Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Solve seal failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

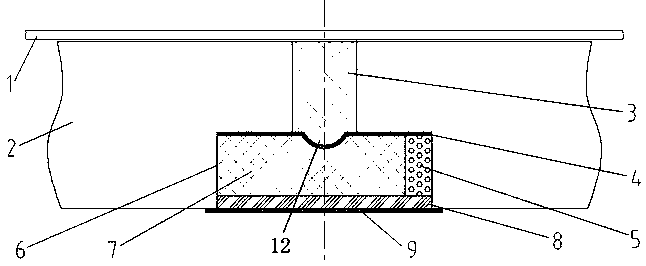

Pressure adaptive mechanical seal

The invention discloses a pressure self-adaptive mechanical seal device, which relates to the field of mechanical seal devices, and comprises a static ring assembly fixedly connected to the static part of the seal and a dynamic ring assembly that can rotate with the shaft. Discontinuous cavities uniformly distributed in the circumferential direction are processed on the radial side. There are through holes on the lower surface of each cavity. The through holes communicate with the low pressure area. The discontinuous cavities are sealed by sealing rings. According to different sealing conditions, the different The continuous cavity can adopt different structural forms to achieve the best sealing effect. This sealing device well solves the problem of seal end face wearing and tearing failure caused by sealing pressure fluctuations. Its notable feature is that it can adapt to sealing conditions with a wide pressure range. As the pressure of the sealed fluid increases, the bearing capacity of the seal will increase. The enhancement is adaptive.

Owner:BEIJING UNIV OF CHEM TECH

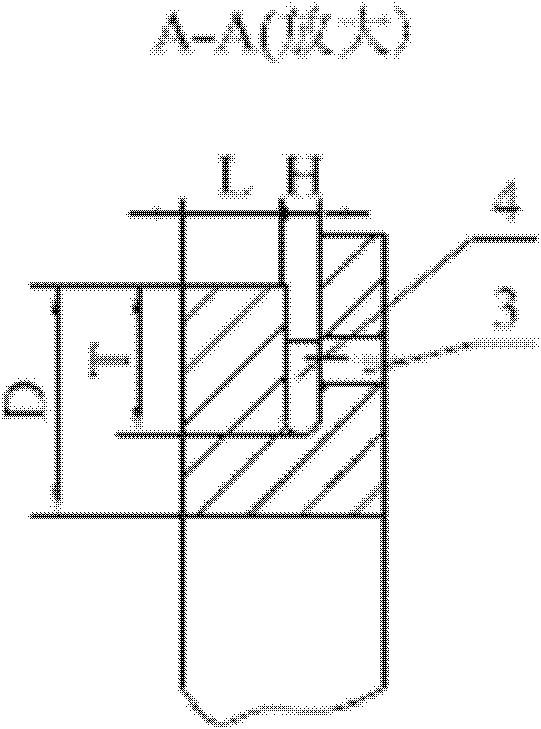

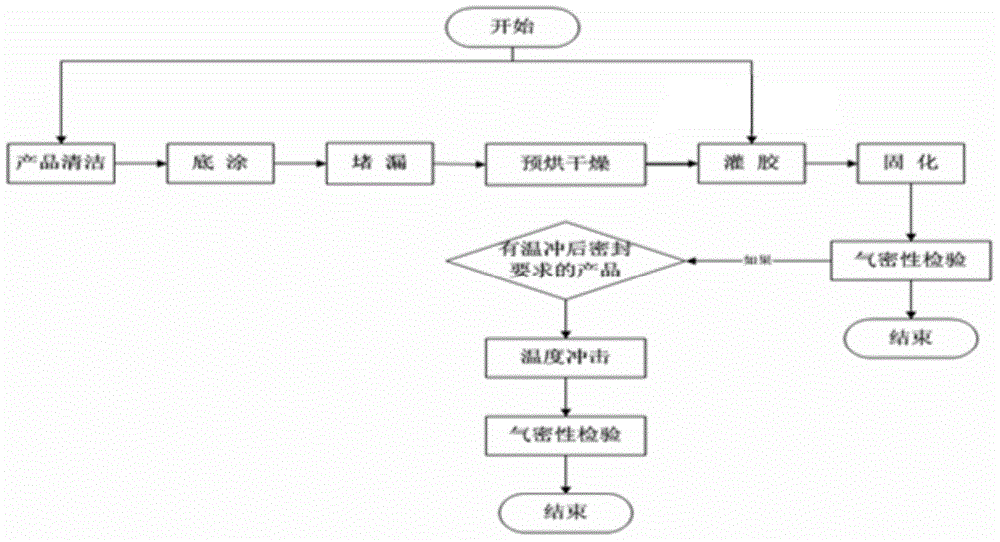

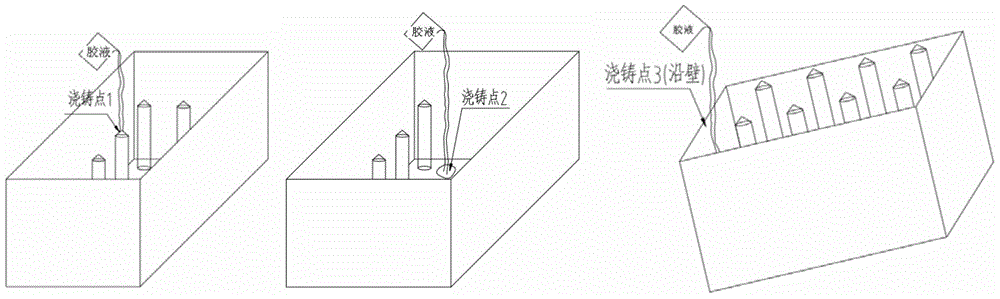

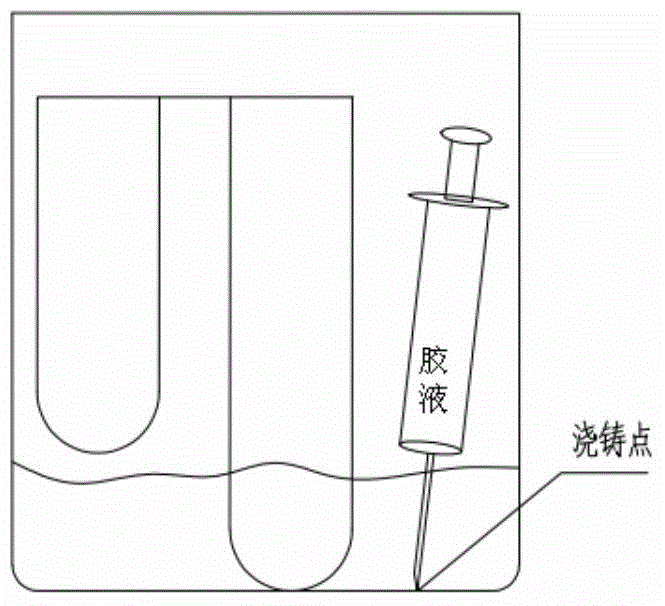

Method for using polyurethane adhesive to encapsulate electrical connector product

ActiveCN104577635AImprove airtight pass rateSolve the sealing problemContact member cases/bases manufactureElectricityPolyurethane adhesive

The invention discloses a method for using a polyurethane adhesive to encapsulate an electrical connector product. The method comprises the steps of cleaning the product, first coating, stopping leakage, pre-drying, pouring the polyurethane adhesive, solidifying, checking the airtightness, and the like, wherein the specific technologic method for each step is provided. According to the method disclosed by the invention, the airtightness qualification rate of the encapsulated product is increased, and the problem that the encapsulated product fails to be sealed or adhesive overflows after temperature shock can be solved.

Owner:杭州航天电子技术有限公司

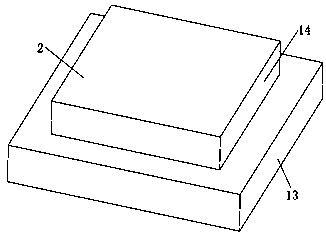

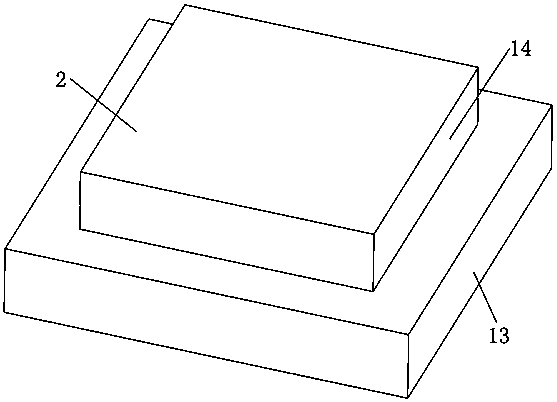

Sealing structure of joint of insulating blocks of B type enclosure system

ActiveCN109606564AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsThermal insulationThermal insulationThermal expansion

The invention discloses a sealing structure of a joint of insulating blocks of a B type enclosure system. The sealing structure comprises a plurality of first insulating blocks fixed on the wall of acargo hold; a first gap filled with a first thermal-insulation buffer material is formed between the lower sides of every two adjacent first insulating blocks; and a second gap for arranging a first aluminum foil, a second insulating block, a second thermal-insulation buffer material, and a sealing elastic material is formed between the upper sides of every two adjacent first insulating blocks; the first aluminum foils are arranged on the first thermal-insulation buffer materials; the second insulating blocks are arranged on the first aluminum foils; the space between the second insulating blocks and the first insulating blocks is filled with second thermal-insulation buffer materials; the sealing elastic materials are arranged on the surfaces of the second insulating blocks; and second aluminum foils are arranged on the surfaces of the sealing elastic materials. Therefore, a problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contractionat the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

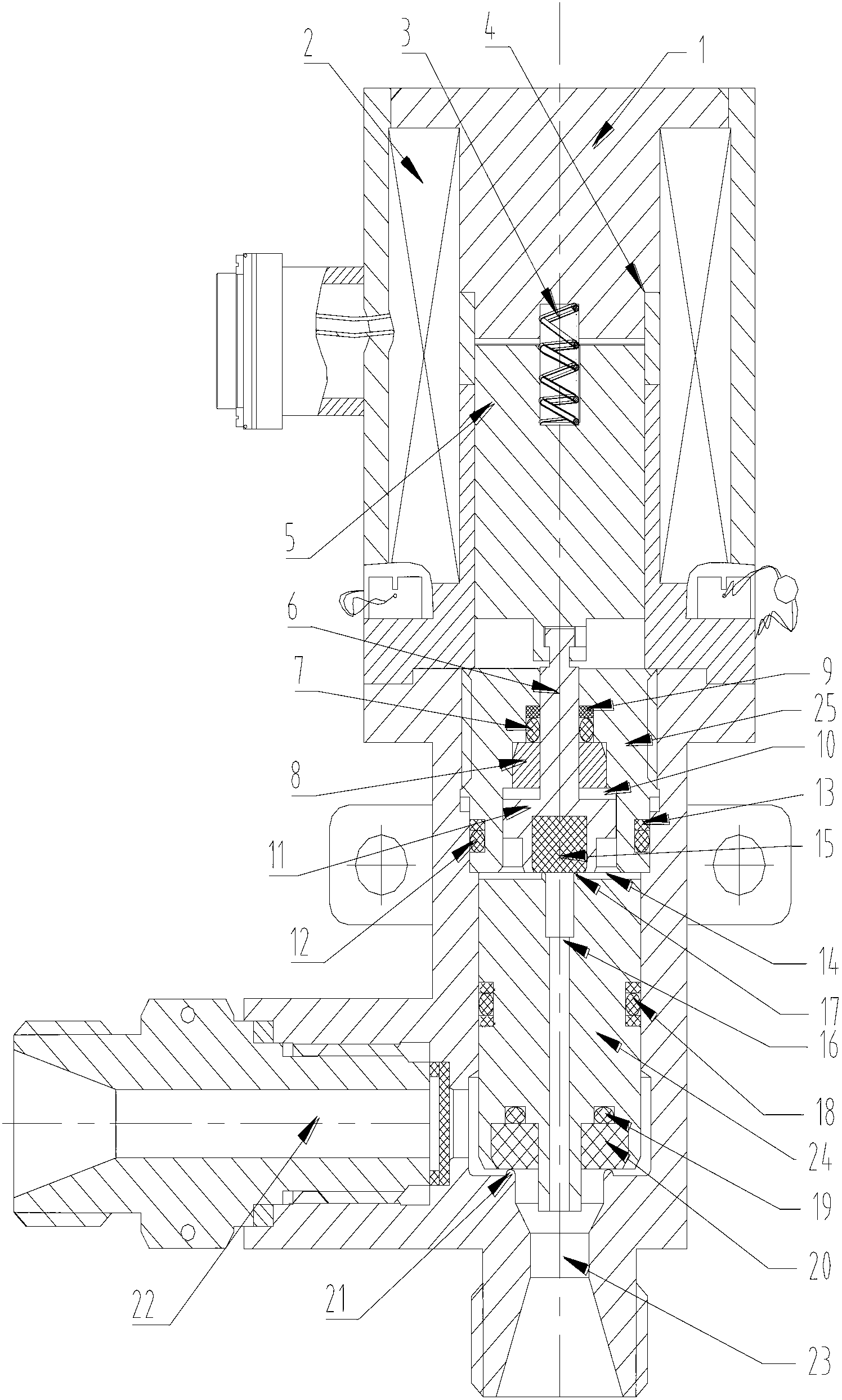

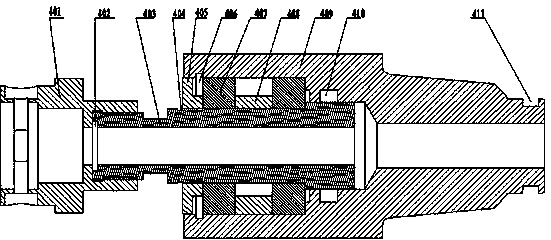

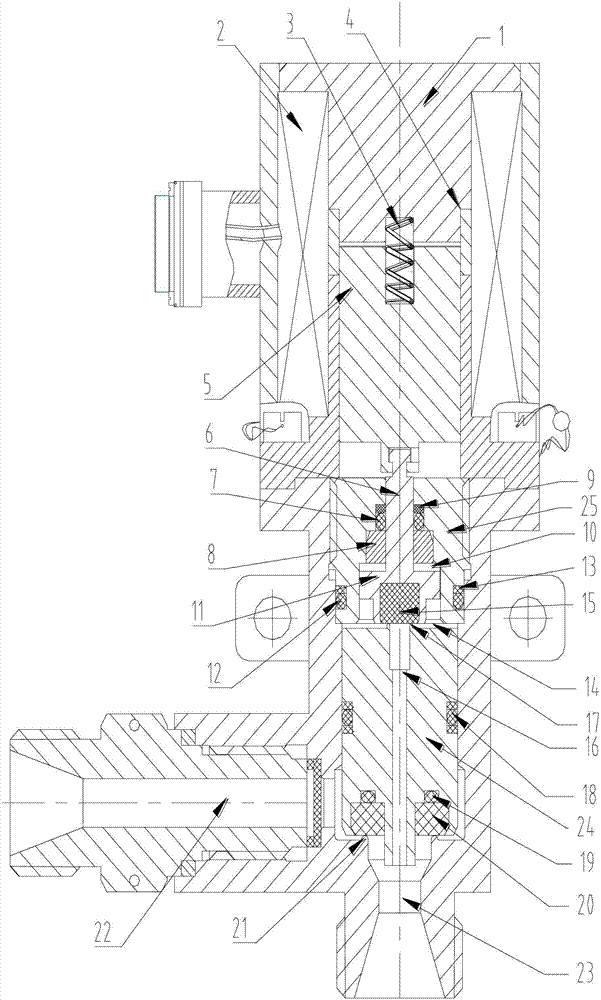

Solenoid valve

ActiveCN103216662ALighten the design burdenAvoid enteringSpindle sealingsOperating means/releasing devices for valvesSolenoid valveSystem pressure

The invention discloses a solenoid valve. A sealing O-shaped ring for preventing gas from upwards extending is arranged between a secondary valve rod and a guide base, so that high-pressure gas is prevented from entering an inner cavity of an electromagnet, the inner cavity of the electromagnet is prevented from being polluted by working medium, and armature blocking caused by the fact that the residual medium enters the inner cavity of the electromagnet in the working process is prevented, so that abrasion is reduced, and the service life of the product is beneficially prolonged; meanwhile, a balancing cavity and a pressure storage cavity are formed on and under the secondary valve core, so that the electromagnet design burden is reduced greater by utilizing upper-lower gas pressure balancing factors of the secondary valve, and therefore, the weight of the product is lowered, the structure is more compact and the functions are more complete. Besides, the solenoid valve can be used for solving the problem that the sealing is invalid as the sealing force of the secondary valve is increased during a system pressure increasing process and the sealing surface of the secondary valve is damaged, and therefore, the structure of the solenoid valve can be used for prolonging the service life of the product and improving the reliability of the product.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

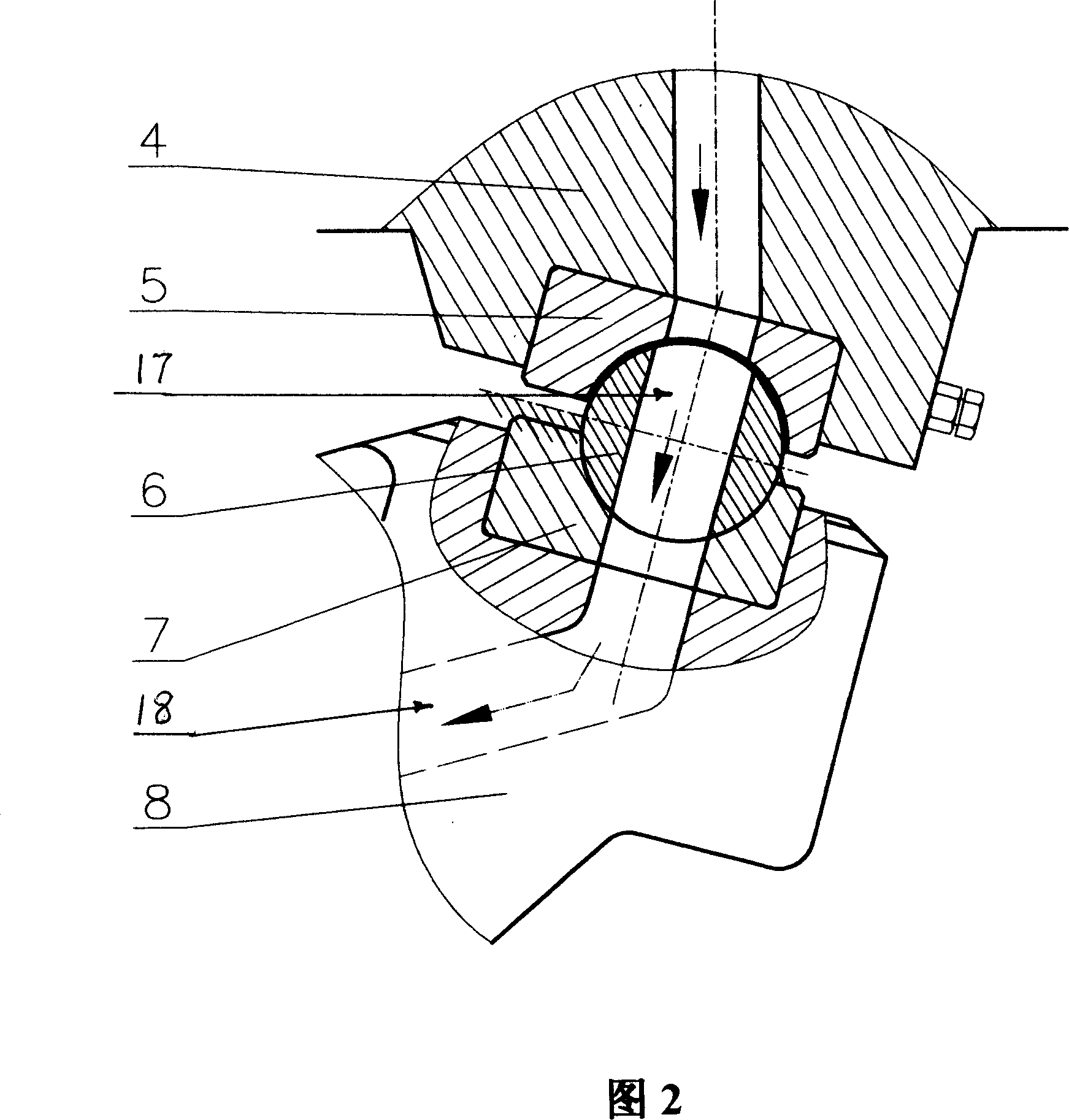

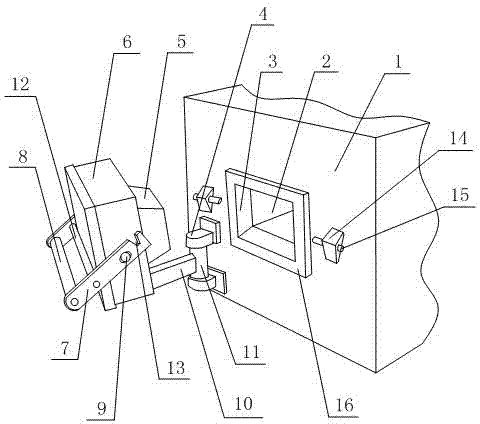

Enclosed air passage system for grinding roll

ActiveCN101007293ASolve seal failureSolve rigid problemsGrain treatmentsPositive pressurePulp and paper industry

Grinding roller sealed air duct system includes fan, external pipe lines, soft connectivity, pipe lines fixed on pressure framework, upper roller seat, sealing roller, lower roller seat, grinding roller frame and grinding roller; its characteristics is said upper roller seat, sealing roller and lower roller seat combine sealed air duct, the sealed air duct is connected with air holes of grinding roller frame. The fan transmits positive pressure wind into the sealed air duct combine by upper roller seat, sealing roller and lower roller seat through external pipe lines and pipe lines fixed on pressure framework, and blowout wind through the air holes of grinding roller frame and the chine between grinding roller frame, grinding roller and grinding roller frame driving rotating components.The invention solves the problem of grinding roller seal failure because of vibration joint wear, while solves the problems of the grinding leakage of loop pipe line and grinding roller frame air-supply line because of long-time mill vibration and dust wind erosion, or rigidity injury even breach lead by mill shape vibration. The invention not only saves a lot of investment, reduces costs, and is a highly reliable grinding roller sealed air duct system.

Owner:沈阳吉大重型机械有限公司

Sealing structure of joint of insulating blocks of B type enclosure system

ActiveCN109606569AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsThermal insulationThermal insulationThermal expansion

The invention discloses a sealing structure of a joint of insulating blocks of a B type enclosure system. The sealing structure comprises a plurality of first insulating blocks fixed on the wall of acargo hold; a first gap filled with a first thermal-insulation buffer material is formed between the lower sides of every two adjacent first insulating blocks; and a second gap for arranging a first aluminum foil, a second insulating block, a second thermal-insulation buffer material, and a sealing elastic material is formed between the upper sides of every two adjacent first insulating blocks; the first aluminum foils are arranged on the first thermal-insulation buffer materials; the second insulating blocks are arranged on the first aluminum foils; the space between the second insulating blocks and the first insulating blocks is filled with second thermal-insulation buffer materials; the sealing elastic materials are arranged on the surfaces of the second insulating blocks; and second aluminum foils are arranged on the surfaces of the sealing elastic materials. Therefore, a problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contractionat the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Magnetic liquid sealing device

ActiveCN112178203AImprove sealingExtended service lifeEngine sealsRolling contact bearingsEngineeringConductive materials

The invention discloses a magnetic liquid sealing device. The magnetic liquid sealing device comprises a shell, a shaft, a first shaft sleeve, a plurality of pole shoes and a permanent magnet. The shaft rotatably penetrates through the shell, the first shaft sleeve is made of a magnetic conductive material, the size of the first shaft sleeve can be changed along with the change of the temperaturein the shell, the first shaft sleeve is arranged on the shaft in a sleeving manner, the pole shoes are arranged on the shaft and the first shaft sleeve in a sleeving manner, and a plurality of pole teeth arranged at intervals in the axial direction of the shaft are arranged on the inner circumferential surfaces of the pole shoes; the shaft and one part of the pole teeth are arranged at intervals in the radial direction of the shaft to form a first interval, the first shaft sleeve and the other part of the pole teeth are arranged at intervals in the radial direction of the shaft to form a second interval, magnetic liquid with small base carrier liquid molecular weight is arranged in the first interval, and magnetic liquid with large base carrier liquid molecular weight is arranged in the second interval; and the permanent magnet is arranged in the shell and sleeves the shaft. The magnetic liquid sealing device can effectively solve the problems of large low-temperature starting torque and sealing failure caused by volatilization of the magnetic liquid-based carrier liquid at high temperature.

Owner:TSINGHUA UNIV

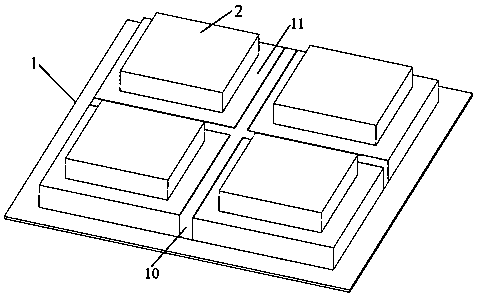

Sealing structure of joint of insulating blocks of B type enclosure system

ActiveCN109606565AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsThermal insulationThermal insulationThermal expansion

The invention discloses a sealing structure of a joint of insulating blocks of a B type enclosure system. The sealing structure comprises a plurality of first insulating blocks fixed on the wall of acargo hold; a first gap filled with a first thermal-insulation buffer material is formed between the lower sides of every two adjacent first insulating blocks; and a second gap for arranging a first aluminum foil, a second insulating block, a second thermal-insulation buffer material, and a sealing elastic material is formed between the upper sides of every two adjacent first insulating blocks; the first aluminum foils are arranged on the first thermal-insulation buffer materials; the second insulating blocks are arranged on the first aluminum foils; the space between the second insulating blocks and the first insulating blocks is filled with second thermal-insulation buffer materials; the sealing elastic materials are arranged on the surfaces of the second insulating blocks; and second aluminum foils are arranged on the surfaces of the sealing elastic materials. Therefore, a problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contractionat the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Sealing structure of joint of insulating blocks of B type enclosure system

ActiveCN109606566AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsThermal insulationThermal insulationThermal expansion

The invention discloses a sealing structure of a joint of insulating blocks of a B type enclosure system. The sealing structure comprises a plurality of first insulating blocks fixed on the wall of acargo hold; a first gap filled with a first thermal-insulation buffer material is formed between the lower sides of every two adjacent first insulating blocks; and a second gap for arranging a first aluminum foil, a second insulating block, a second thermal-insulation buffer material, and a sealing elastic material is formed between the upper sides of every two adjacent first insulating blocks; the first aluminum foils are arranged on the first thermal-insulation buffer materials; the second insulating blocks are arranged on the first aluminum foils; the space between the second insulating blocks and the first insulating blocks is filled with second thermal-insulation buffer materials; the sealing elastic materials are arranged on the surfaces of the second insulating blocks; and second aluminum foils are arranged on the surfaces of the sealing elastic materials. Therefore, a problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contractionat the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

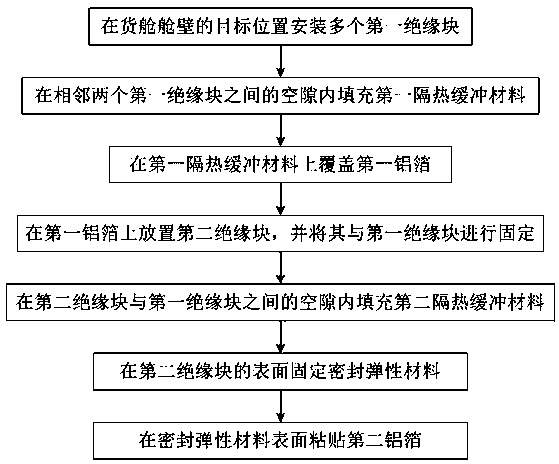

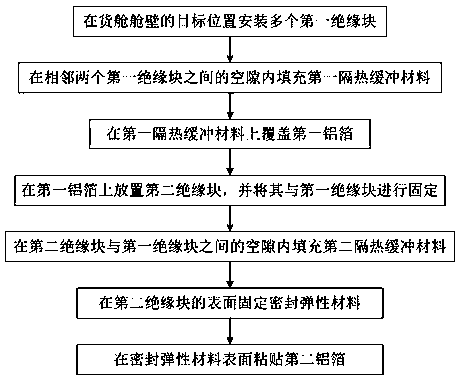

Method for sealing joint of insulating blocks of B type enclosure system

ActiveCN109606554AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsVessel partsThermal insulationThermal expansion

The invention discloses a method for sealing the joint of insulating blocks of a B type enclosure system. The method comprises the following steps: installing a plurality of first insulating blocks attarget positions of a cargo bulkhead; filling a gap between every two adjacent first insulating blocks with a first thermal-insulation buffer material; covering the first thermal-insulation buffer materials with first aluminum foils; placing second insulating blocks on the first aluminum foils and fixing the second insulating blocks with the first insulating blocks; filling gaps among the secondinsulating blocks and the first insulating blocks with second thermal-insulation buffer materials; fixing sealing elastic materials on the surfaces of the second insulating blocks; and pasting secondaluminum foils on the sealing elastic materials. The method is operated simply and installation becomes convenient. A problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contraction at the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

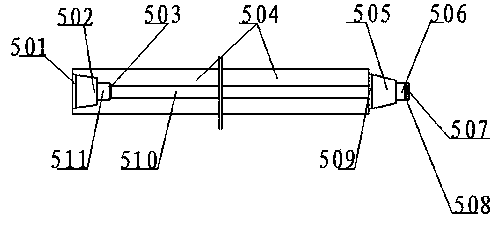

Water conservancy reaming system

InactiveCN104343390ASolve technical problemsImprove performanceDrill bitsDrilling rodsWater sourceEngineering

The invention discloses a water conservancy reaming system which comprises a water source, a connecting pipe, a water pump, a water supply connector, a drill bit and a drill rod, wherein the drill bit and the water supply connector are mounted at the two ends of the drill rod; the water supply connector is connected to the outlet of the water pump; the water inlet of the water pump is communicated with the water source through the connecting pipe. According to the water conservancy reaming system, the performance of the whole system is improved by improving parts in the integral structure, and the technical problems caused by specific parts are solved.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Method for sealing joint of insulating blocks of B type enclosure system

ActiveCN109606553AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsVessel partsThermal insulationThermal expansion

The invention discloses a method for sealing the joint of insulating blocks of a B type enclosure system. The method comprises the following steps: installing a plurality of first insulating blocks attarget positions of a cargo bulkhead; filling a gap between every two adjacent first insulating blocks with a first thermal-insulation buffer material; covering the first thermal-insulation buffer materials with first aluminum foils; placing second insulating blocks on the first aluminum foils and fixing the second insulating blocks with the first insulating blocks; filling gaps between the second insulating blocks and the first insulating blocks with second thermal-insulation buffer materials; fixing sealing elastic materials on the surfaces of the second insulating blocks; and pasting second aluminum foils on the sealing elastic materials. The method is operated simply and installation becomes convenient. A problem of the sealing failure of the insulating block joint due to the thermalexpansion and cold contraction at the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

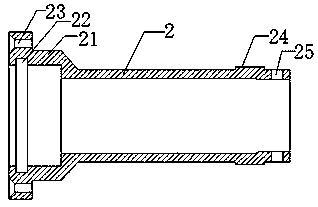

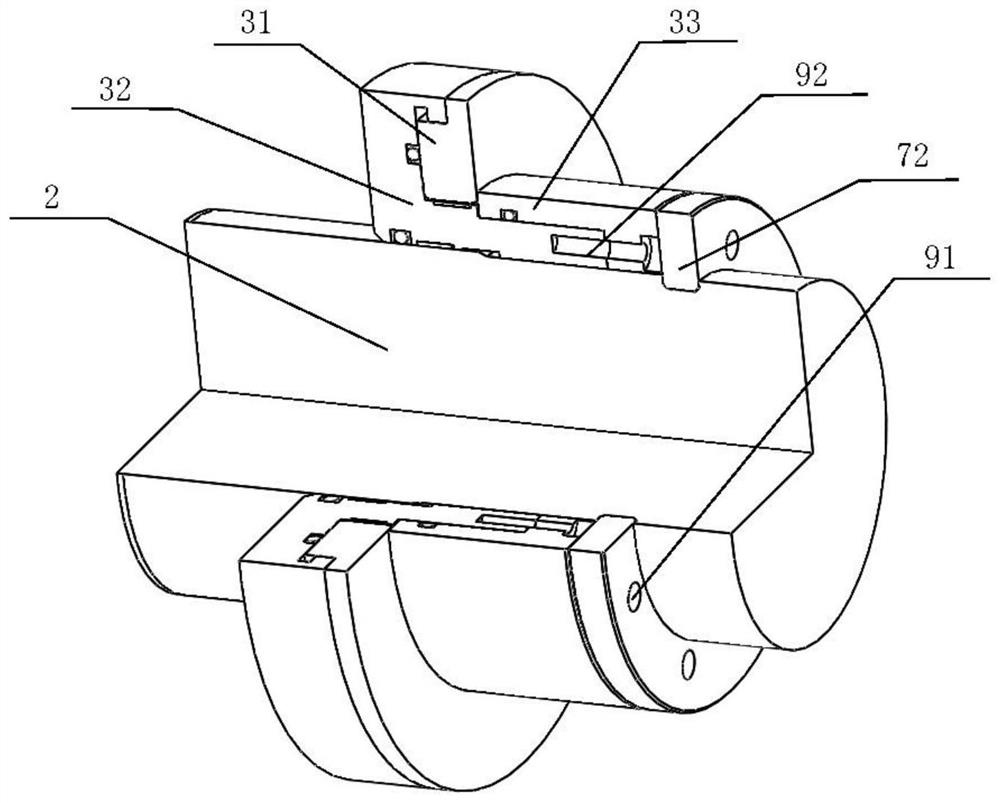

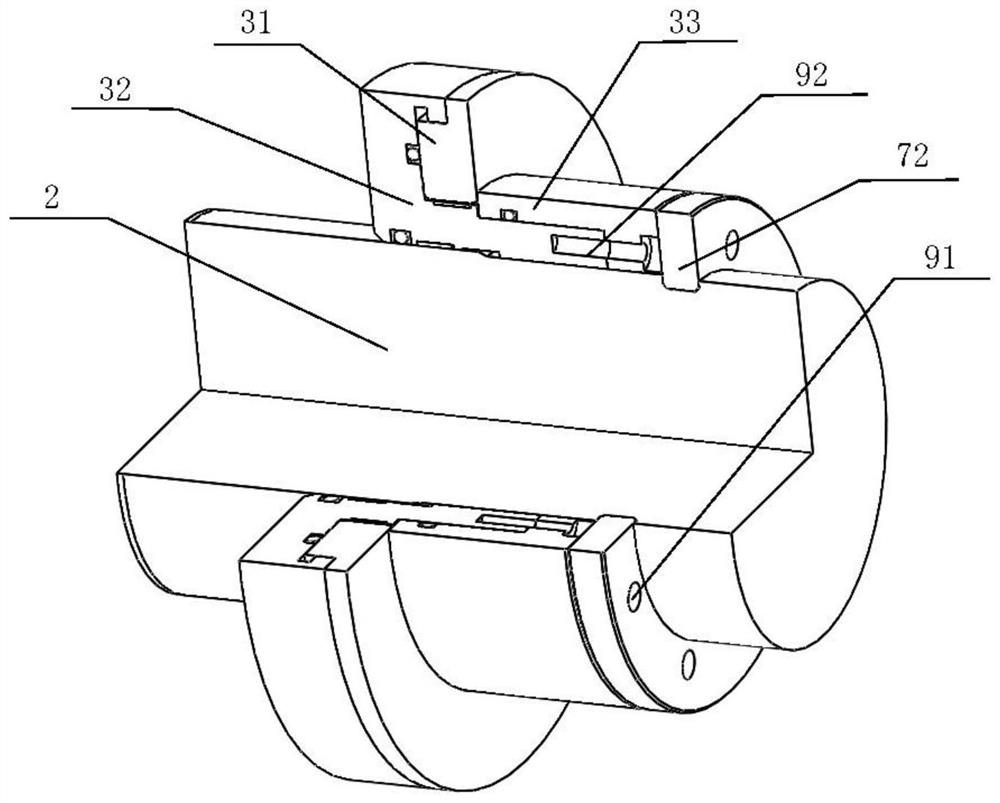

Container packaging type mechanical seal for corrosion-resistant alkali pump

InactiveCN108757550AUniform and stable dispersionEffective coolingPump componentsPumpsConvex structureImpeller

The invention relates to a container packaging type mechanical seal for an alkali pump, in particular to the container packaging type mechanical seal for the corrosion-resistant alkali pump. The container packaging type mechanical seal for the corrosion-resistant alkali pump comprises a shaft sleeve, a gland, a medium end seal and an atmosphere end water seal, wherein the medium end seal is located on the inner side of the gland, and the atmosphere end water seal is located on the outer side of the gland. An impeller is arranged at the end of a pump shaft through an impeller hub, the side, close to the impeller, of the shaft sleeve is provided with a step type structure connected with the shaft sleeve through an inclined face, the side, close to the impeller, of the step type structure isprovided with an annular groove with the opening facing the pump shaft, the step type structure is provided with an axial positioning hole, and the side, away from the impeller, of the shaft sleeve isprovided with a convex structure and a radial positioning hole. Compared with the prior art, the container packaging type mechanical seal for the corrosion-resistant alkali pump has the following advantages that the container packaging type mechanical seal can be used for conveying a medium with the medium solid content being 40% after being installed in the alkali pump, the shaft sleeve structure is reasonably designed, the container packaging type mechanical seal is used for conveying the concentrated alkali medium, the sealing effect is goof, use is safe and environmentally friendly, the environmental protection requirements of industrial production are met, the service life is long, the treatment cost of harmful gas is saved, and economic benefits are remarkable.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

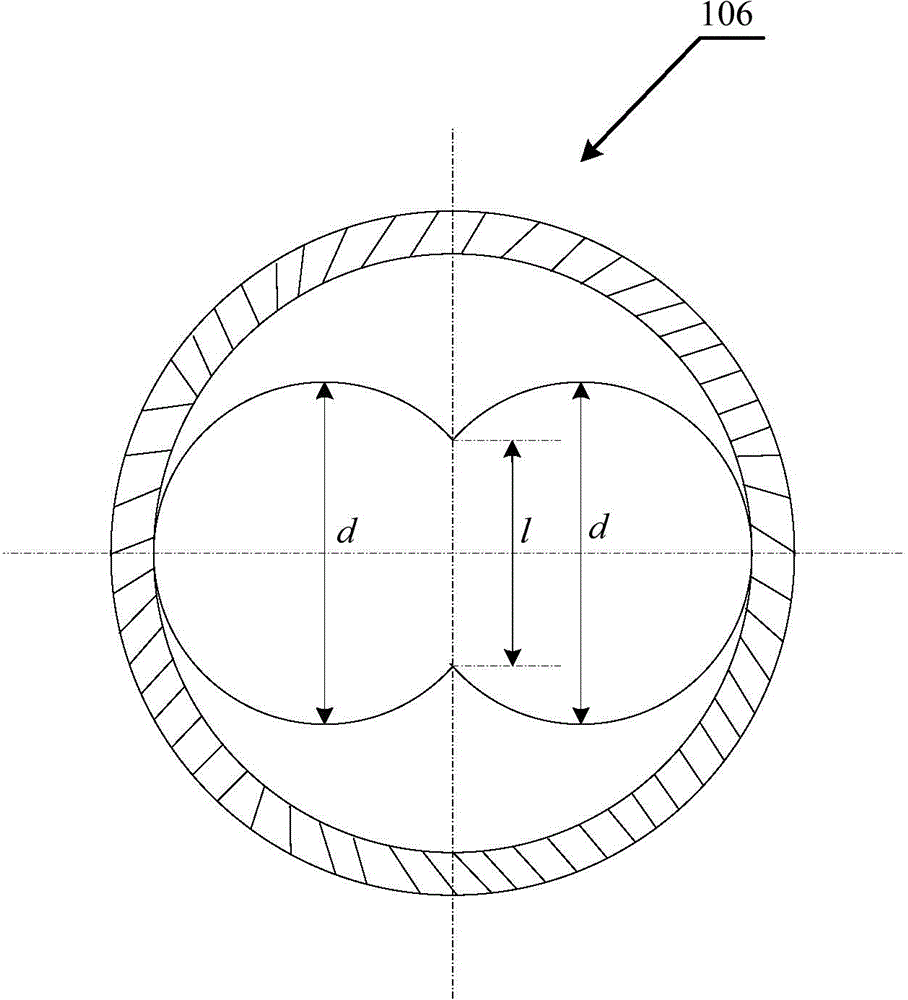

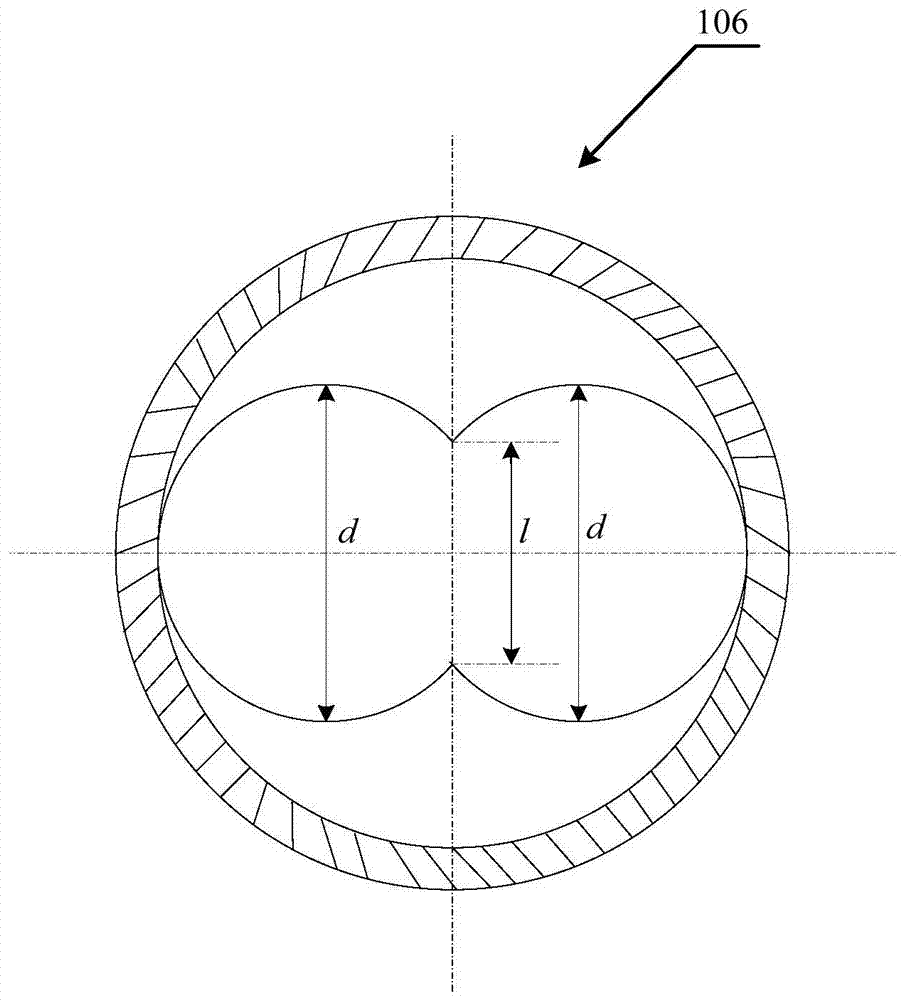

Ball seat

ActiveCN105735941AEasy deliveryWater injection string is effectively sealedFluid removalWell/borehole valve arrangementsInternal cavityEngineering

The invention discloses a ball seat, and belongs to the technical field of oilfield flooding. The ball seat comprises a tubular upper connector, an outer barrel, a core pipe, a self-locking shear pin, a clamp spring, a check ring and a lower connector, wherein the upper connector and the lower connector are both connected with the outer barrel; an inner cavity of the lower connector is provided with a first inclined surface; an inner cavity of the core pipe is provided with a second inclined surface and the core pipe is connected with the outer barrel through the self-locking shear pin; the core pipe is provided with a first clamp spring groove, and the clamp spring is arranged in the first clamp spring groove; an inner cavity of the check ring is provided with a third inclined surface and shaped like a calabash formed by overlapping two communicating cylindrical cavities with the same diameter, the width of the overlapping surface is smaller than the diameter of a thrown ball, and the diameter of the cylindrical cavities is larger than the diameter of the thrown ball; a step is arranged on the wall of an inner cavity of the outer barrel; the upper end of the check ring and the step are coplanar, and the lower end of the check ring and the upper end of the lower connector are coplanar; and a second clamp spring groove is formed in the outer barrel, the self-locking shear pin is shorn off, the core pipe moves downwards, and the clamp spring is clamped in the second clamp spring groove. By means of the ball seat, the problems that the thrown ball is difficult to throw and returns to cause sealing failure of a water injection pipe column are solved, and the effect of effectively sealing the water injection pipe column is realized.

Owner:PETROCHINA CO LTD

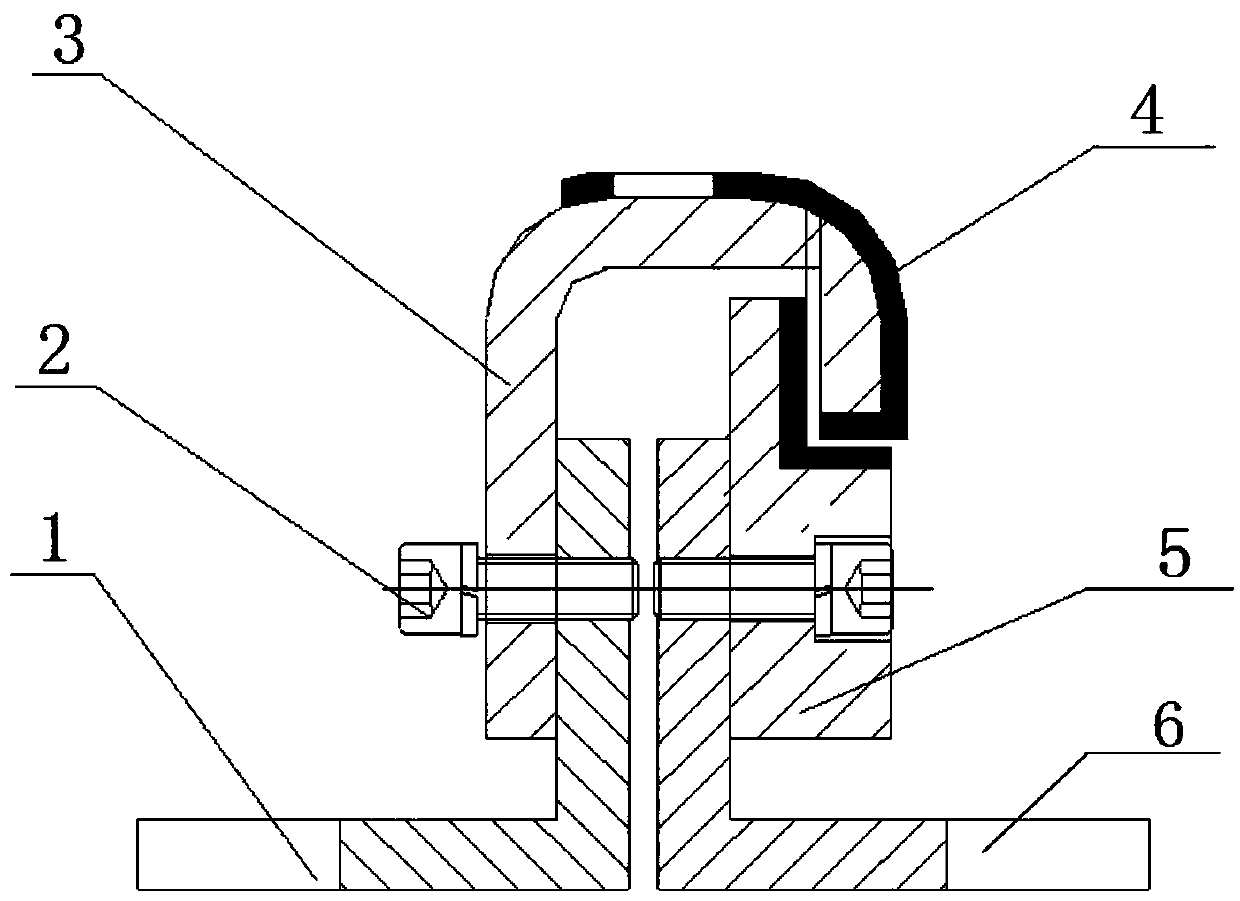

Sealing structure based on non-return stop valve

InactiveCN103953763ATo achieve the purpose of sealingSolve seal failureCheck valvesLift valveStructure basedGlobe valve

The invention discloses a sealing structure based on a non-return stop valve. The sealing structure comprises a stop valve clack, a stop valve sealing ring, a fastening bolt, a non-return valve rod and a cavity, wherein the stop valve clack is in fit and fixed connection with the stop valve sealing ring, and a fixing groove used for fixing the fastening bolt is formed in a direction facing to the cavity; a through hole for arranging the fastening bolt in a penetrating manner is formed in the center position of the stop valve sealing ring, and is formed between the stop valve clack and the non-return valve rod in a close fit manner; the non-return valve rod is in tight fit with the stop valve sealing ring, and a fixing hole for fixing the fastening bolt is formed in the non-return valve rod; the fastening bolt is used for fixing the non-return valve rod, the stop valve sealing ring and the stop valve clack in a tight fit manner; a tapered cavity structure shrinking towards a port direction is formed in the port of the cavity. The sealing structure provided by the invention solves the problem of sealing failure due to structure unbalance of the non-return valve of a low-temperature medium sealing structure after repeated filling and sealing.

Owner:BEIJING XINGSHI HUARONG TECH DEV

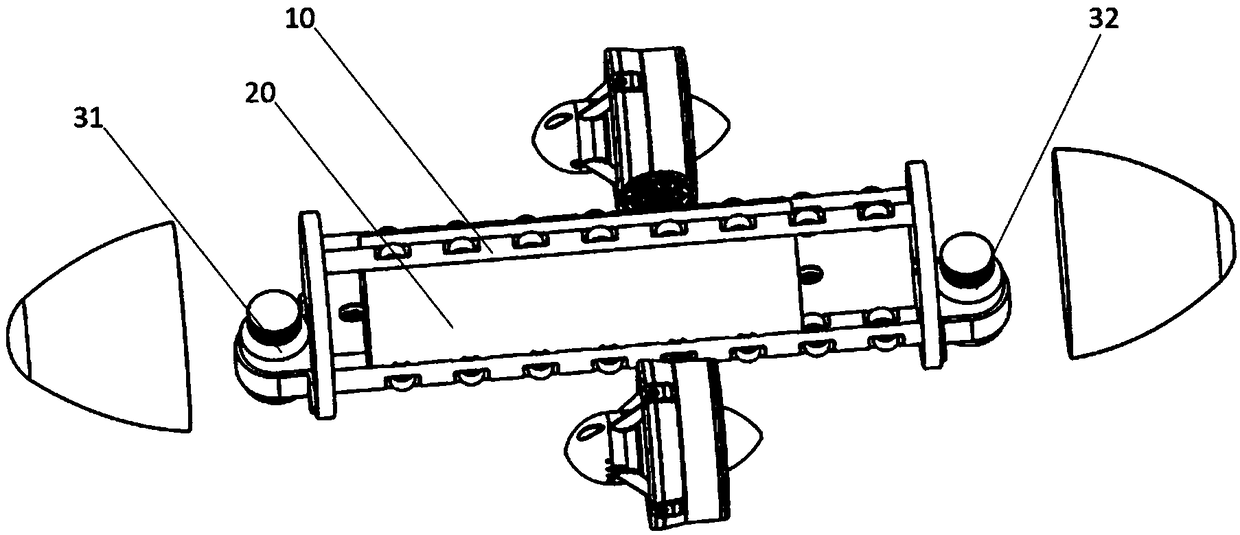

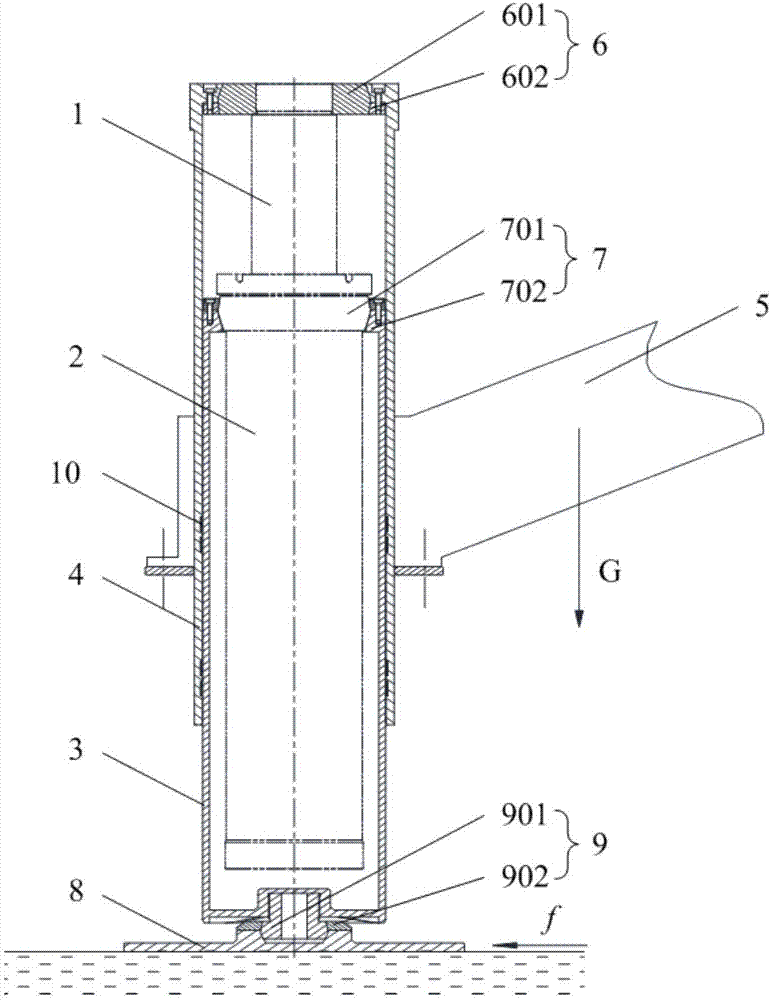

Gravity center adjustment device for underwater submersible vehicle

PendingCN109305313ASolve seal failureWill not cause a collisionUnderwater vesselsUnderwater equipmentInterior spaceGravity center

The invention discloses a gravity center adjustment device for an underwater submersible vehicle. The gravity center adjustment device for the underwater submersible vehicle comprises a sliding frame,a pressure proof cabin and a driving device. The pressure proof cabin is slidably connected to the sliding frame, and the driving device drives the pressure proof cabin to slide on the sliding frameand locks a position of the pressure proof cabin on the sliding frame. By integrally moving the pressure proof cabin, the moving quality of is large, the pressure proof cabin is not limited by internal space of the pressure proof cabin, the gravity center is changed and displacement is larger, the effect is obvious, internal collision of the pressure proof cabin cannot be caused, devices and a pressure proof cabin cover cannot be damaged, more reliability and safety are achieved, the structure is simple, and the problem of disabled invalid sealing of the pressure proof cabin due to the fact that an existing gravity center adjustment device needs to increase pressure proof cabin space during adjusting a battery pack in the pressure proof cabin and is prone to ejecting a sealing cover is solved.

Owner:CETC OCEAN INFORMATION CO LTD

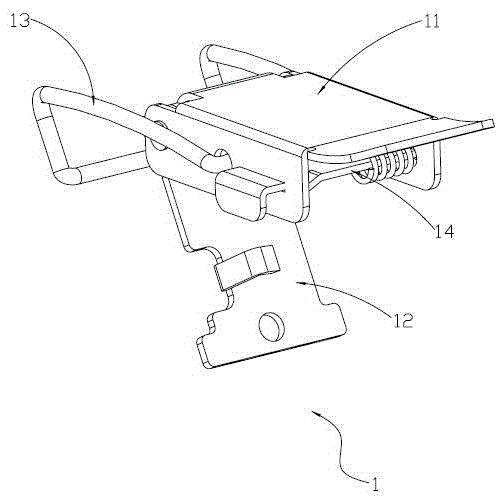

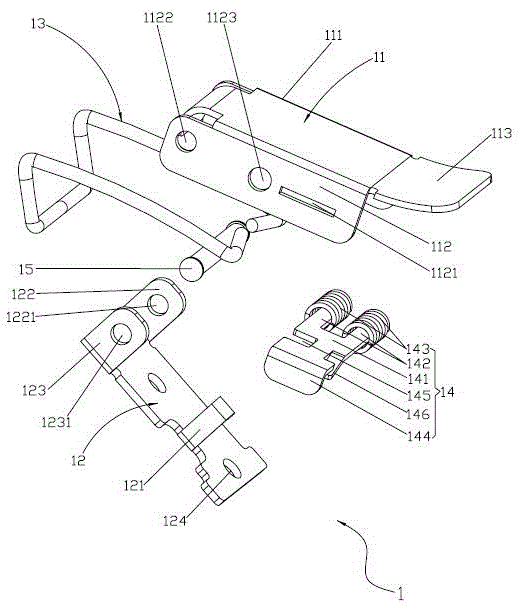

Bag clamping and moving device and bulk fine dried noodle packaging machine

PendingCN111017312ASolve seal failureResolve failurePackagingProcess engineeringIndustrial engineering

The invention relates to the technical field of packaging equipment, in particular to a bag clamping and moving device and a bulk fine dried noodle packaging machine. The bag clamping and moving device comprises a base, two clamping mechanisms and a deduction mechanism, the two clamping mechanisms are both installed on the base, and the two clamping mechanisms are oppositely arranged and used forclamping the two ends, in the length direction, of a bag opening of a packaging bag after fine dried noodles are packaged in the packaging bag. The deduction mechanism is mounted on the base and comprises a deduction piece, and the deduction piece can be relatively close to and far away from the two clamping mechanisms in the direction perpendicular to the length direction of the bag opening of the packaging bag; the deduction piece is provided with a deduction part, and the deduction part corresponds to the upper side or the lower side of the portion, clamped by the clamping mechanisms, of the packaging bag so that the packaging bag can be pushed laterally when the deduction piece and the clamping mechanisms get close to each other. The bag clamping and moving device is used for solving the problem that in the prior art, when bulk fine dried noodles are packaged, part of the fine dried noodles are possibly clamped at a sealing opening of the packaging bag, and sealing of the packagingbag fails.

Owner:郑州启明轩智能装备有限公司

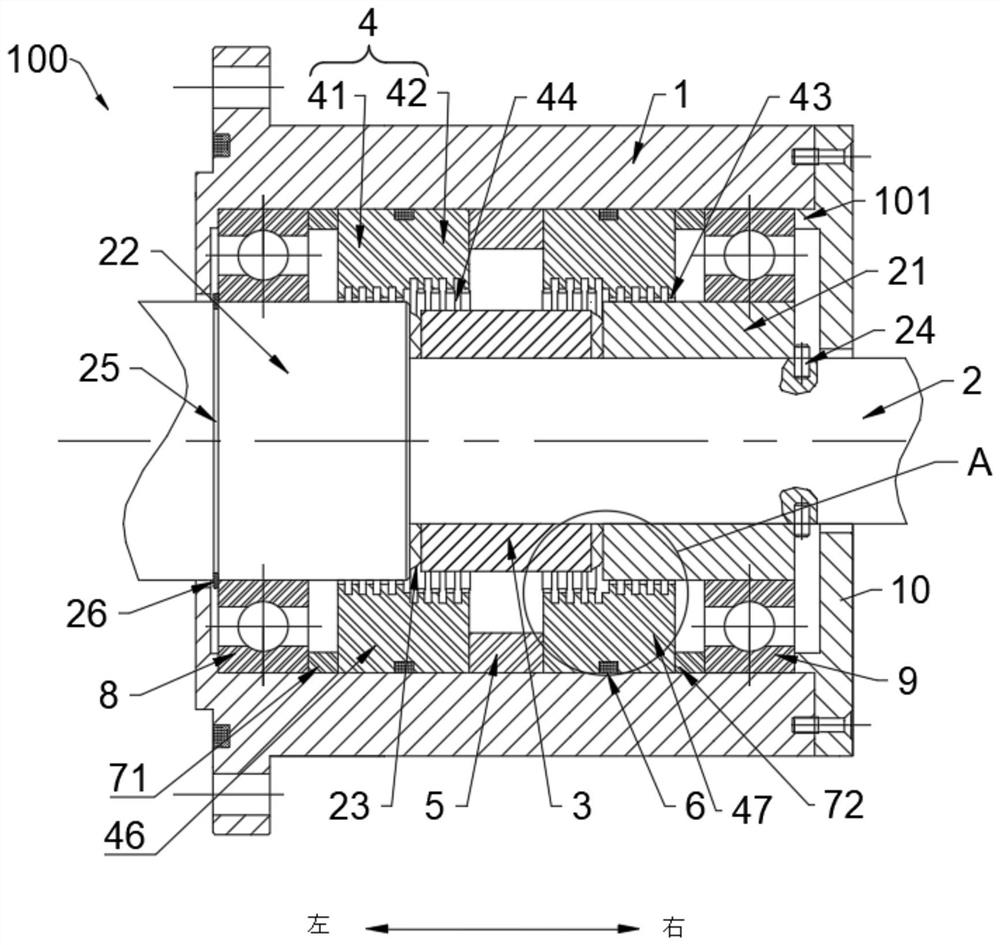

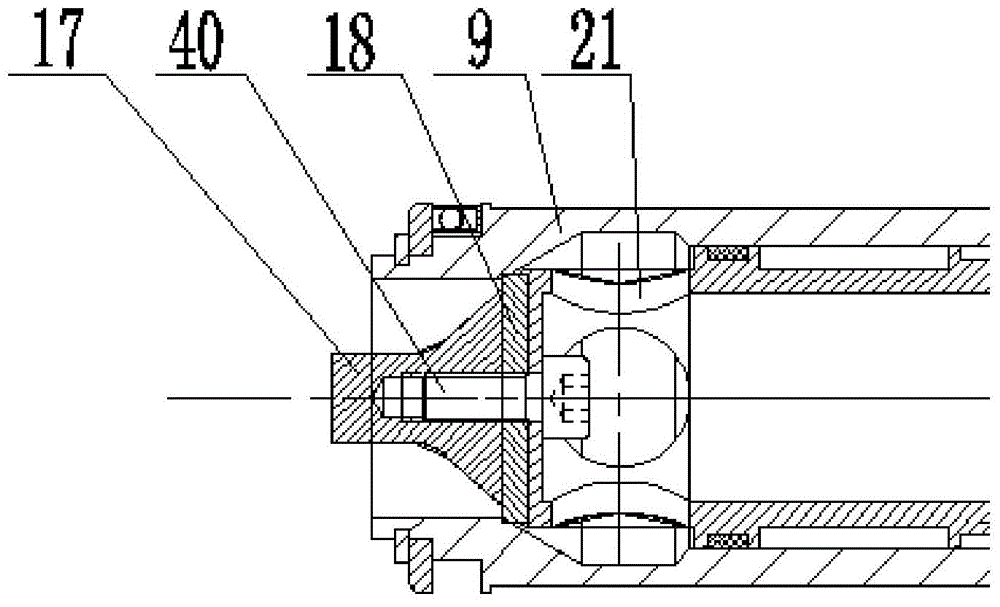

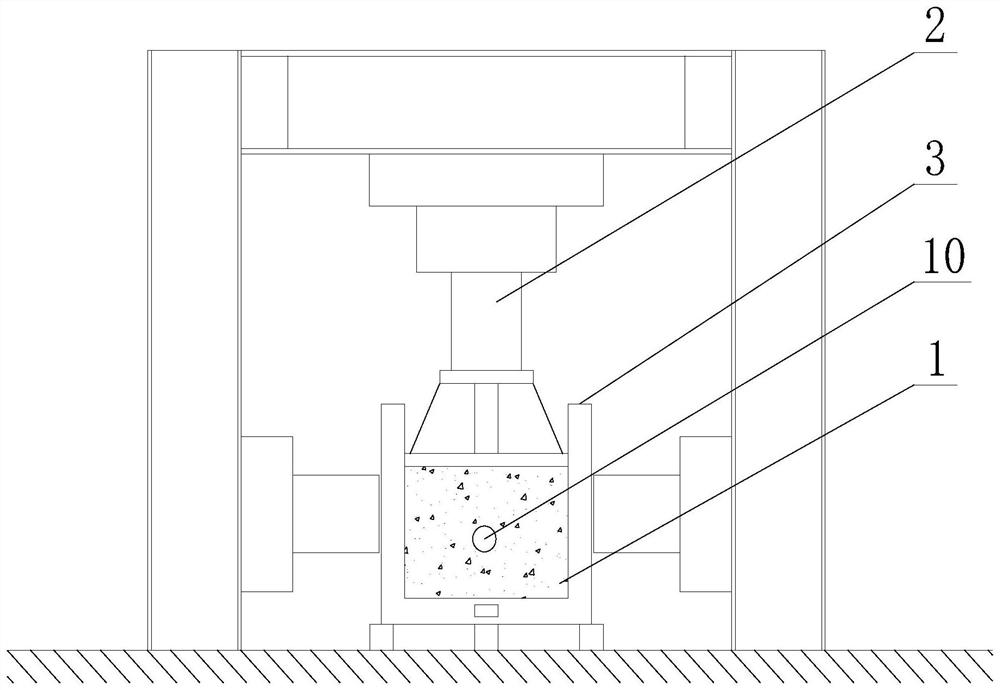

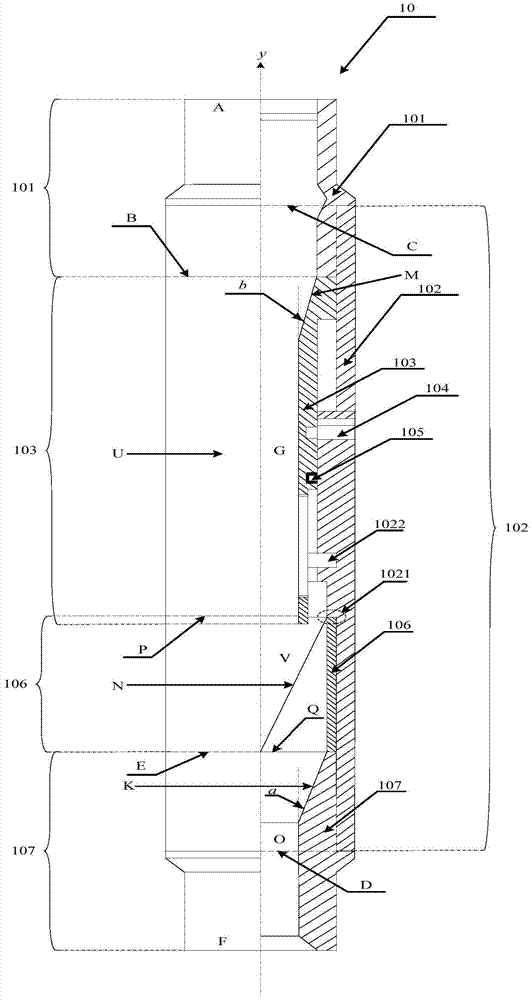

A magnetically coupled dry gas seal structure

ActiveCN112923063BImprove reliabilitySolve the sealing problemEngine sealsMagnetic tension forceCoupling

The invention discloses a magnetic coupling type dry gas sealing structure, which comprises a casing, a rotor, a moving ring assembly capable of rotating with the rotor, and a pushing and static assembly matched with the moving ring assembly, and the moving ring assembly includes a moving ring assembly ring, the static pushing assembly includes a static ring seat, a static ring located in the static ring seat, a number of first permanent magnets magnetically repelling each other are arranged between the outer diameter of the static ring and the inner diameter of the static ring seat, and the static ring is positioned along the A number of second permanent magnets magnetically repelling each other are arranged between one end of the direction away from the moving ring and the seat of the static ring; the first permanent magnet is used to apply a radially inward thrust to the static ring, and the second permanent magnet Magnets are used to apply an axial inward thrust to the stationary ring. The invention is used to solve the problems of the seal interface friction and seal failure of the large shaft diameter dry gas seal device in the prior art under the three high working conditions of high pressure, high temperature and high speed, and realize that the dry gas seal device can be applied to the large shaft In the field of diameter machinery, the purpose of improving sealing reliability.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Gas end face seal anti-interference device and anti-interference method

The invention relates to an anti-jamming device and an anti-jamming method for sealing gas end faces, belonging to the field of devices for sealing the gas end faces. The anti-jamming device comprises a movable sealing ring, a static sealing ring, a film throttle and a gas supply device. Gas supply channels arranged circumferentially and uniformly and not communicated with each other are processed on the static sealing ring; each group of gas supply channels opposite radially are respectively communicated with two sides of a film in the film throttle. Gas provided by the gas supply device is throttled in the film throttle and then conveyed between the end faces to be sealed; the pressure at two sides of the film in the throttle is equal when the sealing runs normally, so the film does not bend and deform; when the static sealing ring deflects angularly, the pressure difference between the two sides of the film in the film throttle is generated; the film bends and deforms by action of the pressure difference; the gas flow resistance at the two sides of the film is changed by bending and deforming so as to be beneficial to recover the sealing to a normal operation condition. The sealing device adaptively provides the anti-jamming capability according to the size of the angular deflection of the static sealing ring.

Owner:BEIJING UNIV OF CHEM TECH

Floating sealing pair

PendingCN110219989AImprove wear resistanceExtended service lifeEngine sealsWear resistantEngineering

Owner:湖北金稽山机械科技有限公司

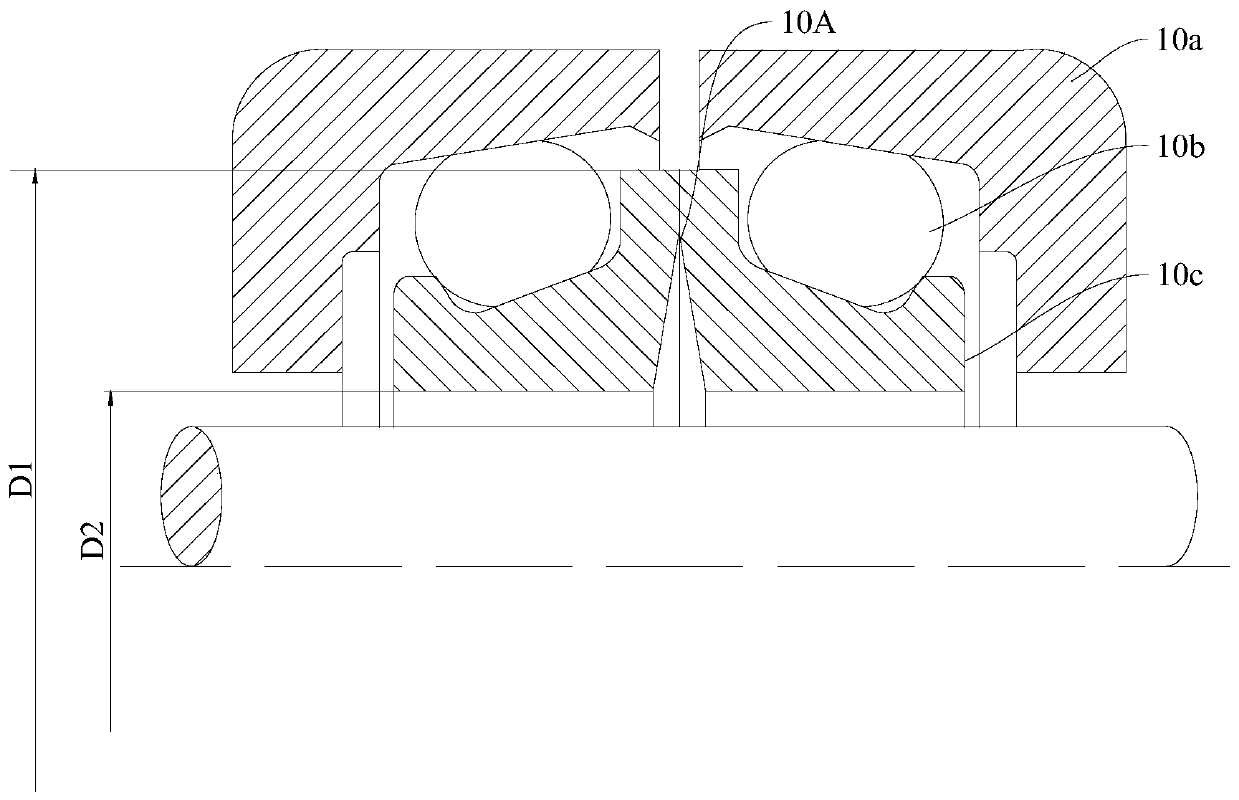

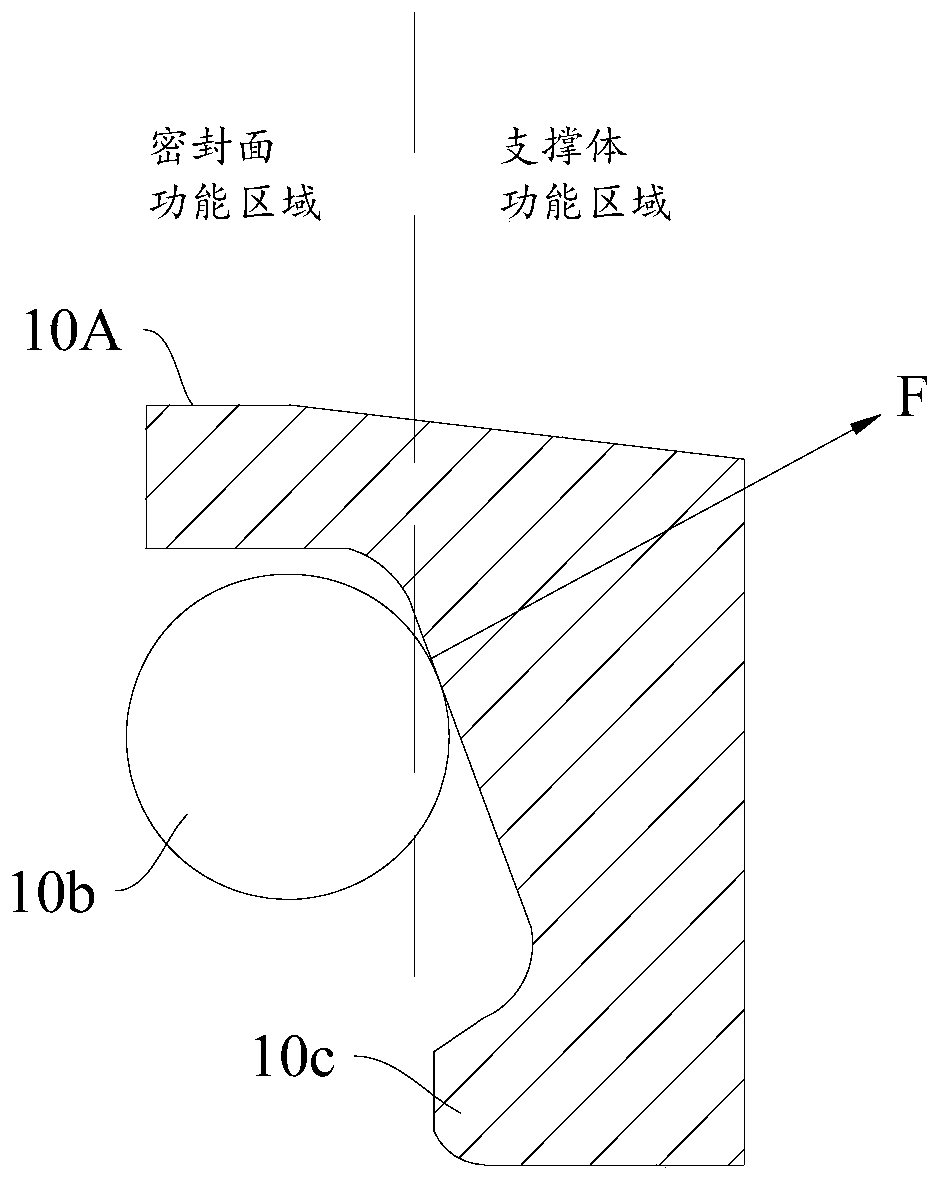

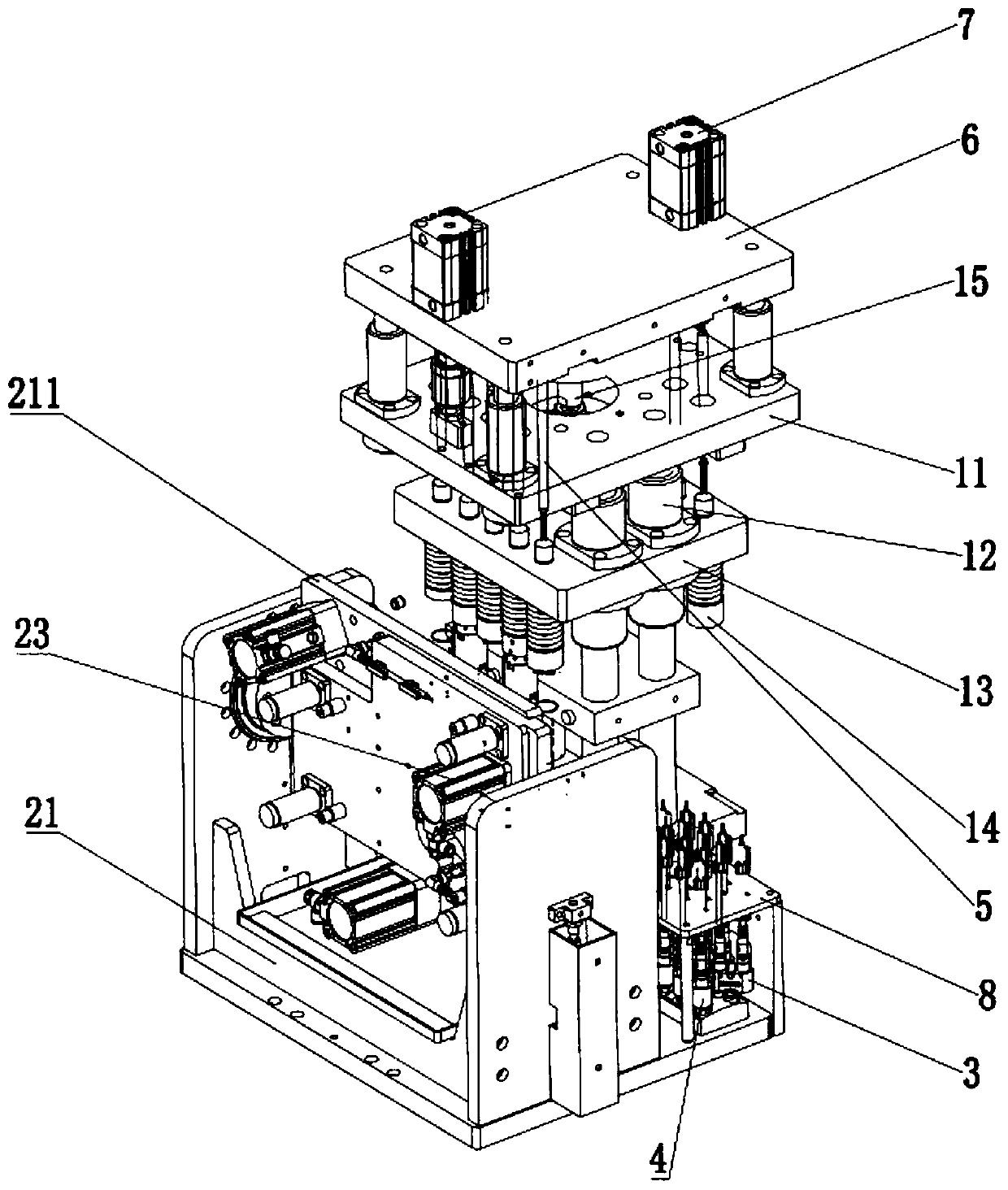

Press-fitting device and press-fitting method for multi-O-ring part

PendingCN110640437ASolve seal failurePress-fit structure is simpleMetal working apparatusPhysicsAutonomation

The invention provides a press-fitting device and a press-fitting method for a multi-O-ring part, and relates to the technical field of industrial automatic assembly. The press-fitting device comprises a press-in mechanism, and comprises a rack, a guide assembly arranged below the rack, a movable plate installed at the bottom of the guide assembly, a plurality of pressing heads installed on the movable plate, a press-fitting air cylinder installed on the rack, a self-centering connecting piece connected with the press-fitting air cylinder and the movable plate correspondingly, and a clamping mechanism arranged below the side of the press-in mechanism; and the clamping mechanism comprises a bottom frame provided with a positioning tooling plate, a positioning clamping device and a clampingair cylinder which are installed on the positioning tooling plate, a hinge connecting head connected with the clamping air cylinder and the positioning clamping device correspondingly, a first adjusting assembly connected with the press-fitting air cylinder, a second adjusting assembly connected with the clamping air cylinder, a displacement sensor arranged on the rack in a penetrating mode, and acontroller connected with the first adjusting assembly, the second adjusting assembly and the displacement sensor. The problem that the O-shaped ring is prone to breakage in the assembling process and cause sealing failure is solved.

Owner:SAIC MAGNETI MARELLI POWERTRAIN

Magnetofluid sealing device

ActiveCN113803470ASolve seal failureSolve the problem of air leakageEngine sealsClassical mechanicsStructural engineering

The invention discloses a magnetofluid sealing device. The magnetofluid sealing device comprises a corrugated pipe, a fixing piece, magnetofluid and a sealing piece. The fixing piece is connected with the corrugated pipe; the magnetofluid is arranged on the outer side wall of the corrugated pipe; and the sealing piece is connected with the fixing piece and sleeved with the corrugated pipe and the magnetofluid. According to the magnetofluid sealing device, the magnetofluid is arranged on the outer side wall of the corrugated pipe and redistributed in the radial movement process of the sealing piece, it is guaranteed that the magnetofluid is evenly distributed on the outer wall of the corrugated pipe, and the problem of air leakage caused by gaps generated when blades are welded to the corrugated pipe can be solved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Magnetic coupling type dry gas sealing structure

The invention discloses a magnetic coupling type dry gas sealing structure, which comprises a shell, a rotor, a moving ring assembly capable of rotating along with the rotor and a pushing static assembly matched with the moving ring assembly; the moving ring assembly comprises a moving ring, and the pushing static assembly comprises a static ring seat and a static ring located in the static ring seat; a plurality of first permanent magnets which are mutually repellent in magnetism are arranged between the outer diameter of the static ring and the inner diameter of the static ring seat, and a plurality of second permanent magnets which are mutually repellent in magnetism are arranged between one end, far away from the direction of the moving ring, of the static ring in the axial direction and the static ring seat; and the first permanent magnets are used for applying inward thrust to the static ring in the radial direction, and the second permanent magnets are used for applying inward thrust to the static ring in the axial direction. The magnetic coupling type dry gas sealing structure provided by the invention is used for solving the problems that in the prior art, a sealing interface of a large-shaft-diameter dry gas sealing device is collided and abraded under the three-high working conditions of high pressure, high temperature and high speed, sealing fails and the like, the dry gas sealing device can be suitable for the field of large-shaft-diameter machines, and the sealing reliability is improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

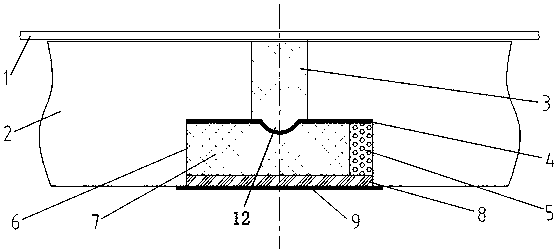

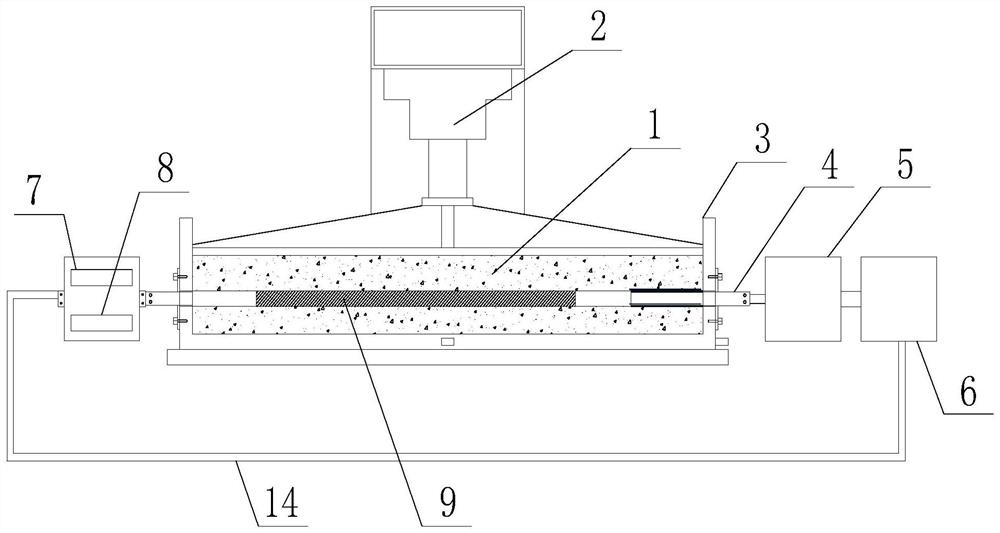

A similar simulation method and device for coal seam water injection sealing hole test

ActiveCN110646584BSolve the technical problems of sealing holesEase of workFuel testingThermodynamicsBriquette

The invention relates to a similar simulation method and device for a coal seam water injection sealing hole test, which belongs to the technical field of coal seam water injection. The similar simulation method for the coal seam water injection sealing hole test includes the following steps: S1 Determine the experimental parameters: build a water injection sealing hole force model, and obtain Simulate the similarity ratio; determine the experimental parameters and coal sample size specifications according to the on-site coal seam thickness and the parameters that affect the similarity ratio; S2 make small coal samples and large coal samples; S3 conduct similar sealing tests to obtain the actual water injection pressure ; S4 According to the simulated similarity ratio and the actual water injection pressure, invert the actual sealing pressure bearing capacity on site. The present invention inverts the actual sealing pressure bearing capacity on site through similar hole sealing experiments, and solves the problem that the sealing cannot be accurately corrected according to the on-site water injection pressure.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Integrated seal structure for high-temperature wear environment

PendingCN109578592ASimple structureHigh molding efficiency at one timeEngine sealsFillet weldWear resistant

The invention relates to an integrated seal structure for the high-temperature wear environment. The integrated seal structure for the high-temperature wear environment is characterized by comprisingan outer seal, an inner seal, a left support and a right support, wherein the left support and the right support are arranged oppositely; the outer seal is fixed onto the left support; the inner sealis fixed onto the right support; the outer seal is an integrated 'J'-shaped plate; the outer seal and the inner seal form a labyrinth seal; a surfacing wear-resistant layer is arranged on the outer surface of the bending part of the outer seal; and a surfacing wear-resistant layer is arranged on the surface, opposite to the bending part, of the inner seal. According to the integrated seal structure for the high-temperature wear environment provided by the invention, a sealing effect is greatly improved; and through the integrated seal structure, the integrality during the manufacturing of a sealing strip is ensured, the wear resistance of the sealing strip is further ensured, and the problem of seal failure caused by wear of a grate cooler during the use process and edge warping and falling off of a fillet weld wear-resistant plate is solved once for all.

Owner:HUAXIN EQUIP MFG +1

Heating machine structure capable of improving sealing stability

The invention discloses a heating machine structure capable of improving the sealing stability. A material opening communicated with the inner portion of a shell is formed in the side wall of the shell. A thermal insulation sleeve is sleeved with the material opening. A through hole is formed in the thermal insulation sleeve. A sealing block is arranged on the shell and of a trapezoid body structure matched with the through hole. The side wall of the sealing block makes seamless contact with the side wall of the through hole. Locking mechanisms are arranged on the shell and symmetrically arranged on the two sides of the thermal insulation sleeve. Each locking mechanism comprises a fixed block and a locking pin, wherein the locking pin penetrates through the fixed block. An isolation block is fixed to the sealing block. Connecting plates are symmetrically arranged on the side walls of the isolation block respectively. Hinge pins are arranged on the connecting plate. One end of each hinge pin is arranged inside the isolation block after penetrating through the corresponding connecting plate. The top ends of the connecting plates cave inwards to form through grooves communicated with the symmetrical side walls of the isolation block. One end of each locking pin is arranged inside the corresponding through groove. The mechanical locking structure is adopted for the heating machine structure, and therefore fixed sealing can be kept under the condition that internal pressure changes, and sealing performance is improved.

Owner:CHENGDU QIAOFENG TECH DEV

Hydraulic car leg oil cylinder

ActiveCN107355445AExtended service lifeReduce wearVehicle fittings for liftingFluid-pressure actuatorsEngineeringPiston rod

The invention relates to a hydraulic car leg oil cylinder, and belongs to the technical field of hydraulic control systems. The problems that in the prior art, due to side force, the surface of a piston rod is mechanically damaged, and seal of a hydraulic car leg oil cylinder fails are solved. The hydraulic car leg oil cylinder comprises a piston rod, an oil cylinder arranged on the outer side of the piston rod in a sleeving manner, an inner sleeve and an outer sleeve arranged on the outer side of the inner sleeve in a sleeving manner; the oil cylinder is in sliding connection with the piston rod, the inner sleeve is in sliding connection with the outer sleeve, the oil cylinder is located in the inner sleeve, the top end of the outer sleeve is connected with the top end of the piston rod, the top end of the inner sleeve is connected with the top end of the oil cylinder, during use, the outer sleeve is fixedly connected with a car leg connecting beam, and the bottom end of the outer sleeve is in contact with the ground. The hydraulic car leg oil cylinder can be used for auxiliary supporting and leveling of a movable platform.

Owner:BEIJING MECHANICAL EQUIP INST

a solenoid valve

ActiveCN103216662BLighten the design burdenAvoid enteringSpindle sealingsOperating means/releasing devices for valvesSolenoid valveSystem pressure

The invention discloses a solenoid valve. A sealing O-shaped ring for preventing gas from upwards extending is arranged between a secondary valve rod and a guide base, so that high-pressure gas is prevented from entering an inner cavity of an electromagnet, the inner cavity of the electromagnet is prevented from being polluted by working medium, and armature blocking caused by the fact that the residual medium enters the inner cavity of the electromagnet in the working process is prevented, so that abrasion is reduced, and the service life of the product is beneficially prolonged; meanwhile, a balancing cavity and a pressure storage cavity are formed on and under the secondary valve core, so that the electromagnet design burden is reduced greater by utilizing upper-lower gas pressure balancing factors of the secondary valve, and therefore, the weight of the product is lowered, the structure is more compact and the functions are more complete. Besides, the solenoid valve can be used for solving the problem that the sealing is invalid as the sealing force of the secondary valve is increased during a system pressure increasing process and the sealing surface of the secondary valve is damaged, and therefore, the structure of the solenoid valve can be used for prolonging the service life of the product and improving the reliability of the product.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

a tee

ActiveCN105735941BSolve seal failureImprove sealingFluid removalWell/borehole valve arrangementsEngineeringSelf locking

The invention discloses a ball seat, and belongs to the technical field of oilfield flooding. The ball seat comprises a tubular upper connector, an outer barrel, a core pipe, a self-locking shear pin, a clamp spring, a check ring and a lower connector, wherein the upper connector and the lower connector are both connected with the outer barrel; an inner cavity of the lower connector is provided with a first inclined surface; an inner cavity of the core pipe is provided with a second inclined surface and the core pipe is connected with the outer barrel through the self-locking shear pin; the core pipe is provided with a first clamp spring groove, and the clamp spring is arranged in the first clamp spring groove; an inner cavity of the check ring is provided with a third inclined surface and shaped like a calabash formed by overlapping two communicating cylindrical cavities with the same diameter, the width of the overlapping surface is smaller than the diameter of a thrown ball, and the diameter of the cylindrical cavities is larger than the diameter of the thrown ball; a step is arranged on the wall of an inner cavity of the outer barrel; the upper end of the check ring and the step are coplanar, and the lower end of the check ring and the upper end of the lower connector are coplanar; and a second clamp spring groove is formed in the outer barrel, the self-locking shear pin is shorn off, the core pipe moves downwards, and the clamp spring is clamped in the second clamp spring groove. By means of the ball seat, the problems that the thrown ball is difficult to throw and returns to cause sealing failure of a water injection pipe column are solved, and the effect of effectively sealing the water injection pipe column is realized.

Owner:PETROCHINA CO LTD

Anti-vibration buckle and lamp using the buckle

InactiveCN103148462BWon't looseEasy to fixLighting support devicesGas-tight/water-tight arrangementsEngineeringMechanical engineering

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com