Planar transformer

A planar transformer, together technology, applied in the direction of transformer/inductor core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of reduced efficiency of transformers, unsuitable for welding, inspection, and maintenance difficulties Increase the magnetoresistance, facilitate automatic generation, and facilitate miniaturization and planarization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0024] This embodiment provides a planar transformer. The planar transformer is a transformer with small volume, easy production and good magnetic flux effect.

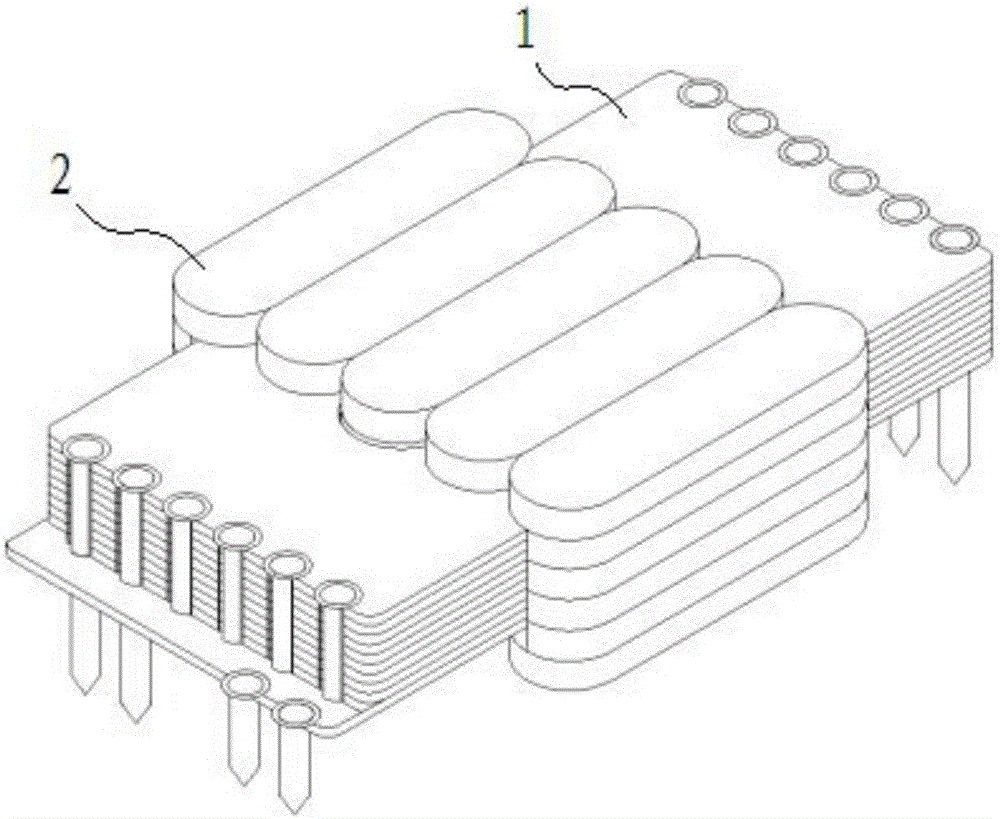

[0025] Such as figure 1 As shown, the planar transformer mainly includes a magnetic core 1 and a coil winding 2 . The magnetic core 1 and the coil winding 2 are mounted together.

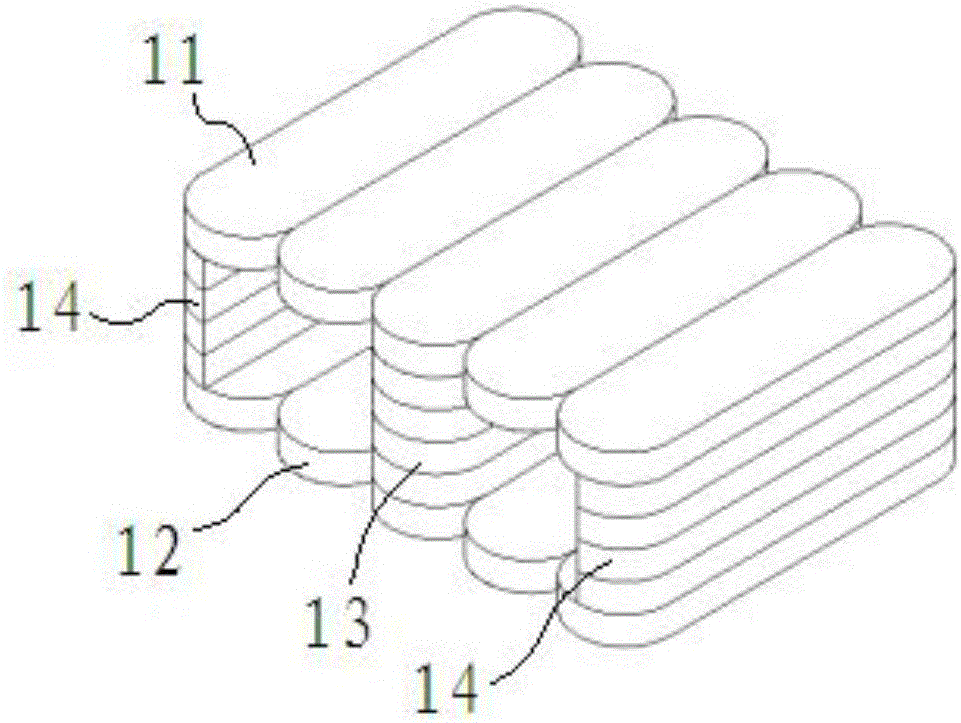

[0026] Such as figure 2 As shown, the magnetic core 1 includes a top plate 11, a bottom plate 12, a center column 13 and a side column 14, the side column 14 has two ends located between the top plate 11 and the bottom plate 12, and the center column 13 is located between the top plate 11 and the bottom plate 12 in the middle. The magnetic core 1 is formed by stacking unit magnetic blocks, and the unit magnetic blocks are fixed together by dispensing glue. The unit magnetic block is a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com