Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Timely lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

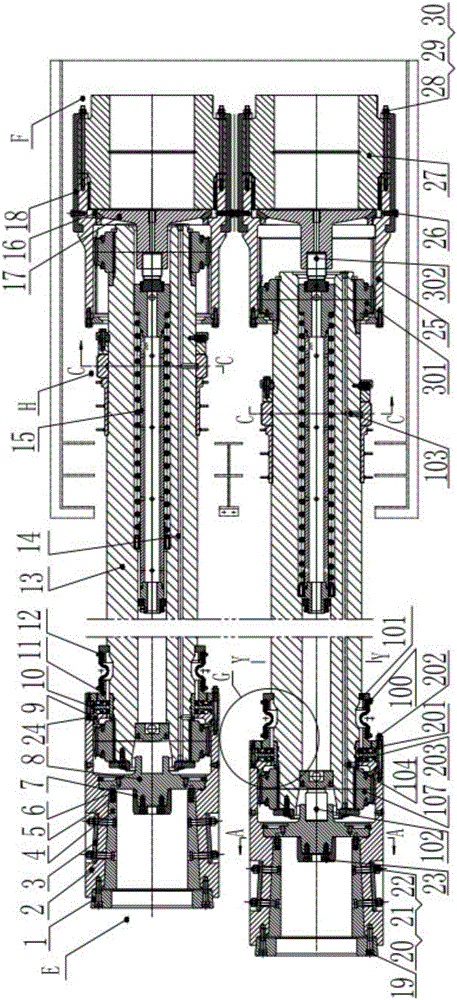

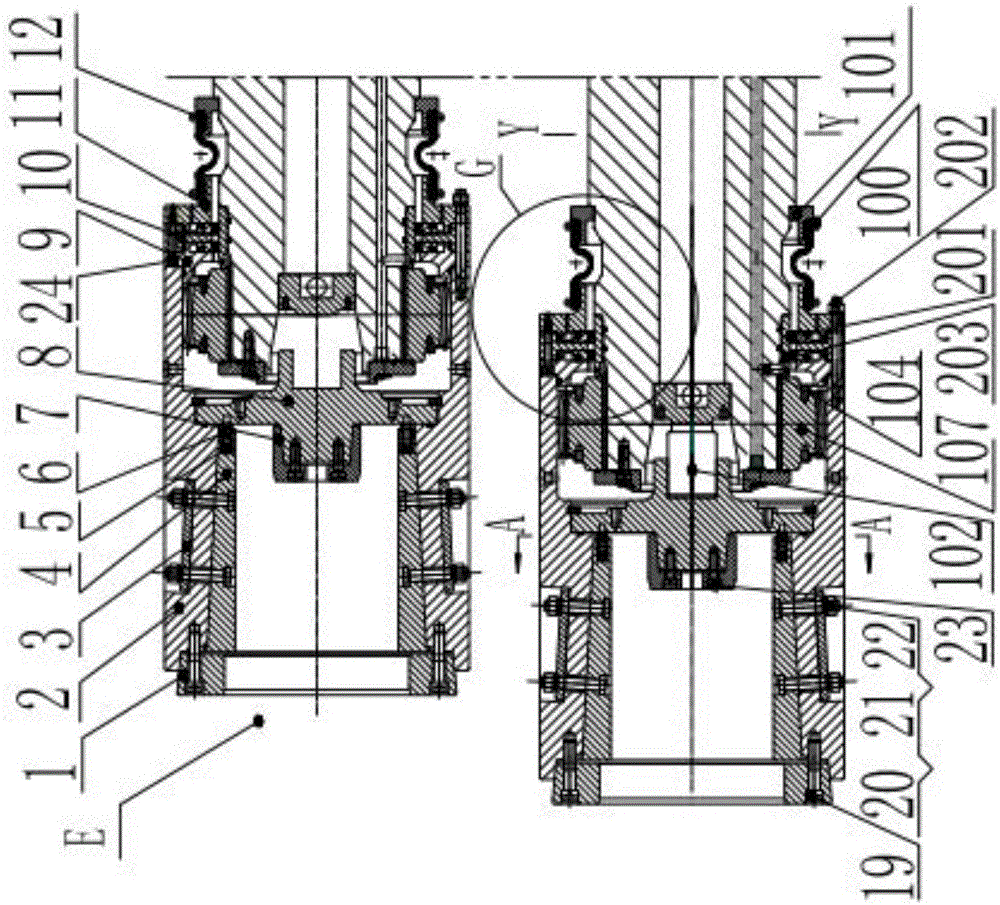

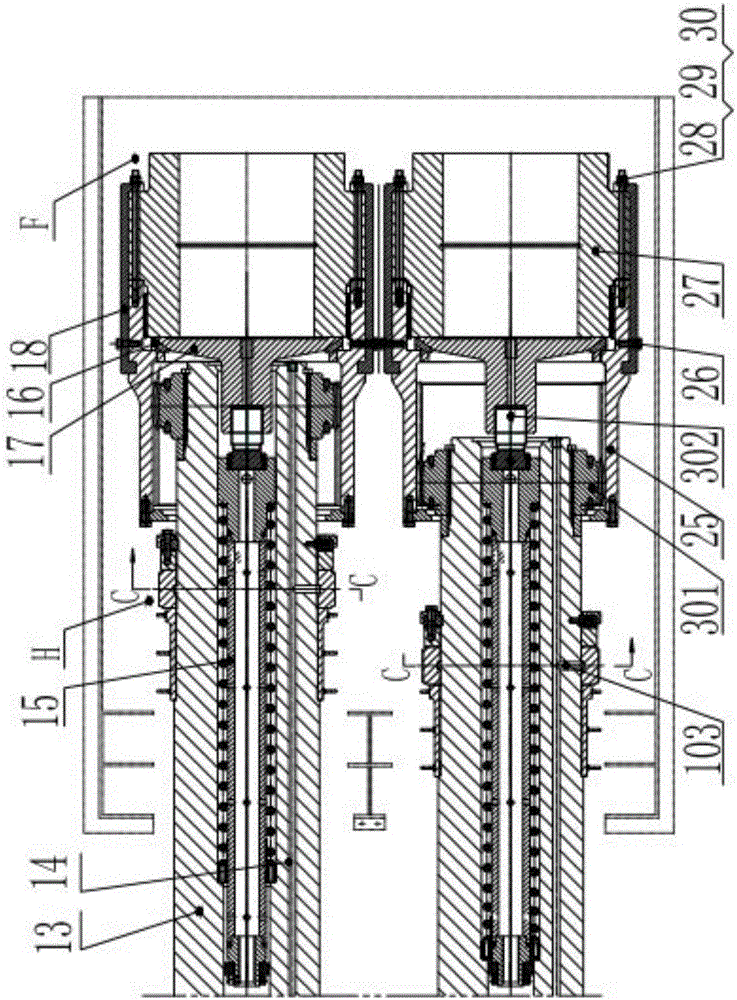

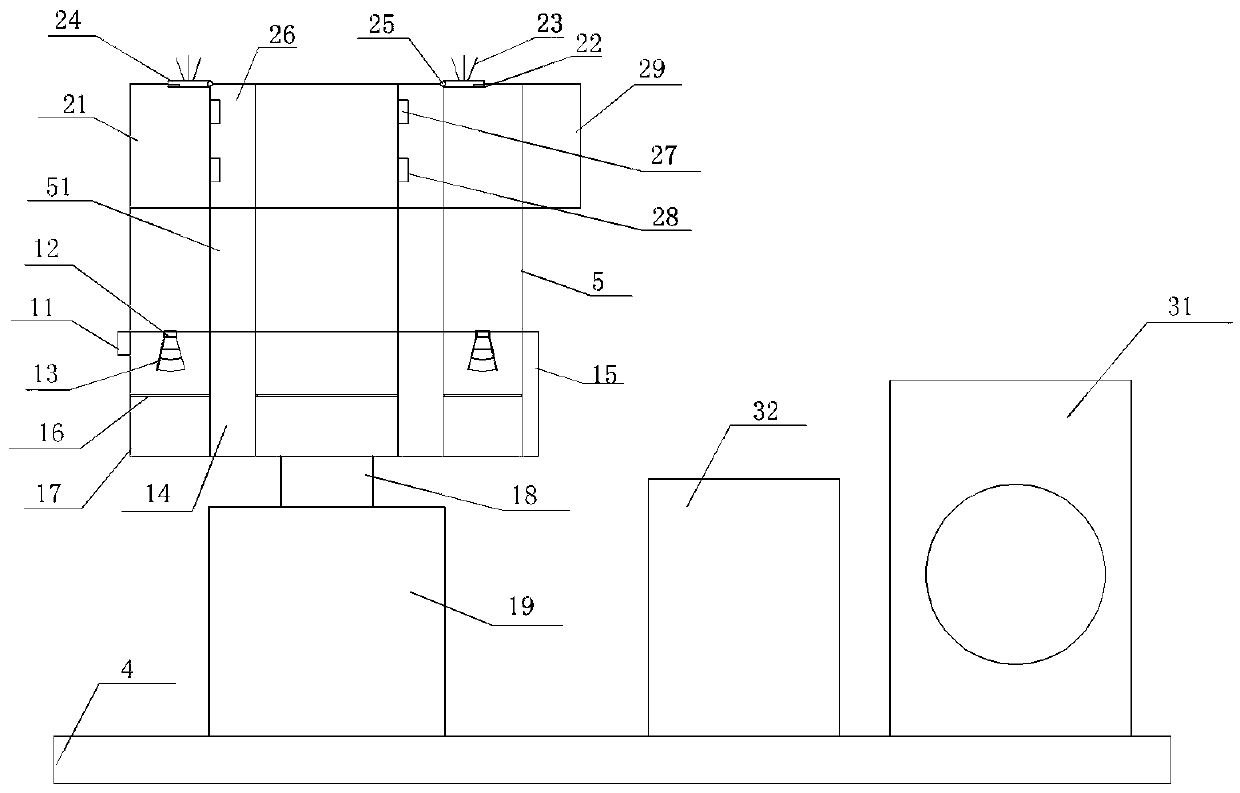

Hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter

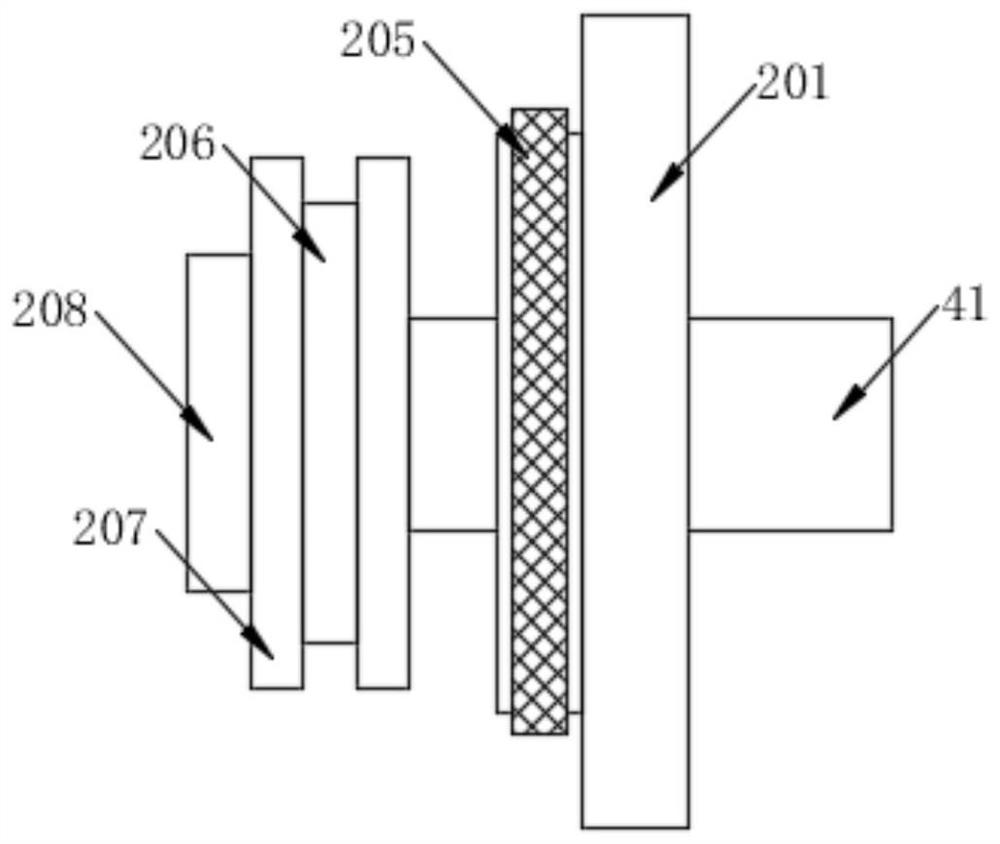

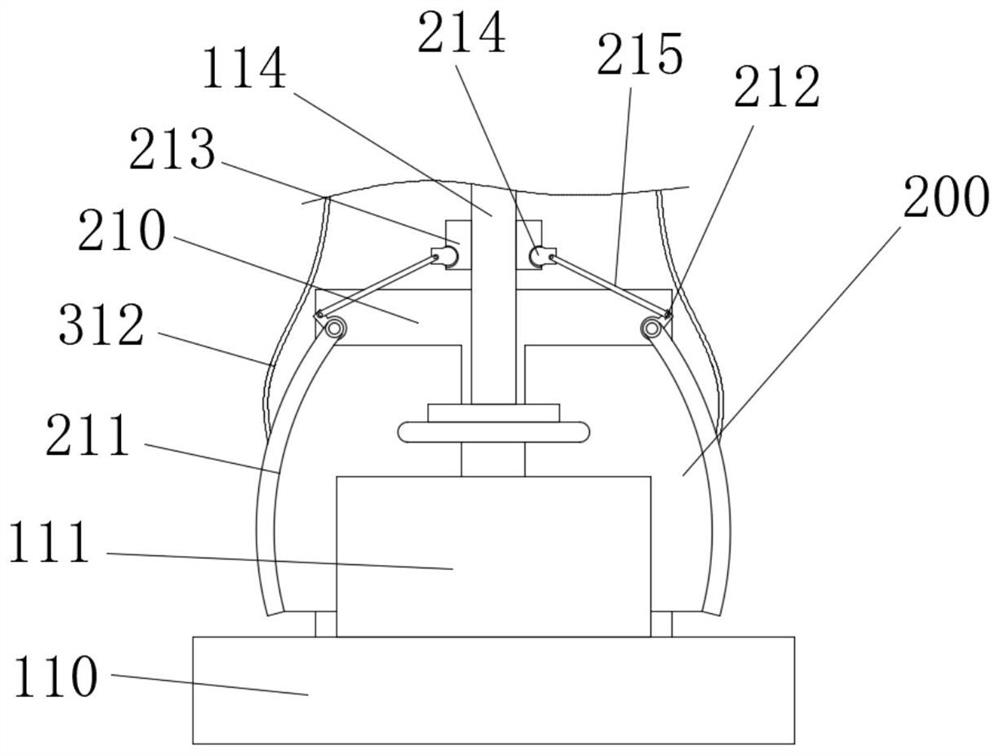

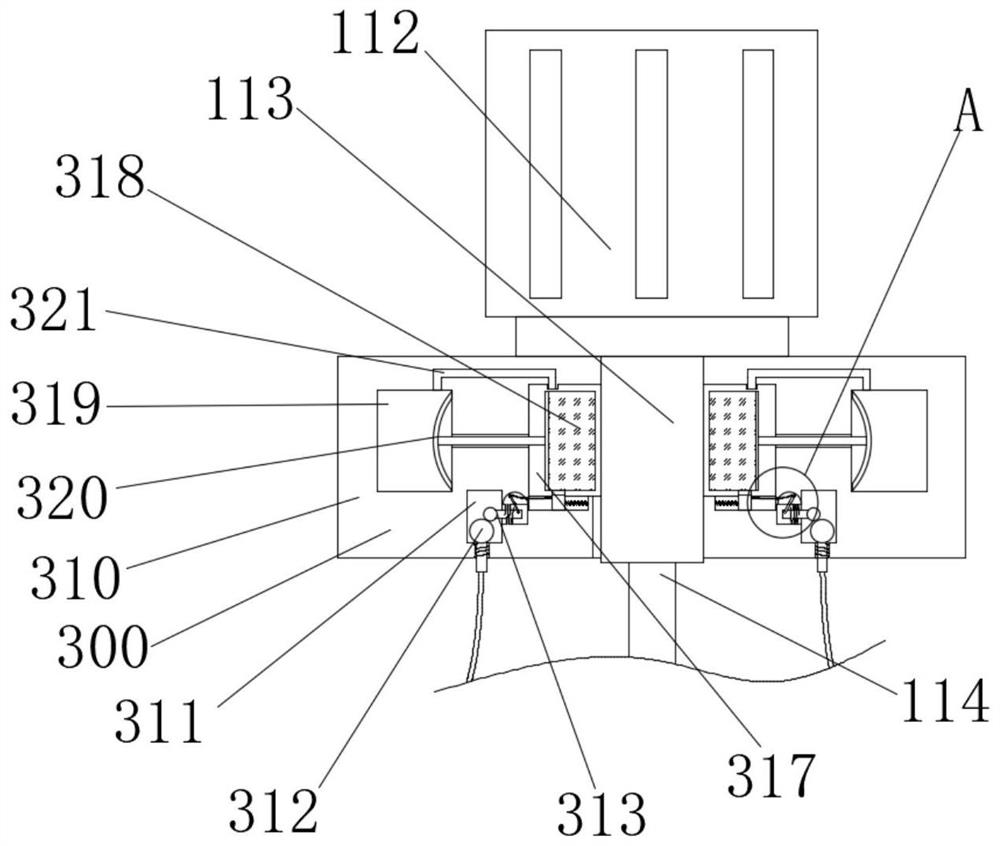

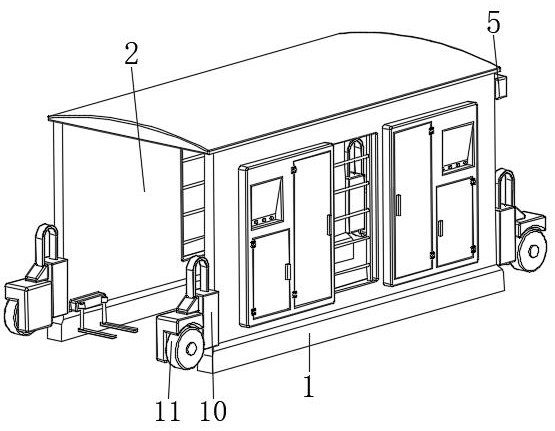

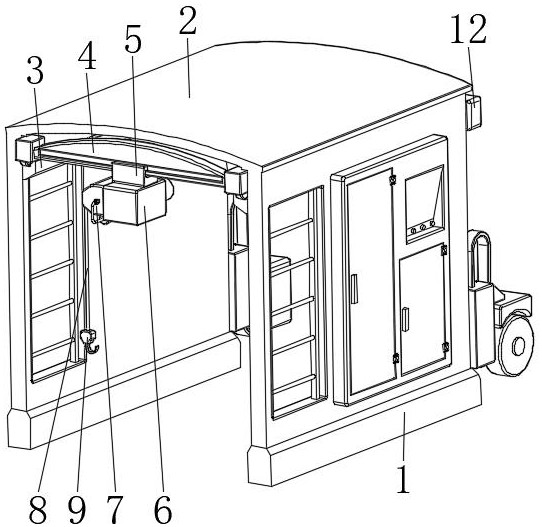

The invention belongs to the technical field of the jumbolter, in particular to a hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter. The hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter solves the problem of the traditional jumbolter. The slide block assembly of the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter comprises two groups of guideposts of a cylindrical structure; a short feeding cylinder is arranged in the slide block assembly; two long feeding cylinders are arranged on the outer side of the slide block assembly; the back of a frame assembly is provided with a dovetail-groove structure in sliding fit with the dovetail-shaped guide rail of a sleeve; the front side of the frame assembly is connected with the guidepost I by a slide block guide block and forms sliding fit with the guidepost I; and a guide connecting plate is connected with the guidepost II and forms sliding fit with the guidepost II. According to the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter, the reliability of the jumbolter performance can be effectively improved, the anchoring and drilling efficiency is greatly improved, and the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter can be used for a smaller size space, has a better adaptability and is coal mine underground supporting equipment with high degree of automation and high reliability.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

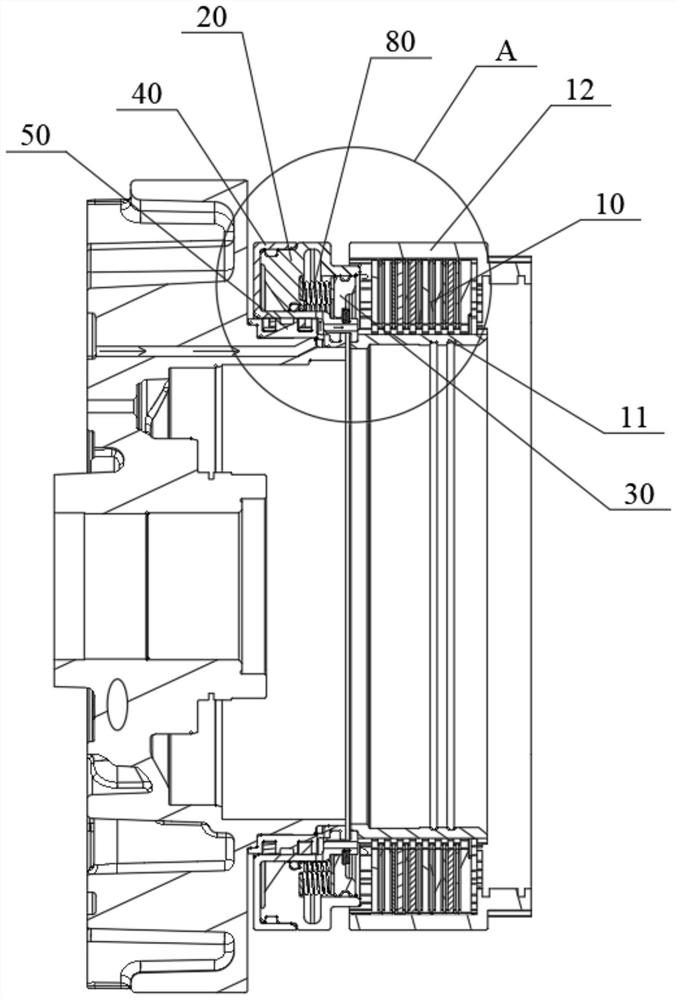

Double-clutch speed changing box and clutch hydraulic control system thereof

ActiveCN104534082AGuaranteed lubrication effectTimely lubricationGearing controlClutch controlControl system

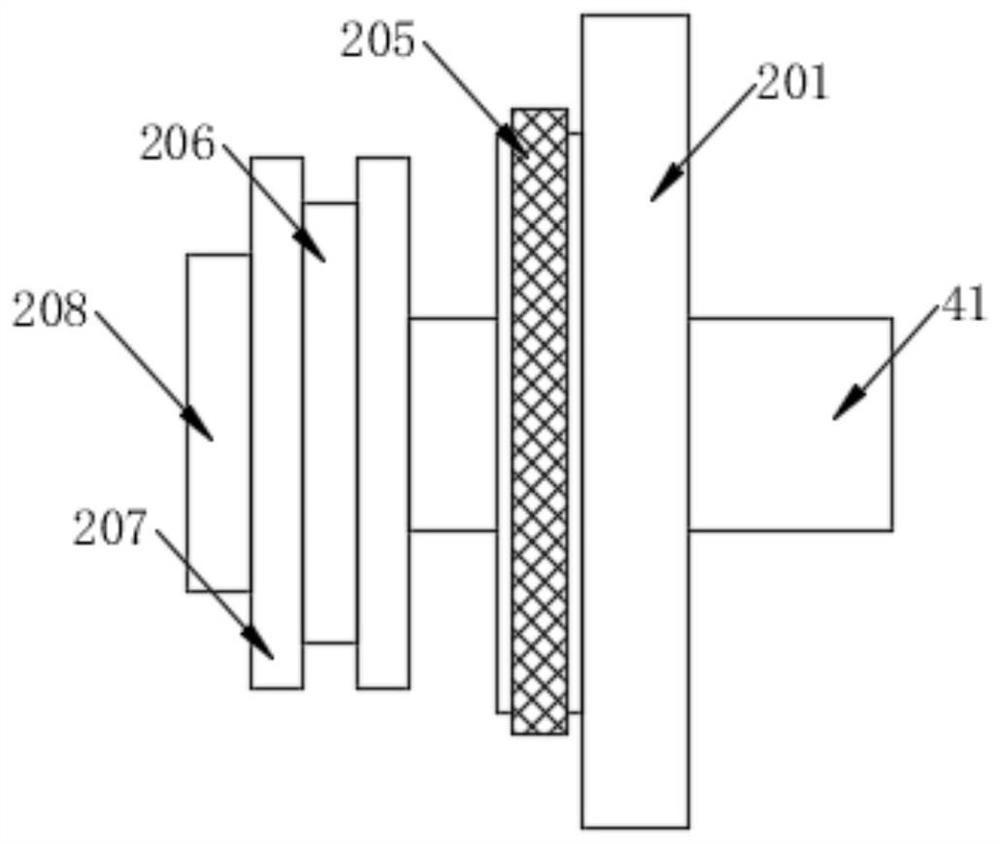

The invention discloses a clutch hydraulic control system and a double-clutch speed changing box thereof. The double-clutch speed changing box comprises a first cooling control oil path and a second cooling control oil path, wherein the second cooling control oil path and a first double-clutch control oil path are connected in parallel. The second cooling control oil path comprises a clutch cooling electromagnetic valve, an oil supply port of the clutch cooling electromagnetic valve is communicated with an oil tank, an oil outlet of the clutch cooling electromagnetic valve is communicated with a clutch cooling oil path through a throttling valve at a first communication position, and the oil outlet of the clutch cooling electromagnetic valve is communicated with the clutch cooling oil path at a second communication position. According to the clutch hydraulic control system, two sources are arranged for cooling lubrication of clutches, another path of cooling channel is formed by additionally arranging the clutch cooling electromagnetic valve on the basis that only a cooling slide valve is used traditionally, so that the lubrication of the clutches is ensured to the maximum degree, the clutches are cooled in time, and the problem of power interruption caused by the excessively high temperature of the clutches is solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Oil supply device

ActiveCN108087700APrevent oil spillsAvoid wastingBearing coolingEngine lubricationOil tankOil supply

The invention relates to the field of automobile performance testing, in particular to an oil supply device. The oil supply device includes an oil tank and further includes a clamping mechanism. The clamping mechanism is fixedly connected to an extruding plate. The extruding plate is provided with an extruding plate and an oil draining groove. The extruding plate is located above the oil draininggroove. The clamping mechanism is fixedly connected with a main gear. The outer side of the main gear is provided with an inner gear in a sleeved mode. An outer gear meshes with the position between the main gear and the inner gear simultaneously. The outer side of the outer gear is provided with a fixing plate. A rotating shaft is connected with the position between the fixing plate and the outergear. One end of the rotating shaft is fixedly connected to the fixing plate. The other end of the rotating shaft is rotatably connected with the outer gear. The outer wall of the inner gear is rotatably connected with a rotating block. The rotating block is connected with an ejector rod in a sliding mode. The oil tank is connected with a hose. The hose communicates with an oil cup. The junctionof the oil tank and the hose is connected with an oil control plate. A gasbag is arranged between the oil tank and the extruding plate. A gas pipe communicates with the position between the gasbag andthe hose. The gasbag is fixedly connected with the oil control plate and the ejector rod. Intermittent oil supply is achieved through the scheme of the oil supply device.

Owner:泾县凡泽科技服务有限公司

Tunneling hydraulic cylinder

ActiveCN110319072ASmooth transmissionAvoid bondingFluid-pressure actuatorsCleaning using toolsHydraulic cylinderHydraulic structure

The invention relates to the field of hydraulic cylinders, in particular to a tunneling hydraulic cylinder. The tunneling hydraulic cylinder comprises a fixing sleeve, a hydraulic structure, a filterscreen, a dust removal structure, an end cover and a lubricating structure, wherein the dust removal structure is matched with the use of the hydraulic structure, so that the hydraulic structure drives a cleaning assembly in the dust removal structure and a hydraulic shaft in the hydraulic structure to rotate while the hydraulic structure extends; the dust removal structure drives the lubricatingstructure, so that lubricating oil liquid is extruded, and the lubricating oil is uniformly smeared on the hydraulic shaft through the dust removal structure, so that the transmission of the hydraulicstructure is more stable; meanwhile, later-stage waste residue is prevented from being adhered to the hydraulic shaft; meanwhile, the dust removal structure blows the hydraulic shaft through gas, sothat the lubricating oil is further smeared on the hydraulic shaft more uniformly, and the waste residue in a coal mine can be prevented from being adhered to the hydraulic shaft during hydraulic driving; and when the hydraulic structure is shortened, the hydraulic structure drives the cleaning assembly in the dust removal structure to rotate, so that sweeps on the hydraulic shaft are scraped, andthe sweeps are prevented from entering the interior of the hydraulic structure.

Owner:济源市丰泽特钢实业有限公司

Engine lubrication control method, control device and oil-electricity hybrid drive vehicle

ActiveCN112554990AReduce lossTimely lubricationMachines/enginesPressure lubrication with lubrication pumpControl theoryHybrid vehicle

The invention belongs to the technical field of engines, and provides an engine lubrication control method and a control device applied to an oil-electricity hybrid drive vehicle and the oil-electricity hybrid drive vehicle. The method comprises the steps that the engine working mode of the vehicle is obtained, and if the engine working mode is a non-running mode, the current state of the vehicleand corresponding monitoring parameters are obtained; and if the monitoring parameters corresponding to the current state of the vehicle meet the corresponding preset conditions, a corresponding firstinstruction is sent to a motor oil pump of the vehicle, and the first instruction is used for indicating the motor oil pump to extract engine oil based on the working parameters of the first instruction and convey the engine oil to a friction pair of the engine. According to the engine lubrication control method, the control device and the oil-electricity hybrid drive vehicle, the friction pair of the engine of the hybrid vehicle can be fully lubricated in time in a non-running state, and the possibility of abrasion during starting and running of the engine is reduced, so that the engine is protected.

Owner:GREAT WALL MOTOR CO LTD

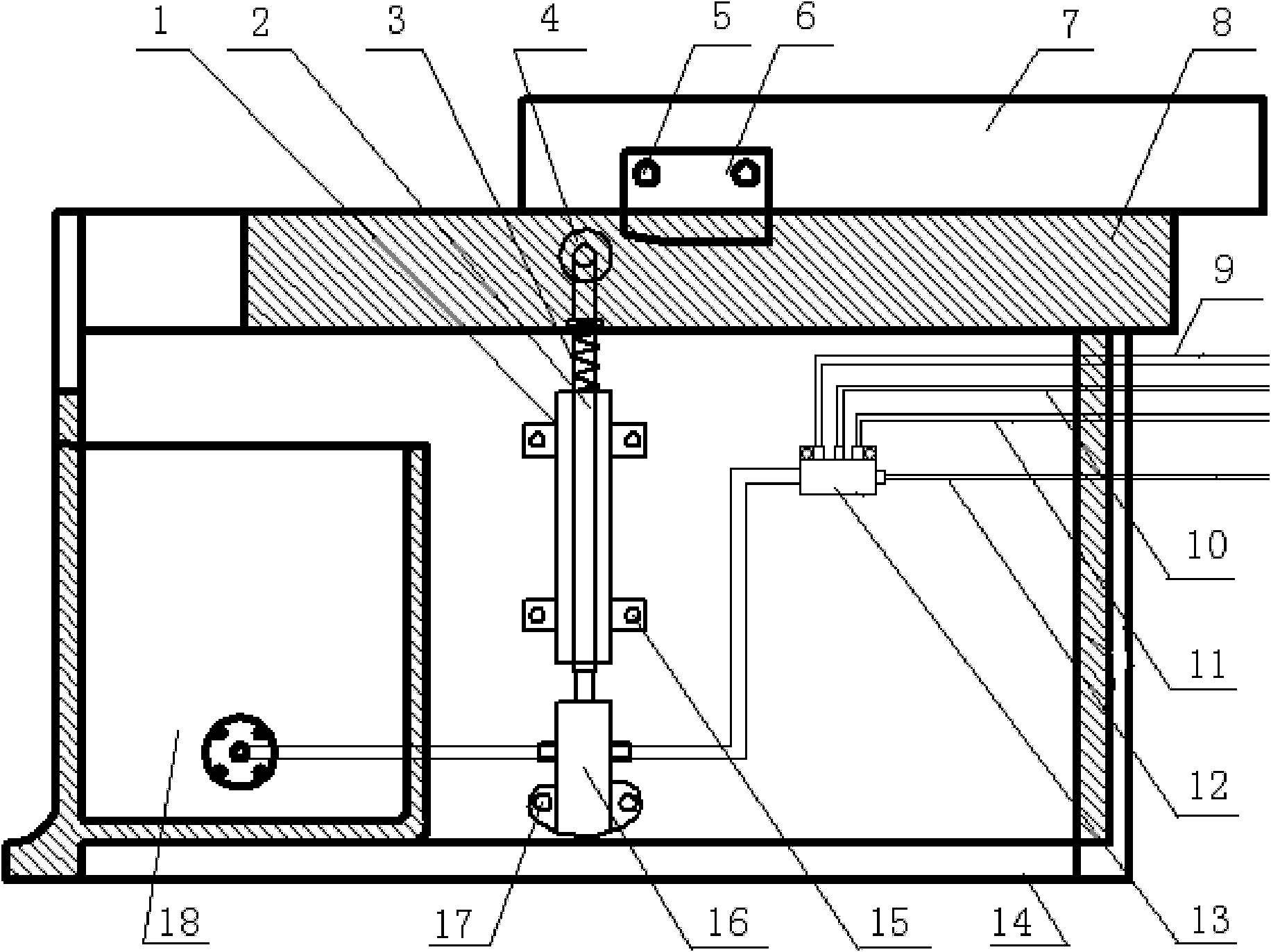

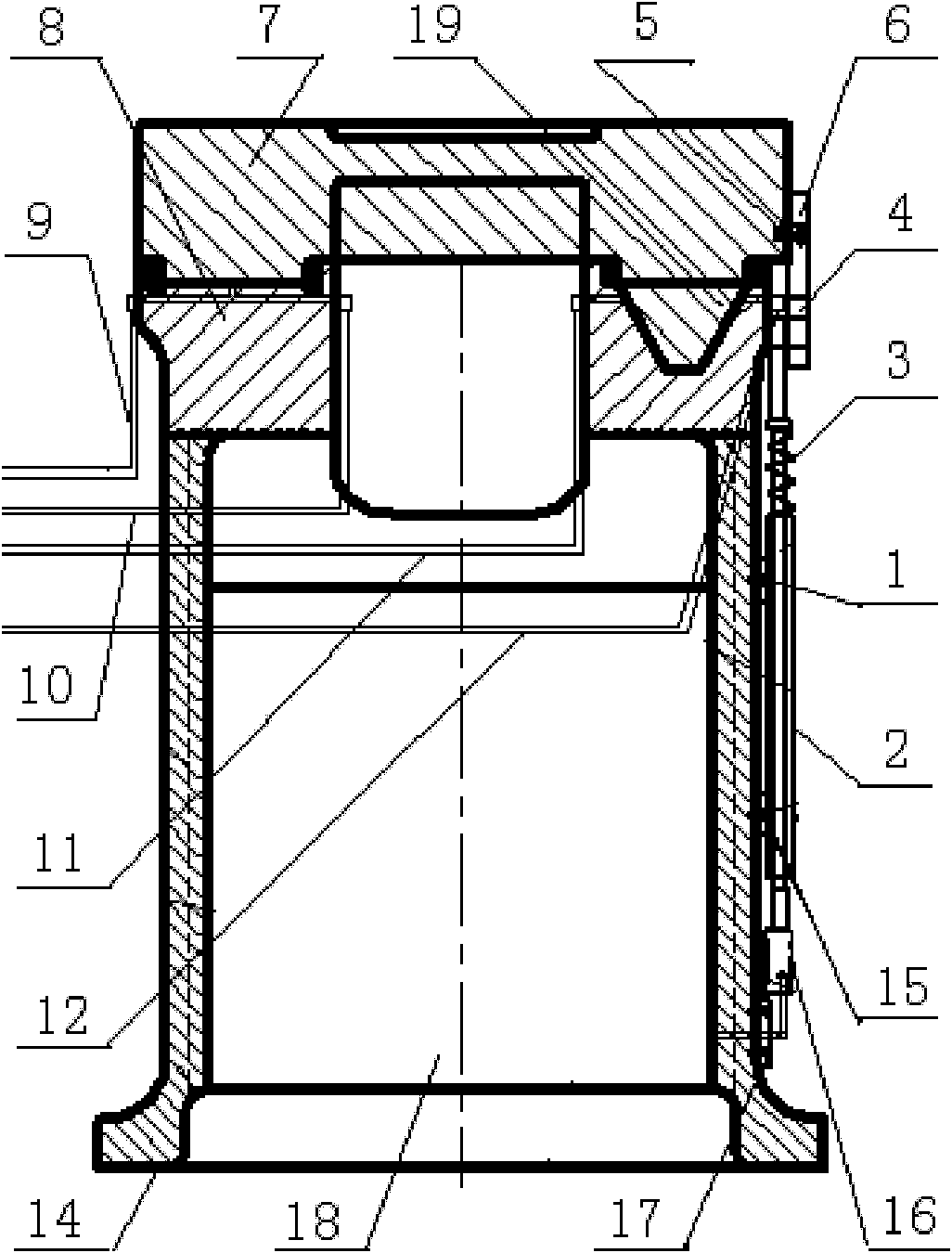

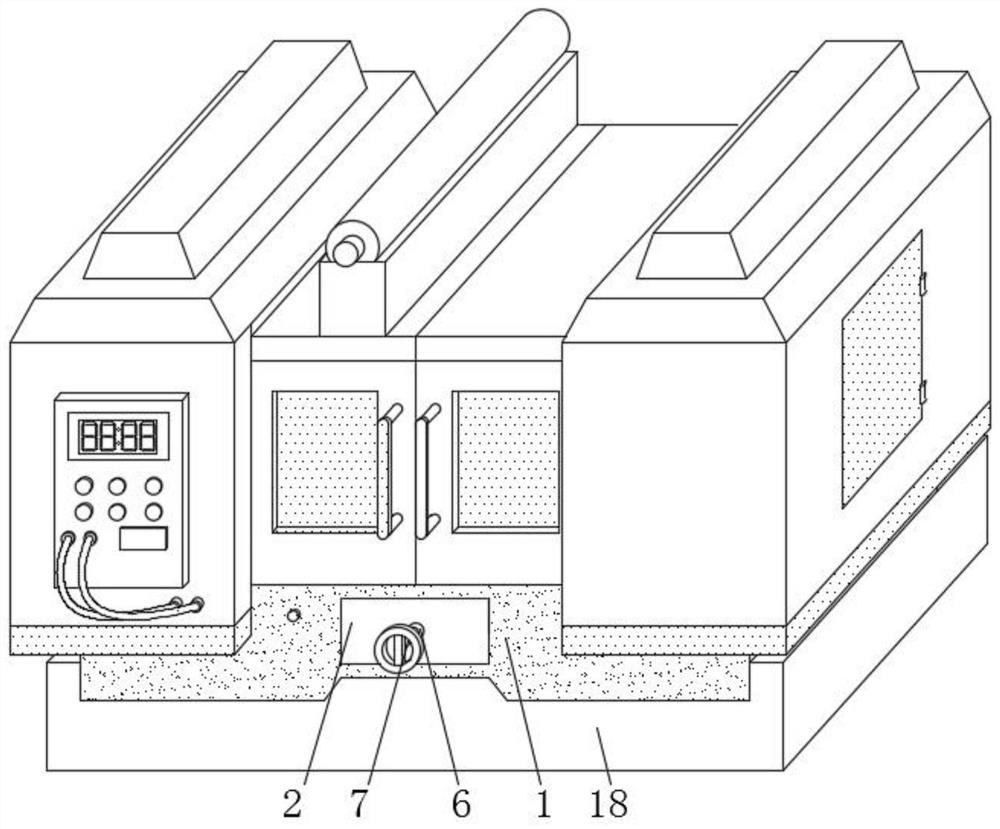

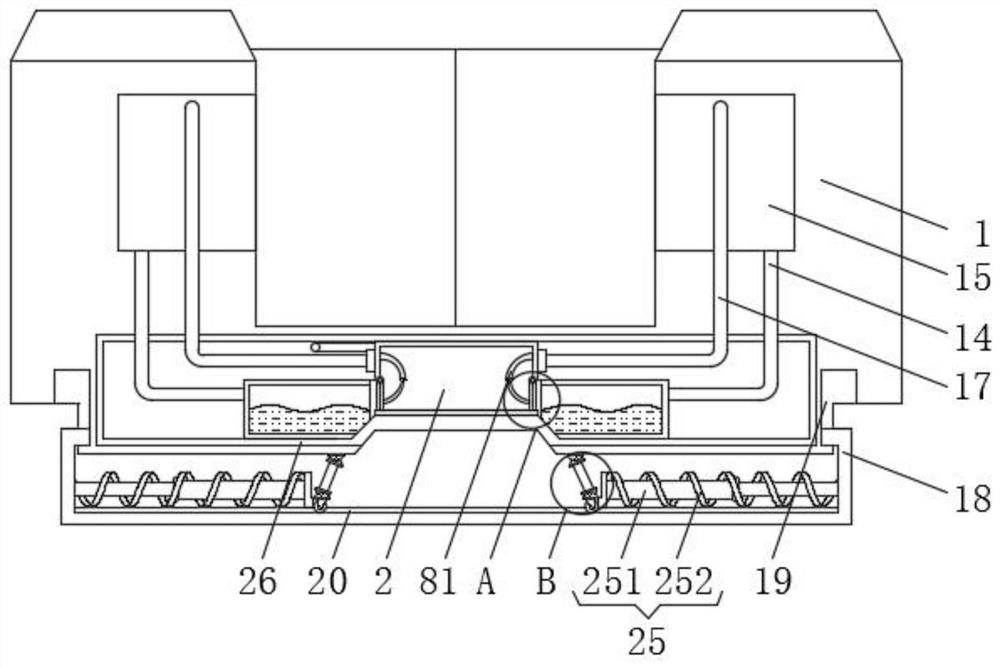

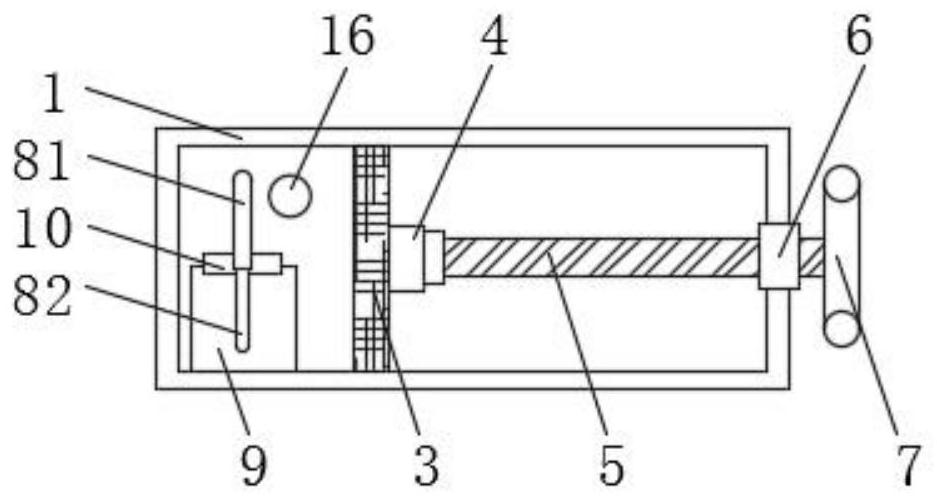

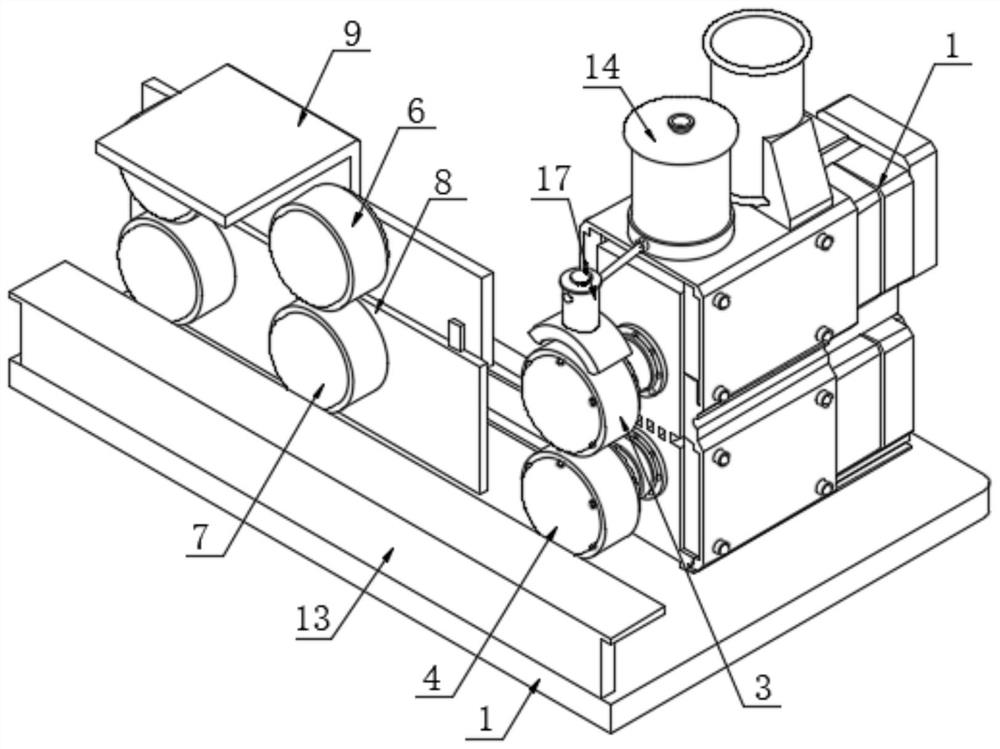

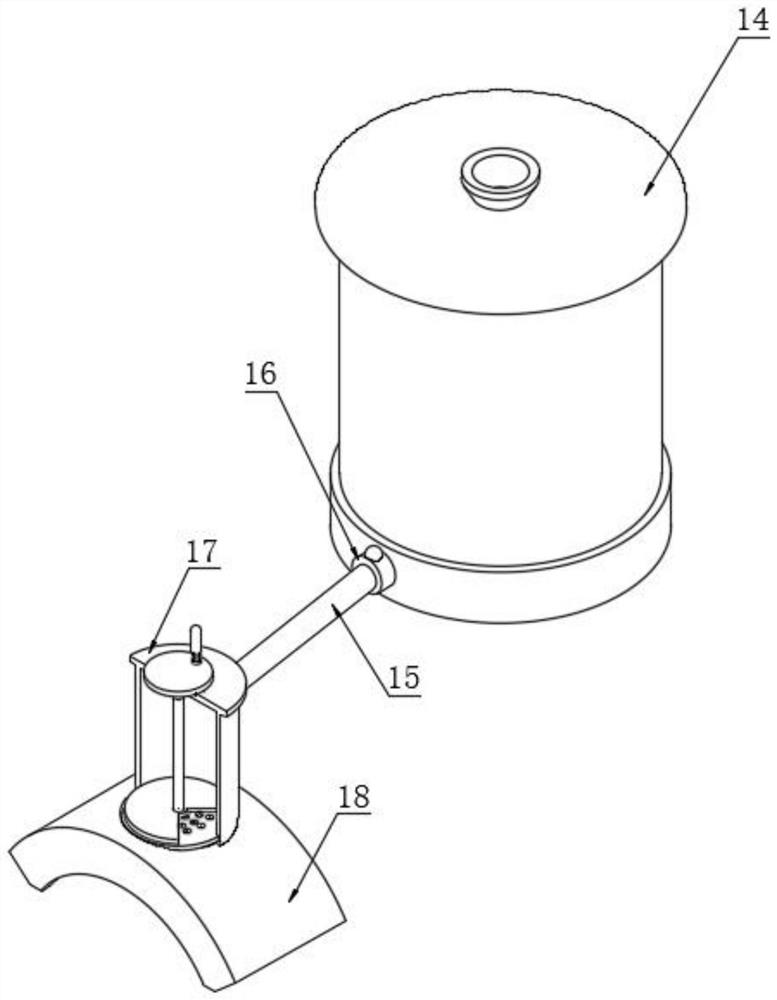

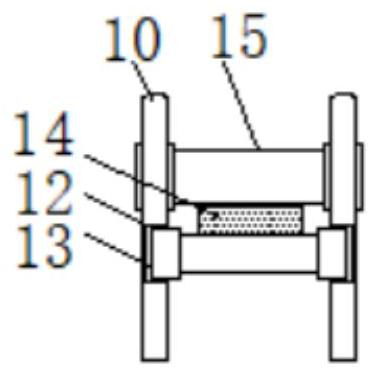

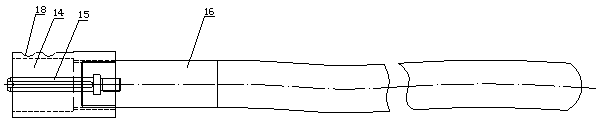

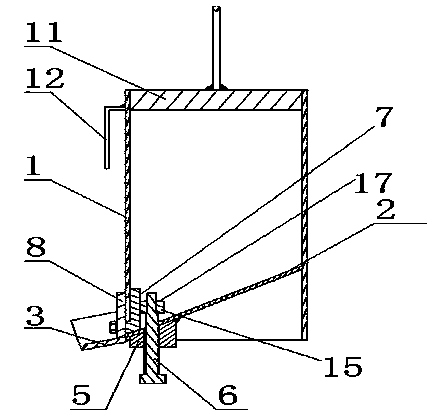

Lubrication device for hydraulic drawing machine

InactiveCN102182905ATimely lubricationImprove the lubrication effectLubricating pumpsDistribution equipmentPlunger pumpLubrication

The invention relates to a lubrication device for a hydraulic drawing machine. The lubrication device comprises a fuel tank (18) arranged below the drawing machine, a path oil distributor (13) and path oil pipes. The lubrication device is characterized in that: the lubrication device is provided with a sliding block (6) arranged on a sliding platform of the drawing machine; an automatic oil injection mechanism for a roller plunger pump is matched with the sliding block (6) and is arranged between the lower side of the sliding block (6) and the fuel tank (18); the automatic oil injection mechanism consists of a rolling pulley (4), a guide rod (2), a spring (3) on the guide rod (2), a guide rod clamp iron track (1) and a fixing bolt (15), and a plunger fuel pump (16) and a fixing bolt (17), wherein the rolling pulley (4) is hinged with the guide rod (2); the rolling pulley (4) and the fixing bolt (15) are installed on the machine body (14) of the drawing machine through the guide rod clamp iron (1); the plunger rod of the plunger fuel pump (16) is connected with the lower end of the guide rod (2); and the pump body of the plunger fuel pump (16) is connected with the fuel tank (18) through a pipeline and then connected with the path oil distributor (13). The lubrication device has the characteristics of simple structure, low manufacturing cost, convenience of operation and maintenance, automatic and adequate oil supply, low abrasion and the like.

Owner:刘立新

Sand pump

The invention discloses a sand pump and relates to the technical field of machine manufacturing. The sand pump comprises a pump shell connected with a water inlet pipe and a water outlet pipe. An impeller is installed in the pump shell. The impeller is connected with a main shaft. The main shaft is installed on a bearing seat. A connecting disk is arranged between the impeller and the bearing seat and is arranged outside the main shaft in a sleeving mode. The portion, sleeved with the connecting disk, of the main shaft is sleeved with a steel sleeve. An O-shaped seal ring is arranged between the steel sleeve and the main shaft. Two framework oil seals are arranged between the steel sleeve and the connecting disk. Two oil holes are formed in the connecting disk and enable the two framework oil seal to be communicated. Forced filling oil cups are installed at the positions of inlets of the oil holes. Lubricating oil can be directly injected into the steel sleeve between the two framework oil seals through the forced filling oil cups and the oil holes. By the adoption of the sand pump, the problems that when framework oil seals are not sufficiently lubricated, high temperature is caused by friction, rubber of the framework oil seals is aged, deteriorates and loses elasticity, the abrasion of metal on the friction surfaces is accelerated due to insufficient lubrication, and accordingly the sand pump leaks sand are solved.

Owner:广西鹿寨县华光机械制造有限责任公司

Automatic lubricating device for steel wire rope for swabbing truck

PendingCN108626558AStable lubricationGuaranteed adequate lubricationWinding mechanismsEngine lubricationTruckEngineering

The invention discloses an automatic lubricating device for a steel wire rope for a swabbing truck. The device comprises a shell, oil cavities, a trigger mechanism and a switching connecting rod, wherein the oil cavities, the trigger mechanism and the switching connecting rod are arranged in the shell; the shell is fixed on a running track of the steel wire rope of the swabbing truck, and a passing channel which allows the steel wire rope to penetrate through the shell is formed in the shell through sliding mechanisms; the oil cavities are distributed on the periphery of the steel wire rope ina surrounding mode, first oil outlet holes are formed in the bottom of the wall surface, facing the steel wire rope, of the oil cavities, and a spigot structure for limiting a switching joint is arranged on the outer sides of the first oil outlet holes; the trigger mechanism is clamped on the steel wire rope, and generates displacement / idling due to friction force in the operation of the steel wire rope; and the switching connecting rod is connected between the parts, at the trigger mechanism and the first oil outlet holes, of the spigot structure, and cooperates with the displacement / idlingstate of the trigger mechanism on the steel wire rope so as to enable the switching joint to be capable of achieving switching between two kinds of stations which allow the first oil outlet holes inthe oil cavities to be opened or plugged. According to the device, the steel wire rope of the swabbing truck can be conveniently, efficiently, timely, fully and stably lubricated.

Owner:SINOPEC SSC +1

Ball-end mill with multifunctional micro-texture in titanium alloy machining

The invention provides a ball-end mill with a multifunctional micro-texture in titanium alloy machining, relates to a ball-end mill, in particular to the ball-end mill with the multifunctional micro-texture in titanium alloy processing, and aims at solving the problems of lower efficiency of processing the surface of a titanium alloy workpiece by a milling cutter,, poorer quality of the processed workpiece surface, no environmental protection in cooling and lubricating modes, untimely tool change and the like. The ball-end mill comprises a cutter head; and a blade part of the cutter head is sequentially provided with at least one arrow-shaped micro-texture, at least one sawtooth-shaped micro-texture, at least one bowl-shaped micro-texture and at least one rectangular micro-texture from outside to inside. The ball-end mill belongs to the field of machining.

Owner:HARBIN UNIV OF SCI & TECH

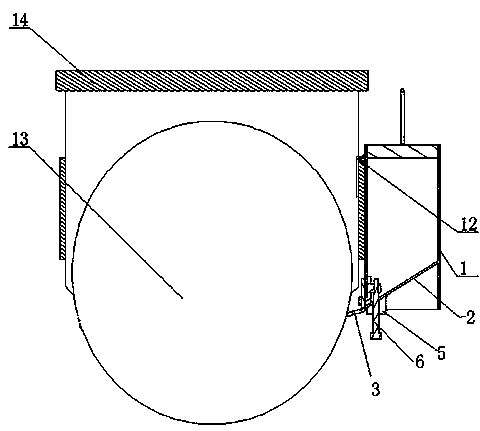

Modified thin oil lubrication drum-shaped tooth type coupling

ActiveCN106424153AOptimized structural formExtended service lifeRolling mill drivesMetal rolling arrangementsCouplingLubrication

The invention discloses a thin oil lubrication drum-shaped tooth type coupling which comprises a spindle, a roller end assembly E, a tooth end assembly F, an oil inlet ring assembly H and a spring assembly. The roller end assembly E, the tooth end assembly F and the oil inlet ring assembly H are arranged on the spindle. The spring assembly is arranged in the spindle. The roller end assembly E is an adjustable roller end assembly and comprises a roller end shaft sleeve, a roller end connecting disc, an outer centering, an inner centering, a roller end top block and a roller end outer tooth ring. The roller end connecting disc and the outer centering are connected with the roller end shaft sleeve. The inner centering and the roller end top block are connected with the roller end connecting disc. The roller end shaft sleeve is engaged with the roller end outer tooth ring through inner teeth. The roller end outer tooth ring is matched with the spindle. By adoption of the thin oil lubrication drum-shaped tooth type coupling, the defects of existing thin oil lubrication drum-shaped tooth type couplings are overcome, the overall service life of the thin oil lubrication drum-shaped tooth type coupling is prolonged, and the requirements of continuous rolling mill characteristics are met; and meanwhile, the production cost of a hot continuous rolling factory is also lowered, and benefits are created.

Owner:TAIER HEAVY IND

Noise reduction device for vertical machining center

InactiveCN111872738ATimely lubricationSimple lubricationMaintainance and safety accessoriesGear driveGear wheel

The invention discloses a noise reduction device for a vertical machining center, and belongs to the technical field of vertical machining centers. The noise reduction device comprises a vertical machining center body, an oil tank is fixedly connected to the lower surface of the inner wall of the vertical machining center body, a piston plate is arranged in the oil tank, and a rotating mechanism is clamped to the front surface of the piston plate; and one end of the front surface of the rotating mechanism is fixedly connected with one end of the back surface of a threaded rod. According to thenoise reduction device for the vertical machining center, through the arrangement of a first connecting pipe, an oil storage tank and the oil tank, a worker can lubricate a transmission mechanism boxin the vertical machining center body in time, the surface of a gear is not prone to being too dry after oil lubrication, due to the fact that a tooth surface of the gear is isolated through oil, direct contact between metal is avoided, dry friction is changed into liquid friction, the loss of the gear is reduced, the service life of the gear is guaranteed, and noise between gear transmission iseffectively reduced.

Owner:襄阳吉盛邦机械有限公司

Multi-stage piston hydraulic tension oil cylinder

PendingCN113944672ATimely lubricationAvoid damageValve arrangementsMagnetic circuit rotating partsGear wheelEngineering

The invention relates to the technical field of hydraulic tension oil cylinders, in particular to a multi-stage piston hydraulic tension oil cylinder which comprises a shell, wherein an oil cylinder body is fixedly mounted on the inner side wall of the bottom of the shell, a limiting plate is fixedly mounted at the top of the oil cylinder body, a rack is fixedly mounted on one side of the oil cylinder body, a control panel is arranged on one side of the shell; a first rotating rod is rotatably mounted on the inner side wall of the shell, a power generation mechanism matched with the rack is arranged in the shell. The rack moves to drive a first gear to drive a second gear to rotate on a second rotating rod, then a coil is driven to cut a magnetic induction line between two magnets, then current is generated; the generated current is transmitted to an electromagnetic valve through a commutator, the electromagnetic valve is started to enable lubricating oil in an oil tank to flow, and finally the lubricating oil arrives at a spray head to lubricate the oil cylinder in time, so that large damage to parts in the oil cylinder caused by abrasion is reduced.

Owner:刘铁军

Trimming circle shear for galvanized steel sheet

PendingCN114406342AGuaranteed service lifeStable and efficient workShearing machinesMaintainance and safety accessoriesCircular discStructural engineering

The invention discloses a galvanized steel sheet trimming circle shear and belongs to the technical field of circle shears, the galvanized steel sheet trimming circle shear comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with the lower surface of a circle shear body, the left side and the right side of the inner wall of the circle shear body are each provided with an upper cutter head and a lower cutter head, and the upper surface of the bottom plate is fixedly connected with the lower surfaces of two baffles; the opposite faces of the two baffles are each provided with two transmission rollers. According to the galvanized steel sheet trimming circle shear, by arranging the material box, the rotating disc, the storage box, the upper cutter disc, the spring, the clamping rod, the clamping groove, the fixing plate, the connecting base, an oil leakage hole, a discharging pipe and a protective cover, the clamping groove is effectively clamped into the corresponding clamping groove, the fixing plate is effectively limited, and compared with a traditional mode that the cutter disc is cleaned or lubricated regularly, the cutting efficiency is improved; according to the scheme, the upper cutter head is effectively lubricated in time, the oil dripping amount can be adjusted according to the machining state of the circle shear, the machining precision is improved while the service life of the circle shear is guaranteed, and efficient and stable work of the circle shear is facilitated.

Owner:襄阳嘉德机械有限公司

Ultrahigh viaduct erection hoisting equipment for traffic construction and hoisting method thereof

PendingCN113023588AIncrease flexibilityNo lagCranesEngine lubricationArchitectural engineeringElectric machinery

The invention discloses ultrahigh viaduct erection hoisting equipment for traffic construction and a hoisting method thereof. The ultrahigh viaduct erection hoisting equipment comprises a bottom plate and a sponge block, a tripod is arranged above the left side of the bottom plate, and a telescopic frame is installed on the right side of the bottom plate. A first air cylinder is installed on the inner side of the upper end of the tripod, and a rotating shaft is arranged at the top end of the tripod. A transverse rod is arranged on the inner side of the rotating shaft, and a winding motor is installed at the left end of the transverse rod. A second air cylinder is arranged above the telescopic frame, a supporting rod is arranged above the second air cylinder, a supporting frame is installed above the supporting rod, a lifting hook is arranged at the right end of the supporting rod, and a notch is formed in the inner side of the supporting frame. A connecting block is arranged on the inner side of the notch, and the sponge block is arranged above the connecting block. According to the ultrahigh viaduct erection hoisting equipment for traffic construction, the sponge block is arranged and has good adsorption capacity, a lubricating agent can be fully absorbed, and a rotating rod can be lubricated in time.

Owner:武汉鑫弘凯交通科技有限公司

Starting clutch for transmission

PendingCN111609050AImprove replenishment efficiencyReduce the temperaturePiston ringsFluid actuated clutchesAutomatic transmissionEngineering

The invention relates to the technical field of automatic transmissions, and provides a starting clutch for a transmission. The starting clutch comprises a piston device and a friction device. The friction device comprises a friction plate set, an inner hub and an outer hub. An oil cavity is formed between the inner hub and the friction plate set. The piston device comprises a main piston and a balance piston, and a balance piston cavity is formed between the main piston and the balance piston. The main piston is arranged on a piston support. The piston support is provided with an oil supply part, an oil supply channel is formed in the oil supply part, a sealing steel sleeve is arranged on the inner side of the piston support, and the sealing steel sleeve is provided with a sealing part. When oil is supplied, part of hydraulic oil enters the balance piston cavity through a first oil way, the other part of the hydraulic oil directly enters the oil cavity of the friction plate set, and the supplementing efficiency of the hydraulic oil is improved; the sealing steel sleeve extends to the inner side of the oil supply part, and a first sealing element is arranged, so that the hydraulicoil is prevented from flowing away from the gap of the clutch, and waste of the hydraulic oil is avoided; and meanwhile, the oil supply amount of the friction plate set is ensured.

Owner:SHENGRUI TRANSMISSION

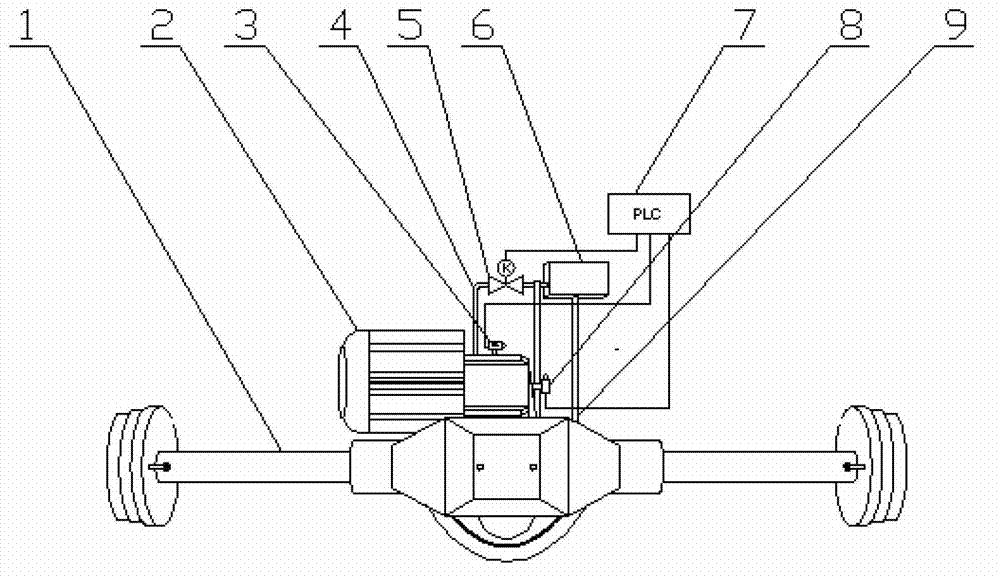

Automatic monitoring and lubricating device for differential motor

InactiveCN103032667ATimely monitoringEasy to operateLubrication elementsBearing coolingBall valveProgrammable logic controller

The invention discloses an automatic monitoring and lubricating device for a differential motor, which belongs to the technical field of differential motor maintenance. The automatic monitoring and lubricating device comprises a gear bearing, a motor, a temperature sensor, an electric ball valve, a lubricating oil tank, a PLC (Programmable Logic Controller) and a support frame, wherein the temperature sensor is arranged at the upper side of the tail end of the motor, and a rotating speed sensor is arranged at the lower side of the tail end of the motor; an acquired signal is transmitted to the PLC by a wire; one end of a lubricating pipeline is arranged in a bearing housing of the motor, and the other end of the lubricating pipeline is connected with the lubricating oil tank; the electric ball valve is arranged in the lubricating pipeline, connected with the PLC by a wire, and opened and closed under the control of the PLC; and the lubricating oil tank is arranged at the upper side of the tail end of the motor by the support frame and supplies oil through the lubricating pipeline. With the automatic monitoring and lubricating device provided by the invention, the differential motor is timely monitored, the use efficiency of the differential motor is further increased, and the service life is prolonged.

Owner:XUZHOU HONGRUNDA ELECTRIC VEHICLE

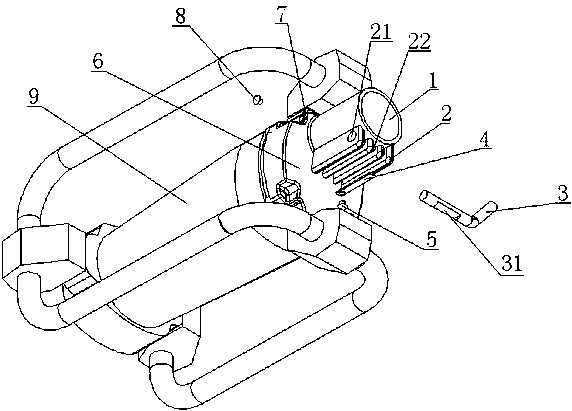

Plug-in type vibrator

ActiveCN104167865AEasy to lockEasy to replaceMechanical energy handlingBuilding material handlingLocking mechanismGear wheel

The invention discloses a plug-in type vibrator comprising a motor and a joint installed at a motor front cover. Besides, the plug-in type vibrator also includes a locking mechanism arranged at the joint, a detachable joint connected with joint, and a segmented shaft connected with a rotor arranged in the motor. The locking mechanism consists of a plurality of reeds, an L-shaped lockpin, a lock catch, and a bolt. The detachable joint includes an inner joint, a flexible shaft, and a vibrating rod; the inner joint is plugged in the joint arranged at the motor front cover; the flexible shaft is arranged at the center inside the inner joint; and one end of the flexible shaft is opposite to the output shaft end of the plug-in type vibrator motor and the other end of the flexible shaft is connected with the vibrating rod. Because of the locking mechanism, the vibrating rod can be locked tightly and effectively; the detachable joint and the joint arranged at the front cover of the plug-in type vibrator motor are connected and the lock pin portion passing through the joints are abutted through the arc grooves, the square groove, and the annular groove that are formed in the surface of the inner joint, so that the joints are connected firmly without disengagement; and the vibrating rod can be replaced conveniently because of the detachable joint. And because the gear wheel unit is separated from the shaft, only the gear wheel needs to be replaced when maintenance is requirement, so that the cost is lowered.

Owner:南通仟得电动工具有限公司

Die bearing not prone to wearing

InactiveCN107830048ANot easy to wearExtended service lifeBall bearingsBearing componentsBearing wearEngineering

The invention provides a mold bearing which is not easy to wear and relates to the technical field of bearings. The wear-resistant mold bearing includes an outer ring and an inner ring. Beads are arranged inside the outer ring and the inner ring. A wear-resistant layer is arranged on the outer surface of the beads. A cage is arranged outside the wear-resistant layer. The rings cooperate to form observation holes, and the top and bottom inside the outer rings are provided with oil injection holes. The wear-resistant mold bearing is provided with a groove on the side close to the first bead groove and the second bead groove, and a ceramic wear-resistant layer is arranged inside the groove, and the ceramic wear-resistant layer is used as the first The receptor, which will greatly reduce the wear of the first bead groove inside the outer ring and the second bead groove inside the inner ring, greatly prolonging the service life of the bearing. By setting a wear-resistant layer on the outer surface of the bead, it is beneficial to reduce The wear of the beads, in summary, makes the bearing for the mold have good wear resistance, which is conducive to improving the service life of the bearing.

Owner:江苏丰禾食品有限公司

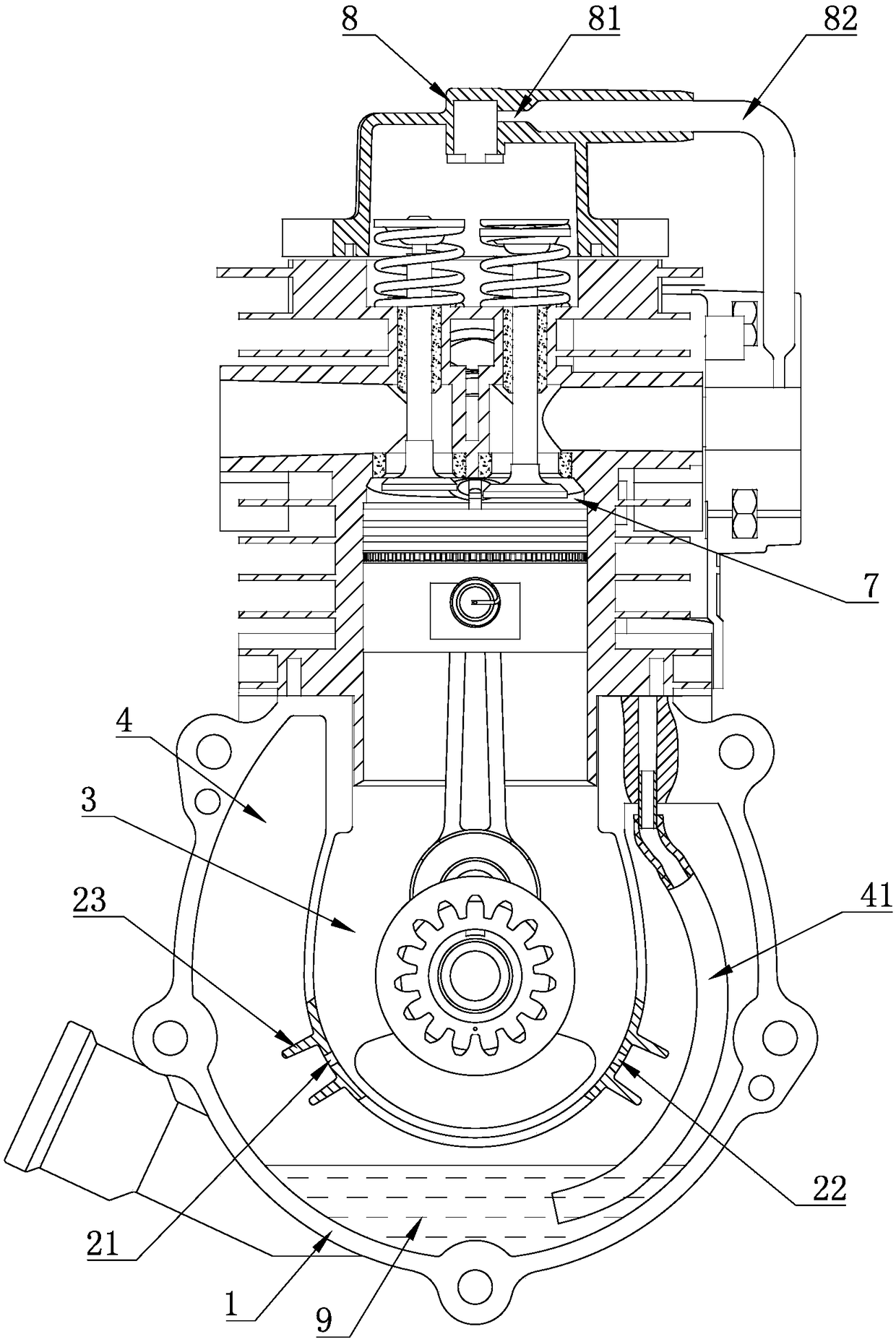

Lubricating system of four-stroke engine and tool equipment with four-stroke engine

PendingCN109268101AStable pressureTimely lubricationLubrication of auxillariesMachines/enginesFour-stroke engineCrankcase

The invention discloses a lubricating system of a four-stroke engine. The lubricating system comprises a crankcase, a lubricating oil tank and a cam chamber, the crankcase is provided with a crank chamber, the lubricating oil tank is positioned outside the crankcase, and the cam chamber is used for storage of a cam. A lubricating oil chamber for storage of lubricating oil is formed between the lubricating oil tank and the crankcase. The crankcase is provided with front oil taking holes in communication with the crank chamber and the lubricating oil chamber, and an oil pipe is connected betweenthe cam chamber and the lubricating oil chamber. By communication between the cam chamber and the lubricating oil chamber through the oil pipe, in operation of the four-stroke engine, vertical movement of a cylinder piston enables lubricating oil to enter the cam chamber through the oil pipe without passing through the crank chamber, and sufficient lubricating oil can enter the cam chamber to timely lubricate structures of the cam and the like to prevent abrasion. The invention further provides tool equipment with the four-stroke engine. The tool equipment comprises the four-stroke engine which adopts the lubricating system.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Lubricating device of simple horizontal belt conveyor

The invention relates to a simple horizontal belt conveyor, in particular to a lubricating device of the simple horizontal belt conveyor. The lubricating device of the simple horizontal belt conveyor comprises supporting legs, a support, a driving roller, a driven roller, a conveying belt, carrier roller racks, carriage rollers, roller supports and a lubricating device body. The horizontally-arranged support is erected on the supporting legs. The roller supports are arranged at the two ends of the support. The driving roller and the driven roller are arranged on the roller supports, and the conveying belt is arranged between the driving roller and the driven roller. The carrier roller racks are arranged on the support, and the carrier rollers are arranged on the carrier roller racks. The lubricating device body mainly comprises a lubricating pump, a pressure gage and lubricating oil pipes. The lubricating pump is fixed to the support. The pressure gage is mounted on the lubricating pump. One end of each lubricating oil pipe is connected with the lubricating pump, and the other ends of the lubricating oil pipes are connected with the corresponding rollers. With the help of the design, operation drive mechanisms can be lubricated in time, smooth operation of all the mechanisms can be kept, and the working efficiency of the conveyor is improved.

Owner:YANTAI LIKAI ELECTRONICS TECH

Lubricating and seedling selecting integrated device for seedling transplanter

The invention relates to a lubricating and seedling selecting integrated device for a seedling transplanter. The device comprises a seedling transplanting disc with a seedling channel, a lubricating disc is arranged below the seedling transplanting disc, and the lubricating disc is hollow and is vertically divided into an oil cavity and an air cavity by a horizontal oil film plate; the air cavityis communicated with an exhaust port of an air generator through an air circulating channel, the oil cavity is communicated with a plurality of oil outlet channels formed in the top surface of the lubricating disc and used for lubricating the seedling transplanting disc; a seedling selecting disc is arranged above the seedling transplanting disc, seedling inlet channels corresponding to the seedling channel are formed in the seedling selecting disc, and a seedling grabbing disc is arranged beside each seedling inlet channel in the seedling selecting disc; an electric claw type seedling grabbing mechanism is arranged on each seedling grabbing disc, the side of the bottom of each seedling grabbing disc is connected with the seedling selecting disc through a rotating shaft, and a speed reducing oil film layer is arranged on the inner wall of each seedling inlet channel. The integrated device is simple in structure, and can effectively achieve timely and efficient lubricating of the seedling transplanting disc. Meanwhile, unqualified seedlings can be removed, the overall service life of the seedling transplanter is prolonged, and the work efficiency of the seedling transplanter is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Numerical control winging head used for engraving machine

InactiveCN105711317ATimely lubricationGuaranteed sliding performanceEngravingNumerical controlEngineering

Disclosed is a numerical control winging head used for an engraving machine. The numerical control winging head comprises a guide rail and a numerical control winging head body. The guide rail is of a long-strip-shaped structure and provided with support parts. The support parts are located on the two sides of the guide rail and of a T-shaped structure. The numerical control winging head body is connected beside the guide rail. An abrasion-resistance part is arranged between the numerical control winging head body and the guide rail and made of copper. The abrasion-resistance part is located on the side edge of the numerical control winging head body and connected with the numerical control winging head body through threads. The abrasion-resistance part is provided with a clamping opening which is in the semicircular arc shape. The guide rail is provided with a lubricating part capable of lubricating the guide rail in time, so that the sliding effect of the numerical control winging head body on the guide rail is ensured, back-and-forth operation can be conducted fast, and the work effect of the engraving machine is improved. A hydraulic lifting component is arranged outside a speed reducer so that lifting of the numerical control winging head body can be faster, the work effect of the engraving machine is optimized, the machining quality can be ensured, and locating is more accurate.

Owner:扬州旺海数控设备科技有限公司

Automatic lubricating device for surface of CSP swing segment wheel

The invention relates to an automatic lubricating device for the surface of a CSP swing segment wheel, and belongs to the technical field of steel rolling equipment. The automatic lubricating device is used for solving the technical problem that due to the fact that a wheel and a guide rail in the prior art cannot be lubricated automatically in good time, the wheel and the guide rail are abraded and damaged. According to the technical scheme, the automatic lubricating device comprises a grease box, an inner flow guide plate and an outer flow guide plate, the inner flow guide plate is fixed to the inner side wall of the grease box, an acute included angle is formed by the inner flow guide plate and a bottom plate of the grease box, an oil hole is formed in the side wall of the grease box, the bottom of the oil hole is located at the connecting position of the lower side of the inner flow guide plate and the side wall of the grease box, the outer flow guide plate is fixed to the position, at the bottom of the oil hole, of the outer side wall of the grease box, and an acute included angle is formed by the plane of the outer flow guide plate and the horizontal plane. The automatic lubricating device can effectively solve the problem that due to the fact that the wheel and the guide rail are abraded due to poor lubrication, the service life of the wheel and the guide rail is prolonged, and the action rate of a heating furnace is improved. The automatic lubricating device is suitable for automatic and timely lubrication of wheels and guide rails in relevant fields, and is wide in popularization prospect.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Efficient and energy-saving water pump

ActiveCN113217407AImprove work efficiencyAchieve energy saving effectPump componentsPump installationsImpellerElectric machinery

The invention discloses an efficient and energy-saving water pump. The water pump comprises a mounting base, wherein two symmetrically-distributed first mounting plates are fixed to each of the front end and the rear end of the mounting base, a first mounting groove is formed in one side of the upper surface of the mounting base, a pump body is arranged above the first mounting groove, a second mounting plate and a third mounting plate are fixed to the upper surface of the mounting base, the second mounting plate is located between the first mounting groove and the third mounting plate, a bearing box is arranged between the first mounting groove and the second mounting plate, a motor is fixed to the upper surface of the third mounting plate, the bearing box is located between the pump body and the motor, and a pump shaft is fixed at the output end of the motor. Water entering the pump body enters an impeller from a baffle and is thrown out of a flow guide groove through centrifugal force generated by high-speed rotation of the impeller, the water entering the pump body is guided, the working efficiency of the water pump is improved, and the energy-saving effect is achieved.

Owner:广东鑫钻节能科技股份有限公司

Polishing device for hardware workpiece machining

InactiveCN113211228AEasy accessEasy to controlEdge grinding machinesGrinding carriagesPolishingElectric machinery

The invention discloses a polishing device for hardware workpiece machining. The polishing device comprises a polishing device assembly, the polishing device assembly comprises a workbench, one side of one end of the workbench is fixedly connected to a lubricating mechanism assembly, one end of the lubricating mechanism assembly is provided with a motor, the surface of an object placing table is provided with a protection mechanism assembly, and the object placing table is located in the middles of two protection plates. According to the polishing device, the protection mechanism assembly is arranged, when a user takes and places a workpiece placed on the surface of the object placing table, the protection plates can be unfolded and folded at the same time when in placing, so that the beneficial effects of blocking splashes and conveniently taking the workpiece can be achieved, through the lubricating mechanism assembly, a collision ball can match with the movement trend of expansion and contraction of a protection plate, so that a sponge plate is well controlled, the effects of lubricating a rotating rod in time and automatically supplementing lubricating oil are achieved, and the practicability of the device in the actual use process is further enhanced.

Owner:阜南县全力工艺品有限公司

Carburized grinding gear drum-shaped gear connecting shaft and installation and disassembly methods thereof

PendingCN111734749AReduce escapeReduce mechanical damageYielding couplingEngine lubricationStructural engineeringMechanical engineering

The invention discloses a carburized grinding gear drum-shaped gear connecting shaft and an installation and disassembly method thereof. The carburized grinding gear drum-shaped gear connecting shaftincludes a pipe connecting structure, a head shaft joint structure is fixed to one end of the pipe connecting structure, a tail shaft joint structure is arranged at the other end of the pipe connecting structure, the pipe connecting structure includes a pipe connecting pipe body, a lubricating oil injection pipe is symmetrically formed in one side of the pipe connecting pipe body, and pipe body external flanges are arranged at the two ends of the pipe connecting pipe body. A connecting shaft and a pipe body are connected and fixed through the head shaft joint structure and the tail shaft jointstructure, so that the installation and fixing of the connecting shaft are easier and more convenient; meanwhile, a L-shaped lubricating oil pipe is symmetrically formed in one side of the pipe body,the L-shaped lubricating oil pipe straightly communicate with the two ends of the pipe body, the head shaft joint structure and the tail shaft joint structure can be lubricated in time, and thereforemechanical damages at joints are reduced; and oil seal baffles are arranged on the outer sides of the head shaft joint structure and the tail shaft joint structure, lubrication oil overflow can be effectively reduced, and time and effort are saved at the time of maintenance and repair.

Owner:ZHENJIANG SUODA COUPLING

Gantry type movable hoisting equipment with early warning and pedestrian collision prevention functions and applied to AGV (Automatic Guided Vehicle)

PendingCN114803880APedestrian strike preventionGood stabilityBase supporting structuresBraking devices for hoisting equipmentsAutomotive engineeringWire rope

The gantry type movable hoisting equipment comprises a base, a gantry rack is fixedly connected to the top of the base, supporting sliding rails are fixedly connected to the positions, close to the top, of the two corresponding sides of the inner wall of the gantry rack, and a cross beam is arranged at the tops of the supporting sliding rails; an electric hoist is arranged at the bottom of the movable crane vehicle, a processing device is arranged on one side of the electric hoist, a lifting hook is arranged at the bottom end of the steel wire rope, a lifting mechanism is arranged at the position, close to the base, of the bottom of the gantry rack, and a moving mechanism is arranged at the working end of the lifting mechanism. According to the gantry type movable hoisting equipment with the early warning and pedestrian collision prevention functions applied to the AGV, the real-time lubricating effect is achieved, movement is rapid and convenient, disassembly is not needed, the steel wire rope can be automatically lubricated in time, lubricating oil is evenly smeared, the lubricating effect is good, safety and reliability are achieved, and the hoisting efficiency and the use performance are improved.

Owner:湖南驰众机器人有限公司

A water pump with high efficiency and energy saving

ActiveCN113217407BImprove work efficiencyAchieve energy saving effectPump componentsPump installationsImpellerElectric machinery

The invention discloses a high-efficiency and energy-saving water pump, which comprises a mounting base, two symmetrically distributed first mounting plates are fixed on the front end and rear end of the mounting base, and a first mounting plate is provided on one side of the upper surface of the mounting base. Mounting groove, the top of the first mounting groove is provided with a pump body, the upper surface of the mounting base is fixed with a second mounting plate and a third mounting plate, and the second mounting plate is located between the first mounting groove and the third mounting plate. Between the plates, a bearing box is arranged between the first installation groove and the second installation plate, and a motor is fixed on the upper surface of the third installation plate, and the bearing box is located between the pump body and the motor, and the motor The output end of the pump is fixed with the pump shaft; the present invention enters the impeller from the baffle through the water entering the pump body, and is thrown out from the diversion groove by the centrifugal force generated by the high-speed rotation of the impeller, so as to guide the water entering the pump body , Improve the working efficiency of the water pump and realize the effect of energy saving.

Owner:广东鑫钻节能科技股份有限公司

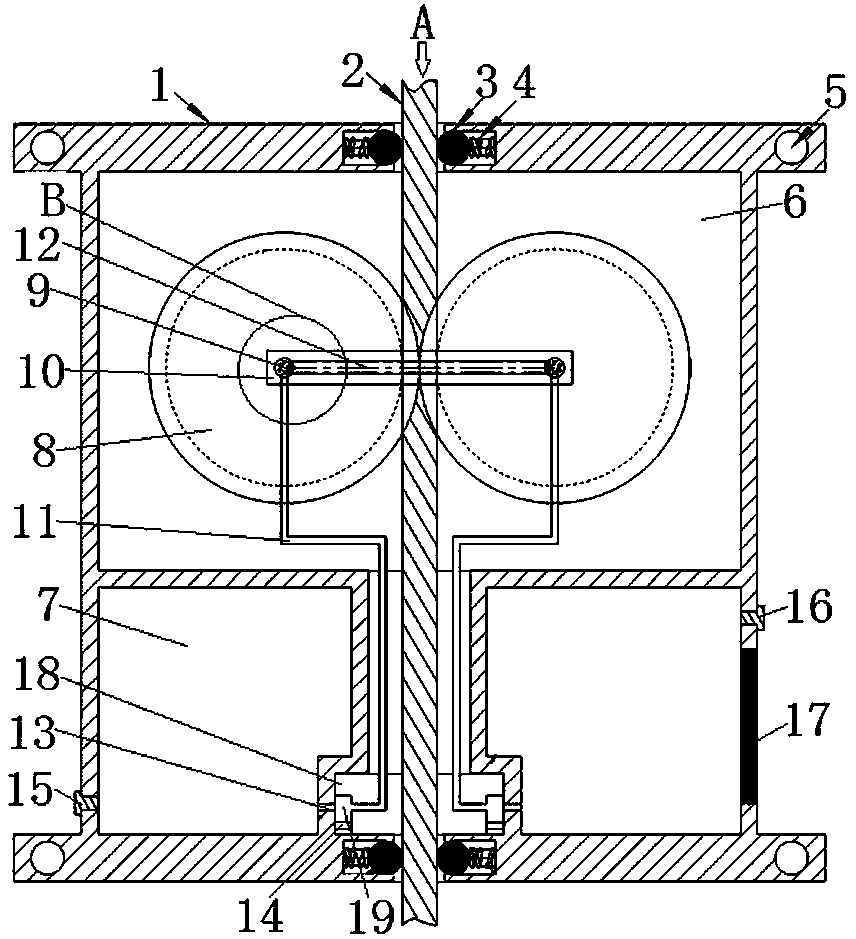

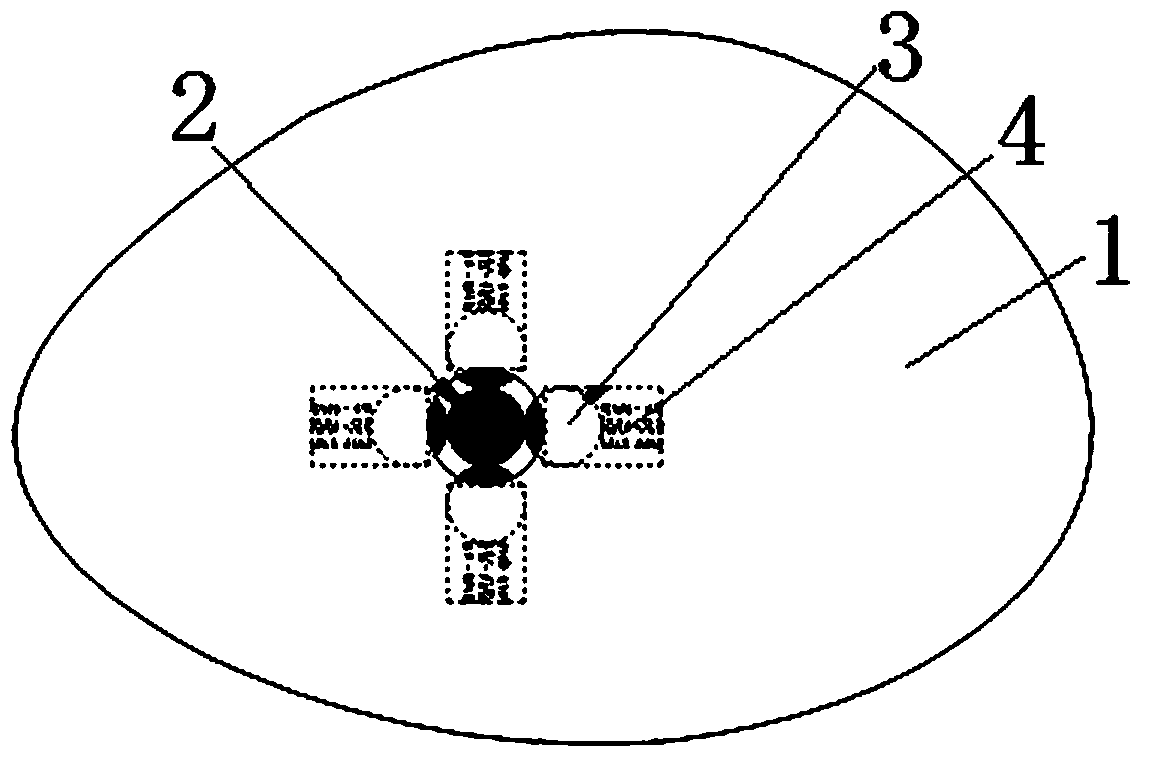

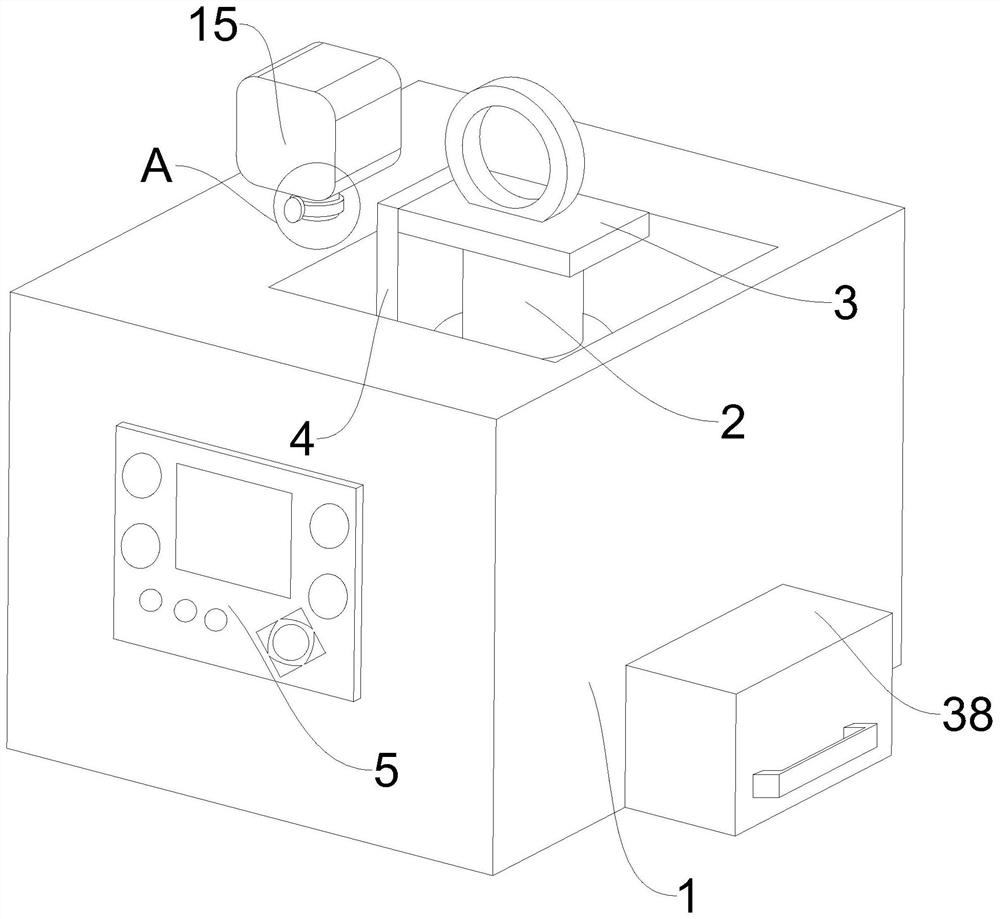

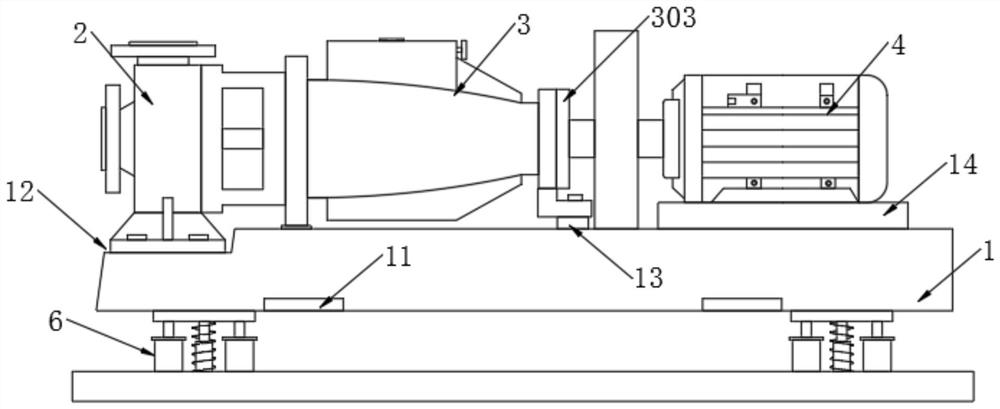

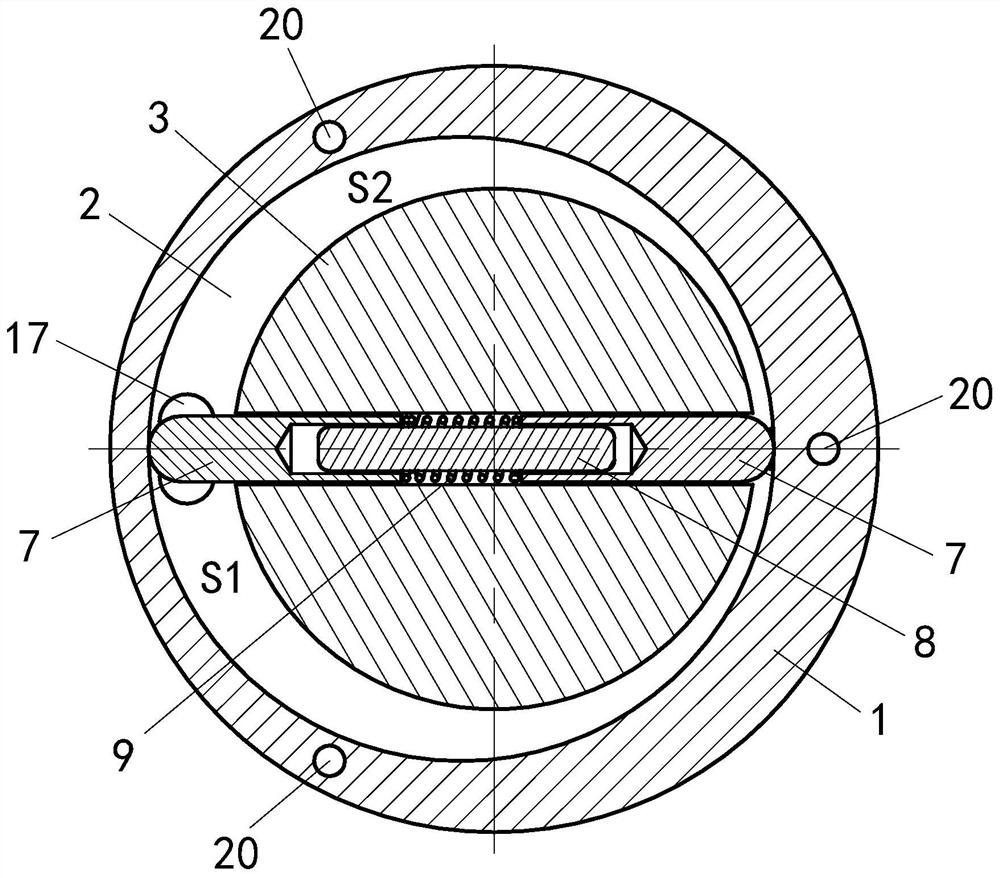

Coaxial self-lubricating device for vertical transmission mechanism

PendingCN112096843AAvoid damageTimely lubricationGear lubrication/coolingLubricating pumpsOil canEngineering

The invention discloses a coaxial self-lubricating device for a vertical transmission mechanism. The coaxial self-lubricating device comprises a pump shell (1), and a cylindrical eccentric containingcavity (2) is formed in the lower end of the pump shell (1); a rotor (3) is arranged in the cylindrical eccentric containing cavity (2), and the bottom end of the rotor (3) is rotationally connected with a pump cover (5) through a bearing (4); the part, located in the cylindrical eccentric containing cavity (2), of the rotor (3) is provided with a blade groove (6), and a pair of blades (7) is arranged in the blade groove (6); and the blades (7) are in sliding connection with the blade grooves (6). According to the device, oil can be pumped during forward and reverse rotation; the working rotating speed range is wide, and the coaxial self-lubricating device is suitable for lubricating low-speed, high-speed and rotating-speed-adjustable transmission devices; and the displacement of the lubricating device can be set through adjusting the eccentric distance of the cylindrical eccentric containing cavity or the axial height of the cylindrical eccentric containing cavity. The coaxial self-lubricating device can synchronously work along with the transmission mechanism without extra power.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

an oil supply device

ActiveCN108087700BPrevent oil spillsAvoid wastingBearing coolingEngine lubricationFuel tankOil supply

The invention relates to the field of automobile performance testing, in particular to an oil supply device. The oil supply device includes an oil tank and further includes a clamping mechanism. The clamping mechanism is fixedly connected to an extruding plate. The extruding plate is provided with an extruding plate and an oil draining groove. The extruding plate is located above the oil draininggroove. The clamping mechanism is fixedly connected with a main gear. The outer side of the main gear is provided with an inner gear in a sleeved mode. An outer gear meshes with the position between the main gear and the inner gear simultaneously. The outer side of the outer gear is provided with a fixing plate. A rotating shaft is connected with the position between the fixing plate and the outergear. One end of the rotating shaft is fixedly connected to the fixing plate. The other end of the rotating shaft is rotatably connected with the outer gear. The outer wall of the inner gear is rotatably connected with a rotating block. The rotating block is connected with an ejector rod in a sliding mode. The oil tank is connected with a hose. The hose communicates with an oil cup. The junctionof the oil tank and the hose is connected with an oil control plate. A gasbag is arranged between the oil tank and the extruding plate. A gas pipe communicates with the position between the gasbag andthe hose. The gasbag is fixedly connected with the oil control plate and the ejector rod. Intermittent oil supply is achieved through the scheme of the oil supply device.

Owner:泾县凡泽科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com