Multi-stage piston hydraulic tension oil cylinder

A technology of oil cylinder and piston, which is applied in the field of multi-stage piston hydraulic tension cylinder, which can solve the problems of damage to oil cylinder parts, affect the use of oil cylinder, reduce the working efficiency of oil cylinder, etc., and achieve the effects of reducing damage, improving lubrication effect and reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

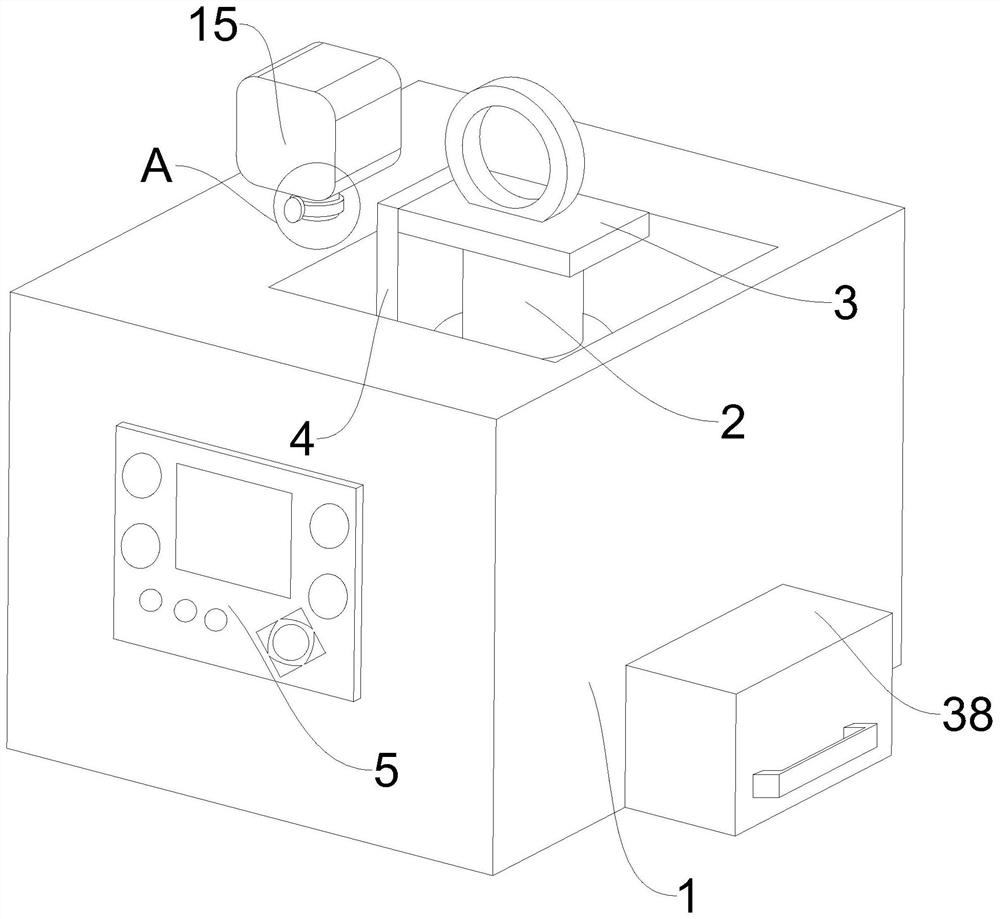

Image

Examples

Embodiment approach

[0044] As an embodiment of the present invention, refer to image 3 , the blowing mechanism includes an air box 23 fixedly installed inside the housing 1, two No. The slider 25 that is fixedly connected, the top of the slider 25 is fixedly installed with the second magnet 26 that cooperates with the first magnet 22, the bottom of the gas box 23 is provided with a first check valve 27, and the bottom of the gas box 23 is provided with a second magnet. The one-way valve 28 is fixed with two air outlet pipes 29 matched with the second one-way valve 28 on the inner wall of the top of the housing 1 , and two air outlets 30 are connected to one end of the two air outlet pipes 29 respectively.

[0045] When the first magnet 22 rotates, when the first magnet 22 reaches the bottom end, it will cooperate with the second magnet 26. According to the principle that the magnets repel each other with the same sex and the opposite sex attracts each other, the second magnet 26 is pushed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com