Press-fitting device and press-fitting method for multi-O-ring part

A press-fitting device, O-ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to adopt long tapered tooling or design, unable to completely solve the damage of O-ring, and strong dependence on lubrication and other problems, to achieve the effect of reducing a lot of lubricating oil consumption, small dependence on hole wall lubrication, light and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

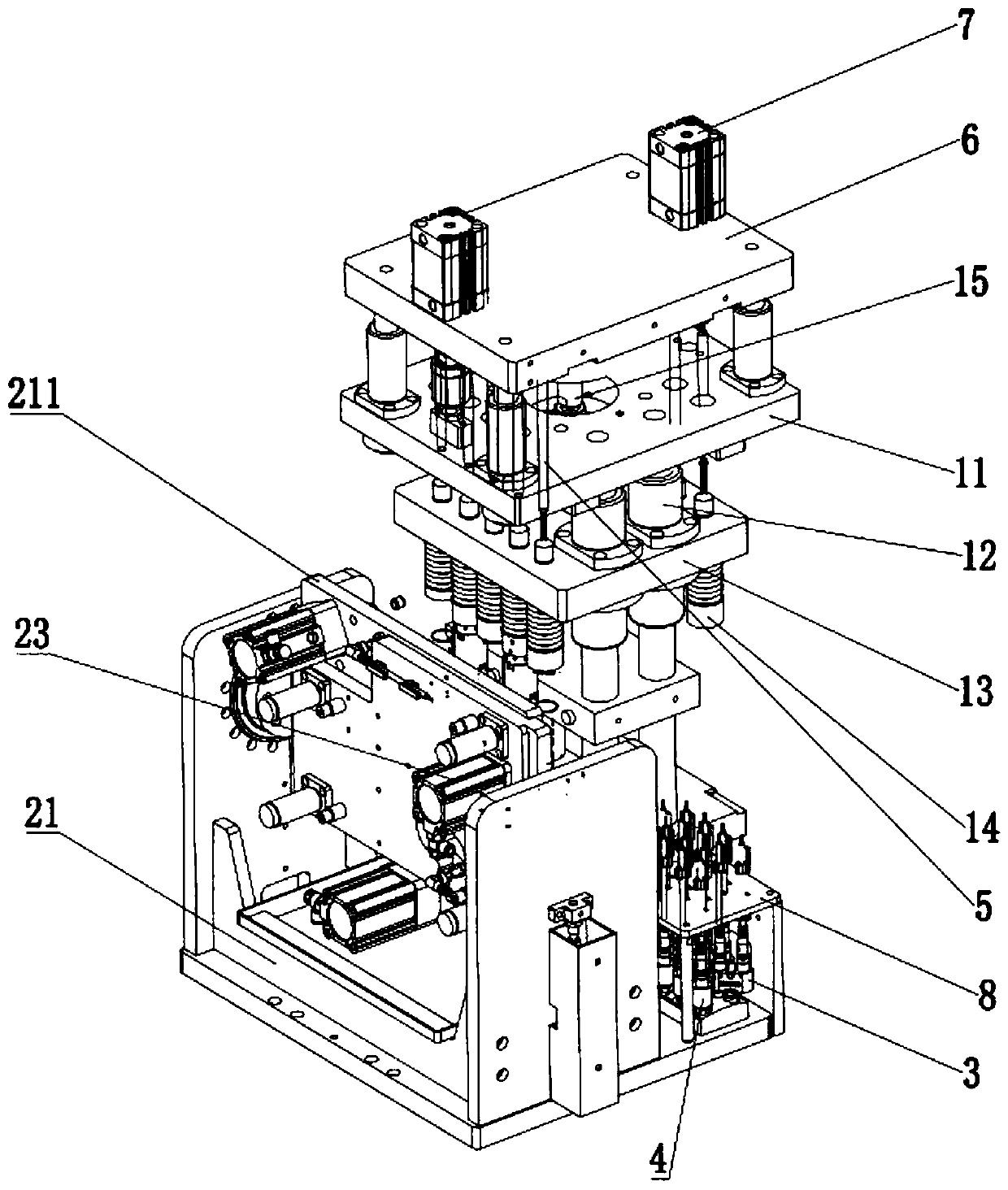

[0068] In a preferred embodiment of the present invention, based on the above-mentioned problems existing in the prior art, a press-fitting device for multiple O-ring parts is now provided, such as Figure 1 to Figure 4 shown, including:

[0069] Press-in mechanism, the press-in mechanism includes a frame 11, also includes:

[0070] The guide assembly 12 is arranged under the frame 11 and is fixedly connected with the frame 11;

[0071] The movable plate 13 is fixedly installed on the bottom of the guide assembly 12;

[0072] A plurality of indenters 14, the top of each indenter 14 is located at the side of the movable plate 13 towards the guide as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com