Heat shield assembly

A heat shielding and heat shielding technology, applied in lighting and heating equipment, combustion methods, combustion chambers, etc., can solve the problem of oxide skin on metal brackets, and achieve the effect of cooling components well, avoiding damage and saving cooling air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

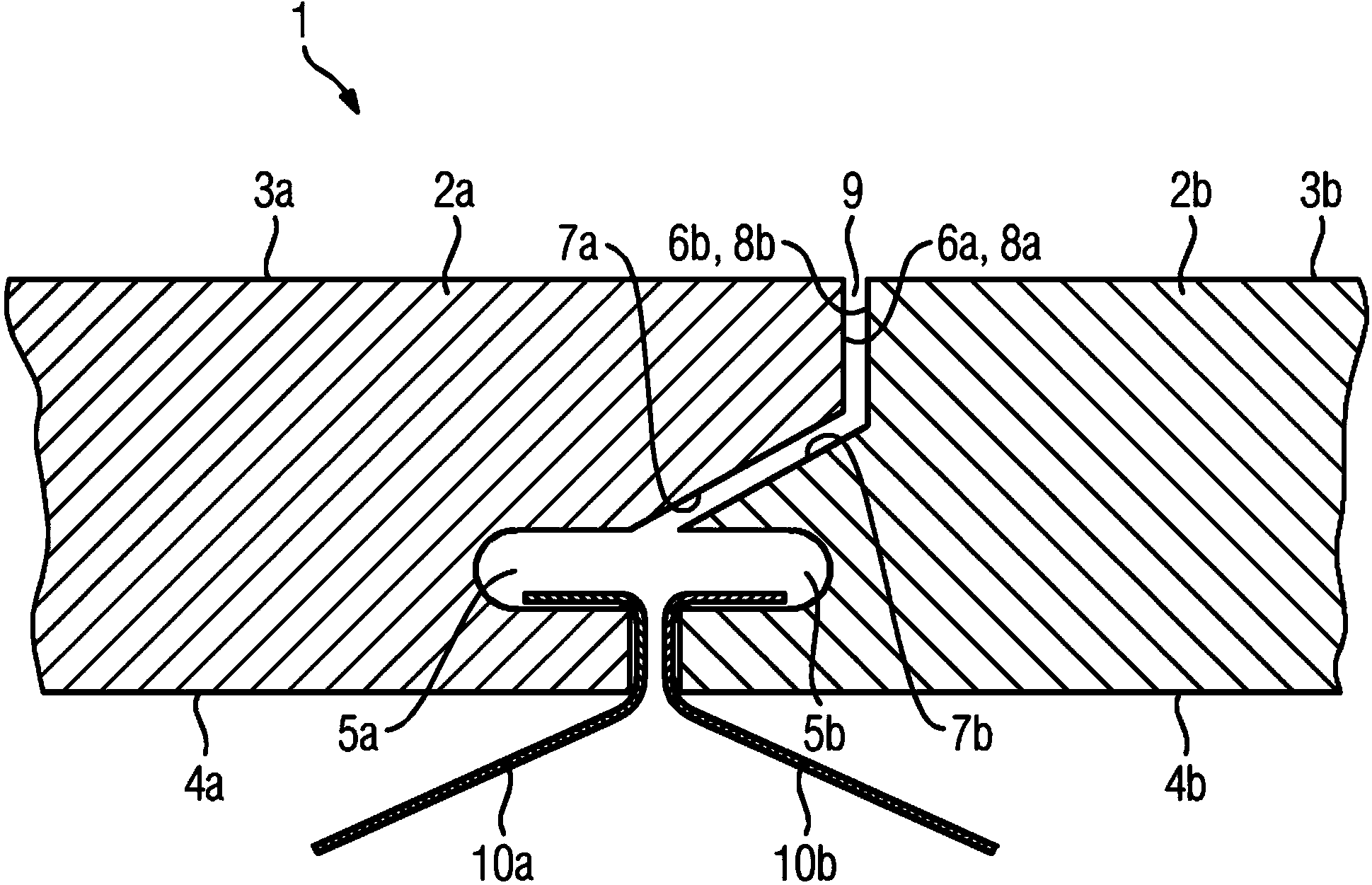

[0014] figure 1 A heat shield 1 according to the invention is shown which has two adjoining heat shields 2a, 2b. In this case, the first heat shield 2a has a hot gas side 3a and a cold gas side 4a. The second heat shield 2b likewise comprises a hot gas side 3b and a cold gas side 4b. The direction from the hot gas side 3a to the cold gas side 4a is called radial direction. The heat shield 2a, 2b comprises at least two side walls 6a, 6b adjoining each other. The first heat shield 2a now has engagement recesses 5a at a distance from the cold air side 4a and the hot air side 3a. Engagement groove 5 a can here be regarded as a groove that does not extend over the entire axial length of side wall 6 a , wherein the axial direction of side wall 6 a is perpendicular to the radial direction. The second heat shield 2b likewise has the same engagement recess 5b. The brackets 10 a , 10 b are now engaged by means of clamping arms from the cold air side 4 a , 4 b into the engagement gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com