Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Stay longer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

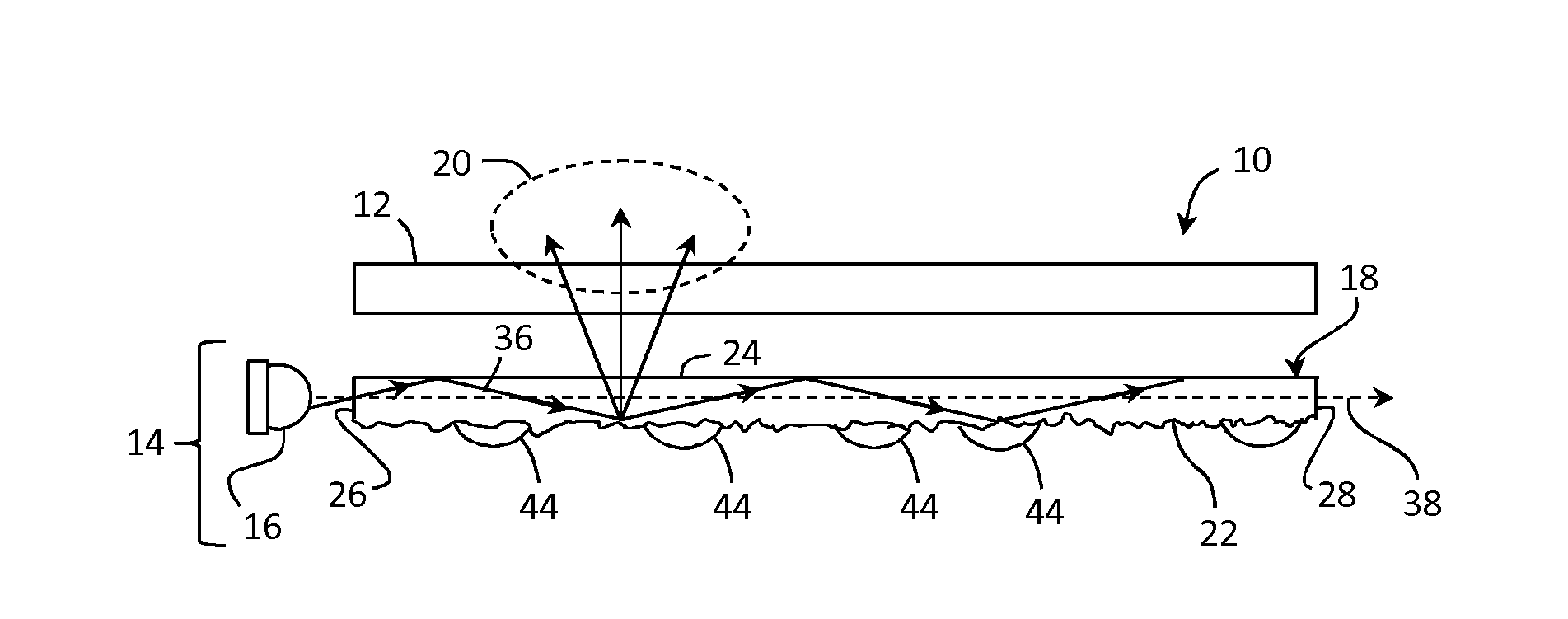

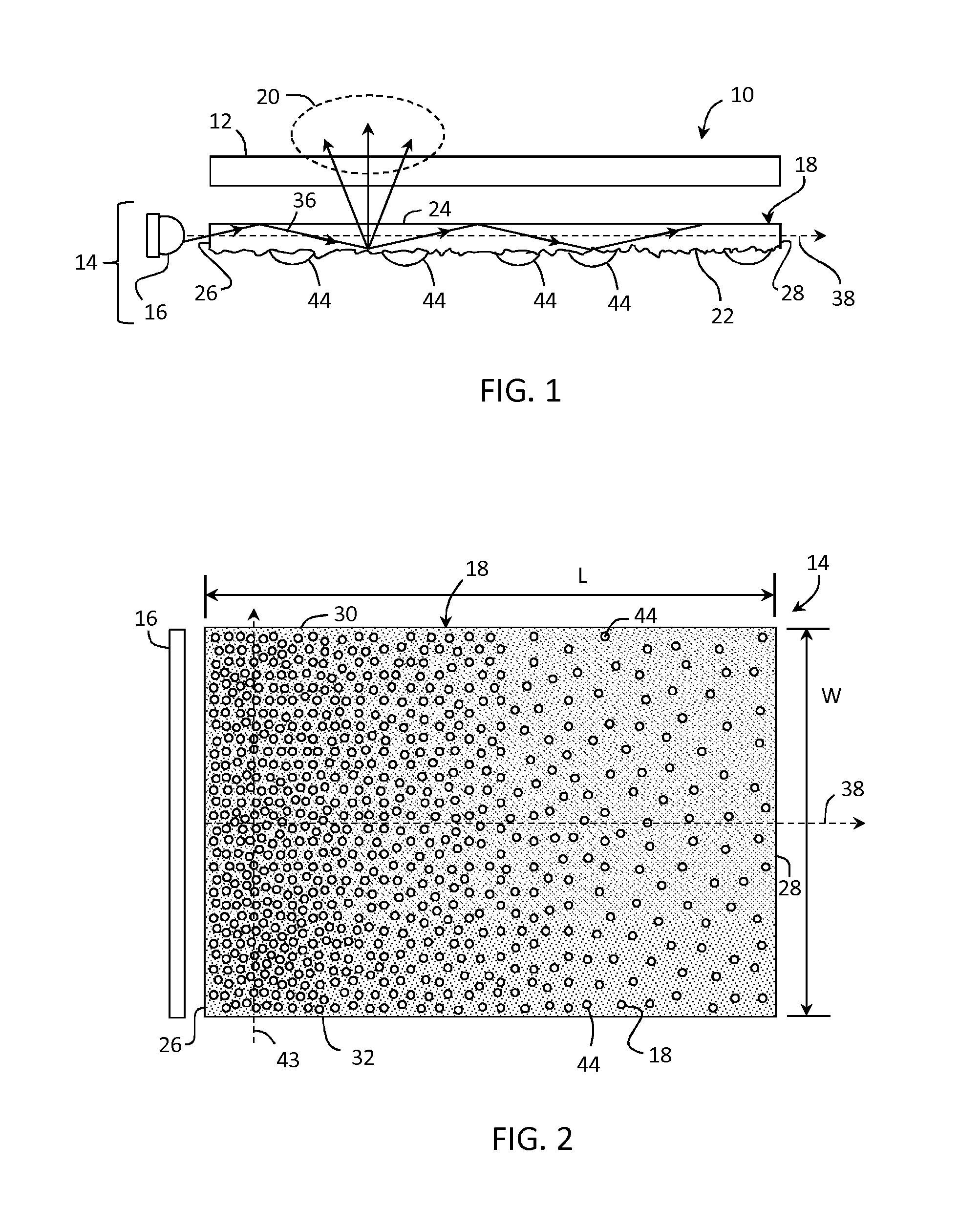

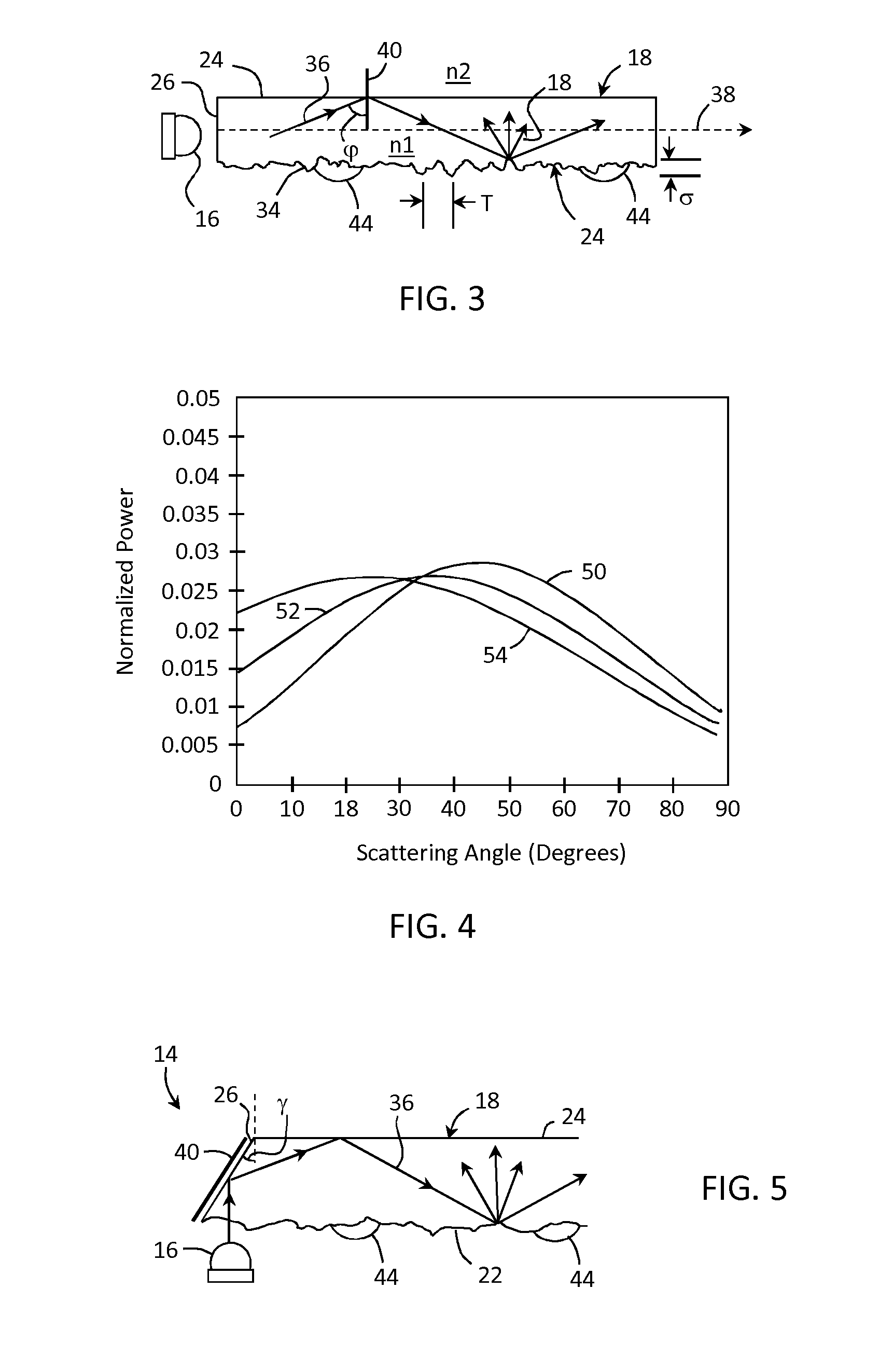

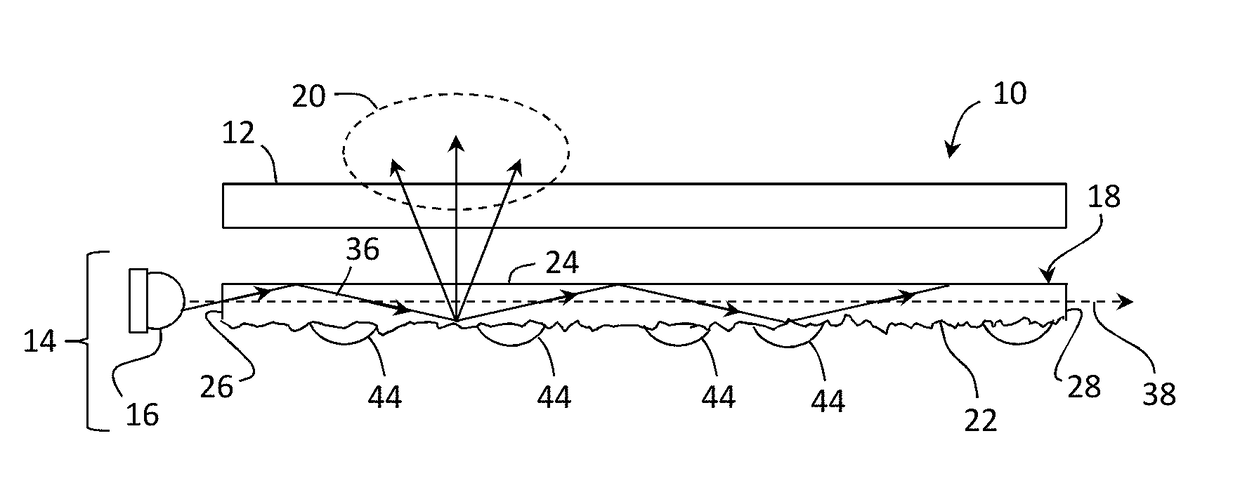

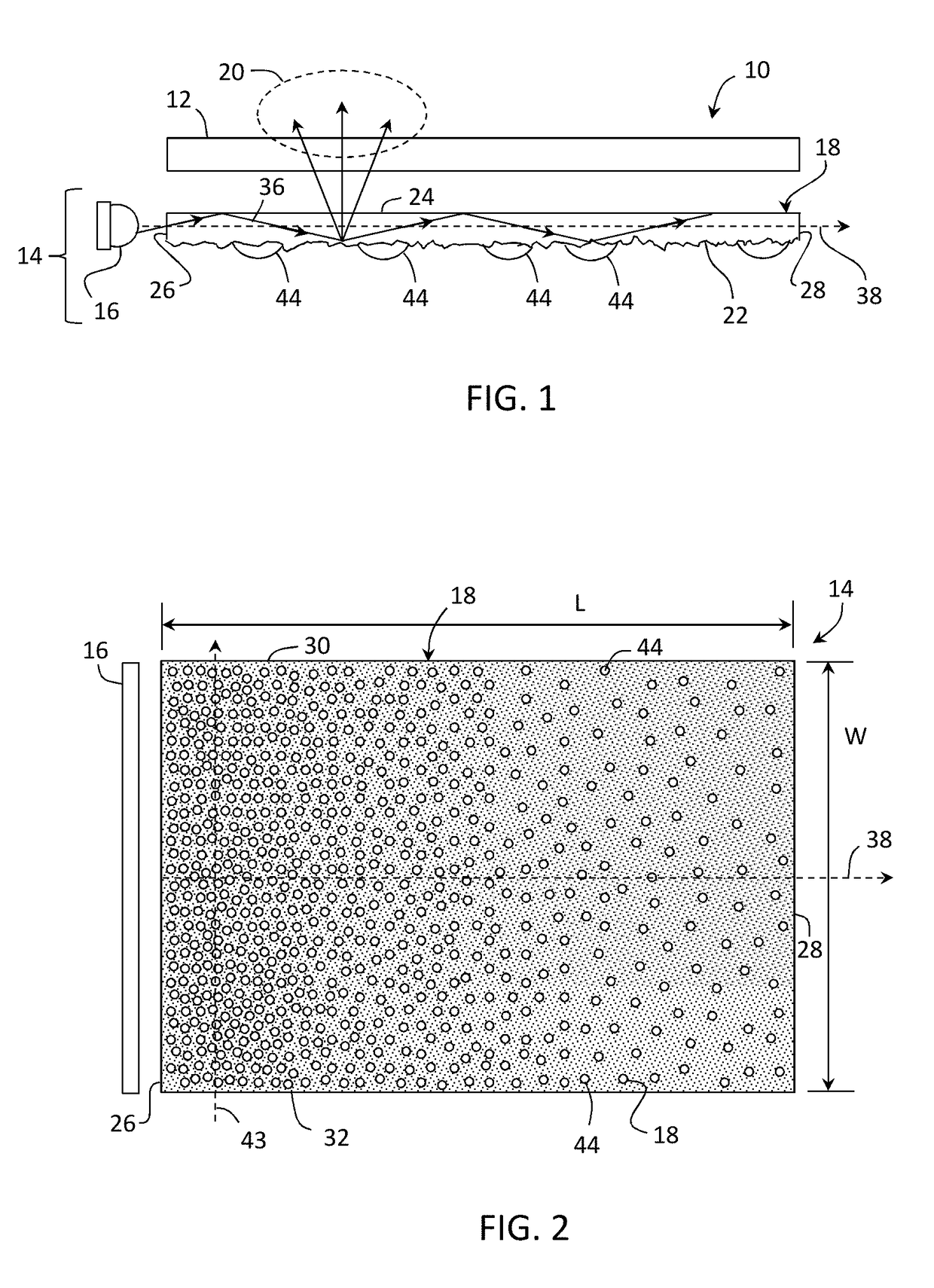

Textured surfaces for display applications

ActiveUS20160313494A1Provide protectionHigh light transmittanceMechanical apparatusDiffusing elementsLight guideDisplay device

A substrate with a textured surface is disclosed. The substrate may be, for example, a light emitter comprising a light guide, for example a backlight element for use in a display device, wherein a surface of the light guide, for example a glass substrate, is configured to have a textured surface with a predetermined RMS roughness and a predetermined correlation length of the texture. A plurality of light scatter supressing features can be provided on the textured surface. Textured surfaces disclosed herein may be effective to reduce electrostatic charging of the substrate surface. Methods of producing the textured surface are also disclosed.

Owner:CORNING INC

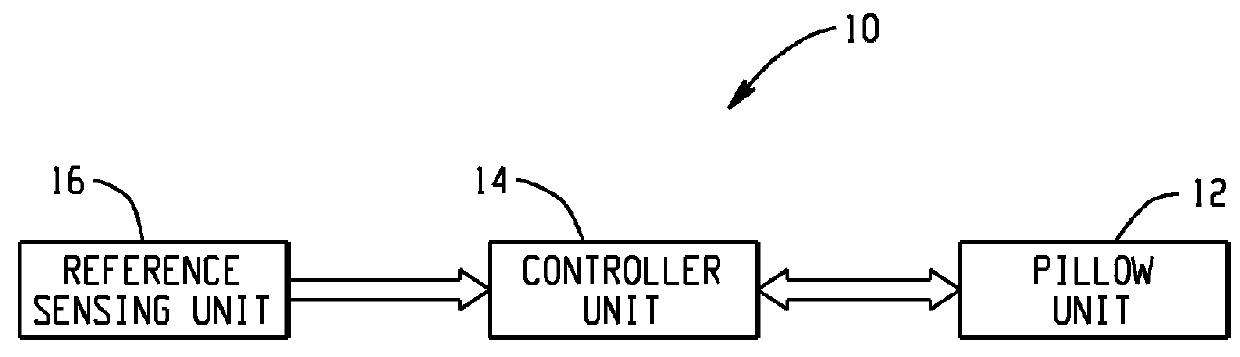

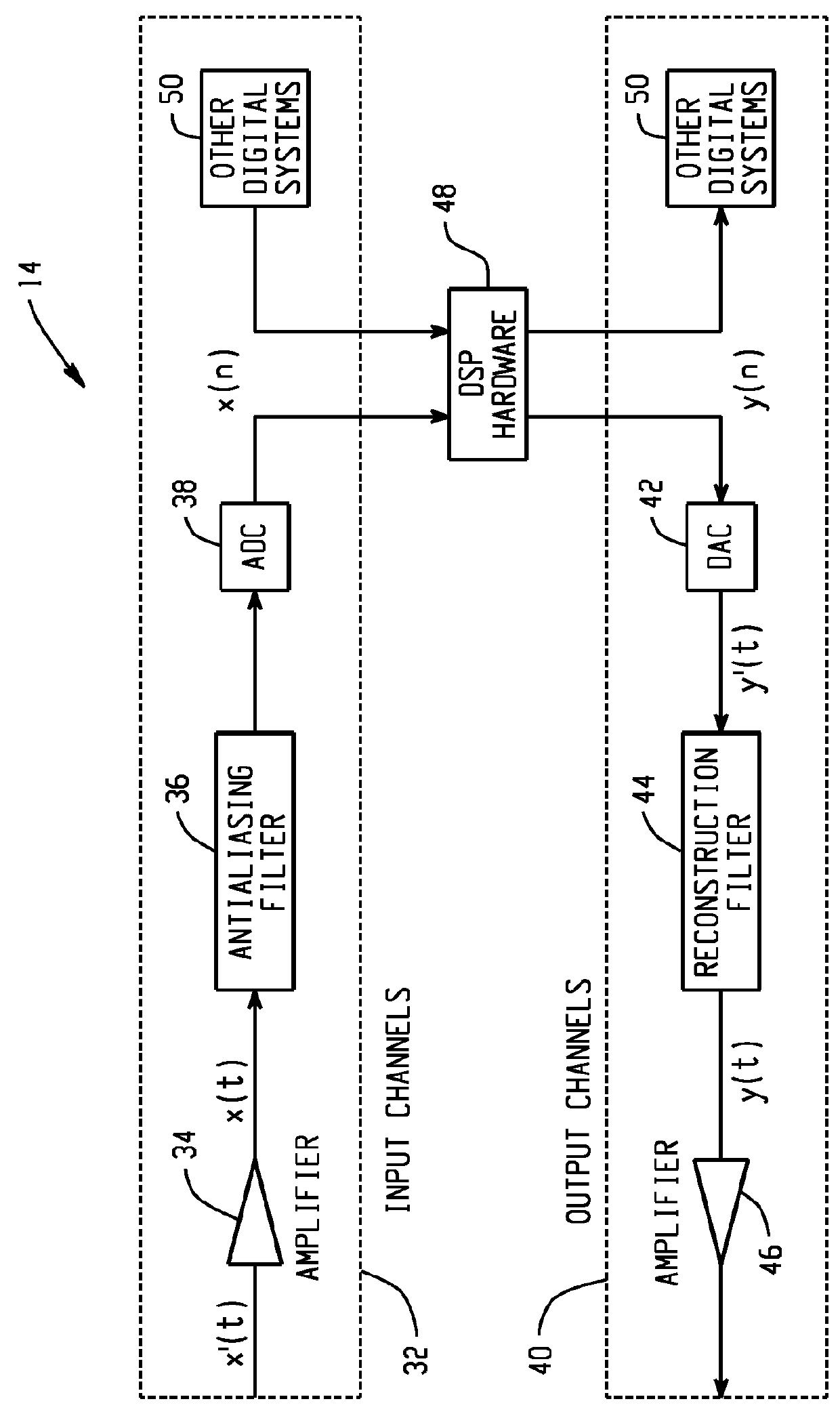

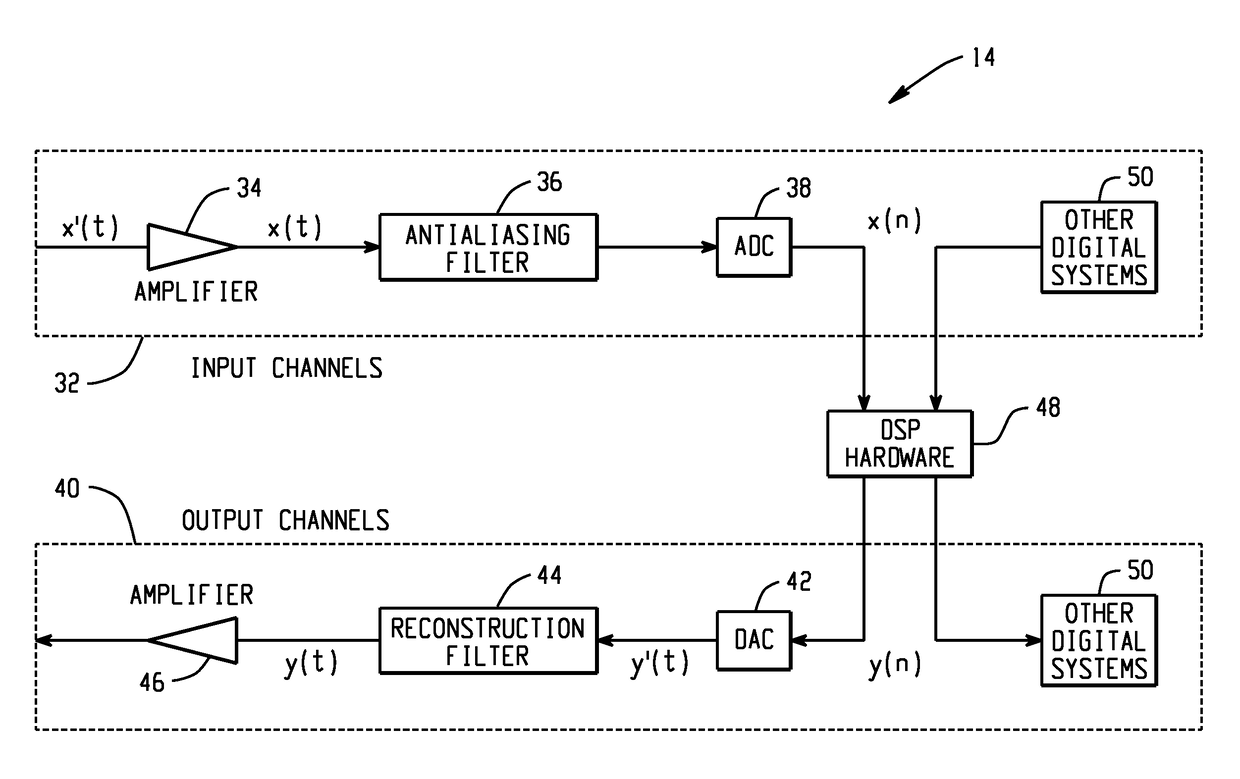

Smart pillows and processes for providing active noise cancellation and biofeedback

ActiveUS20160055842A1Improve sleep qualityShortened sleep latencyPillowsMedical devicesEngineeringActive noise control

Owner:DREAMWELL

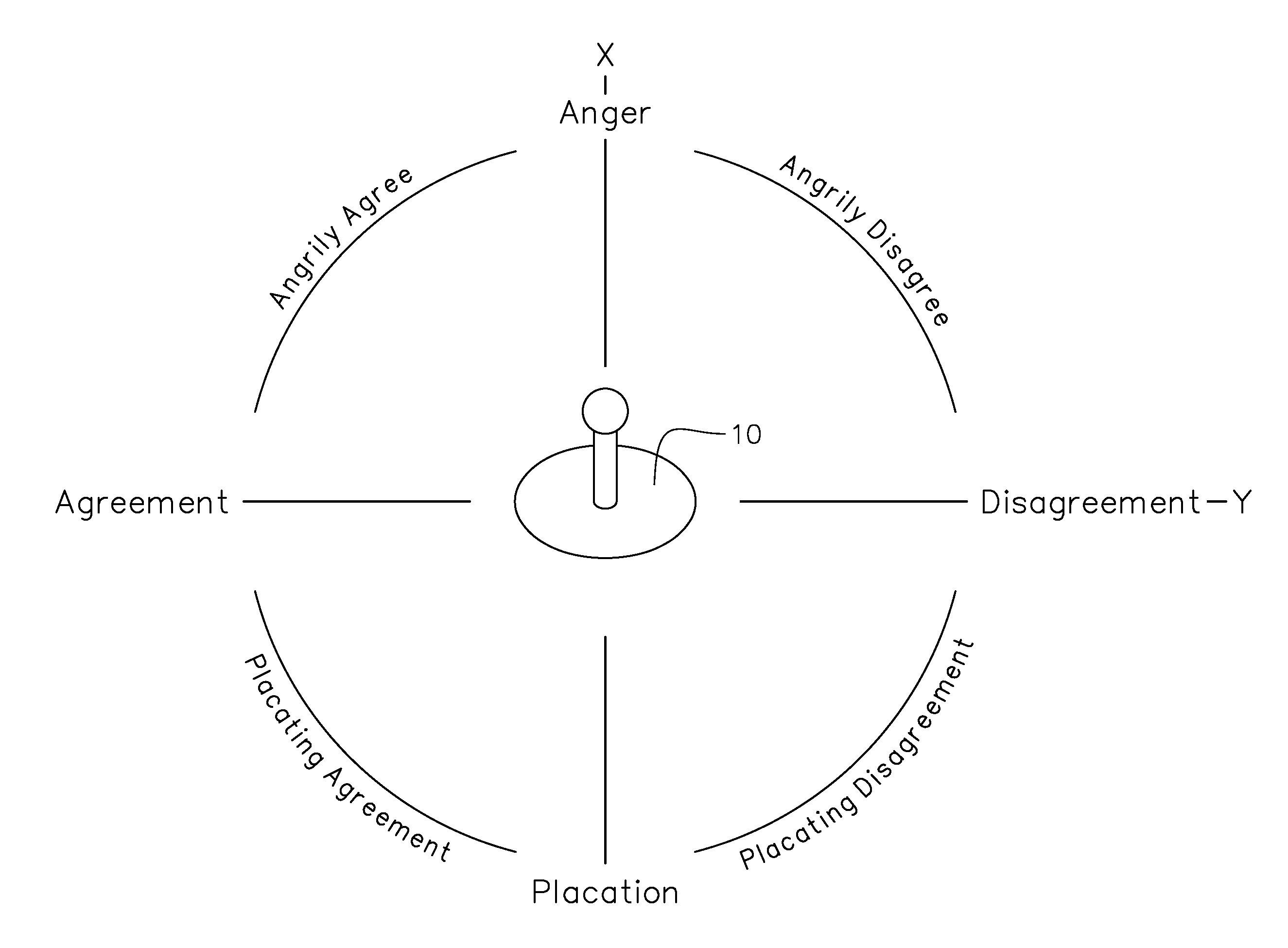

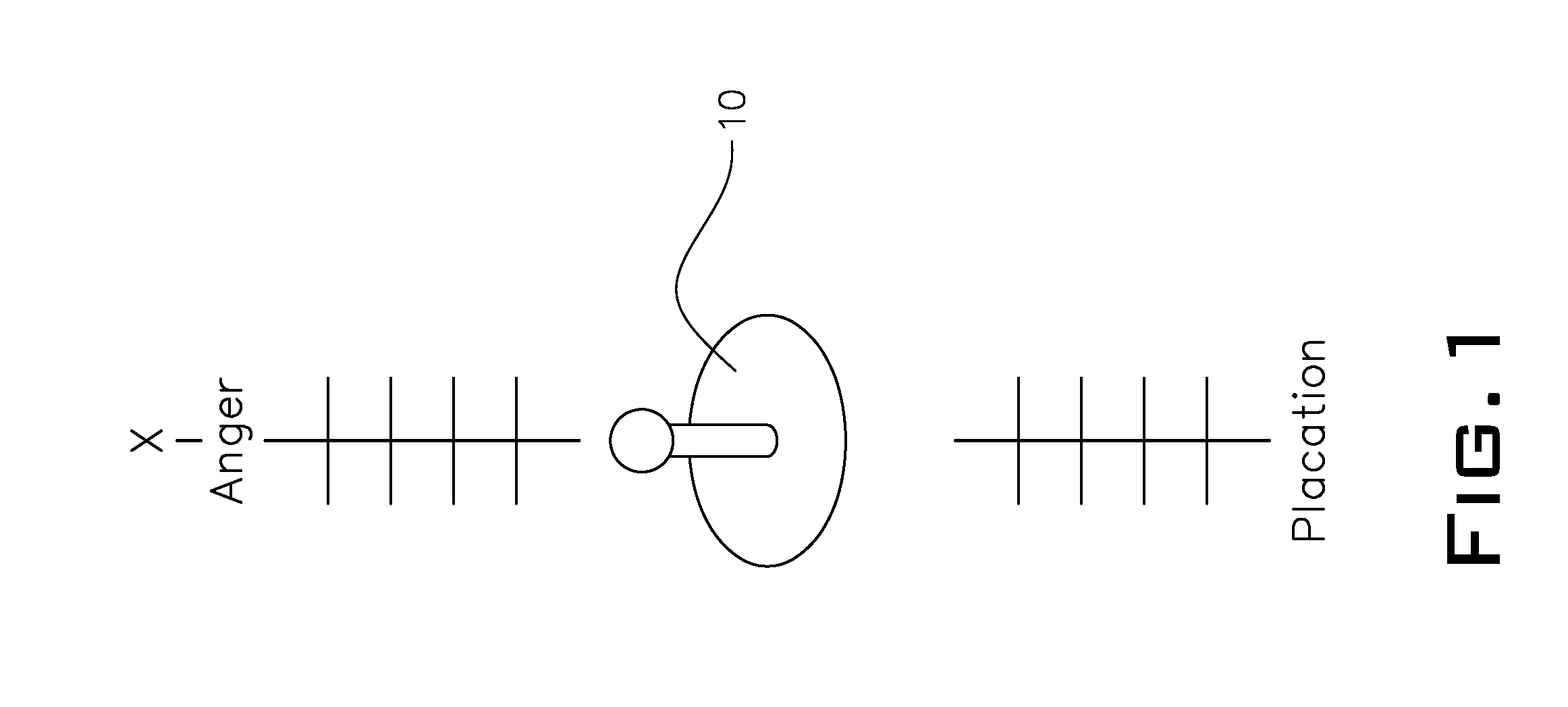

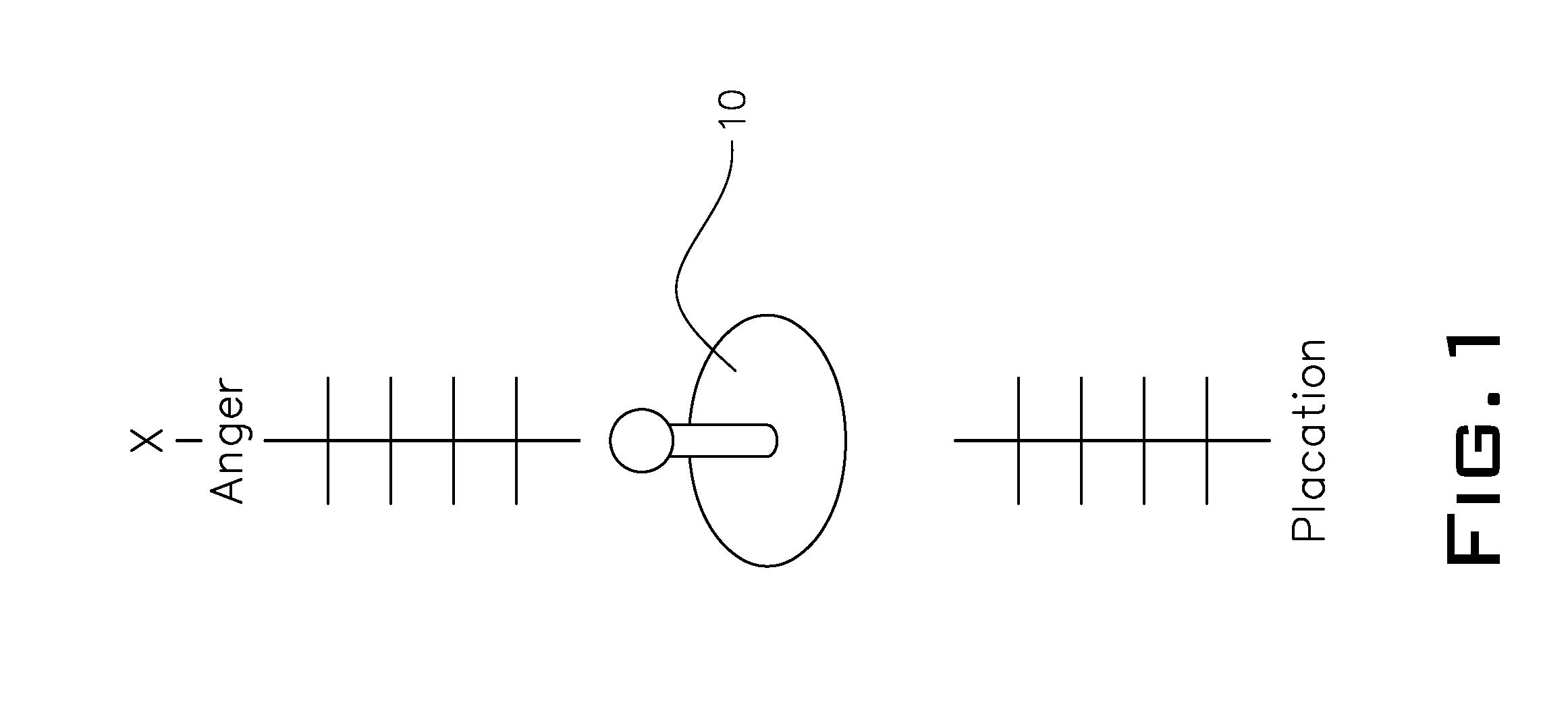

Method and device for controlling player character dialog in a video game located on a computer-readable storage medium

ActiveUS20100267450A1Easy to makeExcessive activityVideo gamesSpecial data processing applicationsGame playerDisplay device

In a computing machine having a processing unit, memory and a display device for playing a video game, the video game comprising at least one or more game characters, the at least one or more game character being controlled by a special purpose computing input device connected to said computer and operable by a game player, the video game further comprising character dialog between or among the at least one or more game characters, the character dialog comprising vignettes of dialog wherein movement from one vignette to another is determined by the game player introducing emotion into the dialog by means of the special purpose computing input device. The special purpose computing input device introduces emotion into the video game during a character dialog or character encounter along an axis of a joystick or other game controller element.

Owner:MCMAIN MICHAEL PARKER

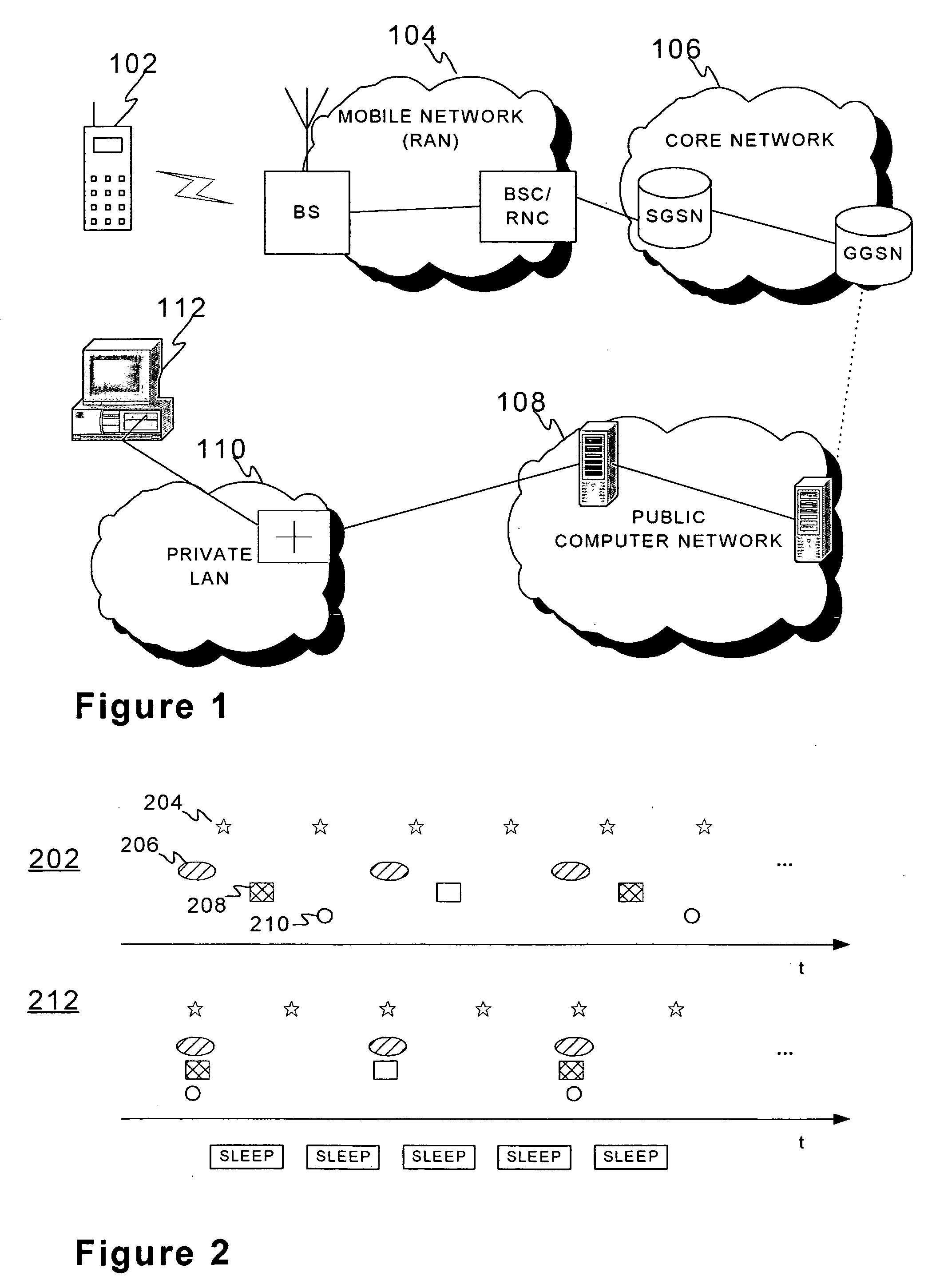

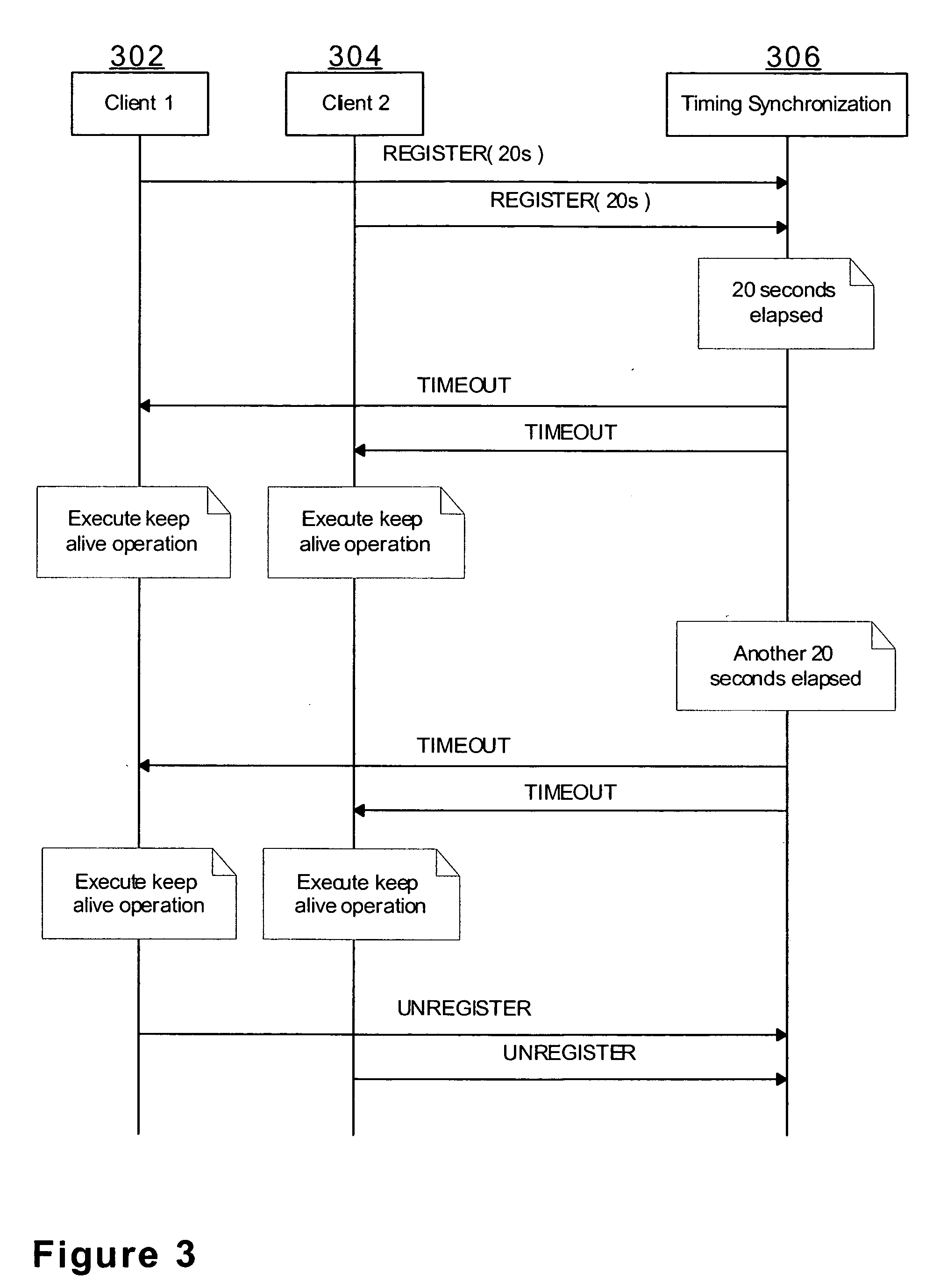

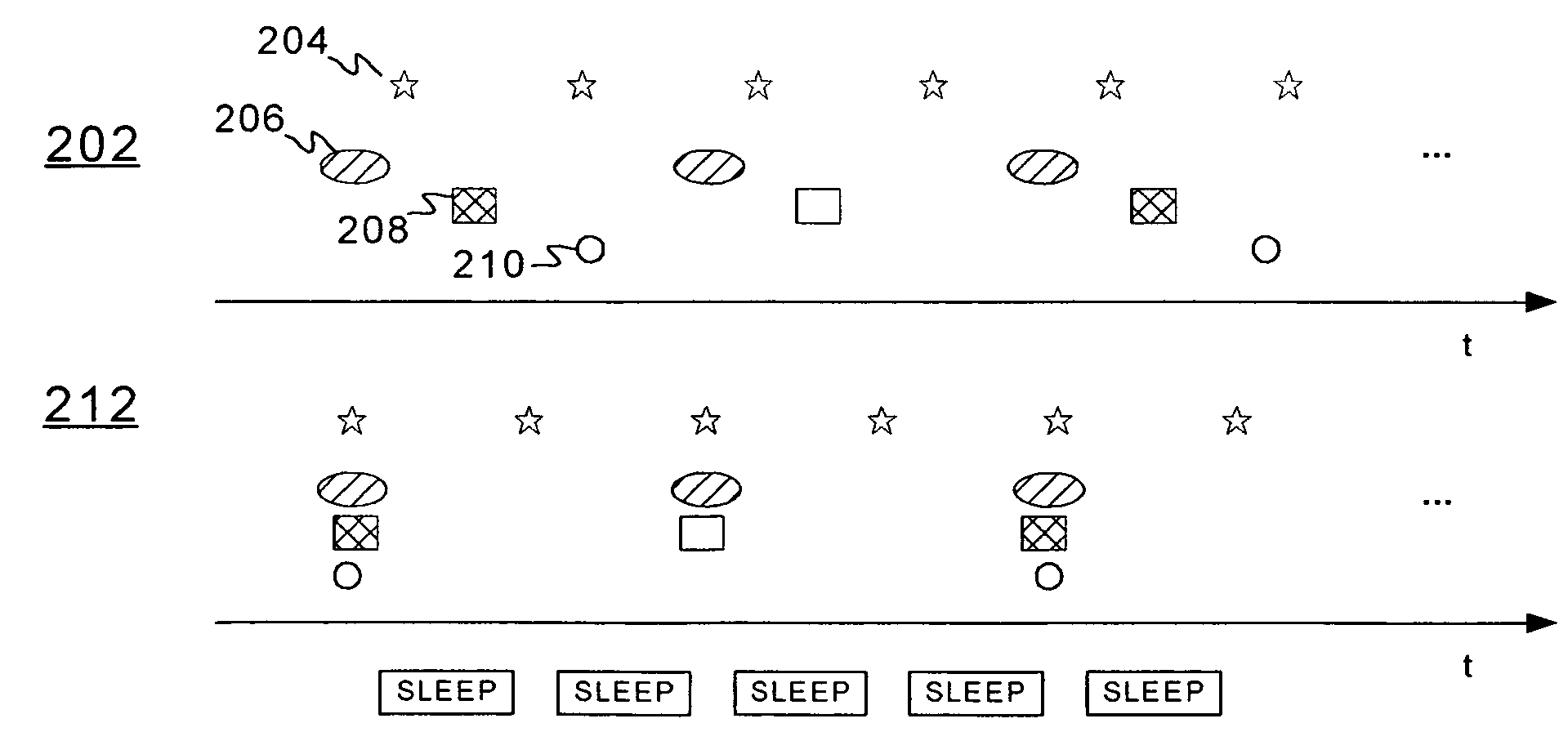

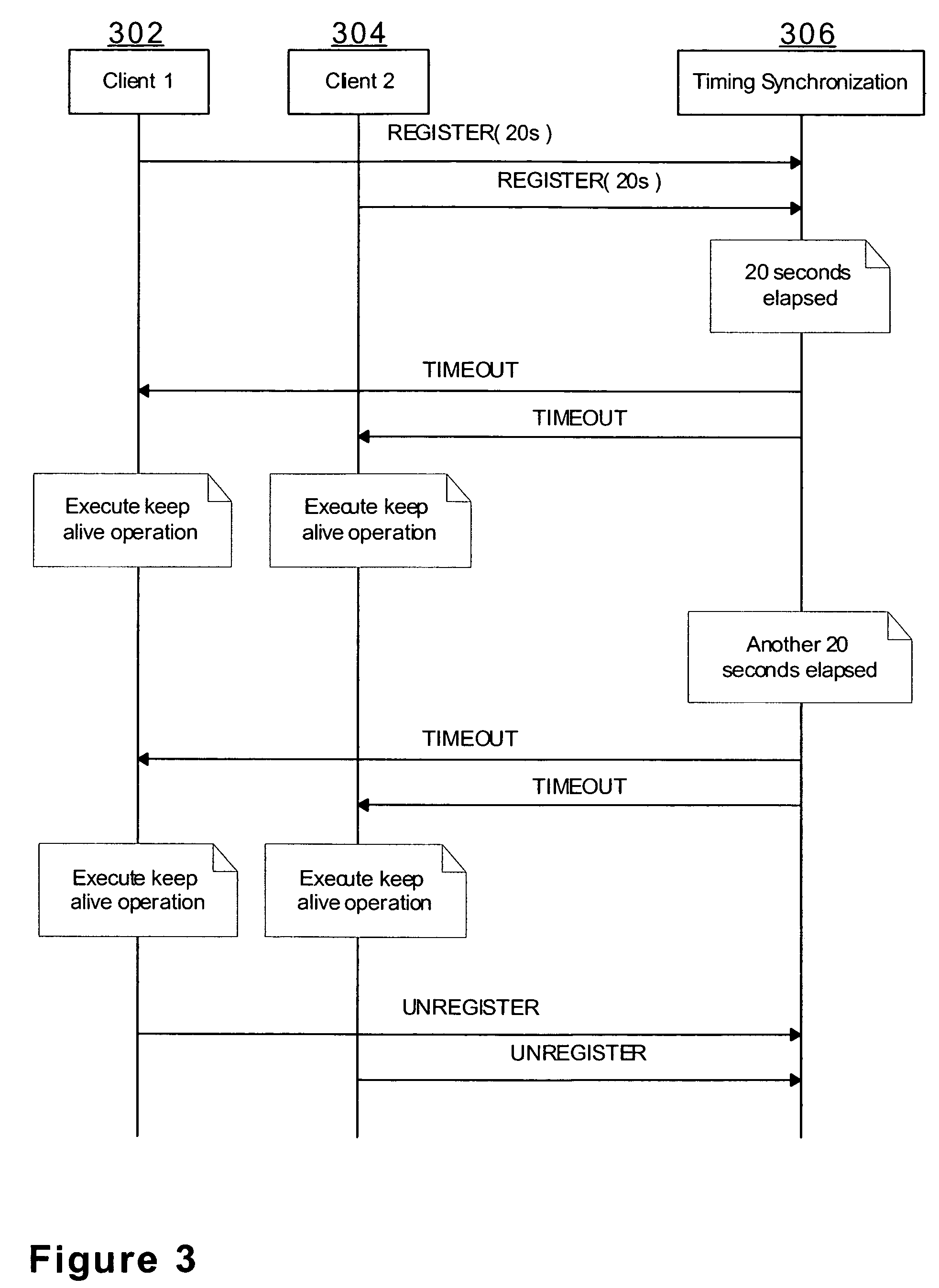

Method and an apparatus for executing timed network operations

ActiveUS20080154913A1Maximize operational timeStay longerConnection managementTransmissionWeb operationsReal-time computing

Owner:NOKIA TECHNOLOGLES OY

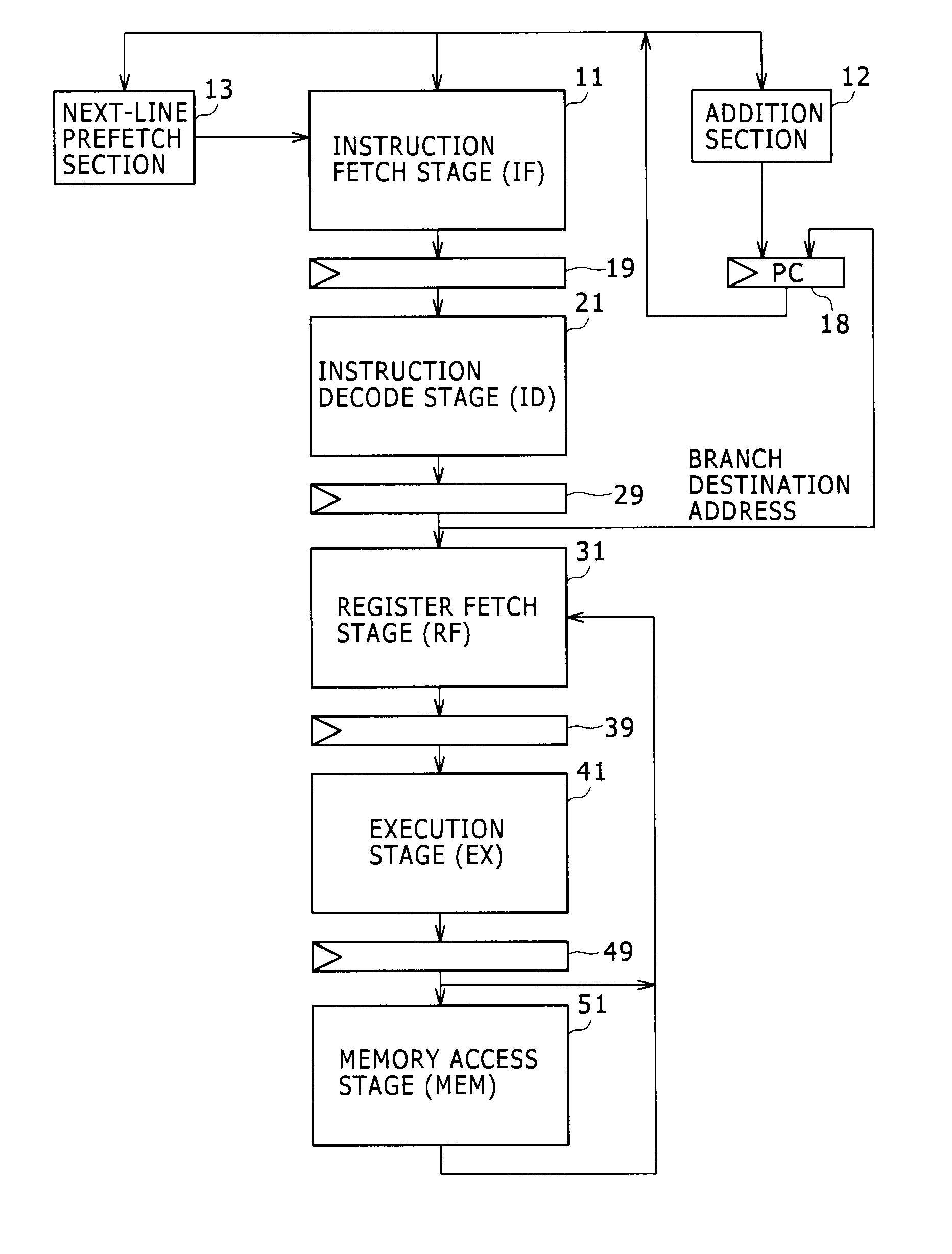

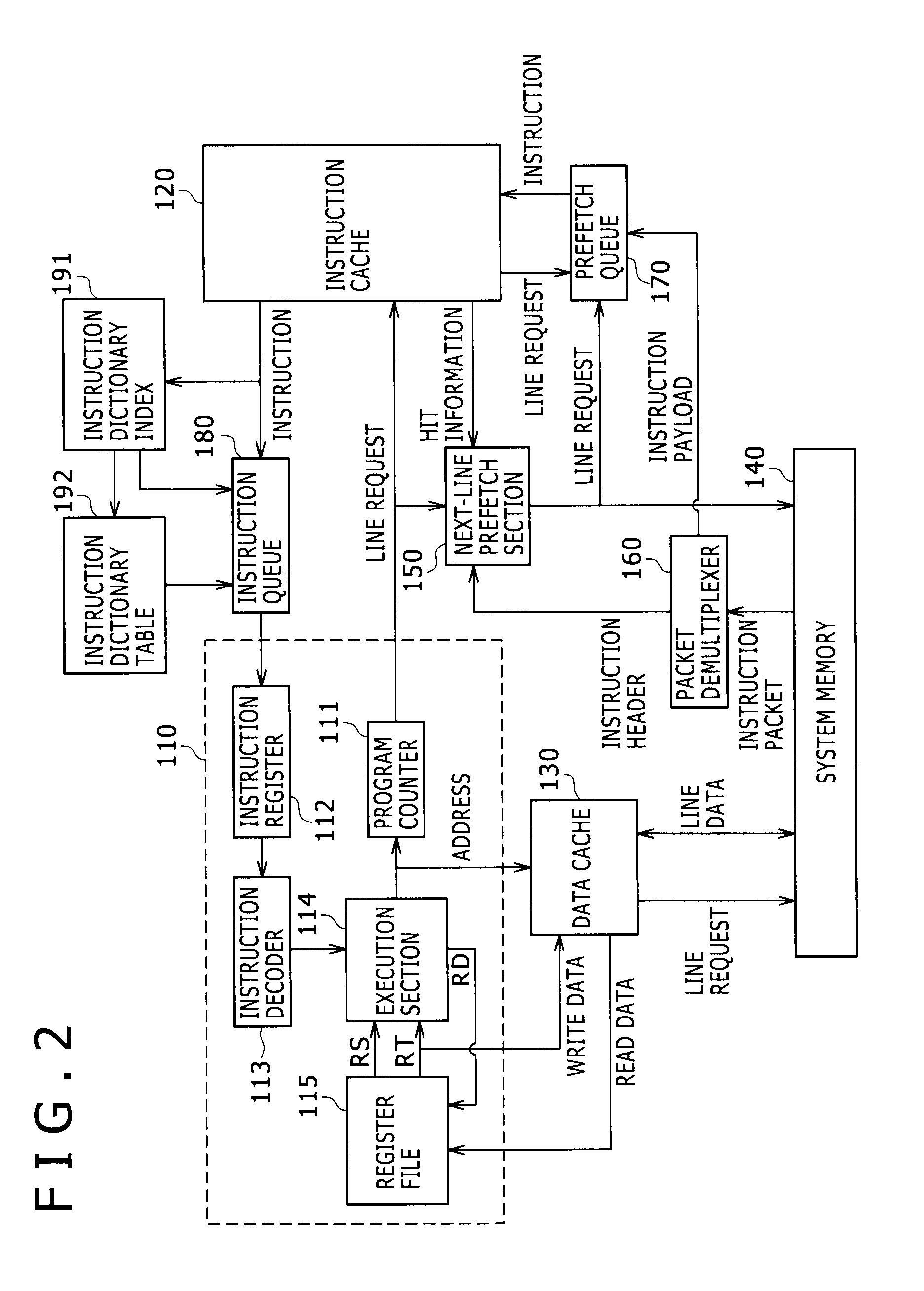

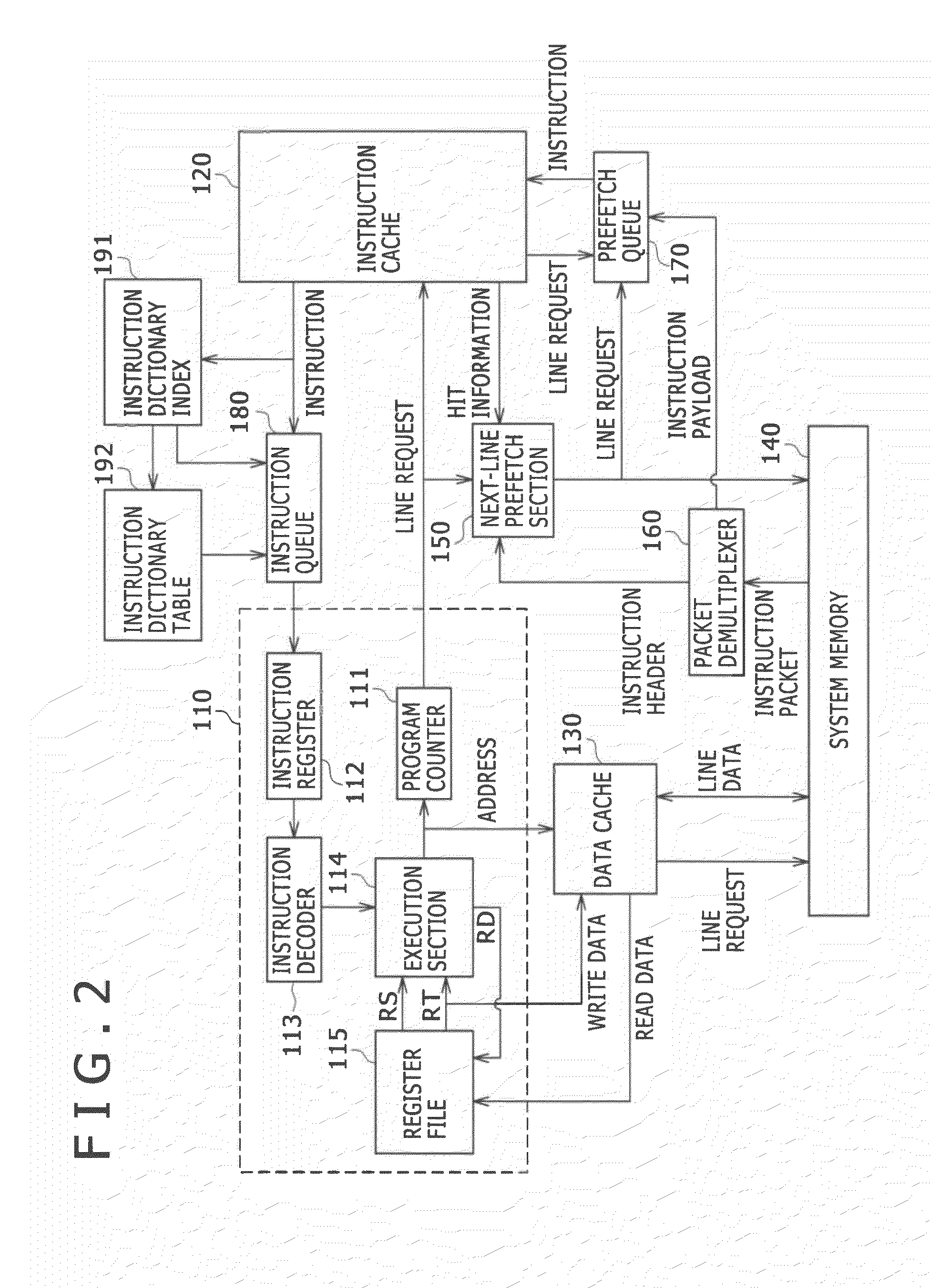

Instruction fetch apparatus and processor

InactiveUS20110238953A1Minimizing penaltyEasy accessDigital computer detailsMemory systemsParallel computingInstruction prefetch

An instruction fetch apparatus is disclosed which includes: a detection state setting section configured to set the execution state of a program of which an instruction prefetch timing is to be detected; a program execution state generation section configured to generate the current execution state of the program; an instruction prefetch timing detection section configured to detect the instruction prefetch timing in the case of a match between the current execution state of the program and the set execution state thereof upon comparison therebetween; and an instruction prefetch section configured to prefetch the next instruction upon detection of the instruction prefetch timing.

Owner:SONY CORP

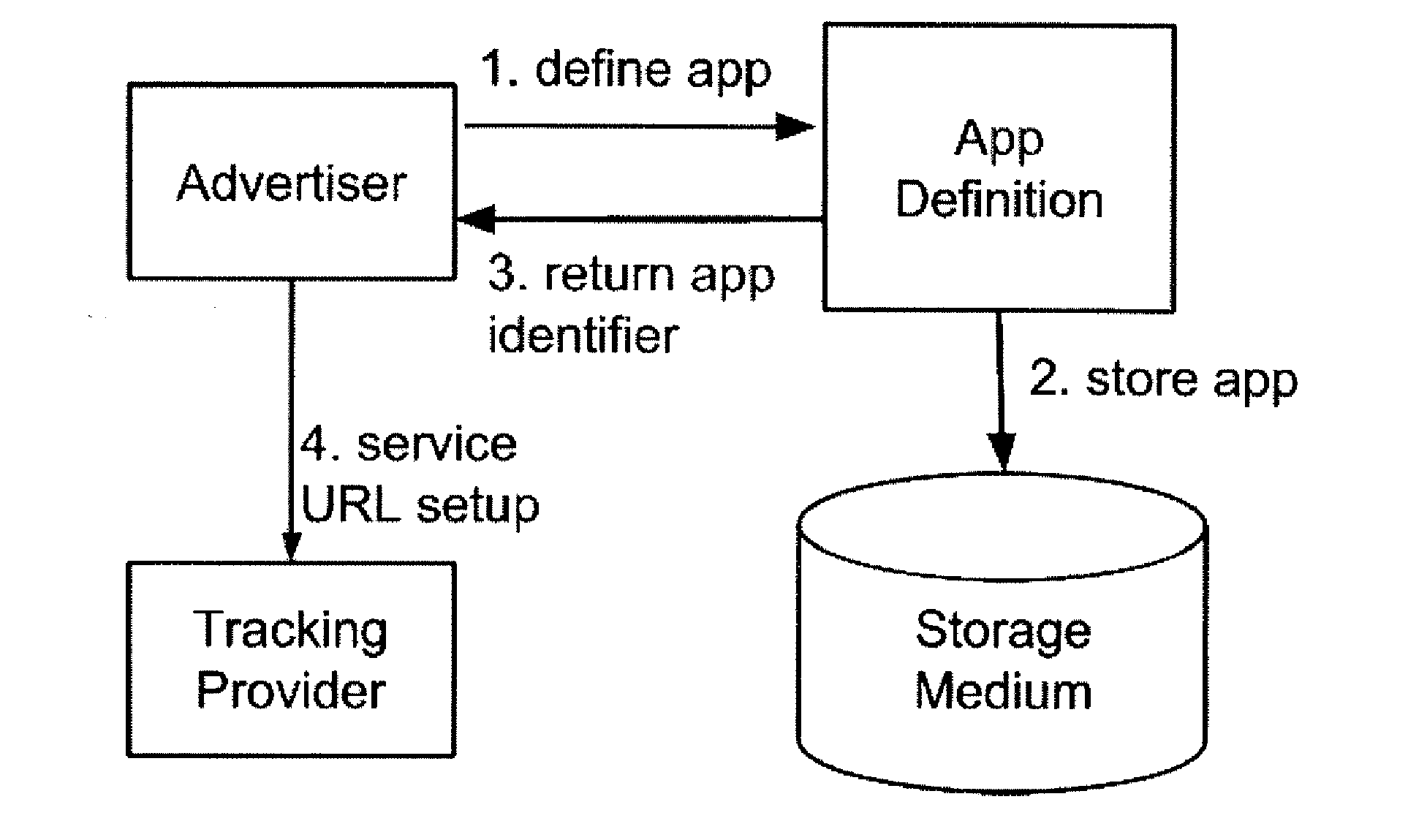

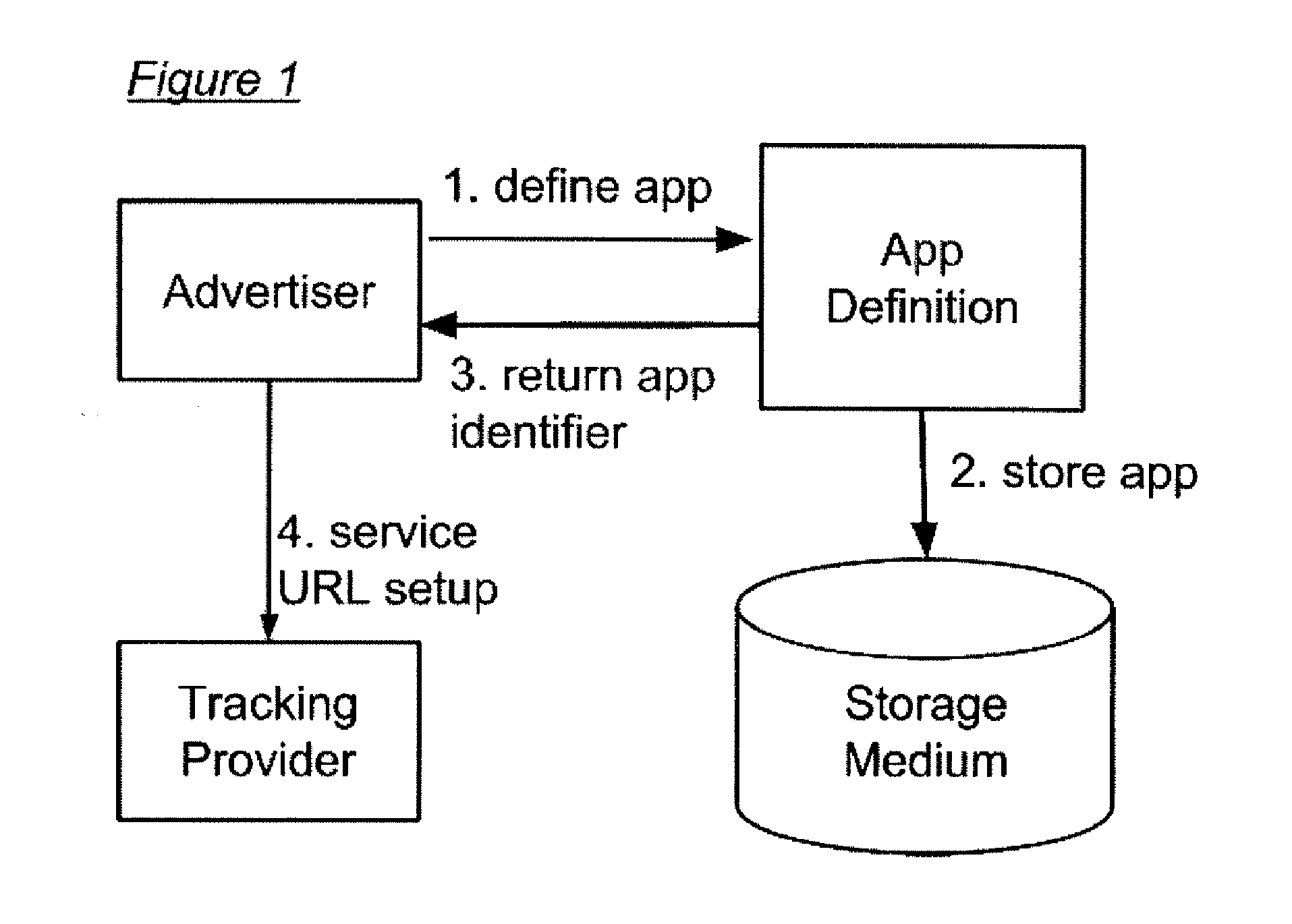

Tracker-mediated mobile in-app contentredemption system for app advertisers over the internet

Computer-implemented offer redemption process including receiving notification from supported trackers, each having a different known configuration, to enable each supported tracker to pass field / s, specific to the configuration, in which an ID of a content offer is stored. The offer is defined as a quantity of a currency, to an advertiser having an account, upon app installation. Responsively to receipt of notification, offer id and / or advertiser account is validated using field / s in which offer's ID is stored. If validated, processor is used for redeeming the offer including generating and storing a voucher with unique voucher ID on computer storage medium, passing voucher ID, user / device id, app identifier, and currency and quantity to advertiser such that advertiser can enable the quantity of the currency in an app identified by the app identifier, for the user / device. Generated voucher is marked “redeemed” to prevent recurring redemption.

Owner:KANKADO CELLULAR SOLUTIONS

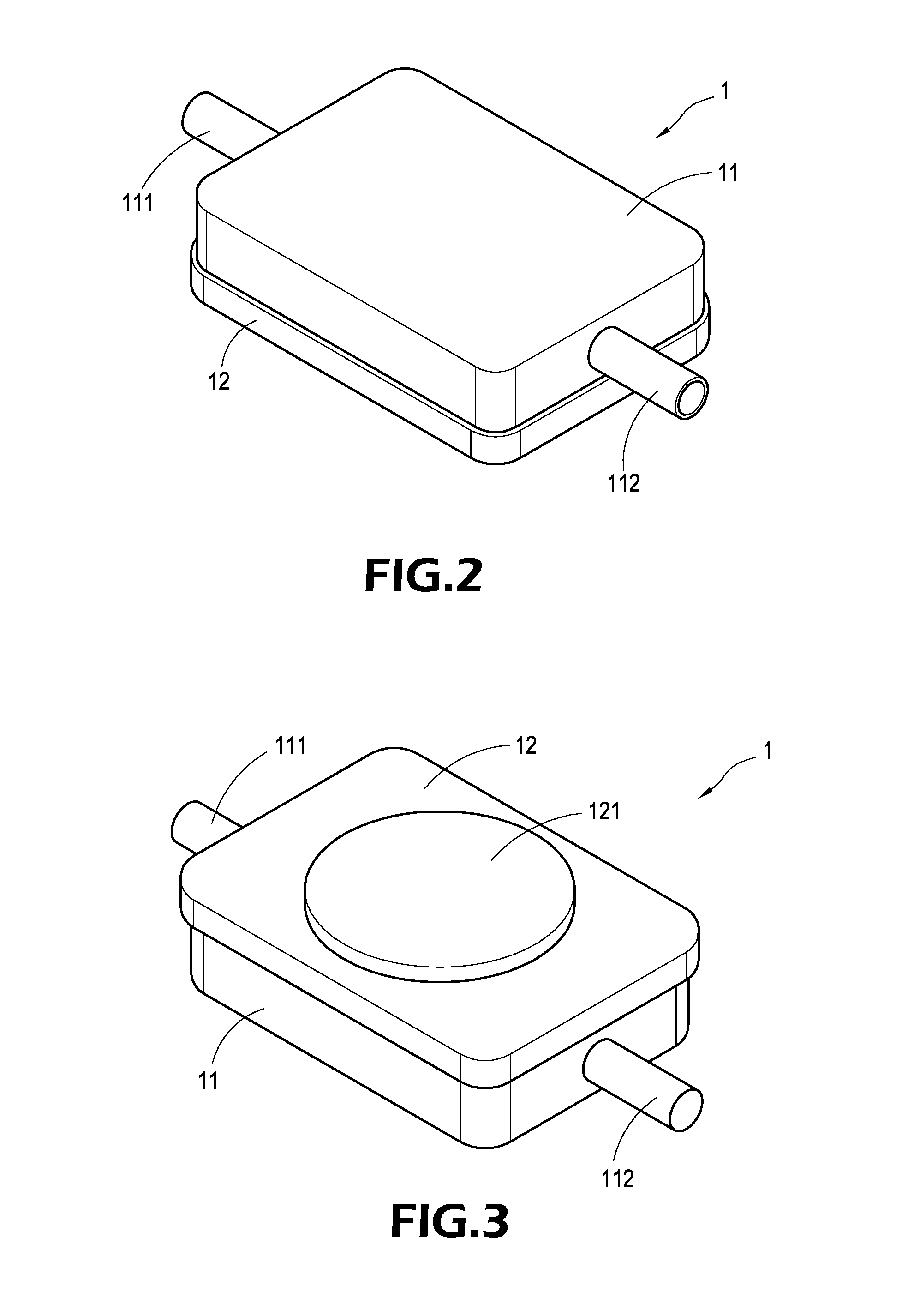

Tool for the production of fiber composite components

InactiveUS20080044506A1Excellent impregnationShort timeConfectionerySweetmeatsWork in processFibrous composites

The present invention provides a tool for the production of fiber composite components. The tool has a surface for depositing semifinished fiber products on the surface, the surface having a number of openings for feeding a matrix to the deposited semifinished fiber products. It is consequently possible to dispense entirely or partly with a conventional flow promoter and possible to achieve a high quality of fiber composite component.

Owner:AIRBUS OPERATIONS GMBH

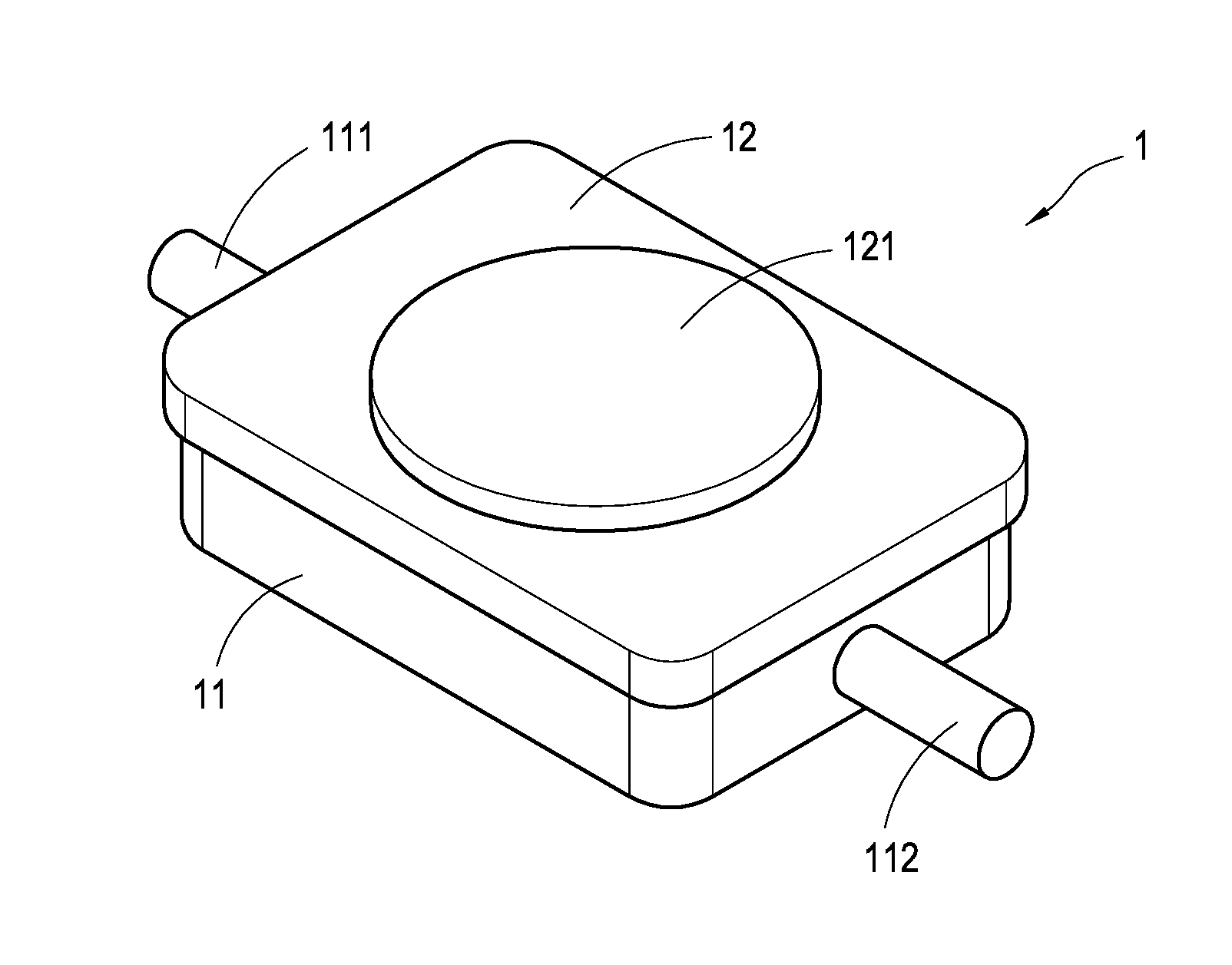

Water Cooling Type Heat Dissipation Apparatus with Parallel Runners

InactiveUS20070107874A1Full heat exchangeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A water cooling type heat dissipation apparatus includes a heat dissipation stage having an upper cover and a lower cover. A first passageway and a second passageway extend from two ends of the upper cover. The upper cover includes a concave on inner side thereof. The lower cover includes a contact face and a heat conduction post arranged on inner bottom side of the lower cover. A plurality of heat dissipation fins is arranged on the heat conduction post and separated to each other to define parallel runners therebetween. Heat from heat source is absorbed by the contact face and conducted to the heat conduction fins through the heat conduction post. Liquid coolant flows into the parallel runners through the first passageway and resisted by the heat conduction post. Therefore, liquid coolant has sufficient heat exchange with the heat conduction fins and then exits through the second passageway.

Owner:COOLER MASTER CO LTD

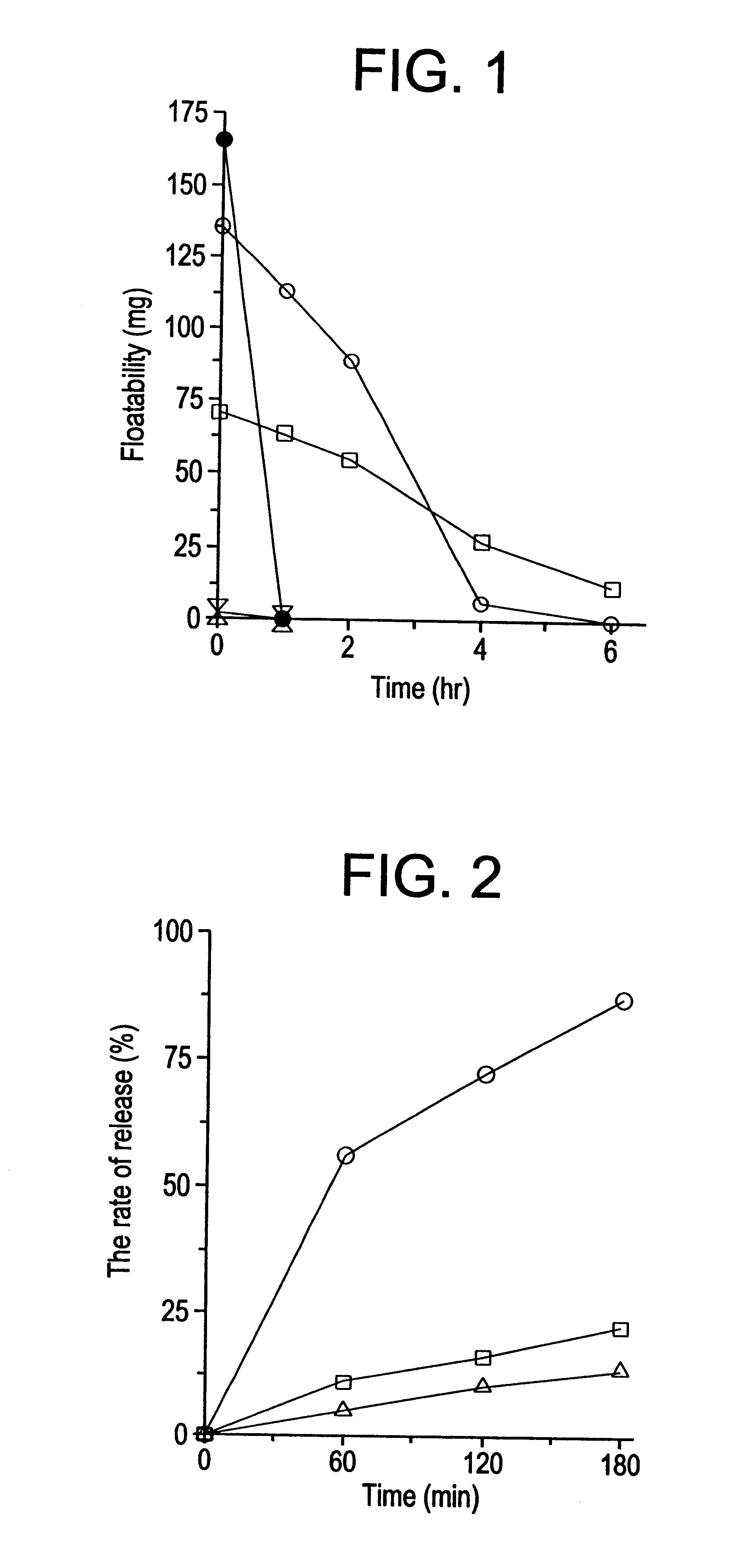

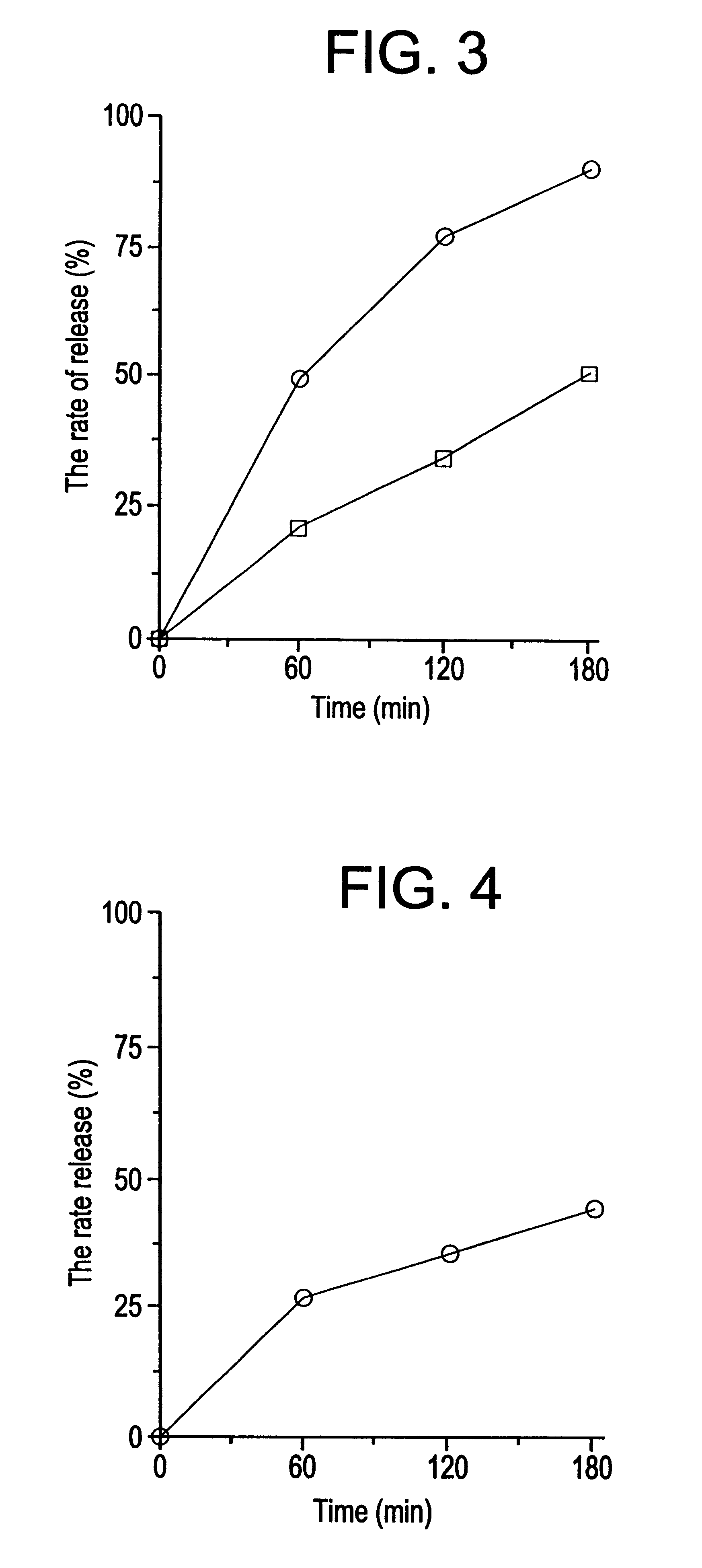

Gastric remaining preparation, swollen molding, and production process

InactiveUS6312726B1Improve floatabilityHigh mechanical strengthPowder deliveryPharmaceutical non-active ingredientsApparent densityBlowing agent

A gastric remaining preparation having a configuration entirely different from that of the conventional ones. It comprises a swollen molding having a mesh-like cross-section and an apparent density of less than 1, containing an acid-resistant polymer compound as a predominant component as well as at least an auxiliary blowing agent and a drug substance. The molding can be produced by using a multi-screw extruder.

Owner:NIPPON SHINYAKU CO LTD

Methods and compounds for obliteration of vessels

InactiveUS20080050436A1High viscosityHigh strengthSalicyclic acid active ingredientsPowder deliverySclerotherapySelf-assembly

A minimally invasive method that allows for complete obliteration of the affected vessels without scarring or any of the other undesirable complications of conventional or foam sclerotherapy. More particularly, the present invention relates to a method for using a non-foaming thickener to reduce dilution and diffusion of the sclerosant in the blood vessel and enhance the efficacy of the sclerotherapy treatment. The thickener can be thickening agent, hydrogel, environmentally sensitive hydrogel, and self-assembly polymer, etc. After it is mixed with sclerosant and injected into the blood vessel through a needle or a catheter, the compound will replace blood and obliterate the affected vessels.

Owner:CHU JACK F

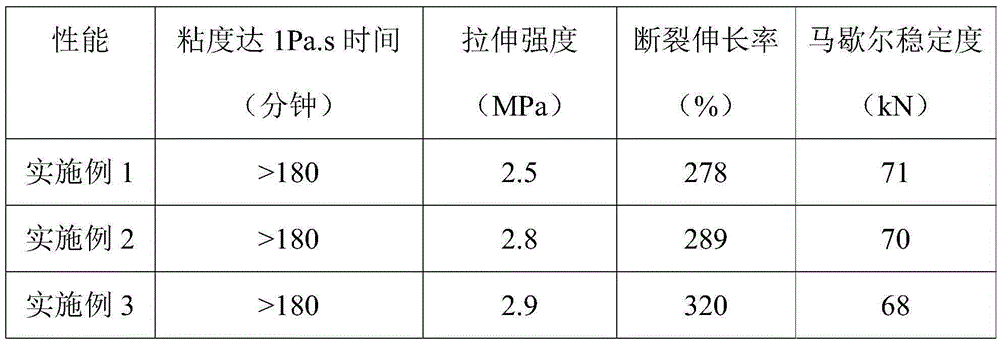

Epoxy resin curing material system for high-temperature mixed epoxy asphalt and preparation method thereof

The invention provides an epoxy resin curing material system for high-temperature mixed epoxy asphalt and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing epoxy resin with a diluting agent to obtain a resin ingredient; secondly, uniformly mixing a curing agent, a toughening agent and a compatibilizer to obtain a curing ingredient; and finally, uniformly mixing the resin ingredient with the curing ingredient to obtain the epoxy resin curing material system. The epoxy resin curing material system and asphalt have a long holding time at a high temperature, and the viscosity of the epoxy resin curing material system and the asphalt can be maintained to be lower than 600mPa.s in 180 minutes at 170 DEG C; quick curing can be achieved under the condition of room temperature, and a curing degree of over 90 percent can be achieved in 1-2 days after the epoxy resin curing material system and asphalt are mixed; an epoxy asphalt material prepared by the epoxy resin curing material system has very high strength, and a casting body of the epoxy asphalt material at 23 DEG C has tensile strength of over 3MPa and elongation at break of over 300 percent, and has good toughness; and the concrete of the epoxy asphalt material has Marshall strength of over 70kN, and has high strength.

Owner:CHANGAN UNIV

Self-foaming soluble beverage powder

InactiveUS6669976B2Increase volumeIncrease foam volumeCoffee extractionProtein foodstuffs working-upSolubilityChemistry

The invention relates to a soluble coffee beverage powder, which, upon the addition of water, is capable of forming a coffee beverage having a foamed upper surface. The soluble coffee beverage powder includes a soluble gas containing matrix comprising soluble coffee solids and a soluble filler, with the soluble filler constituting at least about 35% by weight of the dry matter of the matrix in order to increase the volume of the soluble coffee beverage powder incorporating gas. A particular preferred filler is an oligofructose that has a good solubility and which positively influences on the taste of the prepared coffee beverage. The invention also relates a soluble coffee beverage powder providing a black foamed coffee. The invention also provides a process for preparing such a soluble coffee beverage powder.

Owner:NESTEC SA

Cooling device for packaging product and packaging assembly

InactiveUS20070044488A1Actuation can be preventedNot to wasteCompression machinesPackaging toiletriesRelative motionVALVE PORT

A cooling device and assembly including a cooling device which can cool a packaged product prior to use. According to an example, a pressurized container containing a coolant is located between a base and a support such that relative movement between the base and support causes actuation of a valve of the container. The support supports a packaging device for the product. In addition, one or more advantageous expedients are provided for better cooling. For example, the valve is preferably axially on a side of the packaging device opposite a side having an opening for access to a cosmetic product. In addition, or alternately, the valve preferably does not have a diffuser. As a further alternative, or in addition to the foregoing, the valve opens out into a housing closed off by a cover.

Owner:LOREAL SA

Method and an apparatus for executing timed network operations

ActiveUS7698409B2Maximize operational timeStay longerDigital computer detailsConnection managementNetwork connectionWeb operations

Owner:NOKIA TECH OY

Smart pillows and processes for providing active noise cancellation and biofeedback

ActiveUS9640167B2Decrease audible presence of snoringQuality improvementPillowsMedical devicesEngineeringBiofeedback

Owner:DREAMWELL

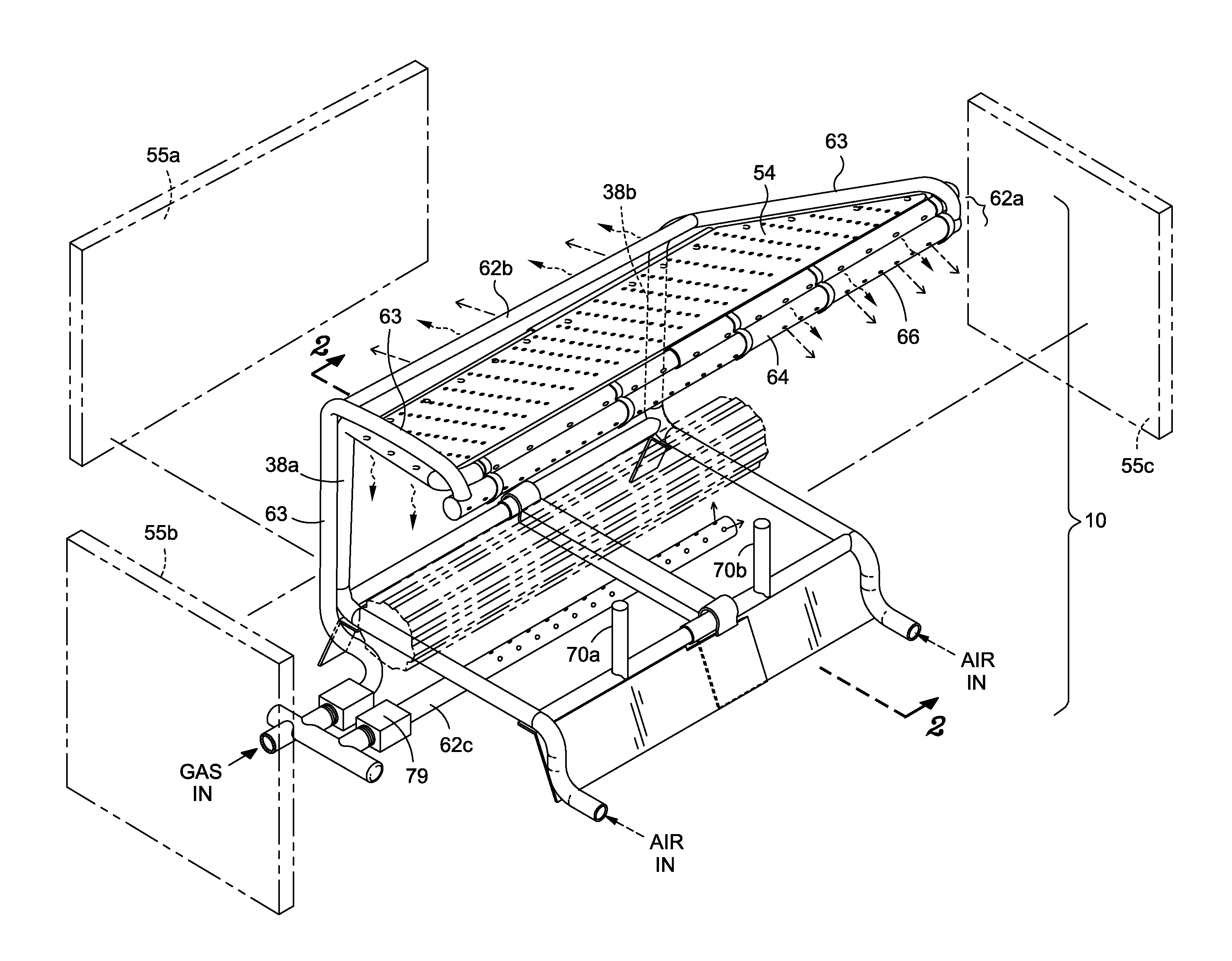

Fire Grate for Enhanced Combustion with Vertical and Horizontal Expansion Sleeves

InactiveUS20110005509A1Reduce harmful emissionsHarmful emissionDomestic stoves or rangesWater heatersParticulatesCombustion chamber

An improved fire grate may provide fresh oxygen rich air to a secondary combustion zone, created by the improved fire grate, of a combustion chamber where a combustion gas stream is typically oxygen starved assisting in the burning process of incompletely burned particulates and reducing other harmful emissions. A baffle plate may be introduced in the secondary combustion zone to increase a combustion chamber temperature, encourage mixing of oxygen starved air with oxygen rich air and increase a residence time of the combustion gas within the combustion chamber. These aspects of the baffle plate promote more efficient burning of the biomass / fuel. Additionally, log lighter(s) may be disposed in the secondary combustion zone to increase a temperature of the combustion chamber for the purposes of reducing harmful emissions. The improved fire grate may be horizontally and vertically adjusted to fit within different sized fireplace combustion chambers.

Owner:EARTHS FLAME

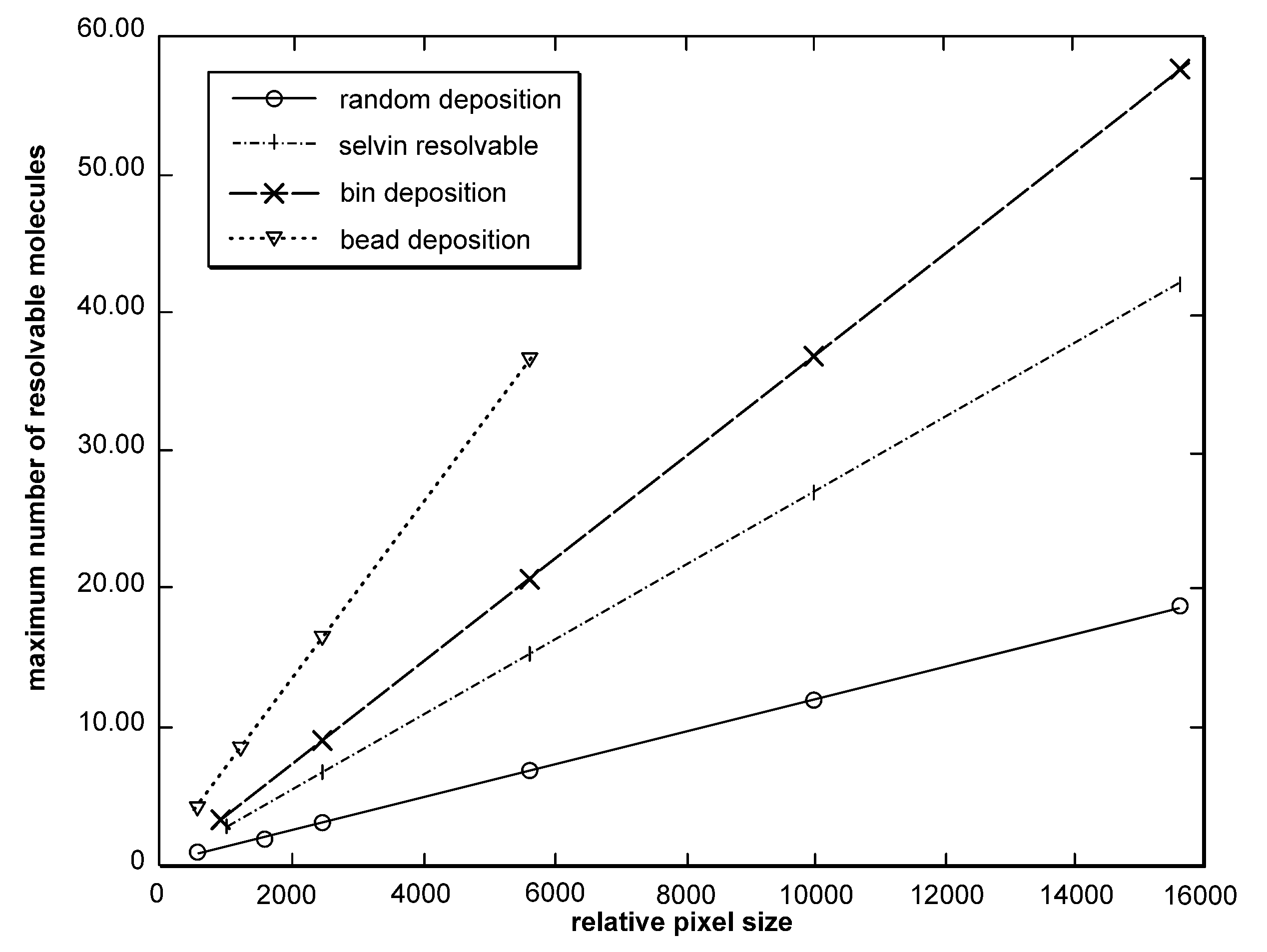

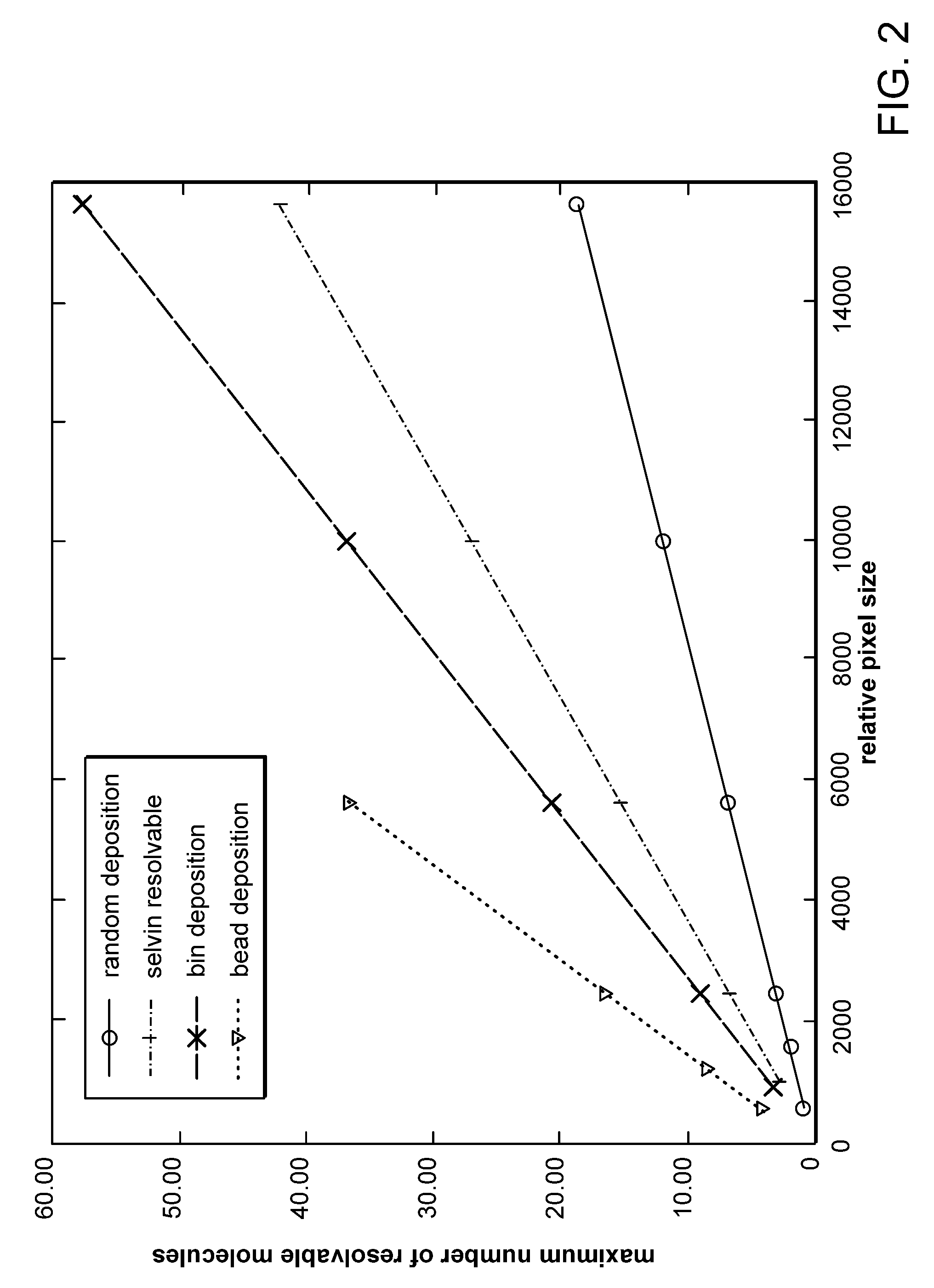

Surface chemistry and deposition techniques

InactiveUS20090053690A1Increase intensityLimitation on improvementMicrobiological testing/measurementBiological testingSurface bindingAnalyte molecule

Surface chemistries for the visualization of labeled single molecules (analytes) with improved signal-to-noise properties are provided. To be observed, analyte molecules are bound to surface attachment features that are spaced apart on the surface such that when the analytes are labeled adjacent analytes are optically resolvable from each other. One way to express this concept is that binding elements should be spaced apart such that the Guassian point spread functions of adjacent labels do not overlap. Another way of expressing this concept is that the surface binding elements should be spaced apart by a distance equal to at least the diffraction limit for an optical label attached to the bound analytes.

Owner:SANDFORD UNIV +2

Interactive system and method of products, services, intelligent information and the like

An interactive system includes an interactive society involving places and products being simulated as a real social network, and an user interactive module adapted for a user to configure a virtual character and to play a role in the interactive society, and a business module implanting different advertisements into places and products in the interactive society to interact with the user.

Owner:DAI JIANLIN

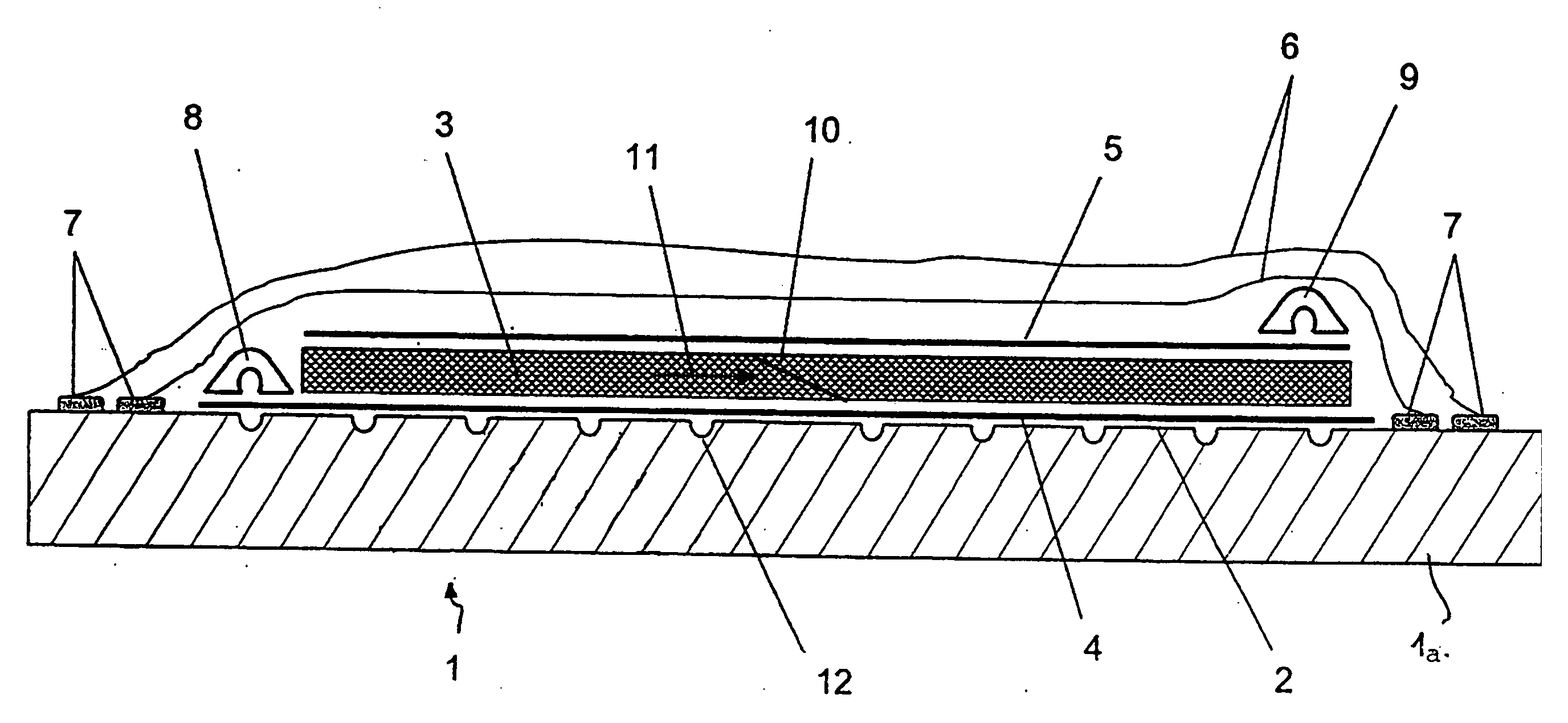

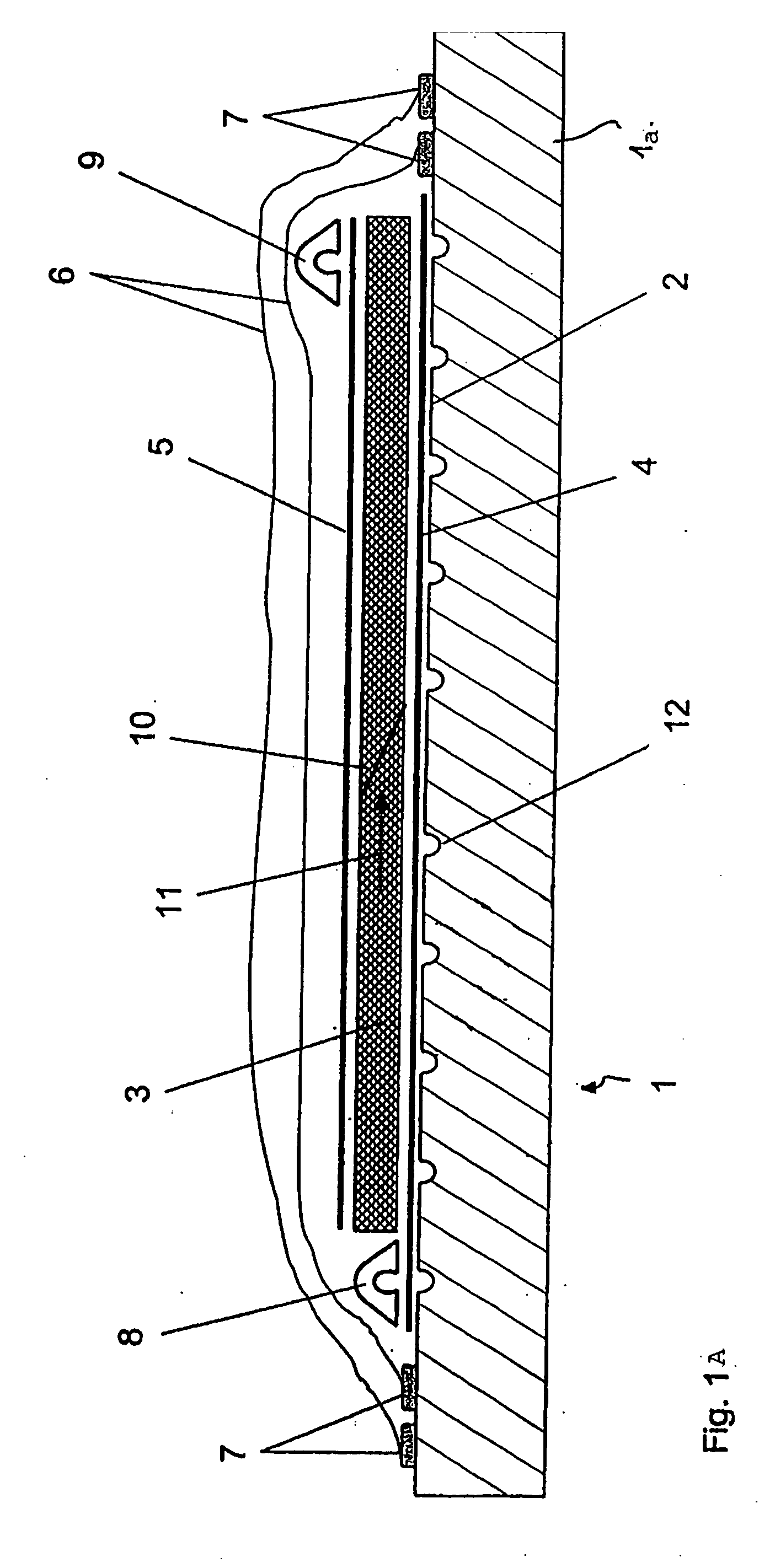

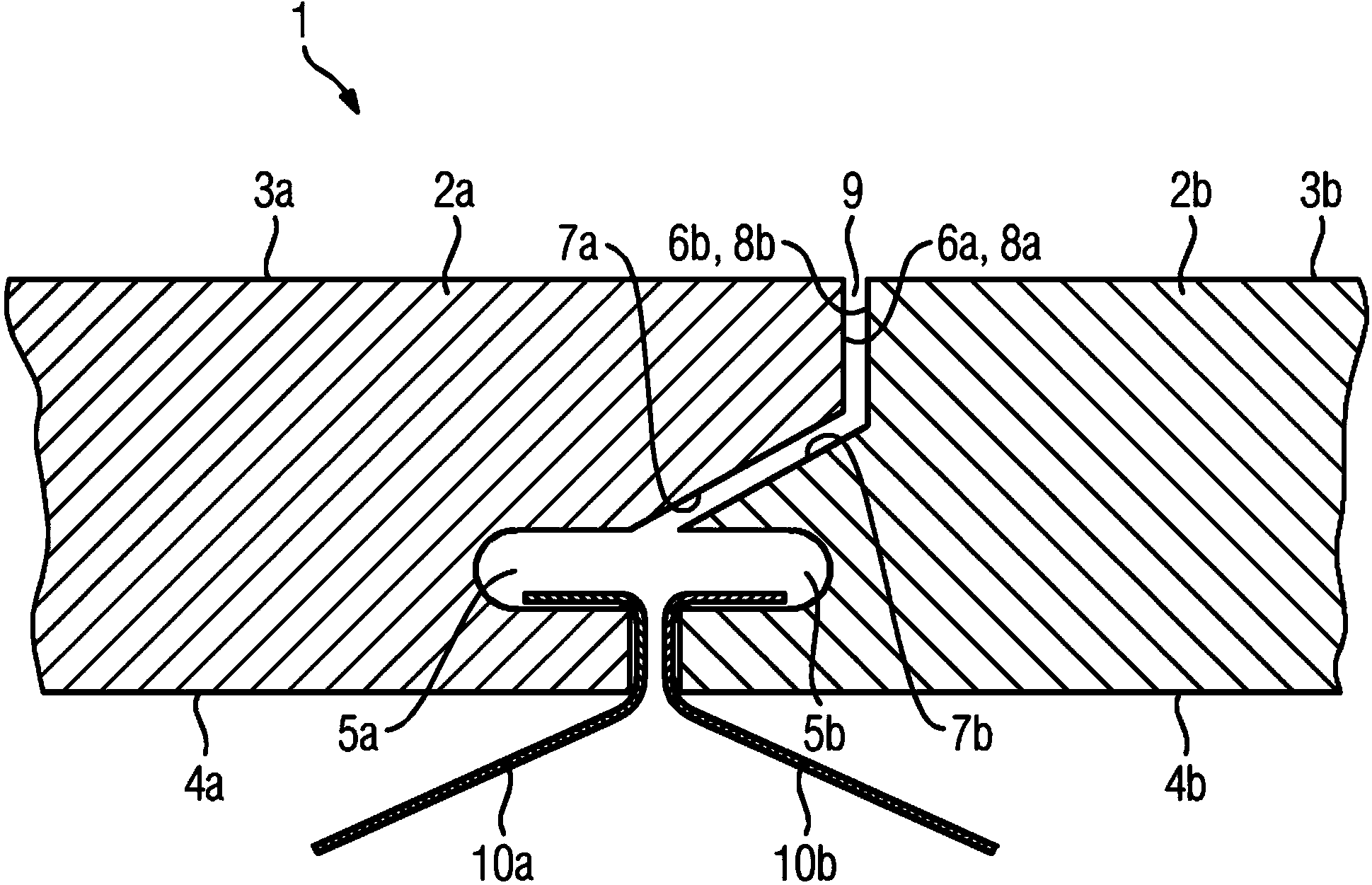

Heat shield assembly

InactiveCN103518100ALess intrusivePrevent intrusionContinuous combustion chamberCasings/liningsFront edgeHeat shield

The invention relates a heat shield assembly (1), comprising at least two neighboring heat shields (2a, 2b), said shields being a first heat shield (2a) and a second heat shield (2b), each having a hot gas side (3a, 3b) and an opposing cold gas side (4a, 4b), wherein the heat shields (2a, 2b) have a neighboring side wall (6a, 6b) that connects the hot gas side (3a, 3b) and the cold gas side (4a, 4b), wherein a respective engagement pocket (5a, 5b), which is spaced from the hot gas side (3a, 3b) and the cold gas side (4a, 4b), is provided in the respective neighboring side wall (6a, 6b), wherein adjacent heat shields (2a, 2b) overlap one another and the one side wall (6a) of the first heat shield (3a) has a protrusion extending from the engagement pocket (5a) in the direction of the hot gas side (3a), wherein the protrusion has at least one protrusion side (7a); and a protrusion front edge (8a) connecting thereto, and wherein the second heat shield (2b) has a cutout that is essentially complementary to the protrusion and extending from the engagement pocket (5b) in the direction of the hot gas side (3b), wherein the cutout has at least one cutout side (7b) and a cutout rear edge (8b) connecting thereto, which are arranged such that, extending from the engagement pocket (5a, 5b), a gap (9) that is open toward the hot gas side (3a, 3b) is formed between the cutout and the protrusion, and wherein both the protrusion side (7a) and the cutout side (7b) have a gradient relative to the respective cold gas side (4a, 4b).

Owner:SIEMENS AG

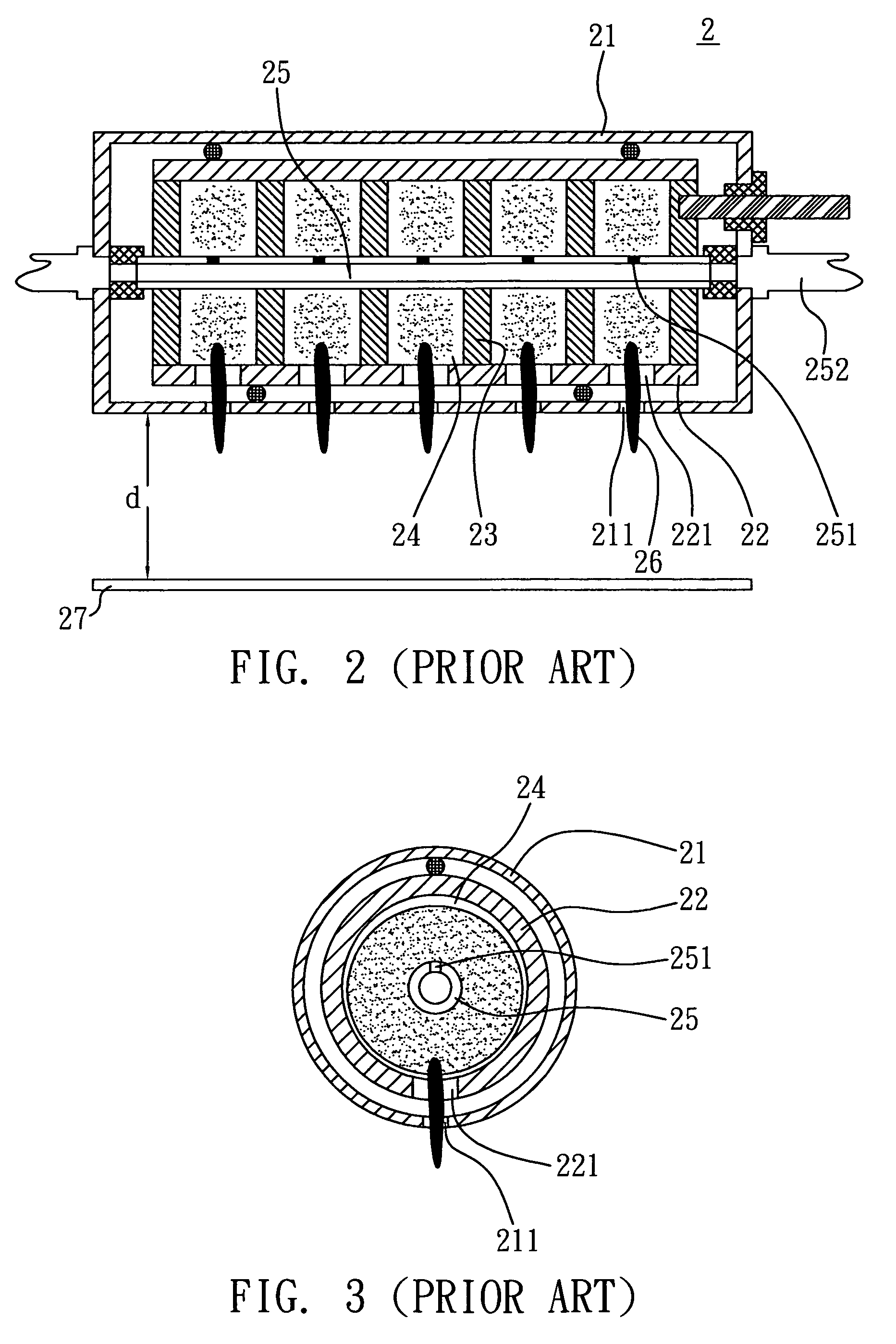

Hollow cathode discharging apparatus

ActiveUS7721673B2Evenly distributedReduce sizeElectric discharge tubesSemiconductor/solid-state device manufacturingReactive gasOptoelectronics

Owner:IND TECH RES INST

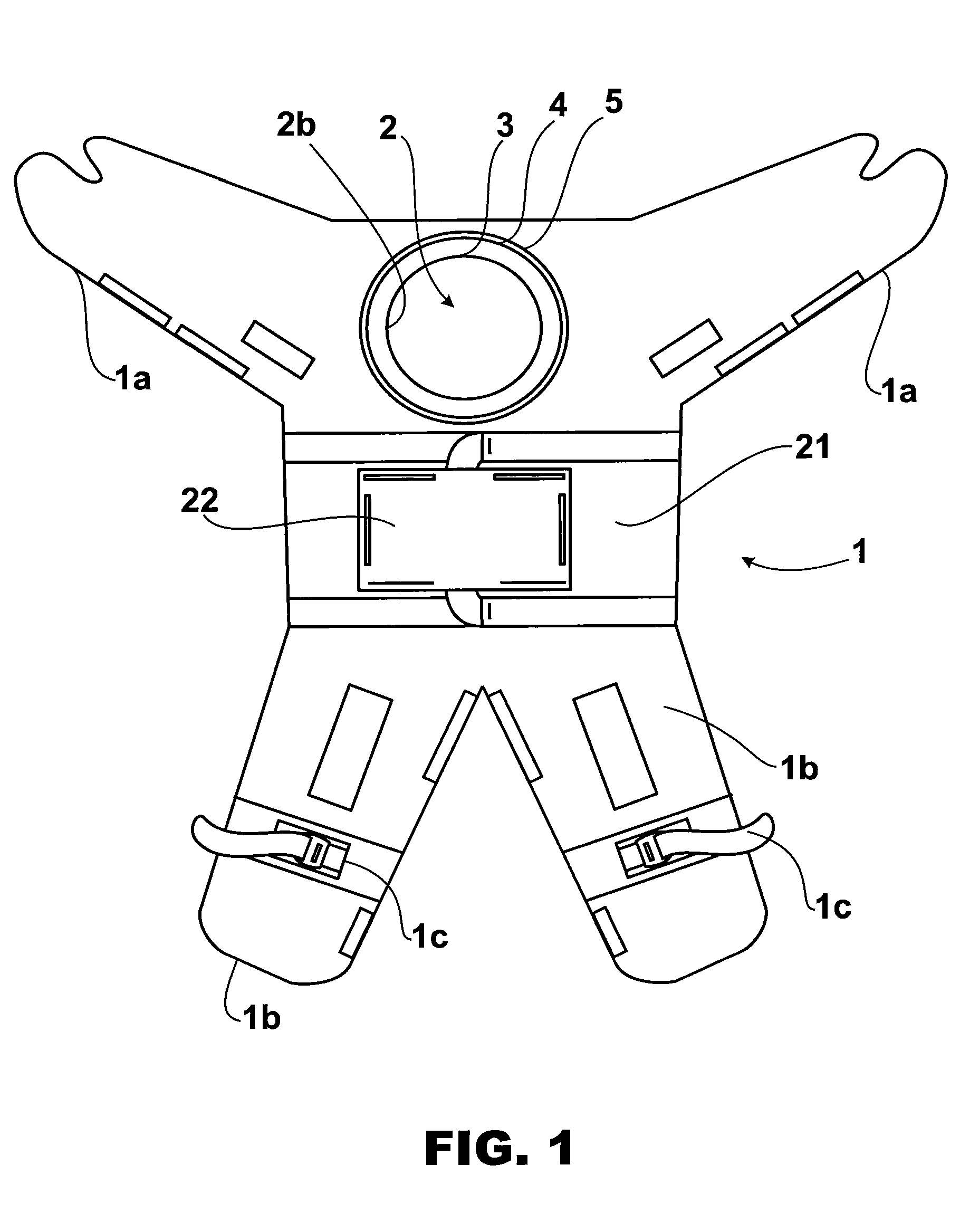

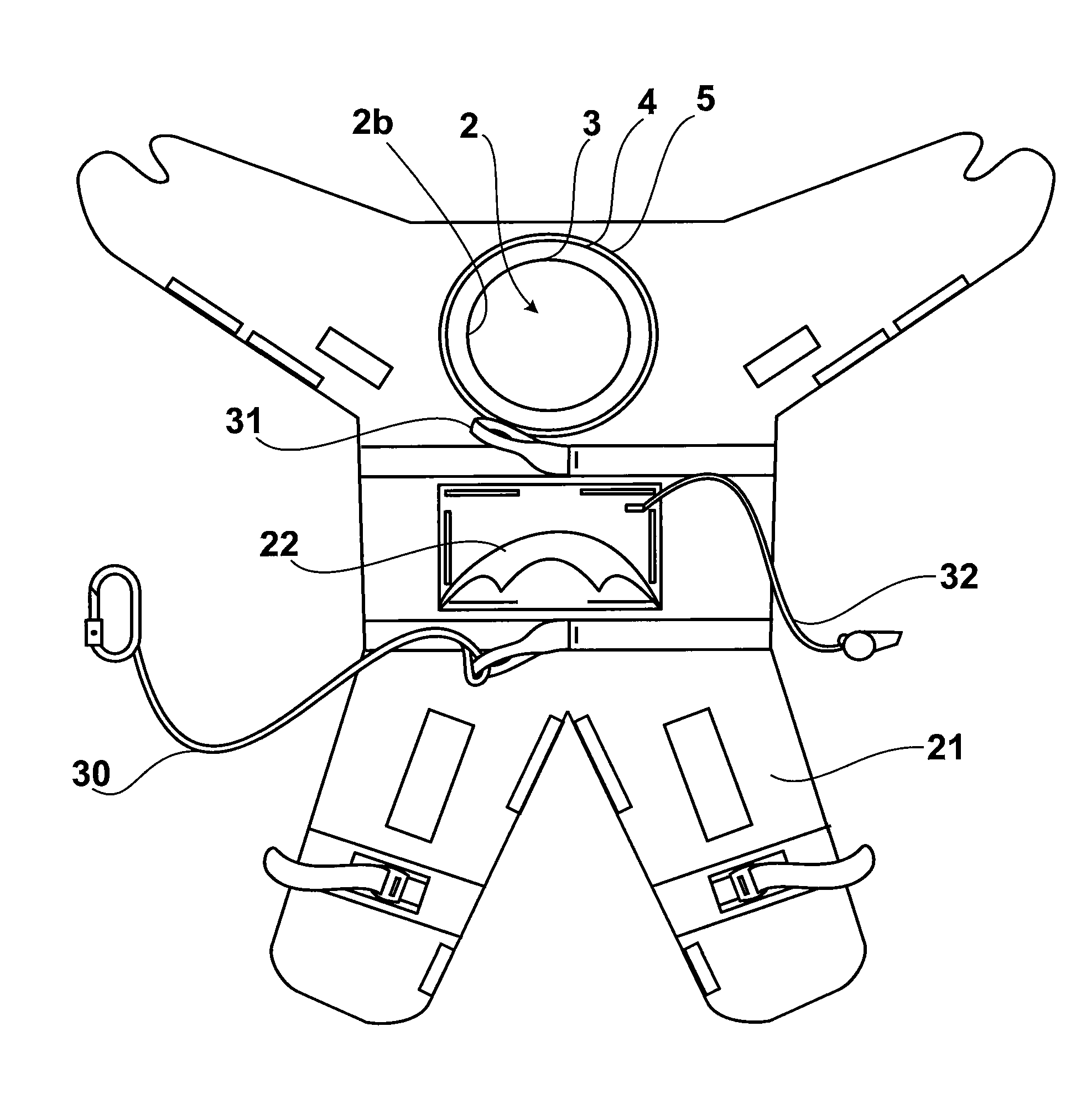

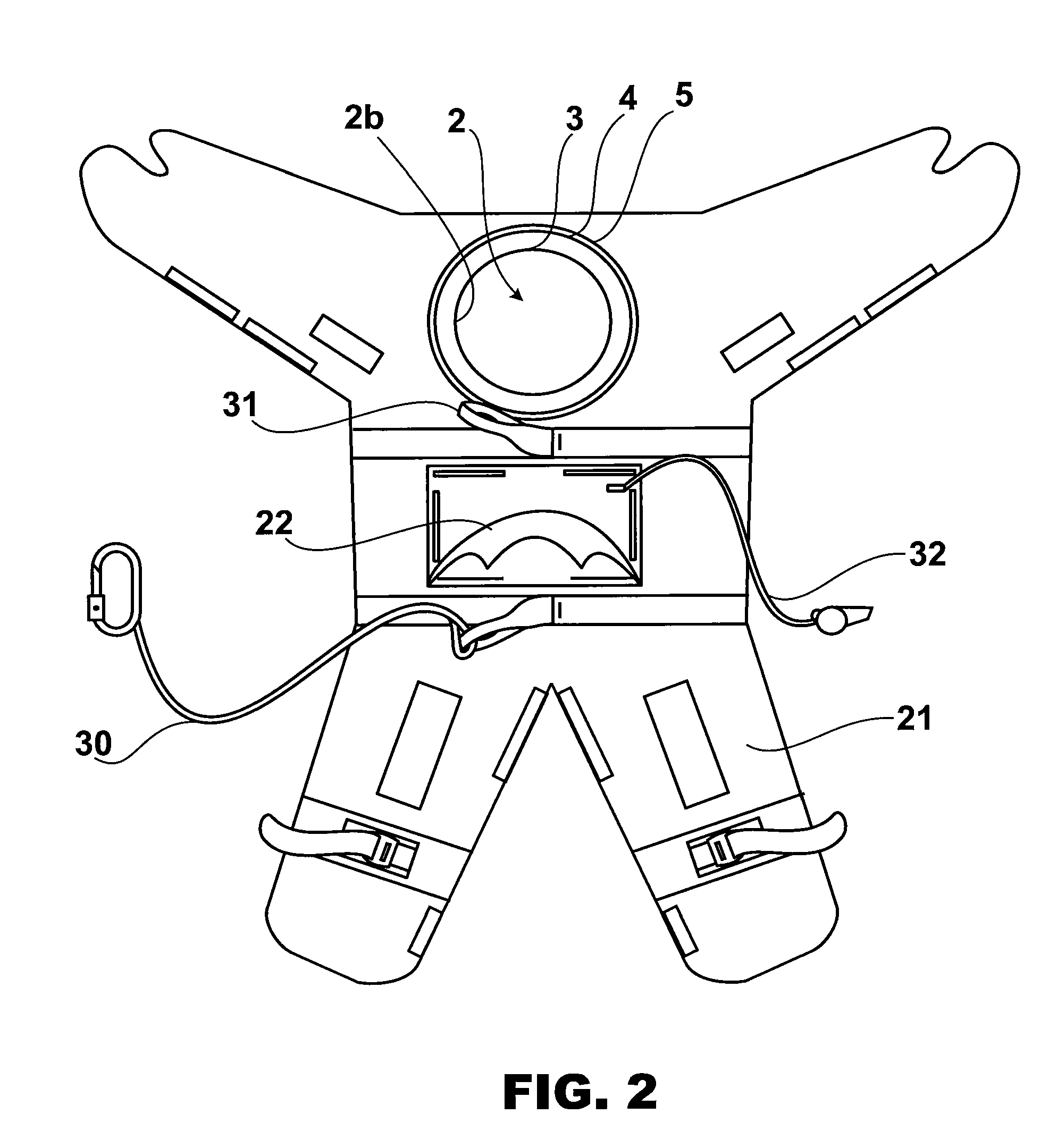

Salvage suit for shipwrecks

InactiveUS20110107504A1Quickly becomes wornMake fastChemical protectionHeat protectionEngineeringStructural engineering

Owner:VIGNOLA MARIO CESAR

Textured surfaces for display applications

ActiveUS20180059309A1Improve viewing angleReduce releaseMechanical apparatusDiffusing elementsLight guideDisplay device

A substrate with a textured surface is disclosed. The substrate may be, for example, a light emitter comprising a light guide, for example a backlight element for use in a display device, wherein a surface of the light guide, for example a glass substrate, is configured to have a textured surface with a predetermined RMS roughness and a predetermined correlation length of the texture. A plurality of light scatter suppressing features can be provided on the textured surface. Textured surfaces disclosed herein may be effective to reduce electrostatic charging of the substrate surface. Methods of producing the textured surface are also disclosed.

Owner:CORNING INC

Feeding fence section

ActiveUS20150322716A1Simple designEasy to installGates/doorsAnimal feeding devicesEngineeringMechanical engineering

Owner:COW WELFARE

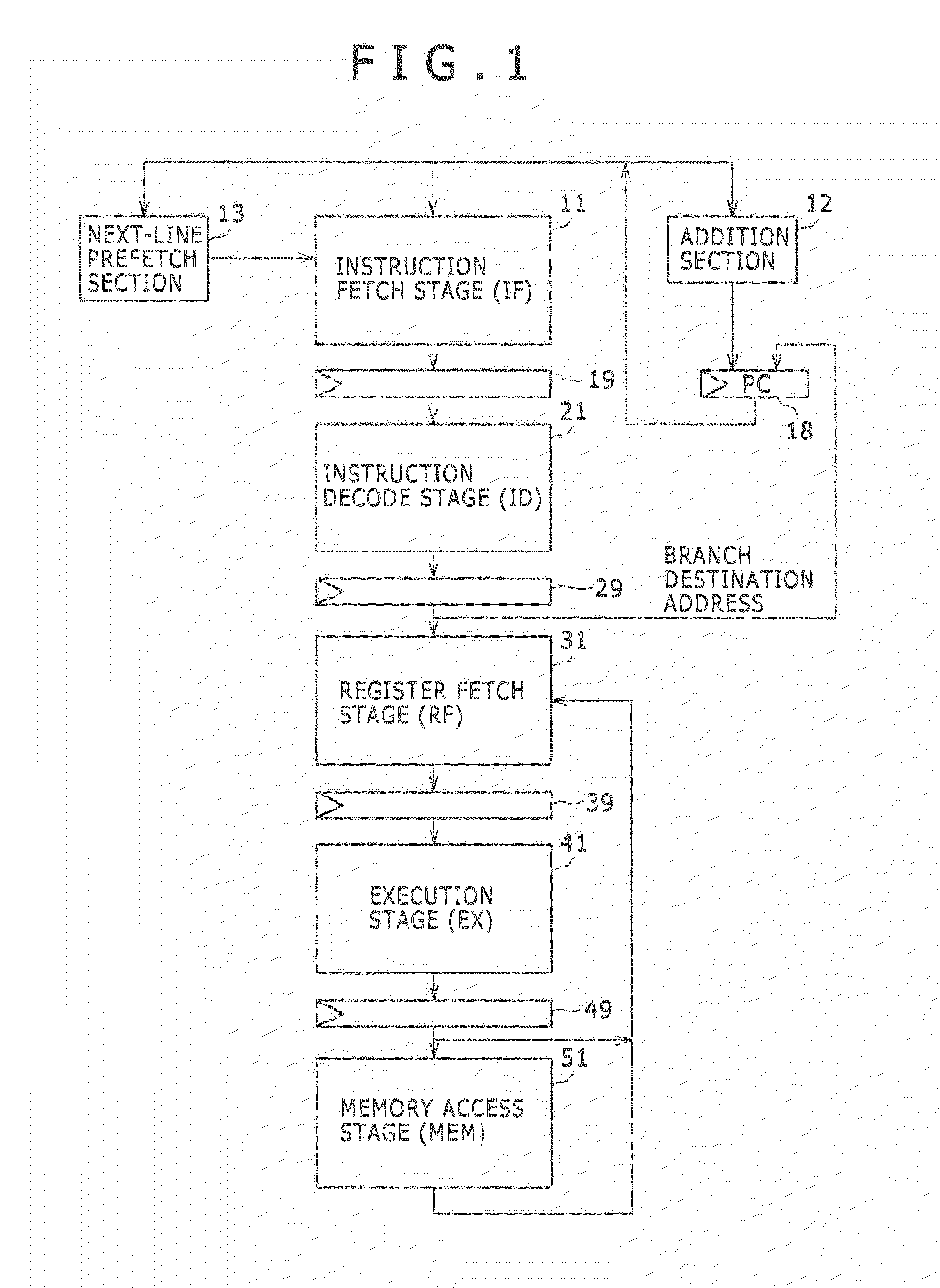

Instruction fetch apparatus, processor and program counter addition control method

InactiveUS20110238952A1Improve throughputEasy accessDigital computer detailsConcurrent instruction executionInstruction sequenceWord length

An instruction fetch apparatus is disclosed which includes: a program counter configured to manage the address of an instruction targeted to be executed in a program in which instructions belonging to a plurality of instruction sequences are placed sequentially; a change designation register configured to designate a change of an increment value on the program counter; an increment value register configured to hold the changed increment value; and an addition control section configured such that if the change designation register designates the change of the increment value on the program counter, then the addition control section increments the program counter based on the changed increment value held in the increment value register, the addition control section further incrementing the program counter by an instruction word length if the change designation register does not designate any change of the increment value on the program counter.

Owner:SONY CORP

A method, an arrangement and use of an arrangement of preparing polymer

ActiveUS20200123279A1Good operability and performanceReduced isolationChemical/physical processesPolymer sciencePtru catalyst

A method and arrangement of producing polymer comprising polymerizing in reactor having a top zone having a generally conical shape, a middle zone in direct contact with and below said top zone having a generally cylindrical shape, a bottom zone having a generally conical shape thereby polymerizing at least one olefin, in the presence of a polymerization catalyst and fluidization gas to obtain (i) a first stream comprising fluidization gas and particles of olefin polymer, (ii) a second stream comprising fluidization gas and agglomerates of olefin polymer, (iii) a third olefin polymer product stream—directing the first stream comprising fluidization gas and olefin polymer particles to a series of at least three cyclones connected to the fluidized bed reactor—separating agglomerates of olefin polymer from the second stream, withdrawing from the fluidized bed polymerization reactor the third olefin polymer product stream.

Owner:BOREALIS AG

Salvage suit for shipwrecks

Owner:VIGNOLA MARIO CESAR

Fire Grate for Enhanced Combustion

InactiveUS20110005510A1Reduce harmful emissionHarmful emissionDomestic stoves or rangesLiquid heating fuelBiomassProcess engineering

An improved fire grate may provide fresh oxygen rich air to a secondary combustion zone, created by the improved fire grate, of a combustion chamber where a combustion gas stream is typically oxygen starved assisting in the burning process of incompletely burned particulates and reducing other harmful emissions. A baffle plate may be introduced in the secondary combustion zone to increase a combustion chamber temperature, encourage mixing of oxygen starved air with oxygen rich air and increase a residence time of the combustion gas within the combustion chamber. These aspects of the baffle plate promote more efficient burning of the biomass / fuel. Additionally, log lighter(s) may be disposed in the secondary combustion zone to increase a temperature of the combustion chamber for the purposes of reducing harmful emissions.

Owner:EARTHS FLAME

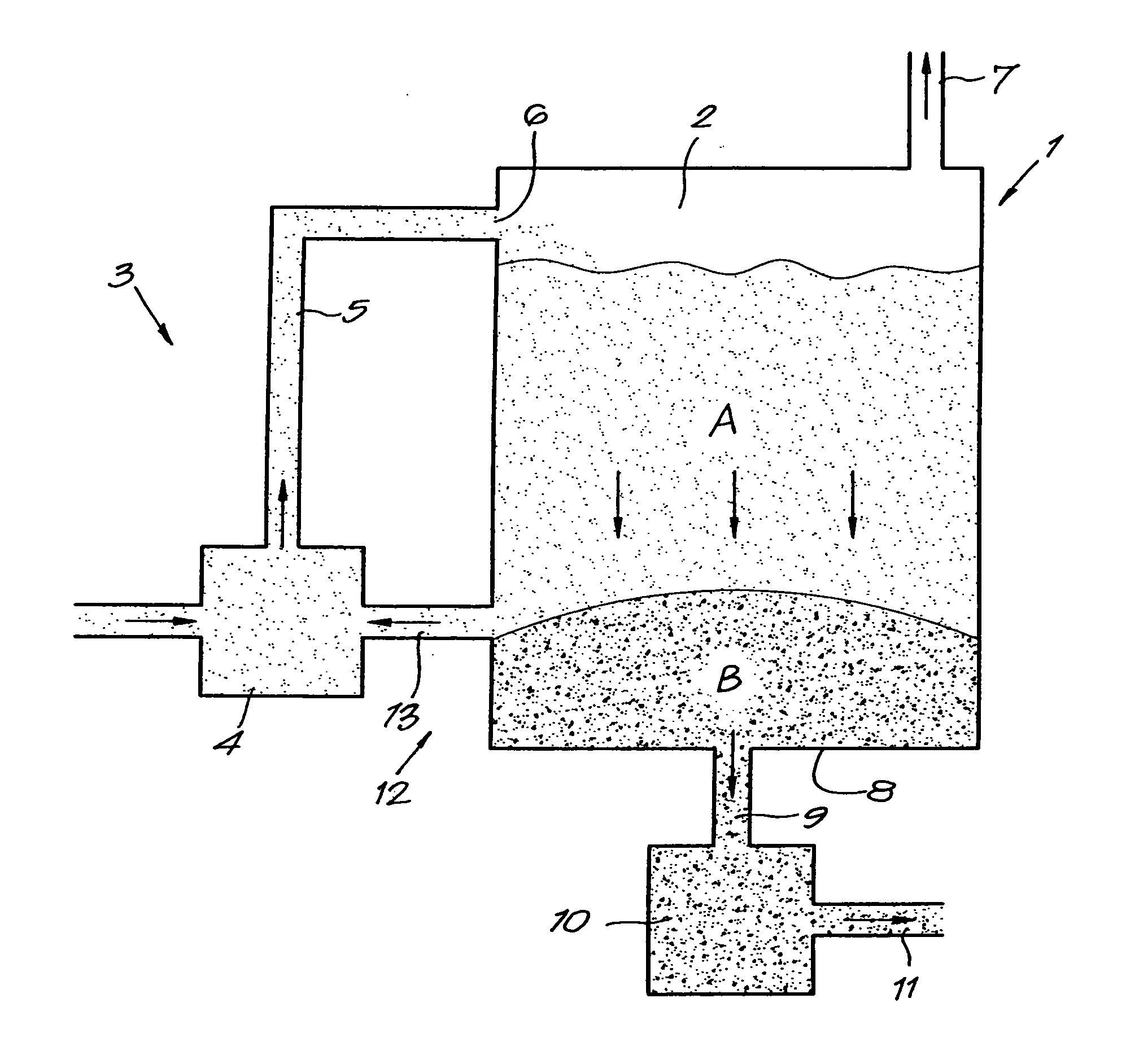

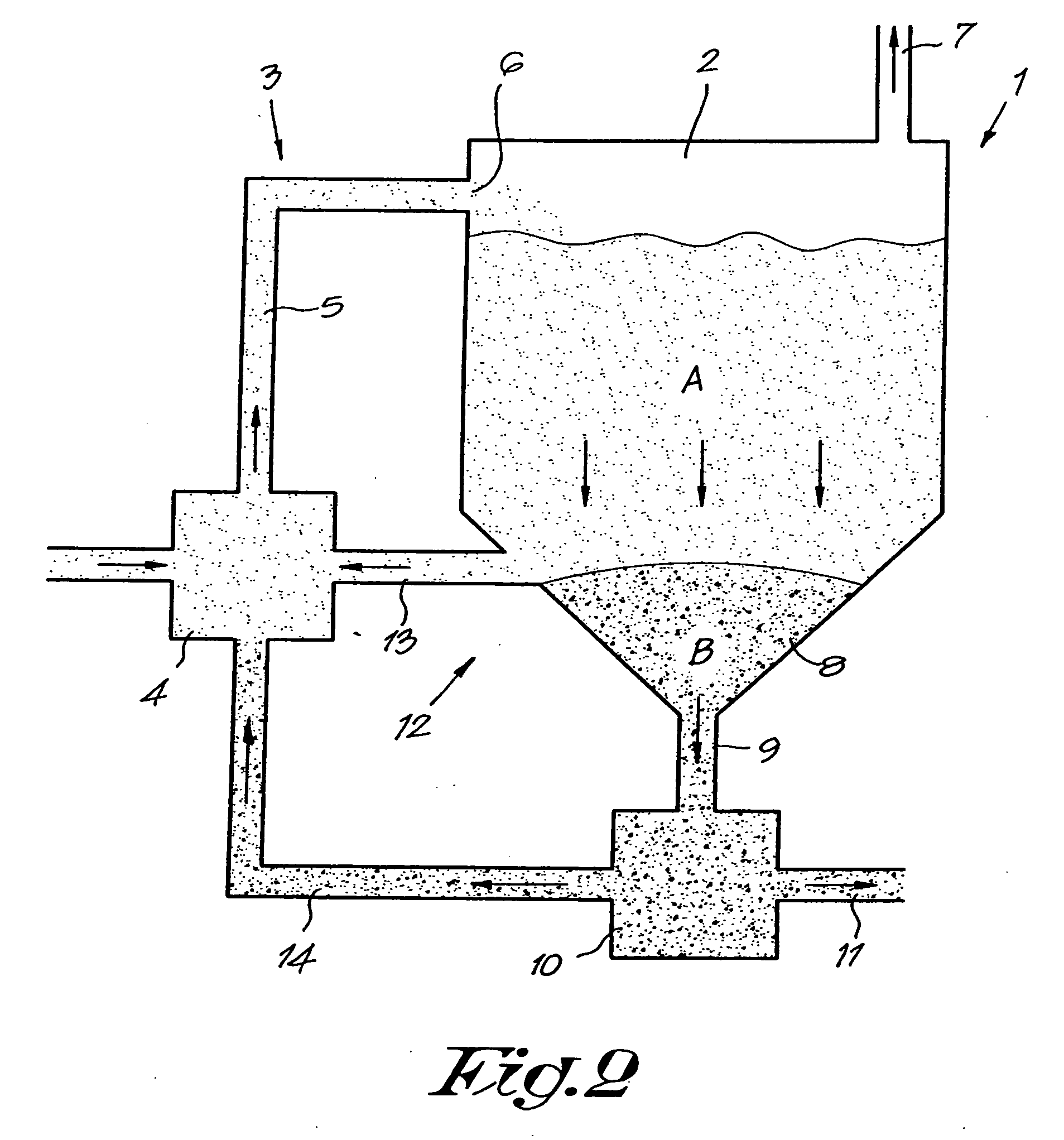

Method and device for the anaerobic fermentation of organic material

InactiveUS20080138885A1Improve stabilityIncrease in sizeBioreactor/fermenter combinationsBiological substance pretreatmentsOrganic matterFermentation

Method for the anaerobic fermentation of organic material, whereby the organic material to be fermented is put in a fermentation tank (1) together with an inoculant and moves or is moved from an inlet (6) of the fermentation tank (1) to an outlet (9) thereof, whereby the fermented material is removed from the tank (1) via the outlet (9), wherein a fraction of the fermenting material which is situated between the inlet (6) and the outlet (9) is removed from the fermentation tank (1) via a return opening (12) and is used as an inoculant, while the fermenting material between the return opening (12) and the outlet (9) is still after-fermented for a certain while before it is removed from the fermentation tank (1) via the outlet (9).

Owner:ORGANIC WASTE SYST

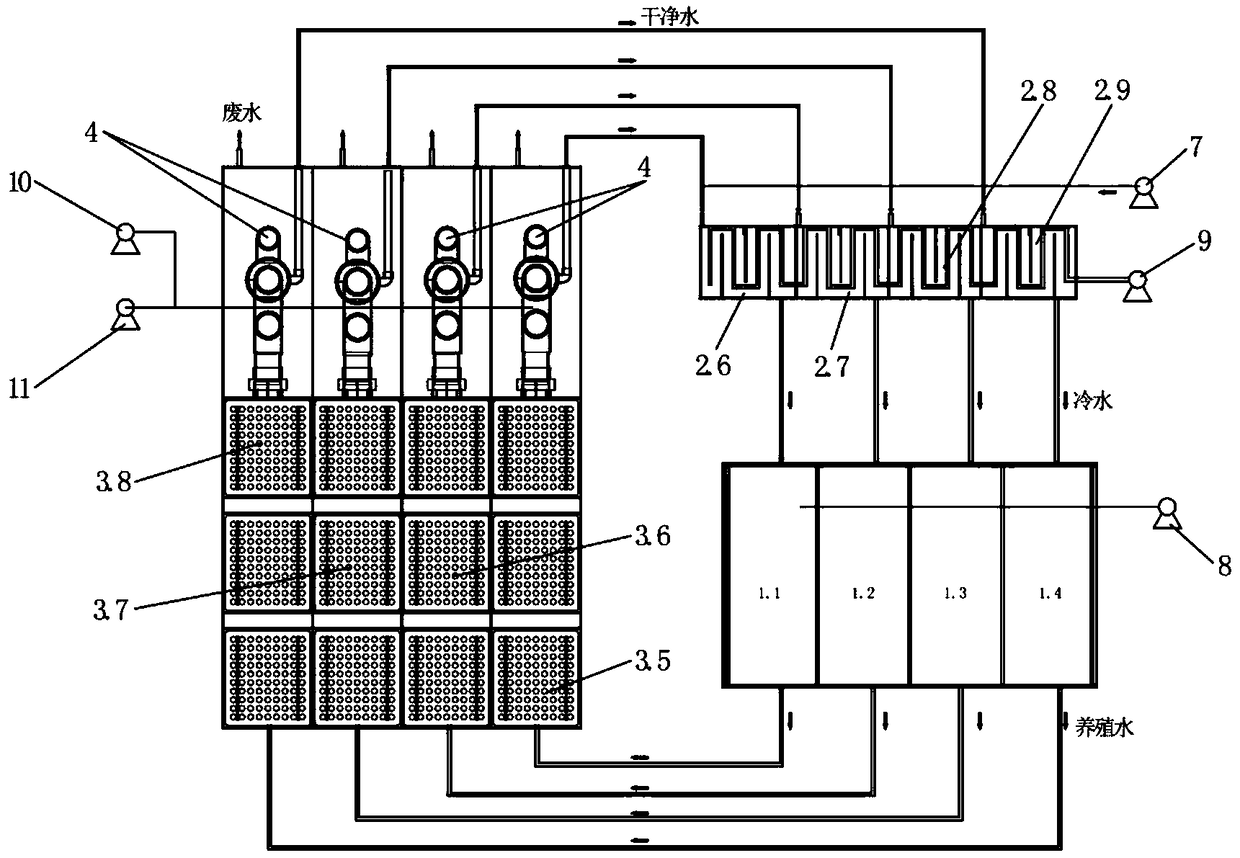

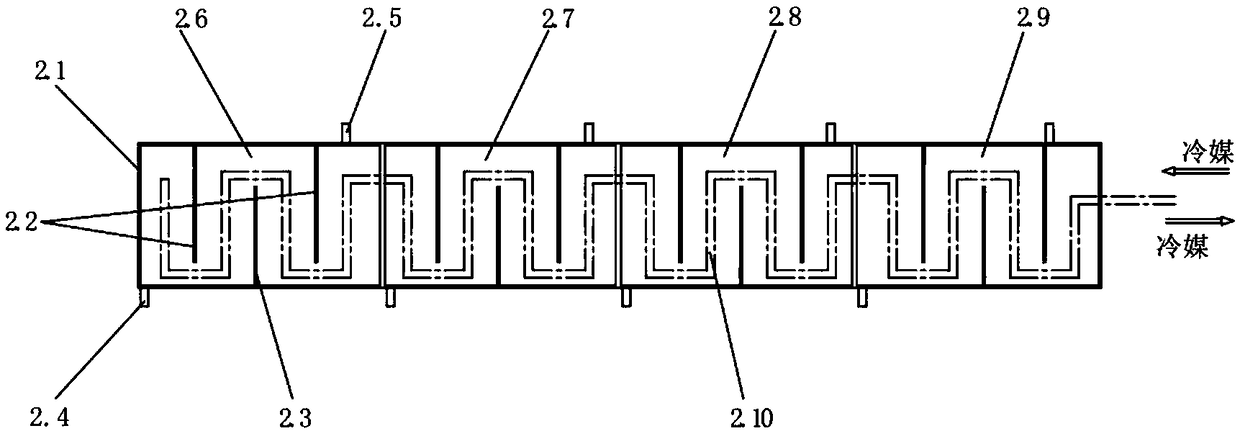

Seafood temporary-culture water circulation purification system and seafood temporary-culture machine using same

InactiveCN108935268AStable water temperatureStay longerPisciculture and aquariaEnvironmental engineeringWater temperature

The invention discloses a seafood temporary-culture water circulation purification system and a seafood temporary-culture machine using the same. The system comprises culture pools, wherein the plurality of culture pools are arranged in parallel; a water inlet of each culture pool individually communicates with a corresponding refrigeration water tank, the plurality of refrigeration water tanks are arranged in parallel, and the number of the refrigeration water tanks corresponds to the number of the culture pools; and a water outlet of each culture pool individually communicates with a corresponding filtration box, the plurality of filtration boxes are arranged in parallel, and the number of the filtration boxes corresponds to the number of the culture pools. Refrigerants are introduced tothe refrigeration water tanks to cool culture waters, a plurality of cold culture waters in different temperature zones are formed, and low-temperature culture waters are respectively fed into the culture pools for seafood temporary-culture. After temporary-culture, culture waters containing impurities and proteins are sent to the filtration boxes to filter, degrade and remove proteins, and thenthe culture waters are reduced to clean waters to cyclic utilization. Water temperatures of the culture pools are constant and stable, temporary-culture time is long, seafood culture in a plurality ofdifferent temperature zones is realized, numbers of temporary-culture varieties are large, and people consumption requirements are satisfied.

Owner:珠海翰爵水产科技有限公司

Method and device for controlling player character dialog in a video game located on a computer-readable storage medium

ActiveUS8262474B2Excessive activityLarge outcomeVideo gamesSpecial data processing applicationsGame playerDisplay device

In a computing machine having a processing unit, memory and a display device for playing a video game, the video game comprising at least one or more game characters, the at least one or more game character being controlled by a special purpose computing input device connected to said computer and operable by a game player, the video game further comprising character dialog between or among the at least one or more game characters, the character dialog comprising vignettes of dialog wherein movement from one vignette to another is determined by the game player introducing emotion into the dialog by means of the special purpose computing input device. The special purpose computing input device introduces emotion into the video game during a character dialog or character encounter along an axis of a joystick or other game controller element.

Owner:MCMAIN MICHAEL PARKER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com