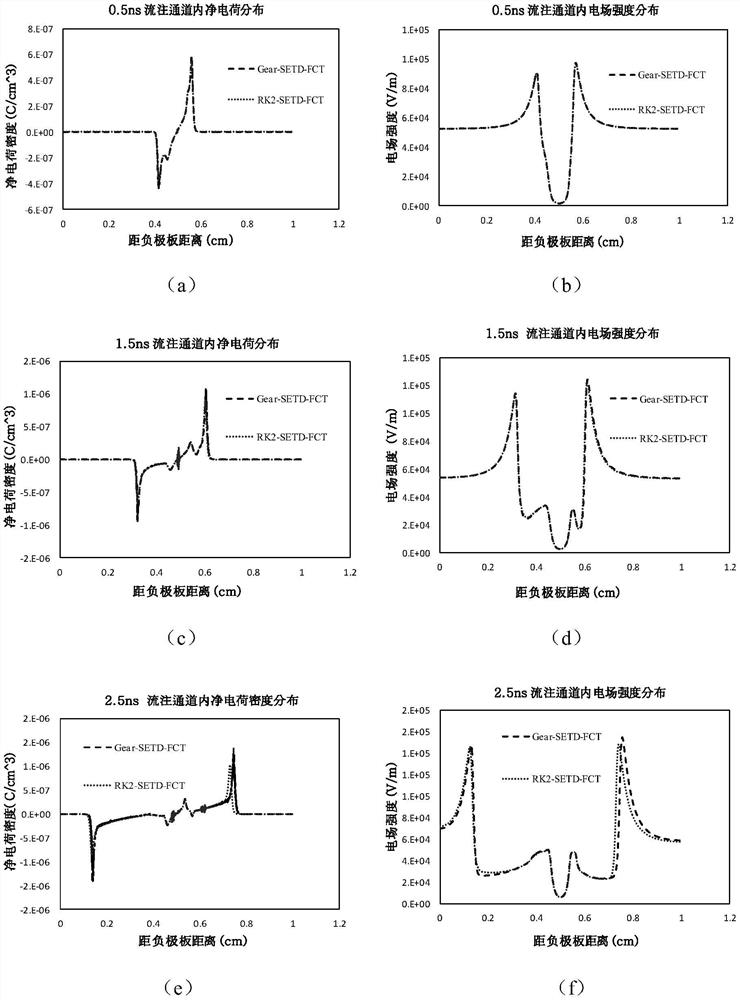

Numerical Simulation Method of Short Gap Gas Discharge Based on Time Domain Spectral Element Method

ActiveCN107729608BIncrease time stepReduced simulation timeDesign optimisation/simulationSpecial data processing applicationsTime domainIon density

Owner:NANJING UNIV OF SCI & TECH

Method and system for predicting growth thickness of lead-free solder joint interface metal compound

ActiveCN106918538BSolve the problem of inaccurate growth thickness prediction resultsSurface/boundary effectMaterial thermal analysisSolderingElectromigration

The invention relates to a leadless solder joint interface metallic compound growth thickness prediction method and a system thereof. The method comprises the following steps: determining a leadless solder joint interface model and a target metal atom, obtaining the electromigration flux, dissolving flux and net-heat diffusion flux, calculating the thickness change rate of a cathode interface metallic compound layer and an anode interface metallic compound layer, according to the thickness change rate and initial thickness, obtaining the thickness of the cathode interface metallic compound layer and the anode interface metallic compound layer at any time. The above method can accurately predict the growth thickness of the interface metallic compound layer.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com