Method for distinguishing gaseous water dispersing mode in bituminous mortar

A diffusion mode, asphalt mortar technology, applied in the field of traffic pavement materials, can solve problems such as inability to distinguish gaseous water diffusion modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: The method for dividing the diffusion mode of gaseous water in asphalt mortar provided in this implementation mode is specifically carried out according to the following steps:

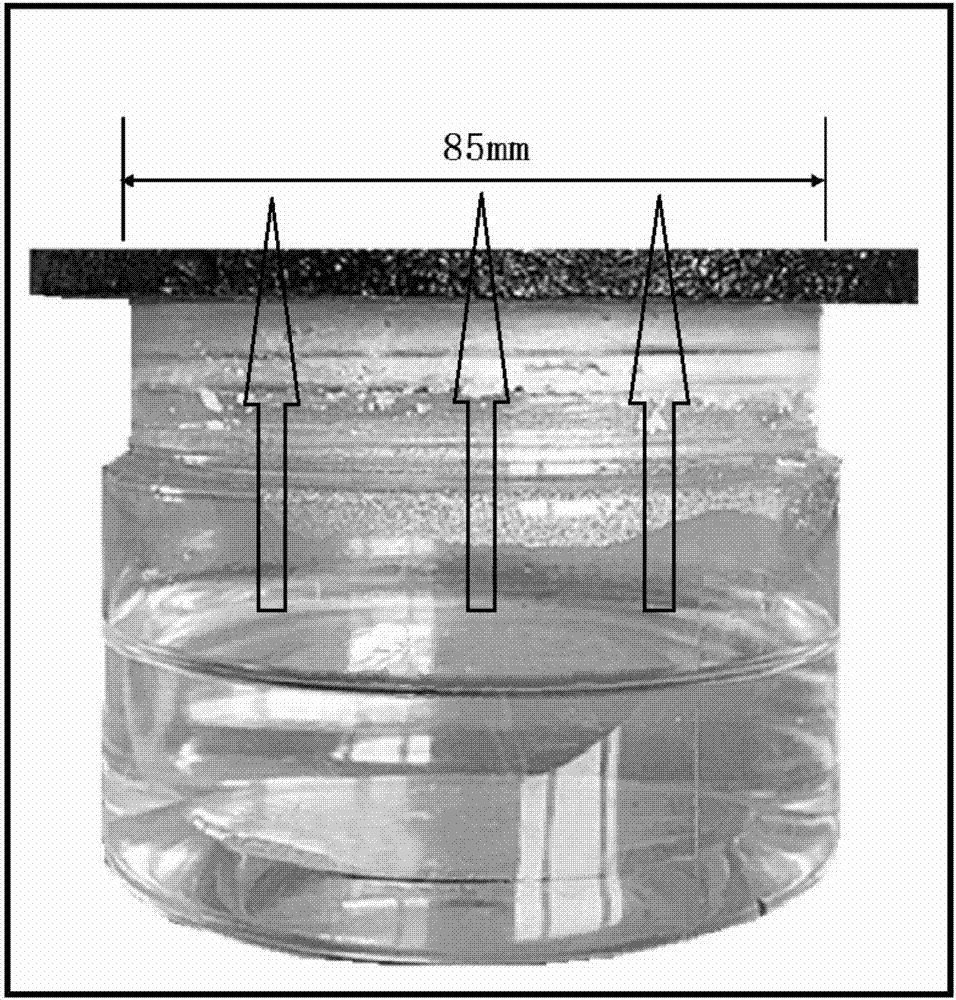

[0020] Step 1. Based on the one-dimensional diffusion theory, prepare a thin-plate asphalt mortar specimen with an aspect ratio greater than 10:1, such as figure 1 , figure 2 As shown, ensure that the diffusion process occurs along the axial direction of the specimen;

[0021] Step 2: Carry out a gaseous water adsorption test under constant temperature T (using thermodynamic temperature, unit is K) and different relative humidity φ conditions, and measure the dry test piece quality W 0 And the mass W of the test piece when the adsorption equilibrium is reached under each humidity condition (the weight gain of the test piece at intervals of more than 24 hours does not exceed the measurement accuracy of the electronic balance) ∞ , according to Calculate the eq...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 3, a constant temperature and humidity incubator is used to provide constant temperature and humidity conditions, the relative humidity inside the container is maintained by saturated saline solution or distilled water, and the relative humidity outside the container is determined by Maintain a constant temperature and humidity incubator.

[0025] Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one is that in step four, the specific steps for calculating the proportion of the diffusion flux in different diffusion modes to the total diffusion flux are as follows:

[0027] Step 41, the effective diffusion coefficient D is calculated using the data in the stable stage of the diffusion test in step 3, as shown in formula (1):

[0028]

[0029] Among them, H is the height of the specimen, the unit is m, is the relative humidity outside the container, Indicates the relative humidity inside the container, △t is the time interval between two mass measurements in the step 3 diffusion test, the unit is s, △m is the mass loss of the test piece device within the given time interval △t, the unit is kg, A refers to is the diffusion area of the specimen, that is, the area of the container opening, in m 2 ,p s is the saturated vapor pressure of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com