A Mesh-shaped Magnetic Integrated Coupled Inductor

A technology of coupled inductance and magnetic integration, which is applied in the field of inductors, can solve the problems of reduction of magnetic core volume loss, long mutual inductance magnetic path of two coils, small self-inductance and mutual inductance, etc., so as to reduce electromagnetic loss and increase self-inductance value and coupling coefficient, the effect of short mutual inductance magnetic circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

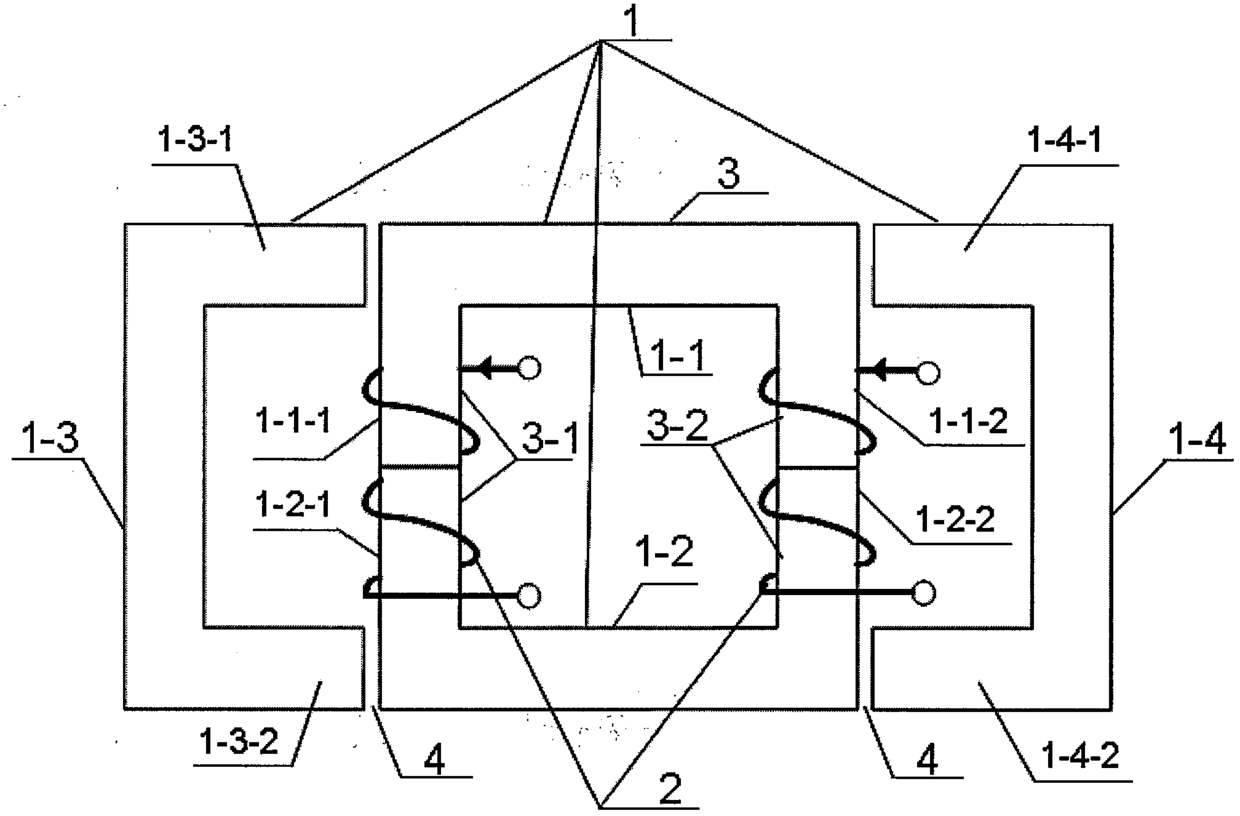

[0022] Refer to attached figure 1 , a "mesh"-shaped magnetically integrated coupled inductor, consisting of a "mesh"-shaped iron core body 1 and a two-phase coil 2, the iron core body 1 consists of four "U"-shaped iron cores 1-1, 1- 2. Composed of 1-3 and 1-4; the magnetic columns 1-1-1, 1-1-2 and 1-2-1 of the two "U" shaped iron cores 1-1 and 1-2, 1-2-2 are relatively placed to form a "mouth"-shaped iron core 3, and the magnetic columns 1-1-1 and 1-2-1 of the two "U"-shaped iron cores 1-1 and 1-2 are opposite to each other , 1-1-2 and 1-2-2 relatively form the two magnetic columns 3-1 and 3-2 of the "口"-shaped iron core 3; The two-phase coils 2 are respectively wound on two magnetic columns 3-1 and 3-2; the other two "U"-shaped iron cores 1-3 and 1-4 are respectively placed on the "mouth"-shaped iron cores The two sides of the magnetic columns 3-1 and 3-2 of 3 are buckled on the two-phase coil 2; the magnetic columns 1-3- of the other two "U" shaped iron cores 1-3 and 1-4 ...

Embodiment 2

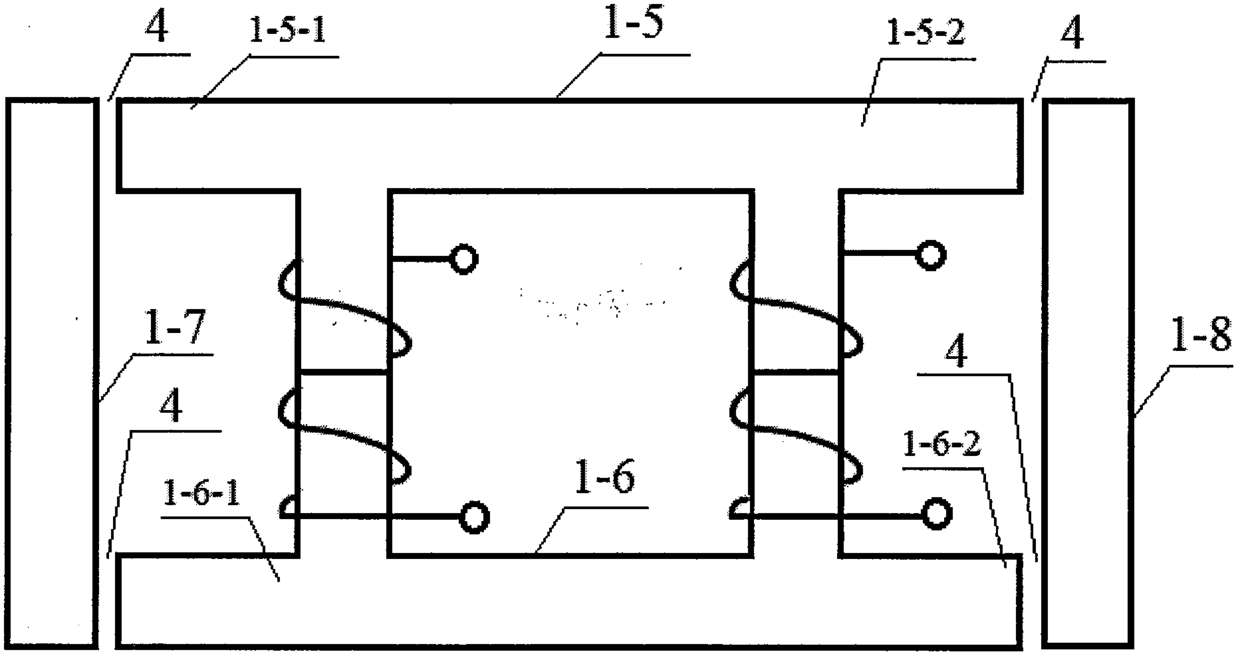

[0024] Refer to attached figure 2 , another application embodiment of a "mesh"-shaped magnetically integrated coupled inductor, the "U"-shaped iron cores 1-1, 1-2 in Embodiment 1 are replaced with "π"-shaped iron cores 1-5, 1-6, replace the "U"-shaped iron cores 1-3, 1-4 in Embodiment 1 with "I"-shaped iron cores 1-7, 1-8; "I"-shaped iron cores 1-7, 1 -8 is formed by keeping a distance between the yokes 1-5-1 and 1-6-1, 1-5-2 and 1-6-2 of the "π"-shaped iron cores 1-5 and 1-6 respectively air gap4.

Embodiment 3

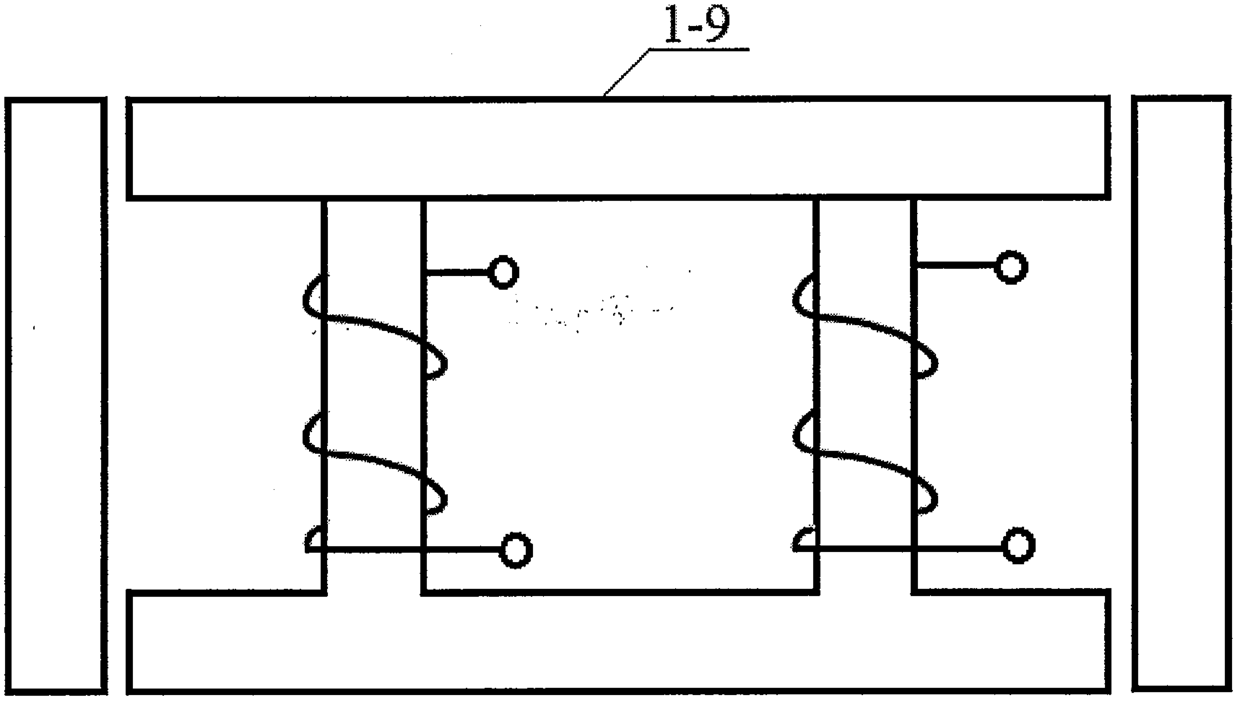

[0026] Refer to attached image 3 , another application embodiment of a "mesh"-shaped magnetically integrated coupled inductor, the "π"-shaped iron core 1-5 in the second embodiment is replaced with a "one"-shaped iron core 1-9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com