Plug-in type vibrator

A vibrator, plug-in technology, applied in the direction of electric components, casing/cover/support, control of mechanical energy, etc., can solve the problems affecting the construction process, lack of lubrication of gears, locking of vibrating rods, etc., and achieve convenient replacement of vibrating rods , prolong the service life, and firmly connect the joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

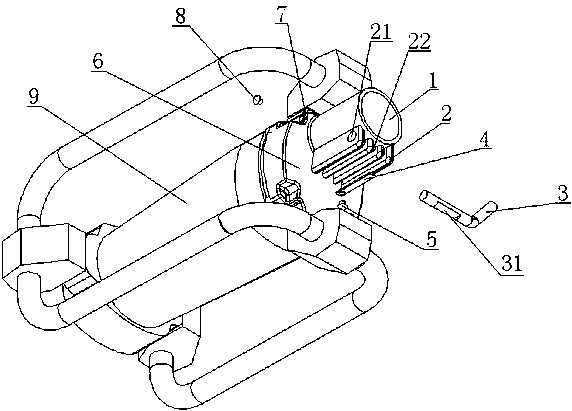

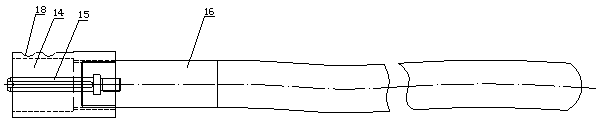

[0027] figure 1 As shown, the plug-in vibrator includes a motor and a joint installed on the front cover of the motor. The plug-in vibrator also includes a locking mechanism on the joint, a detachable joint connected to the joint and a joint connected to the inner rotor of the motor. The segmented shaft, the locking mechanism includes multiple reeds 2, L-shaped lock pins 3, locks 4 and screws 5, multiple reeds 2 ( figure 1 4) are evenly fixed on the outer wall of the joint 1, and the end of each reed 2 away from the front cover 6 of the motor 9 has a mounting hole 21, and the mounting holes 21 of the middle two reeds 2 are installed with the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com