Artificial emerald jade and its manufacturing method and use

A technology of jadeite and jade, applied in the field of artificial microcrystalline stone, can solve the problems of high price, poor corrosion resistance, high temperature resistance, etc., and achieve the effect of low production cost and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

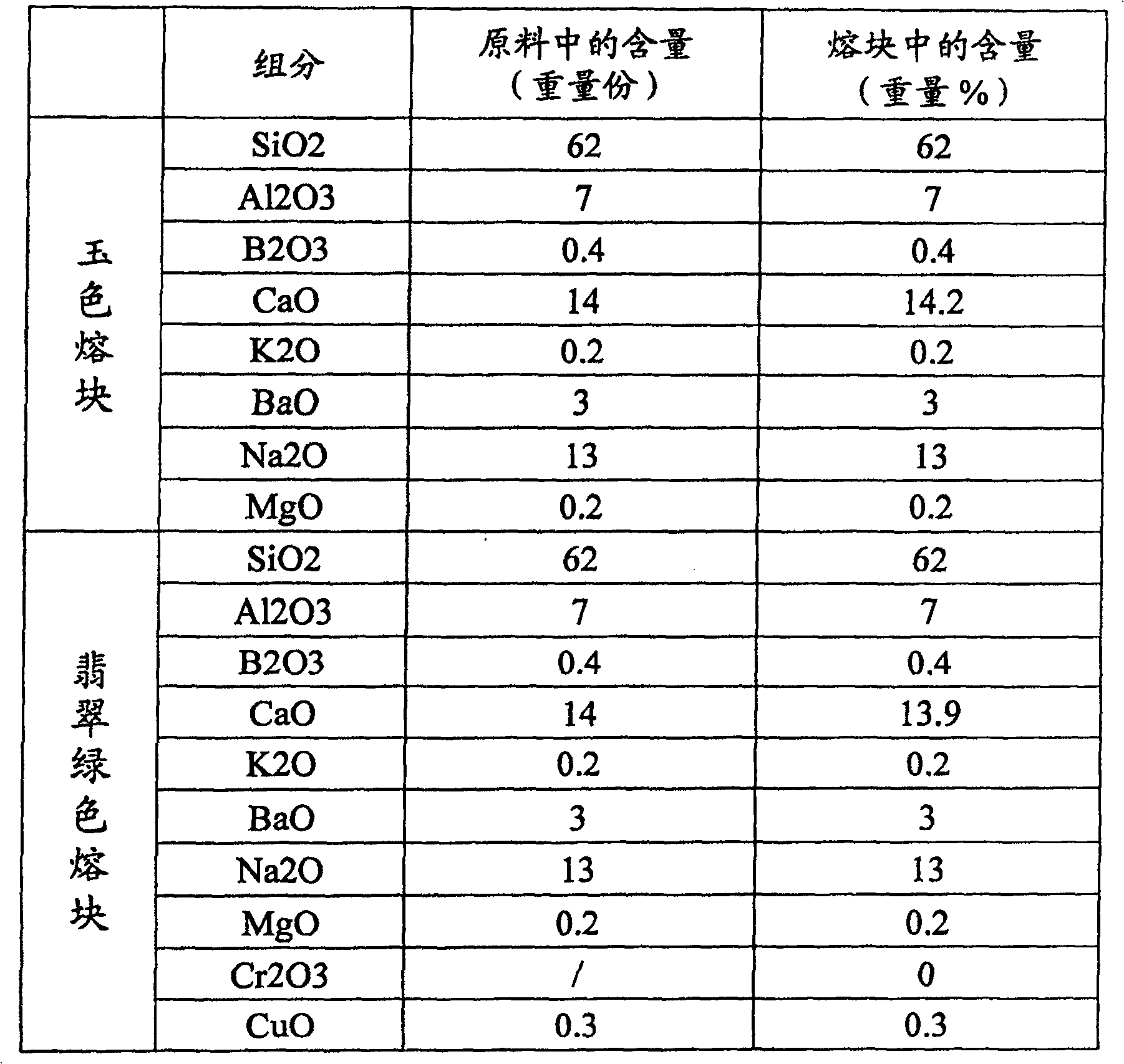

[0040] Use quartz powder, lime powder, feldspar powder, barium carbonate, and soda ash as shown in Table 1, mix and heat to 1400-1430°C to melt the powdery solid material and keep it warm for 1 hour, then put it in water and cool it into a crushed material jade-colored frit.

[0041] Quartz powder, lime powder, feldspar powder, barium carbonate, soda ash, copper oxide, and chromium oxide are mixed and heated to 1400-1430°C as shown in Table 1 below to melt the powdery solid material and keep it warm for 1 hour. Then, put Emerald green frit that cools in water into crumbs.

[0042] Table 1 The raw materials of Example 1 and the content of each component in the jade-colored frit and the emerald-green frit

[0043]

[0044] Mix the jade-colored frit and emerald-green frit in a ratio of 7:3, put it in a steel mold with an asbestos board as the bottom, heat it to 1000°C, keep it warm for 1 hour, cool it naturally to room temperature, and take it out to be the finished product. ...

Embodiment 2

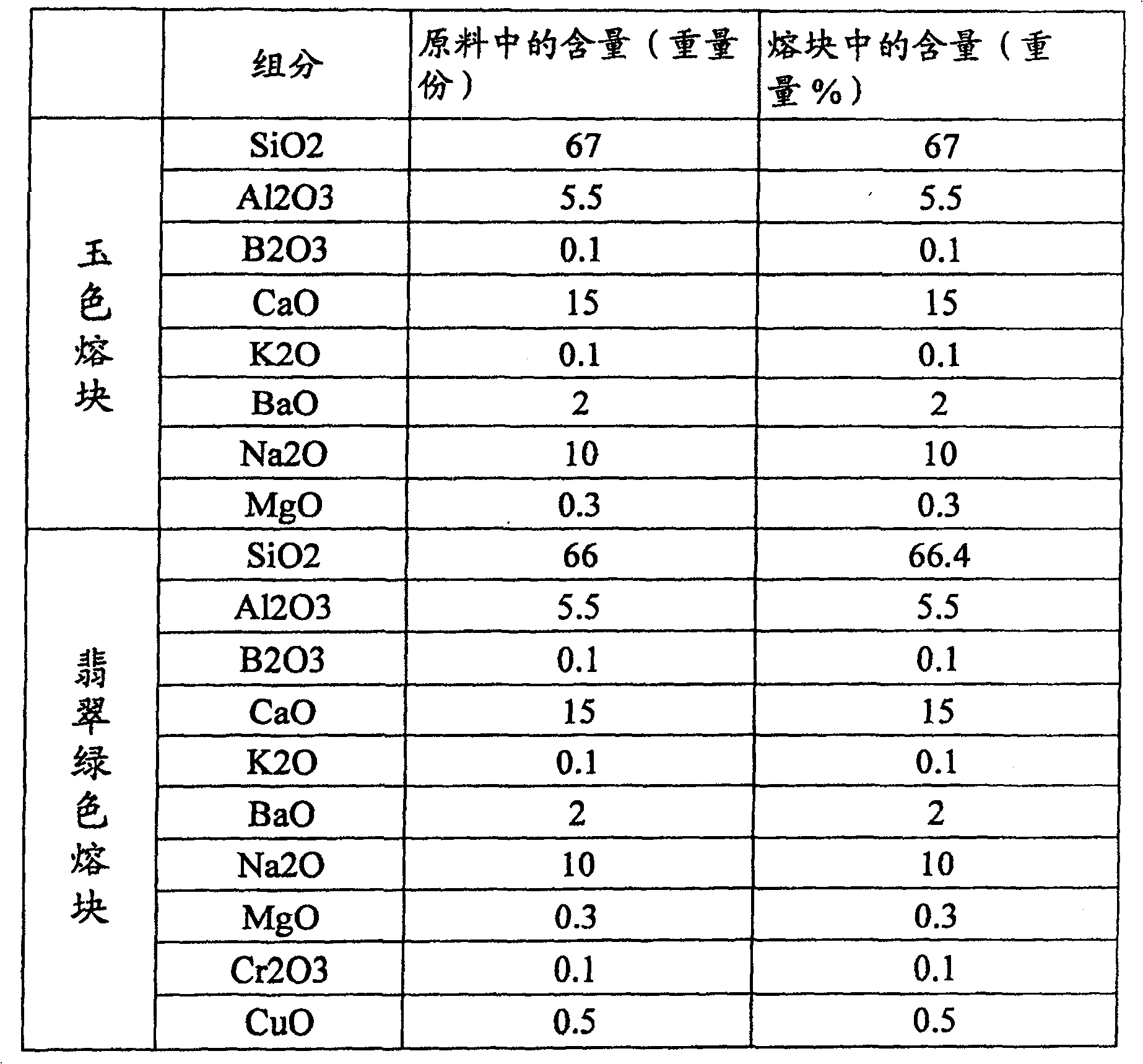

[0048] Use quartz powder, lime powder, feldspar powder, barium carbonate, and soda ash as shown in Table 2, mix and heat to 1570-1600°C to melt the powdery solid material, keep it warm for 1.5 hours, then put it into water and cool it into a crushed material jade-colored frit.

[0049] Quartz powder, lime powder, feldspar powder, barium carbonate, soda ash, copper oxide, and chromium oxide are mixed and heated to 1570-1600°C as shown in Table 2 below to melt the powdery solid material and keep it warm for 1.5 hours. Then, put Emerald green frit that cools in water into crumbs.

[0050] Table 2 The raw materials of Example 2 and the content of jade-colored frit and emerald green frit

[0051]

[0052] Mix the jade-colored frit and emerald-green frit in a ratio of 8:2, put it in a steel mold with an asbestos board as the bottom, heat it to 1100°C, keep it warm for 1.5 hours, cool it naturally to room temperature, and take it out to be the finished product.

[0053] The spec...

Embodiment 3

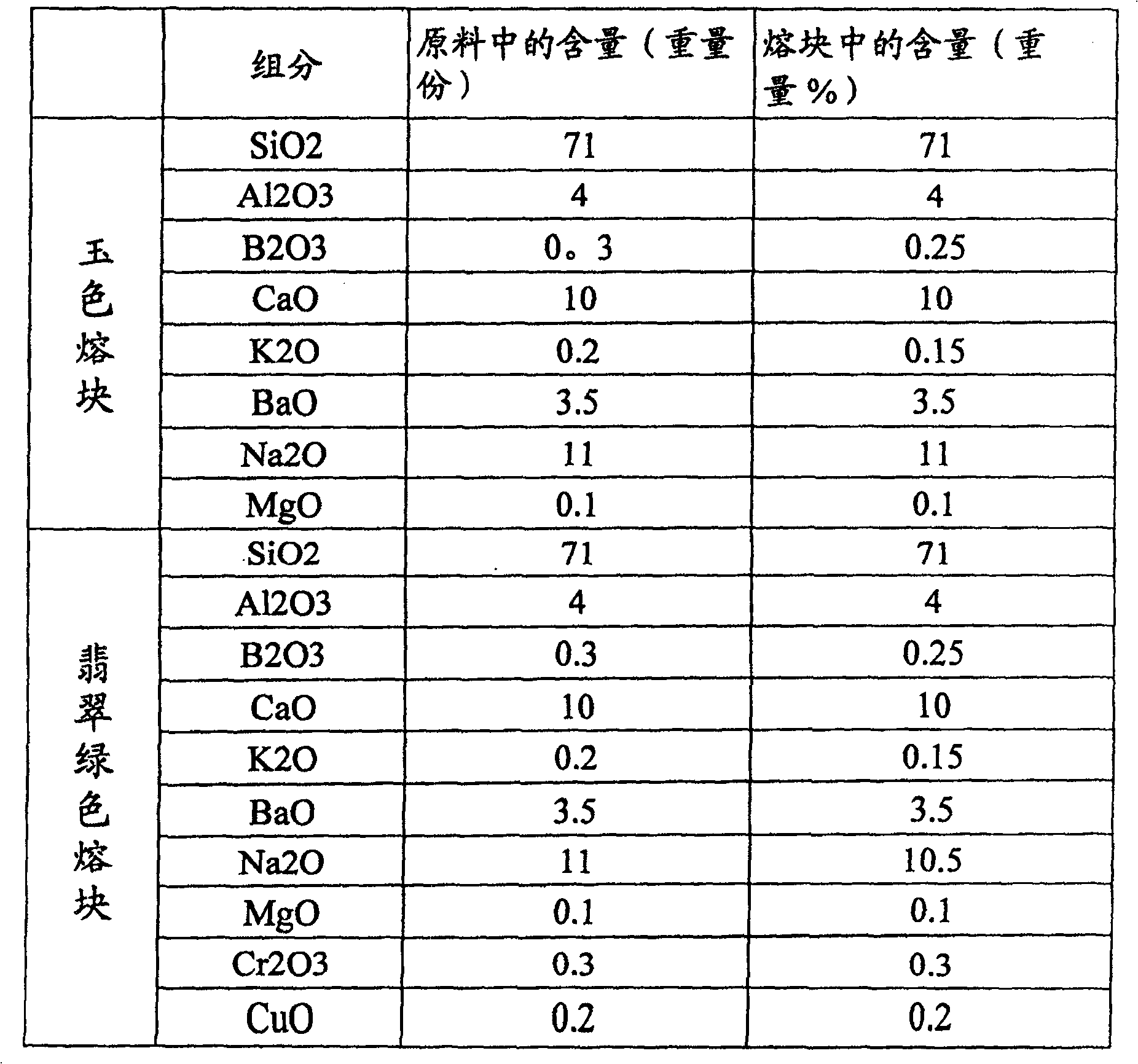

[0056] Use quartz powder, lime powder, feldspar powder, barium carbonate, and soda ash as shown in Table 3, mix and heat to 1480-1510°C to melt the powdery solid material and keep it warm for 2 hours, then put it in water and cool it into a crushed material jade-colored frit.

[0057] Quartz powder, lime powder, feldspar powder, barium carbonate, soda ash, copper oxide, and chromium oxide as shown in Table 1 are used and heated to 1480-1510°C to melt the powdery solid material and keep it warm for 2 hours. Then, put Emerald green frit that cools in water into crumbs.

[0058] The content of each component in the raw material of table 3 embodiment 3 and jade color frit, emerald green frit

[0059]

[0060] Mix the jade-colored frit and emerald-green frit in a ratio of 6:4, put it in a steel mold with an asbestos board as the bottom, heat it to 1200°C, keep it warm for 2 hours, cool it naturally to room temperature, and take it out to be the finished product.

[0061] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com