Lubrication device for hydraulic drawing machine

A lubricating device and wire drawing machine technology, which is applied in the direction of engine lubrication, lubricating pumps, distribution devices, etc., can solve the problems of guide rail slide wear, low working efficiency of wire drawing machine, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

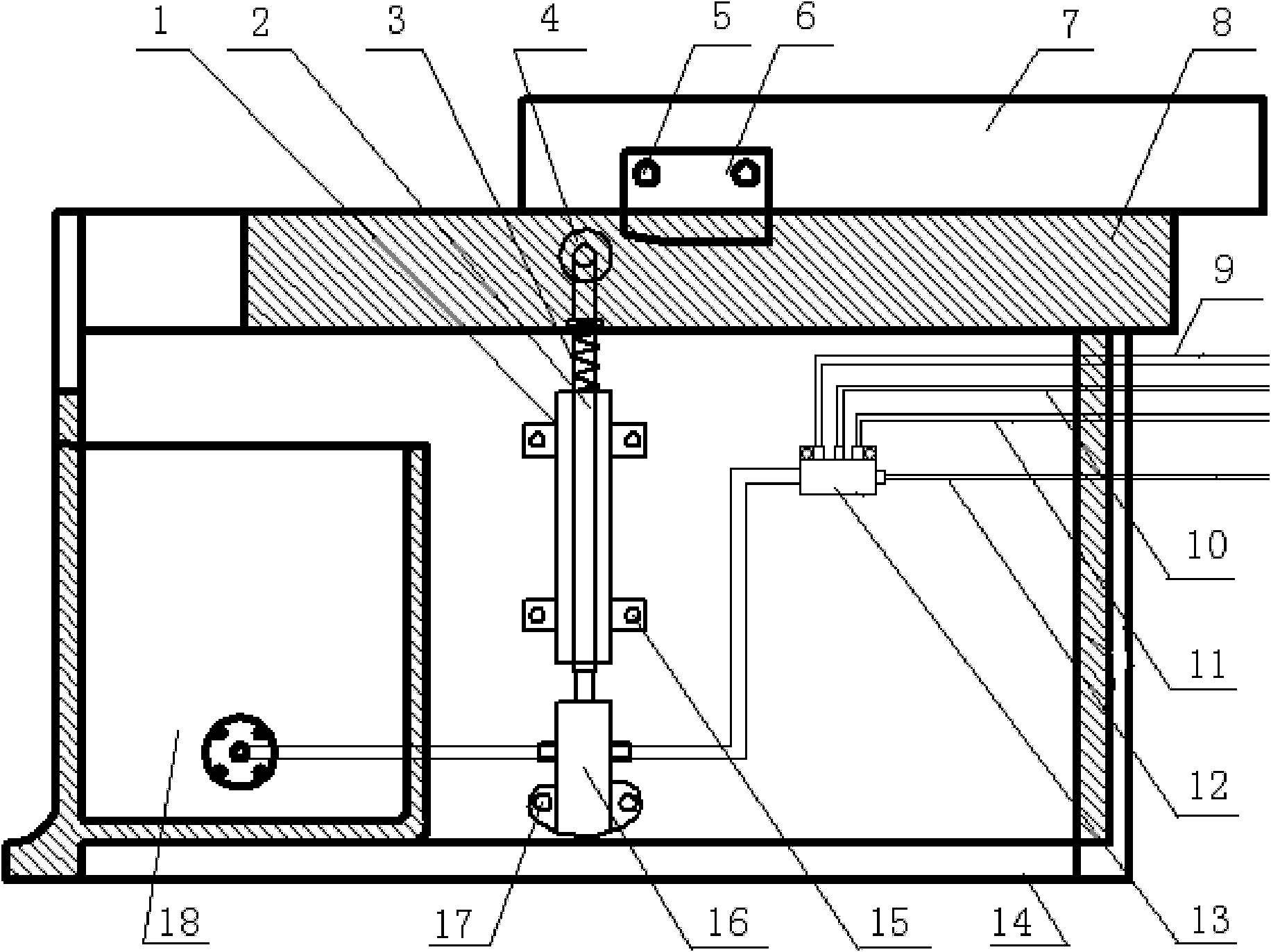

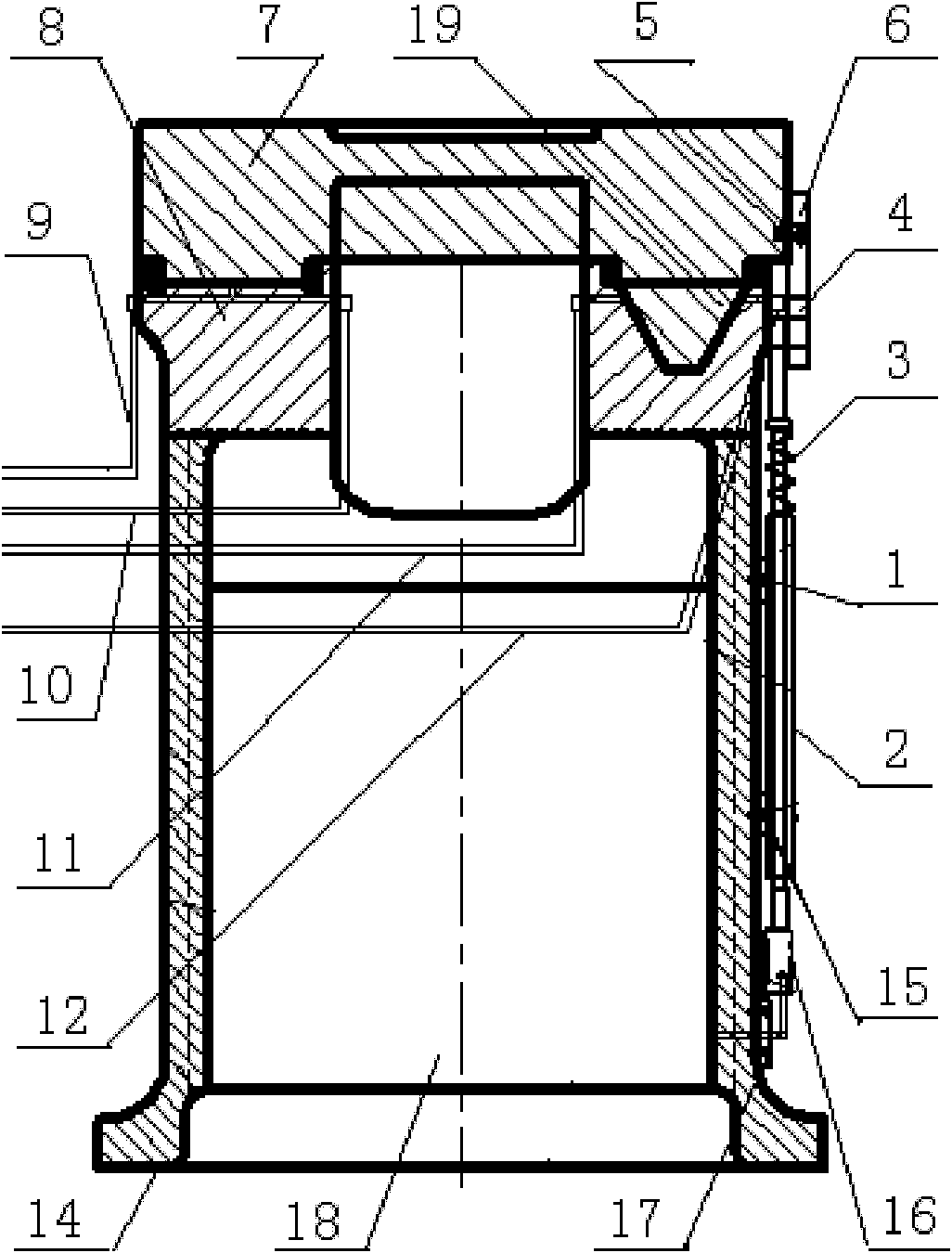

[0011] Specific embodiments of the present invention, such as figure 1 , 2 As shown, a lubricating device for a hydraulic wire drawing machine, a lubricating device for a hydraulic wire drawing machine, includes an oil tank 18 arranged under the wire drawing machine, an oil distributor 13 and various oil pipes, wherein each oil pipe includes a first oil pipe 9, The second oil pipe 10, the third oil pipe 11 and the fourth oil pipe 12 are characterized in that: there is a slide block 6 arranged on the sliding platform 7 of the wire drawing machine, and between the bottom of the slide block 6 and the oil tank 18 The roller plunger pump automatic oiling mechanism that cooperates with the slider 6, specifically the slider 6 of the lubricating device is fixed on the wire drawing machine sliding platform 7 by the slider fixing bolt 5, as figure 1 , 2 shown.

[0012] Said roller plunger pump automatic oil filling mechanism is made up of rolling pulley 4, guide rod 2, spring 3 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com