Series/parallel double-motor and multi-clutch hybrid drive unit for vehicle

一种电驱动单元、混合动力的技术,应用在混合动力电驱动单元,多级混合动力驱动系统,驱动,插电式混合动力汽车领域,能够解决降低能量利用效率、很难保证电机、空间尺寸要求大等问题,达到实现工作模式及档位的变换、实现不间断动力换档、简单有效设计的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

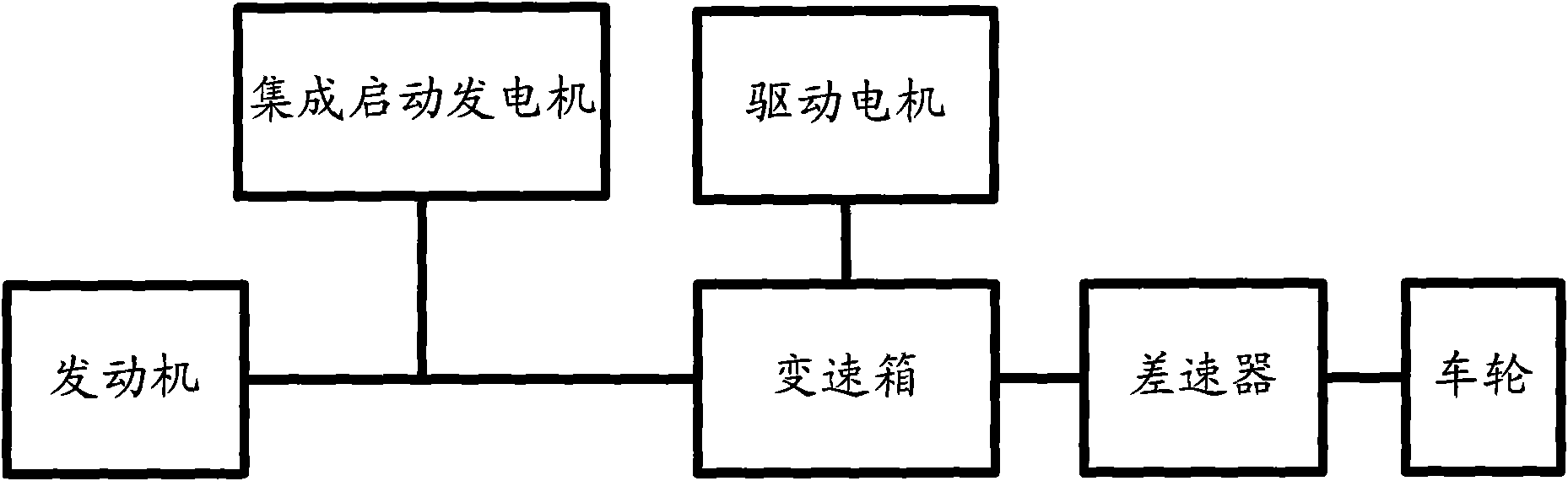

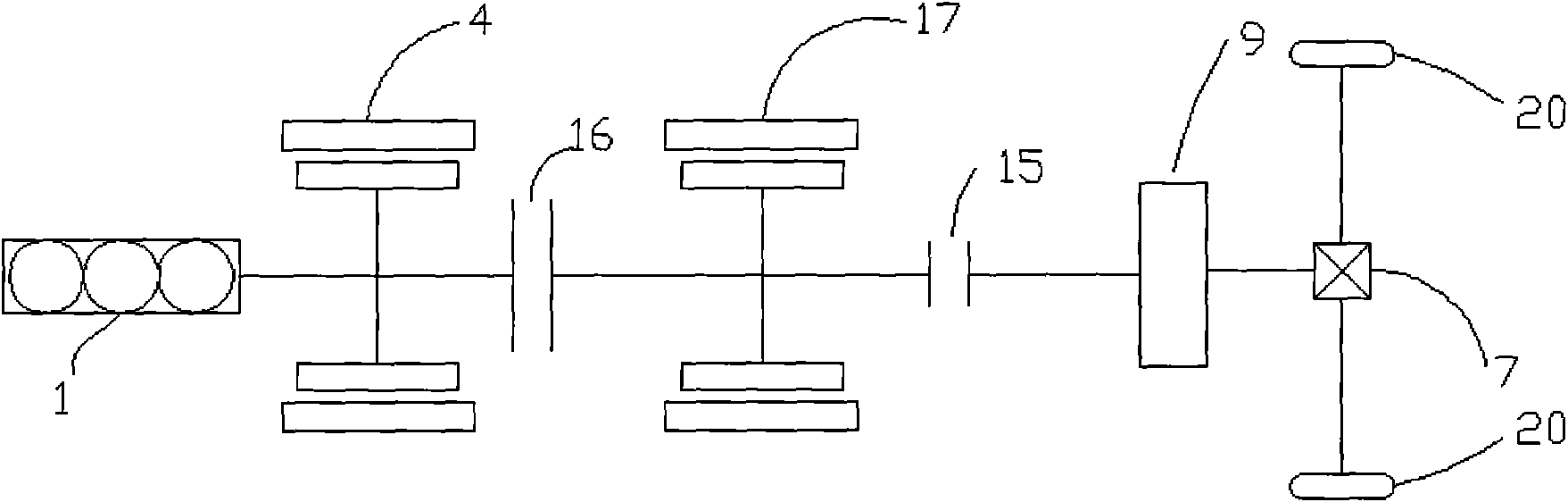

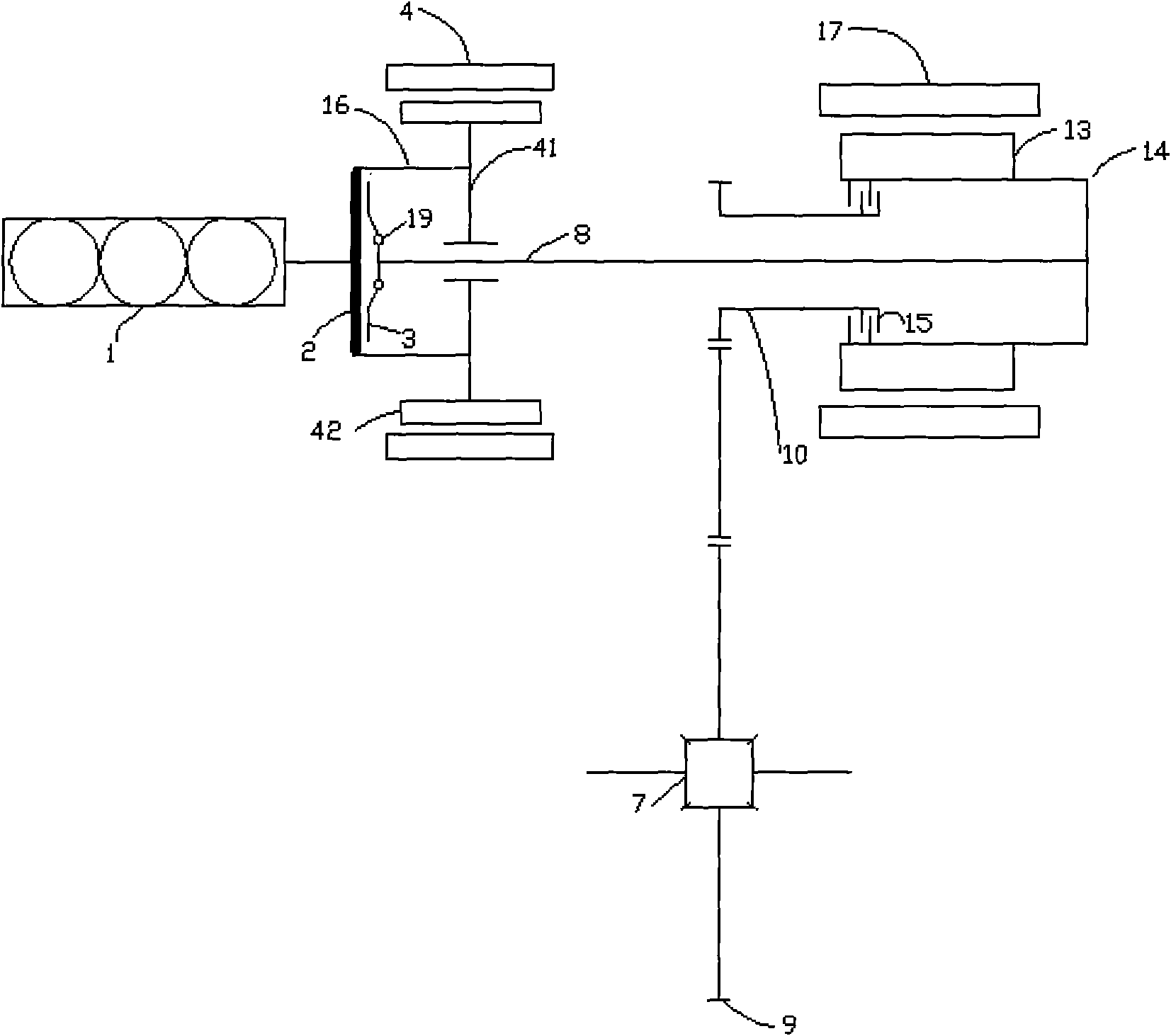

[0039] figure 1 According to a specific embodiment of the present invention, the schematic diagram of the connection relationship between the hybrid drive system and the electric drive unit and other components is shown, that is, the engine and the wheel of the hybrid vehicle applying the hybrid drive system provided by the present invention are shown. , the connection mode of the integrated starter generator, main drive motor, differential and other components of the electric drive unit, wherein the engine and the electric drive unit constitute the hybrid drive system of the present invention. Specifically, the engine is connected to the electric drive unit, and the hybrid power is transmitted to the wheels through the electric drive unit through the differential. Its specific connection mode and working mode will be described in detail in the following specific implementation modes, and will not be repeated here. Those skilled in the art understand that, figure 1 The shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com