Multi-segment air gap type magnetic component

A magnetic component and magnetic technology, applied in the direction of electrical components, magnetic core/yoke, transformer/inductor core, etc., can solve the technical requirements of the magnetic core and other problems, so as to improve work efficiency, disperse magnetic leakage loss, and reduce diffusion The effect of magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

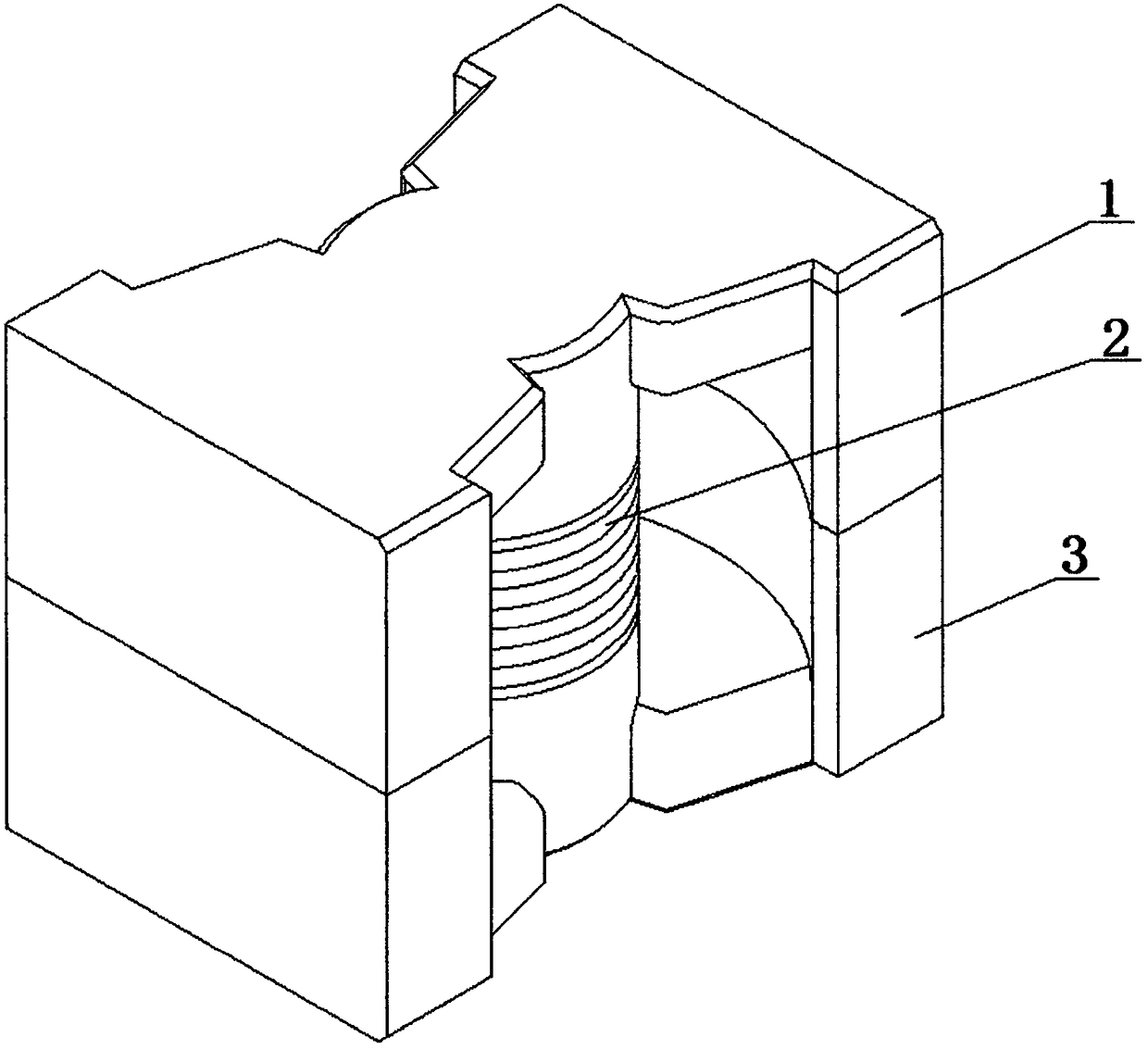

[0019] refer to figure 1 , the multi-stage air-gap magnetic assembly of the present invention includes a first magnetic core 1 and a second magnetic core 3, and the first magnetic core 1 and the second magnetic core 3 are in principle of the same material, shape and size The magnetic cores are arranged symmetrically, and the left and right end sides are respectively butted with each other, and the central columns are opposite. Between the central column of the first magnetic core 1 and the central column of the second magnetic core 3, there are several central column magnetic spacers 2 stacked up and down, and the central column magnetic spacers 2 of each layer adopt a flexible assembly method, both It can be assembled equidistantly or not equidistantly. The shape and size of the center column magnetic spacer 2 are the same as those of the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com