Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Cell culture bioreactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cell culture technicians grow living cells in culture flasks, bioreactors, plates and other kinds of containers. The types of cells they grow can come from plants or animals. Sometimes cell culture technicians start cultures directly from tissues such as umbilical cords or tumor biopsies.

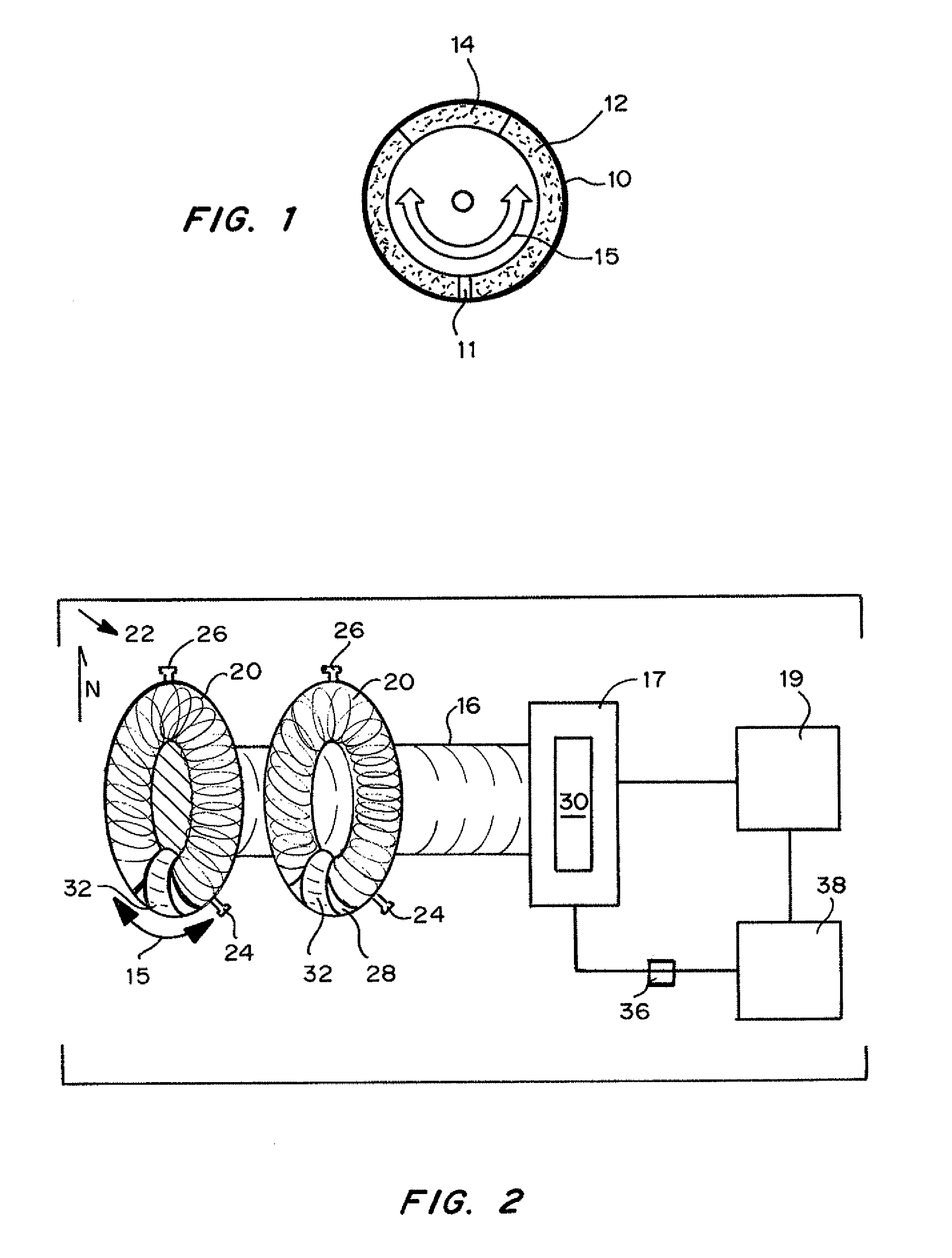

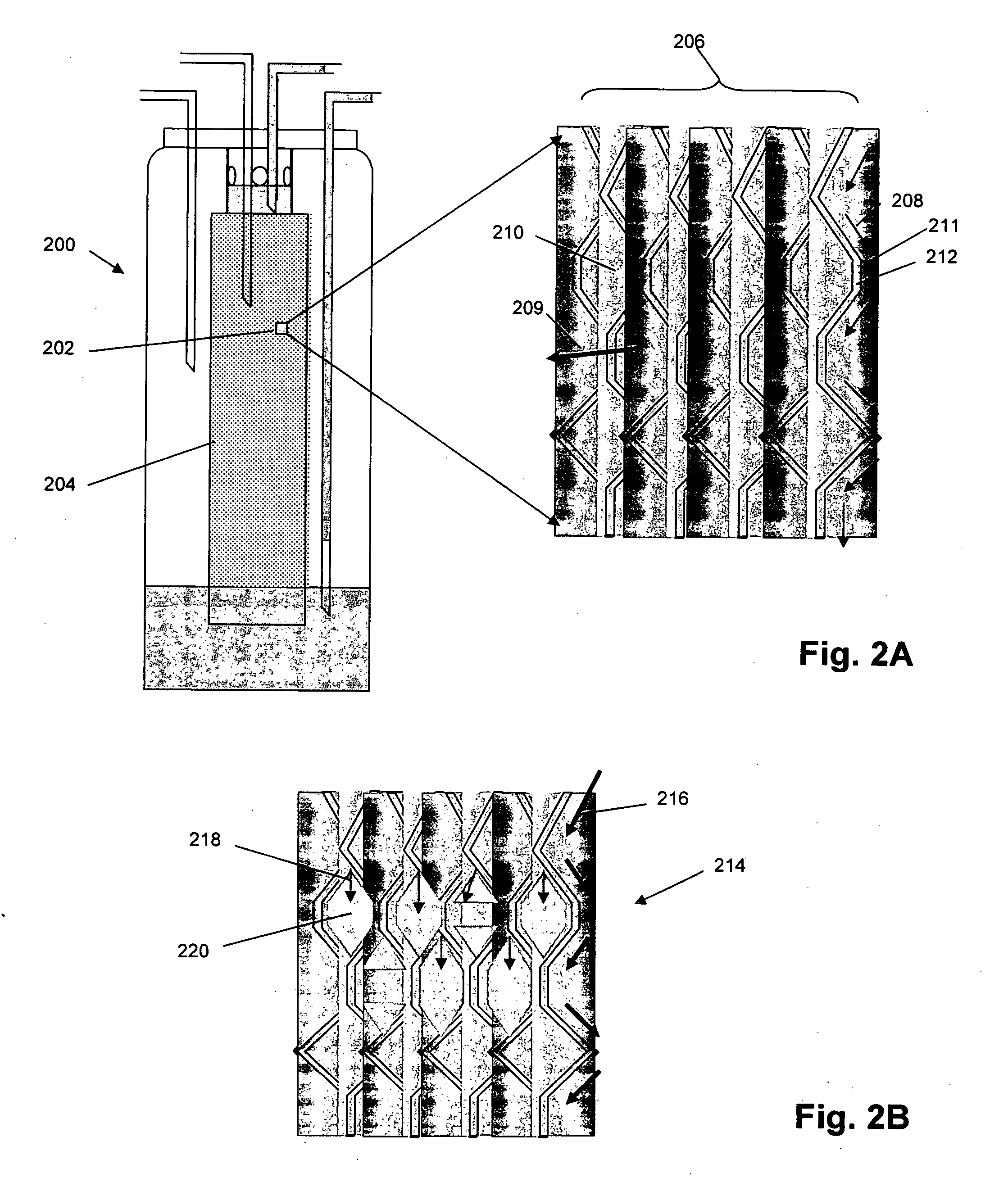

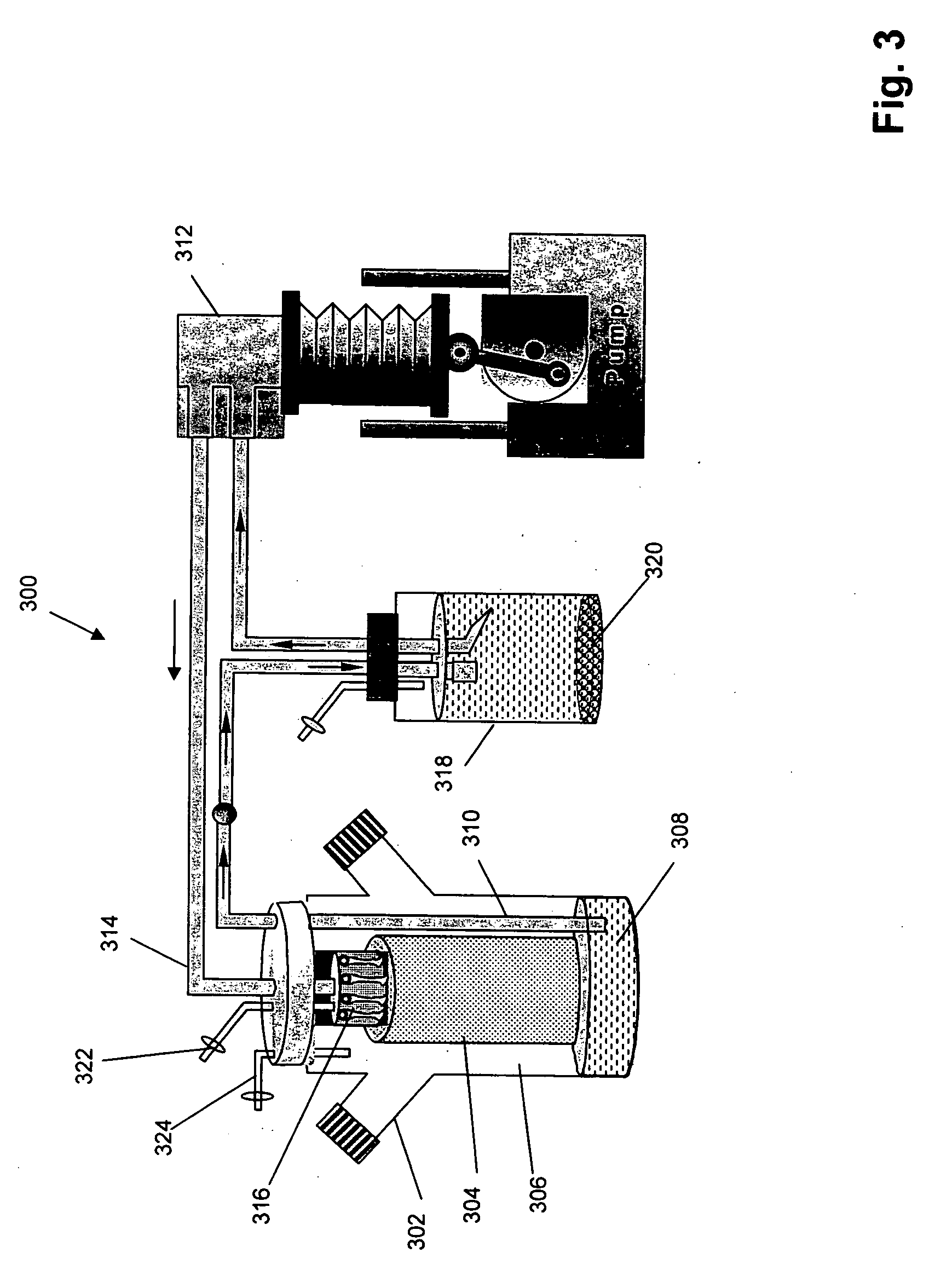

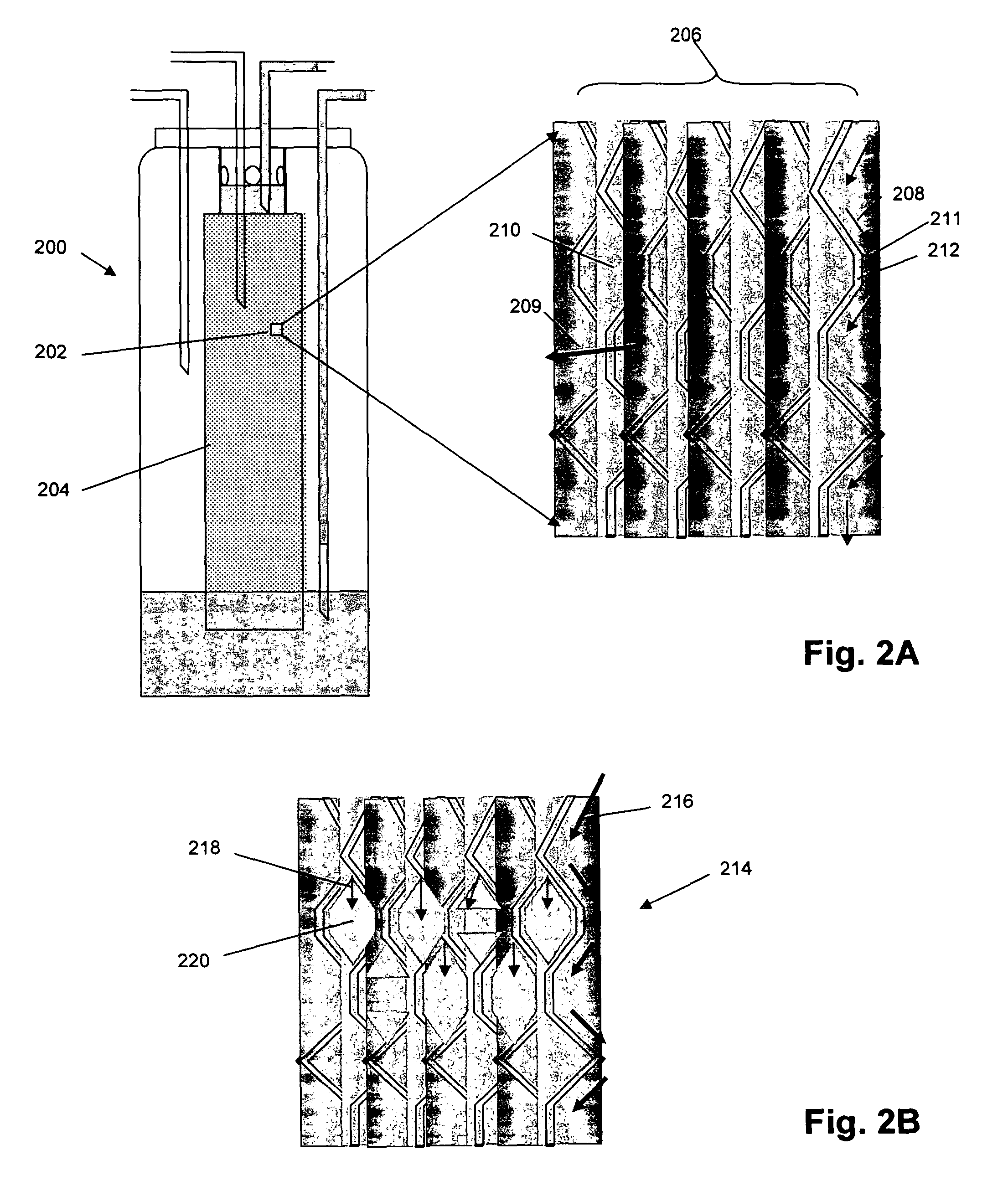

Modular cell culture bioreactor and associated methods

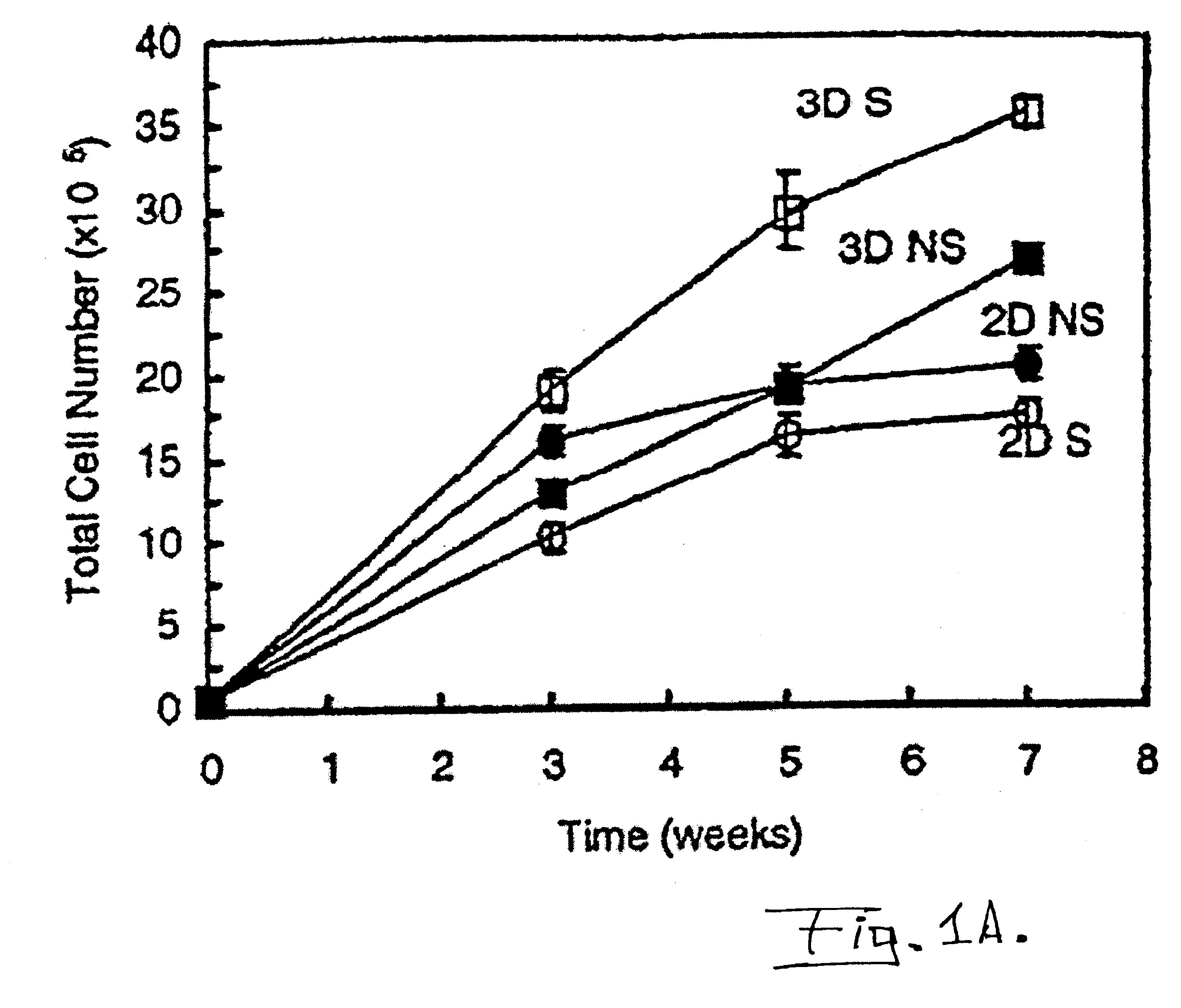

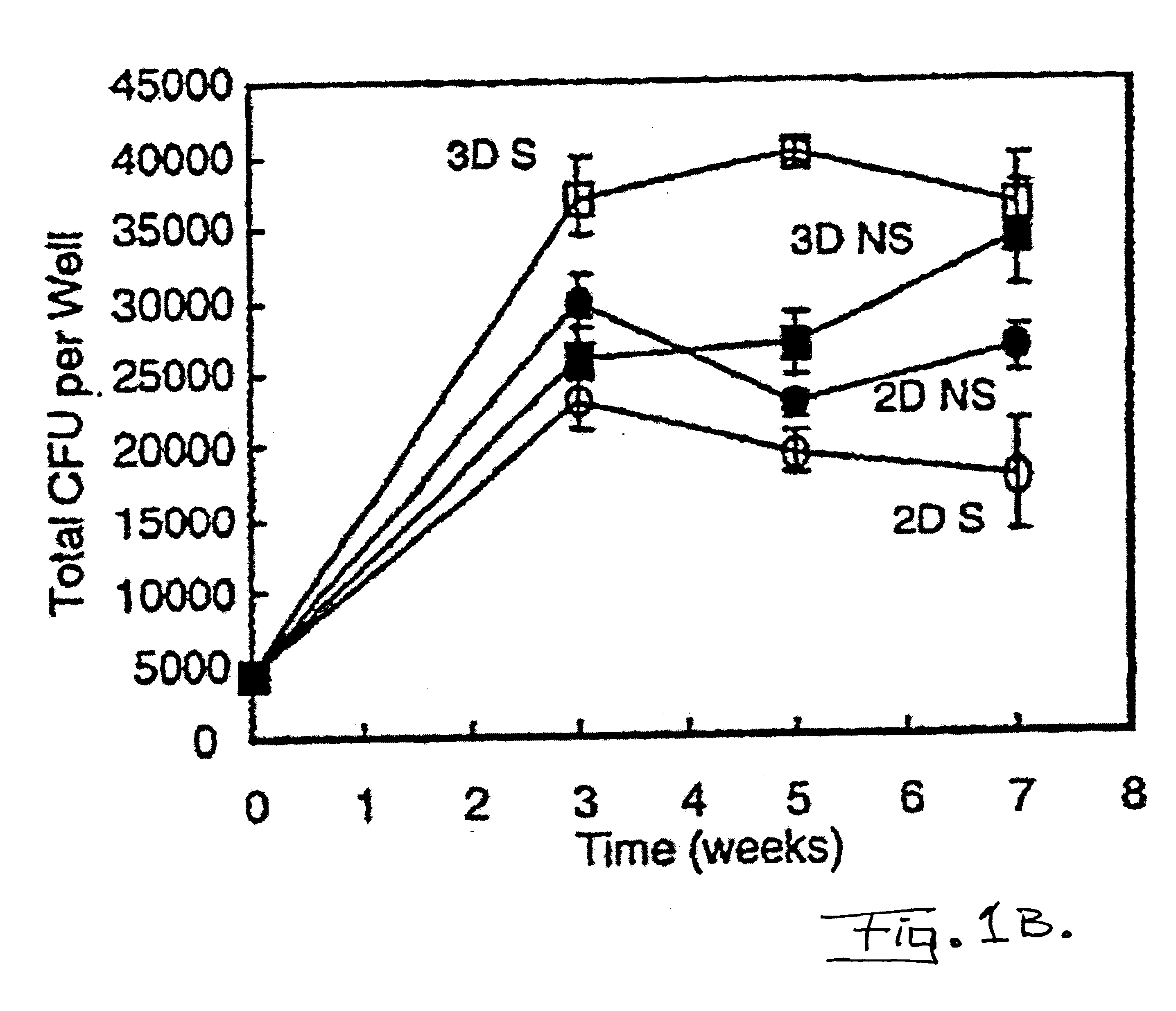

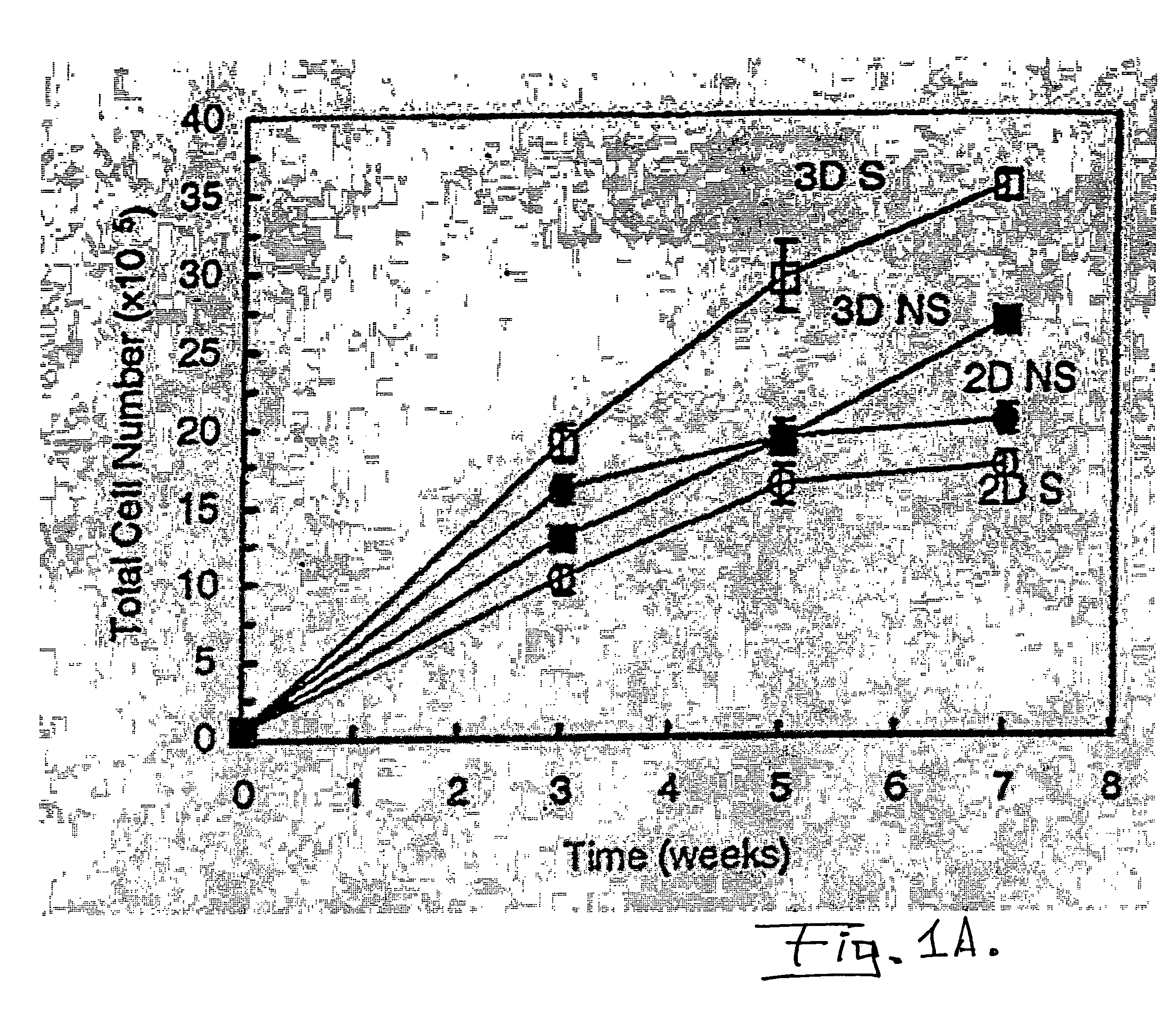

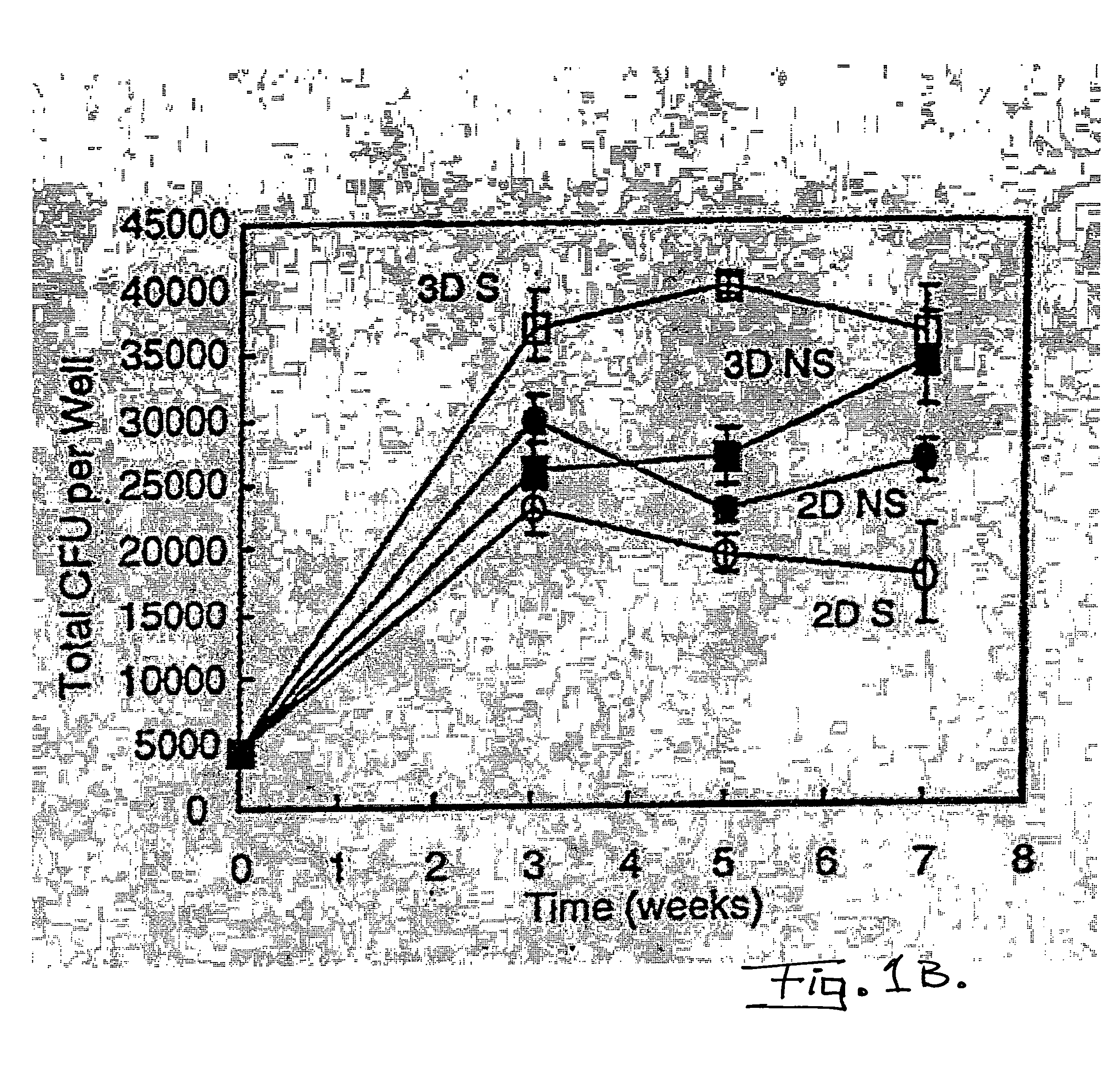

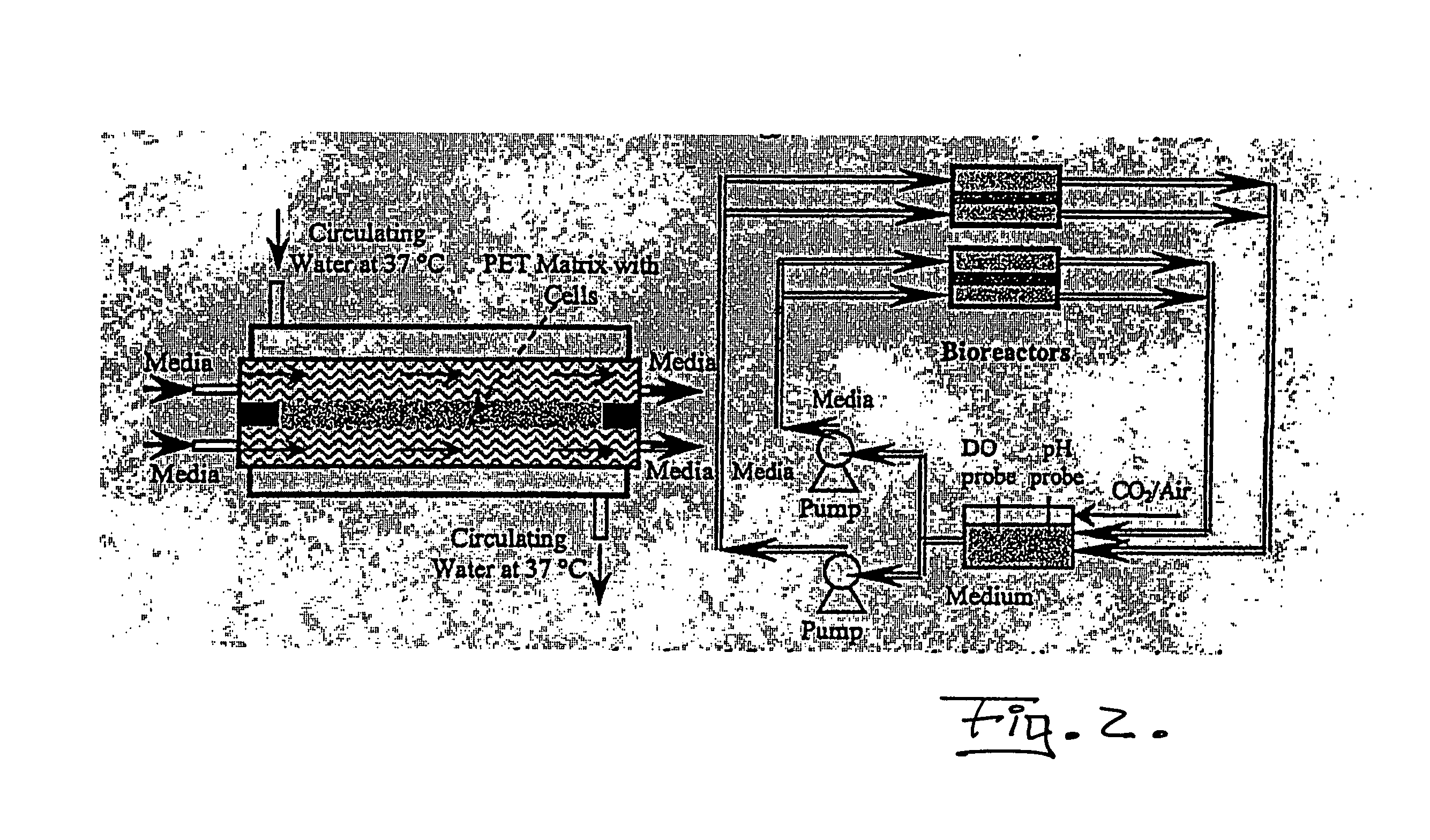

InactiveUS6875605B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPolyethylene terephthalate3D cell culture

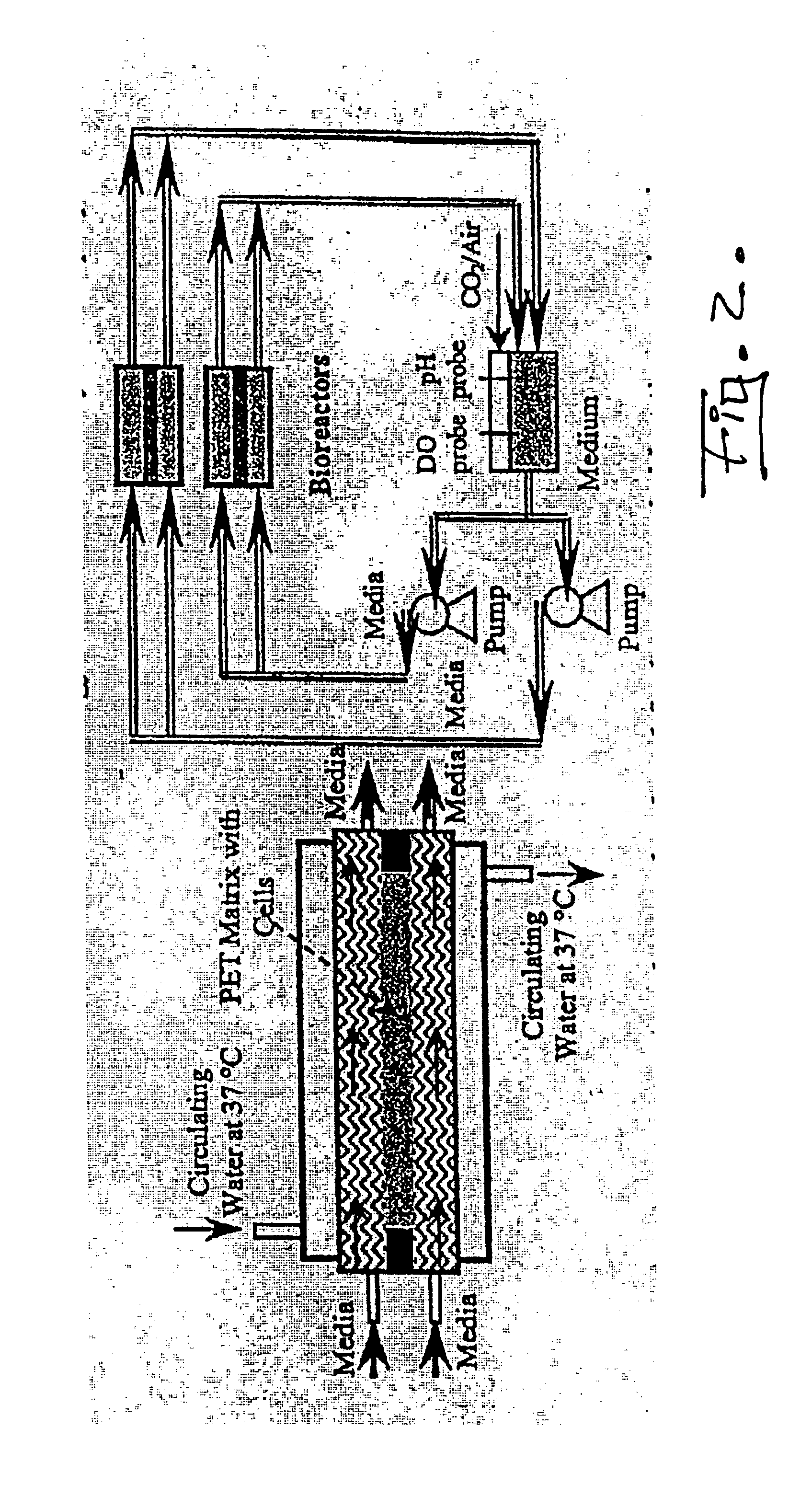

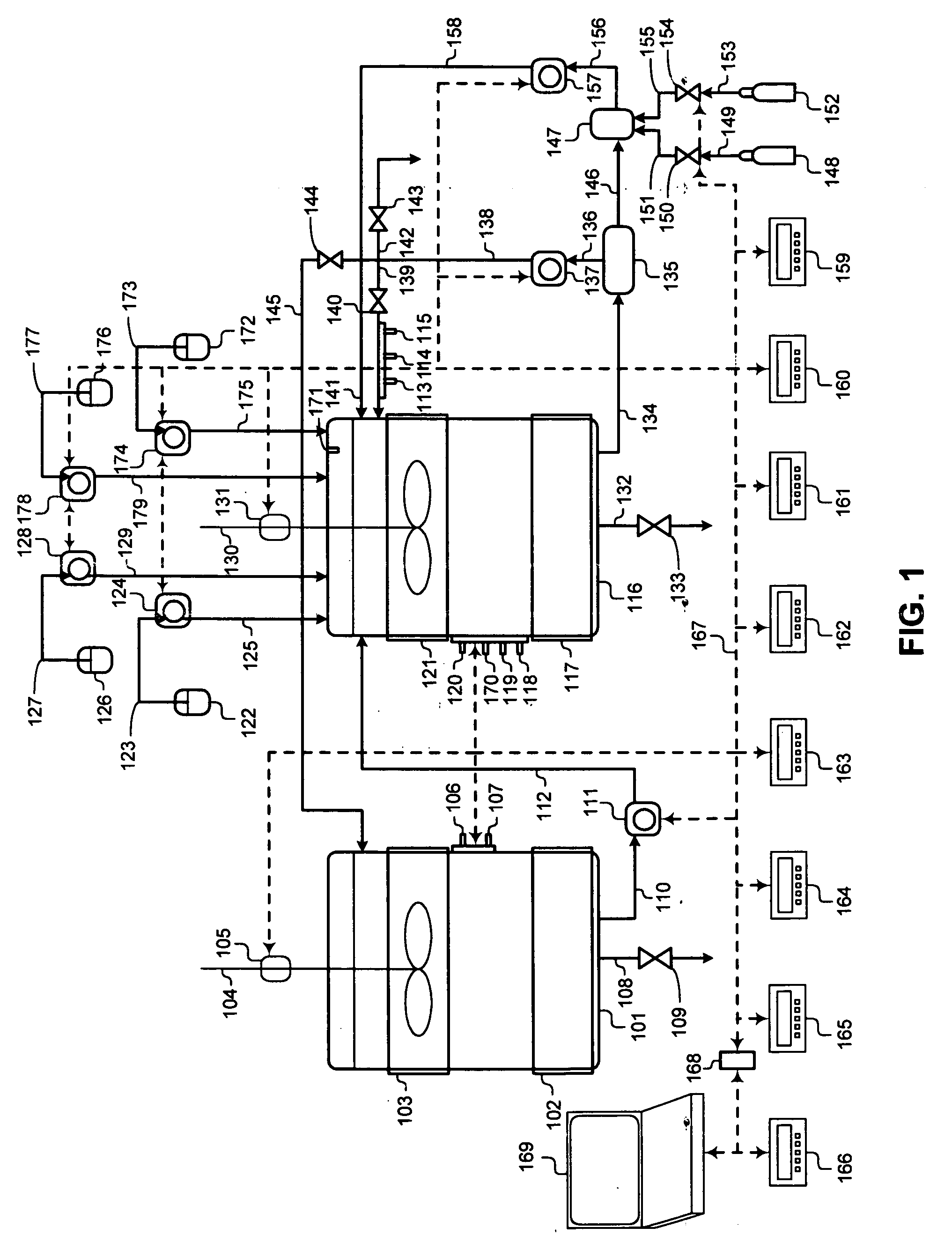

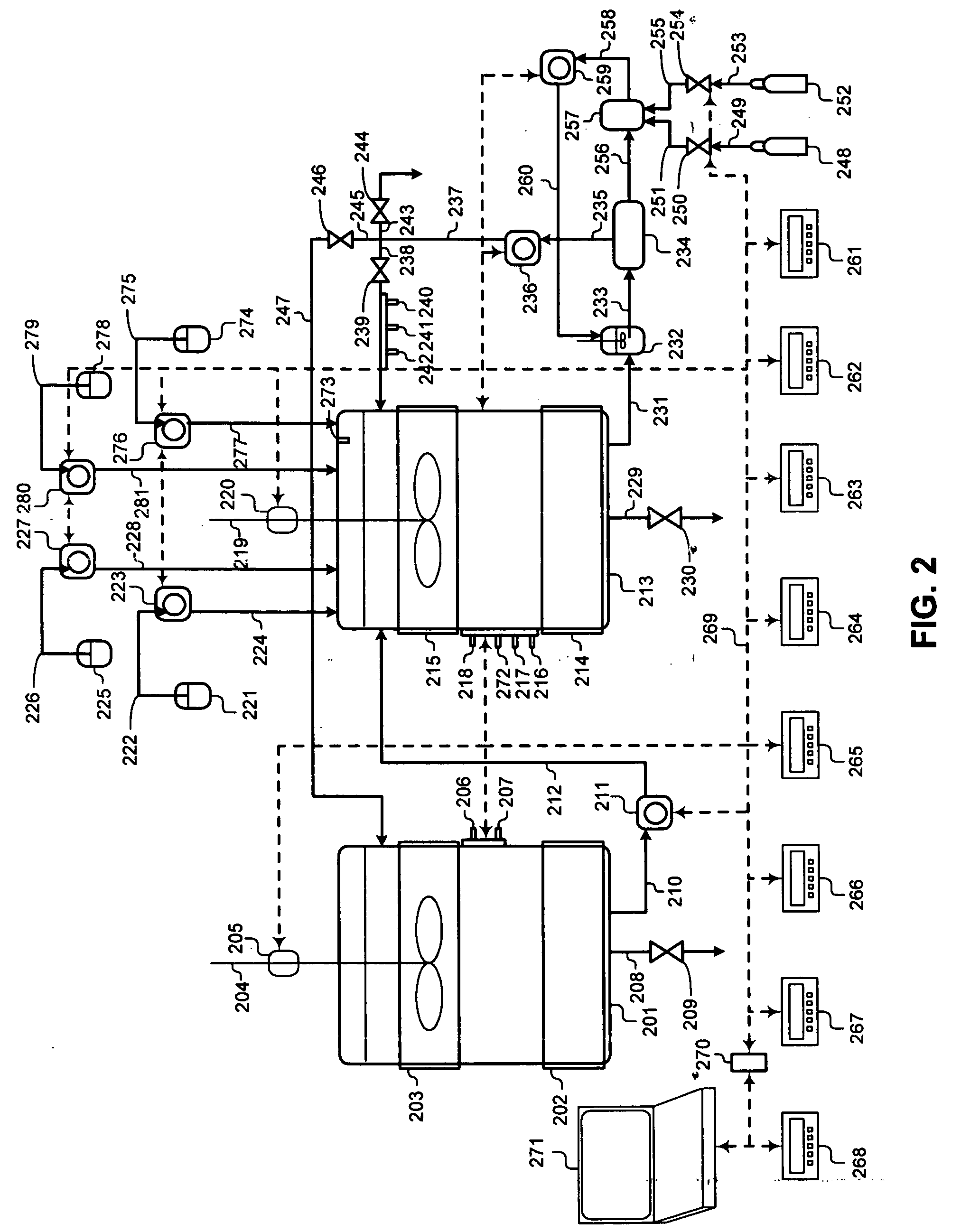

An apparatus and method for a modular cell culture bioreactor comprises a plurality of chambers for cell culture; at least one reservoir containing a cell support medium; a plurality of conduits fluidly connecting the at least one reservoir with the plurality of chambers; and at least one pump fluidly connected through the plurality of conduits with the at least one reservoir and with the plurality of chambers to pump cell support medium therethrough; wherein each individual chamber of the plurality of chambers includes at least one three-dimensional matrix comprising polyethylene terephthalate, a plurality of channels carrying the cell support medium and having the matrix positioned in fluid communication therebetween, and at least two openings into each the channel, wherein a first the opening is in fluid connection with the pump and a second the opening is in fluid connection with the reservoir.

Owner:FLORIDA STATE UNIV RES FOUND INC

Modular cell culture bioreactor

InactiveUS7122371B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPolyethylene terephthalate3D cell culture

An apparatus and method for a modular cell culture bioreactor comprises a plurality of chambers for cell culture; at least one reservoir containing a cell support medium; a plurality of conduits fluidly connecting the at least one reservoir with the plurality of chambers; and at least one pump fluidly connected through the plurality of conduits with the at least one reservoir and with the plurality of chambers to pump cell support medium therethrough; wherein each individual chamber of the plurality of chambers includes at least one three-dimensional matrix comprising polyethylene terephthalate, a plurality of channels carrying the cell support medium and having the matrix positioned in fluid communication therebetween, and at least two openings into each the channel, wherein a first the opening is in fluid connection with the pump and a second the opening is in fluid connection with the reservoir.

Owner:FLORIDA STATE UNIV RES FOUND INC

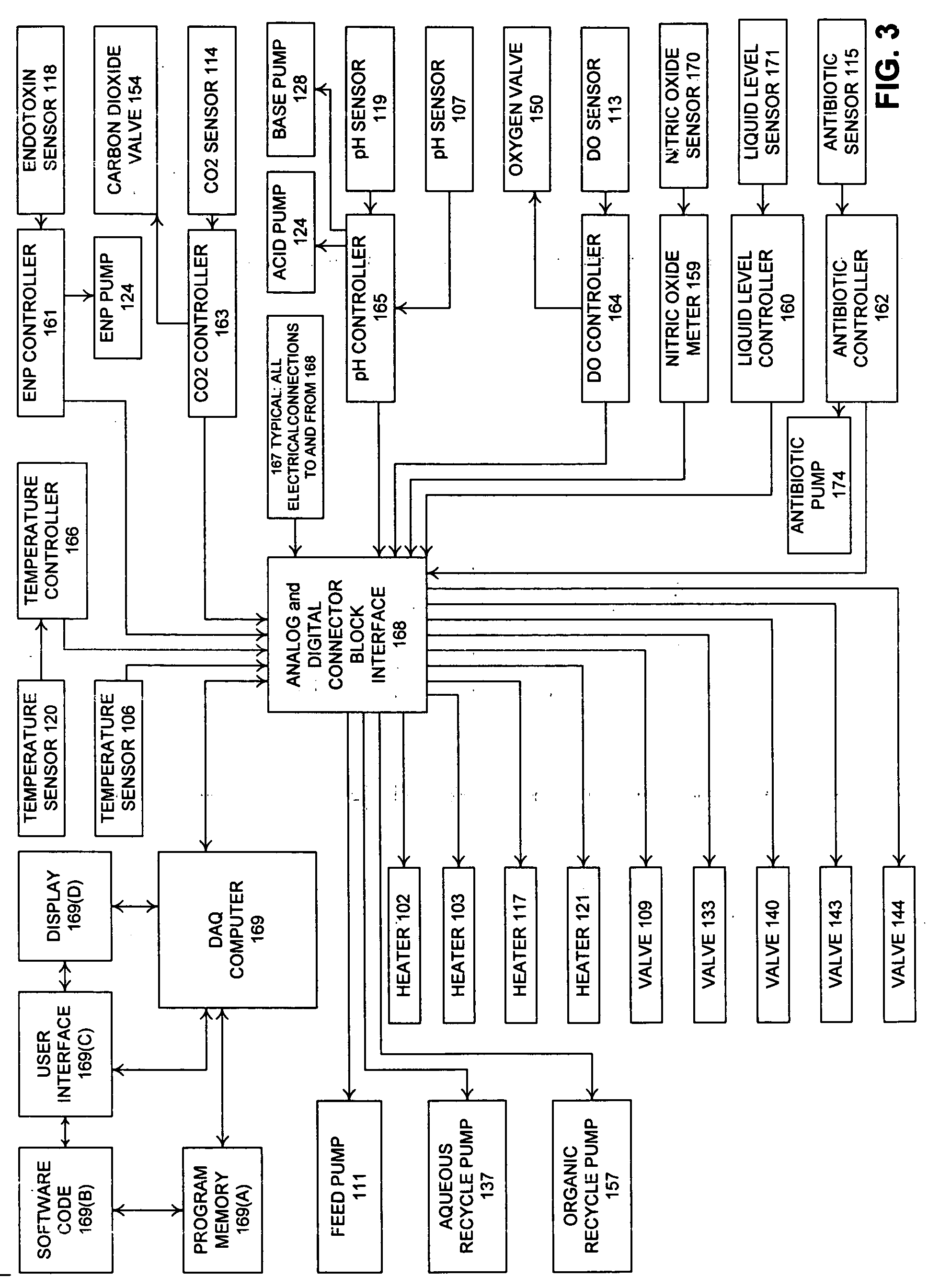

Method and apparatus for cell culture using a two liquid phase bioreactor

InactiveUS20050176140A1Maximize growthMaximize proliferationBioreactor/fermenter combinationsBiological substance pretreatmentsCell phenotypeEmbryo

Advanced Bioreactor Cell Culture Technology presents a method of cell culturing and bioprocessing incorporating molecular biology techniques, advanced process control methodology, and a process control interface applied to a two liquid phase cell culture bioreactors to proliferate, grow, and expand non-differentiated precursor cells, embryonic stem (ES) cells, endocrine progenitor cells, pancreatic progenitor cells, pancreatic stem cells, pancreatic duct epithelial cells, nestin-positive islet-derived progenitor cells (NIPs), or pluripotent non-embryonic stem (PNES) cells in the bioreactor, and influence, stimulate, and induce the non-differentiated precursors and progenitors into fully differentiated beta cell phenotypes; including microprocessor control of cell culture process variables and data acquisition during bioprocessing. The invention may be applied to precursors and progenitor cells either transgenic or non-transgenic derived from animals and mammals.

Owner:BENEDICT DANIEL J +1

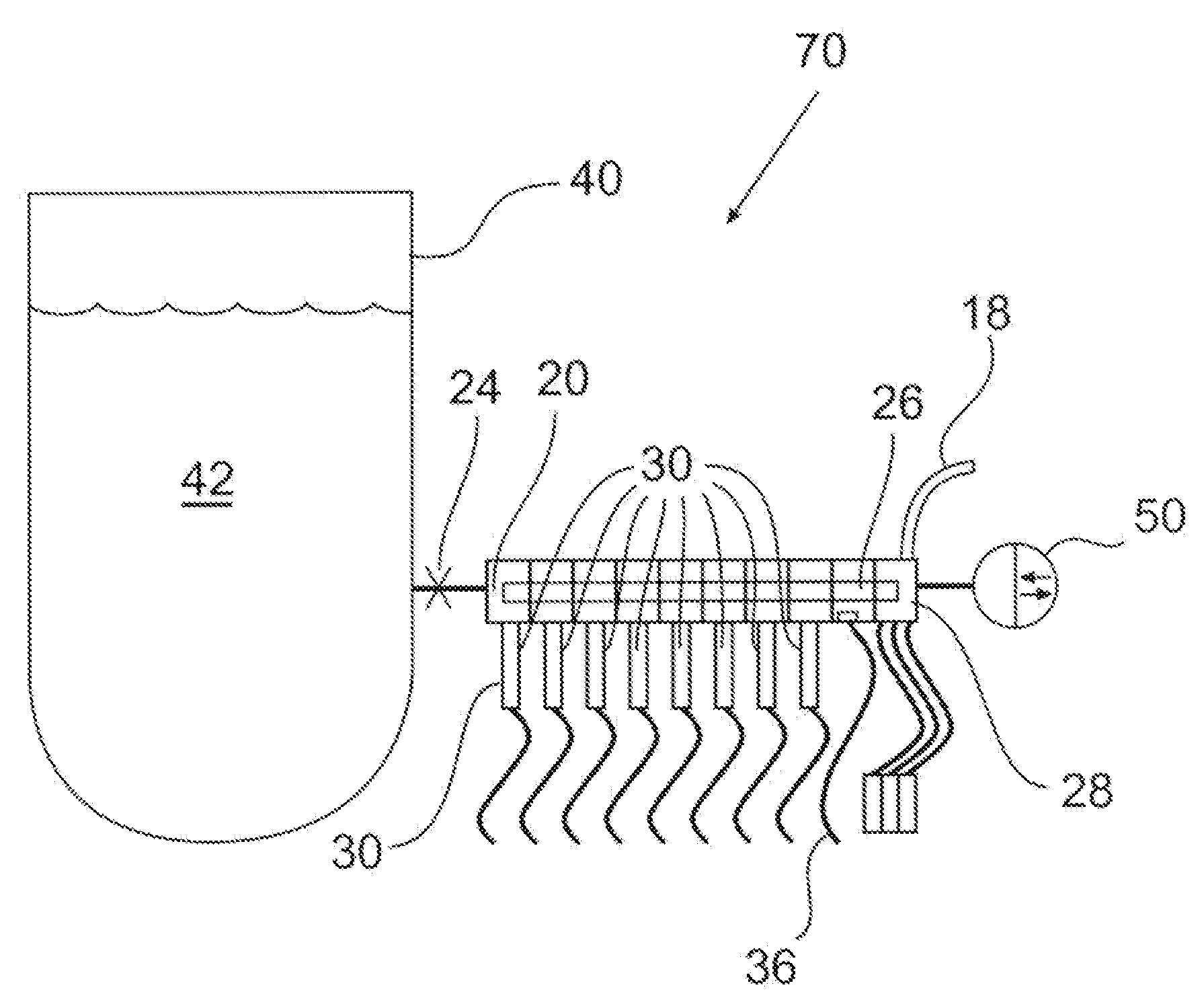

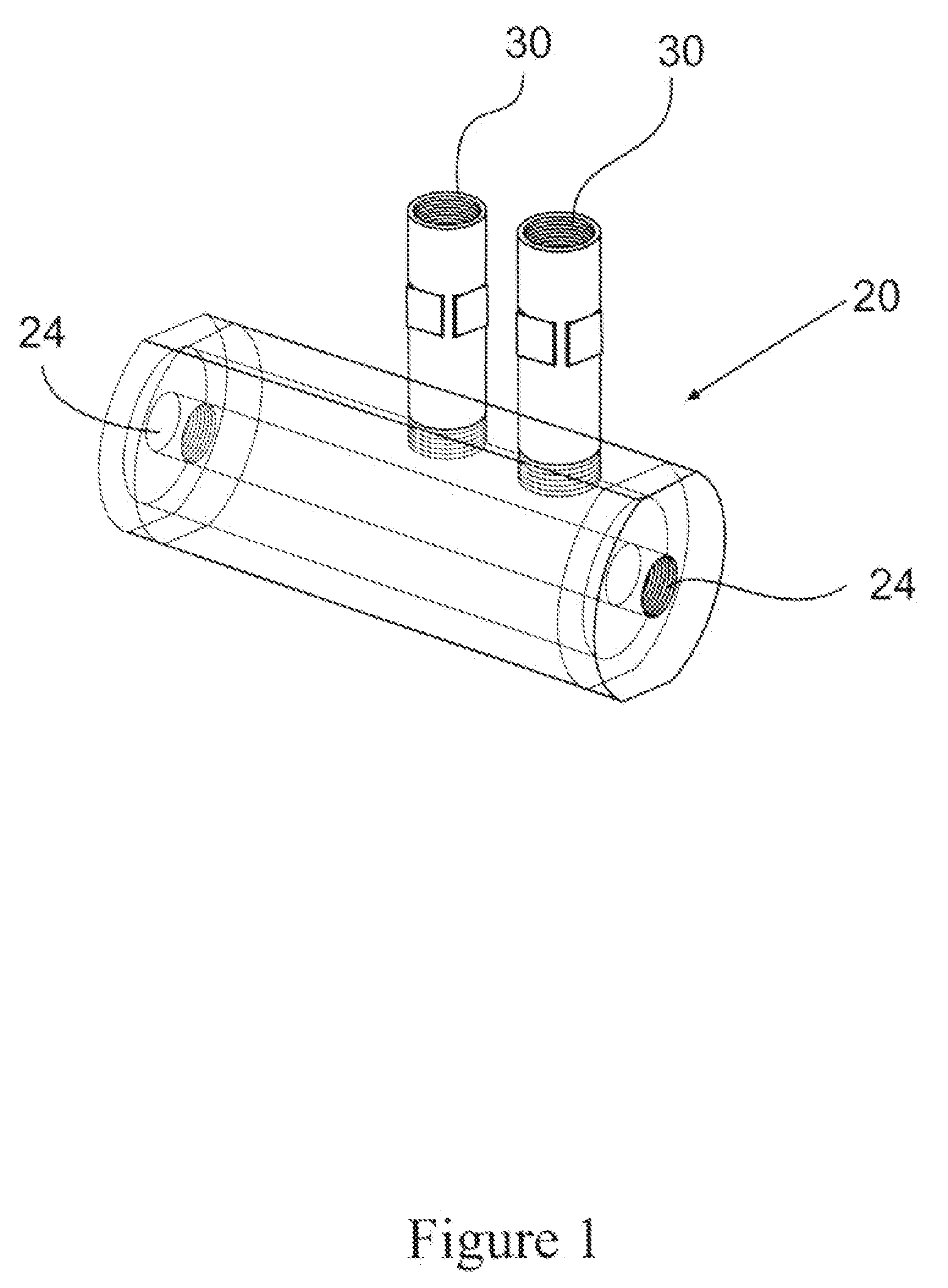

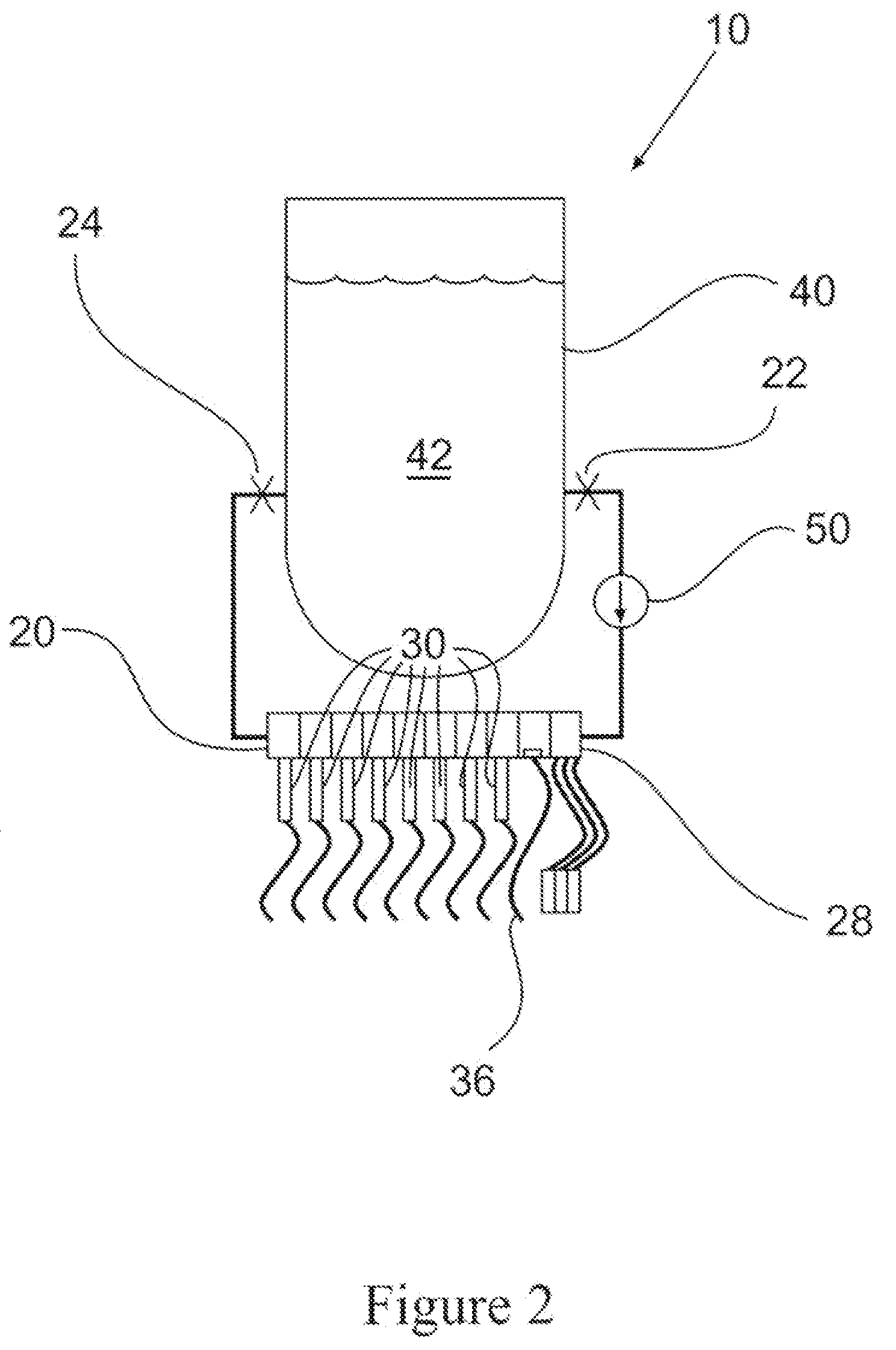

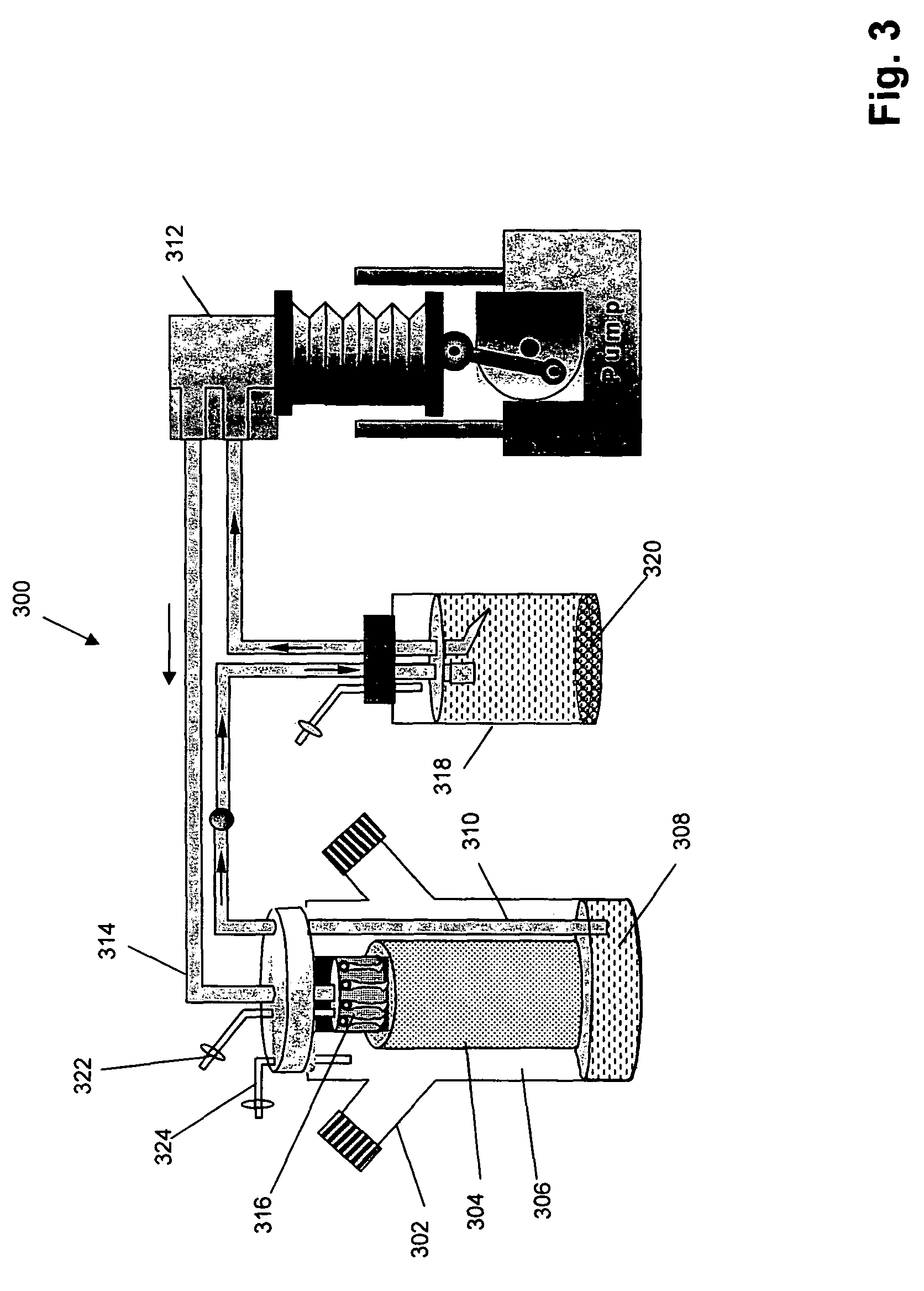

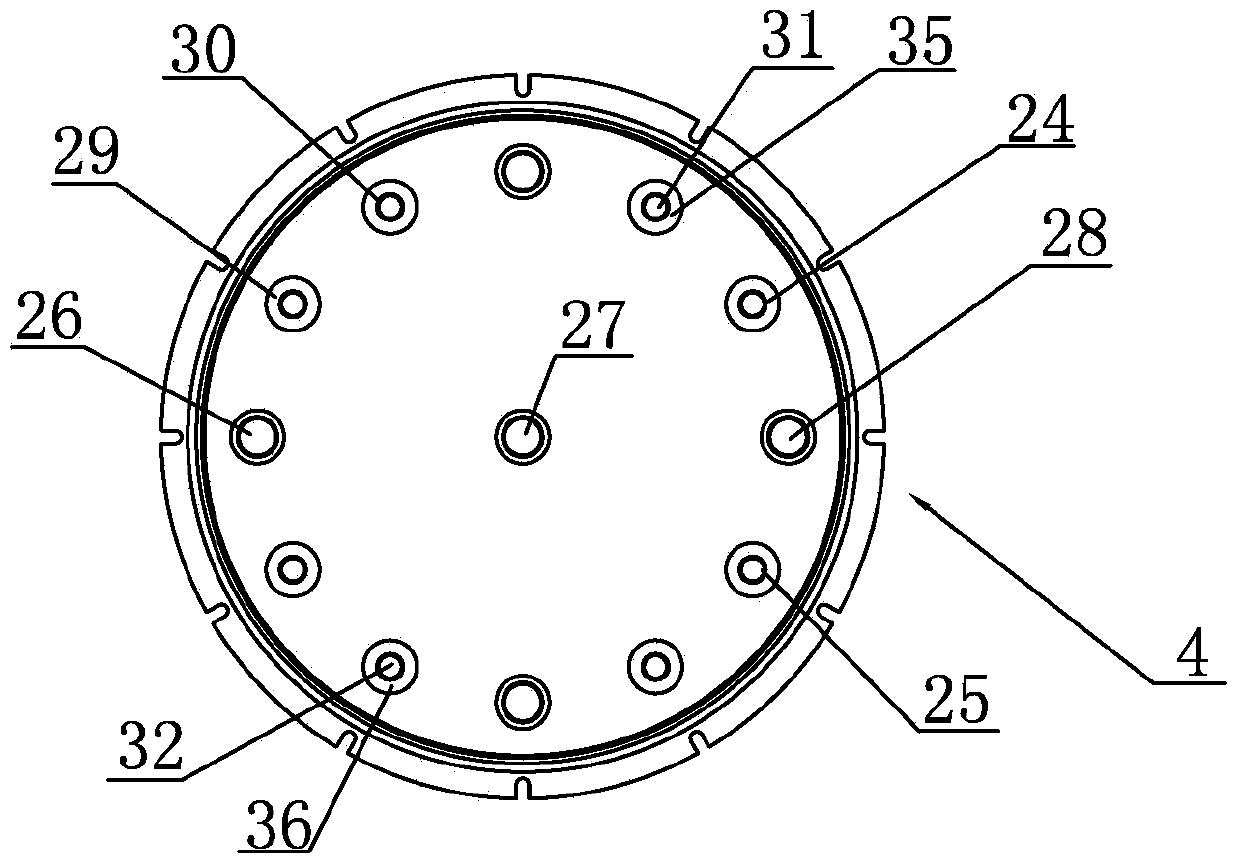

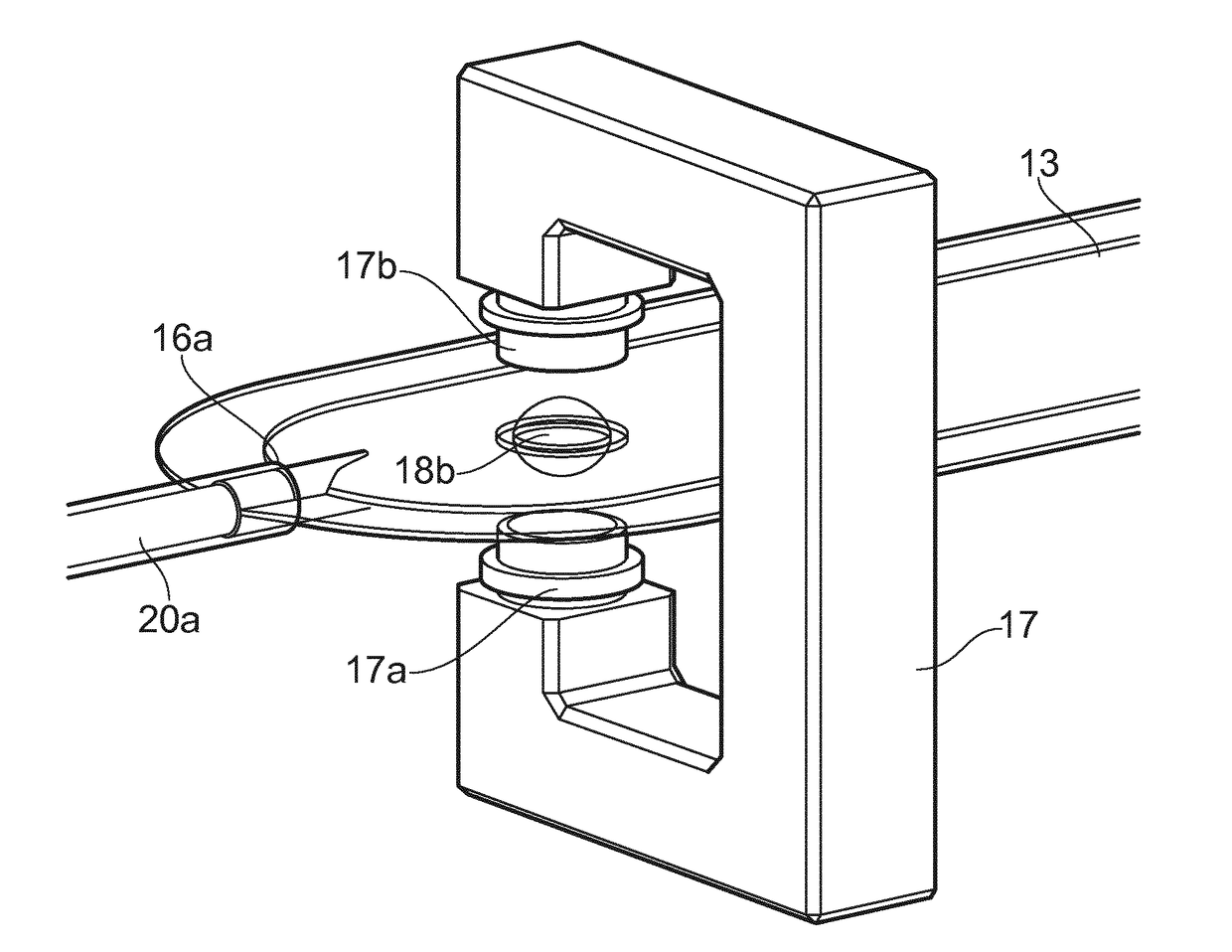

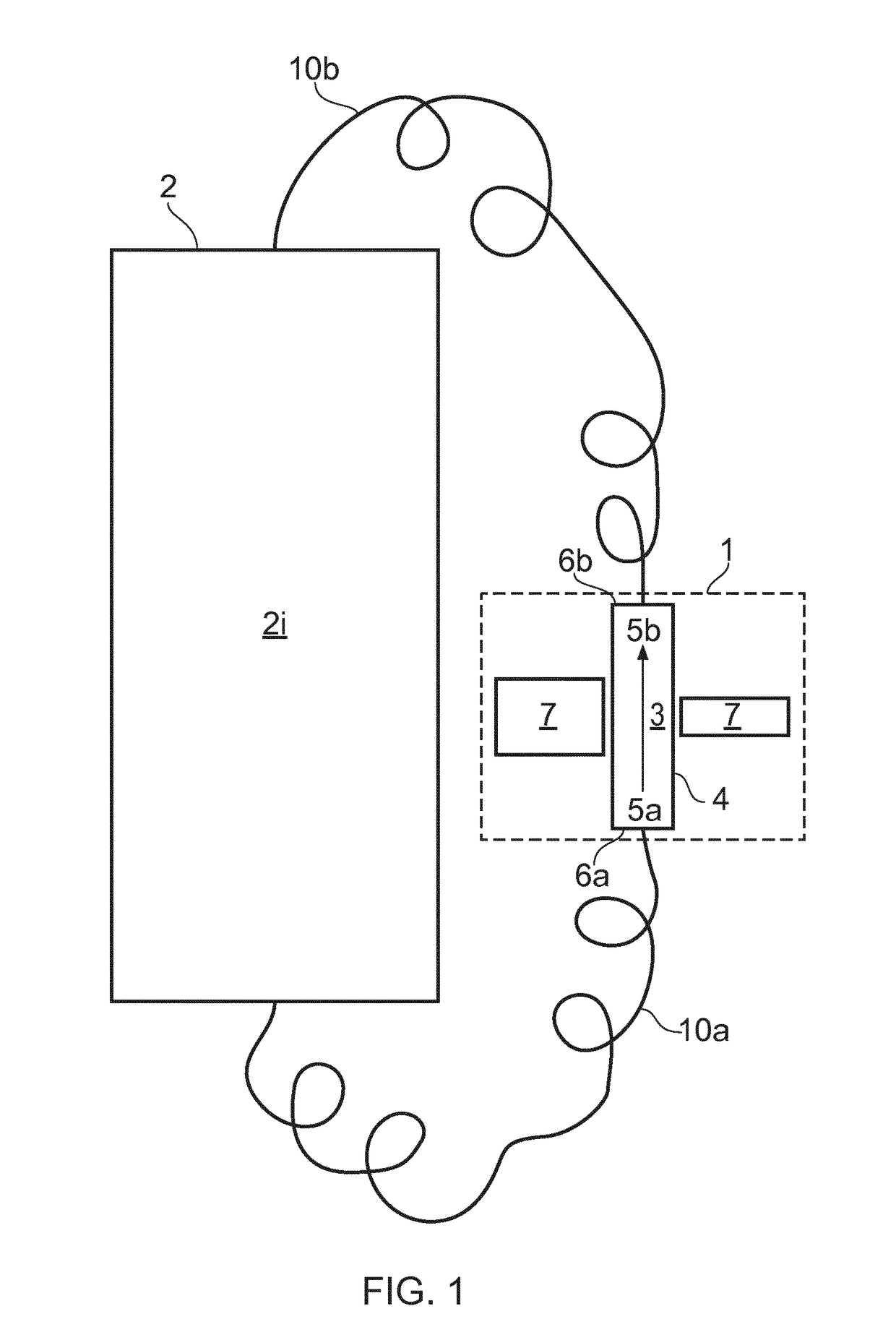

Single use cell culture bioreactor manifold system

InactiveUS20110201100A1Reduce the number of connectionsReduced Possibility of ContaminationBioreactor/fermenter combinationsBiological substance pretreatmentsCatheterCell culture bioreactor

The invention provides a disposable cell culture bioreactor manifold system for use in coupling sensors, fluid samplers, conduits, and the like, to a cell culture bioreactor in a sterile manner. The disposable bioreactor manifold system includes an externally attachable bioreactor manifold connector body for fluidly attaching modular sensor arrangements that measure physical variables and other parameters of medium contained within a bioreactor, as well as medium sampling components, and other connections, as well as at least one conduit fluidly connecting connecting the bioreactor manifold connector body with a pump for pumping fluids between the bioreactor and the bioreactor manifold connector body.

Owner:MILLIPORE CORP

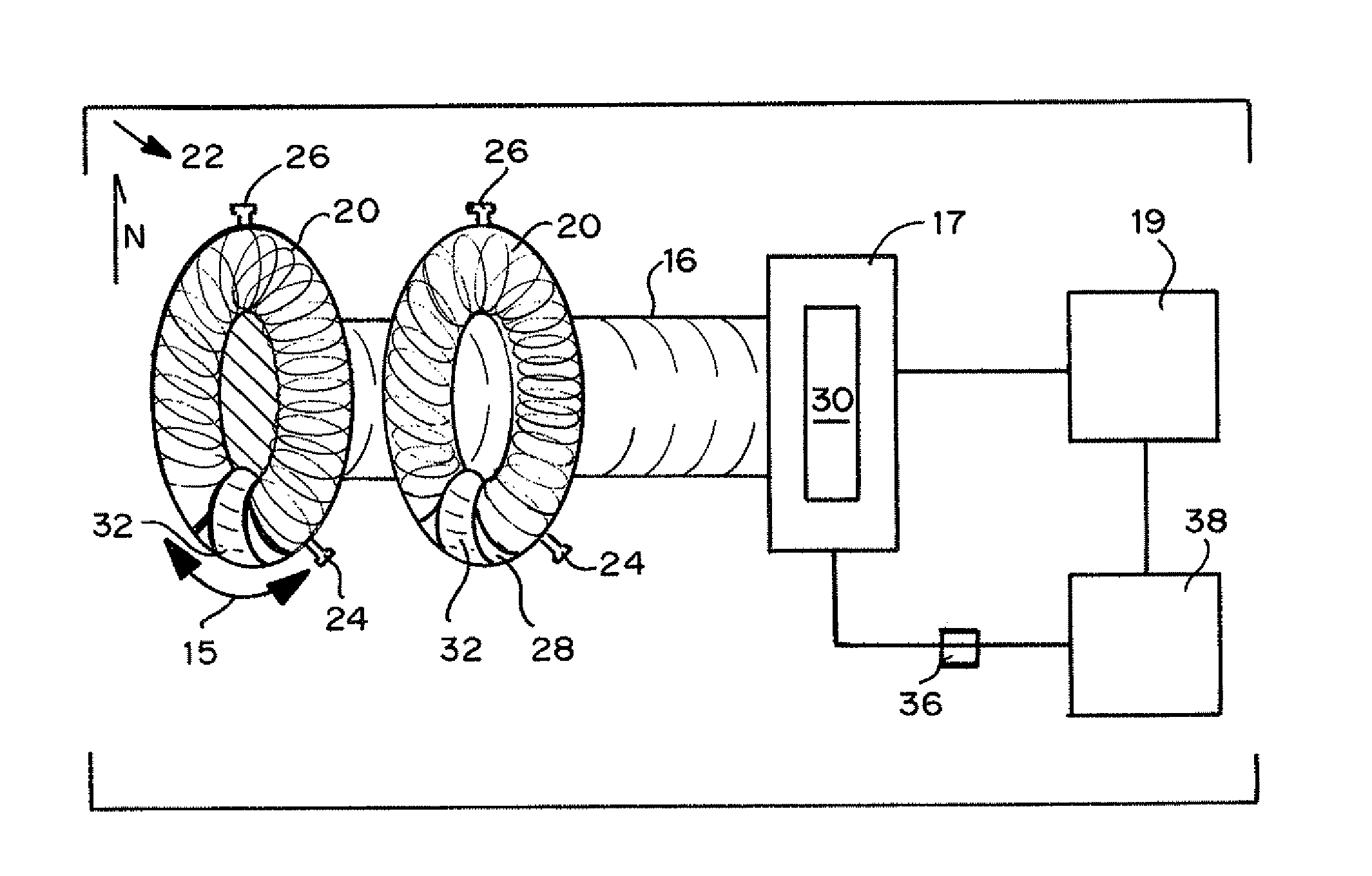

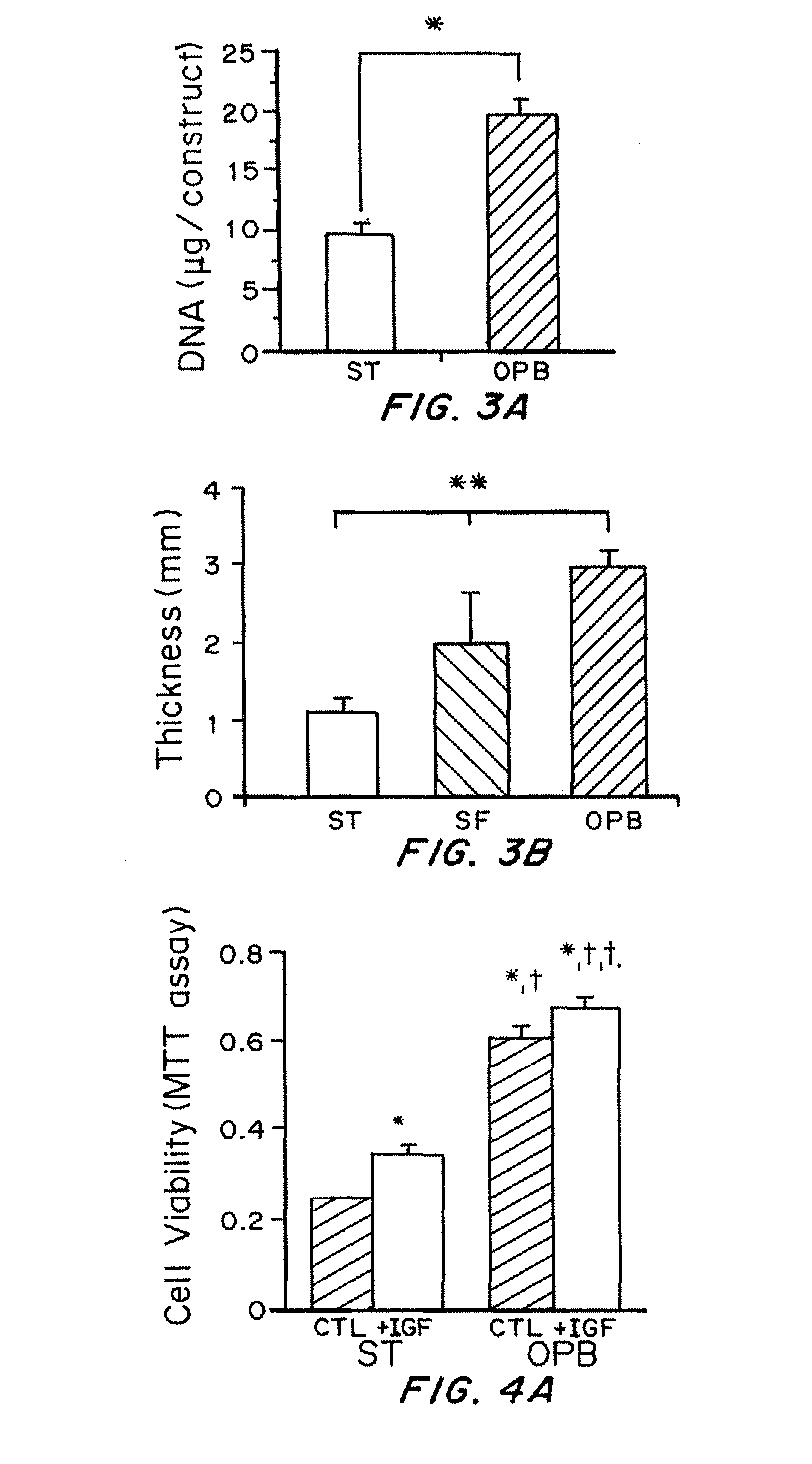

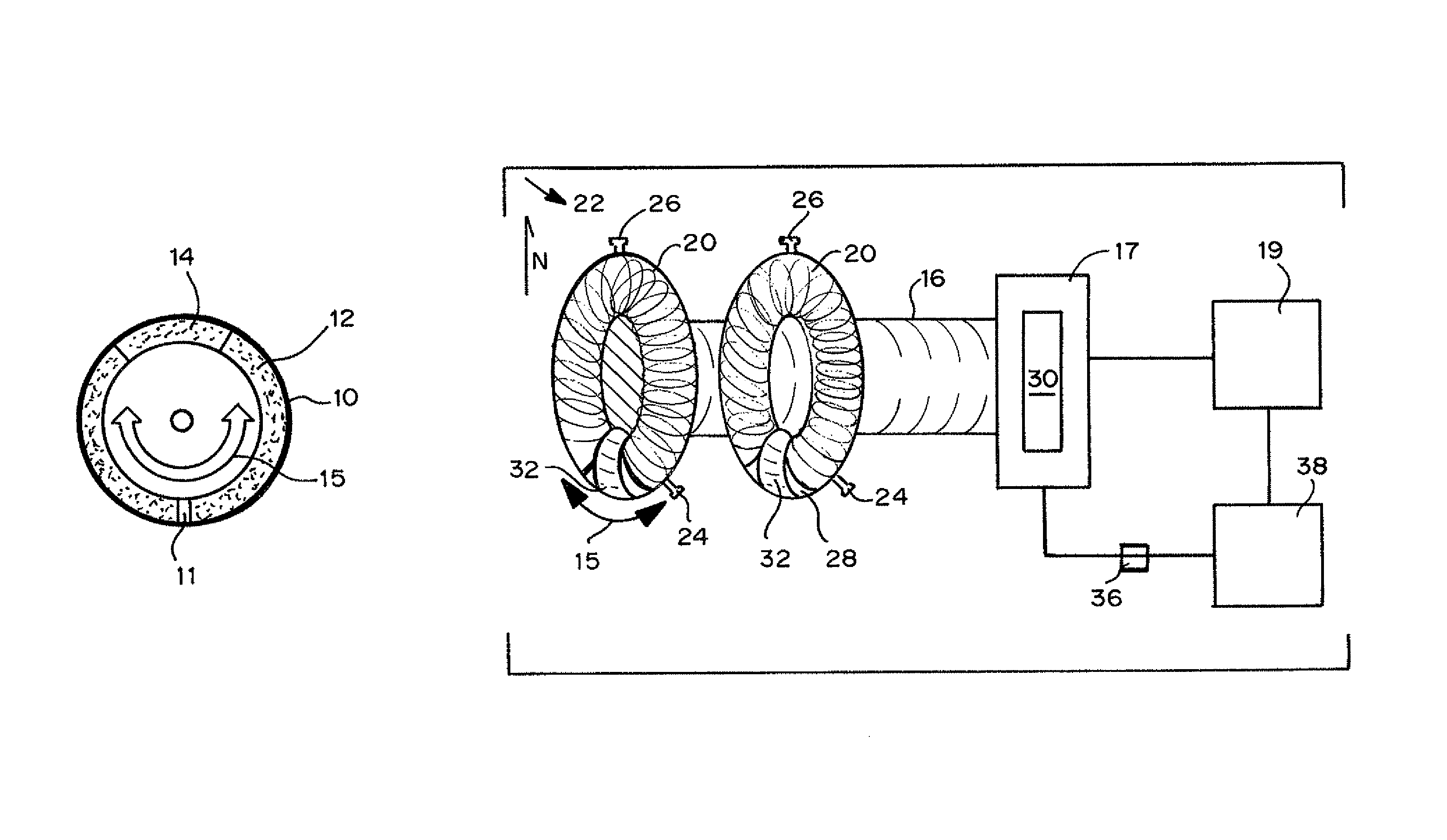

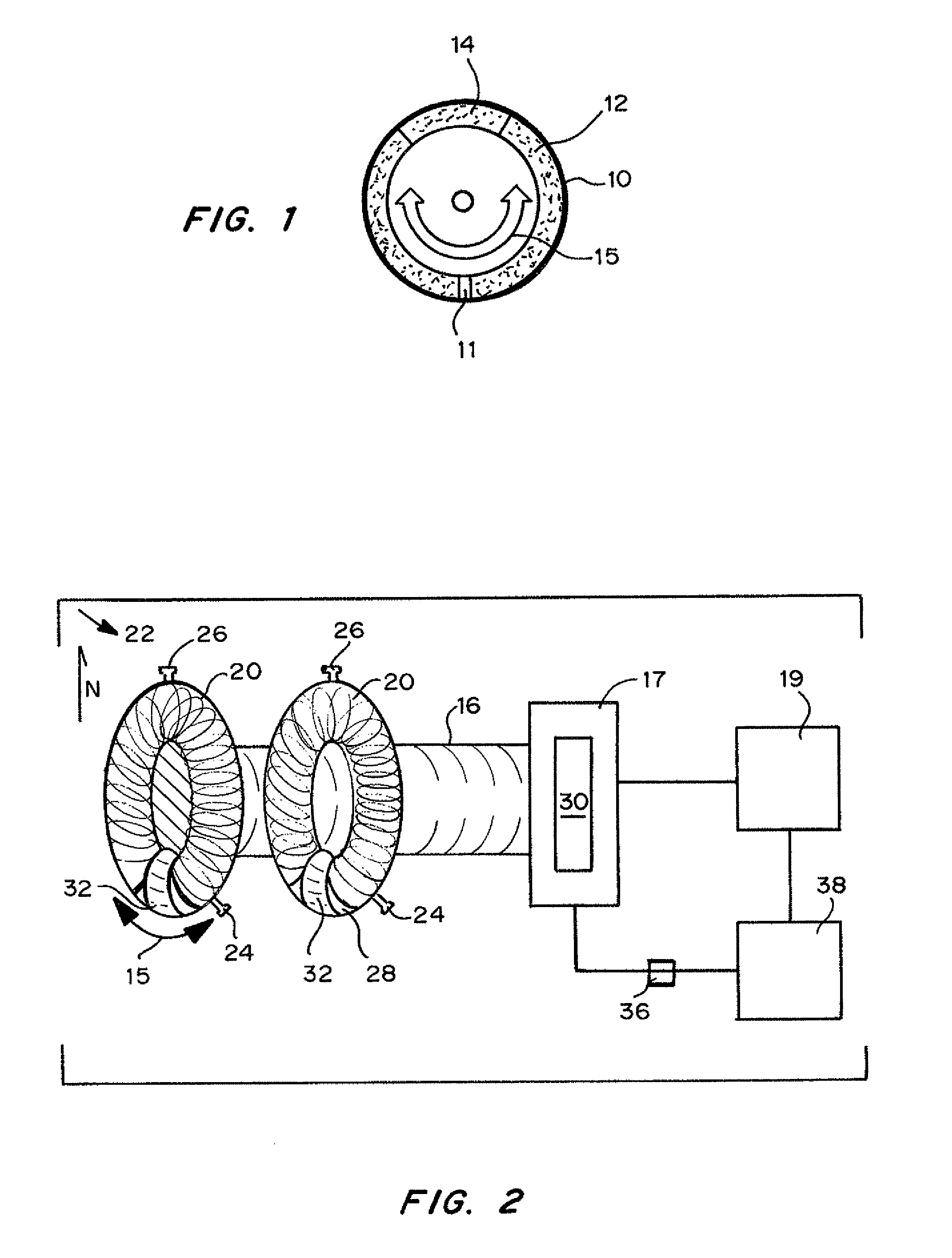

Oscillating cell culture bioreactor

ActiveUS20100297233A1Ease of scale-upEase of automationPowder deliveryBioreactor/fermenter combinationsCulture cellClosed loop

Methods and devices for cell or tissue culture are provided. One aspect provides a bioreactor having a gas permeable, closed-loop chamber for cell or tissue culture, and an oscillating means for moving the gas permeable, closed-loop chamber bidirectionally along an axis horizontal to an axis normal to the closed-loop chamber to force convection of cells and fluid in the gas permeable, closed-loop chamber. The bioreactor optionally includes a tissue engineering scaffold, an inlet means, an outlet means, and integrated sensors. Another aspect provides a bioreactor having a plurality of gas permeable, closed-loop chambers for cell or tissue culture. Methods of culturing cells and producing tissue constructs are also provided.

Owner:MASSACHUSETTS INST OF TECH

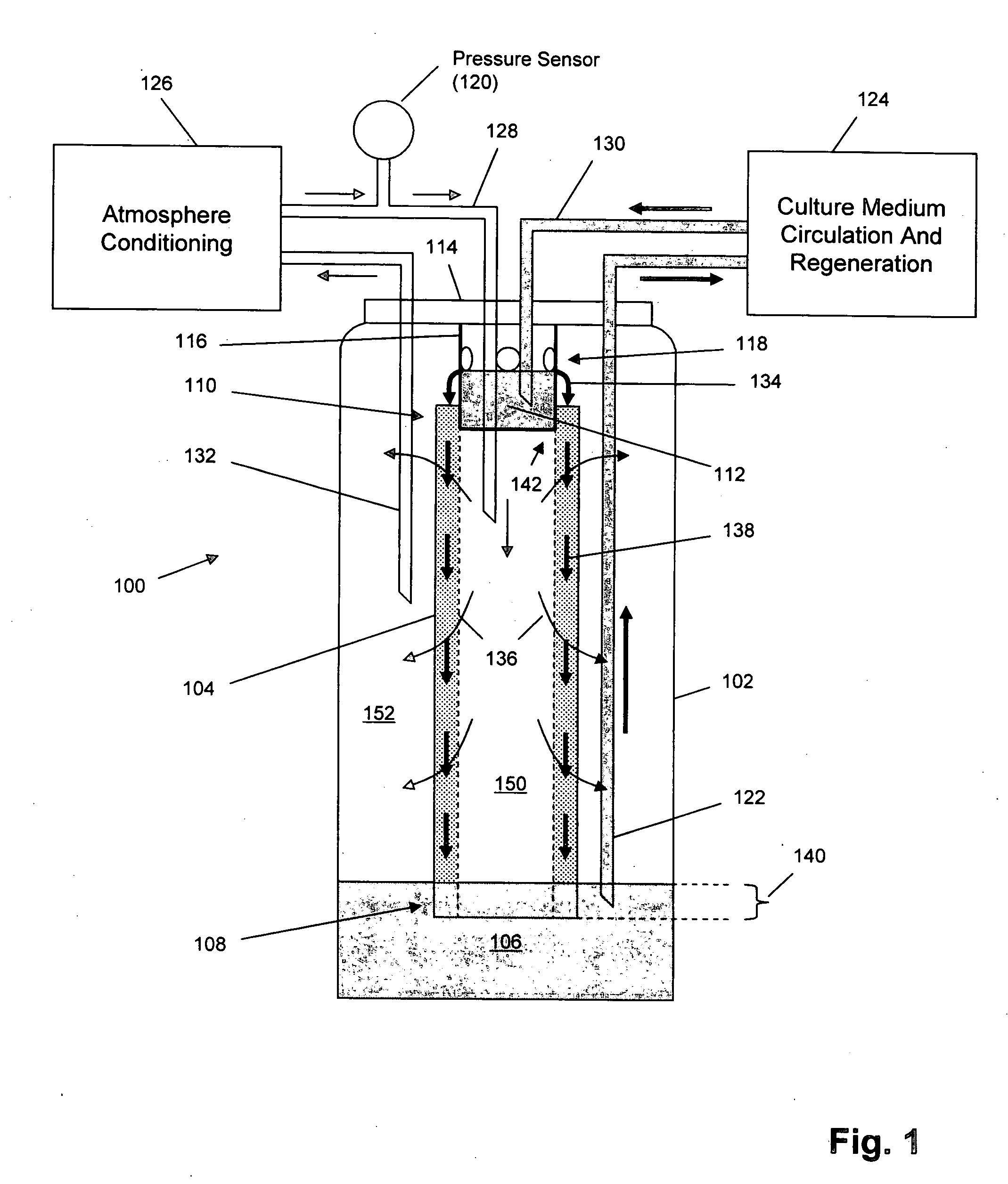

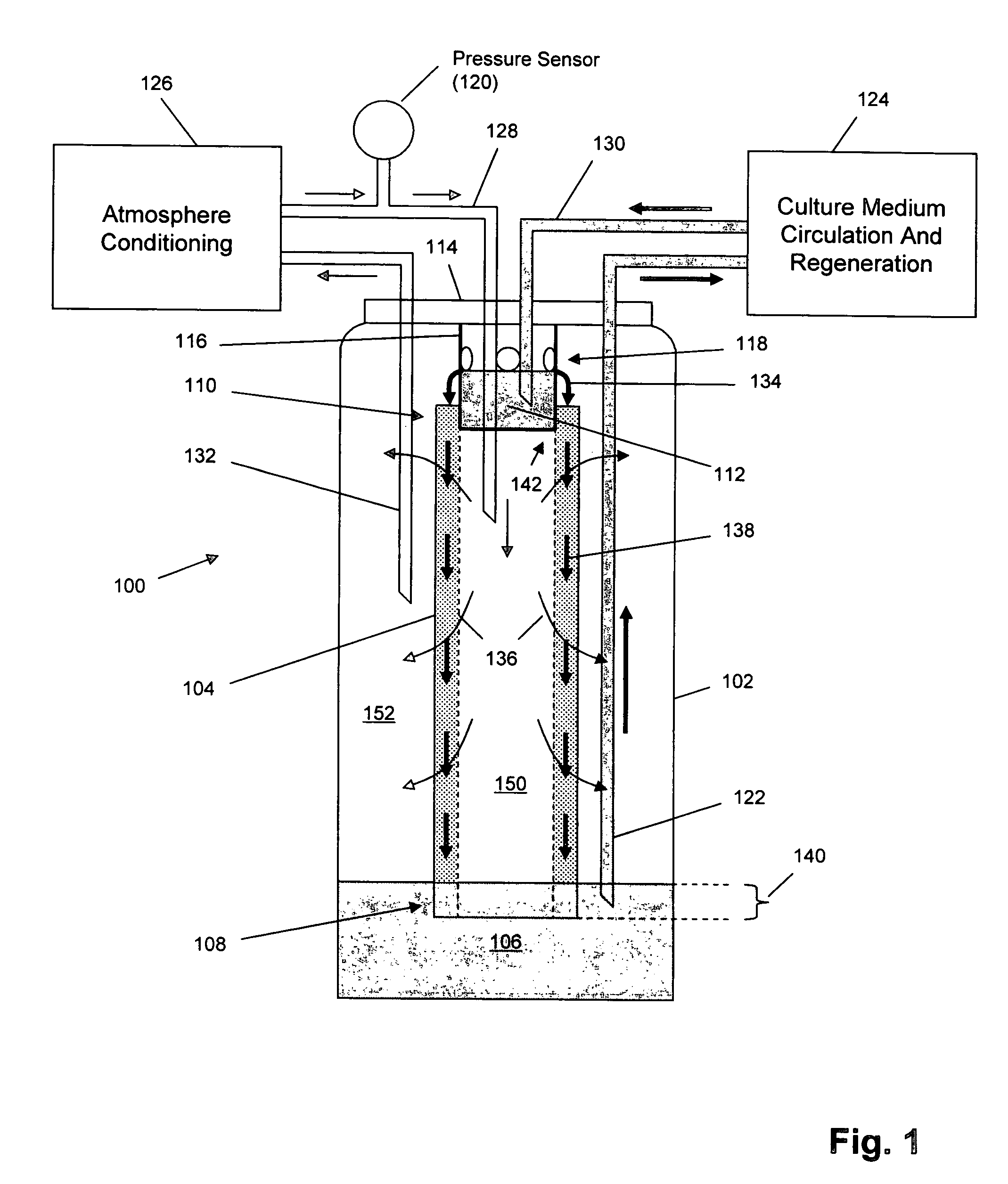

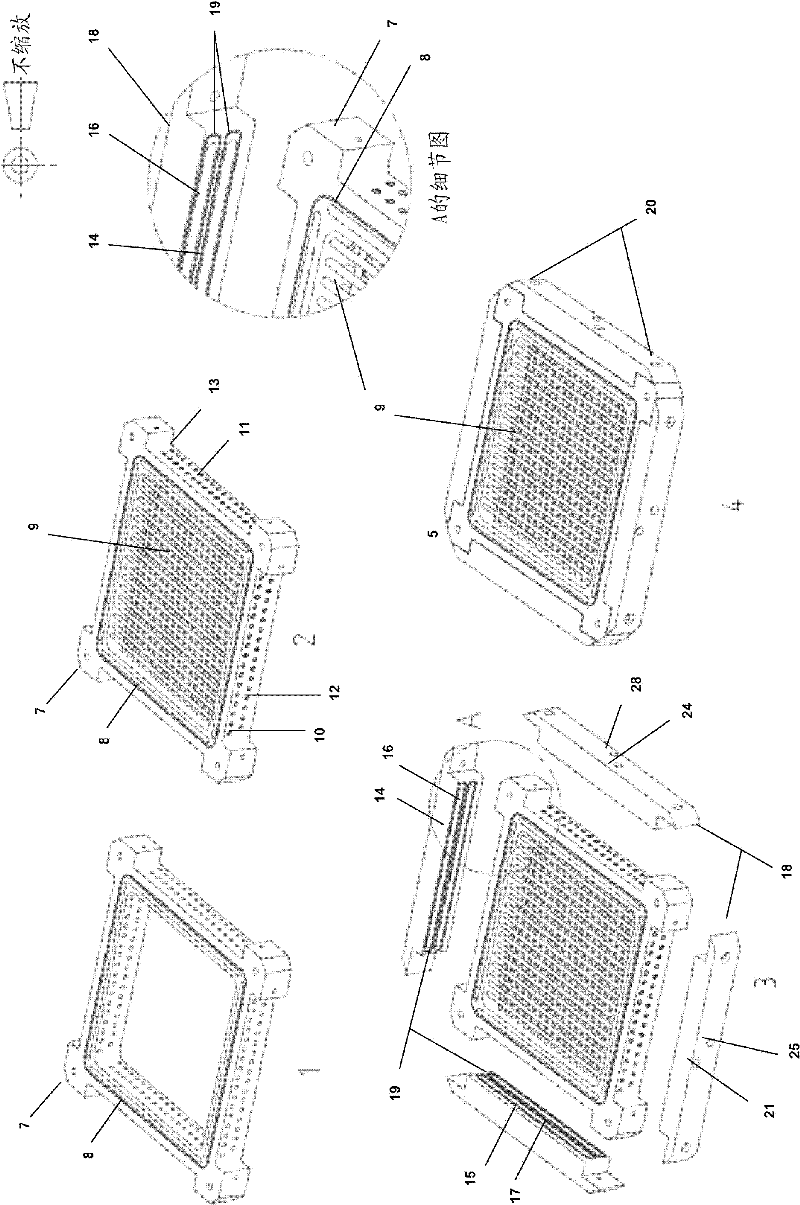

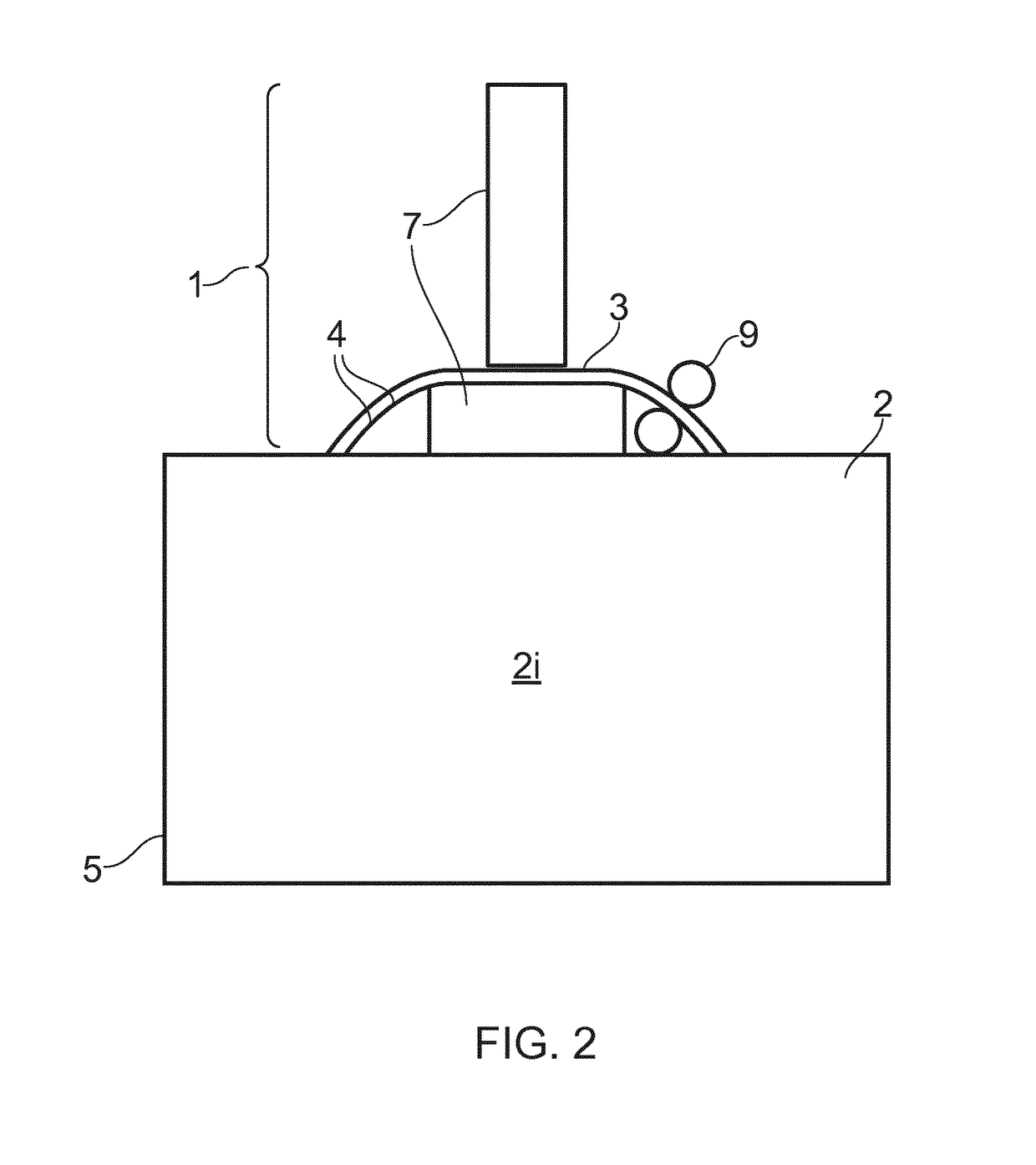

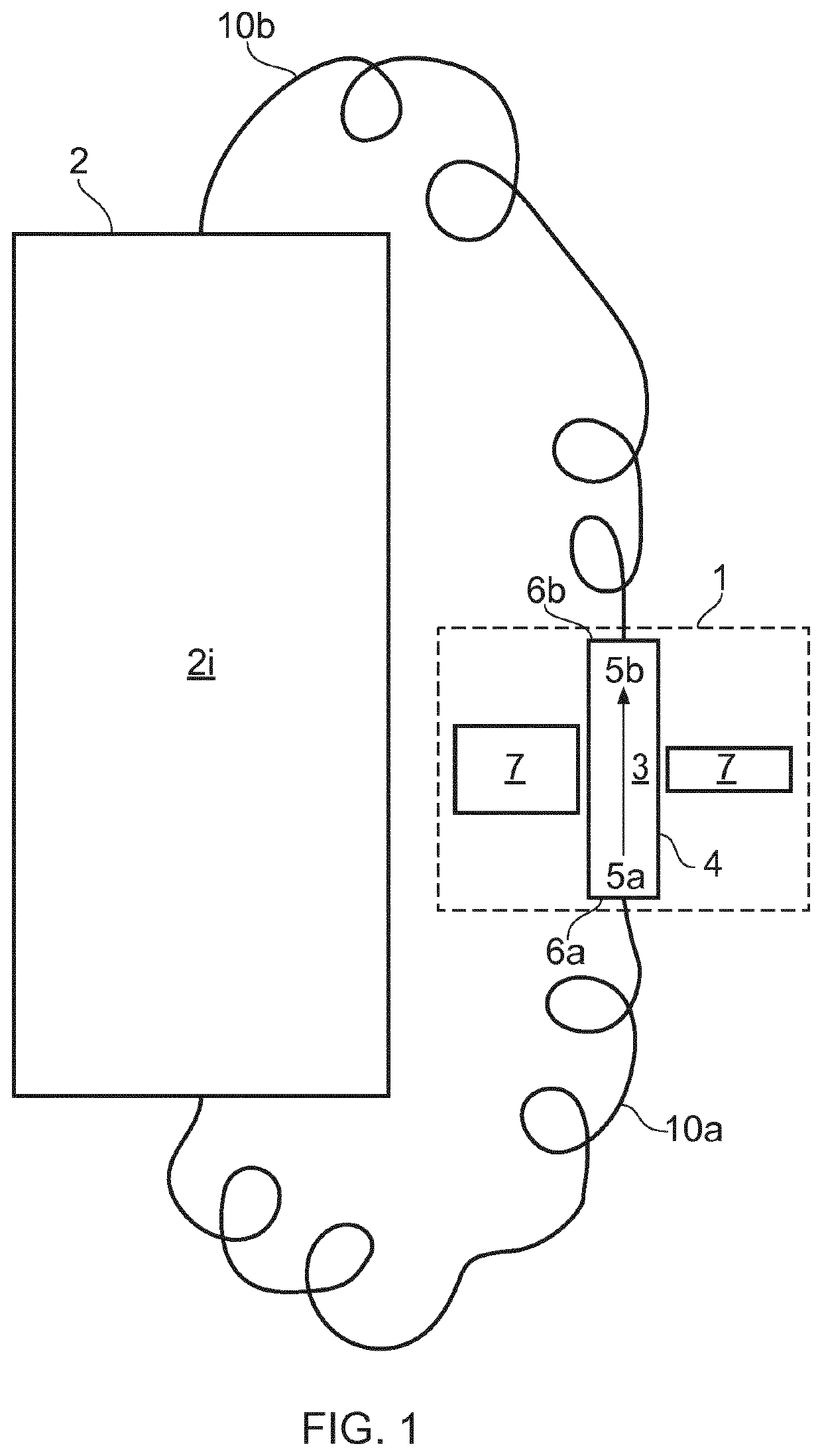

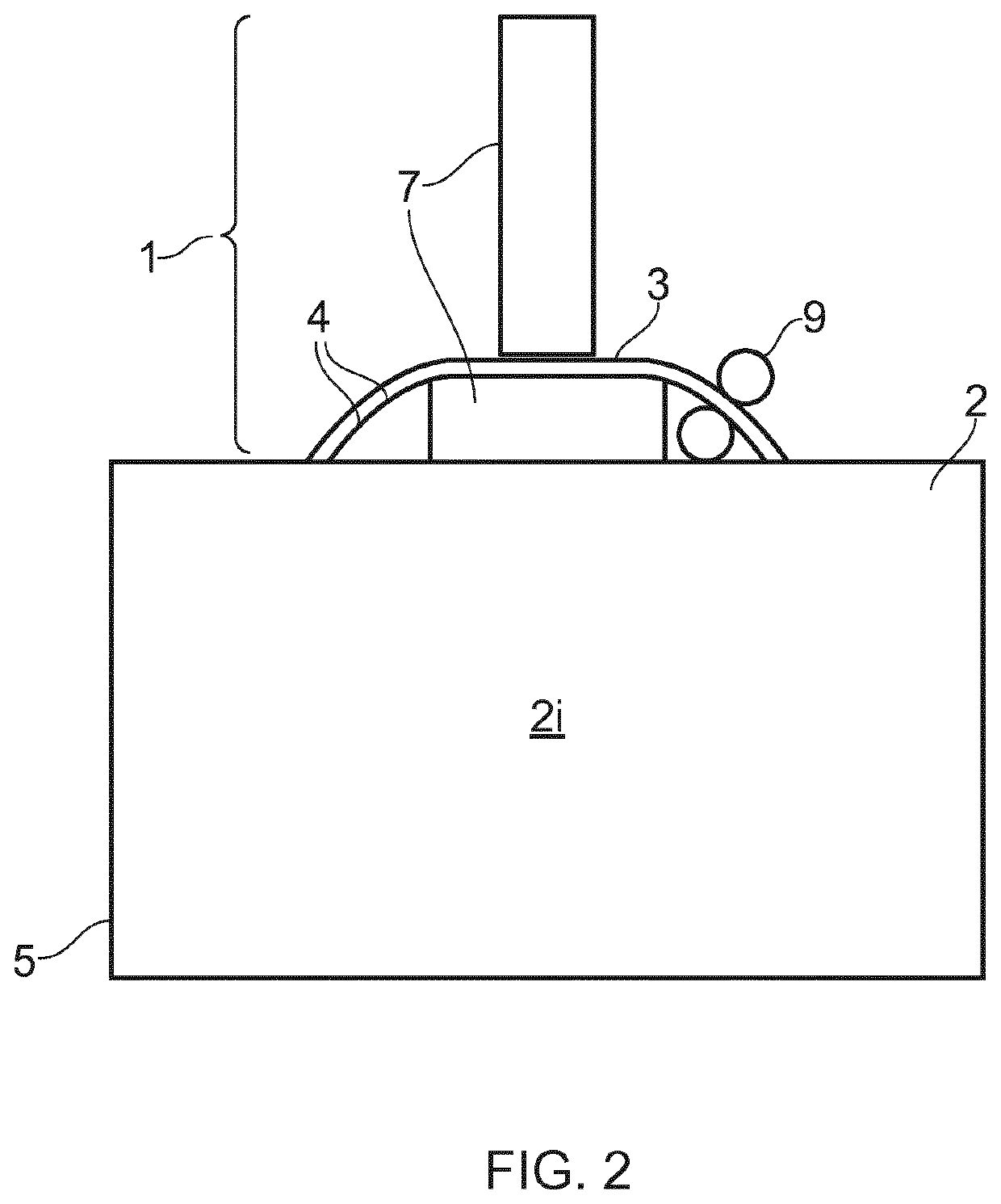

A cell culture bioreactor

ActiveUS20070134790A1Inhibits foam formationBioreactor/fermenter combinationsBiological substance pretreatmentsBiological cellSupport matrix

A cell culture bioreactor having a culture chamber for cell growth, a culture medium reservoir mounted externally to the culture chamber, a fluid circulation mechanism for moving culture medium from the reservoir through the culture chamber, and an aerating mechanism for introducing air into and removing air from the culture chamber is provided. The cell culture bioreactor comprises a manifold mechanism mounted at the top end of the culture chamber, a fluid circulation mechanism fluidly connected to the culture medium reservoir, for receiving culture medium from the culture medium reservoir and distributing culture medium into the culture chamber. A support matrix is mounted within the culture chamber in fluid communication with the fluid circulation mechanism with at least a portion of the support matrix contacting the culture medium wherein the culture medium flows from the manifold means in a thin film over substantially the entire surface of the support matrix allowing the biological cells to grow on the support matrix.

Owner:SEPRAGEN

Single use bag for biological materials and processing

InactiveUS20170175066A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLow-density polyethyleneSurface layer

A single-use bag includes a collapsible a body having a first end and an opposing second end bounding a compartment. The collapsible body comprises at least one flexible sheet having an interior surface and an exterior surface; wherein the interior surface layer comprises low density polyethylene having a melt index from 0.9 to 2.0 g / 10 min with a weight average molecular weight (Mw) greater than 200,000 Da, and an Mz greater than 1,500,000 Da. Optionally, the flexible sheet comprises an oriented film as an additional layer on the exterior surface. The single-use bag is useful in biological processing, including use in a disposable cell culture bioreactor.

Owner:EI DU PONT DE NEMOURS & CO

Oscillating cell culture bioreactor

ActiveUS9217129B2Low and controllable levelImprove efficiencyBiocideBioreactor/fermenter combinationsCulture cellClosed loop

Methods and devices for cell or tissue culture are provided. One aspect provides a bioreactor having a gas permeable, closed-loop chamber for cell or tissue culture, and an oscillating means for moving the gas permeable, closed-loop chamber bidirectionally along an axis horizontal to an axis normal to the closed-loop chamber to force convection of cells and fluid in the gas permeable, closed-loop chamber. The bioreactor optionally includes a tissue engineering scaffold, an inlet means, an outlet means, and integrated sensors. Another aspect provides a bioreactor having a plurality of gas permeable, closed-loop chambers for cell or tissue culture. Methods of culturing cells and producing tissue constructs are also provided.

Owner:MASSACHUSETTS INST OF TECH

A concentration gradient diffusion sampling device for an online detection system of a bioreactor

The invention relates to a sampling device suitable for bioreactors such as microbial fermentation and cell culture, in particular to a concentration gradient diffusion sampling device, which is based on the concentration difference caused by the concentration difference of each component in the liquid in the solution on both sides of the separation membrane. The principle is to form a concentration gradient distribution of components (measured samples) in the sampling pipeline, and the flux or rate of diffusion follows Fick's law. Using this device to sample the samples in the bioreactor has the advantages of effectively preventing sampling pollution and good safety; there is no filtration process of the solution, the membrane pores should not be blocked, and the stability of continuous sampling is high; the sample components are in the sampling pipeline A gradient distribution is formed, which can be measured without cumbersome dilution, making the online detection system simpler, with faster measurement speed and wider linear range, and is especially suitable for on-line detection of various flow injection analysis systems.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

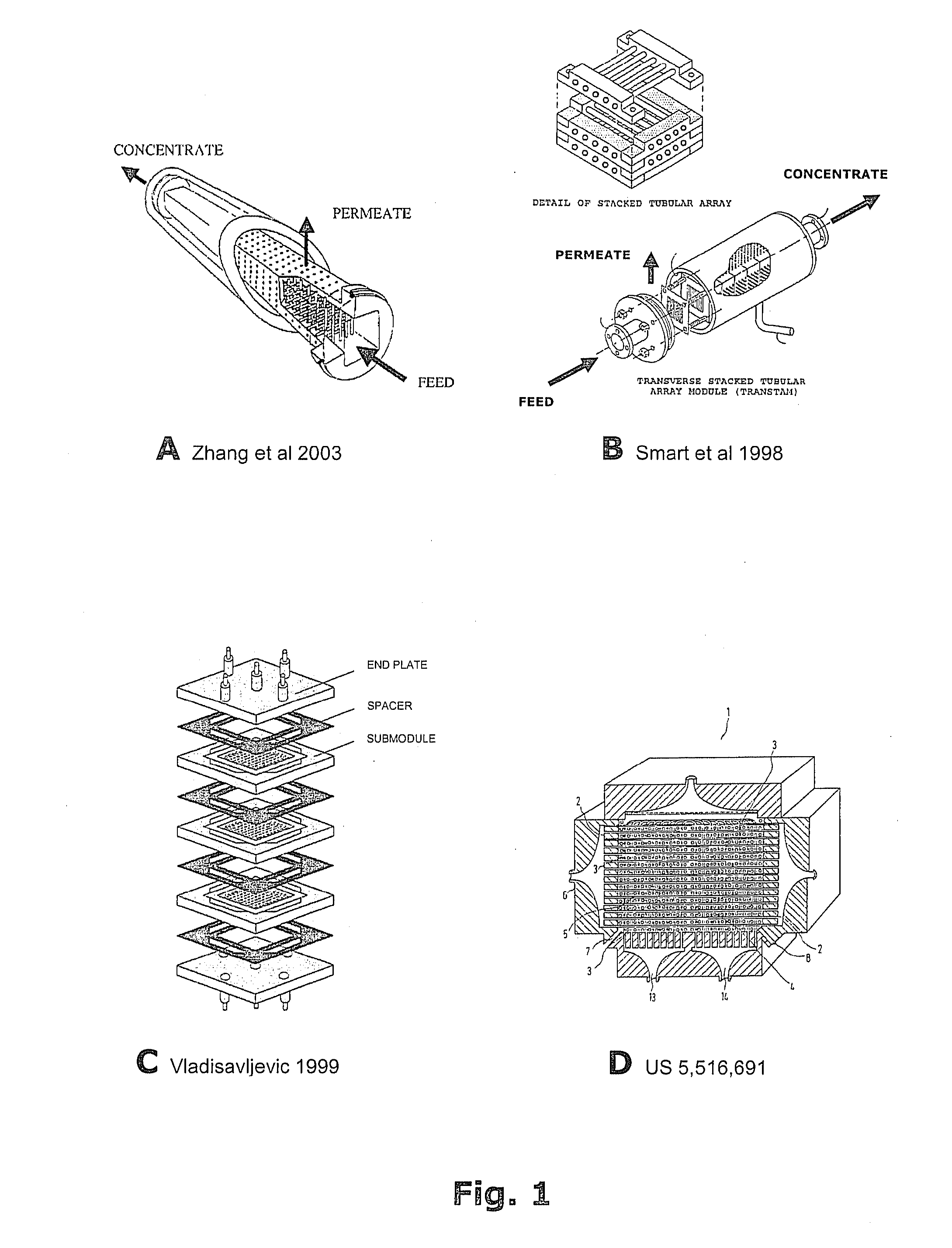

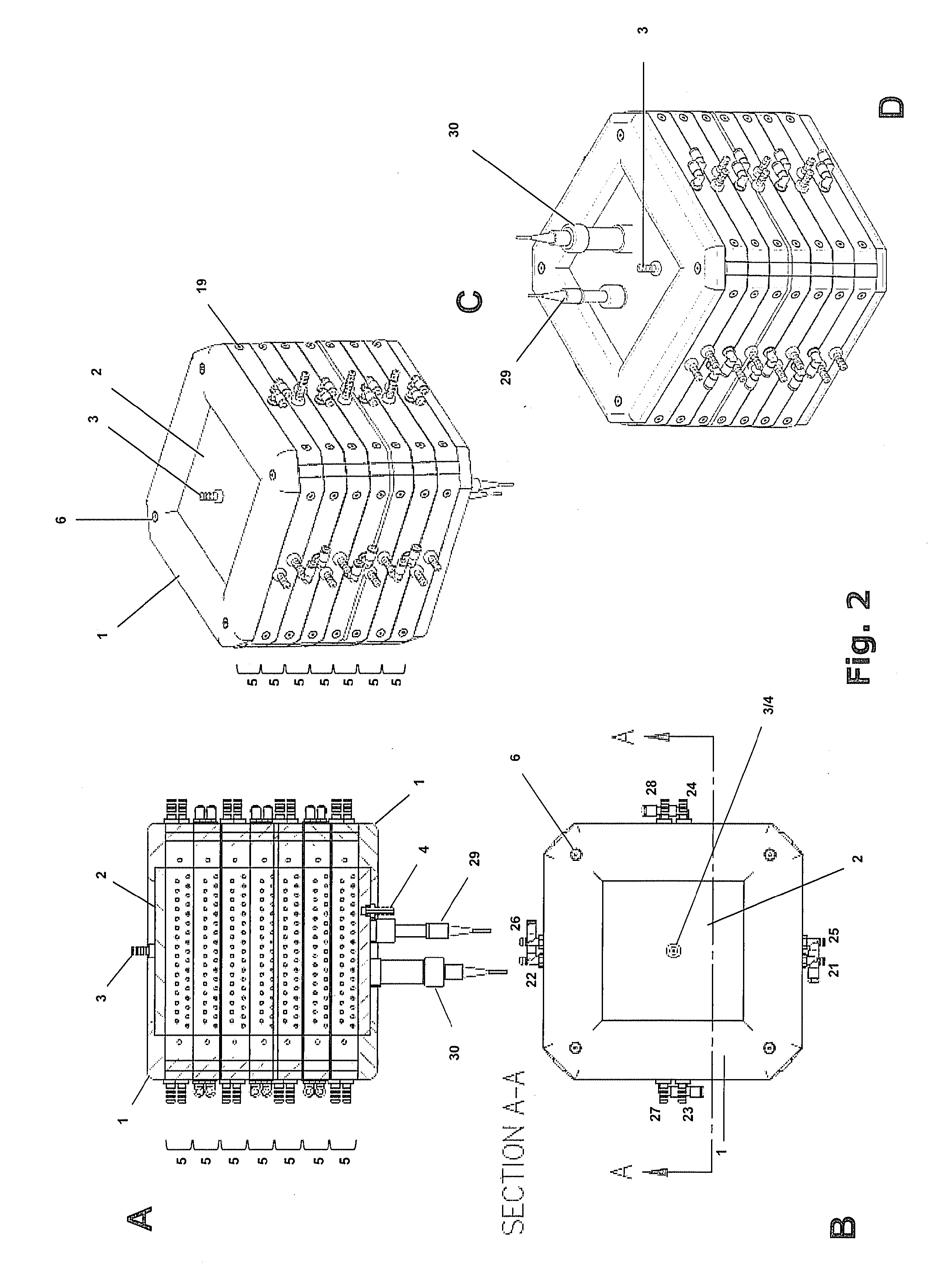

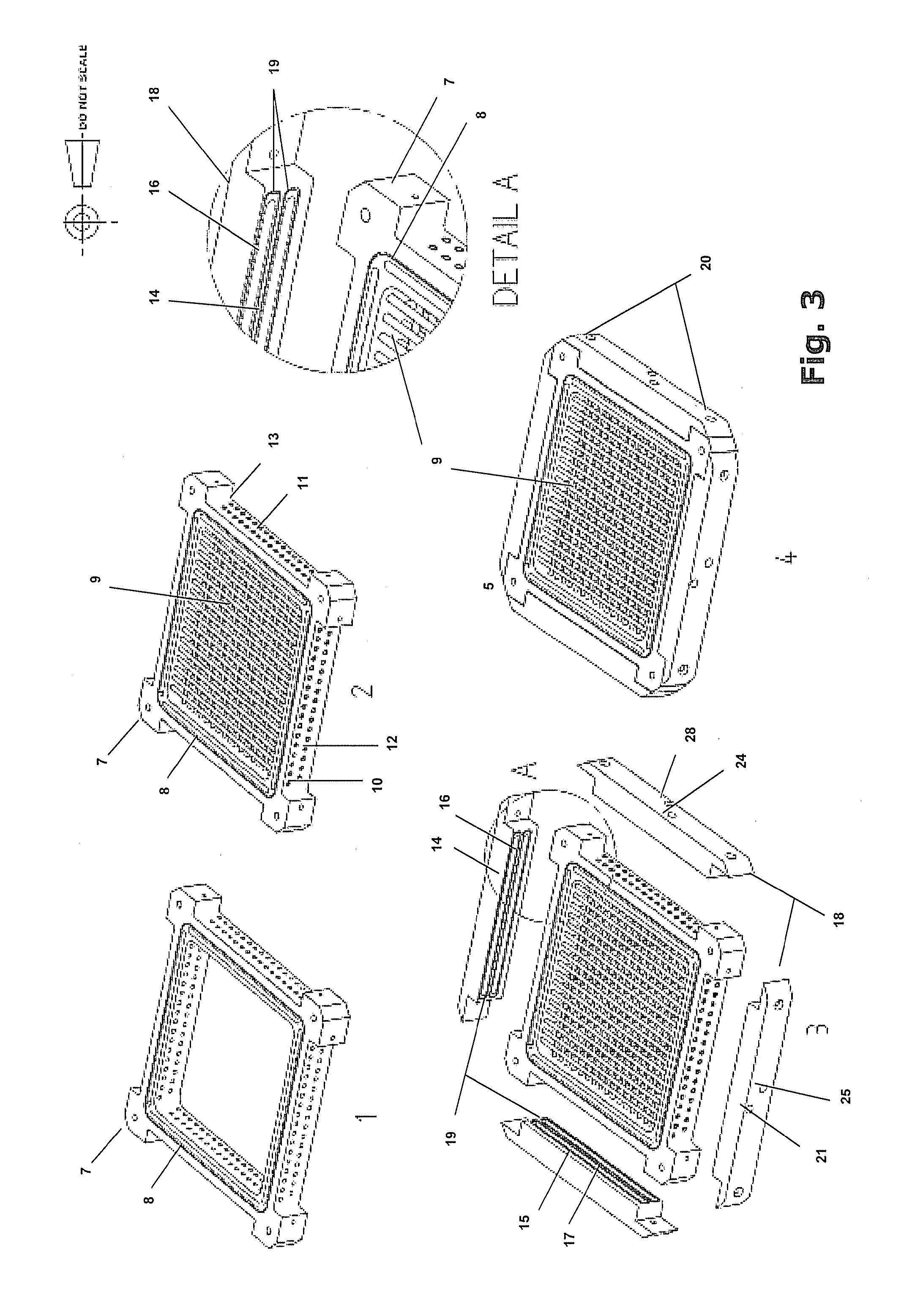

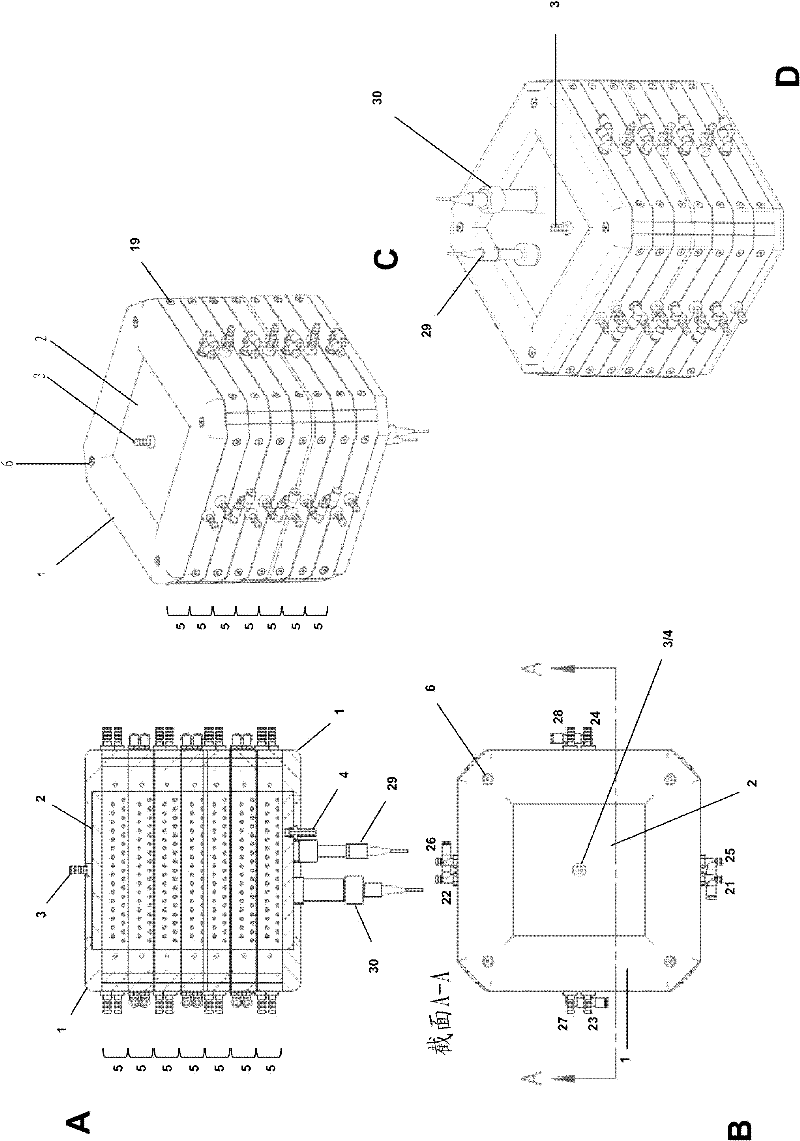

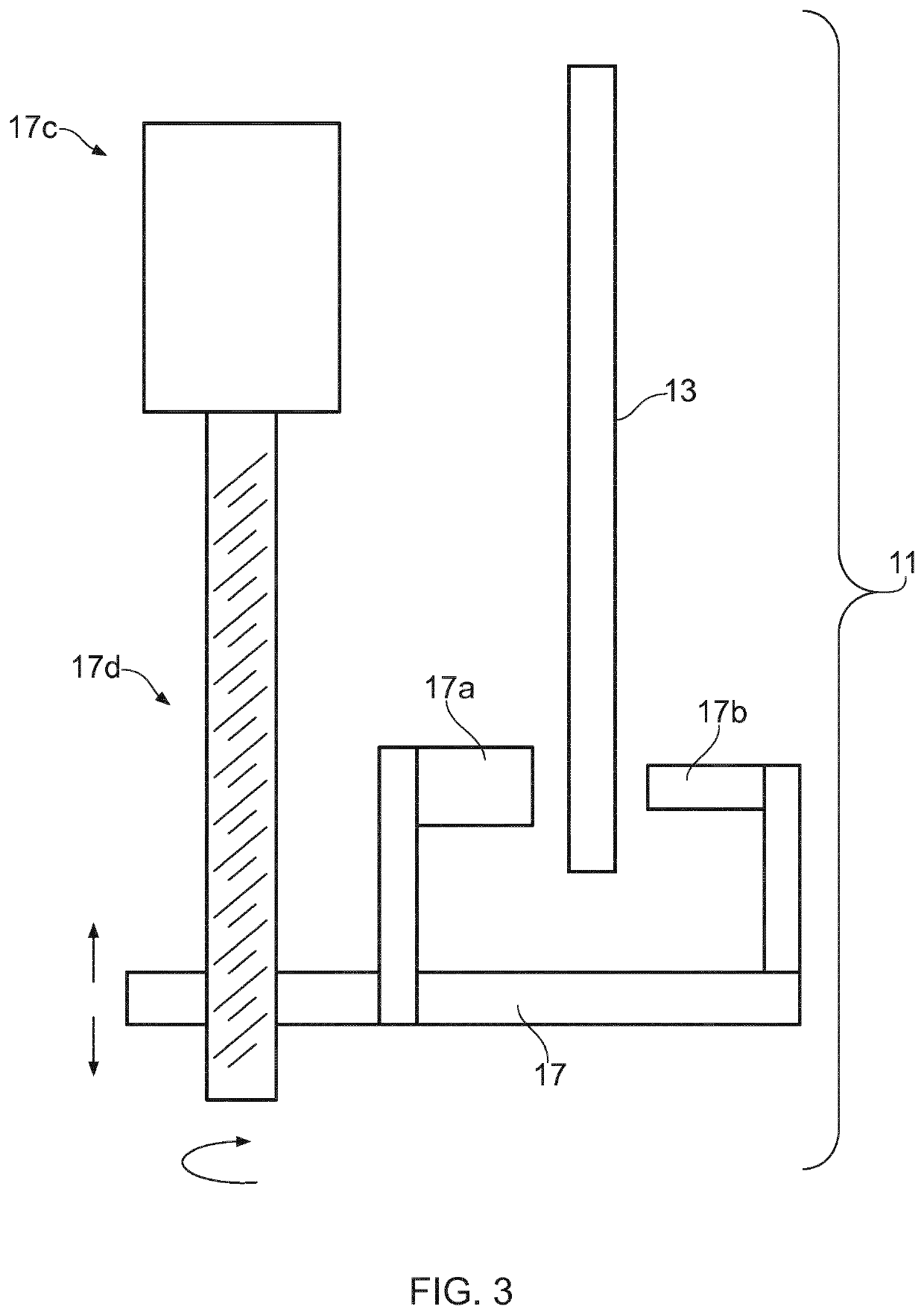

Scalable cell culture bioreactor and cell culture process

InactiveUS20110124078A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFiberMicroorganism

The present invention relates to a scaleable bioreactor comprising at least one cassette comprising a manifold and an arrangement of hollow fibre membranes; an upper headplate; and a lower headplate, wherein the cassette(s) are modular components adapted to co-operate with each other and the headplates to define an internal extracapillary culture space (ECS) and wherein the arrangement of hollow fibre membranes includes a discrete inlet and outlet. The invention further relates to a kit for such a bioreactor, a cassette for use in such a bioreactor and a process for exploiting the metabolism of cells and / or microorganisms, the process including the step of utilising a bioreactor according to the invention.

Owner:SYNEXA LIFE SCI (PTY) LTD

Cell culture bioreactor

ActiveUS8951784B2Bioreactor/fermenter combinationsBiological substance pretreatmentsSupport matrixThin membrane

A cell culture bioreactor having a culture chamber for cell growth, a culture medium reservoir mounted externally to the culture chamber, a fluid circulation mechanism for moving culture medium from the reservoir through the culture chamber, and an aerating mechanism for introducing air into and removing air from the culture chamber is provided. The cell culture bioreactor comprises a manifold mechanism mounted at the top end of the culture chamber, a fluid circulation mechanism fluidly connected to the culture medium reservoir, for receiving culture medium from the culture medium reservoir and distributing culture medium into the culture chamber. A support matrix is mounted within the culture chamber in fluid communication with the fluid circulation mechanism with at least a portion of the support matrix contacting the culture medium wherein the culture medium flows from the manifold means in a thin film over substantially the entire surface of the support matrix allowing the biological cells to grow on the support matrix.

Owner:SEPRAGEN

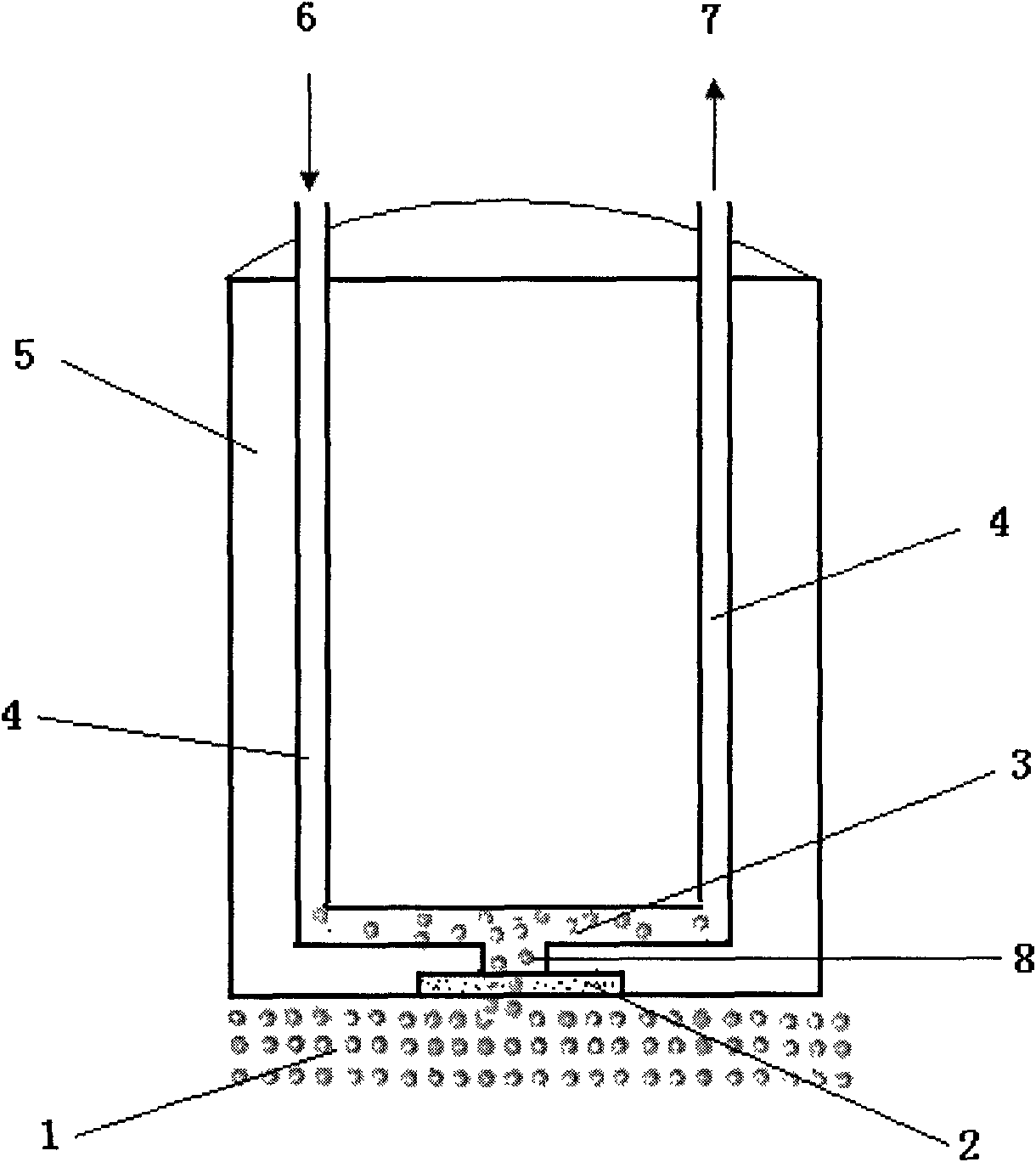

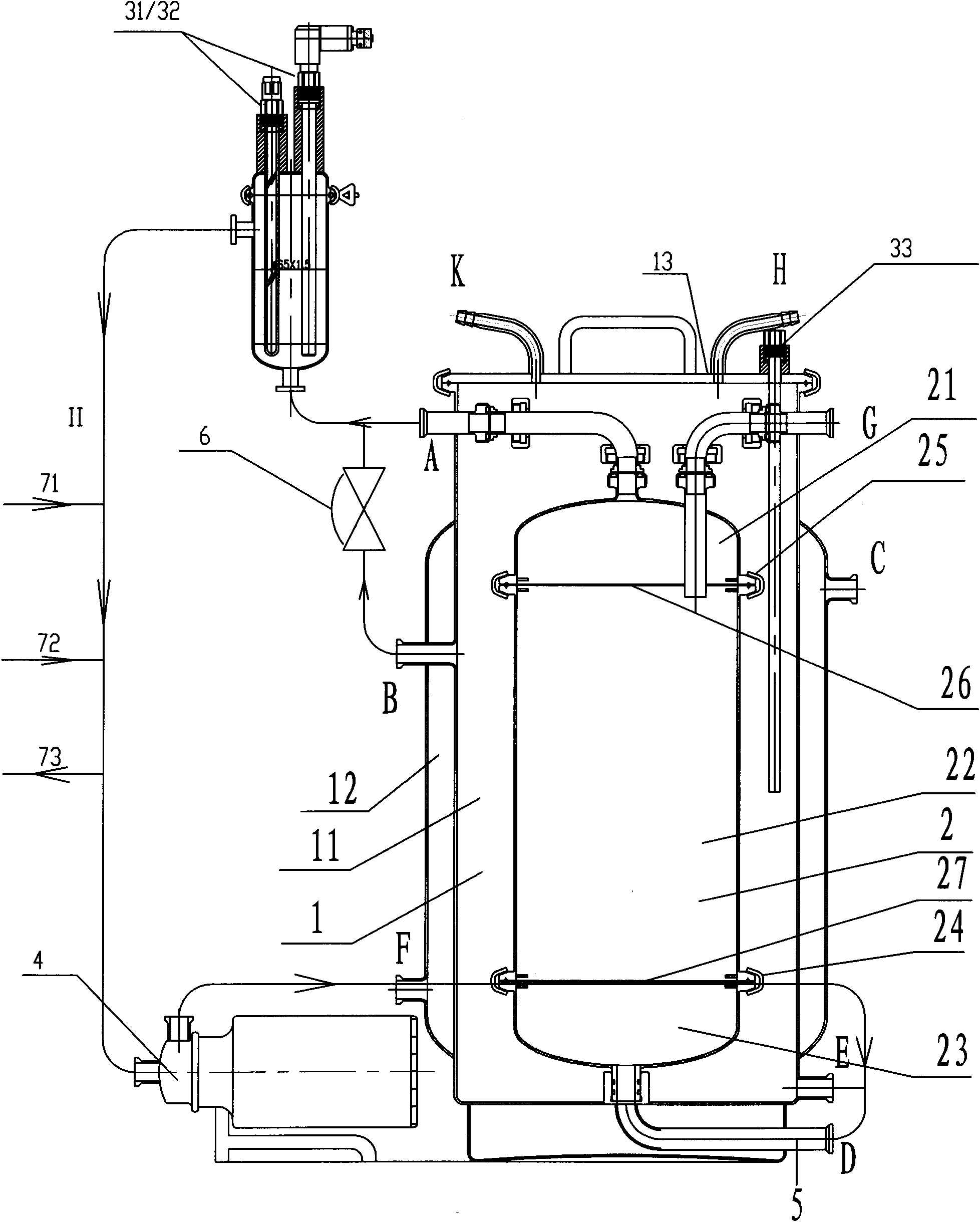

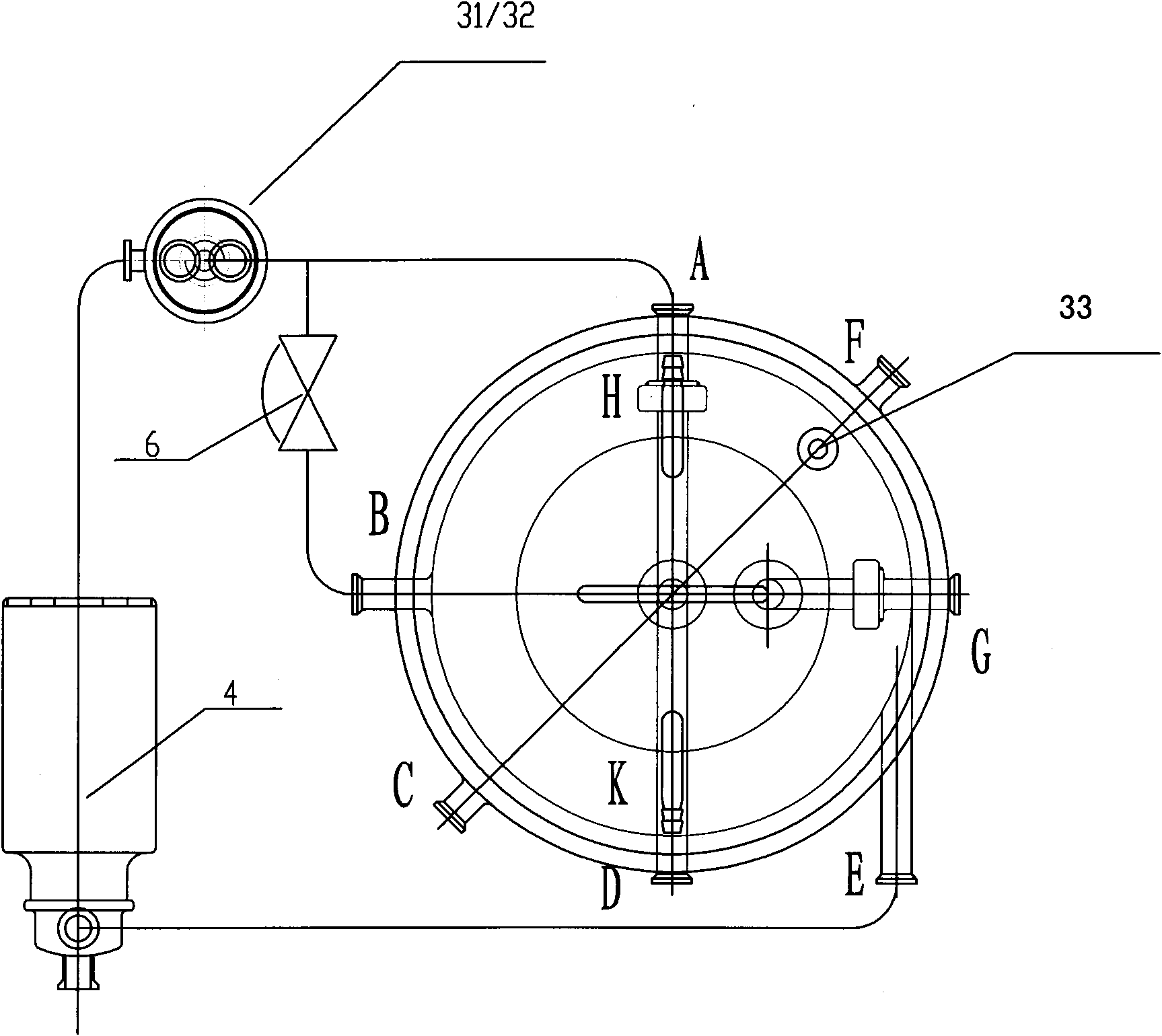

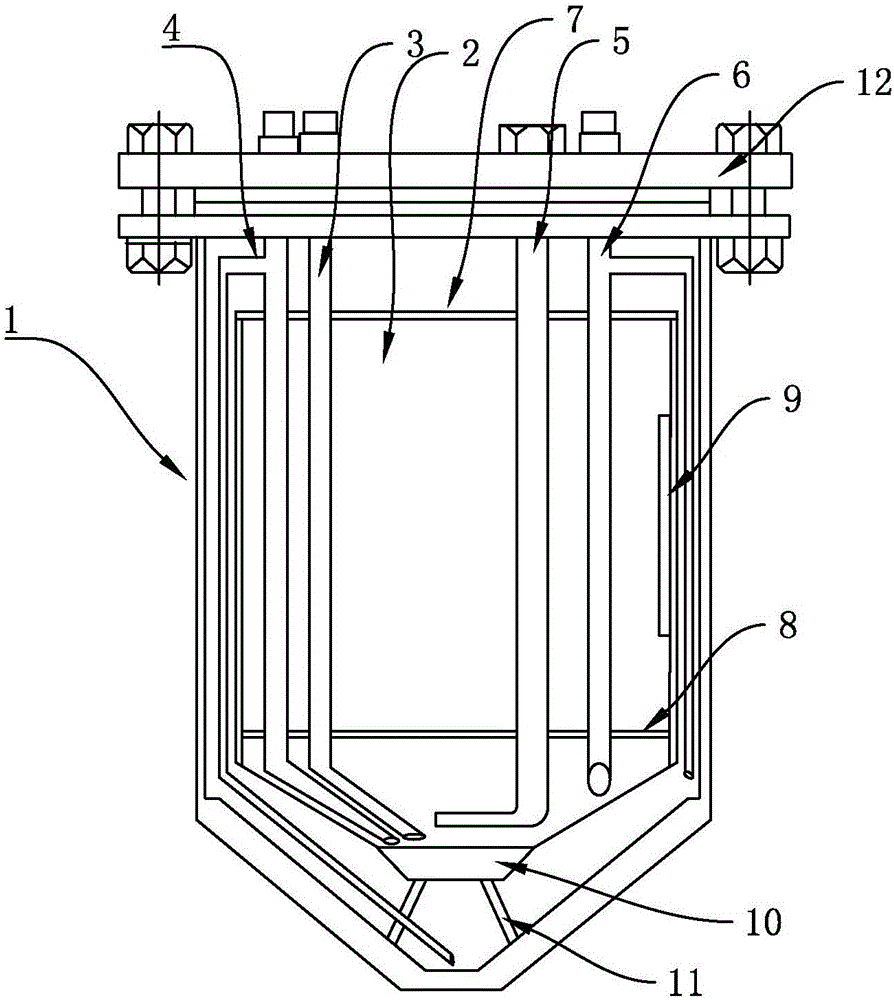

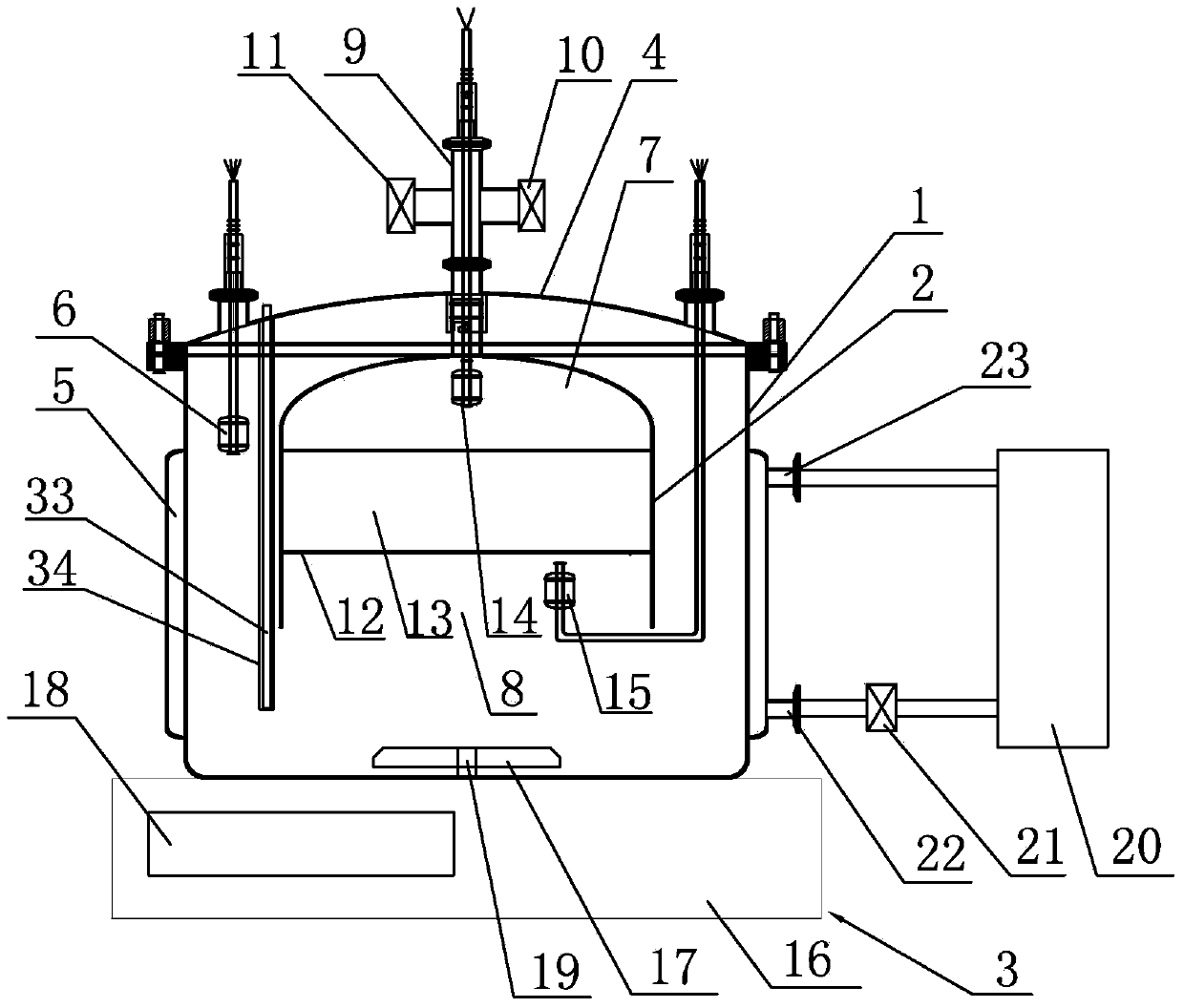

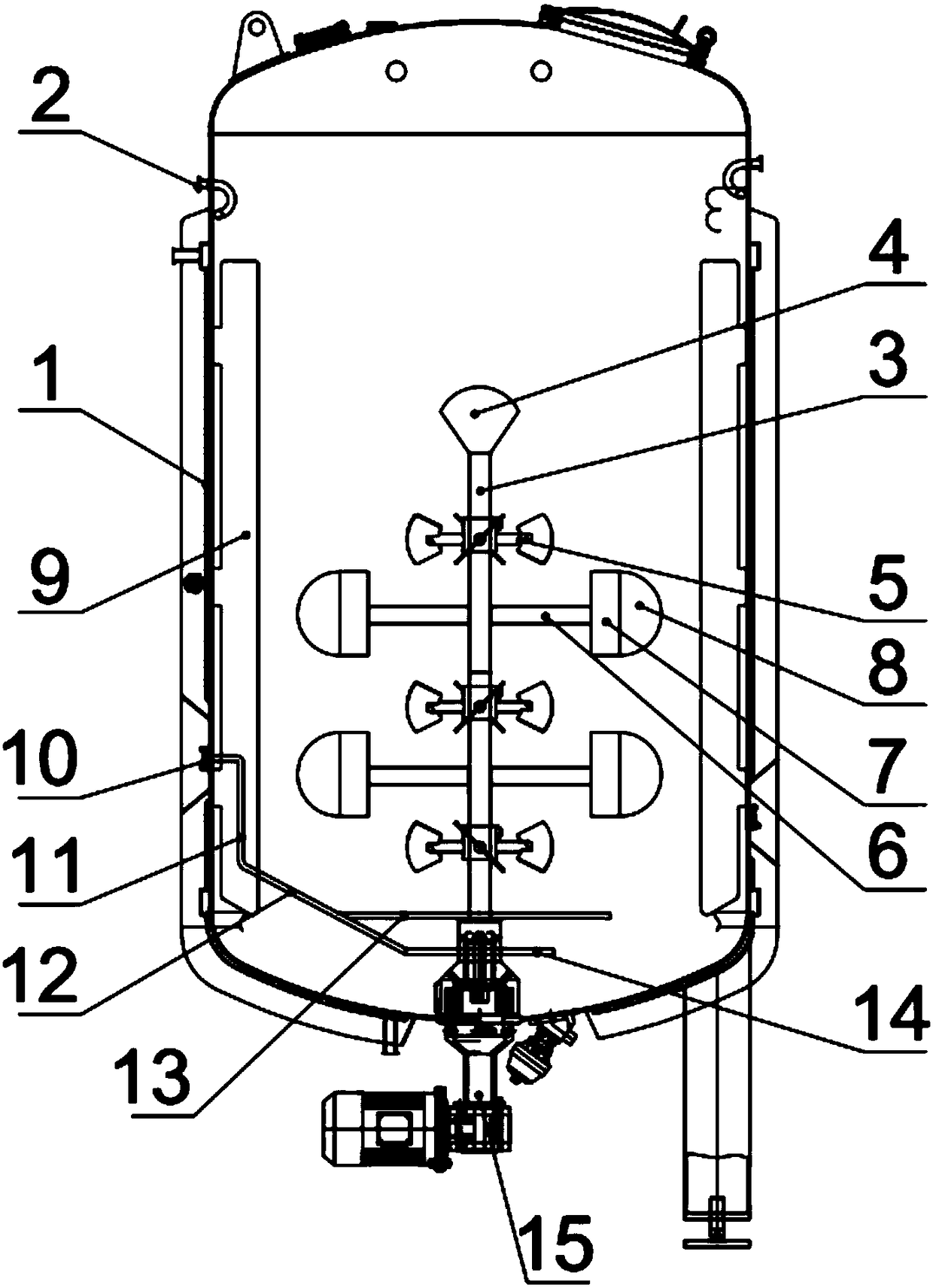

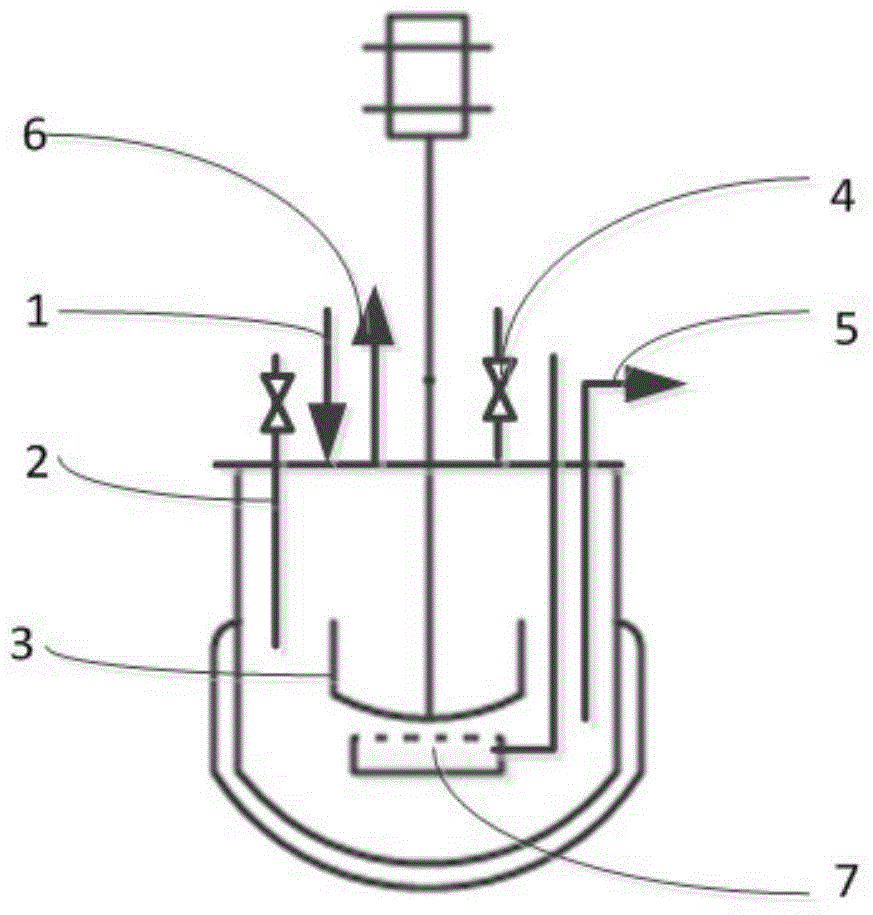

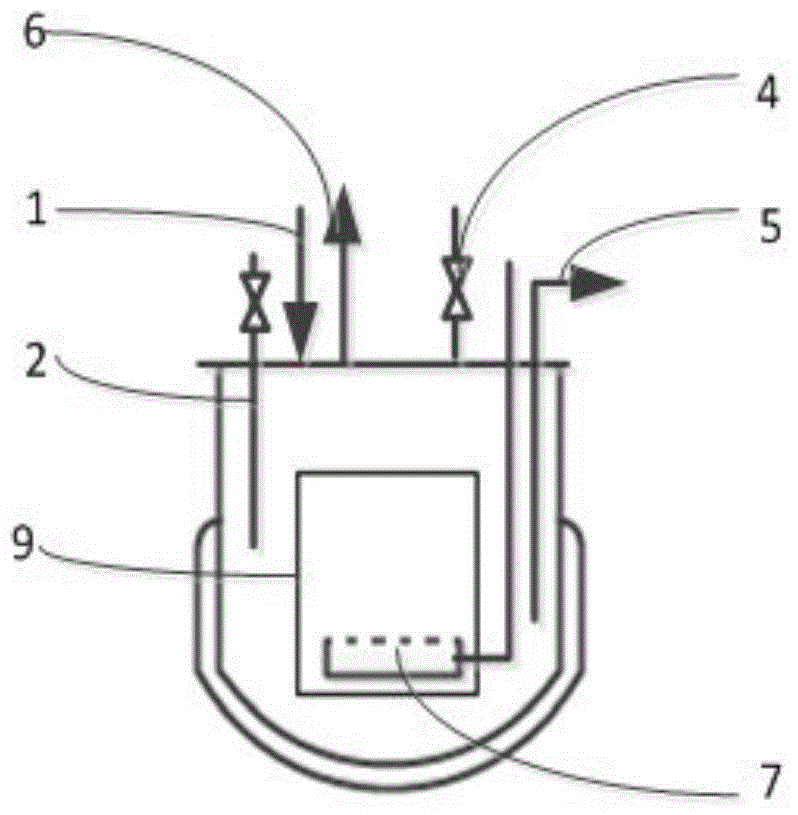

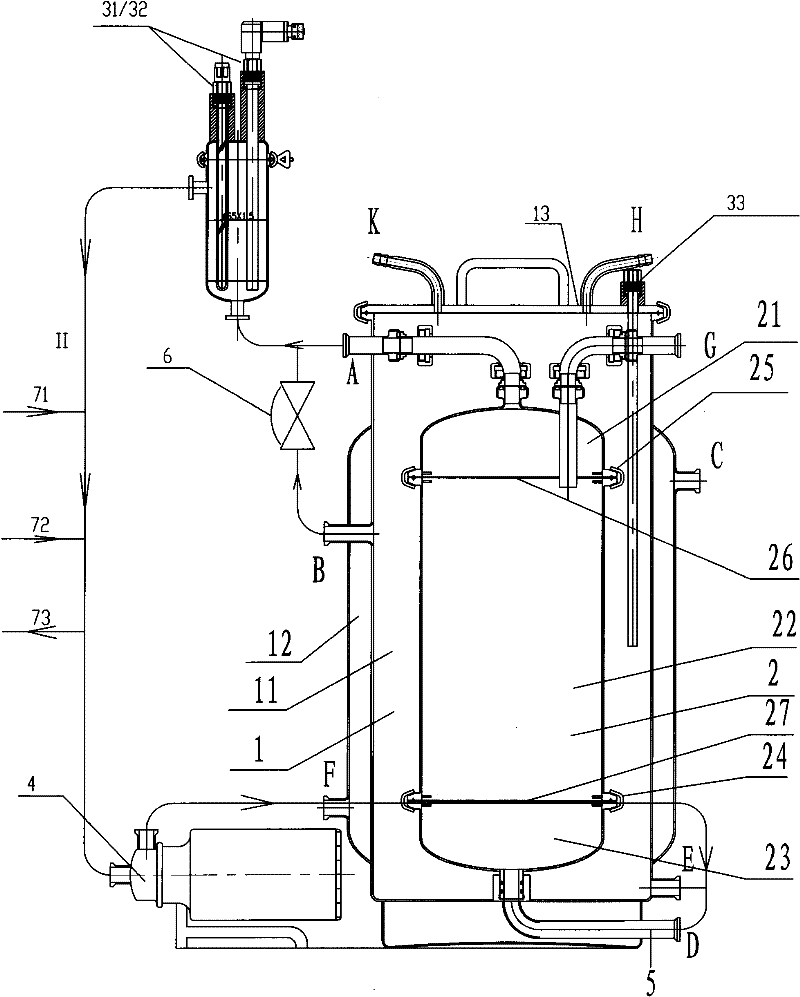

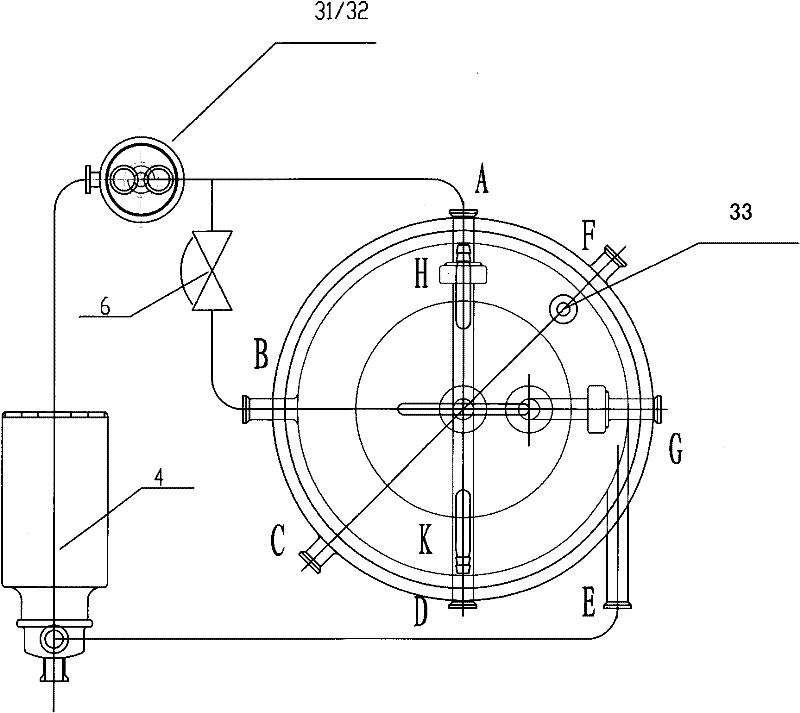

External circulation animal cell culture bioreactor

ActiveCN101899394AOptimize layoutFunctionalBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpControl system

The invention relates to an external circulation animal cell culture bioreactor which comprises a tank body, an external circulation pipeline, a heater, a peristaltic pump and a control system, wherein the tank body comprises a large tank and a small tank; the small tank is sheathed in the large tank and is clamped and fixed with the large tank respectively through ducts D, A and G; the external circulation pipeline comprises a tank external circulation pipeline and ducts A, B, E and D; on the upper part of the outside of the tank body, the ducts A and B are connected with the tank external circulation pipeline through a tee joint; on the lower part of the outside of the tank body, the ducts E and D are connected with the tank external circulation pipeline through a tee joint; the tank external circulation pipeline penetrates through the peristaltic pump; and the lowest position of the duct D is connected with a drainage pipe. The invention fully displays the characteristics of the animal cell large-scale culture technique, has the characteristics of thorough sterilization, simple operation, low pollution rate of cell culture, good quality and high yield, has favorable functionality and economical efficiency, and can be widely used for animal cell microcarrier suspension culture and animal cell suspension culture.

Owner:罗火生

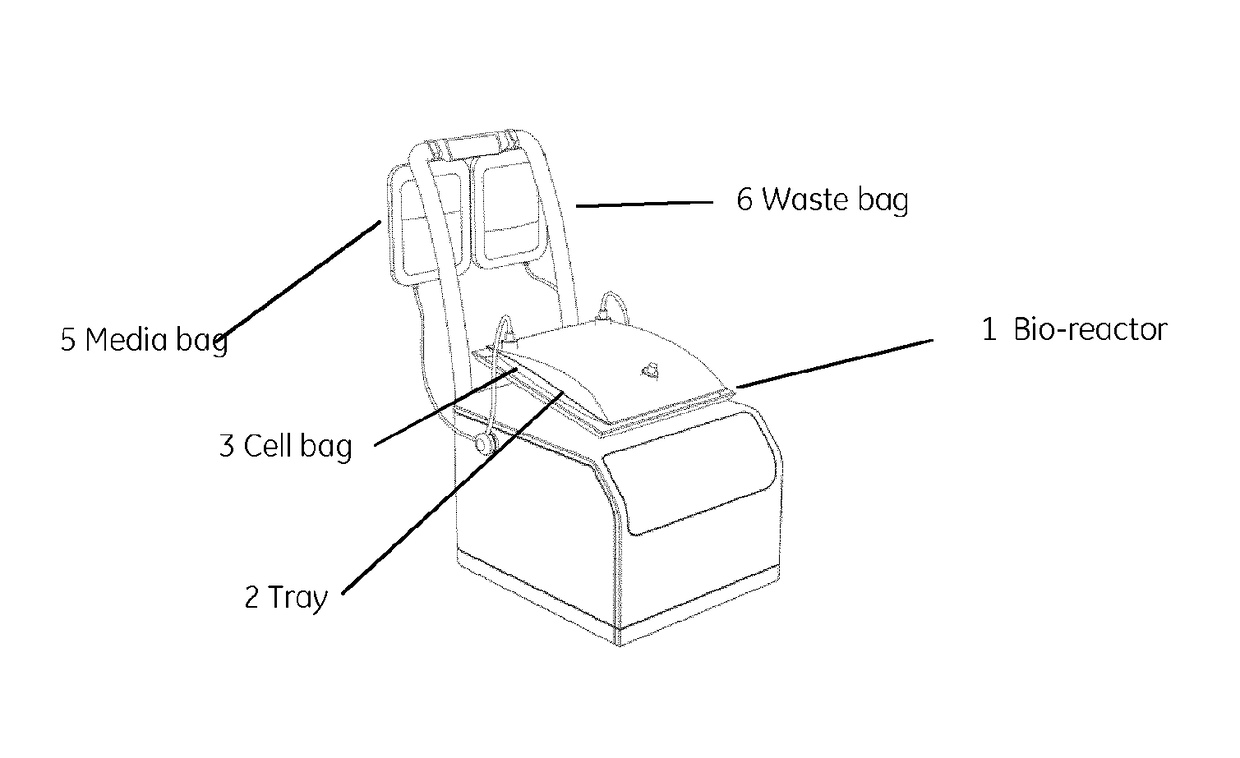

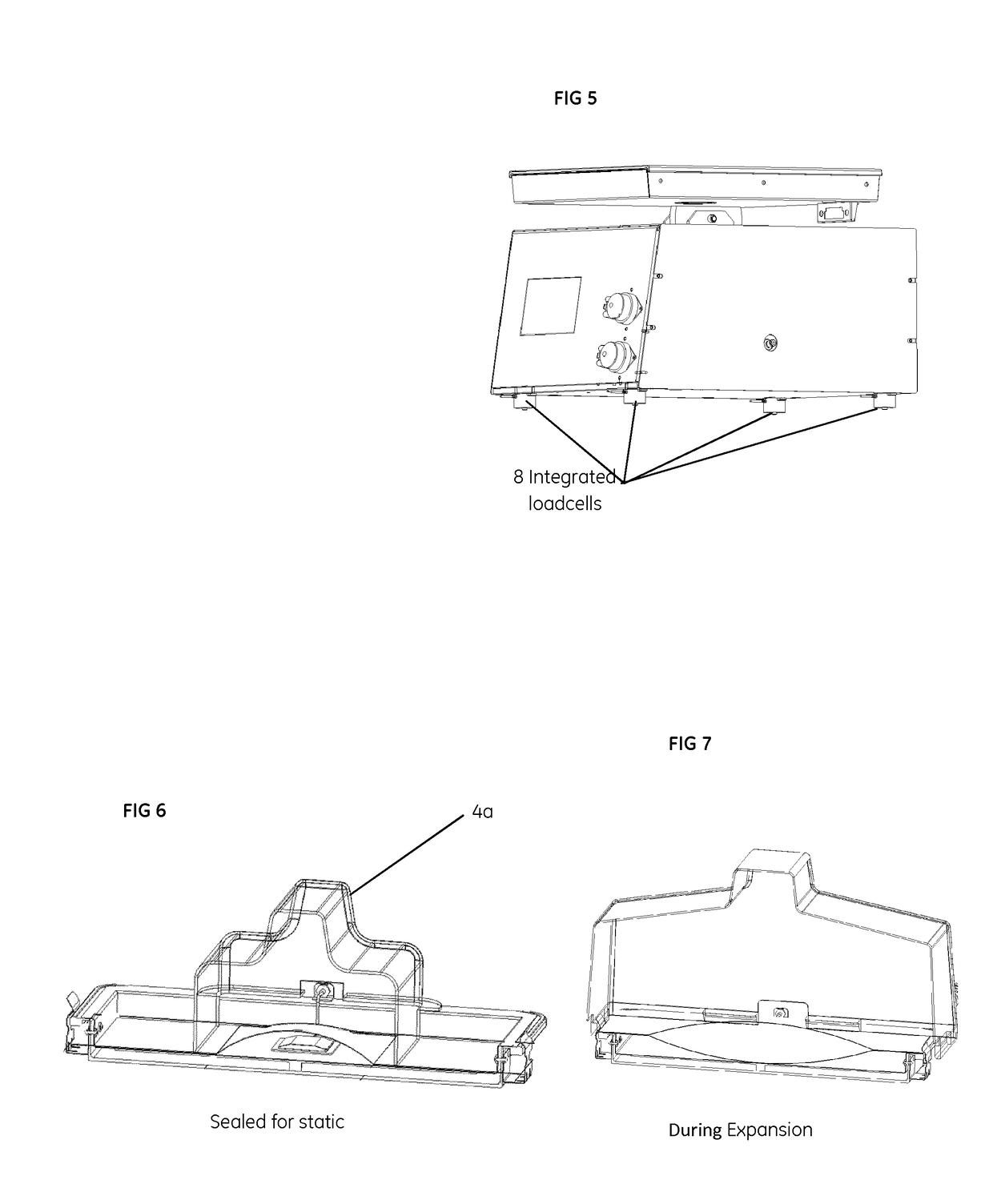

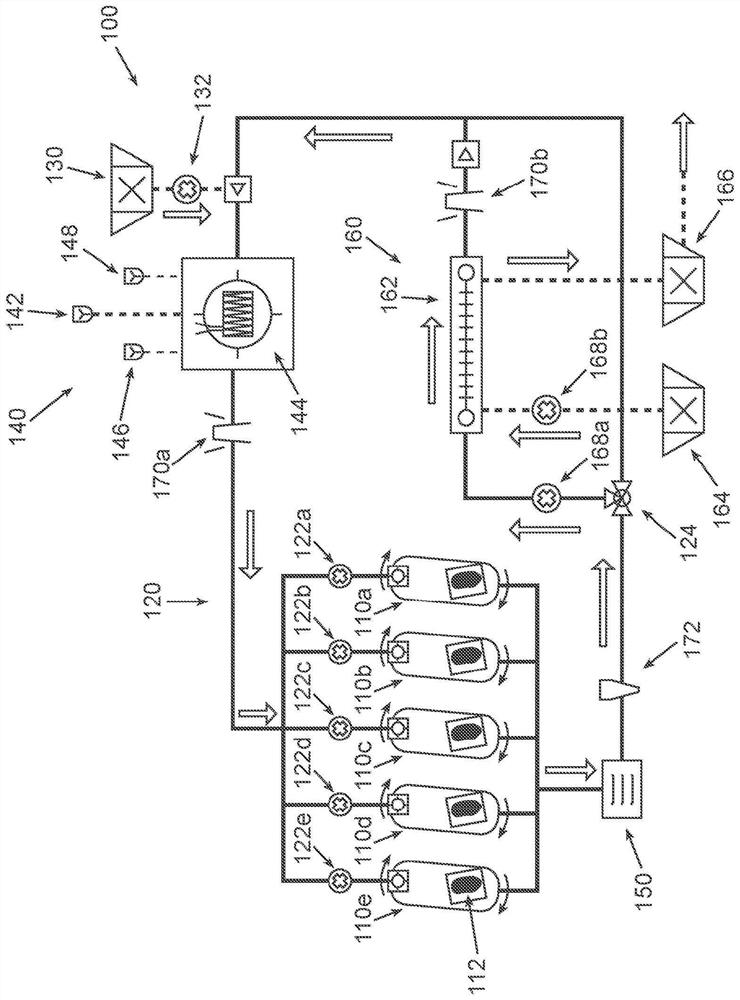

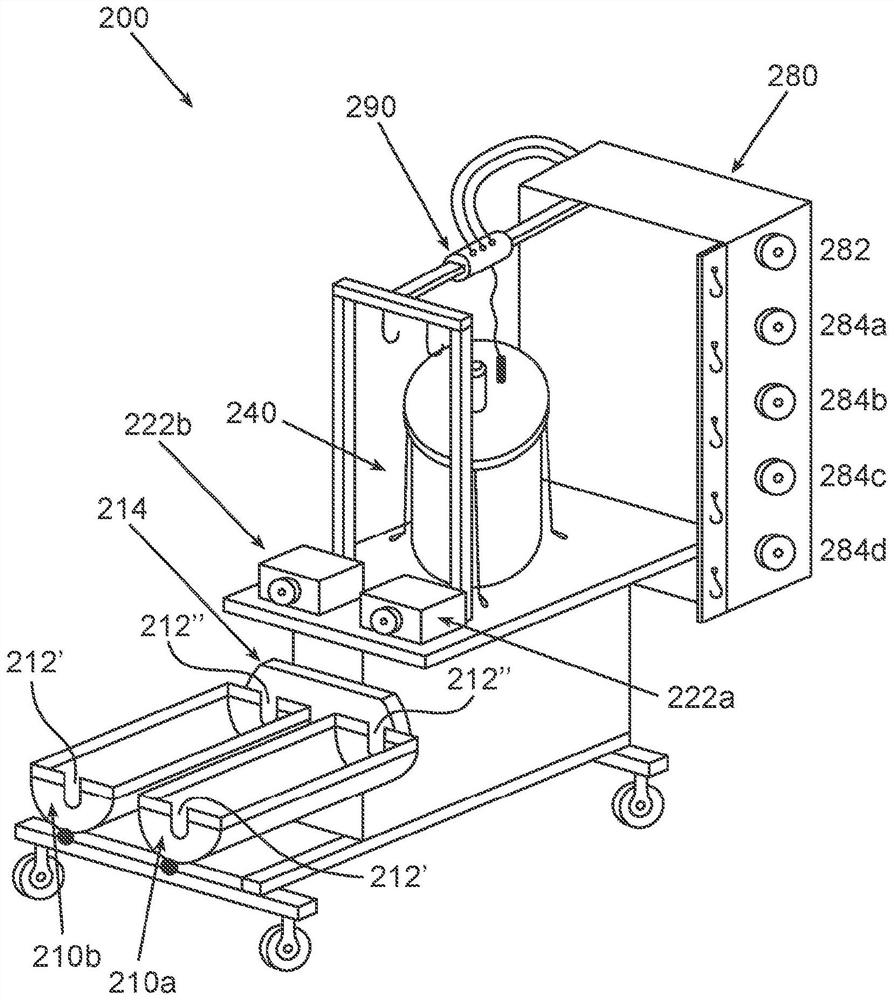

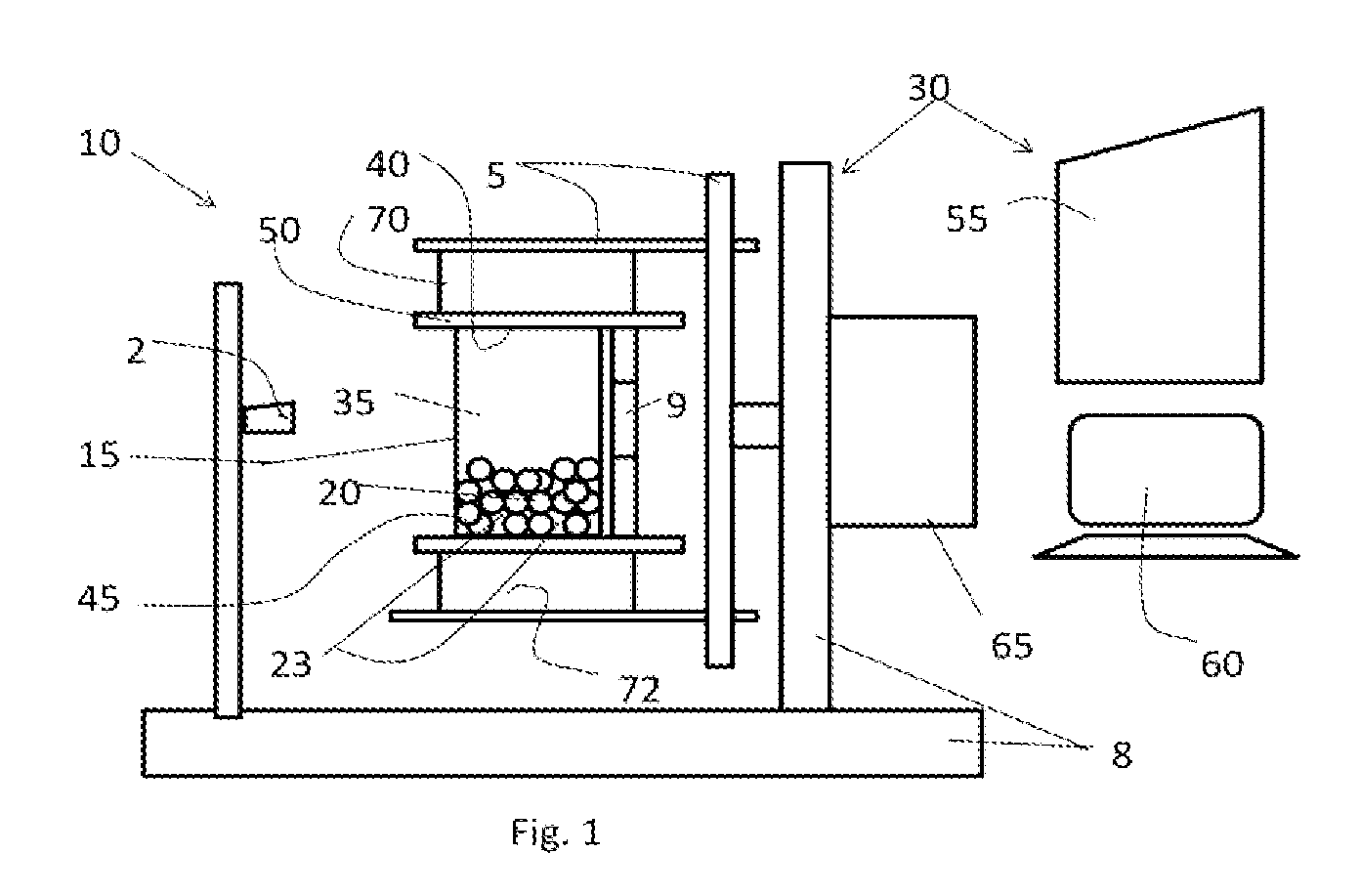

Bioreactor System for Cell Cultivation

ActiveUS20180002655A1Improve overall utilizationSmall sizeBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusionCell biology

The present invention relates to a novel bioreactor system for cell cultivation. More specifically, the invention relates to a compact bioreactor system which has several integrated functions and enables small scale static culture as well as scale-up rocking culture in the same bioreactor. The bioreactor system comprises tray for positioning of a cell culture bag having adjustable volume, a lid covering the cell culture bag and provided with heating function, an integrated perfusion unit, an integrated cell loading unit, and an integrated unit for automatic cell culture sampling, wherein the bioreactor system is controlled by a single control unit. The invention also relates to a method of cell culture using the bioreactor system for culture of therapeutic cells.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

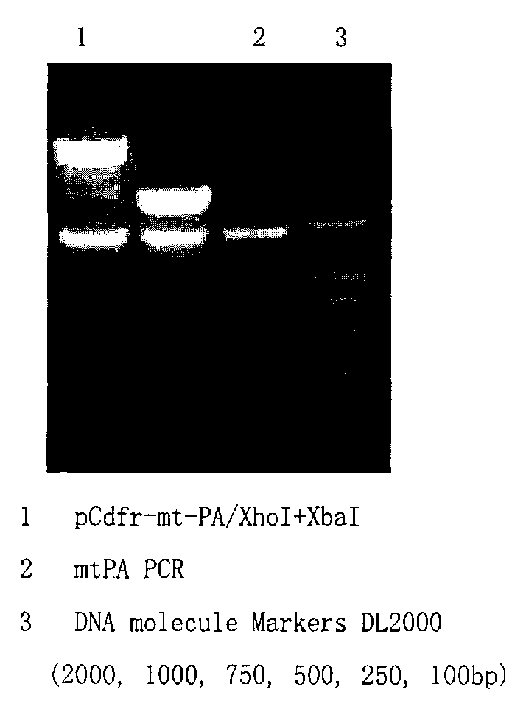

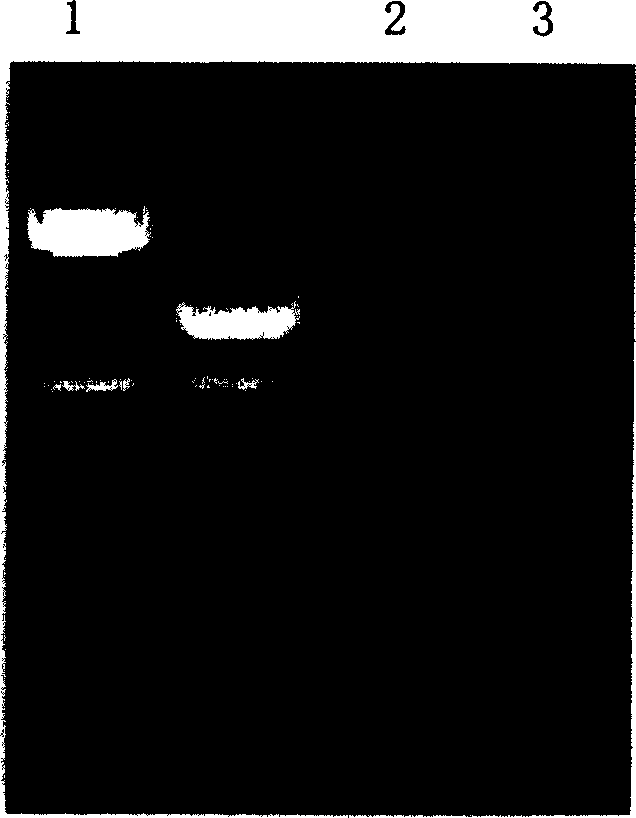

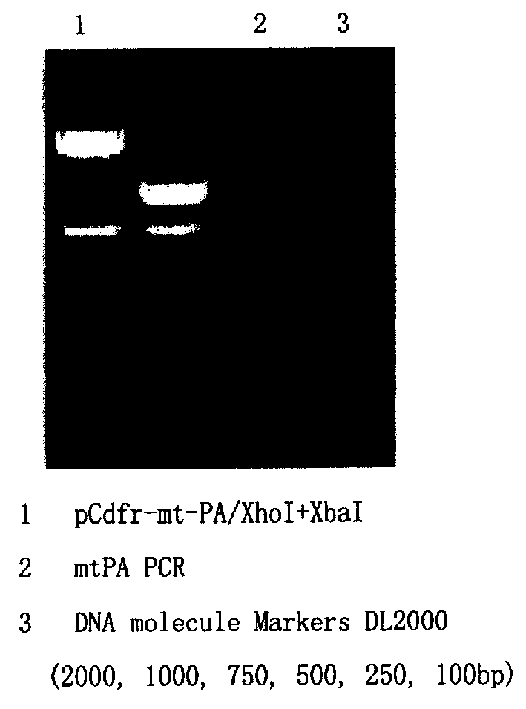

Technological process of producing recombinant human histiotype plasminogen activator TNK mutant

InactiveCN1468862ASimple process conditionsLow costRecombinant DNA-technologyFermentationHamsterSingle strand

The present invention discloses the technological process of producing recombinant human histiotype plasminogen activator TNK mutant. TNK-tPA gene containing said mutant sites is synthesized via full length gene synthesis process and expressed in Chinese hamster ovary cell (CHO-DHFR), and through cloning and screening high-level expressed TNK-tPA engineering cell strain is obtained. By means of sustained culture of the engineering cell in cell culturing bioreactor, collection of the supernatant and serial separation and purification in chromatographic column, rhTNK-tPA product is obtained. The destination gene of the present invention has expression level in cell as high as 18000 IU / 106 cell / d, and the prepared rhTNK-tPA product has single strand rate as high as 80 % and purity up to 95 %. As for industrial scale, the present invention has relatively simple requirement in apparatus, low cost and simple technological requirement.

Owner:石药集团明复乐药业(广州)有限公司

Scalable cell culture bioreactor and cell culture process

InactiveCN102057033AApparatus sterilizationMicroorganism fixing/supporting apparatusMicroorganismFiber

The present invention relates to a scaleable bioreactor comprising at least one cassette comprising a manifold and an arrangement of hollow fibre membranes; an upper headplate; and a lower headplate, wherein the cassette(s) are modular components adapted to co-operate with each other and the headplates to define an internal extracapillary culture space (ECS) and wherein the arrangement of hollow fibre membranes includes a discrete inlet and outlet. The invention further relates to a kit for such a bioreactor, a cassette for ue in such a bioreactor and a process for exploiting the metabolism of cells and / or microorganisms, the process including the step of utilising a bioreactor according to the invention.

Owner:QUORUS BIOTECH

Cell culture biological reactor

ActiveCN106520552AWell mixedGuaranteed uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemBiochemical engineering

The invention discloses a cell culture biological reactor, comprising a big tank, a small tank and a control system; the small tank is arranged in the big tank and supported by a supporting frame at the bottom part of the big tank; the upper end of the small tank is provided with a seal end, and the lower end is provided with a magnetic stirring system; the bottom part closing to the tank bottom position is provided with an isolating plate, and the seal end and the isolating plate are stainless steel mesh plates; a fluid feeding pipe, a fluid discharging pipe, a sensor system, gas inlet and outlet pipes are further arranged in the big tank and the small tank; several clamping devices are further arranged on the tank body of the small tank. Therefore, many forms of cell culture can be realized by one reactor, and the reactor is featured by good sealing property, simple operation, low pollution rate, good cell quality, and high yield. Besides, the reactor has good functionality and economic efficiency, and is widely applied to the large-scale culture of animal cells.

Owner:WEIFANG MEDICAL UNIV

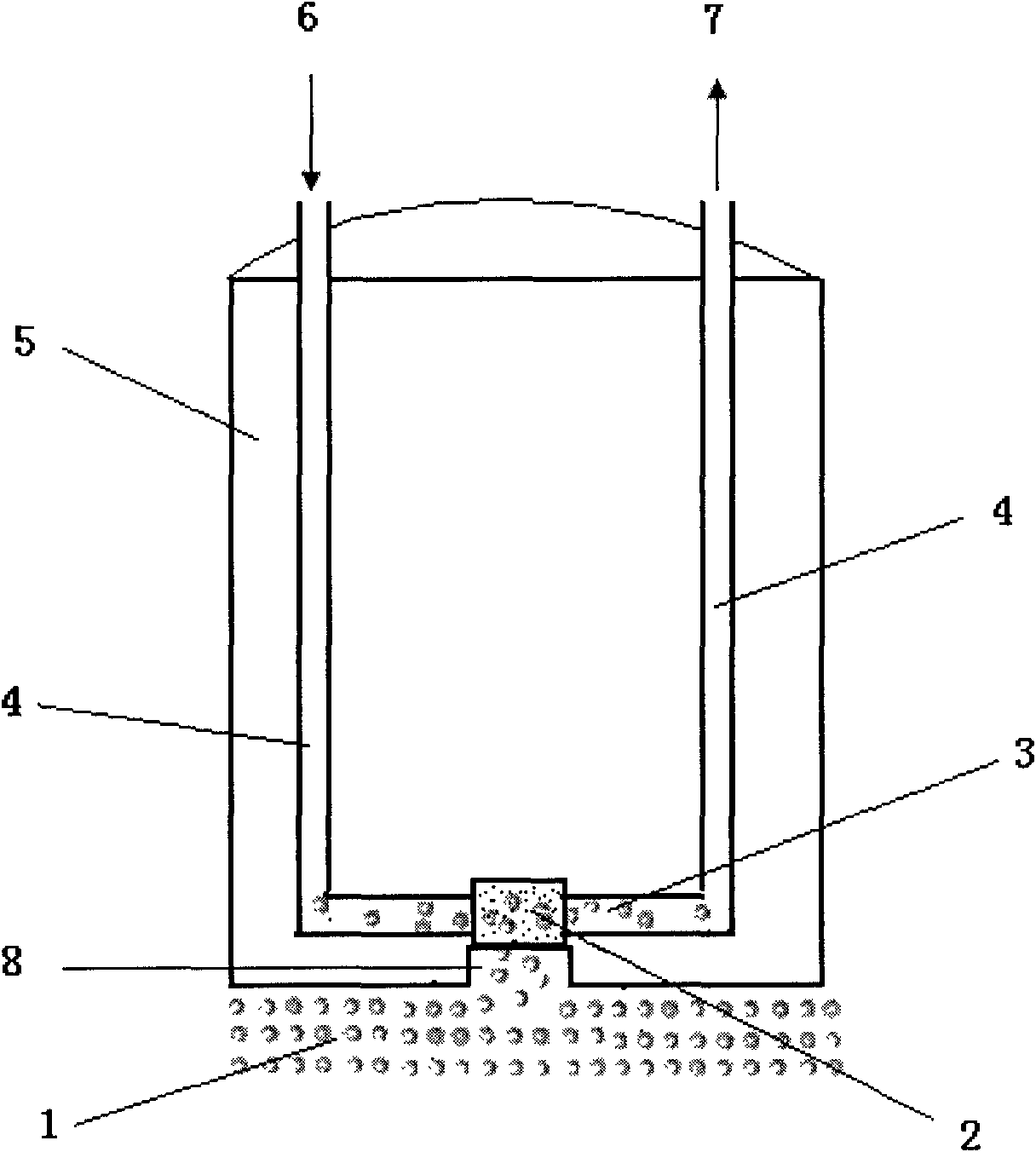

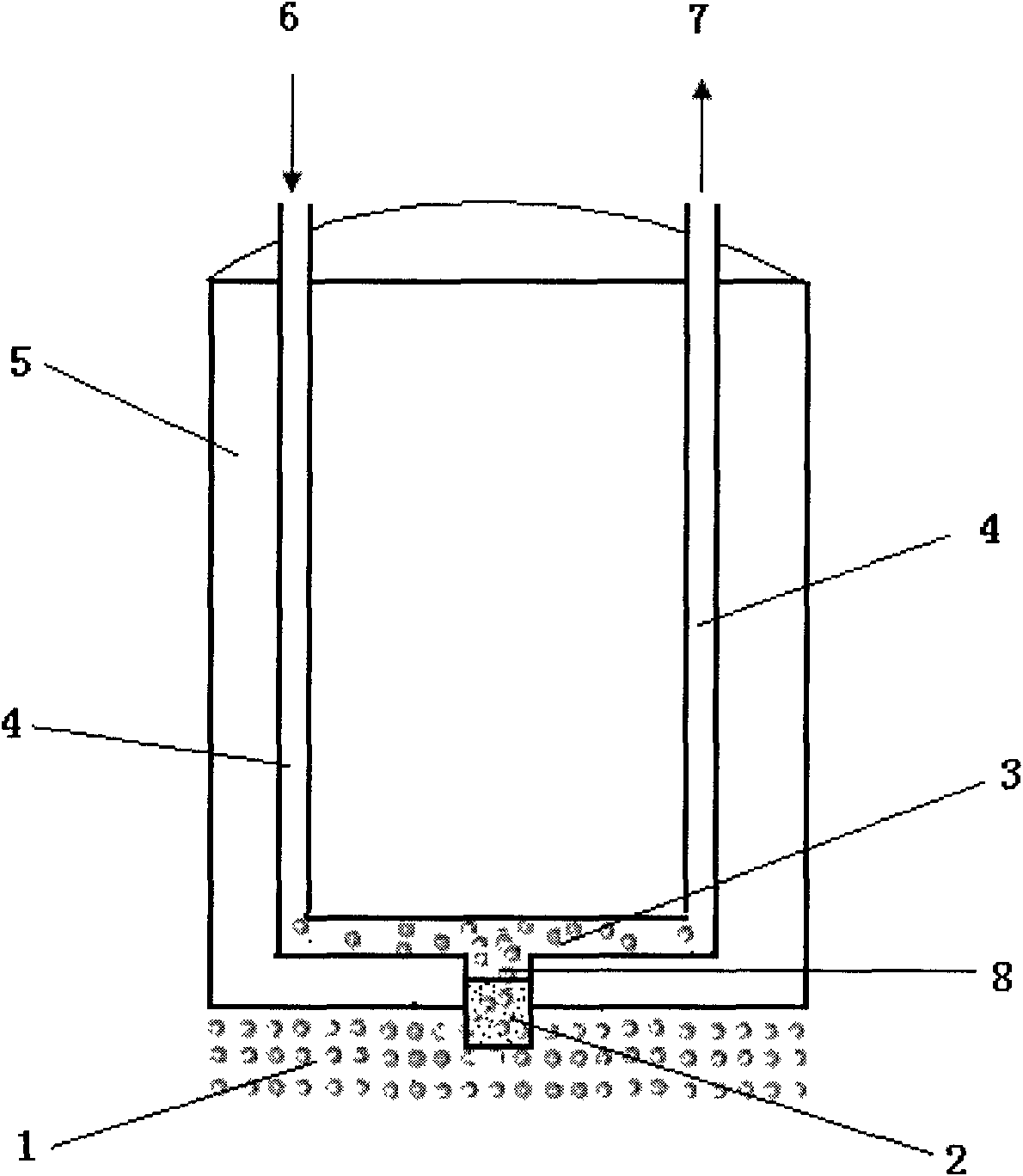

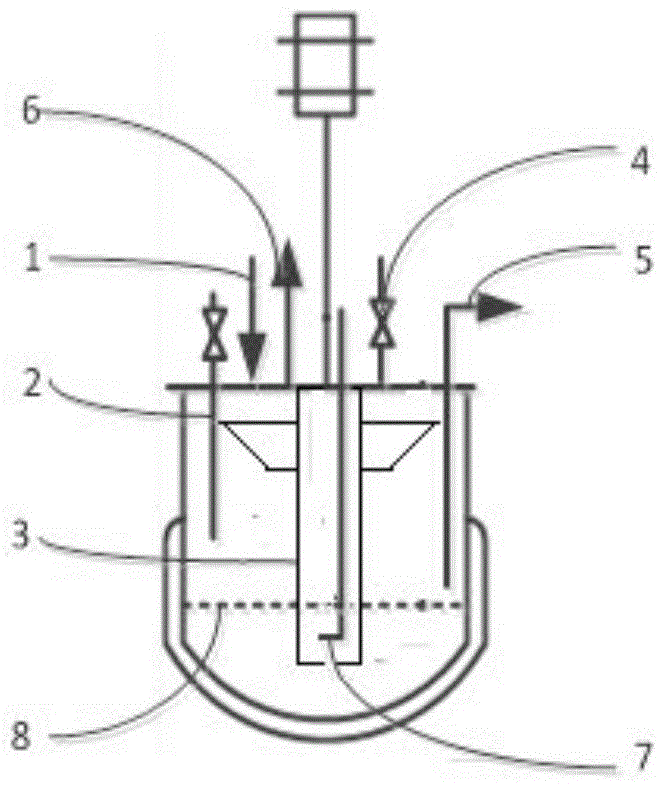

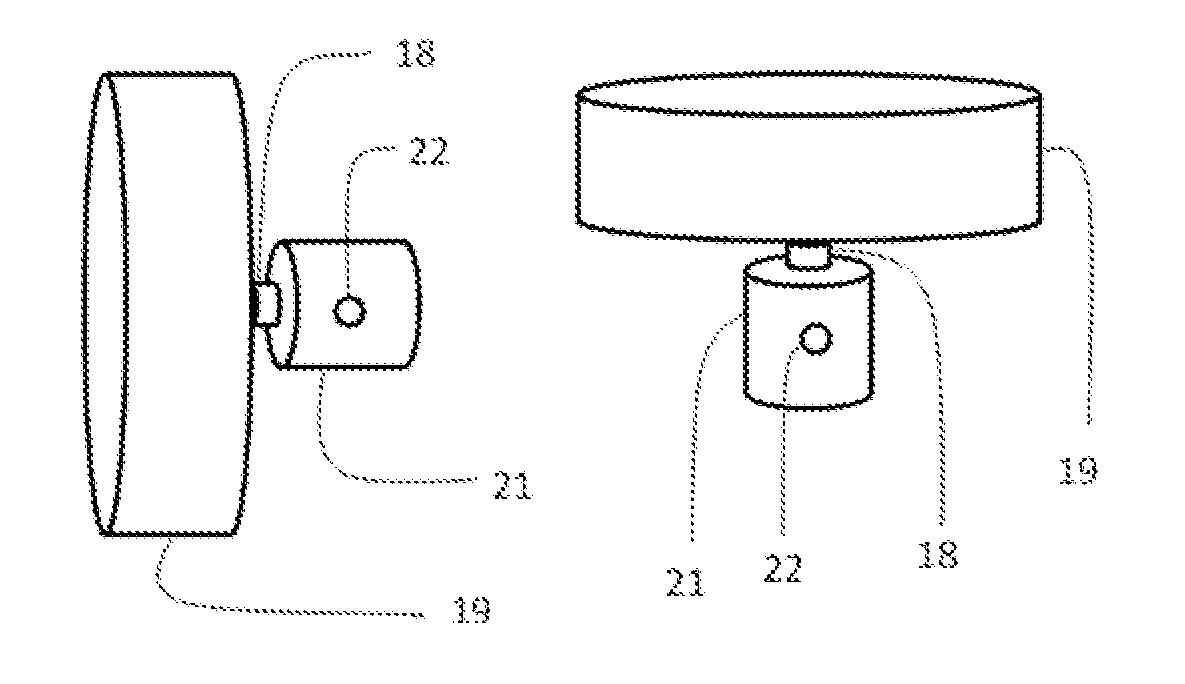

Pneumatic self-circulation animal cell culture bioreactor and application method thereof

ActiveCN103589638BImprove living conditionsGrowth and metabolism without dead endsBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemContamination rate

The invention discloses a pneumatic self-circulation animal cell culture bioreactor and an application method thereof. The bioreactor is characterized by comprising a large tank, a small tank located in the large tank, a magnetic stirring system located at the bottom of the large tank, a heating system and a controlling system, wherein a sealing cover is arranged at the upper end of the large tank, jackets connected with the heating system are arranged on two sides of the large tank, and a highest liquid level sensor of the large tank is arranged at the upper part in the large tank; and a sealing head is arranged at the upper end of the small tank, an opening is formed in the lower end, the sealing head is fixedly connected in a sealing manner with the sealing cover through a breathing pipe, the upper end of the breathing pipe penetrates out of the sealing cover and is connected with a vacuum air pump and an air pressure pump respectively, the lower end penetrates out of the sealing head and enters the small tank, a cavity used for accommodating a cell carrier is defined by two up-and-down horizontal stainless steel wire mesh boards in the middle of the small tank and the inner wall of the small tank, an upper liquid level sensor of the small tank is arranged above the cavity, and a lower liquid level sensor of the small tank is arranged below the cavity. The pneumatic self-circulation animal cell culture bioreactor has the advantages of good air tightness, simplicity in operation, low contamination rate, good cell quality and high yield.

Owner:罗火生

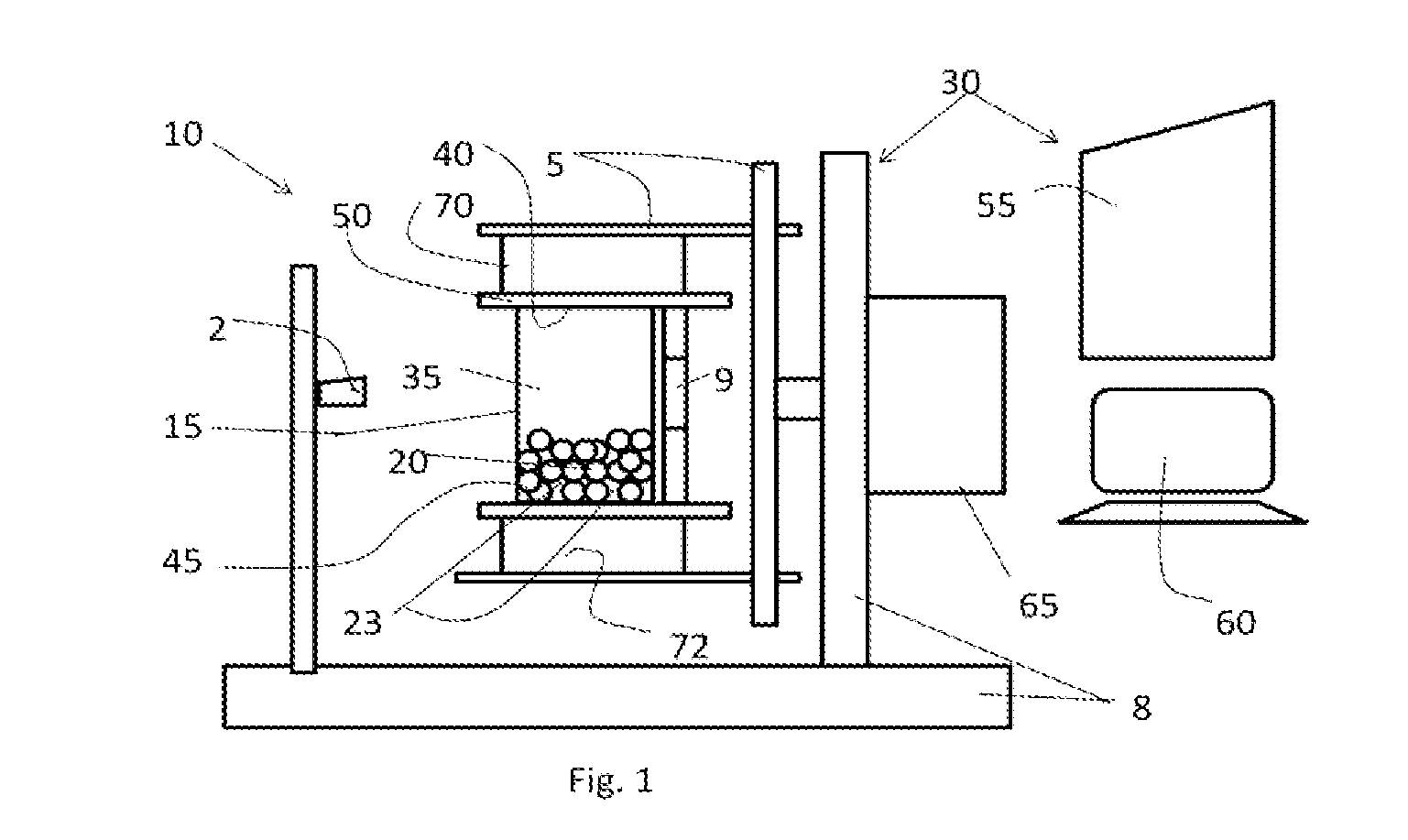

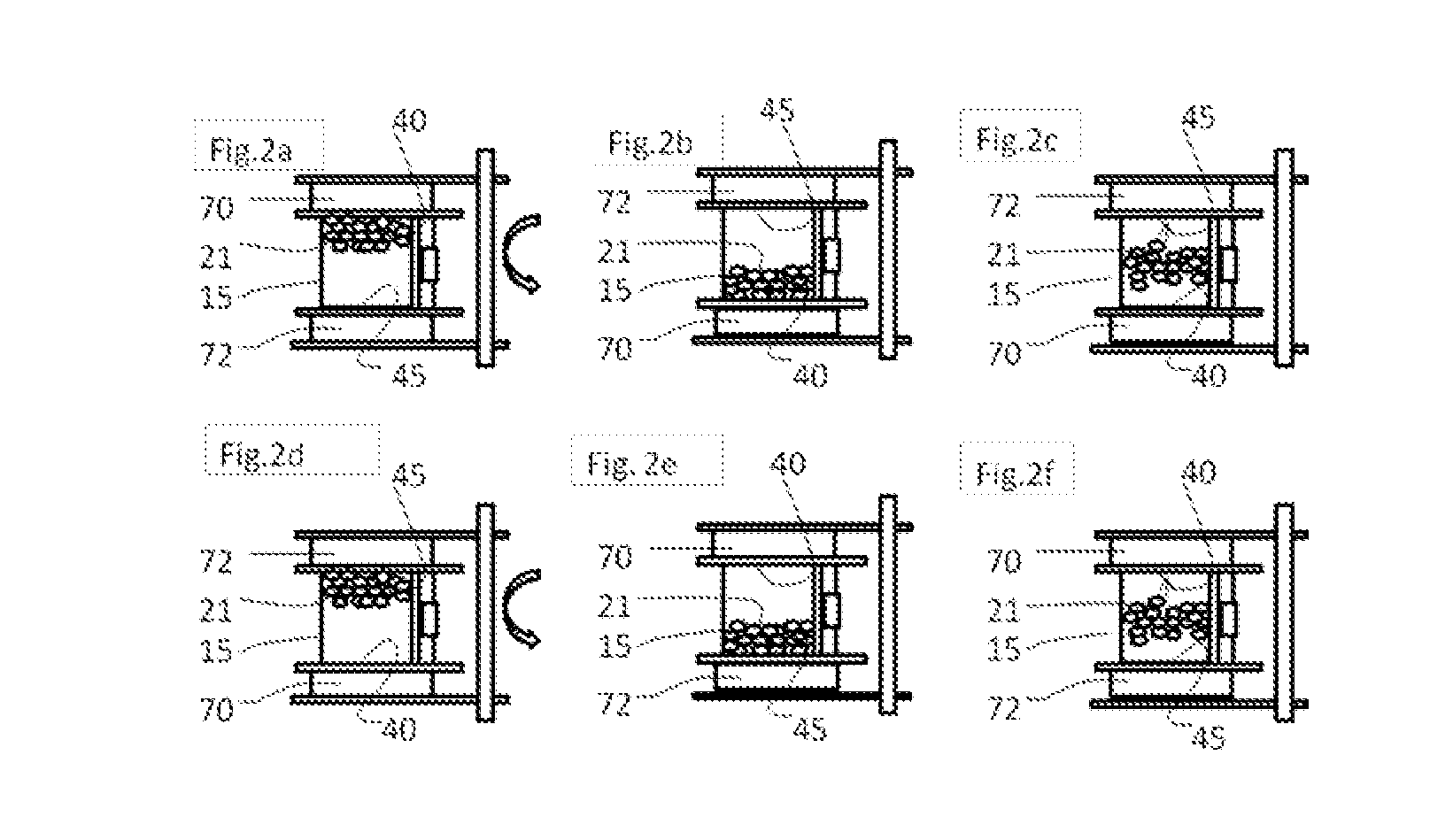

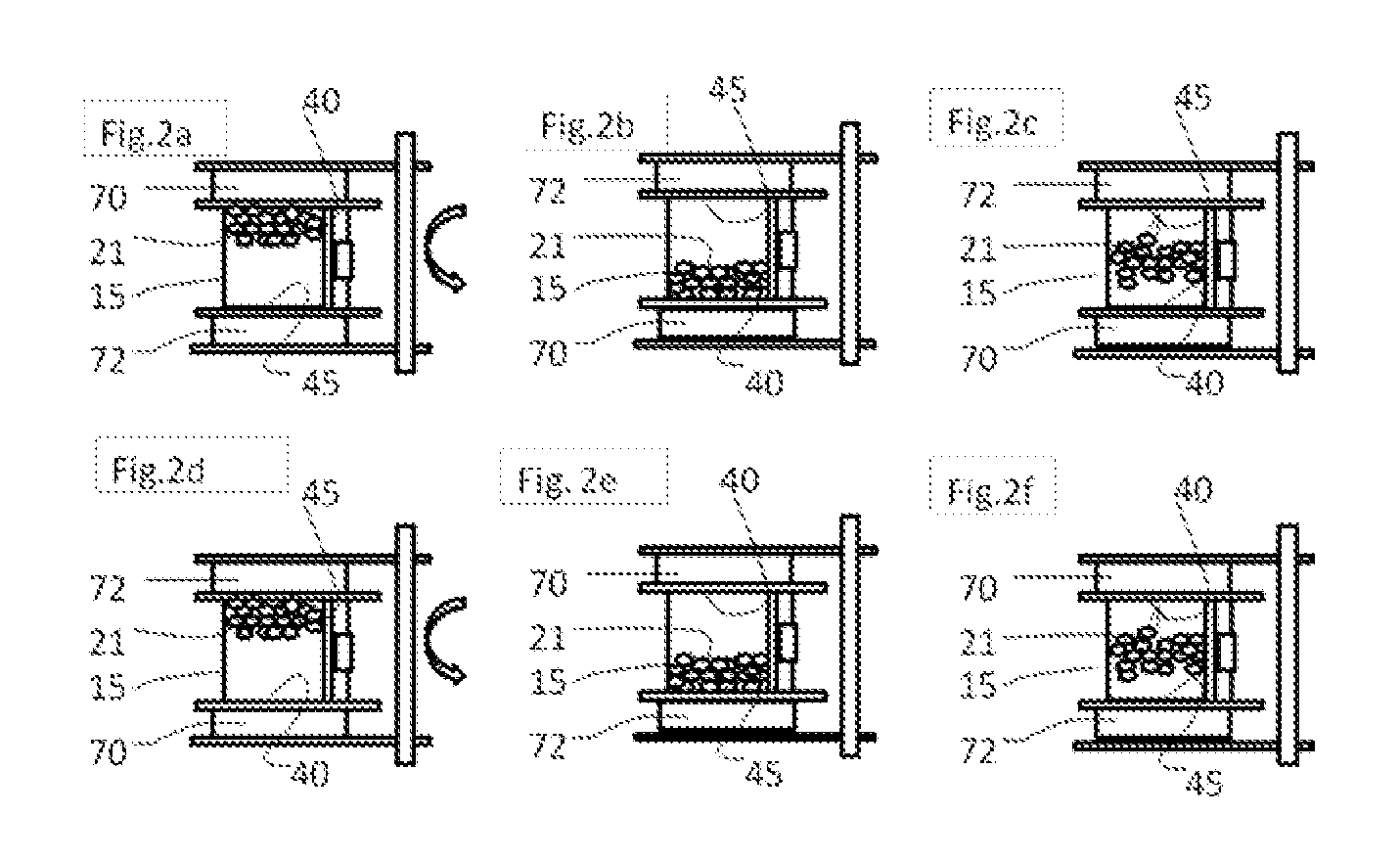

Bioreactor System and Methods for Alternative Cell Culture between Static and Dynamic

ActiveUS20150093819A1Minimize sheer-stressIdeal environmentBioreactor/fermenter combinationsBiological substance pretreatmentsCultured cellBiology

The invention relates to a bioreactor system characterized by its capacity in cultivating cells in all three states: static, dynamic, or alternating between static and dynamic states in the same cell culture container or containers, with the even distribution of cells in cell static culture following a dynamic culture. In the invented bioreactor system, the combined application of the magnetically controlled agitation and the cell culture container inversion as well as the combined application of the vertical rotating culture and horizontal static culture are the two strategies in building ideal bioreactors for the cell culture alternating between static and dynamic states in the same cell culture container, which can minimize the sheer-stress and provide cells an ideal metabolic environment.

Owner:ZHANG YONGXIN

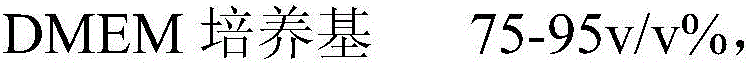

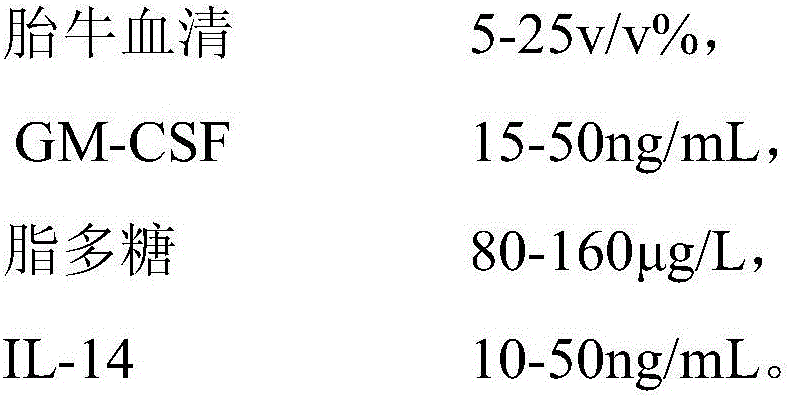

Macrophage medium and culture method

InactiveCN105779392ASimple and fast operationReduce incubation timeMicrocarriersBlood/immune system cellsMicrobiologyMicrocarrier

The invention relates to a macrophage medium and a culture method. The macrophage medium contains a DMEM medium, FBS, GM-CSF, lipopolysaccharide and interleukin-14. In the culture method of macrophage, the macrophage is cultured by use of the macrophage medium provided by the invention, a microcarrier and a shaking bag type cell culture bioreactor. By adopting the macrophage medium and culture method provided by the invention, the culture time is shortened, the consumption of human resources is reduced, and large-scale culture of macrophage can be realized.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

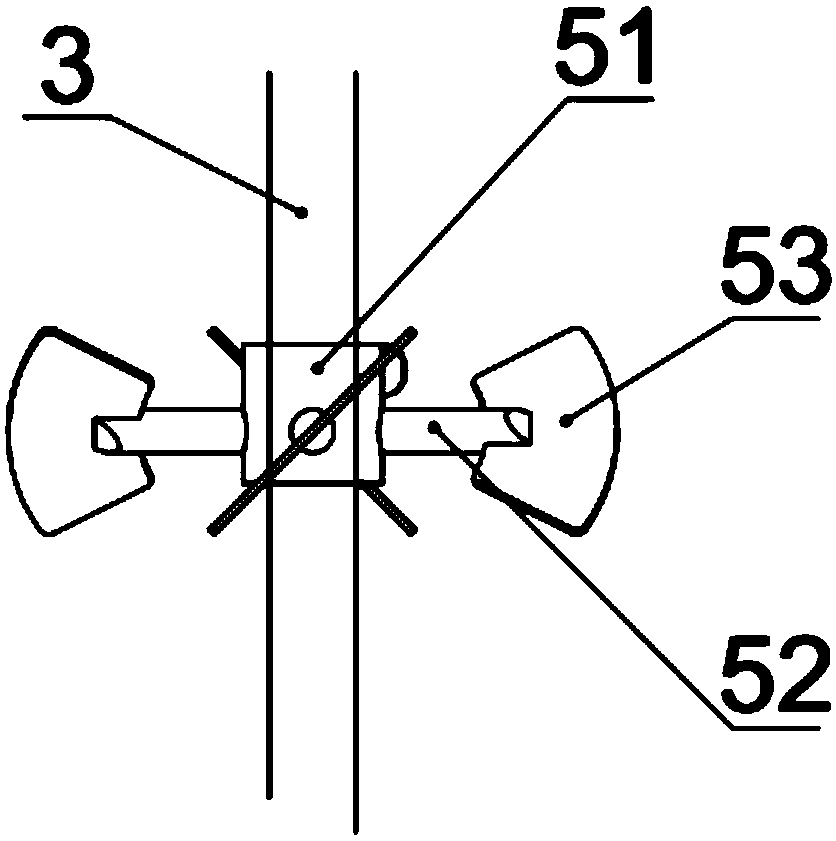

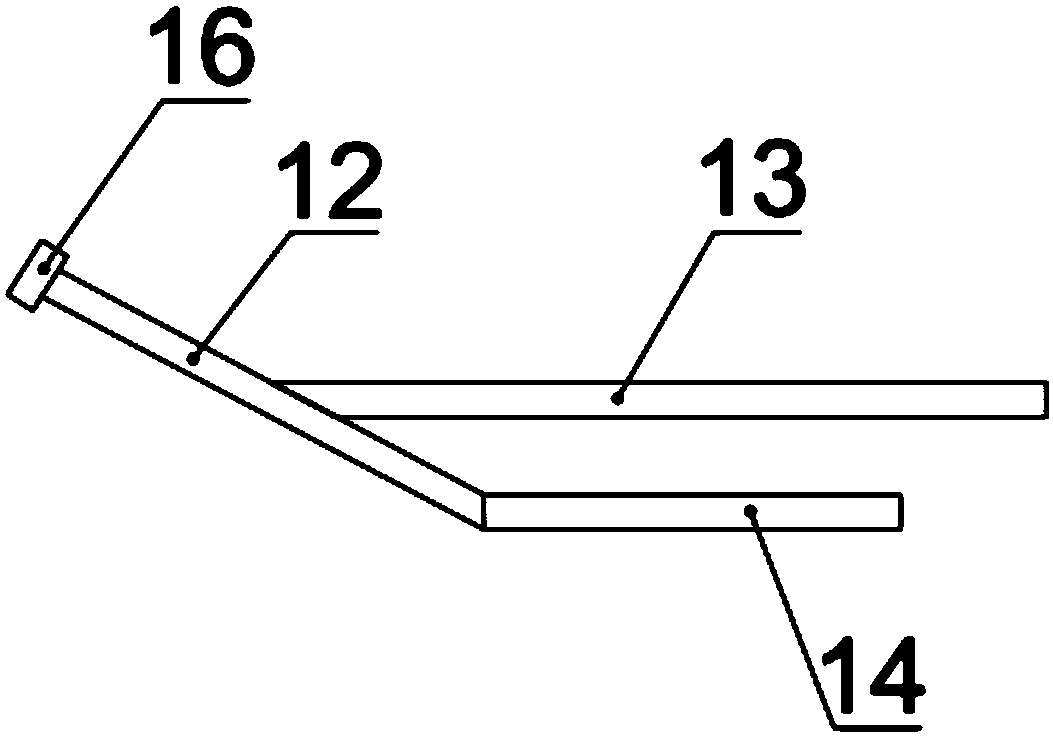

Cell culture bioreactor

PendingCN108410734AWell mixedAvoid cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringNutrients substances

The invention provides a cell culture bioreactor and belongs to the technical field of cell culture. The cell culture bioreactor comprises a tank body, wherein an upper air inlet is formed in the upper part of the tank body, and a lower air inlet is formed in the lower part of the tank body; a magnetic stirring mechanism is arranged in the bottom center of the tank body; the magnetic stirring mechanism is connected with a stirring shaft in the tank body; an upper blade is arranged at the top end of the stirring shaft; a first stirring mechanism and a second stirring mechanism in alternative distribution are sequentially arranged on the stirring shaft from top to bottom; the second stirring mechanism is longer than the first stirring mechanism; a microbubble ring is arranged below the stirring shaft; the microbubble ring comprises at least two hollow sub-rings with diameter gradually reducing from top to bottom and a first air inlet rod connecting the sub-rings; the first air inlet rodis communicated with the lower air inlet by a second air inlet rod; multiple air holes in uniform distribution are formed in the lower surface of the sub-rings. The cell culture bioreactor provided bythe invention has the advantages of uniform ventilation, high efficiency, uniform mixing of cells and nutrient substances, high yield and uniform product quality while meeting the need for large-volume tank production.

Owner:江苏弗洛瑞生物工程设备有限公司

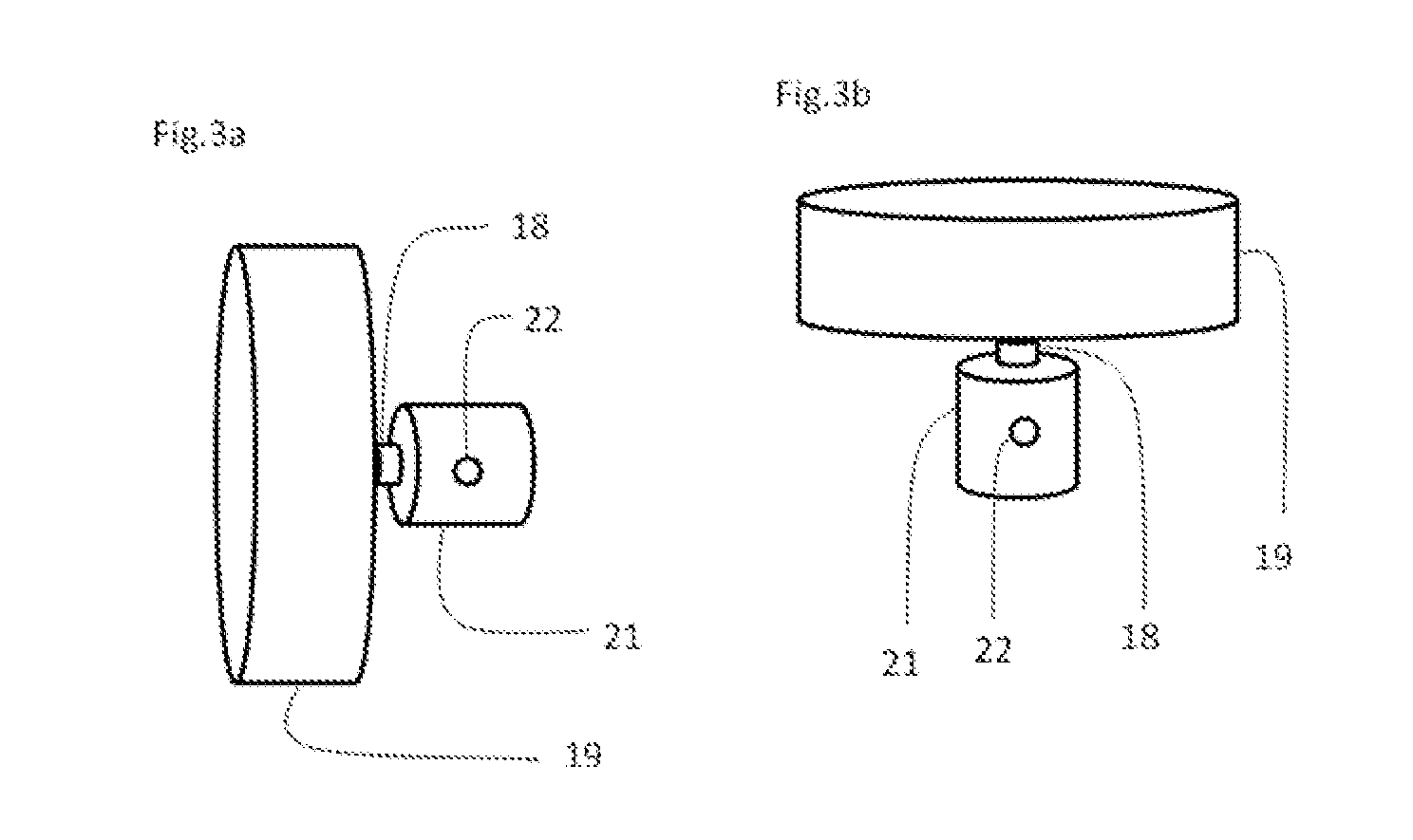

Heatseal Sampling

ActiveUS20180201894A1Easy to handleReduce effortBioreactor/fermenter combinationsBiological substance pretreatmentsQuality controlBiology

The present invention provides a device and method for sampling from a cell culture bioreactor. The invention is useful where it is required to determine the cell count, provide a sample for off-line analyses or remove a sample while at the same time retain sterility of the sample for quality control (QC) assessment. The device of the invention allows for facile aseptic sampling at one or more instances in time during a cell expansion in a bioreactor.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

Cell culture biological production device

The invention relates to a cell culture biological production device, mainly aiming at solving the problem that when the cell culture biological reaction device in the prior art is used for carrying out cell culture, the maximum cell density in the bioreactor is low. The cell culture biological production device comprises a cell culture bioreactor and a culture solution oxygenation tower, wherein the inside of the oxygenation tower has the following arrangement: the upper space is provided with a liquid distributor, the lower space is provided with an oxygenation tower gas distributor communicated with an oxygenation gas inlet, and a filler layer is arranged between the liquid distributor and the oxygenation tower gas distributor; an oxygenation tower tail gas discharge hole is formed in the top of the oxygenation tower; the production device is provided with an oxygenation tower feeding channel I used for taking a liquid material from the reactor and conveying the liquid material to the top of the oxygenation tower and communicated with the liquid distributor; and the production device is provided with a liquid material back conveying channel II used for taking the liquid material from the bottom of the oxygenation tower and conveying the liquid material to the reactor.

Owner:上海尚优生物科技有限公司

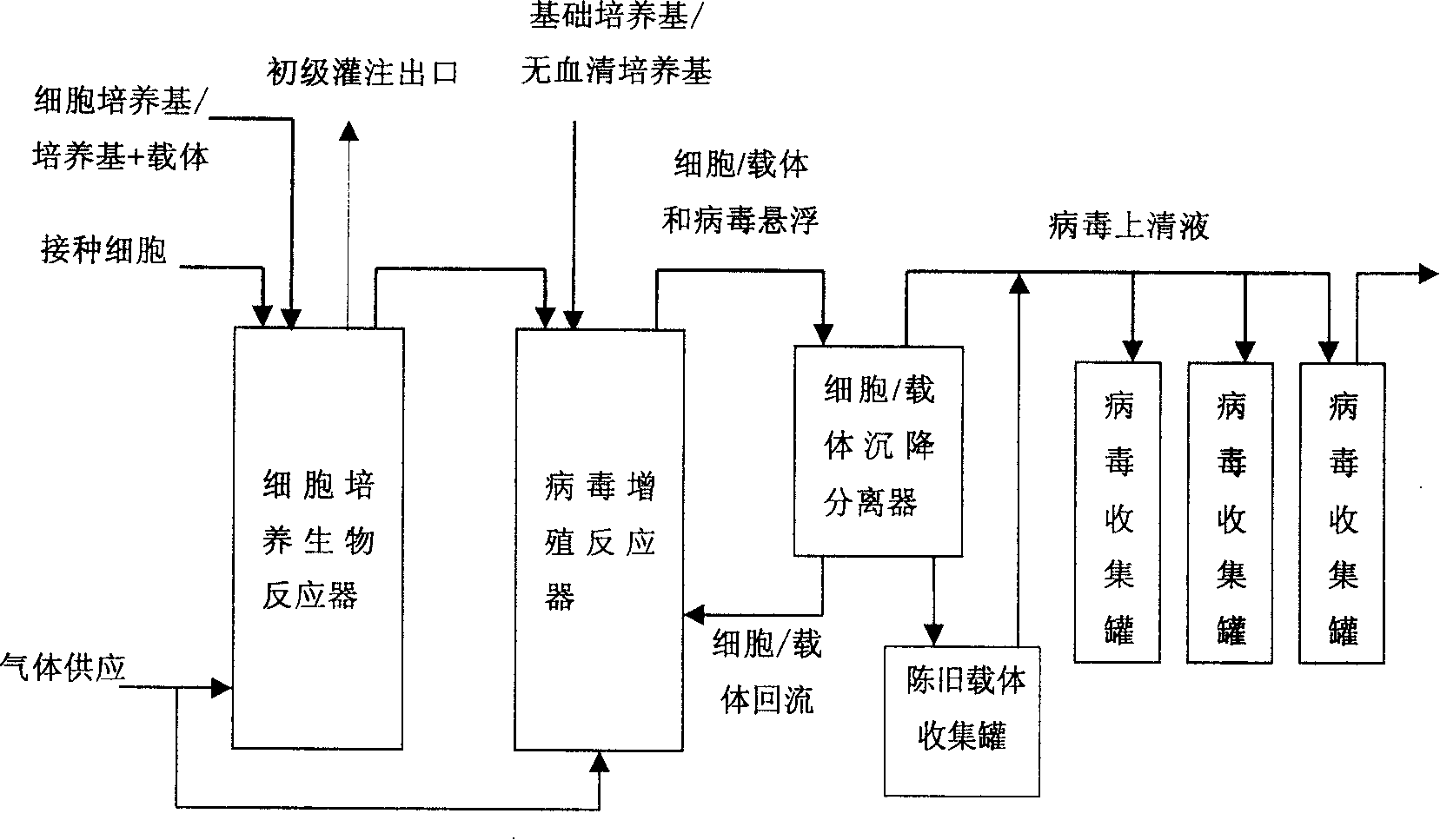

Method for safe continuous enclosed cell culture, virus production/ inactivation

ActiveCN100389193CGreat operating flexibilityImprove production safetyViral antigen ingredientsInactivation/attenuationAutomatic control3D cell culture

A method of cells culture, virus production / deactivation in safe, continuum and blocked style, belonging to bioengineering technical field, compring steps of: 1) Inoculate cells and suspension culture, therebycarry out the primary culture of cells; 2)Flowing add fresh medium, simultly pump out cells suspension to maintain cell culture biological reactor stable and guarantee cell amplificatation during residence time in reactor, accordingly carry out cell's continuous cultivation; 3) Pump out cells suspension into virus-containing virus breeding reactor to make virus infect and amplificate in cells preliminary; 4)As the inflow of cells suspension and outflow of virus-containing upper clean liquid, system dynamic balancing is maintained and virus continuous cultivation is achieved; 5) Collect the upper clean liquid pumped from virus breeding reactor and deactivate the virus, accordingly achieve continuously and obturately cells cultivation and virus deactivation. This method is convenient for automatic control and standardized production, also depresses the pollution chances and heightens production assurance coefficient.

Owner:上海丽坤生物科技股份有限公司

Schizothorax quadricarinatus fin ray cell culture bioreactor

InactiveCN111454822AAvoid damageCharge moreBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryEngineering

A schizothorax quadricarinatus fin ray cell culture bioreactor comprises a base, vertical supporting plates are fixedly installed on the two sides of the base respectively, a motor is fixedly installed in the center of the base, a sliding block with a dovetail-shaped section is arranged in a sliding groove in a matched mode, the bottom end of the sliding block is hinged to the top end of the otherside of a connecting plate, and an air inlet is formed in one side of a sleeve. A pipeline is fixedly connected to the top end of the sleeve and communicated with the interior of the sleeve, and theother end of the pipeline is fixedly connected with the top end of the reactor body through a sealing bearing and communicated with the interior of the reactor body. According to the present invention, the shaking rotation can be performed, the shearing force generated by the machine is reduced, the influence of the mechanical stirring on the cells is avoided, the damage or the infection of the cells caused by the mechanical stirring is avoided, other devices are not required to provide power for the oxygen supply, the oxygen supply is performed through the movement of the reactor body, and the power device is less; better effect.

Owner:TARIM UNIV

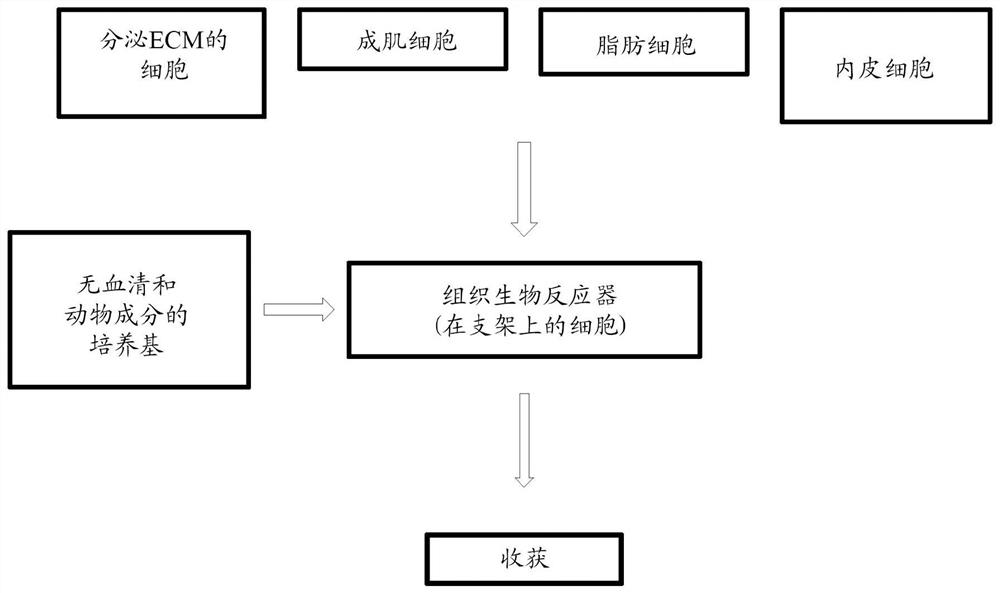

Culture system and method for large-scale production of cultured food

PendingCN114207115ABioreactor/fermenter combinationsBiological substance pretreatmentsCultured meatMicrobiology

Systems and methods are provided for producing a cultured food product, such as a meat cut piece (meat cut) or cultured meat in the form of viscera, including culturing non-human animal adherent cells on an edible scaffold in a culture system. The culture system generally includes more than one cell culture bioreactor that receives culture medium at a controlled flow rate that is adjusted to nourish the non-human animal adherent cells.

Owner:ALEPH FARMS LTD

Heatseal sampling

ActiveUS10858622B2Easy to handleReduce effortBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyBiochemical engineering

The present invention provides a device and method for sampling from a cell culture bioreactor. The invention is useful where it is required to determine the cell count, provide a sample for off-line analyses or remove a sample while at the same time retain sterility of the sample for quality control (QC) assessment. The device of the invention allows for facile aseptic sampling at one or more instances in time during a cell expansion in a bioreactor.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

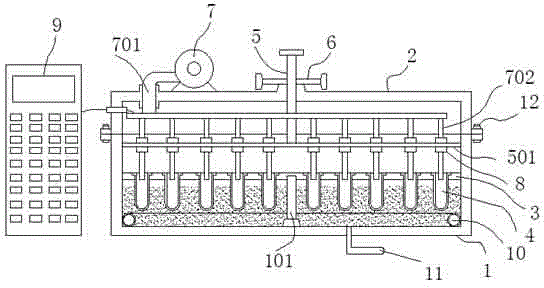

Cell-culture bioreactor

InactiveCN103981095AAvoid it happening againAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyCulture cell

The invention discloses a cell-culture bioreactor. The cell-culture bioreactor comprises a biological culture reaction utensil and a sealing cover, wherein a supporting rod is arranged on a middle position inside the biological culture reaction utensil; the supporting rod is matched with a bracket; a plurality of blocking holes are formed on the bracket; the blocking holes are matched with a test tube; a slide hole is arranged in the middle of the sealing cover; a slide rod is matched in the slide hole; the lower end of the slide rod extends to the biological culture reaction utensil; the lower end of the slide rod is matched with a first bracket; an air blower is arranged on the top of the sealing cover; an air feeding end of the air blower is matched with an air feeding branch tube; a plurality of secondary branch tubes are connected on the air feeding branch tube; solenoid valves are arranged on the tube bodies of the secondary branch tubes; and the cell-culture bioreactor further comprises a control cabinet connected with the air blower and the solenoid valves. The device can effectively culture cell organisms and can avoid cell injuries caused by ventilating; and meanwhile, the device can culture a plurality of cell organisms once, so that culture efficiency is higher.

Owner:杨永明

Technological process of producing recombinant human histiotype plasminogen activator TNK mutant

InactiveCN1221567CSimple process conditionsLow costRecombinant DNA-technologyFermentationHamsterSingle strand

The present invention discloses the technological process of producing recombinant human histiotype plasminogen activator TNK mutant. TNK-tPA gene containing said mutant sites is synthesized via full length gene synthesis process and expressed in Chinese hamster ovary cell (CHO-DHFR), and through cloning and screening high-level expressed TNK-tPA engineering cell strain is obtained. By means of sustained culture of the engineering cell in cell culturing bioreactor, collection of the supernatant and serial separation and purification in chromatographic column, rhTNK-tPA product is obtained. The destination gene of the present invention has expression level in cell as high as 18000 IU / 106 cell / d, and the prepared rhTNK-tPA product has single strand rate as high as 80 % and purity up to 95 %. As for industrial scale, the present invention has relatively simple requirement in apparatus, low cost and simple technological requirement.

Owner:石药集团明复乐药业(广州)有限公司

External circulation animal cell culture bioreactor

ActiveCN101899394BOptimize layoutFunctionalBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpControl system

The invention relates to an external circulation animal cell culture bioreactor which comprises a tank body, an external circulation pipeline, a heater, a peristaltic pump and a control system, wherein the tank body comprises a large tank and a small tank; the small tank is sheathed in the large tank and is clamped and fixed with the large tank respectively through ducts D, A and G; the external circulation pipeline comprises a tank external circulation pipeline and ducts A, B, E and D; on the upper part of the outside of the tank body, the ducts A and B are connected with the tank external circulation pipeline through a tee joint; on the lower part of the outside of the tank body, the ducts E and D are connected with the tank external circulation pipeline through a tee joint; the tank external circulation pipeline penetrates through the peristaltic pump; and the lowest position of the duct D is connected with a drainage pipe. The invention fully displays the characteristics of the animal cell large-scale culture technique, has the characteristics of thorough sterilization, simple operation, low pollution rate of cell culture, good quality and high yield, has favorable functionality and economical efficiency, and can be widely used for animal cell microcarrier suspension culture and animal cell suspension culture.

Owner:罗火生

Bioreactor system and methods for alternative cell culture between static and dynamic

ActiveUS9365813B2Minimize sheer-stressIdeal environmentBioreactor/fermenter combinationsBiological substance pretreatmentsCultured cellBiology

The invention relates to a bioreactor system characterized by its capacity in cultivating cells in all three states: static, dynamic, or alternating between static and dynamic states in the same cell culture container or containers, with the even distribution of cells in cell static culture following a dynamic culture. In the invented bioreactor system, the combined application of the magnetically controlled agitation and the cell culture container inversion as well as the combined application of the vertical rotating culture and horizontal static culture are the two strategies in building ideal bioreactors for the cell culture alternating between static and dynamic states in the same cell culture container, which can minimize the sheer-stress and provide cells an ideal metabolic environment.

Owner:ZHANG YONGXIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com