Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Smooth crushing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

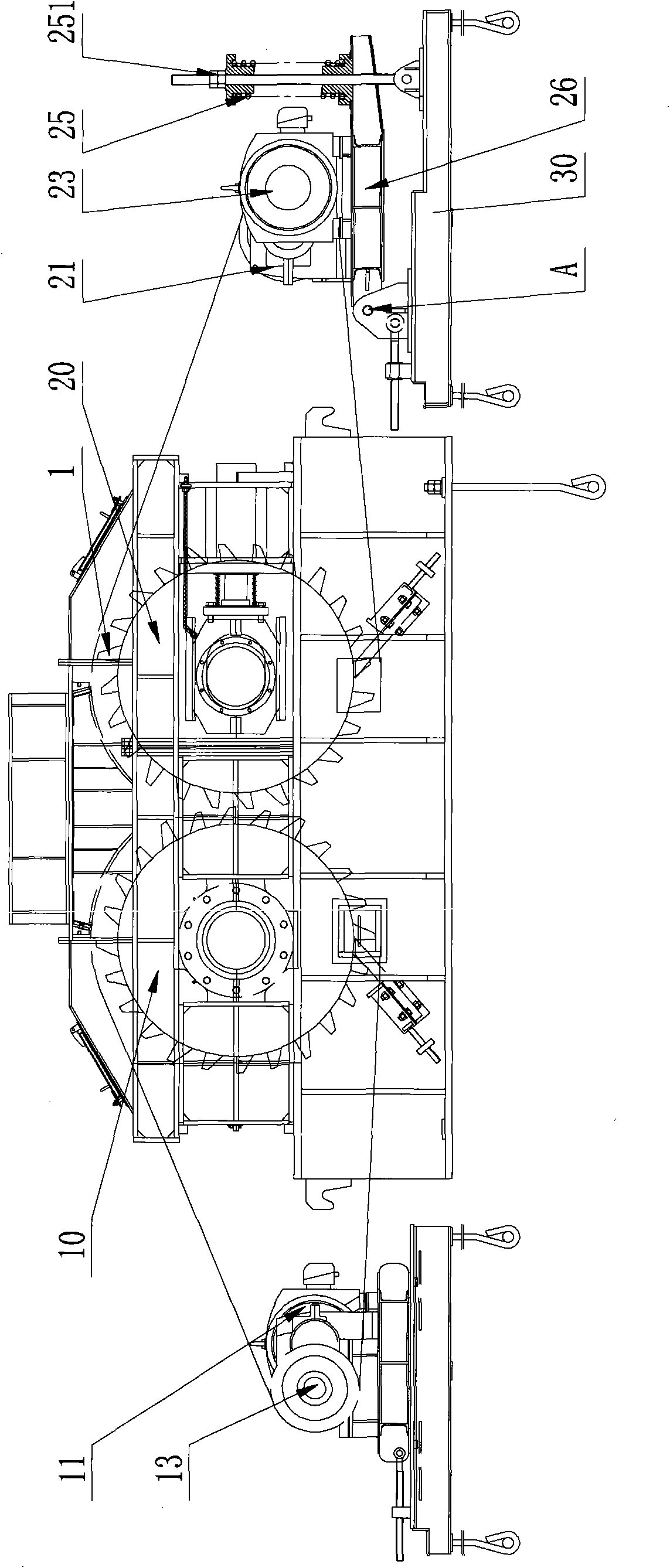

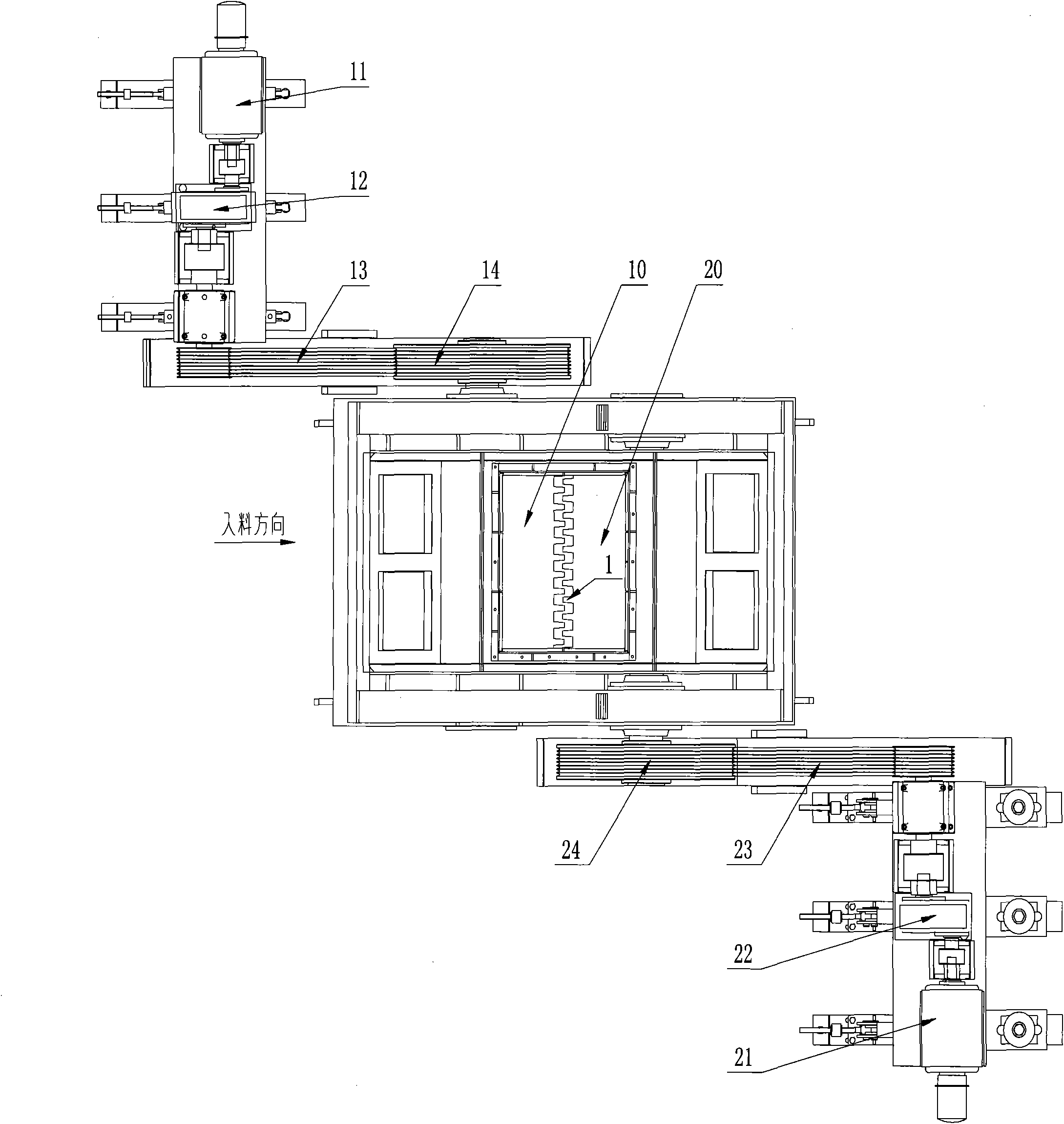

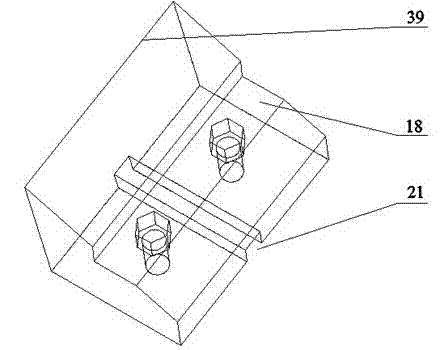

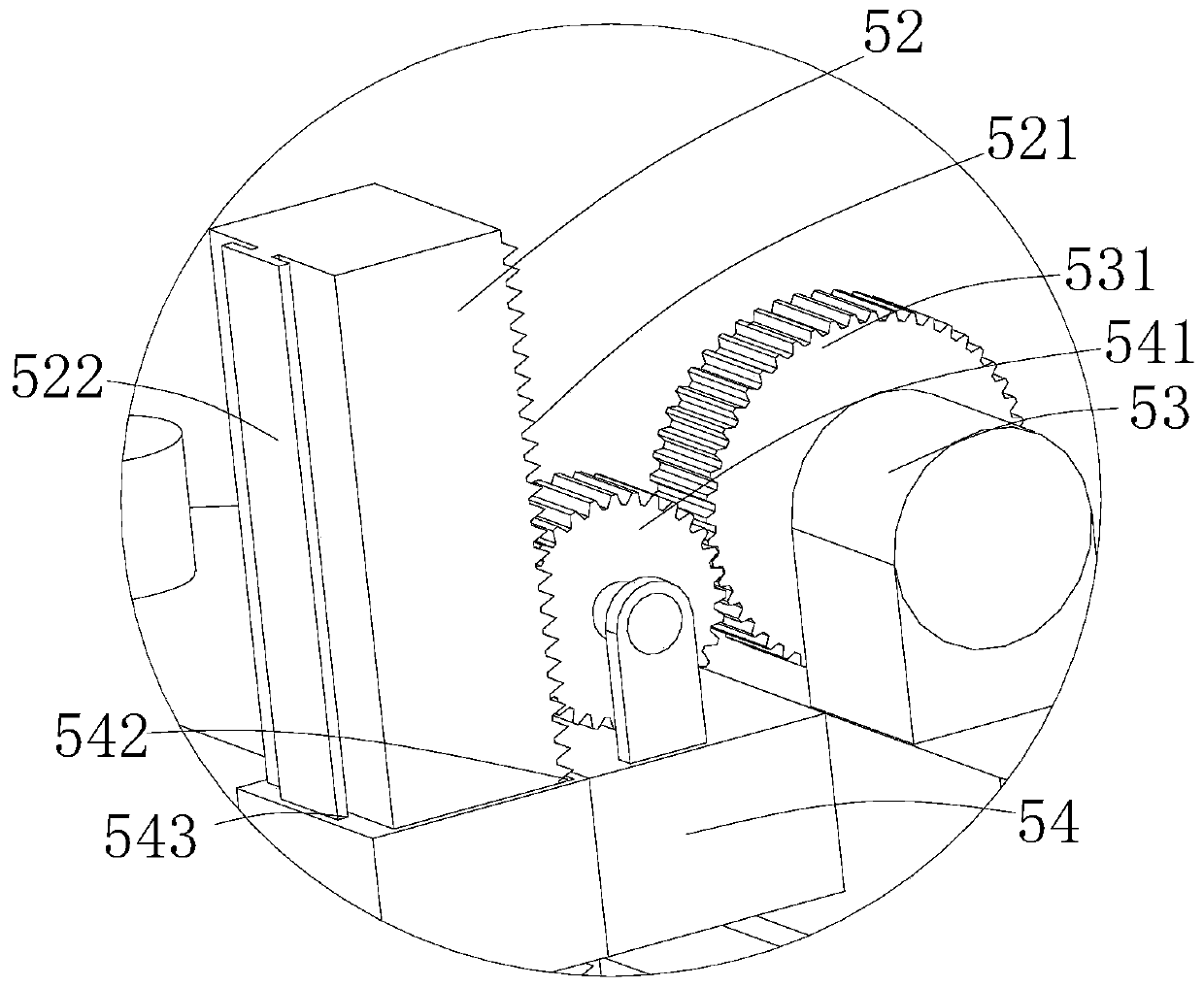

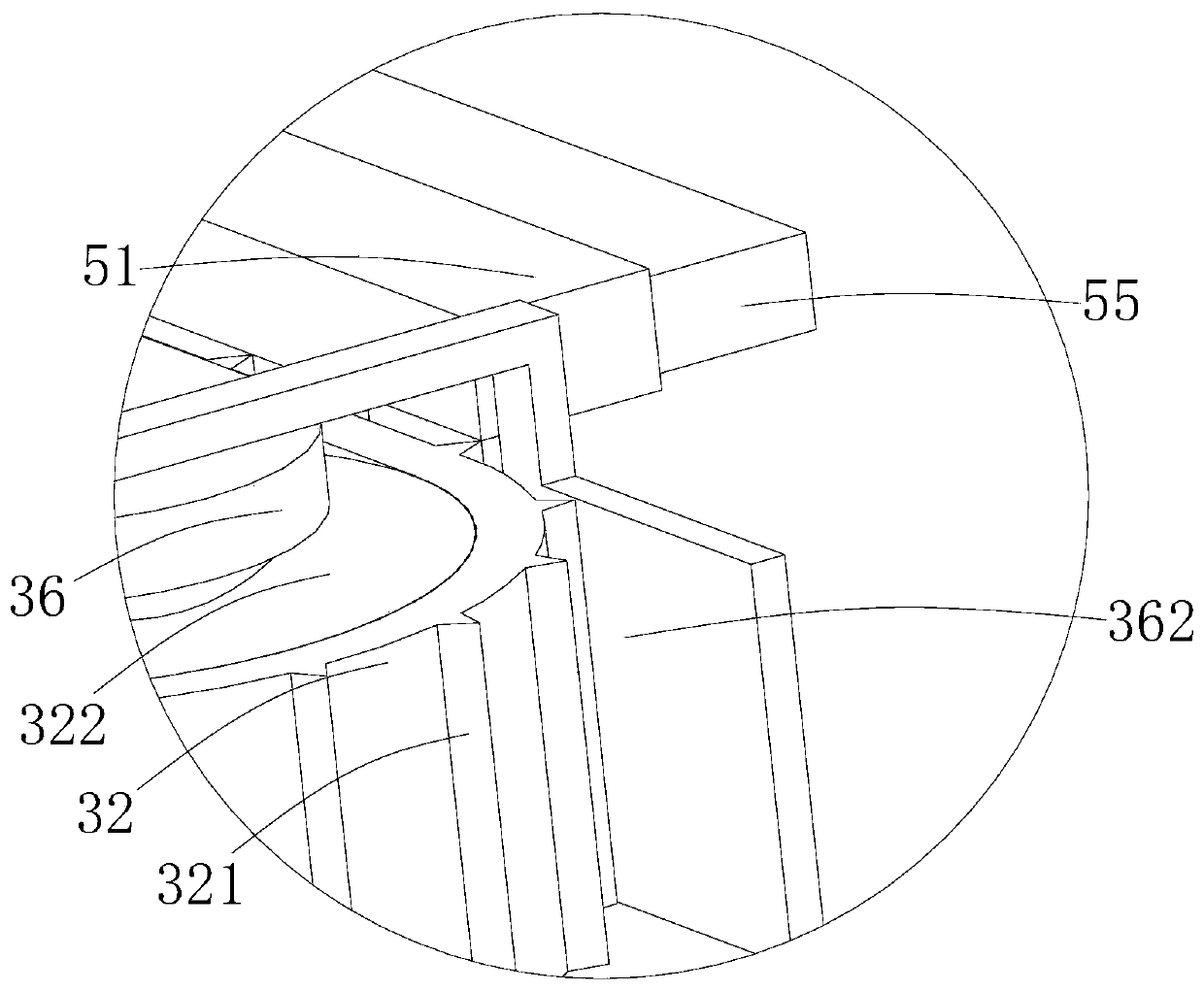

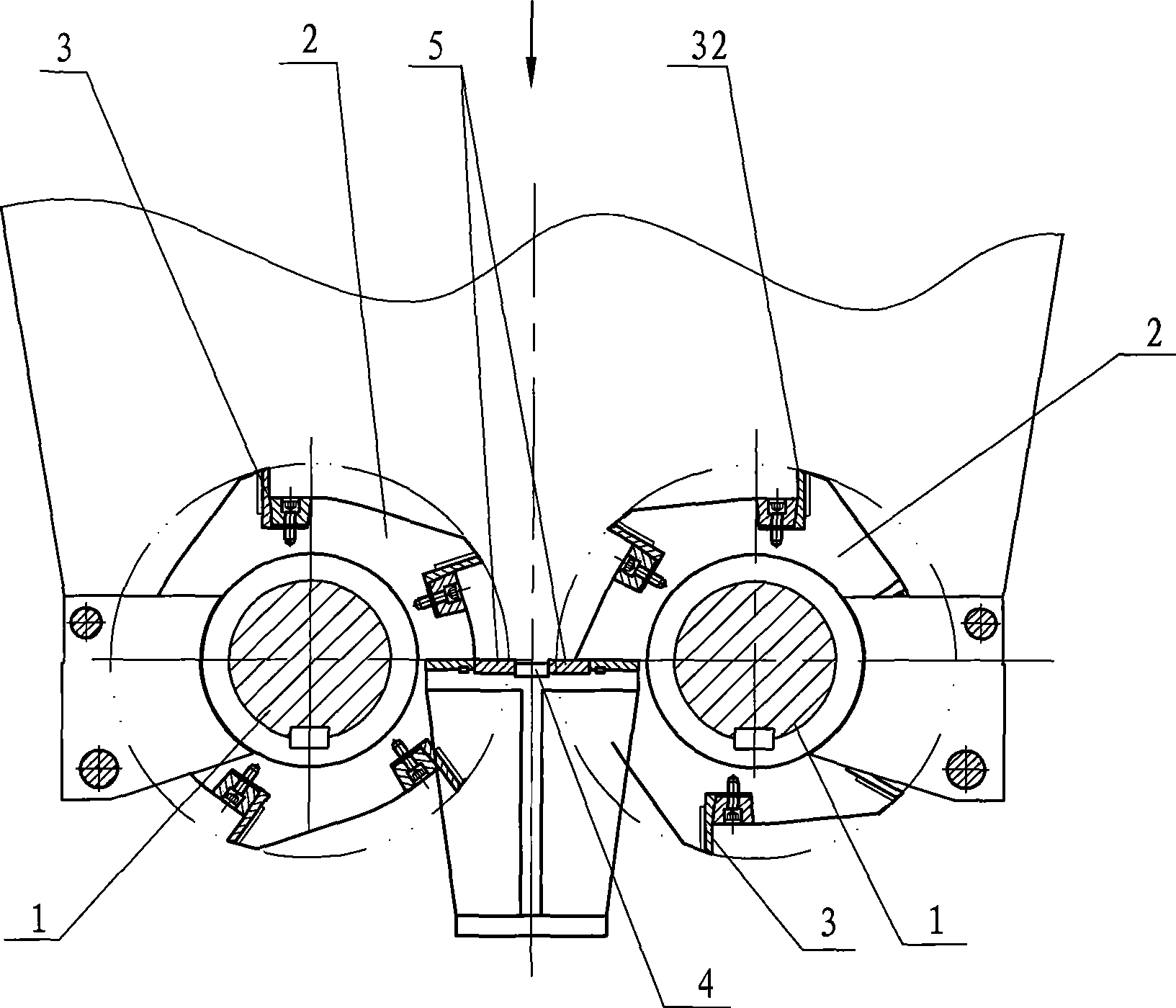

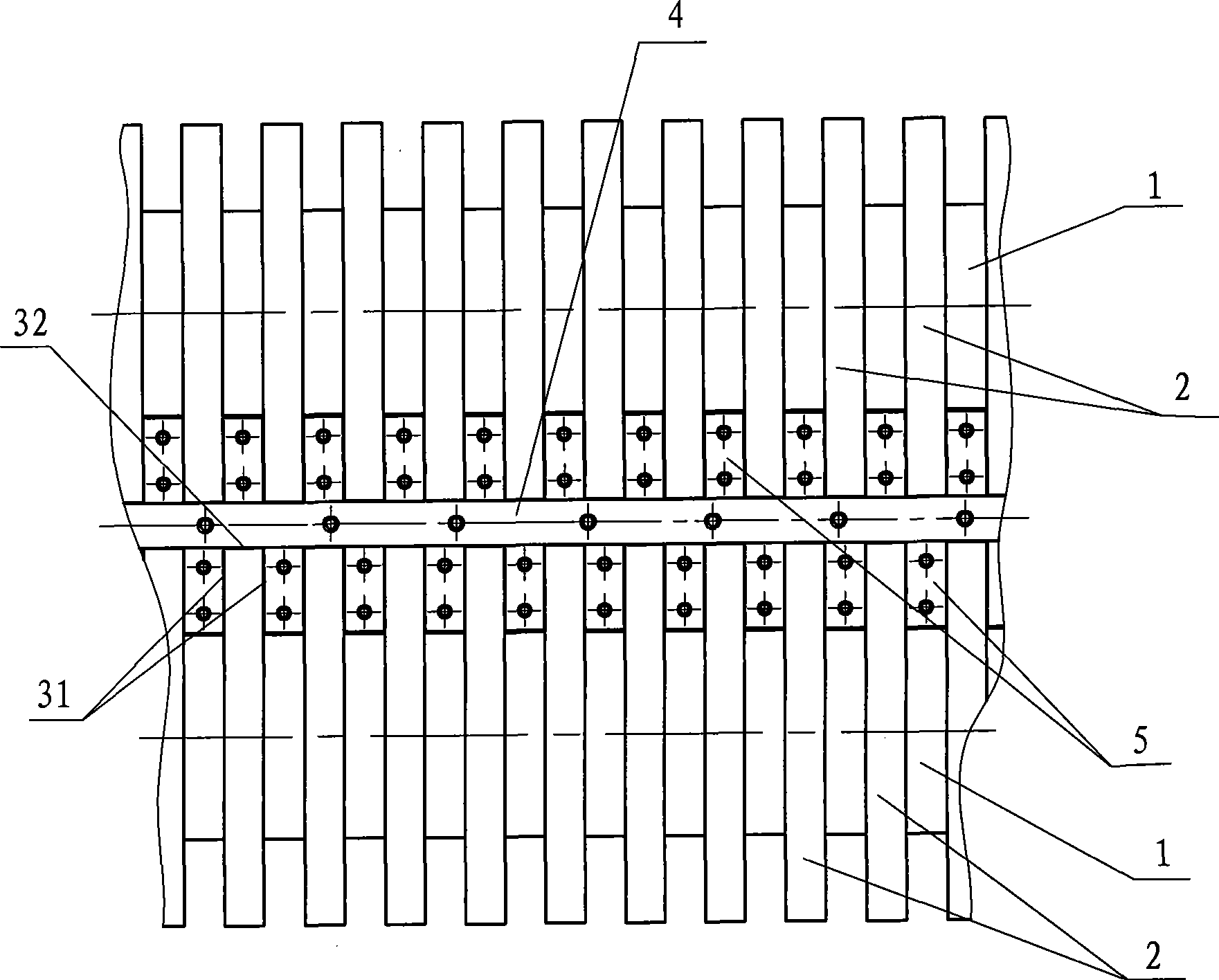

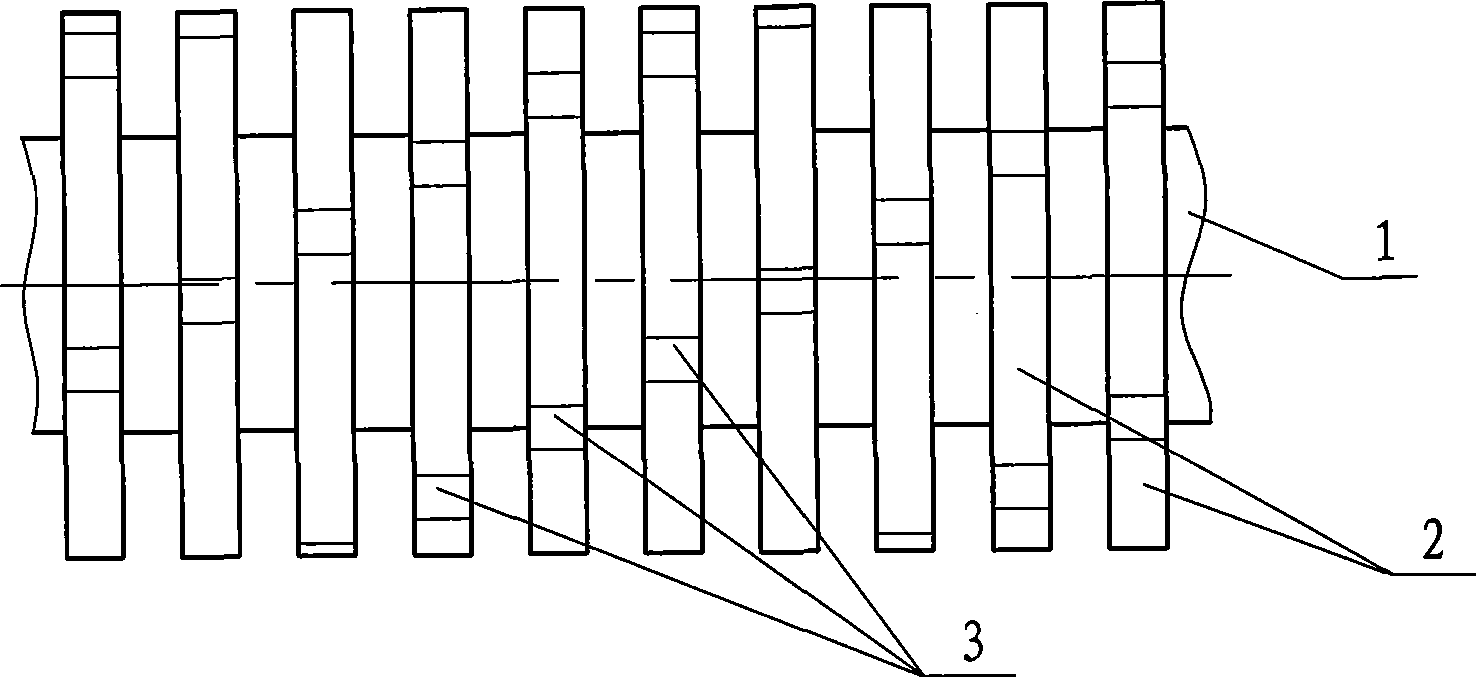

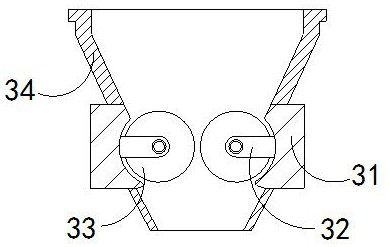

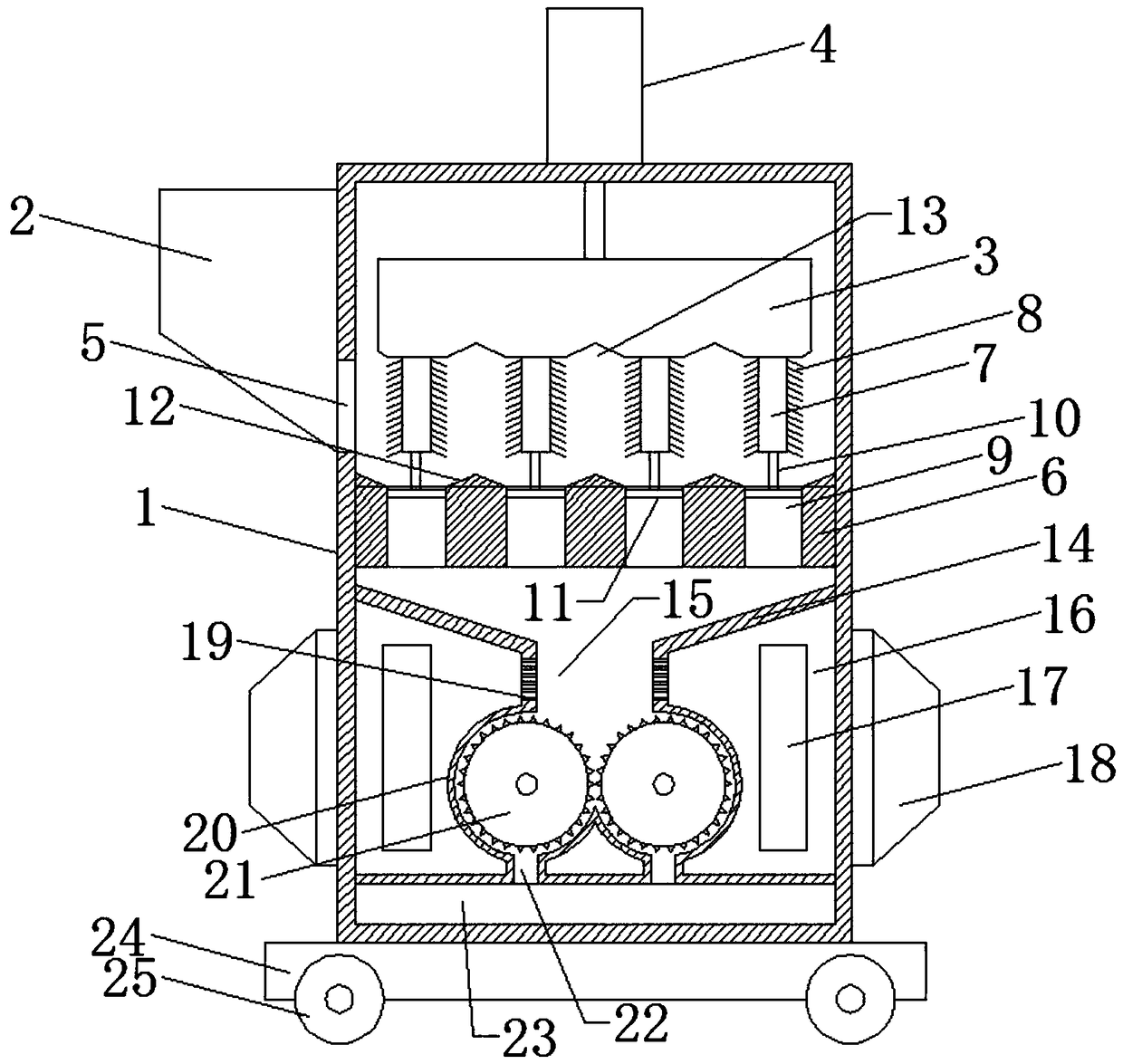

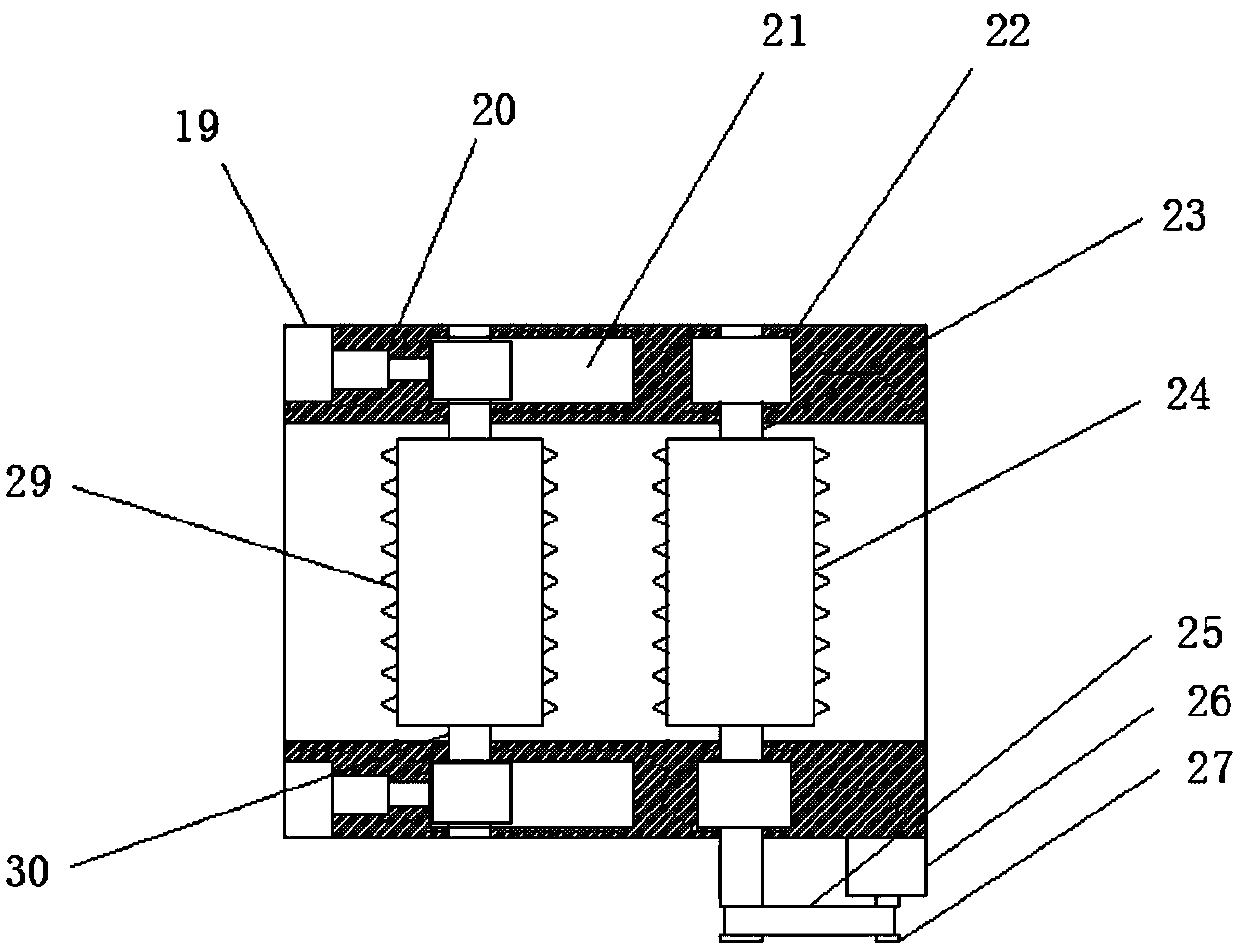

Double-geared roller clay crusher

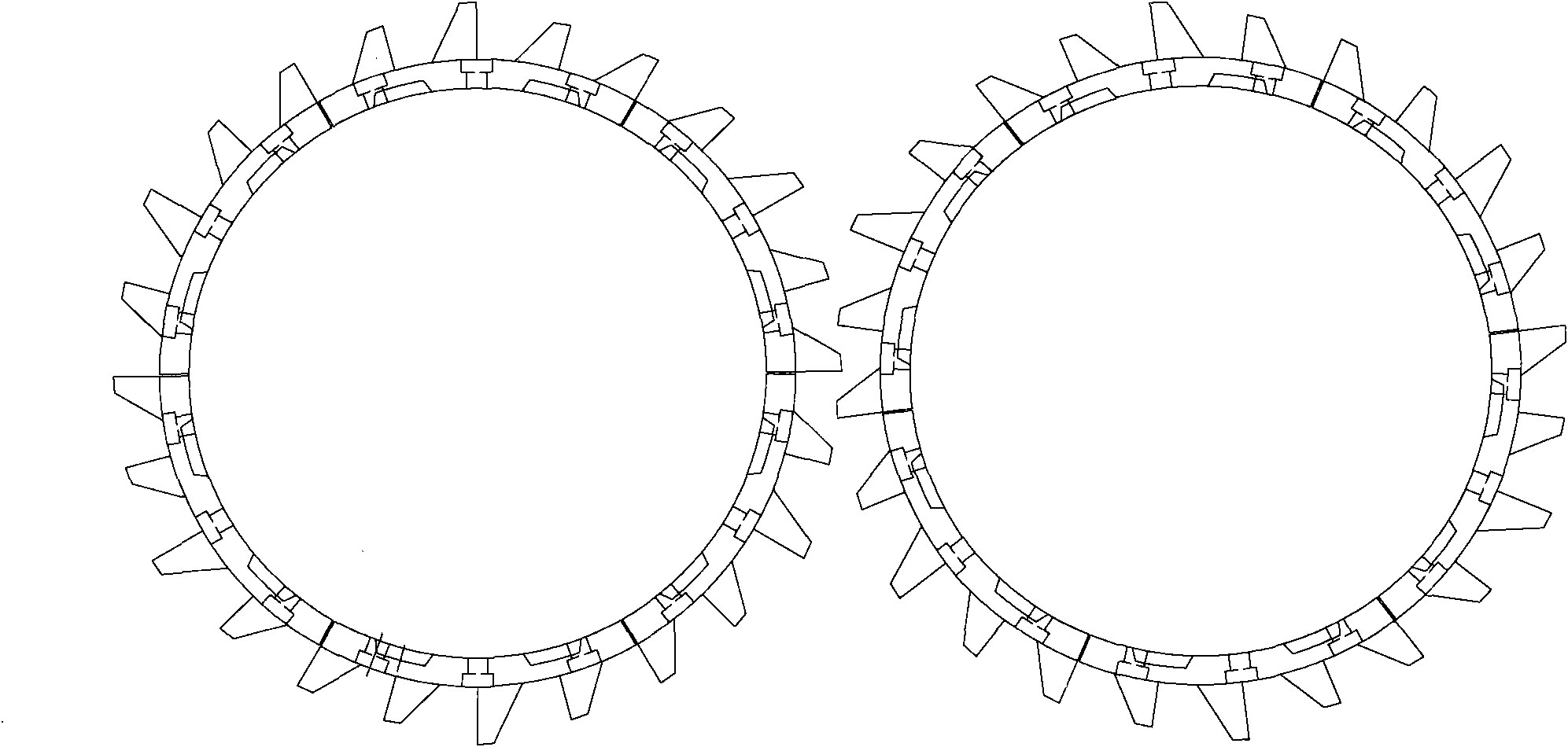

The invention discloses a double-geared roller clay crusher. The crusher comprises a fixed roller and a movable roller, wherein the fixed roller is connected with a fixed roller speed reducer through belt transmission, and the fixed roller speed reducer is driven by a fixed roller motor; the movable roller is connected with a movable roller speed reducer through belt transmission, and the movable roller speed reducer is driven by a movable roller motor; the fixed roller and the movable roller are provided with a crushing toothed plate respectively, a plurality of rows of crushing teeth are arranged on the crushing toothed plates along the axial directions of the rollers, and crushing teeth on the fixed roller and the movable roller are uniformly and circumferentially distributed along the rotary centers of the rollers; and the crushing teeth of the fixed roller and the crushing teeth of the movable roller crush materials in the axial directions of the rollers in a mode that tooth tops and tooth valleys are engaged. In the crusher, long teeth and short teeth are alternately arranged as a tooth profile of each crushing toothed plate; materials among clearances of the short teeth are removed by the long teeth; and scrapers are arranged on the bottoms of the two crushing rollers for scraping materials among the rows of crushing teeth in the axial directions of the crushing toothed plates so as to ensure smooth crushing.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

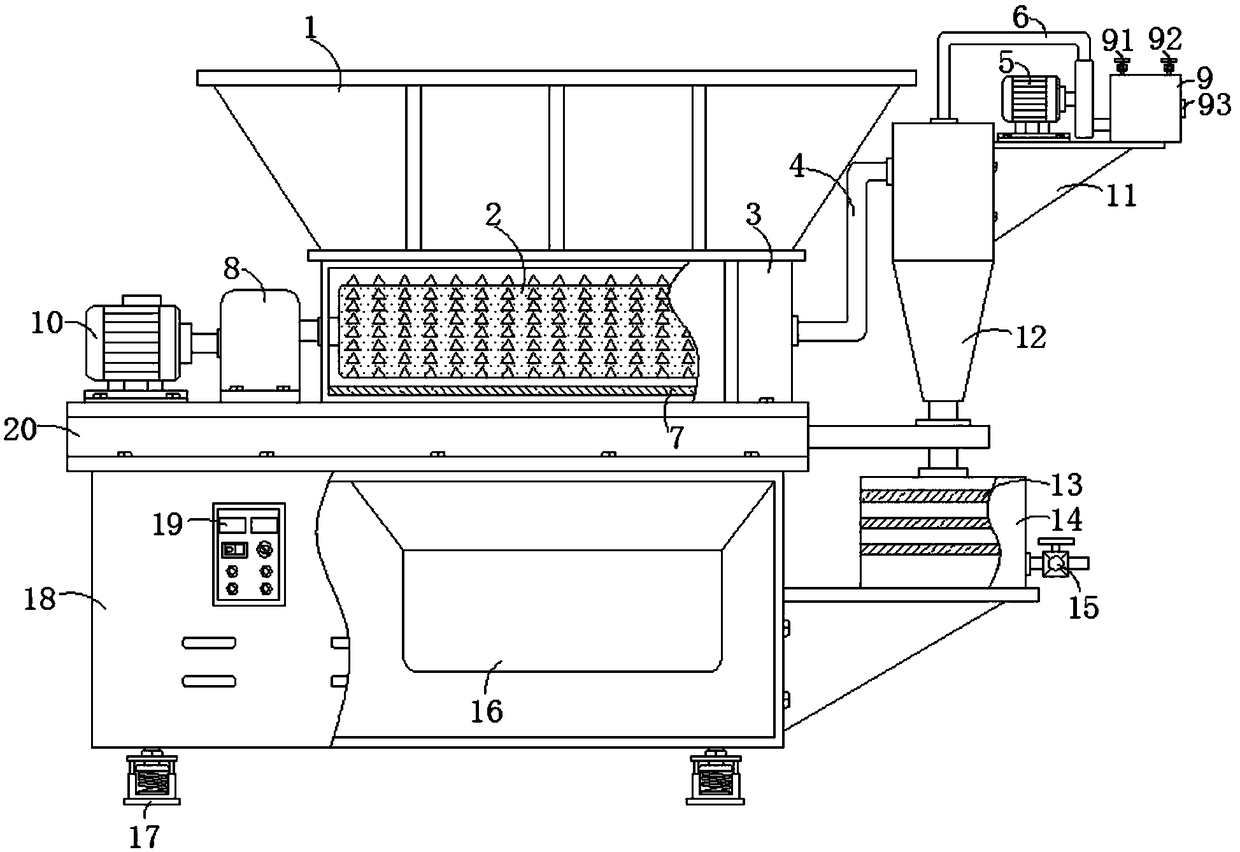

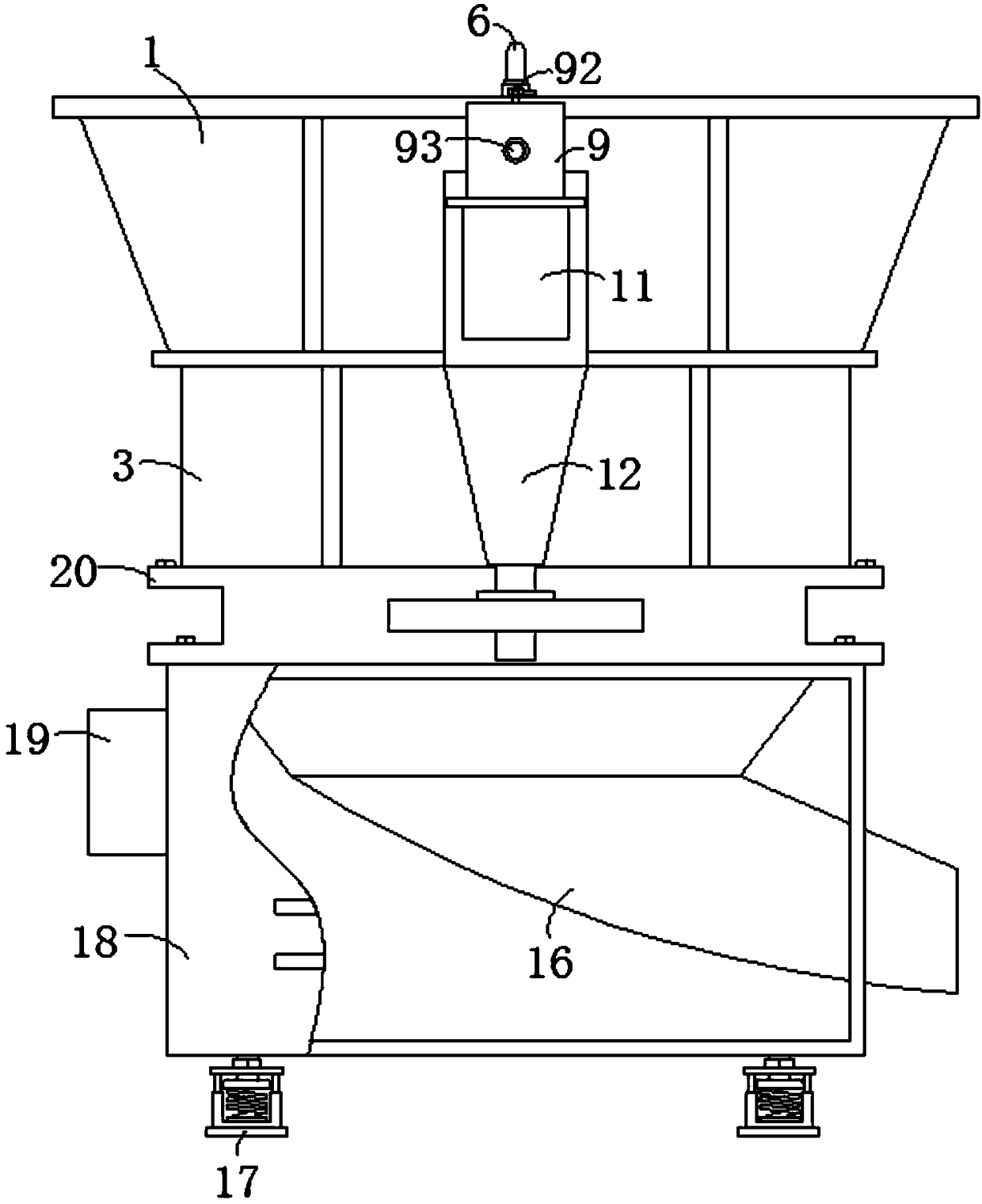

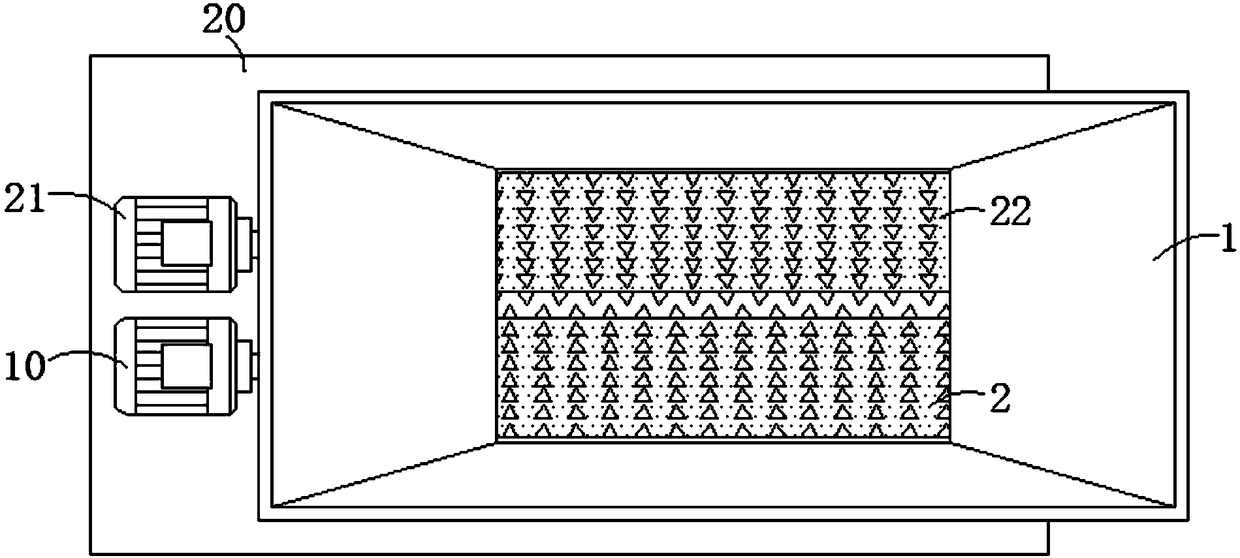

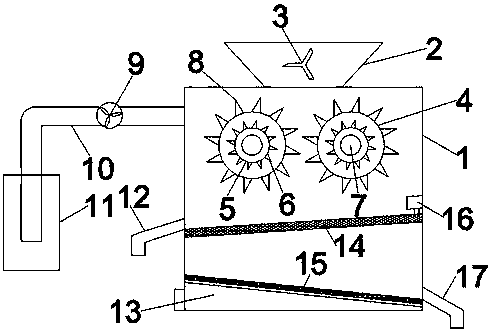

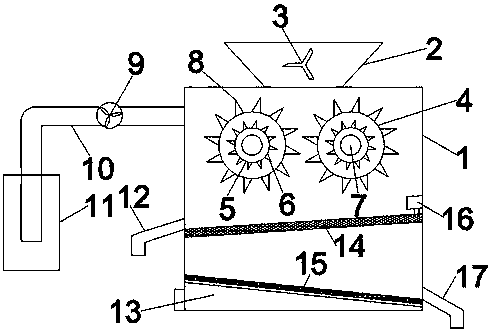

Shock-absorbing ore crushing device with screening function

The invention discloses a shock-absorbing ore crushing device with a screening function, comprising a crushing box, a plurality of crushing teeth are uniformly arranged on the inner wall of the upper part of the crushing box, a connecting frame is fixedly installed horizontally in the crushing box, and a rotating device is installed on the connecting frame. There is a first crushing roller, a waist-shaped through hole is opened on the side of the connecting frame, the limit baffle is located outside the crushing box, and a shock-absorbing spring is arranged between the limit baffle and the crushing box; The guide pulley and the horizontal baffle, the output shaft of the deceleration motor are vertically fixed with the drive shaft through the coupling; the invention has an ingenious structure and a reasonable design, and the second crushing roller can be realized under the action of the shock-absorbing spring during the rotating crushing process. The movement in the left and right direction plays the role of cushioning and shock absorption, the crushing process is more stable, and at the same time, the service life of the second crushing roller and the first crushing roller is improved. The sieve plate is driven by the wire rope and the limit spring. Screening of ore by sieve plate.

Owner:泉州森泸玩具有限公司

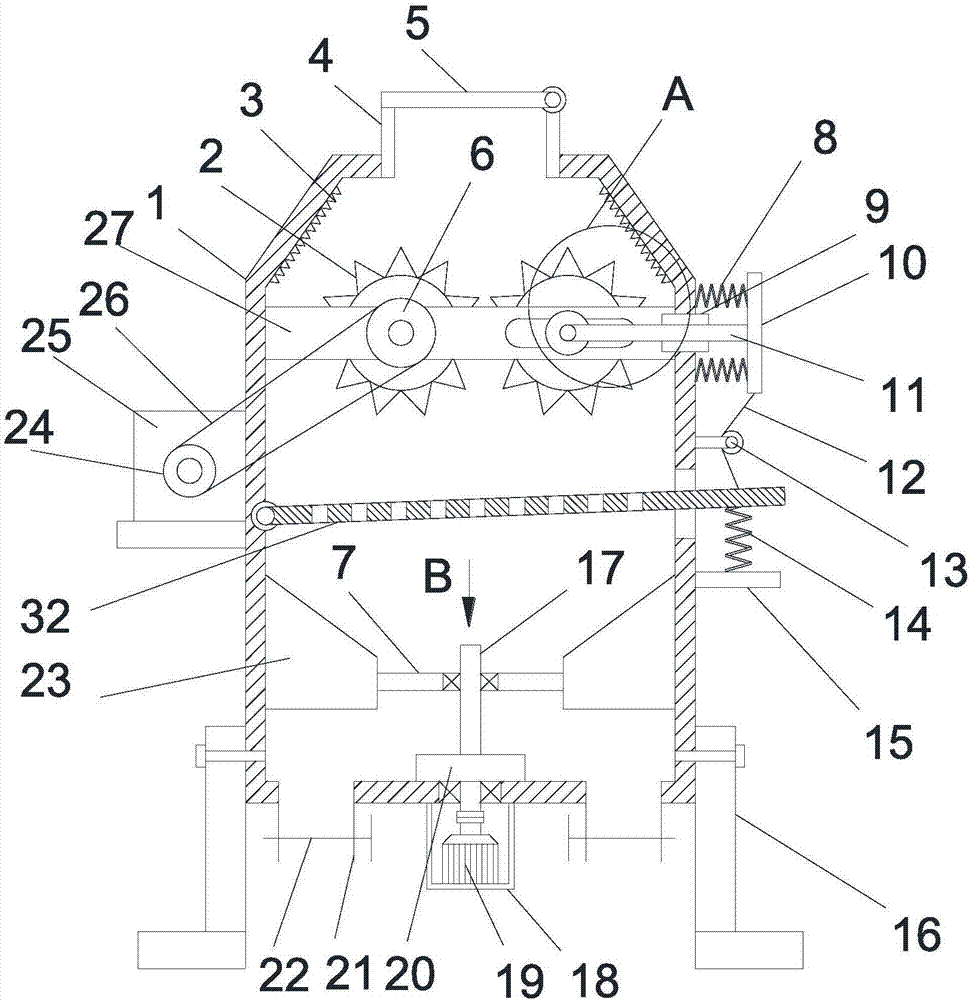

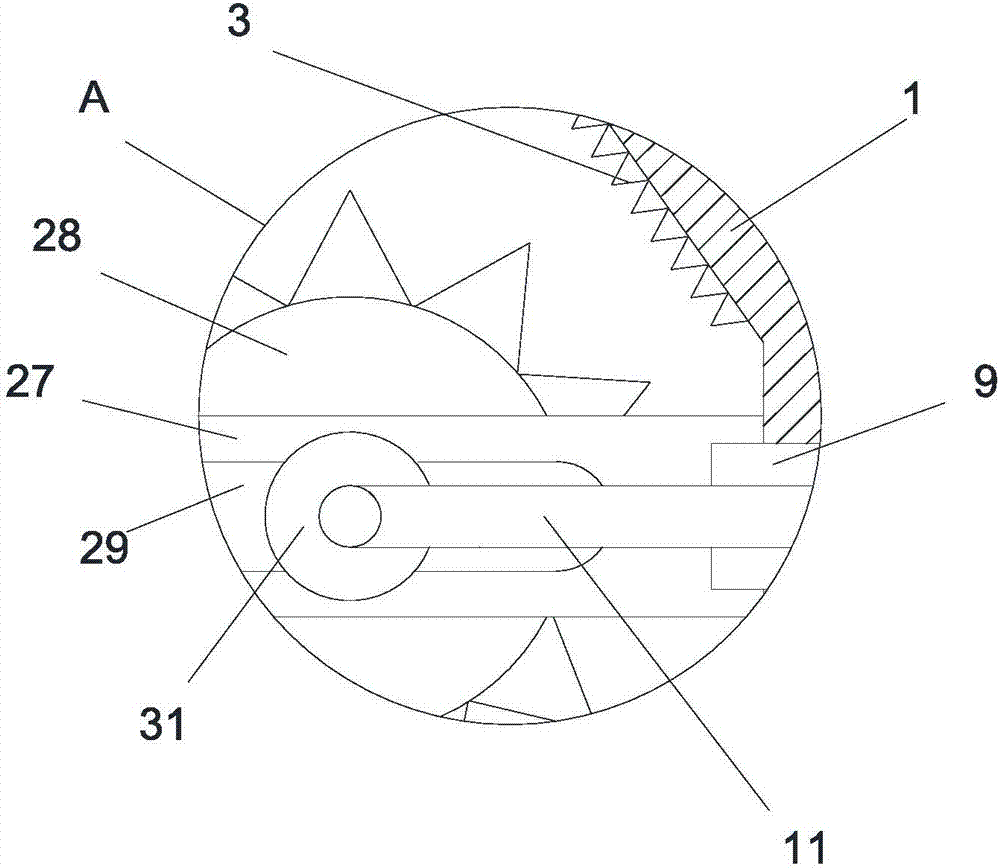

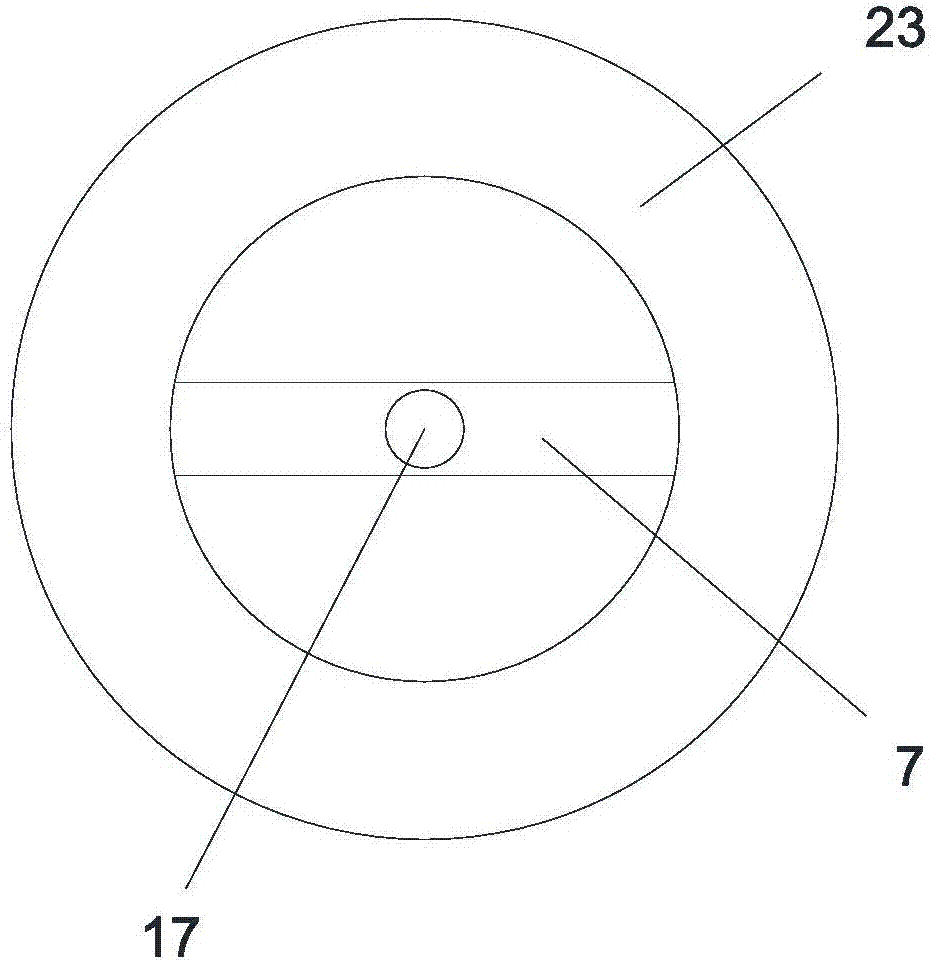

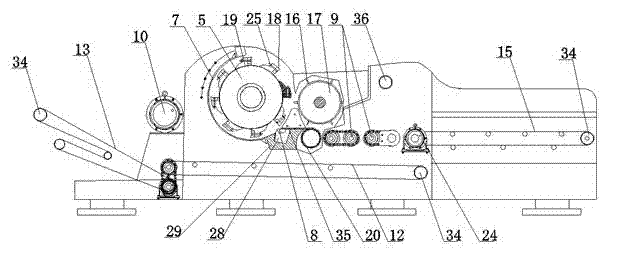

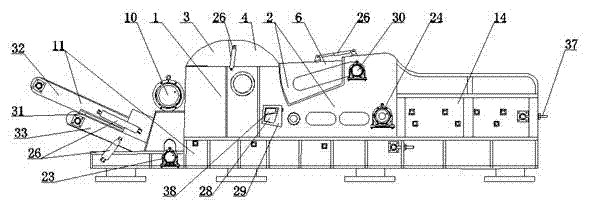

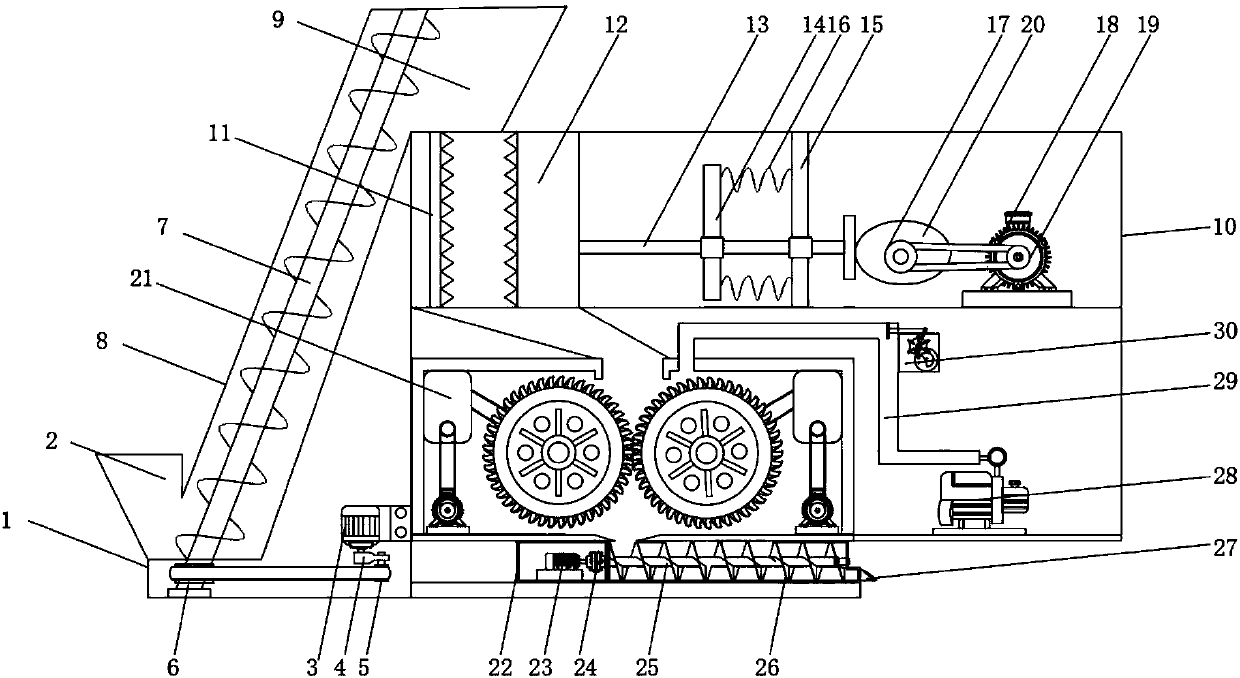

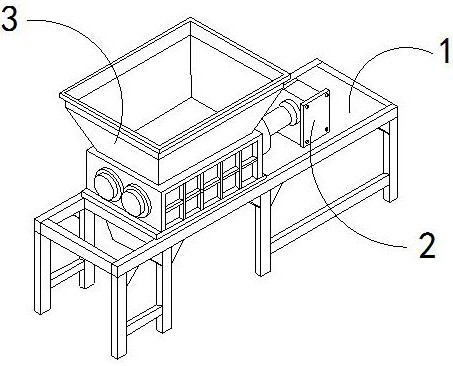

Crusher

InactiveCN102806126AHigh cutting forceSmooth crushing processGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses a crusher. The crusher comprises a charging device, a discharging device, a feeding device and a crushing device; the feeding device consists of feeding rollers and a material poking roller; the crushing device consists of a rotor, a fixed cutter and a filter screen; the circumference of the rotor is provided with fly-cutter seats; the included angles between the adjacent fly-cutter seats are equal on the circumference; fly-cutters are fastened on the fly-cutter seats through bolts; gaps are reserved between blades of the fly cutters and the fixed cutter; the fixed cuter is fastened on a fixed cutter beam by a bolt through a pressing plate; the fixed cutter beam is connected with the feeding rollers through a feeding transition plate; and the feeding rollers are parallel to each other, and the rotation directions of the feeding rollers are consistent with each other; and the material poking roller is fixed on a material fixing roller cover in which a hinge is taken as a rotation center. The crusher is high in crushing efficiency, low in energy consumption, and good in effect of crushing wood, core wood, cotton straw and other biomass, is suitable for crushing municipal solid waste and industrial refuse simultaneously and runs stably.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

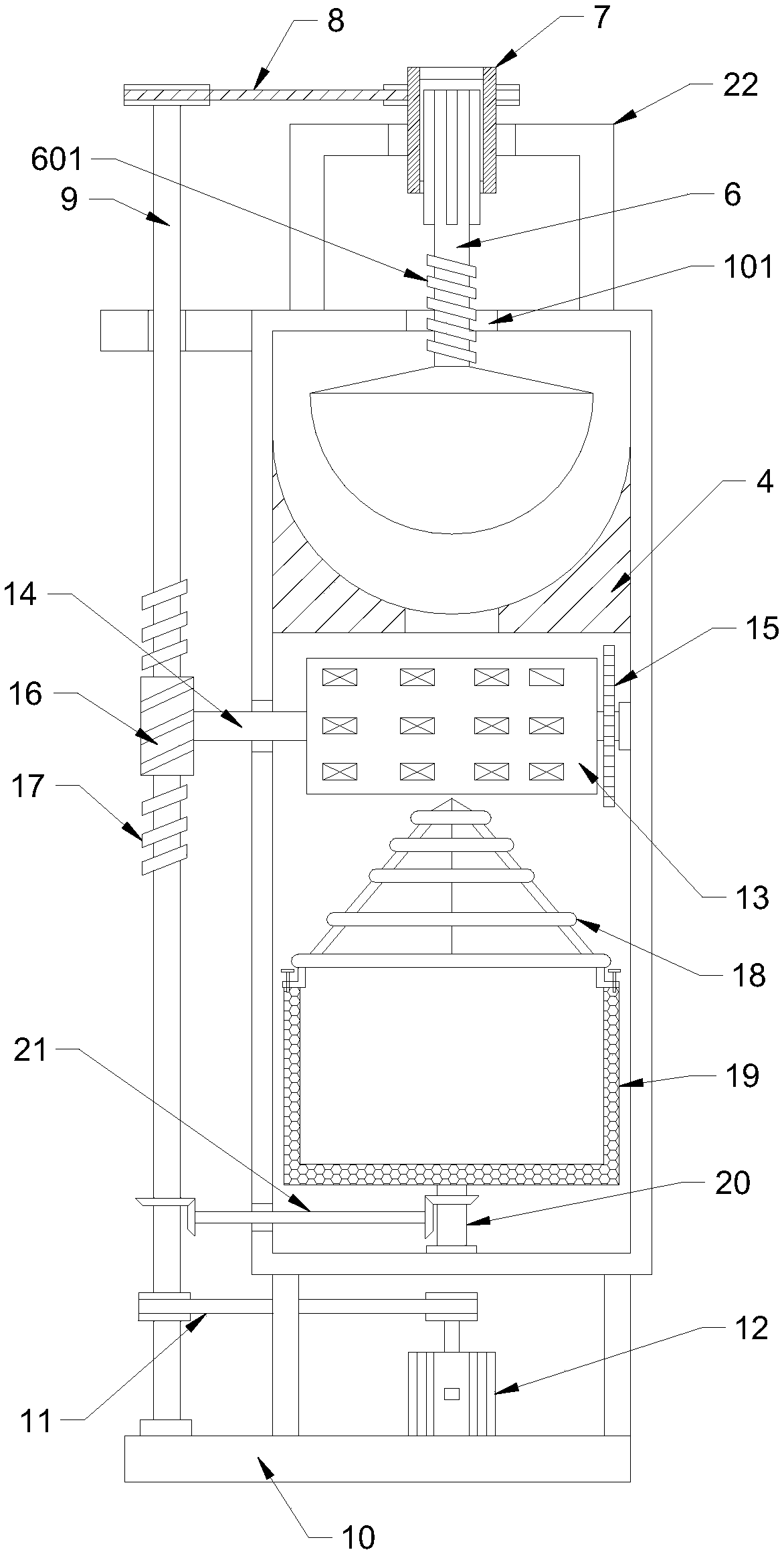

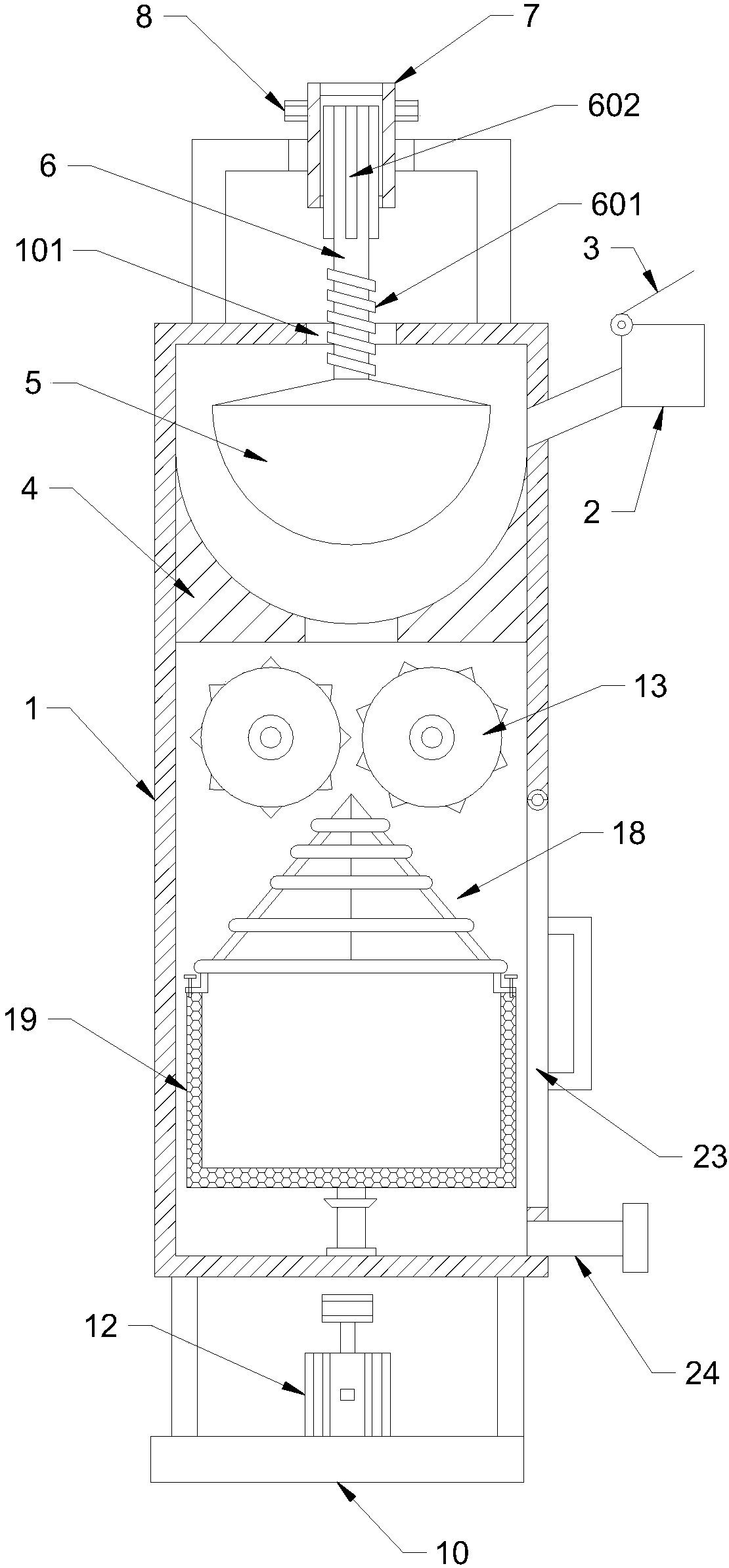

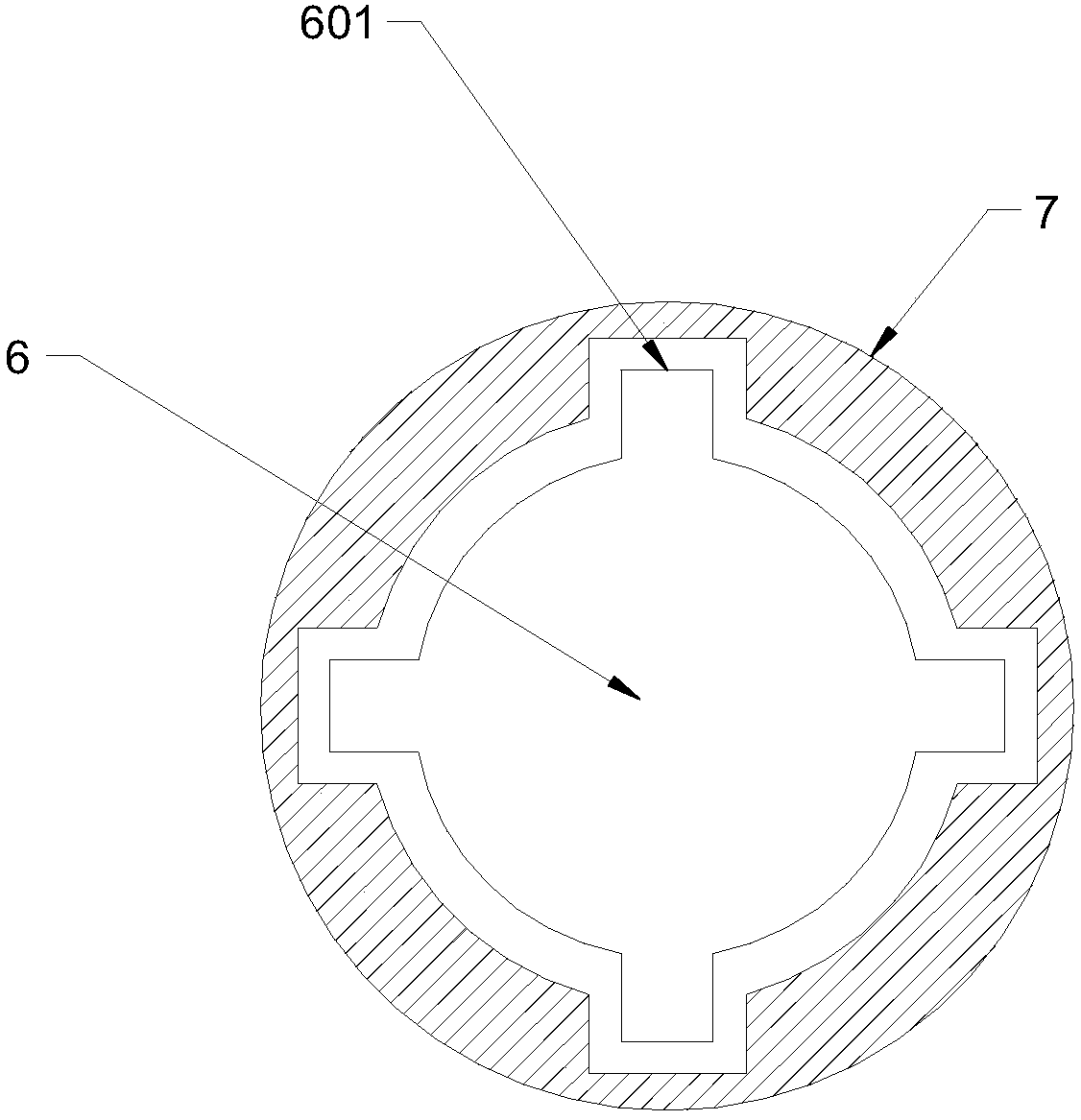

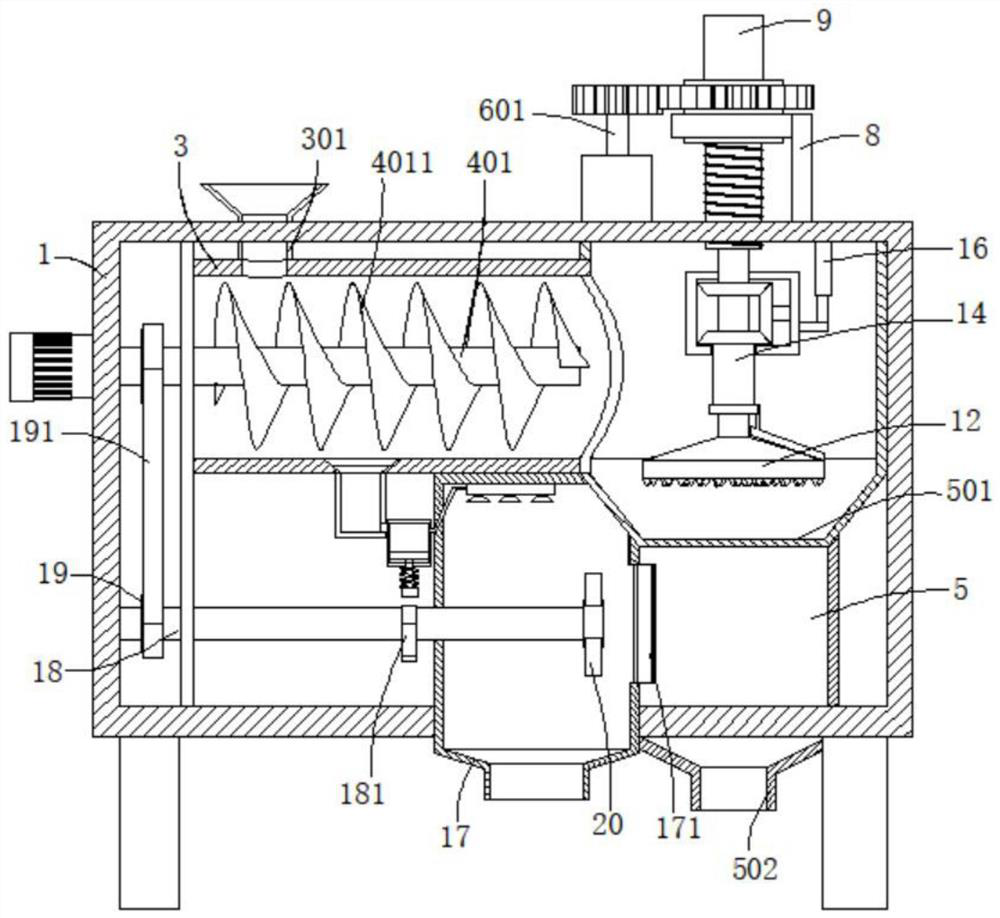

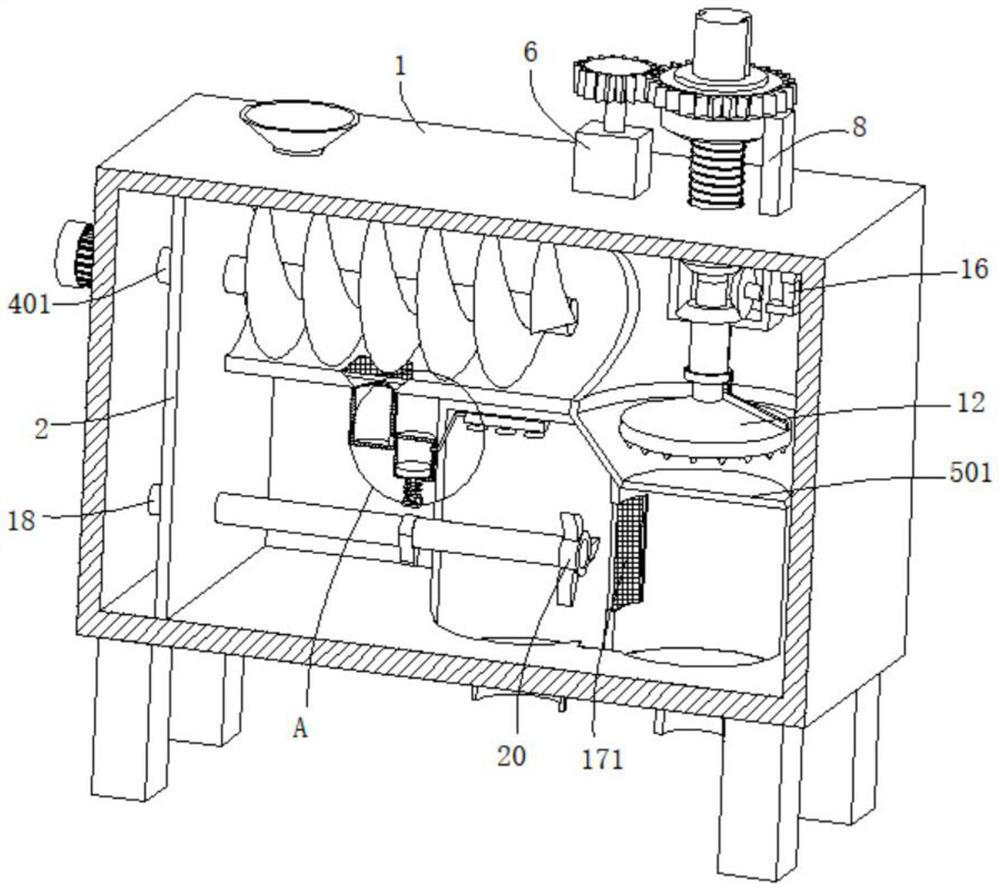

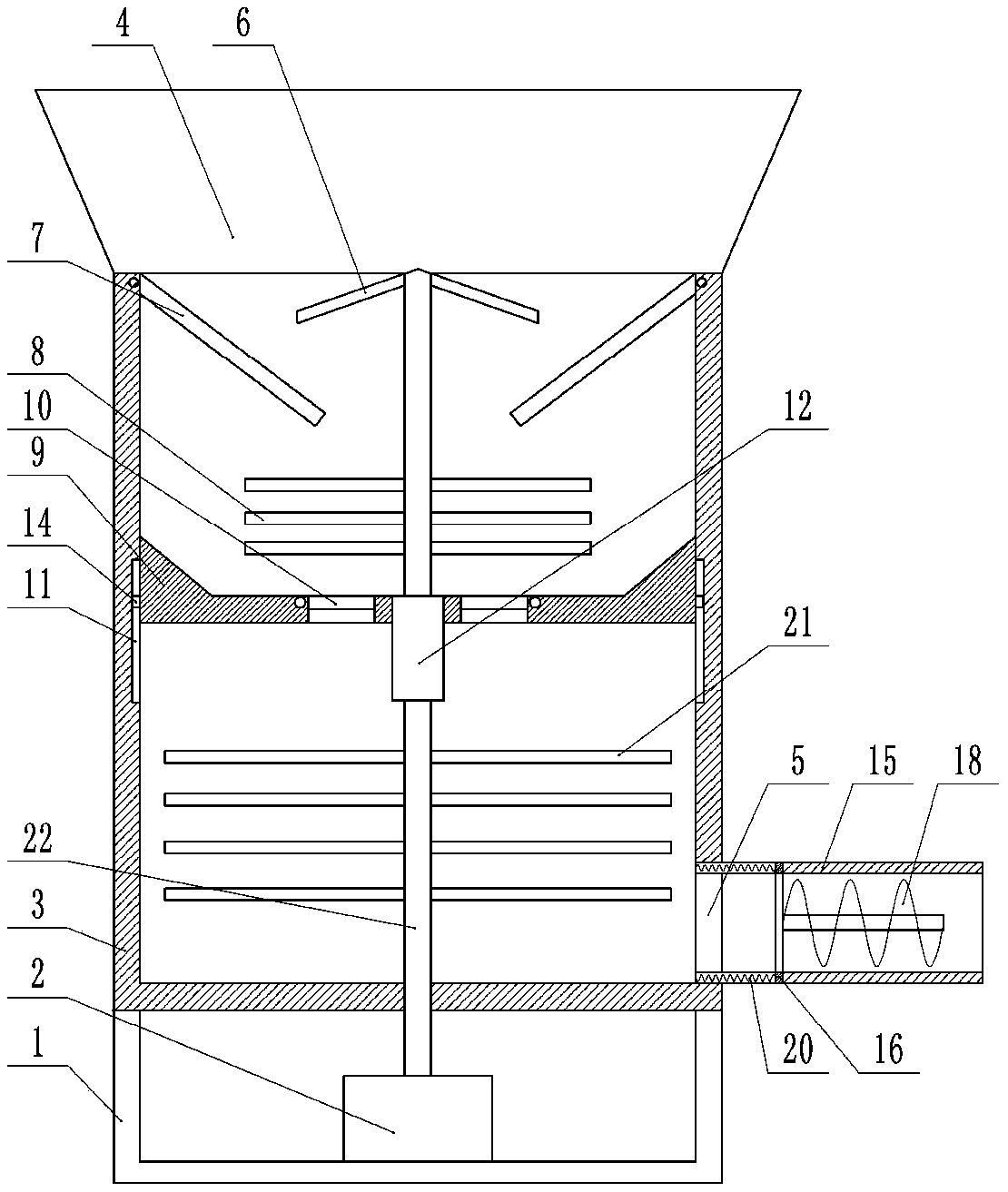

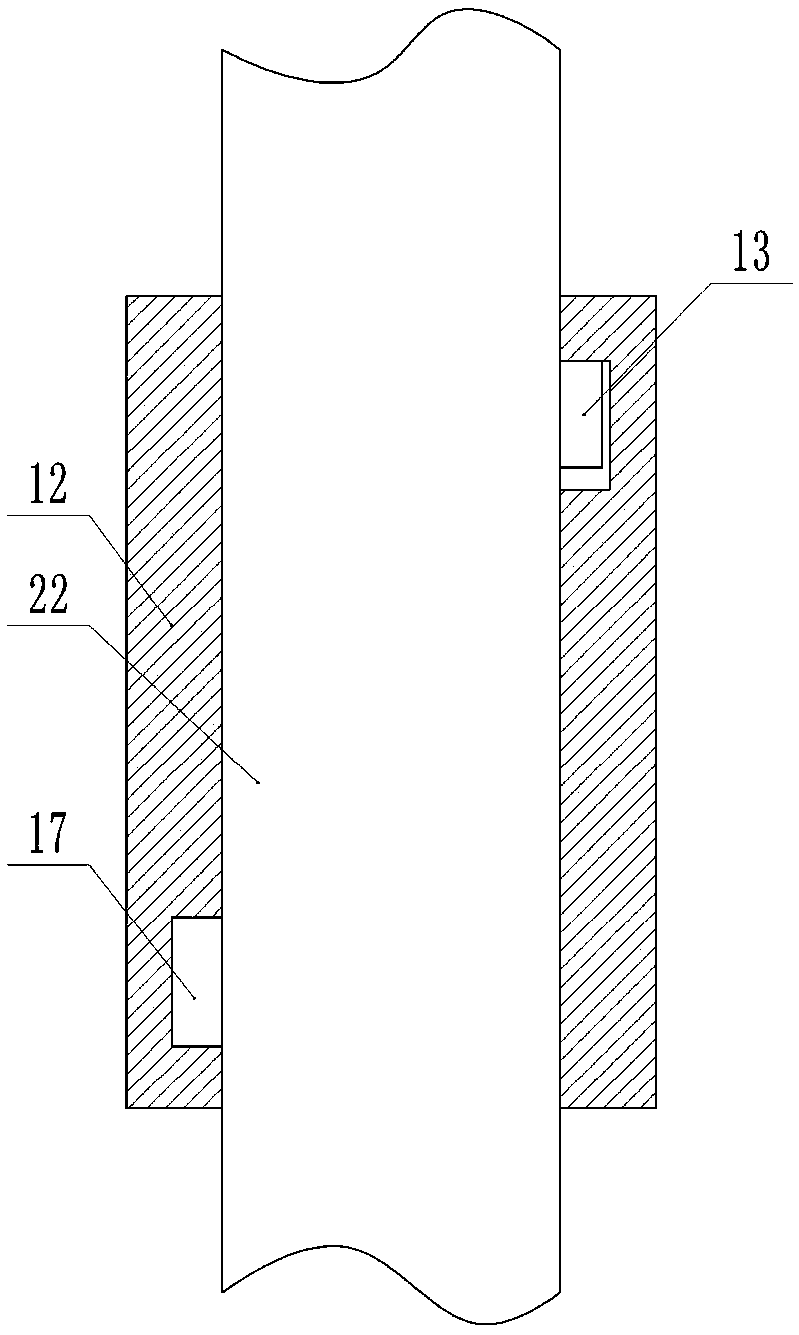

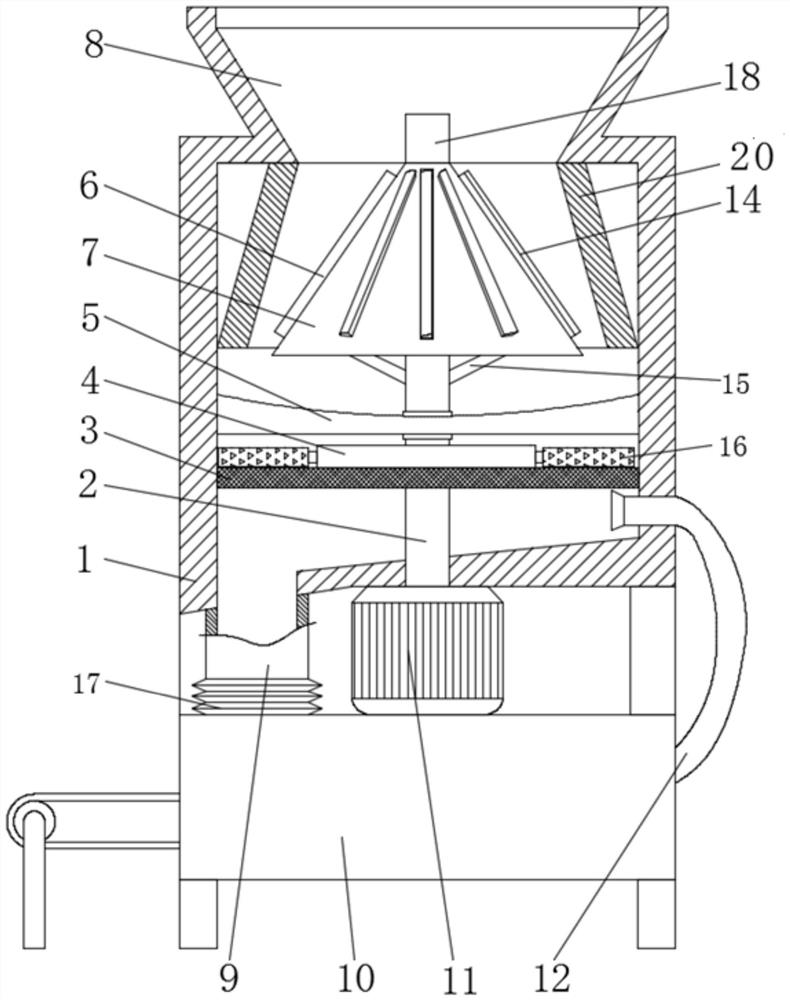

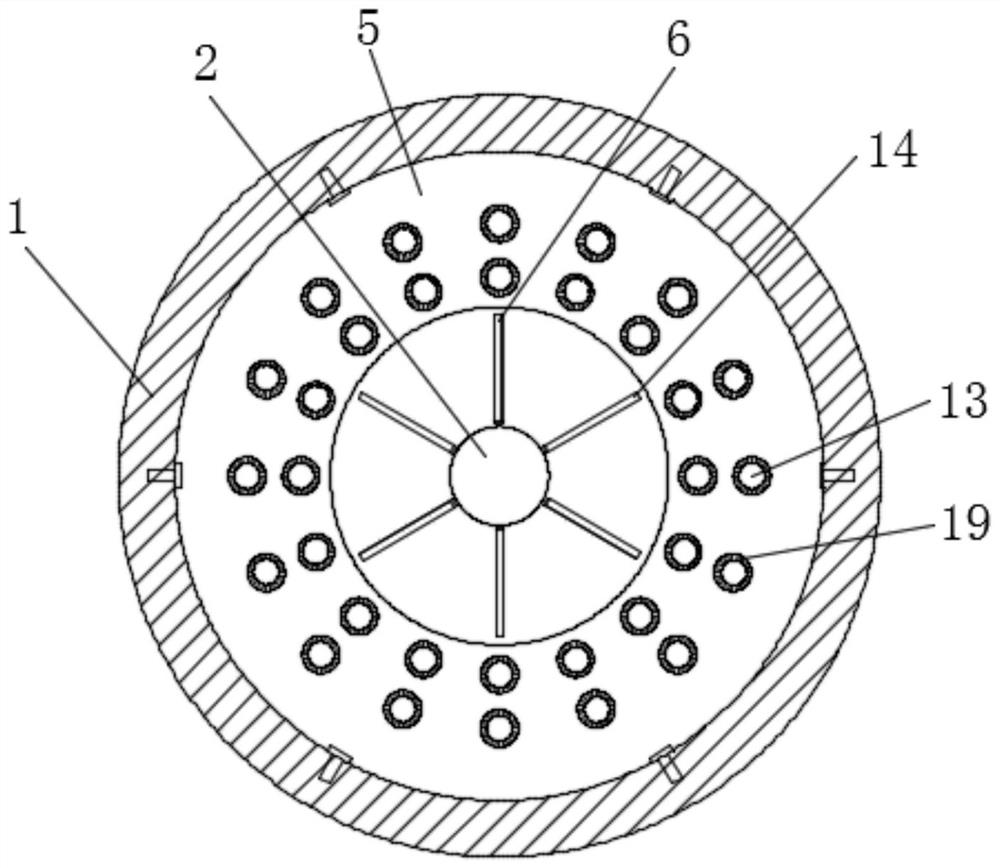

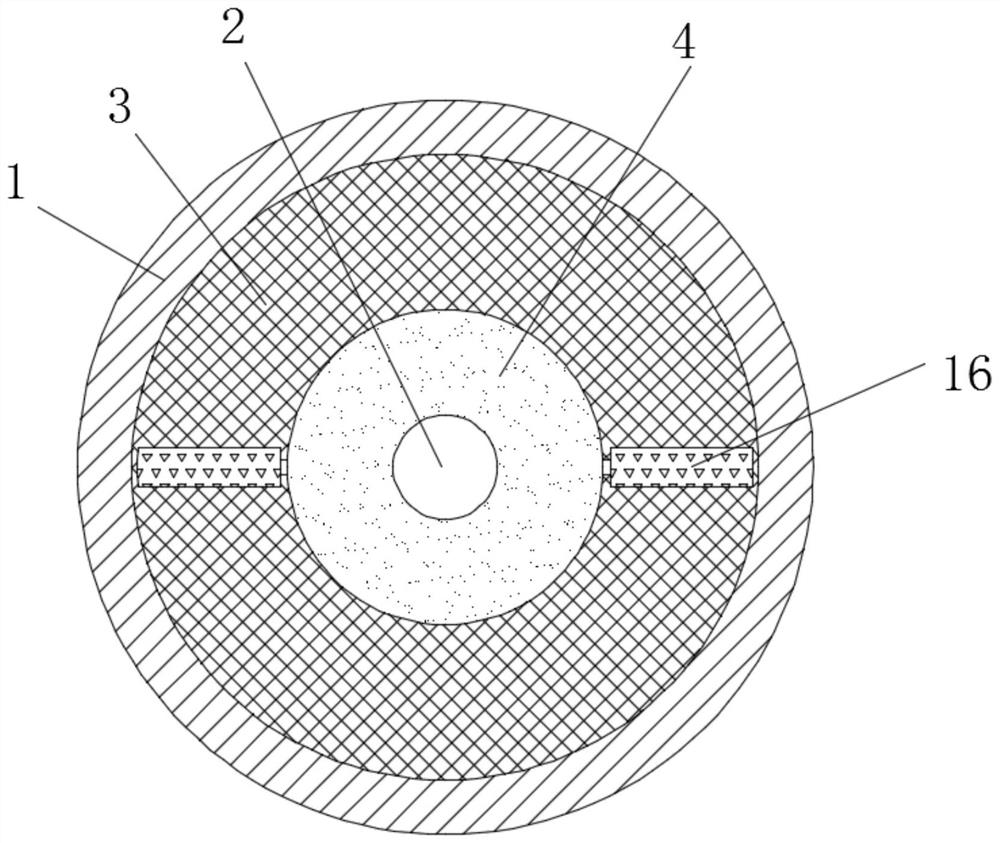

Smashing and drying device for chemical engineering materials

InactiveCN107774425AGuaranteed power outputIncrease profitDrying gas arrangementsGrain treatmentsFixed frameElectric machinery

The invention discloses a smashing and drying device for chemical engineering materials, and relates to the technical field of chemical engineering processing. The smashing and drying device comprisesa feeding cabinet. A feed inlet is fixedly connected to the top of the feeding cabinet. A power motor is fixedly connected to one side of the inner wall of the feeding cabinet through a fixing frame.A speed-reducing connector is connected with the power motor through an output shaft rotationally. A first belt pulley is connected with the speed-reducing connector through an output shaft rotationally. A second belt pulley is connected with the first belt pulley through belt rotation. A conveyor is fixedly connected with the second belt pulley through a flat key. A material conveying tube is arranged on the outer wall of the conveyor, and a material conveying inlet is arranged at the top of the material conveying tube. The smashing and drying device has the advantages that conveying and classified smashing of the chemical engineering materials, conveying of smashed chemical engineering materials and drying of the chemical engineering materials are achieved, thorough smashing is realized, production quality is guaranteed, and output and overall quality of chemical engineering products and stability of the chemical engineering materials are guaranteed.

Owner:湖州城区天顺化工厂

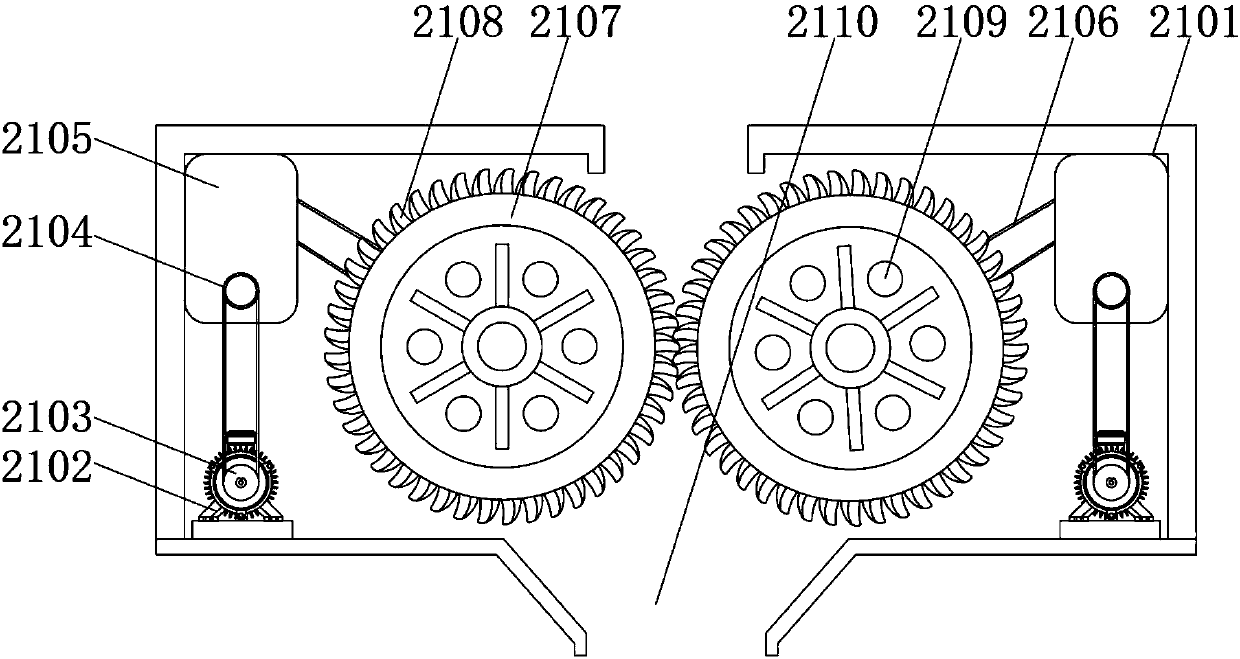

Press waste disposal device with metal recovery function

InactiveCN108543601APrevent overflowSmooth crushing processSievingScreeningMetal recyclingRecovery function

The invention discloses a press waste garbage disposal device with a metal recovery function, the press waste garbage disposal device comprises a box body, a rolling device, a grinding device and a dewatering device; the box body is internally provided with the rolling device, the rolling device comprises a rolling groove and a rolling hammer; a discharging port is arranged at the lower end of therolling groove, the grinding device is arranged below the rolling groove, the grinding device comprises grinding rollers which are front-and-rear symmetrically arranged; a magnetic grille mesh is arranged below the grinding rollers, and the magnetic grille mesh is connected to a rotation drum by bolts. The upwardly rotating rolling hammer is used for preliminary pulverization of medical waste ofdifferent specifications, and the preliminarily-pulverized medical waste is further pulverized by the grinding rollers, so that the pulverizing process is smoother, and the pulverizing efficiency is improved. The magnetic grille mesh is arranged to adsorb and remove metal objects in the waste; and the rotation drum is used for centrifugal separation of waste liquids in the medical waste, thereby facilitating subsequent transportation and incineration treatment.

Owner:赵锦山 +2

Sponge crushing treatment device for waste recovery

ActiveCN110696222ASmooth crushing processReduce volumePlastic recyclingGrain treatmentsEnvironmental engineeringWaste recovery

The invention discloses a sponge crushing treatment device for waste recovery. The sponge crushing treatment device comprises a supporting frame, a plurality of cutting blades used for carrying out pre-cutting treatment on the waste sponge, a first conveying part used for conveying the waste sponge and baffles arranged on the two sides of the first conveying part, and the first conveying part is provided with a second conveying part for conveying the waste sponge, an extrusion mechanism used for extruding and conveying the waste sponge and a crushing mechanism used for crushing the waste sponge. Through the arrangement of the above structure, the waste sponge can be effectively pre-cut through the cutting blades, so that the volume of the waste sponge is reduced, the waste sponge is more labor-saving and convenient to crush, and the crushing efficiency of the waste sponge is effectively improved; and meanwhile, the occurrence of blocking feeding and discharging phenomena of the waste sponge can be avoided, and smooth operation of waste sponge crushing is guaranteed.

Owner:台州逢阳互联网科技有限公司

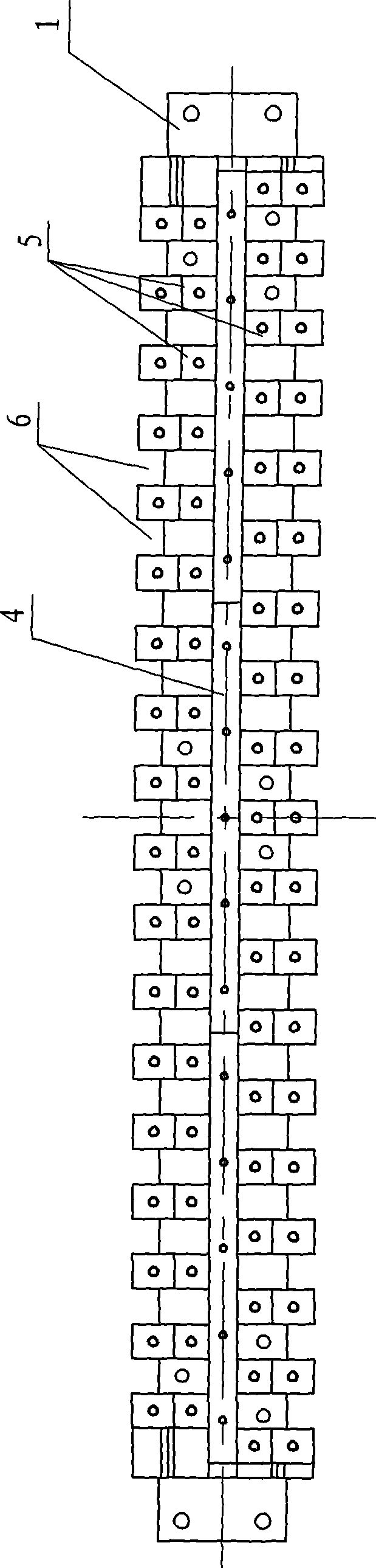

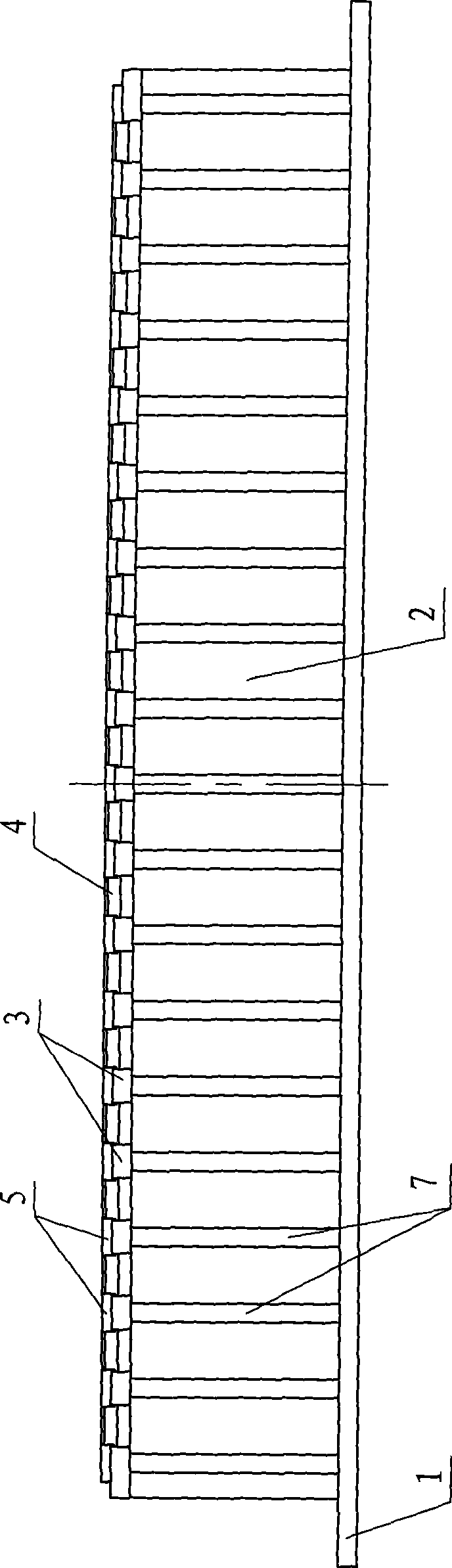

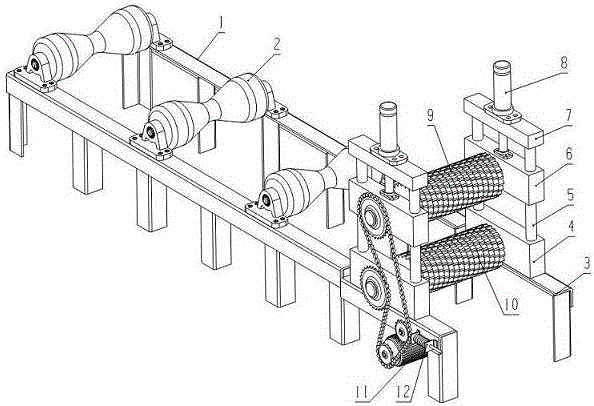

Straw crushing device with combined bed knife

The present invention relates to a crushing processing device which is used for plant stalk in the industries of papermaking, clean energy, etc. Specifically the invention relates to a combined dead knife straw crusher. The device comprises at least one rotatable knife roll which is arranged with a plurality of knife discs. The circumferences of knife discs are uniformly installed with a plurality of fly knife blades. The edges of two sides of each fly knife blade are provided with transverse cutting edges. The radial outer margin of each fly knife blade is provided with a longitudinal cutting edge. The side part of knife roll is fixed with a longitudinal dead knife in longitudinal direction. The rotation track of longitudinal cutting edge of fly knife blade is next to the longitudinal edge of longitudinal dead knife so that the longitudinal cutting edge and the longitudinal dead knife can execute relative shearing movement. The side of knife roll next to the longitudinal is also fixedly installed with a plurality of transverse dead knifes which are transversely installed and are positioned in the clearance between the adjacent knife discs, so that the transverse cutting edges of fly knife blades and the transverse dead knifes can execute relative shearing movement. The crushing processing device of the invention greatly increases the homogeneity of crushing and simultaneously has the advantages of smooth crashing process, little impact vibration and high reliability.

Owner:JIANGSU DATANG MACHINERY

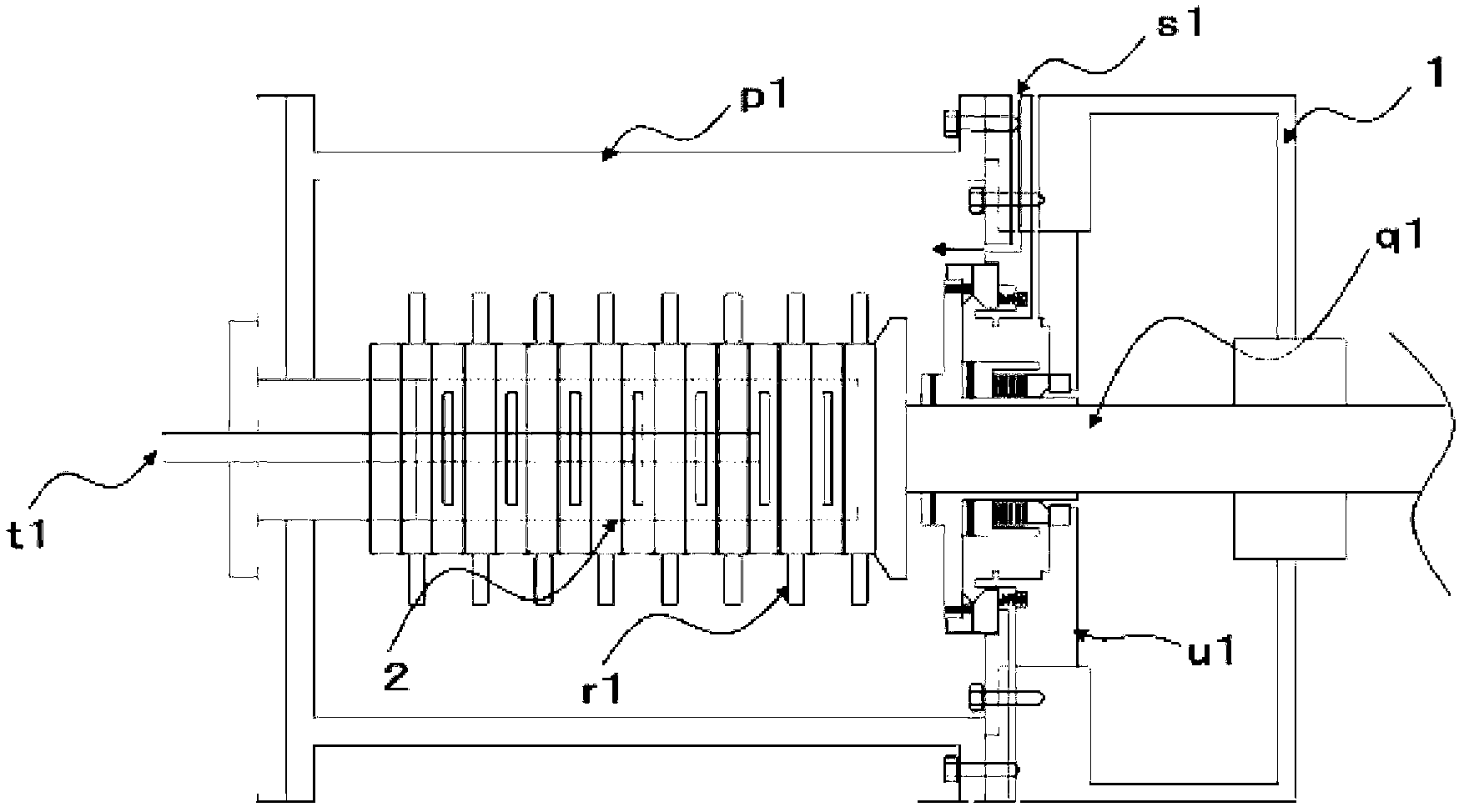

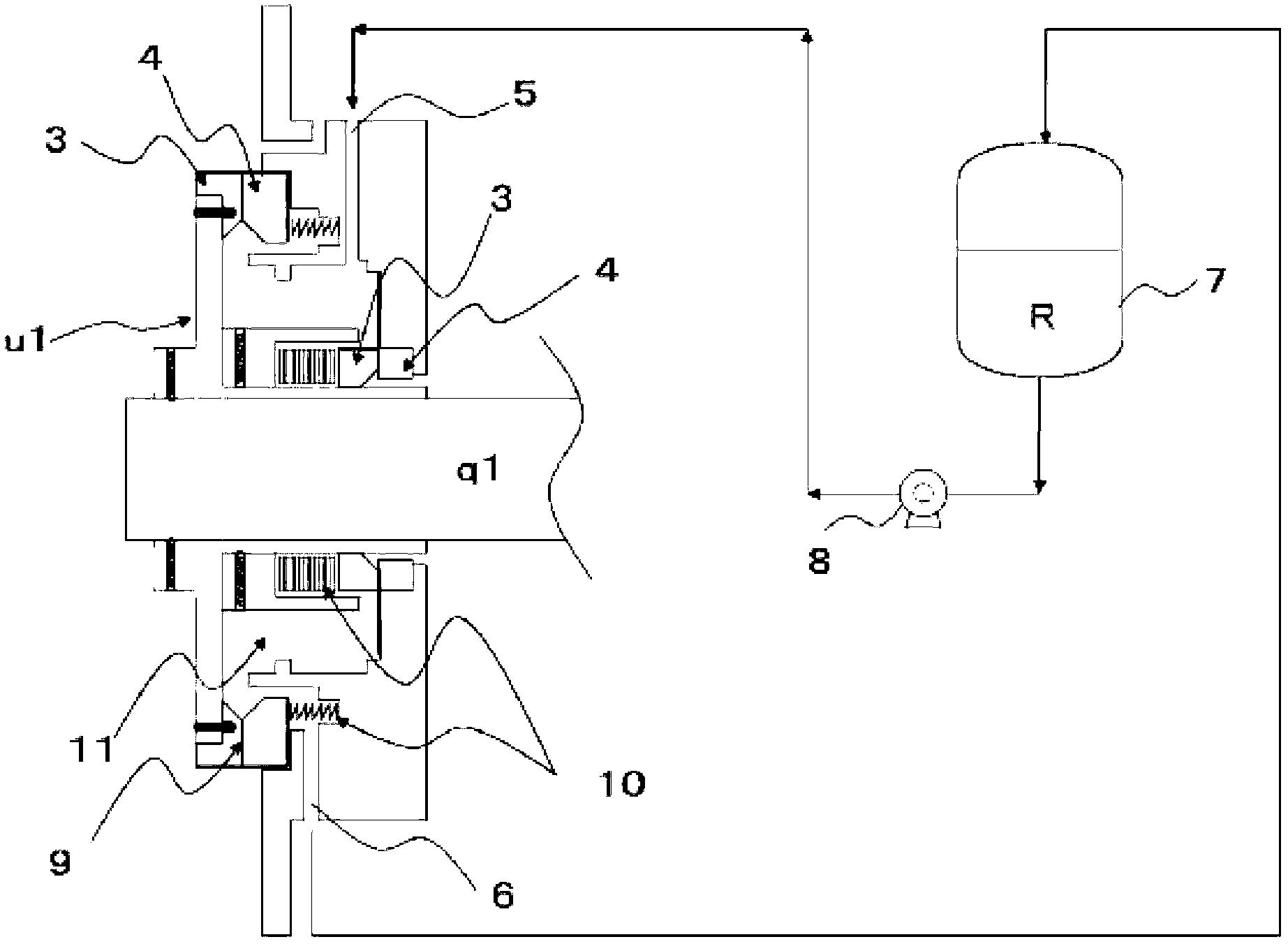

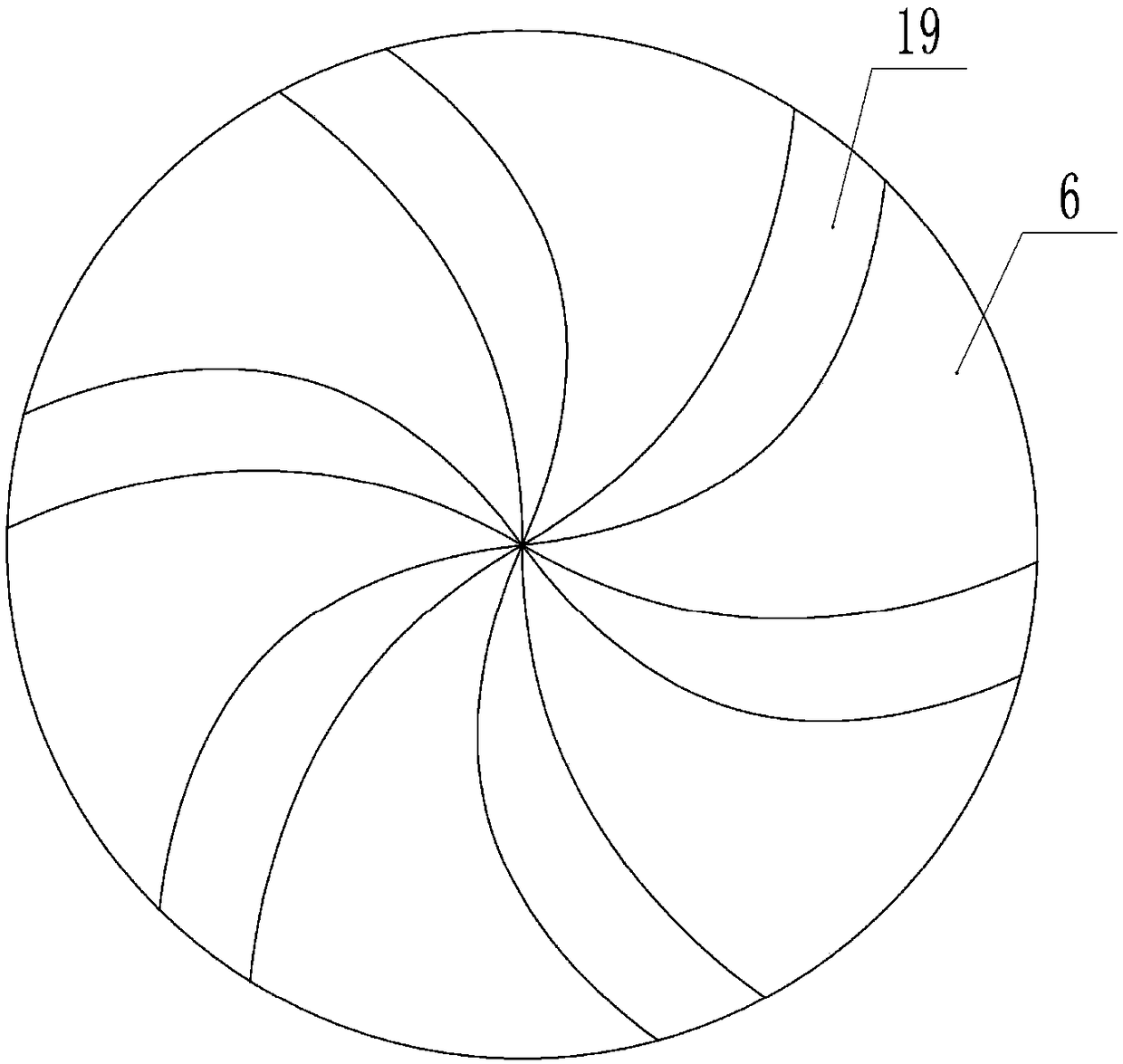

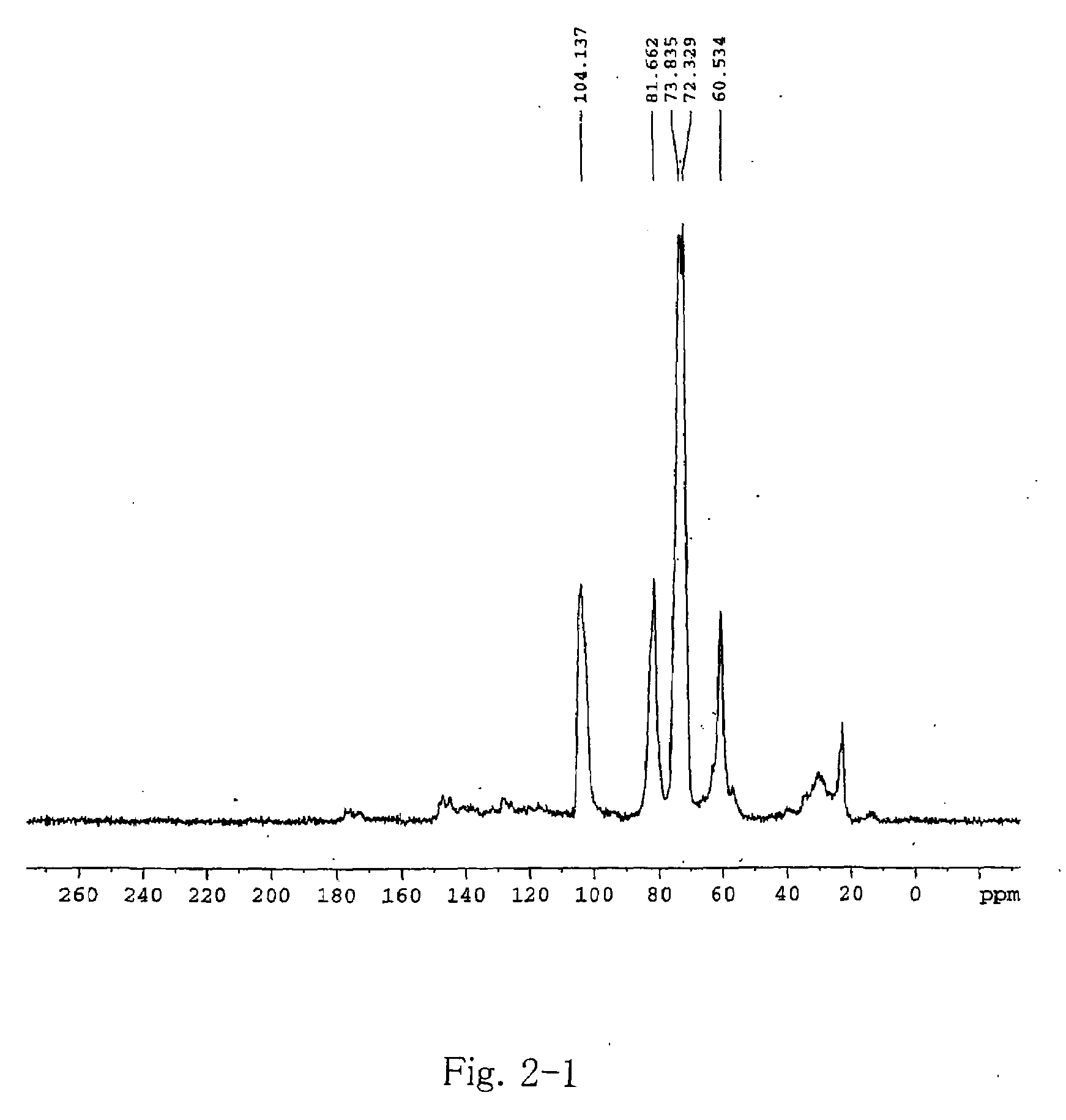

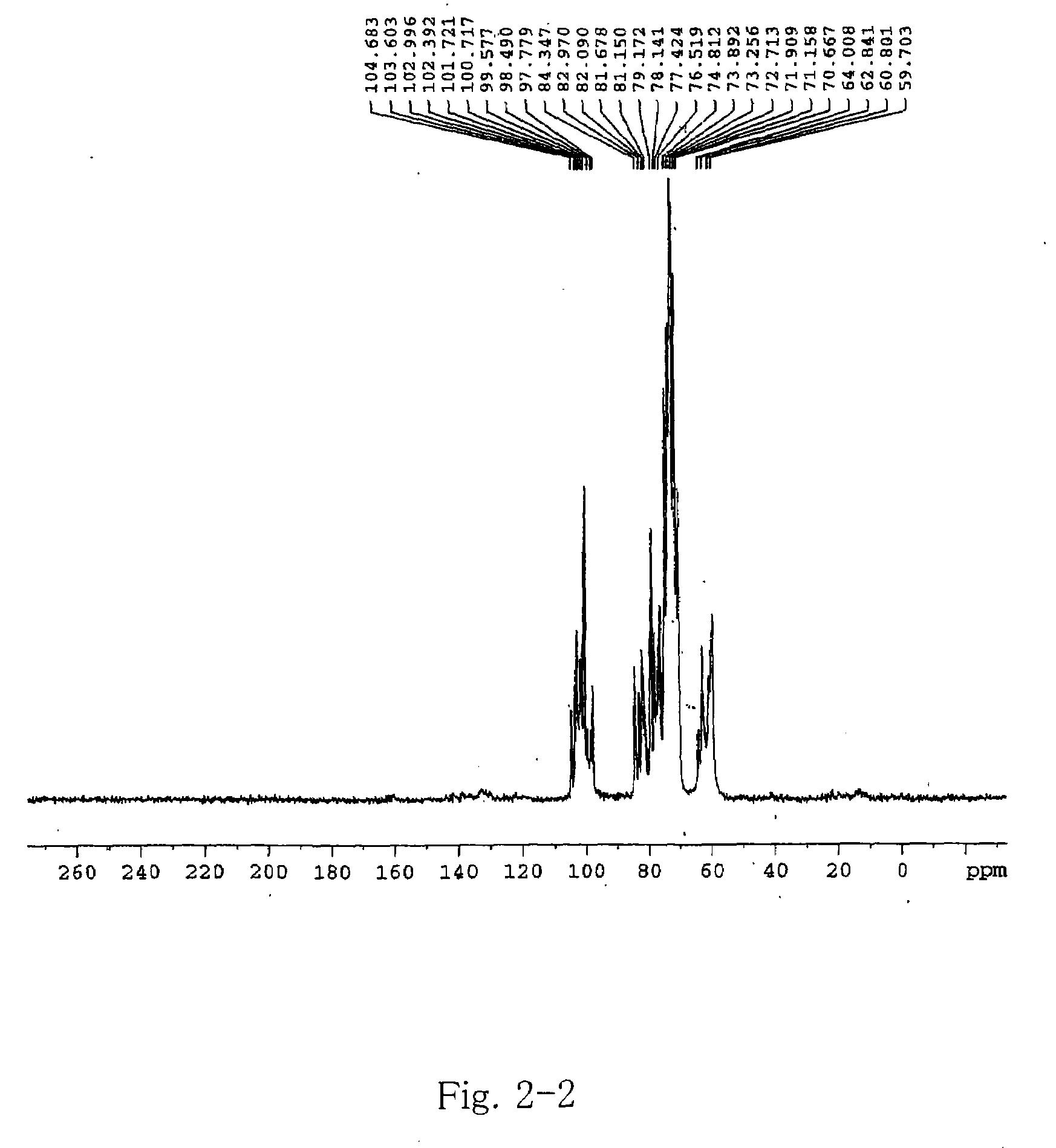

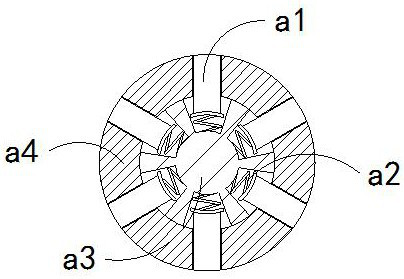

Process for production of dispersion, dispersion, coating material, coating film, and film

ActiveCN103140519ASmooth crushing processGood dispersionFlow mixersRotary stirring mixersImpellerProduction rate

Provided are: a process for producing a dispersion, whereby it becomes possible to perform the milling and dispersion of inorganic microparticles steadily and with good productivity while preventing the increase in viscosity or the occurrence of gelatinization of the dispersion; a dispersion which can provide a cured coating film having both high hardness and high transparency; a coating material prepared using the dispersion; a coating film; and a film produced by forming the coating film. The process is characterized in that a slurry containing an active-energy-curable compound (A), an active-energy-curable compound (B) and inorganic microparticles (C) as the essential components is introduced into a wet ball mill to mill and disperse the inorganic microparticles (C) in the slurry, wherein the wet ball mill comprises a vessel (p) in which a medium is filled, a rotating shaft (q), an impeller (r), a slurry inlet (s), a slurry outlet (t) and a shaft seal unit (u).

Owner:DIC CORP

Environment-friendly tree crusher

InactiveCN108295950ATo achieve the purpose of waste heat recoveryAvoid wastingNon-rotating vibration suppressionVortex flow apparatusWater resourcesUrban water

The invention discloses an environment-friendly tree crusher. The environment-friendly tree crusher comprises a case body, wherein a fixed seat is fixed to the upper surface of the case body, and shock absorbing bases are connected to four corners at the bottom of the case body; a crushing box is fixed to one side of the upper surface of the fixed seat, and a cyclone separator is mounted on one side of the fixed seat through a fixed rack; the bottom end of the cyclone separator is connected to a filter box fixedly connected to the case body through the fixed rack through a pipeline, and a supporting rack is fixed to one side of the top of the cyclone separator; an induced draft fan is mounted on one side of the upper surface of the supporting rack, and a heat recoverer is connected to oneside of the induced draft fan through a pipeline. The environment-friendly tree crusher disclosed by the invention can recover waste heat of gas to avoid energy waste and prevent the gas from being discharged to secondarily pollute the environment, so that the crusher is more environment-friendly, and meanwhile, the water resource in the gas is recycled, so that the waste of the water resource isprevented, the pressure of urban water consumption is alleviated greatly, and the crusher is more energy-saving.

Owner:邱福祥

Industrial solid waste treatment equipment

ActiveCN112403566AReduce volumeImprove processing efficiencyCombination devicesDirt cleaningElectric machineryProcess engineering

The invention provides industrial solid waste treatment equipment. The industrial solid waste treatment equipment comprises a working box, a partition plate is connected to the inner wall of the working box, a conveying pipe is connected to the outer wall of the partition plate, a feeding pipe is connected to the outer wall of the top of the conveying pipe, the end, away from the conveying pipe, of the feeding pipe penetrates through the working box and is connected to a feeding port, a treatment box is connected to the inner wall of the working box, a filter screen plate is arranged on the inner wall of the treatment box, the treatment box penetrates through the bottom of the working box and extends outwards to be connected to a discharging port, the treatment box mutually communicates with the conveying pipe, a second motor is connected to the outer wall of the top of the working box, a second rotating shaft is connected to the output end of the second motor, and a first gear is connected to the outer wall of the second rotating shaft. According to the industrial solid waste treatment equipment, the repeated impact crushing effect on solid waste is achieved, the industrial solidwaste is effectively crushed into particles, the volume of the industrial solid is effectively reduced, the treatment efficiency of the the solid waste is improved, and subsequent transportation and treatment are facilitated.

Owner:深圳市友和环境科技有限公司

Preparation method for superfine zirconium powder

InactiveCN104289709AReduce surface activityInhibition of growth behaviorCoatingsZirconium hydrideMicro nano

The invention relates to a preparation method for superfine zirconium powder, in particular to a technical method utilizing a sodium salt and / or potassium salt to coat zirconium hydride to prepare micro-nano-scale zirconium powder, and belongs to the technical field of superfine metal powder. The technical method comprises the following steps: taking the sodium salt as a coating agent, mixing the zirconium hydride particles with the coating agent according to a mass ratio of (5-15):1, conducting wet grinding and vacuum drying to obtain the superfine zirconium powder of which surface is coated with the coating agent uniformly, dehydrogenizing in a vacuum environment at 550-680 DEG C, and conducting wet grinding dispersion and elution on the product to remove the coating agent so as to obtain the superfine zirconium powder, wherein the vacuum degree is controlled at 0.05-0.1 Pa in the dehydrogenation process. The preparation method disclosed by the invention is simple in preparation technology, convenient to control, and safe in operation technology; the obtained product is good in quality; the preparation method facilitates industrialized application.

Owner:CENT SOUTH UNIV

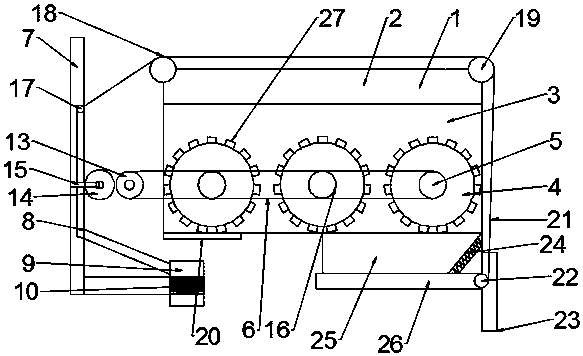

Conveniently used grass feed crushing and stirring device

InactiveCN108889392AShorten the timeGuaranteed work efficiencyFeeding-stuffRotary stirring mixersDrive wheelSpiral blade

The invention discloses a conveniently used grass feed crushing and stirring device which comprises a box body. A first bearing is connected to the left side face of the box body in a clamping manner,a first rotary shaft is connected in the first bearing in a sleeving mode, the left end of the first rotary shaft is fixedly connected to an output shaft of a first motor, spiral blades are arrangedon the surface of the first rotary shaft, the spiral blades are located in the box body, a second bearing is connected to the upper surface of the box body in a clamping manner, a second rotary shaftis connected in a second bearing in a sleeving mode, cutting blades are arranged on the surface of the second rotary shaft, and the cutting blades are located in the box body. According to the conveniently used grass feed crushing and stirring device, by matching the second motor, a driving wheel, a belt, a driven wheel, the second rotary shaft, the second bearing, the cutting blades and a feed inlet, people do not need to stir a grass feed and a green additive manually, so that the time of people is saved, and the work efficiency of people is ensured. By arranging the cutting blades, the crushing effect of the grass feed is better.

Owner:安徽睿科智能制造技术研究院有限公司

Energy-saving and environment-friendly pulping device for paper making and printing

ActiveCN109208363ACrushed fullyGuaranteed crushing timeRaw material divisionPower equipmentPulp and paper industry

The invention belongs to the technical field of papermaking equipment, and specifically discloses an energy-saving and environment-friendly pulping device for paper making and printing, comprising a frame and a power mechanism. A crushing box is disposed on the frame. An upper portion of the crushing box is provided with a feeding port. A lower portion of the crushing box is provided with a discharge port. A rotating shaft is rotatably connected in the crushing box. An upper portion of the rotating shaft is fixedly connected with a plurality of first blades. A lower portion of the rotating shaft is fixedly connected with a plurality of second blades. The part, between the first blades and the second blades, of the rotating shaft is vertically sleeved with a pushing plate in a sliding sealmanner. The pushing plate is in sliding seal connection with an inner wall of the crushing box. The pushing plate is provided with discharging holes. Each discharging hole is provided with a downwardly opening one-way door. The power mechanism drives the rotating shaft to rotate and drives the pushing plate to slide up and down. The pulping device is mainly used for crushing paper pulp, and the problem that the use of power equipment in the pulping process increases the production cost and causes economic pressure on the enterprise is solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

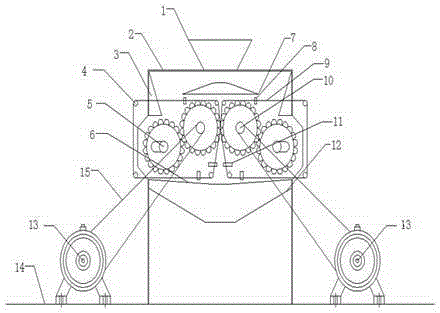

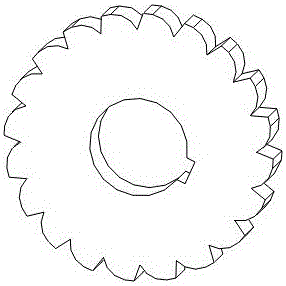

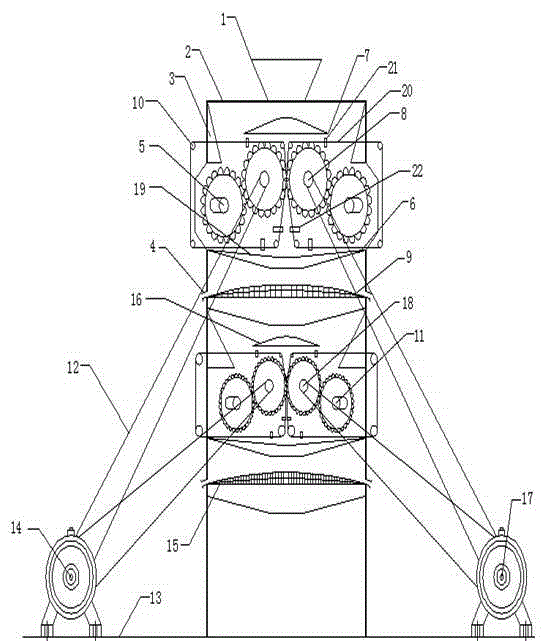

Four-roll crusher

The invention discloses a four-roll crusher which comprises a feeding opening, a stone crushing barrel and a base. The two ends of the base are each fixedly provided with a motor, the stone crushing barrel is arranged between the two motors and fixedly mounted on the base, a feeding opening is formed in the upper end of the stone crushing barrel, a funnel-shaped collecting opening is formed in the lower end of the stone crushing barrel, two through grooves are formed in the two ends of the outer wall on the upper portion of the stone crushing barrel respectively, and two through grooves are formed in the two ends of the outer wall of the lower portion of the stone crushing barrel respectively. Hinges penetrate through the through grooves, the hinges on the outer wall of the stone crushing barrel are fixed through locating roll shafts, the locating roll shafts are fixedly mounted on the outer wall of the stone crushing barrel, and four rollers are arranged on the upper middle portion in the stone crushing barrel. The crusher carries out multiple times of crushing, so that working efficiency is improved, the powder passing rate is decreased, and smaller material blocks can be obtained; meanwhile, the function of the crusher is enhanced, work is stable, noise is low, manufacturing cost and maintenance cost are low, and the service life is longer.

Owner:攀枝花市聚鑫金属结构有限公司

Glass recovery system with self-adaptive crushing cutters

InactiveCN108525800ACrushing effect high speedEfficient crushing effectDrying gas arrangementsCleaning using liquidsEngineeringGlass particle

The invention relates to the technical field of waste glass recovery, in particular to a glass recovery system with self-adaptive crushing cutters. The glass recovery system comprises a cleaning and feeding unit used for cleaning and filtering preliminarily-crushed glass particles. Thus, the crushing cutters arranged in the glass recovery system can adjust the size according to actual needs so asto adapt to different crushing requirements; through the arrangement of connecting ends and connecting plates, the connecting plates shift to form the crushing cutters of different diameters, and therefore the crushing effect of different specifications can be achieved; and the arranged connecting plates can crush glass particles large in particle size, glass particles which are small in particlesize or cannot meet the particle size requirement are ground through the action of arc plates and a cavity, and therefore the fast and efficient crushing effect is achieved.

Owner:ANHUI WANBAO GLASS

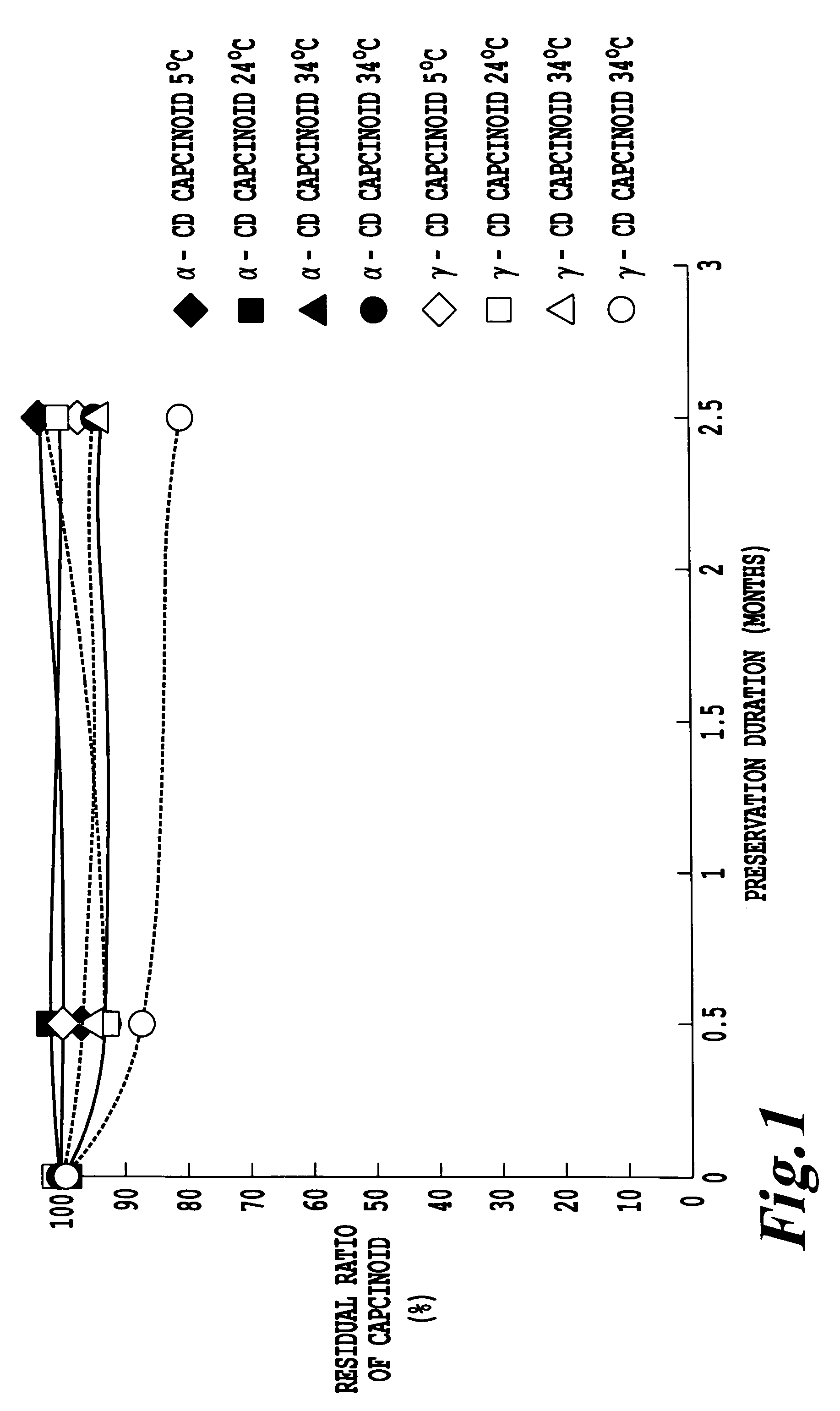

Compositions containing capsinoids

InactiveUS20080213413A1Smooth crushing processEasy to handleBiocidePowder deliveryCyclodextrinProtein C

Problem to be SolvedTo provide a technique for allowing pulverization and water-solubilization of capsinoids while maintaining their stability.SolutionProviding a composition comprising a capsinoid compound and cyclodextrin.

Owner:AJINOMOTO CO INC

Combined bed-knife of straw crusher

The invention relates to a plant straw crushing equipment part for using in papermaking, clean energy source and other industries, in particular to a combined bed knife of a straw crusher. The combined bed knife comprises a bed knife rest which is arranged in a crushing cavity of the straw crusher and positioned between two knife rolls, wherein the bed knife rest comprises a horizontal bedplate and a vertical plate, and a plurality of horizontal upper supporting plates are distributed longitudinally on two sides of the top of the vertical plate respectively; and the top of the vertical plate is horizontally provided with a middle bed plate which extends longitudinally along the whole lengthwise direction, a horizontal side bed knife is arranged horizontally on each upper supporting plate, the end of each side bed knife is attached closely to the side edge of the middle bed knife, and the edges of each two adjacent bed knives and the middle bed knife form a U-shaped blade groove. The part improves the crushing uniformity of a straw crusher and makes the crushing process smooth, small in shock vibration and high in reliability.

Owner:JIANGSU DATANG MACHINERY

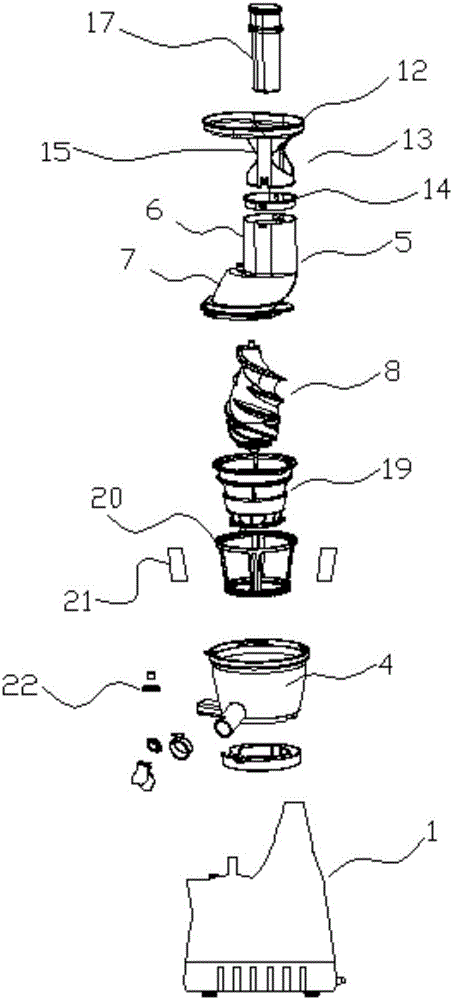

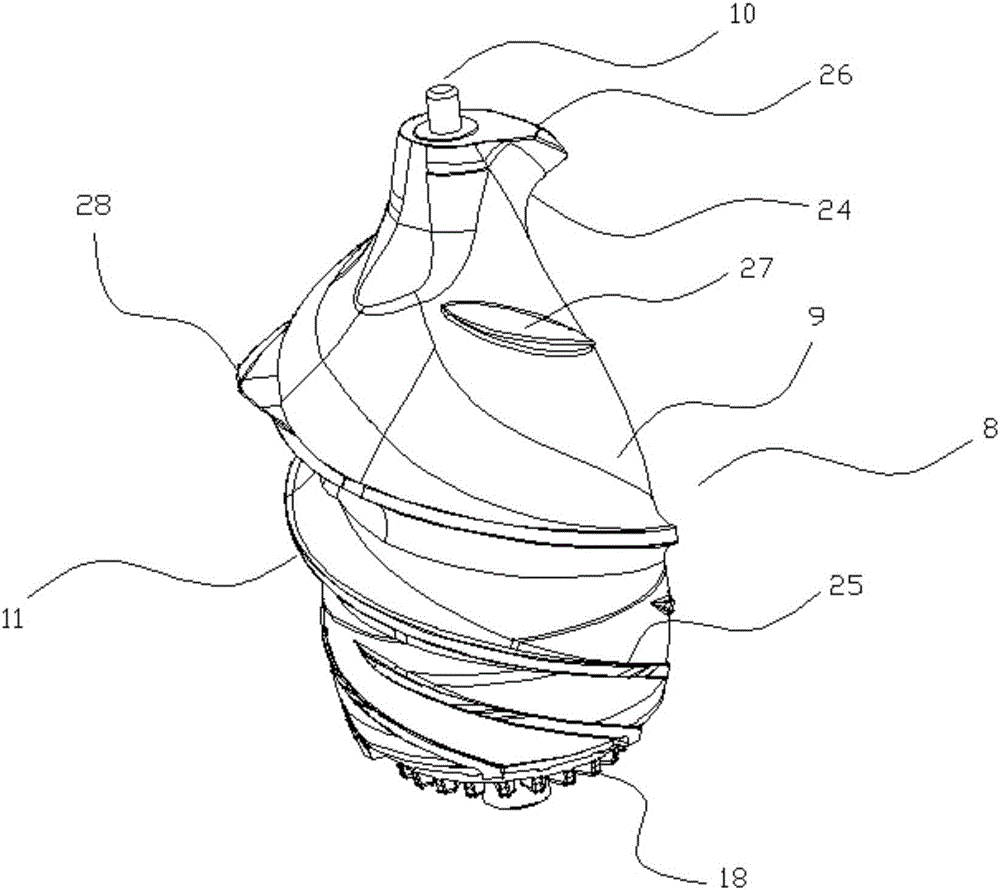

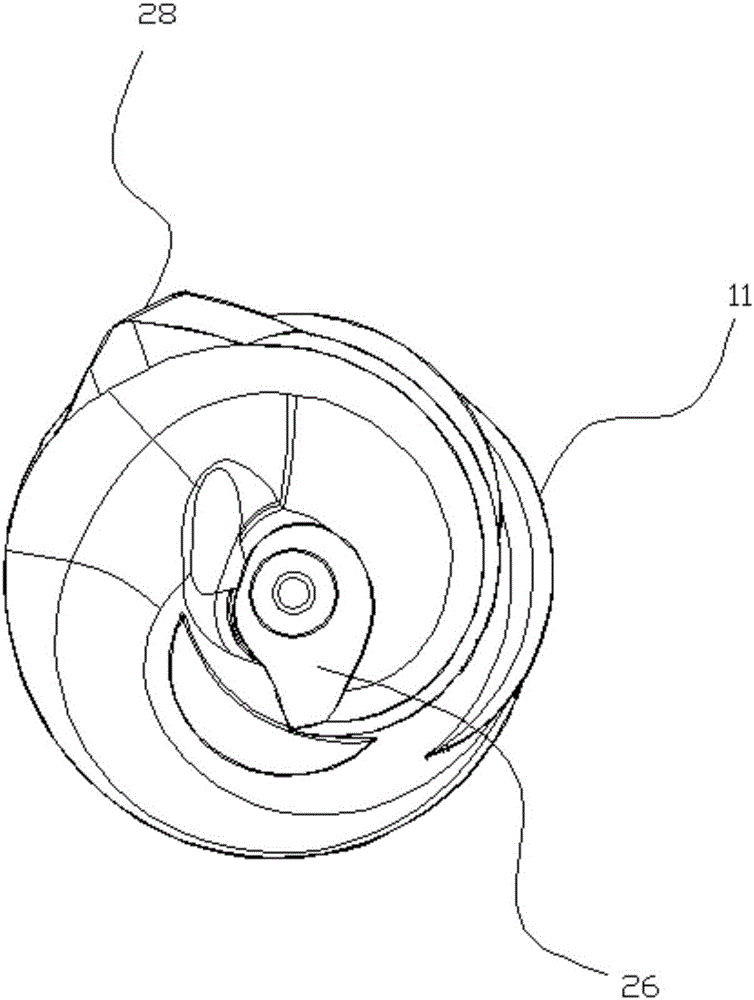

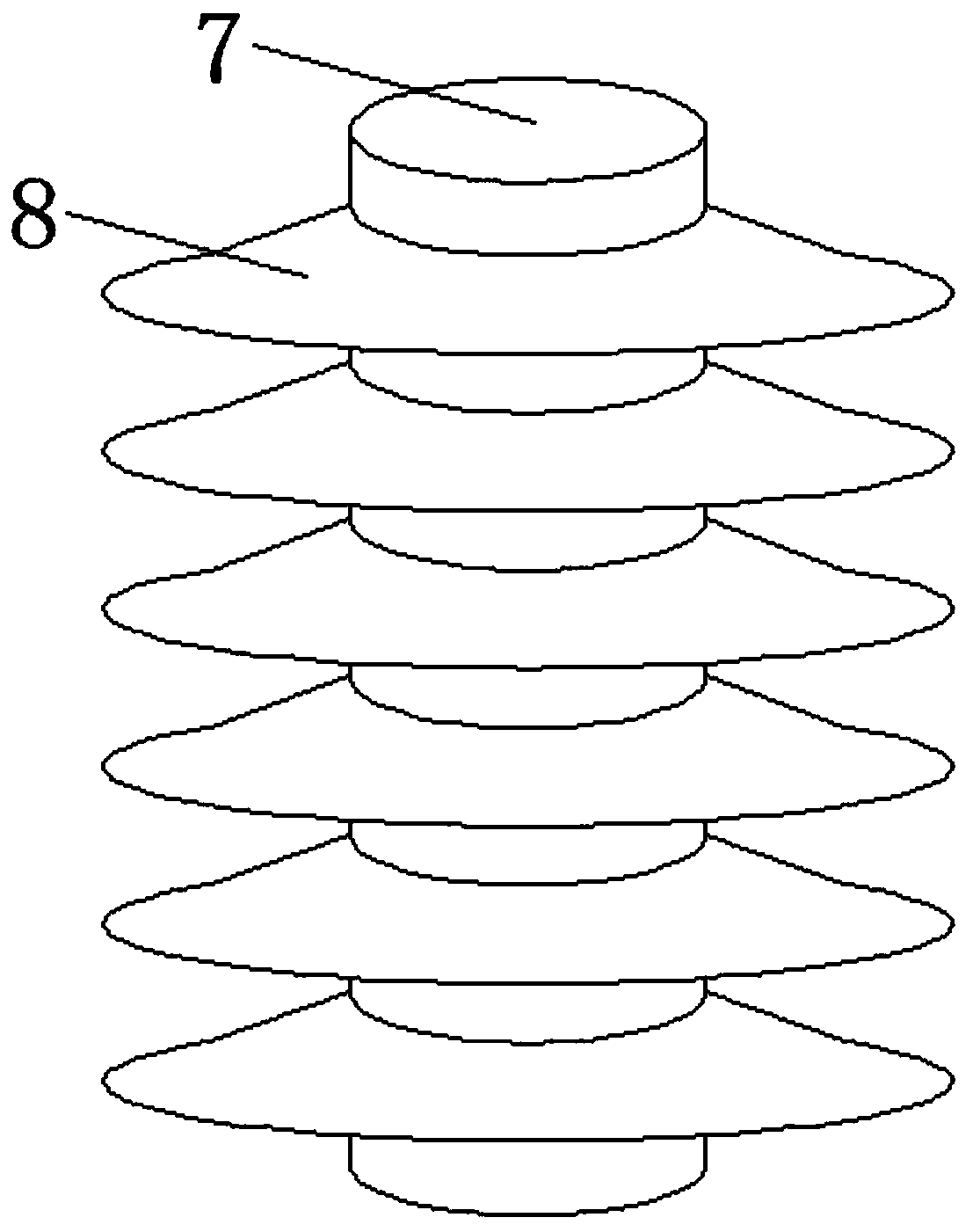

Medium-caliber juicer structure

The invention discloses a medium-caliber juicer structure and aims to provide a juicer structure effective in crushing and juicing of vegetables and fruits, high in juice yield, less waste and stable and efficient in juicing. The juicer structure comprises a lower base, an upper body, a feeding part, a juice collection plate and a main barrel, the main barrel above the juice collection plate comprises a discharging cylinder and a feeding cylinder, an inner space of the feeding cylinder and an inner space of the juice collection plate jointly form a juicing cavity, and a juicing screen component and a juicing screw rod are arranged in the juicing plate. The feeding part comprises a feeding plate and a charging cylinder, the side wall of the charging cylinder is provided with a large main charging opening with a feeding size being 50-65mm. The medium-caliber juicer structure has the advantages that vegetable and fruit materials different in size and hardness can be effectively juiced, and stability in crushing and high juicing rate are achieved; by the aid of a scraping structure, local blockage of an inner juicing screen can be avoided, and high smoothness in a juicing process is realized; automatic heat dissipation of a motor and less proneness to heat accumulation can be realized, and the service life is guaranteed; the juicer structure is high in safety due to a protection structure.

Owner:NINGBO JUSTICE ENG PLASTIC MOULD CO LTD

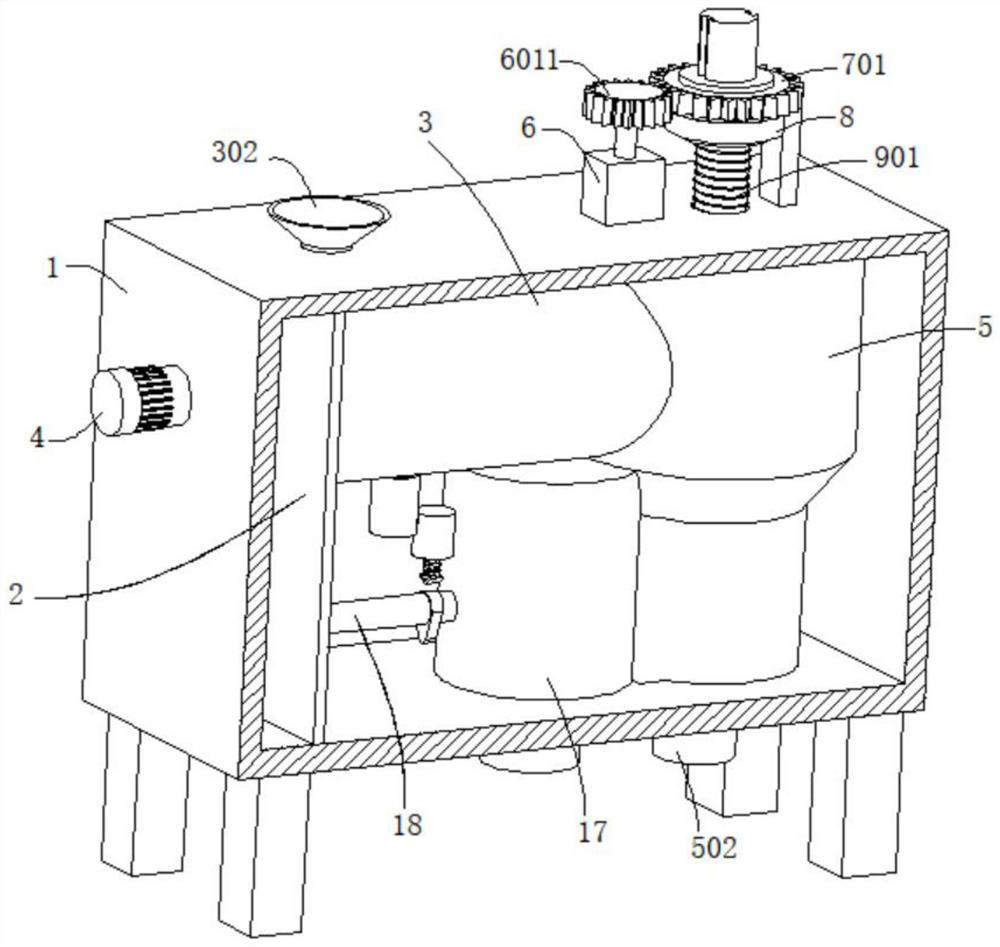

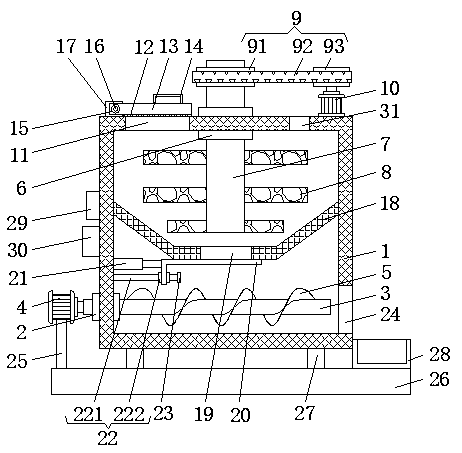

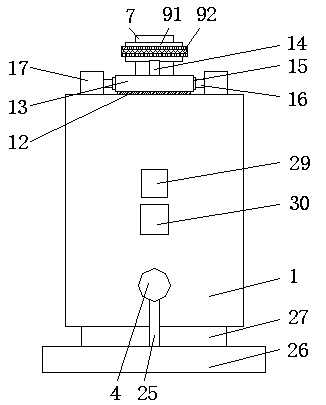

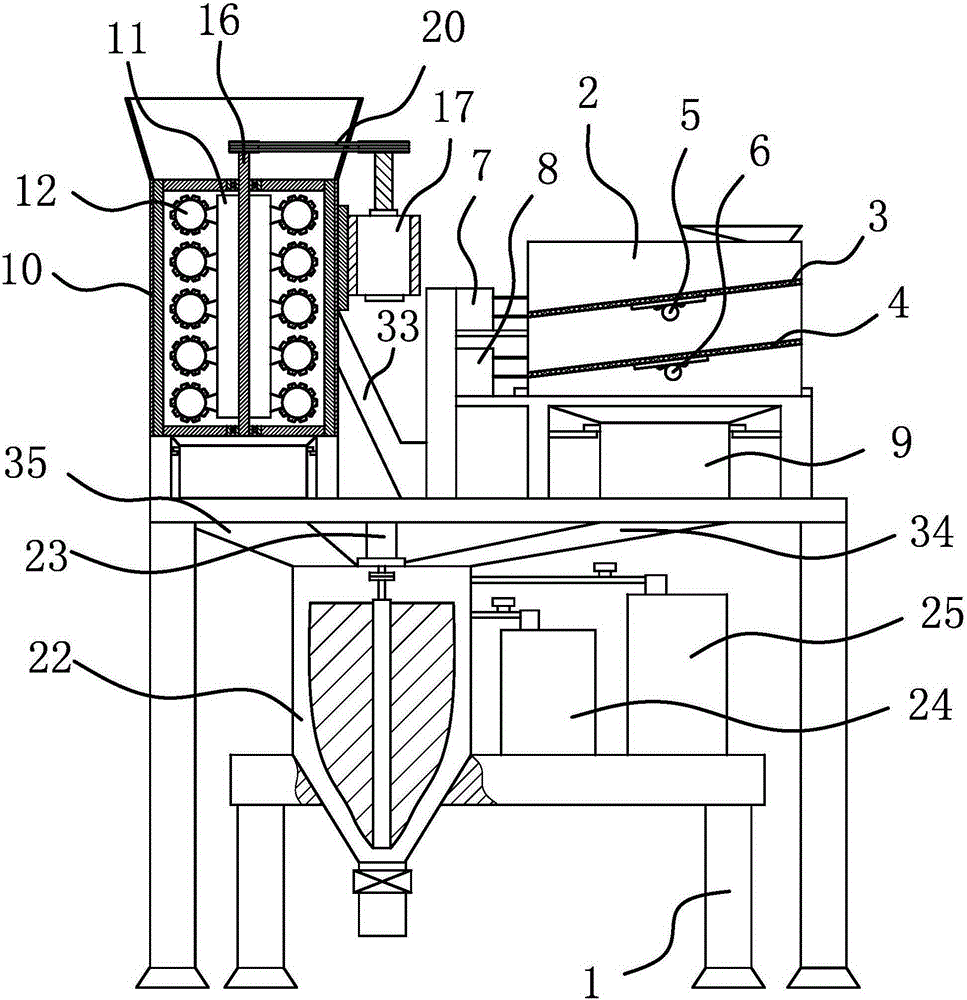

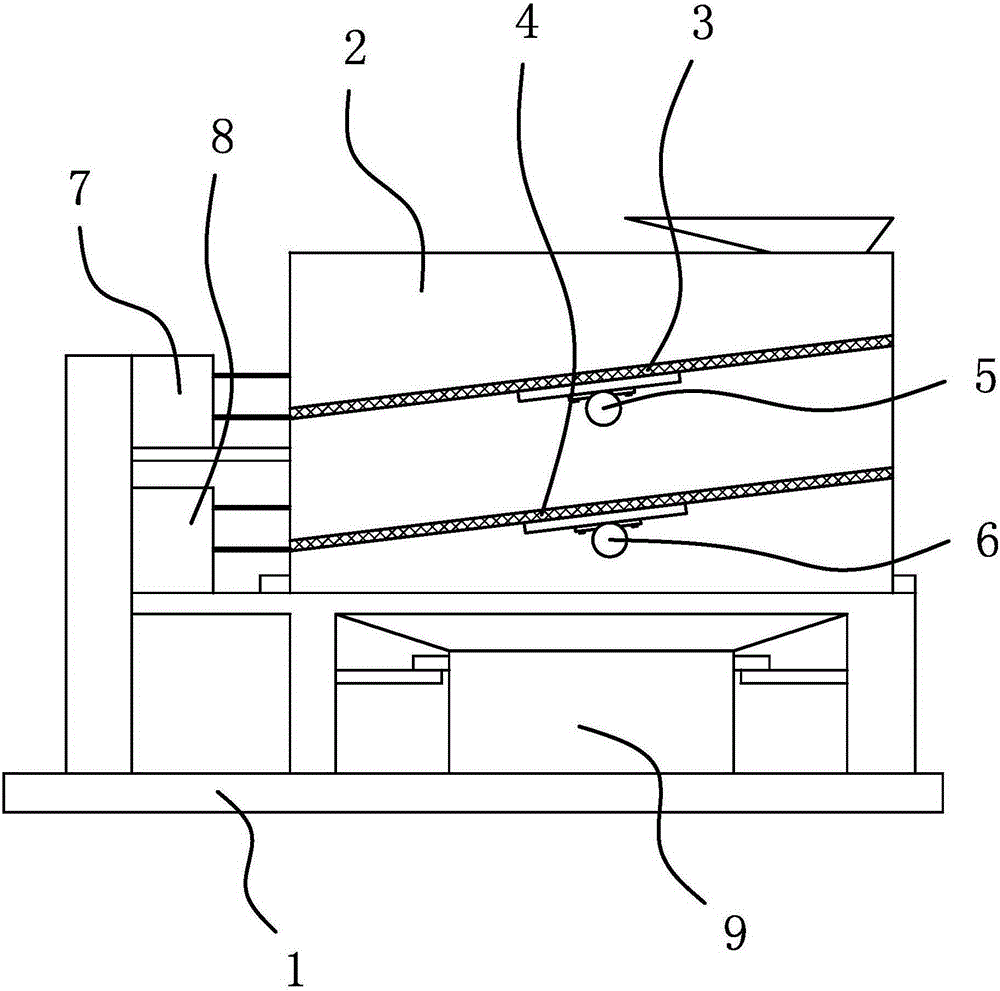

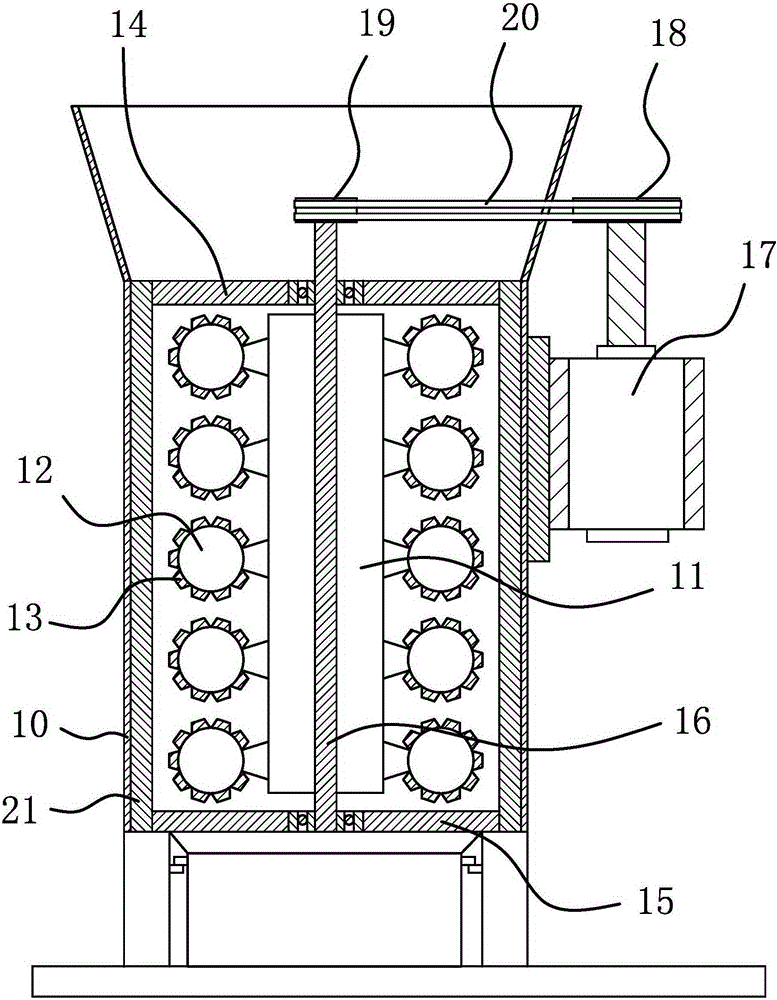

Preparing method for manganese zinc ferrite material and processing device of manganese zinc ferrite material

The invention provides a preparing method for a manganese zinc ferrite material and a processing device of the manganese zinc ferrite material, and belongs to the technical field of machines. The problem that the production efficiency of a manganese zinc ferrite material in the prior art is low is solved. The preparing method for the manganese zinc ferrite material is characterized by including the step that S1, materials are prepared, a main formula mixture including, by molar percentage, 52%-53% of ferric oxide, 19%-21% of zinc oxide and 25%-30% of manganese oxide is taken, and an assisting mixture including, by mass percent, 400 ppm-1,000 ppm of calcium oxide, 100 ppm-600 ppm of niobium pentoxide, 100 ppm-800 ppm of zirconium dioxide, 1,000 ppm-4,000 ppm of cobalt sesquioxide and 100 ppm-300 ppm of tungsten trioxide is taken. The processing device of the manganese zinc ferrite material comprises a machine frame and is characterized in that a screening device and a breaking device are arranged on the machine frame, and a blending device is arranged below the machine frame. The preparing method and the processing device have the advantages of being high in production efficiency and the like.

Owner:HAINING SANHONG ELECTRONICS TECH

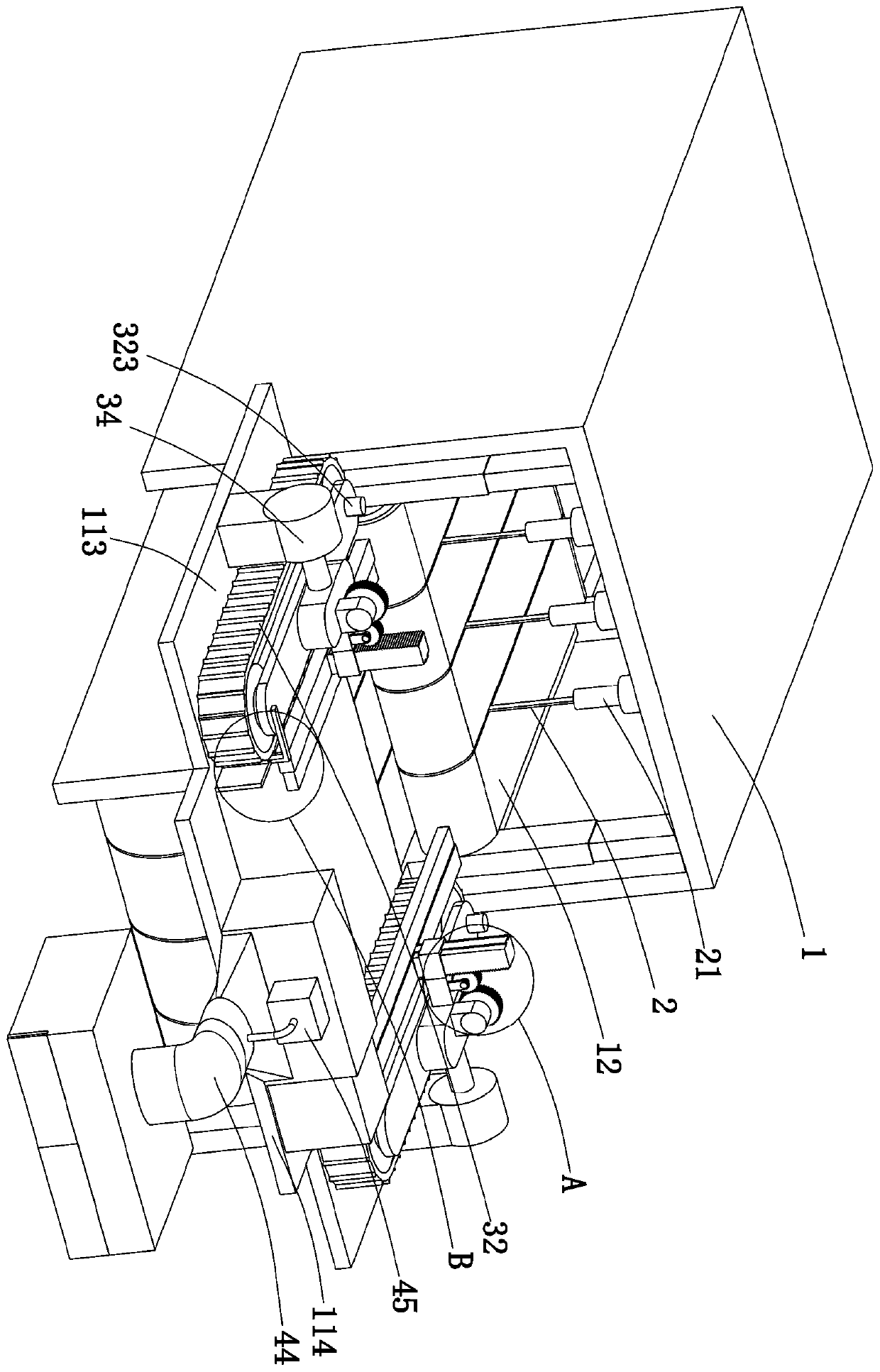

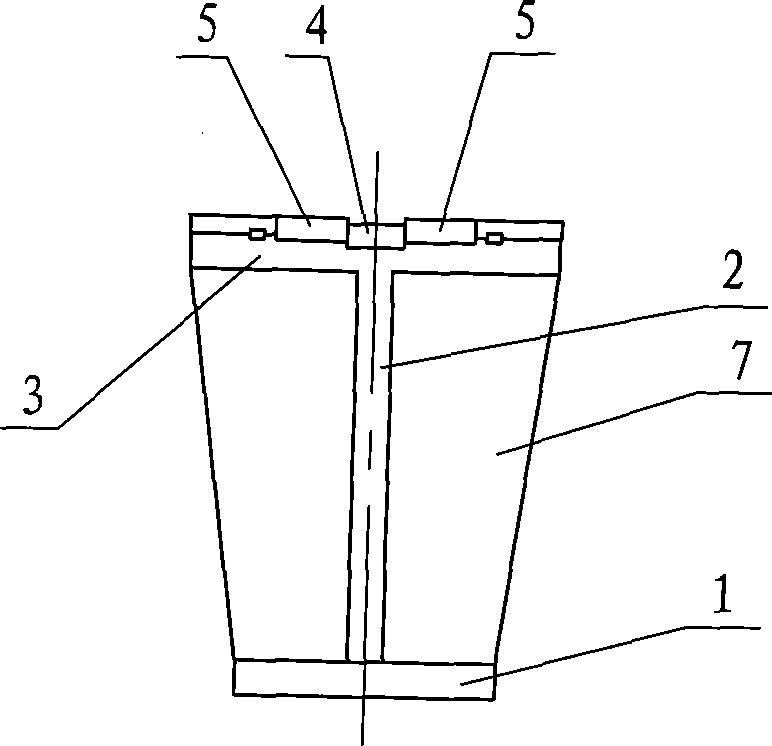

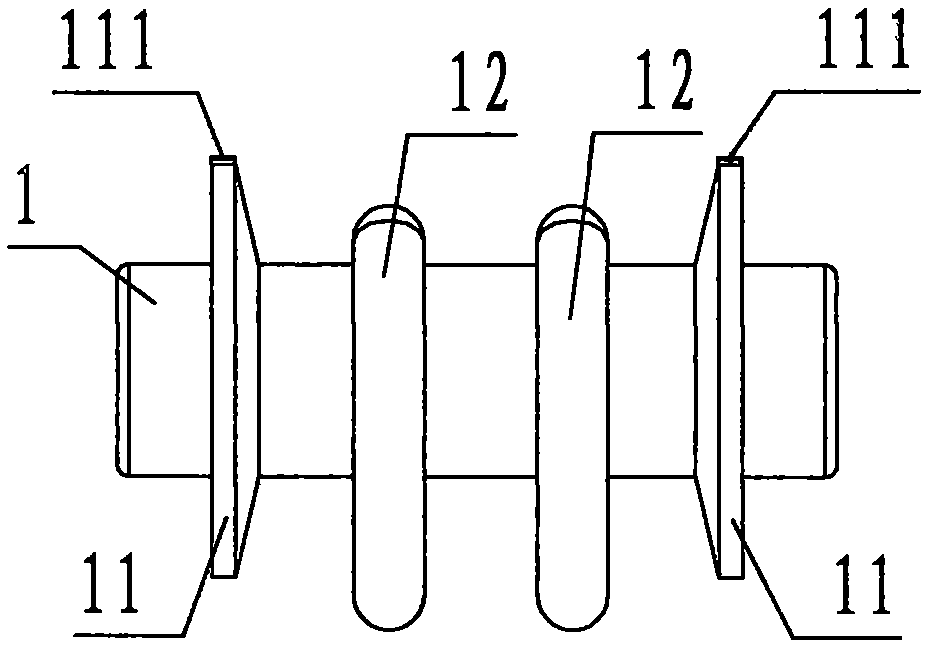

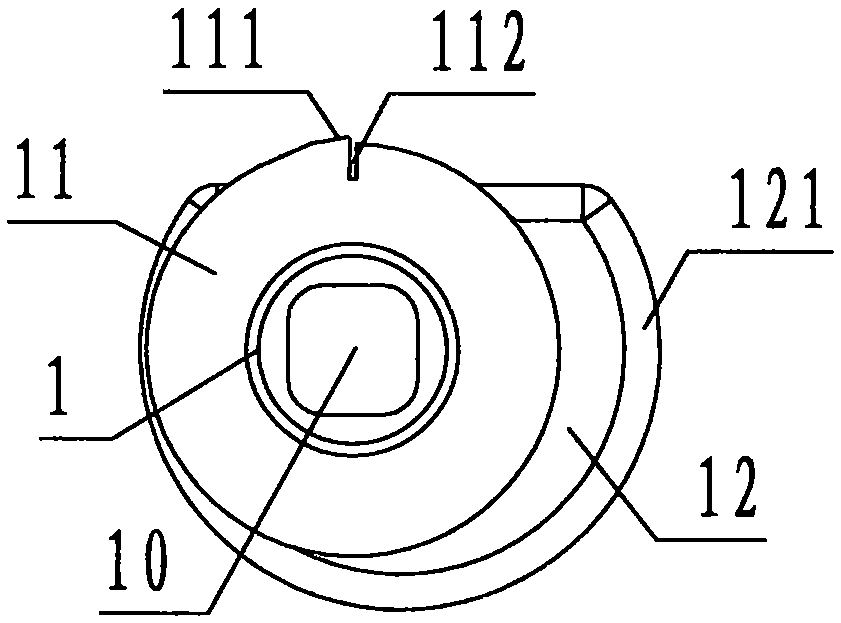

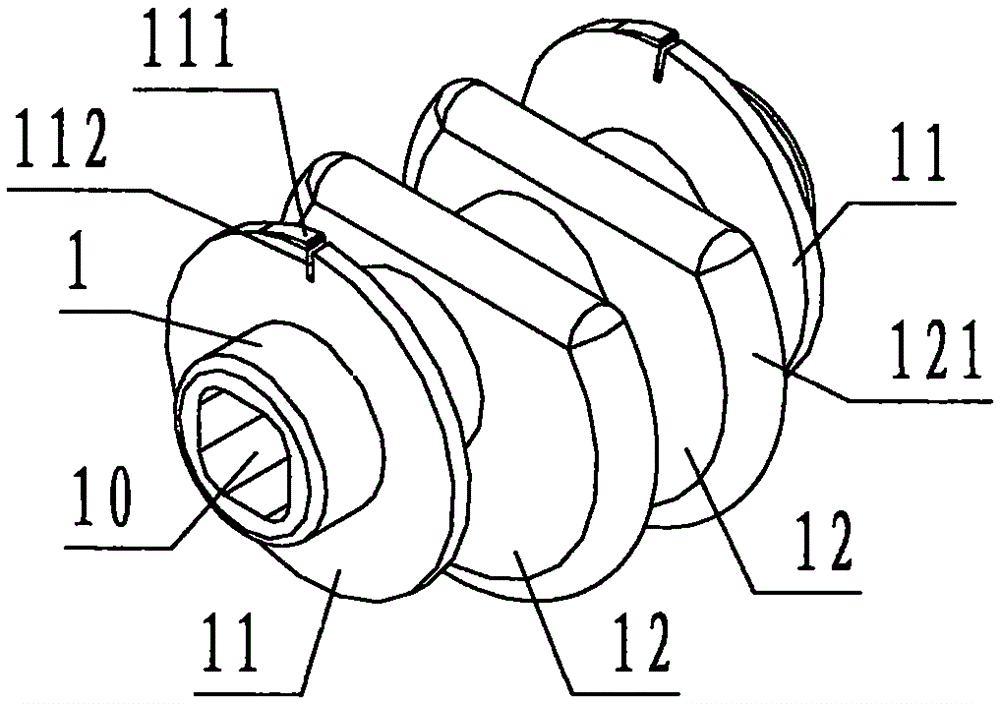

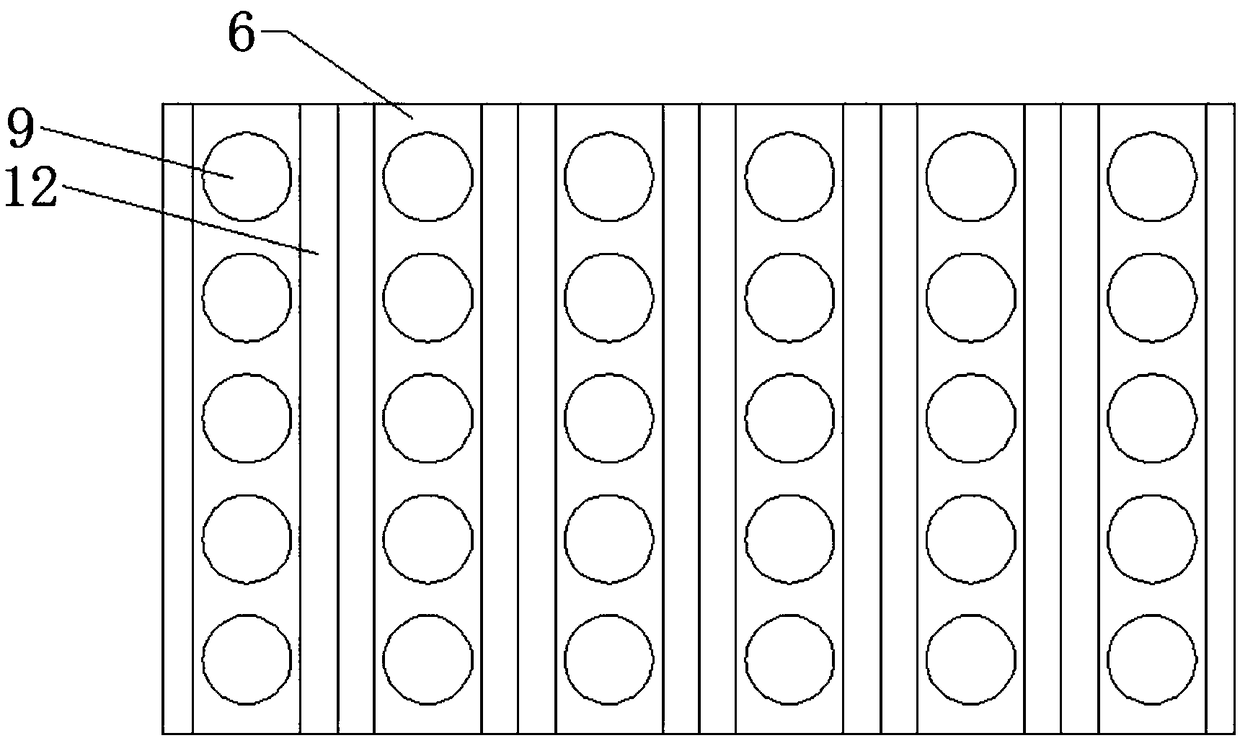

Paper shredder allocating wheel with paper clamping caulking grooves

ActiveCN105562177AStrong ability to pull paperReliable wrappingGrain treatmentsPulp and paper industryPaper sheet

The invention discloses a paper shredder allocating wheel with paper clamping caulking grooves. The paper shredder allocating wheel is called an allocating wheel body (1) for short. The allocating wheel body is provided with a paper shifting wheel and a paper dividing wheel. According to the technical scheme, the paper clamping caulking grooves are formed in convex fingers of the paper shifting wheel, the curly deckle edge of old paper is clamped in the paper clamping caulking grooves in a wound manner to grab and shift the old paper, and therefore the problems that in the prior art, work is not reliable, and use by a user is inconvenient are solved, a stacking paper shredder can adapt to automatic shifting and shredding of any new and old paper, and the aims of being reliable in shifting and convenient for the user to use are achieved.

Owner:广东票友智能科技有限公司

Feed crushing equipment for animal husbandry

InactiveCN108311241ARefined Feed FeedImprove crushing efficiencyShaking/oscillating/vibrating mixersFeeding-stuffEngineeringFodder

The invention discloses feed crushing equipment for animal husbandry. The feed crushing equipment comprises a body, a feed opening, a crushing chamber, rollers, first rotating shafts, a belt and a supporting rod, wherein the feed opening is formed in the upper part of the body; the crushing chamber is arranged at the lower part of the feed opening; a plurality of rollers are arranged inside the crushing chamber; each first rotating shaft is arranged inside the corresponding roller; a second belt rotating wheel is fixedly connected to the front side of each first rotating shaft; the second beltrotating wheels are connected by the belt; a double-shaft motor is arranged on the left side of the body; two ends of the double-shaft motor are respectively and fixedly connected with a first gear and the first belt rotating wheel; the supporting rod is arranged on the left side of the motor; a sliding chute is formed inside the supporting rod; a striking rod is arranged in the sliding chute; arack is arranged on the right side of the striking rod. The feed crushing equipment disclosed by the invention is reasonable in structure and simple in operation; high-efficiency crushing treatment offeed can be realized; meanwhile, quantitative discharging can be realized, so that stacking of the feed is avoided and the crushing time is shortened.

Owner:陈守谦

Feed crushing device

InactiveCN109967163AScreening is reasonableEffective classificationFeeding-stuffUsing liquid separation agentEngineeringWater tanks

The invention discloses a feed crushing device. The feed crushing device comprises a shell, a feeding inlet, a first discharging pipe, a second discharging pipe, a stirring body, a crushing roller shaft, first crushing teeth, second crushing teeth and a vibrator, wherein the bottom end of the feeding inlet and the top end of the shell are in welded connection, the two ends of the stirring body andthe inner wall of the feeding inlet are in welded connection, the stirring body rotates through a rotating shaft, the two ends of the crushing roller shaft are in welded connection with the inner side of the shell, the inner side of a first crushing roller is in welded connection with the outer side of the crushing roller shaft, the inner side of a second crushing roller is also in welded connection with the outer side of the crushing roller shaft, one ends of the first crushing teeth are in welded connection with the side face of the first crushing roller, one ends of the second crushing teeth are in welded connection with the side face of the second crushing roller, one end of a dust suction pipe and the shell are in communicating connection, the other end of the dust suction pipe stretches into a water tank, one side of the vibrator and the shell are in welded connection, and one end of the vibrator is in matched connection with a first screen net. The feed crushing device conductsgraded screening on feed, and using is convenient and flexible.

Owner:杨建

Waste treatment equipment used for magnetic materials

InactiveCN112691747ACases that are not easily crushedSmooth crushing processGrain treatmentsWaste treatmentInertia force

The invention discloses waste treatment equipment used for magnetic materials. The waste treatment equipment structurally comprises a base, a driver and a smashing mechanism. The driver is fixed to the right side position of the smashing mechanism, and the bottom of the smashing mechanism and the upper end of the base are welded. Through throwing force generated by rotating, driving blocks can slide outwards and extend out along the plate surface under the cooperation of linkage rods, and therefore the driving blocks can drive spherical magnetic material waste, outer pushing blocks can slide outwards and extend out along inner fixed plates through inertia force generated by outward extending of the driving blocks, then through throwing force generated by rotation of the outer pushing blocks, grooving blocks can slide outwards and extend out along external rings, and therefore the grooving blocks can hit the outer surfaces of the spherical magnetic material waste out of grooves, and two smashing rollers can smoothly smash the spherical magnetic material waste which is large in size and extremely smooth in surface.

Owner:广州国智机电设备有限公司

Cast tube crusher

ActiveCN106179585AImprove crushing effectEasy to separateGrain treatmentsLow noiseMechanical crushing

The invention discloses a cast tube crusher and belongs to the field of cast tube production and manufacturing. The cast tube crusher comprises a first support and a second support, wherein the first support is horizontally arranged on the ground and supported by a plurality of supporting feet; the second support is mounted on one side of the first support, and the top face of the second support is slightly lower than the first support. A plurality of parallel conveying rollers are mounted on the first support through a plurality of bearing frames symmetrically mounted on the top face of the first support. Bearings are mounted between the conveying rollers and the bearing frames. An extrusion mechanism is fixedly mounted on the surface of the second support. The cast tube crusher is a mechanical crushing device for cast tubes, the cast tubes and cement linings on the inner walls of the cast tubes can be effectively separated, the cast tubes are preliminarily crushed, and the cast tube crusher has the advantages of being high in working efficiency and capable of saving manpower and material resources compared with the prior art. Meanwhile, the crusher has the advantages of long service life, stable operation, low noise and the like.

Owner:XINXING DUCTILE IRON PIPES CO LTD

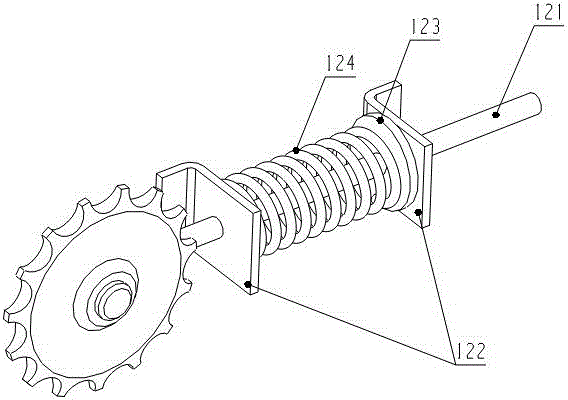

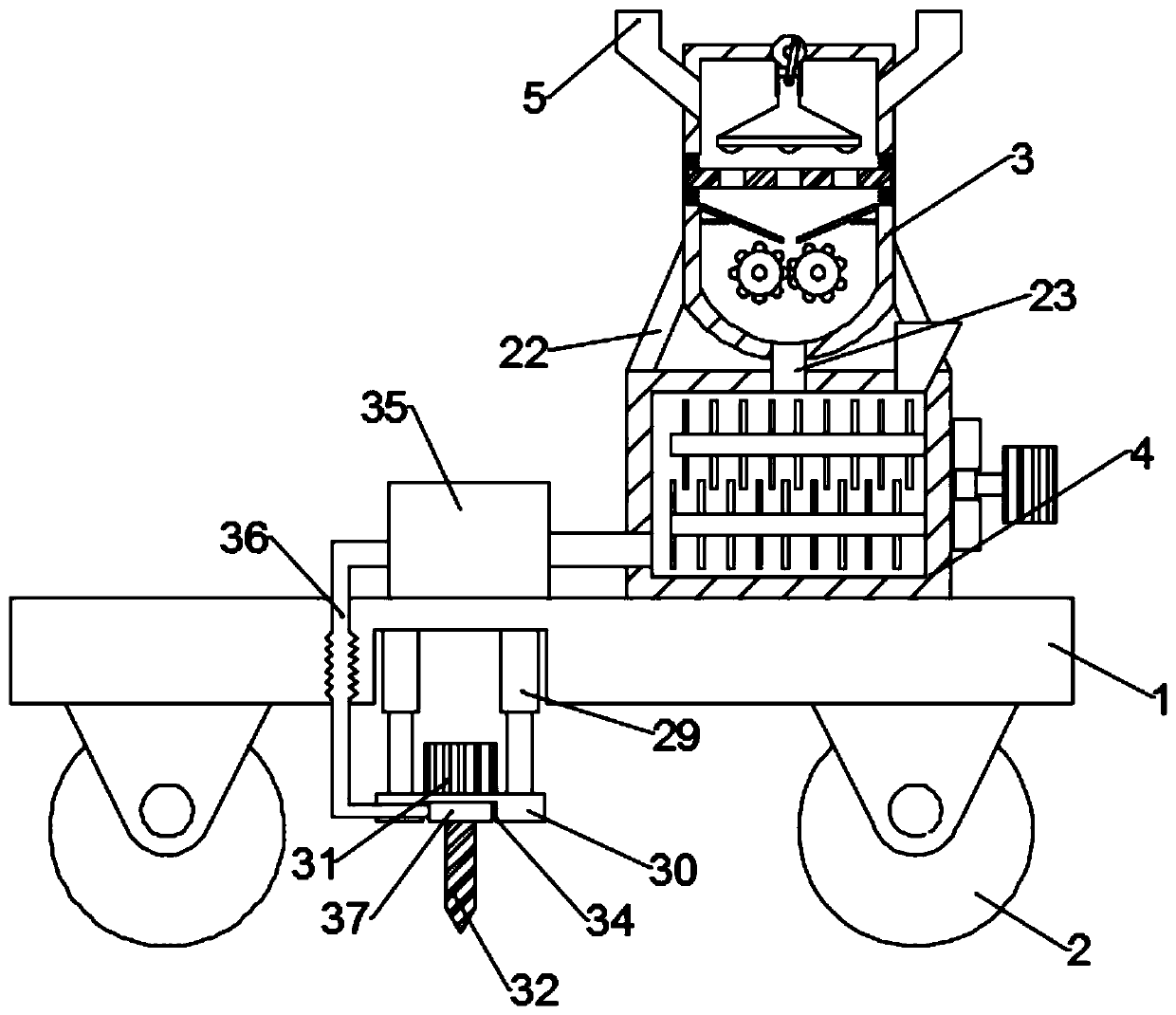

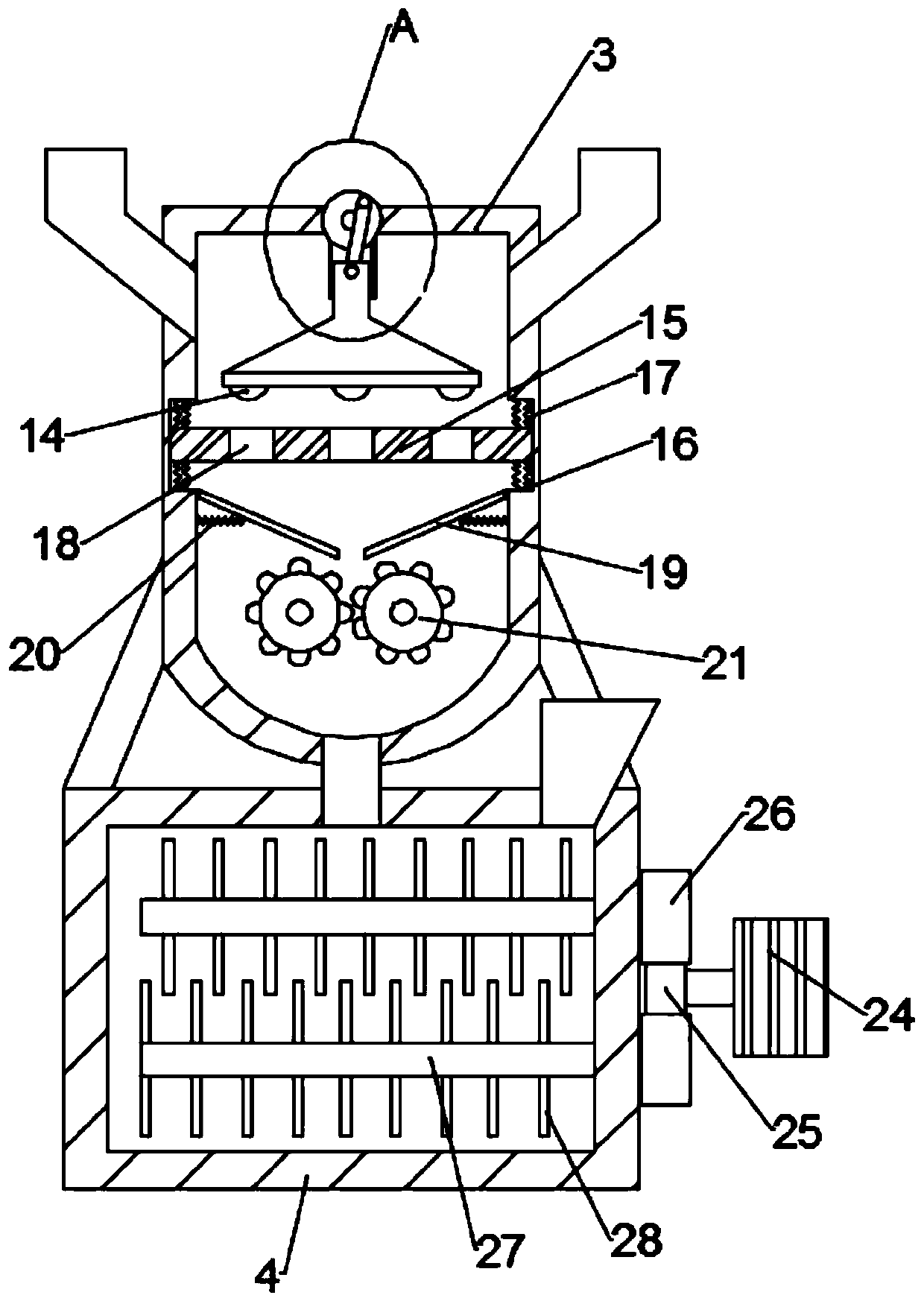

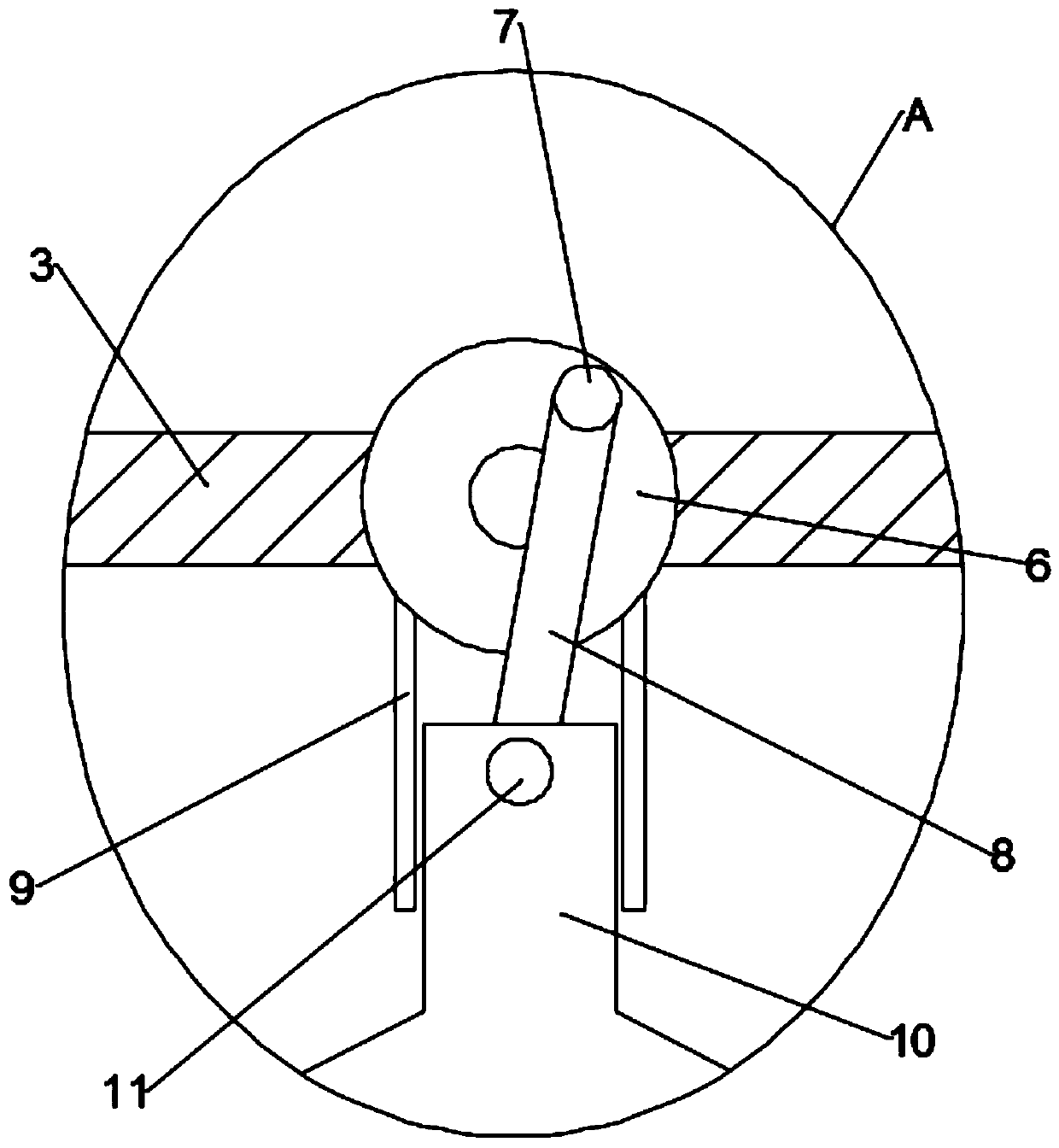

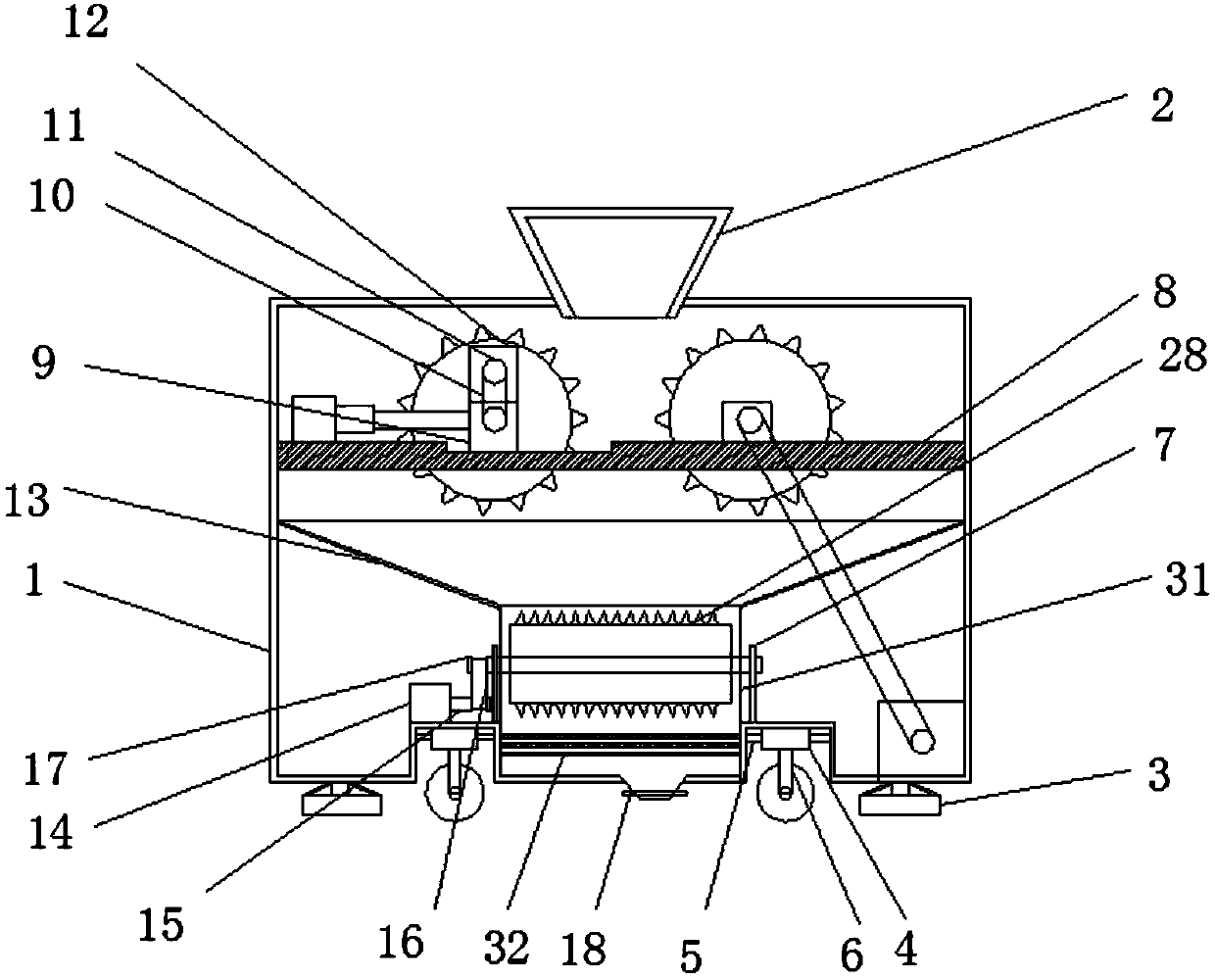

Agricultural soluble-solid-fertilizer applying device

ActiveCN110679260AEasy and quick passSmooth crushing processDirect liquid fertiliser deliveryGrain treatmentsAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural equipment and particularly discloses an agricultural soluble-solid-fertilizer applying device. The agricultural soluble-solid-fertilizer applying device comprises a support plate and is characterized in that the support plate move through traveling wheels, a crushing tank and a dissolving tank which are communicated through a discharge channel are arranged on the upper surface of the support plate, the dissolving tank is fixed below the crushing tank through support rods, and the bottom end of the support plate is provided with a deep fertilizing mechanism; a distribution mechanism and crushing rollers are arranged inside the crushing tank; a fertilizer stirring mechanism is arranged inside the dissolving tank; the dissolving tank and the deep fertilizing mechanism are connected through a water pump. The agricultural soluble-solid-fertilizer applying device has the advantages that the device is used to improve the fertility of land before crop planting so as to increase crop yield, the problem that a farmer needs to manually dissolve fertilizer and manually apply the fertilizer is solved at the same time, fertilizer particles caked due to inappropriate storage can be crushed, manual crushing is not needed, the fertilizer particles can be favorably evenly dissolved in water, and uneven fertilizing can be avoided.

Owner:江西兴旺生态农业综合开发有限公司

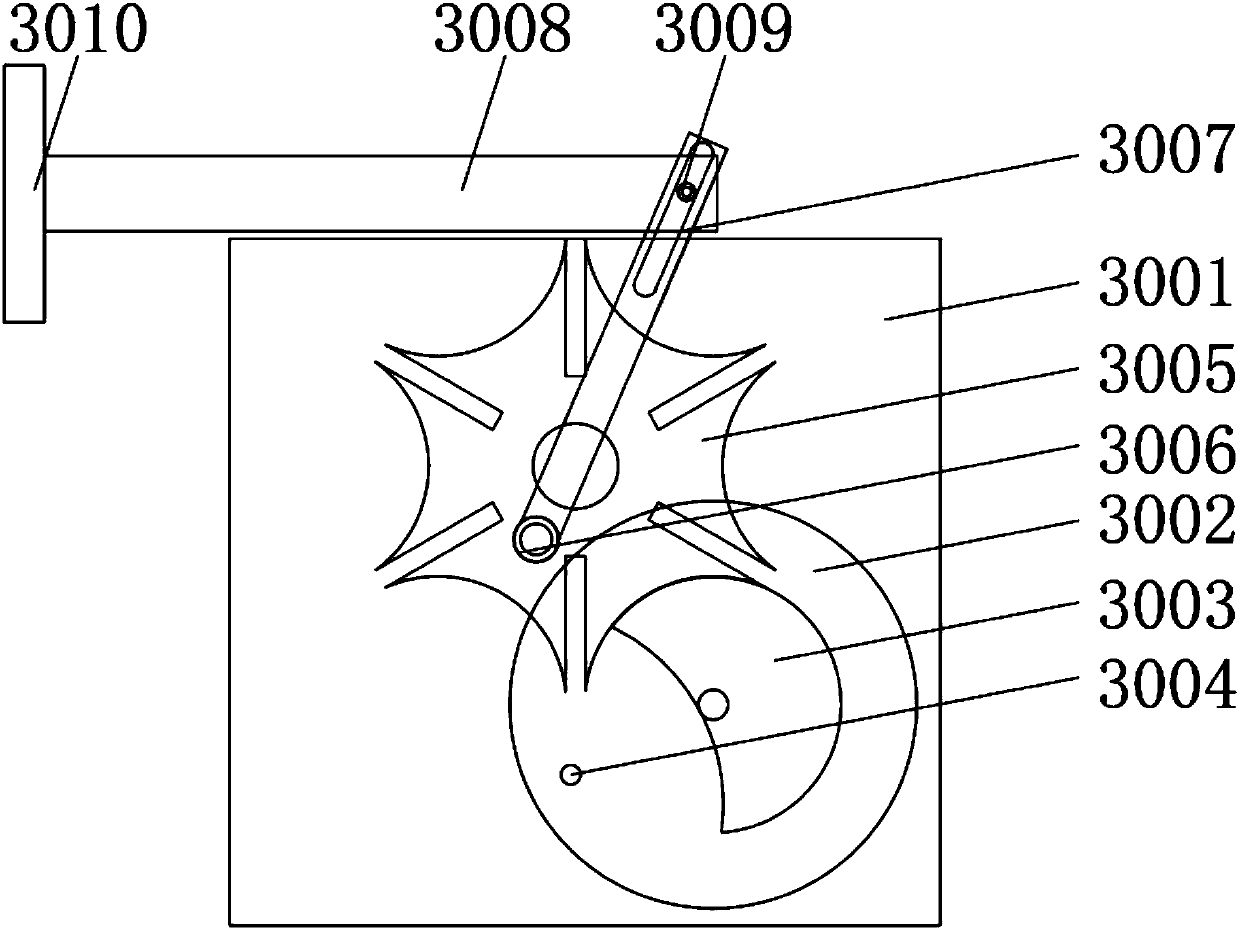

Coal briquette crushing device used for coal mining

InactiveCN113856871ASmooth crushing processIncrease the degree of pre-grindingSievingScreeningCoal briquetteBriquetage

The invention discloses a coal briquette crushing device used for coal mining. The coal briquette crushing device comprises a machine body, a crushing cavity is formed in the upper portion of the machine body, a center shaft is rotationally installed at the bottom of the crushing cavity, a filter screen, a grinding plate, a filter plate and a pre-crushing cone are sequentially installed on the center shaft from bottom to top, the filter screen and the filter plate are fixedly installed on the inner wall of the crushing cavity, the middles of the filter screen and the filter plate are movably connected with the center shaft through lantern rings, the grinding plate and the pre-crushing cone are fixedly connected with the center shaft, adjustable crushing cutters and fixed crushing cutters which are distributed in a staggered manner are installed on the pre-crushing cone, and a coaxial inverted-cone-shaped impact baffle is installed on the outer side of the pre-crushing cone. By means of the coal briquette crushing device , the pretreatment degree is adjustable; the pre-crushing degree to coal briquettes is improved to a great degree, and the pretreatment efficiency is improved; and dust raising during crushing is reduced, the situation of coal briquette blockage is reduced as much as possible in the crushing process, the blocking phenomenon is reduced, and the coal briquette crushing efficiency is improved.

Owner:中煤西安设计工程有限责任公司

Agricultural greenhouse planting soil treatment crushing and refining equipment

The invention discloses agricultural greenhouse planting soil treatment crushing and refining equipment. The equipment comprises a shell, a feed hopper, a driving device, a base and rolling wheels. Ahorizontal squeezing block is fixed to the output end of the driving device. A squeezing block fixed to the inner wall of the shell is arranged under the squeezing block. The squeezing plate is uniformly provided with a plurality of discharge holes. A plurality of squeezing columns corresponding to the discharge holes are fixed to the lower side of the squeezing block. A plurality of equidistant disks are coaxially fixed to each squeezing column. A heating cavity is arranged on the outer side of a discharge barrel and a crushing cavity. The equipment conducts refining on big-size soil fallinginto the equipment through the disks on the squeezing columns and enables the squeezing block to move downwards to crush the soil. Through reasonable utilization of power of the driving device and energy, the squeezing plate is made to squeeze the falling soil to minish the big-size soil so that the soil can be subjected to refinement through crushing rolls. The load of the crushing rolls is reduced, and the soil crushing stability is improved.

Owner:池吉平 +2

Eight-roll type crusher

ActiveCN105195255AAvoid damageReduce powder passing rateGrain treatmentsResource utilizationElectric machinery

A disclosed eight-roll type crusher comprises a feed inlet, a broken-stone cylinder and a pedestal; two ends of the pedestal are respectively fixedly provided with a first motor and a second motor; the broken stone cylinder is arranged between the two motors and is fixedly disposed on the pedestal; the upper end of the broken stone cylinder is provided with the feed inlet, the lower end is provided with a tunnel-type material-receiving port, two ends of the upper part outer wall are both provided with a through groove, and two ends of the upper part outer wall are both provided with a through groove; hinges pass through the thorough grooves, and the parts, at the outer wall of the broken stone cylinder, of the hinges are fixed through positioning rollers which are fixedly installed on the outer wall of the broken stone cylinder; the upper part in the broken stone cylinder is provided with four rolls, and the middle-lower part in the broken stone cylinder is provided with four rolls; and two ends of the broken-stone cylinder outer wall are provided with a plurality of discharge ports. The crusher is capable of performing multiple crushing, is capable of reducing powder passing rate and improving resource utilization rate, also is capable of classifying materials with different sizes, is enhanced in functions, steady in operation, small in noise, low in cost and maintenance cost, and relatively long in service life.

Owner:浙江辉柯纸塑制品有限公司

Crushing equipment

The invention discloses crushing equipment. The crushing equipment comprises a shell, supporting columns are arranged at the lower end of the shell, two symmetric second supporting plates are fixedlyconnected in the shell, the upper end of each second supporting plate is fixedly connected with a second hydraulic cylinder, and the driving ends of the second hydraulic cylinders are connected with second hydraulic rods. The second hydraulic rods are fixedly connected with sliding blocks, sliding grooves matched with the sliding blocks are formed in the upper ends of the second supporting plates,and the upper ends of the sliding blocks are fixedly connected with first motors. The output ends of the first motors are connected with first rotary shafts, a first roller and a third roller are arranged at the upper ends of the second supporting plates, and the third roller is fixedly connected with a sixth transmission shaft. The crushing equipment is good in stability and convenient to move,different products can be obtained through adjusting and crushing, secondary crushing can also be achieved, and crushing is complete.

Owner:陈永

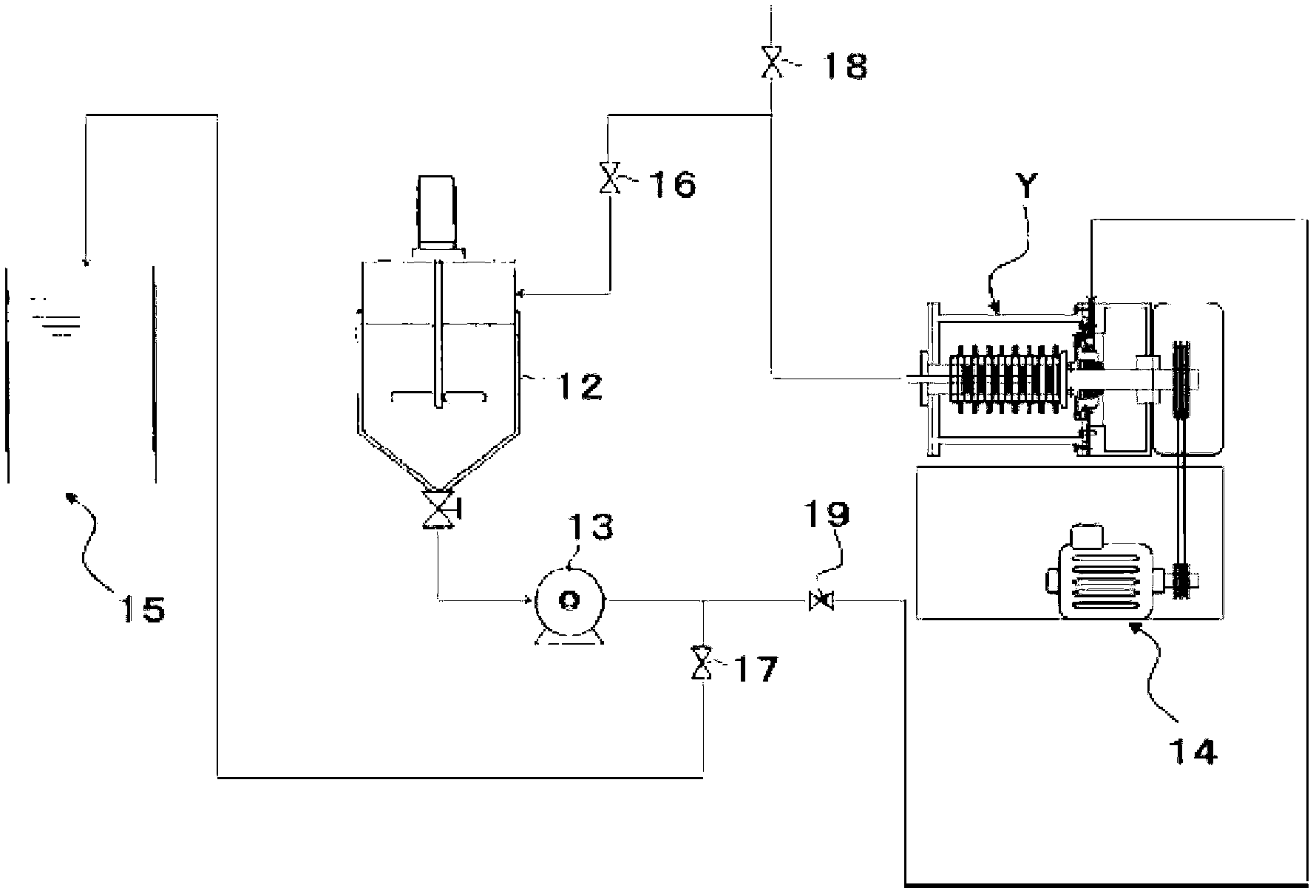

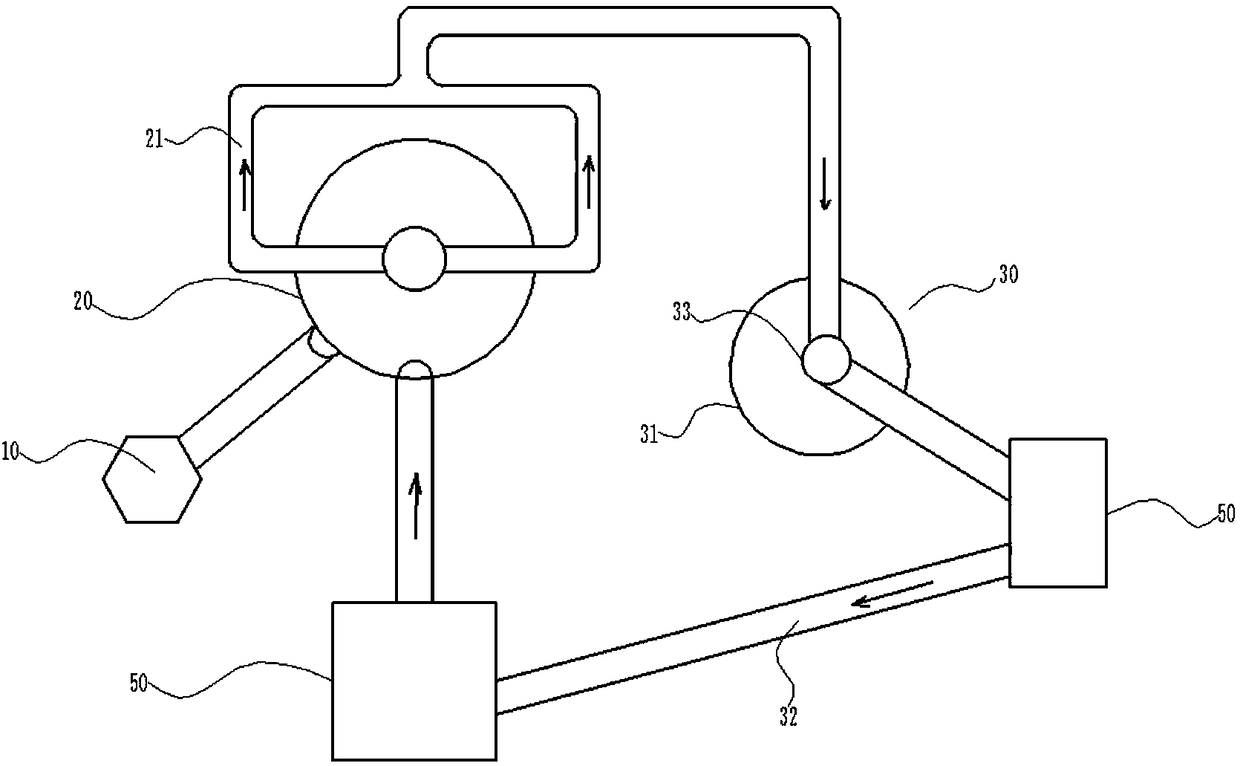

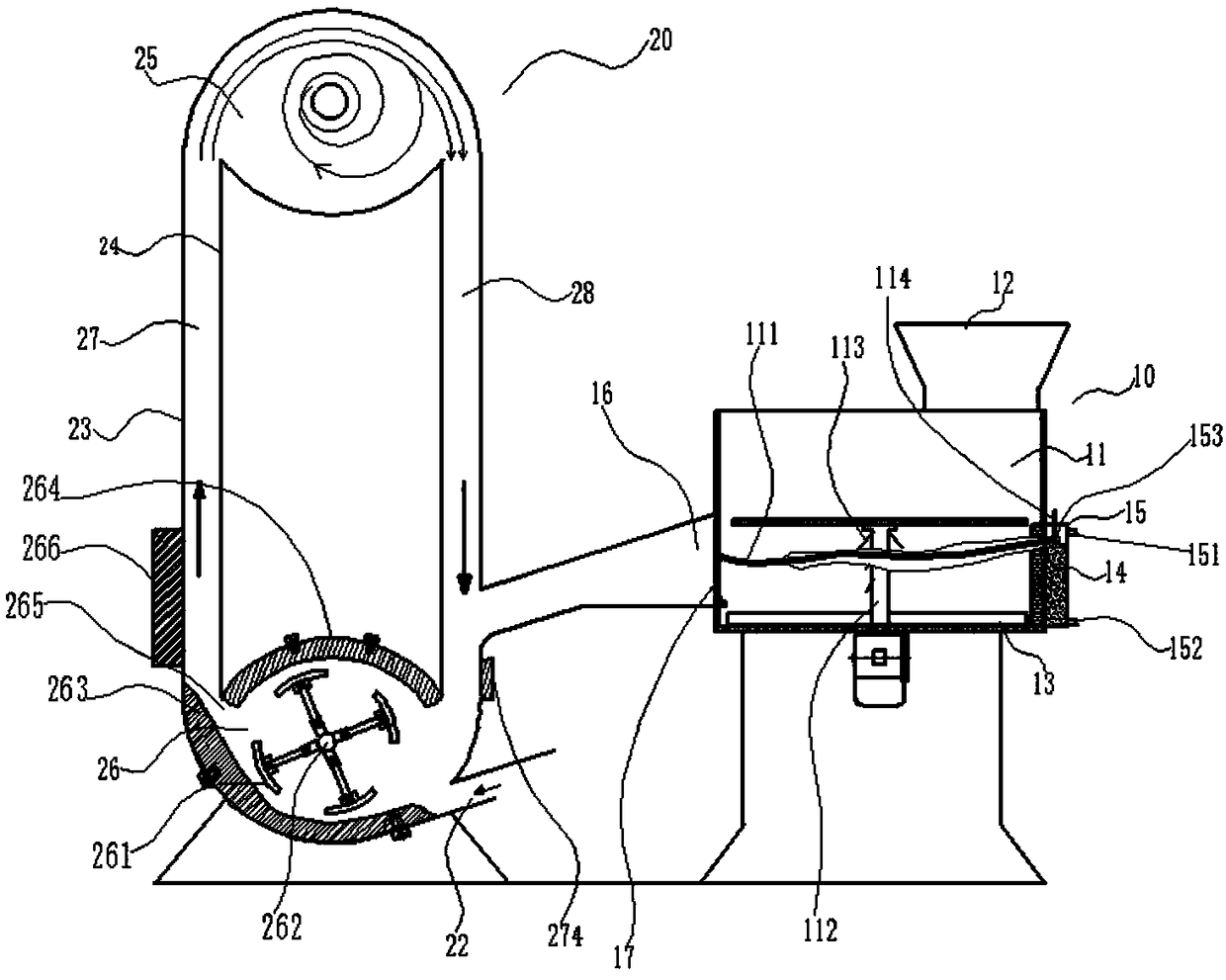

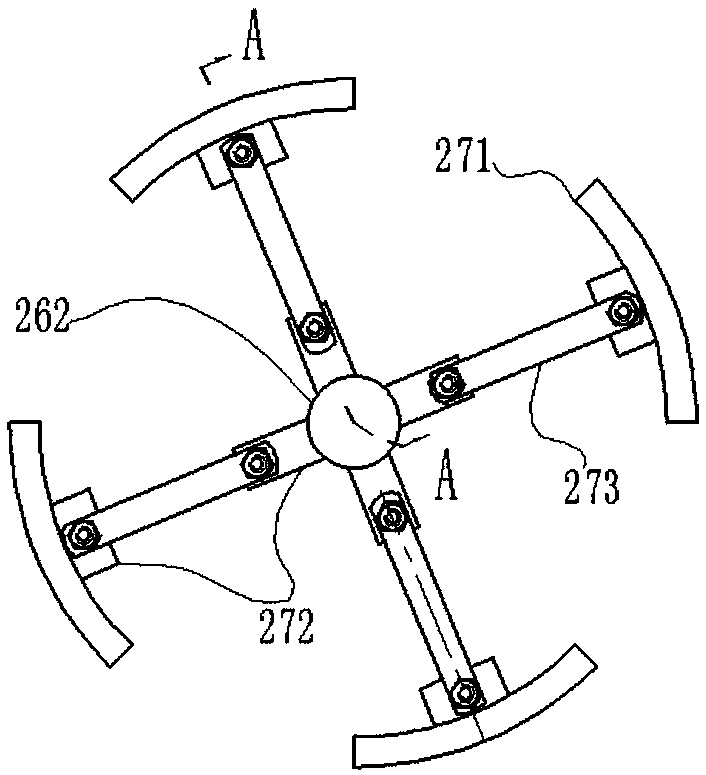

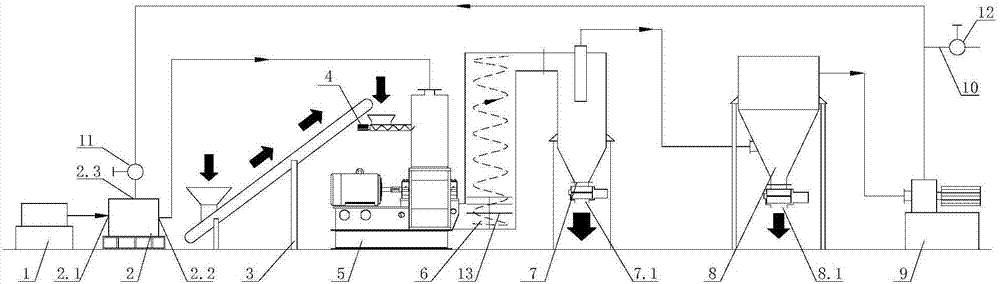

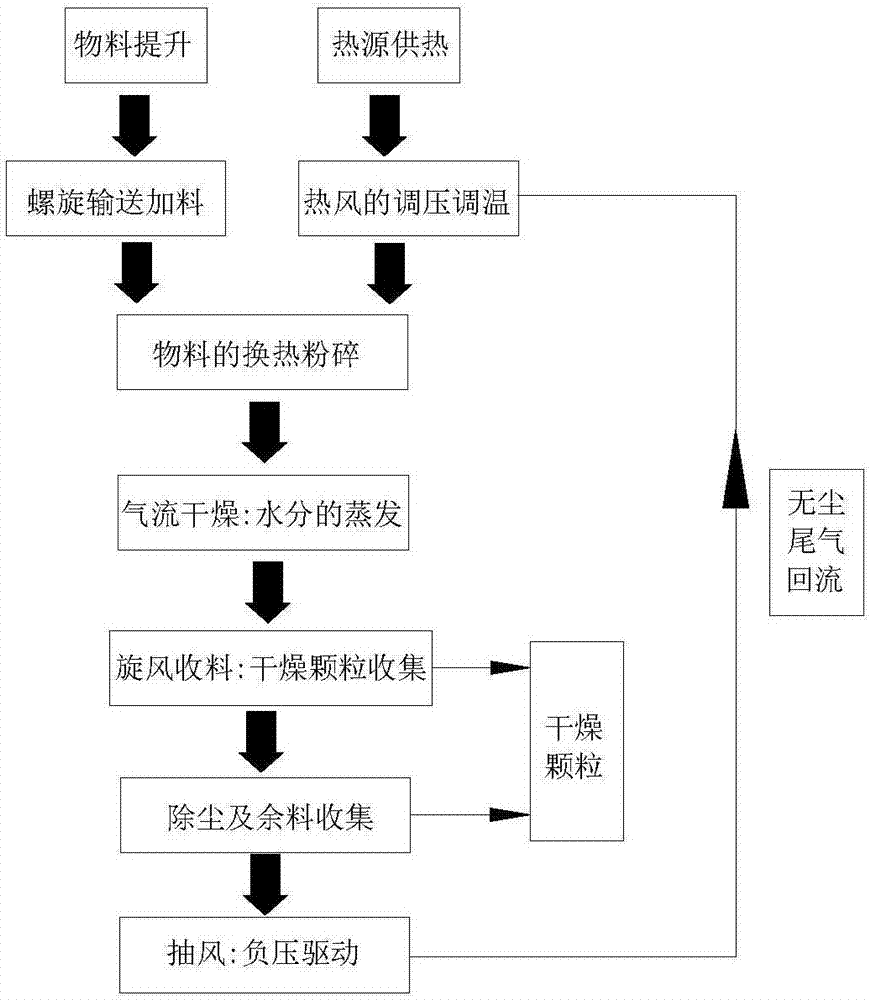

Wet material rapid crushing and drying integrated method and system

PendingCN108007071AIncrease contact areaImprove efficiencyDrying gas arrangementsPreliminary solid treatment for dryingExhaust gasAirflow

The invention discloses a wet material rapid crushing and drying integrated method and system. The wet material rapid crushing and drying integrated method comprises the following steps that (1) heattransfer crushing for materials is performed, specifically, working hot air is introduced in the process of crushing wet materials into material particles, a strong turbulent flow is formed by the material particles and the working hot air, and preliminary dried material particles are obtained; (2) air flow drying for the materials is performed, specifically, further heat-exchange treatment of thematerial particles obtained in step (1) and the working hot air is performed to obtain dried particles; (3) cyclone material receiving is performed, specifically, the dried particles obtained in step2) and the working hot air are subjected to gas-solid separation treatment to separate the dried particles and tail gas; and (4) dust removal and excess material collection are performed. By integrating the crushing and drying process, the wet material rapid crushing and drying integrated method and system can not only enable the crushing progress smoothly, but also enable the drying efficiency to be improved rapidly; and the hot air is introduced into a crusher to enable the crusher to be a part of a dryer and achieve continuous crushing of the wet materials.

Owner:深圳市泽源能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com