Water conservancy reaming system

A water conservancy and water pump technology, applied in drilling equipment and methods, construction, earth-moving drilling, etc., can solve the problems of low wear resistance of drill bits, poor sealing performance of drill pipes, inconvenient use of water supply joints, etc. Improved feed depth and smooth chip evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

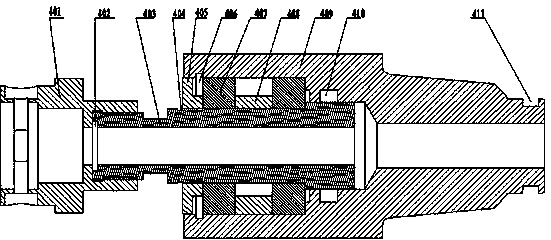

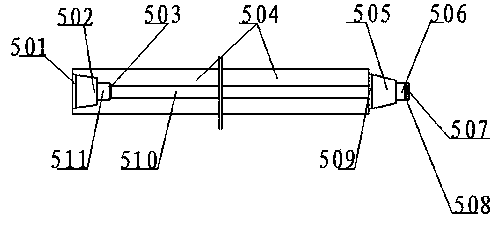

[0033] As shown in the figure, the specific implementation method is as follows:

[0034]A hydraulic hole reaming system, comprising a water source 1, a connecting pipe 2, a water pump 3, a water supply joint 4, a drill bit 6 and a drill pipe 5, the drill bit 6 and the water supply joint 4 are respectively installed at both ends of the drill pipe 5, and the water supply joint 4 is connected to the On the outlet of the water pump 3, the water inlet of the water pump is communicated with the water source through a connecting pipe. The drill bit 6 includes a drill bit upper body 609, a gauge part 608 and a drill bit crown 607. The gauge part 608 is arranged on the drill bit upper body 609, fixed The cutting teeth 605 on the scraper 601 of the gauge part 608 constitute the drill bit crown 607, and the water pump 3 provides cooling water for the drill bit 6 and flows out from the water outlet 603. The scraper 601 of the gauge part 608 is provided with three sets, and A chip removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com