Epoxy resin curing material system for high-temperature mixed epoxy asphalt and preparation method thereof

A technology of epoxy resin curing and epoxy asphalt, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of high cost, long retention time, poor toughness, etc., and achieve high strength, good toughness, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

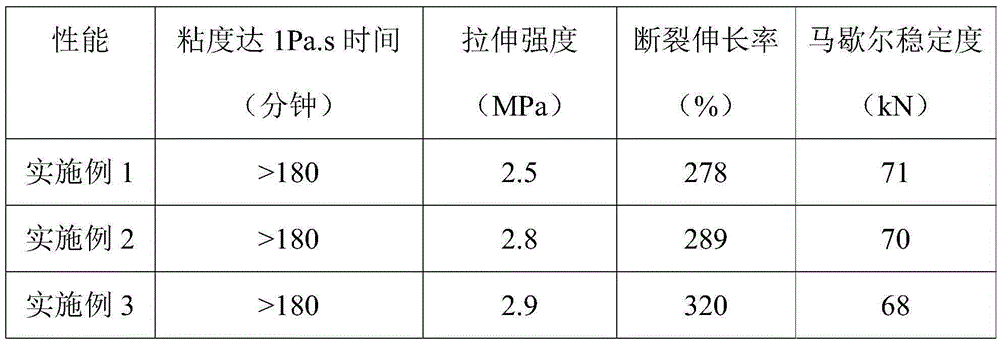

Examples

Embodiment 1

[0027] This example provides a kind of epoxy resin curing material system for high temperature mixing epoxy asphalt, including resin component and curing component; wherein the mass ratio of resin component and curing component is 100:80;

[0028] The resin component is composed of the following materials in parts by mass: 90 parts of hydroquinone diglycidyl ether resin, 10 parts of epoxidized soybean oil;

[0029] The curing component is composed of the following materials in parts by mass: 60 parts of cyanoethylated dodecanediamine, 10 parts of styrene-butadiene-styrene terpolymer, 30 parts of dodecyl alcohol .

[0030] The preparation method of the epoxy resin cured material system for the high temperature mixed epoxy asphalt of the present embodiment is as follows:

[0031] 1) First, mix the epoxy resin and diluent at a mass ratio of 90:10 at 60°C to obtain the resin component;

[0032] 2) Next, take 60 parts by mass of curing agent, 10 parts of toughening agent and 30 p...

Embodiment 2

[0039] This example provides a kind of epoxy resin curing material system for high temperature mixing epoxy asphalt, including resin component and curing component; wherein the mass ratio of resin component and curing component is 100:65;

[0040] The described resin component consists of the following materials in parts by mass: 88 parts of epoxidized polybutadiene resin, 12 parts of epoxidized linseed oil;

[0041] The curing component is expressed in parts by mass, consisting of 70 parts of cyanoethylated isophorone diamine, 20 parts of styrene-isoprene-styrene terpolymer, 10 parts of stearyl alcohol share.

[0042] The preparation method of the epoxy resin cured material system for the high temperature mixed epoxy asphalt of the present embodiment is as follows:

[0043] 1) First, mix the epoxy resin and the diluent at a mass ratio of 88:12 at 60°C to obtain the resin component;

[0044] 2) Secondly, take 70 parts by mass of curing agent, 20 parts of toughening agent and...

Embodiment 3

[0048]This example provides an epoxy resin cured material system for high temperature mixed epoxy asphalt, including a resin component and a cured component; wherein the mass ratio of the resin component to the cured component is 100:70;

[0049] The resin component is calculated in parts by mass and consists of the following materials: 80 parts of a mixture of hydroquinone diglycidyl ether resin and epoxidized polybutadiene resin, linoleic acid dimer diglycidyl ether 20 copies;

[0050] The curing component is composed of the following materials in parts by mass: 80 parts of cyanoethylated menthane diamine, 10 parts of EPDM rubber, and 10 parts of dodecylpropylene diamine.

[0051] The preparation method of the epoxy resin cured material system for the high temperature mixed epoxy asphalt of the present embodiment is as follows:

[0052] 1) First, mix the epoxy resin and the diluent at a mass ratio of 80:20 at 60°C to obtain the resin component;

[0053] 2) Next, take 80 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com