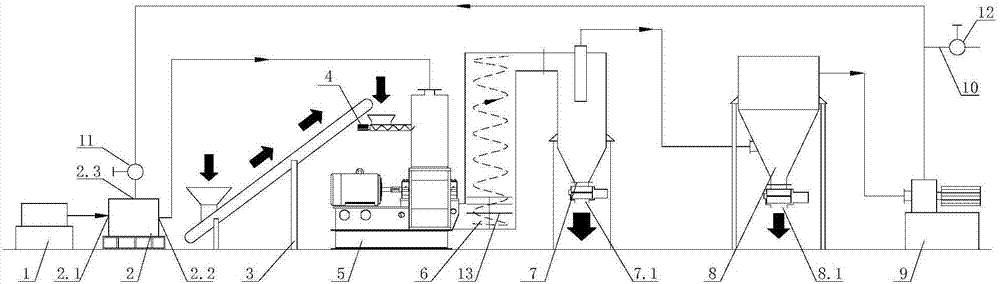

Wet material rapid crushing and drying integrated method and system

A material and wet technology, applied in the field of the integrated method of rapid crushing and drying of wet materials and its system, can solve the problems of large volume of landscaping waste, increased production, and difficulty, and achieves increased energy utilization, reduced airflow damping, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

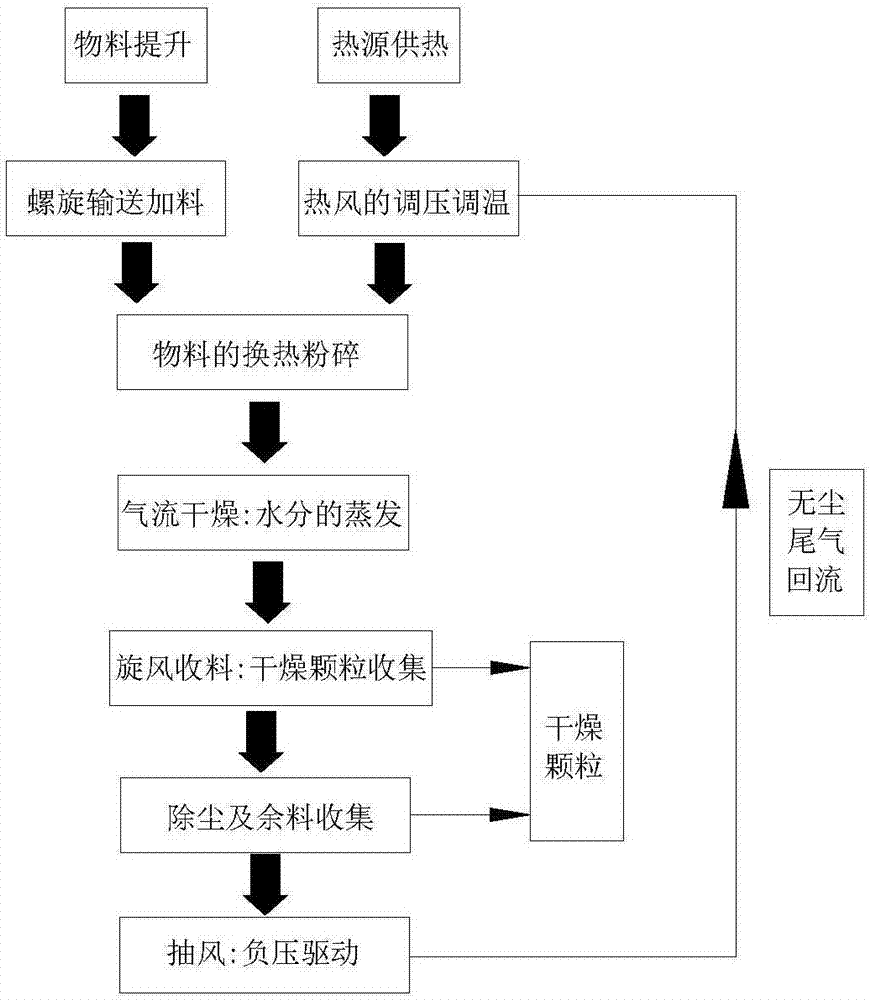

[0053] The integrated method of quickly crushing and drying wet materials (dead branches, wet rotten rhizomes) with a moisture content of 50% comprises the following steps:

[0054] 1) Material heat exchange and crushing: During the process of crushing the wet material into material particles (particle size: 3-4mm), the working hot air is introduced at the same time, the material particles and the working hot air form a strong turbulent flow, most of the moisture in the wet material and The working hot air is heat exchanged into water vapor, and the initially dried material particles are obtained;

[0055] 2) Material air drying: further heat exchange treatment between the material particles obtained in step 1) and the working hot air to obtain dry particles;

[0056] 3) Cyclone collection: the dry particles obtained in step 2) are subjected to gas-solid separation treatment with the working hot air, and the dry particles and tail gas are separated, and the moisture content of...

Embodiment 2

[0060] An integrated method for rapidly pulverizing and drying wet materials (fallen leaves and flowers) with a moisture content of 80% comprises the following steps:

[0061] 1) Material heat exchange crushing:

[0062] During the process of breaking the wet material into material particles (particle size: 4-5mm), the working hot air is introduced at the same time, the material particles and the working hot air form a strong turbulent flow, and most of the moisture in the wet material exchanges heat with the working hot air and becomes water. Steam to get the primary dry material particles;

[0063] 2) Material air drying: further heat exchange treatment between the material particles obtained in step 1) and the working hot air to obtain dry particles;

[0064] 3) Cyclone collection: the dry granules obtained in step 2) are subjected to gas-solid separation treatment with the working hot air, and the dry granules and tail gas are separated, and the moisture content of the dr...

Embodiment 3

[0068] An integrated method for quickly crushing and drying wet materials (twigs and twigs) with a moisture content of 60% comprises the following steps:

[0069] 1) Material heat exchange and crushing: During the process of crushing the wet material into material particles (6-7mm in particle size), the working hot air is introduced at the same time, the material particles and the working hot air form a strong turbulent flow, most of the moisture in the wet material and The working hot air is heat exchanged into water vapor, and the initially dried material particles are obtained;

[0070] 2) Airflow drying of the material: the material particles obtained in step 1) are subjected to secondary crushing treatment, crushed to a particle size of 4-5mm, and further heat exchange treatment with the working hot air to obtain dry particles;

[0071] 3) Cyclone collection: the dry granules obtained in step 2) are subjected to gas-solid separation treatment with the working hot air, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com