Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Cured-in-place pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cured-in-place pipe (CIPP) is one of several trenchless rehabilitation methods used to repair existing pipelines. CIPP is a jointless, seamless, pipe-within-a-pipe with the capability to rehabilitate pipes ranging in diameter from 0.1 to 2.8 meters (2–110 inches). As one of the most widely used rehabilitation methods CIPP has applications in sewer, and chemical pipelines.

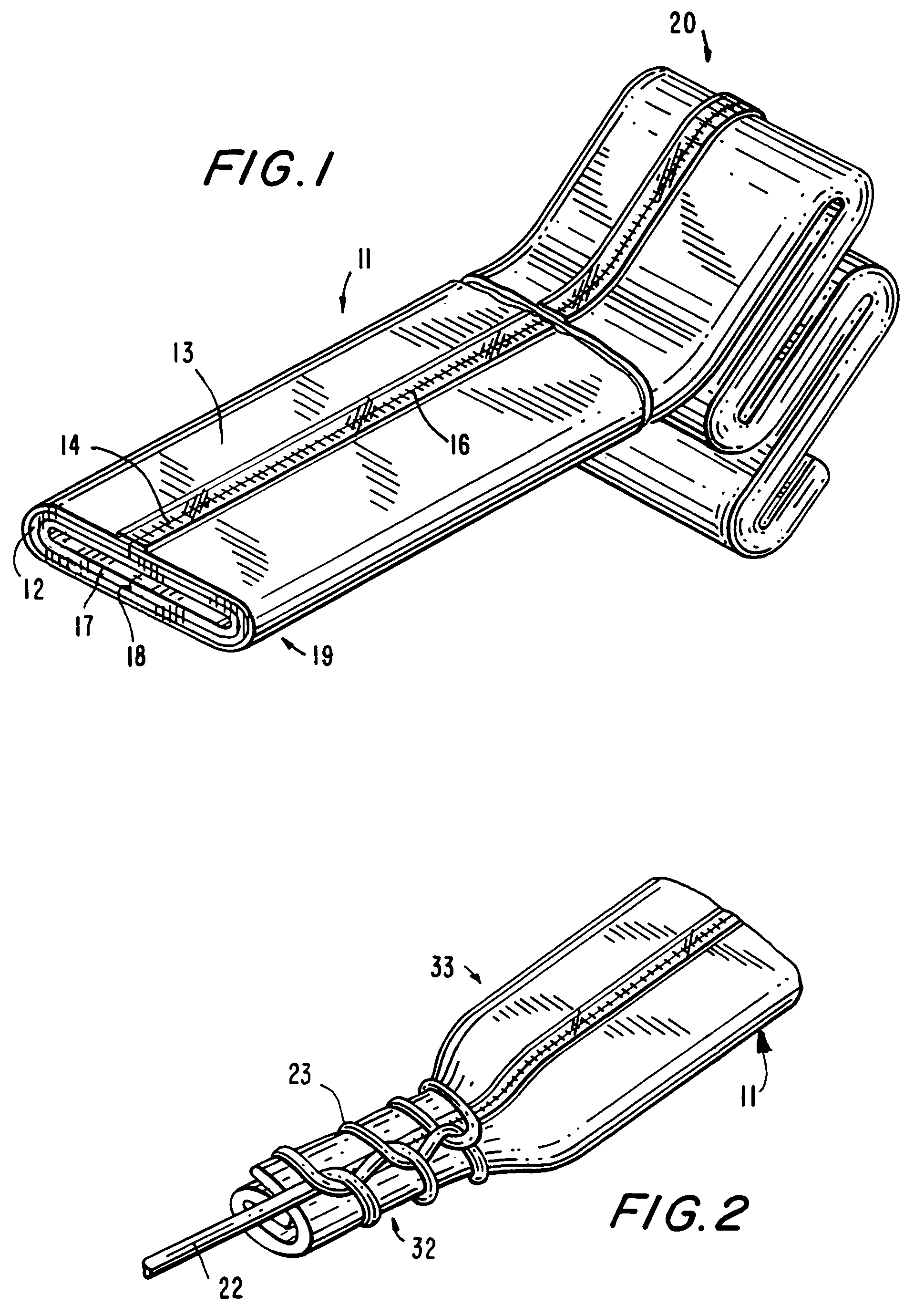

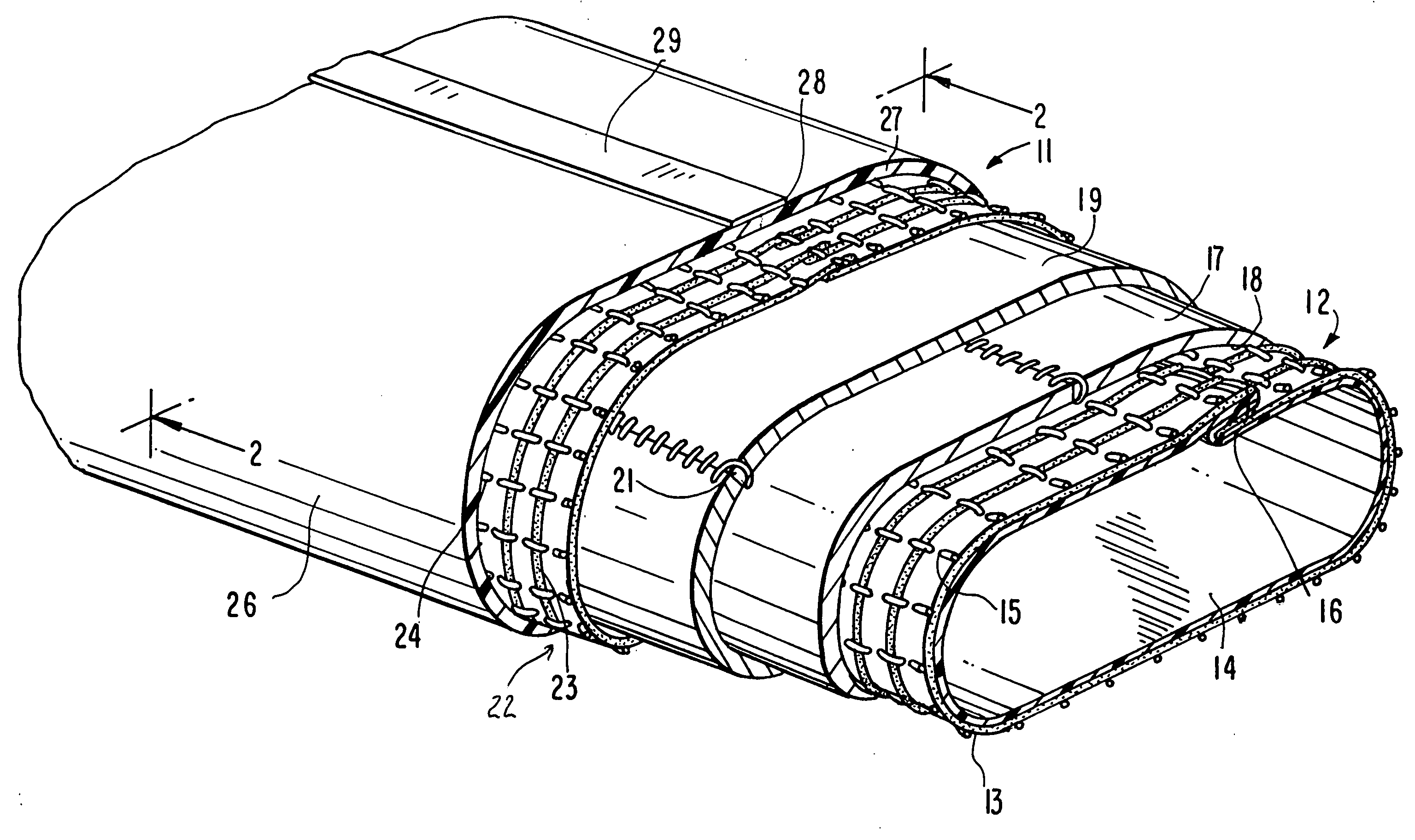

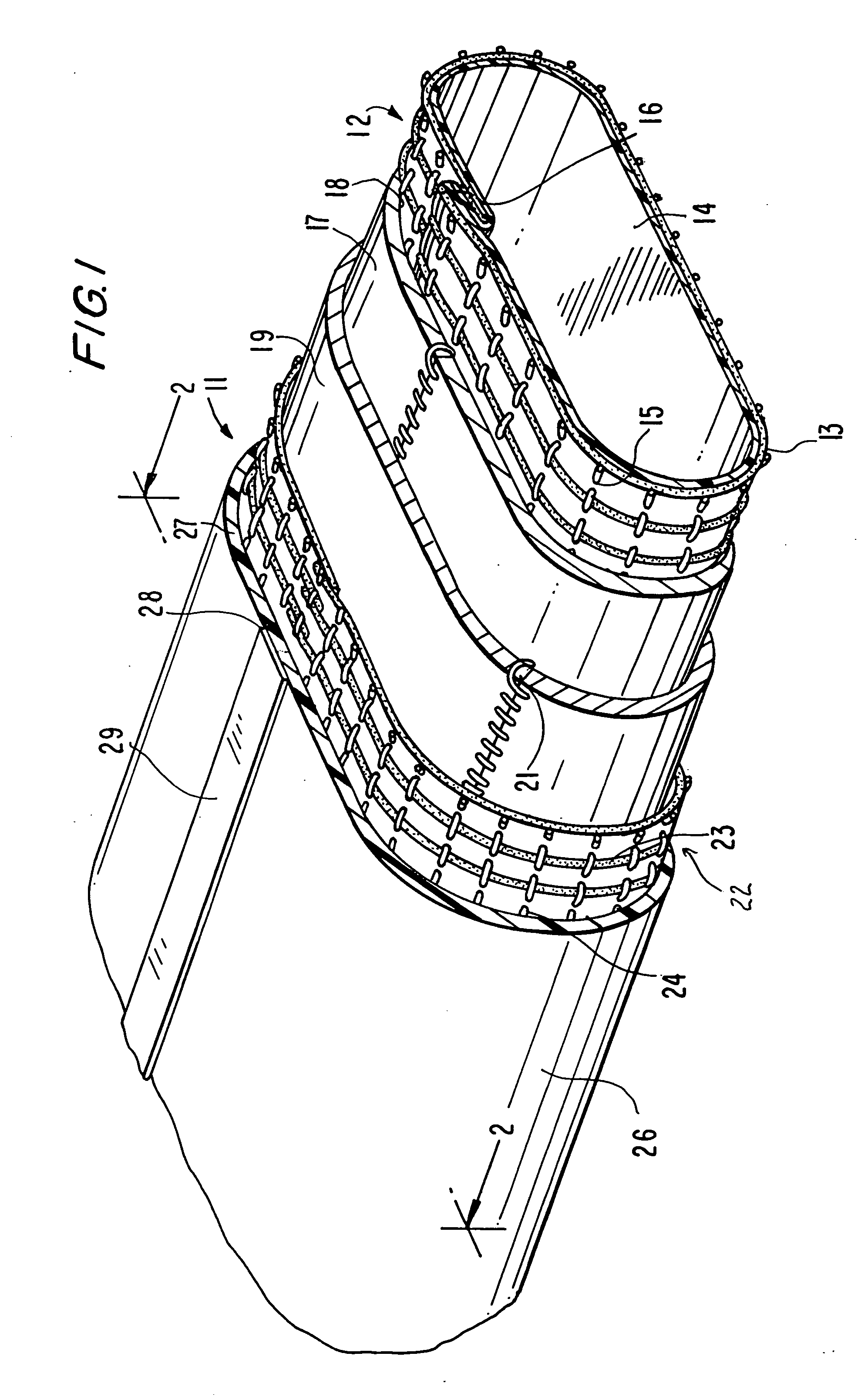

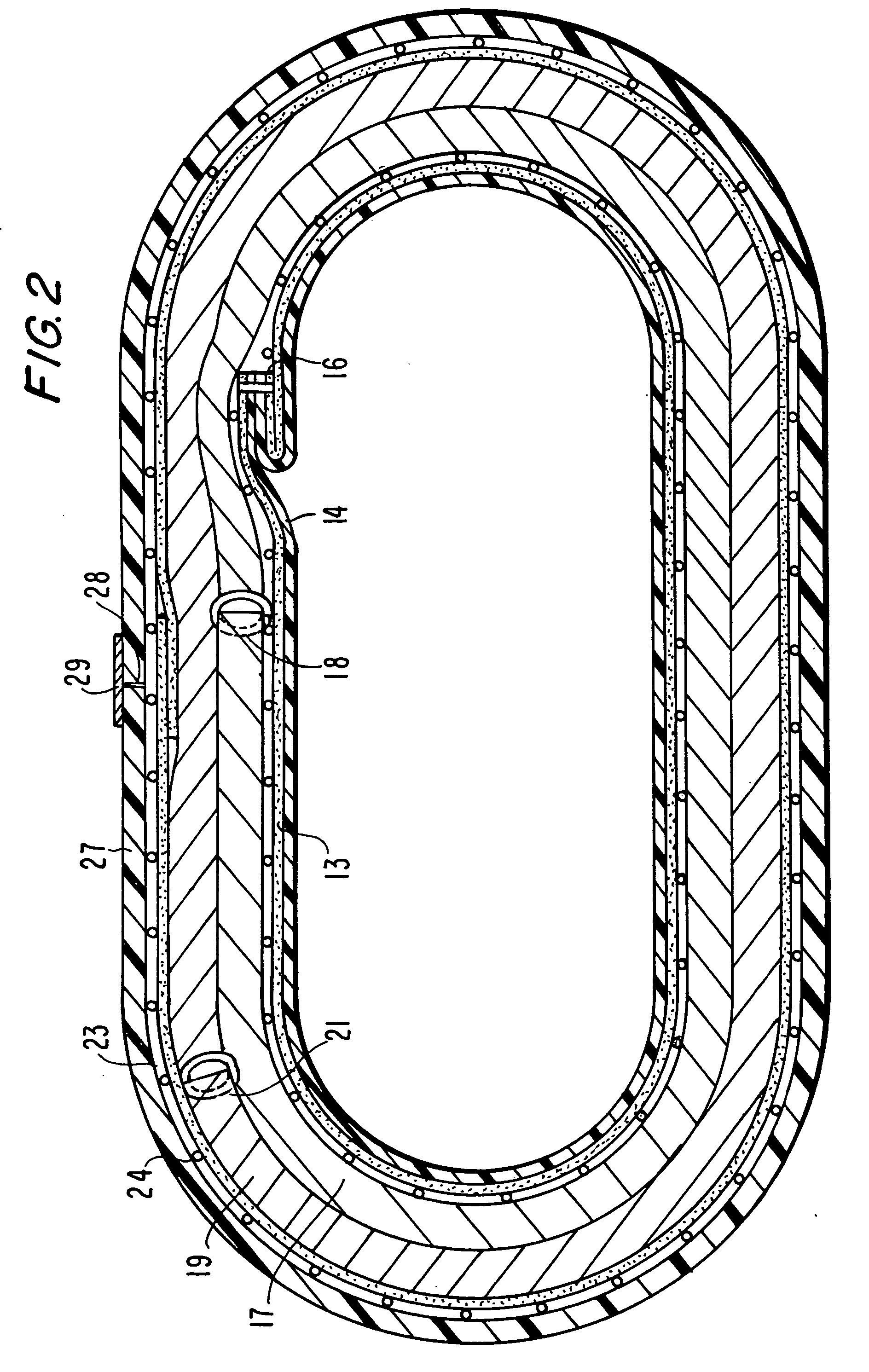

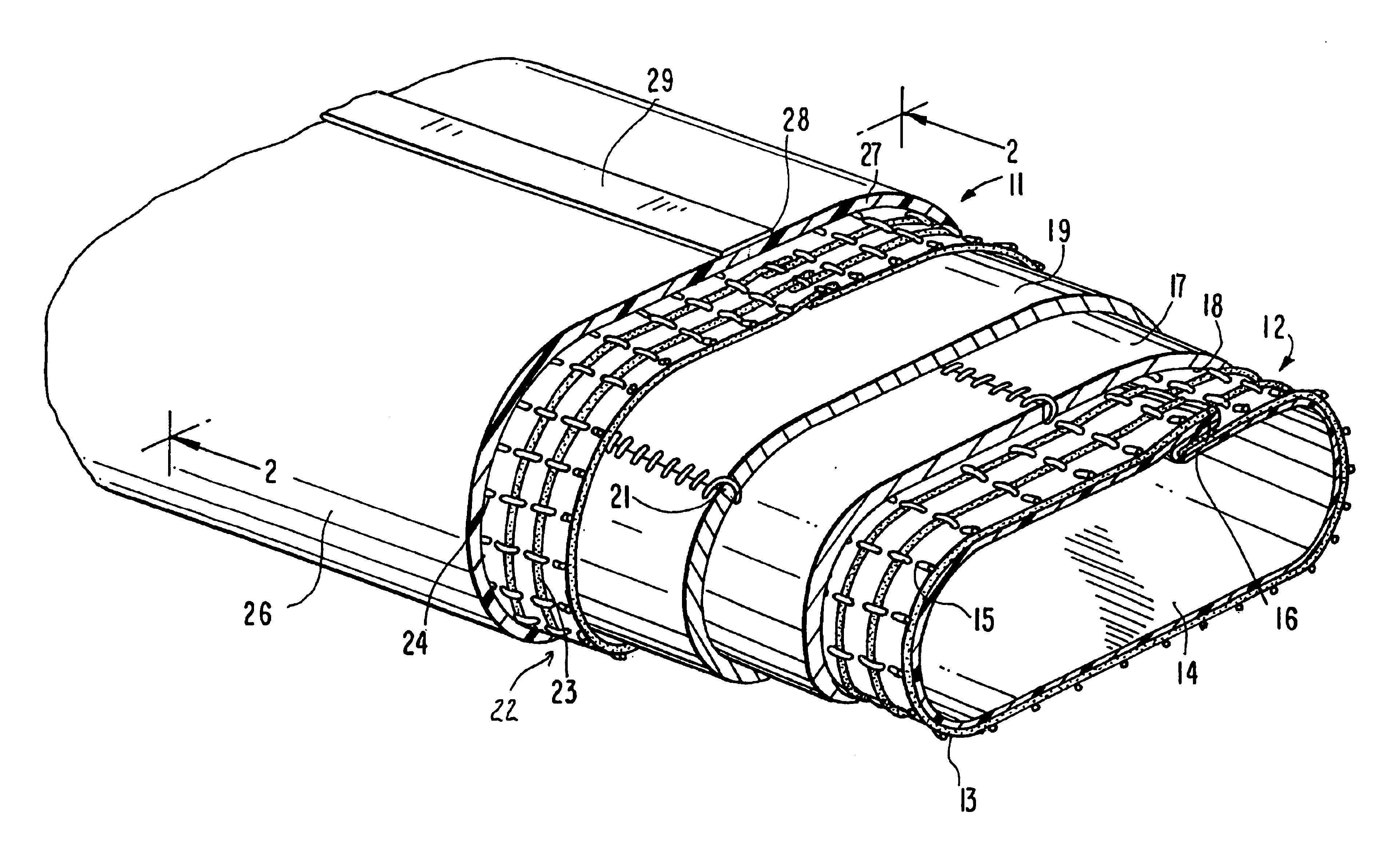

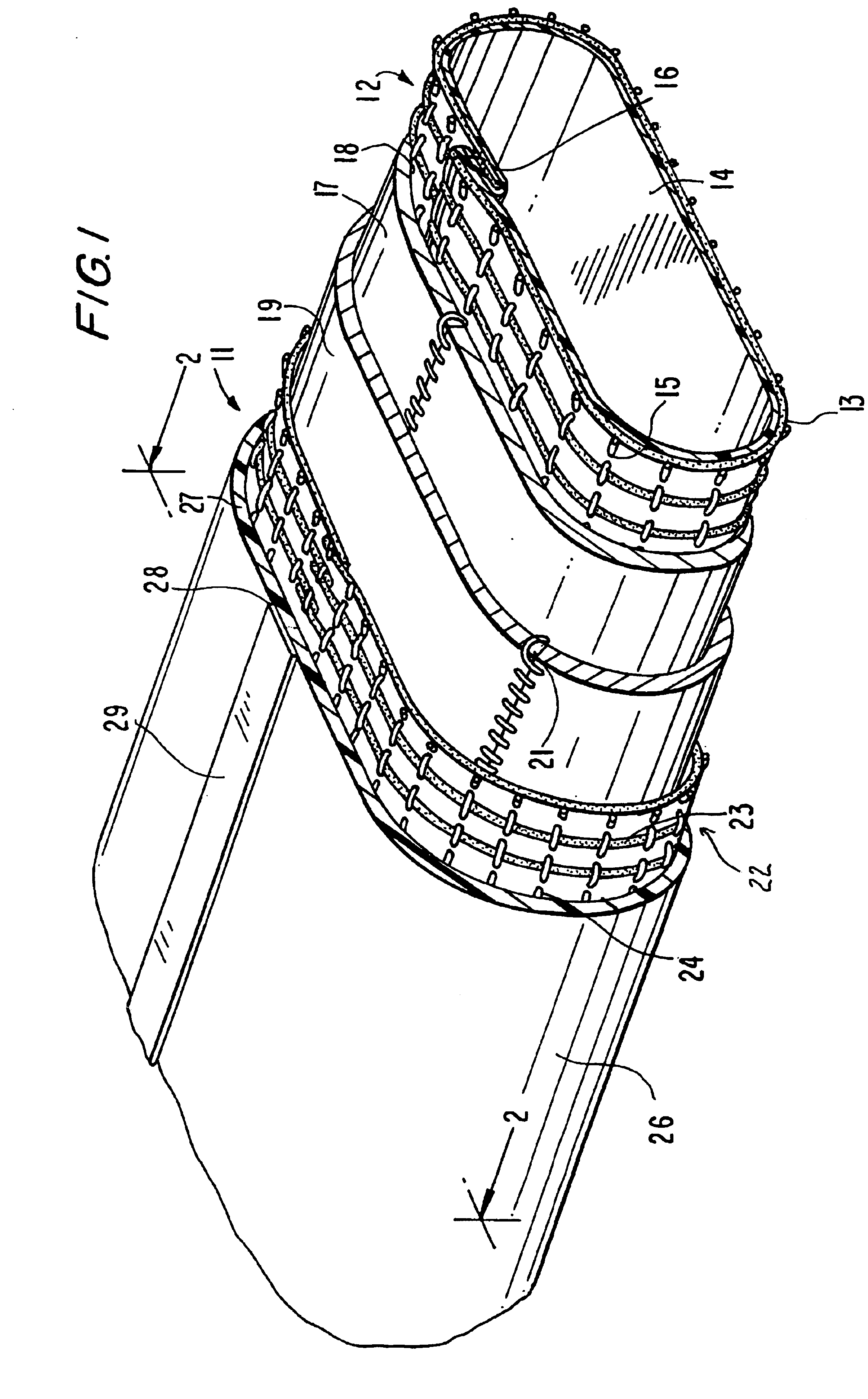

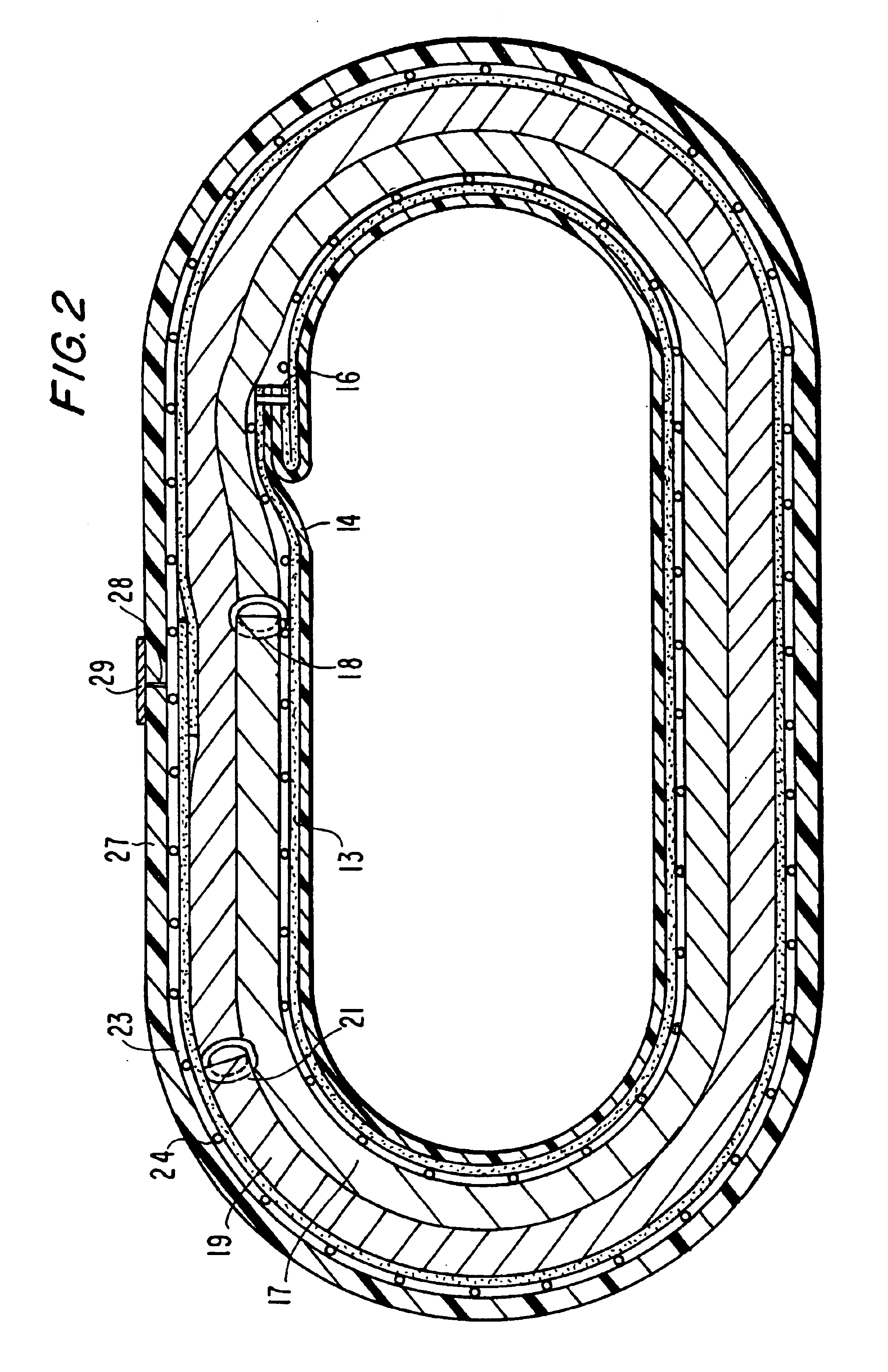

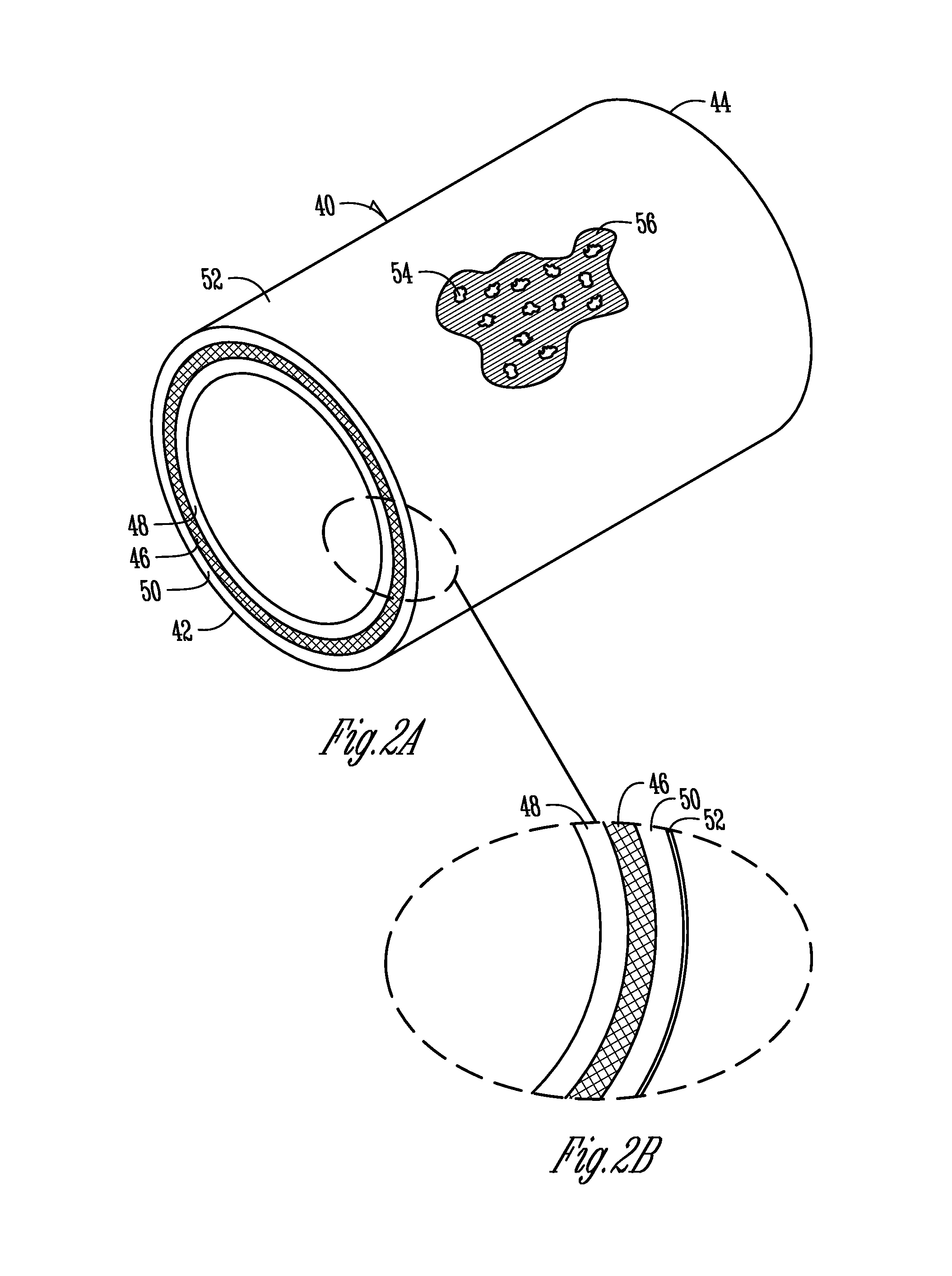

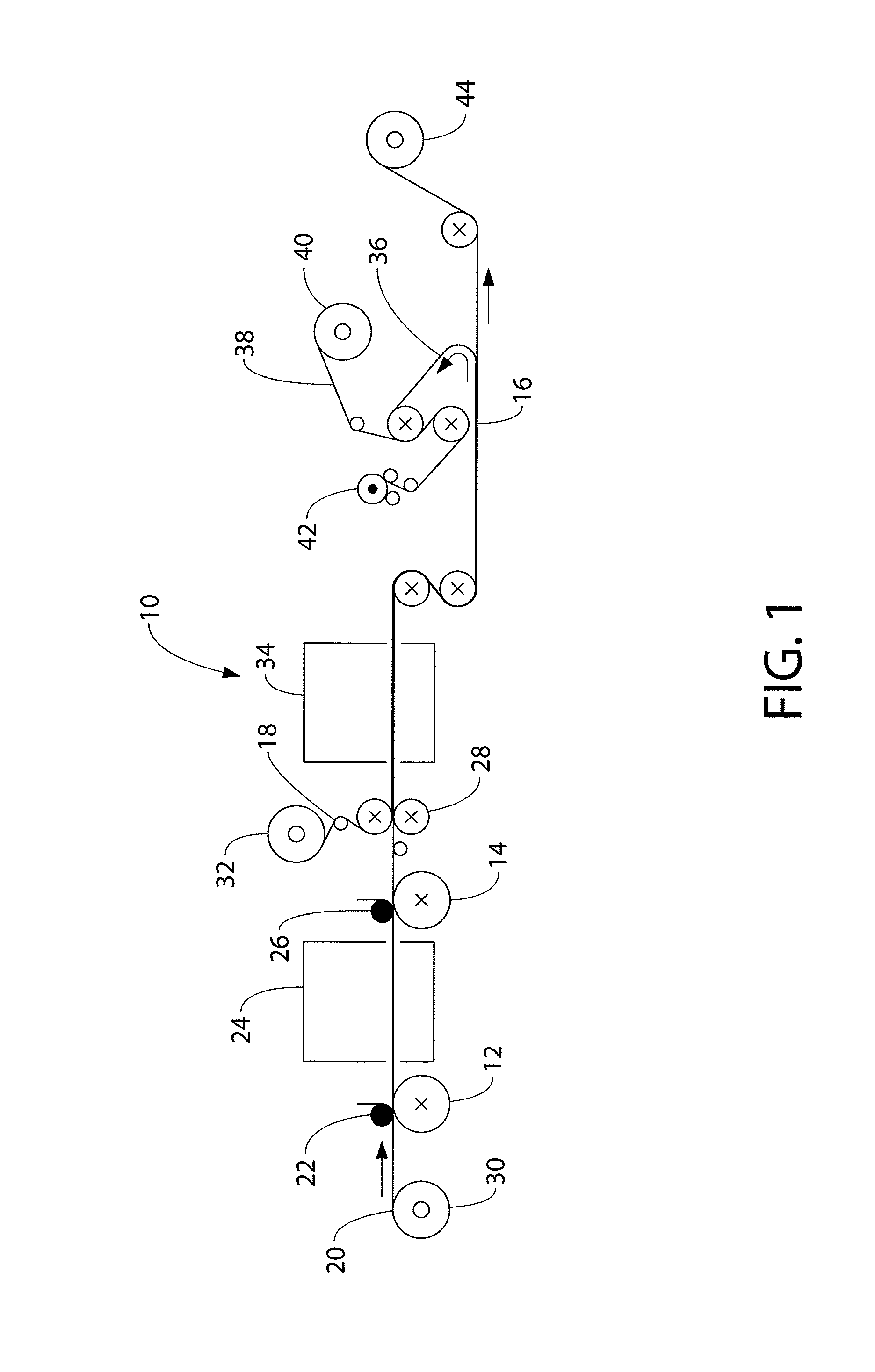

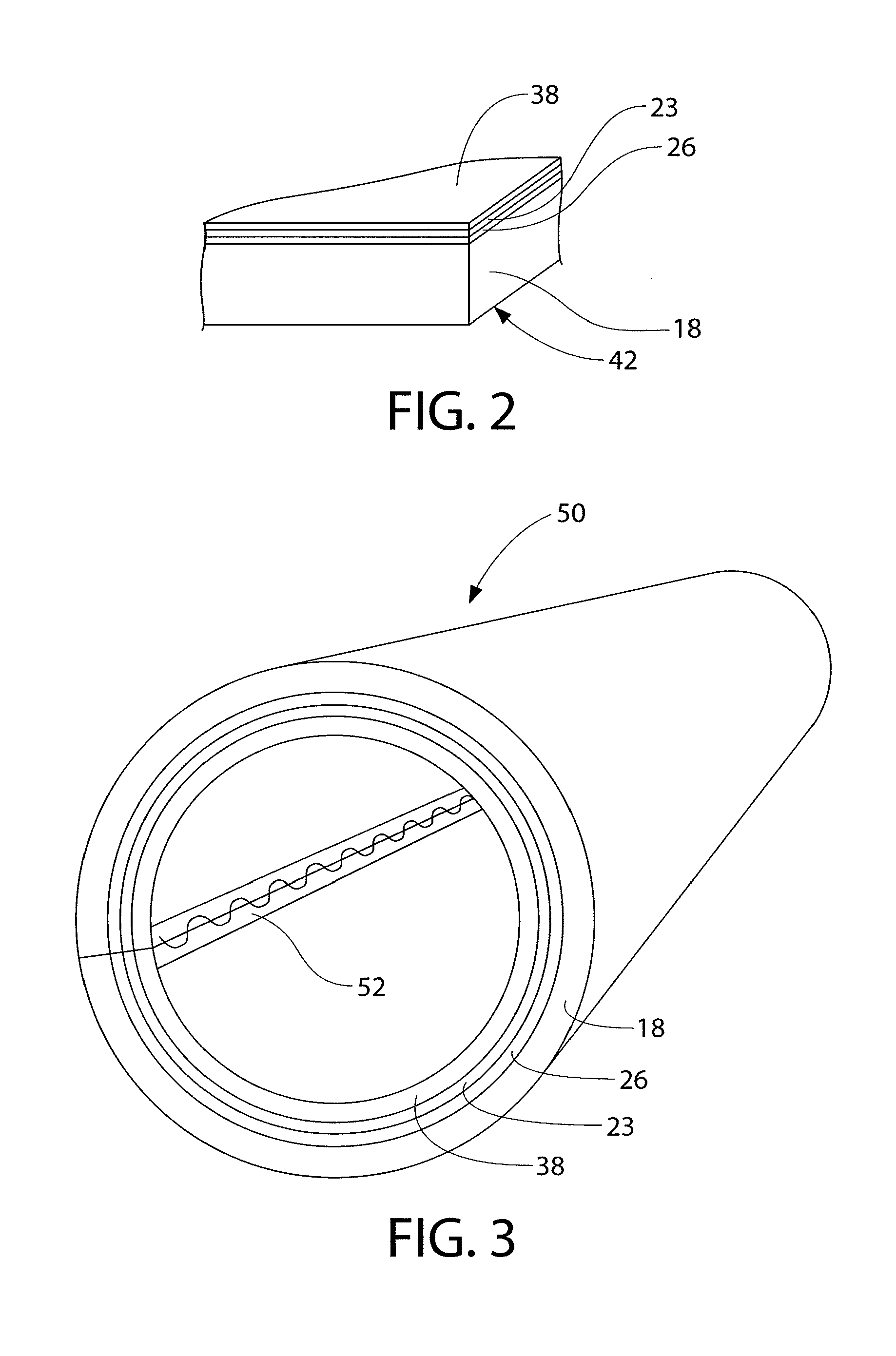

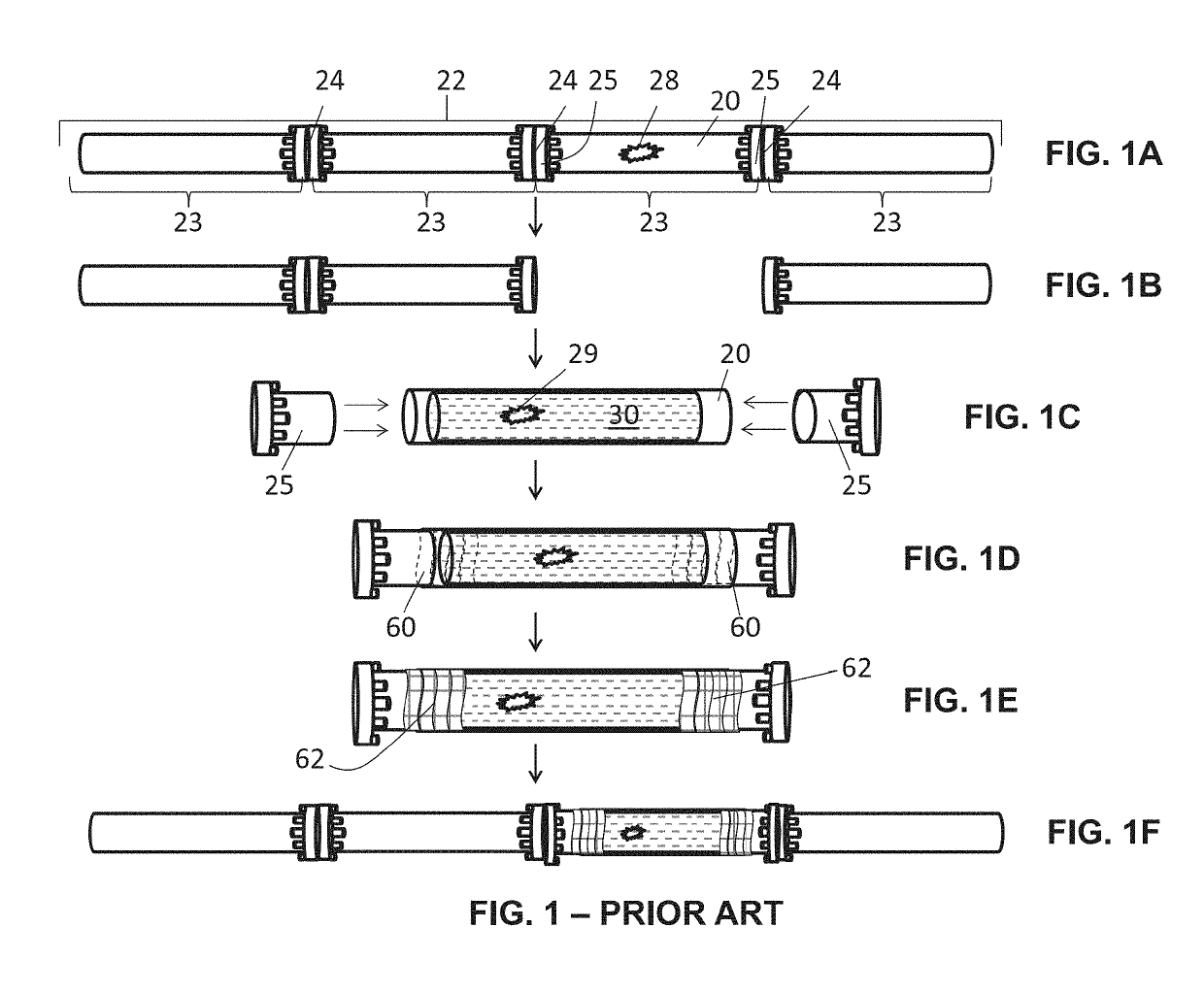

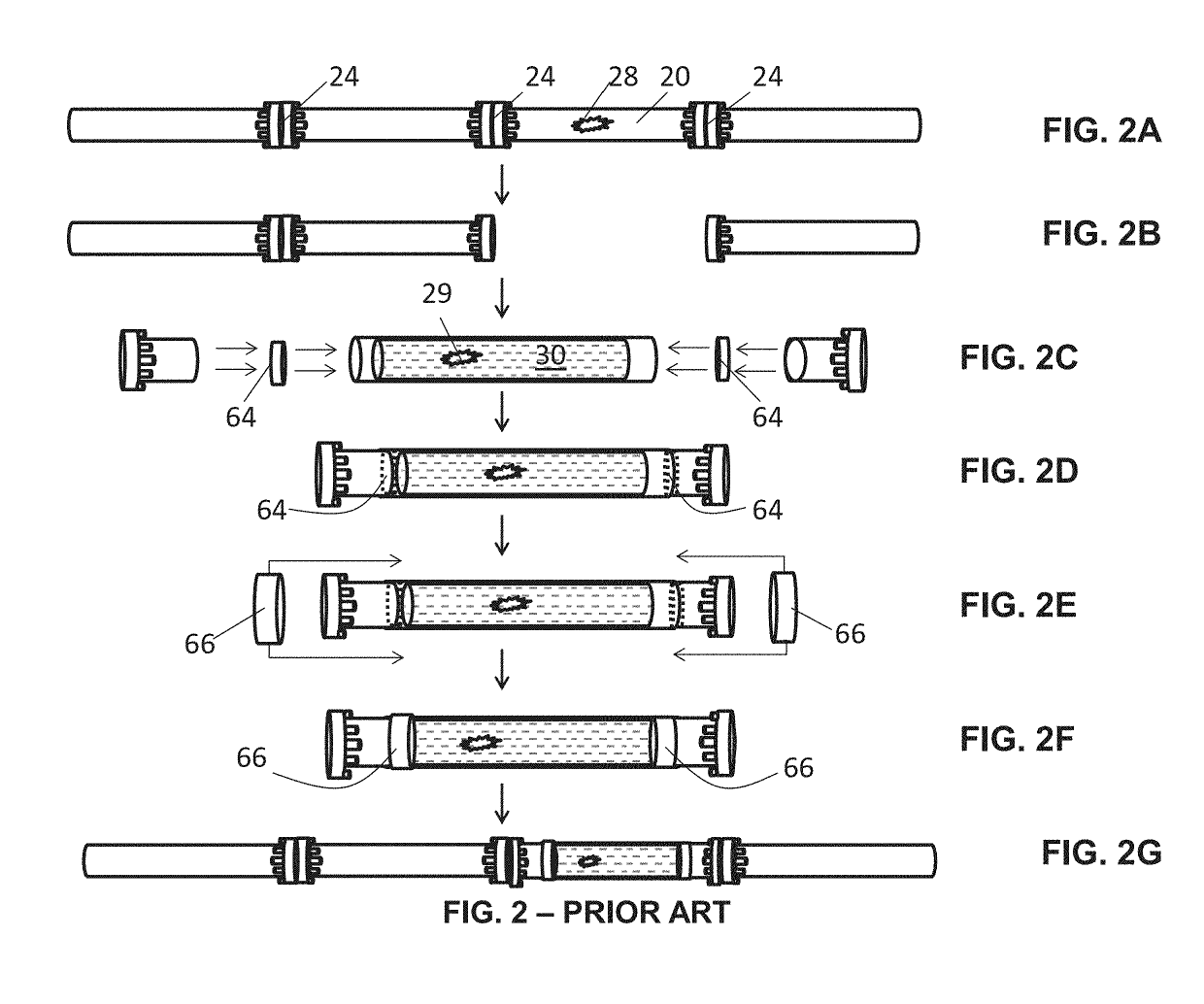

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS6932116B2Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleHigh intensity

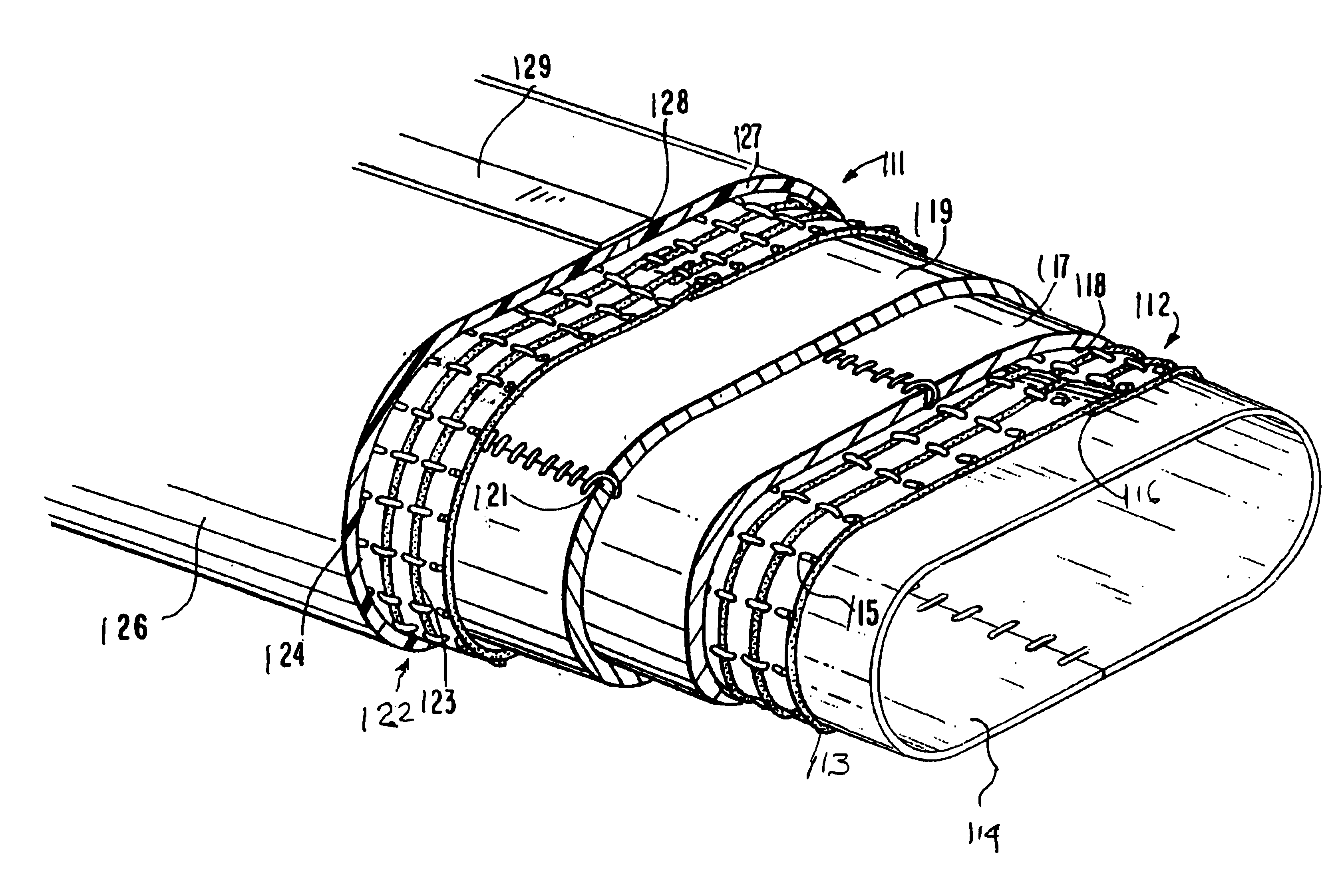

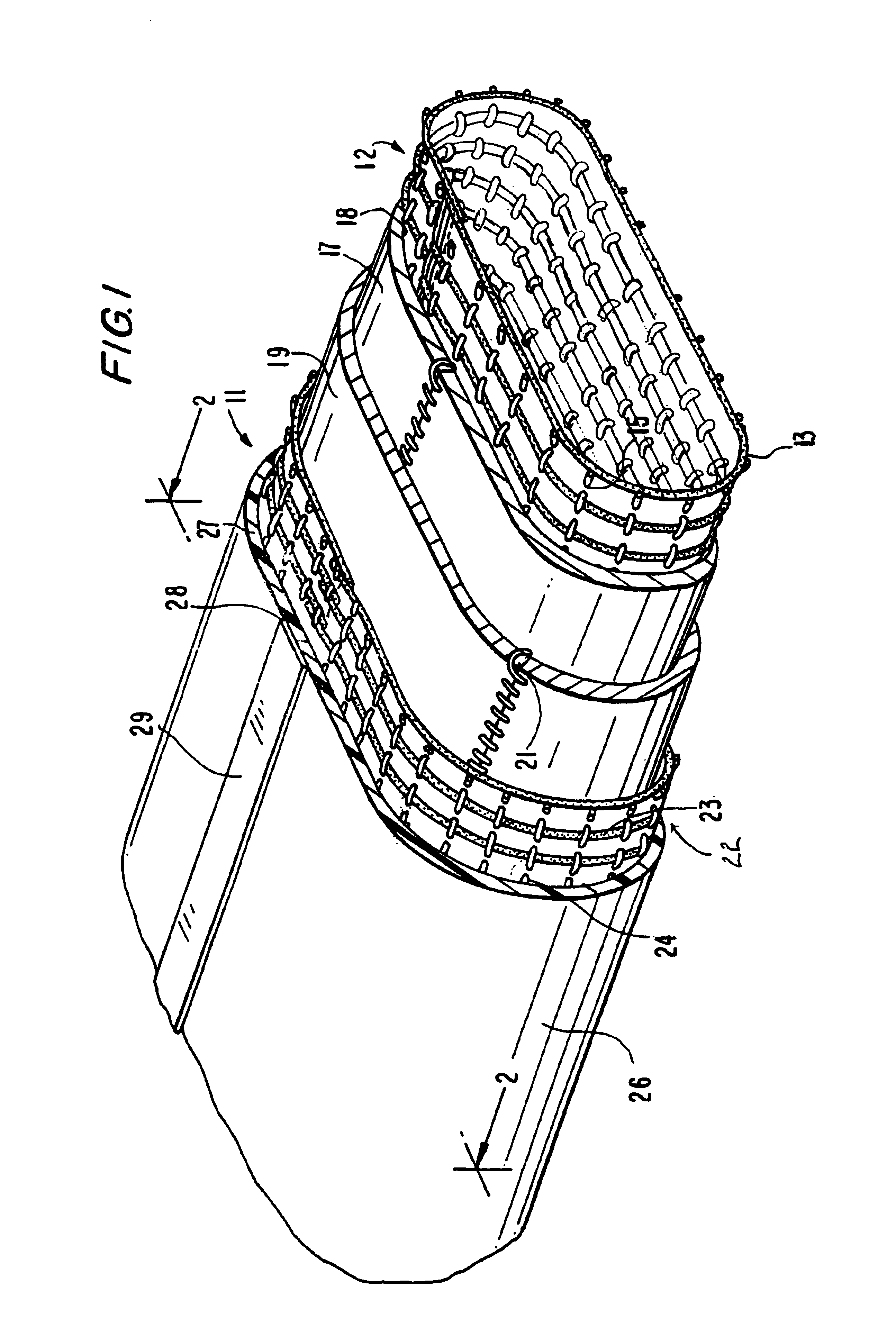

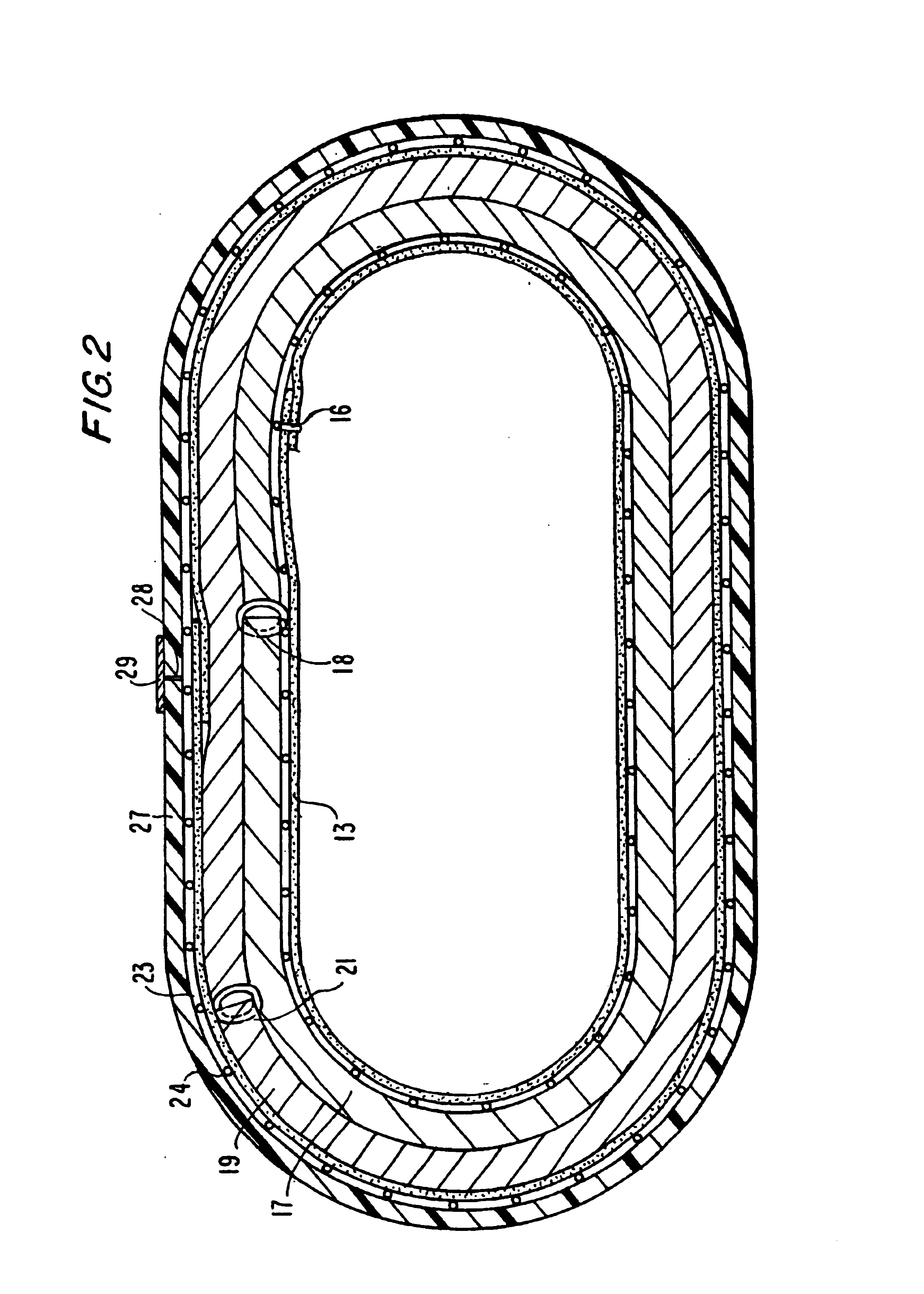

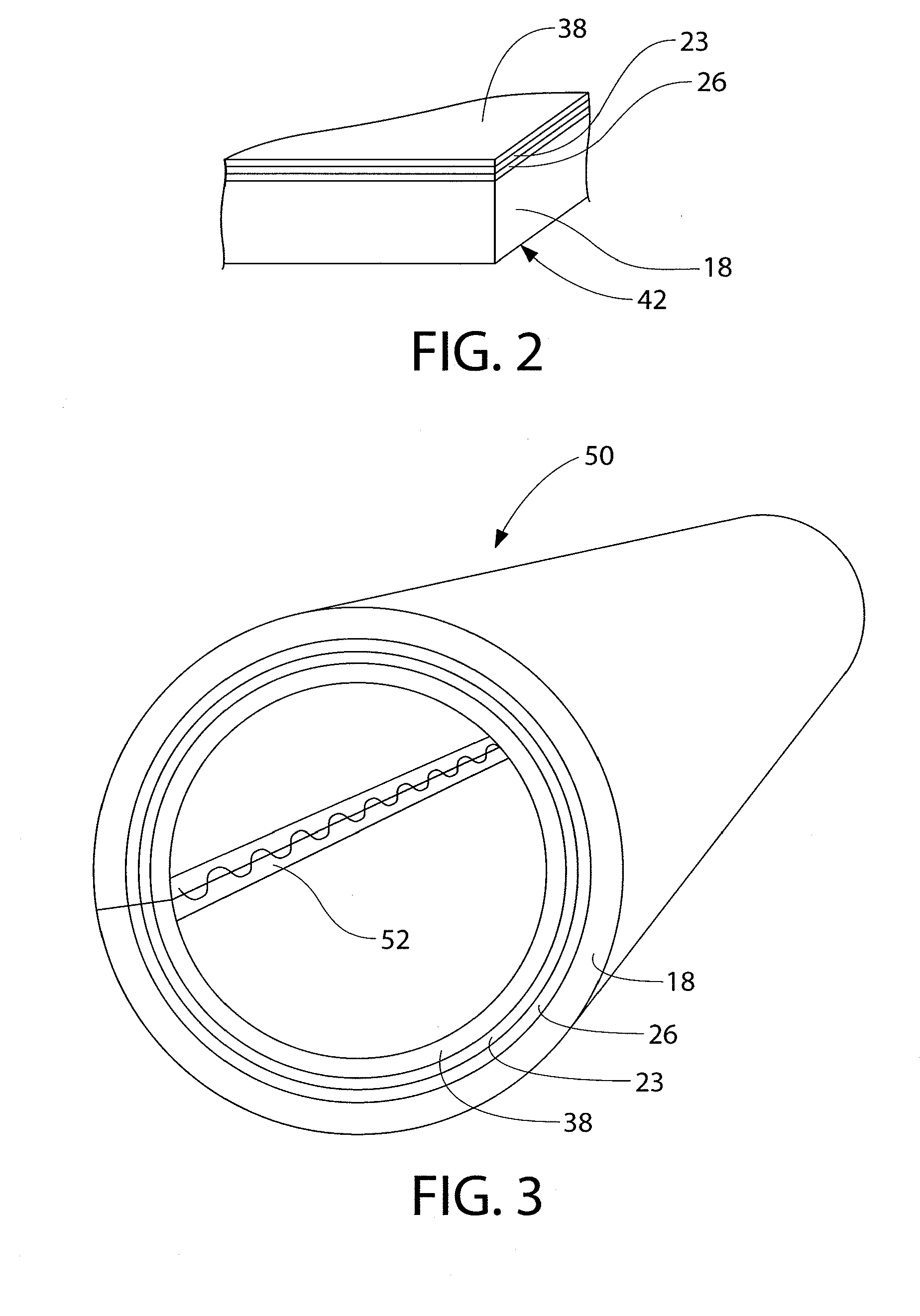

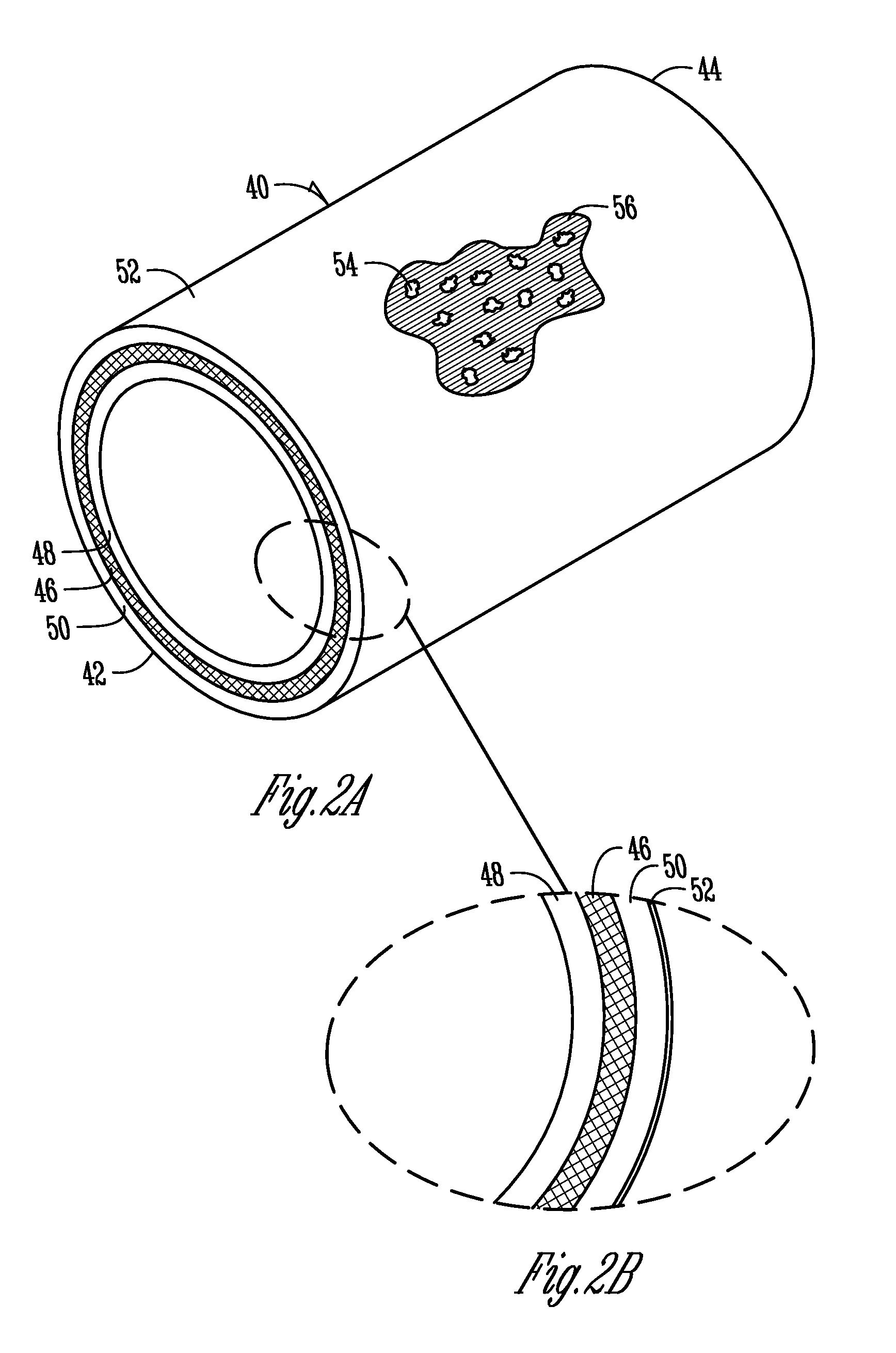

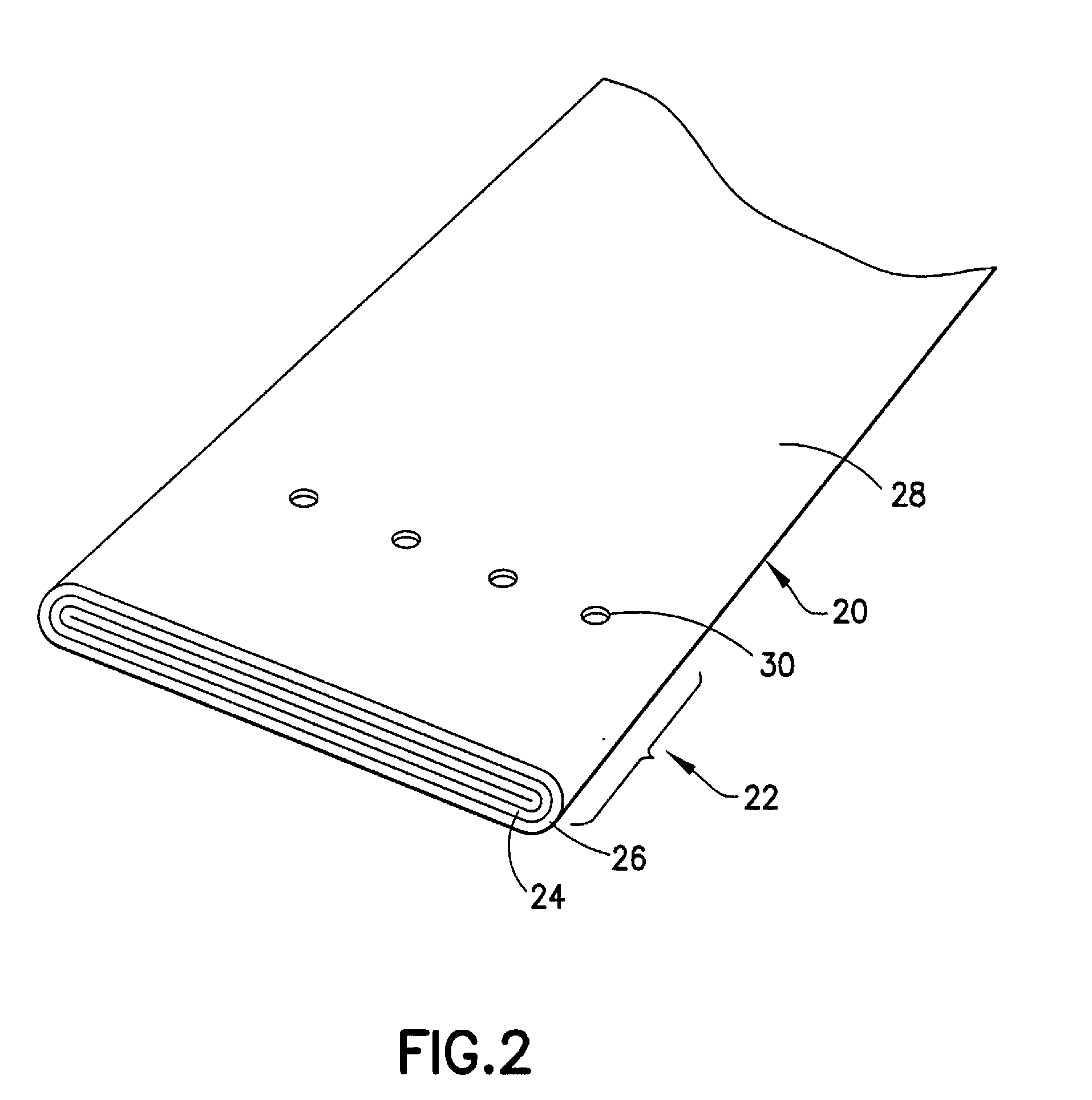

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The ends of reinforcing fibers on the inner and outer reinforcing layers overlap so that the ends slide past each other as the liner is expanded prior to cure. The reinforcing fibers may be secured to a porous scrim to form an inner tubular reinforcing layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

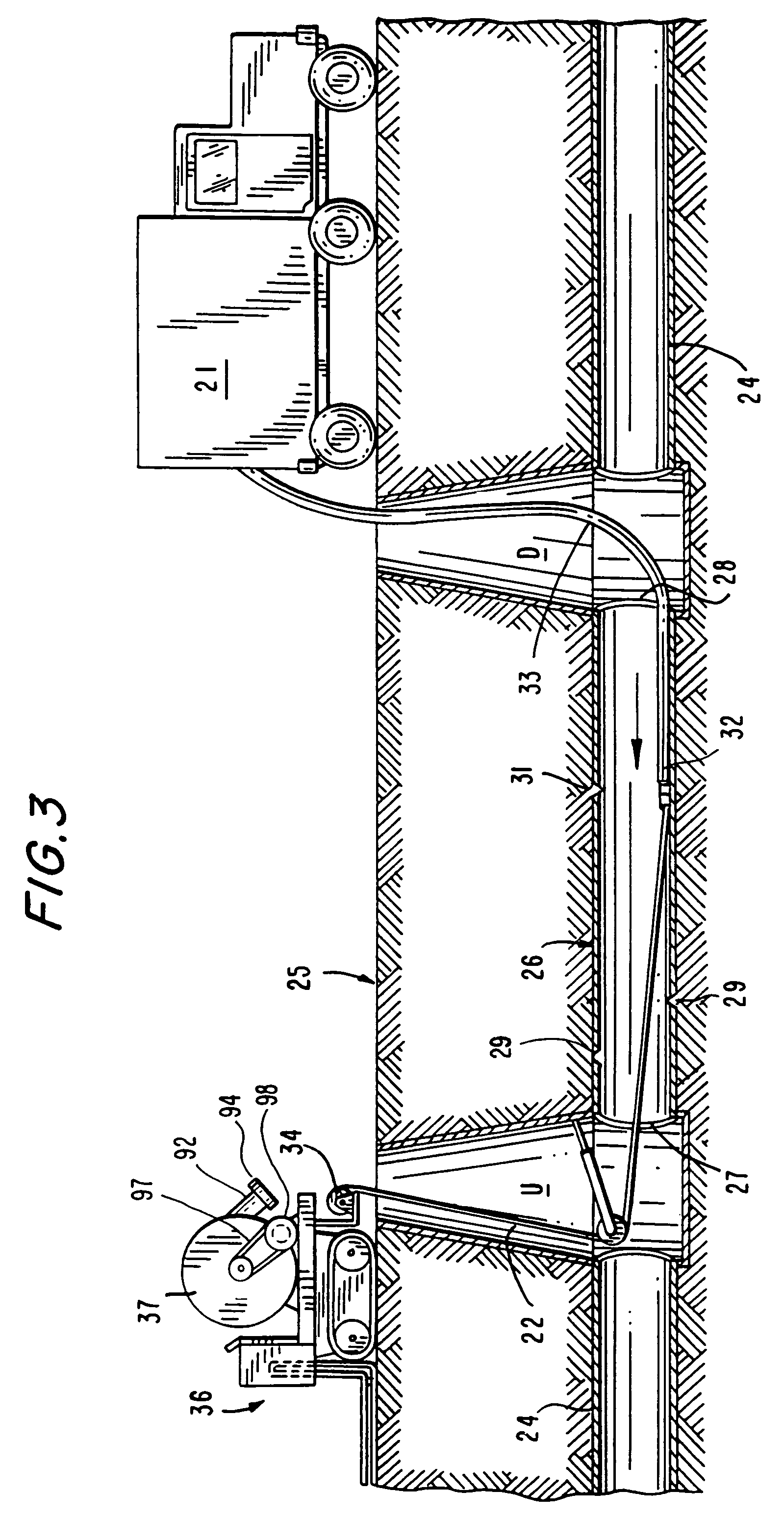

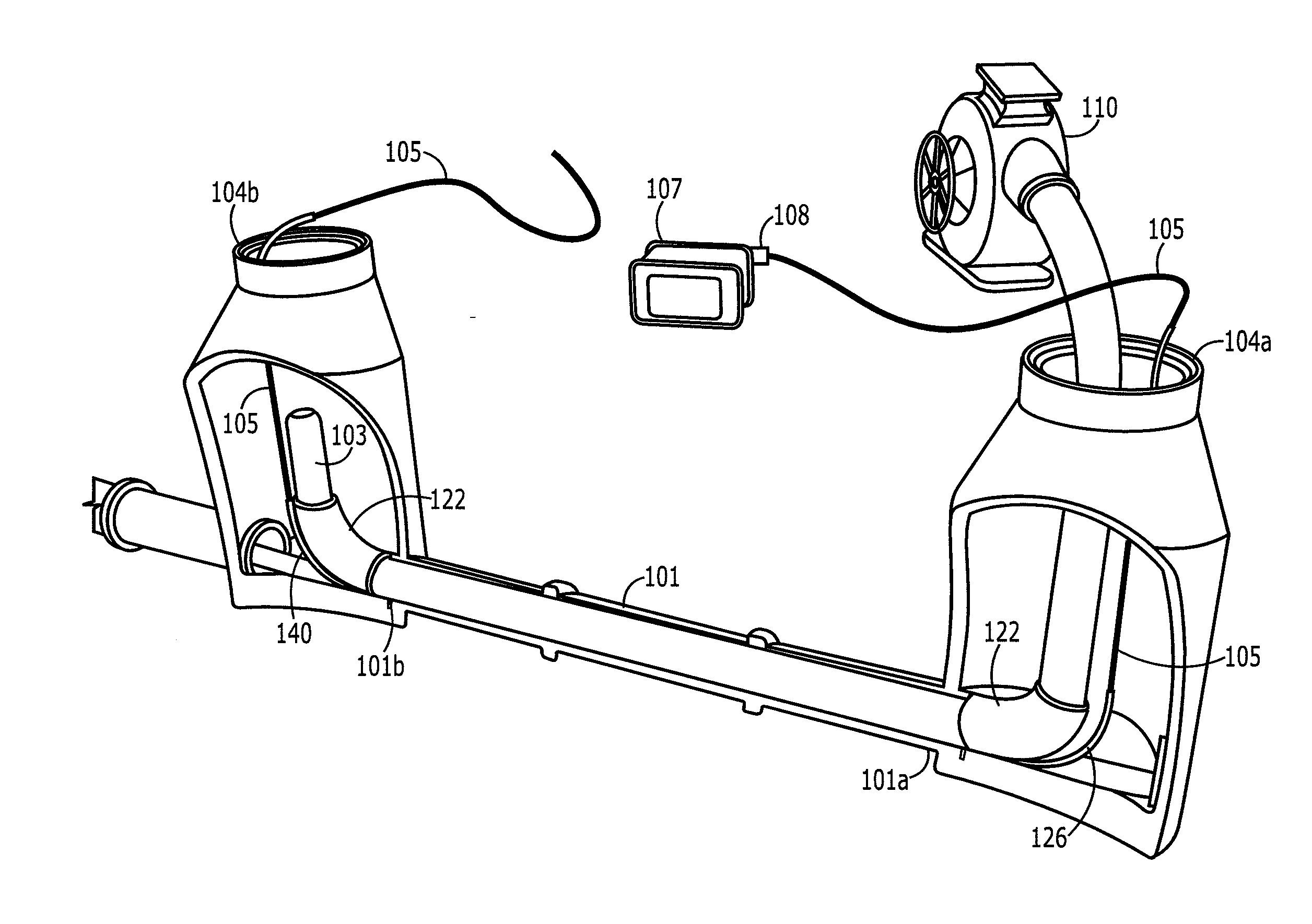

Pressurized bladder canister for installation of cured in place pipe

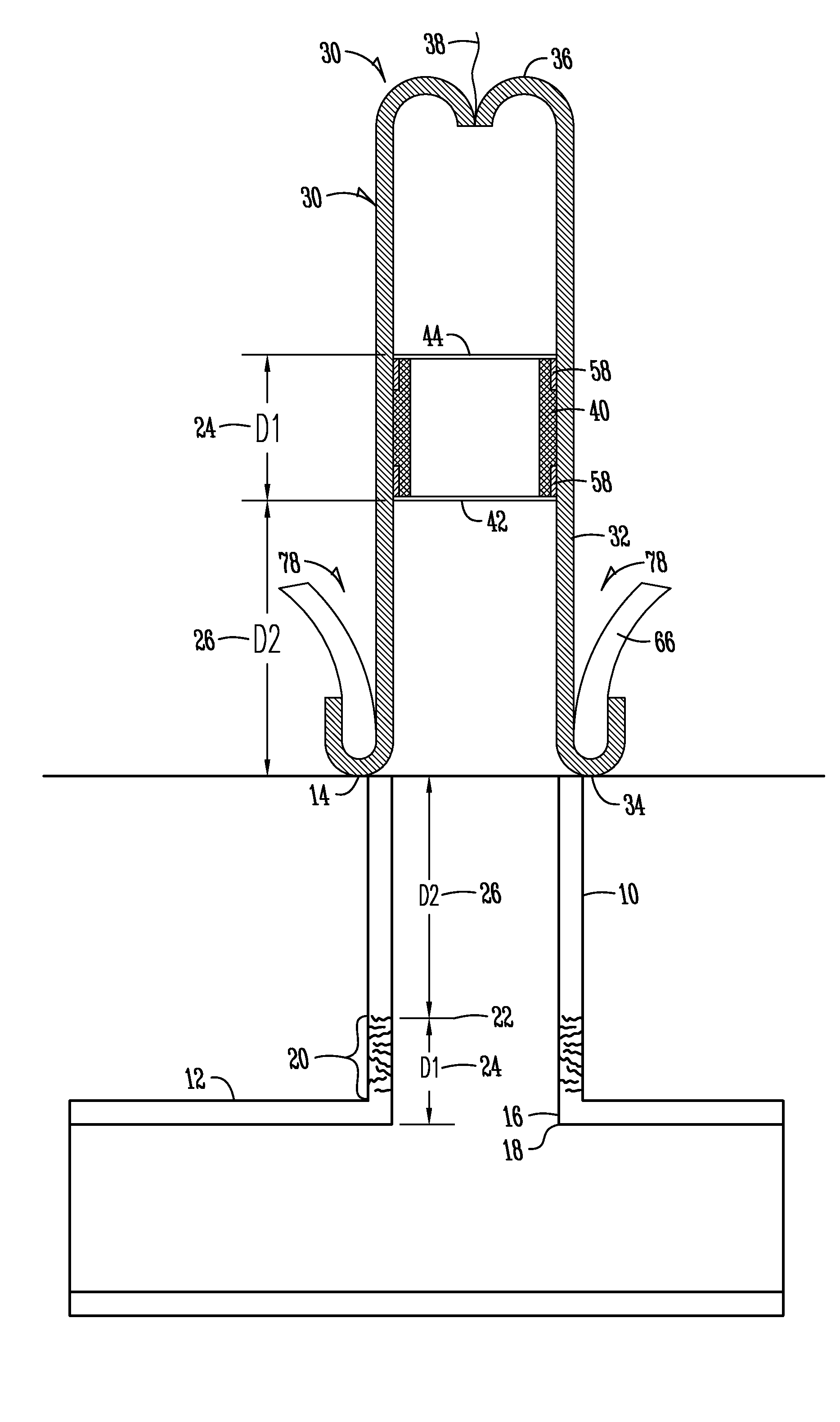

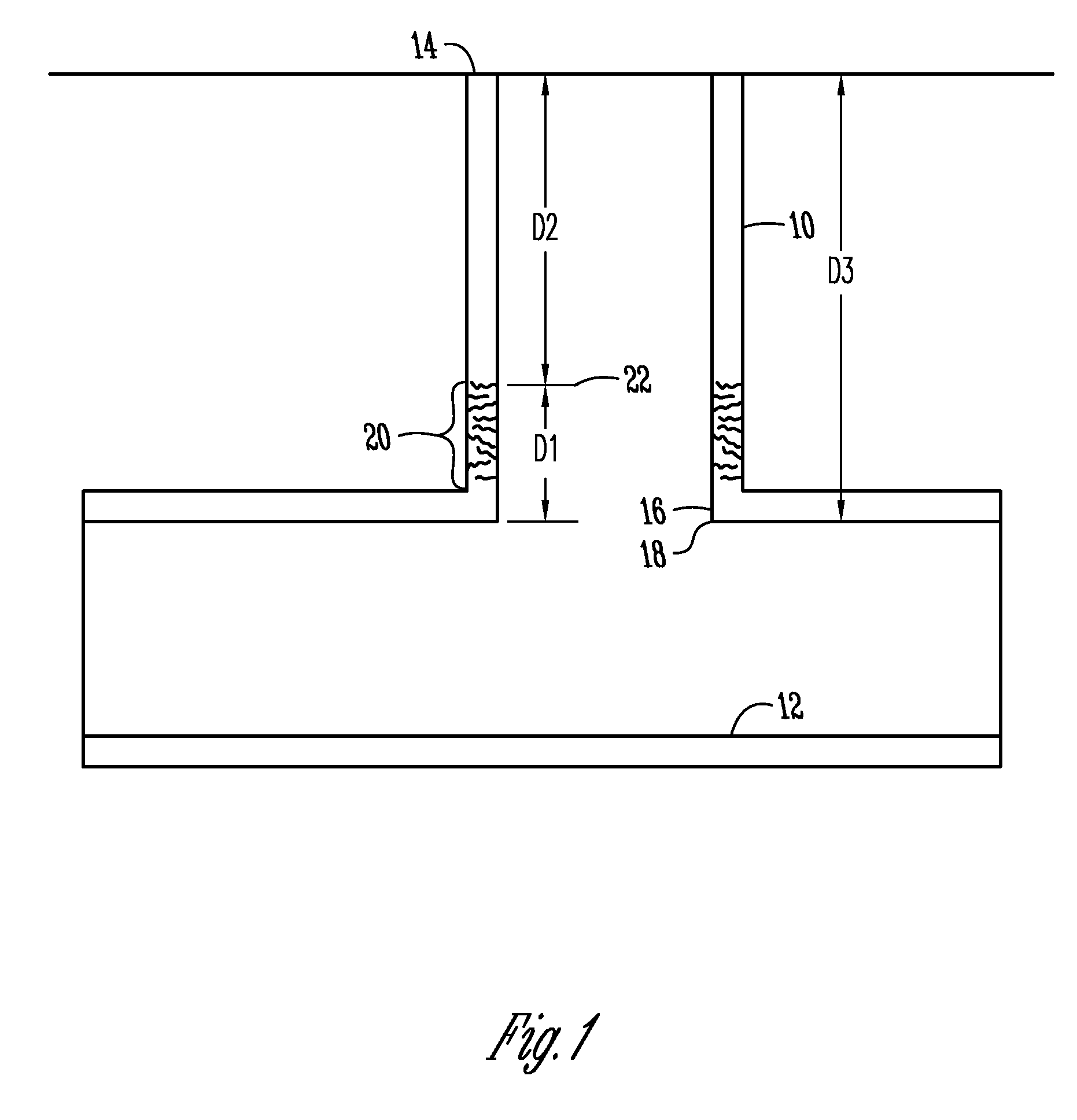

InactiveUS6969216B2Simple methodMaximize coolingUnderground chambersLaminationPinch valveEngineering

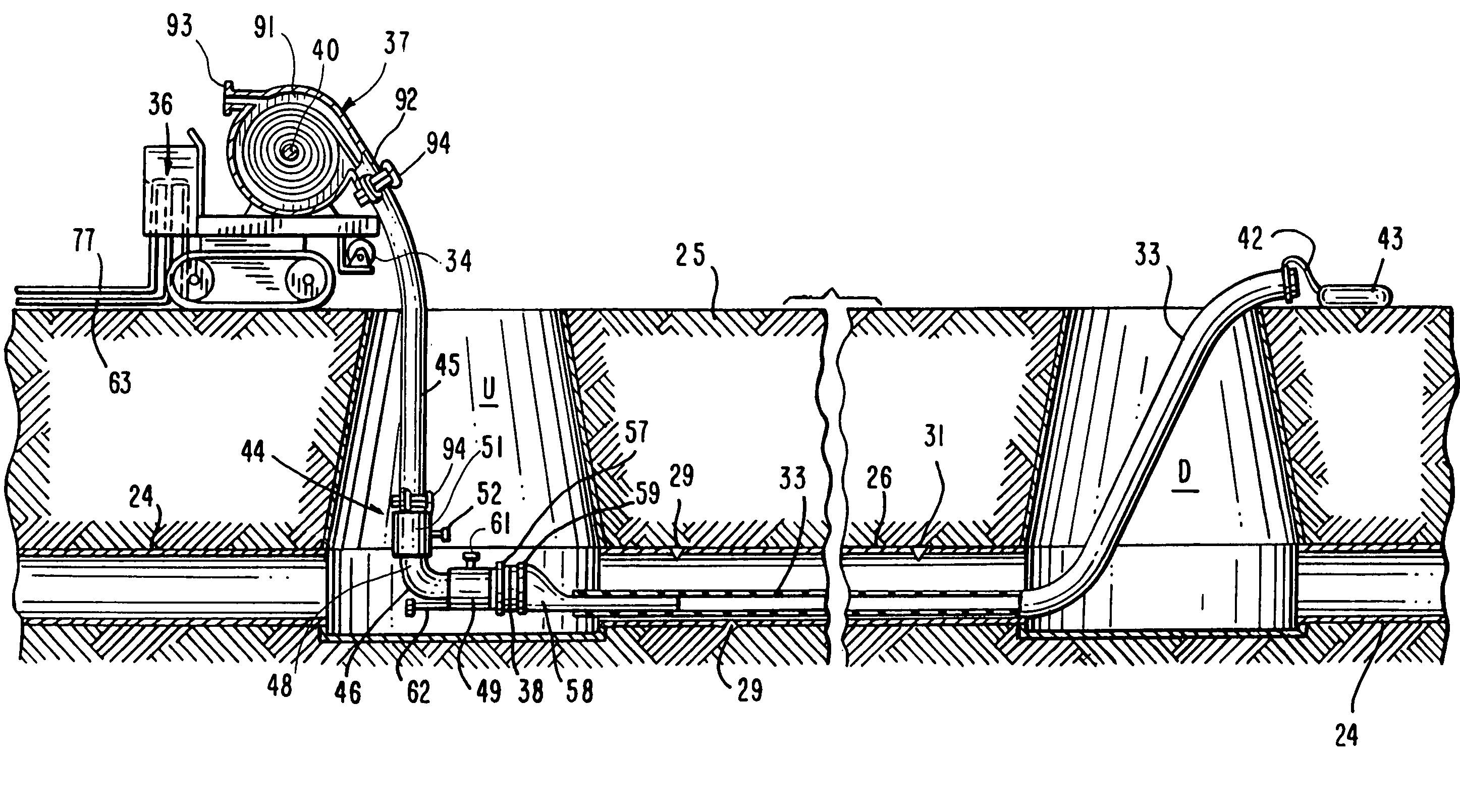

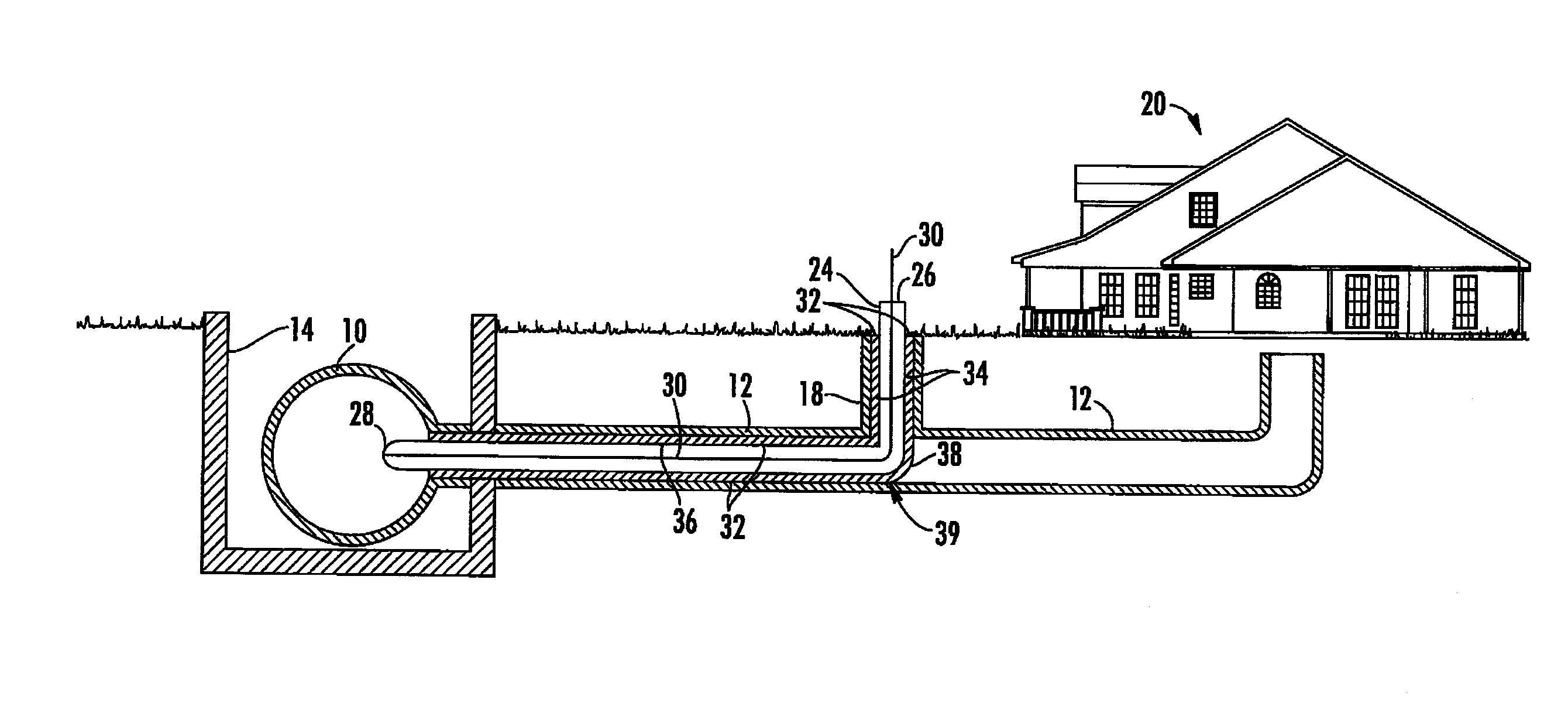

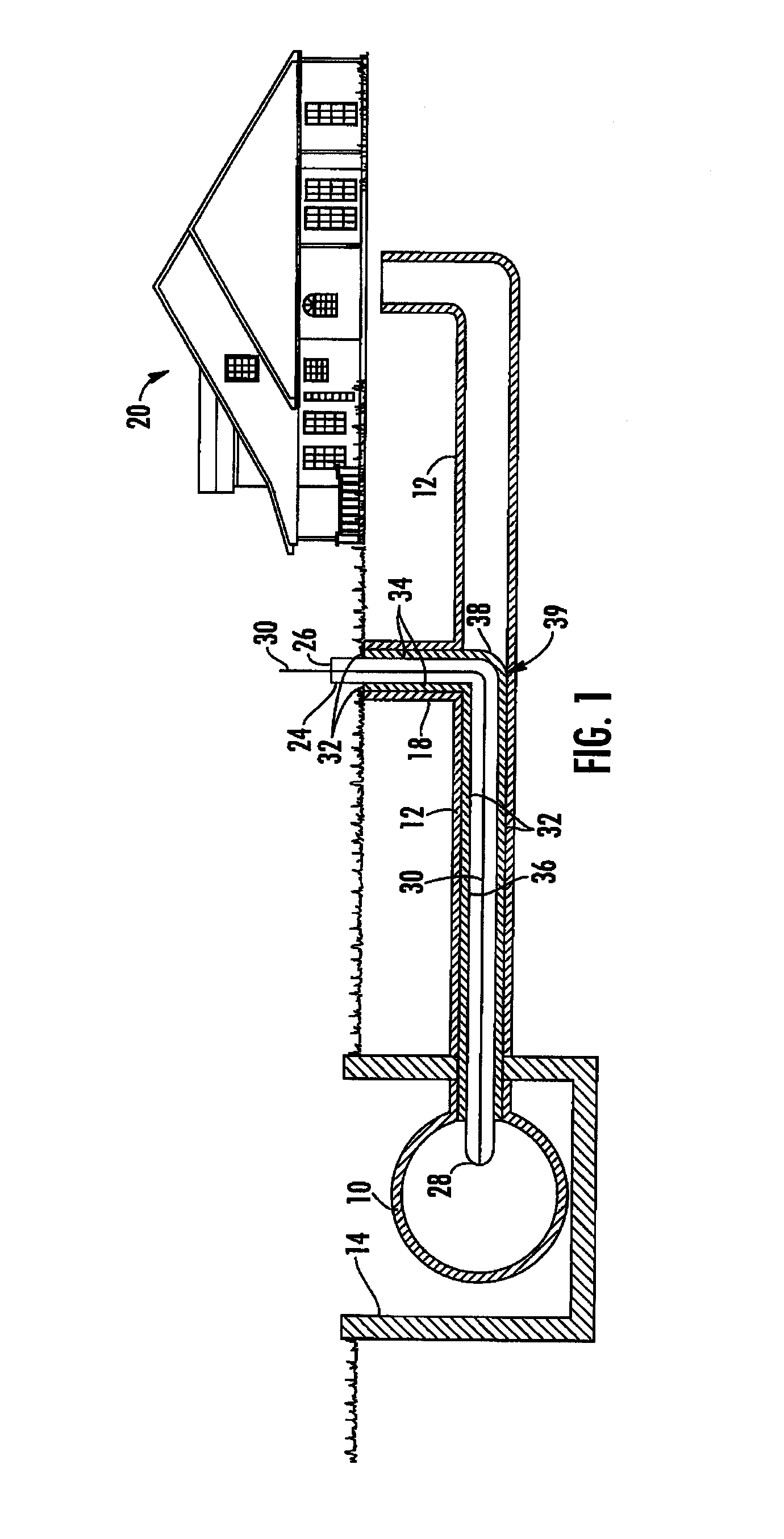

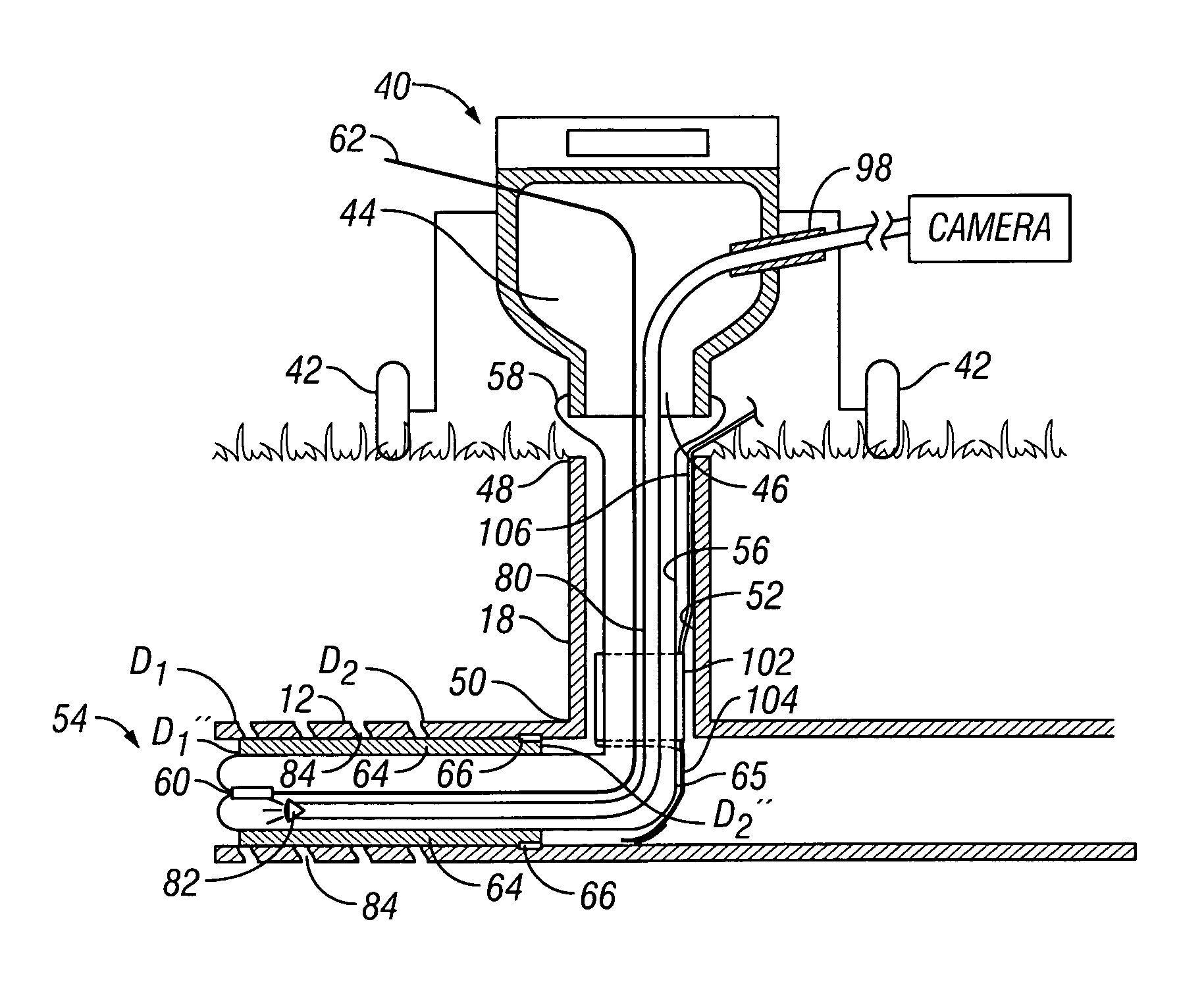

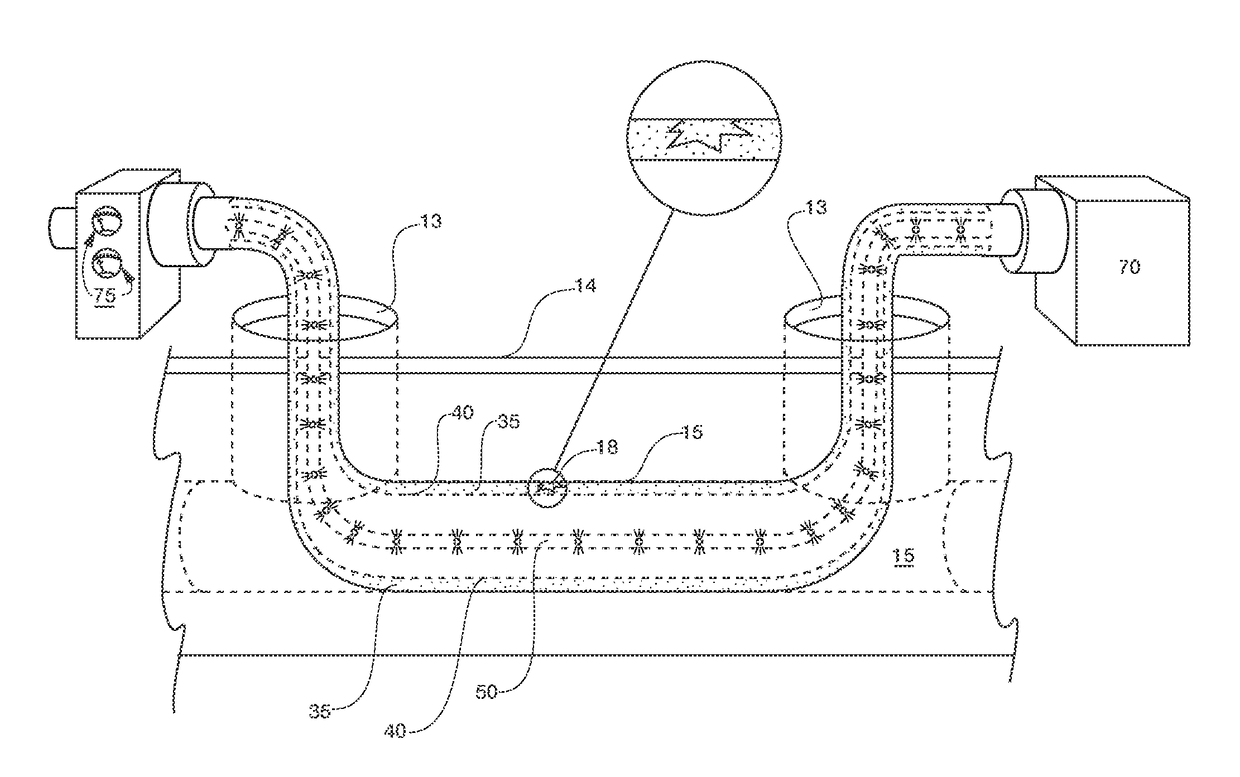

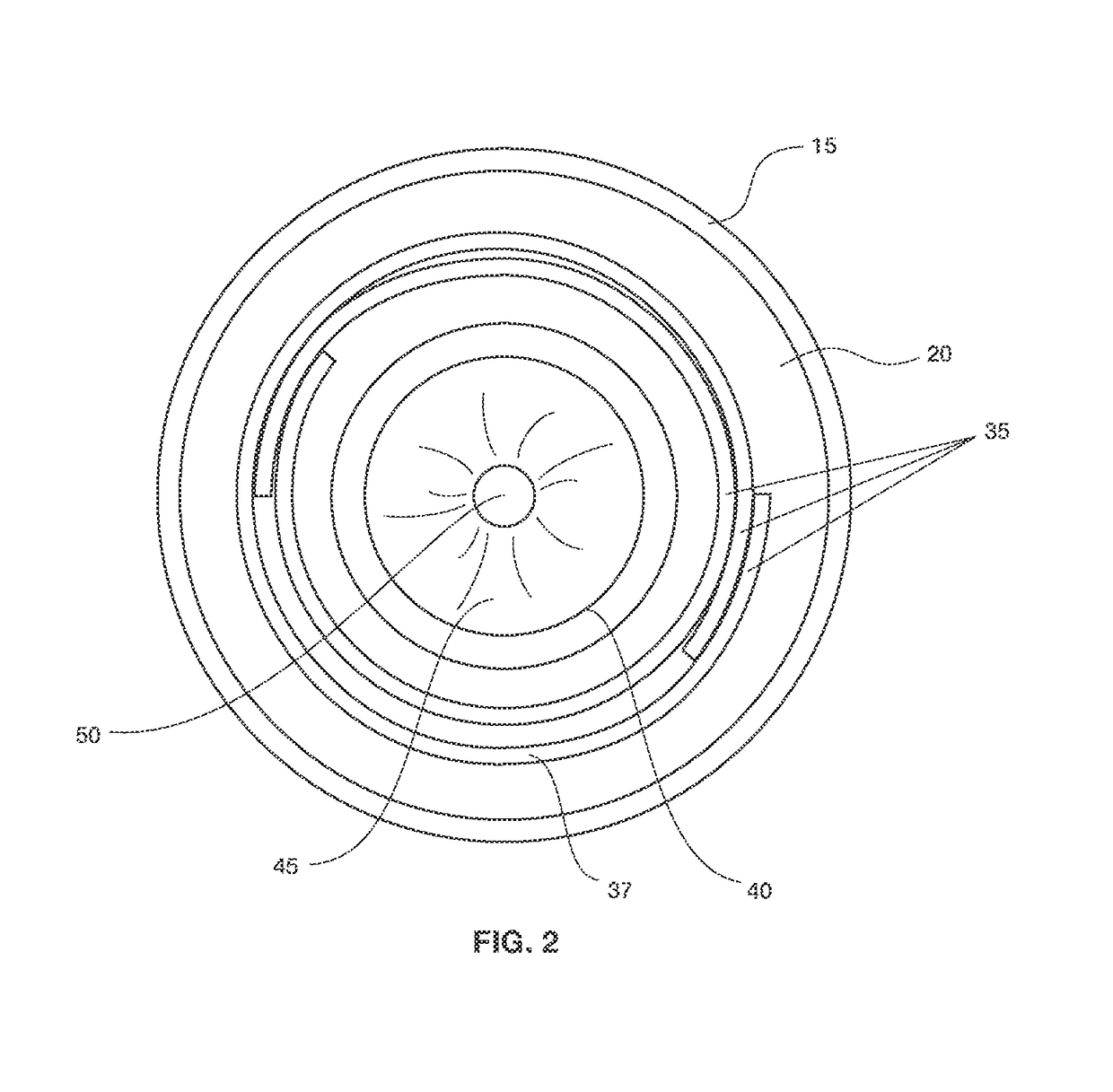

A process for lining an existing pipeline or conduit with a flexible resin impregnated cured in place liner by pulling in the liner and inflating an eversion bladder with air and curing the liner with flow-through steam without loss of pressure is provided. The bladder is stored in a pressure bladder canister coupled to a pressurized downtube and eversion elbow. The bladder is everted by introducing pressurized air into the canister As the bladder reaches the distal manhole, it enters a receiving canister where it is punctured while maintaining air pressure within the bladder a pinch valve between the downtube and elbow isolates the inverted bladder so that steam can be introduced into the bladder to cure the resin and exhaust through the receiving canister. The bladder is then removed and lateral service reinstated.

Owner:INA ACQUISITION

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS20050028880A1Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleFiber-reinforced composite

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The fibers on the inner surface are secured to a porous scrim to form an inner tubular reinforcing layer. A resin absorbent layer is formed into a tube about the inner layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

Fiber reinforced composite liner for lining an existing conduit and method of manufacture

InactiveUS6923217B2Increase stiffnessReduce thicknessUnderground chambersPipe elementsFiber bundleHigh intensity

A reinforced liner for cured in place pipe rehabilitation of an existing pipeline having a plurality of high-strength low-elongation fiber bundles disposed circumferentially around the tubular liner at both inner and outer surfaces of a resin absorbent layer of the liner is provided. The bundles of reinforcing fibers are continuous lengths of high modulus fibers laid circumferentially with the ability to stretch to accommodate variations in host pipe diameter. The fibers on the inner surface are secured to a porous scrim to form an inner tubular reinforcing layer. A resin absorbent layer is formed into a tube about the inner layer. An outer layer of bundles of reinforcing fiber are formed into a tube about the absorbent layer. An outer impermeable tubular layer is wrapped around the inner layers. The reinforcing layer may include longitudinal reinforcing fiber in either or both reinforcing layers to increase the longitudinal strength of the liner.

Owner:INA ACQUISITION

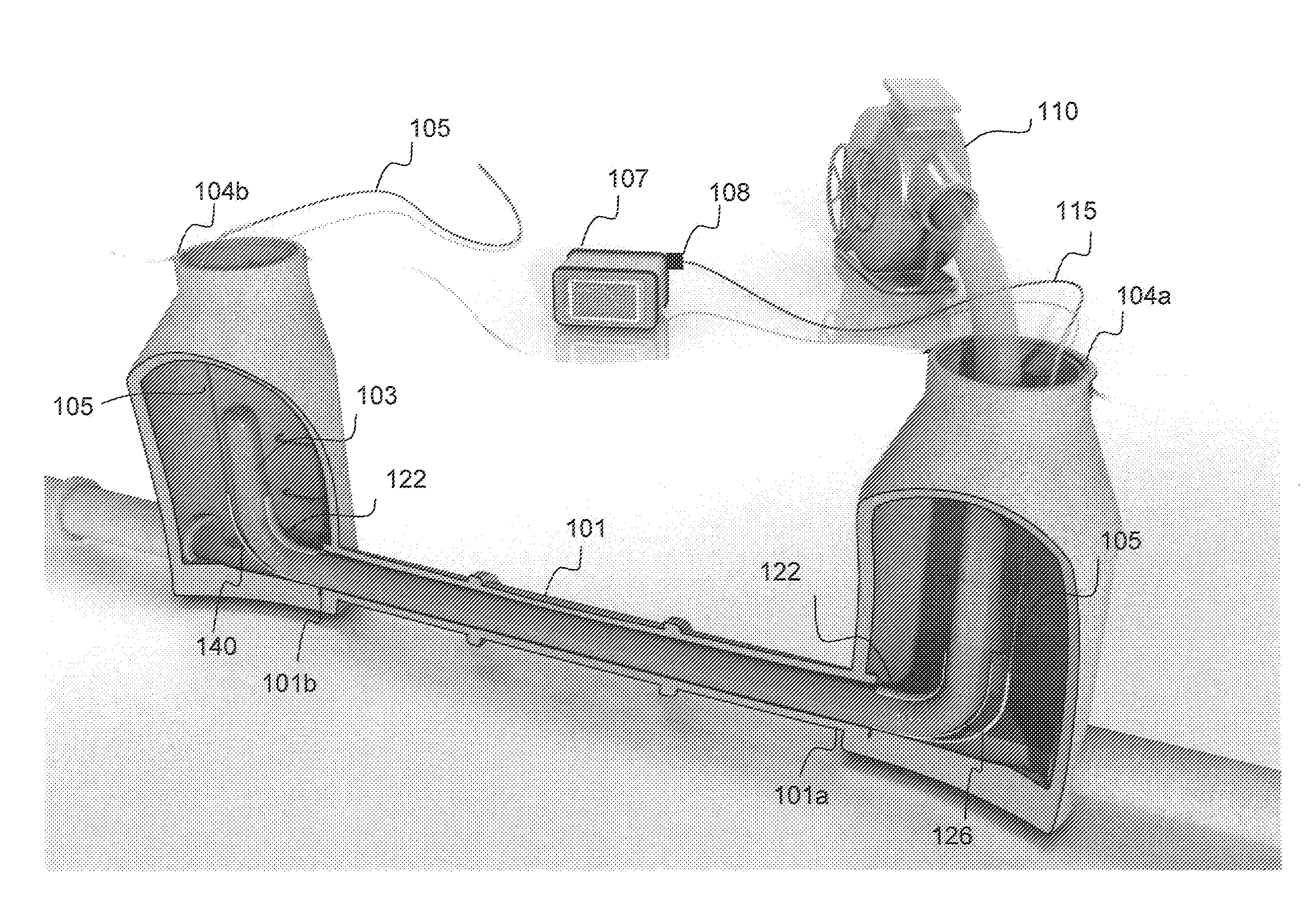

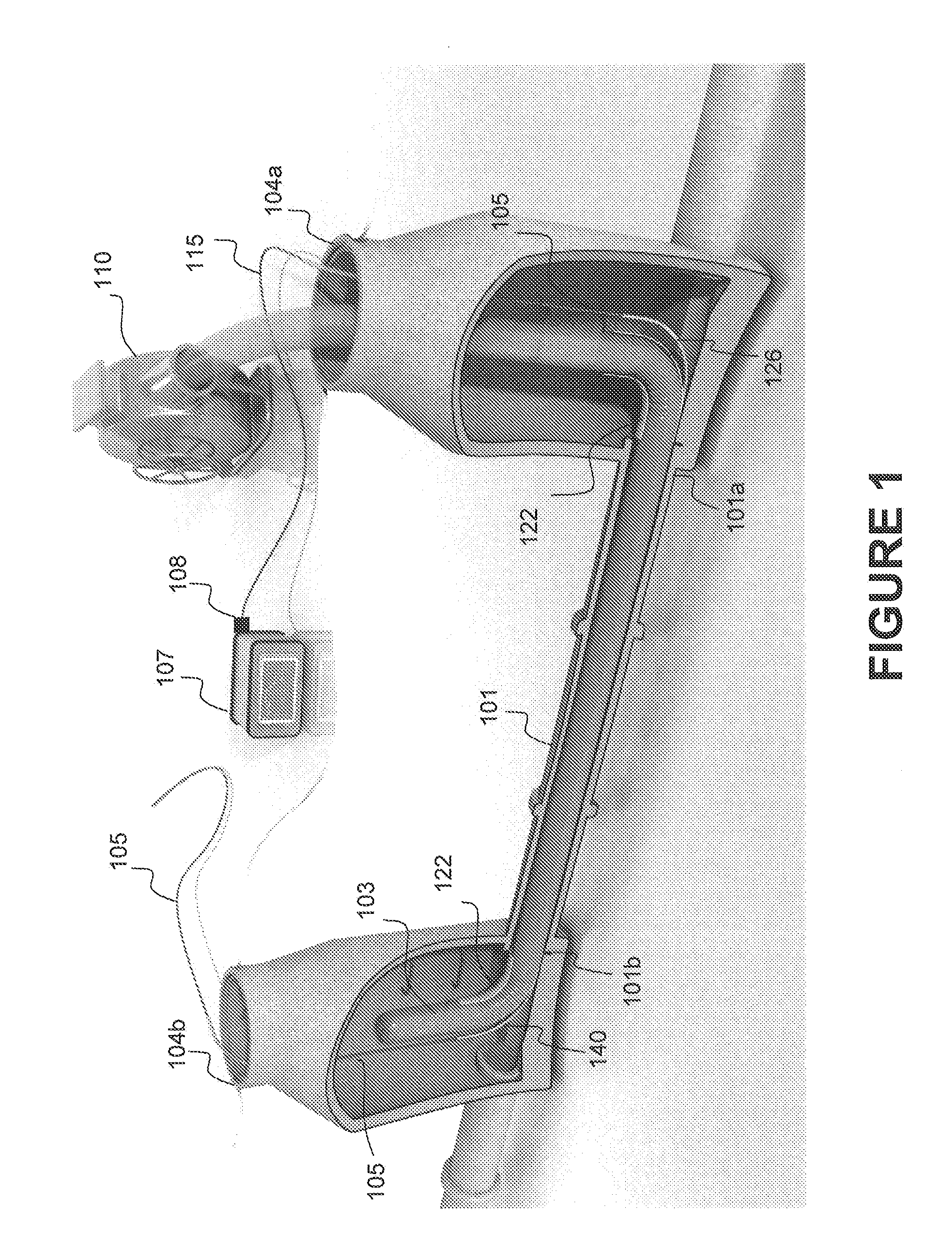

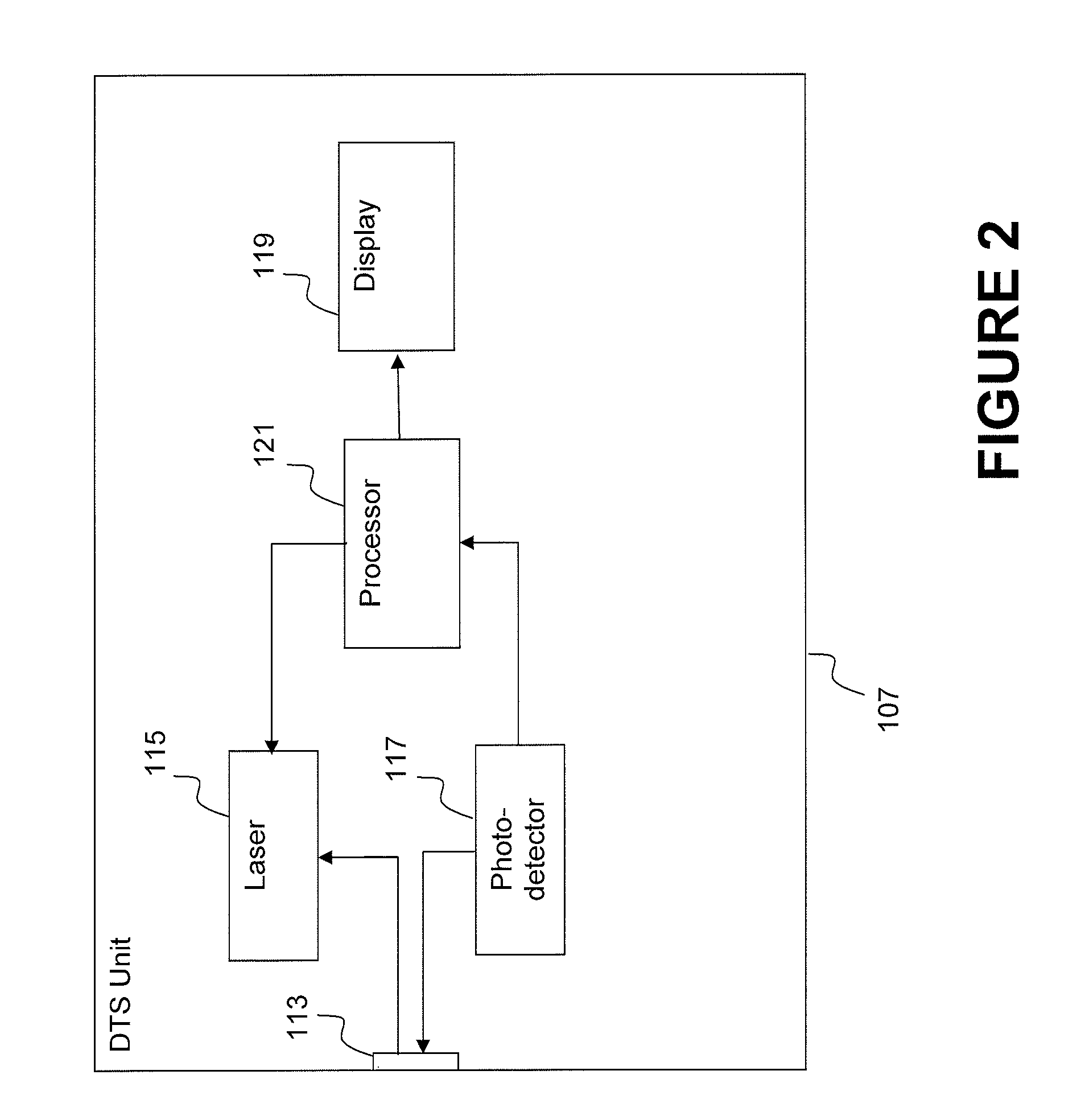

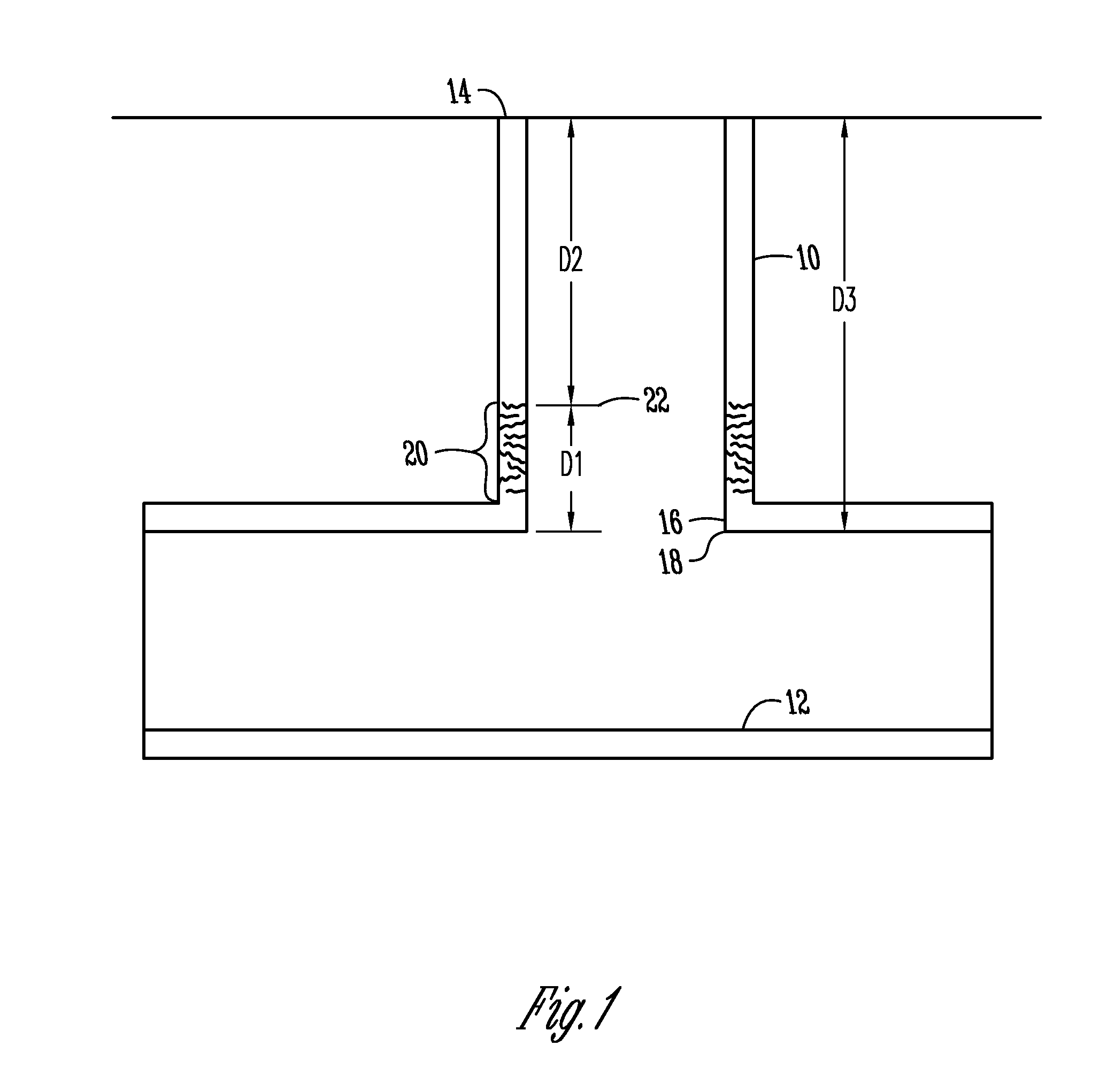

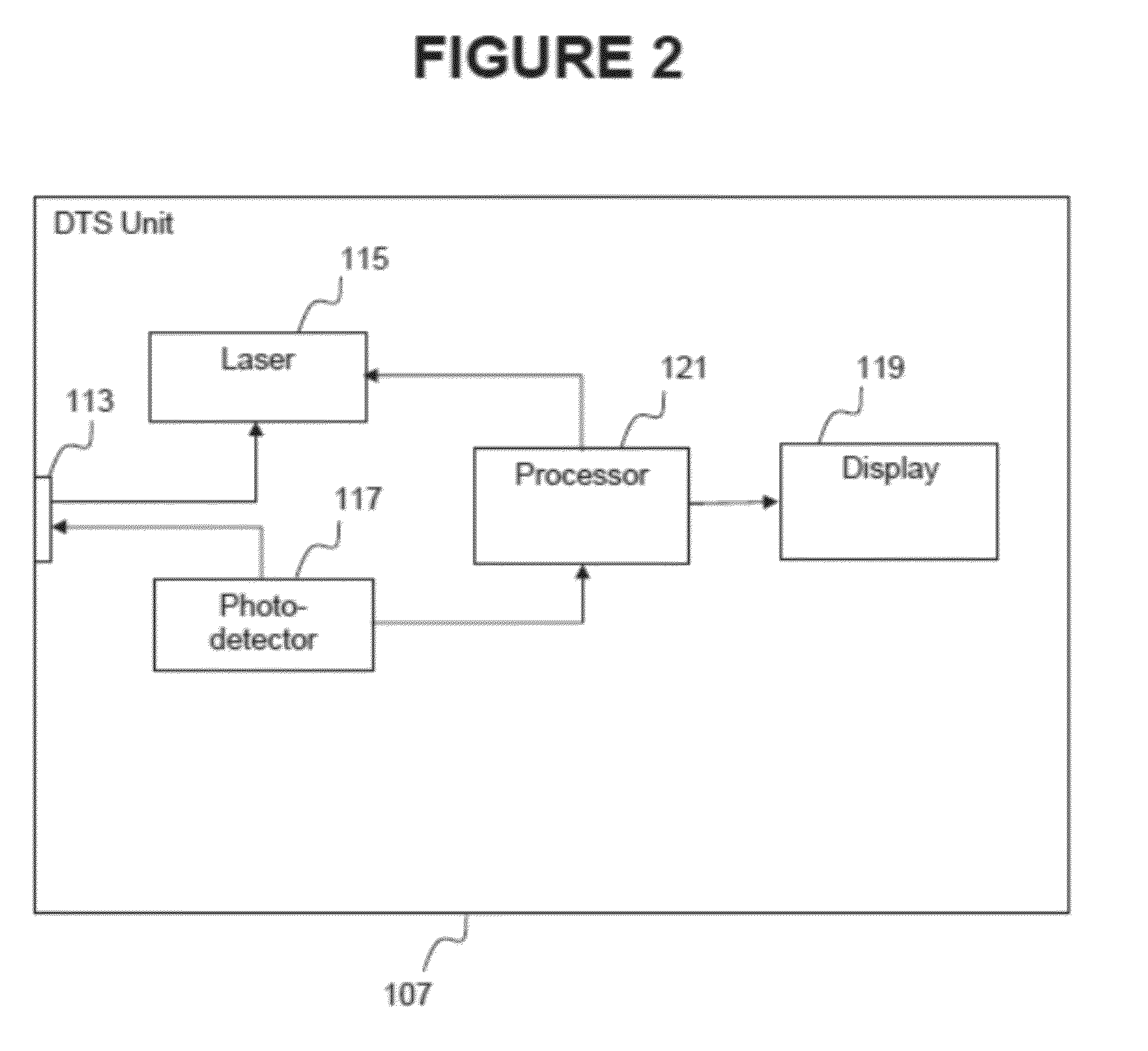

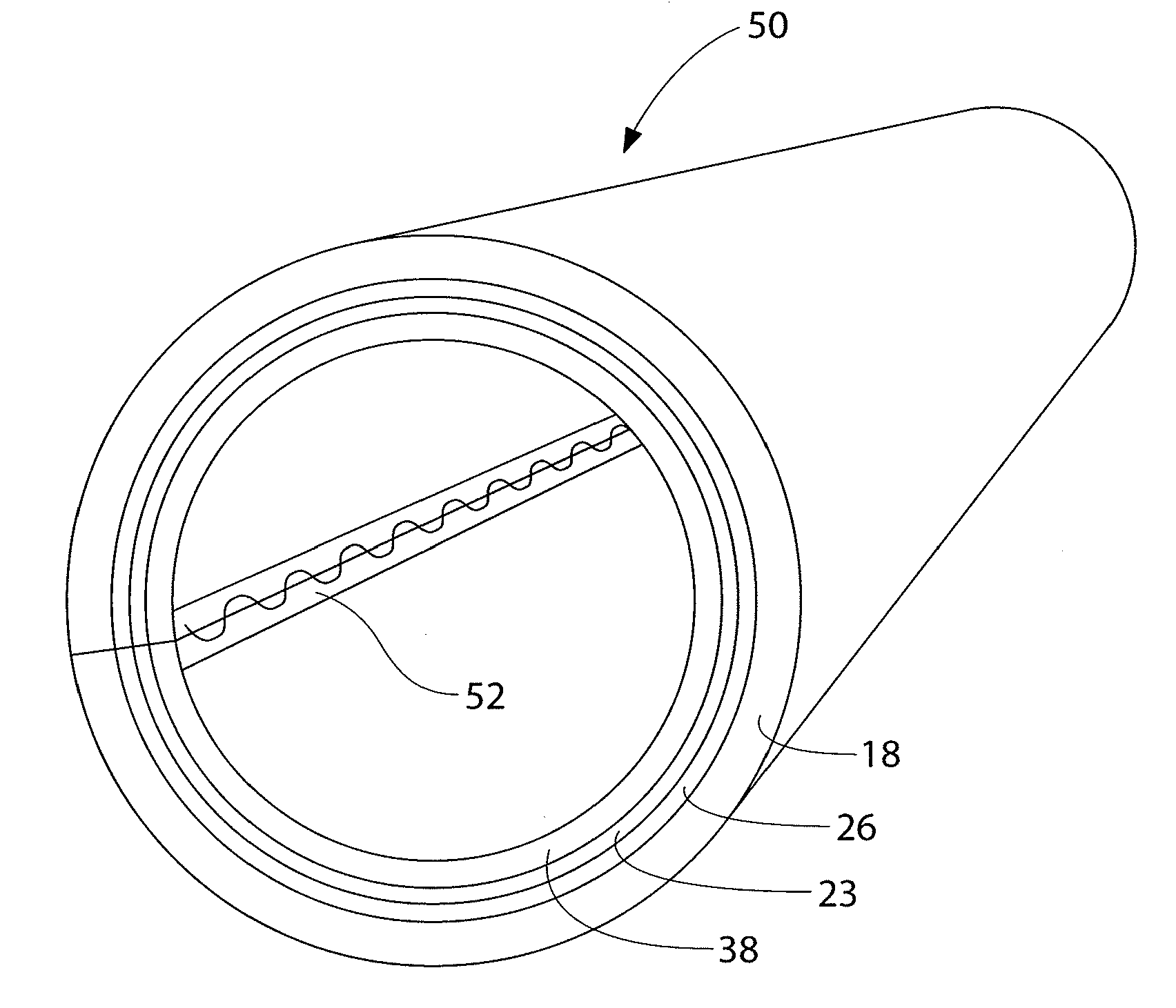

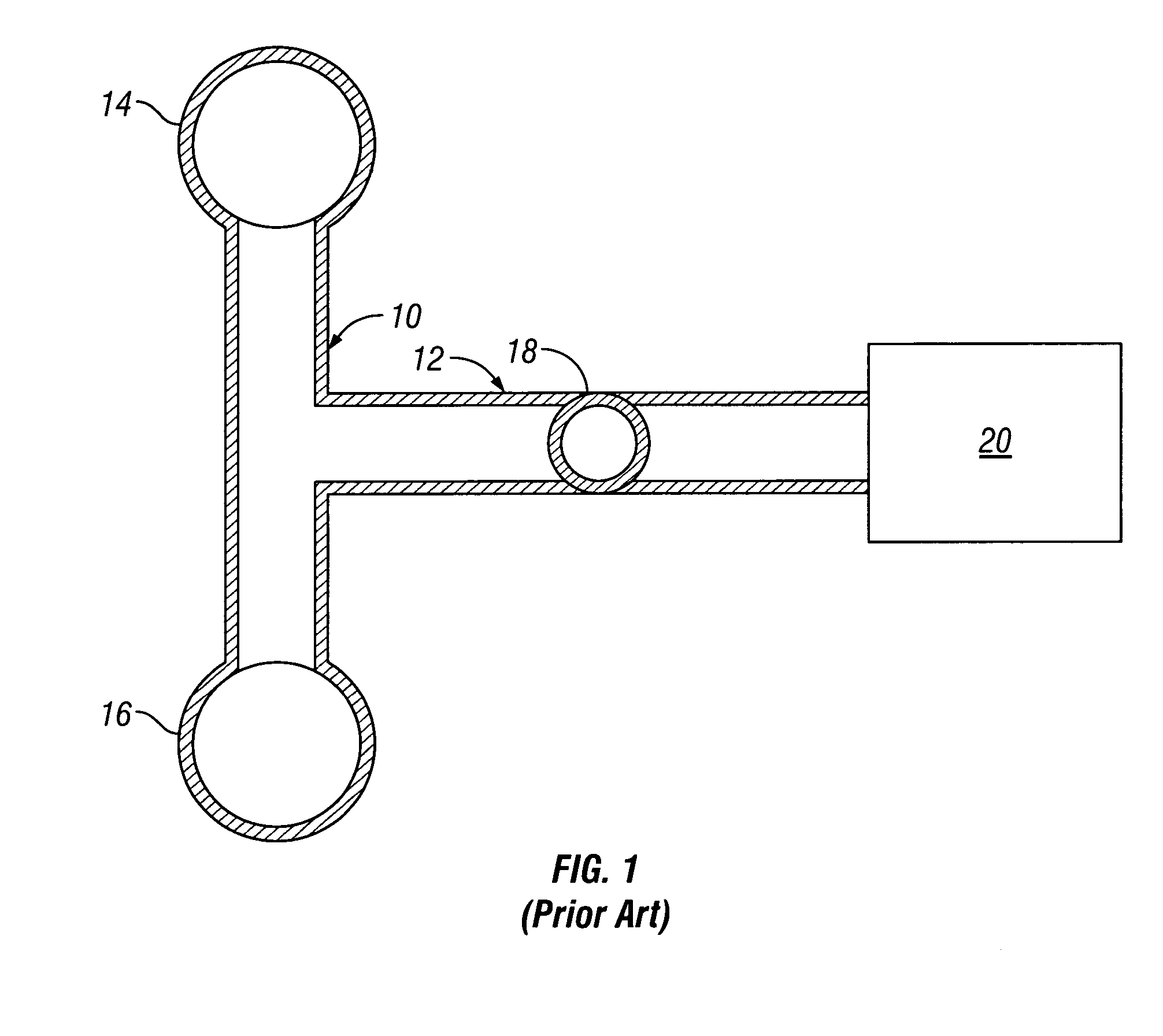

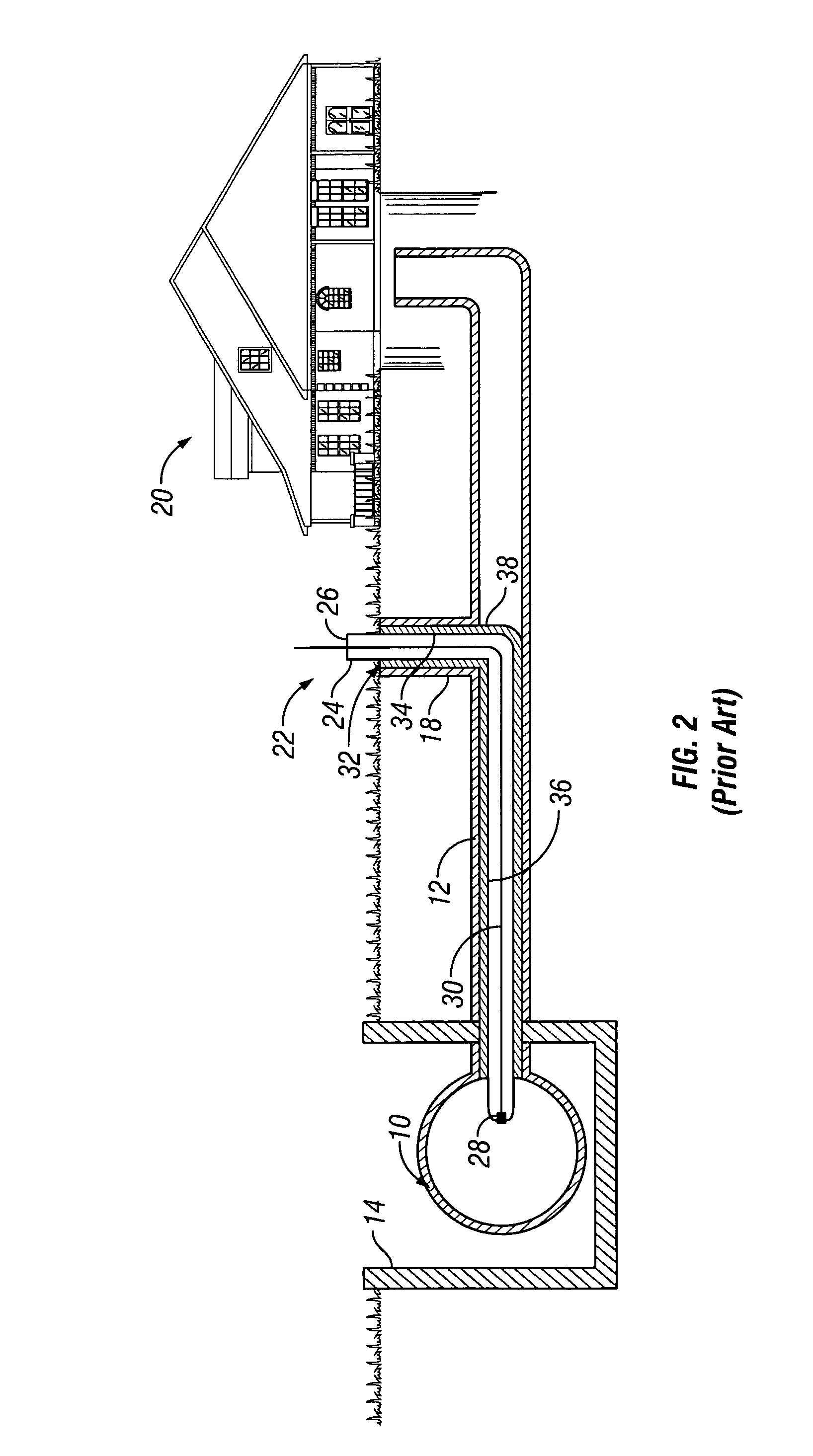

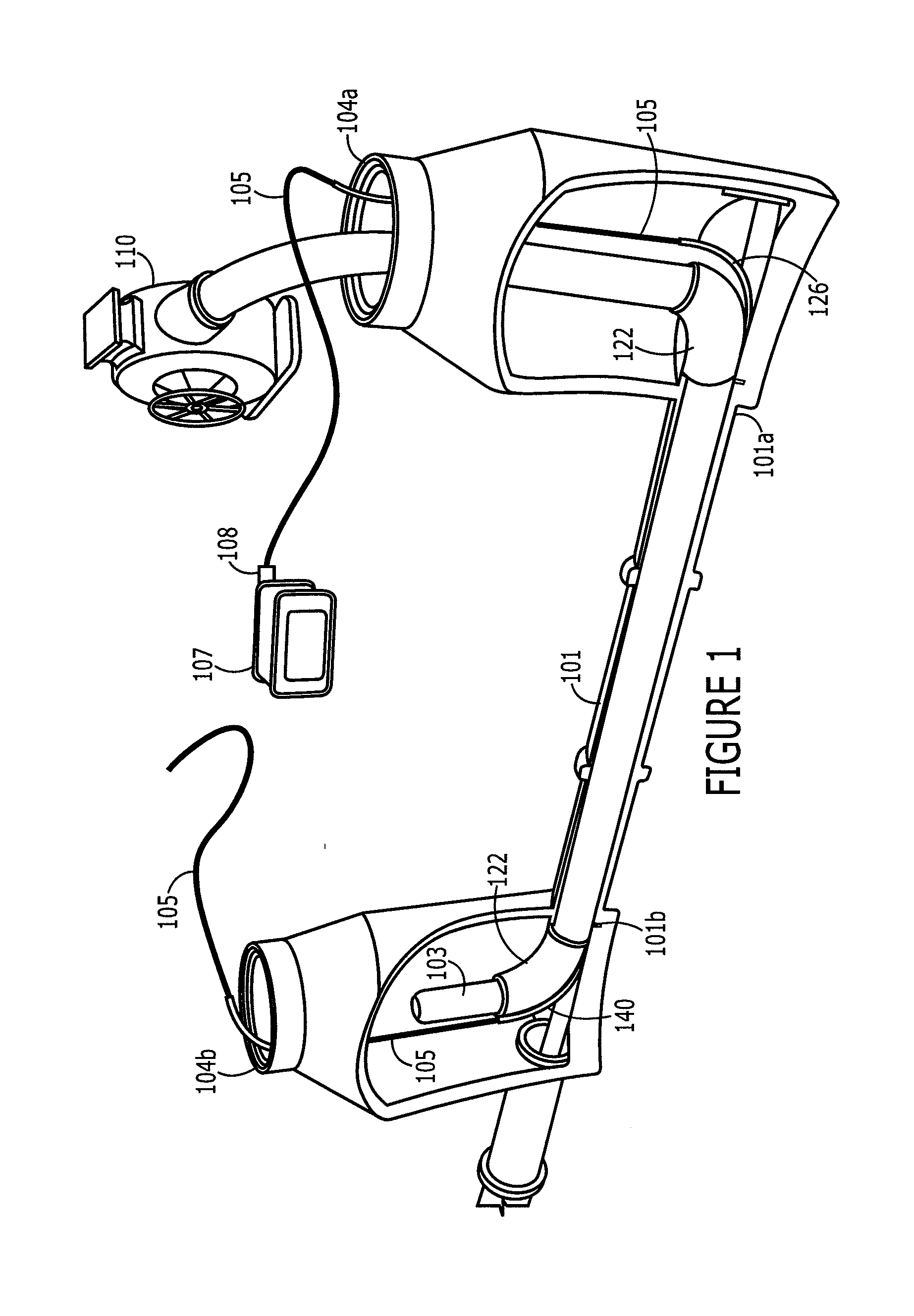

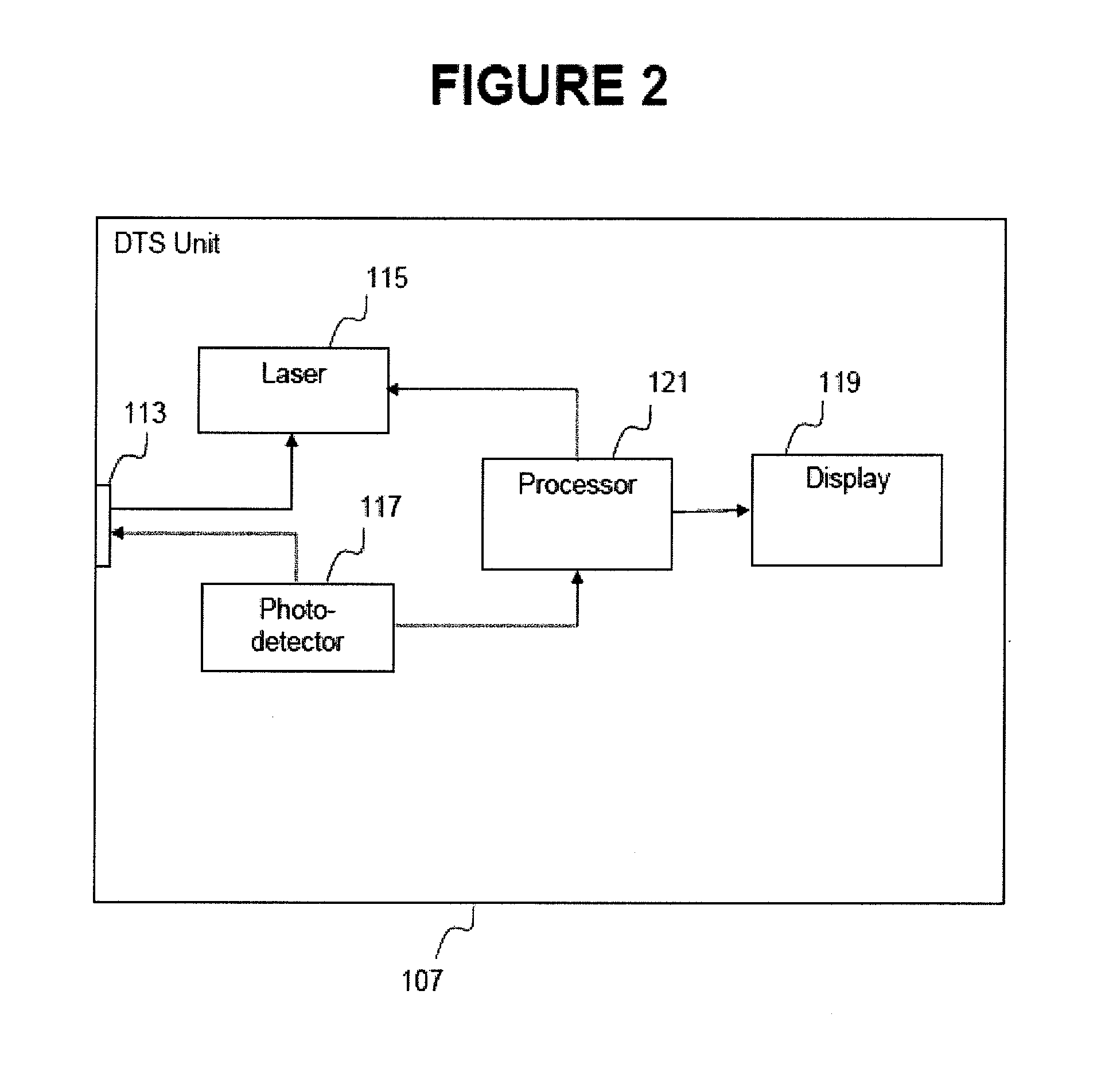

Method and apparatus for determining proper curing of pipe liners using distributed temperature sensing

The present invention relates to method and apparatus utilizing distributed temperature sensing (DTS) to monitor the temperature of a cured-in-place pipe liner to determine if proper curing temperatures and times are achieved. More particularly, an optical fiber is placed in the pipe between the original pipe and the liner running the entire length of the liner. The optical fiber is coupled to a DTS unit at neo end. During curing of the liner, the DTS unit sends light pulses down the fiber from one end and detects the characteristics and time delay of light backscattered to the unit. The characteristics of the backscattered light is indicative of the temperature of the optical fiber, while the time delay between the sending of the light pulse and the detection of any portion of the backscatter signal is indicative of the round trip time of the light within the fiber, and thus the distance down the fiber from the DTS unit from which that particular backscatter signal originated.

Owner:LINDNER RICHARD +1

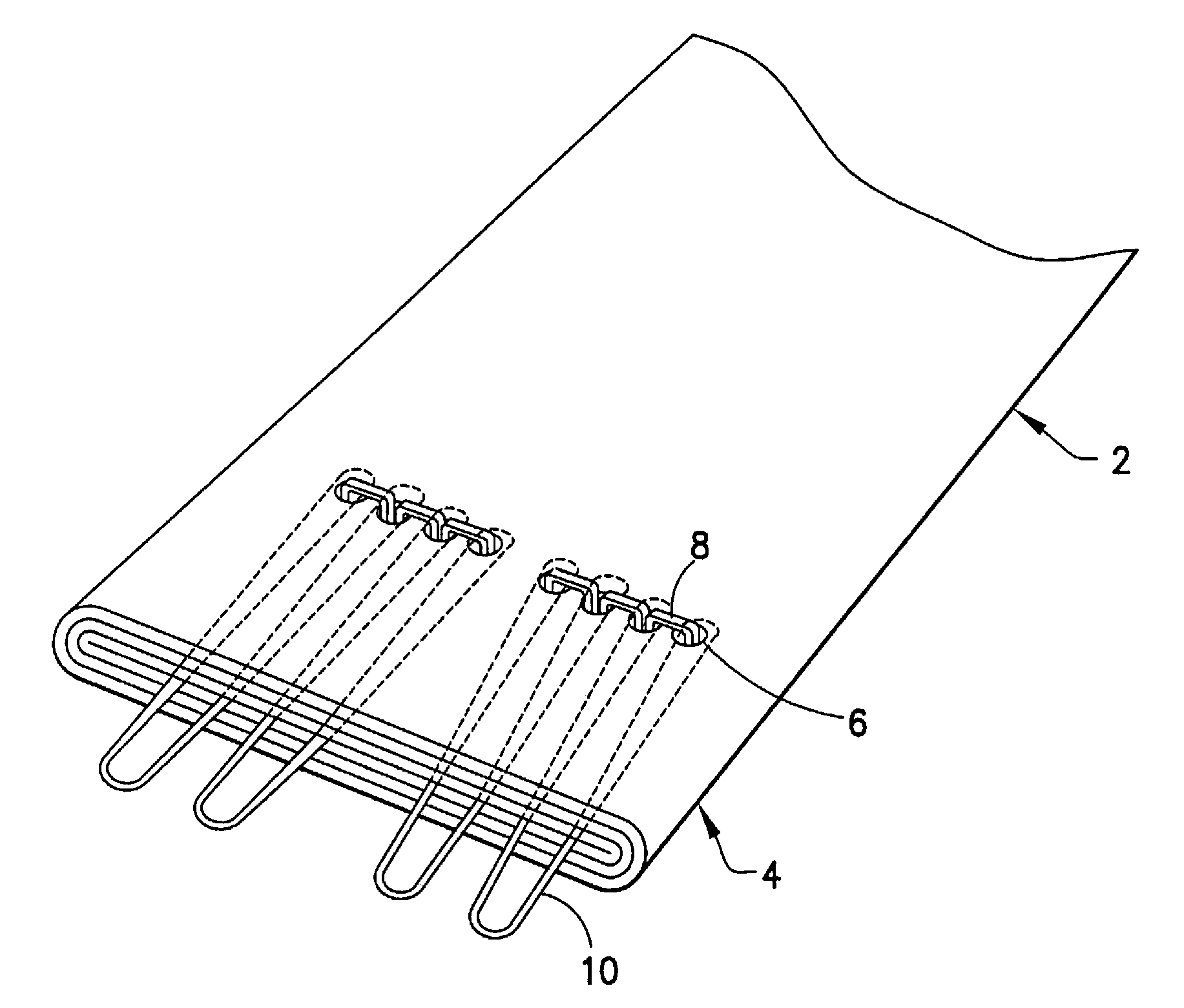

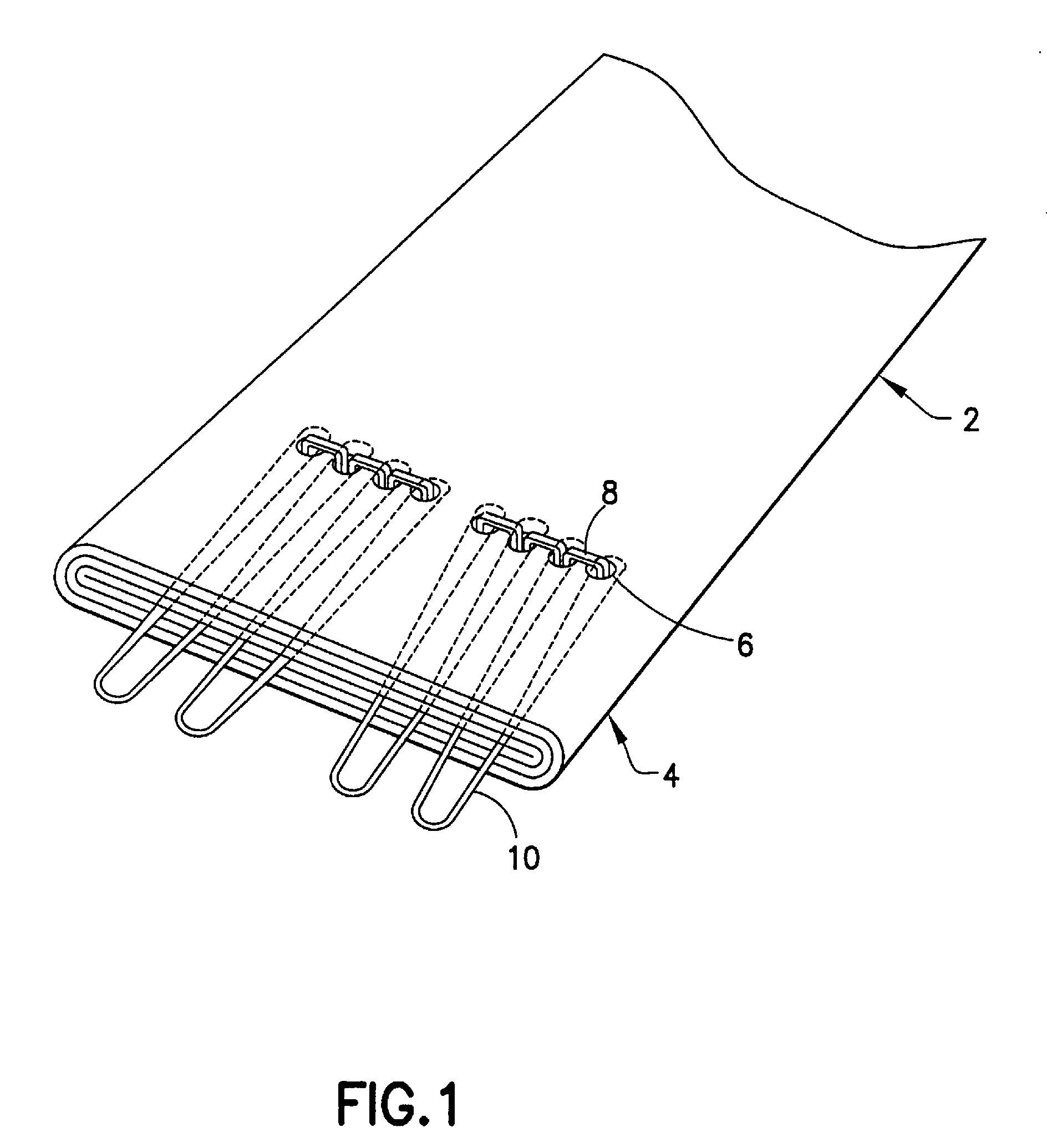

Liner tube with non-stretching material

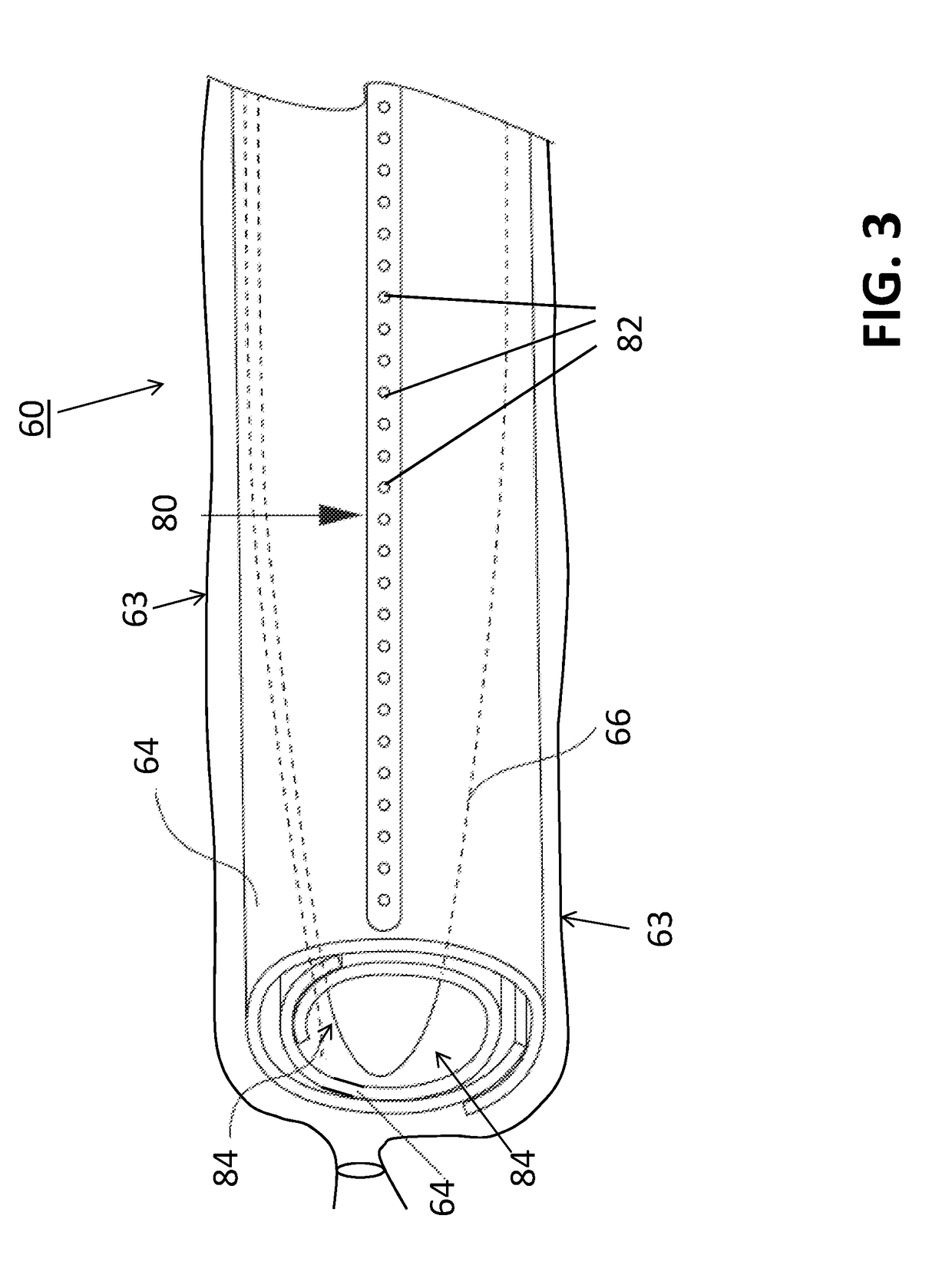

An apparatus and method of making a cured-in-place pipe repair to a lateral pipe having an area in need of repair. The method and apparatus use a liner assembly comprising a bladder tube and a liner tube. The liner tube comprises at least one layer of non-stretching material, which includes strands of non-stretching material oriented in the longitudinal direction of the liner tube. The strands allow radial stretching but ensure that the liner tube does not stretch longitudinally, which prevents the liner tube from stretching into a main pipe or past the area in need of repair during use. The liner tube may also comprise second and third layers of a resin impregnable material, such as felt, which surround the layer of non-stretching material such that the liner tube may be impregnated with a resinous material to repair a pipe having an area in need of repair.

Owner:LMK TECH LLC

Method and apparatus for determining proper curing of pipe liners using distributed temperature sensing

InactiveUS20120255664A1Well formedLamination ancillary operationsControlling laminationFiberTime delays

A method and apparatus utilizing distributed temperature sensing (DTS) to monitor the temperature of a cured-in-place pipe liner to determine if proper curing temperatures and times are achieved. More particularly, an optical fiber is placed in the pipe between the original pipe and the liner running the entire length of the liner. The optical fiber is coupled to a DTS unit at one end. During curing, the DTS unit sends light pulses down the fiber and detects the characteristics and time delay of light backscattered to the unit. The characteristics of the backscattered light is indicative of the temperature of the fiber while the round trip time delay is indicative of the distance down the fiber from the DTS unit from which that particular backscatter signal originated.

Owner:ENVIROSIGHT

Cured in place pipe liner

ActiveUS8047238B2Solve the lack of resistancePedestrian/occupant safety arrangementSynthetic resin layered productsEpoxyHeat resistance

Owner:LUBRIZOL ADVANCED MATERIALS INC

Bladder and method for cured-in-place pipe lining

InactiveUS20090194183A1Reduce manufacturing costEasy to usePipe elementsSurface layering apparatusThermoplasticCured-in-place pipe

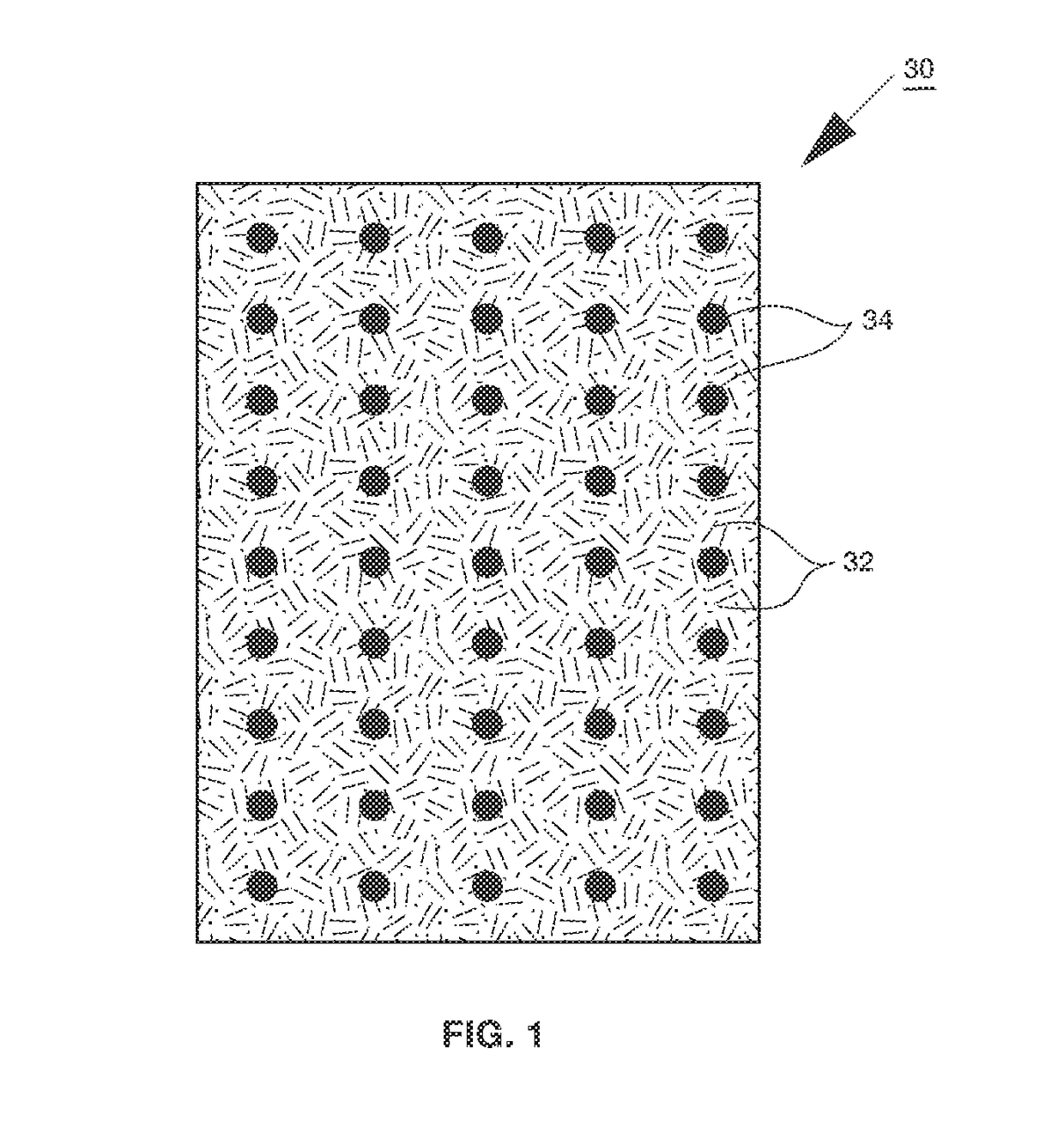

A fiber reinforced non-stick plastic bladder is provided. The bladder preferably includes a bladder body formed of a fiber reinforcing material layer with a coating on the bladder body made of a thermoplastic. The coating preferably has elastomeric properties and is semi-transparent. Methods of lining pipe using the new bladder are also provided.

Owner:LMK TECH LLC

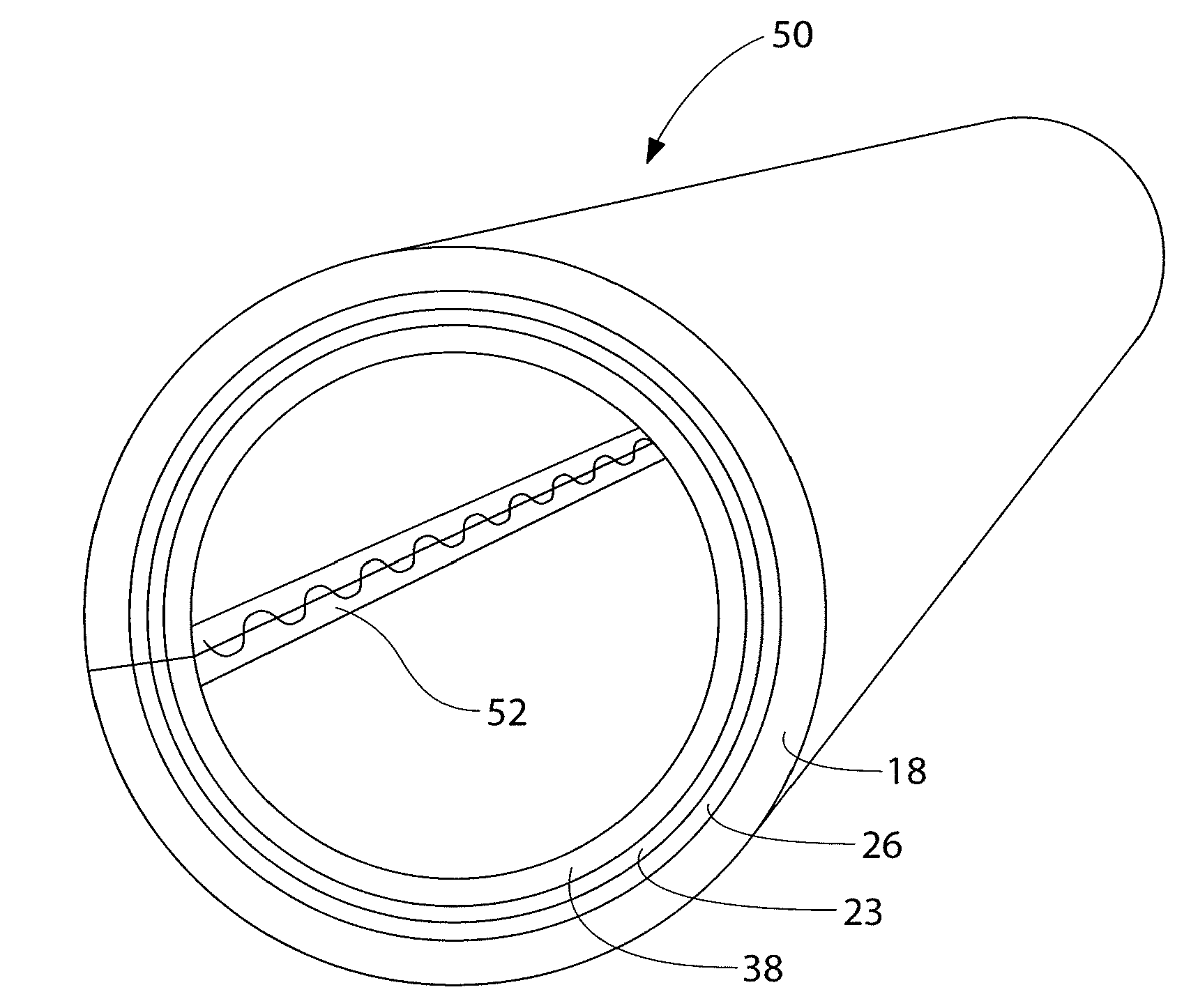

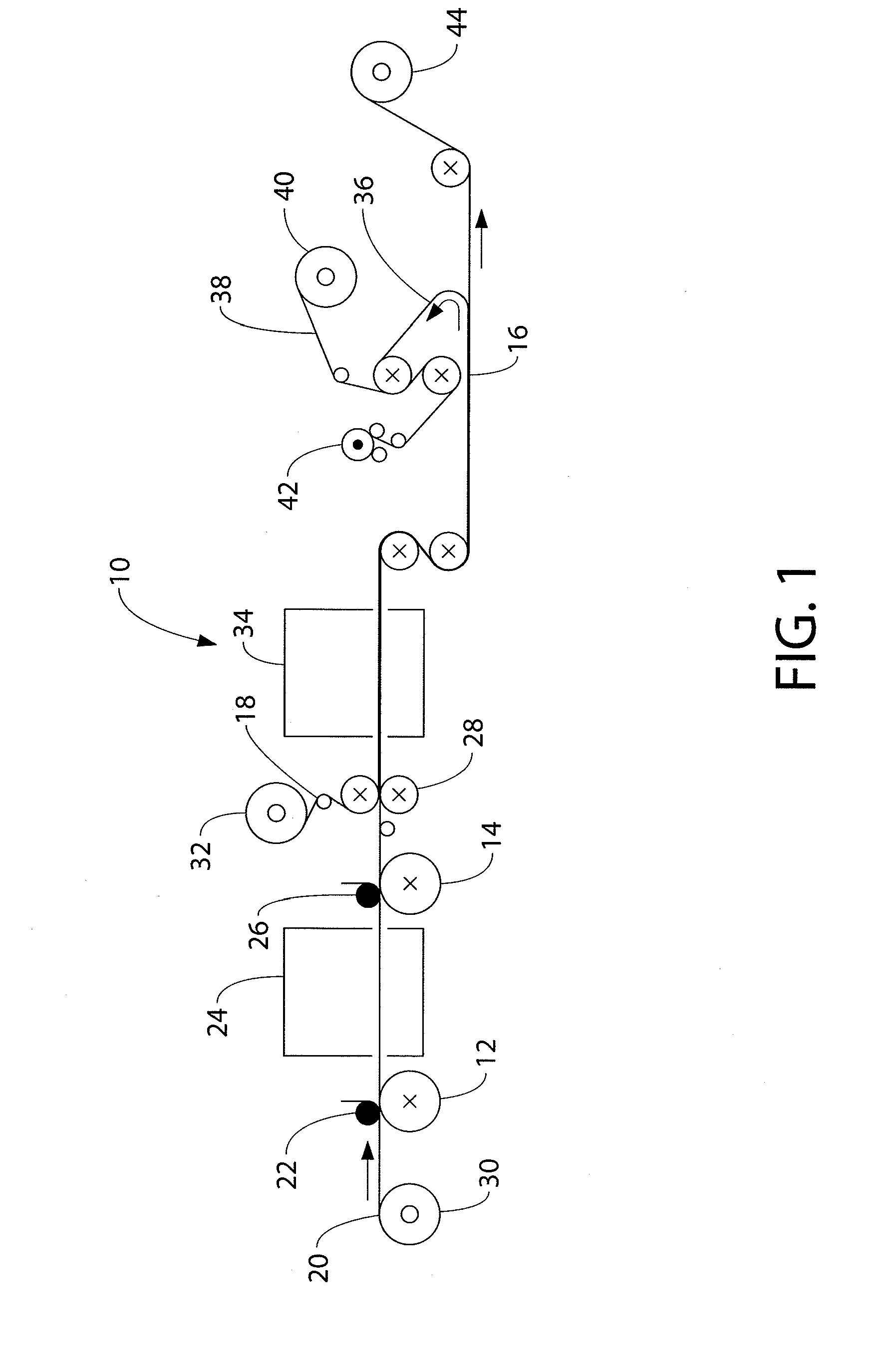

Flexible barrier composite fabrics via an adhered film process

A composite fabric includes: a fabric backing; an adhesive layer; a midlayer barrier bonded to the fabric backing by the adhesive layer; and an external barrier bonded to the midlayer barrier, wherein the composite fabric has a hydrostatic pressure resistance of at least 100 psi and is sufficiently flexible such that it can be formed into a tube and everted. A process and an apparatus for producing the composite fabric are also disclosed. The composite fabric is particularly suitable for use as a liner in a cured-in-place pipe repair method.

Owner:DARTEX COATINGS INC

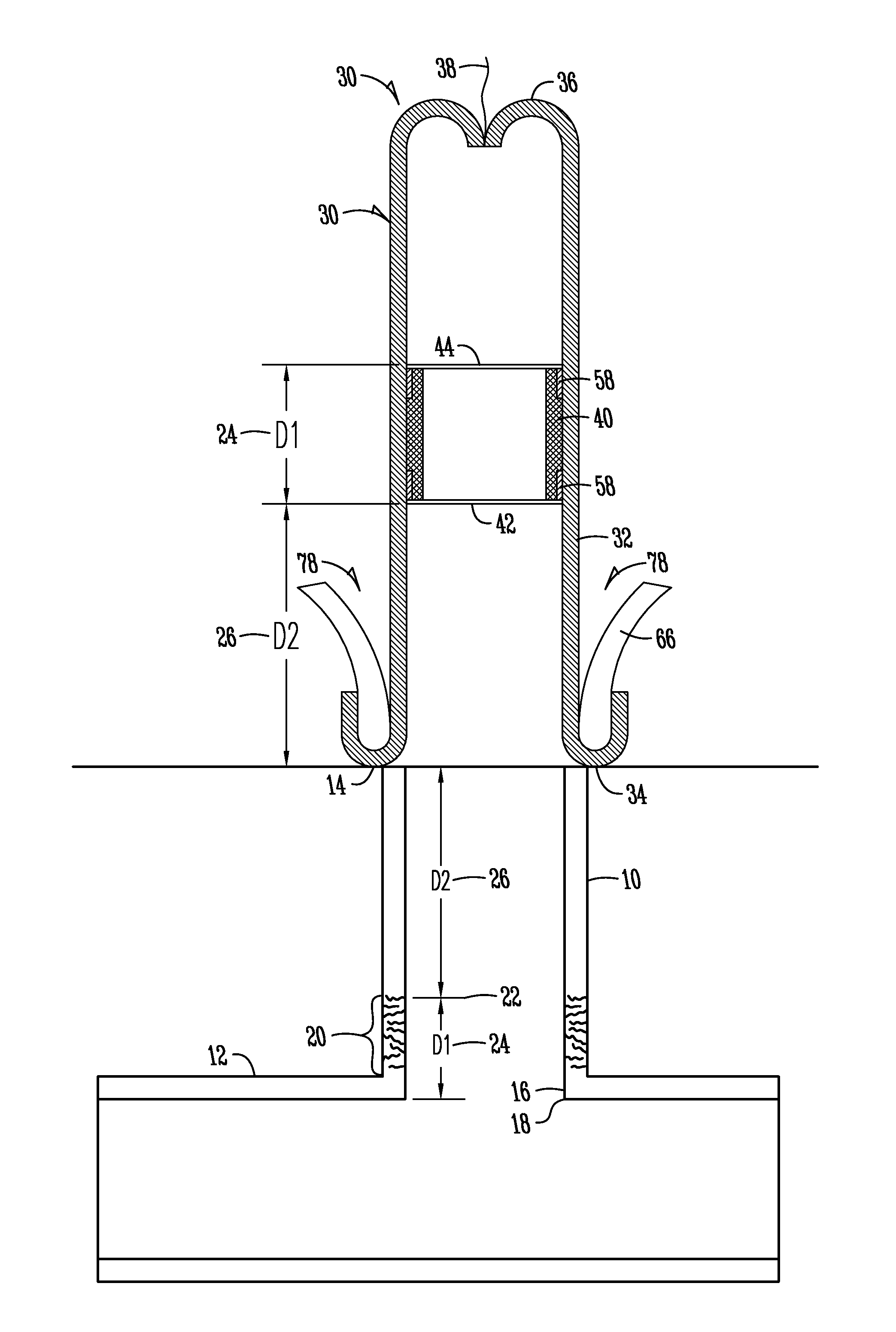

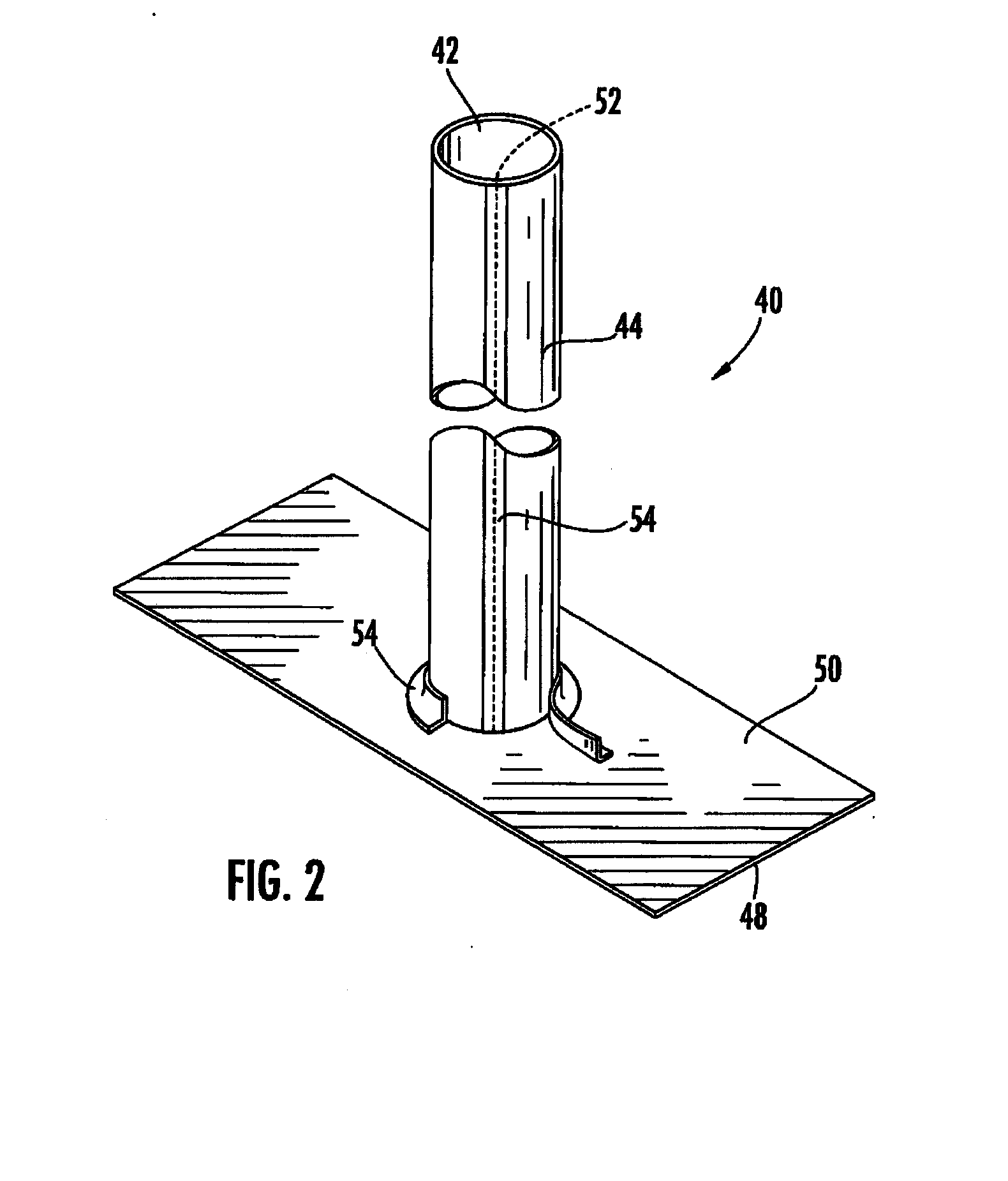

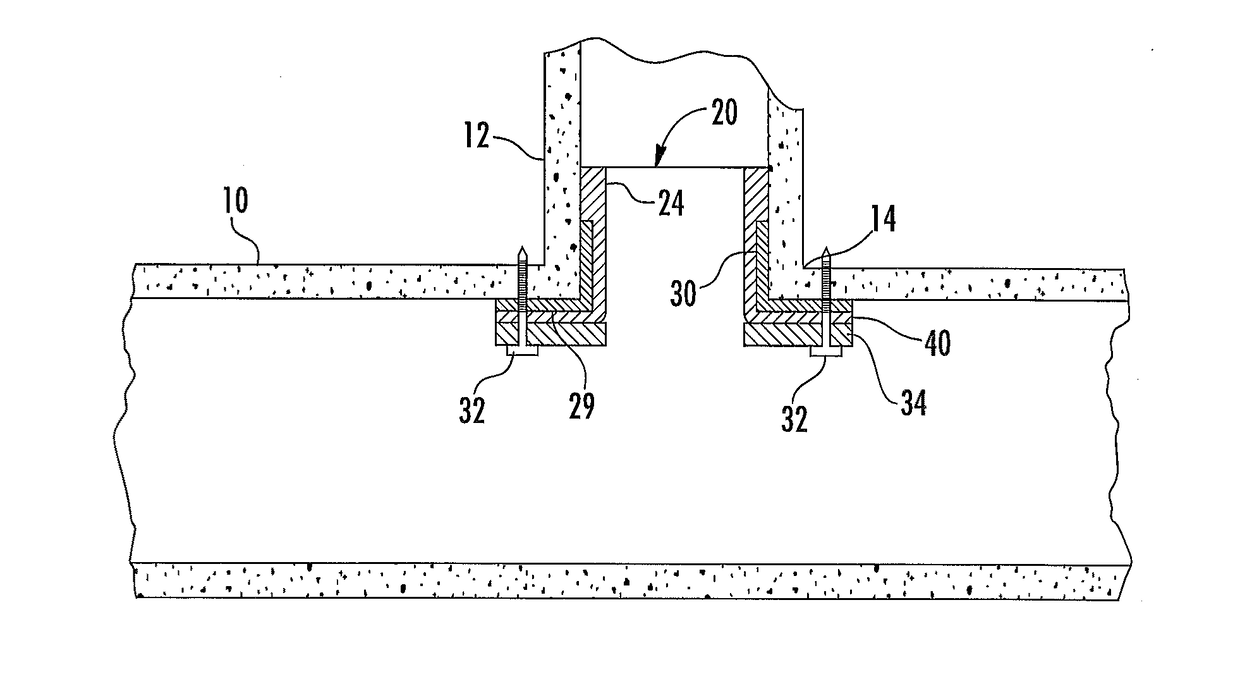

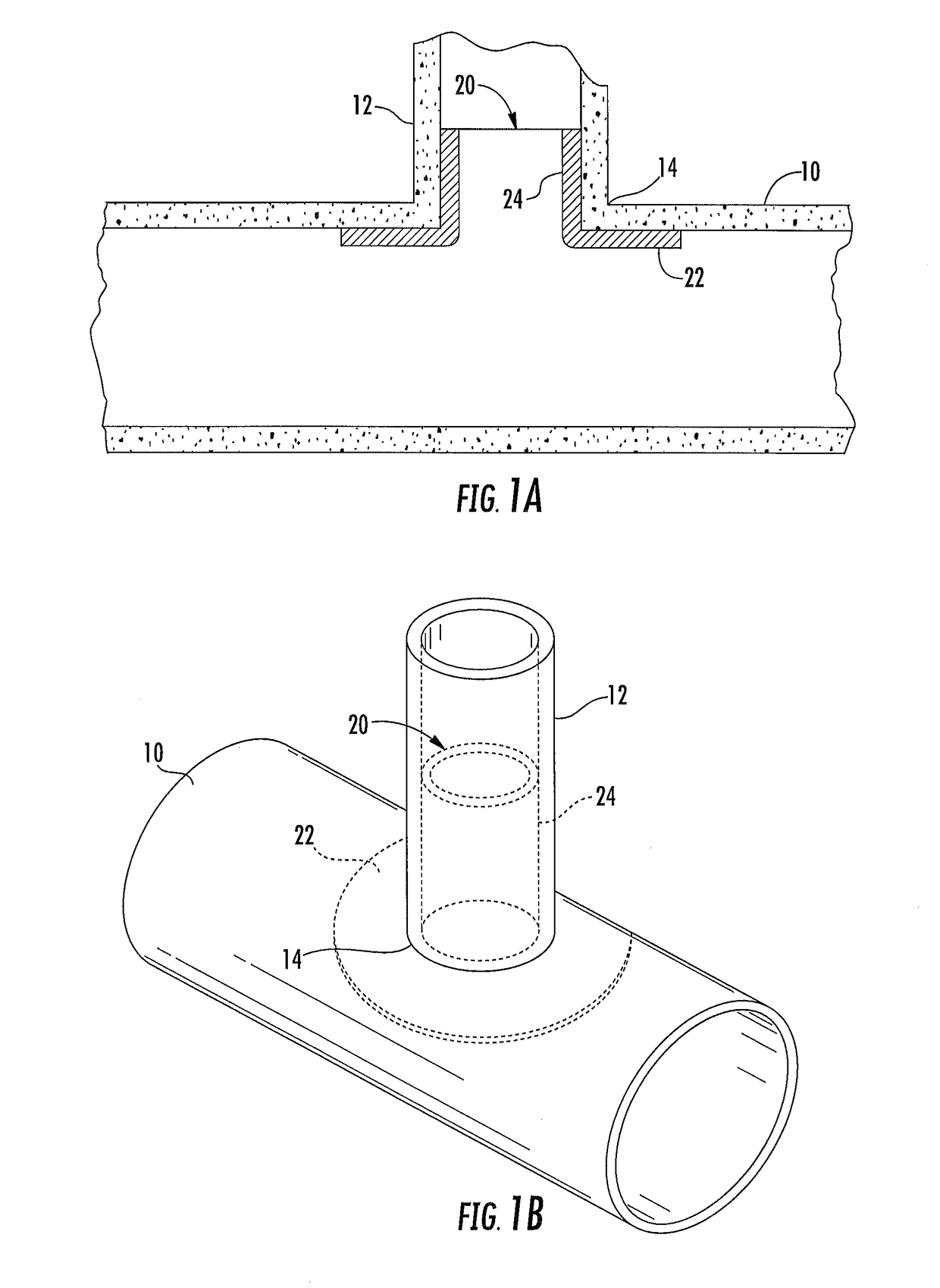

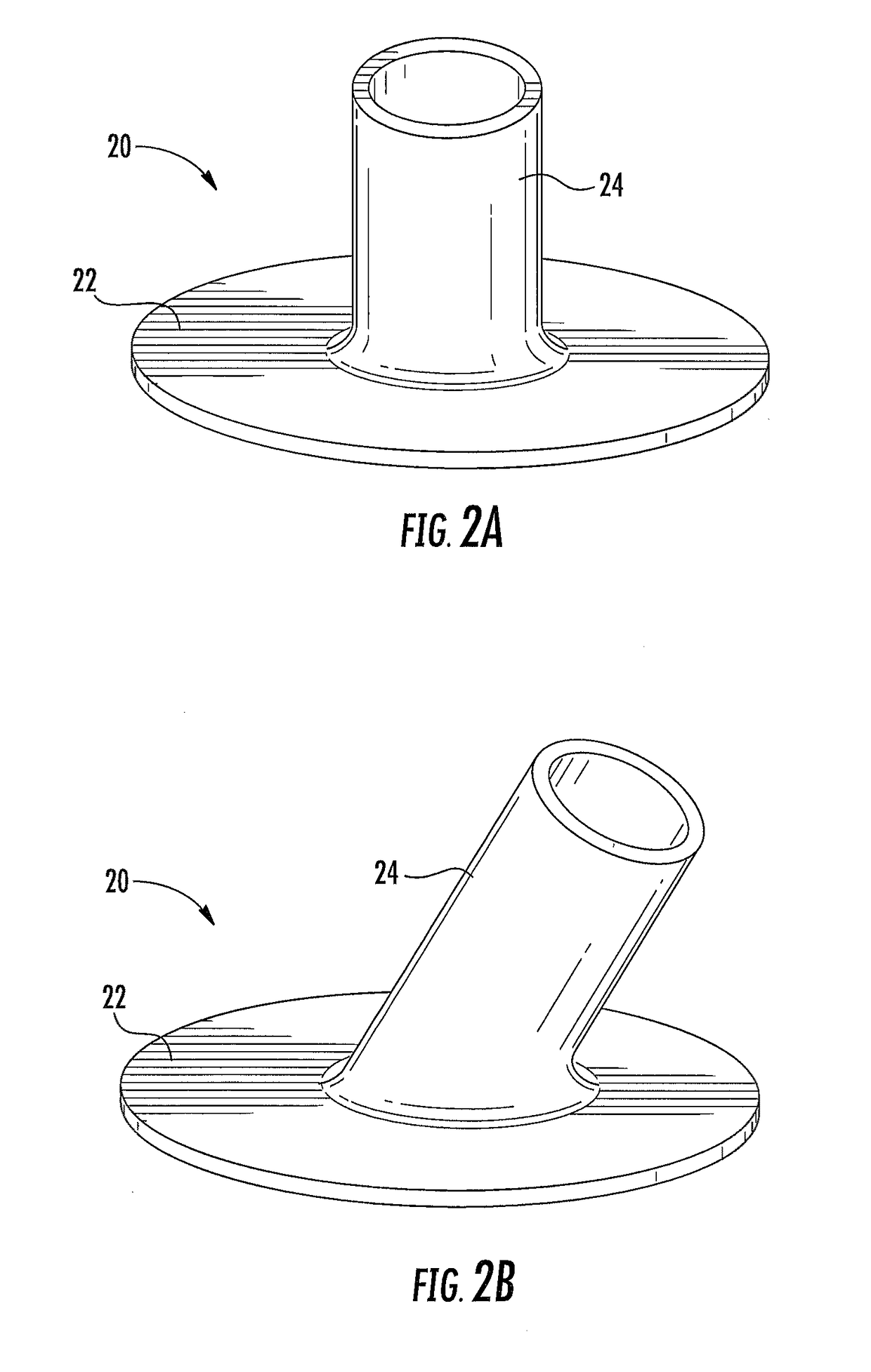

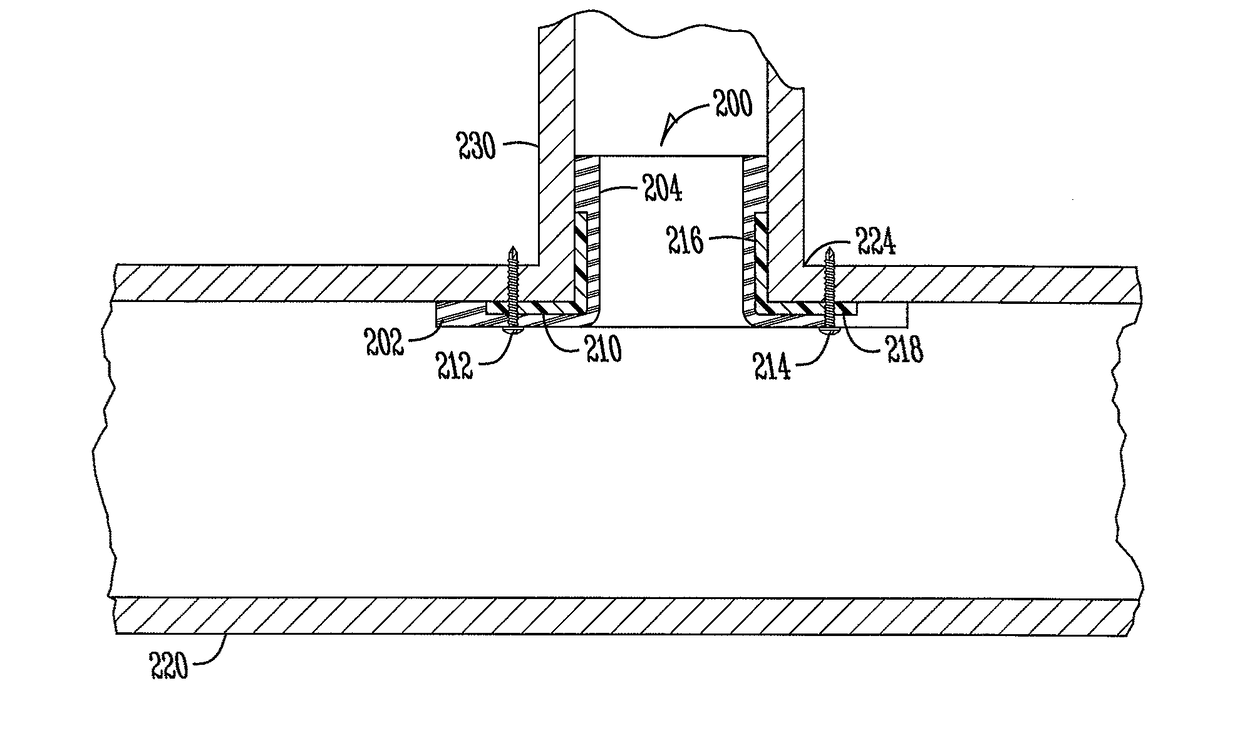

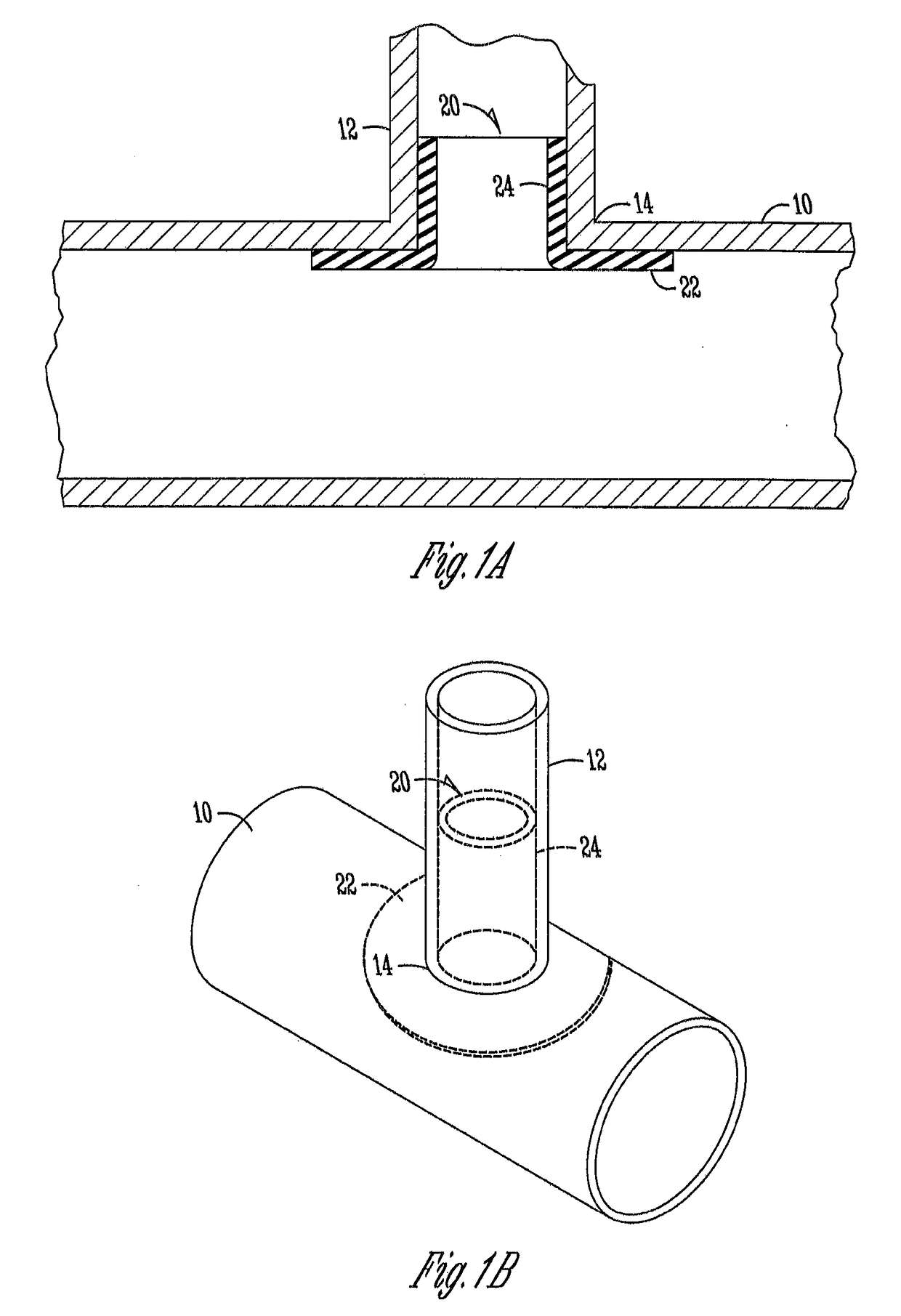

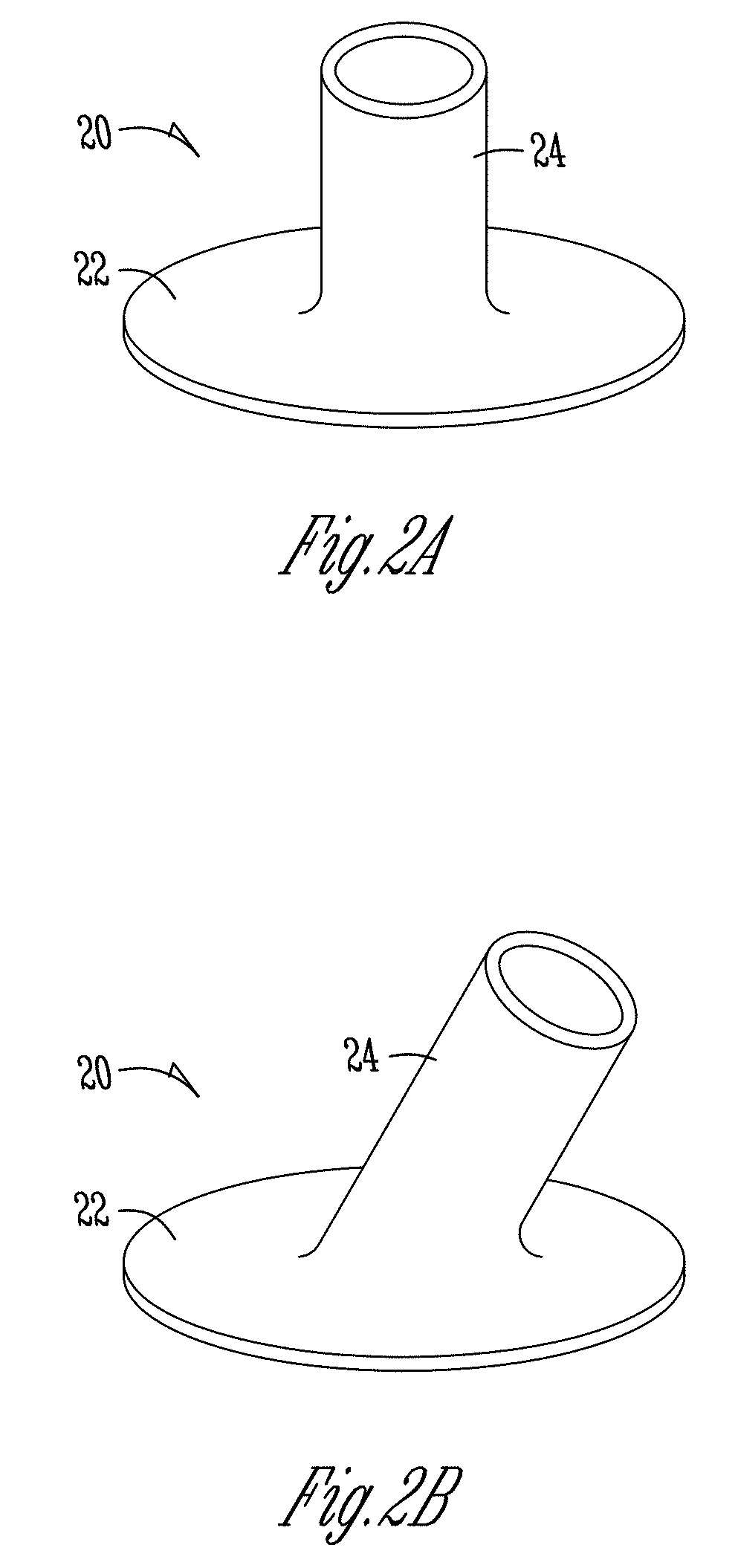

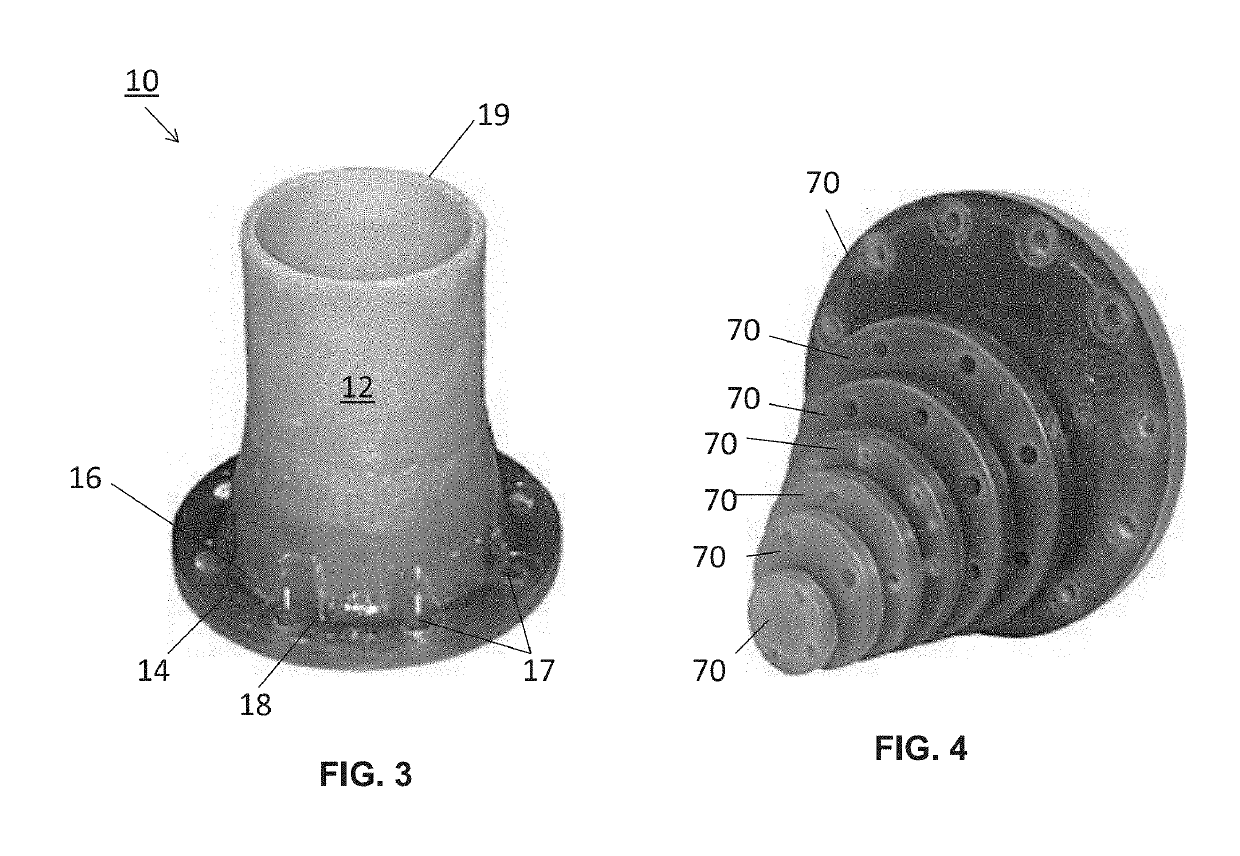

Method and Apparatus for Repairing a Pipe Junction

InactiveUS20170146178A1Easy to manufactureLow costPipe elementsBranching pipesCompressible materialEngineering

An assembly and method of sealing a junction of a pipe and a second structure are provided. The assembly includes a pipe liner having a tubular portion and a brim portion, a compression plate, and a mechanical anchor adapted to secure the compression plate and brim portion of the pipe liner to the second structure. The assembly may further include a gasket for placement between the pipe liner and the pipe or second structure. The gasket may comprise a hydrophilic material, a hydrophobic material, or a compressible material. The methods of using the assembly include, but are not limited to, the use of a cured-in-place pipe liner.

Owner:LMK TECH LLC

Flexible barrier composite fabrics via an adhered film process

ActiveUS20140261972A1Keep in touchDecorative surface effectsWarp knittingHydrostatic pressureCured-in-place pipe

A composite fabric includes: a fabric backing; an adhesive layer; a midlayer barrier bonded to the fabric backing by the adhesive layer; and an external barrier bonded to the midlayer barrier, wherein the composite fabric has a hydrostatic pressure resistance of at least 100 psi and is sufficiently flexible such that it can be formed into a tube and everted. A process and an apparatus for producing the composite fabric are also disclosed. The composite fabric is particularly suitable for use as a liner in a cured-in-place pipe repair method.

Owner:DARTEX COATINGS INC

Cured In Place Pipe Liner

ActiveUS20080173396A1Overcome lack of heat resistanceSolve the lack of resistancePedestrian/occupant safety arrangementSynthetic resin layered productsEpoxyHeat resistance

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on a fibrous mat of non-woven fabric. The TPU coating is a high heat resistance polyester TPU which allows an epoxy resin / amine to be saturated in the non-woven fabric and the cure initiated by the use of steam or hot water. The cured epoxy resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe. The TPU containing liner may also be used with thermoset resins other than epoxy resins, such as polyester resins and vinyl ester resins.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Method of locating liner within sewer pipe

A method of inserting a cured in-place pipe from a cleanout includes positioning a lining along a portion of a length of a bladder, wherein the lining is frangibly connected to the bladder, inserting the bladder through the cleanout, to a position wherein the lining is within the pipe and does not block the pipe.

Owner:LMK TECH LLC

Method and apparatus for determining proper curing of pipe liners using distributed temperature sensing

Owner:ENVIROSIGHT

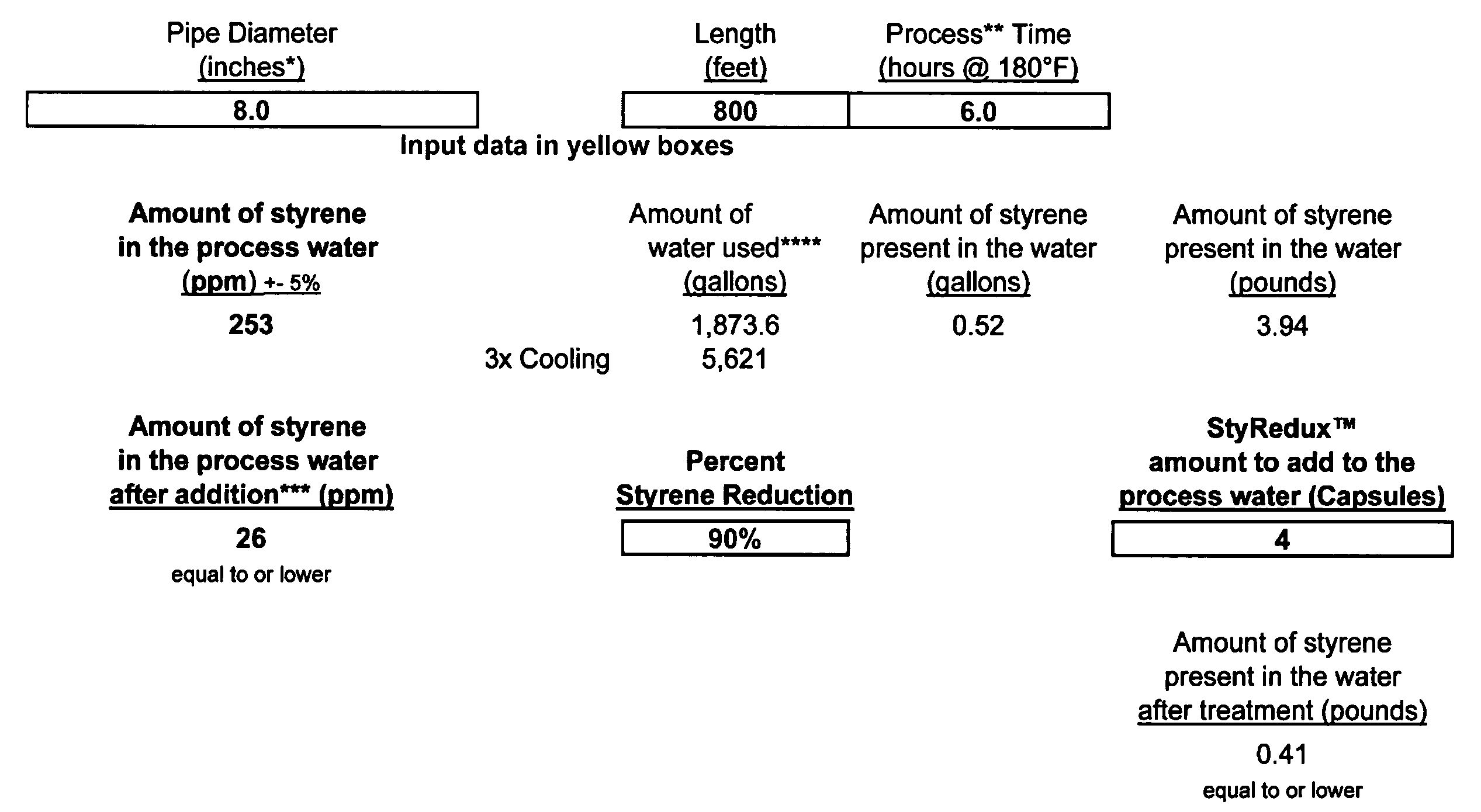

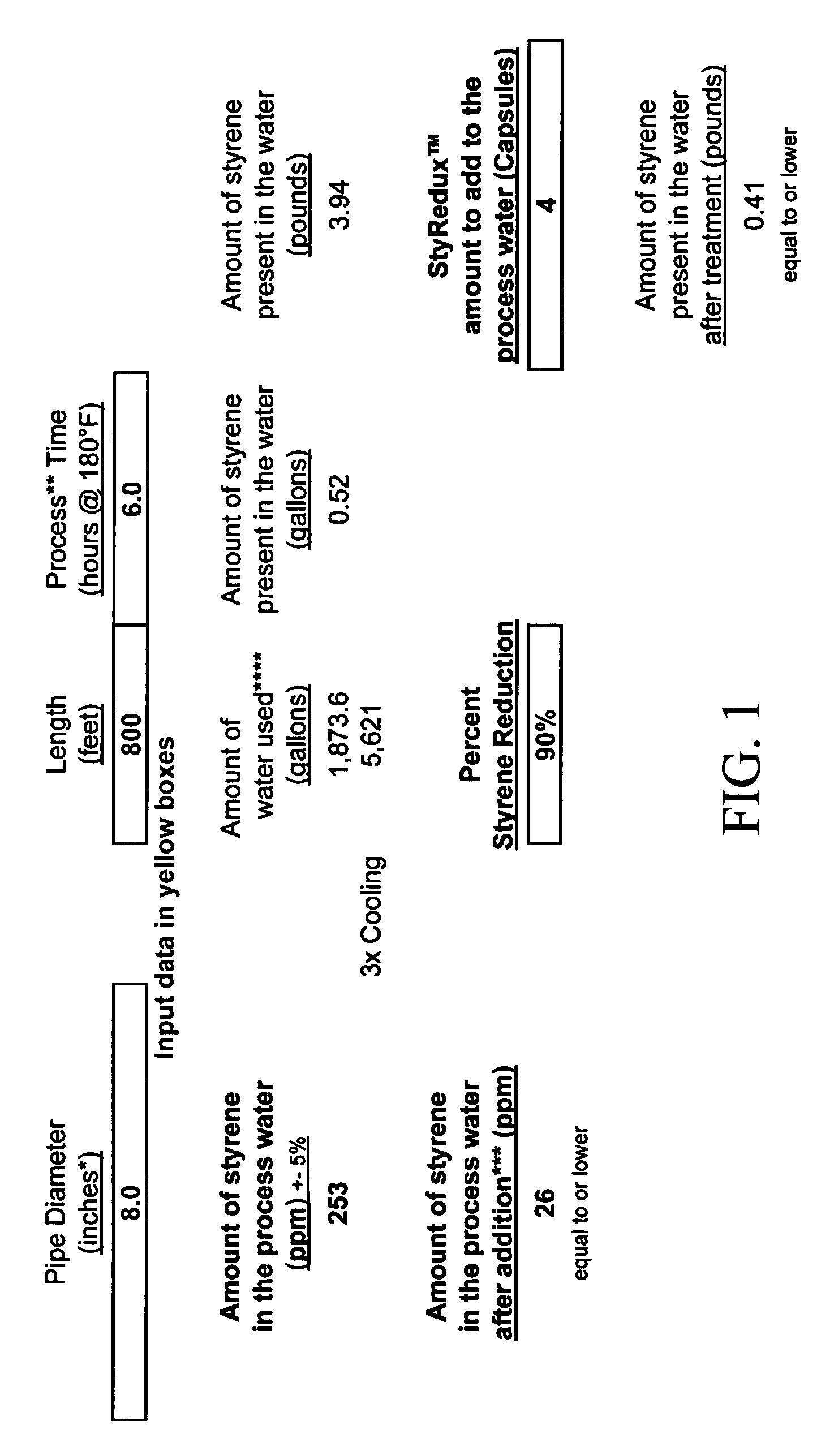

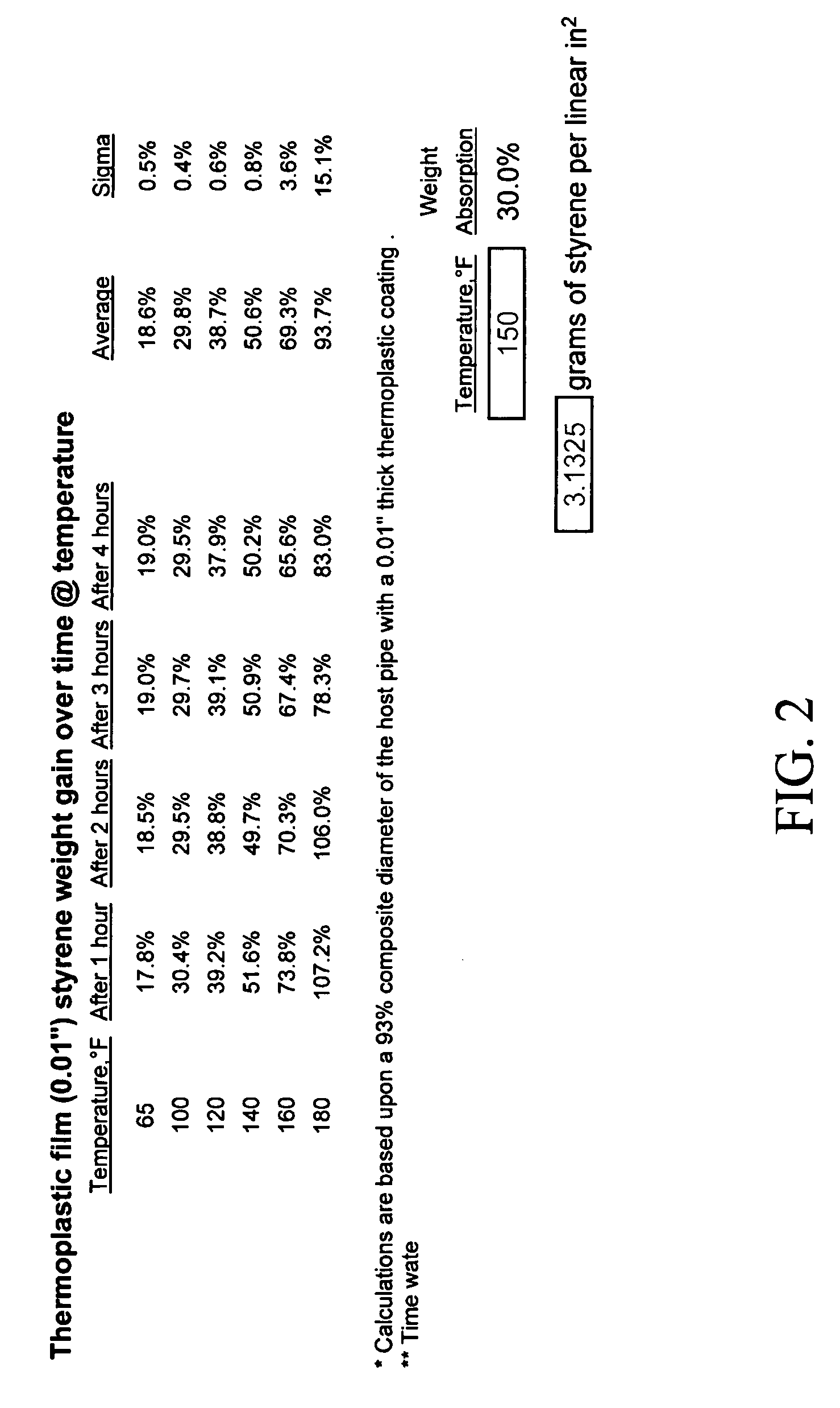

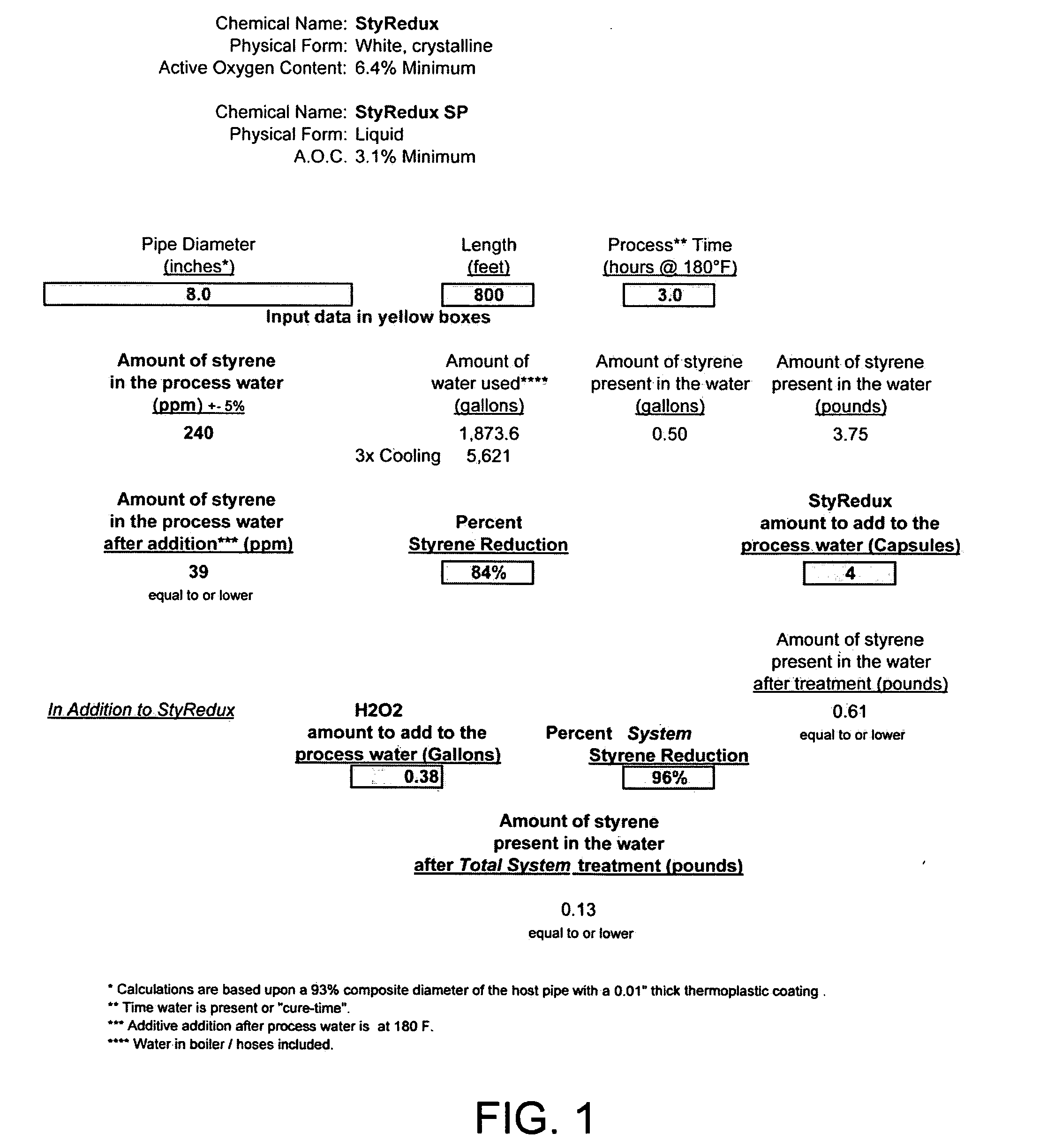

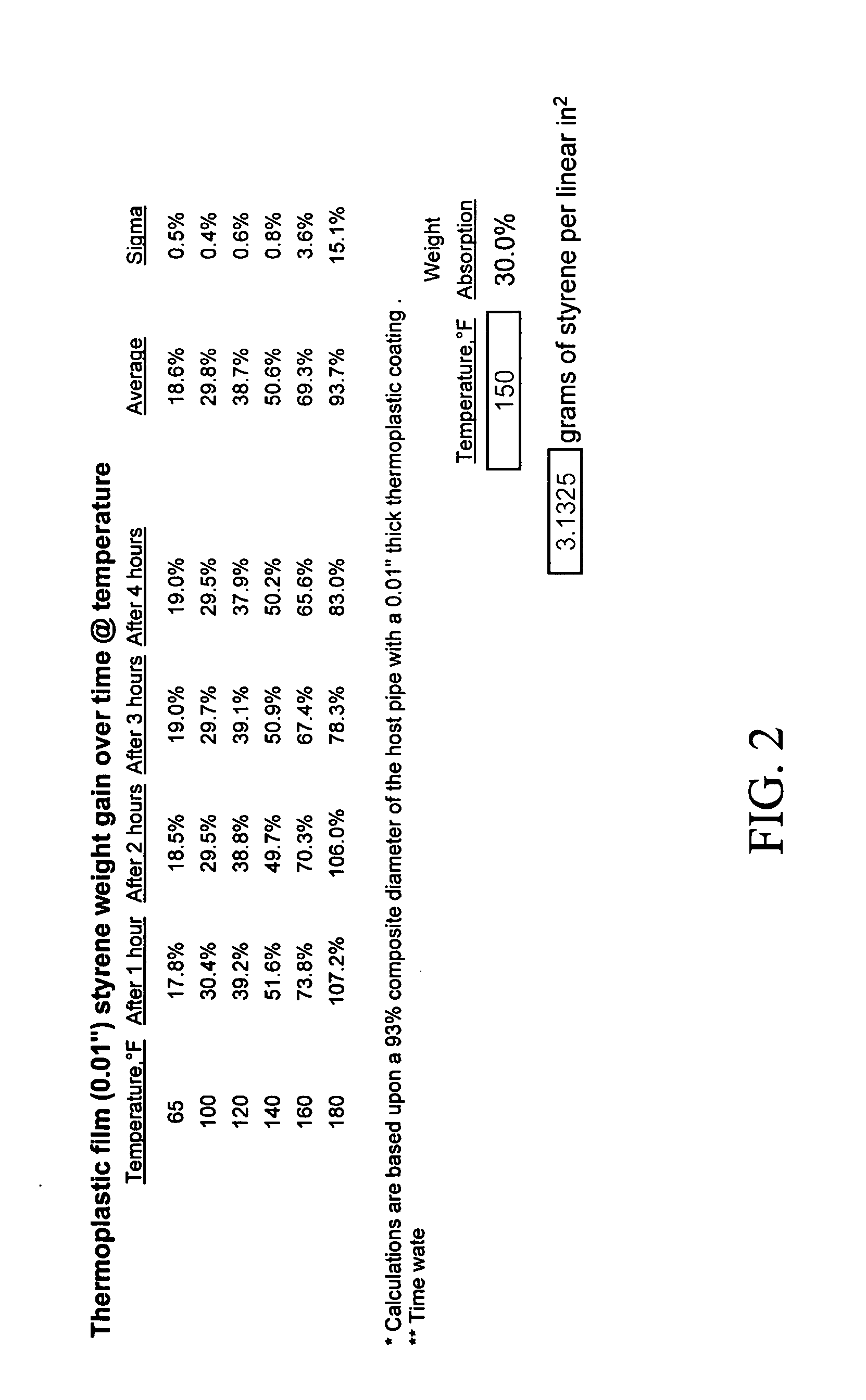

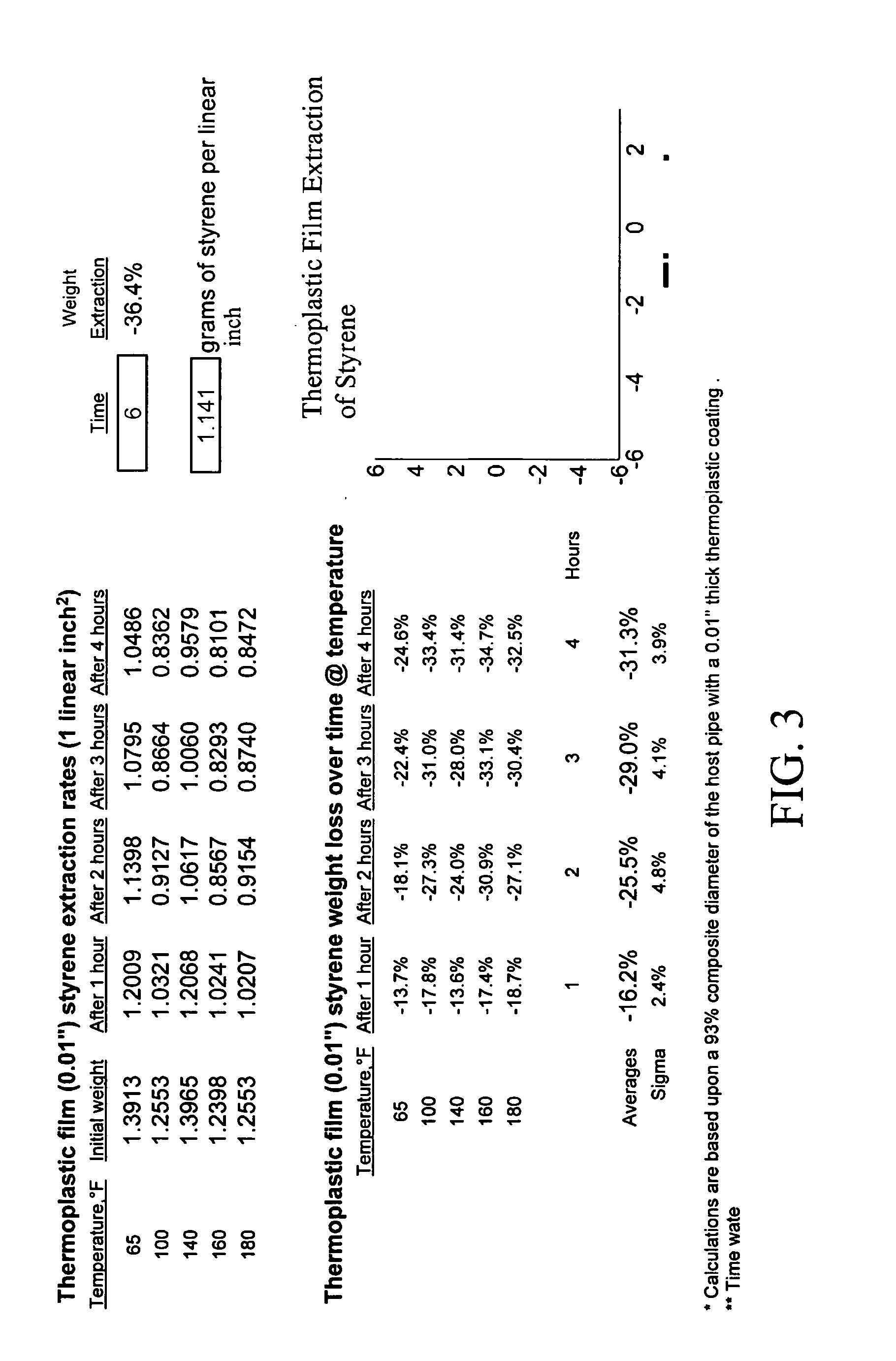

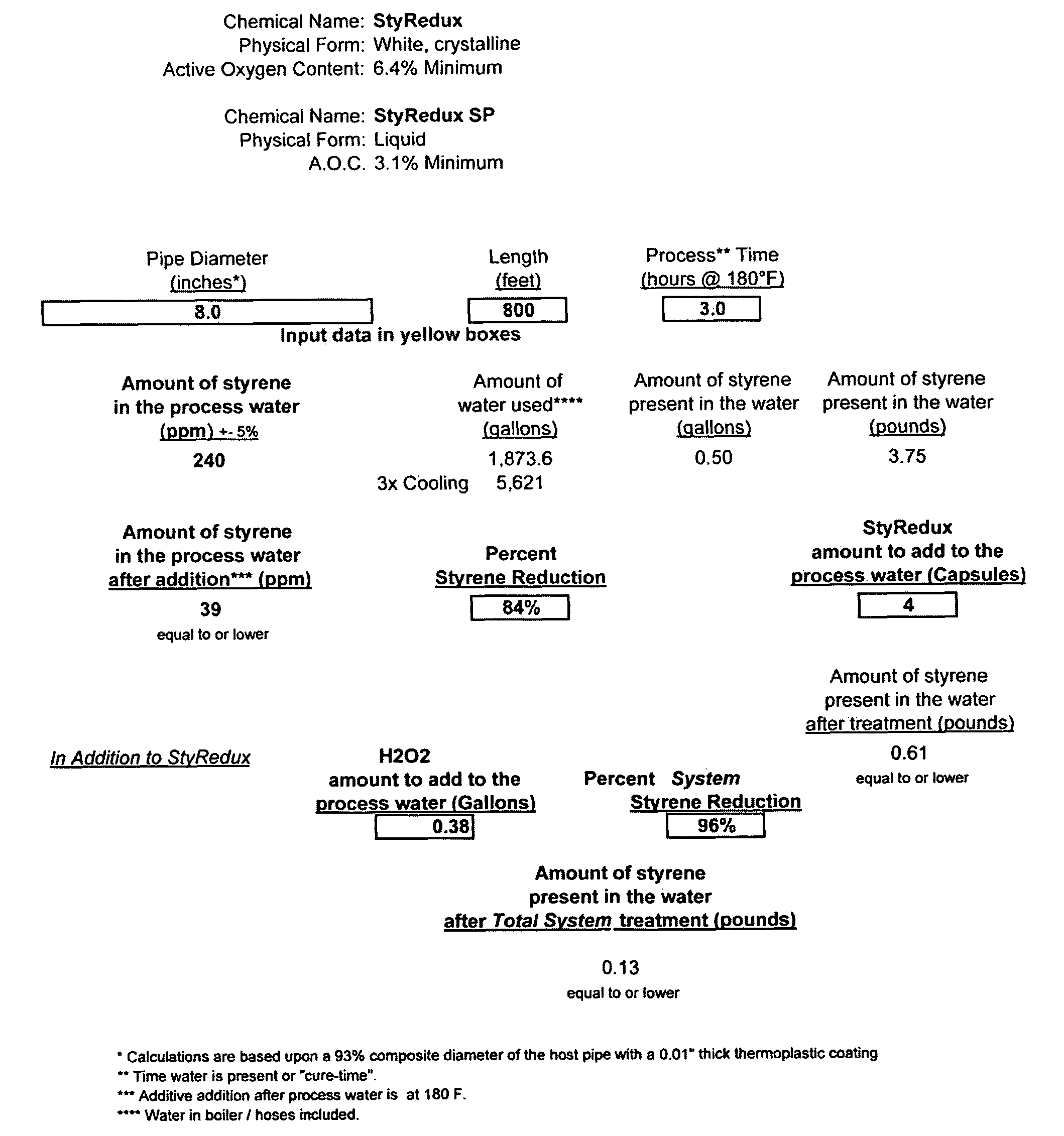

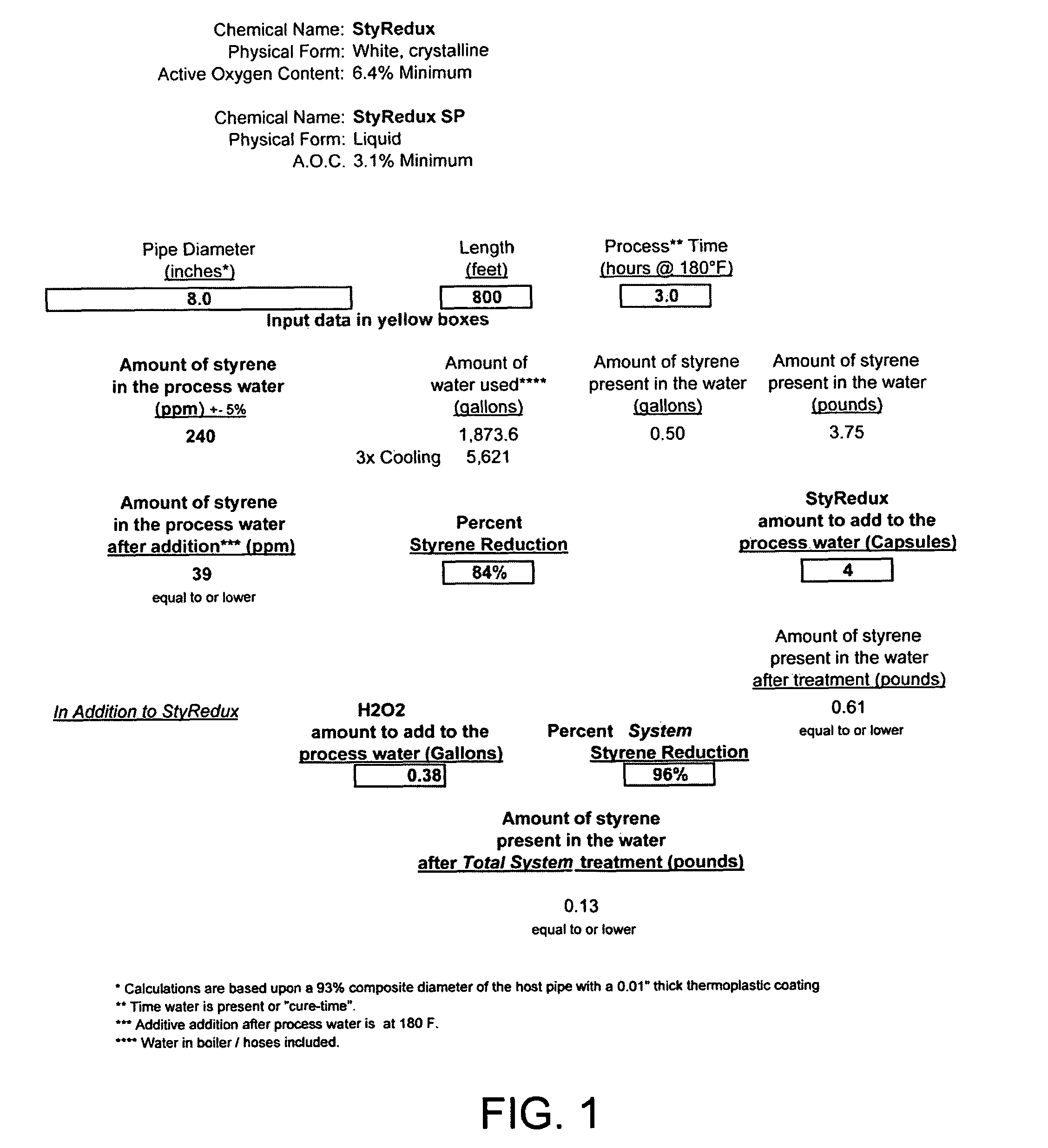

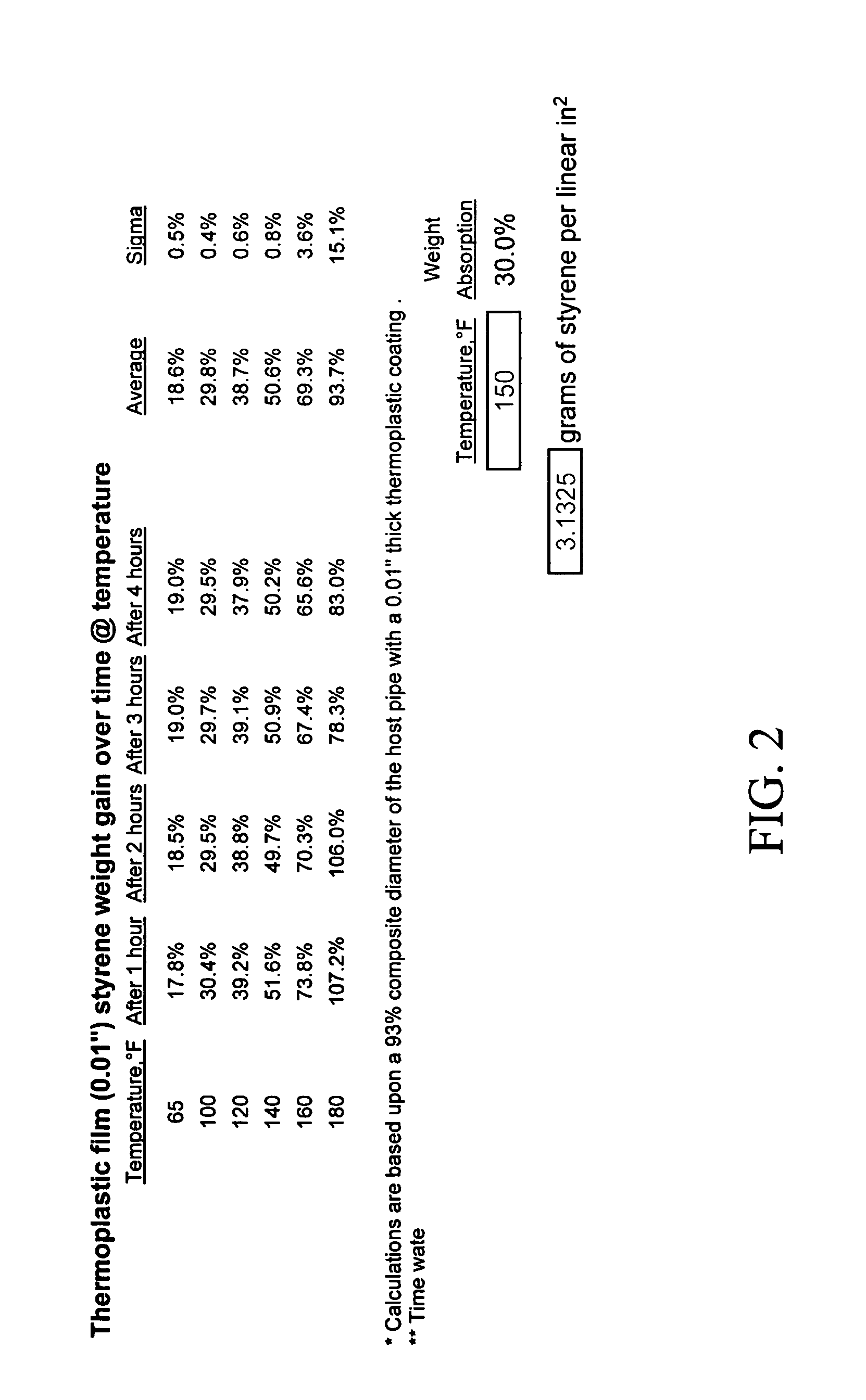

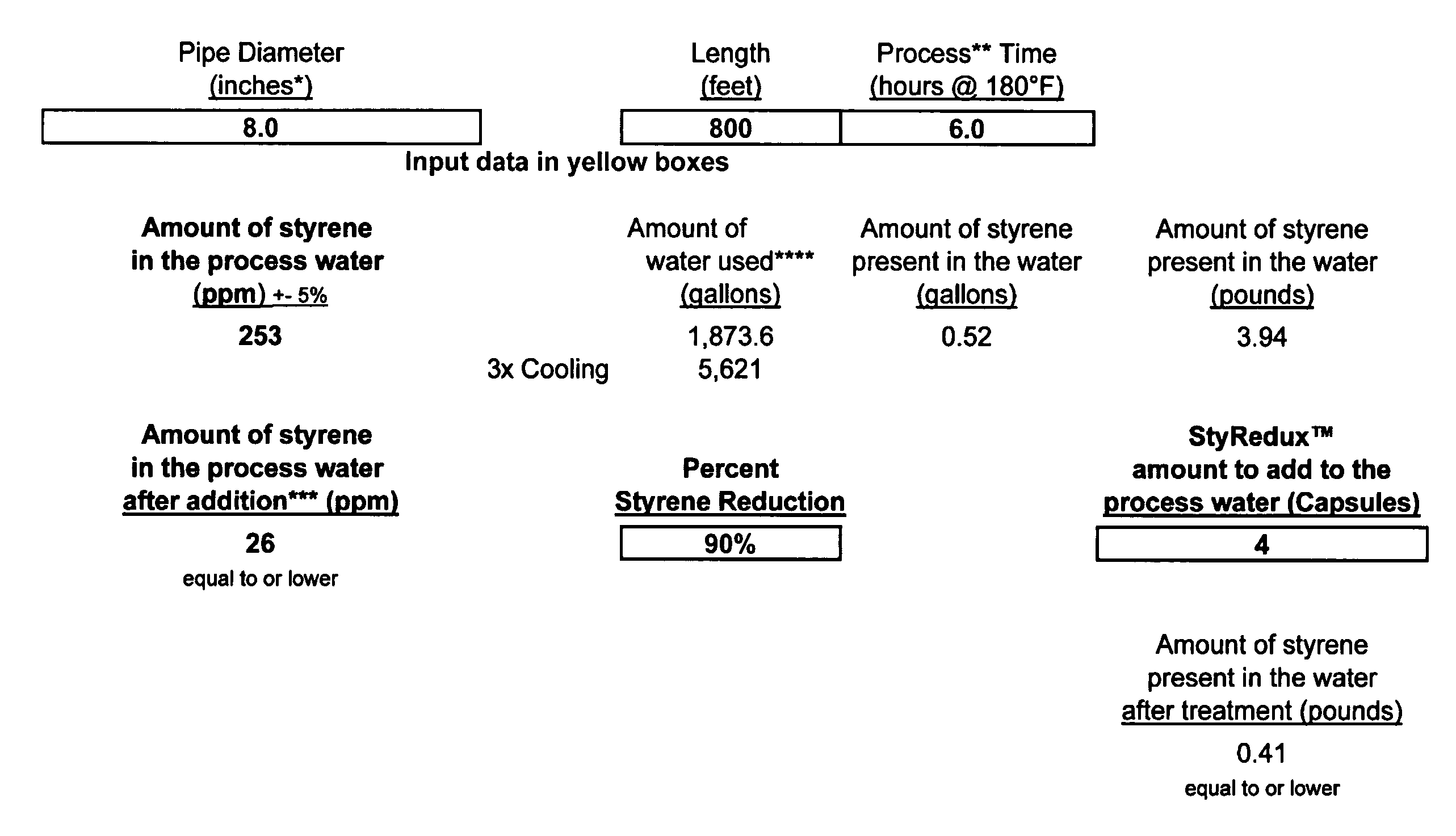

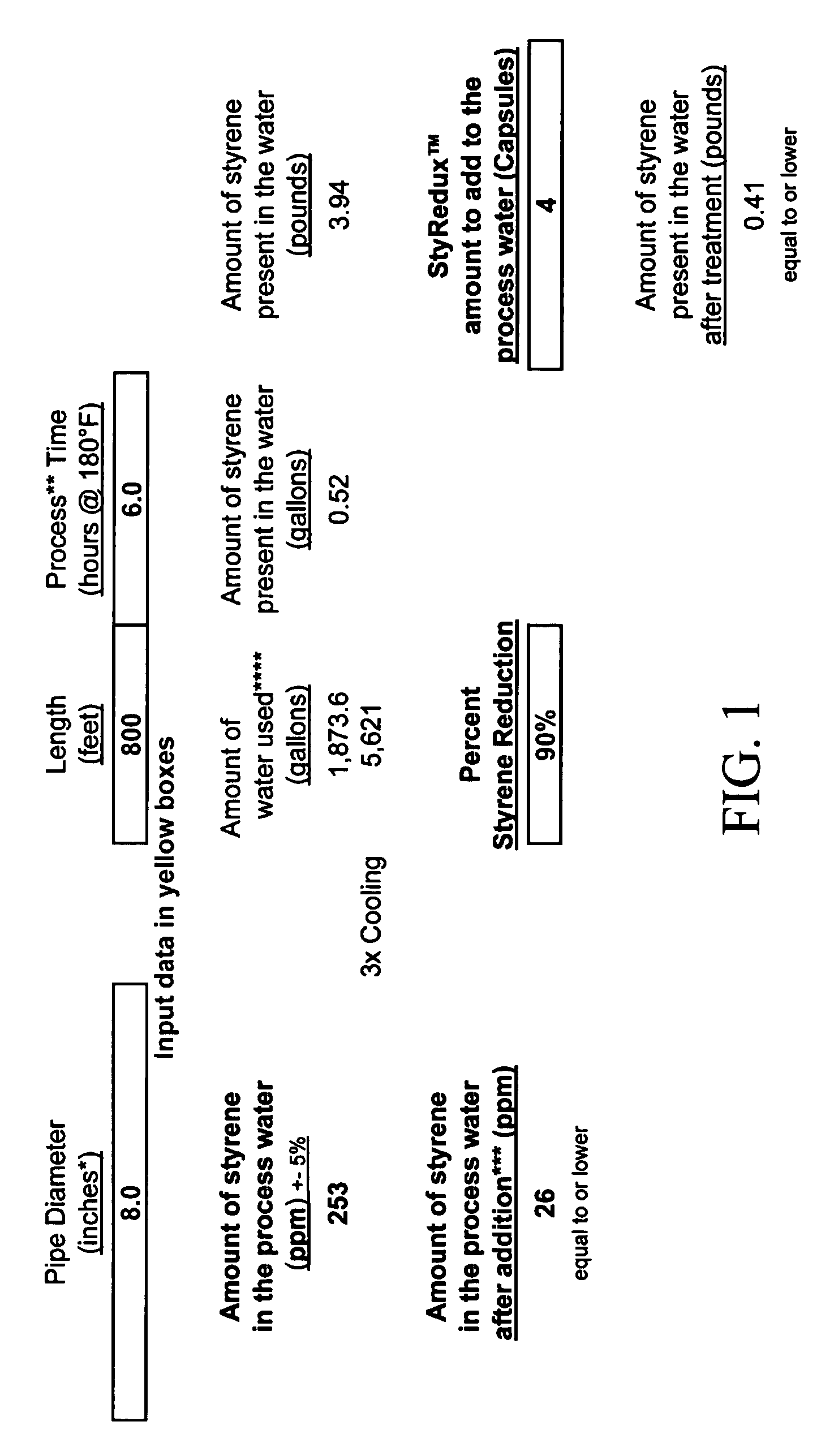

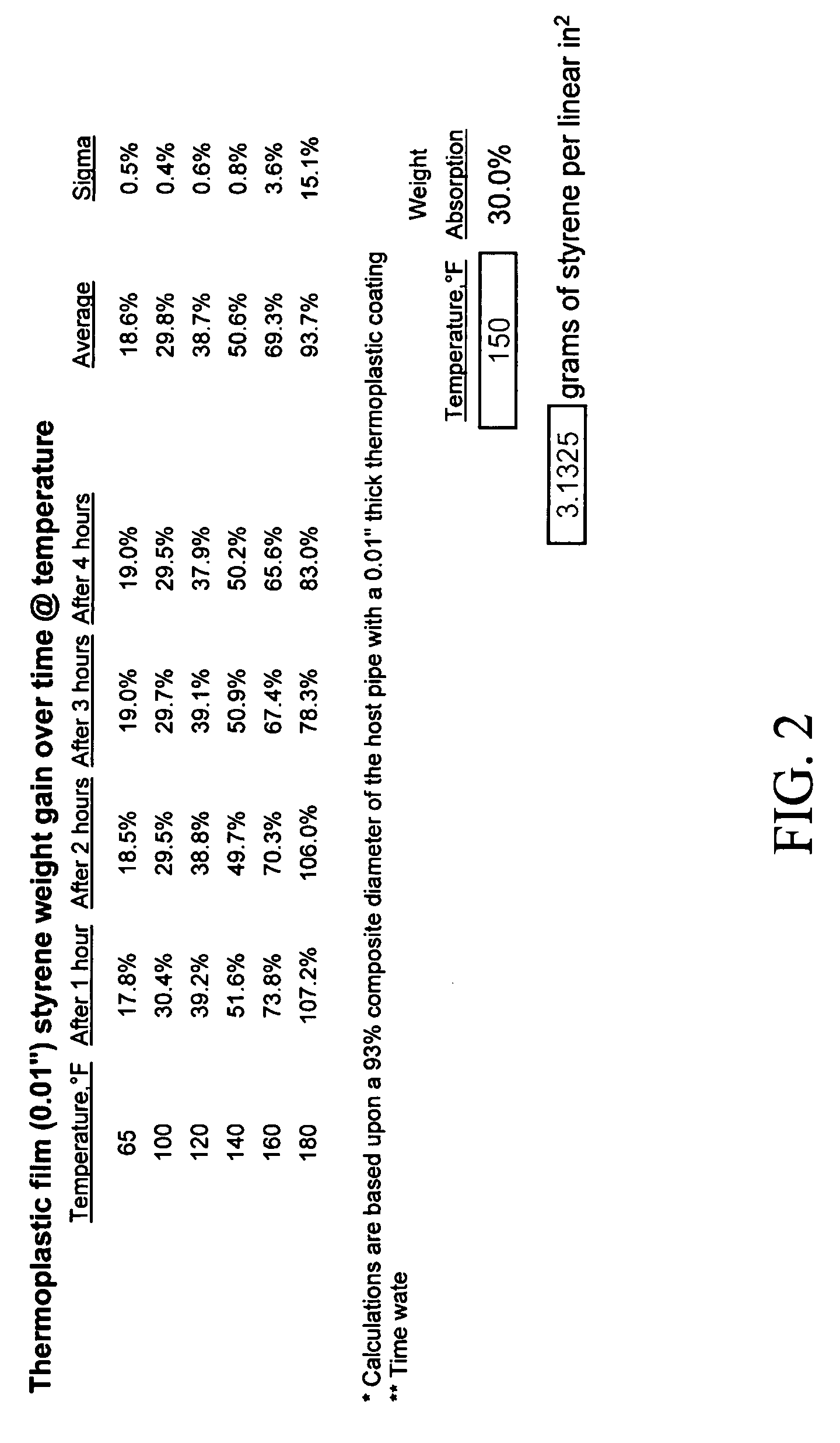

Styrene reduction agent

InactiveUS20060270761A1Reduce decreaseFacilitate quickHydrogen peroxidePeroxyhydrates/peroxyacidsCured-in-place pipeResidual monomer

A styrene reduction agent that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. Capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHEL

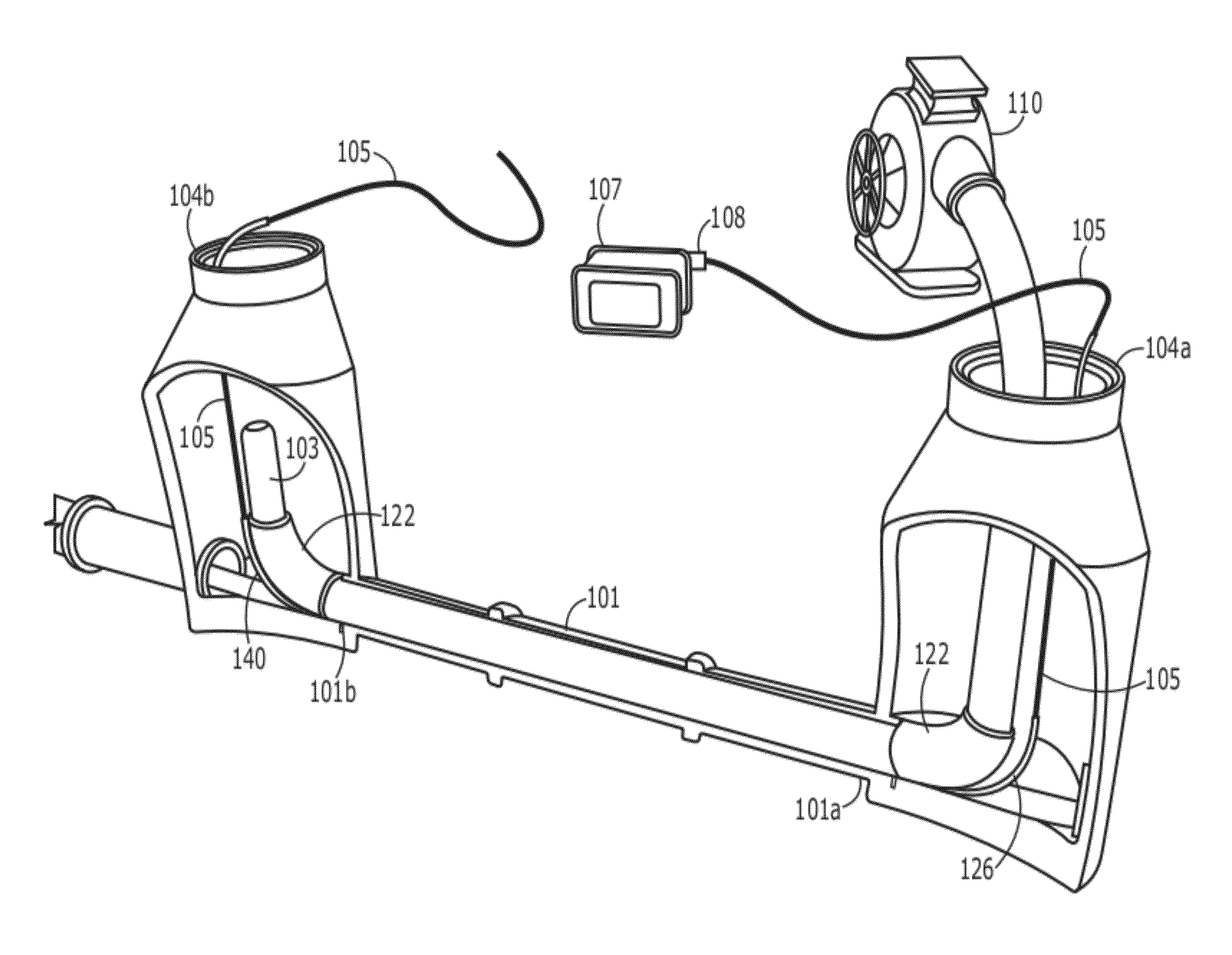

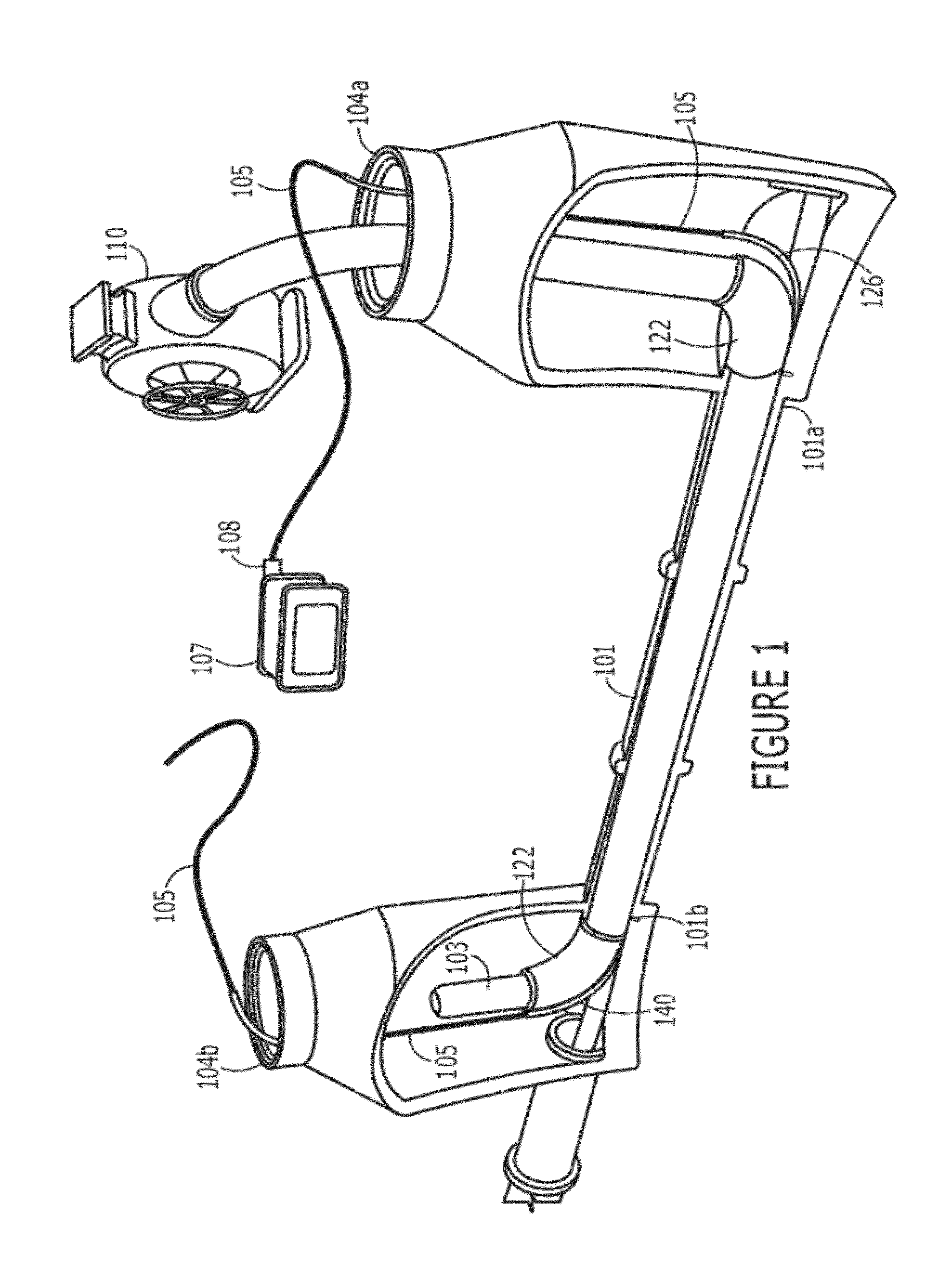

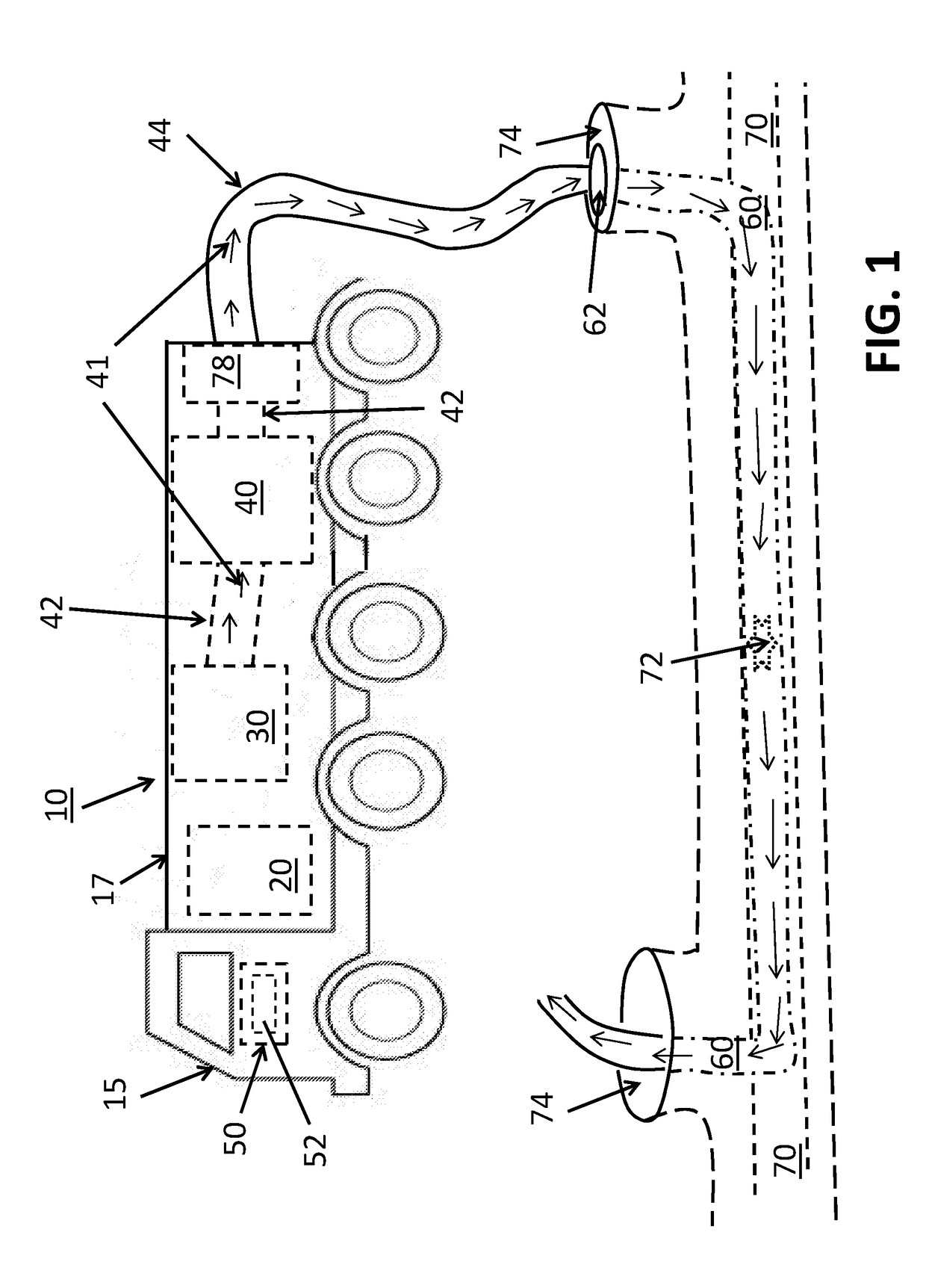

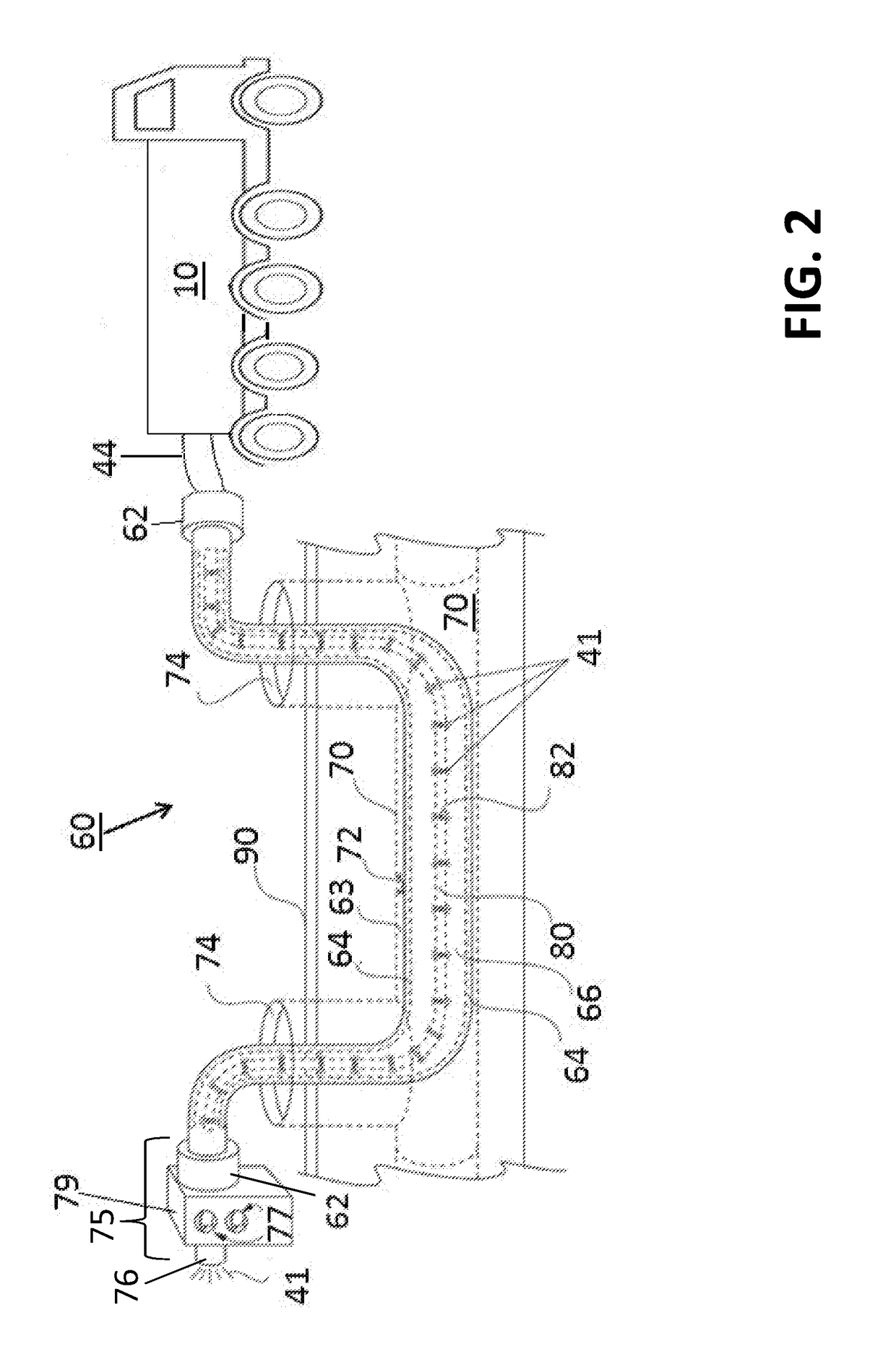

Mobile curing system using superheated air

A curing system for Cured-In-Place-Pipe includes a generator, low pressure high volume blower, heater, upstream sensor and control system housed within a vehicle for mobilization from job site to job site. In use a technician inserts CIPP into a pipe requiring repair, and inputs project specifications such as diameter of CIPP, thickness of CIPP and length of host pipe into the curing system's control system. The technician connects the curing system to the upstream end of the CIPP and initiates the curing process, including the steps of evacuation of ambient air from lining system; pressurizing lining system; superheating lining system; evacuation of superheated air; and relieving pressure after liner has cooled down. During the process, an upstream sensor and a downstream sensor measure parameters such as pressure and temperature and send this data to a control system. The control system includes algorithms that guide the process by adjusting specific parameters such as flow rate, temperature, exhaust rate, and duration, based on upstream and downstream sensor data and differentials there between.

Owner:INFRASTRUCTURE TECH LLC

Liner tube with non-stretching material

An apparatus and method of making a cured-in-place pipe repair to a lateral pipe having an area in need of repair. The method and apparatus use a liner assembly comprising a bladder tube and a liner tube. The liner tube comprises at least one layer of non-stretching material, which includes strands of non-stretching material oriented in the longitudinal direction of the liner tube. The strands allow radial stretching but ensure that the liner tube does not stretch longitudinally, which prevents the liner tube from stretching into a main pipe or past the area in need of repair during use. The liner tube may also comprise second and third layers of a resin impregnable material, such as felt, which surround the layer of non-stretching material such that the liner tube may be impregnated with a resinous material to repair a pipe having an area in need of repair.

Owner:LMK TECH LLC

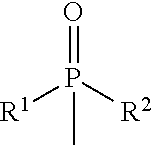

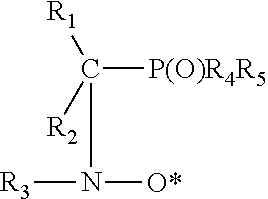

Polymerization controllers for organic peroxide initiator cured composites

InactiveUS20110250373A1Low viscosityReduced responseOther chemical processesLayered productsPolyesterTransfer molding

The use of nitroxides to control free radical cured resin systems used in the production of thermosetting materials such as in vacuum infusion, resin transfer molding and cured in place piping systems is disclosed. The invention could also be employed in other resin systems where control of kinetics would be desirable such as in adhesive formulations, in solid surface composites, and certain types of polyester casting resins.

Owner:ARKEMA INC

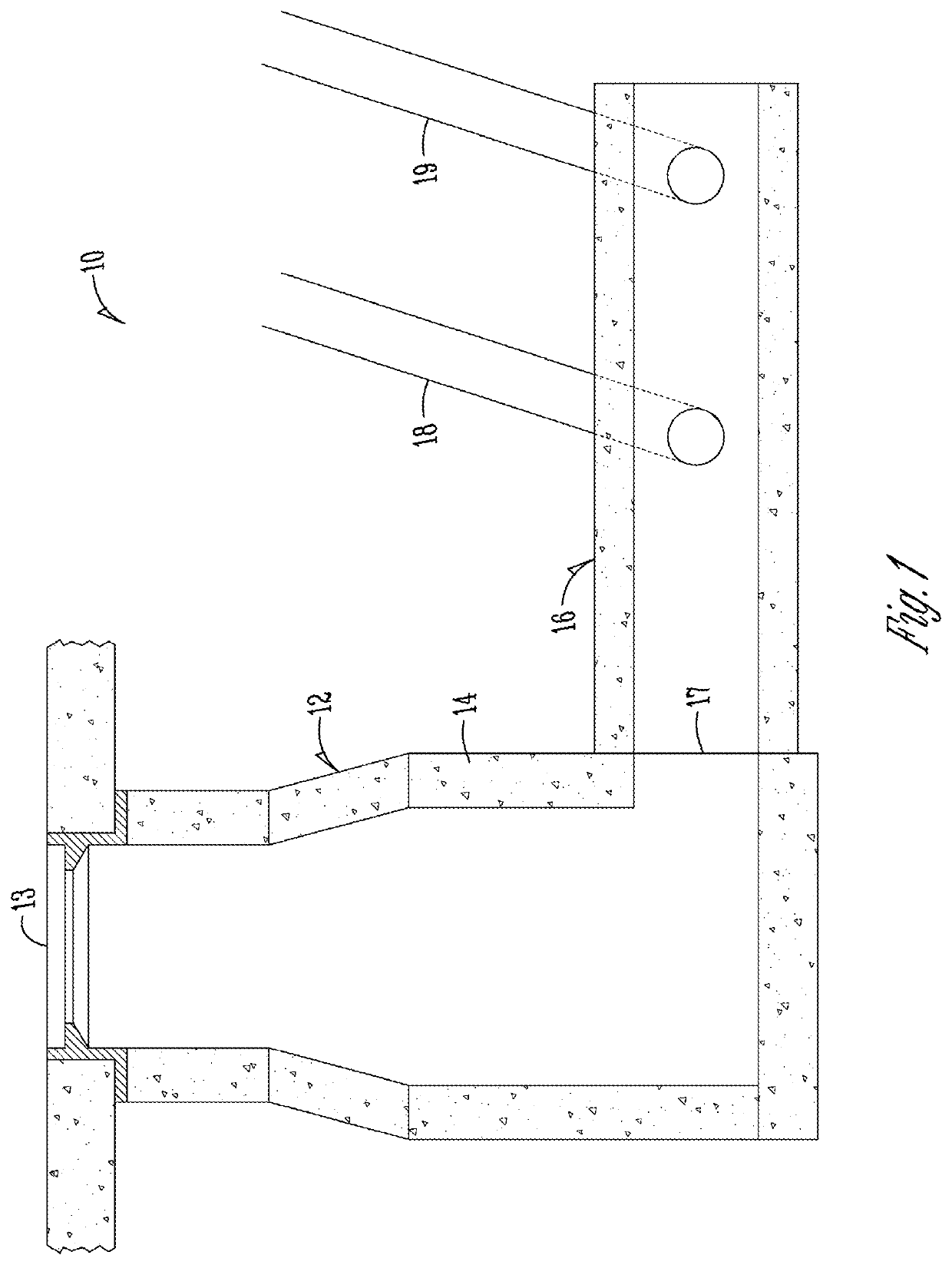

Reinforced Grommet for Cured in Place Pipe

InactiveUS20080265527A1Prevent escapeQuick implementationEngine sealsPipesEngineeringCured-in-place pipe

Method and apparatus for forming a grommet assembly to seal and reinforce holes through a cured in place liner for securing a cable. A first grommet base having a centrally located aperture with wedge shaped grooves is positioned on one side of the hole. A barrel having two opposed sets of wedge shaped projections is inserted into the grommet base and a second grommet base is placed on the barrel and pushed towards the liner until the second base firmly contacts the top surface of the liner and compresses the liner against the first base. The wedge shaped projections on the barrel and the complimentary grooves in the central apertures of the grommet bases prevent the barrel from being pulled out of either grommet base. The end of the barrel which projects out above the second base is cut off flush with the top surface. A hydraulic press to install the grommet assembly is also disclosed.

Owner:INA ACQUISITION

Cured in place pipe system having integrated thermoplastic with improved melt-flow characteristics

ActiveUS20180003332A1Extended shelf lifeReduce stressSynthetic resin layered productsPipe elementsThermoplasticAramides

A Cured In Place Pipe System includes a tubular substrate constructed of needle-punched fibers of carbon, aramid and thermoplastic. The tubular structure defines a longitudinal channel running along the length. Within the channel is an air bladder, preferably including an air duct. The tubular substrate is enclosed within a loose-fitting protective film. The tube is preferably constructed with multiple overlapping layers that aren't permanently bound, thereby allowing for circumferential expansion to accommodate various host pipe sizes, shapes, and configurations. The integrated thermoplastic has a melt / flow point of approximately 300-342° F., a cure point of approximately 330-370° F., and bonding point of approximately 372-412° F. at approximately 5-20 psi.

Owner:INFRASTRUCTURE TECH LLC

Method and apparatus for controlling contamination from pipe coatings

InactiveUS20100029879A1Reduce decreaseImprove responseHydrogen peroxidePeroxyhydrates/peroxyacidsPersulfateAdditive ingredient

A combination of a styrene reduction agent and a catalyst that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. The catalyst is hydrogen peroxide (H2O2). A calibrated amount of the styrene reduction agent capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process, and this is followed by a calibrated amount of the H2O2 catalyst in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHAEL

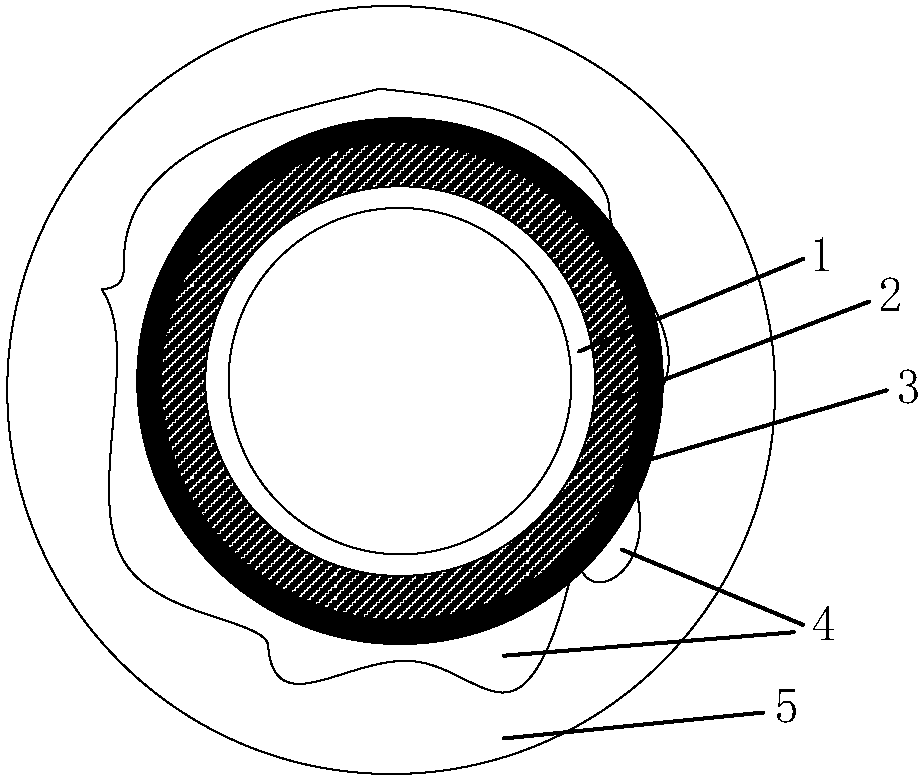

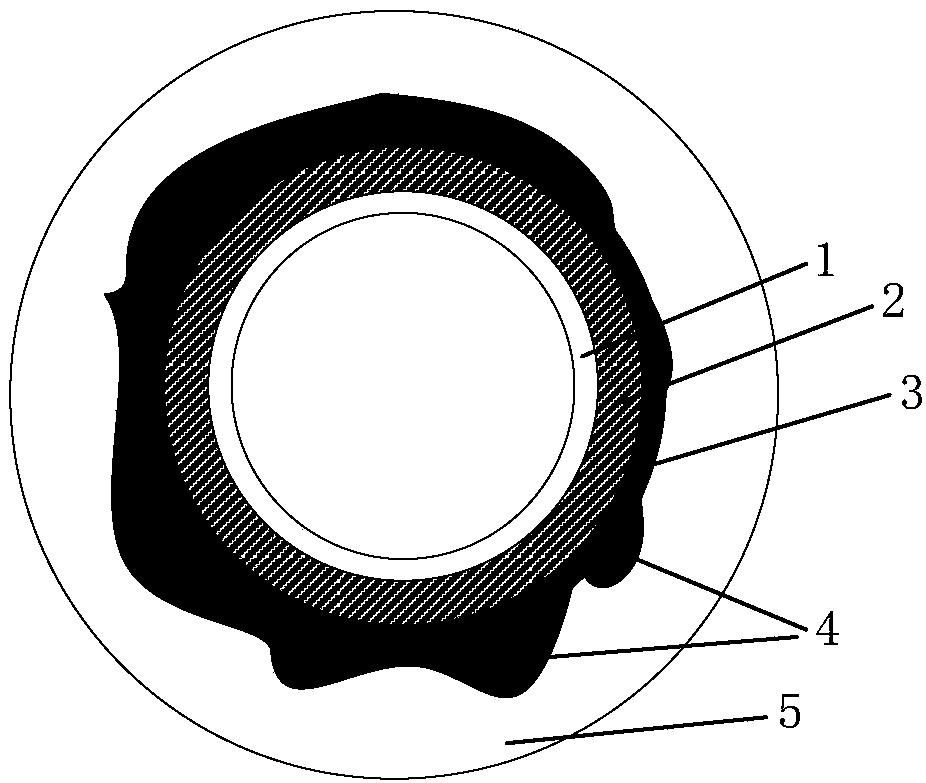

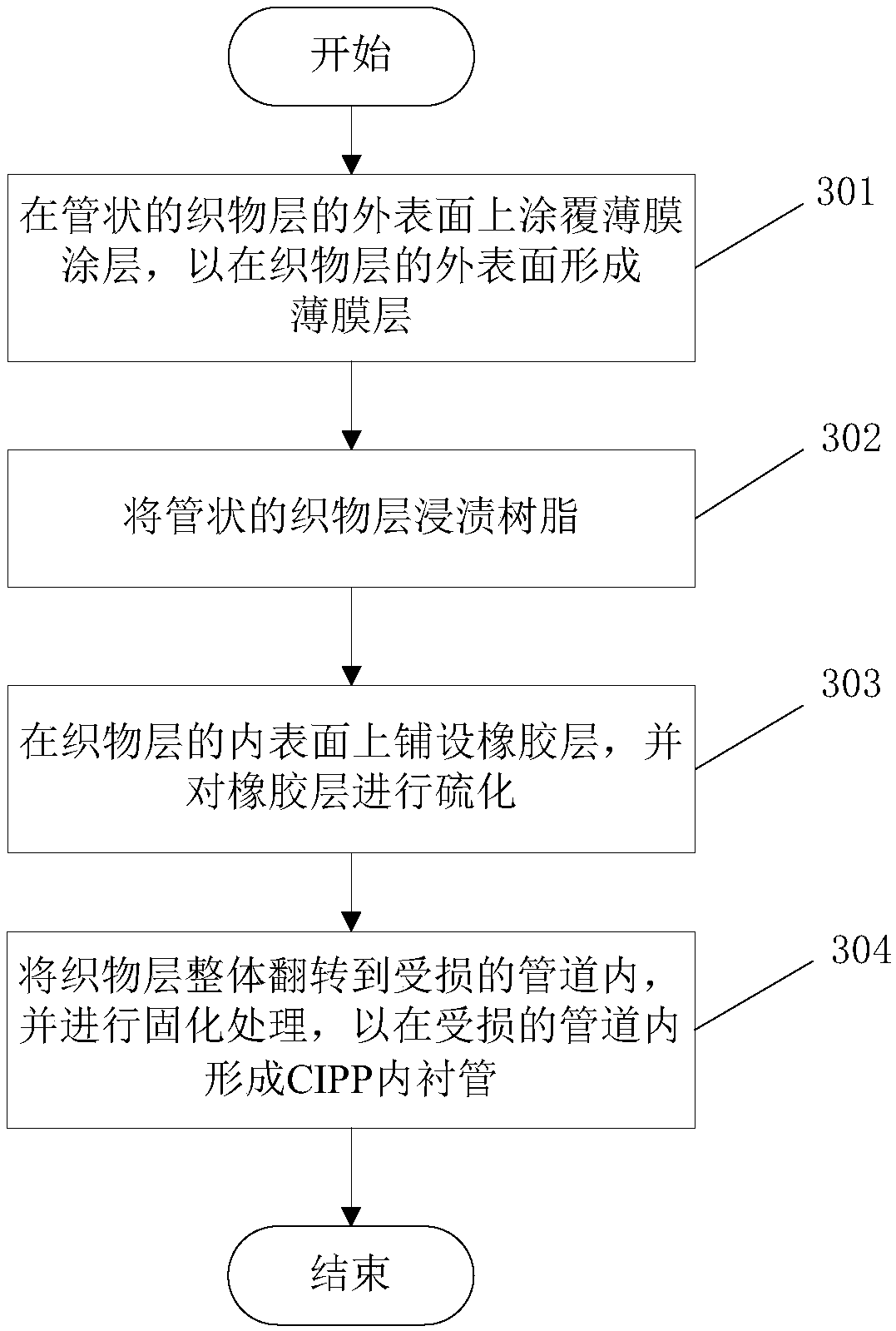

Cured-in-place pipe (CIPP) liner pipe and method for preparing CIPP liner pipe

The embodiment of the invention relates to the field of pipeline repair, and discloses a cured-in-place pipe (CIPP) liner pipe and a method for preparing the CIPP liner pipe. The CIPP liner pipe comprises a fabric layer, a thin film layer and a rubber layer made of rubber which is expandable when meeting water. The fabric layer is in a pipe shape; the thin film layer surrounds the inner surface ofthe fabric layer to form the inner wall of the CIPP liner pipe; and the rubber layer is arranged on the outer surface of the fabric layer. According to the embodiment of the invention, relative to the prior art, the rubber layer made of the rubber which is expandable when meeting the water is arranged on the outer surface (that is, the surface facing the inner wall of a damaged pipeline) of the CIPP liner pipe, when a gap is formed between the CIPP liner pipe and an original pipeline, the intrusive water (that is, groundwater or pipeline sewage entering the gap) can cause spontaneous rapid expansion of the rubber, thus the gap is fully filled with the rubber, and a sealed isolation layer is formed, so that the CIPP liner pipe and the original pipeline are closely attached together, and mutual infiltration of the groundwater and the pipeline sewage is effectively prevented accordingly.

Owner:FUDAN UNIV +1

Method and apparatus for controlling contamination from pipe coatings

InactiveUS7820069B2Improve responseQuicker more complete reductionHydrogen peroxidePeroxyhydrates/peroxyacidsPersulfateWaste stream

A combination of a styrene reduction agent and a catalyst that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. The catalyst is hydrogen peroxide (H2O2). A calibrated amount of the styrene reduction agent capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process, and this is followed by a calibrated amount of the H2O2 catalyst in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHAEL

Styrene reduction agent

InactiveUS7892448B2Effectively and economically reduces styrene, or reactiveSimple taskHydrogen peroxidePeroxyhydrates/peroxyacidsWaste streamPersulfate

A styrene reduction agent that effectively and economically reduces styrene emissions in Cured-In-Place Pipe, closed molding processes. The reduction agent generally comprises a calibrated mixture of salts including sodium chloride plus three persulfate salts: ammonium (APS), potassium (KPS), and sodium (NPS). These ingredients are combined in powder form and are compressed into soluble capsules containing calibrated amounts of the mixture. The capsule(s) may be prescribed through the use of software. Capsule(s) are added to the cure water prior to starting the boiler equipment for the Cured-In-Place Pipe process in order to reduce the residual monomer content in either process or waste streams.

Owner:GOSSELIN MICHEL

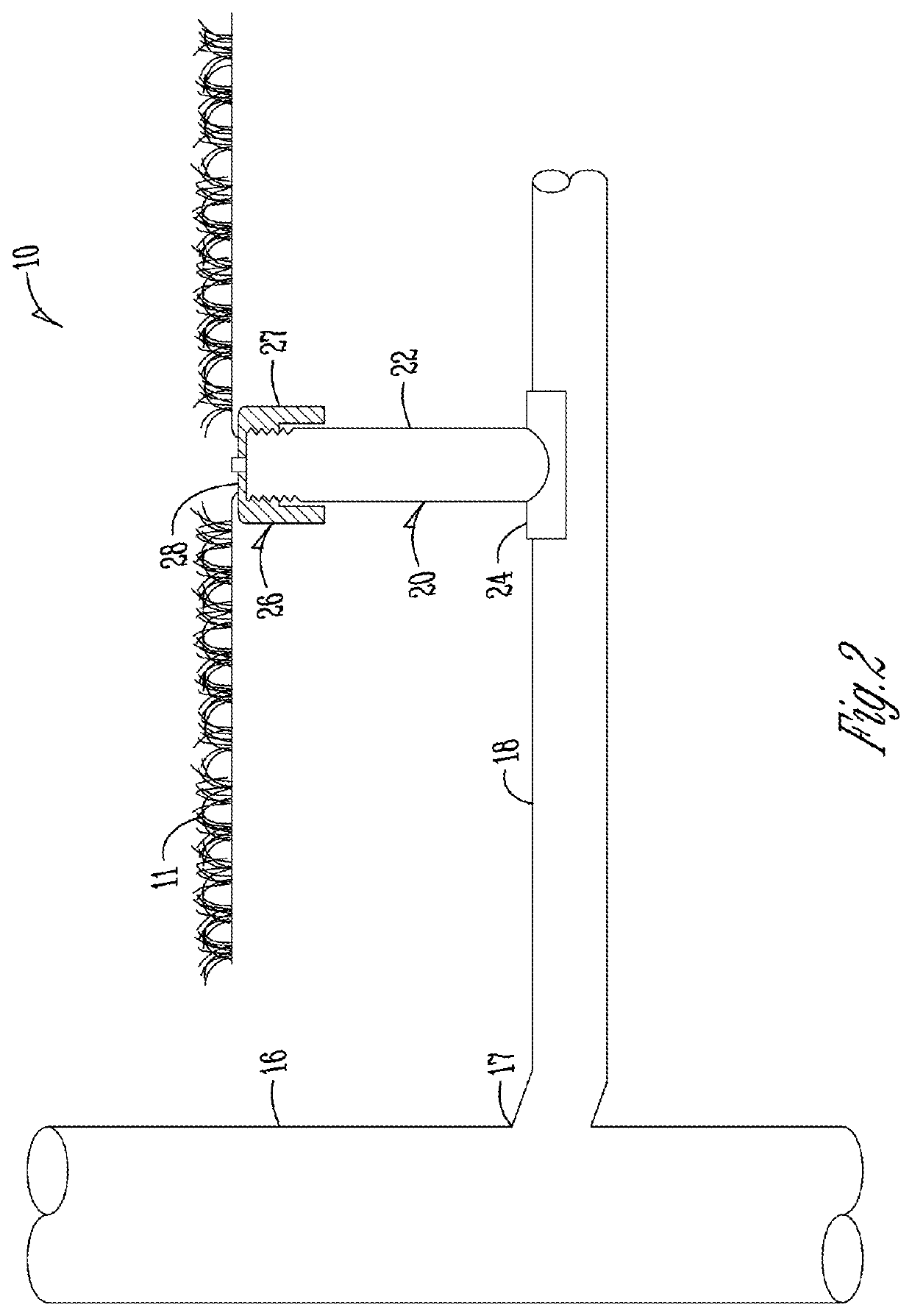

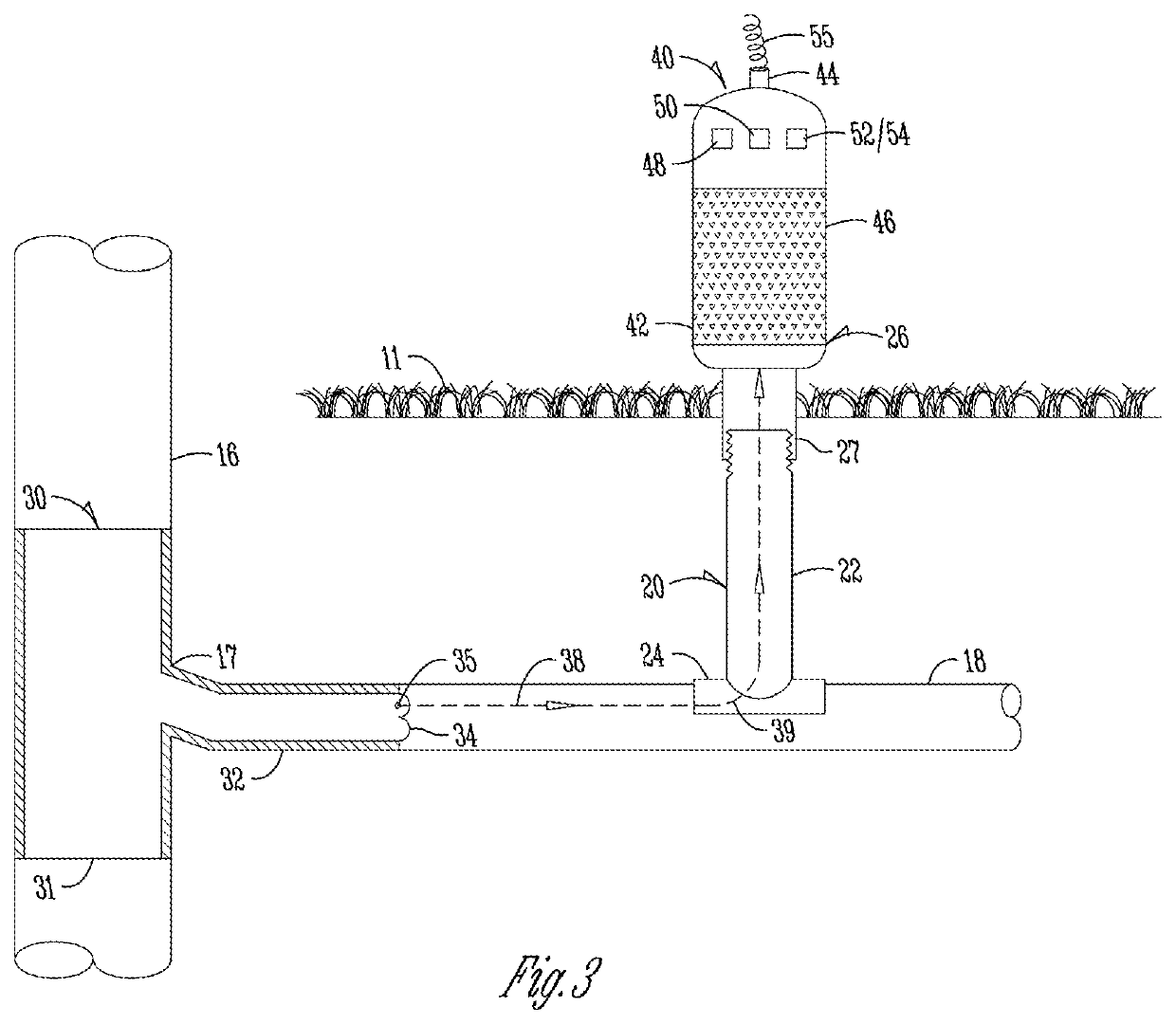

Method and apparatus for repairing a pipe junction

ActiveUS9791089B2Easy to manufactureLow costThermal insulationCombustion enginesCompressible materialEngineering

An assembly and method of sealing a junction of a pipe and a second structure are provided. The assembly includes a pipe liner having a tubular portion and a brim portion, and a mechanical anchor adapted to secure the brim portion of the pipe liner to the second structure. The assembly may further include a compression gasket for placement between the pipe liner and the pipe or second structure. The compression gasket may comprise a hydrophilic material, a hydrophobic material, or a compressible material. The methods of using the assembly include, but are not limited to, the use of a cured-in-place pipe liner.

Owner:LMK TECH LLC

CIPP hose for repairing trenchless underground pipe network, and preparation method and application of CIPP

InactiveCN108192182AAchieving wear resistanceAchieving Corrosion ResistancePipe elementsFiberEngineering

The invention relates to the technical field of pipeline engineering, and discloses a CIPP (cured in place pipe) for repairing a trenchless underground pipe network, and a preparation method and application of the CIPP. The CIPP for repairing the trenchless underground pipe network disclosed by the invention comprises a tubular fiber fabric, resin and a curing agent or a reactive diluent, whereinthe resin, the curing agent and the reactive diluent or the reactive diluent fill the fiber fabric; and the CIPP also comprises ultra-high-molecular-weight polyethylene, wherein the ultra-high-molecular-weight polyethylene is ultra-high-molecular-weight polyethylene particles or ultra-high-molecular-weight polyethylene fibers. The ultra-high-molecular-weight polyethylene has high impact strength,high wear resistance and low friction coefficient, so that the ultra-high-molecular-weight polyethylene is adopted as a single filler, then the CIPP can meet various repair performance requirements such as wear resistance, corrosion resistance, impact resistance, self-lubrication and the like, and meanwhile, the effects of simplifying formula, facilitating stirring and saving construction time areachieved. The ultra-high-molecular-weight polyethylene is safe and nontoxic, so that the CIPP provided by the invention can be used for repairing underground pipelines, and can also be used for repairing drinking water pipelines.

Owner:FUDAN UNIV +1

Thickening agent for cured in place pipe resin

A thickening agent for thickening polyester resin used in Cured-In-Place-Pipe open-molding processes. The thickening generally comprises a calibrated mixture of neutral polyester resin carrier with an active agent comprising approximately 98.5% Magnesium Oxide (MgO) paste and 1.5% anhydrous Calcium Chloride. The Calcium Chloride is powdered and combined in powder form with the MgO paste and binder for addition to the polyester resin prior to curing for the Cured-In-Place process.

Owner:GOSSELIN MICHEL

Pipe renovation filtration system

ActiveUS20210317940A1Reduce appearance problemsQuality improvementDispersed particle filtrationPipe elementsCured-in-place pipePollutant

A filtration system is used with a pipe repair system, such as a cured-in-place pipe lining system. Before, during, and / or after the repair of the pipe with the pipe lining system, air from inside the pipe is directed into a filtration system. The filtration system removes contaminants, such as VOCs and other harmful gases, particles, and the like, with a filter, and then the filtered air is exhausted from the system. The filter can be a carbon filter or other filter that can remove harmful or hazardous materials and particles from the air prior to exhaust. The air is also sensed to acquire information, such as temperature, pressure, composition, flow, or the like.

Owner:PIPE LINING ENTERPRISES INC

Pipe fittings having integrated thermoplastic with improved melt-flow characteristics for cured in place pipe systems and associated method of use

A fitting including a tubular extension, flange with apertures, and interface there between is fused with surrounding cured in place pipe and subsequently connected with an adjoining fitting, to connect two segments of pipe in a pipeline. The tubular extension is sized and shaped to mate with the host pipe with which it is associated, and the flange is sized, shaped, and has an aperture pattern that corresponds with the fitting to which it will be attached.

Owner:INFRASTRUCTURE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com